Patents

Literature

1886 results about "Viscosity modifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid viscosity modifiers are more convenient and economical when large quantities of additives are required and the equipment necessary to granulate the solid form of the product is available. The active thickeners in our viscosity modifiers are ethylene/propylene copolymers or proprietary polymers.

Viscosity index improver for lubricant compositions

Owner:DOW GLOBAL TECH LLC

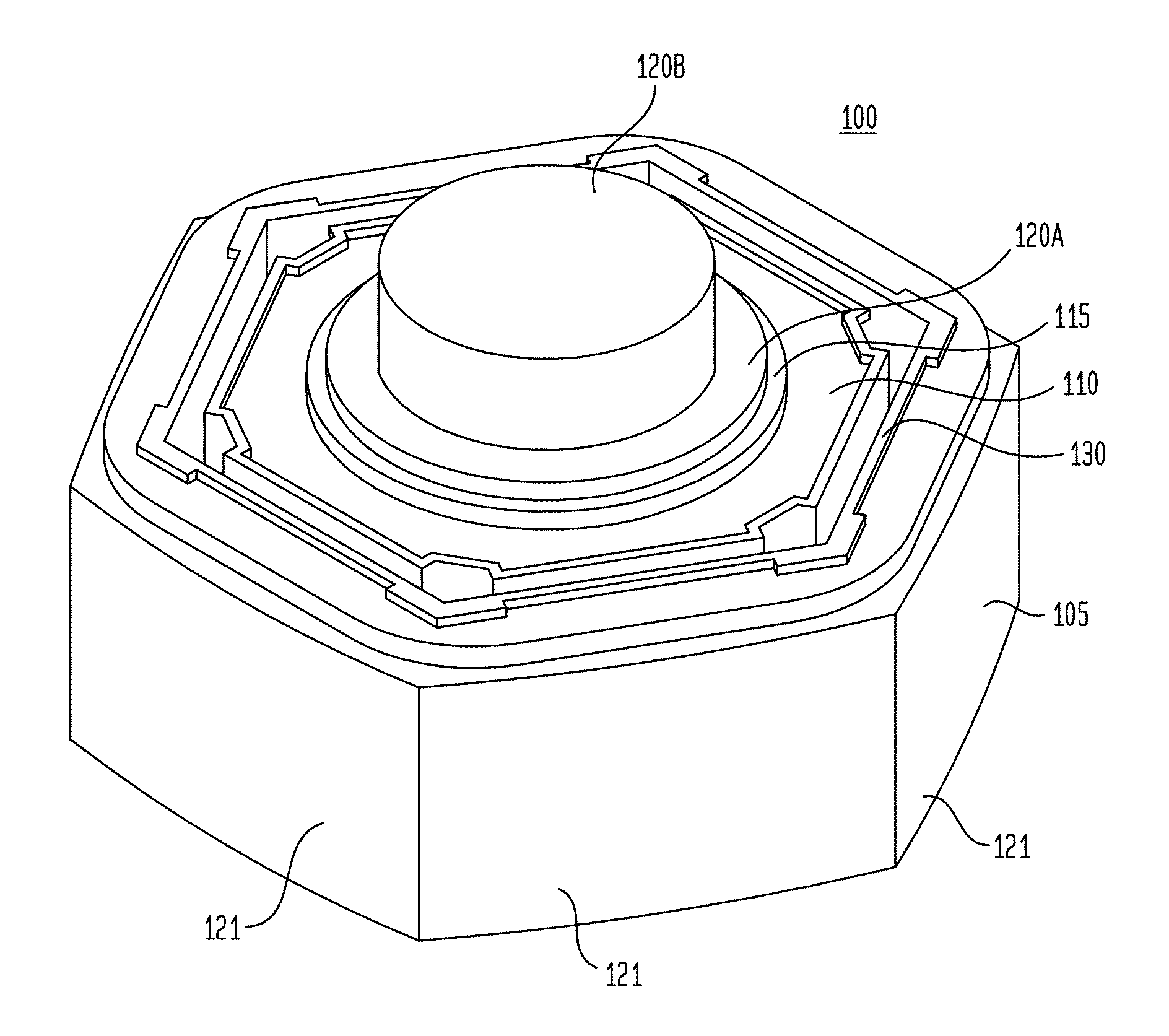

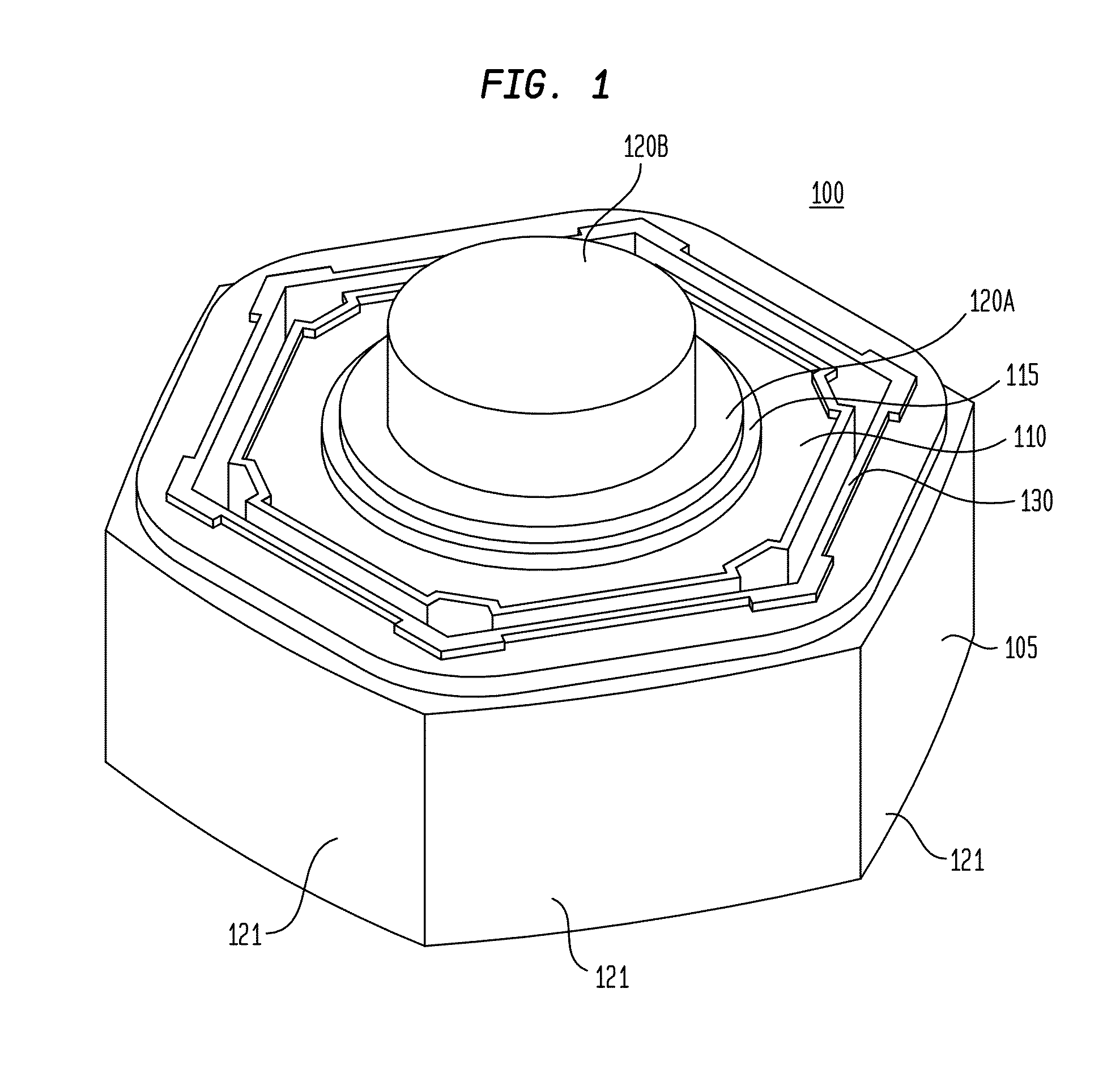

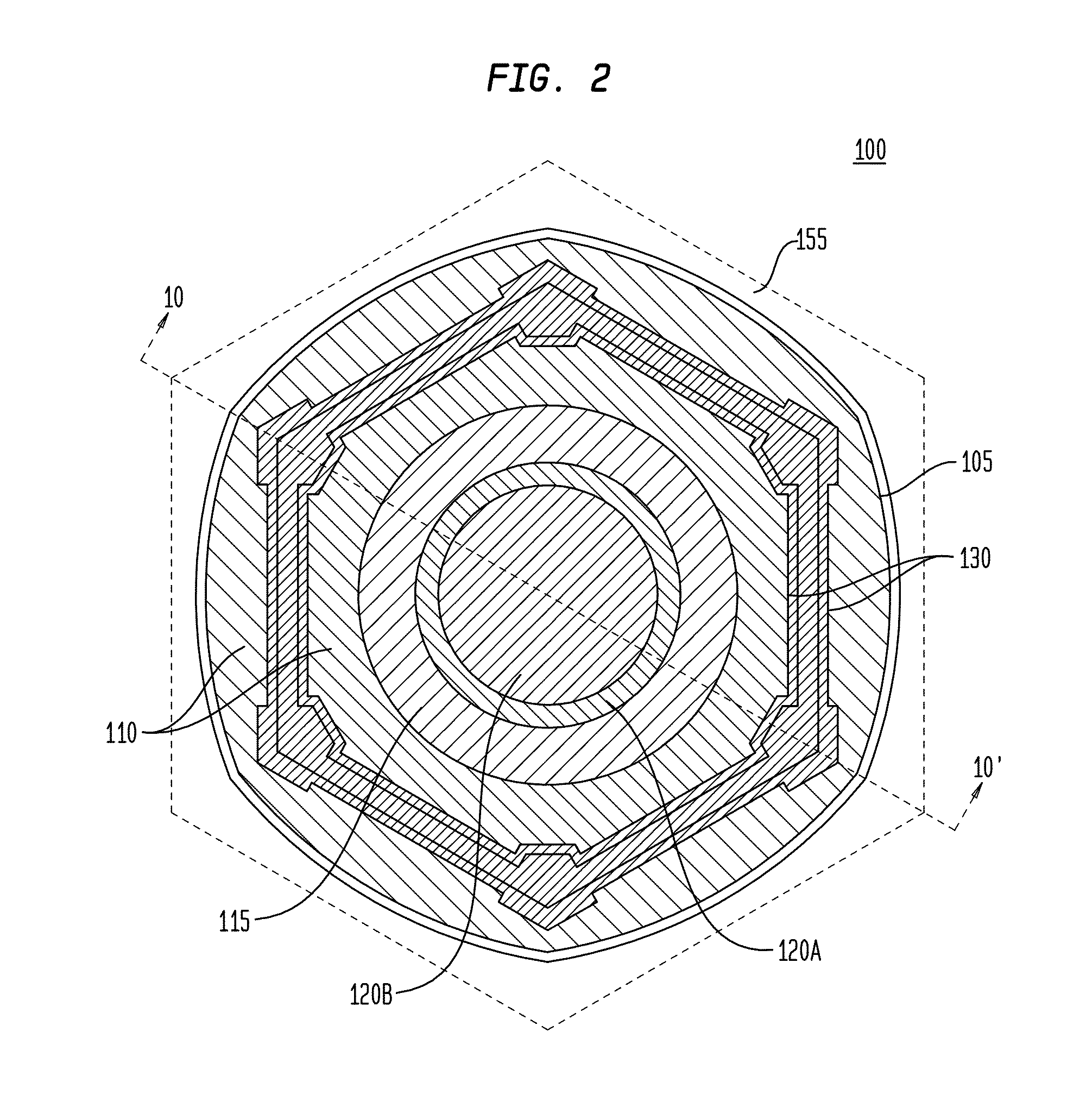

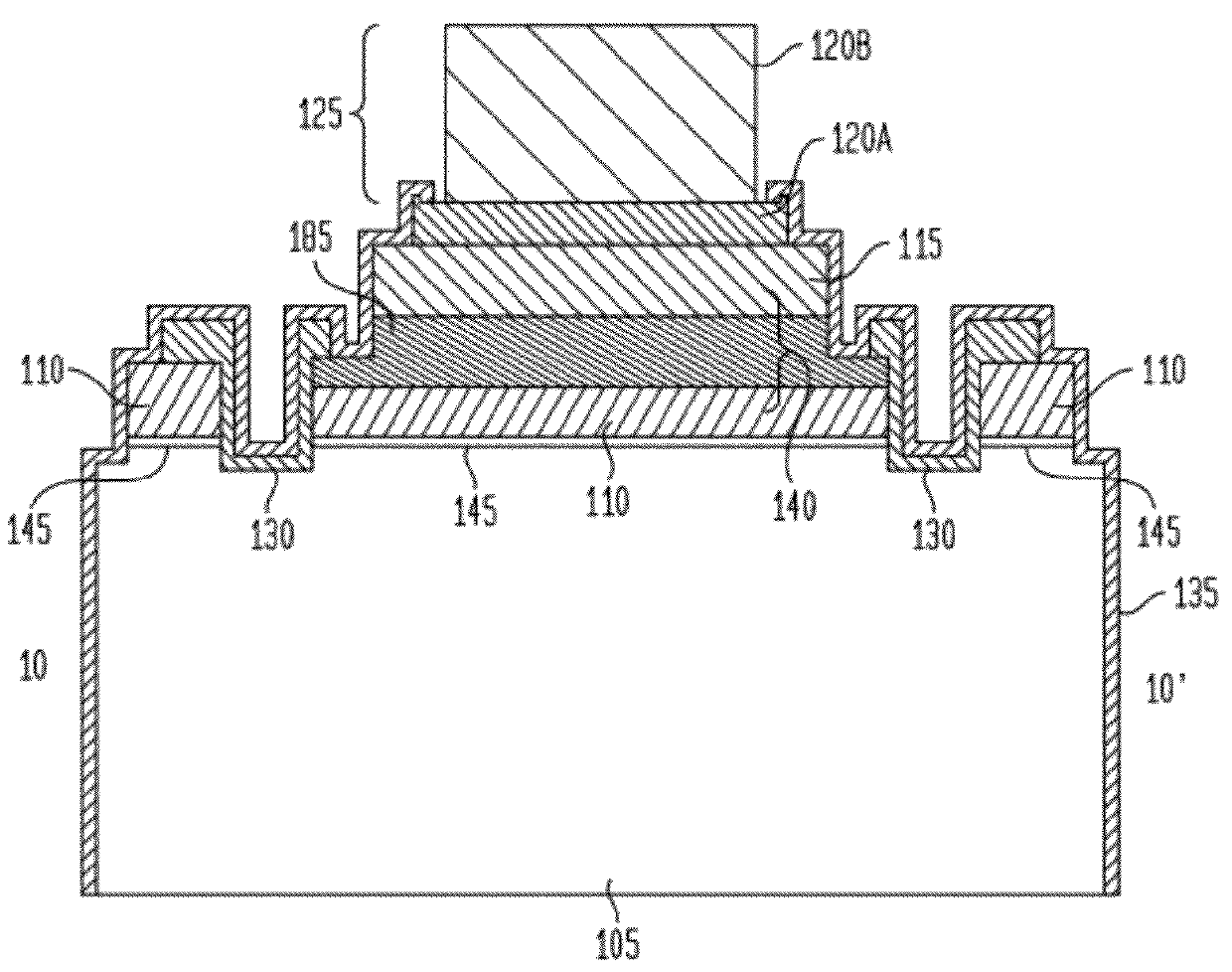

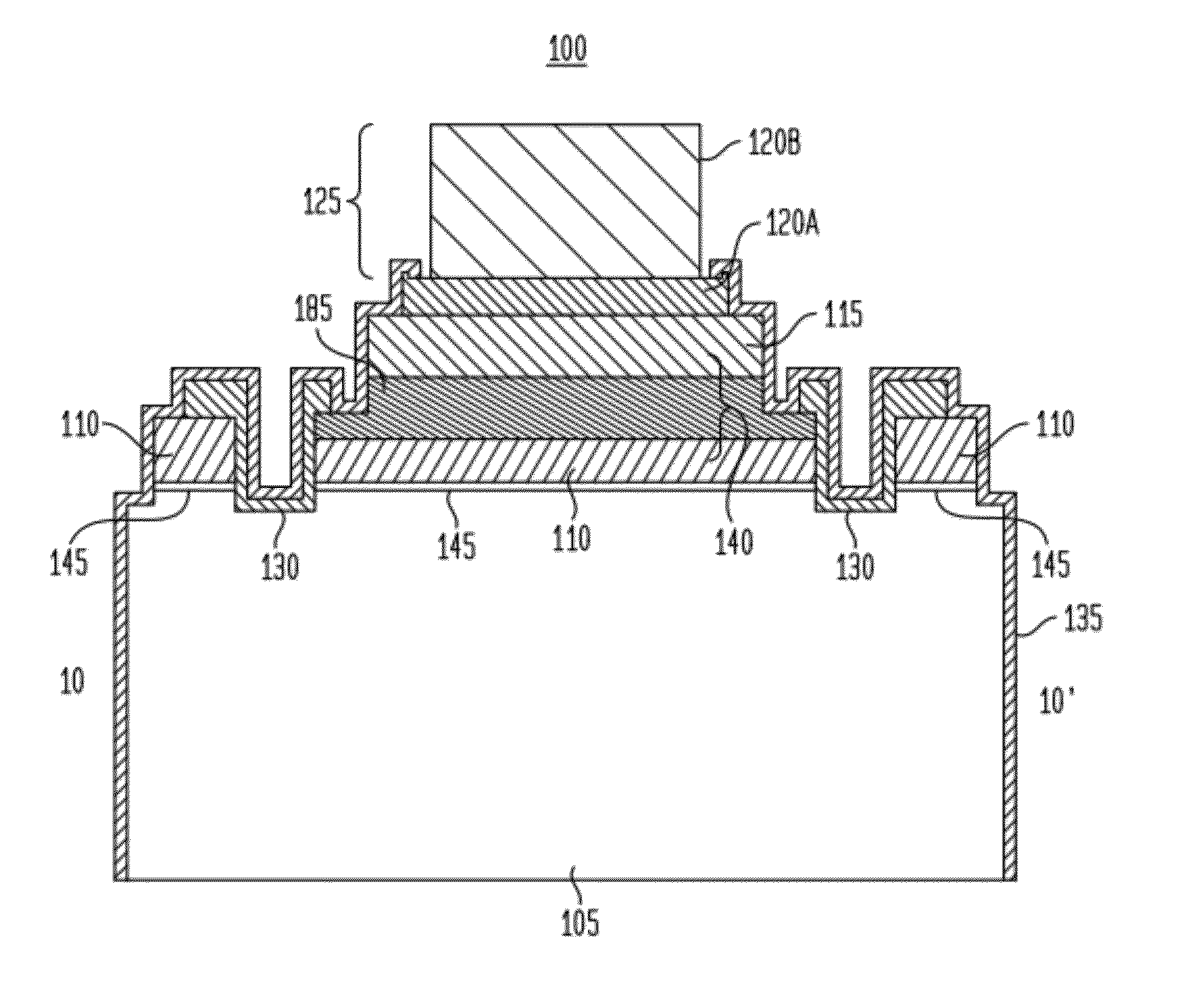

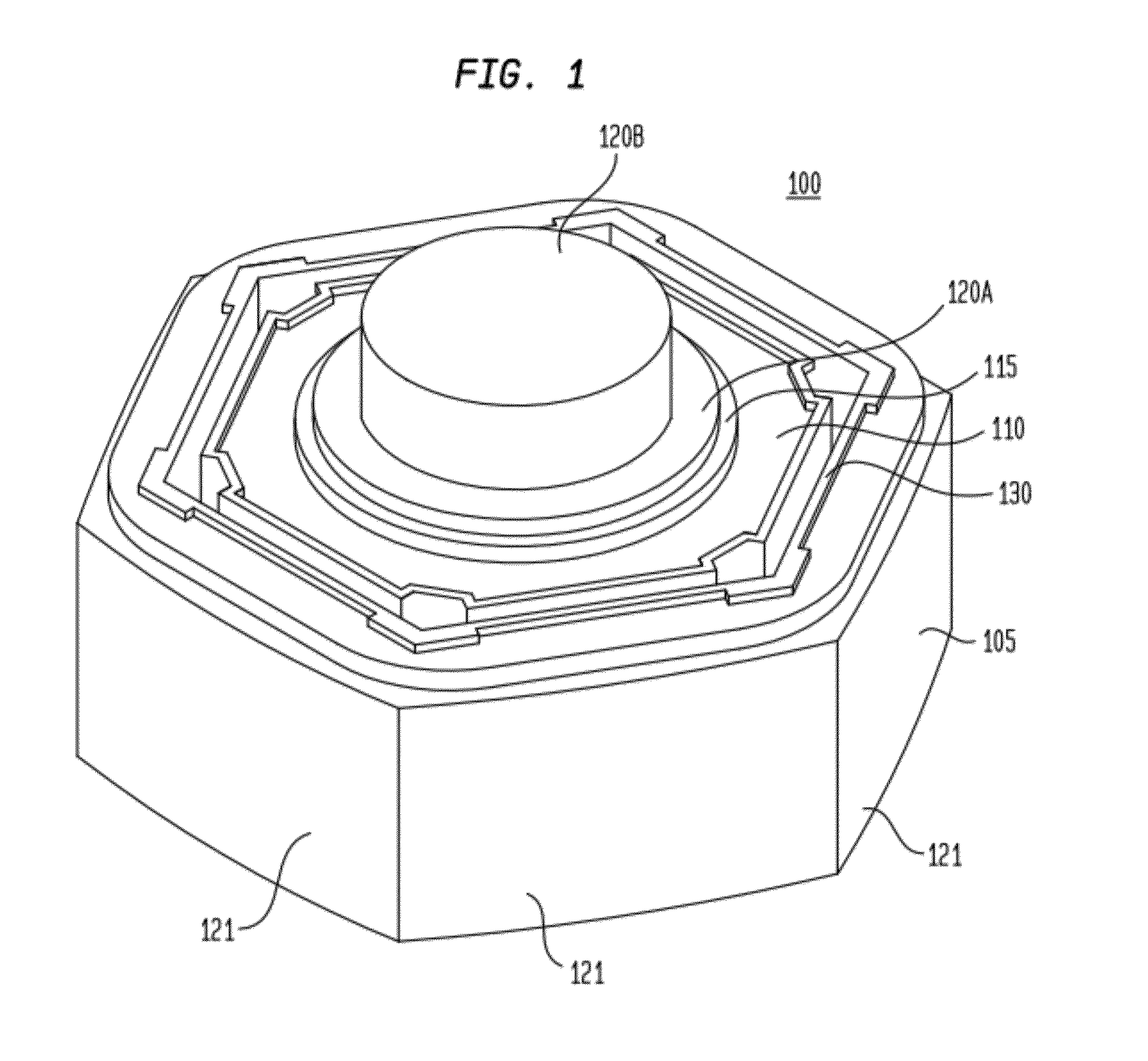

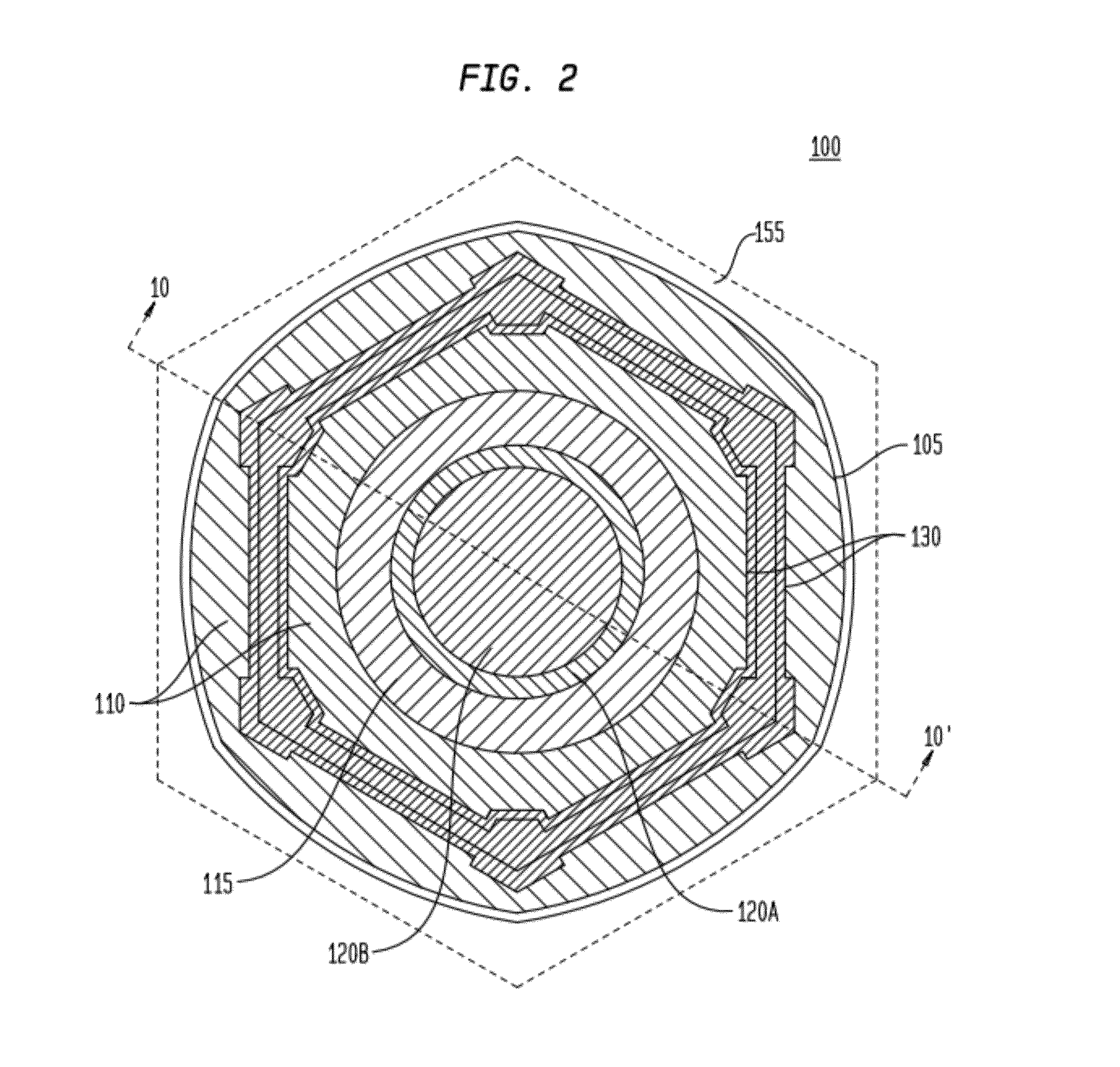

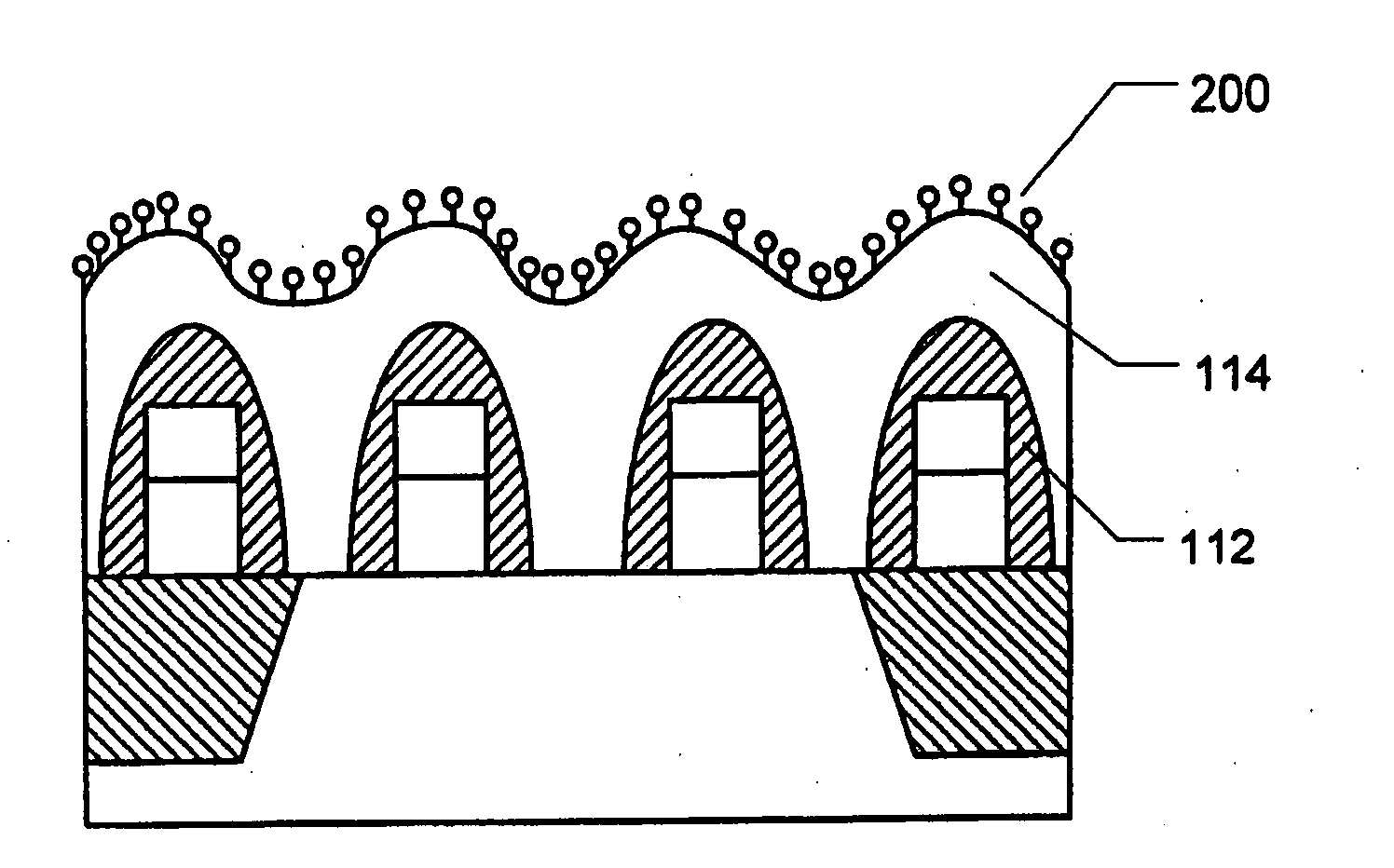

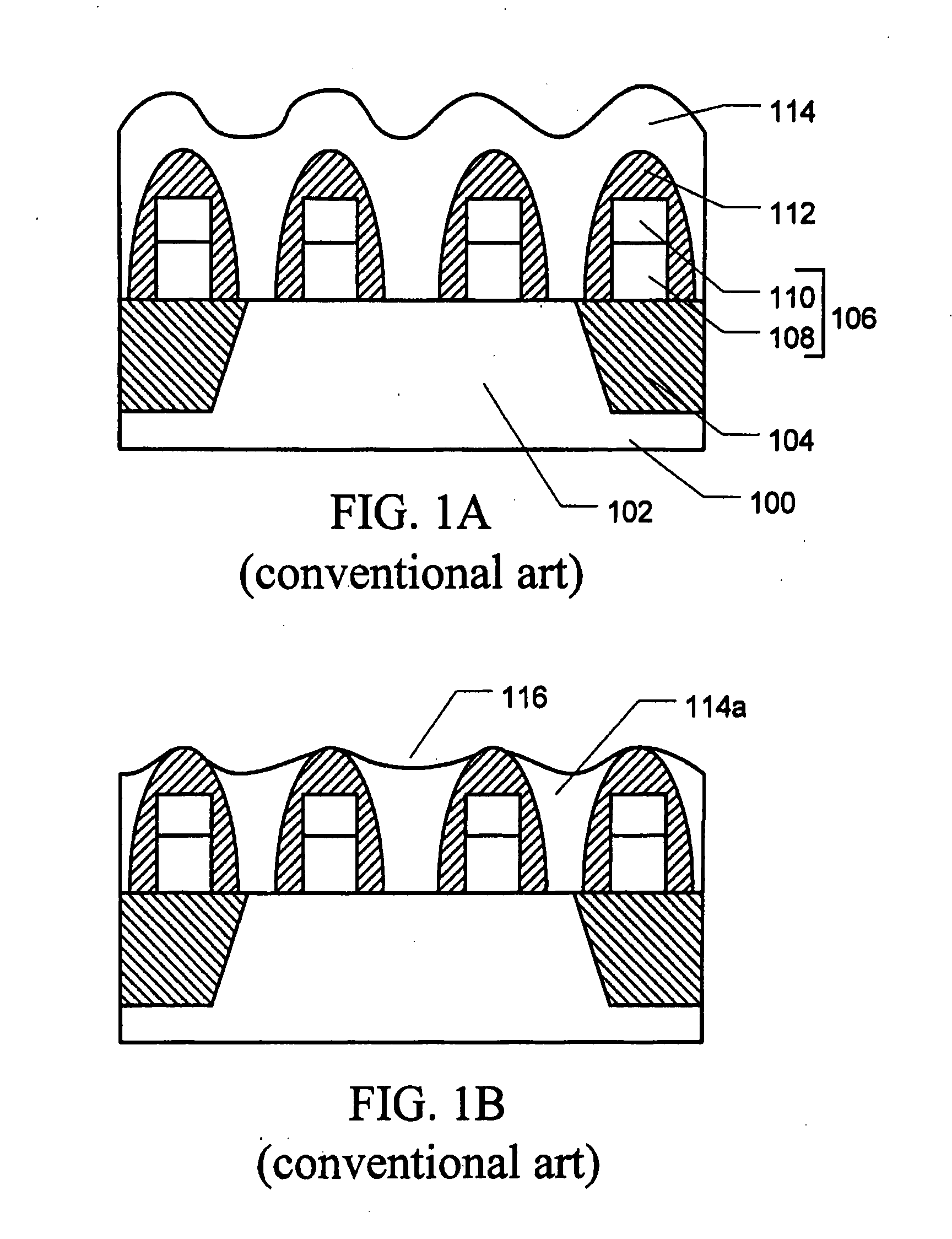

Apparatus with light emitting or absorbing diodes

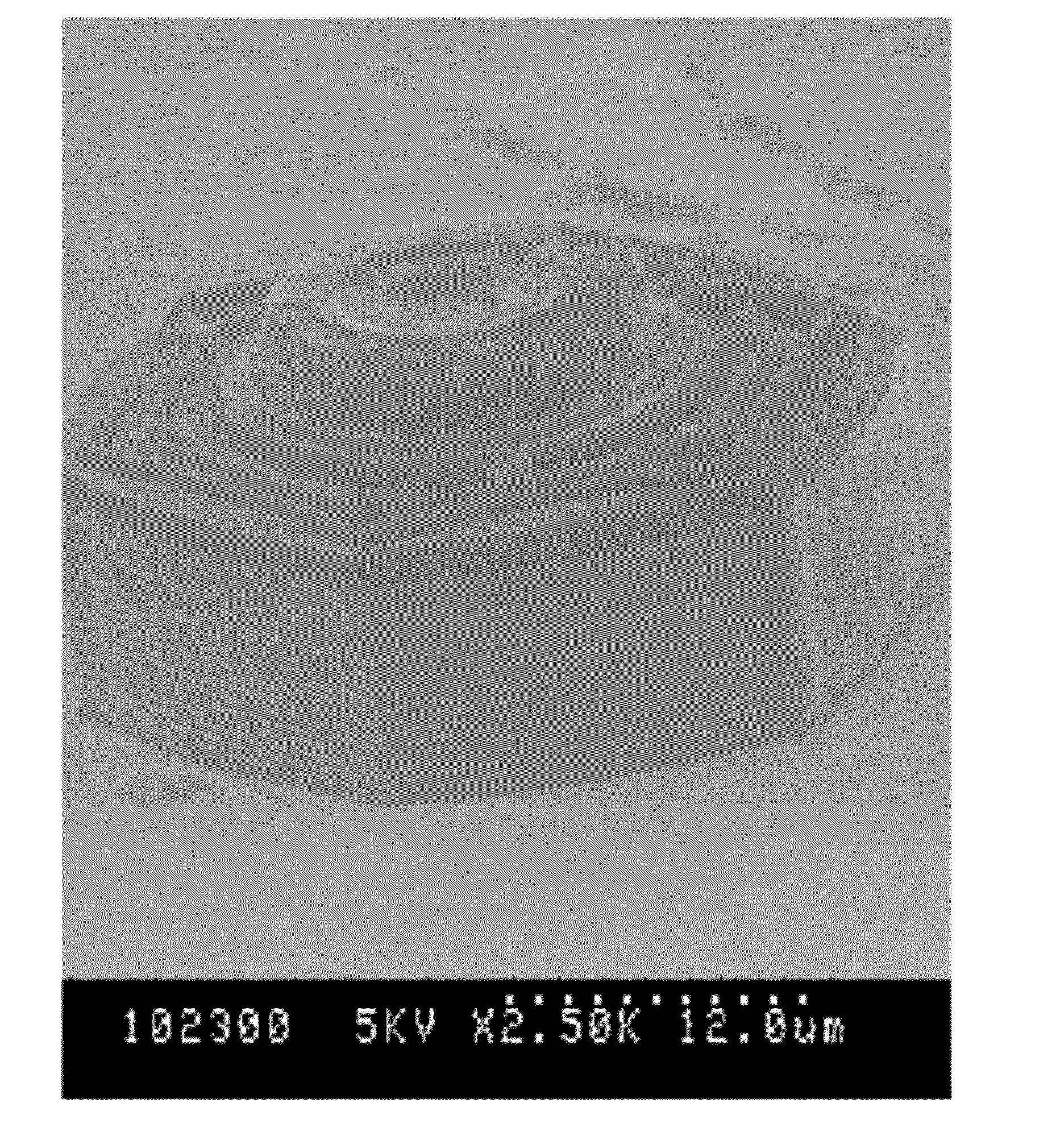

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. An exemplary apparatus comprises: a plurality of diodes; at least a trace amount of a first solvent; and a polymeric or resin film at least partially surrounding each diode of the plurality of diodes. Various exemplary diodes have a lateral dimension between about 10 to 50 microns and about 5 to 25 microns in height. Other embodiments may also include a plurality of substantially chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

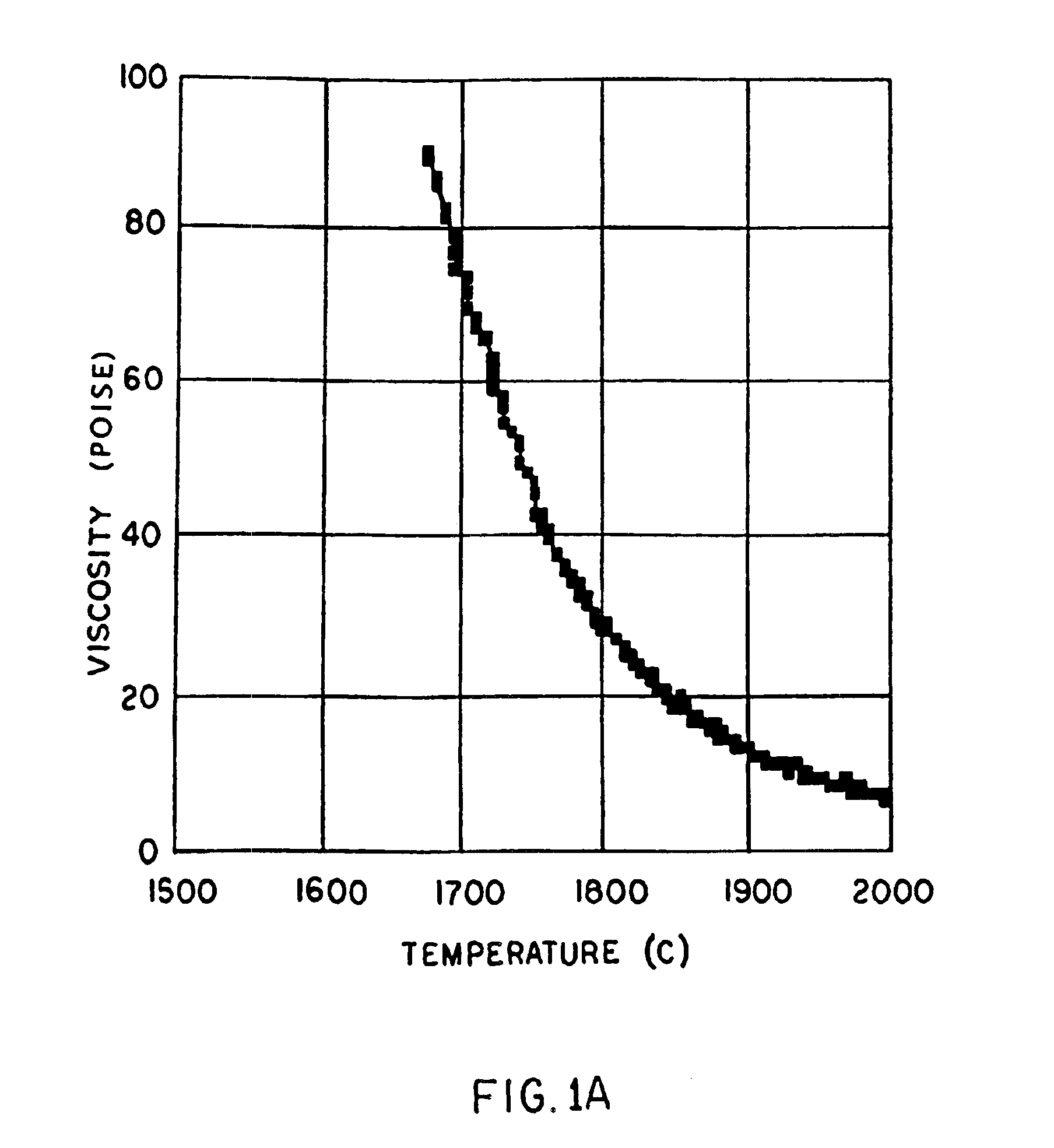

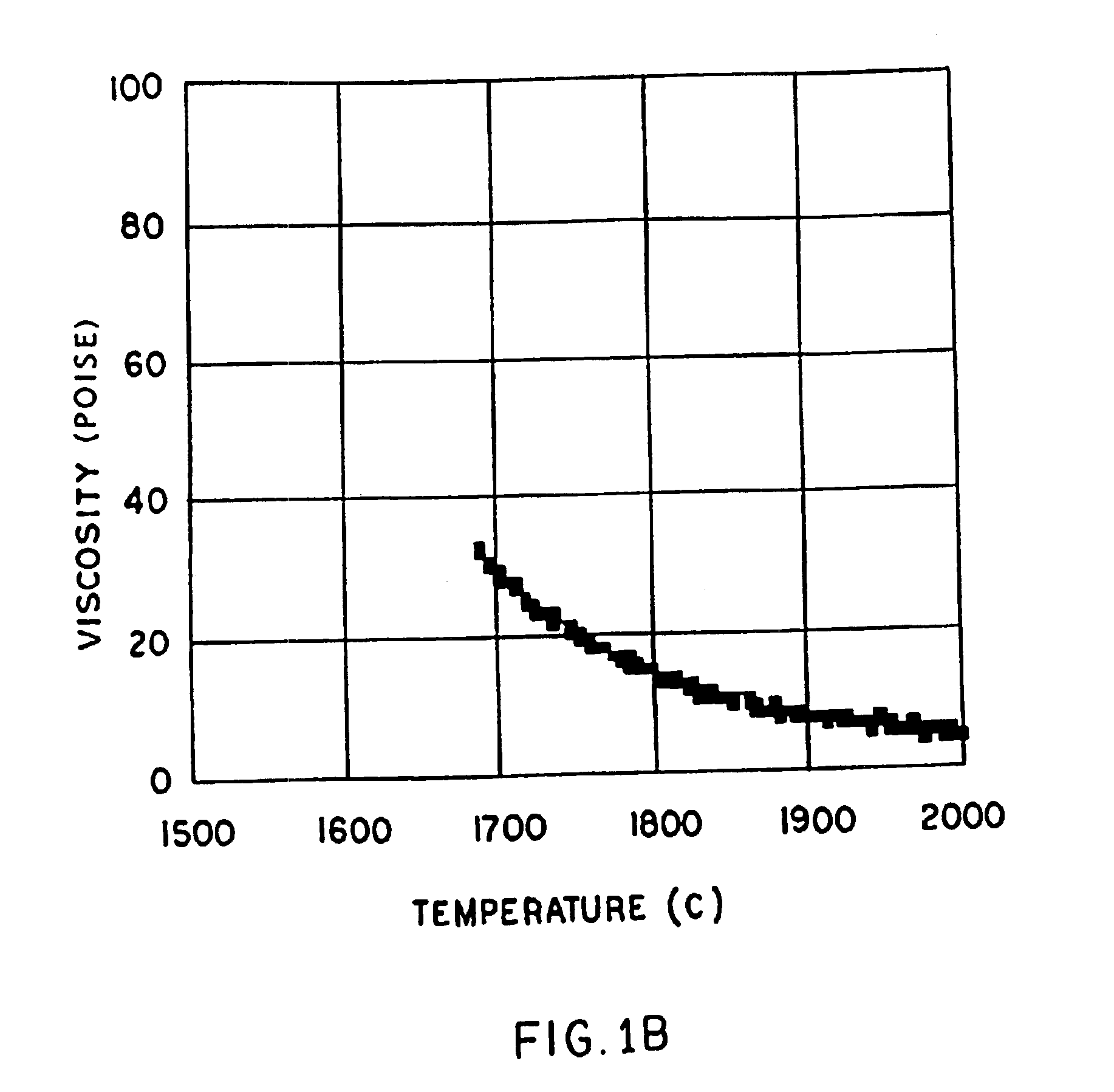

High temperature a resistant vitreous inorganic fiber

InactiveUS6953757B2Easy to manufactureLow shrinkageInorganic fibres/flakesInorganic material artificial filamentsFiberPhysiological fluid

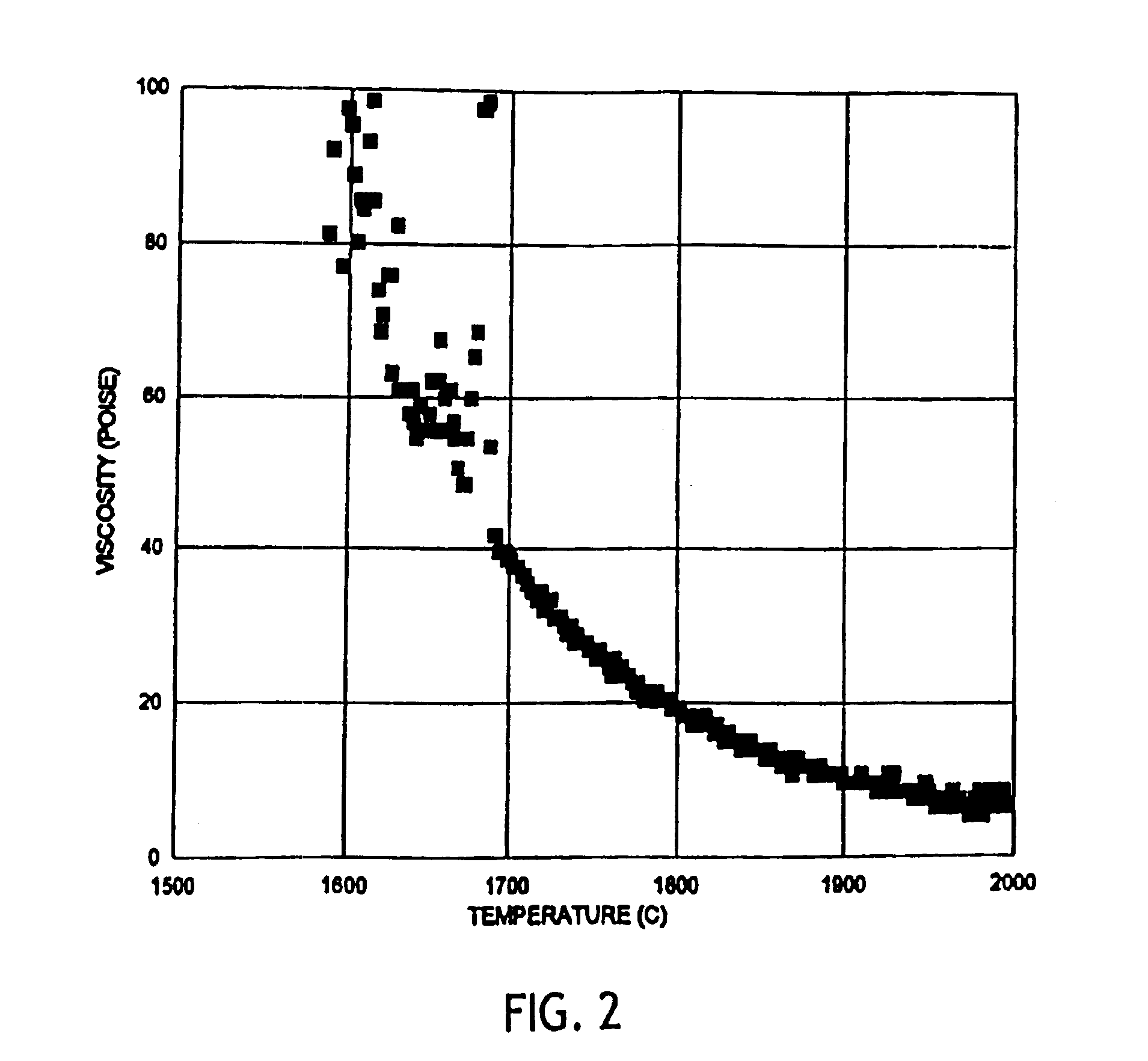

A low shrinkage, high temperature resistant vitreous inorganic fiber having a use temperature up to at least 1330° C., which maintains mechanical integrity after exposure to the use temperature and which is non-durable in physiological fluids, is prepared by the method of forming a melt with ingredients including greater than 71.25 weight percent silica, 0 to about 20 weight percent magnesia, and about 5 to about 28.55 weight percent of calcia, 0 to about 5 weight percent zirconia, and optionally a viscosity modifier in an amount effective to render the product fiberizable; and producing fibers from the melt.

Owner:UNIFRAX I LLC

Delivery of tetrahydrocannabinol

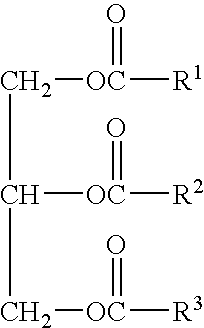

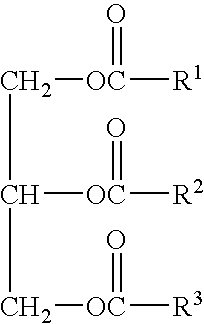

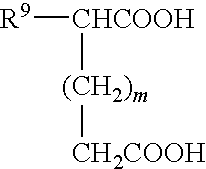

InactiveUS20070104741A1Avoiding hepatic first-pass metabolismGood choiceBiocideNervous disorderChylomicronTG - Triglyceride

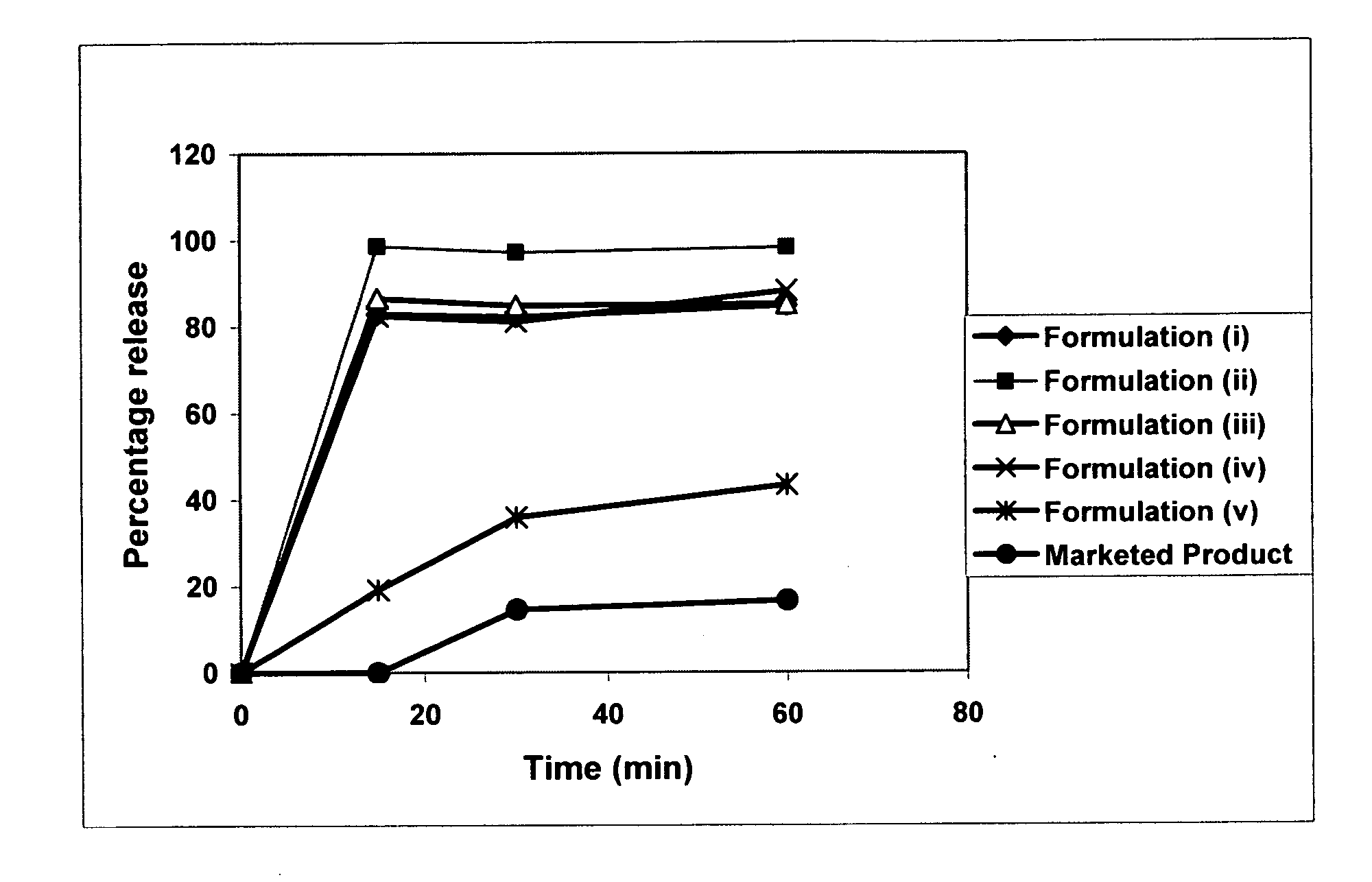

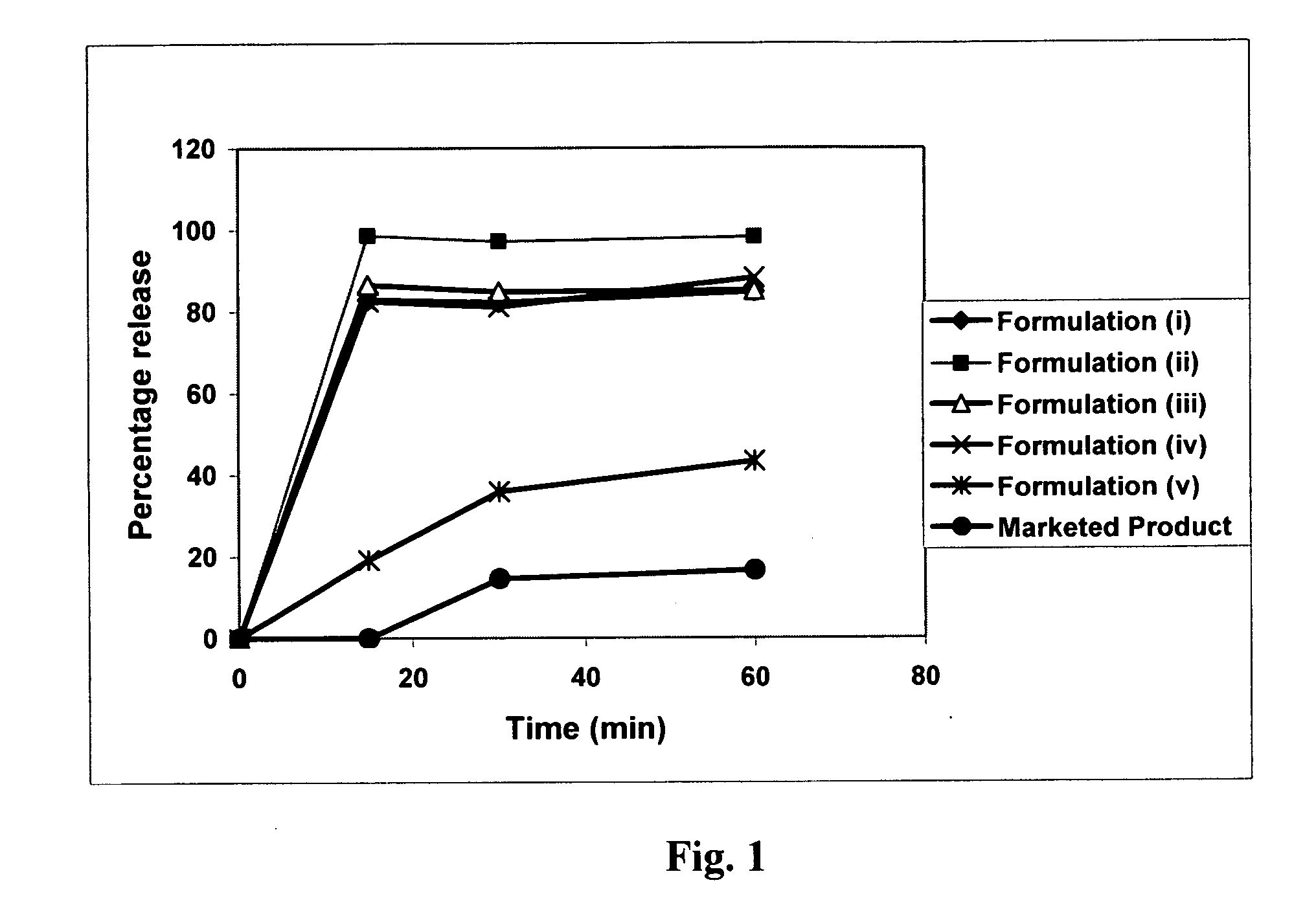

A self-emulsifying drug delivery system to improve dissolution, stability, and bioavailability of drug compounds of dronabinol or other cannabinoids. The drug compound(s) are dissolved in an oily medium (e.g. triglycerides and / or mixed glycerides and / or free fatty acids containing medium and / or long chain saturated, mono-unsaturated, and / or poly-unsaturated free fatty acids) together with at least one surfactant. The surfactant promotes self-emulsification, thereby promoting targeted chylomicron delivery and optimal bioavailability to a mammalian intestinal lumen. A dosage form can optionally include co-solvents, anti-oxidants, viscosity modifying agents, cytochrome P450 metabolic inhibitors, P-GP efflux inhibitors, and amphiphilic / non-amphiphilic solutes to induce semi-solid formation for targeted release rates.

Owner:MURTY PHARMA

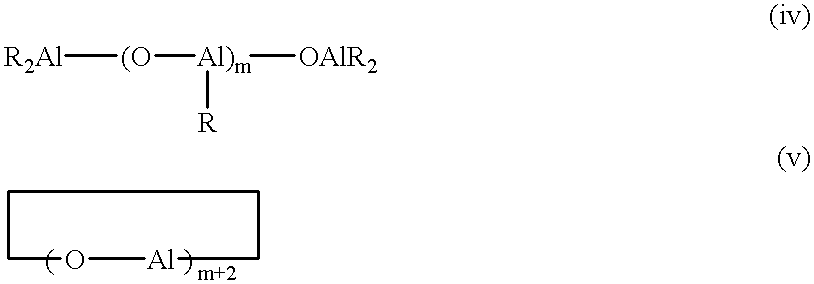

Process for producing liquid polyalphaolefin polymer, metallocene catalyst therefor, the resulting polymer and lubricant containing same

InactiveUS6858767B1Eliminate needHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsPolymer scienceHydrogen

A liquid polyalphaolefin homo- or copolymer, preferably 1-decene, which is substantially amorphous is obtained by a polymerization process employing hydrogen and a particular type of metallocene catalyst. Additionally, liquid polyalphaolefin homo- or copolymer containing from 2 to about 12 carbon atoms possess a unique combination of properties, i.e., low molecular weight (Mw), low polydispersity index (Mw / Mn controllable kinematic viscosity (Kv100), low Iodine Number (I2) and low glass transition temperature (Tg) and are substantially amorphous. The liquid polyalphaolefin homo- or copolymers provided herein are useful for manufacturing a variety of products including lubricating oils in which the polyalphaolefin functions as a viscosity modifier.

Owner:DEUT BANK AG NEW YORK BRANCH

Oligomerization of alpha olefins using metallocene-ssa catalyst systems and use of the resultant polyalphaolefins to prepare lubricant blends

ActiveUS20100317904A1Improve productivityHydrocarbon by hydrogenationAdditivesOligomerViscosity index

This disclosure provides for alpha olefin oligomers and polyalphaolefins (or PAOs) and methods of making the alpha olefin oligomers and PAOs. This disclosure encompasses metallocene-based alpha olefin oligomerization catalyst systems, including those that include at least one metallocene and an activator comprising a solid oxide chemically-treated with an electron withdrawing anion. The alpha olefin oligomers and PAOs prepared with these catalyst systems can have a high viscosity index combined with a low pour point, making them particularly useful in lubricant compositions and as viscosity modifiers.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Rheology modification of settled solids in mineral processing

InactiveUS6365116B1Low viscosityIncrease speedRotary stirring mixersTransportation and packagingEngineeringSlurry

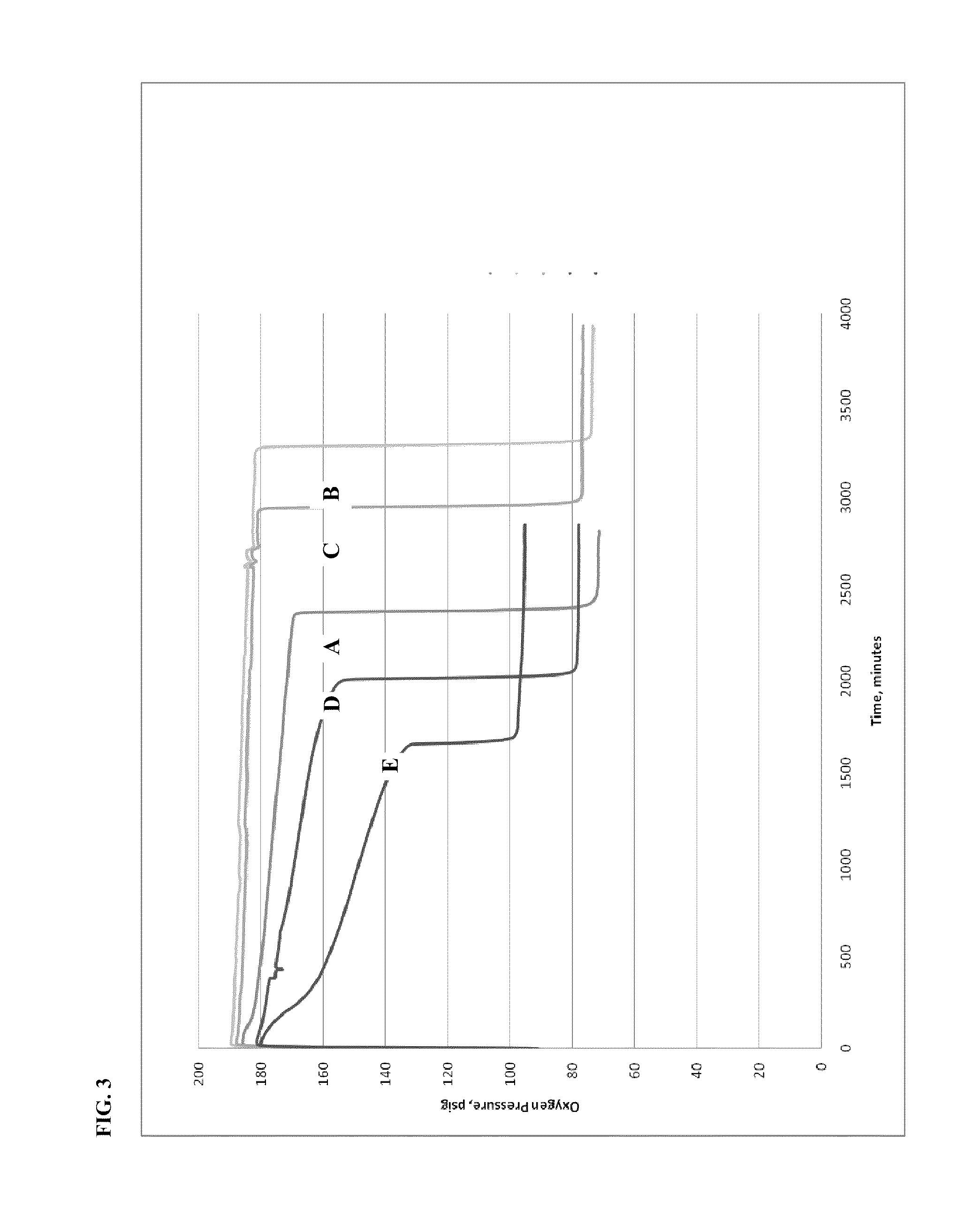

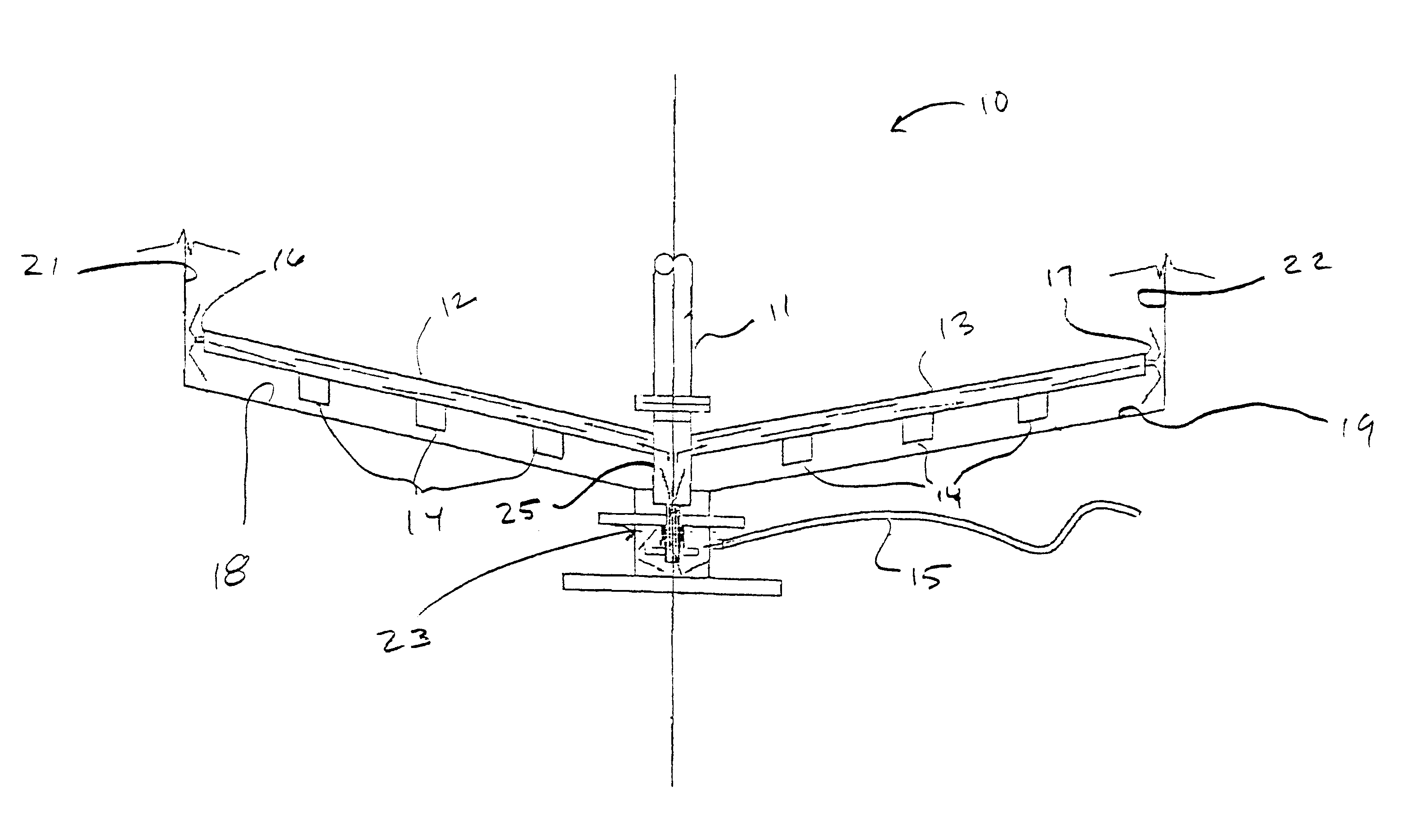

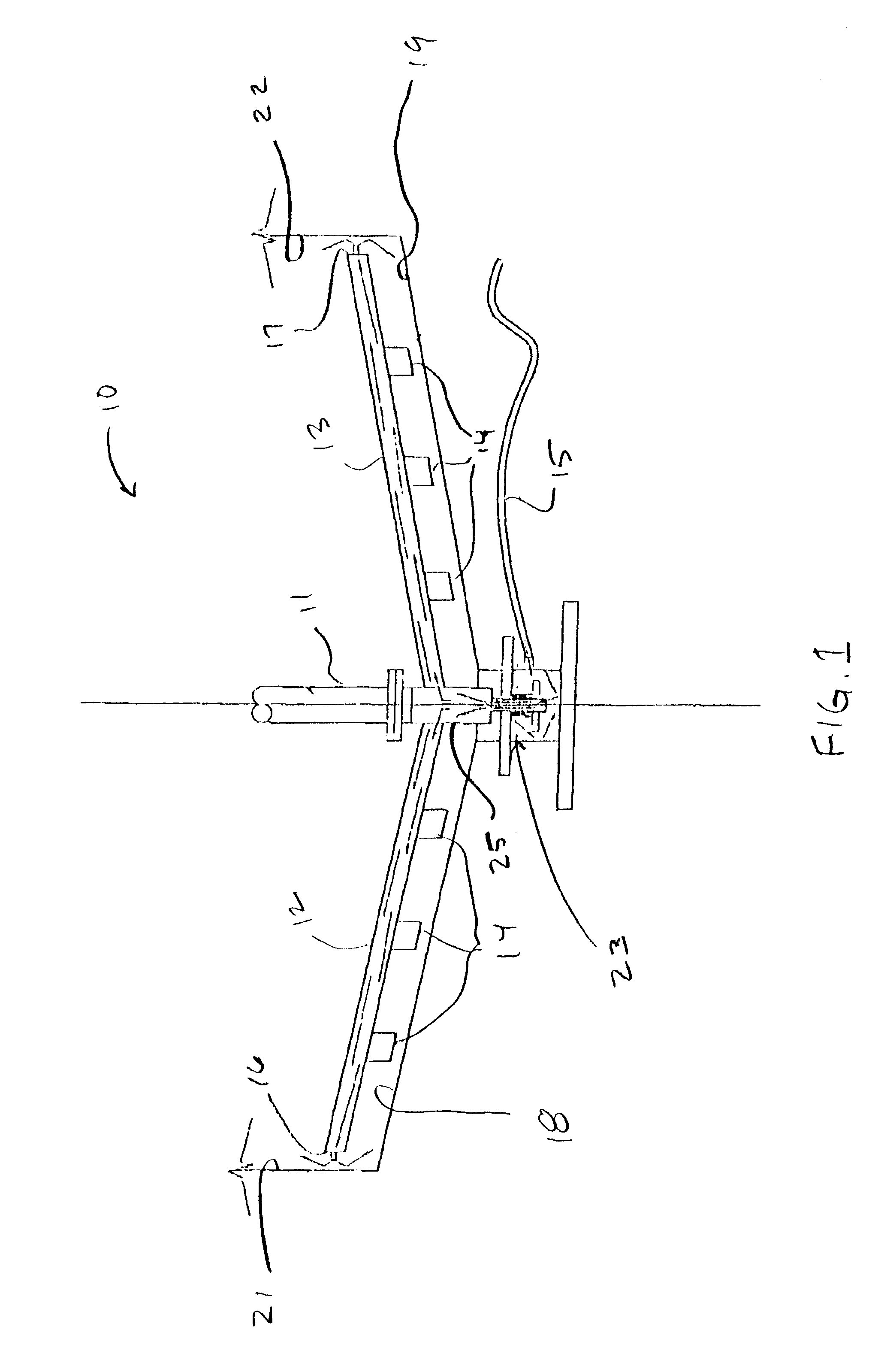

The present invention comprises a method for reducing the viscosity of the settled mud or underflow of a raked thickener thereby reducing the torque necessary to move the rake blade through the settled mud. The method includes the step of delivering a viscosity modifier to the settled mud and in front of the rake blade by pumping the viscosity modifier down the rake arm to an area in front of the rake blade. The method also includes an improved rake mechanism that includes a means for delivering viscosity modifier to the settled mud and in front of the rake blade. The present invention also includes a method for increasing the rate of consolidation of flocculated solids in a slurry.

Owner:ECOLAB USA INC

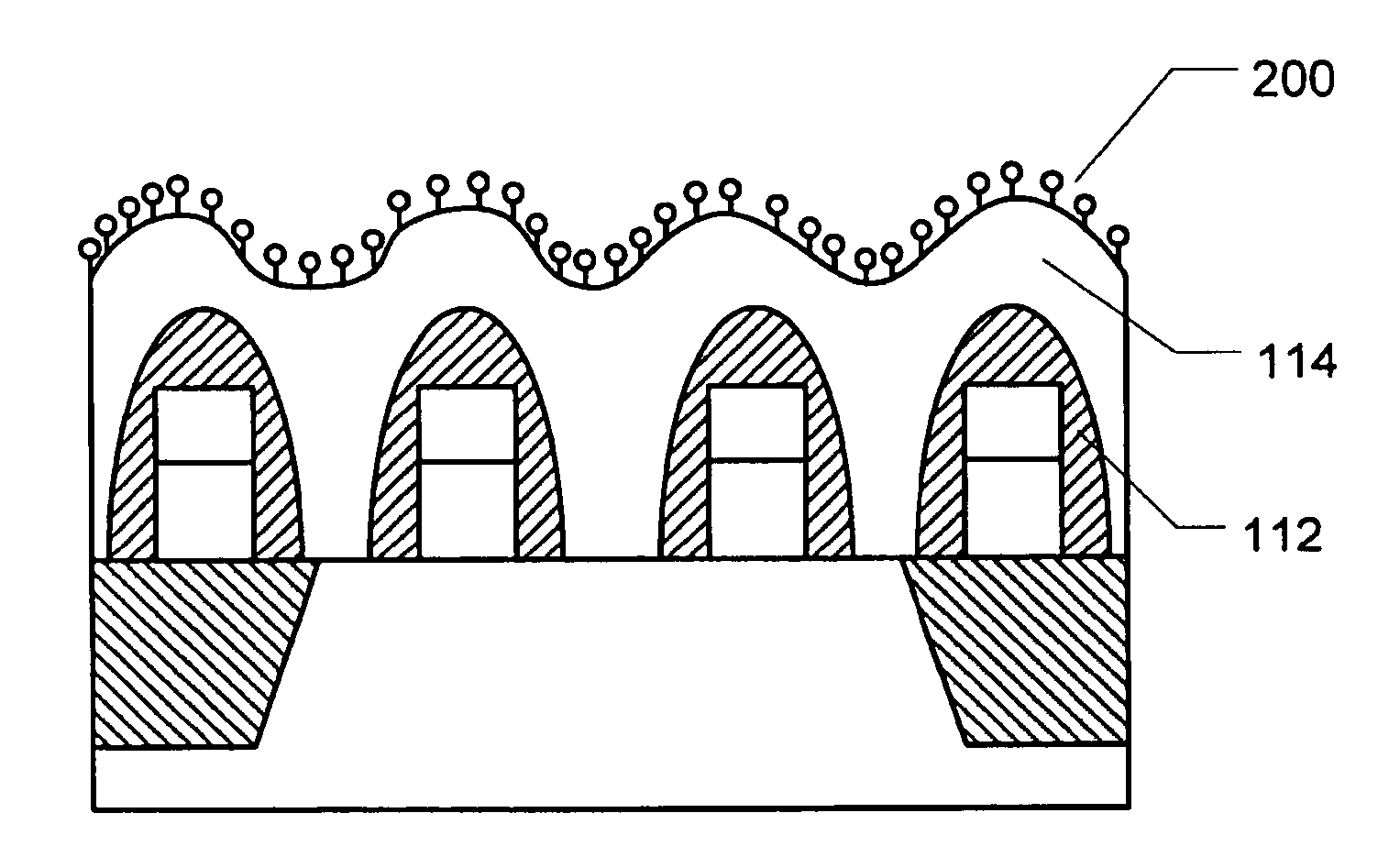

Method of Manufacturing a Printable Composition of a Liquid or Gel Suspension of Diodes

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. An exemplary method of making a liquid or gel suspension of diodes comprises: adding a viscosity modifier to a plurality of diodes in a first solvent; and mixing the plurality of diodes, the first solvent and the viscosity modifier to form the liquid or gel suspension of the plurality of diodes. Various exemplary diodes have a lateral dimension between about 10 to 50 microns and about 5 to 25 microns in height. Other embodiments may also include a plurality of substantially chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

Wood adhesive and method of preparing thereof

InactiveUS20100258033A1Drying rate of adhesiveLow pour pointProtein waste adhesivesStarch adhesivesHigh densityAdhesive

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fibreboard, high density fibreboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

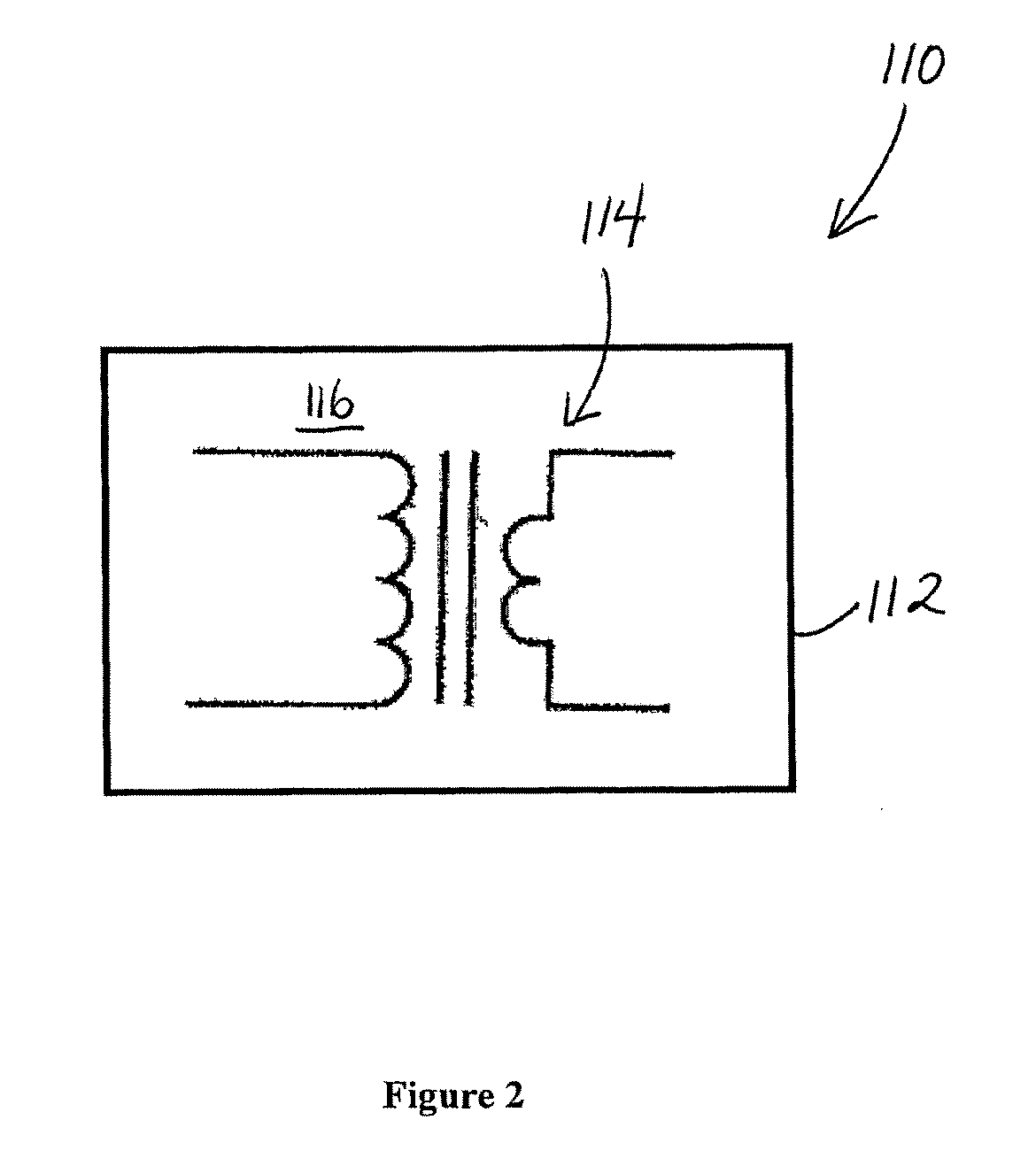

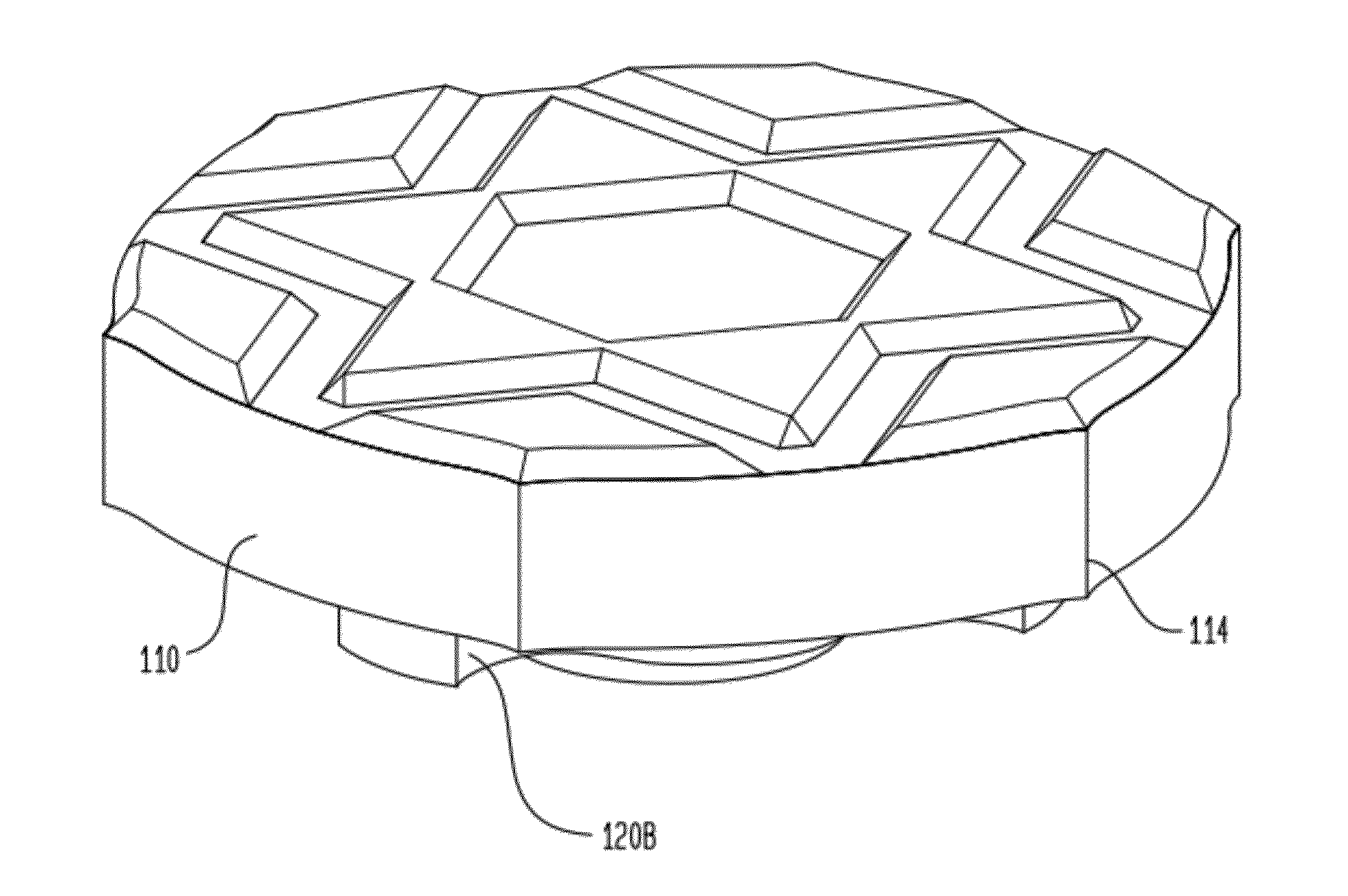

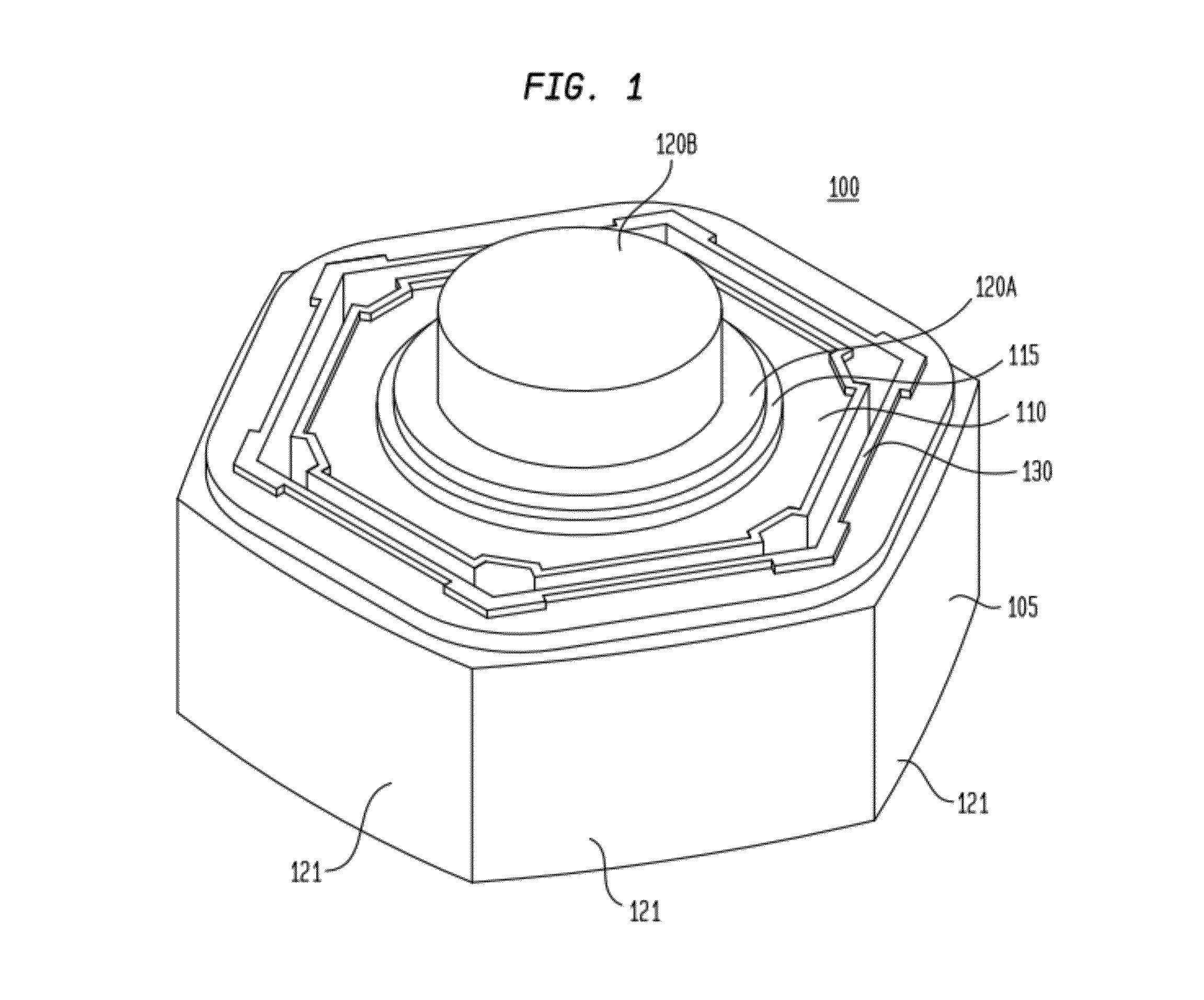

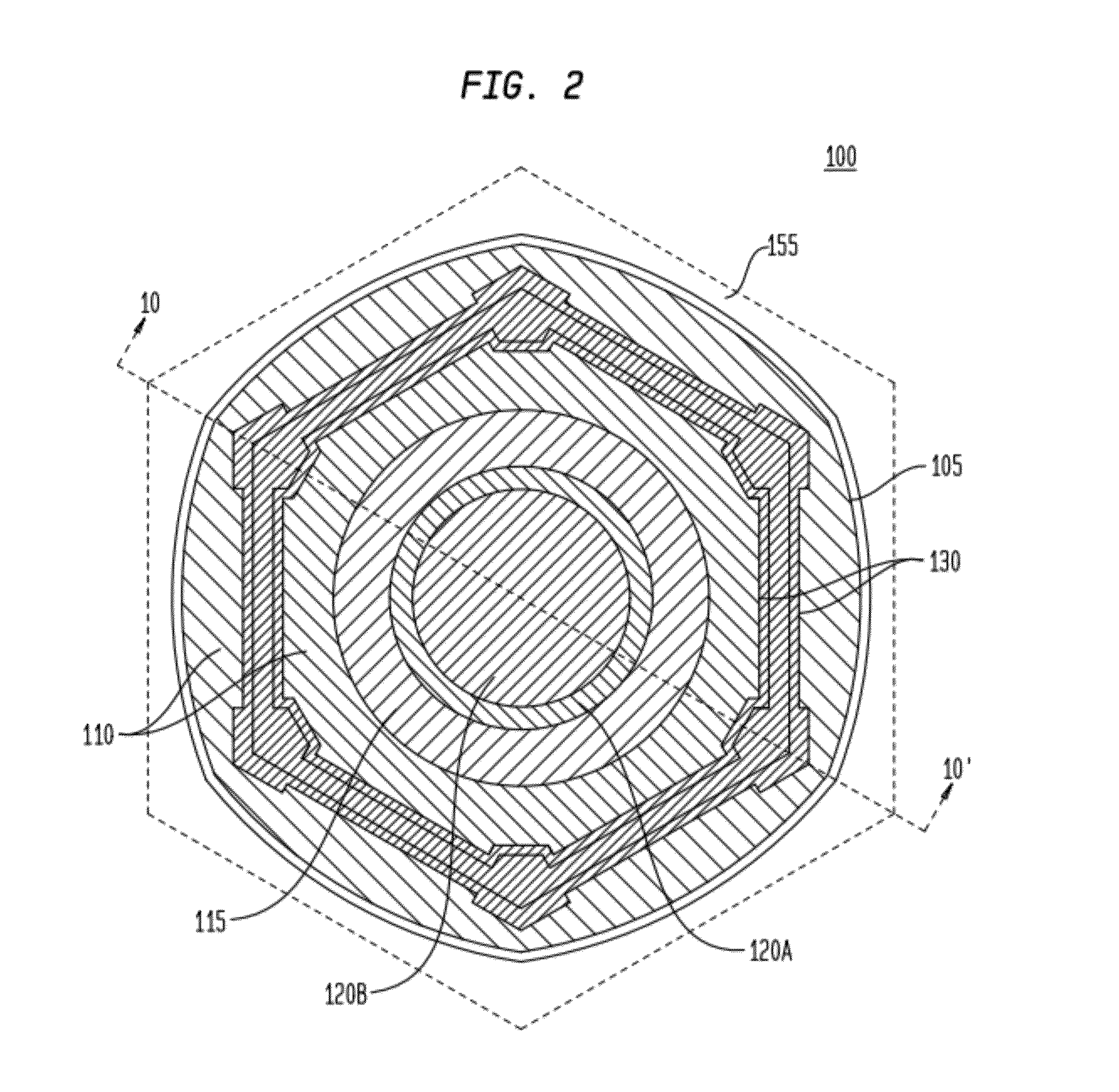

Diode for a printable composition

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. An exemplary diode comprises: a light emitting or absorbing region having a diameter between about 20 and 30 microns and a height between 2.5 to 7 microns; a plurality of first terminals spaced apart and coupled to the light emitting region peripherally on a first side, each first terminal of the plurality of first terminals having a height between about 0.5 to 2 microns; and one second terminal coupled centrally to a mesa region of the light emitting region on the first side, the second terminal having a height between 1 to 8 microns.

Owner:NTHDEGREE TECH WORLDWIDE

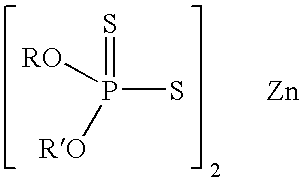

Lubricating Oil Composition

ActiveUS20080020950A1Facilitate depositionEasy to wearOrganic chemistryAdditivesSulfonateAlkaline earth metal

An internal-combustion engine lubricating oil composition has a P content of not greater than 0.09 mass %; a S content of not greater than 0.3 mass %; and a sulphated ash content of not greater than 1 mass %. It contains the following additives: as sole ashless, nitrogen-containing dispersant, and providing from 0.03 to 0.07 mass % of nitrogen in the lubricating oil composition, at least one ashless, nitrogen-containing derivative of a polyalkenyl-substituted mono- or dicarboxylic acid, anhydride or ester, the polyalkenyl-substituted mono- or dicarboxylic acid, anhydride or ester being made from a polyalkene exclusively by the thermal “ene” reaction; as sole overbased metal detergent, at least one overbased alkaline earth metal sulfonate; and at least one viscosity modifier.

Owner:INFINEUM INT LTD

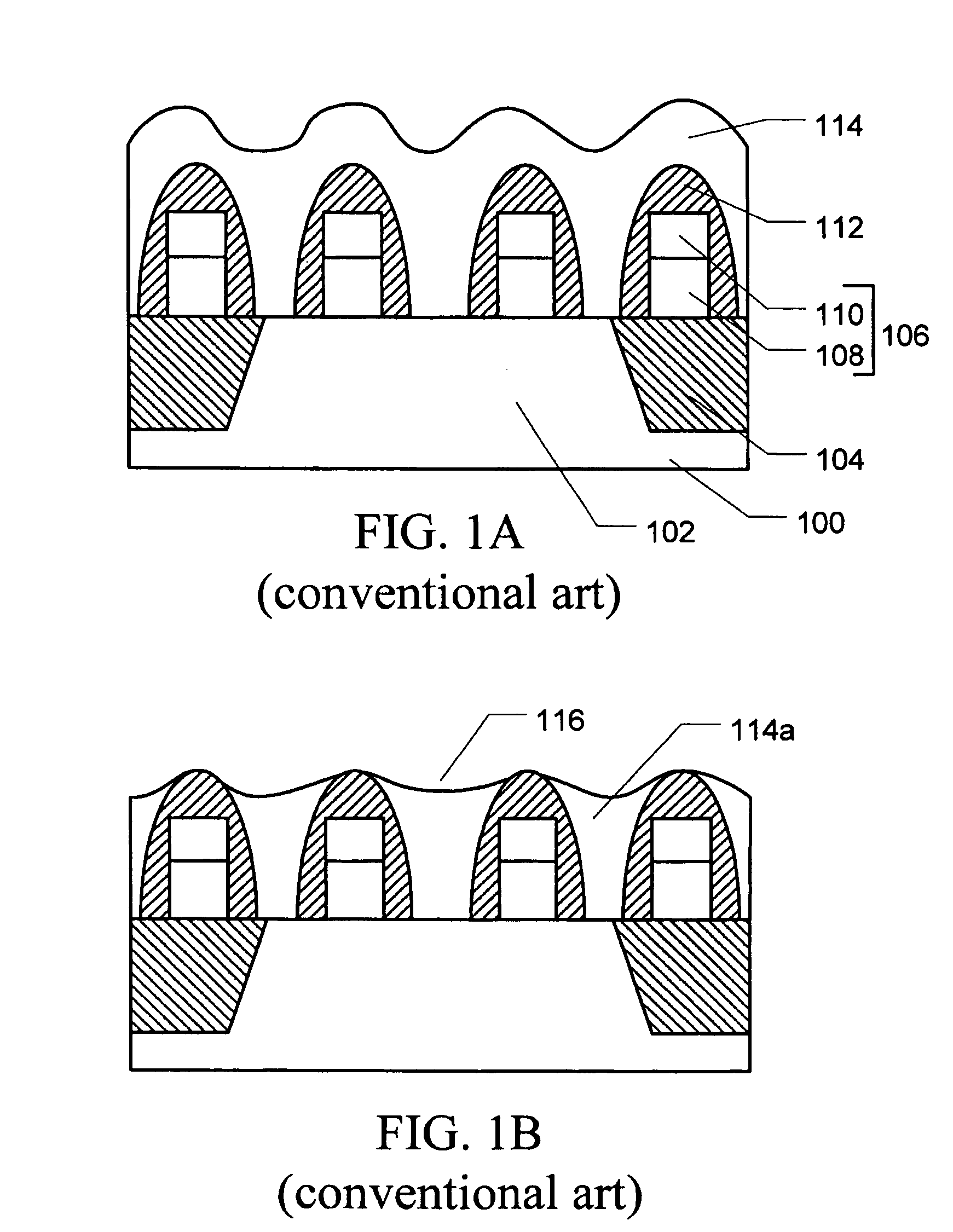

Slurry compositions and CMP methods using the same

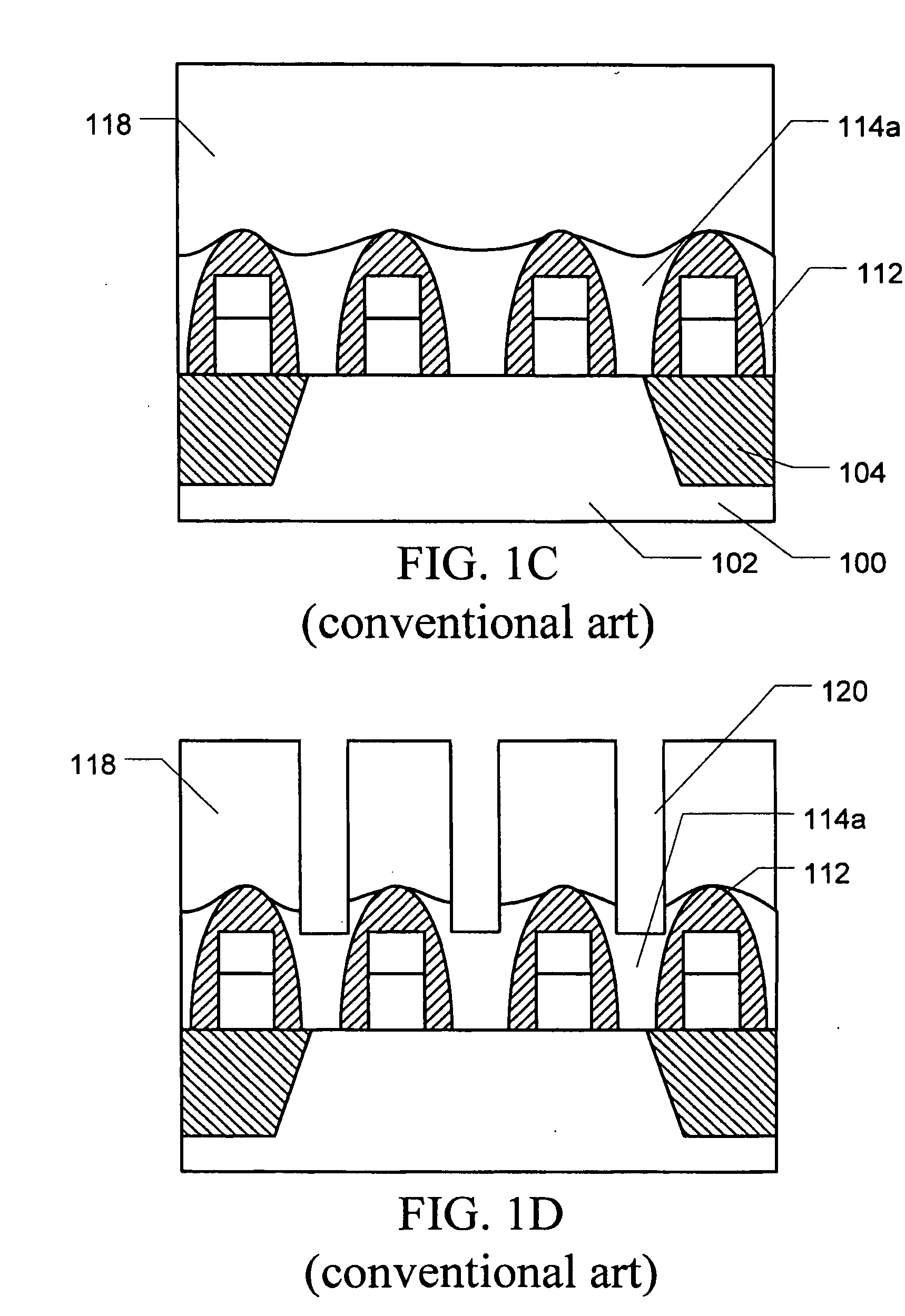

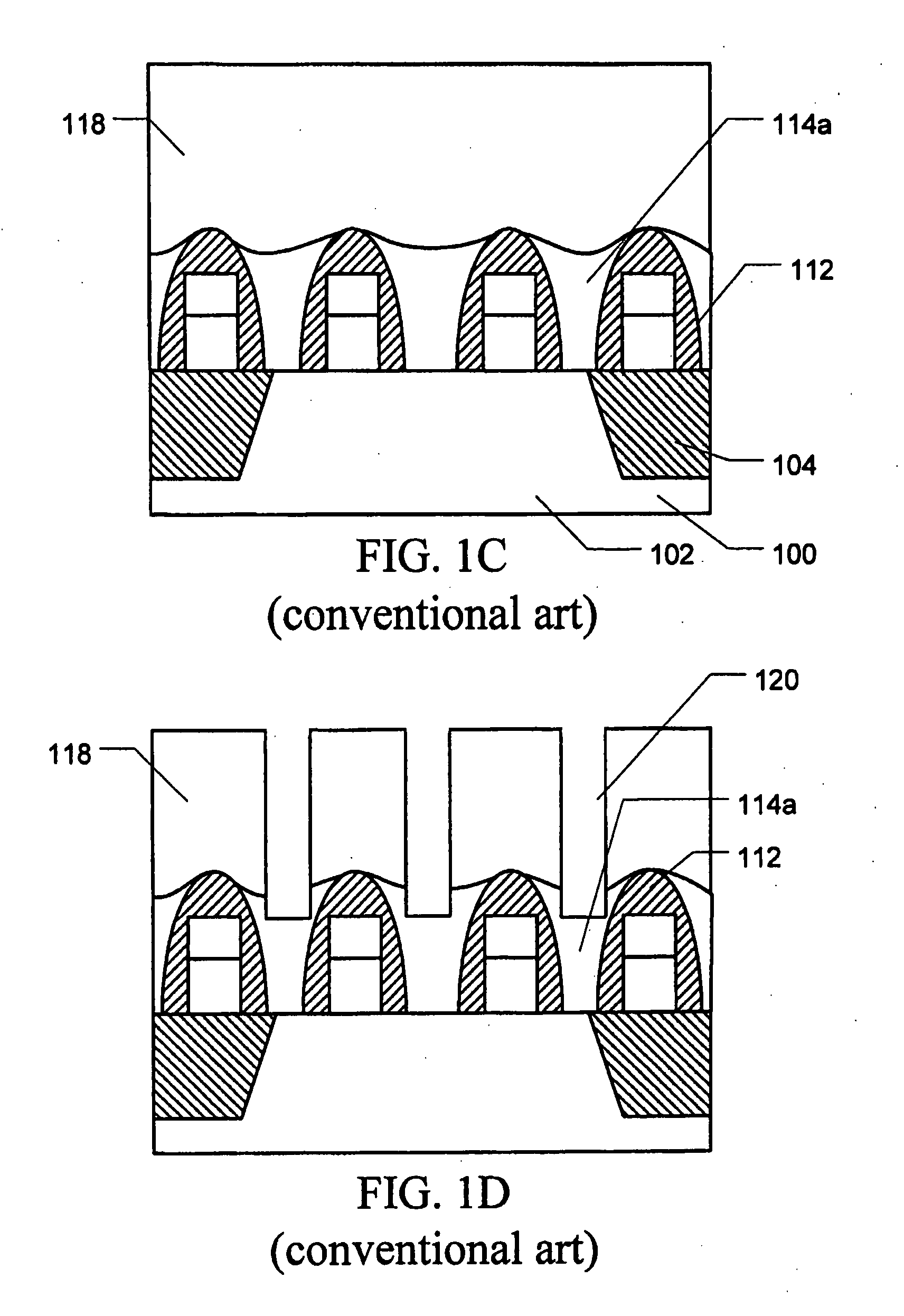

InactiveUS20050130428A1Reduce and eliminate excessive removalOther chemical processesSemiconductor/solid-state device manufacturingArylSlurry

The exemplary embodiments of the present invention providing new slurry compositions suitable for use in processes involving the chemical mechanical polishing (CMP) of a polysilicon layer. The slurry compositions include one or more non-ionic polymeric surfactants that will selectively form a passivation layer on an exposed polysilicon surface in order to suppress the polysilicon removal rate relative to silicon oxide and silicon nitride and improve the planarity of the polished substrate. Exemplary surfactants include alkyl and aryl alcohols of ethylene oxide (EO) and propylene oxide (PO) block copolymers and may be present in the slurry compositions in an amount of up to about 5 wt %, although much smaller concentrations may be effective. Other slurry additives may include viscosity modifiers, pH modifiers, dispersion agents, chelating agents, and amine or imine surfactants suitable for modifying the relative removal rates of silicon nitride and silicon oxide.

Owner:SAMSUNG ELECTRONICS CO LTD

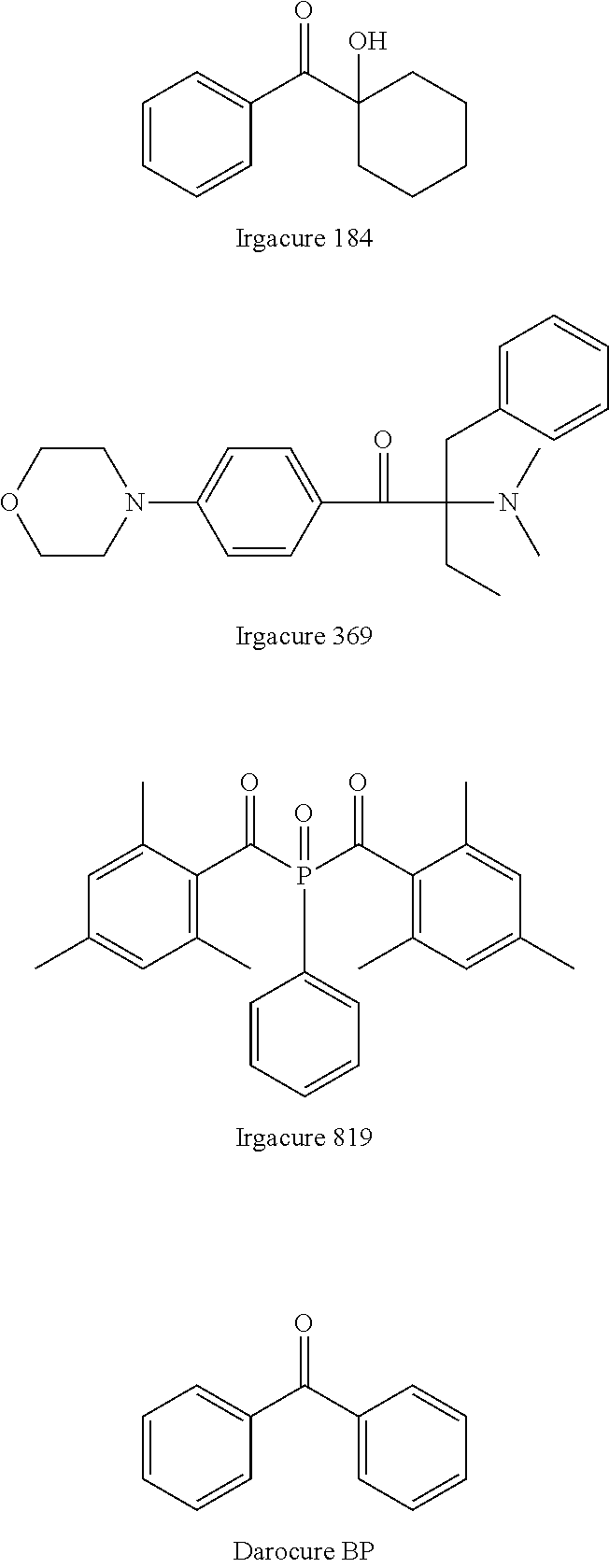

Radiation-curable flame retardant optical fiber coatings

A buffer coating for optical fibers is disclosed which includes a halogenated epoxy resin for flame-retardancy, and elastomer modified epoxy resin for tensile strength and flexibility, a low viscosity bisphenol resin for structural integrity, a viscosity modifier for improved process or extrusion properties, a polyol to increase the cure rate and cross-linking during curing, a slip agent or surfactant to reduce the adhesion of the buffer layer to the cladding and to further improve the flow characteristics during extrusion, and a photo-initiator. The buffer layer is flame-retardant and has a fast UV cure rate.

Owner:ADDISON CLEAR WAVE

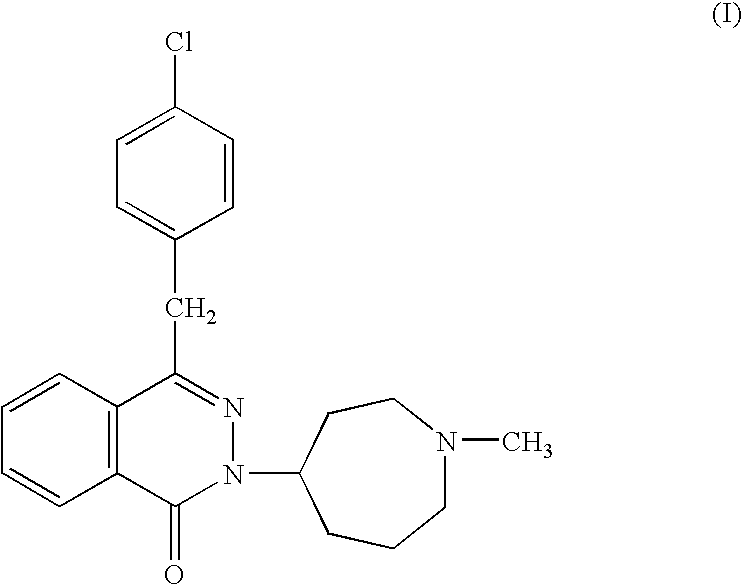

Compositions comprising azelastine and methods of use thereof

The present invention provides pharmaceutical compositions comprising azelastine, or a pharmaceutically acceptable salt or ester thereof including azelastine hydrochloride, and optionally one or more additional active agents. Preferred such compositions further comprise one or more pharmaceutically acceptable carriers or excipients that reduce the amount of post-nasal drip, and / or that minimize or mask the unpleasant bitter taste associated with post-nasal drip, of the compositions into the oral cavity, upon intranasal or ocular administration of the compositions. Especially effective excipients used in the compositions of the present invention are hypromellose as a viscosity modifier and sucralose as a taste-masking agent. The invention also provides methods of treating or preventing certain disorders, or symptomatic relief therefrom, by administering the compositions of the invention to a patient, e.g., for the symptomatic relief of allergic rhinitis, non-allergic vasomotor rhinitis, allergic conjunctivitis, as well as other disorders. The compositions and methods of the present invention provide significant value in terms of patient acceptability, convenience, and compliance.

Owner:MEDA PHARMA INC

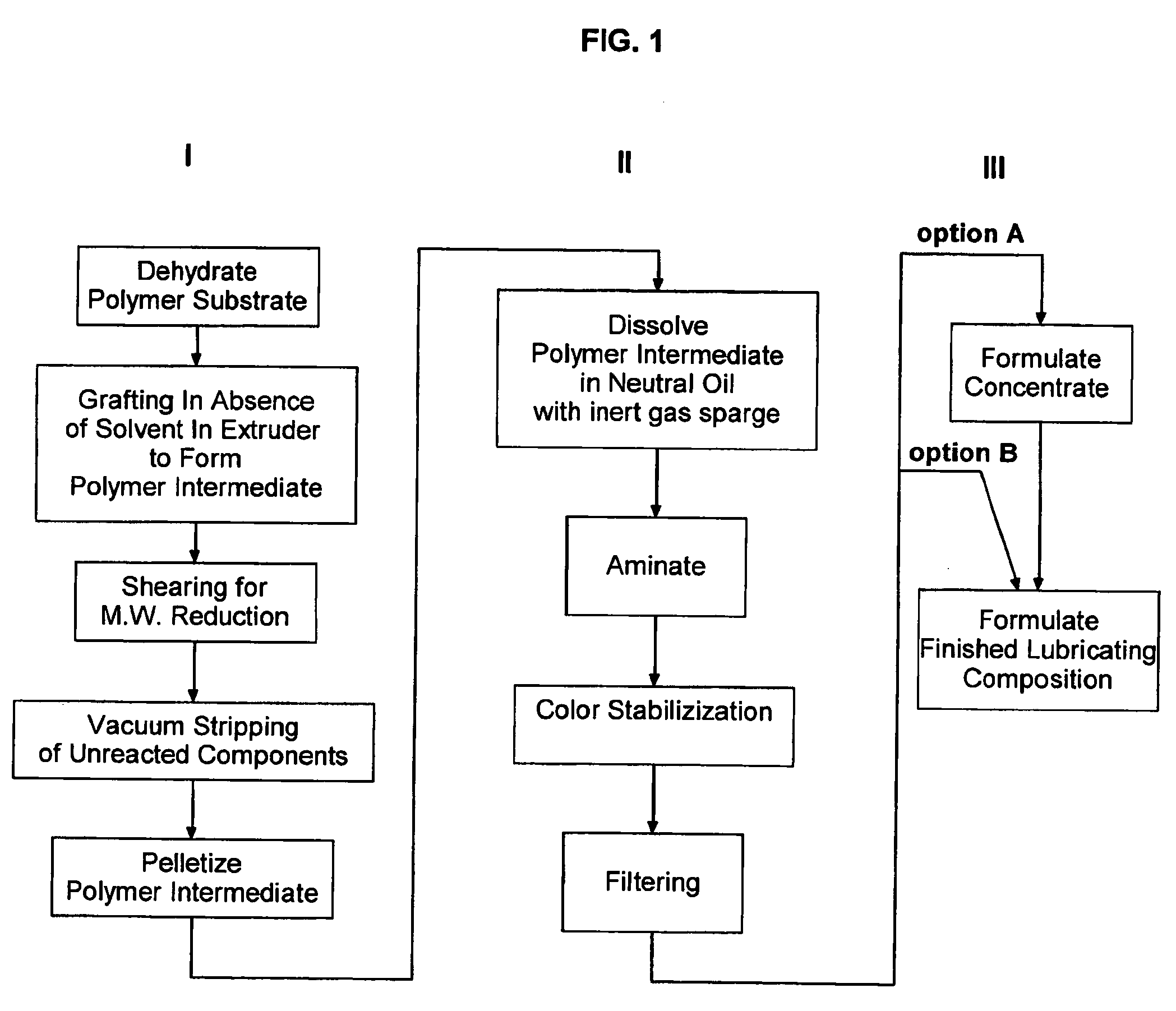

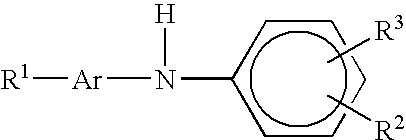

Grafted multi-functional olefin copolymer VI modifiers and uses thereof

ActiveUS7253231B2High activityImprove functionalityLiquid carbonaceous fuelsAdditivesHydrocarbon solventsCanis lupus familiaris

Owner:ARLANXEO NETHERLANDS +1

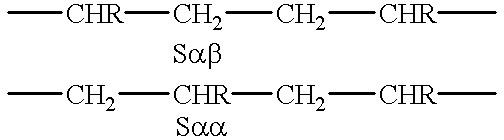

Viscosity modifier for lubricating oil and lubricating oil composition

InactiveUS6589920B2Improve the lubrication effectMaintain good propertiesOrganic chemistrySolid fuelsChemical compositionPolystyrene

The lubricating oil composition of the invention comprises a lubricating oil base (A) and a copolymer (B) of ethylene and an alpha-olefin of 3 to 20 carbon atoms. The copolymer (B) of ethylene and an alpha-olefin of 3 to 20 carbon atoms is contained in the composition in an amount of 1 to 20% by weight and has the following properties:(1) the ethylene content (E) is in the range of 40 to 77% by weight,(2) the weight-average molecular weight (Mw) in terms of polystyrene, as measured by GPC, is in the range of 80,000 to 400,000,(3) Mw / Mn is not more than 2.4,(4) the melting point (Tm), as measured by DSC, is not higher than 60° C.,(5) the ethylene content (E, % by weight) and the melting point (Tm, ° C.), as measured by DSC, satisfy the following relation (I):and(6) the intensity ratio, Salphabeta / Salphaalpha, measured by 13C-NMR spectrum is not more than 0.5.

Owner:MITSUI CHEM INC +1

Diode for a Printable Composition

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. An exemplary diode comprises: a light emitting or absorbing region having a diameter between about 20 and 30 microns and a height between 2.5 to 7 microns; a plurality of first terminals spaced apart and coupled to the light emitting region peripherally on a first side, each first terminal of the plurality of first terminals having a height between about 0.5 to 2 microns; and one second terminal coupled centrally to a mesa region of the light emitting region on the first side, the second terminal having a height between 1 to 8 microns.

Owner:NTHDEGREE TECH WORLDWIDE

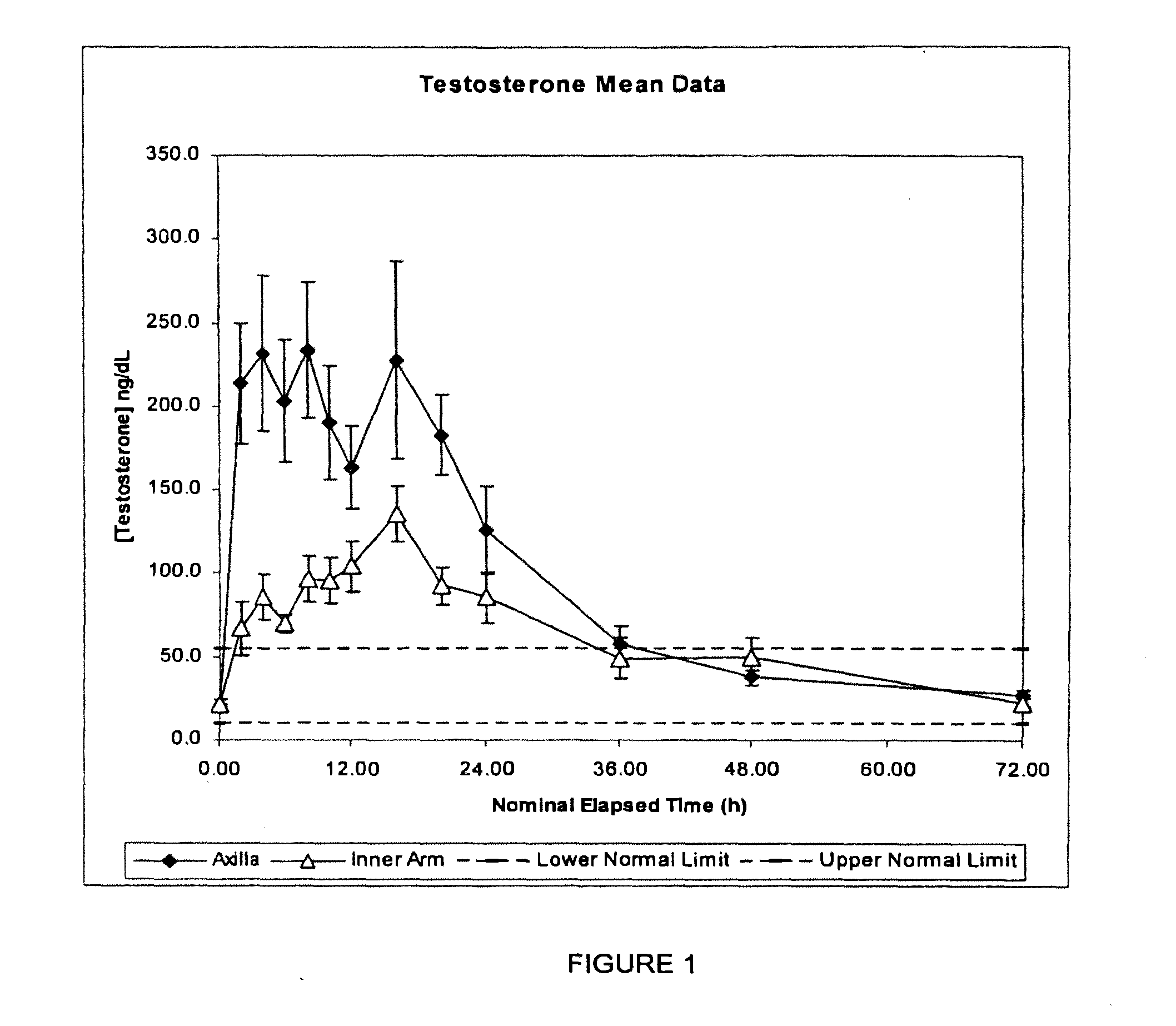

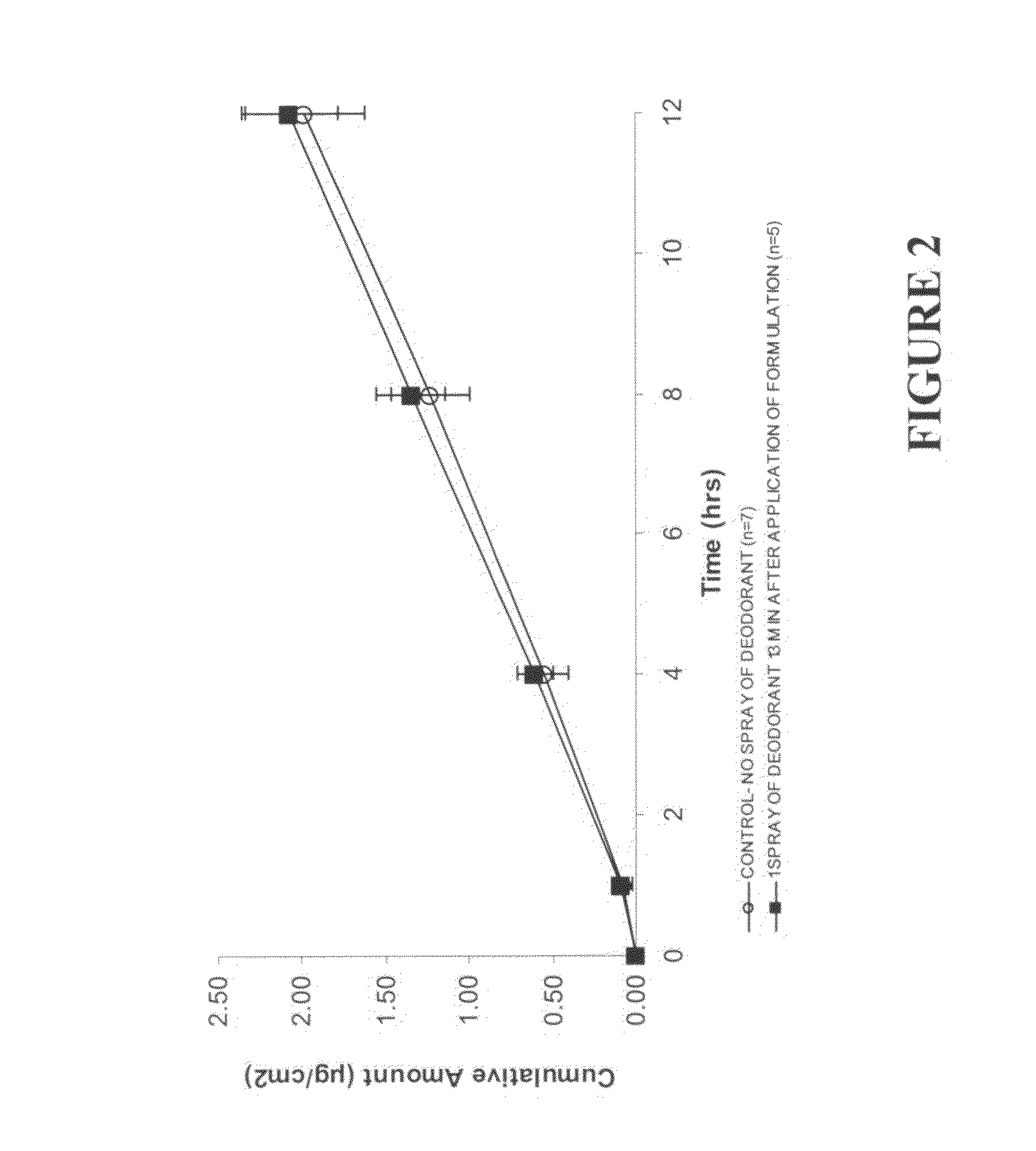

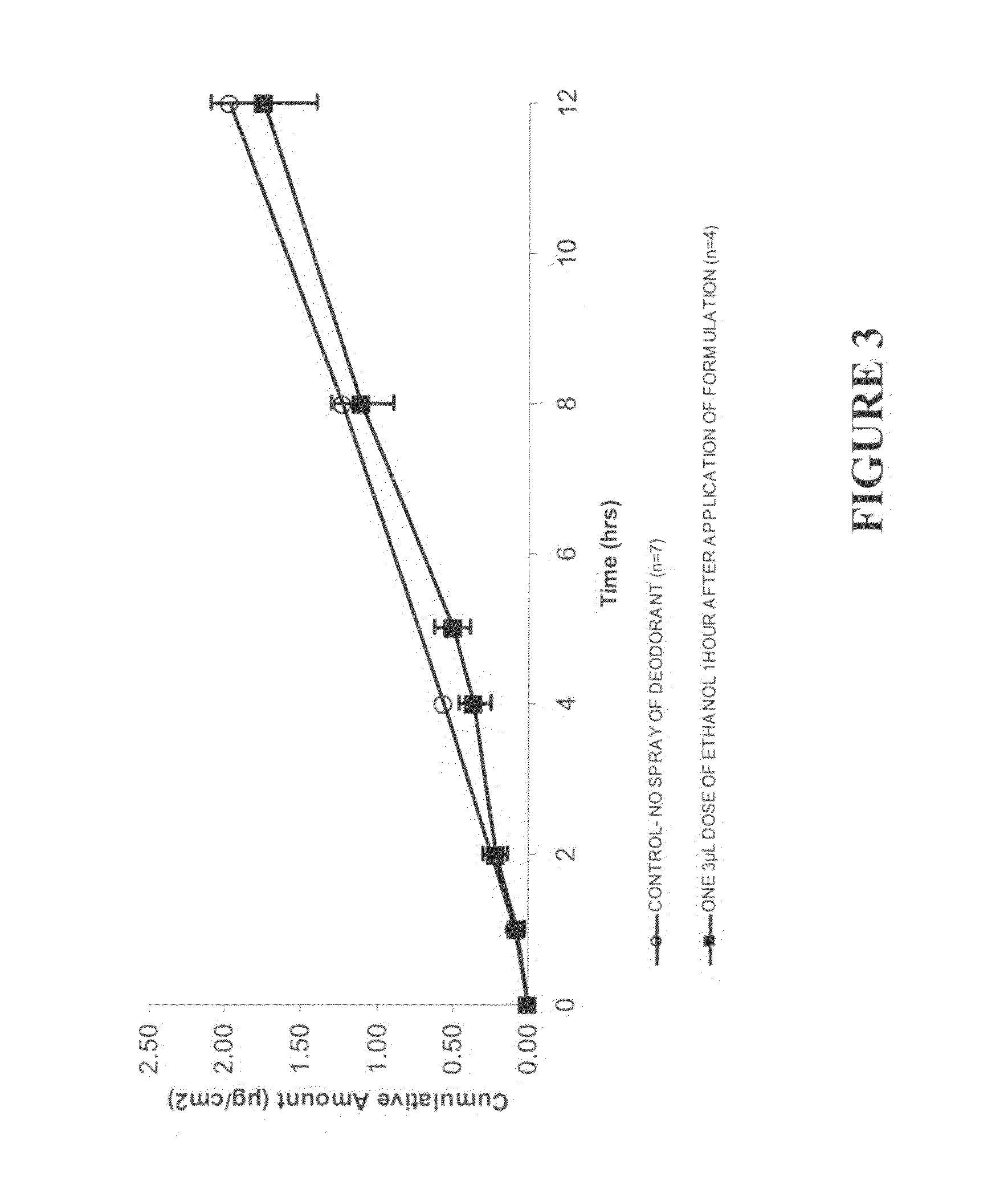

Method and composition for transdermal drug delivery

InactiveUS20100322884A1Minimising effectsMinimising inconvenienceOrganic active ingredientsBiocideActive agentTransdermal medication

The invention is directed to a transdermal drug delivery composition which includes at least one physiologically active agent; and at least one volatile solvent; and at least one viscosity modulating agent. The invention extends to methods of administering such a composition to a subject and treatment of subjects using the composition.

Owner:ACRUX DDS

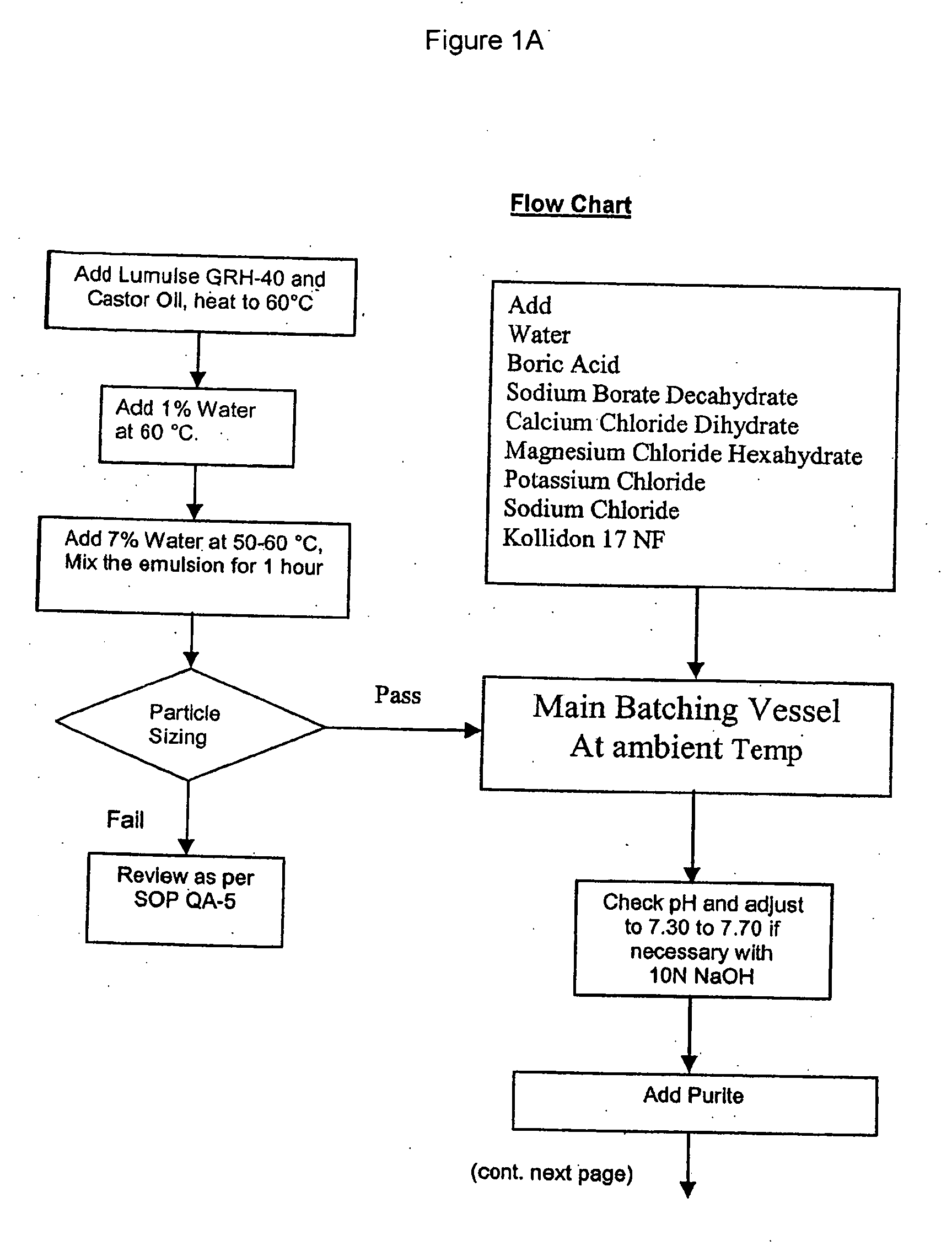

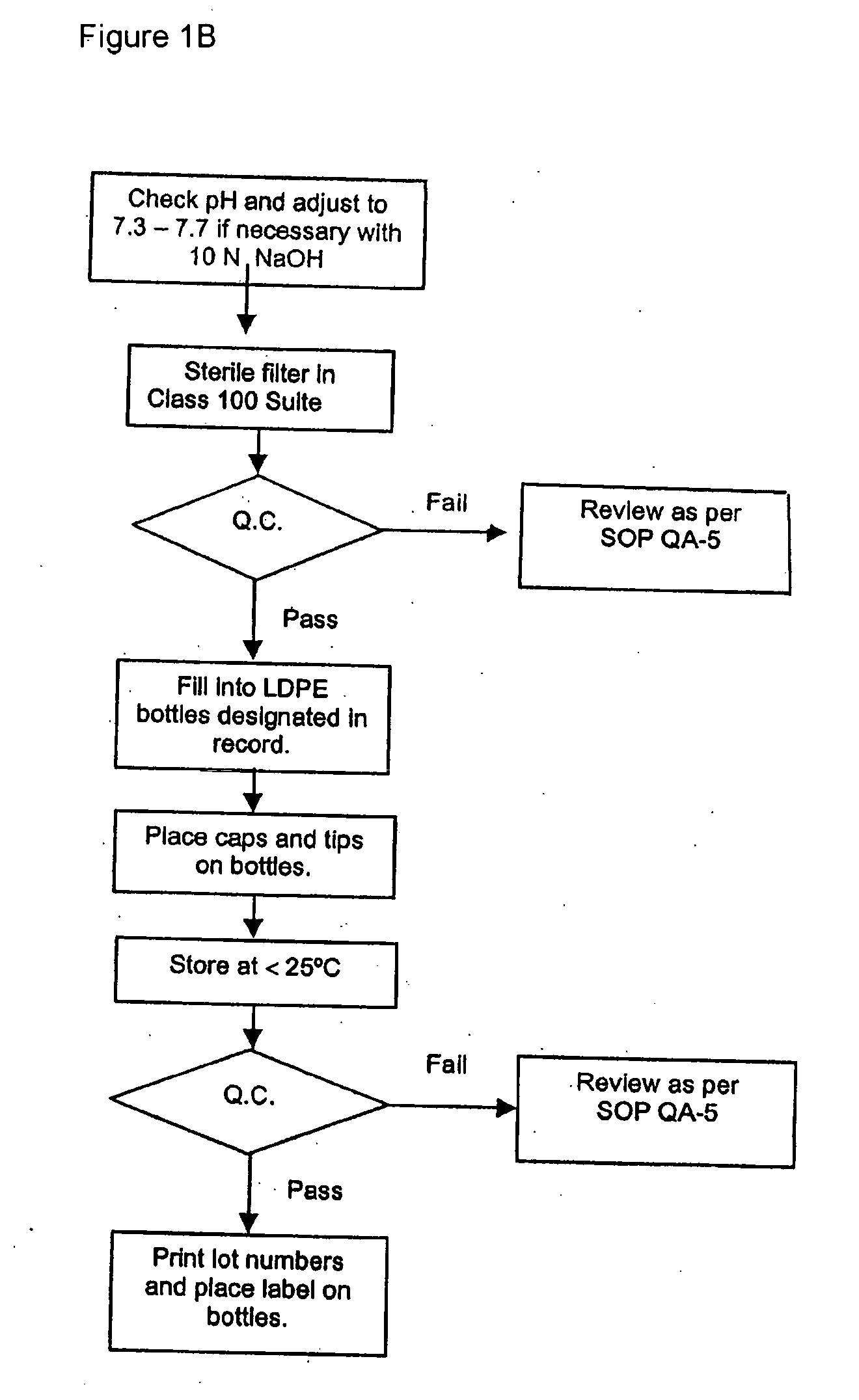

Stable ophthalmic oil-in-water emulsions with Omega-3 fatty acids for alleviating dry eye

An ophthalmic composition includes oil globules dispersed in an aqueous phase. The globules include a surfactant component, a polar oil component that includes an Omega-3 fatty acid and a viscosity modifying agent. The surfactant to oil ratio produces an average size of globules of about 0.1 microns or less. The viscosity is at least as viscous as 0.25% 800K sodium hyaluronate. The composition can be used for treatment of dry eye. The compositions are stable and can have anti-microbial activity sufficient for use as contact lens disinfecting solutions.

Owner:ADVANCED MEDICAL OPTICS

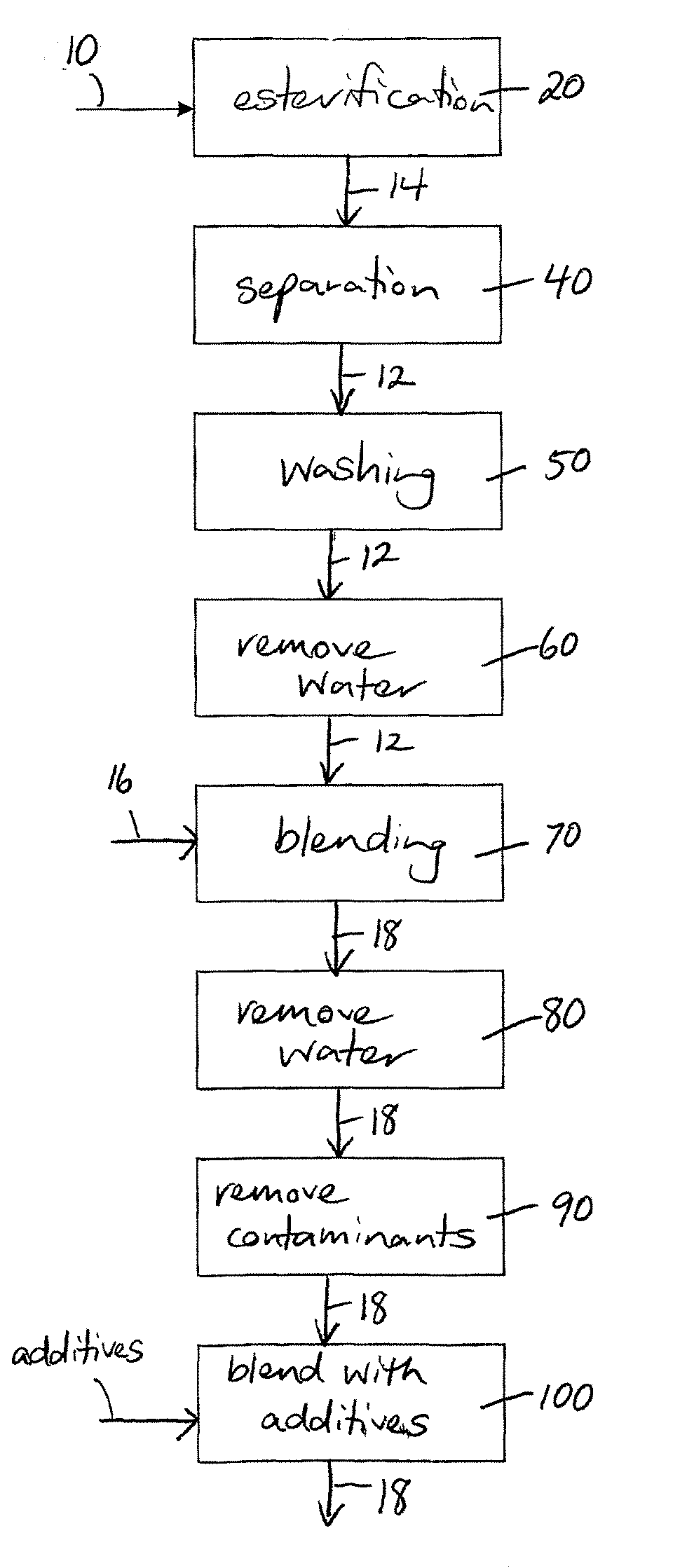

Low Viscosity Mono-Unsaturated Acid-Containing Oil-Based Dielectric Fluids

InactiveUS20090140830A1Low viscosityOther chemical processesTransformers/inductances casingsDielectricVegetable oil

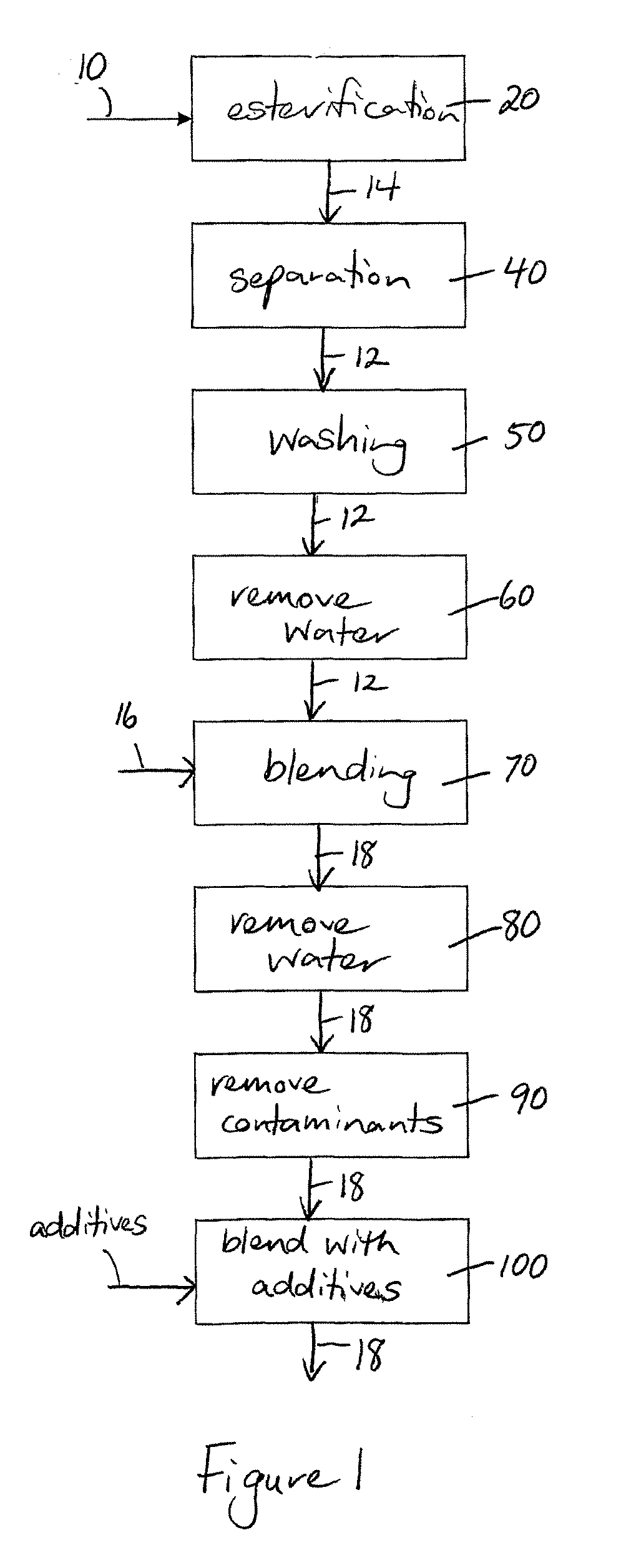

Disclosed herein are a dielectric fluid composition and a method thereof. Also disclosed are viscosity modifiers and a method of lowering the viscosity of an oil-based dielectric fluid. The composition includes an oil with a high mono-unsaturated fatty acid content and one or more fatty acid alkyl esters, each having a fatty acid and an alkyl moiety, wherein the alkyl moiety of the fatty acid alkyl esters has 1 to 4 carbon atoms, and wherein both the oil and the fatty acid alkyl ester are in the range of 40%-60% v / v of the dielectric fluid composition. The viscosity modifier includes one or more fatty acid alkyl esters with an alkyl moiety and a fatty acid moiety, wherein the alkyl moiety has 1 to 4 carbon atoms. The method of lowering the viscosity includes blending the viscosity modifier and a vegetable oil-based dielectric fluid in a ratio of 40:60-60:40.

Owner:BIOLECTRIC

Alcohol-free fountain solution with high viscosity and low surface tension

InactiveCN103935150AHigh effective contentReduce pollutionPrinting pre-treatmentAlcohol freeAqueous alcohol

The invention discloses alcohol-free fountain solution with high viscosity and low surface tension. The alcohol free fountain solution with high viscosity and low surface tension comprises the following components by weight, 30-55 parts of alcohol solvents, 2-6 parts of buffer agents, 3-8 parts of wetting agents, 1-4 parts of surface active agents, 0.3-2.2 parts of antifoaming agents, 0.5-3 parts of thickening agents, 0.5-1.2 parts of anticorrosion and bactericidal agents, 1-3 parts of penetrating agents, 0-2 parts of electrolyte and 20-45 parts of viscosity modifier water. The fountain solution is free of volatile solvents containing alcohol and isopropyl alcohol and pollution to the environment, the surface tension ranges from 4*10-2N / m to 7*10-2N / m, pH ranges from 4.8 to 5.5, the heat conduction rate ranges from 800mus / cm to 1200mus / cm, and therefore, quality requirements of the fountain solution can be met better.

Owner:苏州禾川化学技术服务有限公司

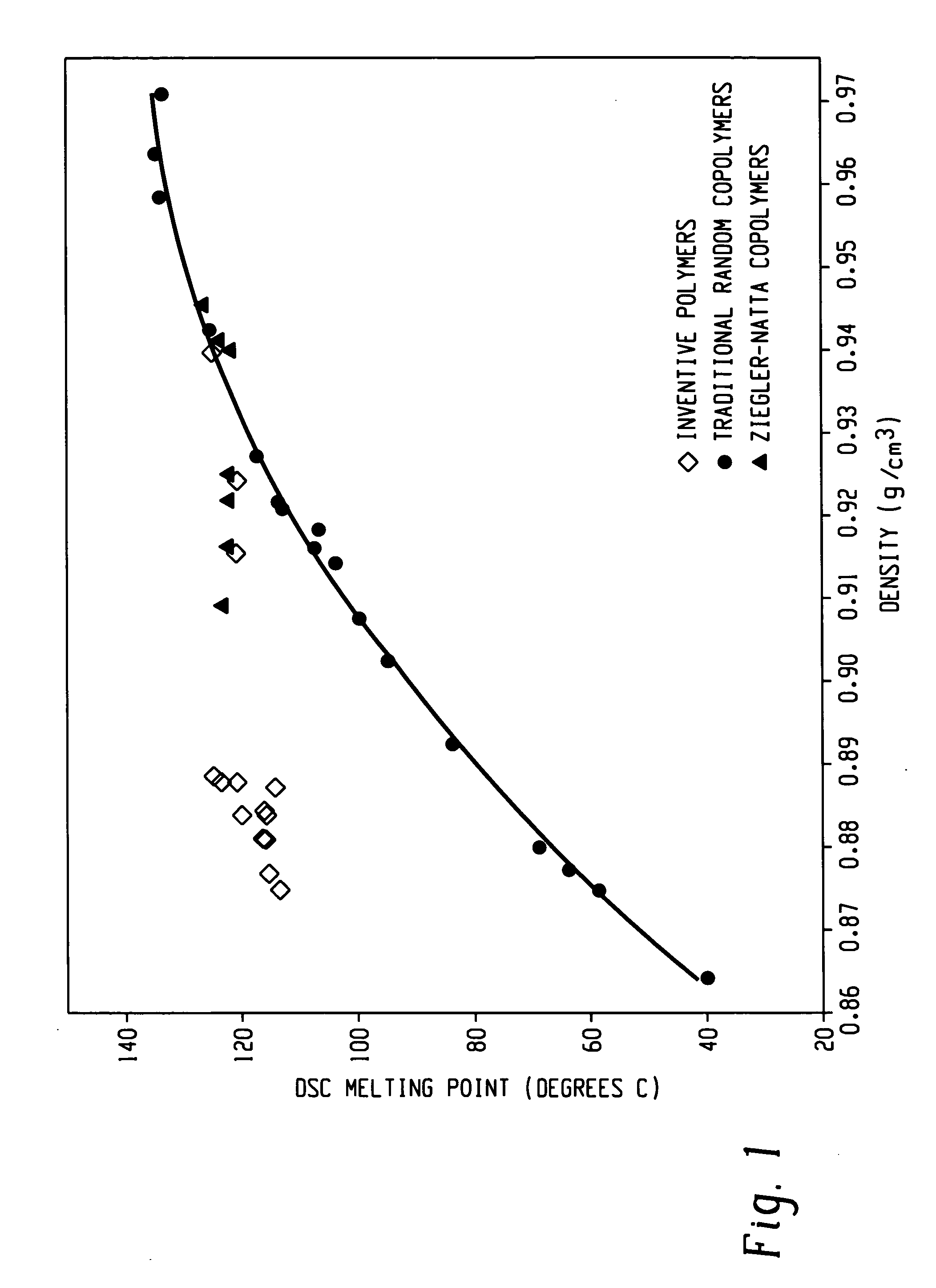

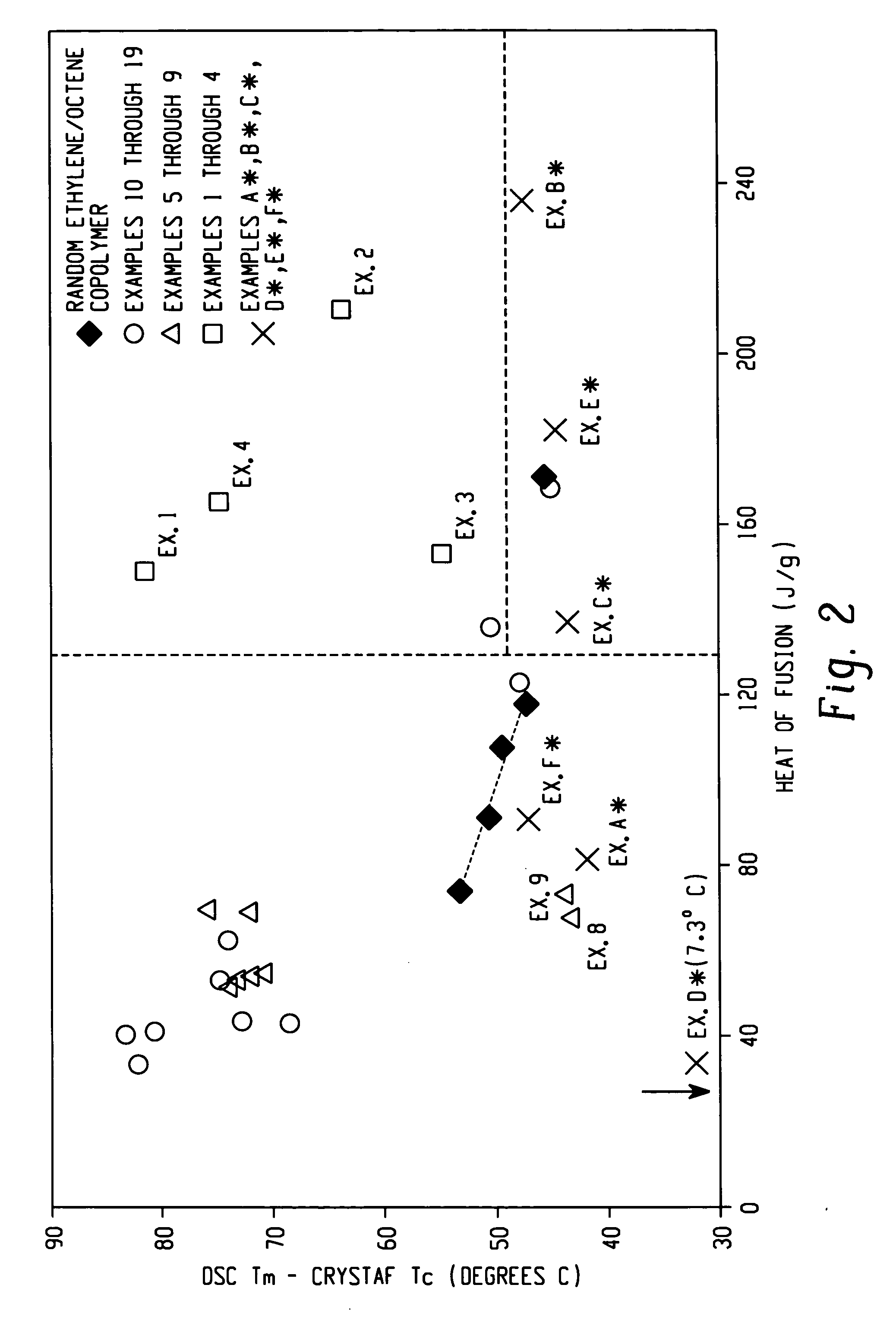

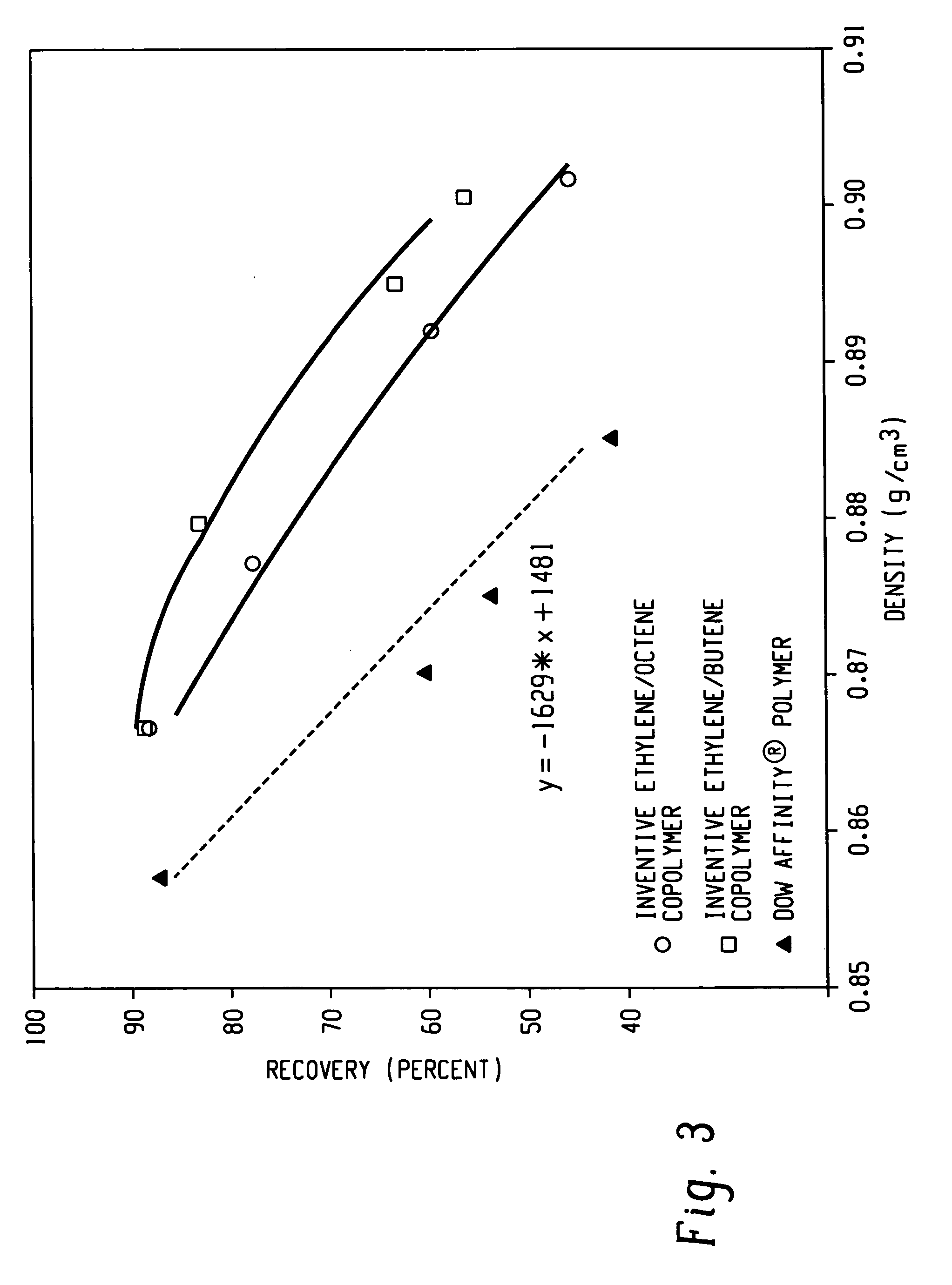

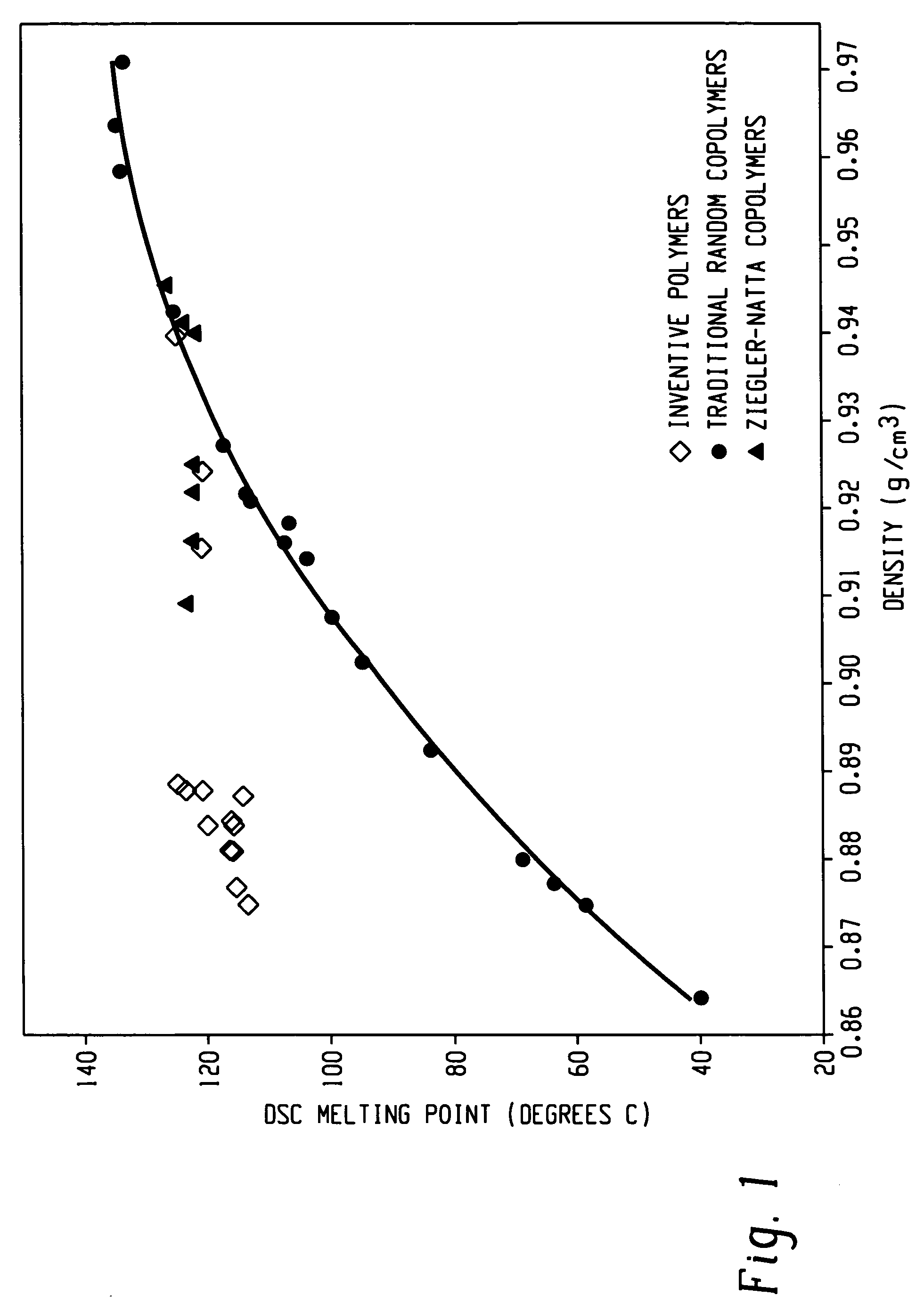

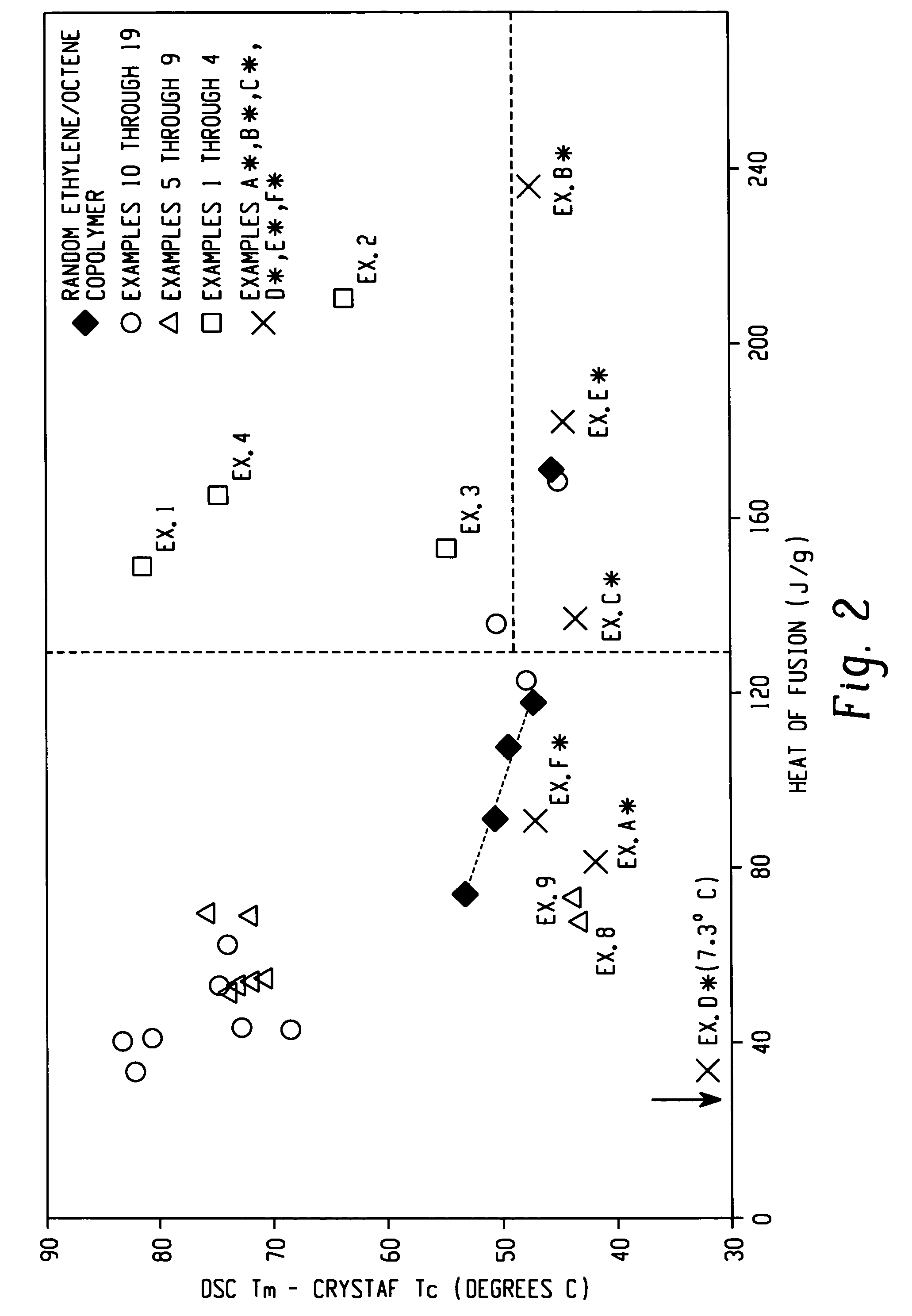

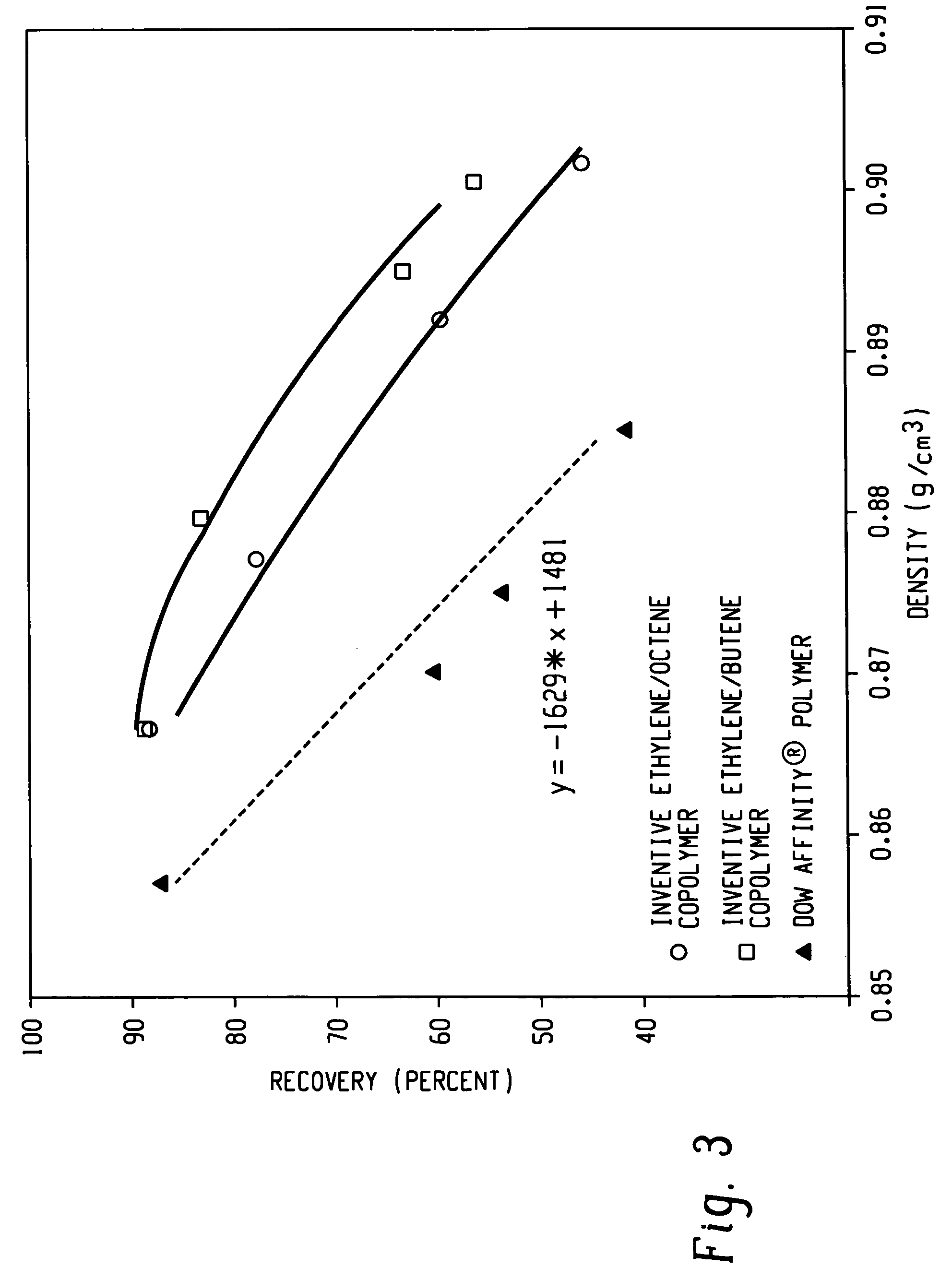

Viscosity index improver for lubricant compositions

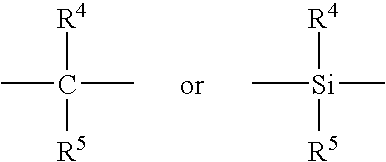

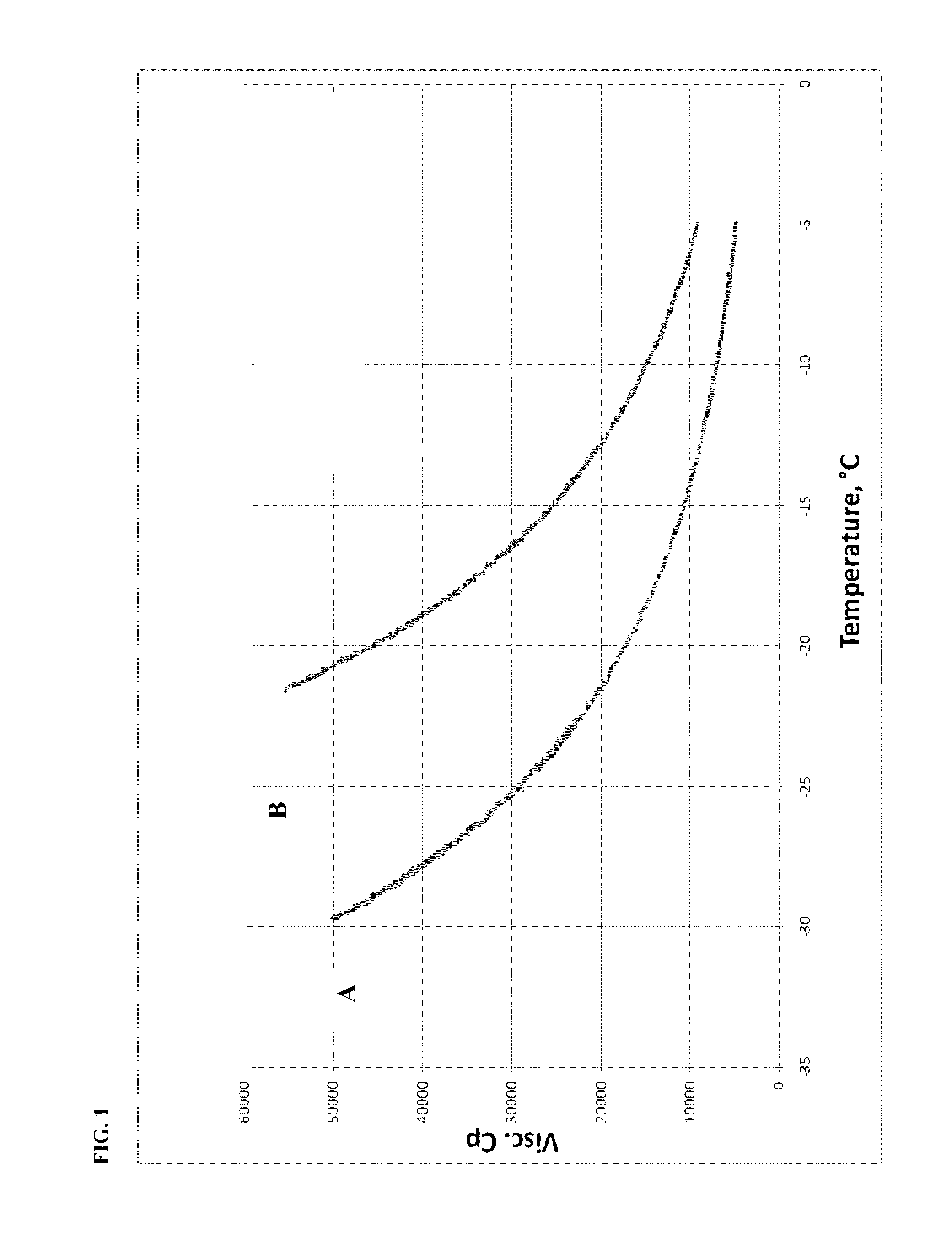

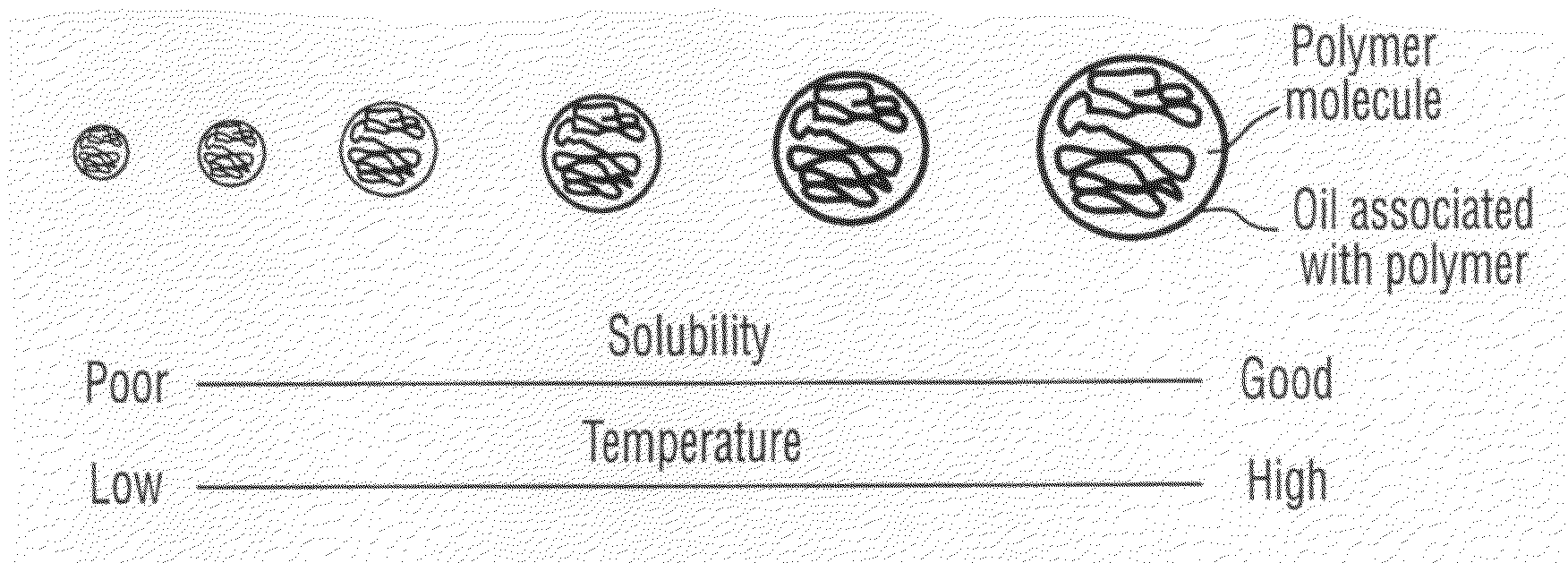

A lubricant composition comprises a base oil and a viscosity modifier including an ethylene / α-olefin interpolymer. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block copolymer has a number of unique characteristics disclosed here. Such block copolymers offer the possibility of improved low temperature performance and flexibility in formulating motor oil, gear lubricants and greases, etc.

Owner:DOW GLOBAL TECH LLC

Support material and applications thereof

In one aspect, support materials operable for use in 3D printing systems are described herein. In some embodiments, a support material comprises a wax component comprising at least one ethoxylated fatty alcohol and a viscosity modifying agent, wherein the support material is water dispersible. In some embodiments, the wax component comprises a mixture of at least one fatty alcohol and at least one ethoxylated fatty alcohol.

Owner:3D SYST INC

Cosmetic and/or pharmaceutical emulsions

A cosmetic and / or pharmaceutical composition containing: (a) an oil component; (b) a viscosity modifier selected from the group consisting of a C6-22 hydroxyfatty acid, a salt of a C6-22 hydroxyfatty acid, and mixtures thereof; and (c) water.

Owner:COGNIS DEUT GMBH & CO KG

Dispersion For Delivering Active Agents

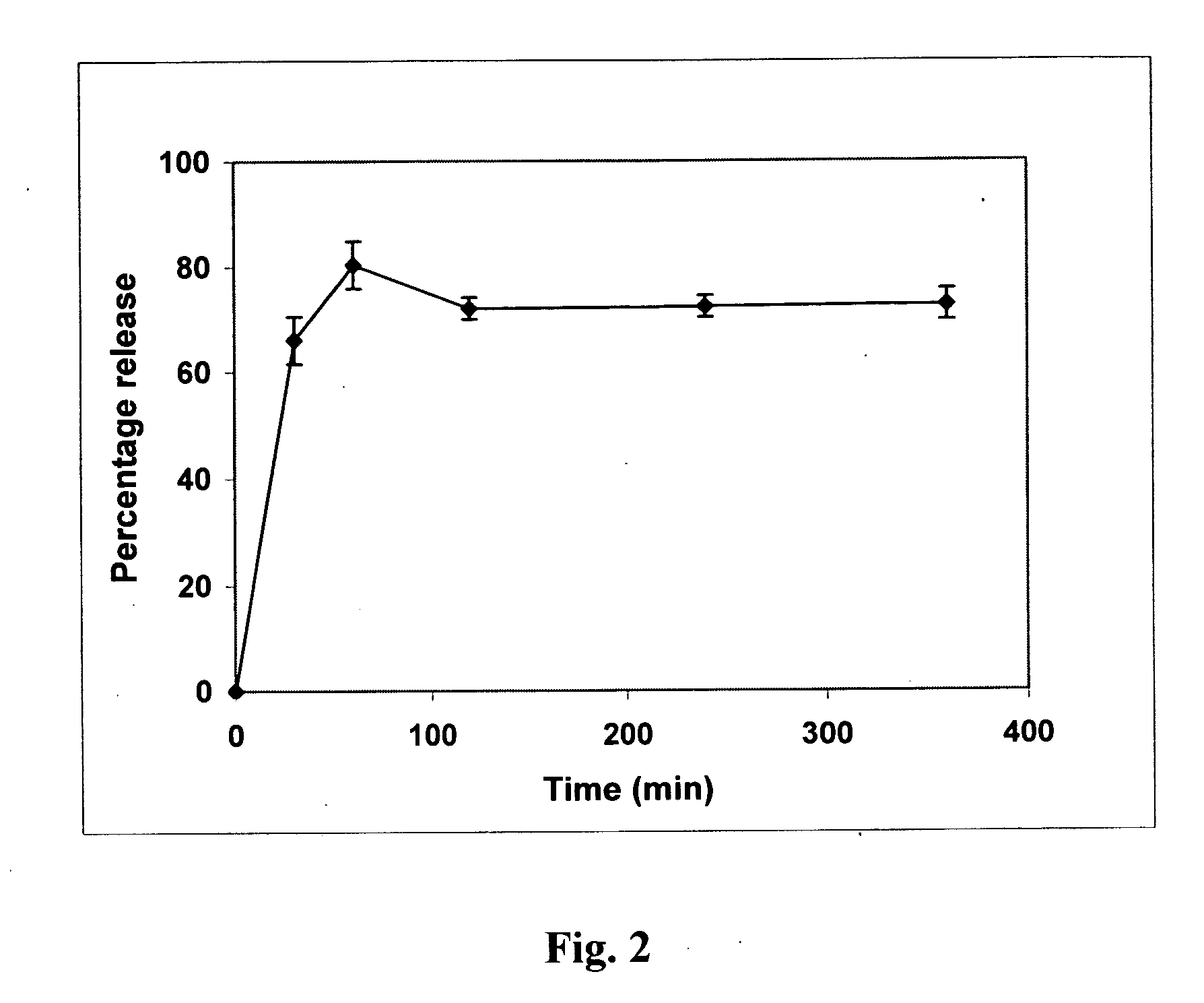

InactiveUS20080132580A1Good spreadabilityRapidly forming delivery systemBiocideHydroxy compound active ingredientsControl releaseActive agent

A composition for topical application comprises a dispersed phase comprising an active agent and a polymer or lipid; and a gelled continuous phase comprising a viscosity modifier and a solvent. The composition can provide an active agent to skin or mucous membranes in a controlled release form.

Owner:DR REDDYS LAB LTD +1

Slurry compositions and CMP methods using the same

InactiveUS20080124913A1Reduce and eliminate excessive removalOther chemical processesSemiconductor/solid-state device manufacturingArylSilicon oxide

The exemplary embodiments of the present invention providing new slurry compositions suitable for use in processes involving the chemical mechanical polishing (CMP) of a polysilicon layer. The slurry compositions include one or more non-ionic polymeric surfactants that will selectively form a passivation layer on an exposed polysilicon surface in order to suppress the polysilicon removal rate relative to silicon oxide and silicon nitride and improve the planarity of the polished substrate. Exemplary surfactants include alkyl and aryl alcohols of ethylene oxide (EO) and propylene oxide (PO) block copolymers and may be present in the slurry compositions in an amount of up to about 5 wt %, although much smaller concentrations may be effective. Other slurry additives may include viscosity modifiers, pH modifiers, dispersion agents, chelating agents, and amine or imine surfactants suitable for modifying the relative removal rates of silicon nitride and silicon oxide.

Owner:SAMSUNG ELECTRONICS CO LTD

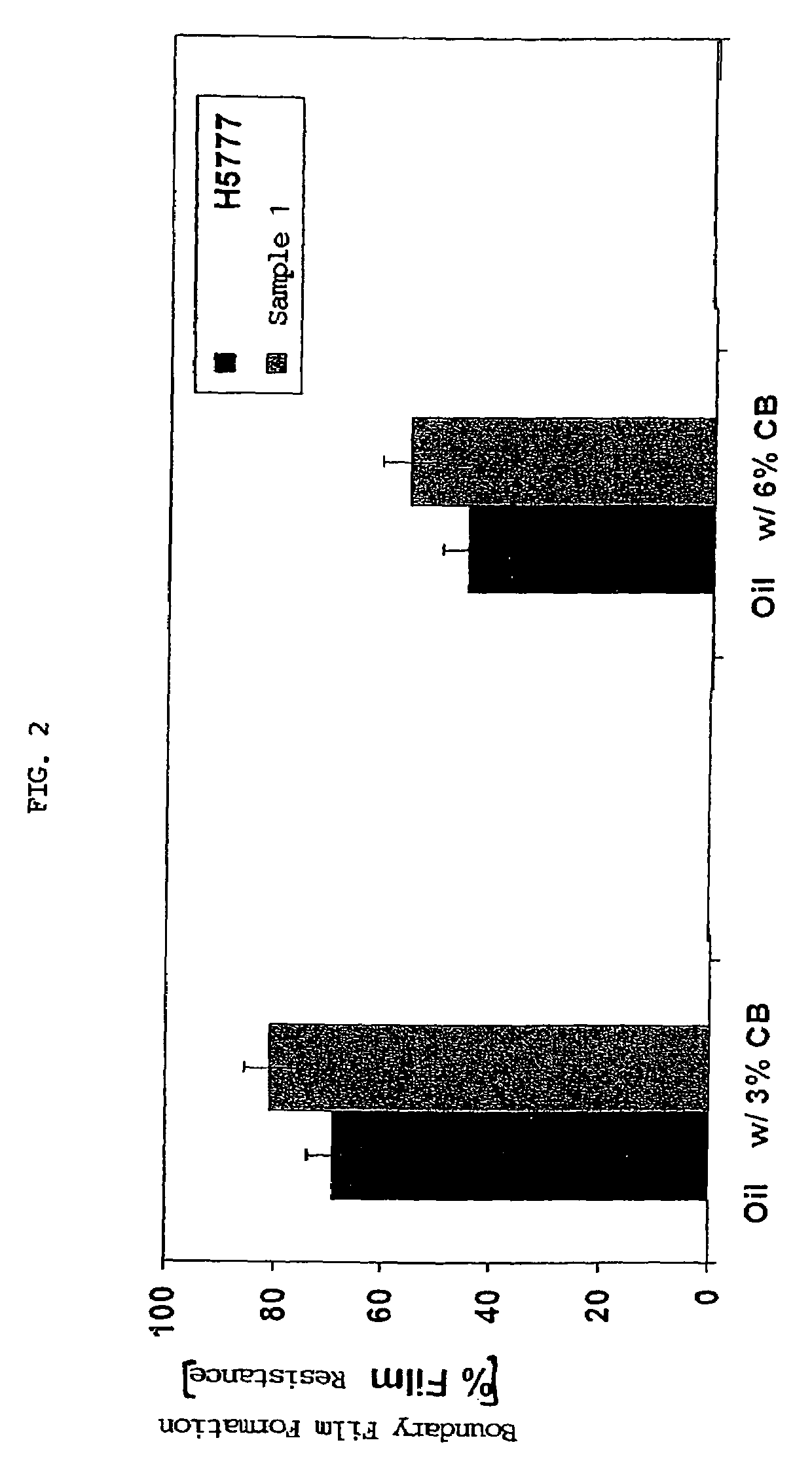

High temperature biobased lubricant compositions from boron nitride

InactiveUS20100105583A1Improve the lubrication effectEnhanced anti-wearBase-materialsBoron nitrideAlpha-olefin

This present invention discloses a method for the preparation of an improved high temperature engine lubricant composition comprising the steps of: 1) providing at least one biobased natural oil or biobased synthetic oil selected from the group consisting of natural or synthetic vegetable oil, natural or synthetic animal oil, genetically modified vegetable oil, genetically modified synthetic vegetable oil, natural or synthetic tree oil, and mixtures thereof; 2) providing at least one boron nitride; and 3) optionally, providing at least one base oil selected from the group consisting of a synthetic ester, solvent refined petroleum oil, a hydrocracked petroleum white oil, an all hydroprocessed synthetic oil, Fischer Tropsch oil, petroleum oil group I, group II, group III, a polyalphaolefin (PAO), and mixtures thereof; 4) optionally, providing at least one additive or combination of additives selected from the group consisting of anti-oxidant(s), corrosion inhibitor(s), metal deactivator(s), viscosity modifier(s), anti-wear inhibitor(s), friction modifier(s), and extreme pressure agent(s); 5) blending 1), 2), 3), and 4) in any sequence to form said composition.

Owner:RENEWABLE LUBRICANTS INC

Printable Composition of a Liquid or Gel Suspension of Diodes

ActiveUS20120161195A1Solid-state devicesSemiconductor/solid-state device manufacturingOctanolSolvent

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

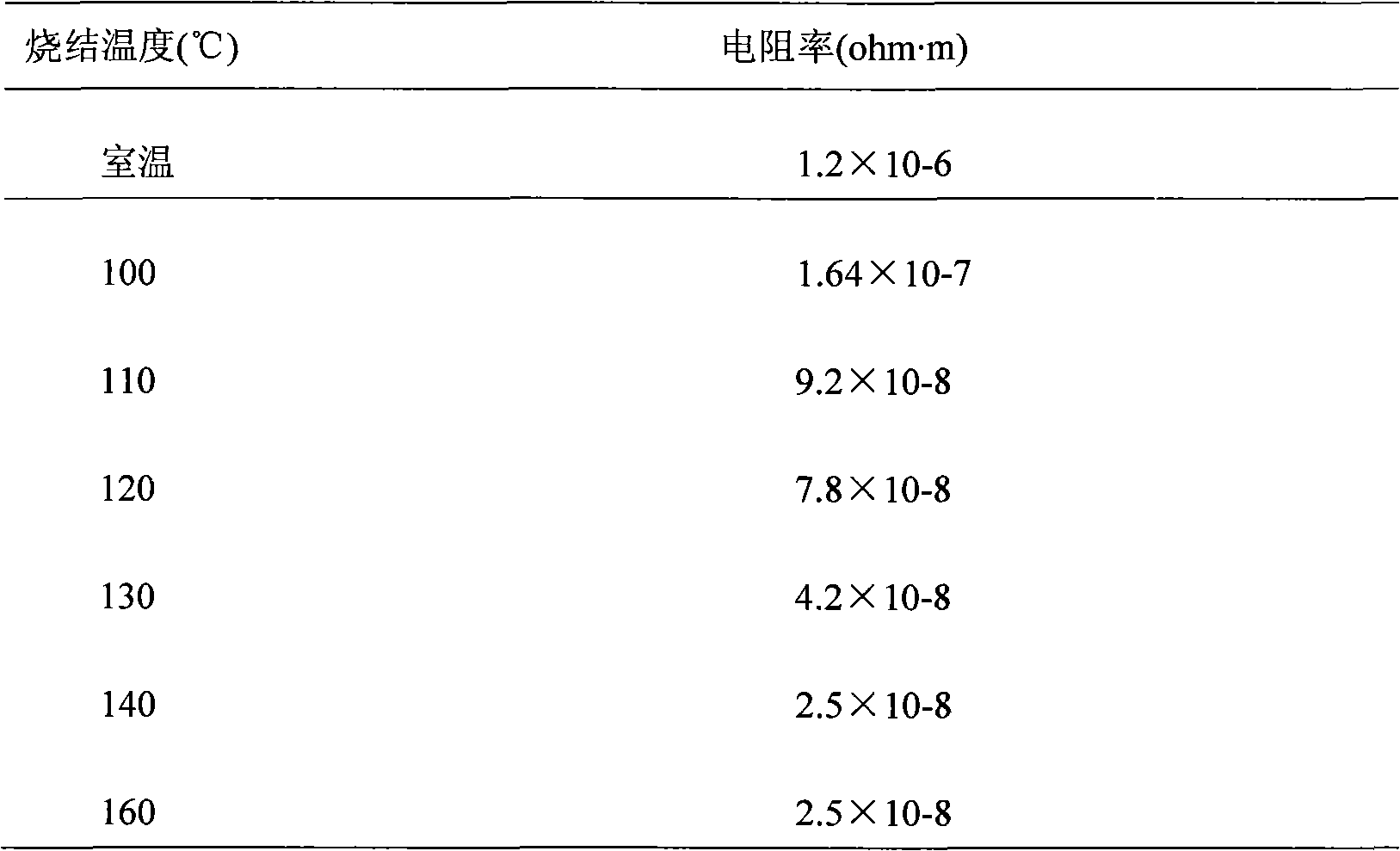

Nanoparticle conductive ink and preparation method thereof

The invention discloses nanoparticle conductive ink and a preparation method thereof. The nanoparticle conductive ink comprises nanoparticles, solvent and viscosity adjusting agent. The preparation method comprises the following steps: respectively preparing solution A containing metal or metallic compound precursor and solution B containing reducing agent; adding the solution A into a reaction kettle and stirring evenly; dropwise adding the solution B into the reaction kettle under the stirring condition, after finishing dropwise adding, continuing to stir for 1-48 hours; taking out the solution A and completely evaporating the solvent in solution A; cleaning and drying to obtain the nanoparticles. The invention has the advantages that the nanoparticle conductive ink is applied to the fields of printed circuit boards, flexible printed circuit boards or radio frequency identification electronic tags and the like; by carrying out spray ink printing on the base materials and low-temperature sintering, the nanoparticles can be connected with each other, thus the excellent electrical conductivity can be obtained.

Owner:微墨智能科技(南通)有限公司

Gear oil composition containing nanomaterial

ActiveUS7449432B2High indexImprove propertiesMaterial nanotechnologyAdditivesNanoparticleEngineering

Owner:VGP IPCO LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com