Nanoparticle conductive ink and preparation method thereof

A nanoparticle and conductive ink technology, which is applied in the formation of conductive patterns, inks, household appliances, etc., can solve the problems of limited application, low resistivity, lack of conductivity data, etc., and achieve the effect of excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In order to obtain nanoscale particles with uniform size dispersion, the preparation method comprises the following steps:

[0035] (1) Prepare solution A containing metal or metal compound precursor and solution B containing reducing agent respectively;

[0036] (2) Solution A is added into the reactor, and stirred evenly;

[0037] (3) While stirring, add solution B dropwise to the reaction kettle, after the dropwise addition, continue to stir for 1 to 48 hours, take out solution A, evaporate the solvent of solution A completely, wash and dry to obtain nanoparticles ;

[0038] Wherein, the metal or metal compound precursor is a complex composed of a metal salt and a stabilizer;

[0039] Examples of the metal salt may be silver nitrate, silver carbonate, silver acetate, silver sulfate, silver oxalate, silver 2-ethylhexanoate, gold acetate, palladium oxalate, copper-ethylhexanoate, iron stearate, formic acid Nickel, zinc citrate, copper cyanide, cobalt carbonate, plat...

Embodiment 1

[0053] 48 grams of silver nitrate and 204 grams of hexadecylamine are dissolved in a mixed solution of 360 milliliters of ethanol and water, wherein the volume ratio of ethanol and water is 4:3, and the temperature of the solution is maintained at 60° C., stirred for 2-12 hours, and then After the solvent was completely evaporated, it was added into a mixed solution of water and chloroform, the chloroform solution was taken out, and 115 g of complex solids were recrystallized with ethanol. 115 grams of complex solids were dissolved in 2 liters of toluene, 22 grams of sodium borohydride was dissolved in 2 liters of deionized water three times, and the aqueous solution of sodium borohydride was added dropwise to the reaction kettle for reduction reaction, and stirred for 6 to 24 hours. After one hour, the upper layer of nano-silver solution was separated by standing. After the solvent was evaporated from the nano-silver solution, it was washed with 400 milliliters of acetone, dr...

Embodiment 2

[0056] The preparation method of conductive ink is the same as example 1.

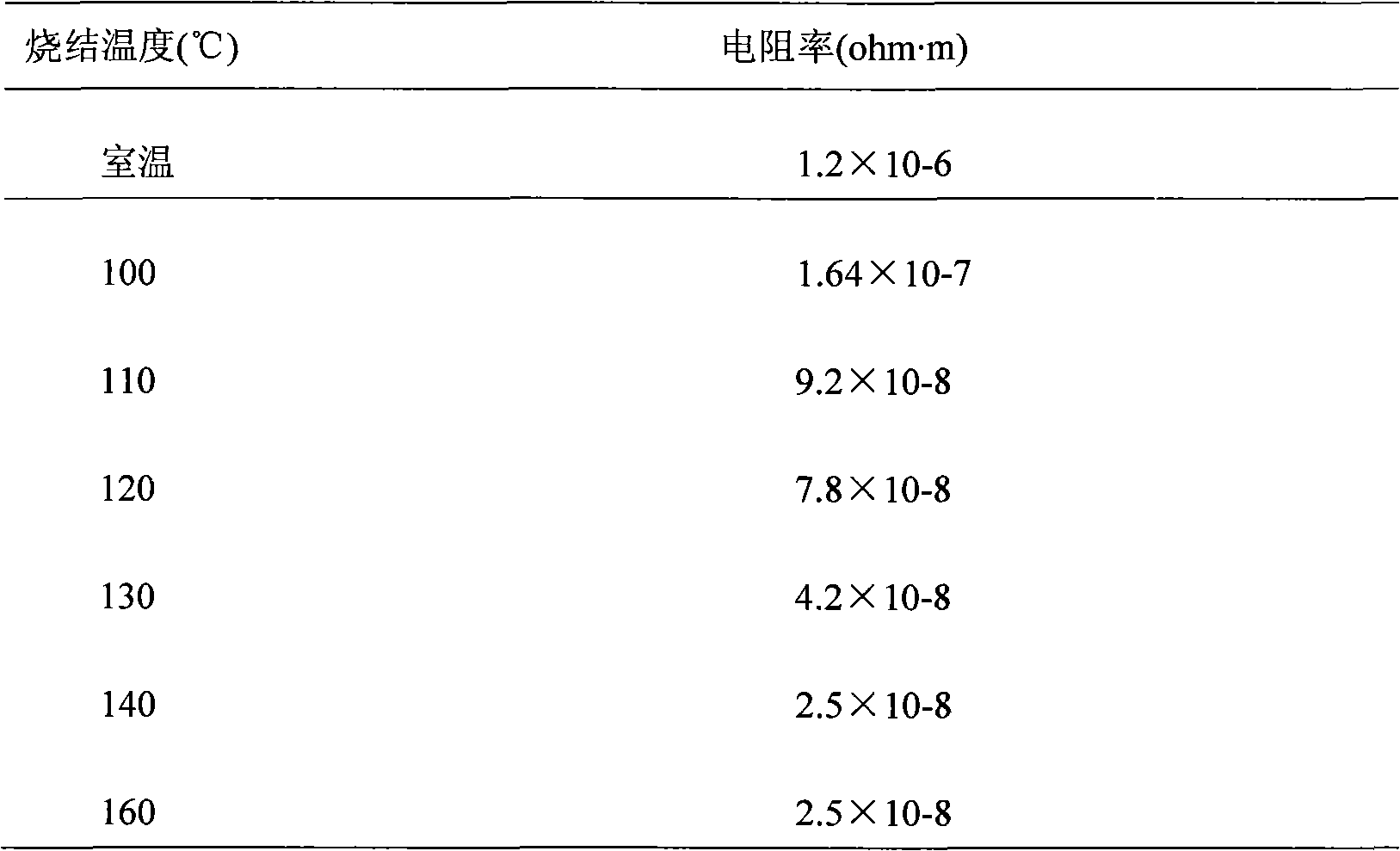

[0057] After printing the conductive ink on the substrate, heat it at 100-160°C for 0.5-5min. It takes longer at room temperature. Use a four-probe resistivity tester to measure the resistivity. The results are shown in Table 1.

[0058] Table 1

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com