Patents

Literature

530 results about "Hardboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hardboard, also called high-density fiberboard (HDF), is a type of fiberboard, which is an engineered wood product. It is similar to particle board and medium-density fiberboard, but is denser and much stronger and harder because it is made out of exploded wood fibers that have been highly compressed. Consequently, the density of hardboard is 31 pounds per cubic foot (500 kg/m³) or more and is usually about 50–65 pounds per cubic foot (800–1,040 kg/m³). It differs from particle board in that the bonding of the wood fibers requires no additional materials, although resin is often added. Unlike particle board, it will not split or crack.

Wood adhesive and method of preparing thereof

InactiveUS20100258033A1Drying rate of adhesiveLow pour pointProtein waste adhesivesStarch adhesivesHigh densityAdhesive

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fibreboard, high density fibreboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

Fire-retardant coating, method for producing fire-retardant building materials

InactiveUS20050229809A1Simple materialIncrease resistanceFireproof paintsAntifouling/underwater paintsCalcium silicateFire retardant

The present invention relates to a fire-resistant coating and method thereof, which confers enhanced flame and heat resistance to substrate such as building materials. The invented coating is especially applicable to cellulose-based building materials including but not limited to fiberboards, wallboards, roofing materials, particleboards, ceiling tiles, soundproofing boards and hardboards. This novel composition is also useful in providing a fire-resistant coating for concrete, metals, foamed polymeric materials, gypsum and other substrates. A preferred embodiment generally comprising: mono potassium phosphate, magnesium oxide, silica powder, calcium silicate, rice hull ash and water. A method for imparting fire-retardancy to substrates using the invented composition is also described

Owner:BONE SOLUTIONS INC

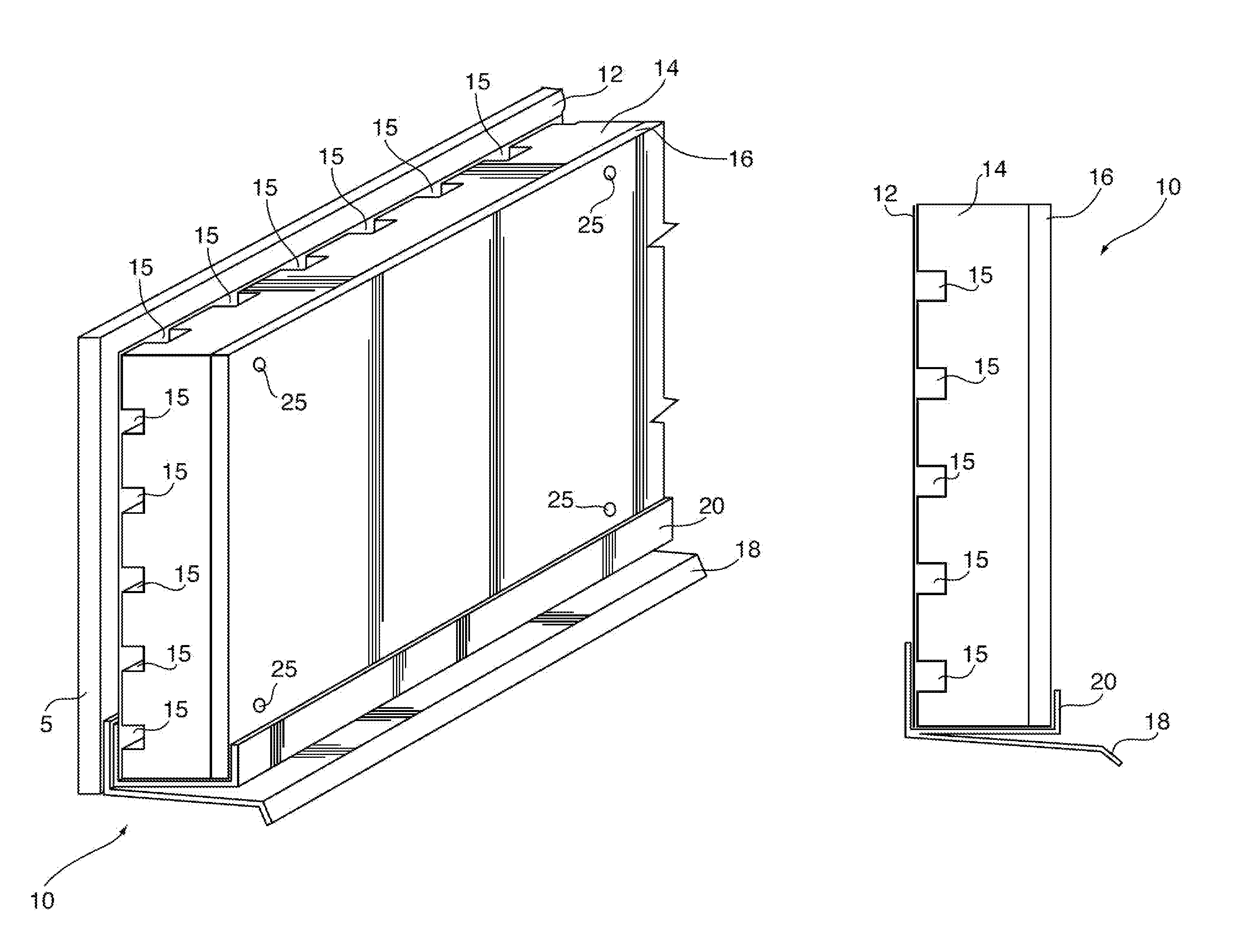

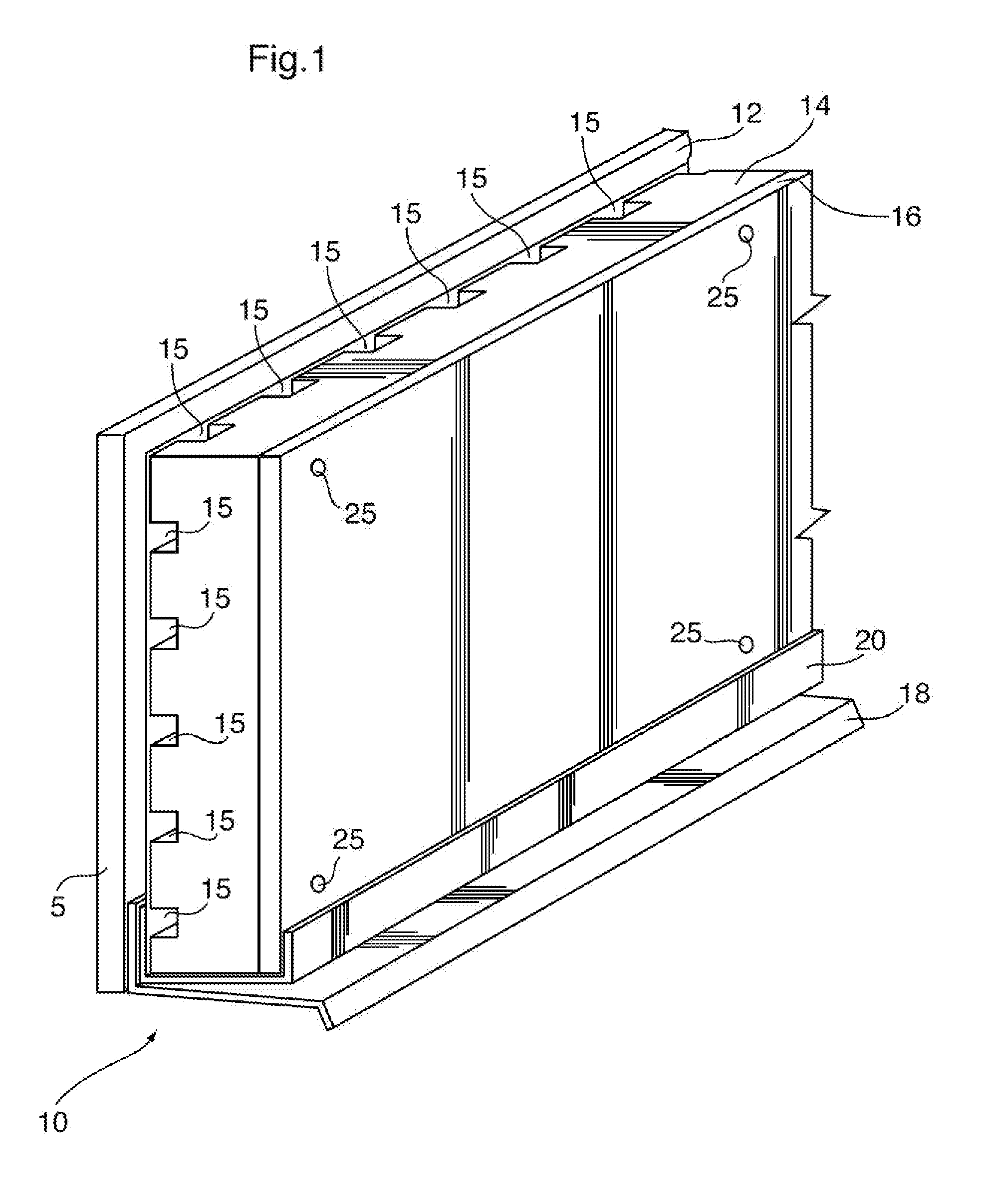

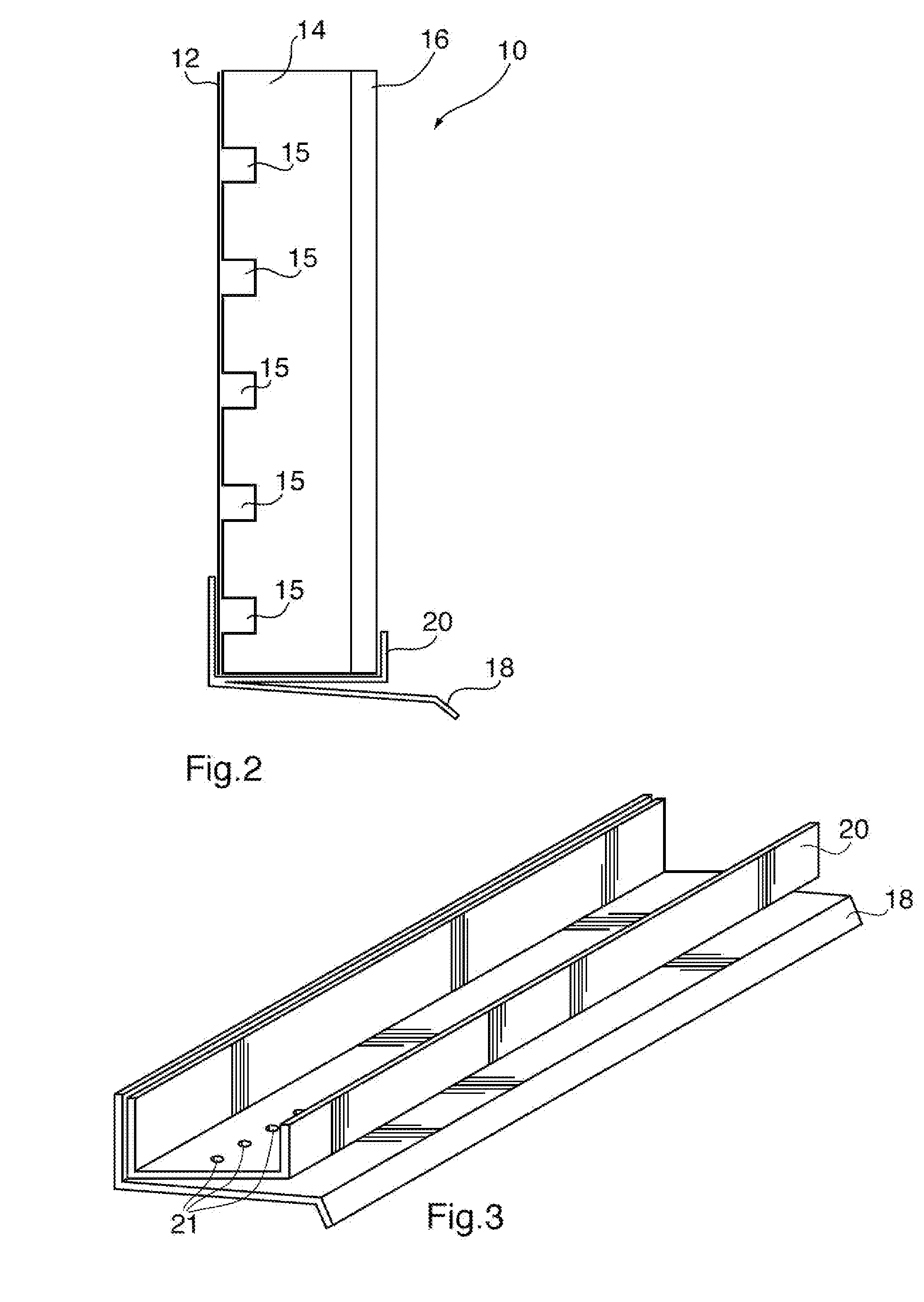

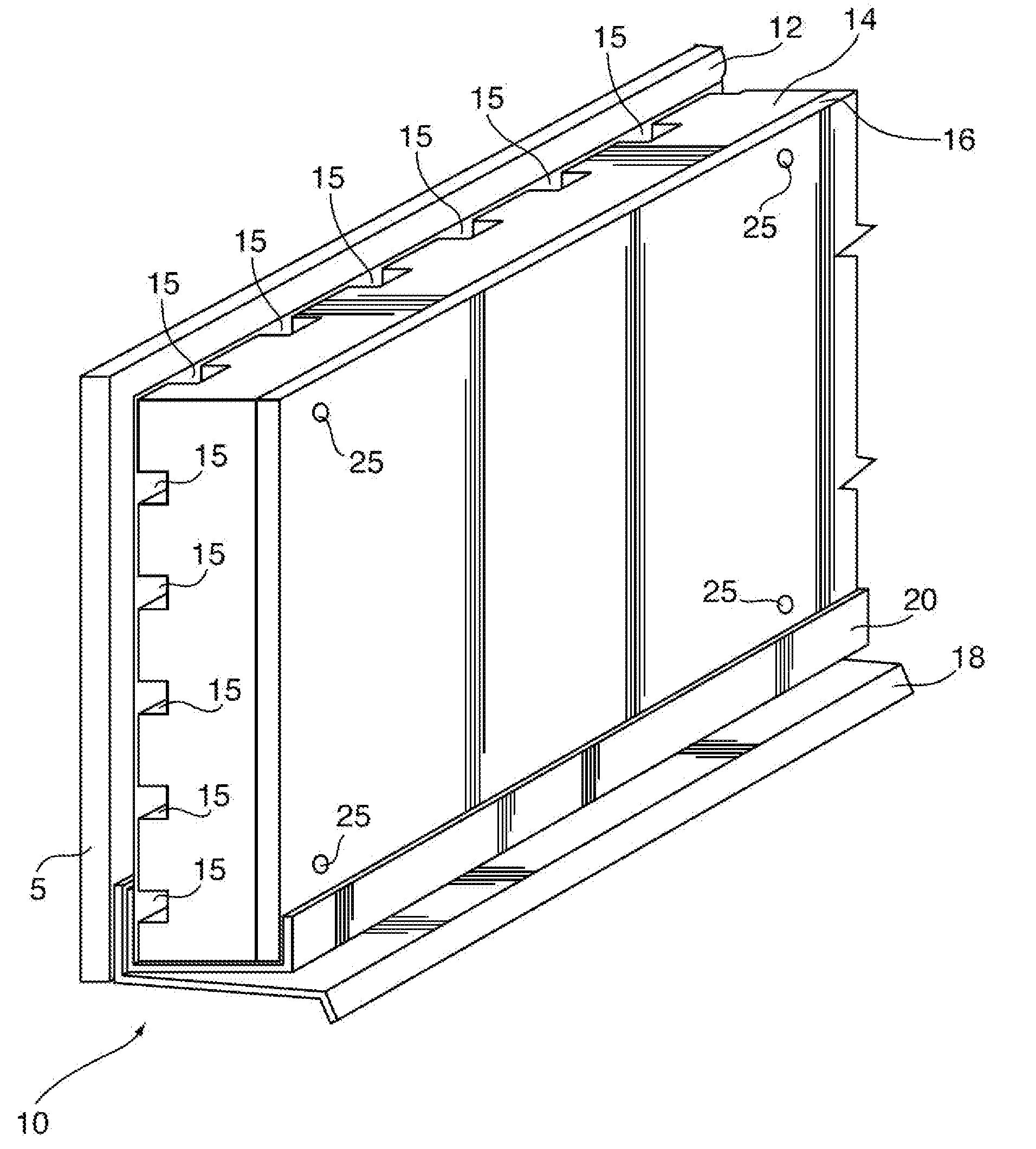

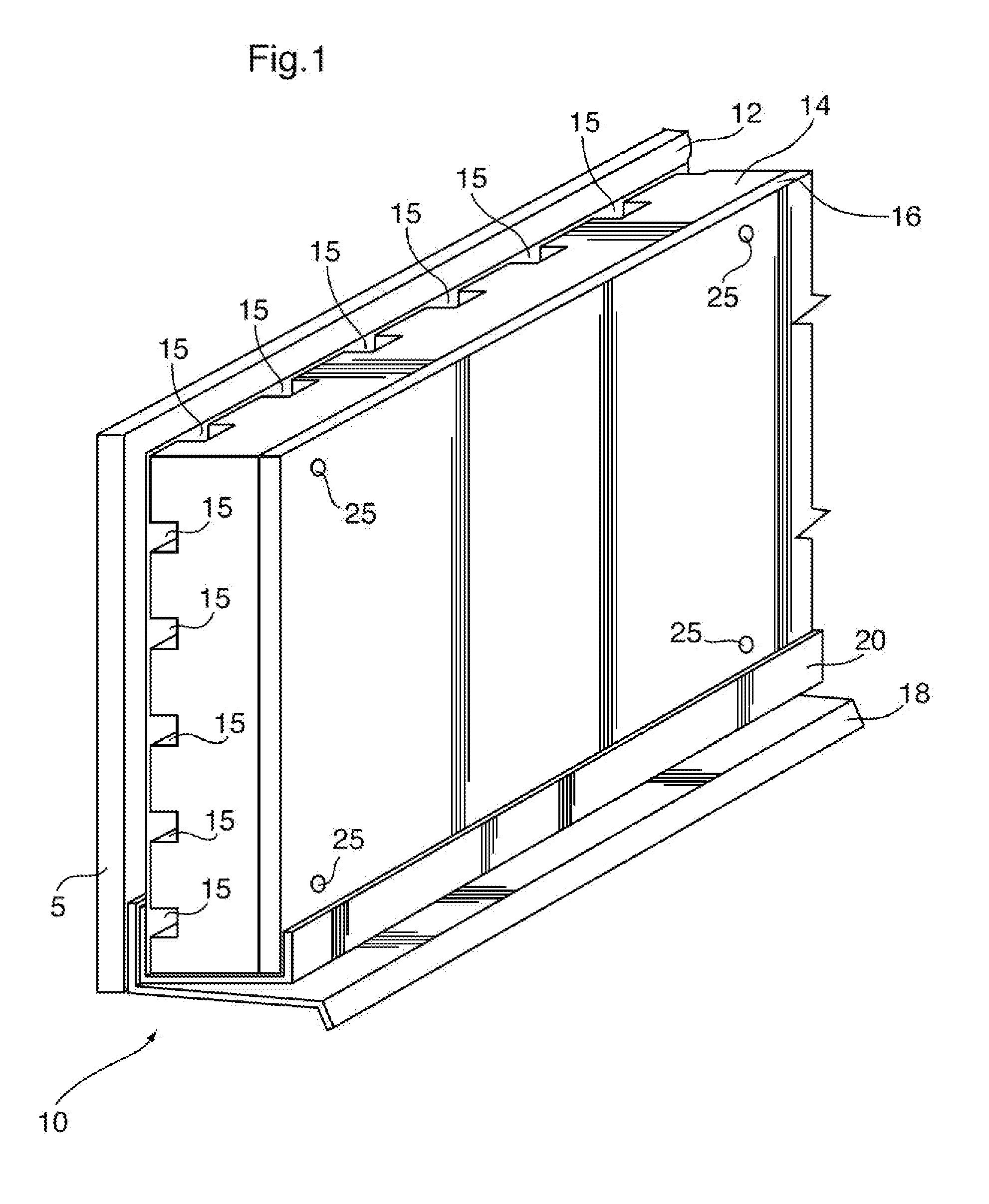

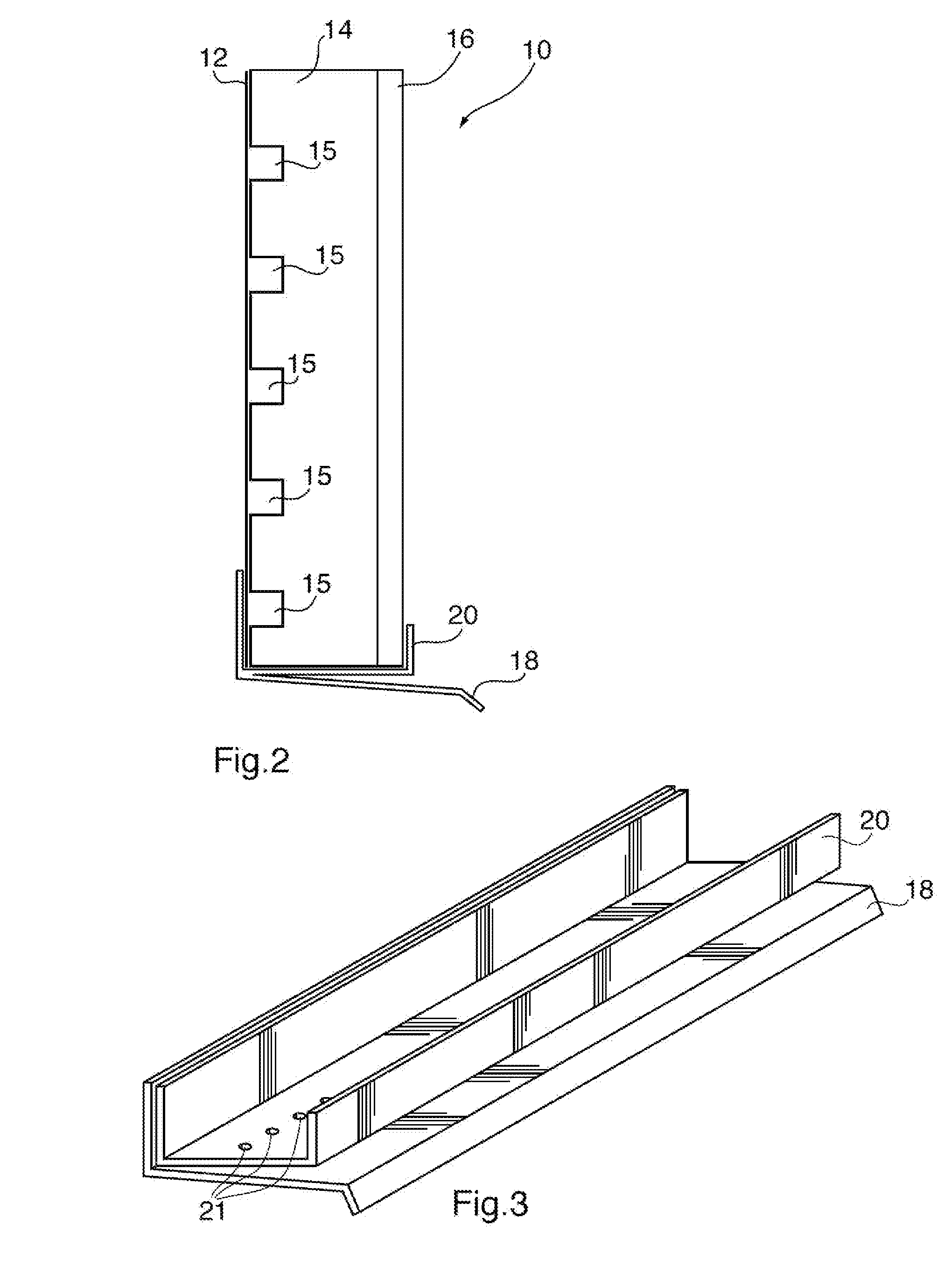

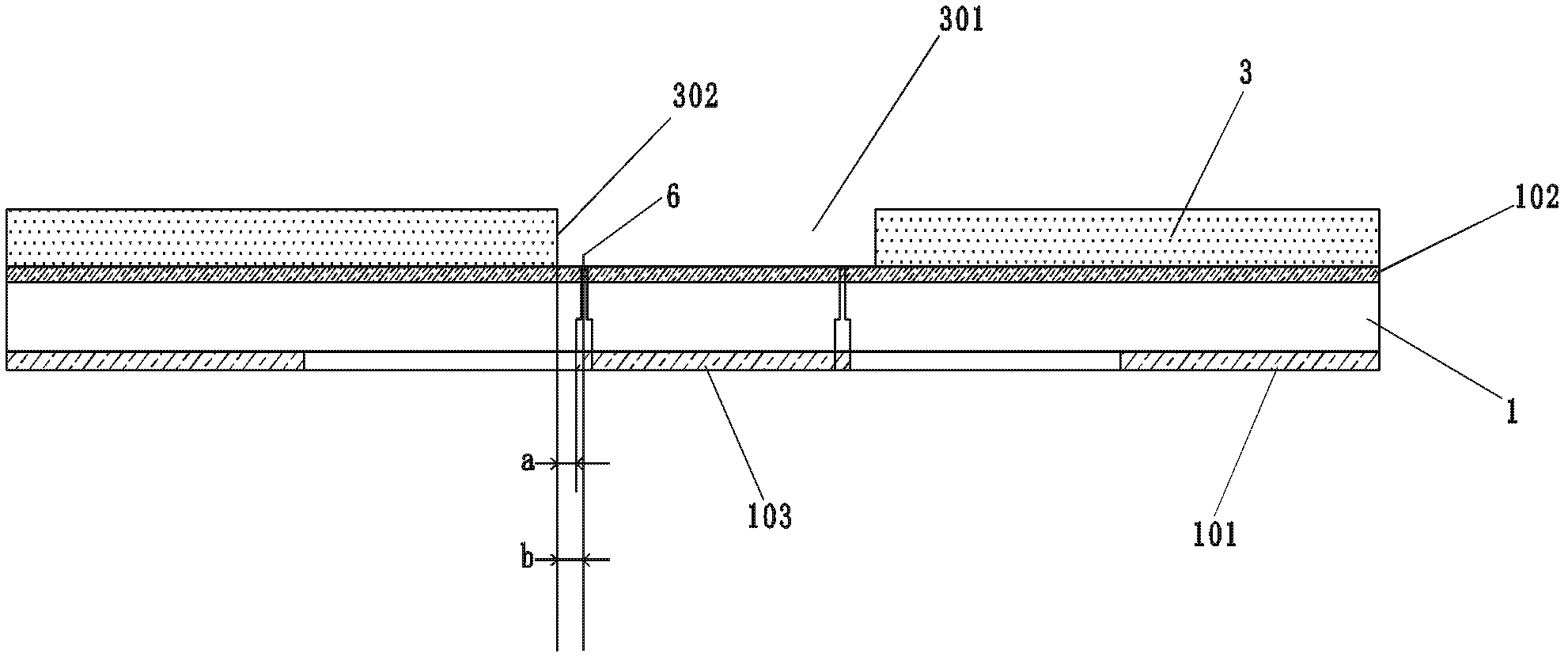

Exterior wall finishing arrangement

ActiveUS8555581B2Improve insulation performanceReduce penetrationCeilingsCovering/liningsMoistureFiberboard

Owner:1254453 ONTARIO INC

Exterior wall finishing arrangement

ActiveUS20120324814A1Improve insulation performanceReduce penetrationCovering/liningsWallsMoistureWater barrier

A finishing arrangement for an exterior wall of a building includes a weather or water barrier against at least the exterior of the wall; an outer hardboard panel; an insulating foam panel between the weather or water barrier and the outer hardboard panel, the insulating foam panel attached to the outer hardboard panel and having drainage channels therein; and a drainage guide that extends from the weather or water barrier to at least the outer hardboard panel, for guiding moisture away from the wall.

Owner:1254453 ONTARIO INC

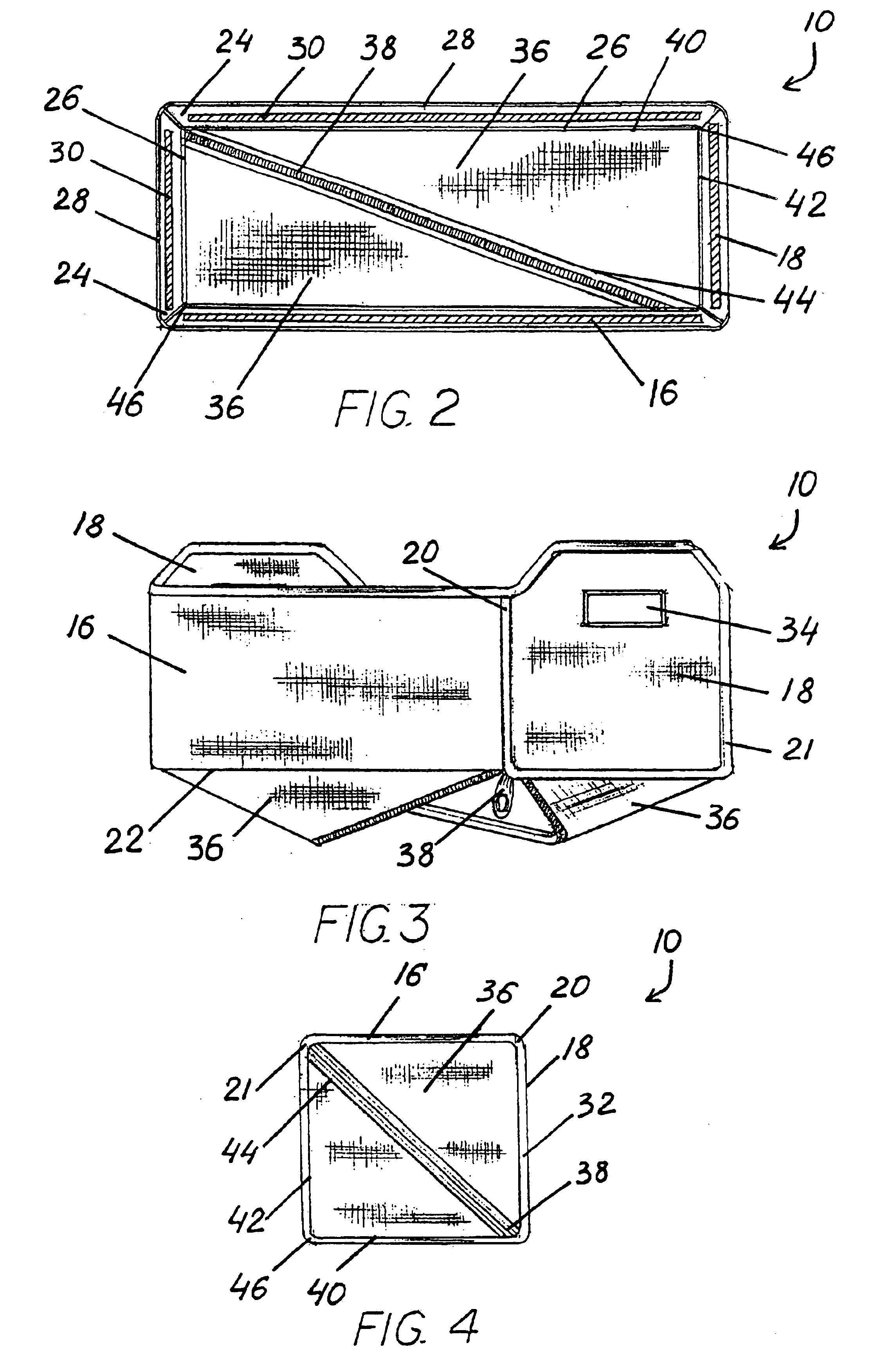

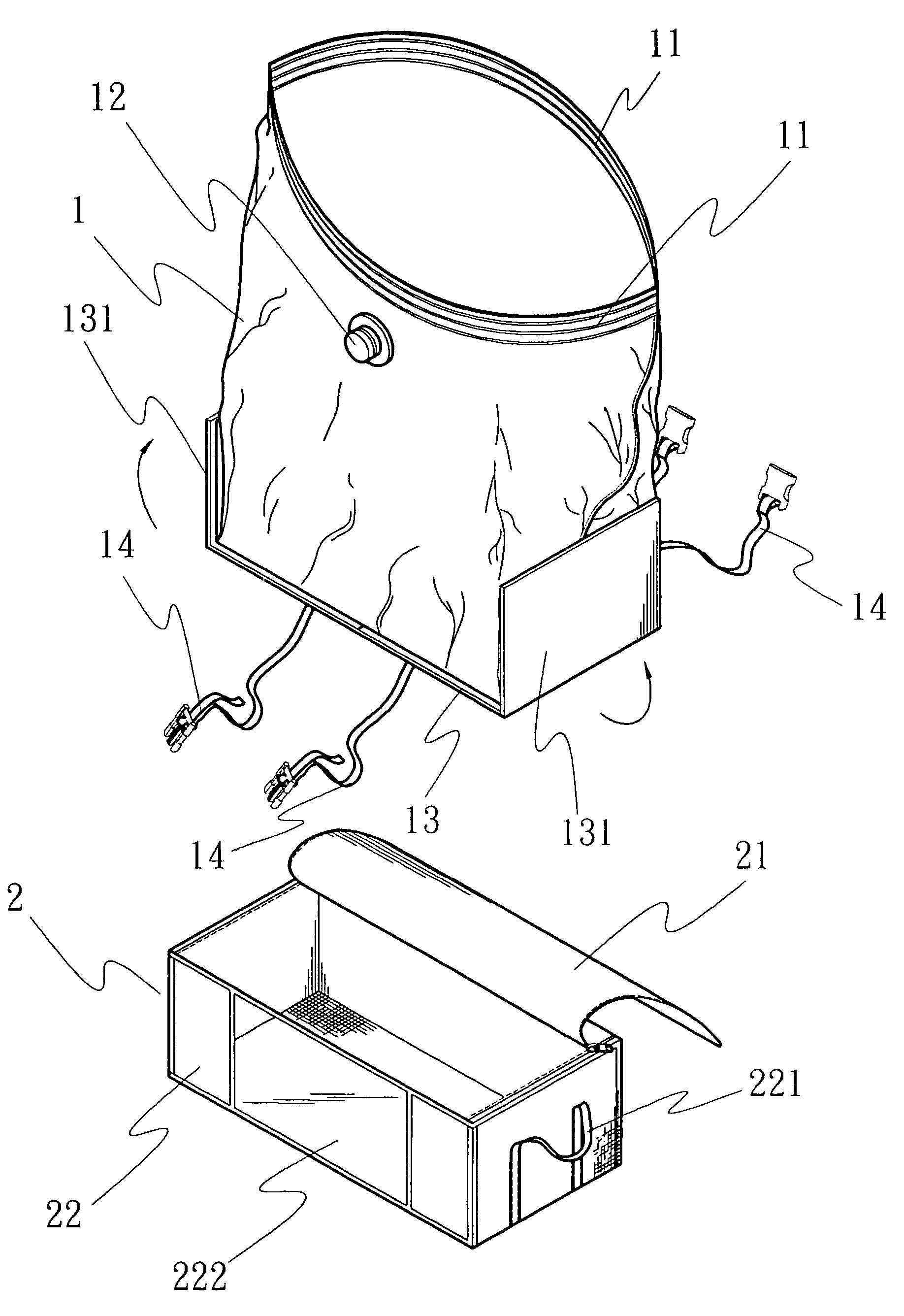

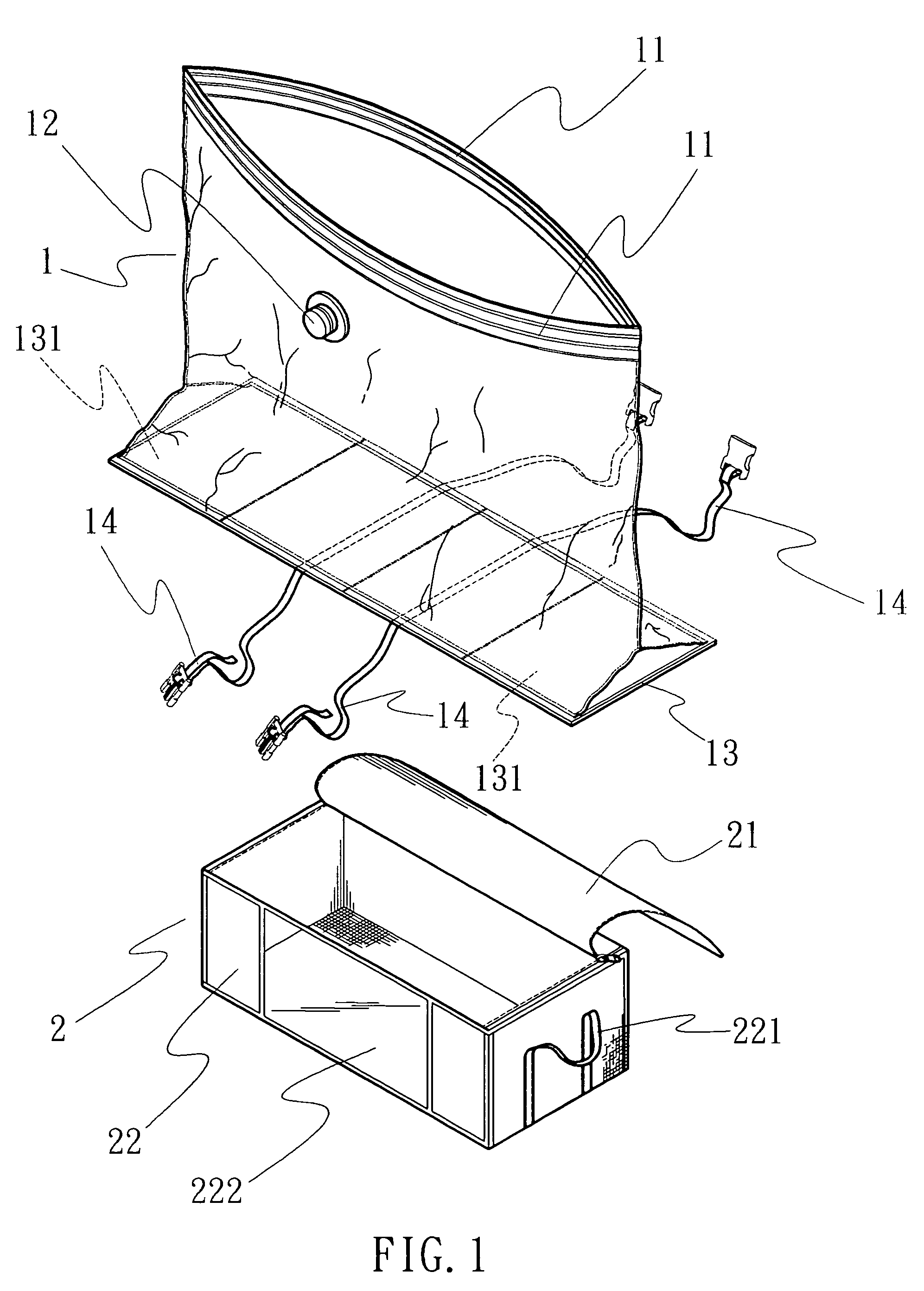

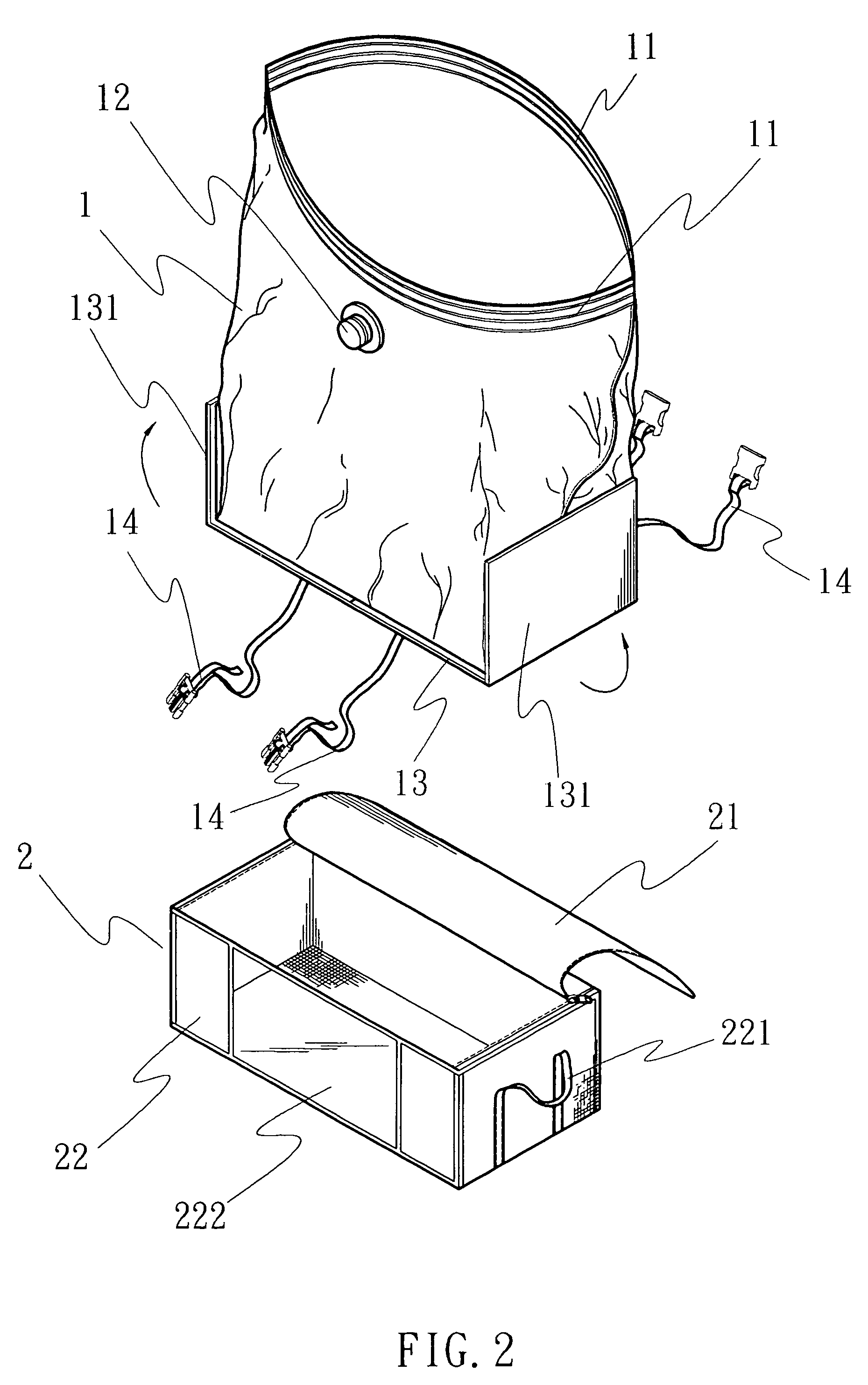

Soft storage container with zip-fastened bottom

An erectable / collapsible soft storage container having a body of flexible material that includes two first sidewalls, two second sidewalls and a bottom. At least three sidewalls are embedded with a hard board. The bottom has two bottom flaps and an edge-fastener engaging one bottom flap to the other. The container is held erect when the bottom flaps are attached and disengaging the flaps allows the container to collapse. Preferably the sidewalls are orthogonal to the bottom and form a rectangular top edge parallel to the bottom. The edge-fastener can be a zip fastener.

Owner:SOURCING SOLUTIONS

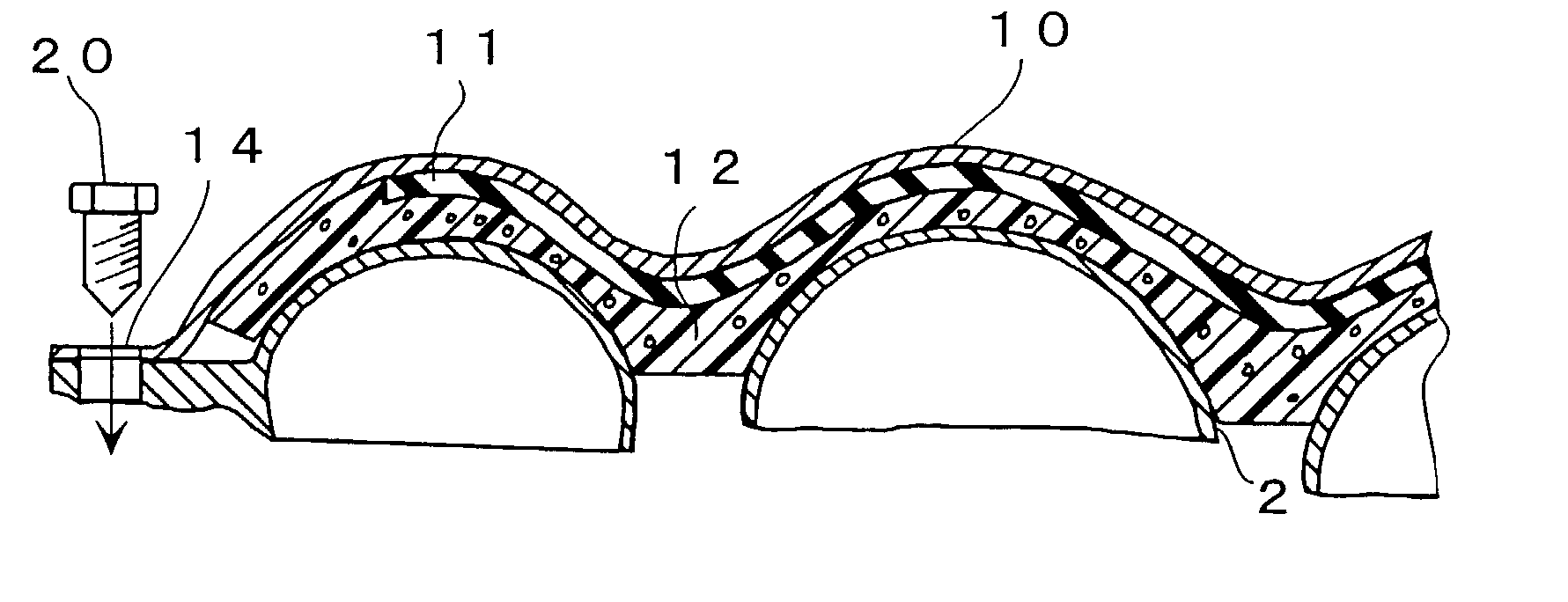

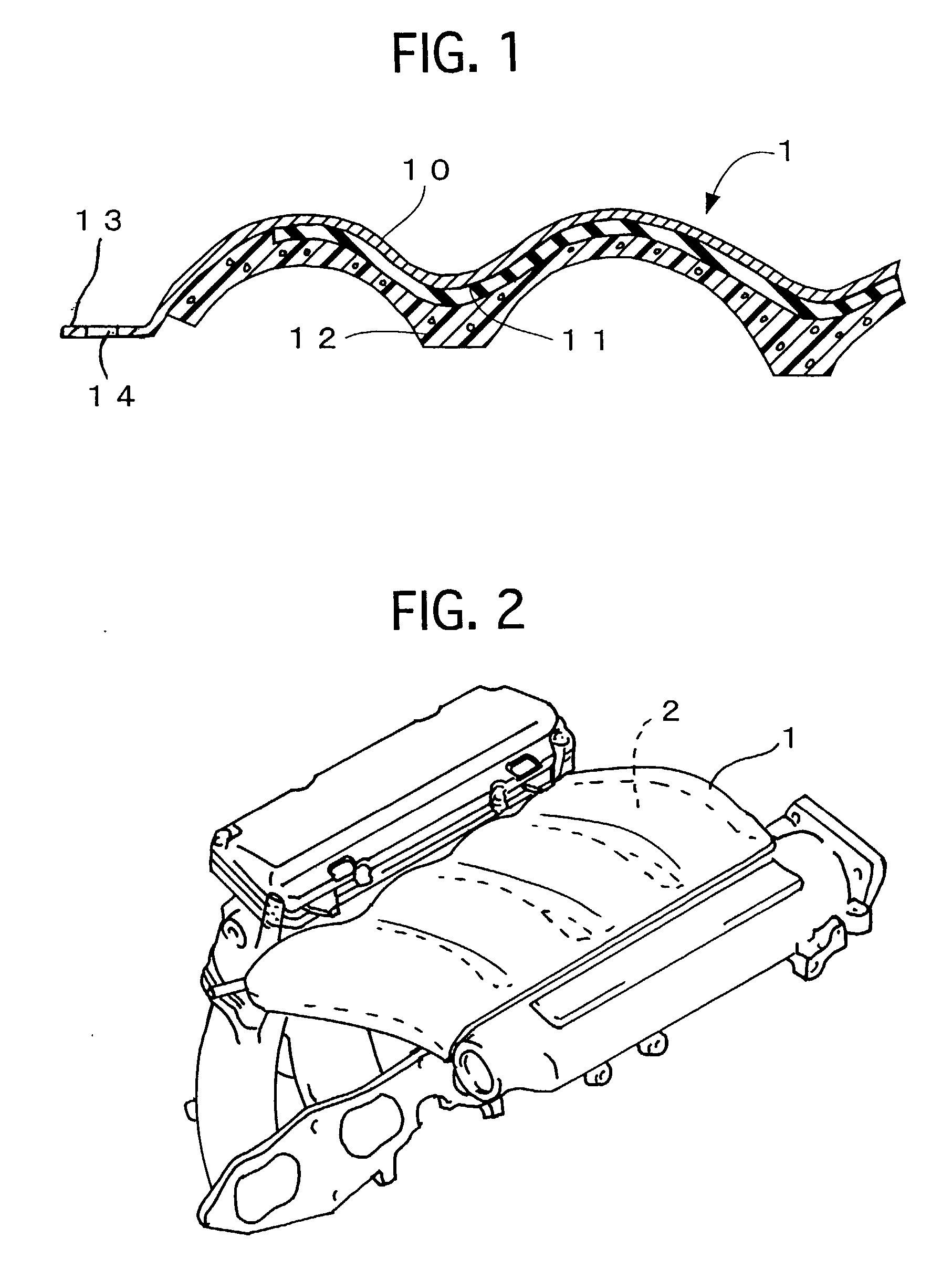

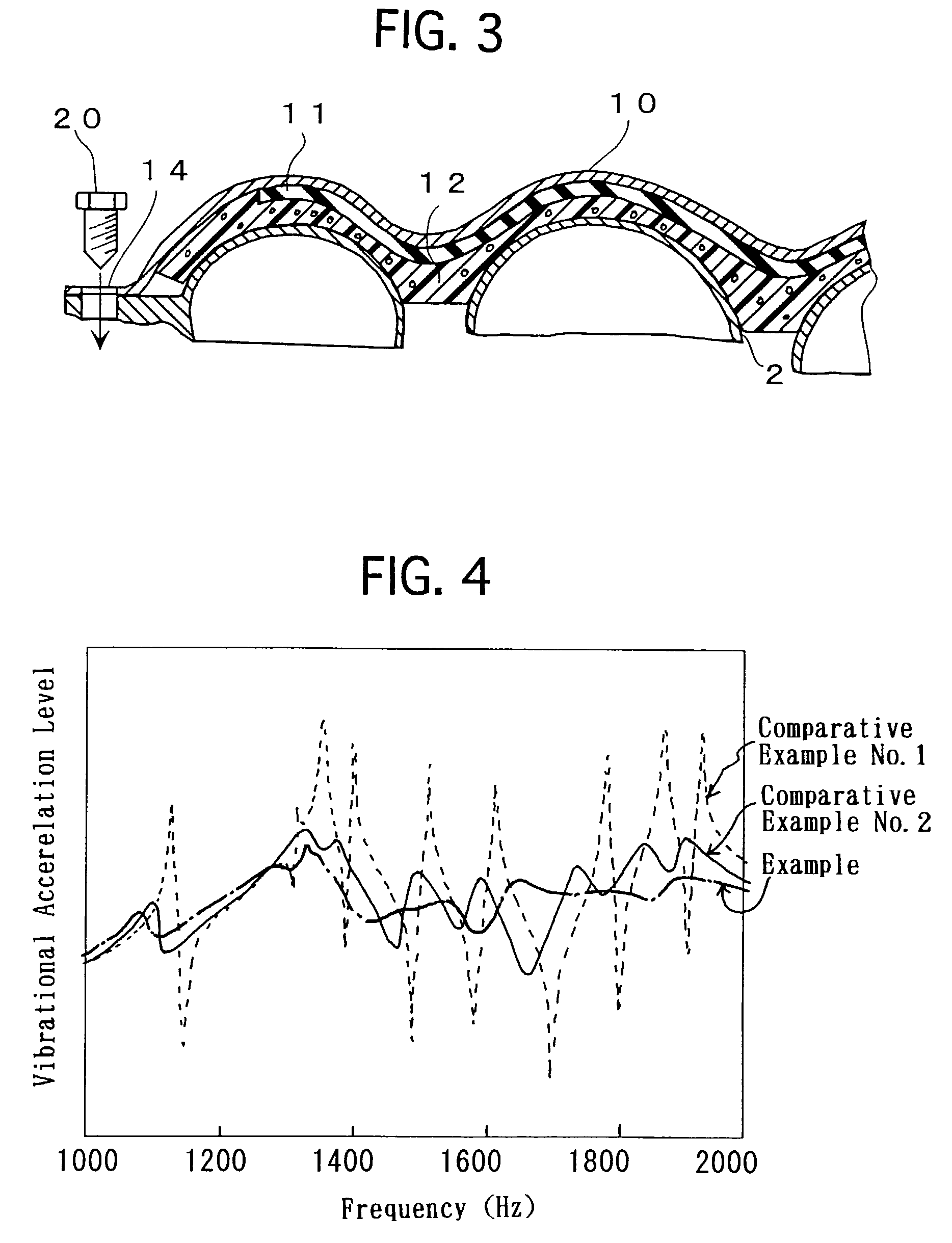

Soundproof cover

InactiveUS20030010566A1Avoid vibrationReduce in quantitySilencing apparatusMachines/enginesInsulation layerEngineering

A soundproof cover includes a sealing layer, a sound insulation layer, and a vibration inhibition layer. The sound insulation layer has a peripheral portion, is to be disposed so as to contact at least the peripheral portion with a noise source, and exhibits elasticity. The sound insulation layer is formed as a hard plate shape, has an installation portion to be fastened to the noise source, and is disposed so as to cover the sealing layer. The vibration inhibition layer is disposed on at least a part of an interface between the sealing layer and the sound insulation layer so as to adhere to the sound insulation layer, and inhibits the sound insulation layer from vibrating.

Owner:SUMITOMO RIKO CO LTD +1

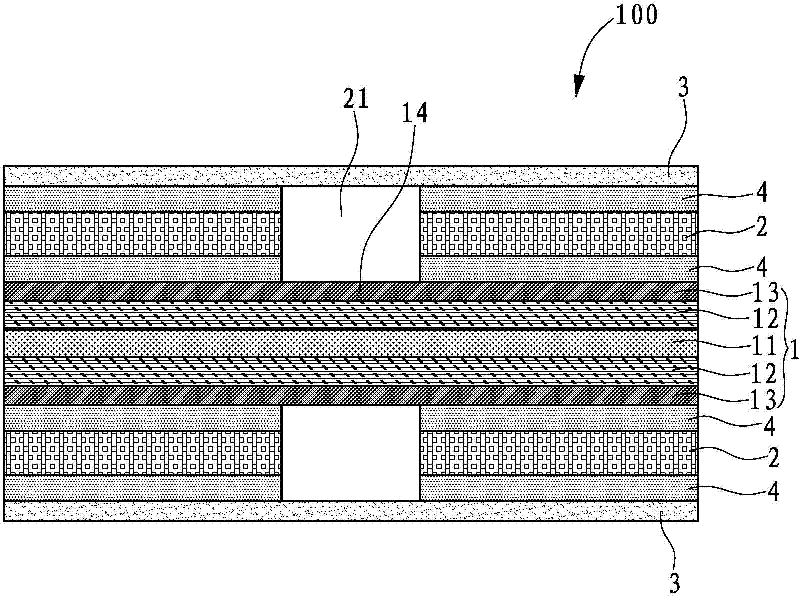

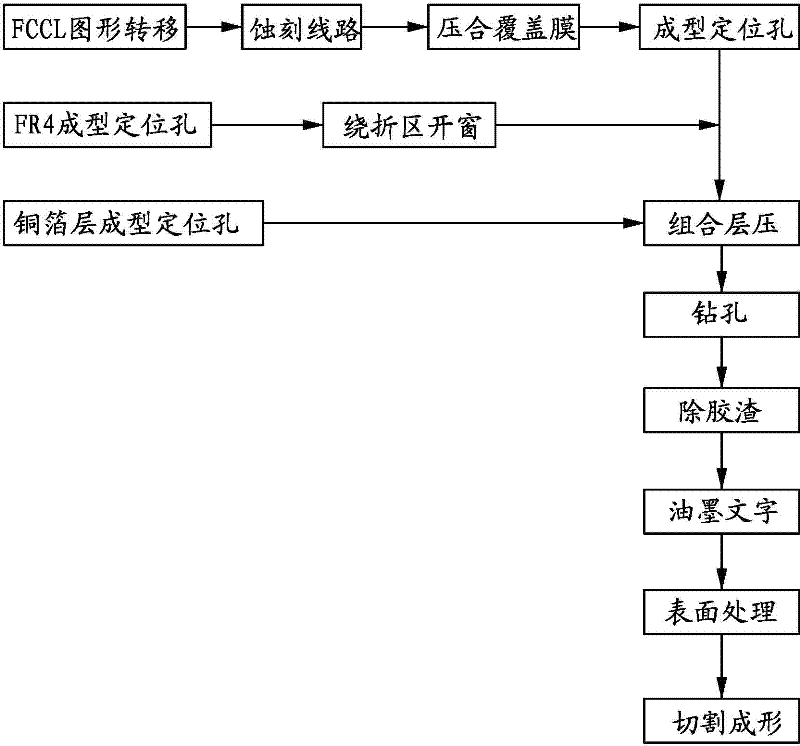

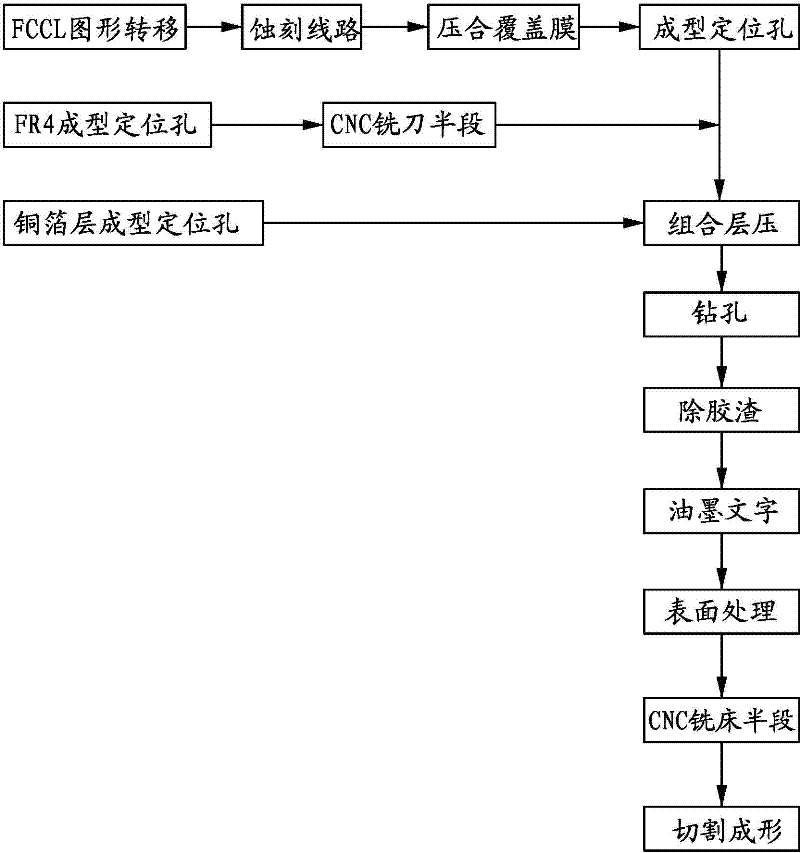

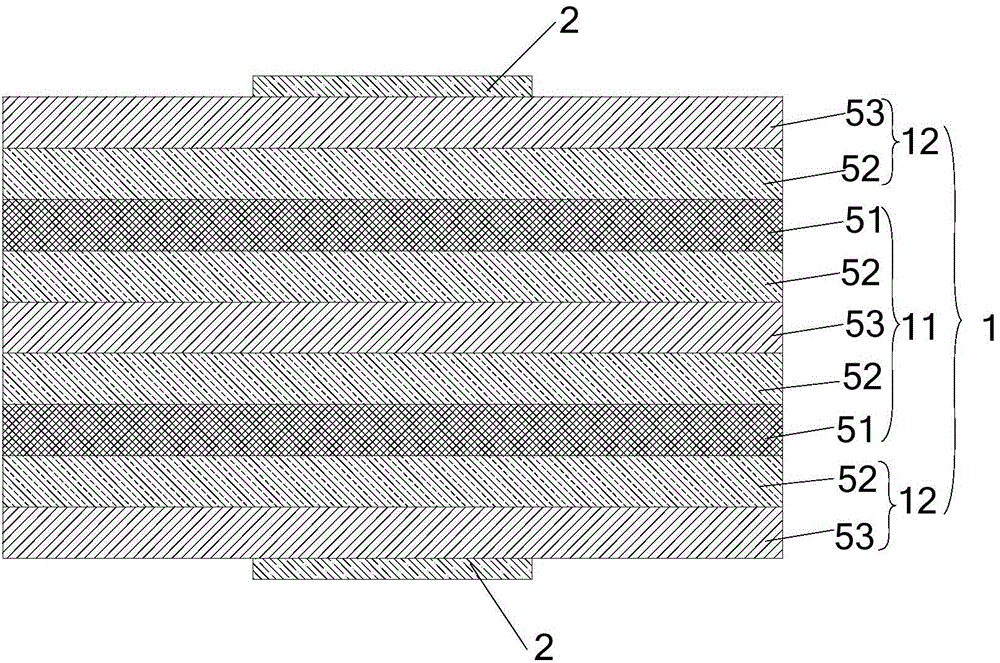

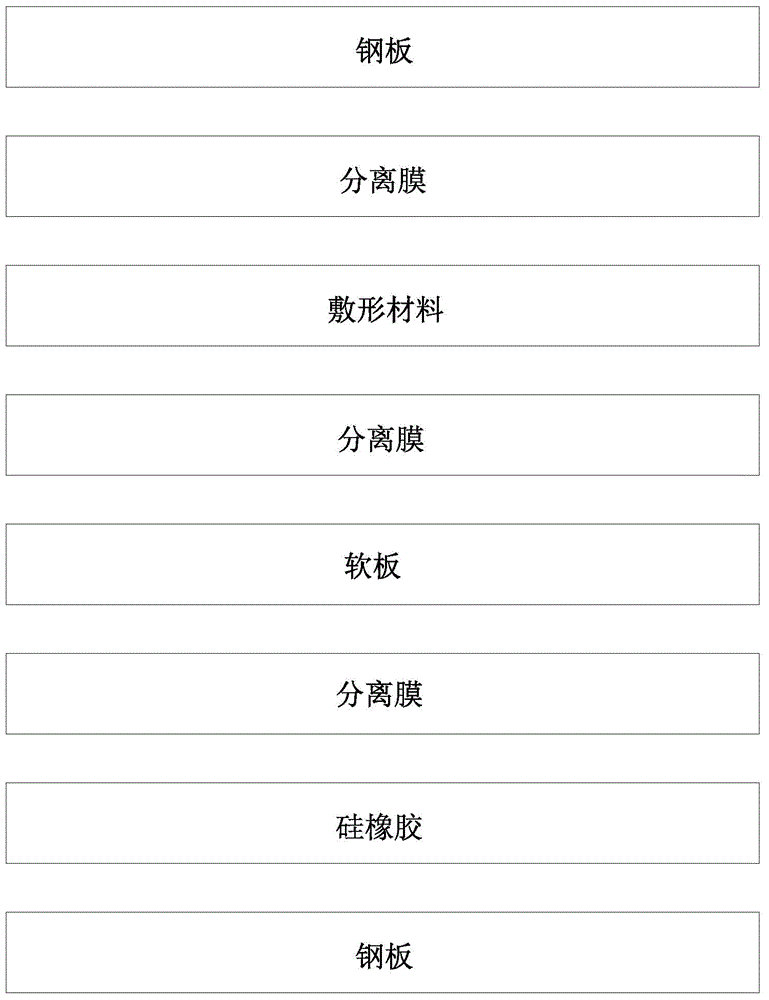

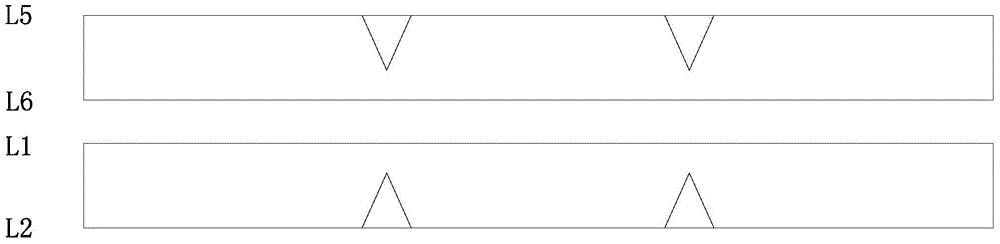

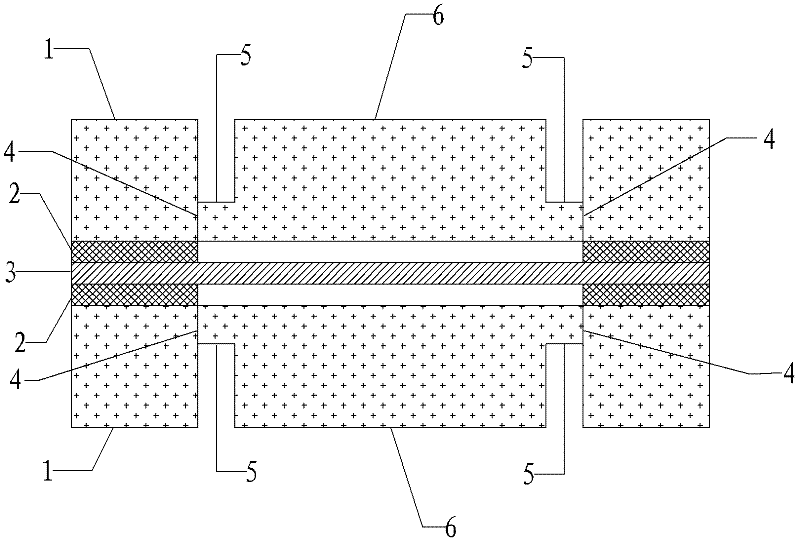

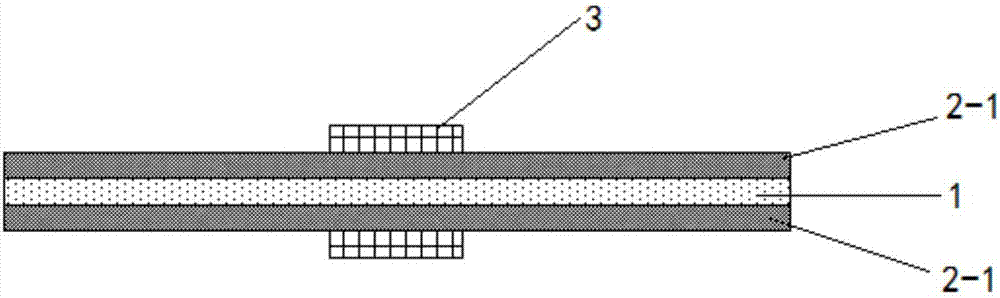

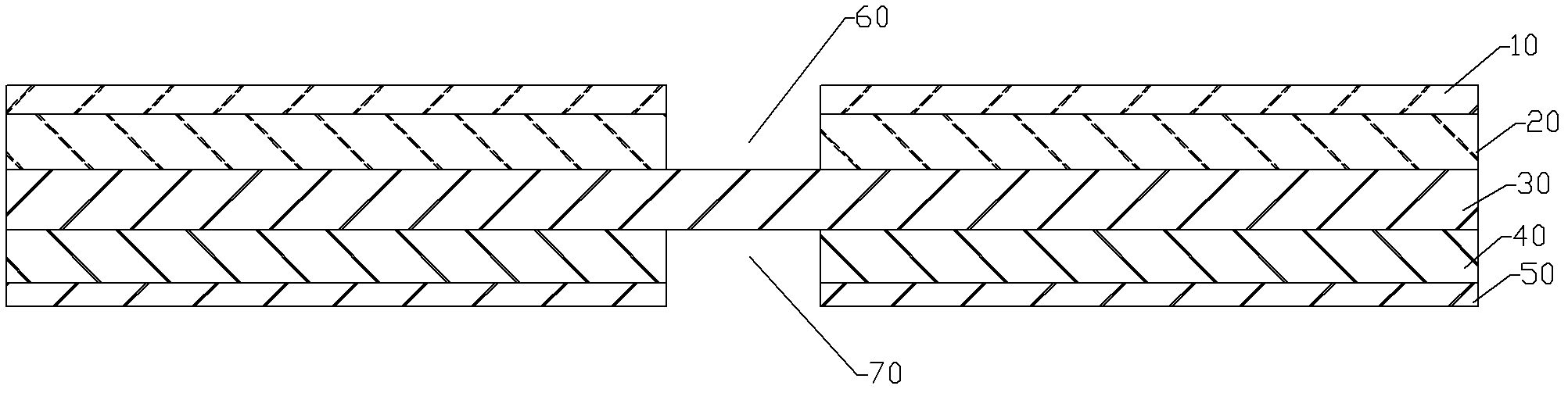

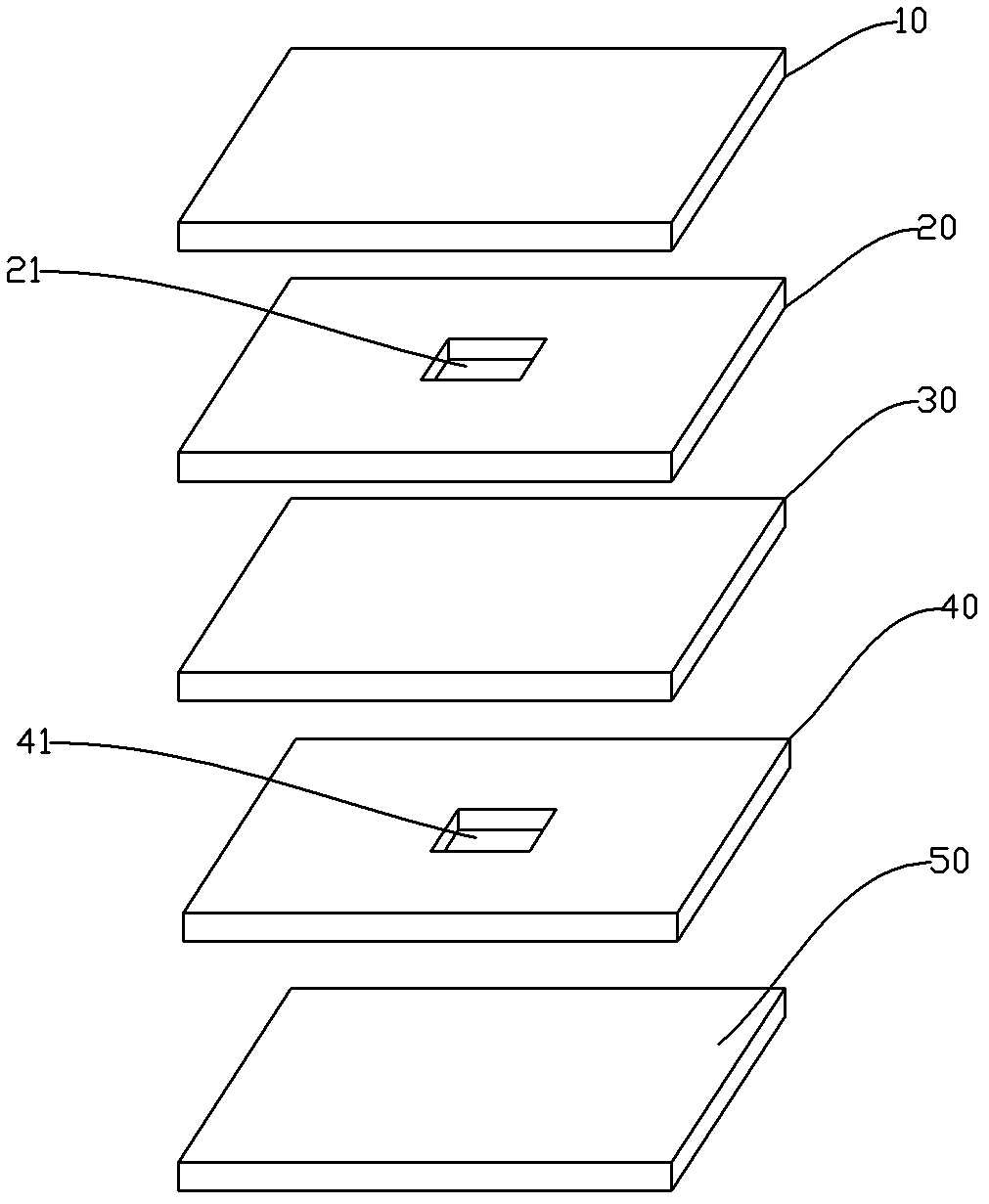

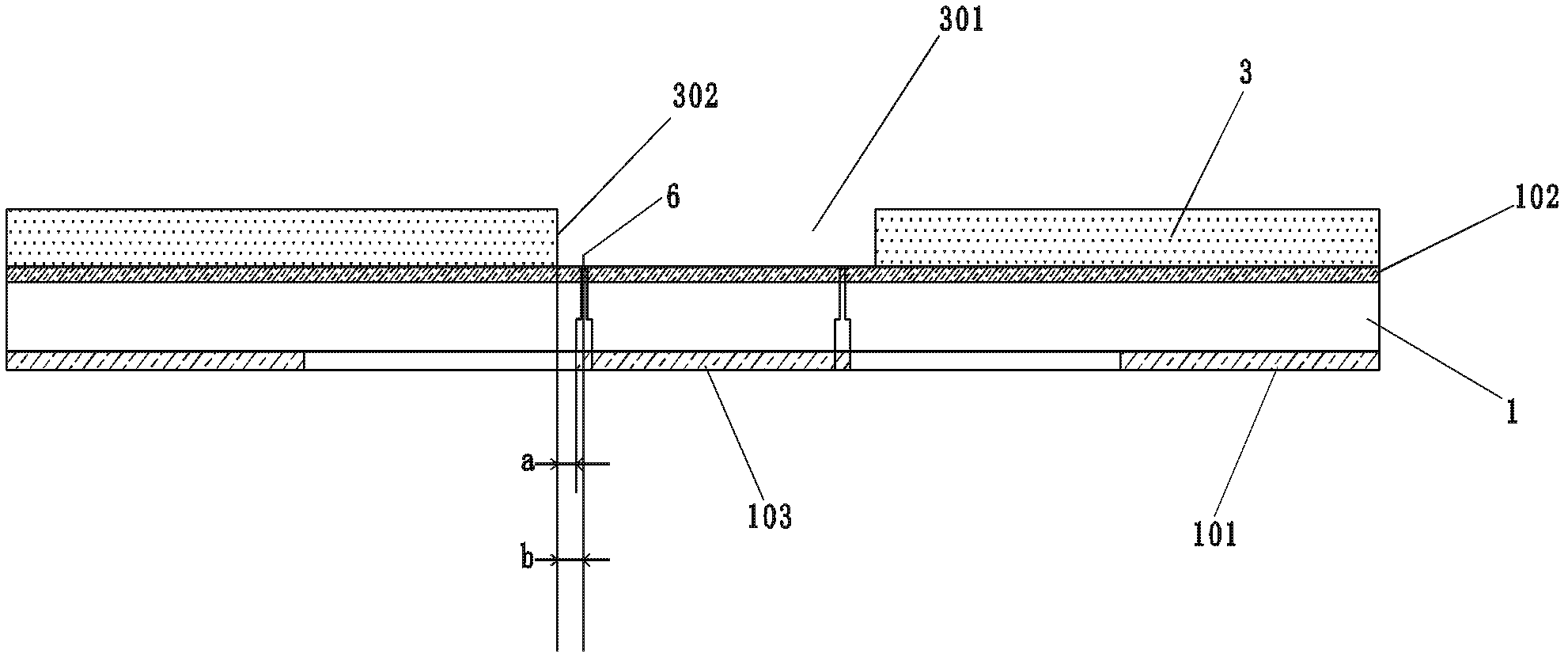

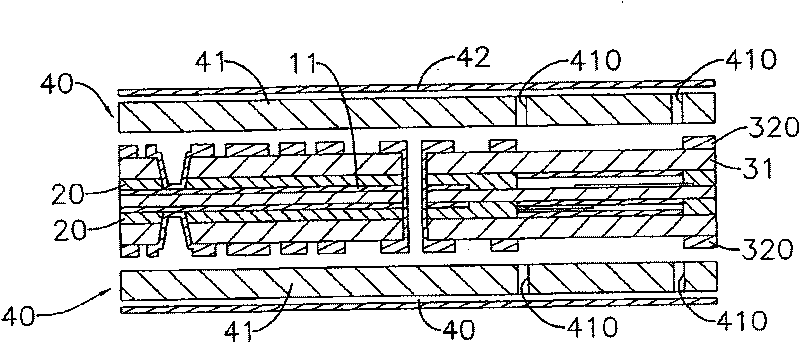

Novel rigid-flexible PCB (printed circuit board) and manufacturing method thereof

ActiveCN102256438AGuaranteed performanceEasy to operatePrinted circuits structural associationsMultilayer circuit manufactureEngineeringCopper foil

The invention discloses a novel rigid-flexible PCB (printed circuit board) and a manufacturing method thereof. The novel rigid-flexible PCB comprises a flexible core board made from an FPC (flexible printed circuit) and two rigid substrates arranged at the two sides of the flexible core board, each rigid substrate and the flexible core board are adhered together through viscose; the flexible coreboard is provided with a winding and folding region, each rigid substrate is provided with a window at the position corresponding to the winding and folding region, and one side far away from the flexible core board, of each rigid substrate is provided with a copper foil layer which can cover the window on the rigid substrate in an adhesion mode. The manufacturing method comprises preliminary treatment, combination lamination treatment and sequent treatment. The invention can play a role in ensuring the performance of the flexible core board; and meanwhile, the moulding mode of the rigid-flexible PCB related in the invention also has the characteristics of low production cost and strong operability.

Owner:XIAMEN INNOV INFORMATION TECH

Fire-retardant coating, method for producing fire-retardant building materials

InactiveUS7429290B2Simple materialIncrease resistanceFireproof paintsAntifouling/underwater paintsCalcium silicateCardboard

The present invention relates to a fire-resistant coating and method thereof, which confers enhanced flame and heat resistance to substrate such as building materials. The invented coating is especially applicable to cellulose-based building materials including but not limited to fiberboards, wallboards, roofing materials, particleboards, ceiling tiles, soundproofing boards and hardboards. This novel composition is also useful in providing a fire-resistant coating for concrete, metals, foamed polymeric materials, gypsum and other substrates. A preferred embodiment generally comprising: mono potassium phosphate, magnesium oxide, silica powder, calcium silicate, rice hull ash and water. A method for imparting fire-retardancy to substrates using the invented composition is also described.

Owner:BONE SOLUTIONS INC

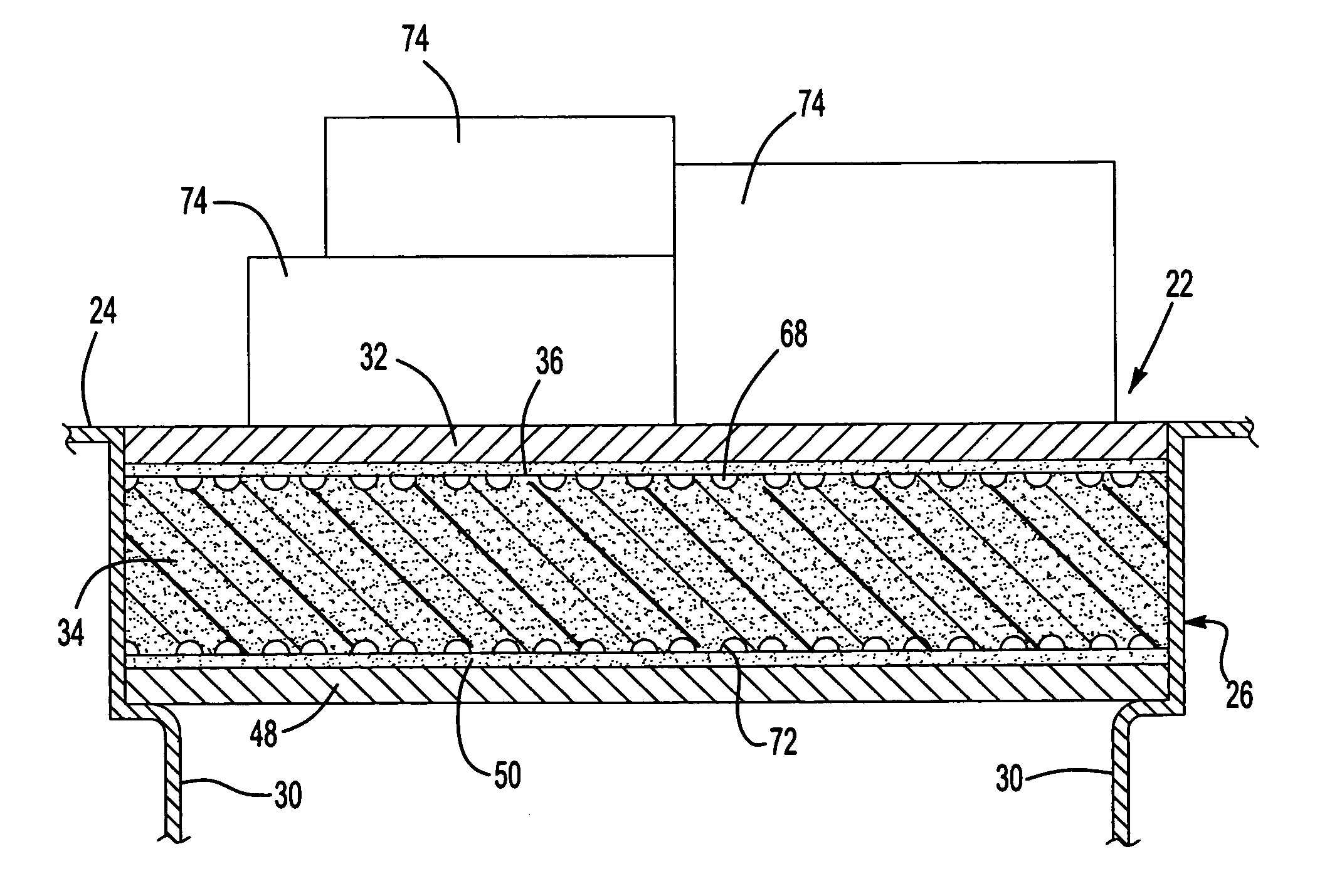

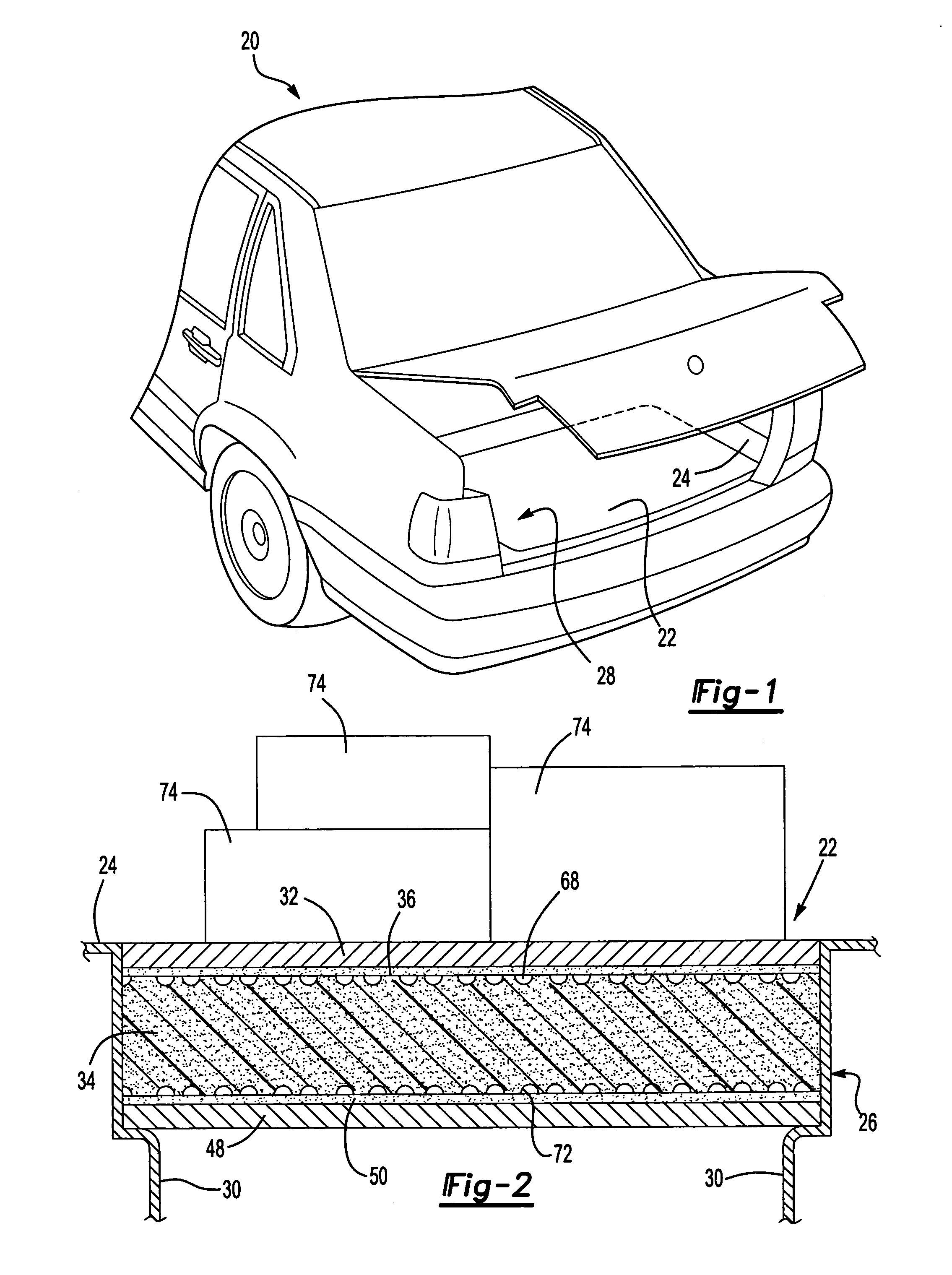

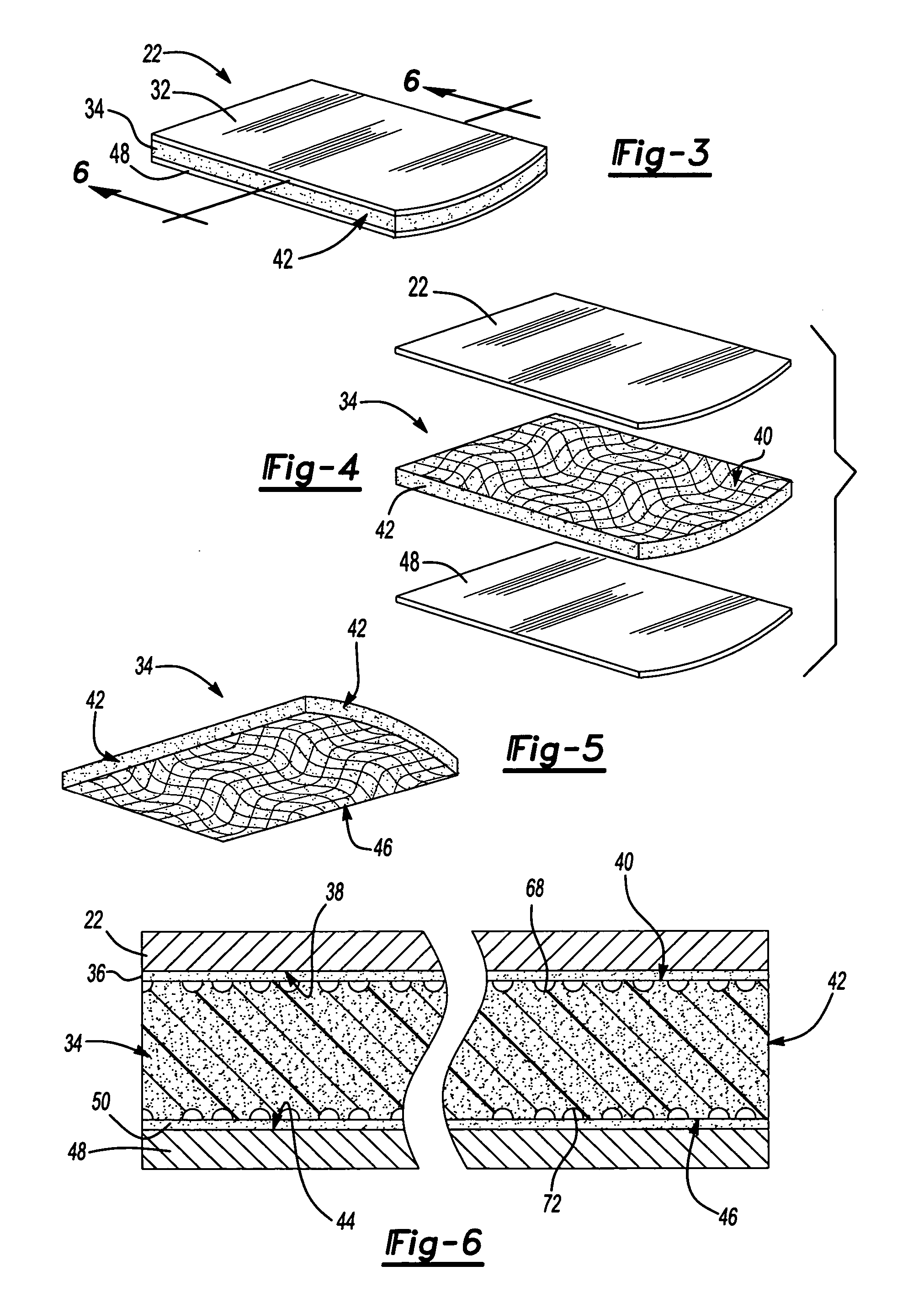

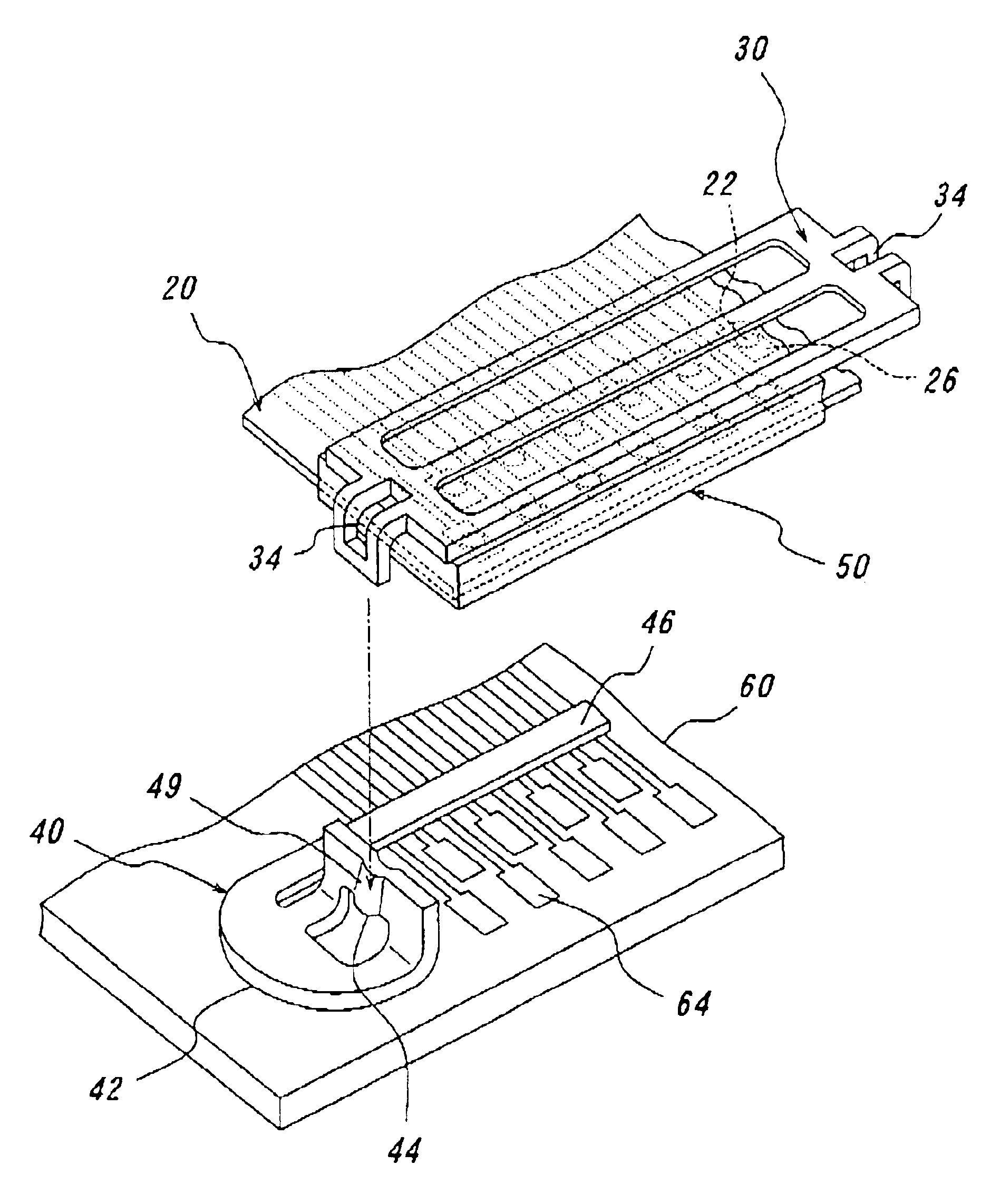

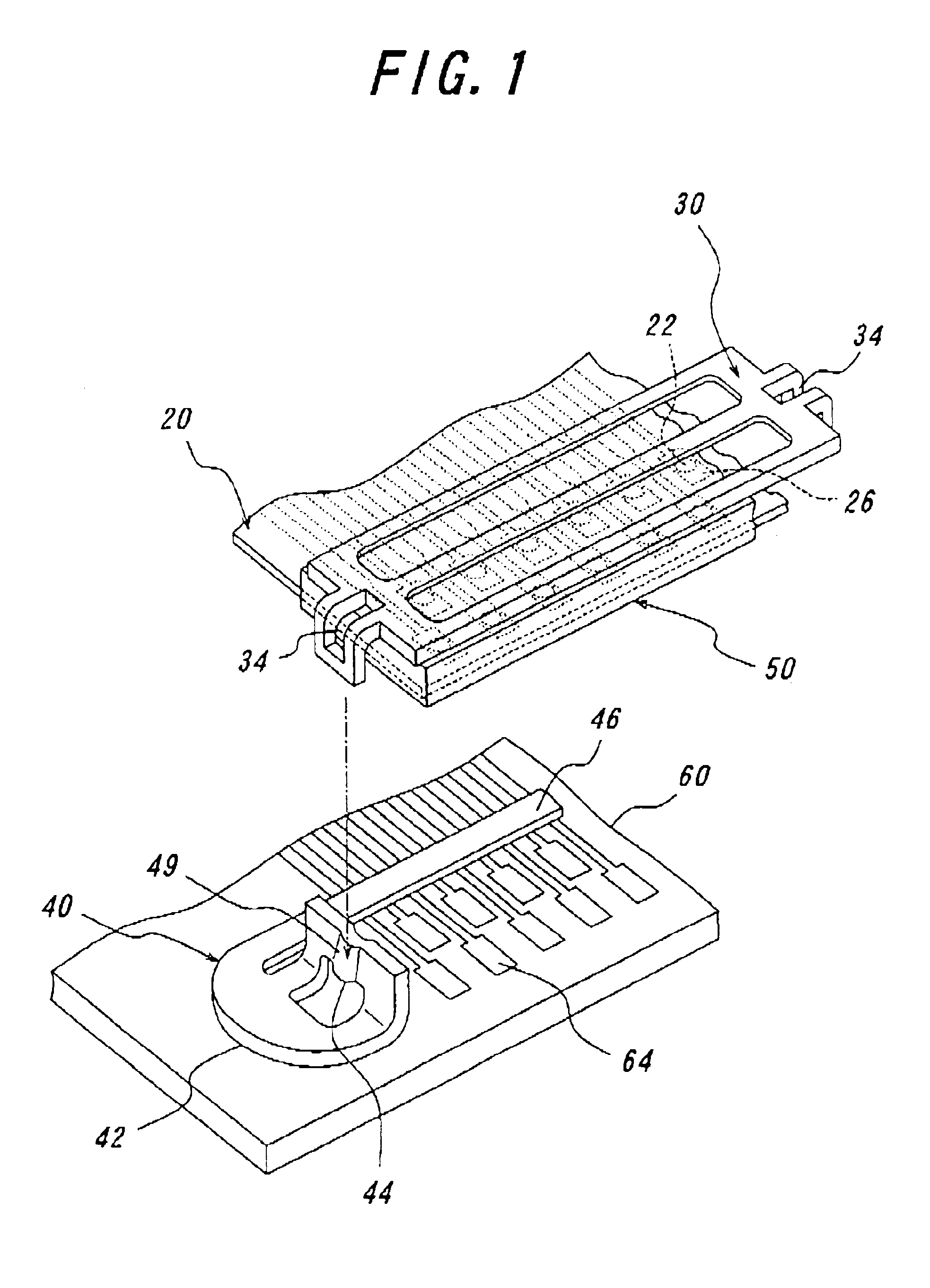

Load floor assembly

A load floor (22) for a motor vehicle (20) has a foamed substrate layer (34) having a peripheral edge (42) and a facing layer (32), formed from hardboard or other sheet material. An adhesive layer (36) adheres the substrate layer (34) to the facing layer (32). Grooves (68, 70) are formed on a top surface (40) of the substrate layer (34) and extend to the peripheral edge (42) to provide an egress for fluids at the peripheral edge (42) during curing of the adhesive layer (36). The grooves (68, 70) are curved to prevent cracking of the substrate layer (34) under an applied load (74).

Owner:BBI ENTERPRISES GROUP

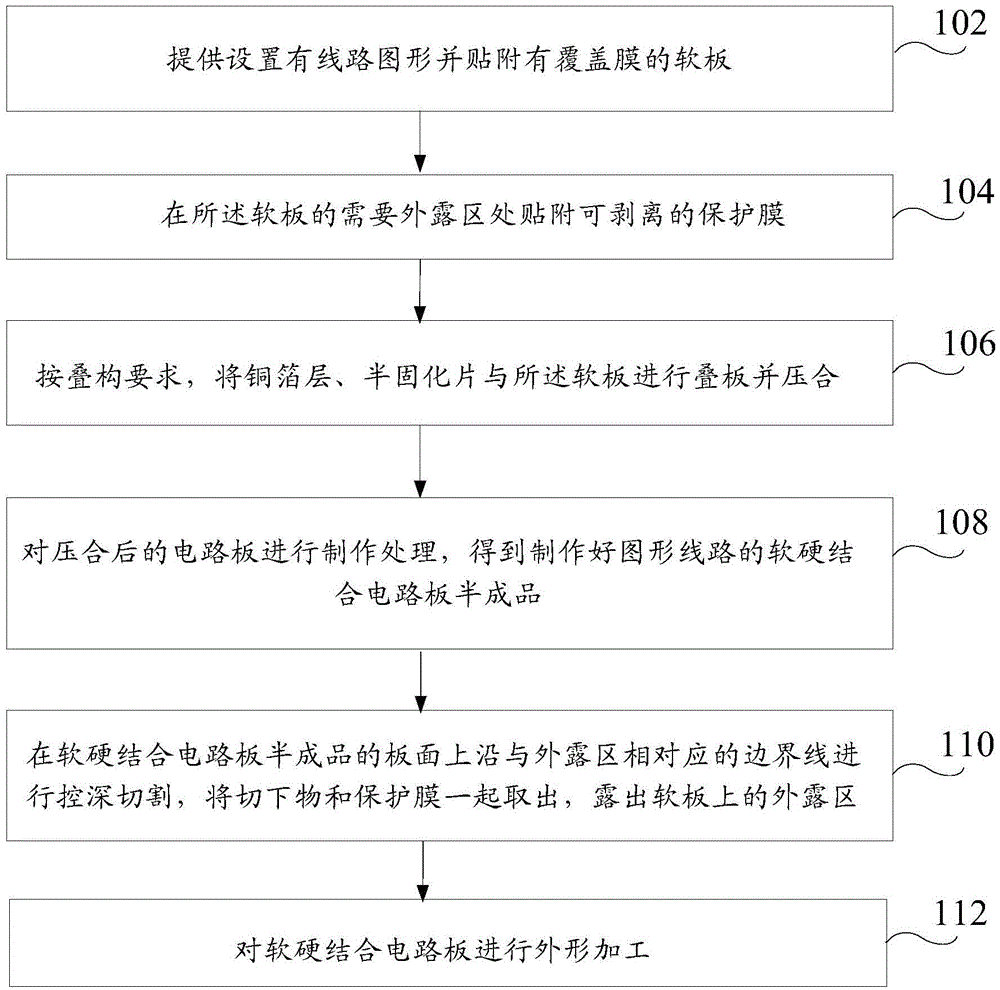

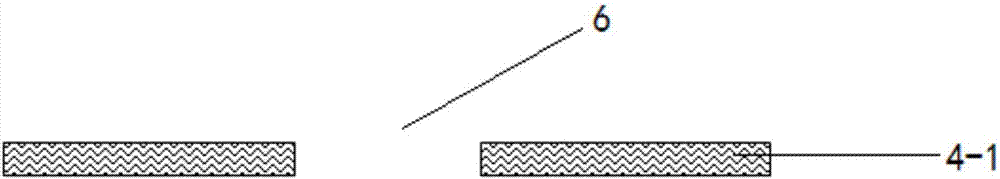

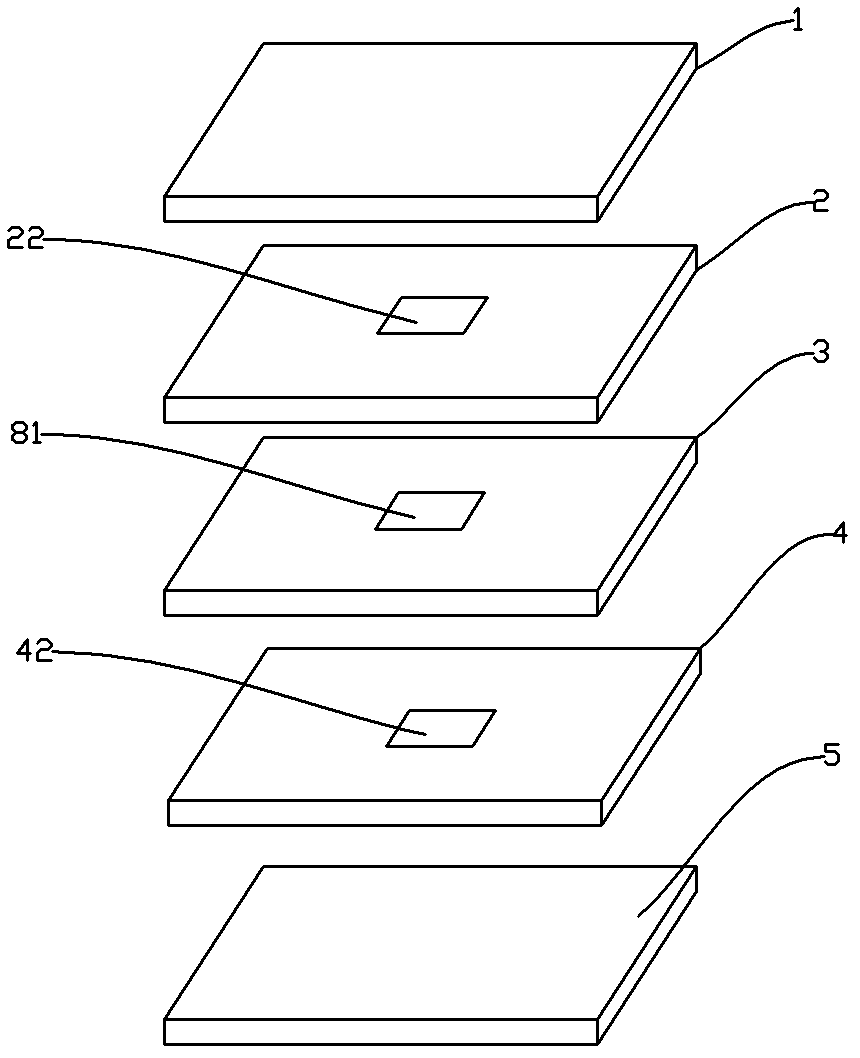

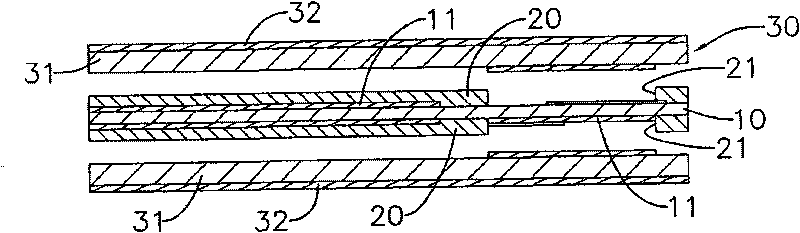

Rigid-flex circuit board and production method thereof

InactiveCN104582309AReduce processing stepsEasy to preparePrinted circuit assemblingGraphicsTectorial membrane

The invention provides a production method of a rigid-flex circuit board as well as the rigid-flex circuit board. The production method of the rigid-flex circuit board comprises the following steps: a flexible board is provided; a strippable protection film is attached to a to-be-exposed area of the flexible board; a copper foil layer, a prepreg and the flexible board, or a rigid board, the prepreg and the flexible board are laminated and compressed according to a stacking requirement; the circuit board after compression is subjected to production processing, and a semi-finished rigid-flex circuit board product with well-produced graphics and lines is obtained; and depth-control cutting is performed on the board surface of the semi-finished rigid-flex circuit board product along boundary lines corresponding to the exposed area, and off-cut materials and the protection film are taken out. According to the production method of the rigid-flex circuit board, windowing on the prepreg or the rigid board is not required during production of the rigid-flex circuit board, and the process is simple; the method is applied to production of the rigid-flex circuit board with thicker or thinner dielectric layer, and the application range is wide; and a gasket is not required during production of the rigid-flex circuit board with the thinner dielectric layer, and the cost is low.

Owner:PEKING UNIV FOUNDER GRP CO LTD +3

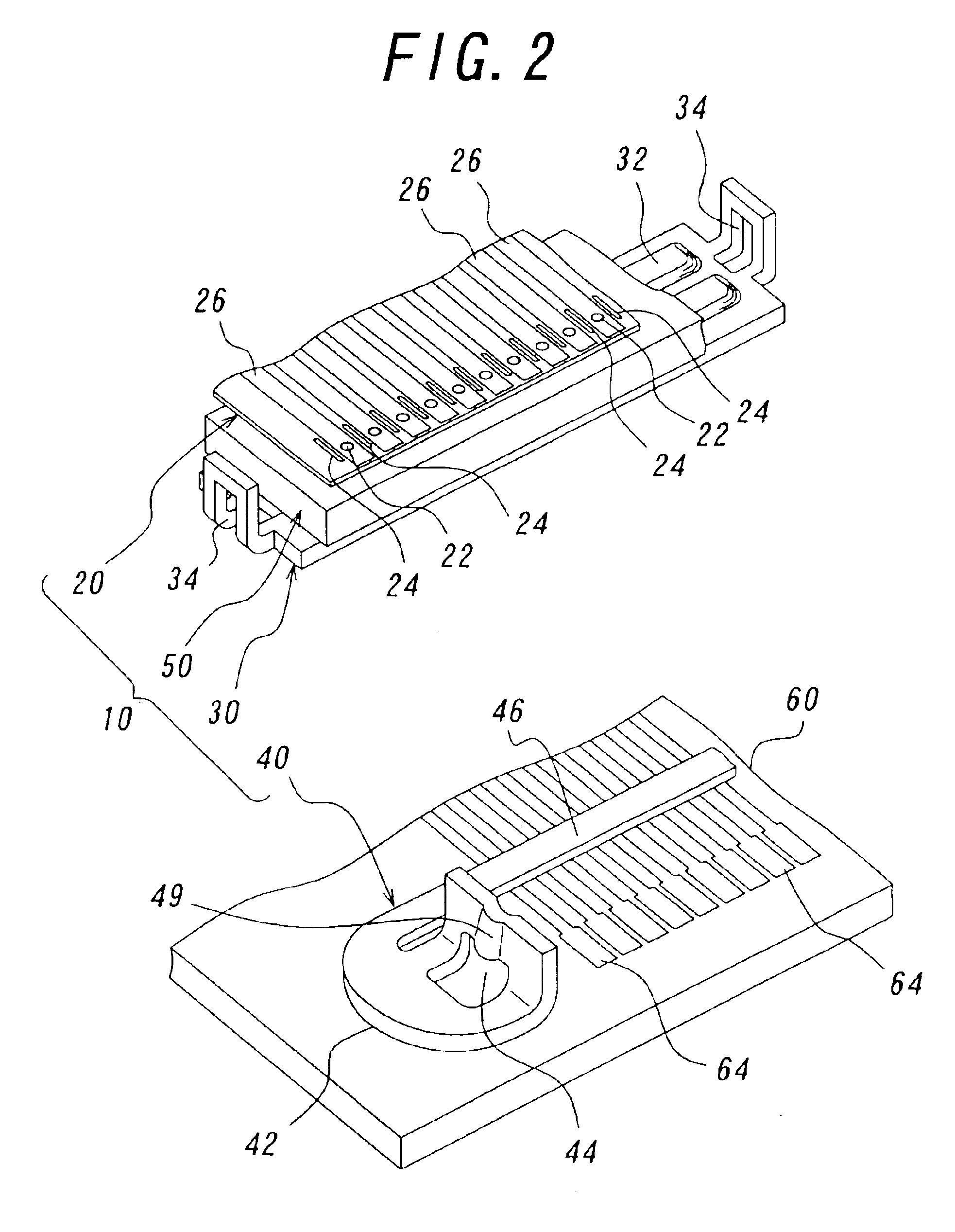

Flat and thin connector for electrically connecting a flexible printed circuit board and a hard board

InactiveUS6960094B2More flatnessThinner and narrow pitch of contactEngagement/disengagement of coupling partsPrinted circuit assemblingEngineeringFlexible electronics

A flat and thin connector for electrically connecting a flexible printed circuit board and a hard board. The connector includes a mounting member fixed to the hard board, and a pusher member cooperating with said mounting member. The pusher member urges the printed circuit board against the hard board by aid of an elastic member. Further, the printed circuit board is provided with slits between the bump contacts to facilitate a uniform pushing force.

Owner:THE FUJIKURA CABLE WORKS LTD

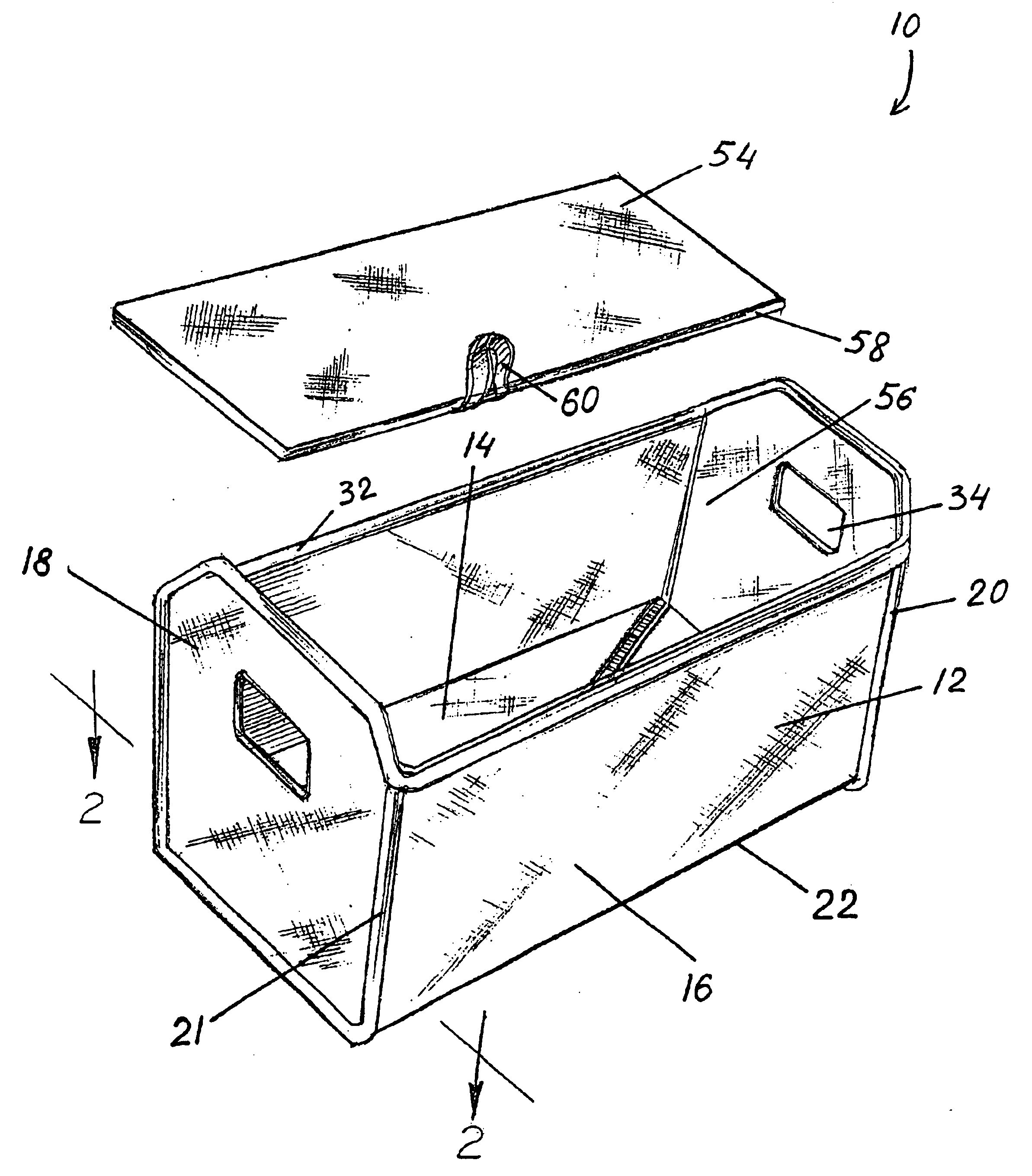

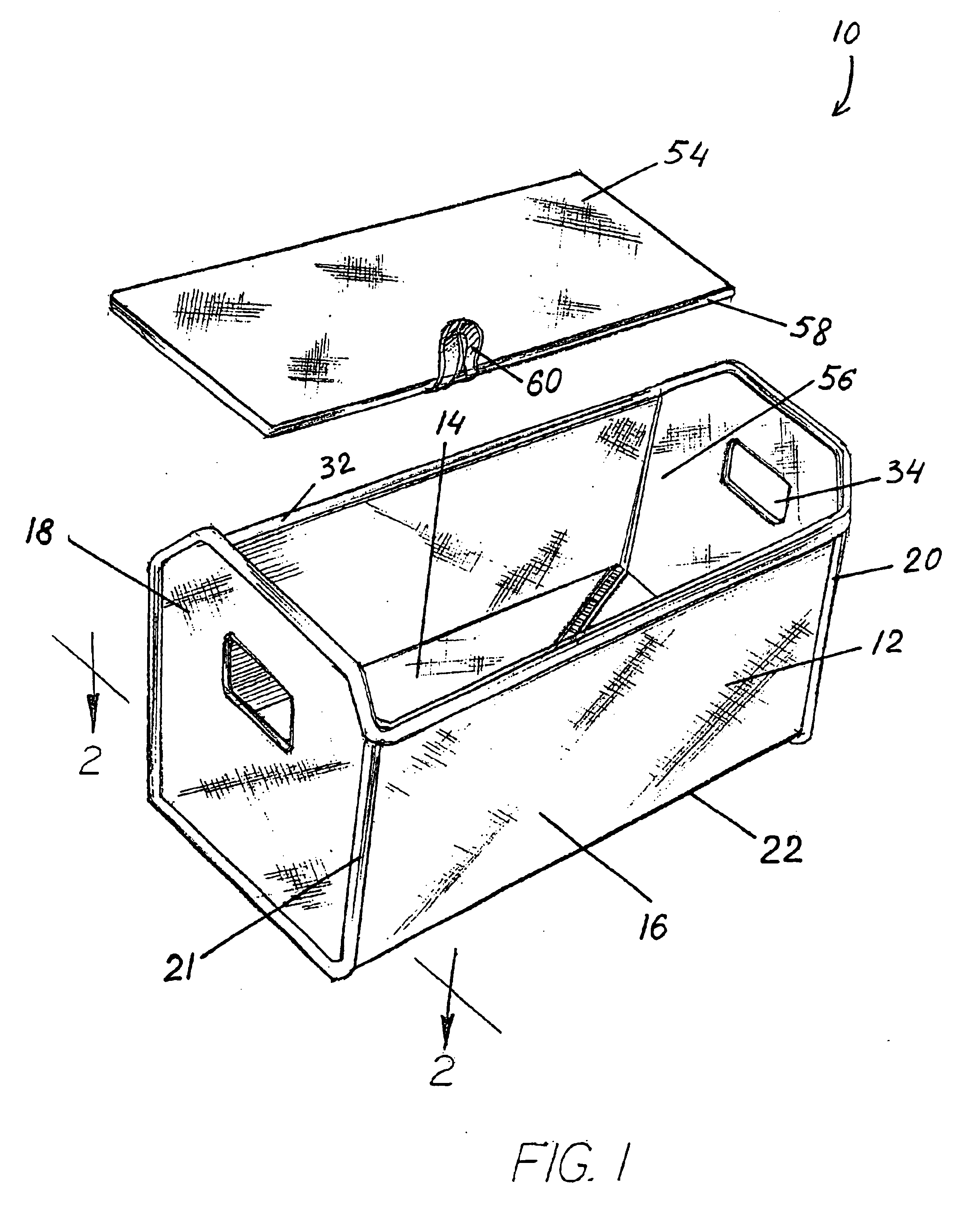

Combined storage apparatus

ActiveUS7588160B2Save spaceSmall shapePositive displacement pump componentsVenting meansEngineeringHardboard

Owner:SC JOHNSON & SON INC

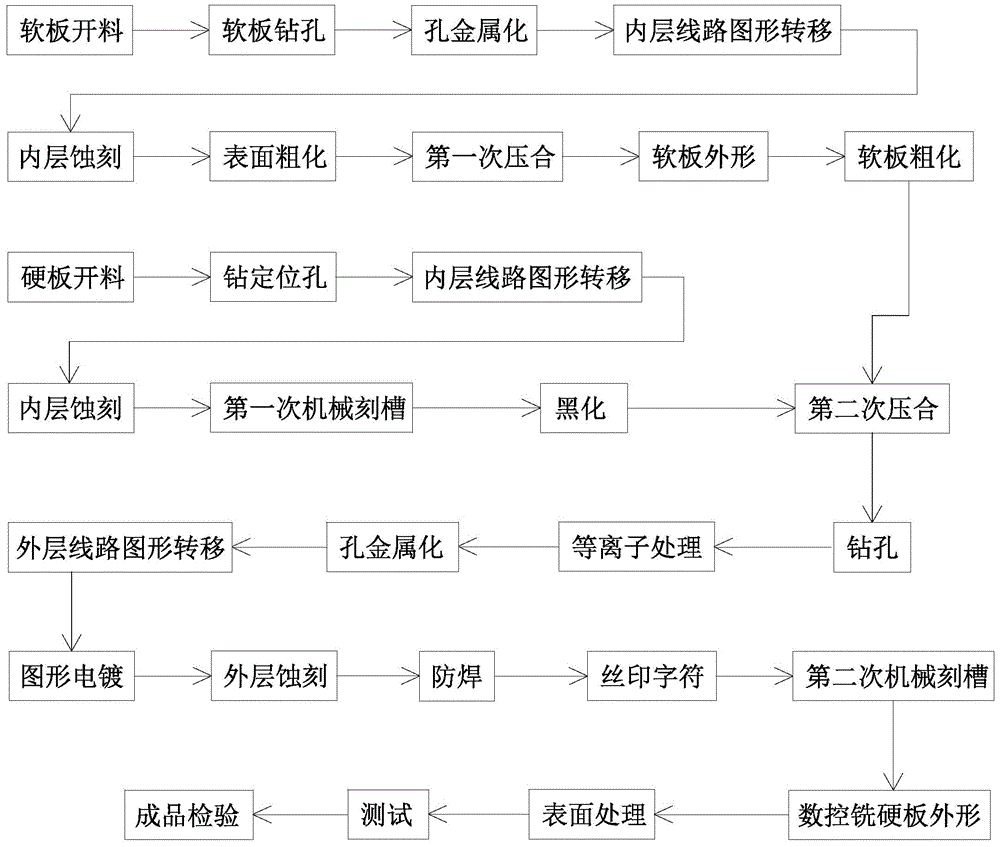

Fabrication method for rigid-flex printed combination board of covering membrane window

InactiveCN104135823AImprove reliabilityImprove manufacturing yieldPrinted circuit assemblingEtchingSurface roughness

The invention provides a fabrication method for a rigid-flex printed combination board of a covering membrane window. The fabrication method comprises the steps of soft board treatment, hard board treatment and treatment after a soft board and a hard board are combined, wherein the step of soft board treatment comprising surface roughening, in which the surface of the soft board is roughened; lamination for a first time, in which a covering membrane is pressed onto the surface of the soft board; soft board appearance, in which the appearance of the soft board is subjected to shaping; and soft board roughening, in which the soft board after being subjected to shaping is roughened; the step of hard board treatment comprises inner layer etching; mechanical groove carving for the first time, in which grooves are carved on the part of a flexible region of the hard board; and blackening, in which the surface roughness of copper foils at an inner layer is enhanced; and the step of treatment after the soft board and the hard board are combined comprises lamination for a second time, in which the roughened soft board and the blackened hard board are laminated to form the soft and hard combination board. Lamination is performed for twice in the fabrication method, the lamination reliability and the fabrication yield can be improved, and plasma treatment is adopted prior to copper deposition, the reliability of a hole wall can be ensured.

Owner:东莞市五株电子科技有限公司

Wood adhesive and method of preparing thereof

InactiveUS8057892B2Improve waterproof performanceAccelerate the drying rate of an adhesive coatingProtein waste adhesivesLayered productsHigh densityPreservative

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fiberboard, high density fiberboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

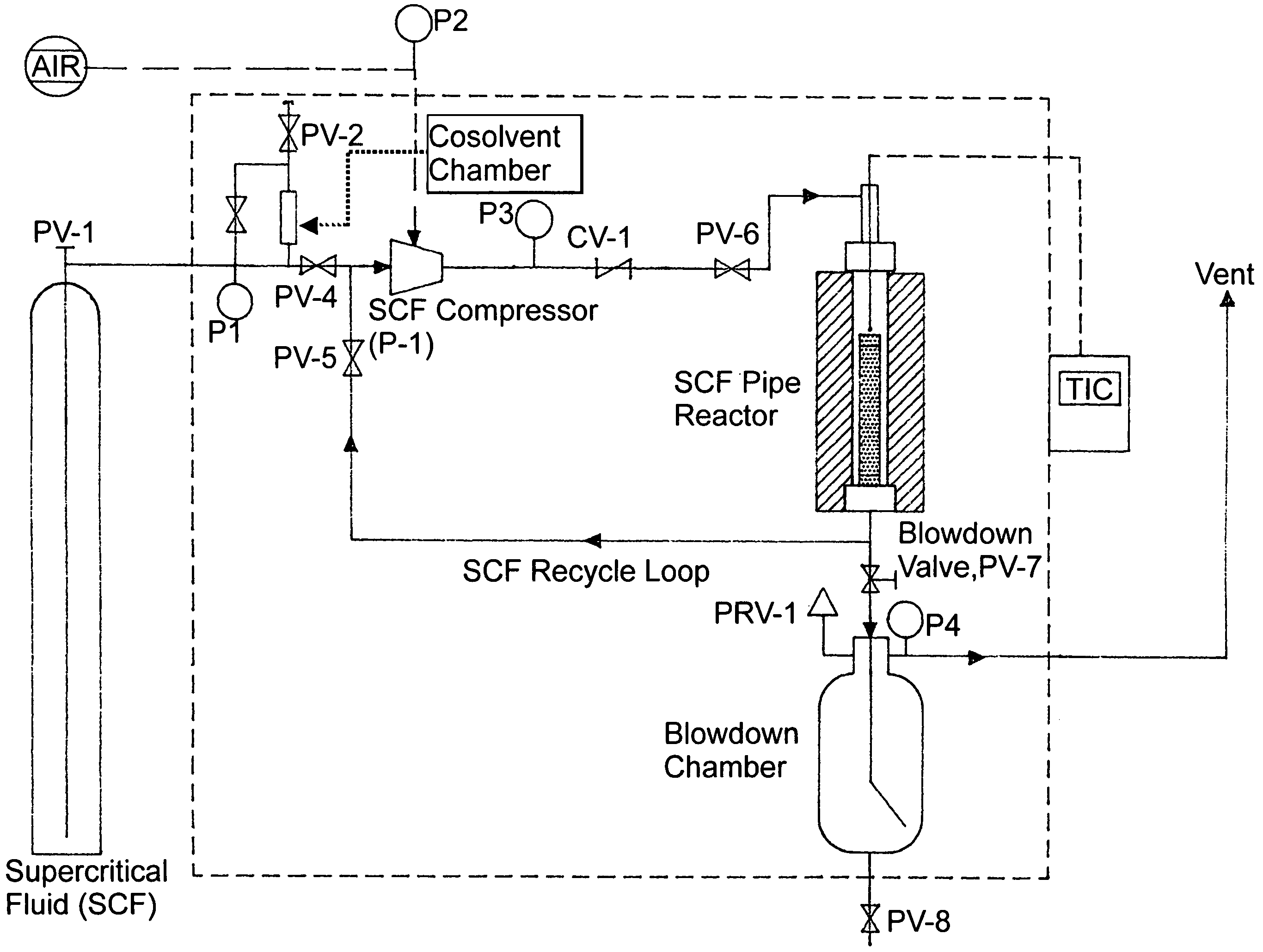

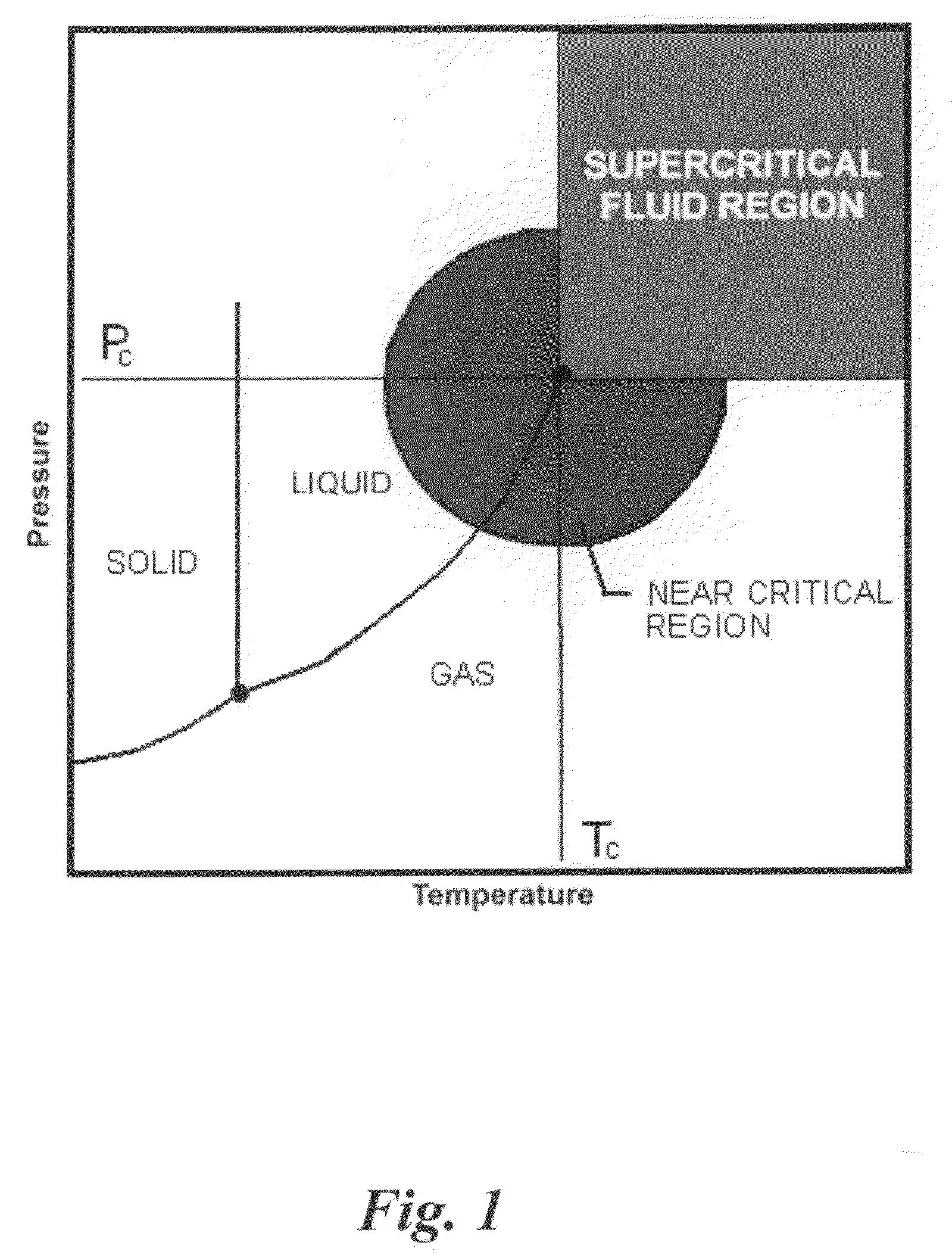

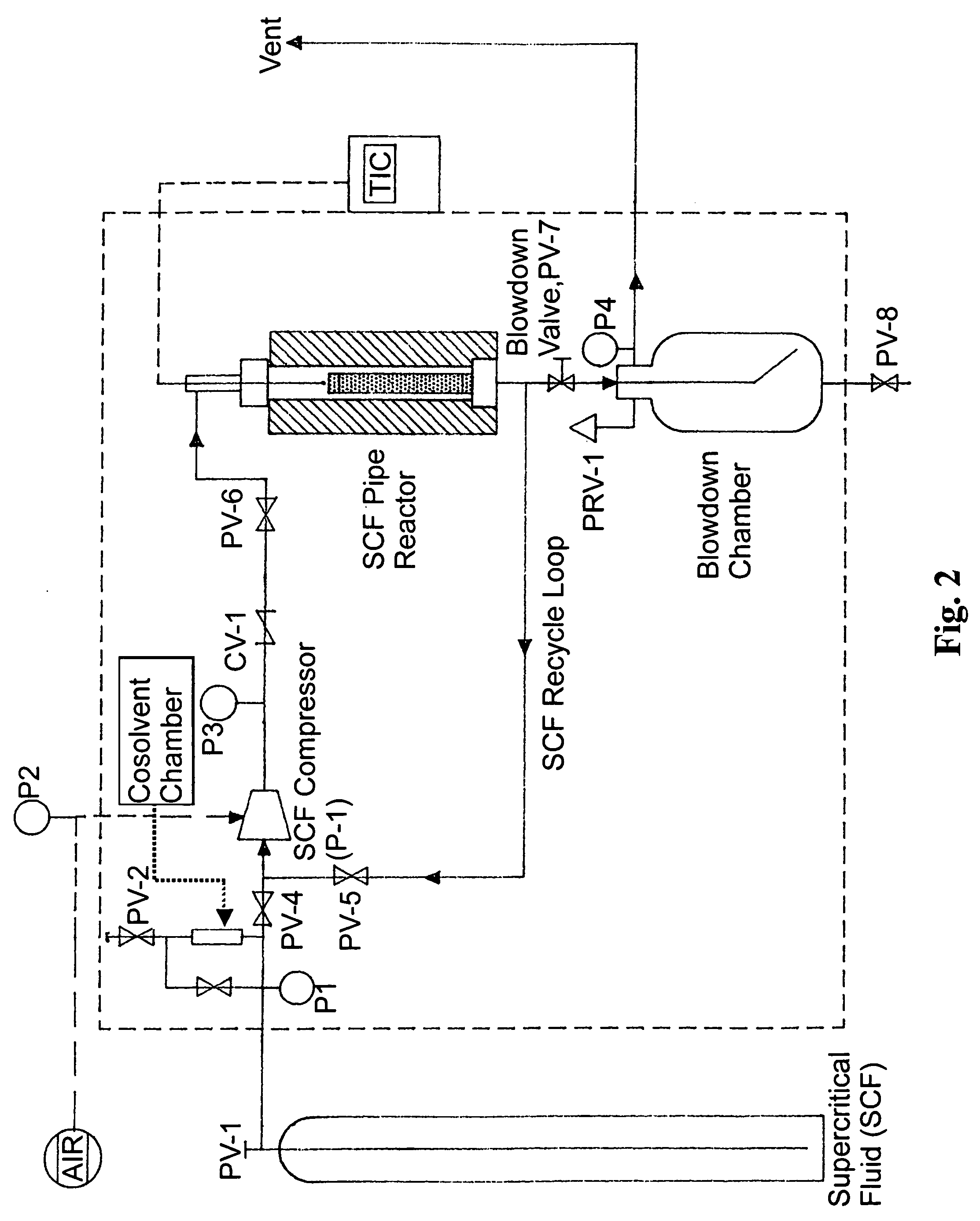

Pretreating cellulosic biomass

InactiveUS20090288788A1Improves cellulosic biomass pretreatmentMachine wet endPulp by-products recoveryCelluloseLiquid waste

The present invention pertains to methods for pretreatment of cellulosic biomass for bioconversion into ethanol and other biofuels and wood-based chemicals, recycling of newsprint and other paper products, microfibrillation of cellulose for use as an additive in the food and cosmetic industries, manufacturing improved hardboard, and producing and improved “super” pulp while reducing chemical usage and spent liquor generation. In particular, the instant invention employs supercritical, critical or near critical fluids with and without polar cosolvents [critical fluid, SuperFluids or SFS] for the pretreatment of cellulosic biomass.

Owner:APHIOS

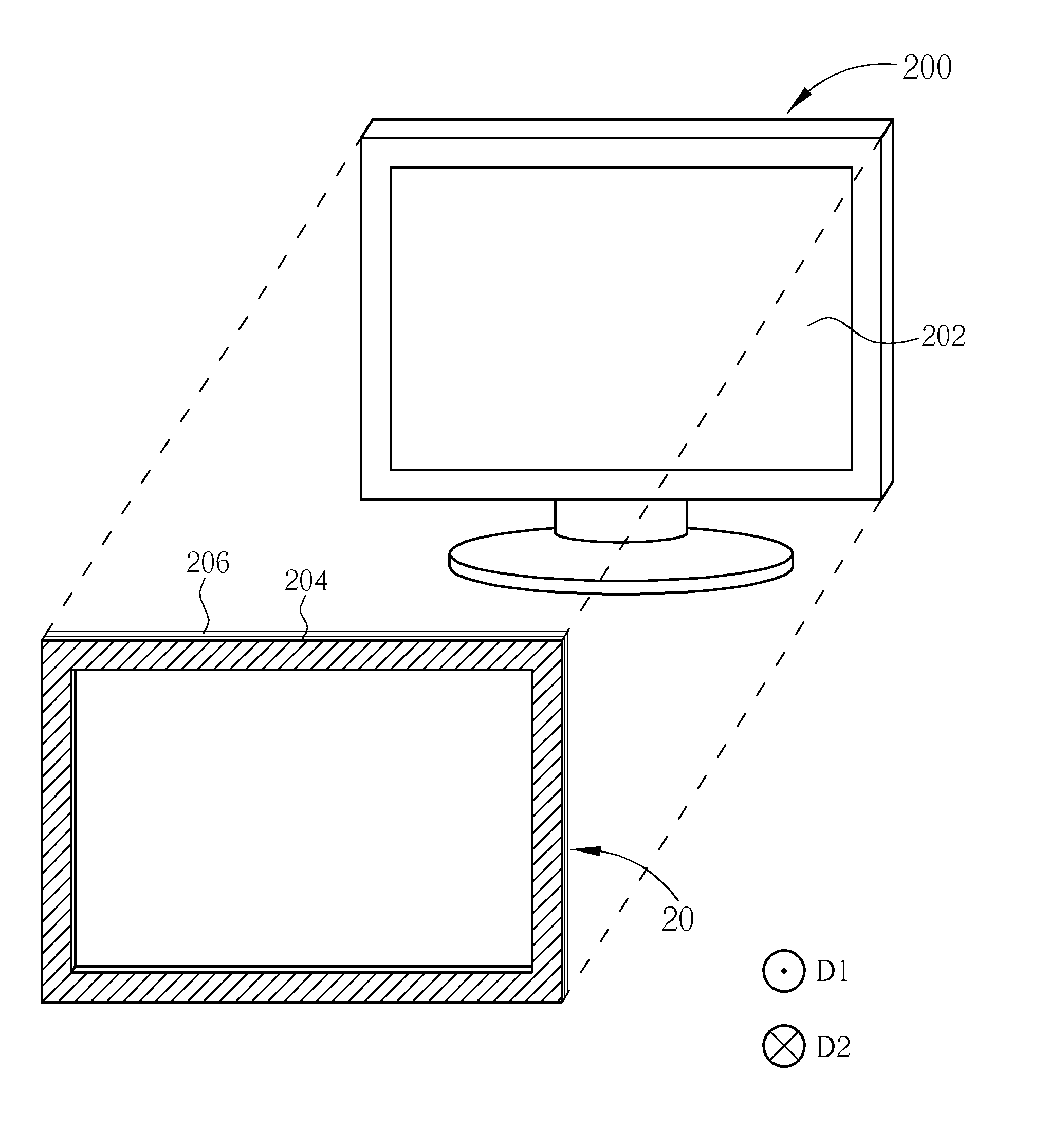

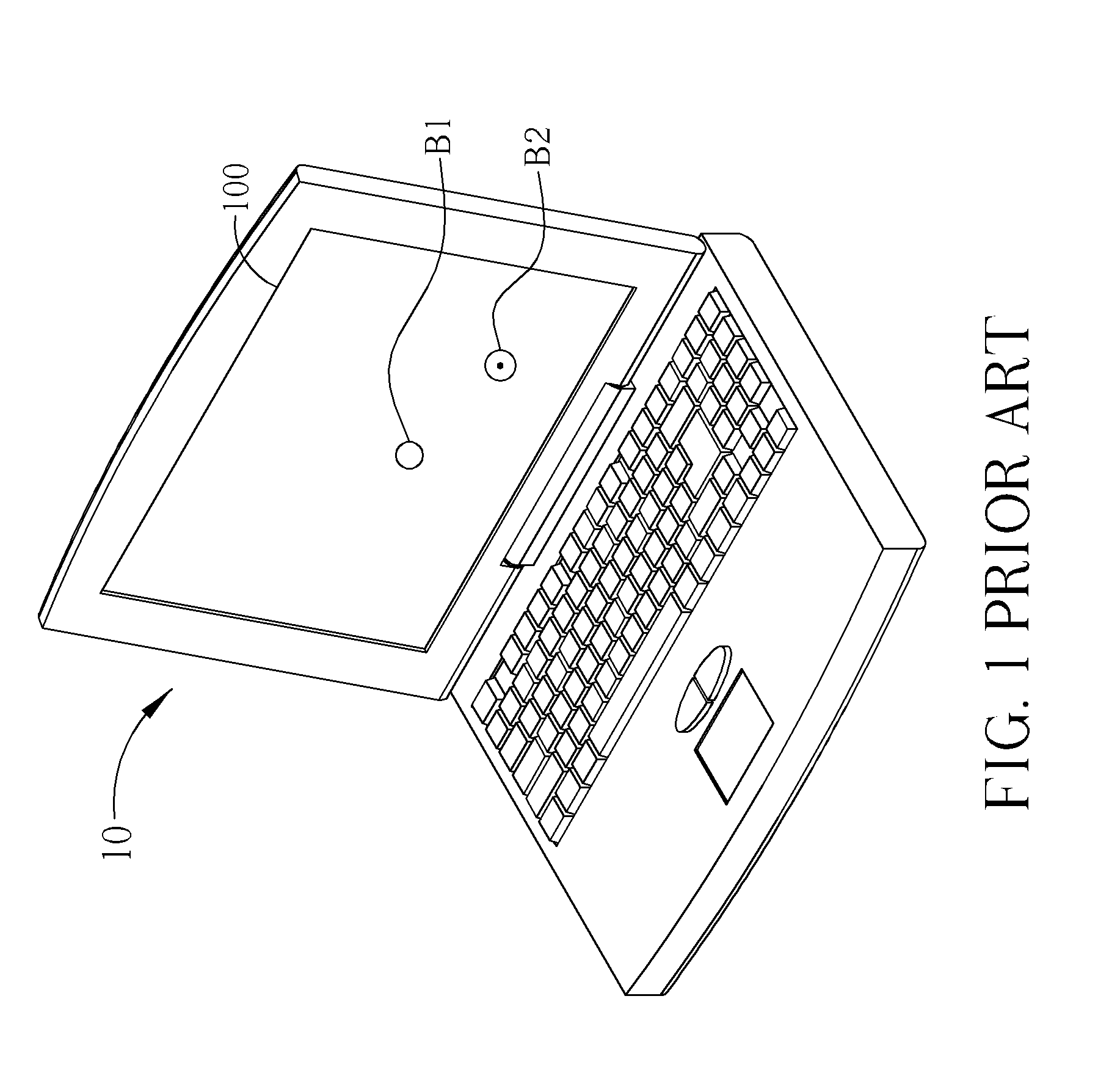

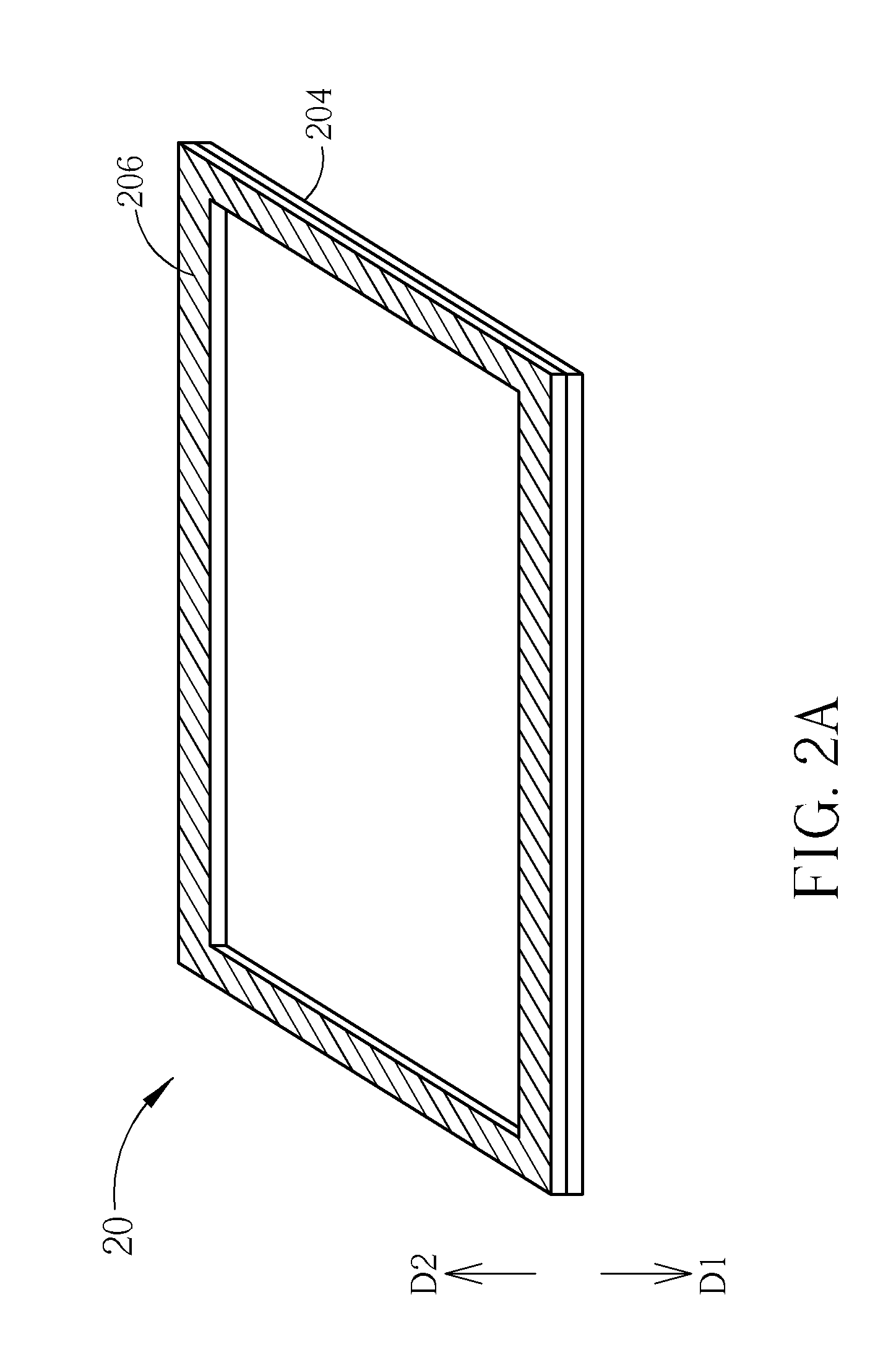

Monitor Protection Device for a Flat Panel Display

InactiveUS20120003431A1Cellulosic plastic layered productsHousing of computer displaysDisplay deviceEngineering

A monitor protection device for a flat panel display includes a transparent hard board, and a bonding film formed around the transparent hard board, including a first plane sticking around the transparent hard board, and a second plane for being pasted with the flat panel display. When the second plane of the bonding film is pasted with the flat panel display, a space is formed between the transparent hard board and the bonding film.

Owner:AEVOE

A kind of processing method of rigid-flex board

ActiveCN102271469AReduce control requirementsAvoid wastingPrinted circuit assemblingResistMilling cutter

The invention relates to a method for processing a rigid-flexible printed circuit board (PCB). The method comprises the following steps: 1. pretreatment before compression: pre-cutting the compression surface of a PCB and removing the wastes of bonding sheets, wherein the pre-cutting treatment is to cut a crevice around a waste region of the PCB with laser, wherein the PCB is not cut off; 2. compression: compressing the PCB, the bonding sheets and a flexible printed circuit (FPC) board into a whole; 3. treatment after compression and before contour processing: drilling, depositing and platingcopper, making circuit and carrying out solder resist; and 4. contour processing: using a milling cutter to mill a groove around the waste region of the PCB, controlling the depth of the milling cutter to communicate the milled groove with the crevice and then removing the wastes of the PCB. The method is convenient for the removal of the wastes of the rigid PCB, and has the beneficial effects ofpreventing the milling cutter from directly milling the flexible PCB, greatly reducing the control requirement for milling cutter depth, reducing the requirement for PCB flatness, improving the processing quality of the product and saving the production cost.

Owner:台山市精诚达电路有限公司

Fire-retardant coating, method for producing fire-retardant and heat-resistnat building materials

InactiveUS20140079942A1Improve flame resistanceImprove heat resistancePaper/cardboard layered productsWood layered productsCardboardFire retardant

The present invention relates to a fire-retardant material and products produced therefrom. More specifically, one embodiment of the present invention relates to a fire-retardant coating that shields underlying substrates from thermal insult, and a method for making such fire-retardant composition, as well as the products resulting therefrom. The invented coating and products are especially applicable to cellulose and gypsum based building materials including but not limited to fiberboards, wallboards, roofing materials, particleboards, ceiling tiles, floor tiles, soundproofing boards and hardboards.

Owner:LALLY THOMAS JOSPEH

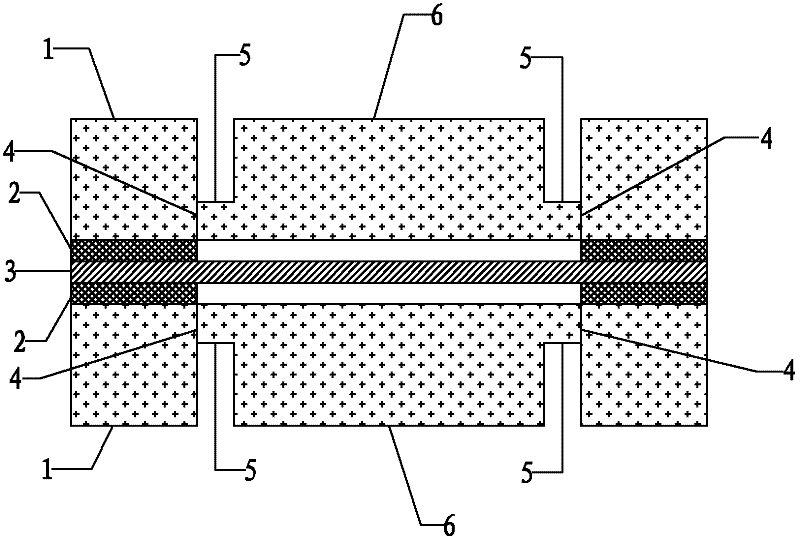

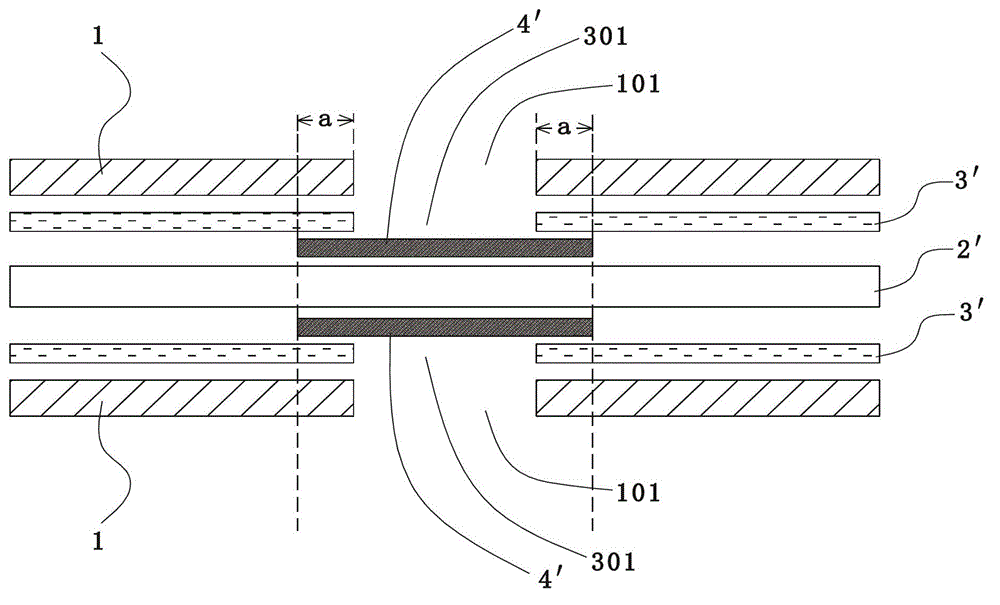

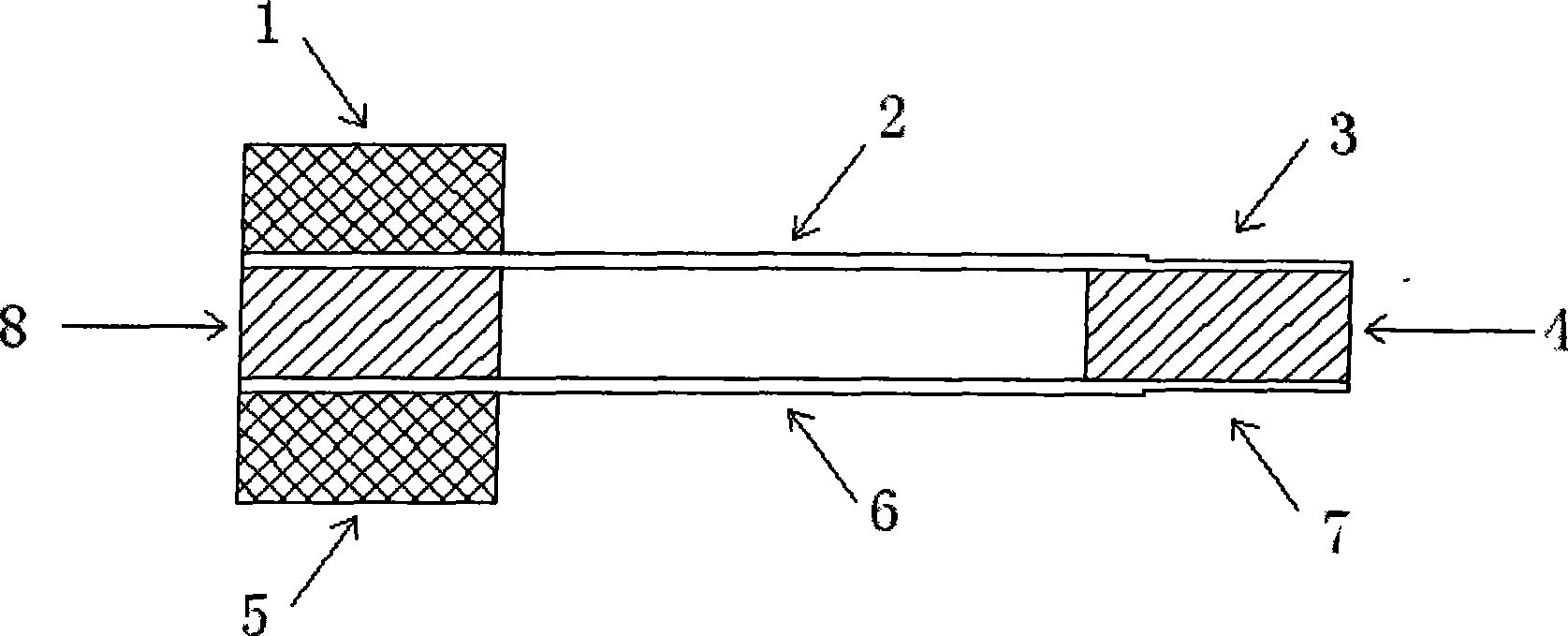

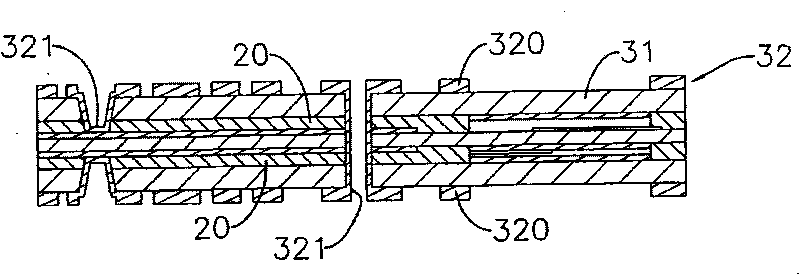

Local-fitting hole-avoiding flex-rigid combined board and manufacturing method thereof

InactiveCN102946687AAvoid too many combinationsImprove bindingPrinted circuit detailsMultilayer circuit manufactureManufacturing technologyHardboard

The invention discloses a local-fitting hole-avoiding flex-rigid combined board and a manufacturing method thereof. The manufacturing method comprises the following steps: S1, manufacturing a soft board; S2, windowing a hard board and a no-flow prepreg, corresponding a hard board window to a no-flow prepreg window in position and ensuring equal sizes of the two windows; S3, manufacturing a covering film, correspondingly fitting the covering film onto the soft board, adhering the no-flow prepreg on the covering film, and correspondingly positioning the covering film under the windowing position of the no-flow prepreg; and S4, laminating the hard board on the covering film to form the flex-rigid combined board. By the method, the bonding capability of the soft board and the hard board is improved, board cracking and layering are avoided, and the electrical conducting property of holes in a product is ensured; the manufacturing technology of the flex-rigid combined board is simple, convenient and controllable; and the reliability of the product is improved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Processing method for UV laser incision butt-joint uncovering

InactiveCN107041066AReduce manufacturing costIncrease productivityPrinted circuits structural associationsMultilayer circuit manufactureUv laserButt joint

The invention relates to a cutting method and specifically relates to a processing method for UV laser incision butt-joint uncovering. The method comprises the following steps: manufacturing a soft plate layer of an inner core plate of a soft and hard combined printed circuit board, adhering, pressing and covering a film in a bent area of an end product; manufacturing a first half-curing chip and designing a window on a position of a corresponding soft area; manufacturing a hard plate layer of the soft and hard combined printed circuit board, manufacturing a second half-curing chip, designing no window in the corresponding inner core plate area and reserving the whole half-curing chip; pressing: successively arranging in the sequence from top to bottom; after the ending of the processing, performing laser incision uncovering on the end product of the plate. According to the cutting method provided by the invention, the paved copper is designed on soft and hard connecting wires at interval in each layer of a cover plate, the stress is fully concentrated at a pre-cut gap on the hard plate layer and the cover plate is broken at the soft and hard connecting wires, so that the uncovering quality is guaranteed, the soft plate is not cut and the product yield is high.

Owner:GULTECH WUXI ELECTRONICS CO LTD

Fabrication method of covered-type flexible-rigid board by laser depth control

InactiveCN108617114AProtection from potion bitesProtect mechanical propertiesPrinted circuit assemblingPrinted circuits structural associationsMechanical wearLaser cutting

The invention discloses a fabrication method of a covered-type flexible-rigid board by laser depth control. The fabrication method comprises the following steps of respectively fabricating inner-layercircuits of a flexible core board and a rigid core board, wherein the flexible core board comprises a flexible board region and a flexible-rigid region; attaching a coverage film onto the flexible board region on the flexible core board in an alignment way; laminating the flexible core plate and the rigid core board by non-flowing glue PP to form a generation plate, and forming a window in a position, corresponding to the flexible board region, on the non-flowing glue PP; sequentially fabricating an outer-layer circuit and a welding-resistant layer on the production plate, and performing surface processing; and performing depth-control cutting on a position, corresponding to the circumference of the flexible board region, on the production plate by employing a laser cutting mode, and removing a part, corresponding to the flexible board region, on the rigid core board after uncovering to fabricate the flexible-rigid board. With the adoption of the method, the flexible board region is effectively prevented from being bitten by a medium, and mechanical wear and scrap are effectively prevented.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

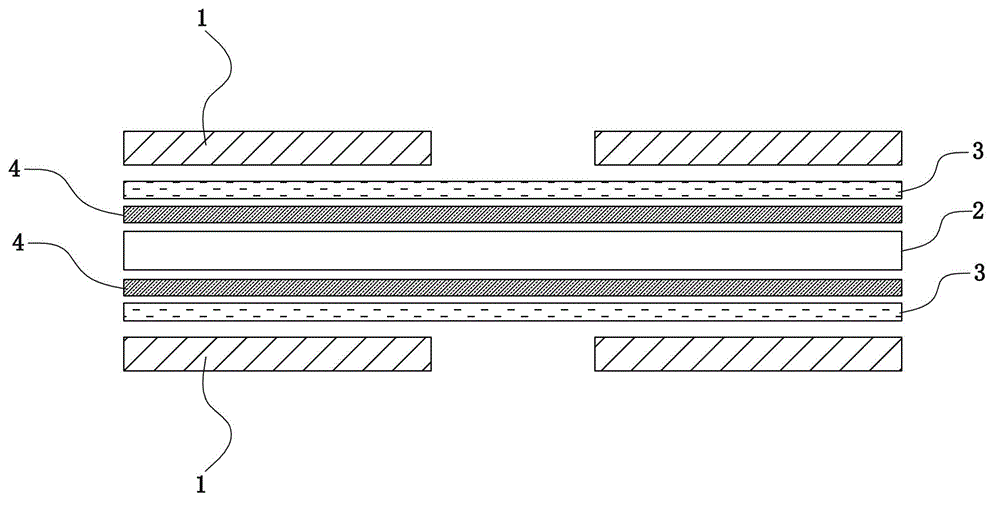

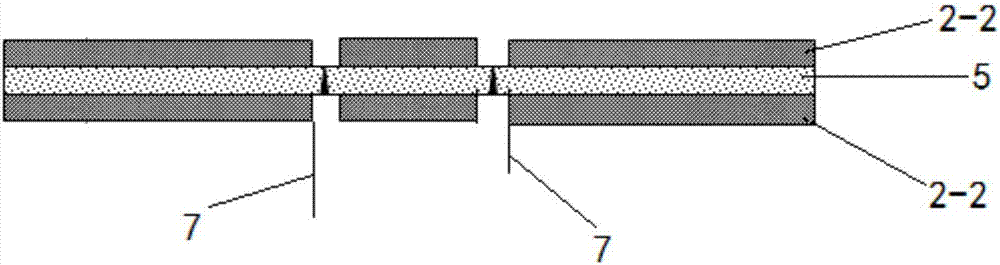

Manufacturing method for flexible and hard combined thin PCB

ActiveCN102573328ASo as not to damageNo damagePrinted circuit assemblingTectorial membraneCopper foil

The invention discloses a manufacturing method for a flexible and hard combined thin PCB, and is characterized by comprising the steps as follows: a) a flexible board with a circuit graphs on the surface thereof is provided; b) a protective film is arranged on the surface of the flexible board provided with the circuit graphs; c) prepregs with windows are provided, the prepregs are stacked on the surface of the flexible plate, and the protective film corresponds to the position of the windows of the pregregs; d) hard boards are provided and stacked on the surfaces of the prepregs, and the prepregs are located among the flexible board and the hard boards; e) the laminating is carried out; and f) the parts of the hard boards corresponding to the position of the protective film are removed. The invention has the benefits that a first hard board and a second hard board located on the most outer layers of the thin PCB can only adopt copper foil, and the problem that an etching solution provided by the copper foil damages the circuit graphs on the flexible board is solved, so that the manufacturing of thinner PCBs is achieved; and after manufacturing the flexible plate, a protective layer is not required before manufacturing the flexible and hard combined thin PCB, and the procedure of the manufacturing is simplified.

Owner:SHANGHAI MEADVILLE ELECTRONICS

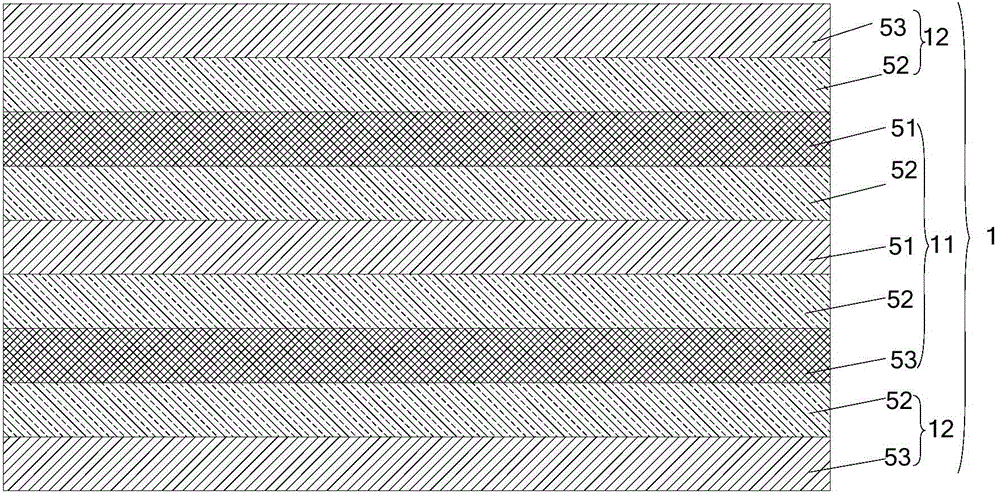

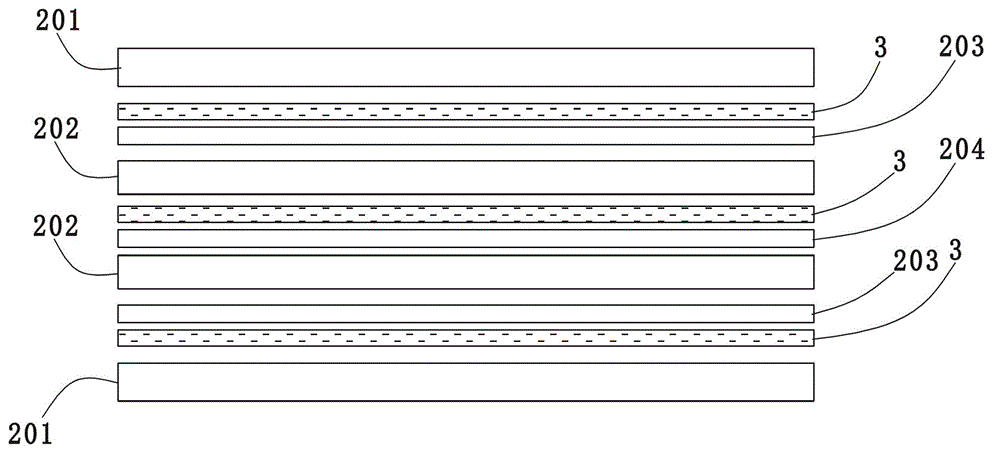

Physical design for four-layer soft and hard combined board

ActiveCN101511147AGuaranteed rigidityGuaranteed flexibilityElectrical connection printed elementsPrinted circuits structural associationsElectrical connectionEngineering

The invention discloses a four-layer rigid- flexible pcb structure, wherein, a double-layer FPC base end connects with a double-face golden finger, but another base end of the double-layer FPC connects with PCB (rigid pcb) mutually, and the double-layer FPC middle forms hollow, the structure makes the golden finger on the FPC base end having certain thickness, keeping strong rigidity, the FPC middle part for connecting the rigid pcb has better flexible, the whole structure can ensure insert and pull out the golden finger on the FPC base end oftenly, electrical connection of the whole product, and keep flexible performance of the FPC middle part.

Owner:SHENZHEN JINGCHENGDA CIRCUIT TECH

Manufacturing method of flexible-rigid circuit board

ActiveCN102711392ASolve the problem of dirt and damageDoes not affect thicknessPrinted circuit assemblingEngineeringRejection rate

Owner:GUANGZHOU MEADVILLE ELECTRONICS

Method for fabricating flexible-rigid board by PP and protection tape

InactiveCN108617113AGuaranteed flatnessAvoid the risk of bad glue fillingPrinted circuit assemblingPrinted circuits structural associationsRigid coreEngineering

The invention discloses a method for fabricating a flexible-rigid board by PP and a protection tape. The method comprises the following steps of respectively fabricating inner-layer circuits of a flexible core board and a rigid core board, wherein the flexible core board comprises a flexible board region and a flexible-rigid region; pasting a coverage film on the flexible board region on the flexible core board in an alignment way; pasting the protection tape on the coverage film; milling a blind groove around a part, corresponding to the flexible board region, on the rigid core board in a depth-controlled way, and reserving a certain residual thickness as a connection rib; laminating the flexible core board and the rigid core board by flowable glue PP to form a generation board, and forming a window in a position, corresponding to the flexible board region, on the flowable glue PP; sequentially fabricating an outer-layer circuit and a welding-resistant layer on the production board, and performing surface processing; and inwards milling a position, corresponding to the blind groove, on the production board to remove the connection rib, and fabricating the flexible-rigid board after uncovering. By employing the method, the flexible board region is effectively prevented from being bitten by a medicine and mechanically worn and scrapped, and an unfavorable risk of glue filling ofthe thick-copper flexible-rigid board is effectively prevented.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

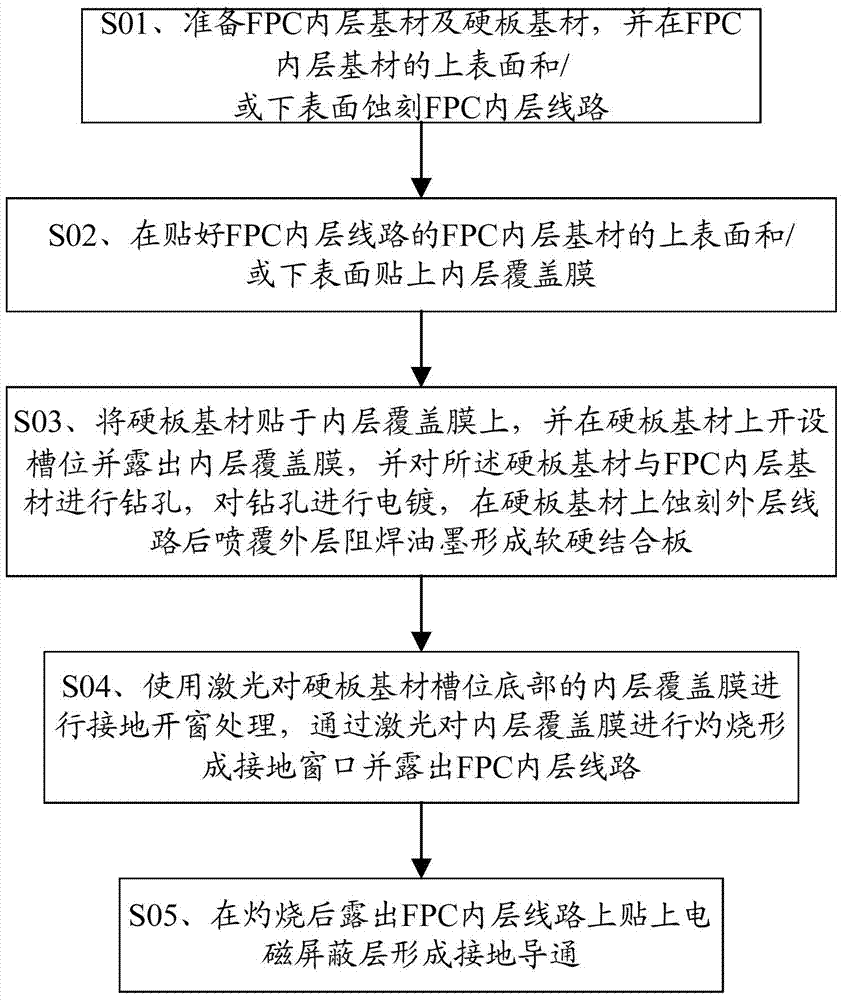

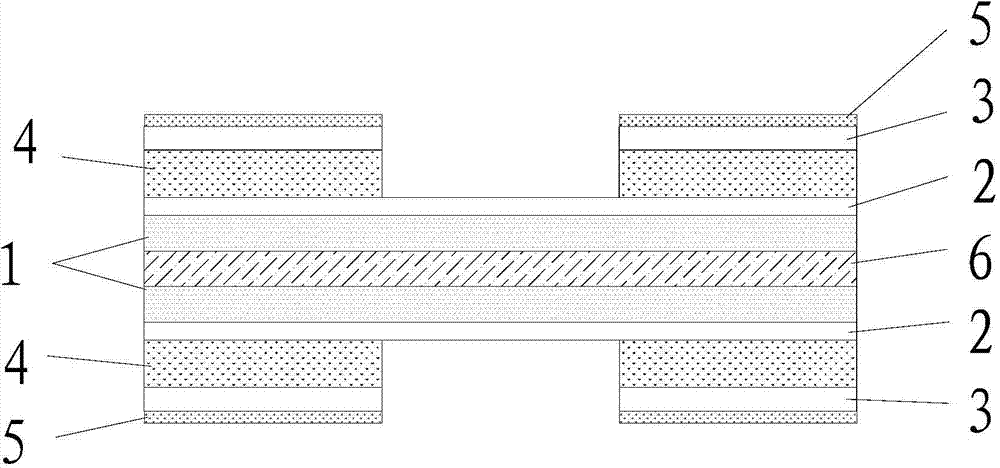

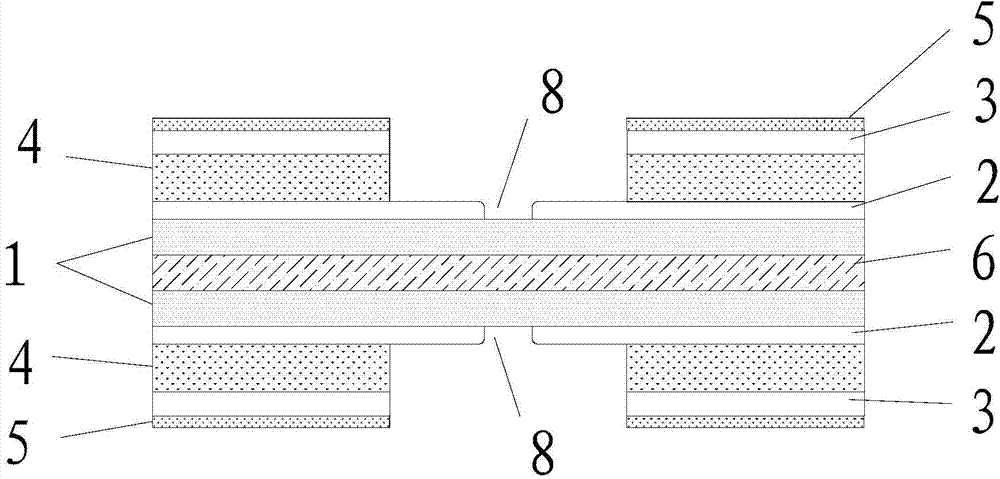

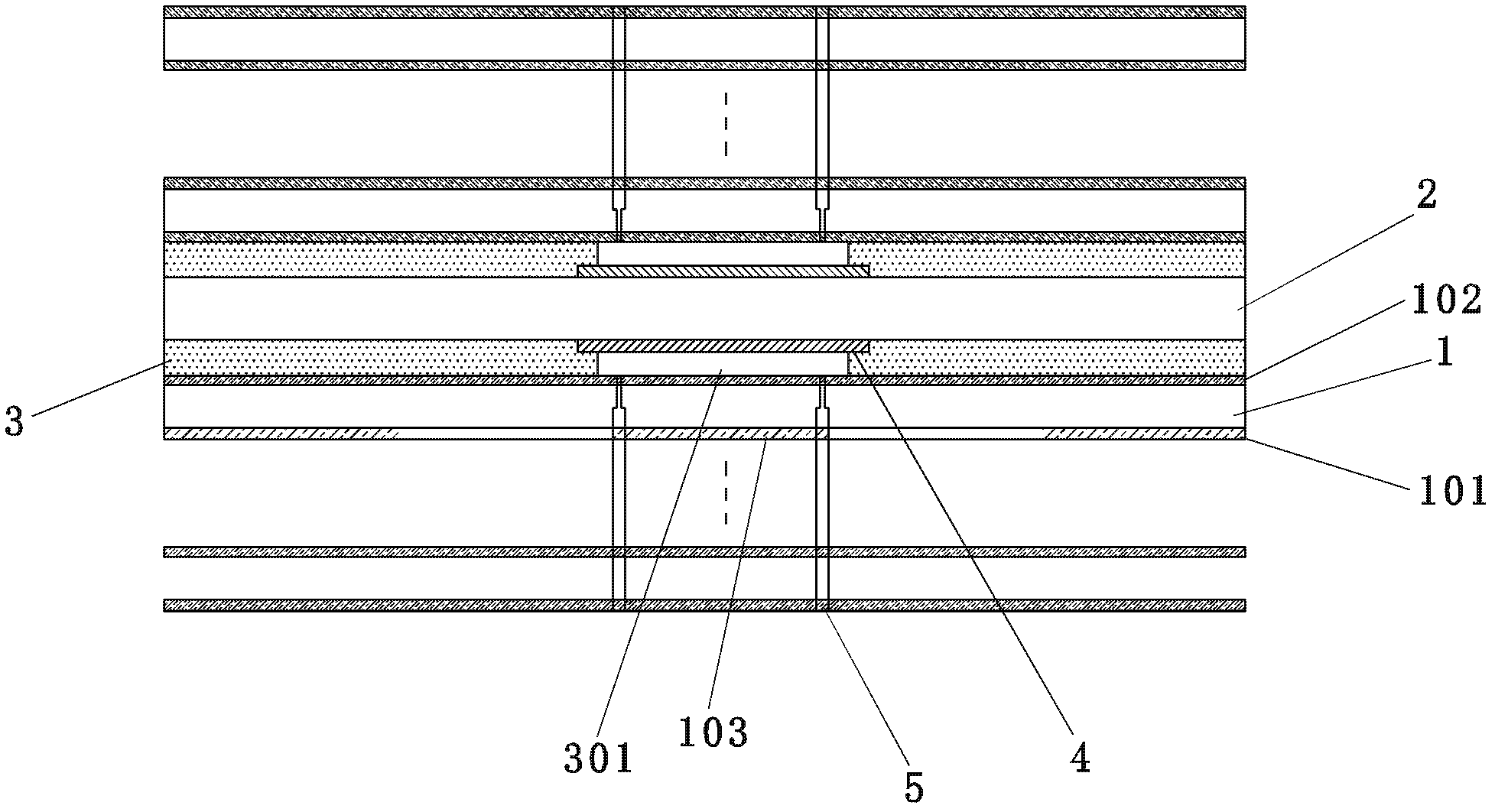

Soft and rigid combination board and cover film windowing and grounding method thereof

ActiveCN104507258AEffective protectionDamage effectivePrinted circuit assemblingMultilayer circuit manufactureElectromagnetic shieldingEngineering

The invention provides a soft and rigid combination board and a cover film windowing and grounding method thereof. The method comprises the following steps of S01, preparing an FPC (Flexible Printed Circuit) internal layer base material and a hard board base material, and etching an FPC internal layer circuit(s) on the upper surface and / or the lower surface of the FPC internal layer base material; S02, pasting an internal layer cover film(s) on the upper surface and / or the lower surface of the FPC internal layer base material pasted with the FPC internal layer circuit(s); S03, pasting the hard board base material on the FPC internal base material on the internal layer cover films, opening a slot in the hard board base material, and exposing the internal layer cover films to form the soft and rigid combination board; S04, using laser to carry out grounding and windowing processing on the internal layer cover films on the bottom part of the slot of the hard board base material, and scorching the internal layer cover films through the laser to form a grounding window, and exposing the FPC internal layer circuits; S05, after scorching, pasting electromagnetic shielding layers on the exposed FPC internal layer circuits to form grounding continuity. According to the soft and rigid combination board and the cover film windowing and grounding method thereof, the production efficiency is high, the quality of the board is good, and the production cost is low.

Owner:台山市精诚达电路有限公司

Method for manufacturing rigid-flexible combined circuit board capable of protecting inner-layer soft board

InactiveCN102595806APrevent cut-through problemsAvoid dentsPrinted circuit assemblingMultilayer circuit manufactureEngineeringLaser cutting

The invention discloses a method for manufacturing a rigid-flexible combined circuit board capable of protecting an inner-layer flexible board. The method comprises the following steps of: etching a copper pad at one side of a rigid board coreboard, which is not in contact with a flexible board coreboard; attaching a windowed prepreg to one side of the rigid board coreboard, which is in contact with the flexible board coreboard; and carrying out laser cutting at the inner side of a window of the prepreg, and enabling the cutting region to be correspondingly positioned inside the copper pad. Compared with the prior art, the method disclosed by the invention has the advantages of effectively preventing the rigid plate coreboard from being cutting through in the laser cutting process by utilizing the blocking of the copper pad and solving the problems of breaking of the rigid plate coreboard, board surface sinking after impressing and laminating on the surface of a flexible board, outer-layer pattern film cavity and the like when the rigid plate coreboard with the thickness being less than 0.3mm is made into the rigid-flexible combined circuit board.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Method for peeling rigid board from flexible board area of flexible-rigid board

ActiveCN101742822ATime-consuming and labor-intensive solutionMultilayer circuit manufactureLaser cuttingCopper

The invention discloses a method for peeling a rigid board from a flexible board area of a flexible-rigid board. The method mainly comprises the following steps of: pressing a flexible board on at least one inner rigid board and allowing part of the flexible board to expose outside to form the flexible board area; and further pressing at least one outer rigid board on the multi-layer structure by another pressing step, wherein the outer rigid board comprises a dielectric layer and a copper sheet, the boundary, corresponding to the flexible board area, of the dielectric layer is punched to form a slot prior to the pressing, and the dielectric layer, at the position of the flexible board area, is peeled along the slot to expose the flexible board after the pressing is carried out and a circuit is formed on the copper sheet. The rigid board part, to be removed, on the flexible-rigid board can be removed through simple mechanical actions by the technology; and thus, the problems of long time and large workload which are caused by process procedures such as laser cutting, exposing and developing, etching, film removing and the like of the traditional technology are solved.

Owner:COMPEQ TECH HUIZHOU CO LTD

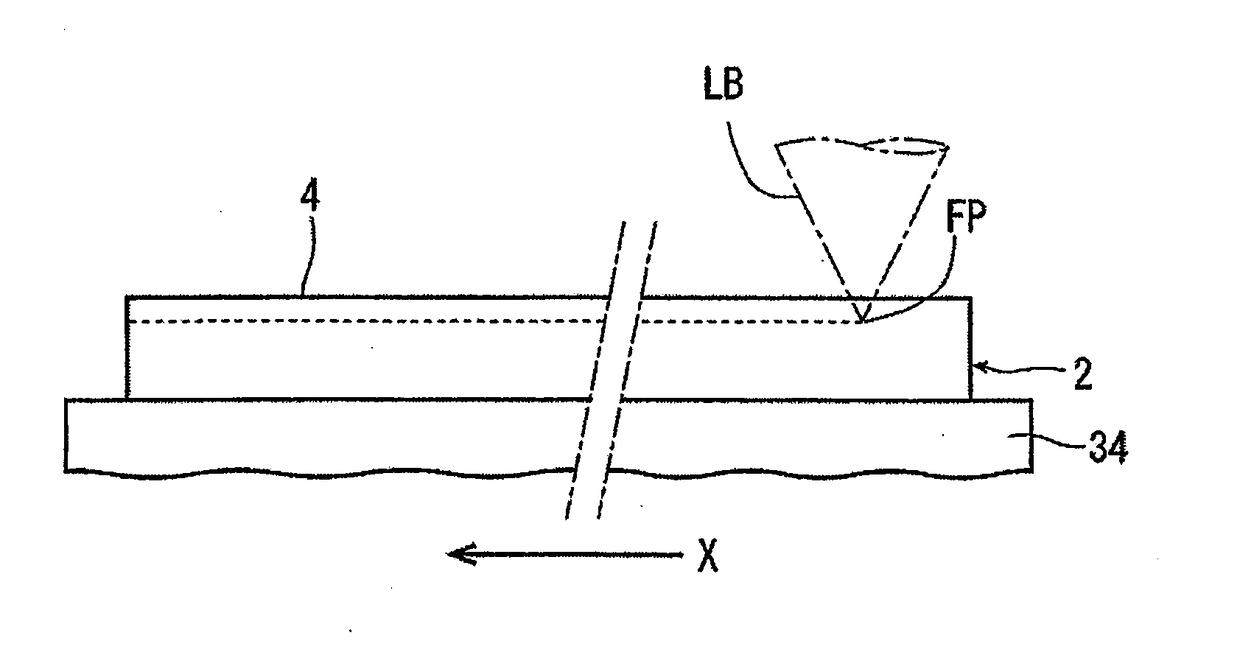

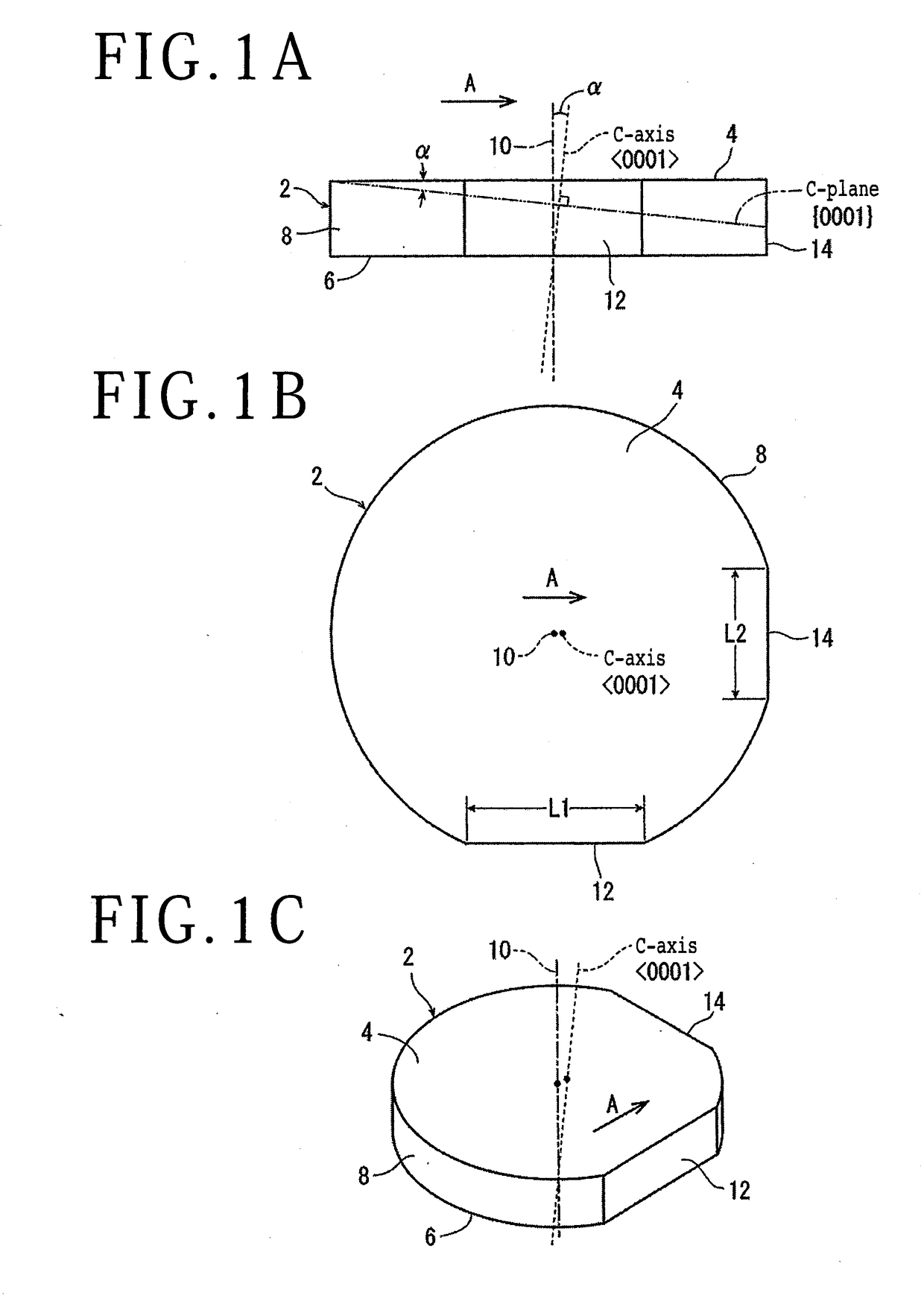

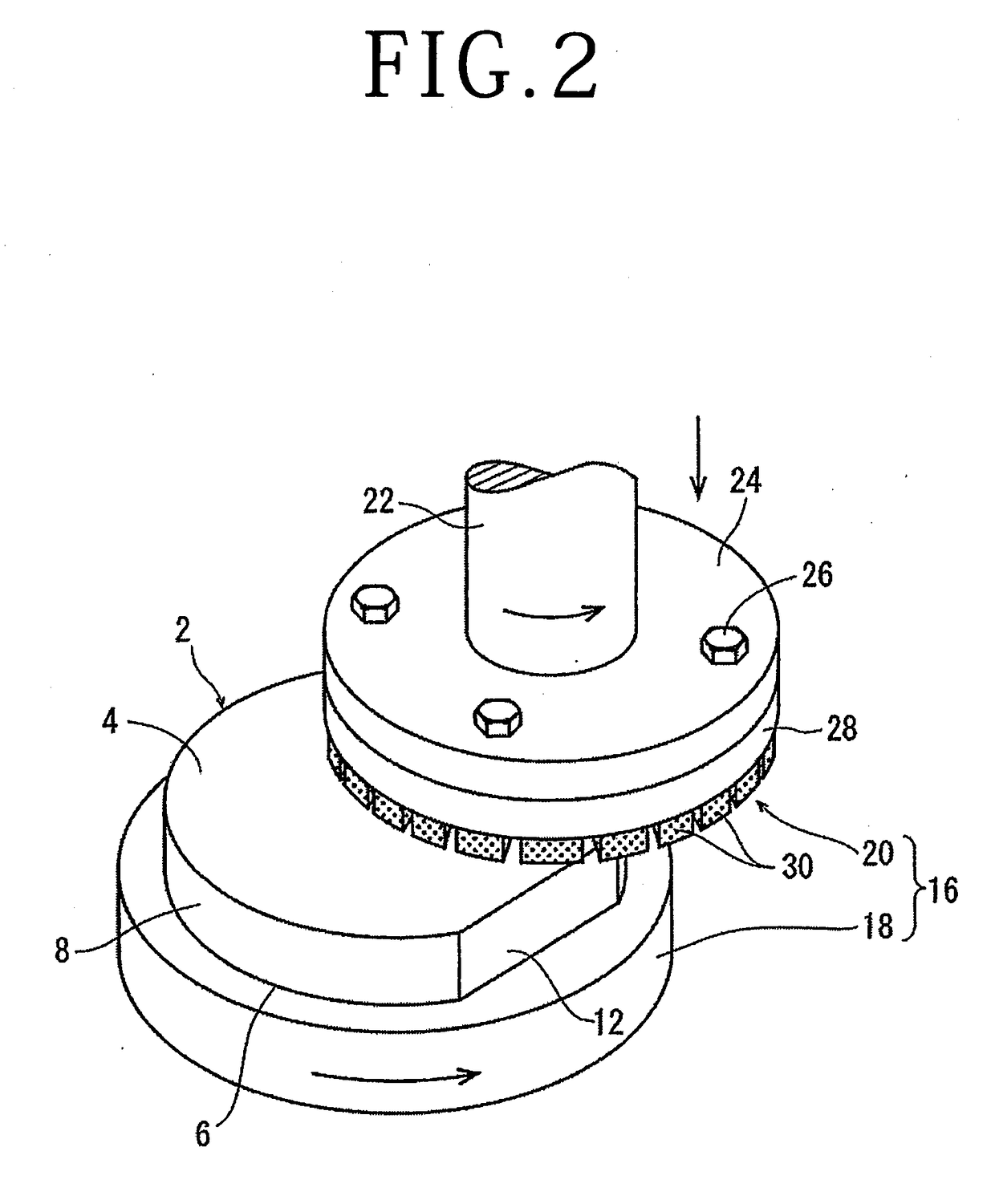

SiC WAFER PRODUCING METHOD

ActiveUS20180218896A1Increase heightImprove cooling effectPolycrystalline material growthAfter-treatment detailsWaferingAdhesive

A method for producing a wafer from an ingot of single crystal SiC includes an end surface planarizing step of planarizing an end surface of the ingot, a separation layer forming step of setting a focal point of a laser beam having a transmission wavelength to single crystal SiC inside the ingot at a predetermined depth from the end surface of the ingot, the predetermined depth corresponding to the thickness of the wafer to be produced, and next applying the laser beam to the ingot to thereby form a separation layer for separating the wafer from the ingot, a hard plate providing step of providing a hard plate through an adhesive on the end surface of the ingot in which the separation layer has been formed, and a separating step of separating the wafer with the hard plate from the ingot along the separation layer.

Owner:DISCO CORP

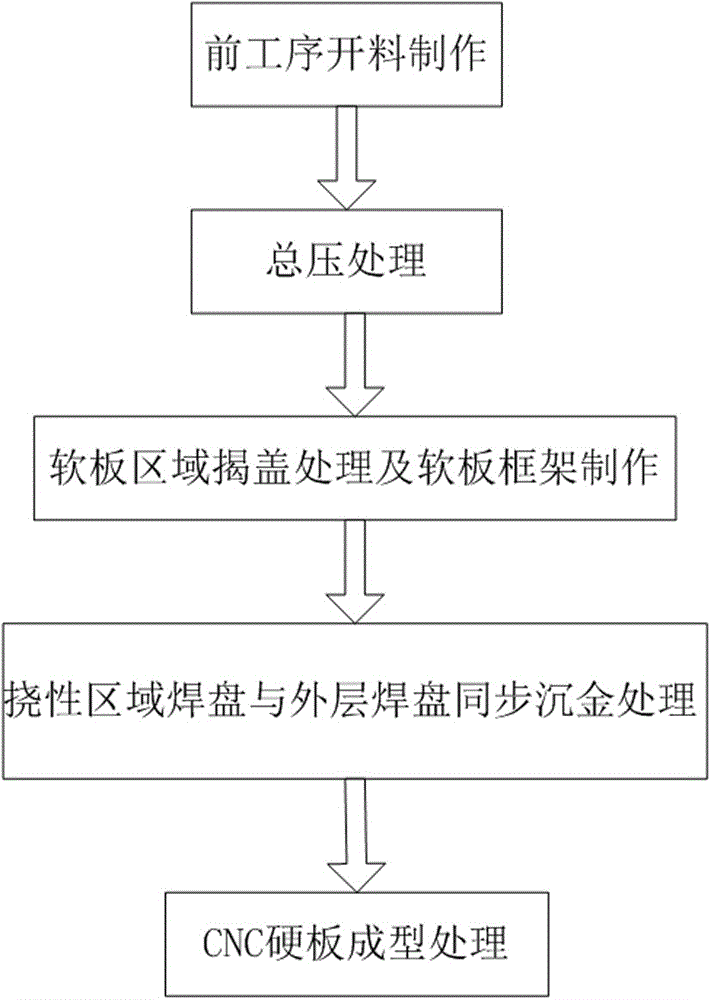

Rigid-flex PCB with flexible region equipped with solder pad and manufacturing method thereof

ActiveCN105430899AReduce the number of immersion goldIncrease productivityPrinted circuit assemblingPrinted circuits structural associationsAbrasive blastingEngineering

The invention discloses a rigid-flex PCB with a flexible region equipped with a solder pad and a manufacturing method thereof. The manufacturing method includes the steps that raw materials of a pre-process flexible board, a PP prepreg and a rigid board are manufactured, manufacturing of internal wiring of the flexible board is completed to a quick pressing cover film, laser winding processing and quick pressing adhesive resistance processing of the cover film are performed on the cover film, and the flexible board with a copper solder pad and the prepreg and the rigid board are laminated together from the top to the bottom in turn and then transferred to a board lamination pressing process to perform total pressing processing; after total pressing processing is completed, the process goes to an external layer solder resistance process according to the conventional process; then flexible board region de-cap processing and manufacturing a flexible board framework are performed, the copper surface is cleaned by an abrasive blasting mode, and then internal and external solder pad synchronous gold immersion processing is performed on the flexible region solder pad and an external solder pad; and finally CNC rigid board formation processing is performed on a rigid board framework so that a finished board meeting the profile dimension required by a client can be obtained. The rigid-flex PCB with the flexible region equipped with the solder pad and the manufacturing method thereof have advantages of being concise in flow, low in cost and environment-friendly and pollution-free without skip plating in gold immersion.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com