Patents

Literature

468results about How to "Improve flame resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microencapsulation of a phase change material with enhanced flame resistance

InactiveUS20100087115A1Improve flame resistanceImprove flame retardant performanceHeat storage plantsHeat resistant fibresMicroencapsulationsFlame resistance

A flame-resistant microcapsule that comprises a core comprising a phase change material and a wall material encapsulating the core. The microcapsules includes at least one of: a flame retardant applied to the wall material and a phase change material having a boiling point of about 230° C. to about 420° C. to provided enhanced flame resistance. The phase change material may have a boiling point of about 280° C. to about 400° C. or about 300° C. to about 390° C.

Owner:MICROTEK LAB

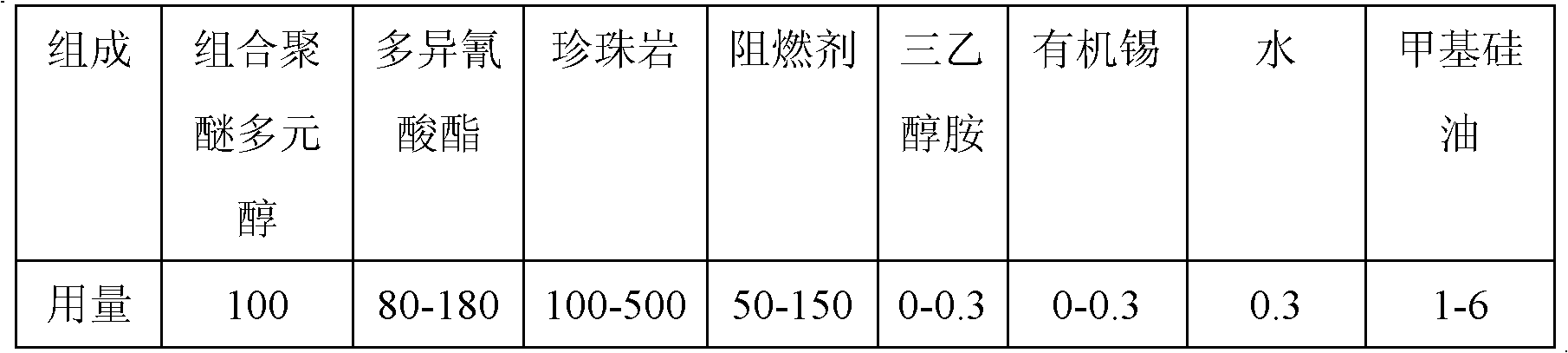

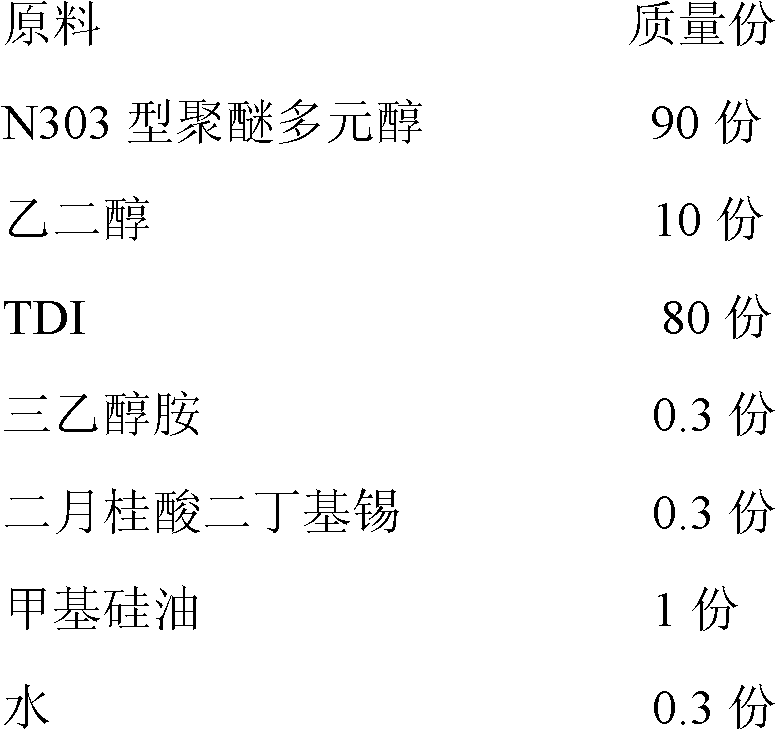

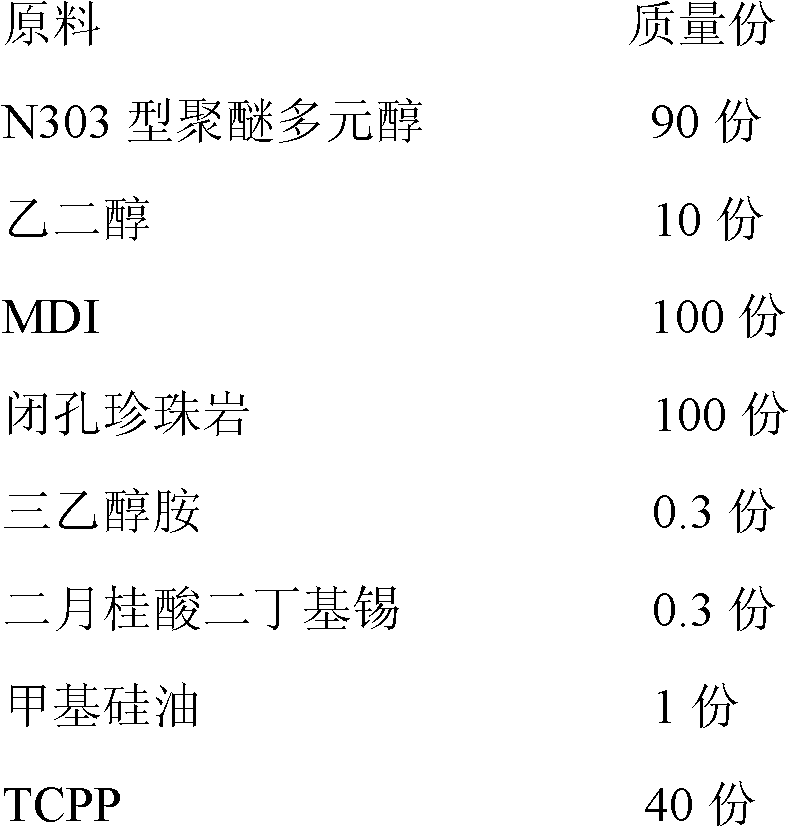

High-flame-retardance temperature preservation plate and preparation method thereof

ActiveCN102633974AMake up for the lack of easy water absorptionLow thermal conductivityHeat proofingPearliteSilicone oil

The invention belongs to the technical field of high polymer materials, and in particular discloses a high-flame-retardance temperature preservation plate and a preparation method thereof. The method is used for producing high-flame-retardance construction temperature preservation plates by utilizing pearlite for filling rigid polyurethane foam materials. The raw materials of the product providedby the invention mainly comprise composite polyether polyalcohol, polyisocyanates, pearlite, flame retardant, hydramine, organic tin, water, silicone oil and the like. The prepared product has bettermechanical property, is much easier for batch production in a plant, and also has a compact crust layer. The compact curst layer of polyurethane can remedy the defect of easiness in water absorption of the pearlite well, and meanwhile, the polyurethane plate material with high flame retardance can even be adaptive to the requirement of flame retardance level of the existing organic temperature preservation material.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

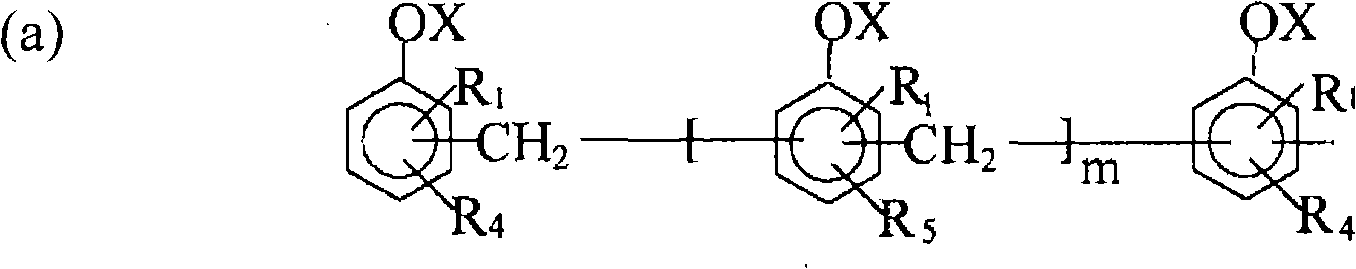

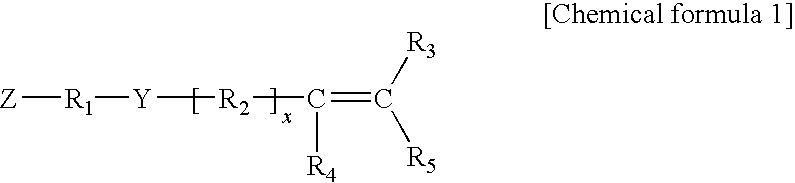

Water-soluble flame-retardant polyester resin, resin composition containing the resin, and fiber product treated with the resin composition

InactiveUS7358323B2Improve flame retardant performanceEliminate the problemSynthetic resin layered productsHeat resistant fibresSolubilityFiber

A water-soluble, flame retardant polyester resin is obtained by a condensation reaction or a polycondensation reaction of a dicarboxylic-acid component, a glycol component, a water-solubility imparting component and a reactive phosphorus-containing compound such that a ratio of the water-solubility imparting component in a total of the dicarboxylic-acid component and the water-solubility imparting component is in a range of 1 to 60 mol %. Since this polyester resin can be dissolved in a solvent by allowing a halogen-free, phosphorus-containing polyester with excellent flame resistance to have water solubility, it is possible to improve applicability and eliminate problems of working environment and environmental destruction resulting from organic solvents. In addition, even when treating substrates such as fibers and PET films with the polyester resin, there is no deterioration of these substrates.

Owner:GOO CHEM IND

Polyvinyl chloride foams

InactiveUS20060264523A1Improve mechanical propertiesImprove foaming efficiencyMaterial nanotechnologyNanostructure manufactureFoaming agentPolyvinyl chloride

The present invention relates to the foams of the polyvinyl chloride nanocomposites comprising of polyvinyl chloride, layered inorganic compounds, and foaming agents. They are effective in that they have superior mechanical strength and non-flammability even with a low specific gravity; demostrates a high foaming efficiency even with a small amount of a foaming agent; and have an even microcellular structure.

Owner:LG CHEM LTD

High heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified material and preparation method thereof

ActiveCN103059465AImprove wear resistance and heat resistanceImprove surface gloss and surface smoothnessPelletizingPlasticizer

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to high heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified materials and a preparation method of the high heat resisting and high abrasion resistant PVC modified materials. The modified materials comprise the following raw materials, by weight, 80-120 parts of PVC resin, 25-60 parts of stuffing bulking agents, 21-60 parts of plasticizer, 1-10 parts of chlorinated polyvinyl chloride, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 1-10 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to parts by weight and are blended. After being blended, the raw materials are extruded out to be granulated through a double-screw extruder to produce the modified materials. The modified materials are good in heat resisting property and abrasion resistant property, environment-friendly, high in strength, good in flame retardant effect, strong in compressing property and toughness, good in processing property and good in comprehensive property. The preparation method is simple in craft, convenient to operate and control, stable in quality and high in production efficiency, and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

Resin composition with high-heat, high-glass transition temperature for printed circuit board, prepreg and coating substance

InactiveCN101343402AImprove heat resistanceImprove flame resistanceSynthetic resin layered productsCircuit susbtrate materialsEpoxyProcedure Agents

The invention relates to resin combination with high thermal conductivity and glass transition temperature used for a printed circuit board. According to the weight percentage, the resin combination comprises brominated epoxy resin occupying 20 percent to 70 percent, hardening agent occupying 1 percent to 10 percent, accelerating agent occupying 0.1 percent to 10 percent, inorganic powder occupying 0 percent to 20 percent, high heat conducting powder occupying 5 percent to 85 percent, and processing auxiliary agent occupying 0 percent to 10 percent. The resin combination has the advantages of high glass transition temperature and heat conducting performance, excellent thermal resistance and flame resistance, which can be applied to the heat conducting insulating layer of the printed circuit board after being made into a high heat conducting preimpregnated body through a containing and soaking way or into a high heat conducting coating through a coating way, thus the printed circuit board has high heat conducting performance, and the heat quantity generated by the operation of the electronic elements on the printed circuit board can be rapidly dissipated to enhance the service life and the stability of the electronic elements.

Owner:NANYA PLASTICS CORP

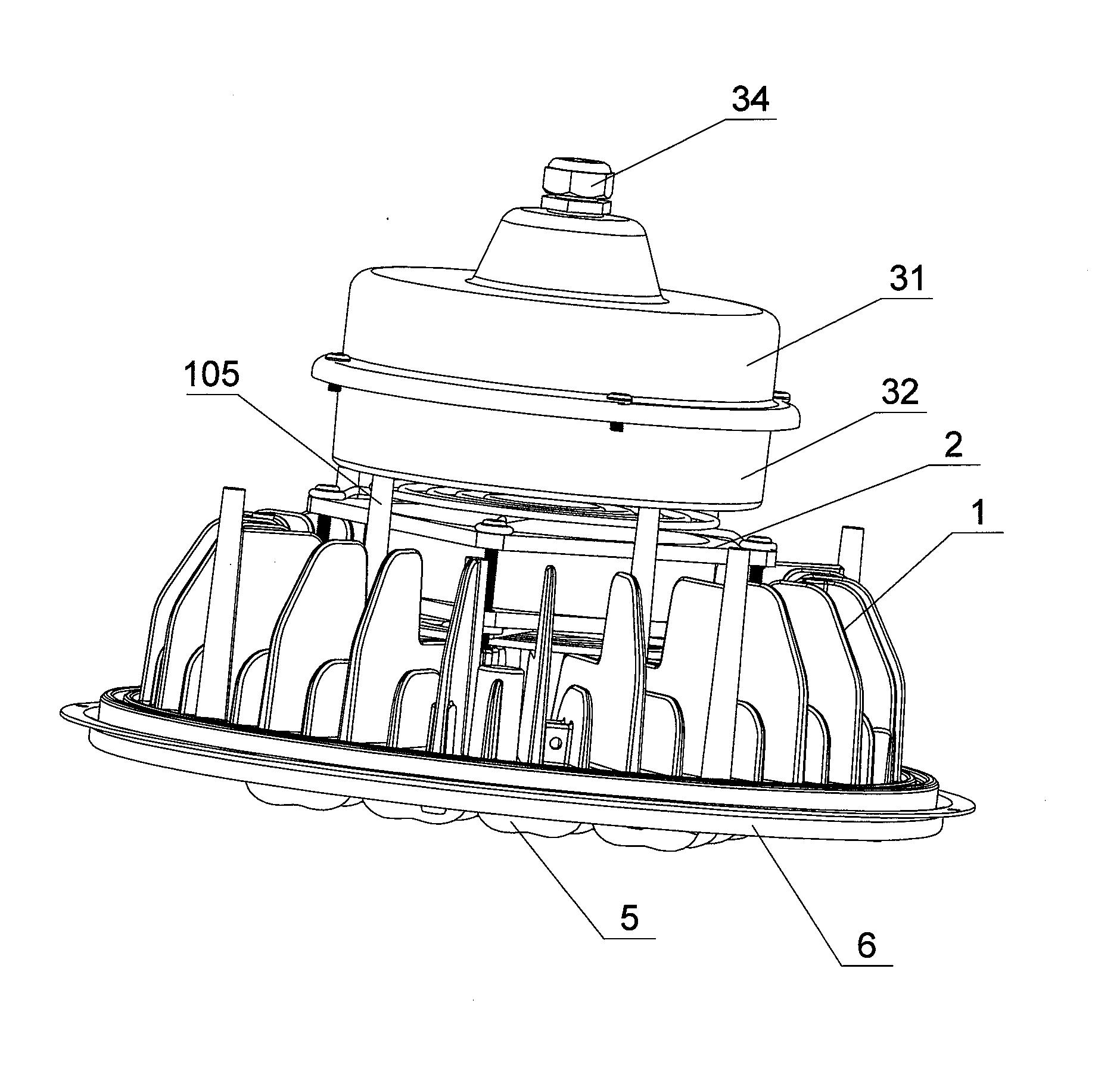

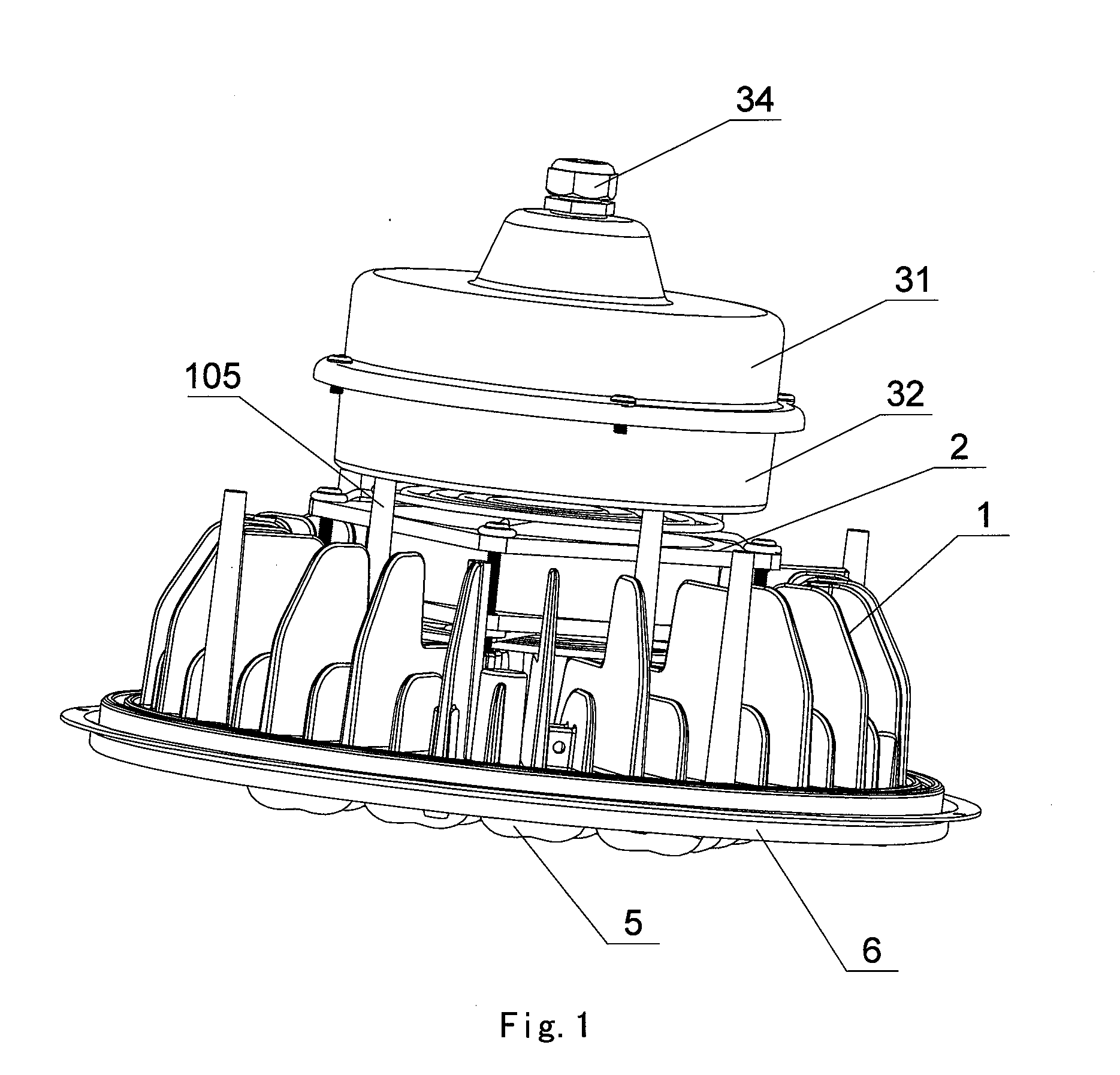

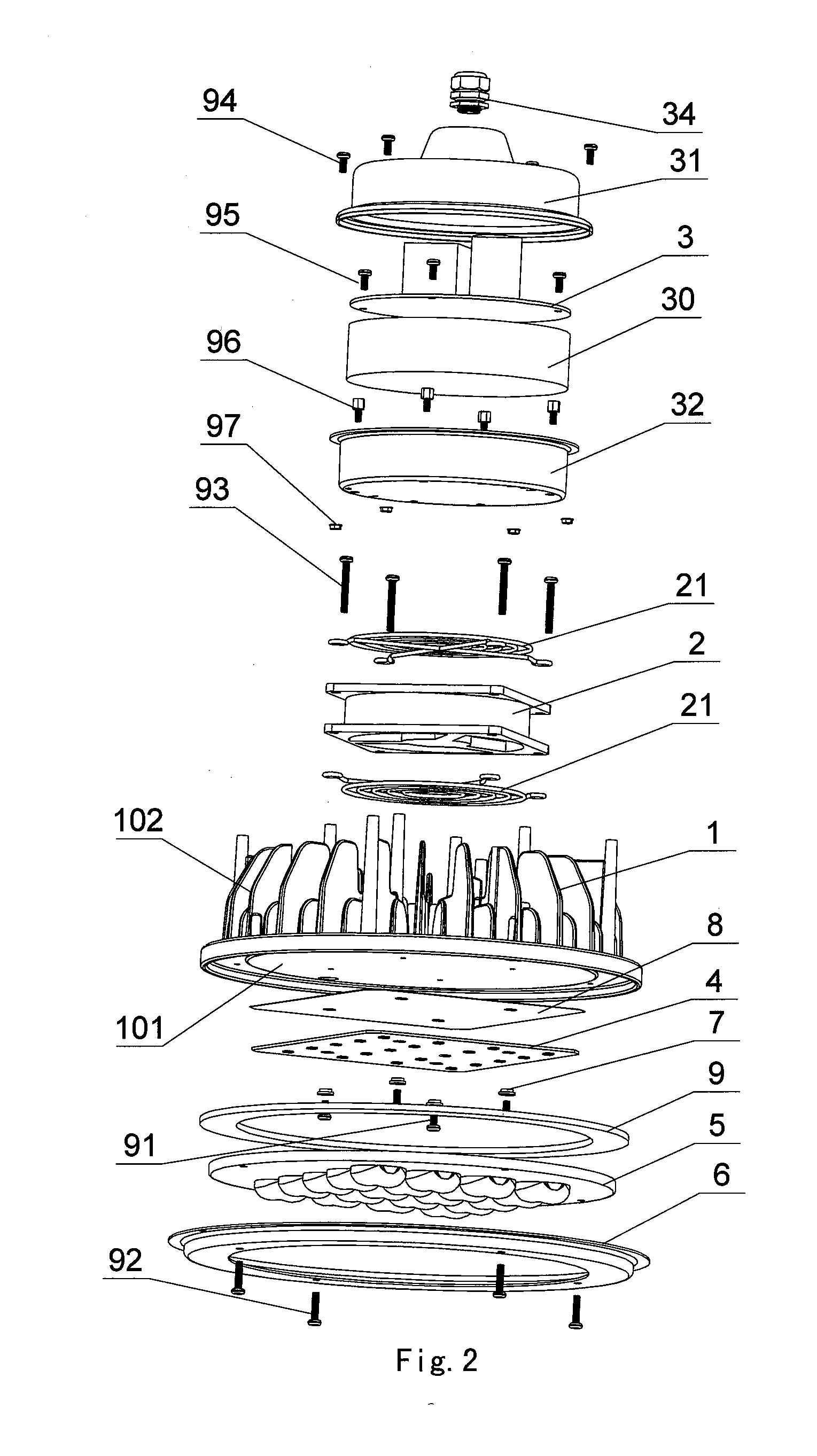

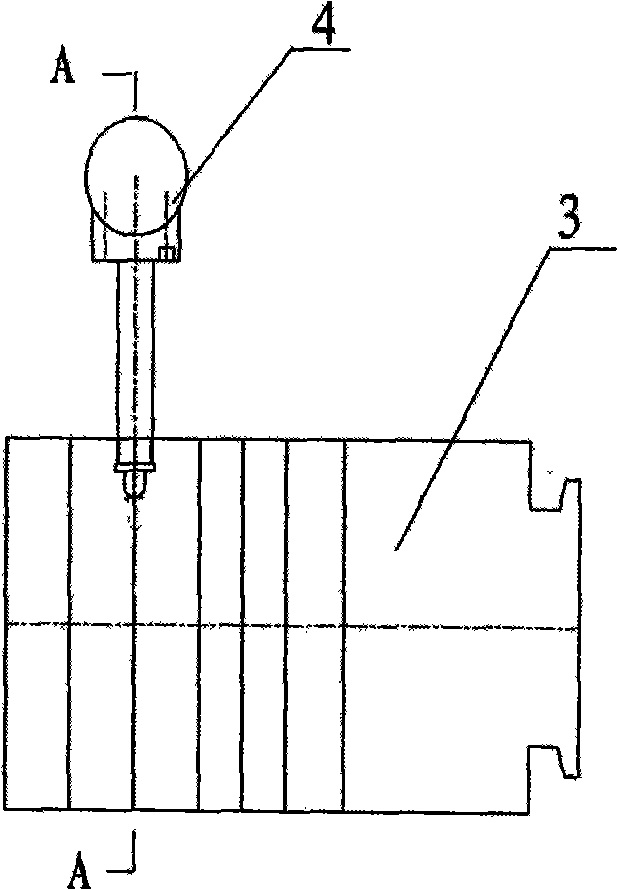

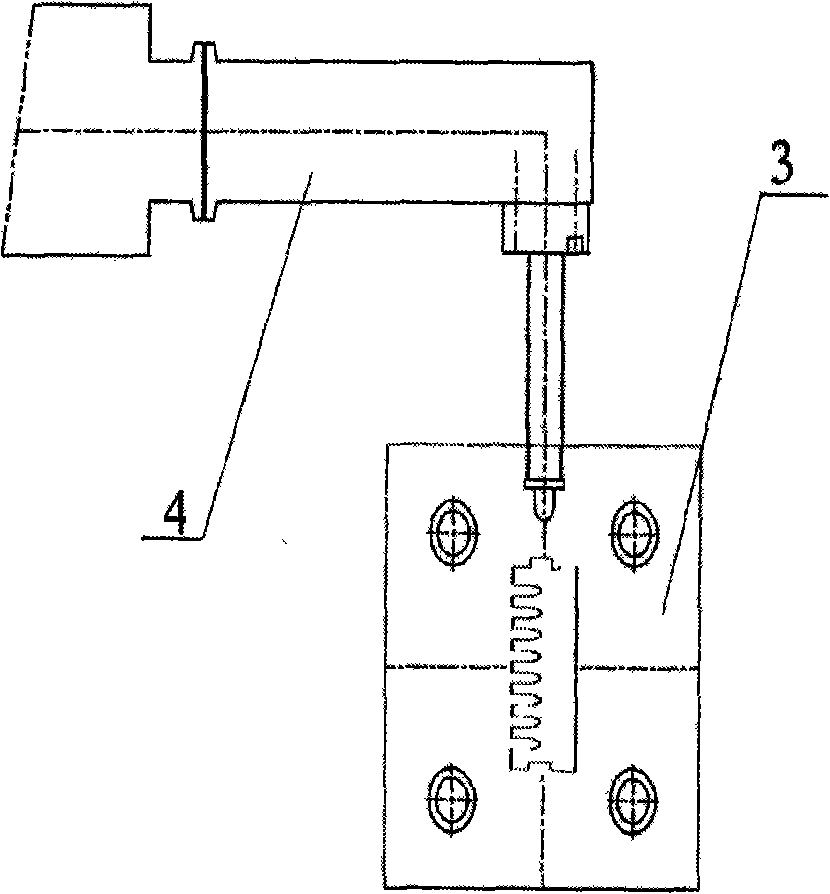

Dustproof and waterproof multipurpose LED-light power source assembly and dustproof and waterproof LED light

InactiveUS20140307441A1Improve insulation performanceImprove flame resistancePlanar light sourcesPoint-like light sourceEngineeringLED lamp

A dustproof and waterproof multipurpose LED-light power source assembly comprises a heat sink, a heat-dispersal fan, a circuit board driver module, an LED light source module, a power-source casing top cover and a power-source casing bottom cover. The LED light source module comprises plural LED chips and an LED heat-dispersing substrate. The heat-dispersal fan is a dustproof and waterproof fan. The heat sink comprises a baseboard to which the LED heat-dispersing substrate is fixedly connected and conducts dispersed heat. At the center of the top of a heat-dispersal member, a space is provided to accommodate the heat-dispersal fan. The power-source casing bottom cover is positioned above the heat-dispersal fan and is fixedly connected to the heat sink. The power-source casing top cover and the power-source casing bottom cover are hermetically connected one to the other. A waterproof bolt assembly is connected to the top of the power-source casing top cover.

Owner:NANKER GUANGZHOU SEMICON MFG

Resin composition with high thermal conductivity, no halogen and difficult fire retardance and pre-impregnated body and coating material thereof

InactiveCN101580626AExtended service lifeImprove the stability of useCircuit susbtrate materialsEpoxyProcedure Agents

The invention relates to a resin composition with high thermal conductivity, no halogen and fire retardance, which is applied to a printed circuit board and used as a thermal-conduction insulating layer. The resin composition comprises 5 to 70 weight percent of phosphorus epoxy resin, 0 to 50 weight percent of epoxy resin with a plurality of functional groups or double functional groups, 1 to 20 weight percent of hardening agent, 0.01 to 10 weight percent of accelerant, 0 to 20 weight percent of inorganic powder, 5 to 85 weight percent of high thermal-conduction powder and 0 to 10 weight percent of processing additive; in addition to high thermal conductivity, excellent thermal resistance and fire retardance, the resin composition does not contain a halogenous fire retardant and does not generate toxic or corrosive gas in combustion and is an environment-friendly material; the resin composition can be prepared into a pre-impregnated body with high thermal conductivity through an impregnation method or prepared into a coating material with high thermal conductivity by a coating method; the pre-impregnated body or the coating material is applied as the thermal-conduction insulating layer of the printed circuit board so that the printed circuit board has high thermal conductivity and is favorable for rapidly dissipating heat generated in the operation of electronic components of the printed circuit board to prolong the life service and the stability of the electronic components.

Owner:NANYA PLASTICS CORP

Production of needled filtering felt of polytef fibre

ActiveCN1982523AHigh temperature resistantGood low frictionFiltration separationNon-woven fabricsAntistatic agentFiltration

Production technology of a kind of teflon fiber needled filter carpet, its main steps include : 1) use antistatic agent to eliminate the static teflon fiber, fully-open, then balanced place into stainless steel drums and make stainless steel drums fully grounding discharge; 2) the carding machine and roll machine fully grounding discharge; 3) the fibers are fed to carding machine, then the regular fiber are laid through network machine, and form hair nets; 4) lay teflon basal cloth bottom of single layer hair net, then basal cloth and single layer hair nets together introduce into needle machine forming carpet; 5) use forming machines to form the carpet by heat, and then deal it with singeing. With the process, can produce 100% teflon fiber needled filter carpet, such acupuncture filter carpet has good chemical properties, good filtration efficiency, good cleaning performance and longer service life.

Owner:厦门佰瑞福环保科技有限公司

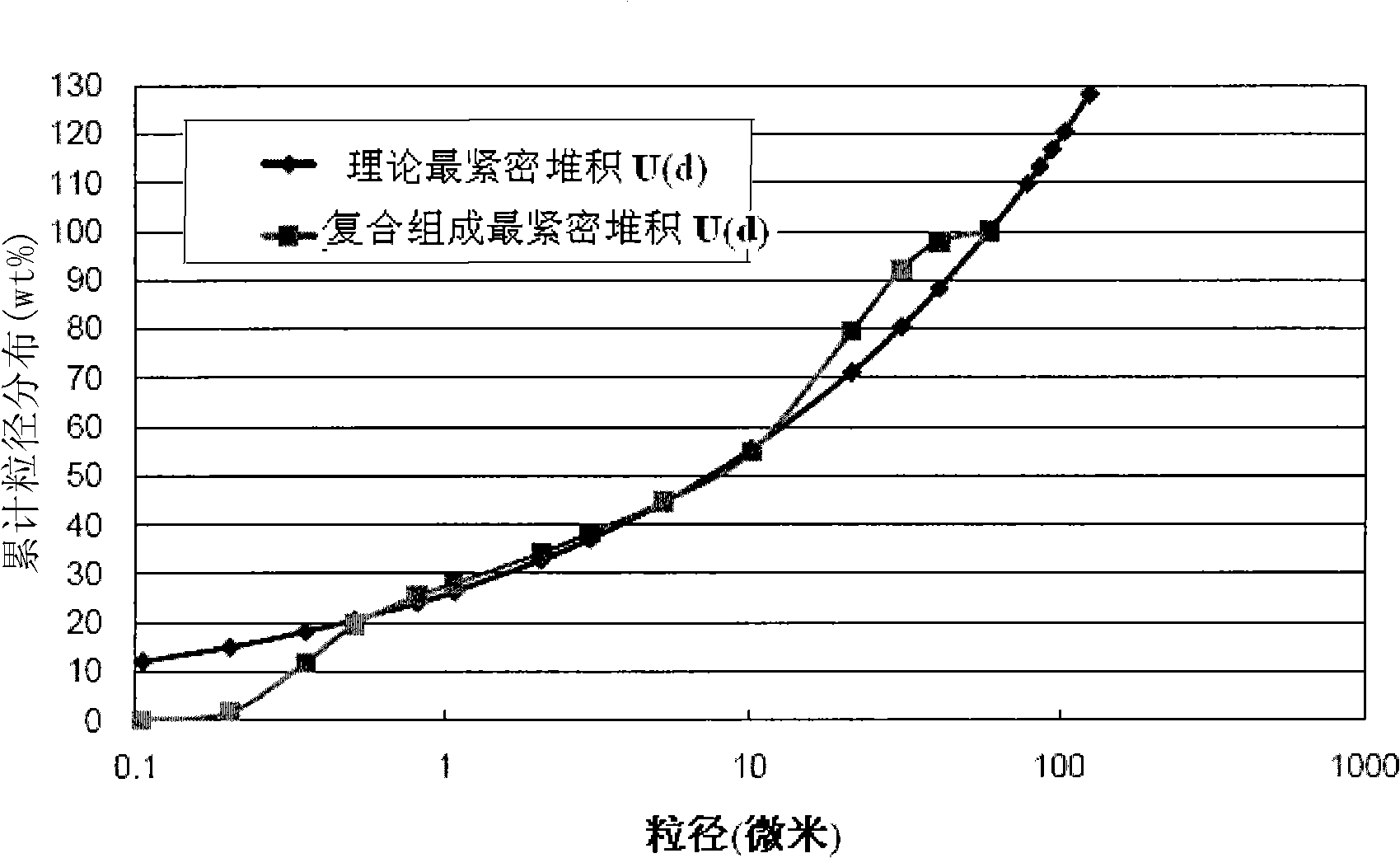

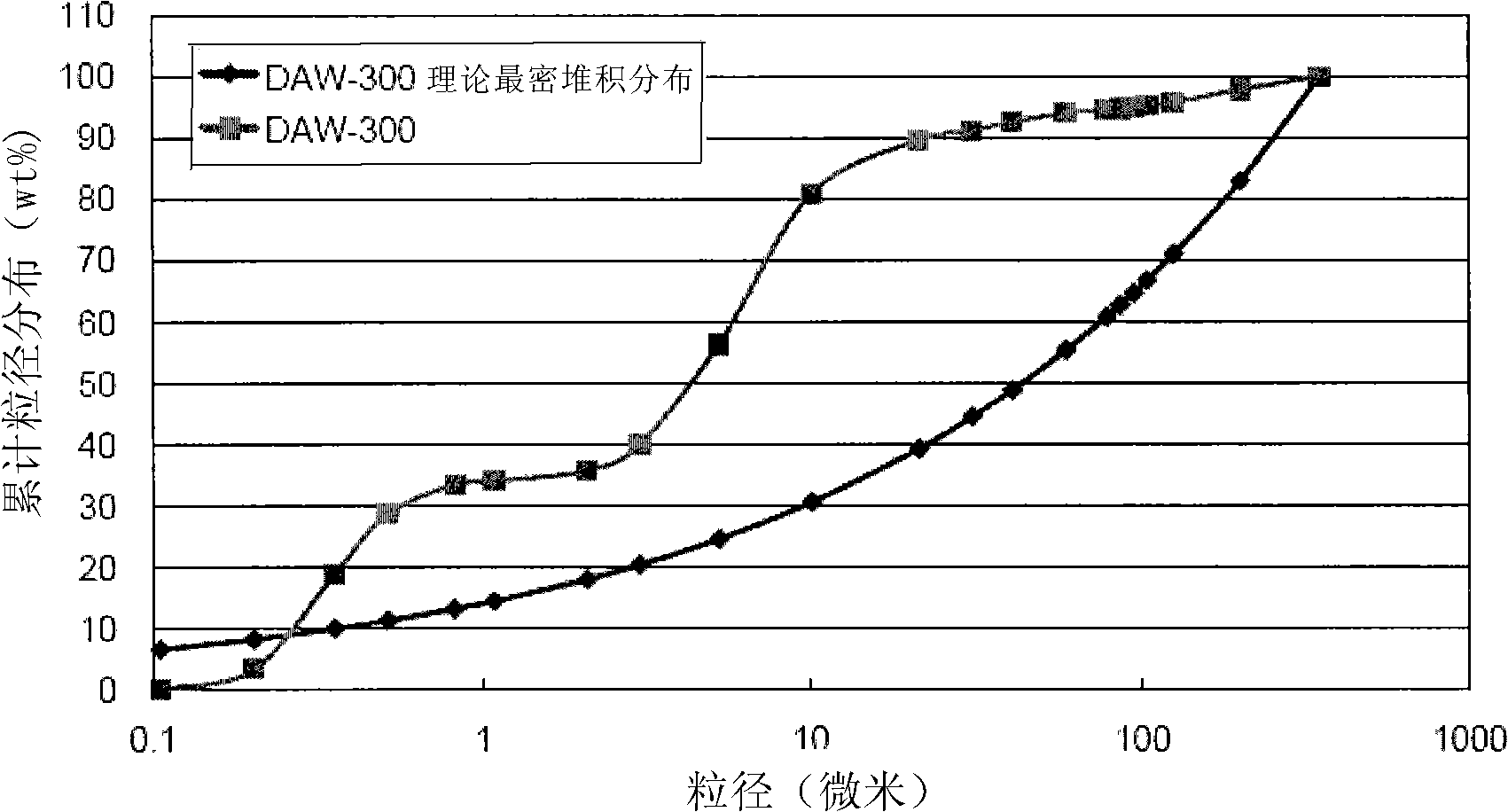

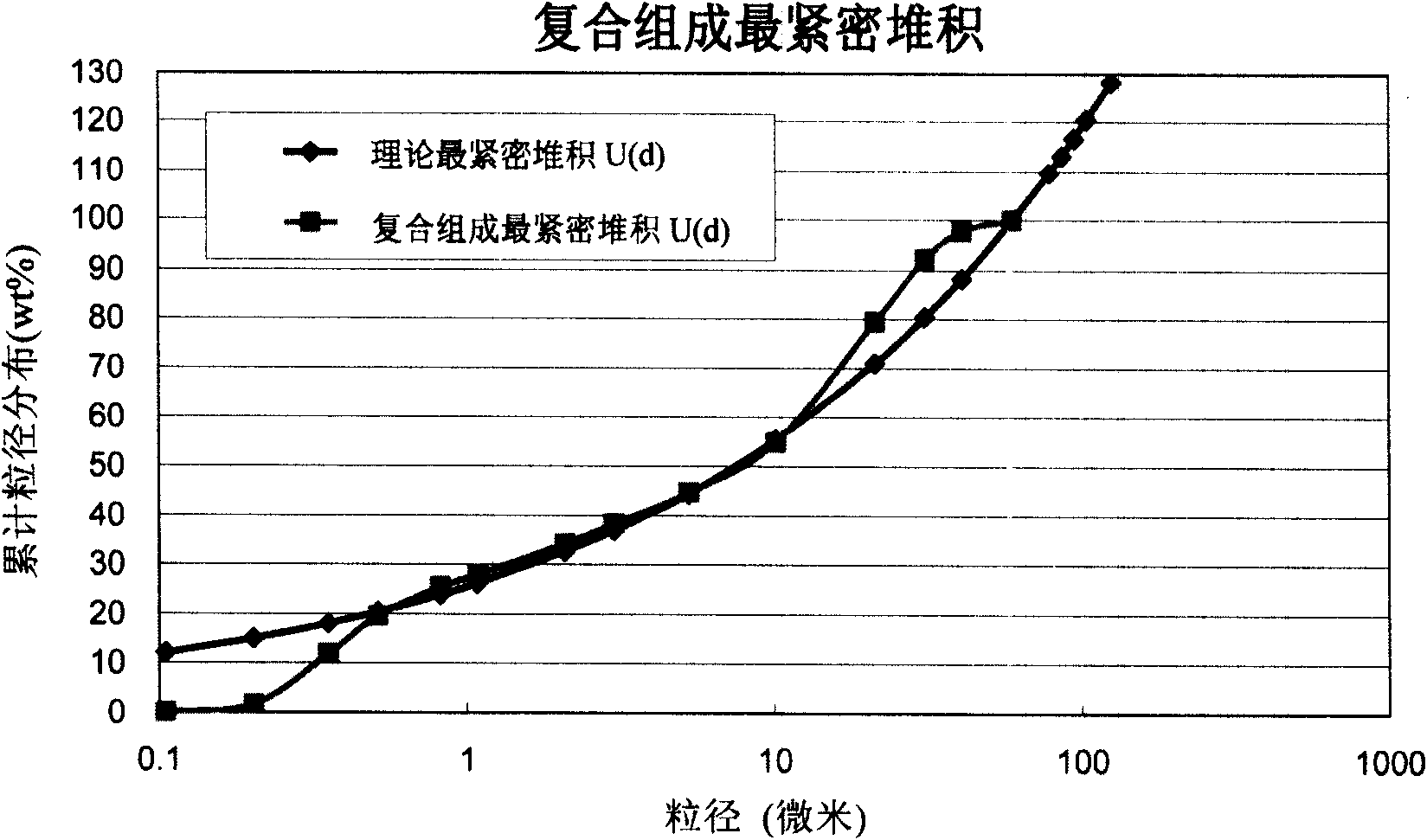

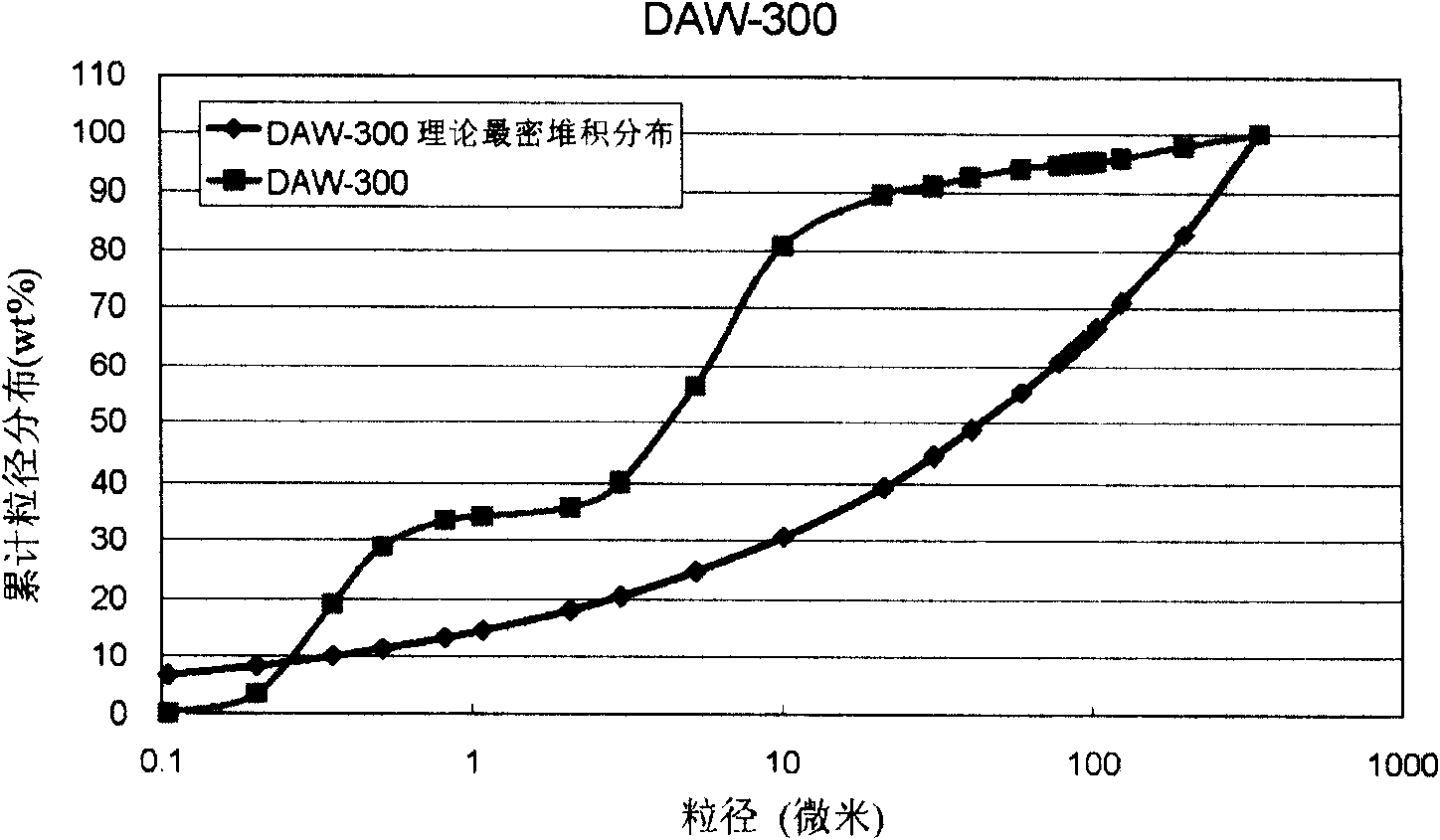

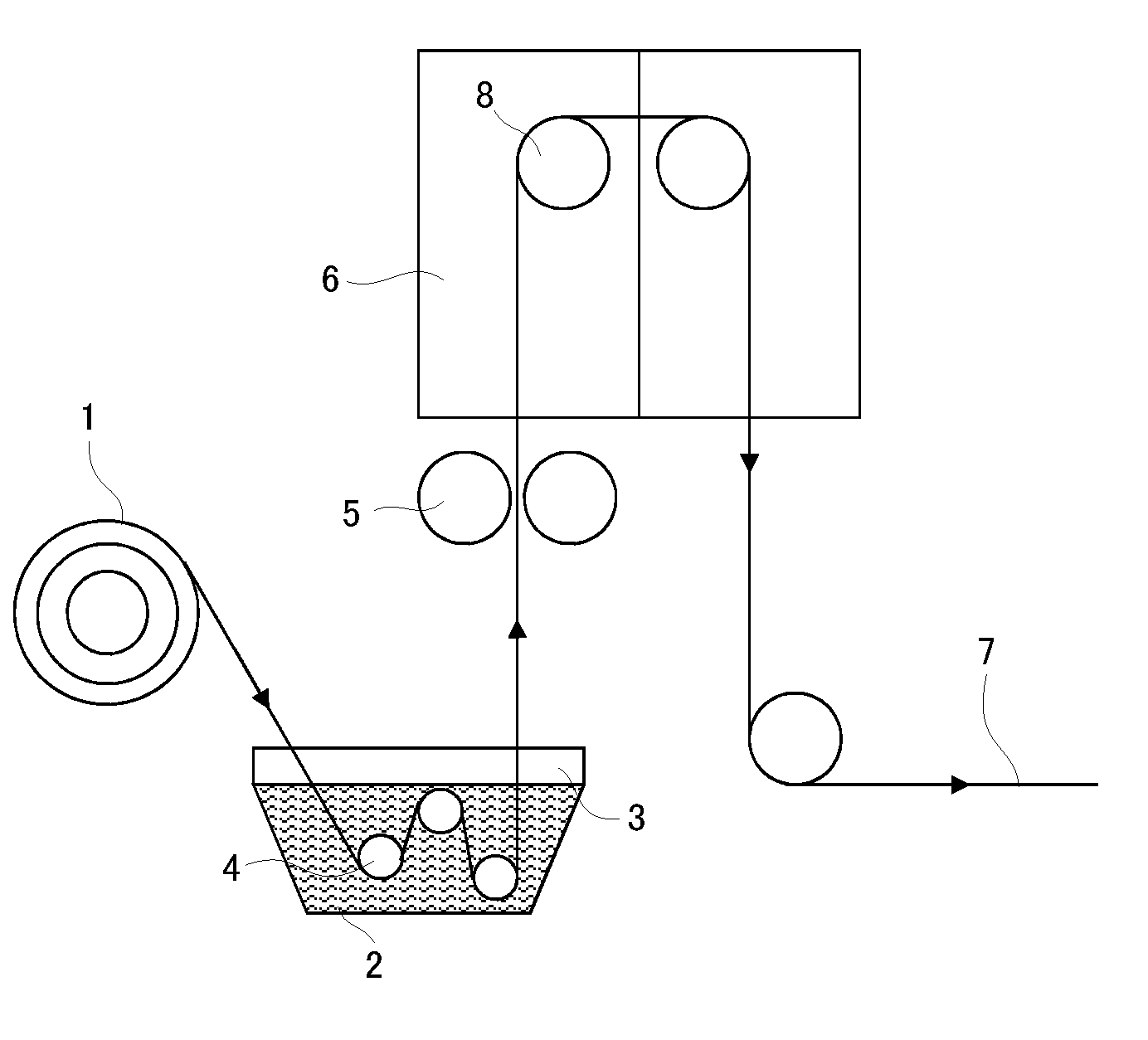

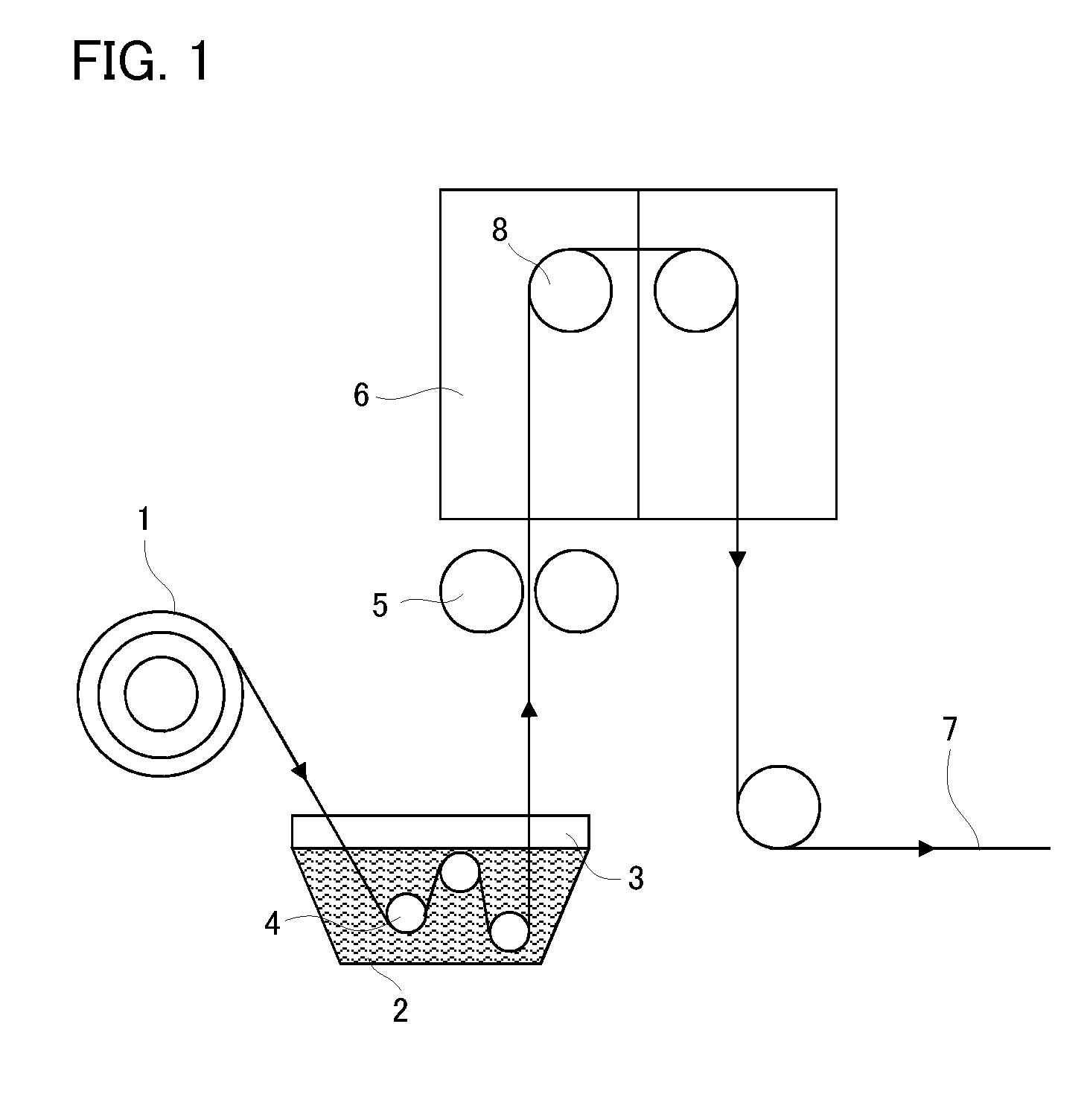

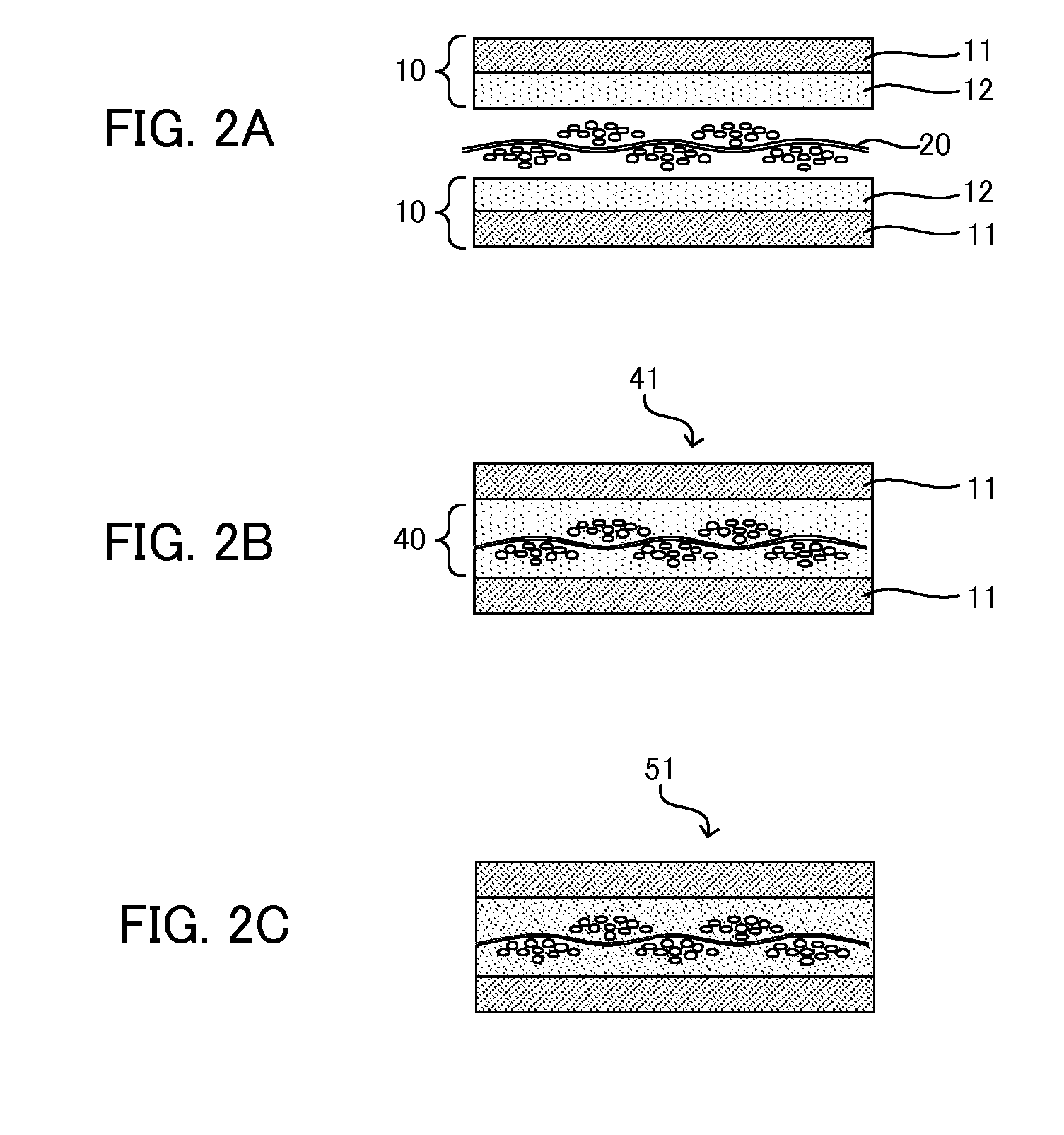

Epoxy resin composition, prepreg, metal-clad laminate, printed wiring board and semiconductor device

InactiveUS20110083890A1Improve flame resistanceImprove heat resistanceMaterial nanotechnologySynthetic resin layered productsSilica nanoparticlesSilica particle

The present invention is to provide an epoxy resin composition uniformly containing a large amount of inorganic fillers, excellent in heat resistance and flame resistance, and having good impregnation into a base material, and a prepreg using the epoxy resin composition, having good tackiness, and being easy in handling. Furthermore, it is to provide a printed wiring board using a metal-clad laminate formed using the prepreg and / or the prepreg or the epoxy resin composition, capable of easily conducting an ENEPIG process, and a semiconductor device using the printed wiring board, excellent in performances. An epoxy resin composition comprises a solid epoxy resin, a silica nanoparticle having an average particle diameter of 1 nm or more and 100 nm or less, and a silica particle having an average particle diameter larger than that of the silica nanoparticle, in the range of 0.1 μm or more and 5.0 μm or less.

Owner:SUMITOMO BAKELITE CO LTD

High-temperature-resistant rubber sealing ring for automobiles

The invention discloses a high-temperature-resistant rubber sealing ring for automobiles. The high-temperature-resistant rubber sealing ring comprises the following raw materials in parts by weight: 70-90 parts of ethylene-propylene-diene-terpolymer rubber, 10-30 parts of chloroprene rubber, 1-4 parts of an anti-aging agent, 0.8-1.5 parts of active zinc oxide, 0.2-0.4 part of magnesium oxide, 0.5-1.0 part of calcium oxide, 0.6-1.5 parts of butyltin mercaptide, 30-40 parts of modified kaolin, 10-15 parts of magnesium methacrylate, 1-3 parts of a promoter, 6-10 parts of soybean oil, 1-2 parts of ethyl methacrylate, 40-80 parts of paraffin oil, 0.2-0.5 part of triallyl phosphate, 1.0-1.5 parts of a crosslinking agent BIBP, 0.5-1.2 parts of an assistant crosslinking agent TAIC, 0.3-0.5 part of microcrystalline wax, 2-3 parts of a vulcanizing agent and 0.5-1 part of phthalic anhydride. The sealing ring disclosed by the invention has strong weather resistance, corrosion resistance and ozone resistance, and can be suitable for being used as the high-temperature-resistant rubber sealing ring for the automobiles.

Owner:TONGLING SANSHENG ELECTRONICS

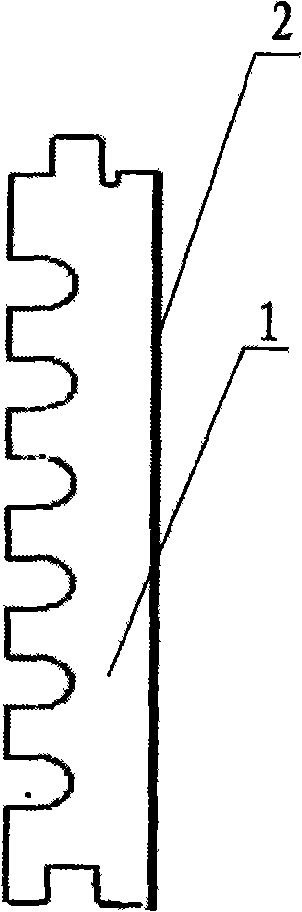

House earth surface sectional material and manufacturing method thereof

InactiveCN101280622AImprove textureGuaranteed structural strengthSynthetic resin layered productsFlooringFoaming agentAdhesive

The invention relates to a sectional material for houses and floors, which comprises two layers of different materials which contain synthetic resin. The ratios of main components of the inner layer material of the sectional material by weight are 100 portions of PVC, 0.8 to 1 portion of foaming agent, 5 to 6 portions of composite stabilizing agent and 7 to 9 portions of regulator; the ratios of the main components of the outer layer material by weight are PVC, plant material, composite stabilizing agent, pigment and adhesive; the two layer materials are pressed, molded and processed to become the sectional material. By adopting the ratios and the processing method provided by the invention, the sectional material produced has a color and a texture which are similar to the wood and a relatively high structural intensity, meanwhile the application of plant materials, such as wood powder, etc., are reduced in the production, thereby protecting the environment.

Owner:莱芜白斗新型建材有限公司

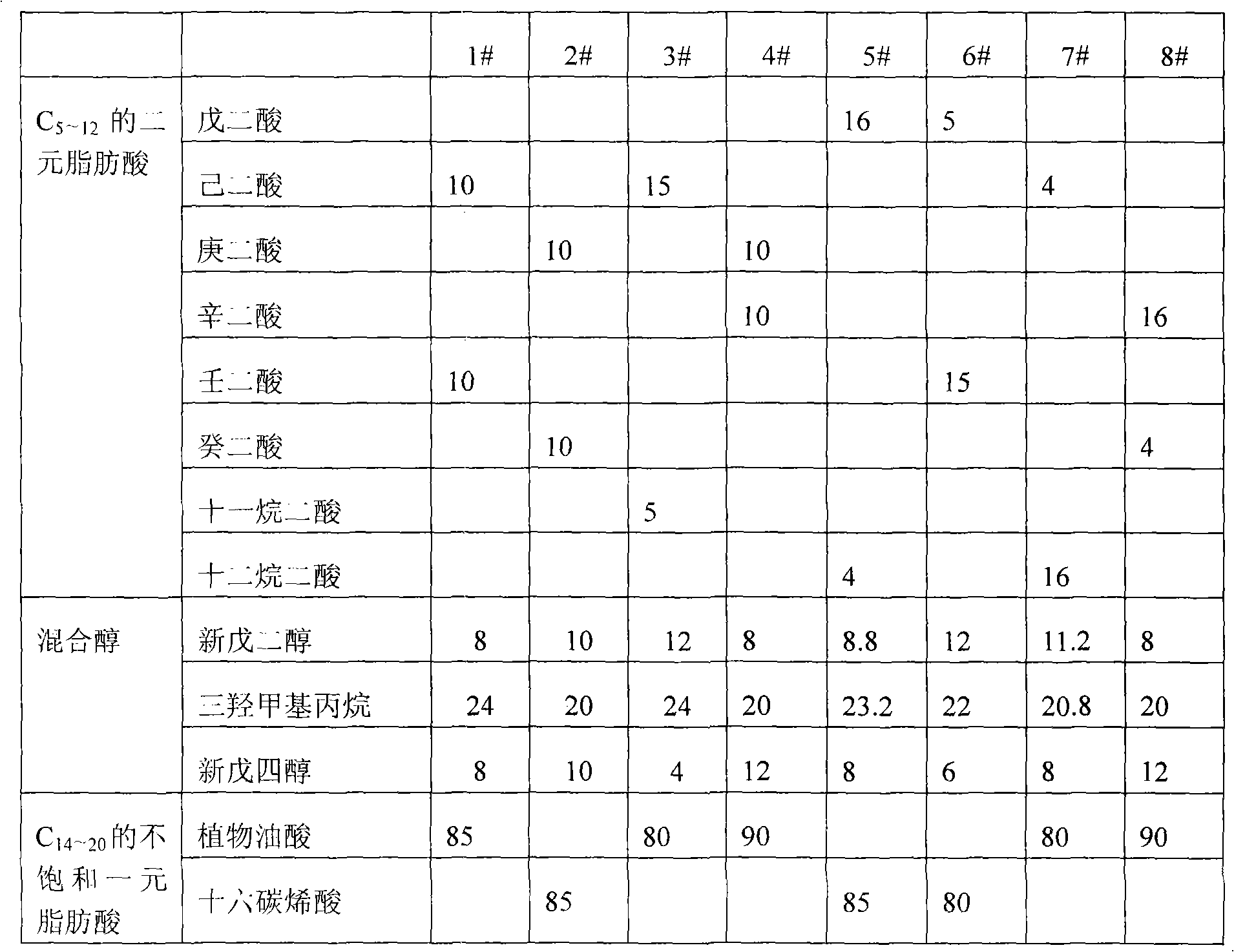

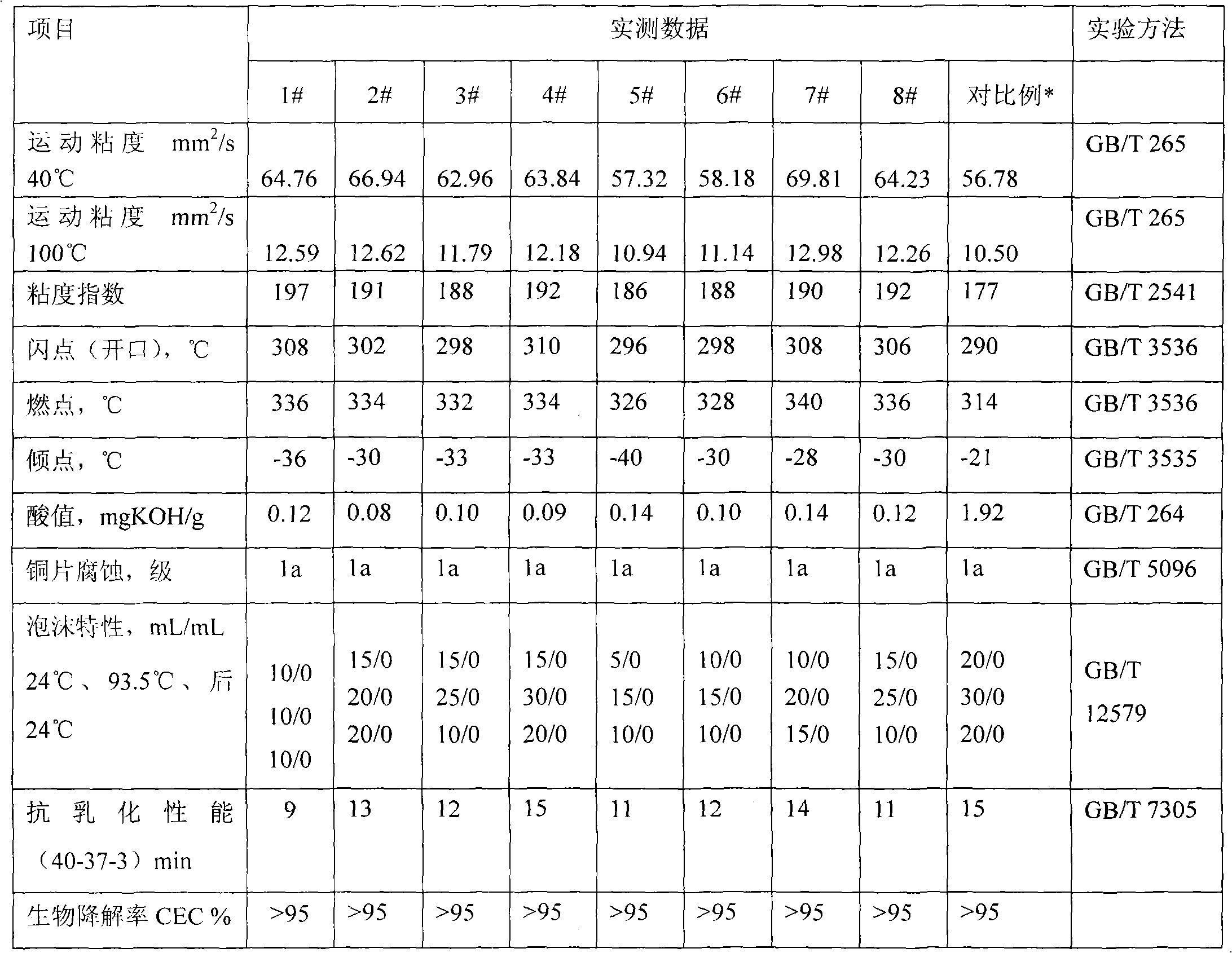

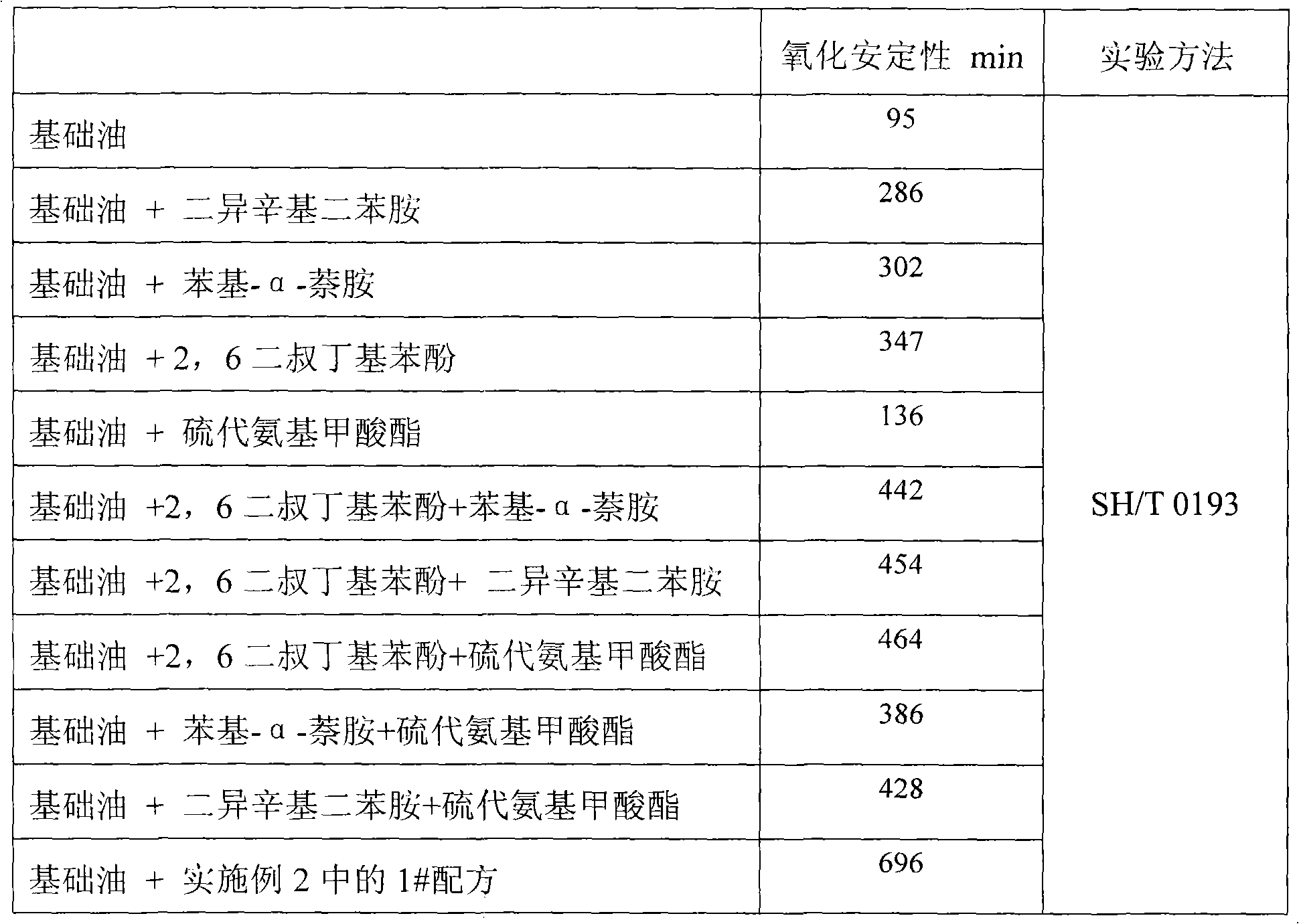

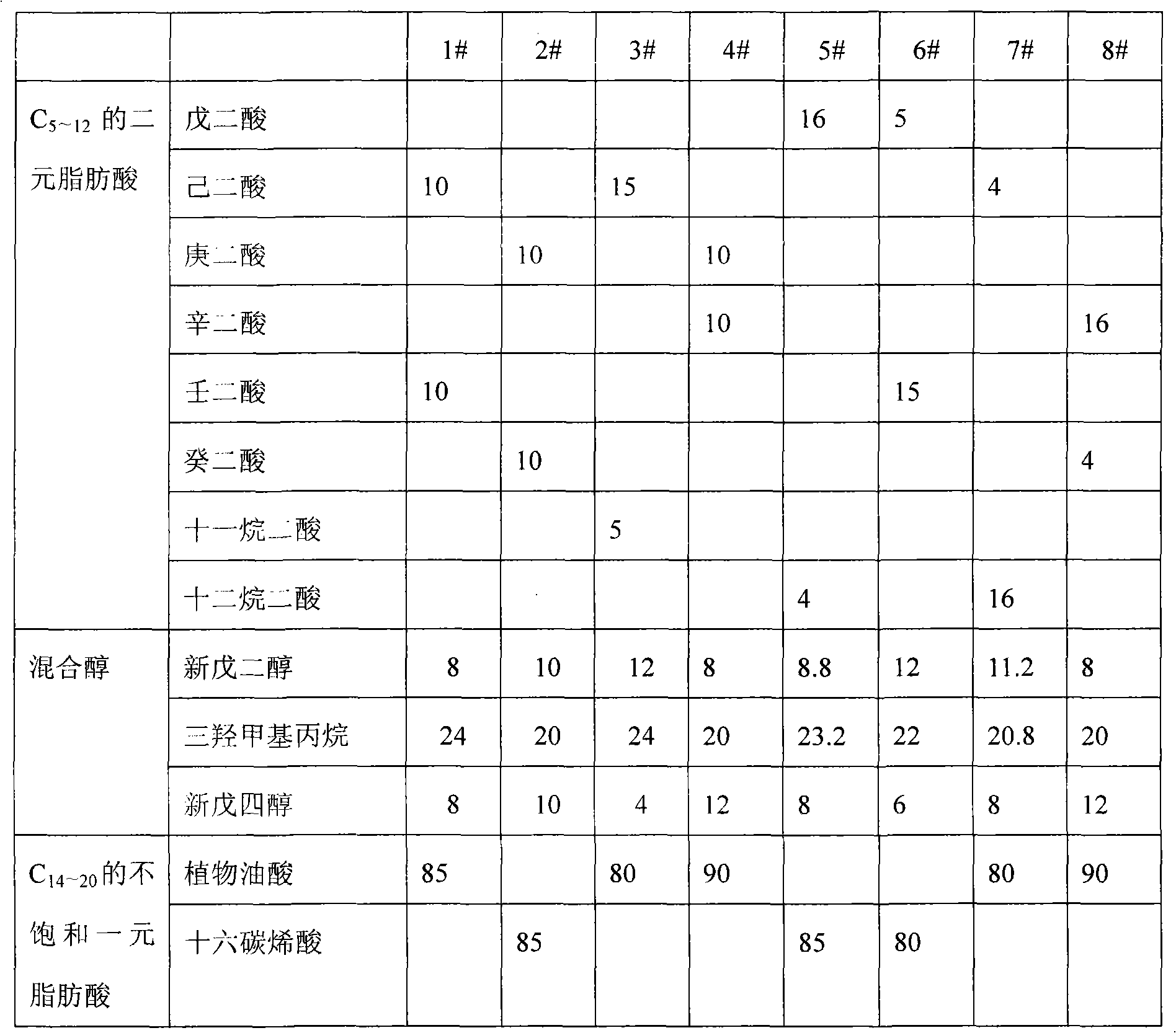

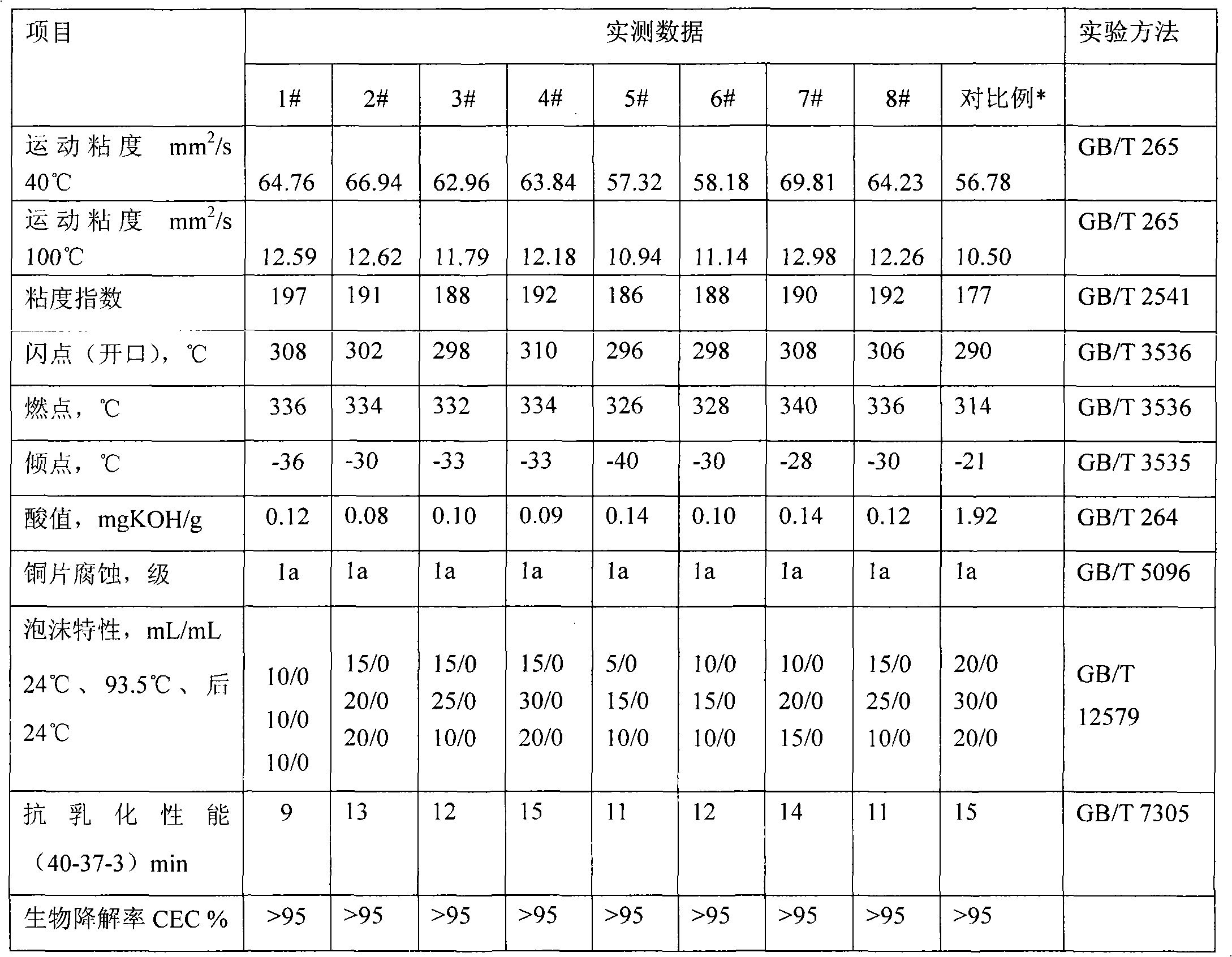

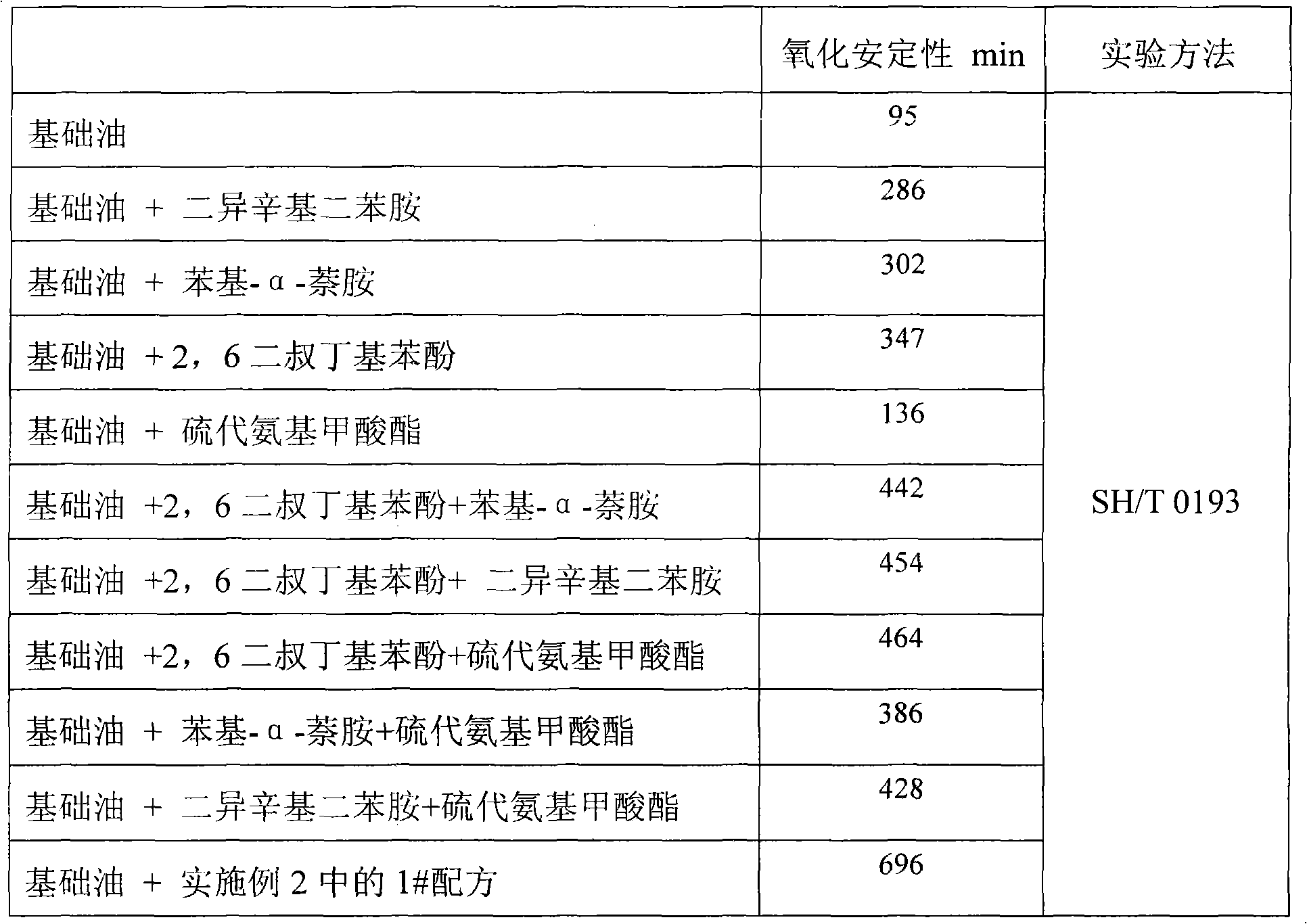

Flame-retardant hydraulic oil and preparation and application thereof

ActiveCN101831346AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceLubricant compositionAntioxidantHigh pressure

The invention provides flame-retardant hydraulic oil, which comprises the following components in percentage by weight: 1.9 to 4.5 percent of antioxidant, 1.5 to 3.5 percent of extreme-pressure abrasion resistant agent, 5 to 50ppm of antifoaming agent, 0.1 to 0.4 percent of anti-rusting agent and 92 to 97 percent of base oil, wherein the base oil is neopentyl polyol diacid composite ester which is prepared by fully esterifying carboxyl of aliphatic dibasic acid of C5-12 with mixed alcohol consisting of neopentyl glycol, trimethylolpropane and pentaerythritol and terminating the esterified product with unsaturated unitary fatty acid of C14-20. The flame-retardant hydraulic oil provided by the invention can be applied to various high-temperature and high-pressure hydraulic systems easy to contact naked flame. Compared with mineral-based (compressor) hydraulic oil, the flame-retardant hydraulic oil has the advantages of energy conservation, reduced oil consumption, reduced environmental pollution and prolonged service life, and can fully meet the working requirements of the high-temperature and high-pressure hydraulic systems easy to contact naked flame.

Owner:上海海都化学科技有限公司 +1

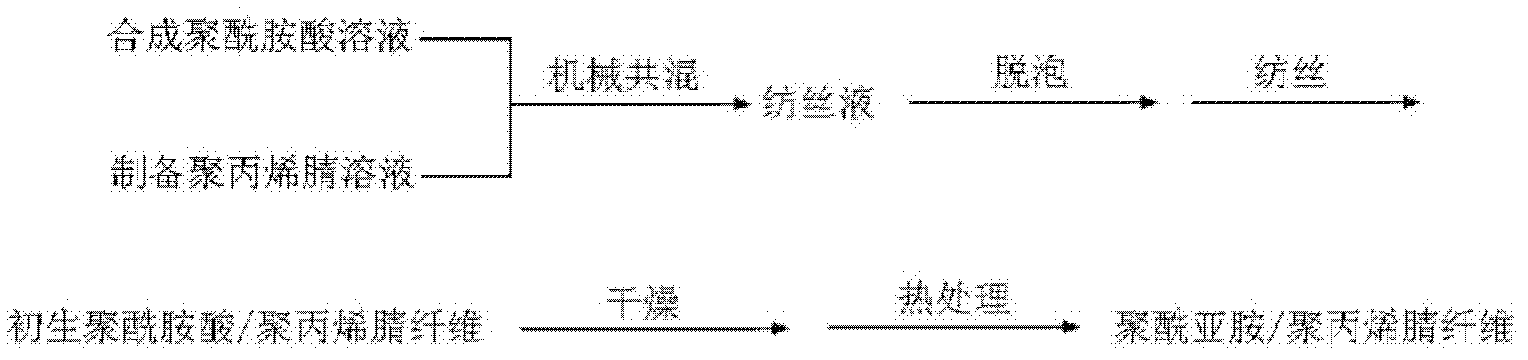

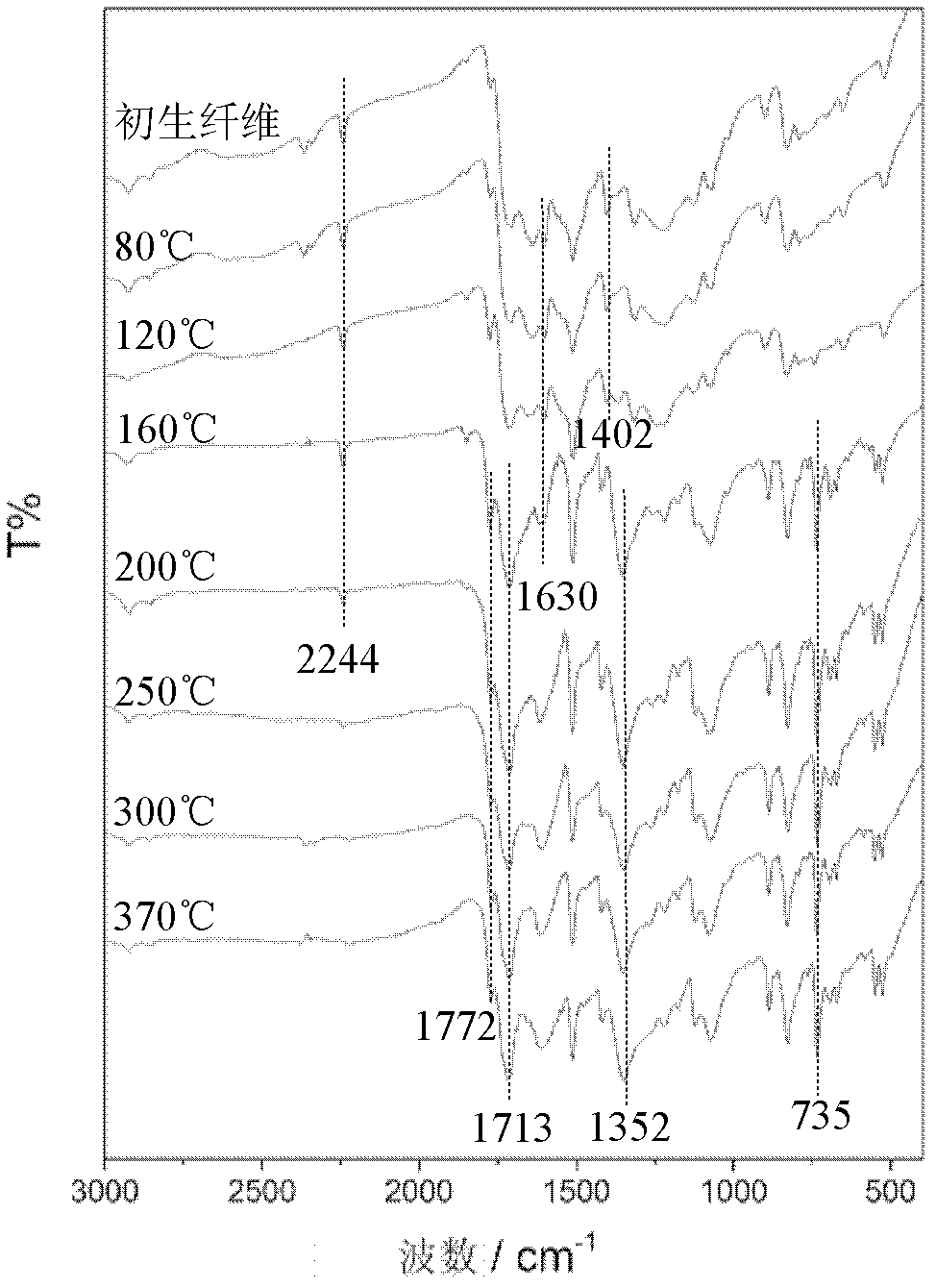

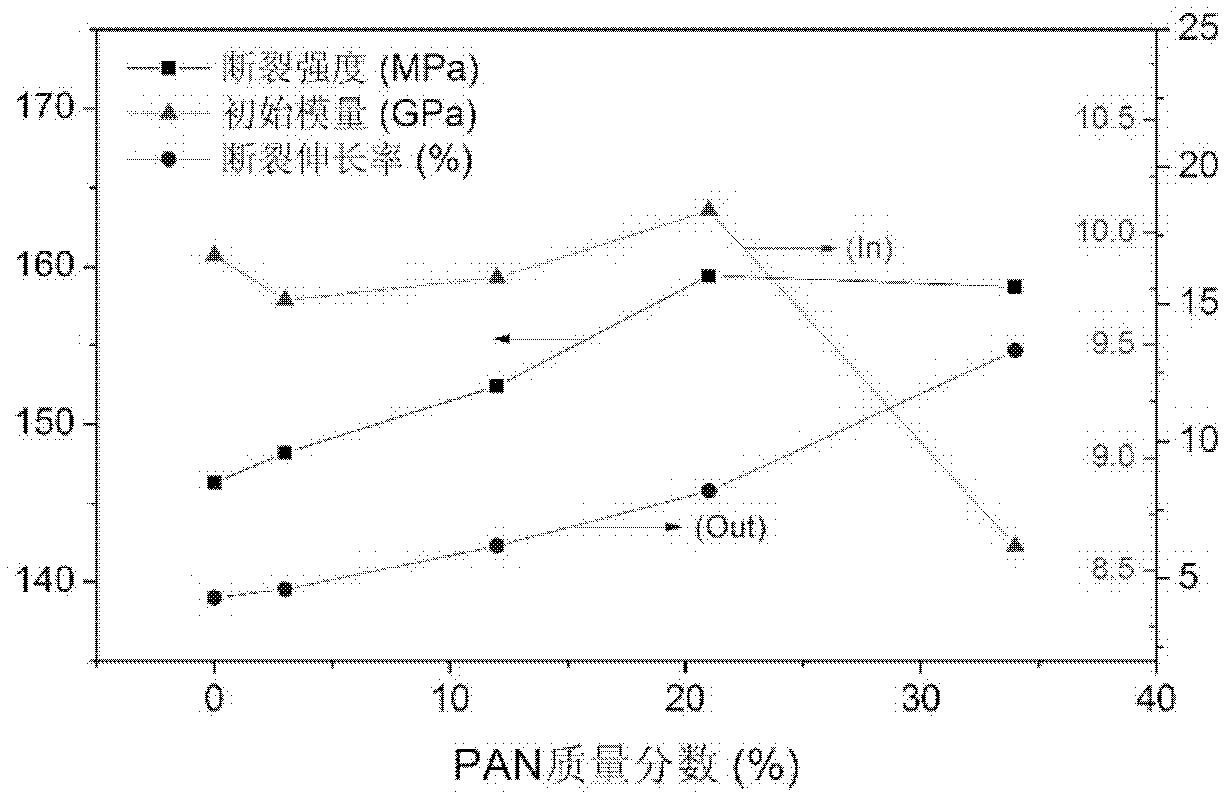

Polyimide/polyacrylonitrile blended fiber and preparation method thereof

ActiveCN102618964AHigh breaking strengthHigh initial modulusArtificial filament heat treatmentWet spinning methodsChemistryMoisture

A polyimide / polyacrylonitrile blended fiber and a preparation method belong to the technical field of blended fibers. The preparation method includes respectively preparing PAA (poly acrylic acid) liquor and PAN (polyacrylonitrile) liquor; blending the PAN liquor with the mass ranging from 3% to 40% of that of total PAA / PAN blended components and the PAA liquor to obtain spinning liquid precursor; removing bubbles in a vacuum manner, realizing wet-method spinning to obtain a PAA / PAN as-formed blended fiber; and realizing heat treatment for the as-formed blended fiber, removing moisture and solvent, completing a pre-oxidation process for the PAN component in the blended fiber and an imide cyclization process for the poly acrylic acid in the blended fiber, and obtaining the PI (polyimide) / PAN fiber. By means of comparing performances of a single component and the blended fiber under identical treatment conditions, a blended system capable of keeping an excellent mechanical performance of the fiber is obtained, and an excellent economic benefit is realized as compared with a PI fiber.

Owner:BEIJING UNIV OF CHEM TECH

Lubricating oil and grease base oil, and preparation method and applications thereof

ActiveCN101812349AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceBase-materialsOil and greaseEvaporation

The invention provides base oil, in particular to a neopentyl polyalcohol dibasic acid complex ester. The neopentyl polyalcohol dibasic acid complex ester is prepared in a way that: completely esterifying C5-12 binary fatty acid carboxyl with the mixture of neopentyl glycol, trimethylolpropane and pentaerythritol, and blocking with C14-20 unsaturated monobasic fatty acid. The base oil provided bythe invention has the characteristics of high flash point, high flammability point, low pour point, high viscosity index, low evaporation loss, high thermal oxidation stability and high biodegradation rate. The invention can be used as syntholube and grease base oil, especially syntholube base oil used under the conditions of high temperature and high pressure. The invention is especially suitable to be used in fire resistant hydraulic fluid, high-temperature chain oil, high-temperature grease and the like in severe working spaces at which naked flame can is accessible under the conditions ofhigh temperature and high pressure.

Owner:上海海都化学科技有限公司 +1

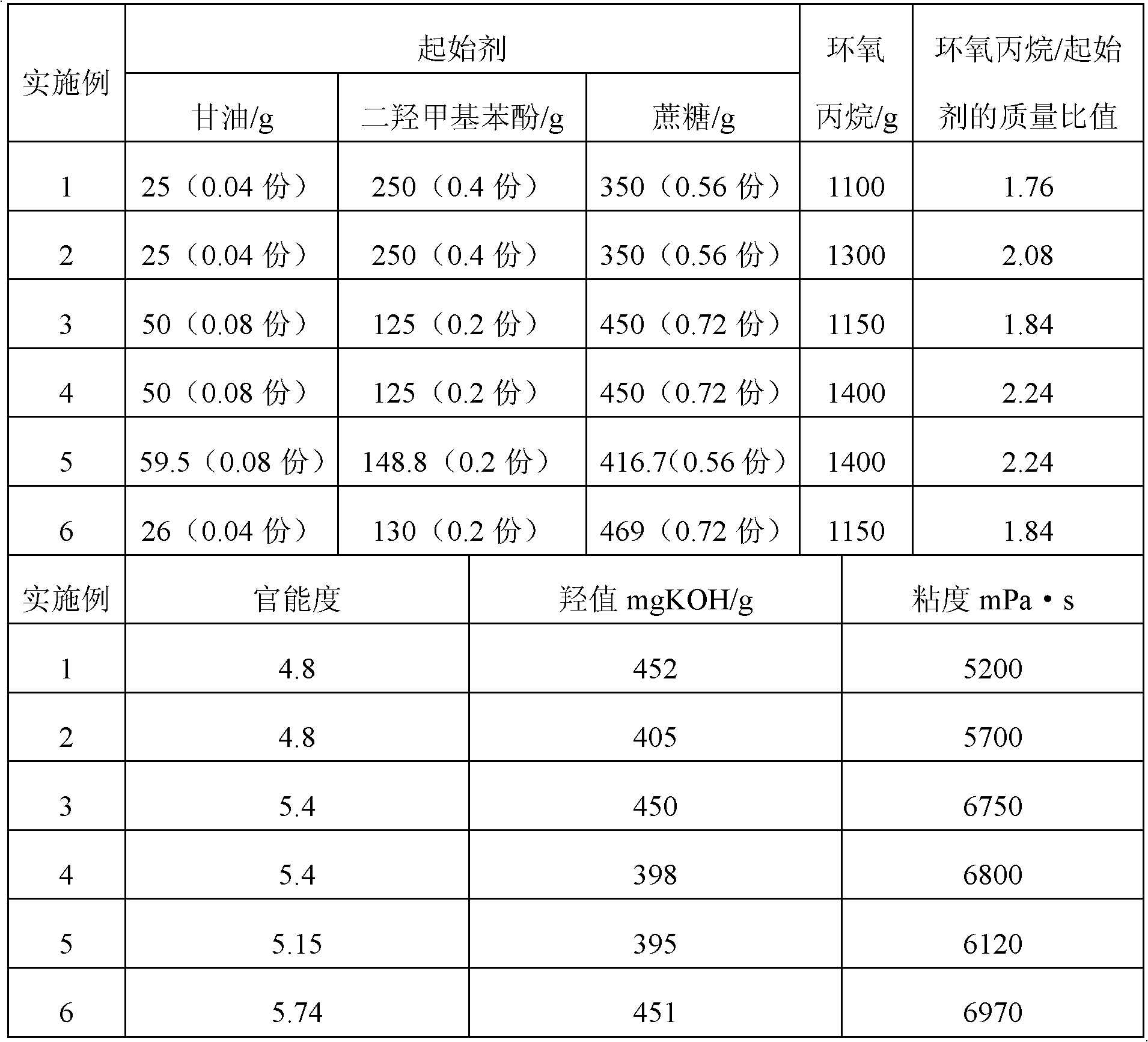

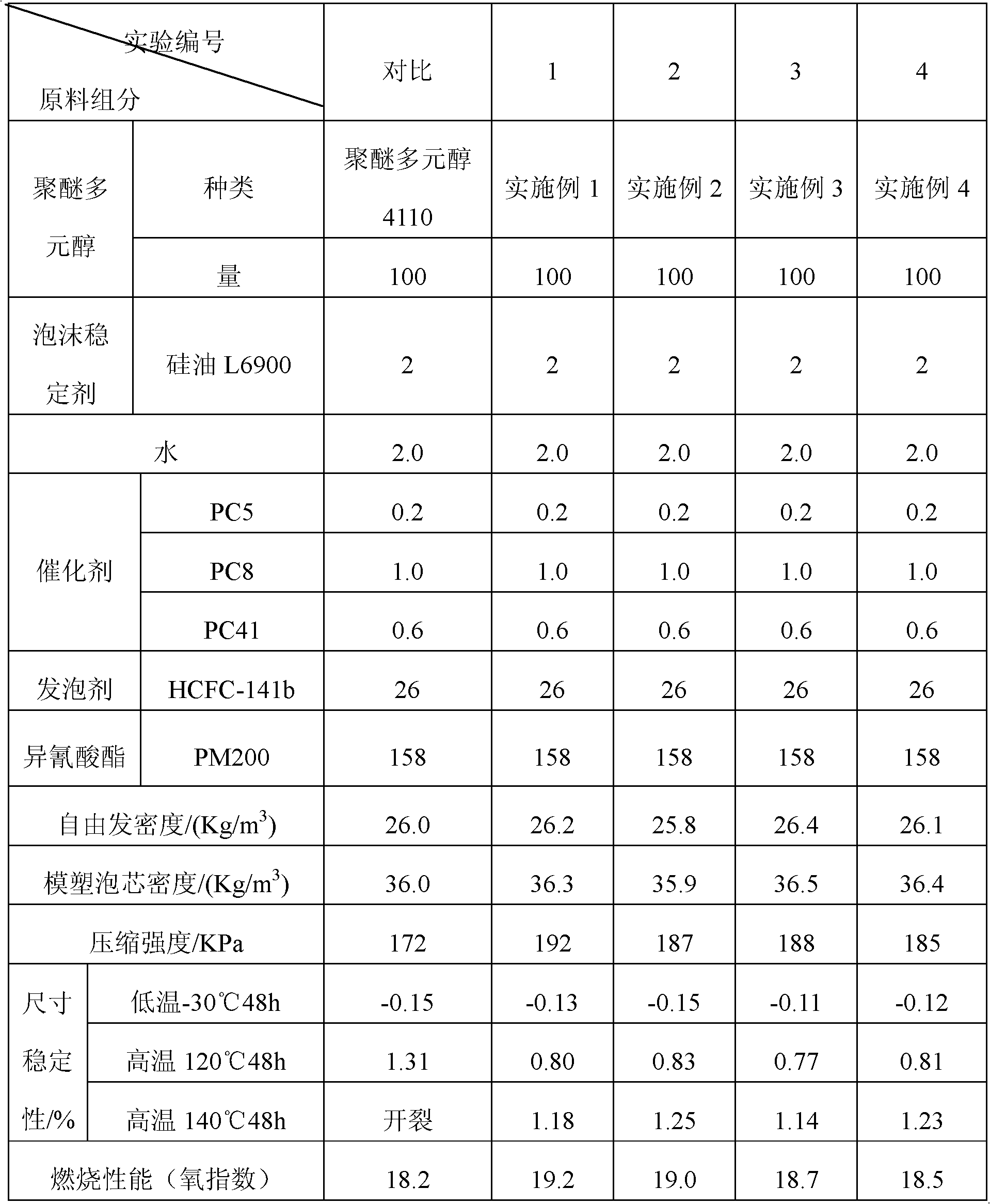

Polyether glycol, polyurethane rigid foamed plastic and preparation methods thereof

InactiveCN102050945ALow viscosityHigh functionalitySugar derivativesEther preparation from oxiranesPolymer scienceSucrose

The invention discloses a preparation method of polyether glycol. The method comprises the following step: preparing the polyether glycol from compound initiator, polyether glycol synthetic catalyst and propylene oxide by using a conventional polyether glycol synthesis method, wherein the compound initiator comprises the following components in parts by weight: 0.04-0.08 part of glycerol, 0.2-0.4 part of dihydroxymethylphenol and 0.56-0.72 part of sucrose; and the mass ratio of the propylene oxide to the compound initiator is 1.7-2.3. The invention also discloses polyether glycol prepared by using the method, a method for preparing polyurethane rigid foamed plastic from the polyether glycol, and polyurethane rigid foamed plastic. The polyether glycol disclosed by the invention has the advantages of low viscosity and high functionality, and has favorable processing properties when being used as a raw material. The polyurethane rigid foamed plastic prepared from the polyether glycol has the advantages of excellent high-temperature resistance, high flame resistance and high compression strength.

Owner:SHANGHAI DONGDA POLYURETHANE

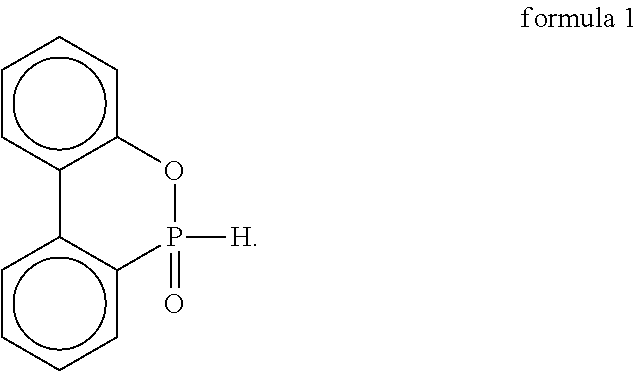

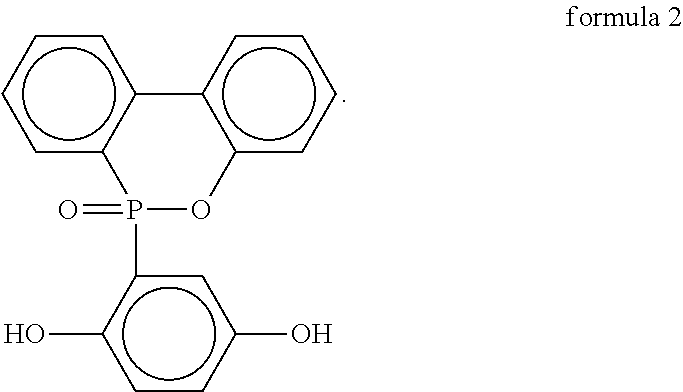

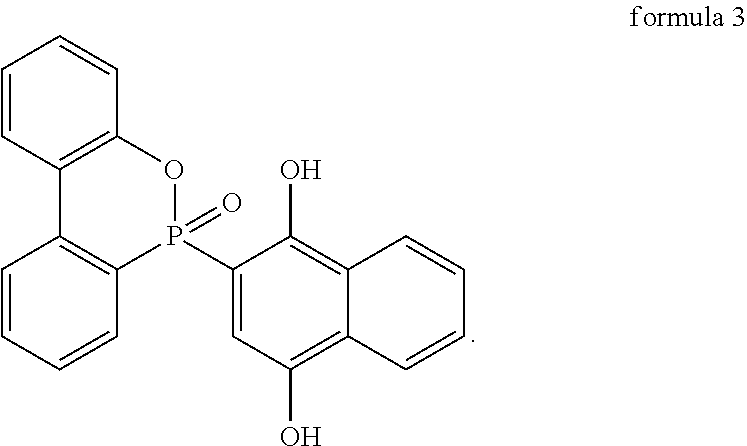

Varnish composition, and pre-impregnated manufacture thereof

ActiveUS20120136094A1Improved anti-flammability/flame resistanceEasy to processPlastic/resin/waxes insulatorsThin material handlingOxazolidonePhosphor

A varnish composition includes composition (A): an epoxy resin, composition (B): a hardener, composition (C): an accelerator, composition (D): phosphor-containing flame retardant, and composition (E): fillers, wherein composition (A) includes composition (A-1): phosphor-containing epoxy resin, phosphor-containing and silicon-containing epoxy resin, or a mixture thereof; composition (A-2): dicyclopentadiene epoxy resin; and composition (A-3): oxazolidone epoxy resin.

Owner:ITEQ CORP

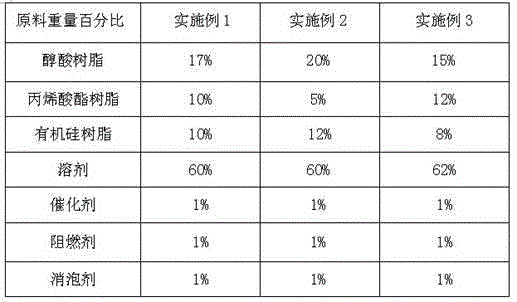

Fire retardation three-proofing lacquer and preparation method thereof

InactiveCN104804626AImprove reliabilityExtended service lifeFireproof paintsPolyester coatingsPolymer sciencePtru catalyst

The invention relates to a fire retardation three-proofing lacquer and a preparation method thereof, wherein the raw materials comprise, by weight, 10-30% of an alkyd resin, 5-20% of an acrylic ester resin, 5-20% of an organic silicon resin, 30-80% of solvent, 0.2-2% of a catalyst, 0.2-2% of a fire retardation agent, and 0.2-2%o of a defoamer. The fire retardation three-proofing lacquer of the present invention is used for production of electronic components, integrated circuits, electronic packaging, LED packaging, printed circuit boards and the like, and has effects of improvement of reliability and service life of circuit boards.

Owner:程威军

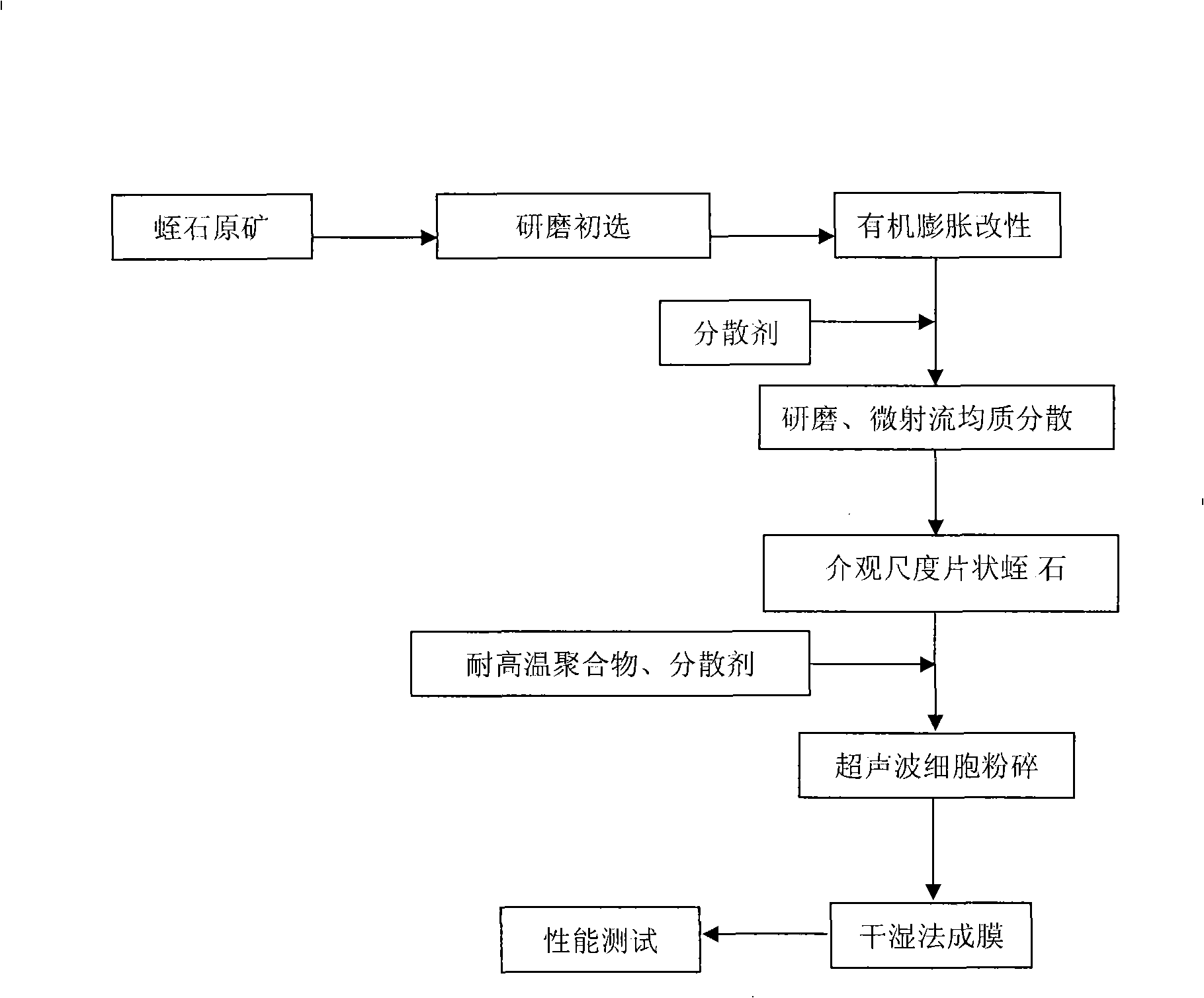

Method for preparing meso-scale flaky vermiculite and heat-resistant polymer heat insulation composite membrane

The invention provides a method for preparing mesoscale flaky vermiculite and high temperature polymer thermal insulation composite membrane. The invention adopts a technical proposal that primary mineral of vermiculite are ground to choose the part of vermiculite with a grain diameter less than 10 mu m; quaternary alkylammonium salt compound with a carbon chain of between 12 and 36 is used to modify the chosen vermiculite by organic expansion; a dispersing agent, grinding and a high-pressure homogenizer are adopted to treat the mesoscale flaky vermiculite; inorganic flaky vermiculite microcrystals are dispersed in organic high molecular polymer materials by using high temperature resistance polymer materials of poly(aryl ether sulfone) and poly(phthalazinone ether sulfone ketone) as continuous phrases and by methods of ultrasonic cell disruption, etc., and are formed into membranes by dry and wet methods. The products made by the method have extremely low heat conductivity, and excellent thermal insulation performance. Meanwhile, the composite membrane can be tightly covered on the surfaces of polysulfonamide and other fiber fabrics to improve the fireproof and thermal insulation properties, particularly the thermal insulation property of the fiber fabrics, can be used to make fire-protection clothing for safe access to fire ground or used as surface material for combat uniform.

Owner:DONGHUA UNIV

Special halogen-free flame retardant reinforced PA (polyamide) 56 composite material for casing of low-voltage circuit breaker

InactiveCN104861648AImprove flame retardant performanceImprove flame resistanceGlass fiberLow voltage circuits

The invention discloses a special halogen-free flame retardant reinforced PA (polyamide) 56 composite material for a casing of a low-voltage circuit breaker. The composite material comprises components in parts by mass as follows: 35-70 parts of PA 56, 20-40 parts of alkali-free glass fiber, 0.1-1.2 parts of a glass fiber dispersing agent, 6-20 parts of halogen-free flame retardant, 12-30 parts of modified filler, 0.3-0.9 parts of an antioxidant, 0.2-0.6 parts of a lubricant and 0.5-1.2 parts of a coupling agent. The composite material can have excellent flame retardance and burning resistance, and can meet the low-voltage circuit breaker industry requirement that the material is contacted with a glow wire for 30 s at the temperature of 960 DEG C and a flame is extinguished within 10 s after the material is separated.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

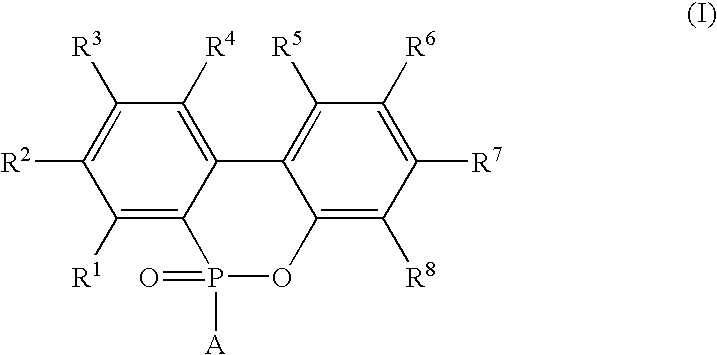

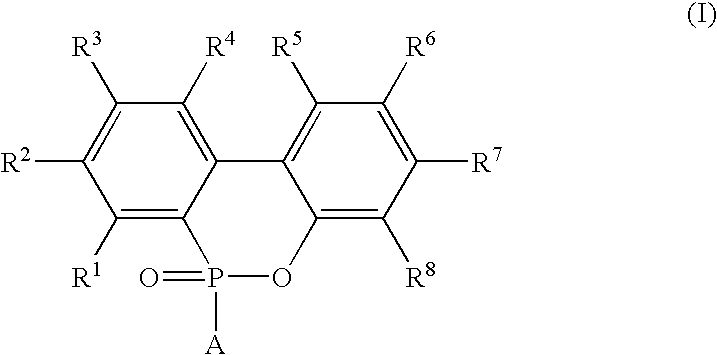

Water-soluble flame-retardant polyester resin, resin composition containing the resin, and fabric product treated with the resin composition

InactiveUS20050261461A1Improve flame retardant performanceImprove fire resistanceHeat resistant fibresThin material handlingFiberSolubility

A water-soluble, flame retardant polyester resin is obtained by a condensation reaction or a polycondensation reaction of a dicarboxylic-acid component, a glycol component, a water-solubility imparting component and a reactive phosphorus-containing compound such that a ratio of the water-solubility imparting component in a total of the dicarboxylic-acid component and the water-solubility imparting component is in a range of 1 to 60 mol %. Since this polyester resin can be dissolved in a solvent by allowing a halogen-free, phosphorus-containing polyester with excellent flame resistance to have water solubility, it is possible to improve applicability and eliminate problems of working environment and environmental destruction resulting from organic solvents. In addition, even when treating substrates such as fibers and PET films with the polyester resin, there is no deterioration of these substrates.

Owner:GOO CHEM IND

Transparent and flame-retardant aromatic polycarbonate resin composite and molded article

InactiveUS20130035429A1Improve flame retardant performanceLow haze valueSemi-permeable membranesOrganic sulfonic acidPolycarbonate

A transparent and flame-retardant aromatic polycarbonate resin composite is provided. A transparent and flame-retardant aromatic polycarbonate resin composite includes (A) 100 parts by mass of a transparent aromatic polycarbonate resin composed of 99 percent by mass to 50 percent by mass of an aromatic polycarbonate resin-A with a viscosity-average molecular weight (Mv) of 3×103 to 2.5×104, and 1 percent by mass to 50 percent by mass of an aromatic polycarbonate resin-B with a viscosity-average molecular weight (Mv) of 5×104 to 9×104, and, (B) 5×10−3 parts by mass to 9×10−2 parts by mass of a flame retardant composed of an alkali metal salt of an organic sulfonic acid, wherein a Q-value is 0.1 cm3 / sec or smaller, a test piece for UL testing of 2.0 mm thickness molded using the aromatic polycarbonate resin composite satisfies UL94V-0, and, a molded article of 3.0 mm thickness shows a haze value of 2% or smaller.

Owner:MITSUBISHI GAS CHEM CO INC

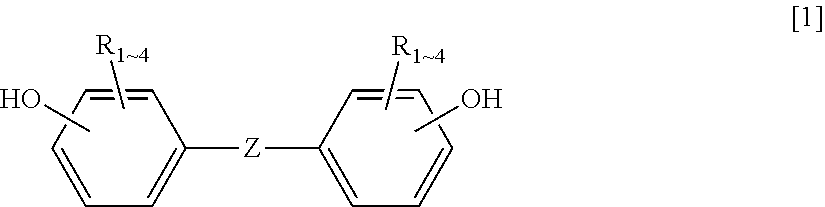

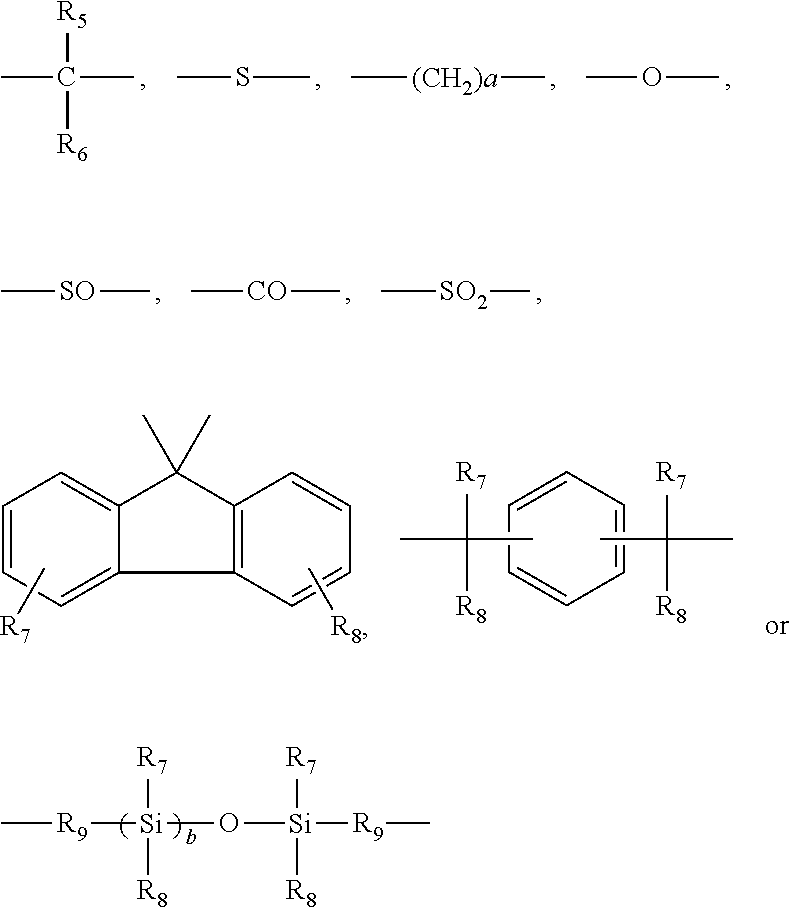

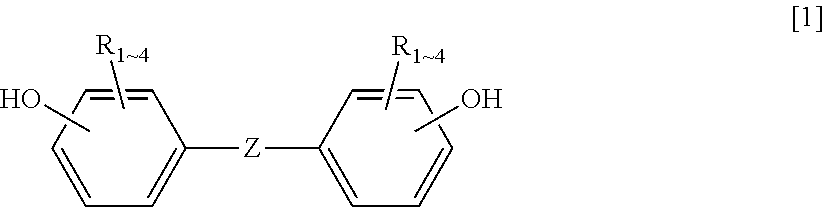

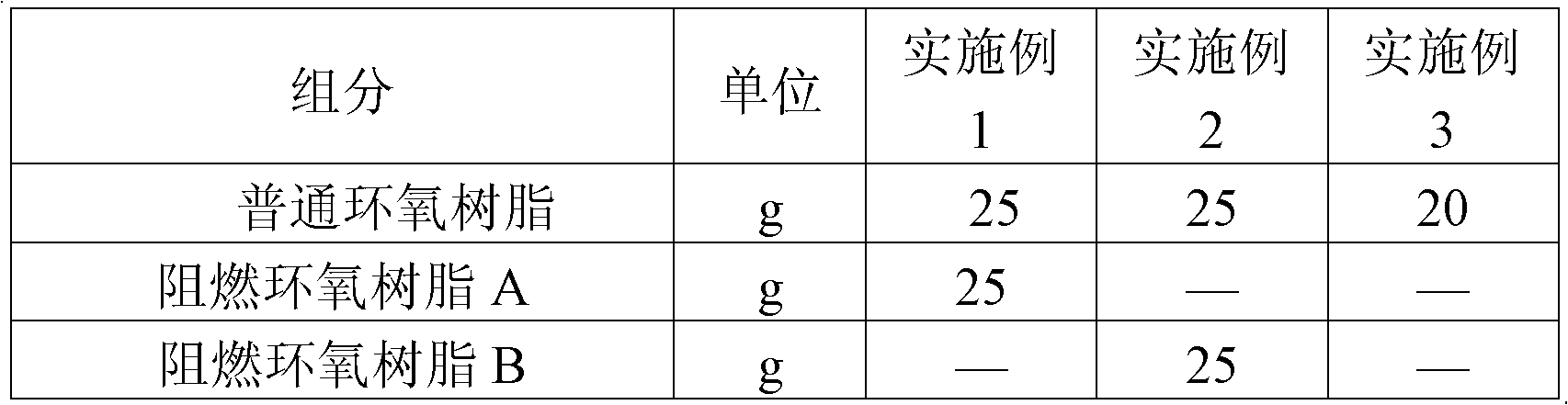

Halogen-free non-phosphorization flame-retardant epoxy resin composition and preparation method thereof

ActiveCN102276959AImprove flame retardant performanceGood electrical performancePolymer scienceFirming agent

The invention provides a halogen-free non-phosphorization flame-retardant epoxy resin composition and a preparation method thereof. The preparation method comprises the following steps of: premixing the common epoxy resin, flame-retardant epoxy resin, a curing agent, a curing accelerator, a flame-retardant synergistic agent and an inorganic filler; melting, mixing and extruding; and crushing and sieving to prepare the halogen-free non-phosphorization flame-retardant epoxy resin composition. The flame-retardant epoxy resin composition does not contain harmful substances such as halogen, diantimony trioxide, phosphorus and the like, has excellent fire resistance which can reach UL94V-O grade flame-retardant standard and high electrical property, can be applied in the fields of electronic packaging and copper-clad laminate.

Owner:天津凯华绝缘材料股份有限公司

Method for manufacturing large-size black bricks

The invention relates to a method for manufacturing black bricks, in particular to a method for manufacturing large-size black bricks, which solves the problem that the traditional baking process of black bricks in conventional sizes cannot manufacture large-size black bricks. Each large-size black brick respectively has the length, the width, and the height of 4.2 m, 2 m and 1 m, and the large-size black brick is made from the following raw materials in percentage by weight: 90 percent of clay, 0.5 percent of coal gangue powder, 7.5 percent of coal powder, 1 percent of coal slime, 0.5 percent of iron powder and 0.5 percent of glass powder. The manufacture process comprises the working procedures of kneading mud, making blanks, drying, loading the blanks into a kiln and roasting. During making the blanks, two fine iron wire nets are put among the brick blanks at intervals; during loading the blanks into the kiln, black bricks in the conventional sizes are palletized and clamped on the peripheries and the upper parts of the large-size black bricks; and during roasting, the brick blanks are roasted twice according to a roasting method of the black bricks in the conventional sizes. The large-size black bricks manufactured by the method have higher strength and no cracks and breakages and fully meet the requirement of brick carving.

Owner:王锁贵

Thermoplastic Resin Composition Having Improved Flowability

ActiveUS20100168292A1Good compatibilityImprove flame resistanceFilm/foil adhesivesPolymer sciencePolyester resin

A thermoplastic resin composition that can have improved flowability of the present invention comprises (A) about 1 to about 98% by weight of a functional group-containing vinyl copolymer resin reactive with polyester; (B) about 1 to about 98% by weight of an aromatic vinyl graft copolymer resin; (C) about 1 to about 98% by weight of a polyester resin; and (D) about 0.5 to about 30 parts by weight of a bromodiphenyl ethane mixture, based on the total weight of a base resin comprising (A), (B) and (C). The resin composition of the present invention can have flame retardancy, excellent impact resistance, and improved flowablity.

Owner:LOTTE ADVANCED MATERIALS CO LTD

High-toughness melamine resin and preparing method thereof

The invention discloses a high-toughness melamine resin and a preparing method thereof. An elastomer is adopted to be added in melamine resin with the form of powder and emulsion, the impact strength of melamine resin is improved, and high-toughness melamine resin is prepared. The preparing method of melamine resin comprises the steps of placing 40-85 parts of melamine-formaldehyde resin prepolymer, 5-50 parts of fiber, 0.1-0.5 part of curing agent, 5-30 parts of elastomer and 0.1-1 part of flowable agent into a kneading machine at 25-80 DEG C to be subjected to kneading for 30-90 min, afterwards placing kneaded materials into a stove at 70-130 DEG C to be subjected to stoving and dehydration, and then conducting ball milling on the kneaded materials and 3-10 parts of inorganic filler in a ball mill for 4-20 h to obtain high-roughness melamine powder. The other preparing method comprises the steps of placing prepolymer, the fiber, the curing agent and the elastomer into the kneading machine to be subjected to kneading, afterwards putting the kneaded materials into the stove to be subjected to stoving and dehydration to obtain irregular blocky solid, and then conducting ball milling on the blocky solid, inorganic filler and elastomer powder in the ball mill according to matching to obtain the high-roughness melamine powder. The preparation of the high-roughness melamine material is beneficial to reducing the breakage rate of a melamine product in use, and prolonging the service life of the melamine product.

Owner:ZHEJIANG UNIV OF TECH +1

Making method of non-circular sectional special-shaped meta-position aromatic polyamide fiber

ActiveCN101302649AChanging the spinning forming processImprove heat resistanceSpinnerette packsFilament/thread formingPolymer scienceDry heat

The invention relates to a method for preparing heterotypic meta-aromatic polyamide (MPIA) fiber with non-circular section. The meta-aromatic polyamide solution is squeezed directly into the low temperature coagulation bath containing surfactant after being neutralized and filtered, and the spinning shaped spun filament is carried out hot water stretching, washing and dry heat stretching to obtain finished MPIA fiber with non-circular section. The MPIA fiber with non-circular section obtained according to the method has larger specific surface area, more excellent textile processing performance, and is more suitable to fabricate high-temperature resistant synthetic fiber papers.

Owner:X FIPER NEW MATERIAL CO LTD +1

Method for preparing special lubricating grease and thickening agent for cylinder of electric tool

The invention relates to a method for preparing special lubricating grease and thickening agent for a cylinder of an electric tool. The lubricating grease and thickening agent mainly comprise the following components: a) base oil; b) at least one thickening agent of compound lithium, compound lithium calcium or carbamido grease, or composite thickening agent of any two of the three substances; c) silicon-containing anti-foaming agent; d) one or more extreme-pressure antiwear agents of borates or vulcanized whale oil substitute; e) one or more anilines antioxygens or dialkyldithiophosphates antioxygens; and f) tripolycyanamide urate; wherein the amount of the base oil in use accounts for 70-95% of the total weight of the lubricating grease, the thickening agent accounts for 5-30% of the total weight of the lubricating grease, the amount of the silicon-containing anti-foaming agent accounts for 5-10% of the total weight of the lubricating grease, the amount of the extreme-pressure antiwear agents accounts for 2-5% of the total weight of the lubricating grease, the amount of the antioxygens accounts for 1-5% of the total weight of the lubricating grease, and the amount of the tripolycyanamide urate accounts for 3-15% of the total weight of the lubricating grease. The lubricating grease, rubber and thermoplastic elastomer which are prepared using the components have good compatibility, excellent extreme-pressure wearability, foaming resistance, lubrication, flame resistance and noise lowering, and the like. The lubricating grease is suitable for the lubrication of the cylinders of various electric hammers and electric picks and in particular suitable for the lubrication and sealing of the cylinders of the electric hammers and electric picks which keeps on operating for a long time at a high speed.

Owner:杭州得润宝油脂股份有限公司

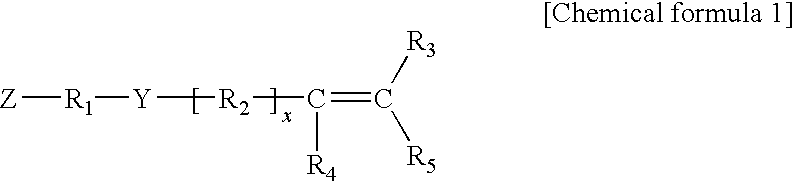

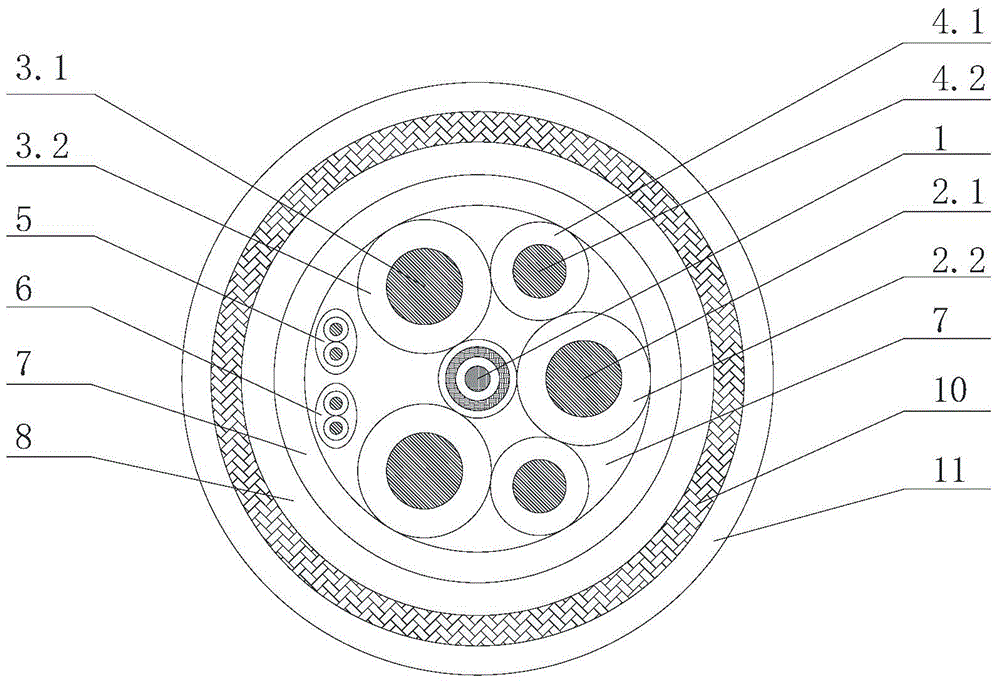

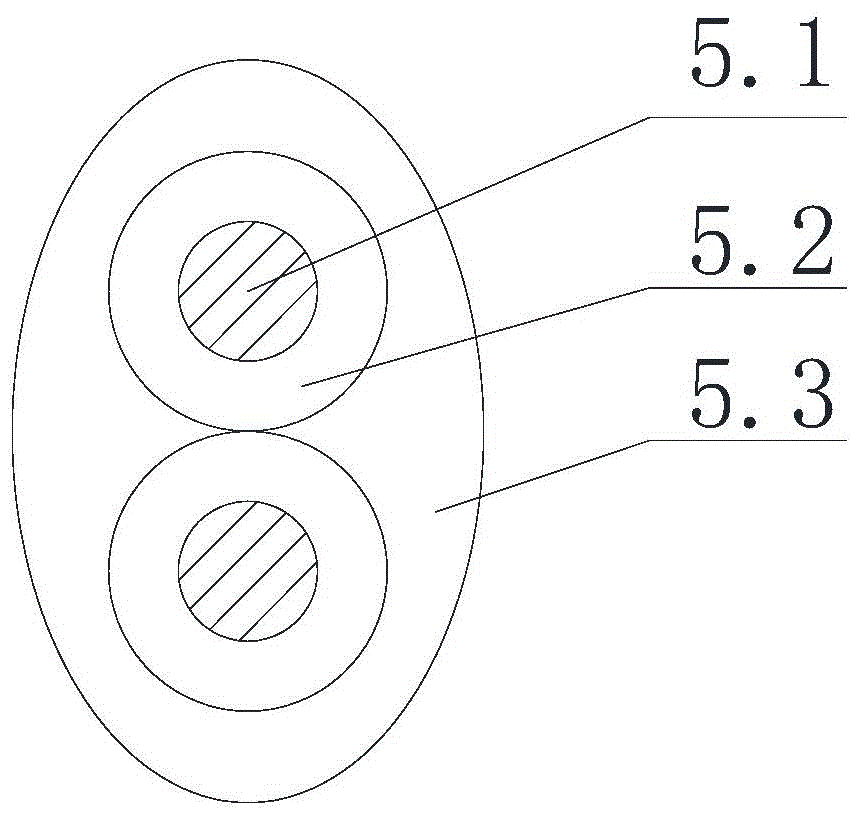

Electric vehicle charging pile cable

InactiveCN104882221AAvoid fireImprove water resistancePlastic/resin/waxes insulatorsClimate change adaptationTemperature controlPower cable

The invention discloses an electric vehicle charging pile cable, and belongs to the power cable technical field; the electric vehicle charging pile cable comprises a feed temperature optical fiber, two main power lines, a ground line, two auxiliary power lines, a pair of charging connection confirm lines, and a pair of charging communication lines; the wire cores are twisted to form a cable, and gaps are filled with filling material; the cable is wrapped in sequence from inside-out by a wrapping tape, an inner sheath, a shield layer and an outer sheath. The electric vehicle charging pile cable is excellent in flexibility, highly flame retardant, wear resistant, high in weatherability and anti-UV property, can feed back temperature control of the cable and contact points, thus preventing fire hazard caused by overheating; a waterstop rope is water resistant, so cable water tree and creep deformation can be prevented, thus prolonging life of the charging pile cable.

Owner:BEIJING HENGTONG SIBO COMM TECH CO LTD

Ethylene propylene diene monomer and chloroprene rubber blended secondary closed pore foaming material and preparation method thereof

The invention relates to a foaming material, in particular to an ethylene propylene diene monomer and chloroprene rubber blended secondary closed pore foaming material and a preparation method thereof. The foaming material is prepared from the following raw materials in parts by weight: 45-100 parts of ethylene propylene diene monomer, 45-100 parts of chloroprene rubber, 8-15 parts of carbon black, 10-18 parts of a fire retardant, 8-15 parts of magnesium powder, 10-35 parts of windsor clay, 12-25 parts of active light calcium, 25-35 parts of naphthenic oil, 0.8-2.5 parts of an anti-aging agent, 1.5-3.5 parts of an antioxidant, 2-4 parts of a foaming agent, 1.4-1.8 parts of a foaming auxiliary, 1-2 parts of a vulcanization accelerator, 2.5-5.2 parts of an activating agent, 2-6 parts of zinc oxide, 1-2 parts of a dispersing agent, and 1-2.5 parts of stearic acid. Compared with the prior art, the foaming material disclosed by the invention greatly reduces the content of halogen, meets the environment-friendly requirement and has good performances of resisting flame, aging, oil and chemical reagents at the same time.

Owner:YIBAO FUJIAN POLYMER MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com