Fire retardation three-proofing lacquer and preparation method thereof

A technology of three anti-paints and flame retardants, applied in the direction of fireproof coatings, coatings, polyester coatings, etc., can solve problems such as health hazards, low safety, and easy induction of occupational diseases, and achieve salt spray resistance and high temperature resistance. Strong wetness, improved reliability and service life, good effect of resistance to cold and heat shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions and effects of the present invention will be further described below through examples, but the present invention is not limited to the following examples.

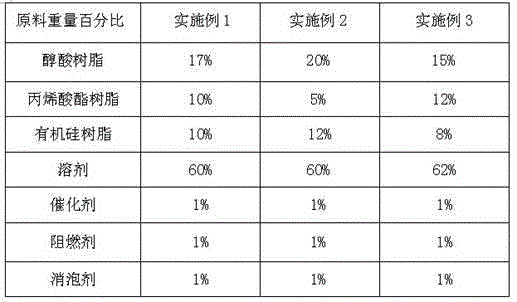

[0028] A flame-retardant three-proof paint and its preparation method, characterized in that the three-proof paint includes alkyd resin, acrylate resin, silicone resin, solvent, catalyst, flame retardant, defoamer, the raw material composition and weight percentage For: alkyd resin 10-30%, acrylate resin 5-20%, silicone resin 5-20%, solvent 30-80%, catalyst 0.2-2%, flame retardant 0.2-2%, defoamer 0.2 -2%. The above-mentioned alkyd resin is one or more mixtures of styrene modified alkyd resin, soybean oil modified alkyd resin and castor palm modified alkyd resin.

[0029] The above-mentioned acrylate resin is one or more mixtures of methacrylic acid, butyl acrylate, butyl methacrylate, hydroxyethyl acrylate and the like.

[0030] The above-mentioned silicone resin is one or more mixtures o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com