Ethylene propylene diene monomer and chloroprene rubber blended secondary closed pore foaming material and preparation method thereof

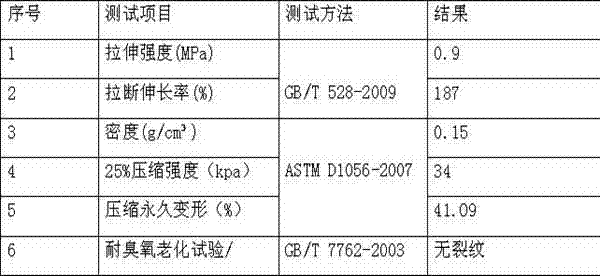

A technology of EPDM rubber and chloroprene rubber, which is applied in the field of foaming materials, can solve the problem of ozone resistance and aging resistance, acid and alkali resistance cannot meet higher requirements, and no secondary closed-cell foaming materials have been found , human and livestock breathing suffocation and other problems, to achieve excellent flame resistance, good performance, and improve the effect of ozone resistance

Inactive Publication Date: 2012-06-20

YIBAO FUJIAN POLYMER MATERIALS

View PDF2 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The foaming materials currently on the market, due to the high content of halogen, will produce hydrogen halide gas when the foaming materials are burned, which will cause suffocation of human and animal breathing, which is not friendly to the environment

At the same time, the existing foaming materials cannot meet higher requirements in terms of ozone resistance, aging resistance, acid and alkali resistance, weather resistance, and flame retardancy.

Therefore, when developing and manufacturing these foam materials, we strive to reduce the content of halogen elements in the materials to achieve the required material effects and make them environmentally friendly products. At present, no relevant environmental protection EPDM rubber and neoprene rubber have been found. A report on the use of secondary closed-cell foaming materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a foaming material, in particular to an ethylene propylene diene monomer and chloroprene rubber blended secondary closed pore foaming material and a preparation method thereof. The foaming material is prepared from the following raw materials in parts by weight: 45-100 parts of ethylene propylene diene monomer, 45-100 parts of chloroprene rubber, 8-15 parts of carbon black, 10-18 parts of a fire retardant, 8-15 parts of magnesium powder, 10-35 parts of windsor clay, 12-25 parts of active light calcium, 25-35 parts of naphthenic oil, 0.8-2.5 parts of an anti-aging agent, 1.5-3.5 parts of an antioxidant, 2-4 parts of a foaming agent, 1.4-1.8 parts of a foaming auxiliary, 1-2 parts of a vulcanization accelerator, 2.5-5.2 parts of an activating agent, 2-6 parts of zinc oxide, 1-2 parts of a dispersing agent, and 1-2.5 parts of stearic acid. Compared with the prior art, the foaming material disclosed by the invention greatly reduces the content of halogen, meets the environment-friendly requirement and has good performances of resisting flame, aging, oil and chemical reagents at the same time.

Description

technical field [0001] The invention relates to a foaming material, in particular to a secondary closed-cell foaming material combined with EPDM rubber and chloroprene rubber and a preparation method thereof. Background technique [0002] The foaming materials currently on the market have a high halogen content, so the foaming materials will produce hydrogen halide gas when burned, which will cause suffocation of humans and animals, which is not friendly to the environment. At the same time, the existing foaming materials cannot meet higher requirements in terms of ozone resistance, aging resistance, acid and alkali resistance, weather resistance, and flame retardancy. Therefore, when developing and manufacturing these foam materials, we strive to reduce the content of halogen elements in the materials to achieve the required material effects and make them environmentally friendly products. At present, no relevant environmental protection EPDM rubber and neoprene rubber have...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/16C08L11/00C08K13/02C08K3/04C08K3/26C08K3/22C08K5/09C08J9/04B29B7/00B29C44/04B29C35/00

Inventor 侯汝红陈奕汲

Owner YIBAO FUJIAN POLYMER MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com