Patents

Literature

65results about How to "Solve heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

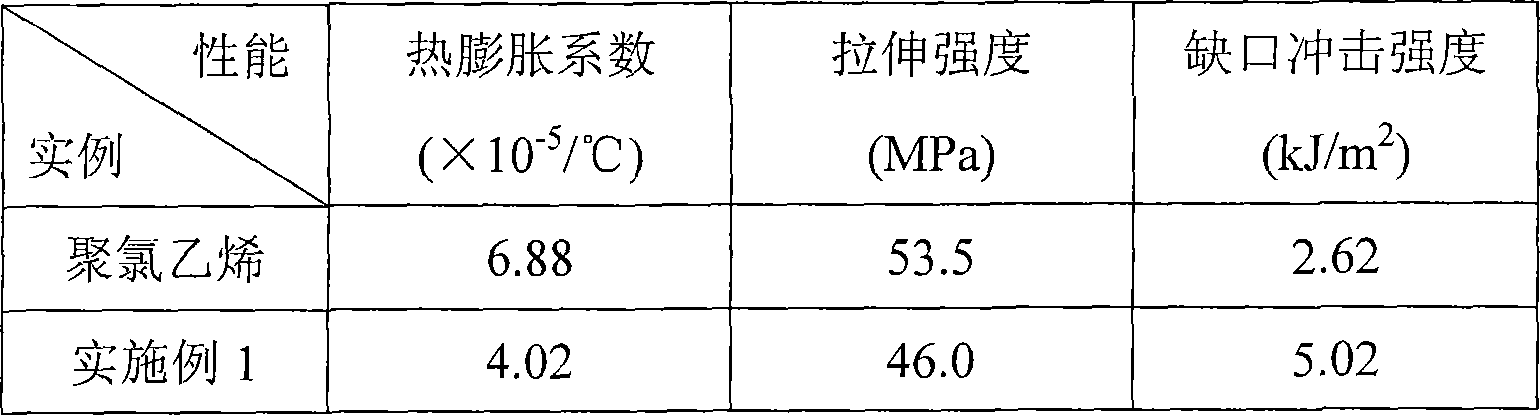

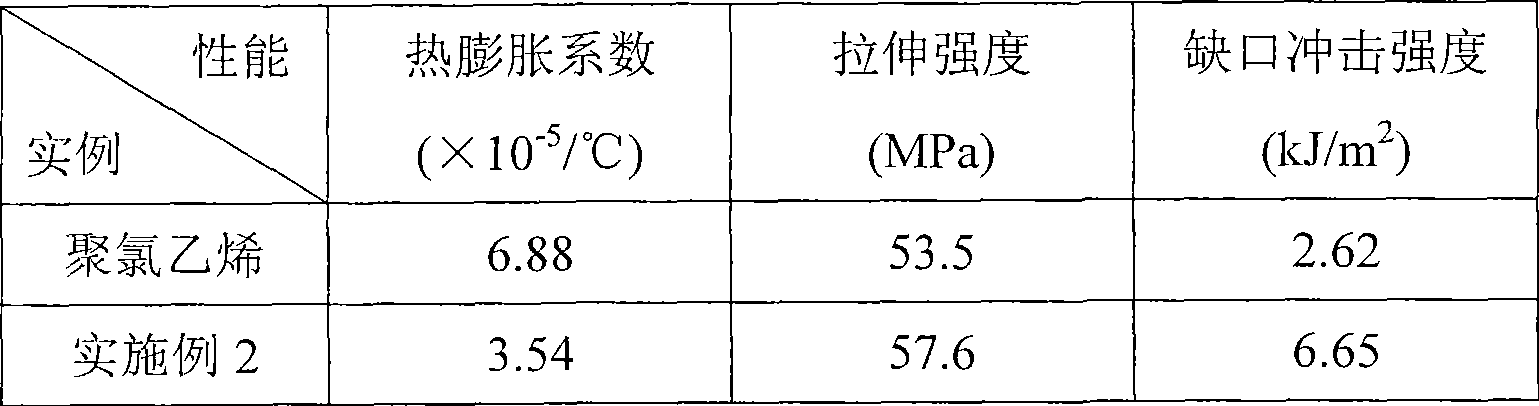

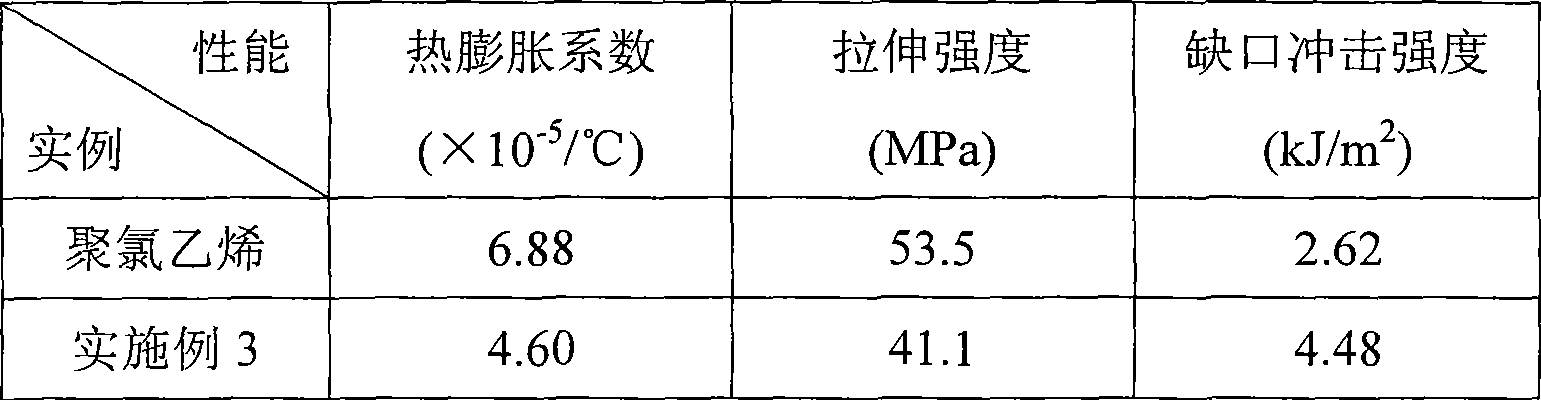

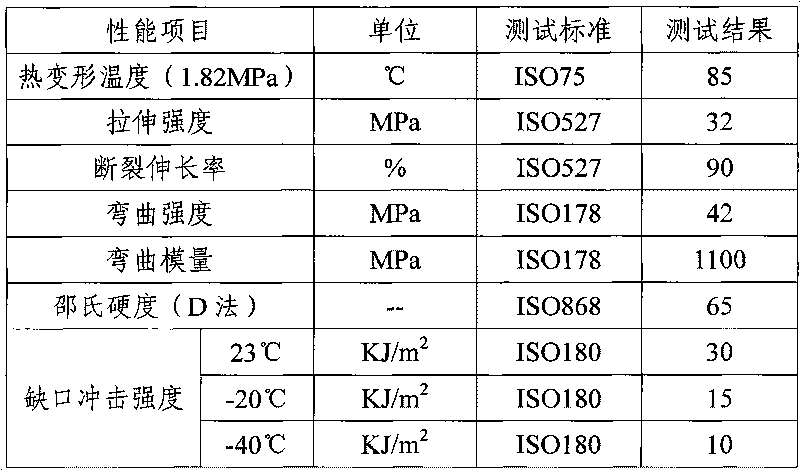

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

Giant engineering tire tread rubber and giant engineering tyre using the same

InactiveCN101440176ASolve wear resistanceSolve heat resistanceSpecial tyresHeat resistanceTear resistance

The invention discloses tread rubber for a large project tire and the large project tire using the tread rubber. The tread rubber for the large project tire consists of (A) tread cap rubber, (B) tread center rubber and (C) tread base rubber. On one hand, the invention adopts rubber matrixes with three different formulas to well solve the problem that an outer layer is easy to overcure if the tread rubber for the large project tire is thick; and on the other hand, the tread rubber prepared by the three formulas of the rubber matrixes can obtain superior equilibrium between abrasion resistance, heat resistance, tear resistance, low heat generation and curing speed.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

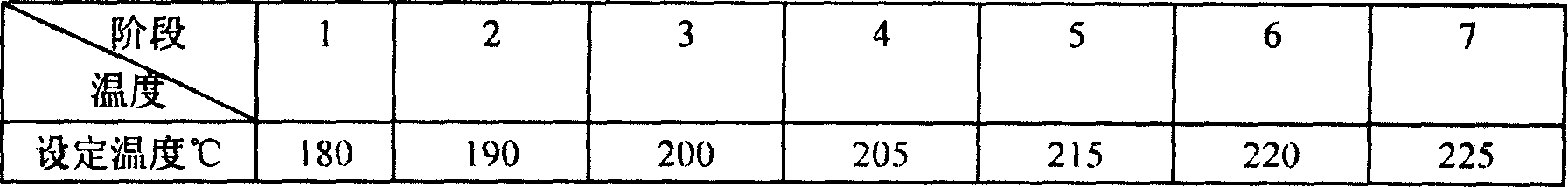

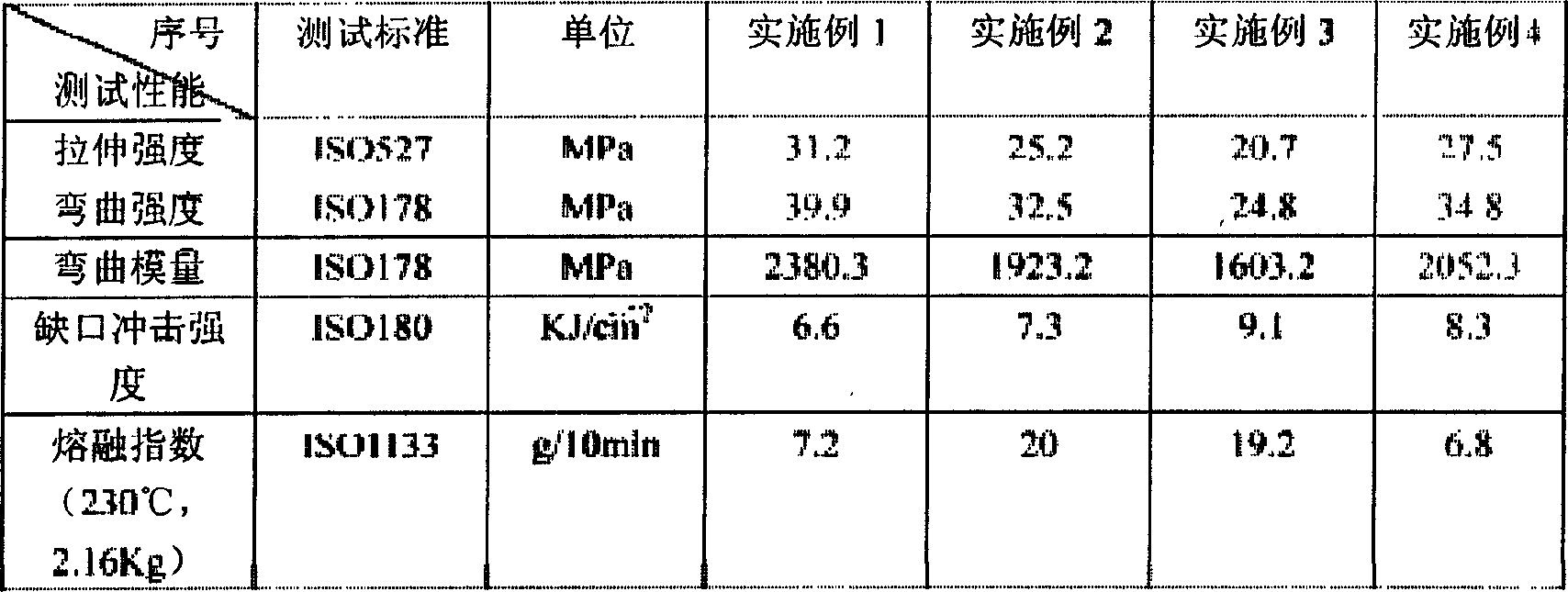

PP/PA composite material used for corrugated pipe and preparation method thereof

InactiveCN101724197ASolve heat resistanceSettle the priceFlexible pipesProcedure AgentsHeat resistance

The invention discloses a PP / PA composite material used for a corrugated pipe, which is prepared by processing polypropylene, nylon, compatilizer, toughening agent, filling master batch, light stabilizer, heat stabilizer and processing aid. The PP / PA composite material is prepared by feeding the components into mixing equipment according to a proportion, and melting, mixing, scattering, extruding and granulating the components at the temperature of between 210 and 280 DEG C. The PP / PA composite material not only has higher toughness, excellent high impact resistance and bending property and extremely good high temperature resistance, but also are excellent in the aspects of surface gloss, abrasion resistance, chemical corrosion resistance, electric insulation and the like, and solves the defect problems of insufficient heat resistance of the conventional PP corrugated pipe, over-high price of the PA corrugated pipe; and in addition, a preparation method for the PP / PA composite material is simple and meets the requirement of industrialized production.

Owner:SHANGHAI KINGFA SCI & TECH +1

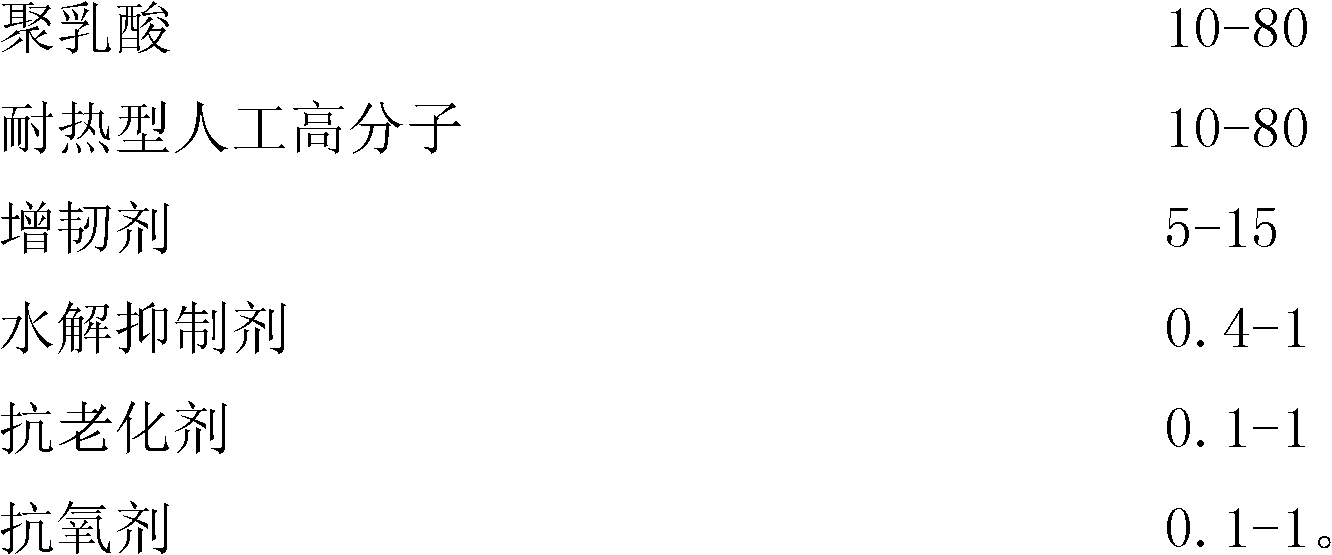

High-toughness and highly heat-resistant polylactic acid (PLA) alloy material and preparation method thereof

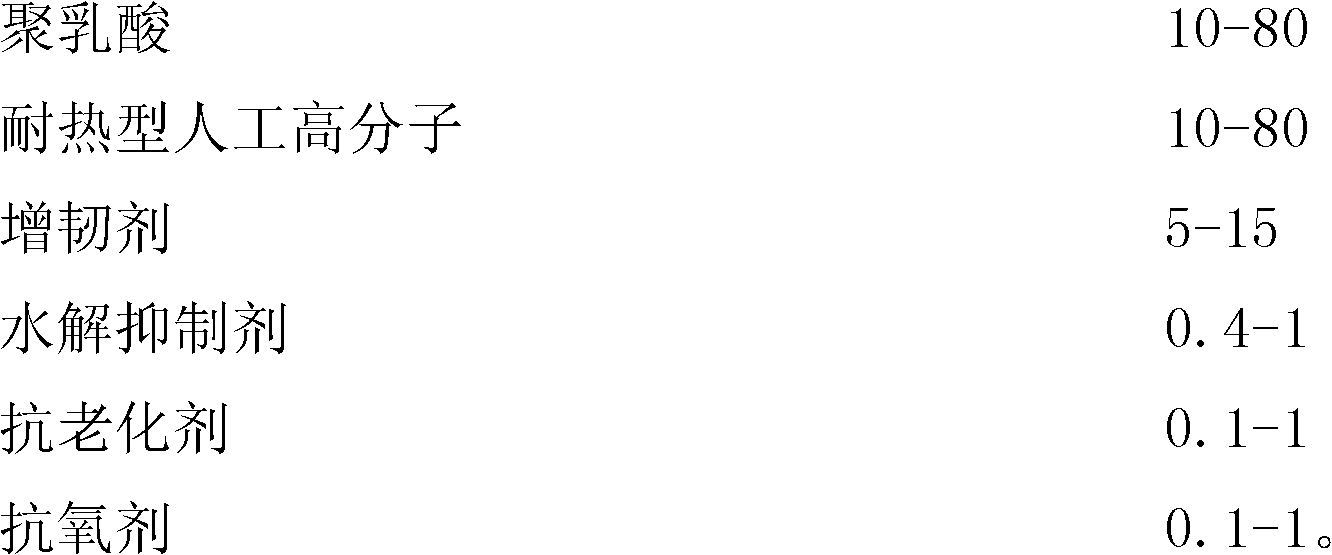

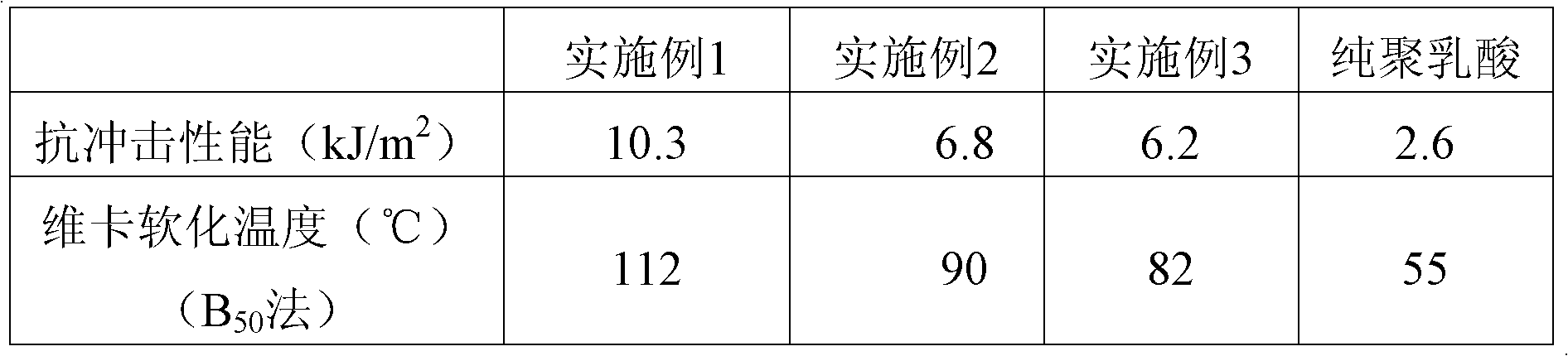

The invention discloses a high-toughness and highly heat-resistant polylactic acid (PLA) alloy material and a preparation method thereof. The material comprises the following components in part by weight: 10 to 80 parts of PLA, 10 to 80 parts of heat-resistant artificial macromolecules, 5 to 15 parts of toughening agent, 0.4 to 1 part of hydrolysis inhibitor, 0.1 to 1 part of anti-aging agent and 0.1 to 1 part of antioxidant. Compared with the prior art, the material has the advantages that: the toughness and heat resistance of a PLA composite material are improved simultaneously; blending modification which is an important way of polymer modification is simple and practicable and low in cost; and by a blending system, the performance of the components can be comprehensively balanced, the components are complemented, and the performance weakness of each single component is avoided, so that a polymer material with ideal comprehensive performance is obtained.

Owner:CHERY AUTOMOBILE CO LTD

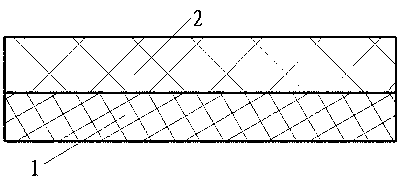

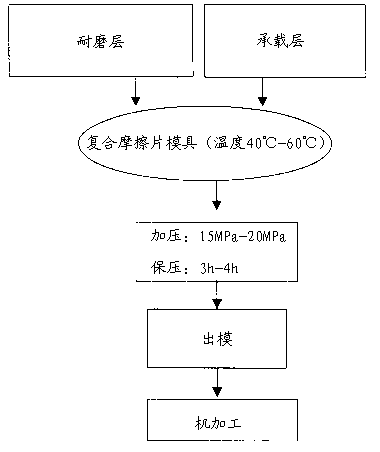

Composite friction plate and preparation method thereof

ActiveCN102705410ASolve wear resistanceSolve the mechanical propertiesFriction liningEpoxyElectricity

The invention provides a composite friction plate and a preparation method thereof. The composite friction plate consists of a wear-resistant layer and a loading layer, wherein the wear-resistant layer is made from basic resin, wear resistant materials and reinforcing materials by blending, modifying and injection molding; the loading layer is a fiber-reinforced epoxy resin composite material; and the loading layer and the wear-resistant layer are bonded by hot pressing to form the composite friction plate. The composite friction plate overcomes the problems in the prior art, such as poor wear resistance, poor mechanical property and poor heat resistance; and has excellent wear resistance and good mechanical property. Besides, the composite friction plate is formed in a way that the loading layer is formed and simultaneously bonded with the wear-resistant layer by hot pressing, which simplifies the production process, increases the production efficiency and ensures stable quality of the product. The product can be widely applied in the fields of automobiles, war industry, wind power generation equipment and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

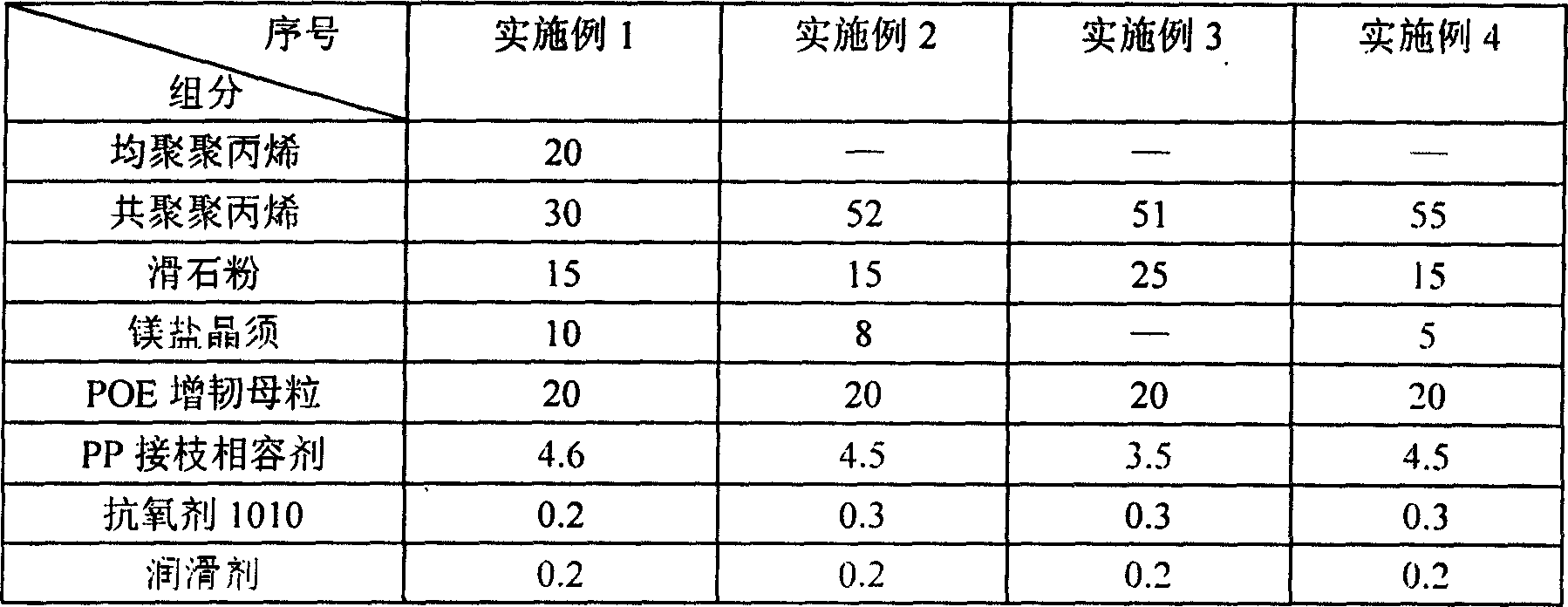

Mineral/ whisker reinforced polypropylene composition

InactiveCN1532221ASolve the stiffness problemSolve the strength problemPolymer scienceMagnesium salt

The mineral / whisker reinforced polypropylene composition consists of polypropylene, mineral reinforcer, toughening agglomarate, PP grafting compatilizer, antioxidant and other assistant and features the addition of / whisker reinforcer. The compounding process includes high speed mixing of the materials except the whisker reinforcer; adding magnesium salt whisker reinforcer and mixing at low temperature; and pelletizing in a special double-screw extruder at 170-240 deg.c and 180-600 rpm. The polypropylene composition has high strength, high rigidity, high impact resistance, high size stability and other features, and may be used in producing parts of automobile, air conditioner, washing machine, etc.

Owner:SHANGHAI WORTH IND CO LTD

Method for manufacturing cast magnesium alloy

The invention discloses a method for manufacturing cast magnesium alloy, omprising the steps: 1, batching: calculating the percentage of elements including Gd, Y, Zr, and Mg as balance; calculating the weight and the respective batching weight of elements; 2: smelting: adding in sequence Mg, Mg-Gd, Mg-Y and Mg-Zr with Gd, Y and Zr as intermediate alloy; feeding in SF6 / CO2 protective gas for refining; dredging up dregs at the bottom of a crucible, then reheating the crucible to 780-800 DEG C, standing the crucible for 30 minutes under heat preservation, and cooling the crucible to 730-740 DEG C along with furnace and subsequently removing scum on the surface; 3: pouring: preheating a mould, adjusting the temperature of magnesium alloy melt and pouring; 4: heat treatment, including: solution treatment and aging treatment. Solving the problems of high cost, low elongation percentage, inadequate heat resistance of the manufactured material, environmental pollution and the like, the method obtains the effect of high strength, good heat resistance, small tendency of incompactness, segregation and crack of the manufactured material.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST +1

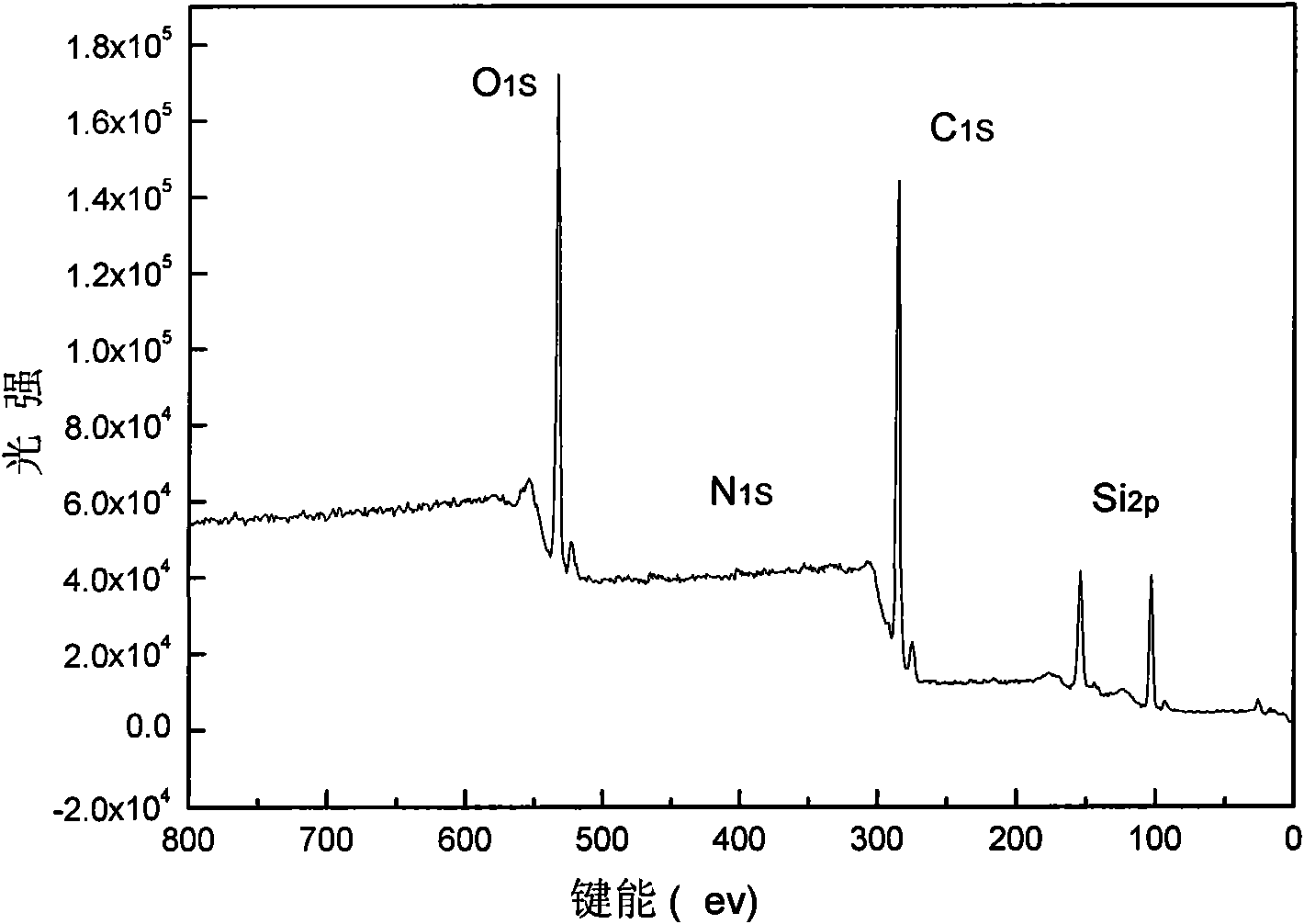

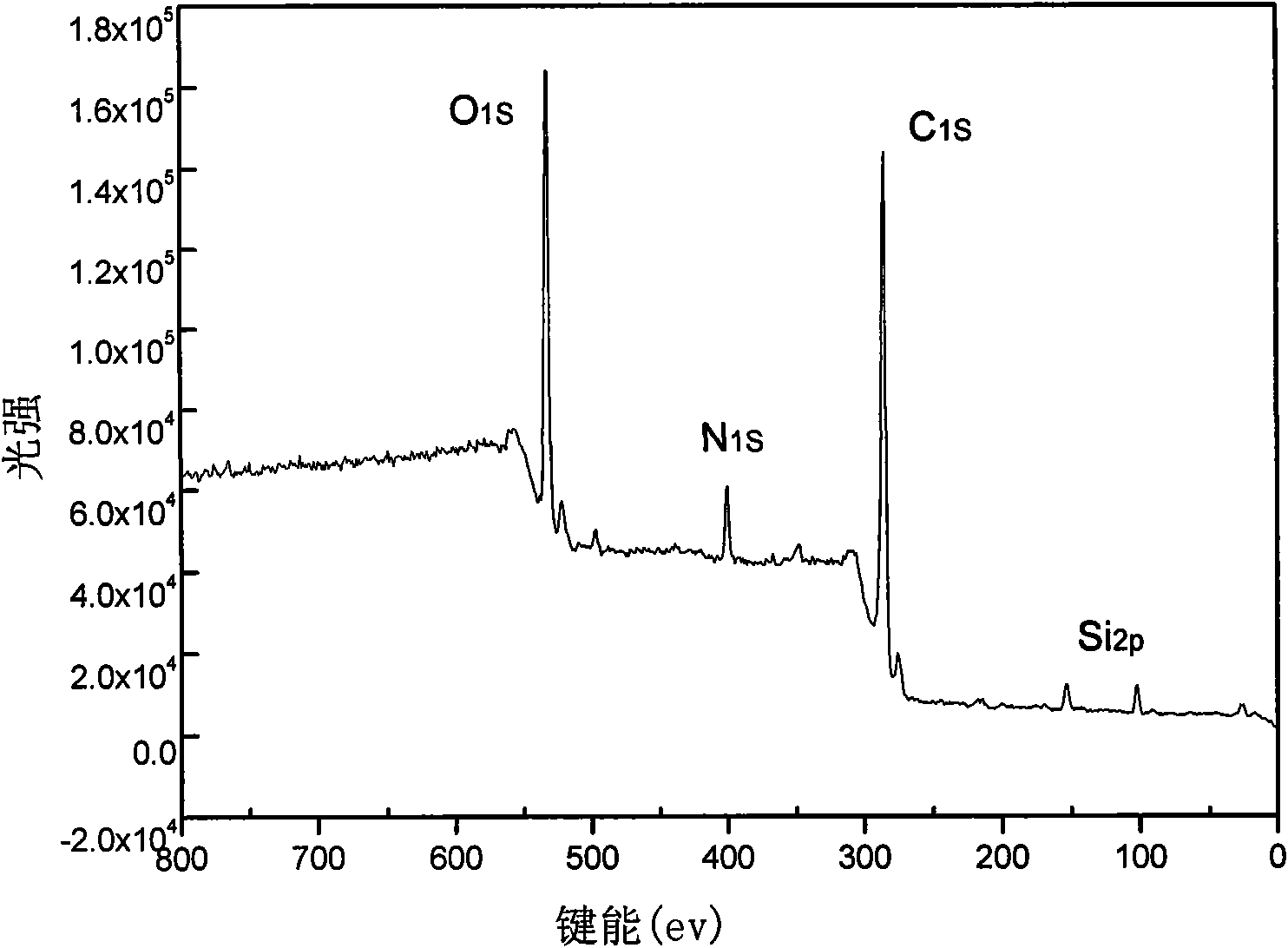

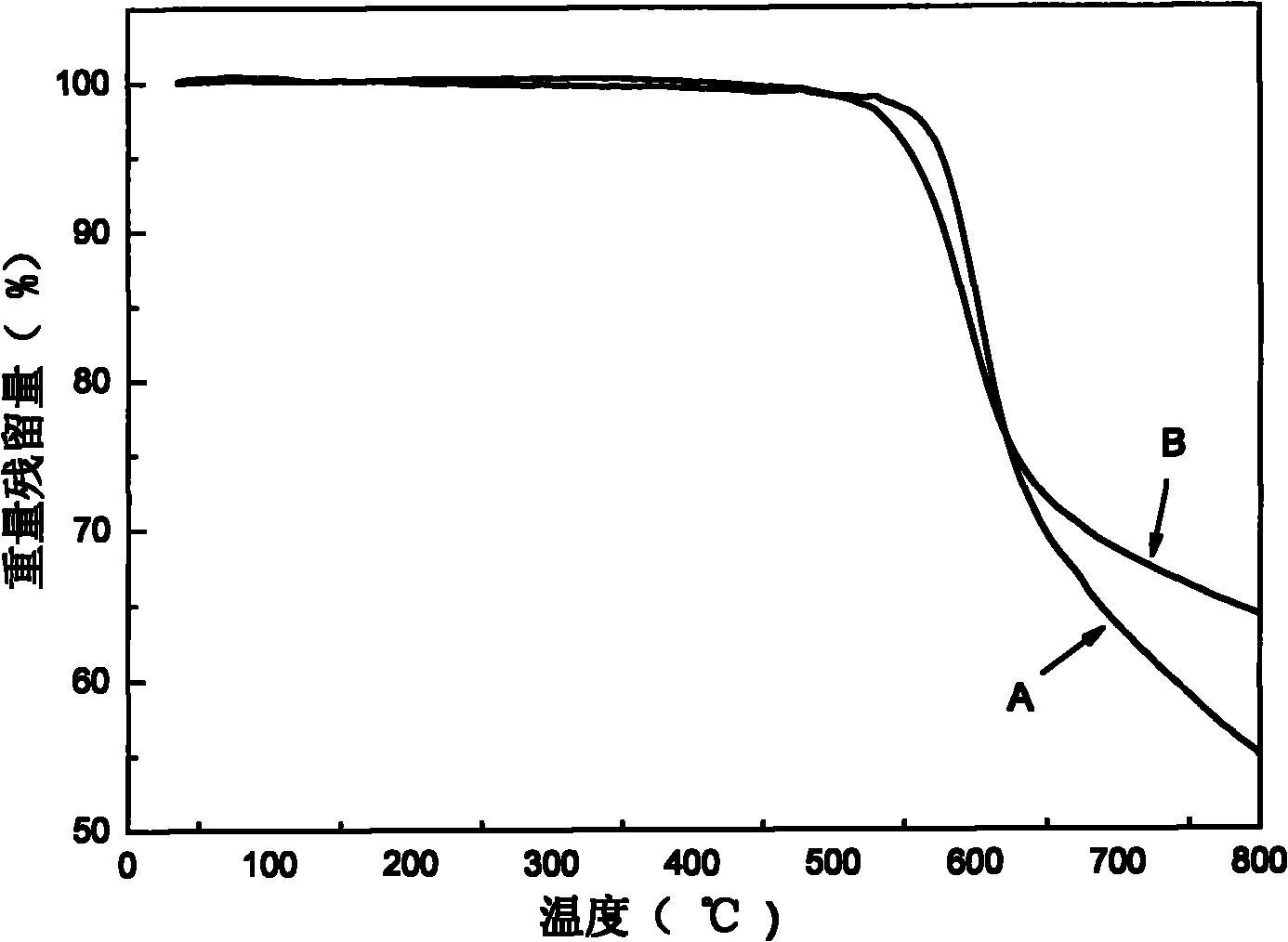

Preparation method of polyimide/ladder-like polysiloxane double-sided anisotropic composite thin film

The invention relates to a preparation method of a polyimide / ladder-like polysiloxane double-sided anisotropic composite thin film, which belongs to the field of polymer materials. The existing polyimide / organic siloxane composite thin film is prepared by introducing a poly-linear siloxane chain segment into a polyimide substrate through the copolymerization method or the doping method, and the prepared thin film has low mechanical property, low thermal resistance and great brittleness. The preparation method comprises the steps of using gamma-aminopropyltriethoxysilane and polyamic acid for carrying out reaction, utilizing hydrolytic condensation of the gamma-aminopropyltriethoxysilane for introducing ladder-like polysiloxane into the polyamic acid, and carrying out curing for preparing the polyimide / ladder-like polysiloxane double-sided anisotropic composite thin film. Compared with the prior art, the method can simultaneously maintain the mechanical property of the thin film while preparing the double-sided anisotropic composite thin film, and also solve the brittleness problem of the thin film and the obvious decline problem of the thermal performance. Simultaneously, the preparation method has the advantages of simple reaction steps, strong operationability, no toxicity, no pollution, easy industrialization and the like.

Owner:BEIJING UNIV OF CHEM TECH

Method for producing decorating part of car boot cover

InactiveCN101654080AReduce weightProcess stabilitySynthetic resin layered productsLaminationWork in processEnvironmental resistance

The invention relates to a method for producing a decorating part of a car boot cover, which belongs to the technical field of interior parts of cars. A low-density PP plate molding material is mainlyadopted as a decorating part basal body of a boot cover and is subjected to press molding, water-jet cutting and inspection to obtain a finished product. The invention solves the problem of meeting the performance indexes of sound absorption, heat resistance, light weight, high strength, and the like of a decorating part assembly of the boot cover and the three-grade international advanced level,greatly reduces the weight of the decorating part of the boot cover, meets the requirement on the lightweight design of the whole car and has stable molding process; a product has high rigidity and can not be broken and sagged; the product is produced by an automatic production line in the whole production process, thereby greatly reducing the labor intensity of workers in the production processand improving the production efficiency; no semi-finished product is stacked in the process, and the manufacture cost is saved; and the product does not generate harmful substances in the whole production process and belongs to an environmental-friendly product.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Production method of automobile skylight sun-shield

ActiveCN101337434ASolve sound absorptionSolve heat resistanceOther domestic articlesSoftened waterHazardous substance

The invention relates to a method for producing a sunroof window visor for an automobile. The method comprises the following steps: substrate PU material pretreatment, sunroof window visor material combination and laying, pressure molding, cooling shaping and waterjet cutting, and the step of substrate PU material pretreatment comprises a substep of rubber rolling and a substep of softened water spray. The method solves the problems of performance indices of sound absorption, heat resistance, light weight and high strength of a sunroof window visor assembly; the weight of the sunroof window visor is greatly reduced, and the requirement on lightweight design of a complete automobile is met; during the PU material pretreatment process, the flow operations of heating of the double-sided PU rolled rubber and softened water treatment are adopted, the technology is stable, the operation security and accuracy are guaranteed, and simultaneously, the operation efficiency is improved; the rigidity of the product is high, without break and sagging; the stack of half-finished products can not happen during the process, and thus the production cost is saved; no harmful substance is generated during the entire production process.

Owner:WUXI GISSING AUTO PARTS CO LTD

Multi-functional polyethylene tube and manufacturing method thereof

The invention discloses a multi-functional polyethylene tube and a manufacturing method thereof, belonging to a polymer composite material. The multi-functional polyethylene tube is prepared by blending and modifying the following raw materials in parts by mass: 30-50 parts of high-density polyethylene (HDPE), 70-90 parts of ultrahigh molecular weight polyethylene (UHMWPE), 10-15 parts of polyoctene rubber (TOR), 1.5-2.0 parts of nano rare earth beta-nucleating agent, 1.0-1.5 parts of dicumyl peroxide (DCP), 3-5 parts of silicone polymer flame retardant and 3-5 parts of color masterbatch. The invention has the advantage that the problems of low-temperature brittleness, abrasive resistance, corrosion resistance, ageing resistance, heat resistance, processability, flame retardancy, and the like of the polyethylene tube are solved. The invention can be widely applied to the fields of water supply and drainage, sewage discharge, oil gas, coal power, mining industry, gas supply, heating, chemical industry, power communication, ocean, dredging, and the like.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

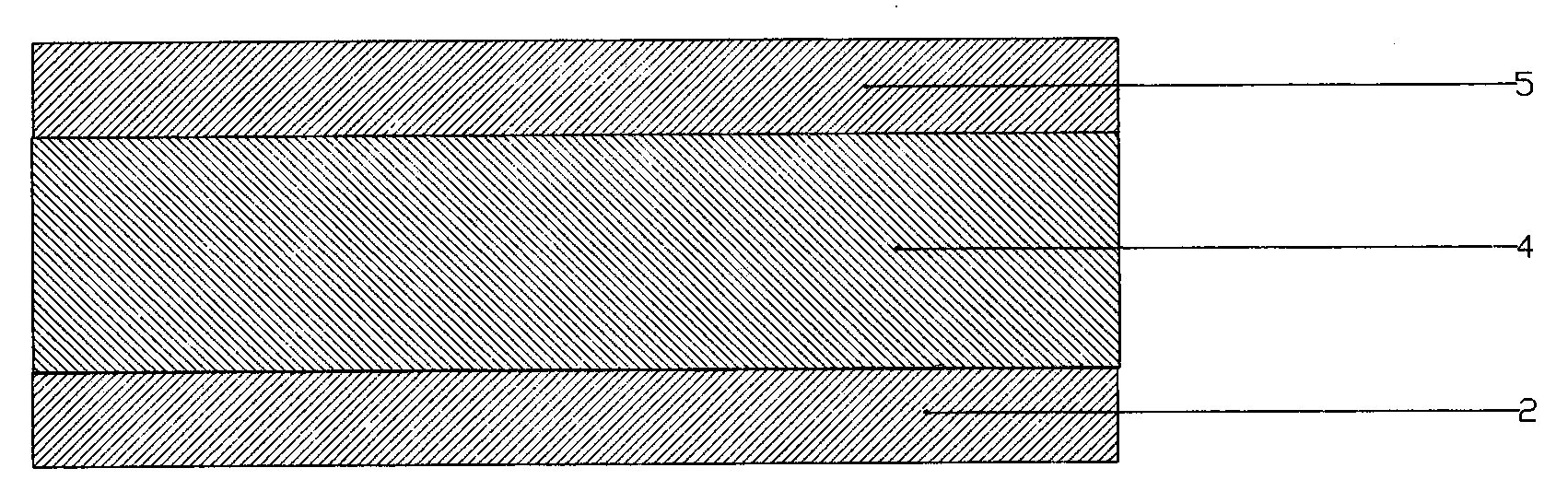

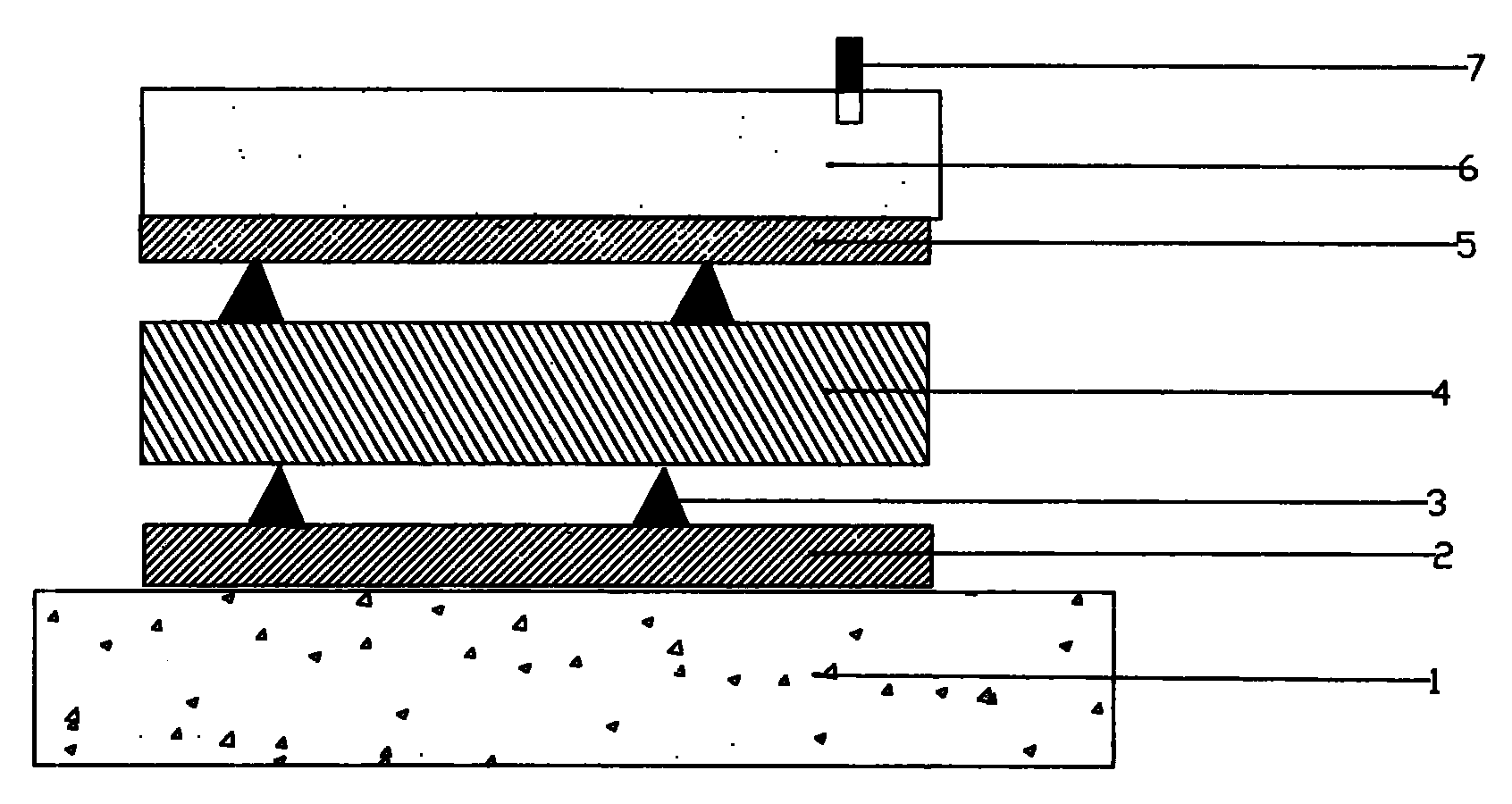

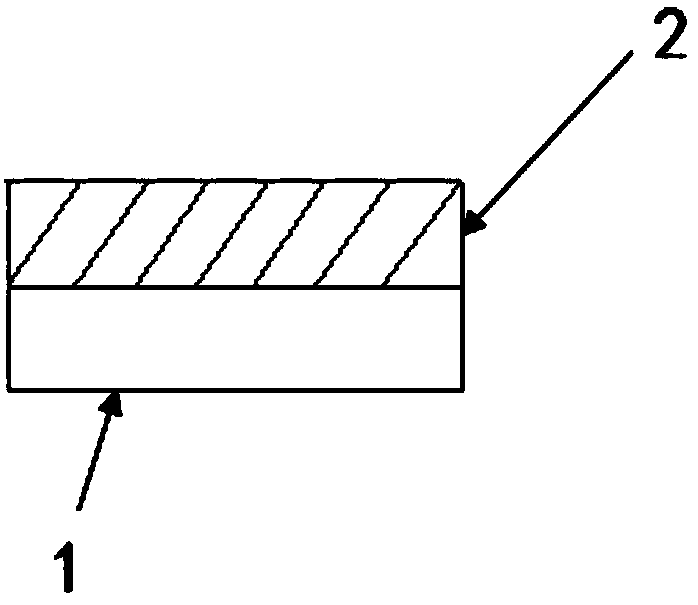

Nickel-base high-temperature alloy/titanium alloy composite material for aero-engine

The present invention discloses a nickel-base high-temperature alloy / titanium alloy composite material for aero-engine. The material comprises the following three layers of metal materials: a nickel-base high-temperature alloy plate (2) on the upper layer, a nickel-base high-temperature alloy plate (5) on the lower layer and a titanium alloy plate (4) in the middle layer, wherein the material trademark of the titanium alloy is Ti-6Al-4V, the chemical components of the titanium alloy comprise 5.5-6.75% of aluminum, 3.5-4.5% of vanadium, and the balance of titanium, the material trademark of the nickel-base alloy is K4169, and the chemical components of the nickel-base alloy comprise 0.5% of aluminum, 0.05% of zirconium, 1.0% of titanium, 3.0% of manganese, 5.2% of niobium, 18.5% of chromium, 52% of nickel, 3.0% of molybdenum, 0.05% of carbon, and the balance of iron. According to the present invention, the bonding rate of the composite material achieves 100% and achieves metallurgical bonding, the nickel-base high-temperature alloy has characteristics of high temperature ablation resistance and high high-temperature strength, and can be used for a long time at a high temperature, the titanium alloy can provide a structure support effect, and the composite material has characteristics of light weight, high temperature resistance and high strength, and is a novel aircraft engine composite material with characteristics of light weight, high strength and high temperature resistance.

Owner:魏玲

Productive technology of automobile rear shelf

ActiveCN101954774ASolve the carrying capacitySolve heat resistanceLamination ancillary operationsSynthetic resin layered productsWork in processEngineering

The invention relates to a productive technology of an automobile rear shelf, which comprises the following steps: (1) laying a glass fiber mat on a lower die and fixing the glass fiber mat and a reinforcing rib on an upper die; (2) evenly spraying polyurethane on the glass fiber mat on the lower die; (3) compressing the glass fiber and the reinforcing rib in a die to form semi-finished products;(4) taking the semi-finished products subject to compression moulding out of the die, and placing the semi-finished products on a cooling jig for carrying out cooling and moulding at normal temperature; (5) polishing the semi-finished products subject to cooling and moulding to smooth the surfaces of the semi-finished products; (6) evenly spraying glue on the two sides of the polished semi-finished products; (7) binding linings on the two sides of the semi-finished products on which glue is sprayed; (8) punching fiber bundles of the glass fiber mat exposed at the edge of the semi-finished products subject to lining binding; (9) installing pull ropes on the punched semi-finished products to obtain the finished products; and (10) inspecting and carrying out vanning. The productive technology of the invention can save manufacturing cost and has the advantages of environmental protection and no pollution.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Metal ceramic die-casting die with tensile prestress and preparation method of metal ceramic die-casting die

InactiveCN108103500AImprove anti-adhesion performanceQuality improvementMetallic material coating processesSelf-propagating high-temperature synthesisManufacturing technology

The invention discloses a metal ceramic die-casting die with tensile prestress and a preparation method of the metal ceramic die-casting die and belongs to the technical field of coating preparation.The metal ceramic die-casting die comprises a die base and a metal ceramic layer which is arranged on the surface of the die base and has tensile prestress. By means of thermal adaptation between thedie base and the prepared metal ceramic layer, the metal ceramic layer has the tensile prestress after being prepared, and the metal ceramic layer and the die base are metallurgically or mechanicallybonded. Preparation of the metal ceramic layer with the tensile prestress comprises the following steps: a, removing an oxidation film from the die base, and performing oil-removal cleaning; b, preparing the metal ceramic coating with the tensile prestress by selecting one of a spray method, a vapor deposition method, a composite coating method, a self-propagating high-temperature synthesis methodand a high-temperature fusion method. With adoption of the coating prepared with the preparation technology, the technical problem that thermal fatigue resistance, wear resistance and heat distortionresistance of the die are not ideal is solved effectively, the service life of the die is prolonged, quality of workpieces is improved, and yield of the workpieces is increased.

Owner:XI AN JIAOTONG UNIV

Modified TPU (thermoplastic polyurethane) composite material for vehicle-mounted charging spring wires for electrical vehicles and preparation method thereof

The invention relates to a modified TPU (thermoplastic polyurethane) composite material for vehicle-mounted charging spring wires for electrical vehicles and a preparation method thereof. The modified TPU composite material comprises the following components in parts by weight: 65-75 parts of thermoplastic polyurethane, 15-30 parts of thermoplastic polyester, 5-10 parts of SBS (styrene-butadiene-styrene), 5-10 parts of a crosslinking agent, 0.05-1 part of an antioxidant, 0.2-1 part of an ultraviolet absorber, and 0.2-2 parts of a stabilizer. The preparation method comprises the steps of mixing the components above in proportion by using a high-speed mixer, extruding the obtained mixture by using a double-screw extruder, and granulating the obtained product. The modified TPU composite material for vehicle-mounted charging spring wires for electrical vehicles prepared according to the invention has the characteristics of high elongation, high elasticity, high temperature resistance, and outdoor UV radiation aging resistance, and is good in processing and molding, and applicable to the outdoor usage of charging vehicles.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

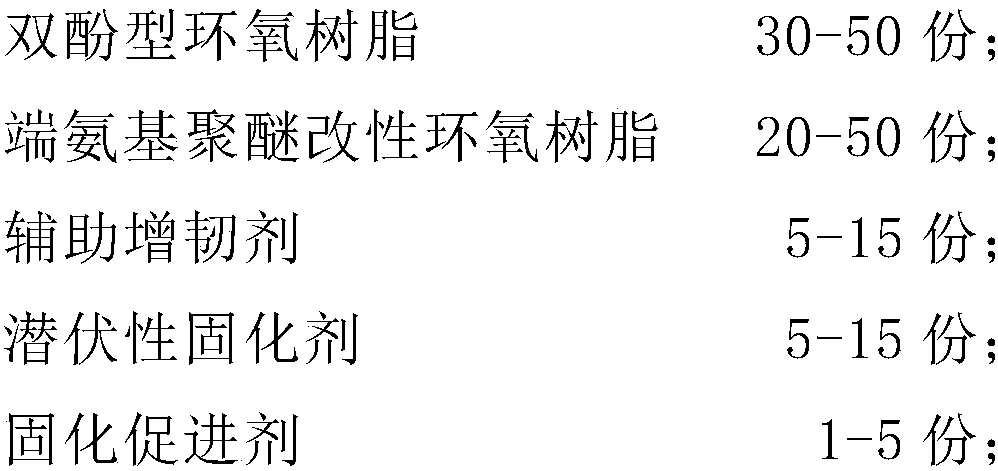

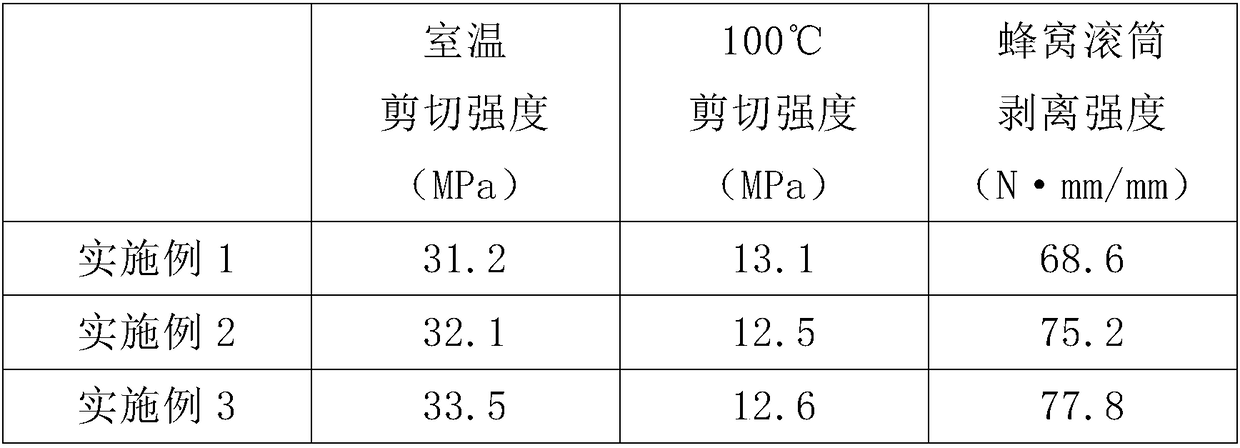

Amino-terminated polyether modified medium temperature curing epoxy glue film and preparation method thereof

ActiveCN108219724ASolve heat resistanceAddress resilienceNon-macromolecular adhesive additivesFilm/foil adhesivesHeat resistanceToughness

The invention discloses an amino-terminated polyether modified medium temperature curing epoxy glue film, which is prepared from the following components: 30 to 50 parts of bisphenol type epoxy resin,20 to 50 parts of amino-terminated polyether modified epoxy resin, 5 to 15 parts of auxiliary toughening agent, 5 to 15 parts of latent curing agent, 1 to 5 parts of curing accelerator, and 0.5 to 3parts of silane coupling agent. The invention also discloses a method for preparing the amino-terminated polyether modified medium temperature curing epoxy glue film. The problem that the medium temperature epoxy glue film prepared by the existing modification method cannot satisfy both good heat resistance and good toughness can be well solved.

Owner:康达新材料(集团)股份有限公司

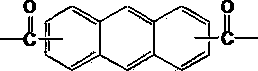

Large-dimension aromatic ring structure-containing polyester for powder coating and preparation method of polyester

InactiveCN104211930ASolve heat resistanceSolve balance problemsPowdery paintsEpoxy resin coatingsAdipic acidGlass transition

The invention discloses a large-dimension aromatic ring structure-containing polyester for a powder coating and a preparation method of the polyester. The adopted technical scheme is that 1,8-anthracenedicarboxylic acid dimethyl ester is selected as a synthesis raw material to introduce a large-dimension anthracene ring to the polyester so that the glass transition temperature of the polyester can be increased; the polyester resin is prepared from the following major components in parts by weight: 12.0-25.5 parts of 1,8-anthracenedicarboxylic acid dimethyl ester, 10.0-32.0 parts of terephthalic acid, 6.5-17.0 parts of m-phthalic acid, 0.5-3.0 parts of adipic acid, 18.0-41.0 parts of C2-C6 polyhydric alcohol and 0.02-2 parts of catalyst through the steps of heating at different stages to arouse an esterification reaction, a condensation polymerization reaction and an acidolysis reaction. The large-dimension aromatic ring structure-containing polyester for the powder coating has the beneficial effects that the obtained polyester resin is capable of solving the contradiction between heat resistance and melting manufacturability to a certain extent, and has the characteristics of high glass transition temperature, low melt viscosity, good storage stability and the like; and an epoxy / polyester powder coating prepared from the polyester is resistant to acids and bases, and also resistant to boiling in water, and has excellent adhesion to metal substrates.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

Lactobacillus rhamnosus probiotic and preparation method thereof

The invention relates to a lactobacillus rhamnosus probiotic and a preparation method thereof and belongs to the technical field of microecologics and feed additives. The lactobacillus rhamnosus probiotic consists of a lactobacillus rhamnosus LT22 culture, a flocculating agent, a freeze-drying protective agent and a filling material. The preparation method of the lactobacillus rhamnosus probiotic comprises the steps of strain activation, strain culture expansion, bacterial cell flocculation, freeze drying of bacterial cells, filling material adsorption and mixing of two preparations. The lactobacillus rhamnosus probiotic prepared by means of the method contains bacterial cells with strong immunity, lactic acid, bacteriostatic active substance, soyabean protein, bran and other beneficial components, can promote digestion of protein, fat and carbohydrate in feeds, improve feed utilization ratio and promote animal growth, prevents pathogenic microorganisms from invading, inhibits growth of harmful bacteria, maintains the microecological balance of digestive tracts, stimulates organism immunity system response, improves the activity and the antibody level of immune cells, enables disease resistance of animals to be improved, and has very wide market prospect.

Owner:GUANGDONG OCEAN UNIVERSITY

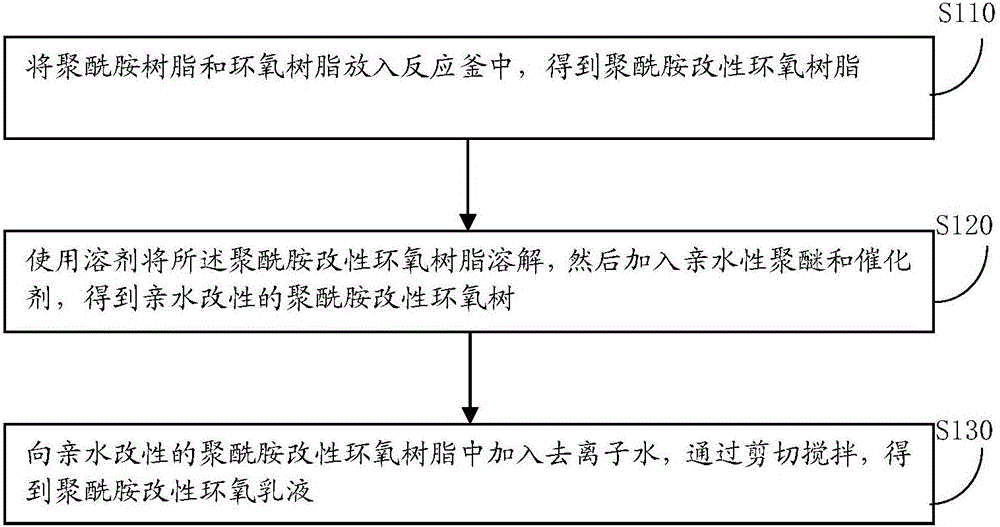

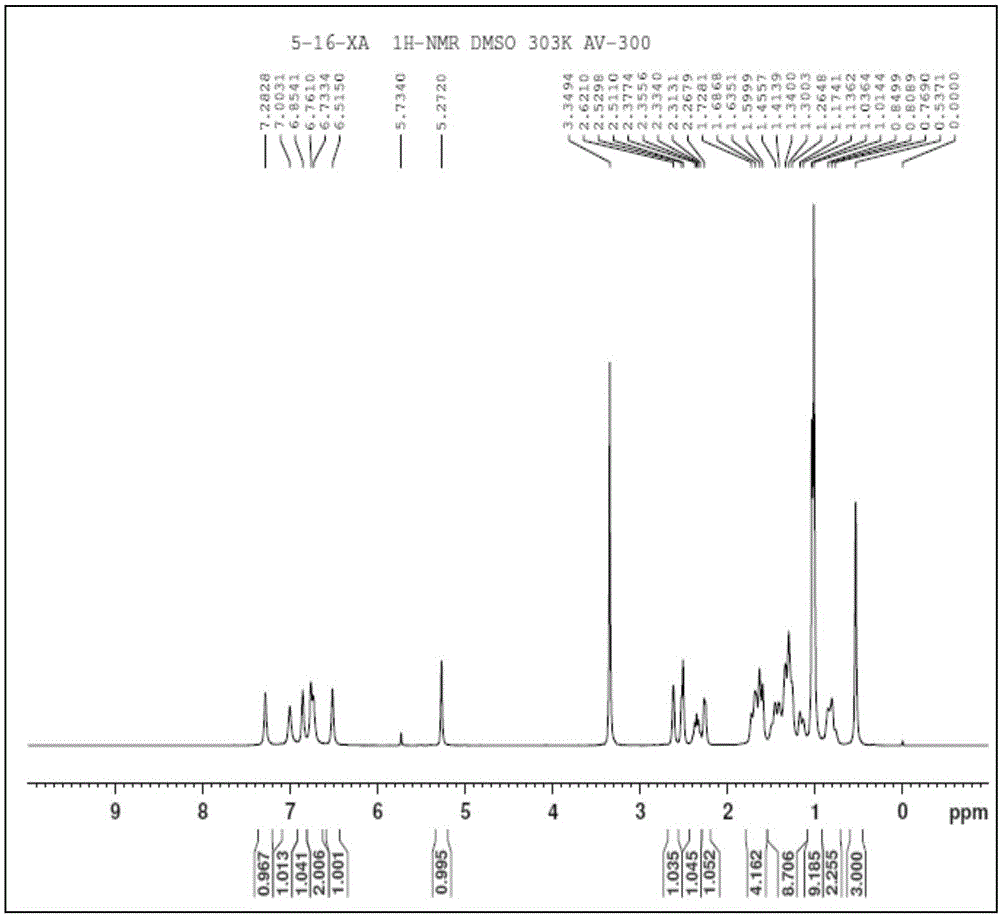

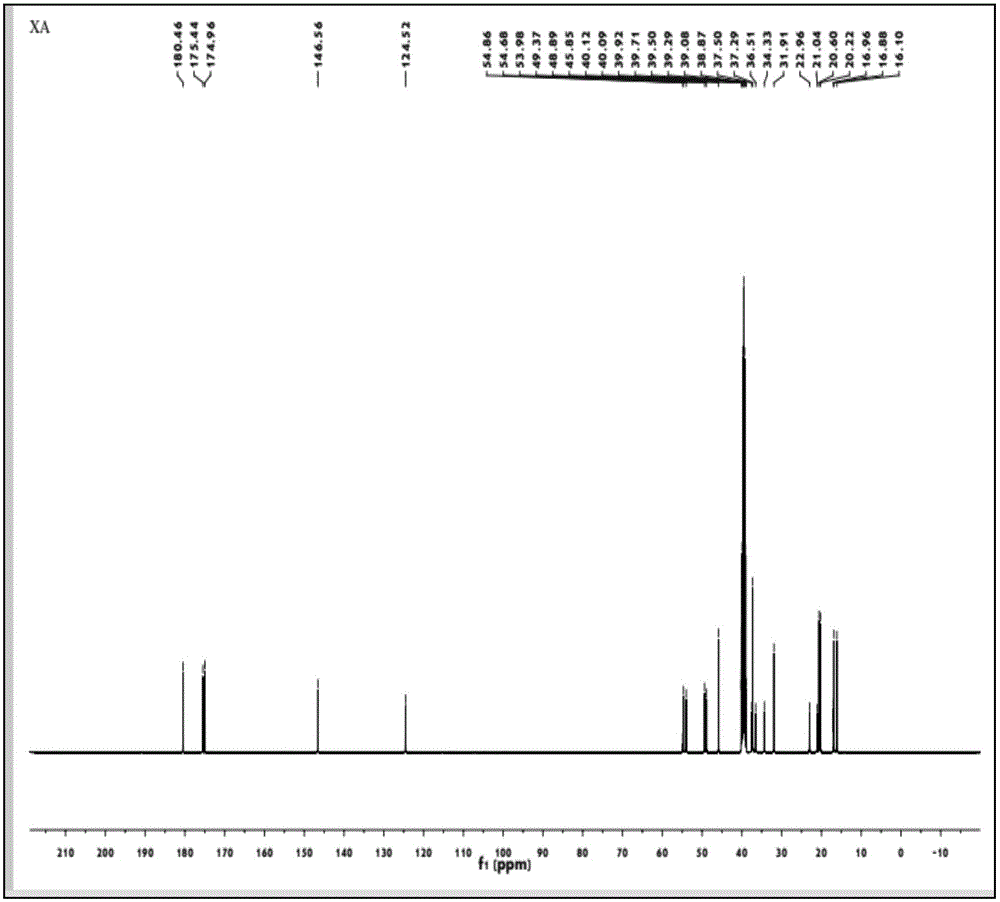

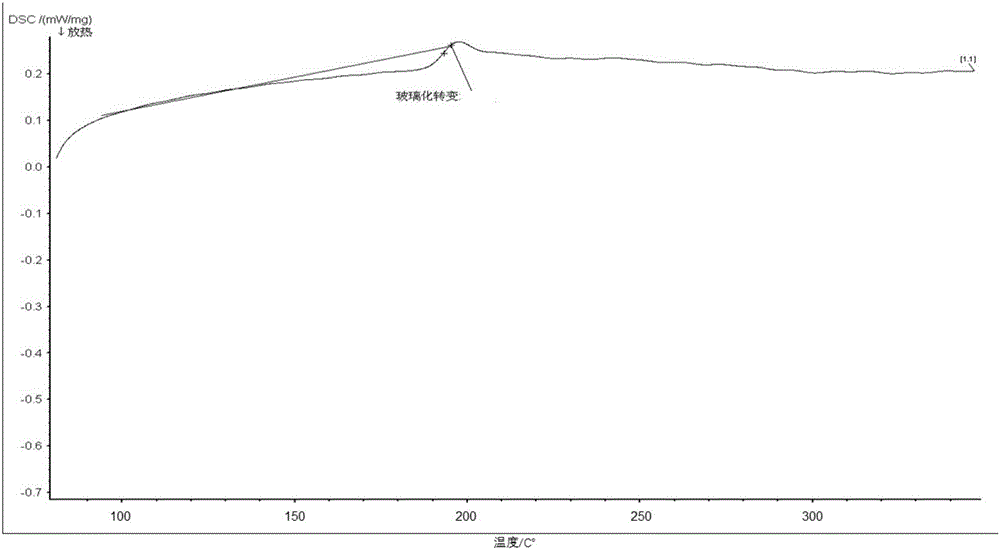

Preparation method for polyamide-modified epoxy resin emulsion

The invention provides a preparation method for polyamide-modified epoxy resin emulsion, and relates to the field of preparation of carbon fibre sizing agent emulsion. The method comprises the following steps: placing polyamide resin and epoxy resin into a reaction kettle to obtain polyamide-modified epoxy resin; dissolving the polyamide-modified epoxy resin by using a solvent; then, adding a hydrophilic polyether and a catalyst to obtain hydrophilic modified polyamide-modified epoxy resin; adding deionized water into the hydrophilic modified polyamide-modified epoxy resin; shearing and stirring to obtain the polyamide-modified epoxy resin emulsion. The deficiencies of poor heat resistance and toughness of a sizing agent used in the prior art are overcome; the polyamide-modified epoxy resin emulsion has high heat resistance and high toughness; when the polyamide-modified epoxy resin emulsion is used as a carbon fibre sizing agent, the technical effects of excellent bundling property, splitting property and wettability with the epoxy resin can be provided for fibre bundles.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

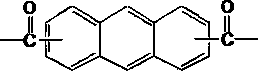

Fumaropimaric acid modified acrylamide compound, preparation method thereof and polymer prepared by fumaropimaric acid modified acrylamide compound

ActiveCN106748855AEnvironmentally friendlyNo pollution in the processOther chemical processesOrganic compound preparationFumaropimaric acidPolymer science

The invention discloses a fumaropimaric acid modified acrylamide compound, a preparation method thereof and a polymer prepared by the fumaropimaric acid modified acrylamide compound. A structural formula of the fumaropimaric acid modified acrylamide compound is shown in the description. As the fumaropimaric acid modified acrylamide compound is synthesized by taking fumaropimaric acid, a by-product of rosin which is a natural biomass resource, as a raw material, and then the fumaropimaric acid modified acrylamide polymer is obtained through polymerization of the fumaropimaric acid modified acrylamide compound, a synthesis step and a reaction device are simple, the operation is convenient, and the problems of poor heat resistance, difficulty in separation, slow reaction speed, low recycling use performance and the like and the technical problems of environment protection and safety are all solved due to excellent heat resistance, excellent adsorption performance to heavy metals and capability of being repeatedly used for multiple times of the obtained polymer.

Owner:NANJING FORESTRY UNIV

High-temperature-resistant and shrinkage-resistant ceramic diaphragm and manufacturing method and application thereof

InactiveCN107910478AAddress strength needsSolve heat resistanceCell component detailsPolyesterLithium

The invention provides a high-temperature-resistant and shrinkage-resistant ceramic diaphragm and a manufacturing method and an application thereof. The high-temperature-resistant and shrinkage-resistant ceramic diaphragm is a non-woven fabric diaphragm composite micropore membrane formed by polyester fiber non-woven fabrics and polyolefin microporous membranes. The invention also provides a preparation method of the ceramic diaphragm; the preparation method comprises the following steps of performing compounding on one or more of polyester fiber non-woven fabrics of 6-20g and one or more of polyolefin microporous membranes of 4-15g by adopting a wet process. The invention also provides a novel lithium ion power battery produced by the non-woven fabric diaphragm composite micropore membranes. The wet method-prepared non-woven fabric diaphragm composite micropore membrane is heat resistant (unshrinkable at 180 DEG C, shrinkage degree less than 1% at 200 DEG C), puncturing resistant, lowin shrinkage, high in electrolyte absorption speed and amount, and high in battery baking time and efficiency, and high in safety.

Owner:广东骏东科技有限公司

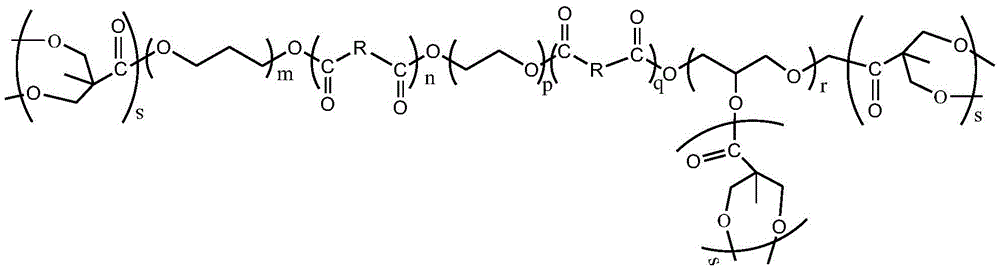

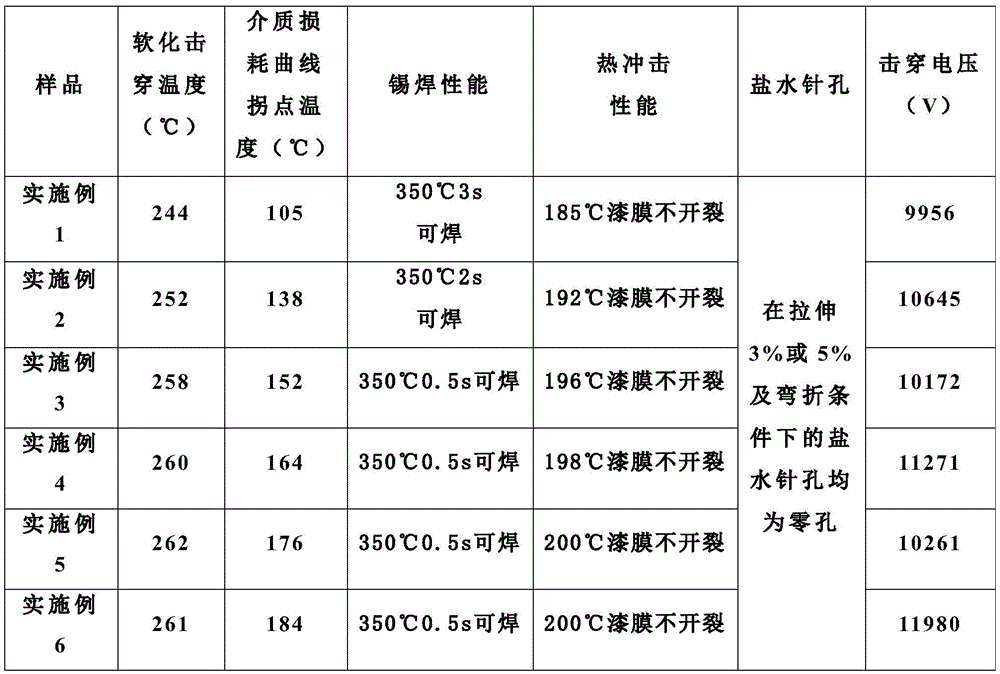

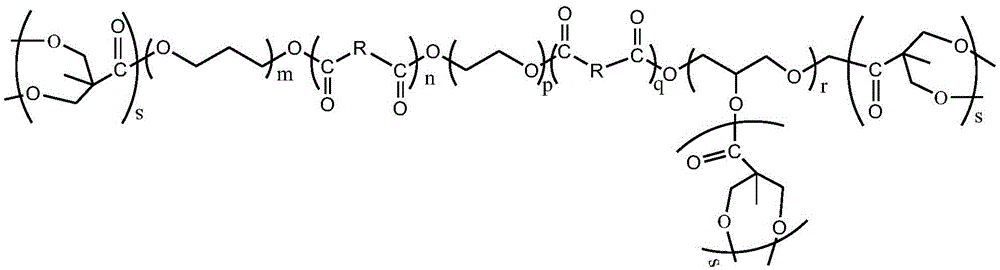

Hyper-branched polyester polyol and preparation method thereof

ActiveCN105622904AMany branchesNot easy to tanglePolyurea/polyurethane coatingsLead bondingConductor Coil

The invention provides hyperbranched polyester polyol for polyurethane wire coating enamel and a preparation method of the hyperbranched polyester polyol. The hyperbranched polyester polyol has the characteristics of high branching, low intermolecular winding possibility, large quantities of branch chains and terminated functional groups, three-dimensional net structure and the like. The preparation method comprises the following steps: taking polyatomic alcohol, polyacidand polybasic anhydride as main raw materials to prepare polyester polyol; then, adding 2,2-dimethylolpropionic acid to prepare the hyperbranched polyester polyol. The preparation method is simple; multistep separation purification is eliminated; the production cost is relatively low; the suitability for large-scale industrial production is high. The wire coating enamel prepared from the hyperbranched polyester polyol is excellent in hot impact resistance and soft breakdown resistance, low in dielectric loss, and high in tin-lead bonding performance.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

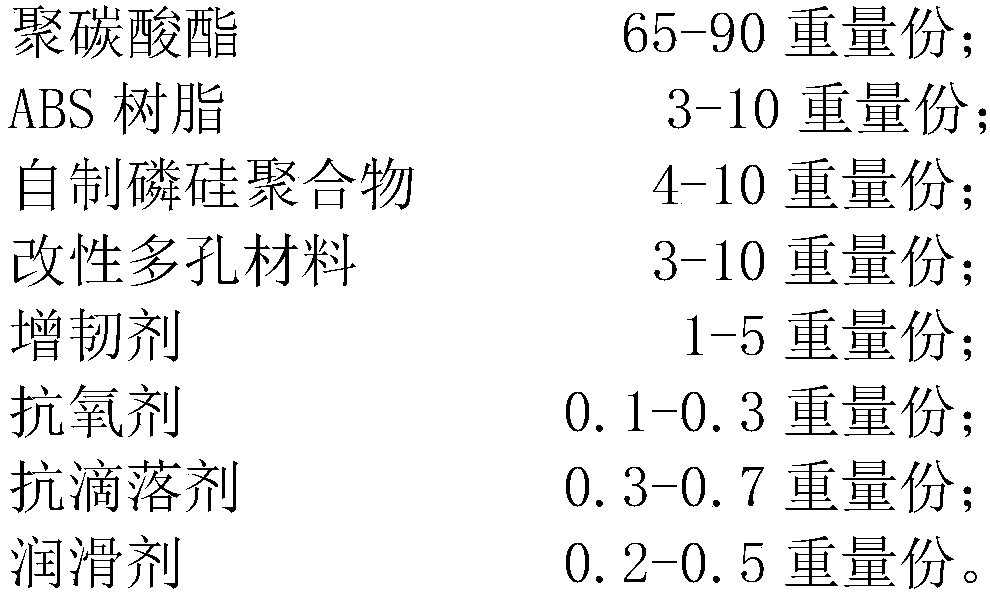

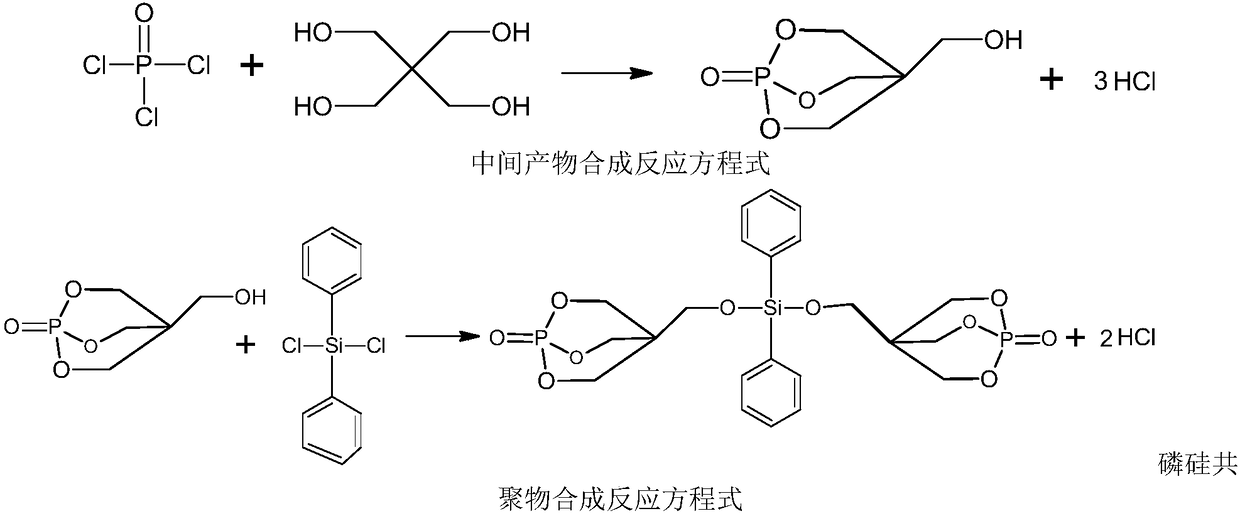

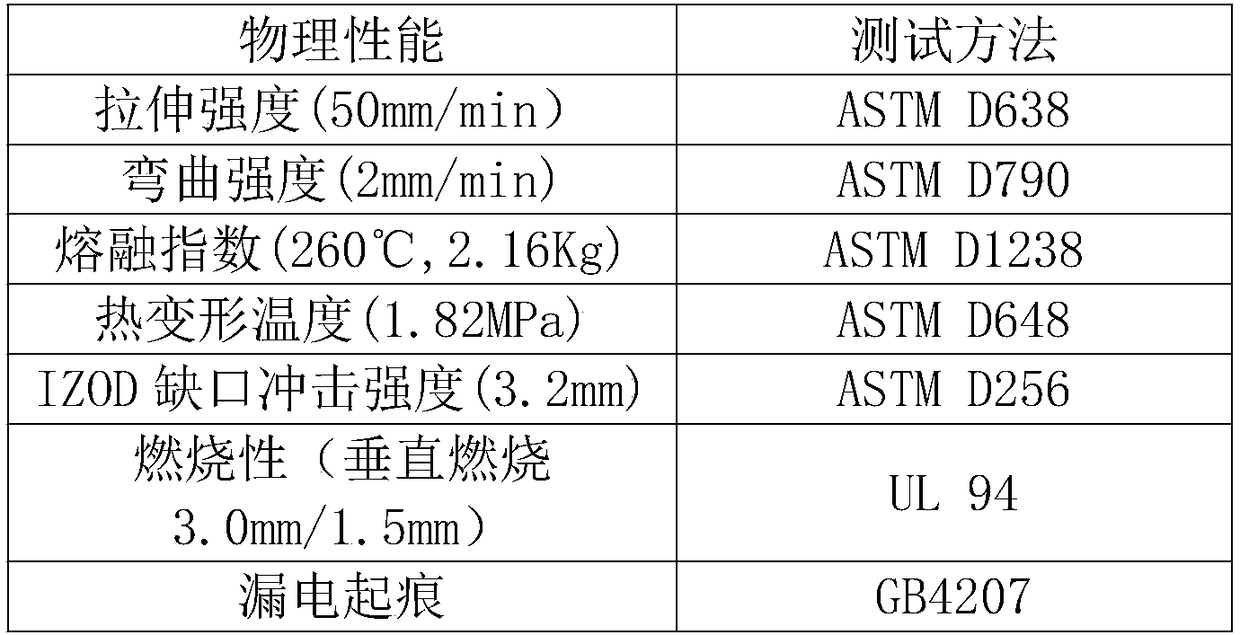

High-CTI, high-heat-resistance, halogen-free and flame-retardant PC/ ABS composition and preparation method thereof

The invention discloses a high-CTI, high-heat-resistance, halogen-free and flame-retardant PC / ABS composition and a preparation method thereof. The composition comprises the following raw materials in parts by weight: 65-90 parts of polycarbonate, 3-10 parts of ABS resin, 4-10 parts of self-made phosphosilicate polymer, 3-10 parts of modified porous material, 1-5 parts of thickening agent, 0.1-0.3 part of antioxygen, 0.3-0.7 part of anti-dripping agent, and 0.2-0.5 part of lubricating agent. According to the high-CTI, high-heat-resistance, halogen-free and flame-retardant PC / ABS composition,the defects of low CTI, high dosage of phosphorus based flame retardant, low flame retarding performance and low thermal deformation temperature of a traditional halogen-free flame-retardant PC / ABSresin are solved; the complex system of the self-made phosphosilicate polymer and the porous material is selected, and a continuous net shaped carbon layer structure is formed through an electric field and electrolyte, so that the resin is high in CTI, and high in thermal deformation temperature; the thermal deformation temperature of the prepared PC / ABS composition is up to 113 DEG C, and the CTI is up to 450V.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

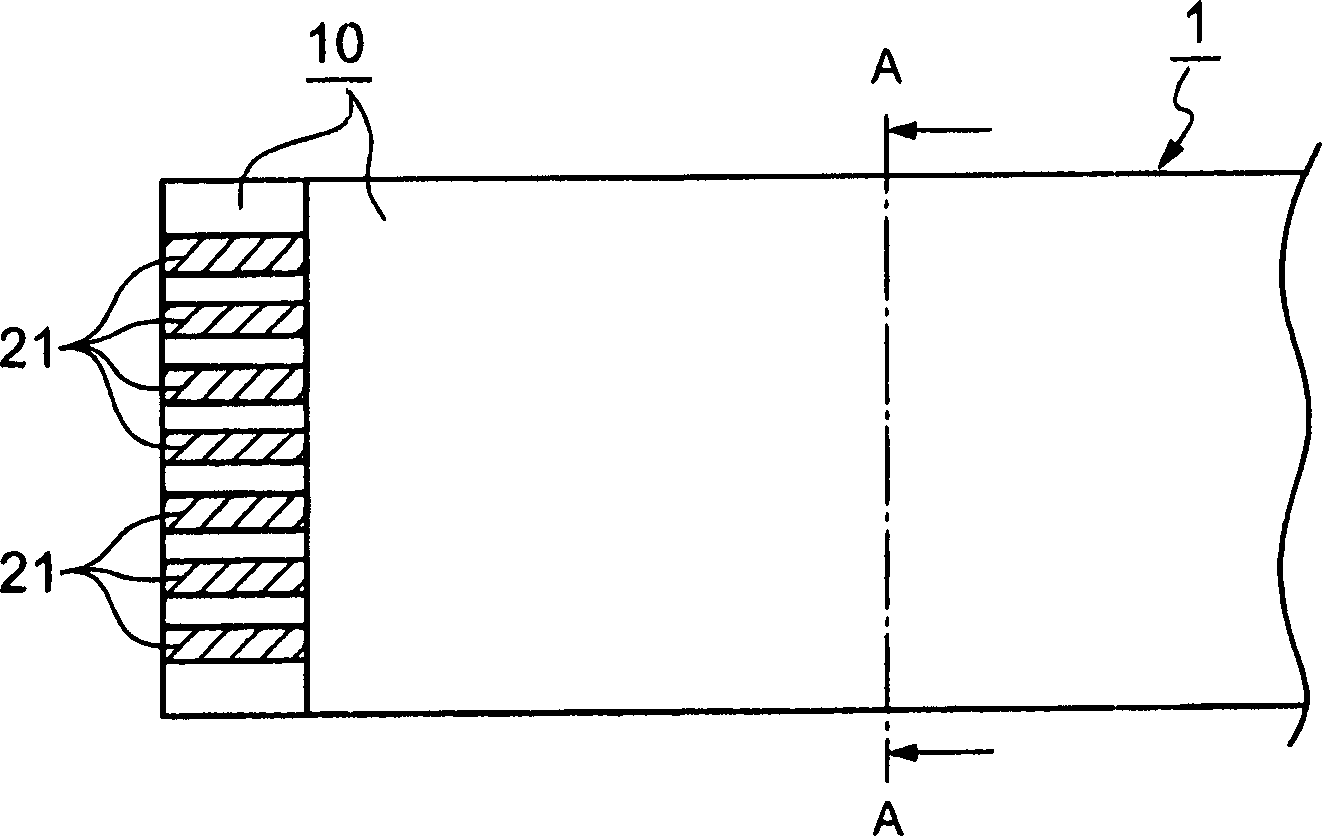

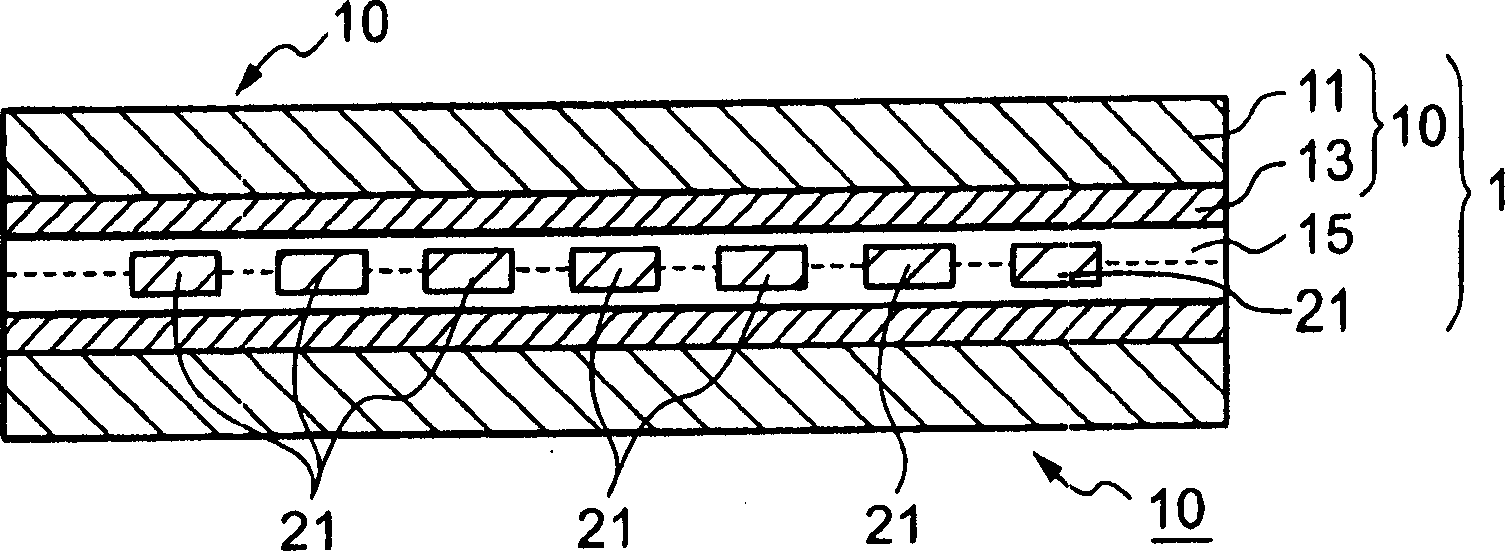

Flat-cable-coating material and flat cable

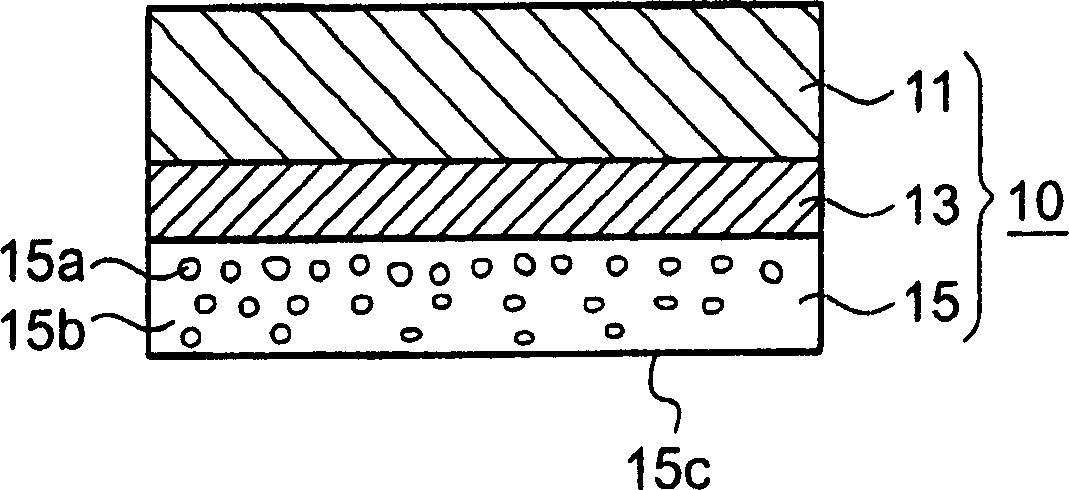

InactiveCN1806297AFlame retardantHeat-sealablePlastic/resin/waxes insulatorsNon-macromolecular adhesive additivesThermal adhesiveMaterials science

A flat cable covering material which has a base material film and, provided on one surface thereof, a thermal adhesive layer (P + V) containing at least a filler (P) and a thermoplastic resin (V), wherein the mass proportion (P) / (P + V) is distributed in a graduated manner in the direction of the thickness of the thermal adhesive layer, preferably, is gradiatedly distributed in such a manner that the mass proportion decreases from the base material film side to the side of the surface of the thermal adhesive layer in the range of (P) / (P + V) = 90 to 50 mass %, or wherein the filler (P) component comprises a hydrated metal compound (P1) and the mass proportion (P1) / (P) is gradiatedly distributed in such a manner that the mass proportion (P1) / (P) decreases from the base material film side to the side of the surface of the thermal adhesive layer in the range of (P1) / (P) = 80 to 0 mass %.

Owner:DAI NIPPON PRINTING CO LTD

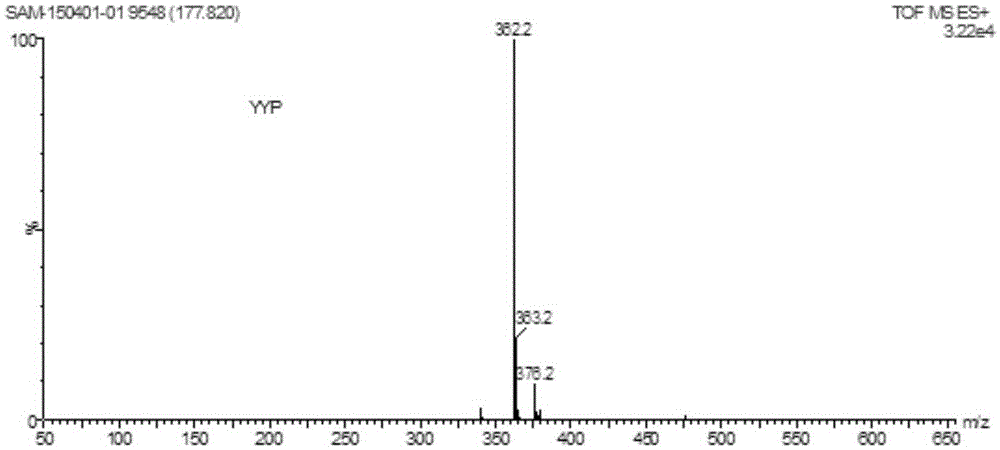

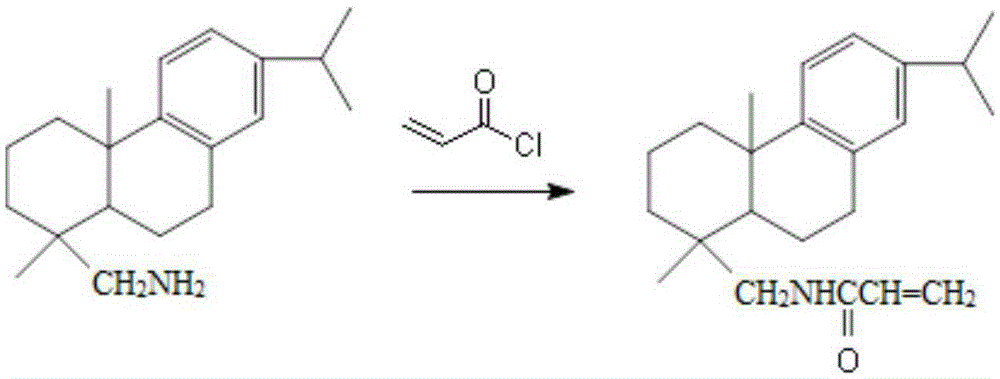

Preparation method of rosinyl acrylamide polymer

InactiveCN105348422ASolve heat resistanceSolve the defect of insufficient salt toleranceChemistryBiomass

The invention discloses a preparation method of a rosinyl acrylamide polymer. The preparation method comprises the following steps in sequence: (1) enabling dehydroabietylamine and acryloyl chloride to react for 2 to 5h at the temperature of 5 to 15 DEG C, so as to prepare a rosinyl acrylamide monomer; (2) enabling the rosinyl acrylamide monomer obtained in the step (1) to react continuously for 0.5 to 4h at the temperature of 60 to 75 DEG C under the condition that an initiator exists after sediments occur during the reaction, so as to prepare the rosinyl acrylamide polymer. According to the rosinyl acrylamide polymer and the preparation method thereof, provided by the invention, natural biomass resources are taken as raw materials to synthesize the rosinyl acrylamide polymer, the synthetic steps are simple, the heat resistance of the polymer is excellent, the defects that an acrylamide polymer is in sufficient in heat resistance and salt tolerance are overcome, and meanwhile, the technical problem of environment protection and safety is also considered.

Owner:NANJING FORESTRY UNIV

Ionic liquid modified bar code carbon strip back coating and preparation method thereof

InactiveCN108485358ASolve heat resistanceFix stability issuesFireproof paintsThermographyOrganic solventDouble bond

The invention relates to an ionic liquid modified bar code carbon strip back coating which is prepared from the following raw materials in parts by weight: 10-50 parts of an acrylic monomer, 0.5-2 parts of a silane coupling agent, 0.5-3 parts of an ionic liquid containing double bonds; 15-30 parts of organic silicon, 13-73.5 parts of an organic solvent and 0.5-2 parts of a catalyst. The inventionprovides the ionic liquid modified bar code carbon strip back coating and a preparation process. By means of block polymerization, the ionic liquid containing double bonds is introduced into a high molecular chain of the polyacrylate back coating, and the high molecular back coating with low resistivity is coated with a bar code carbon strip, so that static electricity generated and accumulated onthe carbon strip are reduced effectively, and therefore, the printing using quality of the back coating is guaranteed.

Owner:HENAN UNIV OF SCI & TECH

Water pipe used in pipeline engineering and preparation method thereof

The invention provides a water pipe used in pipeline engineering and a preparation method thereof, and relates to the technical field of plastic pipes. The water pipe used in pipeline engineering includes the following raw materials in parts by weight: SG-3 type PVC resin, aluminum borate whiskers, acetyl Calcium acetone, 1,2‑polybutadiene, talc, silica gel, polysulfone resin, polyamide resin, polyurethane rubber, phenolic resin, graphite powder, ceramic fiber, nano silicon carbide, 2,6‑di tert-butyl-p-cresol, flame retardant, plasticizer, compatibilizer, heat stabilizer, light stabilizer and curing agent; the preparation method comprises the following steps: (1) weighing raw materials, (2) mixing, (3) ) Melt molding, cooling and shaping. The invention solves the deficiencies of the existing water pipes in flame retardancy, heat resistance and strength.

Owner:ANHUI MEILAN LANDSCAPE ENG CO LTD

Preparation method of nanomaterial modified DMD soft composite

The invention discloses a preparation method of a nanomaterial modified DMD soft composite. The preparation method comprises the following steps: (1) evenly and fully applying a binder to the surface of a polyester film by use of a reverse scraping method, paving a polyester fiber nonwoven fabric on the surface, fully coated with the binder, of the polyester film and then putting the polyester film with the polyester fiber nonwoven fabric into a press for pressing, and curing the pressed film in a drying oven to obtain a DMD composite; (2) adding a prepared class F epoxy resin glue, nanopowder and a dispersing aid to a disperser for mixing, thereby obtaining the class F epoxy resin glue mixed with the nanopowder; and (3) soaking the DMD composite obtained in the step (1) into the class F epoxy resin glue mixed with the nanopowder, and heating the soaked material to obtain the nanomaterial modified DMD soft composite. According to the preparation method of the nanomaterial modified DMD soft composite, the problems of heat resistance, fast curing of coating, coating thickness and homogeneity of the DMD composite are solved successfully, the tearing strength and the dielectric strength of the material are greatly improved, and corona resistance and the partial discharge resistance of the material are improved.

Owner:绵阳润缘电工材料有限公司

Heat-resistant wire and cable material used in electric power line and preparation method thereof

InactiveCN107189279AGood chemical stabilityImprove thermal conductivityPlastic/resin/waxes insulatorsPolymer scienceAntioxidant

The invention provides a heat-resistant wire and cable material used in an electric power line and a preparation method thereof and relates to the field of wire and cable materials. The heat-resistant wire and cable material used in the electric power line is prepared from, by weight, polyvinyl chloride, chloroprene rubber CR121, dimethyl silicone oil, polypropylene fiber, chlorinated polyethylene, nano silicon carbide, heavy calcium carbonate powder, nano active calcium carbonate, trioctyl trimellitate, a Congo red invariant-color calcium zinc stabilizer, a heat-resistant invariant-color calcium-zinc stabilizer, kaolin, PE wax, stearic acid, a flame retardant, an antioxidant, a coupling agent and a plasticizer. The preparation method comprises the following steps of raw material weighing, mixing and granulation. The problems of poor heat resistance, poor flame retardancy, poor toughness and low strength of existing wire and cable materials are solved.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Methyl methacrylate polymer and preparation method thereof

The invention discloses a methyl methacrylate polymer and a preparation method thereof. The methyl methacrylate polymer disclosed by the invention is mainly prepared by carrying out continuous bulk polymerization on 97-99.9 parts by mass of methyl methacrylate and 0.1-3 parts by mass of a comonomer. The polymer with certain molecular weight distribution is prepared by selecting a composite initiating system consisting of two bifunctional initiators with different molecular structures and controlling the ratio of the two initiators. By adopting the method provided by the invention, the processing fluidity of resin can be improved under the condition of keeping the heat resistance and other application performances of the methyl methacrylate polymer basically unchanged.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com