Amino-terminated polyether modified medium temperature curing epoxy glue film and preparation method thereof

A technology of amino-terminated polyether and epoxy glue, which is applied in the direction of epoxy resin glue, adhesive, film/sheet adhesive, etc., which can solve the problem that the medium temperature epoxy film cannot meet the heat resistance and good toughness at the same time and other issues to achieve good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

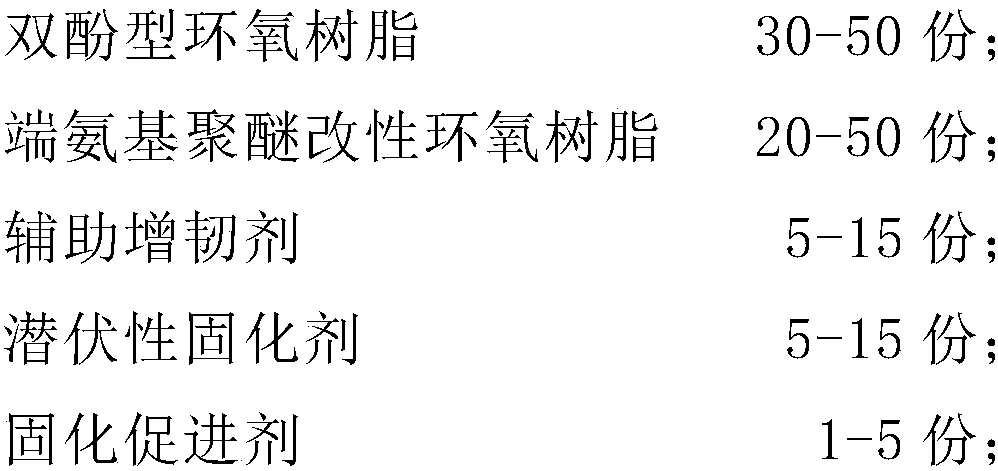

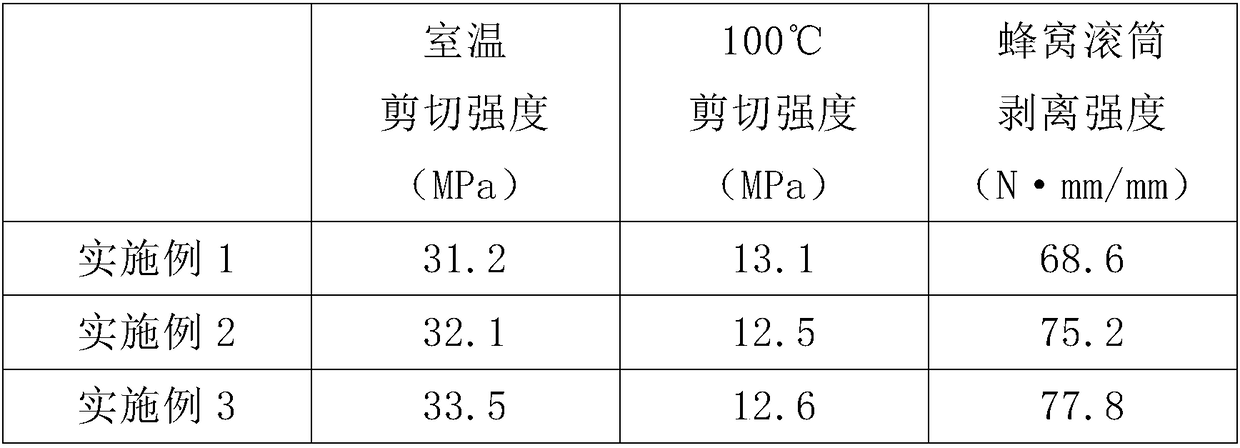

[0022] Embodiment 1: This embodiment is a kind of amino-terminated polyether modified medium-temperature curing epoxy film, which consists of 30-50 parts by weight of bisphenol-type epoxy resin, 20-50 parts of amino-terminated polyether It is prepared by ether modified epoxy resin, 5-15 parts of auxiliary toughening agent, 5-15 parts of latent curing agent, 1-5 parts of curing accelerator and 0.5-3 parts of silane coupling agent.

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the bisphenol epoxy resin is bisphenol A epoxy resin or bisphenol F epoxy resin, wherein the bisphenol A epoxy resin The epoxy value is 0.2-0.58; the epoxy value of bisphenol F epoxy resin is 0.2-0.58. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the amino-terminated polyether modified epoxy resin and the auxiliary toughening agent, wherein the auxiliary toughening agent is core-shell rubber, polysulfone One or more of resin, solid nitrile rubber, epoxy nitrile rubber and carboxylated nitrile rubber are mixed in any ratio. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com