Patents

Literature

198results about How to "Improve corona resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

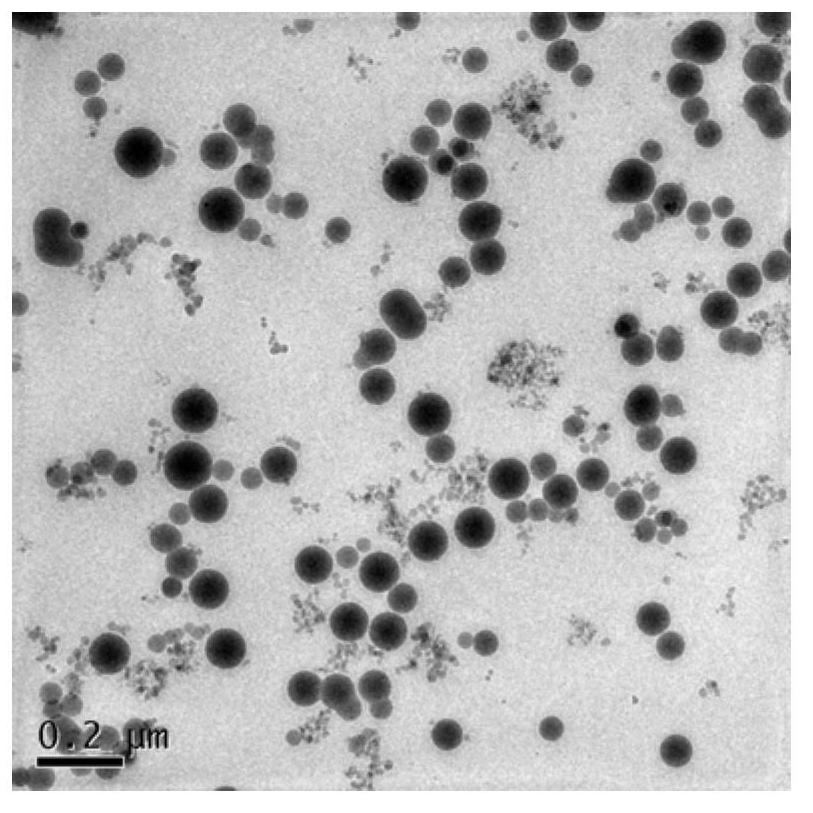

Spherical silica/polyimides composite membrane, preparation thereof and applications

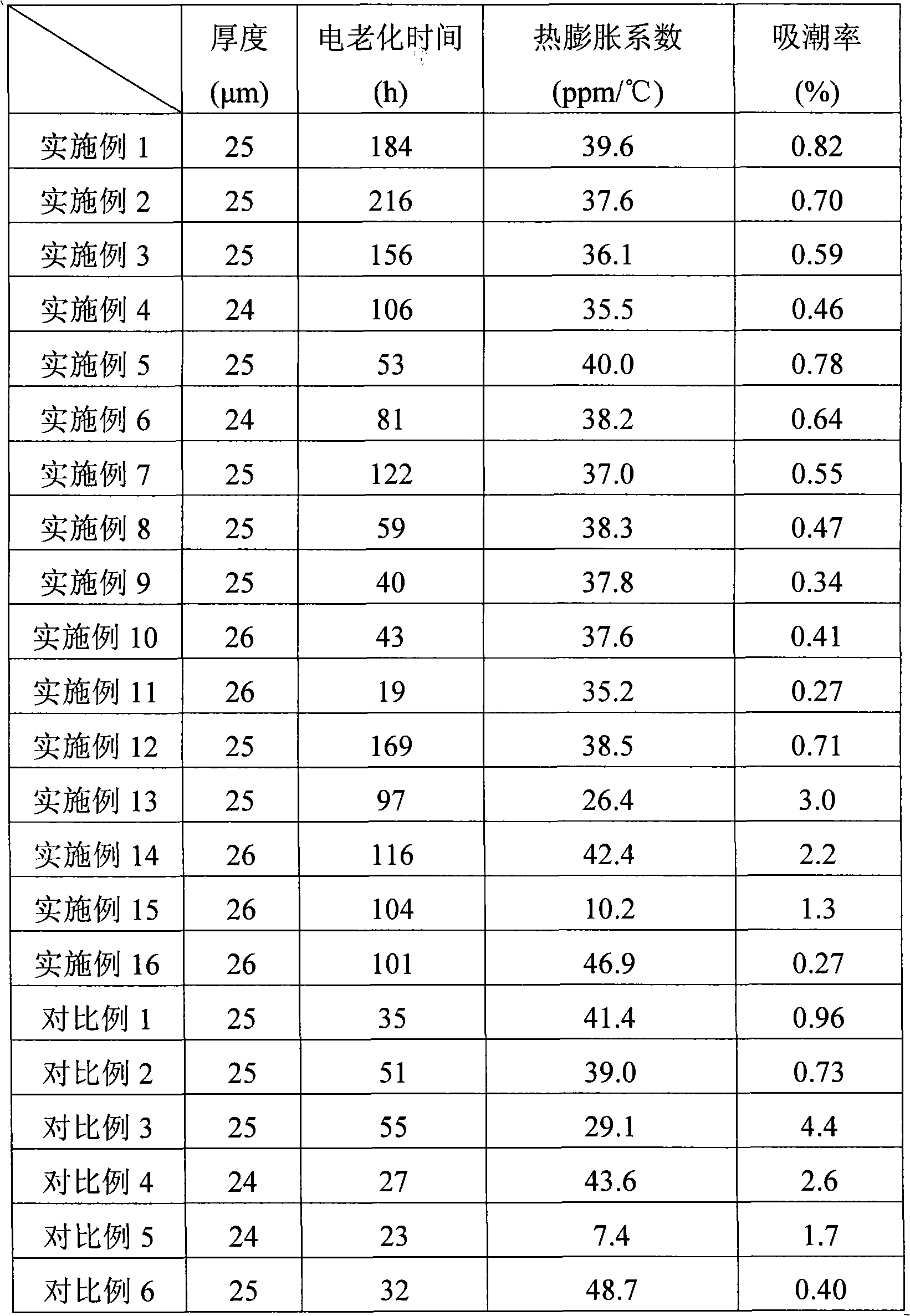

ActiveCN101289542ACorona resistantImprove corona resistanceInsulating bodiesAdhesiveThermal coefficient

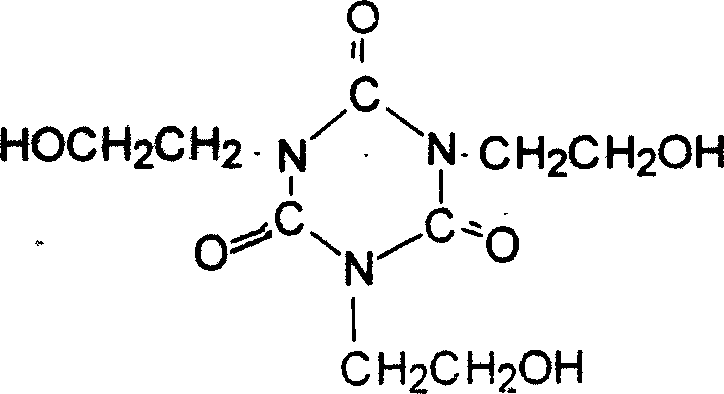

The invention discloses a spherical silicon dioxide / polyimide composite film and a method for making the same as well as an application. The method for making the spherical silicon dioxide / polyimide composite film comprises the following steps that: 1) spherical silicon dioxide particles are scattered into an organic solvent evenly to obtain the spherical silicon dioxide particle suspension liquid; 2) a surface treatment agent, a molecular weight modifying agent, an auxiliary adhesive, a flatting agent and aromatic series diamine are dissolved inside the spherical silicon dioxide particle suspension liquid; organic dicarboxylic anhydride is added to be stirred in order to obtain a spherical silicon dioxide / polyamide acid mixing resin solution; 3) the mixing resin solution is coated on the surface of a flat substrate and is heated up to make the solvent volatilize and complete the imide reaction to obtain the spherical silicon dioxide / polyimide composite film. The spherical silicon dioxide / polyimide composite film has good mechanical property, good corona resistance, low thermal coefficient of expansion and low moisture absorption ratio, and has important application value in an insulating system of a frequency conversion speed motor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

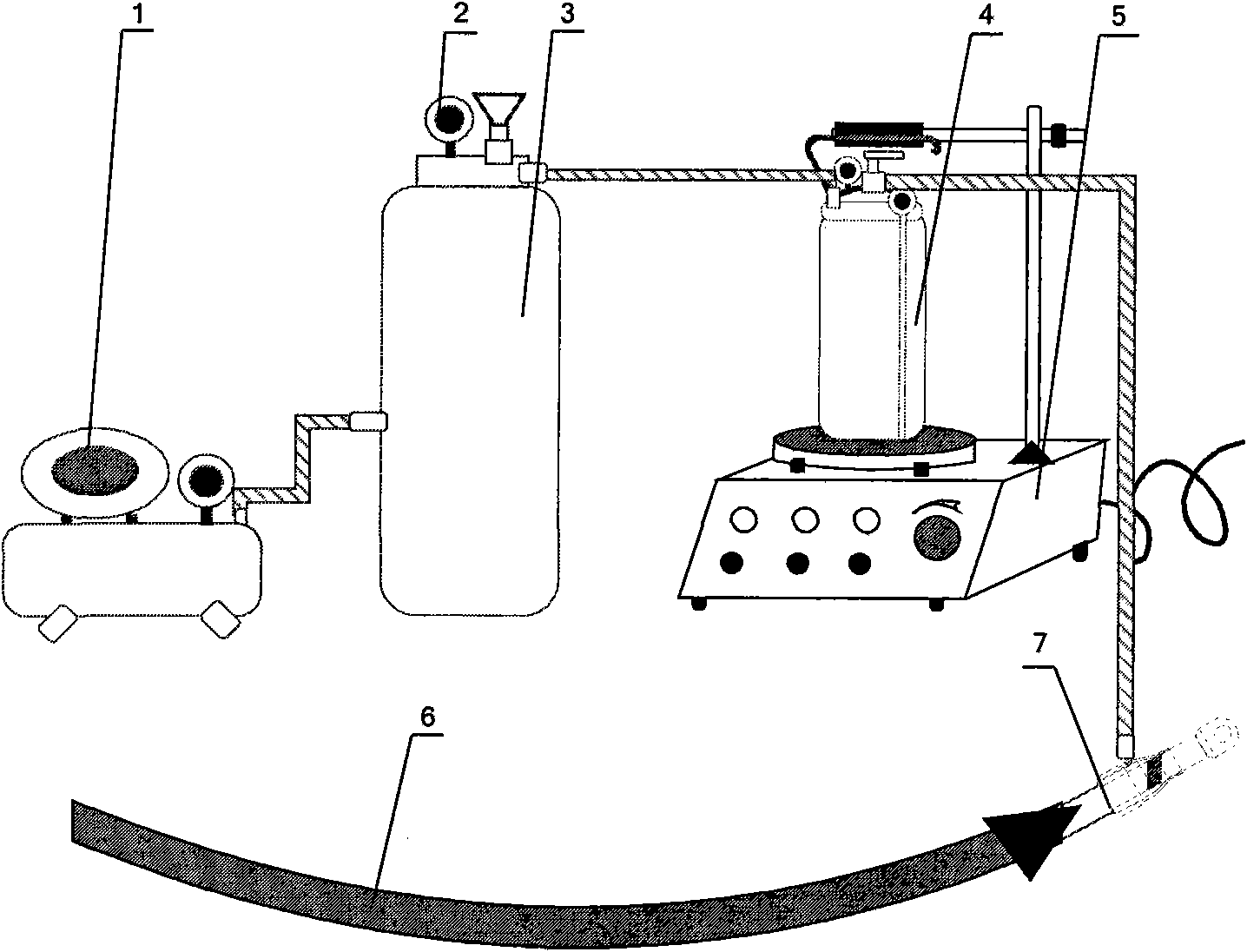

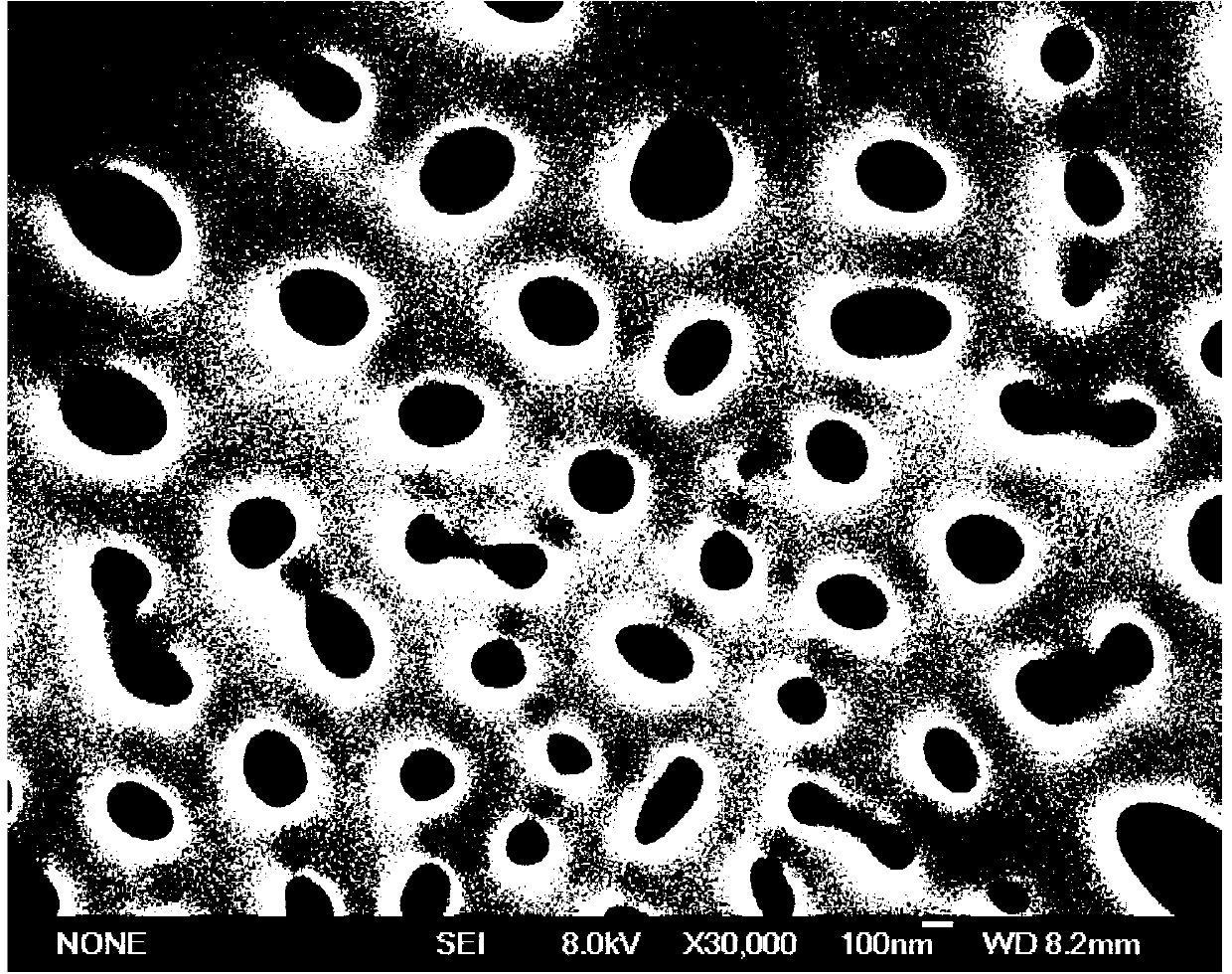

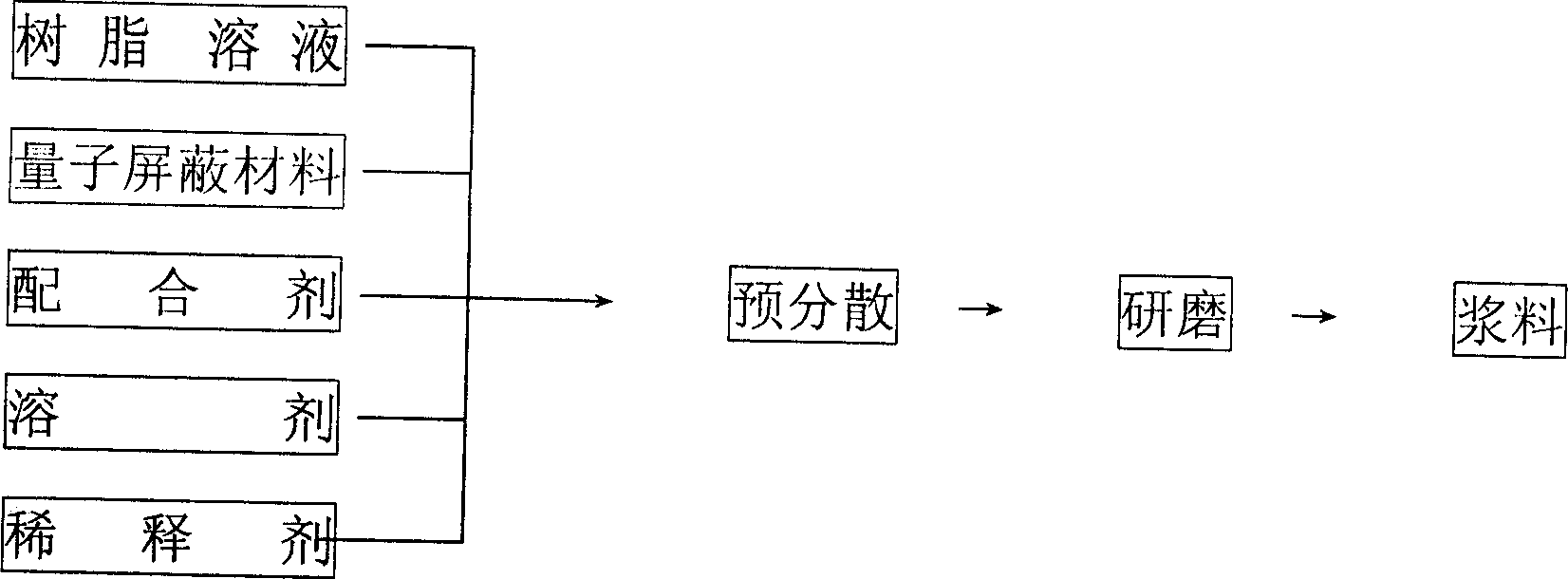

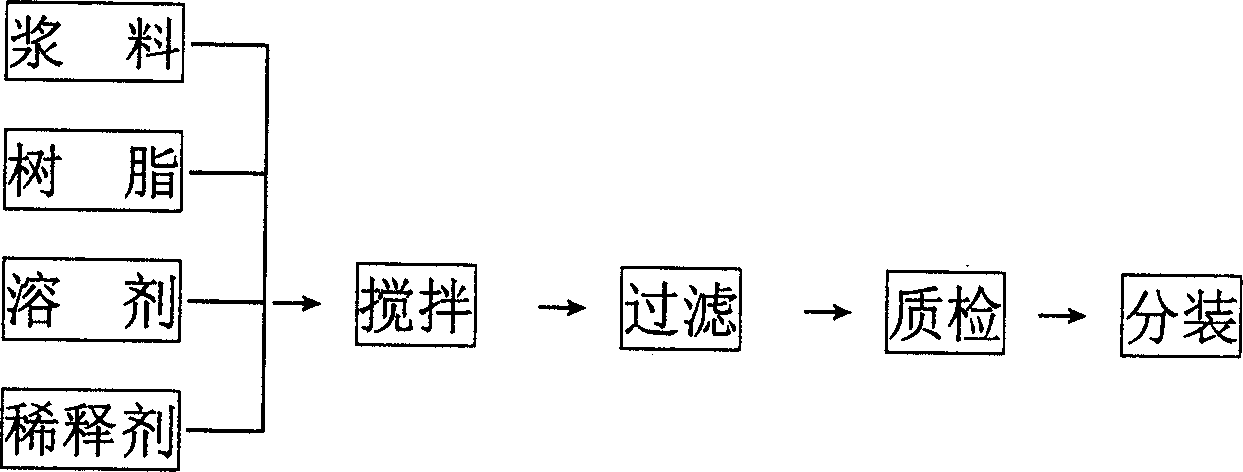

Preparation method of nanometer modified corona-tolerant enamel of enameled wire

ActiveCN1546586AImprove dispersionImprove stabilityPolyurea/polyurethane coatingsPolyester coatingsOrganic solventRoom temperature

The invention discloses a preparation method of nanometer modified corona-tolerant enamel of enameled wire which comprises the steps of, taking 1-20 parts of inorganic oxide nano particles, charging 3-100 organic solvent, dispersing the inorganic oxide into uniform nano dispersed state at room temperature, charging 0.1-1.0 part of modifier for reacting 1-3 hours at 50-140 deg. C, obtaining modified nano material slurry, charging 60-100 parts of insulating resin into modified nano material slurry for reacting 3-6 hours at 70-120 deg. C.

Owner:江苏东材新材料有限责任公司

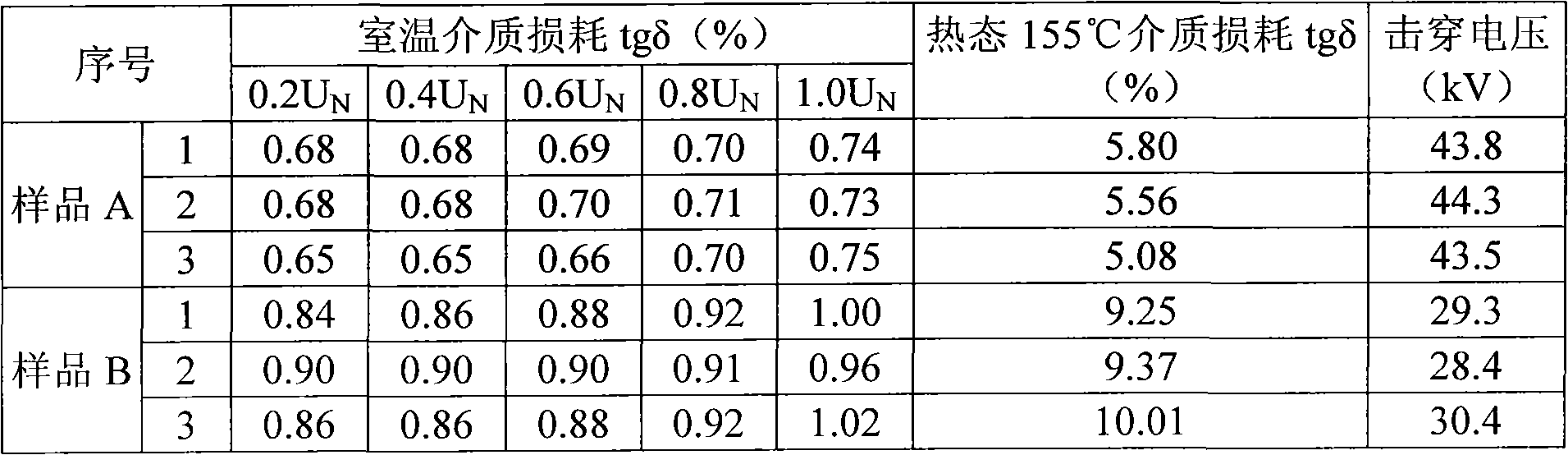

Nano modified epoxy vacuum pressure impregnation resin and preparation method thereof

ActiveCN102690496AImproved low temperature mechanical propertiesImprove thermal conductivityChemical industryEpoxy resin coatingsDefoaming AgentsMaterials science

The invention relates to a nano modified epoxy vacuum pressure impregnation resin, which comprises the following components in percentage by weight: 36 to 45 percent of bisphenol A epoxy resin, 5 to 20 percent of low-viscosity epoxy active diluent with the viscosity of 3-200mps, 40 to 50 percent of liquid anhydride, 1 to 8 percent of nanopowder with the grain size of 1-100nm, 0.2 to 2 percent of dispersing agent, 0.1 to 2 percent of silane coupling agent, and 0.1 to 1 percent of defoaming agent. Compared with the common epoxy vacuum pressure impregnation resin, the nano modified epoxy vacuum pressure impregnation resin has the advantages that the thermal conductivity and corona resistant performance are obviously improved, the heat resistance and electric strength are improved and the nano modified epoxy vacuum pressure impregnation resin can meet requirements in the fields such as high-power variable frequency motors and low temperature superconducting motors.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

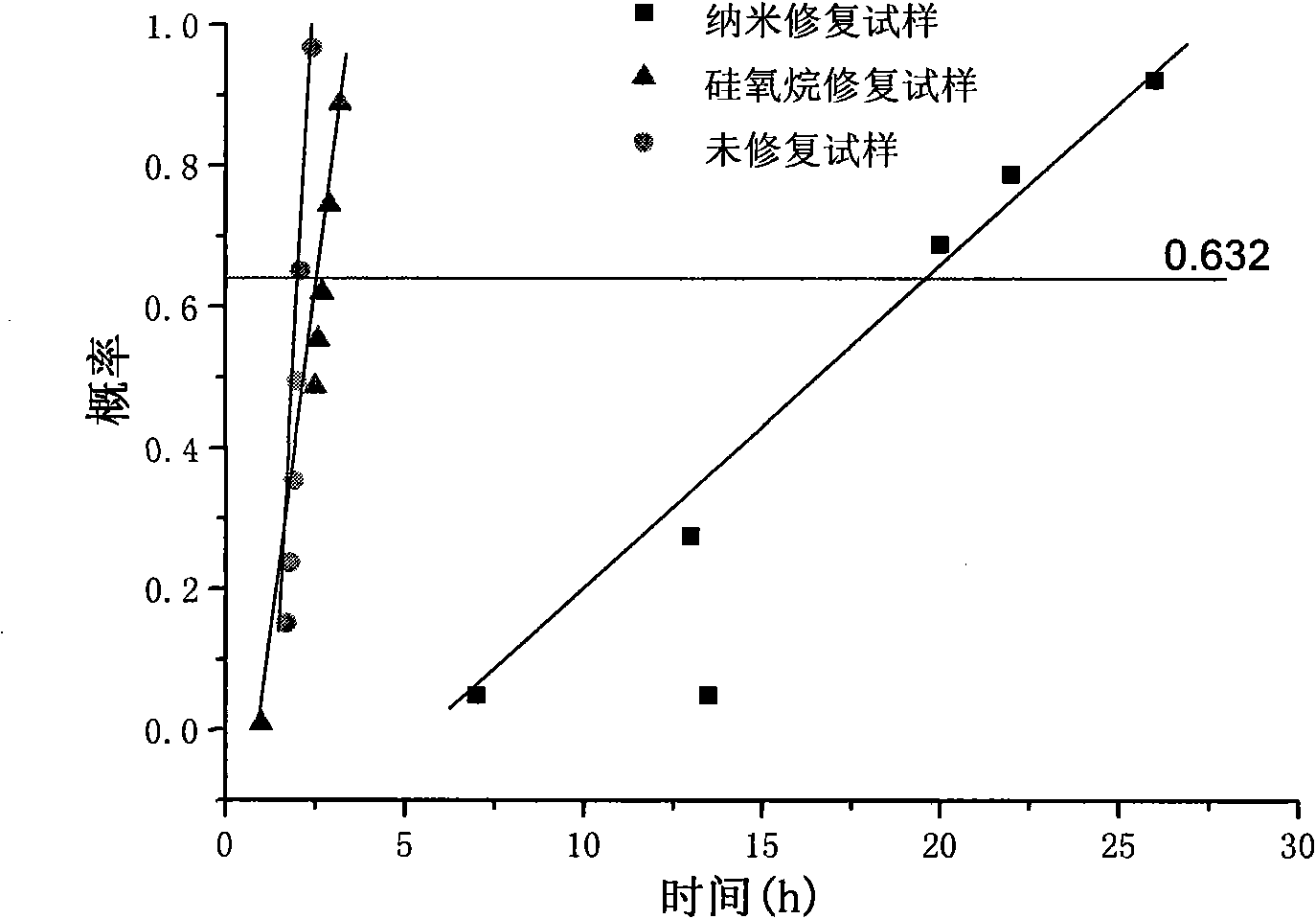

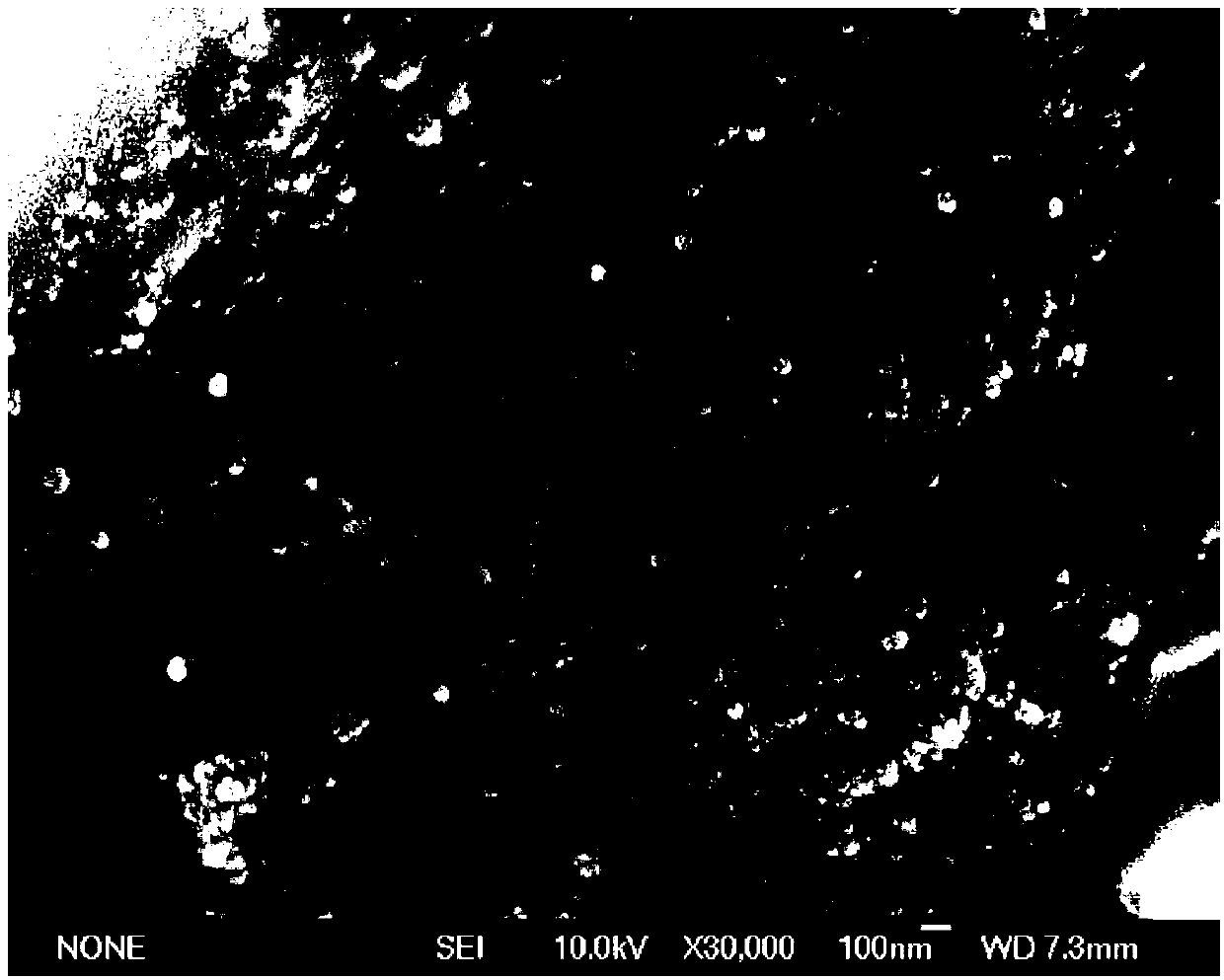

Cross-linked polyethylene power cable nano repairing liquid and repairing method thereof

ActiveCN101866706AEnsure safetyImprove conductivityPlastic/resin/waxes insulatorsApparatus for repairing insulation/armouring cablesOrganic solventPower cable

The invention discloses a cross-linked polyethylene power cable nano repairing liquid and repairing method thereof, which is characterized in that inorganic nano particles and organic solvent form nano dispersion, and a layer of inorganic nano protective film is formed by filing air gaps or micropores inside the cable through the inorganic nano particles based on a siloxane repairing liquid so as to protect a polyethylene insulating layer. Compared with the traditional siloxane repairing technology, the invention can prolong the residual service life of the power cable by 5-10 times, has the advantages of advanced technology, safety and stability, short repairing time and good repairing effect.

Owner:SICHUAN UNIV

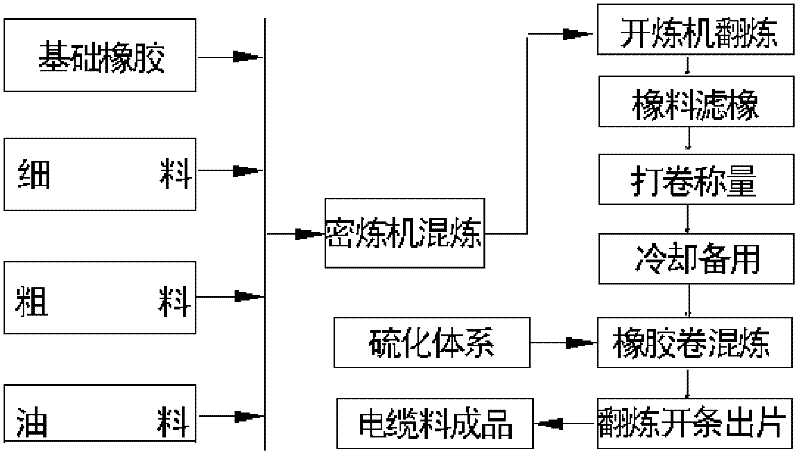

Preparation method of novel insulated rubber

InactiveCN103102502ADo not change the processing methodImprove controllabilityPolymer scienceVulcanization

The invention relates to a preparation method of a novel insulated rubber. The method sequentially includes the steps of: (1) at the mixing stage of rubber processing, on the basis of not changing a rubber system formula, adding a mixed system of a liquid oligomer and its curing agent into raw materials, and under a shearing effect in the mixing process, refining the liquid oligomer into a fine liquid and dispersing it uniformly in a rubber matrix; and (2) at a high temperature vulcanization stage, letting the oligomer undergo in situ polymerization to generate rigid particles and microfiber composed of large molecules, or making the oligomer and rubber molecules form a interpenetrating network structure. The generated rigid particles, microfiber and interpenetrating network structure have a good interface bonding force with the rubber matrix, fillers, metals and the like, and have a substantially improved reinforcement effect on the rubber matrix. The reinforced rubber has corona resistance, insulation life and certain flame retardant effect. With a simple process, the preparation method makes no change to traditional rubber processing methods, and has the characteristics of convenient operation and easily available raw materials. The prepared insulated rubber is applicable to various cables and other low-voltage electrically insulated rubber products.

Owner:QINGDAO UNIV OF SCI & TECH

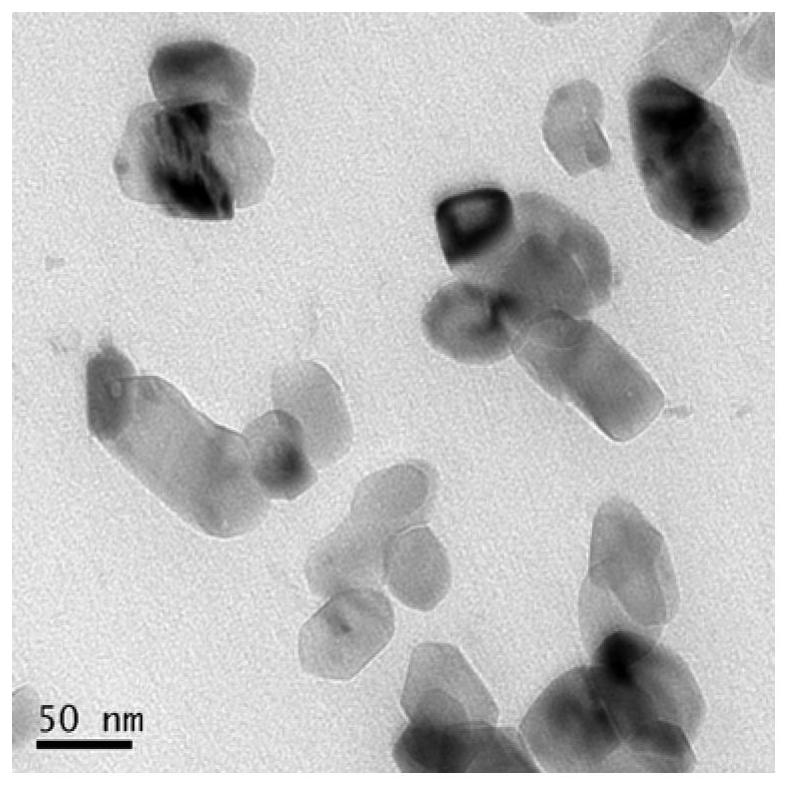

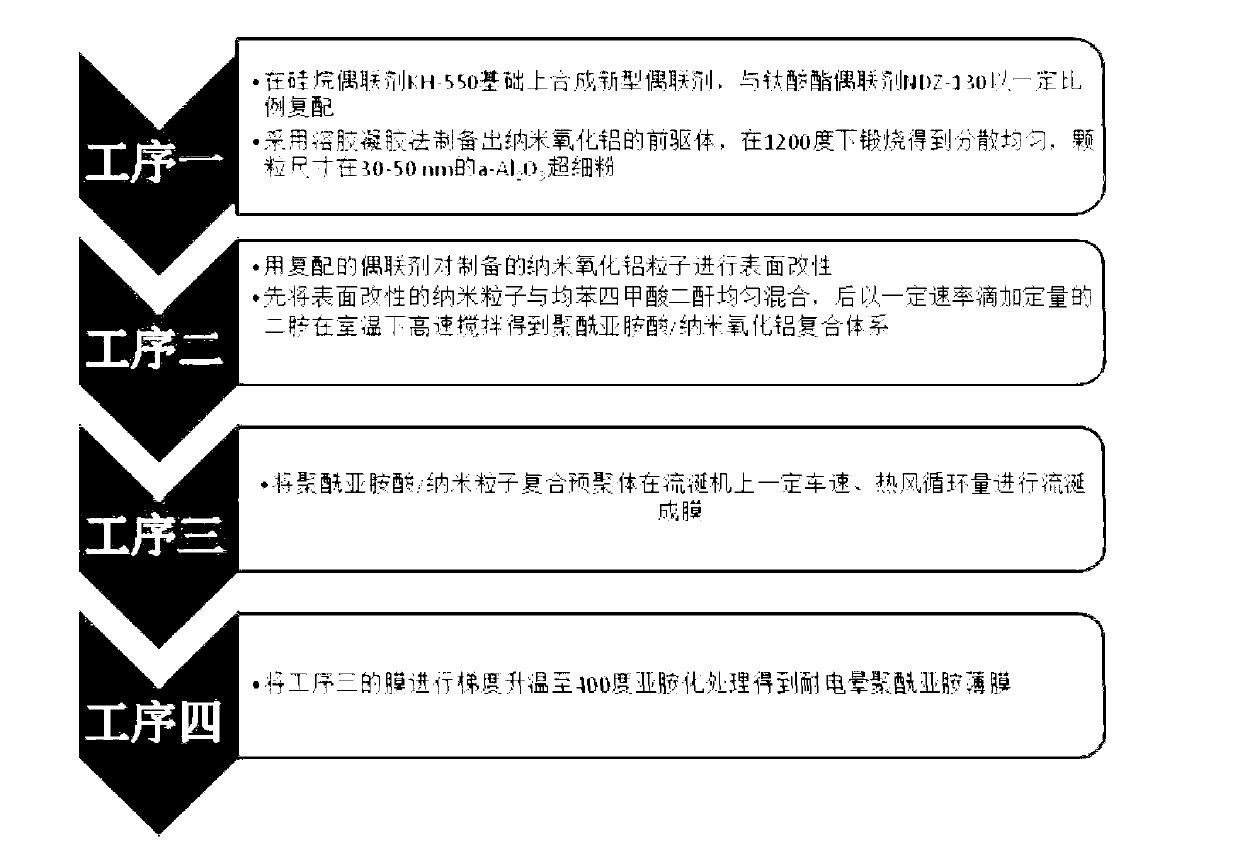

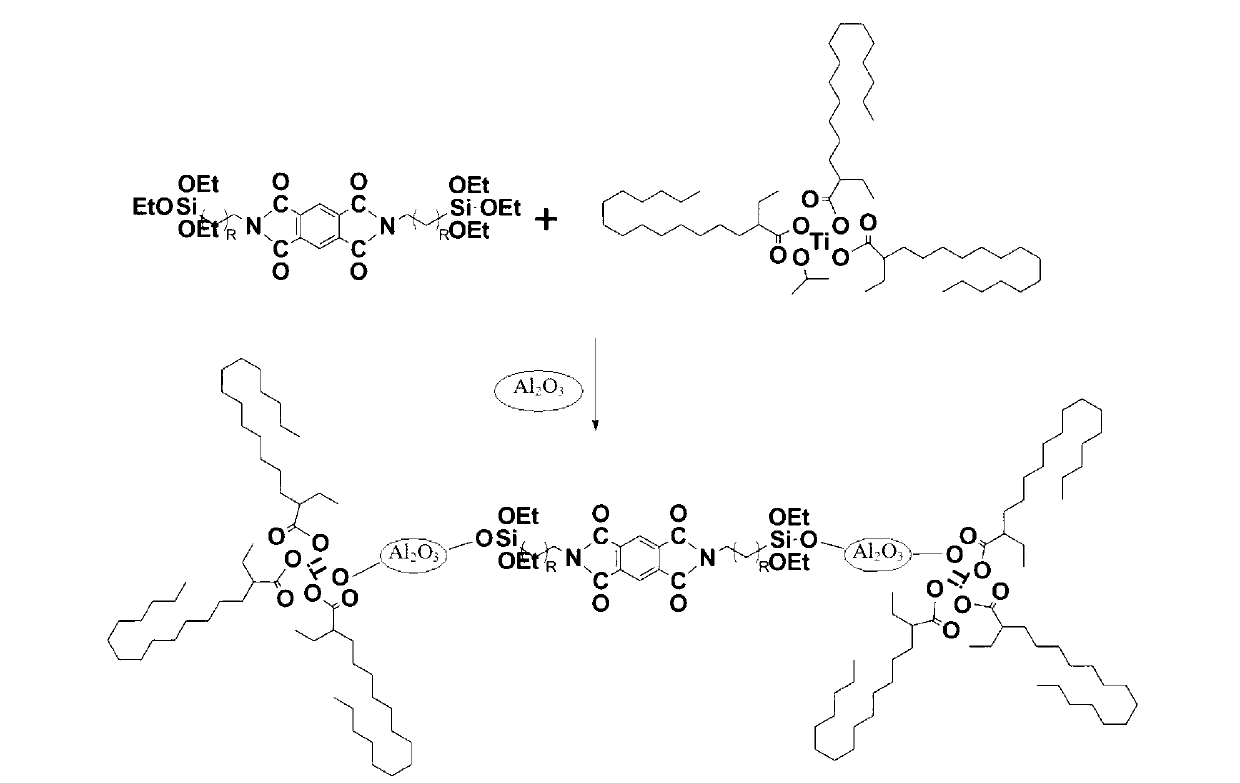

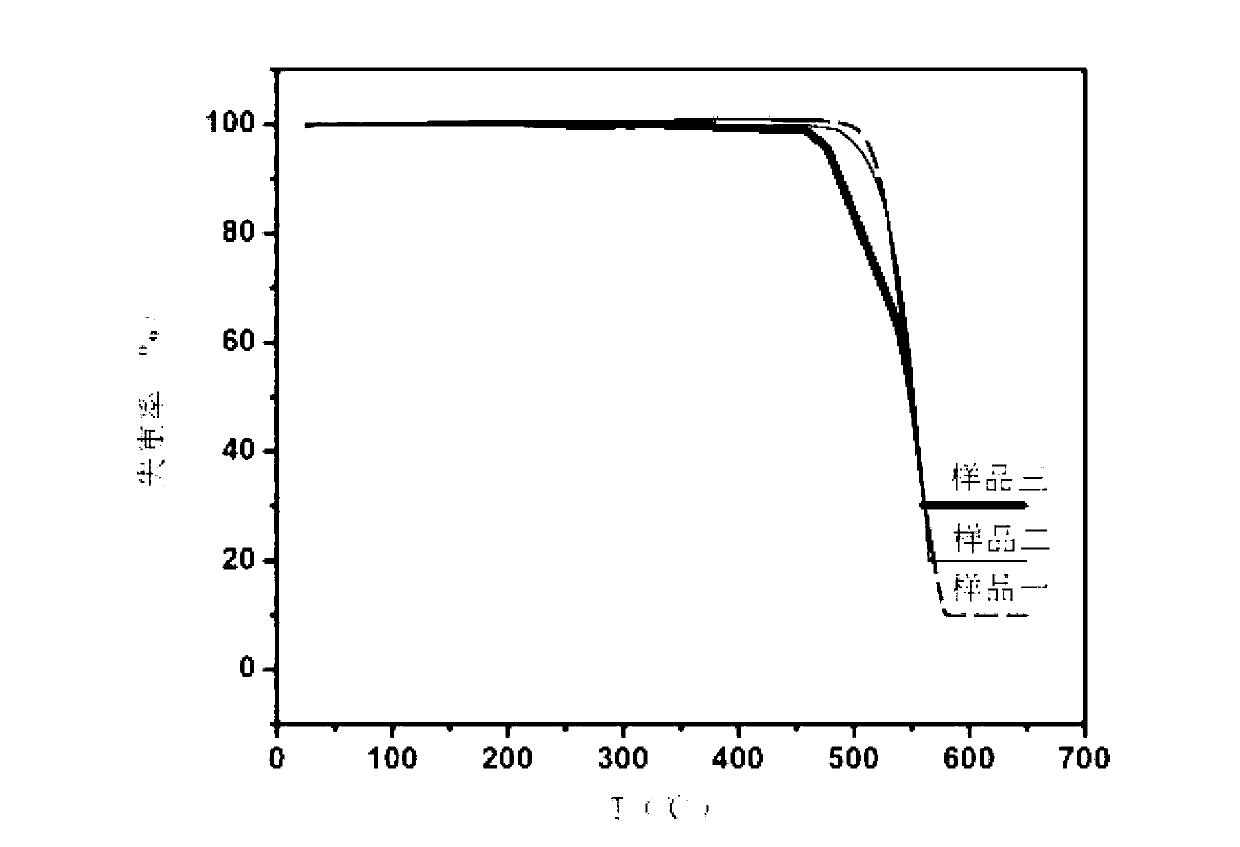

Nano Al2O3 composite corona-resistant polyimide film

The invention relates to a corona-resistant polyimide film containing high-concentration nano metal oxide, which comprises the following main components: benzenetetracarboxylic anhydride, 4, 4'-diamino diphenyl ether and nano-scale aluminum oxide, wherein the particle size of the nano-scale metal oxide is in the range from 30nm to 50nm. The film provided by the invention has the following outstanding advantages that a novel coupling agent is synthesized and is compounded with titanate coupling agent NDZ-130 to conduct surface modification on prepared alpha-Al2O3, thus the modified nano-particles can be steadily and uniformly dispersed in the substrate polyimide film with relatively high mass percentage (can reach 30wt%). By adoption of the above novel technical scheme of the invention, the technical problem that high-concentration nano-metal oxide is very difficultly doped uniformly in the corona resistant polyimide film according to the prior art is solved well, and meanwhile the mechanical strength of the film is kept from dropping.

Owner:UNIV OF SCI & TECH BEIJING

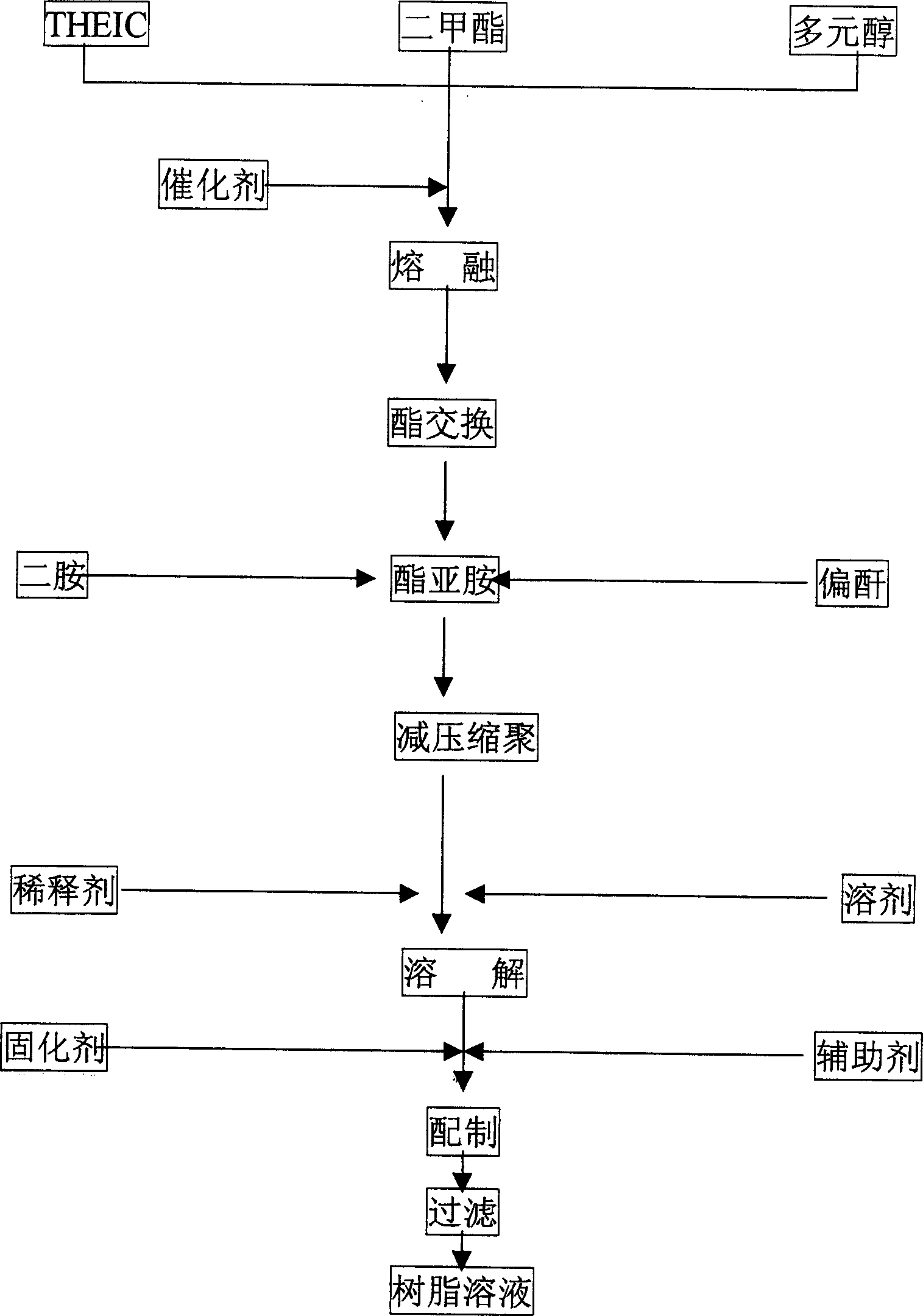

Corona resistant enamel-covered wire paint for variable frequency motor and preparing process thereof

InactiveCN1488697AImprove insulation performanceImprove performanceChemical industryInsulated cablesDimethyl terephthalatePolyester

Owner:上海汉邦化工有限公司

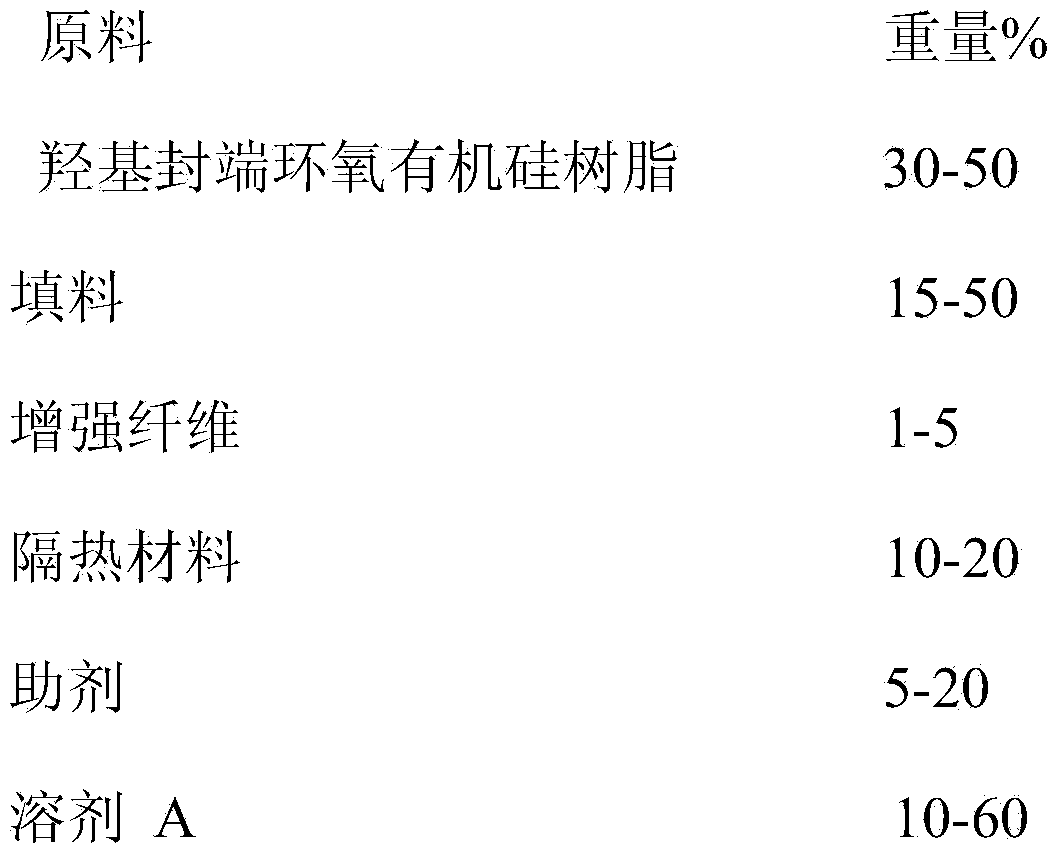

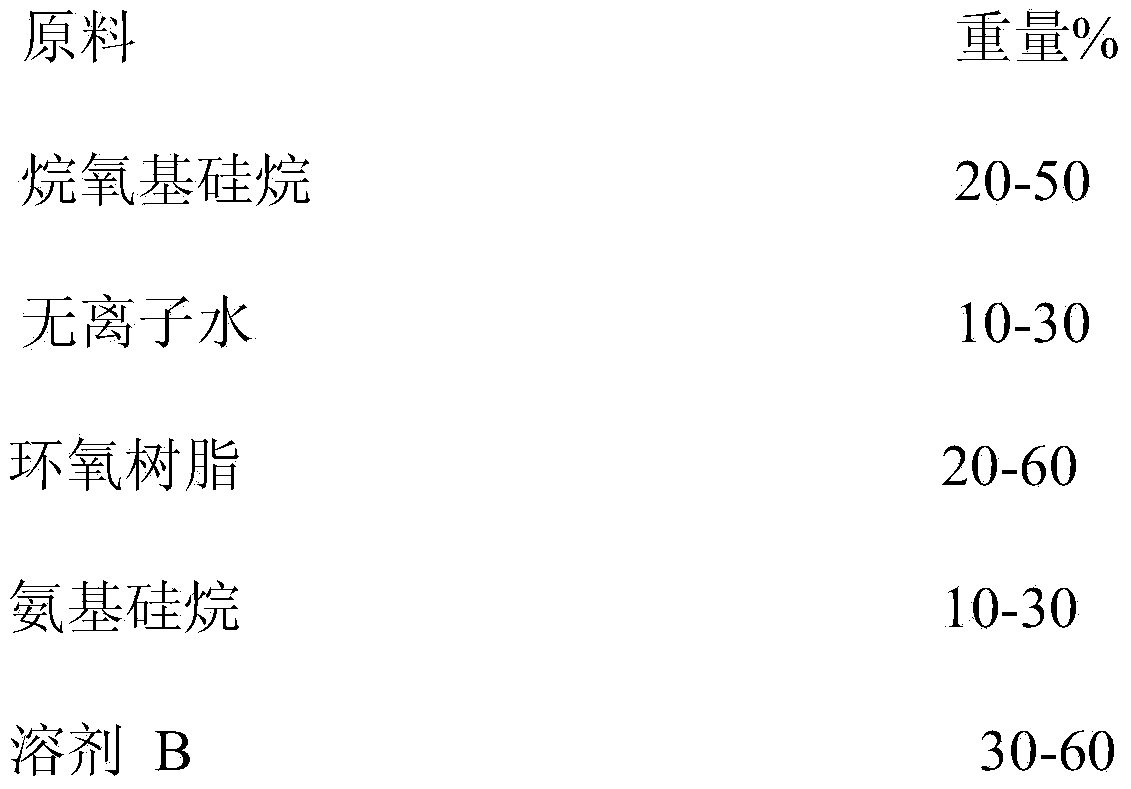

High-elasticity polyurethane modified epoxy-silicone ablation resistance paint

InactiveCN103725179AGood mechanical propertiesGood thermal stabilityPolyurea/polyurethane coatingsSolventSilicone resin

The invention discloses high-elasticity polyurethane modified epoxy-silicone ablation resistance paint. According to the invention, an organic silicon intermediate prepared through alkoxy silane hydrolysis and epoxy resin are condensed into hydroxyl-terminated epoxy-silicone resin with high char yield and excellent ablation resistance; the elongation at break and the tensile strength of the resin system are improved through selecting high-elasticity polyurethane resin to toughen the epoxy-silicone resin; filler, a reinforcing agent, a thermal insulation material, an additive and a solvent are also added, so as to obtain the high-elasticity polyurethane modified epoxy-silicone ablation resistance paint. While the requirement that an outer shell coating is subjected to relatively large deformation due to internal pressure when grains are burnt is met, the coating has excellent ablativity, very low density and high thermal insulation performance.

Owner:中昊北方涂料工业研究设计院有限公司

Corona-resistant polyimide film and preparing method thereof

ActiveCN101323672AImprove corona resistanceSimple preparation processDiphenyl etherPyromellitic dianhydride

The invention relates to a polyimide film with corona resistance, which essentially comprises pyromellitic dianhydride, 4.4' diamido-diphenyl ether and nanoscale metallic oxide; wherein, the particle size of the nanoscale metallic oxide is less than or equal to 50 nanometers. By adopting the technical proposal, the invention has the advantages as follows: as nanophase materials are adopted by the invention and the nanoscale metallic oxide and N, N' dimethylacetamide are prepared into stable and uniform suspended substance in a high-speed cutting and scatter, the product adopting the polyimide film with corona resistance produced in the invention has excellent performance of corona resistance, good production technology and high rate of finished products.

Owner:JIANGSU ICE CITY INSULATION MATERIALS STOCK

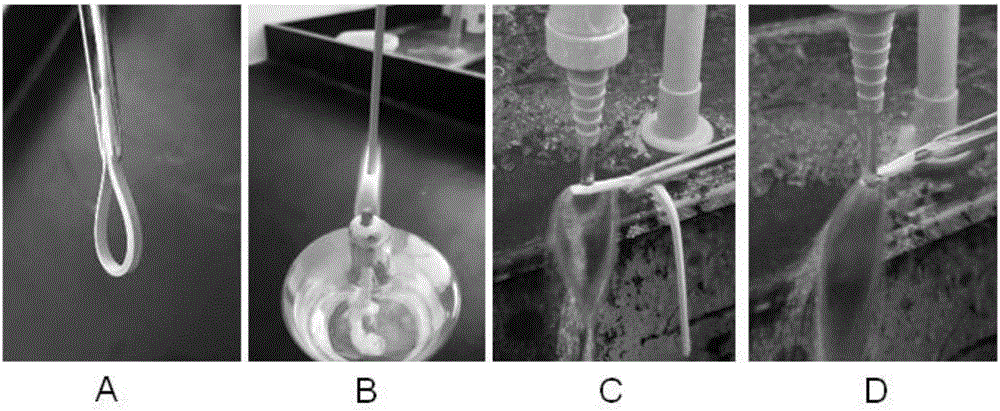

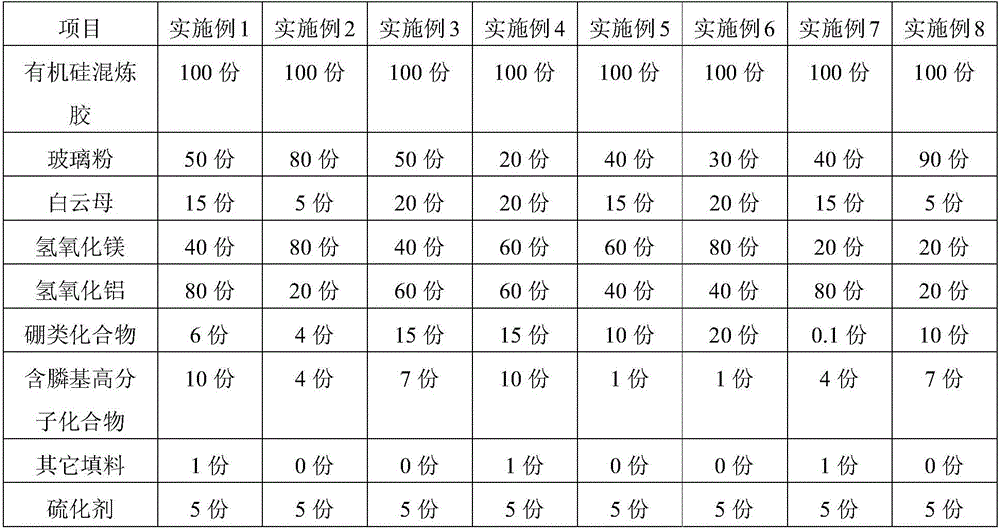

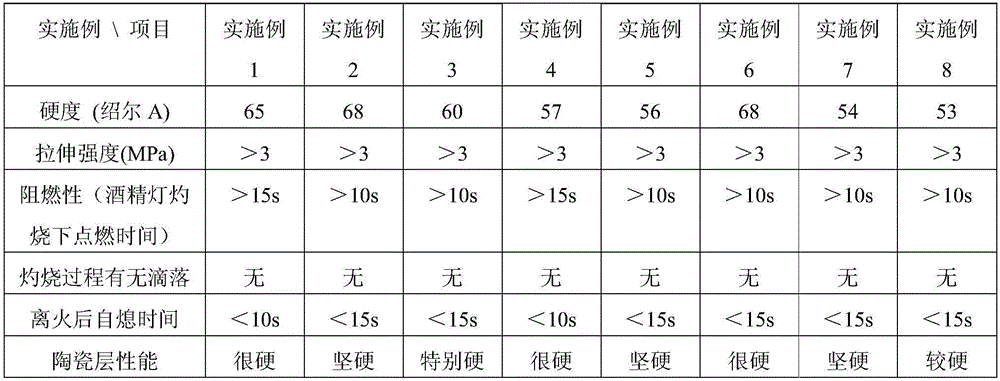

Flame-retardant and drippage-free ceramization silicon rubber and preparation method thereof

ActiveCN105884267AGood physical and mechanical propertiesThe process is simple and easy to controlAluminium hydroxideEconomic benefits

The invention relates to flame-retardant and drippage-free ceramization silicon rubber and a preparation method thereof. The silicon rubber is prepared from components in parts by weight as follows: 100 parts of organic silicon rubber compounds, 1 part to 10 parts of a vulcanizing agent, 100 parts to 150 parts of ceramization powder and 0 to 100 parts of other filler or auxiliaries, wherein the ceramization powder is prepared from raw materials in parts by weight as follows: 1 part to 120 parts of glass powder, 1 part to 20 parts of muscovite, 1 part to 200 parts of magnesium hydroxide, 1 part to 200 parts of aluminum hydroxide, 0.1 parts to 50 parts of boron compounds and 0.1 parts to 20 parts of phosphono-containing polymer compounds. The ceramization silicon rubber prepared with the method has advantages of good flame retardance and self-extinguishment performance; a ceramic layer formed after firing has good compactness and insulativity, external force resistance and the like. The preparation process is simple, raw materials are cheap, and accordingly the silicon rubber is expected to be applied to fields such as wires and cables, the electronic and electrical technology, aerospace engineering and the like and has quite good economic benefits and popularization value.

Owner:SHANDONG UNIV

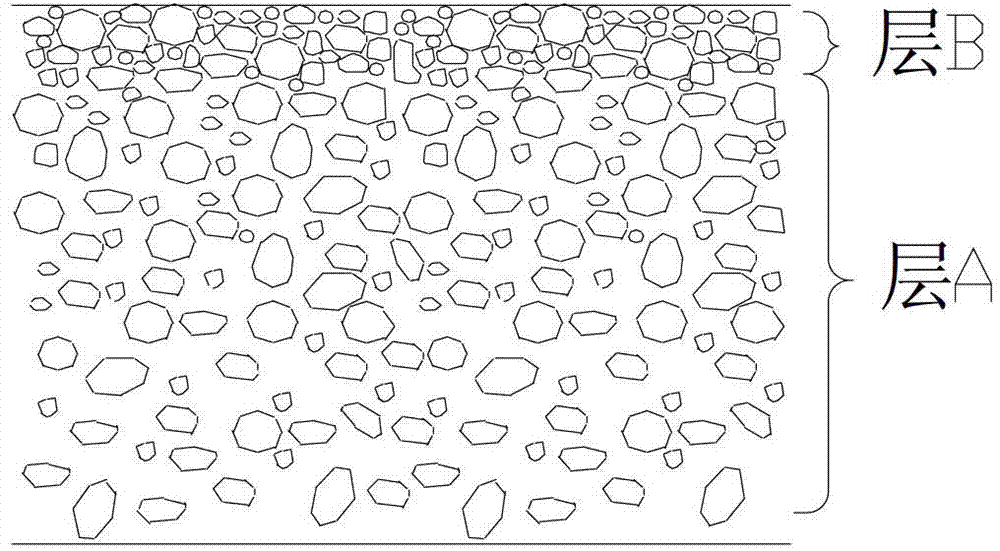

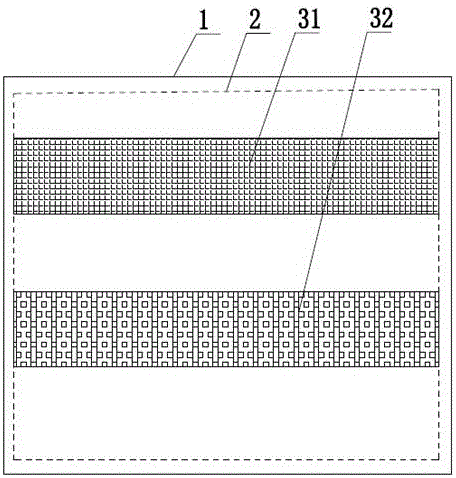

Corona-resistant polyimide film material and preparation method thereof

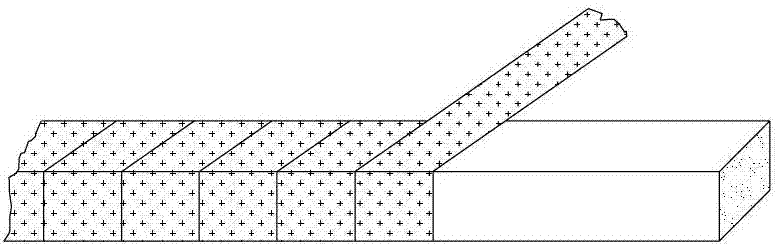

ActiveCN103029395AOvercome the disadvantage of poor mechanical strengthContinuous mass productionSynthetic resin layered productsLaminationTotal thicknessFilm material

The invention relates to a corona-resistant polyimide film with a double-layer structure, and a preparation method thereof. The corona-resistant polyimide film material comprises a film layer A and a film layer B, wherein the film layer A serves as the main body structure of the polyimide film material and comprises polyimide resin and inorganic filler filled in the polyimide resin; the thickness of the film layer A accounts for 90 to 99.9 percent of the total thickness of the material; the film layer B comprises polyimide resin and inorganic filler filled in the polyimide resin; the thickness of the film layer B accounts for 0.1 to 10 percent of the total thickness of the material; the content of inorganic filler A; the film layer A and the film layer B are integrally formed; and no obvious boundary exists between the film layer A and the film layer B. The film with the structure has excellent physical and electrical properties and also has excellent corona resistance.

Owner:RAYITEK HI TECH FILM CO LTD

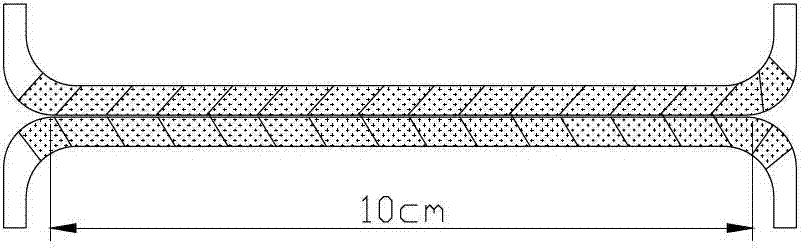

Formula and production process of dual-layer thermal shrinkage-chilling shrinkage composite sleeve

ActiveCN102558657AImprove reliabilityImprove electrical performanceLow-density polyethylenePolymer science

The invention provides a formula and a production process of a dual-layer thermal shrinkage-chilling shrinkage composite sleeve which comprises an inner sleeve and an outer sleeve, wherein the inner sleeve comprises an ethylene vinyl acetate copolymer, low-density polyethylene, a maleic anhydride grafted polymer, a surface treatment ultrathin active magnesium hydroxide, surface treatment ultrathin active aluminium hydroxide, a lubricating agent, an antioxygen, a light stabilizer and a sensitive cross-linking agent; and the outer sleeve comprises ethylene propylene diene monomer, ultrathin surface treatment active kaoline, ultrathin surface treatment active talcum powder, a lubricating agent and colorant. The dual-layer thermal shrinkage-chilling shrinkage composite sleeve obtained by the production process has no gap between the inner sleeve and the outer sleeve and high connection reliability; and the inner sleeve has good elasticity, weather resistance, ozone resistance, heat resistance, acid and alkaline resistance, water vapor resistance, corona resistance and high electric insulation property.

Owner:HONGSHANG HEAT SHRINKABLE MATERIALS

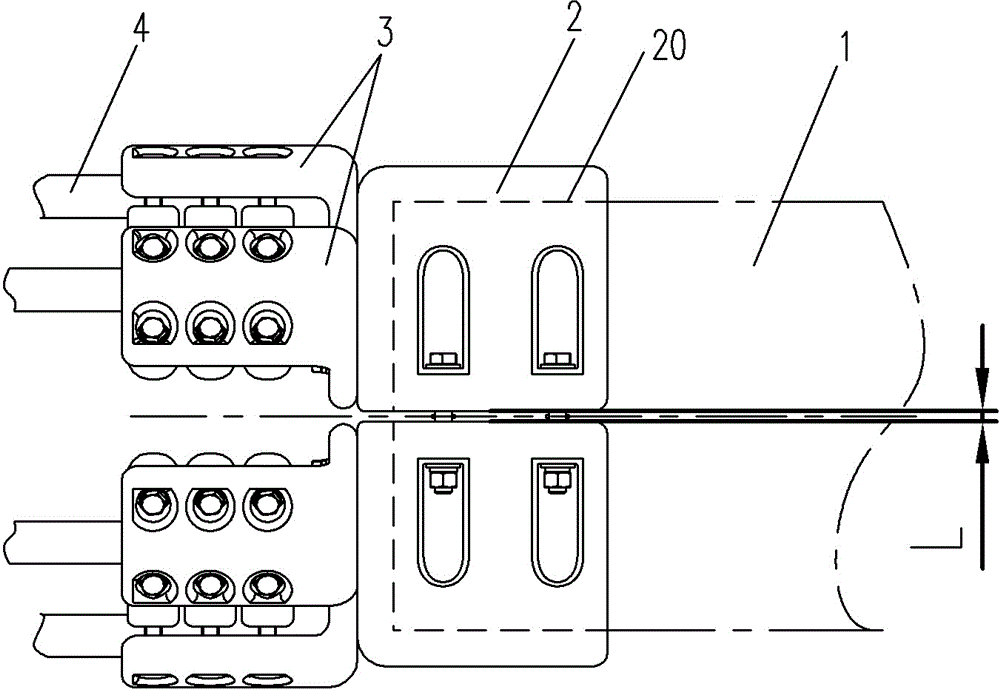

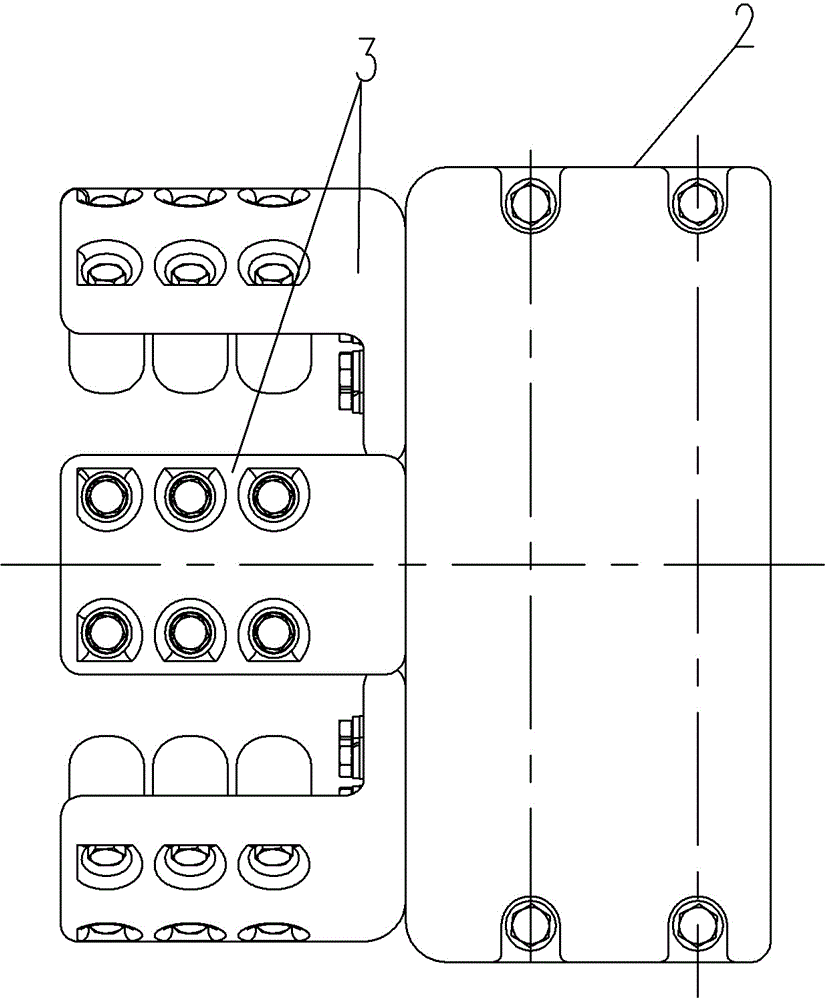

Divided conductor clamp fitting for EHV (Extra-High Voltage) DC (Direct Current) convertor station and branch clamps thereof

ActiveCN104362444AGuaranteed anti-corona performanceGood anti-corona performanceElectric connection structural associationsClamped/spring connectionsBusbarMechanical engineering

The invention provides a divided conductor clamp fitting for an EHV (Extra-High Voltage) DC (Direct Current) convertor station and branch clamps thereof. The clamp fitting comprises a bus-bar clamp, wherein one end of the bus-bar clamp axially extending along a busbar hole is fixedly provided with at least two branch clamps peripherally distributed around the busbar hole; each branch clamp comprises a finger-type support body and a pressing block, a branch hole is defined by the finger-type support body and the pressing block, and the finger-type support body is in an L shape; the finger-type support body is provided with an axial installation section axially extending along the branch hole and a radial installation section which is integrally installed along the radial extending direction of the branch hole or is separately and fixedly arranged on the busbar clamp, the pressing block is located inside the L-shaped finger-type support body and is fixedly arranged on the axial installation section, and the opposite sides of the axial installation section and the pressing block are provided with branch slots for forming the branch holes; the outside parts of the corners of the L-shaped finger-type support bodies are connected in an circular arc transition way, and the pressing blocks on the branch clamps are located inside the corresponding branch clamps toward the central axes of the busbar holes. The clamp fitting is convenient to install and use and good in anticorona.

Owner:PINGGAO GRP +1

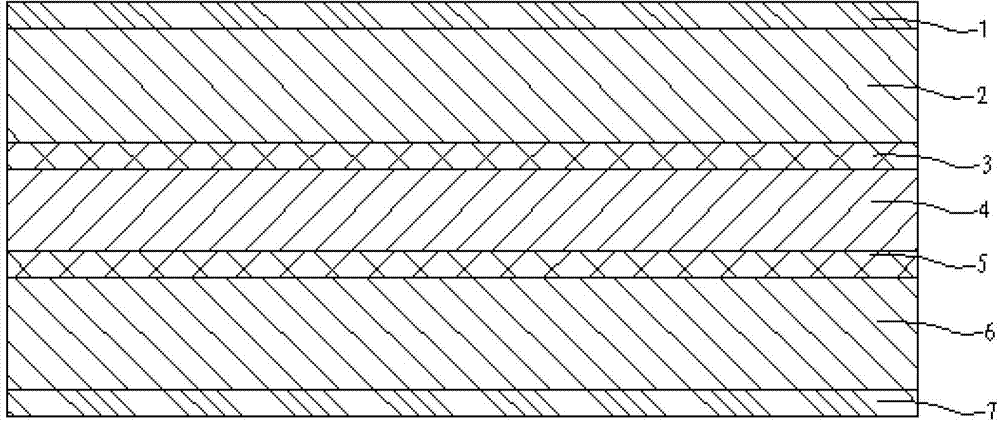

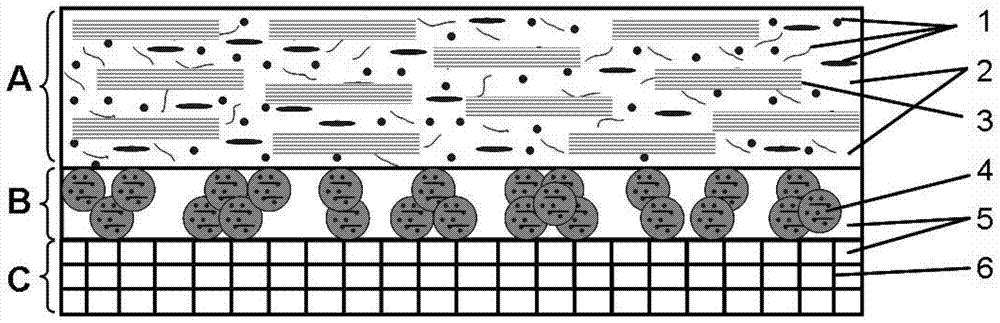

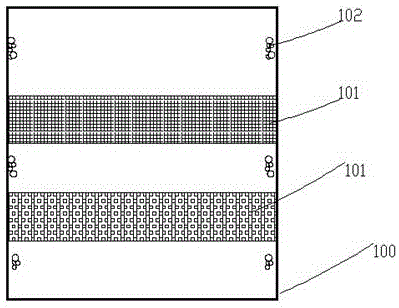

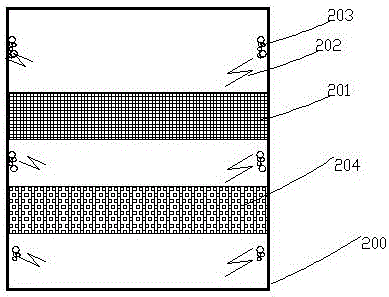

Corona-resistant groove insulation material and preparation method thereof

ActiveCN103400638AImprove corona resistanceReduce partial dischargeWindings insulation materialPlastic/resin/waxes insulatorsNanometreMica

The invention relates to a corona-resistant groove insulation material and a preparation method thereof. The groove insulation material sequentially comprises a first adhesive layer, a first mica paper layer, a second adhesive layer, a film layer, a third adhesive layer, a second mica paper layer and a fourth adhesive layer from top to bottom, wherein the first adhesive layer, the second adhesive layer, the third adhesive layer and the fourth adhesive layer are respectively formed by nano modified adhesive, the nano modified adhesive is the adhesive which is mixed with nano powder body, the content of the nano powder body in the nano modified adhesive is 15 to 25 percent, and the granularity of the nano powder body is 20nm to 100nm. The corona-resistant service life of the insulation material can be improved by more than 50 times compared with the existing groove insulation material; and meanwhile, the paint quantity in the resin immersing process can be increased, and the mechanical property and the electric insulation performance of a curing system can be improved. In addition, the cost of the groove insulation material is lower, so that the industrialized mass production and popularization of the groove insulation material can be favored.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Impregnating resin applied to wind driven generator insulating vacuum pressure impregnating treatment and impregnating method

InactiveCN101967267AHigh strengthImprove heat resistanceManufacturing dynamo-electric machinesWind energy generationWind drivenVacuum pressure

The invention relates to an impregnating resin applied to wind driven generator insulating vacuum pressure impregnating treatment and a method for manufacturing a rotor winding and a stator winding of a wind driven generator made of the material. The impregnating resin applied to wind driven generator insulating vacuum pressure impregnating treatment is mixed by components A and B, wherein the components A and B are respectively packaged and separately stored; and in actual production, 100 weight parts of component A and 80 to 120 weight parts of components B are uniformly mixed so as to prepare the uniform and transparent faint yellow impregnating resin. The rotor winding or the stator winding of the wind driven generator is subjected to vacuum pressure impregnation by the impregnating resin and then is baked and cured, so that a mica tape layer around the rotor winding or the stator winding and an insulating layer of the impregnating resin are cured to form the rotor winding or the stator winding of the wind driven generator with insulating effect.

Owner:上海同立电工材料有限公司

Preparation method of coal ash modified nanometer aluminum oxide/polyimide composite film

ActiveCN103232609AImprove corona resistanceExcellent dielectric propertiesInorganic pigment treatmentComposite filmNano al2o3

The invention discloses a preparation method of a coal ash modified nanometer aluminum oxide / polyimide composite film. The preparation method can be used for preparing the nanometer aluminum oxide hybrid polyimide film by utilizing nanometer aluminum oxide sol, so that corona-resistant characteristics and dielectric performances of the polyimide film can be remarkably improved, and the corona-resistant service life of the nanometer aluminum oxide hybrid polyimide film is 8-9 times that of the pure polyimide film. The preparation method further can be used for improving and overcoming the defects of the pure polyimide film, remarkably improving the mechanical strength, the hardness, the abrasion performance and thermal decomposition temperature of the pure polyimide film, so that the comprehensive performances of the pure polyimide film are improved. Moreover, the novel polyimide nanometer composite film prepared by the preparation method disclosed by the invention has the characteristics of being high temperature resistance, good in mechanical performances, excellent in electrical performances, easy to machine and form, low in cost and the like, so that the development requirements of high and new technologies including the aerospace technology, the micro-electronics technology, the electrical technology, the chemical technology, the energy technology and the like can be completely satisfied.

Owner:安徽朝日电子新能源有限公司

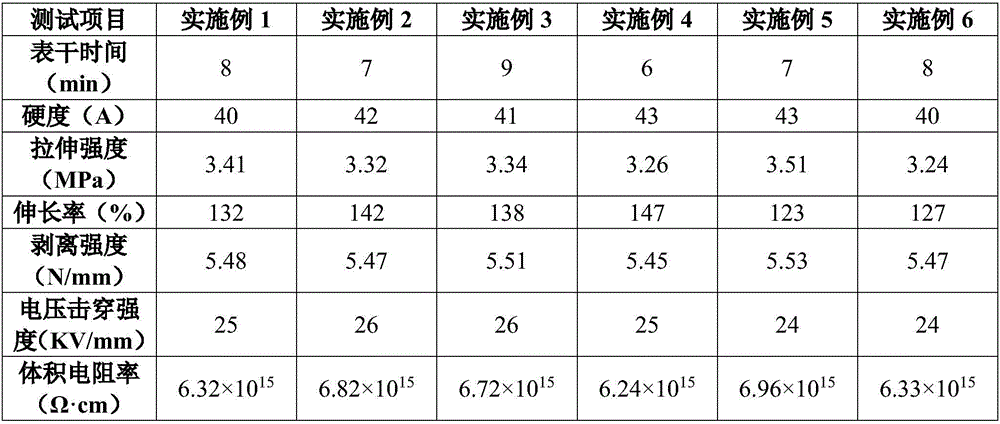

Solvent-free type organosilicone coating adhesive and preparation method thereof

ActiveCN106190015AImprove compactnessGood high and low temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryOrganosilicon

The invention discloses a solvent-free type organosilicone coating adhesive and a preparation method thereof. The organosilicone coating adhesive is prepared from, by mass, 70-100 parts of hydroxyl end-blocked dimethylsiloxane, 10-30 parts of adhesive film enhancer, 2-6 parts of cross-linking agent, 0.1-0.8 part of catalyst and 0.5-1.5 parts of tackifier. The preparation method of the solvent-free type organosilicone coating adhesive includes the following steps that hydroxyl end-blocked dimethylsiloxane and the adhesive film enhancer are added into a reaction still and stirred and mixed to be uniform under the vacuum condition, the cross-linking agent, the catalyst and the tackifier are added, and the mixture is stirred and mixed to be uniform under the vacuum condition. When the organosilicone coating adhesive is used, no organic solvent is needed for dilution, safety and environment friendliness are achieved, the compactness of cured adhesive film is high, and good high and low temperature resistance, insulating performance, binding performance, dampness resistance, earthquake resistance and corona resistance are achieved; the production process of the organosilicone coating adhesive is simple, the production cost is low, and the product is easy to construct.

Owner:新亚电子制程(广东)股份有限公司

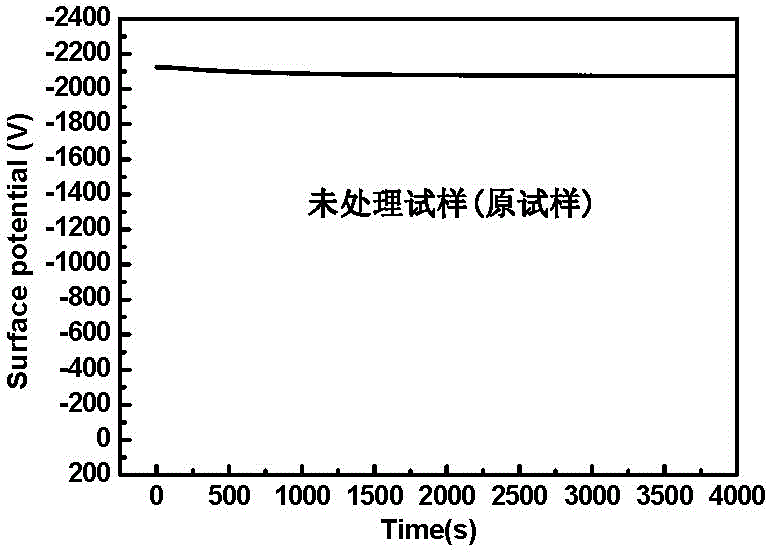

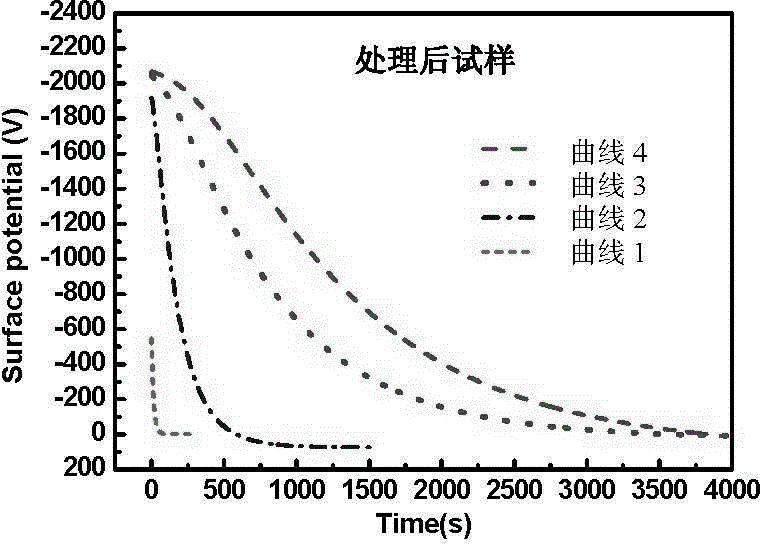

Method for inhibiting charge accumulation on polyimide insulation film

The invention relates to a method for inhibiting charge accumulation on a polyimide insulation film, and aims to effectively prevent charge accumulation on the polyimide insulation film and prolong the service life of electric apparatus. The method comprises the following steps: placing the polyimide insulation film in a reaction chamber for vacuumizing at first; then, introducing a mixed gas composed of fluorine, oxygen and nitrogen into the reaction chamber, and under the action of the mixed gas, conducting a 2-20 minutes' gas-phase oxygen-fluorine fluoridation reaction on the polyimide insulation film at 18-200 DEG C, wherein the mixed gas comprises 1-20% of fluorine, 1-20% of oxygen and the balance of nitrogen according to a volume ratio. The method is easy, simple to operate, low in cost and good in effect, and can be effectively utilized for inhibiting charge accumulation on the polyimide insulation film, thereby improving the corona resistance of the polyimide insulation film as well as the stability and service life of the polyimide insulation film in the technical filed of small-sized motor and electric apparatus frequency conversion.

Owner:SHANGQIU NORMAL UNIVERSITY

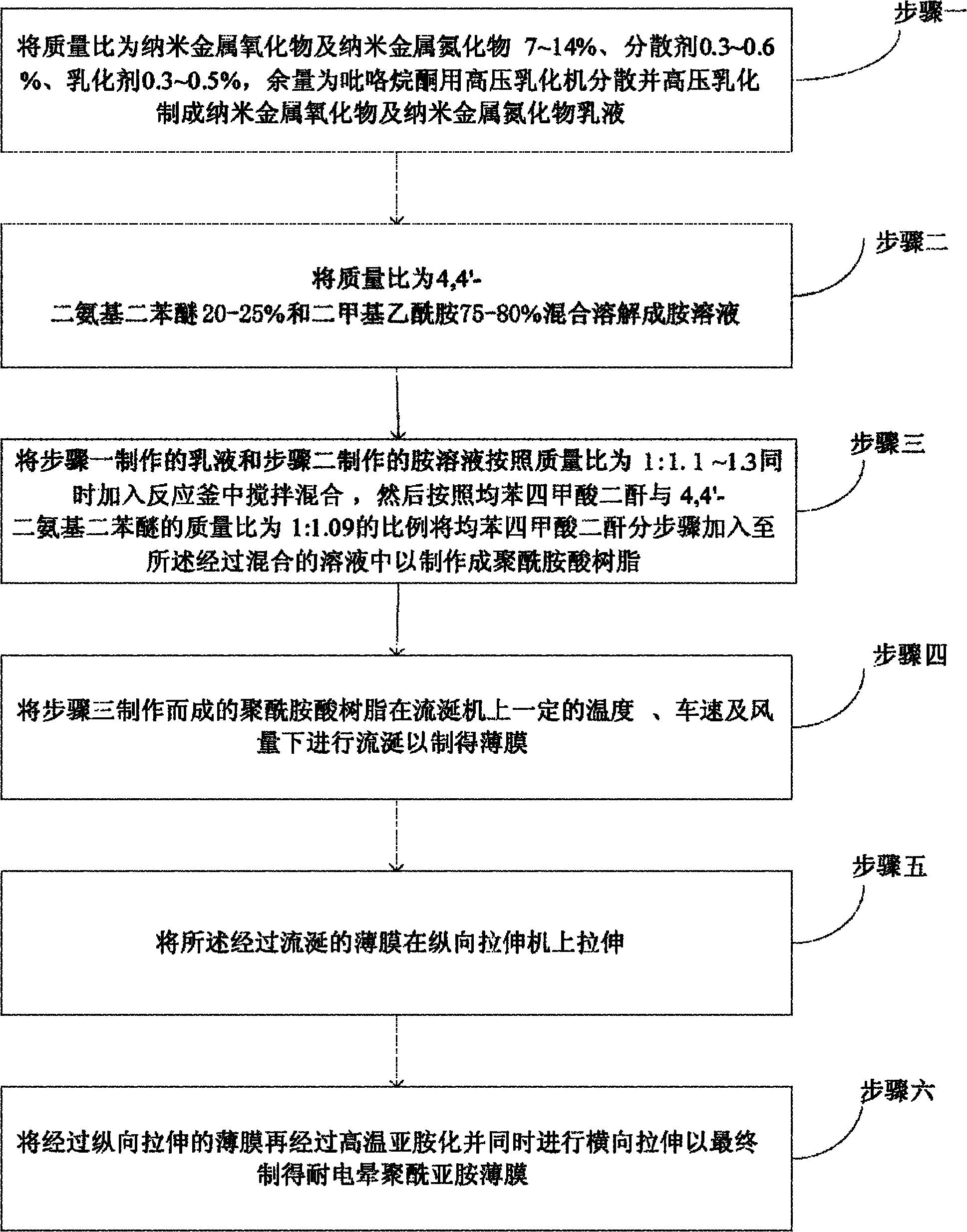

Corona-resistance polyimide film and manufacturing method thereof

The invention discloses a corona-resistance polyimide film, which comprises emulsion, amine solution and pyromellitic dianhydride, wherein the emulsion comprises 7 to 14 mass percent of nano metal oxide and nano metal nitride, 0.3 to 0.6 mass percent of dispersant, 0.3 to 0.5 mass percent of emulsifier and the balance of pyrrolidone; the amine solution comprises 20 to 25 mass percent of 4,4'-diamino-diphenyl ether and 75 to 80 mass percent of dimethylacetylamide, and the mass ratio of the emulsion to the amine solution is 1:(1.1-1.3); and the mass ratio of the pyromellitic dianhydride to the 4,4'-diamino-diphenyl ether is 1:(1.09). The invention also discloses the manufacturing method of the corona-resistance polyimide film. In the invention, the nano metal oxide and nitride are fully dispersed in polyamic acid resin by adding the emulsifier and dispersant and by a high-pressure emulsification technique, and the content of the nano metal oxide and nitride in the polyamic acid resin is high. Therefore, the produced film has high corona resistance and small astigmatic aberration, and at the same time, the film has high mechanical performance, electrical performance and the like.

Owner:TIANJIN TIANYUAN ELECTRONICS MATERIAL

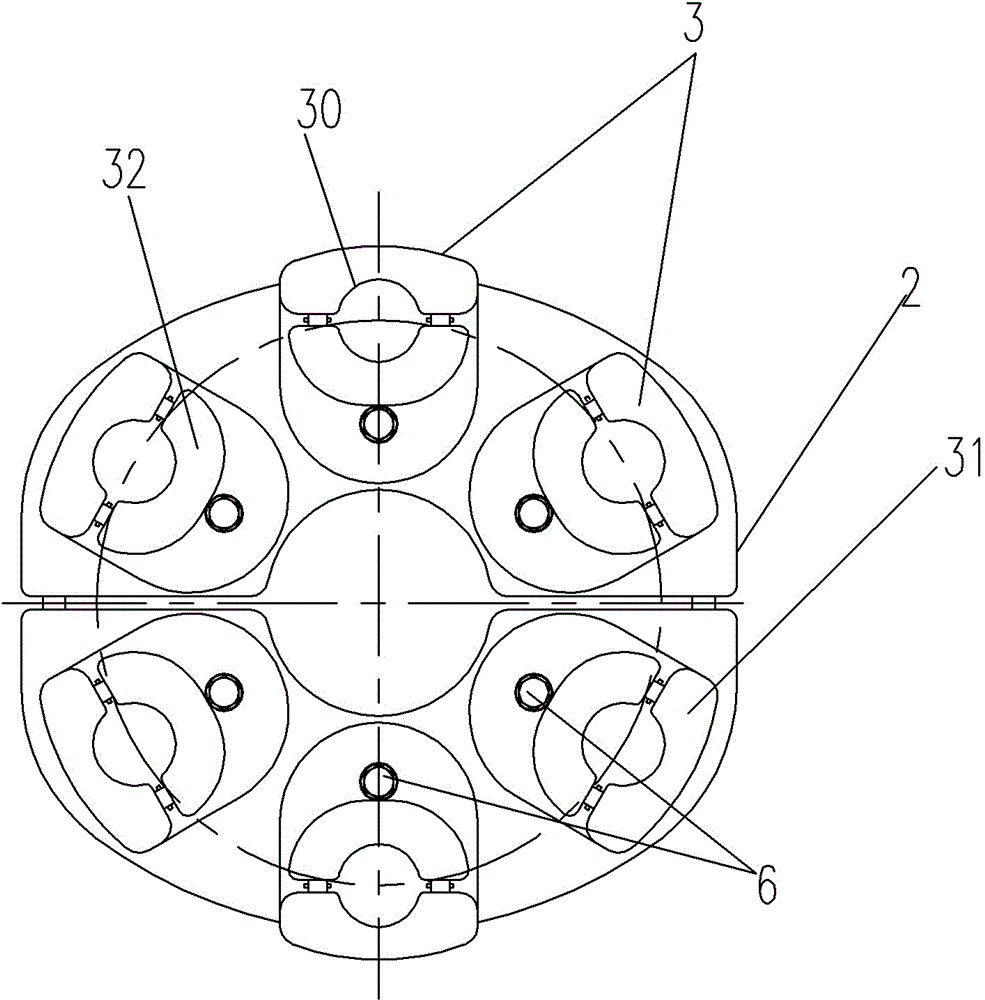

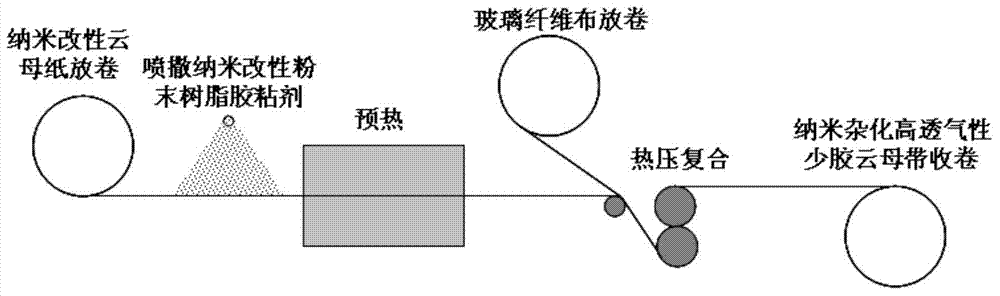

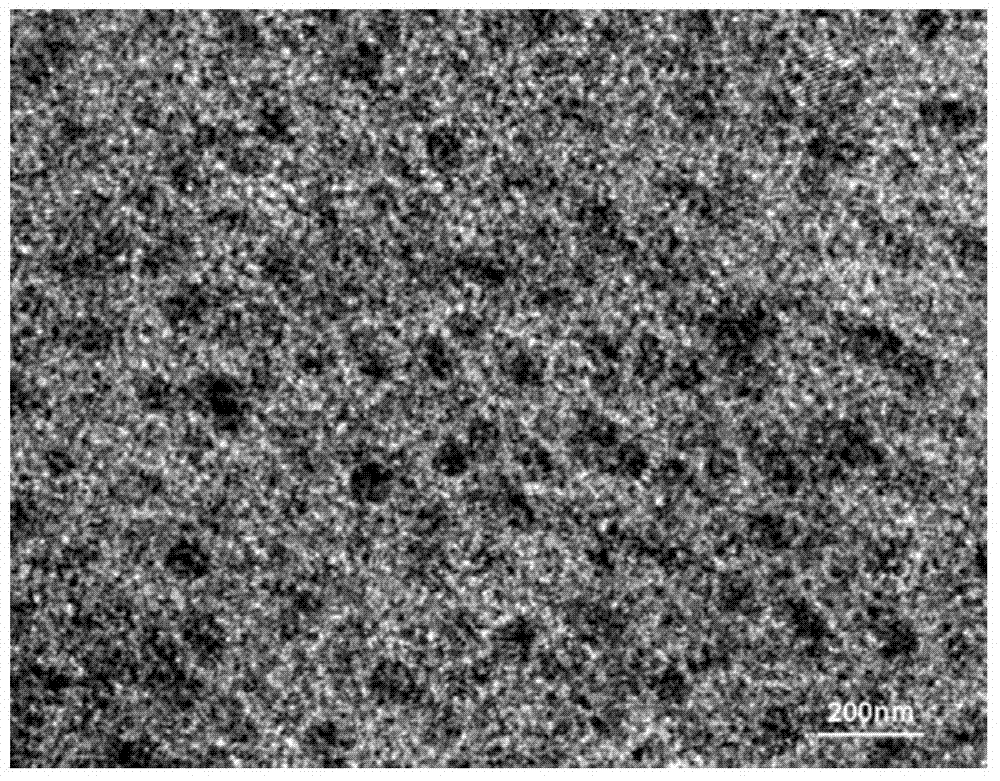

Corona-resistant and high-frequency-impulse-resistant high-breathability little-resin mica tape suitable for variable-frequency high-voltage motors and preparation method thereof

ActiveCN103489543AImprove breathabilityExcellent corona resistanceMicaNatural mineral layered productsMicaHigh frequency

The invention relates to corona-resistant and high-frequency-impulse-resistant high-breathability little-rein mica tape which comprises a mica paper layer, a reinforcing material layer and an adhesion agent layer. The adhesion agent layer is formed by powder adhesion agents which are distributed in a dotted mode, and a large number of pore channels exist among the powder adhesion agents which are distributed in the dotted mode. The mica paper layer is formed by nano-modified mica paper, and the content of nanometer materials in the nano-modified mica paper is 20-100g / m<2>. The powder adhesion agents are nano-modified powder resin adhesion agents with the particle size ranging from 60 to 150 meshes and the melting temperature ranging from 60 to 160 DEG C, the content of nanometer materials in the nano-modified powder resin adhesion agents is 20wt%-50wt%, and the content of nanometer materials in the adhesion agent layer is 4-20g / m<2>. The mica tape is high in breathability, excellent in corona resistance and high-frequency impulse resistance performance and capable of prolonging the insulation life of variable-frequency (high-voltage) motors.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

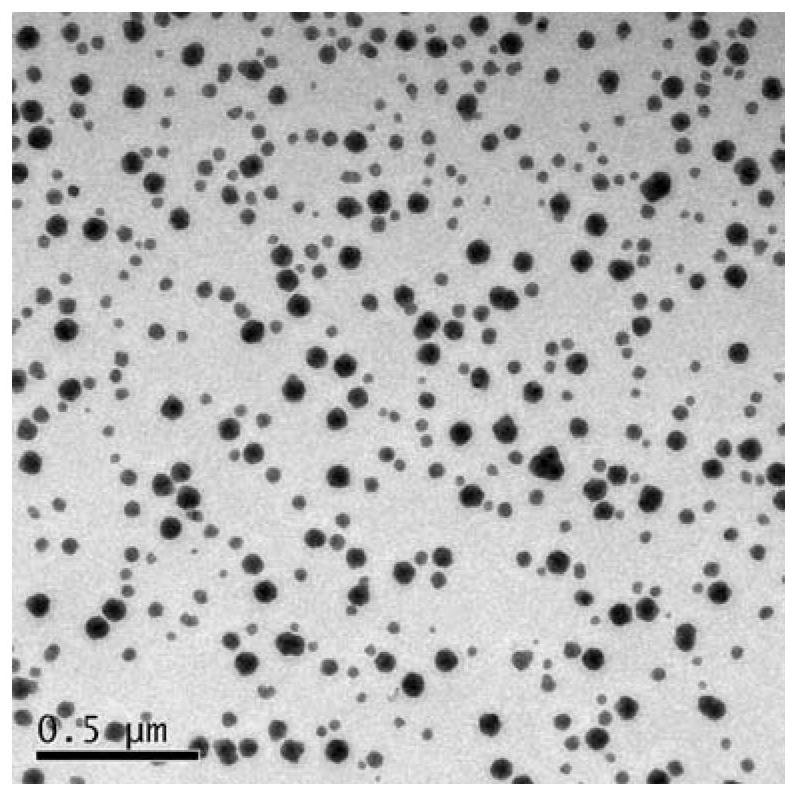

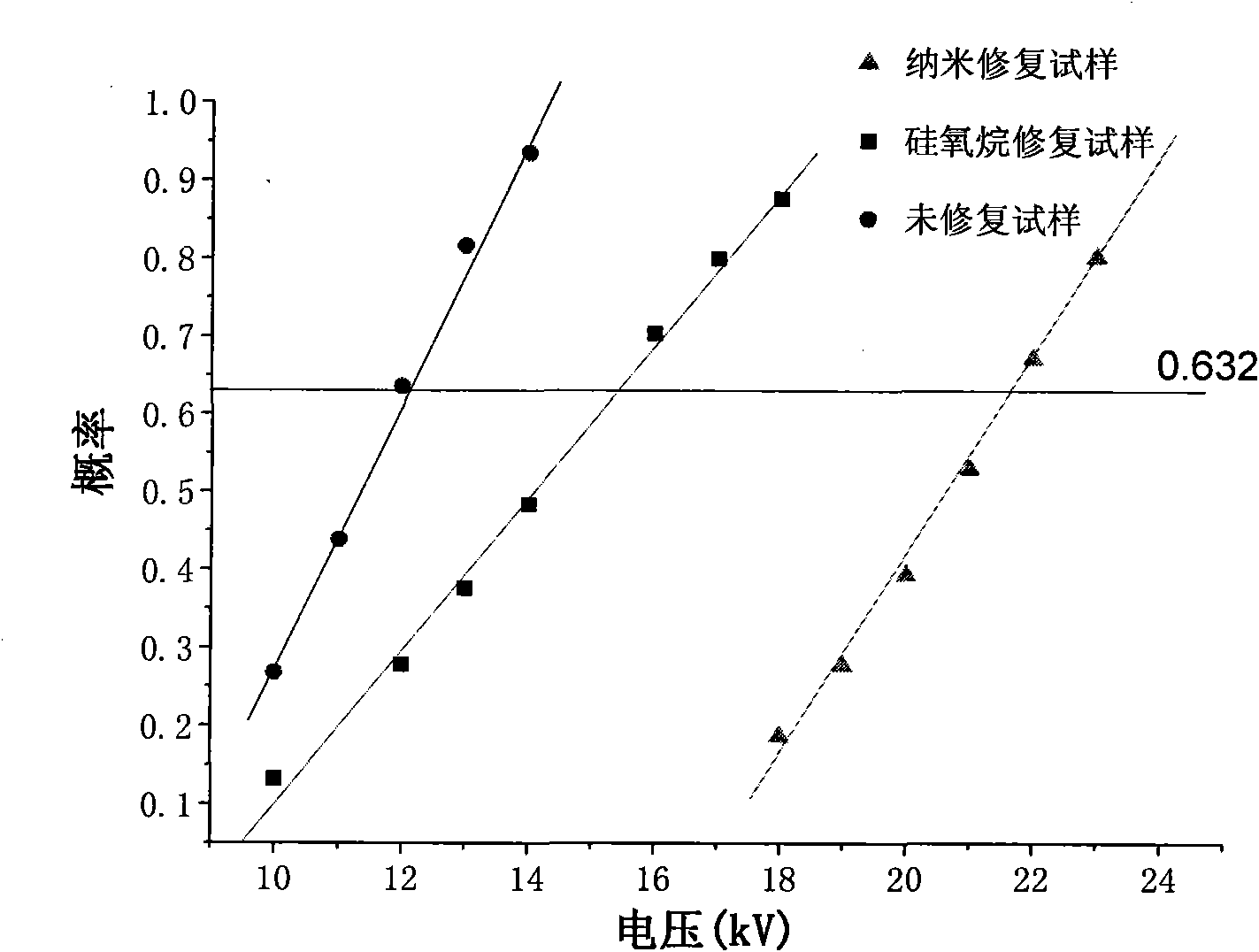

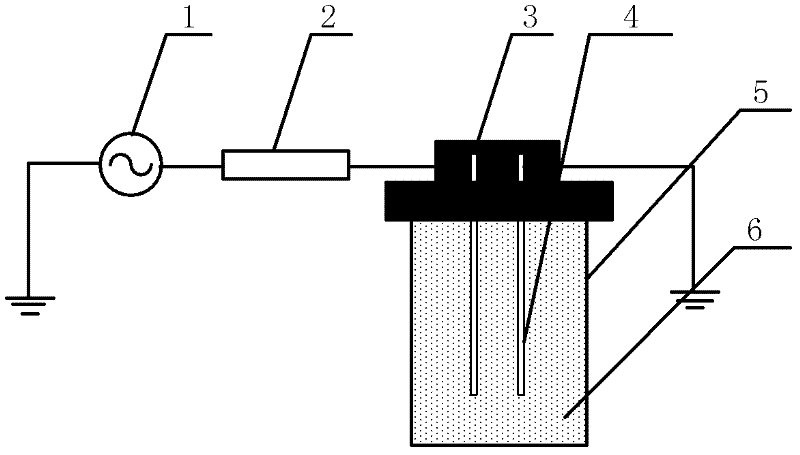

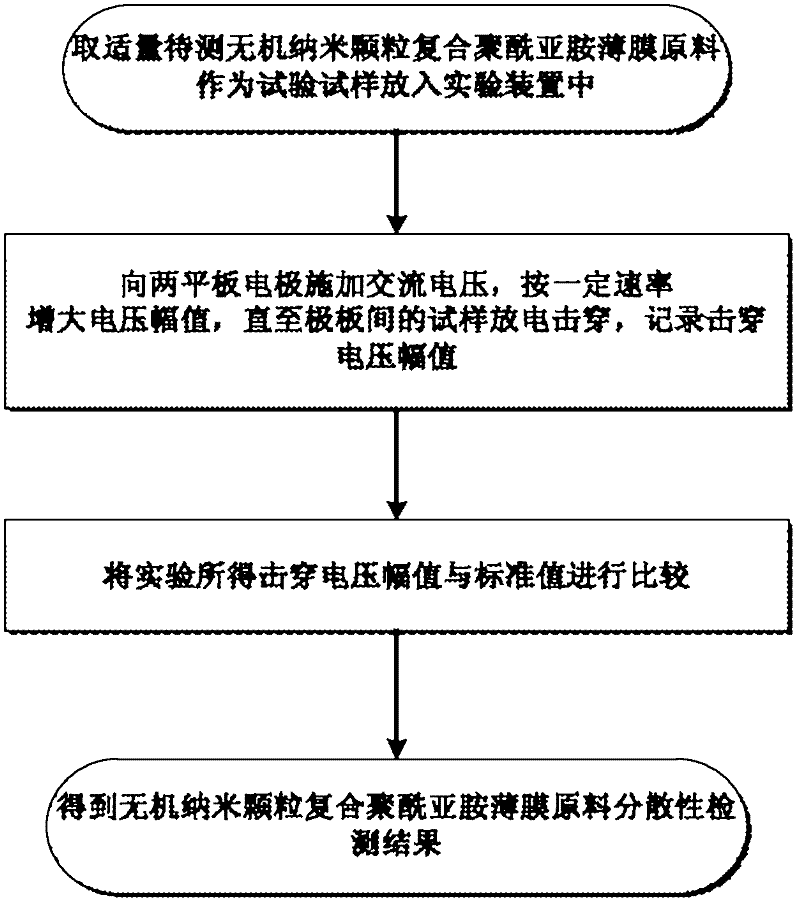

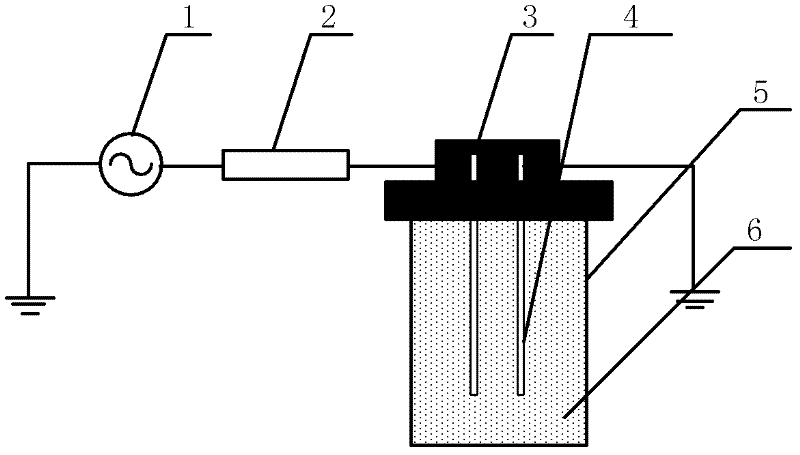

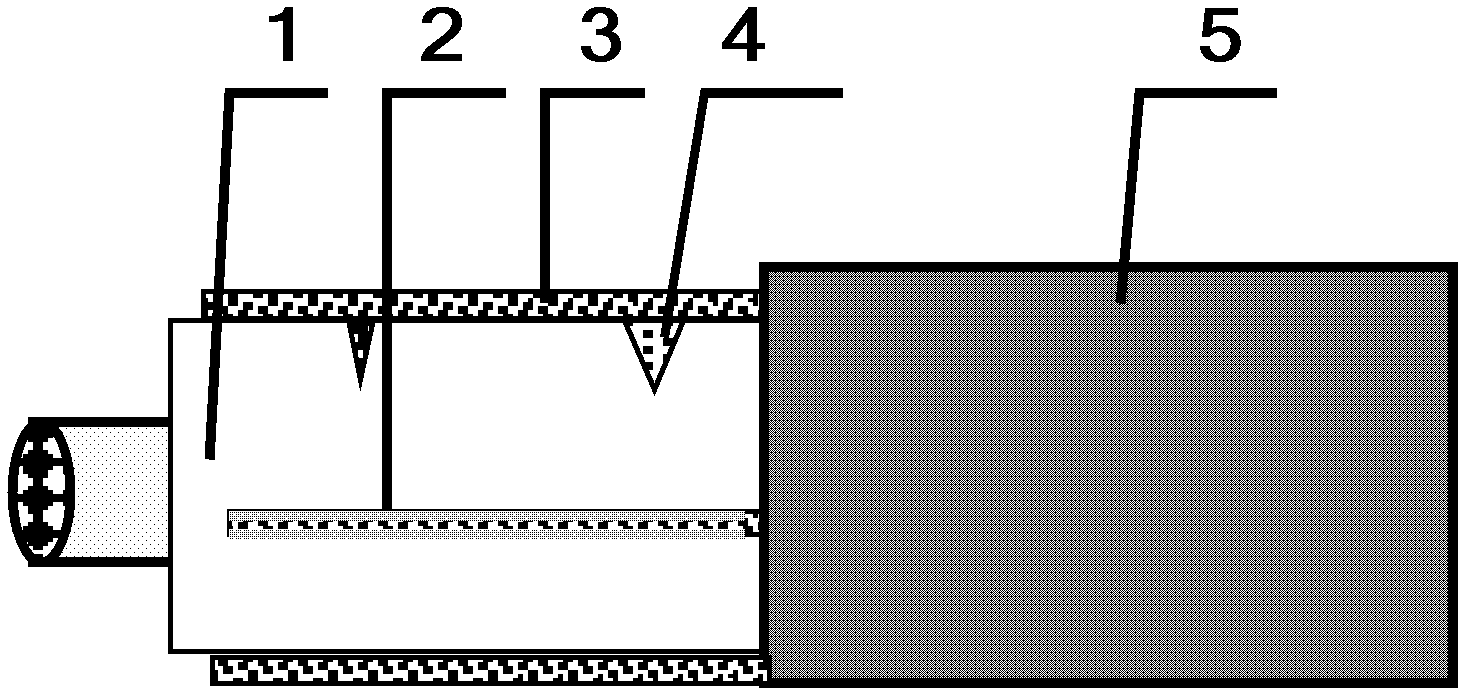

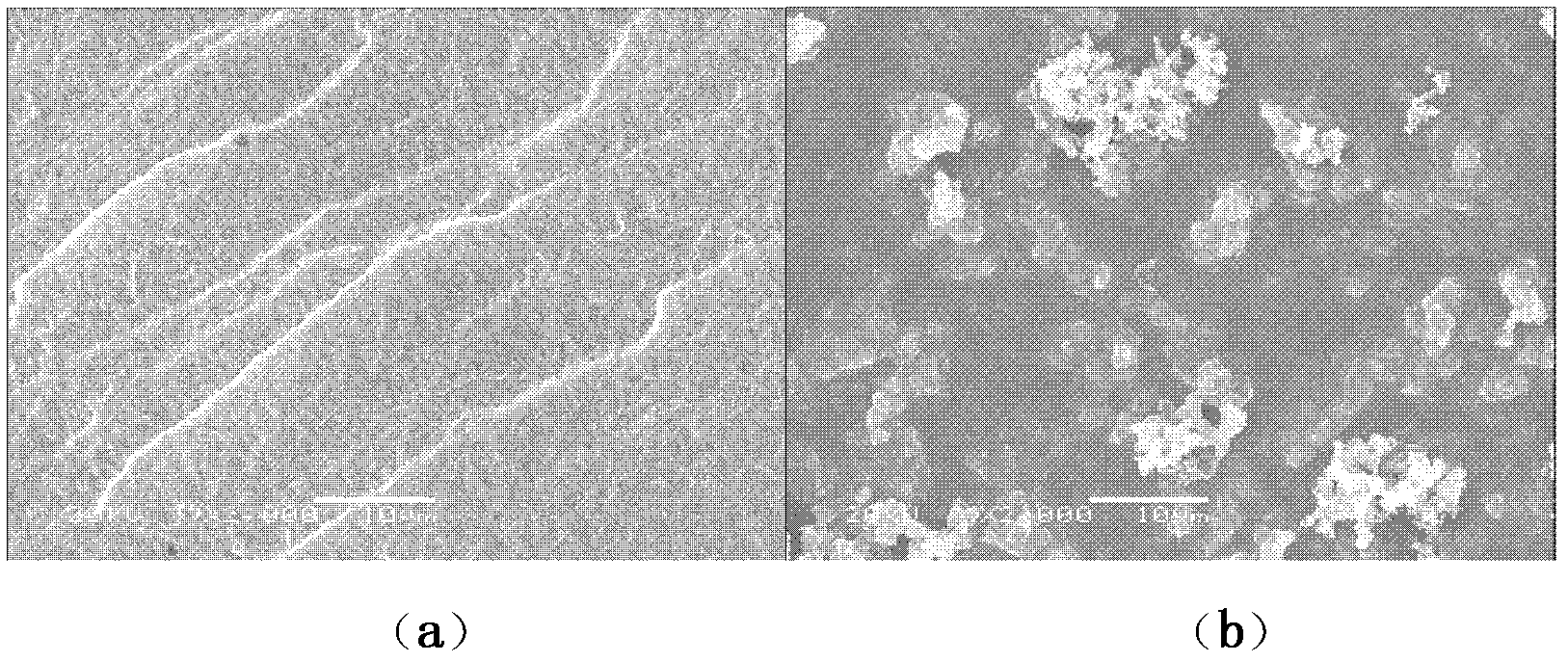

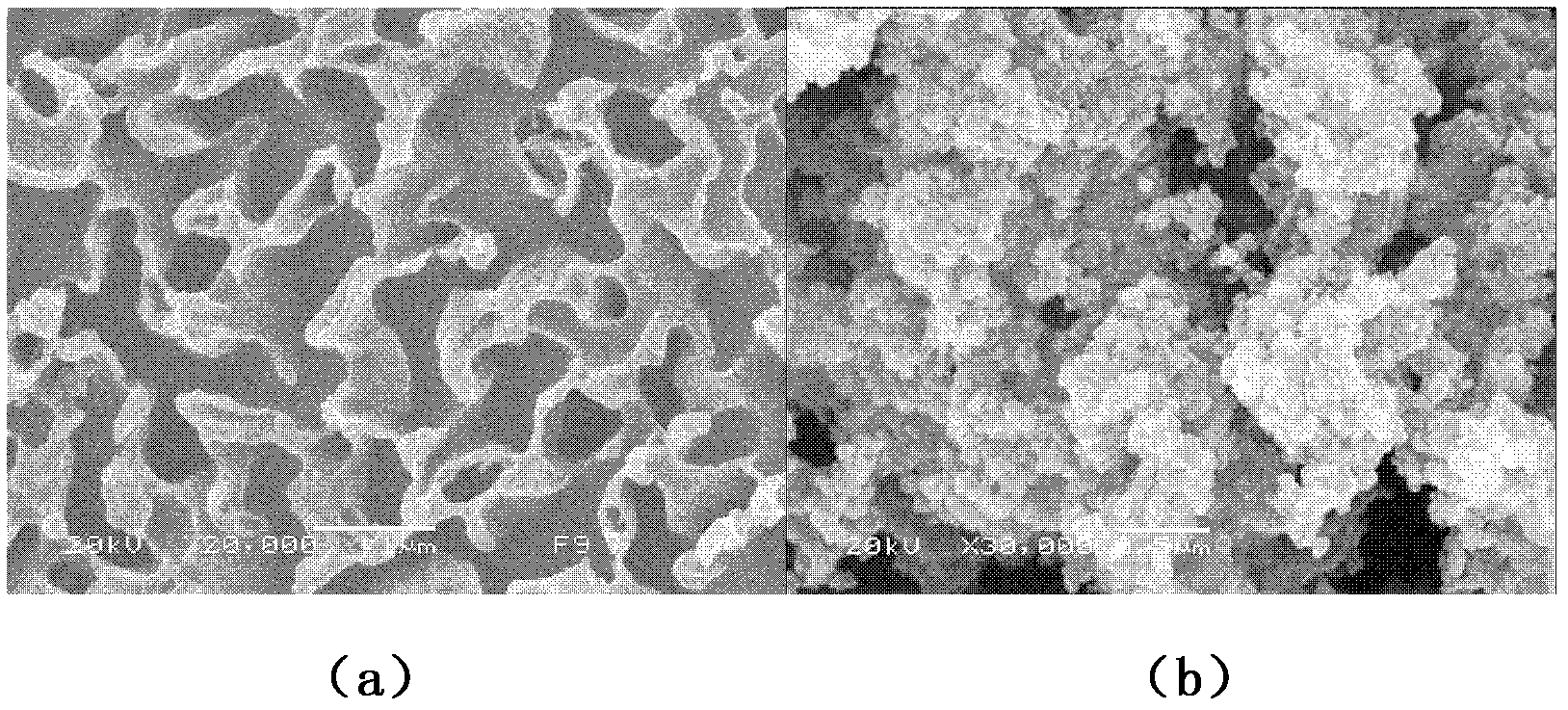

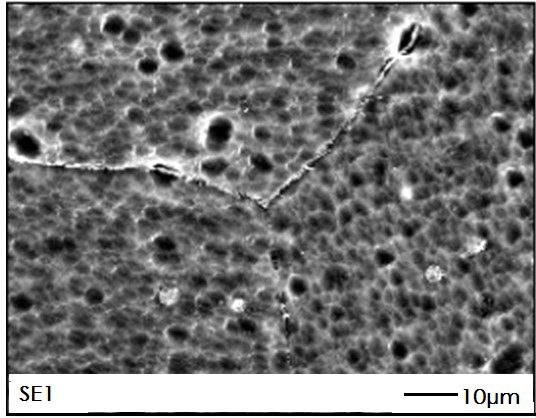

Dispersion measurement method of inorganic nano-particle composite polyimide film raw material

ActiveCN102590047AImprove corona resistanceMeet the requirements of insulation and high frequency pulse resistanceMaterial analysisDispersion stabilityVoltage amplitude

The invention relates to a dispersion measurement method of an inorganic nano-particle composite polyimide film raw material, comprising the following steps of: (1) placing a proper amount of a sample into a measurement container and then placing a metal plate electrode into the measurement container; (2) applying an alternative current voltage on two electrode plates, gradually increasing the voltage amplitude and recording a breakdown voltage measurement value; ( 3) comparing the measurement value with the standard value and analyzing; and (4) analyzing the measurement result, wherein the closer the measurement value and the standard value are, the more uniform the dispersion of the nano particles in the sample is. The time is saved, the dispersion is directly measured free from the limit of various dispersion stability mechanisms, the experiment device is simple, the measurement operation is convenient, and the experiment result is visual and accurate. The dispersion measurement method is mainly used in the technical field of the electronic insulation.

Owner:TIANJIN UNIV

Inorganic nano compound and preparation method and application thereof

The invention discloses an inorganic nano compound and a preparation method and application thereof. The inorganic nano compound is characterized in that the preparation method of the inorganic nano compound comprises the steps of adding 10-15 weight parts of nano silica coated nano titanium oxide, 0.5-2 weight parts of nano alumina, 0.5-2 weight parts of nano silica and 0.5-2 weight parts of nano zinc oxide into a mixing container, grinding and carrying out ultrasonic dispersion to be uniform; adding the above mixture and 40-80 weight parts of a solvent and 1-2 weight parts of a dispersant into a container, further dispersing to be uniform to obtain nano particle dispersion, filtering the nano particle dispersion with a filter screen of 800-1,000 meshes, adding 0.5-1 weight parts of a film-forming agent and 0.5-1 weight parts of a neutralizer into the above filtrate, stirring uniformly at a stirring speed of 500-600rpm to obtain the inorganic nano compound with a solid content of 2-7% and a pH value of 6-7.

Owner:SICHUAN UNIV

Ion wind air purifier with inner cavity easy to clean

PendingCN106594895AGuaranteed uptimeExquisite designMechanical apparatusLighting and heating apparatusAir purifierAir cleaner

The invention discloses an ion wind air purifier with an inner cavity easy to clean. The ion wind air purifier comprises a shell and a purification device for purifying air. An inner cavity lining is arranged between the inner wall of the shell and the purification device. The inner cavity lining is detachably connected with the inner wall of the shell. The purification device comprises a first purification filtering device and a second purification filtering device. The first purification filtering device and the second purification filtering device are arranged inside the inner cavity lining in a staggered mode and assembled with the inner cavity lining through a locking and releasing mechanism or connected with the inner cavity lining in a pluggable mode. The ion wind air purifier is ingenious in design and simple in structure, due to the fact that the inner cavity lining and the purification filtering devices inside the purifier are all of a detachable structure, detaching and cleaning can be conducted conveniently when pollutants adhere to the inner wall of the inner cavity lining, and accordingly the operation effect of the whole air purifier is guaranteed; and in addition, the inner cavity lining can be replaced conveniently when the inner cavity lining is damaged or cannot be washed.

Owner:SUZHOU BEIANG TECH LTD

Low-viscosity neutral organic silicone and application thereof

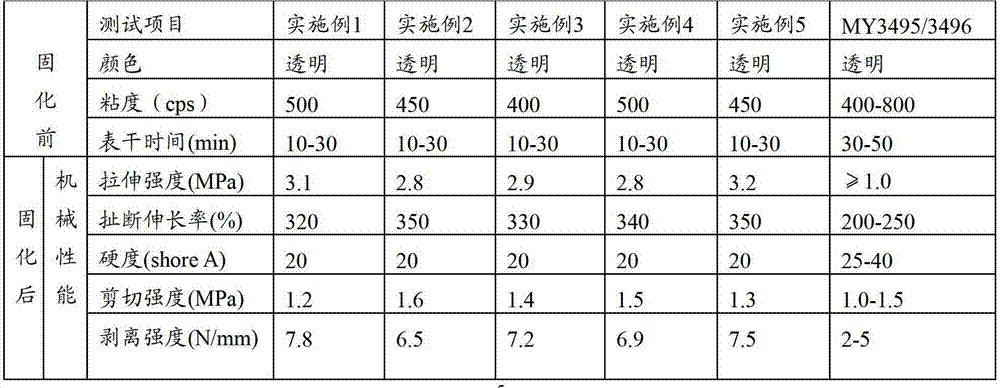

ActiveCN103205234AGood high and low temperature resistanceImprove aging resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPlasticizerSilica gel

The invention relates to low-viscosity neutral organic silicone and an application of thereof. Raw materials for preparing the organic silicone includes, by weight, 100 parts of polydimethylsiloxane of hydroxyl end, 20-50 parts of plasticizer, 5-10 parts of cross-linking agent, 0.5-2 parts of catalyst and 5-7 parts of film enchanter. The low-viscosity neutral organic silicone is fast in setting time and strong in viscosity; and stripping performance of the low-viscosity neutral organic silicone is significantly improved by above 5N / mm.

Owner:YANTAI DARBOND TECH

Method for manufacturing insulation structure of rotor coil of wind driven generator

InactiveCN102158023AReduce volumeReduce weightApplying solid insulationHigh resistanceFrequency changer

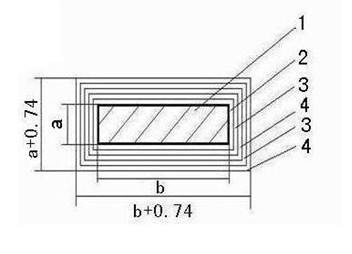

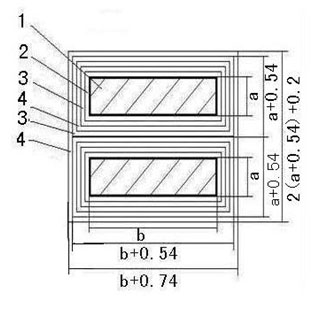

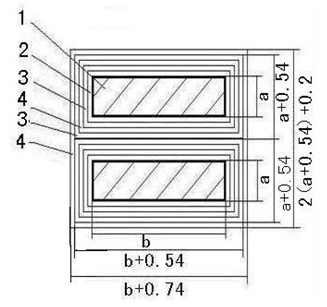

The invention provides an insulation structure of a rotor coil of a wind driven generator, wherein the insulation structure is manufactured by a method comprising the following steps of: setting a multi-layer corona resistant with polyimide film tape and a mica tape in single-side reinforcing with a multi-layer corona resistant with polyimide film by means of half wrapping; and then setting a layer of polytetrafluoroethylene film tape by means of half wrapping. In the insulation structure provided by the invention, the insulation thickness is reduced from 1.52 mm to 0.74 m, the electrical strength is high, the breakdown voltage is more than 15 KV, and the safety margin of electric property is large. The insulation structure provided by the invention has the advantages that the corona resistant service life is long, the requirements of power supplying performances of a transducer can be met, and the insulation structure also has a high resistance to salt fog corrosion and a high capability of other chemical materials in insulation erosion; the insulation structure is suitable for installing in a rotor coil of the double-fed wind-driven generators of megawatt and several megawatts grades on the sea, the coast and the inland areas with large day and night temperature difference.

Owner:JIANGSU ICE CITY INSULATION MATERIALS STOCK

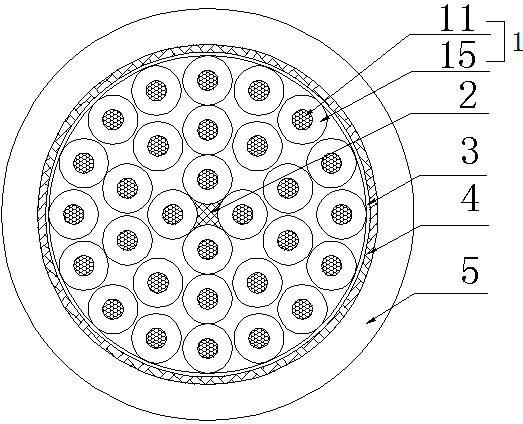

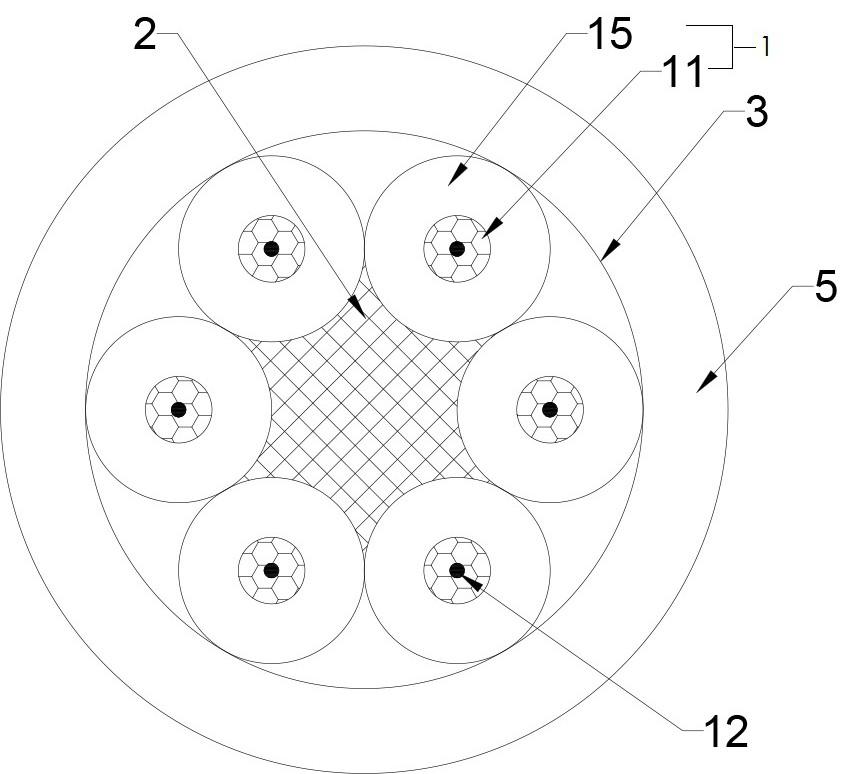

Aluminum alloy conductor flexible cable and preparation method thereof

ActiveCN112259284AHigh strengthAnti-agingClimate change adaptationConductive materialCompressive creepElectro conductivity

The invention discloses an aluminum alloy conductor flexible cable and a preparation method thereof, and belongs to the field of flexible cables. The aluminum alloy conductor flexible cable comprisesone or more cabling sheath layers, a cabling and belting layer and conductor insulating wire cores from outside to inside in sequence, wherein the number of the conductor insulating wire cores is oneor more, cabling fillers are filled between the conductor insulating wire cores, and each conductor insulating wire core sequentially comprises a tensile strand, an aluminum alloy conductor and a wirecore insulating layer from inside to outside. The aluminum alloy conductor flexible cable not only has high conductivity, but further has excellent tensile strength and compressive creep resistance,the possibility of replacing copper with aluminum in the flexible cable is realized, the use cost of the flexible cable is reduced, and the wear resistance and the service life of the cable are improved due to light weight and excellent characteristics.

Owner:TBEA DEYANG CABLE CO LTD

Ethylene-propylene rubber insulating mouse-proof insect-proof low-smoke halogen-free flame-retardant direct-current high-voltage cable insulating material used for rail traffic

InactiveCN102682870AImprove heat resistanceImprove vulcanization characteristicsRubber insulatorsLow-density polyethyleneMicrocrystalline wax

The invention discloses an ethylene-propylene rubber insulating mouse-proof insect-proof low-smoke halogen-free flame-retardant direct-current high-voltage cable insulating material used for rail traffics. The insulating material is formed by the following raw materials by weight: 100 parts of ethylene-propylene rubber, 2.3-3.2 parts of vulcanizing agent, 0.3-1.2 parts of co-vulcanizing agent, 50-67 parts of reinforcing agent, 5-7 parts of microcrystalline wax, 5-7 parts of epoxy soybean oil; 0.8-1.2 parts of coupling agent, 8-10 parts of low-density polyethylene, 5-8 parts of zinc oxide nano-powder, 1.2-1.6 parts of anti-aging agent, 5-7 parts of red lead, 1.0-5 parts of magnesium oxide nano-powder, and 15-25 parts of white carbon black. The ethylene-propylene rubber insulating mouse-proof insect-proof low-smoke halogen-free flame-retardant direct-current high-voltage cable insulating material used for rail traffics has the advantages that the mechanical property and electric property of the direct-current high-voltage cable are enhanced effectively and the weather resistance is excellent.

Owner:ANHUI JIANGHUAI CABLE GROUP

Ethylene-propylene-diene monomer rubber foam material and preparation method thereof

The invention relates to an ethylene-propylene-diene monomer rubber foam material and a preparation method thereof. The foam material comprises, by weight, 100-150 parts of ethylene-propylene-diene monomer rubber, 5-15 parts of nano-silica gel, 3-8 parts of accelerant, 1-6 parts of hydrogenated vegetable oil, 3-15 parts of azodicarbonamide, 1-5 parts of sulfur, 2-8 parts of rare earth oxide and 5-15 parts of stearic acid. The rubber foam material is high in tensile strength.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

Manufacturing method of F-level electromagnetic wire

ActiveCN102412026AImprove corona resistanceImprove thermal conductivityInsulating conductors/cablesHeat resistanceCopper wire

The invention relates to a manufacturing method of a single-side reinforcement F-level electromagnetic wire, and the manufacturing method provided by the invention is lower in manufacturing cost, is suitable for energy conservation and emission reduction, and can be used for reducing the environmental pollution and ensuring the product performance to be higher. The manufacturing method comprises the following steps: adding a polyester resin into a nano material subjected to surface activation treatment and uniformly stirring to obtain an insulation resin for later use; delivering the insulation resin into an extruder hopper, enabling the insulation resin to be in a high-temperature viscous flow state by virtue of an extruder and continuously extruding the insulation resin from the die sleeve port of the extruder; meanwhile, aligning and preheating a bare copper wire, enabling the aligned and preheated bare copper wire to pass through a forming die of a machine head of the extruder, and packaging the insulation resin extruded from the die sleeve onto the bare copper wire; and cooling the bare copper wire covered with the insulation resin so as to obtain the F-level electromagnetic wire. The proportion of an inorganic nano material is suitable for improving the heat resistance of an insulating layer, and the manufactured electromagnetic wire can achieve F-level insulation; and the coefficient of heat conductivity achieves 0.55 W / Mk, and the thickness of the insulating layer is adjusted within a range of 0.15-1.4 mm ( bifacial thickness).

Owner:JIANGSU BINGCHENG HYDROGEN ENERGY TECH CO LTD

Novel method for preparing nanoparticle/polyimide three-layer composite film

InactiveCN106084271AImprove mechanical propertiesImprove thermal performanceFilament/thread formingNon-woven fabricsComposite filmNanoparticle

The invention relates to a novel method for preparing a nanoparticle / polyimide three-layer composite film. By using the nanoparticles to modify the polyimide film, the corona resistance of the film can be obviously enhanced, but the mechanical properties of the polyimide film are correspondingly lowered as the doping amount of the nanoparticles continuously increases. The method comprises the following steps: (1) preparing biphenyl type polyamic acid; (2) preparing a polyamic acid microporous film by electrostatic spinning; (3) preparing nanoparticle-doped pyromellitic polyamic acid; (4) applying the nanoparticle-doped polyamic acid on both sides of the microporous film; and (5) carrying out hot imidization on the nanoparticle / polyamic acid three-layer composite film. The invention discloses a novel method for preparing a nanoparticle / polyimide three-layer composite film.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com