Corona-resistance polyimide film and manufacturing method thereof

The technology of a polyimide film and a manufacturing method, which is applied in the field of electrical insulation of motors, can solve the problems of poor dispersion effect, poor film yield, corona resistance and uniformity, etc., and achieve the effect of good mechanical properties and electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

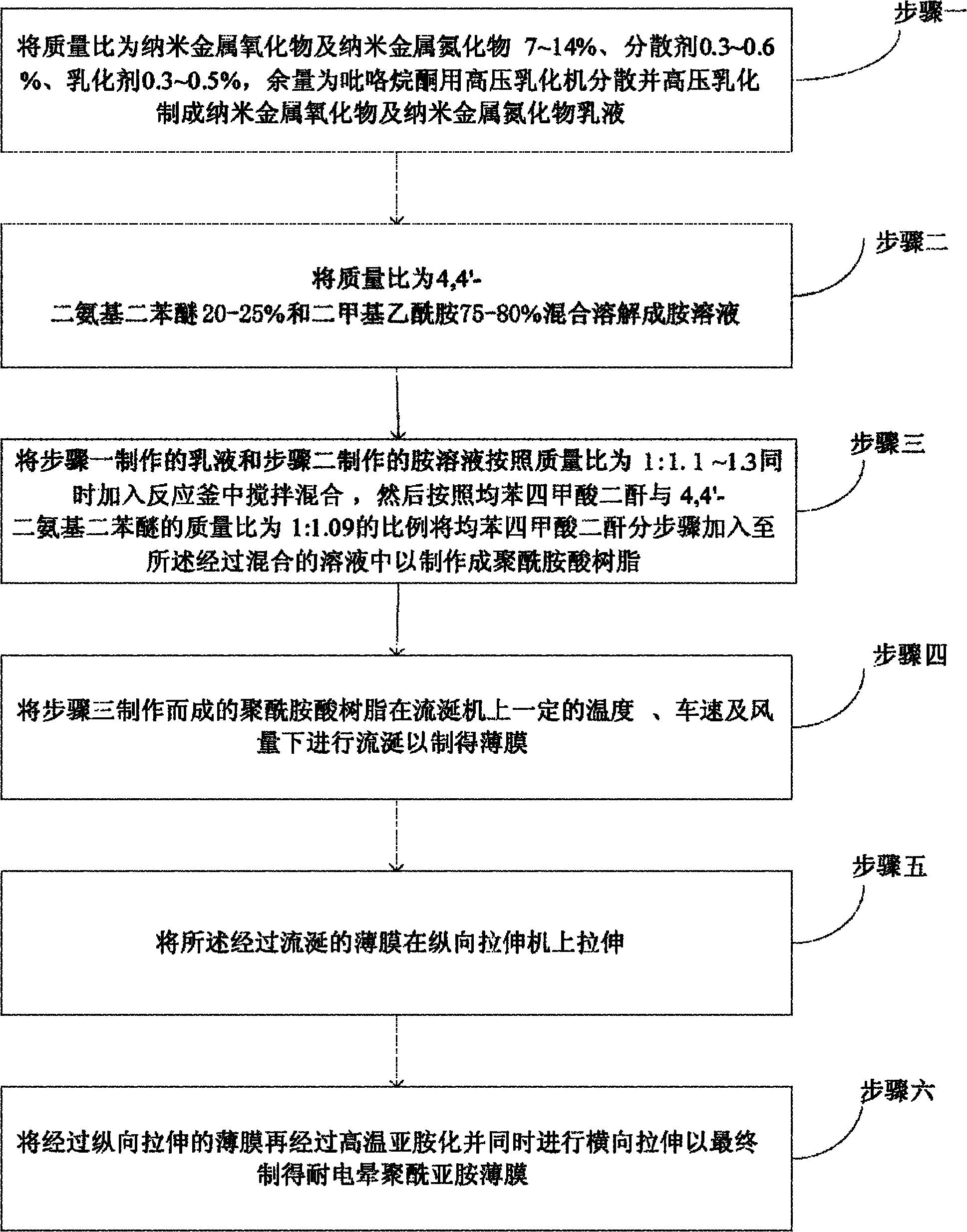

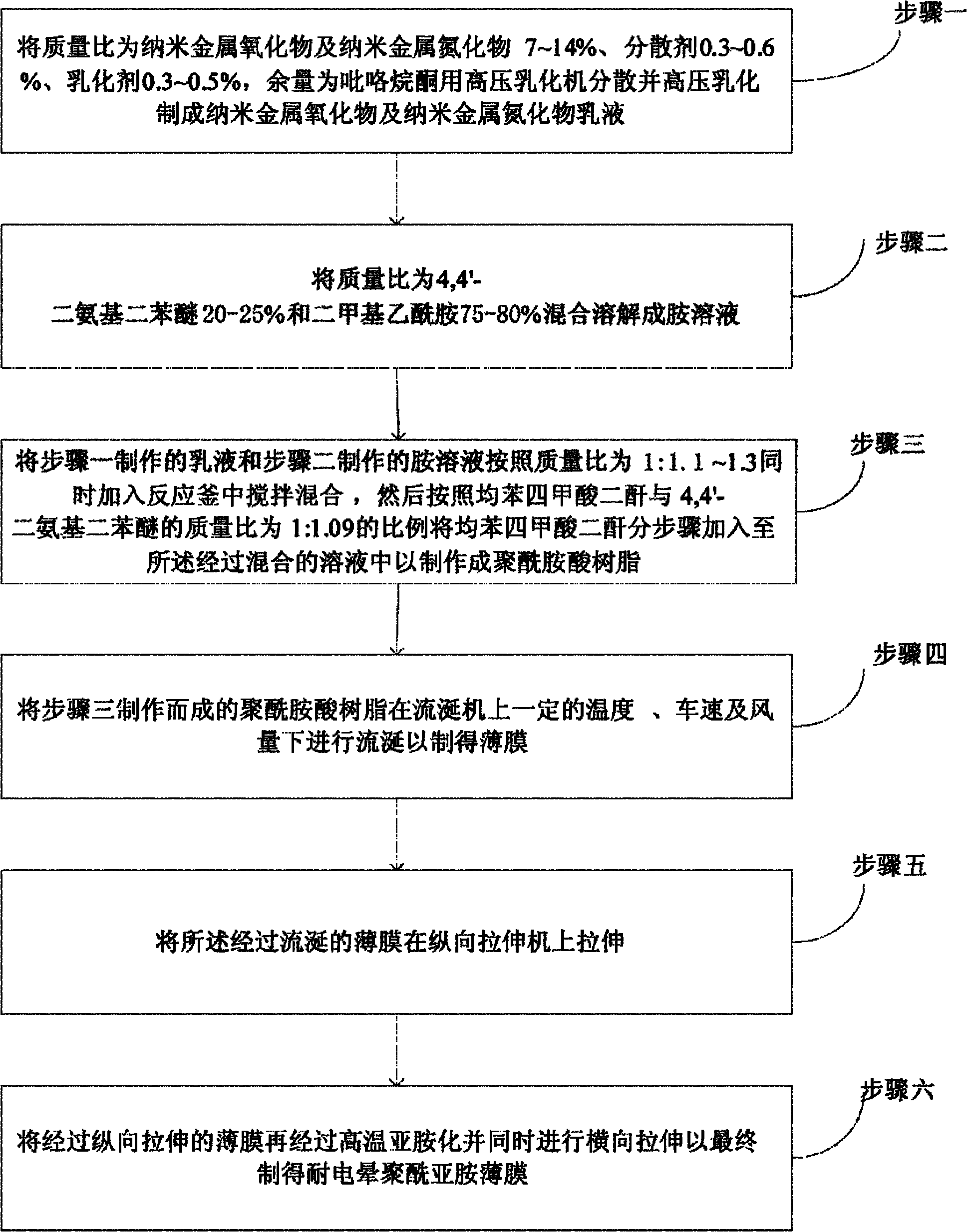

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0020] The corona resistant polyimide film of the present invention mainly comprises pyromellitic dianhydride (dianhydride), 4,4'-diaminodiphenyl ether, dimethylacetamide, pyrrolidone and nano metal oxide, nano metal Nitride, emulsifier, dispersant, etc., the particle size of the metal oxide and nitride is less than 15 nanometers, and the nanometer metal oxide and nitride are fully dispersed in the resin by a high-pressure emulsifier device, and the dispersant and nitride are added during the dispersion process. emulsifier. A large amount (15-25%) of nanometer metal oxides and nitrides can be added, and can be fully and uniformly dispersed in the polyamic acid resin, thereby further improving the uniformity of its corona resistance and the mechanical properties of the film. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com