Patents

Literature

238 results about "Diphenyl Oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diphenyl oxide. (C6H5)2O A colorless liquid or crystals with a melting point of 27°C and a boiling point of 259°C; soluble in alcohol and ether; used in perfumery, soaps, and resins for laminated electrical insulation. Also known as diphenyl ether; phenyl ether.

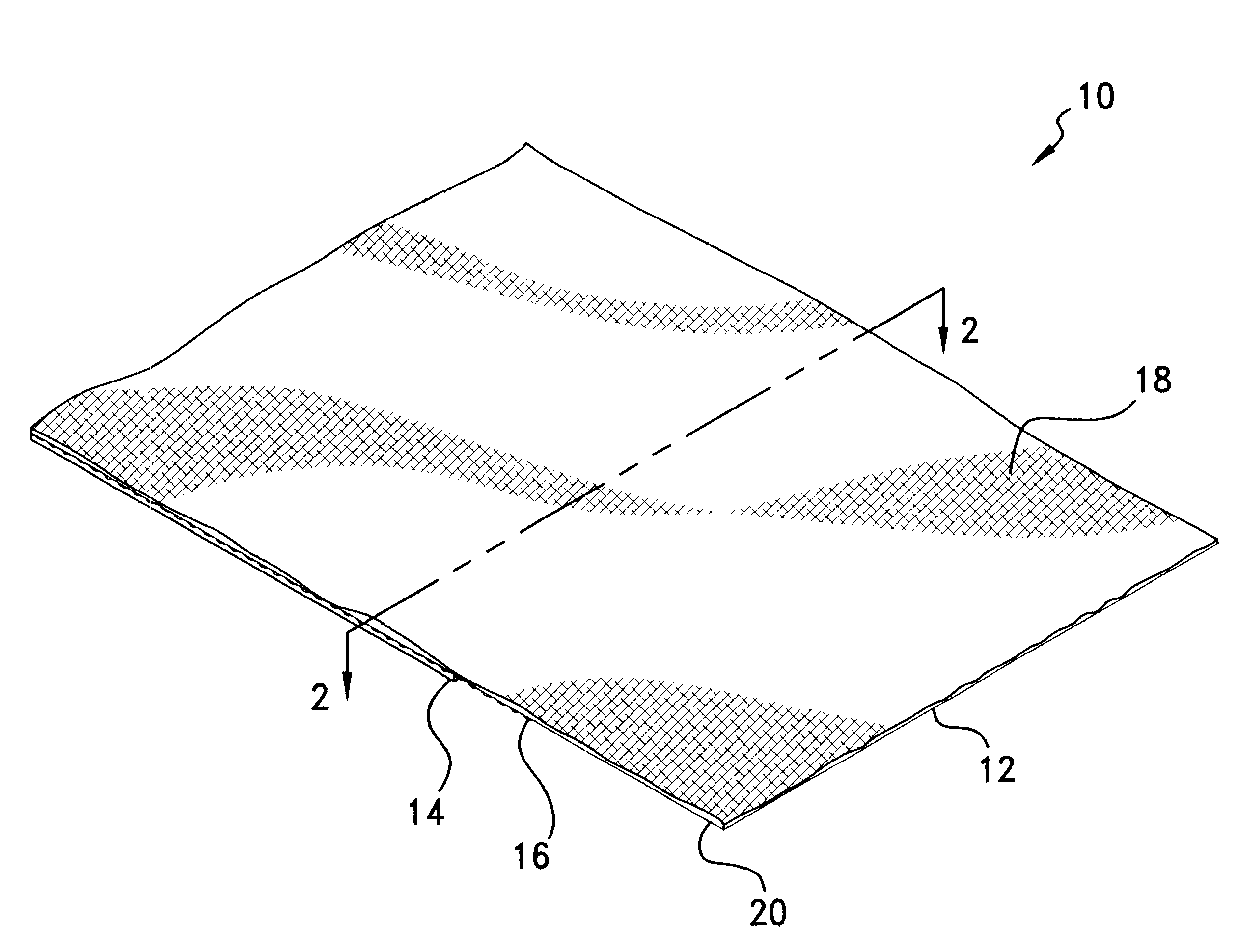

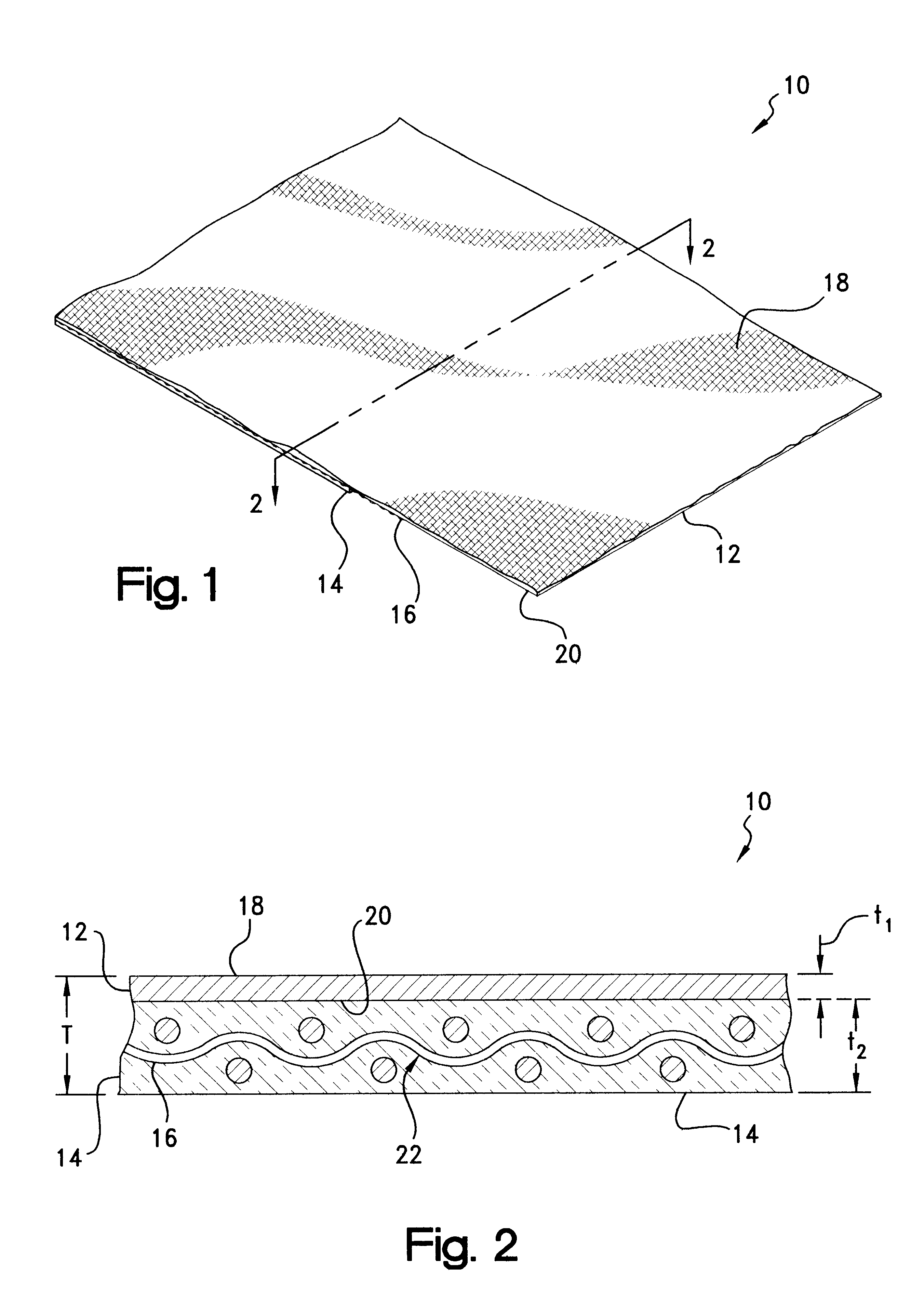

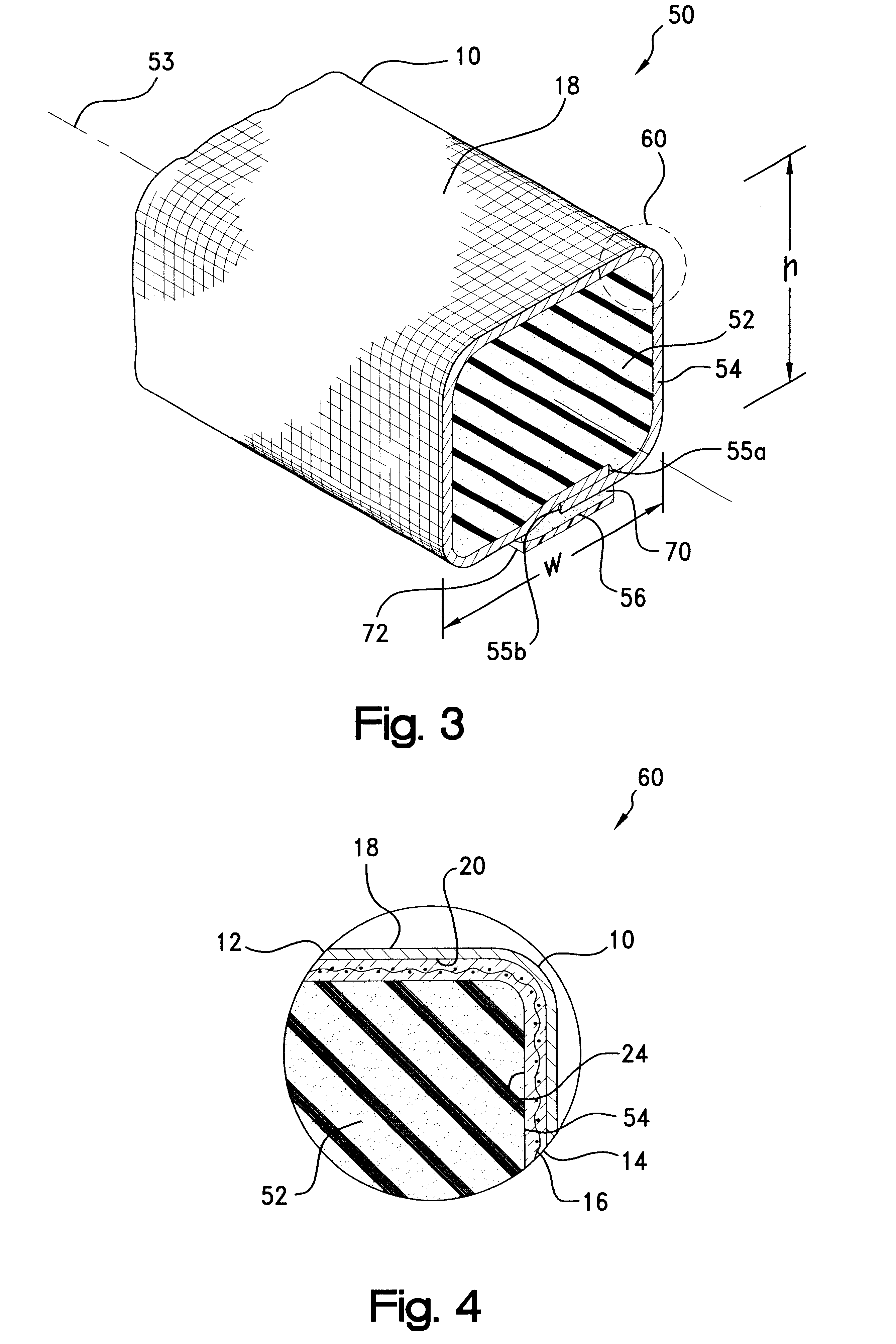

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

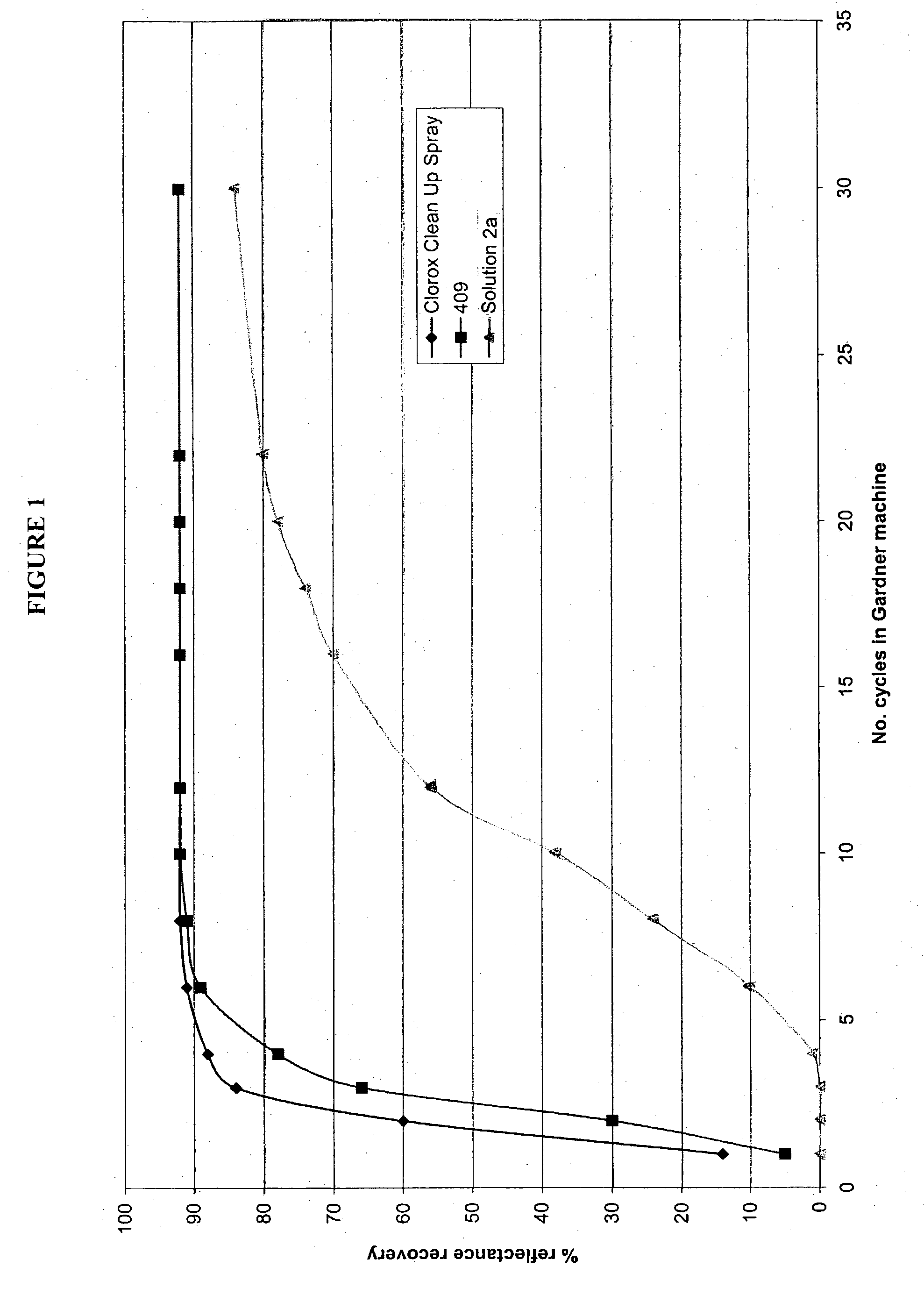

Hydrogen peroxide disinfectant with increased activity

InactiveUS6346279B1High activityReduced activityBiocideInorganic phosphorous active ingredientsDisinfectantPhosphoric acid

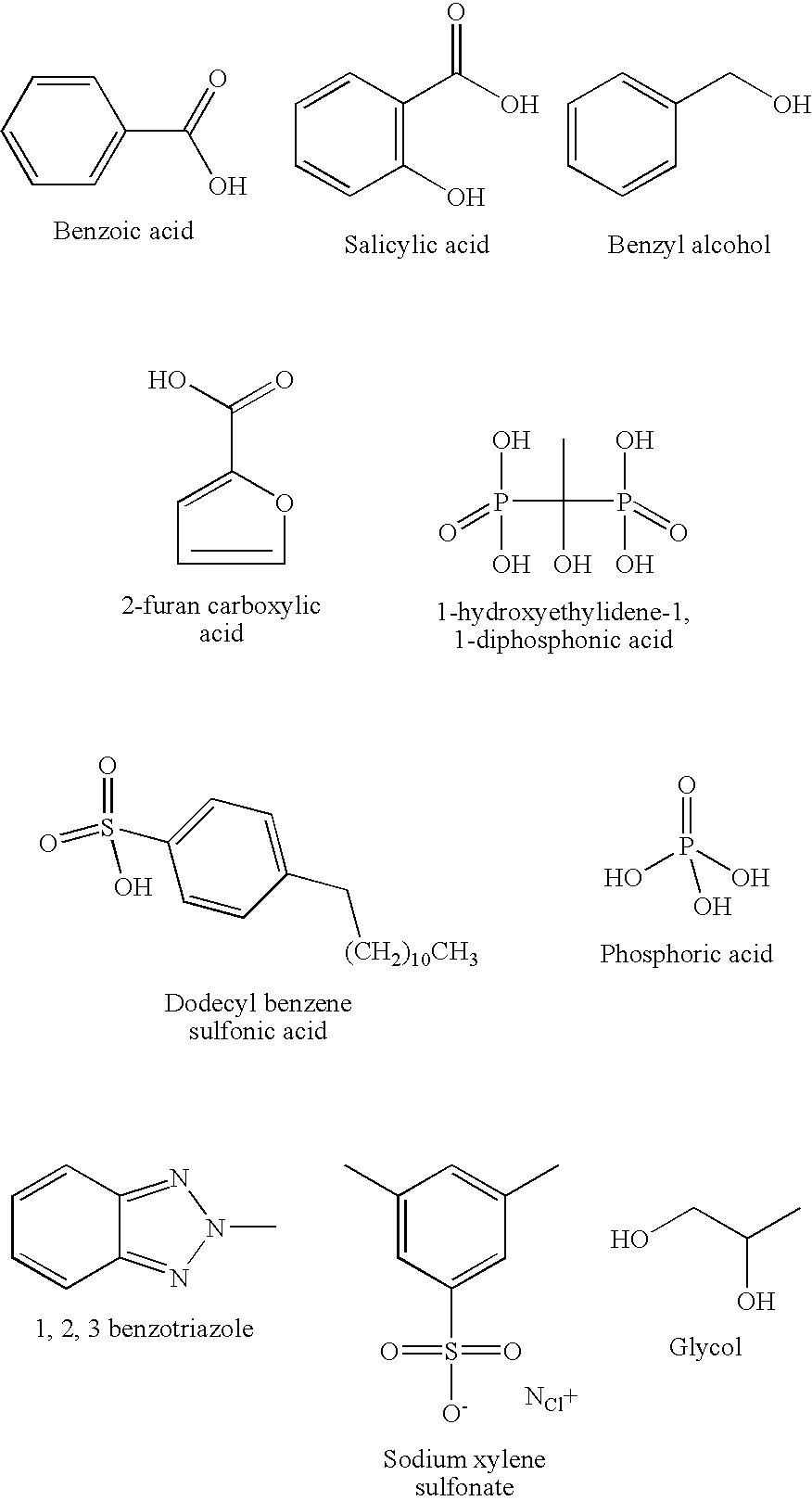

An acidic aqueous hydrogen peroxid solution is provided, with improved disinfectant activity. Concentrated solutions preferably contain up to about 8% and as-used concentrations contain about 0.5% peroxide. The solution also contains from 0.1 to 5.0% of at least one acid compound, e.g. phosphoric and / or a phosphonate with from 1 to 5 phosphonic acid groups, and from 0.02 to 5% of at least one anionic surfactant. The surfactant is selected from C8 to C16-alkyl aryl sulphonic acids, sulphonated C12 to C22 carboxylic acids, C8 to C22-alkyl diphenyl oxide sulphonic acids, naphthalene sulphonic acids, C8 to C22 alkyl sulphonic acids, and alkali metal and ammonium salts thereof, and alkali metal C8 to C18 alkyl sulphates, and mixtures thereof. Most preferably the solution has an emulsifier, e.g. a salt of an alkylated diphenyl oxide. The solution may also contain corrosion inhibitors and / or lower alcohols.

Owner:VIROX TECH

Enhanced activity hydrogen peroxide disinfectant

An enhanced activity aqueous disinfecting solution having a pH of from about 0.5 to about 6 and consisting essentially of (i) hydrogen peroxide in a concentration of from about 0.05 to about 8 w / w % of the solution; (ii) at least one anionic surfactant selected from the group consisting of C8 to C16 alkyl aryl sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, sulfonated C12 to C22 carboxylic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C6 to C22 alkyl diphenyl oxide sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, naphthalene sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C8 to C22 alkyl sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, alkali metal, ammonium, calcium and magnesium C8 to C18 alkyl sulfates, alkyl or alkenyl esters or diesters of sulfosuccinic acid in which the alkyl or alkenyl groups independently contain from six to eighteen carbon atoms and alkali metal, ammonium, calcium and magnesium salts thereof, and mixtures thereof, in a concentration range of from about 0.02 to about 8 w / w % of the solution. Optionally, the solution may contain (iii) at least one additional ingredient chosen from a monocarboxylic acid, a polycarboxylic acid, and mixtures thereof, in a concentration of from about 0.05 to about 4 w / w % of the solution; and (iv) at least one further additional ingredient chosen from benzyl alcohol, an alcohol comprising one to six carbon atoms, and mixtures thereof, in a concentration of from about 0.1 to about 10 w / w % of the solution.

Owner:TRIKON TECH LTD +1

Hydrogen peroxide disinfectant containing a cyclic carboxylic acid and/or aromatic alcohol

An aqueous disinfecting solution and dry powdered composition which may be dissolved in water to provide the solution. The solution has a pH of from 0.6 to 7 and comprises (a) hydrogen peroxide in a concentration of from 0.01 to 6% w / w; and (b) at least one component chosen from cyclic carboxylic acids and aromatic alcohols, in a concentration of from 0.01 to 4 w / w %, all based on the total weight of the solution. The cyclic carboxylic acids are preferably 2-furan carboxylic acid, benzoic acid and salicylic acid. Furthermore, the solution preferably contains at least one C6-C12 alkyl diphenyl oxide sulfonate surfactant and a nonionic surfactant. Additional optional ingredients include anionic surfactants, corrosion inhibitors, cation sequestering agents, and buffers.

Owner:JOHNSONDIVERSEY INC

Flame-retardant and environmentally-friendly polyurethane cable material and its preparation method

ActiveCN102977585AImprove flame retardant performanceExcellent non-flammabilityElastomerDecabromodiphenyl ether

The invention provides an flame-retardant and environmentally-friendly polyurethane cable material. The cable material is prepared from the following raw materials, by weight, 20-30 parts of chloroprene rubber, 60-80 parts of a polyurethane thermoplastic elastomer, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of chlorinated paraffin, 0.5-1.0 part of stearic acid, 1-3 parts of barium stearate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of precipitated silica, 10-13 parts of modified argil, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenyl oxide, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance, and the cables processed through using the cable material can prevent the harms of mice and termites and simultaneously have the efficacies of low smoke, environmental protection and flame retardation.

Owner:蚌埠尚维知识产权运营有限公司

Enhanced activity hydrogen peroxide disinfectant

InactiveUS20070059380A1Commercially acceptable stability and cleaning abilityWithout usingAntibacterial agentsBiocideMagnesium saltDisinfectant

An enhanced activity aqueous disinfecting solution having a pH of from about 0.5 to about 6 and consisting essentially of (i) hydrogen peroxide in a concentration of from about 0.05 to about 8 w / w % of the solution; (ii) at least one anionic surfactant selected from the group consisting of C8 to C16 alkyl aryl sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, sulfonated C12 to C22 carboxylic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C6 to C22 alkyl diphenyl oxide sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, naphthalene sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C8 to C22 alkyl sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, alkali metal, ammonium, calcium and magnesium C8 to C18 alkyl sulfates, alkyl or alkenyl esters or diesters of sulfosuccinic acid in which the alkyl or alkenyl groups independently contain from six to eighteen carbon atoms and alkali metal, ammonium, calcium and magnesium salts thereof, and mixtures thereof, in a concentration range of from about 0.02 to about 8 w / w % of the solution. Optionally, the solution may contain (iii) at least one additional ingredient chosen from a monocarboxylic acid, a polycarboxylic acid, and mixtures thereof, in a concentration of from about 0.05 to about 4 w / w % of the solution; and (iv) at least one further additional ingredient chosen from benzyl alcohol, an alcohol comprising one to six carbon atoms, and mixtures thereof, in a concentration of from about 0.1 to about 10 w / w % of the solution.

Owner:JOHNSONDIVERSEY INC

Enhanced activity hydrogen peroxide disinfectant

InactiveUS7632523B2Commercially acceptable stability and cleaning abilityWithout usingAntibacterial agentsBiocideDisinfectantMagnesium salt

An enhanced activity aqueous disinfecting solution having a pH of from about 0.5 to about 6 and consisting essentially of (i) hydrogen peroxide in a concentration of from about 0.05 to about 8 w / w % of the solution; (ii) at least one anionic surfactant selected from the group consisting of C8 to C16 alkyl aryl sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, sulfonated C12 to C22 carboxylic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C6 to C22 alkyl diphenyl oxide sulfonic acids and alkali metal, ammonium, ethanolamine, calcium and magnesium salts thereof, naphthalene sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, C8 to C22 alkyl sulfonic acids and alkali metal, ammonium, calcium and magnesium salts thereof, alkali metal, ammonium, calcium and magnesium C8 to C18 alkyl sulfates, alkyl or alkenyl esters or diesters of sulfosuccinic acid in which the alkyl or alkenyl groups independently contain from six to eighteen carbon atoms and alkali metal, ammonium, calcium and magnesium salts thereof, and mixtures thereof, in a concentration range of from about 0.02 to about 8 w / w % of the solution. Optionally, the solution may contain (iii) at least one additional ingredient chosen from a monocarboxylic acid, a polycarboxylic acid, and mixtures thereof, in a concentration of from about 0.05 to about 4 w / w % of the solution; and (iv) at least one further additional ingredient chosen from benzyl alcohol, an alcohol comprising one to six carbon atoms, and mixtures thereof, in a concentration of from about 0.1 to about 10 w / w % of the solution.

Owner:JOHNSONDIVERSEY INC

Hydrogen peroxide disinfectant with increased activity

An acidic aqueous hydrogen peroxide solution is provided with improved disinfectant activity. Concentrated solutions preferably contain up to about 8 wt. / wt. % H202 and as-used concentrations contain about 0.5 % wt. / wt. % H202. The solution also contains from 0.05 to 8.0 wt. / wt. % of at least one phosphorous-based acid, e.g. phosphoric acid and / or a phosphonic acid with from 1 to 5 phosphonic acid groups, and from 0.02 to 5 wt. / wt. % of at least one anionic surfactant. The surfactant is selected from C8 to C16 alkyl aryl sulfonic acids, sulfonated C12 to C22 carboxylic acids, C8 to C22 alkyl diphenyl oxide sulfonic acids, naphthalene sulfonic acids, C8 to C22 alkyl sulfonic acids, and alkali metal and ammonium salts thereof, and alkali metal C8 to C18 alkyl sulfates, and mixtures thereof. Most preferably the solution has an emulsifier and / or hydrotrope, e.g. an alkylated sulfonated diphenyl oxide salt, an alkyl aryl polyoxyethylene surfactant, and / or a polyoxyethylene surfactant. The solution may also contain corrosion inhibitors and / or lower alcohols.

Owner:VIROX TECH

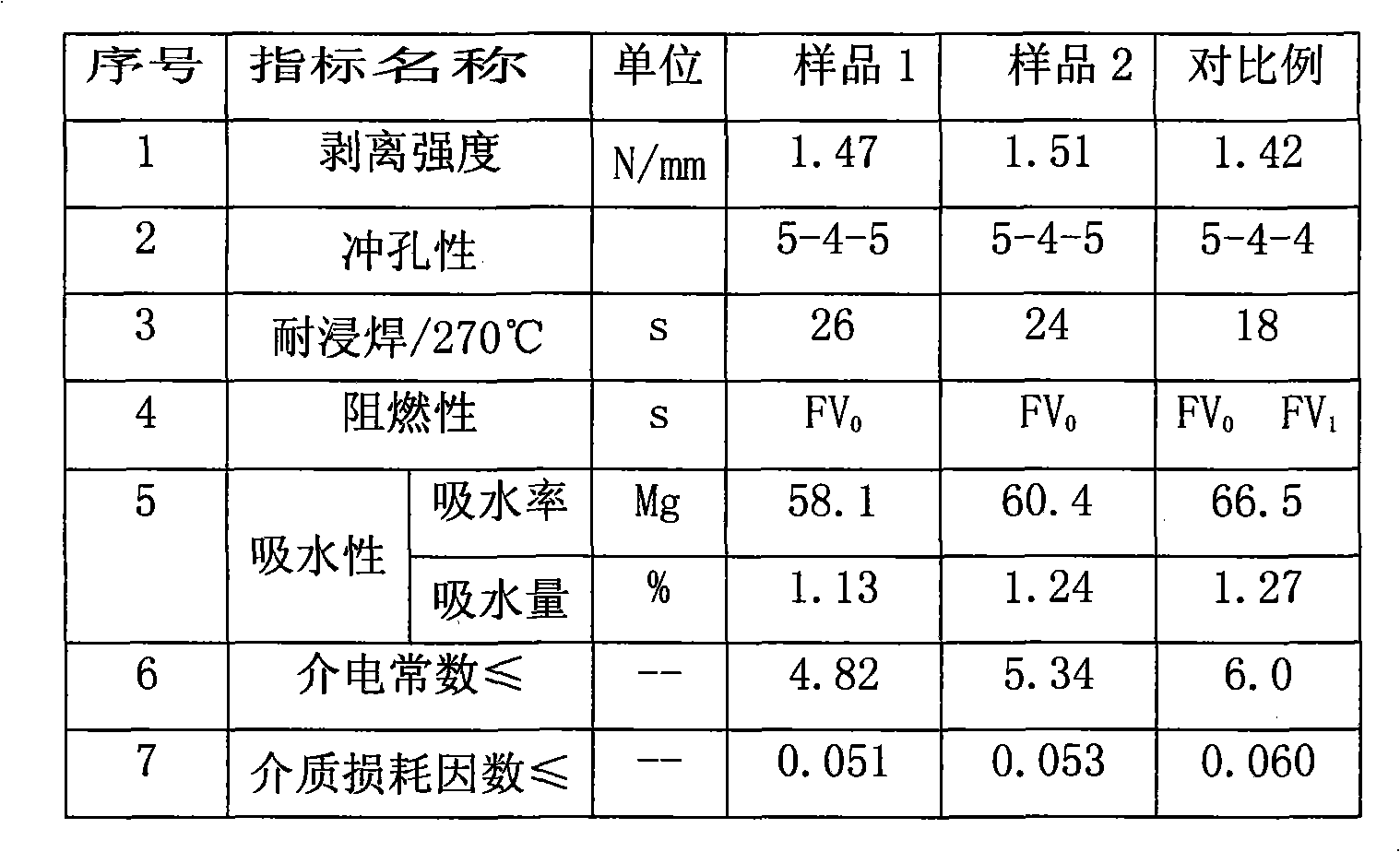

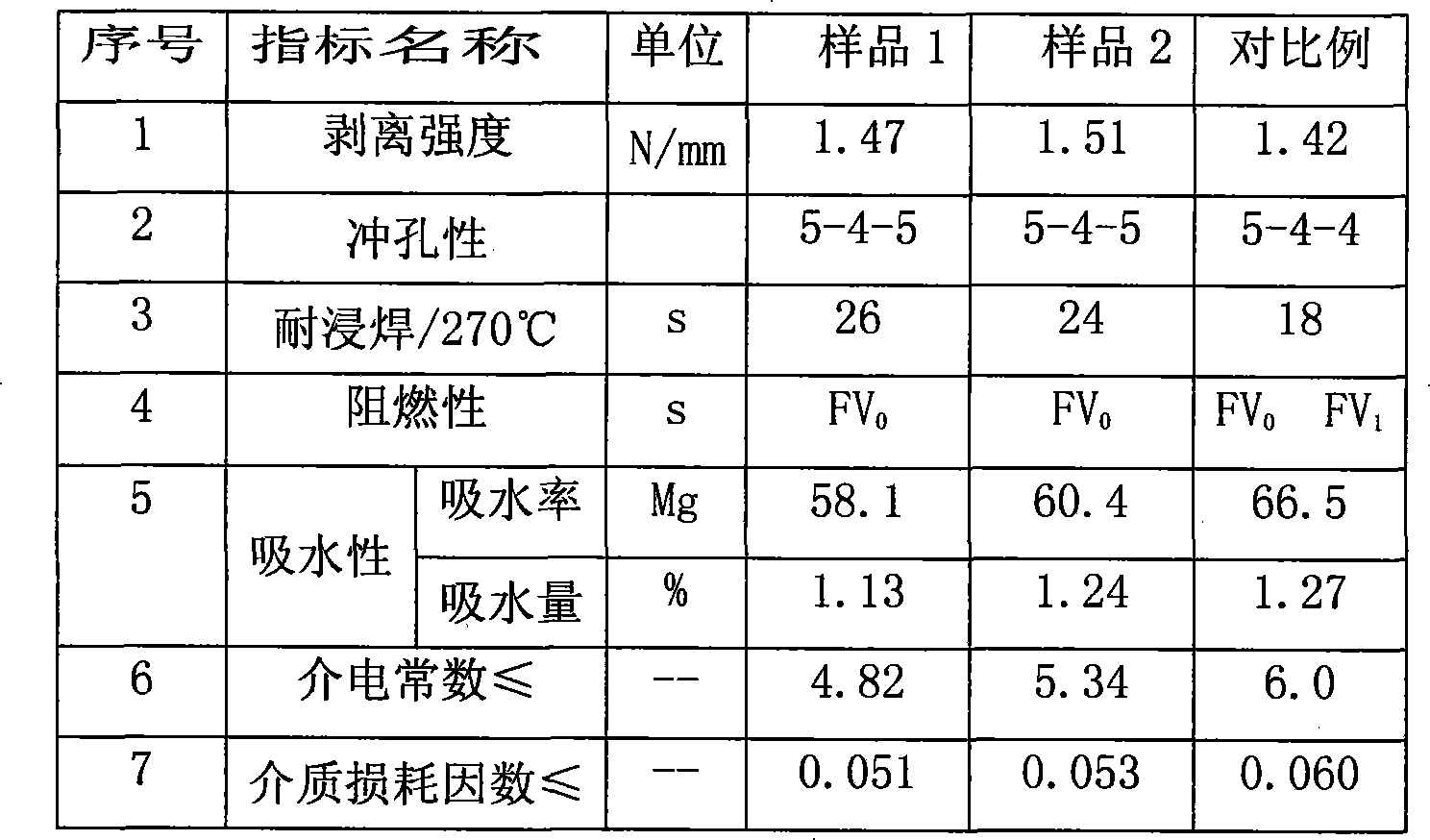

Cardanol modifying phenolic resin composition and method for producing environmental protection type flame-proof paper-base copper-coating board

ActiveCN101265352ALow costImprove heat resistanceCircuit susbtrate materialsFiberTetrabromobisphenol A

The invention relates to a cardanol modified phenol-formaldehyde resin and a method for producing an environmentally protective flame-retardant paper-based copper-covering plate by using the resin compound, and belongs to the technology field of the production method of the copper-covering plate. The cardanol modified phenol-formaldehyde resin is used for producing the copper-covering plate with cheap cardanol substituting for industrial phenyl hydroxide and tung oil partly. The cardanol is refined and abstracted from the raw oil extracted from fruits grown on a cashew which is a tropical plant. The modified resin compound contains flame retardants, such as nitride, phosphide, tetrabromobisphenol A and so on, and the flame retardants are free of such hazardous materials as polybrominated biphenyl, polybrominated diphenyl oxide and so on. Wood chip paper is dipped with the modified resin to form prepregs. Subsequently, a plurality of pieces of prepregs are stacked up, and are compressed into the copper-covering plate at a certain temperature and certain pressure. The copper-covering plate can reduce the product cost and ensure the performance, and is friendly to the environment.

Owner:SHANDONG JINBAO ELECTRONICS

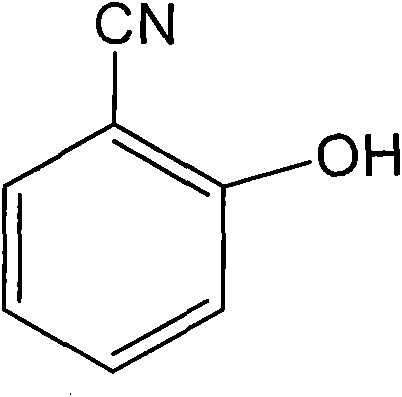

Method for preparing 2-hydroxybenzonitrile from ammonium salicylate as raw material

InactiveCN102174002AIncrease contentPreparation by ammonia-carboxylic acid reactionSalicylic acidMethyl salicylate

The invention discloses a method for preparing 2-hydroxybenzonitrile from ammonium salicylate as a raw material, comprising the following steps of: introducing ammonia gas or ammonia water to a salicylic acid slurry until the pH of the solution is 7.5-13.0, then evaporating to obtain ammonium salicylate solid; forming a mixture from the ammonium salicylate solid, urea, sulfamic acid, a catalyst and a solvent, wherein the catalyst is prepared from 0.0001-10 of magnesium oxide, 0.0001-5 of aluminum oxide, 0.0001-8 of calcium oxide, 0.0001-8 of silicon oxide and 0.0001-10 of artificial zeolite, and the solvent is prepared from 0.0001-10 of o-methyl phenol, 0.0001-6 of p-methyl phenol, 0.0001-8 of diethylene glycol, 0.0001-9 of methyl salicylate, 0.0001-10 of diphenyl oxide and 0.0001-12 of dichlorophenol; and after insulating at 150-180 DEG C for 0.5-10.0 hours and insulating at 190-260 DEG C for 0.5-10.0 hours, filtering or centrifuging the material, evaporating to remove the solvent, crystallizing, recrystallizing, and drying to obtain the 2-hydroxybenzonitrile product of which the mass percentage composition is greater than 90%.

Owner:YANCHENG INST OF TECH

Sterilizing and algae-removing agent and application thereof

InactiveCN102578131AEfficient sterilization and algae killing performanceReduce dosageBiocideDisinfectantsIsothiazolinoneEpoxiconazole

The invention discloses a sterilizing and algae-removing agent and an application thereof. The sterilizing and algae-removing agent consists of the following components in parts by weight: 100 parts of dodecyl dimethyl benzyl ammonium chloride, 4-6 parts of sulfamic acid, 60-80 parts of isothiazolinone, 10-20 parts of crylic acid-acrylic ester-sulfonate terpolymer, 60-80 parts of attapulgite clay, 0.2-0.4 parts of 4,4' dichloro-2-hydroxy diphenyl oxide, 4-6 parts of dodecyl ethoxy imidazolidine, 10-18 parts of sodium dichloro isocyanurate, 10-18 parts of methane dithiocyanate and 1-2 parts of epoxiconazole. The sterilizing and algae-removing agent has the advantages of efficient sterilizing and algae-removing performance, small using amount, safety, nontoxicity and environmental friendliness. The sterilizing and algae-removing agent is applied to sterilizing treatment of a circular water system.

Owner:SHANGHAI TAOHONG CHEM TECH

Halogen-free low-dielectric-loss epoxy resin composition and prepreg and laminated board prepared by using halogen-free low-dielectric-loss epoxy resin composition

InactiveCN104761870AReduce decreaseMeet the requirements of dielectric propertiesSynthetic resin layered productsLaminationDiphenyl etherDiphenylmethane

The invention provides a halogen-free low-dielectric-loss epoxy resin composition, which comprises the following components in parts by weight: 5-20 parts of a SMA resin, 150-200 parts of an epoxy resin, 60-90 parts of a curing agent A, 40-70 parts of a curing agent B, 70-100 parts of packing, 0-13 parts of a flame retardant, 0.3-1 part of a curing accelerator, 0.7-1 part of a coupling agent, and 70-100 parts of a solvent, wherein the curing agent A is one or more of diamino sulfobenzide, diamino diphenylmethane, diamino diphenyl ether, amino paraxylene, dicyandiamide, phenolic novolac resin, bisphenol-A phenolic resin, and phosphorus-containing phenolic resin; and the curing agent B is an active ester curing agent. The invention also provides a prepreg and a laminated board prepared by using the composition. The epoxy resin composition and prepreg and laminated board disclosed by the invention can achieve a halogen-free flame retardant effect, and have low dielectric constants and dielectric losses.

Owner:GUANGDONG GOWORLD

Polyaryl thioether sulfone and its preparation method

A polyaryl thioether sulfone is disclosed, which has the characteristic viscosity for its solution of 0.15-0.54, the vitrification temp higher than 210 deg.C, the thermal deformation temp higher than 180 deg.C and thermal decomposing temp higher than 480 deg.C and thermal decomposing temp higher than 480 deg.C. Its preparing process features that the halogenated aryl compound is added to the reaction system of Na2S.xH2O and bichlorodiphenyl sulfone, and composite catalyste and assistant are used.

Owner:SICHUAN UNIV

Flame-retardant rubber material capable of protecting high-risk chemicals and method for preparing same

ActiveCN102977478AEffective protectionSolve the problem of large polarity differenceRubber materialDecabromodiphenyl ether

The invention discloses a flame-retardant rubber material capable of protecting high-risk chemicals and a method for preparing the same, belongs to the technical field of rubber and solves the problems of single function and poor quality due to single rubber type, and difficult formation of homogeneous phase while compounding a plurality of types of rubbers of the existing rubber. The flame-retardant rubber material capable of protecting high-risk chemicals is composed of the following components according to parts by weight: 30-80 parts of chlorinated butyl rubber, 30-10 parts of butadiene styrene rubber, 40-10 parts of neoprene, 2.0 parts of sulfur, 0.8-1.2 parts of accelerant TT, 0.8-1.2 parts of accelerant DM, 30 parts of high abrasion proof carbon black, 8-15 parts of decabromodiphenyl ether, 8-20 parts of antimonous oxide, 5-15 parts of chlorcosane, 5.0 parts of zinc oxide, 2.5 parts of stearic acid and 2.0 parts of antiager D. The flame retardant rubber material effectively overcomes the shortcomings of single function and poor quality of single rubber type; the product is capable of effectively protecting high-risk chemicals and highly corrosive materials, and thus can be widely applied to effectively protecting the feet, the head and the skin.

Owner:SHANXI XINHUA CHEM +1

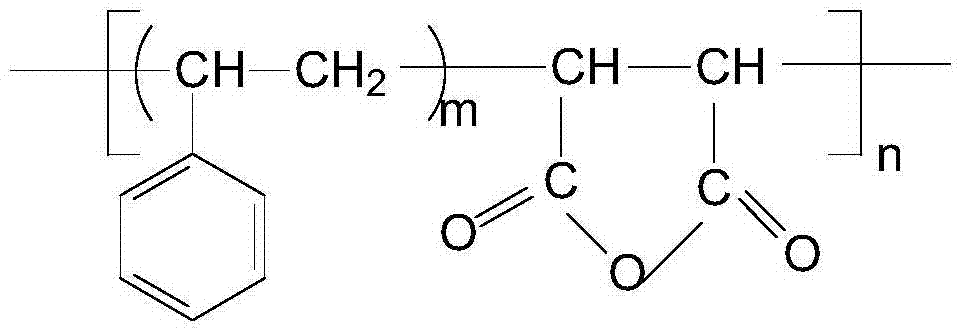

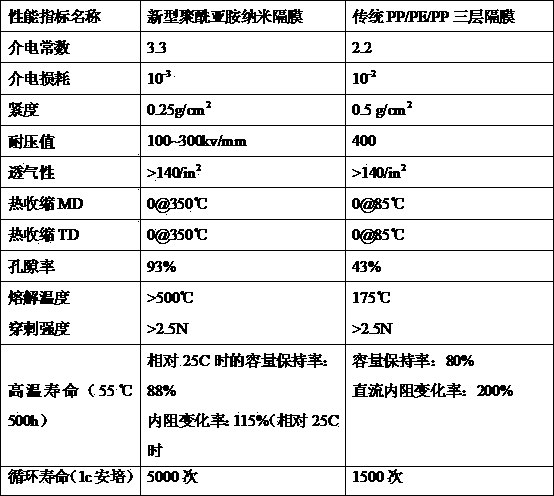

Preparation method of polyimide nanometer lithium ion battery diaphragm and product thereof

InactiveCN103915593AImprove electrochemical stabilityExcellent heat shrinkageMaterial nanotechnologyCell component detailsDiaminodiphenyl etherPolyamide

The invention discloses a preparation method of a polyimide nanometer lithium ion battery diaphragm and a product thereof. The preparation method comprises the following steps: preparing a polyamide acid solution, namely, performing condensation polymerization on 4,4'-diaminodiphenyl ether and 4,4'-oxydiphthalic anhydride in dimethylacetamide (DMAc) in a certain ratio; preparing a melt, namely, curing the obtained polymer solution at a certain temperature to obtain a condensate, and melting the condensate within the range of 20-30 DEG C below a melting point to obtain a semi-crystalline melt; preparing a diaphragm, namely, treating the obtained melt through a series of process including melt spinning, recrystallization, cold and thermal stretching and heat setting to obtain a nanometer diaphragm; carrying out diaphragm post-treatment, namely, removing a diluent and a part of remaining solvent in the diaphragm, and drying a polyamide acid diaphragm in vacuum; carrying out imidization treatment, namely, performing high-temperature imidization treatment on the prepared polyamide acid nanometer diaphragm to obtain the polyimide nanometer diaphragm. The prepared product is excellent in performance, and easy and convenient to process.

Owner:CENT SOUTH UNIV

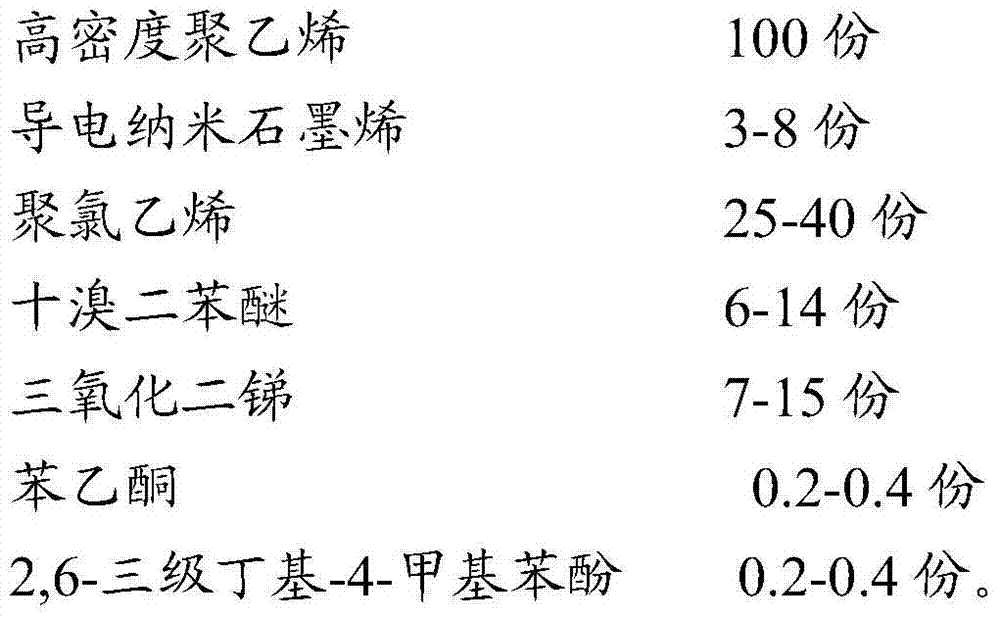

High density polyethylene pipe

InactiveCN104262740AImprove antistatic performanceImprove impact resistanceMasterbatchAntistatic agent

The invention relates to a high density polyethylene pipe. An antistatic agent, a toughener, a flame retardant, a photostabilizer and an antioxidant are added into a base material of high-density polyethylene. The manufacturing technique comprises the following steps: adding 50 parts of high-density polyethylene and additives into a high-speed mixer, carrying out extrusion granulation to prepare an antistatic high-toughness master batch, mixing the master batch with the rest of high-density polyethylene, adding into an extruder, forming the extruded material through a die orifice, cooling, pulling, and cutting to obtain the pipe which conforms to the operating requirements. The high density polyethylene pipe is prepared from the following raw materials in parts by weight: 100 parts of high-density polyethylene, 3-8 parts of conducting nano graphene, 25-40 parts of polyvinyl chloride, 6-14 parts of decabromodiphenyl oxide, 7-15 parts of antimony trioxide, 0.2-0.4 part of hypnone and 0.2-0.4 part of 2,6-tert-butyl-4-methylphenol.

Owner:王晓伟

Polyimide film and production process thereof

The invention relates to a polyimide film and a production process thereof. The polyimide film is mainly formed by the polymerization of material A 4,4'-bis(4-aminophenoxy)diphenylether and material B biphenyl tetracarboxylic acid dianhydride, wherein the ratio of the number of imide groups to the molecular weight of chain links is 2 / 678. The production process comprises the following steps: weighing the material A and the material b according to a weight ratio of 1.3:(0.99-1.0), and using N,N'-dimethyl acetamide as a solvent; throwing the material A into the solvent, stirring until the material A is dissolved, throwing the material B into the solvent in multiple times at a time interval of 20-50 minutes, and stirring, wherein the temperature is limited to 20-70 DEG C, and the weight of the solvent is 3-9 times of the total weight of the material A and the material B; and stopping throwing the material B when the resin viscosity reaches the reaction end point (4.0-7.0*10<5> centipoises) at 30 DEG C, continuing to stir for 4-6 hours to obtain a polyamic acid resin solution, casting into a film, and carrying out imidization; and regulating the viscosity when the material B remains 0.3-0.5 kilogram, wherein 0.03-0.1 kilogram of the material B is thrown each time, and the throwing amount is gradually reduced. The imide group content of the film is greatly reduced, and the alkali resistance and the moisture resistance of the film are greatly improved.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

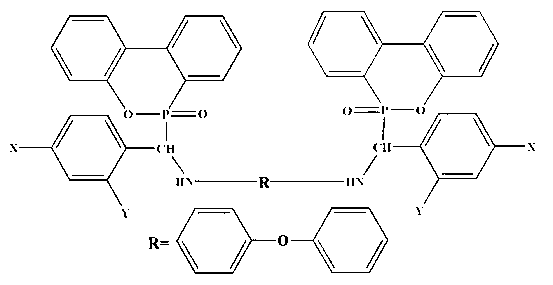

Efficient nitrogen and phosphorus fire retardant for epoxy resin and preparation method of efficient nitrogen and phosphorus fire retardant

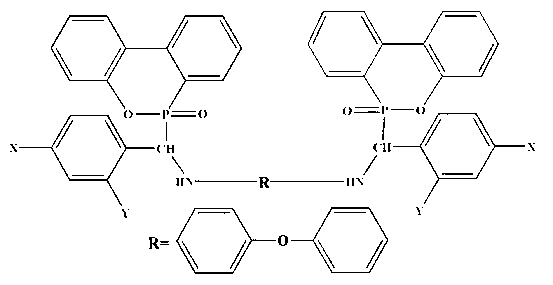

InactiveCN103012847AThe process steps are simpleFacilitate industrial mass productionGroup 5/15 element organic compoundsEpoxyDiaminodiphenyl ether

The invention relates to an efficient nitrogen and phosphorus fire retardant for epoxy resin, and a preparation method of the efficient nitrogen and phosphorus fire retardant. The method comprises the steps of allowing 4,4'-diaminodiphenyl ether (DDE) and aromatic aldehyde to conduct condensation reaction, and adding DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) to a reacted mixture for reaction to prepare the nitrogen and phosphorus fire retardant. According to the method, an intermediate product is not required to be separated; the method has simplified processing steps, is efficient, safe and environment-friendly and facilitates industrial batch production. Molecules of the obtained fire retardant are higher in activity; the fire retardant can facilitate epoxy resin curing; after the fire retardant is added into the epoxy resin, a cured epoxy condensate has better flame resistance; when the phosphorus content of an epoxy curing system reaches 0.75-1.0wt%, the vertical burning grade reaches UL94V-0; the limit oxygen index is greater than 38; and the char yield reaches 21.2-22.7% at 800 DEG C.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Composition of wear-resistant polyethylene pipe for underground coal mine, and preparation method of composition

InactiveCN102850637AHigh flame retardant efficiencyAdd lessRigid pipesProcedure AgentsWear resistant

The invention relates to a wear-resistant polyethylene pipe for an underground coal mine, belonging to one of polyethylene modified materials. The wear-resistant polyethylene pipe comprises the raw materials by weight percent: 2-5% of super wear-resistant carbon black, 10-20% of superconducting carbon black, 10-20% of decabromodiphenyl ether, 5-10% of antimony trioxide, 5-10% of POE, 0.5-1% of antioxidant, 2-4% of processing agent and the balance of high density polyethylene. The super wear-resistant carbon black has the required particle size of 11-15nm, the iodine absorption value of 145-152g / kg and the dibutyl phthalate (DBP) absorption value of 113-120cm<3> / 100g. The wear-resistant polyethylene pipe has the advantages that excellent flame retardant and antistatic performance is excellent, and wear resistance is high, so that the flame retardant and the antistatic performance and the mechanical property of the pipe are guaranteed not to be reduced due to dragging and friction in the processes of installation and use, and the safety factor of underground coal mine operation can be improved.

Owner:TIANJIN JUNXING PIPE GRP CO LTD

Flame retarding anti-static plastic braiding bags

A flame-retarded and antistatic Polywoven Bag is used to solve the problem that whose average surface resistance is sharply lower than that of the national standards and is prepared by: (1) Making flame-retarded masterbatch A by mixture and plastication of the antimony oxide and the polypropylene; (2) Making flame-retarded masterbatch B by mixture and plastication of the Decabromobiphenyl ether and the polypropylene; (3) Making antistatic masterbatch by mixture and plastication of the static agent and the polypropylene; (4) Making the mixture of the flame-retarded masterbatch A, B,antistatic masterbatch and the polypropylene through the high rate agitator; (5) Making the filamentus disk through drawing it to pellicle and filamentus using the plastic machine; and (6) Surface treating using the static agent. It can be used in coal mine and chemical lines.

Owner:吴珍山

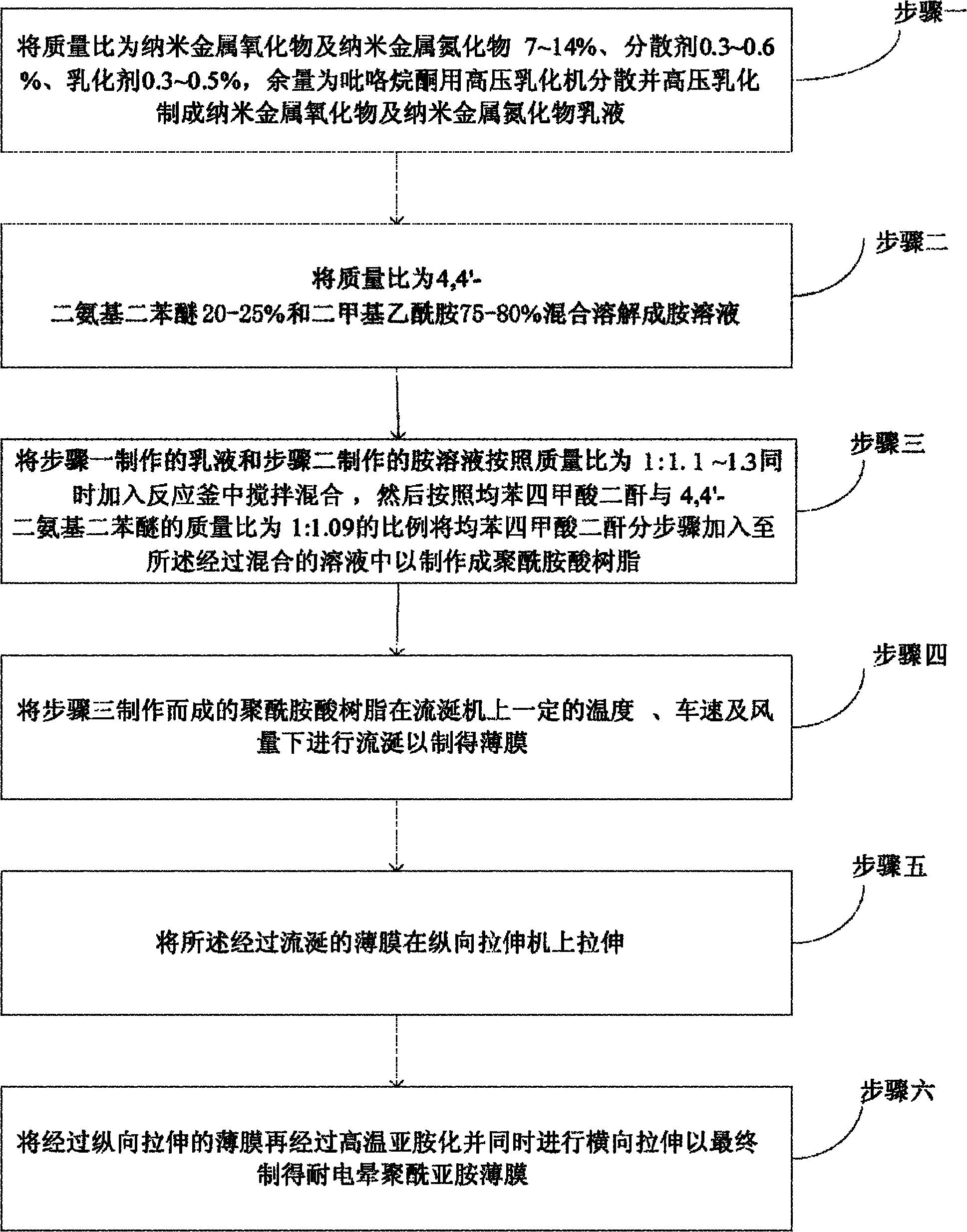

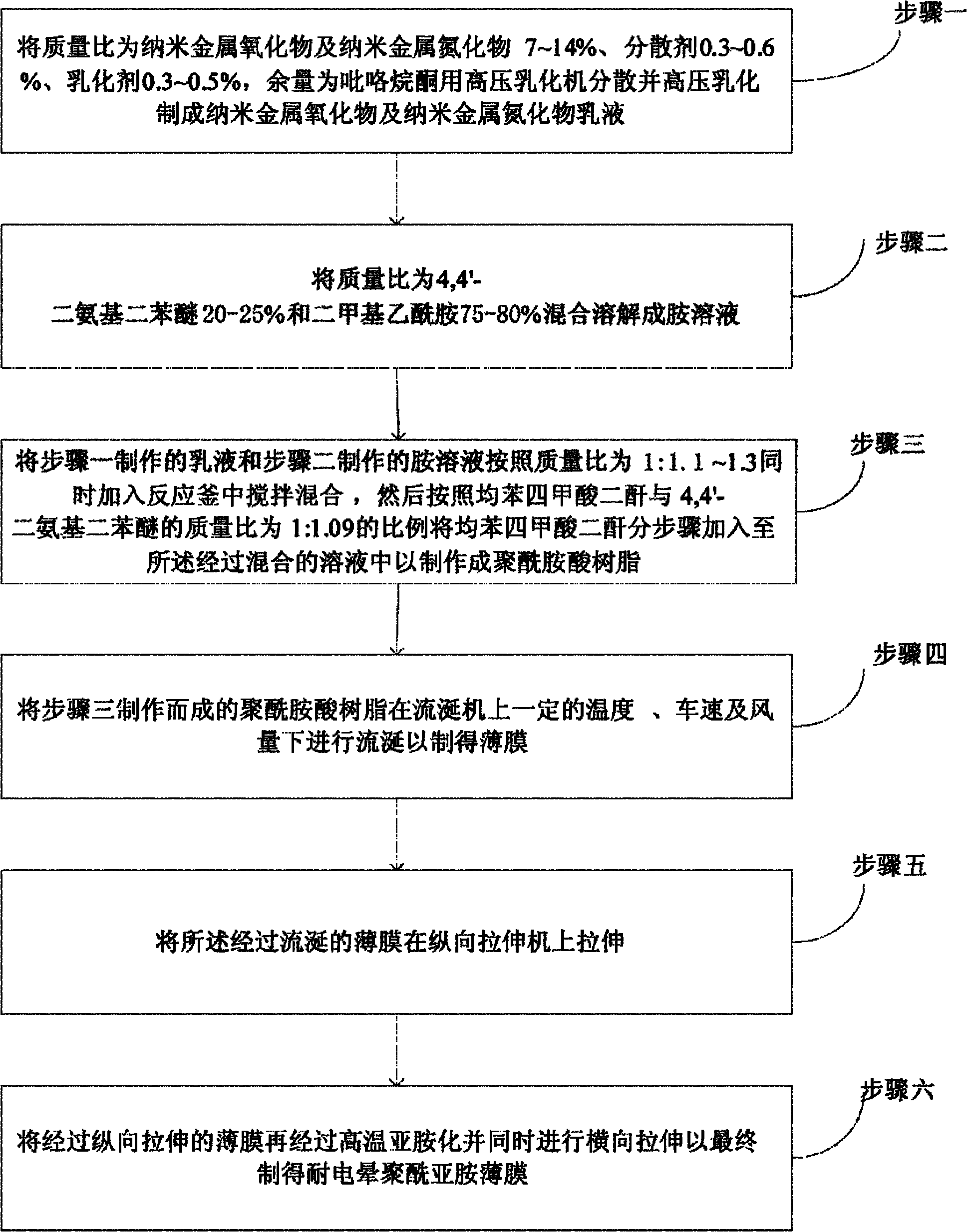

Corona-resistance polyimide film and manufacturing method thereof

The invention discloses a corona-resistance polyimide film, which comprises emulsion, amine solution and pyromellitic dianhydride, wherein the emulsion comprises 7 to 14 mass percent of nano metal oxide and nano metal nitride, 0.3 to 0.6 mass percent of dispersant, 0.3 to 0.5 mass percent of emulsifier and the balance of pyrrolidone; the amine solution comprises 20 to 25 mass percent of 4,4'-diamino-diphenyl ether and 75 to 80 mass percent of dimethylacetylamide, and the mass ratio of the emulsion to the amine solution is 1:(1.1-1.3); and the mass ratio of the pyromellitic dianhydride to the 4,4'-diamino-diphenyl ether is 1:(1.09). The invention also discloses the manufacturing method of the corona-resistance polyimide film. In the invention, the nano metal oxide and nitride are fully dispersed in polyamic acid resin by adding the emulsifier and dispersant and by a high-pressure emulsification technique, and the content of the nano metal oxide and nitride in the polyamic acid resin is high. Therefore, the produced film has high corona resistance and small astigmatic aberration, and at the same time, the film has high mechanical performance, electrical performance and the like.

Owner:TIANJIN TIANYUAN ELECTRONICS MATERIAL

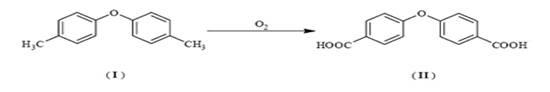

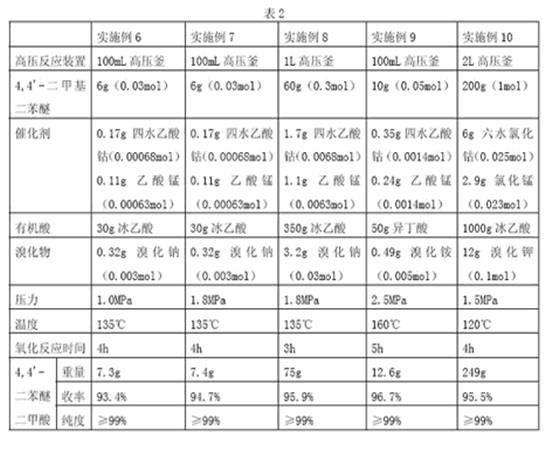

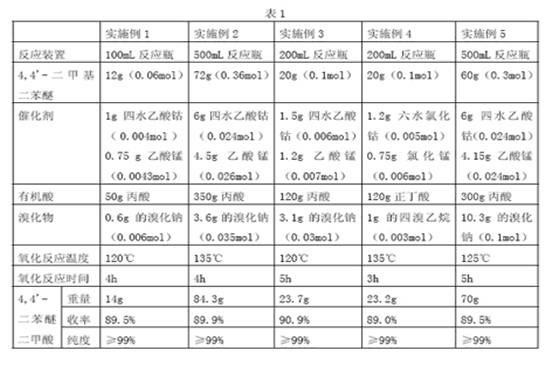

Method for preparing 4, 4'-diphenyl ether dicarboxylic acid

ActiveCN101774909AFew stepsShorten the timeOrganic compound preparationCarboxylic compound preparationOrganic acidPtru catalyst

The invention discloses a method for preparing 4, 4'-diphenyl ether dicarboxylic acid, which comprises the following steps: 1, adding 4, 4'-dimethyl ether, catalysts, organic acids as solvents and bromide as oxide additives into a reaction device; 2, adopting a bubbling method for introducing oxygen under the liquid level of the solvent in the reaction device, and heating the mixture to 110 to 160 DEG C for oxidation reaction for 1 to 10 h, or adopting an intermittent method for pressing the oxygen into the reaction device in two to five times, pressurizing to 1.0 to 4.0 MPa, and simultaneously raising the temperature to 110 to 160 DEG C for oxidation reaction for 1 to 10 h; and 3, carrying out cooling, suction filtration, washing and drying on materials after the reaction. The method of the invention has few steps, short time and easy post treatment, and is applicable to industrial large-scale production, wherein the high-pressure oxidation method also has the advantages of little catalyst consumption, high yield and the like.

Owner:CHANGZHOU SUNLIGHT PHARMA +1

Preparation method for disperse violet 26

ActiveCN102618058AReduce generationShort reaction timeAmino-hydroxy-anthraquinone dyesAnthraquinonesOrganic solvent

The invention relates to a preparation method for disperse violet 26. In the method, 1,4-diamino-2,3-dichloroanthraquinone and phenol undergo a condensation reaction in the presence of an acid-binding agent, so that 1,4-diamino-2,3-diphenyl oxide anthraquinone is generated; particularly, the condensation reaction is undergone in a water-insoluble inertial organic solvent of which the boiling point is 120-175 DEG C; the feeding weight ratio of the inertial organic solvent to phenol to 1,4-diamino-2,3-diphenyl oxide anthraquinone to the acid-binding agent is (1.5-2.5):(3-5):(0.9-1.1):1; and in the process of the condensation reaction, and water in a system is brought out by using the inertial organic solvent. In the preparation method, water (mainly water generated through a condensation reaction) in the system is brought out quickly by using a solvent, forward proceeding of the reaction is facilitated, the reaction time is greatly shortened, and the generation of a byproduct is reduced, so that the product has high yield and high purity, and the production cost is lowered.

Owner:苏州市罗森助剂有限公司

Cardanol modifying phenolic resin composition and method for producing environmental protection type flame-proof paper-base copper-coating board

ActiveCN101265352BLow costImprove heat resistanceCircuit susbtrate materialsEnvironmental resistanceTetrabromobisphenol A

The invention relates to a cardanol modified phenol-formaldehyde resin and a method for producing an environmentally protective flame-retardant paper-based copper-covering plate by using the resin compound, and belongs to the technology field of the production method of the copper-covering plate. The cardanol modified phenol-formaldehyde resin is used for producing the copper-covering plate with cheap cardanol substituting for industrial phenyl hydroxide and tung oil partly. The cardanol is refined and abstracted from the raw oil extracted from fruits grown on a cashew which is a tropical plant. The modified resin compound contains flame retardants, such as nitride, phosphide, tetrabromobisphenol A and so on, and the flame retardants are free of such hazardous materials as polybrominated biphenyl, polybrominated diphenyl oxide and so on. Wood chip paper is dipped with the modified resin to form prepregs. Subsequently, a plurality of pieces of prepregs are stacked up, and are compressed into the copper-covering plate at a certain temperature and certain pressure. The copper-covering plate can reduce the product cost and ensure the performance, and is friendly to the environment.

Owner:SHANDONG JINBAO ELECTRONICS

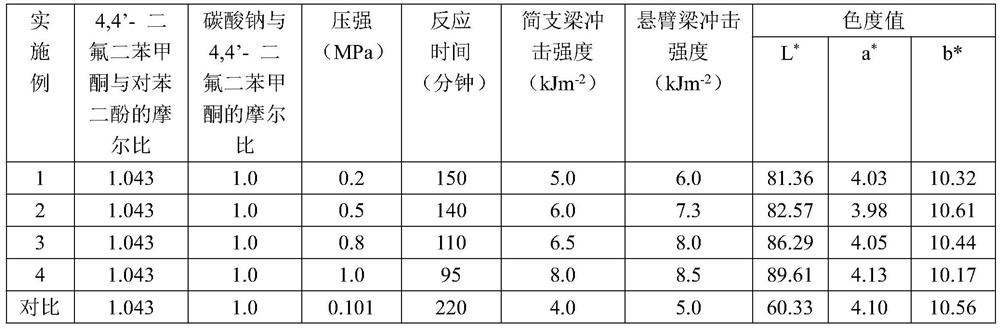

High-strength low-chroma polyether-ether-ketone and preparation method thereof

The invention discloses high-strength and low-chroma polyether-ether-ketone and a preparation method thereof. The preparation method of the polyether-ether-ketone comprises the following steps: carrying out nucleophilic polycondensation reaction on a first polymeric monomer and a second polymeric monomer in an inert aprotic solvent in the presence of alkali carbonate under the pressure of 0.15-1.0 MPa in an inert atmosphere to obtain the polyether-ether-ketone, wherein the first polymeric monomer is hydroquinone, biphenol, 4, 4'-dihydroxybenzophenone, 2, 2-bis (4-hydroxyphenyl) propane, 1, 3-bis (p-hydroxybenzoyl) benzene, 1, 4-bis (p-hydroxybenzoyl) benzene, alpha-naphthol, beta-naphthol and the like; the first polymeric monomer is 4, 4'-difluorobenzophenone, the second polymeric monomer is 4, 4'-difluorobenzophenone, 2, 4'-difluorobenzophenone, 4-fluoro-4'-chloro-benzophenone, 2-fluoro-4'-chloro-benzophenone, 2-chloro-4'-fluoro-benzophenone, diphenyl ether, 4, 4'-diphenoxy benzophenone and the like. The reaction time can be shortened, the reaction temperature can be reduced, and energy and cost can be reduced; the impact strength of the polymer is improved, and the color is brighter and whiter.

Owner:JILIN ZHONGYAN HIGH PERFORMANCE PLASTIC

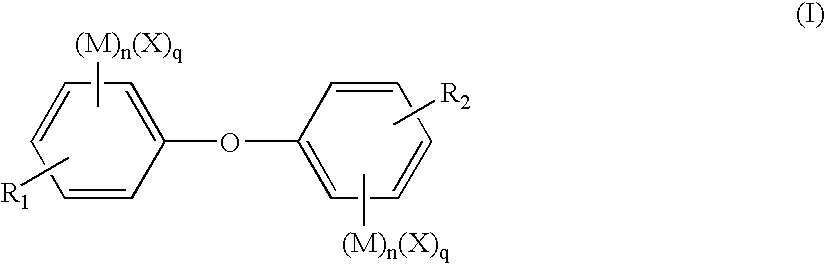

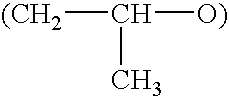

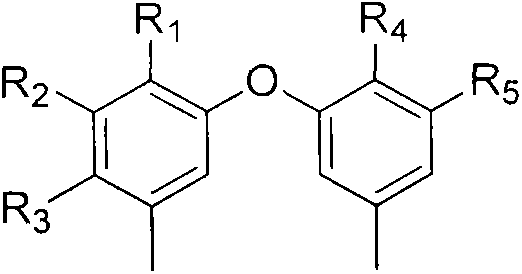

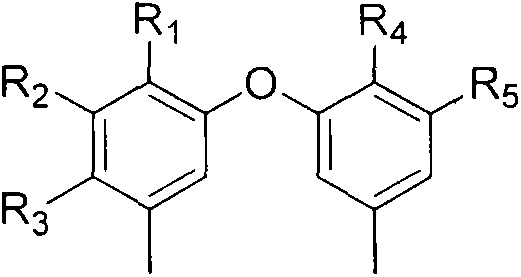

Photoresist processing aid and method

InactiveUS6900003B2Reduce the amount requiredFormation is also reduced and inhibitedOrganic detergent compounding agentsPhotoprinting processesProcessing aidAntifoam agent

A composition and method to reduce photolithographic residue and scum formation on a substrate or in a solution, and to reduce or prevent foam formation. The composition contains a diphenyl oxide compound in combination with an antifoam agent. The composition may be added to developer solutions and stripper solutions used in manufacturing printed wiring boards.

Owner:SHIPLEY CO LLC

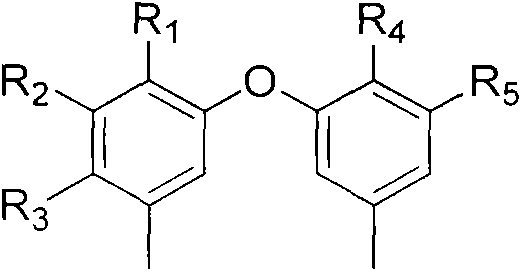

Preparation method of diphenyl oxide compound and application of the compound as natural marine organism antifouling agent

ActiveCN103214364ALow toxicityEnhanced inhibitory effectBiocideOrganic chemistryChromatographic separationBiofouling

A preparation method of a diphenyl ether compound and application of the compound as a natural marine organism antifouling agent. The preparation method is as below: culturing marine fungus Aspergillus sp. (HM535361) in a fungus culture medium; conducting fermentation culture on the fungi in a fermentation medium; then soaking the fermentation products with methanol; conducting decompression concentration to obtain a methanol crude extract; suspending the extract in water; extracting the extract with ethyl acetate, conducting vacuum concentration on the extract and conducting chromatographic separation; and concentrating the eluent to obtain four colorless or light red oil, 4-methoxycarbonyl-diorcinol, 3, 3 '-O-dimethyl-violaceol-I, cordyolC and diorcinol. The invention provides an environment-friendly natural marine organism antifouling agent, which is characterized by using the diphenyl ether compound as an effective ingredient. The antifouling agent can be used for the prevention and treatment of marine organism biofouling caused by attachment of barnacle Balanus Amphitrite larvae, and has the advantages of high efficiency and low toxicity. The raw material can be obtained from mass production by fungal fermentation, and is not subjected to resource constraints; therefore, the invention has wide application prospect.

Owner:OCEAN UNIV OF CHINA

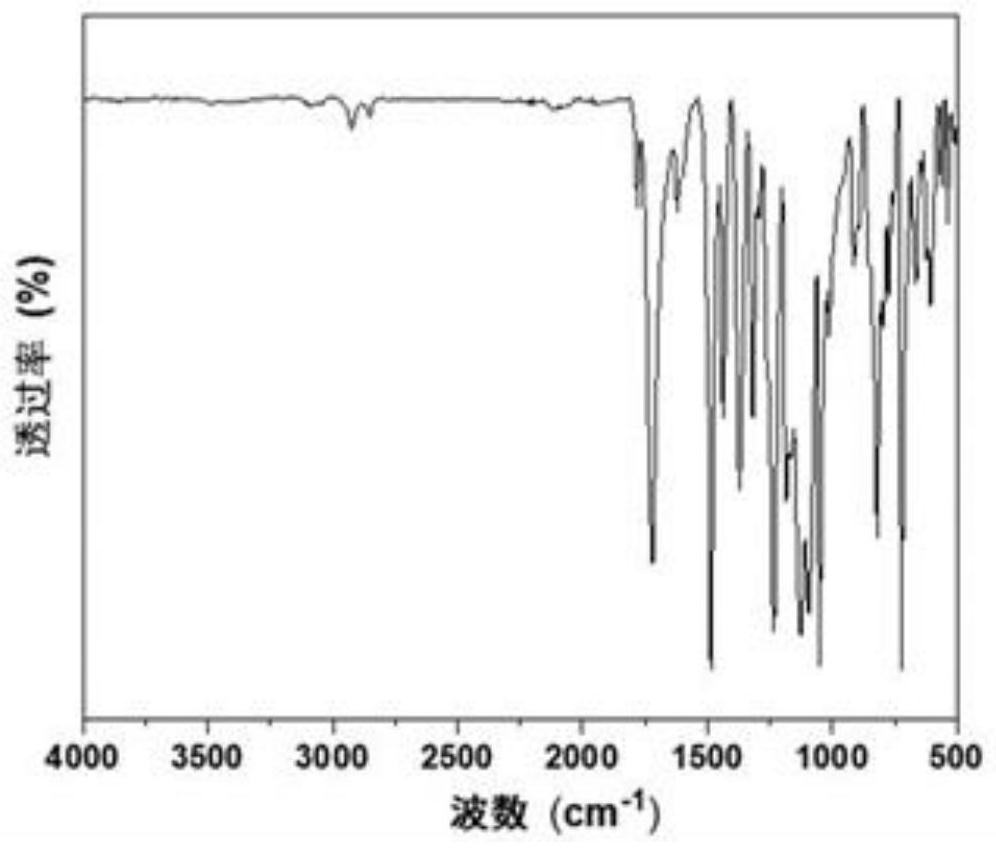

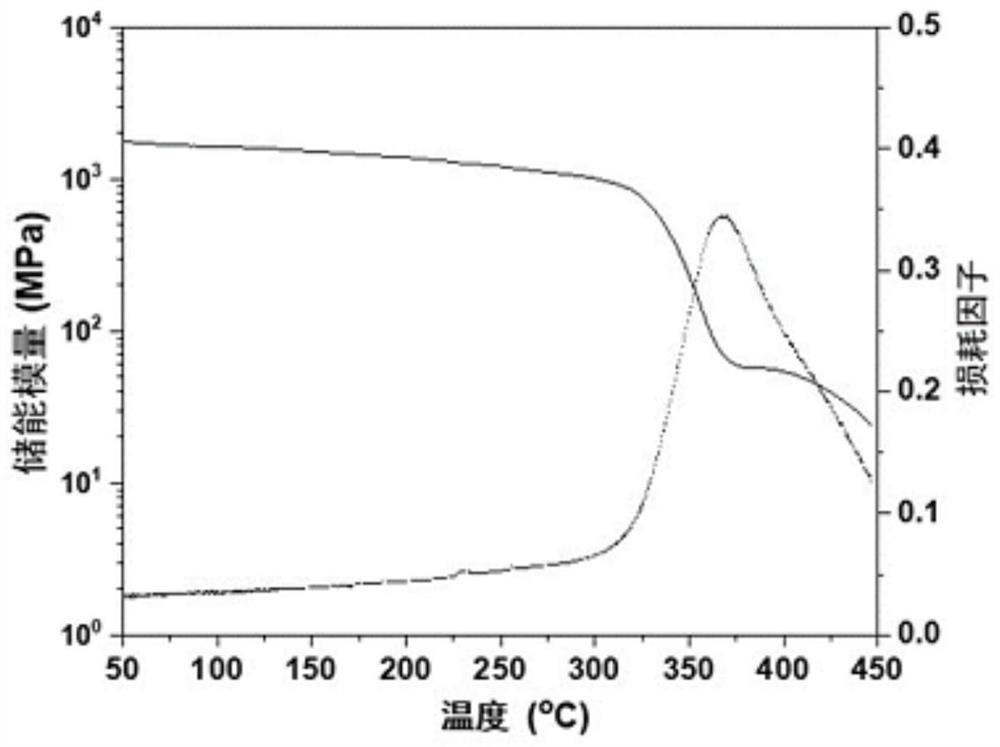

Polyimide adhesive film with excellent comprehensive performance as well as preparation method and application thereof

ActiveCN113248708AImprove hot melt effectSmall dielectric lossFilm/foil adhesives without carriersPolymer scienceDielectric loss

The invention relates to a polyimide adhesive film with excellent comprehensive performance as well as a preparation method and application thereof, belongs to the technical field of polyimide, and solves the problem that an existing polyimide adhesive film can hardly have excellent heat resistance, good adhesive property, low dielectric constant at high frequency and low dielectric loss. The polyimide adhesive film is mainly prepared from aromatic dianhydride, aromatic diamine containing a diphenyl ether structure and diamine containing a siloxane structure. The polyimide adhesive film has excellent heat resistance, high-frequency low dielectric property and good adhesive property. The glass-transition temperature is higher than 330 DEG C, the dielectric constant (Dk) at 10 GHz is smaller than 3, the dielectric loss (Df) value is 0.003-0.006, and the peel strength after the polyimide adhesive film is in hot-pressing adhesive connection with a copper foil is larger than 10 N / cm. The application requirements of flexible printed circuit board manufacturing and interlayer bonding and insulation in multi-layer circuit board lamination wiring processing can be met. The polyimide adhesive film provided by the invention can be widely applied to the fields of high-frequency flexible printed circuit boards, high-frequency film antennas and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polyethylene/polybutylece terephthalate (PBT) coated coconut shell powder particle blending foam material and preparation method thereof

InactiveCN103030869AImprove interfacial bond strengthHigh strengthPhosphorous acidLinear low-density polyethylene

The invention discloses a polyethylene / polybutylece terephthalate (PBT) coated coconut shell powder particle blending foam material. The material is prepared from the following materials in part by weight: 60 to 80 parts of LLDPE (Linear low density polyethylene), 20 to 40 parts of HDPE (high-density polyethylene), 30 to 40 parts of PBT, 10 to 15 parts of tourmaline, 15 to 20 parts of water glass, 5 to 10 parts of coconut shell powder, 1 to 2 parts of anilino-methyl-triethoxysilane, 5 to 8 parts of decabromodiphenyl oxide, 4 to 6 parts of di-butyl nylonic acid ester, 5 to 8 parts of epoxy octyl stearate, 3 to 5 parts of foaming agent, 1 to 2 parts of diperoxycarbamate, 1 to 2 parts of zinc oxide, 1 to 2 parts of calcium stearate, 0.5 to 1 part of dibasic lead phosphite, 2 to 3 parts of glycol tristearate, 3 to 5 parts of modified tree ash, and 1 to 2 parts of antioxidant 2461. The polyethylene / PBT coated coconut shell powder particle blending foam material is light in weight, flexible, high in strength, good in resilience, ideal in foaming effect, uniform in cell, compact, high in flame resistance, ageing resistant and durable.

Owner:滁州凯凯建筑节能有限公司

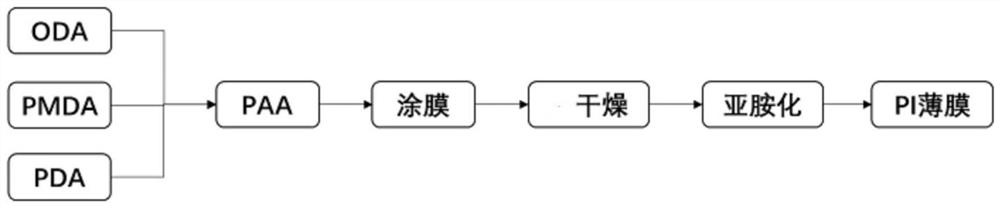

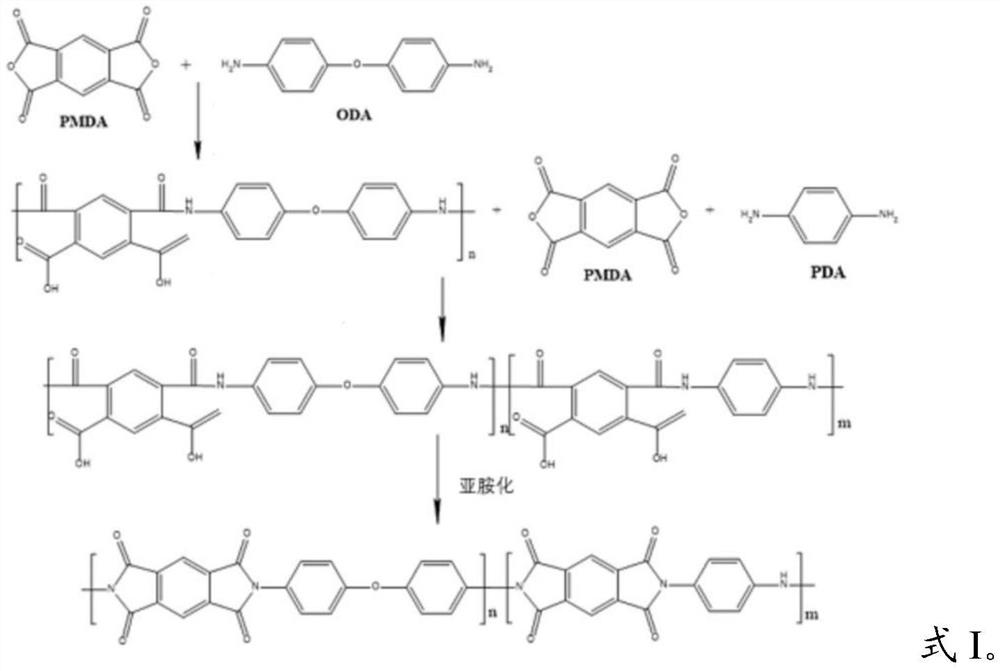

Polyimide film and preparation method thereof

The invention provides a polyimide film and a preparation method thereof, and belongs to the technical field of films. The invention provides a polyimide film preparation method, which comprises: mixing 4, 4 '-diaminodiphenyl ether, an organic solvent and pyromellitic dianhydride, and carrying out a first polymerization reaction to obtain a first precursor solution; mixing the first precursor solution with p-phenylenediamine, an organic solvent and pyromellitic dianhydride, and carrying out a second polymerization reaction to obtain a second precursor solution; and coating a substrate with the second precursor solution, and then carrying out imidization treatment to obtain the polyimide film. Experimental results show that the thermal expansion coefficient and the mechanical property of the polyimide film prepared by the preparation method provided by the invention are superior to those in the prior art.

Owner:上海炫柔电子材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com