Patents

Literature

95results about How to "Improve hot melt effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite pipe made of non-cross-linking refractory polyethylene and cross-linking polyethylene

A composite pipe is composed of a an internal layer made of crosslinked polyethyene and an external layer made of non-crosslinked refractory polyethene which is combined with the internal layer. Its advantages are low cost, high resistance to high temp. thermal ageing, gasoline and arylhydrocarbon, high thermal strength and anti-creeping performance, and long service life.

Owner:DONGTAI NEW MATERIAL SCI ANG TECH SICHUAN

Method for producing hot-melting artistic anti-fake paper

ActiveCN101250838AGood compatibility and binding forceGood mix distribution characteristicsWater-repelling agents additionPulp beating methodsFiberHot melt

The invention relates to a method for preparing hot melt art antifalsification paper, which comprises the following steps: firstly, selecting wood fiber to do fluff and one-time beating, selecting RRXW commodity fiber and fluorescent fiber to process and beat, mixing wood fiber pulp, RRXW fiber pulp and fluorescent fiber pulp according to the proportion of 82: 15: 3, doing blending and beating, charging chemical findings and assistant to blend, dehydrating, modeling, decorating, adopting hot wind dry, far infrared dry and seal dry to do polybasic modeling dry, gluing paper to do non-contact dry, and improving the gluing effect. The multiple fiber allocation of the invention enables pulp to be provided with good compatibility connection and even blend distribution property, higher dry-wet strength, physics, appearance property and the polybasic modeling drying ensures the paper dry effect and the RRXW fiber against damaging. The method for preparing hot melt art antifalsification paper is simple in preparation, reliable in preparation technique, strong in operation and superior in hot melt property and antifalsification property.

Owner:SHANDONG KAILI SPECIAL PAPER

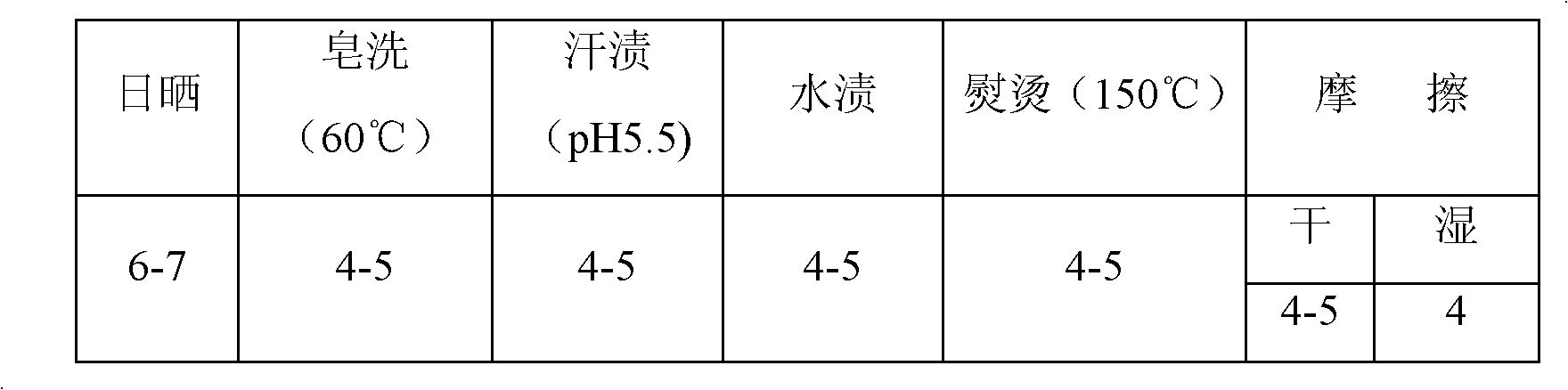

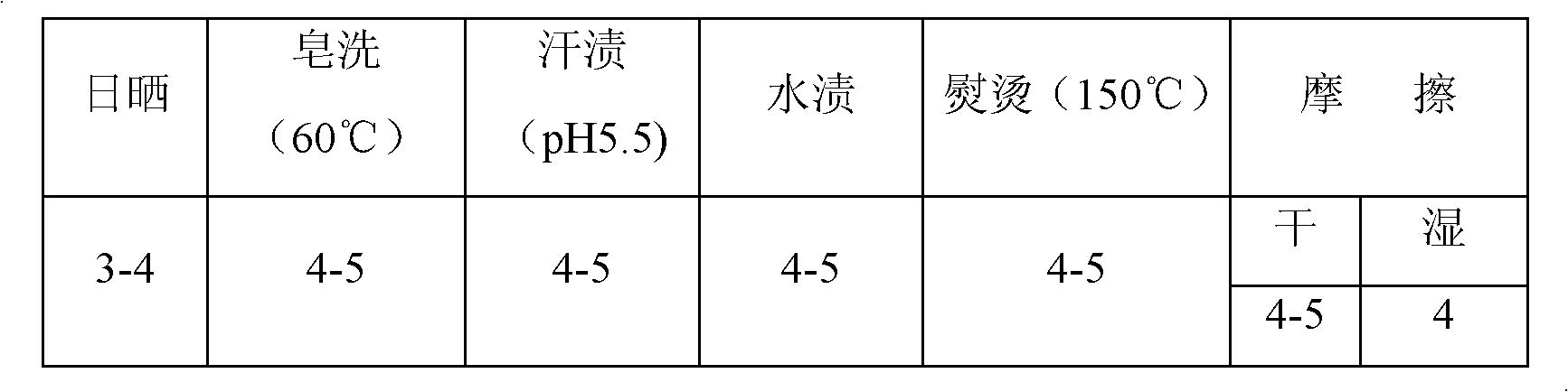

Fabric pattern transfer ink and preparing method thereof

The invention discloses fabric pattern transfer ink which comprises the following components by weight percent: 0.1-40% of dye, 8-50% of saccharide, 0-8% of thickening agent and 2-81.9% of solvent, wherein the saccharide is any one or mixture of monosaccharide, disaccharide and oligosaccharide as well as ramifications thereof; and the solvent is water or organic solvent or mixture of water and organic solvent or mixture of organic solvents. The invention also discloses a preparing method of the fabric pattern transfer ink, a transfer method of fabric pattern of the ink and a fabric pattern transfer film. According to the invention, the content of hot-melting components in the hot-melting printing ink is greatly improved, the hot-melting performance of the printing ink is excellent, and the product quality is more stable. The price cost of the original hot-smelting printing ink is greatly reduced, and high cost performance is achieved. Materials are easy to obtain, and the technology is easy to popularize.

Owner:常州涵源新印花有限公司

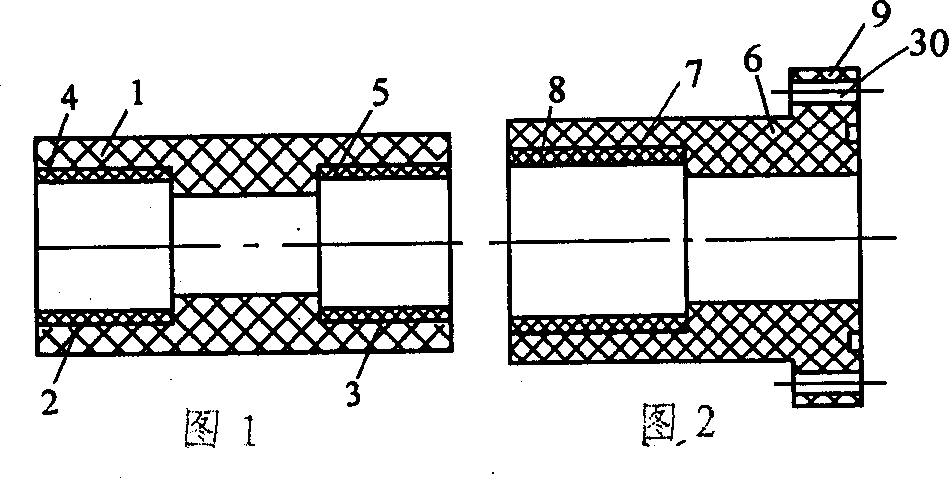

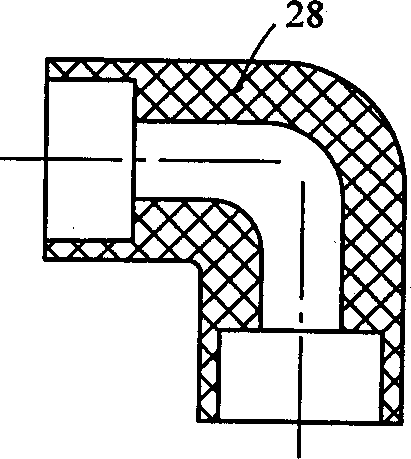

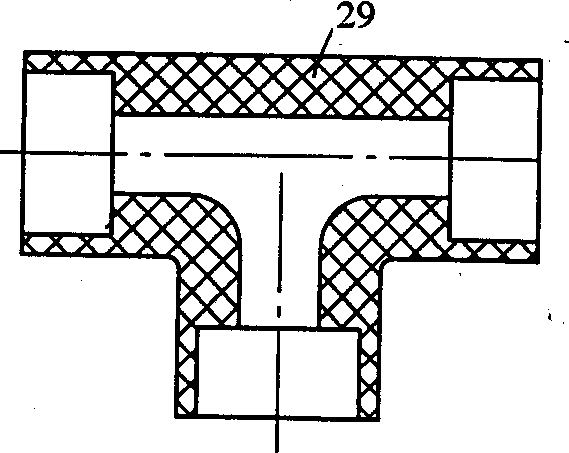

Silane crosslinked polyethylene pipe connecting piece

InactiveCN1344881AOvercoming temperature resistanceOvercoming pressure resistancePipe connection arrangementsPolymer scienceSilanes

The silane crosslinked polyethylene pipe union includes a silane crosslinked polyethylene pipe body produced by using the material comprising at least organosilicon monomer as grafting initiator, hydrolytic polycondensation catalyst and polyethylene as well as through extrusion or injection and reaction of crosslinking polycondensation and with spigots added. It is used to consitute permanent connection with silane crosslinked polyethylene pipe.

Owner:DONGTAI NEW MATERIAL SCI ANG TECH SICHUAN

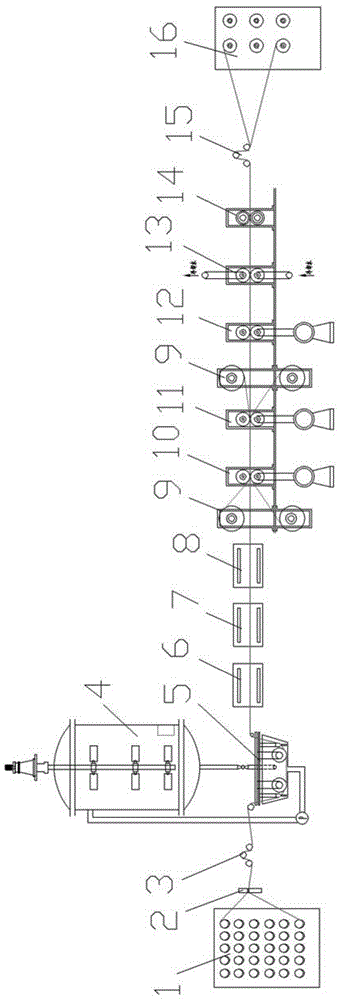

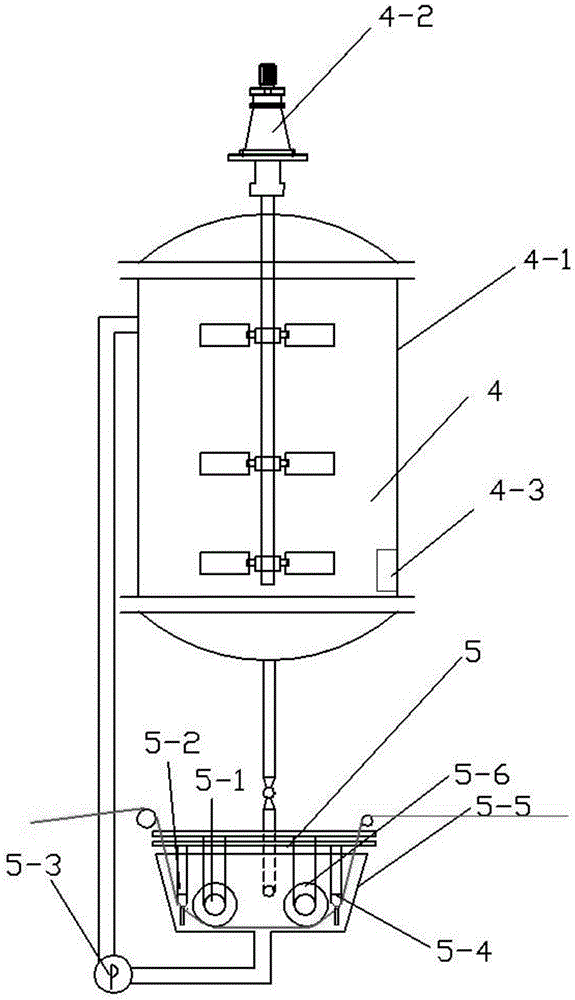

Impregnating equipment for producing high-temperature-resisting thermoplasticity composite material unidirectional prepreg tape

The invention provides impregnating equipment for producing high-temperature-resisting thermoplasticity composite material unidirectional prepreg tape. The equipment comprises a yarn discharging device, a yarn binding hole disc, a yarn spreading device, a slurry impregnation device, a pre-baking device, an isolating membrane unwinding and winding device, a hot melt impregnation device, a molding device, a cooling and press polish device, a slitting device, a tension detection device and a spiral winding device. The yarn discharging device, the yarn spreading device, the slurry impregnation device, the pre-baking device, the isolating membrane unwinding and winding device, the hot melt impregnation device, the molding device, the cooling and press polish device, the slitting device, the tension detection device and the spiral winding device are sequentially arranged. The resin content of prepreg prepared through the impregnating equipment for the prepreg tape is uniform and stable, and the hot melt effect is promoted. The resin content of the prepreg tape can be effectively controlled, and the high-temperature-resisting thermoplasticity composite material unidirectional prepreg tape which is uniform and low in porosity is prepared.

Owner:余姚中国塑料城塑料研究院有限公司

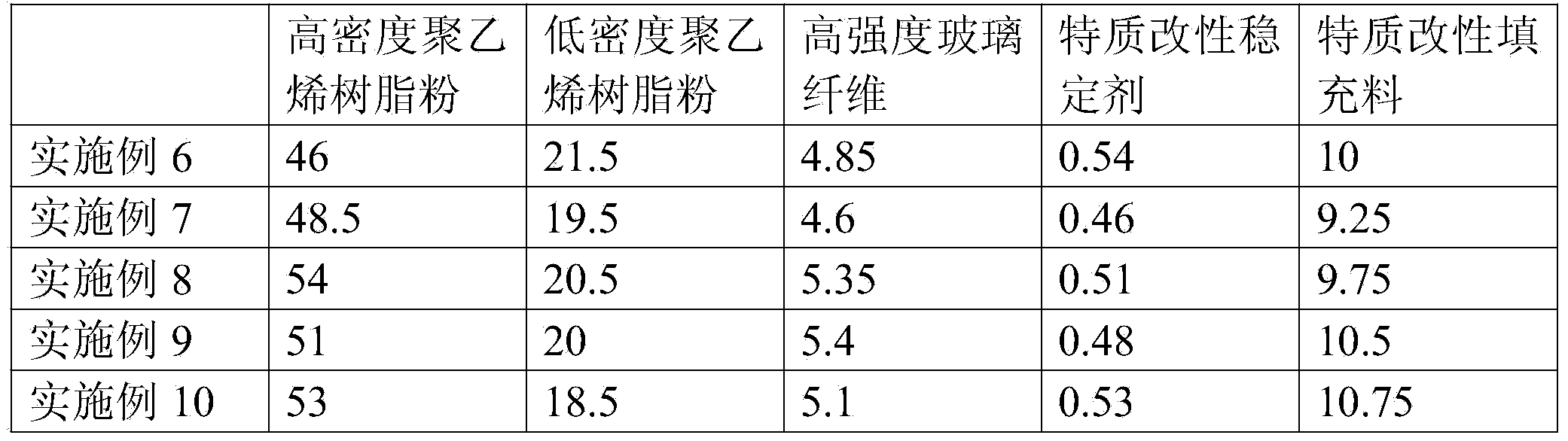

Porous plum-blossom-shaped pipe and preparation method thereof

ActiveCN104212046ANo pollution in the processSave labor costsLow-density polyethyleneEnvironmental resistance

The invention discloses a porous plum-blossom-shaped pipe, and belongs to the technical field of high-molecular materials. The raw materials comprises the following substances in parts by weight: 45-55 parts of high-density polyethylene resin powder, 18-22 parts of low-density polyethylene resin powder, 4.5-5.5 parts of high-strength glass fiber, 0.45-0.55 parts of a property modification stabilizer, and 9-11 parts of a property modification filling material. The plum-blossom-shaped pipe is relatively smooth in inner wall, cables can directly pass through the pipe without using other utensils, and time and labor are saved; the plum-blossom-shaped pipe is resistant to acids and bases, resistant to salts and alkalis, resistant to corrosion, resistant to oxidation, resistant to ageing, suitable in structure, high in usage value, long in service life, green and environment-friendly, and helps to improve the construction speed and substantially reduce the construction cost of an engineering unit.

Owner:陕西中昌科技有限公司

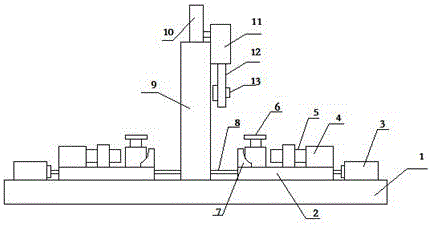

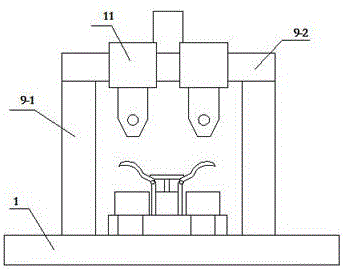

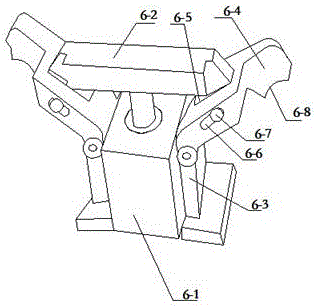

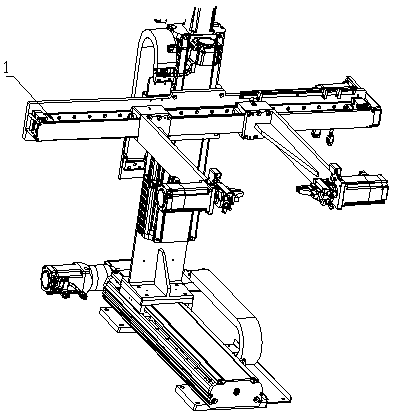

Automatic polypropylene random (PPR) pipe assembly hot-melt welding device

The invention discloses an automatic polypropylene random (PPR) pipe assembly hot-melt welding device which comprises a base, wherein a portal frame is arranged above the middle of the base; a hot melt machine is arranged on a beam; a hot-melt die head is arranged below the hot melt machine; pipe transfer mechanisms are symmetrically arranged on the front and rear sides of the portal frame; the pipe transfer mechanisms comprise sliding seats capable of moving back and forth; two groups of pipe assembly clamping mechanisms are arranged on the left and right sides of the sliding seats in parallel; down pressing pipe mechanisms are arranged on the sliding seats between the two groups of pipe assembly clamping mechanisms; the pipe assembly clamping mechanisms comprise positioning blocks and telescopic cylinders; the positioning blocks are arranged at one ends, which are close to the portal frame, of the sliding seats; the telescopic cylinders are arranged at one ends, which are far away from the portal frame, of the sliding seats; piston rods of the telescopic cylinders are connected with top pipe columns of the positioning blocks. The invention has the beneficial effects that the hot-melting and fitting operations of the pipe assemblies can be mechanically completed, the hot-melting effect is good, the fitting is accurate, high sealing property is guaranteed, the manual labor is saved, and the working efficiency is greatly improved.

Owner:SHANDONG AIRPOWER ENERGY SAVING EQUIP CO LTD

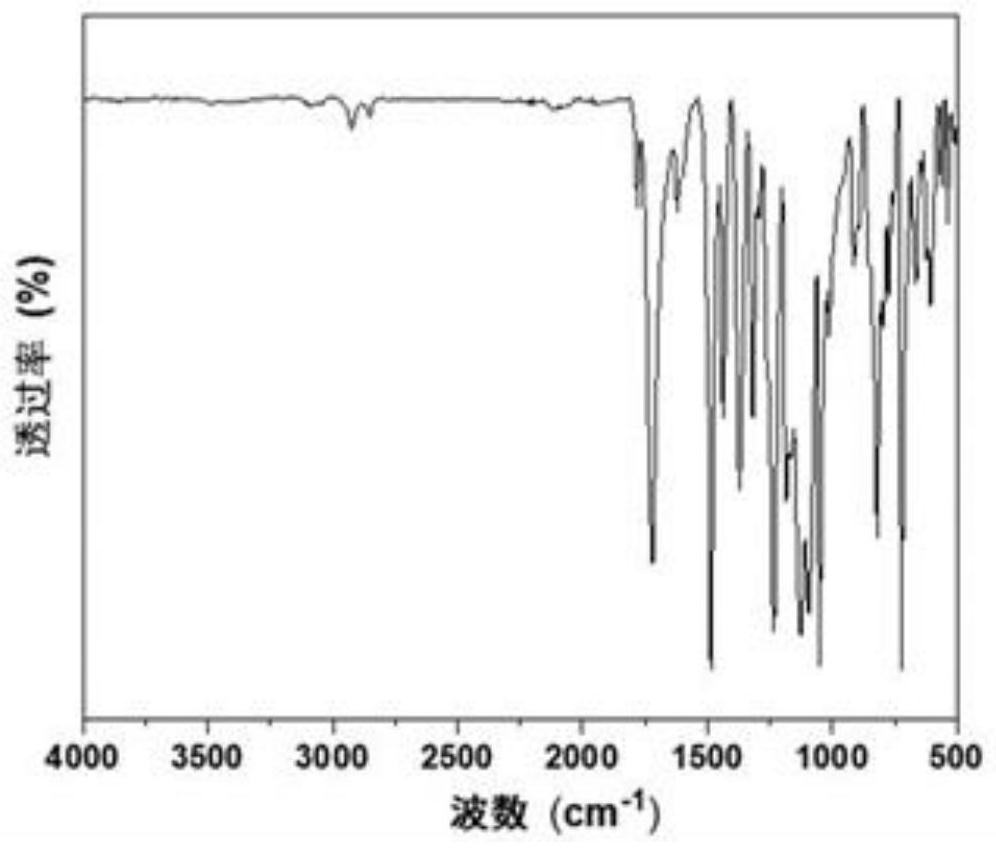

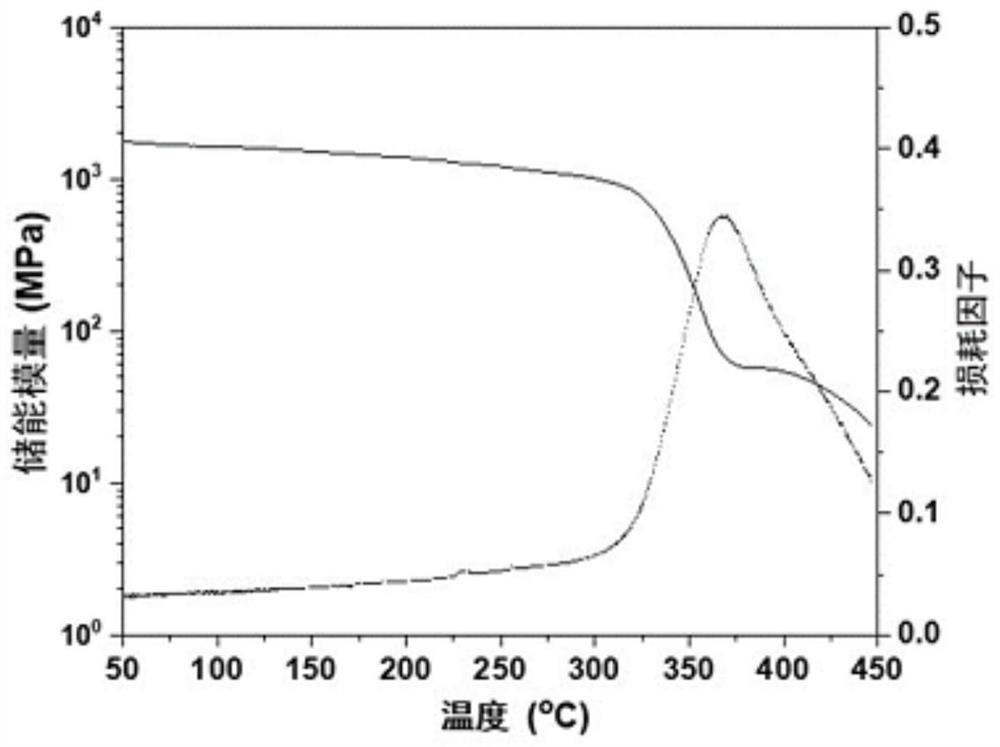

Polyimide adhesive film with excellent comprehensive performance as well as preparation method and application thereof

ActiveCN113248708AImprove hot melt effectSmall dielectric lossFilm/foil adhesives without carriersPolymer scienceDielectric loss

The invention relates to a polyimide adhesive film with excellent comprehensive performance as well as a preparation method and application thereof, belongs to the technical field of polyimide, and solves the problem that an existing polyimide adhesive film can hardly have excellent heat resistance, good adhesive property, low dielectric constant at high frequency and low dielectric loss. The polyimide adhesive film is mainly prepared from aromatic dianhydride, aromatic diamine containing a diphenyl ether structure and diamine containing a siloxane structure. The polyimide adhesive film has excellent heat resistance, high-frequency low dielectric property and good adhesive property. The glass-transition temperature is higher than 330 DEG C, the dielectric constant (Dk) at 10 GHz is smaller than 3, the dielectric loss (Df) value is 0.003-0.006, and the peel strength after the polyimide adhesive film is in hot-pressing adhesive connection with a copper foil is larger than 10 N / cm. The application requirements of flexible printed circuit board manufacturing and interlayer bonding and insulation in multi-layer circuit board lamination wiring processing can be met. The polyimide adhesive film provided by the invention can be widely applied to the fields of high-frequency flexible printed circuit boards, high-frequency film antennas and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Nitrile rubber and preparation method thereof

The invention discloses nitrile rubber in the technical field of rubber production. The nitrile rubber is prepared from the following ingredients in parts: 100phr of nitrile rubber, 60 to 80phr of carbon black, 30 to 40phr of dioctyl sebacate, 50 to 60phr of modified talcum powder, 5 to 8phr of zinc oxide, 1 to 3phr of stearic acid, 5 to 8phr of coumarone, 2 to 3phr of anti-aging agents RD, 1.5 to 4phr of anti-aging agents 4010NA, 2 to 4phr of dispersing agents, 15 to 20phr of moisture absorbents, 3 to 5phr of sulphur S, 1 to 2phr of accelerators D, 2 to 4phr of accelerators M and 2 to 4phr of accelerators DPTT. According to the vulcanization process, extrusion products are subjected to microwave vulcanization molding through first-section microwave and second-section hot air vulcanization equipment. The nitrile rubber has the advantages that the low-temperature resistant performance is good; the intensity is high; the pressure change is low; the anti-aging performance is realized; the service life is long; the forming is realized through a microwave vulcanization method; the cost is low; the efficiency is high and the finished product rate is high.

Owner:扬州华通橡塑有限公司

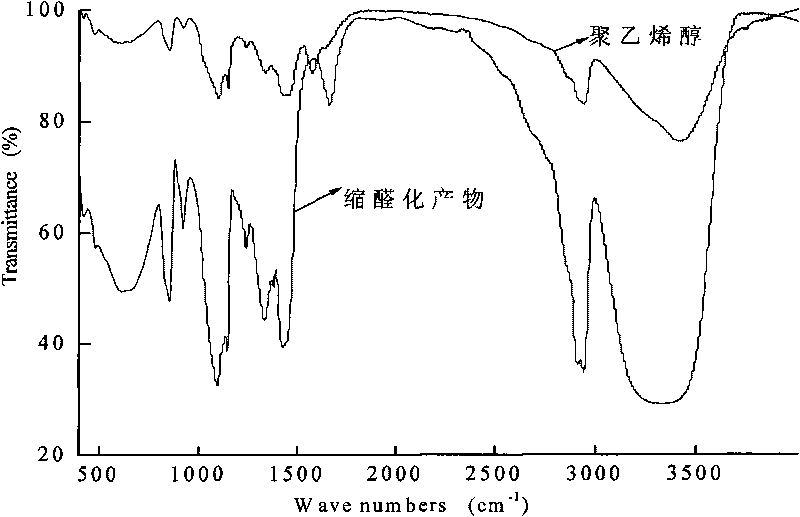

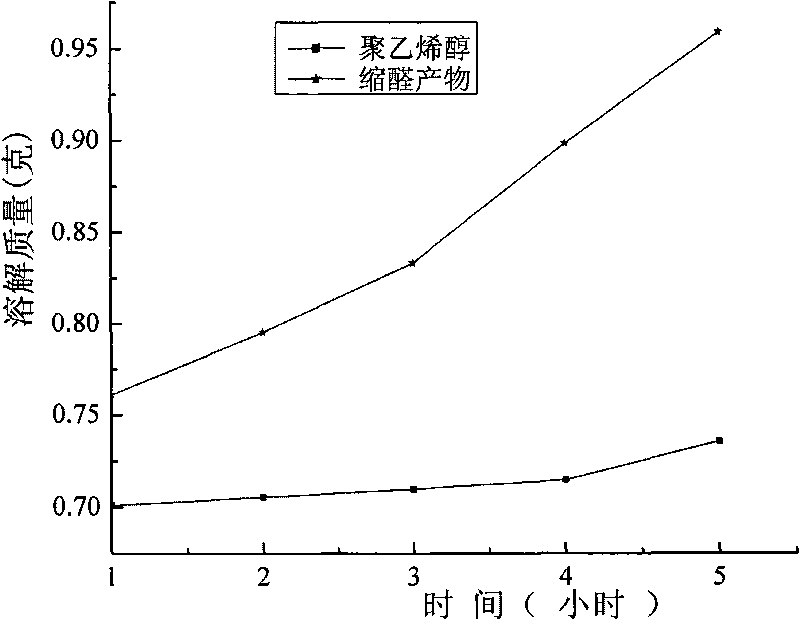

Method for synthesizing glucose modified polyvinylalcohol resin

The invention provides a method for synthesizing glucose modified polyvinylalcohol resin, relating to a synthesis method for a chemical material and comprising the following steps: taking gluecose and polyvinylalcohol water solution as raw materials, and obtaining a thermoplastic polyvinyl alcohol / gluecose acetalation resin product under the action of acidic catalyst after salting-out, drying and dehydrating, wherein the product has the structural formula as follows. The acetalization product prepared by the invention has the advantages of good hygroscopicity and water solubility at room temperature, enhances the application prospect thereof and broadens the application fields of polyvinyl alcohol; and the value of the softening point thereof conforms to the user performance of the thermoplastic glue.As resin has the advantages of free of methanol, safety and stability, no toxicity, no pollution, no volatilization, excellent natural degrading property and the like, the resin has important actual meanings in the aspects of recycling, reducing environment pollution, lowering production cost and the like.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

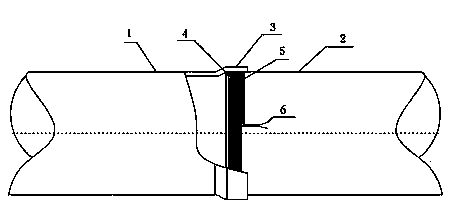

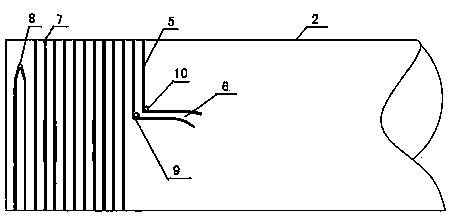

Steel framework enhancement composite pipe material bearing inserting and welding method

InactiveCN103486387AImprove reliabilityImprove sealingPipe connection arrangementsEngineeringHeat fusion

The invention discloses a steel framework enhancement composite pipe material bearing inserting and welding method, which comprises the following steps of (1) opening expansion: adopting a heater for heating a bearing opening, and starting an opening expansion machine for carrying out extrusion type opening expansion on the bearing opening section; (2) grooving: adopting a grooving wire distributing machine for realizing grooving on an inserting opening section, and the groove depth of a wire distributing groove is smaller than the thickness from the outer protecting layer to a steel formwork enhancement layer; (3) wire distribution; (4) insertion: inserting an inserting opening of the second pipe materials into the bearing opening of the first pipe material until the inserting opening is completely inserted into the bearing opening, and the concentricity of the two pipe materials maintains consistent; (5) fusion welding: respectively connecting two output power supply wires of an electric fusion welding machine onto binding terminals of electric heating wires, switching on a power supply, and carrying out segmented heating according to the pipe diameter parameters. The method provided by the invention has the advantages that the process design is reasonable, the method has good heat fusion performance and welding intensity, the pipe material connecting quality reliability, the pipe sealing performance and the pressure bearing capability are greatly improved, and the service life of the pipeline is obviously prolonged.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

Novel wood floor adhesive

InactiveCN105368353AHigh adhesiveness and hot melt performanceGood bonding effectNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesN-Butyl acetateNatamycin

The invention discloses a novel wood floor adhesive. The novel wood floor adhesive comprises the following raw materials in parts by weight: 1.5-3.7 parts of silica sol, 0.8-1.7 parts of polyepoxy glyceryl ether, 2-3.7 parts of n-butyl acetate, 3-7 parts of asbestos powder, 0.6-1.5 parts of diisocyanate, 2-3.5 parts of urea, 1.3-3.5 parts of glycidyl trimethyl ammonium chloride-gliadin-glyoxal resin, and 0.5-2.7 parts of natamycin. Compared with the prior art, the novel wood floor adhesive has the advantages of no toxicity and no formaldehyde containing, has high adhesive property and hot melting property to the glycidyl trimethyl ammonium chloride-gliadin-glyoxal resin which is environmentally friendly, has the advantages of good bonding effect and long service life. The novel wood floor adhesive has the advantages of high bonding effect and good mechanical property, and has insect-prevention effect, combination of natamycin and urea can effectively prevent termite erosion and reduce possibility of insect pest, and a production method for the novel wood floor adhesive has the advantages of simple process, low production cost and easy popularization.

Owner:黄艳

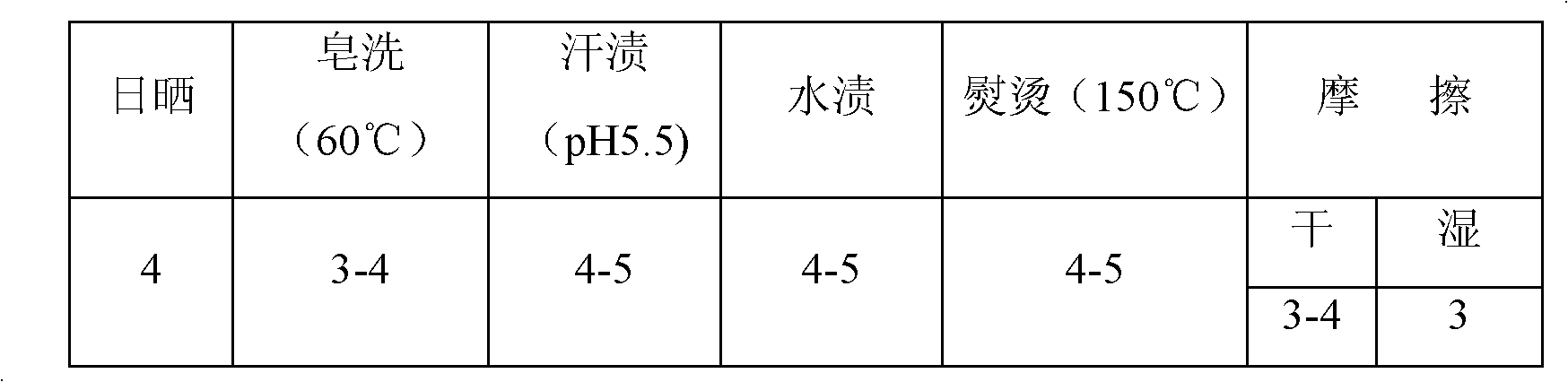

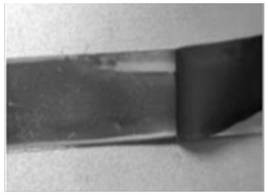

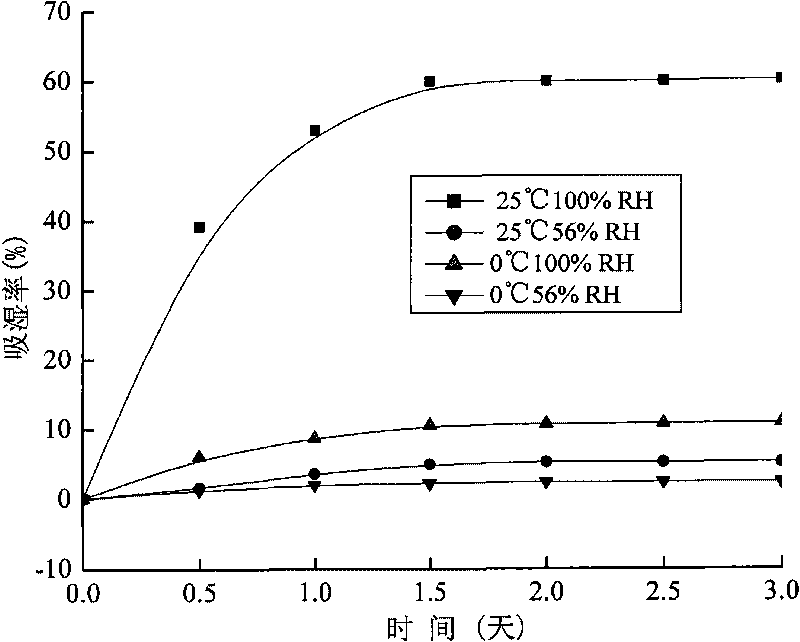

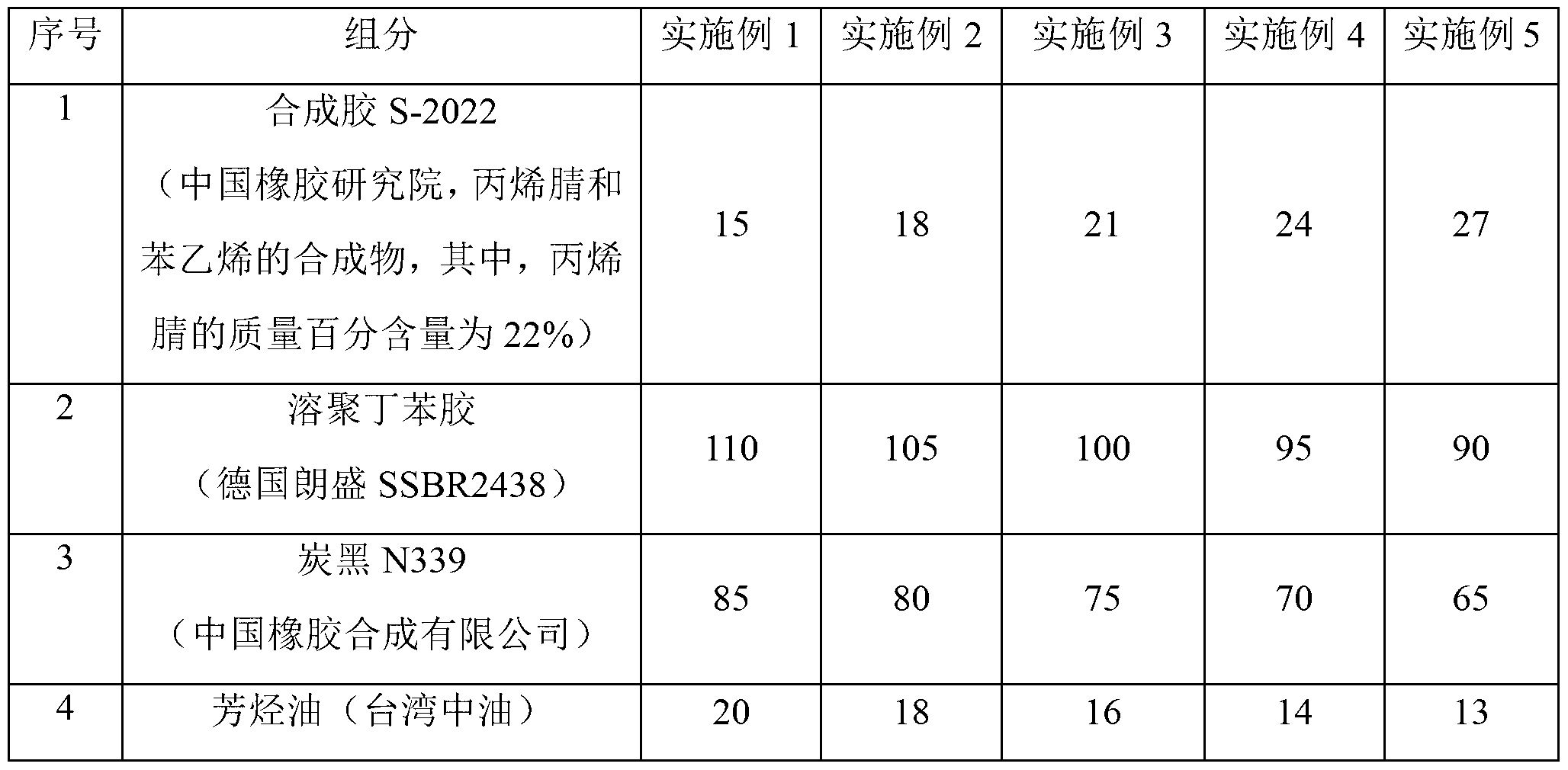

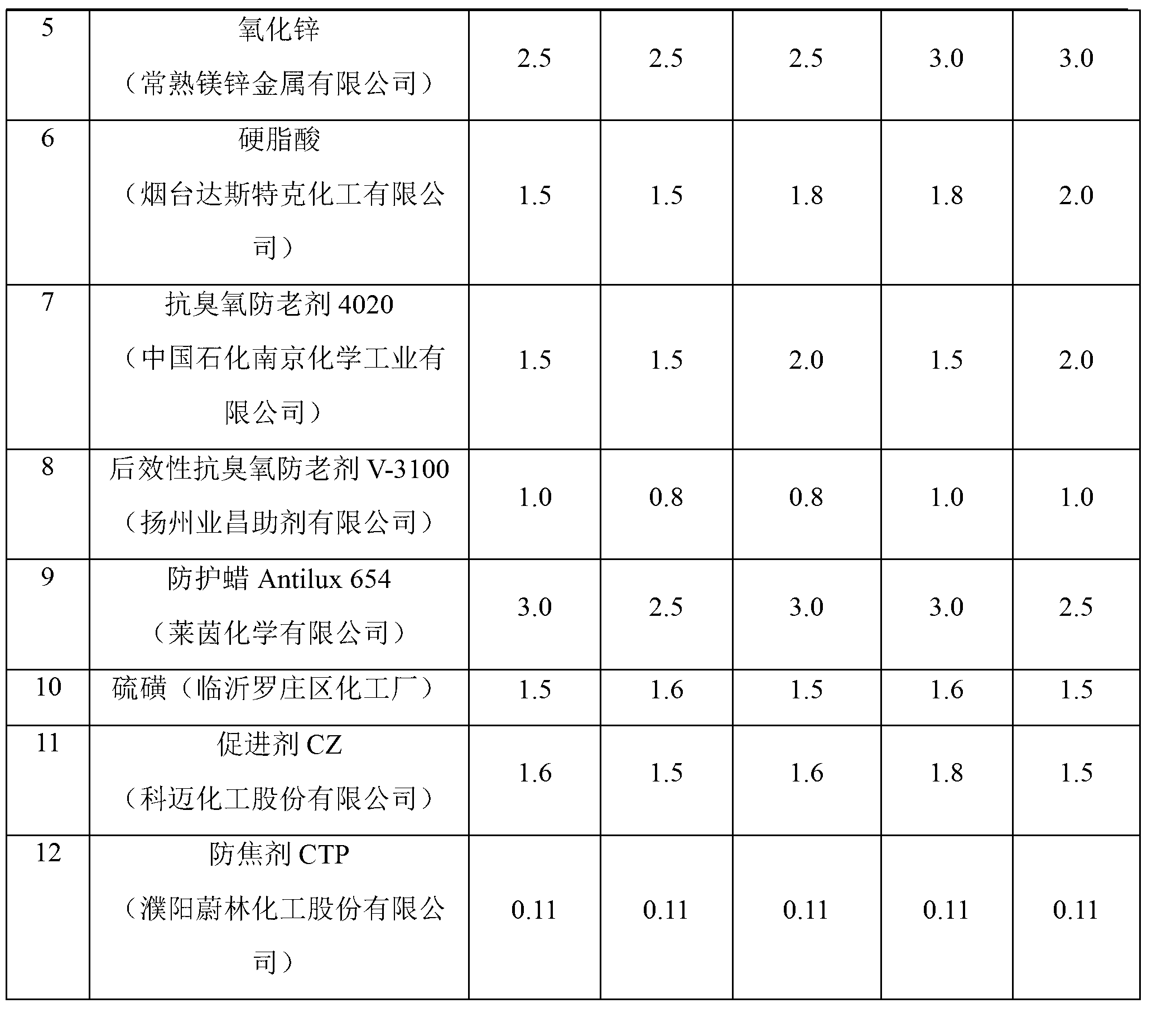

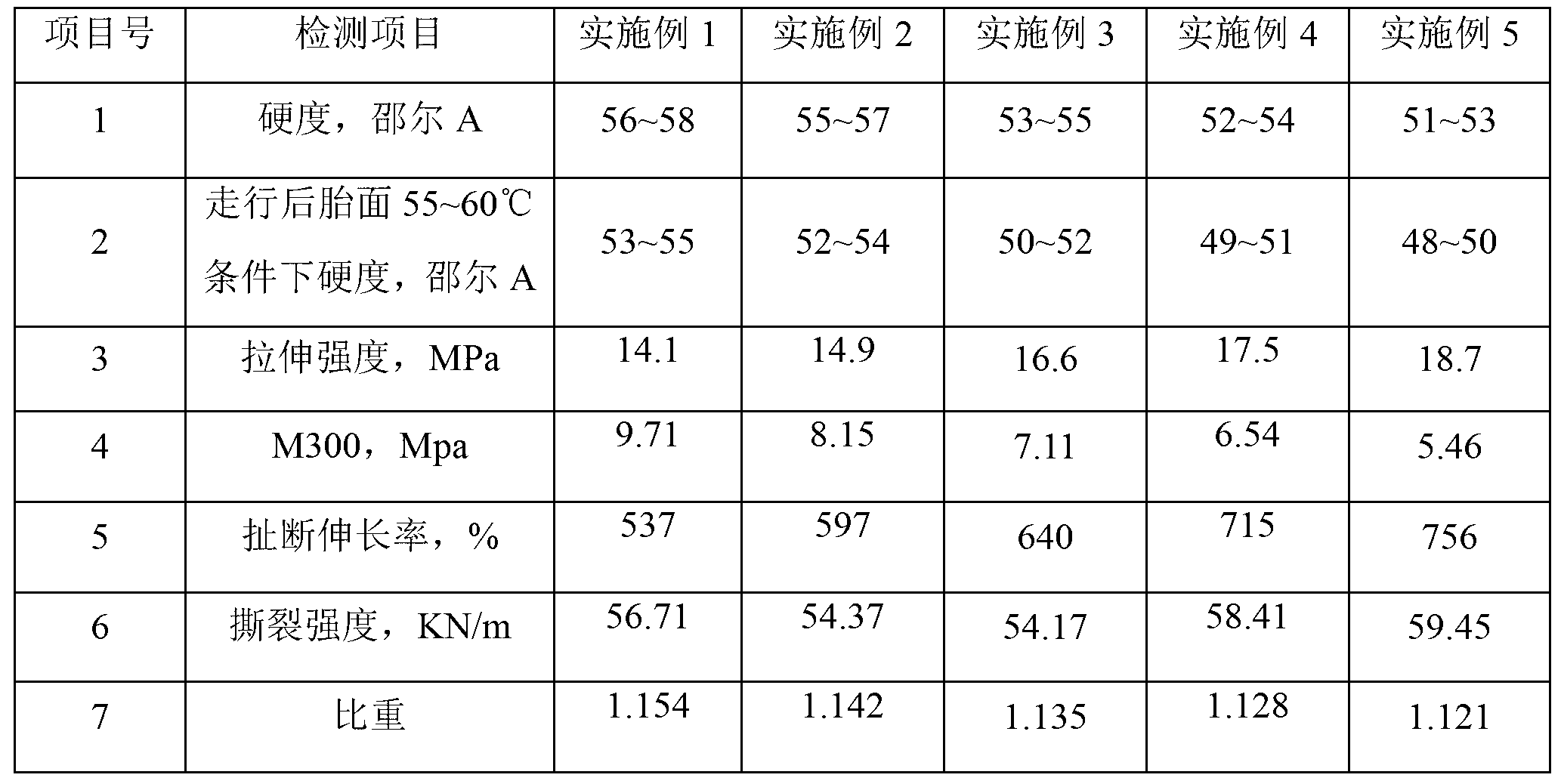

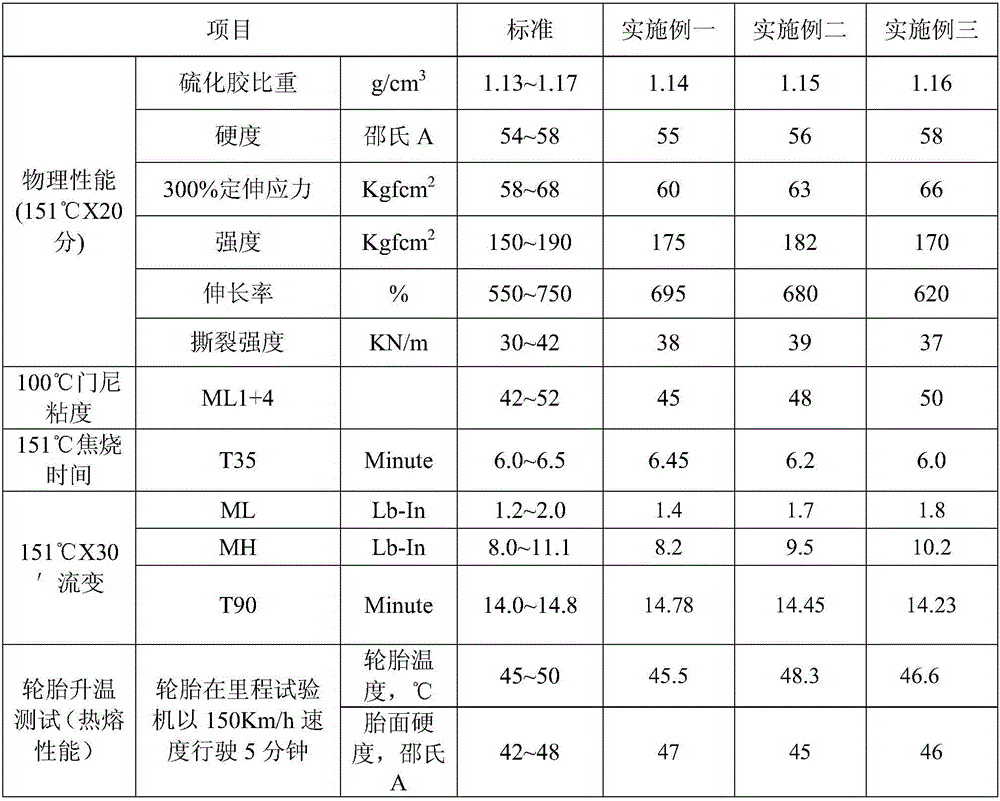

Half-hot-melting motorcycle tyre and preparation method thereof

ActiveCN103319755AImprove hot melt effectWork around limited usageSpecial tyresMotorcycle tyreStearic acid

The invention relates to a half-hot-melting motorcycle tyre and a preparation method of the half-hot-melting motorcycle tyre. The half-hot-melting motorcycle tyre is prepared by mixing and vulcanizing the raw materials comprising synthetic adhesive, solution polymerized styrene butadiene rubber, carbon black N339, aromatic hydrocarbon oil, zinc oxide, stearic acid, an anti-ozone age resister, protective wax, sulfur, an accelerant and a scorch retarder. Compared with the prior art, the half-hot-melting motorcycle tyre effectively solves the problem that the use of the conventional full-hot-melting tyre is limited, the road holding of the tyre is improved, the tyre is prevented from adsorbing too many foreign objects such as gravel and dust as a result of soft and sticky tyre surface, the phenomena of out of control of the tyre and excursion at a corner cannot occur frequently, so that the operation safety of vehicles is greatly improved, sufficient guarantee is provided for high road holding, operability and safety of vehicles. The half-hot-melting motorcycle tyre is suitable for being popularized and applied to tyres of motorcycles and the like.

Owner:TIUMSUN RUBBER TIRE WEIHAI

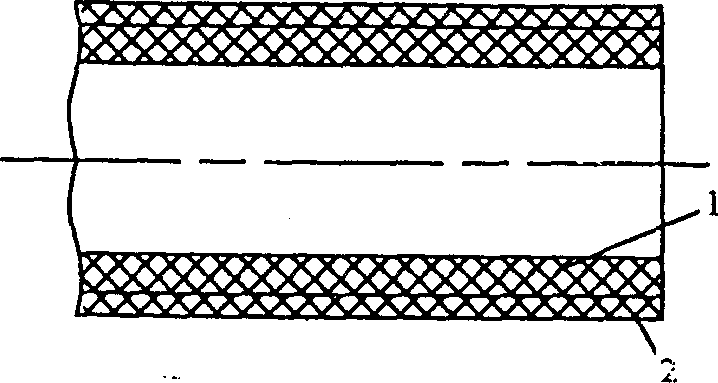

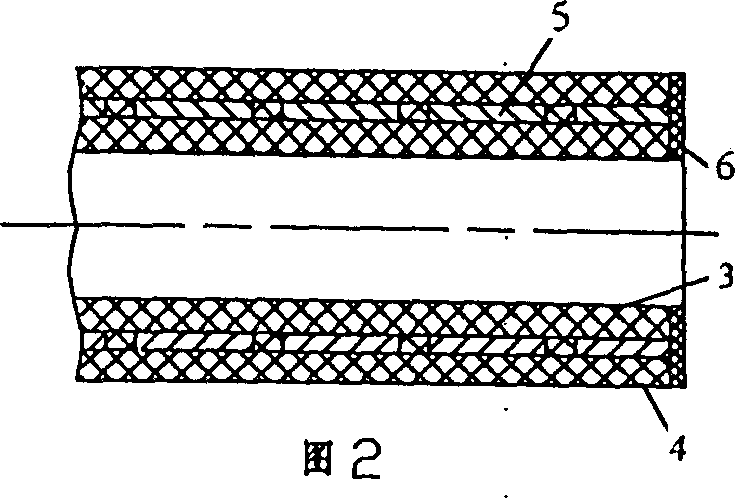

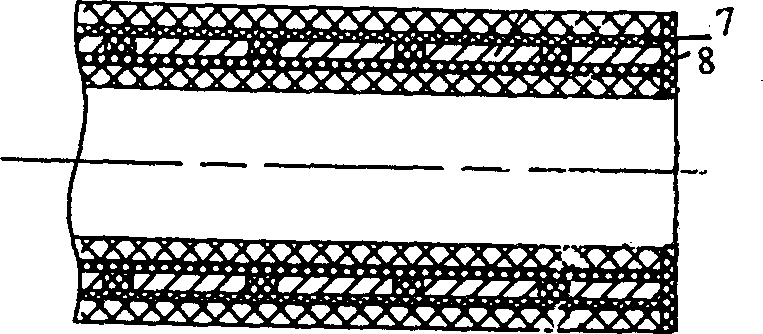

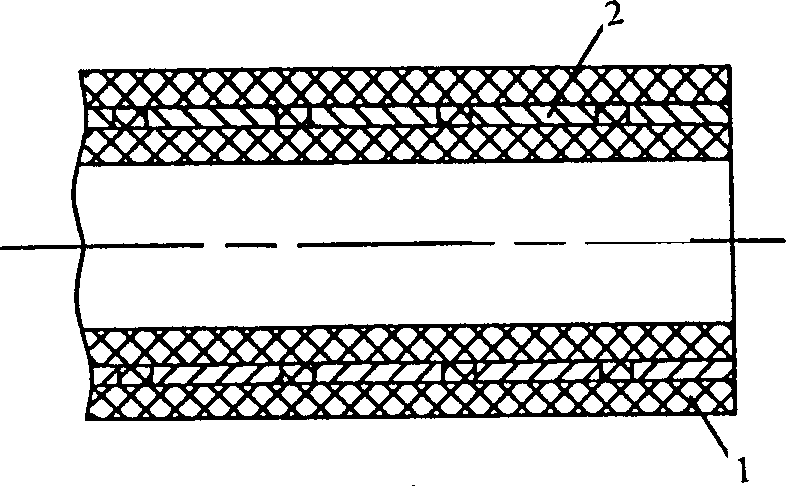

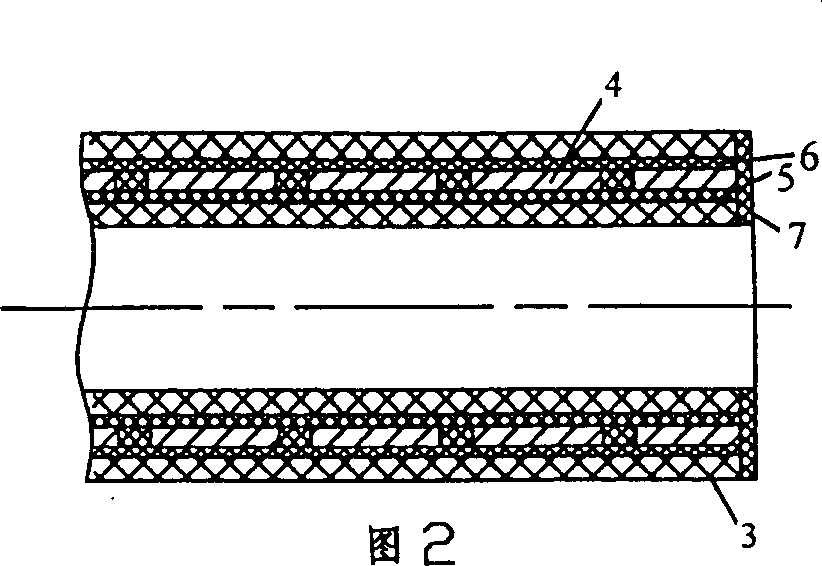

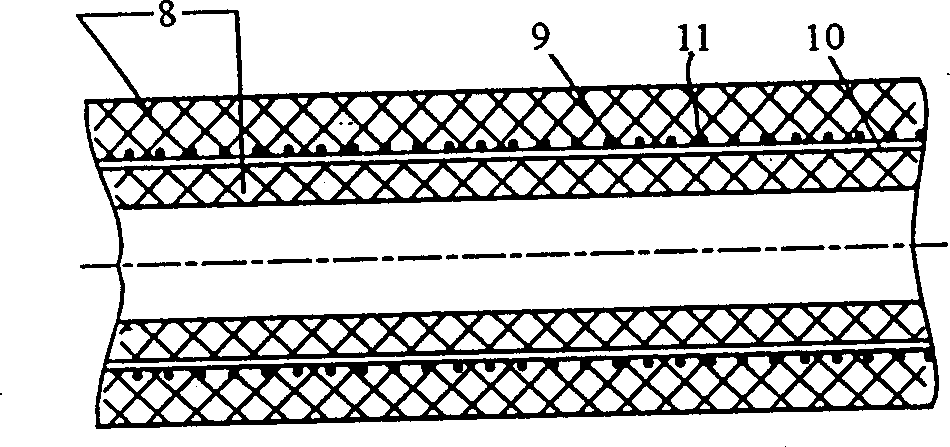

Metal skeleton reinforced non-cross-linking refractory polyethylene pipe

InactiveCN1396400AImproved environmental stress cracking resistanceImprove hot melt effectRigid pipesCross-linkHigh resistance

a non-crosslinked refractory polyethene pipe reinforced by metal skeleton is composed of a main body made of non-crosslinked refractory polyethene and a cylindrical reinforcing metallic skeleton skeleton embedded in the main body and made of curled reticular steel sheet or wound and welded steel wires. Its advantages are high resistance to low temp., high temp. and environment stress, good thermofusibility and long service life.

Owner:DONGTAI NEW MATERIAL SCI ANG TECH SICHUAN

Acrylic acid series hot melt adhesive and preparation method thereof

PendingCN110373135AIncrease stickinessHigh peel strengthAmide/imide polymer adhesivesEster polymer adhesivesPolymer scienceHot melt

The invention discloses an acrylic acid series hot melt adhesive. The acrylic acid series hot melt adhesive is prepared from the following raw materials in parts by weight: 60-95 parts of 2-ethylhexylacrylate, 20-26 parts of vinyl acetate, 13-16 parts of hydroxypropyl acrylate, 1.5-6 parts of acrylamide, 5.5-8 parts of 2-acetamidoacrylic acid, and 1.6-1.9 parts of azodiisobutyronitrile. Accordingto the acrylic acid series hot melt adhesive, through selection of raw material compositions, the content of the raw materials is optimized, the 2-ethylhexyl acrylate, the vinyl acetate, the hydroxypropyl acrylate, the acrylamide, the 2-acetamidoacrylic acid and the azodiisobutyronitrile with the appropriate proportion are selected, the respective advantages are fully played, mutual complementation and mutual promotion are also achieved, thus the prepared acrylic acid series hot melt adhesive the large holding power (holding force) and the high 180-degree peel strength, and that is, the binding performance is good; and the acrylic acid series hot melt adhesive has the good hot melt performance and the good flowing performance at the high temperature, and is more convenient to use.

Owner:浙江铂淳新材料股份有限公司

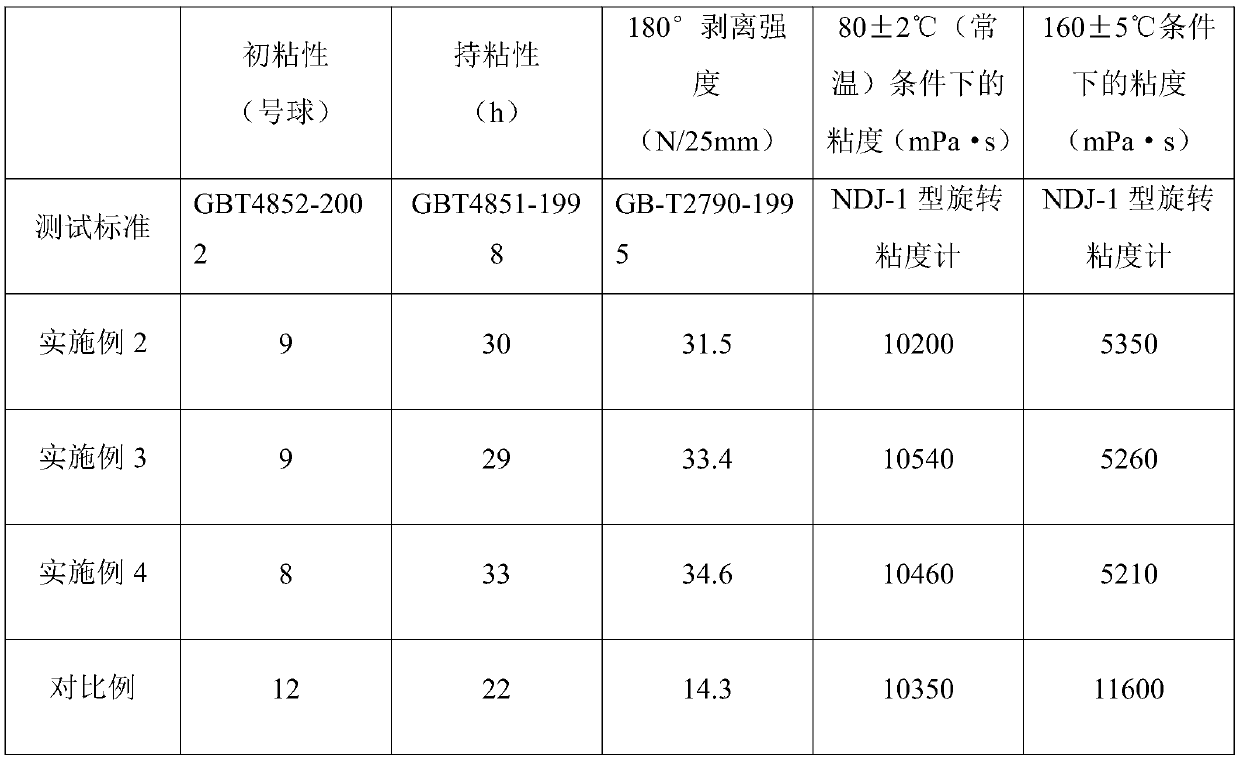

Motorcycle tire semi-hot melt adhesive and preparation method thereof

ActiveCN105802545AImprove wear resistanceHigh tear strengthNon-macromolecular adhesive additivesConjugated diene hydrocarbon adhesivesPolymer scienceMotorcycle tyre

The invention relates to a motorcycle tire semi-hot melt adhesive and a preparation method thereof. The motorcycle tire semi-hot melt adhesive is prepared from the following ingredients in parts by weight: 114.1 to 119.6 parts of oil-extended butadiene-styrene rubber, 13 to 17 parts of styrene-butadiene-acrylonitrile copolymers, 70 to 75 parts of carbon black, 2 to 3 parts of zinc oxide, 1.5 to 2 parts of stearic acid, 12 to 16 parts of aromatic oil, 1.3 to 1.8 parts of anti-aging agents 4020, 0.6 to 1 part of anti-aging agents DTPD, 2.5 to 3.5 parts of protection wax, 1 to 2 parts of auxiliaries, 1 to 2 parts of homogenizing agents, 1.2 to 1.6 parts of sulphur, 1.5 to 2.5 parts of accelerants CBS and 0.1 to 0.3 part of accelerants DM. During the preparation, an internal mixer is used for performing primary mixing on the raw materials to prepare primary rubber master batch; then, still standing is performed; finally, the internal mixer is used for final mixing to obtain the finished product of the semi-hot melt adhesive. The preparation method is simple; the operation of the steps is easy; the prepared semi-hot melt adhesive tire rubber has better hot melting performance, so that a tire can fast become hot during running, and good ground grasping force can be provided; therefore a motorcycle has good starting accelerating performance and driving turn road safety performance.

Owner:JIANGSU GENERAL SCI TECH

Polyimide material and preparing method and application thereof

ActiveCN106519685AImprove hot melt effectLow dielectric constantLaminationLamination apparatusOrganic solventThio-

The invention discloses a polyimide material. The preparing method of the material comprises the steps of adding other aromatic diamine monomers, then adding diphenyl ketone-4, 4'-double(4-thio-1, 8-naphthalene anhydride) and 3, 3', 4, 4'-tetracarboxydiphthalic ether dianhydride, as well as other diphenyl ketone-4, 4'-double(4-thio-1, 8-naphthalene anhydride) and other 3, 3', 4, 4'-tetracarboxydiphthalic ether dianhydride, and then adding an organic solvent into the mixture of 3, 5-diaminobenzoic-4'-diphenyl ester and 2, 2'-bis[4-(4-aminophenoxy)phenyl]propane(bapp) to react to obtain polyimide precursor solution; smearing the polyimide precursor solution on a glass plate, removing the solvent, and performing solidification to obtain a polyimide film; heating the polyimide film to 400-420 DEG C, and keeping for 3-10 minutes; afterwards, reducing the temperature of the polyimide film to room temperature to obtain the polyimide material. The invention further discloses the application of the polyimide material.

Owner:NANJING ZHONGHONG RUNNING ADVANCED MATERIAL TECH CO LTD

Preparation method of environment-friendly veneer board

InactiveCN107932652AImprove hot melt effectDoes not affect adhesive propertiesNon-macromolecular adhesive additivesStarch adhesivesAdhesivePulp and paper industry

The invention discloses a preparation method of an environment-friendly veneer board. The preparation method comprises the following steps that raw wood is processed, specifically the raw wood is dried, more specifically, wood pieces generated after annular cutting are placed into a drying chamber, the temperature is controlled to be 50-80 DEG C, and continuous drying is conducted for 12-24 h; adhesive applying is conducted, specifically, an adhesive is applied to the wood pieces; softening is conducted, specifically, the wood pieces are heated to be softened, the heating temperature is 50-70DEG C. the softening time is 0.1-0.4 h, and then the wood pieces are flattened through a press roller; pre-pressing is conducted, specifically, the wood pieces are subjected to assembling and then placed into a hot pressing machine to be pre-pressed, and then a rough board is obtained; edge cutting and hot pressing are conducted, specifically, the rough board is cut into a stock board, then hot pressing is conducted, and a board is obtained; and the board is repaired and polished, and finally the board is subjected to edge sawing forming and overhauling to obtain the veneer board. According tothe preparation method of the environment-friendly veneer board, through the adhesive prepared by the applicant, the holt melting performance of the adhesive is good, the temperature of the veneer board in pre-pressing is reduced, the adhesion performance of the adhesive is not affected, the wood pieces can be more easily adhered and flattened in low-temperature pre-pressing, and the veneer boardlayer is more compact and stable in structure.

Owner:黄桂凤

Improved wood floor adhesive

InactiveCN104403614AGood adhesionImprove hot melt effectNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesEpoxyAdhesive cement

The invention discloses an improved wood floor adhesive which is prepared from the following raw materials in part by weight: 1.5-3.7 parts of diethanol amine maleic anhydride complex ester, 0.8-1.7 parts of poly(epoxy glycerin ether), 2-3.7 parts of butyl acetate, 3-7 parts of asbestos powder, 0.6-1.5 parts of diisocyanate, 2-3.5 parts of monoglyceride decanoate, 1.3-3.5 parts of glycidyl trimethyl ammonium chloride-gliadin-glyoxal resin, and 0.5-2.7 parts of natamycin. Compared with the conventional product, the improved wood floor adhesive is nontoxic, contains no methanal, does not pollute the environment, has excellent bonding effect as the adhesive property and hot-melting performance of the glycidyl trimethyl ammonium chloride-gliadin-glyoxal resin are high, and is long in service life; the improved wood floor adhesive is high in bonding performance and excellent in mechanical property, and has insect prevention effect; the termite erosion can be effectively prevented by virtue of the combination of the natamycin and the monoglyceride decanoate, so that the possibility of insect attack is reduced; the production technology is simple, the production cost is low, and the popularization is facilitated.

Owner:QINGDAO LAOXIANG TEA PROD

Hot melting technological method for cellulose acetate fiber particles

The invention relates to the technical field of hot-melt technology, in particular to a hot-melt technology for cellulose acetate particles. The steps of the process are: baking particles, color mixing, extrusion, crushing, mixing and hot melting. The present invention maximizes the hot melting effect of acetate cellulose particles and prevents the gap between the two color particles. The mutual penetration of colors improves the color recognition of finished products.

Owner:温州中慧塑胶有限公司

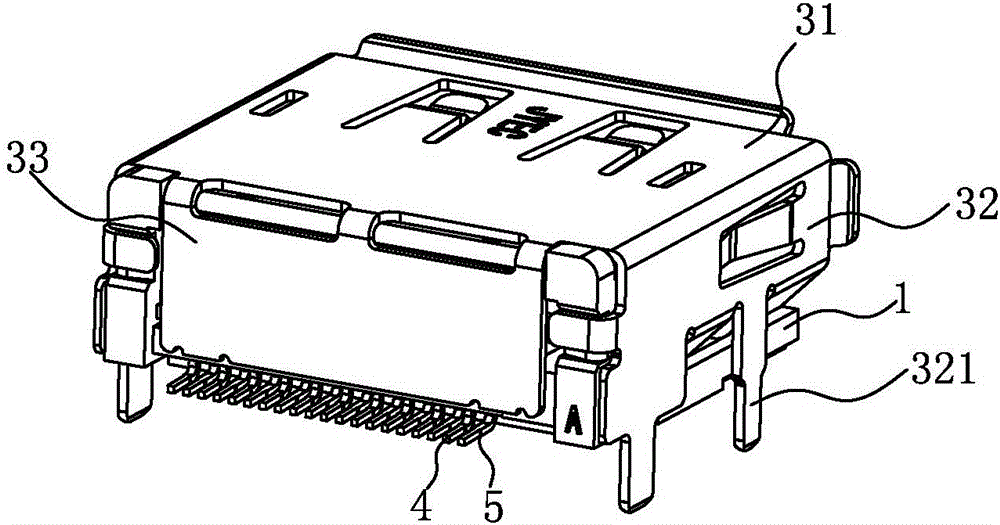

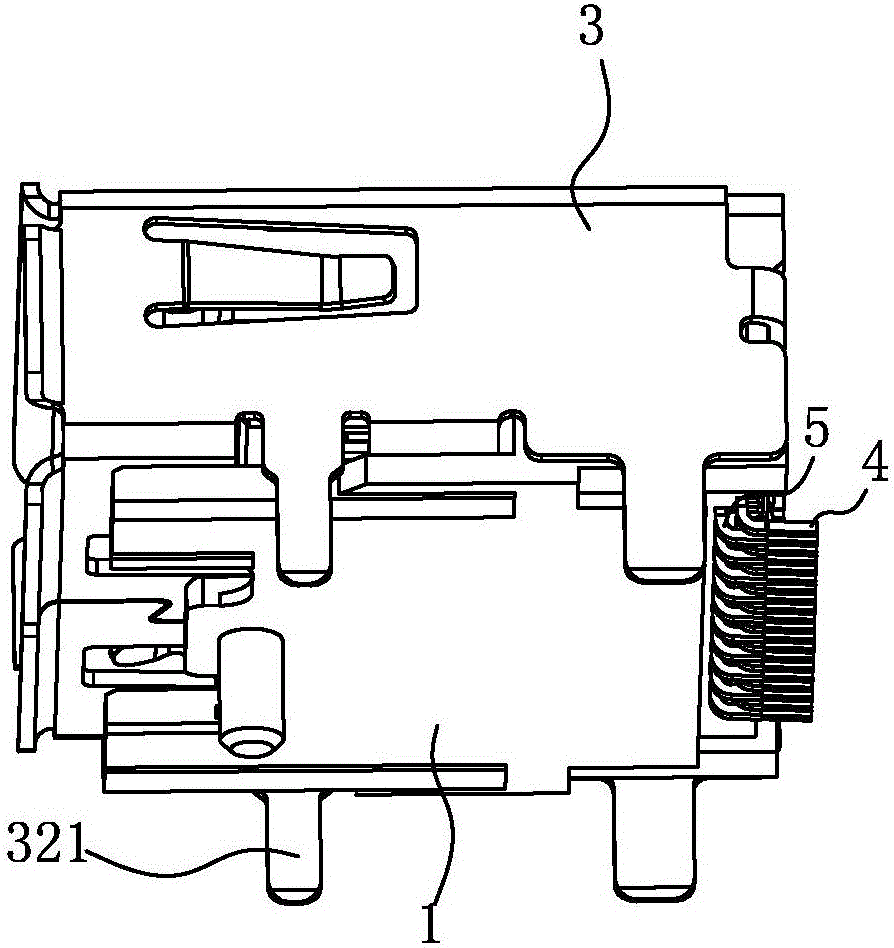

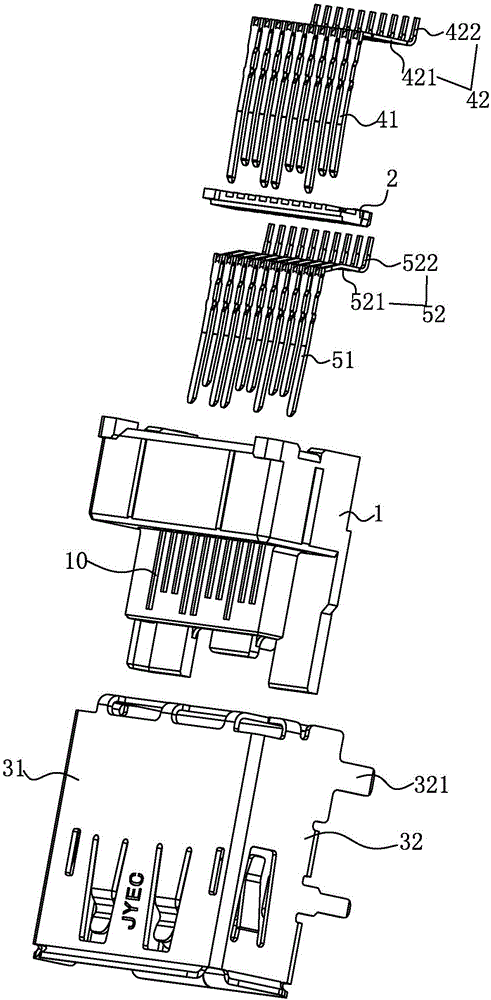

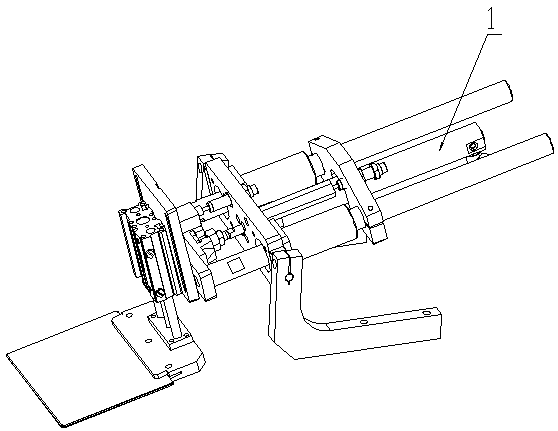

Display connector and fabrication method thereof

InactiveCN106207586AGood for hot melt operationGood hot melt effectContact member assembly/disassemblyCoupling contact membersEngineeringCrosstalk

The invention discloses a display connector and a fabrication method thereof. The display connector comprises an insulation base, a terminal group, an insulation rear plug and a metal shell, wherein the insulation rear plug is used for limiting and hot-melting wrapping the terminal group. In the display connector, the insulation rear plug is additionally arranged at a rear end of the insulation base, a second contact part surface of a lower-layer terminal is in contact with a bottom surface of the insulation rear plug by the insulation rear plug, a first contact part surface of an upper-layer terminal is flush with a boss surface of the insulation rear plug, the insulation rear plug is subjected to hot melting by a jig to form plastic barriers so as to wrap contact parts of the upper-layer terminal and the lower-layer terminals and achieve a fixing effect, the coplanarity and the alignment degree of welding parts of the upper-layer terminal and the lower-layer terminal can be effectively ensured, high stability is achieved, terminal pins are not needed to be adjusted by manual, and the production efficiency is improved; and moreover, after the upper-layer terminal and the lower-layer terminal are assembled, a first pin part and a second pin part are staggered vertically, and crosstalk can be enabled not to be generated in high-frequency signal transmission of the upper-layer terminal and the lower-layer terminal very well.

Owner:东莞市竞跃电子有限公司

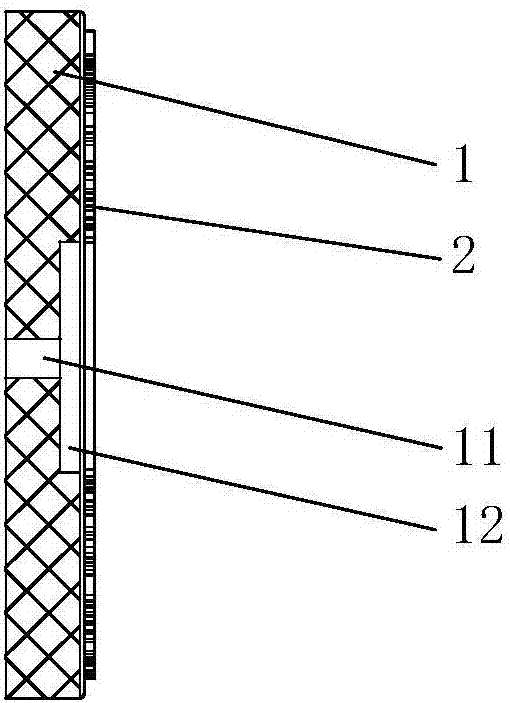

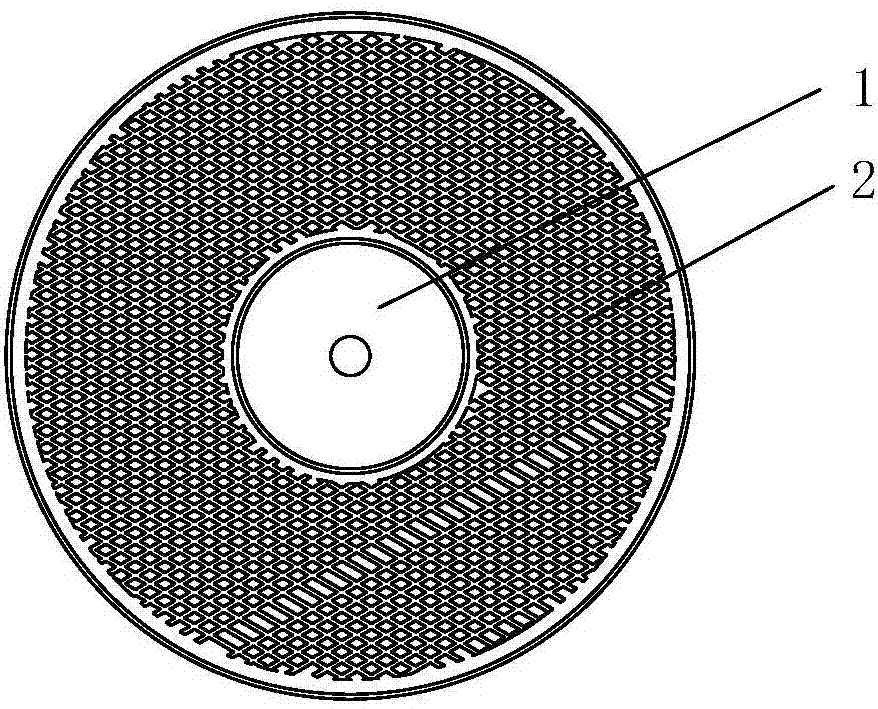

Plastic and iron sheet composite gasket and electromagnetic welding equipment

PendingCN107116863AFast heatingGood hot melt effectLaminationLamination apparatusPorous sheetMagnet coil

The invention discloses a plastic and iron sheet composite gasket and electromagnetic welding equipment. The plastic and iron sheet composite gasket comprises a plastic sheet and an iron sheet, wherein a first through hole is formed in the plastic sheet; a second through hole is formed in the iron sheet; the plastic sheet and the iron sheet are connected together to form the composite gasket; the second through hole is directly communicated with the first through hole; the iron sheet is a net-shaped or porous sheet; the plastic sheet is provided with a first concave cavity, and the concave cavity is communicated with the first through hole. The electromagnetic welding equipment comprises an electromagnetic control box and an electromagnetic gun, wherein a control driver is arranged in the electromagnetic control box; the electromagnetic gun comprises a gun cylinder, a gun handle, an electromagnetic coil, a non-magnetic conduction press ring and a switch; the gun handle is structurally connected with the gun cylinder; the electromagnetic coil is fixedly arranged at the front end of the interior of the gun cylinder, and is electrically connected with the control driver, and the electromagnetic coil is used for heating the iron sheet; the non-magnetic conduction press ring is fixedly arranged at the frontmost end of the gun cylinder and is close to the electromagnetic coil; the switch is electrically connected with the control driver, and is used for controlling the energizing or deenergizing of the electromagnetic coil. The plastic and iron sheet composite gasket and the electromagnetic welding equipment have the beneficial effects that the heating speed is high, the heat melting effect is good, the adhering is firm, and the damage to the plastic plate surface is avoided.

Owner:WENZHOU YONG HENG TECH

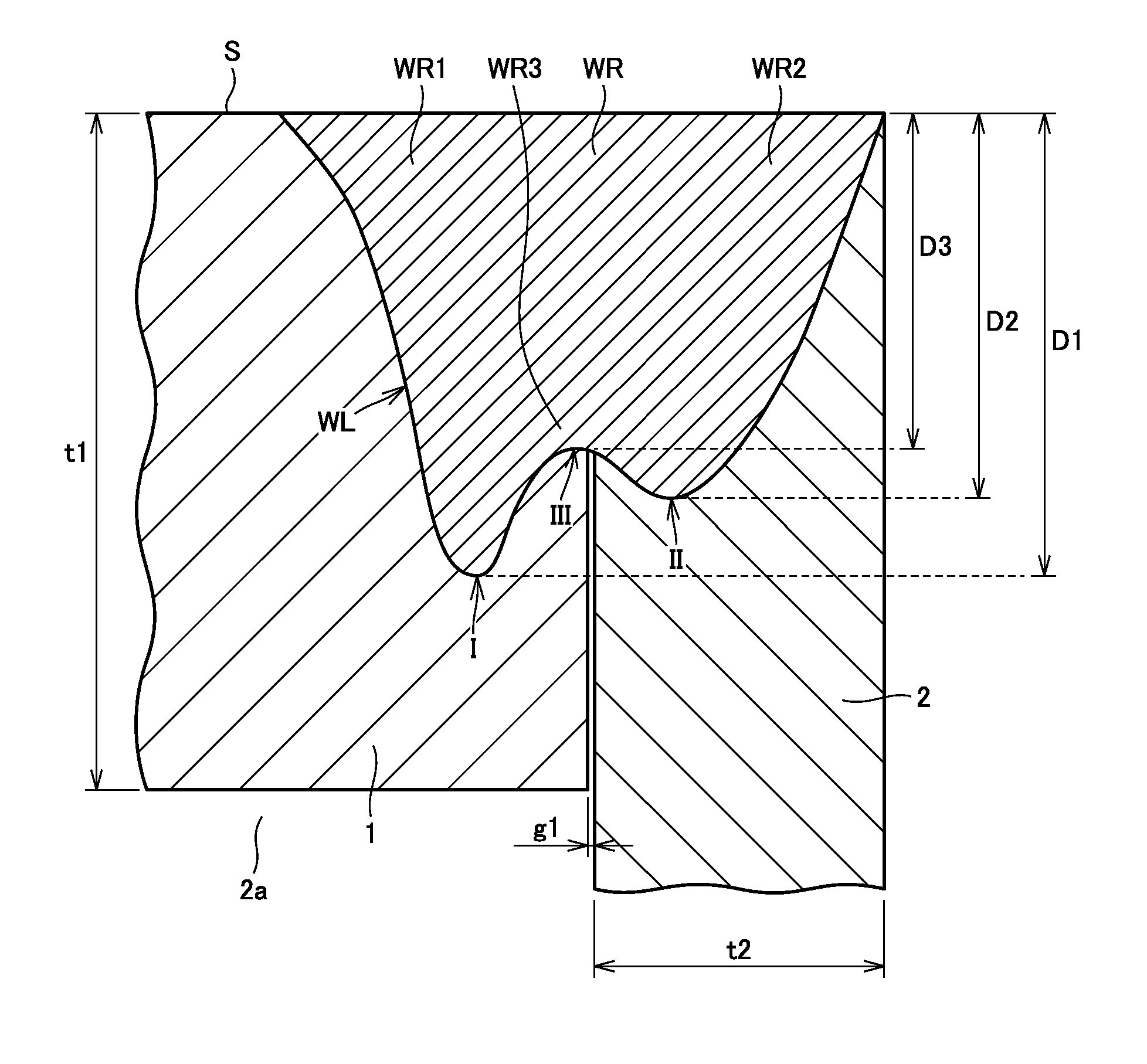

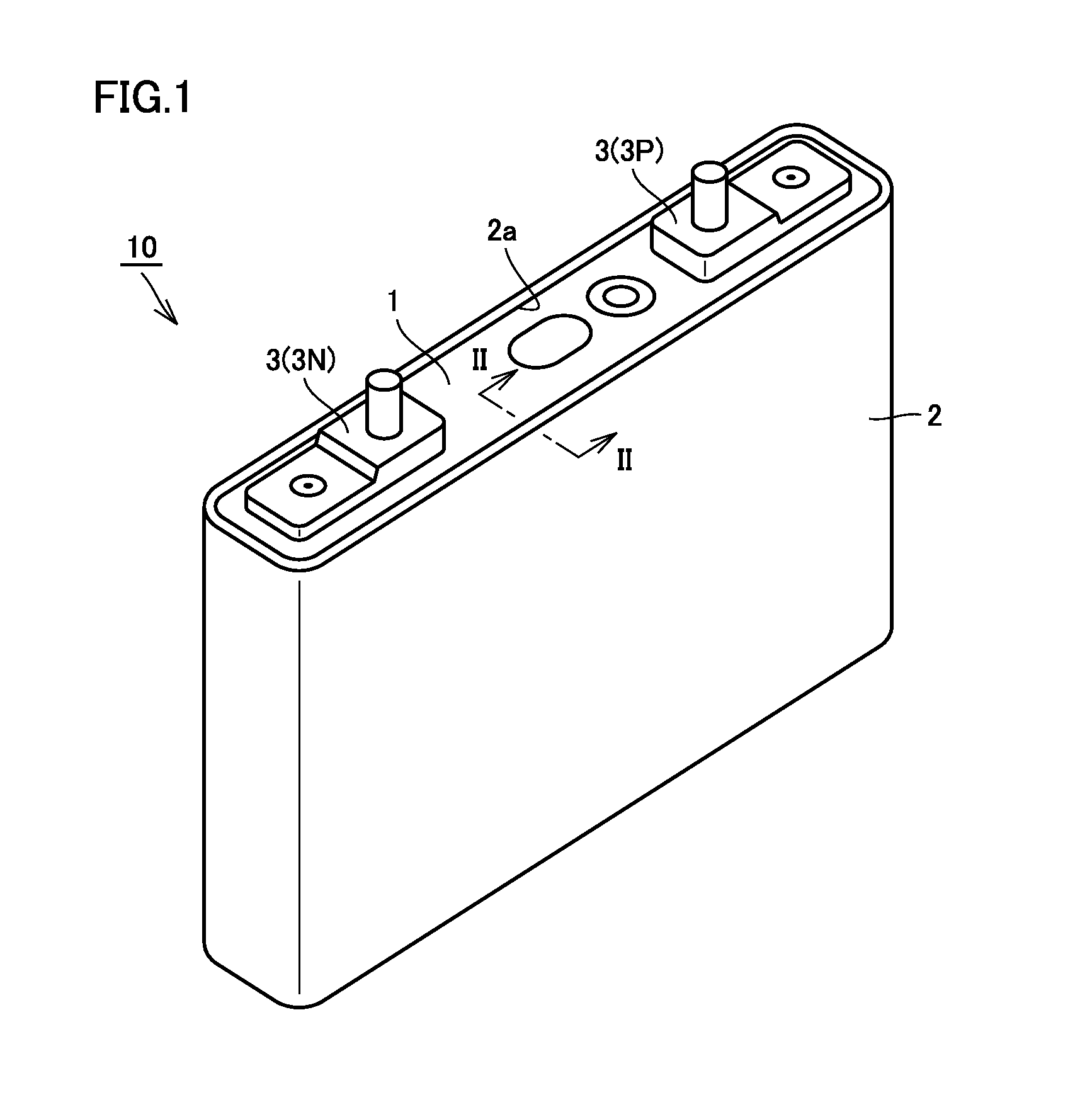

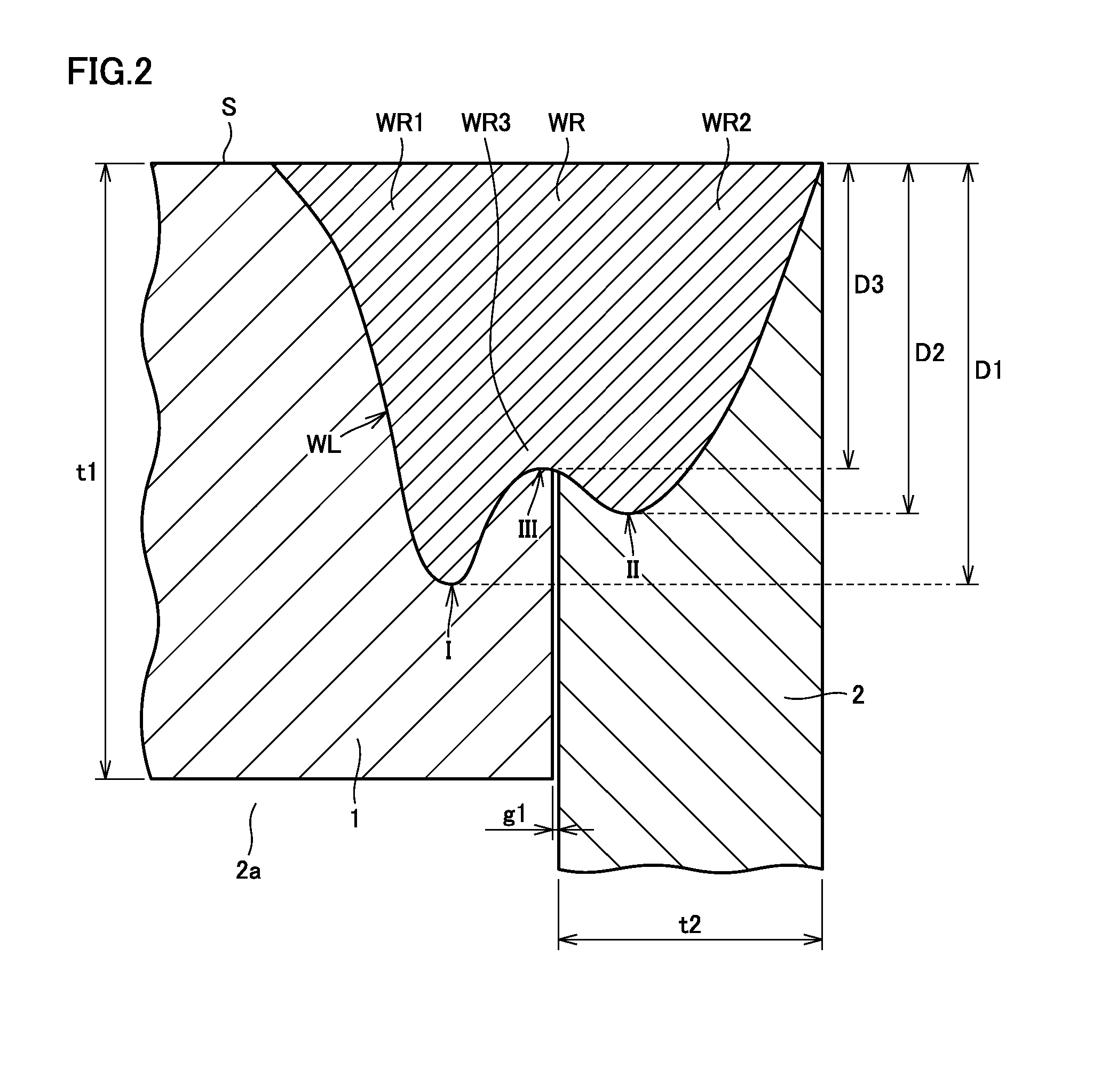

Secondary battery and method for manufacturing the same

ActiveUS20150349303A1Large capacityIncrease capacityFinal product manufactureSecondary cells manufactureButt weldingElectrical battery

Provided is a secondary battery in which a battery lid is fixed to a battery case by inserting the battery lid into an opening of the battery case having the opening, and emitting laser beams to a butting portion between the battery case and the battery lid to perform butt welding, wherein, when a battery lid-side welding mark formed in the battery lid has a distance from a surface of the battery lid to a lower end of the battery lid-side welding mark which is defined as a battery lid-side welding depth, and a battery case-side welding mark formed in the battery case has a distance from the surface of the battery lid to a lower end of the battery case-side welding mark which is defined as a battery case-side welding depth, the battery lid-side welding depth is deeper than the battery case-side welding depth.

Owner:TOYOTA JIDOSHA KK

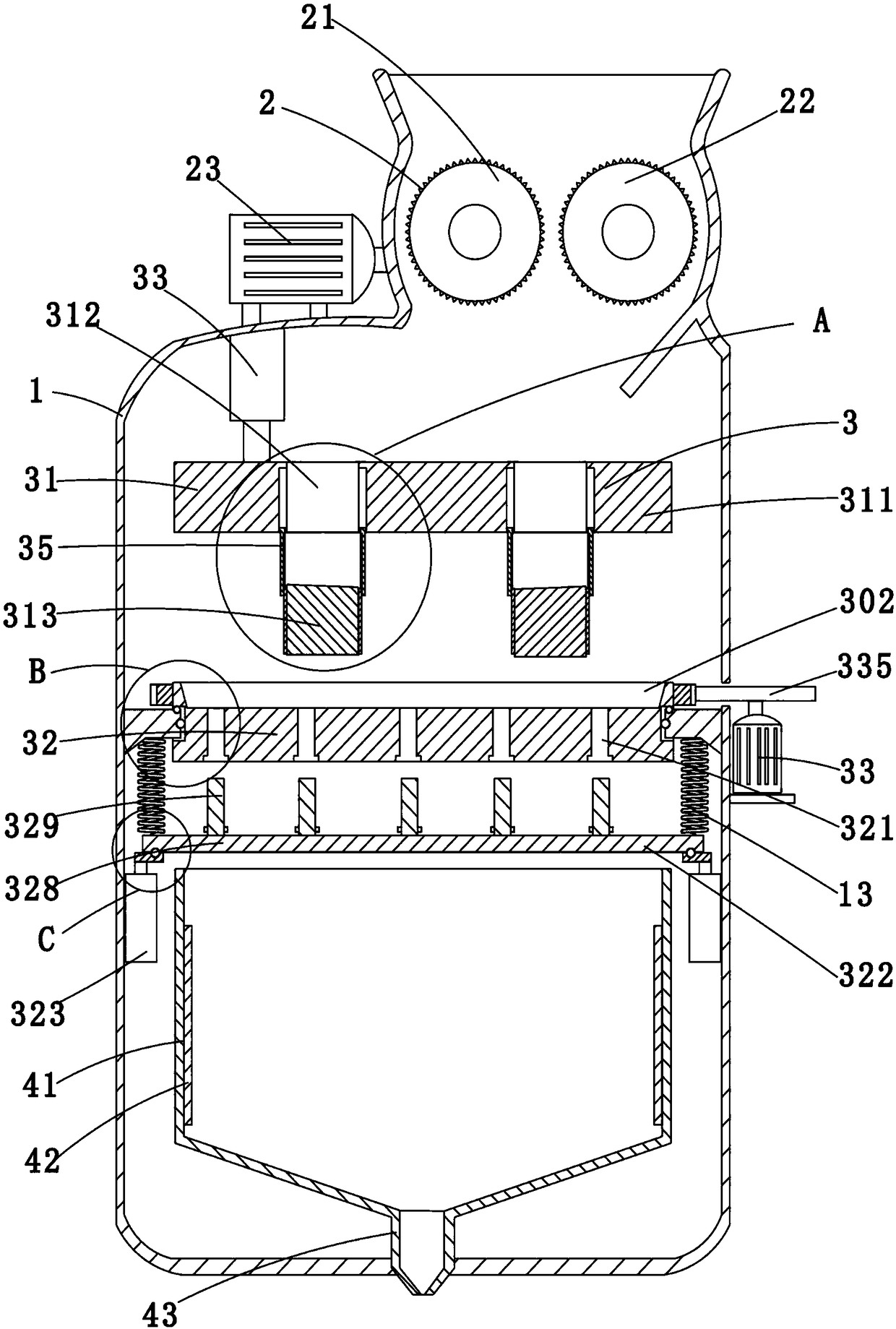

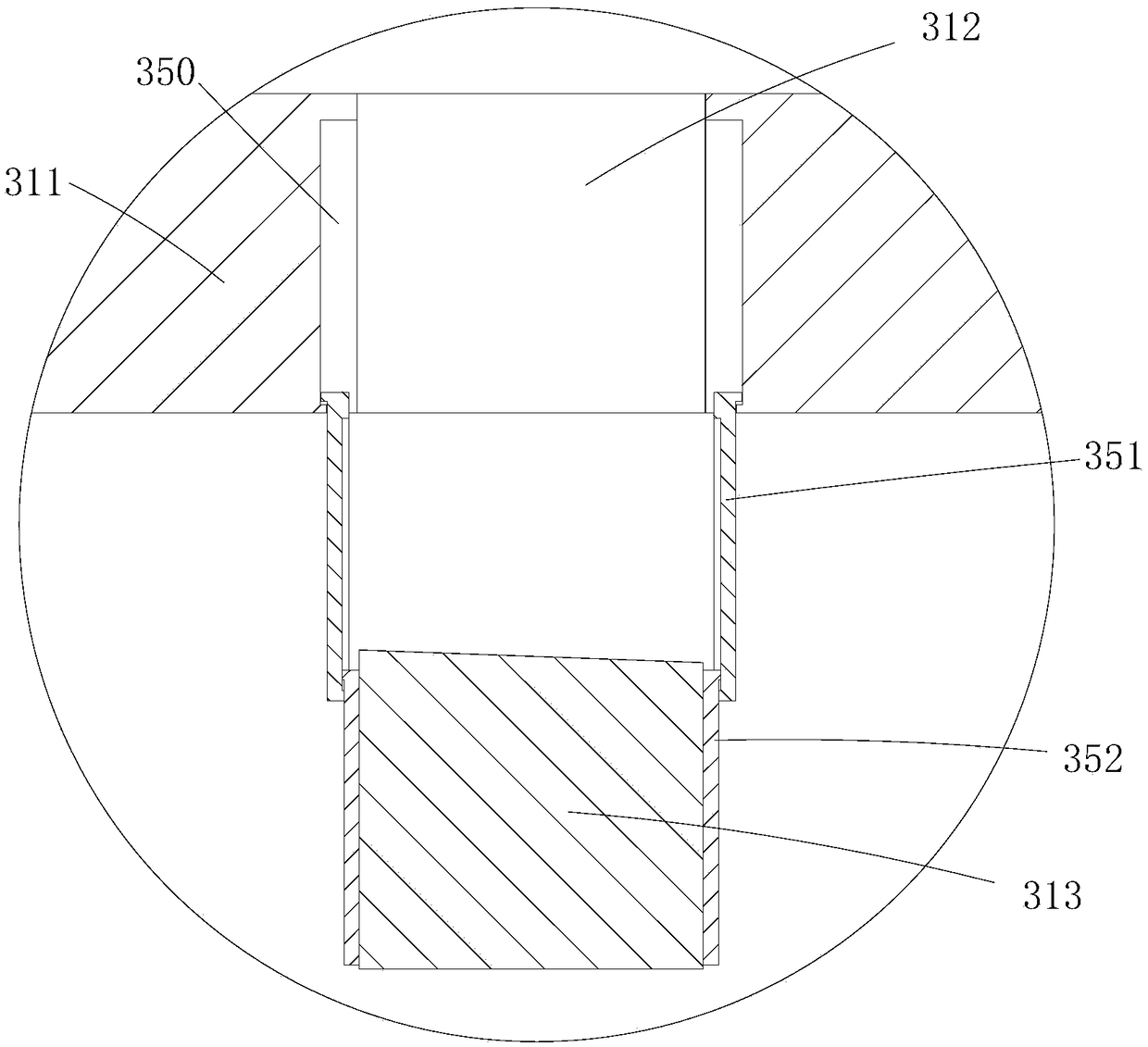

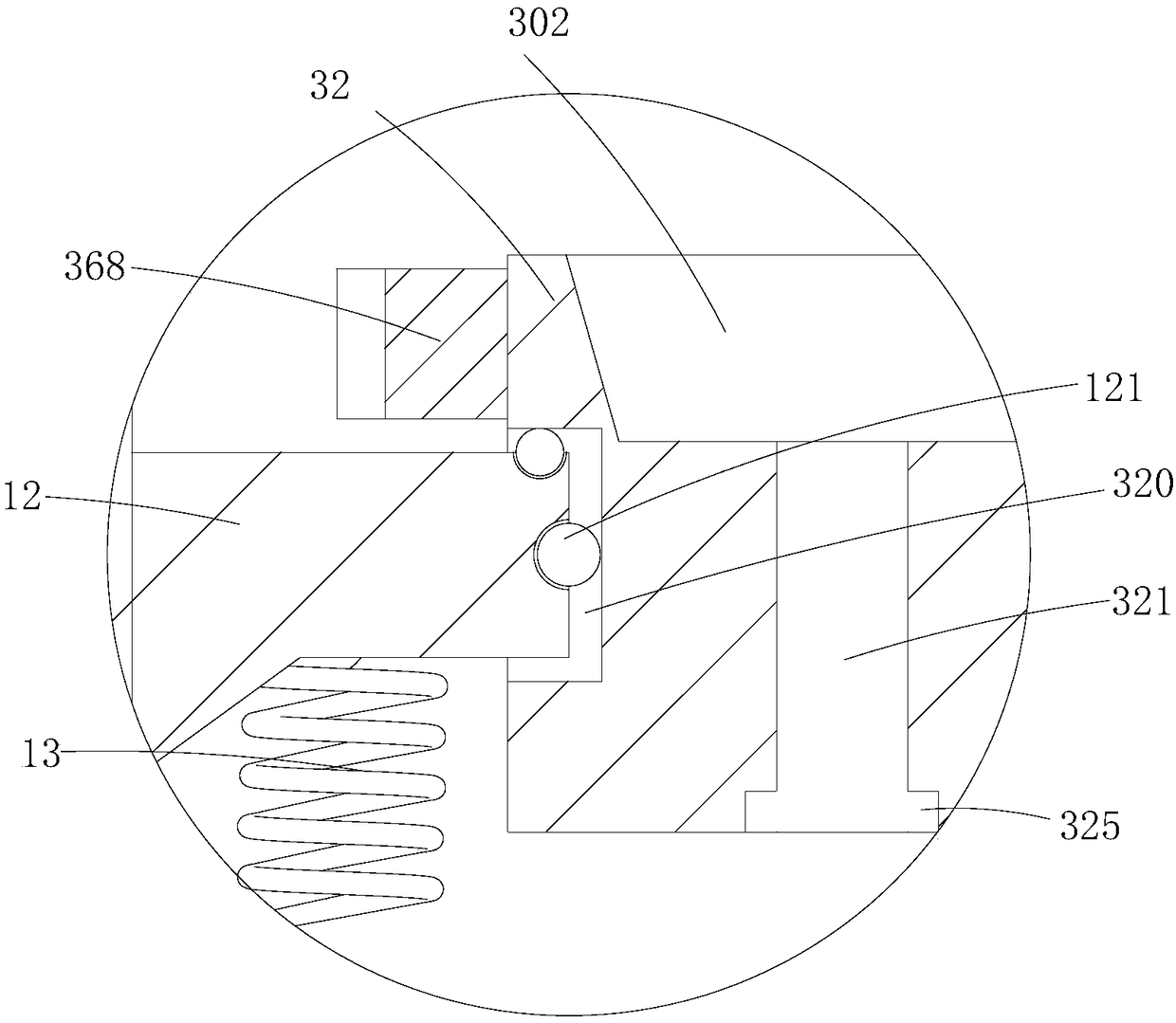

Packaging machine capable of achieving bean screening

The invention relates to a packaging machine capable of achieving bean screening. The packaging machine comprises a rack and a power distribution control box. A packaging box conveying device matched with a packaging box vibration feeding plate is arranged on the rack. A bean feeding hopper and a film pressing mechanism are sequentially arranged above the packaging box conveying device. The bean feeding hopper is matched with a screening device. The screening device comprises a screening seat. A shaking device is arranged on the screening seat. The shaking device comprises a shaking motor arranged on the screening seat. The shaking motor is matched with a shaking movable seat through a shaking rotating handle. The shaking movable seat is connected with a shaking frame through a shaking connecting rod, and the middle portion of the shaking connecting rod is hinged to the shaking seat. The shaking frame is provided with a screen matched with beans, and a screening discharging sliding groove matched with the screen is formed in the end portion of the shaking seat. The screening discharging sliding groove is matched with the bean feeding hopper. The packaging machine can be in well butt joint with the bean feeding hopper while a good screening function is achieved, and the bean feeding efficiency is improved.

Owner:安徽茉莉花食品科技发展有限公司

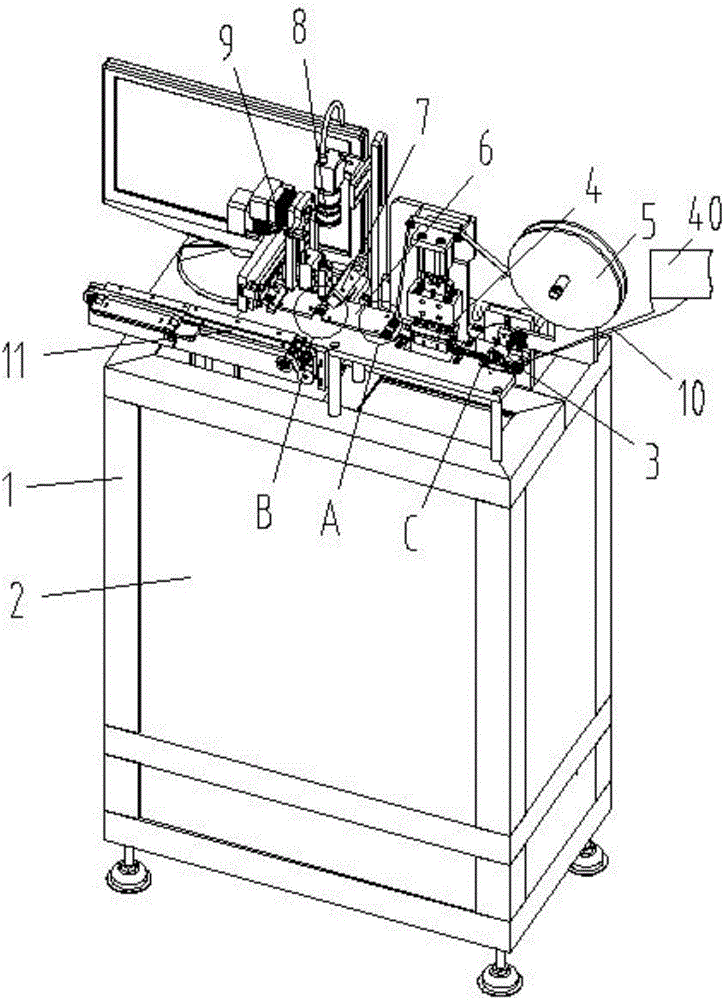

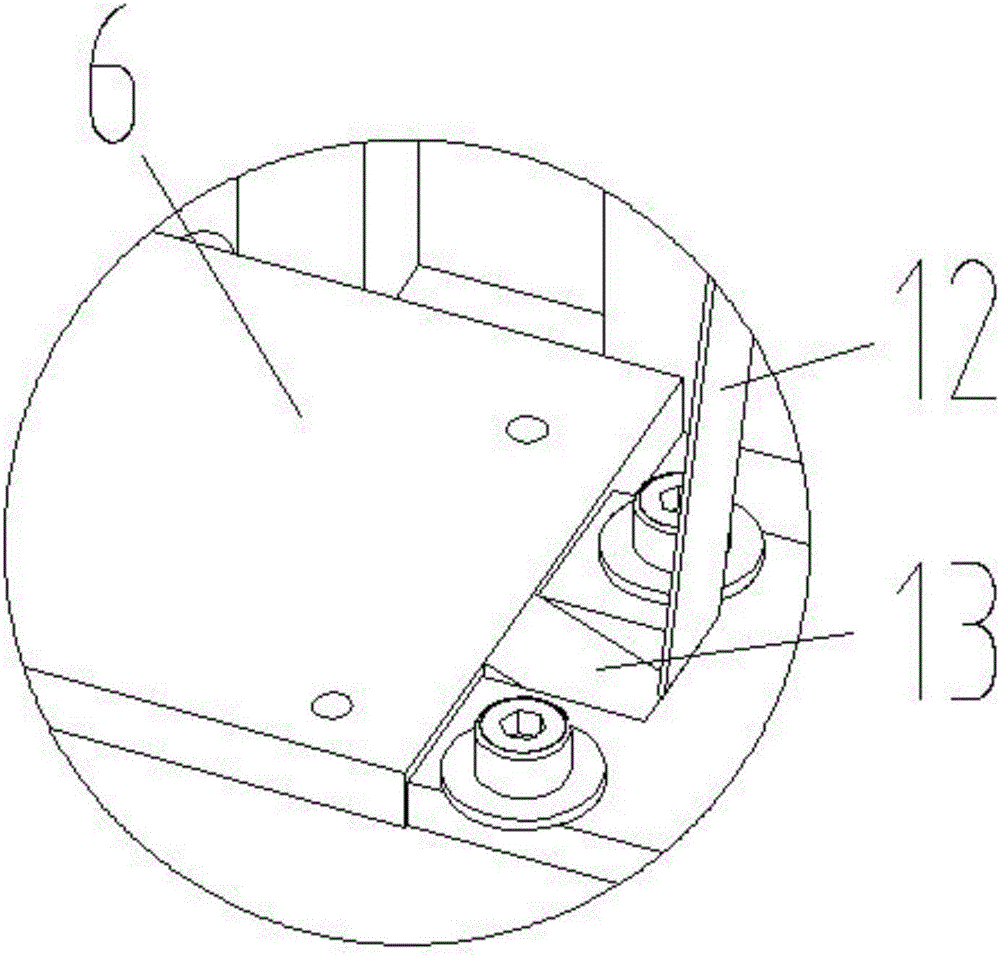

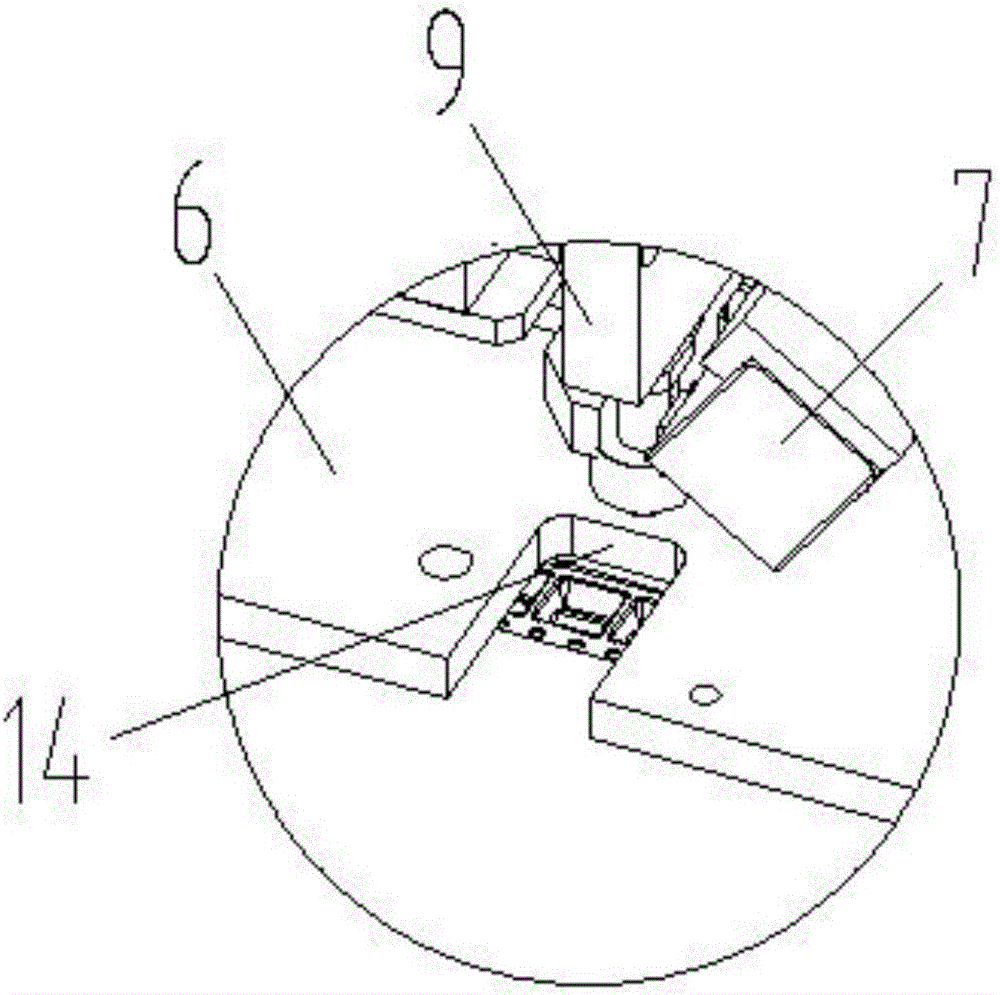

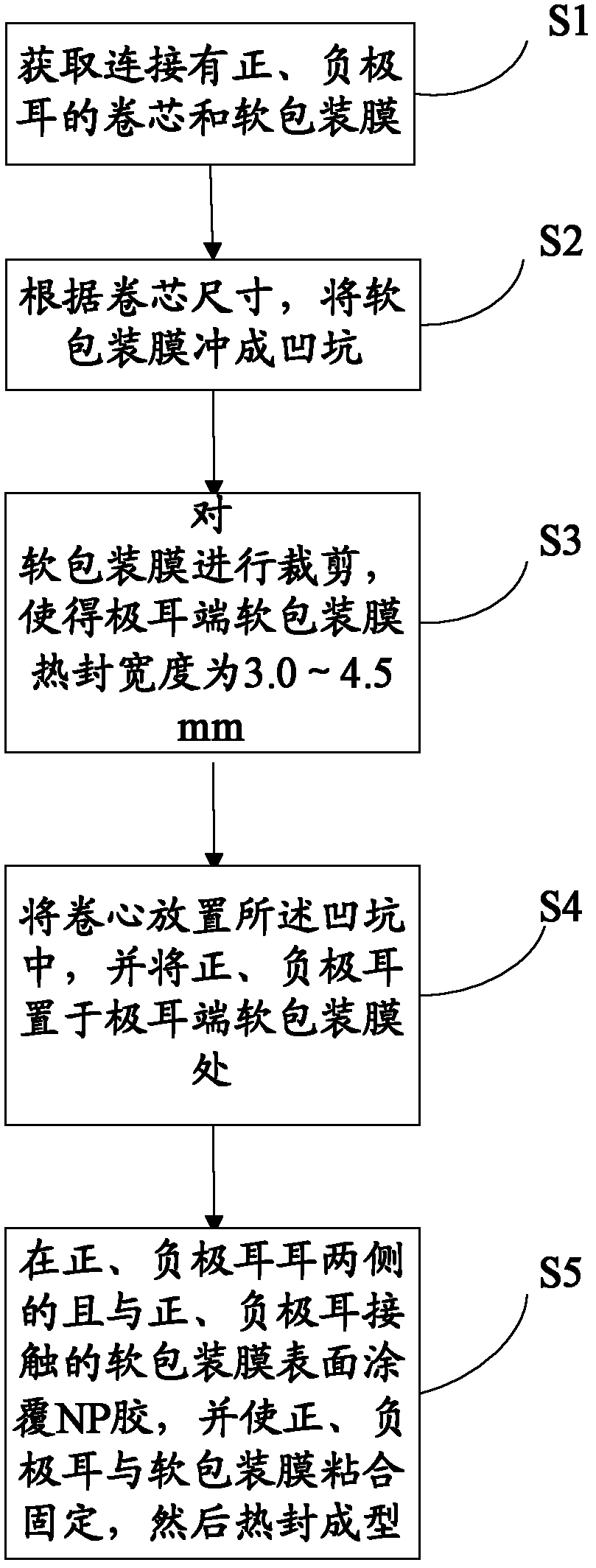

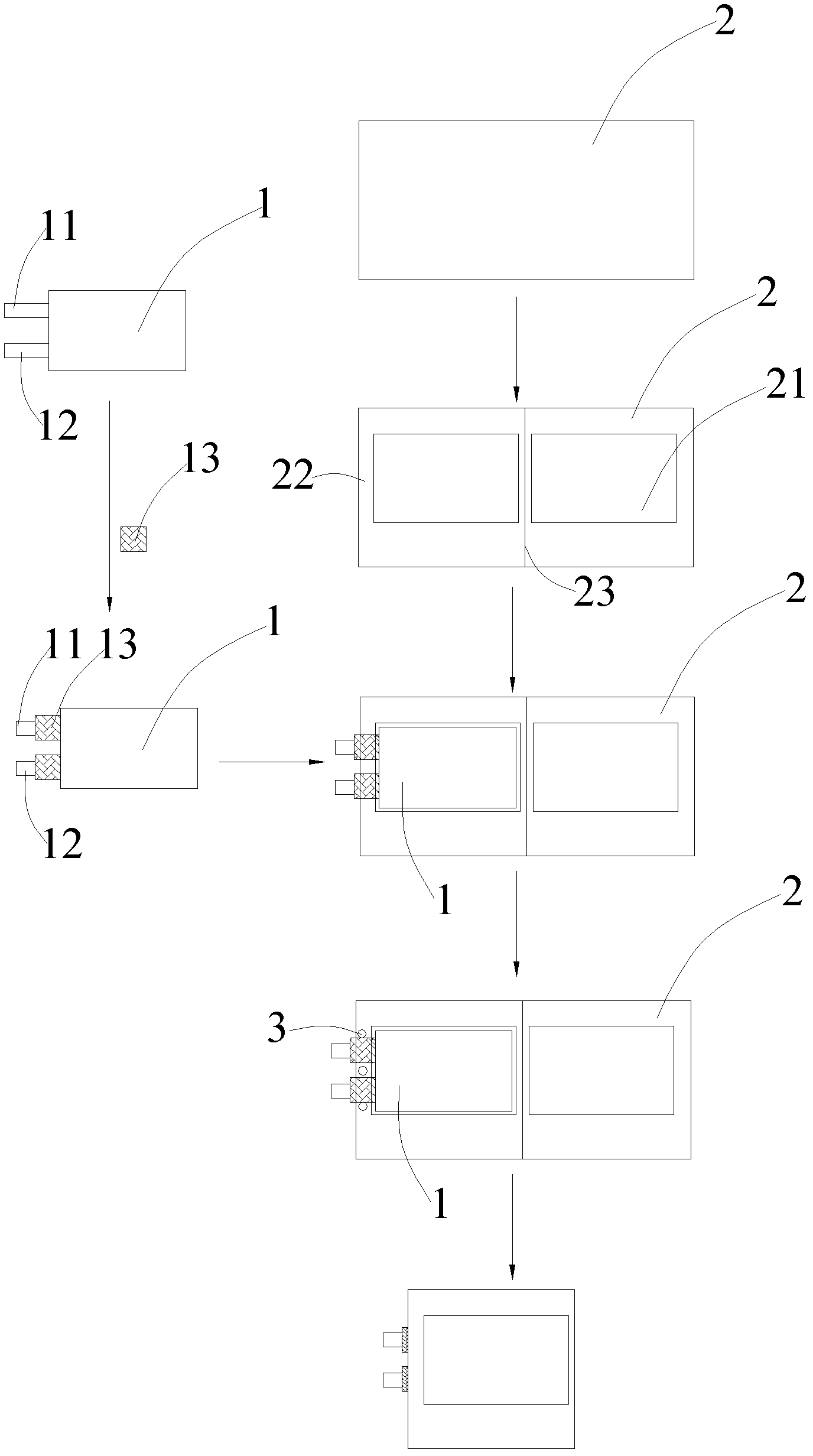

Method for packaging flexible package cell

ActiveCN102324548BImprove packaging efficiencySimple processFinal product manufactureSecondary cells manufactureEngineeringMechanical engineering

The invention discloses a method for packaging a flexible package cell. The method comprises the following steps of: acquiring a winding core connected with a positive lug and a negative lug and a flexible package film; punching the flexible package film into a pit according to the size of the winding core; cutting the flexible package film on which the pit is punched to enable the heat sealing width of the flexible package film at the lug end to be 3.0-4.5mm; placing the winding core in the pit and placing the positive lug and the negative lug at the flexible package film with the heat sealing width of 3.0-4.5mm; and coating NP glue on the surfaces of the flexible package films which are arranged at two sides of the positive lug and the negative lug and in contact with the positive lug and the negative lug, enabling the positive lug and the negative lug to be fixedly bonded with the flexible package films and then heat sealing and forming. According to the method for packaging the flexible package cell, which is disclosed by the invention, the NP glue is coated at two sides of the lugs before heat sealing, so that the flexible package film is relatively fixed with the lugs, the malposiiton of the flexible package films at the lugs during heat sealing is effectively prevented, further the defects of battery electrolyte leakage and poor attractiveness are effectively avoided and the qualified rate of the battery is improved.

Owner:SHENZHEN CHAM BATTERY TECHNOLOGY CO LTD

Novel wood floor adhesive

InactiveCN105778838AGood adhesionImprove hot melt effectNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesEpoxyAdhesive cement

The invention discloses a novel wood floor adhesive, which is composed of the following raw materials in parts by weight: 1.5 to 3.7 parts of silica sol, 0.8 to 1.7 parts of poly(epoxy glycerin ether), 2 to 3.7 parts of butyl acetate, 3 to 7 parts of asbestos powder, 0.6 to 1.5 parts of diisocyanate, 2 to 3.5 parts of urea, 1.3 to 3.5 parts of glycidol trimethyl ammonium chloride- gliadin-glyoxal resin, and 0.5 to 2.7 parts of natamycin. Compared with the conventional products, the wood floor adhesive is nontoxic, does not contain any formaldehyde, and is pollution-free to the environment. The adhesive performance and hot melting property of glycidol trimethyl ammonium chloride- gliadin-glyoxal resin are good, the bonding effect is good, the service life is long; the provided wood floor adhesive has the advantages of strong bonding performance, good mechanical property, and insect-proof effect; the combination of natamycin and urea can effectively prevent termites, the production technology is simple, the production cost is low, and thus the adhesive is easy to popularize.

Owner:QINGDAO JINLIANXIN BUSINESS & TRADE

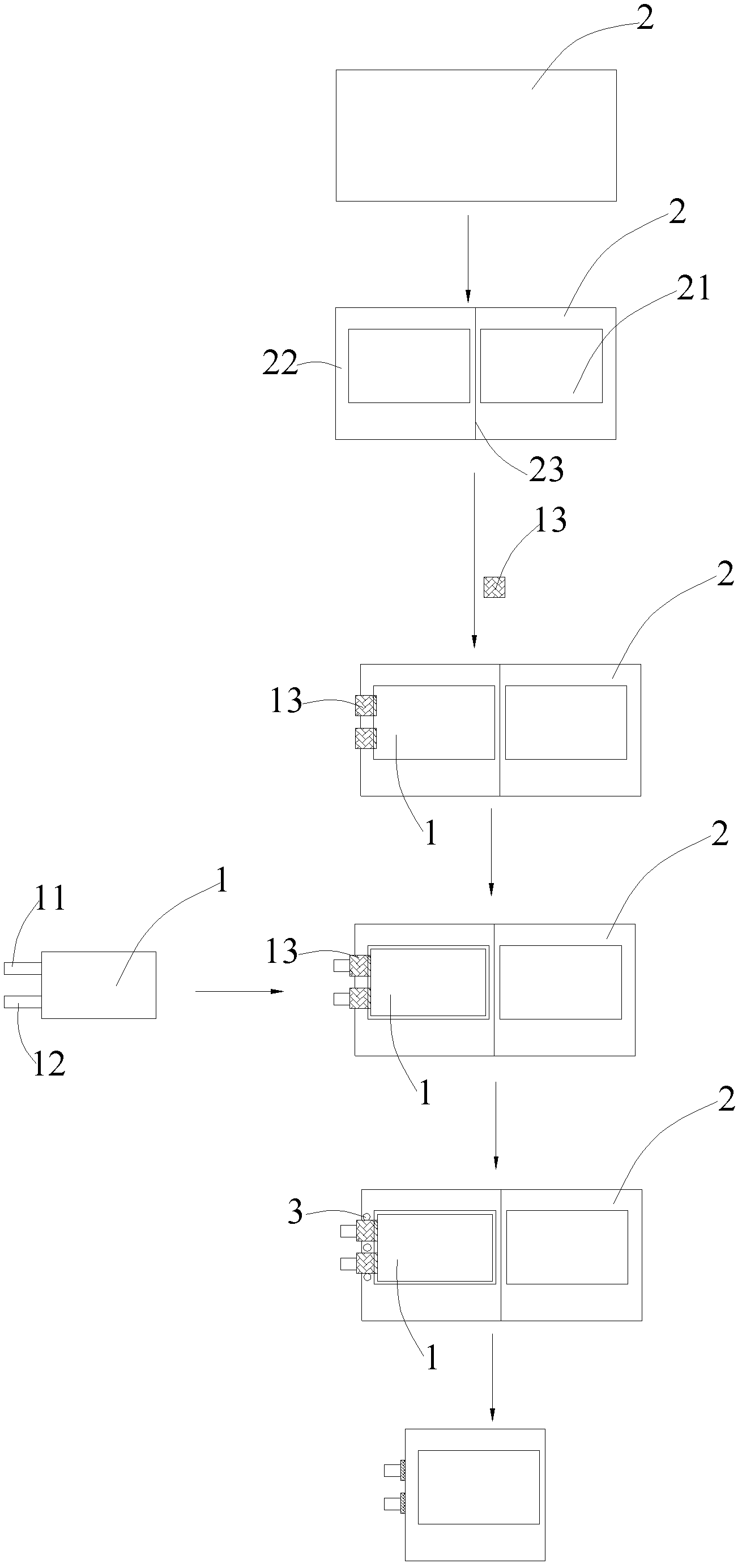

Battery cap assembling equipment and assembling method thereof

InactiveCN110911593AImprove stabilityHigh precisionFinal product manufactureNon-aqueous electrolyte cellsPhysicsEngineering

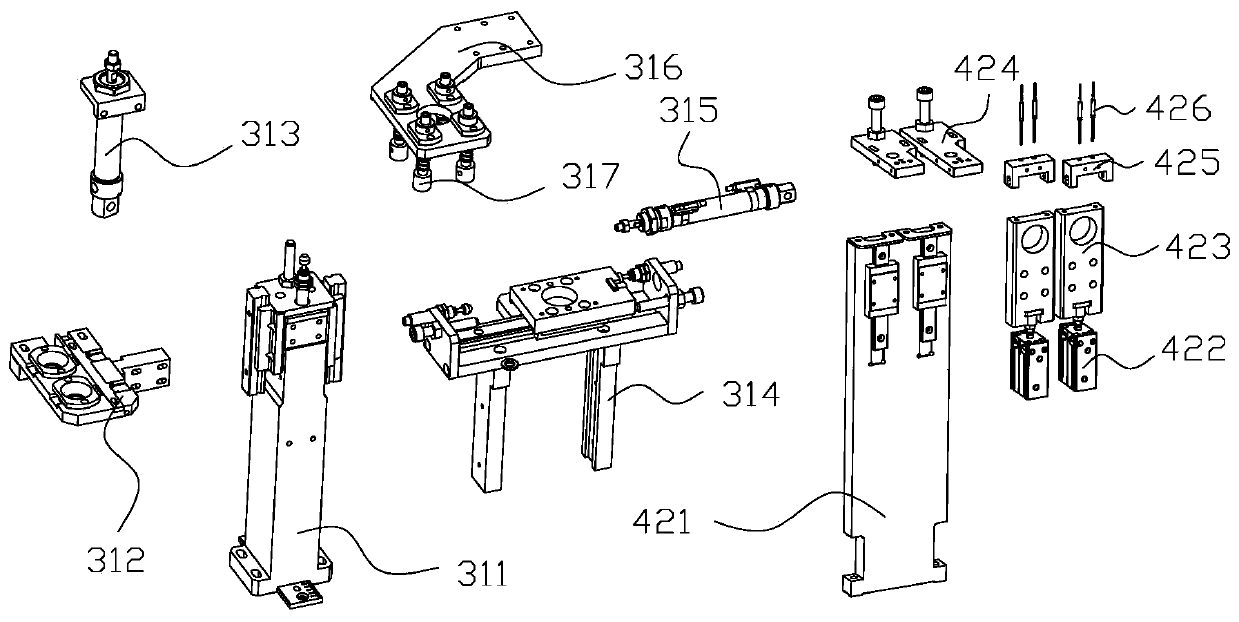

The invention relates to the field of lithium battery anti-fitting production. Battery cap assembling equipment comprises a rack, an index plate rotating device, an anti-explosion piece feeding device, a pore plate feeding device, a rubber ring feeding device, a waste discharging device, a transferring device, a pore plate hot melting device, an anti-explosion piece hot melting device and a finished product conveying device, wherein the index plate rotating device, the anti-explosion piece feeding device, the pore plate feeding device, the waste discharging device and the transferring device are arranged on the rack. The explosion-proof sheet feeding device is used for conveying and feeding explosion-proof sheets to a jig set, and the pore plate feeding device is used for conveying and feeding pore plates to the explosion-proof sheets; the rubber ring feeding device is used for conveying and feeding rubber rings into the pore plate; the transferring device is used for conveying the material combination body to the pore plate hot melting device and the explosion-proof sheet hot melting device respectively, and the pore plate and the explosion-proof sheet are subjected to hot meltingprocessing through the pore plate hot melting device and the explosion-proof sheet hot melting device respectively. The conveying device has the advantages that the conveying stability of the explosion-proof piece, the pore plate and the rubber ring is improved; waste discharging and collecting are facilitated; multiple materials can be stably conveyed at the same time, and the conveying efficiency is improved; the hot melting stability and the hot melting quality are improved.

Owner:孙广静

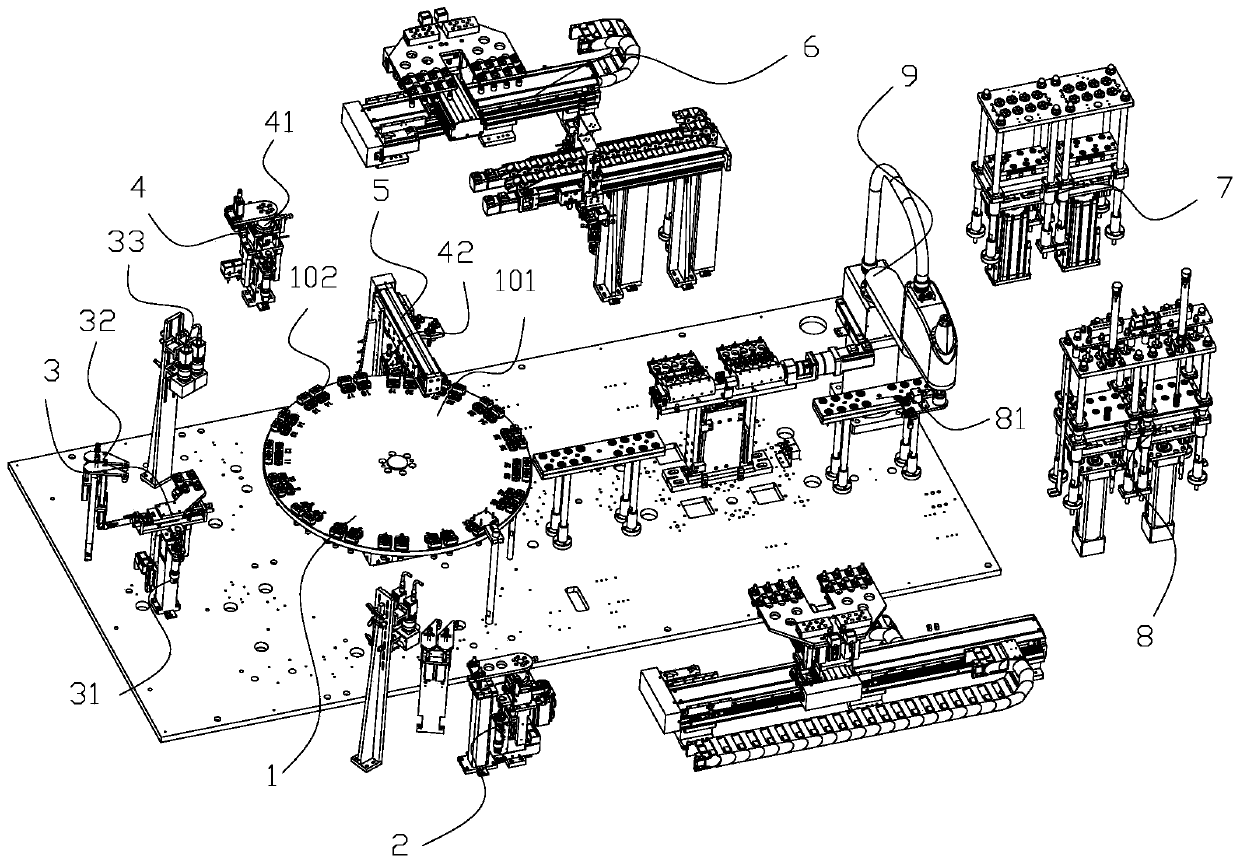

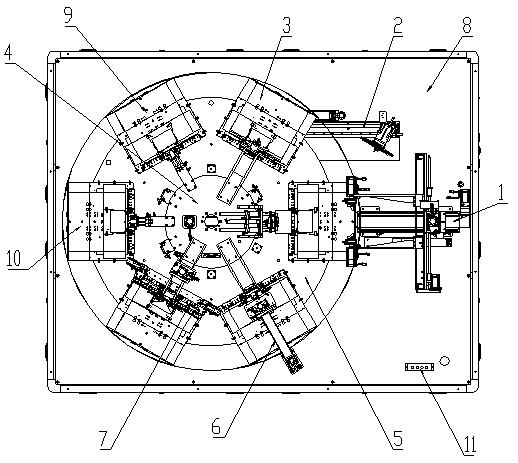

Turntable-type coating machine for lithium battery

ActiveCN110783500APromote meltingAvoid scratchesFinal product manufactureNon-aqueous electrolyte cellsMechanical engineeringBattery cell

The invention discloses a turntable-type coating machine for a lithium battery, which includes a frame. A Mylar coating front mechanism is fixedly installed on the center of the left side of the frontsurface of the frame. A turntable is fixedly installed on the center of the right side of the front surface of the frame. A bottom fuse mechanism is fixedly installed on the left side of the top of the rear surface of the turntable. A loading clamp fixture is fixedly installed on the left side of the top of the front surface of the turntable. A battery cell positioning device is fixedly installedon the right side of the top of the front surface of the turntable. An unloading clamp fixture is fixedly installed on the center of the left side of the front surface of the turntable. A side fuse mechanism is fixedly installed on on the left side of the bottom of the front surface of the turntable. A top fuse mechanism is fixedly installed on the right side of the bottom of the front surface ofthe turntable. A follower mechanism is fixedly installed on the center of the front surface of the turntable. A button box is fixedly installed on the bottom of the left side of the front surface ofthe frame. In the turntable-type coating machine for a lithium battery, six stations are arranged on the turntable, and the next station arrives after the turntable is rotated by one shift, thereby avoiding robotic transplanting, acheiving high efficiency, easy maintenance, less floor space, and convenient loading and unloading.

Owner:深圳市中基自动化股份有限公司

Waste plastic crushing and reprocessing apparatus

ActiveCN109080039AReduce vibrationReduce volumePlastic recyclingMechanical material recoveryThermal insulationEngineering

The invention discloses a waste plastic crushing and reprocessing apparatus, comprising: a housing; a damping component for supporting the housing and buffering vibration of the housing; a first crushing component arranged at the upper portion of the housing and used for roughly crushing large plastic; a second crushing component arranged below the first crushing component and used for grinding the plastic, wherein the second crushing component includes a first grinding part, a second grinding part arranged below the first grinding part, and a driving part that drives the second grinding partto rotate; a hot melting component that melts the plastic crushed by the second crushing component into a liquid. A thermal insulation component is arranged on the housing herein; temperature in the housing can be lowered; outward loss of heat can be decreased; more heat can be used to melt plastic particles; therefore, the waste plastic crushing and reprocessing apparatus has good hot melting effect, and a heater has low heating power.

Owner:平顶山神马工程塑料科技发展有限公司

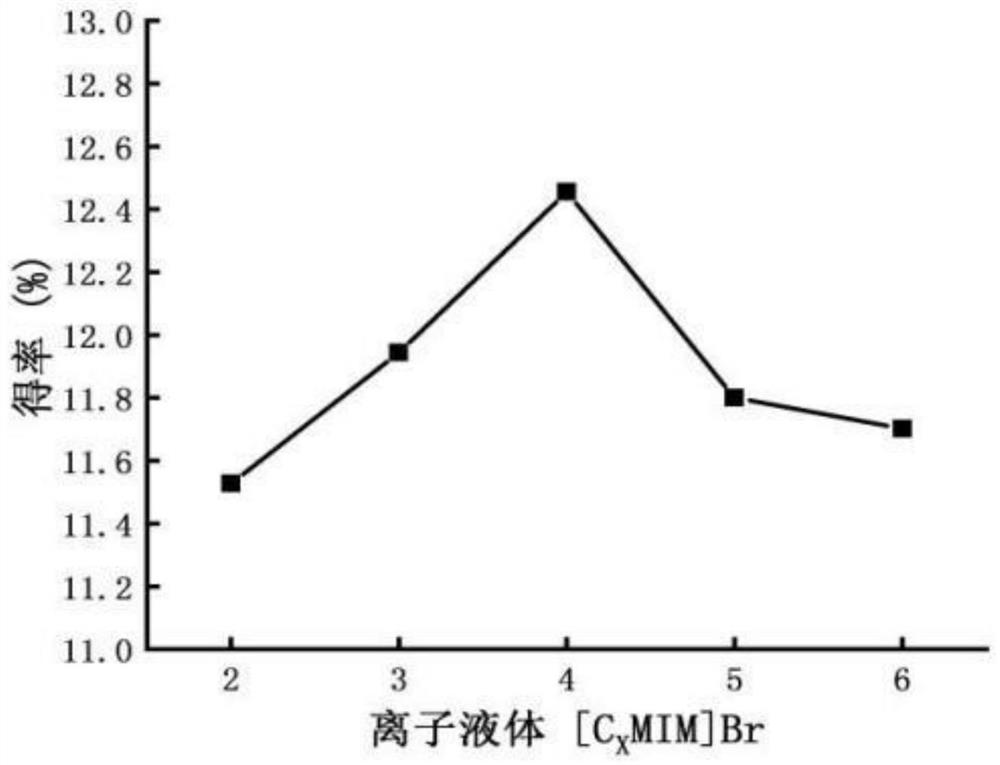

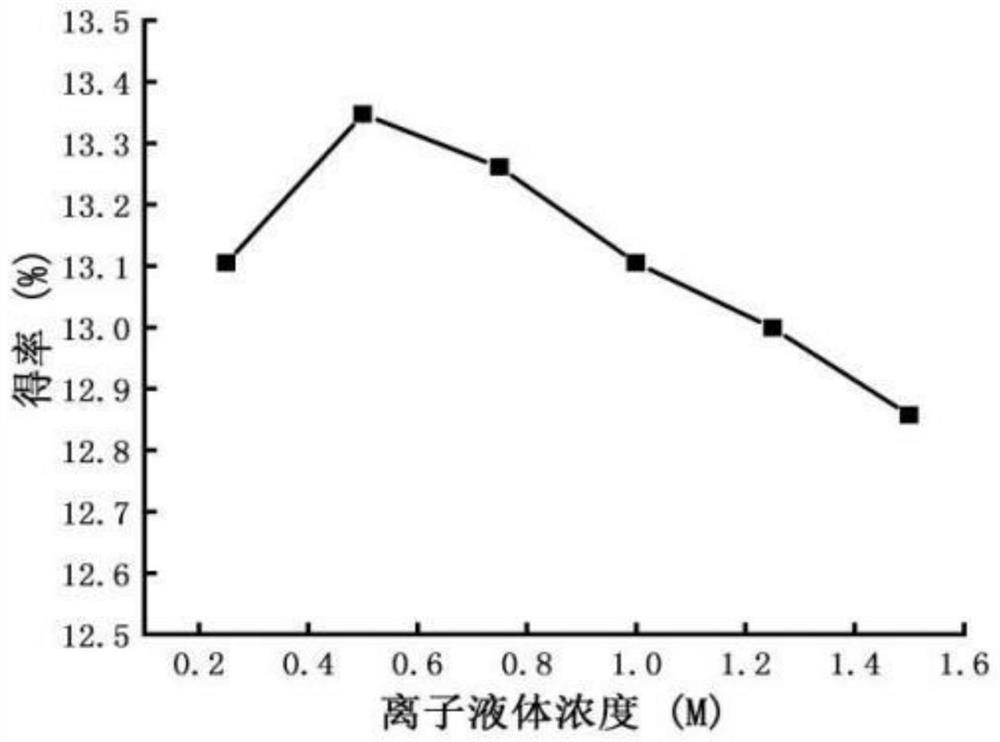

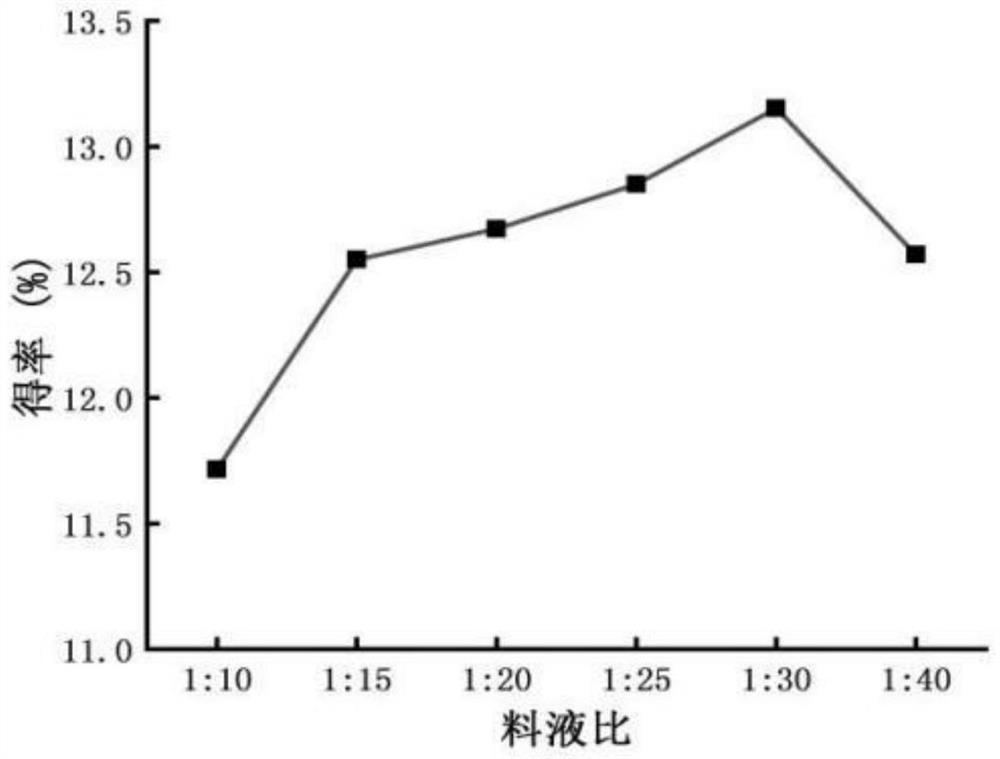

Quinoa saponin and wild chrysanthemum flower composition as well as preparation method and application thereof

PendingCN113876824AAchieve re-useReduce extraction timeAntibacterial agentsDigestive systemChrysanthemum FlowerDendranthema boreale

The invention discloses a quinoa saponin and wild chrysanthemum flower composition as well as a preparation method and application thereof, and relates to the technical field of medicines and foods. The quinoa saponin and wild chrysanthemum flower composition comprises the following components in parts by weight: 69.82-70.02 parts of a quinoa total saponin extract and 29.08-30.18 parts of a wild chrysanthemum flower extract, and 10% of pregelatinized starch is supplemented. The preparation method comprises the steps of raw material drying, saponin extraction, wild chrysanthemum flower extraction, organic extraction, purification, elution, rotary evaporation concentration, vacuum drying and particle preparation. Prepared quinoa saponin and wild chrysanthemum flower composition particles have good application prospects in the aspect of intestinal disease prevention and treatment. Quinoa bran is extracted and processed, ultrasonic-assisted ionic liquid is used for extracting quinoa saponin from the quinoa bran, reutilization of the quinoa bran is achieved, the extraction time is shortened, the quinoa saponin extract and the wild chrysanthemum flower extract are combined to be made into the medicinal granules, colibacillosis can be effectively prevented and treated, and the composition has good economic benefits and practical significance.

Owner:HEBEI AGRICULTURAL UNIV.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com