Plastic and iron sheet composite gasket and electromagnetic welding equipment

A technology of electromagnetic welding and composite mat, applied in chemical instruments and methods, layered products, building components, etc., can solve the problems of low melting efficiency, long melting time, poor bonding quality, etc. Good hot melt effect and fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

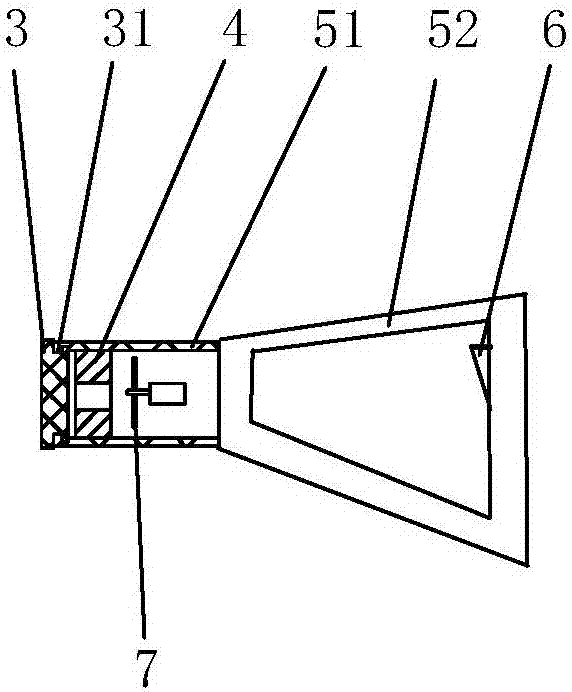

[0028] The present invention will now be further explained in conjunction with the drawings:

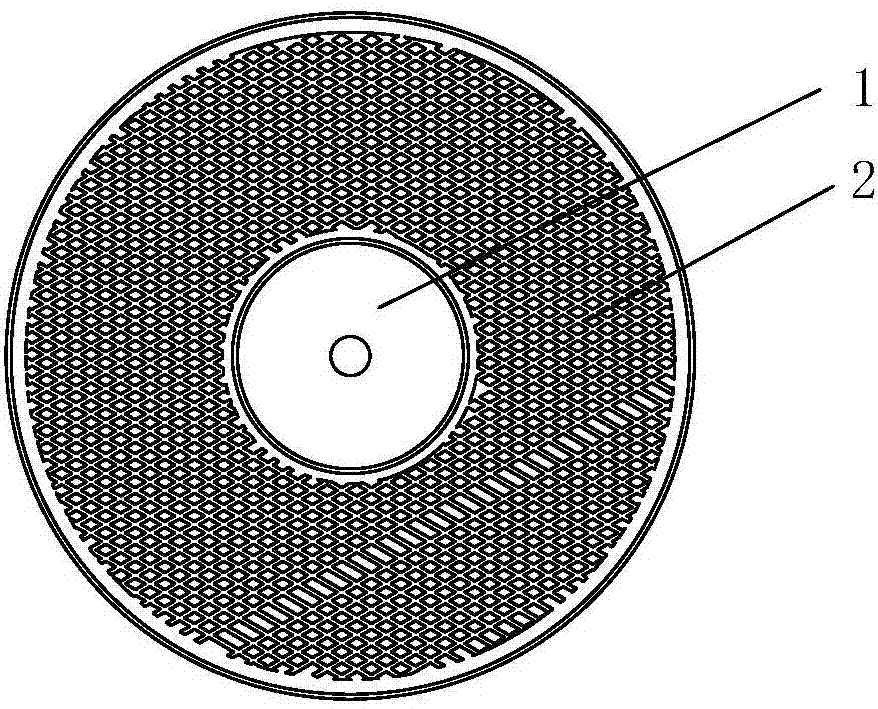

[0029] As shown in the figure, a plastic iron sheet composite gasket includes:

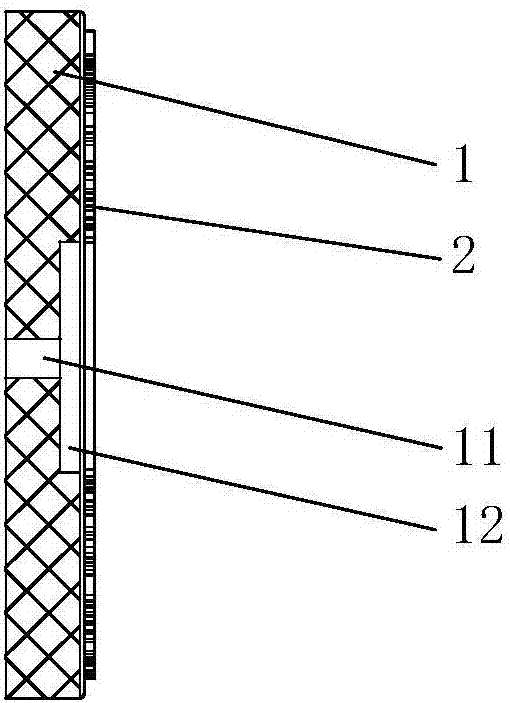

[0030] The plastic sheet 1 is provided with a first through hole 11;

[0031] The iron sheet 2 is provided with a second through hole, the plastic sheet 1 and the iron sheet 2 are connected to form a composite gasket, and the second through hole is directly connected to the first through hole 11.

[0032] The iron sheet 2 is a mesh sheet or a porous sheet.

[0033] The plastic sheet 1 is provided with a cavity 12 that communicates with the first through hole 11.

[0034] The composite gasket is round or polygonal.

[0035] The plastic sheet 1 and the iron sheet 2 are integrally connected by injection molding, glue bonding, rivet riveting or metal nails to form a composite gasket.

[0036] The iron sheet 2 is turned into a cover shape, and the cover-shaped iron sheet 2 is covered outside the plastic sheet 1.

[0037] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com