Patents

Literature

461results about How to "Achieve re-use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

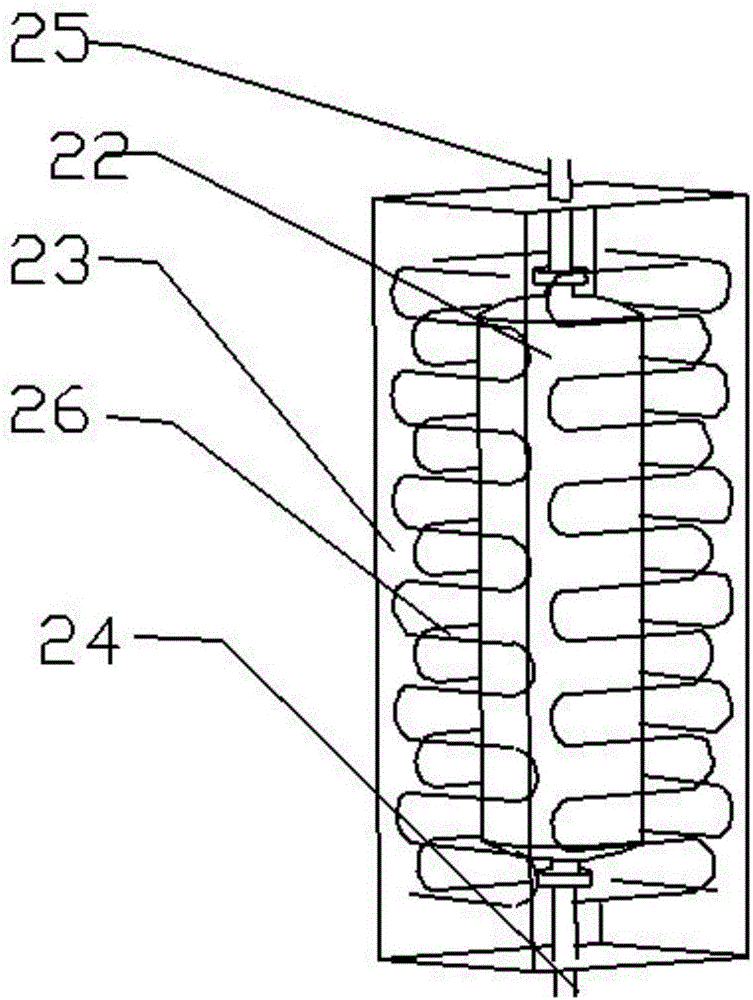

Ceramic composite electronic cigarette heating pipe and electronic cigarette atomizing core employing same

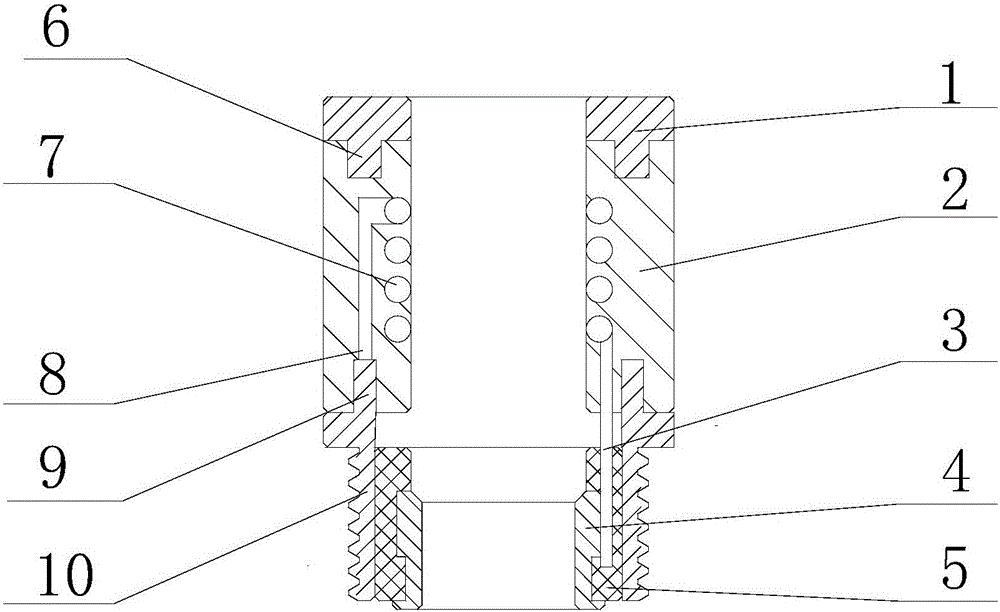

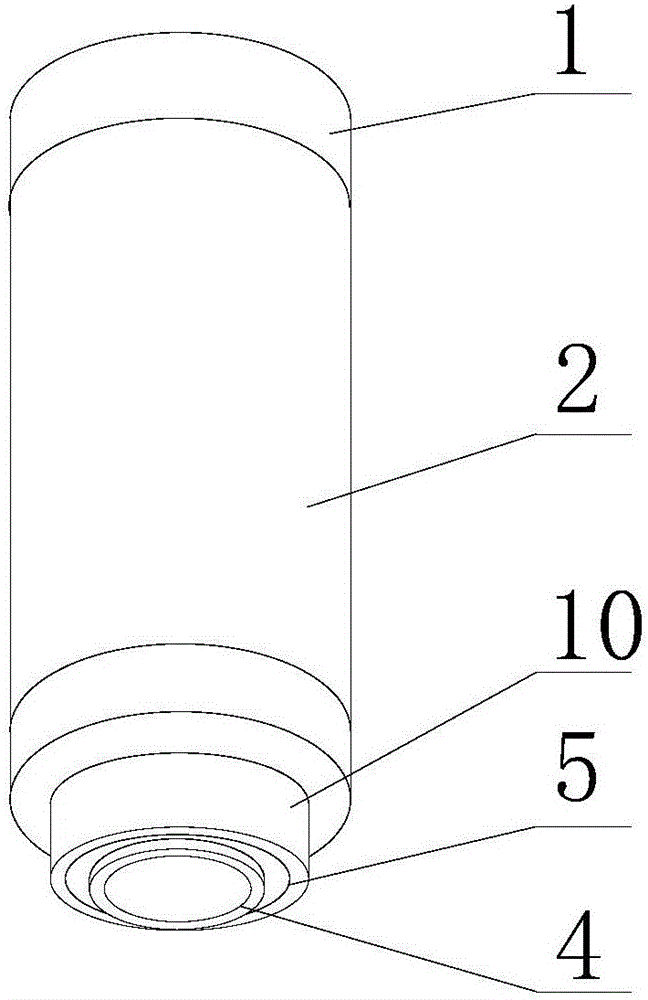

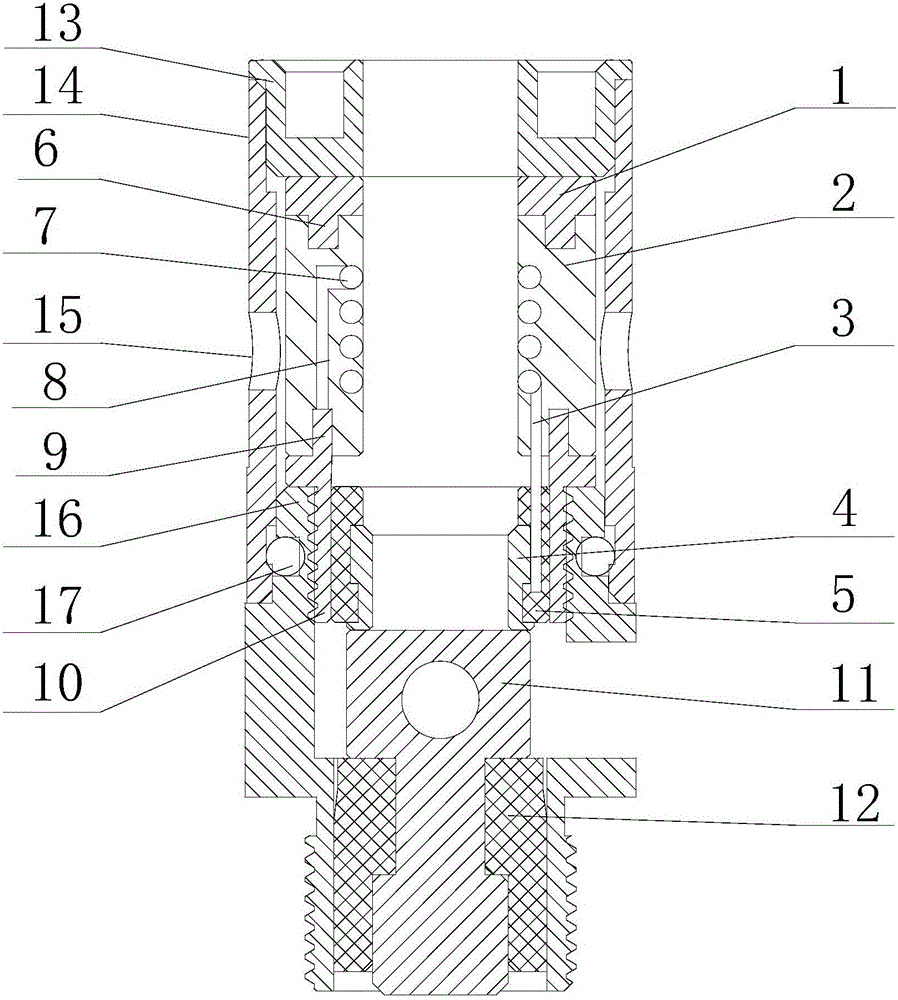

The invention discloses a ceramic composite electronic cigarette heating pipe which comprises an electric heating wire and a micro-porous ceramic pipe; a main body part of the electric heating wire is pre-embedded in the pipe wall of the micro-porous ceramic pipe; the electric heating wire is led out of the outside of the micro-porous ceramic pipe through connecting pins. A compact connecting piece is arranged at each of the upper and lower ends of the micro-porous ceramic pipe. The two connecting pins of the electric heating wire are lead out from the lower end of the micro-porous ceramic pipe; the compact connecting piece at the lower end is a metal connecting ring; a connecting pile protruding into the pipe wall of the micro-porous ceramic pipe is arranged on the upper side of the metal connecting ring. A double-electrode conductive connecting ring consists of an inner ring electrode and an outer ring electrode and is arranged on the lower side of the metal connecting ring; the outer ring electrode is electrically connected or integrally formed with the metal connecting ring; an insulating ring is arranged between the outer ring electrode and the inner ring electrode. The inner ring electrode and the outer ring electrode of the double-electrode connecting ring are respectively electrically connected with the two connecting pins of the electrical heating wire. When the heating pipe disclosed by the invention is in use, the double-electrode conductive connecting ring and a double-electrode conductive connecting column of an atomizing core are designed to be in threaded connection for realization.

Owner:INNOKIN TECH

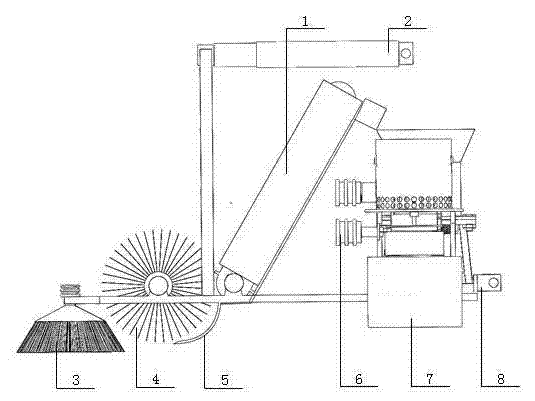

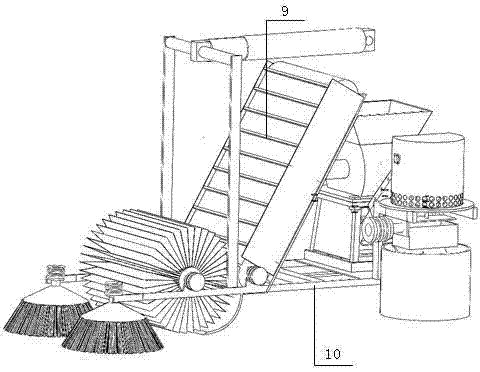

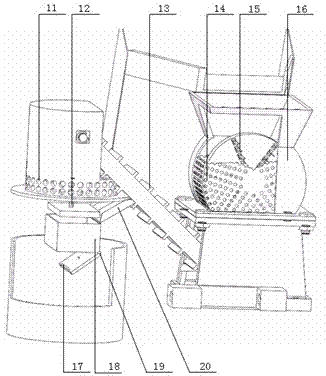

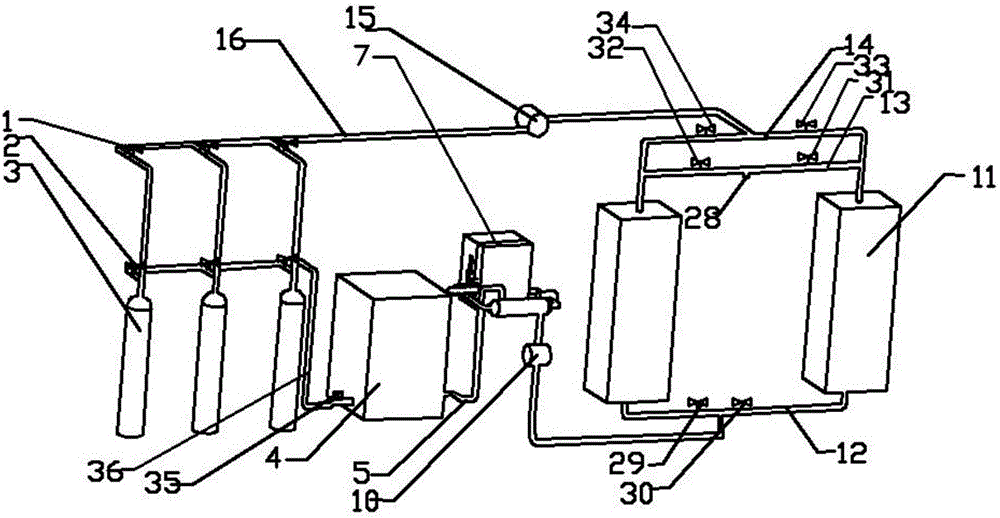

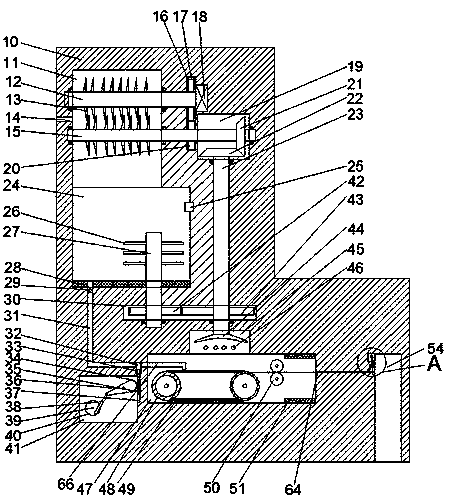

Fallen leaf sweeping equipment integrating automatic sweeping, smashing and extrusion forming and capable of being used with motor vehicle

The invention provides fallen leaf sweeping equipment integrating automatic sweeping, smashing and adhering extrusion forming and capable of being used with a motor vehicle such as a tractor or a gasoline engine. The fallen leaf sweeping equipment completes integrated operation including collection, smashing and adhering extrusion forming of fallen leaves by combining sweeping rollers with a conveying belt, combining the conveying belt with a smashing bin and combining the smashing bin with an adhering extrusion forming device. The technical scheme includes that the fallen leaf sweeping equipment comprises an inward-cleaning sweeping roller, an ascending sweeping roller, the scraper conveying belt, the smashing bin, the adhering extrusion forming device and the like, wherein the inward-cleaning sweeping roller collects the fallen leaves in front of and on two sides of the fallen leaf sweeping equipment to the position between the two sweeping rollers, the collected fallen leaves are conveyed to the smashing bin by the ascending sweeping roller and the scraper conveying belt which are in tangent connection, and smashed fallen leaf residues are mixed with adhesives prior to entering the adhering extrusion forming device to be compressed to form blocks. The fallen leaf sweeping equipment has the advantages that the fallen leaf sweeping equipment completes collection, smashing and adhering extrusion forming of the fallen leaves by means of mechanical force to achieve recycle of the fallen leaves, the problem of difficulty in fallen leaf recycle is solved, resource waste and environmental pollution are avoided, and good economic benefits and popularization value are achieved.

Owner:QINGDAO AGRI UNIV

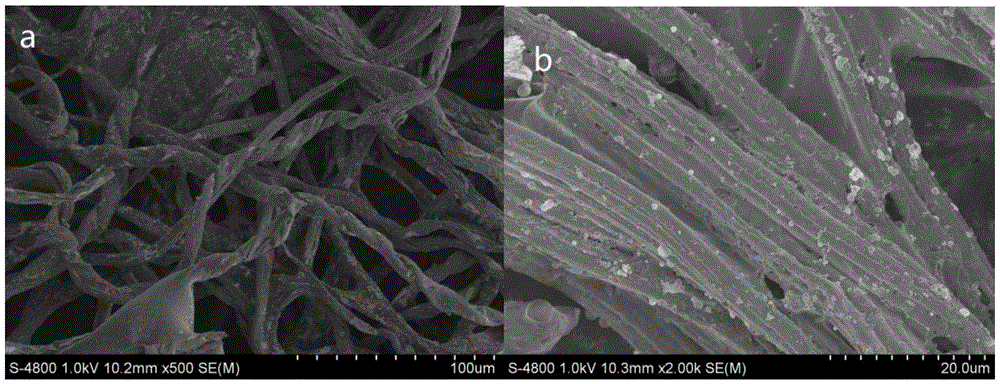

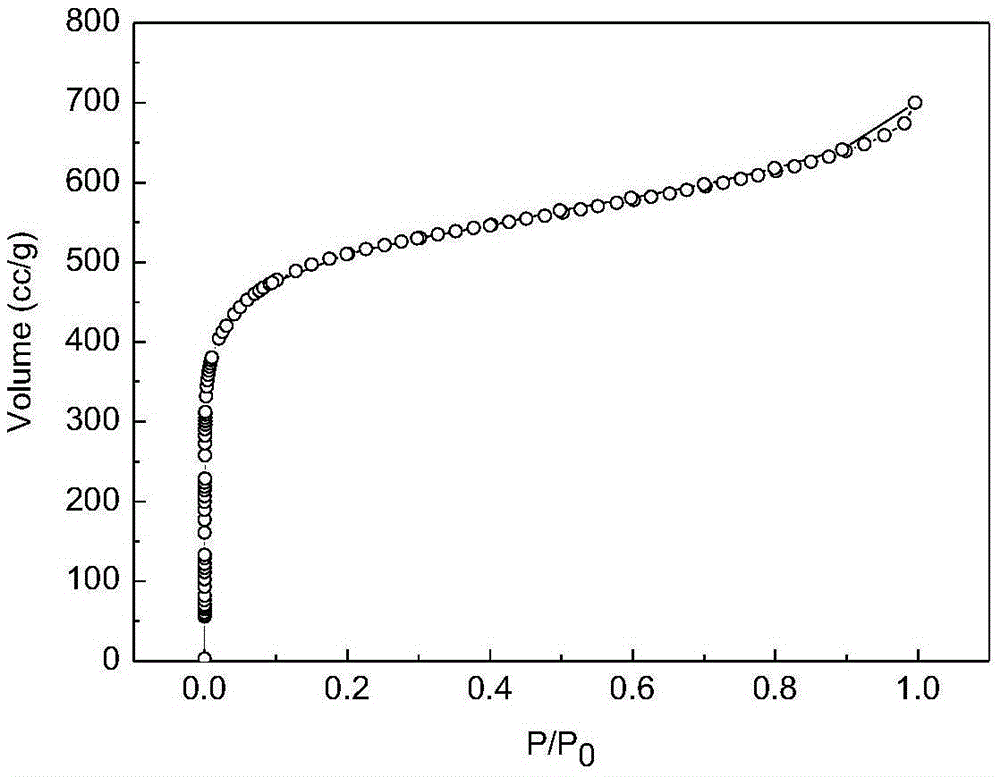

Method for efficiently preparing cotton based mesoporous activated carbon fiber

InactiveCN105480973AWide range of sourcesLow priceFibre chemical featuresChemistryHydrothermal carbonization

The invention relates to a method for efficiently preparing cotton based mesoporous activated carbon fiber. The method comprises a step (1) of washing cotton, placing the cotton in a hydrothermal reaction kettle, performing heating to 150-200 DEG C at the heating rate of 5-30 DEG C / min, performing hydrothermal carbonization, performing heat preservation for 1-3 hours and then performing cooling to room temperature; a step (2) of dipping carbonization materials obtained from the step (1) into activator solution, performing microwave-ultrasonic joint dipping for 5-30 minutes and then performing filtration, sending filtration materials to a microwave heating device, performing activation for 5-15 minutes at 250-350 DEG C and then stopping microwave output, and a step (3) of washing the activated materials to be neutral and performing drying to obtain the activated carbon fiber. According to the method, the characteristics of microwave inner heating and selective heating are fully utilized, the technological process is simple, the activation temperature is only 250-350 DEG C, the activation time is only 5-15 minutes, the mesoporous proportion of the activated carbon fiber of the product reaches 50-90%, and the adsorptive property is good.

Owner:HEBEI UNIV OF TECH

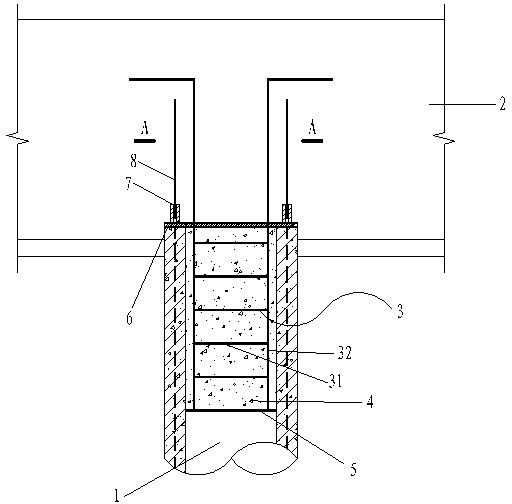

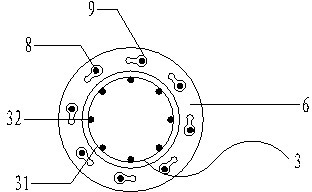

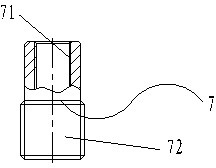

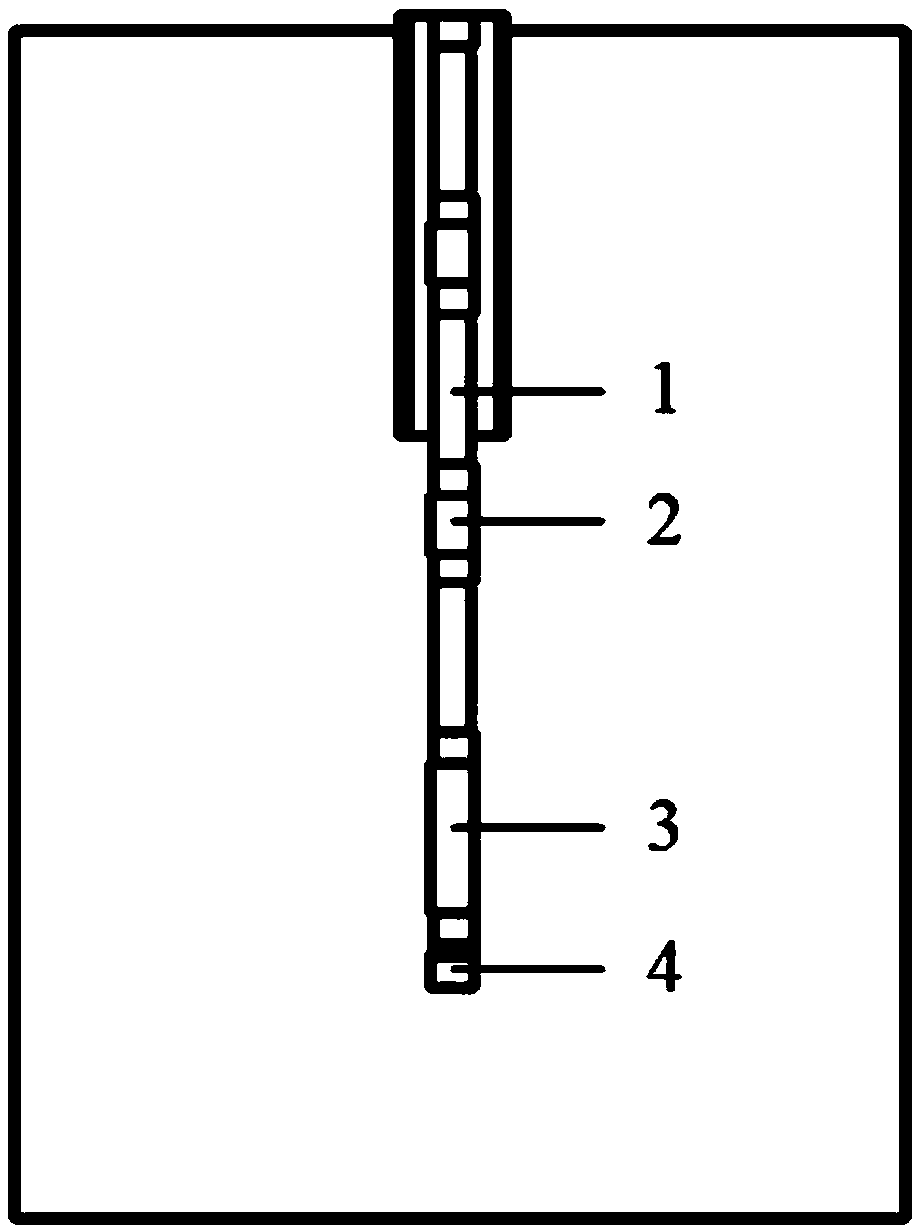

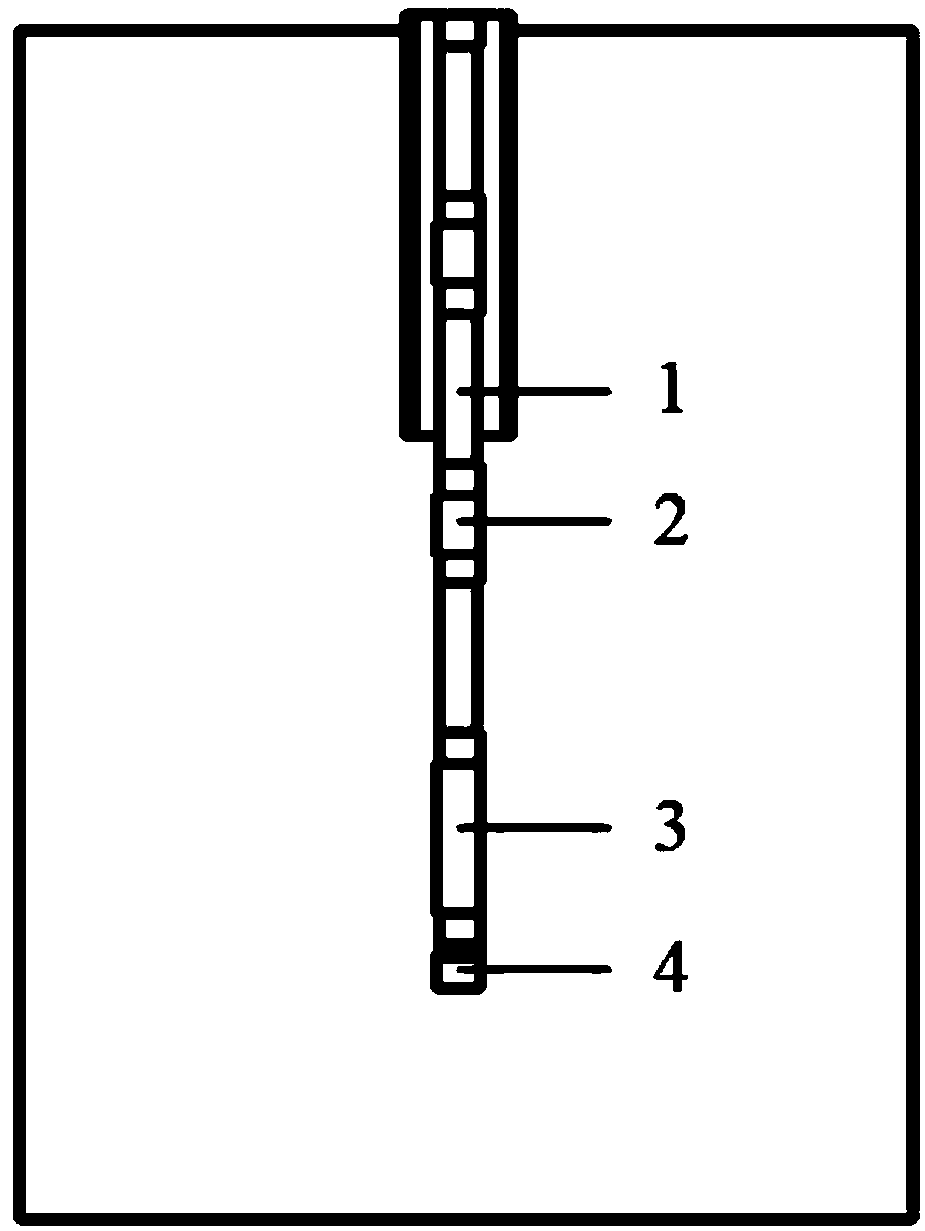

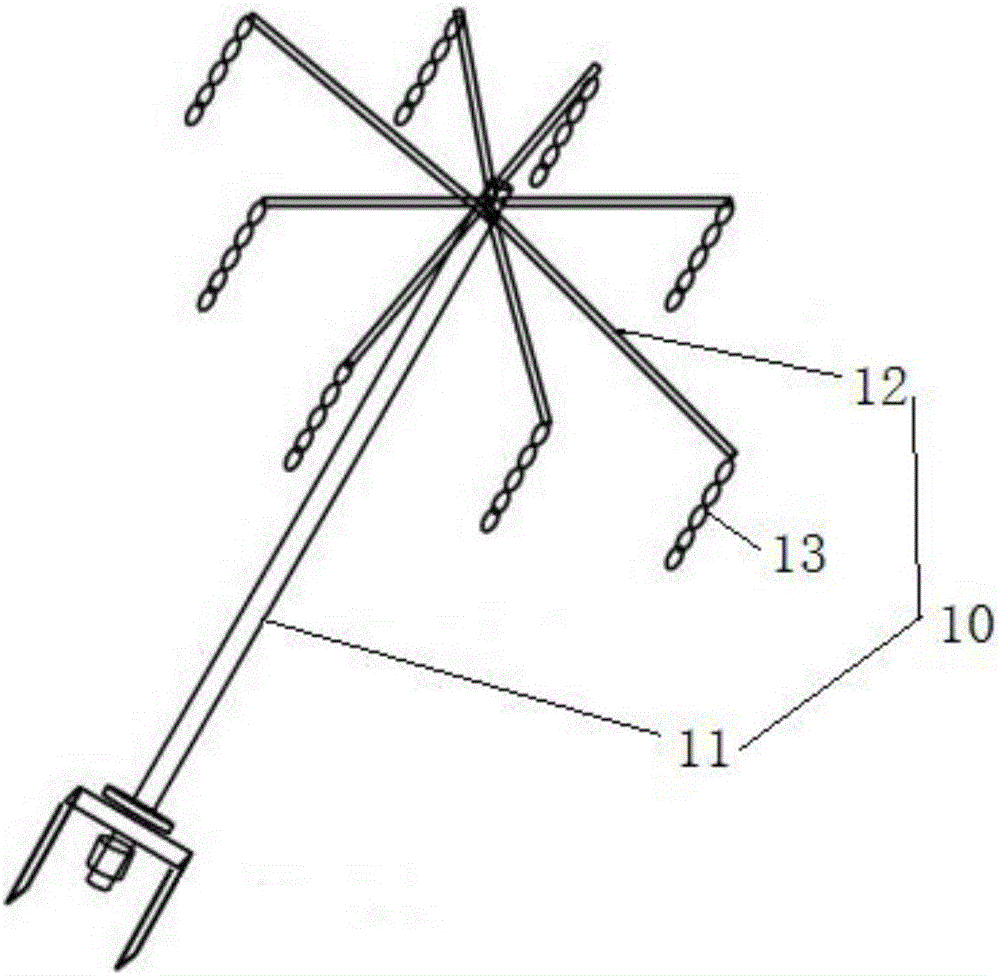

Method for connecting concrete pile and bearing platform

ActiveCN102127913ASimple structureSave engineering comprehensive costFoundation engineeringRebarBuilding construction

The invention provides a method for connecting a concrete pile and a bearing platform. The method comprises the following steps of: firstly, measuring the actual pile top elevation of the concrete pile after pile foundation construction is finished; mounting a plurality of connecting steel bushings on tension screw holes of an end plate of the concrete pile when the practical pile top elevation of the concrete pile equals to or is lower than a designed elevation; then, mounting threaded steel bars connected with a basic bearing platform on the connecting steel bushings to realize the connection of the end plate and the threaded steel bars; and casting common concrete on the basic bearing platform connected with the concrete pile so as to realize the connection of the concrete pile and the basic bearing platform; and when the practical pile top elevation of the concrete pile is higher than the designed elevation, truncating the pile, keeping original steel bars and end plate of the pile body after truncation, mounting the end plate of the concrete pile on the heading ends of the steel bars and fixing the end plate in situ with reinforcing ribs to realize the reconnection of the end plate and the steel bars, and casting the common concrete to the basic bearing platform connected the concrete pile so as to realize the connection of the concrete pile and the basic bearing platform.

Owner:JIANHUA CONSTR MATERIALS (CHINA) CO LTD

Method for cultivating straw mushrooms by utilizing pleurotus eryngii fungi residues

InactiveCN102498930AAchieve re-useReduce pollutionHorticultureFertilizer mixturesBiotechnologyCulture mediums

The invention relates to the technical field of production of edible fungi and particularly relates to a method for cultivating straw mushrooms by utilizing pleurotus eryngii fungi residues. The method sequentially comprises the following steps of: processing the pleurotus eryngii fungi residues, preparing a culture medium, fermenting the culture medium, sowing the straw mushrooms, culturing, growing the fungi, performing fruiting management and harvesting. The method disclosed by the invention has the beneficial effects that the reutilization of the pleurotus eryngii fungi residues is realized and environmental pollution caused by stacking of the fungi residues is reduced. According to the method disclosed by the invention, the species of raw materials for cultivating the straw mushrooms are increased; and furthermore, the newly increased cultivating raw material is the waste of the edible fungi of a factory, and the high cost caused by allocation and transportation from other places is reduced.

Owner:成都中延菌菇业有限公司

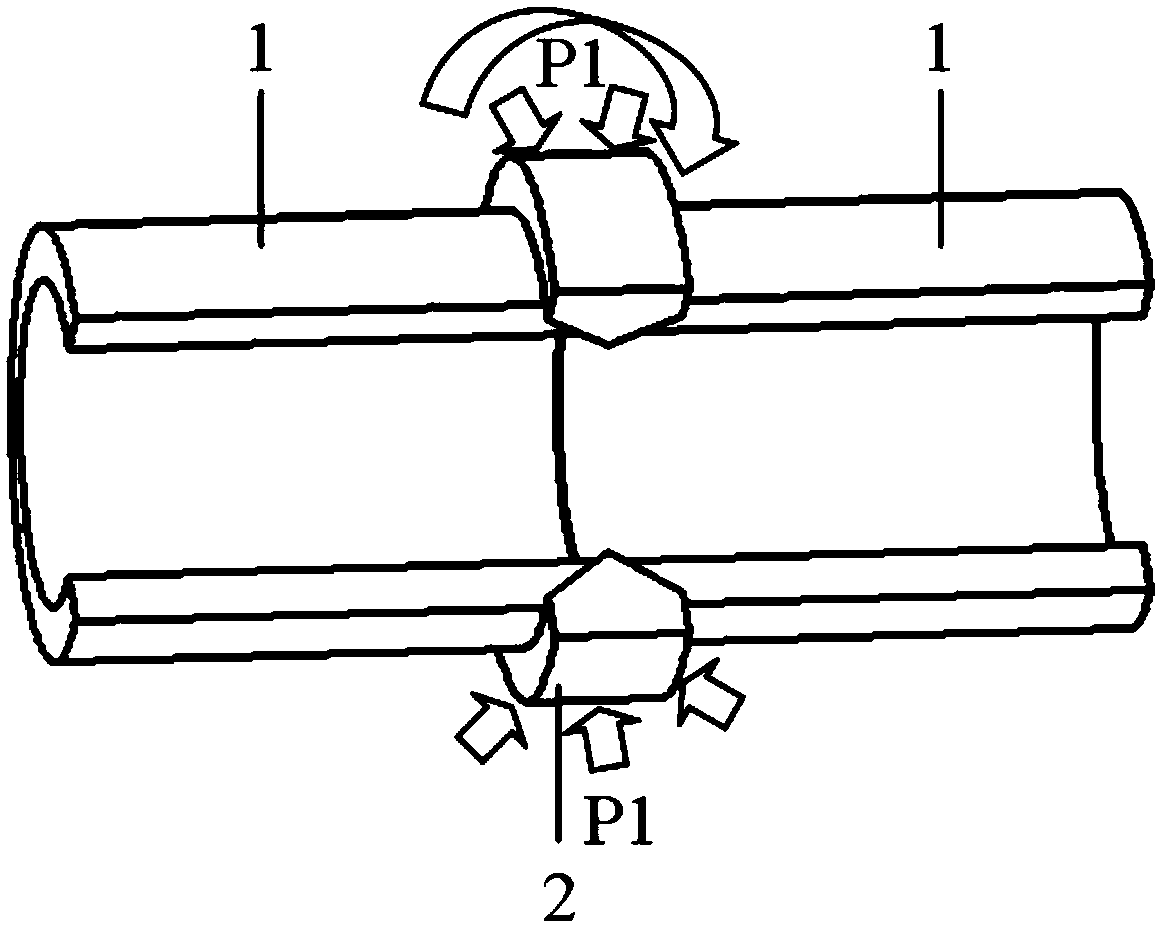

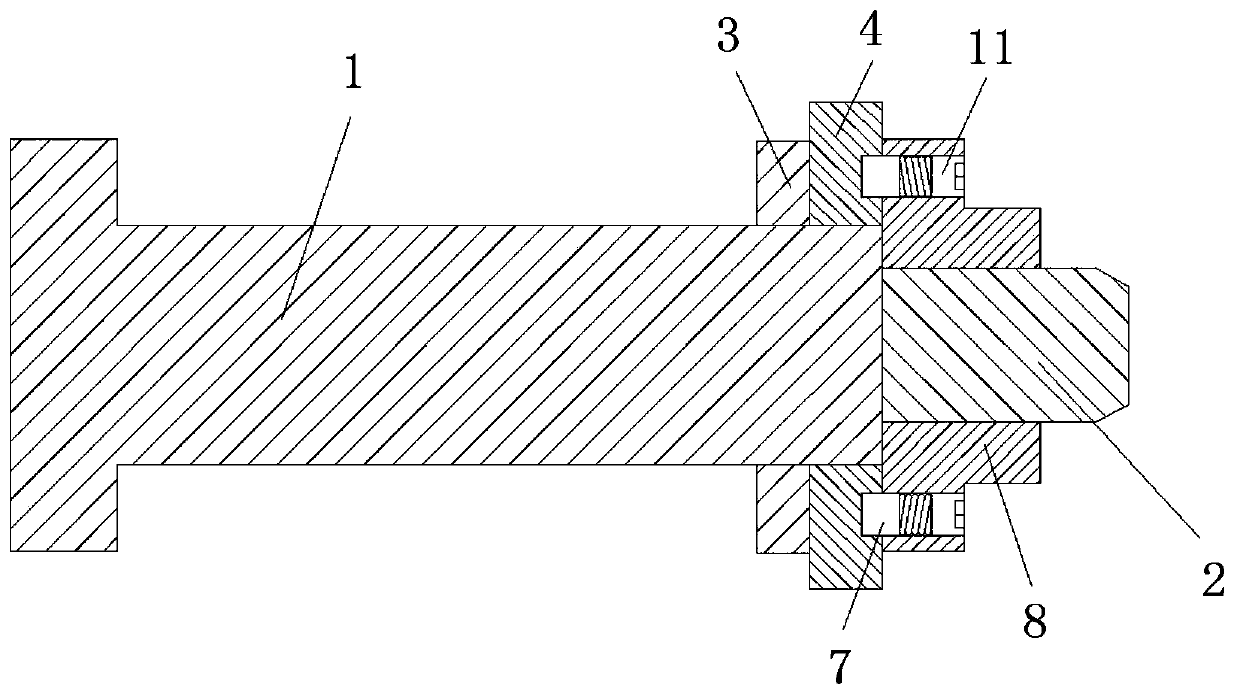

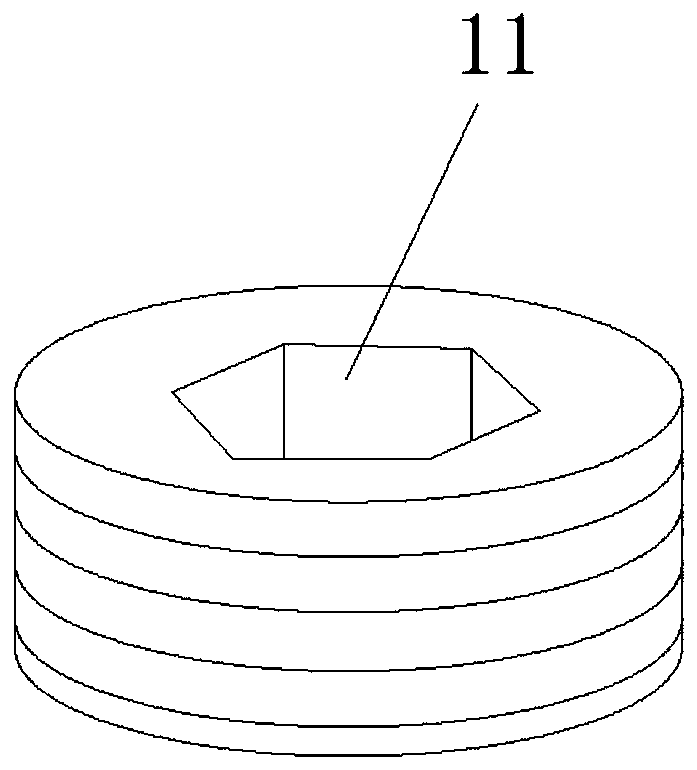

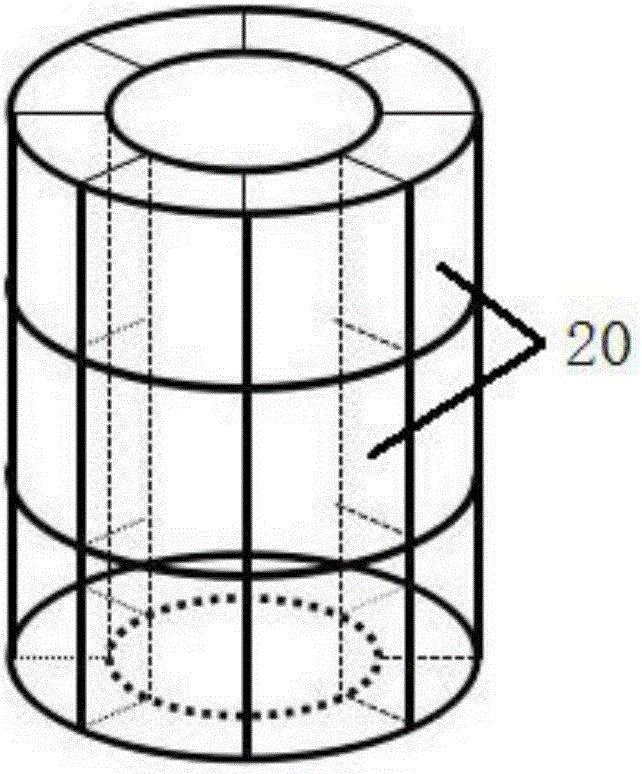

Axial friction welding process method of high-nitrogen austenitic stainless steel and non-magnetic drill collar

InactiveCN108907447AAchieve weldingGuaranteed normal work requirementsTubular articlesHollow articlesFriction weldingNon magnetic

The invention relates to an axial friction welding process method of a high-nitrogen austenitic stainless steel and non-magnetic drill collar and belongs to the field of preparation of oil-gas drilling tools. The method comprises the application steps: workpieces made from high-nitrogen austenitic stainless steel are clamped into a friction welding machine, then, workpieces in a clamp of a rotating end and a clamp of a moving end are welded, the workpiece of the moving end moves towards the workpiece of the rotating end when welding is started, at this time, the workpiece of the rotating end starts to rotate, the workpiece of the rotating end and the workpiece of the moving end start to produce heat due to friction under the action of frictional pressure after contact, rotation is stoppedwhen a friction amount of deformation reaches a set value, upset forging is started, upset forging pressure is applied to the workpieces along the axial direction of the workpieces and is maintained,and a workpiece is taken out after the upset forging pressure is unloaded, thereby obtaining the non-magnetic drill collar. According to the method, the non-magnetic drill collar is processed and repaired by an axial friction welding method, so that the problems, i.e., material waste, relatively high cost and relatively low production efficiency of the existing processing methods are improved, andthe problem that a failed drill collar is difficult to repair is solved.

Owner:SHANDONG UNIV

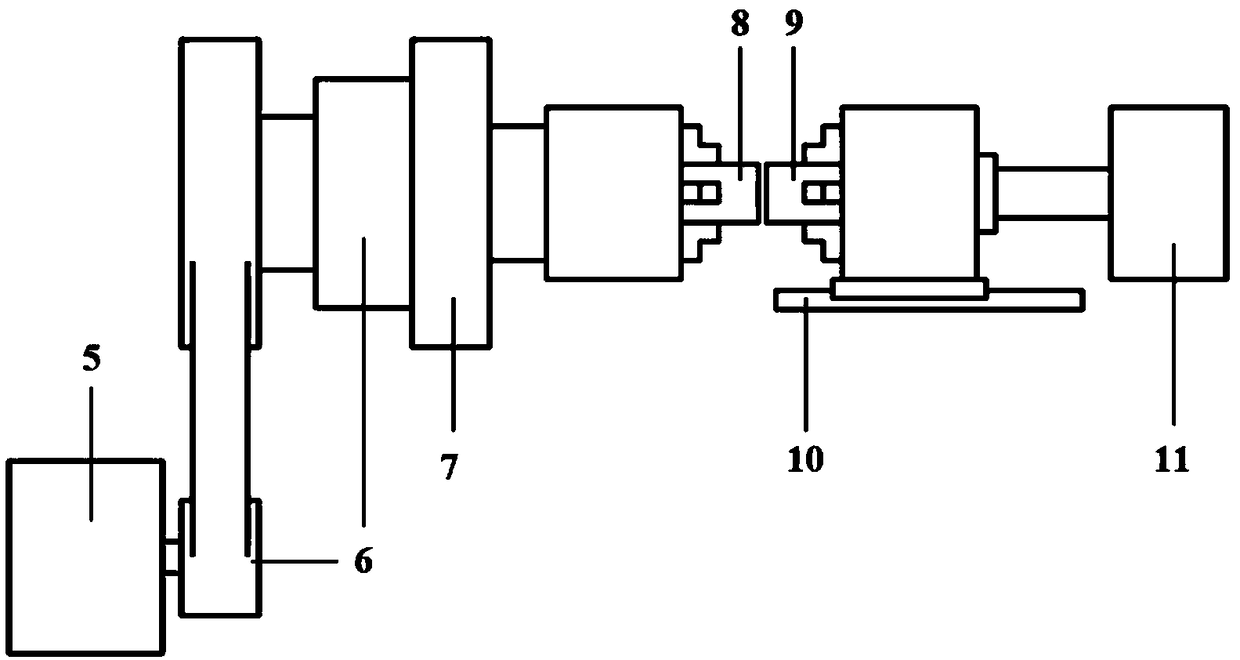

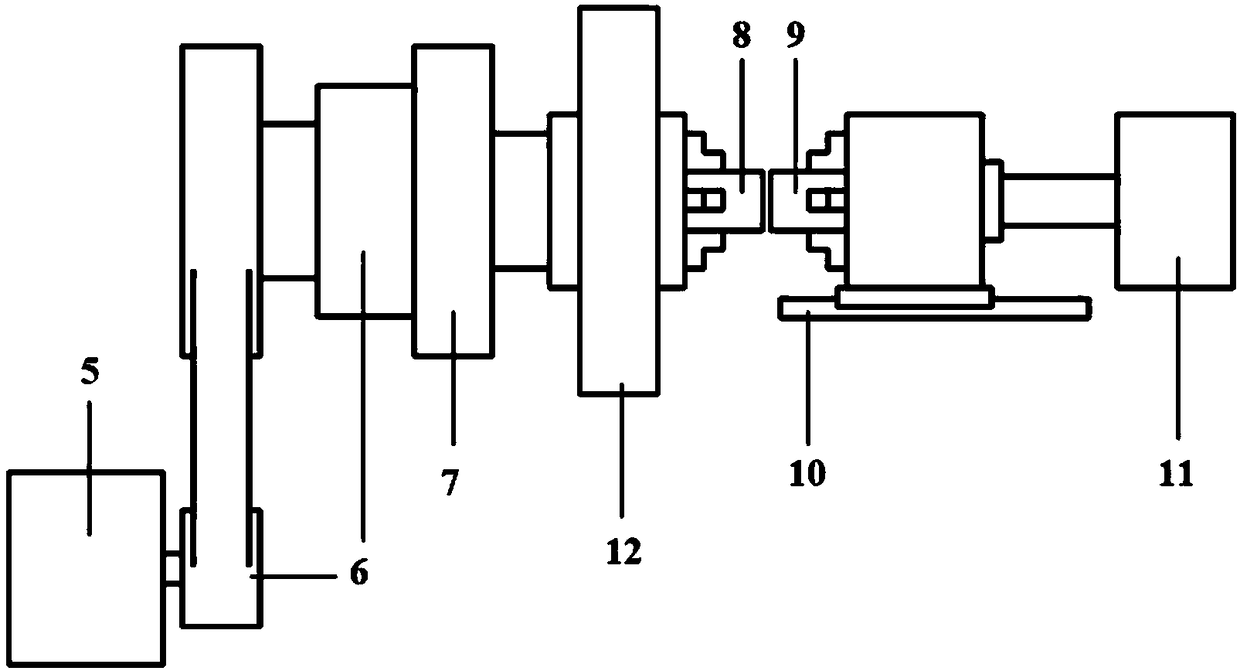

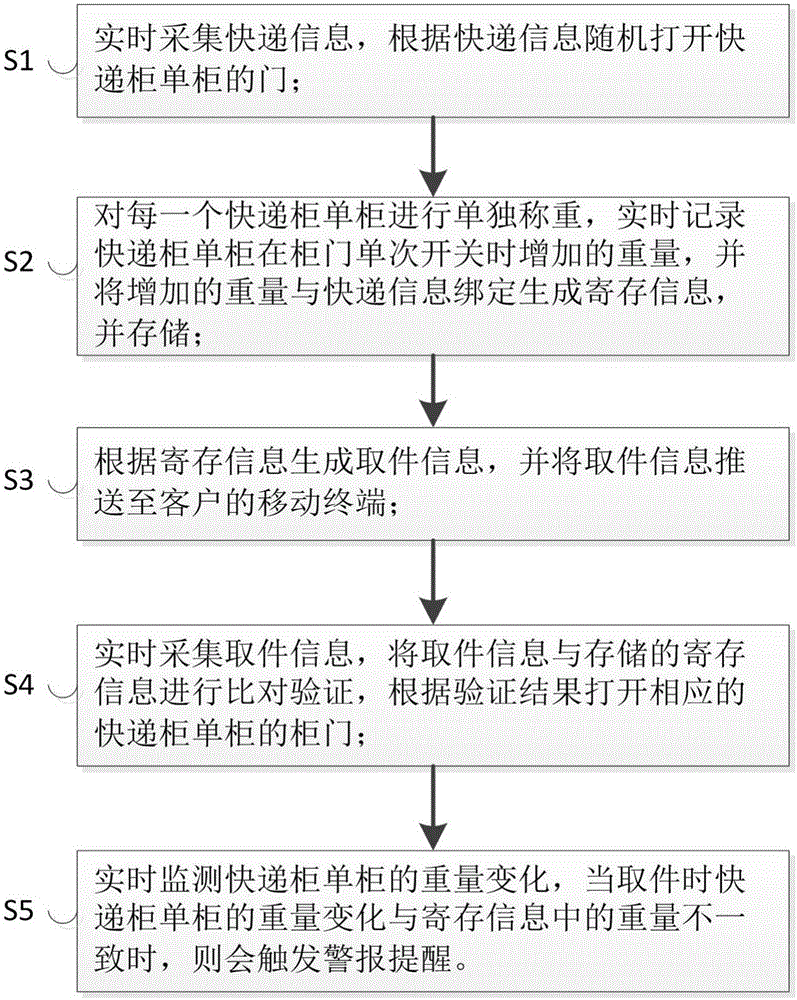

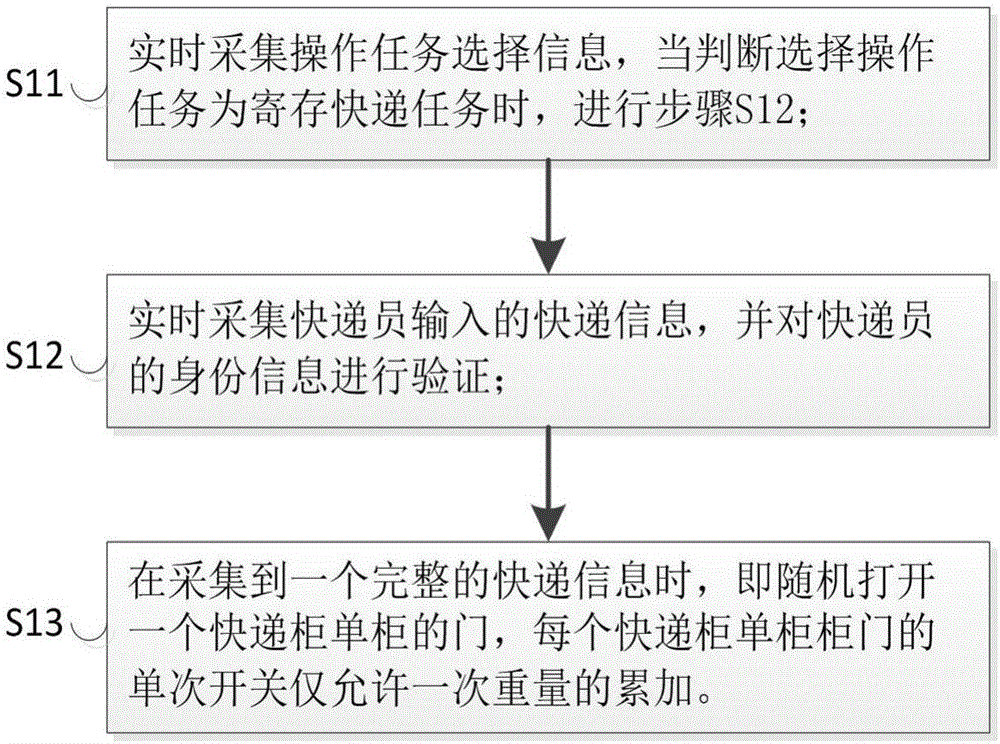

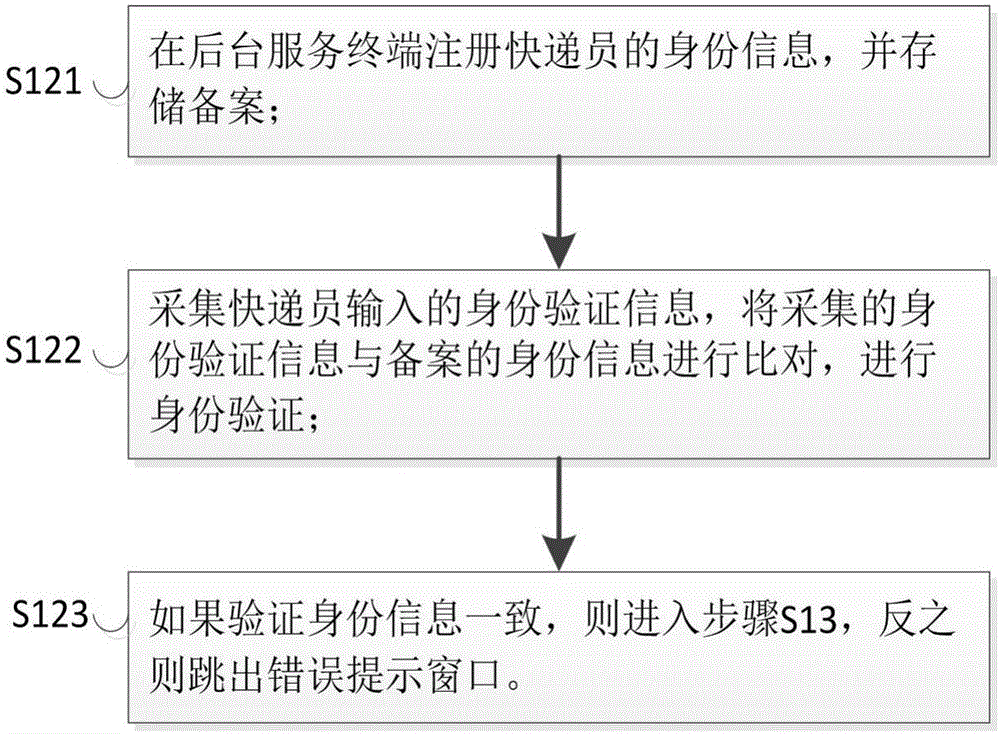

Control method and system for intelligent express package cabinet with ultra-large capacity

InactiveCN106296921AReal-time monitoring of weight changesAchieve re-useApparatus for meter-controlled dispensingIndividual entry/exit registersControl systemComputer science

The invention discloses a control method and a control system for an intelligent express package cabinet with ultra-large capacity. The method comprises the following steps: recording in real time a weight increased when a locker door of a single locker of the express package cabinet is opened and closed at single time, binding the increased weight with acquired express package information to generate register information, and storing the register information; generating a package pickup information according to the register information, and pushing the package pickup information to a mobile terminal of a client; when the client picks up a package, monitoring a weight change of the single locker of the express package cabinet in real time, and when the weight change of the single locker of the express package cabinet is inconsistent with the weight in the register information when the package is picked up, triggering a warning prompt. By independent weighing of each single locker of the express package cabinet, the weight increased when the locker door of the single locker of the express package cabinet is opened and closed at single time is recorded in real time, and the increased weight is bound with the express package information for storage; meanwhile, a delivery condition for single opening / closing and single accumulation of the express package cabinet is set, so that the single locker of the express package cabinet can store multiple express packages, and reuse of the single locker with a redundant space of the express package cabinet is realized.

Owner:武汉三车科技有限公司

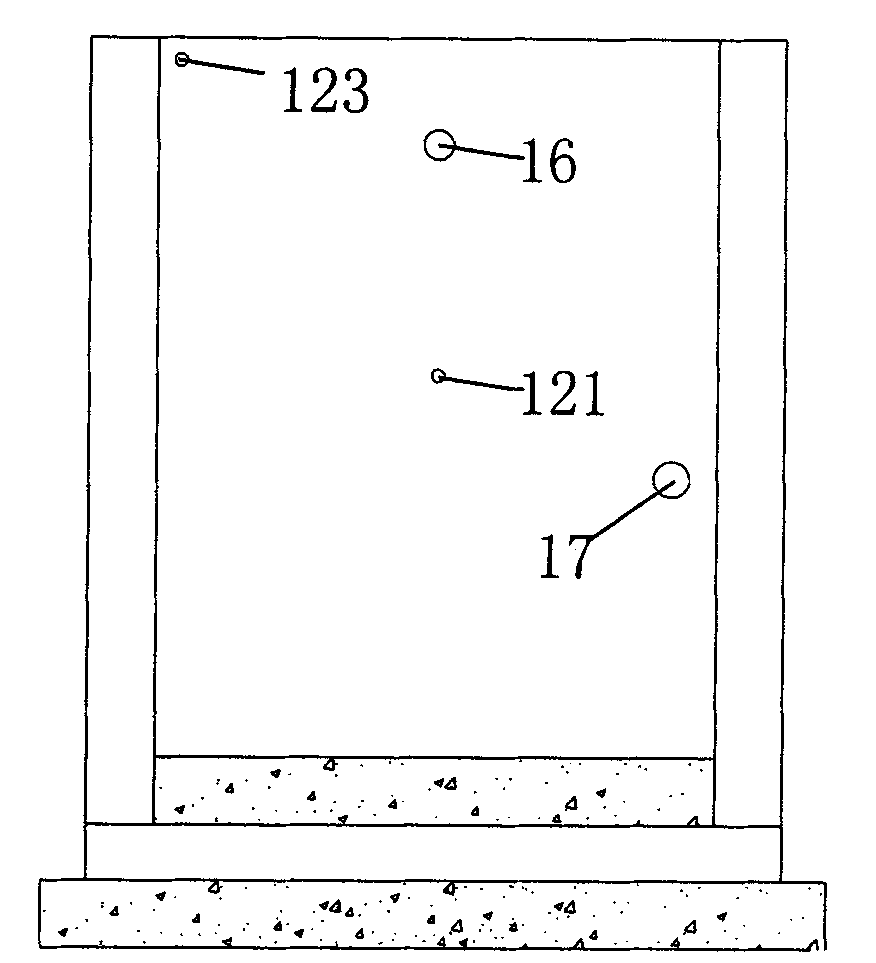

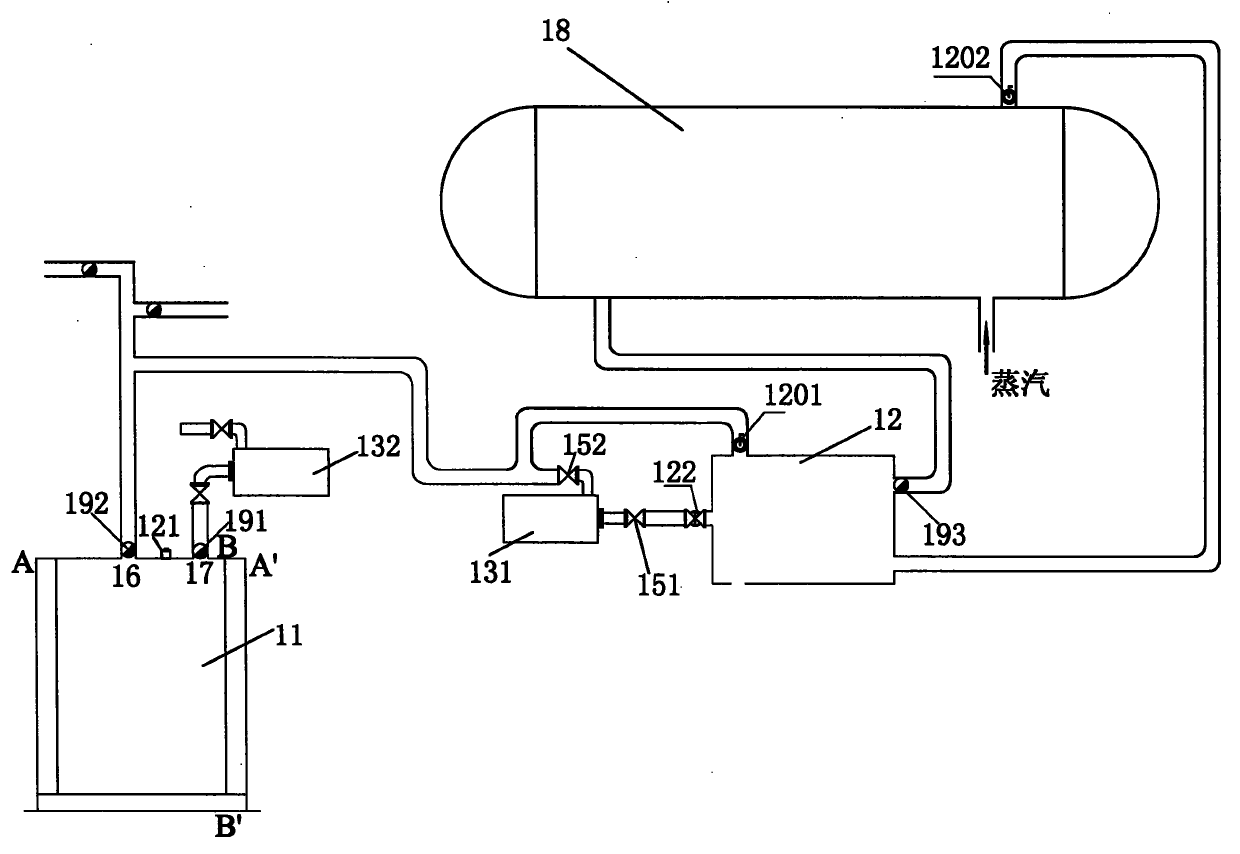

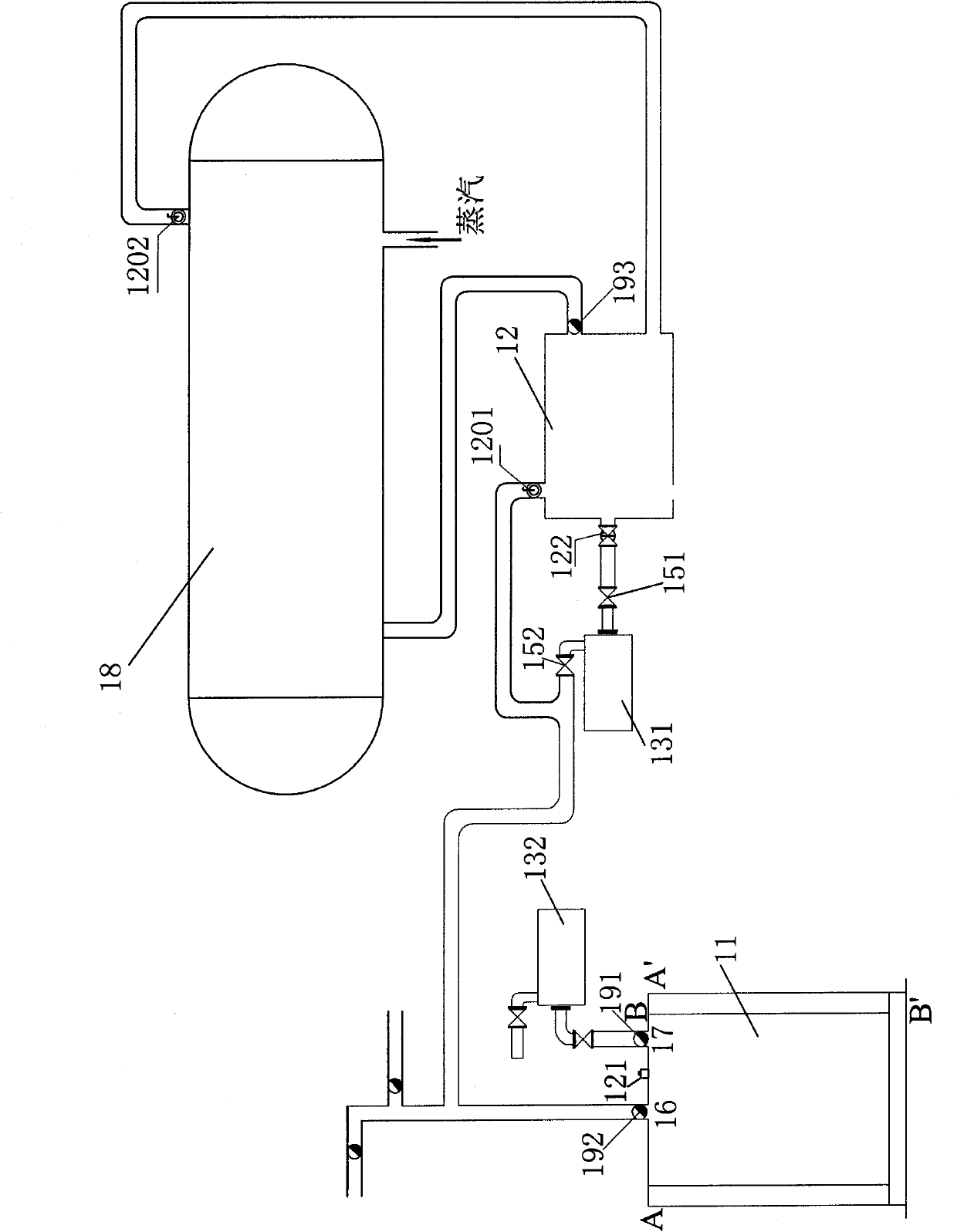

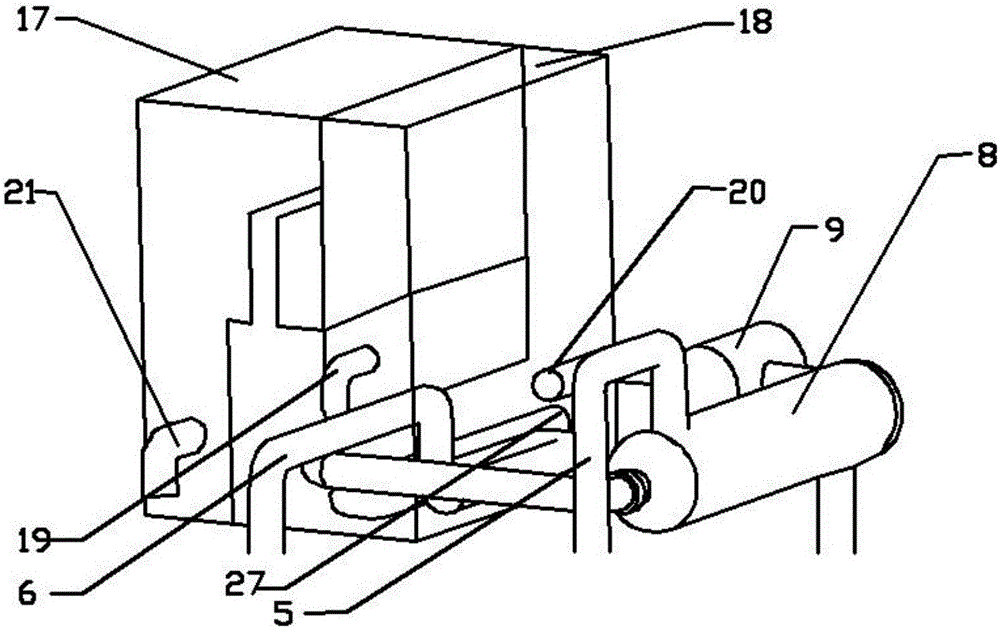

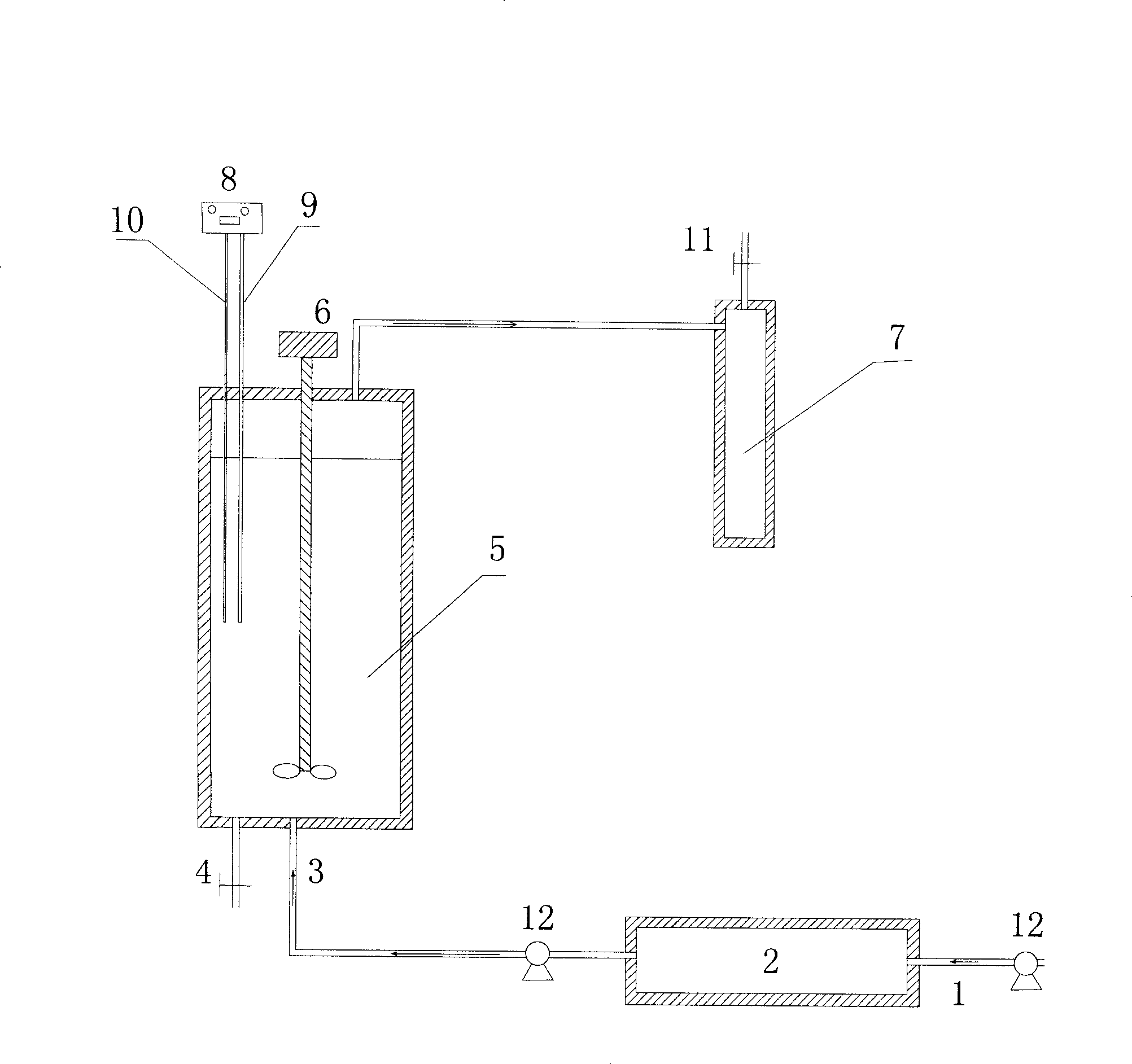

Water curing method and device for centrifuged pretensioned prestressed concrete pipe pile

ActiveCN101905486ATo overcome the lack of maintenance technologyRealize environmentally friendly productionCeramic shaping apparatusWater storage tankEngineering

The invention relates to a pipe pile water curing method. In the method, a water storage tank is arranged, and condensate water and residual steam in a still kettle are guided into the water storage tank; a pipe pile is placed in a steaming and curing pool, the condensate water in the water storage tank is guided into the steaming and curing pool, and the residual steam in water storage tank is guided into the steaming and curing pool; and steaming and curing the pipe pile in the steaming pool for 4-5 hours at 80-90 DEG C. The curing device comprises the steaming and curing pool, the water storage tank and the still kettle, wherein the steaming and curing pool is provided with a water-steam port; the water storage tank is provided with a residual steam outlet, a residual steam inlet, a condensate water outlet and a condensate water inlet; and the still kettle is provided with a steam inlet and a steam outlet. A condensate channel is arranged between the water-steam port of the steaming pool and the condensate water outlet of the water storage tank, and a steam channel is arranged between the water-steam port of the steaming pool and the residual steam outlet of the water storage tank. The condensate water inlet of the water storage tank is communicated with the condensate water outlet of the still kettle through a third electric control valve and a pipeline, and the steam inlet of the water storage tank is communicated with the steam outlet of the still kettle through a second steam valve and a pipeline.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

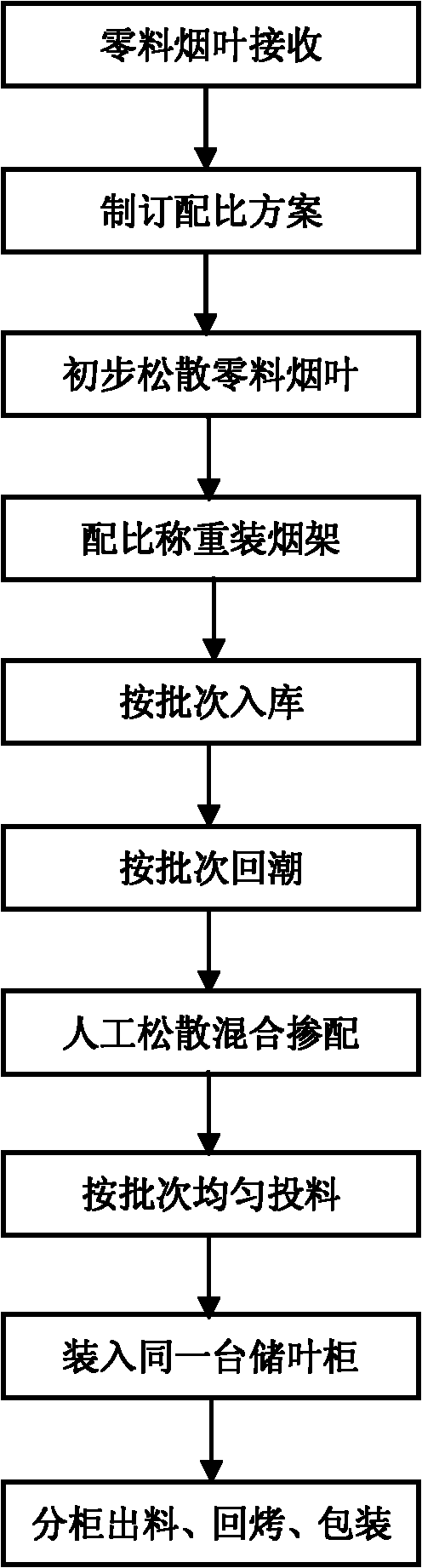

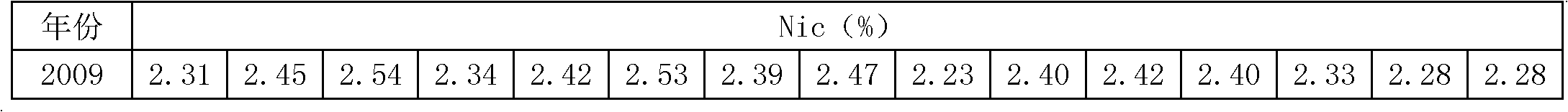

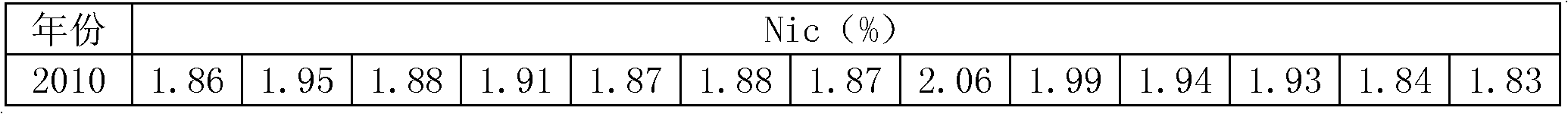

Uniformly blending back curing method for remnant flaky tobacco and application of remnant flaky tobacco

The invention belongs to the field of blending and back curing processing of tobacco leaves, and particularly relates to a uniformly blending back curing method for remnant flaky tobacco and application of the remnant flaky tobacco. The method comprises the following steps of: determining batches of a certain number of remnant flaky tobacco by calculating in a threshing and re-drying enterprise according to a remnant flaky tobacco uniformly blending back curing formula scheme re-determined by the cigarette enterprise, performing manual accurate metering and packing according to the batches, dampening, feeding the dampened remnant flaky tobacco according to the batches, manually loosening and uniformly blending the dampened easily-loosened remnant flaky tobacco in the feeding process, and filling the remnant flaky tobacco blended in each batch into a leaf storage cabinet to realize re-blending. By manual packing and accurate metering blending, manual loosening and re-blending and blending through the leaf storage cabinet, the purpose of fully and uniformly blending the remnant flaky tobacco is fulfilled. The method can be widely applied in the cigarette production, realizes reutilization of the remnant flaky tobacco, and can ensure the homogeneity of cigarette products.

Owner:HUAHUAN INT TOBACCO

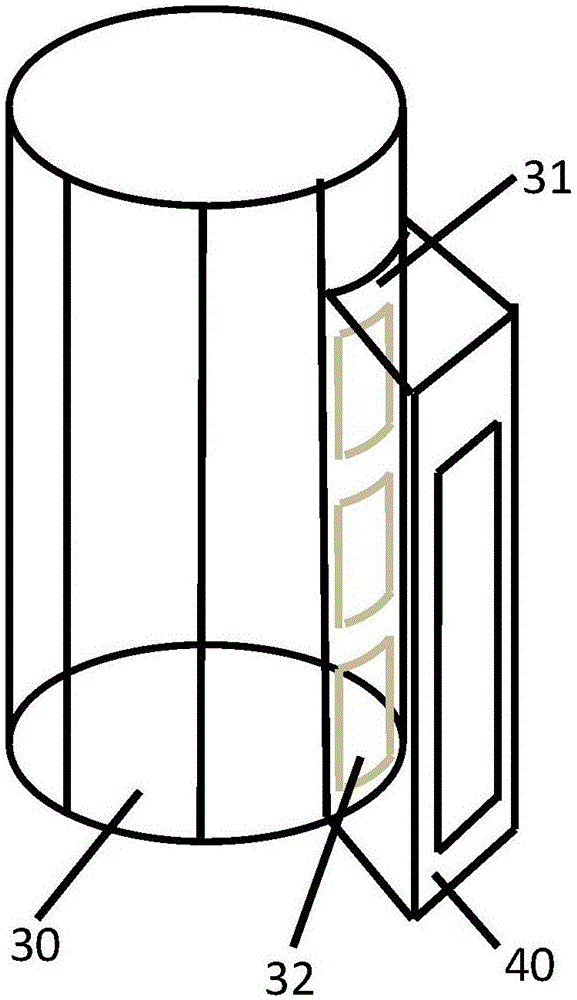

Radial friction welding process method for connecting austenitic alloy steel and non-magnetic drill collar

InactiveCN108907446AAchieve weldingGuaranteed normal work requirementsTubular articlesHollow articlesFriction weldingRadial position

The invention relates to a radial friction welding process method for connecting austenitic alloy steel and a non-magnetic drill collar, and belongs to the field of preparation of oil and gas drillingtools. The radial friction welding process method comprises the following steps: clamping a workpiece made of the austenitic alloy steel and a radial ring into a fixture of a friction welding machine, and then welding the workpiece in the fixture; at the beginning of welding, rotating the radial ring, and applying frictional pressure to the radial ring along the radial direction thereof to drivethe radial ring and the welded workpiece to make relative movement and friction to generate heat; when a friction interface and metal in the vicinity thereof reach a thermoplastic state, stopping applying the friction pressure under certain conditions, and applying upset pressure to the radial ring and keeping the pressure; and unloading the upset pressure and then taking out the workpiece, so asto obtain the non-magnetic drill collar. In the method, the non-magnetic drill collar is machined and repaired by the radial friction welding method, so as to solve the problems of material waste, high cost and low production efficiency of existing processing methods, and overcome the problem that a failed drill collar is difficult to repair.

Owner:SHANDONG UNIV

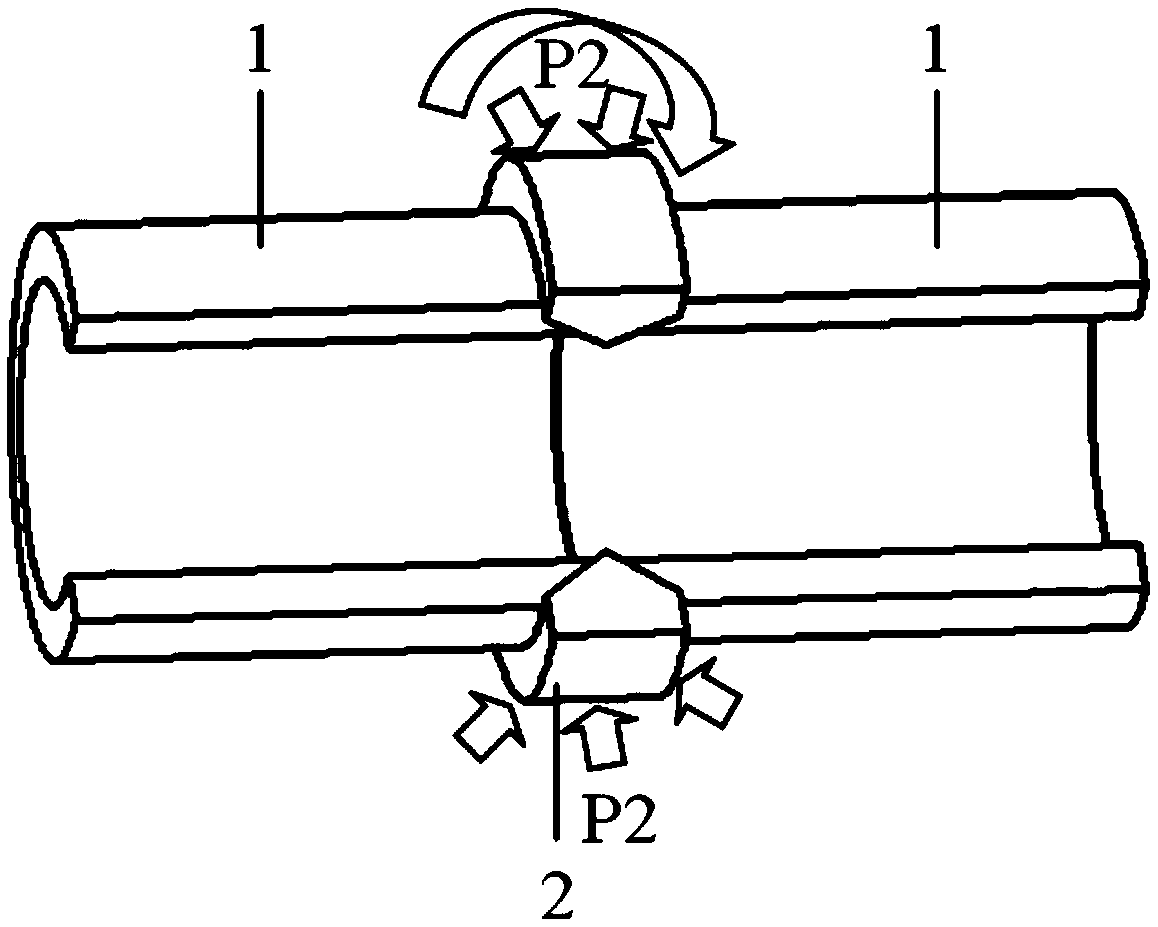

Public bike management system and method

InactiveCN106297041AImprove reliabilityLow costApparatus for meter-controlled dispensingBuying/selling/leasing transactionsUser needsEngineering

The invention discloses a public bike management system and method. The public bike management system comprises an upper computer and a bike provided with a vehicle manager, wherein the upper computer is a vehicle management center or cloud, a communication module used for communicating with mobile communication equipment is arranged in the vehicle manager, and during operation, the communication module establishes communication connection with the mobile communication equipment used by a user and establishes communication with the upper computer through bridging or switching of the mobile communication equipment. The public bike management system disclosed by the invention has the advantages that only the communication module used for communicating with the mobile communication equipment of the user needs to be added in the vehicle manager, connection establishment and communication transmission with the upper computer are realized by utilizing a network of the mobile communication equipment of the user, and a communication module which establishes communication with the upper computer does not need to be directly arranged in the vehicle manager, so that cost is greatly reduced, and communication reliability is effectively improved.

Owner:JIANGSU HONGPU TECH LTD

Production method of lactobacillus micro-ecological preparation for cultivation water regulation

InactiveCN101353636AReduce investmentAchieve re-useBacteriaMicroorganism based processesCulture fluidAdditive ingredient

The invention discloses a production method of lactobacillus microecologics which is used for regulating and controlling culture water quality, comprising the following steps of: (1) tube culture; (2) shaking culture; (3) seed tank culture; and (4) fermentor culture: culture solution in the seed tank is inoculated into the fermentor filled with culture solution, and placed for culturing of 24 to 36 hours at the temperature of 25 to 35 DEG C; when the final pH of the fermenting liquid is 3.0 to 4.0 and the density of the lactobacillus is 5 billion / ml, the fermentation is stopped; the pH of the culture solution of the step (3) and the step (4) is 5.5 to 6.5; the culture solution comprises the following ingredients in 1L of water by weight portion: 3 to 5 portions of molasses, 3 to 5 portions of yeast extract, 0.8 to 1 portion of corn steep liquor, 0.1 to 0.3 portion of KH2PO4, 0.3 to 0.5 portion of MgSO4, 3 to 5 portions of NaCl, 8 to 10 portions of glucose and 0.8 to 1 portion of peptone; the method adopts a totally open culture mode to carry out the production of lactobacillus microecologics which is used for regulating and controlling the culture water quality, and is characterized by little equipment investment, little energy consumption, simple technique and low production cost.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

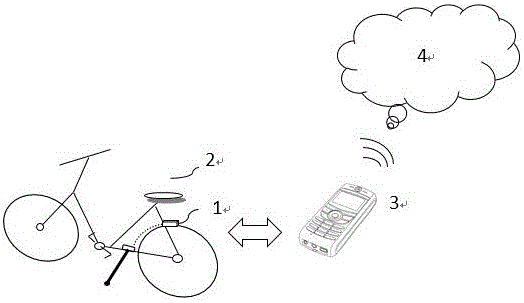

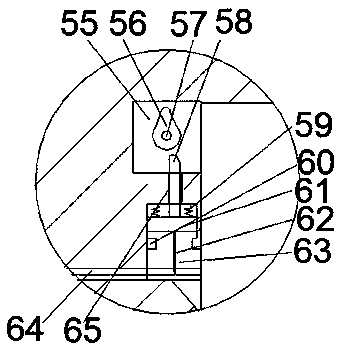

Anti-loosening mechanism for installing robot

InactiveCN110566565AMutual lock implementationWon't looseNutsBoltsArchitectural engineeringThreaded rod

The invention discloses an anti-loosening mechanism for installing a robot. The anti-loosening mechanism comprises a bolt bar and a fastening nut. A section is axially formed on the bolt bar, a left-hand threaded rod is integrally formed at the top end of the bolt bar, the bolt bar is sleeved with a gasket, a through hole matched with the bolt bar is formed in the gasket, the fastening nut is connected to the side, corresponding to the gasket, of the bolt bar in a threaded mode, a first threaded hole is formed in the middle of the fastening nut, an arc groove is formed in the part, corresponding to the periphery of the first threaded hole, on the fastening nut, a limiting nut is connected to the side, corresponding to the fastening nut, of the outer side wall of the left-hand threaded rodin a threaded mode, a second threaded hole is formed in the middle of the limiting nut, fixing holes are formed in the part, corresponding to the periphery of the second threaded hole, of the limitingnut, and fixing mechanisms are connected to the position, corresponding to the arc groove, in the fixing holes in an inserted mode. Compared with a traditional bolt, the anti-loosening mechanism is not likely to loosen, the loosening dropping phenomenon can be avoided, and safety accidents can be avoided; and meanwhile, disassembling is convenient, the anti-loosening mechanism can be used again,and waste can be avoided.

Owner:南京斯杩克机器人技术有限公司

Ultra-large-capacity intelligent express cabinet

InactiveCN106204951ARealize individual weighingAchieve re-useApparatus for meter-controlled dispensingIndividual entry/exit registersWeight changeComputer module

The invention discloses an ultra-large-capacity intelligent express cabinet. A weighing device is arranged under express row cabinets so that each row of express row cabinet can be independently weighed; the increased weight of the express row cabinets is acquired through a weight change acquisition module when cabinet doors are opened in single time, and the increased weight and depositing information is bound and stored; meanwhile, an express single cabinet space information judgment module is arranged so that a plurality of pieces of expresses can be stored in one express single cabinet and residual space express single cabinets are reutilized, and the problem that the quantity of express single cabinets of an existing express cabinet is made up; meanwhile, an access control module is controlled according to the weight change acquisition module to manage and control the opening and closing of an express taking room outlet; the access control module ensures that a receiver can smoothly take away the expresses only if the receiver takes the expresses meeting the weight of the own expresses, so that the express single cabinets can contain the plurality of expresses and phenomena of incorrectly taking and taking by mistakes do not occur, and furthermore, the space is extremely saved and the utilization rate of a cabinet body is improved; and the anti-theft aim is realized.

Owner:武汉三车科技有限公司

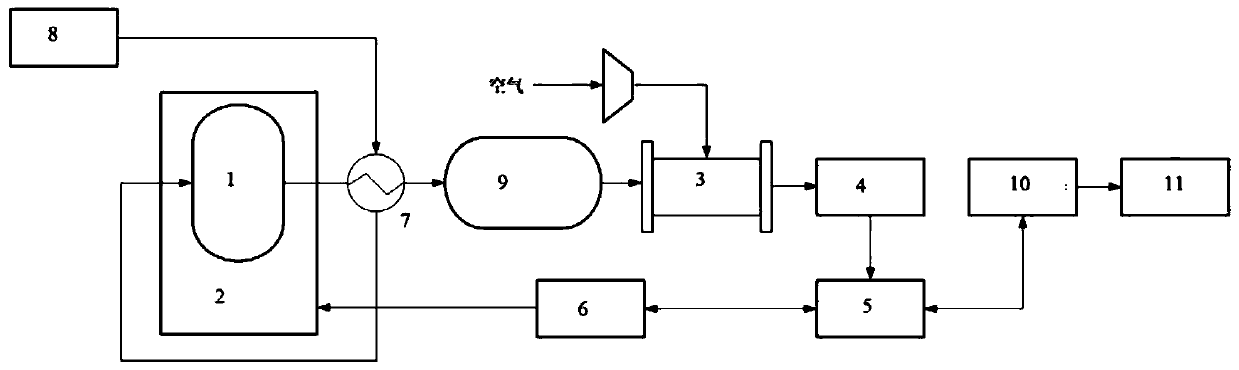

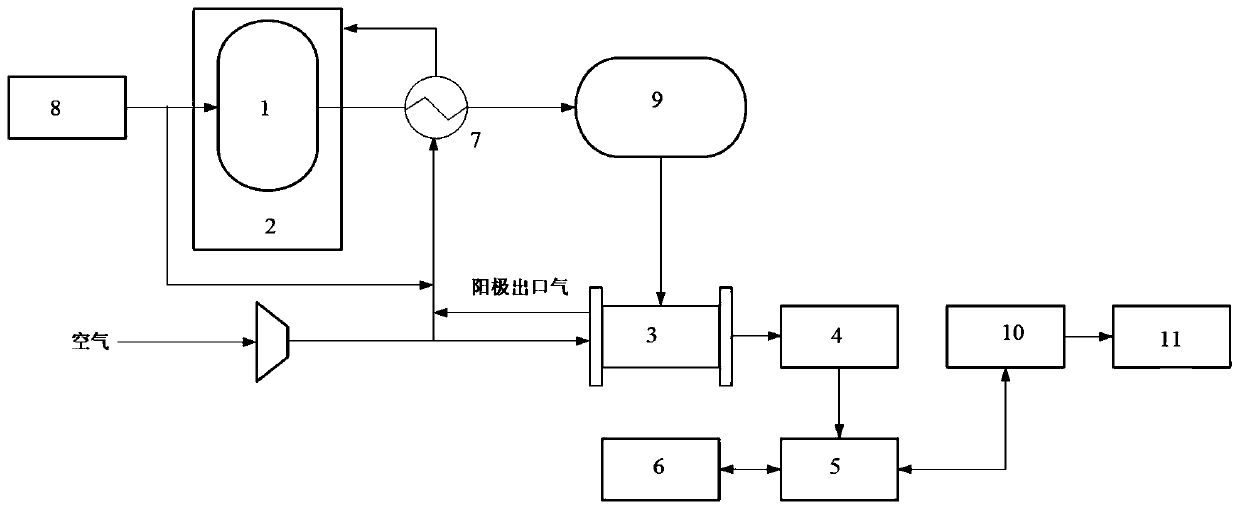

Exhaust gas recycling device of fuel cell

InactiveCN106229528AAchieve re-useIncrease profitFuel cells disposal/recyclingWater heatersElectrochemical responseFuel cells

The invention discloses an exhaust gas recycling device of a fuel cell, and belongs to the field of fuel cells. The exhaust gas recycling device comprises a hydrogen storage tank, a galvanic pile, a heat exchanger, a heat conversion device, a gas-water separator, a drying tower and a compressor, wherein hydrogen in the hydrogen storage tank is introduced into the galvanic pile for electrochemical reaction to generate electric energy, and the remaining hydrogen exhaust gas enters the heat exchanger for heat recovery, sequentially passes through the gas-water separator, the drying tower and the compressor and finally enters the hydrogen storage tank; air is introduced into the galvanic pile for electrochemical reaction to generate electric energy, and the remaining air exhaust gas enters the heat conversion device and provides the heat conversion device with heat; and a high-temperature medium generated by the heat conversion device enters the drying tower to provide heat for absorbent regeneration and returns to the heat conversion device again after heat supply. By the exhaust gas recycling device of the fuel cell disclosed by the invention, the residual fuel and heat in the exhaust gas of the fuel cell are fully recycled, so that improvement of the fuel utilization rate of the fuel cell is facilitated; energy is saved; the power generation efficiency is improved; and the cost is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

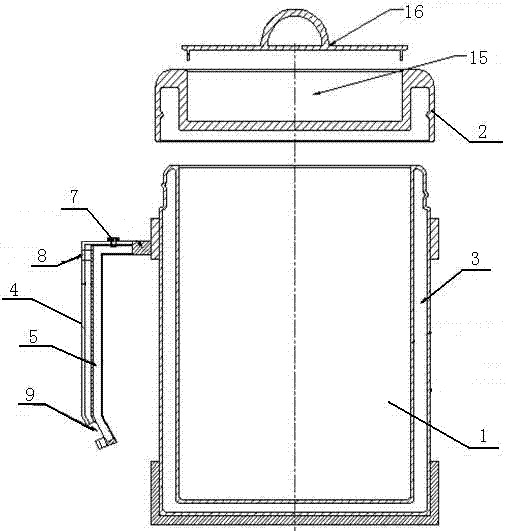

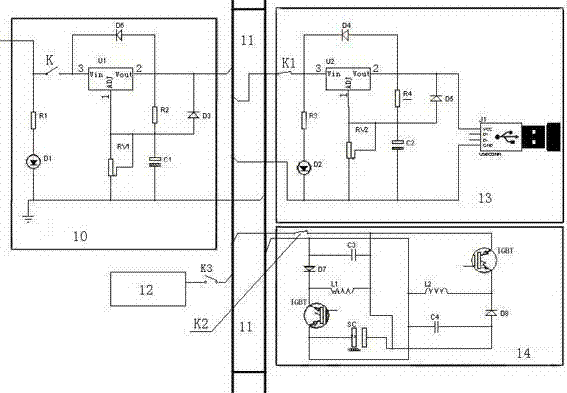

Intelligent cup based on thermoelectric power generation

InactiveCN104207588AImprove thermoelectric conversion efficiencyPracticalGenerators/motorsDrinking vesselsCapacitanceTemperature control

The invention relates to an intelligent cup based on thermoelectric power generation. An existing cup with a large structure is not easy to carry, rapid in temperature difference drop and low in energy utilization rate. A cup body of the intelligent cup based on thermoelectric power generation is vacuum and provided with a vacuum cavity, a cavity is formed in a cup handle, a thermoelectric power generation module is arranged in the vacuum cavity, a control circuit is arranged in the cavity, a control switch, a temperature display and a USB (universal serial bus) interface are arranged on the cup handle and connected with the control circuit, and the control circuit comprises a thermoelectric power generation control circuit, a direct-current bus, a temperature control module, a load control circuit and a super-capacitor control circuit. By the aid of stable and long temperature difference between the inner wall and the outer wall of the vacuum cavity of a current vacuum cup, thermoelectric conversion efficiency is improved, the intelligent cup is practical and easier to implement and can store power when people usually and normally drink water, designed charging is omitted, and the intelligent cup can solve the requirements of people in emergency situations and can be usually used.

Owner:XIAN TECHNOLOGICAL UNIV

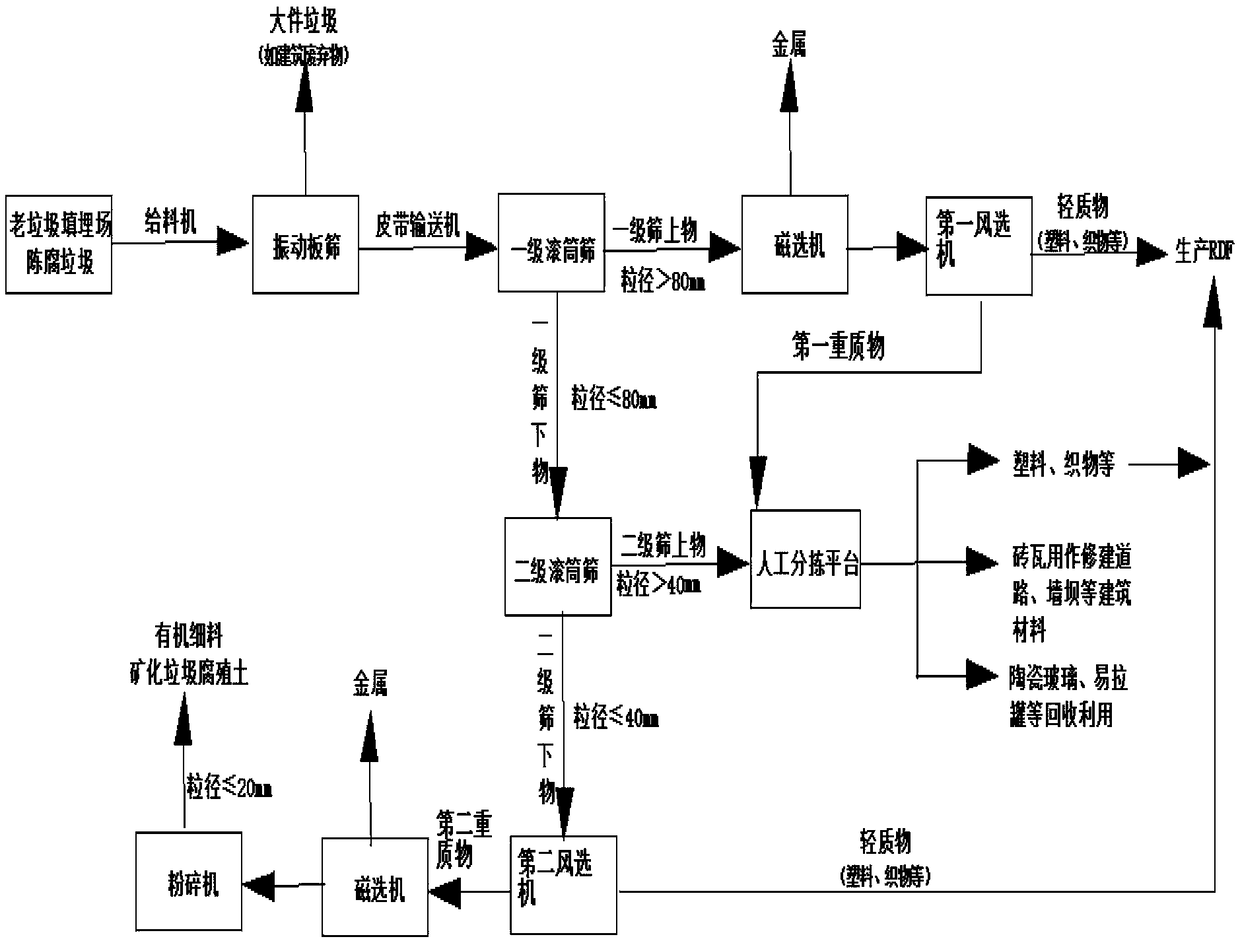

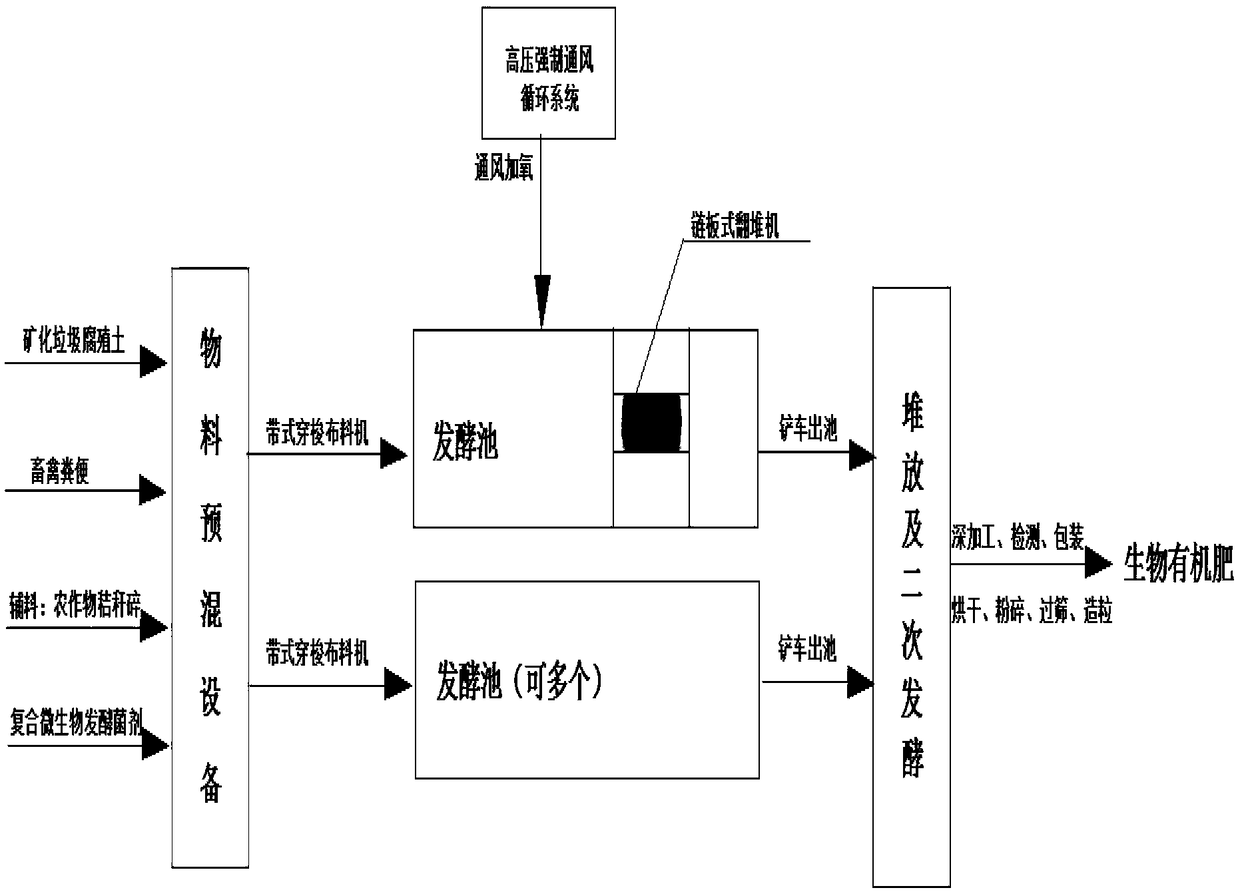

Method for comprehensively treating and recycling stacked rubbish

InactiveCN108976081AClear classificationShort timeBio-organic fraction processingSolid waste disposalSubstance useMagnetic separator

The invention discloses a method for comprehensively treating and recycling stacked rubbish. The method comprises the following steps: 1) digging rubbish; 2) sorting: adopting mechanical sorting and manual sorting, wherein mechanical sorting comprises first-level sieving and second-level sieving; the process is as follows: sieving and removing major rubbish by using a vibrating plate, entering into a first-level rotary screen, using a magnetic separator for removing secondarily used metal from the first-level oversize substances in grain size more than 80 mm and then entering into a first winnower, and winnowing, thereby acquiring light substances and first heavy substances, and then manually sorting the first heavy substances; pouring the first-level undersize substances in grain size less than or equal to 80 mm into a second-level rotary screen, manually sorting the secondary oversize substances in grain size more than 40 mm, using the magnetic separator for removing metal from the secondary undersize substances in grain size less than or equal to 40 mm and then entering into a second winnower, and winnowing, thereby acquiring the light substance used for preparing rubbish derivative fuel RDF and mineralized refuse humus used for preparing fertilizer. The method is capable of quickly and efficiently distinguishing and screening the mineralized refuse and realizing recycling rational utilization.

Owner:SHENZHEN SANLIN BIOTECH ENG

Novel preparation method of nano selenium-catathelasma ventricosum polysaccharide complex

ActiveCN104800240AMild reaction conditionsLow costOrganic active ingredientsMetabolism disorderVitamin CCatathelasma ventricosum

The invention provides a novel preparation method of a nano selenium-catathelasma ventricosum polysaccharide complex. Catathelasma ventricosum polysaccharides are taken as a dispersing agent, waste (an ethanol scrubbing solution) in the catathelasma ventricosum polysaccharide extraction process is taken as a reaction reducing agent, the waste is reused, compared with traditional reducing agents such as vitamin C and the like, the novel reducing agent has the better reducing property (the particle size of nano selenium is decreased by 23.8%); (2) in the whole preparation process, reaction conditions are mild, the cost is low, operation is simple, industrial popularization is easy, the particle size of the obtained nano selenium-catathelasma ventricosum polysaccharide complex is only 32.7 nm and can still be kept to be 62.7 nm after stored for 60 days, and the complex has very good bioavailability and stability; (3) the catathelasma ventricosum polysaccharides and the nano selenium in the nano selenium-catathelasma ventricosum polysaccharide complex can have a synergistic effect to promote the antioxidant activity of the complex.

Owner:成都雅乐鲜生物科技有限公司

Method for preparing mesoporous activated carbon from shell of jatropha curcas

The invention relates to a method for preparing mesoporous activated carbon from shell of jatropha curcas. The waste shell of the jatropha curcas is taken as a raw material, subjected to cleaning and impurity removal, and is carbonized at certain temperature; the obtained carbonized material is conveyed to a microwave oven, and is activated in the vapor atmosphere; and the activated material is dried and screened to obtain the mesoporous activated carbon. The method adopts microwave radiation for heating and raising temperature, and adopts the vapor for activation to prepare the activated carbon; a microwave radiation heating device can control the atmosphere, has adjustable power, and can accurately maintain the stability of the temperature of the material; the method has the advantages of short time of microwave radiation and activation, quick heating, clean and pollution-free preparation process and the like; the mesoporous volume of the product activated carbon reaches 50 to 84 percent; and the main quality index, namely iodine adsorption capacity meets the state grade 1 standard.

Owner:KUNMING UNIV OF SCI & TECH

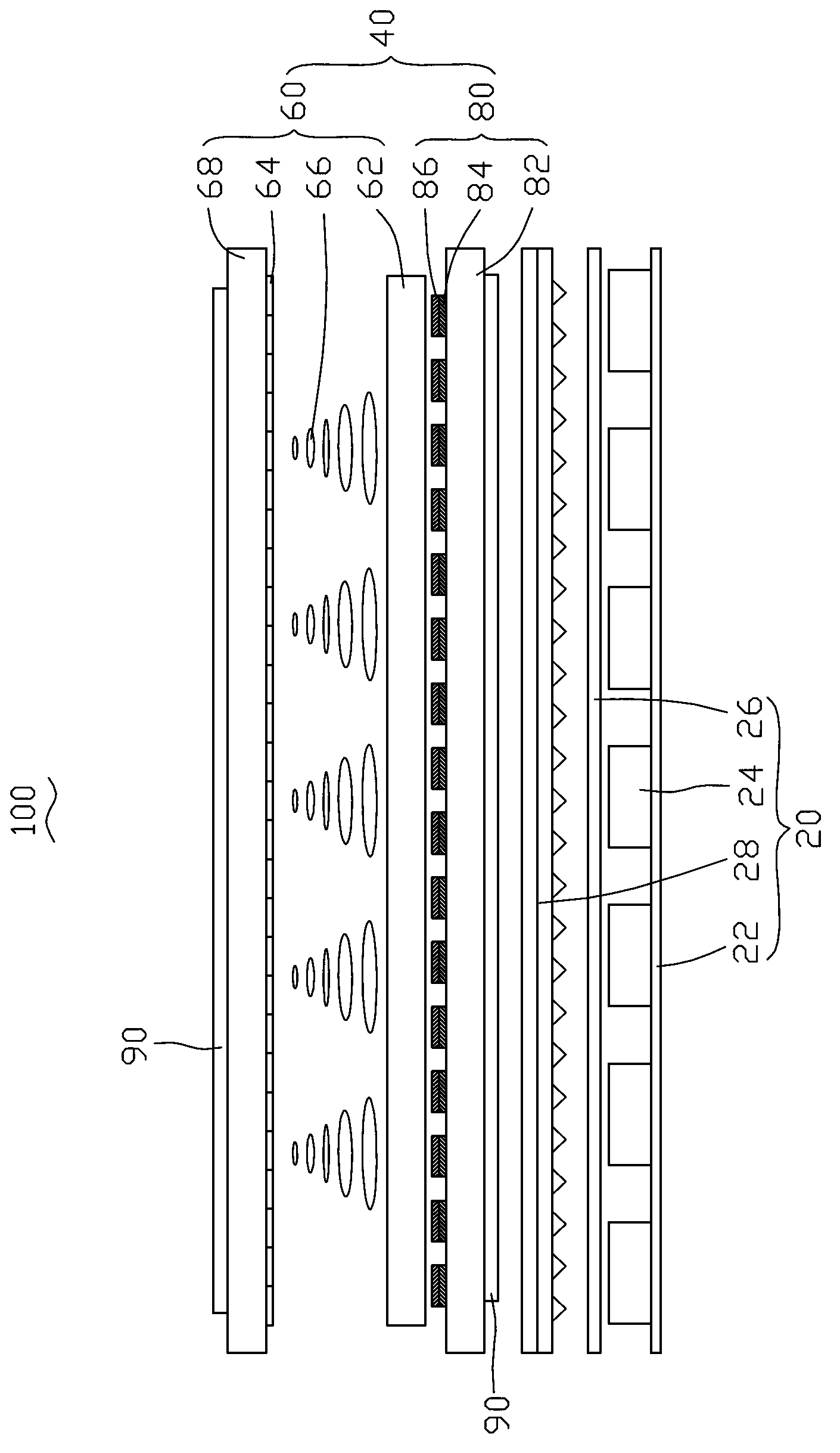

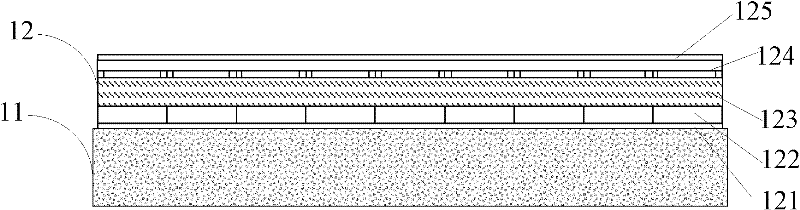

Double-vision display module

ActiveCN103018953ARaised light rateGuaranteed brightnessNon-linear opticsOptical elementsGratingLight energy

The invention relates to a double-vision display module which comprises a backlight source and a display panel, wherein the display panel comprises a display screen and a shading grating; the shading grating which is positioned between the display screen and the backlight source comprises a base plate, a reflective film layer and a shading film layer, wherein the reflective film layer is formed on the base plate, and the shading film layer is formed on the reflective film layer; a slit is formed in the shading film layer for light to emit, and the light emitting part and the non light emitting part of the shading film layer are proportionally and periodically distributed; and the shape and the structure of the reflective film layer are the same as those of the shading film layer. Light rays which are irradiated by the backlight source on the reflective film layer are reflected to the backlight source, so that recycling of light energy is realized, the light emitting rate of the display module is increased, and the light emitting brightness of the display module is guaranteed on the premise that the brightness of the backlight source does not need to be enhanced.

Owner:芜湖天马汽车电子有限公司

Method and apparatuses for pretreating sewage plant excess sludge by microwave method and producing hydrogen by fermentation

The invention discloses a method and a device for pretreating excess sludge of a sewage plant by a microwave method for fermentation to produce hydrogen. The method comprises the following steps: microwave is utilized to pretreat the excess sludge of the sewage plant for 2 to 20 minutes, then the sludge pretreated by the microwave is placed into a sealed fermentation hydrogen production reactor, hydrogen production seed sludge which accounts for 5 to 15 percent of the volume of the excess sludge is grafted, the temperature is controlled to between 25 and 45 DEG C for fermentation hydrogen production, and hydrogen is produced after 8 to 15 hours. The device comprises a microwave generator, the fermentation hydrogen production reactor and a hydrogen collection device, wherein the top of the fermentation hydrogen production reactor is provided with a hydrogen outlet, while the bottom is provided with a sludge inlet and a sludge discharge outlet; the microwave generator is connected with the sludge inlet of the fermentation hydrogen production reactor; the hydrogen collection device is connected with the hydrogen outlet of the fermentation hydrogen production reactor; and the fermentation hydrogen production reactor is provided with a stirrer and a heater. The method has the advantages that the method has large hydrogen yield and short delay time, can improve the biological redegradation capability of the sludge, can release heavy metals in the sludge, reduce the pollution of landfill treatment to soil, and has simple equipment, low cost and less energy consumption.

Owner:HUNAN UNIV

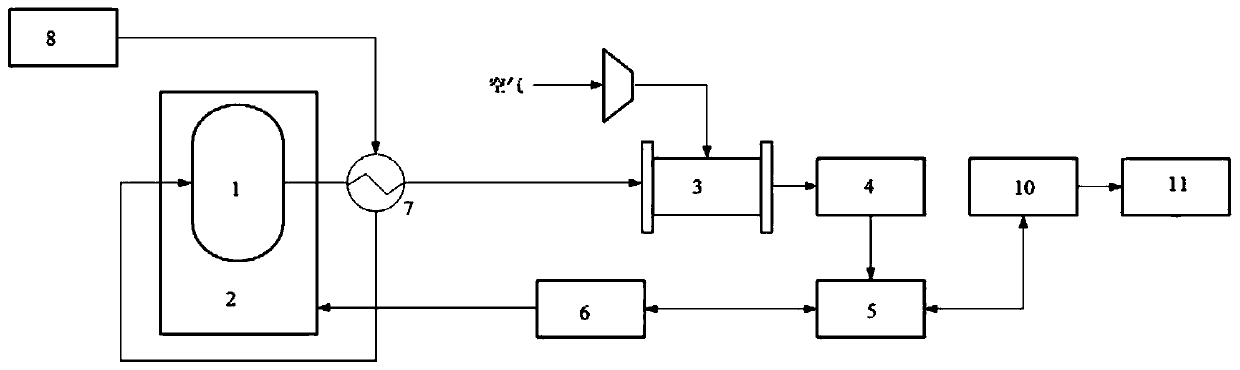

Ammonia fuel cell system and electric device

PendingCN110277578AGuaranteed uptimeIncrease flexibilityFuel cell heat exchangeHydrogen/synthetic gas productionExternal energyDecomposition

The invention belongs to the technical field of ammonia decomposition, in particular to an ammonia fuel cell system and an electric device. The ammonia fuel cell system comprises an ammonia decomposition reaction device, a heating device, a hydrogen fuel cell, a DC / DC converter and an inverter which are connected in sequence, a battery pack and a heat exchanger. The ammonia fuel cell system can run stably for a long time and form recycling utilization and have the advantages of high flexibility, low energy consumption and high system utilization rate. The heat exchanger of the system can make the energy produced by ammonia decomposition preheat ammonia gas and realize recovery and utilization of waste heat. The battery pack can make the battery pack respond quickly and output stably and can deal with acceleration and deceleration of the electric device quickly so as to improve the stability of system operation and can transmit the electric energy generated by the hydrogen fuel cell or the electric energy in the battery pack to the outside. The battery pack or the heating device of the system can provide energy for the ammonia decomposition reaction device without external energy for the ammonia decomposition reaction device.

Owner:福大紫金氢能科技股份有限公司

Method for preparing jatropha curcas shell-based activated carbon

The invention relates to a method for preparing jatropha curcas shell-based activated carbon, which uses vapor or a carbon dioxide gas as an activator to activate waste jatropha curcas shells to obtain high-quality activated carbon. The method adopts high-temperature carbonization in the carbonization process, adopts different rates of temperature rise for raising the temperature sectionally in the activating process, and has the advantages of short activating time, low energy consumption, high product yield, cleanness, environment protection and the like. The point adsorption capacity of the product namely the activated carbon reaches the national primary standard. The method has a rich material source, can make full use of the waste jatropha curcas shell resource, decreases the stack of the waste jatropha curcas shells, solves the problem of environmental pollution caused by combustion and opens up a new path for the comprehensive use of jatropha curcas.

Owner:KUNMING UNIV OF SCI & TECH

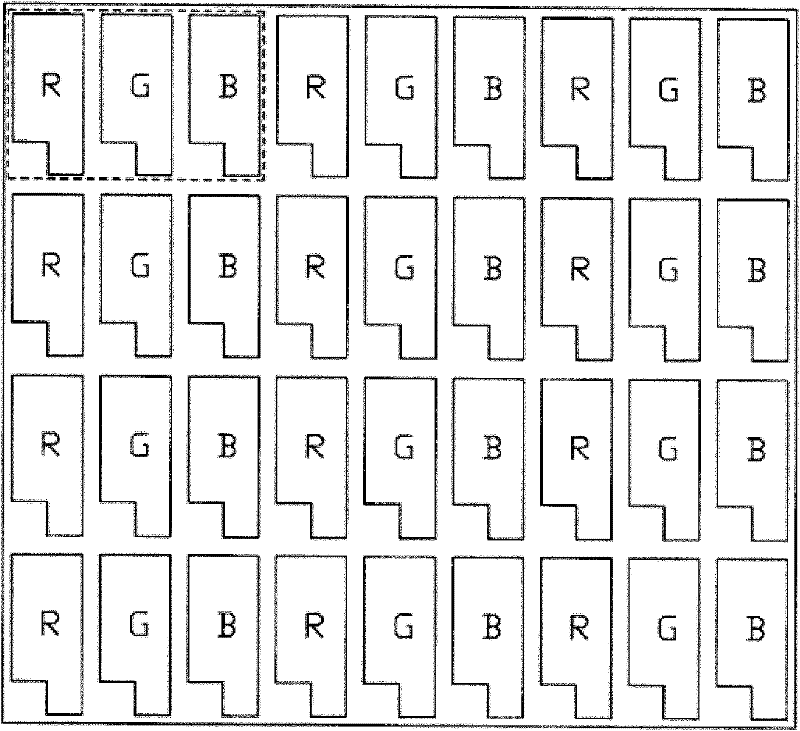

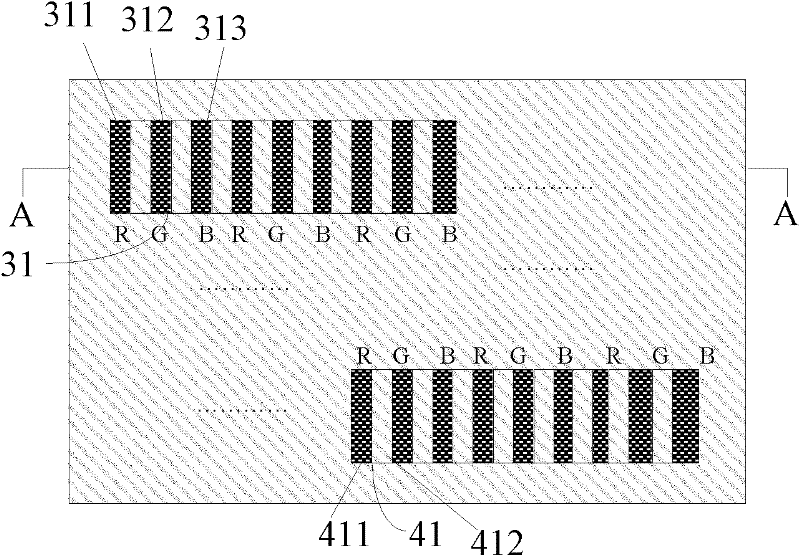

Grating, liquid crystal display device and manufacture methods of grating and liquid crystal display device

InactiveCN102540306AAchieve normal displayAchieve re-useOptical filtersSolid-state devicesBlock matrixLiquid-crystal display

The embodiment of the invention discloses a grating, a liquid crystal display device and manufacture methods of the grating and the liquid crystal display device, relating to the field of liquid crystal display and solving the problems of light waste caused in a manner that one part of light radiated by a backlight source is absorbed by a block matrix region and poorer utilization rate in the prior art. The grating provided by the embodiment of the invention comprises a plurality of three-primary-colour gratings arranged in parallel, each three-primary-color grating comprises a red R sub grating, a green G sub grating and a blue B sub grating which are arranged in parallel, each sub grating comprises an open region and a reflection region, the reflection region is arranged around the open region, and the sub grating corresponds to a pixel unit on an array substrate. The grating, the liquid crystal display device and manufacture methods of the grating and the liquid crystal display device, provided by the embodiment of the invention are applied to a system with liquid crystal display.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Construction waste activating method

The invention provides a construction waste activating method which comprises the following steps: performing primary calcination on construction wastes at a temperature of 600-800 DEG C for 3-5 hoursso as to obtain a first calcined material; mixing the first calcined material and gypsum powder, lime powder and slag powder, and performing secondary calcination on the obtained mixed material at atemperature of 850-950 DEG C for 2-5 hours so as to obtain a second calcined material; and performing chemical excitation on the second calcined material in an alkaline environment, thereby obtainingthe activated construction powder. According to the activating method provided by the invention, the obtained activated construction powder has characteristics of binding materials, so that the construction powder can serve as a binding material to be applied to non-sintered building materials, and reutilization of the construction wastes is realized. Experimental results in the embodiment show that the activated construction powder has high activity index, the activity index within 3 days is 83.9, and the activity index within 28 days is 92.9.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

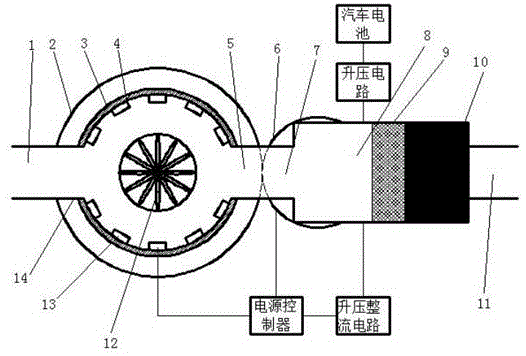

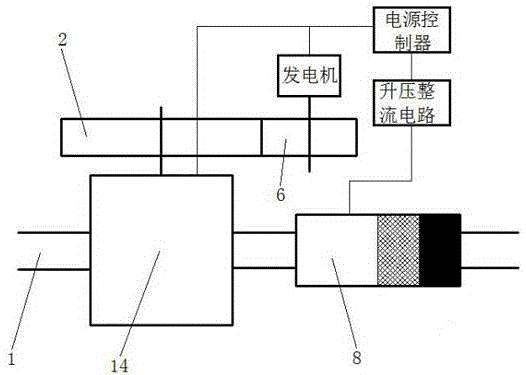

Automobile exhaust treatment device based on automobile exhaust power generation and control system of automobile exhaust treatment device

InactiveCN105464767AAchieve re-useEasy to handleInternal combustion piston enginesExhaust apparatusControl systemLow temperature plasma

The invention discloses an automobile exhaust treatment device based on automobile exhaust power generation. The automobile exhaust treatment device comprises an automobile exhaust power generation device and an automobile exhaust treatment device body. The automobile exhaust power generation device is composed of a power generation device shell, a turbine, a thermoelectric module and a generator. The automobile exhaust treatment device body is composed of an automobile exhaust treatment device gas inlet, a low-temperature plasma reactor, a filter screen, a catalyst cavity and an automobile exhaust treatment device gas outlet. A control system is composed of a second power voltage detection module, an MCU and a first power control module. According to the exhaust treatment device, energy in automobile exhaust can be utilized, the problem that exhaust is not fully purified when an automobile just starts can be solved, and electric energy can be saved.

Owner:CHENGDU DESHANNENG TECH CO LTD

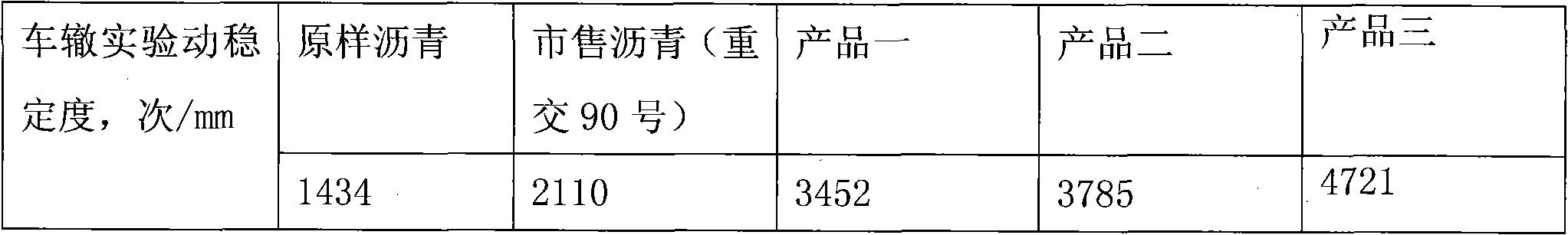

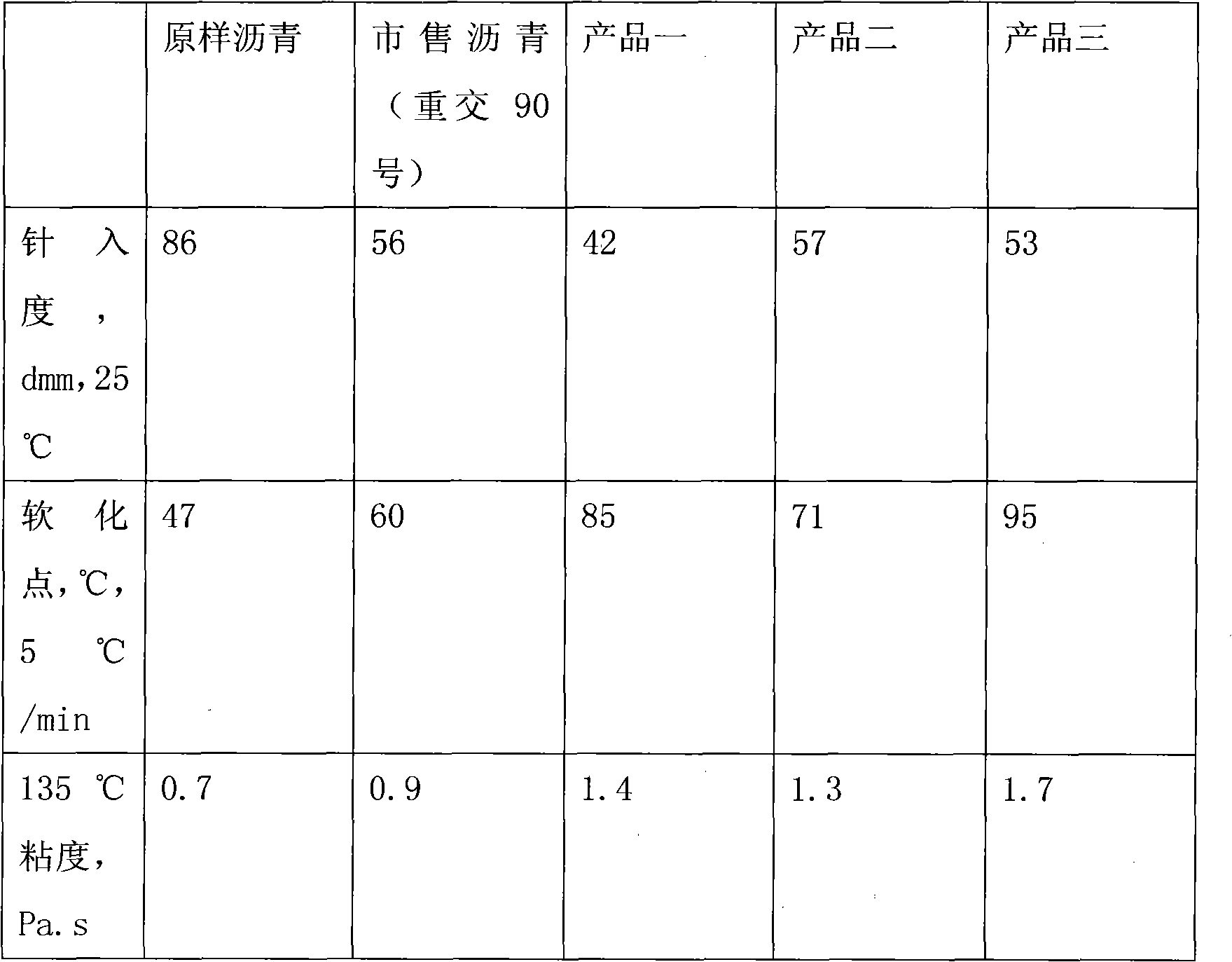

Modified road asphalt and preparation method thereof

ActiveCN102093725APrevent road crackingEnhance heat storage performance and temperature resistanceBuilding insulationsWaste tiresWaste treatment

The invention discloses modified road asphalt and a preparation method thereof. The modified road asphalt consists of an asphalt substrate, waste tire rubber powder, a copolymer, a cross linking agent and a phase change modifier. The recycling of wastes is fully realized, and the defects of easiness in cracking and poor thermal stability of asphalt obtained by modifying and mixing the ordinary waste tire rubber powder are overcome because the phase change modifier is added. The cross linking agent is added, so that the stability of the asphalt is greatly enhanced. An effect test indicates that the asphalt has very high pressure resistance and deformation resistance. Waste treatment and material modification are comprehensively considered, so that very good economic benefits and social benefits are achieved.

Owner:BEIJING EURO & AMERICAN INST OF SCI & TECH

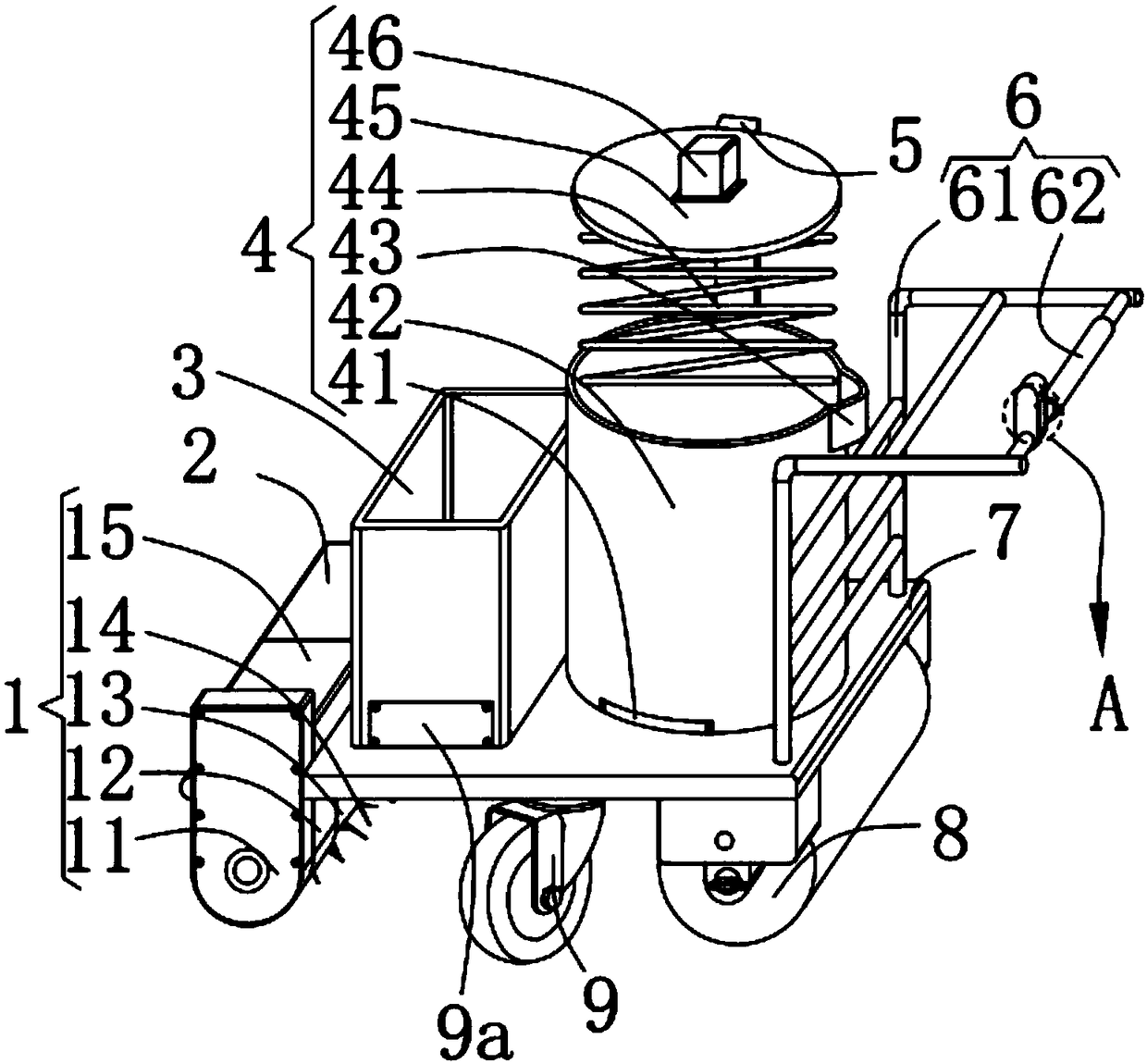

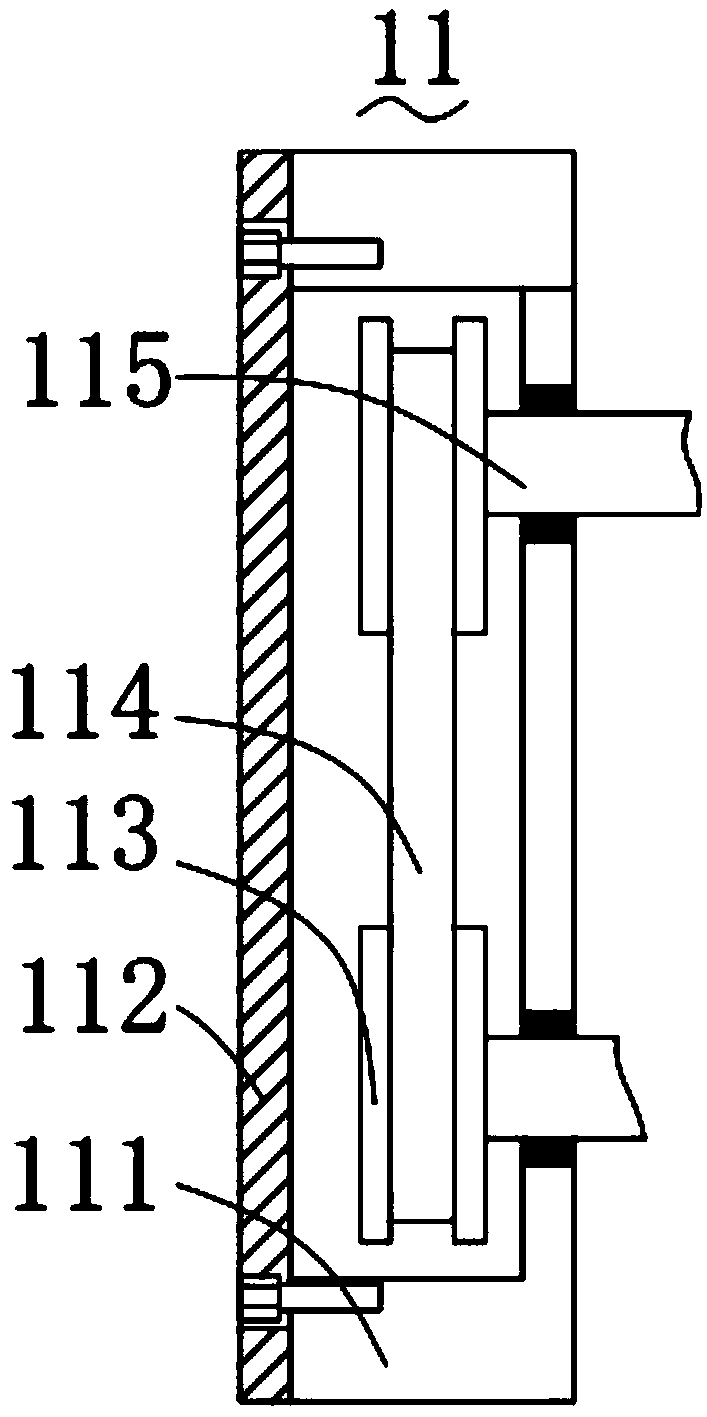

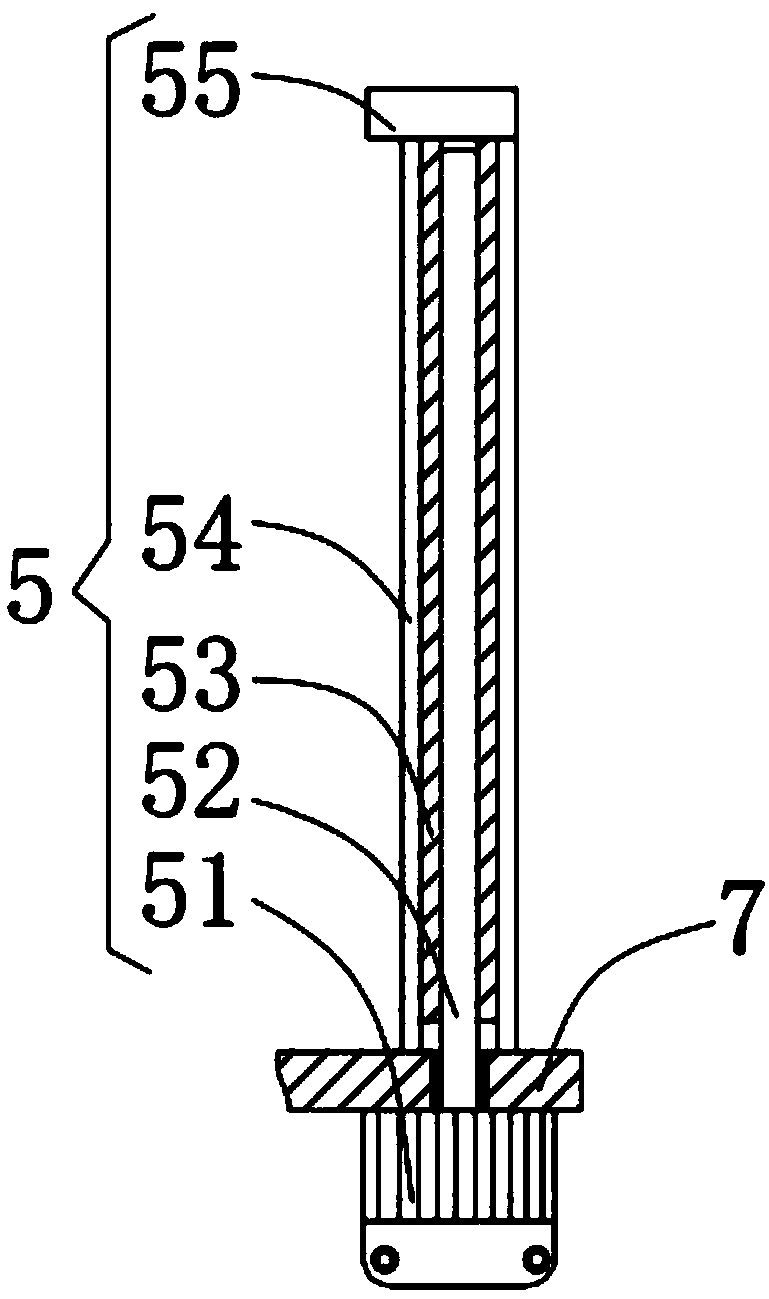

Bituminous pavement crack maintenance and repair device

InactiveCN108330797AImprove adhesionIncrease contact areaRoads maintainenceWaste collectionRoad surface

The invention relates to the field of roads, in particular to a bituminous pavement crack maintenance and repair device. The bituminous pavement crack maintenance and repair device comprises a grinding structure, an accumulator, a waste collection box, a stirring structure, a driving structure, a lifting structure, a bottom plate, a rolling structure, universal wheels, a draught fan and a junctionbox. The grinding structure is used for cutting a foundation trench pavement, and the accumulator is used for supplying power; the waste collection box and the draught fan are convenient for collecting waste; the stirring structure is used for preventing bituminous raw materials from solidifying; the driving structure is convenient for cleaning the stirring structure; the lifting structure improves using comfort; the rolling structure is used for leveling the bituminous pavement; and the junction box can be controlled conveniently. According to the bituminous pavement crack maintenance and repair device, the grinding structure can cut the foundation trench pavement conveniently, the contact area of the foundation trench pavement and the repaired bituminous pavement is increased, the adhesion of the repaired bituminous pavement is increased, the draught fan facilitates the cleaning of the waste in a foundation pit after cutting, the cleaning efficiency and repair effect are improved, the stirring structure is convenient for stirring the raw materials of bituminous concrete raw materials during transportation and construction, and the leveling of the pavement is good.

Owner:济宁市融旺建筑工程有限公司

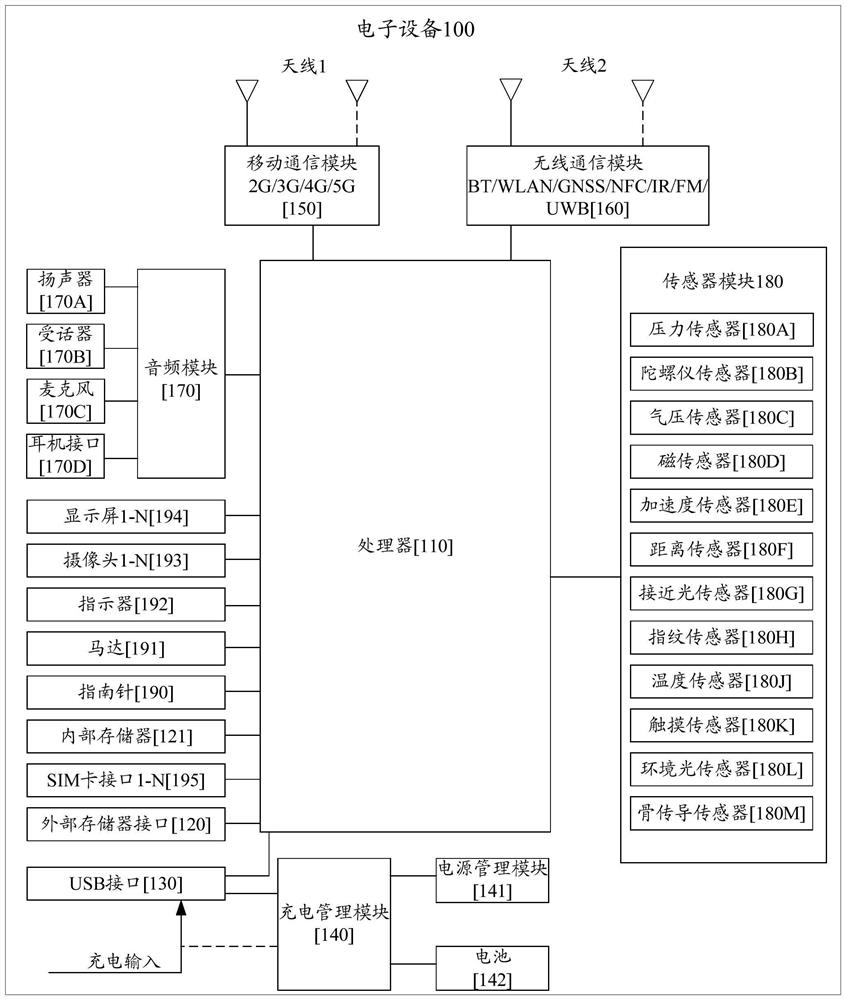

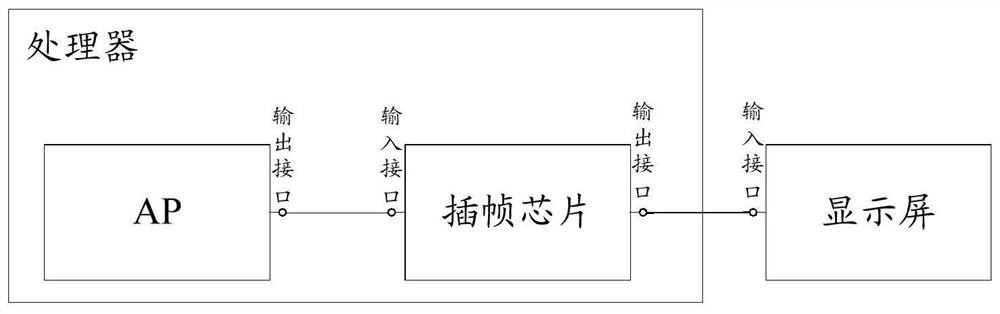

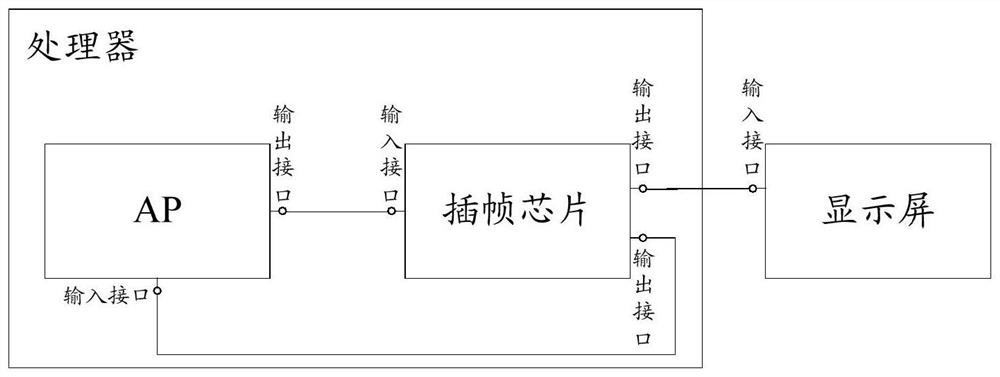

Video data processing method and device

ActiveCN112004086AAchieve re-useReduce power consumptionDigital video signal modificationComputer hardwareEngineering

The invention discloses a video data processing method and device, which are applied to electronic equipment comprising an AP, a frame insertion chip, a display screen and a memory, and the method comprises the following steps: the AP sends image data of a target video to the frame insertion chip; the frame insertion chip performs frame insertion processing on the received image data of the targetvideo; and the frame insertion chip sends the image data after frame insertion of the target video to the display screen and sends target information to an AP, and the target information is used forstoring the image data after frame insertion of the target video into the memory. By adopting the embodiment of the invention, the video after frame insertion can be reused, and finally the purpose ofreducing power consumption is achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Sheet feeding table of printing machine

InactiveCN109056396ASimple structureEasy to usePaper recyclingPulp bleachingPulp and paper industryPrinting press

The invention discloses a sheet feeding table of a printing machine. The sheet feeding table of the printing machine comprises a sheet feeding table body, wherein the sheet feeding table body is arranged above the printing machine, the sheet feeding table body is internally provided with a waste paper treatment cavity, the inner wall of the left side of the waste paper treatment cavity is providedwith a paper inlet groove communicated with the outer portion, the waste paper treatment cavity is internally provided with a first cutting shaft, the left side end of the first cutting shaft is rotationally and cooperatively connected with the inner wall of the left side of the waste paper treatment cavity, and the sheet feeding table body at the right side of the waste paper treatment cavity isinternally provided with a first cavity. The sheet feeding table of a printing machine has the advantages that through the mutual cooperation of a threaded rod and a sliding block, the automatic processing operation is completely achieved, the manpower waste is greatly reduced, the use of a stirring arm greatly quickens the waste paper treatment process, so that the processing efficiency is quicker, the needed time is shorter, the speed of pulp flowing can be controlled through the vertical movement of the sliding block, thereby being capable of processing the pulp more conveniently, new paper is made, and the reuse of resources is achieved.

Owner:WENLING QIHAO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com