Method for connecting concrete pile and bearing platform

A technology of concrete pile and connection method, which is applied in construction, infrastructure engineering and other directions, can solve problems such as difficulty in controlling the construction quality of core-filled concrete, influence of core-filled concrete on the anti-pulling quality, and inability to clean the inner wall mud, so as to avoid engineering safety. Accidents, reducing engineering safety hazards, and improving the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

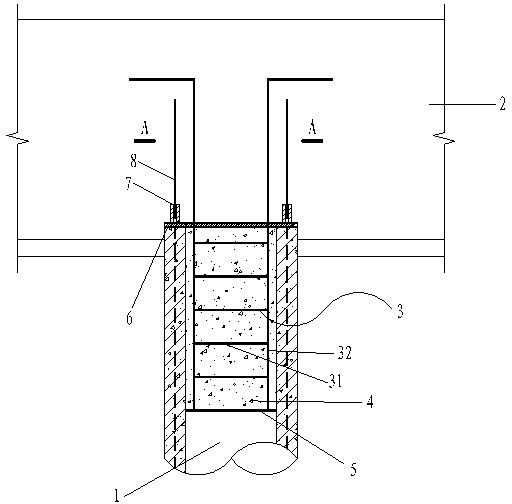

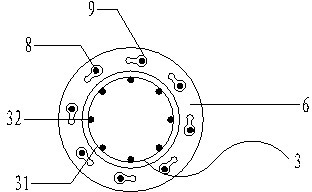

[0026] Such as figure 1 , 2 , 3, 4, 5 and 6: a method for connecting a concrete pile to a cap, comprising the following steps:

[0027] First, after the pile foundation construction is completed, measure the actual elevation of the top of the concrete pile 1;

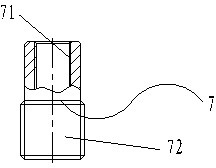

[0028] When the actual elevation of the pile top of the concrete pile 1 is equal to or lower than the design elevation, a plurality of connecting steel sleeves 7 are installed on the tension screw holes 9 of the end plate 6 of the concrete pile 1, and then the screw thread connected with the foundation cap 2 The steel bar 8 is installed on the connecting steel sleeve 7 to realize the connection between the end plate 6 and the threaded steel bar 8, and then ordinary concrete is poured on the foundation cap 2 connected with the concrete pile 1, so that the concrete pile 1 and the foundation ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com