Patents

Literature

169results about How to "Guaranteed homogeneity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-concentrate type fermented total mixed ration for dairy cows and preparation method thereof

InactiveCN101828635ALow costIncrease contentFood processingAnimal feeding stuffAdditive ingredientTrace element

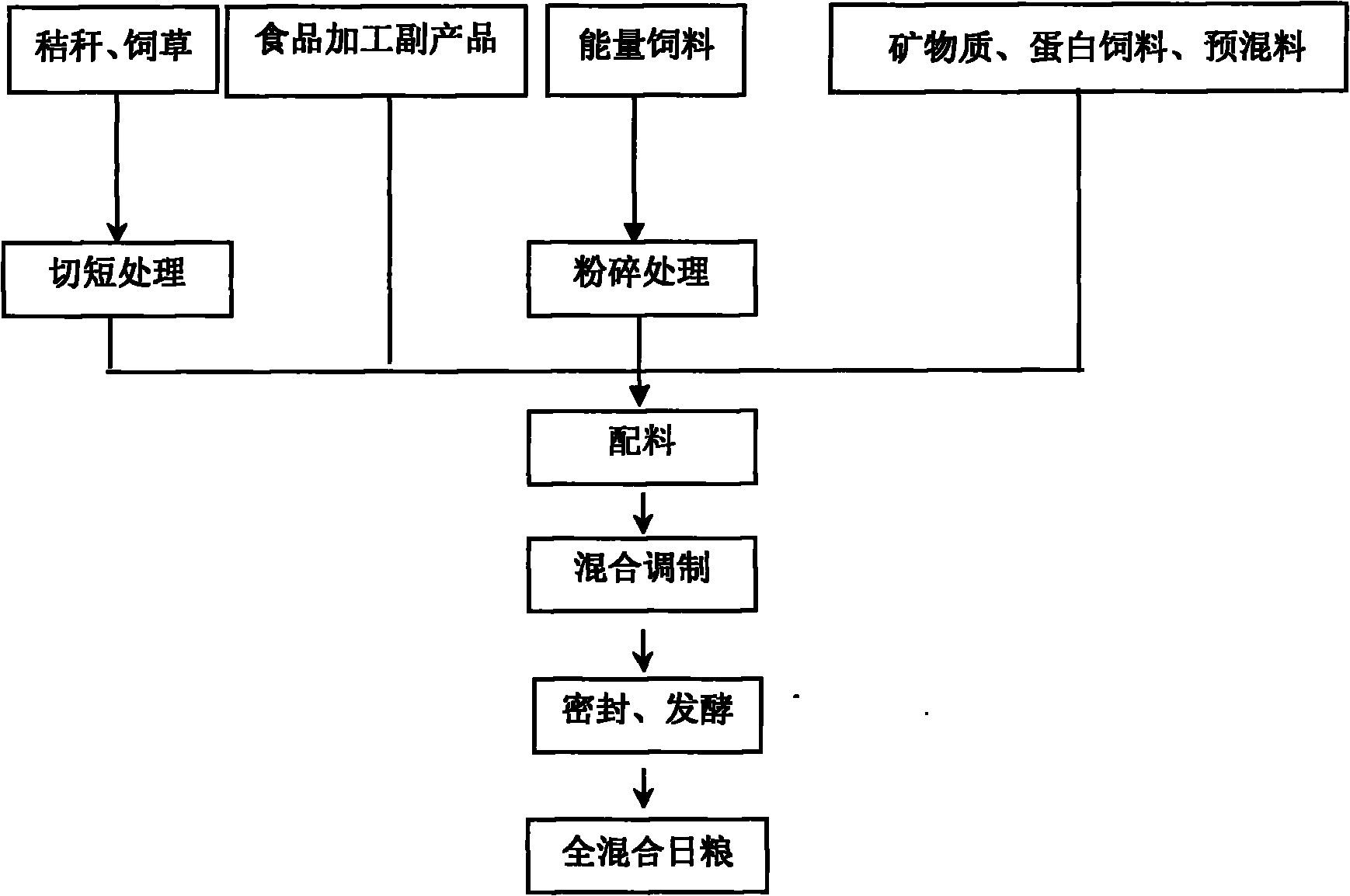

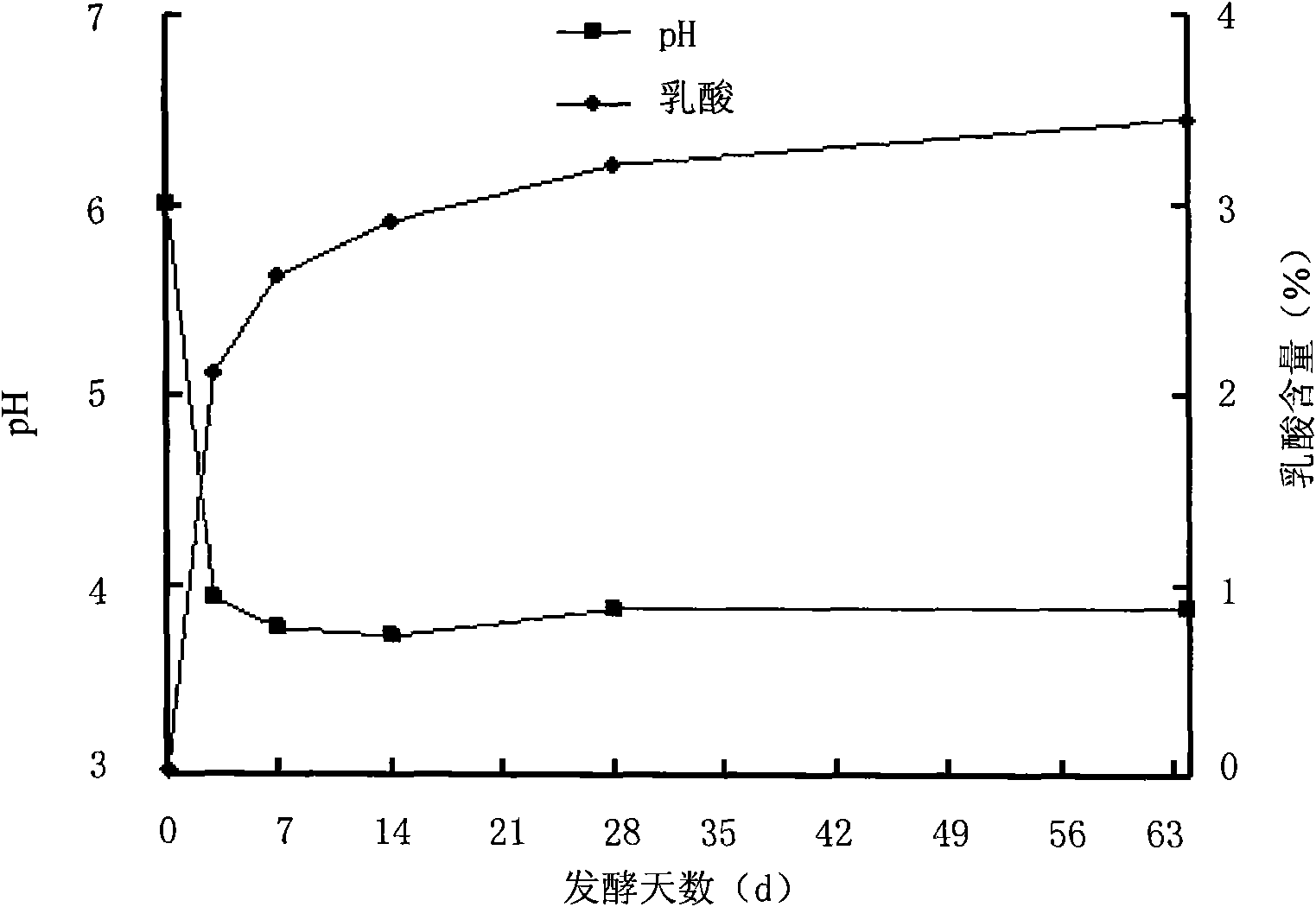

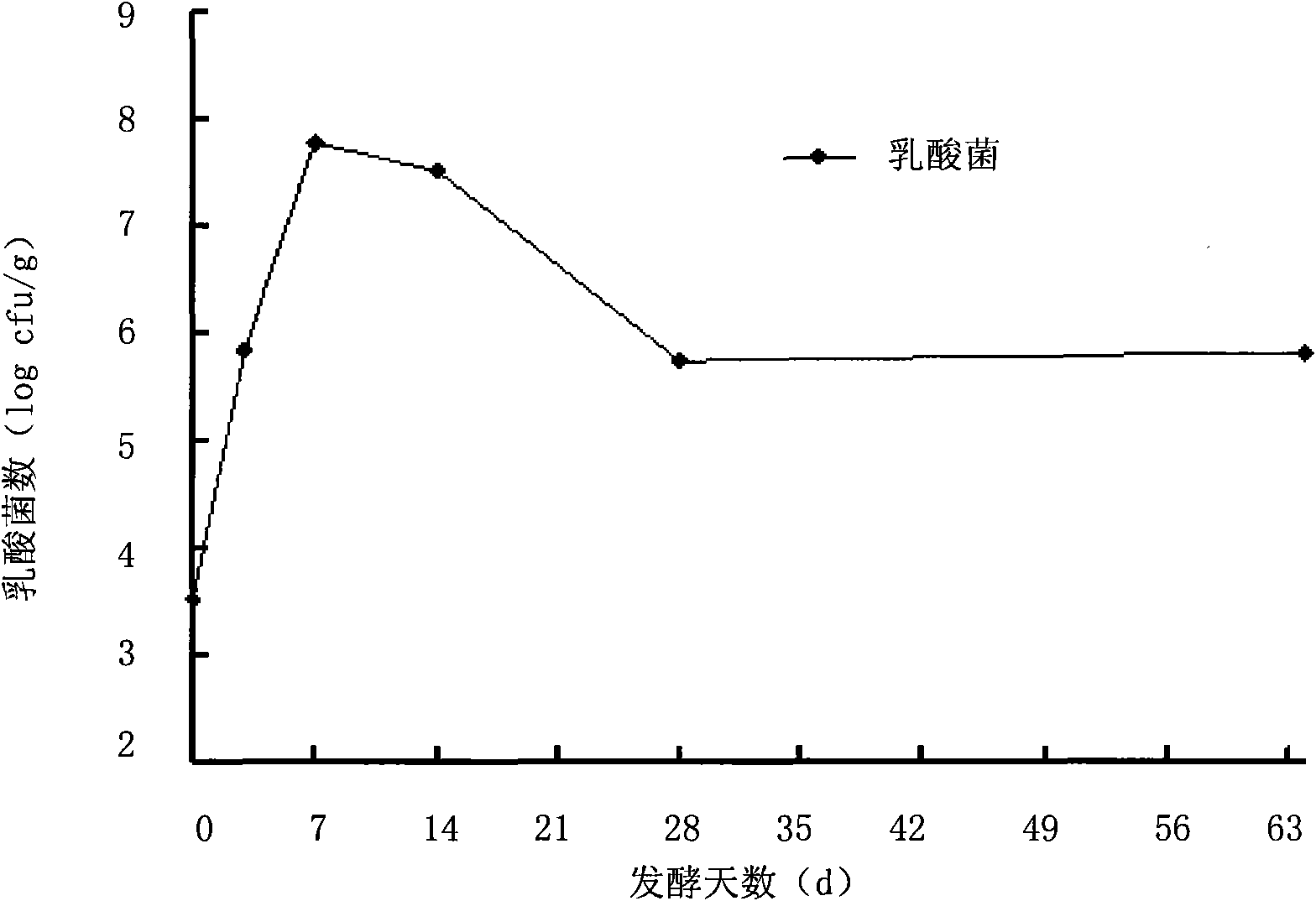

The invention discloses a low-concentrate type fermented total mixed ration (TMR) for dairy cows and a preparation method thereof. The TMR is prepared by the following steps of: (1) mixing the following materials in part by mass to obtain a mixture: 15 to 20 parts of straw, 4 to 8 parts of fodder grass, 6 to 12 parts of protein feed, 25 to 30 parts of energy feed, 3 to 6 parts of minerals and molasses, 40 to 45 parts of food processing by-products and 0.5 to 1 part of premix compound of trace elements and vitamins; (2) adjusting the moisture content of the mixture of the step (1) to be between 40 and 50 percent; and (3) sealing and fermenting the mixture of the step (2) for more than 14 days to obtain the ration for the dairy cows. The TMR of the invention has the following advantages of: low cost; complete nutrition and homogeneous components to avoid animal picky eaters and significantly improve the production performance of animals; and high aerobic stability. The low-concentrate type fermented total mixed ration for the dairy cows opens up a new technique and an effective way for efficient utilization of the resources of the straw and the food processing by-products, and has important practicability and application promotion values.

Owner:CHINA AGRI UNIV

Premixed and pumped heavy concrete

InactiveCN101676239AGuaranteed homogeneityGuaranteed uniformitySolid waste managementApparent densityParticle accelerator

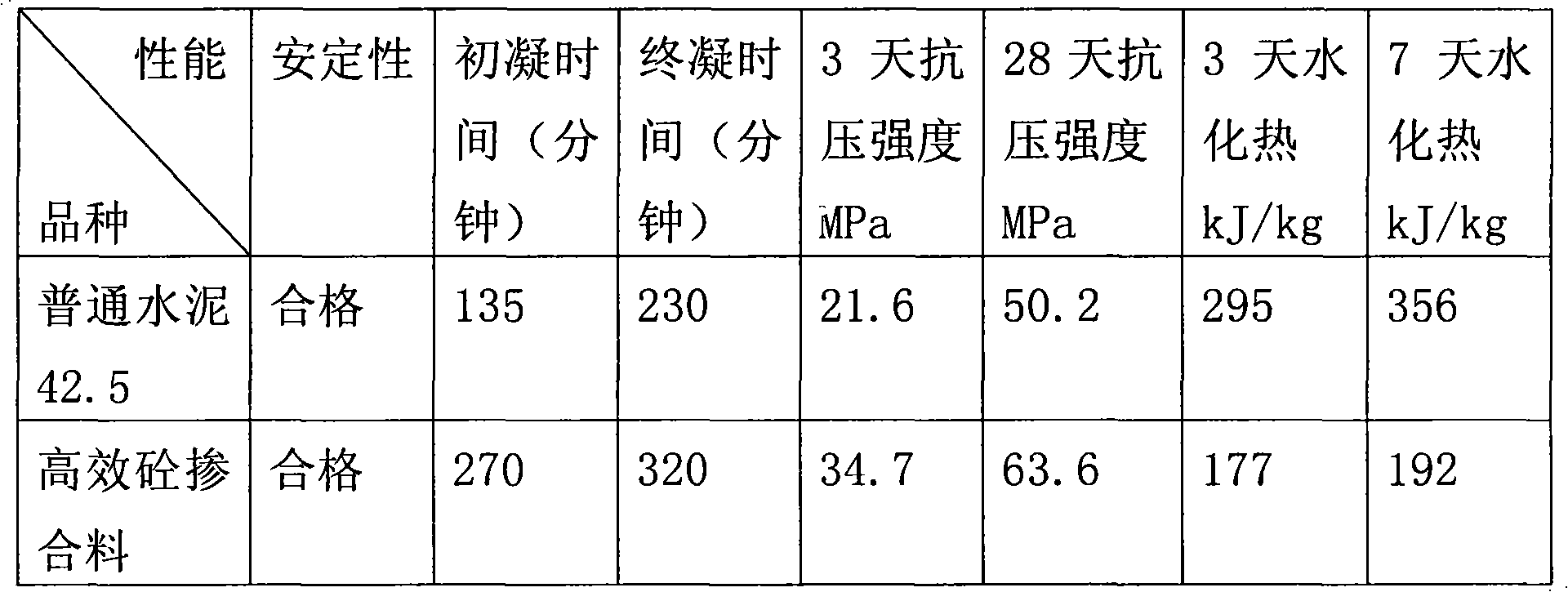

The invention relates to a premixed and pumped heavy concrete which comprises 80-93 parts by weight of heavy aggregate, 6-15 parts by weight of cement materials, 2-5 parts by weight of water, less than 0.4 part by weight of concrete additive and less than 0.01 part by weight of function regulator. The apparent density of the concrete is more than 3500kg / m<3>, the mixture has no phenomena of lamination and segregation, and the concrete has good cohesion and plasticity protection, thereby being applicable to long-distance pumping. The concrete selects a high-performance concrete admixture and can avoid the occurrence of cracks of the large-volume concrete caused by hydration heat of cement. The concrete is applicable to an anti-radiation heavy concrete engineering with the thickness of morethan 1500mm. The concrete can be widely used in shielding places of nuclear reactors, medical particle accelerators, customs inspection, scientific research laboratories and other applications of therelated nuclear industry and the radioactive isotope technology.

Owner:HUNAN NO 6 ENG CO LTD

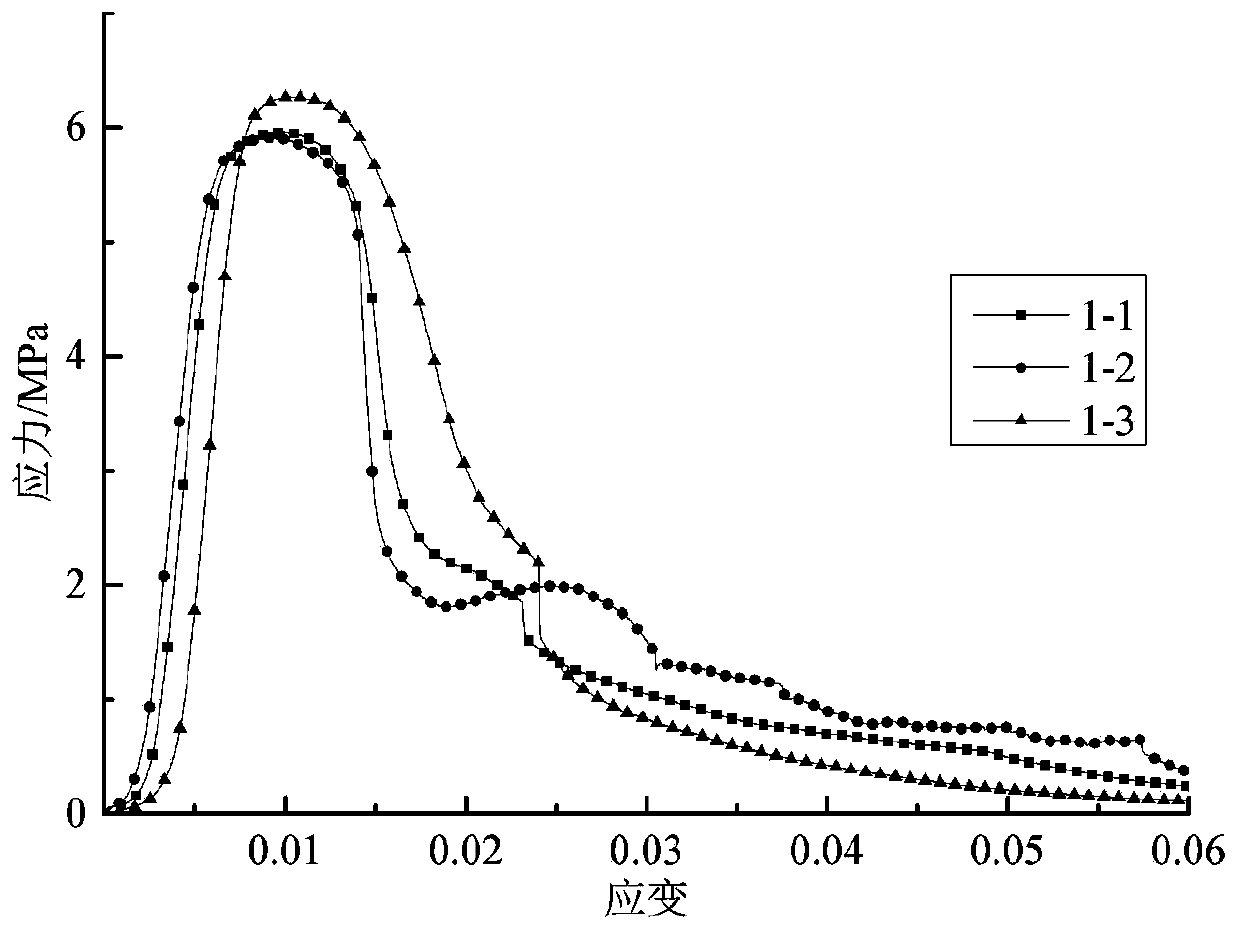

Concrete with common strength and high elastic modulus and preparation method thereof

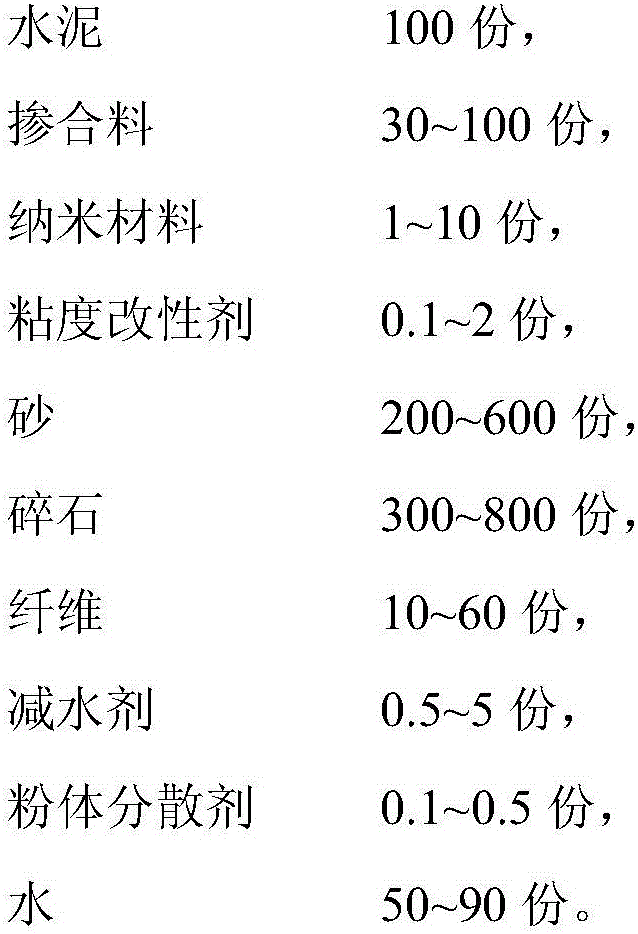

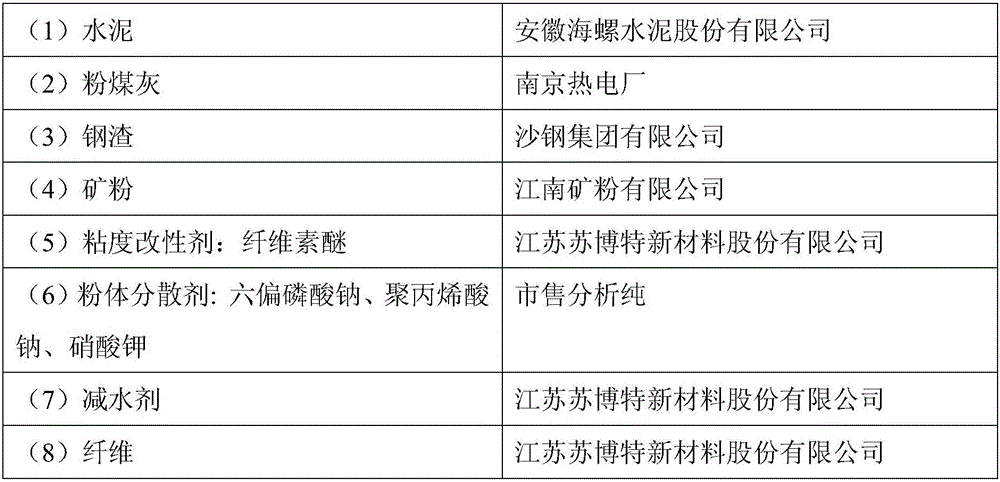

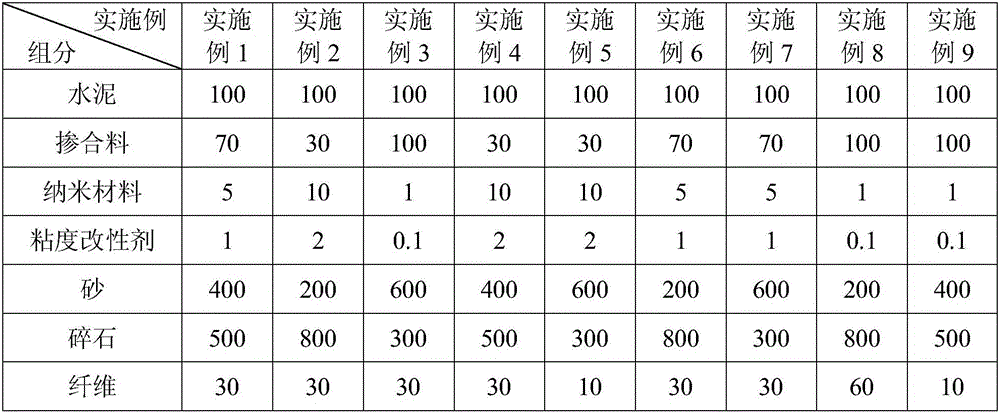

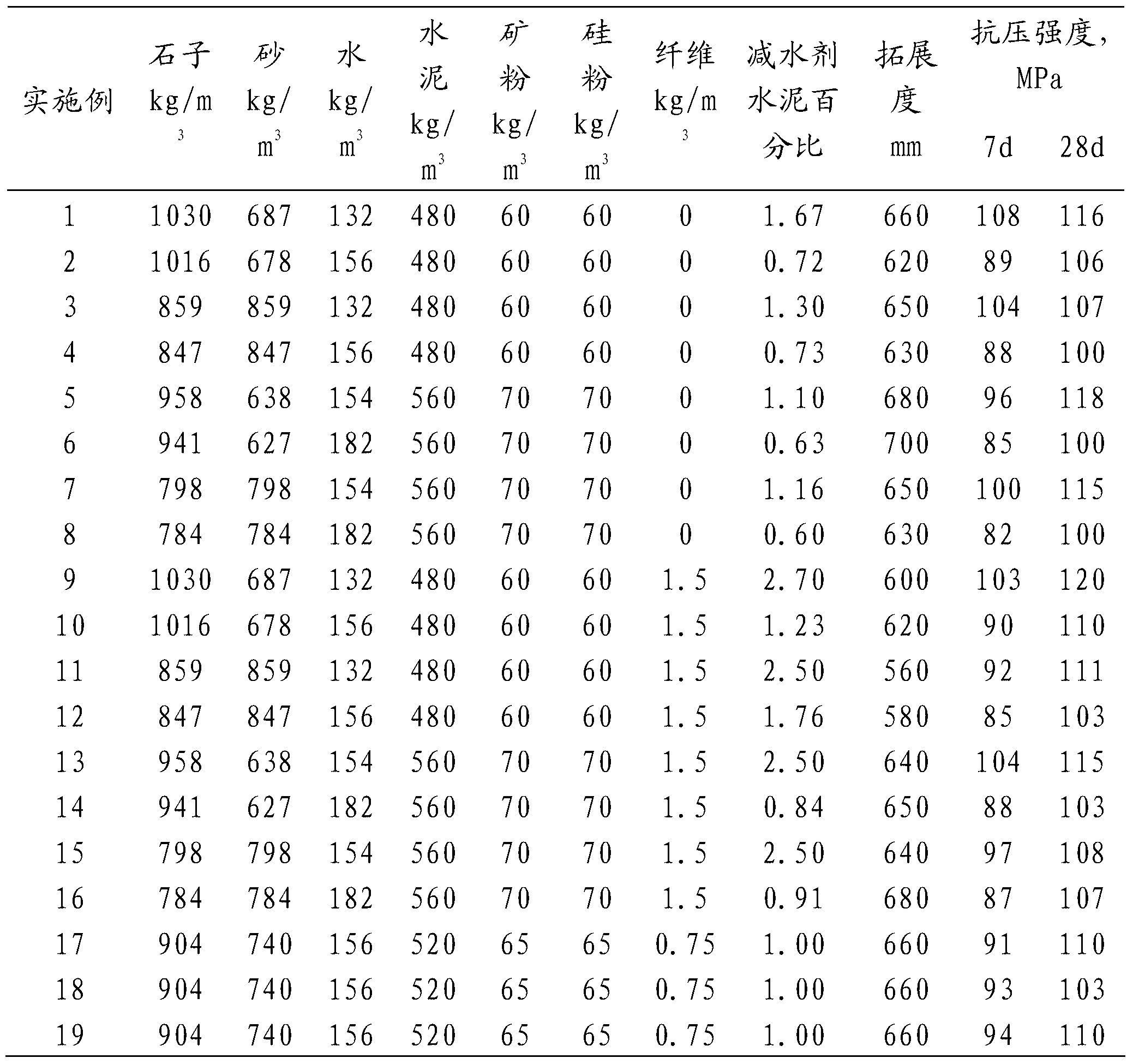

The invention discloses concrete with common strength and high elastic modulus and a preparation method thereof. The concrete with common strength and high elastic modulus, disclosed by the invention, is prepared from the following components in parts by mass: 100 parts of cement, 30-100 parts of an admixture, 1-10 parts of a nano material, 0.1-2 parts of a viscosity modifier, 200-600 parts of sand, 300-800 parts of crushed stones, 10-60 parts of fibers, 0.5-5 parts of a water reducing agent, 0.1-0.5 part of a powder dispersant and 50-90 parts of water. After the concrete with common strength and high elastic modulus, disclosed by the invention, is subjected to standard curing or natural curing for 28d, the strength grade of the concrete is C40-C50, and the elastic modulus can reach 50GPa or more; and the concrete has excellent working performance and endurance performance.

Owner:JIANGSU SOBUTE NEW MATERIALS

Ultrahigh-strength self-compacting concrete and preparation method thereof

InactiveCN103304206AImprove microscopic propertiesImprove the interface transition areaFiberPolyvinyl alcohol

The invention discloses an ultrahigh-strength self-compacting concrete and a preparation method thereof. The ultrahigh strength self-compacting concrete is mainly composed of a cementing material, an efficient water reducer, a fine aggregate, a coarse aggregate, water and PVA (Polyvinyl Alcohol) fibers, wherein the cementing material is composed of 70%-80% of common silicate cement, 10%-20% of mineral slag and 5%-10% of silicon powder by weight percentage; the fine aggregate is medium sand; the coarse aggregate is granite macadam. The ultrahigh-strength self-compacting concrete has the beneficial effects that the advanced techniques of the ultrahigh-strength concrete and the self-compacting concrete in the field of the concrete materials at present are studied, the advantages of the two concrete techniques are combined so that the dosage of the cement is reduced while ultrahigh performance of the concrete is realized, and furthermore, the purposes of emission reduction of CO2, materials saving and environmental protection as well as green construction are achieved.

Owner:SHENZHEN UNIV

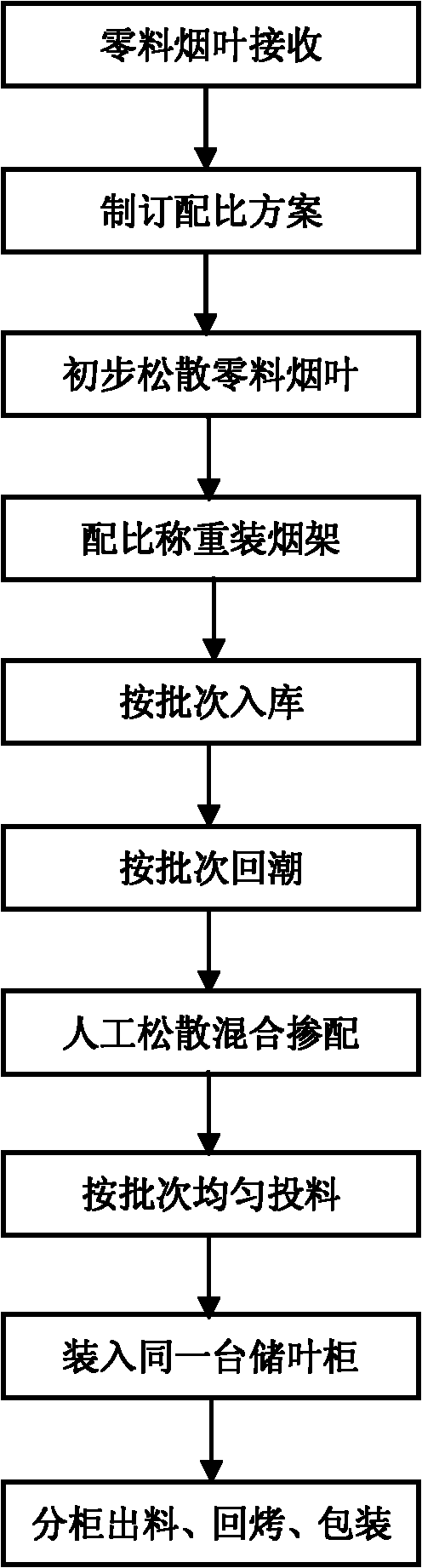

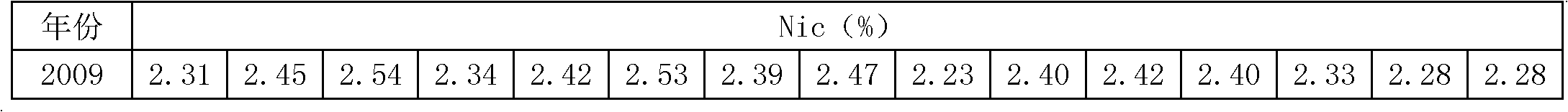

Uniformly blending back curing method for remnant flaky tobacco and application of remnant flaky tobacco

The invention belongs to the field of blending and back curing processing of tobacco leaves, and particularly relates to a uniformly blending back curing method for remnant flaky tobacco and application of the remnant flaky tobacco. The method comprises the following steps of: determining batches of a certain number of remnant flaky tobacco by calculating in a threshing and re-drying enterprise according to a remnant flaky tobacco uniformly blending back curing formula scheme re-determined by the cigarette enterprise, performing manual accurate metering and packing according to the batches, dampening, feeding the dampened remnant flaky tobacco according to the batches, manually loosening and uniformly blending the dampened easily-loosened remnant flaky tobacco in the feeding process, and filling the remnant flaky tobacco blended in each batch into a leaf storage cabinet to realize re-blending. By manual packing and accurate metering blending, manual loosening and re-blending and blending through the leaf storage cabinet, the purpose of fully and uniformly blending the remnant flaky tobacco is fulfilled. The method can be widely applied in the cigarette production, realizes reutilization of the remnant flaky tobacco, and can ensure the homogeneity of cigarette products.

Owner:HUAHUAN INT TOBACCO

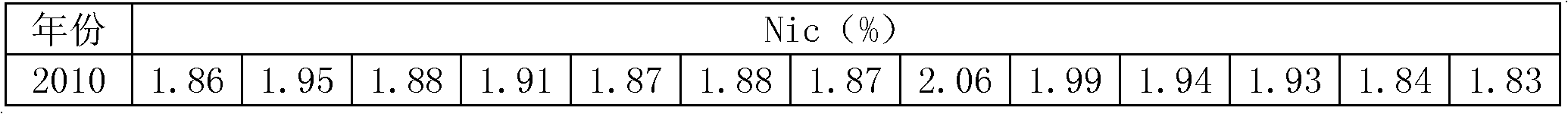

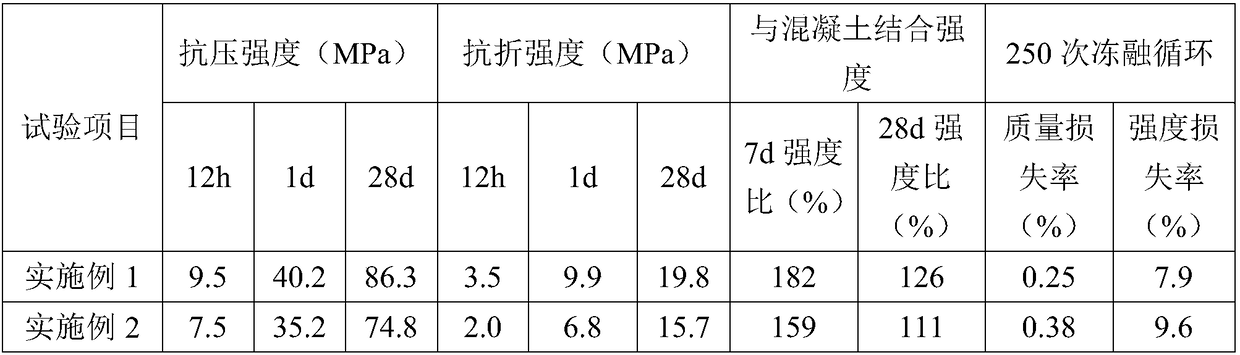

Micro-expansion grouting material for grouting tunnel lining vault with mold

The invention discloses a micro-expansion grouting material for grouting a tunnel lining vault with a mold. The micro-expansion grouting material is made of, by mass, 52.5-60% of cement, 35-40% of graded aggregate, 2-3% of viscosity modifier, 0.02-4% of expansion agent, 0.03-0.43% of early strength agent, 0.2-0.26% of water reducing agent, 0.01-0.03% of water retention agent and 0.01-0.02% of defoaming agent; the cement is one or more of Portland cement, ordinary Portland cement and sulphate aluminium cement, and the strength level of the cement is not lower than 42.5; the water retention agent is one or more of a cellulose ether polymer compound and biopolysaccharide gum. The micro-expansion grouting material for grouting the tunnel lining vault with the mold has better fluidity and micro-expansion performance, and the bonding strength with concrete and the bonding performance with RPC grouting pipes can be significantly improved.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

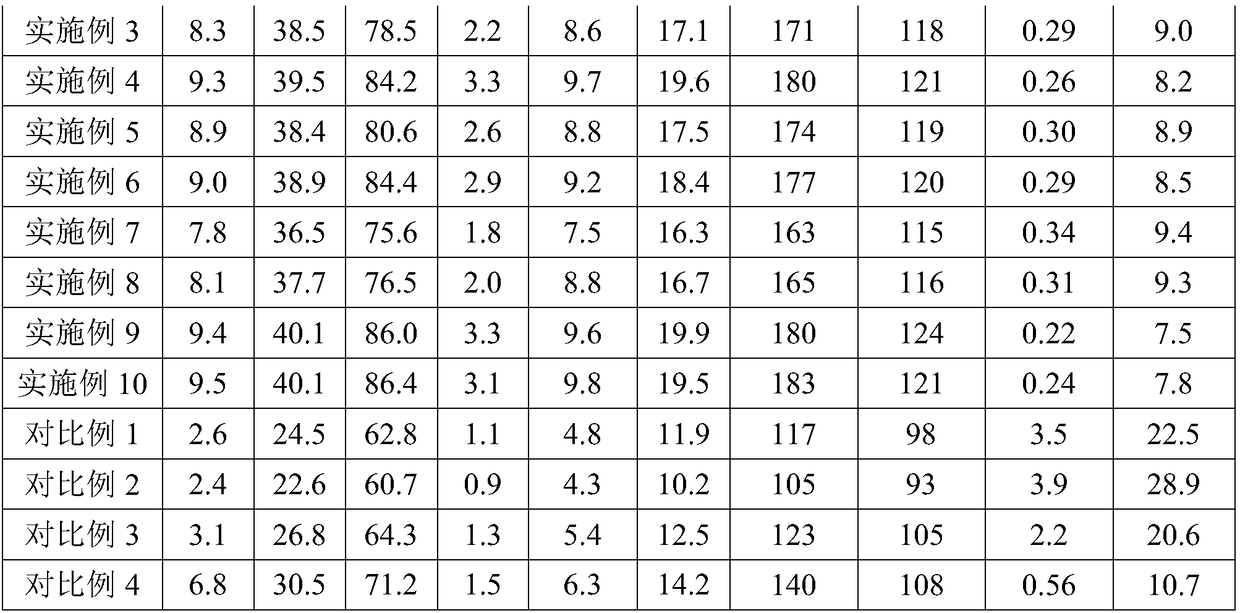

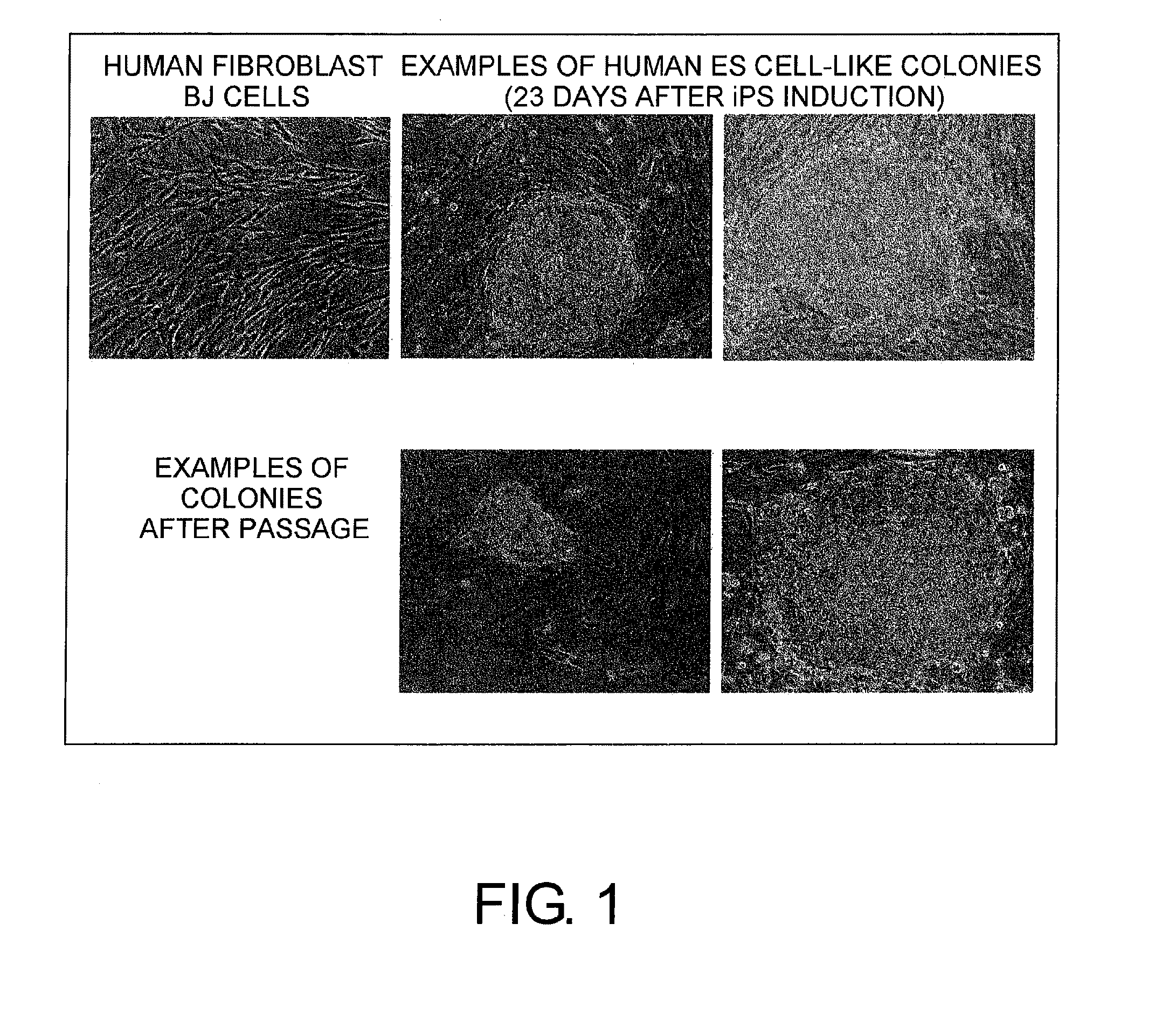

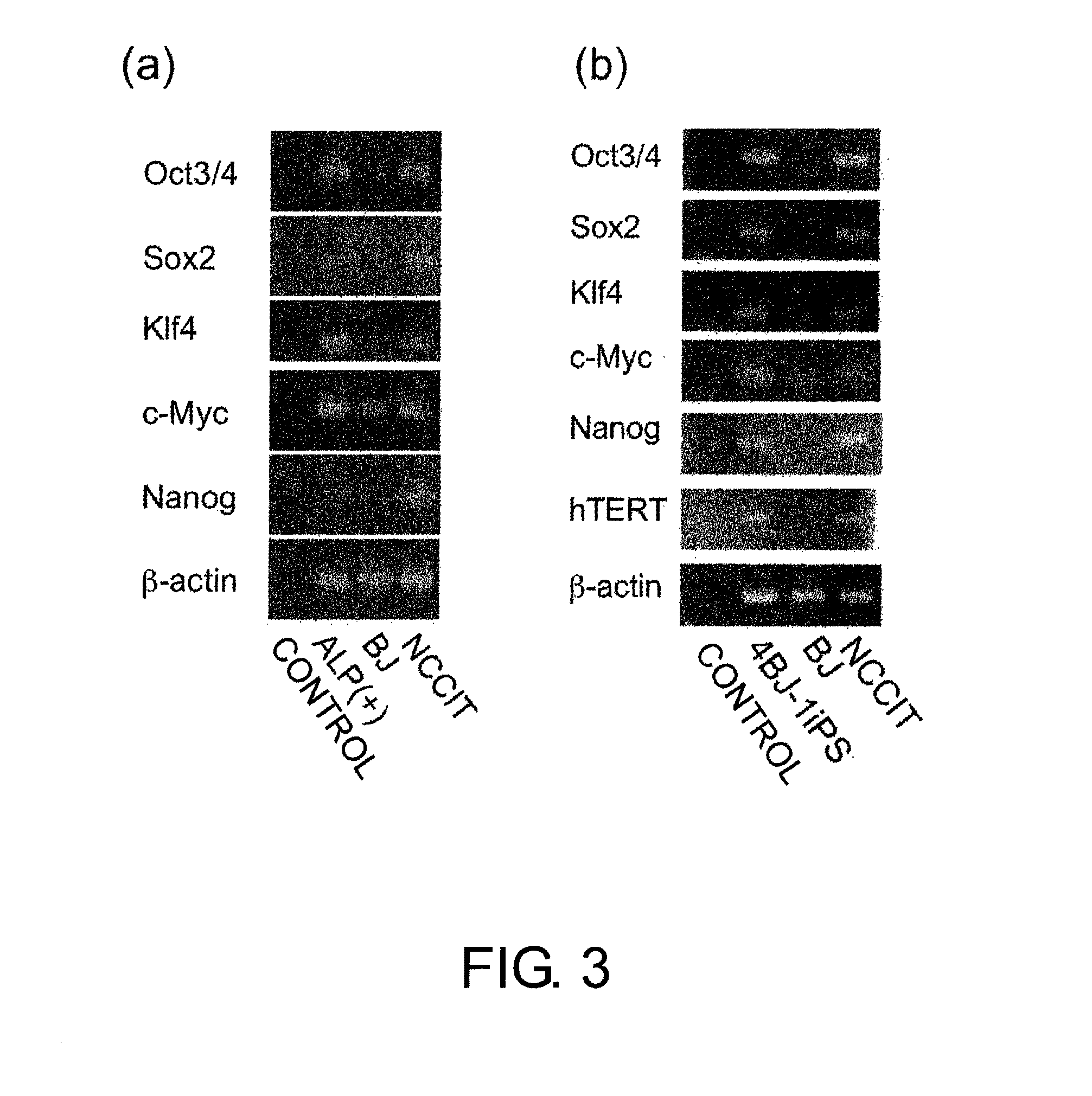

Method for production of reprogrammed cell using chromosomally unintegrated virus vector

ActiveUS20110287538A1Avoid immune rejection problem and ethical problemImprove efficiencySsRNA viruses negative-sensePeptidesDiseaseSomatic cell

An objective of the present invention is to provide vectors for conveniently and efficiently producing ES-like cells in which foreign genes are not integrated into the chromosome. The present inventors discovered methods for producing ES-like cells from somatic cells using chromosomally non-integrating viral vectors. Since no foreign gene is integrated into the chromosome of the produced ES-like cells, they are advantageous in tests and research, and immunological rejection and ethical problems can be avoided in disease treatments.

Owner:ID PHARMA

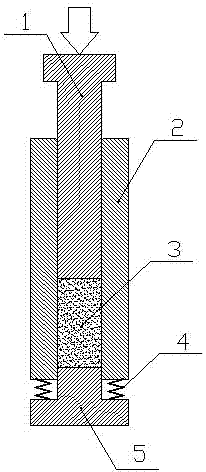

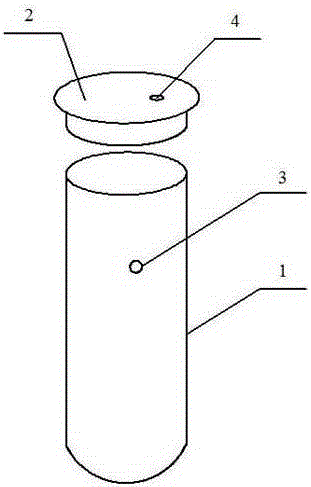

Briquette coal sample making tool and method

InactiveCN102928272AUniform density distributionGuaranteed homogeneityPreparing sample for investigationEngineeringBriquette

The invention discloses a briquette coal sample making tool and method. The method comprises the following steps of: putting a wet coal powder between an upper pressing head and a lower pressing head in a coal pressing tube by using the briquette coal sample making tool which comprises the upper pressing head, the lower pressing head, a coal pressing tube spring and a sampling device; applying a load to the upper pressing head downwards by using a press machine; compacting the wet coal powder so as to form a coal sample and then stopping the applying of the load; and then unloading the spring and the lower pressing head; and pressing the upper pressing head downwards, so as to press the coal sample out of the coal pressing tube. According to the invention, technical defects in the traditional briquette coal sample making are solved; and the effective coal sample making tool and method are provided, so that the uniformity and making success rate of the briquette sample are increased.

Owner:HENAN POLYTECHNIC UNIV

Preparation method of high-quality prebaked anode for 500KA electrolytic cell

The invention relates to a preparation method of a high-quality prebaked anode for a 500KA electrolytic cell. The method comprises the following steps of: (1) storing petroleum coke at different storage locations according to different producing areas; (2) crushing the petroleum coke blocks having the granularity greater than 200mm with a sledge hammer, sieving the petroleum coke blocks with the granularity less than 200mm, delivering the petroleum coke with the granularity less than 70mm into a petroleum coke conveyer belt, recrushing the petroleum coke with the granularity greater than 70mm so as to deliver the petroleum coke with the granularity less than 70mm into the petroleum coke conveyer belt; (3) feeding different petroleum cokes into a specified blending cabin, wherein the petroleum coke of one producing area is placed in each of the four blending cabins, and a belt weigher is arranged at the bottom of each blending cabin; (4) preparing calcined coke; (5) preparing rough coke, middle coke, fine coke and powdery coke; (6) preparing boiler-out thickeners; (7) preparing cooled thickeners; (8) preparing green bodies; (9) feeding the green bodies into a stacking storeroom for stacking; and (10) roasting the green bodies to obtain a prebaked anode. By using the preparation method, the electrolysis preparation requirement can be met, and safe and sable operation of the electrolytic cell is ensured.

Owner:嘉峪关索通预焙阳极有限公司

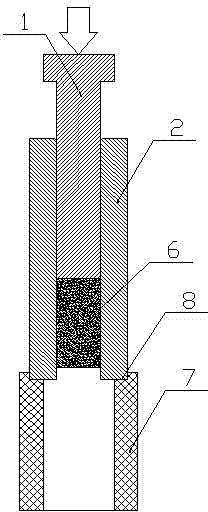

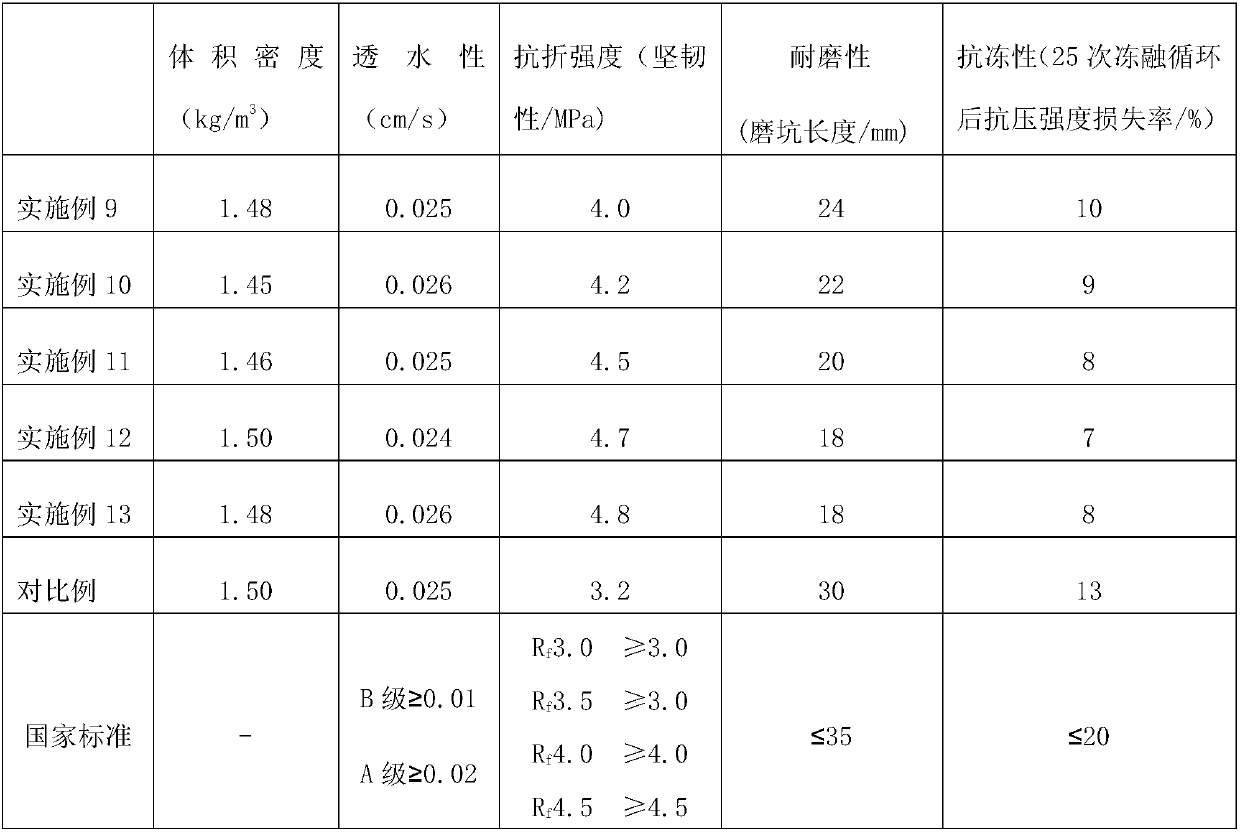

Water permeable brick based on graphene and solid wastes and preparation method thereof

ActiveCN107602072AHigh strengthImprove high temperature resistanceCeramic materials productionCeramicwareSodium BentoniteBrick

The invention provides a water permeable brick based on graphene and solid wastes. The water permeable brick is prepared from municipal sludge, municipal waste soil, construction waste, coal ash, nonmetal tailings, graphene, bentonite, sodium silicate, pore forming substance and hydroxypropyl methyl cellulose. The water permeable brick with excellent performances is acquired in the manner of utilizing the construction waste, coal ash, graphene and nonmetal tailings as aggregates and utilizing the municipal sludge, municipal waste soil, bentonite and sodium silicate to bond the aggregate grainsand thus is endowed with the performances, such as, high strength, high temperature resistance and high wearing resistance. A large amount of municipal sludge, municipal waste soil and construction waste are effectively utilized and the recycling of the coal ash and the nonmetal tailing waste resources is realized, so that the environment protection is benefited, the industrial and regional economy and the development of urbanization are promoted.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

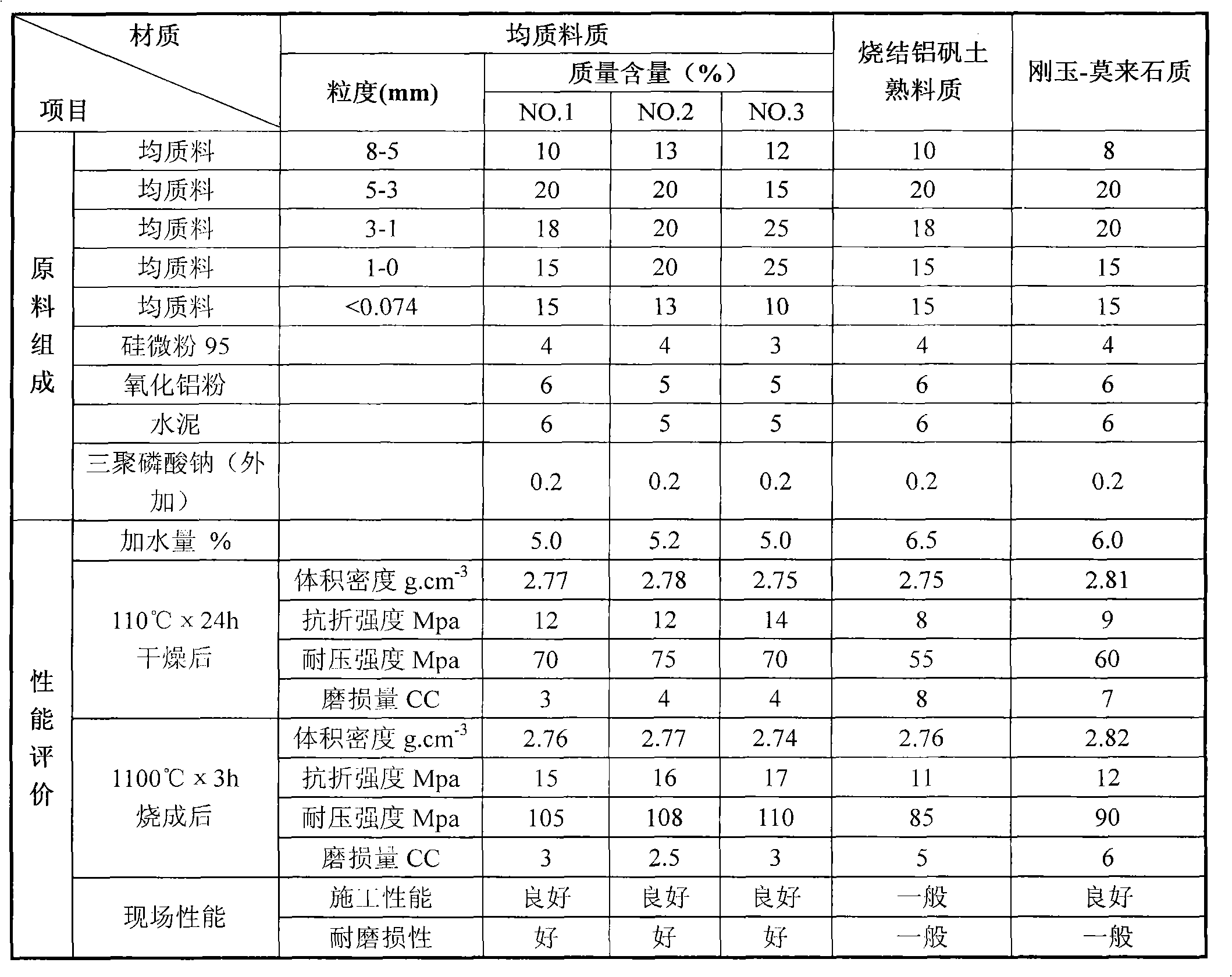

Corundum-mullite high strength and wear resistant casting material containing homogenous material

The invention relates to a corundum-mullite high strength and wear resistant casting material containing a homogenous material, belonging to the field of high temperature wear resistant and fireproof materials. The corundum-mullite high strength and wear resistant casting material comprises the raw materials of a high-alumina homogenous material, alumina micro powder, silicon dioxide micro powder, pure calcium aluminate cement, additives, and the like, wherein the homogenous material has the characteristics: the content of Al2O3 is 70-90%, and the volume density is 2.9-3.5g.cm<-3>. The corundum-mullite high strength and wear resistant casting material is characterized in that the traditional composite raw material system of sintered bauxite clinker or corundum and mullite with high water absorption rate, high porosity and poor uniformity is replaced by utilizing an artificially synthesized homogenous material with low water absorption rate, low porosity and high uniformity to produce the homogenous corundum-mullite high strength and wear resistant casting material. Because a method of pouring construction is adopted, the material has favorable construction performance, high strength, favorable wear resistance and optimal use effect on site, the service life of a furnace liner is beneficially prolonged; the utilization rate of a high temperature kiln is improved; and the corundum-mullite high strength and wear resistant casting material is widely applied to wearable, penetrative and corrosive parts of thermal equipment, such as blast furnaces, hot blast furnaces, recirculating fluidized beds, garbage incinerators, catalytic cracking units, and the like.

Owner:TONGDA REFRACTORY TECH CO LTD

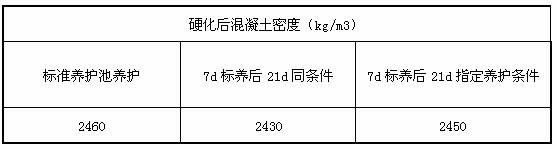

High-flow low-shrinkage C30 concrete capable of shielding radiation

The invention relates to high-flow low-shrinkage C30 concrete capable of shielding radiation. The concrete is prepared by mixing cement, mineral powder, fly ash, sand, gravels, additive and water, wherein the concrete comprises the following components in cubic amount kg / m<3>: 220-240 kg / m<3> of cement, 80-125 kg / m<3> of mineral power, 80-35 kg / m<3> of fly ash, 795-820 kg / m<3> of gravels with fineness modulus of 2.3-2.6, 1,000-1,025 kg / m<3> of gravels with maximum particle diameter of not greater than 25 mm, 3.0-4.0 kg / m<3> of additive and 150-155 kg / m<3> of water; the dry density of the concrete is greater than 2,350 kg / m<3>; the content of internal moisture of the concrete is not less than 0.35 percent within all operation time of a structure space cast by using the concrete; the expansion degree of the concrete is 550+ / -75 mm; the contents of cobalt Co, silver Ag and iridium Ir in the cement, the mineral powder and the fly ash are less than 50 ppm respectively; and the contents of europium Eu, samarium Sm, gadolinium Gd, dysprosium Dy and thulium Tm are less than 10 ppm respectively. According to the concrete provided by the invention, shielding can be effectively produced for a proton flow and a neutron flow produced by hospital proton heavy ion equipment; and meanwhile, the concrete has the characteristics of high fluidity and low shrinkage.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +2

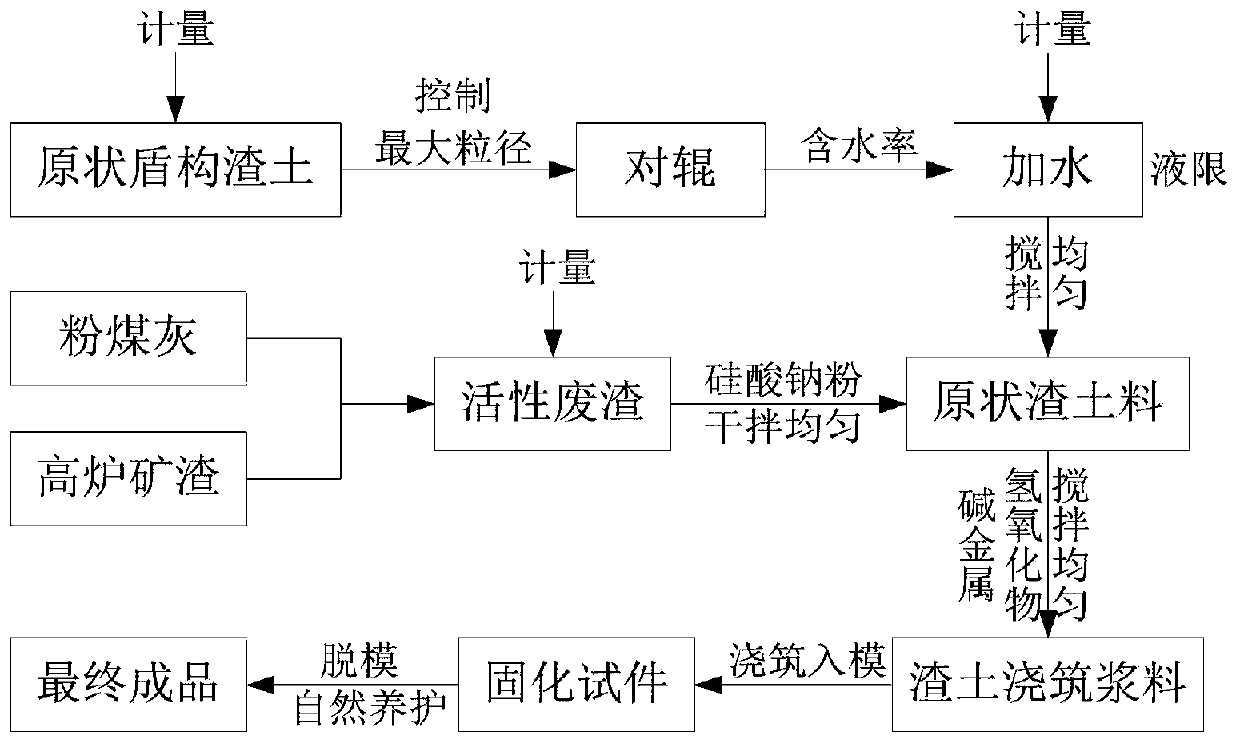

Water-containing undisturbed shield muck baking-free building material and preparation method thereof

ActiveCN111393117AUniform flow stateLittle homogeneitySolid waste managementTransportation and packagingSodium silicateMineralogy

The invention relates to a water-containing undisturbed shield muck baking-free building material and a preparation method thereof. The baking-free building material is prepared from the following rawmaterials in parts by weight: 1-80 parts of water-containing undisturbed shield muck, 1-30 parts of active waste residues, 0.1-5 parts of sodium hydroxide, 0.1-10 parts of sodium silicate and 1-20 parts of water. The method comprises the following steps: weighing the active waste residues, the sodium silicate, the water-containing undisturbed shield muck and the water, mixing, and crushing untilthe content of particles of 4.75 mm or above in the water-containing undisturbed shield muck does not exceed 10% to obtain a mixture I; adding the sodium hydroxide into the mixture I to obtain a mixture II; and pouring the mixture II into a mold to obtain the water-containing undisturbed shield muck baking-free building material. According to the method, intermediate dehydration and screening processes and links are omitted, and the production cost is greatly reduced. The invention also discloses the water-containing undisturbed shield muck unfired building material prepared by the method.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

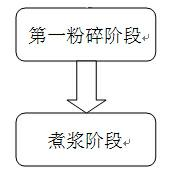

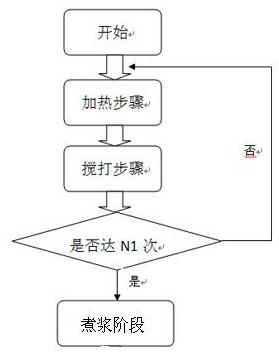

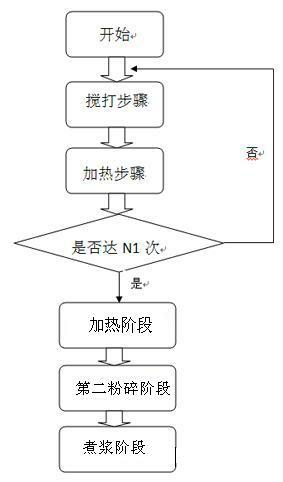

Originally ground soybean milk preparation method of soybean milk grinder and soybean milk grinder for preparing originally ground soybean milk

InactiveCN102144889ANot easy to burnImprove homogeneityBeverage vesselsMilk substitutesFlavorLiquid temperature

The invention relates to an originally ground soybean milk preparation method of a soybean milk grinder, which comprises: (a) a first grinding stage and (b) a boiling stage, wherein in the first grinding stage, materials for preparing soybean milk are ground by a grinding blade under the driving of an electric motor of the soybean milk grinder, and the liquid temperature during the first grinding stage is not more than 70 DEG C; and in the boiling stage, the soybean milk is heated by a heating component of the soybean milk grinder until the soybean milk is boiled up, and the heating component is used for persistently or interruptedly heating the materials in a cup during the first grinding stage. The soybean milk prepared according to the soybean milk preparation method has bean flavor and better mouthfeel.

Owner:JOYOUNG CO LTD

Method for processing meat paste product by utilizing livers of livestock and poultry

ActiveCN103340420ATo keep freshPlay a role in suppressing fishy smellFood preparationBiotechnologyEmulsion

The invention discloses a method for processing a meat paste product by utilizing livers of livestock and poultry. The method for processing the meat paste product by utilizing livers of livestock and poultry comprises the following steps of: with livers of livestock and poultry and fat and lean of the livestock and poultry as raw materials and milk protein, seasoners and blending materials as auxiliary materials, processing the livers, processing meat material, pickling, preparing concentrated milk protein, preparing liver emulsion, preparing meat paste, filling, carrying out two-stage hot processing and high temperature sterilization, and cooling. Therefore, the meat paste product with good slicing property, taste and flavour is processed, the utilization rate of the livers of the livestock and poultry is increased, content of vitamin A in the meat paste product is increased, ordinary people can take in required vitamin A while eating meat, and improvement on deficiency of the vitamin A in the ordinary people, especially children and the aged can be facilitated.

Owner:CHENGDU UNIV +1

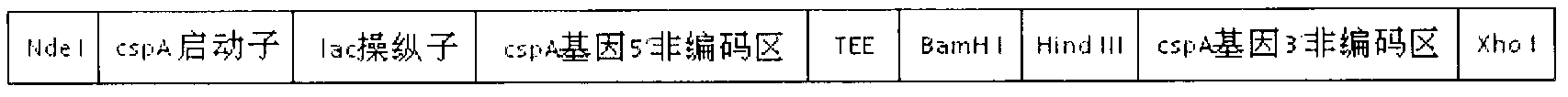

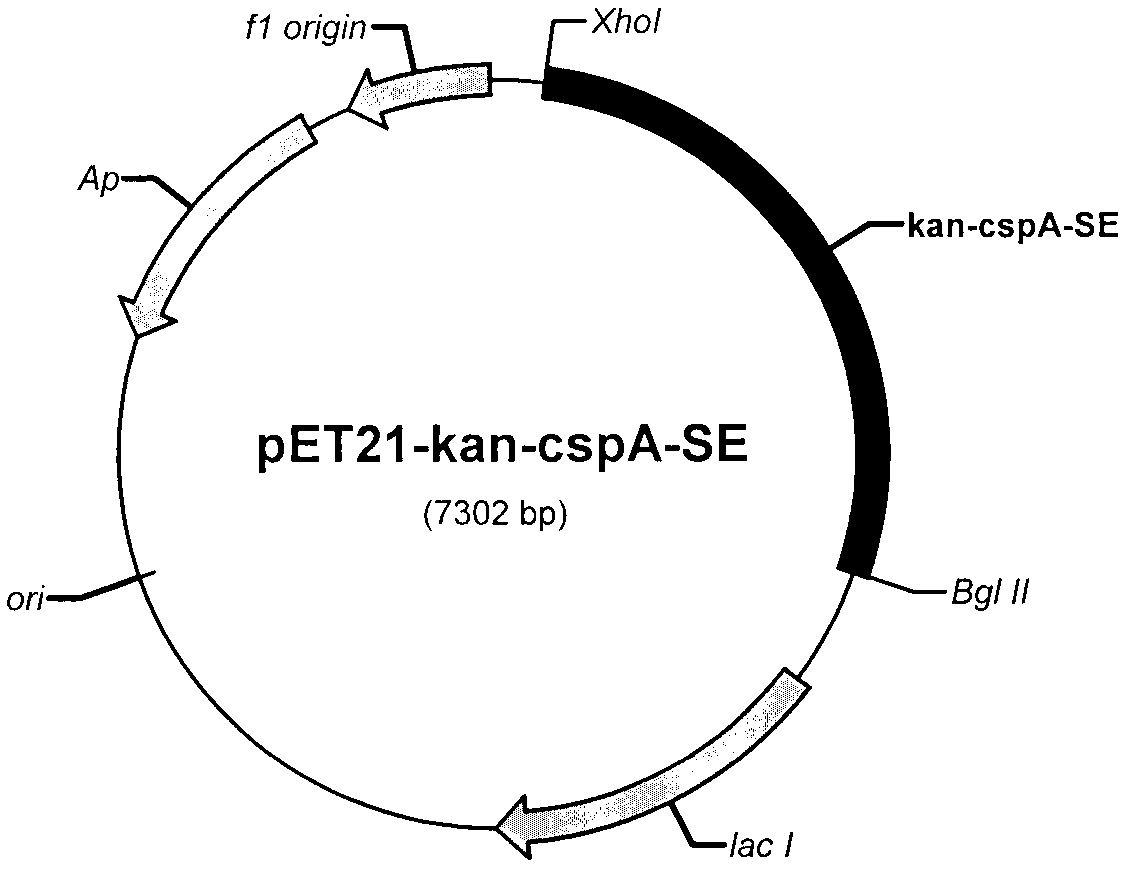

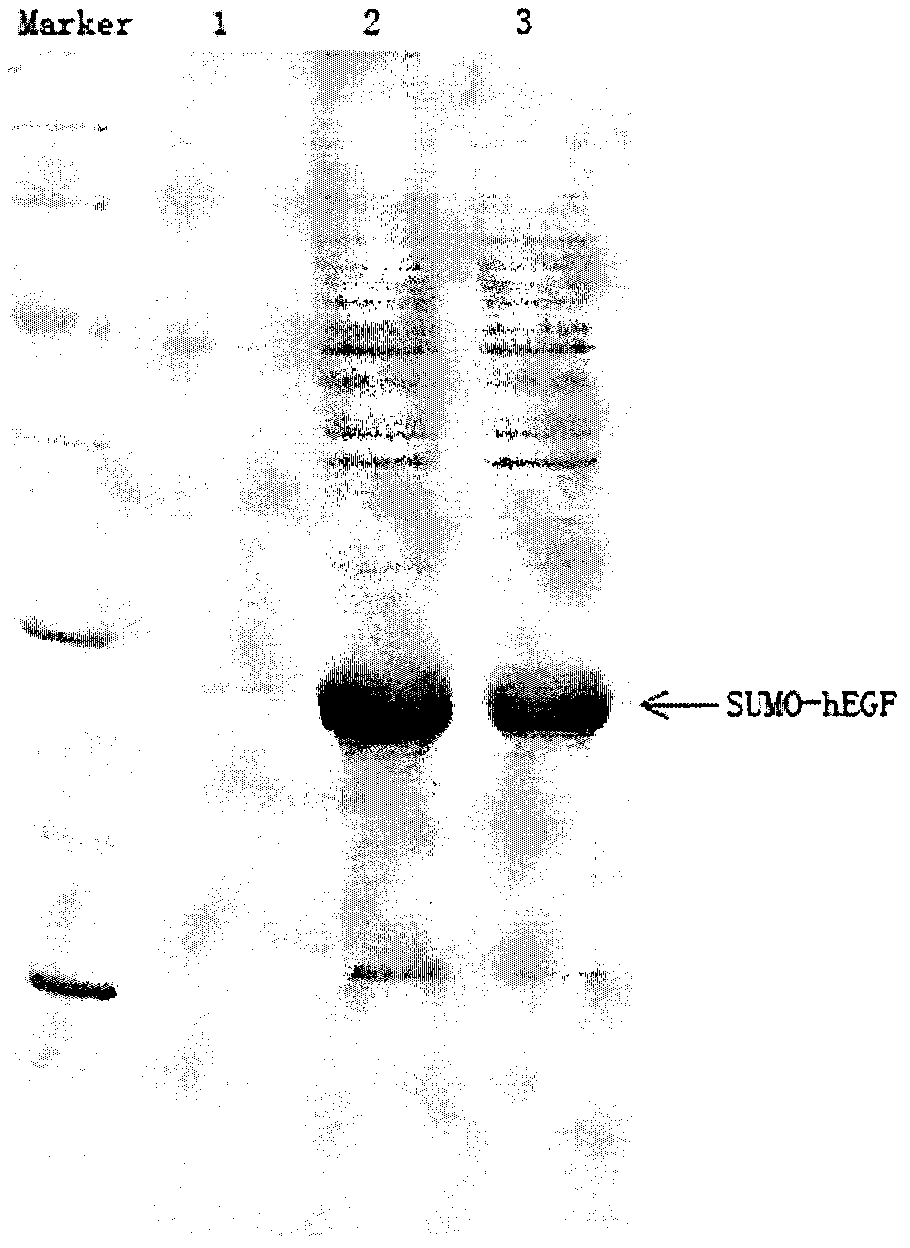

Construction and screening method for recombinant human epidermal growth factor engineering bacteria

InactiveCN102978231AGuaranteed homogeneityImprove stabilityBacteriaMicroorganism based processesChemical synthesisEscherichia coli

The present invention provides a construction and screening method for recombinant human epidermal growth factor (hEGF) engineering bacteria. The construction and screening method comprises the following main steps: 1, adopting a PCR technology to obtain kanamycin resistance gene, and adopting a chemical synthesis method to obtain an escherichia coli cspA gene function element; 2, respectively optimizing gene sequences encoding SUMO protein and hEGF, and then adopting chemical synthesis to obtain a large amount of expressed fusion protein gene sequences OPT-SUMO-hEGF; 3, linking the fragments obtained from the previous two steps into pET21 plasmid to obtain pET-Kan-cspA-SE plasmid; 4, adopting the pET-Kan-cspA-SE plasmid as a template to construct a transposition body; 5, transforming the transposition body into escherichia coli Origami 2 (DE3); and 6, screening a strain having high fusion protein SUMO-hEGF expression. According to the present invention, genome of the obtained strain is stable, a soluble rate of the expressed hEGF is high, and the method is suitable for large-scale industrial production.

Owner:天津强微特生物科技有限公司

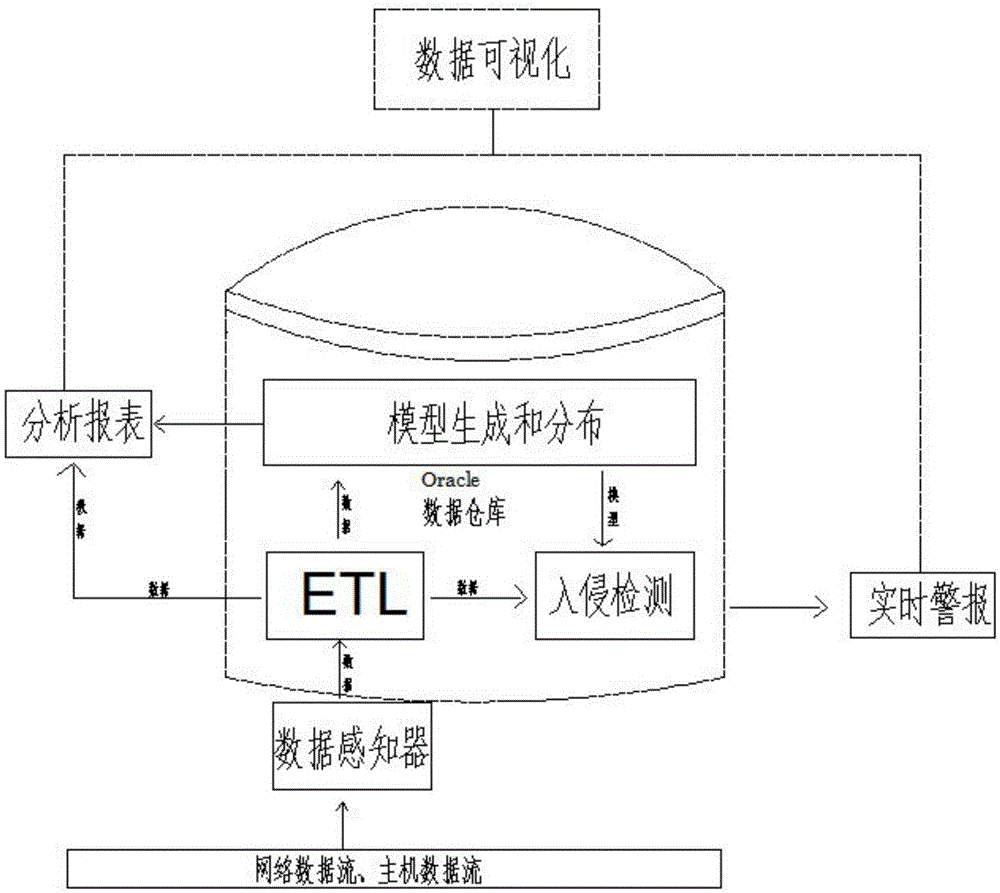

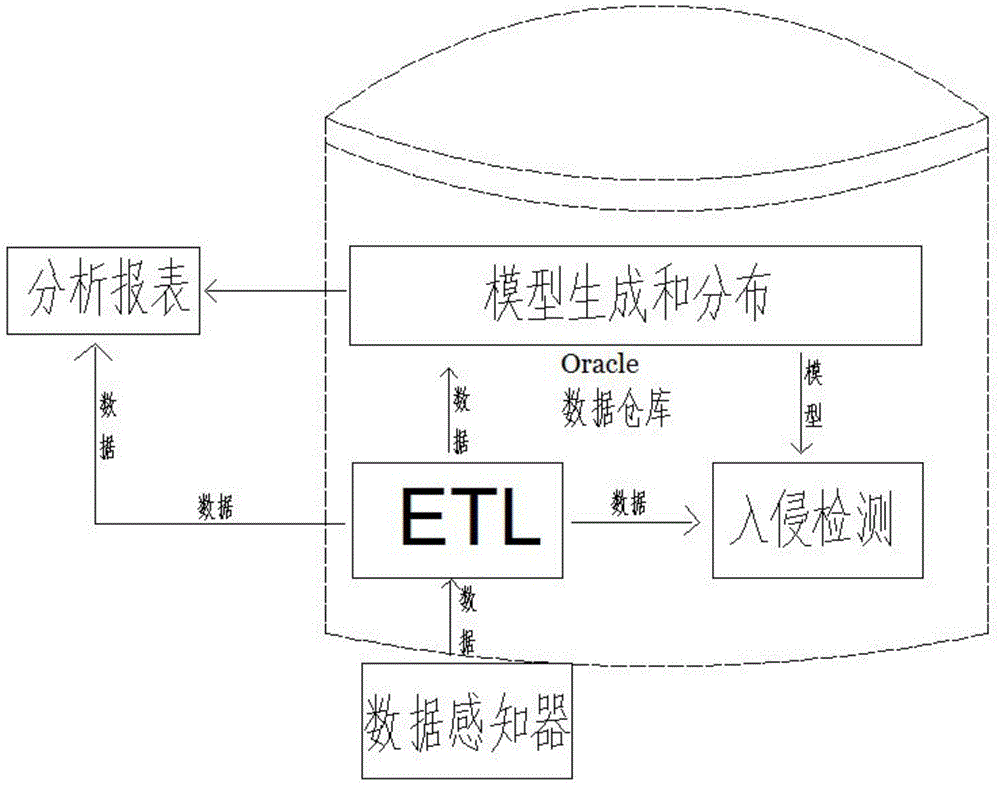

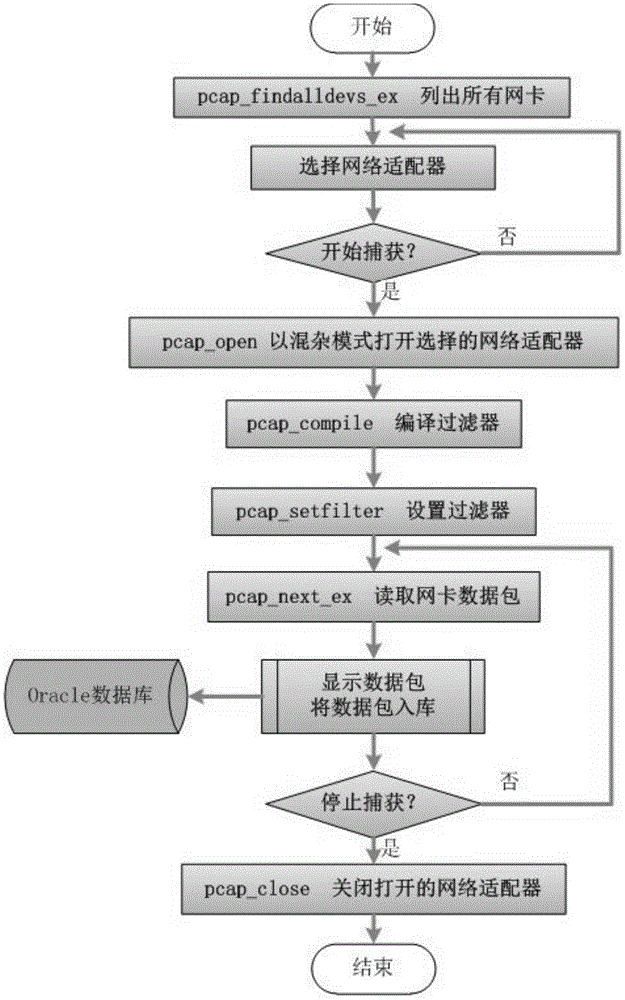

Data mining based invasion detection system with Oracle as core

InactiveCN105468995AEnsure safetyGuaranteed homogeneityDigital data protectionSpecial data processing applicationsData conversionOracle database

The invention relates to an invasion detection system, in particular to a data mining based invasion detection system with Oracle as a core. The system comprises a data sensor module, an ETL module, a data warehouse module, a model generation and distribution module, an invasion detection module and a data visualization module. According to the system, data conversion and storage, model generation and release as well as invasion detection and alarming are all realized in an Oracle database, and real-time detection and offline detection are unified, so that the security and homogeneity of data and the system response time are ensured, the integration of model generation, model storage, model updating and detection alarming is realized, the problem in a system without a database as a core at present is solved, and the security of the whole network is improved.

Owner:JILIN UNIV

Process for oligomerizing olefins using a catalyst based on silica-alumina

ActiveUS8222470B2Guaranteed homogeneityImprove catalytic performancePhysical/chemical process catalystsLiquid hydrocarbon mixtures productionAlkeneSilicon dioxide

A process for oligomerizing an olefinic hydrocarbon feed is described which consists of bringing said feed into contact with a catalyst comprising a silica-alumina, the silica content of said catalyst being in the range 5% to 95% by weight, said catalyst being prepared using a process comprising at least:a) mixing at least one alumina compound which is partially soluble in an acid medium with either at least one silica compound which is completely soluble in the reaction mixture or a combination formed by at least one silica compound and at least one alumina compound, said silica and alumina compounds being completely soluble in the reaction mixture, in order to form a solid precursor of said catalyst;b) hydrothermal treatment of the solid derived from step a) by calcining in moist air for a period in the range 4 to 7 hours.

Owner:INST FR DU PETROLE

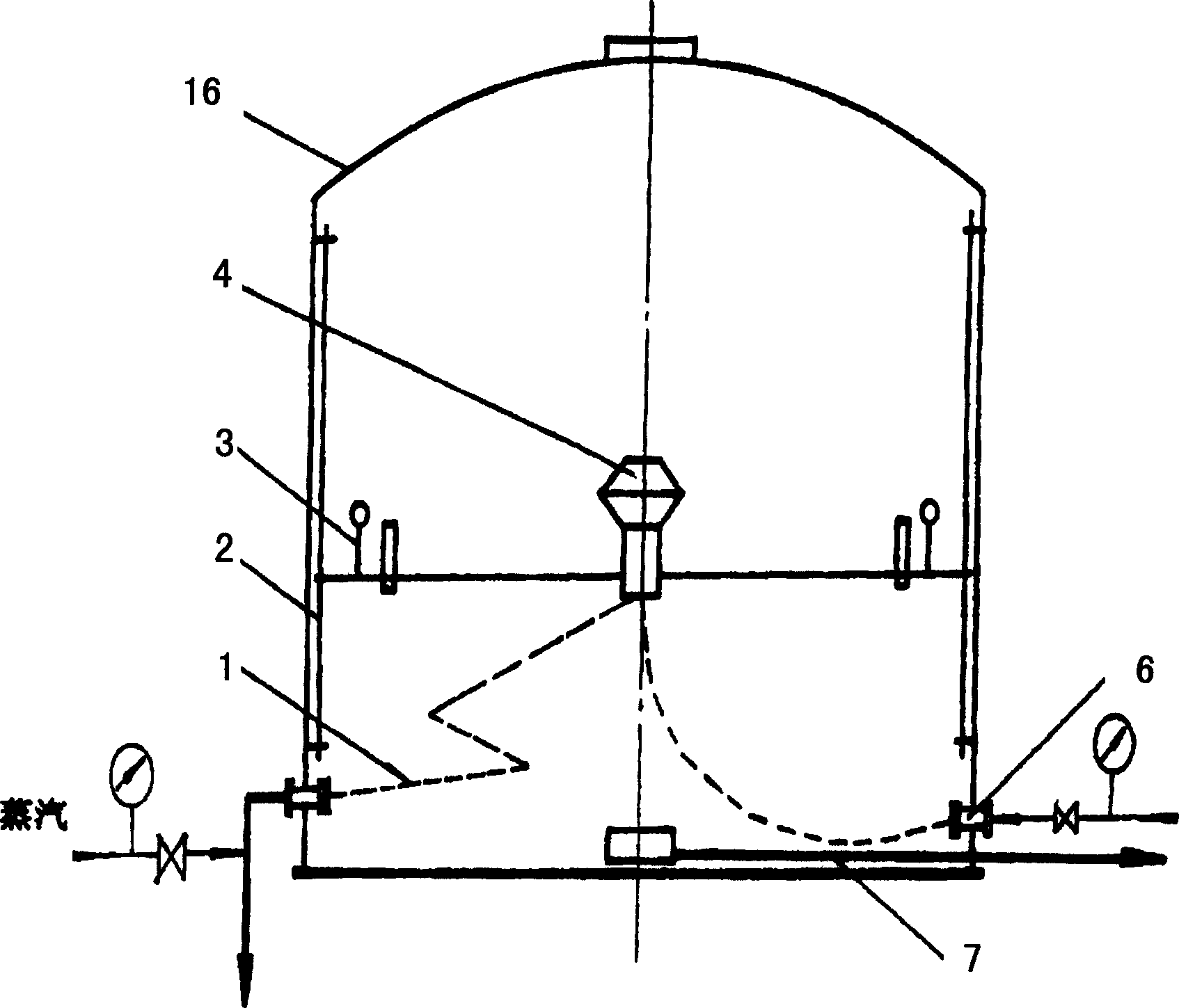

Floating circular current oil receiver and circular current separating method

ActiveCN1613536AGravity Separation AchievedSmall buoyancy distanceLiquid separationFuel tankPetrochemical

Floating circulation oil collector and circulation separation method are suitable for on-site treatment of oily sewage in oil exploration, collection, storage and transportation, processing and other petrochemical processes; pre-treatment of oily sewage treatment plants, replacing oil separation, air flotation and other mixing with different specific gravity Separation and removal of liquids. The oil collection tank is connected with the ring pipe, and the lower part is provided with a support rod; the oil collection bucket in the oil collection ring at the upper part of the oil collection tank is connected with the oil outlet pipe; the water outlet of the oil collection tank at the lower part of the oil collection tank is connected with the peripheral pumping equipment; the lower part of the container is provided with a water outlet pipe; An oil collection tank buoy is arranged on the outer surface of the oil collection tank; a buoy, a ring pipe buoy and a water injection pipe are arranged on the ring pipe; the water inlet pipe system is connected with the ring pipe; the ring pipe matches the pulley on the guide rod. The circulation separation method is: the oily sewage enters the water inlet pipe system from the water inlet, so that the floating oil on the liquid surface flows to the oil collection tank and the oil collection bucket, and is discharged through the oil outlet pipe; the separated clean water is discharged from the water outlet pipe; the water outlet and The peripheral pumping equipment is connected to form a circulation loop and reciprocate. It has the advantages of saving energy and reducing land occupation.

Owner:抚顺市明尧石油机械有限公司

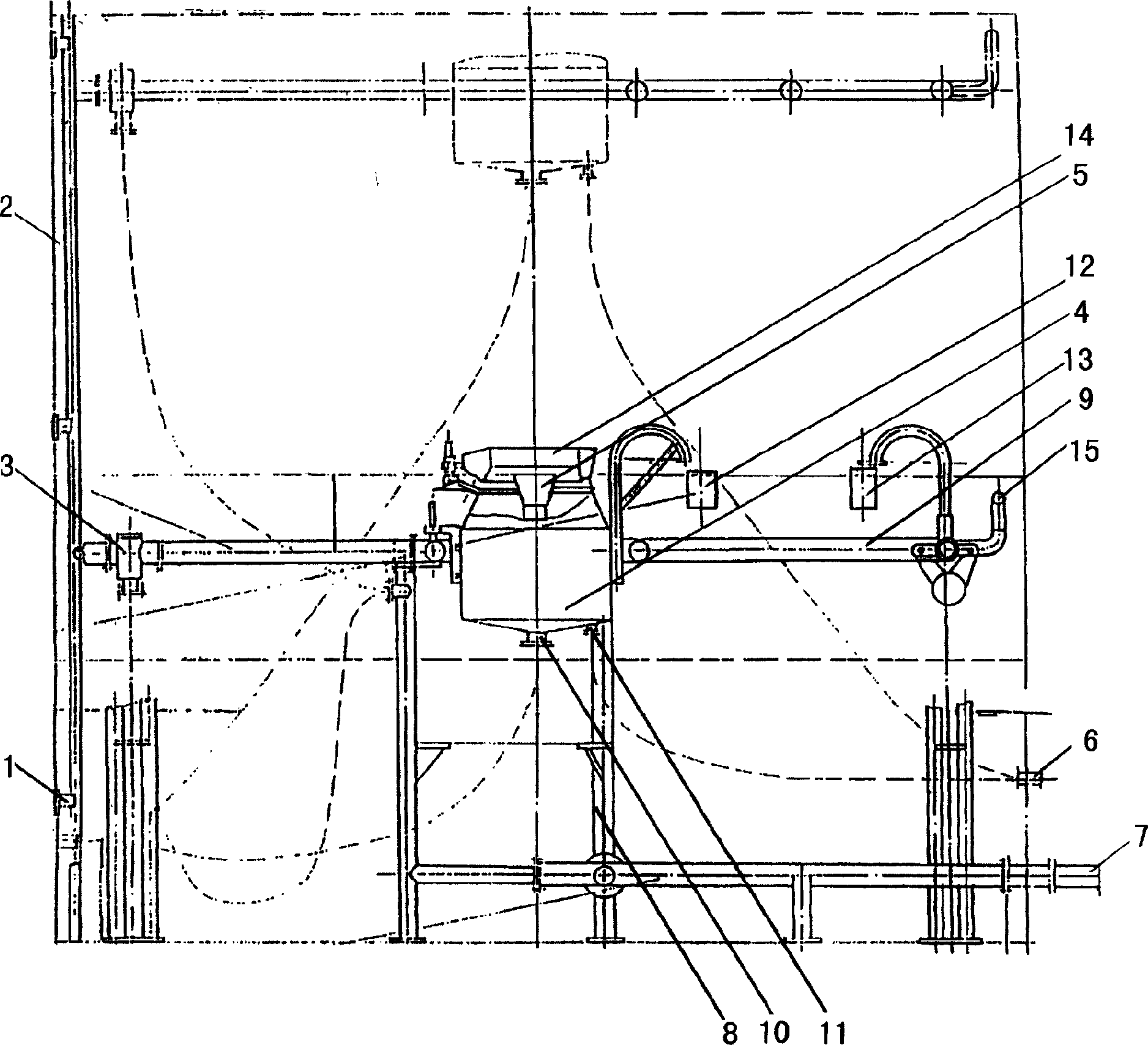

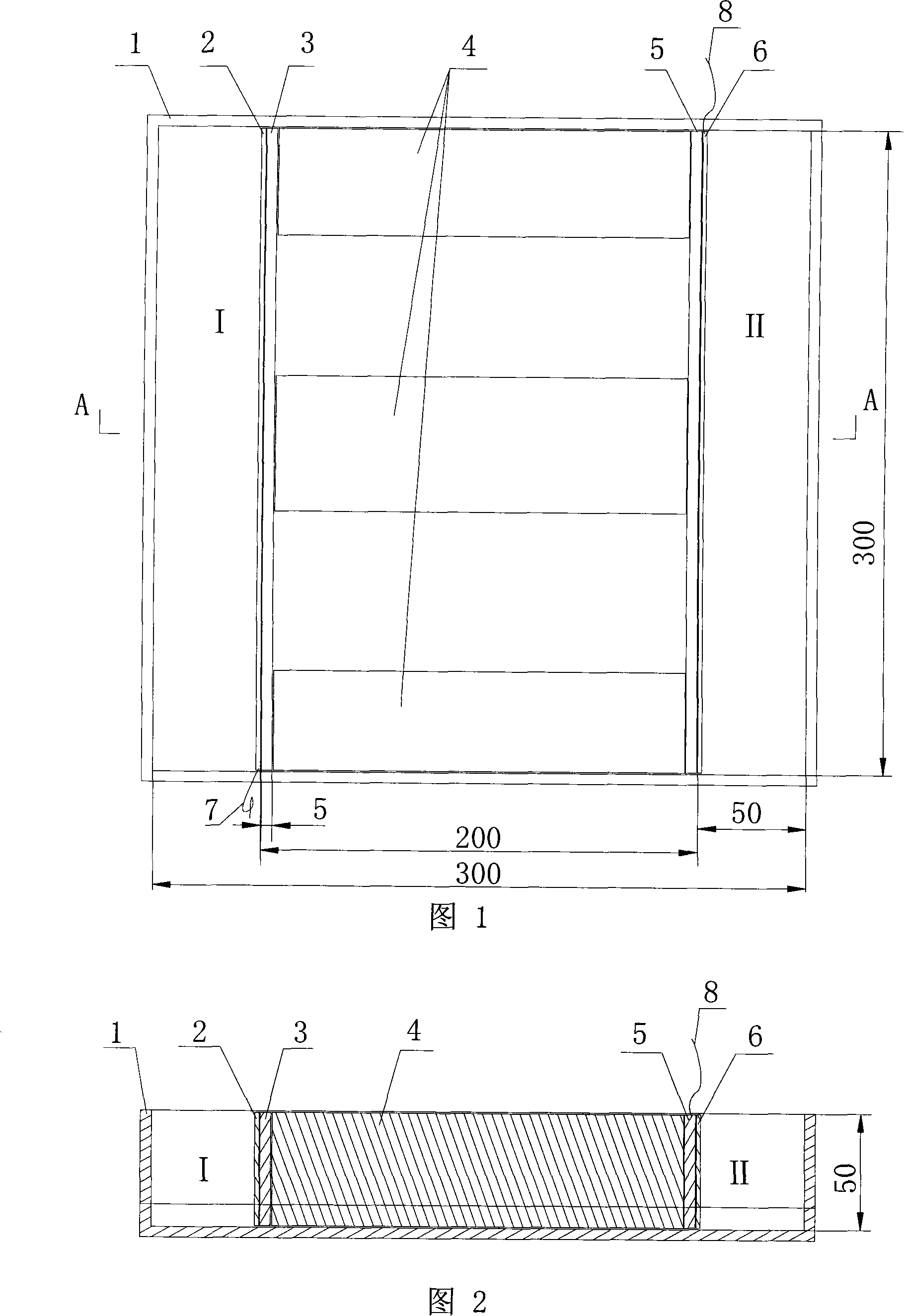

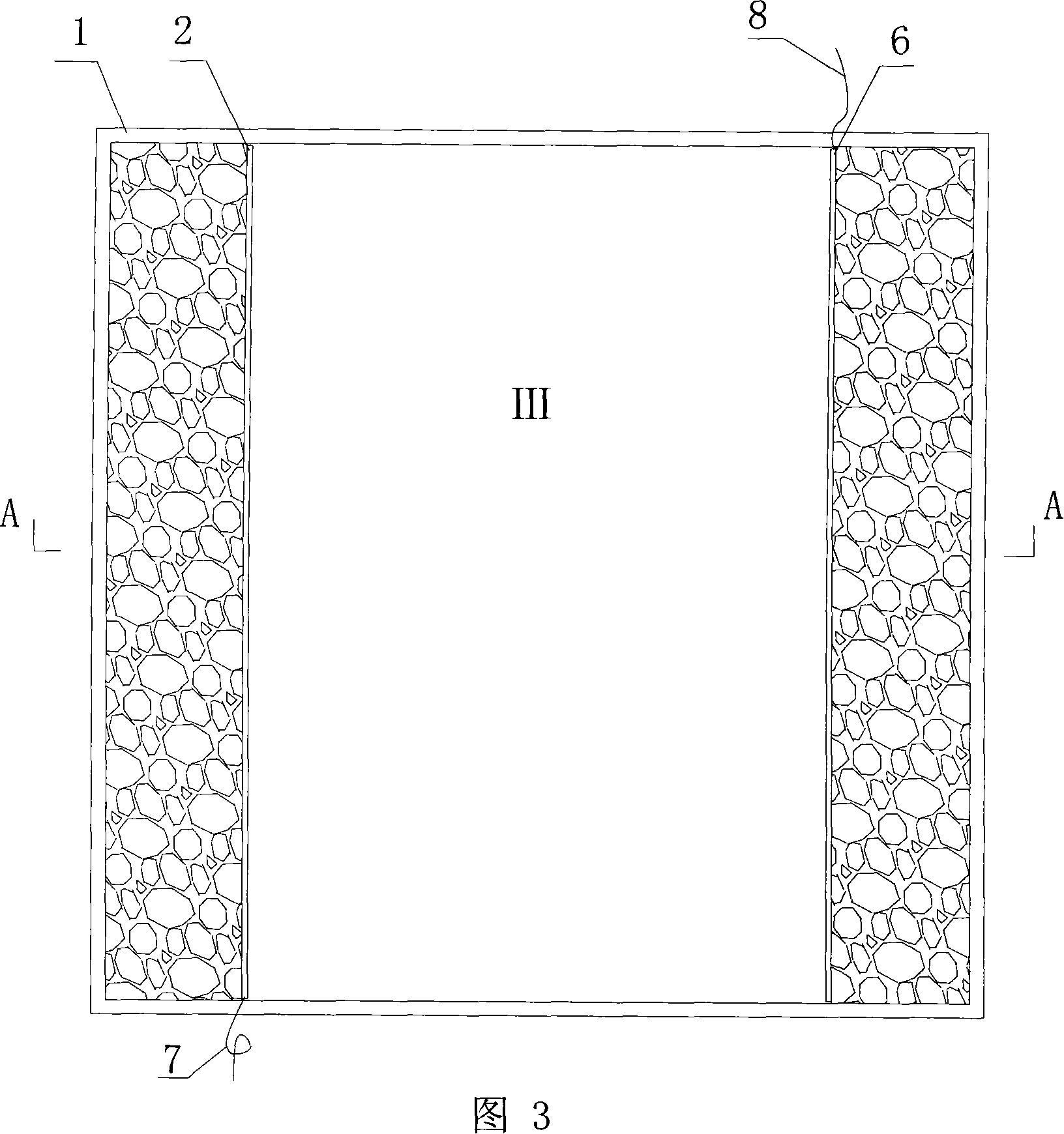

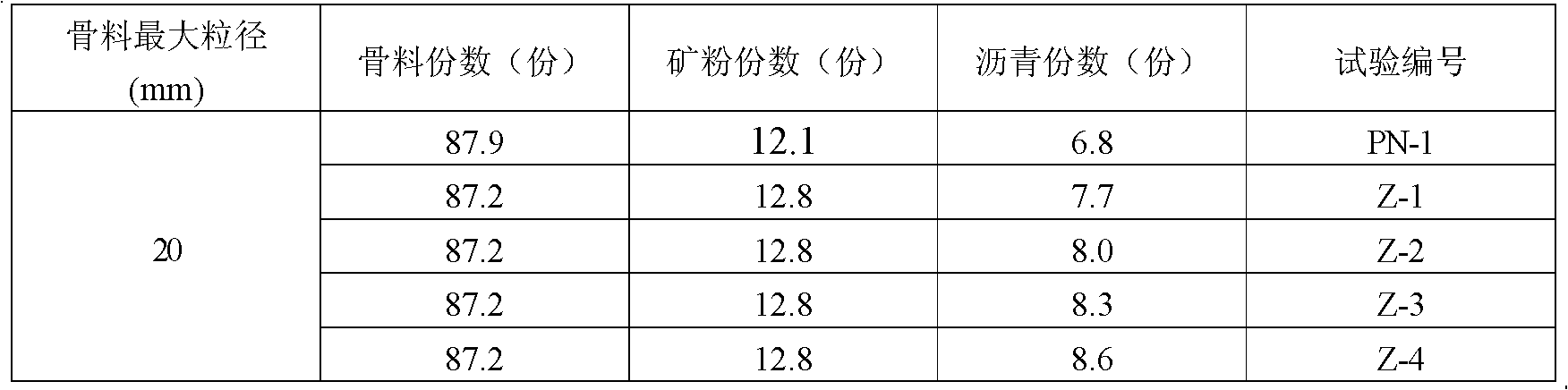

Conductive asphalt concrete resistance test method

InactiveCN101169457ASimple conductivityAccurate conductivityResistance/reactance/impedenceElectrical resistance and conductanceElectrical resistance survey

The invention relates to a resistance testing method of conduction asphalt concrete used for roads; the invention is characterized in that the testing method comprises the steps as following: firstly, the preparation of a testing device: the testing device is formed by a testing die (1), a first electrode (2), a first steel-made clapboard (3), a supporting block (4), a second steel-made clapboard (5), a second electrode (6), a first lead (7), a second lead (8) and a resistance measuring meter; secondly, leading the tested and heat mixed conduction asphalt concrete evenly to be filled into an area 1 and an area 2 of the testing die (1) according to the total amount of the conduction asphalt concrete needed for the area 1 and the area 2; thirdly, leading the tested and heat mixed conduction asphalt concrete to be evenly filled into an area 3 of the testing die (1) according to the total amount of conduction asphalt concrete needed for the area 3, and unmolding after the maintenance of indoor temperature within 24 hours; fourthly, leading the input end of a resistance meter to be respectively connected with the first lead (7) and the second lead (8) to measure the resistance value of the conduction asphalt concrete. The invention is simple and highly accurate.

Owner:WUHAN UNIV OF TECH

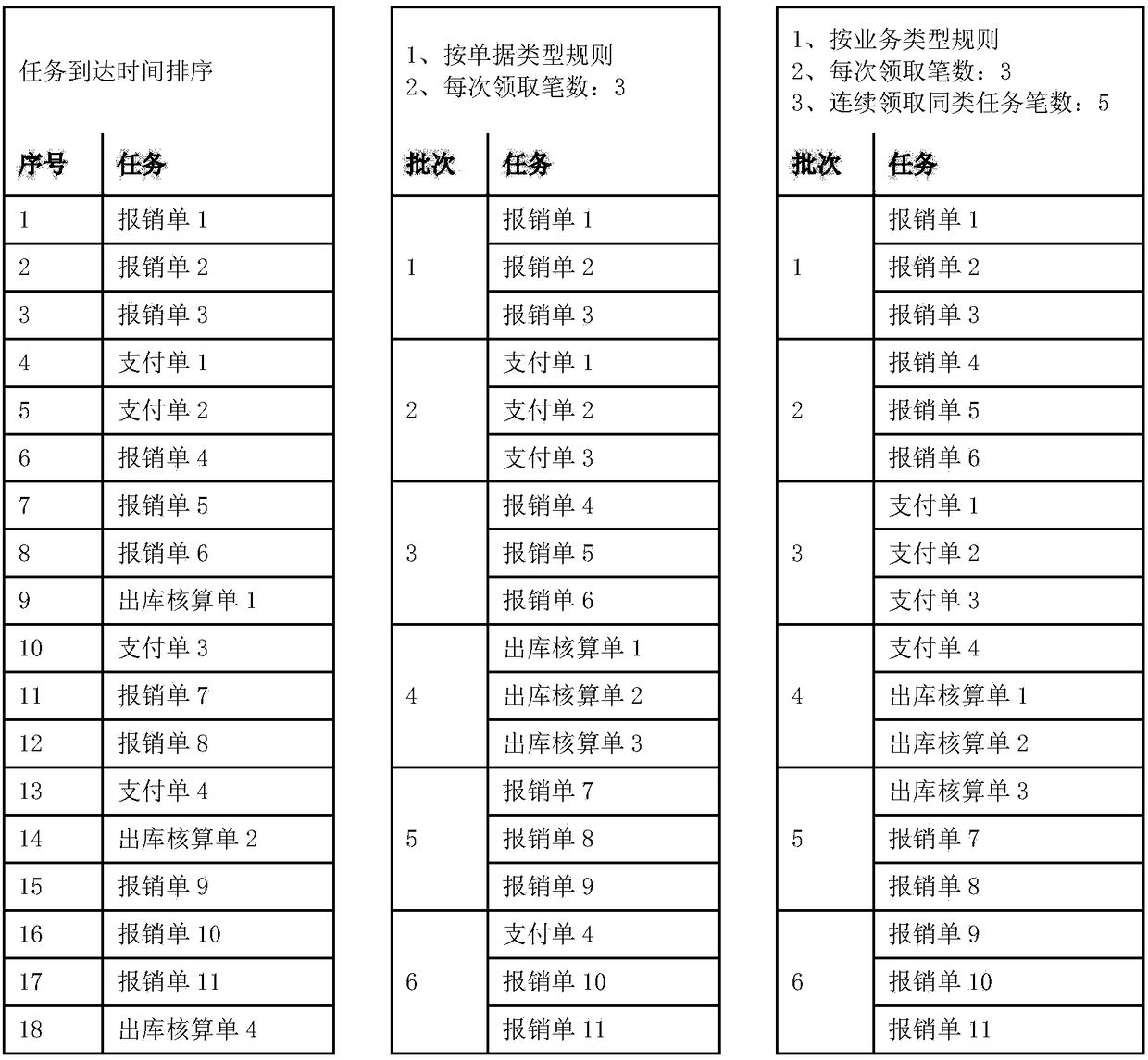

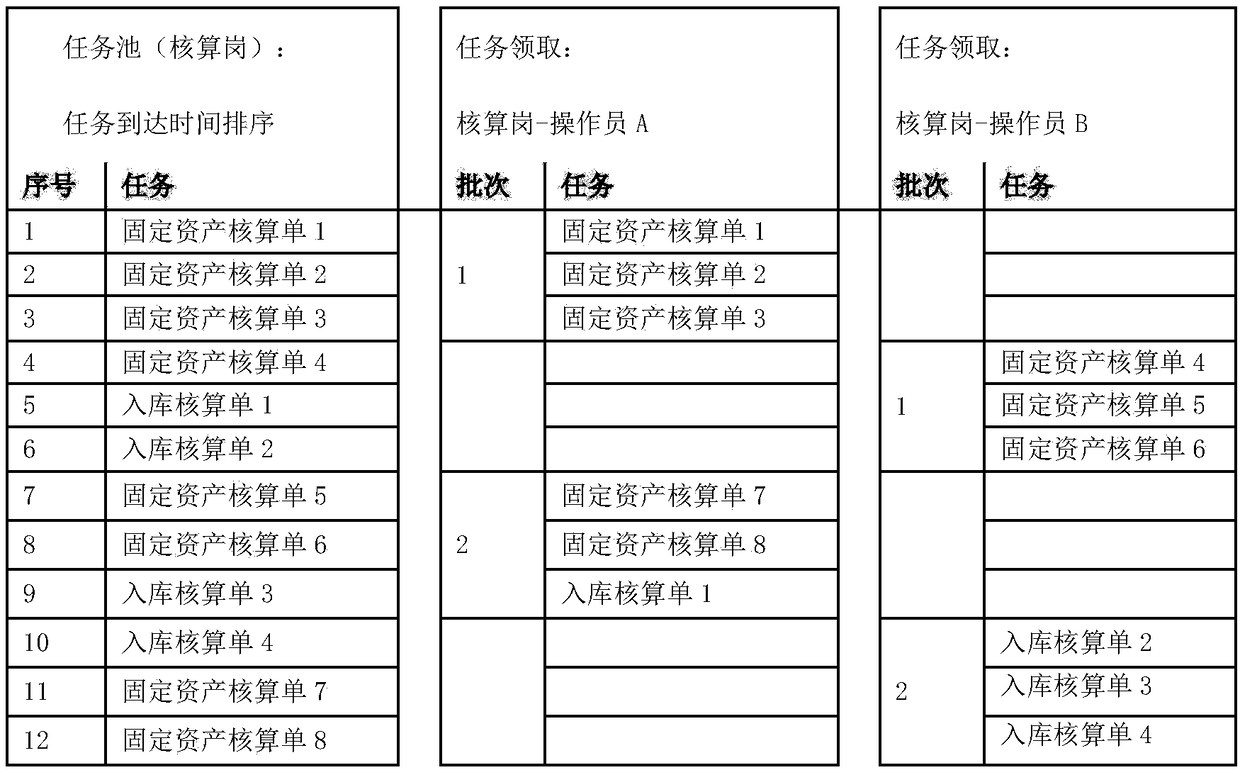

Task allocation method and device

InactiveCN108197778AGuaranteed homogeneityHomogeneousFinanceOffice automationDistribution methodOperating system

The invention relates to a task allocation method and device. The method includes the following steps: an operator log in a system to get a task, whether it is the first time for the operator to log in the system to get a task is judged, if yes, the task is allocated to the operator according to a task allocation rule, otherwise, the task is allocated to the operator according to the following steps: obtaining the type of the task that the operator gets the last time, and judging whether the number of the operator successively getting the tasks of this type reaches a threshold value of tasks of the same property, if not, allocating a task of the same type as that of the task got the last time to the operator, and if yes, allocating the task to the operator according to the task allocationrule; and the abovementioned steps are repeated till allocation of tasks in a task pool is completed. The method provided by the invention can improve efficiency of task processing of the operator, and ensure balanced allocation of the tasks at the same time.

Owner:YGSOFT INC

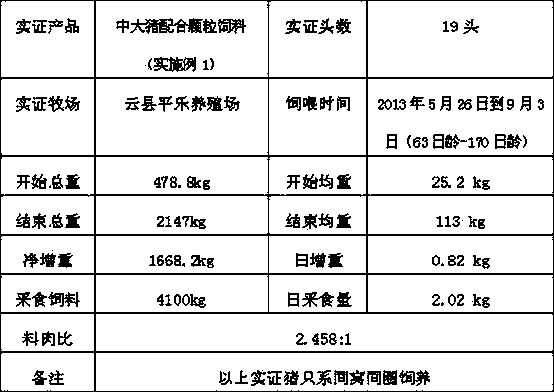

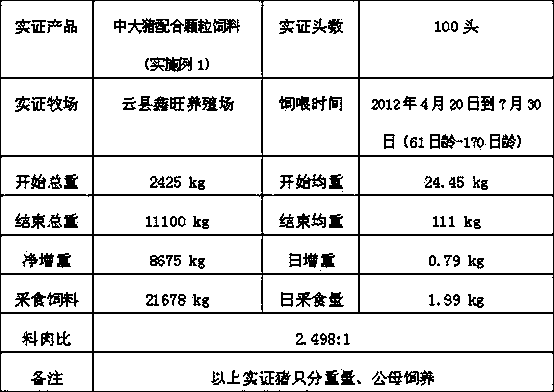

Large/medium-granularity compound pig feeds and preparation method

The invention discloses large / medium-granularity compound pig feeds which is prepared from 700 to 790 kilograms of corn, 40 to 60 kilograms of brewer grain, 140 to 180 kilograms of soybean meal, 3.5 to 5.5 kilograms of soybean oil, 0.2 to 0.3 kilogram of agrabond, 1.7 to 1.9 kilograms of calcium carbonate powder, 8.2 to 10 kilograms of dicalcium phosphate, 3 kilograms of salt, 2 to 2.3 kilograms of L-lysine hydrochloride, 0.1 to 0.2 kilogram of DL-methionine, 0.4 to 0.6 kilogram of L-tryptophan, 0.5 kilogram of choline chloride, 0.3 to 0.5 kilogram of 513D pig vitamin premix, 1.5 kilograms of baking soda, 0.5 kilogram of a sweetening agent, 0.5 kilogram of multiplied enzyme T10, 0.3 kilogram of ethoxyquin and 9 to 11 kilograms of 5012S premix by a certain method. The large / medium-granularity compound pig feeds are precisely prepared by utilizing high proteins and high amino acid of the brewer grains produced by beer brewing and dietary fibers, and are high in quality and pig palatability and comprehensive and balanced in nutrition, and pigs have strong appetite, and have ruddy and bright furs and enhanced disease resistance after being fed with the large / medium-granularity compound pig feeds.

Owner:YUNXIAN XINWANG ECOLOGY CULTURE

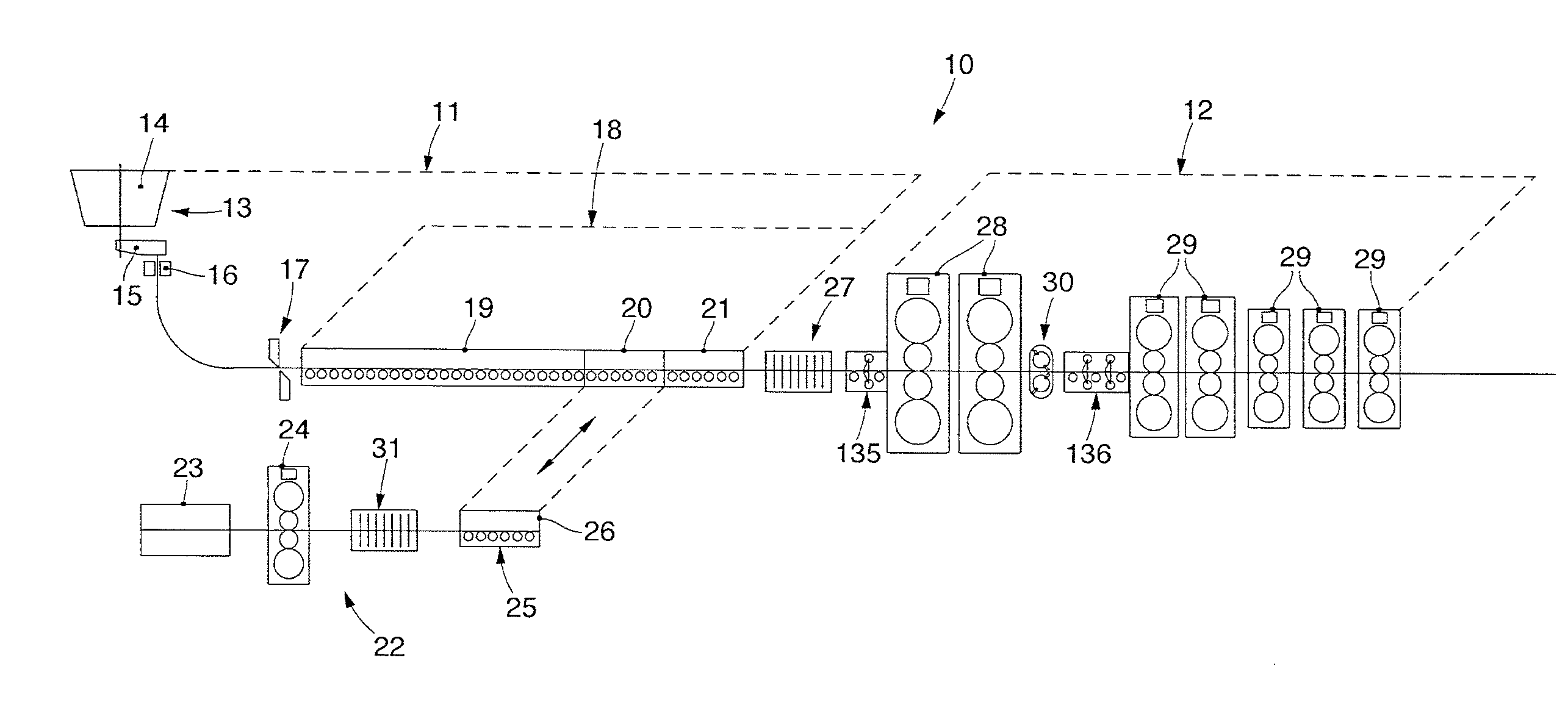

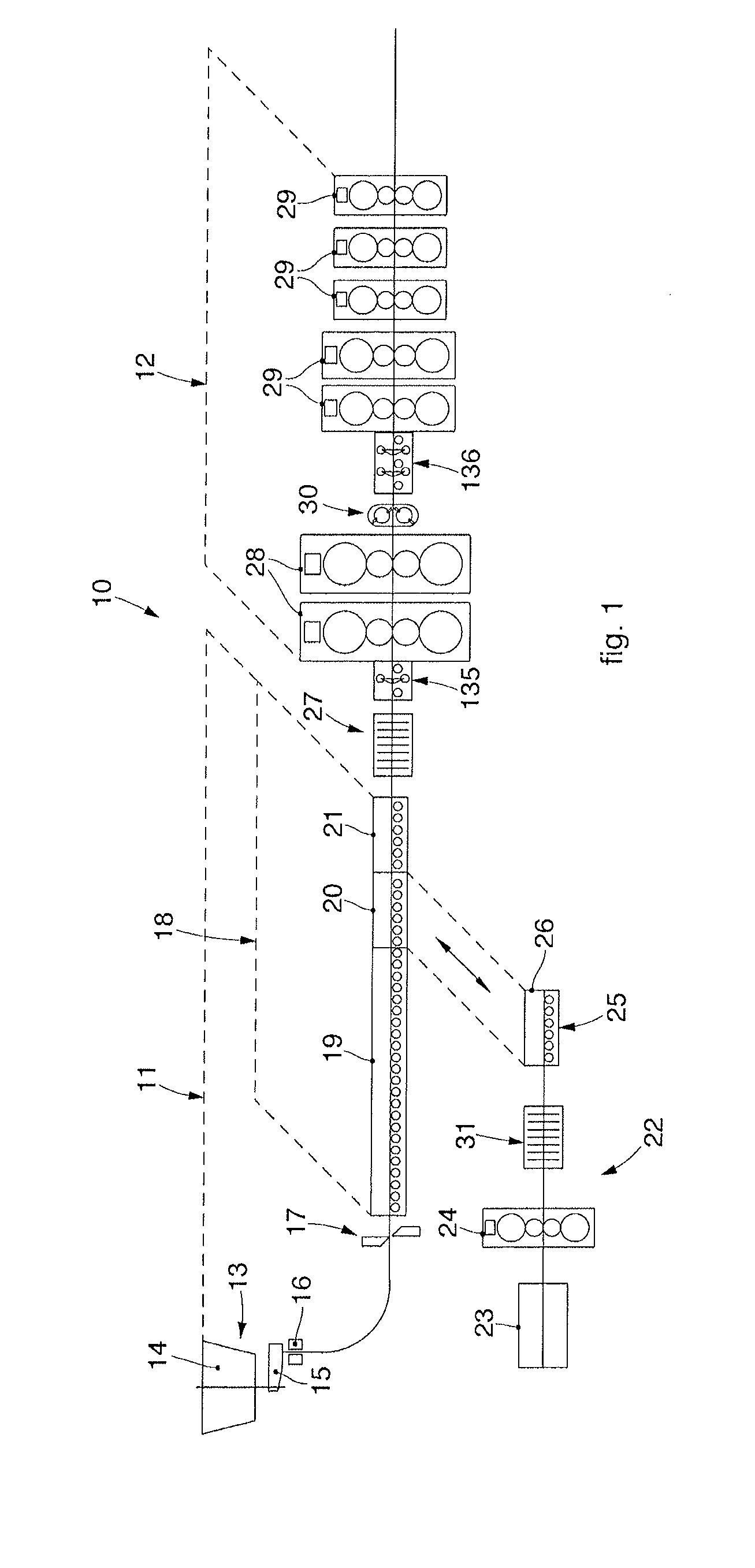

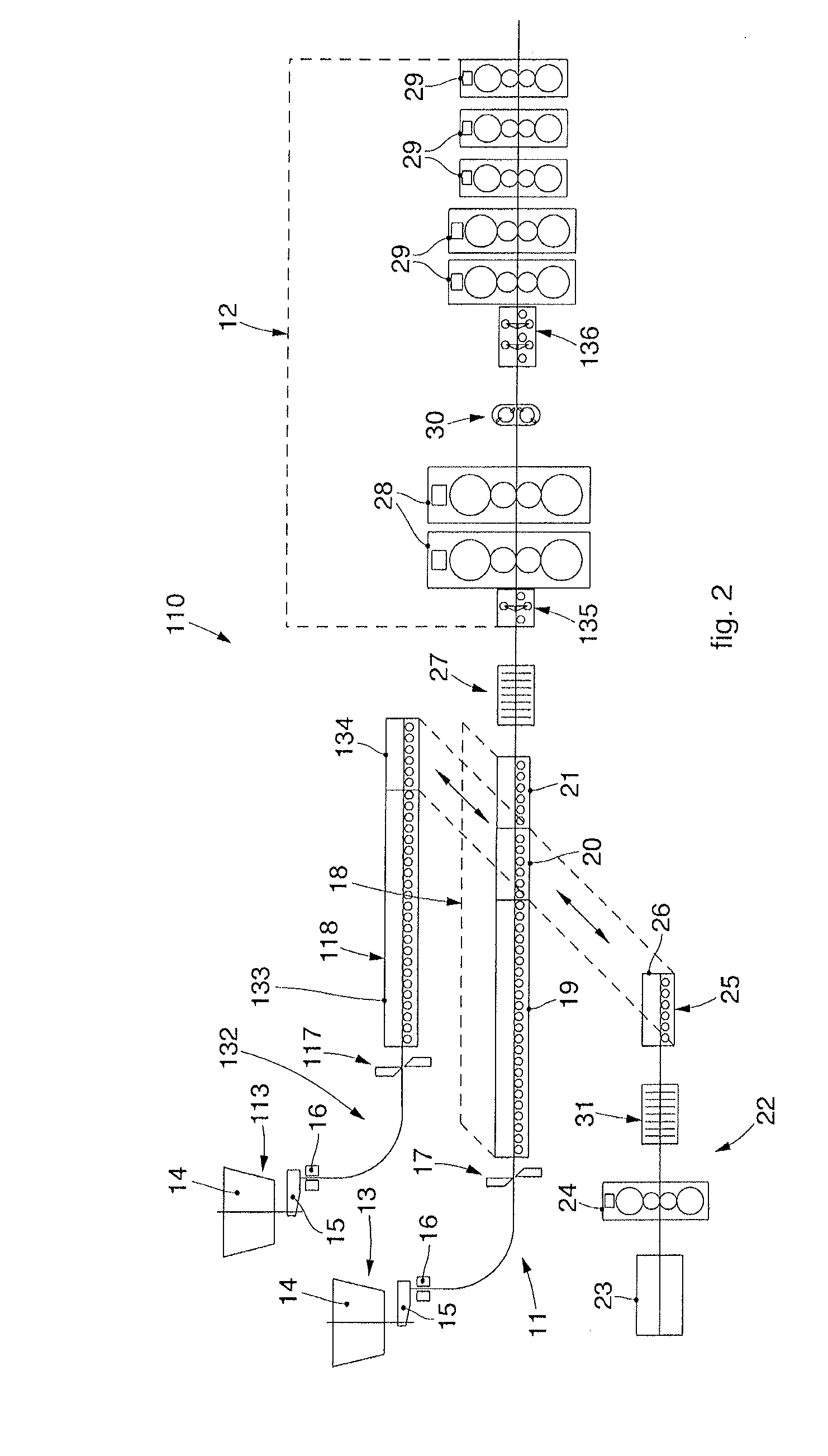

Plant and method for the production of metal

InactiveUS20170002439A1Increase flexibilityEasy to adjustMetal rolling stand detailsIncreasing energy efficiencyMetalCasting

Plant for the production of metal products comprising:a main rolling line configured to roll thin slabs;a main casting line of thin slabs associated downstream to a heating and / or maintenance furnace to heat and / or maintain the cast thin slabs at a uniform temperature, the main casting line being positioned upstream of and aligned with said main rolling line, the main rolling line being configured to roll the thin slabs arriving at least from the heating and / or maintenance furnace;an auxiliary rolling line provided with at least one rolling unit configured to roll conventional slabs and obtain thin slabs, and with a transfer unit positioned downstream of the rolling unit and configured to transfer the thin slabs rolled by the latter to the heating and / or maintenance furnace.

Owner:DANIELI & C OFF MEC SPA

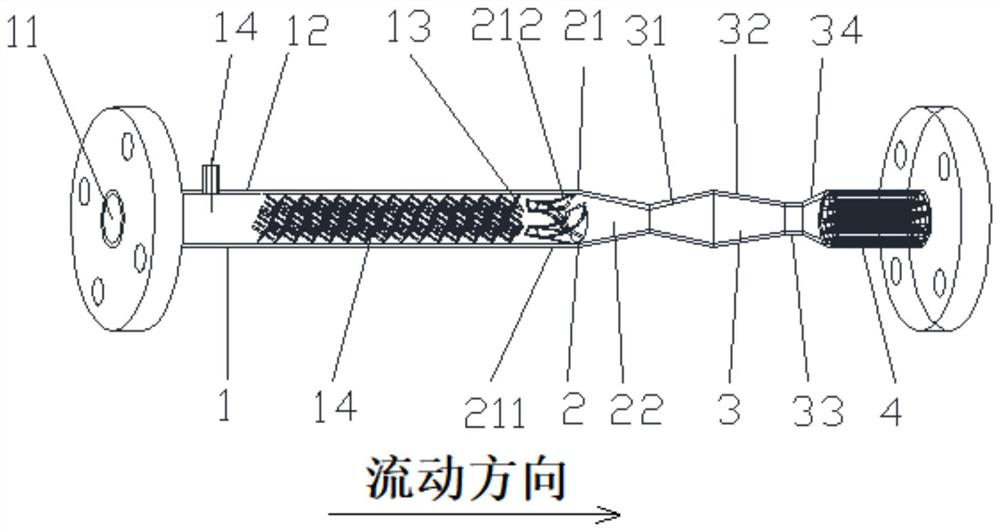

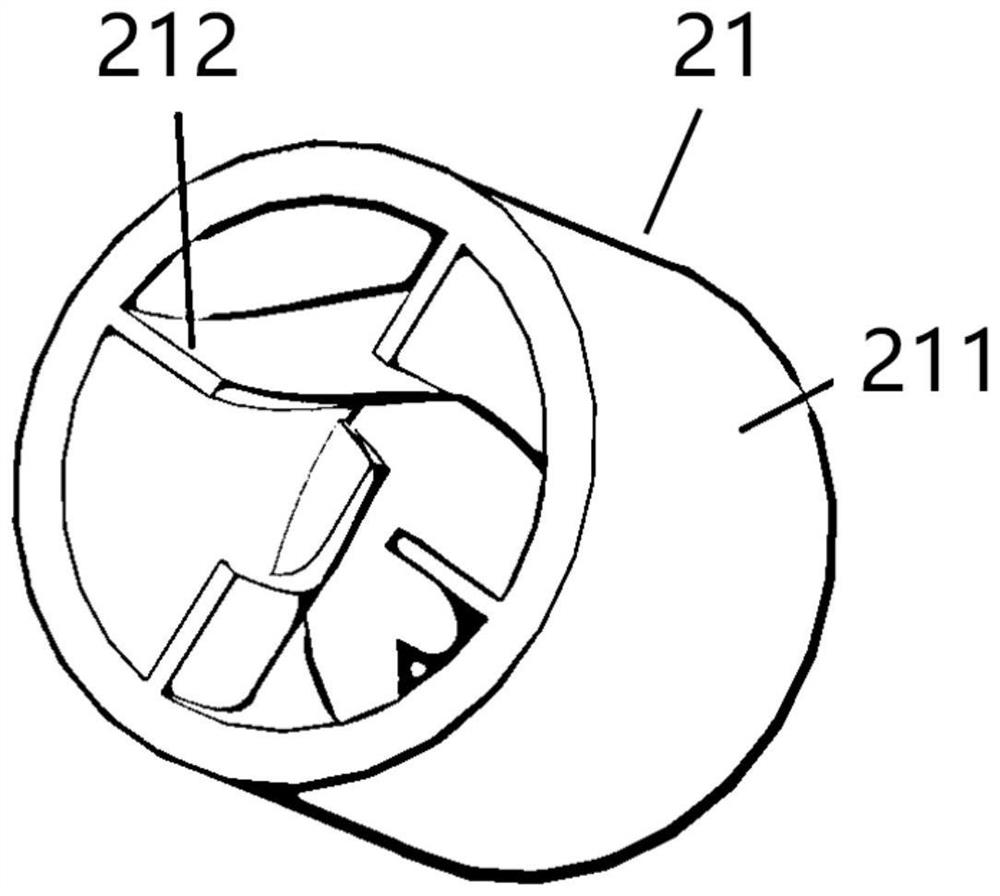

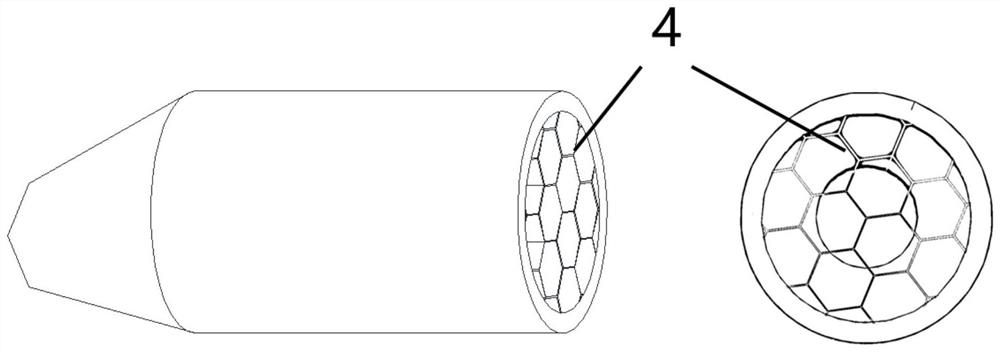

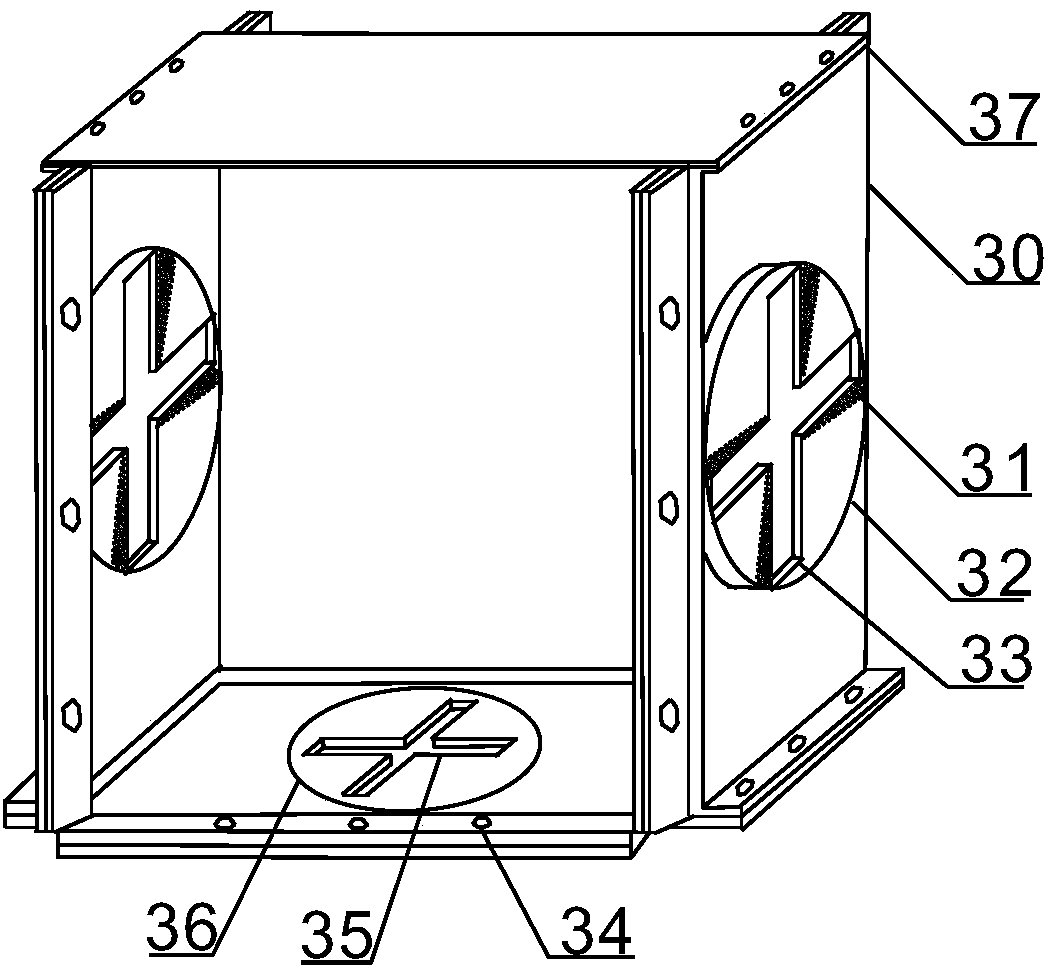

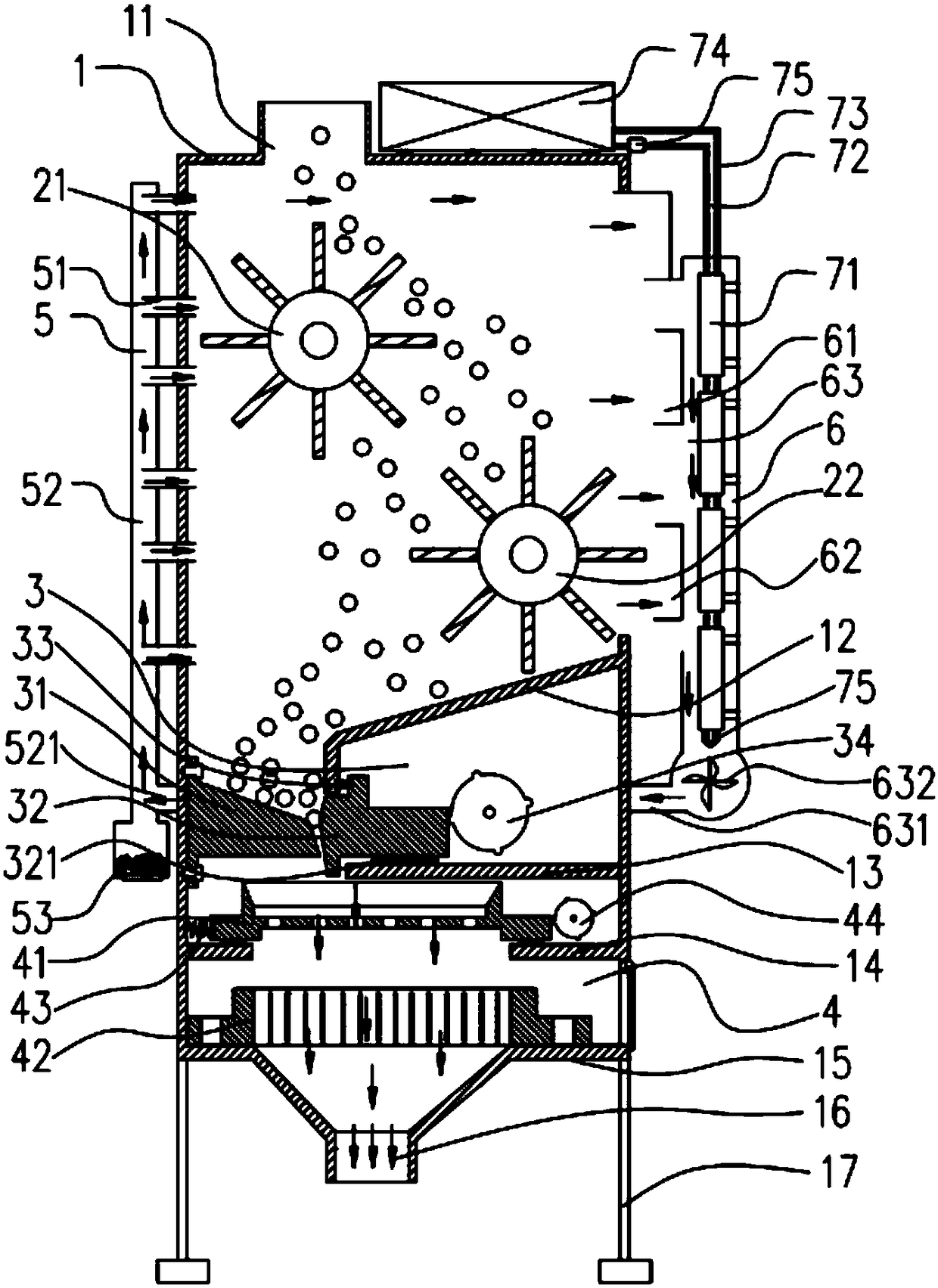

Premixing and homogenizing coupling type bubble generator

ActiveCN113144929AGuaranteed mixing effectReduce stratified flowFlow mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a premixing and homogenizing coupling type bubble generator. The bubble generator comprises a gas-liquid premixing section, a gas-liquid intensified mixing section, a gas-liquid homogenizing section and a vortex breaking section which are connected in sequence; the gas-liquid pre-mixing section is configured to perform primary shearing dispersion on gas-liquid two phases by utilizing high-speed turbulent flow to form a gas-liquid mixing dispersion field; the gas-liquid reinforced mixing section comprises a swirling section and a contraction section which are sequentially distributed, and a multi-dimensional swirling flow field is formed in the swirling section and is configured to induce the gas-liquid mixed phase from the gas-liquid premixing section to generate swirling flow motion; a flow channel of which the diameter is gradually reduced along the flowing direction of the gas-liquid mixed phase is formed in the contraction section; at least two stages of venturi tube-shaped flow channels which are connected in series are formed in the gas-liquid homogenizing section; and a micro-channel is formed in the vortex breaking section.

Owner:CHINA NATIONAL OFFSHORE OIL (CHINA) CO LTD +1

Insertion type vibration rolling construction method of asphalt concrete core of earth and rockfill dam

ActiveCN102493402AReduce viscoelasticityHigh viscoelasticityFoundation engineeringEarth-fill damsMixed materialsMaterials science

The invention relates to an insertion type vibration rolling construction method of an asphalt concrete core of an earth and rockfill dam, belonging to a construction method of an asphalt concrete watertight core of an earth and rockfill dam. The method comprises the steps of: paving an asphalt mixed material and a transition material, vibrating and compacting the asphalt mixed material, rolling the transition material and the asphalt mixed material, and preserving heat and maintaining. The construction method sufficiently utilizes the characteristic of high-temperature quick compaction of the vibration construction while considering the advantages of large scale and high mechanical degree of the rolling construction.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

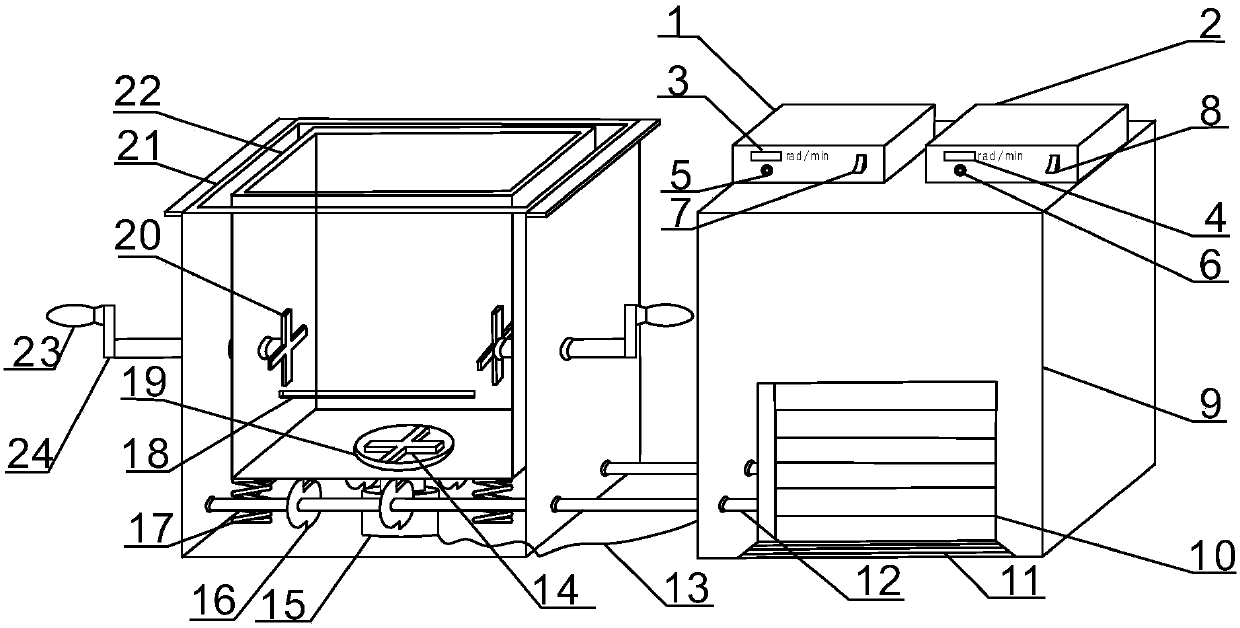

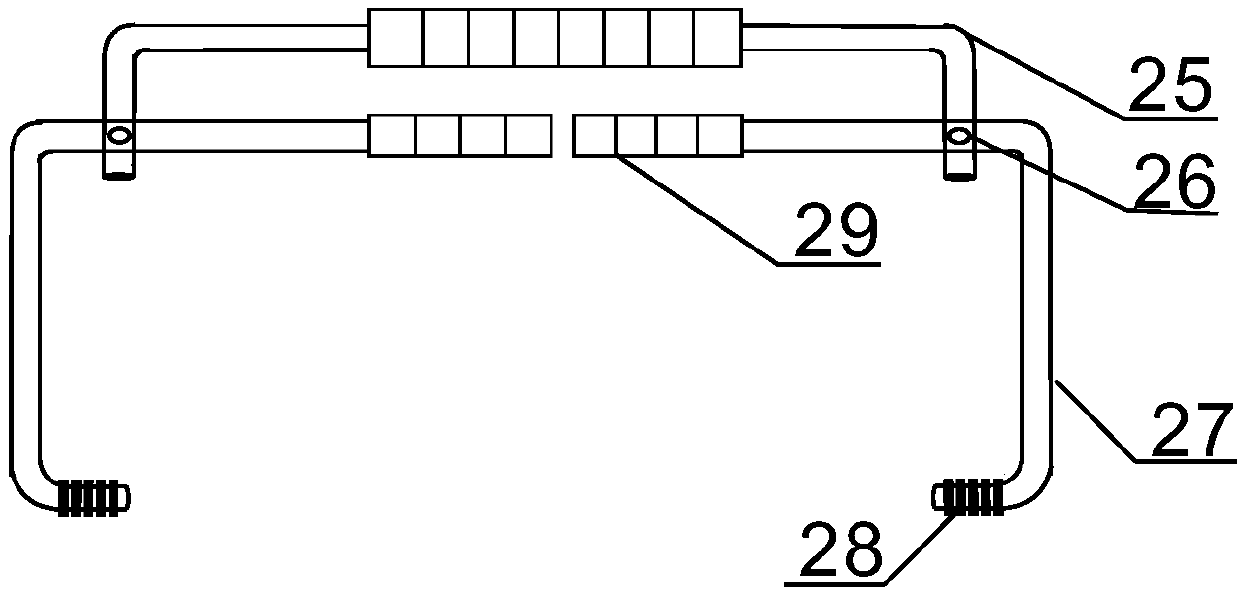

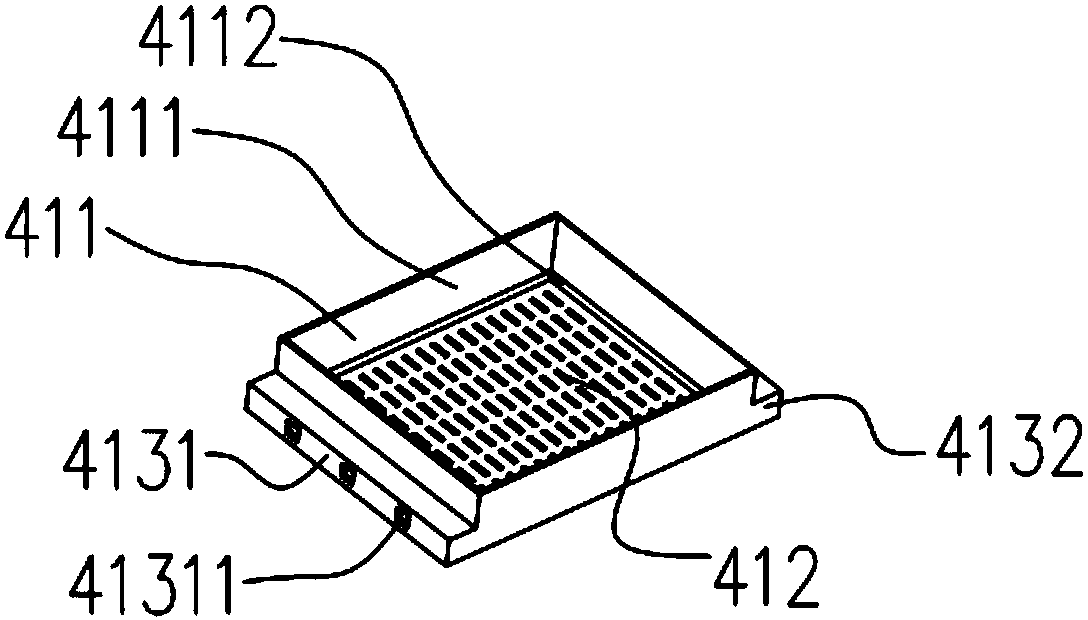

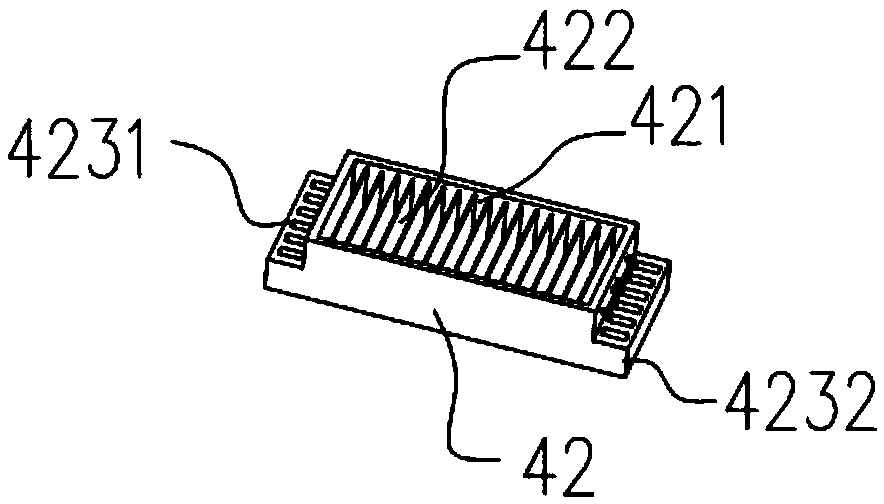

Small concrete compaction and curing slowing device used for experiment and its implementation method

PendingCN107639718AReduce noise pollutionReduce lossCeramic shaping plantsEngineeringExperimental methods

The invention relates to a small concrete compaction and curing slowing device used for an experiment. The device includes a vibration mechanism, a centrifugal mechanism, a curing slowing mechanism, amaterial loading and unloading mechanism and a clamping mechanism; the vibration mechanism is located on the outermost layer of the device, the centrifugal mechanism is located on the middle layer ofthe device, the curing slowing mechanism is located on the secondary inner layer of the device, and the material loading and unloading mechanism is located on the innermost layer of the device. The invention further discloses a concrete compaction and curing slowing method by means of the concrete compaction and curing slowing device. According to the small concrete compaction and curing slowingdevice used for experiment and its implementation method, solid compaction and curing slowing functions are both achieved, there is a big difference between the existing experimental method and corresponding instruments and the small concrete compaction and curing slowing device and its implementation method, the characteristics such as low noise, low loss, low splashing, disassembly, matching, uniform sample discharge and compaction in the compaction process of concrete are taken into consideration, and the device is very high in feasibility and practicability.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Frozen section embedding agent

InactiveCN106018050AGood water solubilityHigh transparencyPreparing sample for investigationSolubilityPolyvinyl alcohol

The invention discloses a frozen section embedding agent, which comprises the following components in parts by mass: 1000 parts of purified water, 80-100 parts of polyvinyl alcohol, 30-50 parts of polyvinylpyrrolidone, sodium carboxymethyl cellulose 10-20 parts and polyethylene glycol 300 50-80 parts. The embedding agent designed in the present invention has good thermal conductivity, transparency, viscosity, water solubility and ductility, and its hardness is suitable. The frozen section embedding agent of the present invention can be applied to the embedding of tissue for pathological diagnosis in surgery, and can also be used for conventional pathological diagnosis, immunohistochemical diagnosis technology and molecular biology diagnosis technology.

Owner:北京九州柏林生物科技有限公司

Environmental-protection molding sand cooling recovery device

InactiveCN108436030AGuaranteed homogeneityReduce the temperatureMould handling/dressing devicesCooling effectEngineering

The invention discloses an environmental-protection molding sand cooling recovery device. The device comprises a tower body, and a first separation plate, a second separation plate and a blanking collecting plate arranged in the tower body in sequence from top to bottom; a crushing bin is fixedly connected with a fixed inclined surface end, a slide inclined surface end and a first driving cam in sequence from left to right; a first return spring is arranged between the slide inclined surface end and the first separation plate; the first driving cam is matched with the right side surface of theslide inclined surface end, and can butt against the slide inclined surface end to move to the left side to realize pressing of the first return spring; when the first return spring is reset, the slide inclined surface end can be driven to move to the right side; a discharge port is formed in the lower part of the blanking collecting plate; and the tower body is provided with a cooling intake endon the left side wall and an air collecting device on the right side wall. The device cools molding sand through the cooling intake end and the air collecting device, achieves better cooling effect,and is compact in structure, convenient to use, energy-saving, environment-friendly and suitable for wide application in cooling recovery of the molding sand.

Owner:李同贵

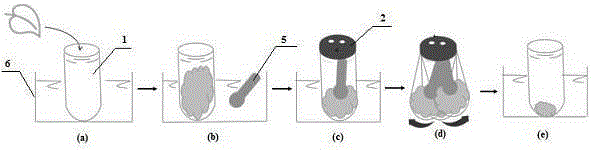

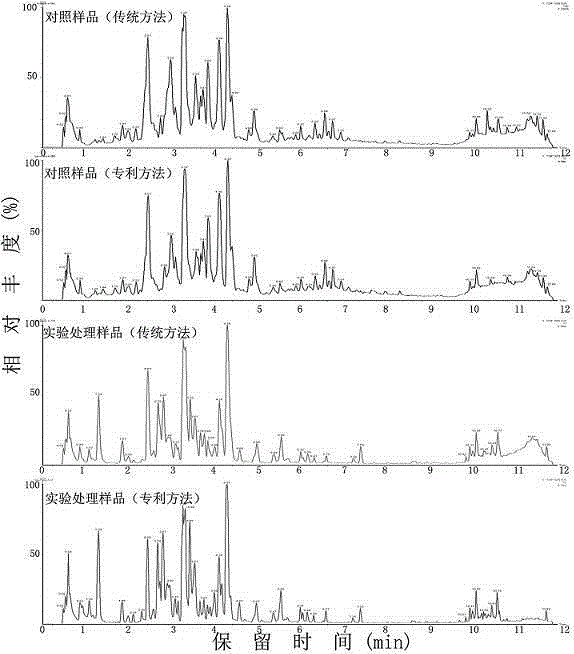

Sample pretreatment method for plant metabolome analysis

ActiveCN105289773AReduce direct contactAvoid direct contactPreparing sample for investigationLaboratory glasswaresBiotechnologyPretreatment method

The invention discloses a sample pretreatment method for plant metabolome analysis. The method comprises the following steps: sampling and inactivating, sample homogenizing and grinding, centrifugal filtration and the like; various tissue parts are separately sampled, are frozen and inactivated quickly by adopting liquid nitrogen, and are homogenized and ground by high-speed oscillation in a liquid nitrogen environment; a mixed sample is extracted by adopting ultrasonic in an assistant manner after being obtained; finally, protein is removed through high-speed centrifugation. According to the sample pretreatment method, the defects of temperature change, easiness in pollution, serious sample waste, relatively poor repeatability, uneven sample mixing, relatively low work efficiency, high operating danger coefficient, high requirements on the proficiency and work experience of operating personnel and the like are overcome. The sample pretreatment method can be well applied to hard tissue sampling, homogenizing, grinding and extracting of woody plant samples of tea trees and the like, and is a rapid, nondestructive and pollution-free sample pretreatment technology for performing a metabonomics analysis test. The sample pretreatment method can also be applied to a quality component analysis, RNA (Ribonucleic Acid) extraction, a proteomics analysis and the like.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Low-viscosity flow-second grouting material capable of being used in a nuclear power industry

The invention aims at the problem that a common cementitious grout has high viscosity after stirred and cannot satisfy a test requirement by a flow cone method, and is intended to prepare a low-viscosity cement-based grouting material without settlement or water segregation when water consumption is high. When the fluidity of the low-viscosity grouting material is measured, the flow second is 18-30s, so as to satisfy of the requirement of equipment manufacturers and design companies on the flowing property of the grouting material. In addition, a composite expanding agent is used to compensate the contraction of the cement-based grouting material, thereby avoiding later-stage contraction cracks of the cementitious grout.

Owner:GAOBEIDIAN CITY DAAO NEW TYPE BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com