Patents

Literature

41results about How to "Homogeneous" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

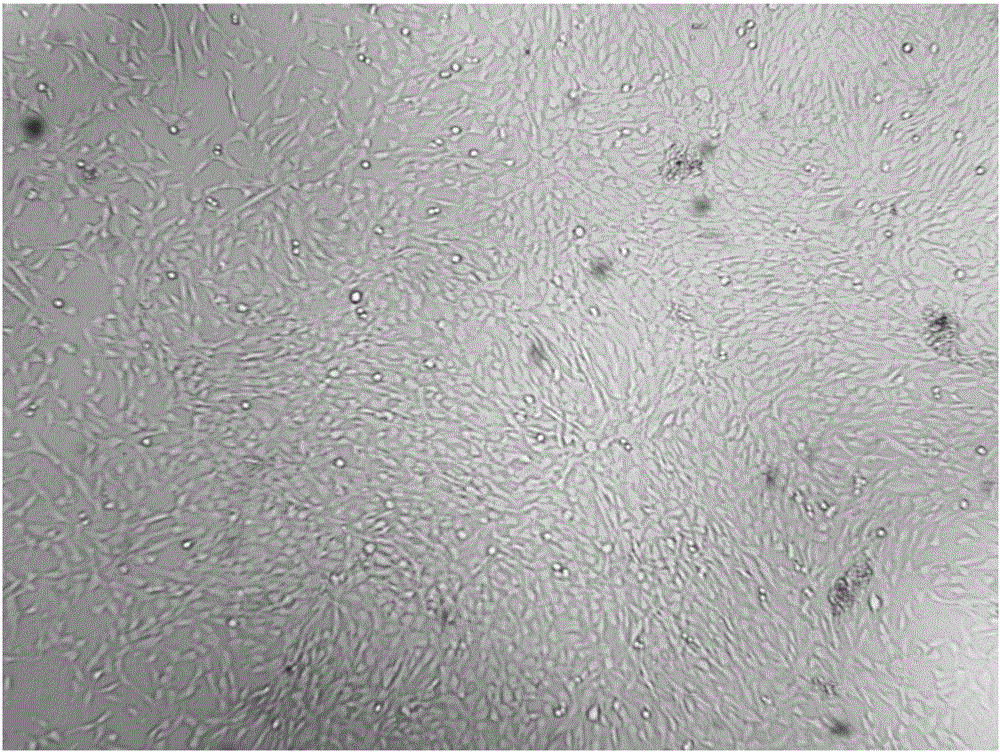

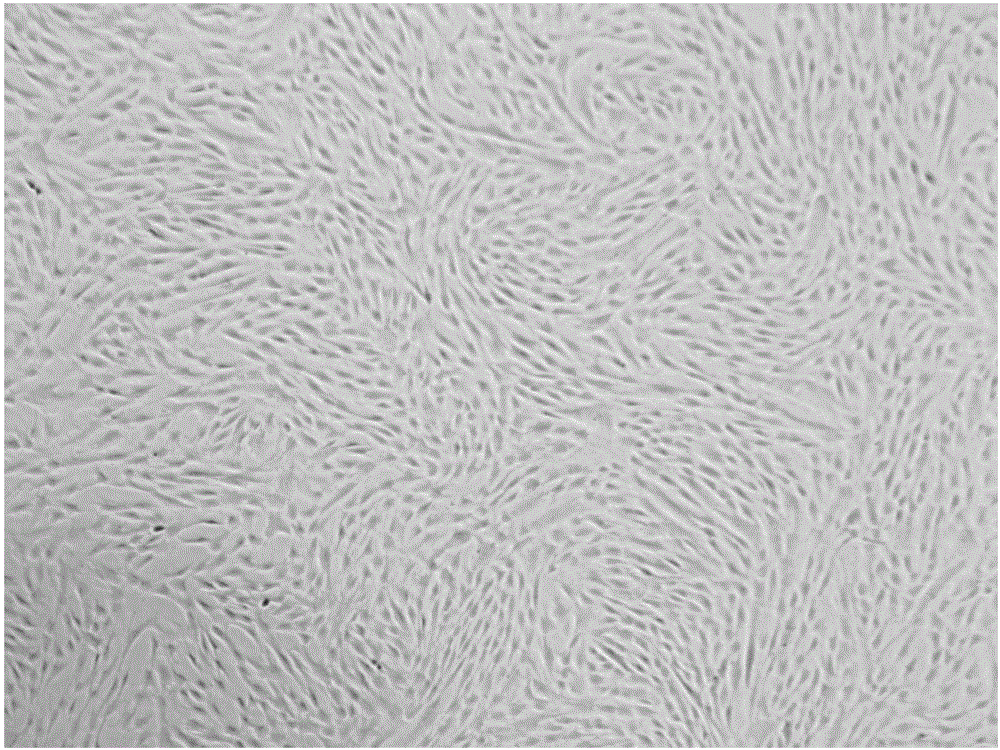

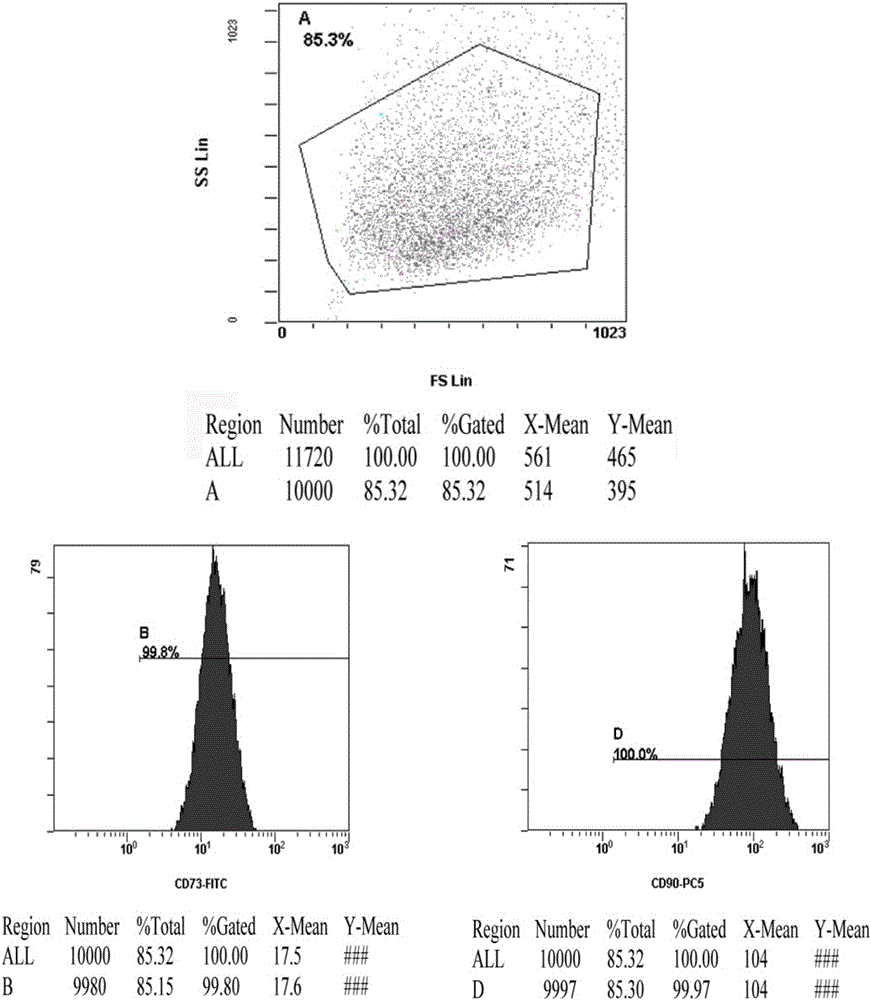

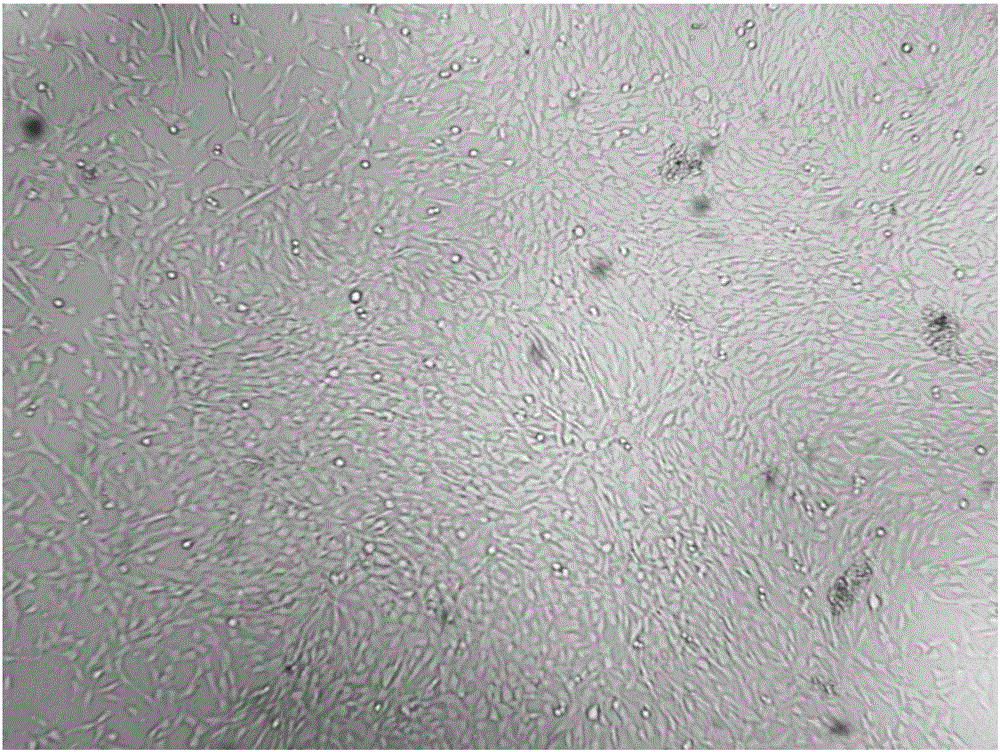

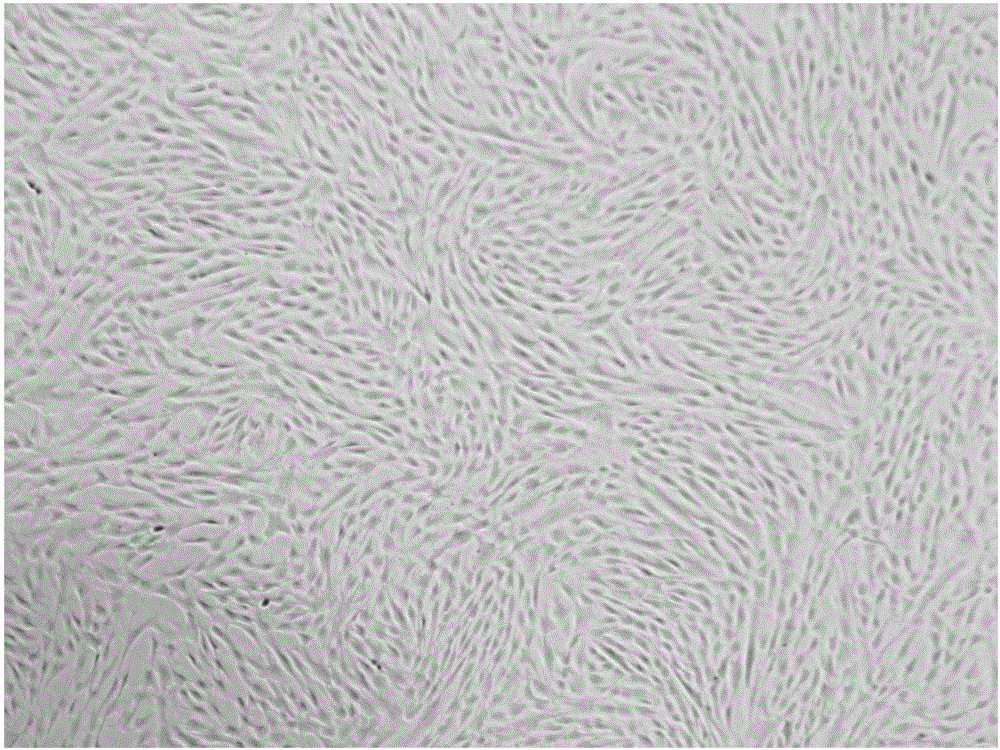

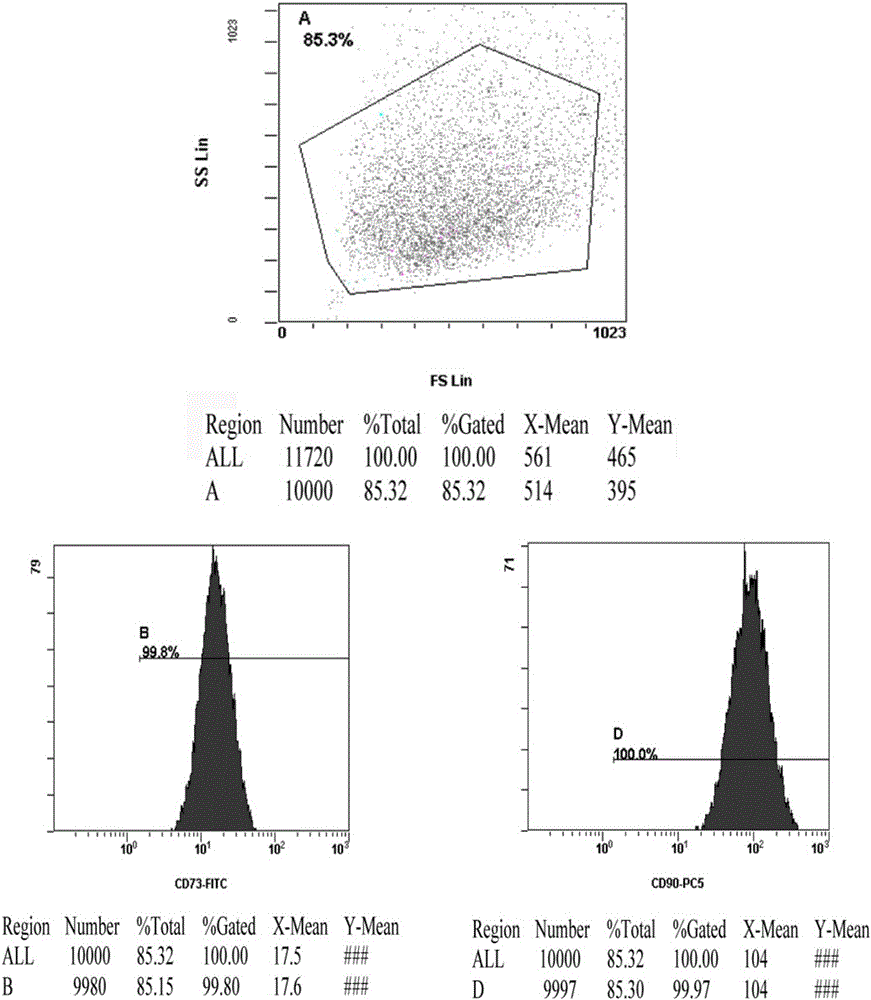

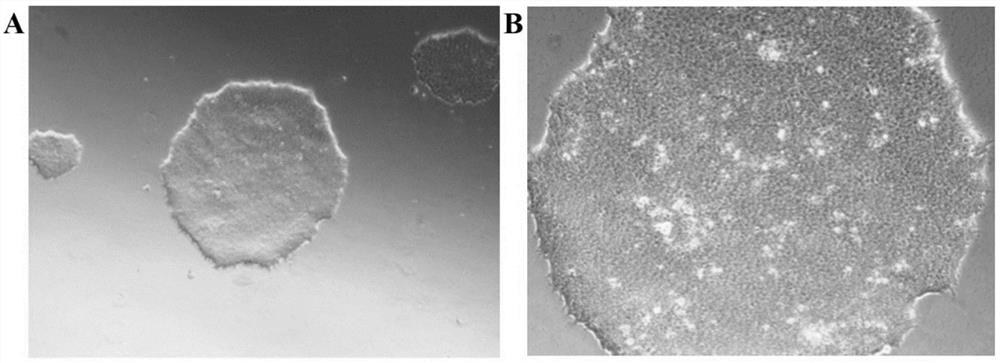

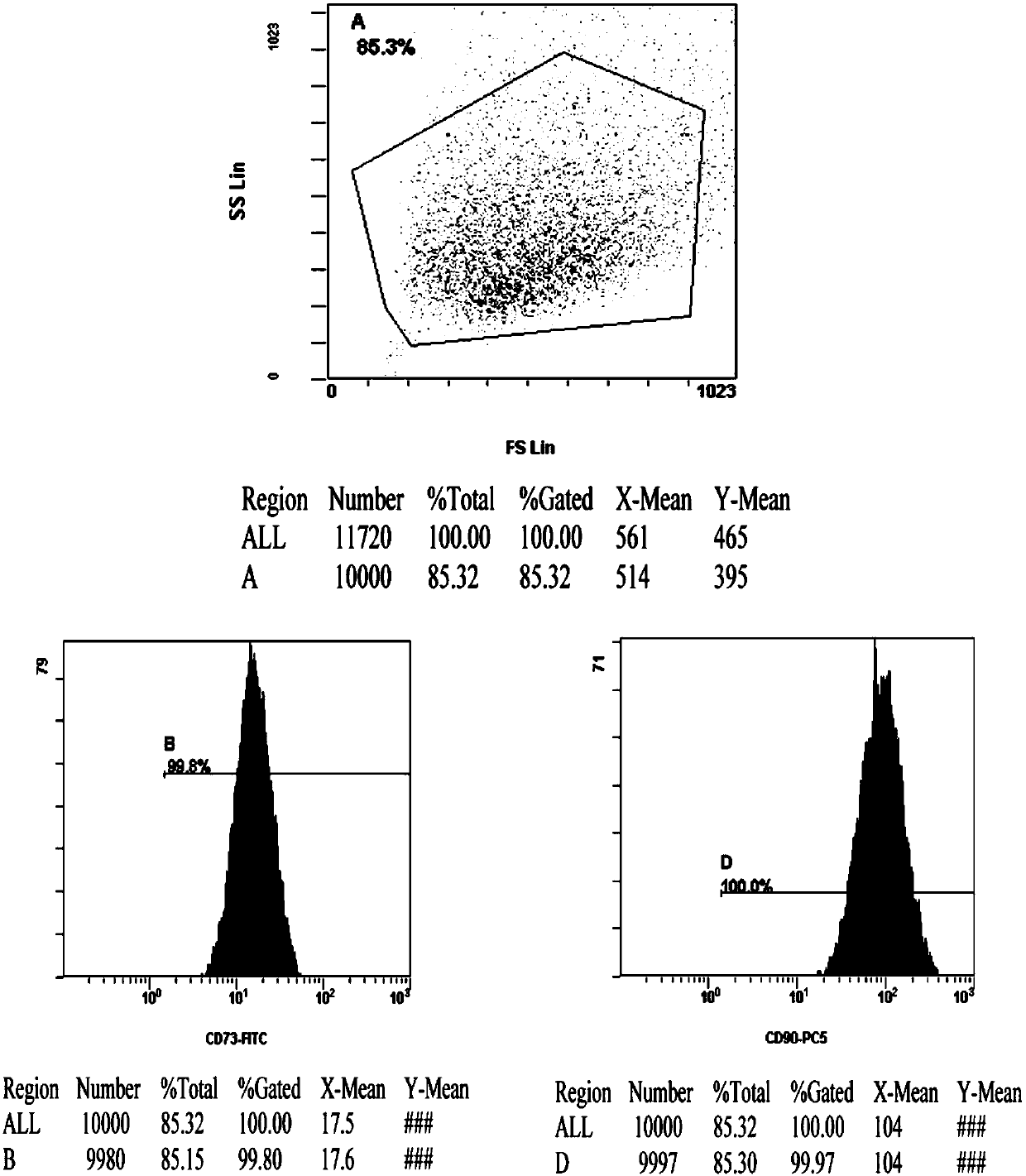

Method for preparing stem cell active factor

ActiveCN106381284AHomogeneousIn line with biological characteristicsCosmetic preparationsToilet preparationsFreeze-dryingMesenchymal stem cell

The invention relates to a method for preparing a stem cell active factor, and on one hand, in particular relates to a method for preparing the stem cell active factor. The method comprises the following steps of: (1) acquiring umbilical cord placenta derived mesenchymal stem cells; (2) performing cell amplification; (3) performing cell identification detection; (4) preparing the stem cell active factor; and (5) performing optional freeze-drying. Furthermore, the invention relates to a stem cell active factor freeze-dried powder agent prepared by using the method demonstratively. The method provided by the invention has the beneficial effects as shown in the specification of the invention.

Owner:BOYALIFE

Foam concrete containing recycled inorganic lightweight aggregate and preparation method thereof

InactiveCN105777018AHigh strengthSmall shrinkageSolid waste managementCeramicwareBuilding materialWater reducer

The invention discloses foam concrete containing recycled inorganic lightweight aggregate. The foam concrete is prepared from 20-60 parts of cement, 20-60 parts of slag, 0-50 parts of sand, 0.5-3 parts of a water reducer, 0.1-3 parts of fibers, 25-60 parts of water, foam with the addition amount accounting for 1-80% of the total volume of the foam concrete and the recycled inorganic lightweight aggregate with the addition amount accounting for 1-80% of the total volume of the foam concrete, wherein the recycled inorganic lightweight aggregate is obtained by smashing, screening and grading one or more inorganic heat insulation building materials including but not limited to aerated concrete, foam concrete, foamed ceramic and foamed glass. The invention further discloses a preparation method of the foam concrete. The foam concrete containing the recycled inorganic lightweight aggregate has the advantages of being high in strength, small in shrink, free of formwork collapse, good in fluidity, homogeneous, low in cost and the like and is especially suitable for cast-in-situ lightweight walls, roofs, lightweight cement product elements and the like.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +1

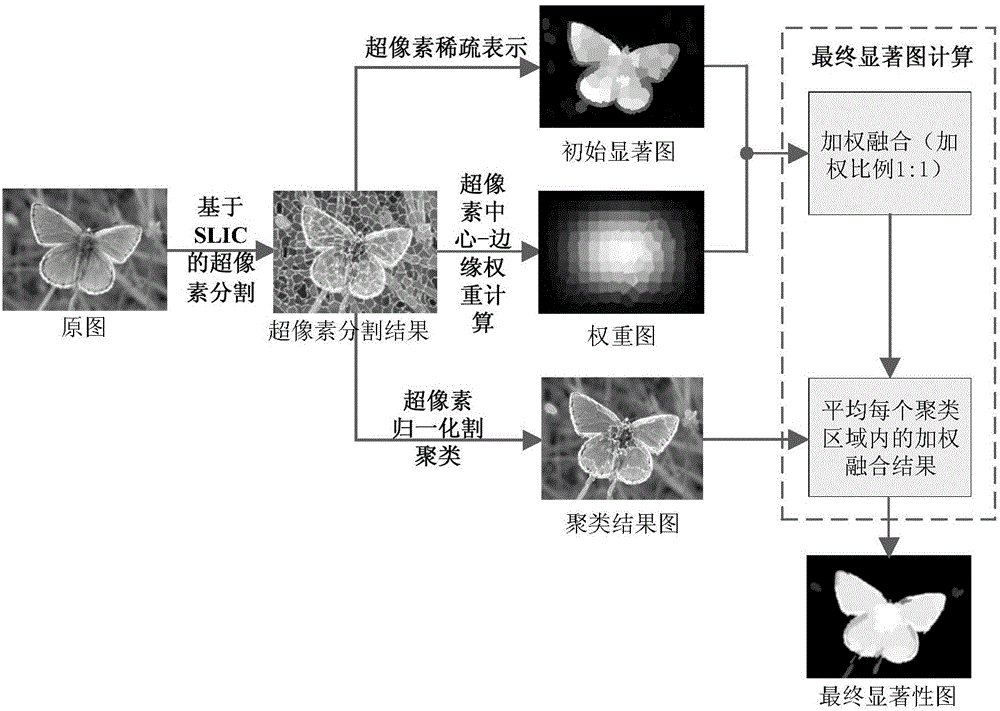

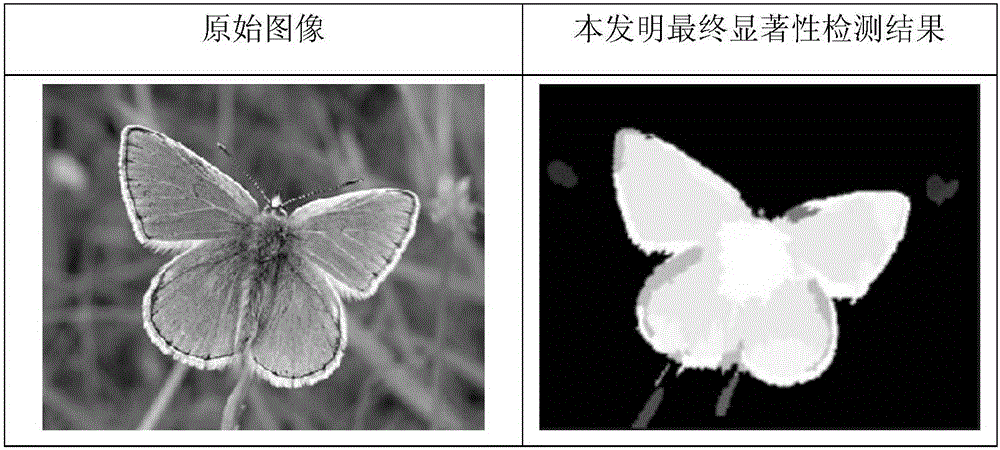

Improved super-pixel-based image significance detection method

ActiveCN106815842AResolve boundary blurResolve inhibitionImage analysisPattern recognitionSaliency map

The present invention discloses an improved super-pixel-based image significance detection method. The method comprises the following steps: firstly, segmenting an original image into super-pixels consistent in color and texture based on the simple and linear iterative clustering super pixel segmentation algorithm; secondly, for the image super-pixel segmentation result, calculating the initial saliency map of the original image based on the sparse representation theory; thirdly, for the image super-pixel segmentation result, calculating the center-edge weight map of the original image based on the center-edge idea; fourthly, for the image super-pixel segmentation result, clustering the super-pixels based on the normalized theory so as to obtain a plurality of clustering areas; fifthly, based on the above result, calculating the final saliency map of the original image. According to the technical scheme of the invention, compared with the traditional super-pixel-based image saliency detection method, the problems, including the fuzzy boundary of a saliency object, the inhibited interior of the saliency object and the like, can be solved. The saliency object can be highlighted more uniformly. Meanwhile, the background is effectively suppressed, so that a better detection result is obtained.

Owner:HOHAI UNIV

Stem cell active factor and lyophilized powder thereof

ActiveCN106344492AHomogeneousIn line with biological characteristicsCosmetic preparationsToilet preparationsGlycineMANNITOL/SORBITOL

The invention relates to a stem cell active factor and lyophilized powder thereof, in particular to a stem cell active factor lyophilized powder on the one hand. The stem cell active factor lyophilized powder comprises a stem cell active factor and a lyophilization protecting agent, and the lyophilization protecting agent is selected from trehalose, mannitol, chitosan, dextran, glycine, arginine and glycine. The invention further relates to a preparation method for preparing the stem cell active factor lyophilized powder. The method has the beneficial effects as described in the specification of the invention.

Owner:BOYALIFE

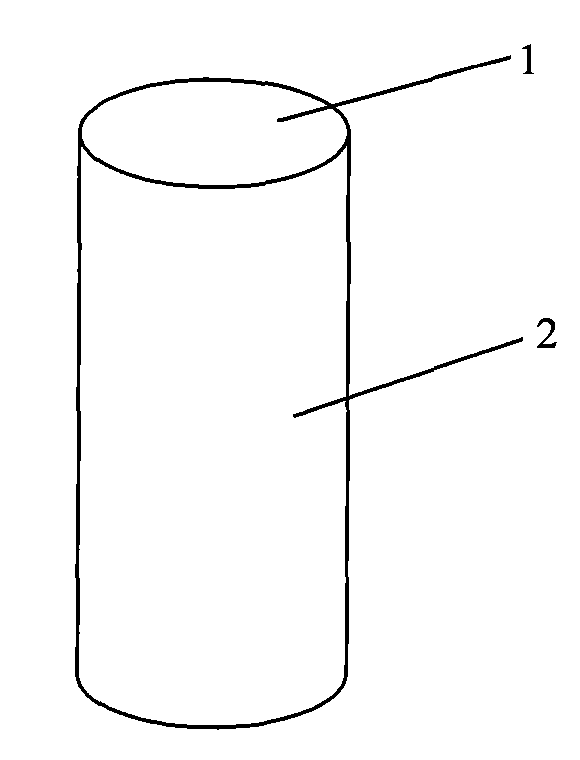

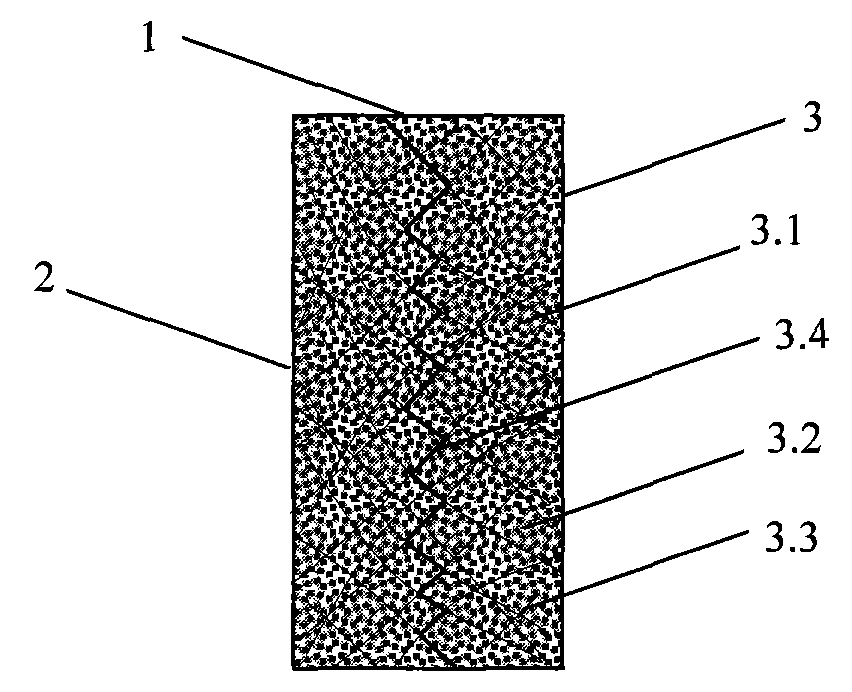

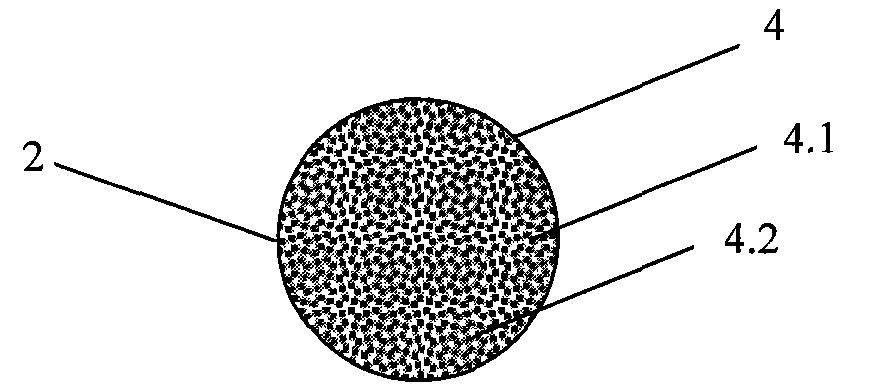

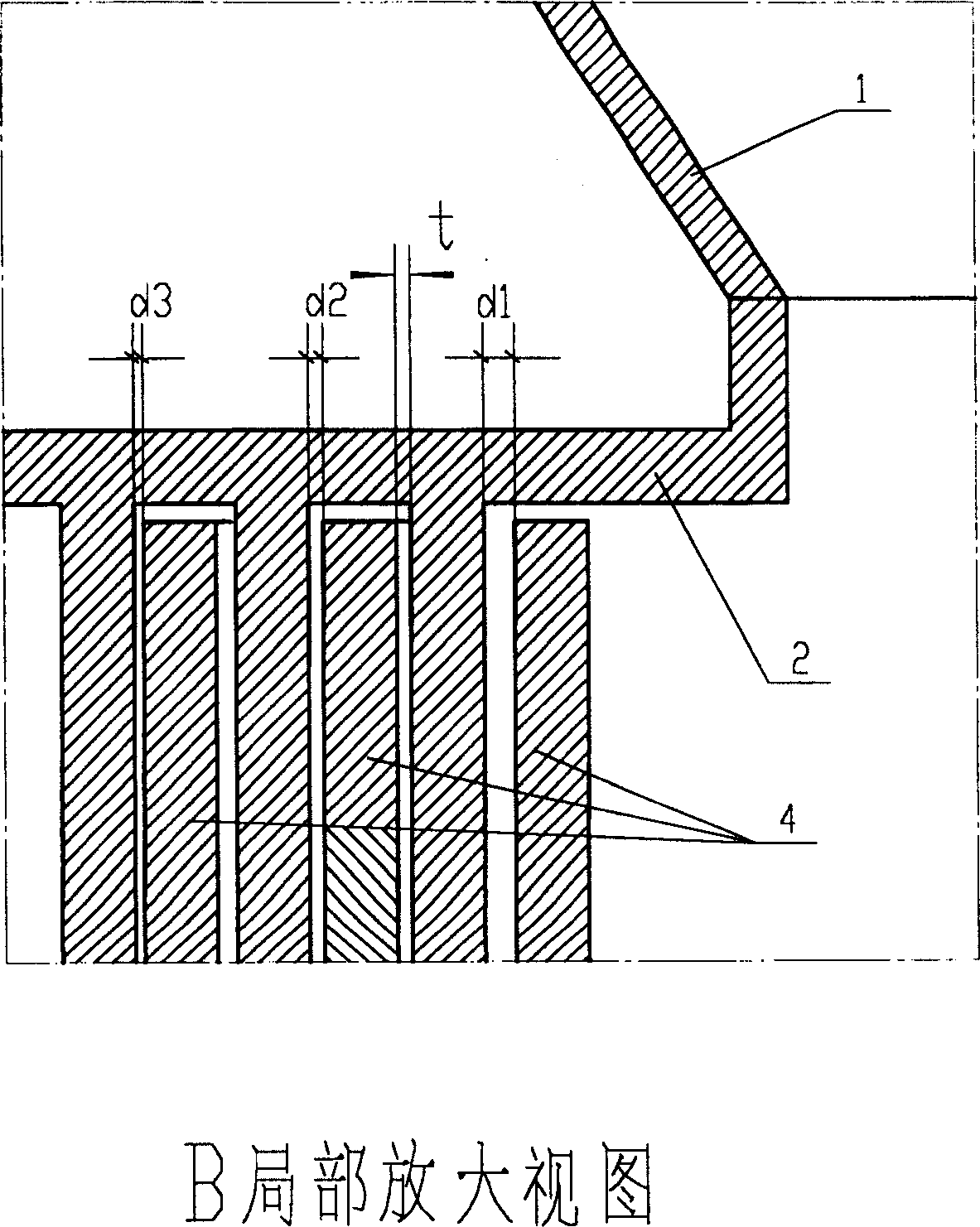

Standard test piece based on calibration permeability test

InactiveCN101587055ASolve the problem of changing permeability coefficientPrecise specification of permeabilitySurface/boundary effectPermeability/surface area analysisHeat resistanceOsmotic coefficient

The invention discloses a standard test piece based on a calibration permeability test. The standard test piece is in the shape of a solid cylinder and composed of a solid framework, gaps and pore canals. The solid framework has a firm structure and stably material properties. The material has high rigidity, good toughness, corrosion resistance, rust resistance, heat resistance and pressure resistance. The gaps are near-spherical, the aperture sizes are uniform, and the apertures are controlled in the range of 1-50 microns, the gaps are uniformly distributed inside the test piece and on surface thereof. The pore canals are intersected and the average pore opening extent of the interconnected pore canals passing through two end faces is controlled in the range of 0.1-5% on the cross section. The invention is detected by permeation for a long time, has constant permeability parameters, high efficiency, high reliability and strong practicality. By using the permeation coefficients of the invention as a reference standard, the invention provides a detection method and tool as reference for global permeability test technique. The standard test piece based on a calibration permeability test is applicable to all permeability tests and in particular to the precision and measuring range of a calibration low-permeability testing method and device.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

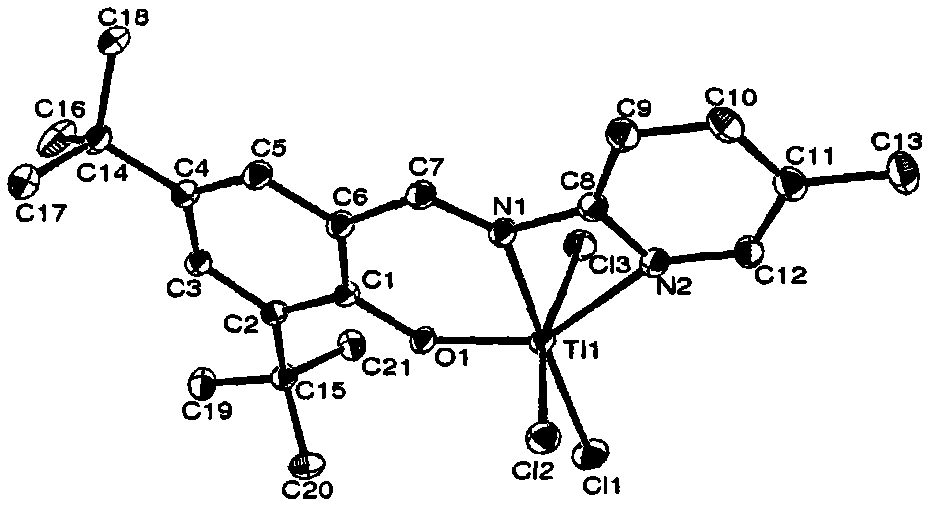

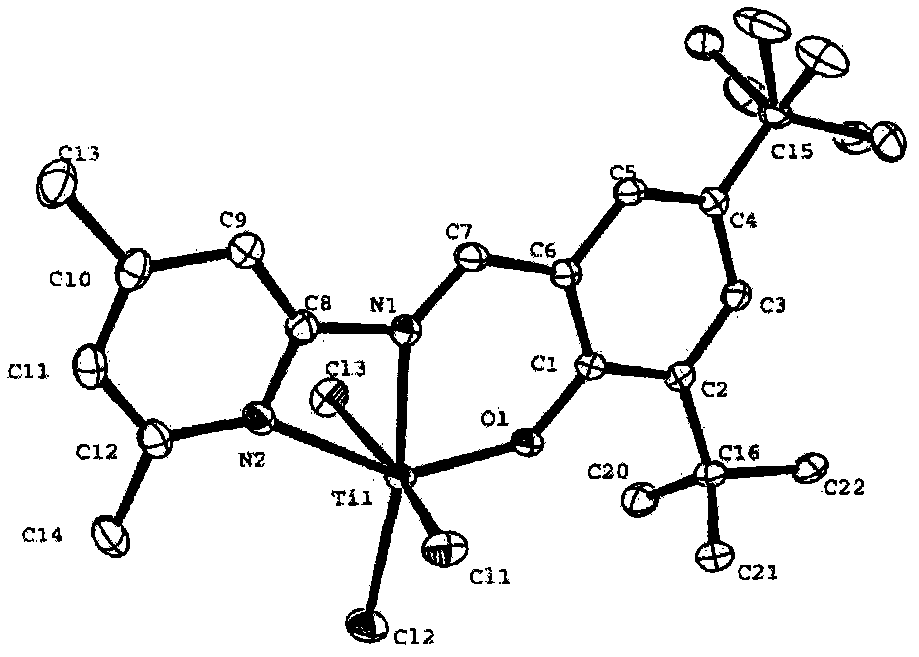

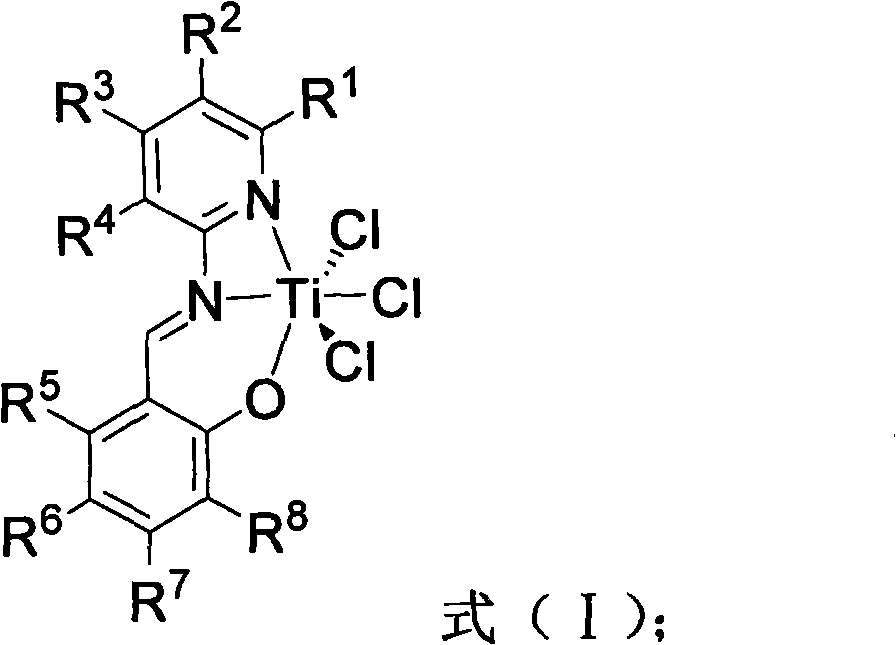

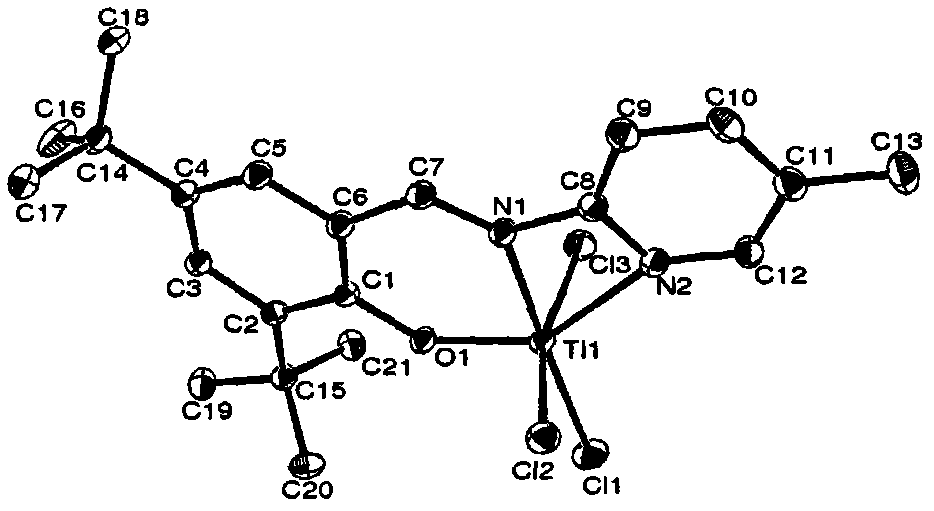

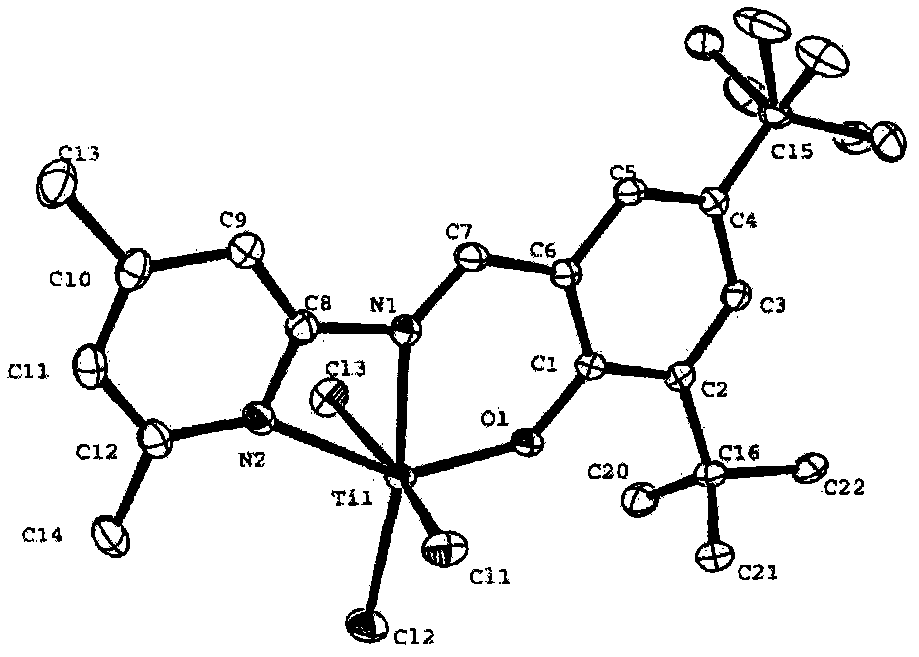

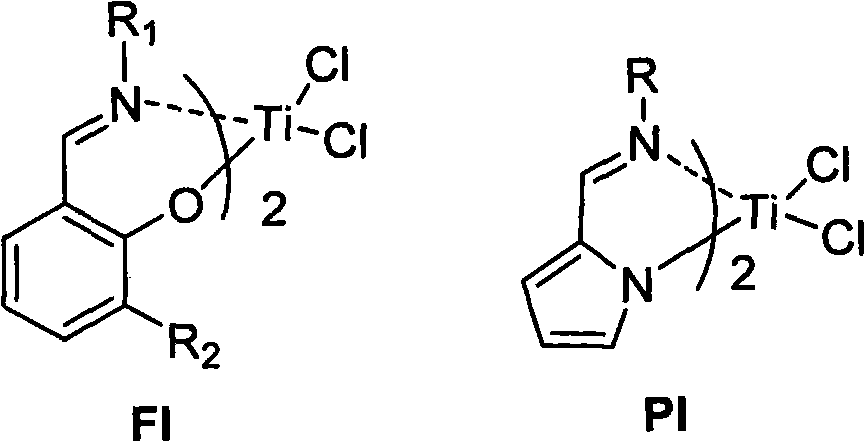

Salicylaldehyde pyridine imido titanium trichloride complex, its preparation method and application thereof, and polymerization method of ethene

ActiveCN102850391AHigh catalytic activityHomogeneousTitanium organic compoundsPolymer scienceAlpha-olefin

The invention discloses a salicylaldehyde pyridine imido titanium trichloride complex, its preparation method and an application thereof, and is characterized in that the complex has a structure as shown in the formula (I), wherein R1-R8 each is hydrogen, a substituted or unsubstituted C1-C8 alkyl group or halogen. The invention also discloses a polymerization method of ethene and an ethene polymer prepared by the method. According to the method, alkene undergoes polymerization in the presence of an organic solvent, a cocatalyst and a main catalyst and under the condition of alkene polymerization, wherein the alkene is ethene or a mixture containing ethene and C4-C10 alpha-alkene. The method is characterized in that the main catalyst is the above salicylaldehyde pyridine imido titanium trichloride complex.

Owner:CHINA PETROLEUM & CHEM CORP

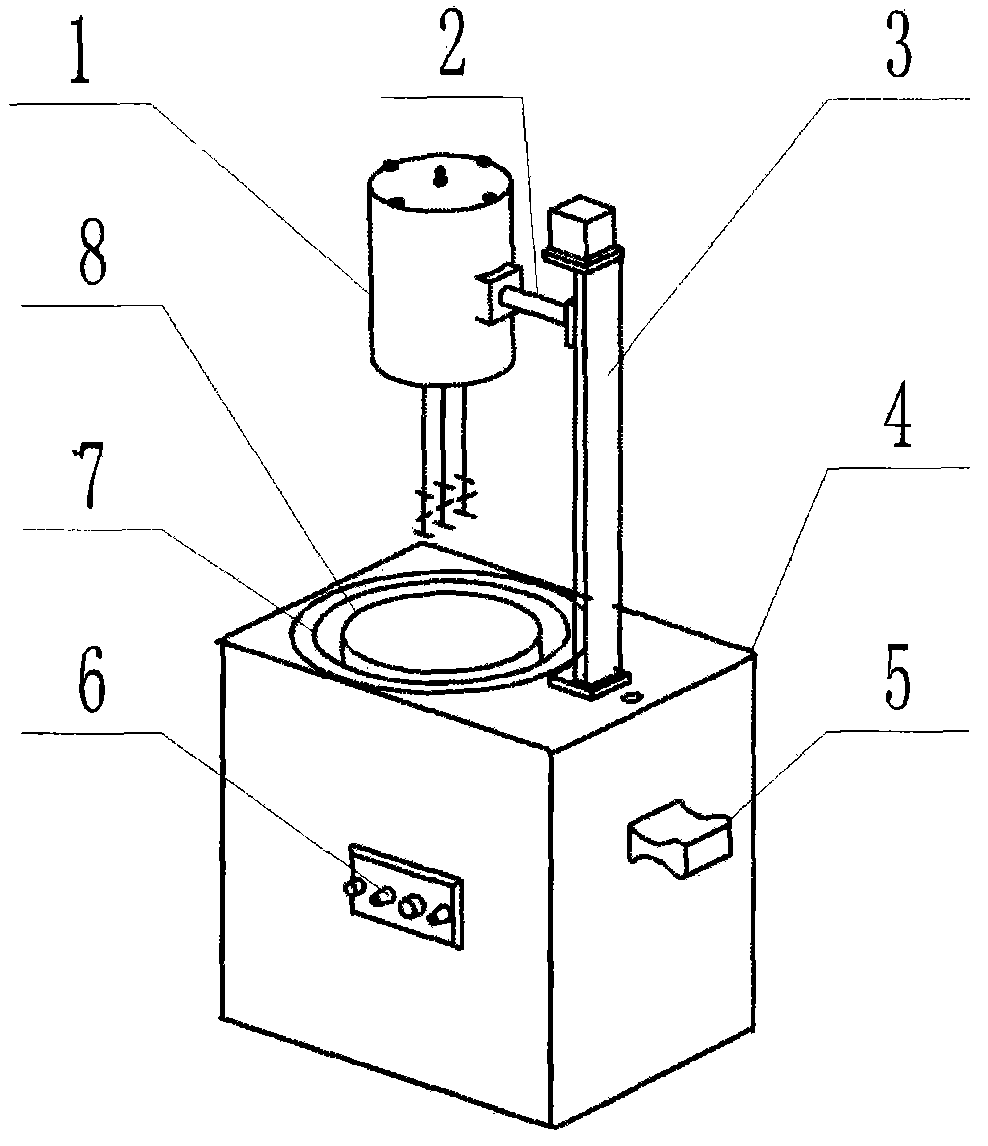

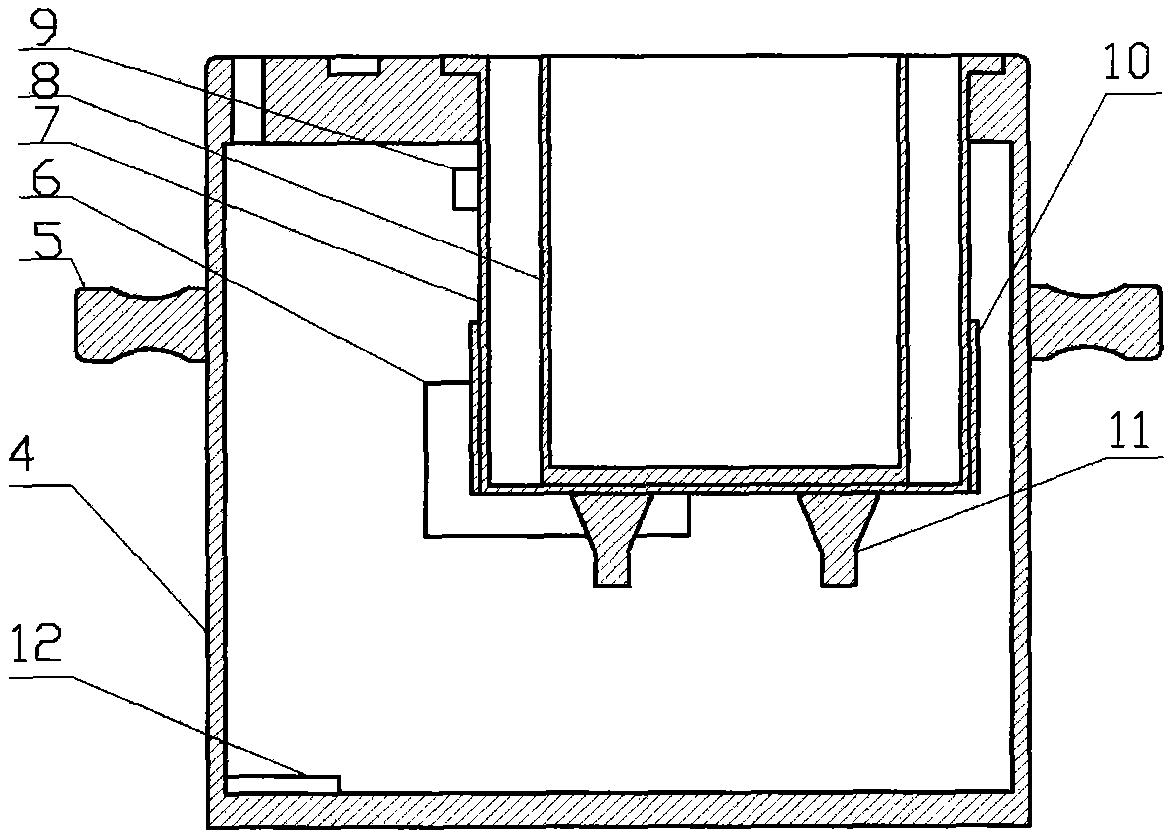

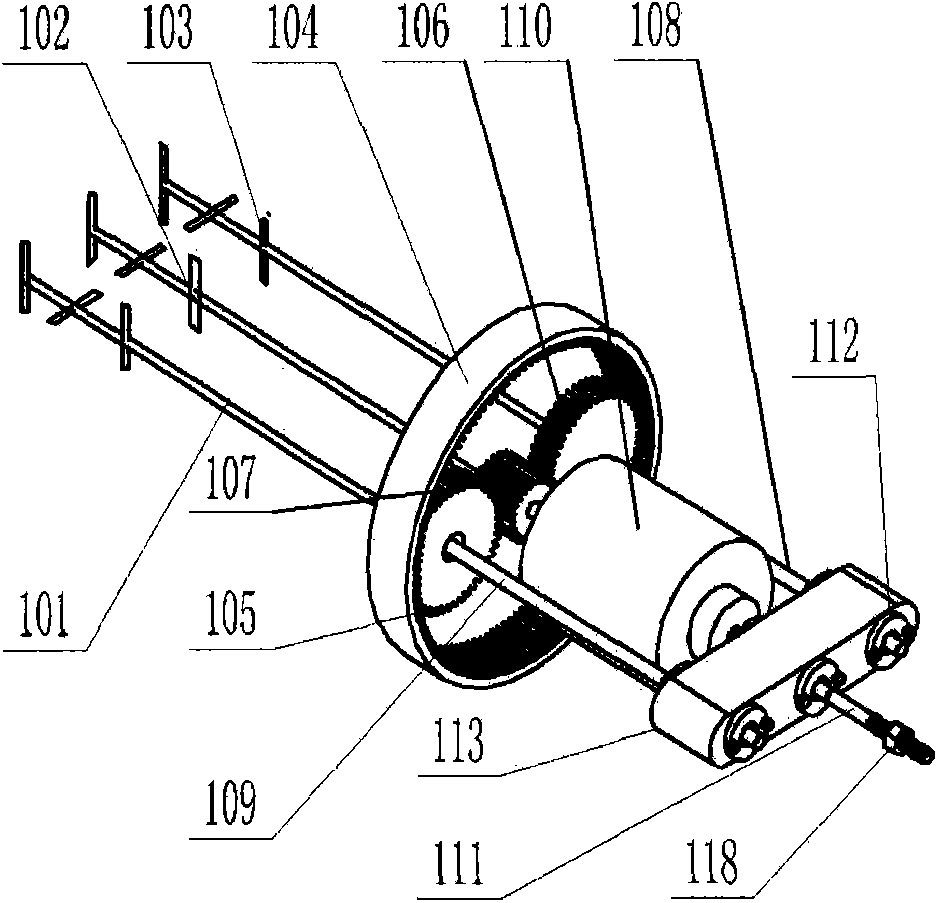

Ultrasonic temperature-controlled reinforced mixer

InactiveCN103623734AWith emulsificationWith decentralizationShaking/oscillating/vibrating mixersMixer accessoriesMicrocontrollerInterference fit

The invention provides a reinforced mixer with ultrasonic dispersion and temperature control functions. The mixer mainly comprises a planetary gear stirring mechanism, a lead screw sliding table, a case mechanism, an inner container, a heating ring, an ultrasonic vibration head, a beaker, a temperature sensor, a one-chip microcomputer and a control panel. An inner gearing big gear wheel of the planetary gear stirring mechanism is connected with a sleeve to form one body through interference fit; a revolution fixing mechanism controls stable rotation of a planetary gear; a driving motor drives running of a planetary gear train to realize a stirring function; a screw joint at the end part of a fixed axle balances torque of the planetary gear train, and the screw joint and a butt nut bear the weight of the planetary gear train and the stirring mechanism together. The side surface of the sleeve is provided with a fixed rod connected with a slide block of the lead screw sliding table; a stepping motor controls rotation of a lead screw so as to realize elevation and falling of the stirring mechanism; the inner container is embedded into the upper surface of a case, the ultrasonic vibration head is adhered on the lower transverse plane of the inner container, and the heating ring is fixed at the lower end of the inner container, thereby achieving heating, ultrasonic dispersion and mechanical reinforced stirring functions.

Owner:ANYANG INST OF TECH

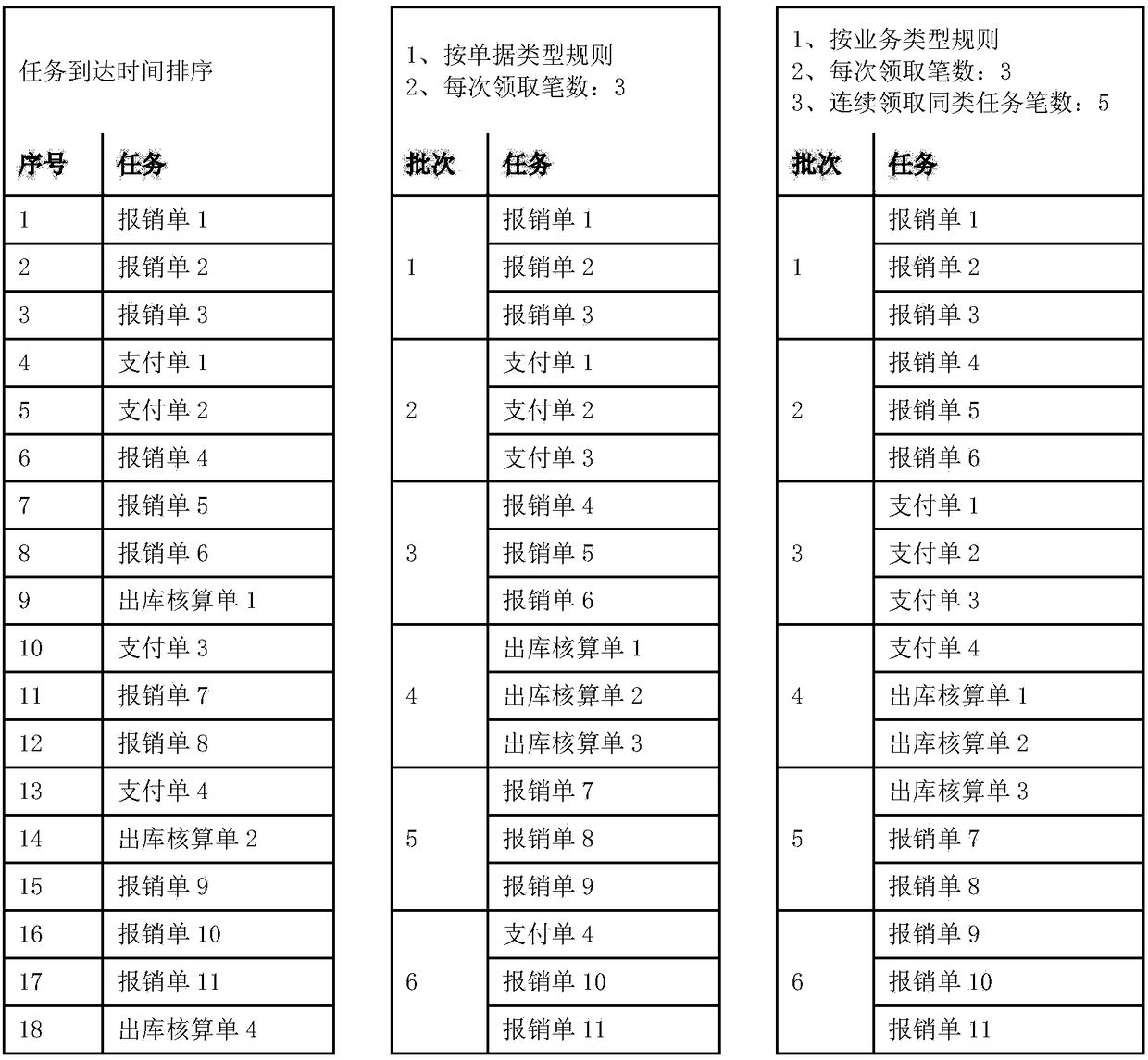

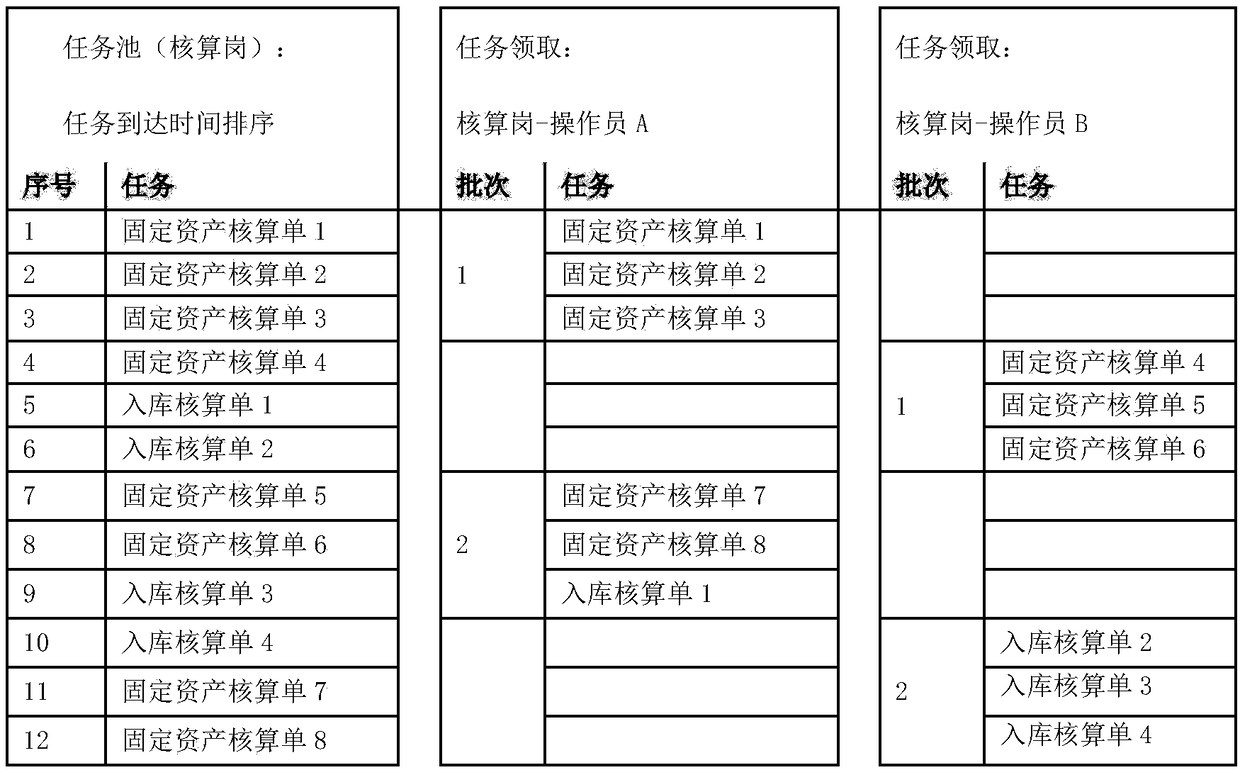

Task allocation method and device

InactiveCN108197778AGuaranteed homogeneityHomogeneousFinanceOffice automationDistribution methodOperating system

The invention relates to a task allocation method and device. The method includes the following steps: an operator log in a system to get a task, whether it is the first time for the operator to log in the system to get a task is judged, if yes, the task is allocated to the operator according to a task allocation rule, otherwise, the task is allocated to the operator according to the following steps: obtaining the type of the task that the operator gets the last time, and judging whether the number of the operator successively getting the tasks of this type reaches a threshold value of tasks of the same property, if not, allocating a task of the same type as that of the task got the last time to the operator, and if yes, allocating the task to the operator according to the task allocationrule; and the abovementioned steps are repeated till allocation of tasks in a task pool is completed. The method provided by the invention can improve efficiency of task processing of the operator, and ensure balanced allocation of the tasks at the same time.

Owner:YGSOFT INC

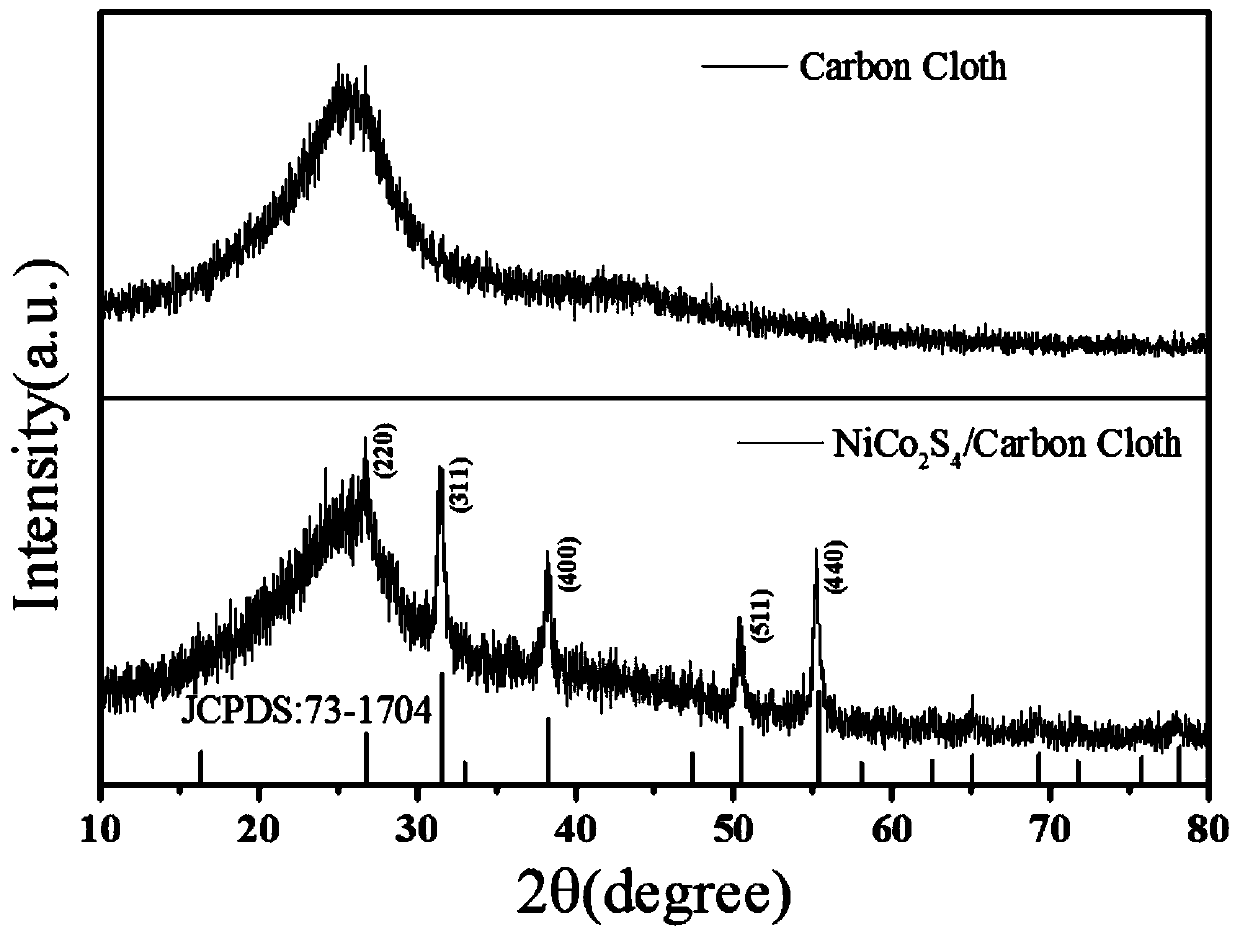

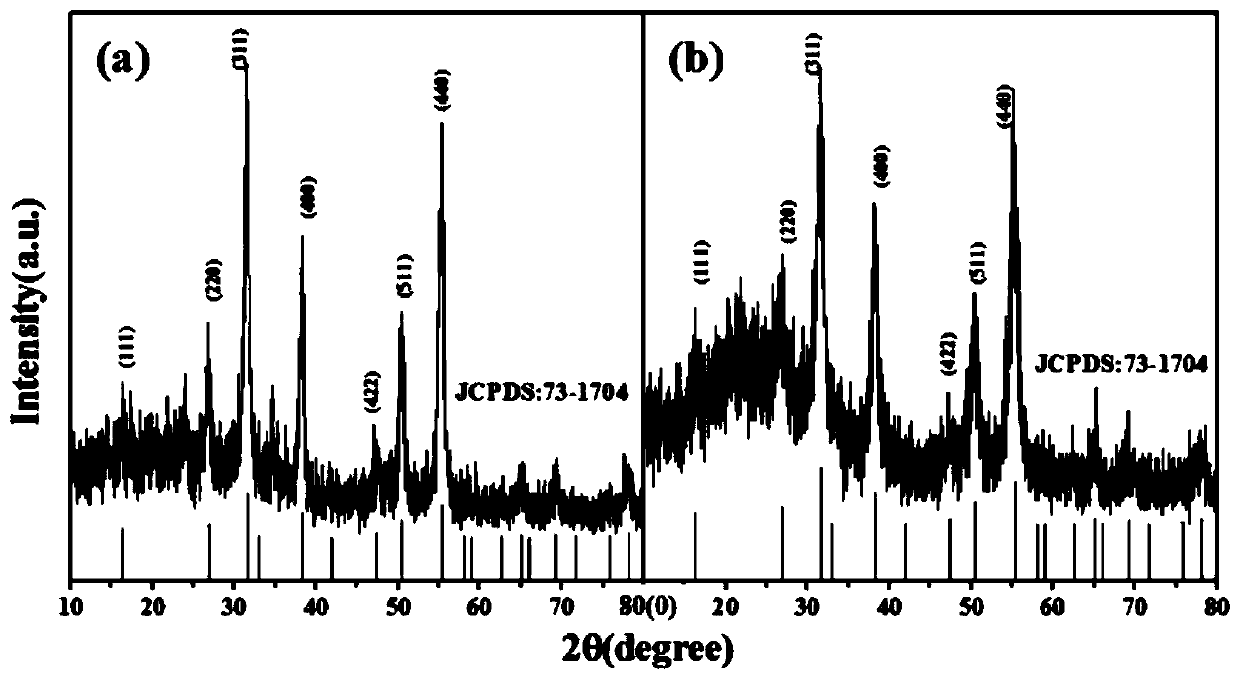

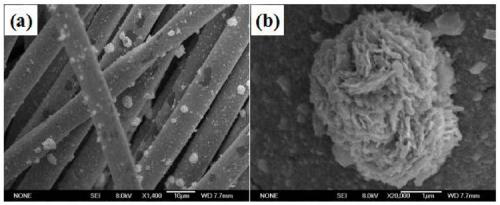

Preparation of bimetallic sulfide with conductive carbon cloth as substrate and application thereof in negative pole of lithium-ion battery

ActiveCN110299510AShape is easy to controlHomogeneousSecondary cellsChemical electrode manufacturingThioureaPhenanthroline

The invention relates to a preparation method for directly growing a bimetallic sulfide on conductive carbon cloth and an application thereof as a negative pole of a lithium-ion battery. The materialis synthesized by a one-step hydrothermal method by taking ammonia water and phenanthroline as double templates, adding nickel nitrate hexahydrate and cobalt nitrate hexahydrate, adding thiourea as asulfur source and using conductive carbon cloth as a substrate. The material can be directly used as a negative pole of a lithium-ion battery without any binder. The material has excellent cycle performance at the current density of 1000mA.g<-1>. The preparation method of the material is simple. A battery assembly process is omitted. Mass production is facilitated.

Owner:青岛鸿硅高沃新材料科技有限公司

Freeze-drying method for preserving cytokine activity

InactiveCN109619090AGuaranteed secretionEasy for long-distance transportationDead animal preservationMolecular biologyFreeze dry

The invention relates to a freeze-drying method for preserving cytokine activity. The method comprises the steps of selecting a stem cell active factor and a cryoprotectant of which the purity is 99%or more, wherein the cryoprotectant is prepared from, 1-10wt.% of mannitol, 1-3wt.% of trehalose, 1-5wt.% of dextran, 1-3wt.% of human albumin, 1-4wt.% of chitosan, 0.1-0.3wt.% of glycine, 3-4wt.% ofglycine and 0.1-0.3wt.% of an ascorbic acid; preparing cytokine freeze-dried powder by using the stem cell active factor and the cryoprotectant. Compared with the prior art, a cell source of the method has homogeneity and conforms to the biological characteristics of stem cells, thereby ensuring the secretion amount of a stem cell-derived active factor and stability of performance; a medium does not contain sensitizing components, and is suitable for various people; a freeze-dried powder preparation provides convenience for long-distance transportation and long-term preservation.

Owner:深圳光彩生命工程技术有限公司

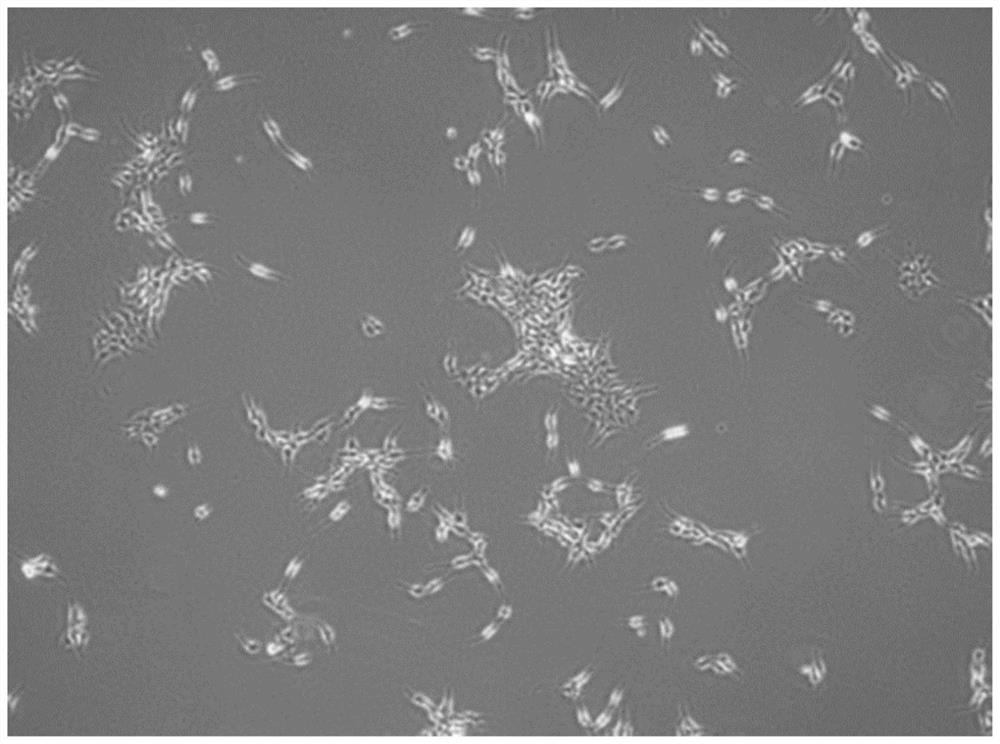

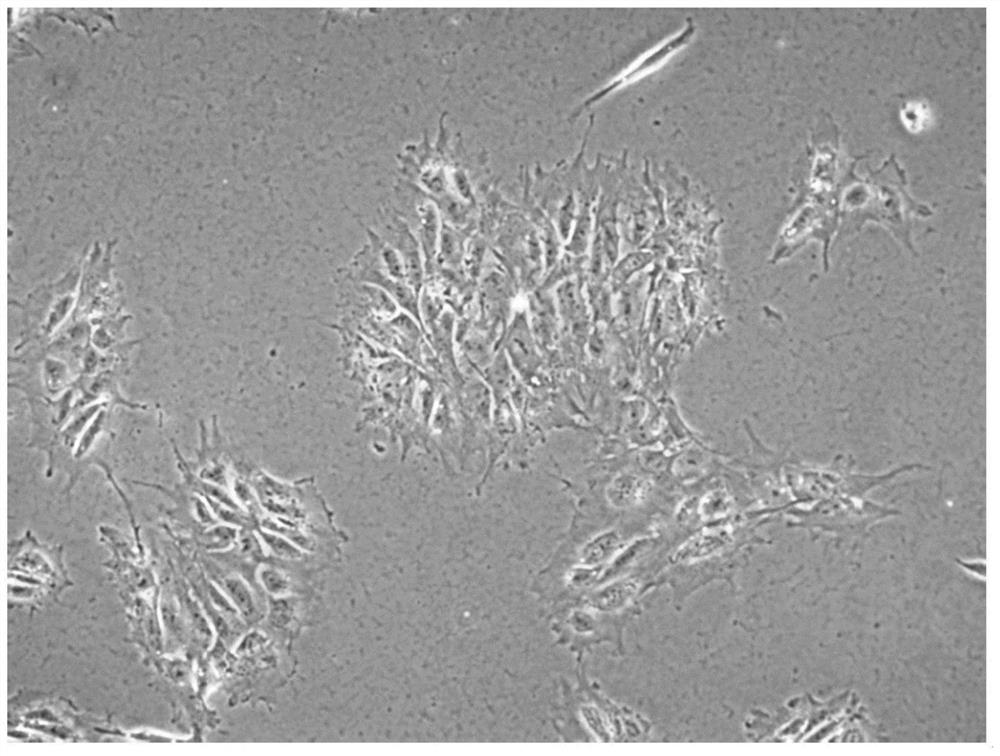

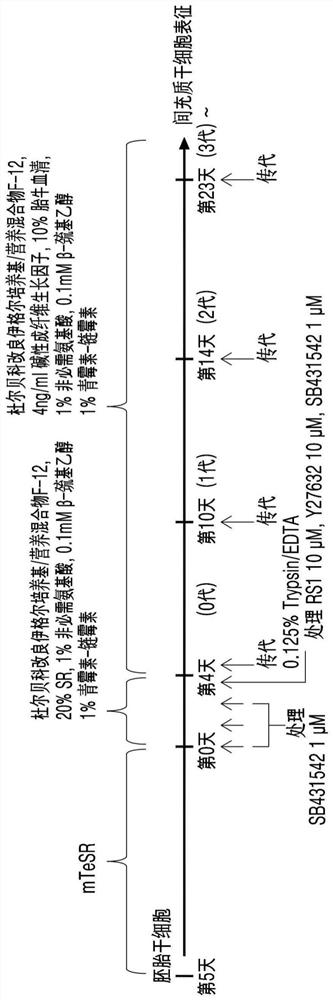

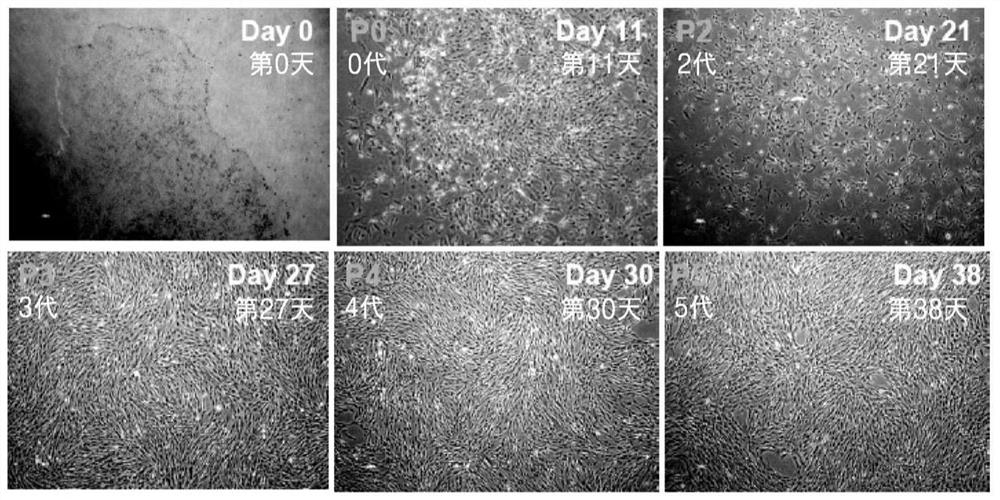

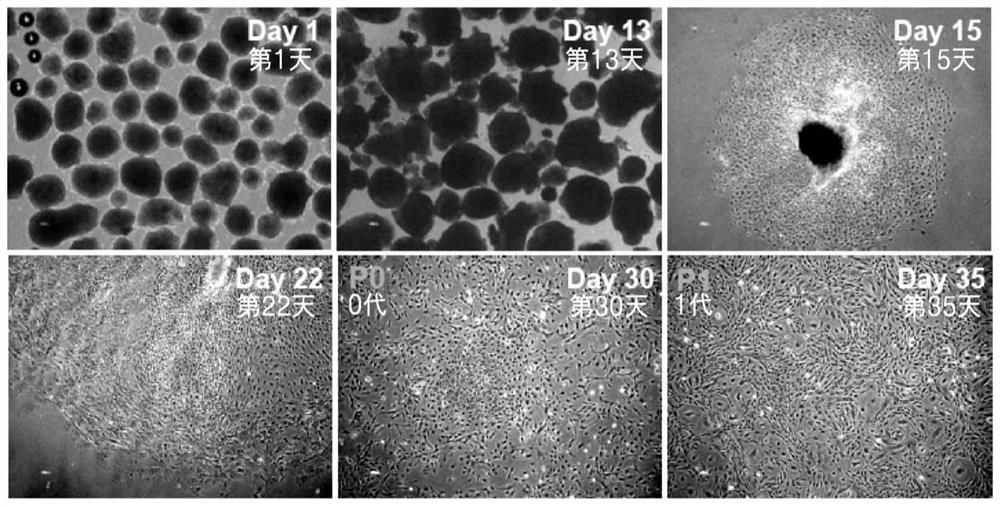

Rapid induced differentiation method of mesenchymal stem cells, kit and application of rapid induced differentiation method

InactiveCN113462642AImprove proliferative abilityEnergeticNervous disorderSkeletal disorderCell activityMesenchymal stem cell proliferation

The invention discloses a rapid induced differentiation method of mesenchymal stem cells, a kit and application thereof. The rapid induced differentiation method of mesenchymal stem cells provided by the invention can be used for preparing enough number of mesenchymal stem cells capable of meeting clinical requirements in a short time at high yield, because there is no step of forming an embryoid body, the preparation process is simple, and the method has the advantages of high differentiation efficiency, convenience in purification and separation and the like. In addition, animal serum and other non-human additives are not involved in the differentiation process, the mesenchymal stem cells are more suitable for clinical requirements, and the mesenchymal stem cells obtained through differentiation are high in multiplication capacity and vigorous in cell activity.

Owner:CHENGNUO REGENERATIVE MEDICINE TECH (ZHUHAI HENGQIN NEW AREA) CO LTD

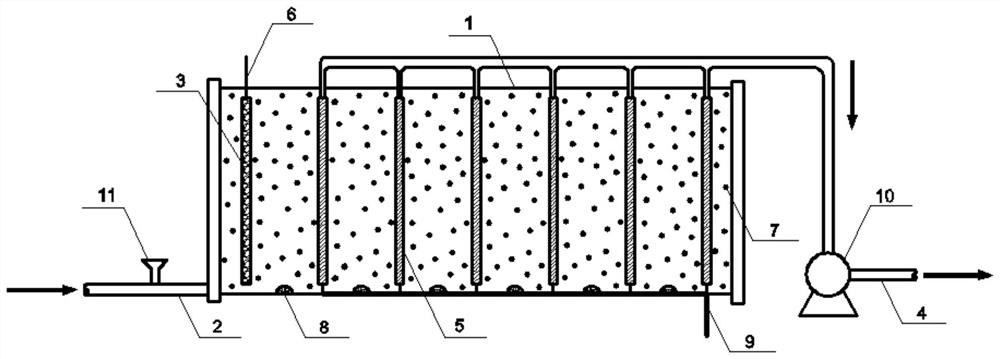

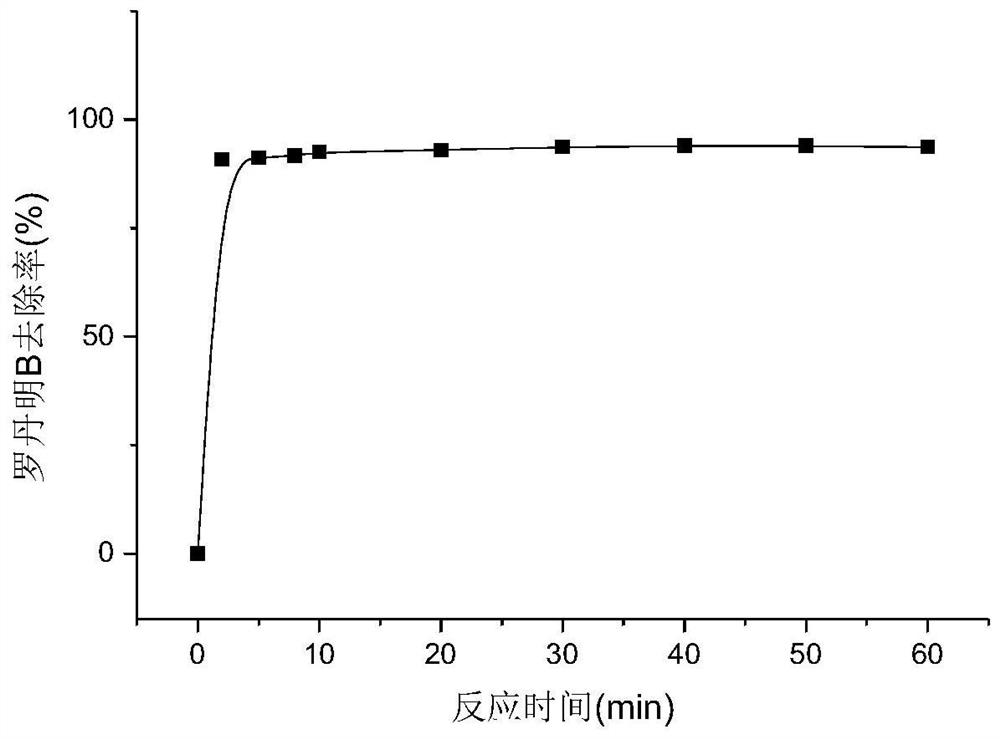

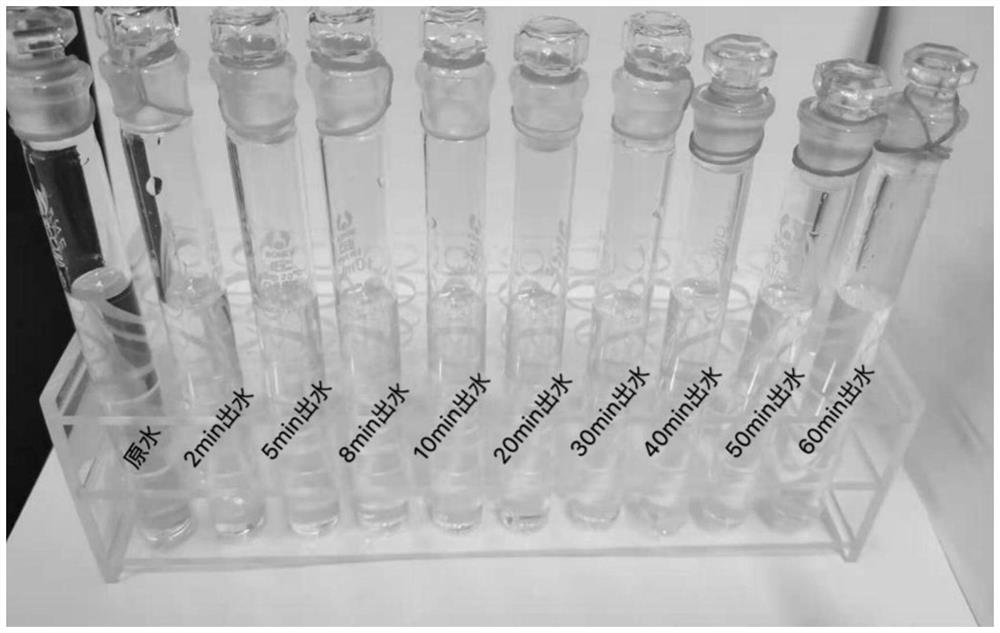

Method for deeply treating refractory pollutants by using conductive filter membrane-heterogeneous Fenton-like water treatment device

PendingCN113735337AShort processEasy to handleWater treatment compoundsWater contaminantsAdvanced oxidation processFiltration

The invention relates to a method for deeply treating refractory pollutants by using a conductive filter membrane-heterogeneous Fenton-like water treatment device. The deep treatment method combines a conductive filter membrane and a heterogeneous Fenton-like oxidation method, takes an electrode plate as an anode, takes the conductive filter membrane as a cathode, and the space between the conductive filter membranes is filled with a carbon material with catalytic performance, so that a reactor can synchronously complete the Fenton-like reaction and the membrane filtration effect, the water treatment process is greatly shortened, and the water treatment effect is improved. The treatment method disclosed by the invention has the advantages of inhibiting the deposition and enrichment of pollutants on the membrane, reducing the use of a catalytic agent in an advanced oxidation process and the discharge of metal ions such as iron and manganese, improving the Fenton-like treatment efficiency, shortening the water treatment flow and improving the water treatment effect of the refractory pollutants.

Owner:SHANDONG UNIV

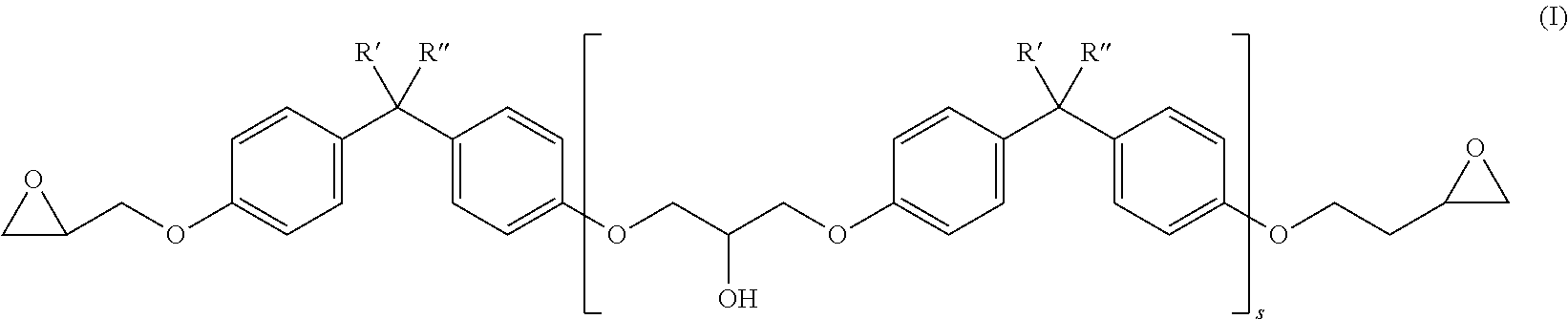

Multi-component composition

InactiveUS20160368822A1Flat surface can be ensuredImprove distributionSolid waste managementEpoxy resin coatingsEpoxyCompressive strength

A multi-component composition is described that includes an epoxy component having at least one reactive epoxy resin, one hardener component that includes at least one hardener for the epoxy resin, one cement component including cement and at least one filler, and also from 0.1% to 1% by weight, based on the total weight of the multi-component composition, of at least one polymeric binder that is solid at 23° C. Addition of the at least one polymeric binder can significantly improve relevant properties of the multi-component composition, examples being more particularly adhesion thereof, compressive strength thereof and shrinkage thereof. Also described, is a process for producing a coated substrate with the aid of the composition described above, and also coated substrates that can be produced by a corresponding process.

Owner:SIKA TECH AG

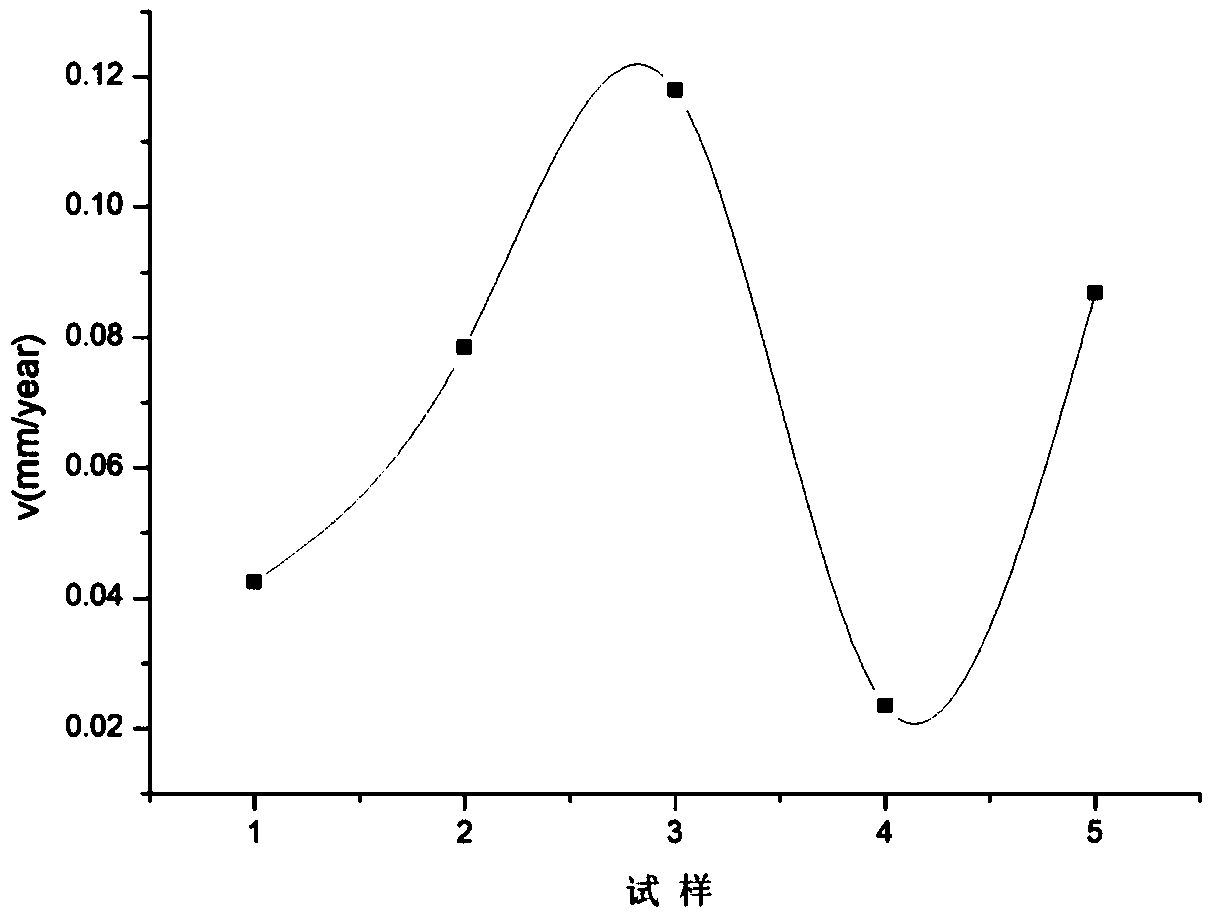

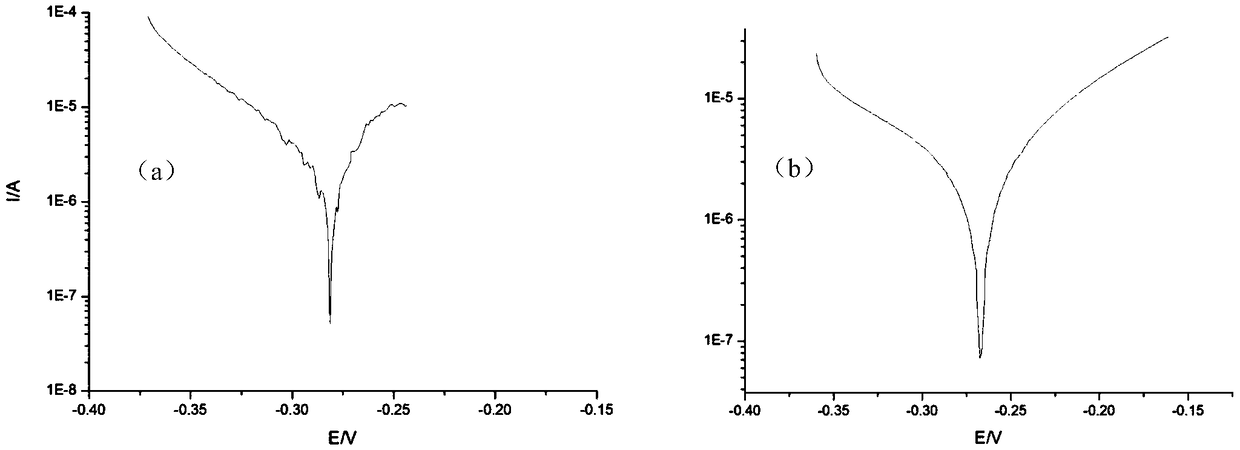

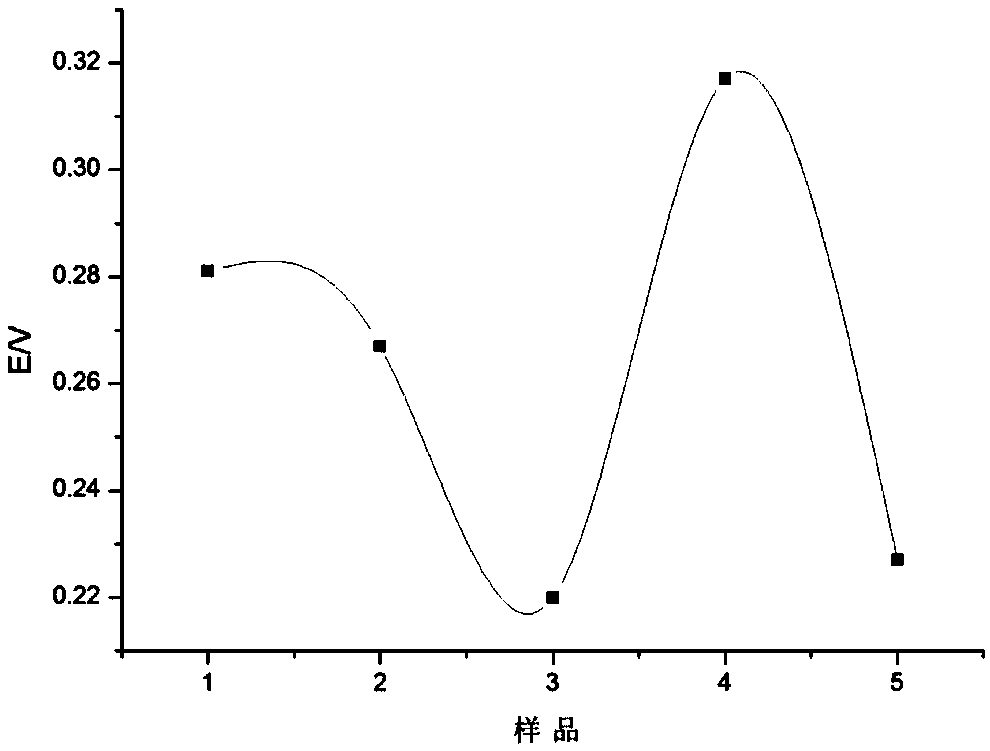

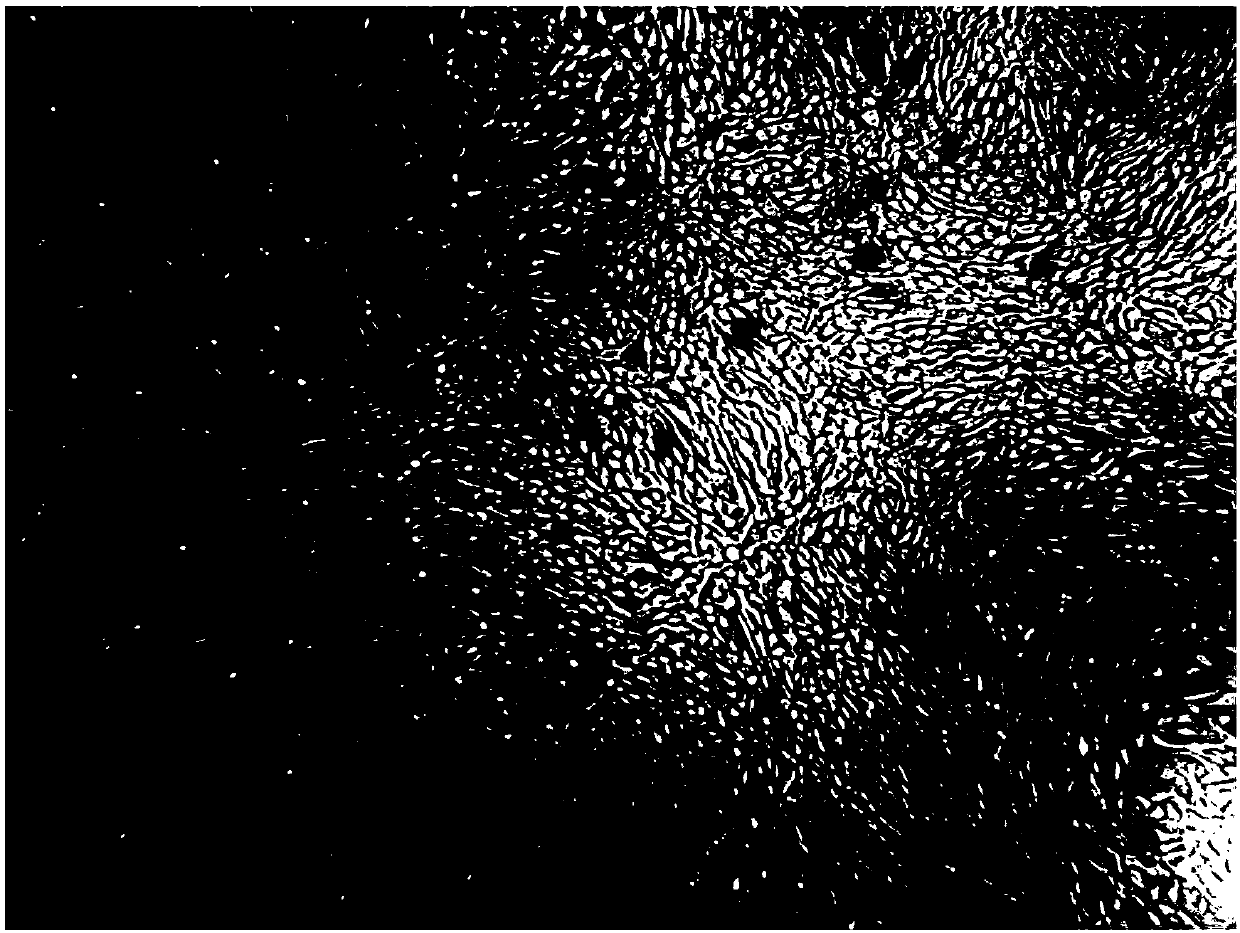

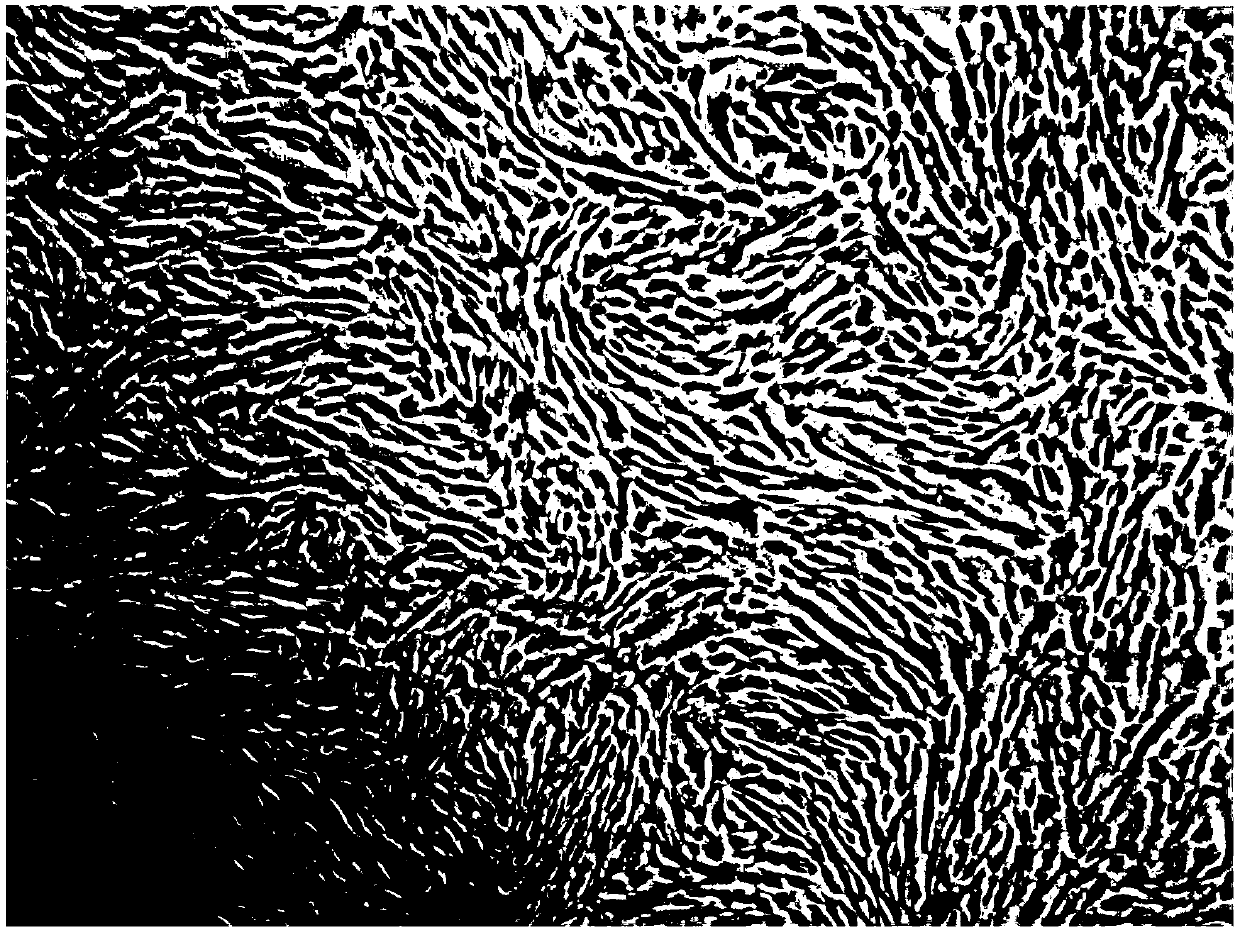

Preparation method of high-corrosion-resistance NiMnInCo magnetic shape memory alloy

The invention relates to a preparation method of a high-corrosion-resistance NiMnInCo magnetic shape memory alloy, and belongs to the technical field of corrosion resistance of intelligent materials and magnetic shape memory alloys. The preparation method of the high-corrosion-resistance NiMnInCo magnetic shape memory alloy comprises the following specific steps: materials are taken according to the atomic percents for uniform mixing and sintering to obtain the high-corrosion-resistance NiMnInCo alloy. The novel NiMnInCo magnetic shape memory alloy is synthesized by adopting a combustion reaction for the first time, so that the thought for application of the high-corrosion-resistance shape memory alloy is widened; and the prepared NiMnInCo magnetic shape memory alloy has the advantage of corrosion resistance.

Owner:DALIAN UNIV

Stem cell active factor and its freeze-dried powder

ActiveCN106344492BHomogeneousIn line with biological characteristicsCosmetic preparationsToilet preparationsGlycineArginine

The invention relates to a stem cell active factor and lyophilized powder thereof, in particular to a stem cell active factor lyophilized powder on the one hand. The stem cell active factor lyophilized powder comprises a stem cell active factor and a lyophilization protecting agent, and the lyophilization protecting agent is selected from trehalose, mannitol, chitosan, dextran, glycine, arginine and glycine. The invention further relates to a preparation method for preparing the stem cell active factor lyophilized powder. The method has the beneficial effects as described in the specification of the invention.

Owner:BOYALIFE

Anti-bacterial, anti-inflammation and anti-oxidizing mung bean alcohol-effect-dispelling nutritional jelly and preparation method thereof

InactiveCN105942352AClear juiceUniform textureNatural extract food ingredientsFood ingredient functionsGrape seedAnti inflammation

The invention discloses anti-bacterial, anti-inflammation and anti-oxidizing mung bean alcohol-effect-dispelling nutritional jelly and a preparation method thereof. The nutritional jelly is composed of the following raw materials including, by weight, 500-550 parts of mung beans, 30-35 parts of malt extract liquid, 15-17 parts of amomum tsao-ko, 20-23 parts of peach gum, 10-12 parts of houttuynia cordata, 23-25 parts of sophora flower honey, 8-9 parts of sophora flavescens, 10-12 parts of flos puerariae, 20-23 parts of lentinan, 23-25 parts of edible gelatin, 30-35 parts of pea seedlings, 10-12 parts of chili leaves, 10-12 parts of peel of oranges, 10-12 parts of rose hips, 2-2.3 parts of an extract of grape seeds, 5-6 parts of locust bean gum, 30-35 parts of lotus root flour, and 23-25 parts of superfine powder of cashew nuts. The nutritional jelly has abundant nutrients, sour-and-sweet moderated taste, gentle and mild color and uniform texture. The effective components are anti-bacterial, anti-inflammation and anti-oxidizing, and have the effects of beautifying and nourishing face, clearing heat and dispelling the effects of alcohol.

Owner:ANHUI JIASHILE FOOD PROCESSING

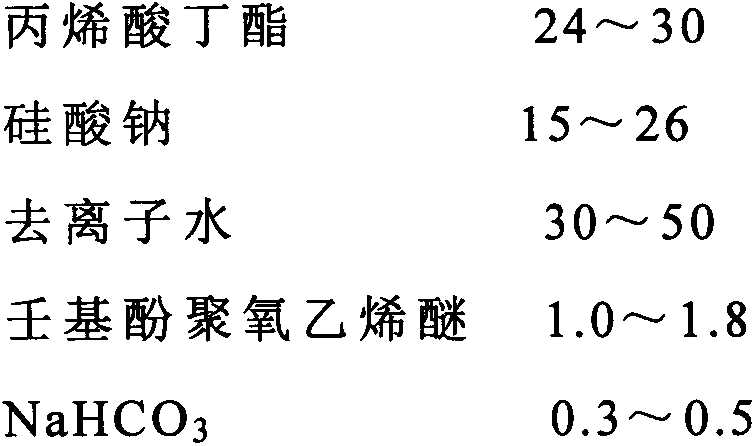

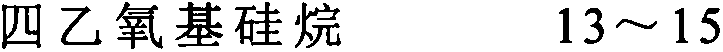

A kind of maintenance method of concrete member

ActiveCN103496037BReasonable compositionGood component compatibilityCeramic shaping apparatusUltimate tensile strengthMoisture

The invention discloses a maintenance method for a concrete member. The maintenance method for the concrete member specifically comprises the steps that in a ventilation environment, after pouring of the concrete member is completed, the surface of the concrete member is coated with a layer of homemade curing agents which have the function of preventing water loss inside concrete; after the curing agents become drier, a layer of homemade moisture preserving mould inhibitor is sprayed to achieve the functions of absorbing air moisture and ensuring the humidity of the surface of the concrete member; last, maintenance of the concrete member is completed as long as another layer of the homemade curing agents is smeared. The maintenance method for the concrete member is good in maintenance effect, environmentally friendly, and low in cost, and the concrete maintained through the maintenance method has the advantages of being high in strength, excellent in durableness, and excellent in anti-mold property, thereby being capable of being applied to the field of modular construction.

Owner:ZHENJIANG ATLANTIC MODULAR SYSTEM LIMITED

Summer-heat-relieving and face-nourishing mung bean alcohol-effect-dispelling nutritional jelly and preparation method thereof

InactiveCN105942357AClear juiceUniform textureNatural extract food ingredientsFood ingredient functionsPropolisFreeze-drying

The invention discloses summer-heat-relieving and face-nourishing mung bean alcohol-effect-dispelling nutritional jelly and a preparation method thereof. The nutritional jelly is composed of the raw materials including, by weight, 500-550 parts of mung beans, 30-35 parts of malt extract liquid, 15-17 parts of amomum tsao-ko, 20-23 parts of peach gum, 50-60 parts of watermelon fermentation raw liquid, 10-12 parts of plantain herb, 13-15 parts of honey-processed pericarpium citri reticulatae, 20-23 parts of collagen protein, 20-23 parts of edible gelatin, 25-30 parts of molasses, 13-15 parts of white tea, 10-12 parts of flos panax notoginseng, 23-26 parts of freeze-dried powder of juice of lily, 15-18 parts of rice vinegar, 10-12 parts of stevia rebaudiana, 5-6 parts of propolis, and 9-11 parts of tangerine peel oil. The nutritional jelly has abundant nutrients, gentle color, uniform texture and comfortable mouth feel. The effective components have the effects of relieving summer heat, nourishing face, clearing heat, nourishing stomach, moistening lung and dispelling the effects of alcohol.

Owner:ANHUI JIASHILE FOOD PROCESSING

Blood-nourishing, qi-tonifying and heat-clearing mung bean alcohol-effect-dispelling nutritional jelly and preparation method thereof

InactiveCN105942376AClear juiceUniform textureFood ingredient as clouding agentNatural extract food ingredientsAlcoholAmomum tsao-ko

The invention discloses blood-nourishing, qi-tonifying and heat-clearing mung bean alcohol-effect-dispelling nutritional jelly and a preparation method thereof. The nutritional jelly is composed of the following raw materials including, by weight, 500-550 parts of mung beans, 30-35 parts of malt extract liquid, 15-17 parts of amomum tsao-ko, 20-23 parts of peach gum, 10-12 parts of green skin of chestnuts, 10-12 parts of superfine powder of vanilla, 5-6 parts of colla corii asini, 10-12 parts of scorched malt superfine powder, 30-35 parts of raw juice of lily, 30-35 parts of freeze-dried powder of fructus hippophae, 15-18 parts of edible gelatin powder, 15-18 parts of concentrated juice of cornus officinalis, 10-12 parts of avocado, 13-15 parts of preserved hawthorns, 10-12 parts of rice vinegar and 18-20 parts of rock candy. The nutritional jelly has various nutrients, attractive color, crystal-like appearance and uniform texture. The effective components have the effects of nourishing blood, tonifying qi, clearing heat and resolving phlegm, promoting appetite, dispelling the effect of alcohol and improving immunity.

Owner:ANHUI JIASHILE FOOD PROCESSING

Appetite-improving and face-nourishing mung bean alcohol-effect-dispelling nutritional jelly and preparation method thereof

InactiveCN105942380AClear juiceUniform textureFood ingredient as mouthfeel improving agentDioscorea polystachyaNutrient

The invention discloses appetite-improving and face-nourishing mung bean alcohol-effect-dispelling nutritional jelly and a preparation method thereof. The nutritional jelly is composed of the raw materials including, by weight, 500-550 parts of mung bean, 30-35 parts of malt extract liquid, 15-17 parts of amomum tsao-ko, 25-30 parts of peach gum, 5-6 parts of volatile oil of purple perilla, 15-18 parts of green persimmon juice, 20-23 parts of sugar-pickled Chinese yam, 50-60 parts of yogurt, 30-35 parts of edible pectin, 20-23 parts of sophora flower honey, 13-15 parts of ginger candy, 15-18 parts of chrysanthemum freeze-dried powder, 20-23 parts of candied wax gourd, 13-15 parts of rice vinegar, 10-12 parts of superfine powder of dried small shrimps, 20-23 parts of waxberries, and 10-12 parts of broadleaf holly leaves. The nutritional jelly has abundant nutrients, has a full-round appearance and attractive color, and has an ice-cool mouth feel and uniform texture. The effective components have the effects of improving appetite, nourishing the face, resisting senility, dispelling the effect of alcohol, promoting urination, dispelling swelling and reducing fire.

Owner:ANHUI JIASHILE FOOD PROCESSING

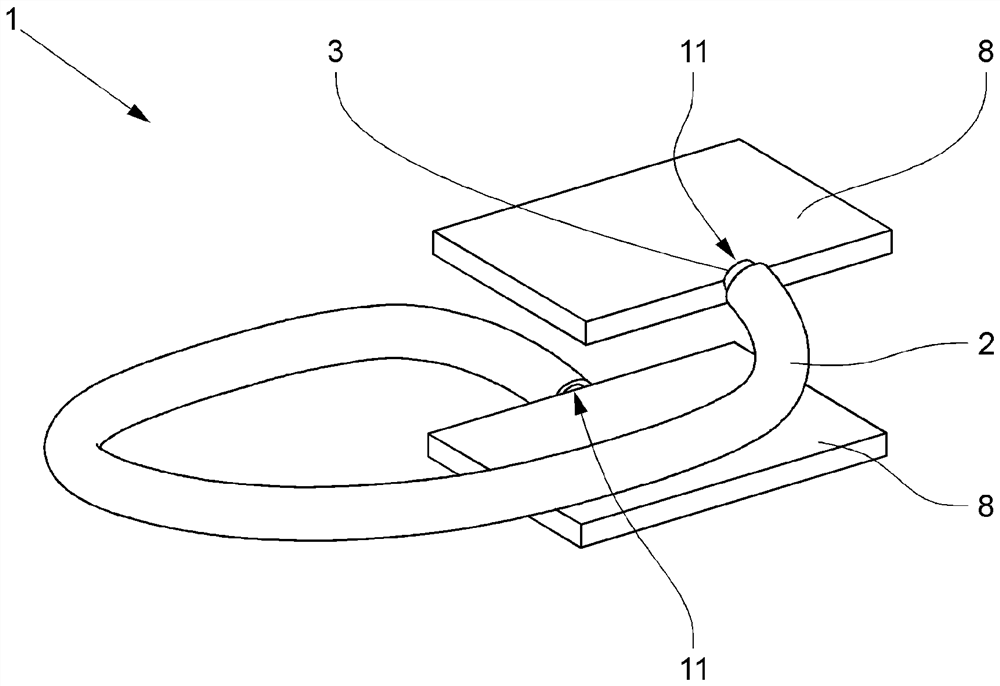

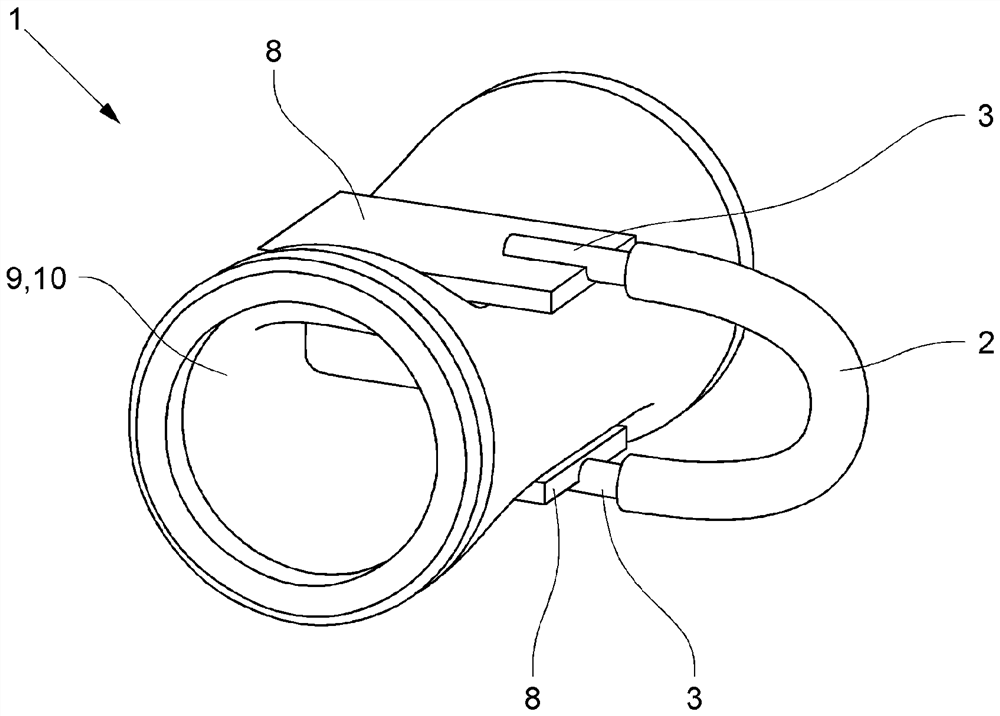

Magnetic circuit device for a magnetic-inductive flow meter and method for manufacturing a magnetic circuit device

PendingCN113720405AHomogeneousHas a magnetic field strengthElectromagnets without armaturesTransformers/inductances coils/windings/connectionsEngineeringMechanical engineering

The invention relates to a magnetic circuit device (1) for a magnetic-inductive flowmeter, having a coil (2) that has a coil core (3). The magnetic circuit device (1) enables an increased range of application, in that it can be flexibly adapted to the geometries of the respective magnetic flow meter due to the fact that the coil core (3) is designed to be flexible in such a way that the coil (2) can be bent from a first shape into a second shape. In addition, a method (100) for manufacturing such a magnetic circuit device (1) involves the steps of provisioning, winding, heating, connecting, bending and fixing of the coil.

Owner:KRONE GMBH

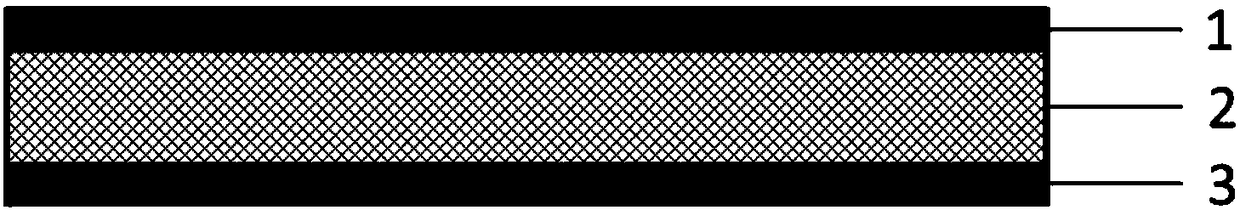

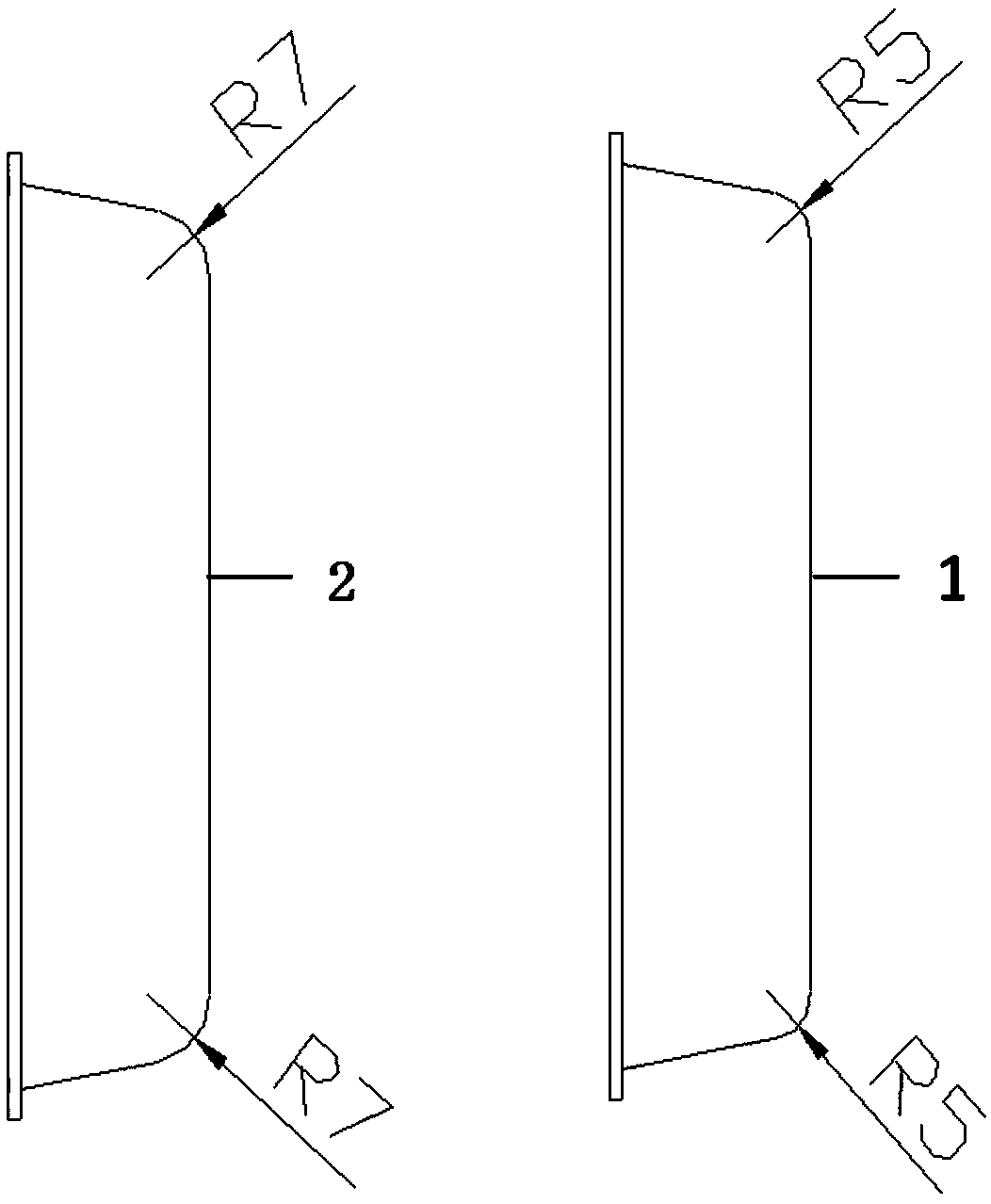

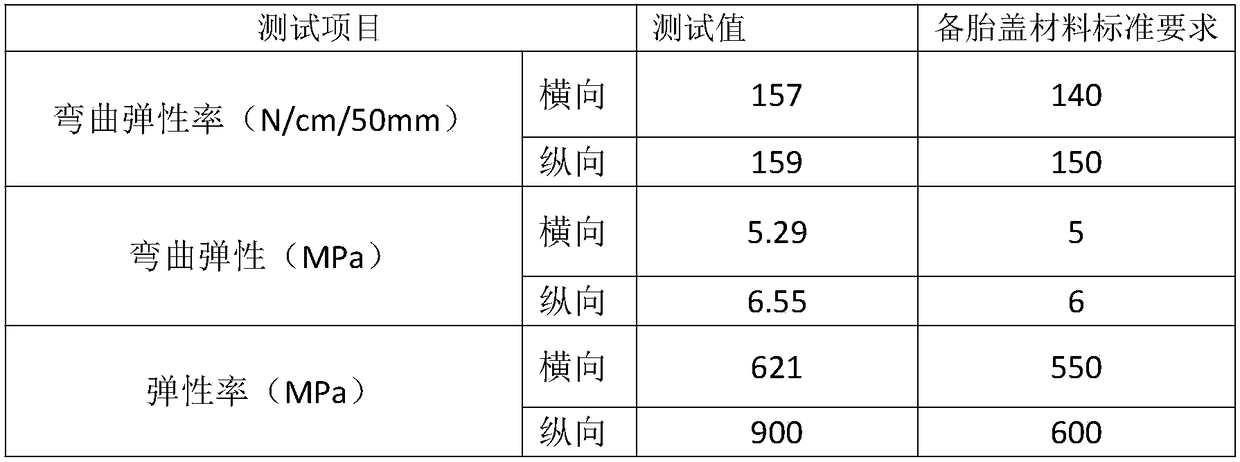

A Lightweight and Low Cost Impact Resistant Laminated Prepreg Composite Sheet

ActiveCN106427133BImprove adhesionSmooth skinSynthetic resin layered productsGlass/slag layered productsGlass fiberComposite plate

The invention discloses a lightweight, low-cost and impact-resistant laminated prepreg composite board. The composite board is of a sandwich structure compounded by a prepreg upper surface, a functional core material and a prepreg lower surface. Chopped glass fiber reinforced thermoplastic resin for the laminated prepreg composite board disclosed by the invention is smooth in surface and strong in bonding force; the laminated prepreg composite board disclosed by the invention can be taken as the surface of any material, has an obvious enhancement effect and can also be separately used as a board. The laminated prepreg composite board disclosed by the invention is simple in process, low in equipment investment and less in process; compared with a thermosetting fiber reinforced material, the laminated prepreg composite board has the characteristic of thermal plasticity, can be molded for multiple times and is granulated and recycled after being crushed.

Owner:浙江华江科技股份有限公司

Spirit-refreshing, face-nourishing and stomach-nourishing mung bean alcohol-effect-dispelling nutritional jelly and preparation method thereof

InactiveCN105942358AClear juiceUniform textureFood ingredient as thickening agentNatural extract food ingredientsBiotechnologyThirst

The invention discloses spirit-refreshing, face-nourishing and stomach-nourishing mung bean alcohol-effect-dispelling nutritional jelly and a preparation method thereof. The nutritional jelly is composed of the raw materials including, by weight, 500-550 parts of mung beans, 30-35 parts of malt extract liquid, 15-17 parts of amomum tsao-ko, 30-35 parts of peach gum, 10-12 parts of lemon peel, 10-12 parts of hazel nuts, 13-15 parts of liquor-processed honeysuckles, 30-35 parts of fish skin collagen protein, 25-30 parts of gelatin, 13-15 parts of black date gum, 30-35 parts of honey-pickled cherries, 1-1.2 parts of ginger oil, 23-25 parts of lotus root flour, 10-12 parts of arctium lappa, 1-1.2 parts of pearl powder, 20-23 parts of vinegar-processed fructus lycii, and 5-6 parts of extract of fetus of cervn selapnus. The effective components have the effects of refreshing spirit, nourishing face, resisting senility, nourishing stomach, eliminating inflammation, relieving thirst and dispelling the effects of alcohol.

Owner:ANHUI JIASHILE FOOD PROCESSING

Mung beans nutritive parfait capable of protecting tooth, nourishing stomach and dispelling effects of alcohol as well as preparation method thereof

InactiveCN105962222AClear juiceUniform textureNatural extract food ingredientsFood ingredient functionsFreeze-dryingBULK ACTIVE INGREDIENT

The invention discloses a mung beans nutritive parfait capable of protecting tooth, nourishing stomach and dispelling effects of alcohol as well as a preparation method thereof. The mung beans nutritive parfait comprises the following raw materials in parts by weight: 500-550 parts of mung beans, 30-35 parts of a malt extract, 15-17 parts of tsaoko fruit, 20-23 parts of peach gum, 20-23 parts of xylitol, 8-9 parts of ginger leaves, 18-20 parts of coffee bean, 25-30 parts of longan honey, 30-35 parts of cucumber concentrated juice, 15-18 parts of edible gelatin, 13-15 parts of Korean pine juice, 30-35 parts of raspberry fruit freeze-dried powder, 20-23 parts of Chinese yam freeze-dried powder, 10-12 parts of pseudo-ginseng processed with wine, 10-12 parts of licorice, 10-12 parts of loquat fruit, 18-20 parts of rock sugar, and 50-60 parts of coconut milk. According to the mung beans nutritive parfait, the active ingredients have functions of protecting tooth, nourishing stomach, clearing internal heat, promoting dieresis, and dispelling effects of alcohol.

Owner:ANHUI JIASHILE FOOD PROCESSING

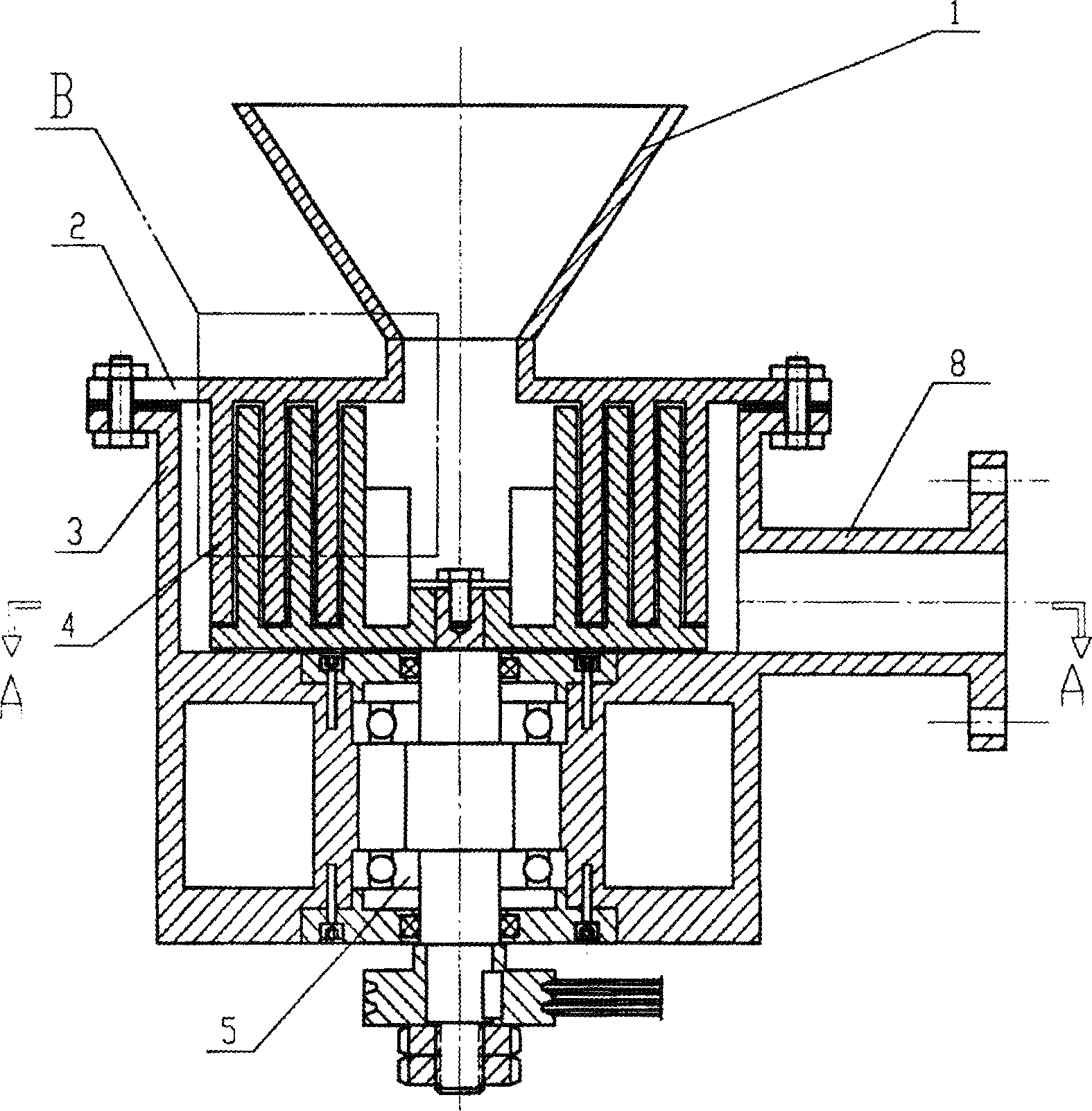

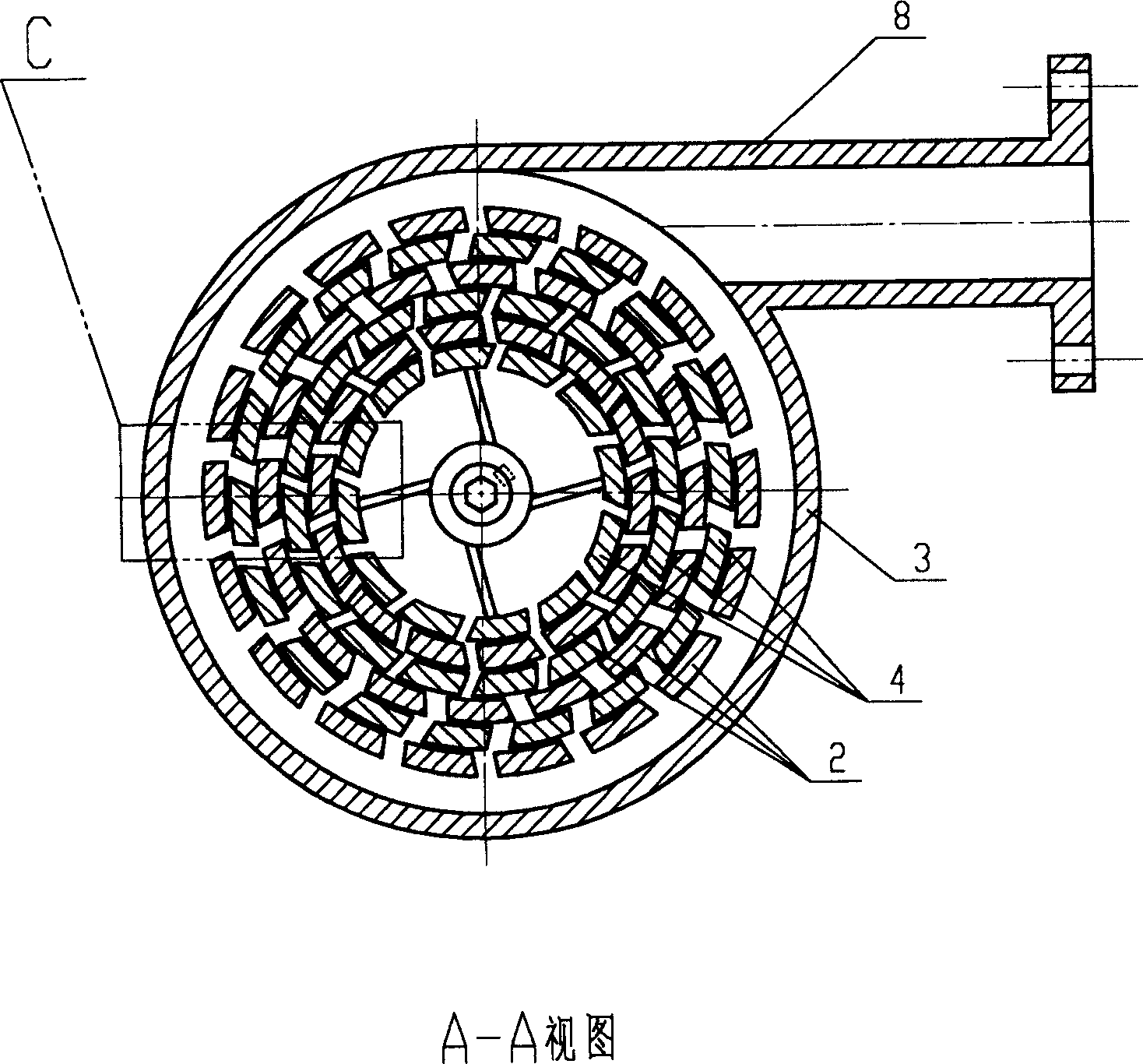

Fluid continuous mixing device

The continuous fluid mixer includes the following members: inlet pipe, stator, casing, mixing rotor, driver and material outlet, and its stator, casing and mixing rotor are set coaxially. Each of the stator and the mixing rotor includes 2-20 layers of teeth in different diameters crossly arranged radially, and each of stator layers and rotor layers has 6-40 teeth. The angle between adjacent rotor teeth and stator teeth decreases gradually with the increasing stator layer and rotor layer diameters. The mixer can on-line mix continuously in high mixing efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Salicylaldehyde pyridine imine titanium trichloride complex, its preparation method and application, and the method of ethylene polymerization reaction

ActiveCN102850391BHigh catalytic activityHomogeneousTitanium organic compoundsSalicylaldehydePolymer science

Owner:CHINA PETROLEUM & CHEM CORP

Diuretic and detoxifying calcium-added mung bean alcohol-effect-dispelling nutritional jelly and preparation method thereof

InactiveCN105942361AClear juiceUniform textureFood ingredient as thickening agentLipidic food ingredientsAmomum tsao-koAlcohol

The invention discloses diuretic and detoxifying calcium-added mung bean alcohol-effect-dispelling nutritional jelly and a preparation method thereof. The nutritional jelly is composed of the raw materials including, by weight, 500-550 parts of mung beans, 30-35 parts of malt extract liquid, 15-17 parts of amomum tsao-ko, 20-23 parts of peach gum, 20-23 parts of fresh lotus leaf juice, 10-12 parts of alpinia katsumadai, 10-12 parts of hawthorn seeds, 20-23 parts of apple vinegar, 9-11 parts of superfine powder of fishbone, 30-35 parts of strawberry juice, 13-15 parts of wine, 20-23 parts of cotton candy, 20-23 parts of edible gelatin, 10-12 parts of loquat flowers, 3-35 parts of freeze-dried powder of pumpkin juice, 5-6 parts of vanilla and 10-12 parts of apricot kernel oil. The nutritional jelly is diuretic, can detoxify body, and can clear lung to relieve cough, improve appetite and promote digestion, dispel the effect of alcohol and nourish face.

Owner:ANHUI JIASHILE FOOD PROCESSING

Anti-inflammation and immunity-enhancing mung bean alcohol-effect-dispelling nutritional jelly and preparation method thereof

InactiveCN105942379AClear juiceUniform textureNatural extract food ingredientsFood ingredient functionsPolygonum fagopyrumArtemisia carvifolia

The invention discloses anti-inflammation and immunity-enhancing mung bean alcohol-effect-dispelling nutritional jelly and a preparation method thereof. The nutritional jelly is composed of the raw materials including, by weight, 300-320 parts of mung beans, 30-35 parts of malt extract liquid, 15-17 parts of amomum tsao-ko, 20-23 parts of peach gum, 50-60 parts of fermented watermelon juice, 10-12 parts of kudzu roots, 8-9 parts of folium isatidis, 30-35 parts of buckwheat, 30-35 parts of vinegar-brewed lotus seeds, 20-23 parts of extract liquid of platycodon grandiflorum, 20-23 parts of artemisia carvifolia powder, 20-23 parts of maltose, 25-30 parts of edible pectin, 20-23 parts of jujube peel powder, 20-23 parts of rice wine, and 10-12 parts of fructus lycii. The nutritional jelly has abundant nutrients, smooth mouth feel and uniform texture. The effective components of the nutritional jelly have the effects of resisting inflammation, dispelling alcohol effect, clearing fire and enhancing immunity.

Owner:ANHUI JIASHILE FOOD PROCESSING

Medium for direct differentiation of pluripotent stem cell-derived mesenchymal stem cell, method for preparing mesenchymal stem cell by using same, and mesenchymal stem cell prepared thereby

PendingCN112996903AHomogeneousSimple preparation processCulture processUnknown materialsMedicineMesenchymal stem cell

Owner:车比奥泰有限公司

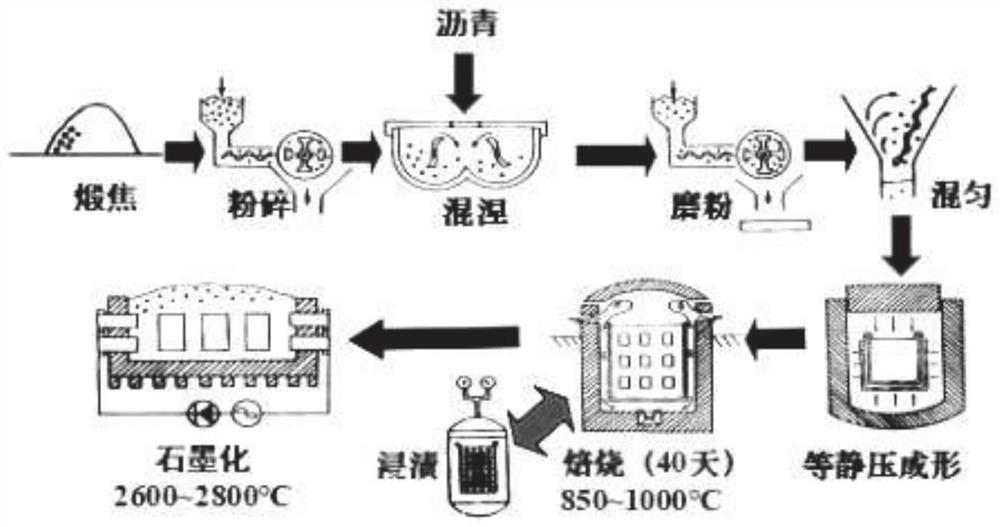

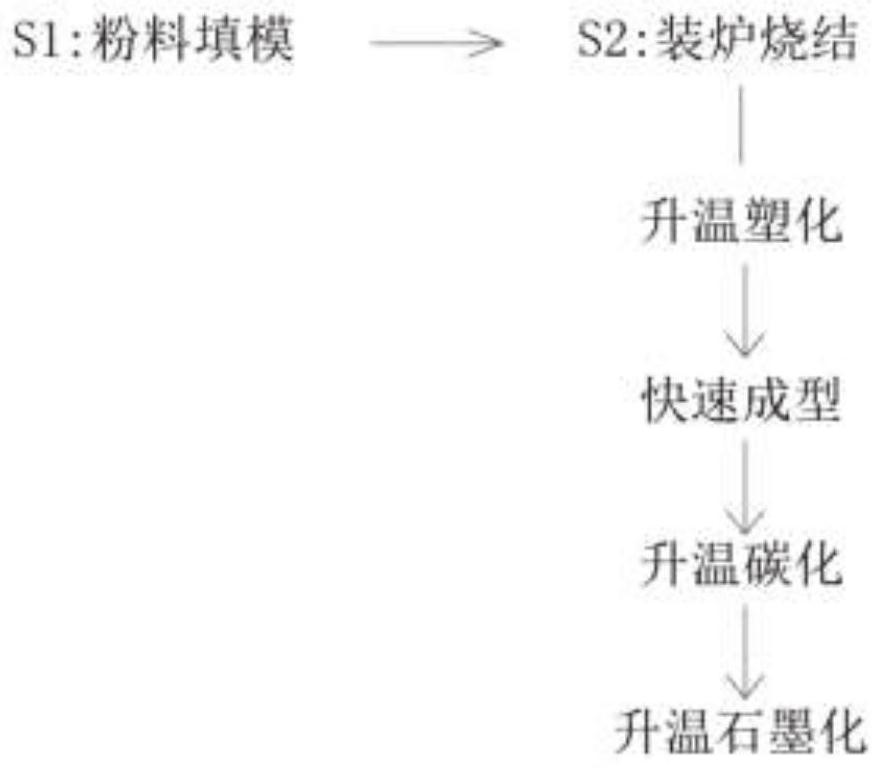

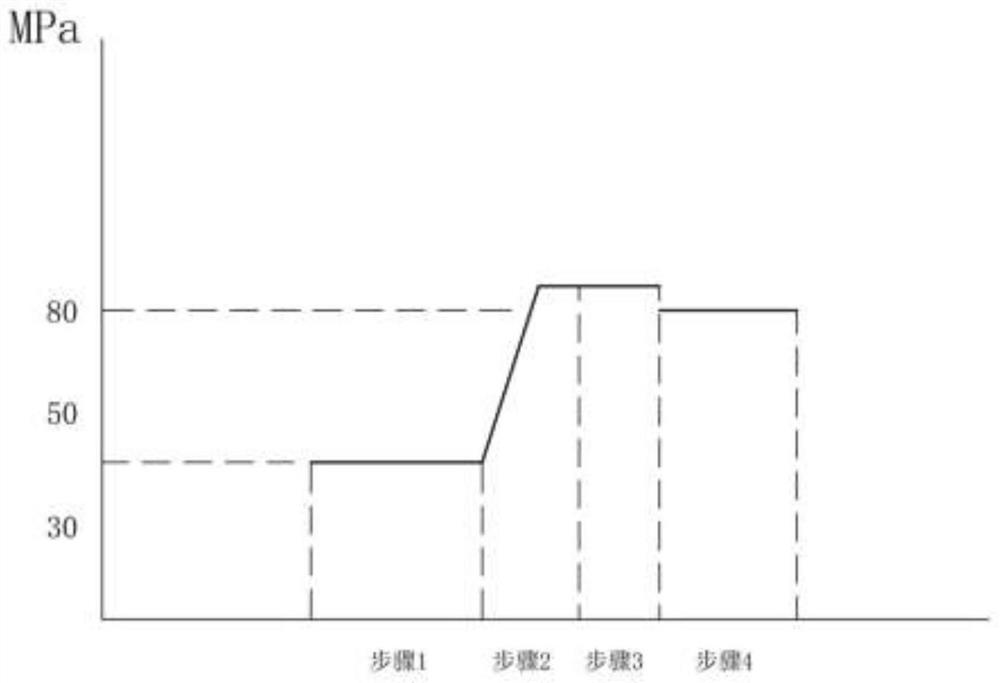

Graphite workpiece hot-pressing rapid forming method

The invention discloses a graphite workpiece hot-pressing rapid forming method which comprises the steps of powder mold filling and furnace charging sintering. Wherein the charging sintering specifically comprises the steps of heating and plasticizing, namely, quickly plasticizing graphite powder at a certain heating rate under a specific pressure condition, quickly forming, namely, heating and keeping the temperature for a period of time under the specific pressure condition to complete tight forming of a workpiece, and heating and carbonizing, namely, keeping the temperature for a certain time at a specific temperature to sufficiently carbonize the graphite workpiece; heating and graphitizing, namely keeping the temperature for a certain time under the conditions of specific pressure and temperature to graphitize the workpiece; compared with a traditional mould pressing circulation soaking and baking process, the temperature in a vacuum state is lower than that of a common process, isotropic uniformity is achieved, the sintering, carbonization and graphitization time is short due to different temperature rise heating modes, and the efficiency of the process is high due to the efficient continuity of the whole production; the prepared graphite workpiece is more uniform in material, higher in strength, better in compactness and more stable in performance.

Owner:佛山市南海宝碳石墨制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com