Graphite workpiece hot-pressing rapid forming method

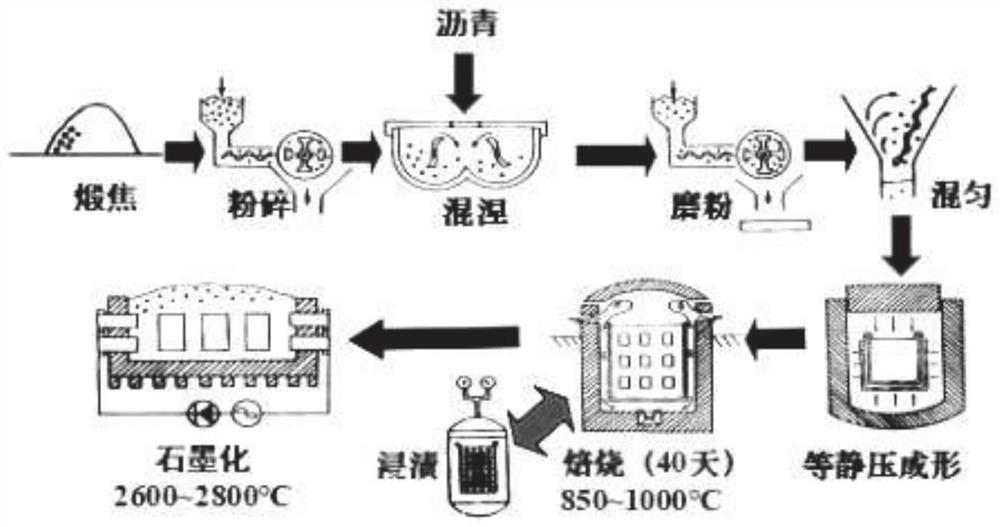

A molding method and fast technology, which is applied in the field of graphite workpiece molding, can solve the problems of graphite workpiece interface defects, uneven internal and external structures, poor heat conduction effect, etc., and achieve efficient and consistent production, good compactness, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so as to more clearly understand the technical idea claimed in the present invention.

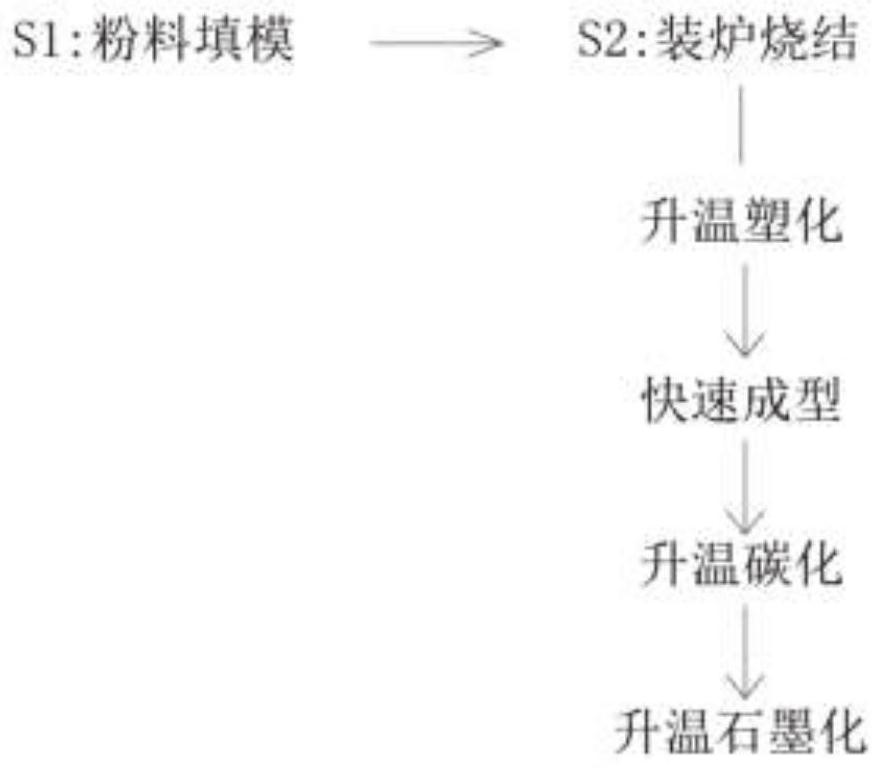

[0020] like Figure 2-4 The shown method for rapid prototyping of graphite workpieces by hot pressing includes the following steps,

[0021] Step S1, filling the mold with powder, that is, filling the powder into the mold according to the specific technical requirements, wherein it is best to ensure the uniformity of the powder filling in the mold under the premise that the graphite powder is fully broken and ground;

[0022] Step S2, sintering in a furnace;

[0023] Wherein step S2 specifically includes:

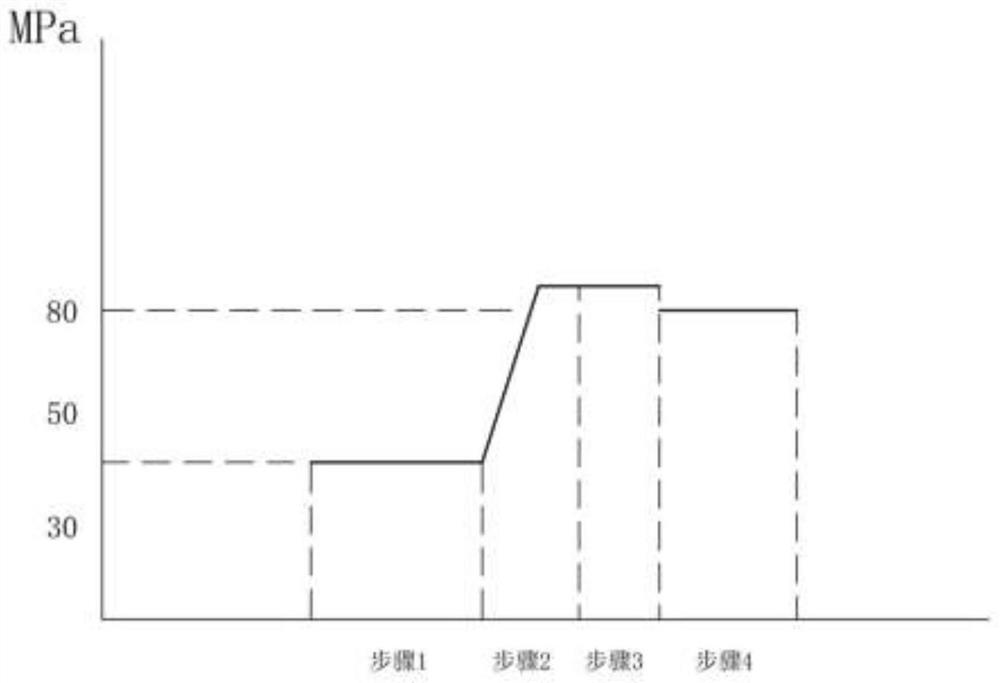

[0024] Step 1. Heat up and plasticize. In a vacuum environment, under the pressure condition of 30-50Mpa, the graphite powder is rapidly plasticized at a heating rate of 55°C / min, that is, the graphite powder is softened, compressed, and accompanied by a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com