Fluid continuous mixing device

A mixer and fluid technology, applied in fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of low mixing efficiency, large energy consumption, and greater energy consumption, and achieve high mixing efficiency and energy consumption. The effect of small and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This example illustrates that two fluids with high viscosity can be uniformly mixed by using the mixer provided by the present invention, and has high mixing efficiency.

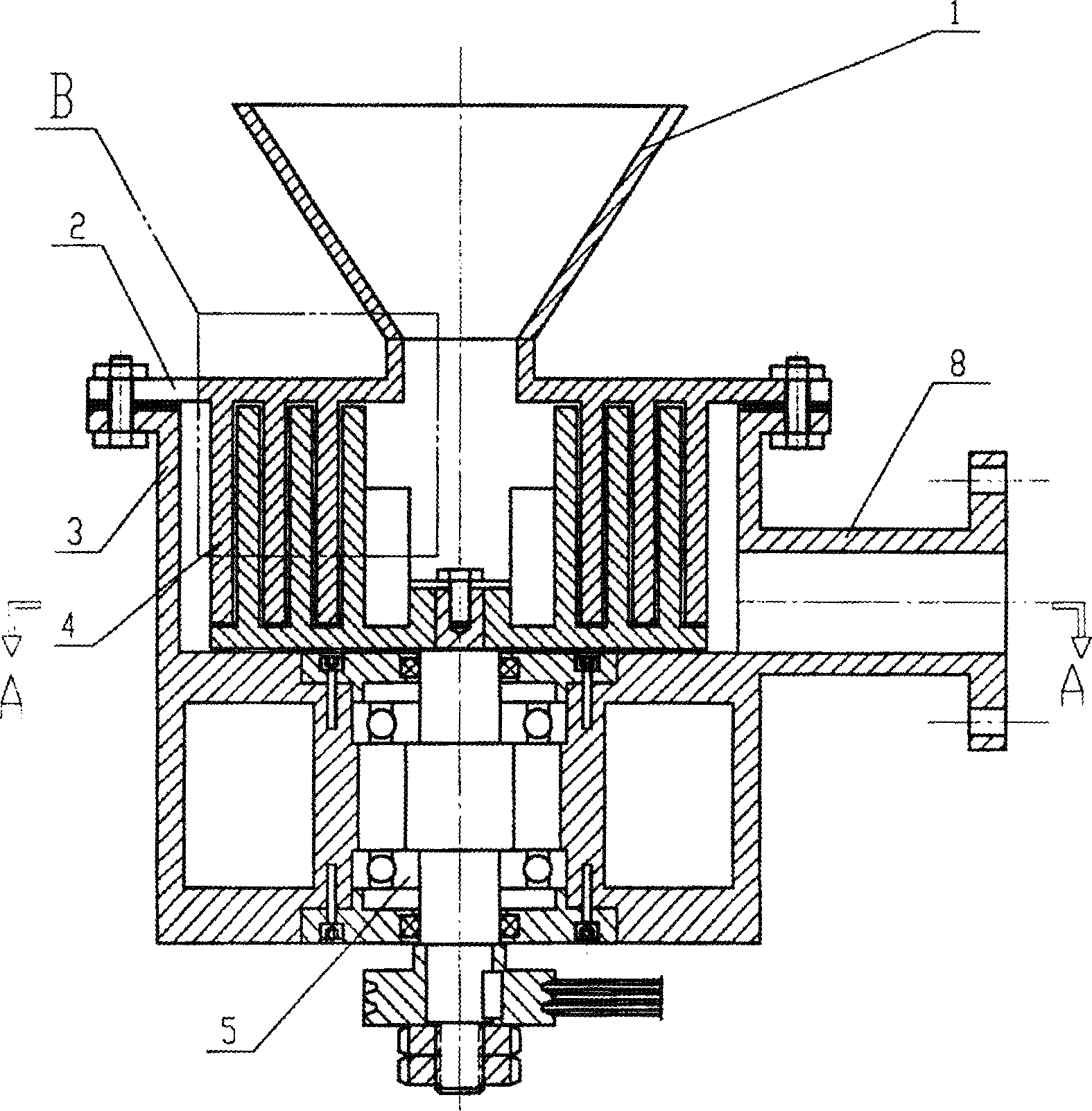

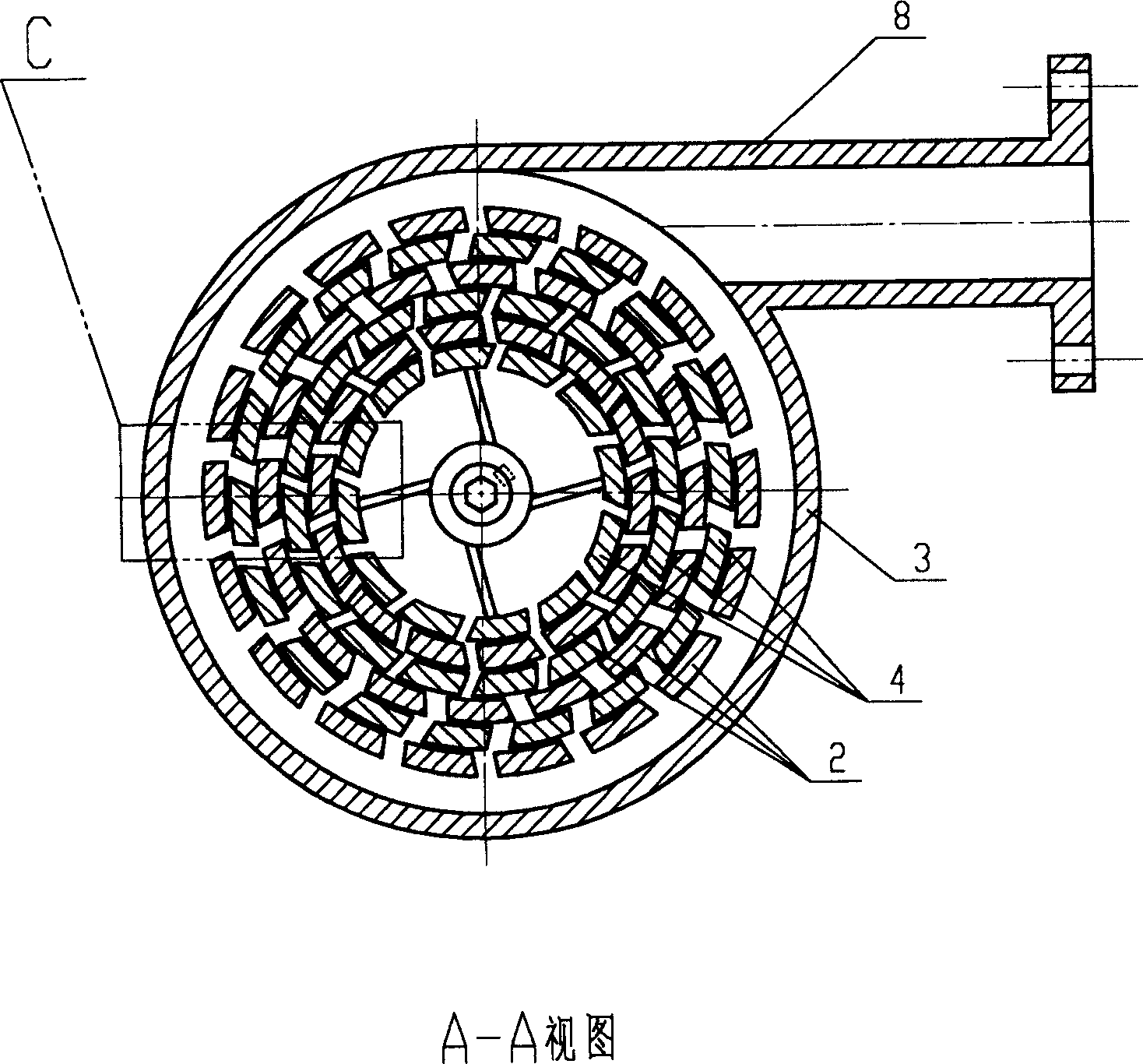

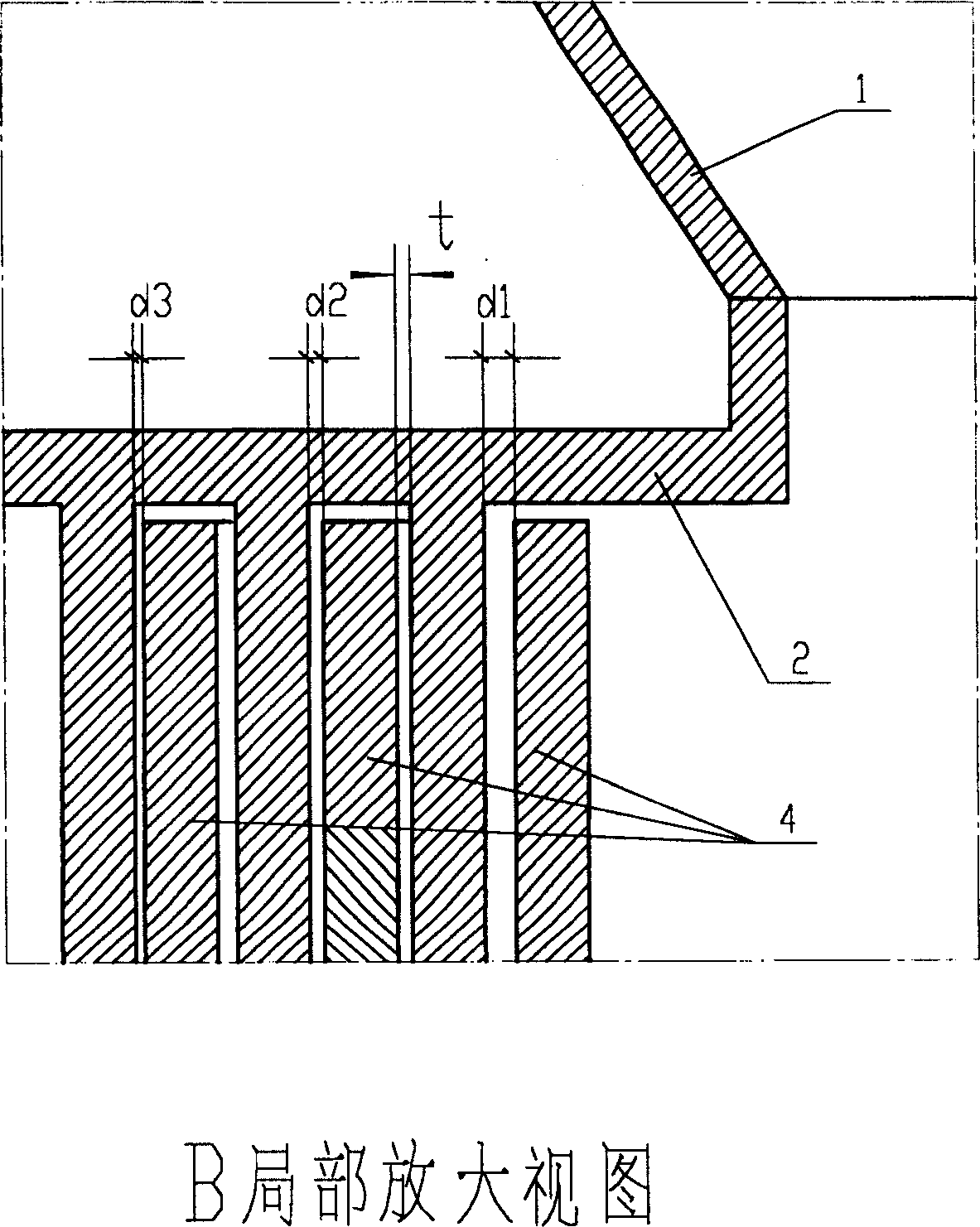

[0025] The structure of the mixer used in this embodiment is as figure 1 As shown, the inner diameter of the mixer shell is 200mm, the diameter of the feed hopper is 200mm, the height of the mixer shell is 300mm, the tooth height of the mixer stator and rotor is 50mm, the stator is composed of three layers of teeth, the first layer is 14 teeth, the second layer is 16 teeth, the third layer is 18 teeth; the rotor is also composed of three layers of teeth, the first layer is 14 teeth, the second layer is 16 teeth, and the third layer is 18 teeth; the stator and The rotor clearance is d1=0.6mm, d2=0.4mm, d3=0.25mm, d=2mm; the angle between the rotor and stator is α1=45°, α2=35°, α3=30°. This embodiment mixes two kinds of colloids, and the solid content of colloid A is about 25% by weight, and particle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com