Near sound field ultrasonic reactor

An ultrasonic and reactor technology, applied in the field of near-sound field ultrasonic reactors, can solve the problems of limited service life of parallel plates, uneven ultrasonic field, poor compatibility, etc., to improve utilization efficiency, small footprint, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

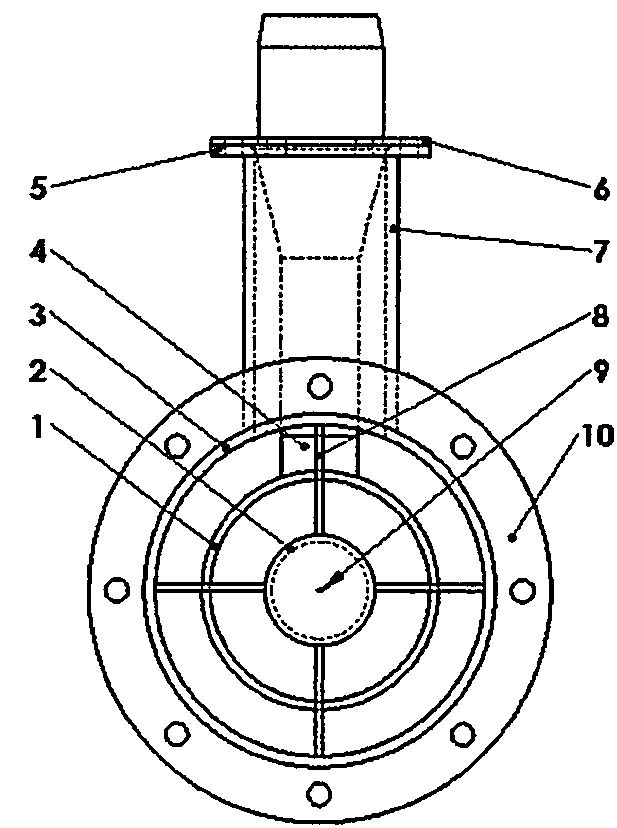

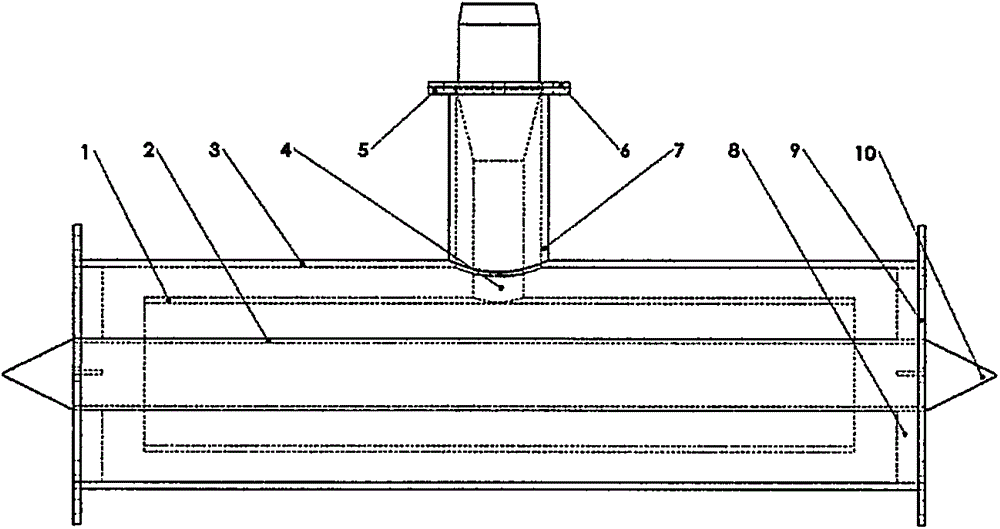

[0036] see figure 1 with figure 2 , which is a schematic structural view of Embodiment 1 of a near-acoustic field ultrasonic reactor of the present invention. Such as figure 1 with figure 2 As shown: it includes ultrasonic vibration tube 1, ultrasonic internal reflection tube 2, ultrasonic external reflection tube 3, ultrasonic horn 4, connecting ultrasonic horn flange 5, ultrasonic horn flange 6, fixed horn sleeve Tube 7, fixed internal reflection tube rib 8, internal reflection tube splitter cone 9, and outer reflection tube flange 10. Among them, the ultrasonic vibrating tube 1 is the core component, and its material can be ordinary metal materials, or titanium alloys, alloys, stainless steel, aluminum alloys, copper and other metal materials according to different working fluids for ultrasonic treatment. The ultrasonic vibrating tube 1 and the ultrasonic horn 4, the ultrasonic transducer and the ultrasonic drive power supply are connected in sequence to form a comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com