Automatic fire extinguishing system for vehicle

An automatic fire extinguishing system and vehicle technology, which is applied in the field of vehicle automatic fire extinguishing systems, can solve the problems of oil circuit, circuit aging, omission, negligence, etc., and achieve the effects of reducing casualties and property losses, increasing flexibility, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

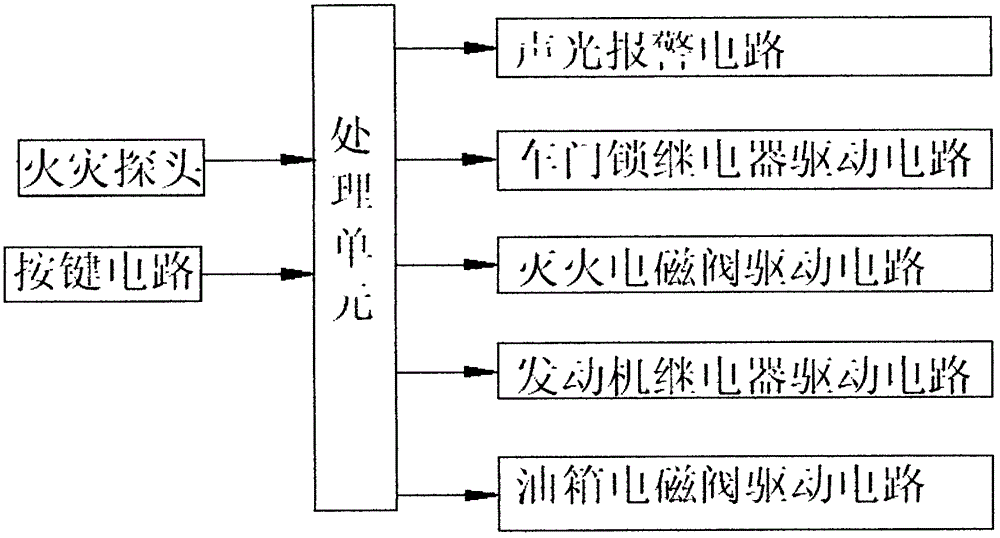

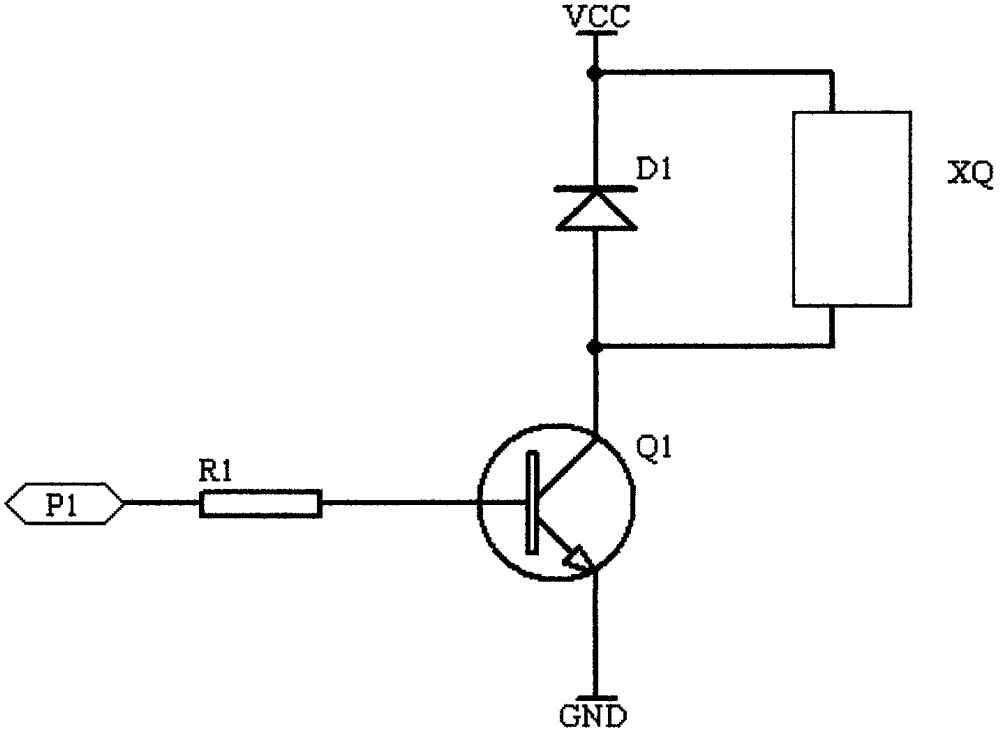

[0040] Embodiment 1, a kind of vehicle automatic fire extinguishing system, such as figure 1 As shown, it includes the fire extinguishing agent container, fire detector, power module and system central control module located inside the vehicle; the power module provides DC power for the system to work.

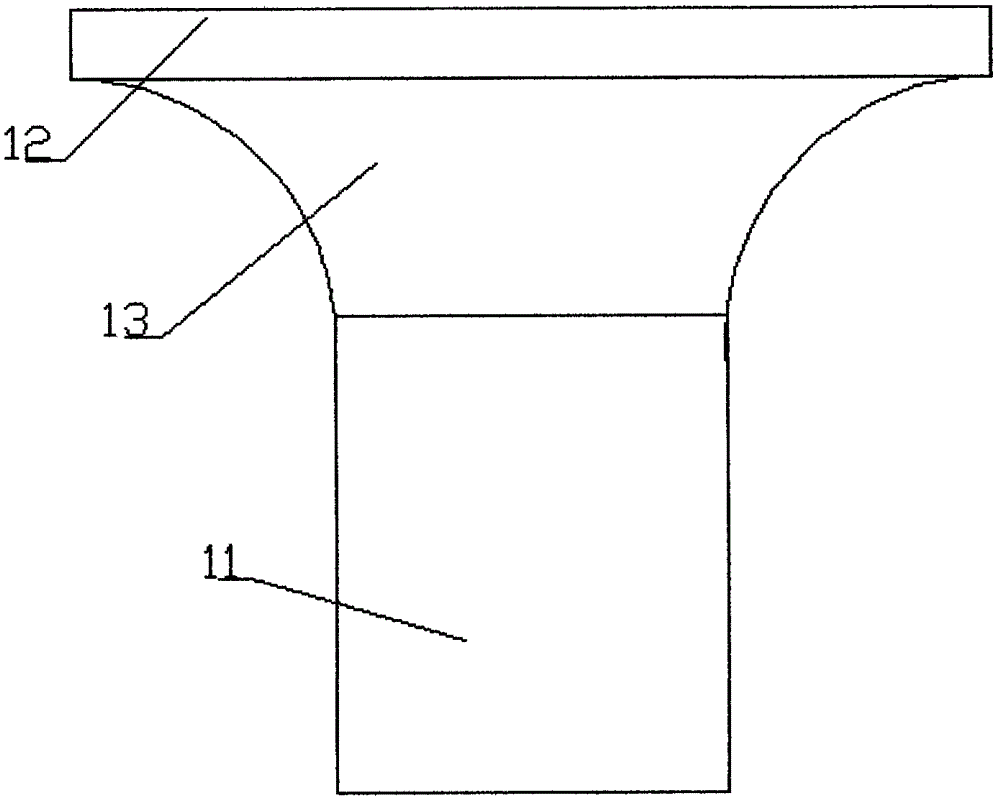

[0041] The fire extinguishing agent container is a steel cylinder or a carbon fiber pressure bottle, which can withstand relatively high pressure and ensure safety during use. The outlet of the fire extinguishing agent container is connected with a fire extinguishing pipeline, and the fire extinguishing pipeline is provided with a fire extinguishing solenoid valve, so that the fire extinguishing solenoid valve controls whether the fire extinguishing pipeline is cut off. There is a fire extinguishing nozzle at the end of the fire extinguishing pipe. In order to improve the effect, the fire extinguishing nozzle and the fire detector are set close to each other. The proximity mea...

Embodiment 2

[0068] Embodiment 2. The difference between this embodiment and Embodiment 1 is that this embodiment is suitable for an open cargo transport vehicle, and the installation of the fire extinguishing nozzle and the fire extinguishing probe is as follows:

[0069] For the engine compartment: the fire detectors are installed directly above and on both sides above the engine, and the fire extinguishing nozzles are installed adjacent to the detectors.

[0070] For the cockpit: the fire detector is installed directly above the cockpit, and the fire extinguishing nozzle is installed adjacent to the fire detector.

[0071] For open warehouses: the fire detectors are respectively installed on the top of the carriage and around the carriage, and the fire extinguishing nozzle is installed close to the fire detector. When installing, pay attention to the distance between the fire detector and the fire extinguishing nozzle and the cargo, otherwise it will affect the fire extinguishing agent w...

Embodiment 3

[0072] Embodiment 3, the difference between this embodiment and Embodiment 1 is that this embodiment is suitable for medium-sized and large passenger vehicles, and the installation of the fire extinguishing nozzle and the fire extinguishing probe is as follows:

[0073] For the engine compartment: the fire probe is installed directly above the engine and on both sides above the engine, and the fire extinguishing nozzle is installed adjacent to the probe.

[0074] For the passenger space: fire detectors are installed above each column, below the luggage rack, in the middle of the height direction of the column, and at a position 200mm from the vehicle ground on the column; and the fire extinguishing nozzle is installed close to the fire sensor. Due to the large luggage space in the lower part of the passenger car, the fire extinguishing agent container can be installed in this space. The pillars are existing components of the vehicle interior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com