Patents

Literature

1144 results about "Fire detector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire Suppression System

InactiveUS20070221388A1Satisfied with the resultMore cost-effectivelyFire rescueBoring toolsElectricityFire detector

Owner:LUBRIZOL ADVANCED MATERIALS INC

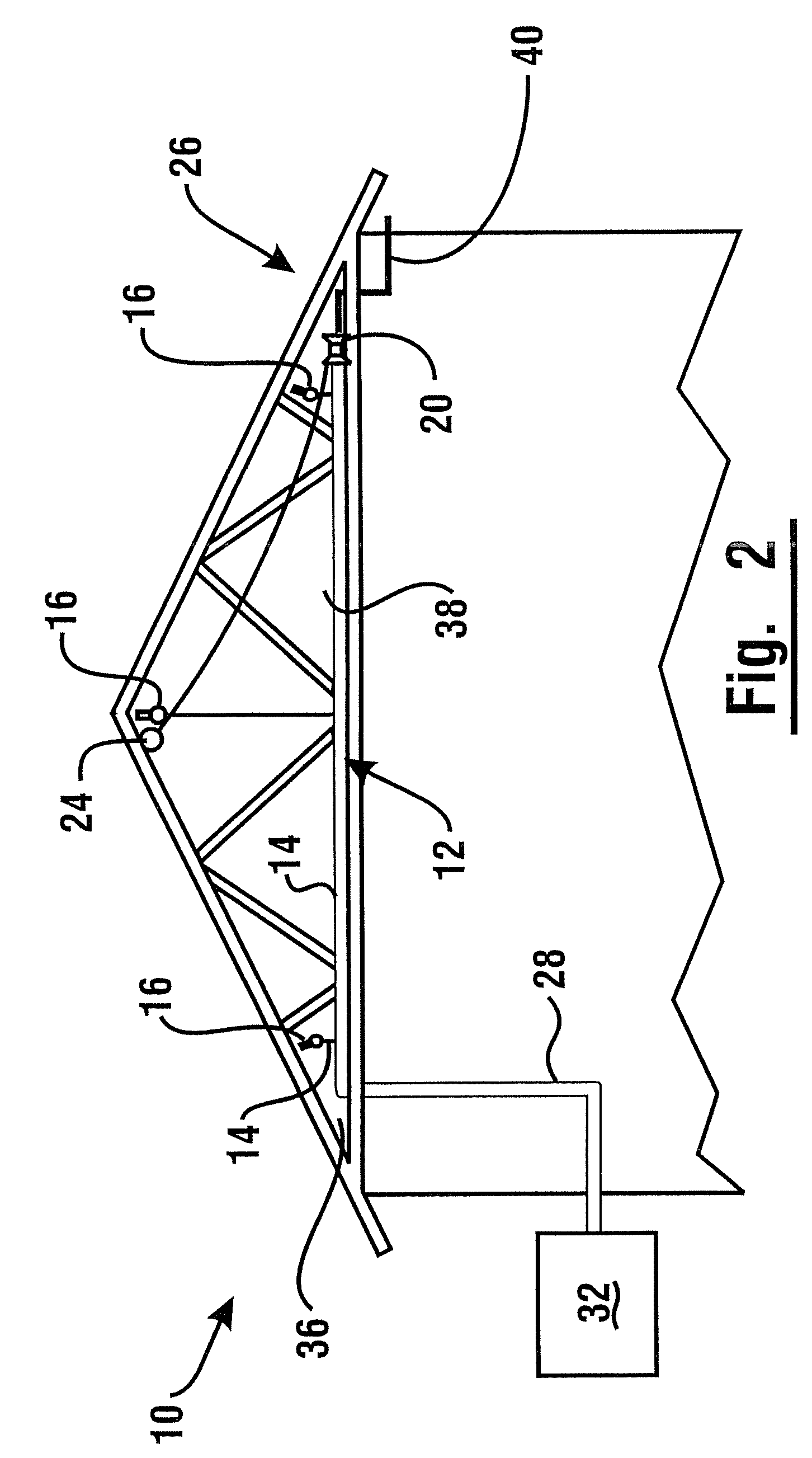

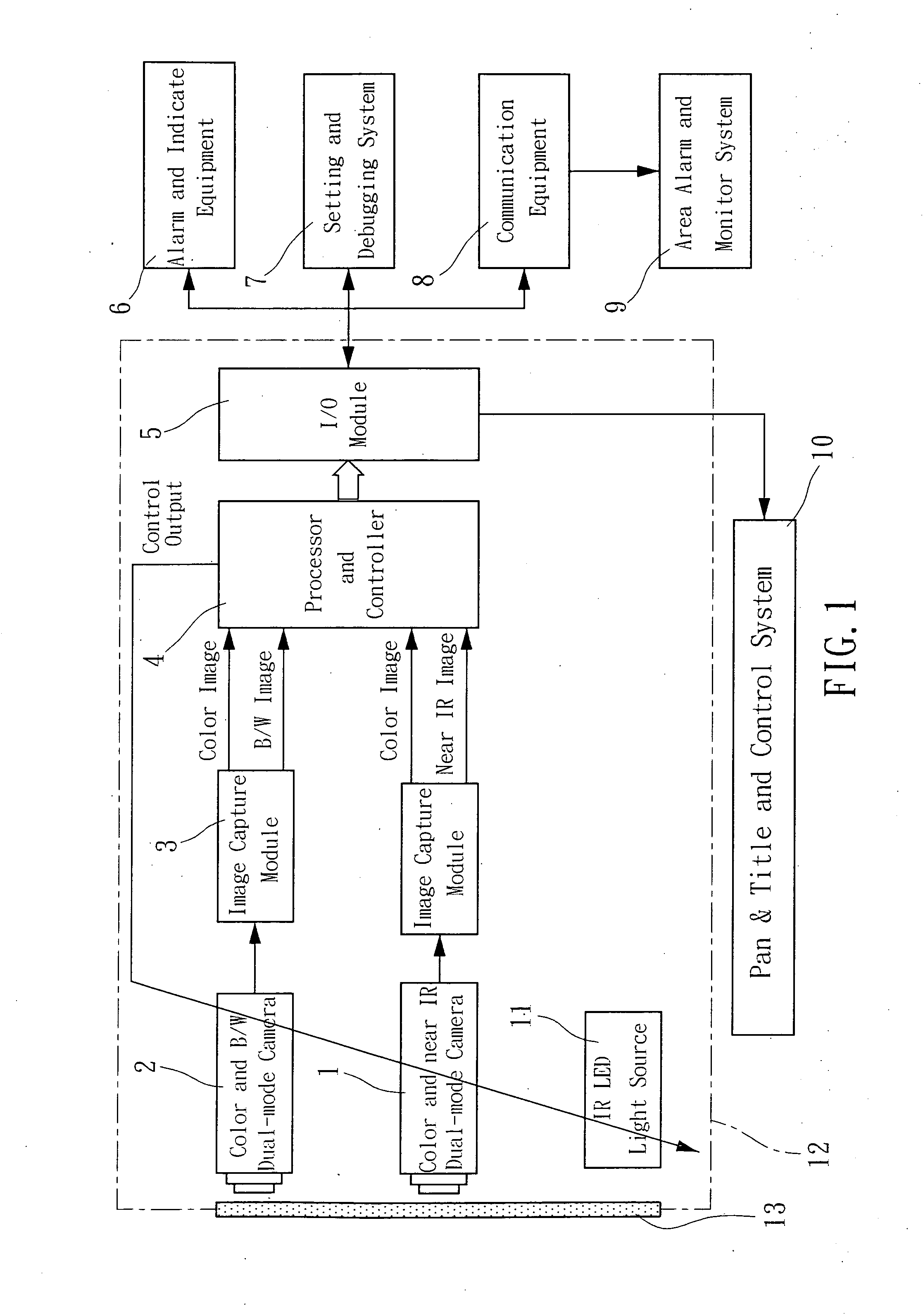

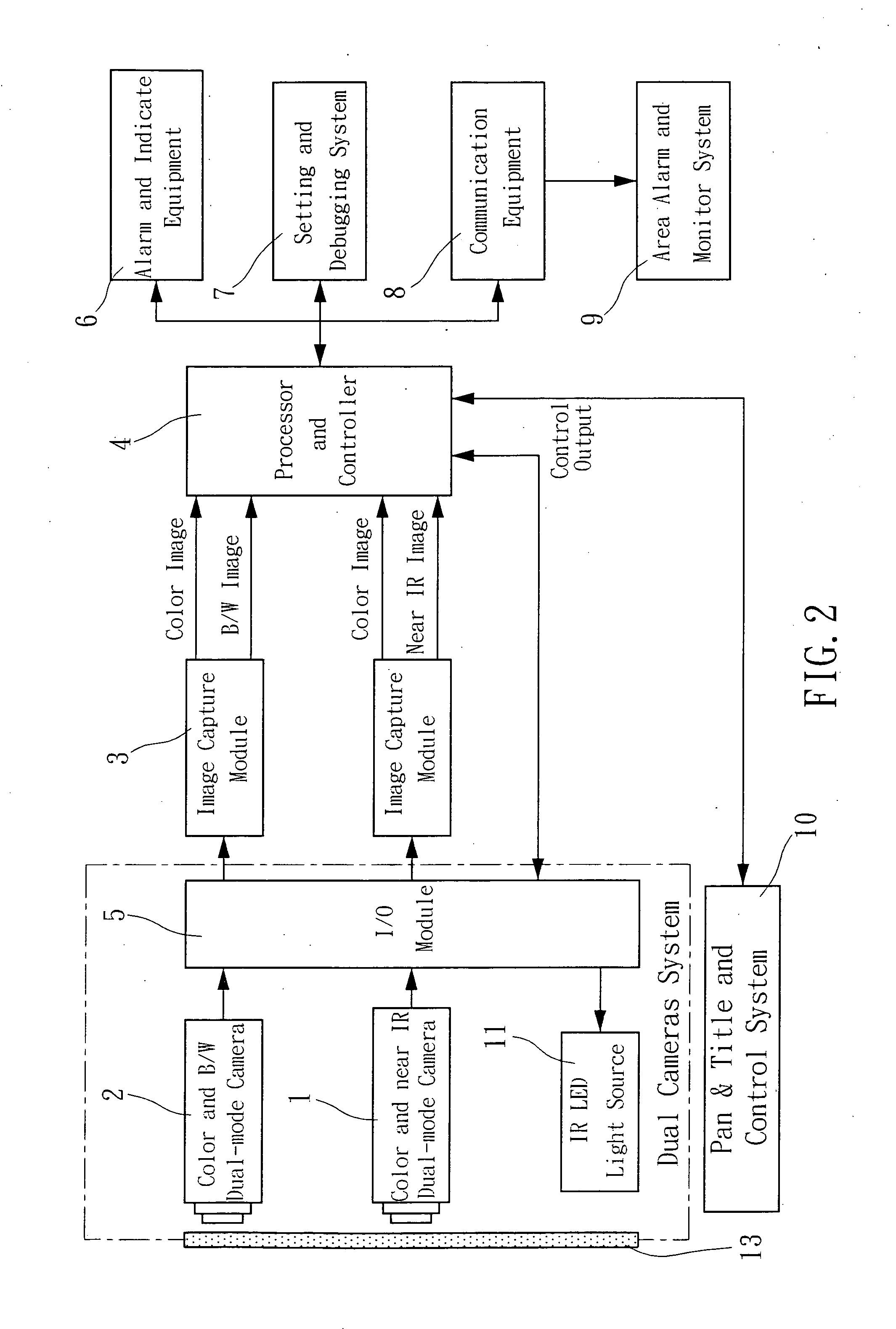

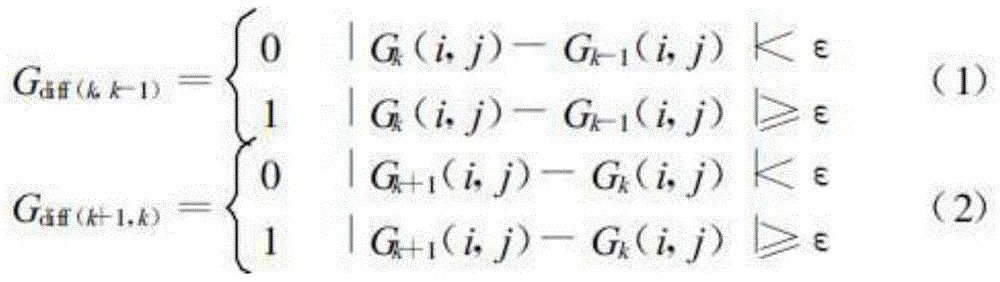

Multi-wavelength video image fire detecting system

InactiveUS20090315722A1Image information is clearReliable detectionSensing radiation from gases/flamesPyrometry for hot spots detectionDual modeAlarm Failure

To eliminate the drawbacks of false alarm problems due to mimic flame features of sunlight or moonlight reflecting on wave or mimic flame features of fabrics, animals or stage flames and alarm failures of methanol or ethanol burning flames or flames under a high illumination background condition, a multi-wavelength video image fire detecting system is disclosed consisting of a multi-wavelength video image fire detector, which is comprised of a color and near IR dual-mode camera, a color and B / W dual-mode camera, an image capture module, a processor and controller, an I / O module, a housing and a visible light and near IR view window, an alarm and indicate equipment, a setting and debugging system, a communication equipment, an area alarm and monitor system, and a pan & title and control system.

Owner:INNOSYS IND

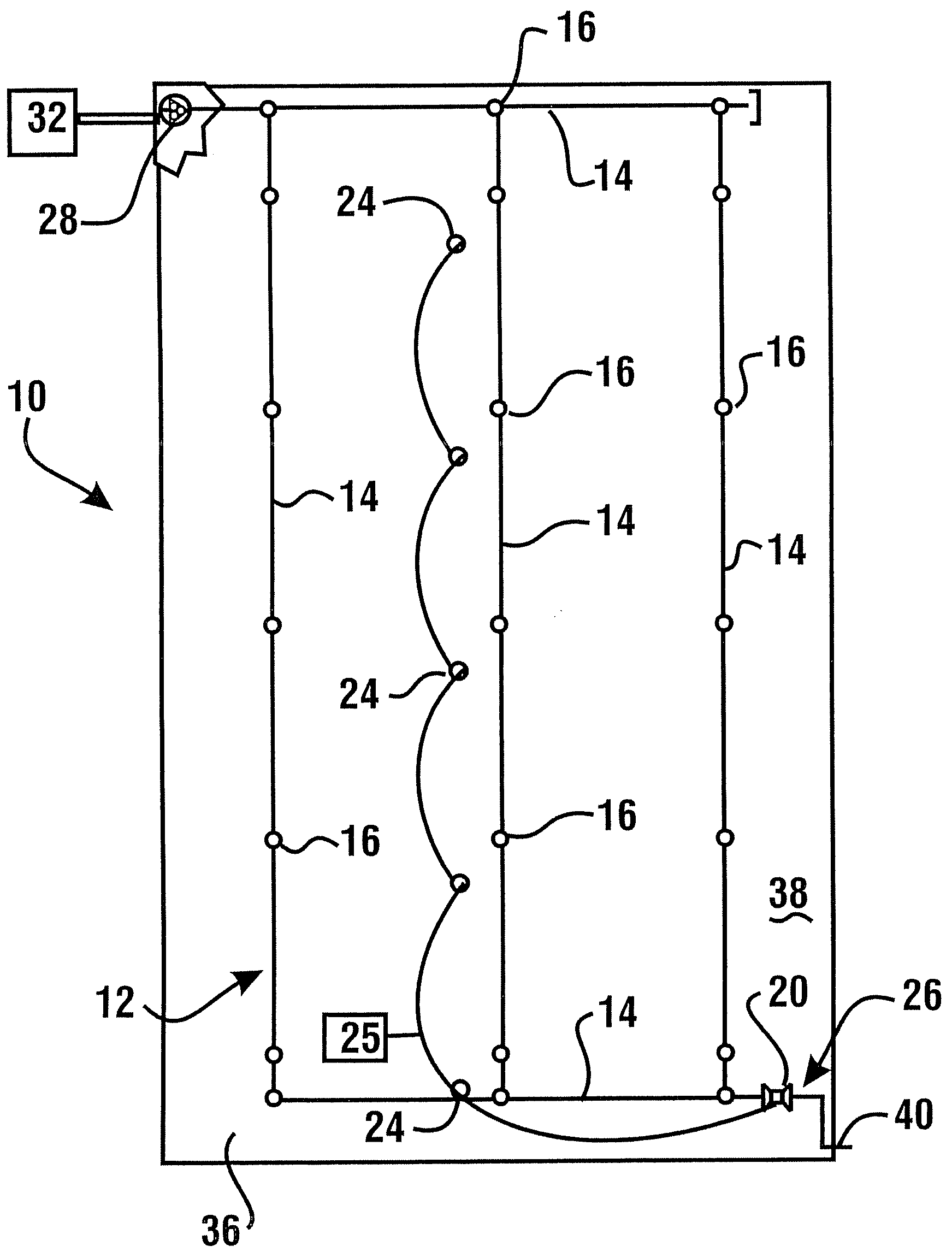

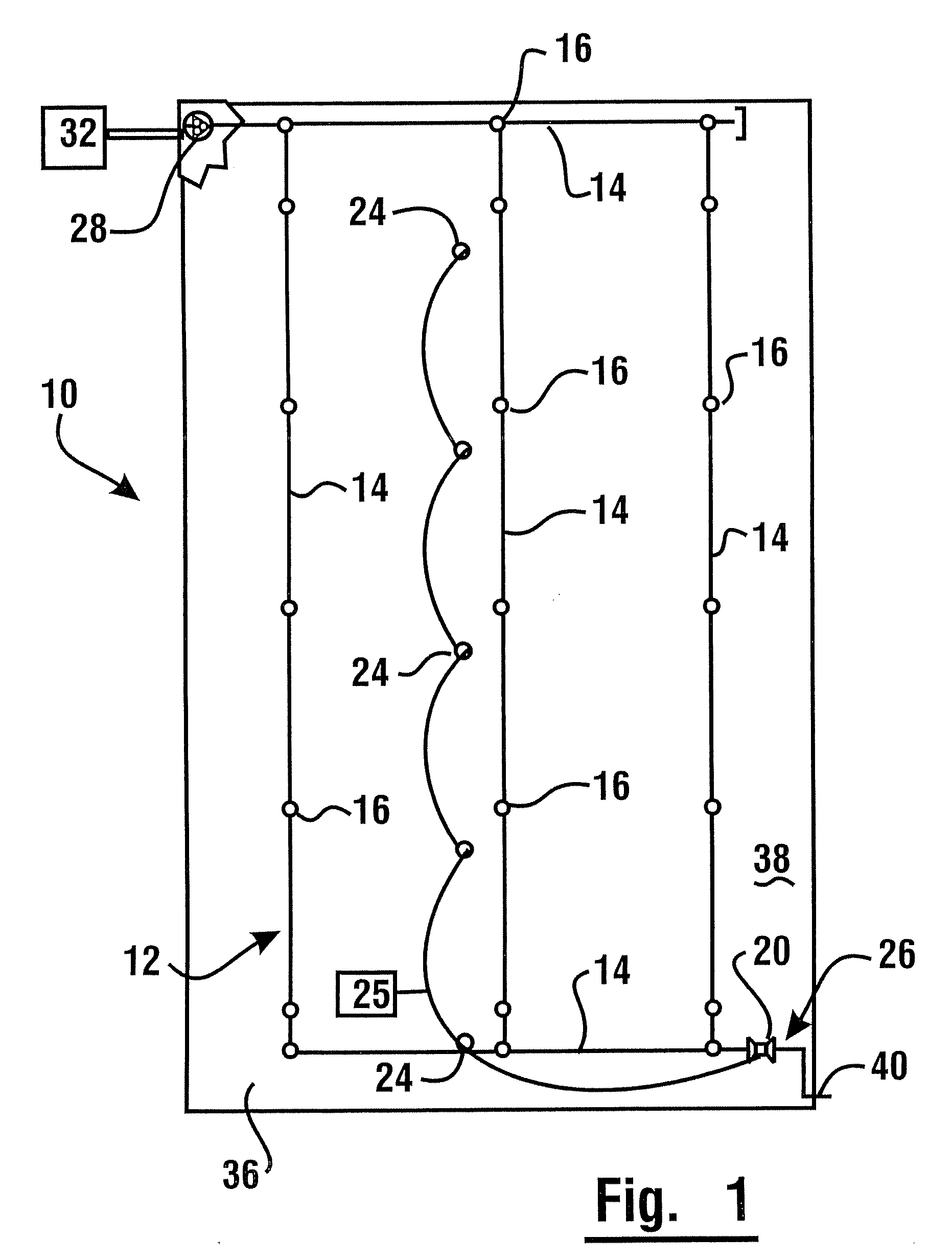

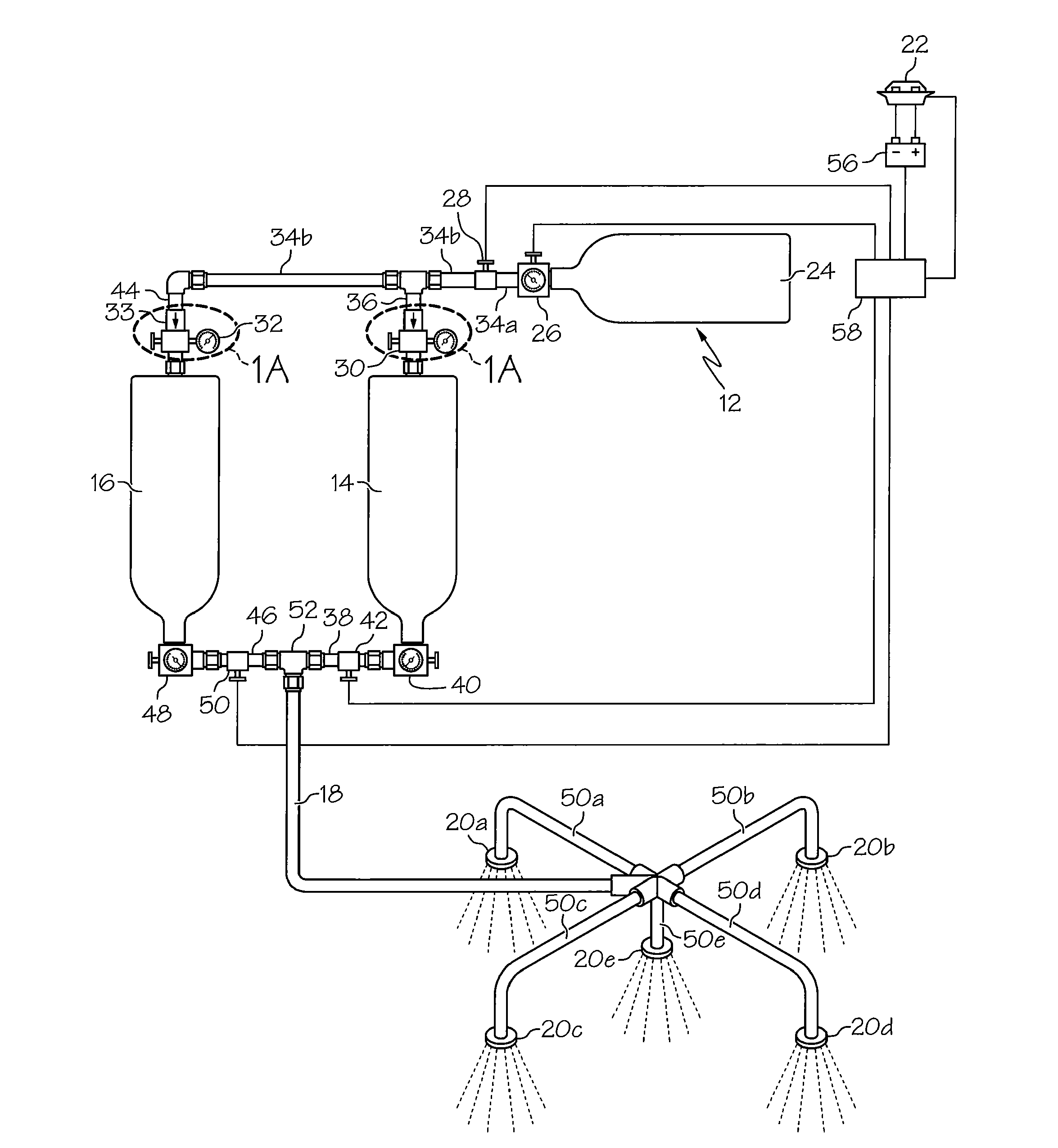

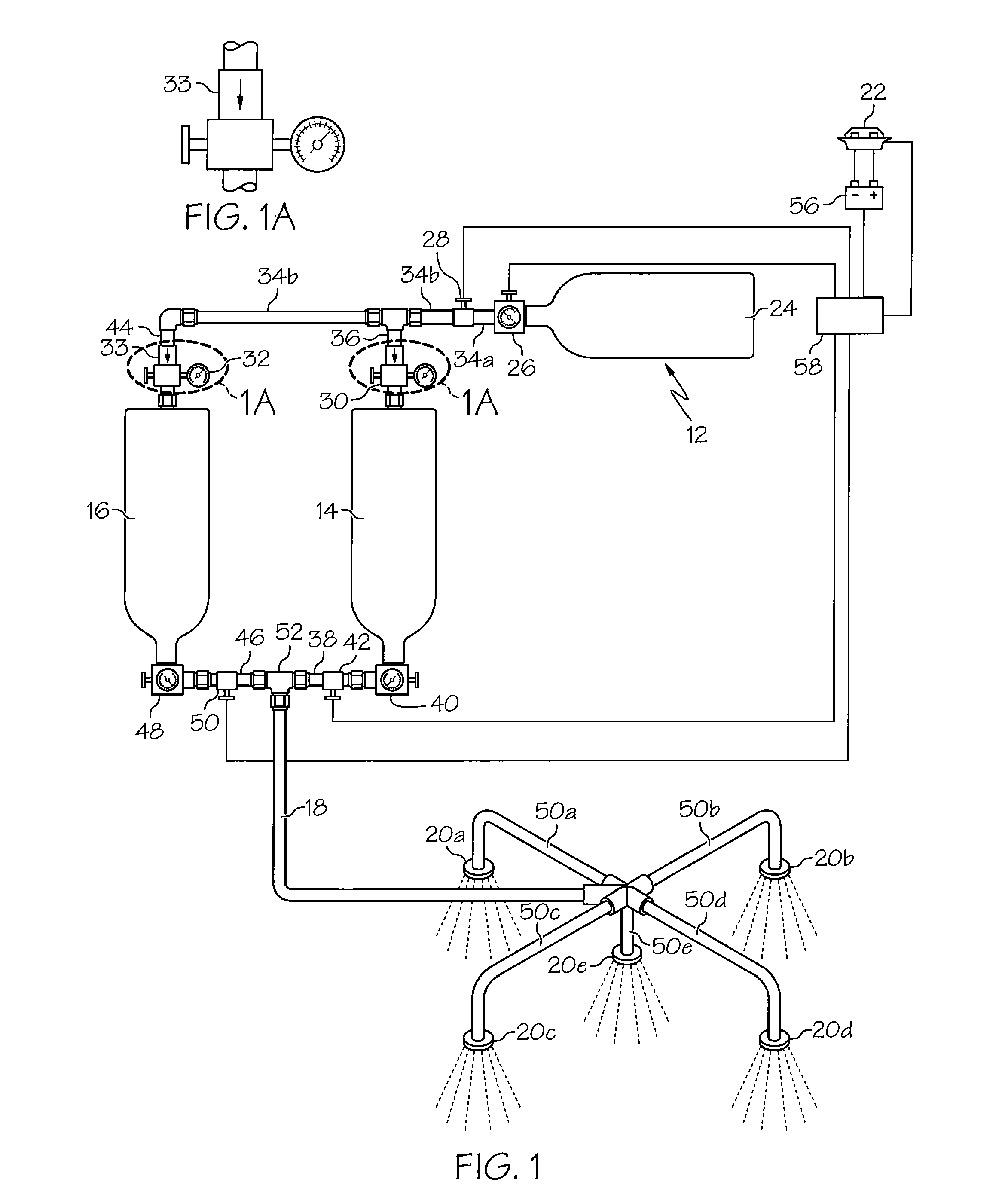

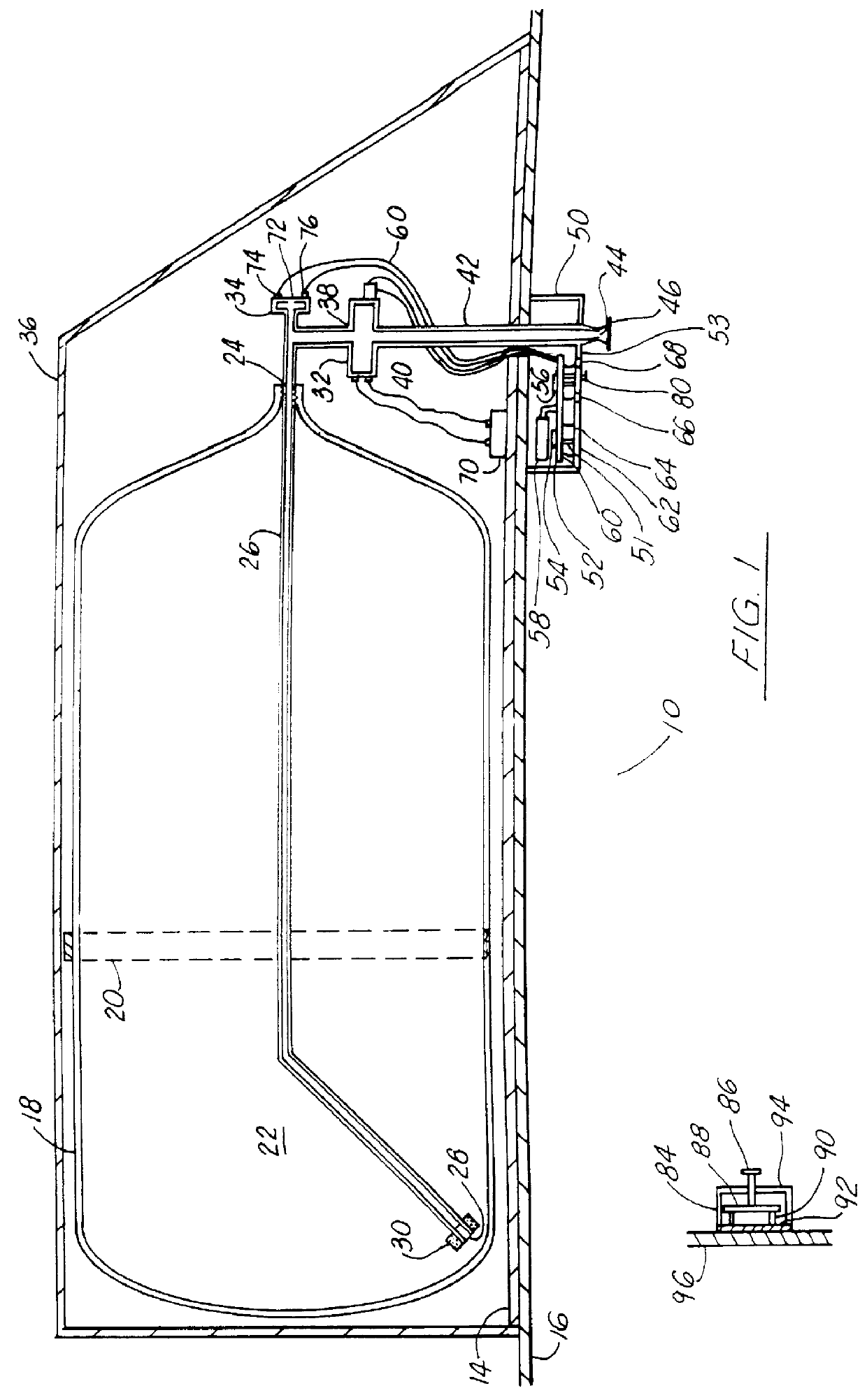

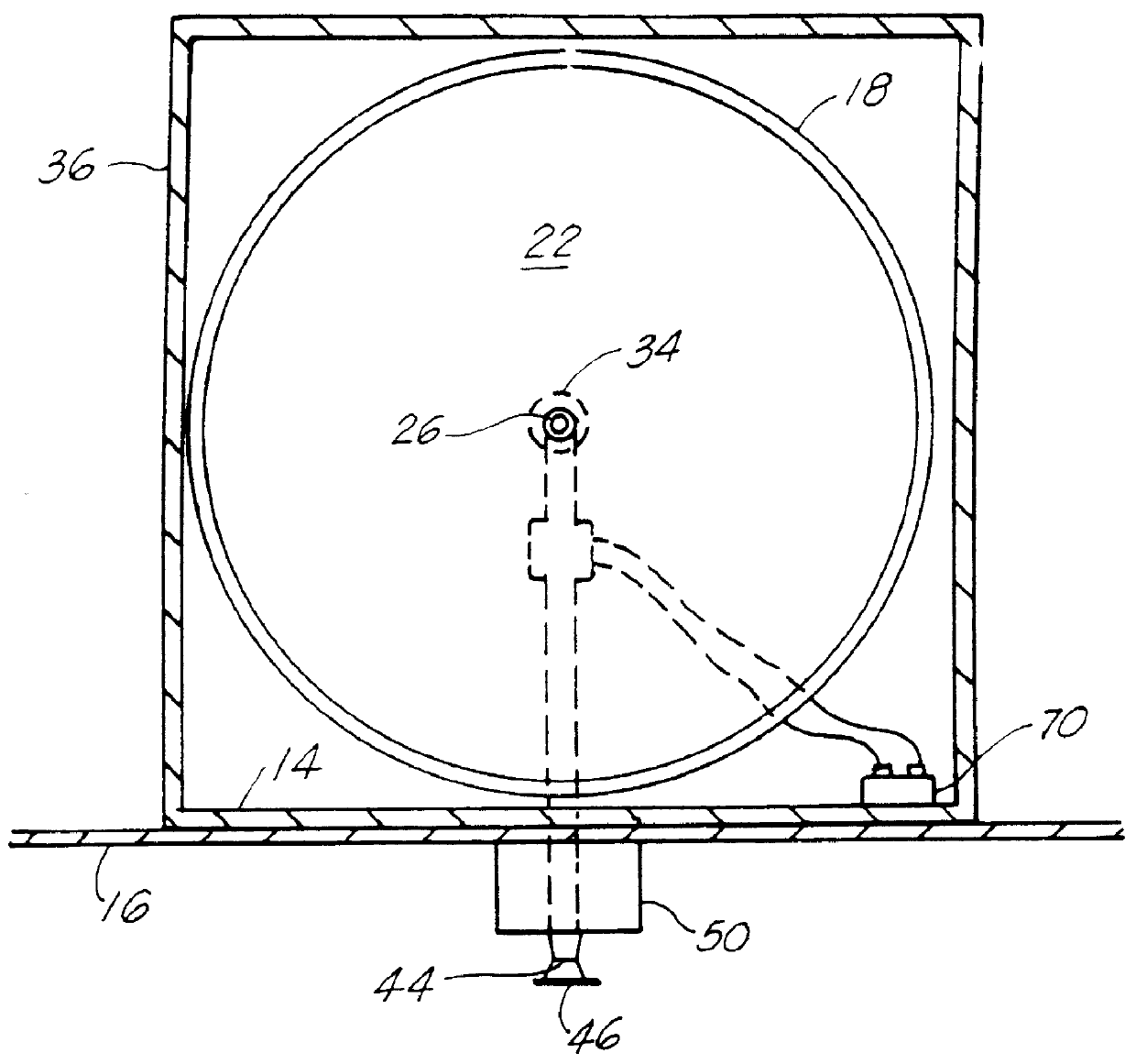

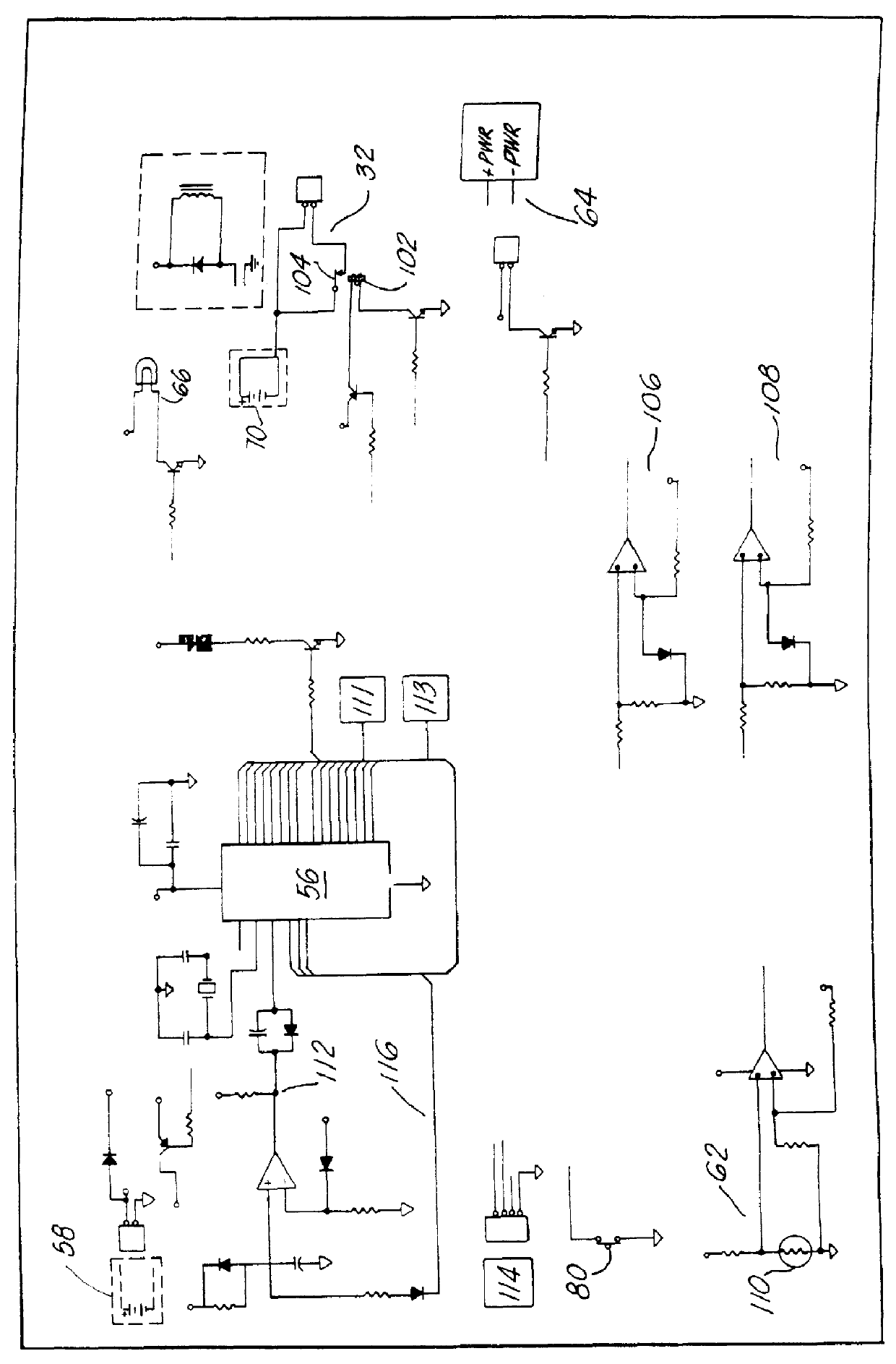

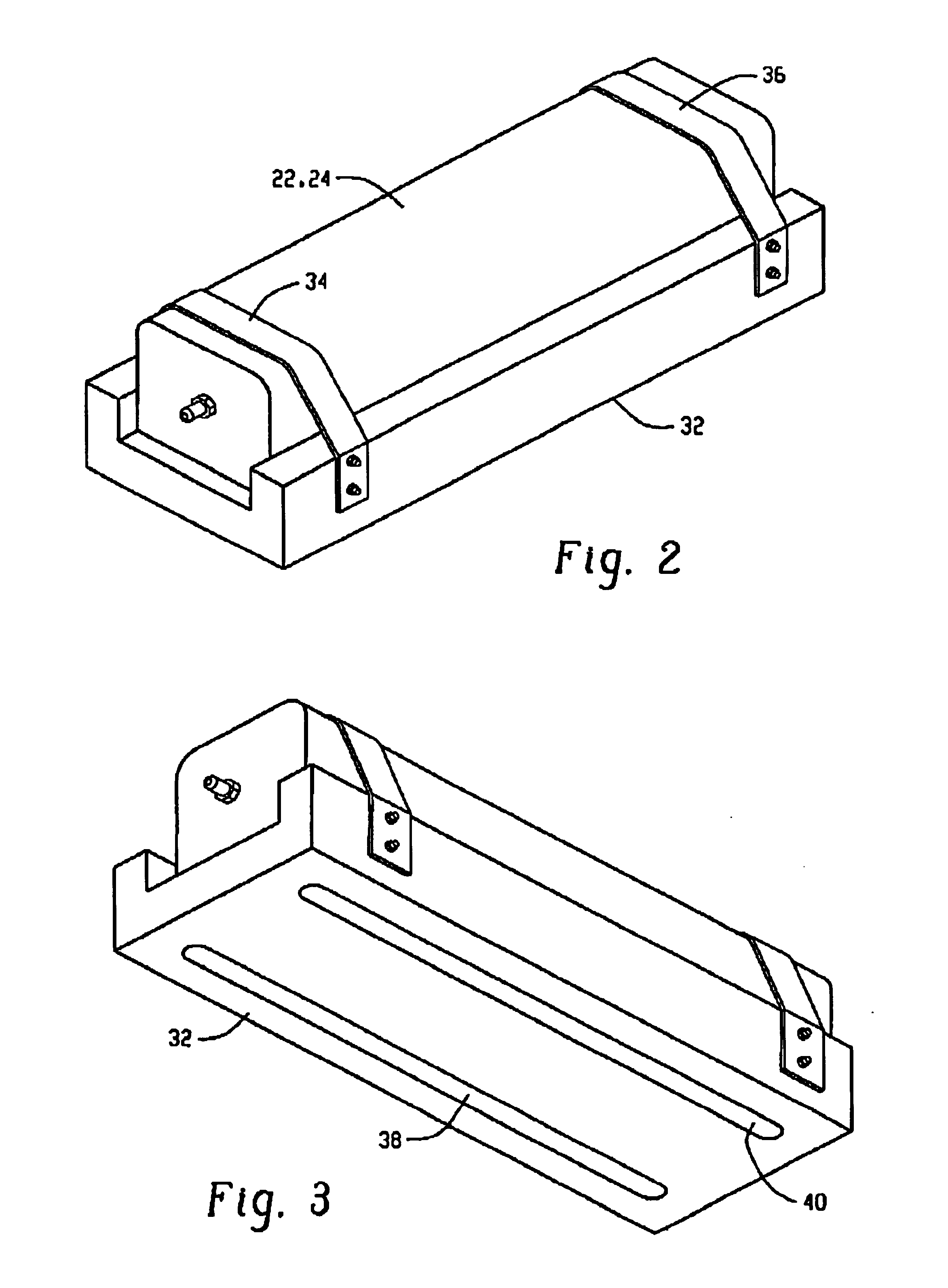

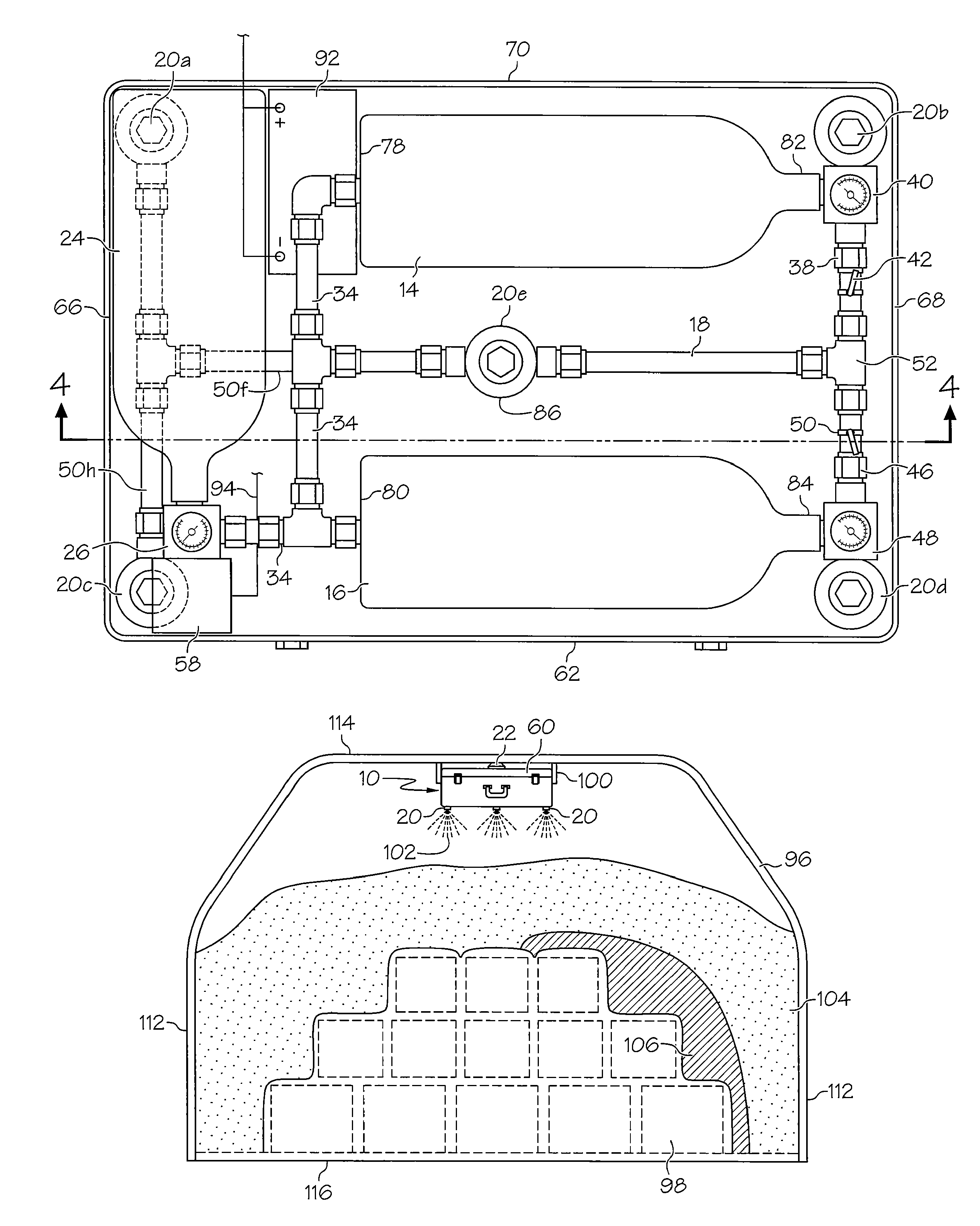

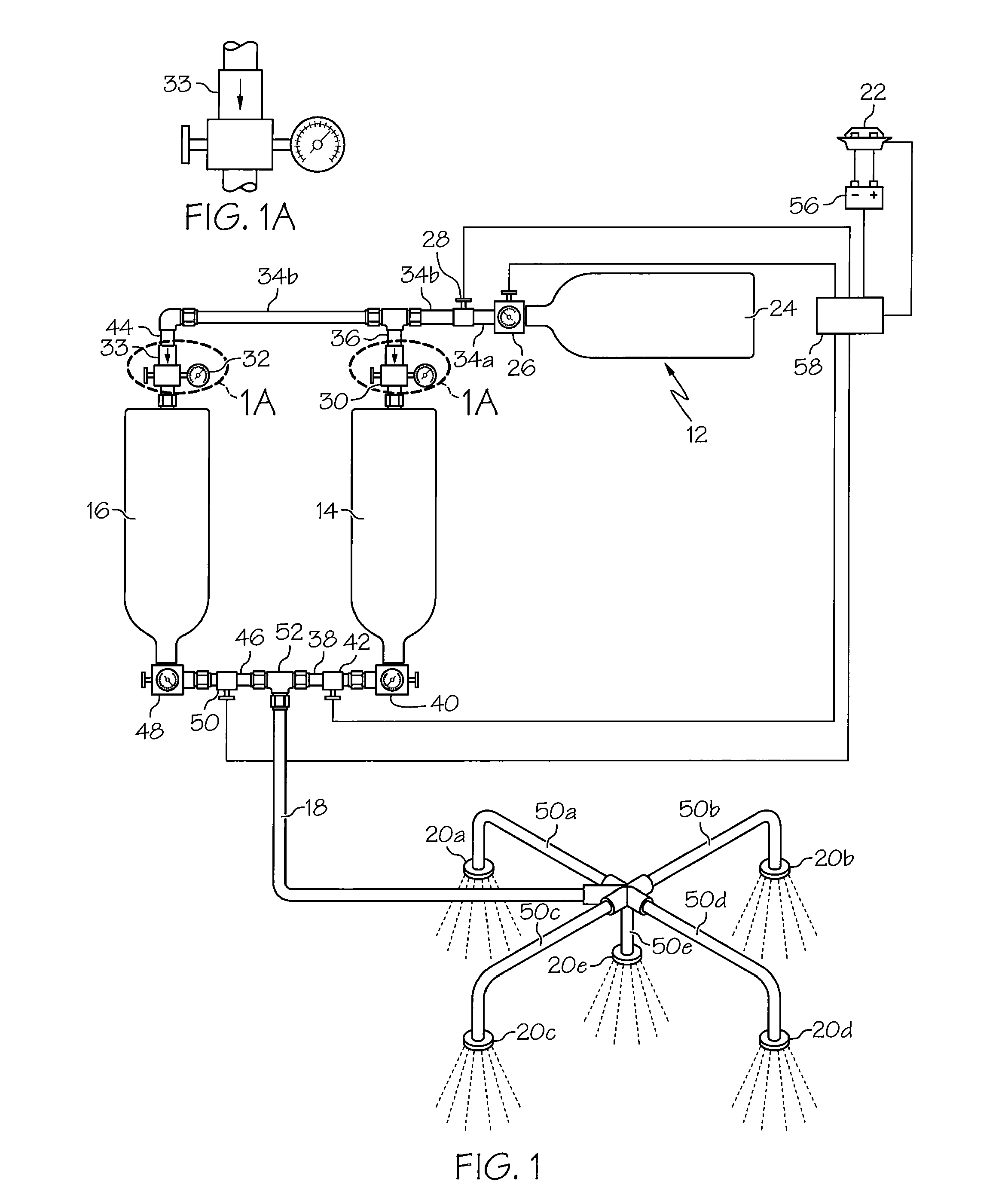

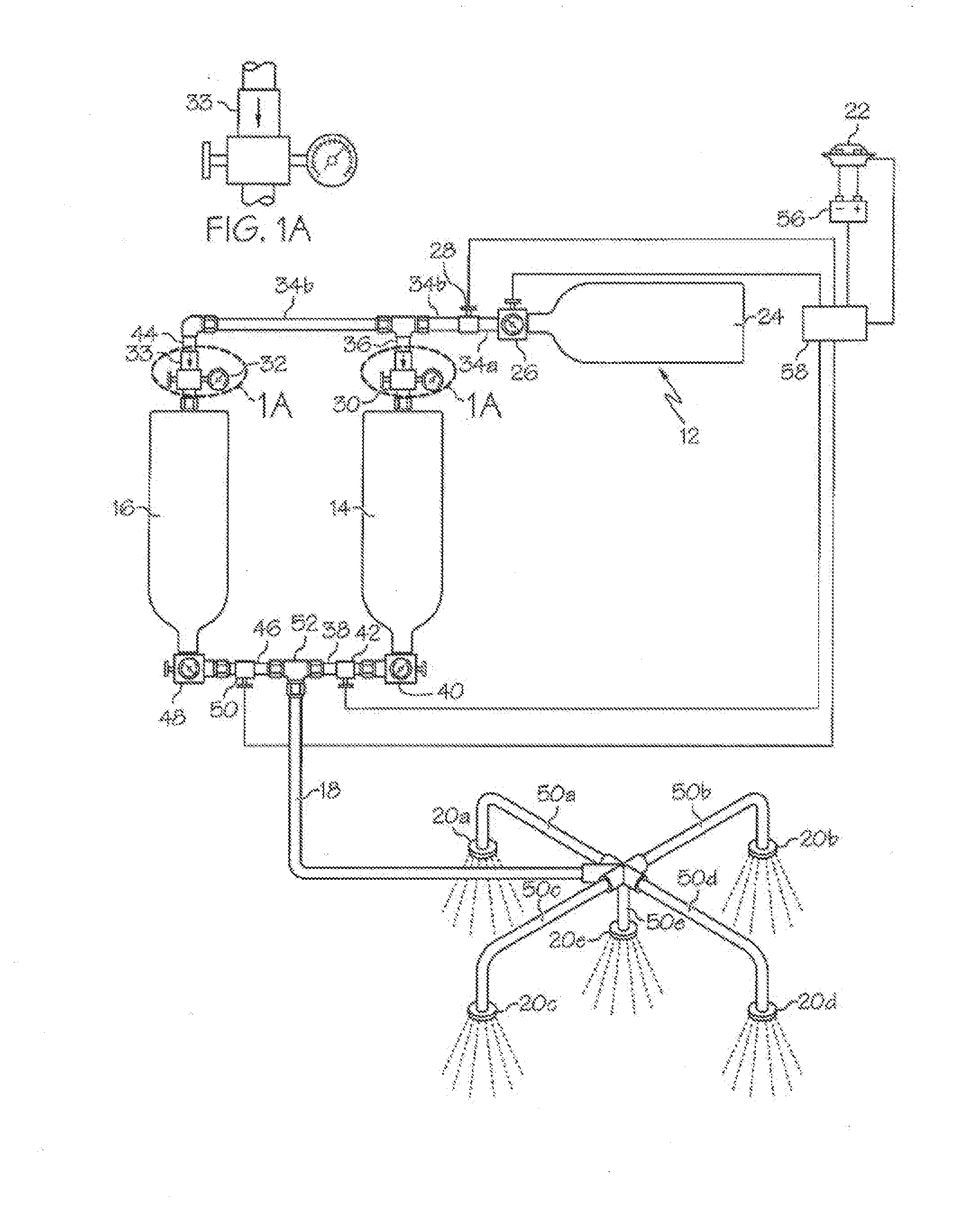

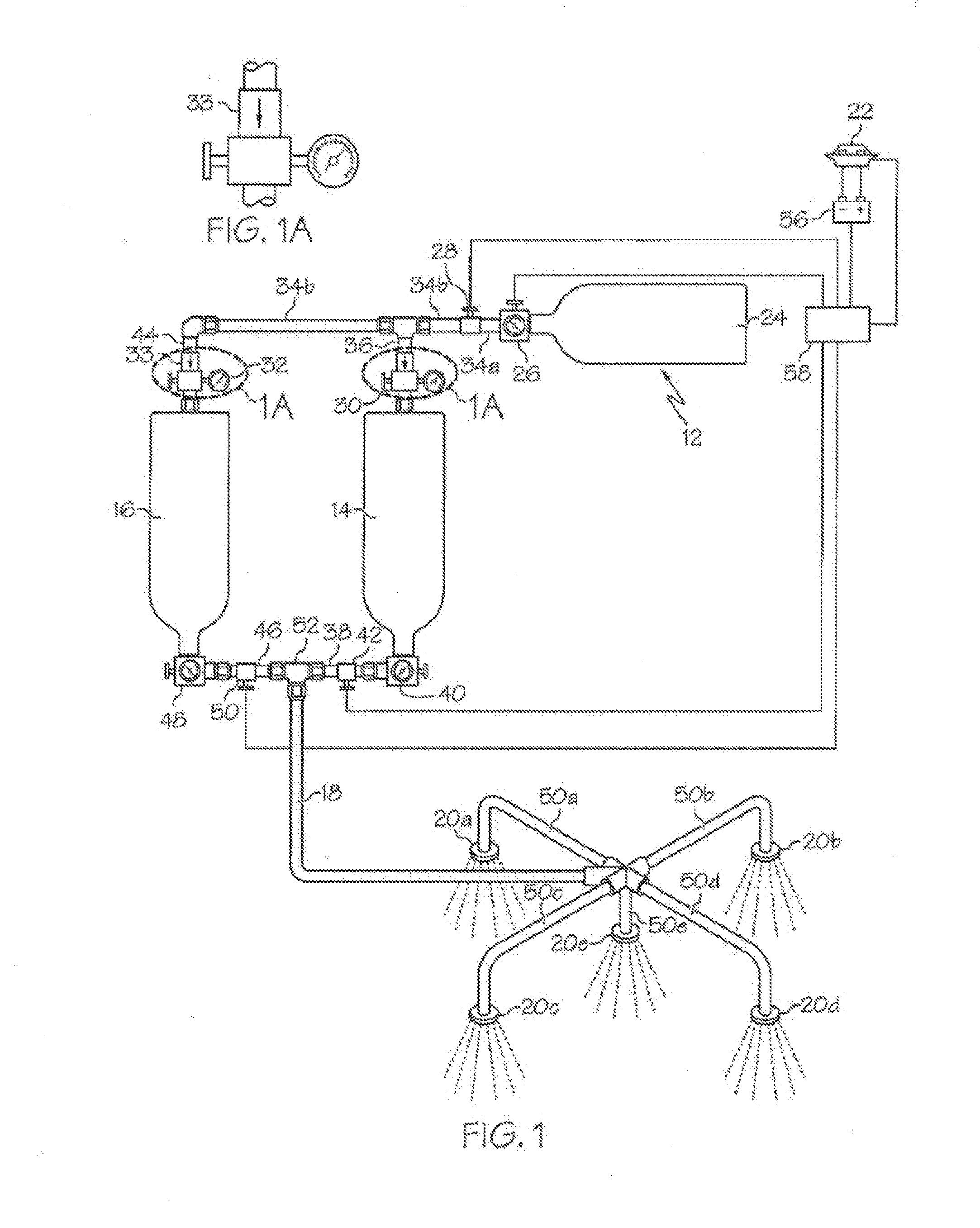

Fire Suppression System

ActiveUS20120168184A1Prevent and lessen possibilityEffective fire protectionFire rescueFire detectorSpray nozzle

A fire suppression system for a container including a first tank containing a first liquid component of a two-part foam and a second tank containing a second liquid component of the foam. The system also includes at least one liquid component release device configured to be selectively capable of releasing the first and second components from their respective containers upon receipt of a signal from a fire detector upon detection of a fire. The two-part foam components are propelled through the system by a pressurized propellant that, upon release of the release device, causes the exit of the foam components from their respective tanks, through a mixing conduit to at least one nozzle. The nozzle is configured to spray the liquid component foam mixture into the container wherein the foam cures into a substantially semi-rigid, closed cell foam that is substantially impermeable and may have charring and / or intumescence properties.

Owner:ENK SR WILLIAM ARMAND

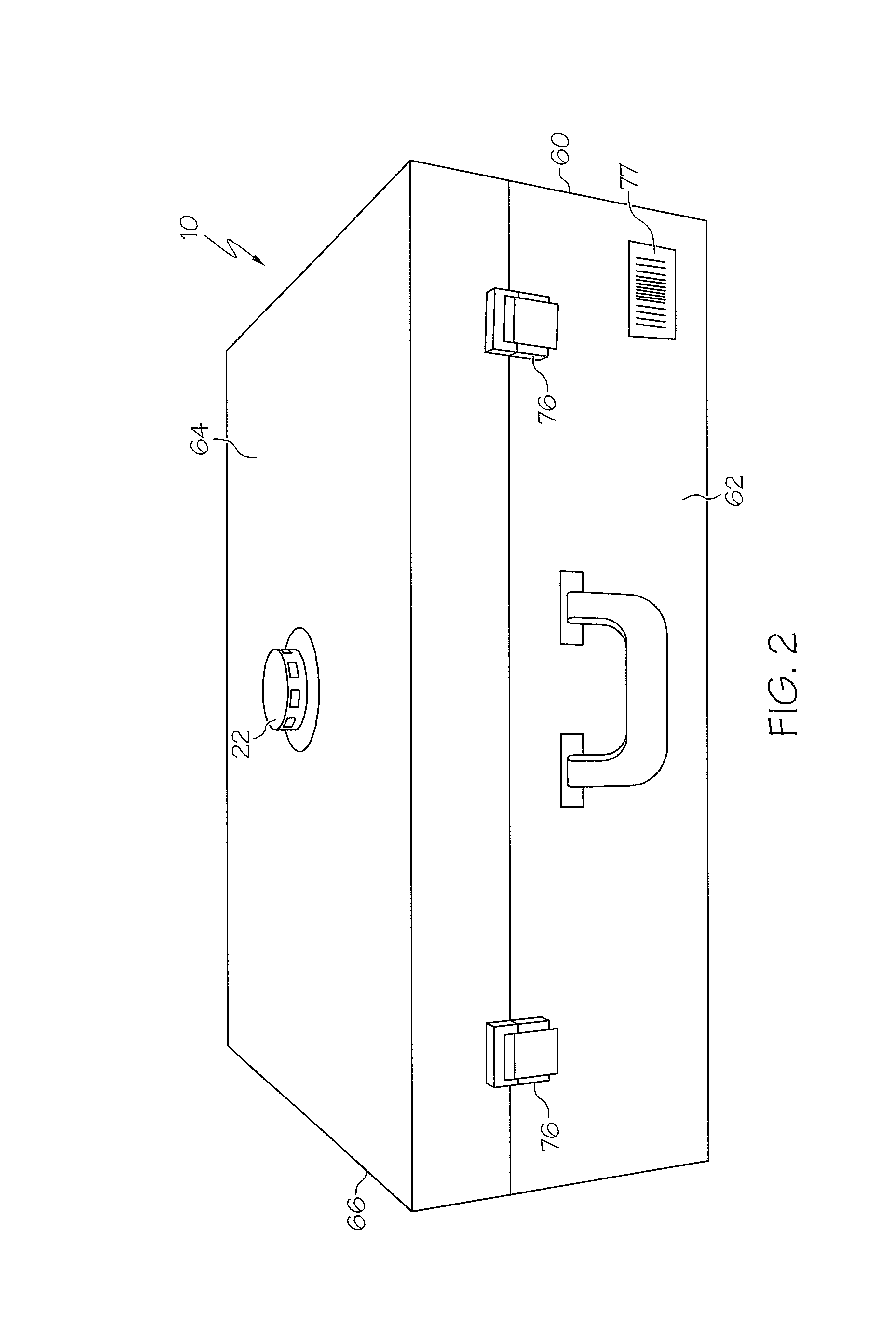

Hazard detection, warning, and response system

The invention provides a self-contained automatic fire detection, warning, and suppression life safety system having an extinguishant source and a fire detector coupled to an electronic processor. The processor has logic to interface with components for detecting and warning of a fire and releasing the extinguishant. Self-diagnosis logic checks the entire system's function, pressure, power level, and power source. Additional sensors are provided for detecting various hazards, and the processor has logic for proper response.

Owner:GOLDEN PATRICK E

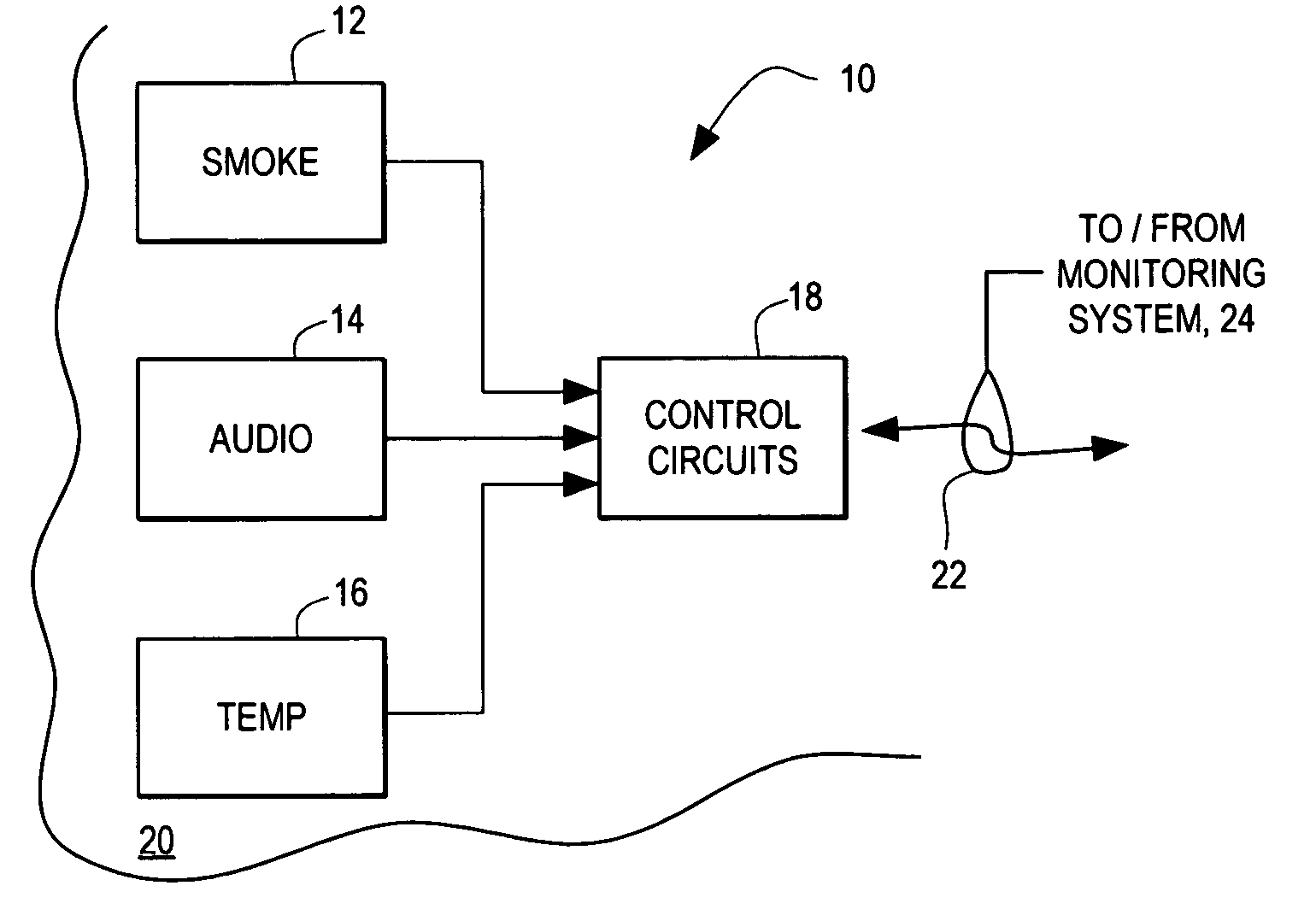

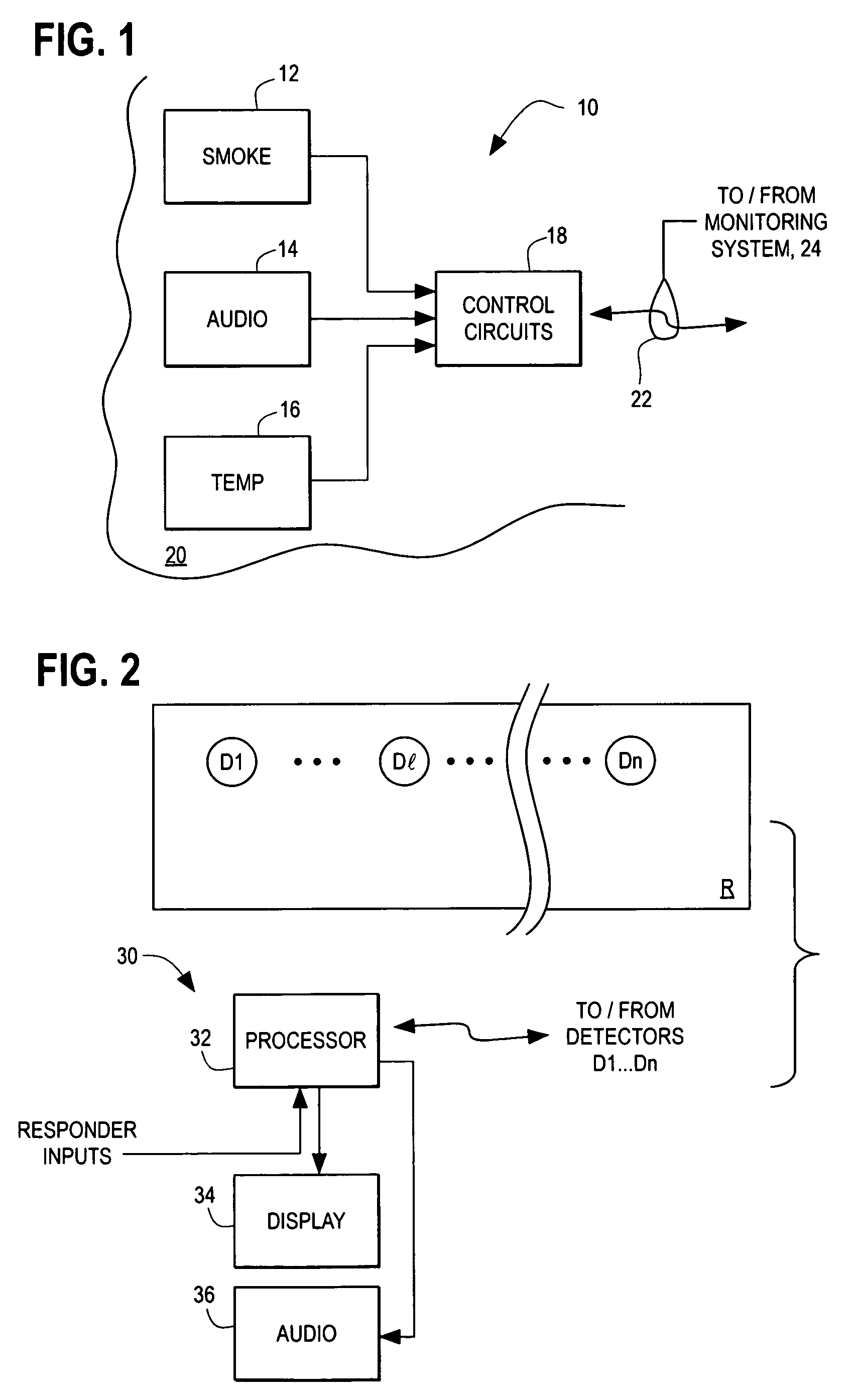

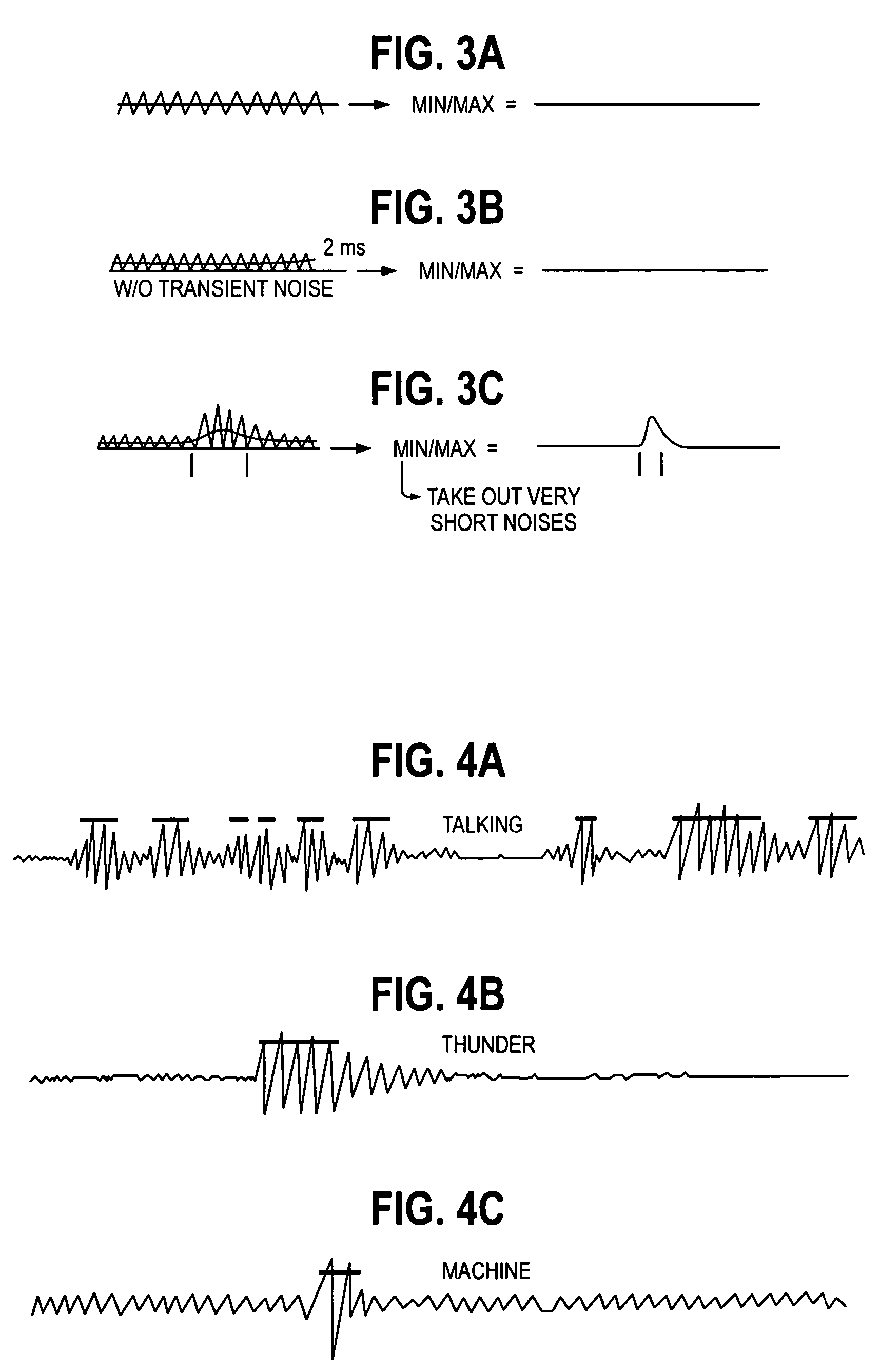

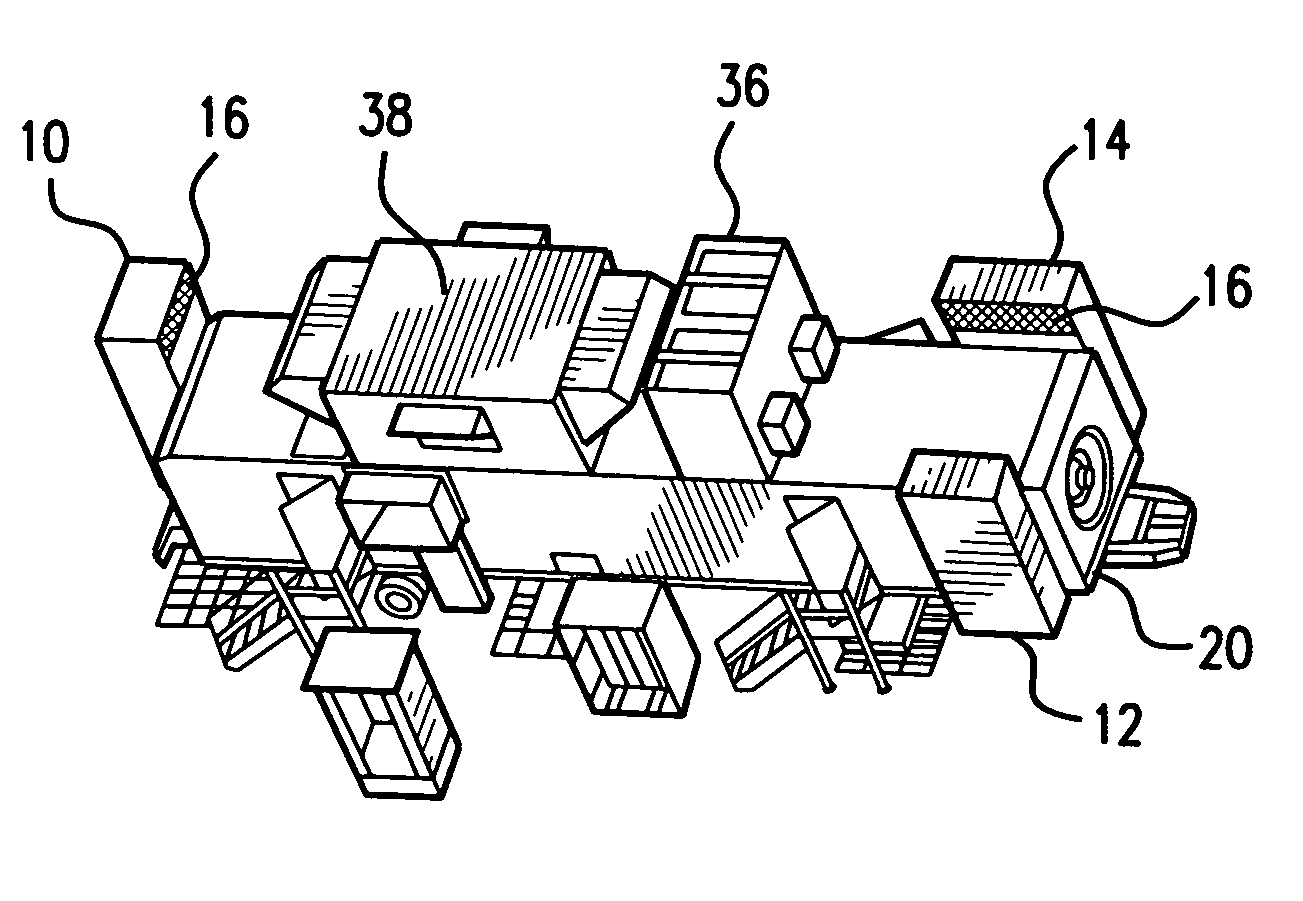

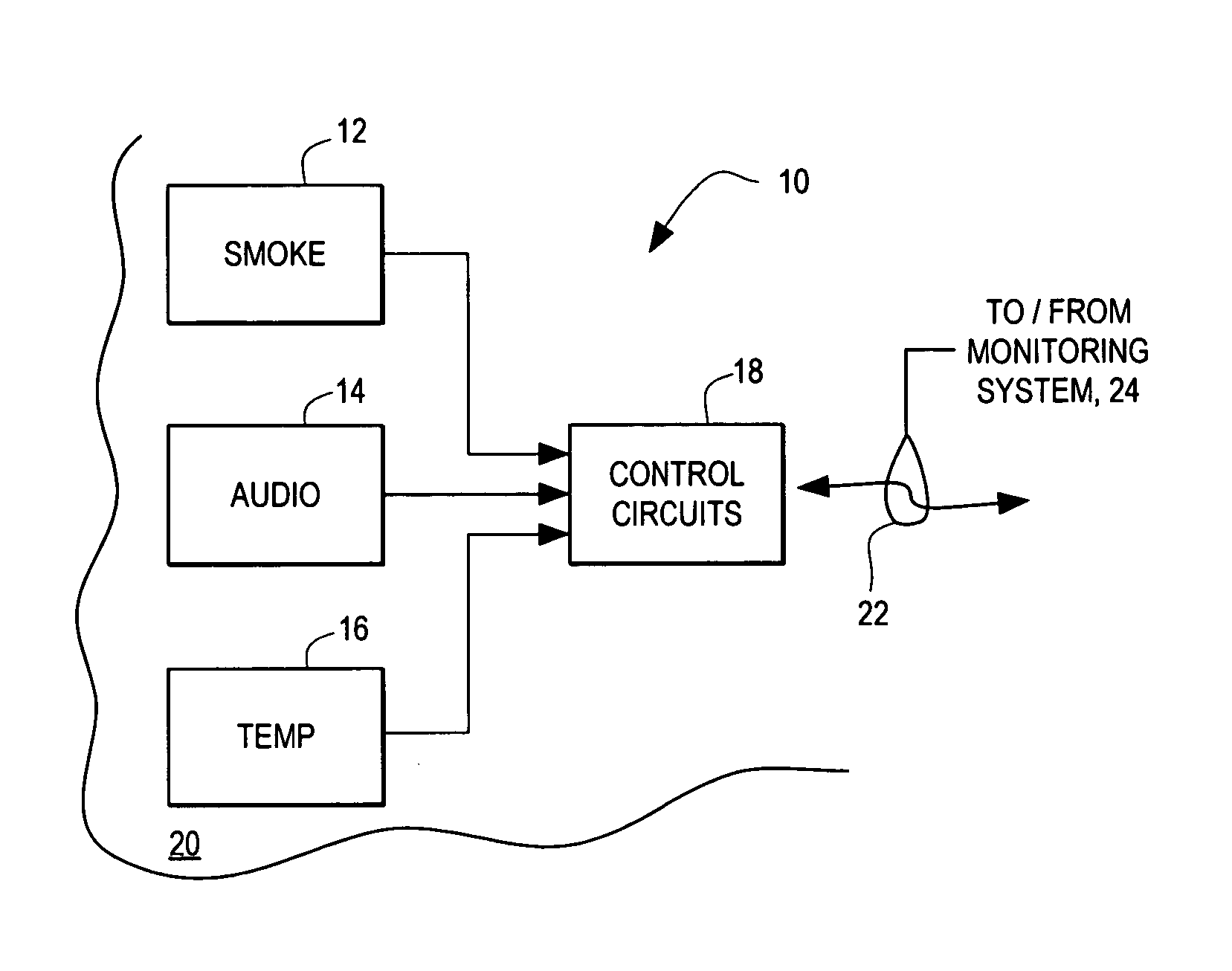

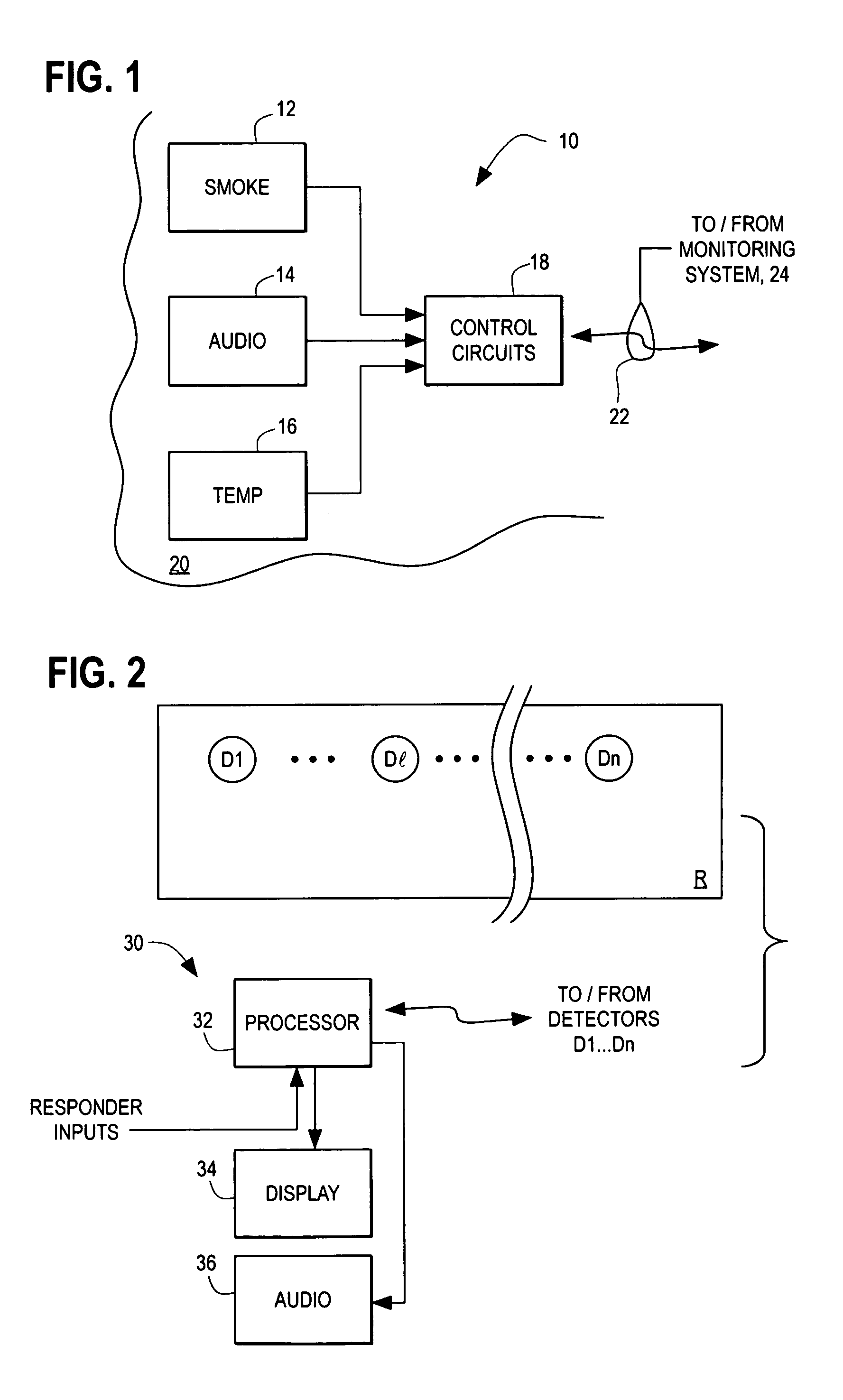

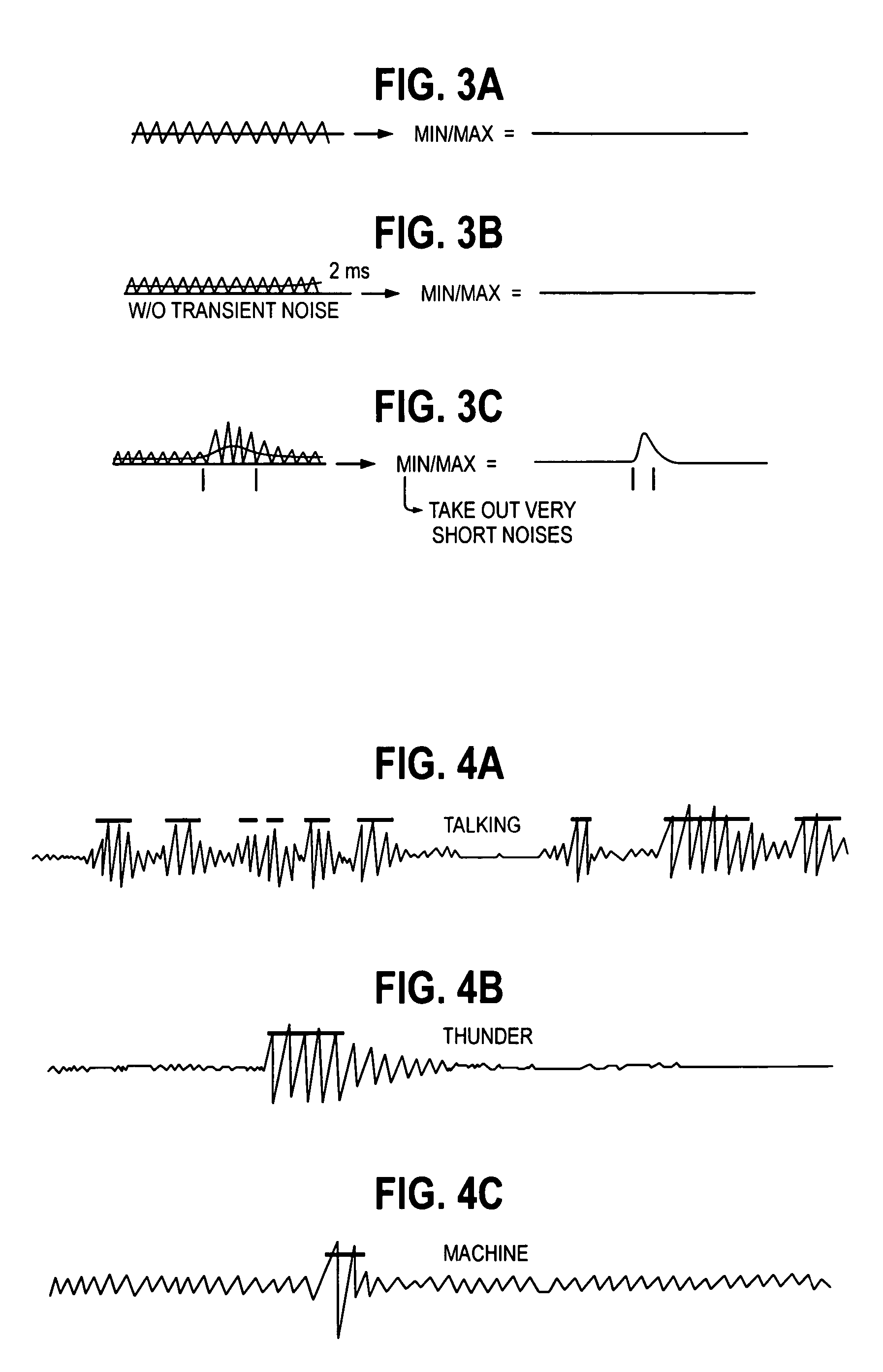

Multi-sensor fire detectors with audio sensors and systems thereof

InactiveUS7221260B2High sensitivityMore sensitiveElectrical apparatusElectric lighting sourcesFire detectorTransducer

Owner:HONEYWELL INT INC

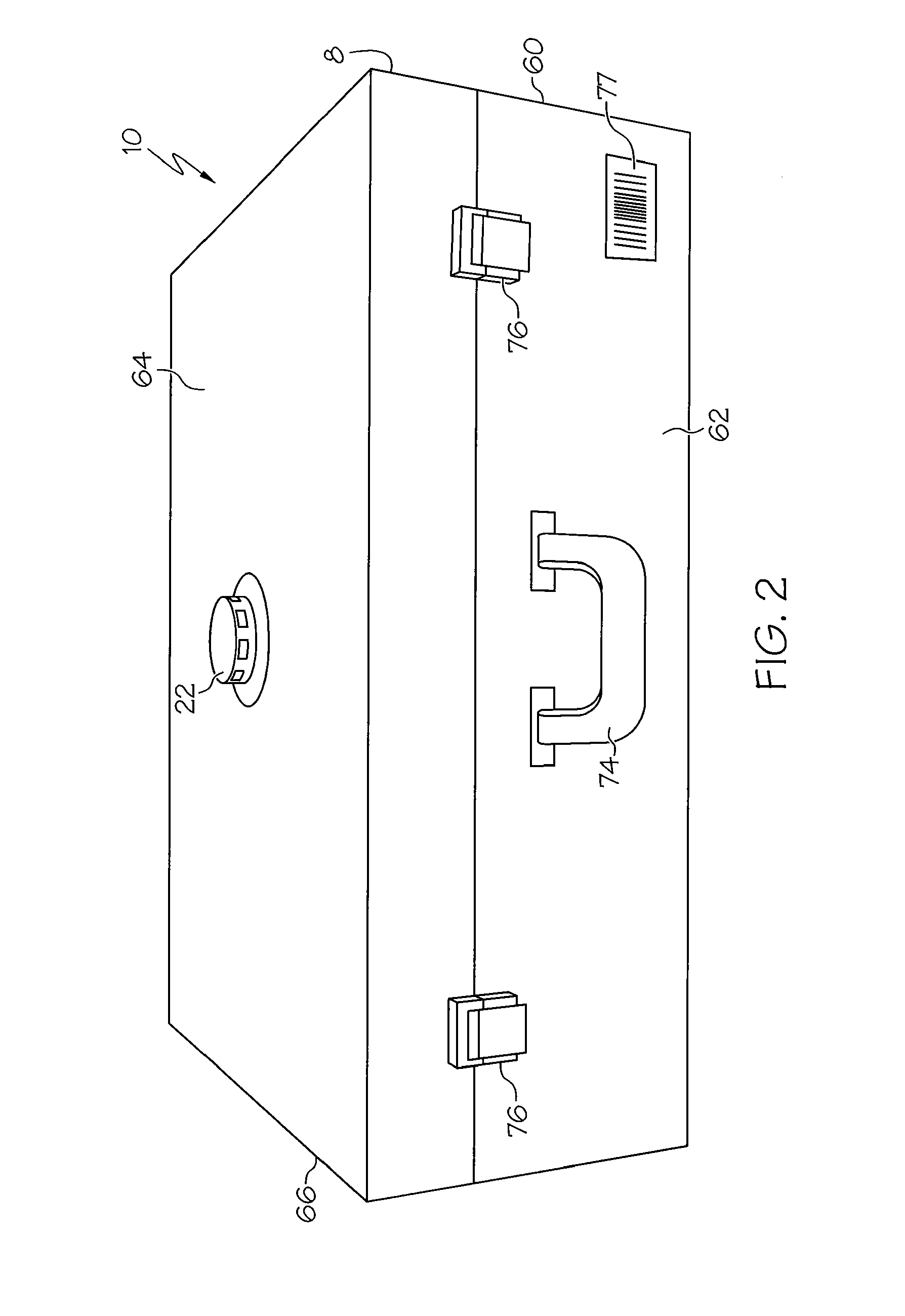

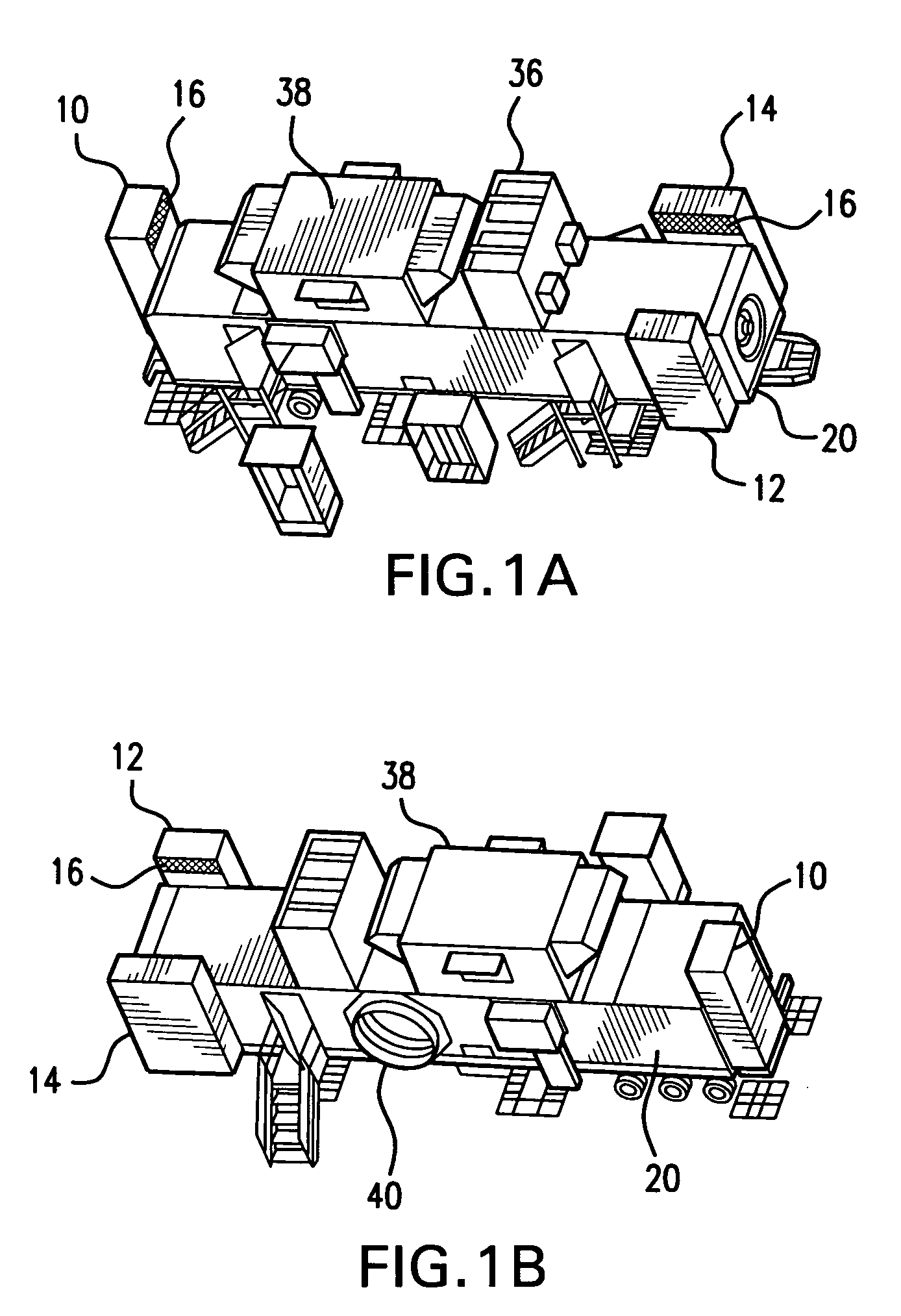

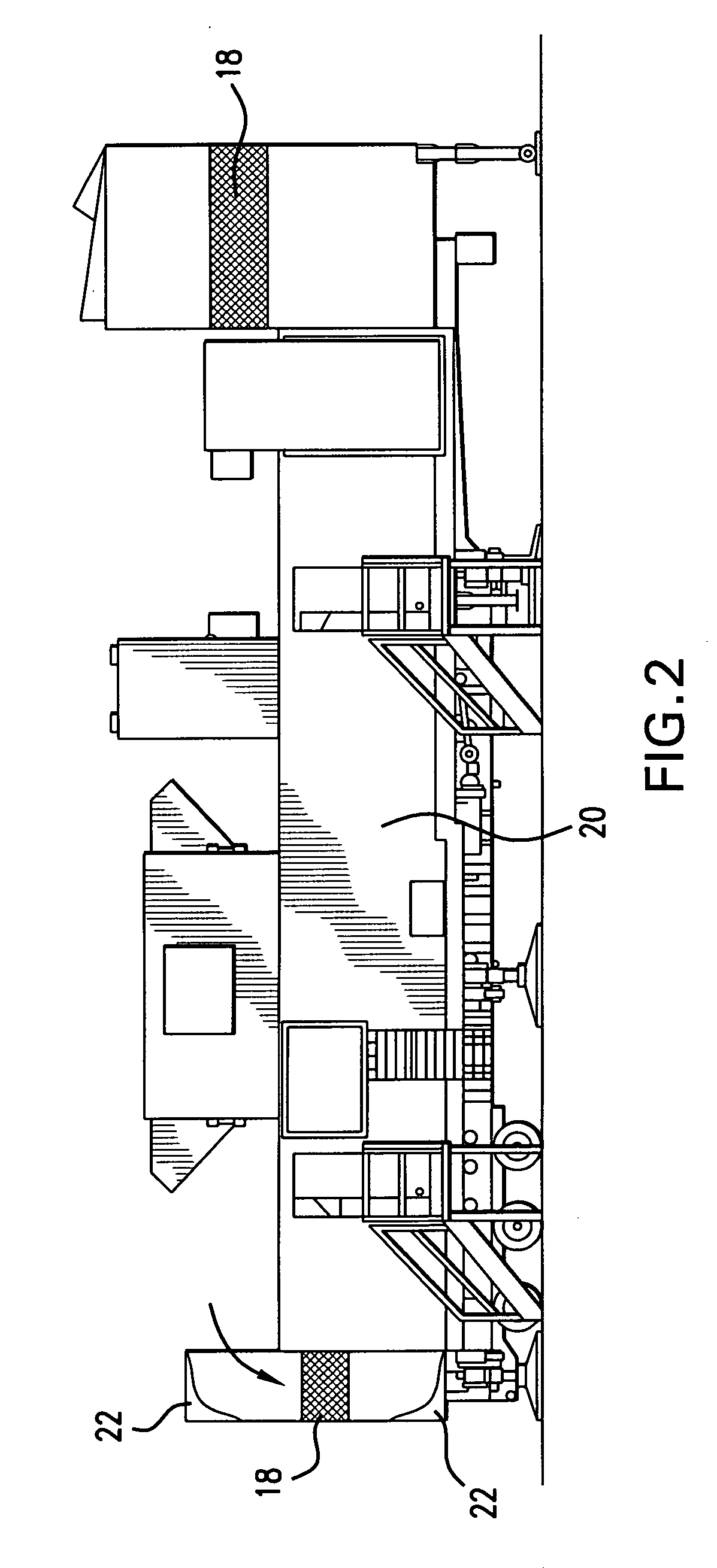

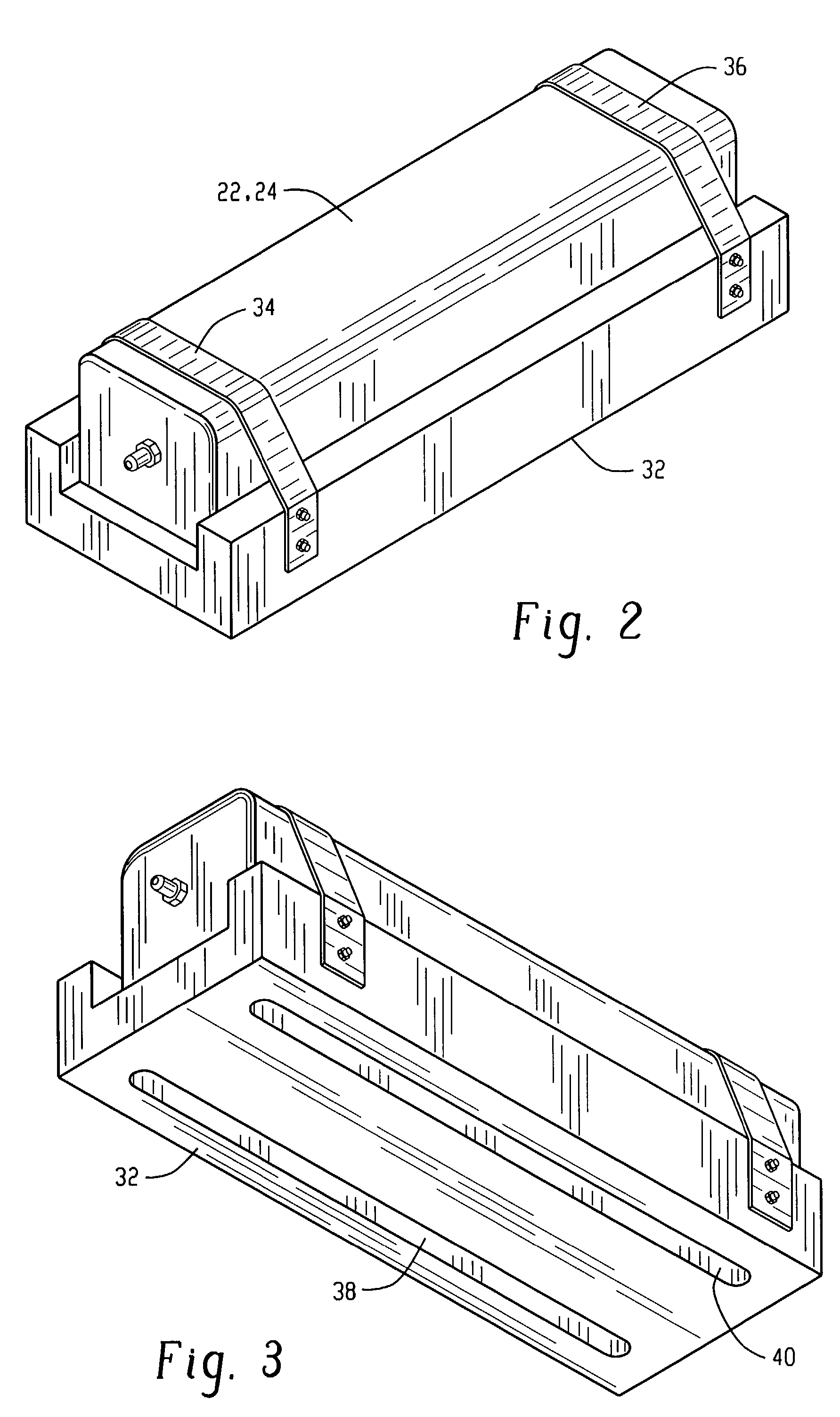

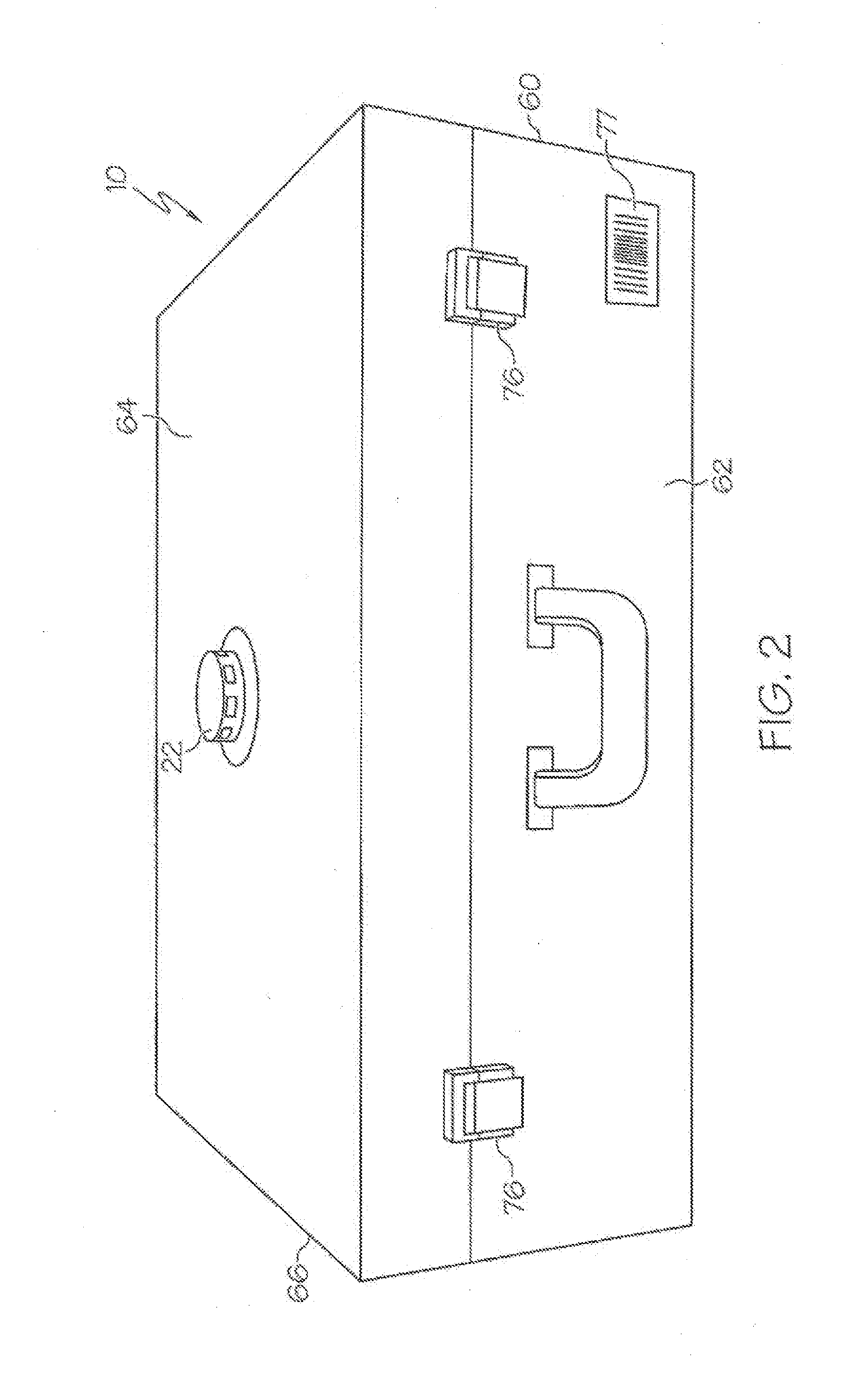

Power trailer structural elements for air flow, sound attenuation and fire suppression

An enclosure comprising elements for air management, sound attenuation and fire suppression in a trailer-mounted mobile electrical power generation system. Air management is provided by ducts, fans, seals and a barrier wall. In addition, by establishing airflow away from spark-producing equipment, any fuel that might leak will not accumulate near the spark-producing equipment, and thus fire and explosion risks are reduced. Targeted sound suppression in the ducts, walls, floor and ceiling of the enclosure provides acceptable noise levels. Fire detectors, a fire suppression system and dampers allow for quickly controlling fires inside the enclosure. A roof panel sealing system provides access into the enclosure during assembly and maintenance while providing a watertight and noise tight seal during transit and operations.

Owner:VULCAN ADVANCED MOBILE POWER SYST

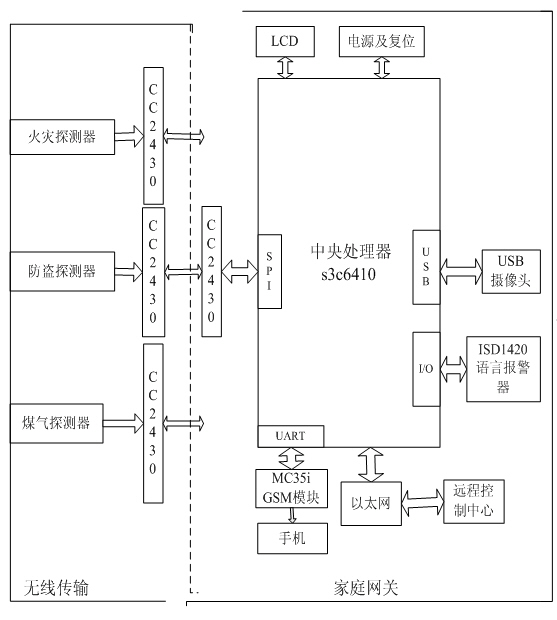

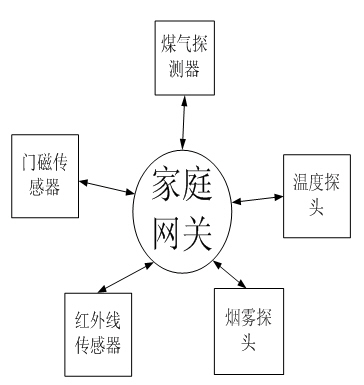

Household security system

InactiveCN102355391AImprove securityImprove reliabilityNetwork topologiesData switching by path configurationSerial digital interfaceWireless transceiver

The invention provides a household security system which comprises a home gateway, sensors and a zigbee wireless transceiver, wherein the zigbee wireless transceiver is used for providing information interchange between the sensors and the home gateway; the home gateway comprises a central processor and further comprises a camera interface for connecting a camera, a UART (Universal Asynchronous Receiver / Transmitter) serial port interface, an Ethernet interface, an SPI (Single Program Initiation) interface, an LCD (Liquid Crystal Display) interface and an I / O (Input / Output) interface which are arranged on the central processor; the central processor comprises a master chip s3c6410 based on an ARM11 framework and a peripheral circuit; the camera interface is a USB (Universal Serial Bus) interface capable of connecting a USB camera; the UART serial port interface is connected to a MC35iGSM module; the I / O interface is connected to a voice alarm; and the sensors comprise a fire detector, an antitheft detector and a gas detector. A complex wiring process for mounting the household security system is omitted, thereby realizing multi-point and remote transmission of security information, promoting safety and reliability as well as hidden performance of the household security system, and lowering the cost.

Owner:GUANGDONG UNIV OF TECH

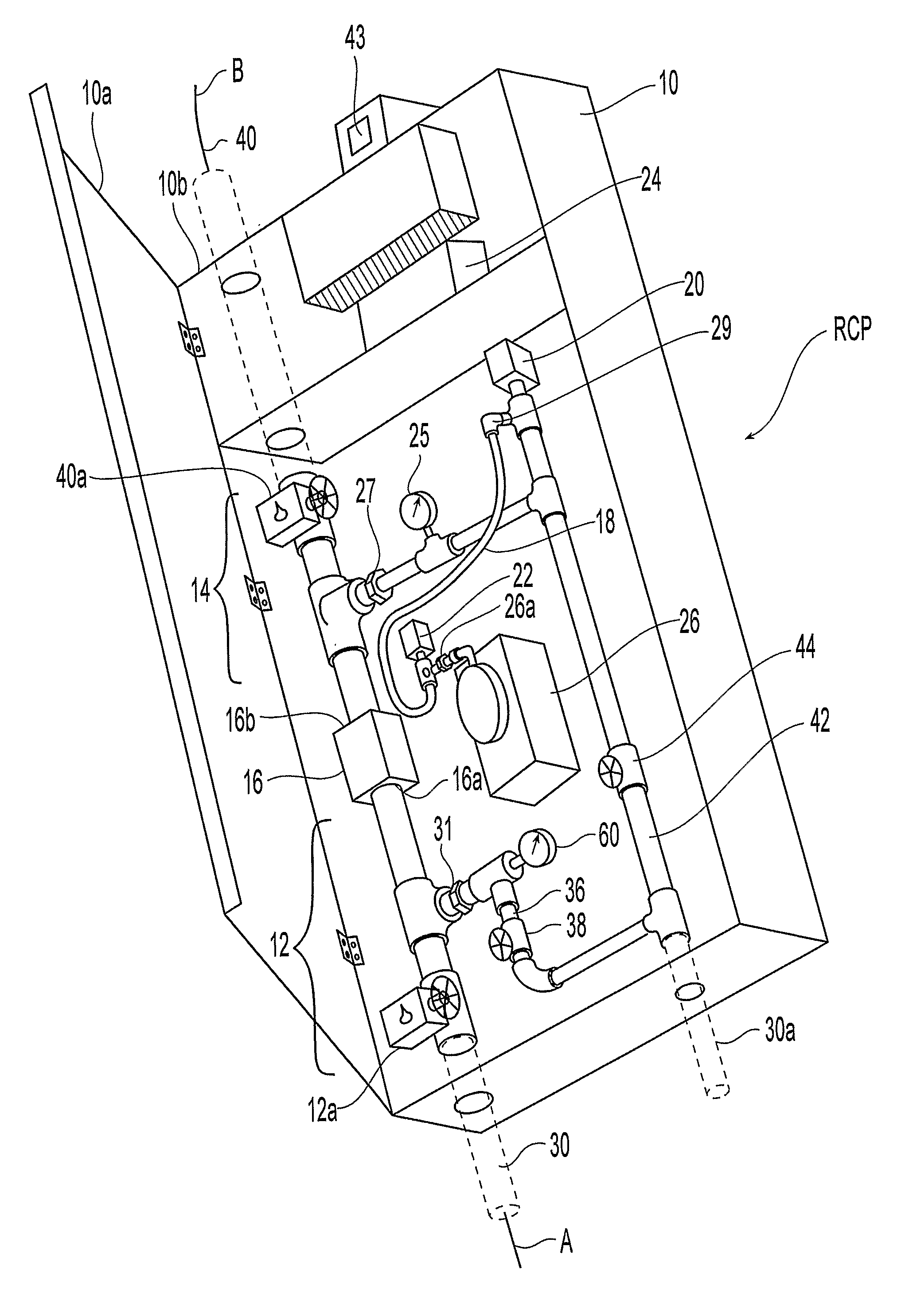

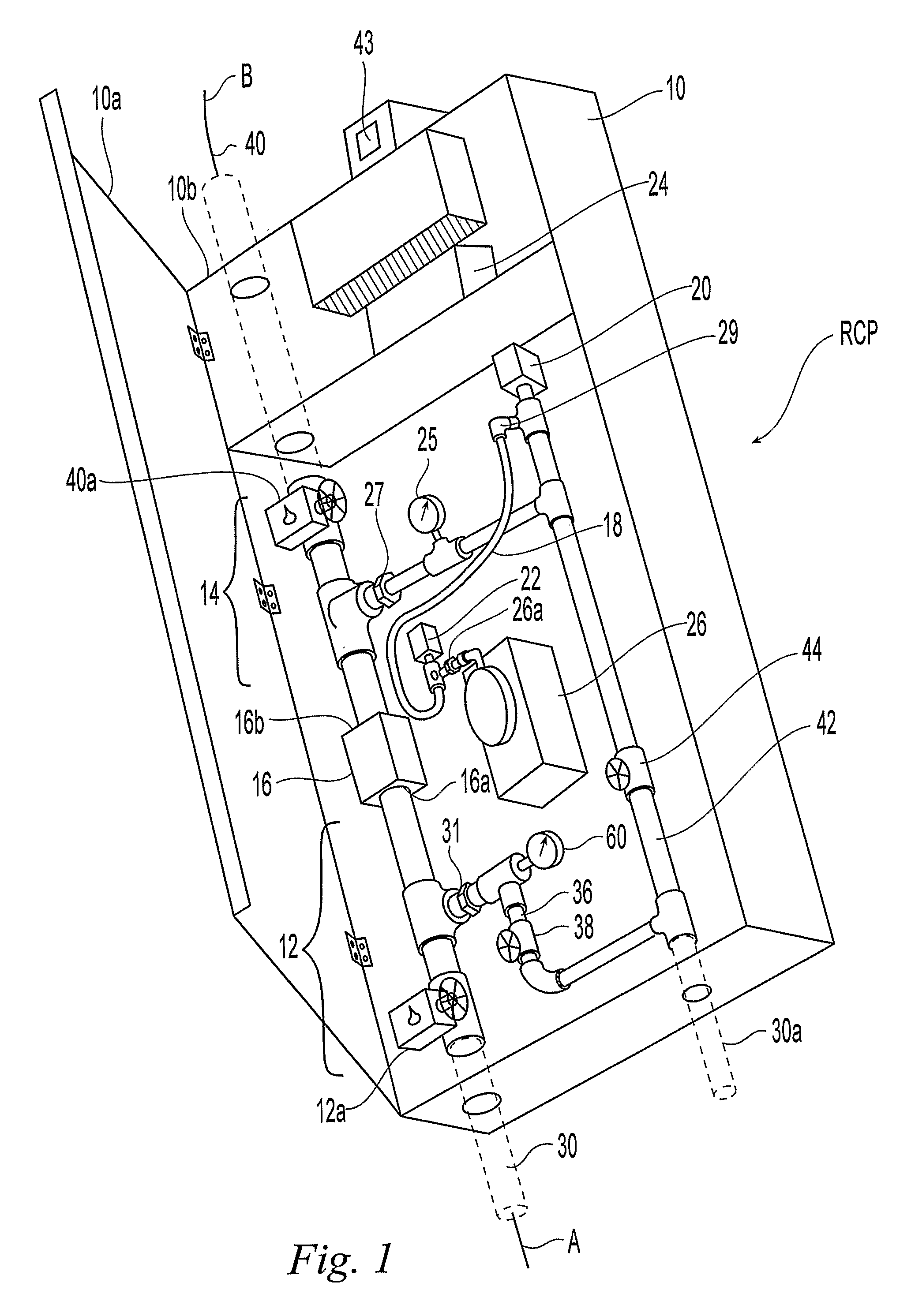

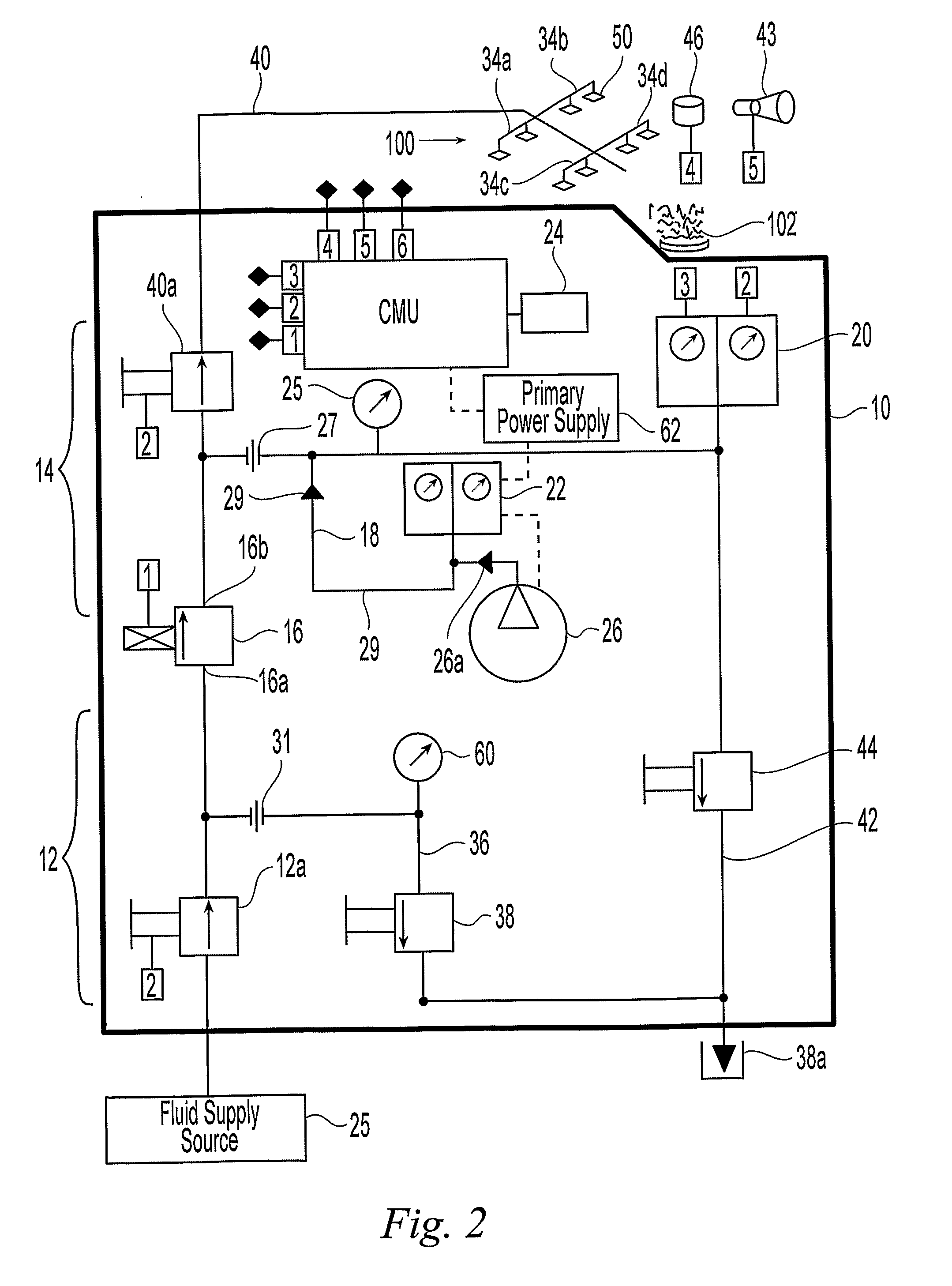

Releasing Control Unit For a Residential Fire Protection System

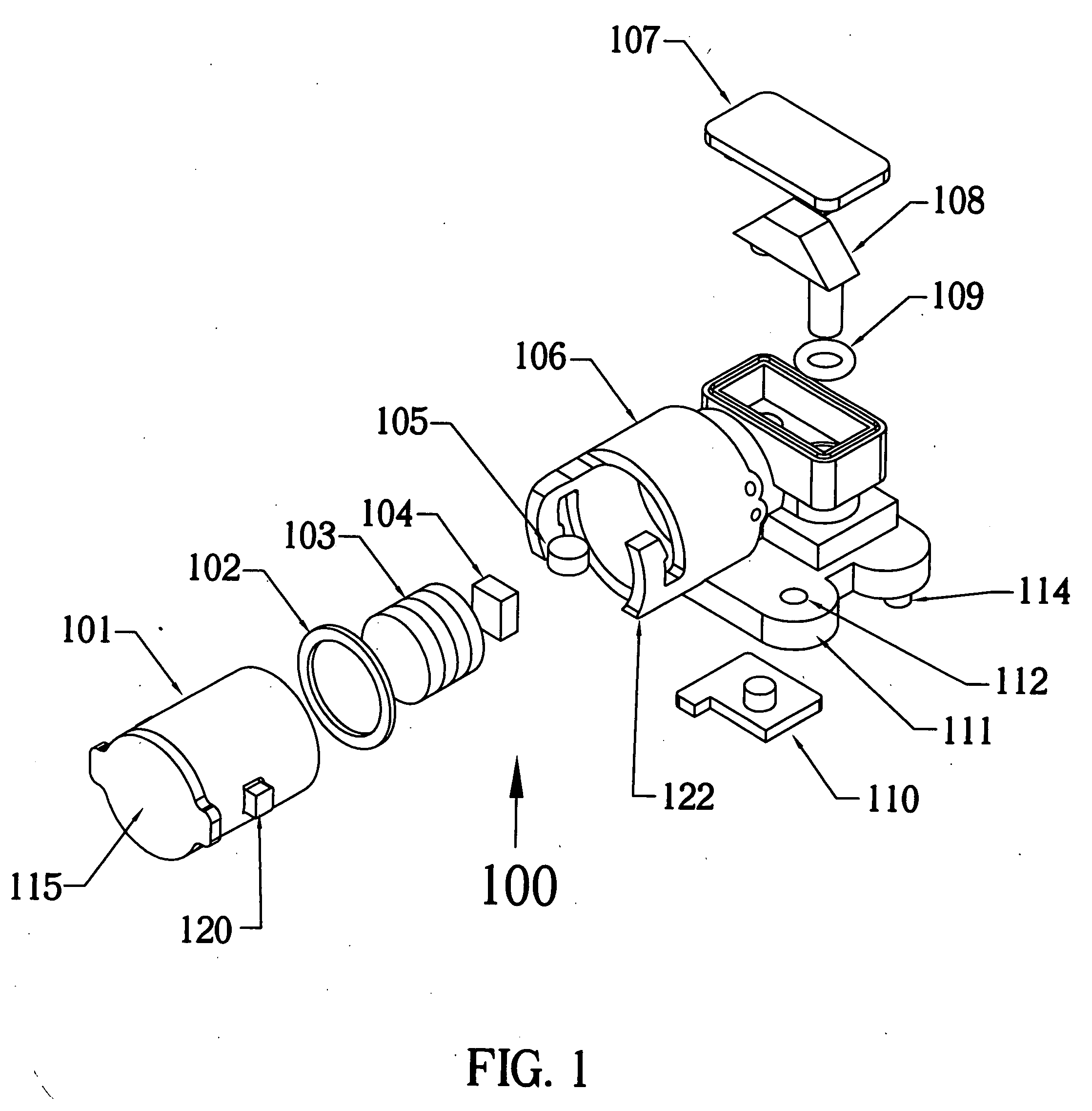

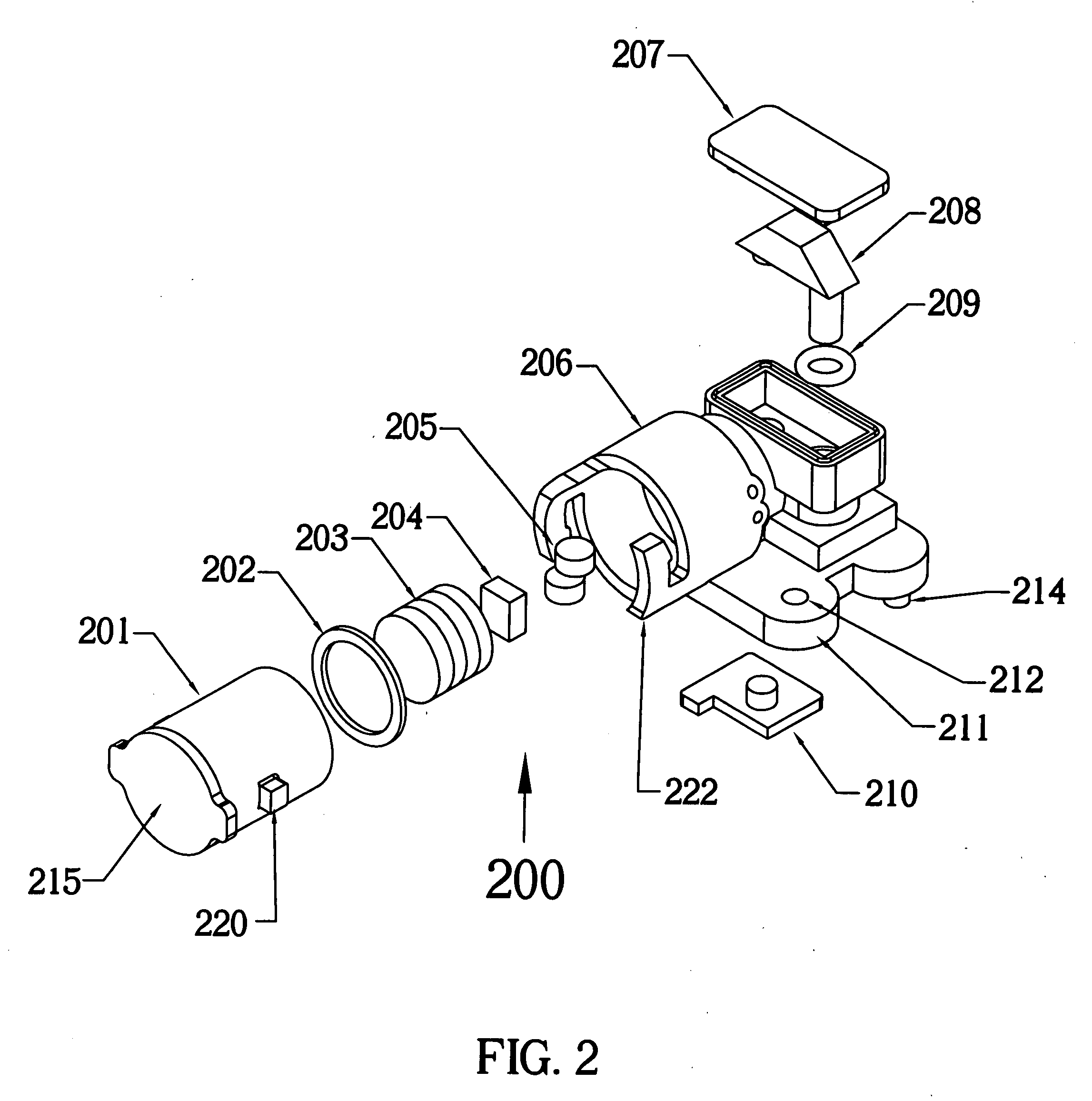

ActiveUS20080277125A1Easy to transport waterEasy to operateFire rescueBoring toolsControlled releaseFire detector

Owner:TYCO FIRE PRODS LP

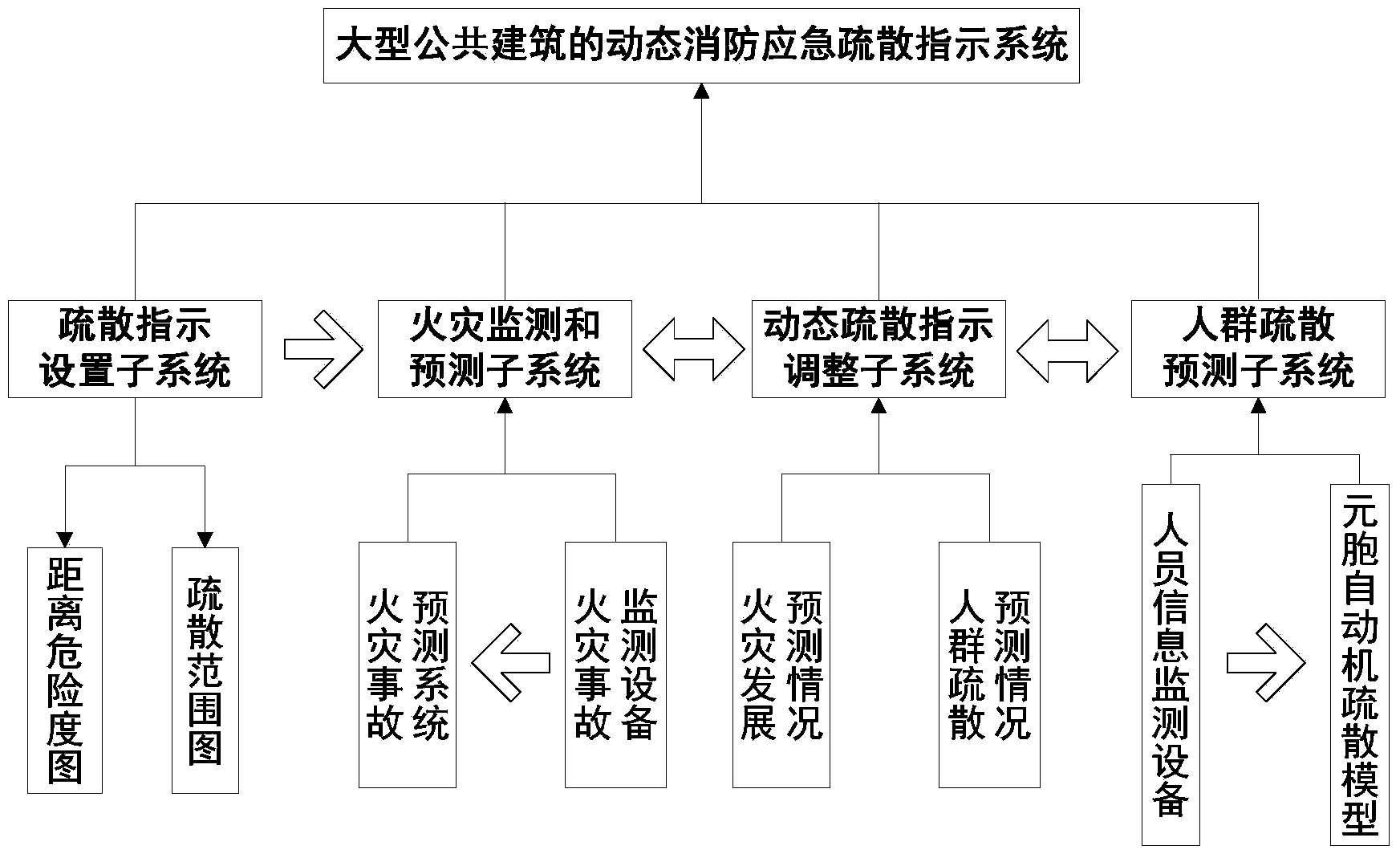

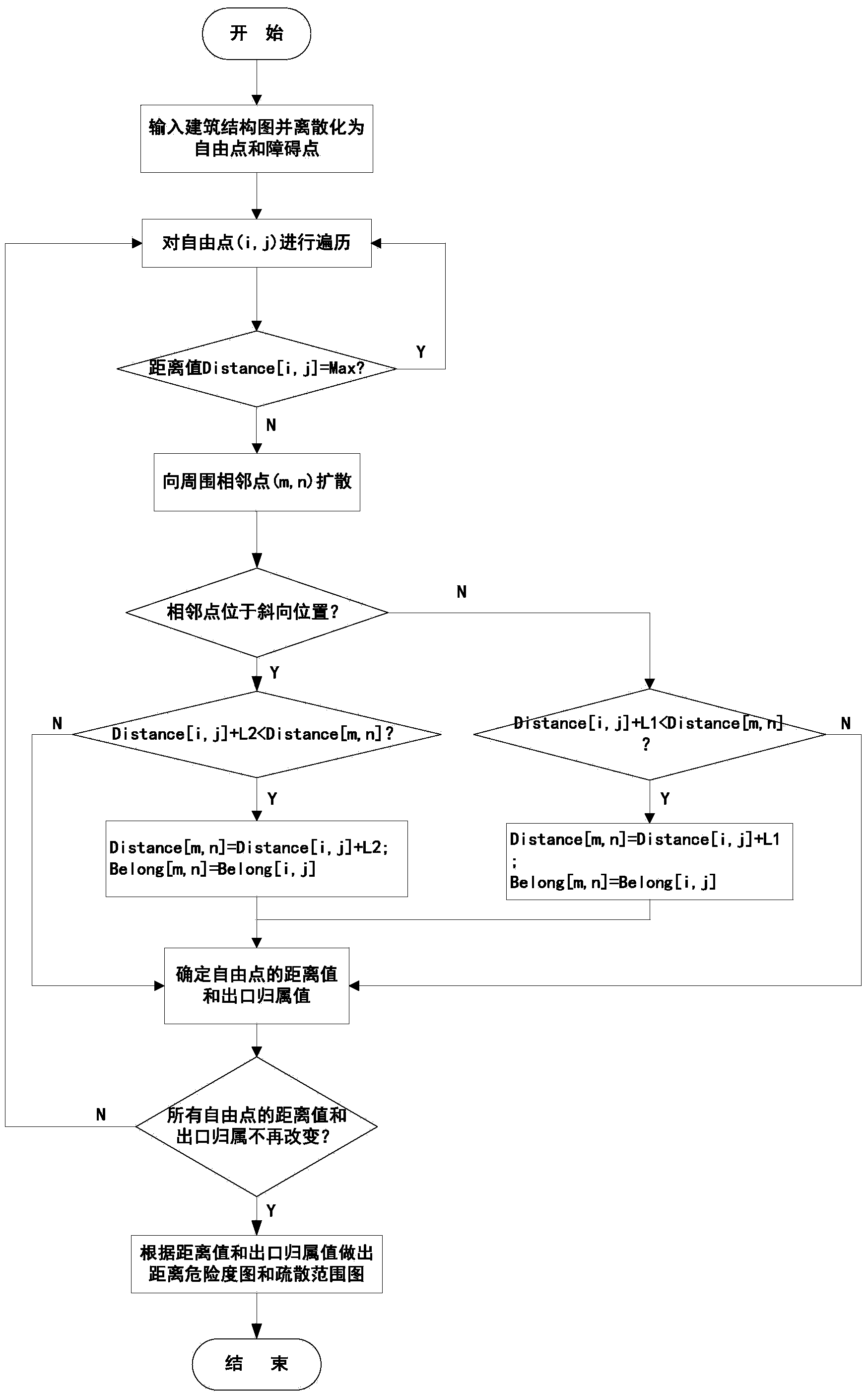

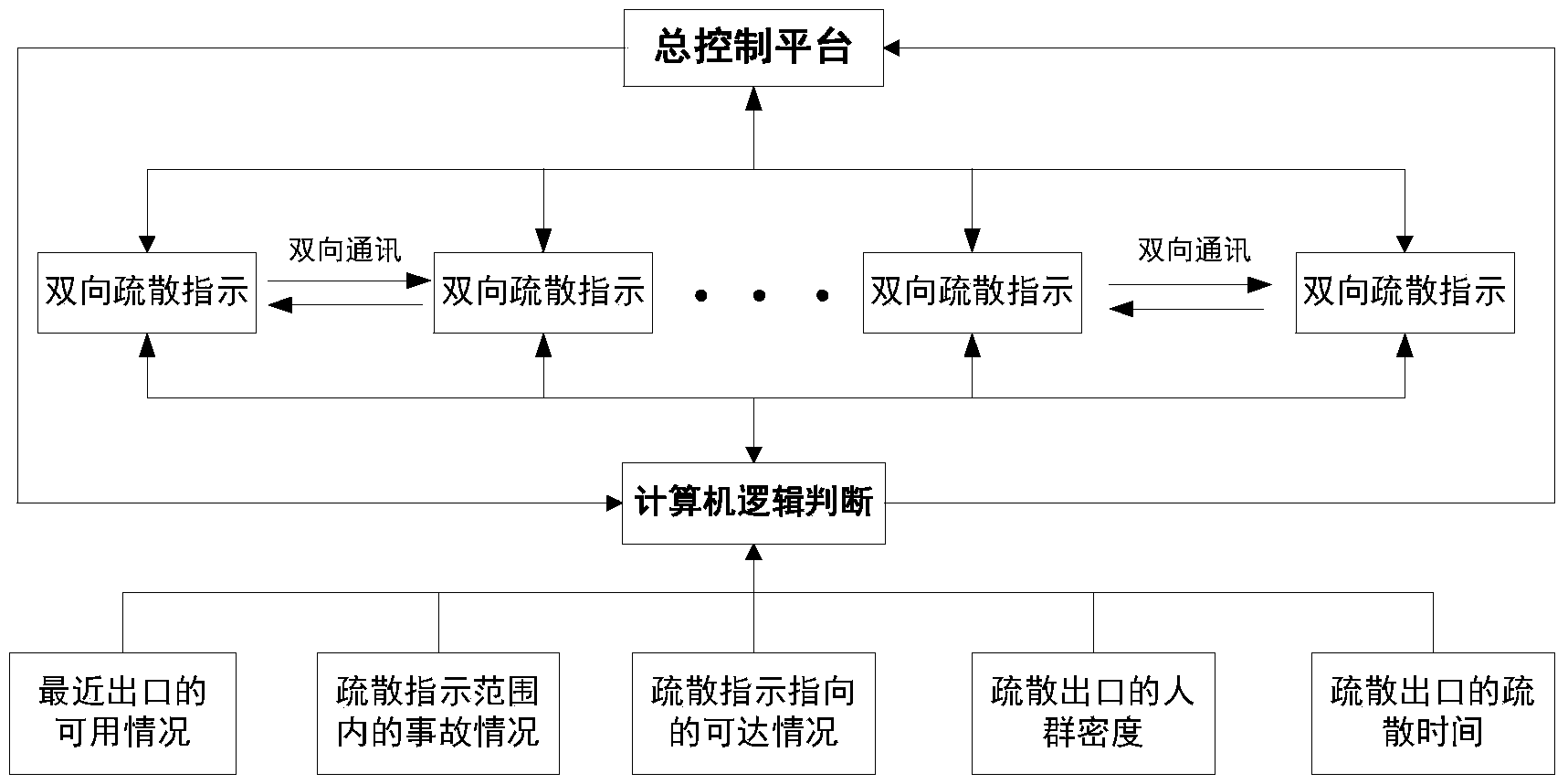

Dynamic firefighting emergency evacuation indicating system for large-scale public building

ActiveCN103830855AReduce casualtiesIntuitive accident informationBuilding rescueFire detectorCellular automation

The invention discloses a dynamic firefighting emergency evacuation indication system for a large-scale public building. The dynamic firefighting emergency evacuation indication system comprises an evacuation indication setting subsystem, a firefighting monitoring and predicating subsystem, a dynamic evacuation indication adjusting subsystem and a crowd evacuation predicating subsystem. Firstly, evacuation indication distribution in the large-scale public building is set according to the evacuation indication setting subsystem; secondly, firefighting accidents happening in the large-scale public building are considered, multiple fire detectors are used for obtaining information such as the position and the intensity of a fire, and a computer model is used for predicating the development of the fire; thirdly, the development of the fire is used for dynamically adjusting evacuation indication to ensure that the evacuation indication points to a safe area; finally, a built cellular automaton evacuation model considering the evacuation indication function is adopted to predict crowd evacuation and feeds back a predication result to the dynamic evacuation indication adjusting subsystem. The evacuation indication is corrected again according to the crowd density, the evacuation time and the like, and the evacuation efficiency is improved.

Owner:UNIV OF SCI & TECH OF CHINA

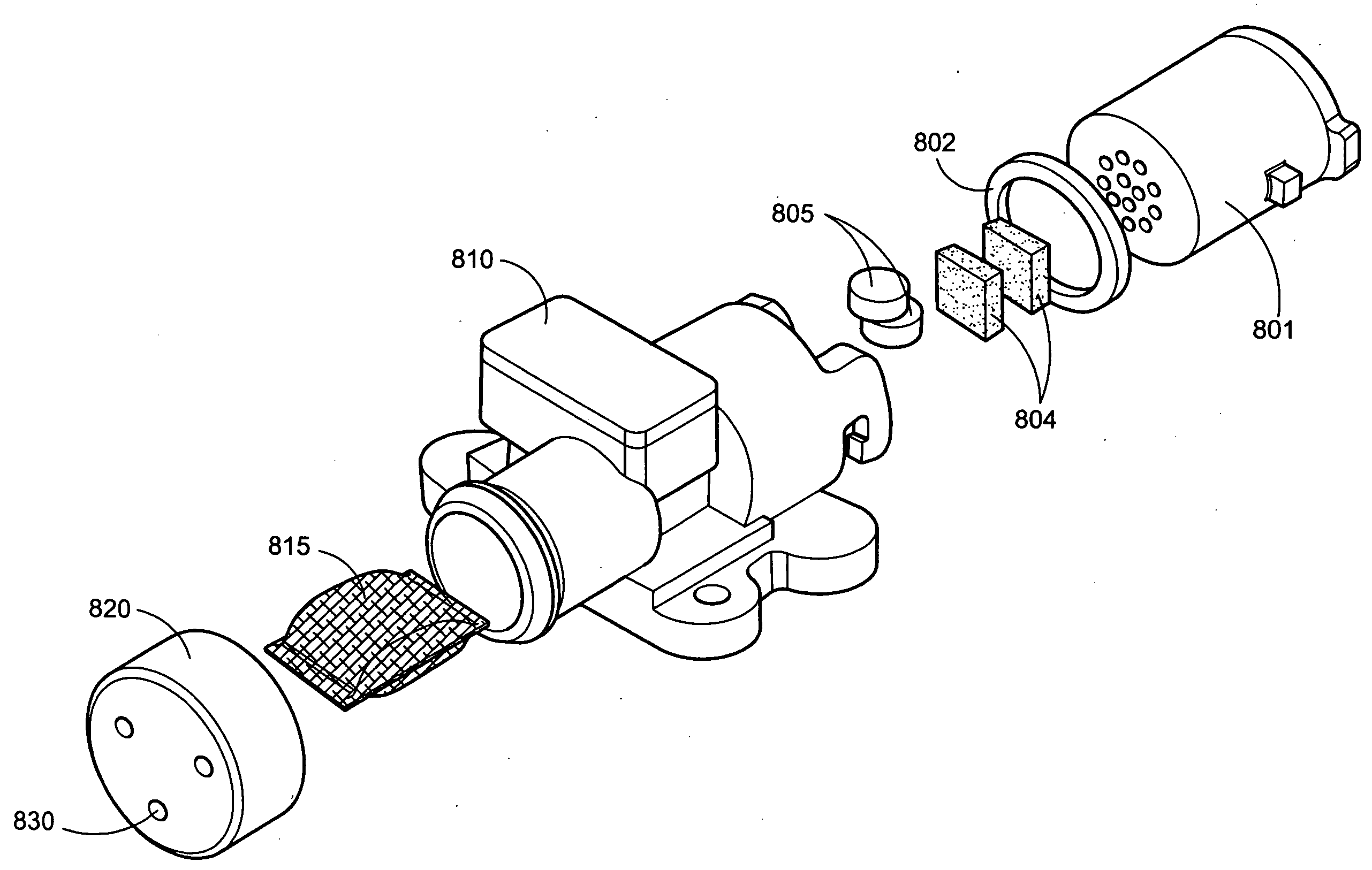

Carbon monoxide (CO) microsir sensor system

InactiveUS20080173817A1Different in diameterDifferent in structureRadiation pyrometryAnalysis using chemical indicatorsDual sensorReservoir system

The present invention provides very small low cost apparatus and method for determining the concentration and / or hazard from a target gas by means of optically monitoring one or more sensors that responds to carbon monoxide. The apparatus comprises a photon source optically coupled to the sensor and the photon intensity passing through the sensor is quantified by one or more photodiode(s) in a system, so that the photon flux is a function of at least one sensor's response to the target gas, e.g., transmits light through the sensor to the photodiode. The photocurrent from the photodiode is converted to a sensor reading value proportional to the optical characteristics of the sensors and is loaded into a microprocessor or other logic circuit. In the microprocessor, the sensor readings may be differentiated to determine the rate of change of the sensor readings and the total photons absorbed value may be used to calculated the CO concentration.There are a number of methods to compute the CO hazard and these is subject of another patent to be filed. In addition, a preferred method to meet the BSI and European CO Standards is described using two sensor systems with two different sensors each having different sensitivity within one housing. The single housing dual sensor uses one LED and two photodiodes. The novel two sensors method to meet the European (BSI) CO standard is similar to the method developed to meet the Japanese standard.The major advantages of MICROSIR over SIR are: 1. Lower cost (estimates saving of US$1.25 per sensor, 2. Better controlled gas path therefore more accurate and more precision, 3. Better getter system therefore longer life (as shown by ammonia accelerated age tests), and 4. Better RESERVOIR SYSTEM THEREFORE BETTER humidity CONTROL AT BOTH LOW AND HIGH (as shown by sensor response curves).5. The MICROSIR Edgeview is faster and meets the Japanese standard for CO and the European Standard for CO enhanced smoke, 6. More easily automated as the board of alarms use surface mount and MICROSIR is a surface mount part that attaches over surface mounted optics after the soldering, 7. small size, and 8. approved UL recognized component.The MICROSIR device can also be used to detect the CO, which may be combined with temperature and smoke in a very small package. The detection of one or more indicators such as smoke and CO; increases the sensitivity of the other indicators. Combining signals produces an improved fire detector comprising a CO sensor and a smoke sensor in one unit. The smoke detection sensor may be either ionization or photoelectric either or both may be combined with the CO sensor to provide earlier warning to fire and reduce false alarms.

Owner:THE QUANTUM GROUP

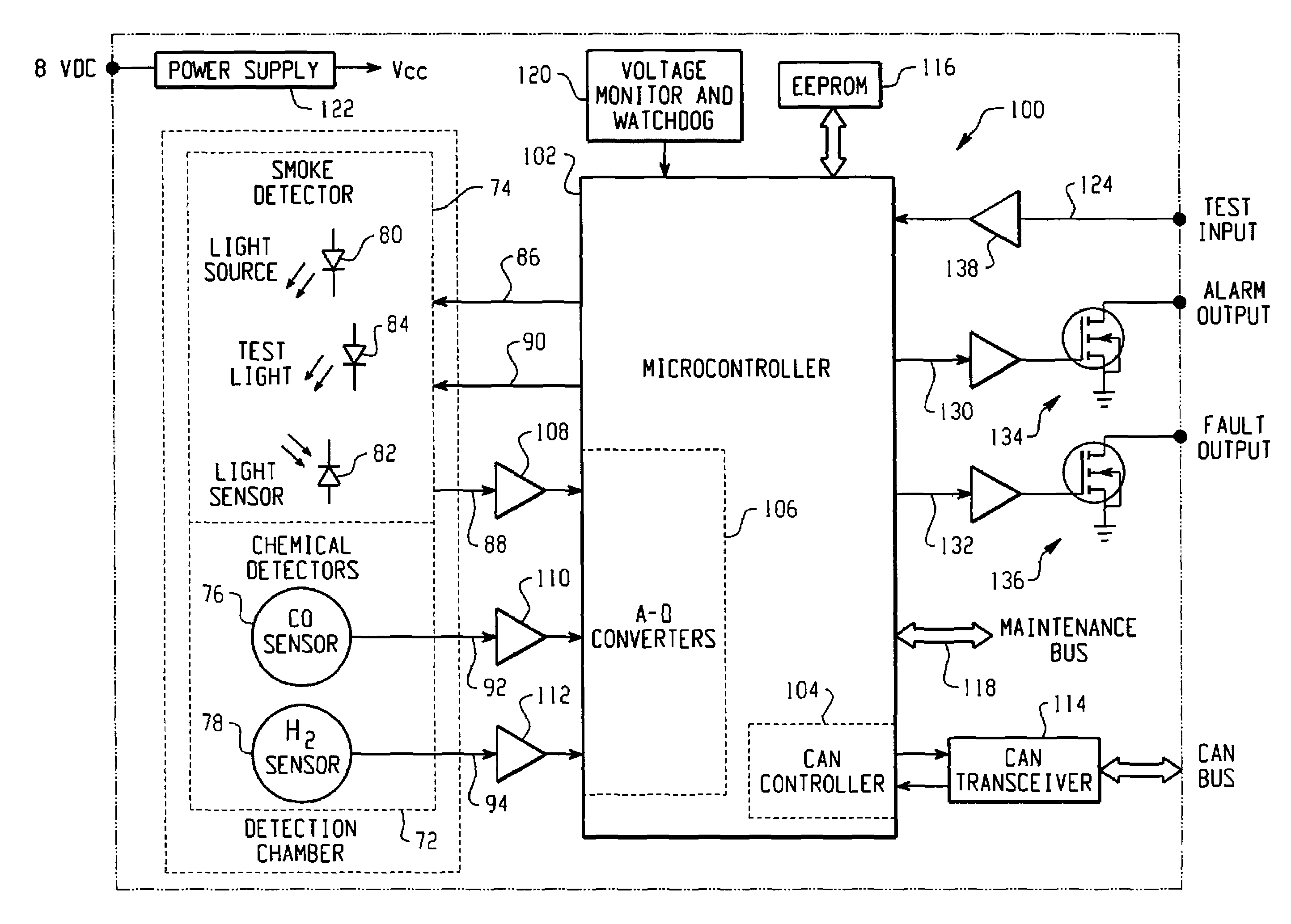

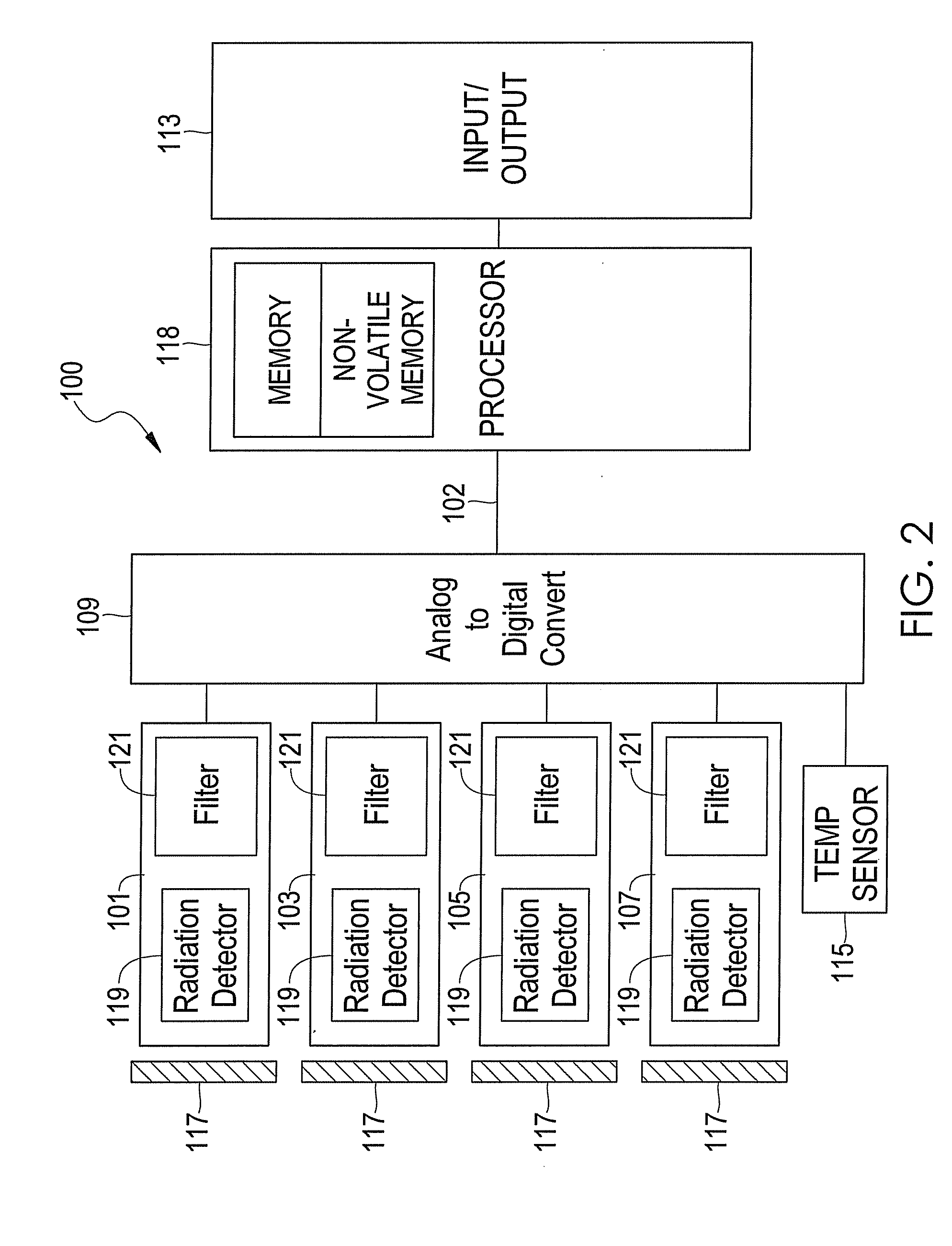

Multi-sensor fire detector with reduced false alarm performance

A method of detecting a combustion chemical in a region and setting an alarm based on concentration levels of the combustion chemical comprises the steps of: monitoring the region for a combustion chemical with a sensor having a measurable parameter which changes in value proportional to concentration levels of the monitored combustion chemical, the measurable parameter being ambient temperature dependent; generating an ambient temperature measurement of the sensor; reading the measurable parameter and ambient temperature measurement; processing the measurable parameter and ambient temperature measurement readings to generate a temperature compensated concentration level of the monitored combustion chemical; and setting an alarm based on the generated temperature compensated concentration level. A fire detector unit for implementing the foregoing described method is also disclosed.

Owner:ROSEMOUNT AEROSPACE

Fire suppression system

ActiveUS8973670B2Prevent and lessen possibilityEffectiveFire rescueBoring toolsFire detectorClosed cell

A fire suppression system for a container including a first tank containing a first liquid component of a two-part foam and a second tank containing a second liquid component of the foam. The system also includes at least one liquid component release device configured to be selectively capable of releasing the first and second components from their respective containers upon receipt of a signal from a fire detector upon detection of a fire. The two-part foam components are propelled through the system by a pressurized propellant that, upon release of the release device, causes the exit of the foam components from their respective tanks, through a mixing conduit to at least one nozzle. The nozzle is configured to spray the liquid component foam mixture into the container wherein the foam cures into a substantially semi-rigid, closed cell foam that is substantially impermeable and may have charring and / or intumescence properties.

Owner:ENK SR WILLIAM ARMAND

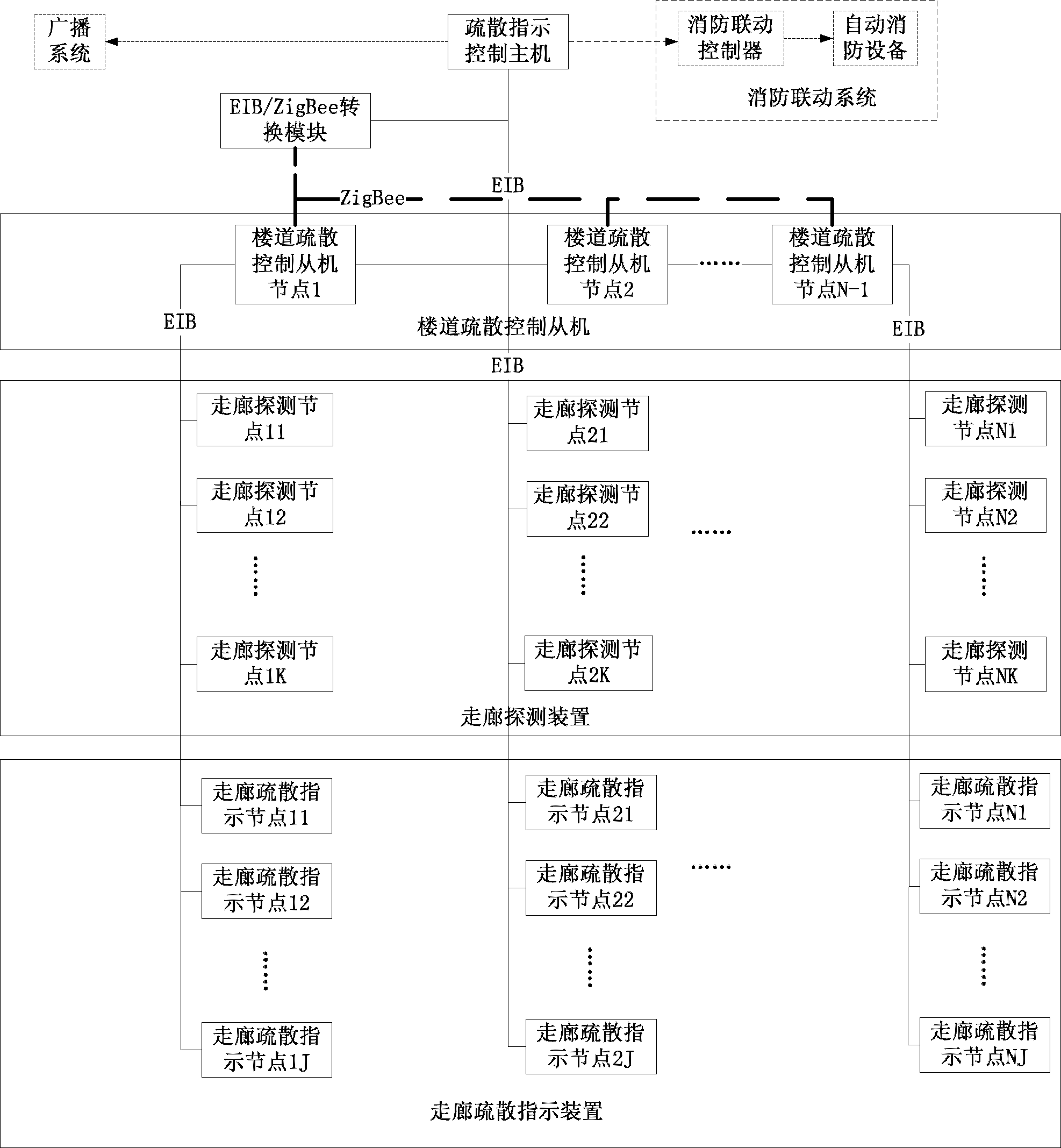

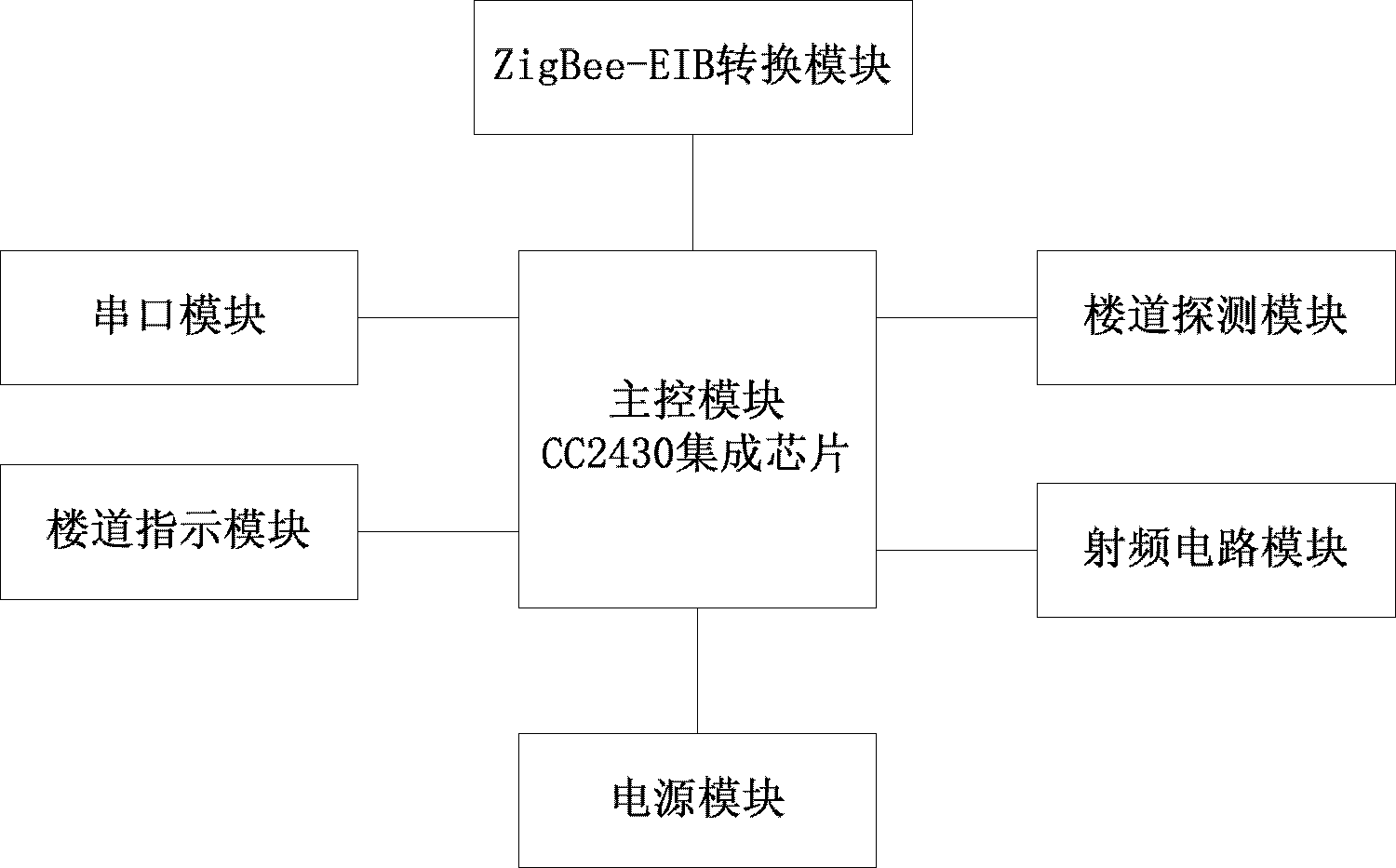

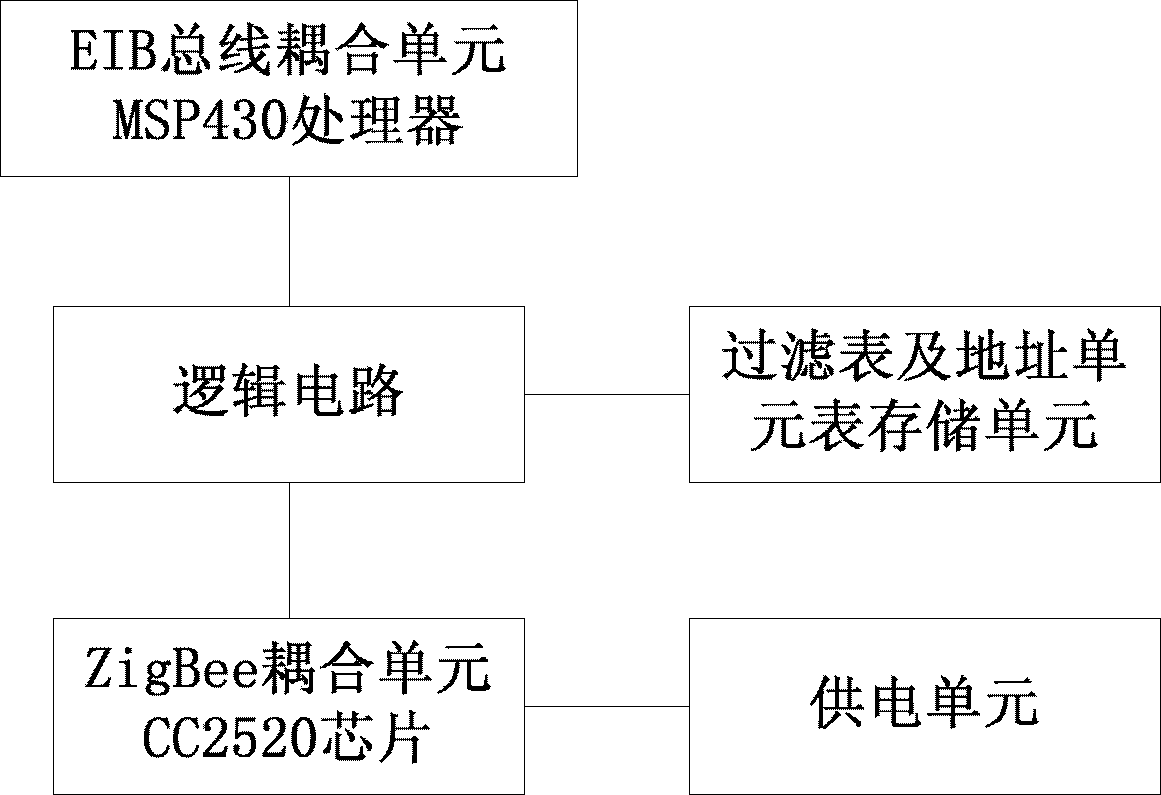

Intelligent fire evacuation escape indicating system and method

InactiveCN102509410AImprove reliabilityImprove usabilityNetwork topologiesFire alarmsInformation processingFire evacuation

The invention discloses a high-usability high-reliability and high-efficiency fire evacuation indicating system and a method. The system adopts a three-layer system structure formed by an evacuation indicating control host machine, passageway evacuation indicating control sub machines and passageway detection / indicating devices, wherein the passageway evacuation indicating control sub machines are positioned at stairs of each floor, each unit of the system exchanges information through an element interconnect bus (EIB), and the passageway detection / evacuation indicating devices are directly embedded into the control sub machines. Wireless backup communication is additionally added between the host machine and the sub machines (the passageway detection / evacuation indicating devices), and the integral reliability and the usability of the system are enhanced. The secondary threshold warning strategy of a composite fire hazard detector is adopted, a corresponding information processing method is used as an auxiliary measure, in addition, evacuation paths are continuously regulated according to the real-time fire conditions, the goals of shortening the warning time and reducing the mistake warning rate are reached, and the usability of the evacuation indicating system is further improved. The space positions of the detection / indicating devices are shown according to the floors on the basis of the three-dimensional geographical characteristics of the tall building evacuation paths, the building typical evacuation structure and the Dijkstra algorithm with an improved data structure are adopted, and the route planning efficiency of the escape route is improved.

Owner:ZHEJIANG UNIV

Multi-sensor fire detectors with audio sensors and systems thereof

InactiveUS20050110632A1High sensitivityMore sensitiveElectrical apparatusElectric lighting sourcesFire detectorTransducer

An ambient condition detector incorporates an audio transducer for discrimination between alarm and non-alarm conditions. The transducer can provide occupancy information. In addition, a monitoring system can graphically present information as to the location of individuals, such as firefighters, in the region.

Owner:HONEYWELL INT INC

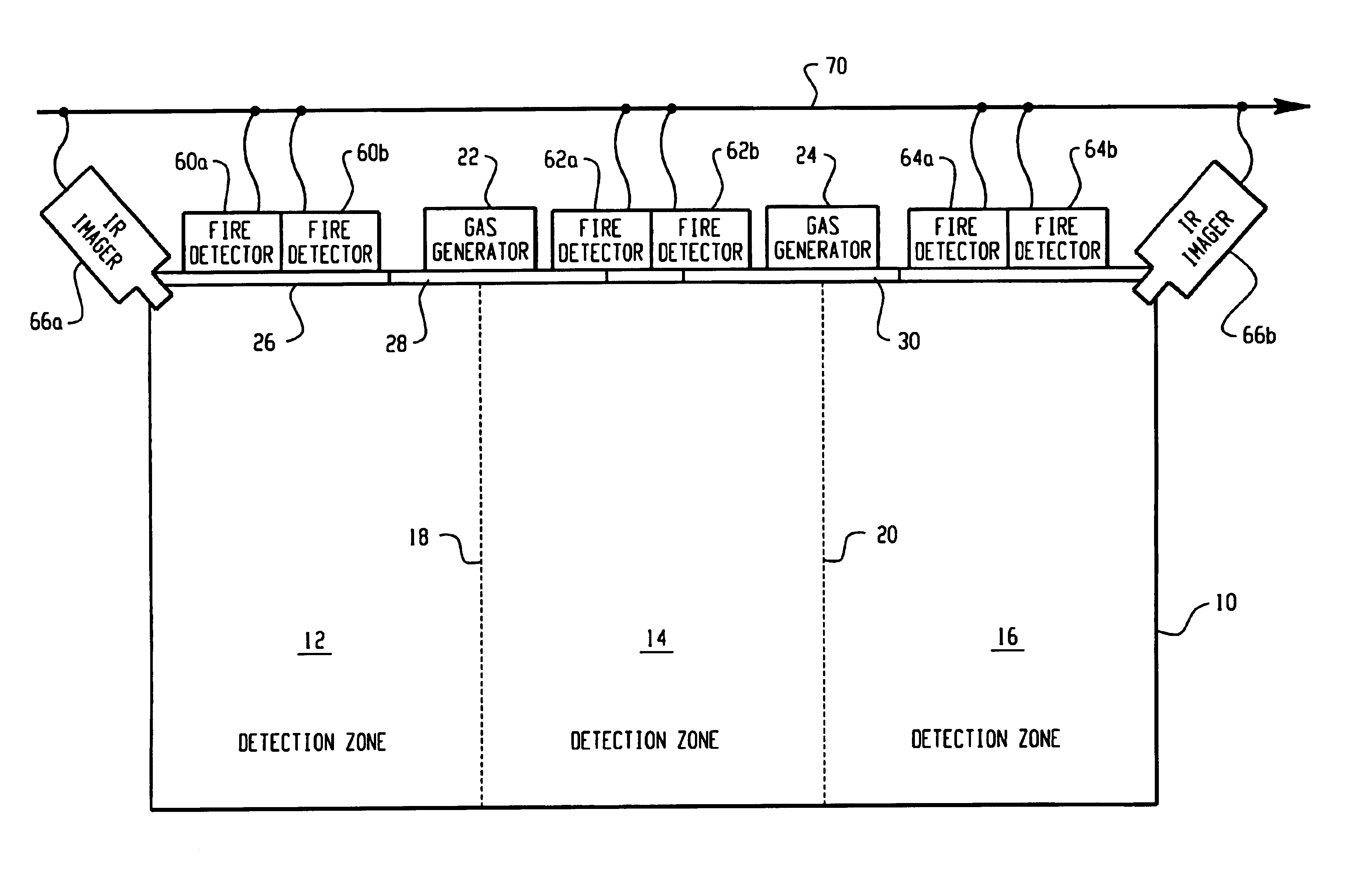

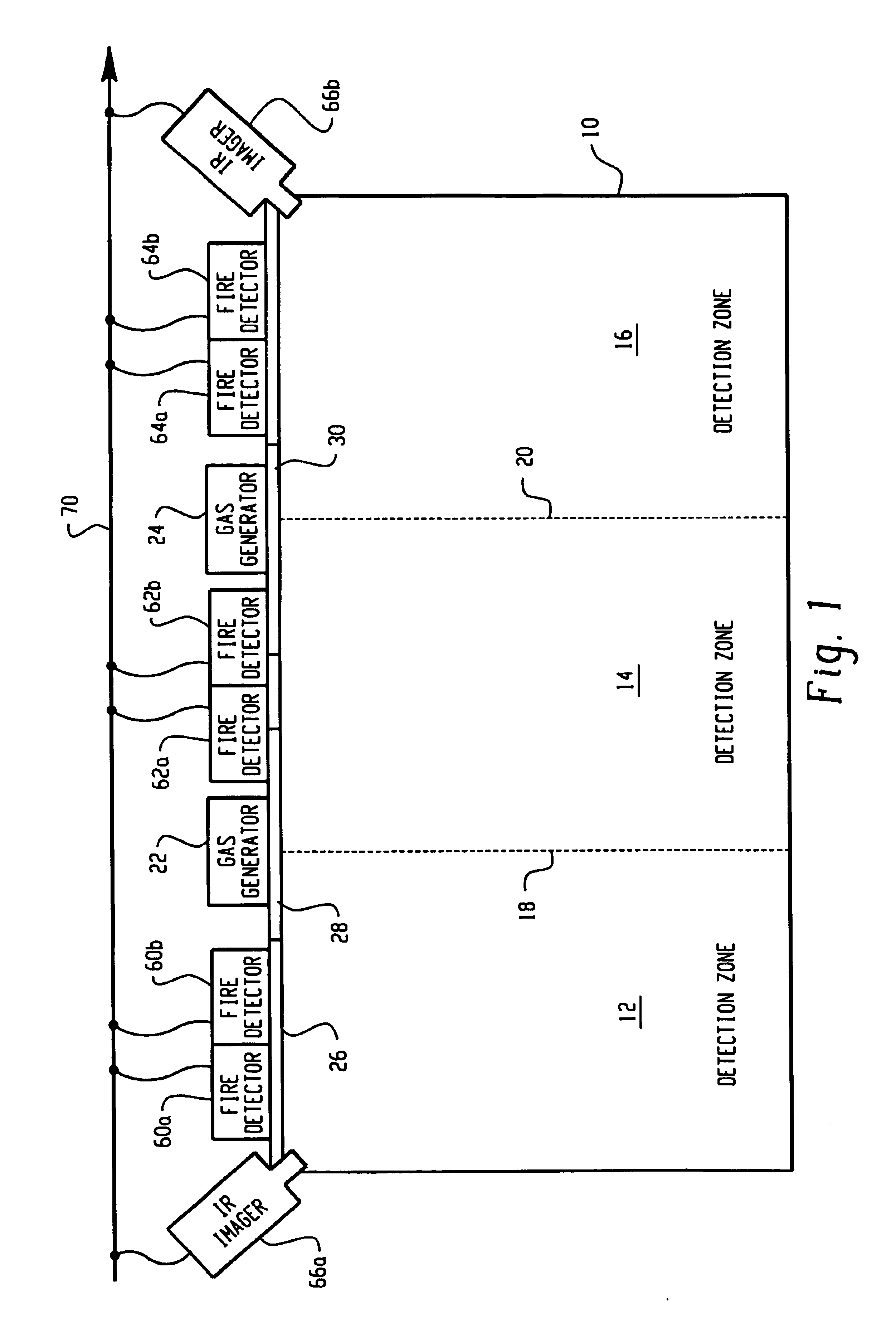

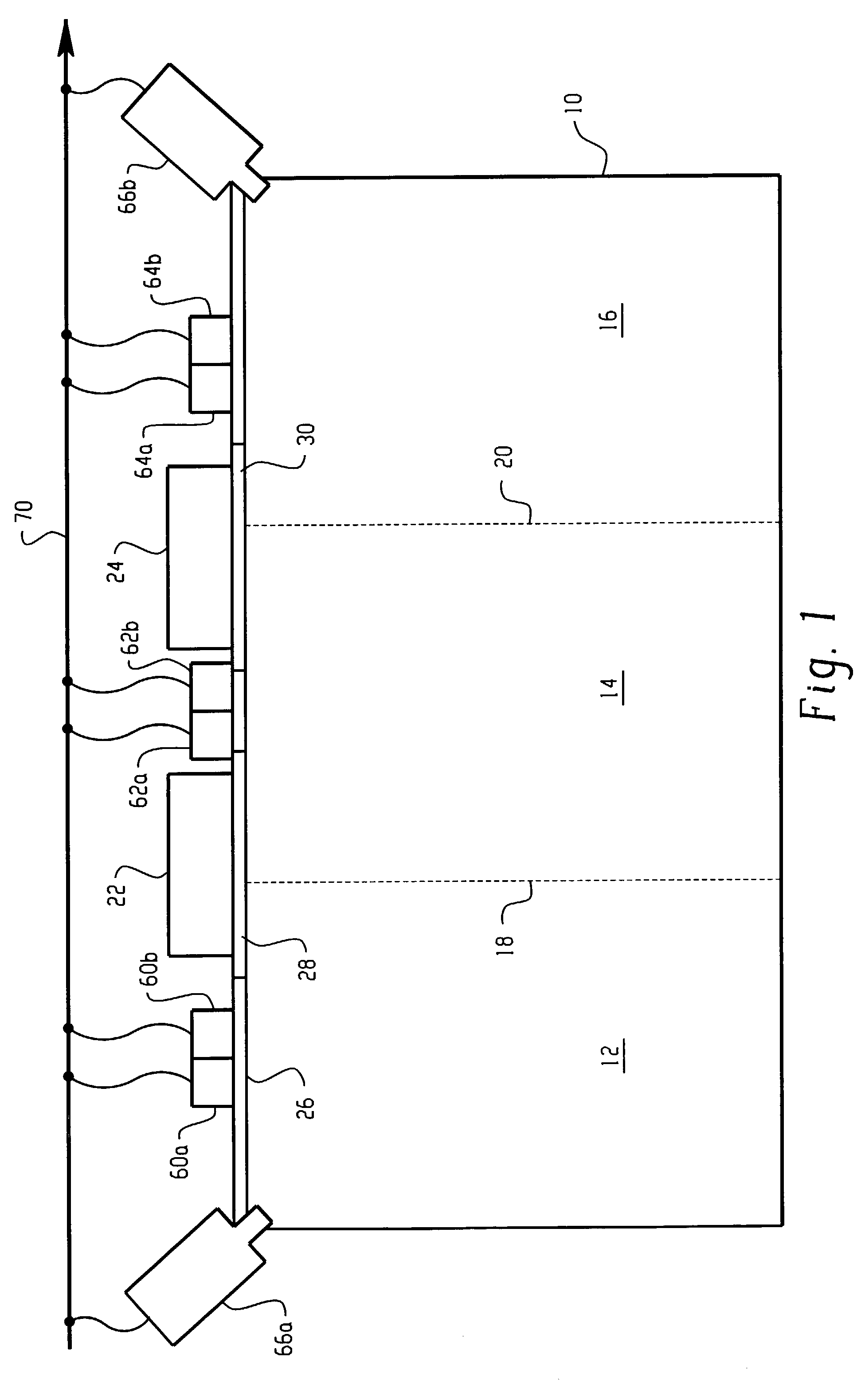

Fire detection system

A fire detection system for an enclosed area comprises: at least one infrared (IR) imager for generating infrared images of at least a portion of the enclosed area, for determining from the images that a fire is perceived present in the enclosed area, and for generating a first signal indicative of the perceived presence of fire; at least one fire detector for monitoring at least a portion of the enclosed area, the fire detector comprising at least one fire byproduct chemical sensor for generating at least one second signal representative of the presence of at least one fire byproduct chemical in the enclosed area; and a controller governed by the first and second signals to confirm that a fire is present in the enclosed area. In one embodiment, the enclosed area is divided into a plurality of detection zones with at least one fire detector disposed at each detection zone. In this embodiment, the controller includes a first controller governed by the second signals for generating a third signal indicative of the presence of fire in the corresponding detection zone; and a second controller governed by the first and third signals to confirm that a fire is present in at least one detection zone of the enclosed area.

Owner:ROSEMOUNT AEROSPACE

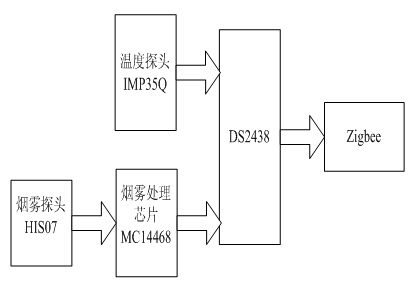

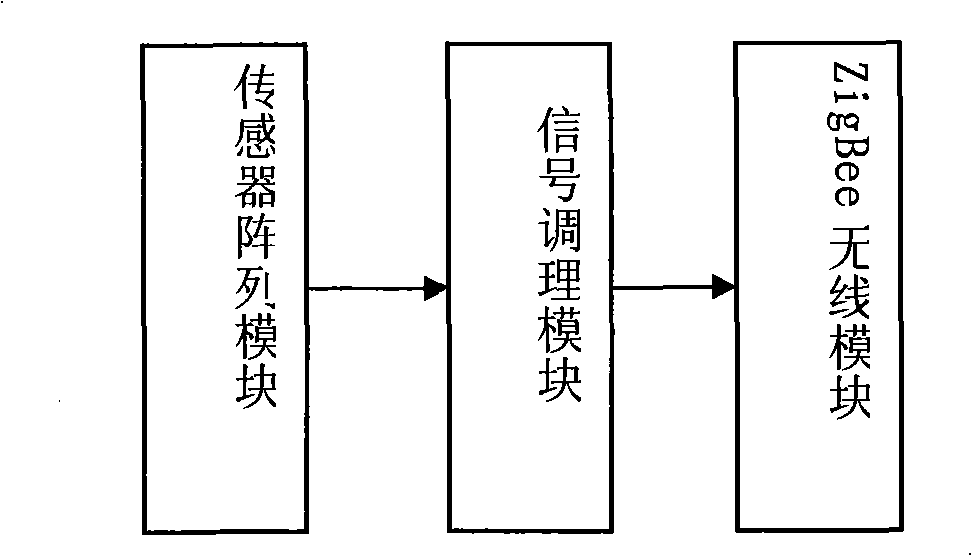

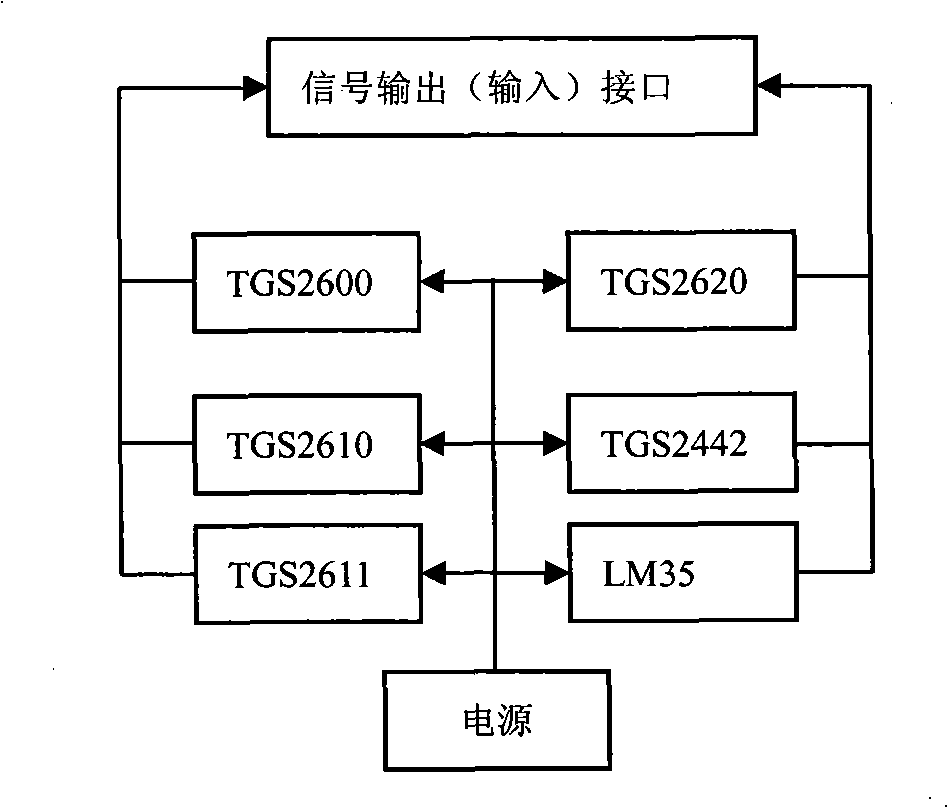

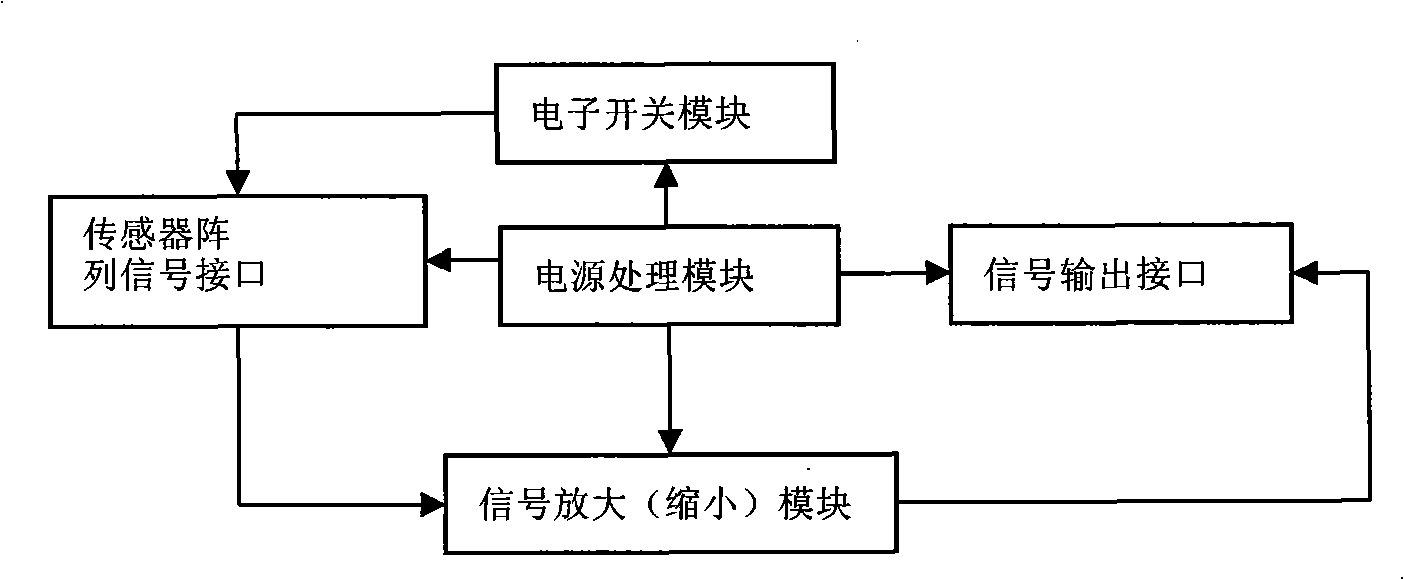

Wireless fire detector for early fire recognition

InactiveCN101577032AAchieve positioningTemperature measurement of flowing materialsFire alarmsSensor arrayFire detector

The invention relates to a fire alarm, in particular to an early fire recognition detector based on the combination of a sensor array technique and a ZigBee wireless technique. The detector is achieved by a sensor array module, a mode recognition module and the ZigBee wireless technique, wherein the sensor array module consists of a plurality of paths of gas sensors and temperature sensors; and after the processing by a signal processing module, a fire recognition algorithm is adopted to detect and recognize the gas generated at an early stage of fire; a ZigBee sends the result of the recognition, the temperature and the smoke intensity to a monitoring center in a wireless mode; and a computer of the monitoring center achieves the positioning of a fire source point and the description of a three-dimensional space of a temperature field and a smoke field. The detector has the advantages of the early fire recognition, the positioning of the fire source point, and visual descriptions of the temperature field and the smoke field.

Owner:SHANTOU UNIV

Fire urgency estimator in geosynchronous orbit (FUEGO)

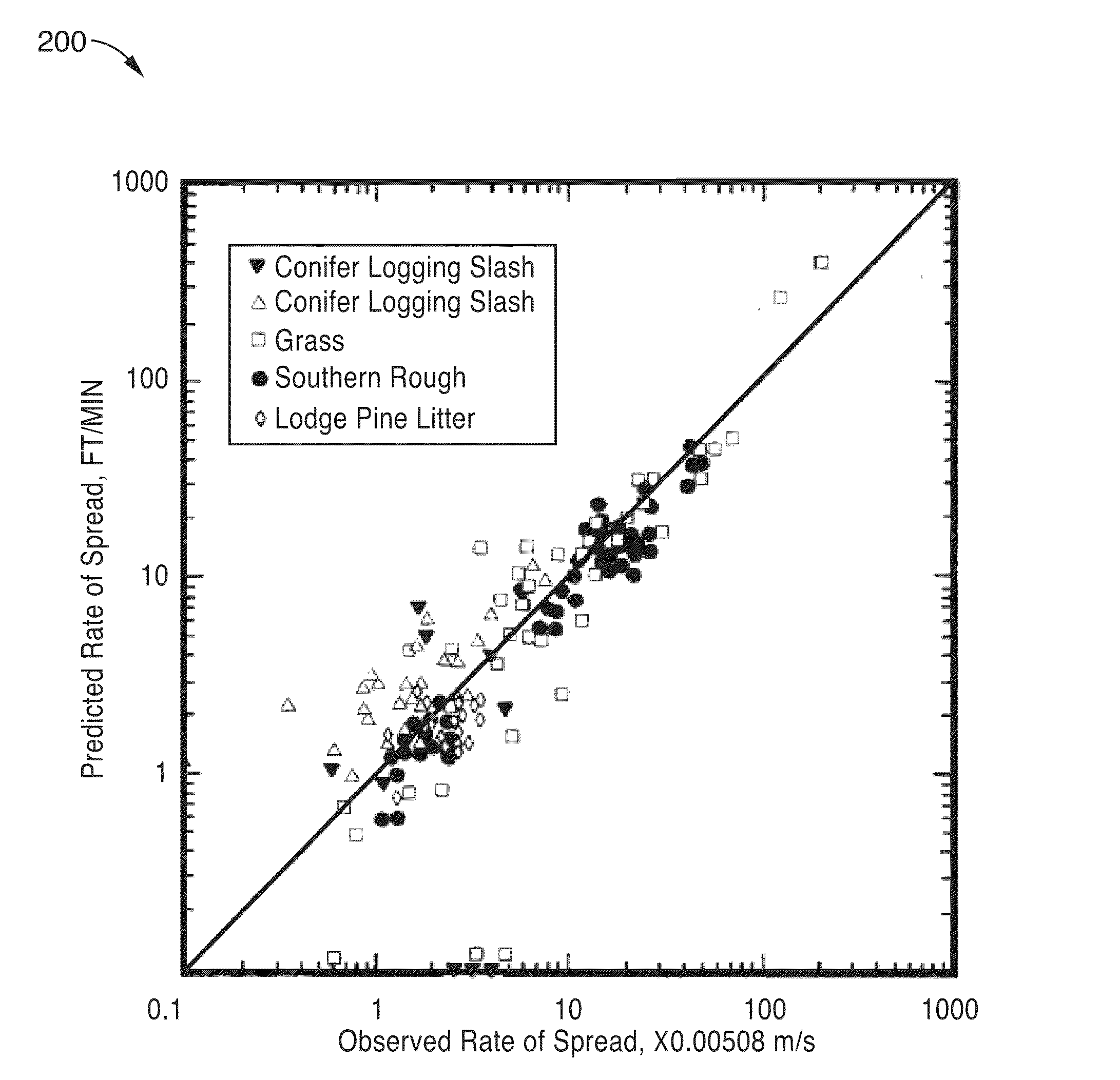

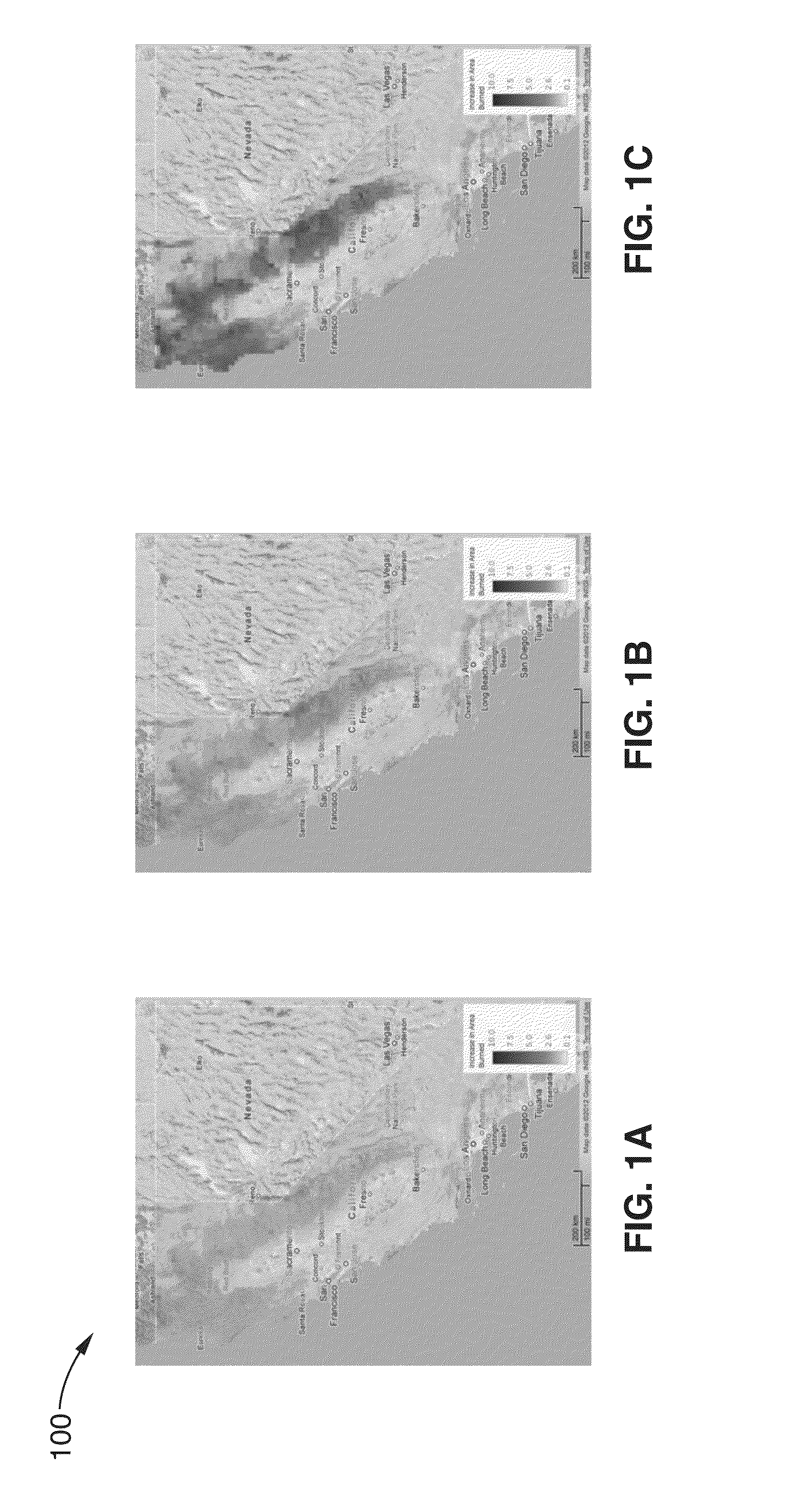

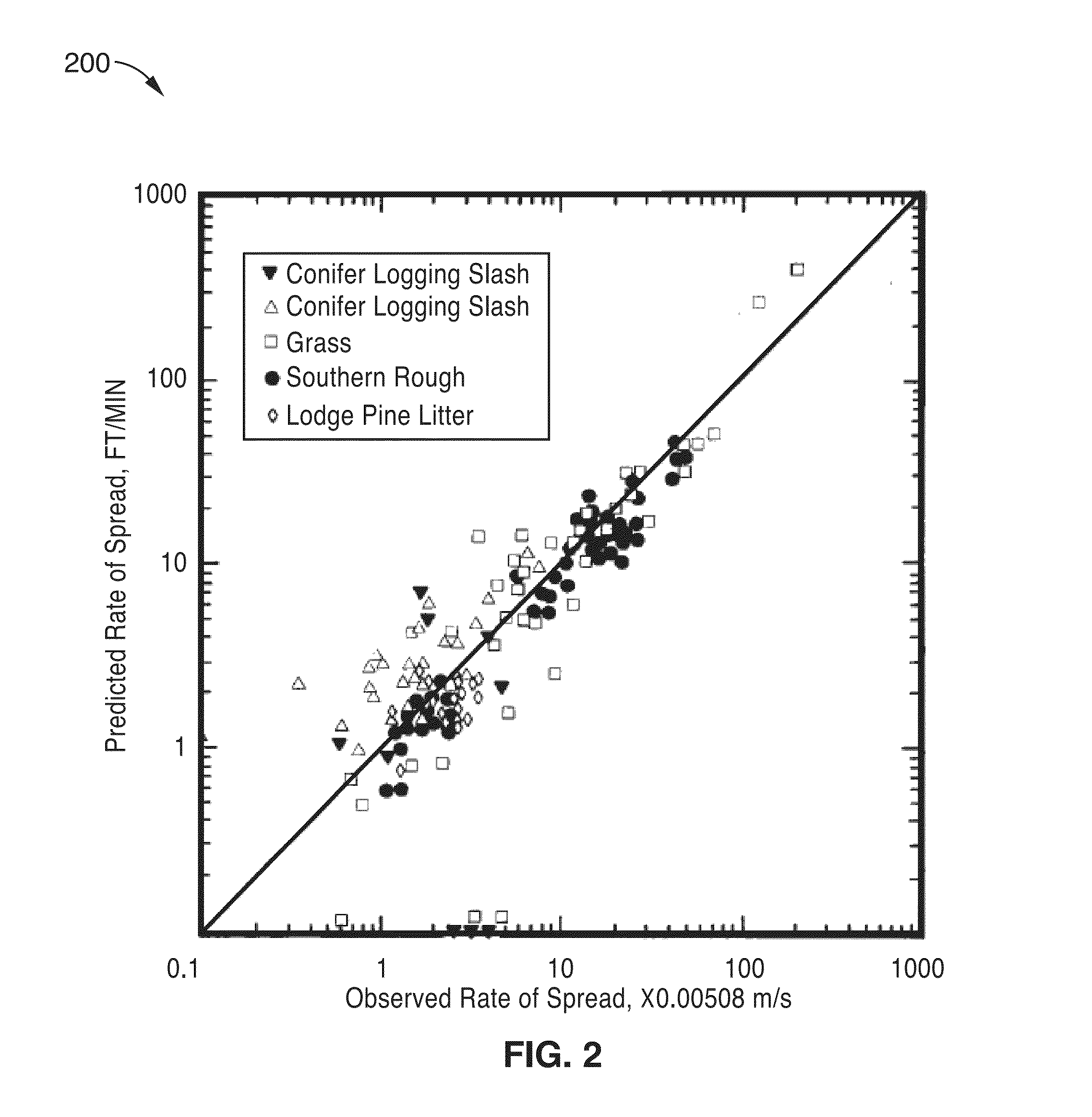

ActiveUS20160132714A1Quality improvementEliminate artifactsTelevision system detailsImage enhancementFire detectorSignal-to-noise ratio (imaging)

A fire detector is disclosed that successively images a particular area from geosynchronous Earth orbit satellite to attain very good signal-to-noise ratios against Poisson fluctuations within one second. Differences between such images allow for the automatic detection of small fires greater than 12 square meters. Imaging typically takes place in transparent bands of the infrared spectrum, thereby rendering smoke from the fire and light clouds somewhat transparent. Several algorithms are disclosed that can help reduce false fire alarms, and their efficiencies are shown. Early fire detection and response would be of great value in the United States and other nations, as wild land fires destroy property and lives and contribute around five percent of the US global carbon dioxide contribution. Such apparatus would incorporate modern imaging detectors, software, and algorithms able to detect heat from early and small fires, and yield detection times on a scale of minutes.

Owner:RGT UNIV OF CALIFORNIA

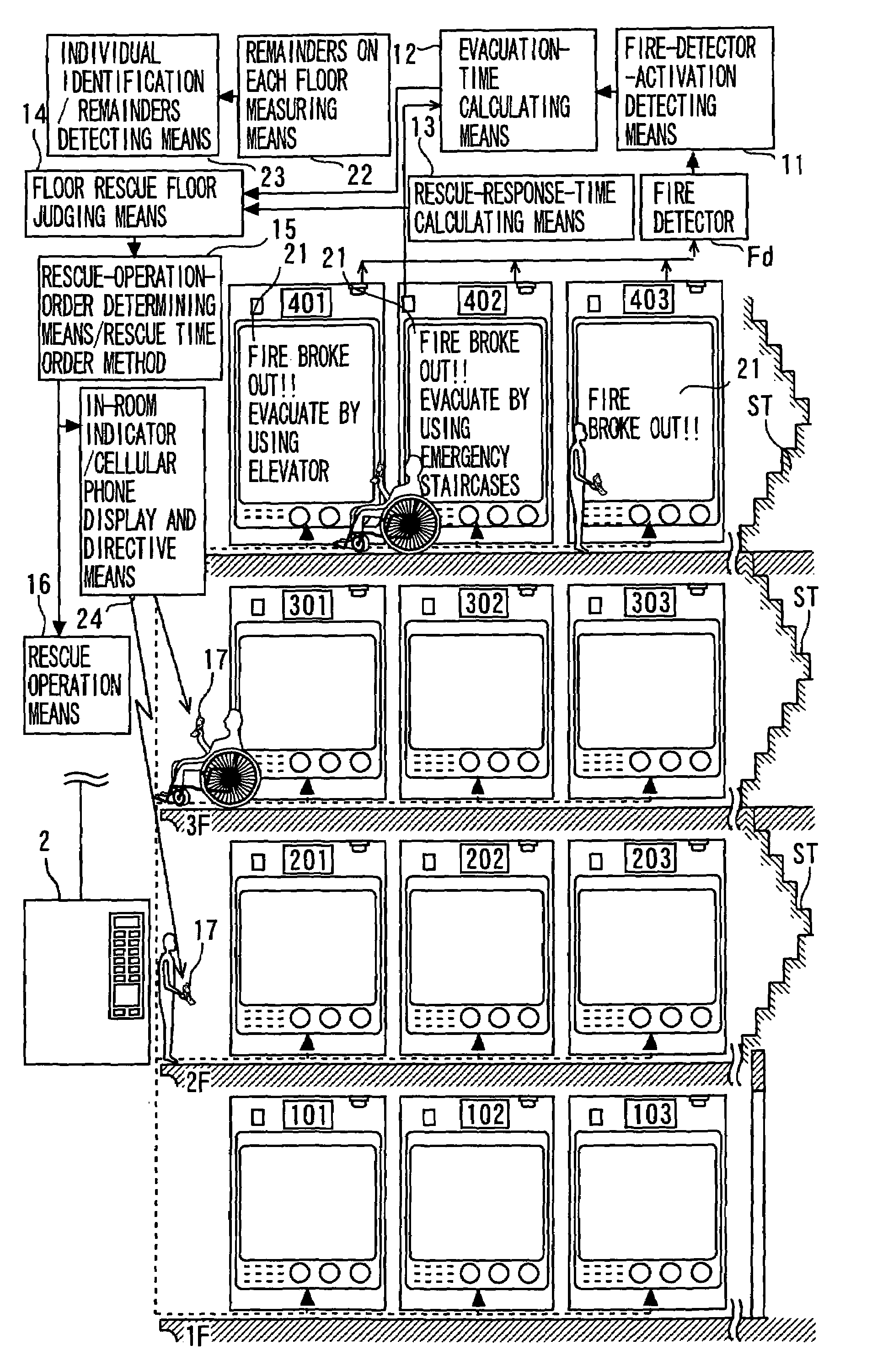

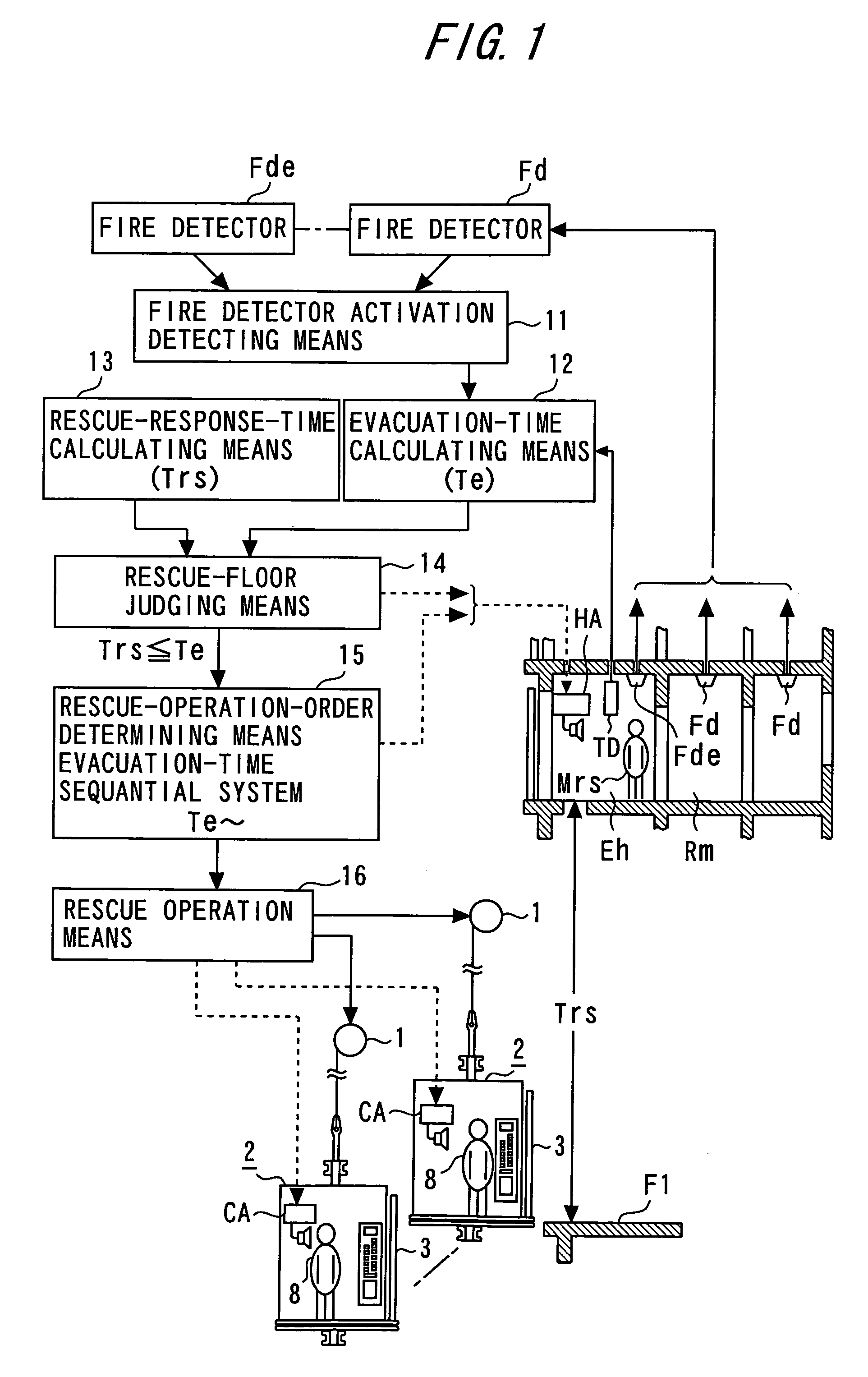

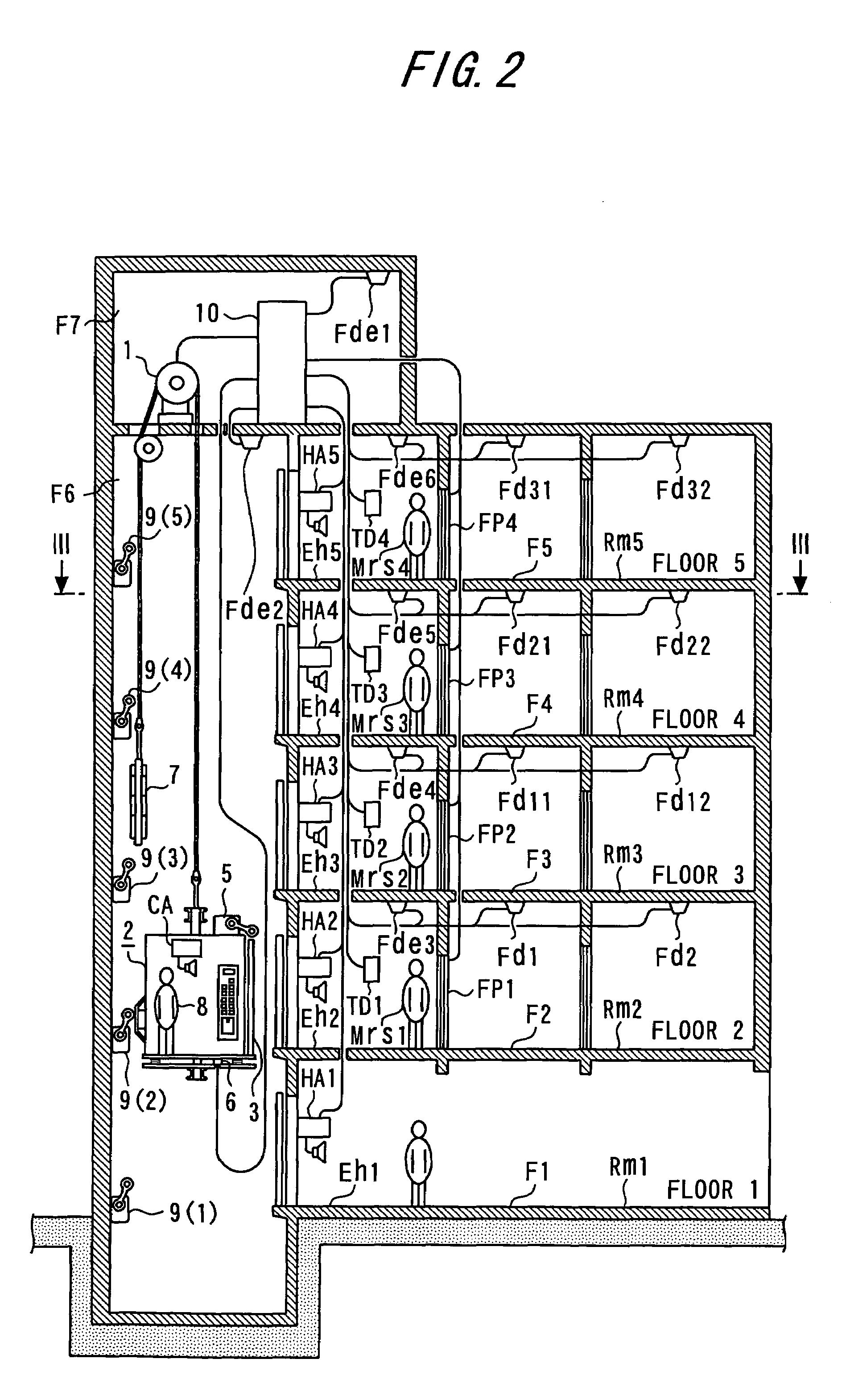

Fire control system of elevator

Provided is a fire control system of an elevator which rescues remainders in a building to a rescue floor by causing an elevator car to perform evacuating operations when a fire detector installed in the building works, characterized in that the fire control system of an elevator includes: individual identification sending means which each individual who utilizes the elevator carries and in which a resident room number, a resident floor, information on characteristics of each individual, etc. are registered; individual identification receiving means provided in each elevator hall; and a controller which calls an elevator car and performs car-call registration of a destination floor on the basis of information sent from the individual identification sending means to the individual identification receiving means. The controller includes remainders -on-each-floor measuring means which calculates the number of remainders on each floor from car-call registration information of the destination floor, remainders -on-each-floor detecting means which detects the calculated number of remainders on each floor, evacuation guiding and direction giving means which performs evacuation guidance and giving directions during a fire on the basis of the detected number of remainders on each floor, and rescue operation means which performs rescue operations.

Owner:MITSUBISHI ELECTRIC CORP

Lithium ion battery fire test cabinet with self-assembled automatic alarm and fire extinguishment system

The invention discloses a lithium ion battery fire test cabinet with a self-assembled automatic alarm and fire extinguishment system. The lithium ion battery fire test cabinet with the self-assembled automatic alarm and fire extinguishment system mainly comprises a fire cabinet main body, an automatic alarm system, a battery fixing bracket, a heat source simulation system, a measuring and monitoring system, a fire extinguishing system and a smoke discharging system. By virtue of multi-modulation, the sensitivity and response characteristics of different types of fire detectors (smoke sensing detectors, temperature sensing detectors or integrated smoke and temperature sensing detectors and the like) after the lithium ion battery is fired can be simulated; the lithium ion battery fire test cabinet with the self-assembled automatic alarm and fire extinguishment system is suitable for researching the factors such as the fire extinguishment effects (comprising actual fire extinguishing time and the use amount of fire extinguishing agents and the like) of various gas fire extinguishing agents in lithium ion battery fire, the influence of different fire extinguishing agents on the performance of the lithium ion battery after extinguishing the fire and the like. According to the lithium ion battery fire test cabinet with the self-assembled automatic alarm and fire extinguishment system, a vertical fire extinguishing agent releasing pipeline is self-designed according to a fire cabinet body, so that the fire extinguishing agent can be fully released into a battery cabinet within short time after the battery is fired, thus the fire extinguishing time is greatly shortened, the use amount of the fire extinguishing agent is reduced, the fire extinguishing cost is reduced, and the damage to the lithium ion battery is reduced.

Owner:SOUTHERN POWER GRID PEAK LOAD & FREQUENCY REGULATION GENERATING CO LTD +1

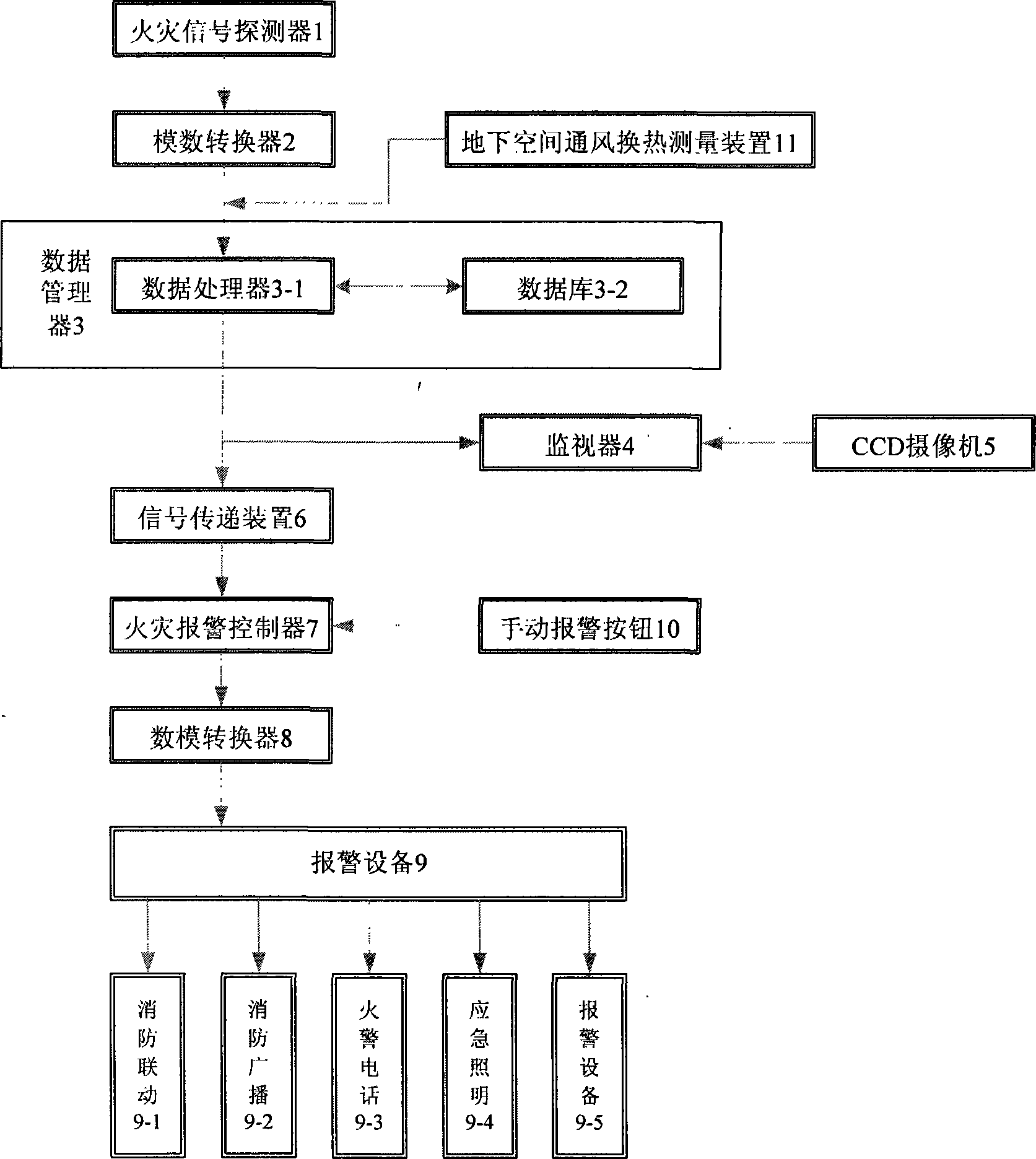

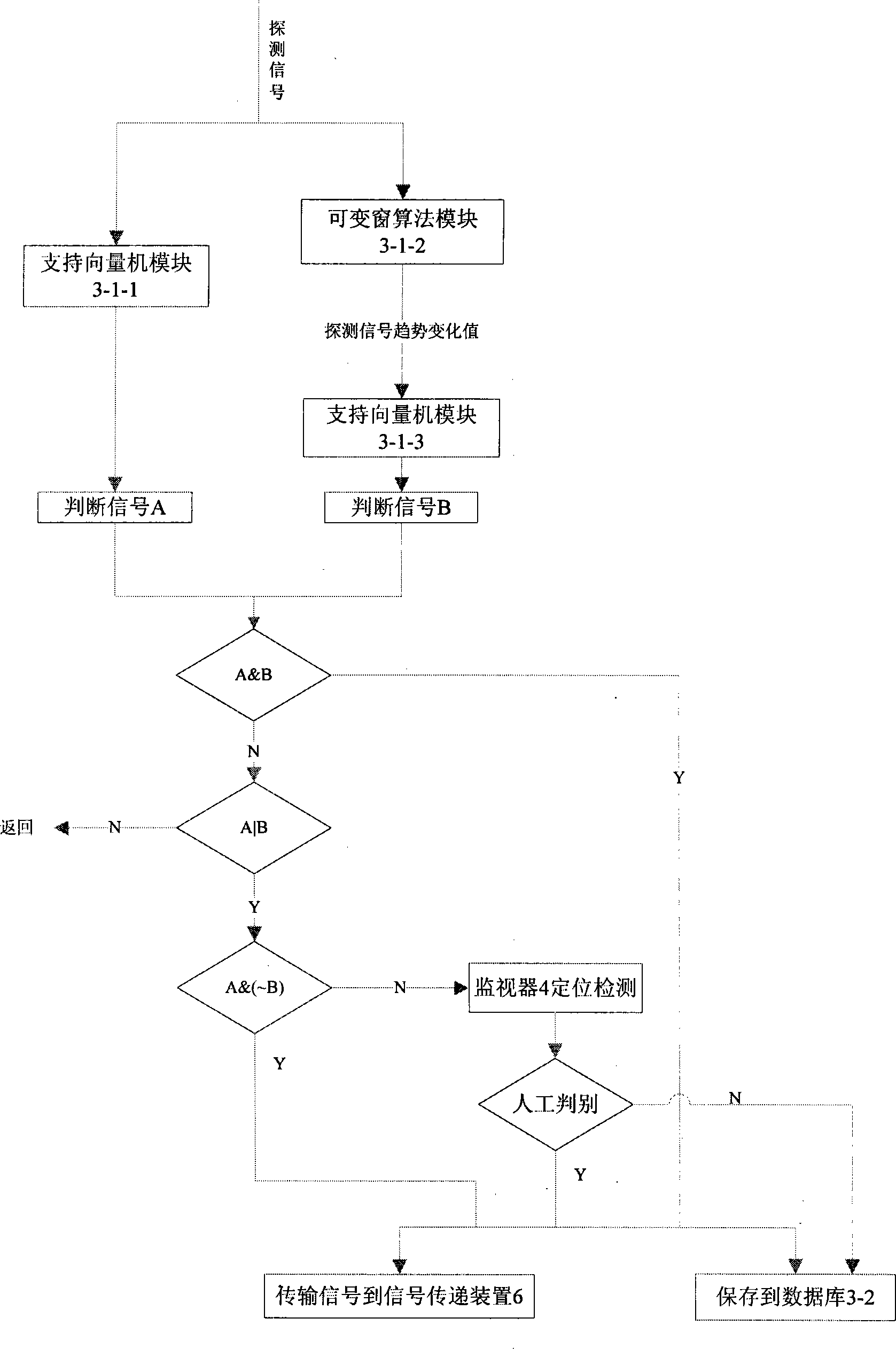

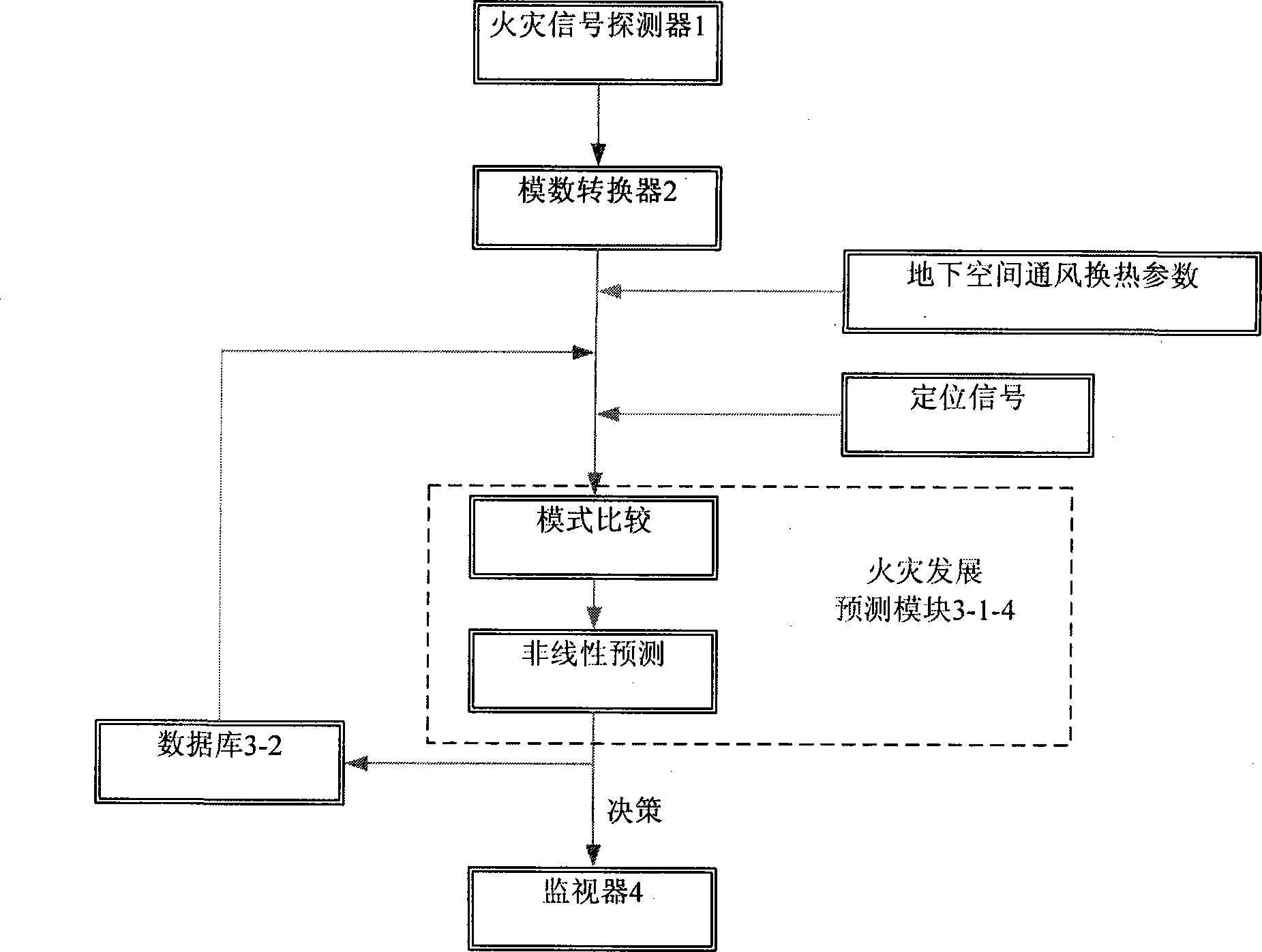

Underground space fire intelligent detection early alarming and forecasting method and apparatus

The invention discloses a method for intelligently detecting, early warning and forecasting a fire in an underground space and a device using the method comprising a fire signal detector, an analog-to-digital converter, a data manager, a monitor, a CCD camera, a signal transfer device, a fire alarm control unit, a digital-to-analog converter, a warning device and an underground space ventilation and heat exchange measuring device, wherein the fire signal detector transfers a detected signal to the data manager via the analog-to-digital converter, the information is processed by the data manager and is transferred to the fire alarm control unit via the signal transfer device, and is transferred to the warning device via the digital-to-analog converter, and the data manager processes the information and displays the processed information on the monitor; the CCD camera is connected with the monitor; the underground space ventilation and heat exchange measuring device transfers the information to the data manager. The method and the device adopt a plurality of fire detectors to detect a fire so as to improve an accuracy of a system, return a forecasted result to the system, and use a self-learning capability of a support vector machine to realize high fault tolerance and intellectualization of the system.

Owner:SOUTH CHINA UNIV OF TECH

Fire detector

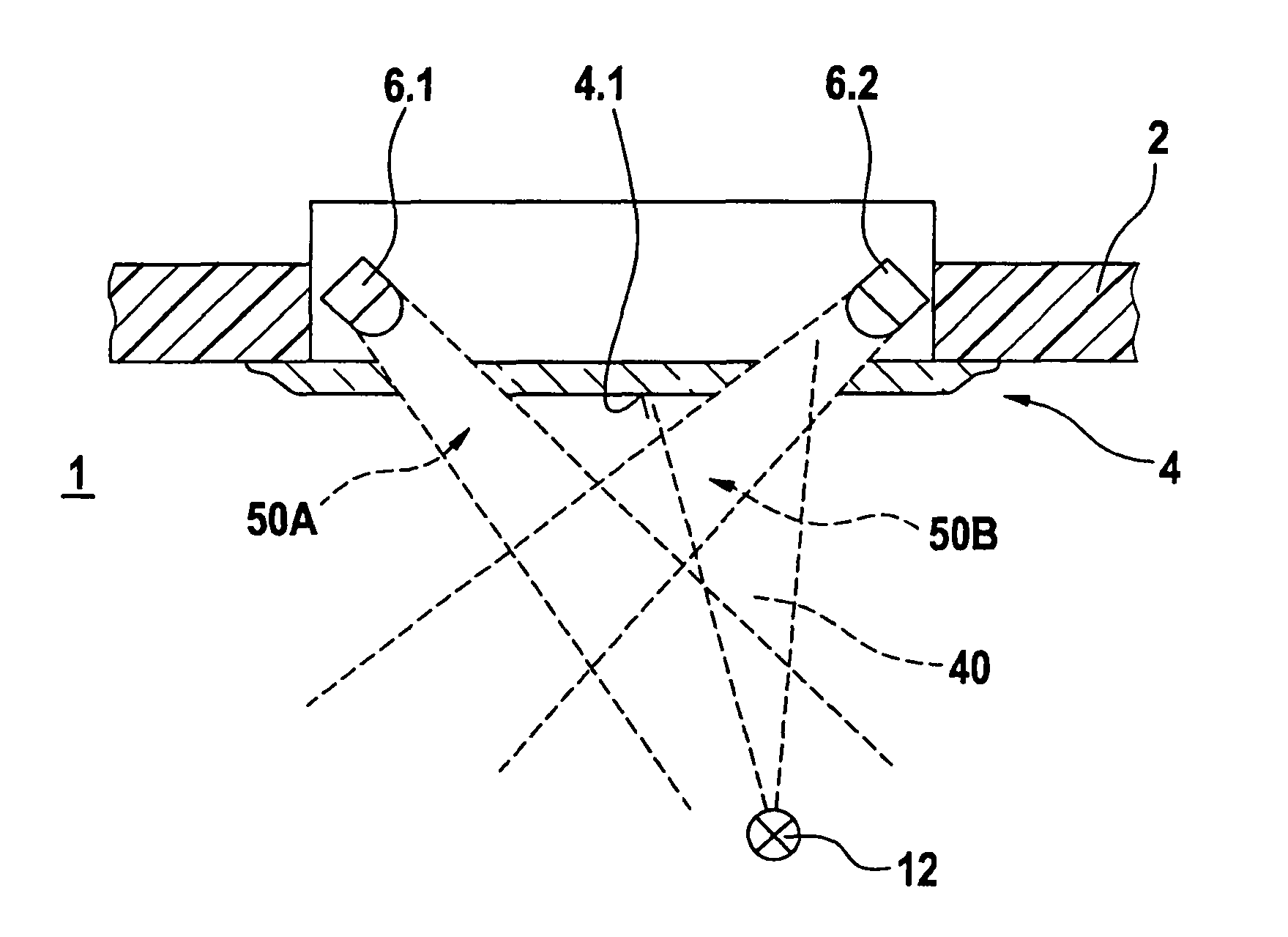

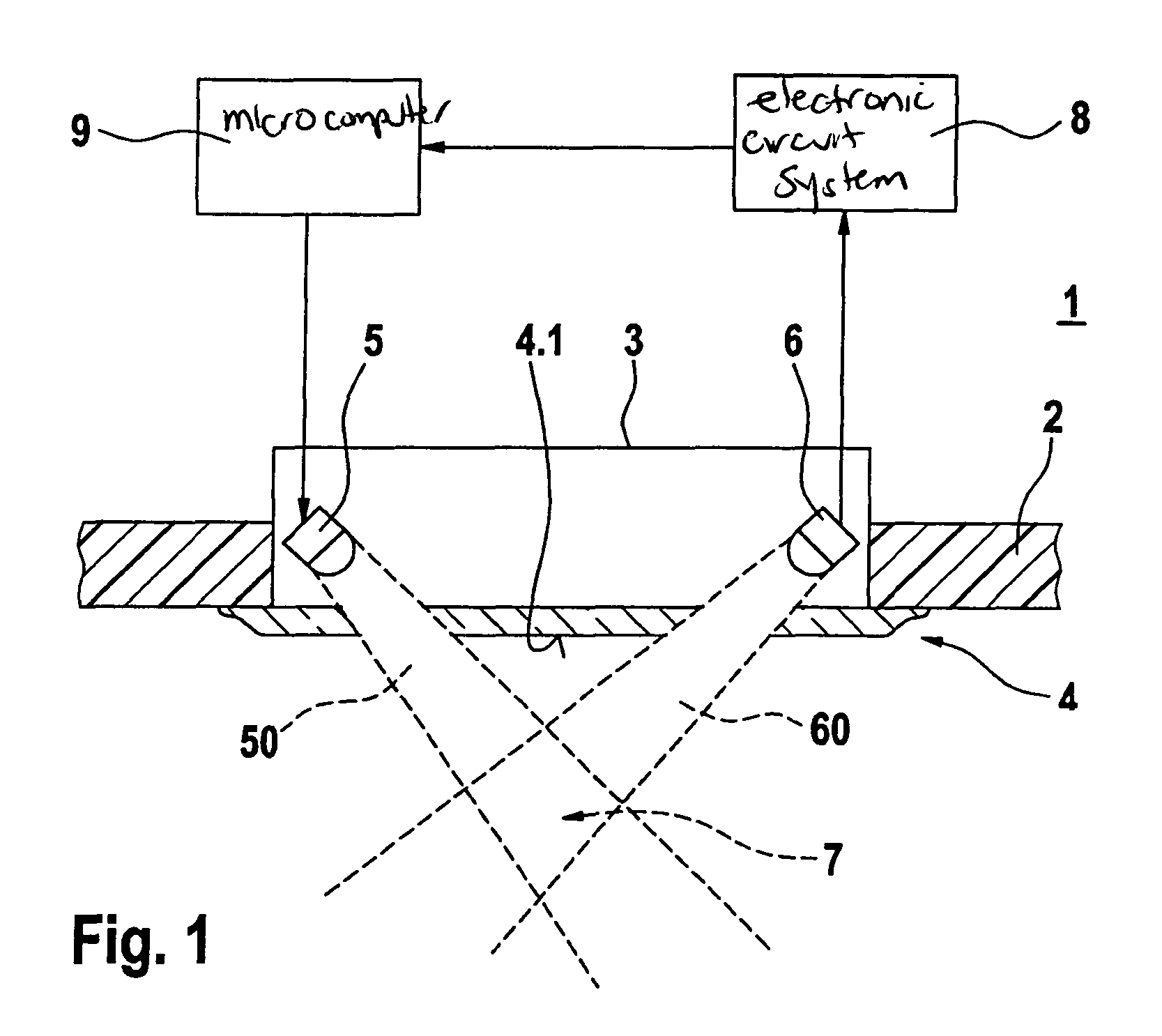

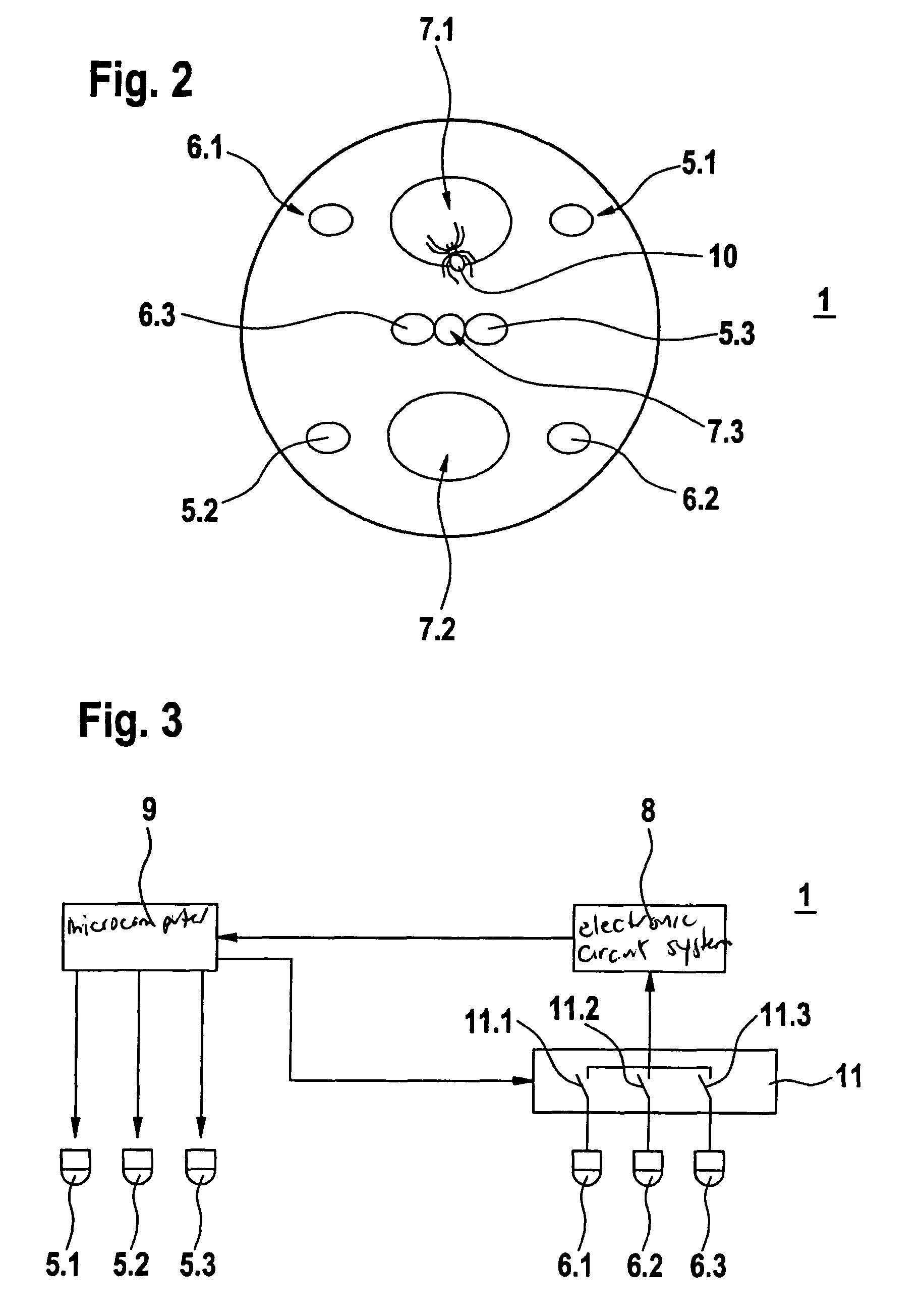

InactiveUS7978087B2Operating reliability can be highReduce sensitivityInvestigating moving fluids/granular solidsScattering properties measurementsFire detectorLight beam

A fire detector operating by the scattered radiation principle is described, having at least one radiation transmitter and at least one radiation receiver, whose beam paths form a scattering volume. The fire detector includes, in addition to at least one first radiation transmitter and one first radiation receiver, at least one second radiation transmitter and one second radiation receiver, whose beam paths form at least two spatially separated scattering volumes.

Owner:ROBERT BOSCH GMBH

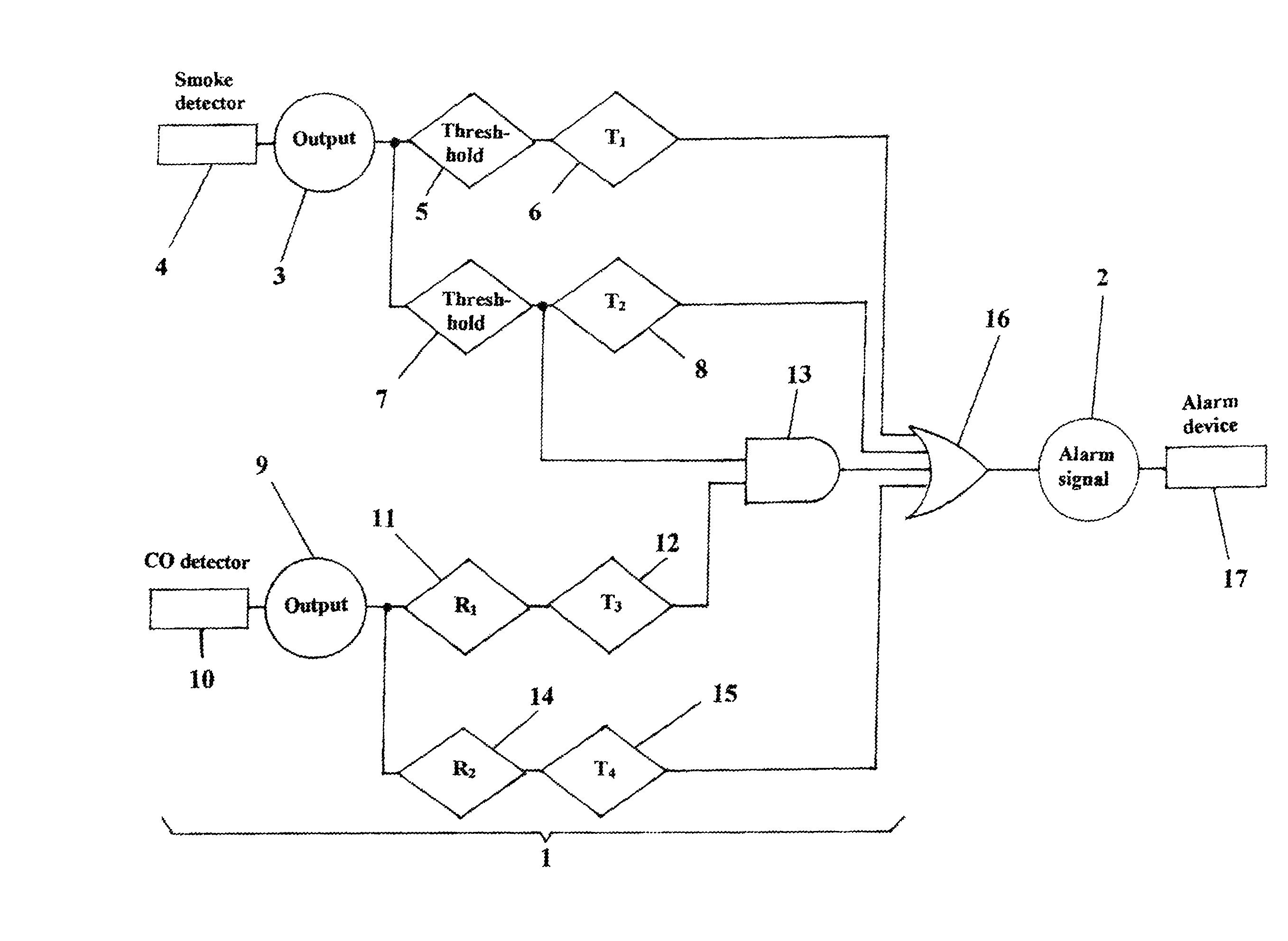

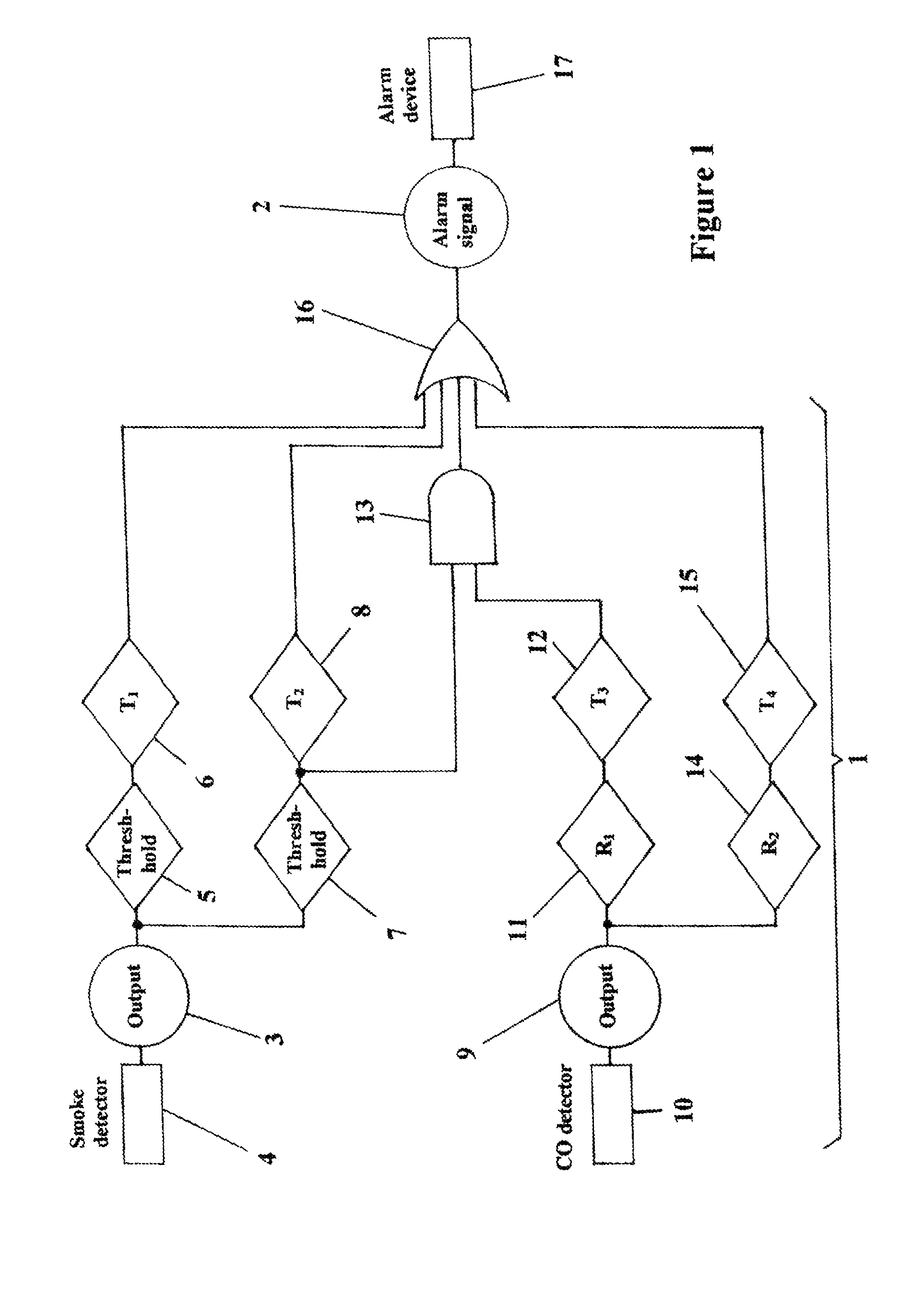

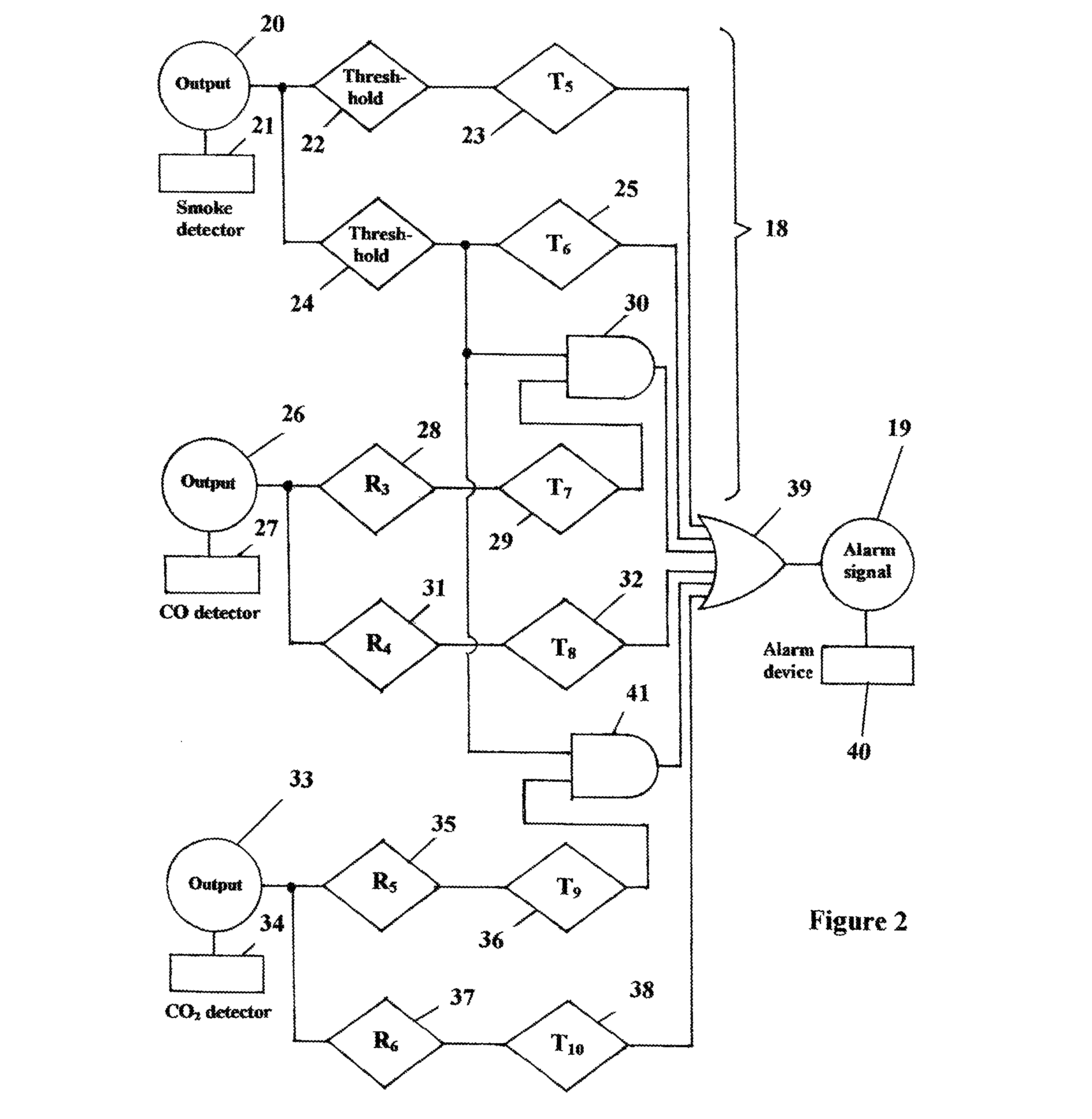

False alarm resistant and fast responding fire detector

InactiveUS8077046B1Fire alarm smoke/gas actuationFire alarm radiation actuationSmoke detectorsFire detector

A fire detector and method of using it generate a fire alarm through use of a smoke detector and a carbon monoxide detector once the smoke detector detects a threshold level of light obscuration for greater than a first pre-selected time period or a reduced threshold level of light obscuration for greater than a second pre-selected time period or the CO detector detects a rate of increase in CO concentration which exceeds a first preselected CO rate for a third pre-selected time period and the smoke detector detects the reduced threshold level of light obscuration or the rate of increase in CO concentration exceeds a second preselected CO rate for a fourth pre-selected time period. The fire detector and method can also use a carbon dioxide detector and generate the fire alarm when either a rate is of increase in concentration of CO2 exceeds a first CO2 predetermined rate for a fifth pre-selected time period and the smoke detector detects a reduced threshold level of light obscuration or the rate of increase in concentration of CO2 exceeds a second CO2 predetermined rate for a sixth pre-selected time period.

Owner:AIRWARE INC

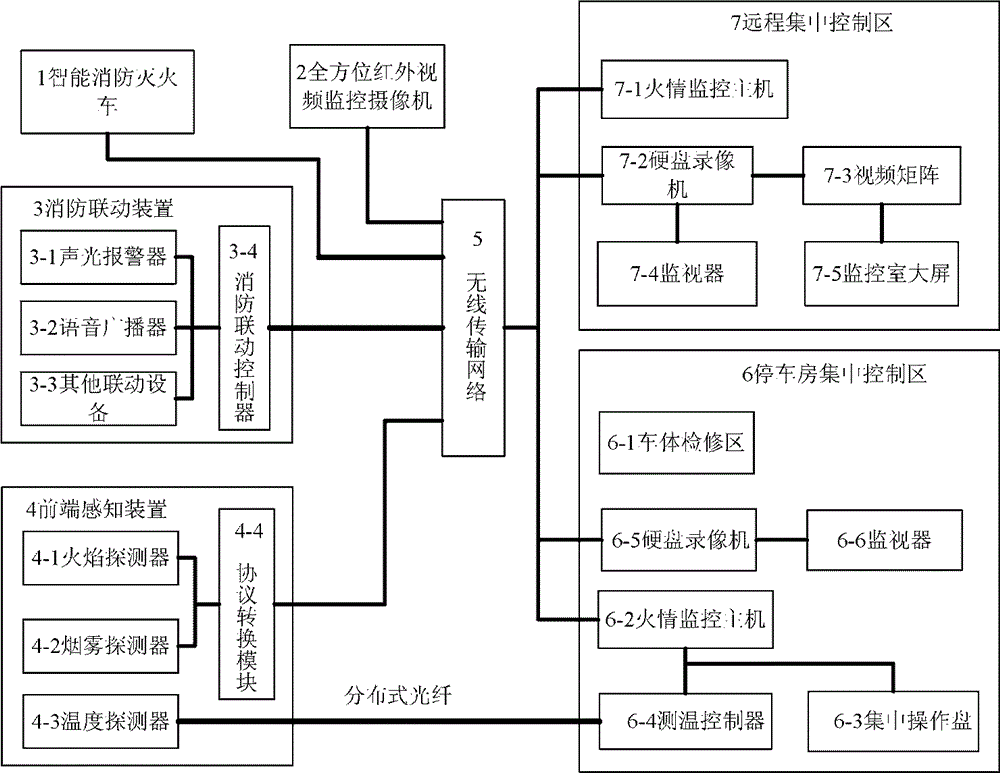

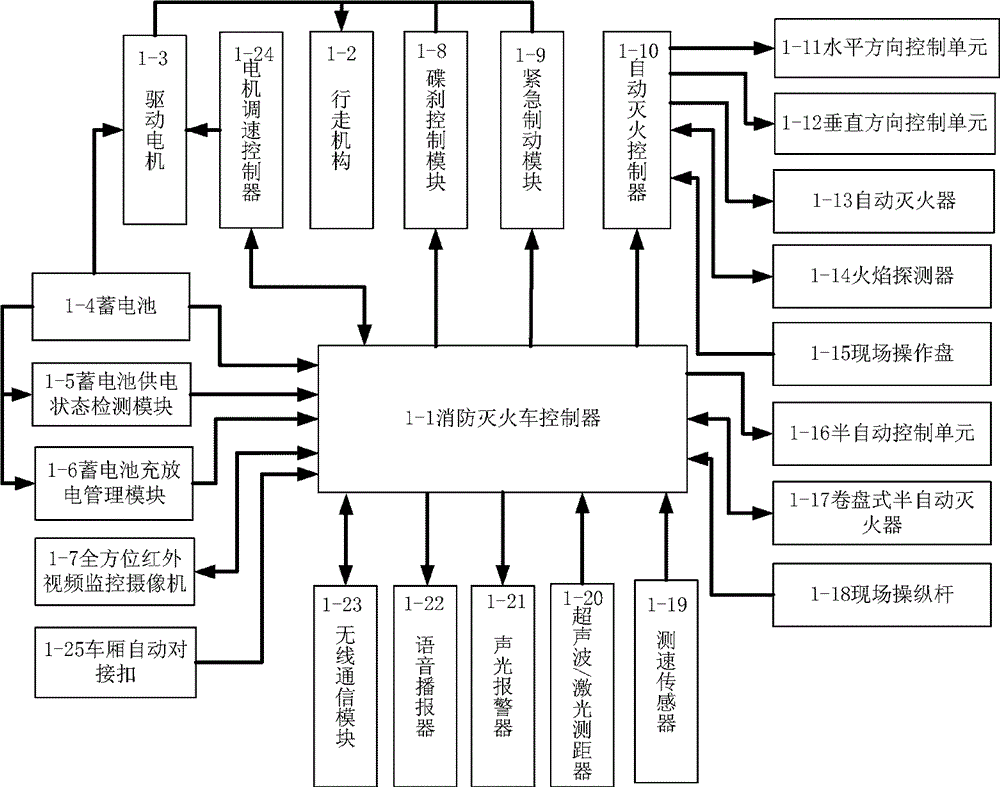

Suspended intelligent mobile fire extinguishing system

The invention relates to a suspended intelligent mobile fire extinguishing system, and in particular relates to a suspended intelligent mobile fire extinguishing system for a highway tunnel. The system comprises a suspended track, an image monitoring device, a fire-fighting linkage device, a front-end sensing device, an intelligent fire-fighting car, a wireless transmission network, a garage concentrated control zone and a remote concentrated control zone; the image monitoring device is composed of a spherical infrared video network camera and is used for collecting image information in the monitored area of the tunnel; the fire-fighting linkage device is composed of an audible and visual alarm, a voice broadcaster, a fire-fighting linkage controller and other linkage equipment, and is used for achieving fire alarm and remote voice broadcasting in the tunnel; and the front-end sensing device is composed of a fire detector, a smoke sensor, a protocol conversion module and a temperature detector. The intelligent mobile fire extinguishing system for tunnels is capable of rapidly reacting, timely arriving at the scene, carrying out effective rescue on personnel near a fire accident, controlling early fire development, and putting out the fire as soon as possible.

Owner:山东科一力电气有限公司

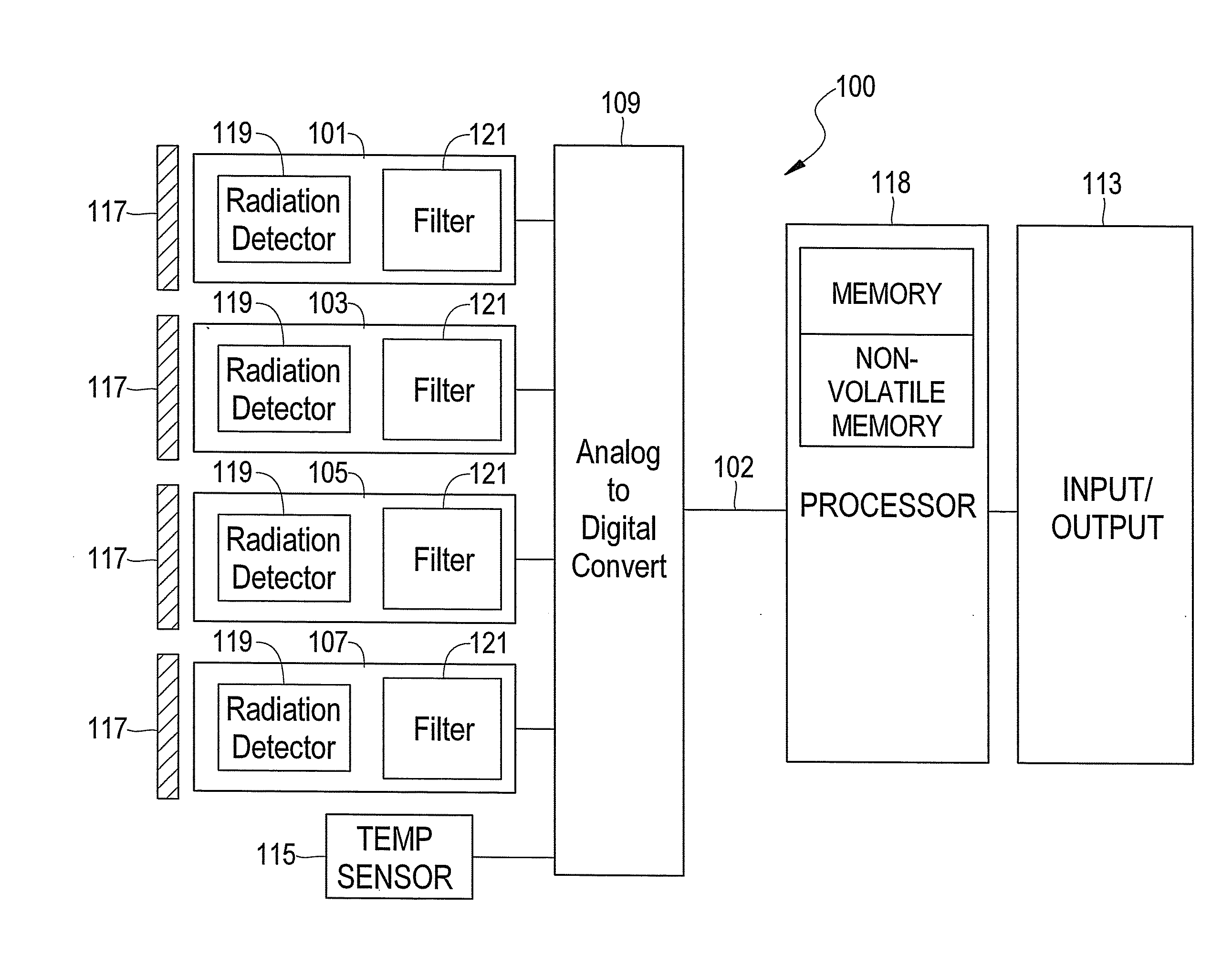

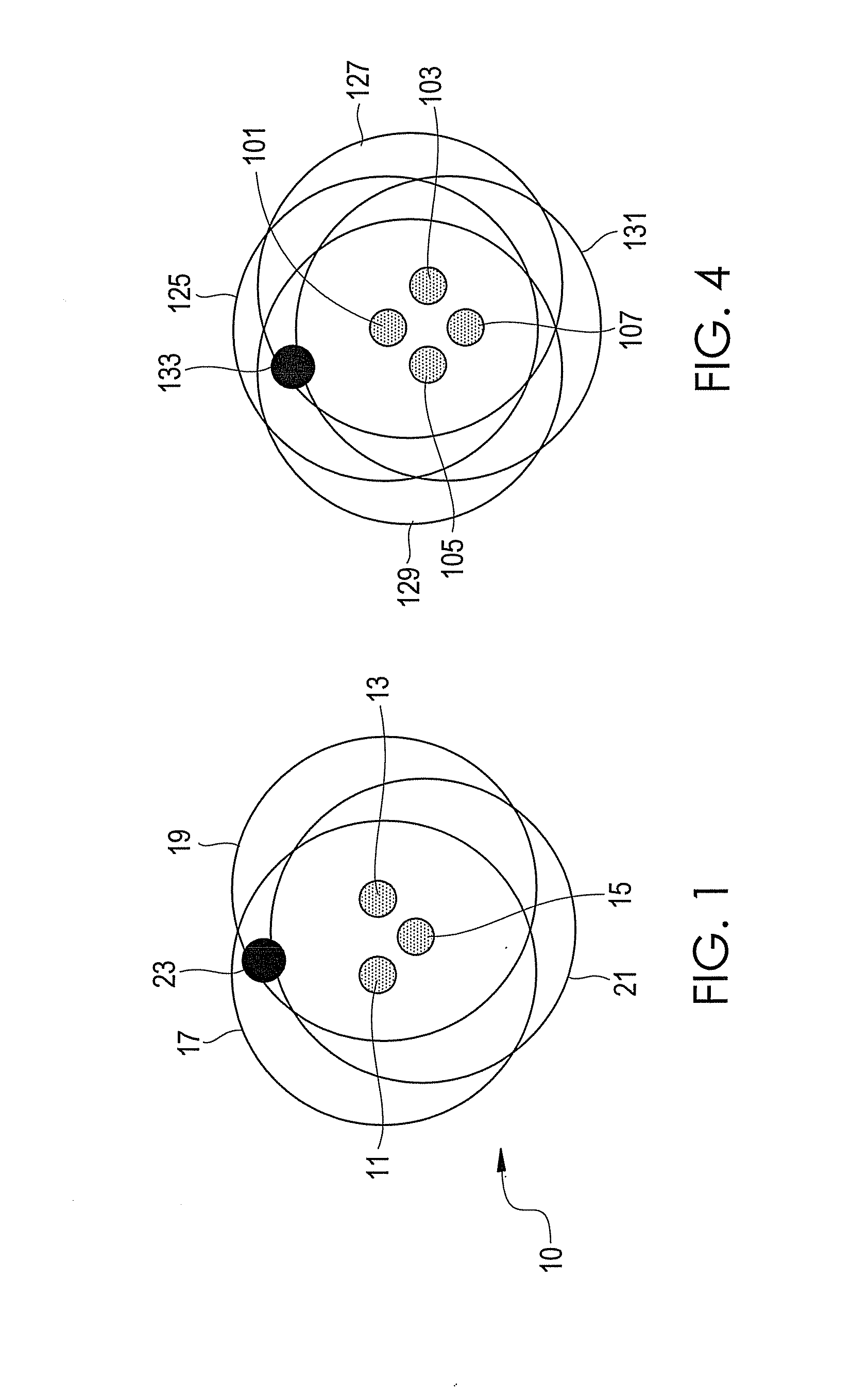

Optically Redundant Fire Detector for False Alarm Rejection

ActiveUS20120001760A1Solve the high false alarm rateAnti-theft devicesOptical signallingFire detectorSpectral transmission

A system for confirming the detection of a fire using a plurality of radiation or flame sensors each equipped with a radiation detector and an optical filter having a spectral transmission characteristic in which at least one optical filter is redundant to at least one other optical filter. The result is a system having operationally redundant sensors. In use, if a fire is detected by one of the redundant sensors without including the other redundant radiation sensor in the fire detection calculation, then a fire detection algorithm can switch to the other operationally redundant sensor to check for confirmation of a fire. Due to the spatial separation and if the object is small and close, a different result will be obtained with the redundant detector being used in the calculation compared to the primary detector that is associated with the redundant detector.

Owner:TYCO FIRE PRODS LP

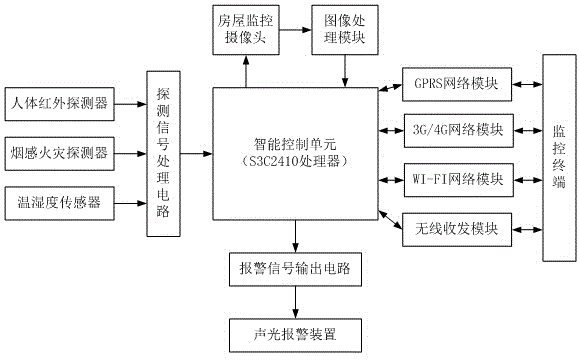

Security monitoring system and monitoring method

The invention relates to a security monitoring system and monitoring method. The monitoring system includes an alarm danger signal acquisition module, an intelligent control unit, a network transmission unit, an alarm information processing unit, and a monitoring terminal. The alarm danger signal acquisition module includes a human body infrared detector, a smoke and fire hazard detector, a humiture sensor, and a house monitoring pick-up head. The human body infrared detector includes a plurality of sets of thermopile infrared temperature sensor arrays. The intelligent control unit uses an ARM processor. The network transmission unit includes an Ethernet module, a GPRS network module, a 3G / 4G network module, a Wi-Fi module, and a wireless transmit-receive module. The wireless transmit-receive module includes a wireless transmitting end and a wireless receiving end. The alarm information processing unit includes a detection signal processing circuit, an image processing module, an alarm signal output circuit, and an acousto-optic alarm device. The monitoring terminal includes a PC client and a mobile phone client. The security monitoring system and monitoring method can solve the problems of a security monitoring system in the prior art, and meet the requirements of an intelligent monitoring system.

Owner:ANHUI CREARO TECH

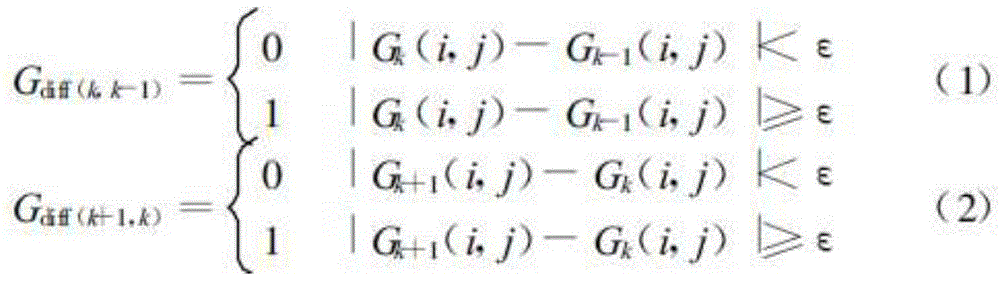

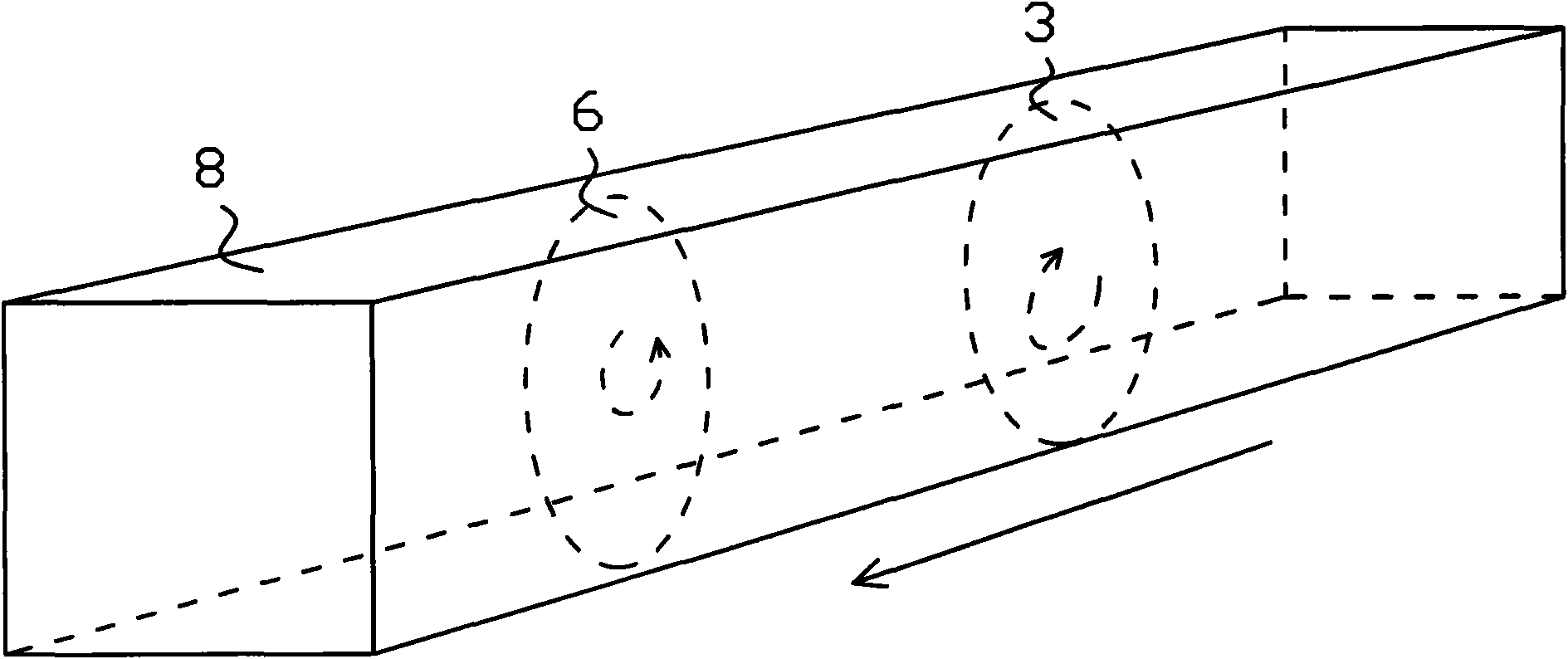

Smoke-sensitive fire detector auto-calibrating device

ActiveCN101923767AImprove consistencyAvoid reworkFire alarm smoke/gas actuationFire detectorElectricity

The invention discloses a smoke-sensitive fire detector auto-calibrating device, relating to a smoke-sensitive sensor calibrating device, mainly comprising a controller, a smoke box, a wind speed controller, a consistence measuring device, a smoke-adding controller, a smoke stirrer, an observation window, an air duct and a smoke exhaust device, further comprising a detector car. The detector car is arranged in the smoke box and is used for detecting alarm threshold of a detector. The controller and the smoke box are electrically connected, communicate signals and information with the wind speed controller, the consistence measuring device, the smoke-adding controller and the smoke stirrer, and are simultaneously communicated with the detector on the detector car so as to receive a consistence signal of the consistence measuring device and transmitting calibrating information. The invention has the advantages that although the consistency of sensor sensitivities of the detector is different, the consistency of the detectors calibrated by the auto-calibrating device is very high, each detector can pass through the test, the product rework situation is prevented, and the production efficiency is improved.

Owner:蚌埠依爱消防电子有限责任公司

Fire suppression system

ActiveUS20160263410A1Prevent and lessen possibilityEffectiveSpray nozzlesFire rescueFire detectorEngineering

A fire suppression system for a fire zone including a first tank containing a first liquid component of a two-part foam and a second tank containing a second liquid component of the foam. The system includes at least one liquid component release device configured to be selectively capable of releasing the first and second components from their respective containers upon receipt of a signal from a fire detector upon detection of a fire. The two-part foam components are propelled through the system by a pressurized propellant that, upon release of the release device, causes the exit of the foam components from their respective tanks, through a mixing conduit to at least one nozzle. The nozzle is configured to spray the liquid component foam mixture into the fire zone wherein the foam cures into a substantially semi-rigid, closed cell foam that is substantially impermeable and may have charring and / or intumescence properties.

Owner:ENK SR WILLIAM ARMAND

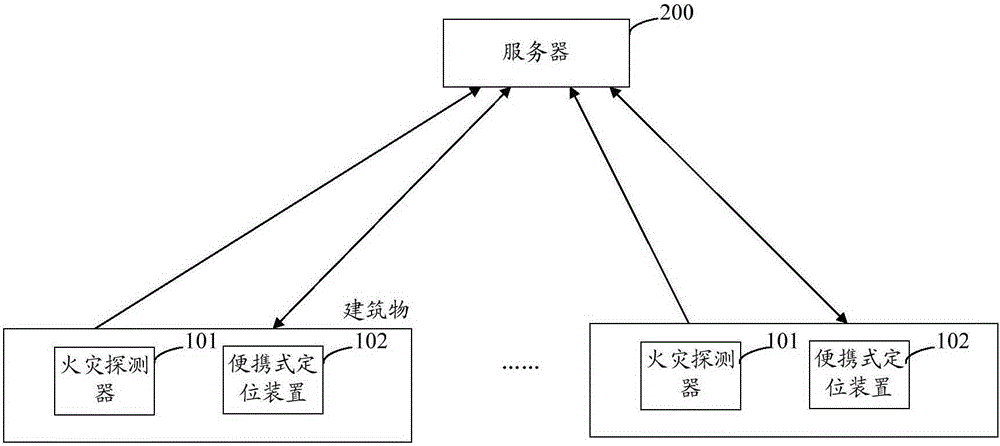

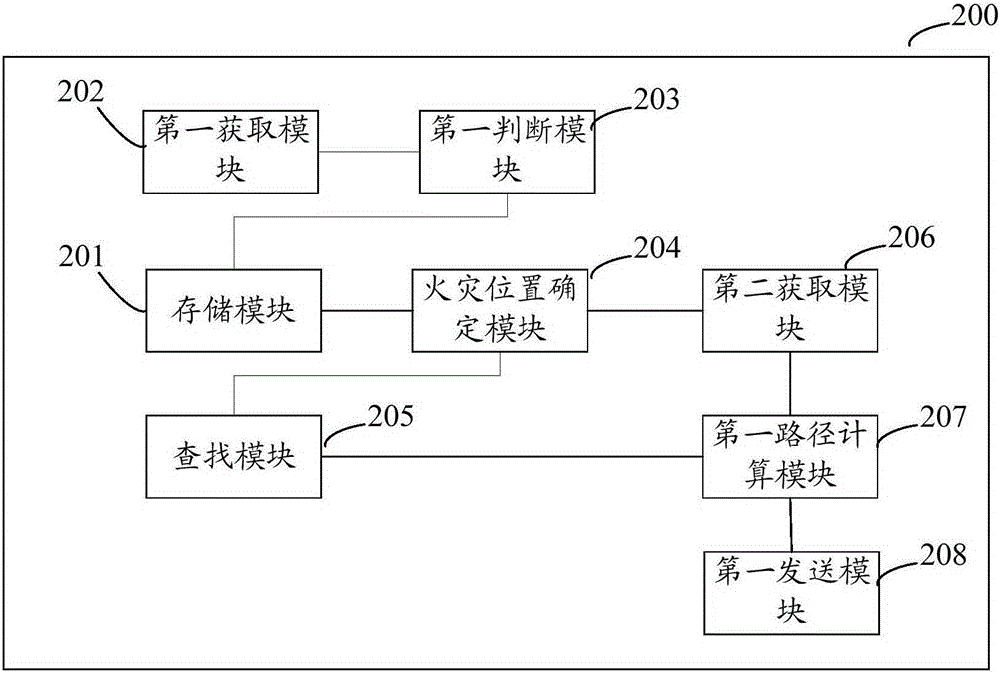

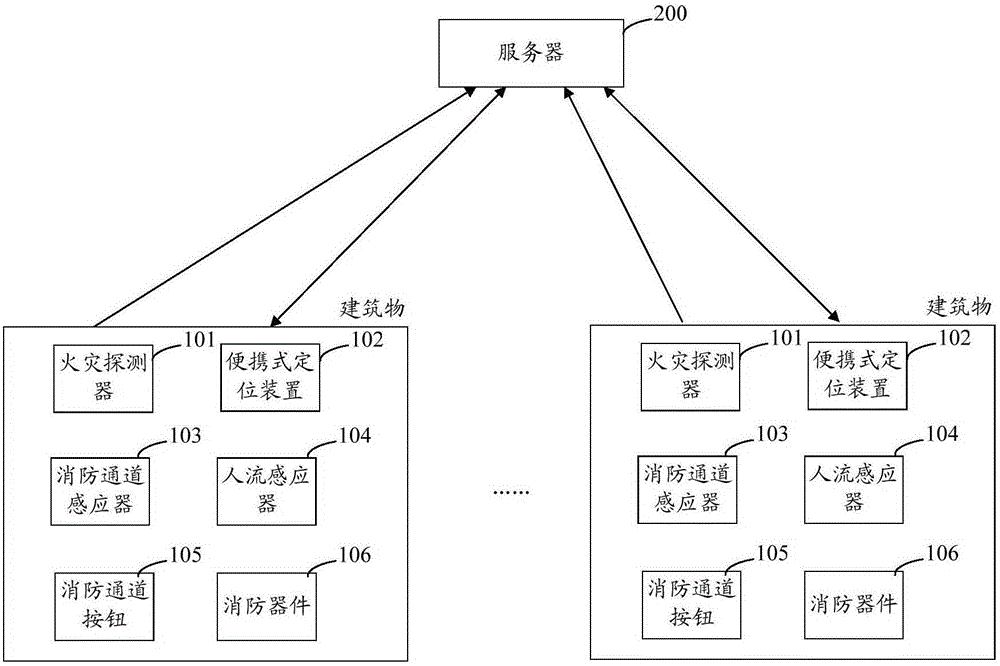

Fire-fighting evacuation system and method thereof

ActiveCN105243764ABest evacuation pathAvoid the fire sourceSignalling system detailsCounting mechanisms/objectsFire detectorFire evacuation

The invention relates to a fire-fighting evacuation system and an evacuation method thereof. The system comprises fire detectors, portable positioning devices and a server. The fire detectors are arranged in a building, and the position of the building on fire and a specific fire source position can be obtained via information of the fire detectors when outbreak of fire in the building is judged. Meanwhile, position information of portable positioning device carriers in the building on fire is acquired, and an optimal evacuation path for the portable positioning device carriers can be calculated according to information of the building on fire, the position information of the portable positioning device carriers, fire source position information and fire-fighting channel information. The fire source position can be effectively avoided by the optimal evacuation path, the nearest or safest fire-fighting channel and safety exit to the portable positioning device carriers can be rapidly found, and the optimal evacuation path is the customized optimal evacuation path for the portable positioning device carriers so that the fire-fighting evacuation system and the evacuation method thereof are high in evacuation efficiency and safe.

Owner:HUNAN HUIBO ELECTRONICS TECH

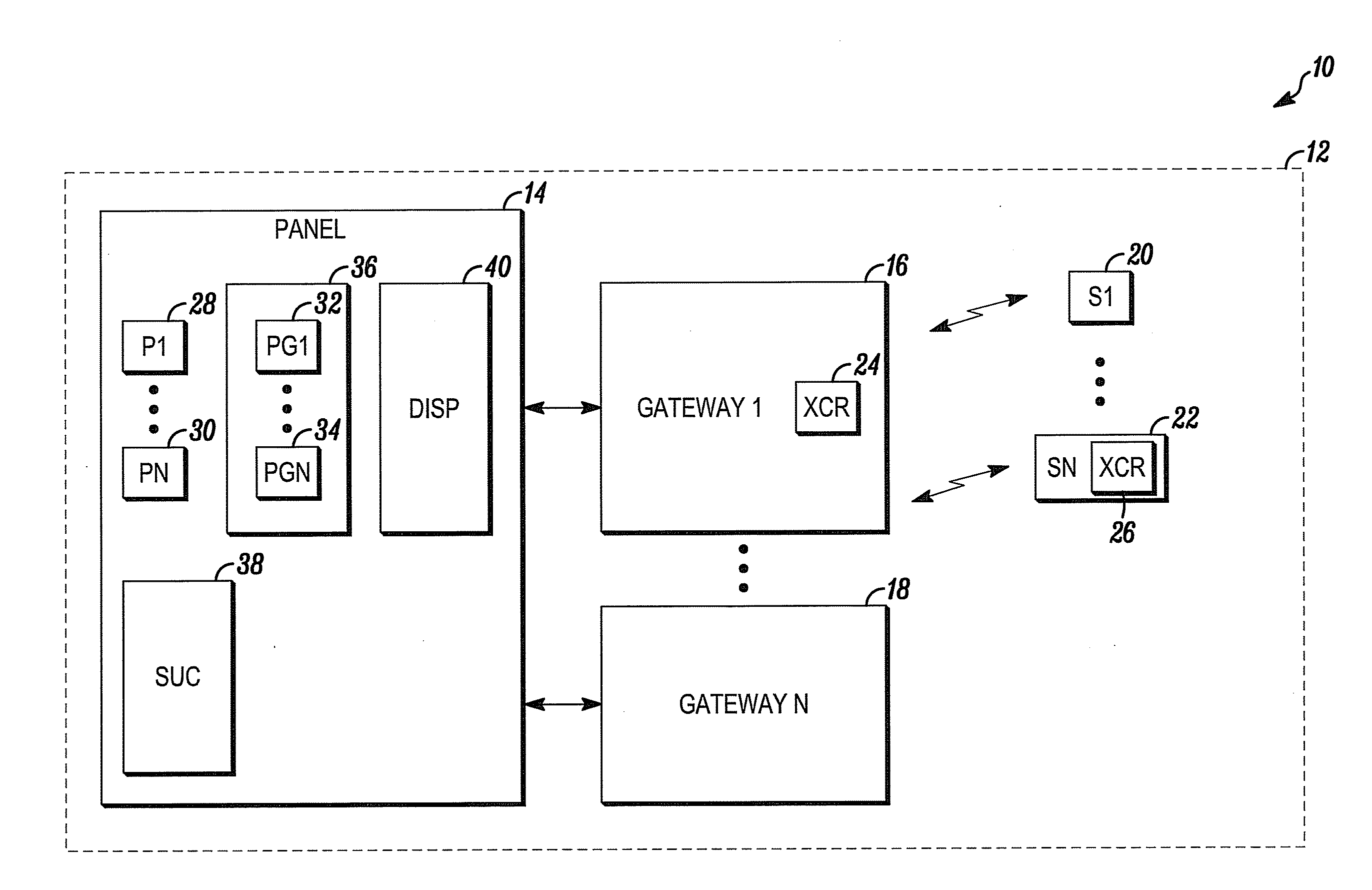

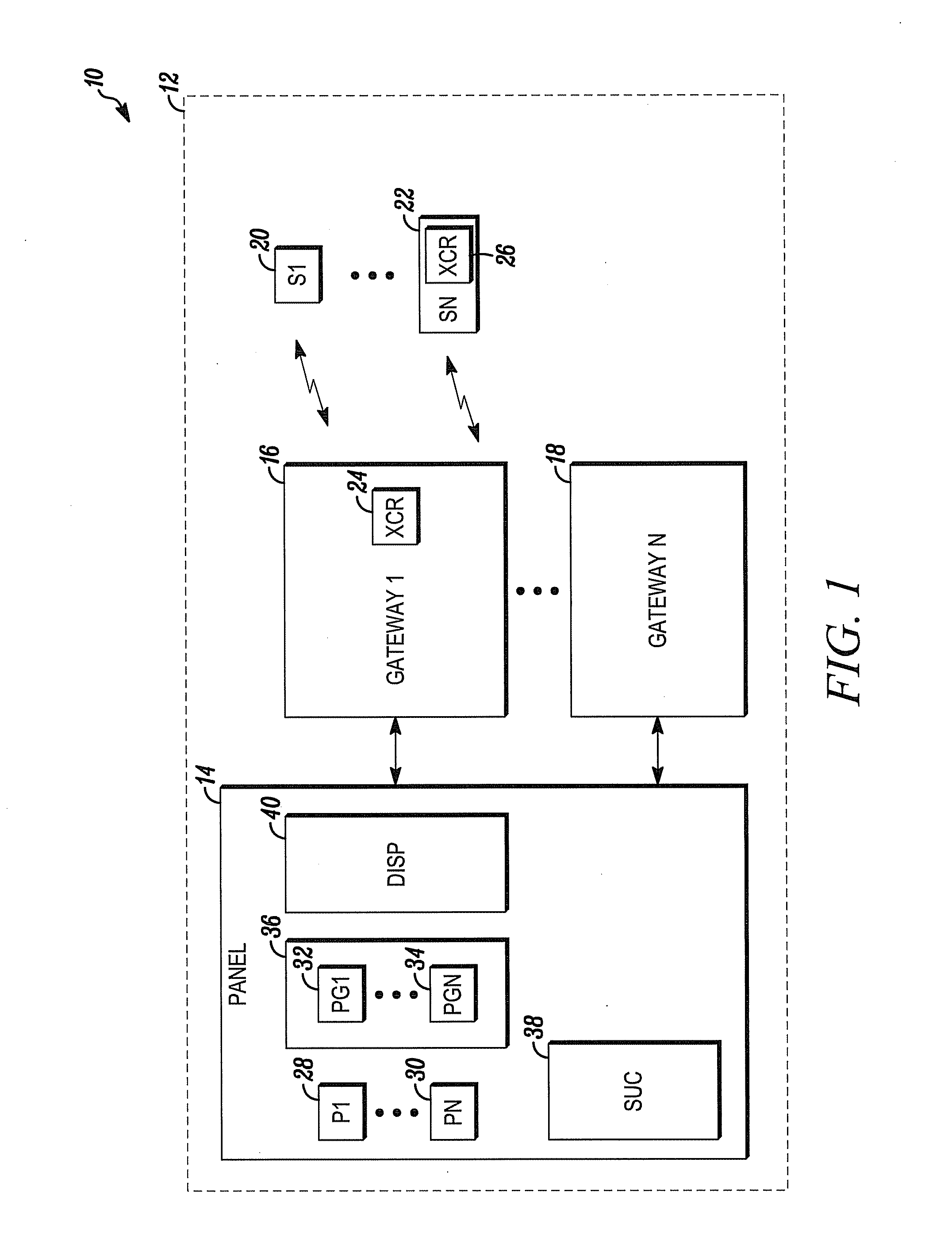

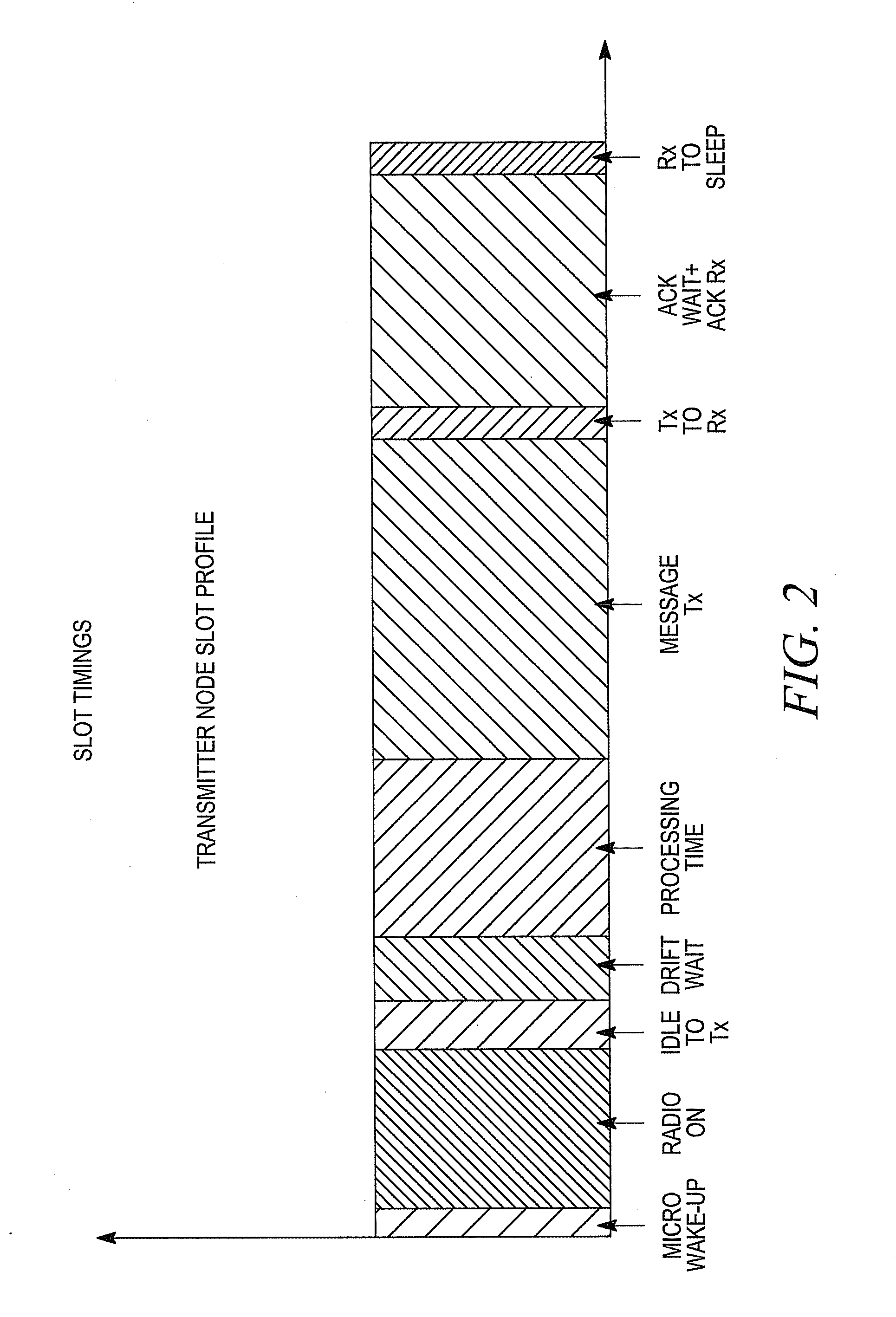

Field optimized, configurable wireless fire system

A method and apparatus are provided for setting up a fire alarm system. The method includes the steps of coupling a user interface to a wireless fire detection system having a wireless gateway and a plurality of wireless fire detectors, receiving a selection through the user interface of a wireless transmission parameter used in transmitting messages between the wireless gateway and the plurality of wireless fire detectors, determining a latency time value associated with use of the received selection of the wireless transmission parameter in the transmission of messages between the wireless gateway and the plurality of fire detectors, displaying the calculated latency time value on the user interface and changing an operating mode of the plurality of wireless fire detection devices in accordance with the received selection. In addition to latency, the fire alarm system may receive a selection and determine the battery life and sensor / output device capacity that is possible and display these parameters for the benefit of a user.

Owner:HONEYWELL INT INC

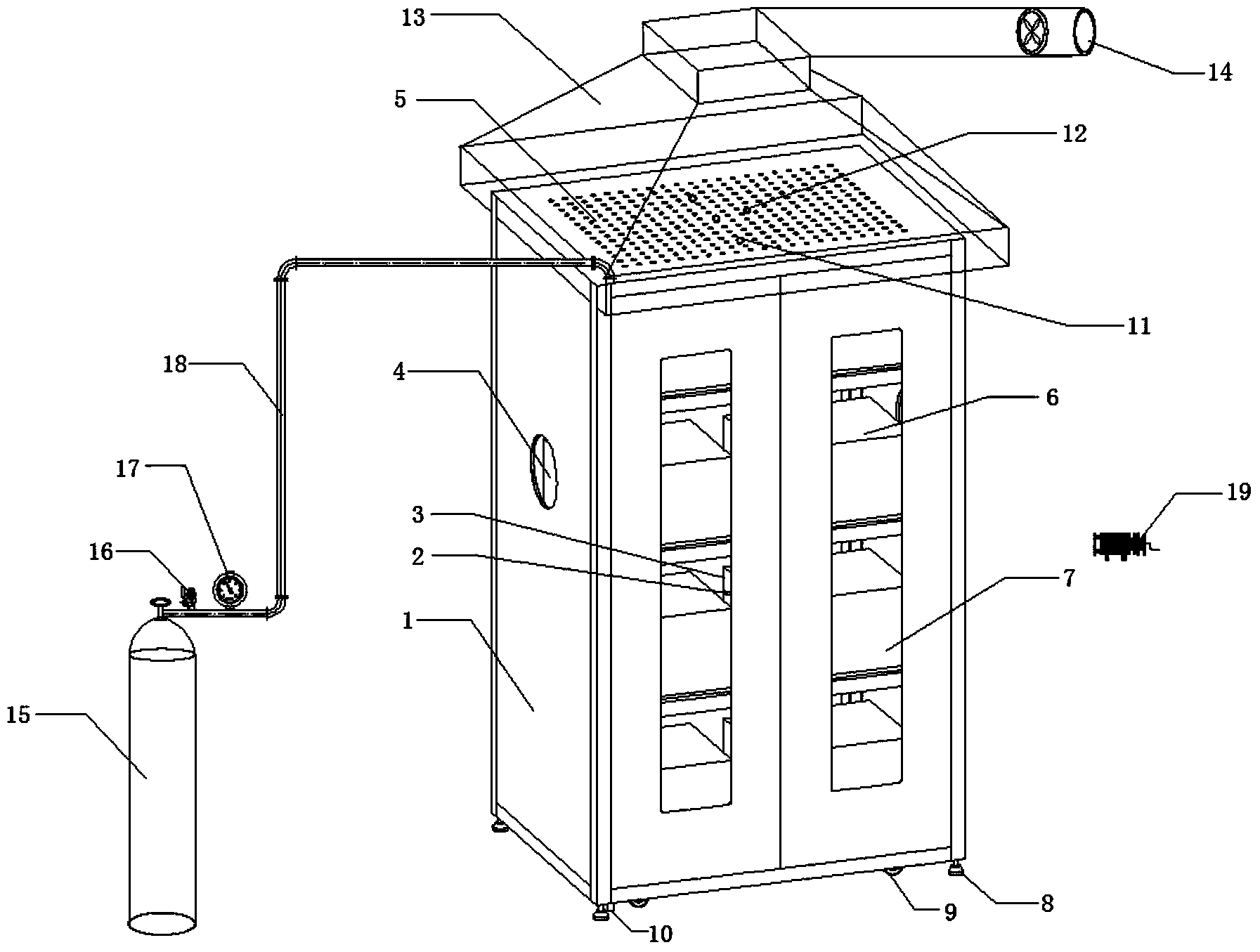

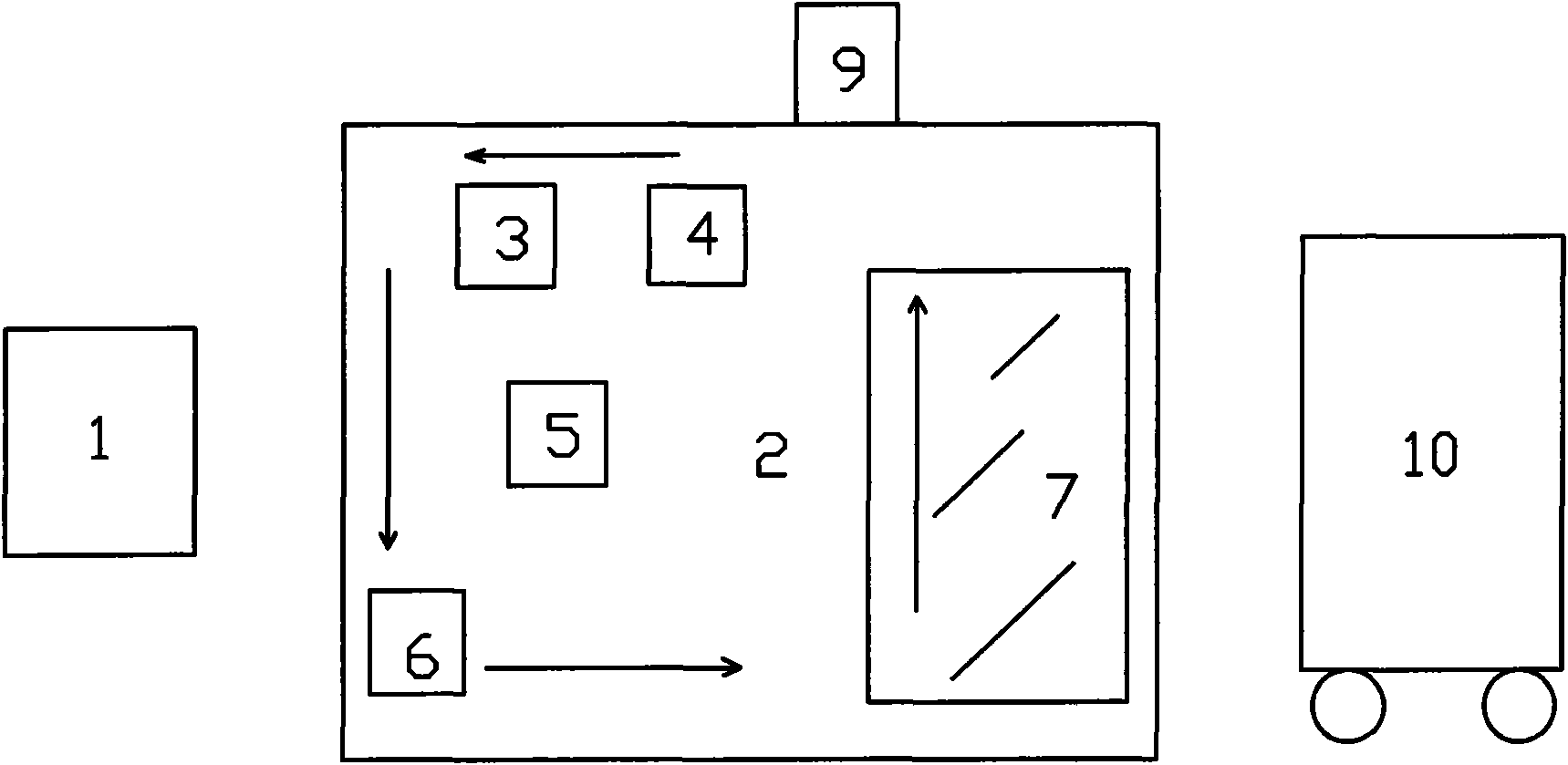

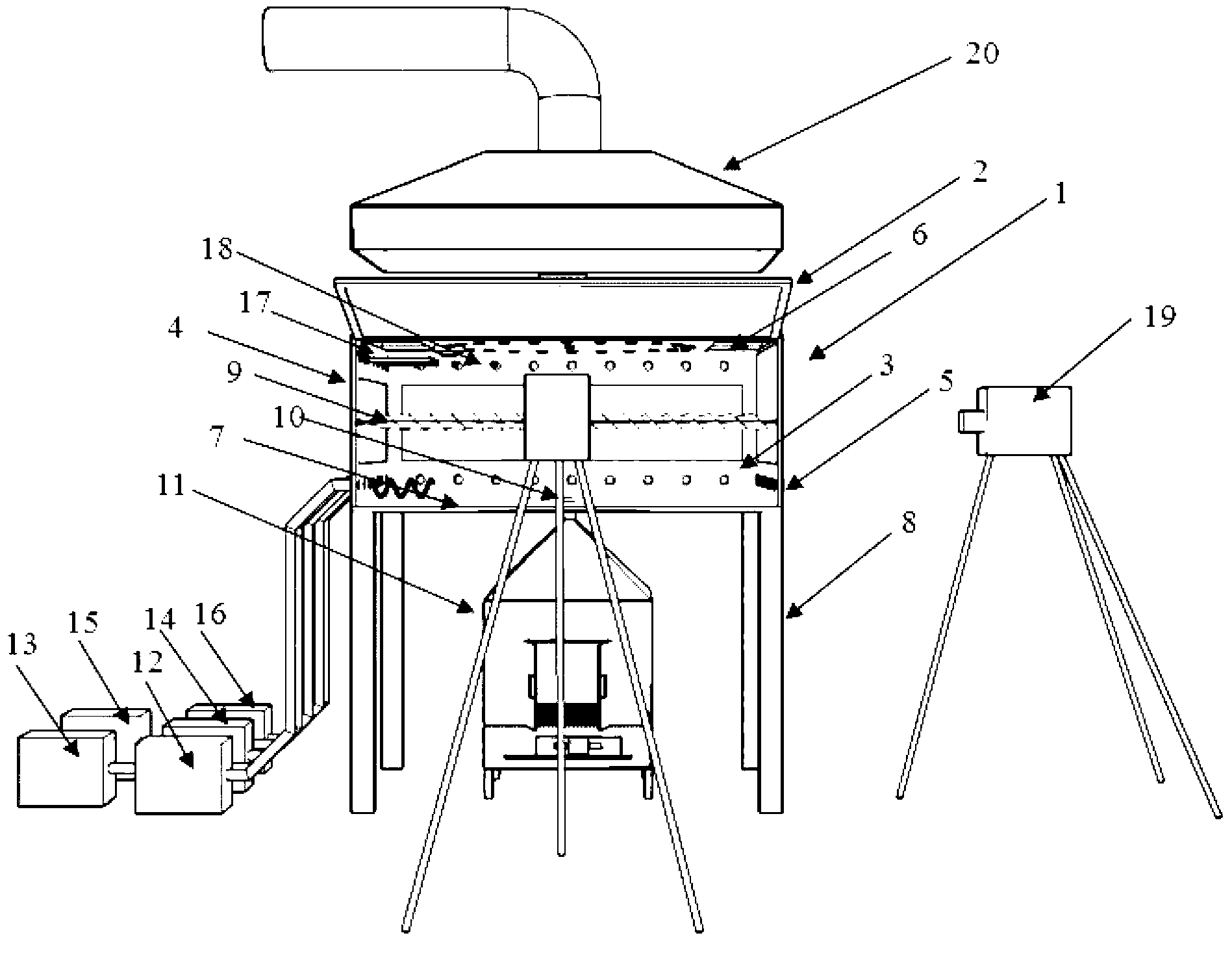

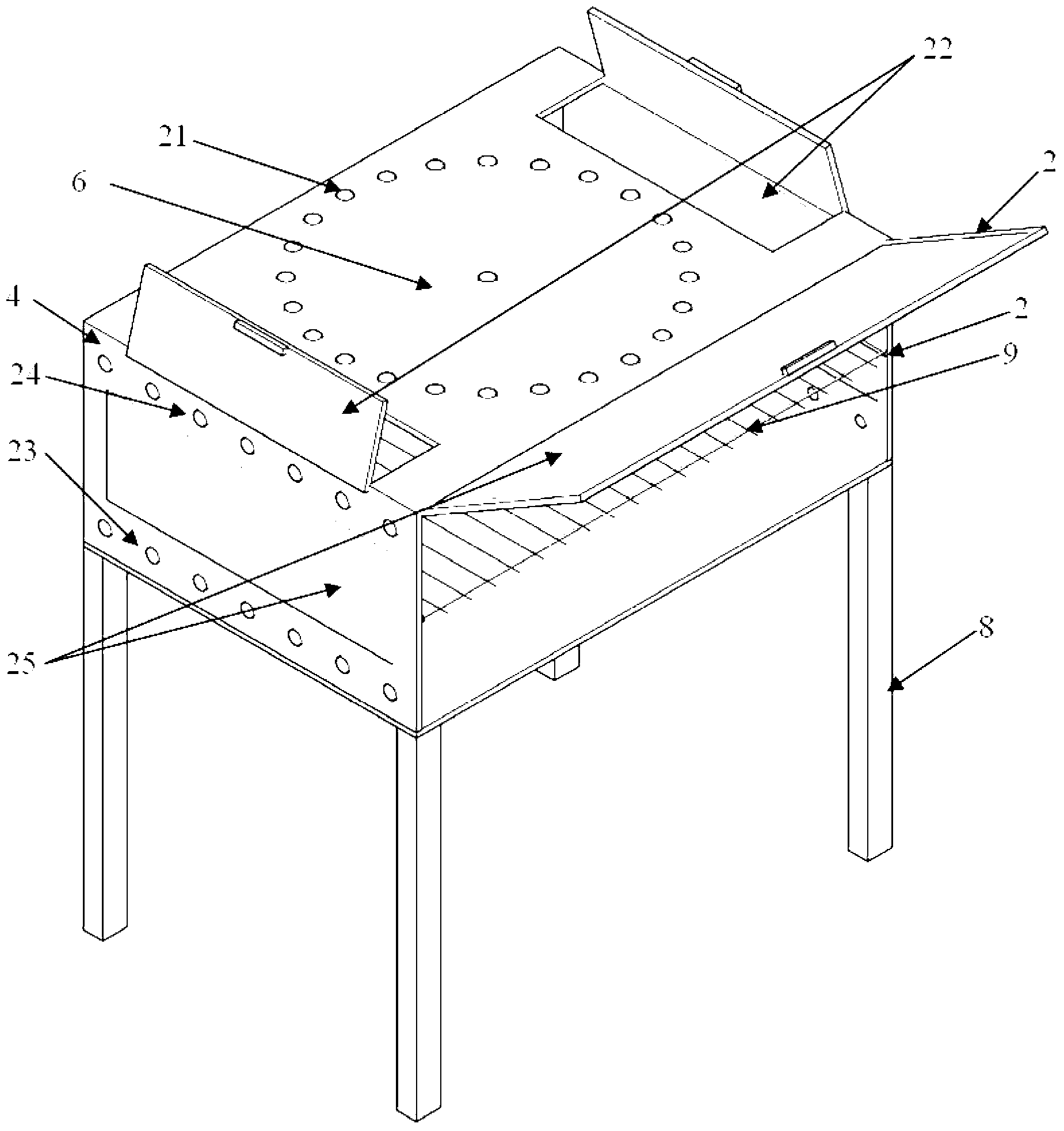

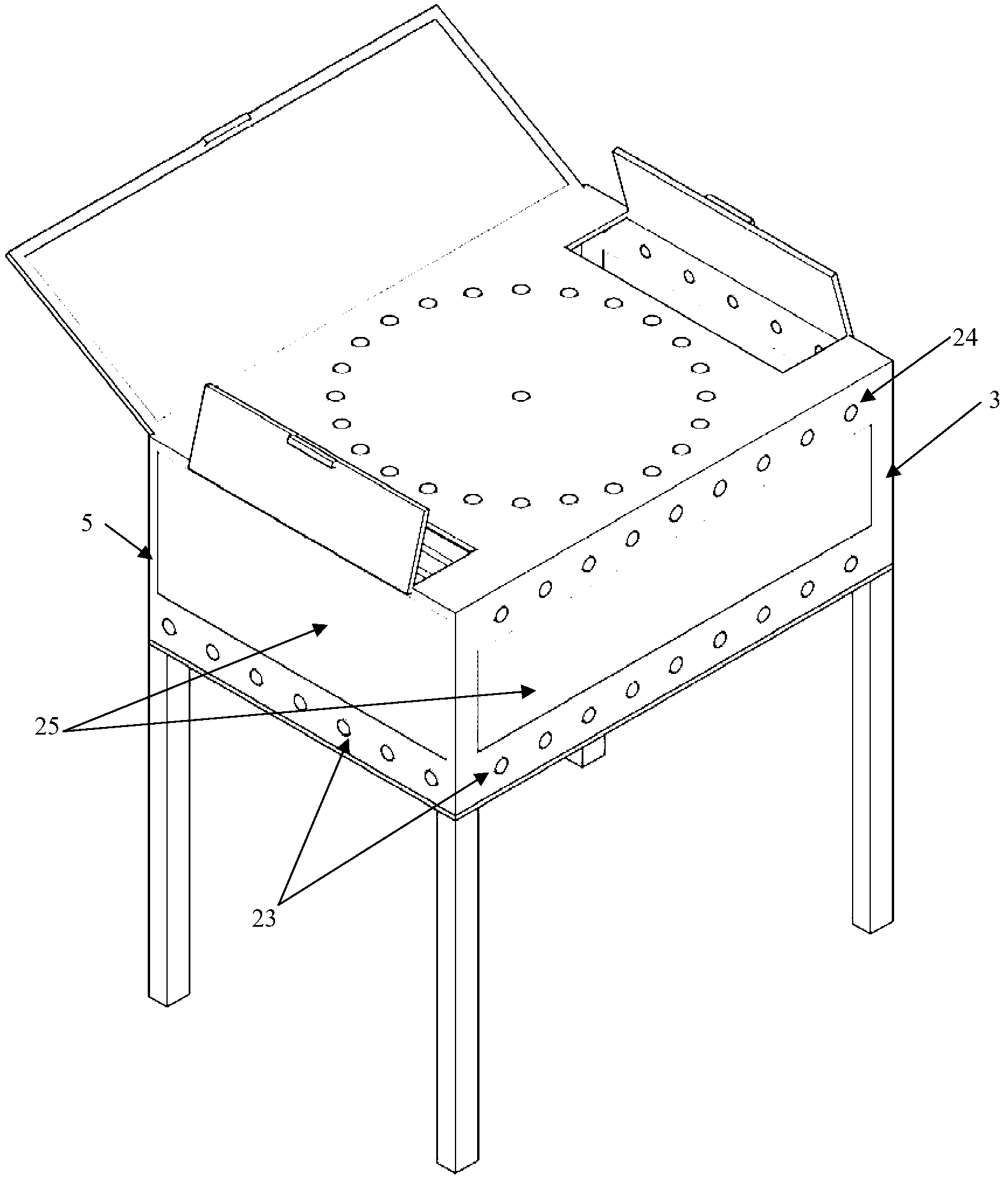

Comprehensive detection simulation experiment device for fire detection performance

ActiveCN103292835ATo overcome the disadvantage of probing performance impactFunction increaseInstrumentsFire detectorCombustion chamber

The invention provides a comprehensive detection simulation experiment device for fire detection performance. The comprehensive detection simulation experiment device comprises an experiment table body (1), a matched simulation generation device, a measuring and controlling system and a fume extractor (20). The experiment device has a conventional fire detection performance detection function, can be combined according to conditions of detectors and characteristics of suitable places, is capable of overcoming the defects that existing devices do not take fume distribution characteristics and dust, water mist and wind speed changes into consideration and detection performance is affected by the positions of the detectors, and has the advantages of multiple functions, simple structure, high reliability, convenience in assembly and disassembly and low cost. The device is capable of performing various experiments of small-size standard fire experiments, flow equalizing fume simulation, practical application environment simulation and the like, and influences on fire detection performance by the positions of fire detectors relative to a fire source are considered. Enough detected fire detector mounting threaded holes are formed in a ceiling of a firing chamber, so that positions of the fire detectors in the firing chamber are changed conveniently according to practical situations of the fire detectors.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com