Patents

Literature

186 results about "Spectral transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

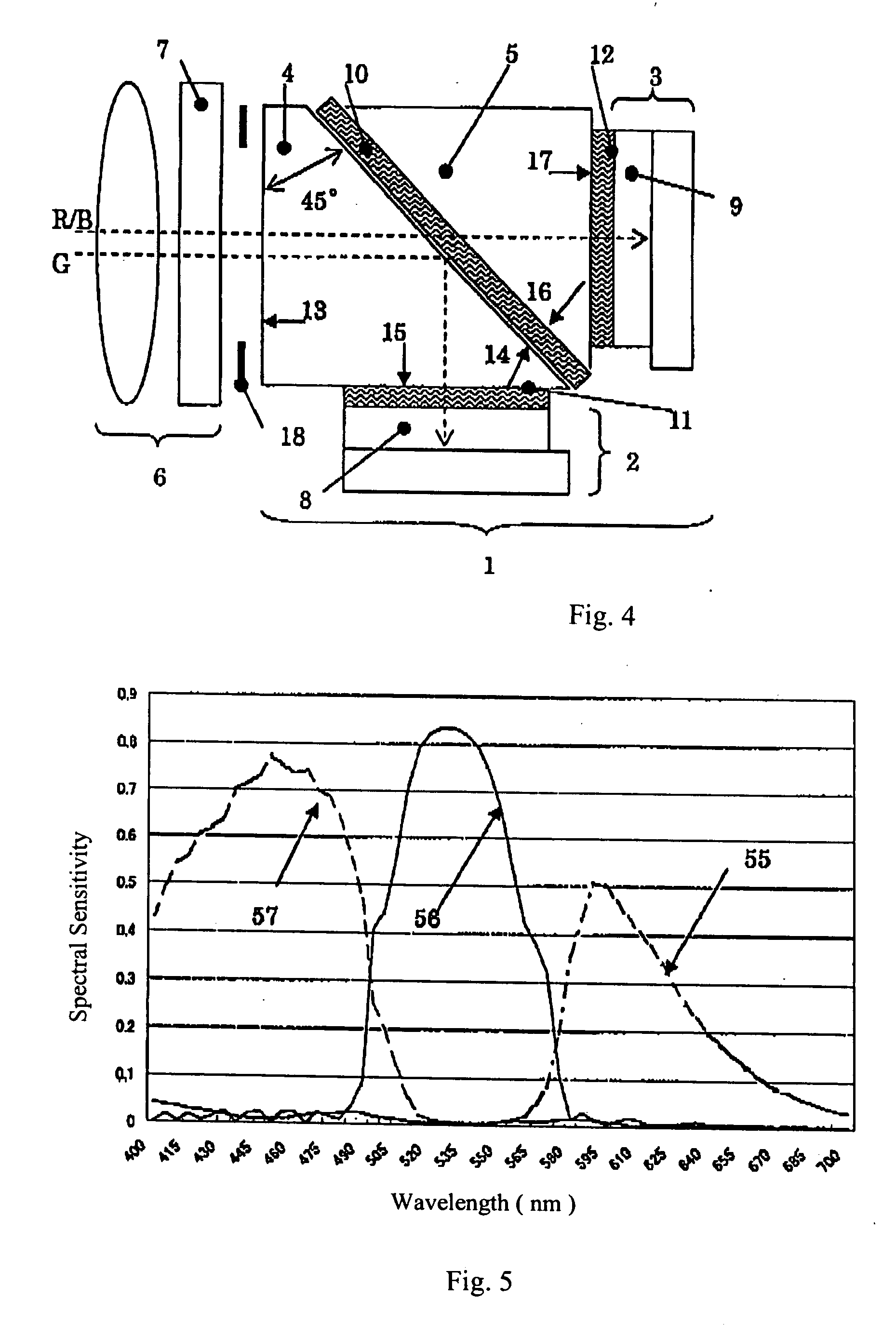

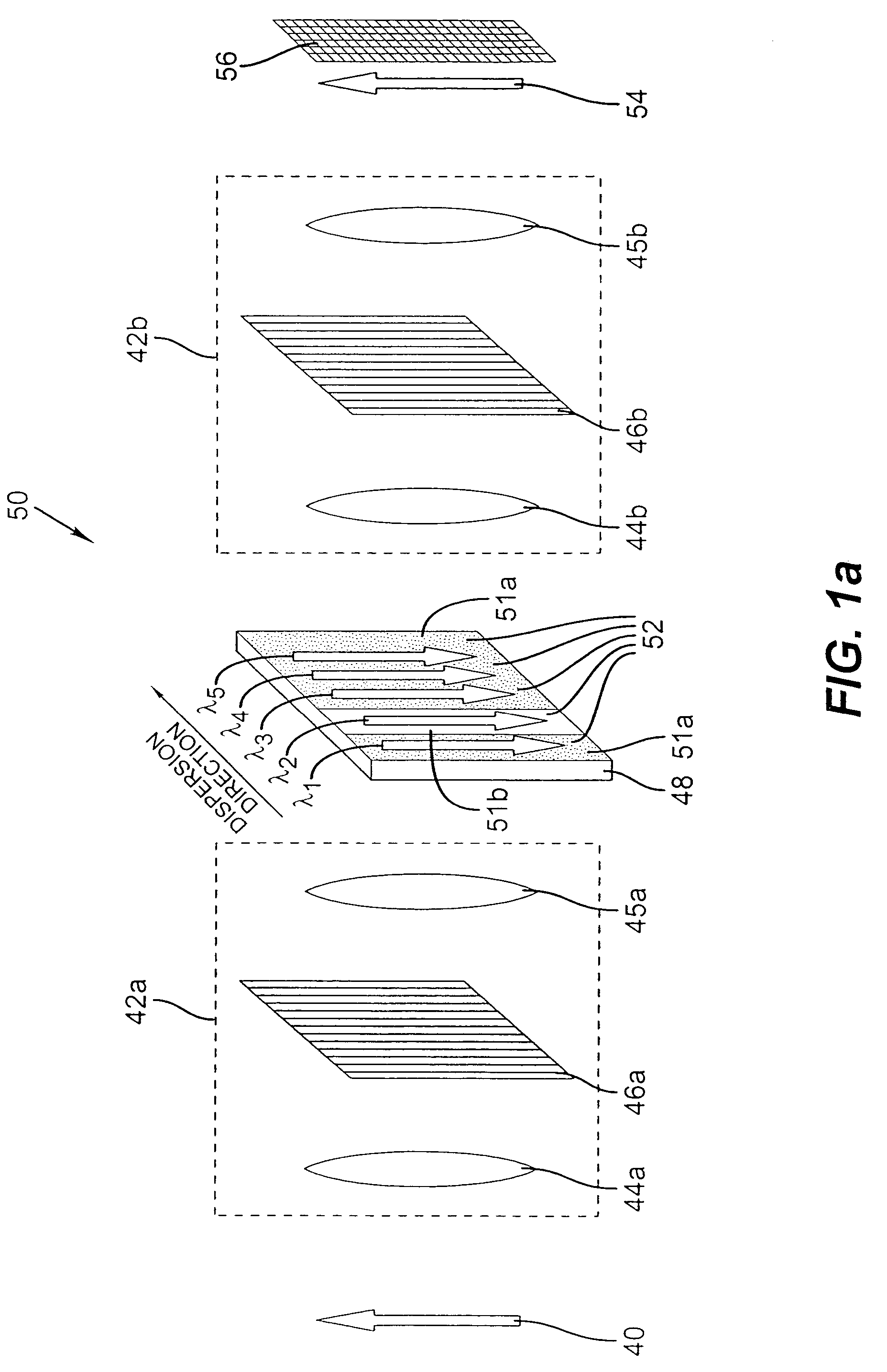

Programmable spectral imaging system

InactiveUS7342658B2Improve efficiencyHigh resolutionRadiation pyrometryAbsorption/flicker/reflection spectroscopySpectral transmissionSpatial light modulator

Owner:EASTMAN KODAK CO

Filter for enhancing vision and/or protecting the eyes and method of making a filter

ActiveUS7106509B2Lack of visionImprove eyesightPolarising elementsOptical partsSpectral transmissionProtecting eye

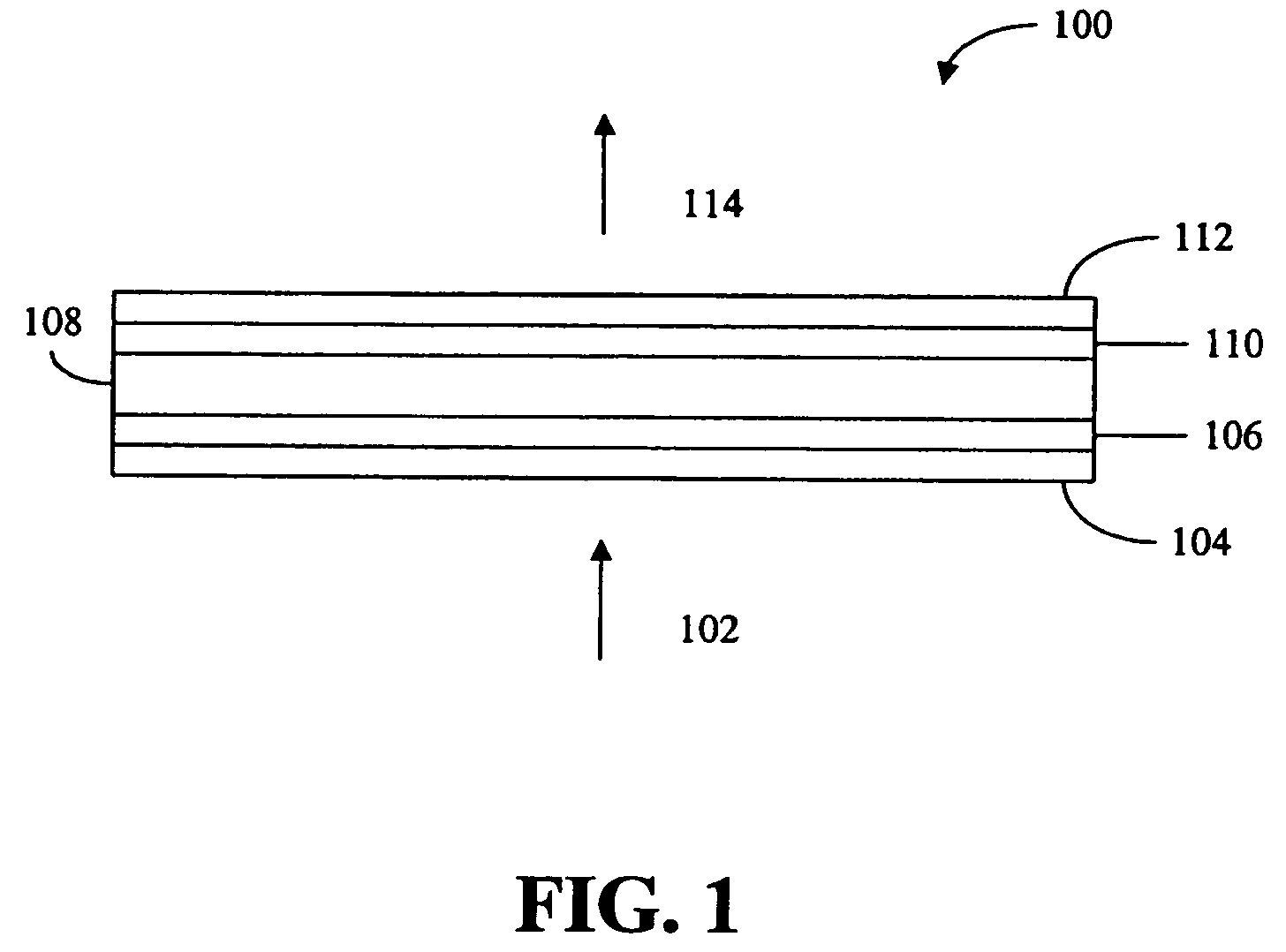

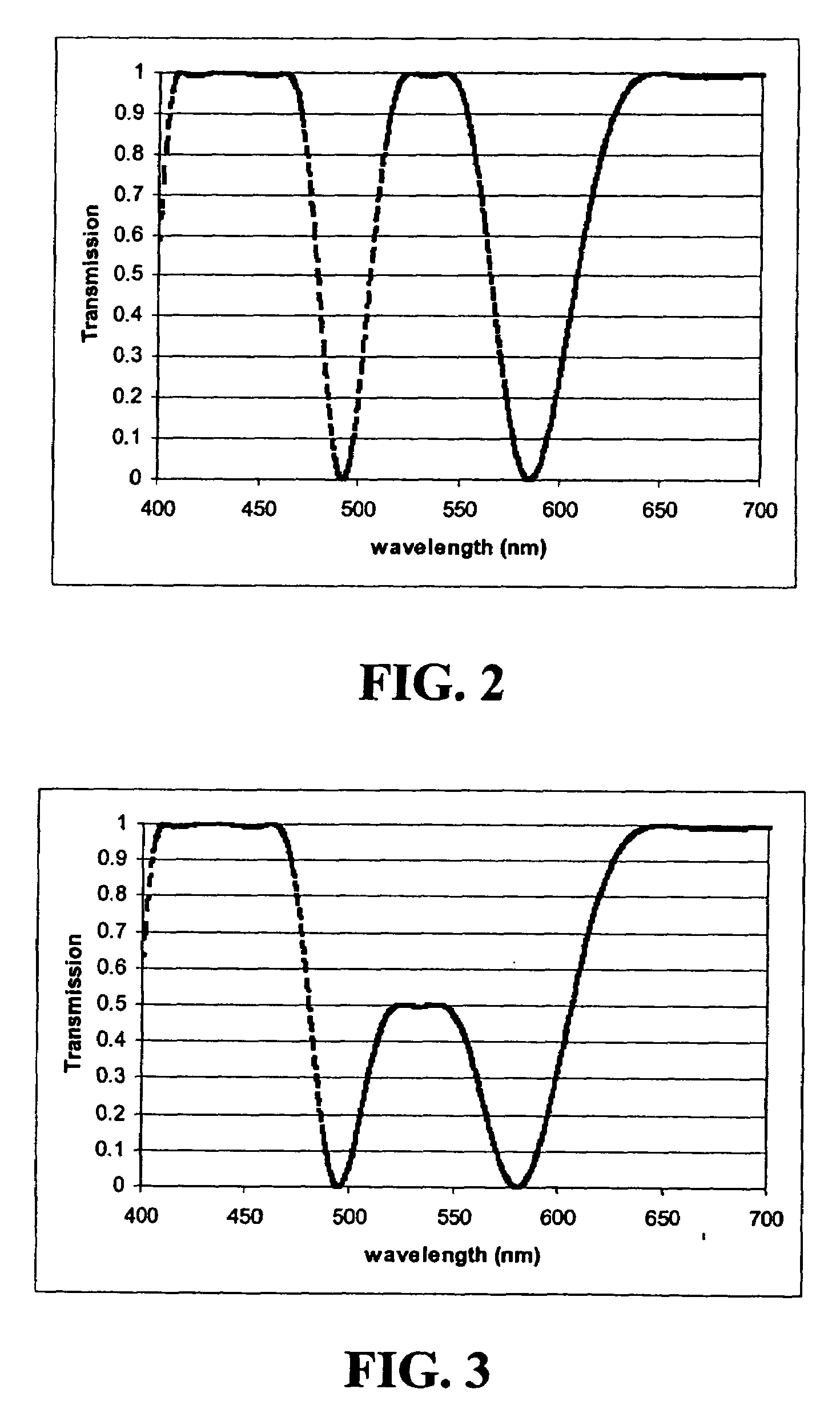

The selective filtering of light by polarization interference may be used to enhance vision and / or protect eyes from harmful light rays. For example, such filtering may be used in sunglasses, color corrective eyewear or protective eyewear. The selective filtering of incident light may provide any desired spectral transmission (including visible light and light not visible to the eye) and is performed by a pair of polarizing elements that sandwich a retarder stack. The filtering structure may be formed by multi-layer polarizing structures and may be formed by fabricating sheet laminates that are die cut to form inexpensive laminates. The laminates may be flat or curved in one (e.g., wrap-around) or more dimensions.

Owner:REAID INC

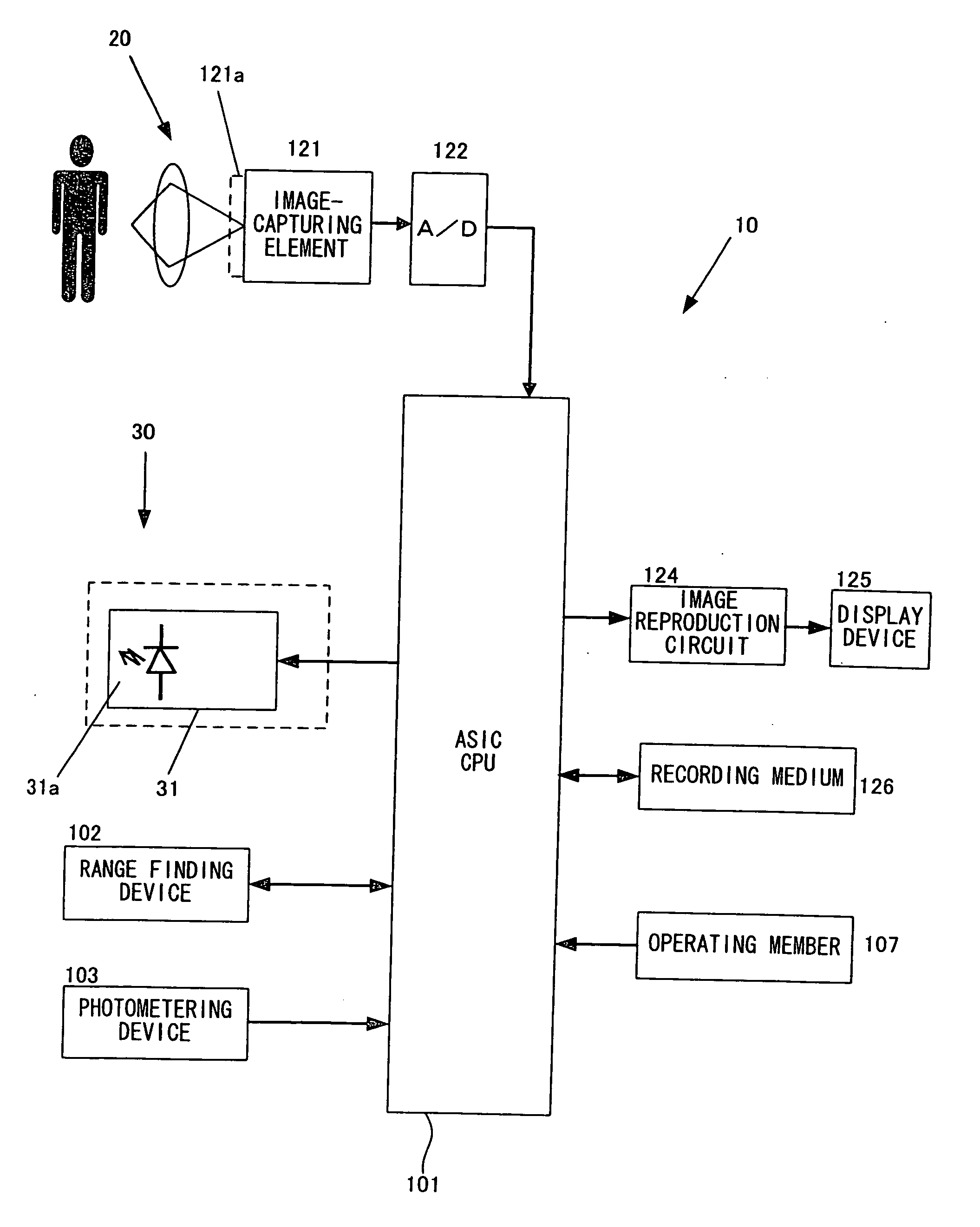

Image pickup apparatus having two image sensors

InactiveUS20070115376A1High return on investmentQuality improvementTelevision system detailsSignal generator with multiple pick-up deviceSpectral transmissionPrism

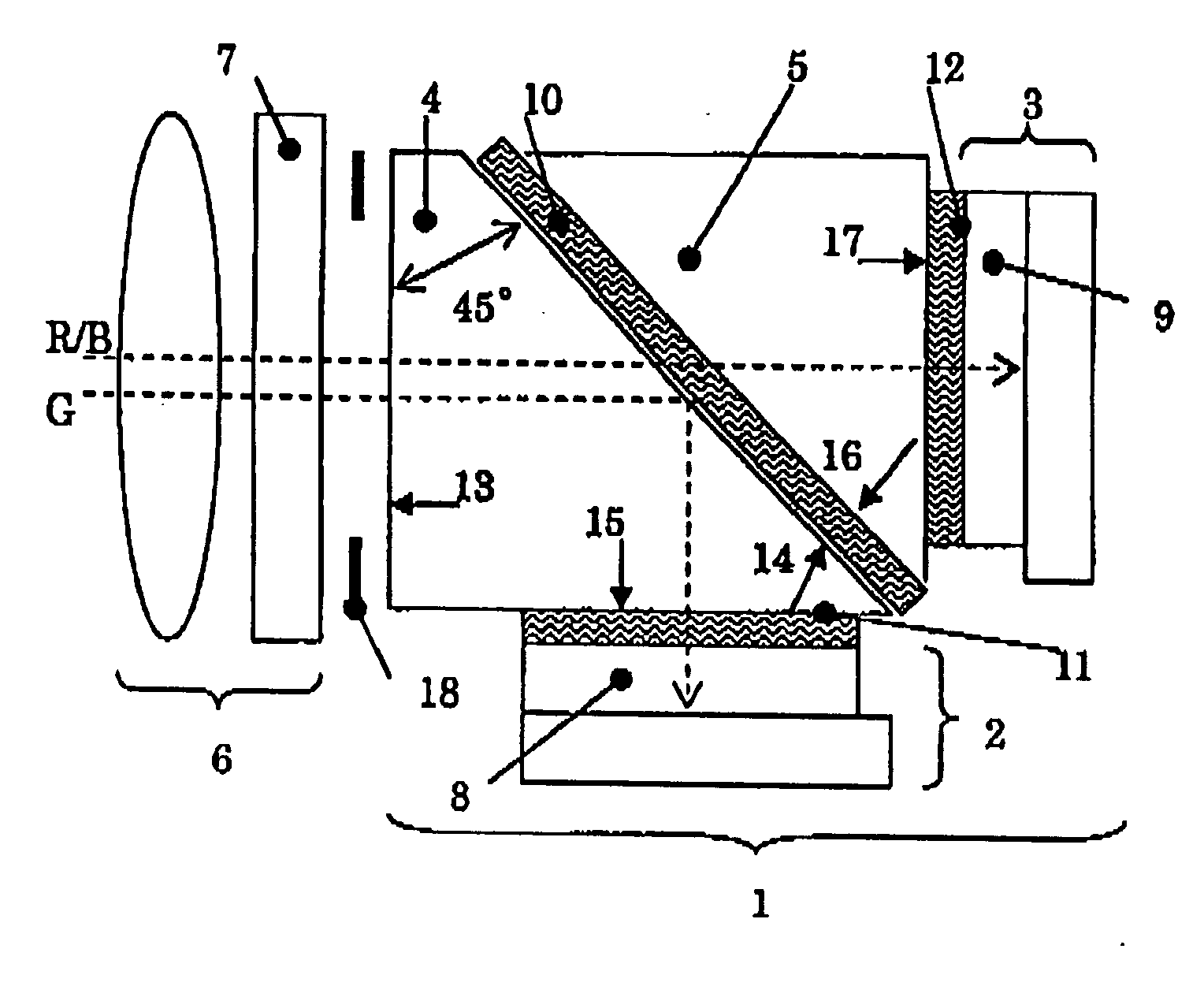

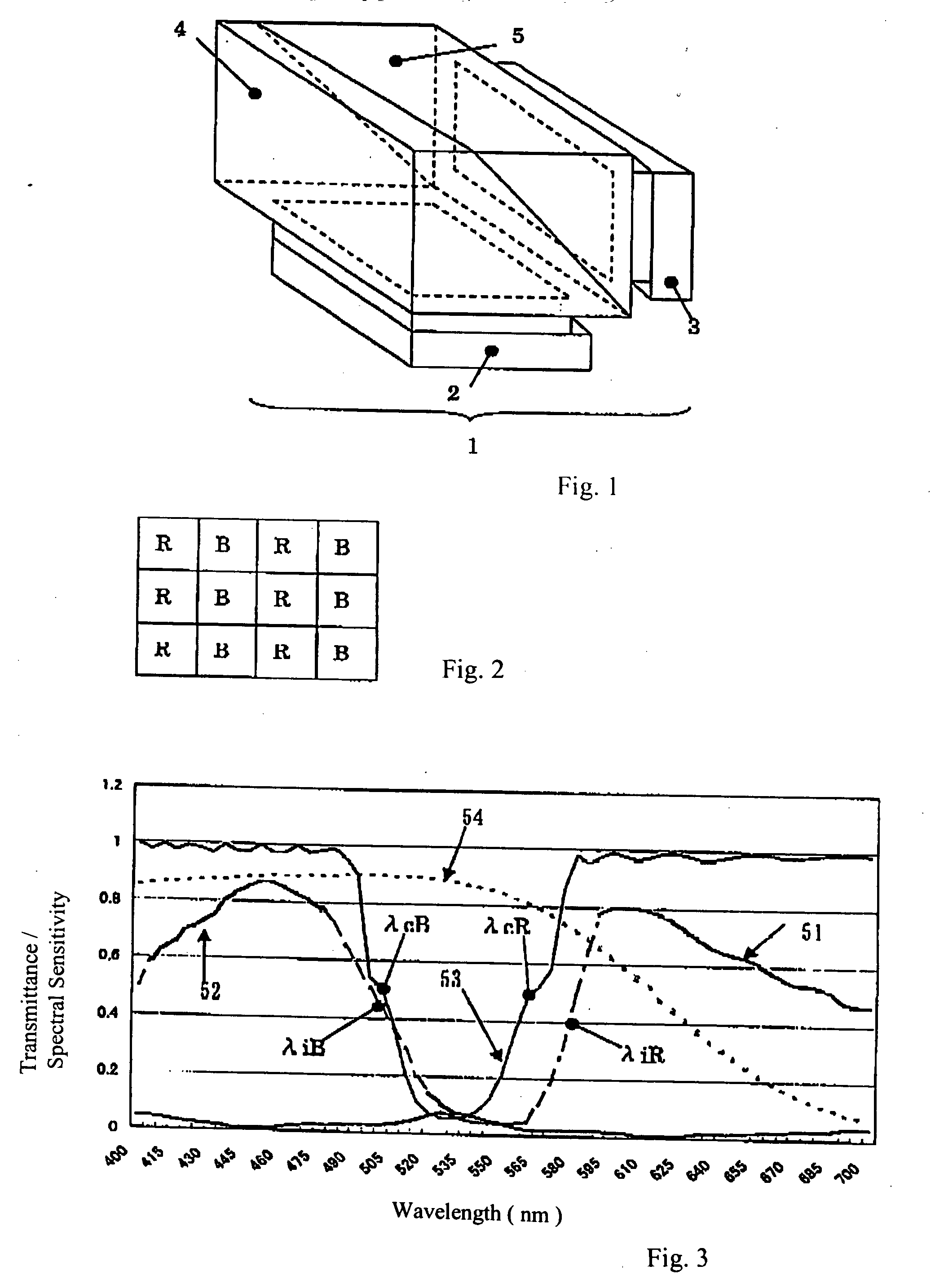

An image pickup apparatus having two image sensors includes two solid state image pickup devices and a prism group that includes a color separation coating that reflects green light. Red and blue transmitting “on chip” color filters are supported on one of the two solid state image pickup devices. The image pickup apparatus has a spectral design to control color shading in changing environments, and is also designed for easy assembly. The spectral design requires that the spectral transmission characteristics of the color separation coating, the red and blue transmitting color filters, and the spectral sensitivity characteristics of pixels of the solid state image pickup devices satisfy certain conditions that pertain to boundaries between the red, blue, and green light. Image readout is provided by combining two adjacent pixels of the image field. A method of manufacturing such an image pickup apparatus is also disclosed.

Owner:OLYMPUS MEDICAL SYST CORP

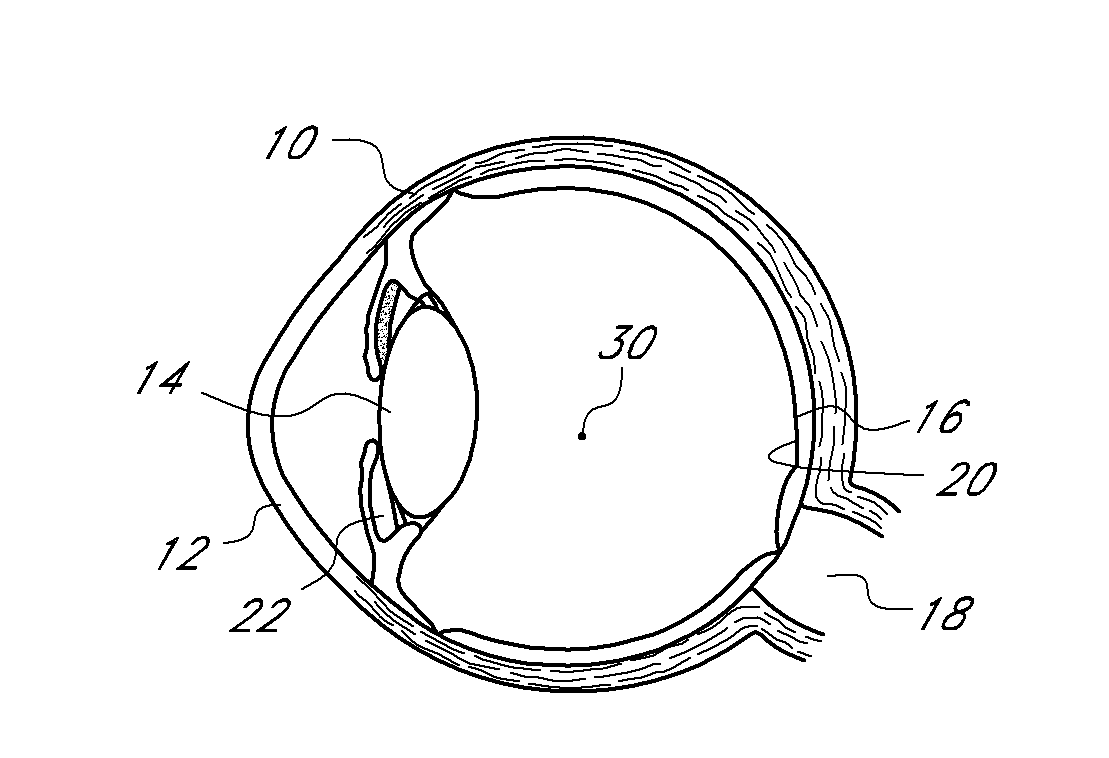

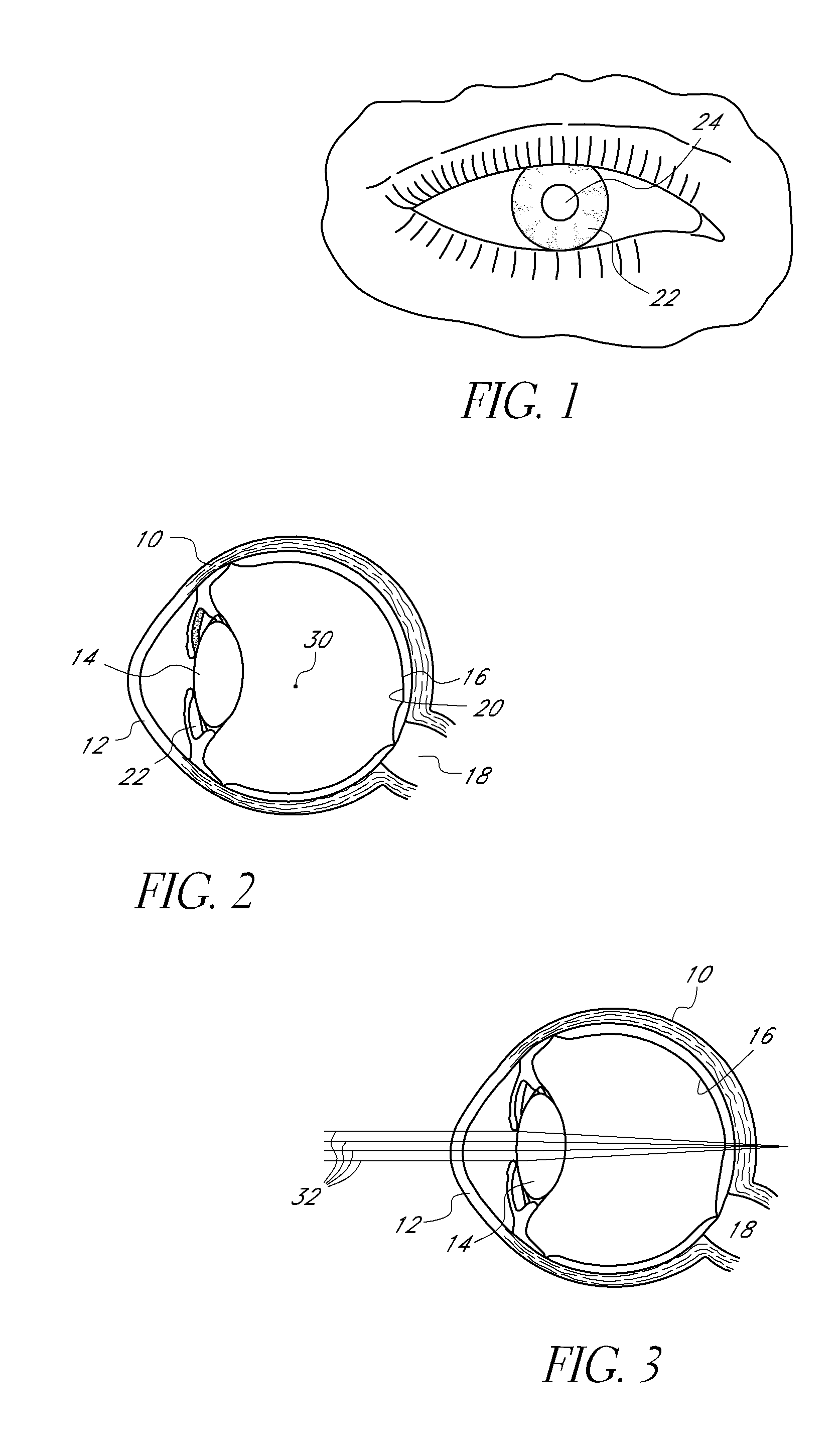

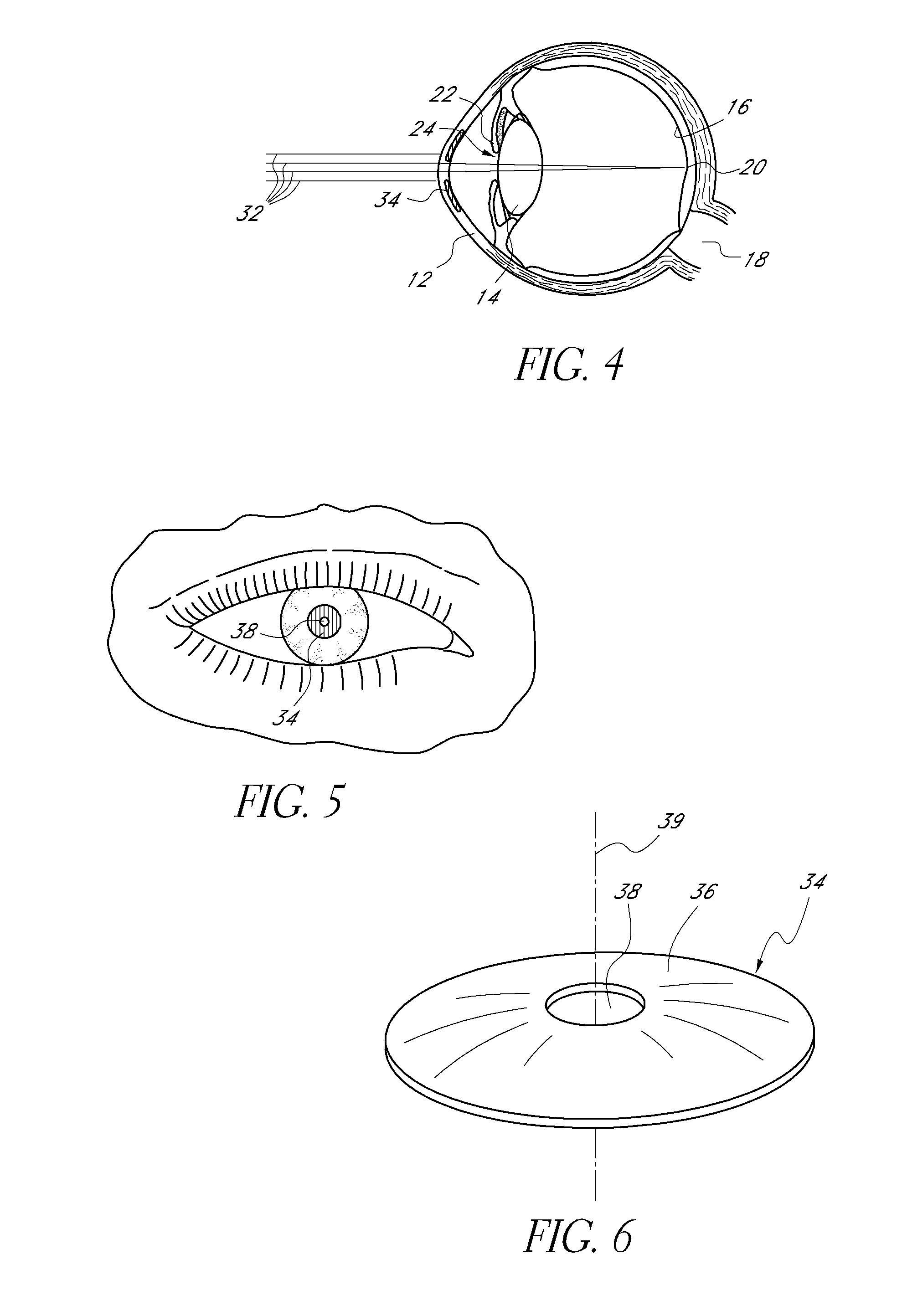

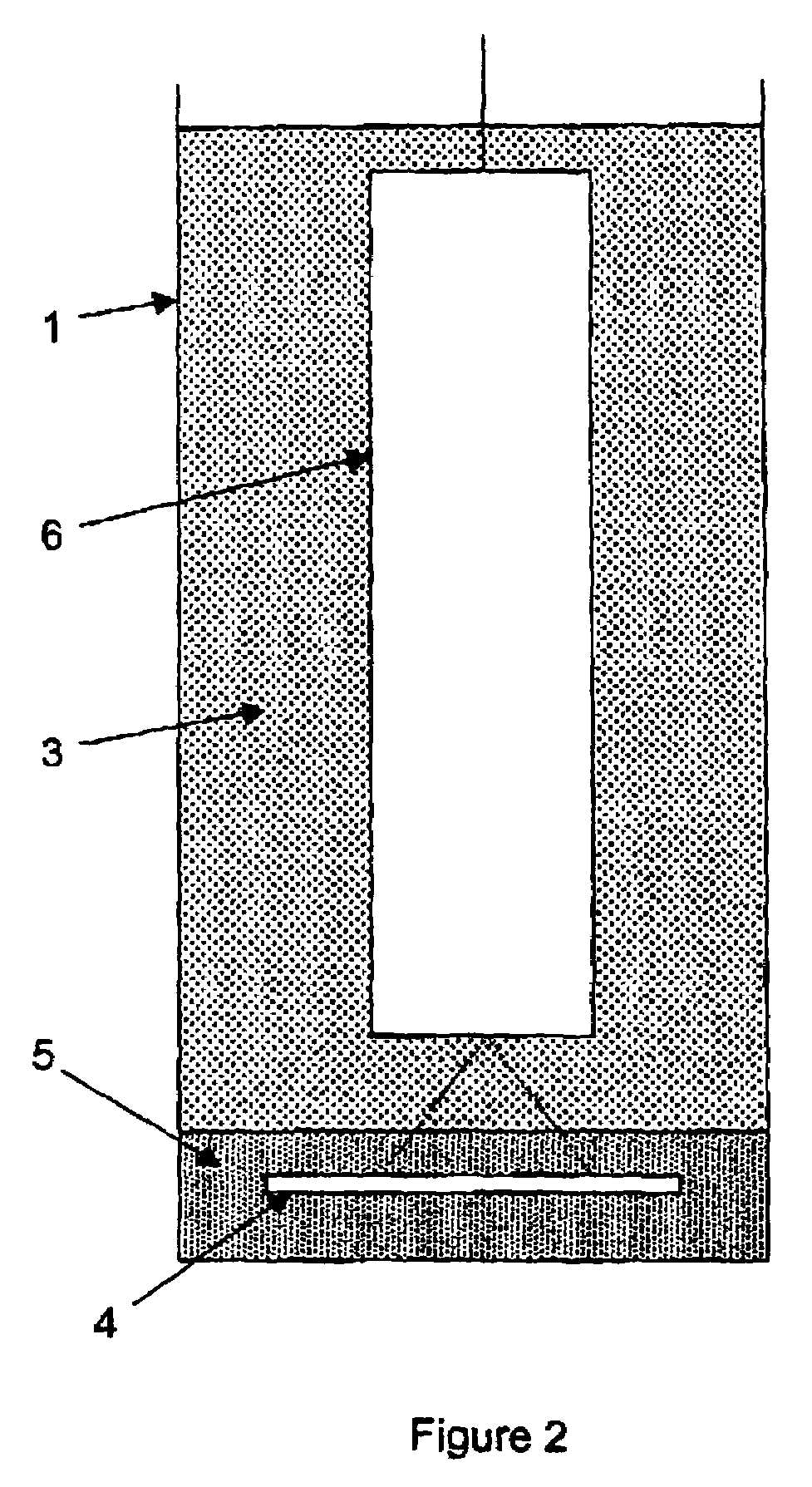

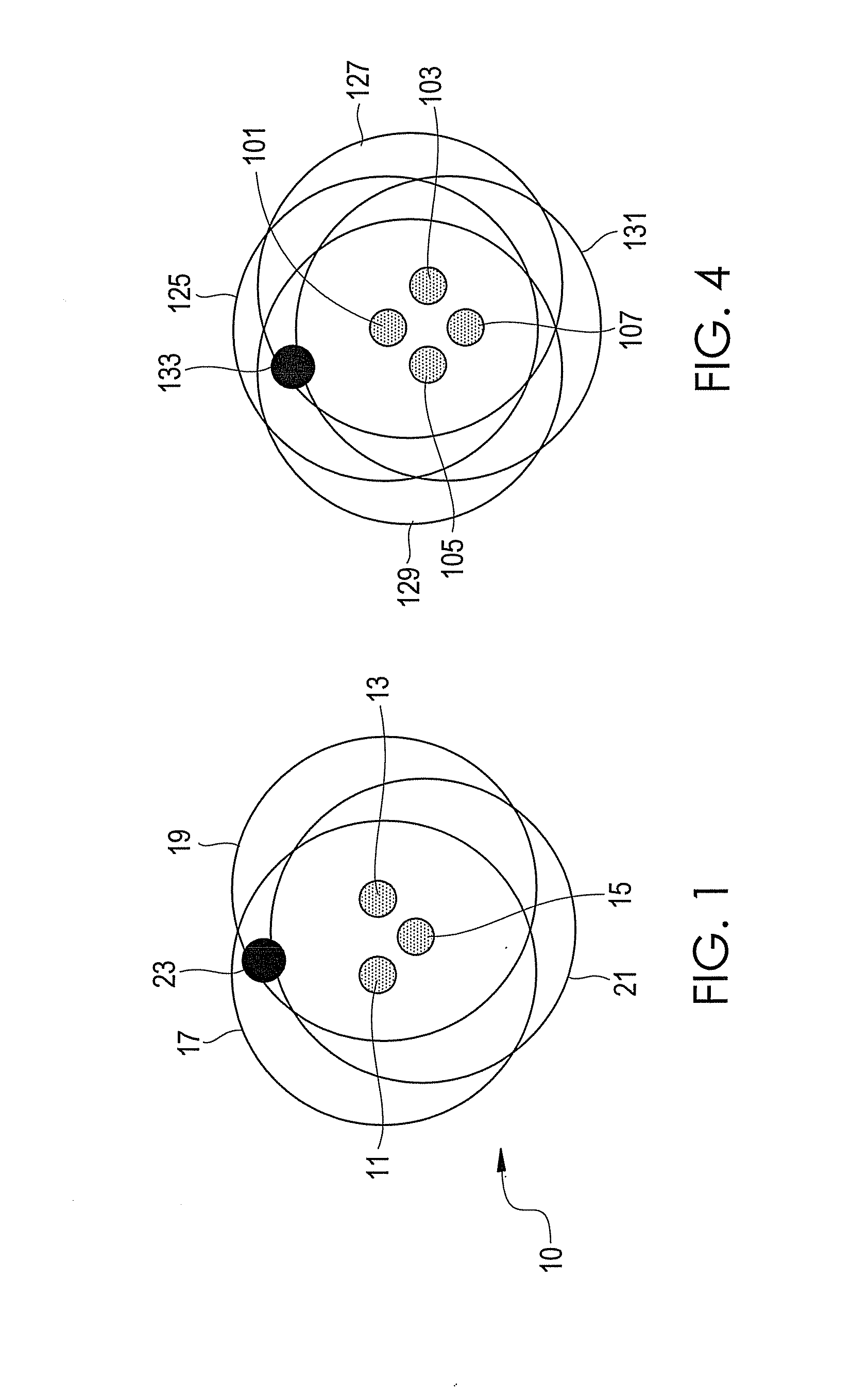

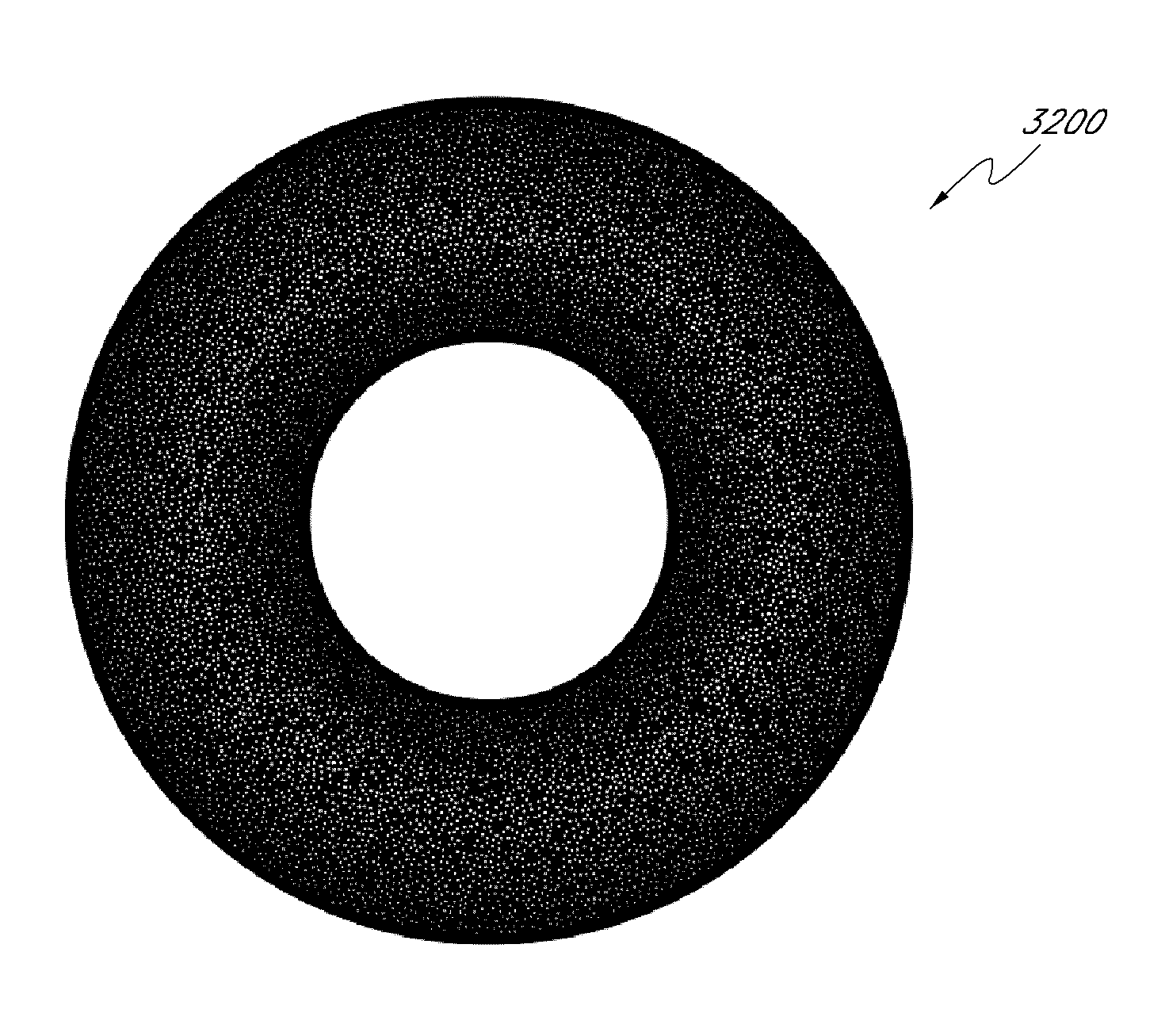

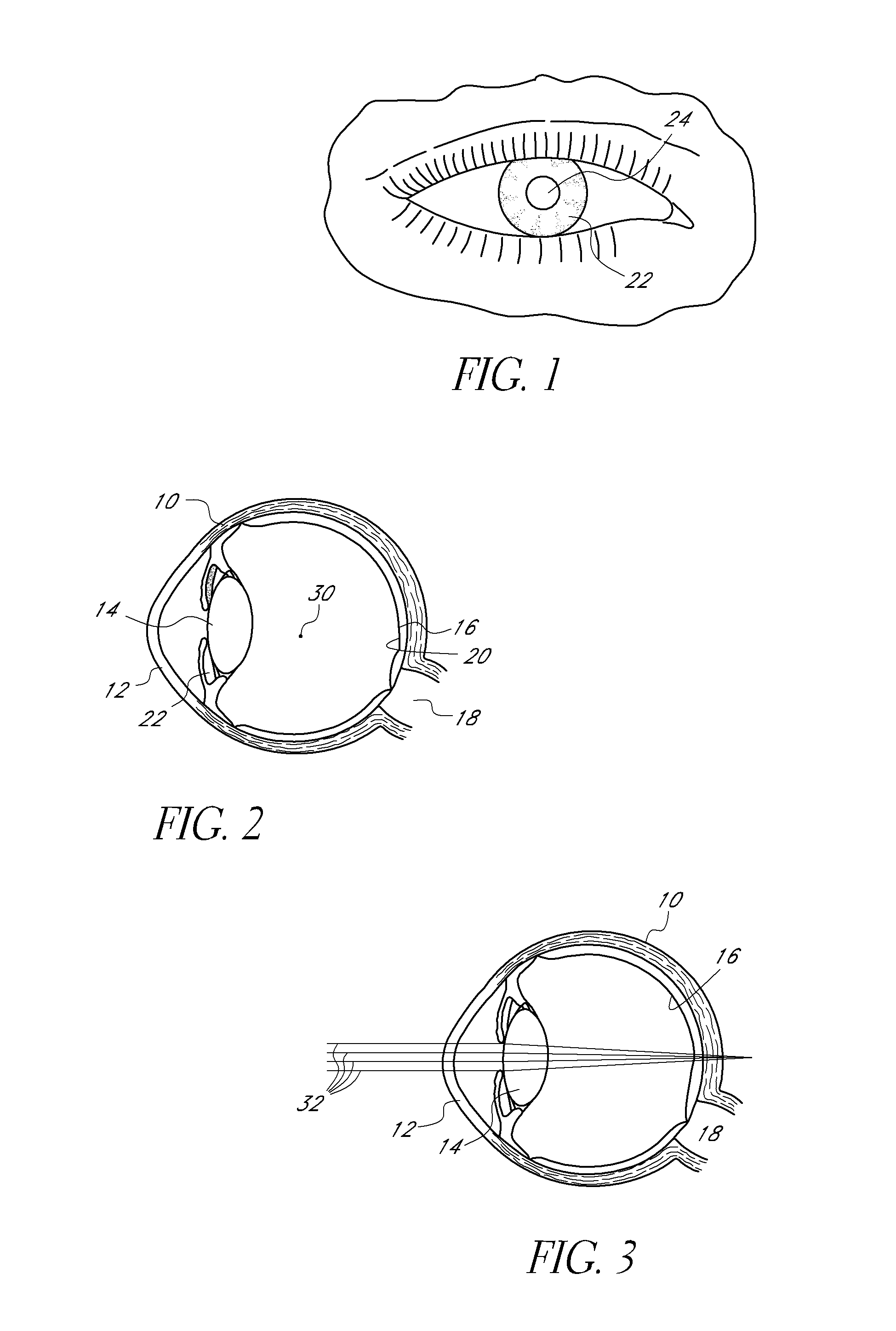

Ocular mask having selective spectral transmission

ActiveUS20130268071A1Increase depth of focusEye-masksEye diagnosticsSpectral transmissionOptical axis

A mask is provided that is configured to increase the depth of focus of a patient. The mask can include an aperture configured to transmit along an optical axis substantially all visible incident light. The mask can further include a portion surrounding at least a portion of the aperture. The portion may be configured to be substantially opaque to visible electromagnetic radiation and be substantially transparent to electromagnetic radiation transmitted from an ocular examination device (e.g., substantially transparent to at least some non-visible electromagnetic radiation with a wavelength between about 750 nm and about 1500 nm).

Owner:ACUFOCUS

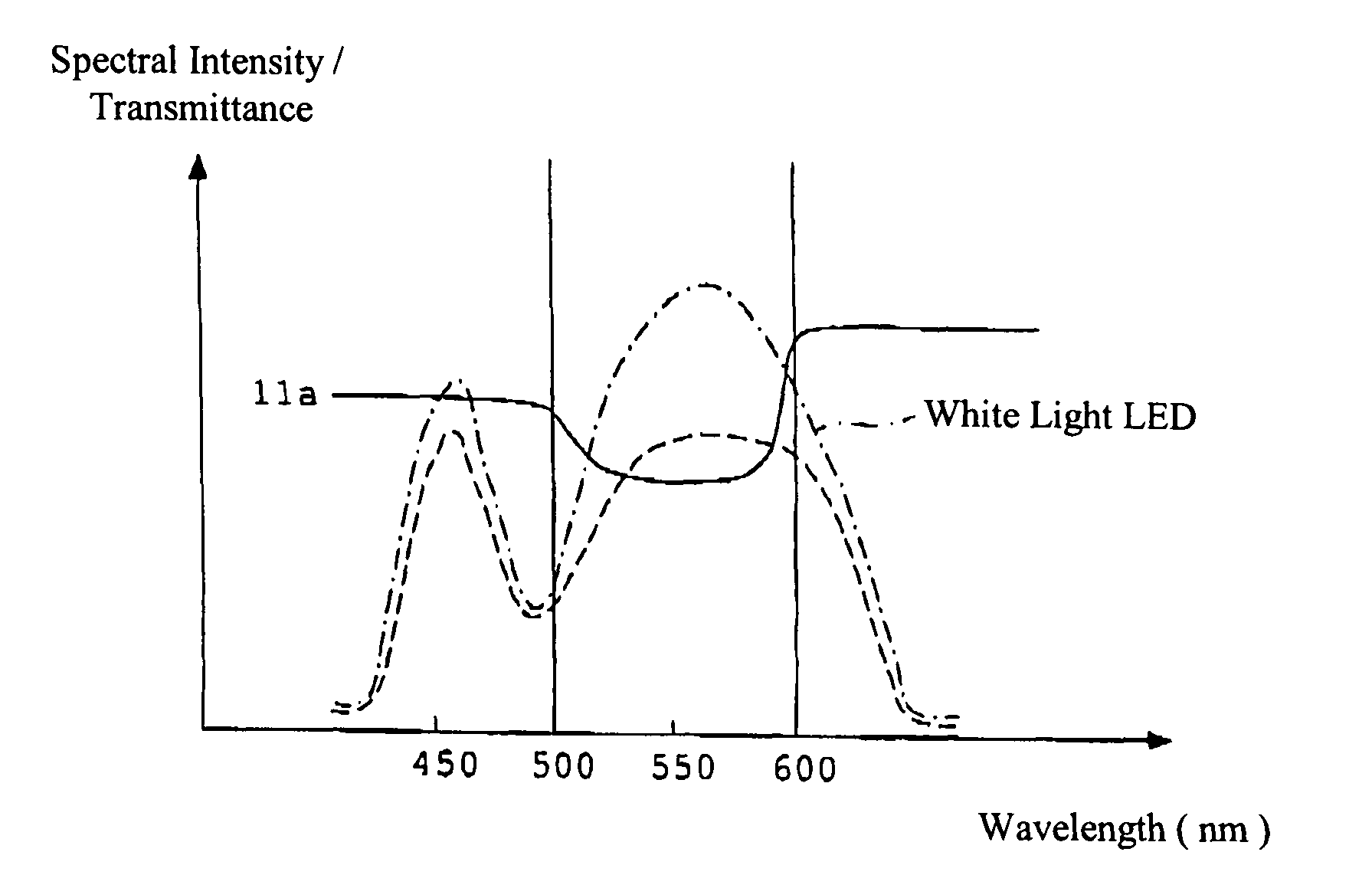

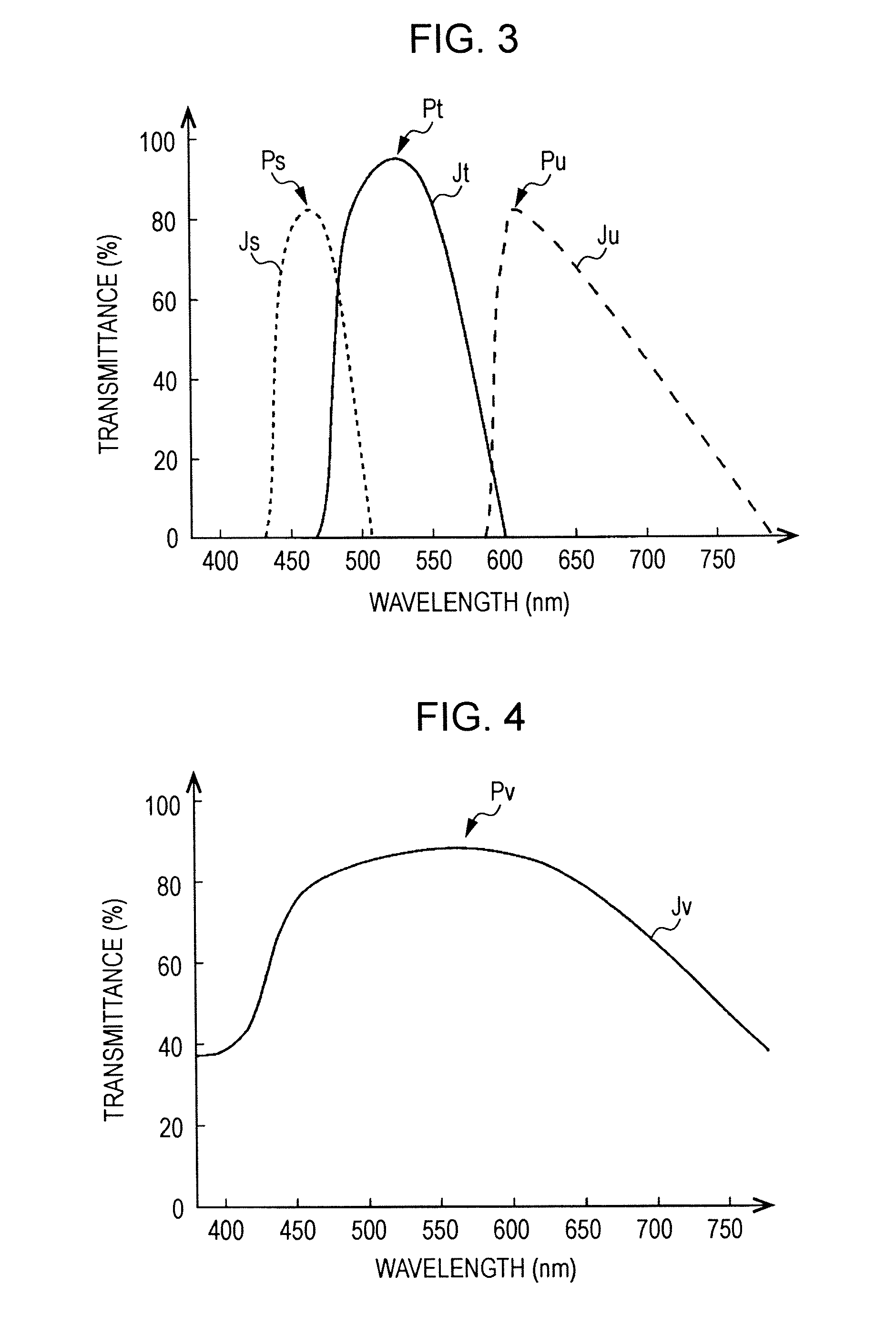

Display apparatus

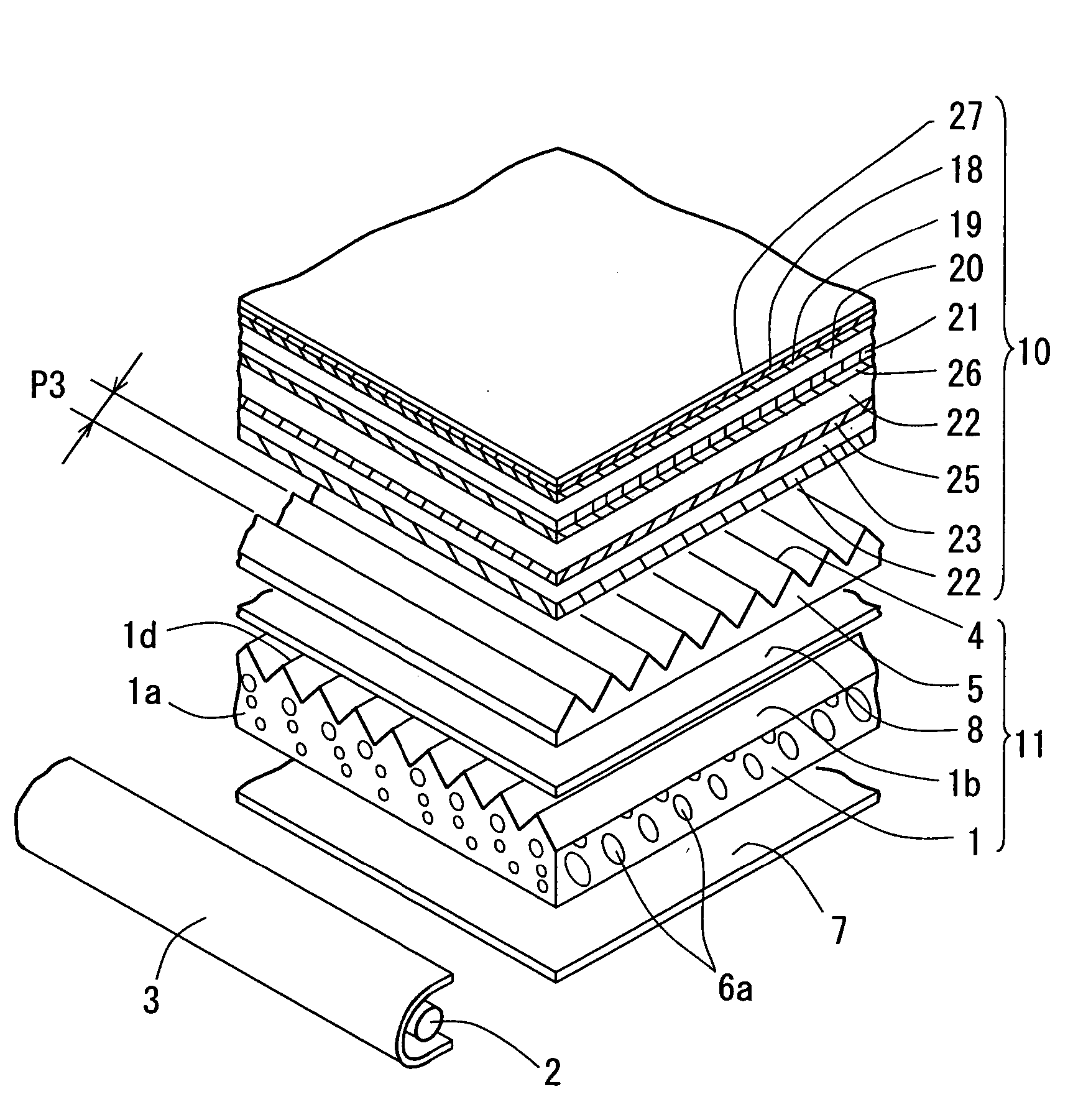

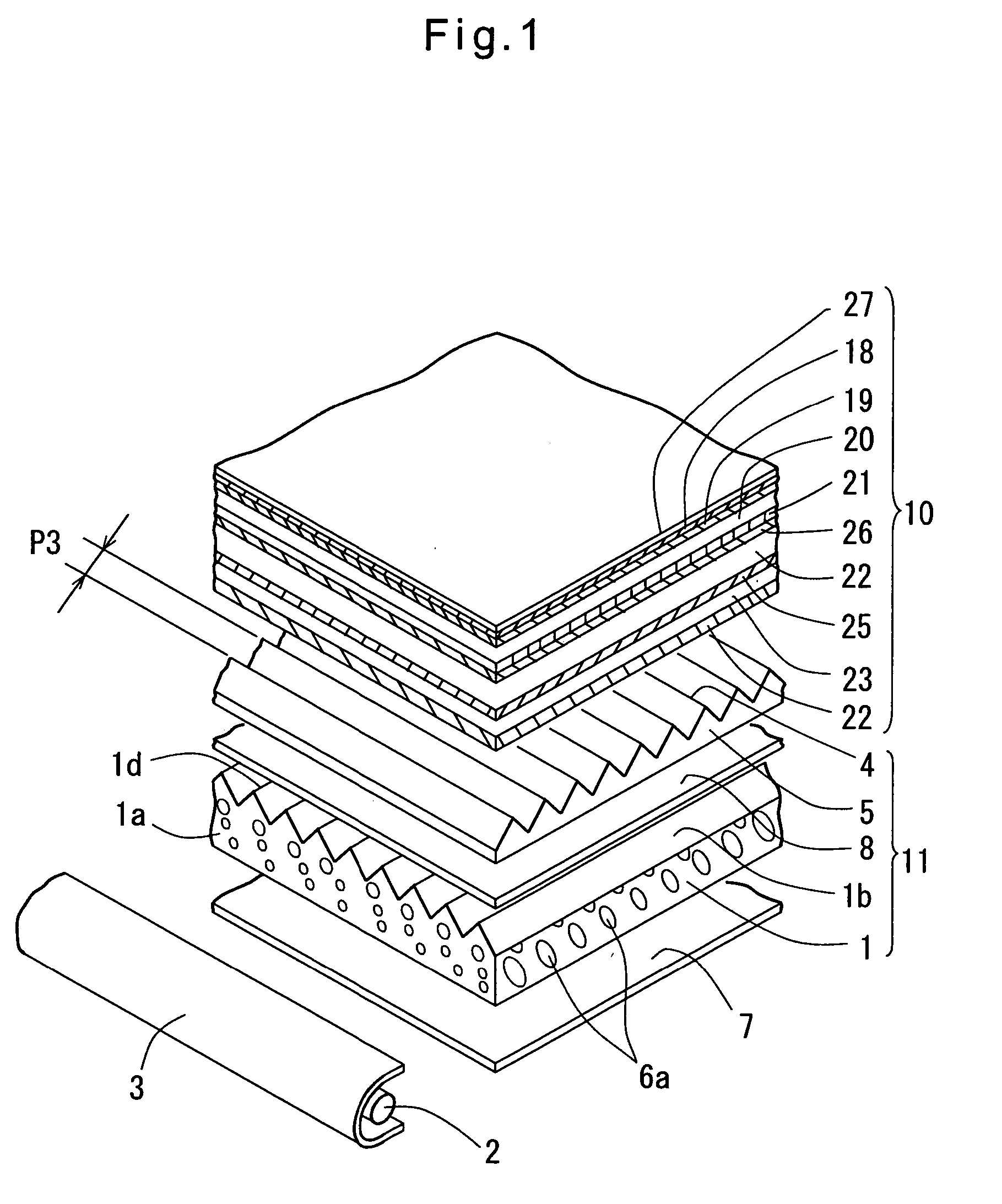

InactiveUS20050046321A1Improve emission efficiencySimple designIncadescent screens/filtersElectric discharge tubesSpectral transmissionColor correction

In a display device having a color filter, a color material dispersed layer having the function of absorbing light of specific wavelengths in the visible light beam region is provided on the optical path so that the light absorption peak of this color material dispersed layer in the visible light beam region is located in the range of ±30 nm from the overlap point in the spectral transmission properties of each color of the color filter. Further, the color material dispersed layer is provided on a filter as a constituent part of the back light of the display. This filter has, as its substrate, a thermoplastic resin having a thickness of 30-350 micrometers and has a transmission in the maximum absorption wavelength in the color material dispersed layer of not more than 75%. The back light has, as its light source, a fluorescent lamp comprising a three band tube, and its emission color is subjected to color correction by an auxiliary filter having an organic color material dispersed layer provided on the illuminating light path.

Owner:MITSUBISHI CHEM CORP

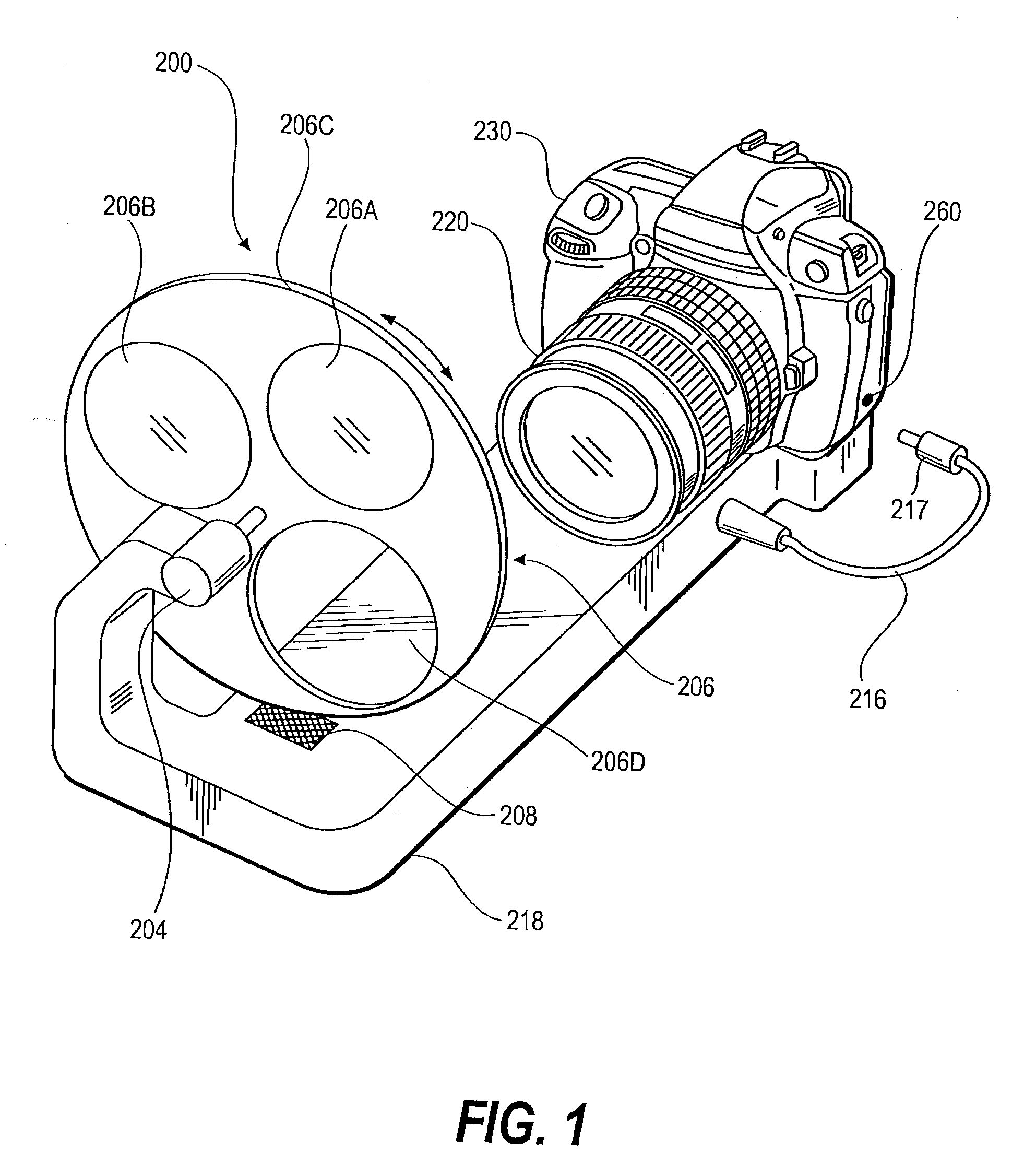

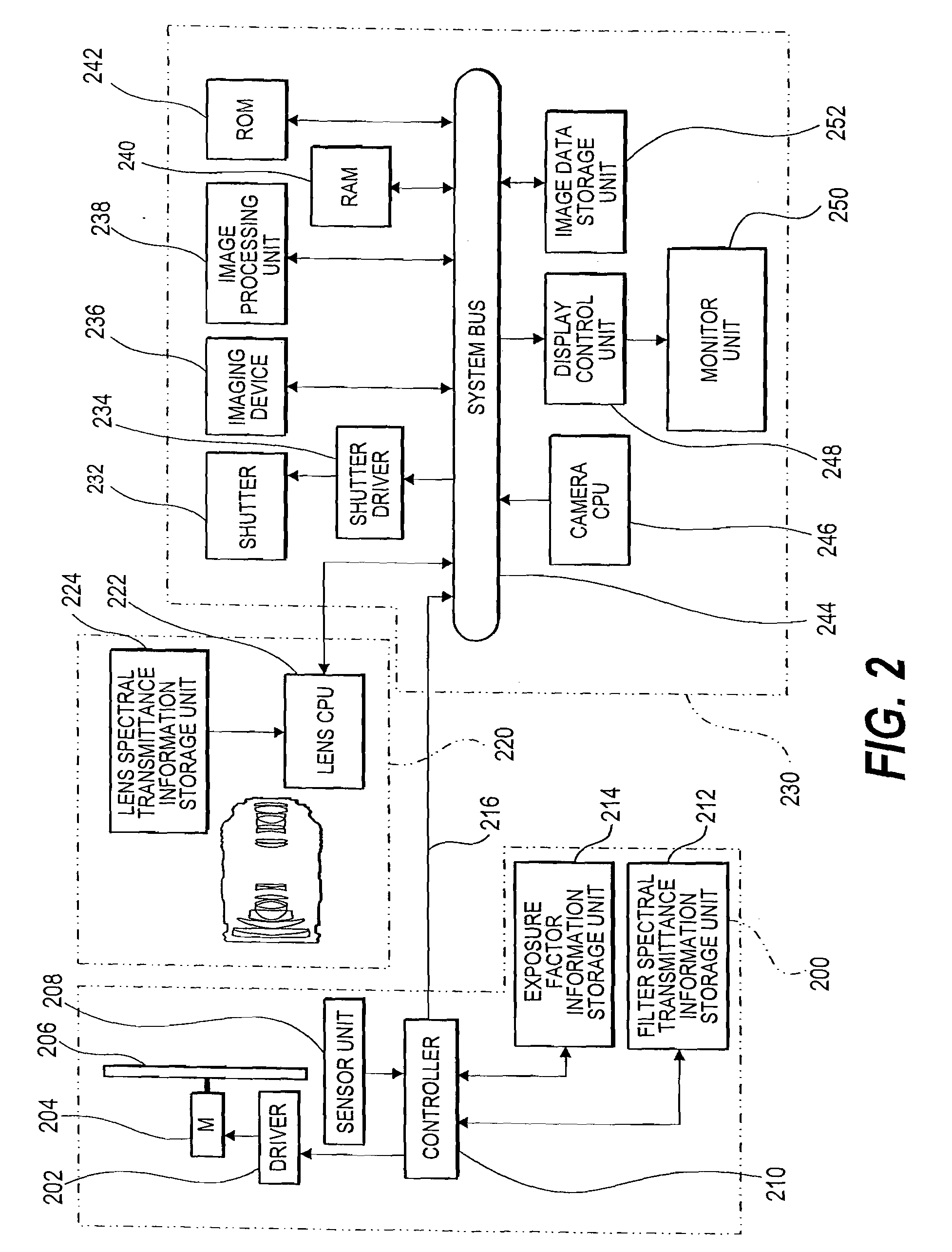

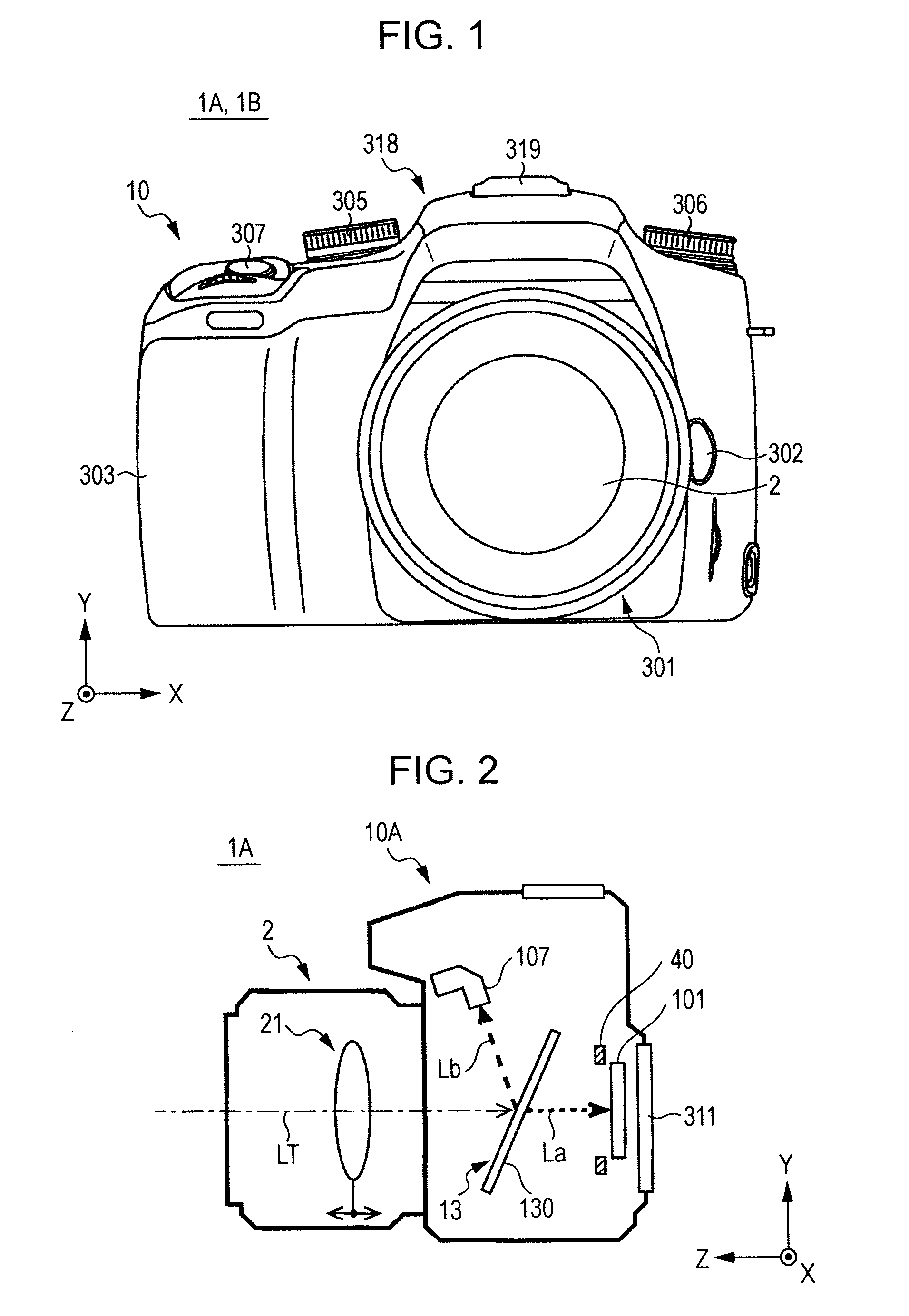

Filter switching device, photographing lens, camera, and image pickup system

InactiveUS20090244355A1Enable error-free image data processingSimple procedureTelevision system detailsColor television detailsSpectral transmissionFrequency spectrum

A filter switching device includes: an optical filter unit that is disposed on an optical path of an object light that passes through an image pickup lens of a camera, and can be switched to any one of a plurality of spectral transmission characteristics; a spectral transmission characteristic switching unit that switches a spectral transmission characteristic of the optical filter unit to one of the plurality of spectral transmission characteristics; a filter spectral transmission characteristic information storage unit that stores filter spectral transmission characteristic information, which is information relating to each of the plurality of spectral transmission characteristics; and a filter spectral transmission characteristic information output unit that outputs filter spectral transmission characteristic information corresponding to the spectral transmission characteristic of the optical filter unit to the camera when the spectral transmission characteristic of the optical filter unit is switched.

Owner:OLYMPUS CORP

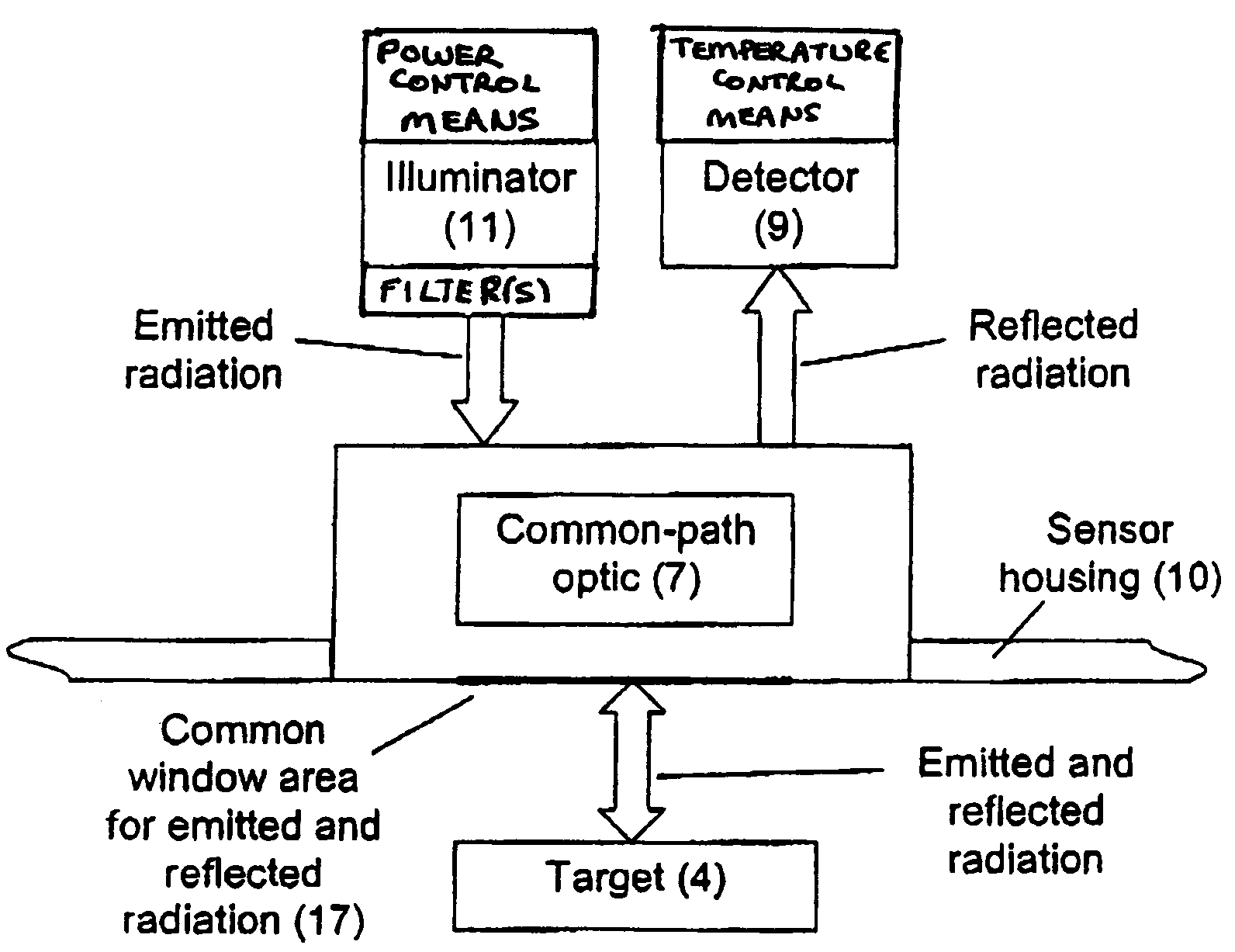

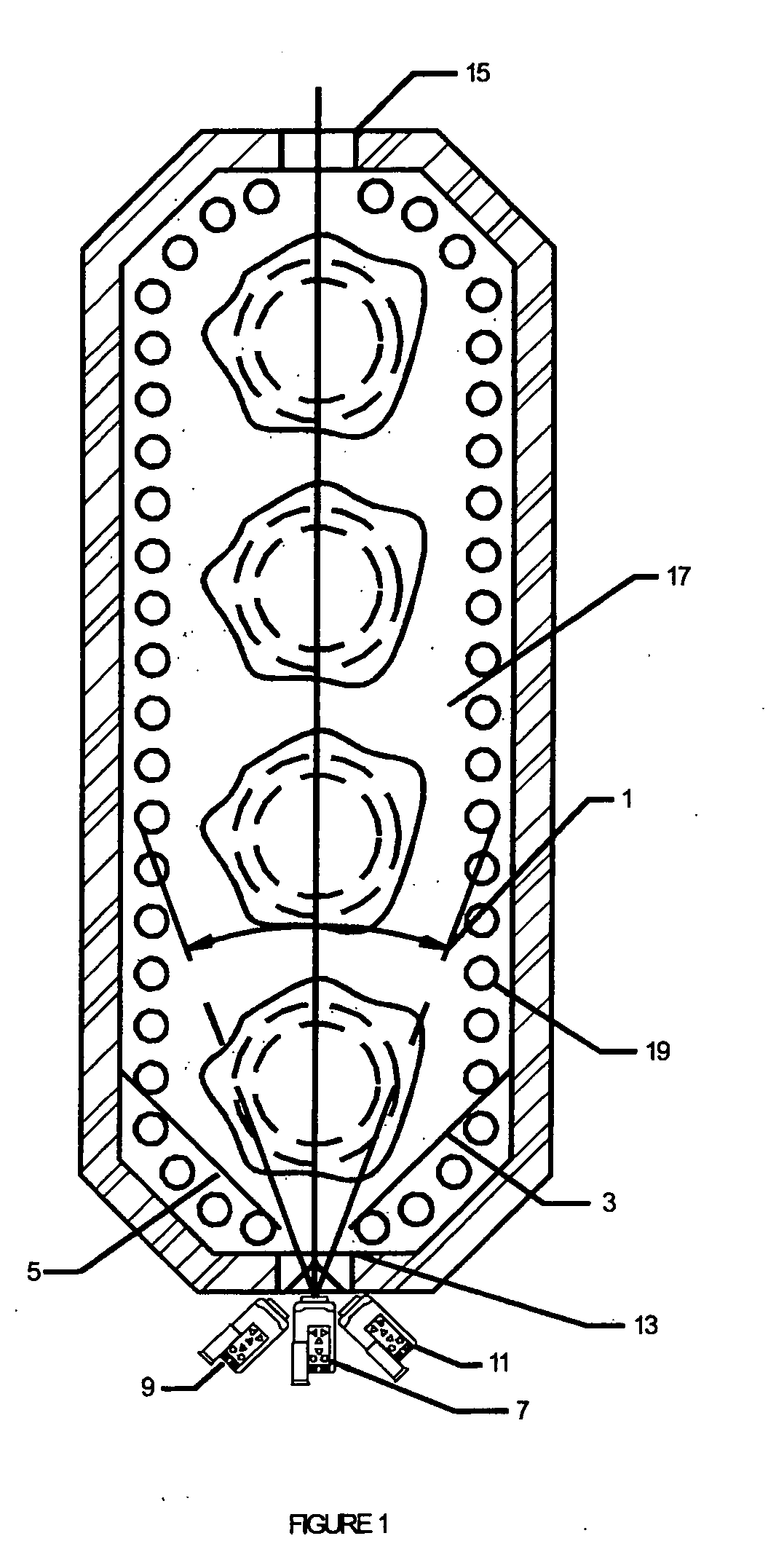

Imaging sensor optical system

InactiveUS7212283B2Eliminate the effects ofTransmission limitElectric/magnetic detection for well-loggingSurveySpectral transmissionAudio power amplifier

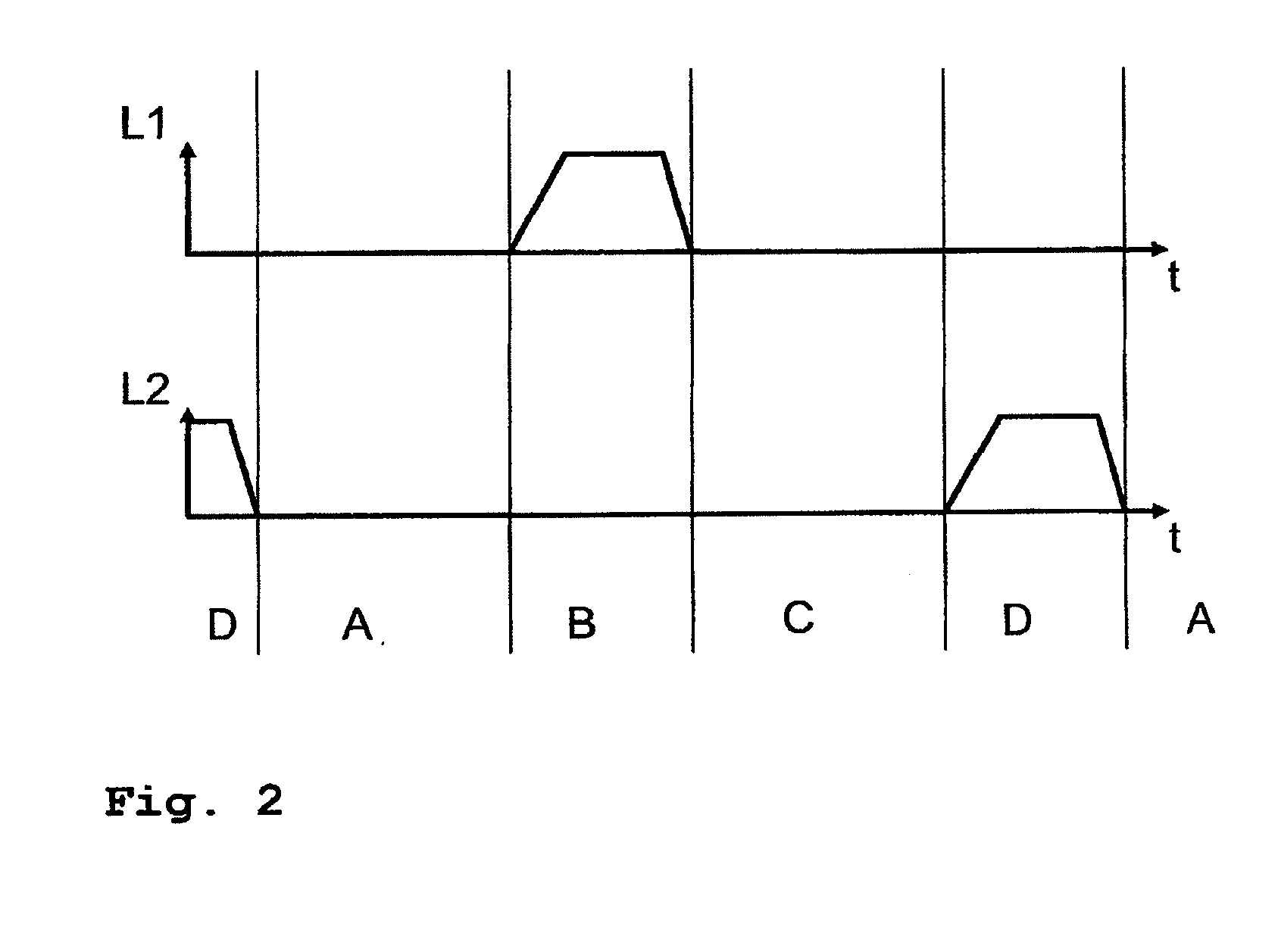

The present invention relates to an in-vessel or down-hole optical imaging sensor or system for operating in structures which may contain media with different spectral transmission characteristics. The imaging sensor of the present invention selectively emits and / or detects two or more independently controllable wavelengths or wavebands. The imaging sensor comprises an illuminator for emitting radiation of a specified wavelength or waveband through a medium to a target, at least one detector for detecting the radiation deflected by said target and at least one amplifier for providing non-linear amplification of the detector output.

Owner:PRONETA

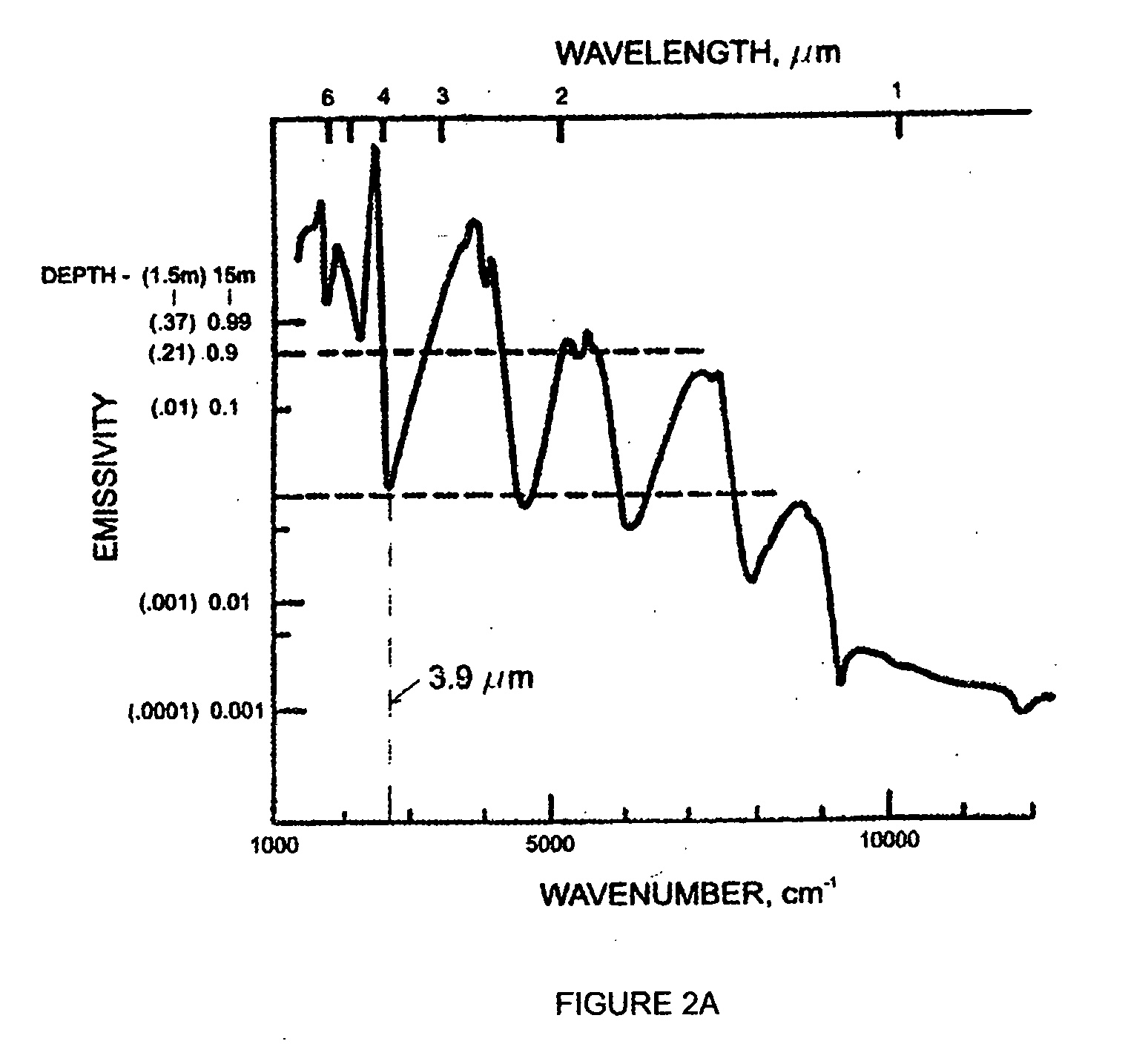

Apparatus for thermal imaging

InactiveUS20060049352A1Radiation pyrometryMaterial analysis by optical meansSpectral transmissionTarget surface

A device for thermal imaging of target surfaces includes a housing (12) with an opening (14) for directing incident infrared rays along an optical path through an optical assembly (40) optimized to have a spectral band width of 3 to 14 um, onto a UFPA detector (48) having a spectral transmission window (84) which has a bandwidth 3 to 14 um sufficient to pass all infrared rays of interest over a broad temperature range. Filter means (44) including at least two filters (78, 80), having a band width in the ranges of 3 to 8 um and 8 to 14 um, respectively, allow for the placement of either specialized IR filter in the optical path so as to attenuate and / or pass certain wavelengths of the infrared rays depending on the specific application in a broad range between −40° C. to 2000° C. The device allows for thermal imaging even in daytime applications in sunlight.

Owner:LUMASENSE TECH HLDG

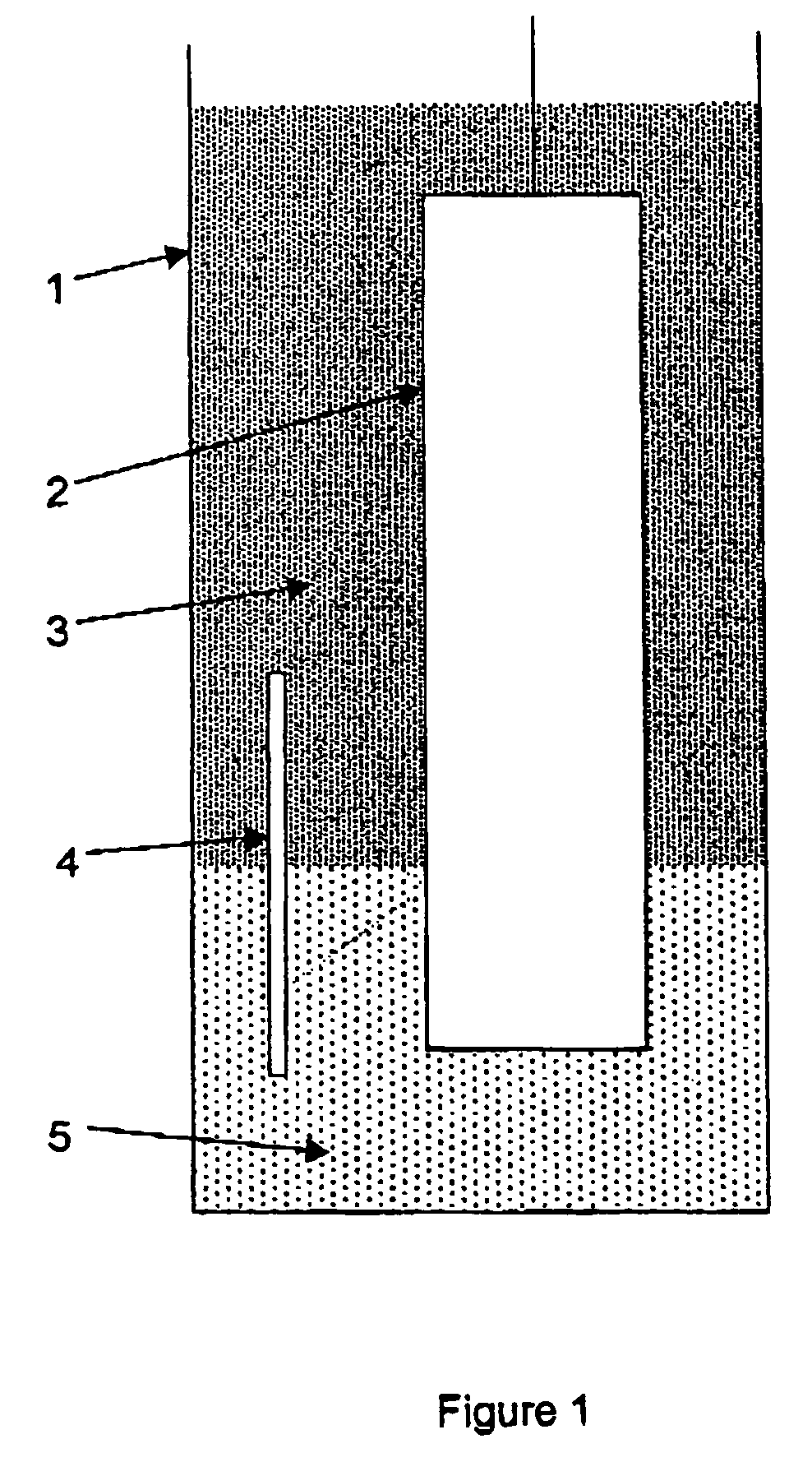

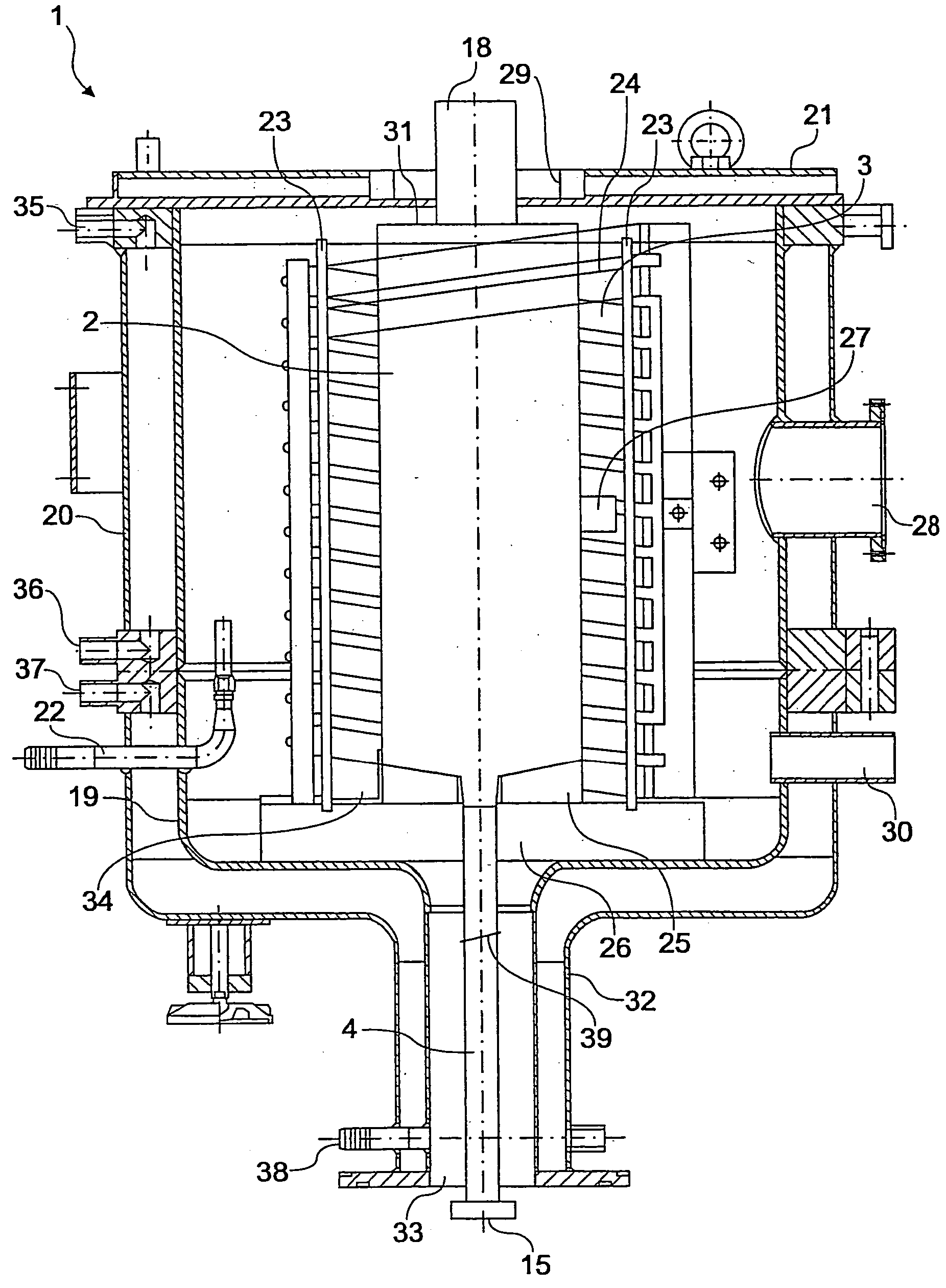

Device and method for the production of high-melting glass materials or glass ceramic materials or glass material or glass ceramic material

InactiveUS20050109062A1Maintain good propertiesQuality improvementPot furnacesGlass drawing apparatusIridiumSpectral transmission

The invention relates to a device for the production of high-melting glass materials or high-melting glass ceramic materials, comprising a vessel for accommodating molten glass and a container that accommodates the vessel, whereby the vessel has a tubular outlet. According to the invention, the device is characterised by the fact that the vessel and a first section of the tubular outlet if formed of iridium or a material with a high iridium content, whereby the container is designed to accommodate the vessel and the first section of the tubular outlet under a protective gas atmosphere. The invention also relates to a corresponding method. The molten glass is shaped into a formed part in a discontinuous operation. The choice of the material for the vessel used as the crucible allows the attainment of high temperatures according to the invention which enables glass materials or glass ceramic materials with a much higher spectral transmission in the visible wavelength range. The use of an inert protective gas enables the prevention of unwanted oxide formation on the vessel and the tubular outlet. According to the invention, the glass can be used as a transitional glass between types of glass with very different coefficients of thermal expansion.

Owner:SCHOTT AG

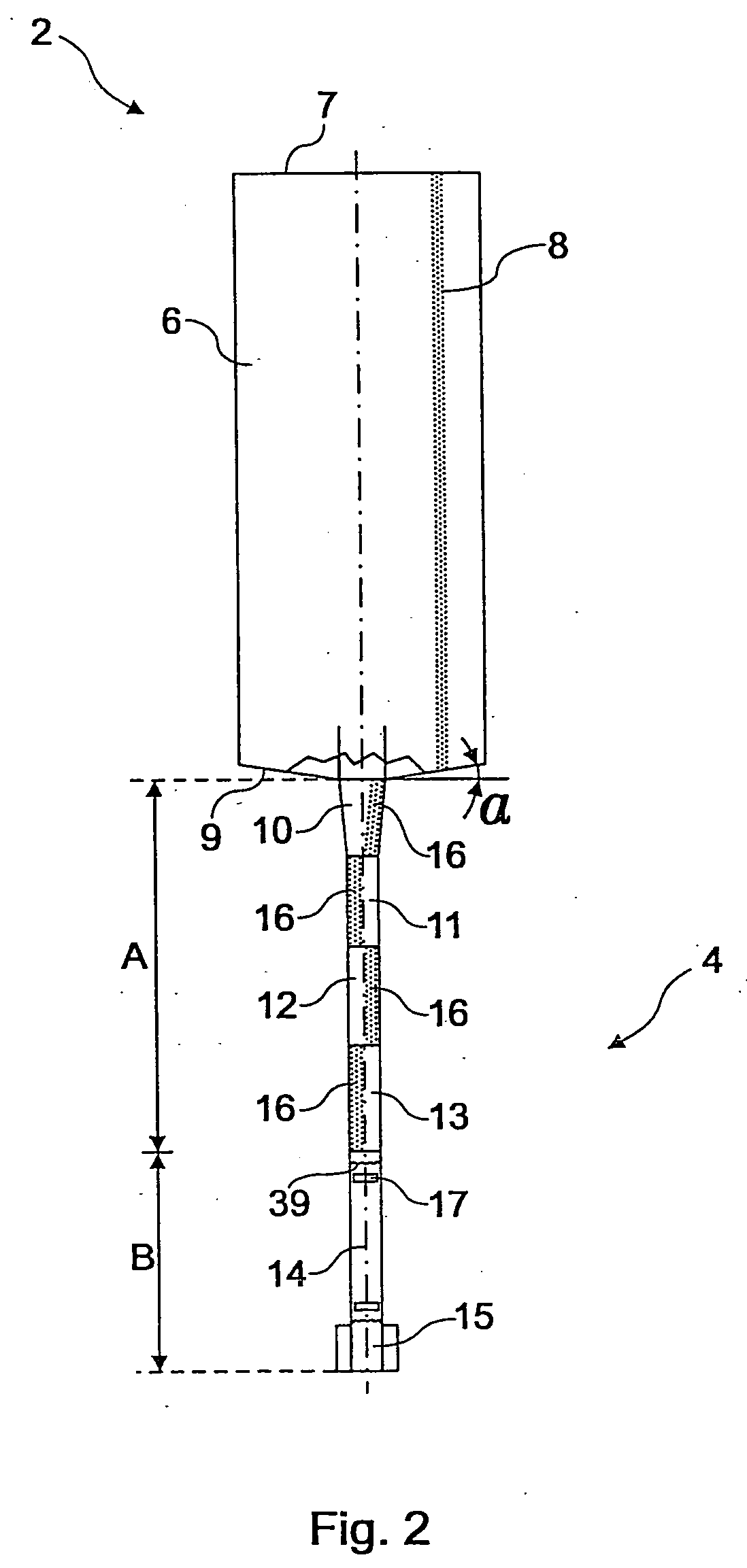

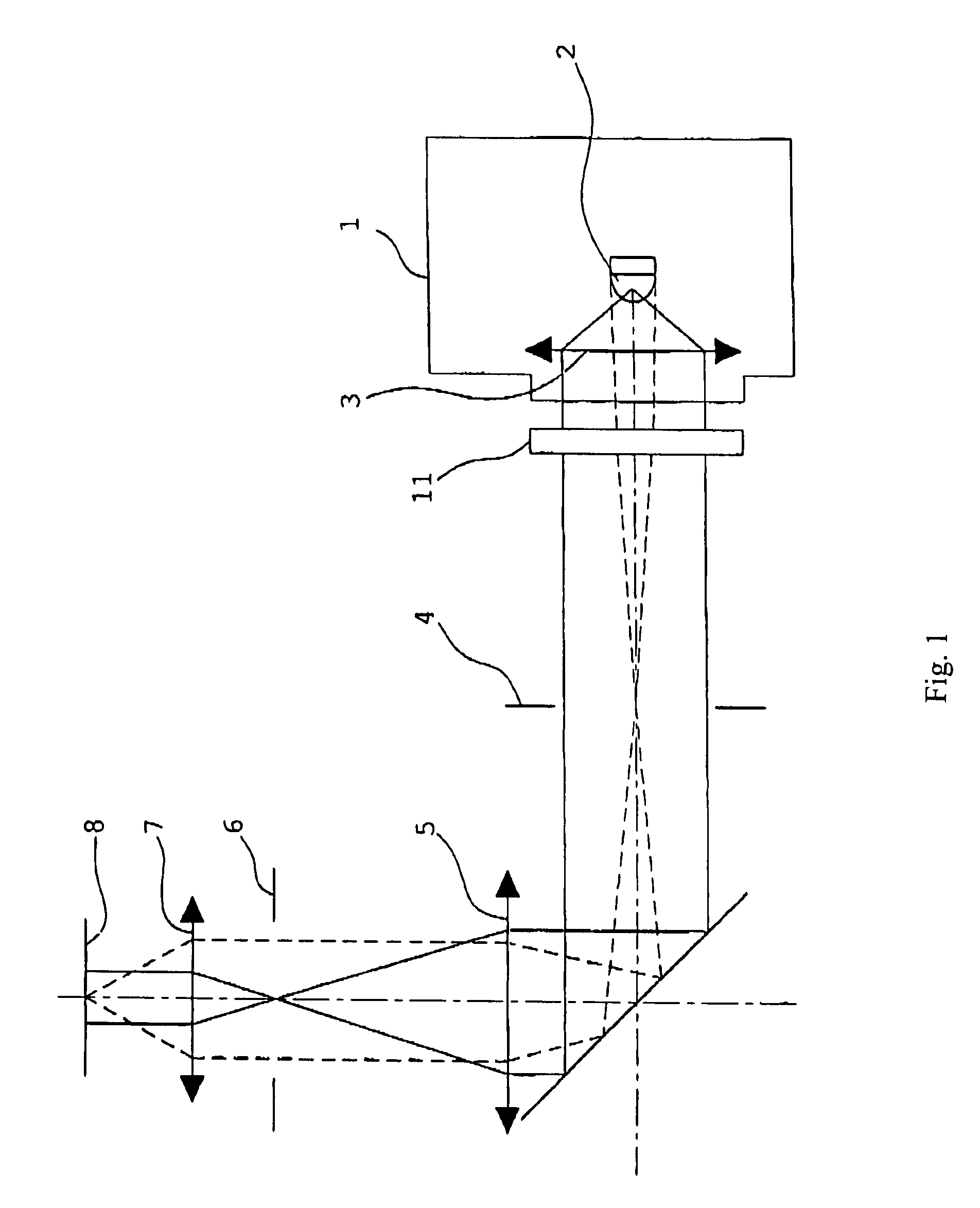

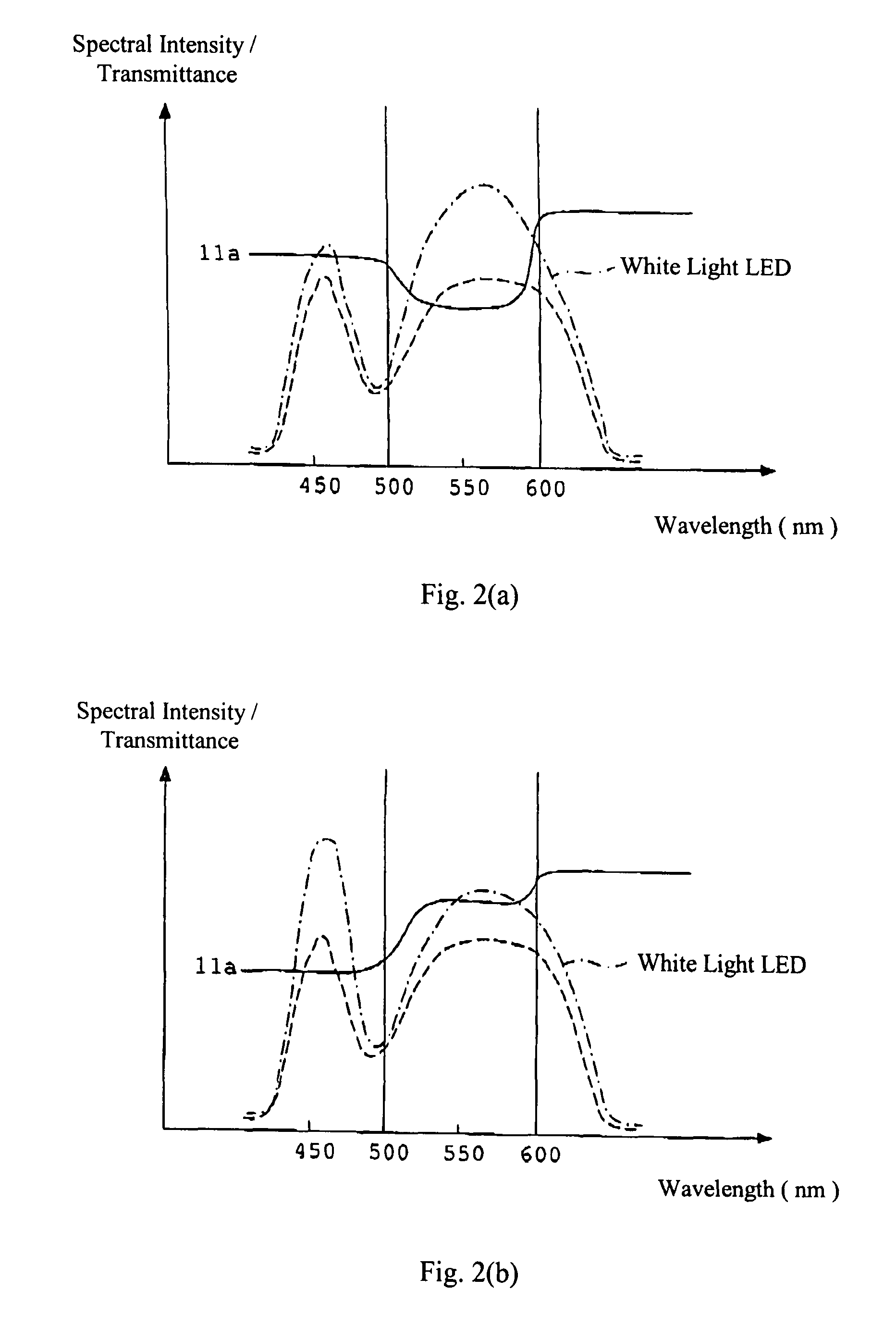

Illumination optical system that uses a solid-state lighting element which generates white light, and an optical device equipped therewith

An illumination optical system for use in a microscope or electronic endoscope includes a solid-state lighting element that generates light having a spectral profile with peak intensities at multiple wavelengths such that the light output by said solid-state lighting element is perceived by an observer as being white in color, and a wavelength distribution conversion element having a spectral transmittance profile that includes specified wavelength regions within which the transmittance is nearly constant with increasing wavelength so as to form a step of nearly even intensity, and having specified wavelength regions within which the transmittance changes with increasing wavelength so as to form a transition region. By the combined effect of the solid-state lighting element and the wavelength distribution conversion element, the wavelength distribution of the light generated by the illumination optical system more closely resembles the wavelength distribution of daylight than the light generated by the solid-state lighting element.

Owner:EVIDENT CORP

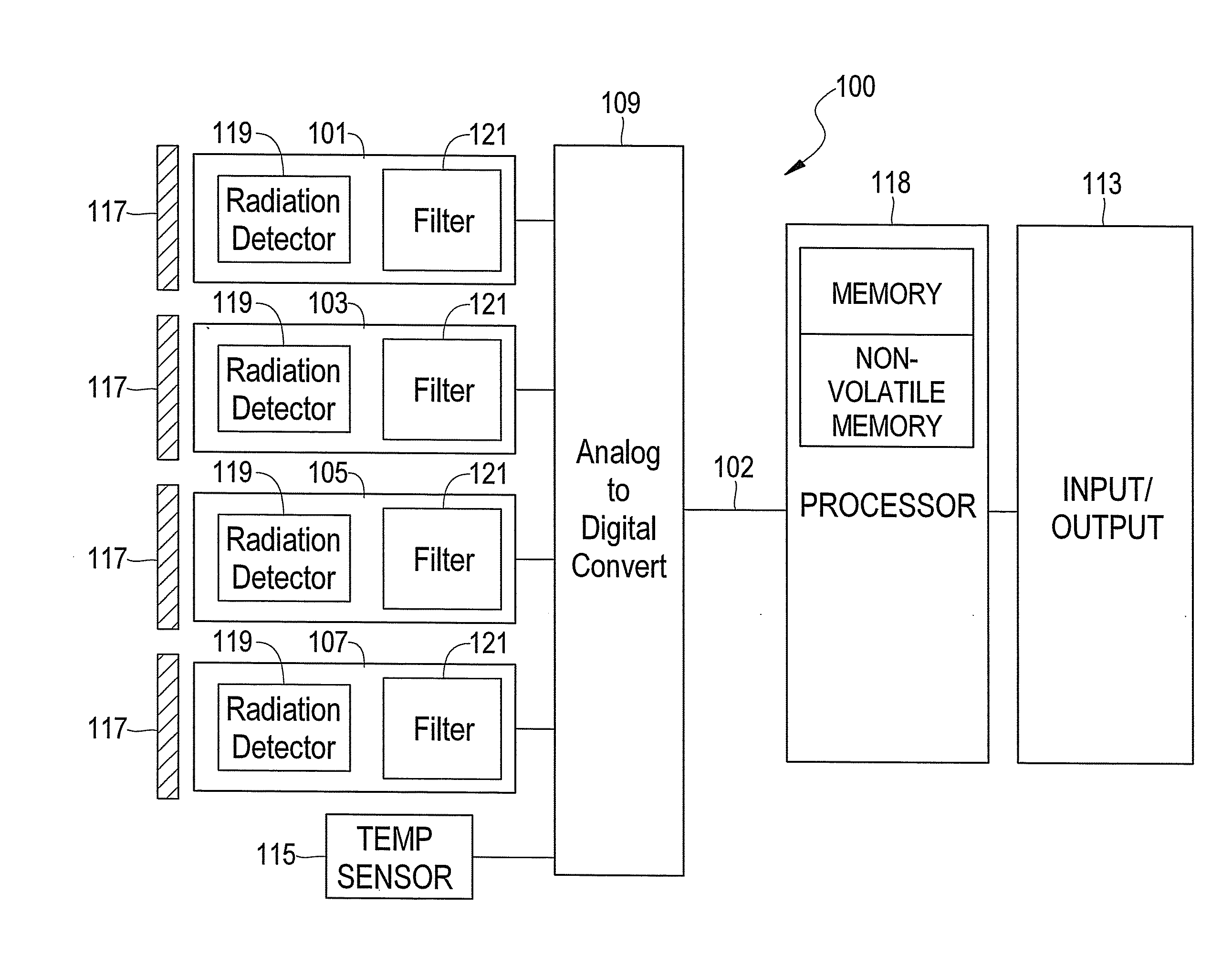

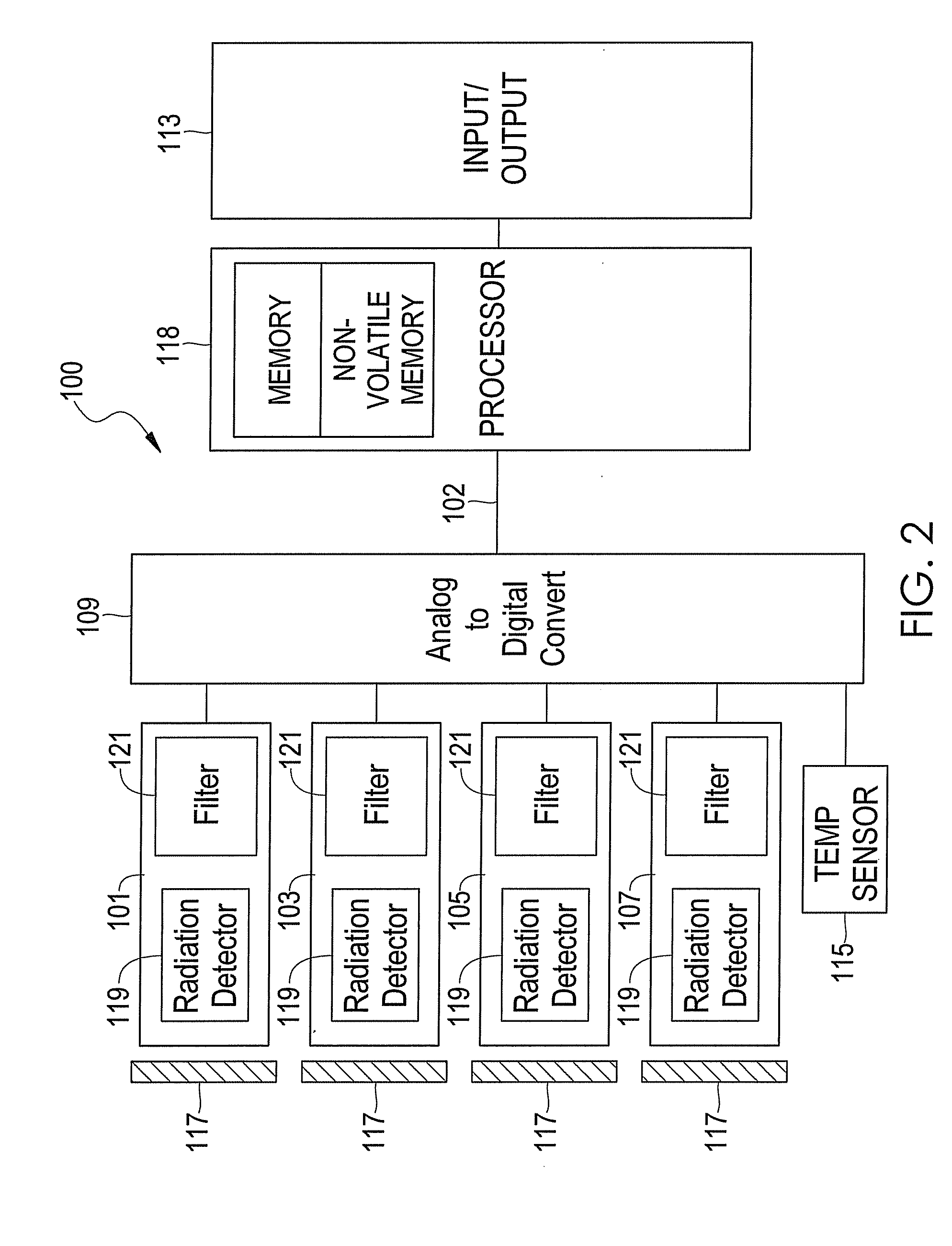

Optically Redundant Fire Detector for False Alarm Rejection

ActiveUS20120001760A1Solve the high false alarm rateAnti-theft devicesOptical signallingFire detectorSpectral transmission

A system for confirming the detection of a fire using a plurality of radiation or flame sensors each equipped with a radiation detector and an optical filter having a spectral transmission characteristic in which at least one optical filter is redundant to at least one other optical filter. The result is a system having operationally redundant sensors. In use, if a fire is detected by one of the redundant sensors without including the other redundant radiation sensor in the fire detection calculation, then a fire detection algorithm can switch to the other operationally redundant sensor to check for confirmation of a fire. Due to the spatial separation and if the object is small and close, a different result will be obtained with the redundant detector being used in the calculation compared to the primary detector that is associated with the redundant detector.

Owner:TYCO FIRE PRODS LP

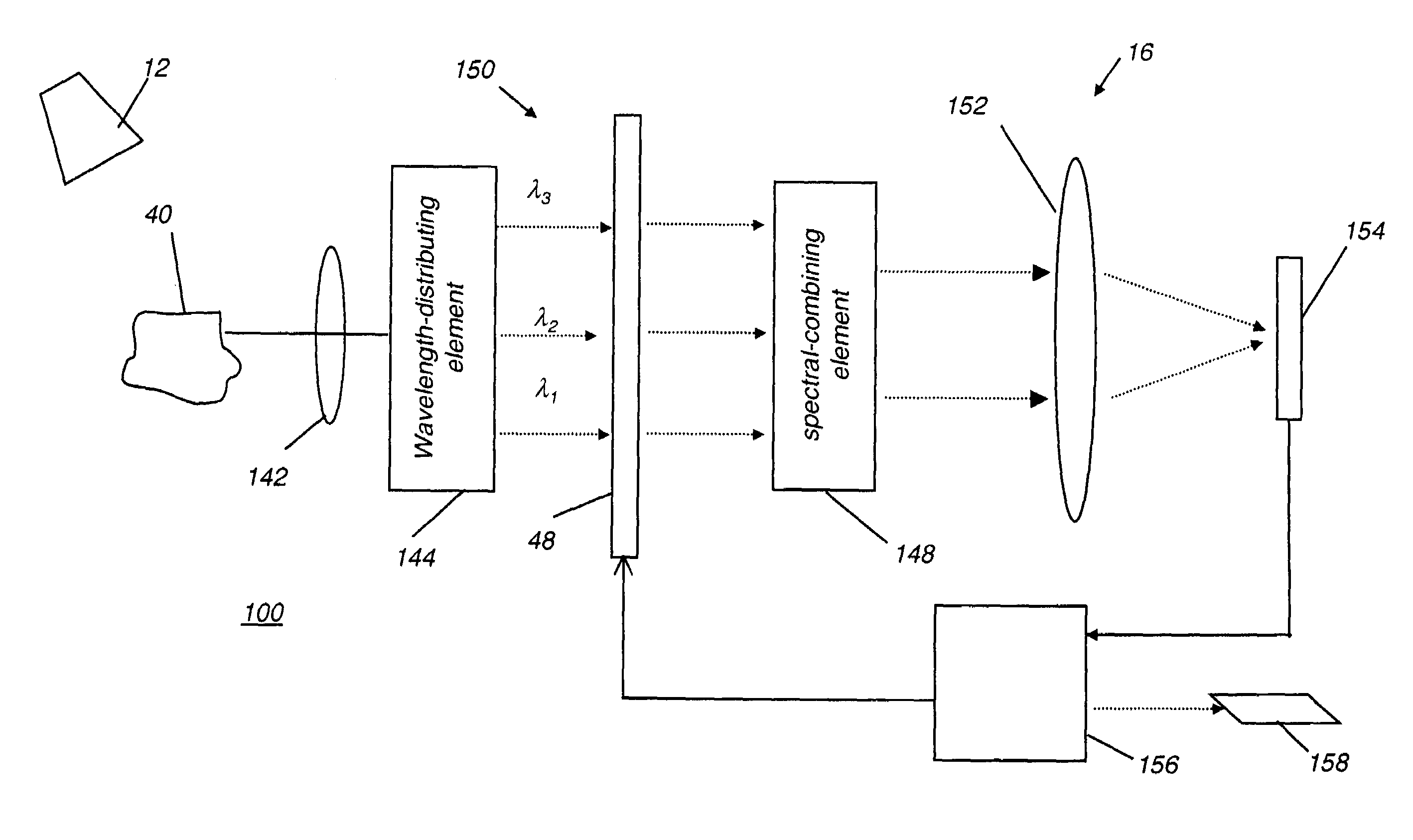

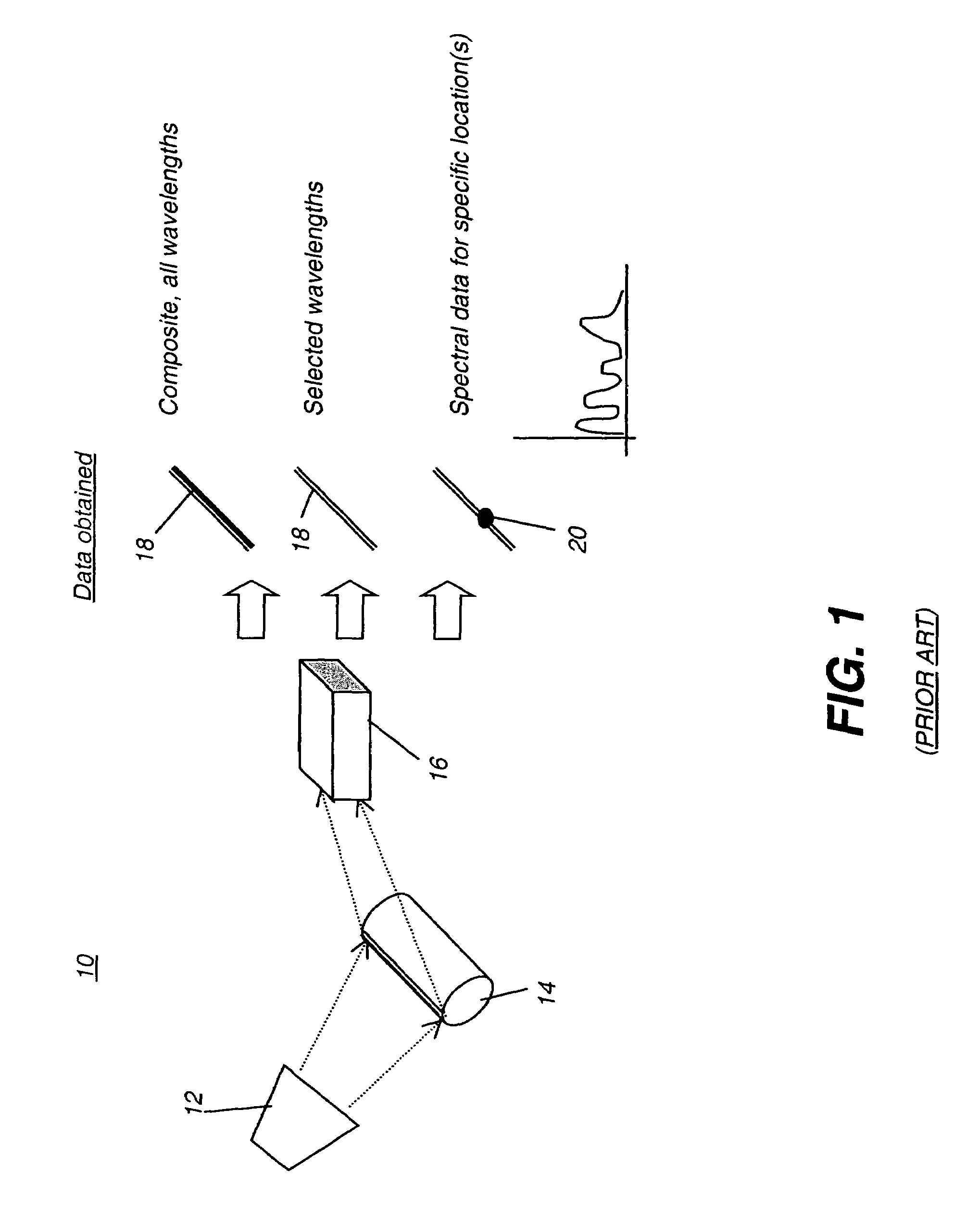

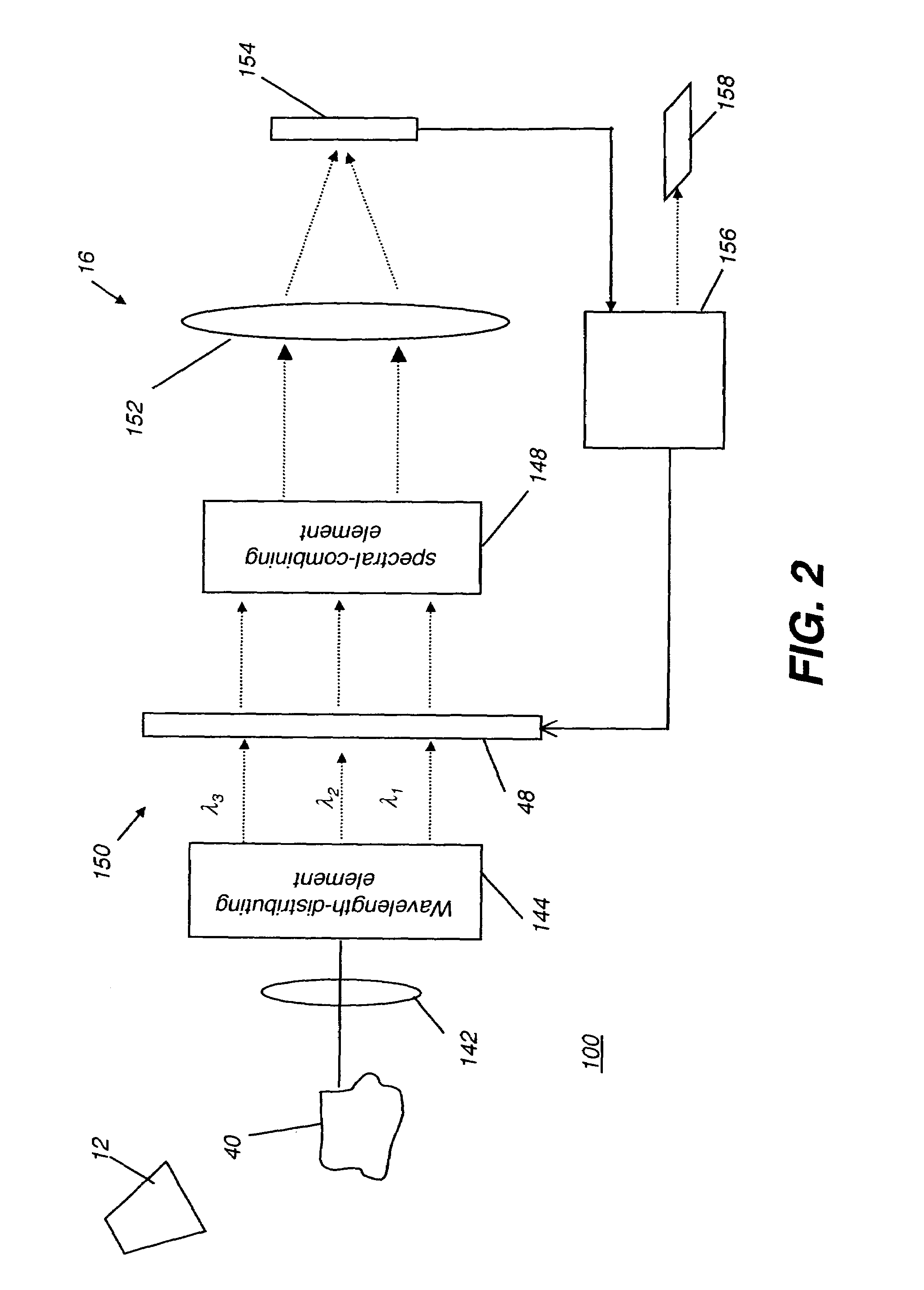

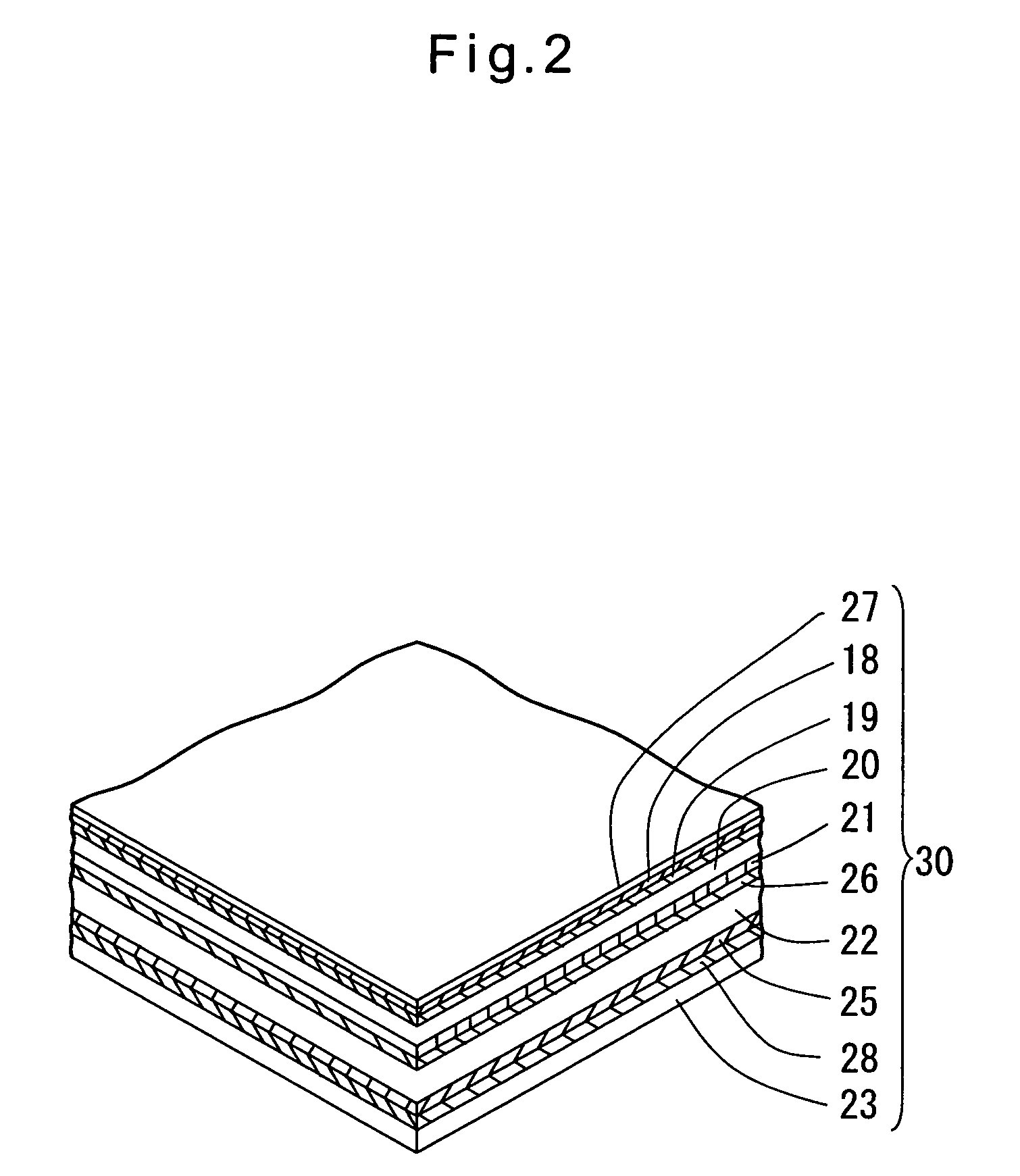

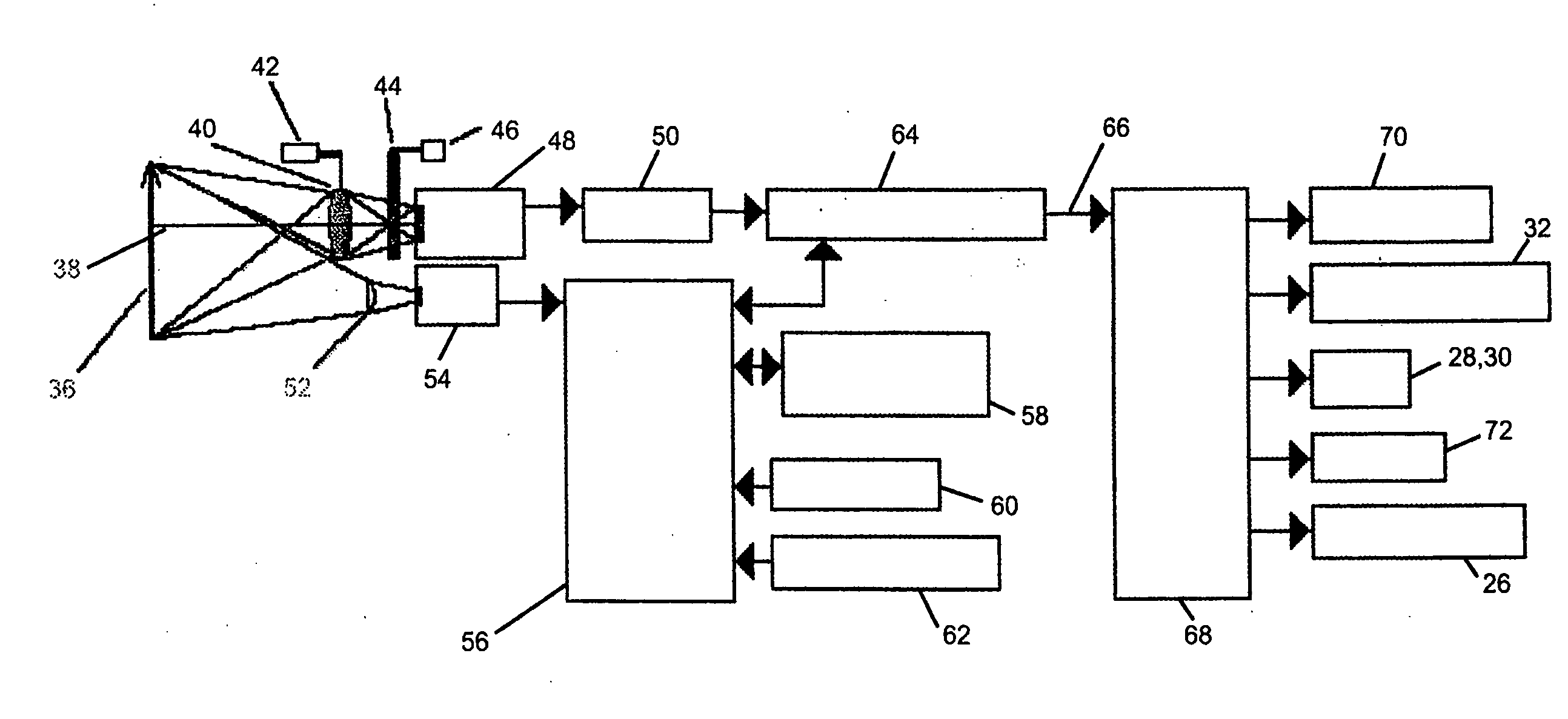

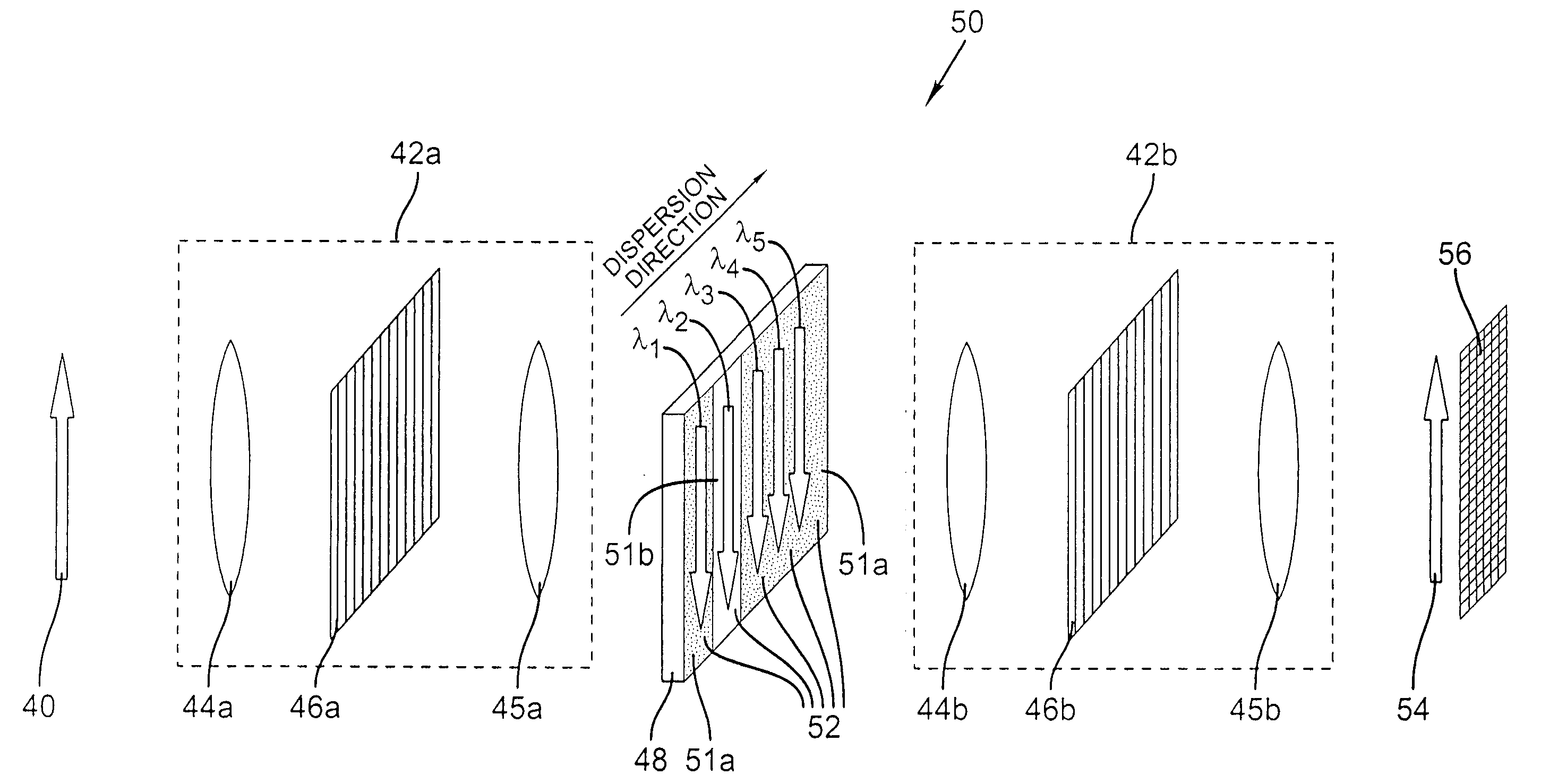

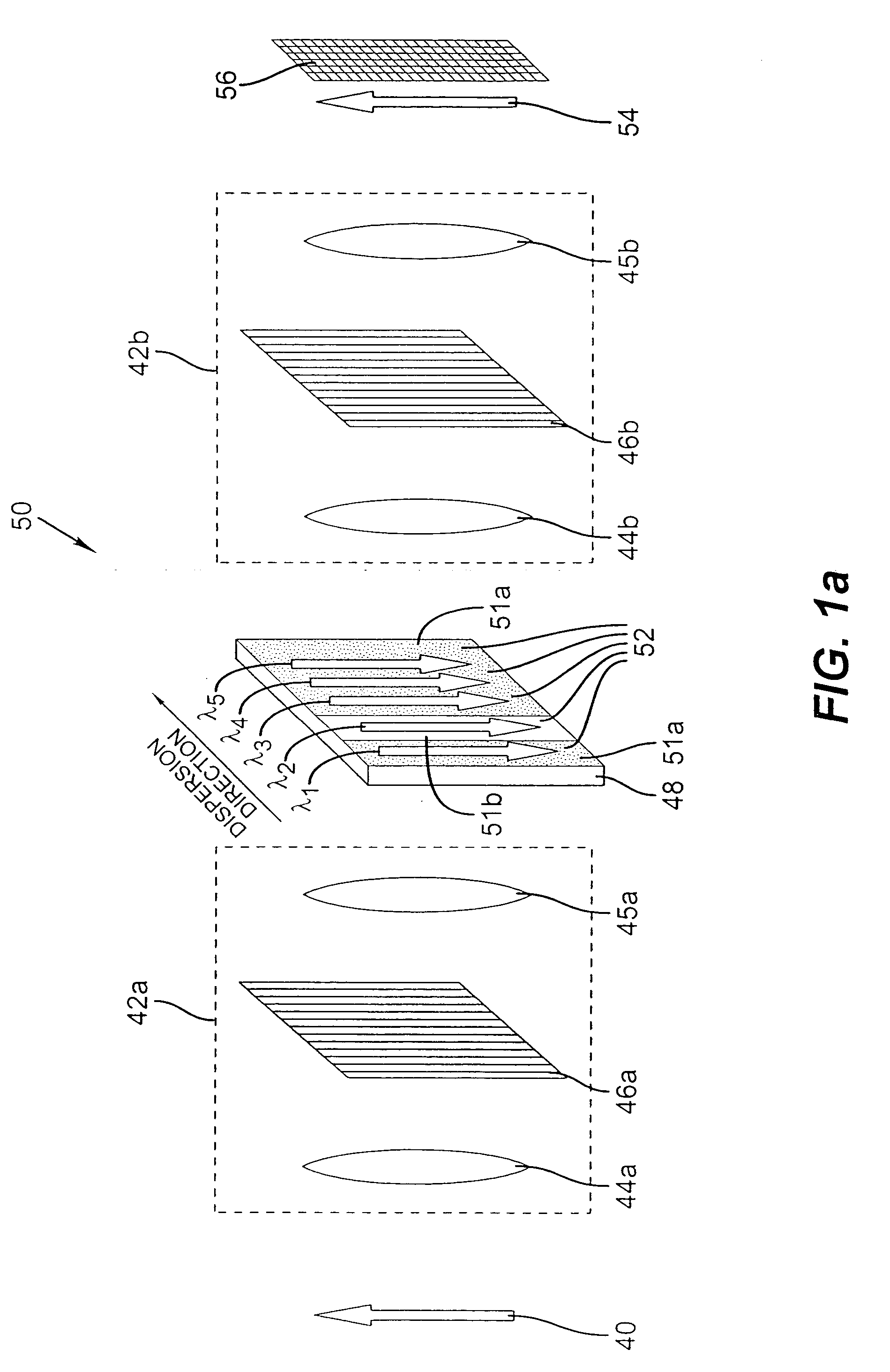

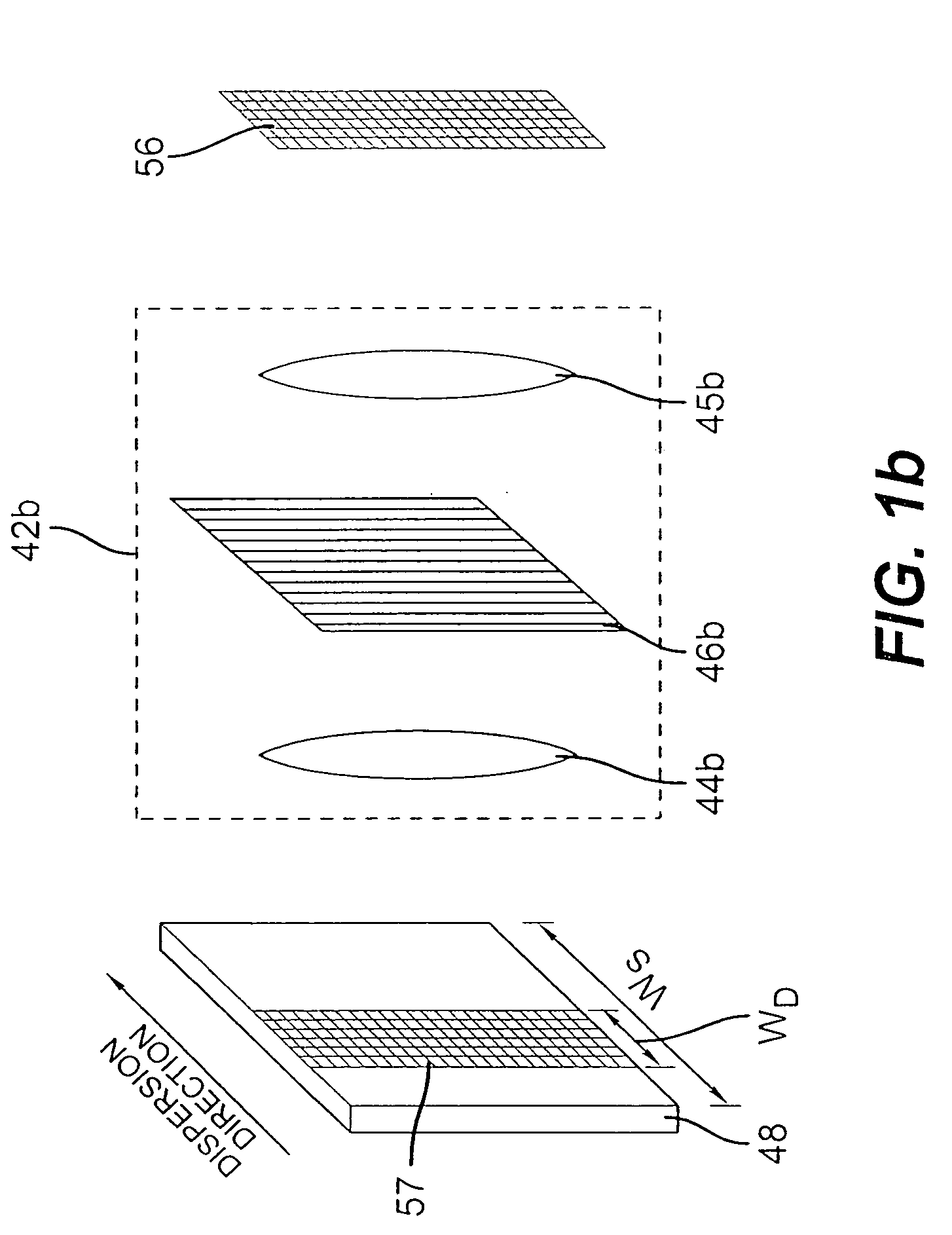

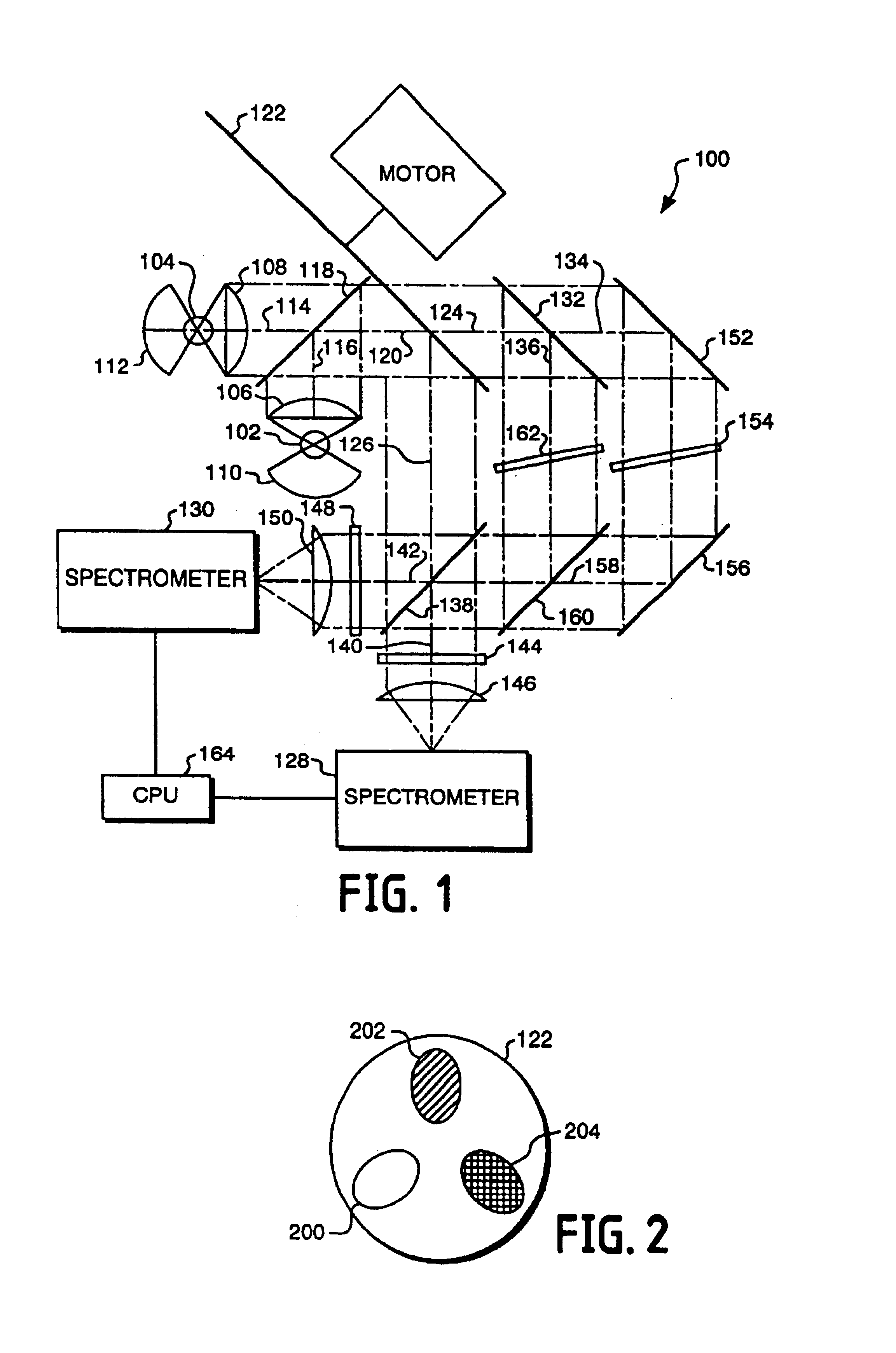

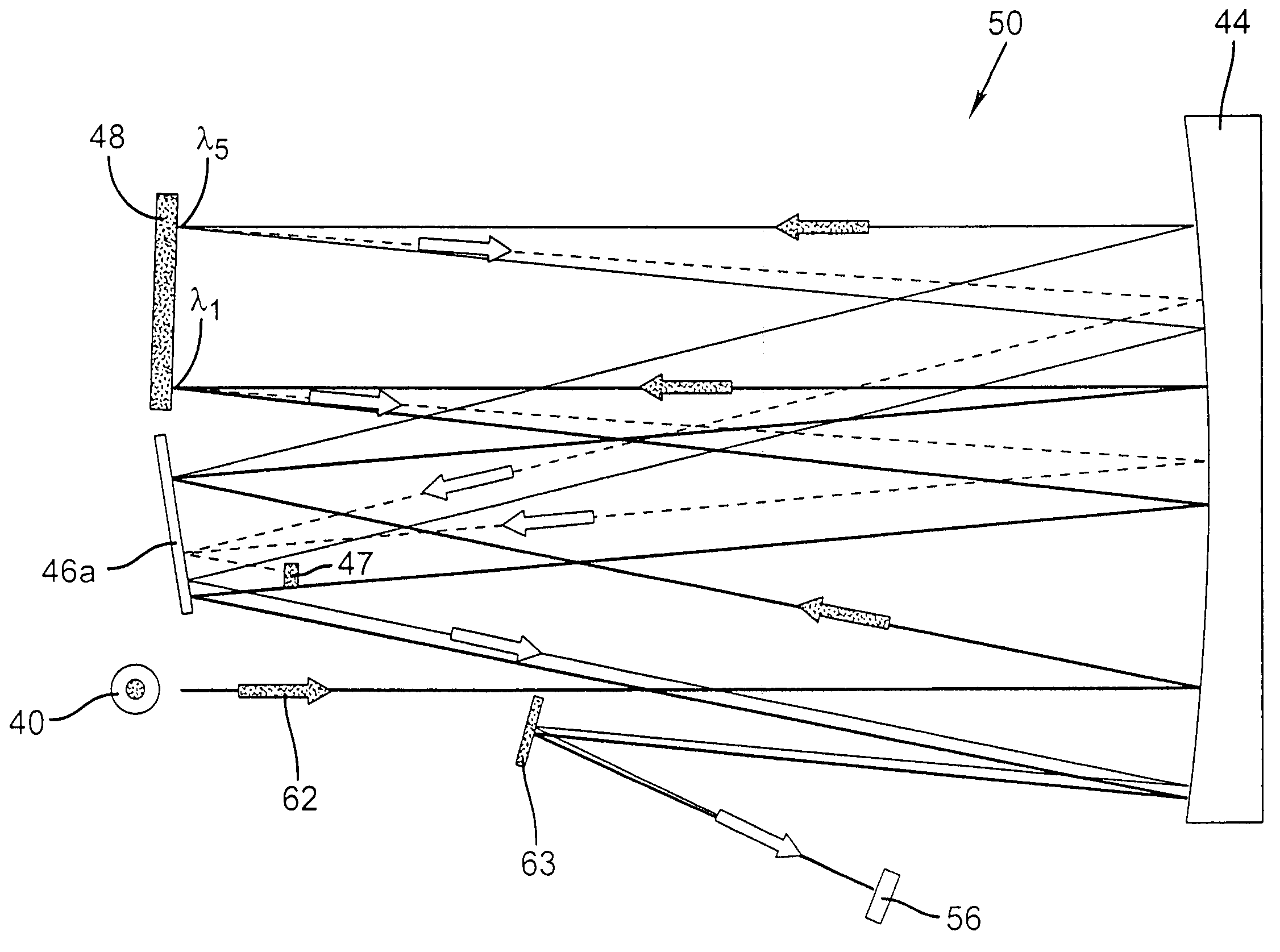

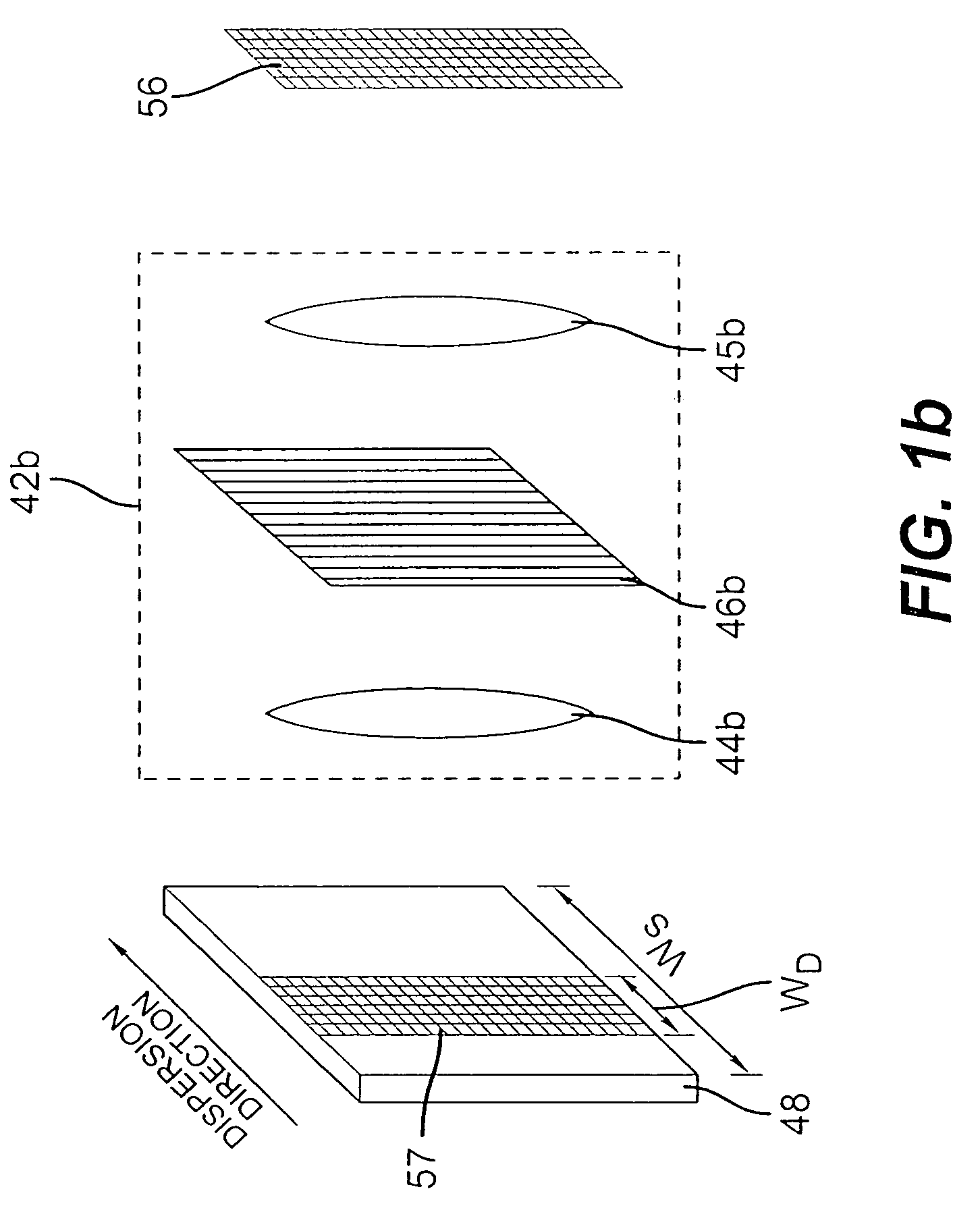

Programmable spectral imaging system

ActiveUS20060017924A1Radiation pyrometrySpectrum investigationSpectral transmissionSpatial light modulator

An imaging system having a programmable spectral transmission function, that includes an input image plane for passing input imaging light into the imaging system; a dispersive optical system for separating the input imaging light into its corresponding spectral components, thus creating spectrally-dispersed image components along a spectrally-dispersed direction. Also included is a spatial light modulator, having a plurality of operational states, for selecting spectral components for imaging; and having a width along the spectrally-dispersed direction; a de-dispersive optical system for re-combining the selected spectral components for imaging onto a detector array; and means for scanning the input imaging light from an object of interest to generate an output area image.

Owner:EASTMAN KODAK CO

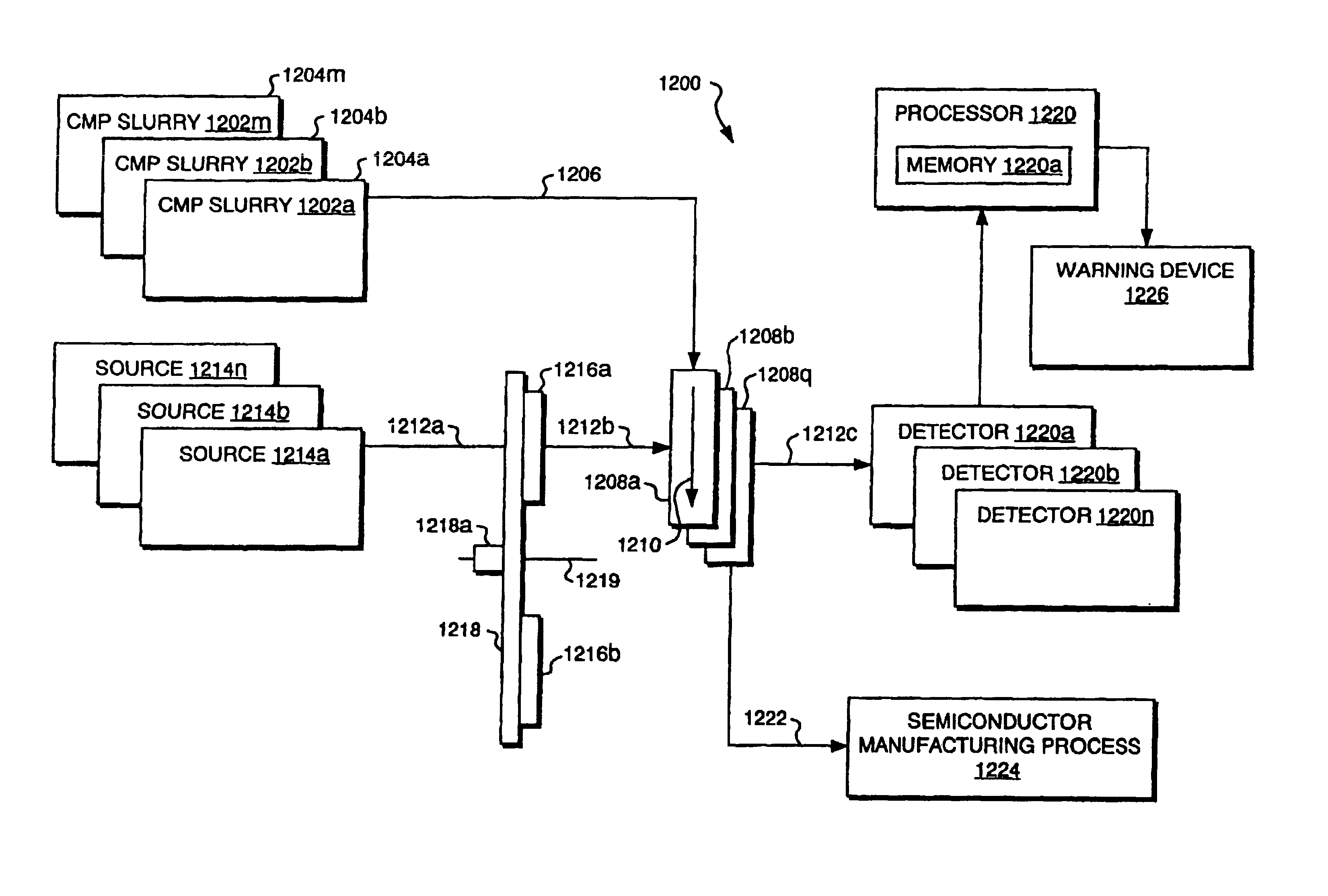

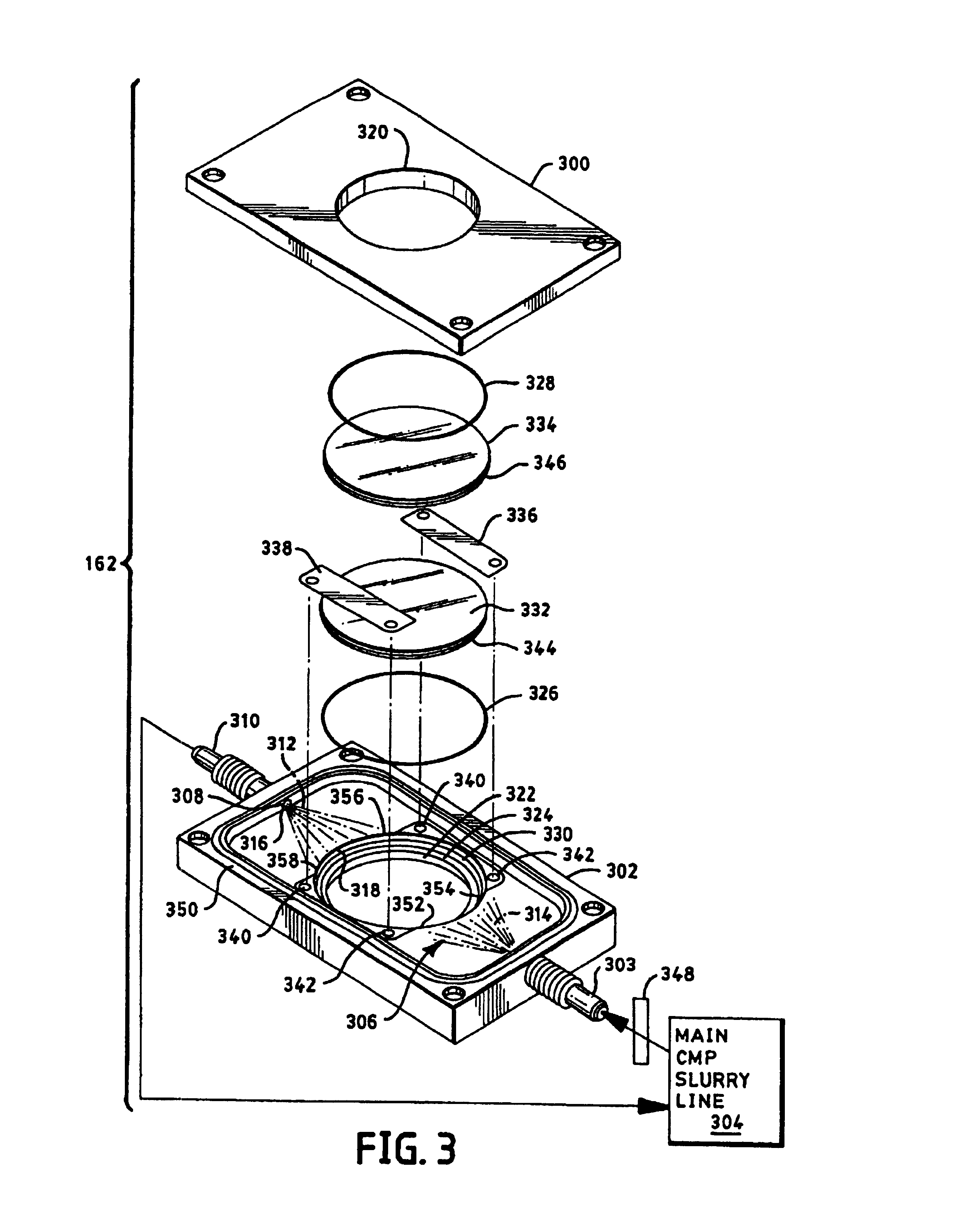

Chemical mechanical planarization (CMP) slurry quality control process and particle size distribution measuring systems

InactiveUSRE39783E1Improve accuracyEasy to measureDiagnosticsSemiconductor/solid-state device manufacturingSpectral transmissionGrating

A sensitive particle distribution probe uses special processing including a modified Twomey / Chahine iterative convergence technique and a specially constructed sample cell to obtain particle size distribution measurements from optically dense slurries, such as the slurries used in the semiconductor industry for chemical mechanical planarization. Spectral transmission data is taken over the spectral range of 0.20-2.5 microns, utilizing specially constructed, chemically resistant sample cells of 50-2000 microns thickness, and miniature, fixed grating, linear detector array spectrometers. At wavelengths greater than one micron, the preferred design utilizes InGaAs linear detector arrays. An ultrasonic disrupter can be employed to breakup harmless soft agglomerates. In addition to direct particle size distribution measurement, the invention described here could be used to detect other fundamental causes of slurry degradation, such as foaming and jelling. The probe accomplishes continuous, real time sampling of undiluted slurry. A three-position chopper allows automated operation in an industrial environment without the need for frequent reference spectra, which would require taking the probe off-line. In other embodiments, the invention provides a quality control and / or particle size measuring system for CMP slurries using transmission data through an as-used CMP slurry flow. The process of the invention detects transmission through the flow, at select wavelengths, and determines changes in the logarithmic slope of transmission versus wavelength to detect acceptable or unacceptable CMP slurries. The process can further determine CMP slurry particle size through empirical extinction data stored in memory.

Owner:PARTICLE MEASURING SYST

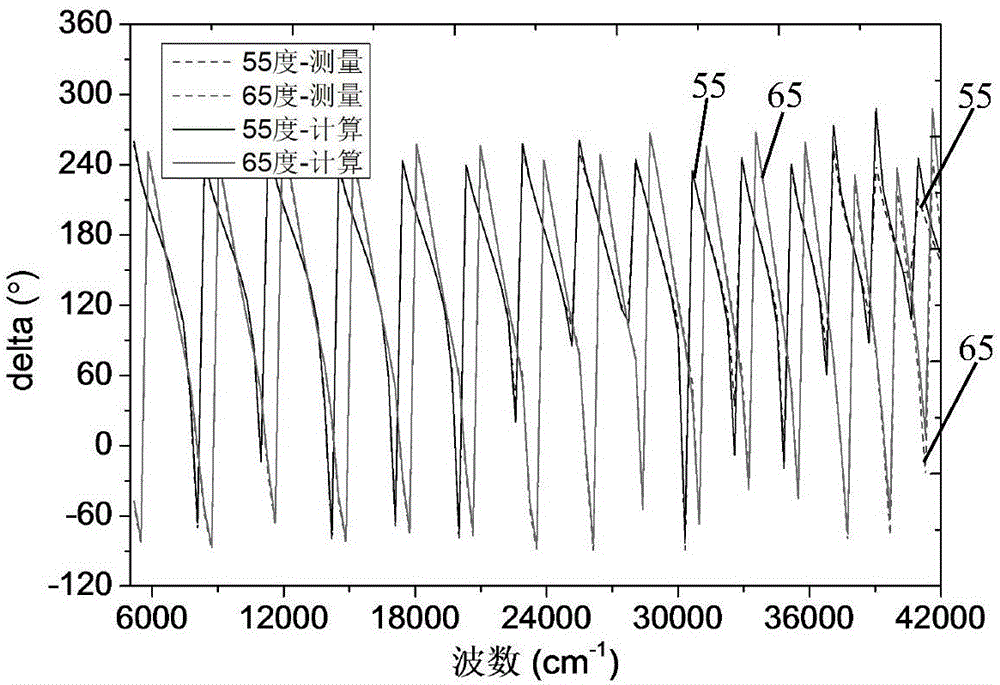

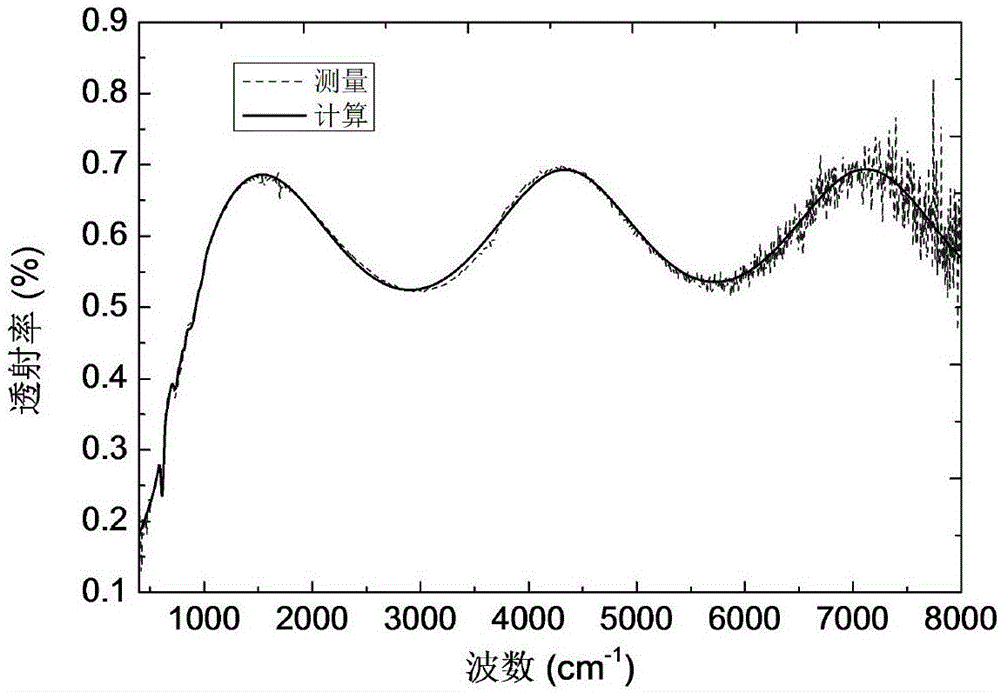

Optical film ultra wide band optical constant testing method

ActiveCN106706521AAvoid the problem of large calculation errors in sub-bandsColor/spectral properties measurementsSpectral transmissionSpectral transmittance

The invention discloses an optical film ultra wide band optical constant testing method for calculating an optical constant of a whole spectrum range from a visible light band to an infrared band of an optical film material. Particularly, a spectral transmission factor of a substrate-film transparent zone and the spectral transmission factor of a non-transparent zone are compounded as a target spectrum in the wavelength range of 0.3 microns-20 microns, a vibrator model is adopted as a chromatic dispersion model of the optical constant, and the ultra wide band optical constant of the film is calculated through target spectrum data back calculation. The optical film ultra wide band optical constant testing method has universality for film materials.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

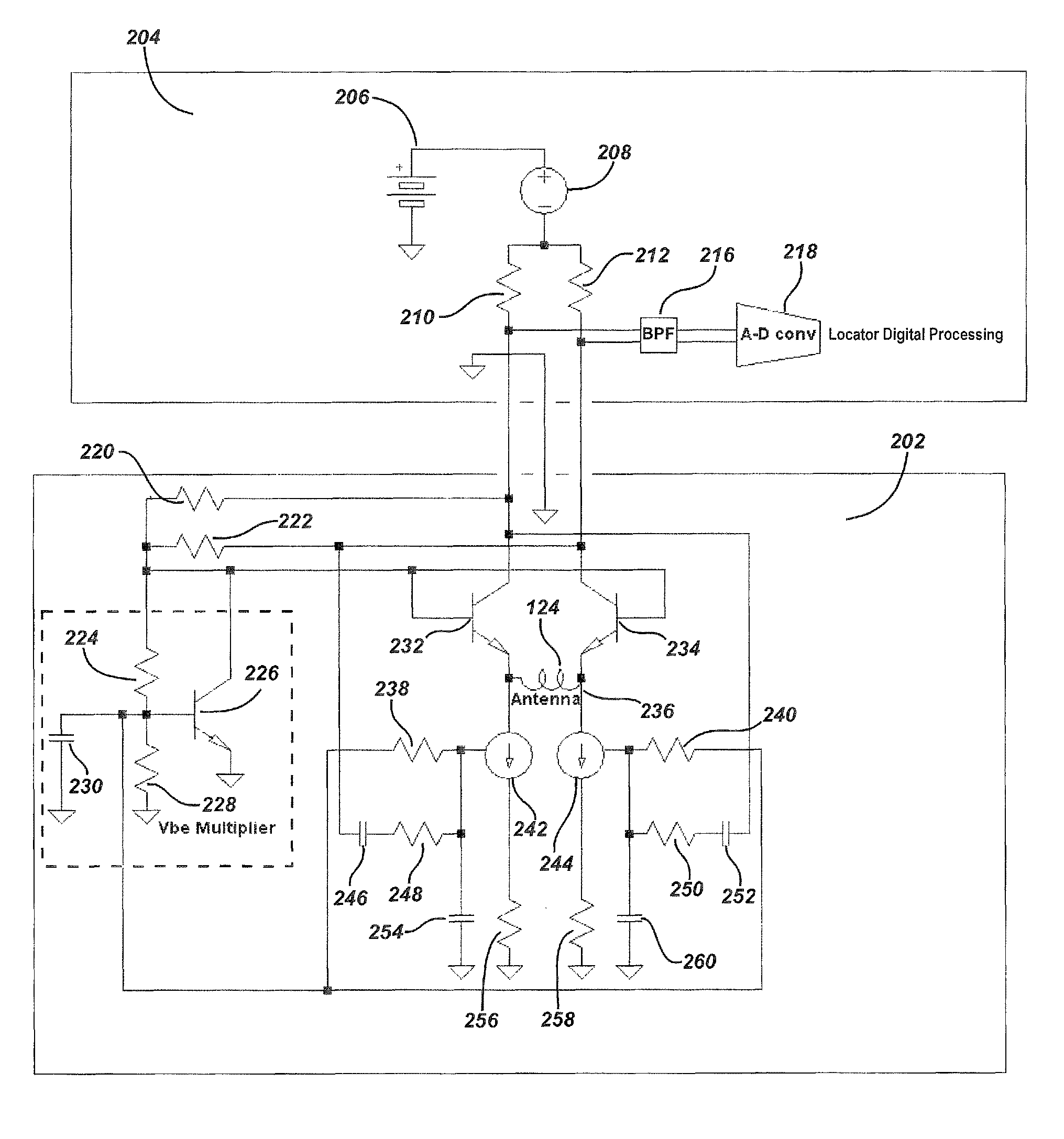

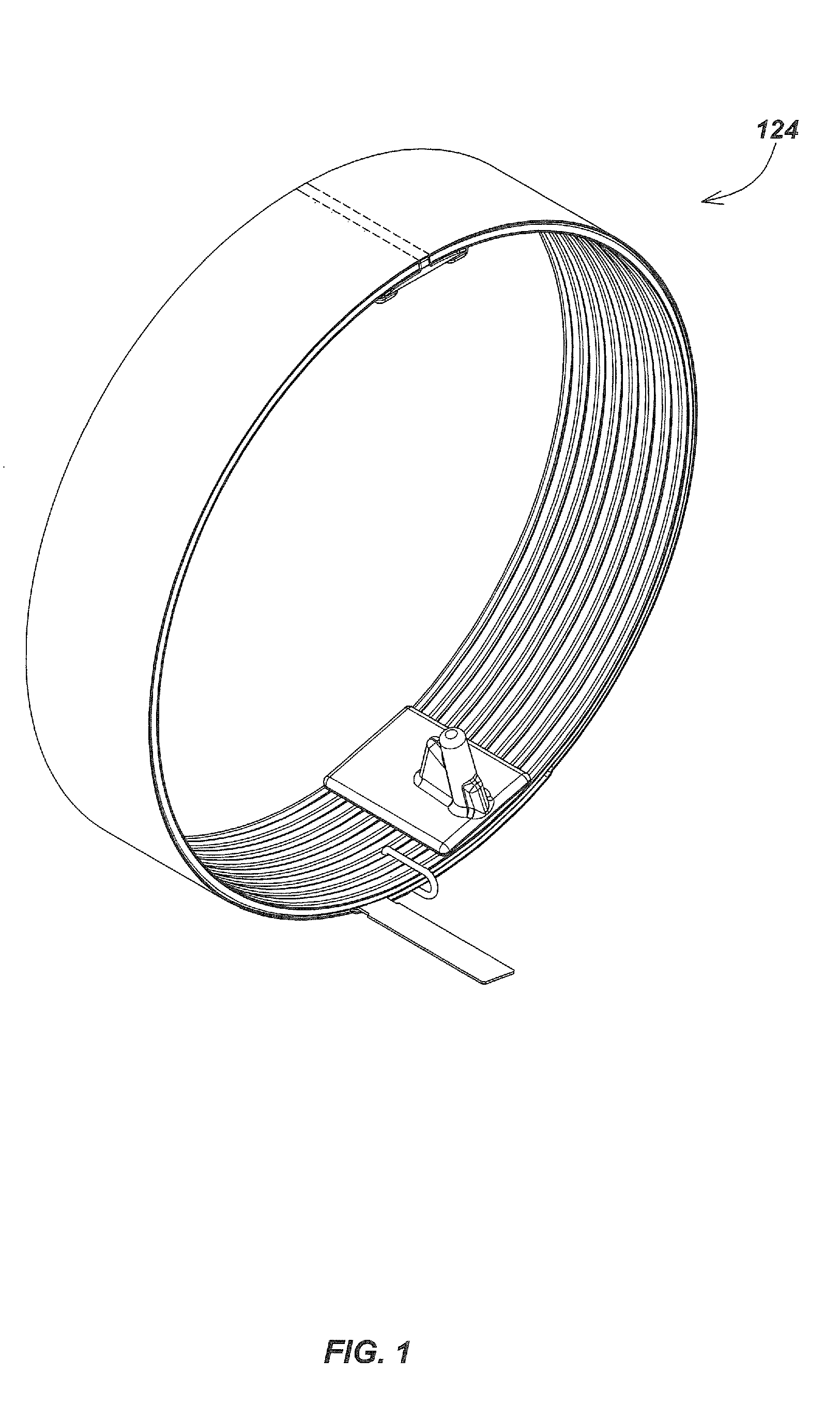

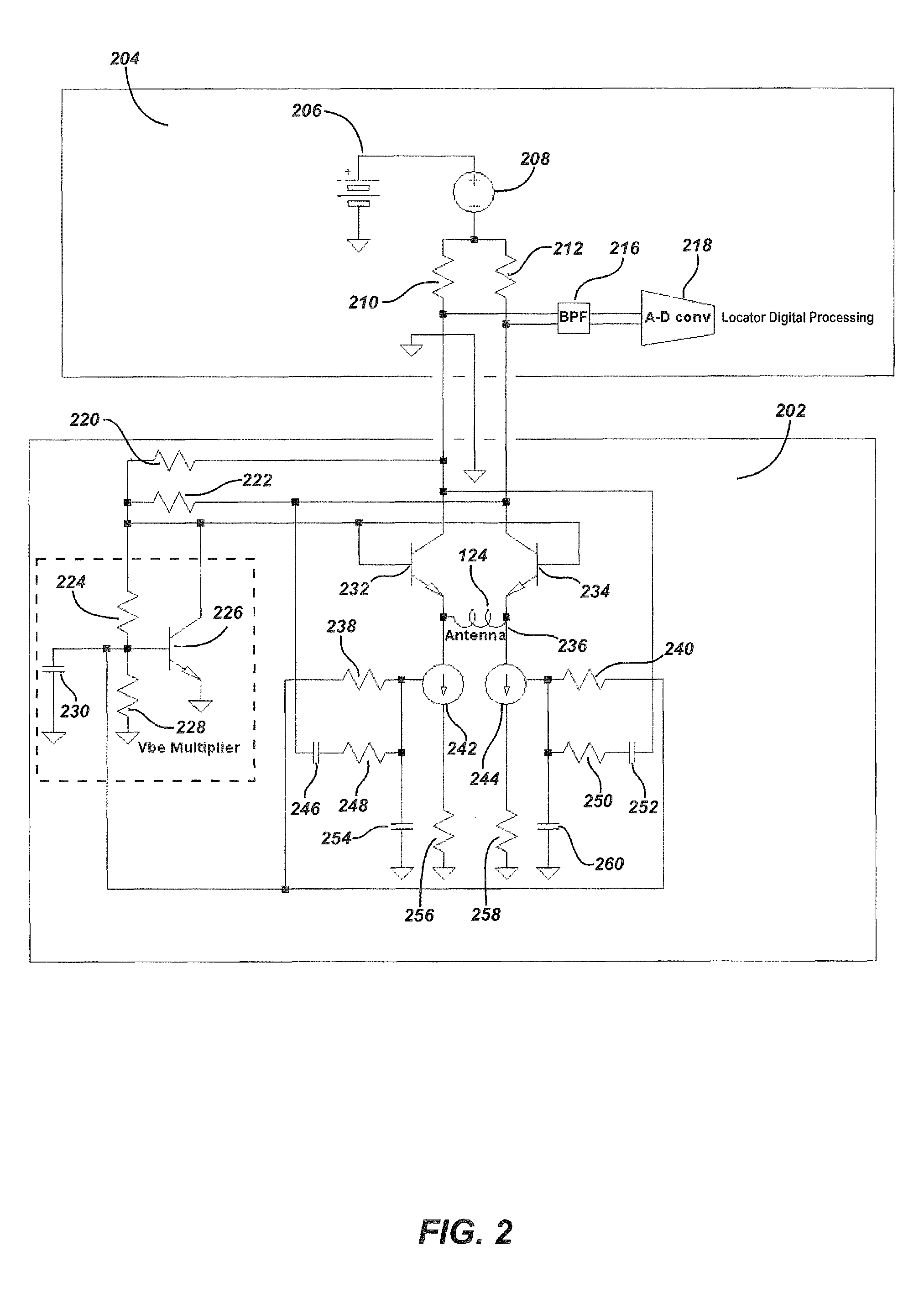

Pre-amplifier and mixer circuitry for a locator antenna

A pre-amplifier circuit for connection to an antenna of a human-portable locator includes a differential amplifier / mixer pair and means for allowing a common-mode “phantom” signal to modulate a transfer function of the differential amplifier / mixer pair. The common-mode phantom signal modulates the transfer function of the differential pre-amplifier “onboard” the antenna without the usual requirement for onboard power supply and signal oscillator. This technique uses the same electronic components to provide both pre-amplification and mixing functions, thereby improving circuit performance-to-cost ratio, reducing mixer power consumption, situating the necessary signal oscillator remotely from the mixer, and greatly improving the available system bandwidth by limiting spectral transmission demands to the mixed signal bandwidth alone.

Owner:SEEKTECH

Transmission duplitized display materials with biaxially oriented polyolefin sheets

InactiveUS6017685ABrighter imageEfficient diffusion of lightRadiation applicationsMulticolor photographic processingSpectral transmissionPolyolefin

The invention relates to a photographic element comprising a transparent polymer sheet, a biaxially oriented polyolefin sheet laminated to said transparent polymer sheet, one image layer coated on the top of said biaxially oriented polyolefin sheet and one image layer coated on the bottom of said transparent polymer sheet wherein said polymer sheet has a stiffness of between 20 and 100 millinewtons, and said biaxially oriented polyolefin sheet has a spectral transmission of at least 40% and a reflection density less than 60%.

Owner:EASTMAN KODAK CO

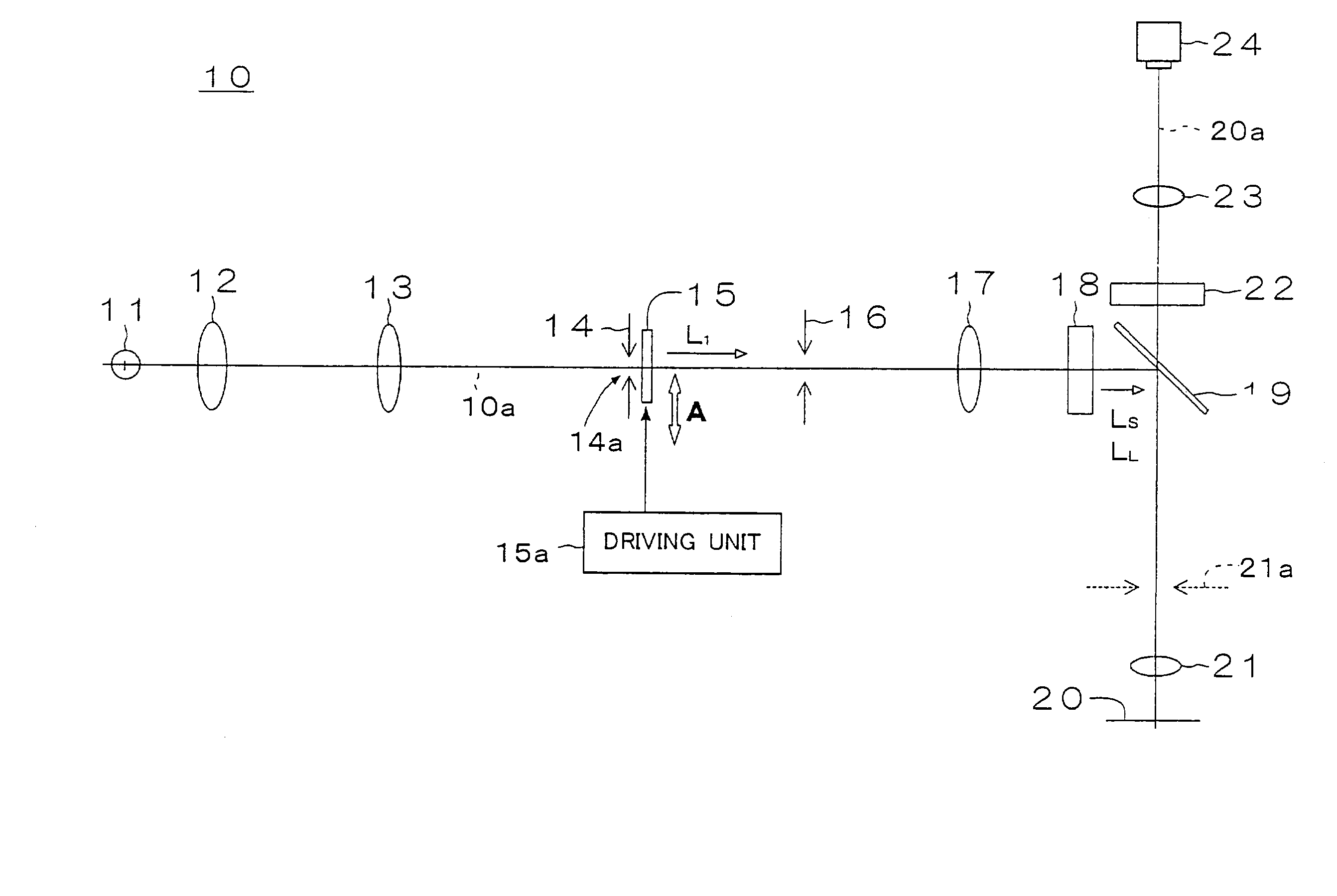

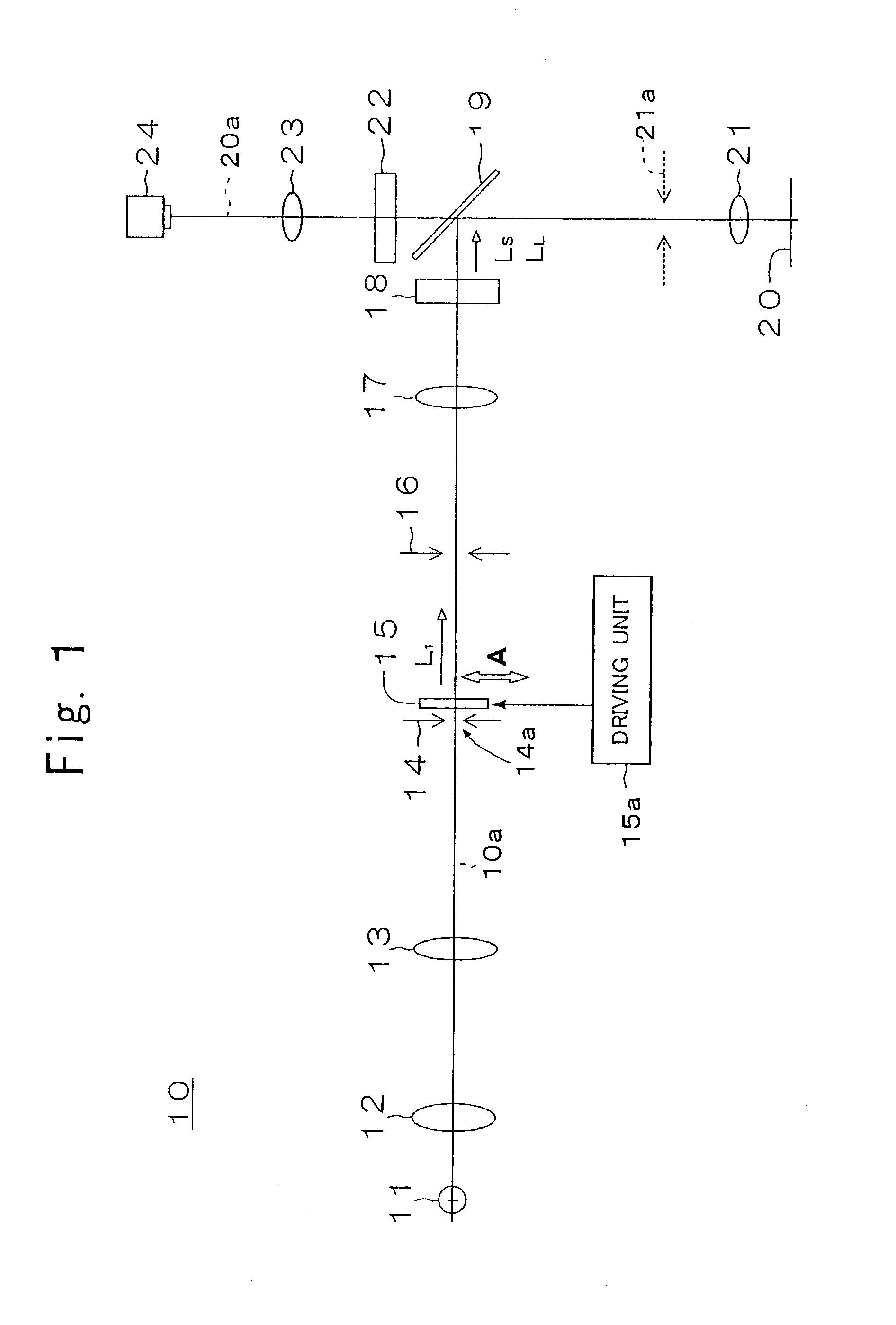

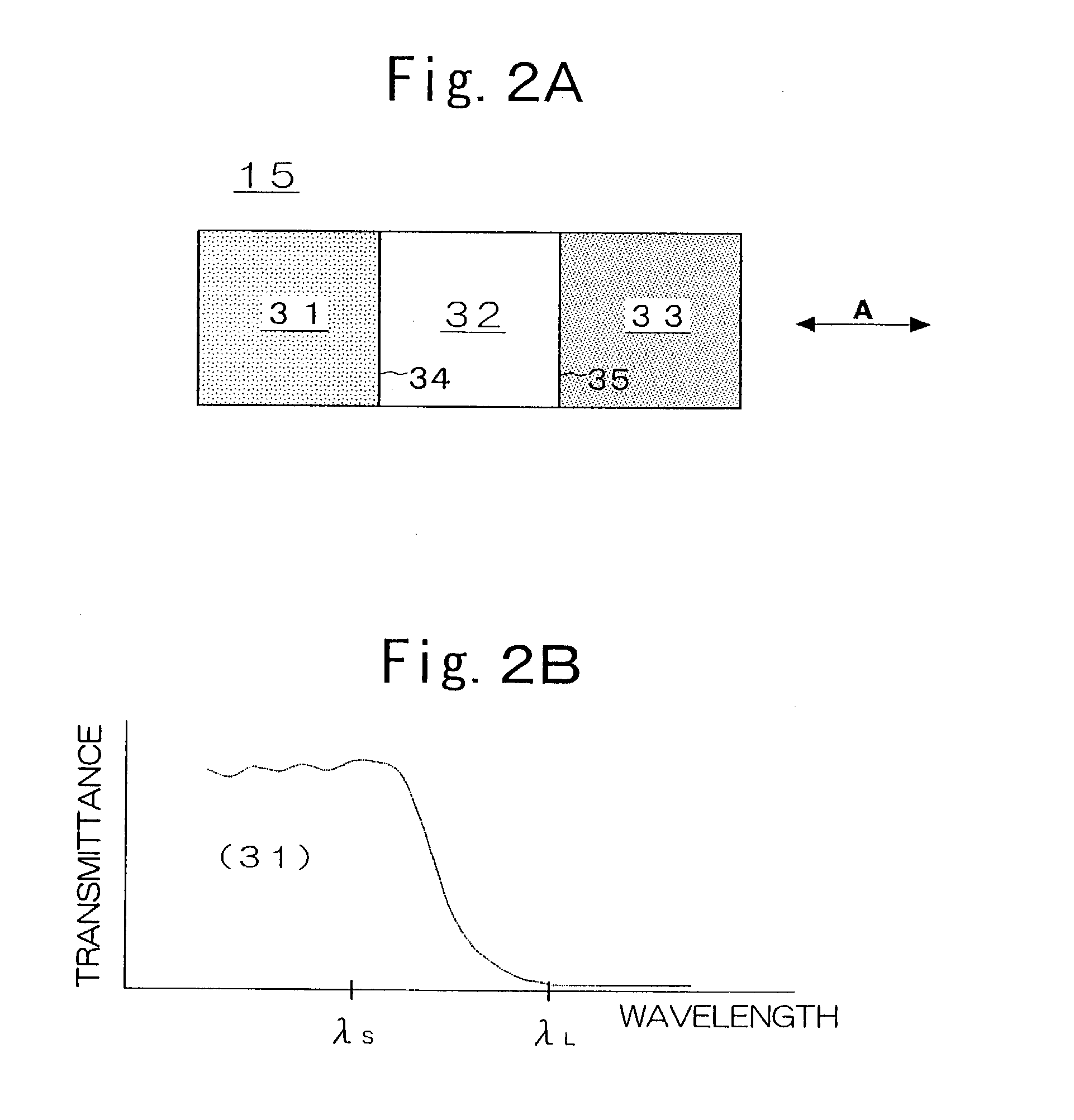

Epi-illumination apparatus for fluorescent observation and fluorescence microscope having the same

ActiveUS20030227674A1Easy to adjustInexpensively formedPhotometryLuminescent dosimetersSpectral transmissionEpi illumination

An epi-illumination apparatus for fluorescent observation, adjusting light intensities of a plurality of illuminations on a sample over a wide wavelength band continuously and being configured inexpensively, and a fluorescence microscope having the same are provided. A light source, extracting means, an aperture stop, and a filter are arranged on a predetermined optical axis. The aperture stop is arranged on a plane generally conjugated with a pupil plane of an objective. The filter is placed near the aperture stop. The extracting means extracts a plurality of narrow wavelength bands from the wavelength band of the illumination emitted from the light source. The filter has regions of different spectral transmission characteristics to the narrow wavelength bands. The adjusting means for adjusting light intensities of transmitted light from the filter in the narrow wavelength bands independently by moving the filter in a direction orthogonal to the optical axis is provided.

Owner:NIKON CORP

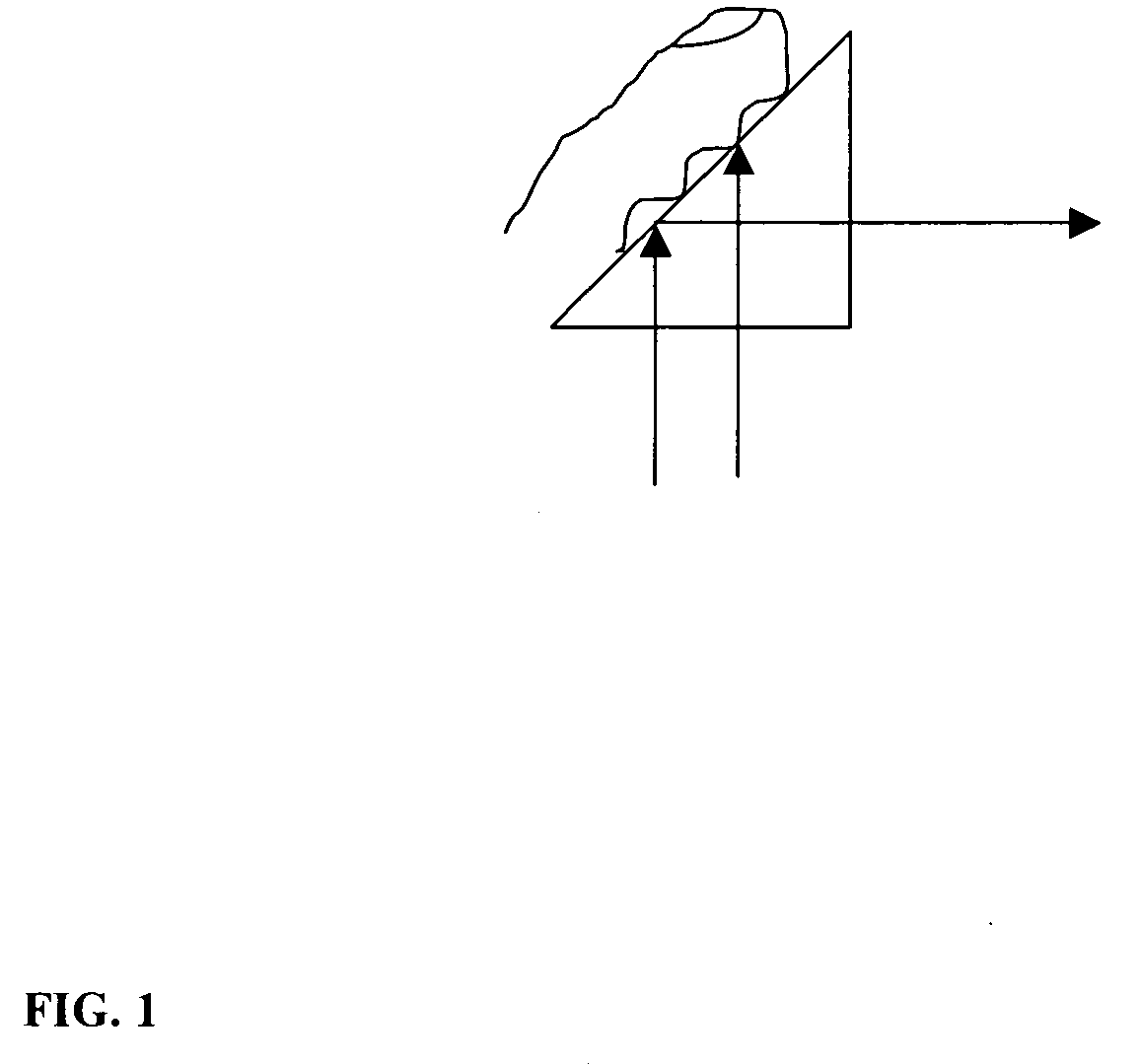

Fingerprint sensor using a spectral filter and a holographic optical element

InactiveUS20090116030A1Aberrated with astigmatismEliminate aberrationsCharacter and pattern recognitionUsing optical meansSpectral transmissionAngle of incidence

In one embodiment, a fingerprint sensing system includes a interference narrow band pass filter, a holographic optical element, a transparent slab stacked together with optical cement. The finger is placed on the filter and illuminated by a narrow band source, the center of its band shifted appropriately with respect to the pass band of the interference filter. A camera on the other side of the slab receives the fingerprint image. The light from the valleys and ridges propagating in the direction of the camera are blocked by the interference filter. The light from the ridges at steep angles are bent by the holographic optical element and then directed towards the lens. This way the ridges are seen by the camera, but not the valleys. In another embodiment, a miniaturized version, the interference filter, a modified holographic optical element, and a blocking filter (if necessary) to block room light can be sequentially attached to the image sensor. In yet another embodiment, the interference filter can be directly coated over an image sensor creating a very simple fingerprint sensor. The principle behind all of the above embodiments is the same, viz: the spectral transmission band of an interference filter shifts with change in the angle of incidence.

Owner:BAHUGUNA RAMENDRA DEO

Programmable spectral imaging system

ActiveUS7289209B2Radiation pyrometrySpectrum investigationSpectral transmissionSpatial light modulator

An imaging system having a programmable spectral transmission function, that includes an input image plane for passing input imaging light into the imaging system; a dispersive optical system for separating the input imaging light into its corresponding spectral components, thus creating spectrally-dispersed image components along a spectrally-dispersed direction. Also included is a spatial light modulator, having a plurality of operational states, for selecting spectral components for imaging; and having a width along the spectrally-dispersed direction; a de-dispersive optical system for re-combining the selected spectral components for imaging onto a detector array; and means for scanning the input imaging light from an object of interest to generate an output area image.

Owner:EASTMAN KODAK CO

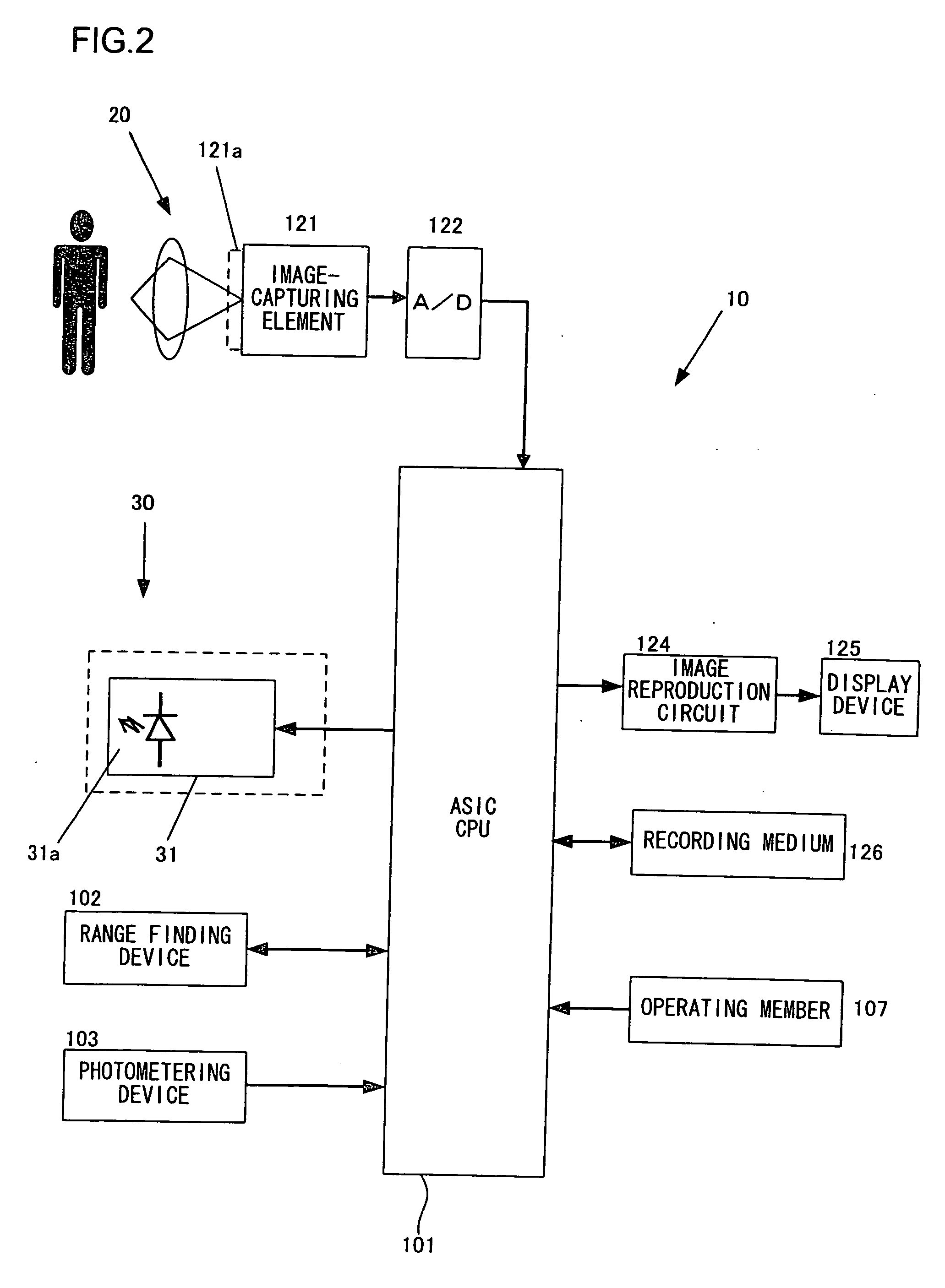

Illumination device for photographing and camera system

InactiveUS20050264685A1Television system detailsElectroluminescent light sourcesSpectral transmissionLength wave

An illumination device includes a light source constituted with an LED which is a trichromatic (three-wavelength) light source achieving maximum light emission wavelengths in separate wavelength ranges corresponding to the three primary colors of light, blue, green and red. As the shutter is released at an electronic camera set in a portrait photographing mode, the electronic camera transmits a light emission command for the illumination device to illuminate the main subject with illuminating light emitted from the LED. The LED assumes a structure that allows it to emit light at maximum light emission wavelengths matching maximum transmission wavelengths achieved through the spectral transmission characteristics of a color filter disposed at an image-capturing element.

Owner:NIKON CORP

Ocular mask having selective spectral transmission

A mask is provided that is configured to increase the depth of focus of a patient. The mask can include an aperture configured to transmit along an optical axis substantially all visible incident light. The mask can further include a portion surrounding at least a portion of the aperture. The portion may be configured to be substantially opaque to visible electromagnetic radiation and be substantially transparent to electromagnetic radiation transmitted from an ocular examination device (e.g., substantially transparent to at least some non-visible electromagnetic radiation with a wavelength between about 750 nm and about 1500 nm).

Owner:ACUFOCUS

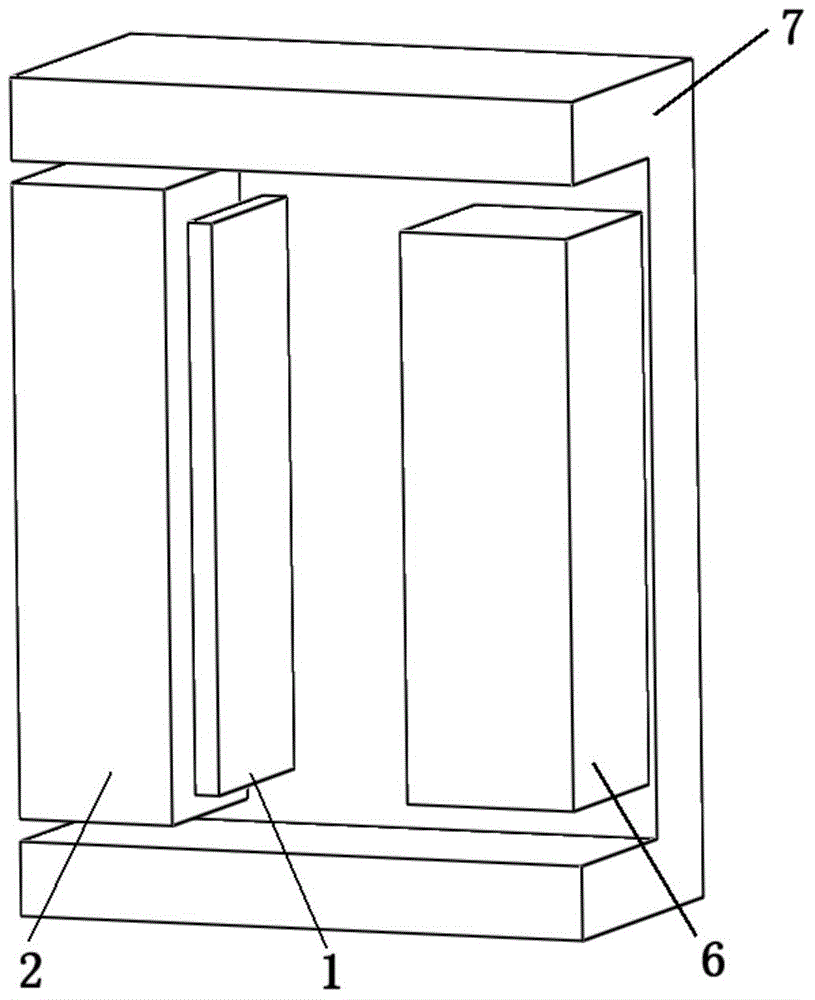

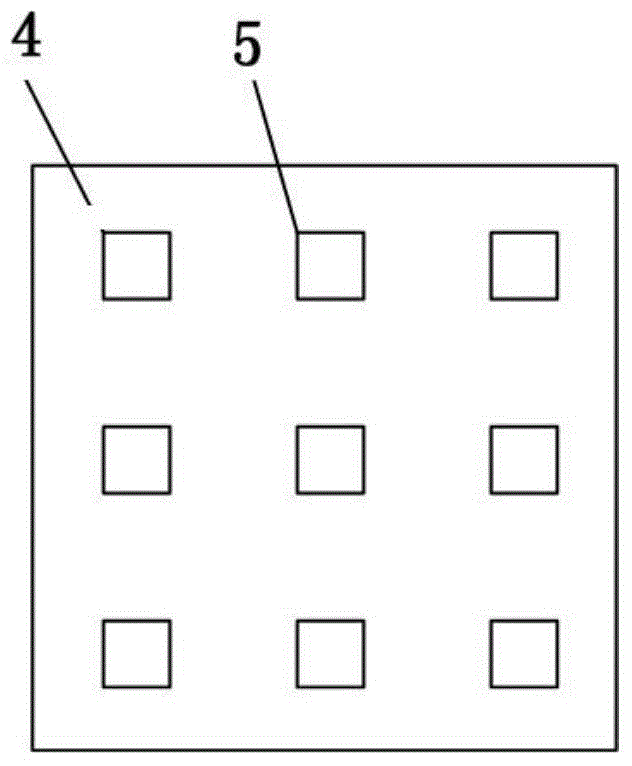

Chip spectrograph with sub-wavelength metal structure

ActiveCN105628199ASolve the problem of miniaturizationSimple structureSpectrum investigationSpectral transmissionPhotovoltaic detectors

The invention provides a chip spectrograph with a sub-wavelength metal structure, comprising a sub-wavelength filter unit array and a photoelectric detector array. The photoelectric detector array is arranged on the light-out side of the sub-wavelength filter unit array. The sub-wavelength filter unit array includes a substrate and a metal film adhered to the substrate. The metal film is provided with multiple openings arranged in an array, and the opening cycle of each row of openings is determined by the spectral transmission characteristic of a sub-wavelength metal hole array. The chip spectrograph has a simple structure, and needs no mechanical movement. All the optical components are on the same optical axis and can be integrated easily. By using a nanometer-level film, the problem on how to miniaturize a spectrometer to the chip scale is solved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

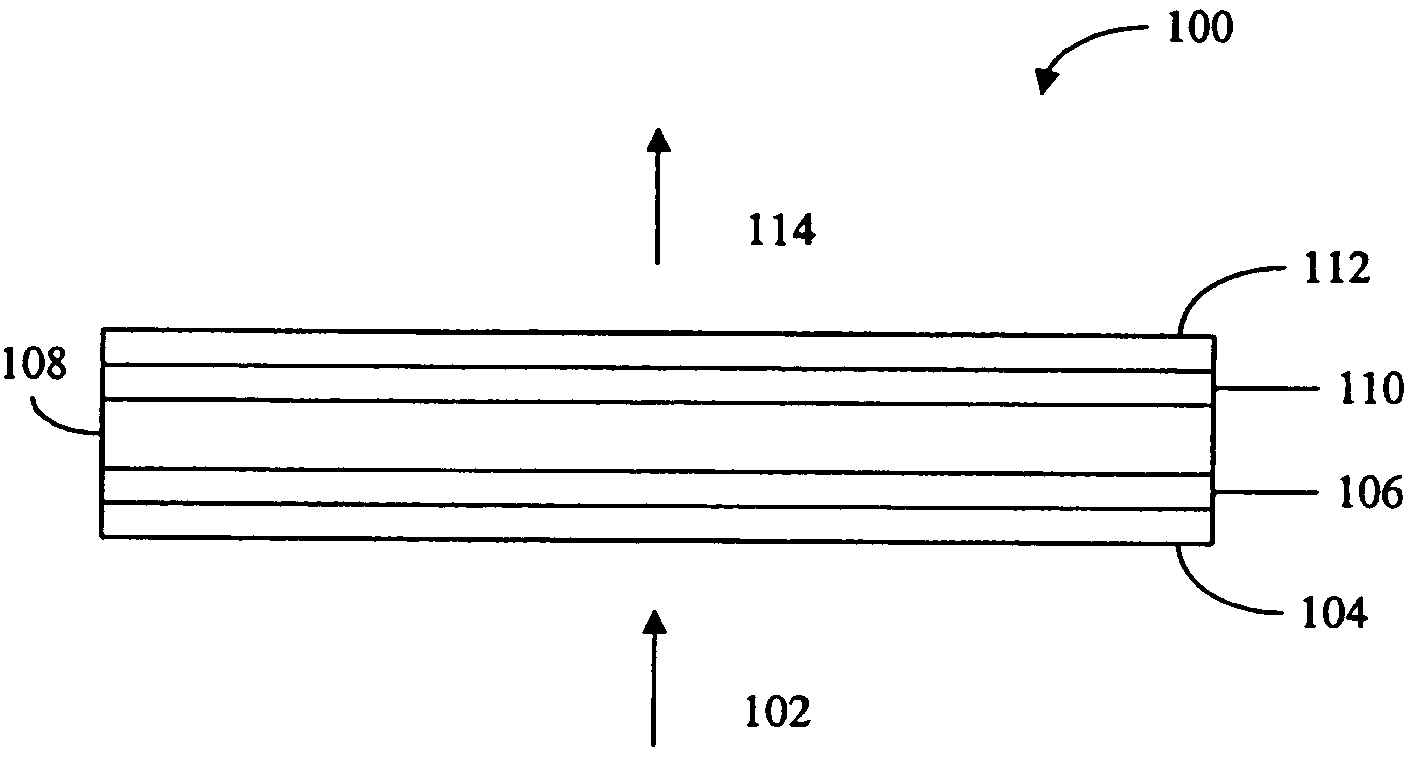

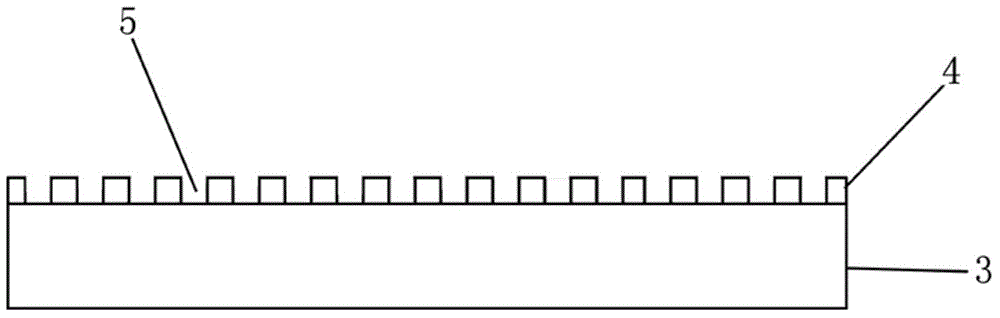

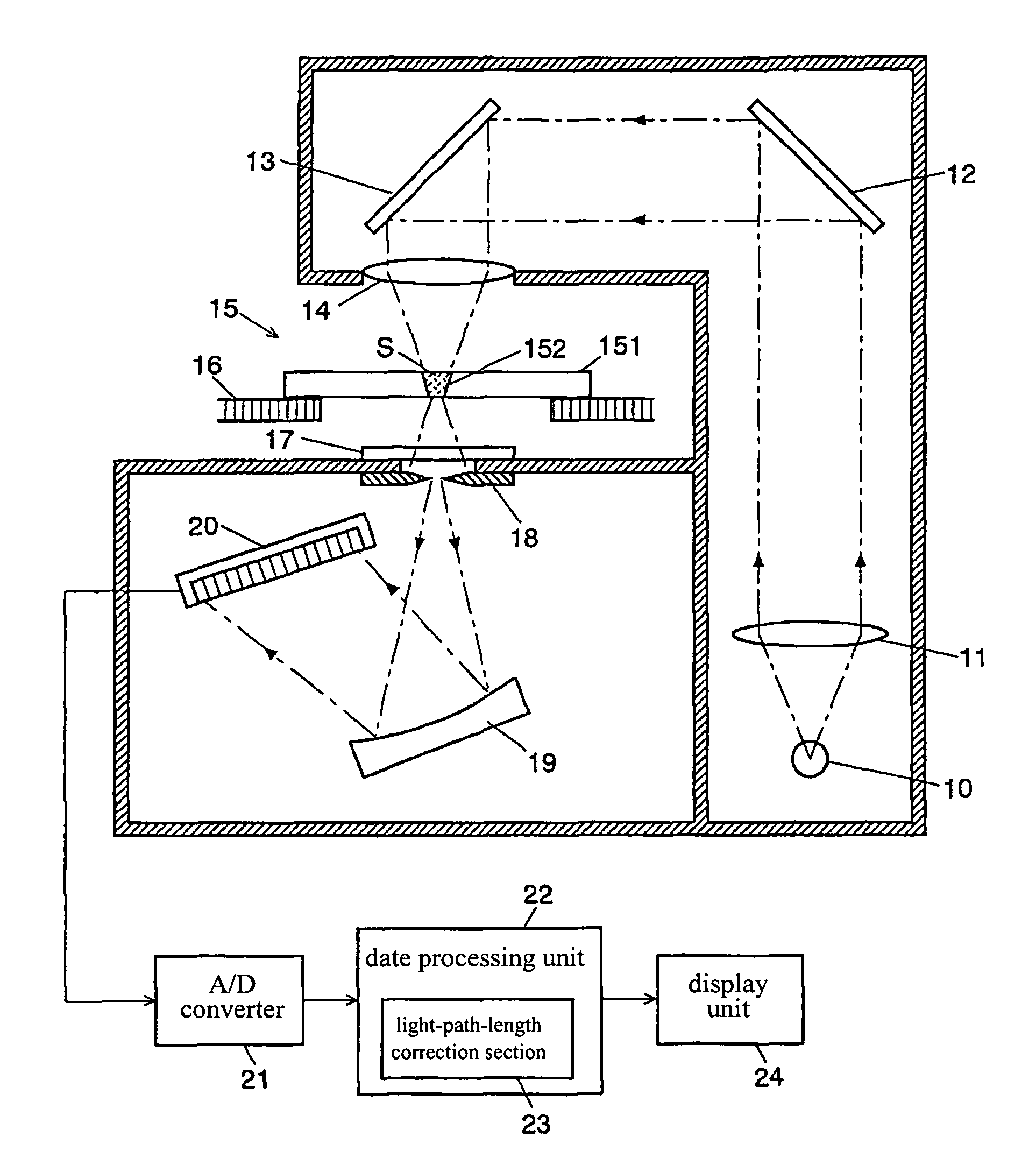

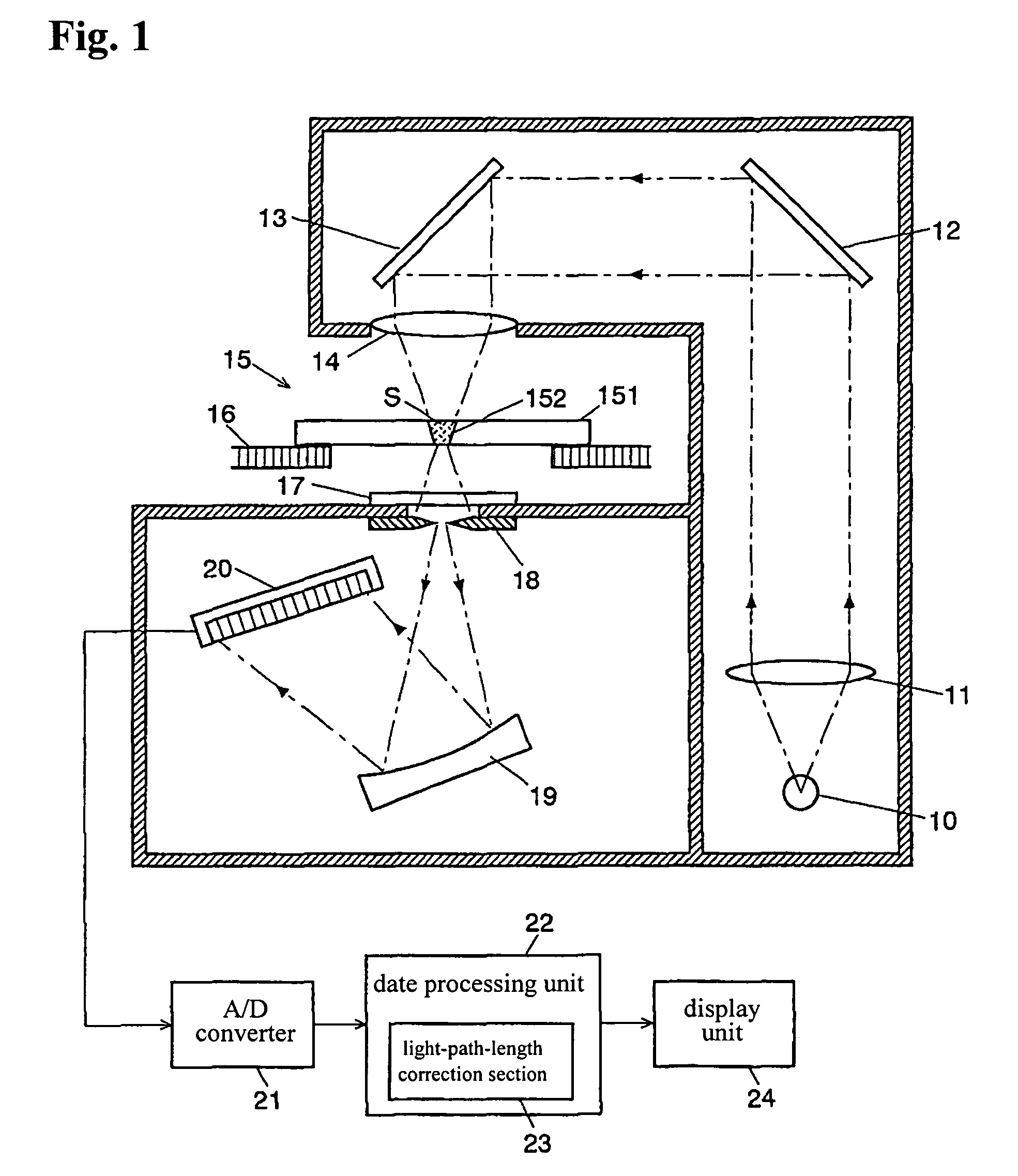

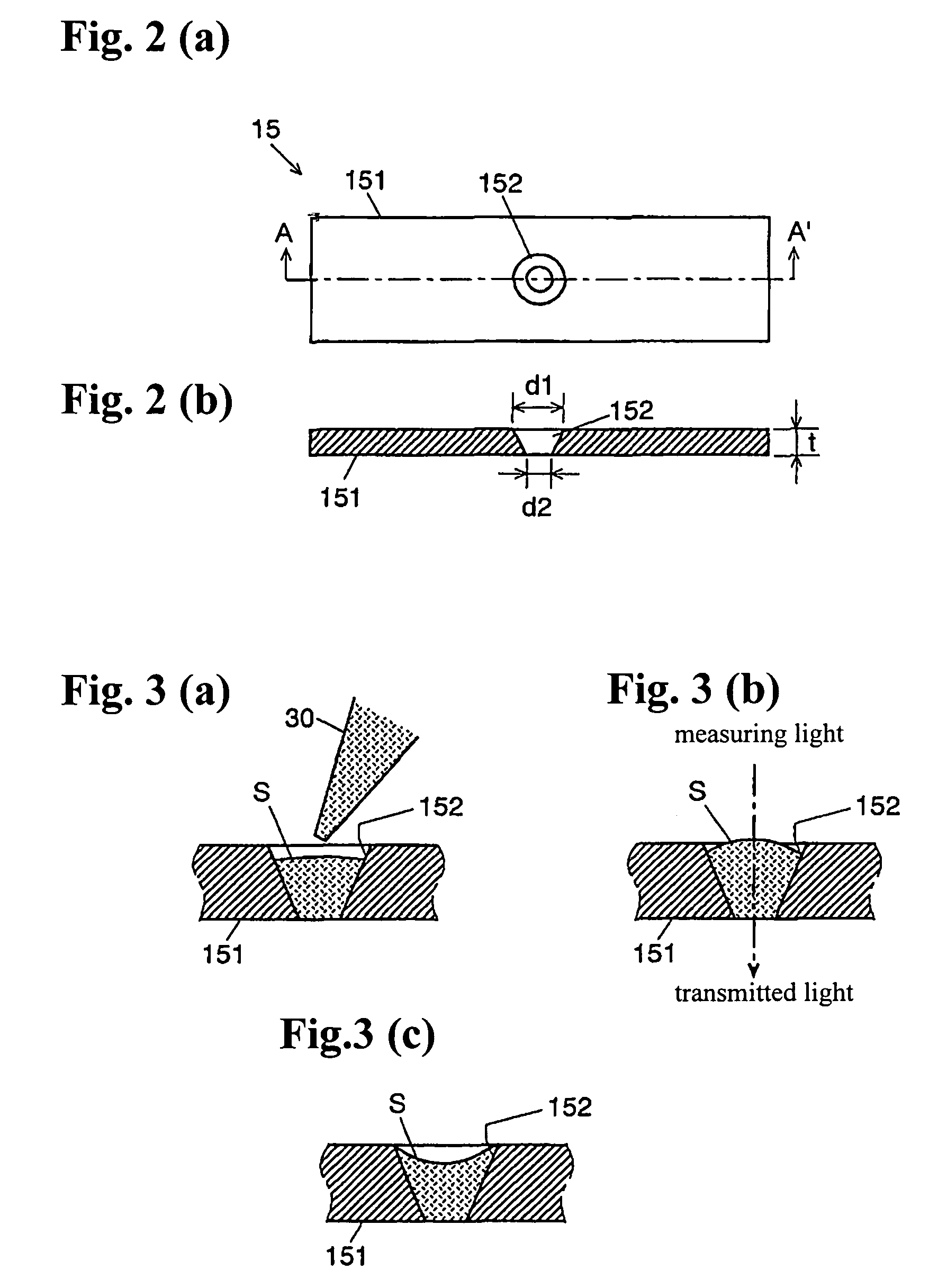

Spectrophotometric method and apparatus

InactiveUS7576855B2Simple structureOperationBioreactor/fermenter combinationsRadiation pyrometrySpectral transmissionLength wave

Disclosed is a spectrophotometry for a spectral transmission measurement of an extremely small volume of sample solution. A sampler 15 is formed of a flat plate member formed with a sample-holding hole 152 which penetrates the flat plate member in its thickness direction and has a reverse truncated cone shape, and a target sample solution is dropped into the sample-holding hole 152 of the sampler 15 positioned approximately horizontally and held in the hole 152 based on a surface tension of the sample solution in the form of a droplet S. Then, a measurement light is emitted to the held droplet S from directly above. A transmitted light getting out of the droplet S downward is introduced to a diffraction grating 19 through a window plate 17 and a slit 18, and dispersed in a wavelength dependent manner. The resulting light with dispersed wavelength components is detected by a multichannel detector 20 approximately simultaneously.

Owner:SHIMADZU CORP

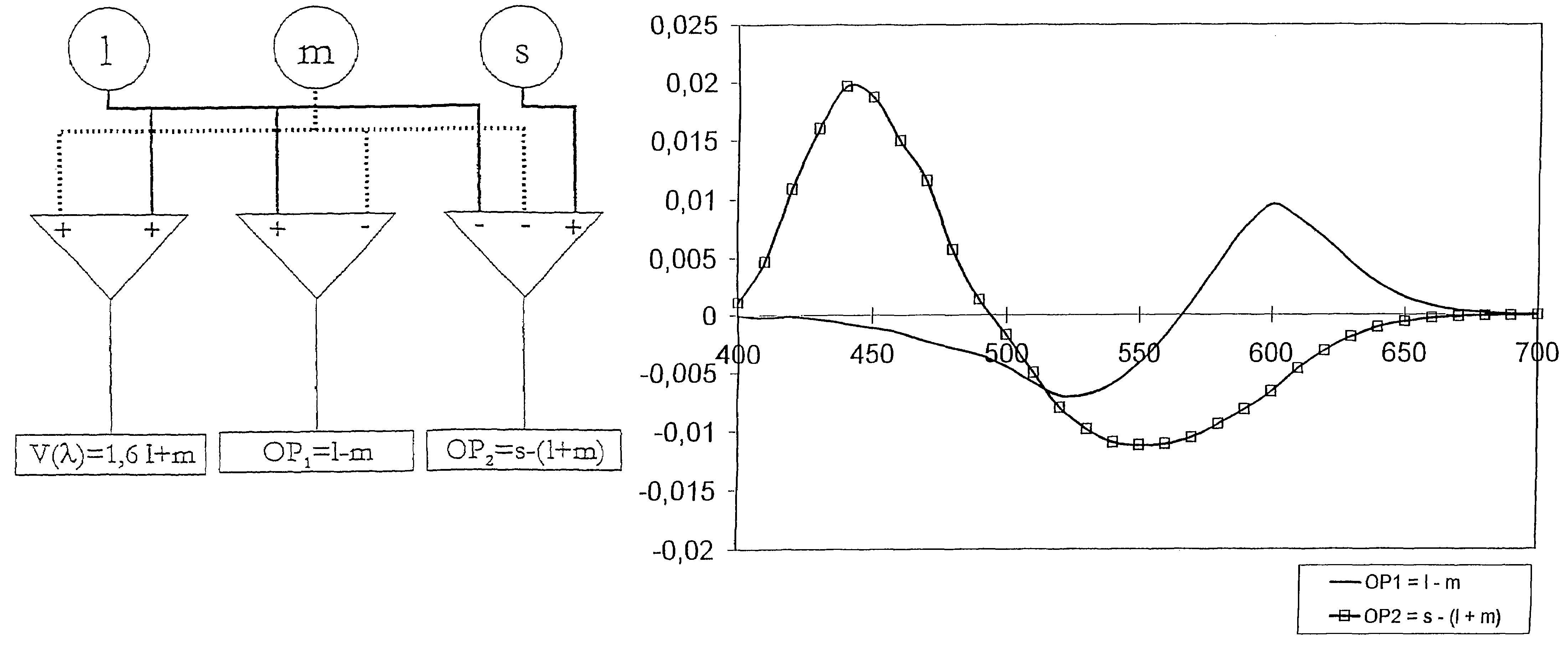

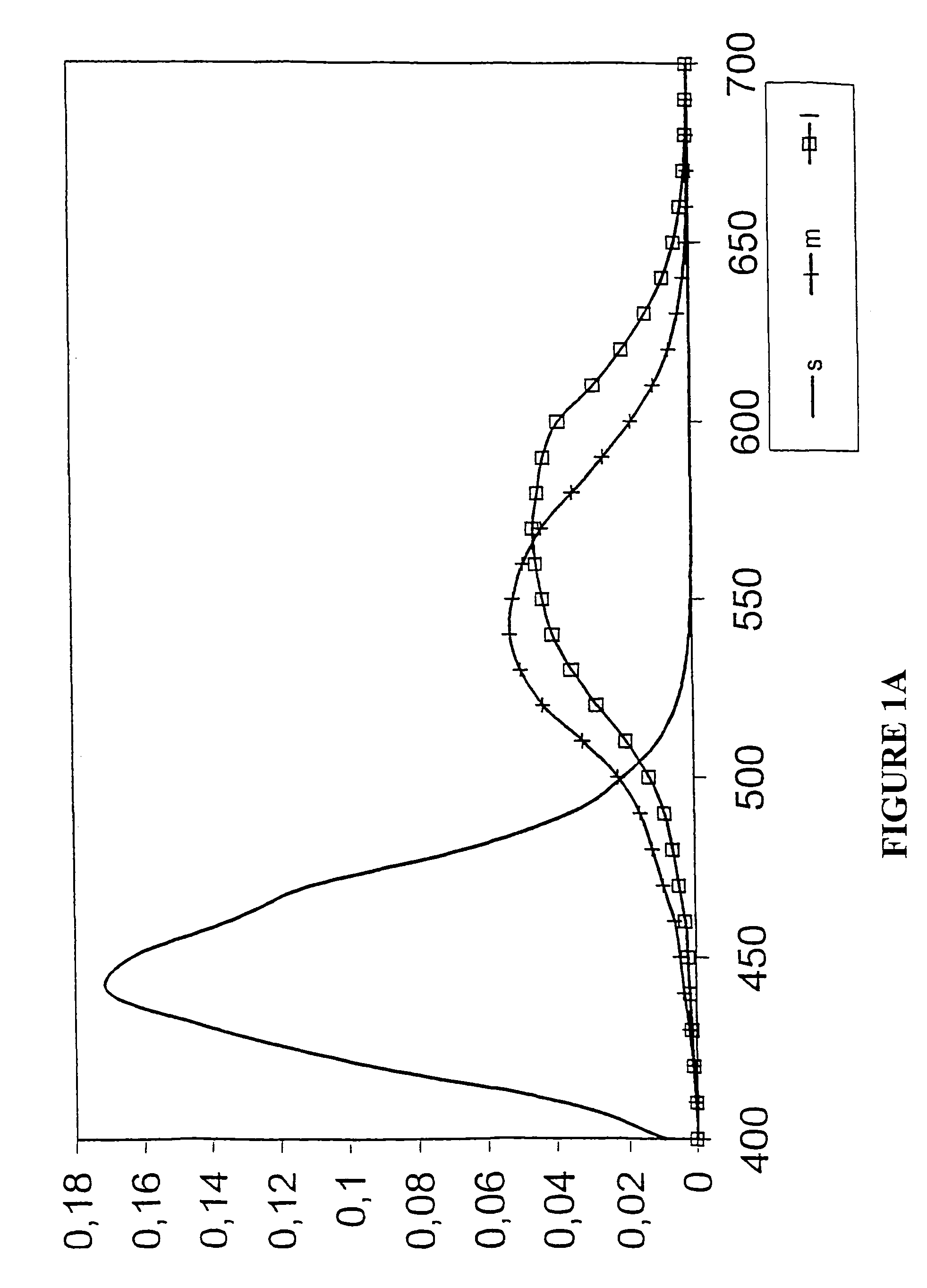

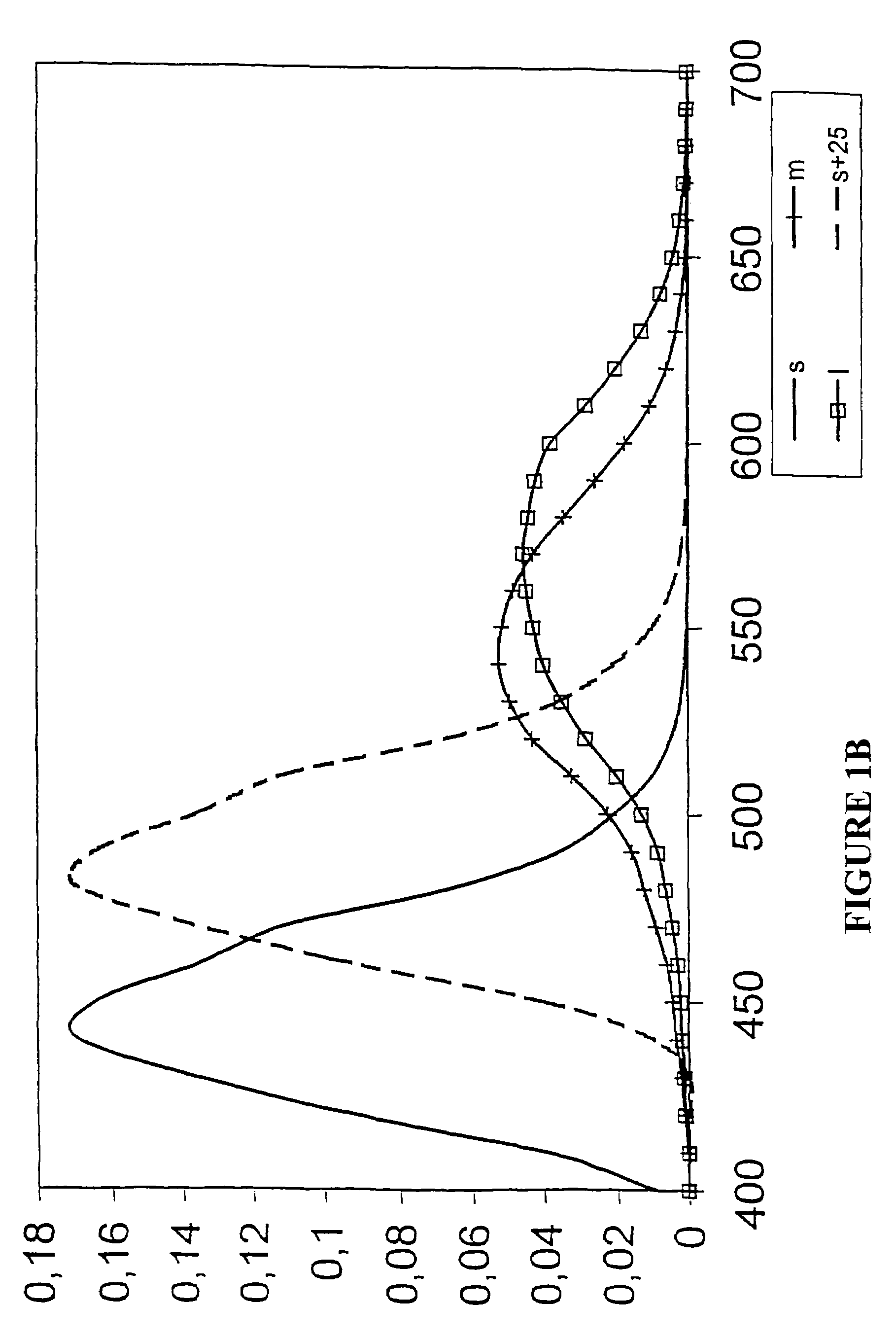

Method for designing color filters which improve or modify color vision of human eye, and color filter means designed by the method

The invention relates to a method for designing color filters which improve or modify color vision of the human eye. According to the invention a desired opponent signal function to be attained is divided by a real opponent signal function characteristic of the eye color vision to be improved or modified, the negative range of the resulting function is replaced by zero, the whole function is normalized to give a spectral transmission function, and, if desired, one or more section(s) of this spectral transmission function is modified. The invention also relates to color filter means designed by the above method.

Owner:DUHA TIBOR +2

Ultraviolet vacuum ultraviolet spectroscopy radiation transfer characteristic test device

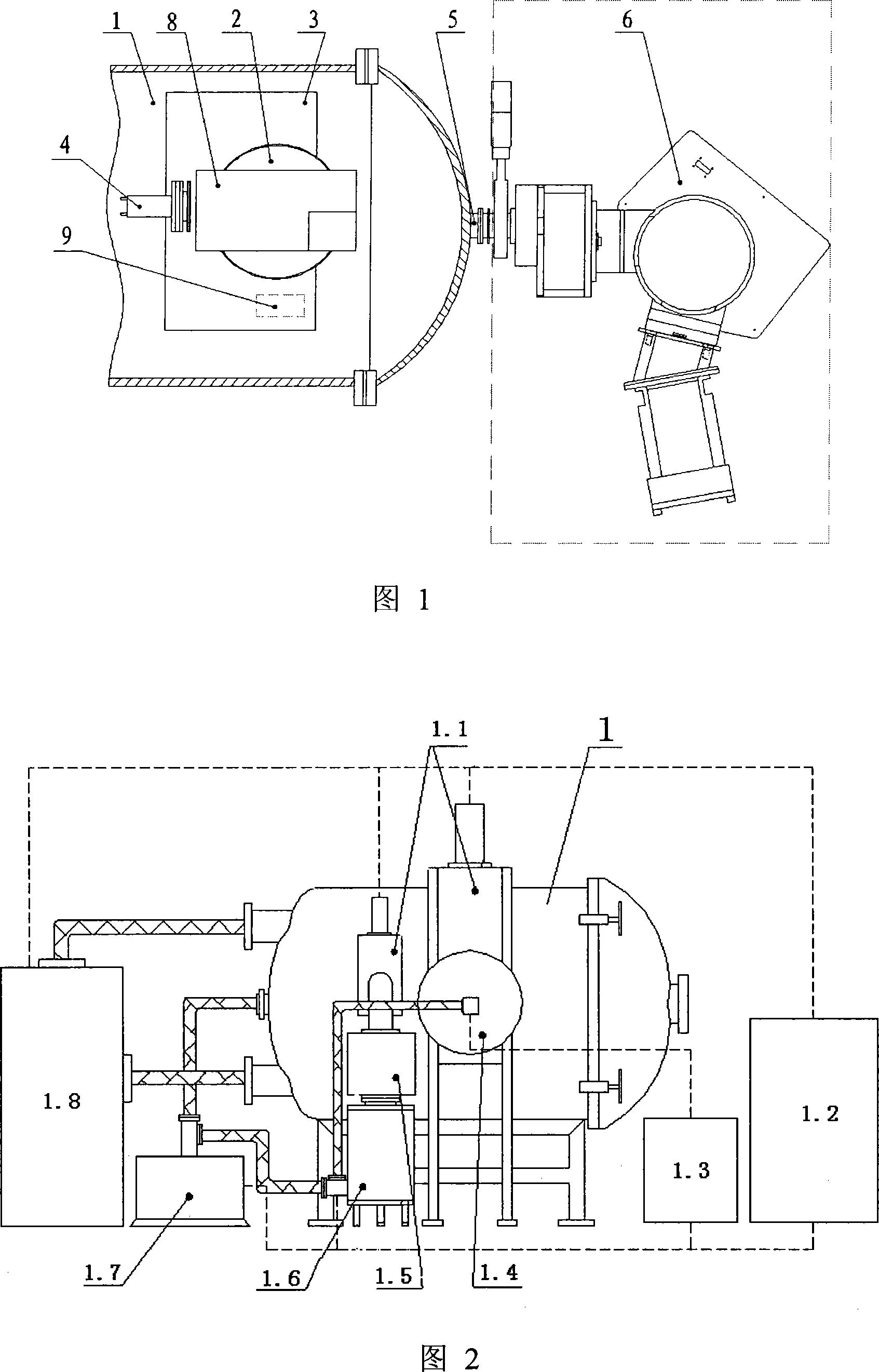

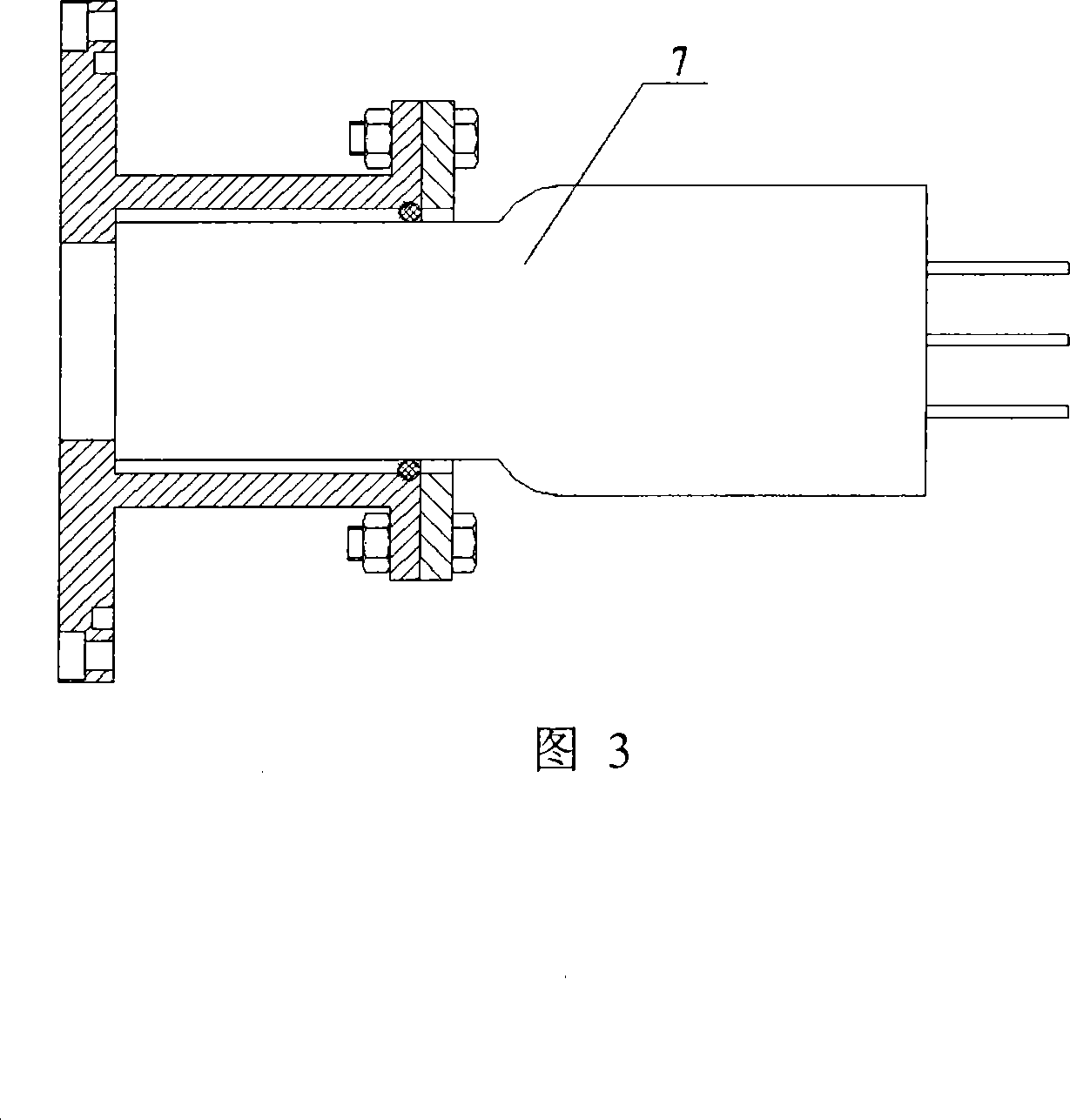

The invention relates to a testing technique for testing transmission characteristics of spectral radiation, particularly to a testing device for testing transmission characteristics of ultraviolet-vacuum ultraviolet spectral radiation. The testing device comprises a monochrometer, a standard light source, a vacuum container, a photomultiplier tube disposed in the vacuum container and fixed at one side of a rotary table, a cryogenic pump and a molecular pump respectively communicated with the cavity of the vacuum container via two gate valves, a dry vacuum pump communicated with the cavity pipeline of the vacuum container, and a cryogenic unit communicated with the vacuum container via a pipeline, wherein a flange interface is provided at one end of the vacuum container and used for alternatively connecting with the monochrometer or standard light source; the movement platform capable of performing translational movement with respect to the vertical direction of the axial line of the interface is disposed in the vacuum container, and the rotary table is disposed on the movement platform. The invention can be used for high-precision calibration of the spectral radiation brightness and the spectral irradiance responsibility of the entire machine of an ultraviolet spectra remote sensing instrument; and can be used for testing the spectral responsibility of an ultraviolet detector and testing the spectral transmission characteristics of an ultraviolet optical element.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

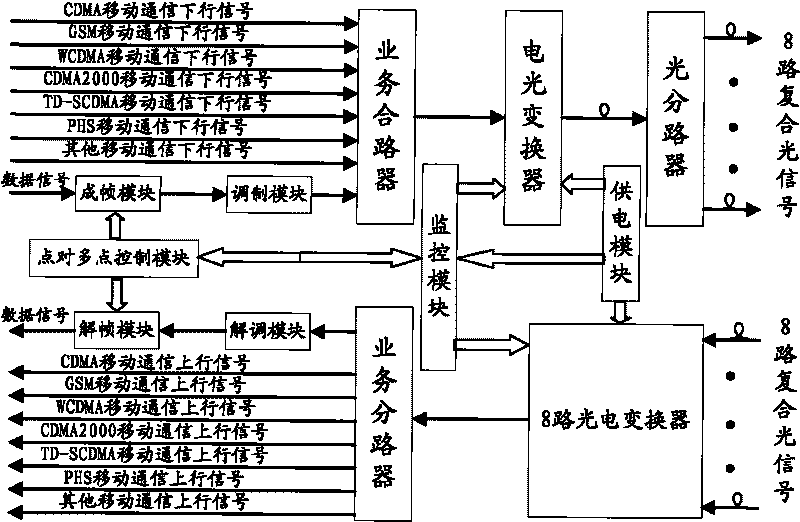

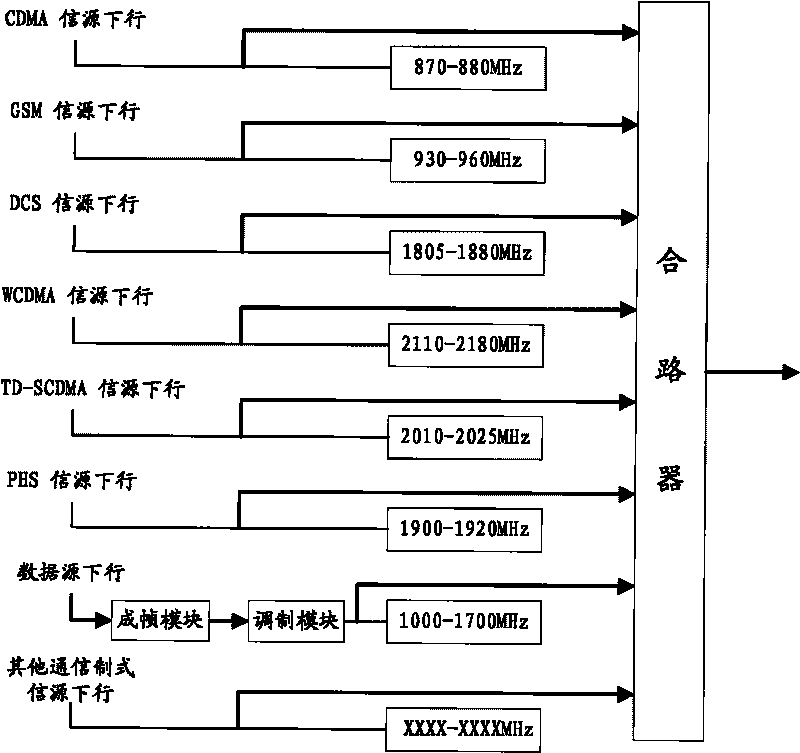

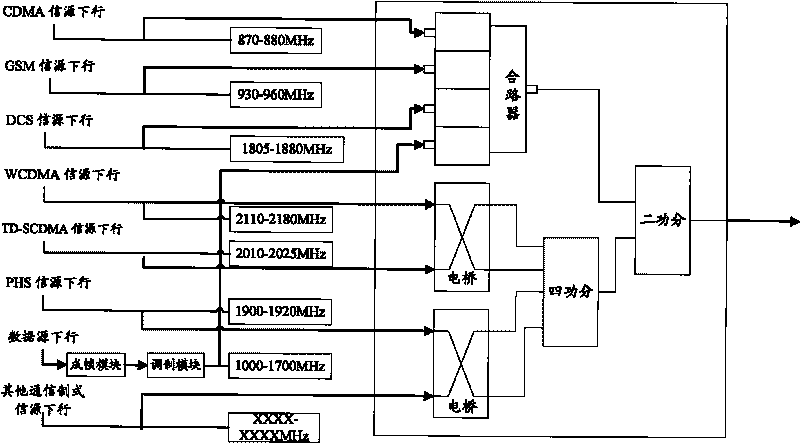

Device for realizing access of multiple information resources

InactiveCN101742675ARealize unified accessElectromagnetic transmissionWireless communicationSpectral transmissionTransport system

The invention discloses a device for realizing the access of a plurality of information resources. The device comprises a downlink unit and an uplink unit, wherein the downlink unit is used for compositing an original data signal with each standard signal of mobile communication after modulating the original data signal, performing photoelectric conversion on a composite signal, and dividing the converted composite signal into at most eight selfsame composite optical signals for outputting; and the uplink unit is used for performing the photoelectric conversion on the at most eight received composite optical signals respectively, compositing the at most eight converted electric signals, separating each corresponding standard signal of the mobile communication and a data signal from a composite electric signal, recovering the data signal into the original data signal through demodulation, and sending the original data signal to respective information resource. The device realizes the access of the information resource of an overall transmission system, converts the information to be transmitted into spectral transmission, and meets the access requirement on the plurality of information resources.

Owner:北京东方信联科技有限公司

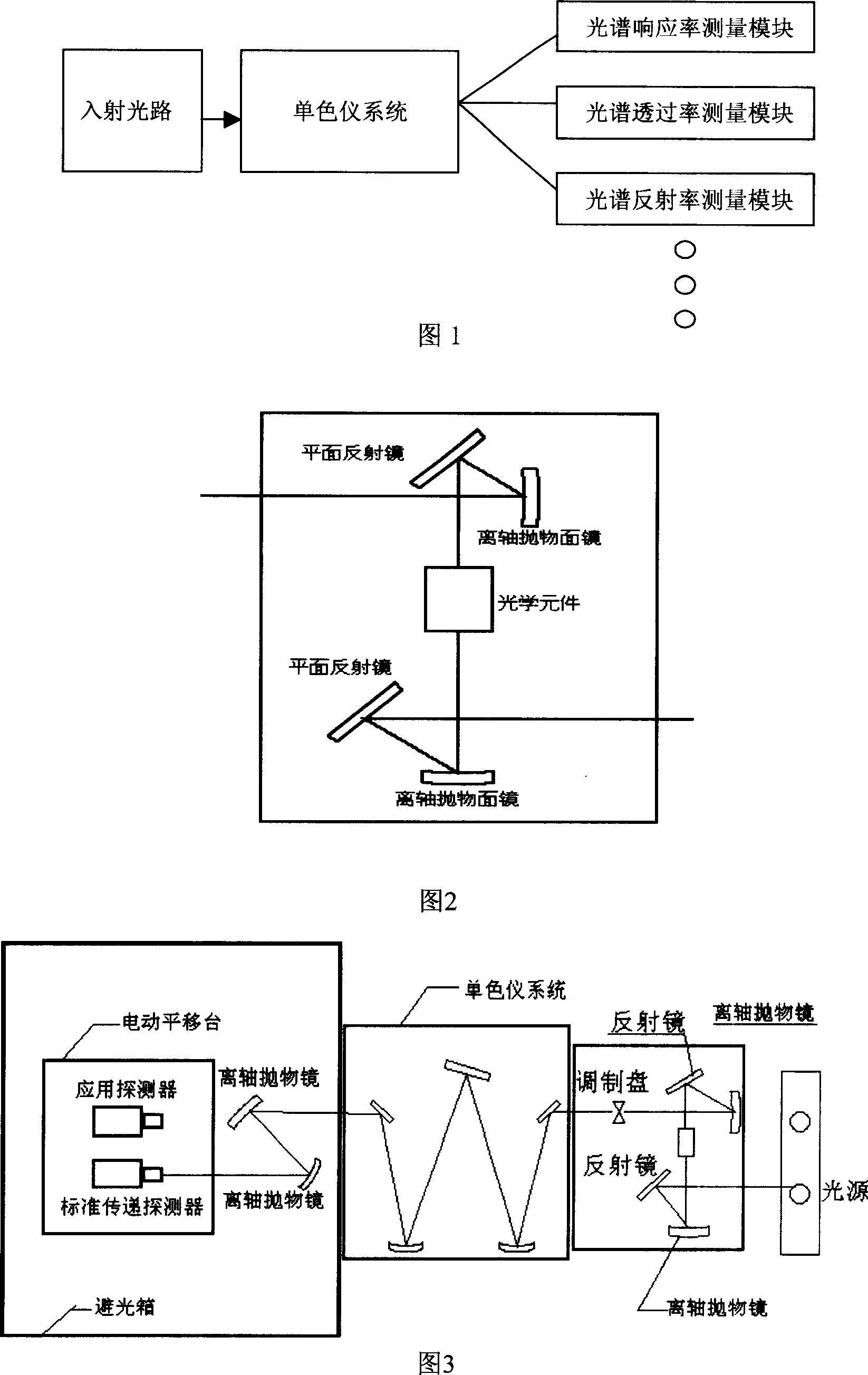

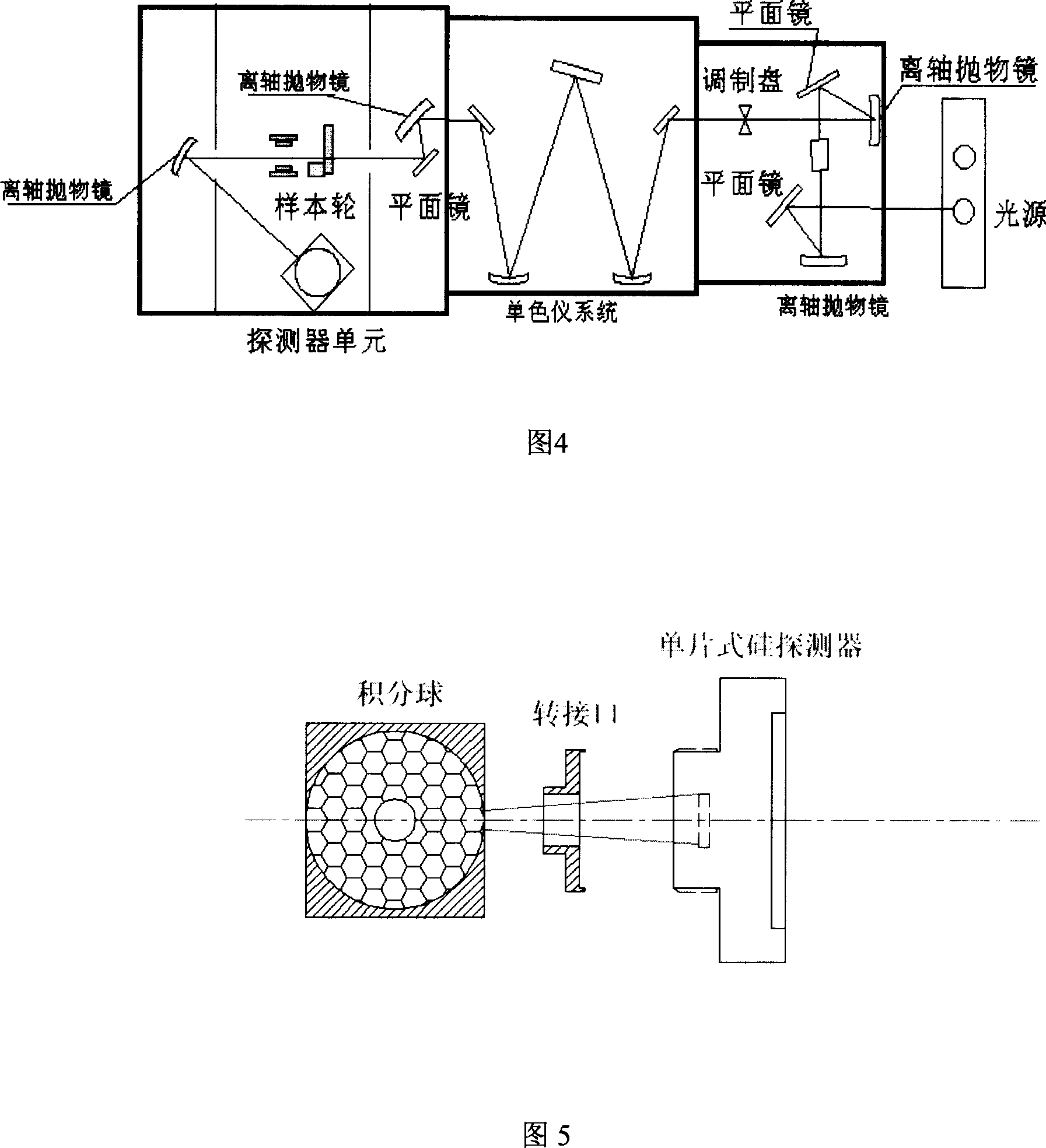

High-accuracy multifunctional wide-spectrum radiation comparison system

InactiveCN1995971AHigh measurement accuracyHigh degree of automationMaterial analysis by optical meansSpectral transmissionSpectral response

The high precision multifunctional wide spectrum radiation comparison system comprises the light source, incoming light path, monochrometer, spectral response ratio inspection module and spectral transmission ratio inspection module. It combines detector spectral response ratio, material spectral feature, using grating double monochromator DK242 and standard detector based on low temperature radiometer delivered information, realizing optical sensor and material high precision spectral feature inspection using special light path design. It solves the analytical contradiction well, effectively improves the inspection precision. It finds that the uncertainty level of the system is 10-3-10-4. It provides convincing theoretical reference and testing instrument for all kinds of sensor calibration and material spectral feature analysis.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

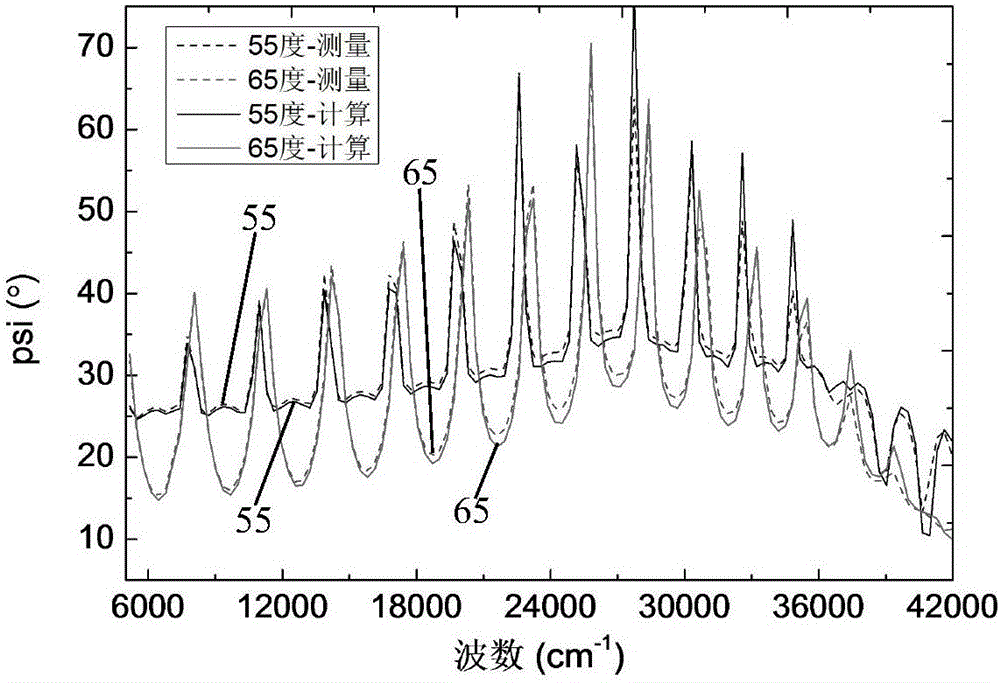

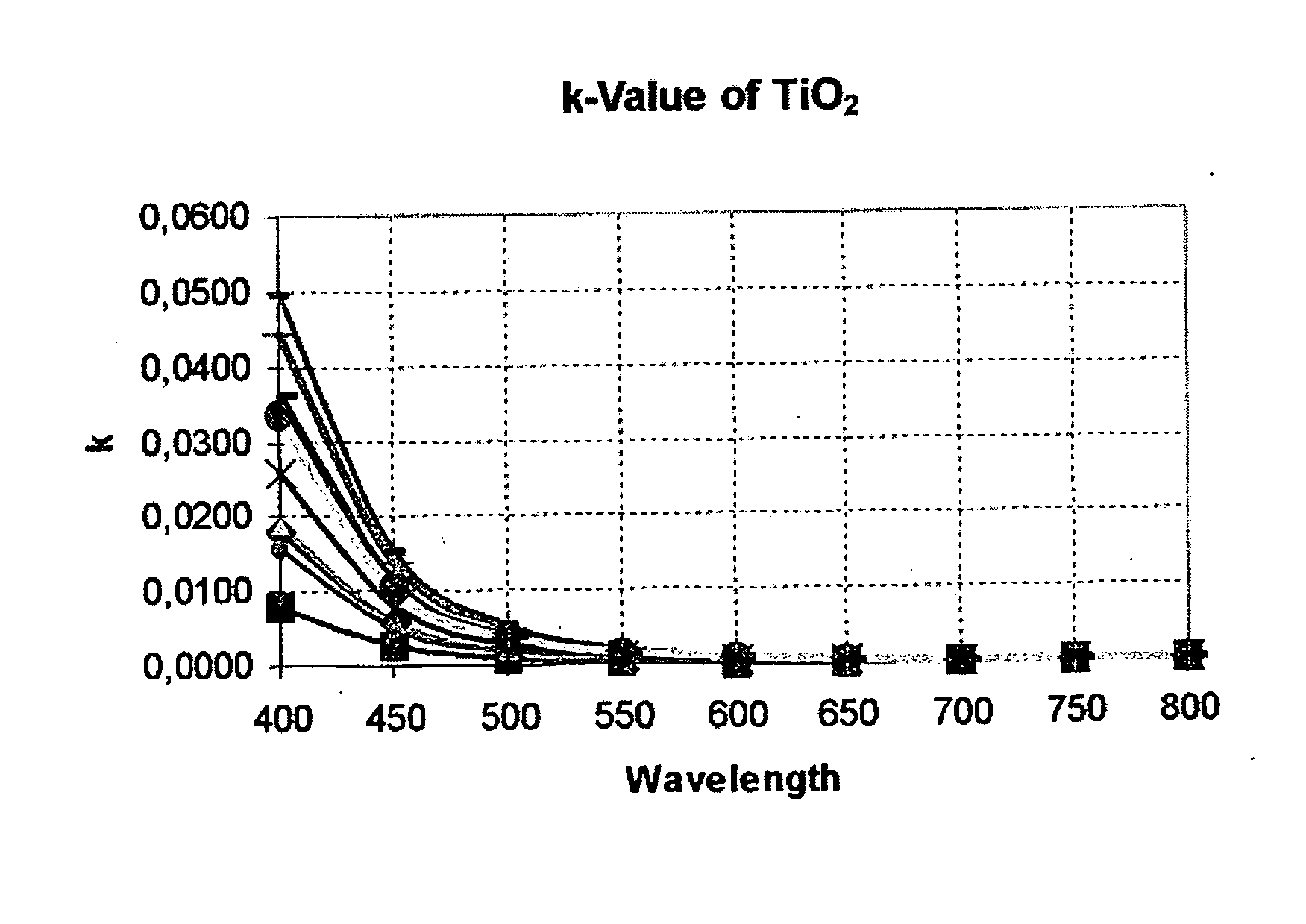

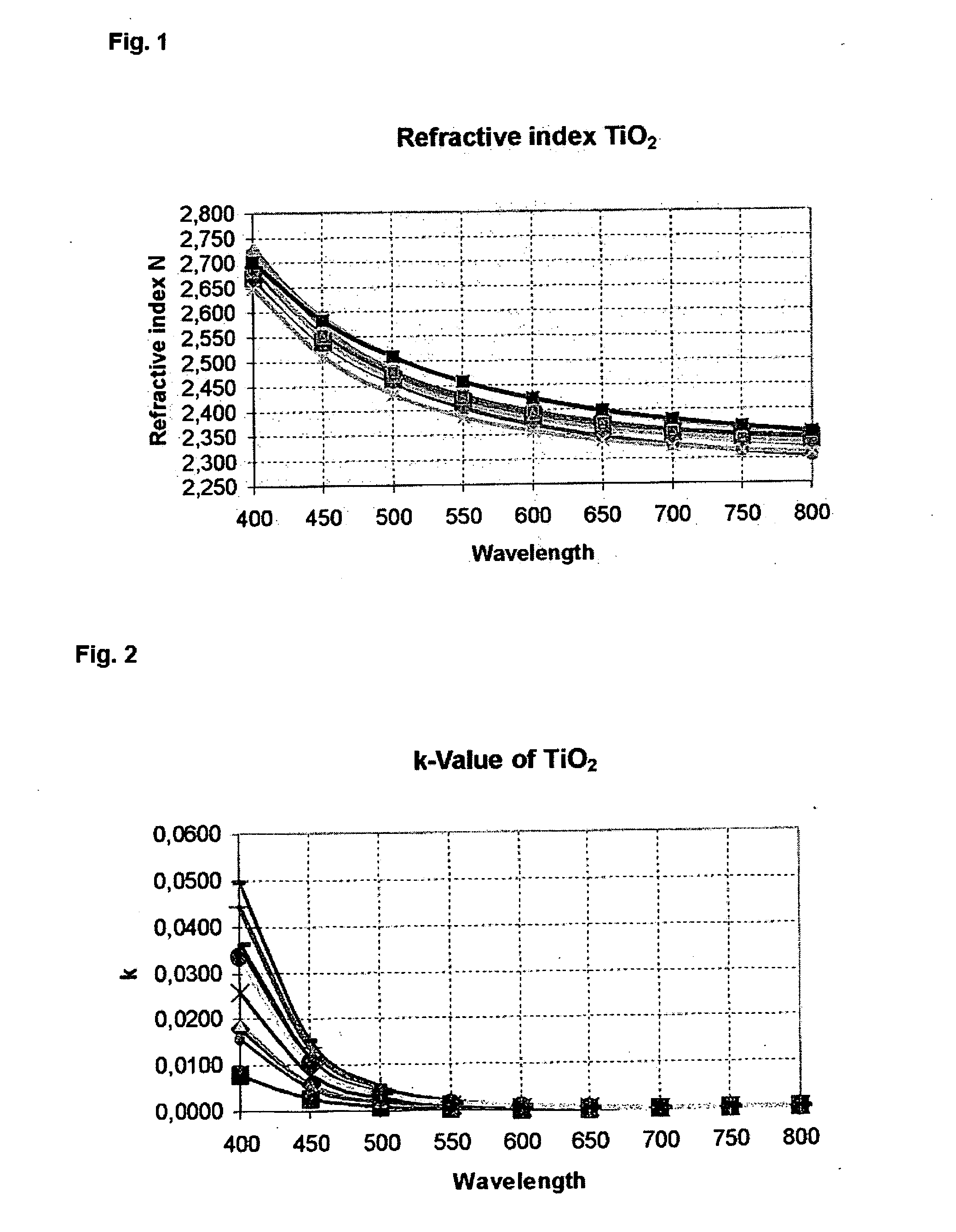

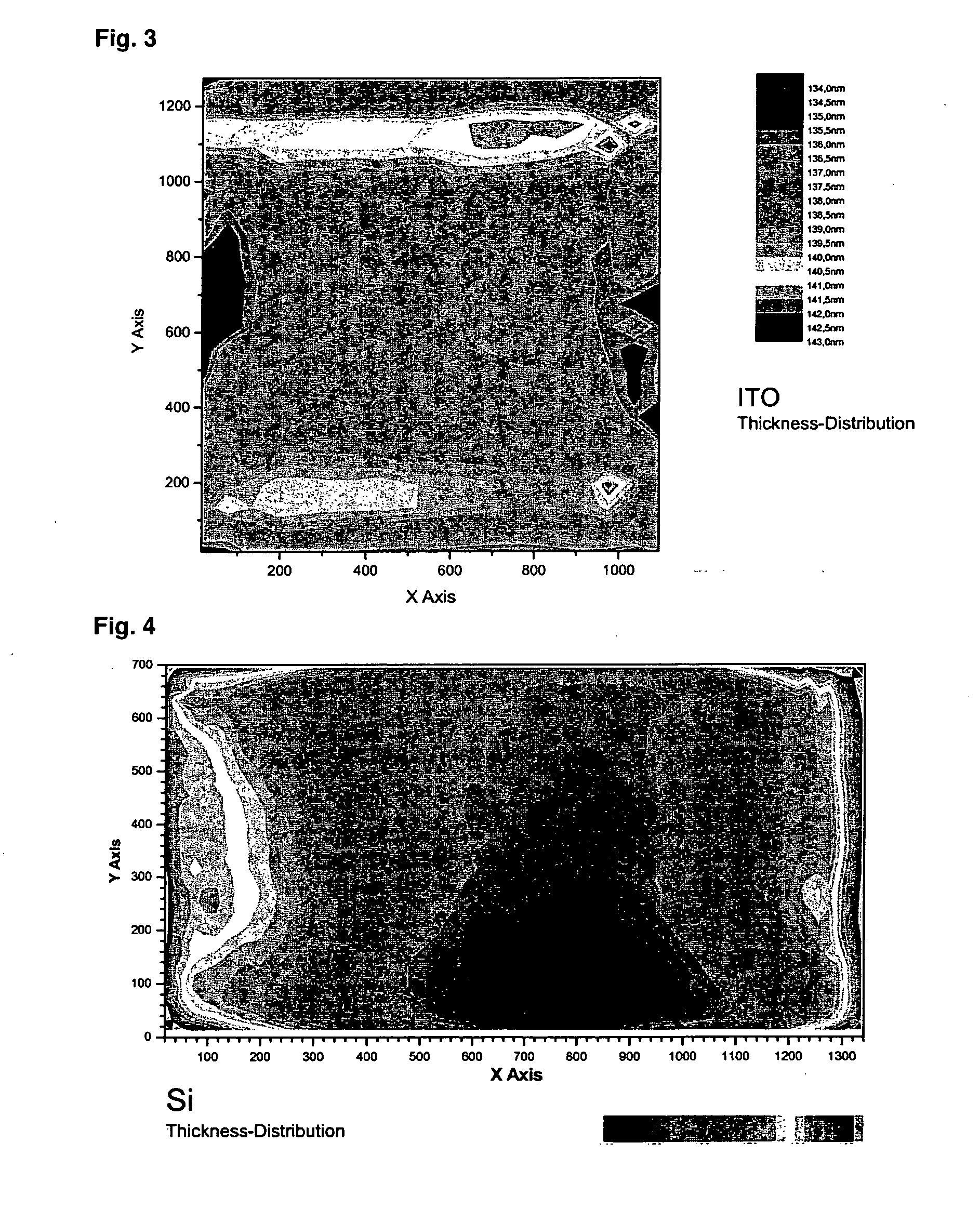

Method of determining physical properties of an optical layer or layer system

InactiveUS20060007430A1Effective and rapid determinationSimple wayPhase-affecting property measurementsVacuum evaporation coatingSpectral transmissionExtinction

The present invention relates to a method of determining physical properties of an optical layer or layer system by means of spectral transmission and / or reflection measurements, whereby in accordance with the spectrum of the transmission and / or reflection measurement, reference values for the wavelength-dependent refractive indices n0 and / or extinction coefficients k0 are chosen from known values or are determined experimentally and the variation that characterizes the layer is described by wavelength-independent variation constants Kn and Kk for the refractive indices and extinction coefficients.

Owner:APPLIED MATERIALS GMBH & CO KG

Imaging apparatus

InactiveUS20110164157A1Reduce the amount of lightReduce the amount requiredTelevision system detailsTelevision system scanning detailsSpectral transmissionLength wave

An imaging apparatus includes a half mirror that splits light from a subject having passed through a photographic optical system into transmitted light and reflected light, a first light receiving sensor that receives the transmitted light, the first light receiving sensor having a spectral sensitivity characteristic with a sensitivity peak at a specific wavelength of light, and a second light receiving sensor that receives the reflected light. The wavelength of a transmission peak in the spectral transmission characteristic of the half mirror matches the wavelength of the sensitivity peak of the first light receiving sensor.

Owner:SONY CORP

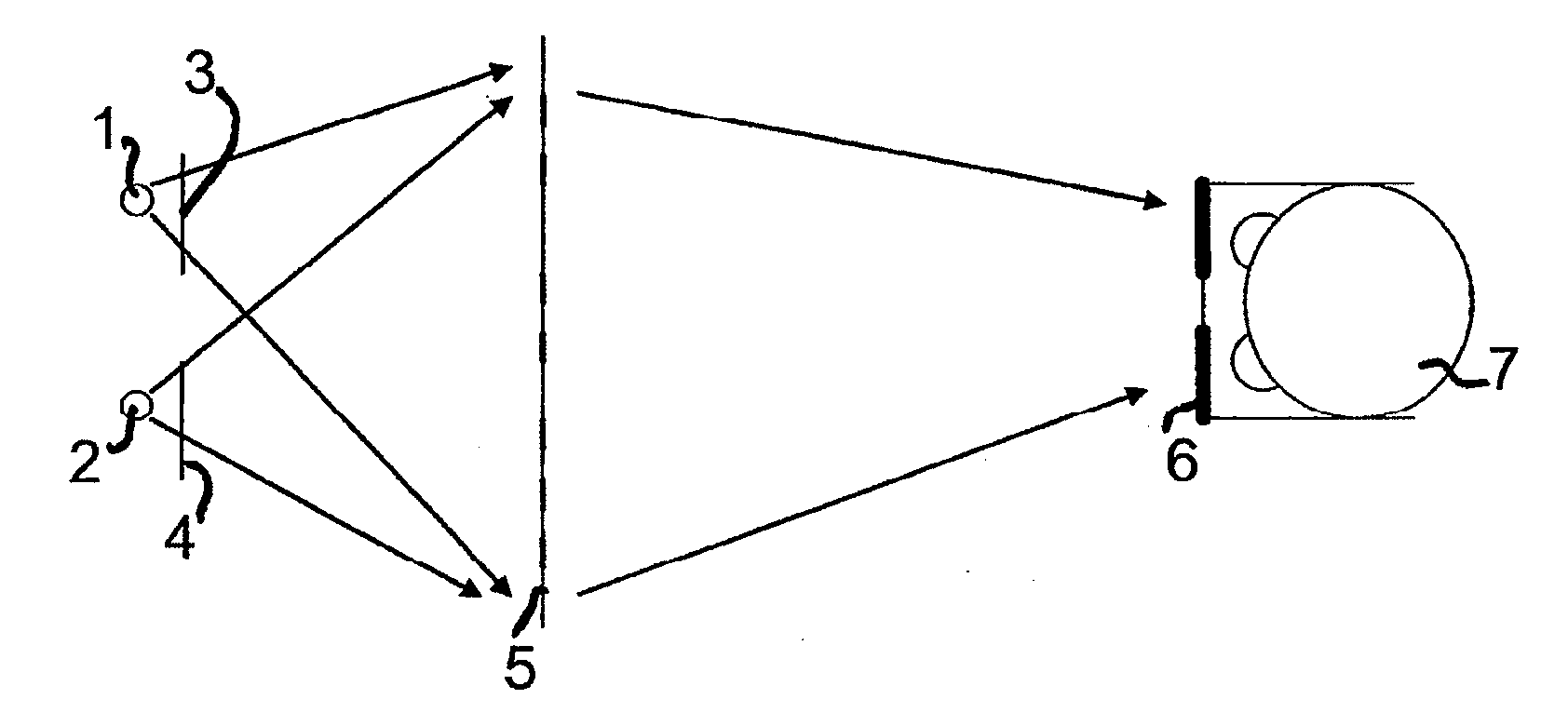

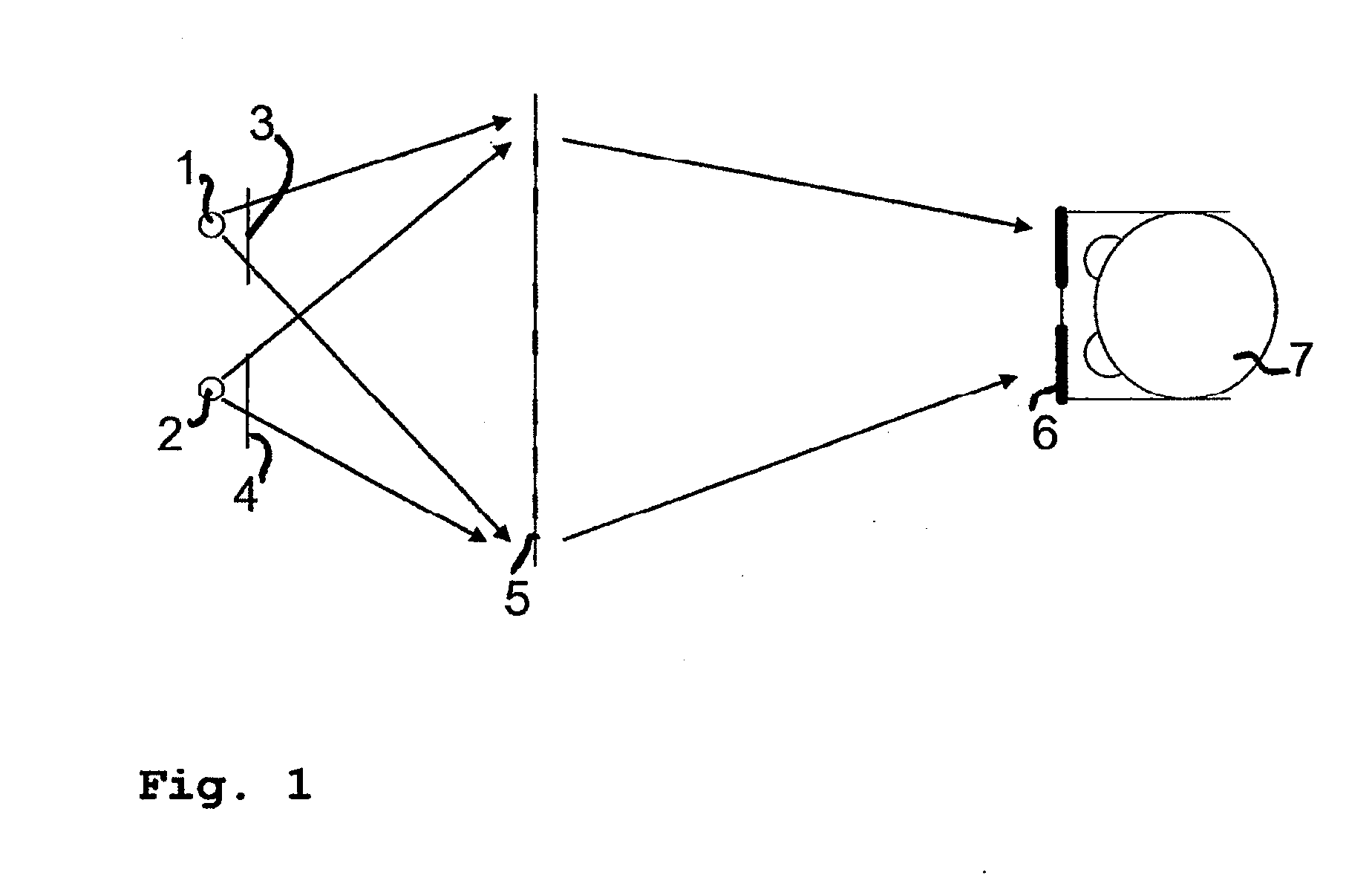

System for reproducing stereographic images

ActiveUS20100149635A1High color reproductionSimple and reasonably priced designStereoscopic photographySteroscopic systemsSpectral transmissionData control

A system for reproducing stereographic images is provided that includes a display unit that has a pixel array for representing image data which reproduces the same when controlled with stereoscopic image data, and a light source for fully illuminating the pixel array. The system further includes a pair of glasses that are suitable to make the reproduced stereoscopic image data available to a wearer of the pair of glasses in an eye-selective manner. The display unit has at least one additional light source for fully illuminating the pixel array. Every light source is additionally configured to emit light in a plurality of narrow spectral ranges, thereby defining a color range, the spectral ranges of the light sources being orthogonal to each other. They system also includes a control unit that sequentially operates the light sources. The pair of glasses has optical glasses, spectral transmission ranges of which are orthogonal to each other and correspond to the spectral ranges of the light sources in such a manner as to allow the reproduction of stereographic images in a reliable and cost-effective manner.

Owner:INFITEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com