Patents

Literature

804results about How to "Avoid rework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

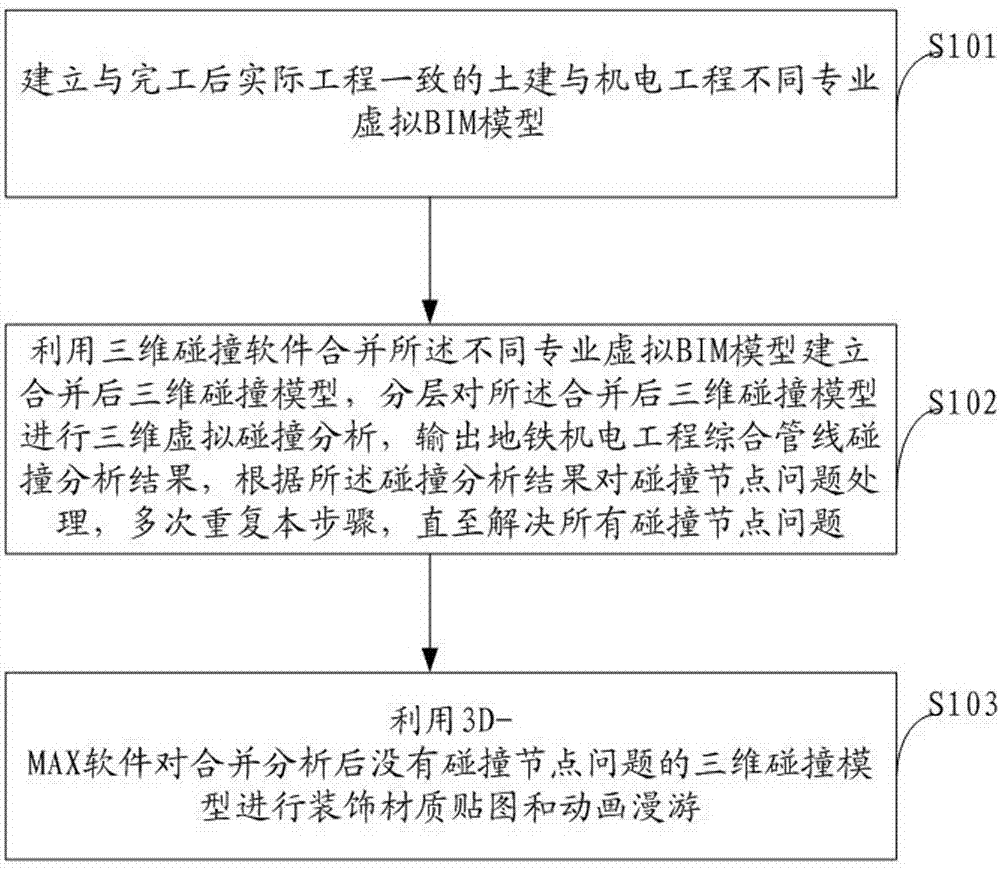

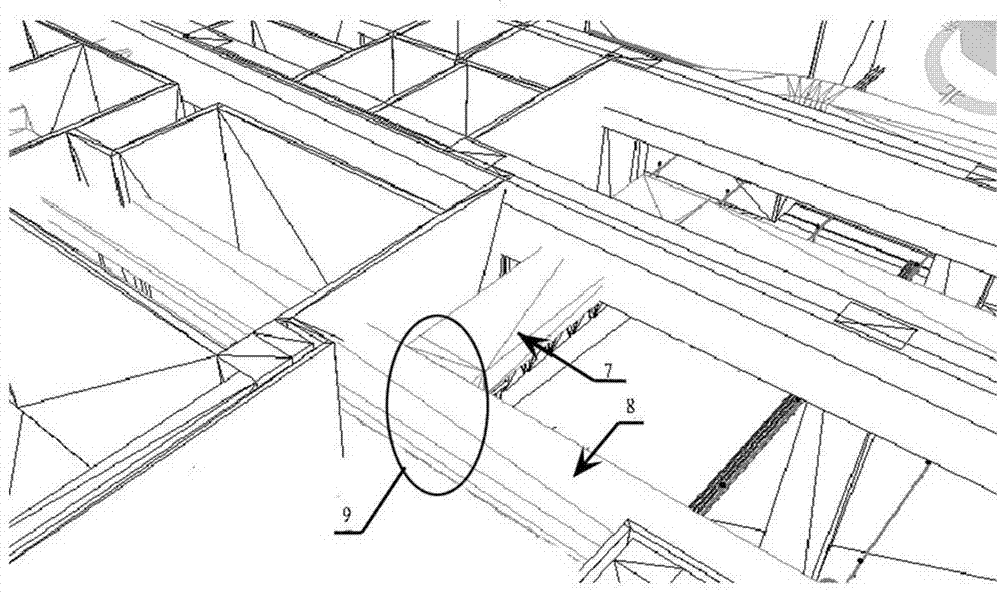

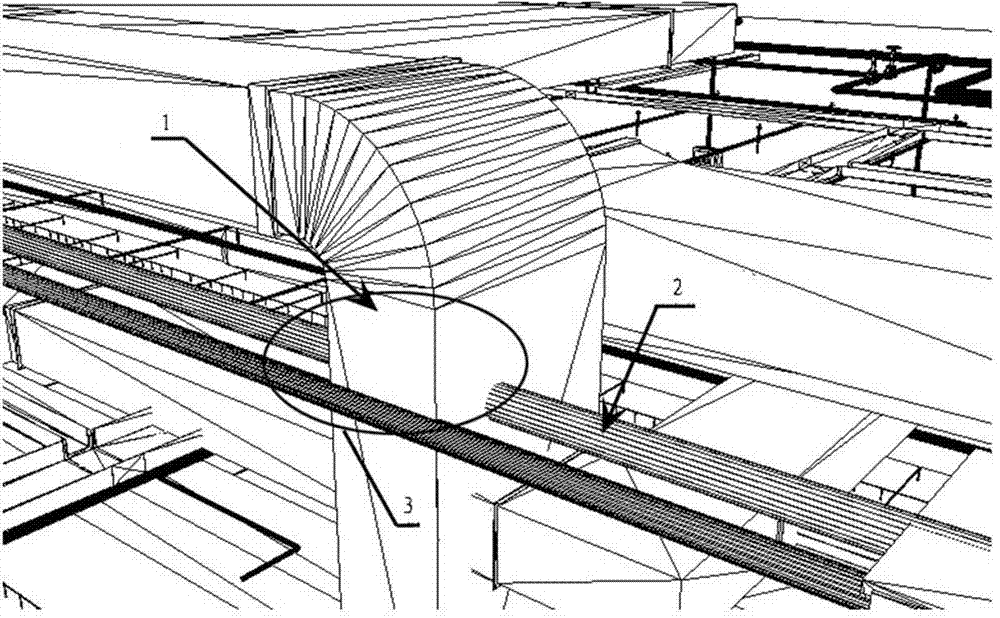

Complex pipeline collision optimization method of subway electromechanical engineering

ActiveCN103093061AOvercome the shortcomings of error-prone, omission and bump-to-missSolving technical issues with cross collisionsSpecial data processing applicationsNODALCollision analysis

The invention belongs to the technical field of electromechanical device installation and discloses a complex pipeline collision optimization method of subway electromechanical engineering. According to the method, three-dimensional bus interface module (BIM) software is used for establishing different professional virtual BIM models which are consistent with completed engineering and then output to three-dimensional collision software for establishment of a combined three-dimensional collision model for collision analysis, collision nodes are then processed and optimized, and then decorative texture mapping and animation roaming are carried out on the combined, analysed and processed three-dimensional collision model without the collision node problem through 3D - MAX software, and therefore collision optimization of complex pipelines of the subway electromechanical engineering is achieved. According to the complex pipeline collision optimization method of the subway electromechanical engineering, the BIM technology is utilized to solve the problem that collision of various complex pipelines causes construction ceasing during electromechanical installation, reasonable planning and utilization of electromechanical pipeline equipment and the like are achieved by means of the optimized design, construction waste is reduced, construction time is shortened, working efficiency at site is improved greatly, and initial investment of a proprietor is reduced.

Owner:ELECTRIFICATION ENG CO LTD OF CHINA RAILWAY 22TH BUREAU GRP +1

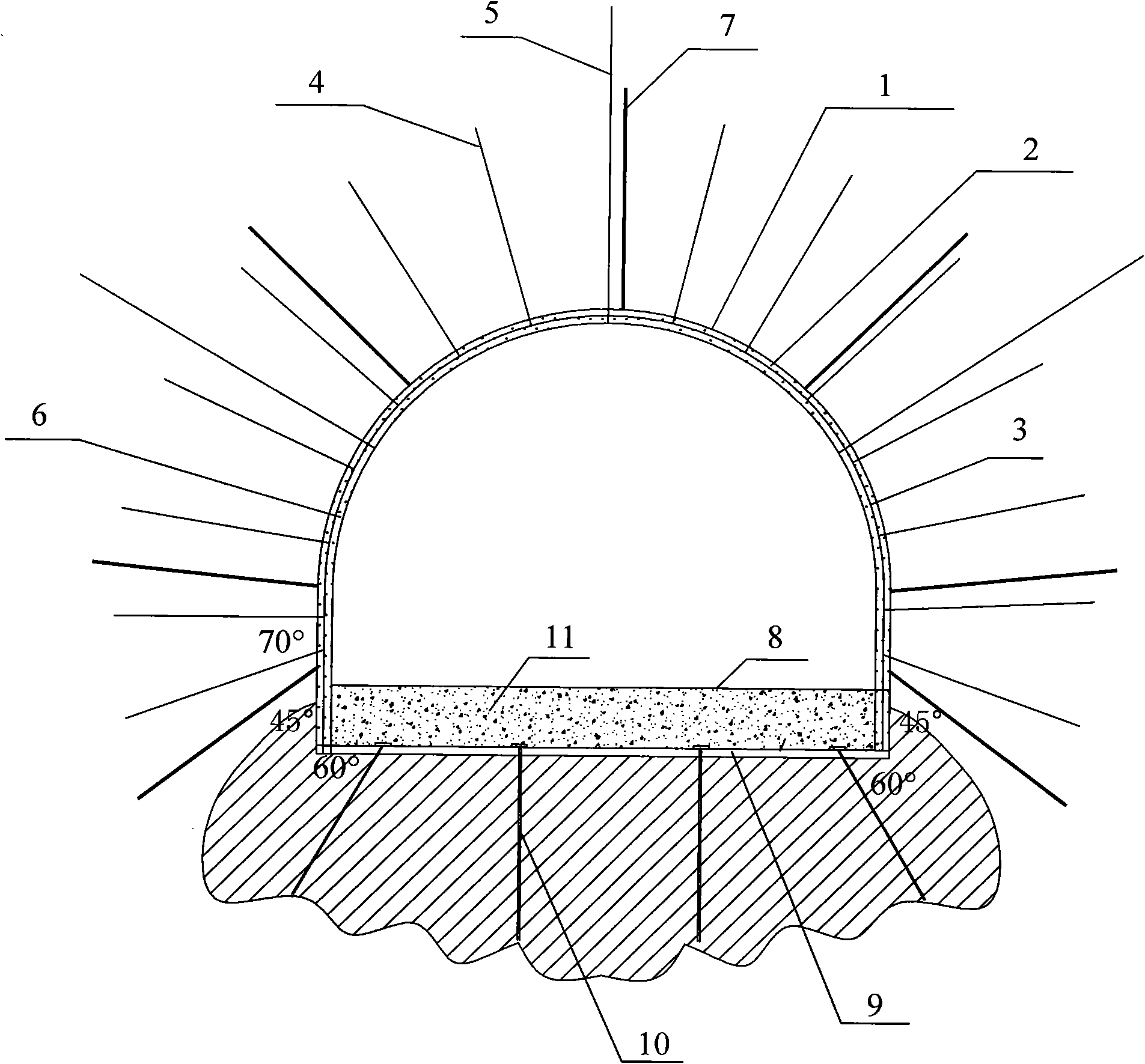

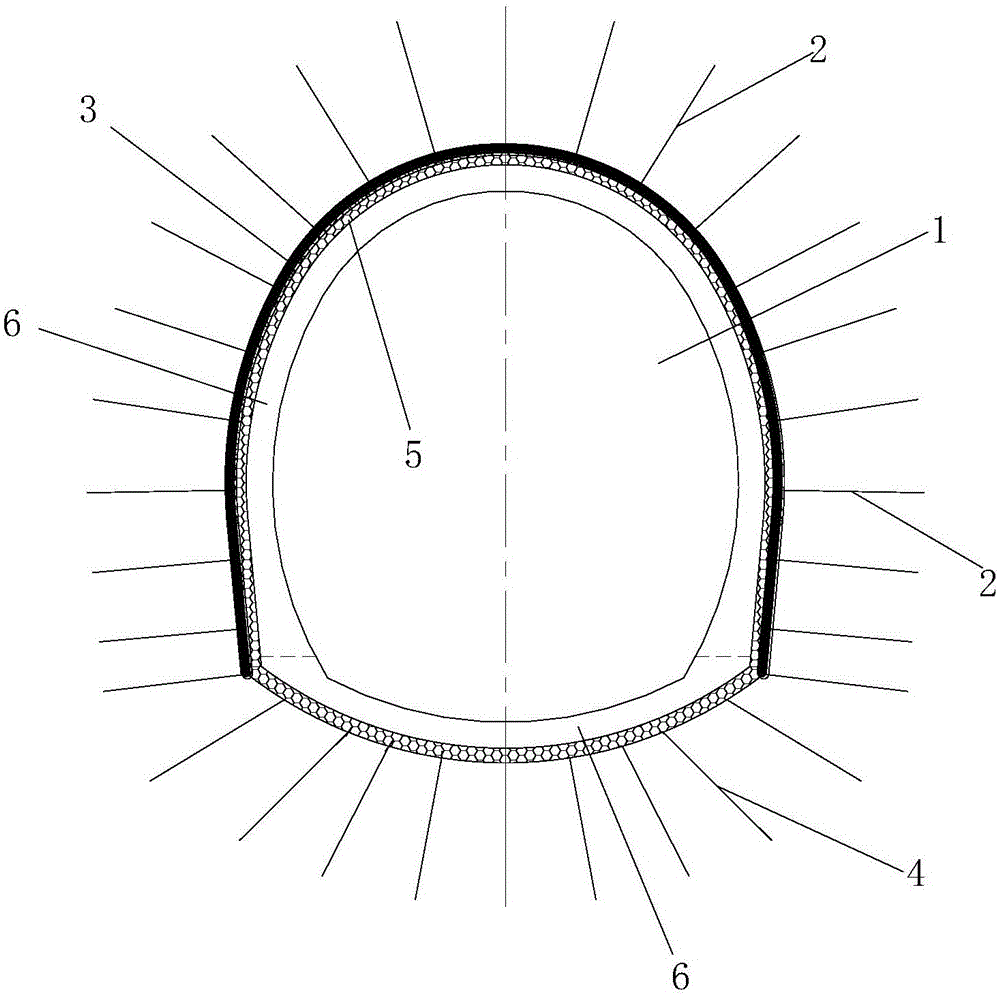

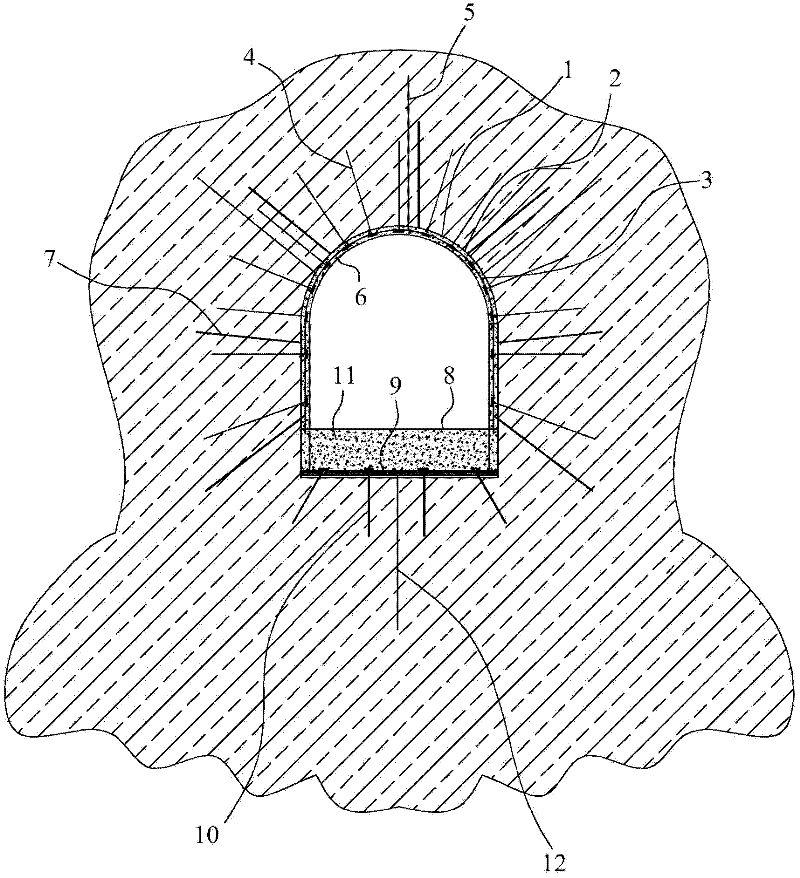

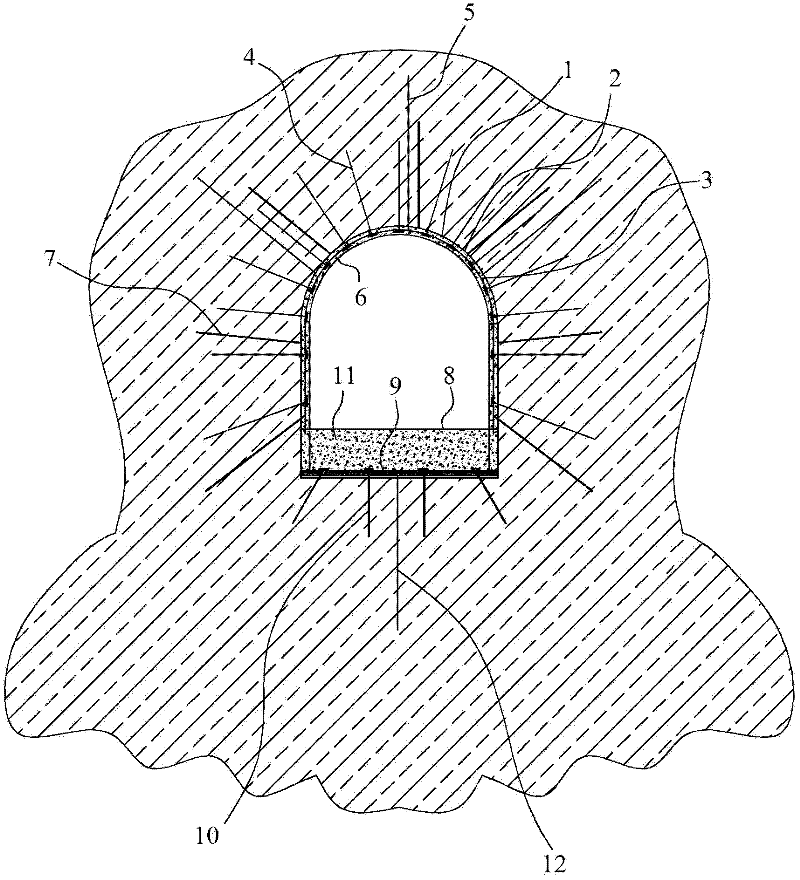

Deep well tunnel cable anchor rigid-flexible coupling support and surrounding rock overall reinforced support method

InactiveCN101967984AImprove carrying capacityPrevent shear deformationUnderground chambersTunnel liningPre stressCoupling

Owner:ANHUI UNIV OF SCI & TECH

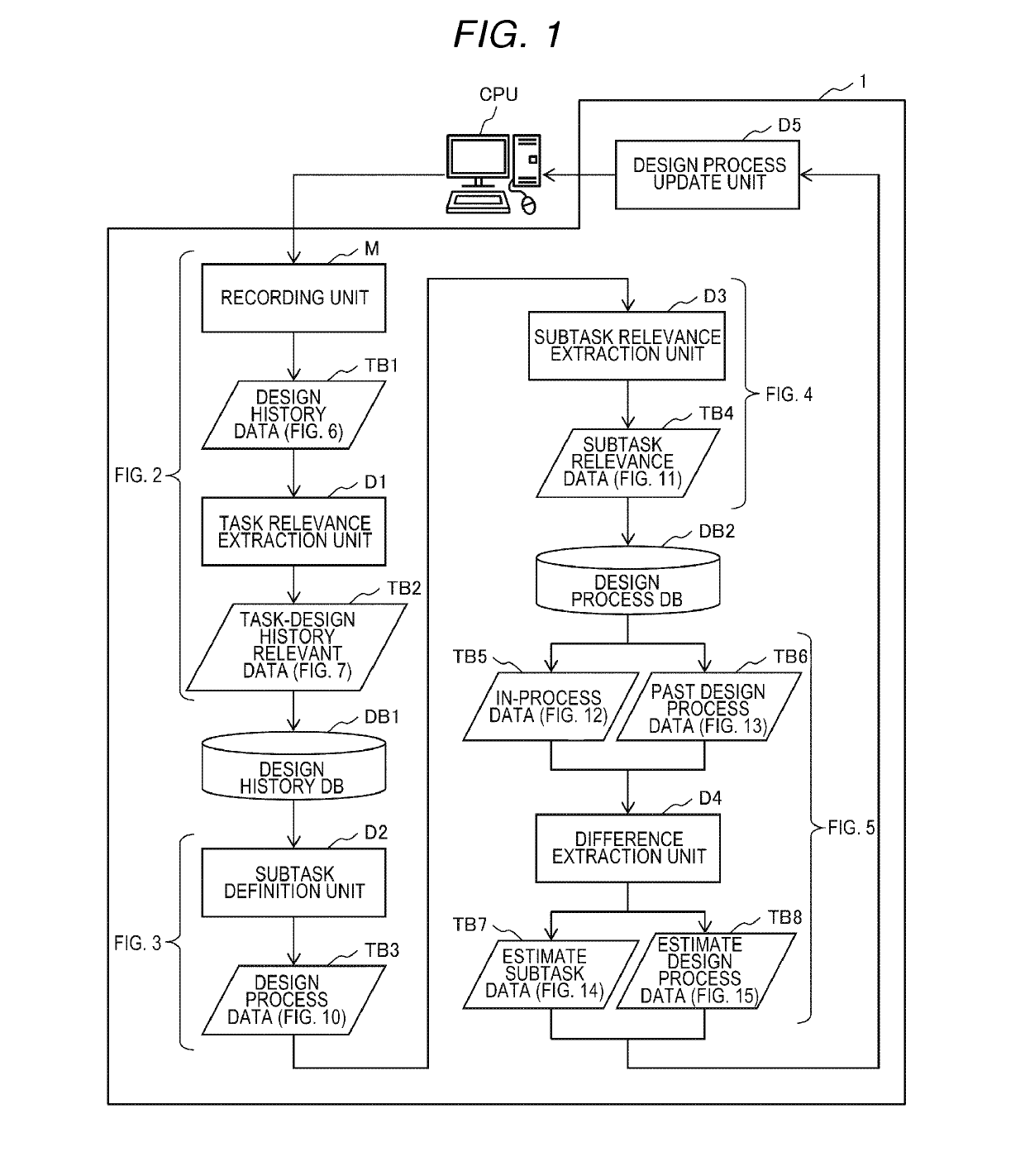

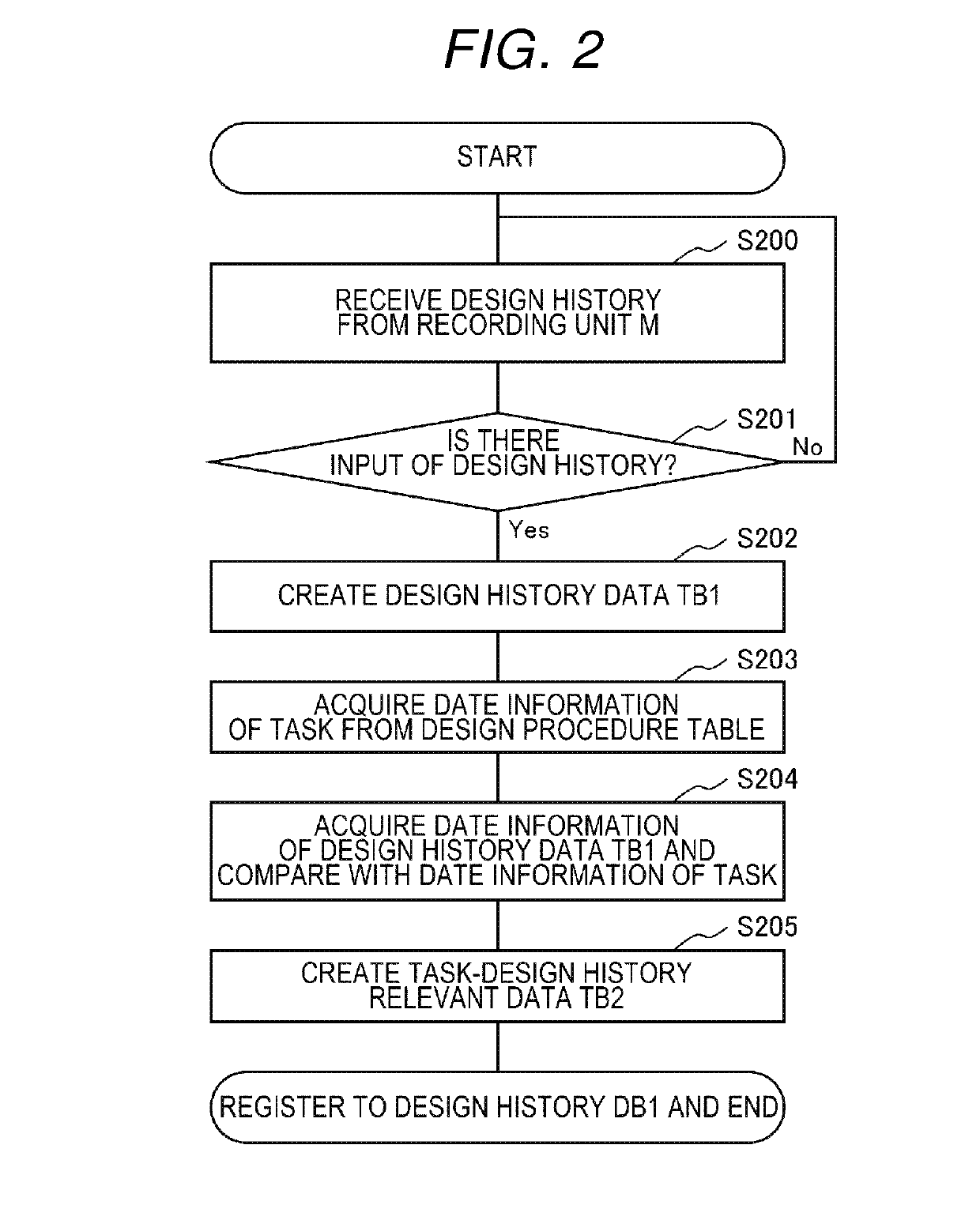

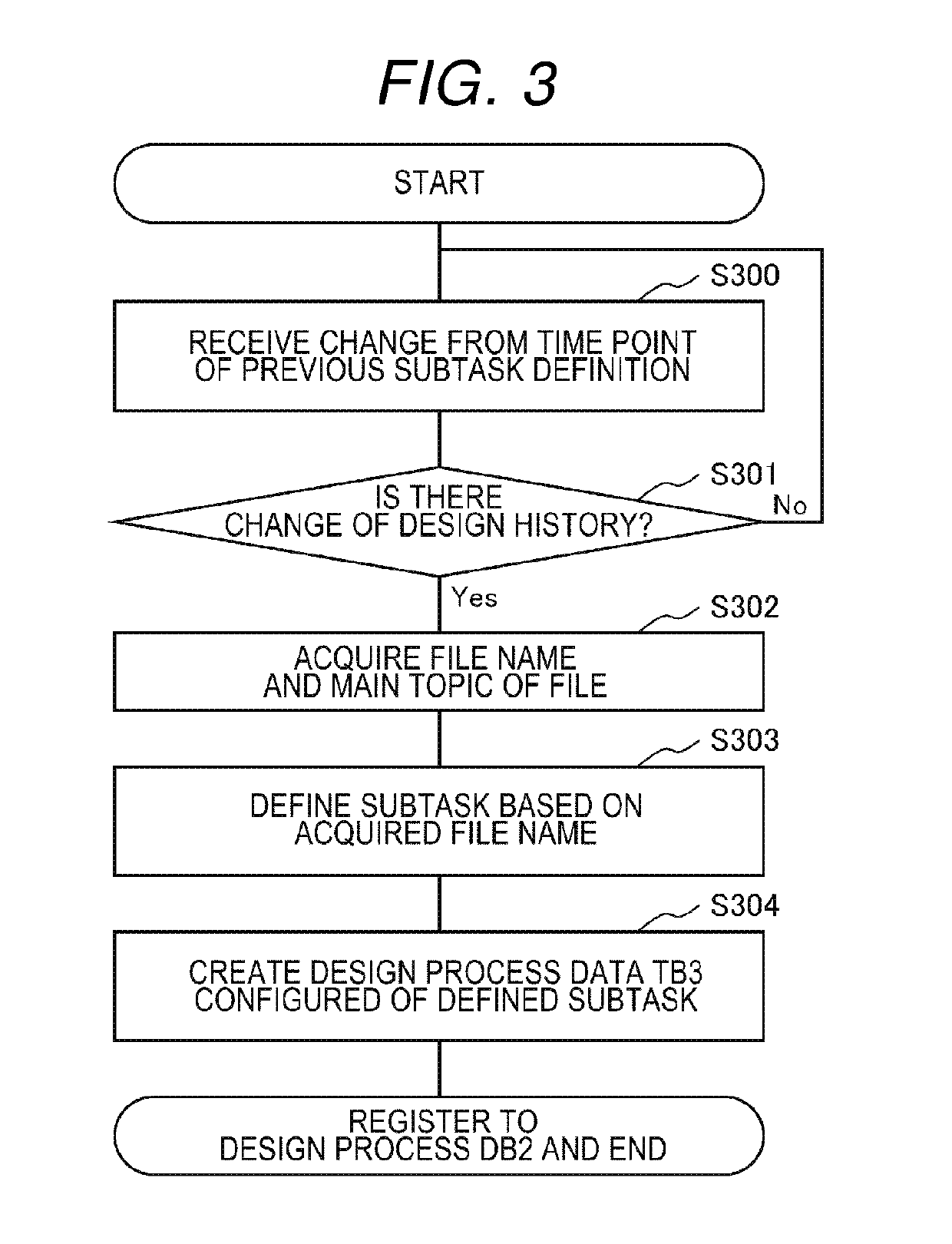

Design support device and design support method

InactiveUS20190095839A1Maintain qualityAvoid reworkResourcesSpecial data processing applicationsDesign supportGenerative Design

A design support device supports a design project achieved by executing a plurality of tasks including subtasks. The design history data of the design performed by a designer is sequentially stored and associated with a task to sequentially generate task-design history relevant data. A subtask is defined with respect to the task-design history relevant data to sequentially generate design process data. Subtask relevant data indicating a relevance between subtasks with respect to the plurality of pieces of design process data is generated, and a subtask to be performed in a later design work is estimated with respect to an in-process design work from a difference between past design process data of a project performed in the past and in-process data in a project performed currently to obtain an estimate subtask. An optimal execution order is calculated to obtain estimate design process data and the estimate design process data is output.

Owner:HITACHI LTD

BIM-based pre-assembling method for double-curved glass curtain wall

ActiveCN106013535AEliminate biasImprove installation accuracyWallsBuilding material handlingSolid componentPoint cloud

The invention relates to a BIM-based pre-assembling method for a double-curved glass curtain wall. The method includes the following steps that three-dimensional models of glass curtain wall components are established according to a modeling standard; detailed glass curtain wall component drawings are guided out and numbered, and then processing and production are carried out; three-dimensional scanning is carried out on the processed glass curtain wall components, point cloud data are obtained, and three-dimensional point cloud models are established through the point cloud data; the three-dimensional point cloud models and the three-dimensional models are compared to obtain deviation values of glass curtain wall component solid bodies, and glass curtain wall component information is adjusted till the deviation values meet glass curtain wall standard requirements; and overall pre-assembling of the three-dimensional point cloud models meeting the requirements is simulated in Revit, accumulative errors in the assembling process are eliminated till the pre-assembled three-dimensional point cloud models are completely matched with the three-dimensional models, and then the glass curtain wall components are delivered out of a factory and delivered to a construction site for solid component installation. By means of the method, the problems that the double-curved glass curtain wall is large in field installation difficulty, low in installation efficiency and low in precision are solved.

Owner:SHANGHAI BAOYE GRP CORP

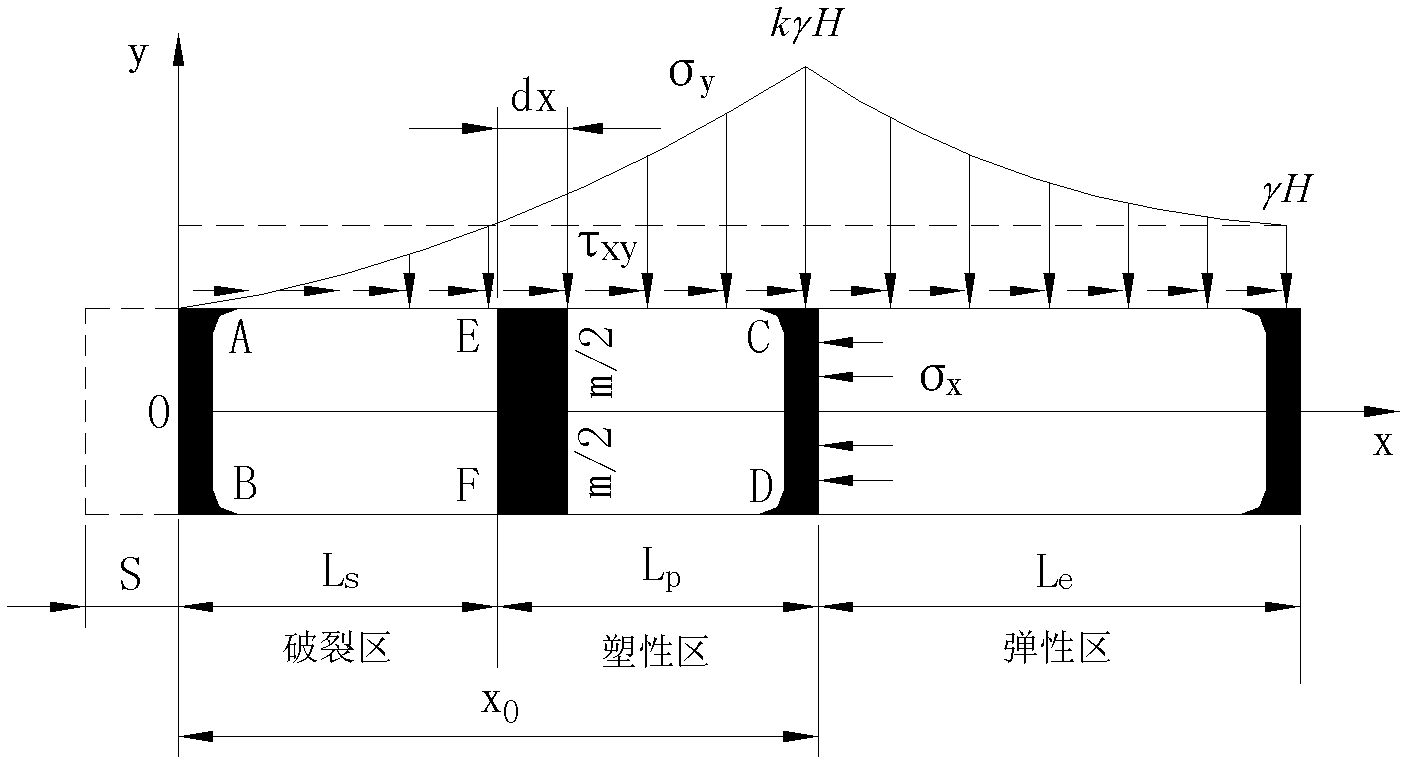

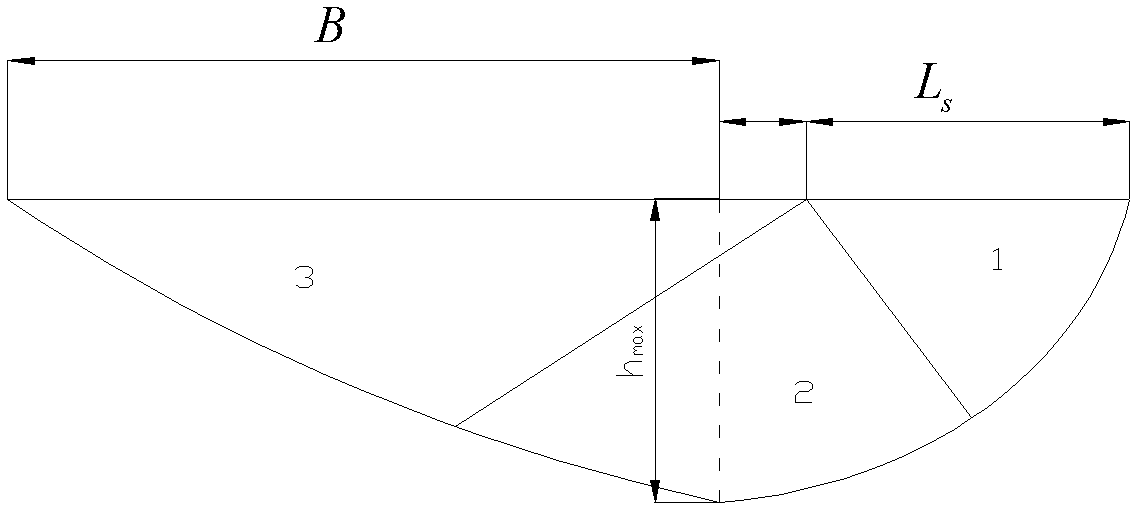

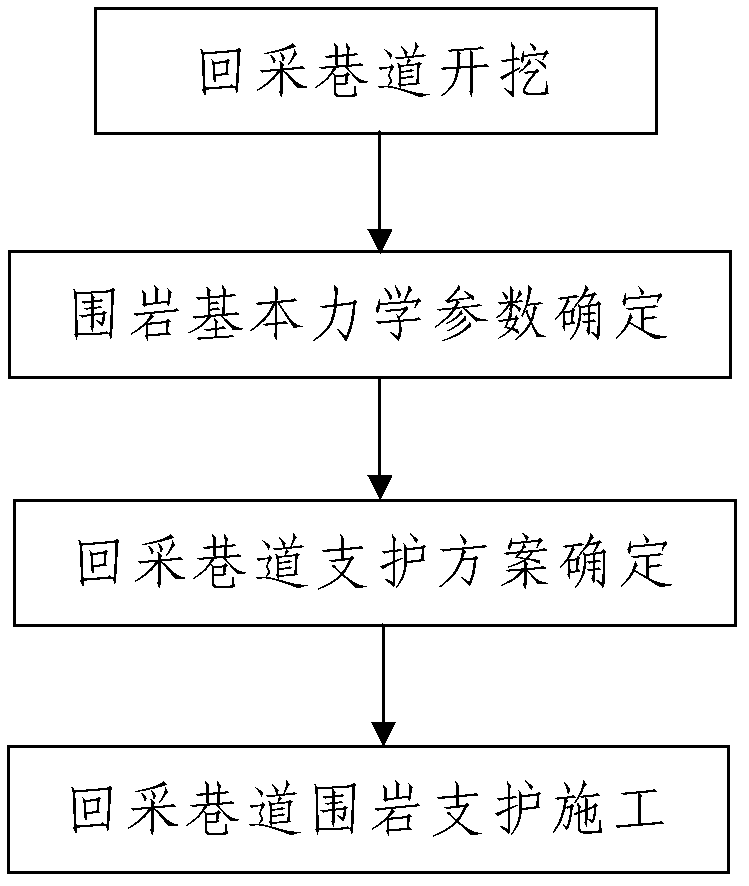

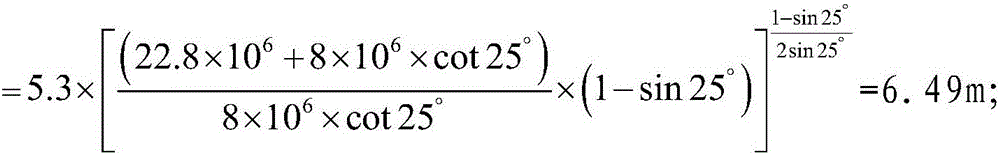

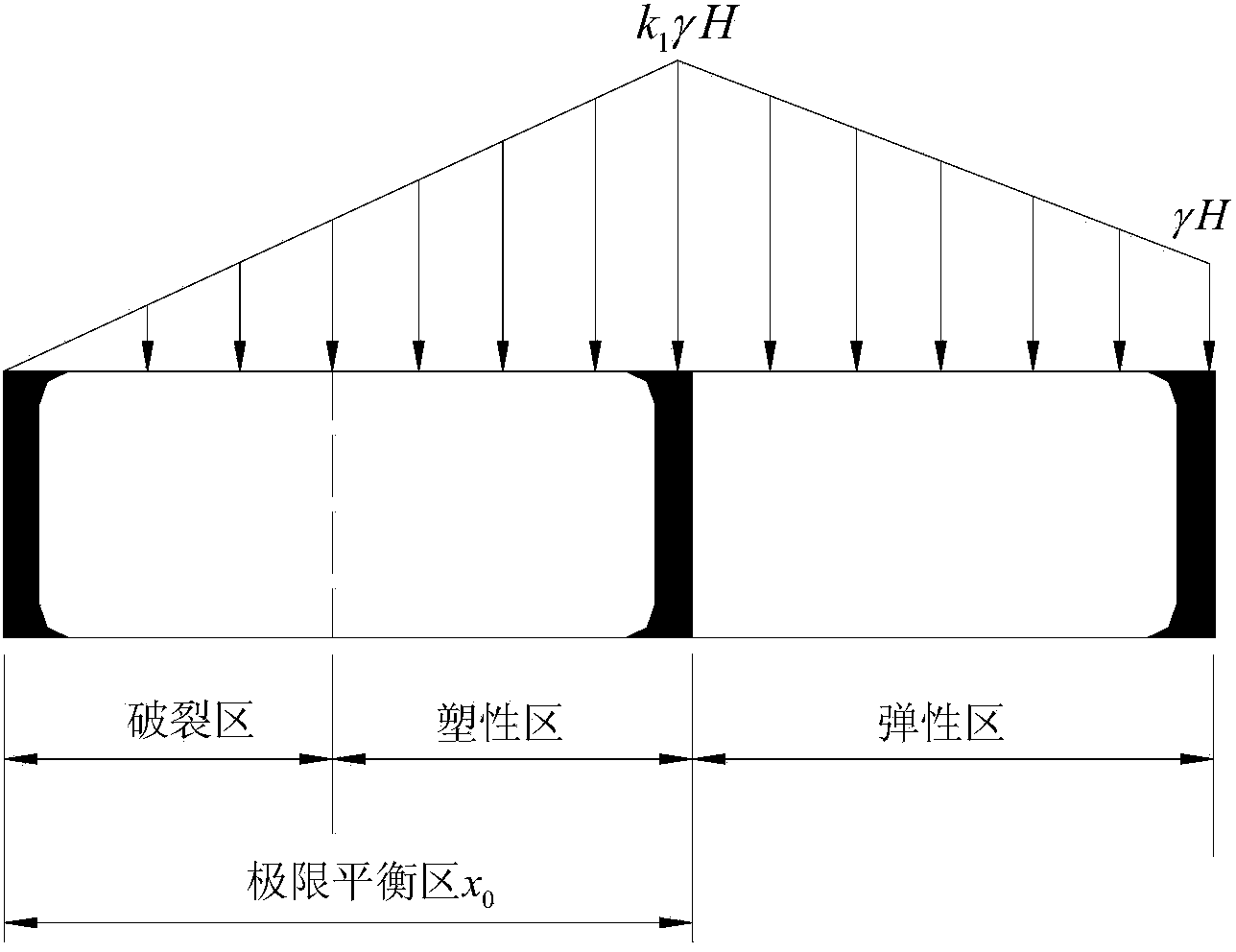

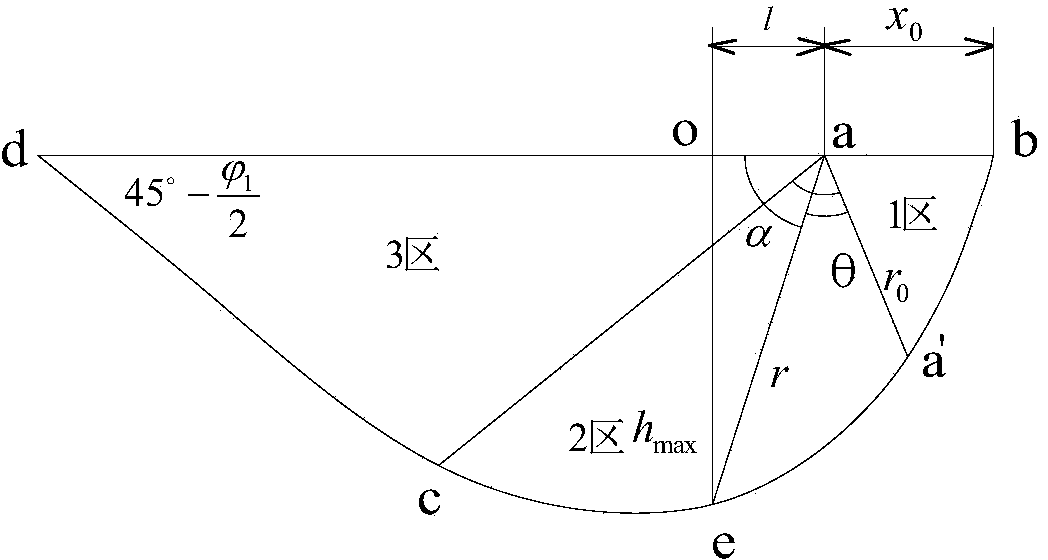

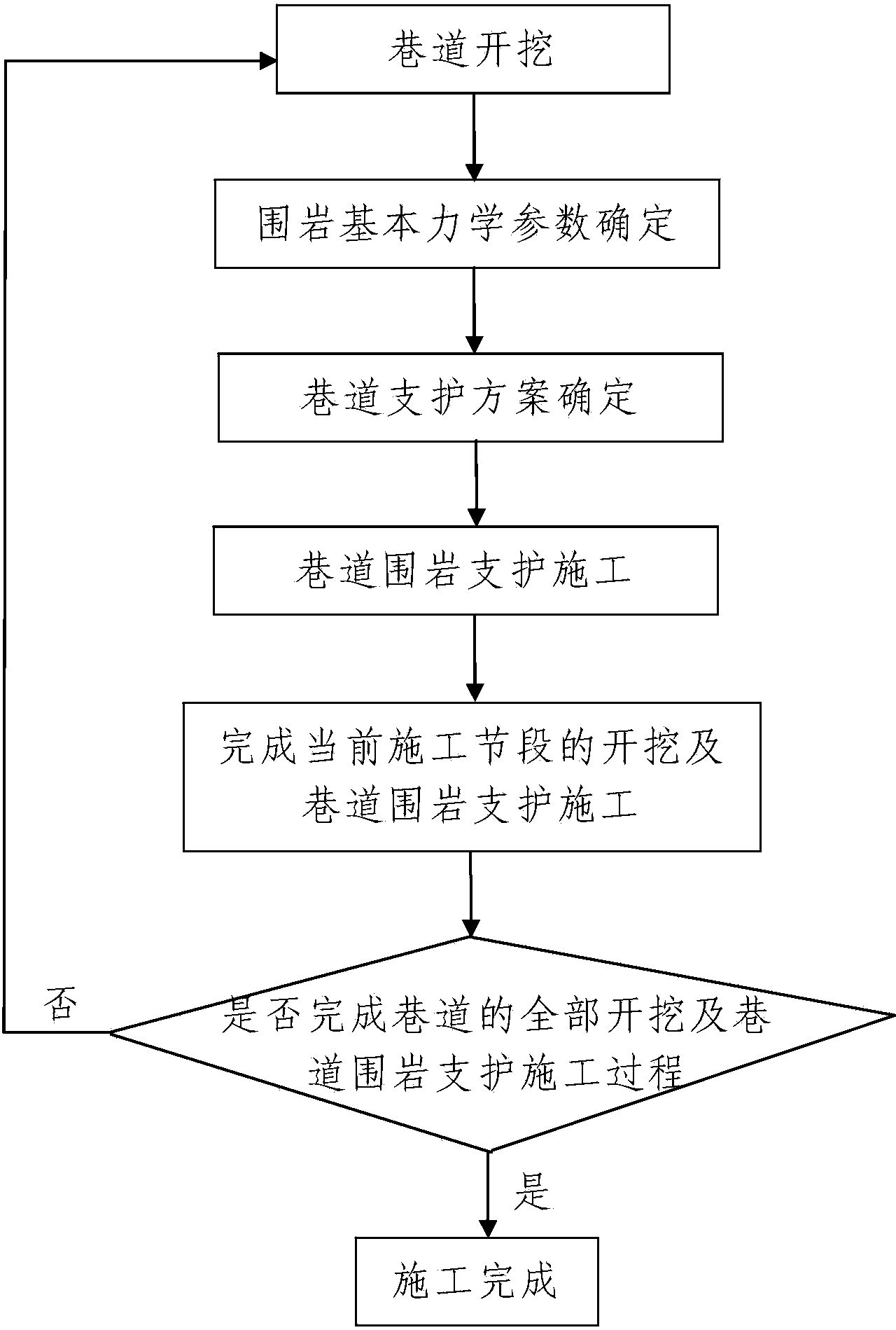

Method for preventing and controlling bottom heaving disaster of mine stoping tunnel

The invention discloses a method for preventing and controlling a bottom heaving disaster of a mine stoping tunnel. The method comprises the following steps: 1) digging a stoping tunnel; 2) confirming a mechanical parameter of a surrounding rock substrate; 3) confirming a supporting scheme for the stoping tunnel: respectively confirming supporting structures adopted by a top plate supporting system, a tunnel side part supporting system and a base plate supporting system, wherein the supporting structure is confirmed by adopting the top plate supporting system according to a conventional confirming method for a tunnel top plate supporting scheme, the supporting structure is confirmed by adopting the tunnel side part supporting system according to the width of a coal side breaking area, andthe supporting structure is confirmed by adopting the base plate supporting system according to the maximum breaking depth of the tunnel base plate and the horizontal distance from the maximum breaking depth of the tunnel base plate to a side wall of an adjacent tunnel; and 4) constructing the supporters of surrounding rocks of the stoping tunnel. The method provided by the invention is simple insteps, is conveniently realized, is low in invested cost and is good in use effect. The bottom heaving problem of the mine stoping tunnel under a complex condition is solved. The repairing operation of the stoping tunnel is avoided and the construction cost is low.

Owner:XIAN UNIV OF SCI & TECH

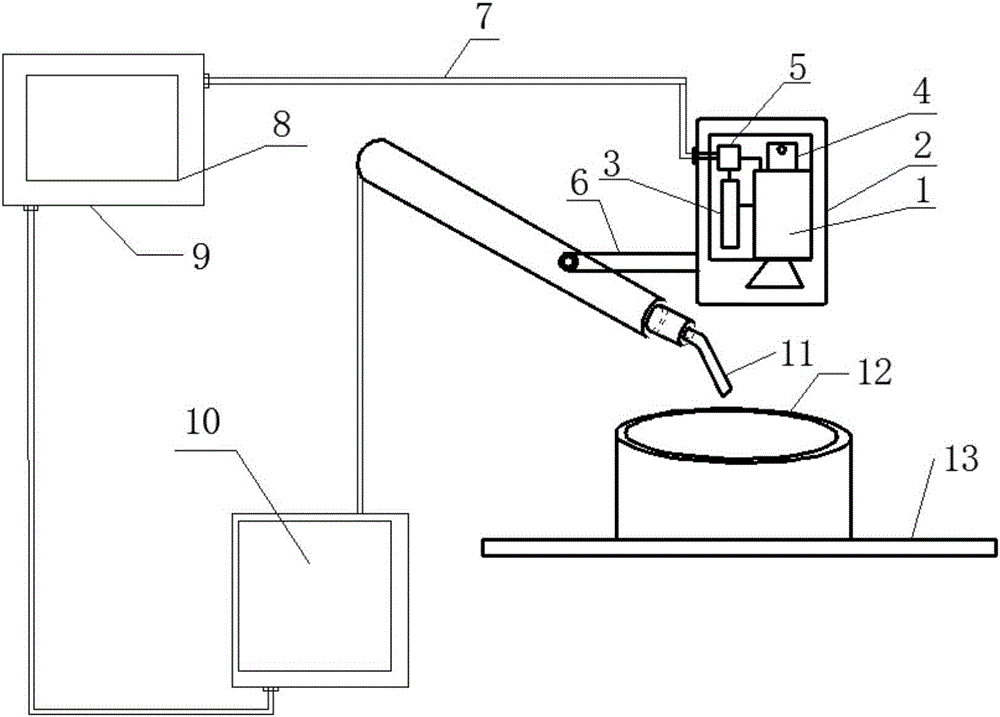

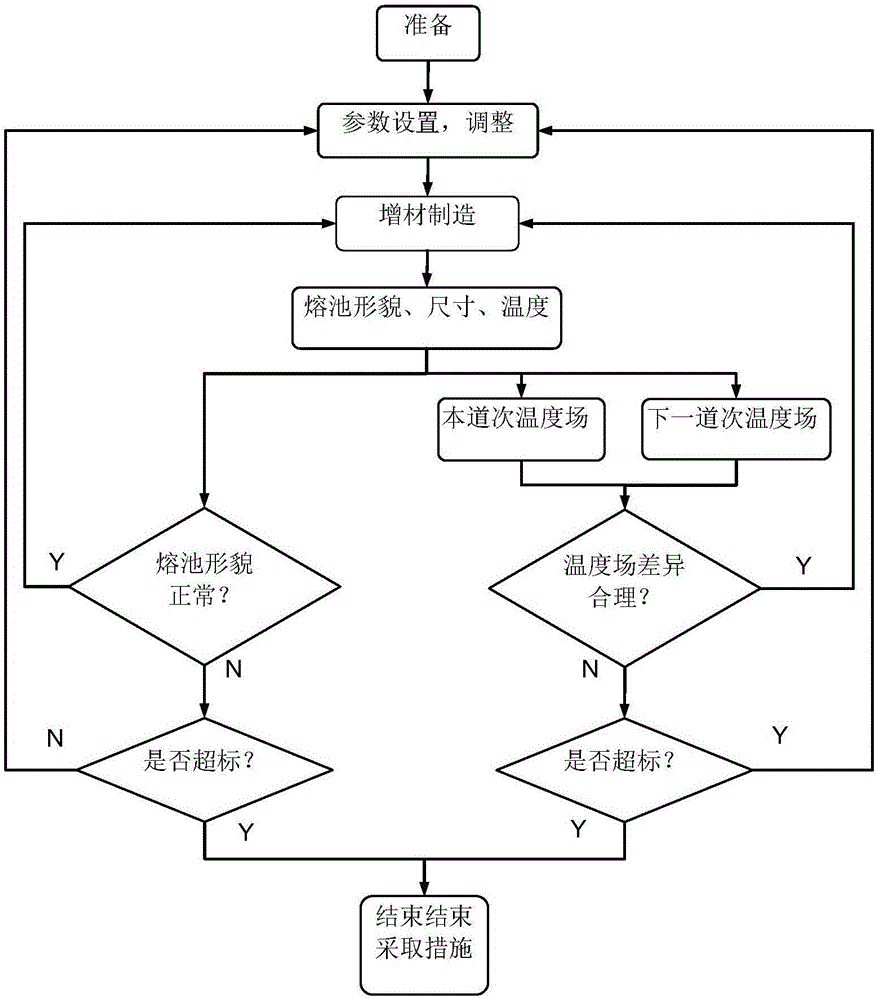

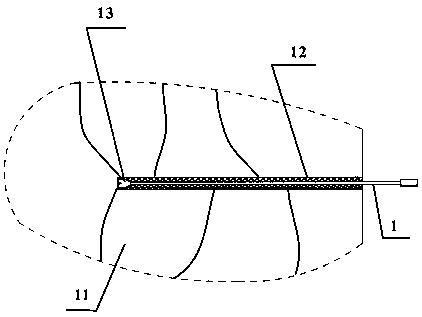

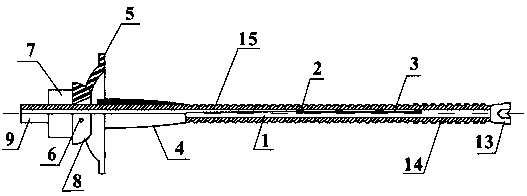

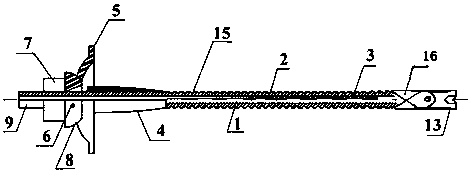

Infrared information-based metal additive manufacturing process control apparatus and method

PendingCN106404795ARealize real-time quality monitoringInhibition of Defect ExpansionRadiation pyrometryOptically investigating flaws/contaminationImaging processingFeedback control

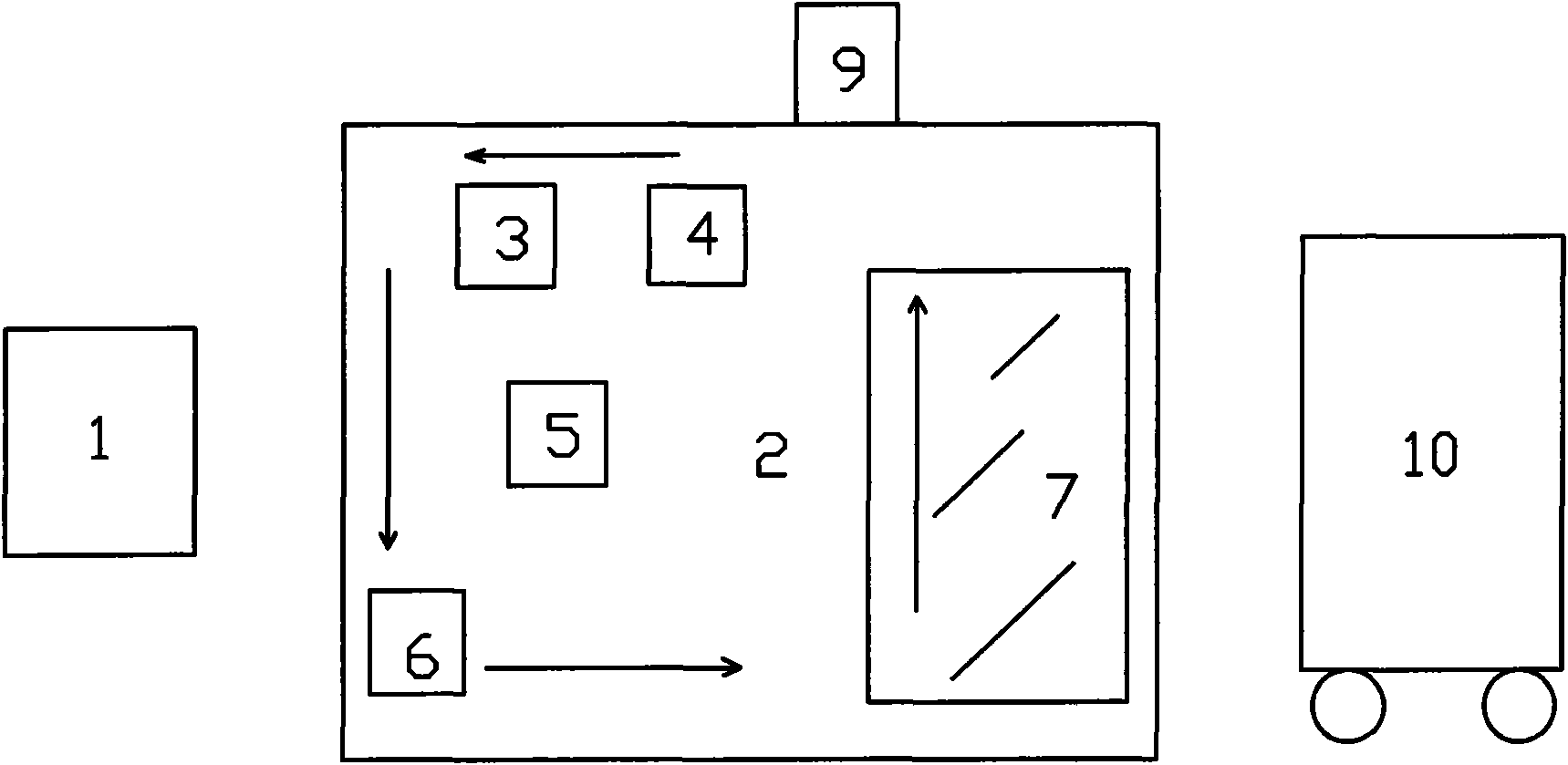

The invention discloses an infrared information-based metal additive manufacturing process control apparatus. The apparatus comprises: an additive manufacturing operating unit used for manufacturing a metal workpiece; an infrared image information acquisition unit comprising an infrared acquisition device (1) and used for acquiring infrared temperature field images of a melting bath of the workpiece and the circumference of the melting bath in real time; an image processing unit (9) connected with the infrared image information acquisition unit through a data bus (7) and used for processing the infrared temperature field images and generating a feedback instrument; and a feedback control unit (10) used for controlling the additive manufacturing operating unit to adjust parameters in order to eliminate defect or alarm shutdown. The invention also discloses a control method applying the apparatus. The apparatus can realize real-time quality detection of the whole metal additive manufacturing process, and can timely adopt measures to inhibit defect expansion or timely stop operation in order to prevent product discard or repairing after completion.

Owner:HUAZHONG UNIV OF SCI & TECH

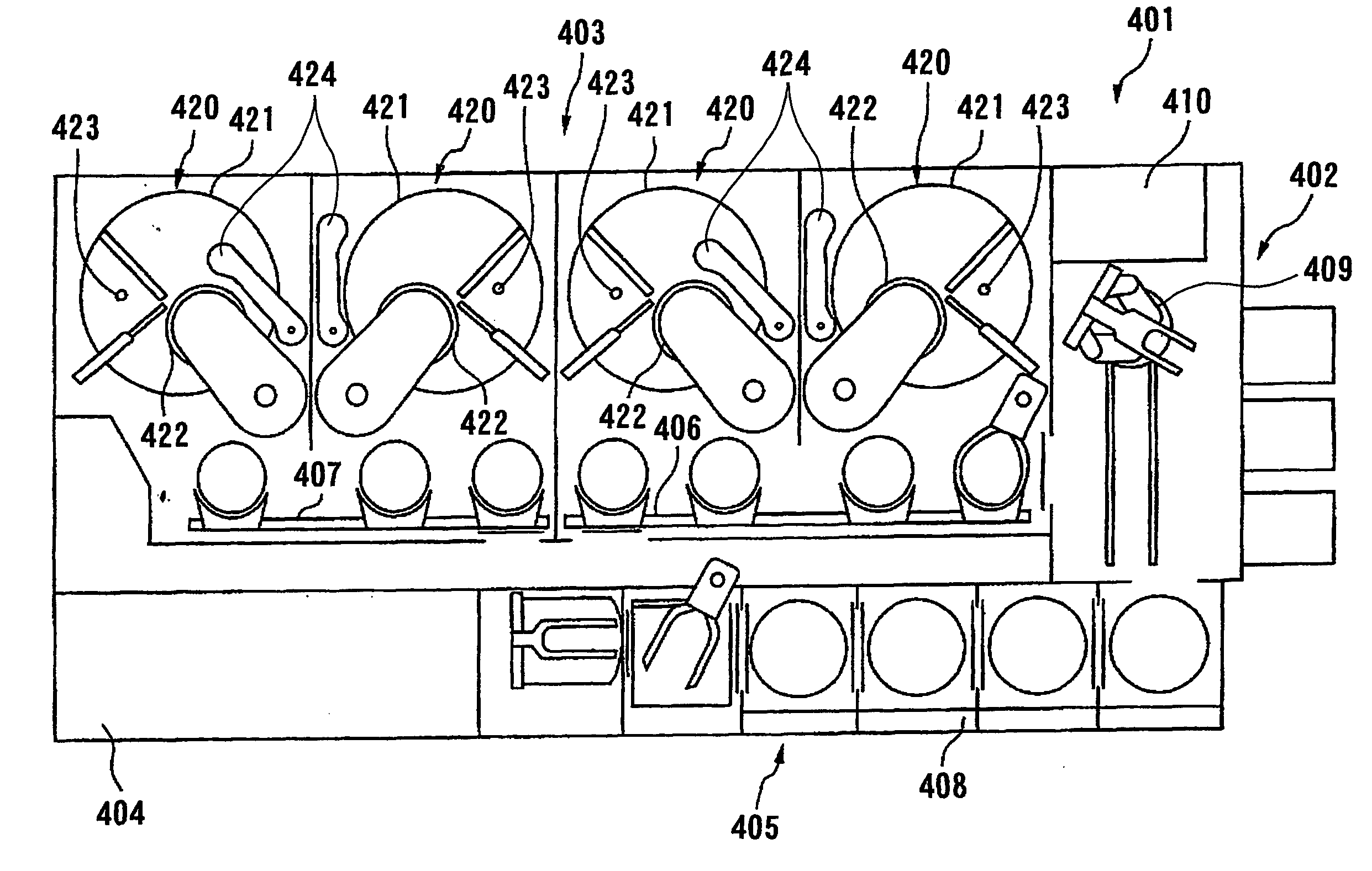

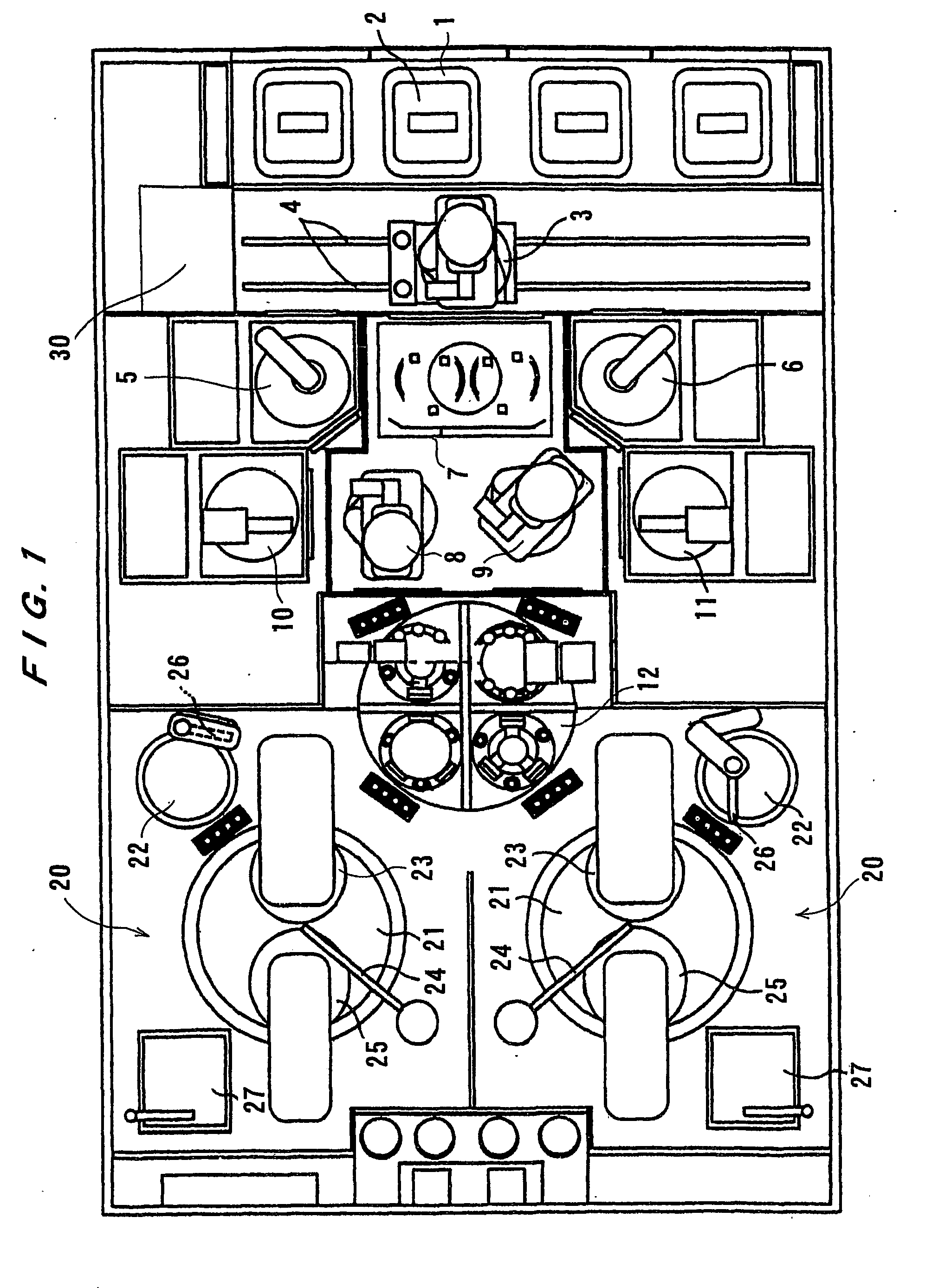

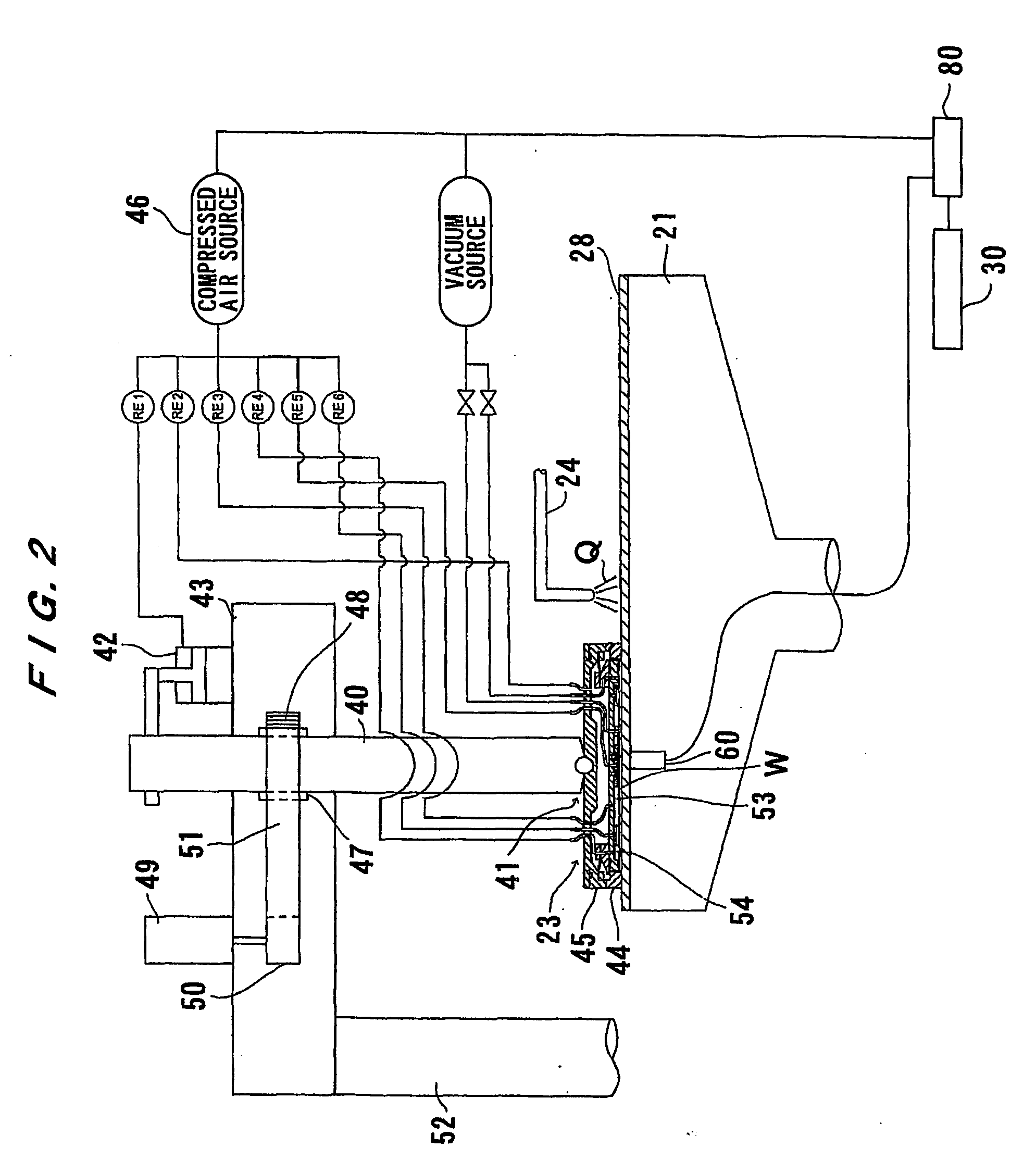

Polishing apparatus and polishing method

ActiveUS20060166503A1Prevent manufacturing yieldIncrease manufacturing costDecorative surface effectsSemiconductor/solid-state device manufacturingWeighted average methodEngineering

A polishing apparatus has a polishing section (302) configured to polish a substrate and a measurement section (307) configured to measure a thickness of a film formed on the substrate. The polishing apparatus also has an interface (310) configured to input a desired thickness of a film formed on a substrate to be polished and a storage device (308a) configured to store polishing rate data on at least one past substrate therein. The polishing apparatus includes an arithmetic unit (308b) operable to calculate a polishing rate and an optimal polishing time based on the polishing rate data and the desired thickness by using a weighted average method which weights the polishing rate data on a lately polished substrate.

Owner:EBARA CORP

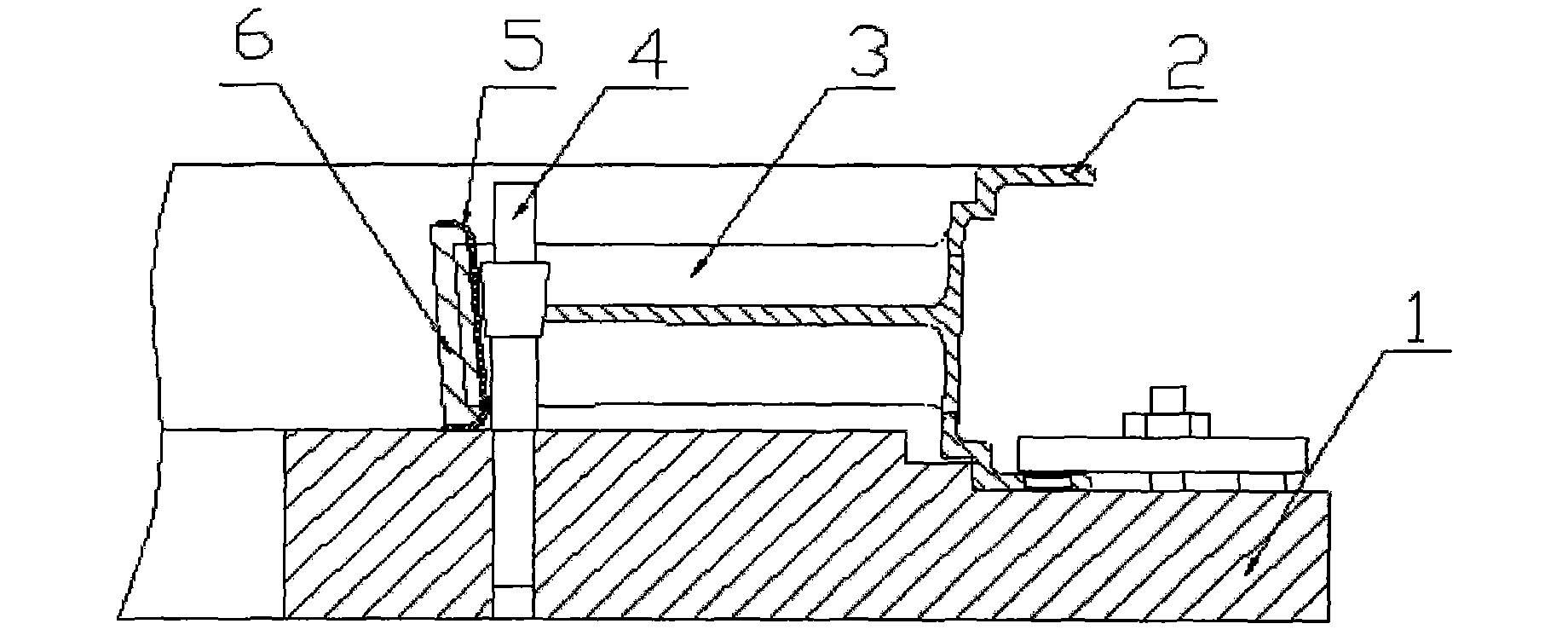

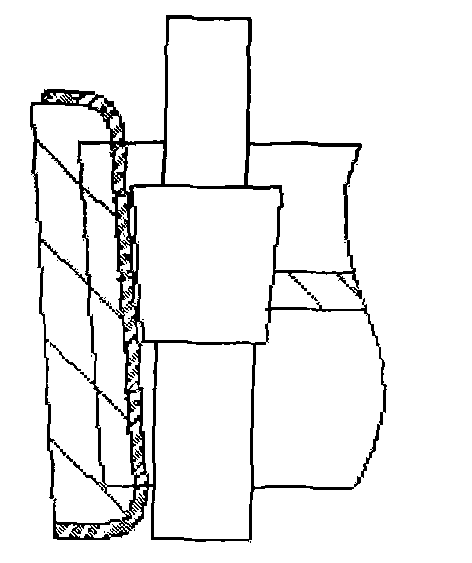

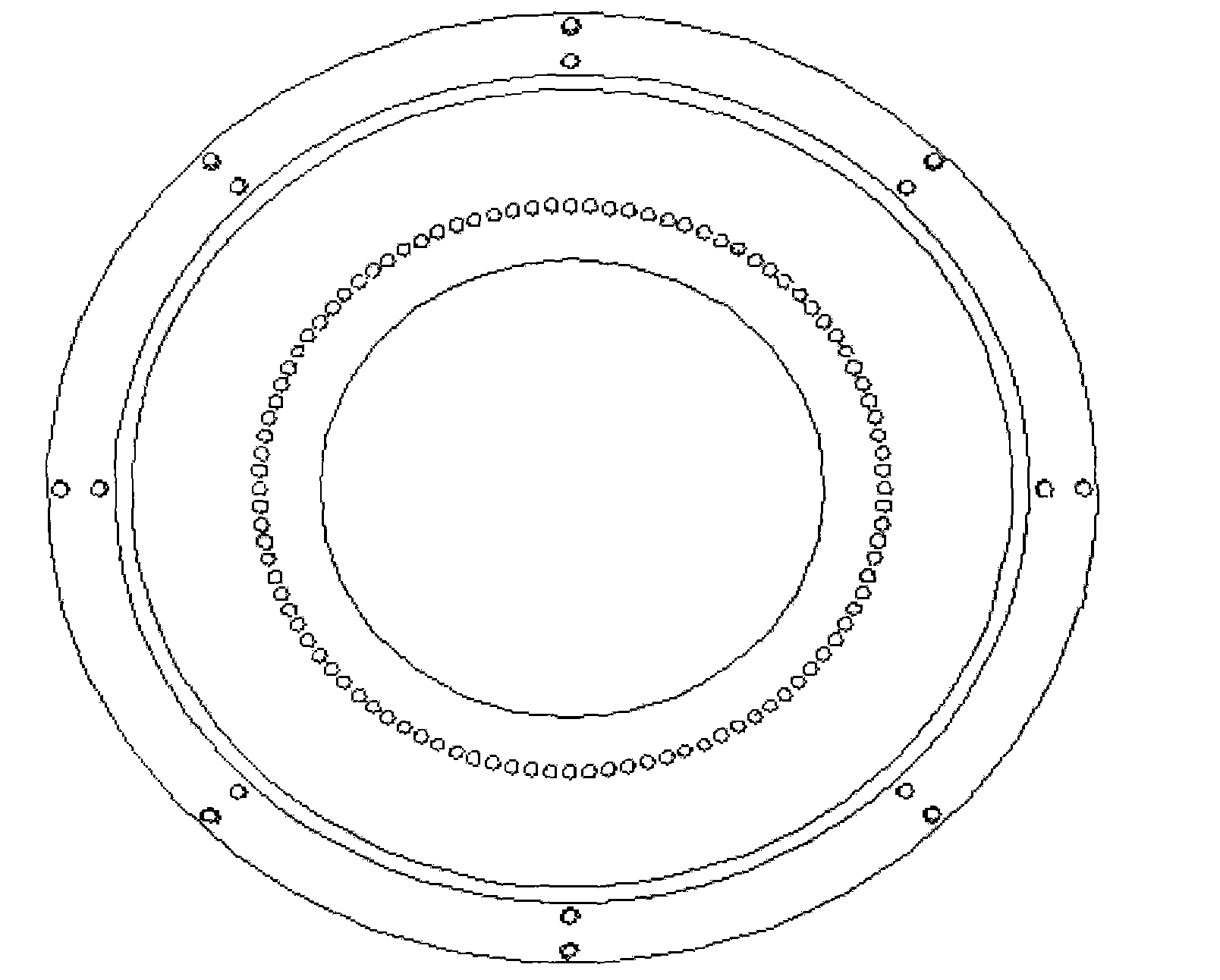

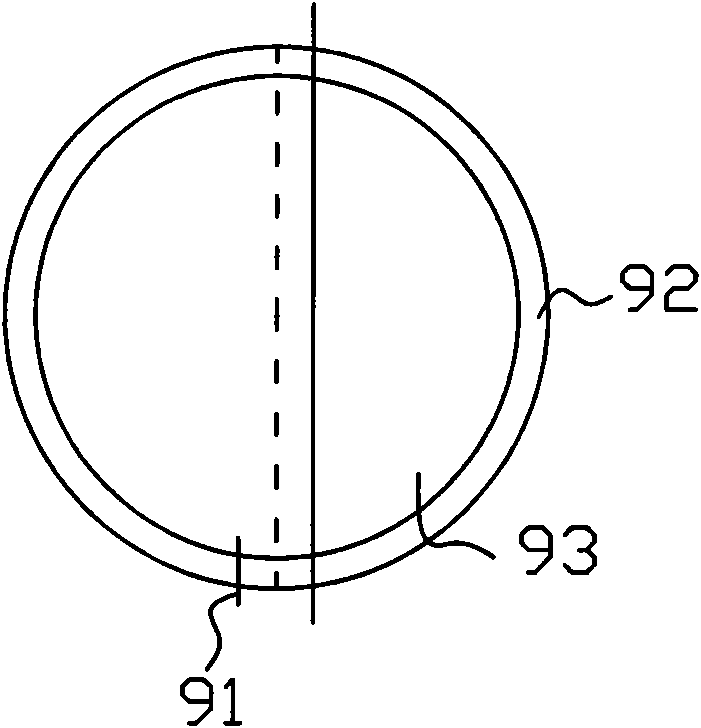

Correction device and correction method for inner ring of engine crankcase

The invention provides a correction device and a correction method for an inner ring of an engine crankcase. The correction device comprises a correction clamp base, positioning pins and a pressure plate; the tooling surface of the correction clamp base is provided with a circular seam allowance, and the inner side of the seam allowance is provided with a circle of uniform positioning pin holes; and the middle section of the positioning pin has a round table step-shaped columnar structure, the taper of the round table of the middle section is as same as that of the inner ring of the crankcase, and the maximum diameter of the positioning pin enables the positioning pin inserted into the positioning hole not to interfere with a blade of the crankcase. The correction method comprises the following steps of: jointing the seam allowance of the crankcase and the seam allowance on the correction clamp base; inserting the positioning pins into the positioning pin holes, positioning the positioning pins and the inner ring of the crankcase in a two-section contact mode, and then fixing the crankcase on the correction clamp base through the pressure plate; welding the inner ring and the blade of the crankcase; and finally, pouring a glue layer into the inner side of the inner ring of the crankcase, and gluing the inner ring and the blade of the crankcase. The device and the method ensurethe concentricity of the easily-deformed inner ring and the outer crankcase and the ellipticity of the inner ring.

Owner:AECC AVIATION POWER CO LTD

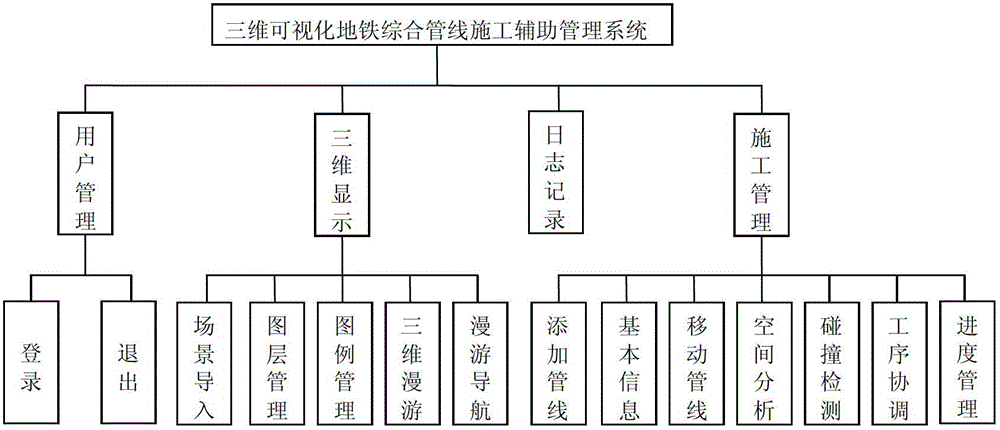

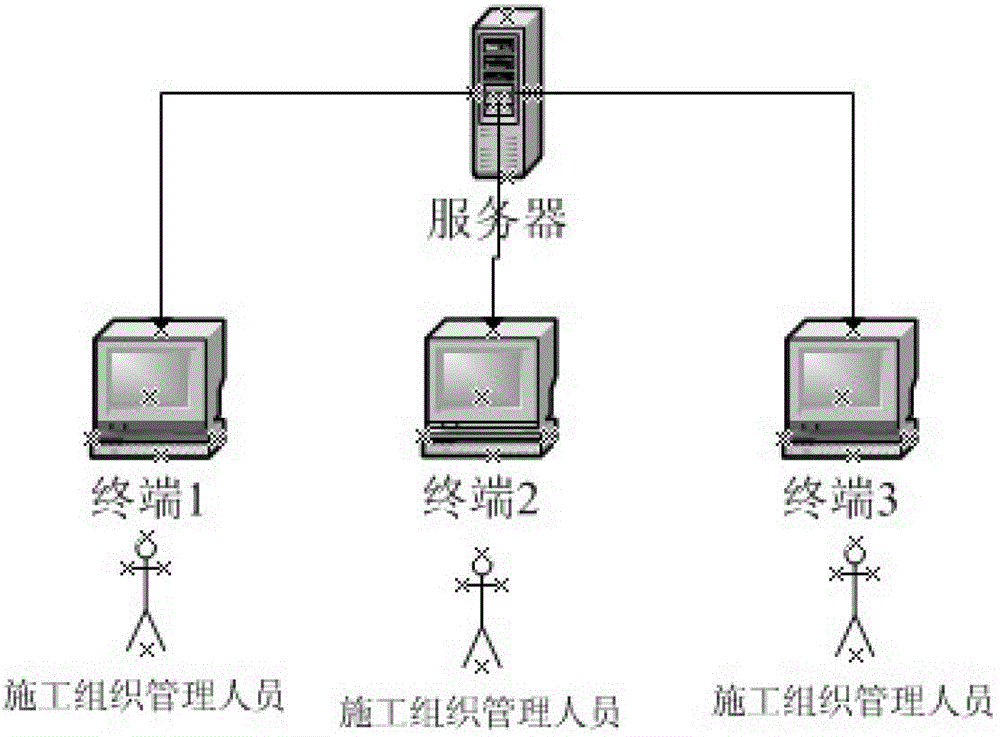

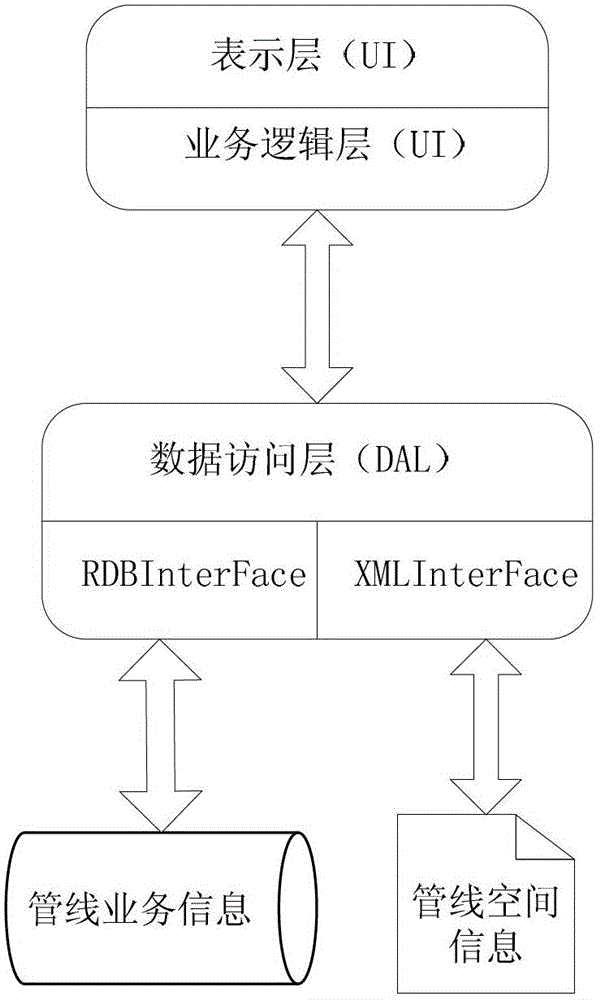

{0>Auxiliary management system for subway integrated pipeline construction and implementation method thereof

ActiveCN102750618ARealize 3D visualizationHelps to grasp the macroscopicResourcesSpecial data processing applicationsCollision detectionSpatial analysis

The invention relates to an auxiliary management system for subway integrated pipeline construction. The system comprises a user management module, a three-dimensional management module, a construction management module and a logging module, wherein the user management module comprises user login authentication and logging off function; the three-dimensional management module comprises scene import, three-dimensional roaming, layer management, legend management and navigation functions; the construction management module comprises basic information management, pipeline modification management, spatial analysis, pipeline collision detection, process coordination, construction schedule management functions; and the logging module can record information on user operation on pipelines in real time. The auxiliary management system for subway integrated pipeline construction provided by the invention has the beneficial effect that three-dimensional visualization of construction process management is realized, so that construction schedule is more visual, and the representation of construction management effect is enhanced, and rework in pipeline construction process is effectively avoided; and through spatial analysis and pipeline collision detection means, the problem of spatial collision between professional pipelines can be effectively solved, and the smooth progress of projects is ensured.

Owner:XIAN UNIV OF TECH

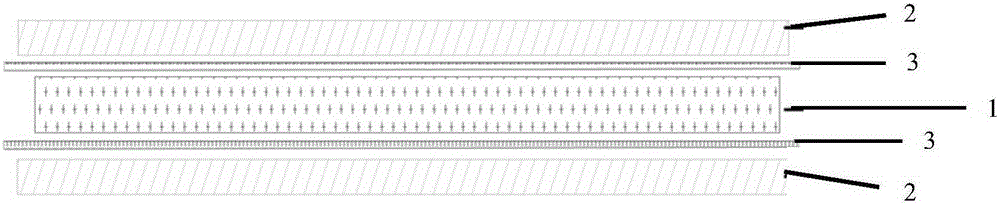

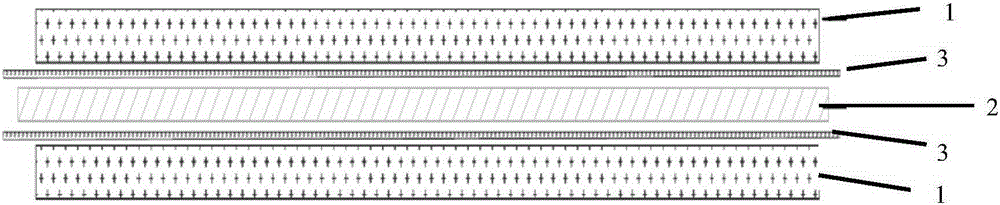

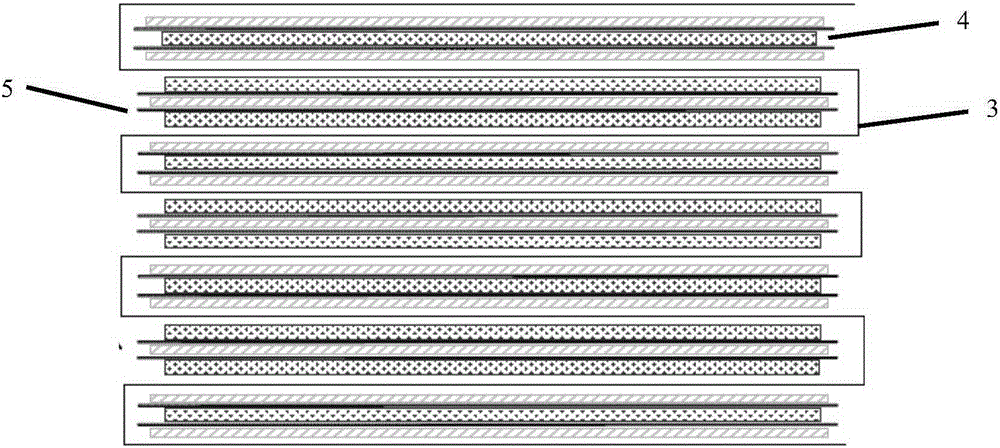

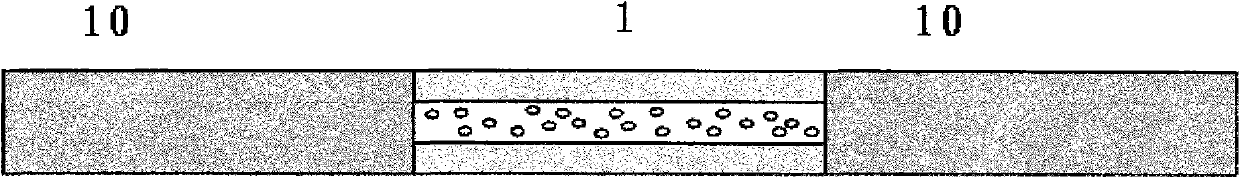

Lithium ion battery lamination unit, battery cell, battery cell preparing method and lithium ion battery

InactiveCN105336976AIncrease productivityAvoid misalignmentLarge-sized flat cells/batteriesFinal product manufactureElectrical polarityEngineering

The invention relates to a lithium ion battery lamination unit, a battery cell, a battery cell preparing method and a lithium ion battery and belongs to the technical field of lithium ion batteries. The lithium ion battery lamination unit comprises an inner electrode slice, membranes and outer electrode slices, wherein the polarity of the inner electrode slice and the polarity of the outer electrode slices are opposite, the membranes are attached to the two side faces of the inner electrode slice respectively through a binder, and the outer electrode slices are attached to the outer side faces of the membranes through the binder. According to the lithium ion battery lamination unit, on one hand, dislocation of the membranes relative to the electrode slices can be prevented, and a short circuit between a positive plate and a negative plate can not be formed; on the other hand, during battery cell manufacturing, due to the fact that part of procedures of clamping membranes in the electrode slices are omitted, battery cell manufacturing time is shortened greatly, and the production efficiency of the lithium ion battery is improved.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

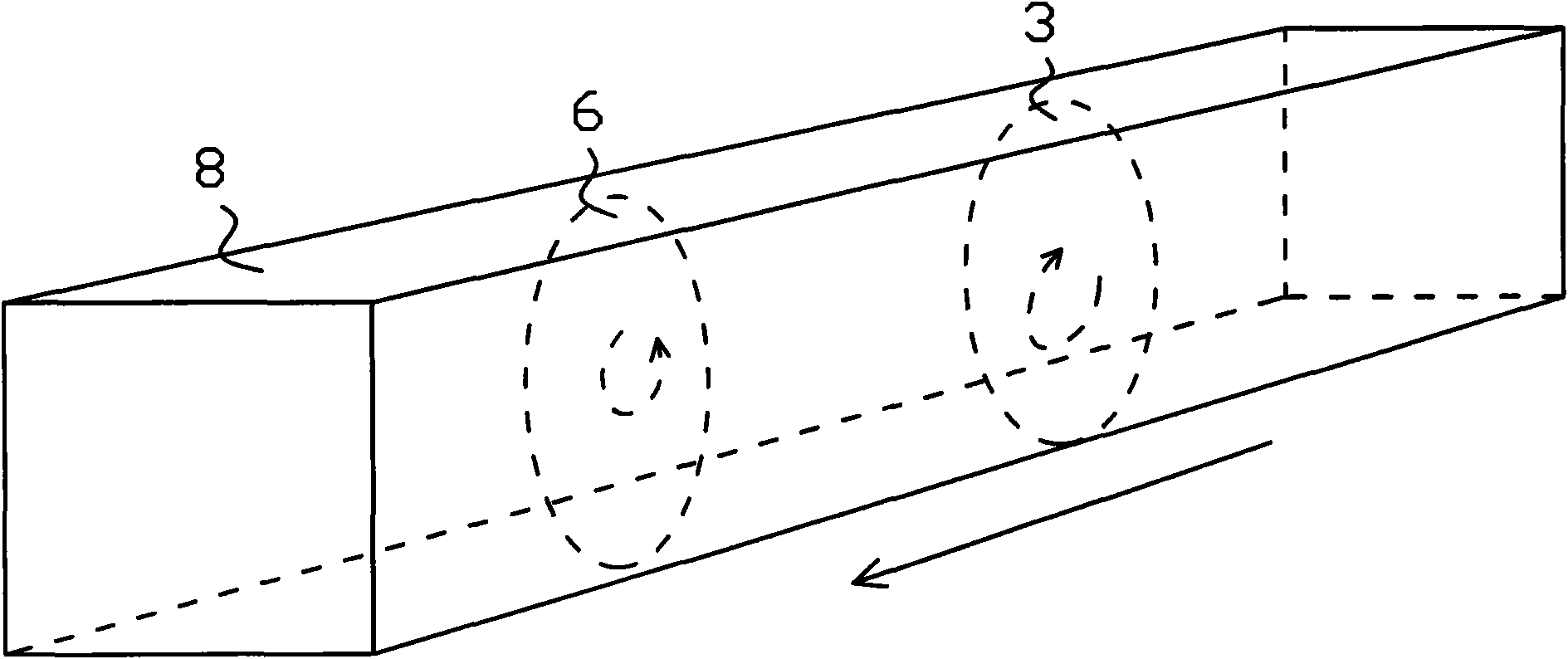

Smoke-sensitive fire detector auto-calibrating device

ActiveCN101923767AImprove consistencyAvoid reworkFire alarm smoke/gas actuationFire detectorElectricity

The invention discloses a smoke-sensitive fire detector auto-calibrating device, relating to a smoke-sensitive sensor calibrating device, mainly comprising a controller, a smoke box, a wind speed controller, a consistence measuring device, a smoke-adding controller, a smoke stirrer, an observation window, an air duct and a smoke exhaust device, further comprising a detector car. The detector car is arranged in the smoke box and is used for detecting alarm threshold of a detector. The controller and the smoke box are electrically connected, communicate signals and information with the wind speed controller, the consistence measuring device, the smoke-adding controller and the smoke stirrer, and are simultaneously communicated with the detector on the detector car so as to receive a consistence signal of the consistence measuring device and transmitting calibrating information. The invention has the advantages that although the consistency of sensor sensitivities of the detector is different, the consistency of the detectors calibrated by the auto-calibrating device is very high, each detector can pass through the test, the product rework situation is prevented, and the production efficiency is improved.

Owner:蚌埠依爱消防电子有限责任公司

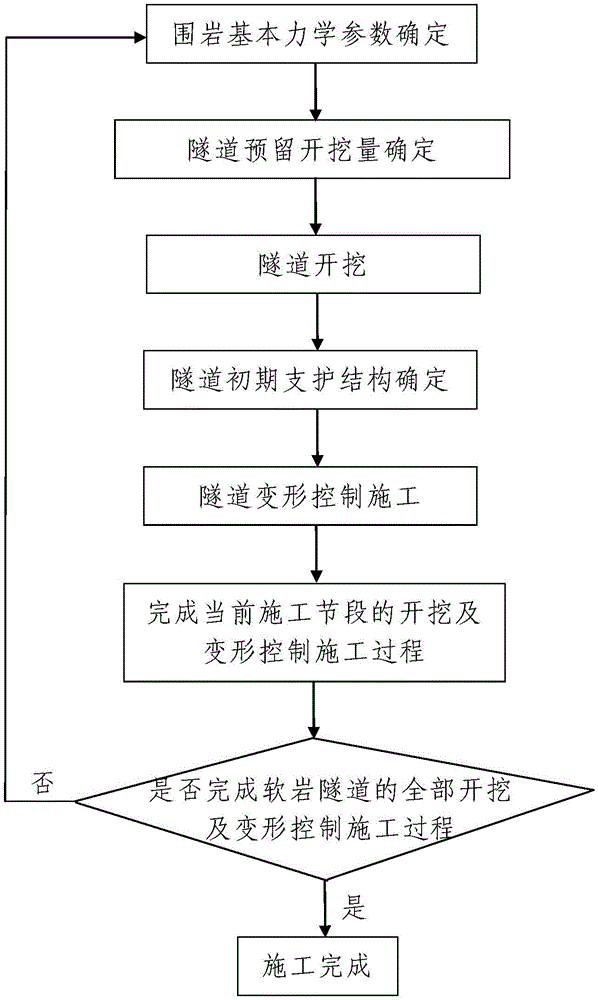

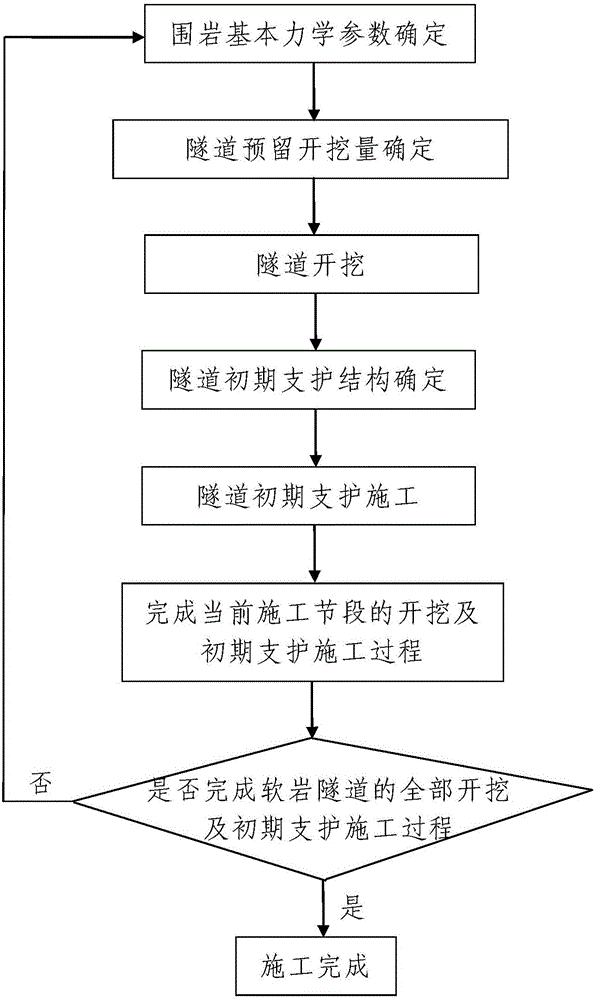

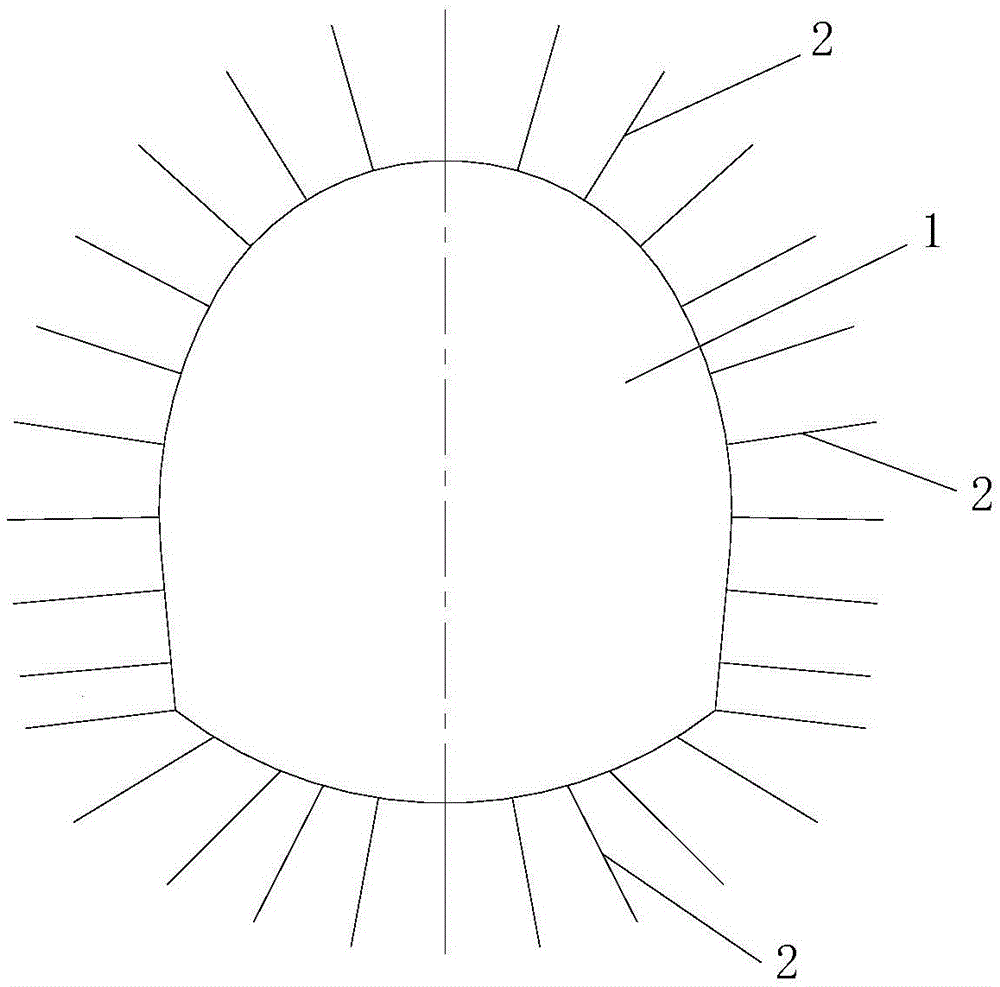

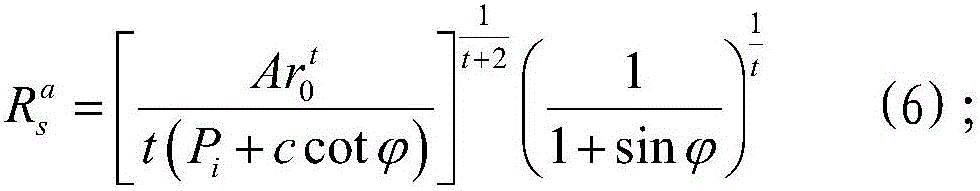

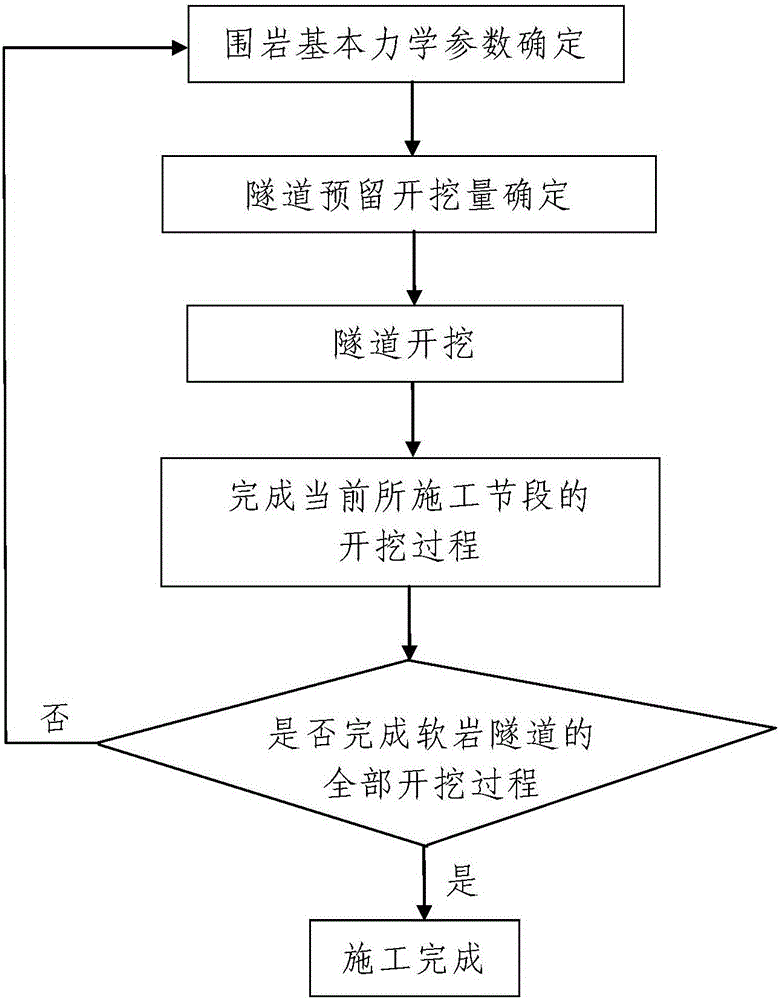

Soft rock tunnel deformation control method based on anchor rod force analysis

InactiveCN106499397AThe method steps are simpleEasy to implementUnderground chambersTunnel liningStructure of the EarthForce analysis

The invention discloses a soft rock tunnel deformation control method based on anchor rod force analysis. A soft rock tunnel is excavated and subjected to deformation control construction from back to front according to multiple segments, and when any segment is excavated and subjected to deformation control construction, the method includes the steps that 1, surrounding rock basic mechanical parameters are determined; 2, the tunnel reserved excavated volume is determined; 3, the tunnel is excavated; 4, a tunnel preliminary bracing structure is determined; 5, tunnel deformation control construction is carried out, wherein in the tunnel preliminary bracing construction process, a flexible mold bracing structure is constructed from back to front; 6, a next segment is excavated and subjected to deformation control construction; 7, the step 6 is repeated multiple times till the full excavation and deformation control construction process of the soft rock tunnel is completed. The soft rock tunnel deformation control method is reasonable in design, convenient to achieve and good in use effect, the reserved excavated volume is determined according to the surrounding rock deformation condition of the soft rock tunnel, the flexible mold bracing structure is adopted for carrying out full-section bracing on the tunnel, the flexible mold bracing structure and the tunnel preliminary bracing structure are in coordination deformation, and deformation of the soft rock tunnel can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

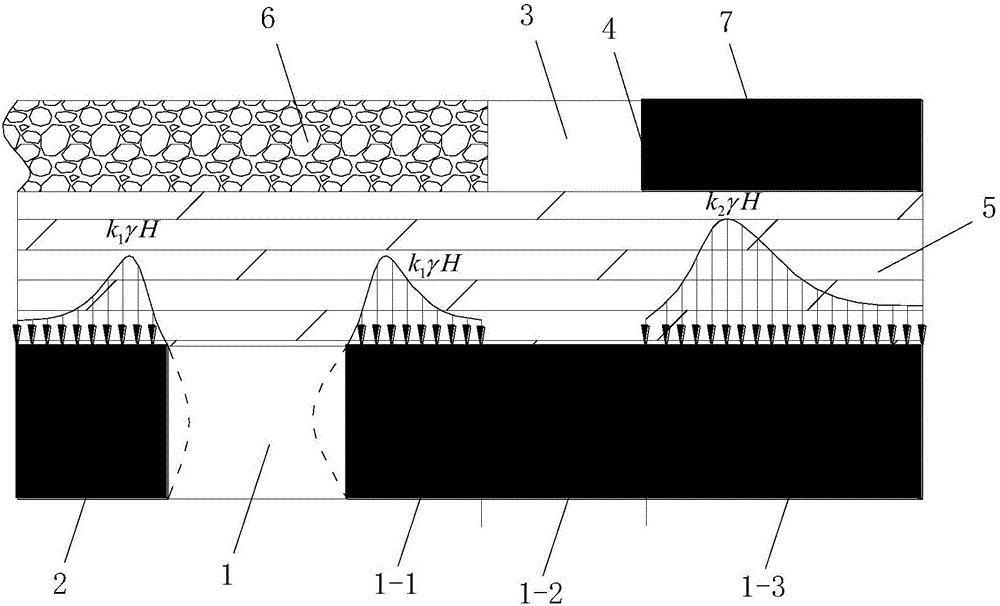

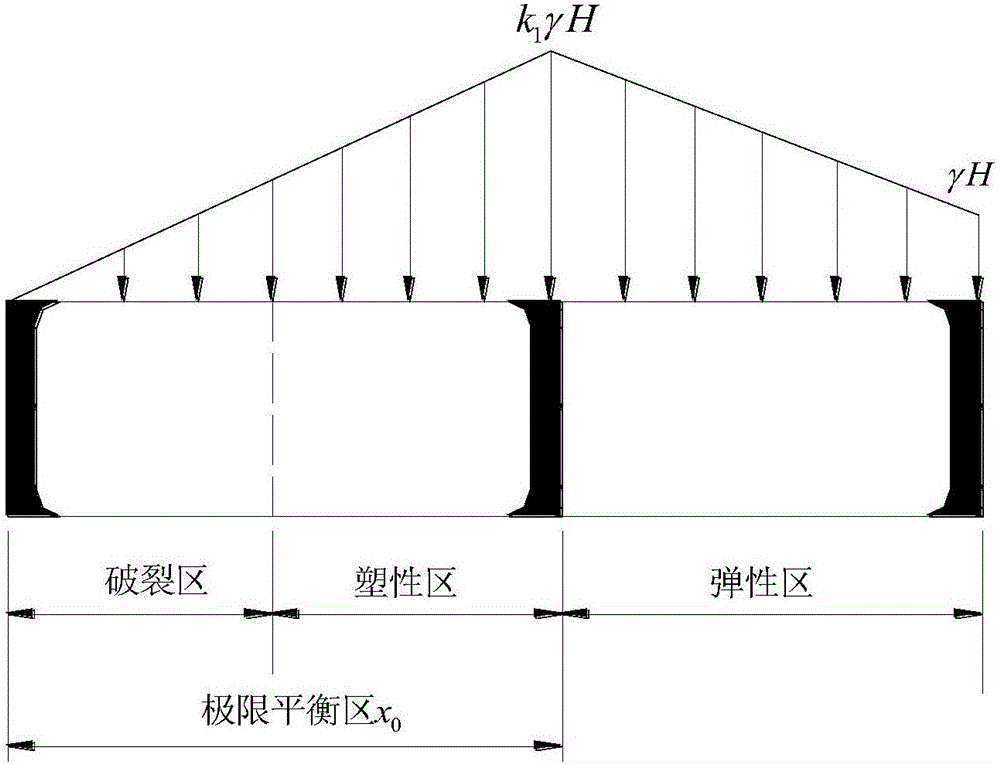

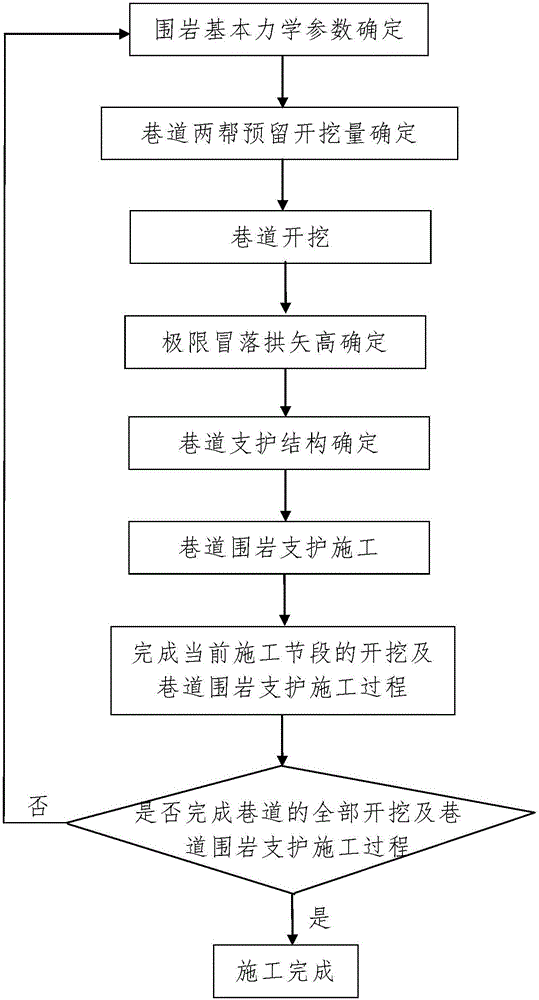

Rectangular roadway surrounding rock deformation and failure control method

The invention discloses a rectangular roadway surrounding rock deformation and failure control method which comprises steps as follows: 1), a roadway is excavated; 2), basic mechanical parameters of a surrounding rock are determined; 3), a roadway support scheme is determined as follows: roadway side unstability is judged, the caving arch rise is determined when the roadway side is in a stable state, the width of roadway side olistolith, the caving arch rise, the roadway side limit equilibrium area width, the maximum failure depth of a roadway bottom board and a horizontal distance between the maximum failure depth position and an adjacent roadway side wall are determined when the roadway side is in an unstable state, and a roadway support unit structure is determined; 4), a roadway surrounding rock support is constructed; 5), the next section is excavated, and the roadway surrounding rock support is constructed; and 6), the step 5) is repeated until all excavation and roadway surrounding rock support construction processes of the rectangular roadway are completed. The method is simple in step, convenient to implement and good in use effect, the roof caving and bottom swelling problems of the rectangular roadway can be effectively solved, and deformation and failure of the roadway surrounding rock can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

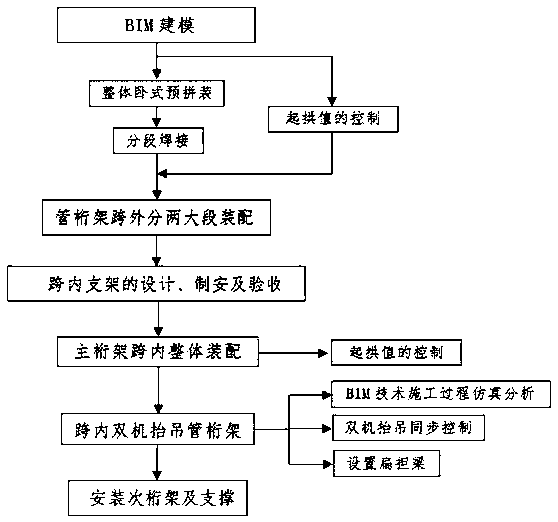

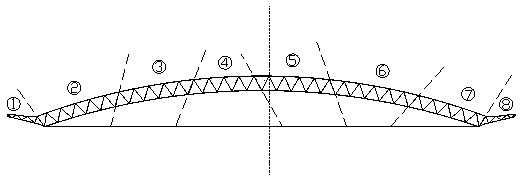

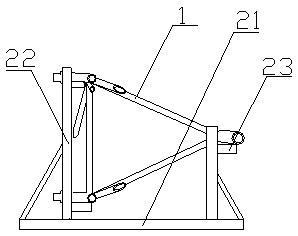

Rapid construction method of arched pipe truss

InactiveCN110259145ASee the connectionAccurately determine the center of gravityGeometric CADBuilding material handlingRisk strokeRapid construction

The invention discloses a rapid construction method of an arched pipe truss. The rapid construction method comprises the following steps that (1) a BIM structural model of the arched pipe truss is established; (2) horizontal integrated pre-assembly and segment welding are performed in a factory for the pipe truss to form truss bodies to be transport to a site; (3) the truss bodies are assembled to form two main trusses; (4) in-span brackets are installed; (5) the two main trusses are lifted and welded to connect the two main trusses into the pipe truss; (6) the assembled pipe truss is lifted in place to complete installation of the pipe truss; (7) the steps 2-6 are repeated to form two pipe trusses, a secondary truss and a roof support are installed, so that the installed part forms a whole force system; and (8) the steps 2-7 are repeated until all pipe trusses are installed. According to the rapid construction method of the arched pipe truss, in-span vertical one-time splicing rapid construction of the arched pipe truss can be completed in the case of poor on-site site conditions, the risks of working at height are reduced, the construction period is ensured, the construction cost is saved, and multiple purposes are achieved at one stroke.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

BIM technology-based curtain wall mounting design method

InactiveCN108460189AEliminate biasImprove installation accuracyGeometric CADDesign optimisation/simulationPoint cloudEngineering

The invention discloses a BIM technology-based curtain wall mounting design method. The method comprises the following steps of (1) importing a two-dimensional drawing of a curtain wall to BIM software Revit, and building three-dimensional models of to-be-mounted curtain wall unit members according to modeling specifications; (2) exporting detail drawings according to the three-dimensional modelsof the to-be-mounted curtain wall unit members, and performing processing production according to the detail drawings of the curtain wall unit members by a factory; (3) building three-dimensional point cloud models of the curtain wall unit members by utilizing fixed point cloud information; (4) adjusting information of the curtain wall unit members by using a processing device; and (5) simulatingwhole pre-mounting of the curtain wall in the Revit according to the three-dimensional point cloud models of the curtain wall unit members meeting specification requirements, and according to a pre-mounting process, performing entity member mounting. The BIM technology-based curtain wall mounting design method solves the problems of high field mounting difficulty, low mounting efficiency and low precision of the curtain wall.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Excavation and preliminary bracing method for soft rock tunnel

InactiveCN106481343AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelWall rock

The invention discloses an excavation and preliminary bracing method for a soft rock tunnel. The excavation and preliminary bracing construction for the soft rock tunnel are performed in sections from back to front. When any section is subjected to excavation and preliminary bracing construction, the method comprises the following steps: 1) confirming basic mechanical parameters of the surrounding rock; 2) confirming the reserved excavated volume of the tunnel: confirming the reserved excavated volume of the currently constructed section according to a theoretical value of inward displacement of the surrounding rock of the soft rock tunnel after being braced; 3) excavating the tunnel; 4) confirming a preliminary bracing structure of the tunnel; 5) constructing the preliminary bracing of the tunnel; 6) performing the excavation and preliminary bracing construction of the next section; and 7) repeating the step 6) till all the processes of the excavation and preliminary bracing construction of the soft rock tunnel are completed. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in realization and good use effect; the reserved excavated volume is confirmed according to the surrounding rock deformation condition of the soft rock tunnel; and the steel bracket and the anchoring net sprayed preliminary bracing structure are coordinated for performing all-section preliminary bracing on the tunnel.

Owner:XIAN UNIV OF SCI & TECH

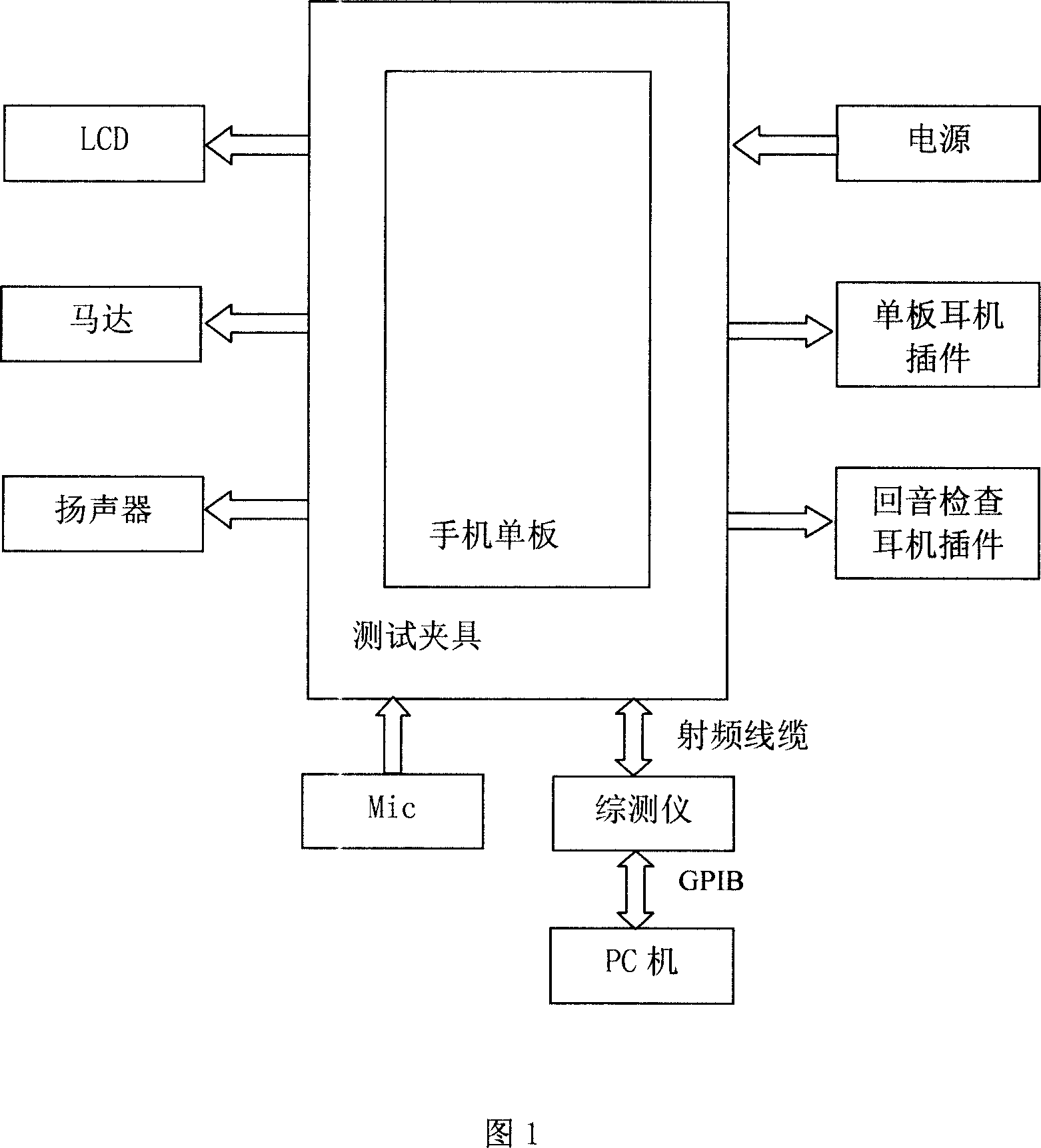

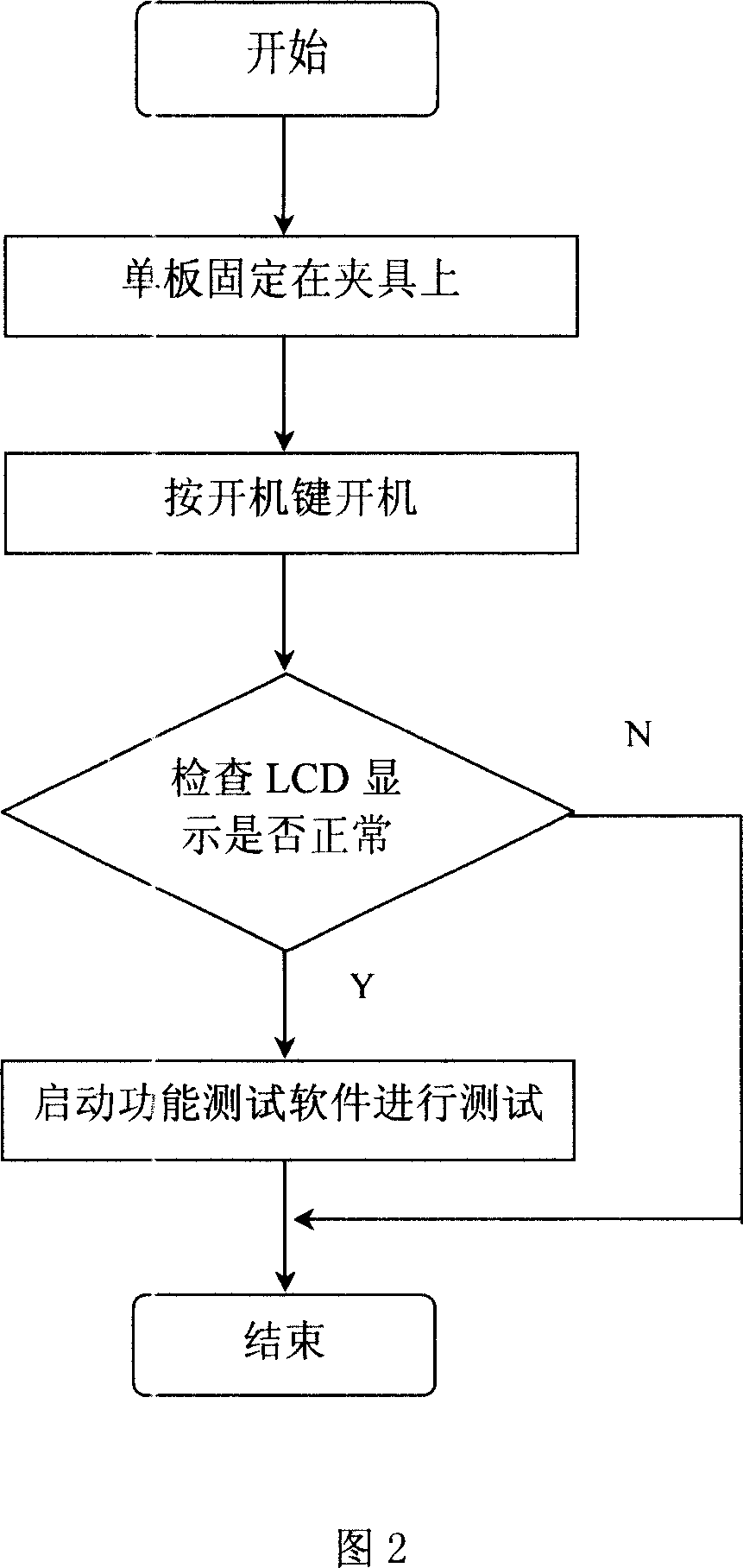

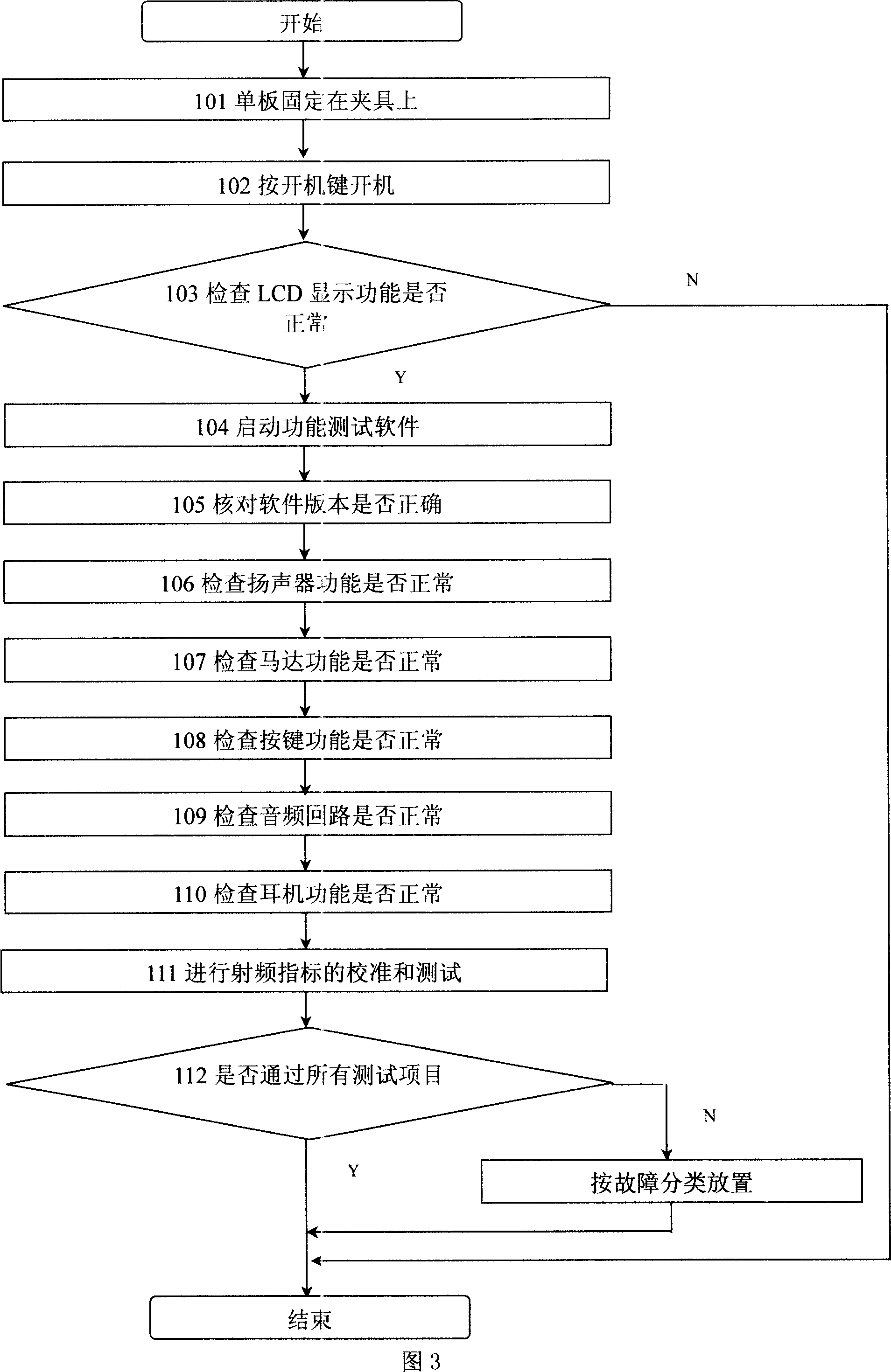

Testing system and method for mobile phone single board

InactiveCN101145859AShort development cycleLow costSubstation equipmentRadio/inductive link selection arrangementsFunctional testingSingle plate

The invention discloses a system and a method for the functional test of a mobile phone single board. Aiming to solve the problems of high cost but low efficiency of functional test technology of the existing mobile phone single board, the mobile phone single board test system of the invention comprises a test fixture, functional components, a power supply, a synthetic tester and a computer. The mobile phone single board is fixed on the test fixture, and the mobile single board test point contacts the test probe of the test fixture. The power supply provides power for the mobile phone single board. The functional components fixed on the test fixture are used for the functional test to the mobile single board. The computer controls the synthetic tester to calibrate and test the radio frequency of the mobile phone single board by the test fixture. The test method comprises the followings steps. Firstly, the mobile phone single board is fixed on the test fixture. Secondly, the mobile phone single board is started. Thirdly, a LCD displays images. If the display is normal, the fourth step can be carryout out; otherwise the test ends. Fourthly, the mobile phone single board is tested. The invention has the advantages of low cost as well as high efficiency.

Owner:ZTE CORP

Soft rock tunnel excavation method based on anchor bolt stress

InactiveCN106499398AThe method steps are simpleEasy to implementTunnelsAnchoring boltsRock tunnelRock bolt

The invention discloses a soft rock tunnel excavation method based on anchor bolt stress and the soft rock tunnel is excavated by a plurality of sections in a longitudinally direction of the tunnel from rear to front. The method for excavating any section of the soft rock tunnel comprises the following steps: first, determing the basic mechanical parameters of surrounding rock; second, determing the reserved excavation capacity of tunnels: determing the capacity of reserved excavation of the current construction section according to a theoretical value S of the soft rock tunnel inward displacement after the completion of supporting, the S is the sum of plastic displacement of surrounding rock in soft rock tunnel and displacement after shaping deformation of surrounding rock in soft rock tunnel; third, the tunnel is excavated; fourth, the next section is excavated; fifth, repeating step fourth until the full excavation of the soft rock tunnel is completed. The soft rock tunnel excavation method has the advantages of simple steps, reasonable design and convenient implementation, and has good effect. The excavation capacity is determined according to the deformation of the surrounding rock of the soft rock tunnel, which can solve the problem of the reserve deformation of the soft rock tunnel, avoid the problem of soft rock tunnel repair work and cost less.

Owner:XIAN UNIV OF SCI & TECH

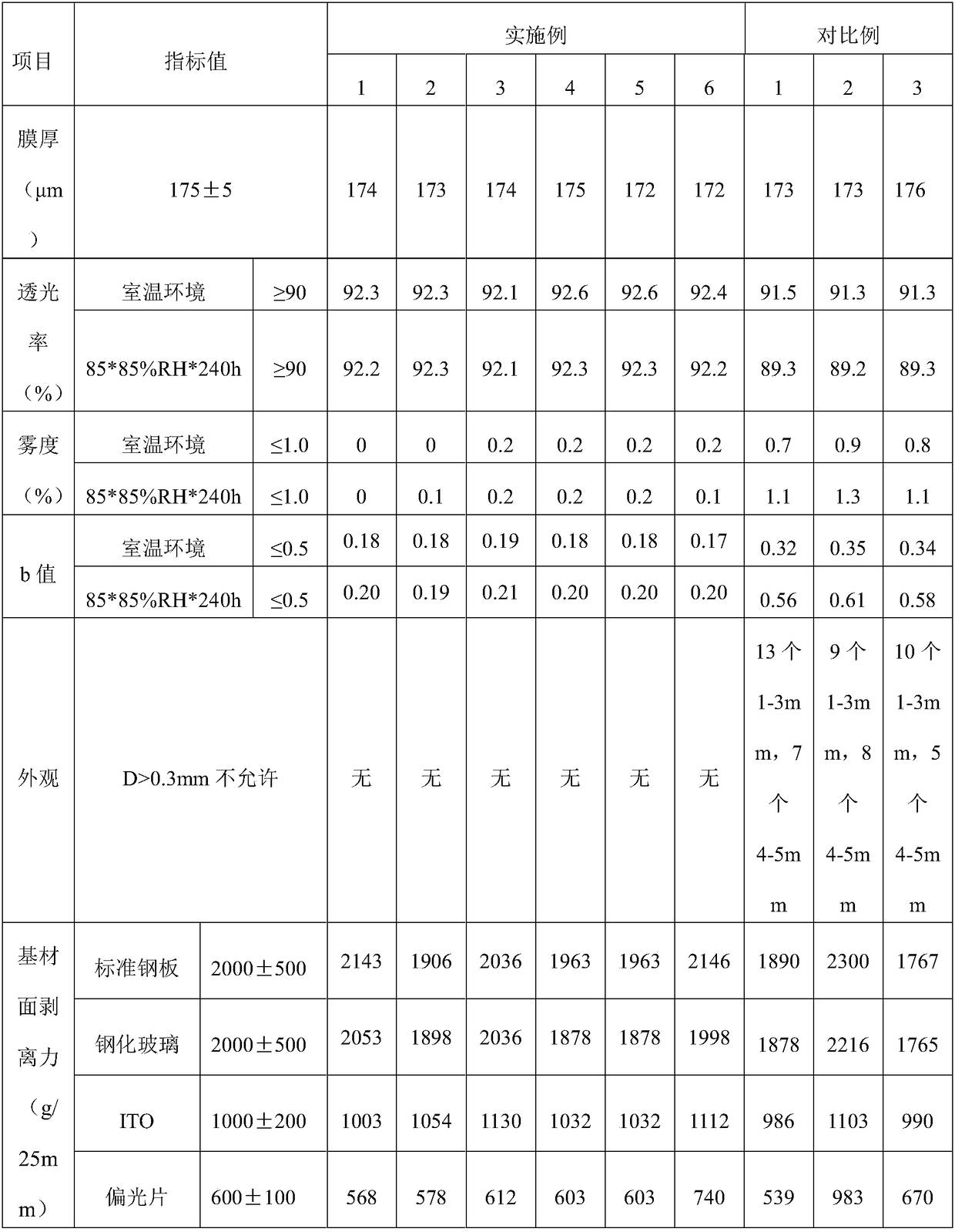

Optical film adhesive used for full bonding, preparation method and application of adhesive and optical film based on adhesive

InactiveCN108587484AGood gap filling abilityAvoid high temperature and high humidityFilm/foil adhesivesOrganic non-macromolecular adhesivePolymer scienceOrganic solvent

The invention belongs to the technical field of adhesives, and discloses an optical film adhesive used for full bonding, a preparation method and application of the adhesive and an optical film basedon the adhesive. The adhesive composition disclosed by the invention has the characteristics of having excellent segment difference filling performance, having no corrosivity while satisfying the characteristics of preventing high temperature, high humidity and whitening because of water boiling, and being easy to peel off when being reworked. The optical film adhesive comprises the following components in parts by mass: 40-50 parts of an acrylate copolymer, 0.5-5 parts of a crosslinking agent, 0.5-10 parts of an acrylate monomer, 0.02-0.4 part of a photoinitiator, 0.01-1 part of an adhesion modifier, and 20-50 parts of an organic solvent. The optical film adhesive disclosed by the invention improves hydrophilicity of a material by controlling glass transition temperature Tg of the material and introduction of a hydroxyl group, achieves the effect of preventing whitening and fogging in high-temperature high-humidity or water boiling environments, and reacts with the crosslinking agent;and addition of a silane coupling agent is combined, so that the technical effect of easy reworkability is realized.

Owner:GUANGZHOU HUMAN ENG MATERIAL

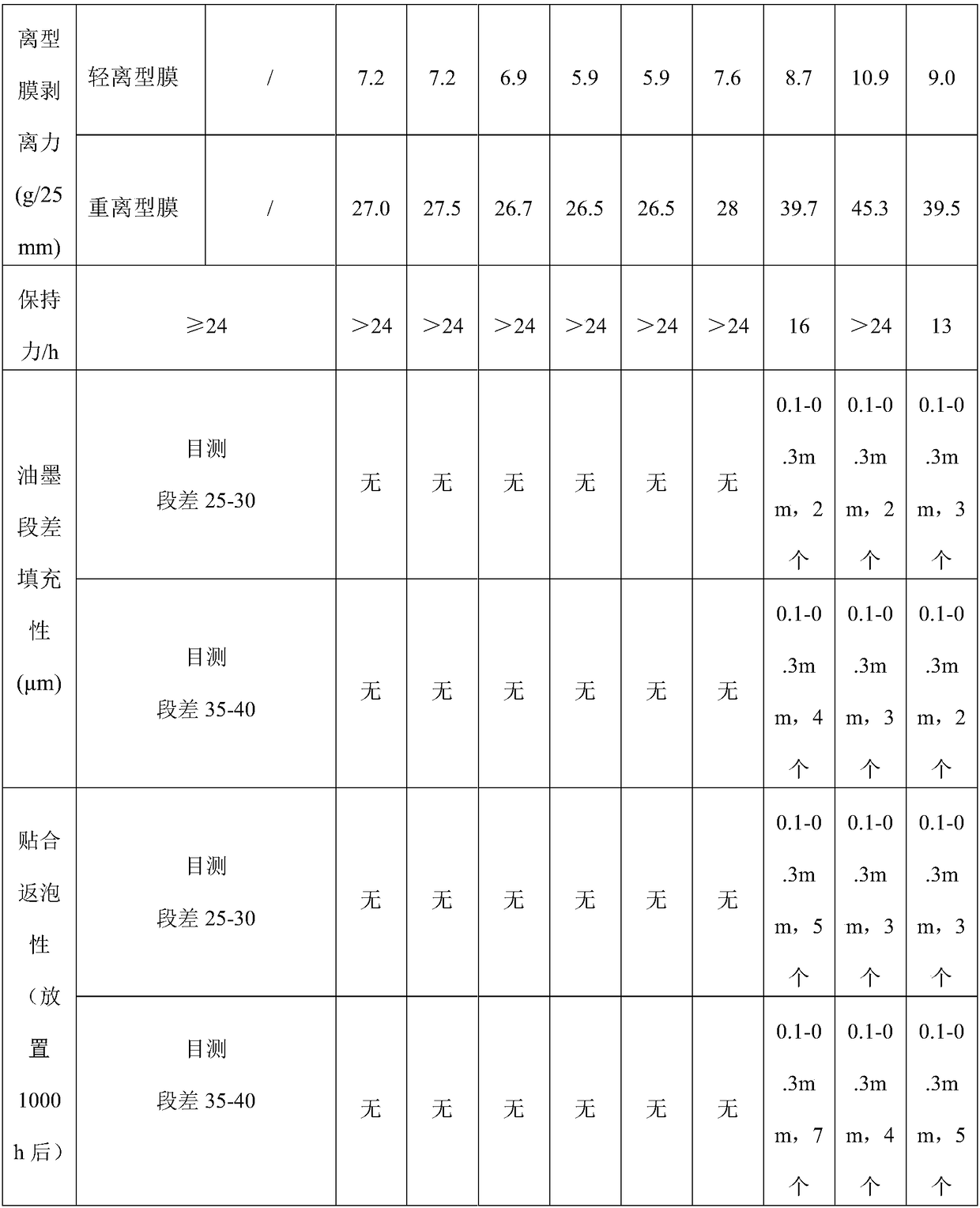

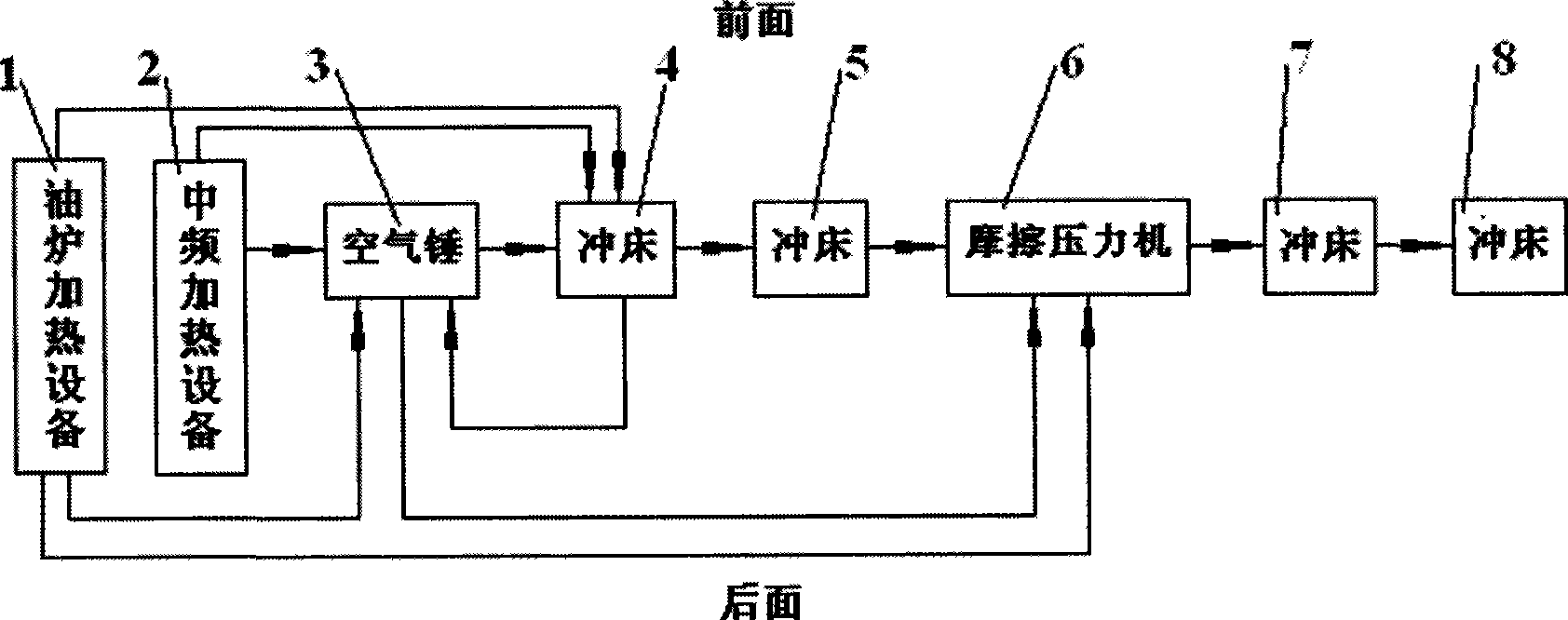

Forging device pipeline of complicated forging piece and forging production technique thereof

InactiveCN101456060AImprove surface qualitySolve billet problemsForging hammersForging press detailsProduction lineEngineering

The invention discloses a forging device production line for a complex forged piece, which comprises heating devices, a forging device and a transfer device. The forging device is a friction press (6) and is arranged according to forging technology, the number of the heating devices is two, and the two heating devices are arranged at two sides of the transfer device of the production line in parallel, wherein one heating device is a main heating device (1), and the other heating device is a double-heating device (2). The invention also provides corresponding forging production technology. The invention adopts a technical proposal to heat the shaped forged piece twice so as to meet the requirement of the forged piece with special request, and solves the repair problem of part of unqualified forged pieces at the same time.

Owner:安徽凯宇机械制造有限公司

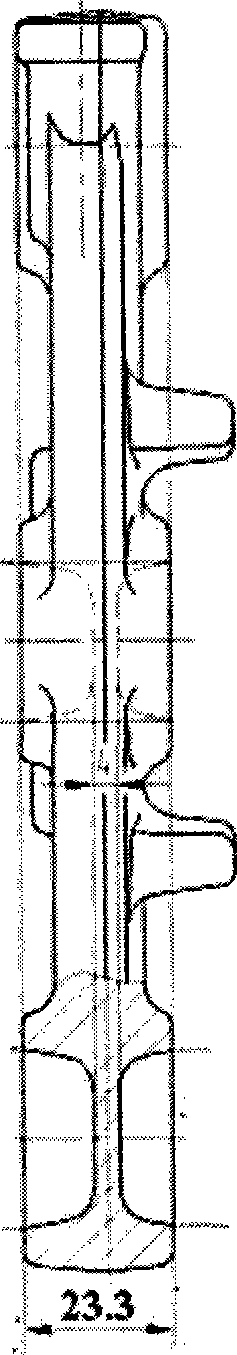

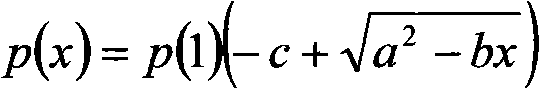

Manufacture method of all-optical fiber heavy pressure gas chamber based on hollow photon crystal optical fibre

InactiveCN101285908AGuaranteed certaintyGuaranteed vacuumCladded optical fibreOptical waveguide light guideDistillationEngineering

The invention discloses a manufacturing method for a full optical fiber high-pressure gas chamber based on a hollow-core photon crystal fiber. The steps of the invention are as follows: a) two ends of a hollow-core photon crystal fiber (1) are respectively communicated with an airtight A chamber (2) and an airtight B chamber (3), and one end of gas distribution equipment (4) is communicated with the airtight B chamber (3), and the other end of the gas distribution equipment (4) is respectively connected with a vacuum pump (5) and a gas source (6) to be inflated; b) the airtight B chamber (3) is connected with the vacuum pump (5) through the gas distribution equipment (4) first, after the required vacuum degree is achieved, the airtight B chamber (3) is connected with the gas source (6) to be inflated again through the gas distribution equipment (4) until air pressure of the airtight A chamber (2) is more than or equal to one atmospheric pressure; c)the two ends of the hollow-core photon crystal fiber (1) are successively welded with a standard single film fiber (10) within a range of less than or equal to 1.5 min; d) a distillation function p(x) of air pressure of a fiber core in the hollow-core photon crystal fiber (1) is derived from a formula p(x)=p(1)(-c+a2-bx); e) a final air pressure value of the full optical fiber high-pressure gas chamber is calculated by more than one p(x). The p(x) can accurately determine the air pressure value of the full optical fiber high-pressure gas chamber.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

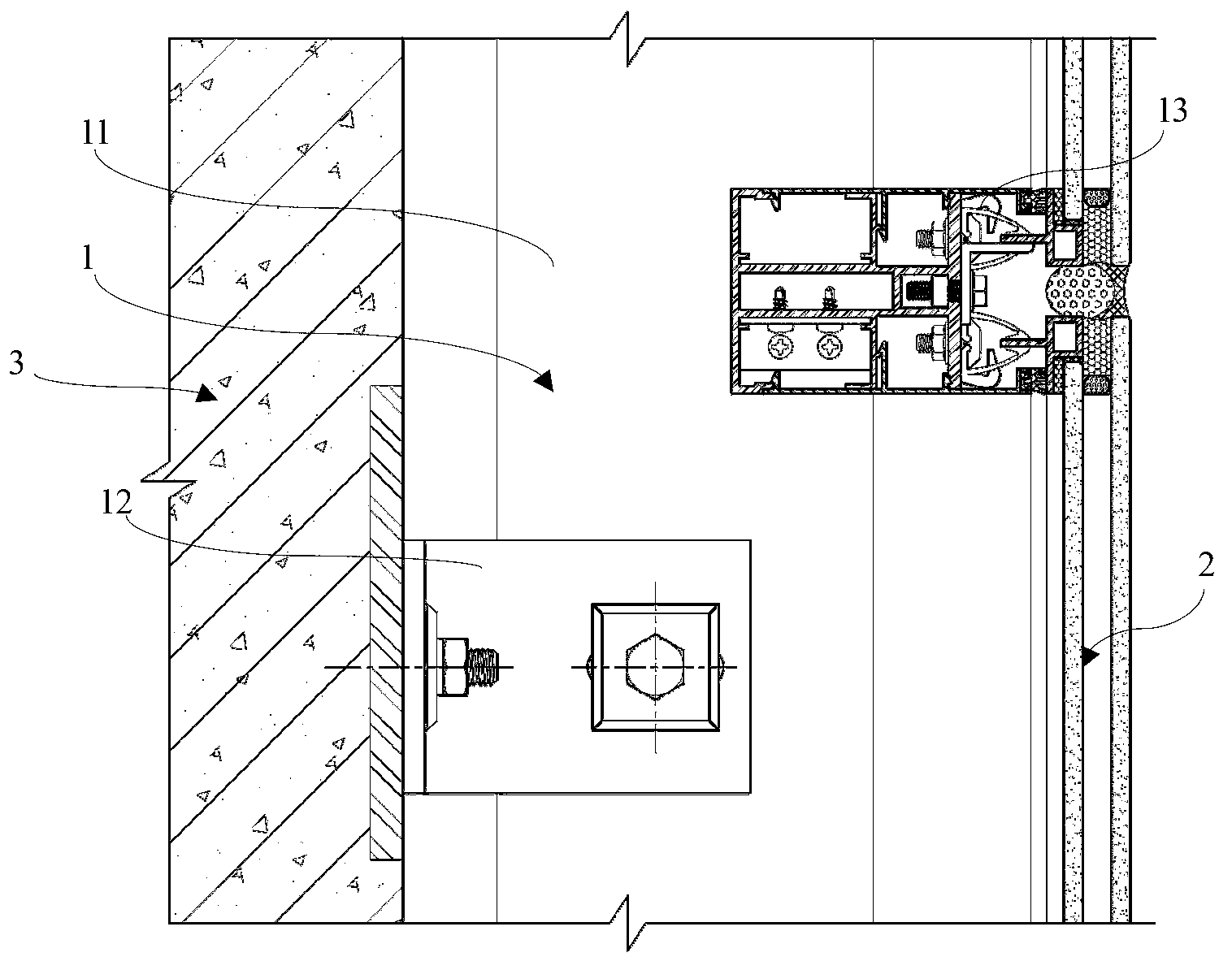

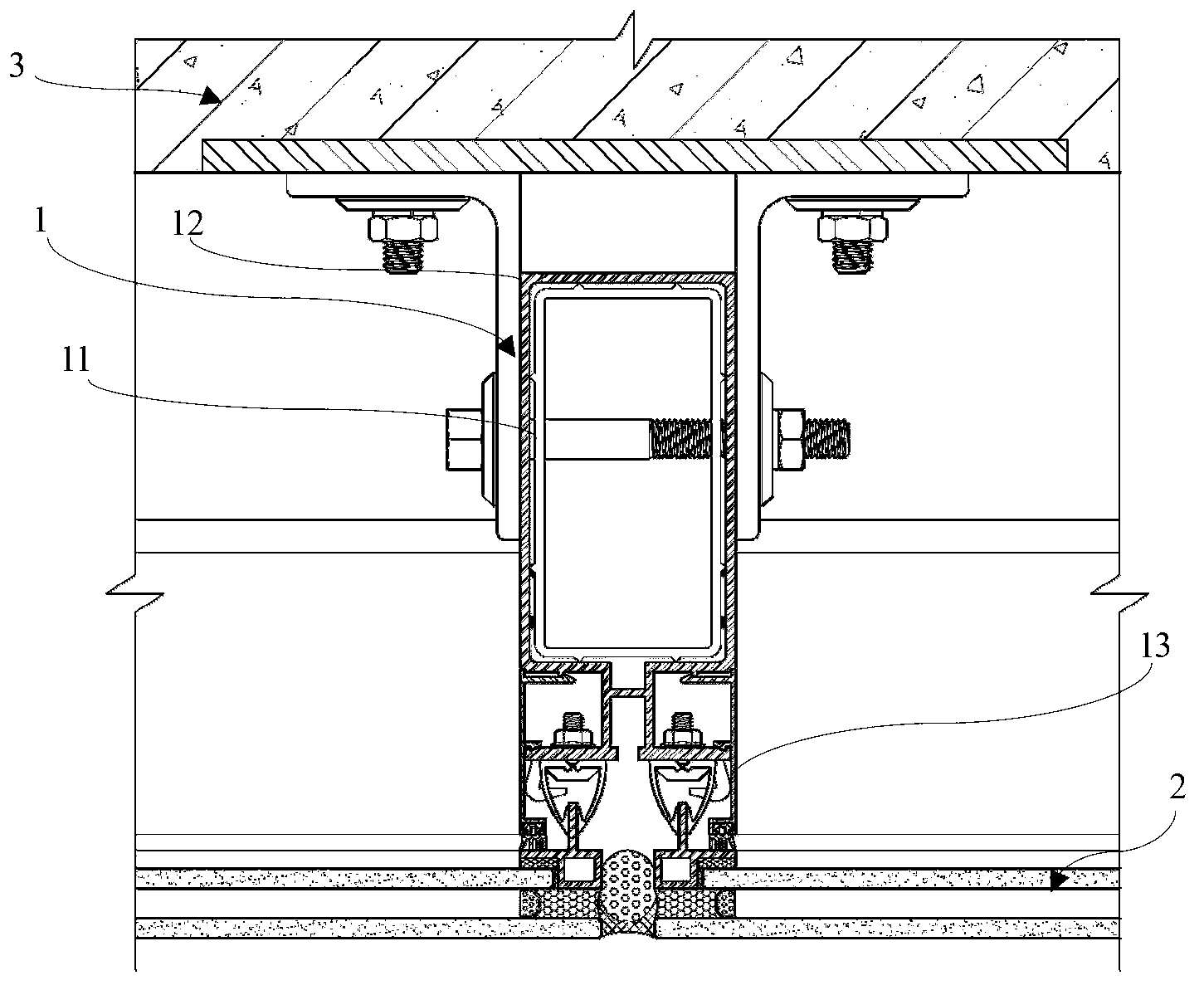

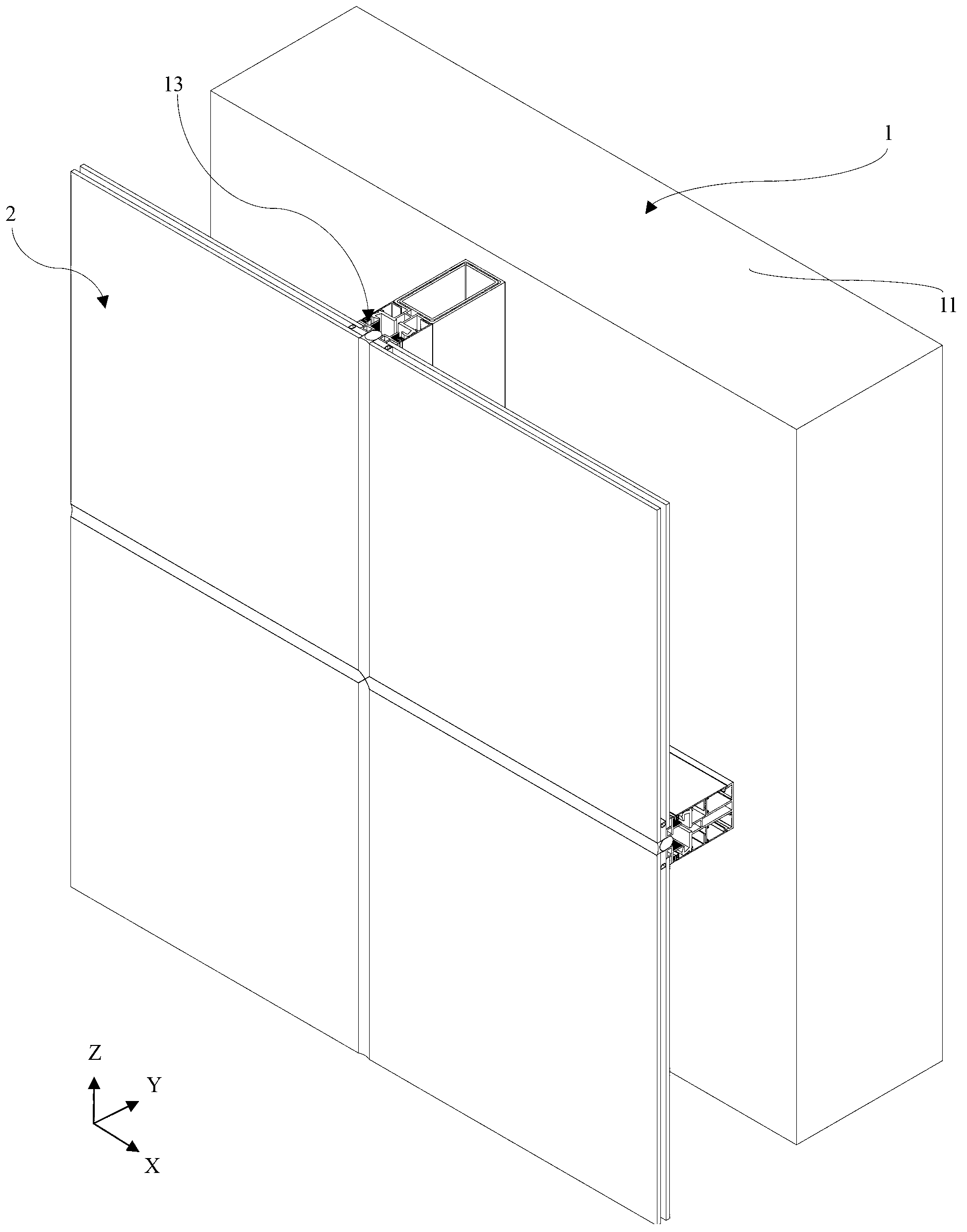

Hidden frame glass curtain wall installation structure and hidden frame glass curtain wall installation method

ActiveCN103306409AEffective prestressed fasteningMeet the requirements of installation accuracyCovering/liningsWallsChassisPrestressed structure

The invention discloses a hidden frame glass curtain wall installation structure which comprises a building main body and a glass curtain wall installed on the building main body, wherein the installation structure further comprises an installation chassis, the glass curtain wall is regulated through the installation chassis to a set position and is fastened, and the position of the glass curtain wall is unchanged in the fastening process. Due to the adoption of the hidden frame glass curtain wall installation structure, the hidden frame glass curtain wall installation structure exciting and controlling the dynamic production process of prestress of an elastic material to form a stable prestress structure and conducting three-dimensional regulation in the installation process to substantially improve the installation accuracy is provided, and the hidden frame glass curtain wall installation structure has the characteristics of excellent firmness, accuracy, safety, convenience and replacement.

Owner:明威科技集团股份有限公司

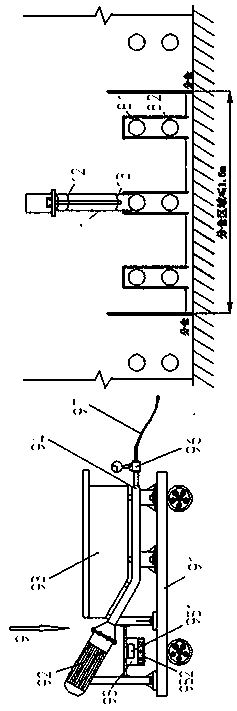

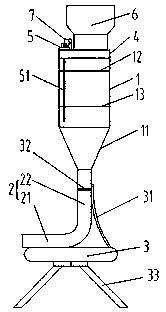

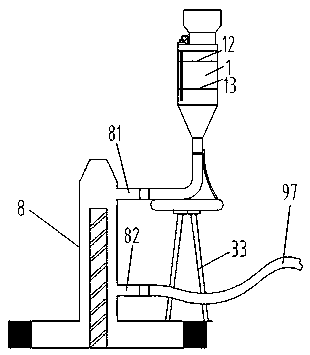

Fabricated type building automatic grouting equipment and method

PendingCN110043039AGuaranteed compactnessGrouting pressure guaranteeBuilding reinforcementsBuilding material handlingEngineeringElectric control

The invention relates to fabricated type building automatic grouting equipment and method. The grouting equipment includes a grouting machine and a grout replenishing device; the grouting machine includes a base frame, a grouting pump is arranged on the base frame, a material bin is connected to the inlet end of the grouting pump, and a grouting pipeline is connected to the outlet end of the grouting pump for the outlet end of the grouting pump communicating with a grouting opening of a grouting sleeve conveniently; the grout replenishing device comprises a vertical grout replenishing main cylinder body, and a communicating pipe is arranged at the lower end of the grout replenishing main cylinder body for the lower end of the grout replenishing main cylinder body communicating with a groutoutlet of the grouting sleeve conveniently; a pressurizing mechanism is arranged at the upper end of the grout replenishing main cylinder body for providing additional grout replenishing pressure besides gravity grout replenishing during grout replenishing; the grout replenishing main cylinder body is further provided with a liquid level sensor for detecting the liquid level height of a groutingmaterial entering the grout replenishing main cylinder body; and the base frame is provided with a controller, and the controller is in signal connection with the liquid level sensor and is connectedwith the grouting pump in an electronic control mode for controlling starting and stopping of the grouting pump according to detection signals of the liquid level sensor. The fabricated type buildingautomatic grouting equipment and method have the effects that construction can be more convenient, and grouting quality can be effectively guaranteed.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

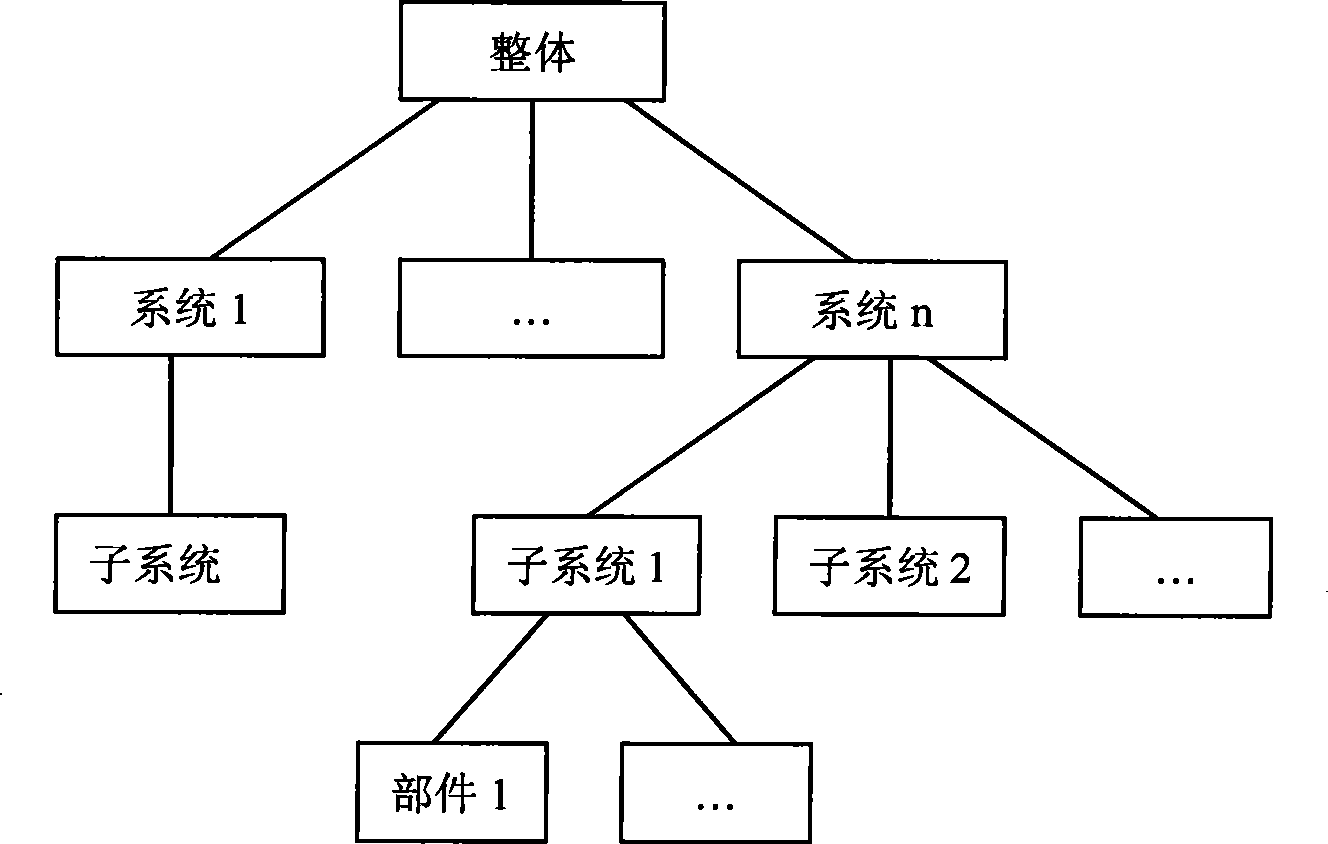

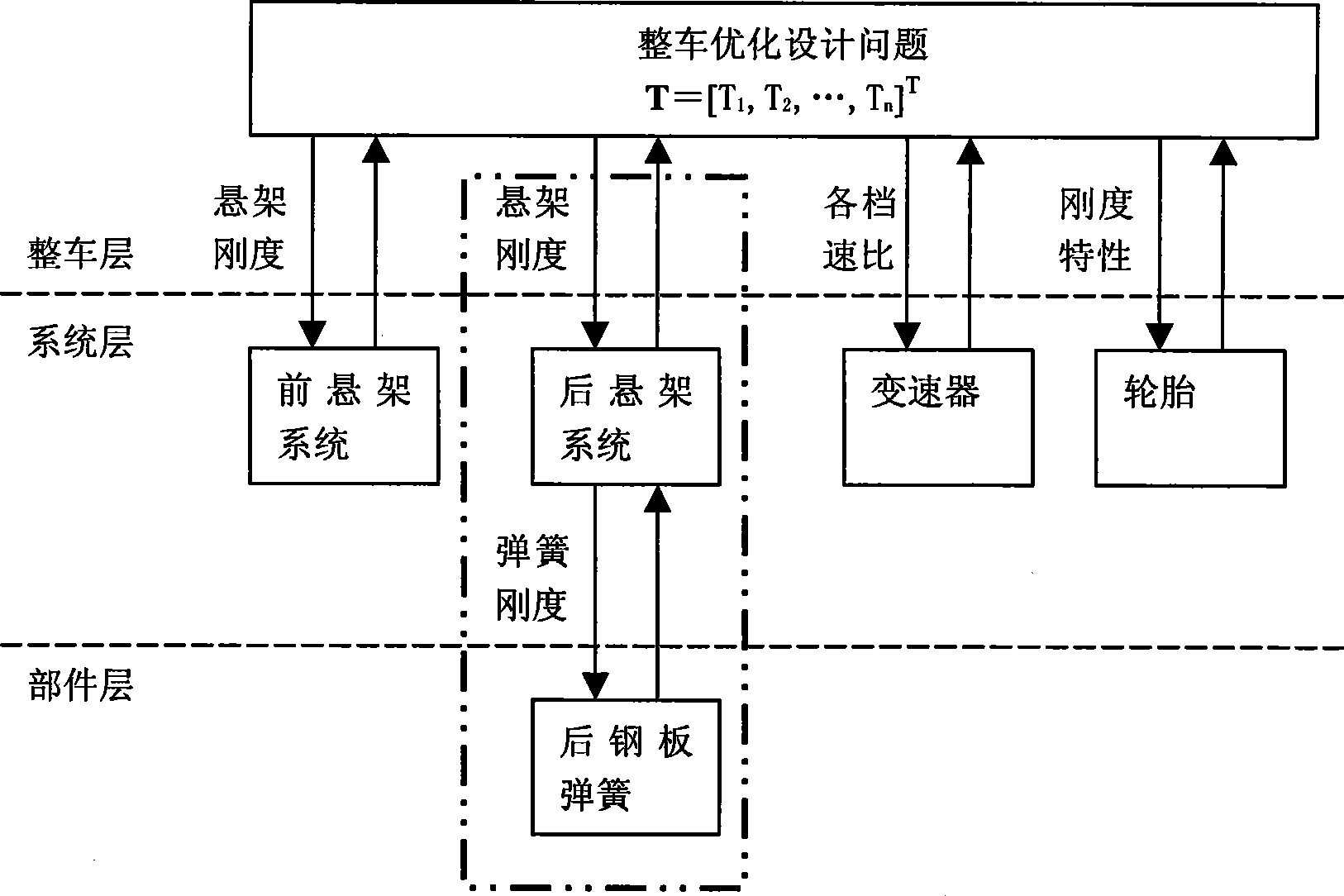

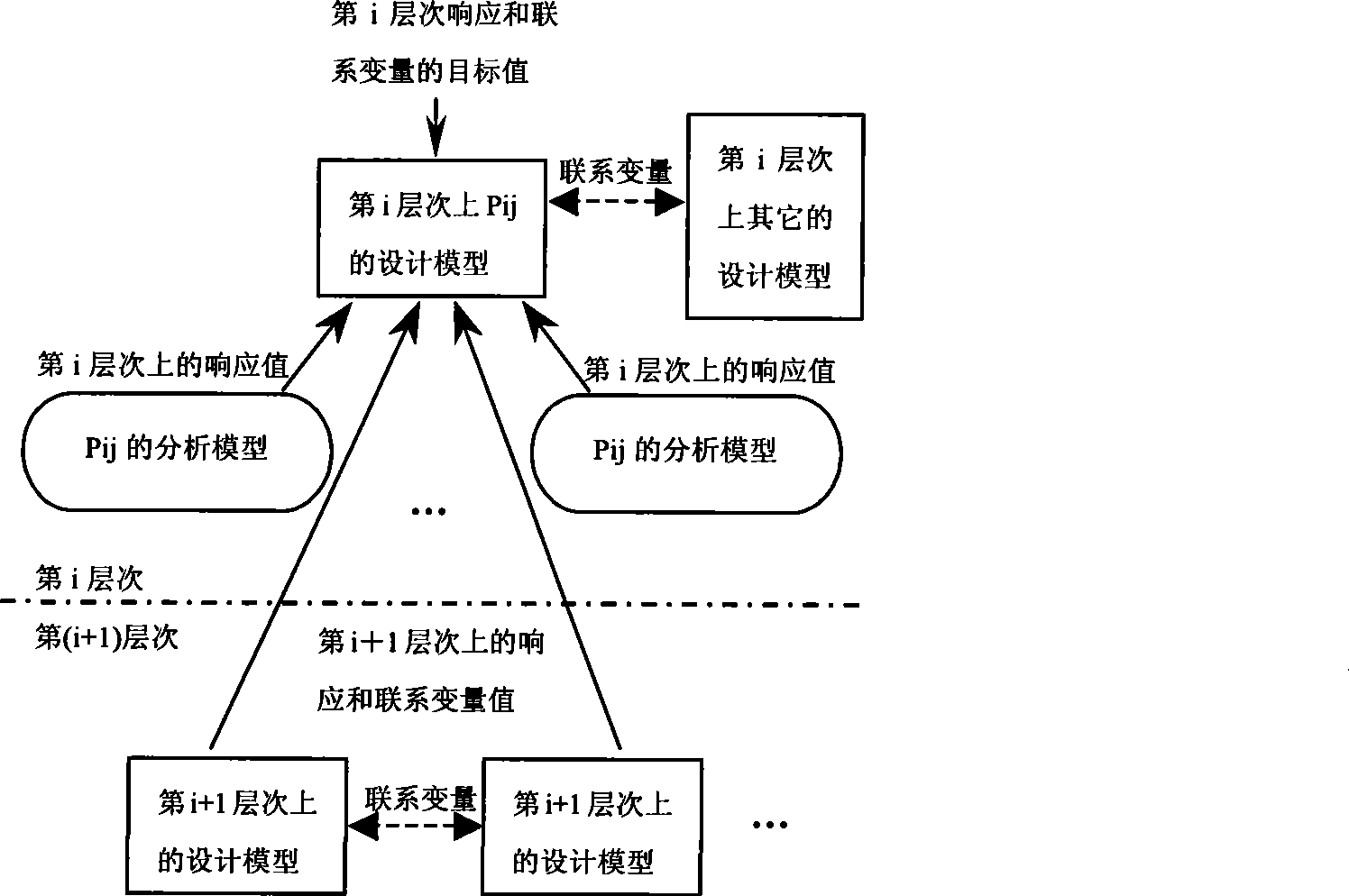

Method for optimizing automobile product development system based on hierarchical decomposition

InactiveCN101436219AStrong independenceIncrease flexibilityAerodynamics improvementSpecial data processing applicationsModularityPerformance index

The invention relates to a method for optimizing an automobile product development system based on hierarchical decomposition. The method comprises: determining an optimized product development target; transmitting the development target in the entire vehicle hierarchy to lower hierarchies, namely the system hierarchy and the component hierarchy; realizing synergistic optimized solving among various hierarchies; and realizing the flexibility of a development task and modularized execution of development subtasks by combing the method with a multidisciplinary design optimization method. The invention provides the method which has quick convergence speed and high solving quality and can simultaneously realize optimization of development performance indexes and a design proposal in the entire vehicle hierarchy, the system hierarchy and the component hierarchy.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

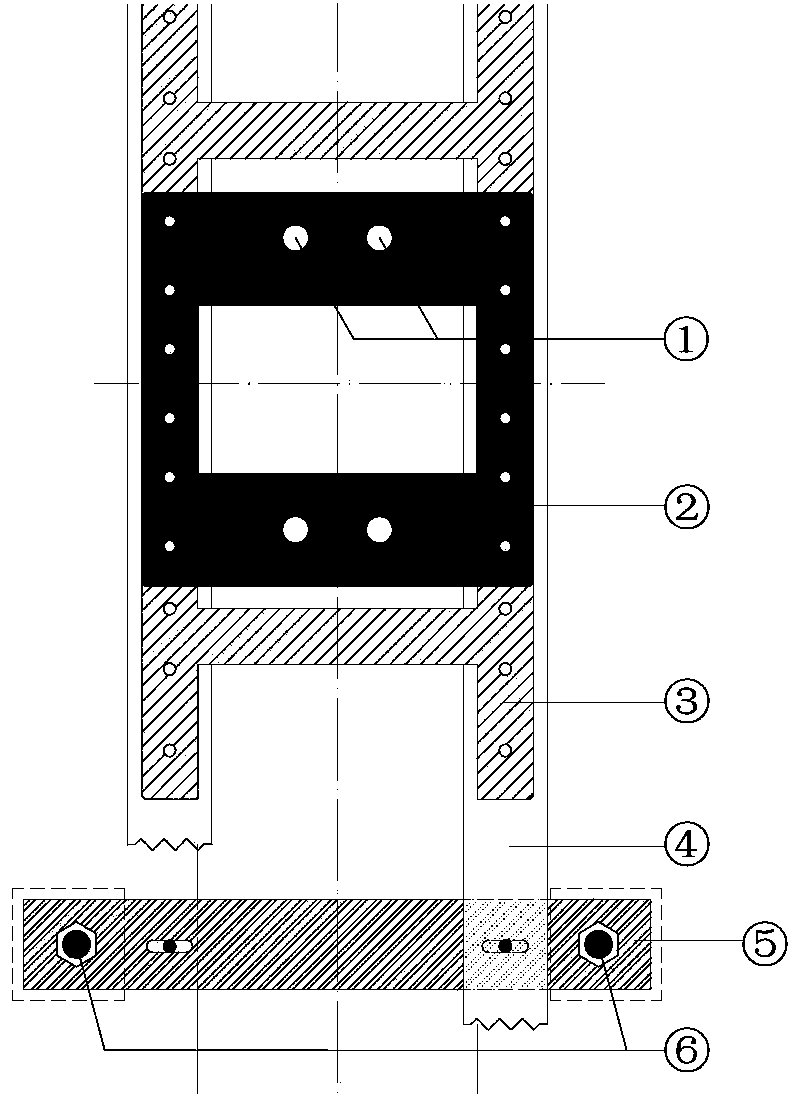

Self-propelled hollow slip casting anchor rod with stress-measuring function and operating method

InactiveCN107905827ASimplify the construction processImprove construction efficiencyAnchoring boltsStress measuresStress conditions

The invention relates to the technical field of tunnel and underground construction anchoring equipment, in particular to a self-propelled hollow slip casting anchor rod with a stress-measuring function and an operating method. The self-propelled hollow slip casting anchor rod with the stress-measuring function includes a rod body with a hollow structure, a self-propelled drill is connected at thefront end of the rod body, and the back end of the rod body is provided with a slip casting opening which communicates with an inner cavity of the rod body; and the rod body is further provided witha stress-measuring device and an anchoring structure which is close to the self-propelled drill. According to the self-propelled hollow slip casting anchor rod with the stress-measuring function, thestress-measuring device is arranged to combine the processes of drilling, anchoring and slip casting into the same construction process, and the anchoring can be achieved in short time; and stress conditions of all sections of the anchoring rod in the supporting process can be monitored, so that the supporting mechanism of action and the stress conditions of the anchoring rod under the various kinds of surrounding rock conditions can be known, and critical evidences and references are supplied to the research of design parameters for the anchoring rod, improvement of the construction techniqueand the surrounding rock failure mechanism.

Owner:SOUTHWEST PETROLEUM UNIV

Non-metal pipeline hydraulic pressure seepage verifying attachment

InactiveCN102426084ALess investmentLow costMeasurement of fluid loss/gain rateExhaust valveWater flooding

The invention provides a non-metal pipeline hydraulic pressure seepage verifying attachment. A system of the non-metal pipeline hydraulic pressure seepage verifying attachment comprises a rectangle framework body, a bell end bulkhead, a jack bulkhead, a pipeline holt hoop iron, a jack, a water flooding pressure measurement system on the bell end bulkhead, and an operation method. The invention is characterized in that: the rectangle framework body forms a rectangle through channel steel welding, length of the rectangle is set according to length of a segment of pipeline, width of the rectangle is set according to a maximal diameter of a detected pipeline, and the rectangle framework body is provided with the pipeline holt hoop iron inside; one end of an intake and exhaust connecting pipe is connected with the bell end bulkhead, the other end of the intake and exhaust connecting pipe is connected with one end of a pressurization opening valve, an intake and exhaust valve and a pressure maintaining opening valve respectively, the other end of the pressurization opening valve is connected with a pressurization pressure gauge, and the other end of the pressure maintaining opening valve is connected with a pressure maintaining pressure gauge; the operation method is carried out according to certain steps. The verifying attachment has small investment, low cost and low technology difficulty, and is applied to a field pipeline construction site and a small scale pipeline production manufacturer.

Owner:YUNNAN NO 5 CONSTR ENG

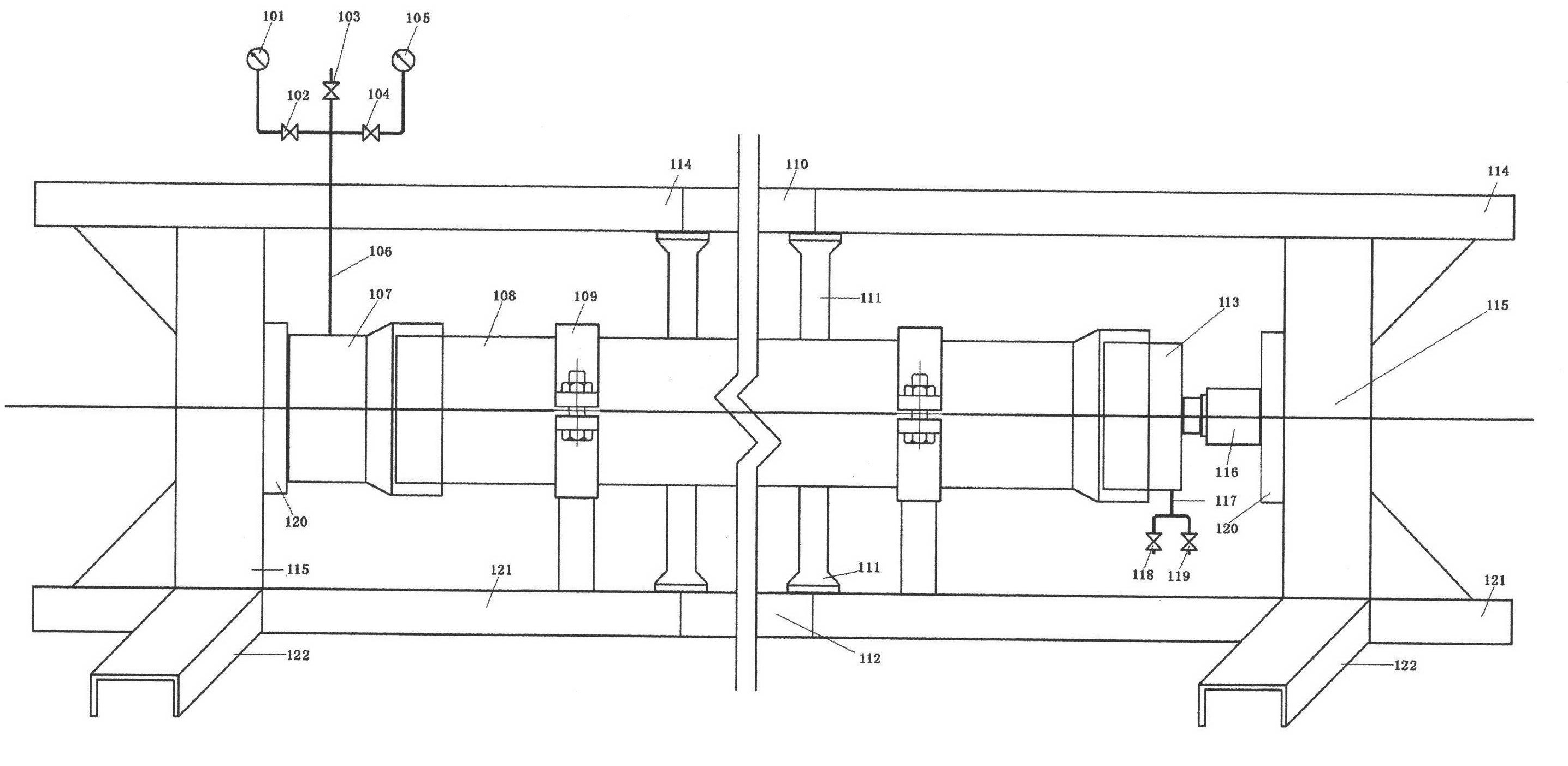

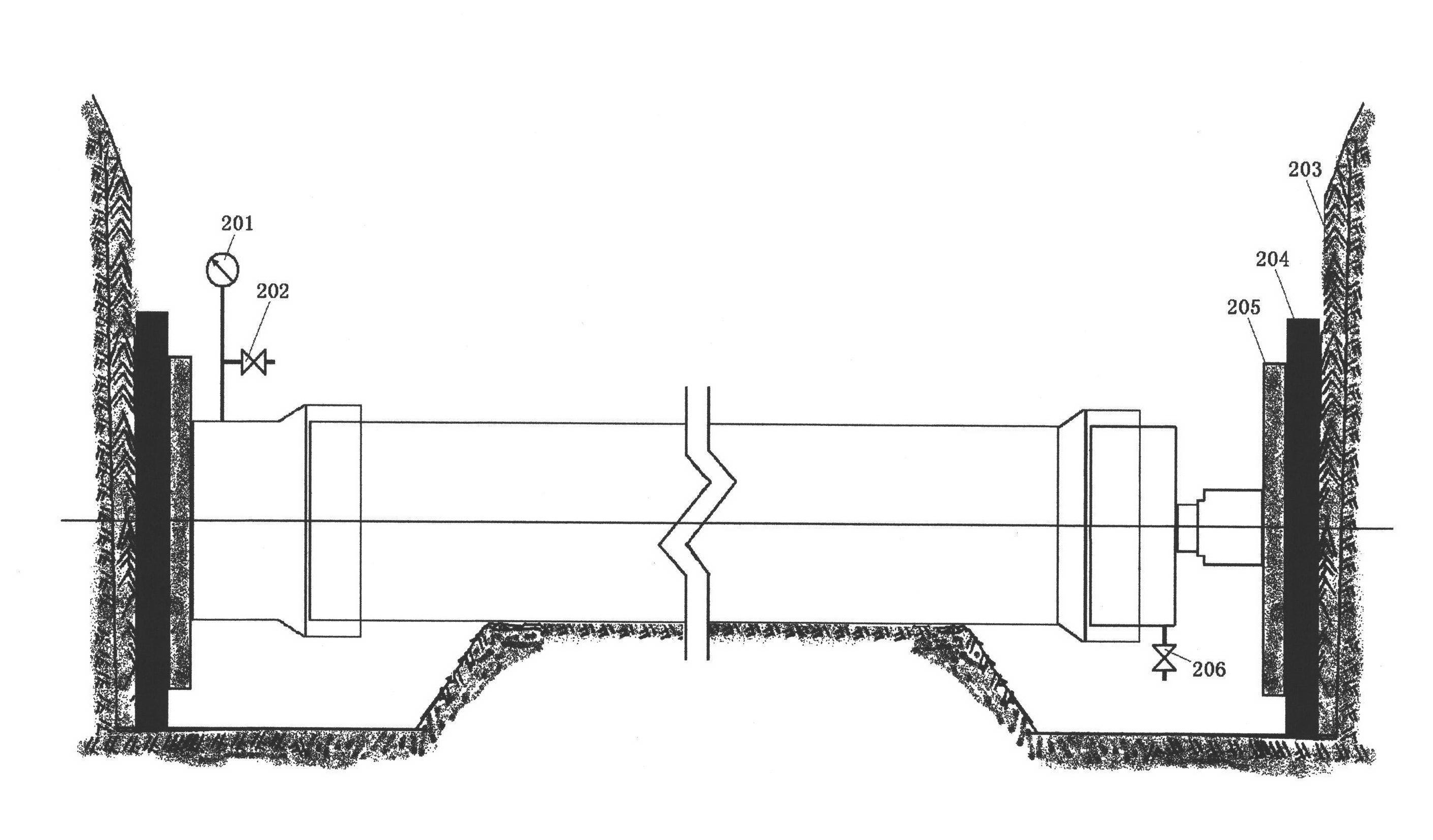

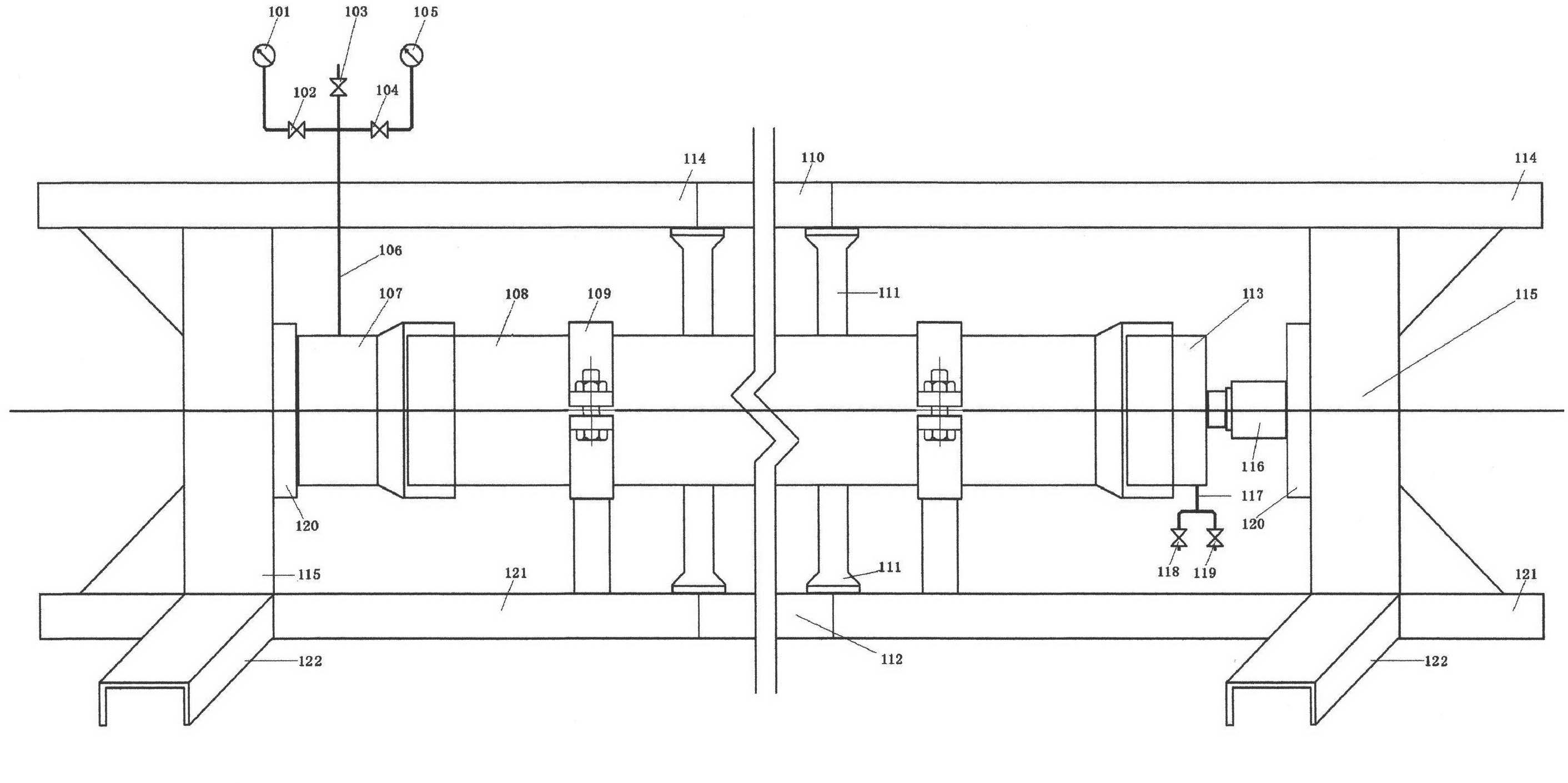

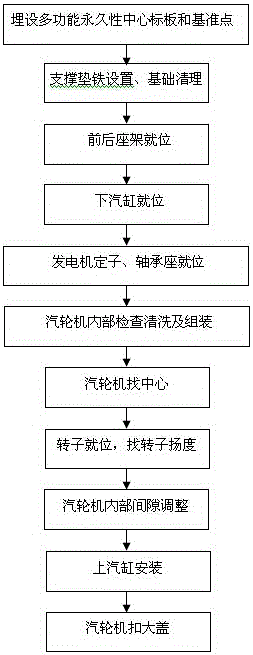

Method for mounting condensing steam turbines

ActiveCN106285793AReference measurement error minimizationReduce labor efficiencyMachines/enginesEngine componentsImpellerStator

The invention particularly discloses a method for mounting condensing steam turbines. The method is characterized by comprising embedding multifunctional permanent central standard plates and reference points; arranging support sizing blocks and cleaning foundations; mounting front and rear seat frames; mounting lower steam cylinders; mounting stators of power generators and bearing blocks; checking, cleaning and assembling the insides of the steam turbines and centering the steam turbines; finding up-rising inclination of rotors of the steam turbines and adjusting internal clearance of the steam turbines; mounting upper steam cylinders; assembling large covers of the steam turbines by means of fastening. The method has the advantages that reference measurement errors due to reference point and central standard plate embedding can be minimized; environmental influence on the labor efficiency when the steam cylinders are centered can be reduced; the accuracy of clearance between impellers and steam seals can be guaranteed; the mounting quality can be guaranteed by quality pre-control processes, accordingly, reworking phenomena can be completely eradicated, work can be effectively carried out at one step, the labor productivity can be improved, and the mounting construction periods can be guaranteed; the purpose of carrying out successful trial run at one step can be achieved, and excellent technical and economical effects can be realized.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Short-distance coal seam roadway excavating and supporting method

ActiveCN106014423AThe method steps are simpleEasy to implementUnderground chambersTunnel liningSupporting systemShortest distance

The invention discloses a short-distance coal seam roadway excavating and supporting method. The method comprises steps as follows: 1, basic mechanical parameters of surrounding rock are determined; 2, reserved excavated volumes of two sides of a roadway are determined; 3, the roadway is excavated; 4, a roadway side supporting structure is determined and comprises roadway supporting units and grouted rock bolts which are arranged in a staggered manner, and the roadway supporting units comprise top plate supporting systems, bottom plate supporting systems and roadway side supporting systems; and the limit caving arch rise is determined; 5, the roadway supporting structure is determined; 6, roadway surrounding rock supporting construction is performed; 7, excavation of the next section and roadway surrounding rock supporting construction are performed; 8, the step 7 is repeated multiple times, and the short-distance coal seam roadway construction process is completed. The method is simple, reasonable in design, convenient to realize and good in use effect, the reserved excavated volumes of the two sides of the roadway are determined respectively according to surrounding rock deformation conditions of the short-distance lower coal seam roadway, and whole section supporting is performed on the roadway through combination of the grouted rock bolts with the roadway supporting units.

Owner:鄂尔多斯市国源矿业开发有限责任公司

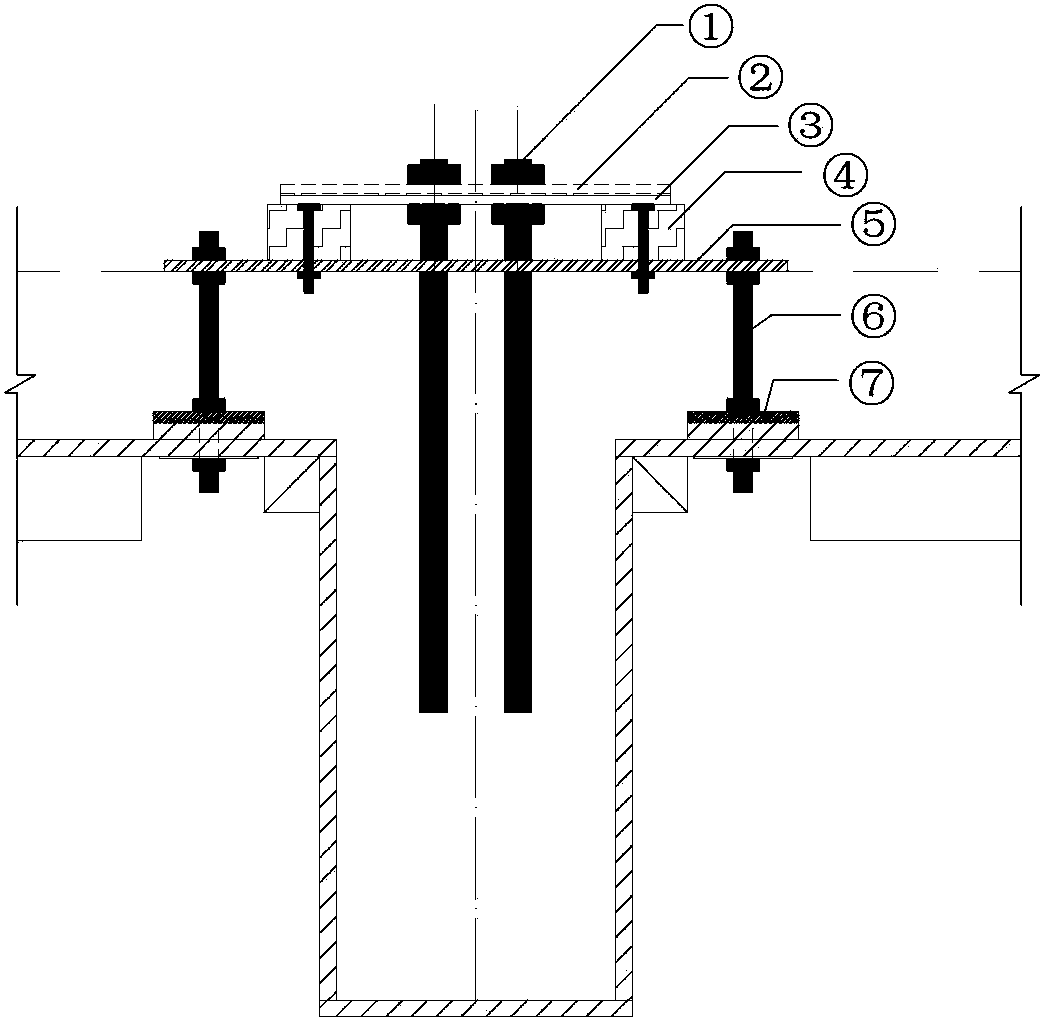

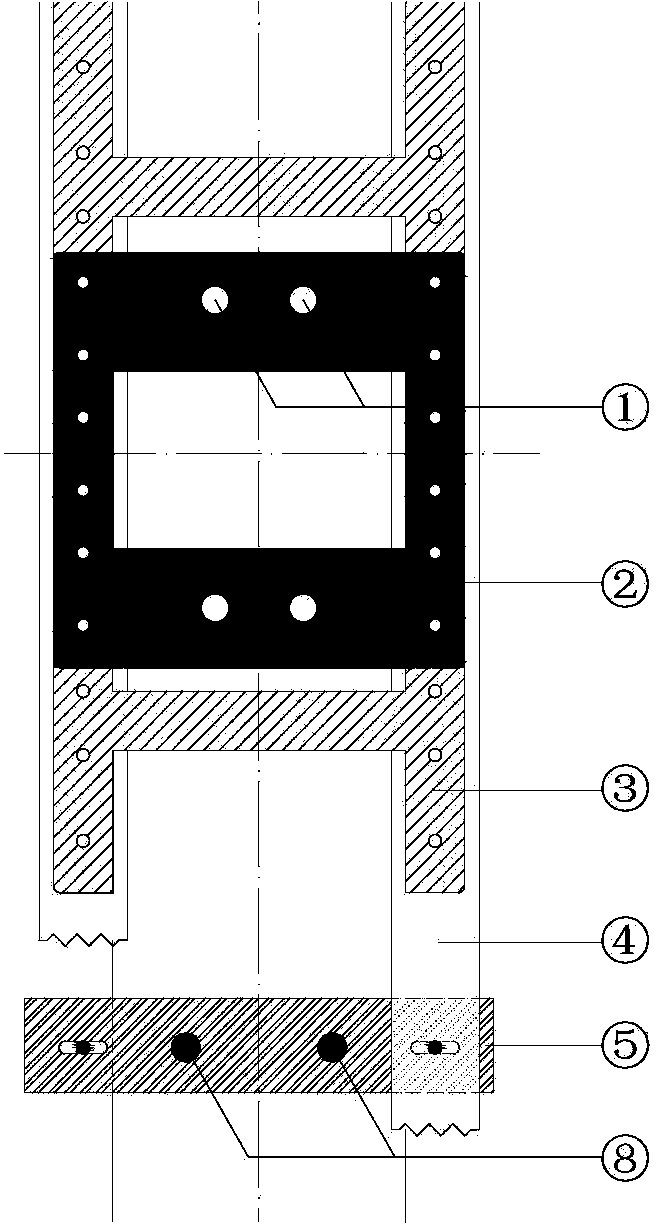

Adjustable positioning structure for pre-buried bolt double-layered positioning plate and construction method

ActiveCN103397701AGuaranteed accuracyGuaranteed installation accuracyFoundation engineeringBuilding material handlingProcess qualityBuilding construction

The invention discloses an adjustable positioning structure for a pre-buried bolt double-layered positioning plate and a construction method. The structure comprises four additional pre-buried bolts vertically arranged at the four corners of a rectangle, wherein additional iron plates are arranged on the front side edge and the back side edge of the rectangle; two wood beams are parallelly arranged between the two additional iron plates; position adjusting holes are formed in the additional iron plates; a michinaga positioning plate adopting a frame structure is mounted on the wood beams; a socle positioning plate is mounted on the michinaga positioning plate in a hanging manner; socle pre-buried bolts are mounted on the socle positioning plate. During the whole process of mounting the adjustable positioning structure for the double-layered positioning plate, the mounting of each step is adjustable, the process quality control is facilitated, the mounting precision of pre-buried bolts is ensured, and the reworking is avoided. Through the practical application on the construction site, and through the adoption of the adjustable positioning structure for the double-layered positioning plate provided by the invention to carry out the construction of the pre-buried bolts, the allowable deviation of the pre-buried bolts in a practical project is larger than the national regulation requirement.

Owner:ZHONGTIAN CONSTR GROUP +1

Method of active coupling support in time and space for control of minimum deformation of surrounding rock of deep well roadway

InactiveCN102337903AEffective control with minimum deformationInhibits the evolution of deformation damageUnderground chambersTunnel liningCouplingPre stress

The invention discloses a method for active coupling support in the time and space for control of minimum deformation of surrounding rocks of a deep well roadway, which is characterized by comprising: excavating a roadway according to the shape of the cross section of the roadway; immediately supporting the surrounding rocks of the roadway with steel bar nets and high-strength prestressed anchor rods so as to promptly limit the deformation of the surrounding rocks; reinforcing the support with high-strength prestressed anchor ropes in the middle of the top plate of the roadway and two spandrels of the roadway to inhibit expansion of destruction; within 20-30 days after roadway tunneling, installing grouted anchor tubes on the surrounding rocks of the top plate, two shoulder supports and abottom plate of the roadway, and grouting cement slurry into the surrounding rocks of the roadway for grouting reinforcement to maintain the stability of the surrounding rocks; and finally backfilling concrete to level the bottom plate of the roadway. In the method, supports of different strengths are emphasized in different periods and on different parts of the roadway, the best active coupling support in the time and space can be achieved for roadway supporting, the deformation of the surrounding rocks of the roadway can be controlled within the minimum range, the repair of the roadway can be avoided, and the long-term safety and stability of the roadway can be achieved.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com