Patents

Literature

89 results about "Maximal diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

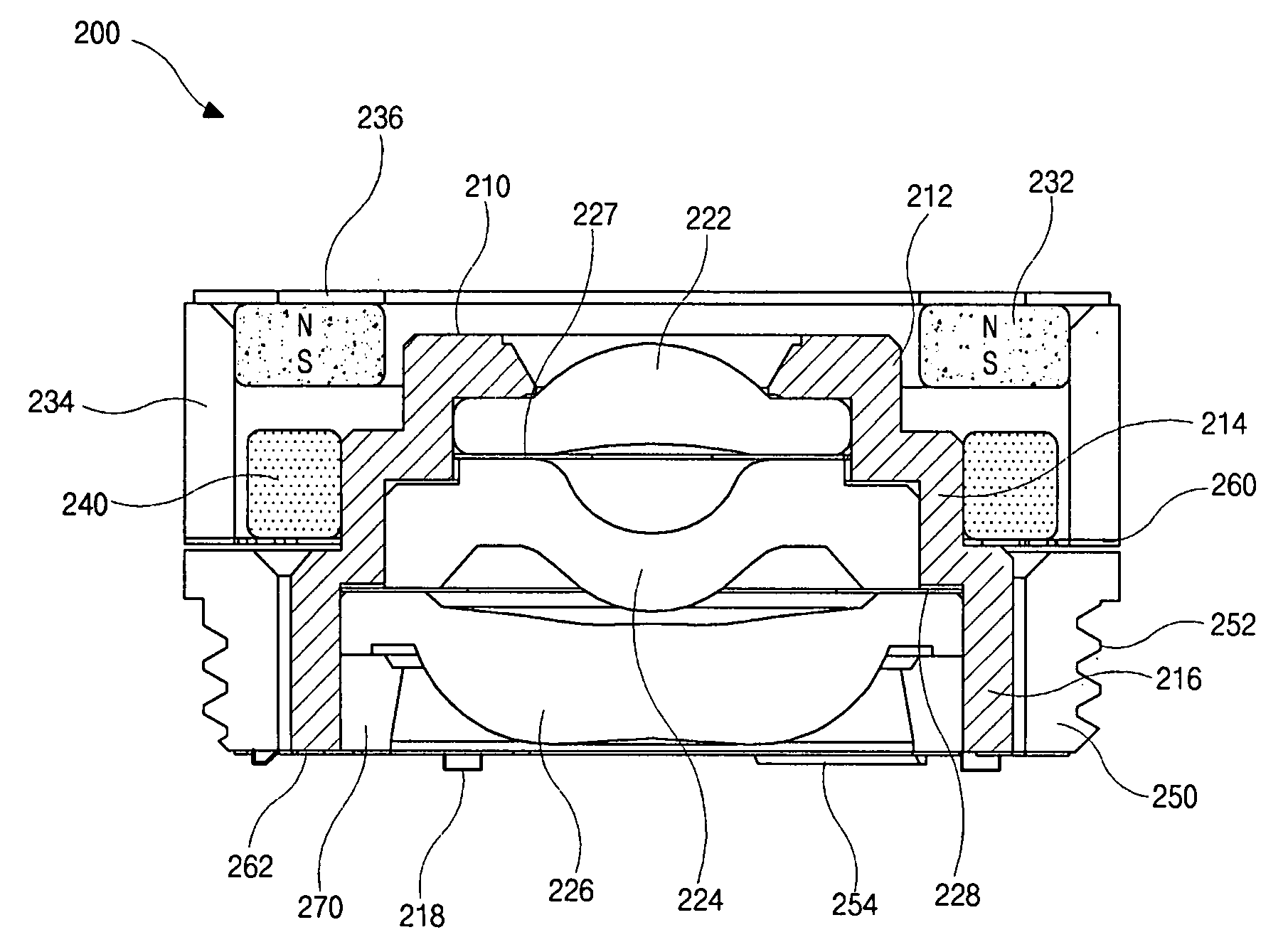

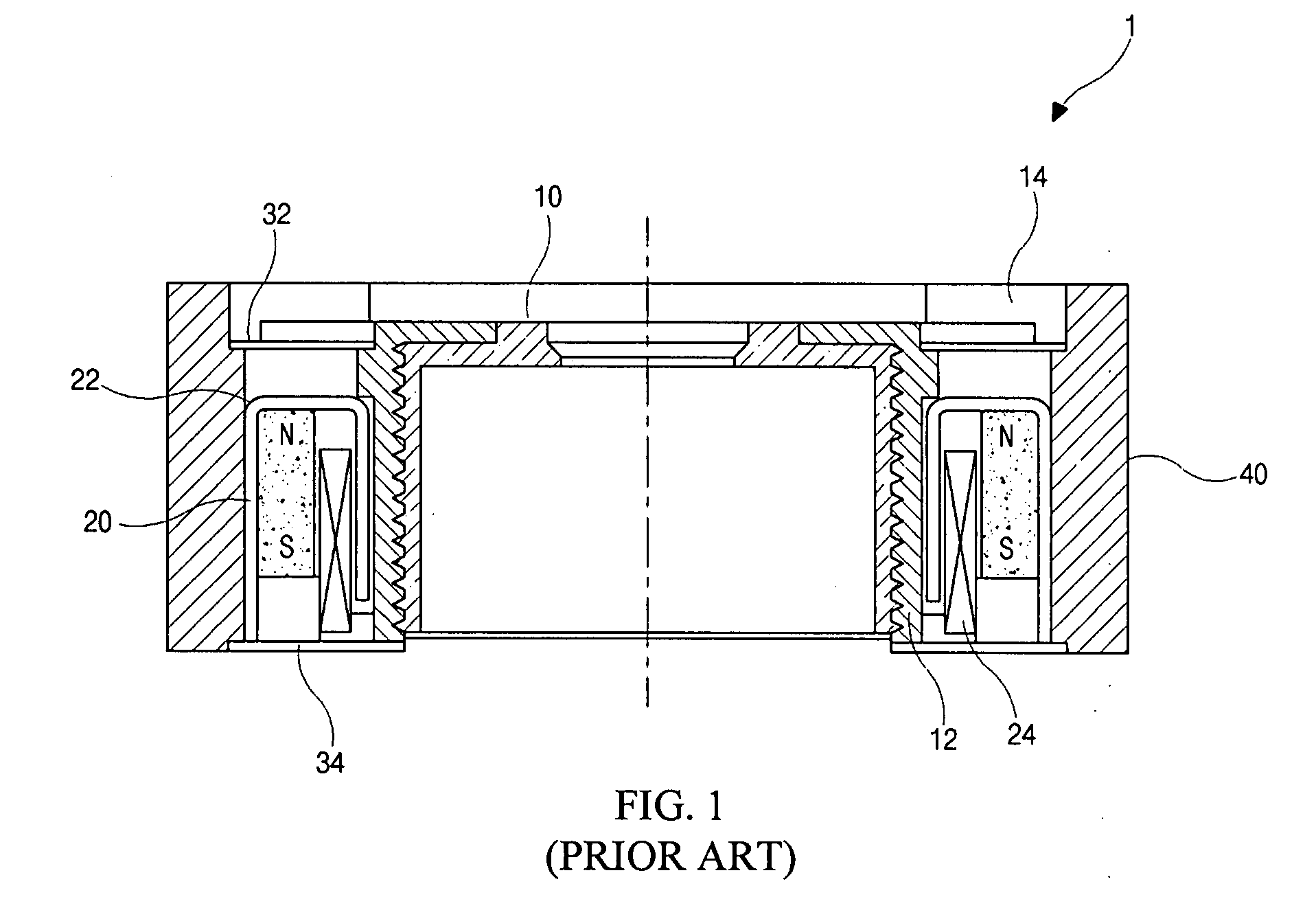

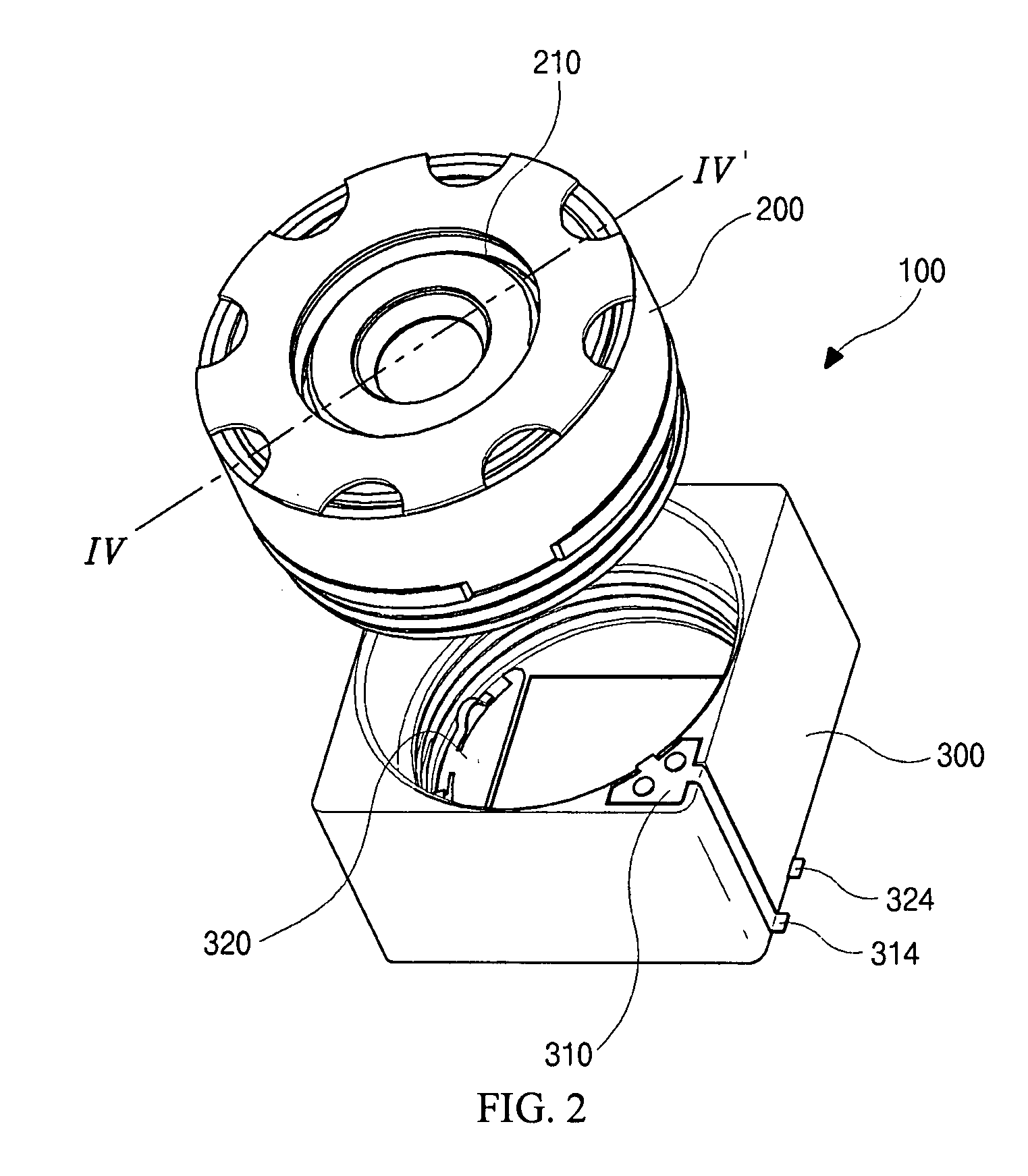

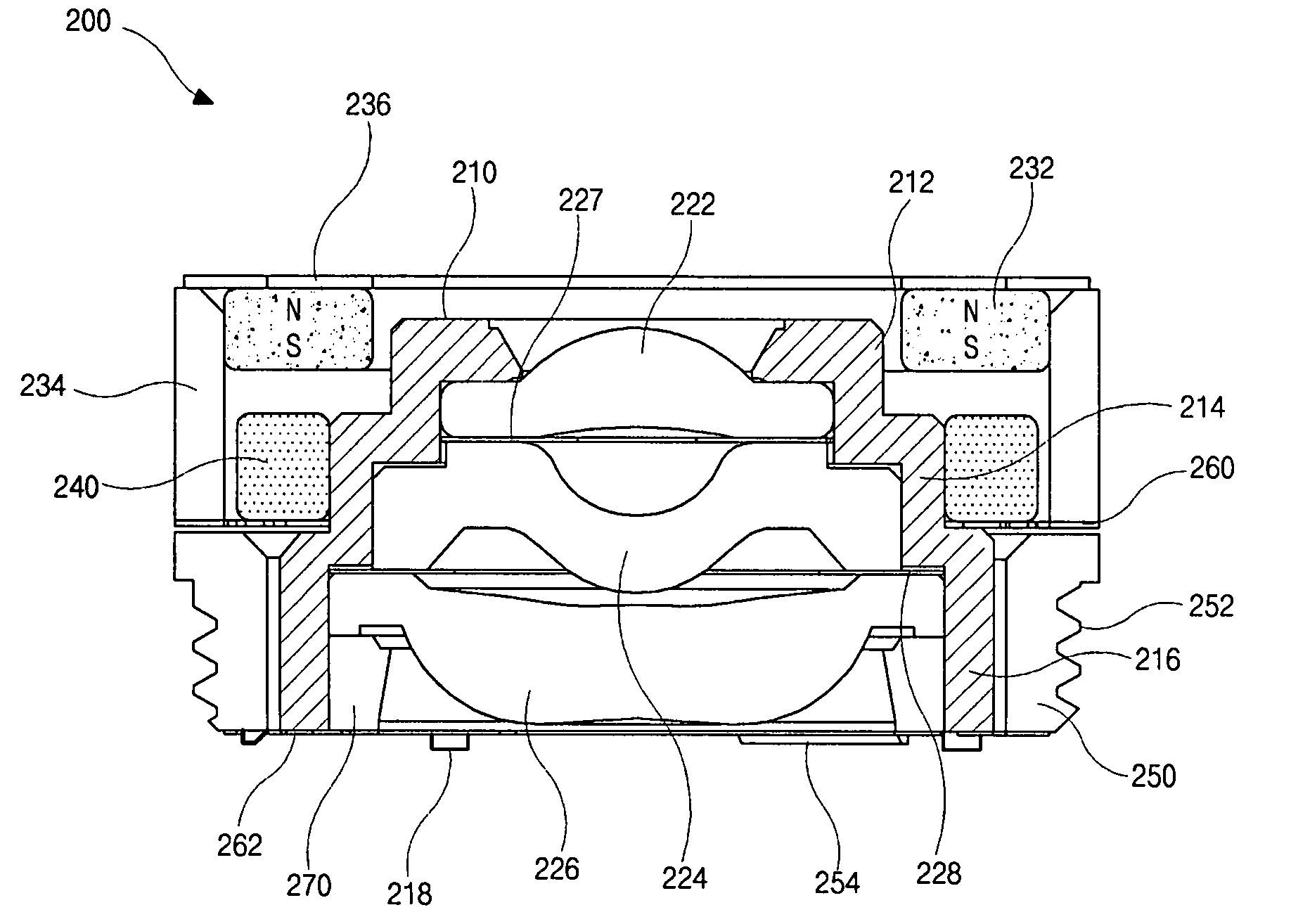

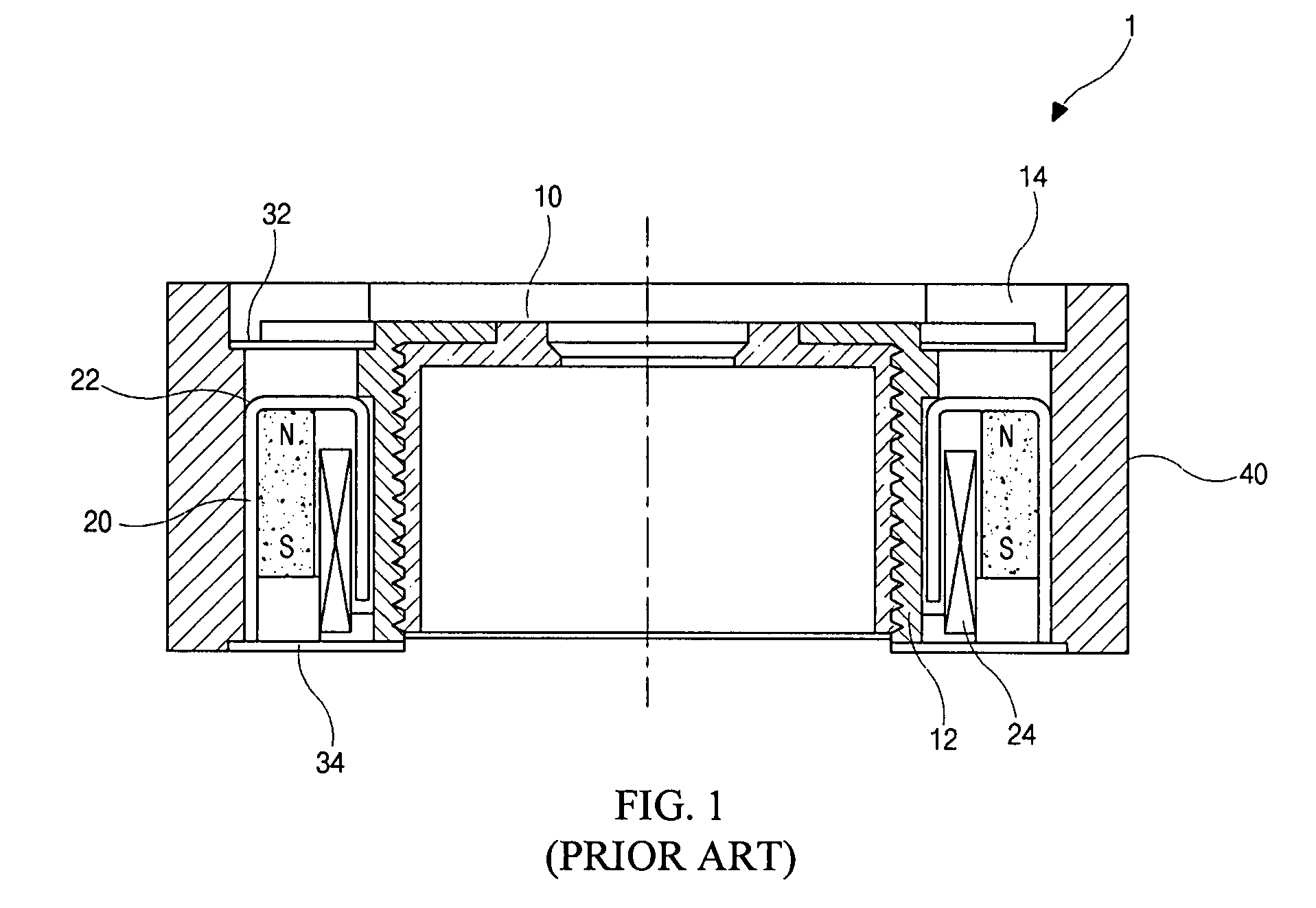

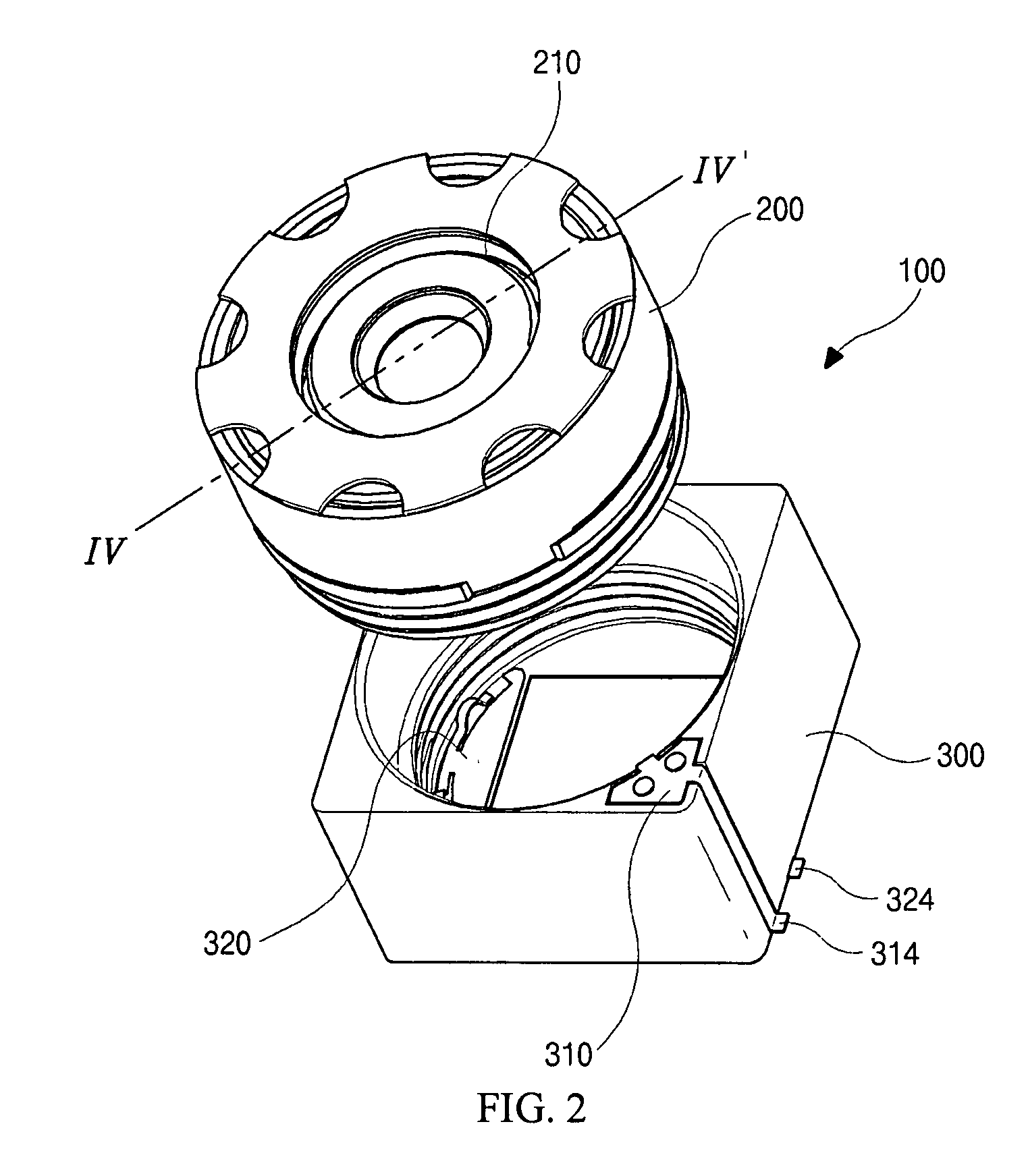

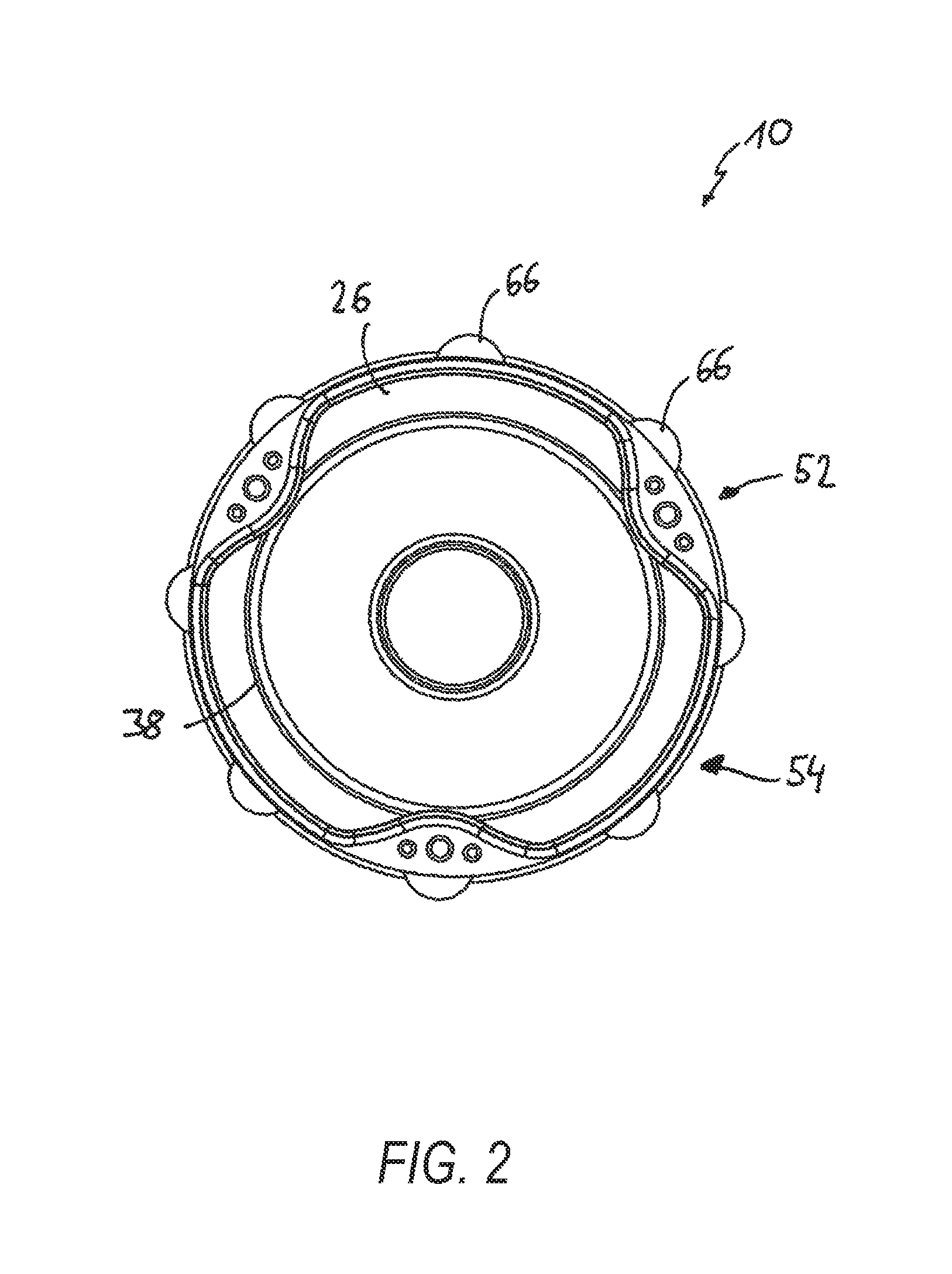

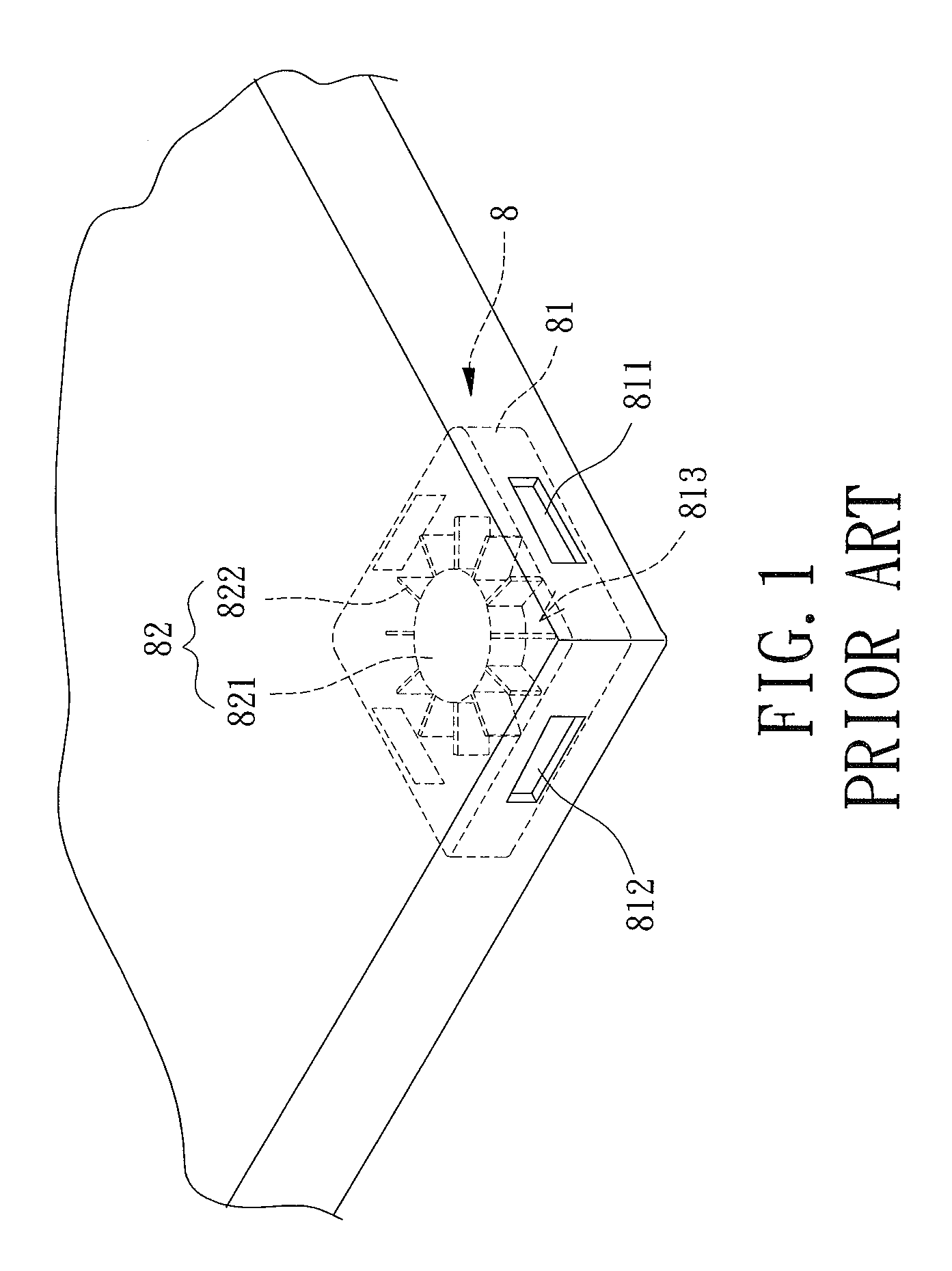

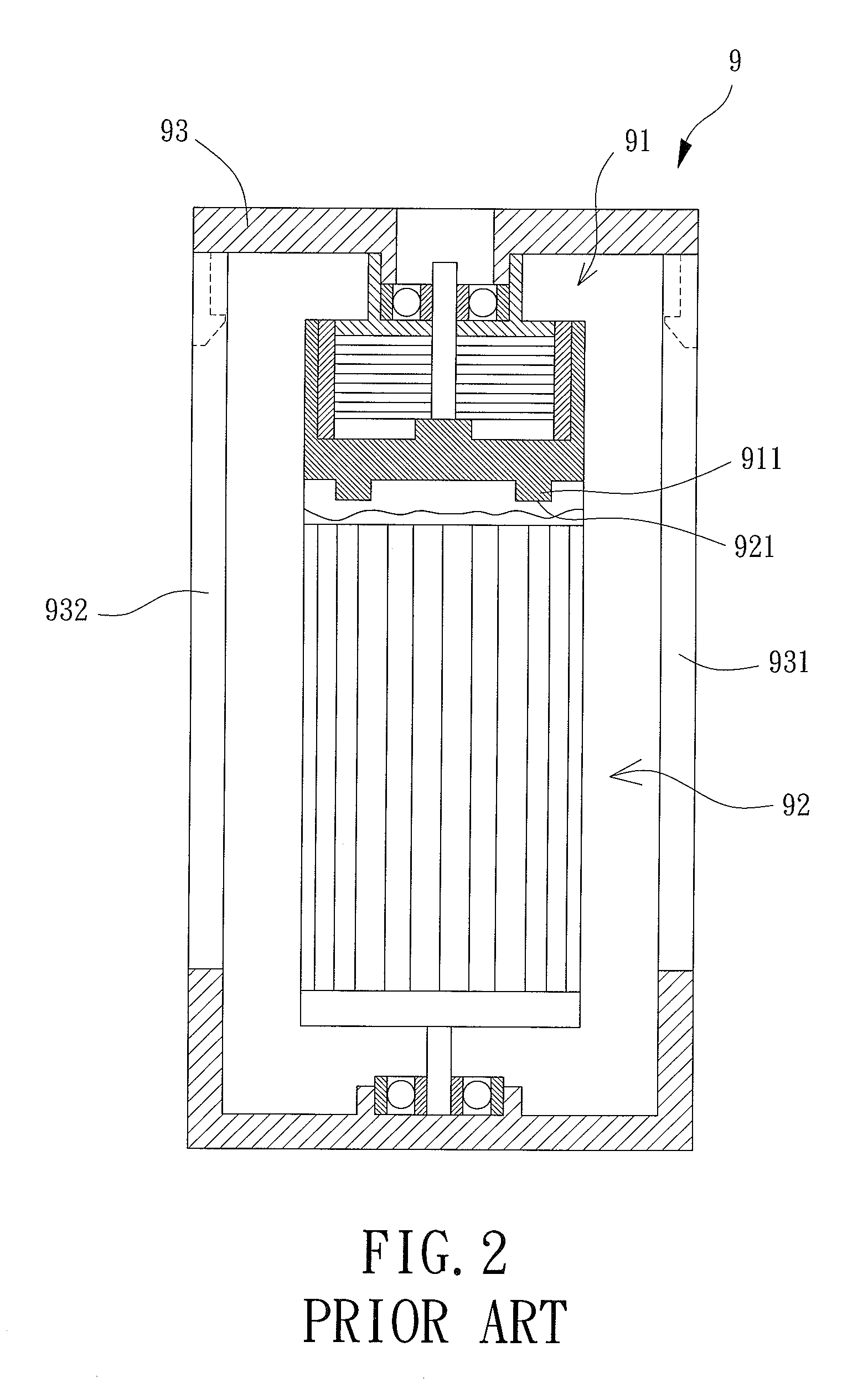

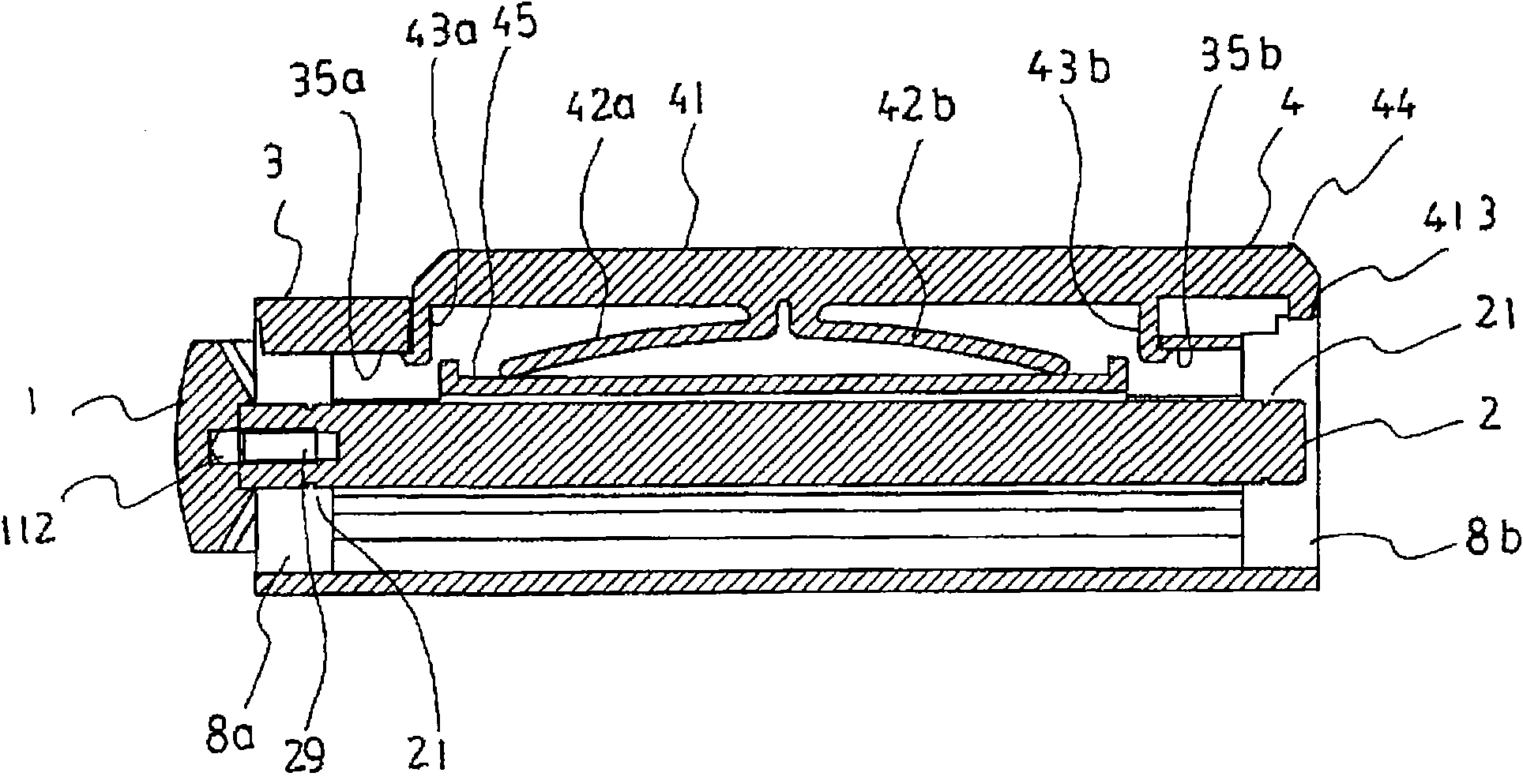

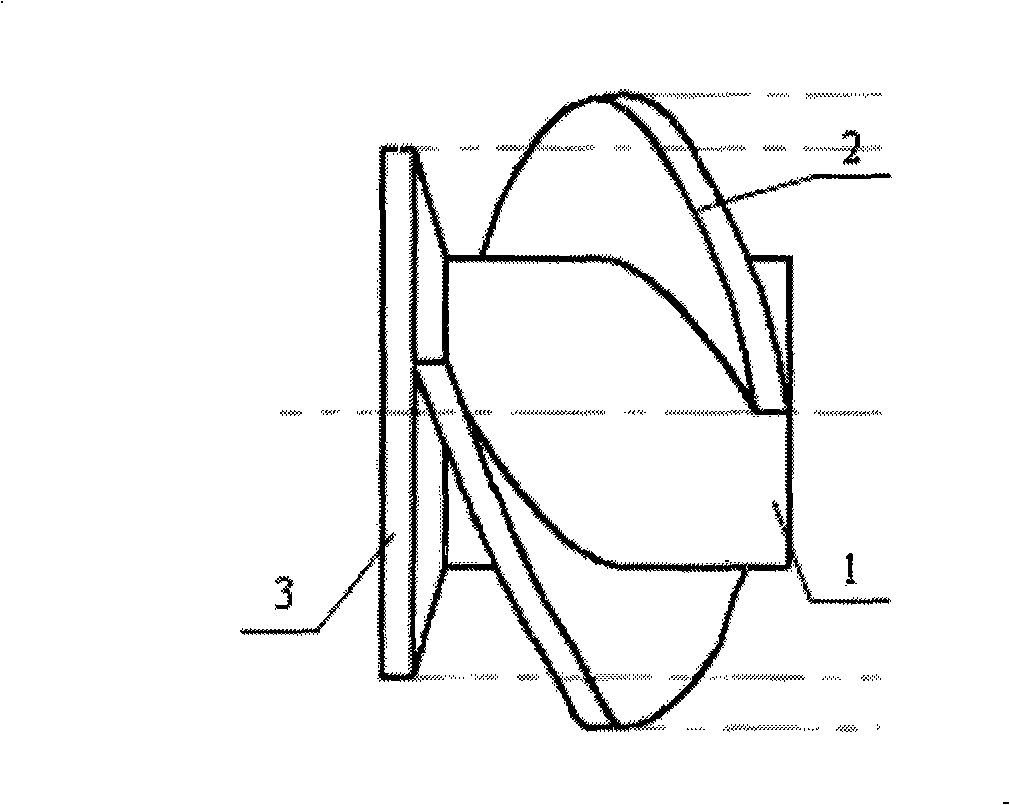

Lens assembly with actuating means and auto-focus controlling apparatus having the same

InactiveUS20080037143A1Avoid excessive currentSmall sizeMountingsFocusing aidsSmall lensCamera module

A lens assembly has a driving actuator which includes a magnet, a yoke and a coil and is formed along a lens barrel that accommodates a lens unit for focusing and an auto-focus controlling apparatus comprises the lens assembly for camera module. The magnet or the coil has an internal diameter smaller than a maximal diameter of the lens barrel. Therefore, it is possible to manufacture much smaller lens assembly according to the present invention compared to the conventional ones and to reduce the possibility of component damages in the lens assembly in operating the camera module.

Owner:DIOSTECH

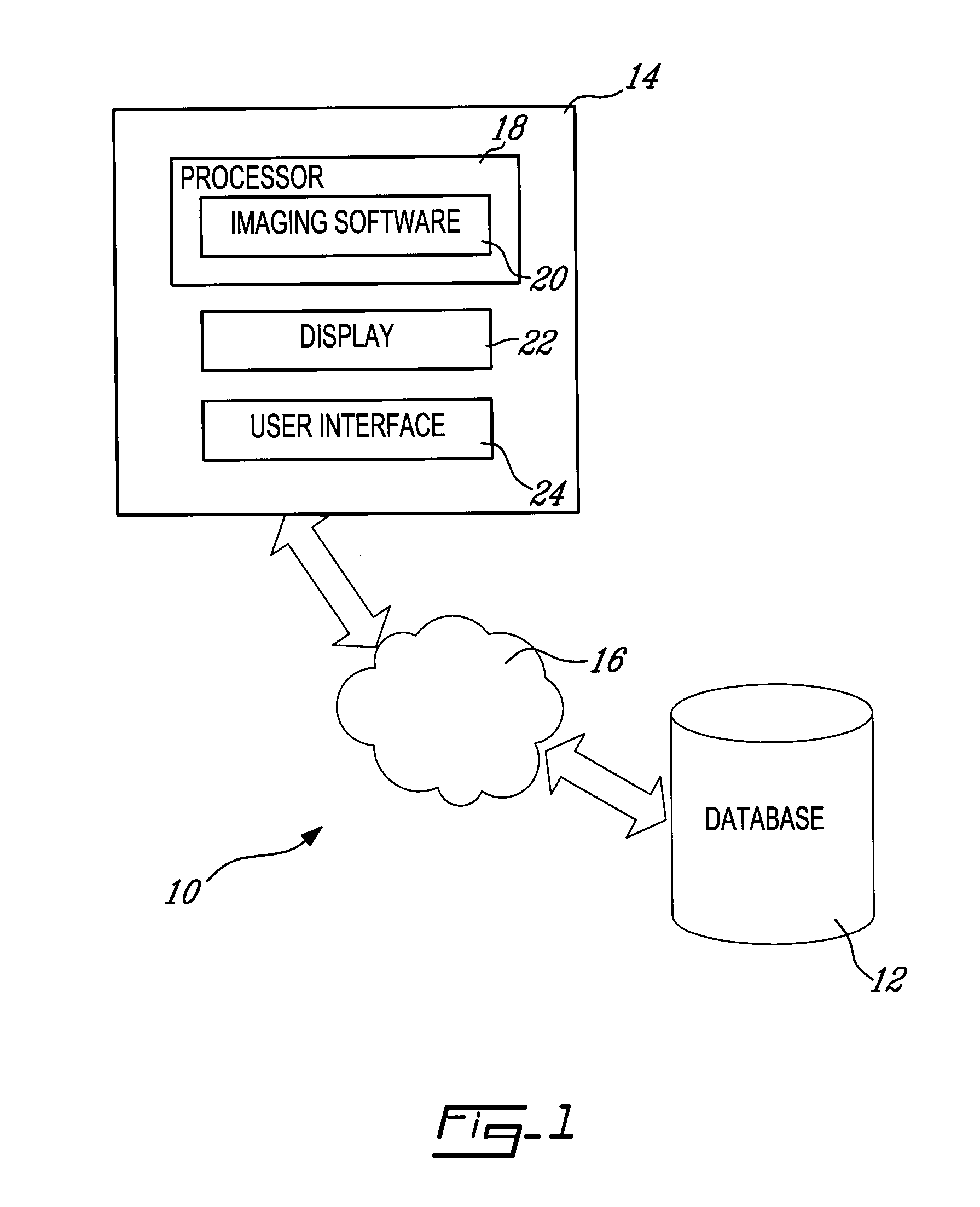

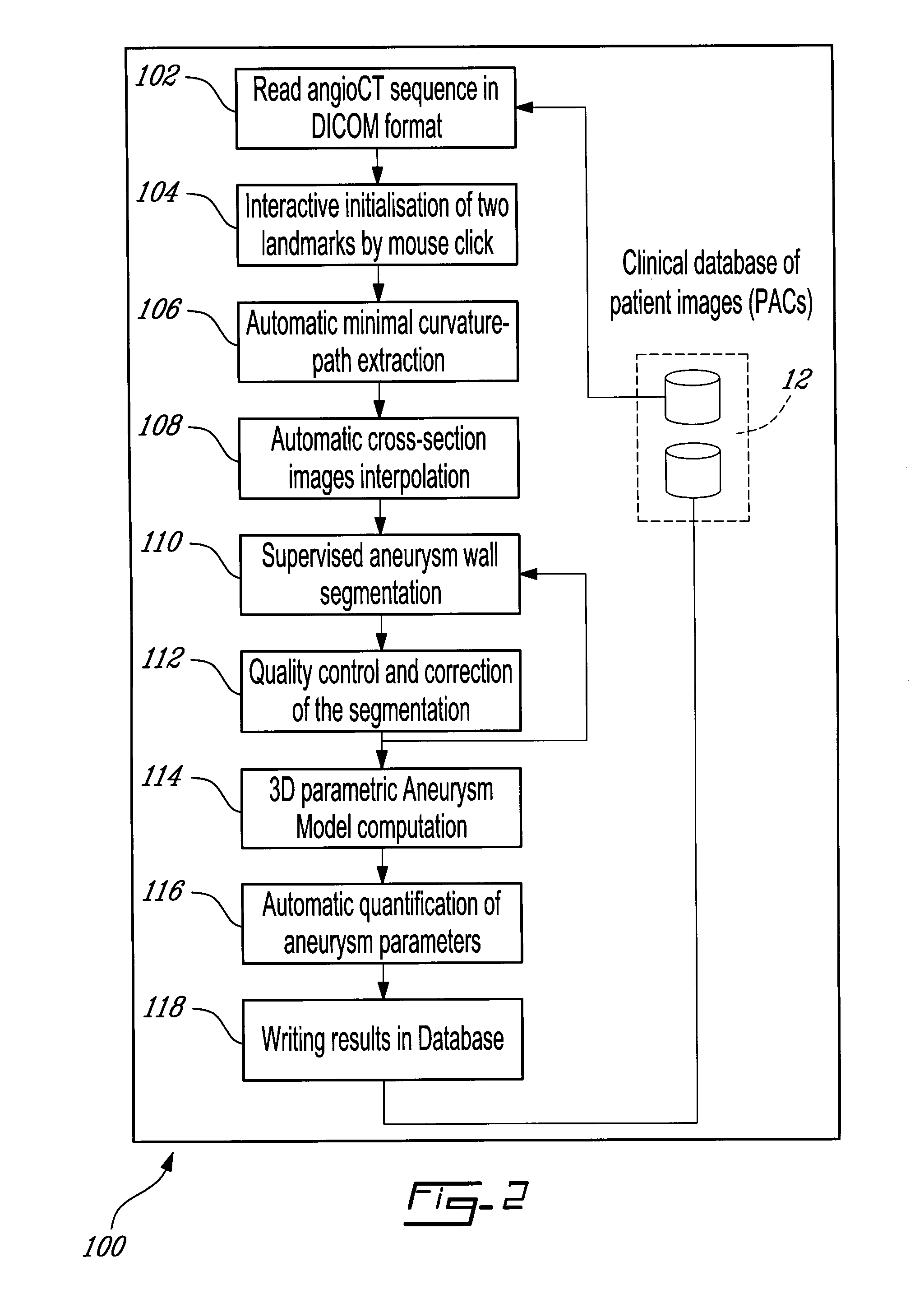

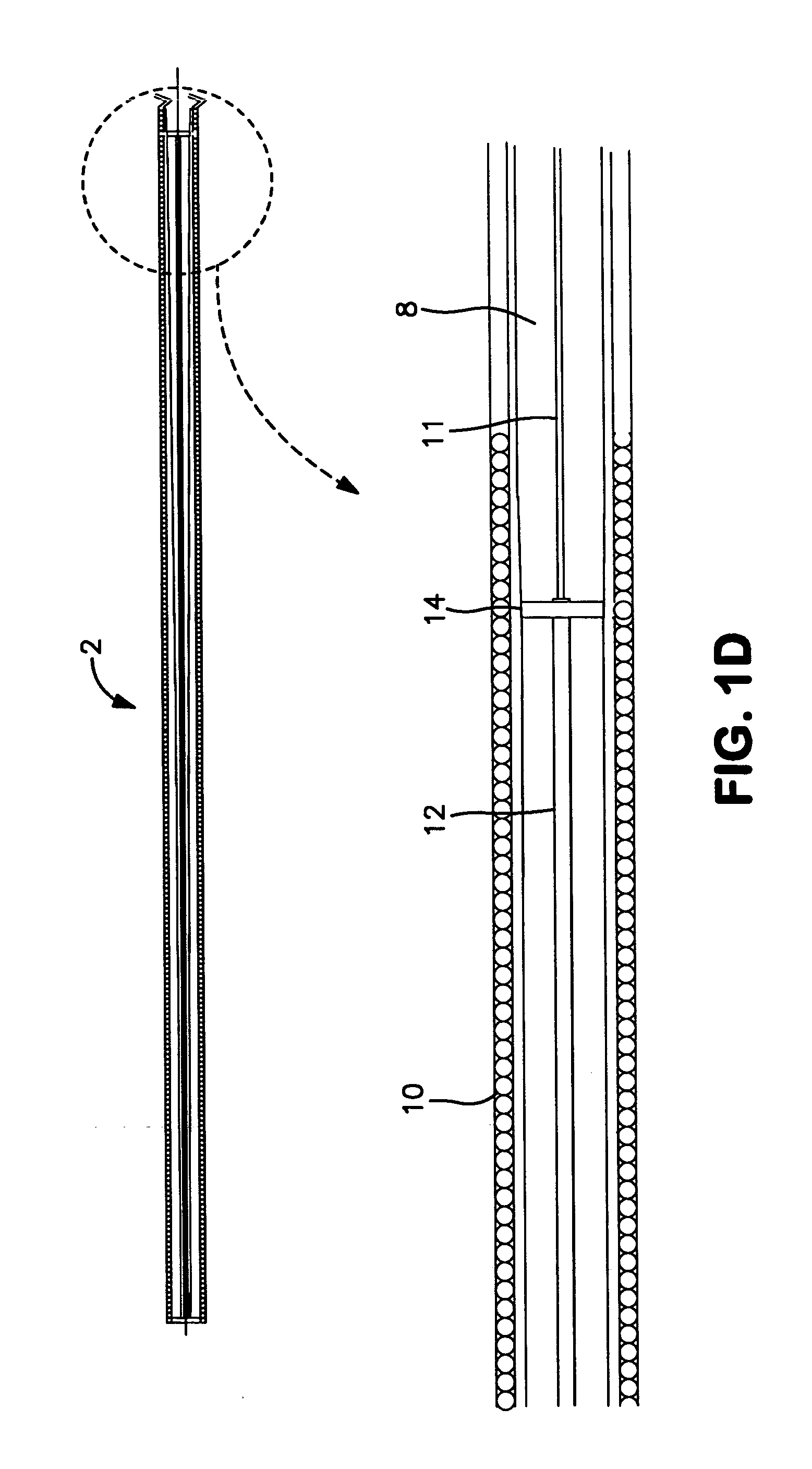

Method for tracking 3D anatomical and pathological changes in tubular-shaped anatomical structures

InactiveUS20100309198A1Image enhancementDetails involving processing stepsAnatomical structures3d image

A method for visualizing the anatomy of a region of interest of a tubular-shaped organ based on acquired three-dimensional image slices of the region of interest. Prior to segmentation, reference markers are positioned interactively in the image slices, a minimum curvature path connecting the reference markers is automatically extracted and cross-sectional images are interpolated along a plane normal to a tangent vector of the minimum curvature path. A segmented area corresponding to the region of interest is then delimited in each cross-sectional image and, using this segmented area, a three-dimensional surface representation of the region of interest is computed to readily quantify attributes, such as a maximal diameter and a volume, of the region of interest. When the image sets are acquired in different imaging geometries, the image sets may further be co-registered prior to segmentation, resulting in image sets superimposed in the same geometrical reference frame.

Owner:VAL CHUM PARTNERSHIP

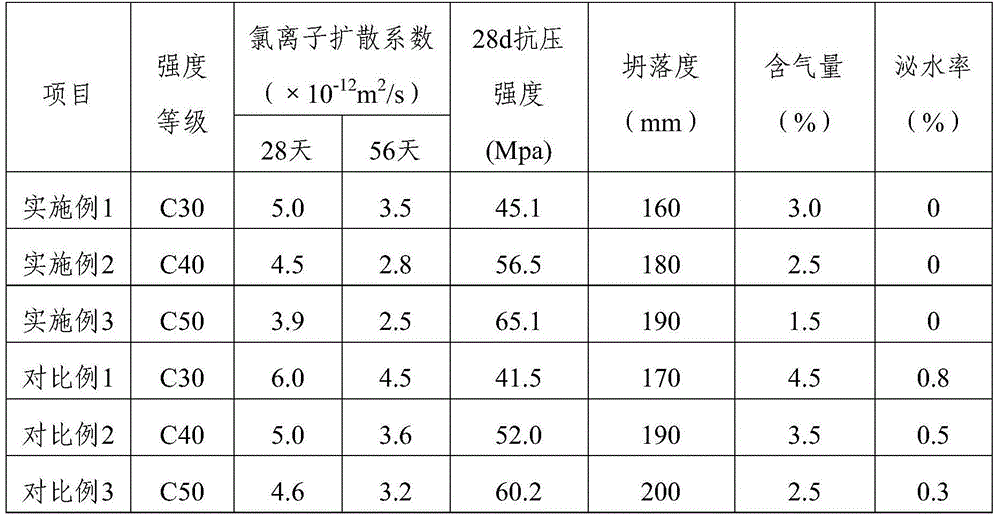

Fair-faced concrete and application thereof

The invention relates to fair-faced concrete. The fair-faced concrete is prepared from a binding material, a composite water reducer, water and aggregate, wherein the amount of the binding material in the fair-faced concrete is 380-480kg / m<3>; the binding material comprises the following components in parts by weight: 45-70 parts of cement, 10-30 parts of coal ashes and 20-50 parts of granulated blast-furnace slag; the amount of the composite water reducer accounts for 0.5%-1.1% of the binding material; the composite water reducer comprises a polycarboxylate superplasticizer, a defoamer, an air entraining agent and a tackifier; the amount of water accounts for 0.32-0.45 times of the binding material; and the balance is the aggregate. The invention further relates to an application of the fair-faced concrete in ocean engineering construction. The fair-faced concrete provided by the invention is excellent in chloride ion permeability resistance, smooth in surface, and uniform in color and luster; the sum of the area of air bubbles of which the surface area is greater than 1m<2> is not greater than 6*10<-4>m<2>; the maximal diameter of the air bubbles is not greater than 5mm; the depth is not greater than 5mm; and the fair-faced concrete is low in air content and bleeding rate, and can be used in an ocean environment for a long period of time.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

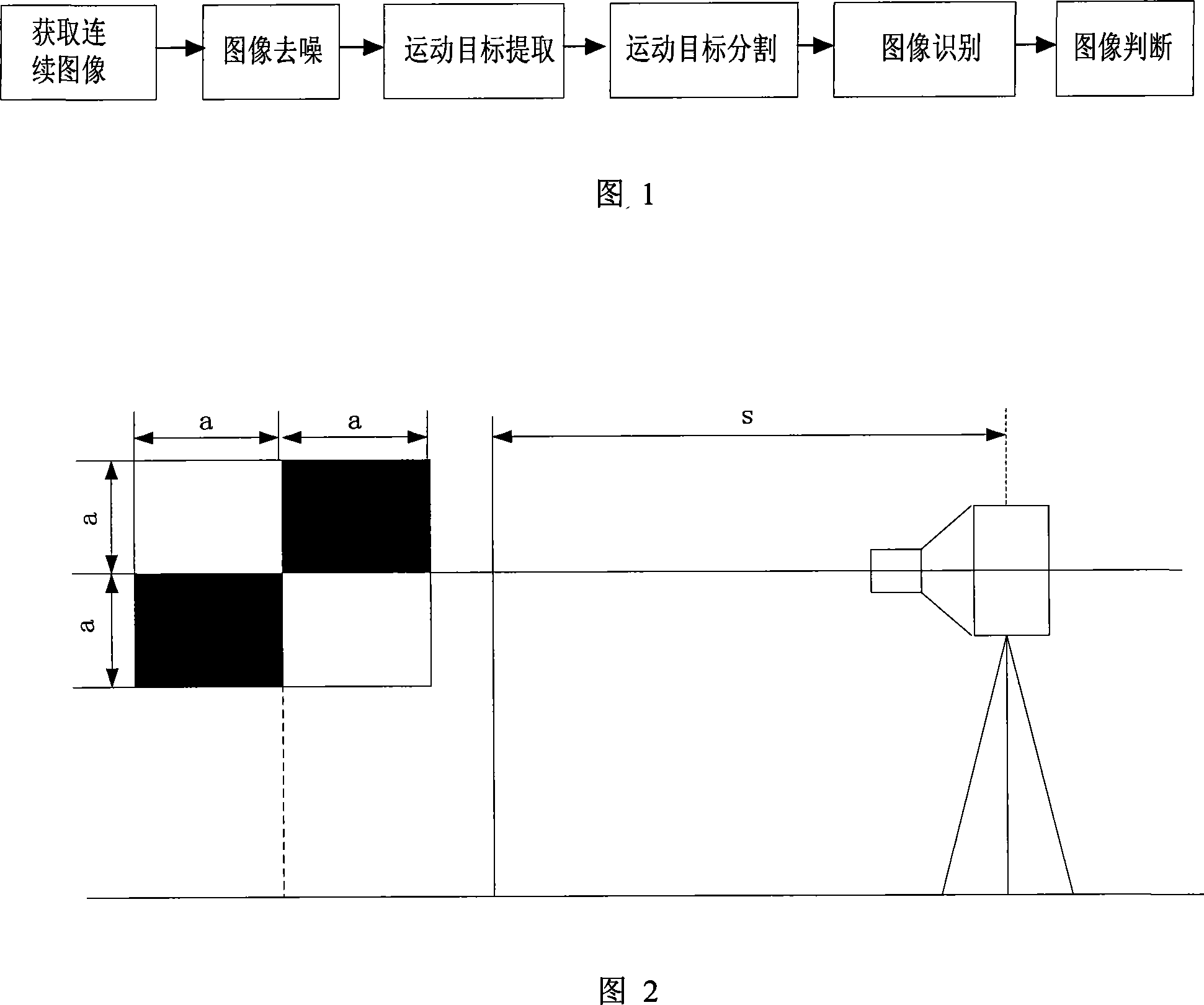

Medical large transfusion machine vision on-line detection method

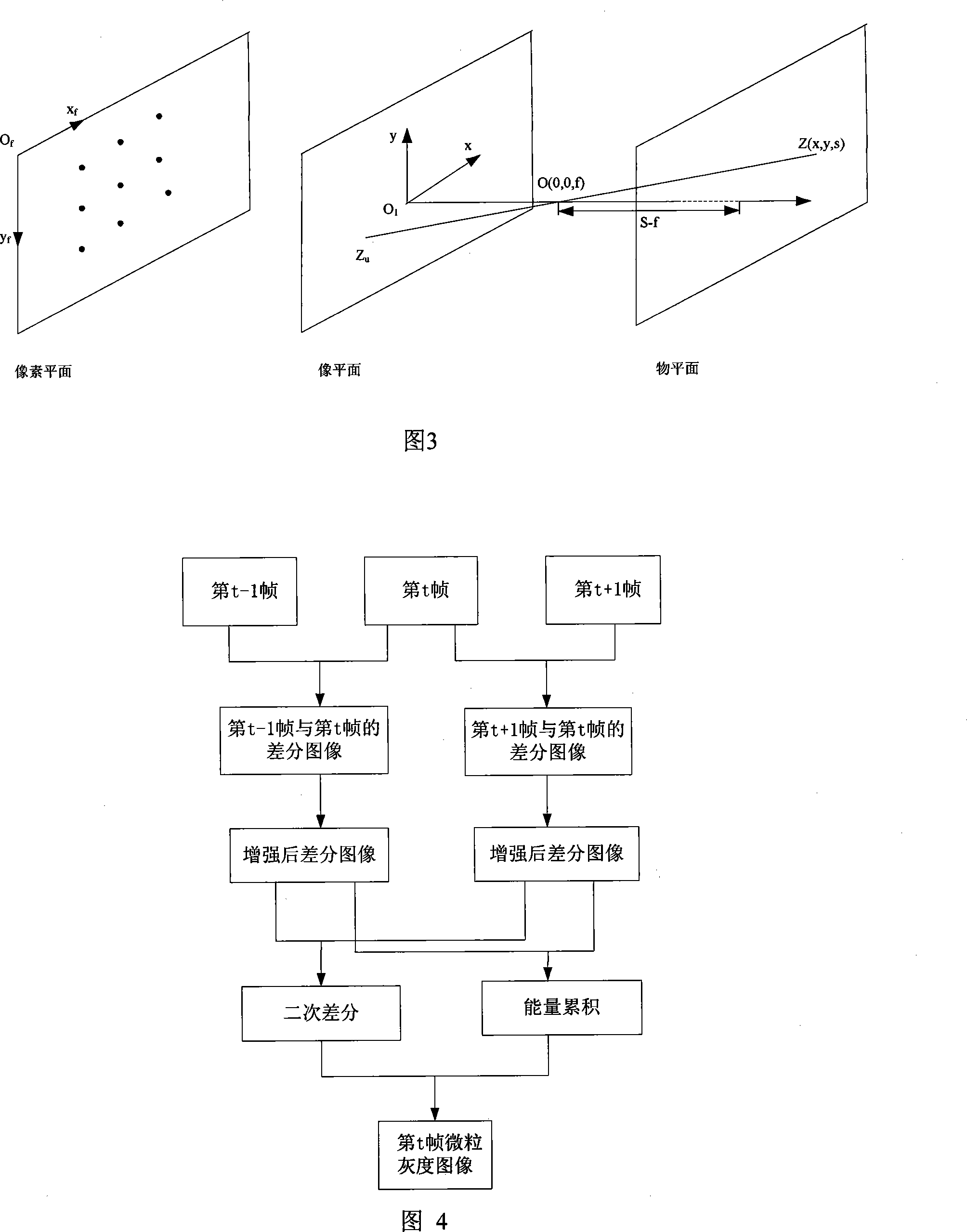

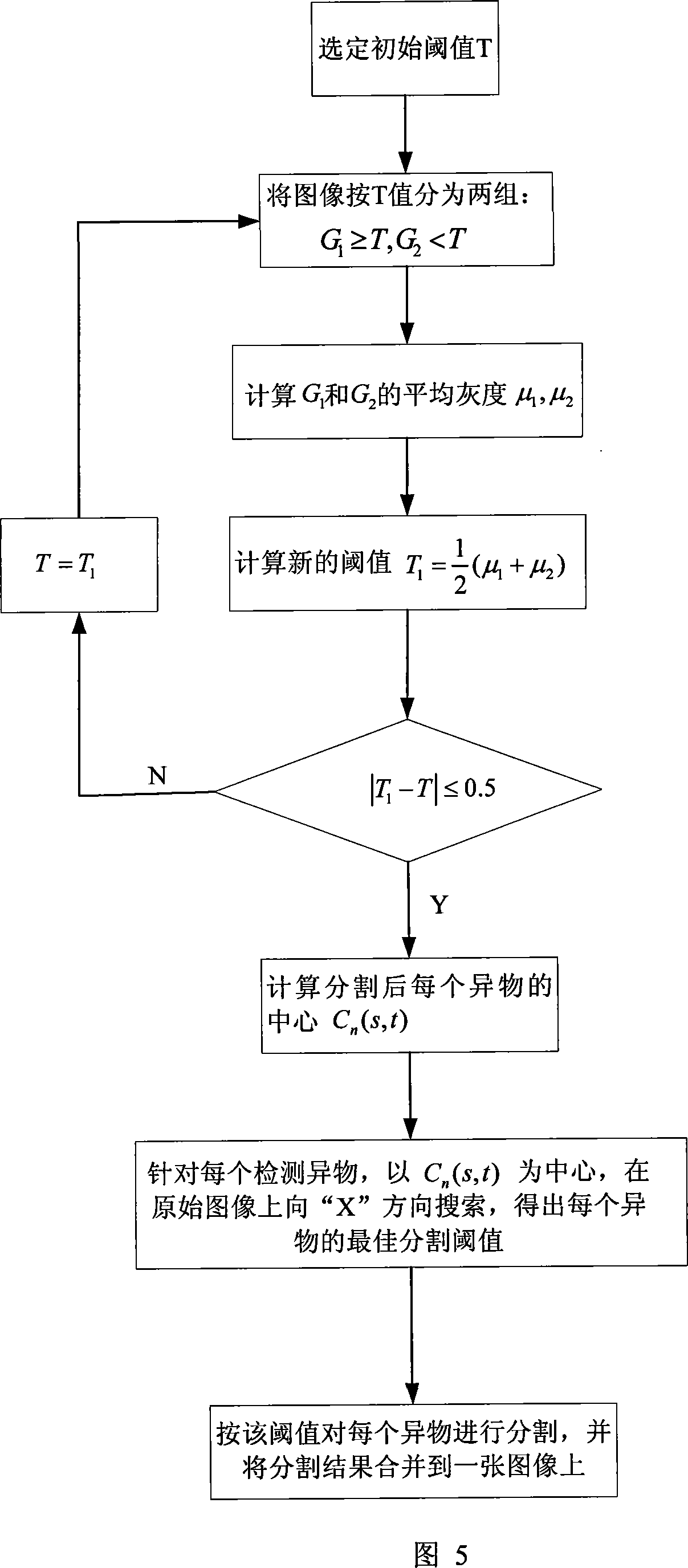

The method comprises: 1) getting the sequence image after the massive transfusion rotation stops in crash; 2) making preprocess for the sequence image; 3) completing the extraction of motion particle in the sequence image; 4) selecting the multi-step threshold method to gradually determining the optimal partitioning threshold of the micro foreign substance grey scale image to realize the partitioning for the motion target; 5) using the eight connected domain mark to mark the connected area of foreign substance, and calculating the internal maximal diameter of same connected area; 6) making calculation for the target maximal diameter and eccentricity to estimate the quality state of the transfusion and to make classification for the type of the foreign substance; finally, sending out the control signals.

Owner:HUNAN UNIV

Adhesive Resin Composition, Its Cured Product And Adhesive Film

InactiveCN102559113AHard to reduce adhesionDifficult to reduce insulationNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesion forceEpoxy

The present invention provides an adhesive resin composition which has high heat conductivity and no easy adhesion force and insulation reduction. The adhesive resin composition comprises the following components: epoxy resin (which comprises epoxy resin of which the mass is above 50wt% relative to total mass of the epoxy resin and epoxide equivalent is 150-220), curing agent which is composed of imidazolium compound, phenoxy resin and aluminum oxide powder, wherein ammonium ion in the cured object is less than 50wtppm. Maximal diameter of the aluminum oxide powder is less than 120 mu m, and the proportion of crystal spherical aluminum oxide in total aluminum oxide powder is above 90wt%. The diameter arrangement of the crystal spherical aluminum oxide satisfies the following conditions: i) the particles of which the average diameter D50 is 35-50 mu m and the ratio (volume average diameter) / (number average diameter) is 1.2-2.0 account for 30-50wt%; ii) the particles of which the average diameter is 5-15 mu m and the ratio (volume average diameter) / (number average diameter) is 2.0-3.5 account for 30-50wt%; and iii) the particles of which the average diameter D50 is 0.1-2 mu m account for 10-30wt%.

Owner:NIPPON STEEL CHEMICAL CO LTD

Lens assembly with actuating means and auto-focus controlling apparatus having the same

Owner:DIOSTECH

Explosive welding method for zirconium-steel-zirconium three layer pipe

ActiveCN101837512ATake advantage of corrosion resistanceTake full advantage of abrasion resistanceNon-electric welding apparatusExplosive claddingPressure reduction

The invention relates to an explosive welding method for a zirconium-steel-zirconium three layer pipe. An outer zirconium pipe in an outer zirconium pipe-steel pipe-inner zirconium pipe has the diameter of 60-505 mm and the thickness of 1-8 mm, and a steel pipe has the diameter of 55-500 mm and the thickness of 8-200 mm; the inner diameter of the steel pipe is 4-6 mm larger than the outer diameter of an inner zirconium pipe, and the inner diameter of the outer zirconium pipe is 4-6 mm larger than the outer diameter of the steel pipe; the inner diameter of the inner zirconium pipe is 10-15 mm larger than the maximal diameter of a buffer cone; the explosive welding method comprises the following steps of carrying out the surface treatment and alignment of a base pipe, treating the zirconium pipe; guaranteeing the straightness of the zirconium pipe; assembling which comprises the steps of matching, vertically mounting the inner zirconium pipe, the outer zirconium pipe and the steel pipe on a technological bottom plate and mounting a pressure reduction cone at the center inside the inner zirconium pipe; carrying out re-explosive-cladding which comprises the steps of horizontally placing the device assembled on an explosive table, additionally mounting a pipe-shaped outer frame at the outer part of an outer steel pipe, and uniformly placing explosives around the pipe-shaped outer frame and the buffer cone of the inner pipe and denotating through detonators placed at the top of the buffer cone; and firmly binding the surfaces of the zirconium pipe and the steel pipe under high braking pressure.

Owner:黄山顺钛新材料科技有限公司

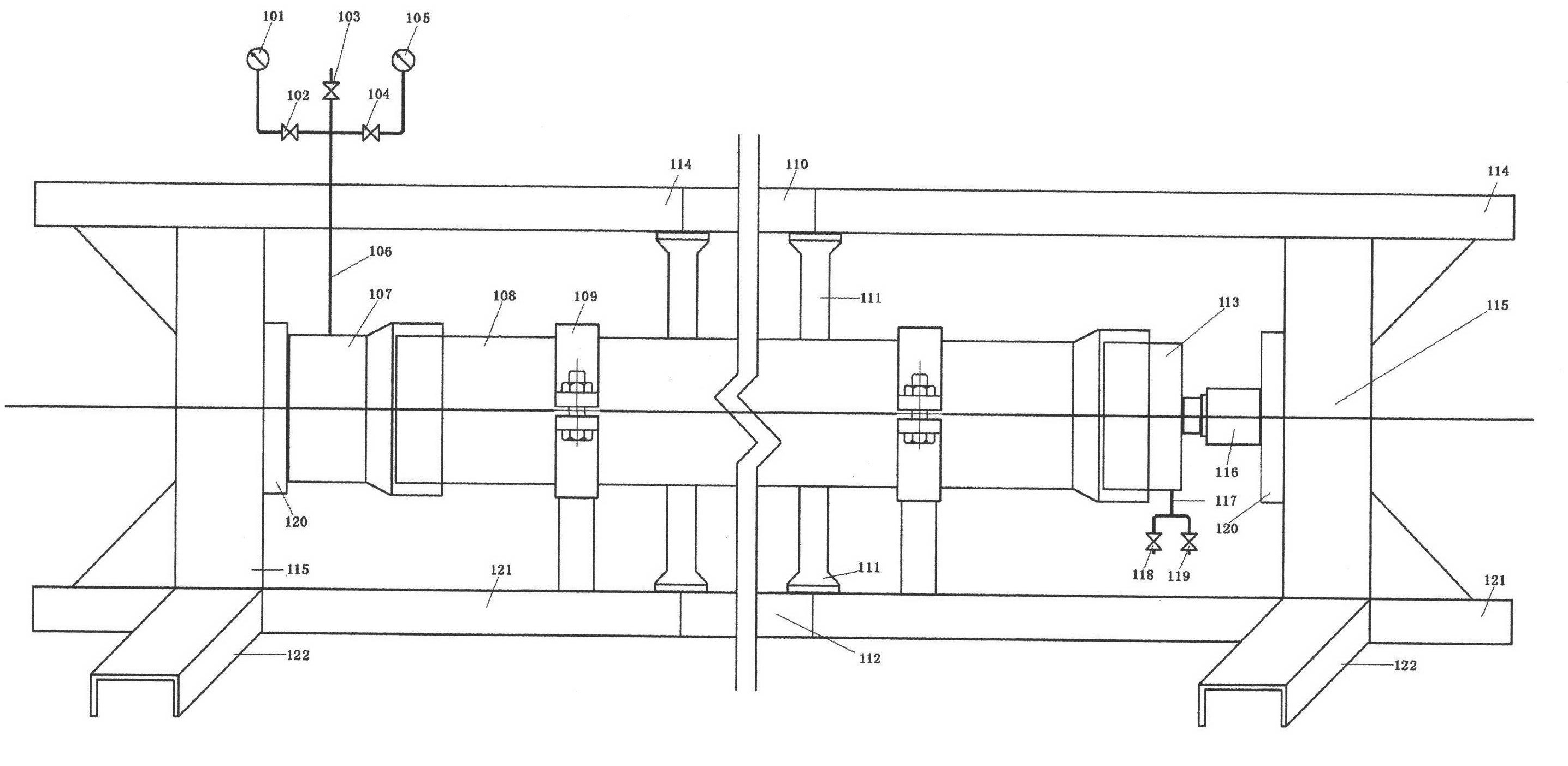

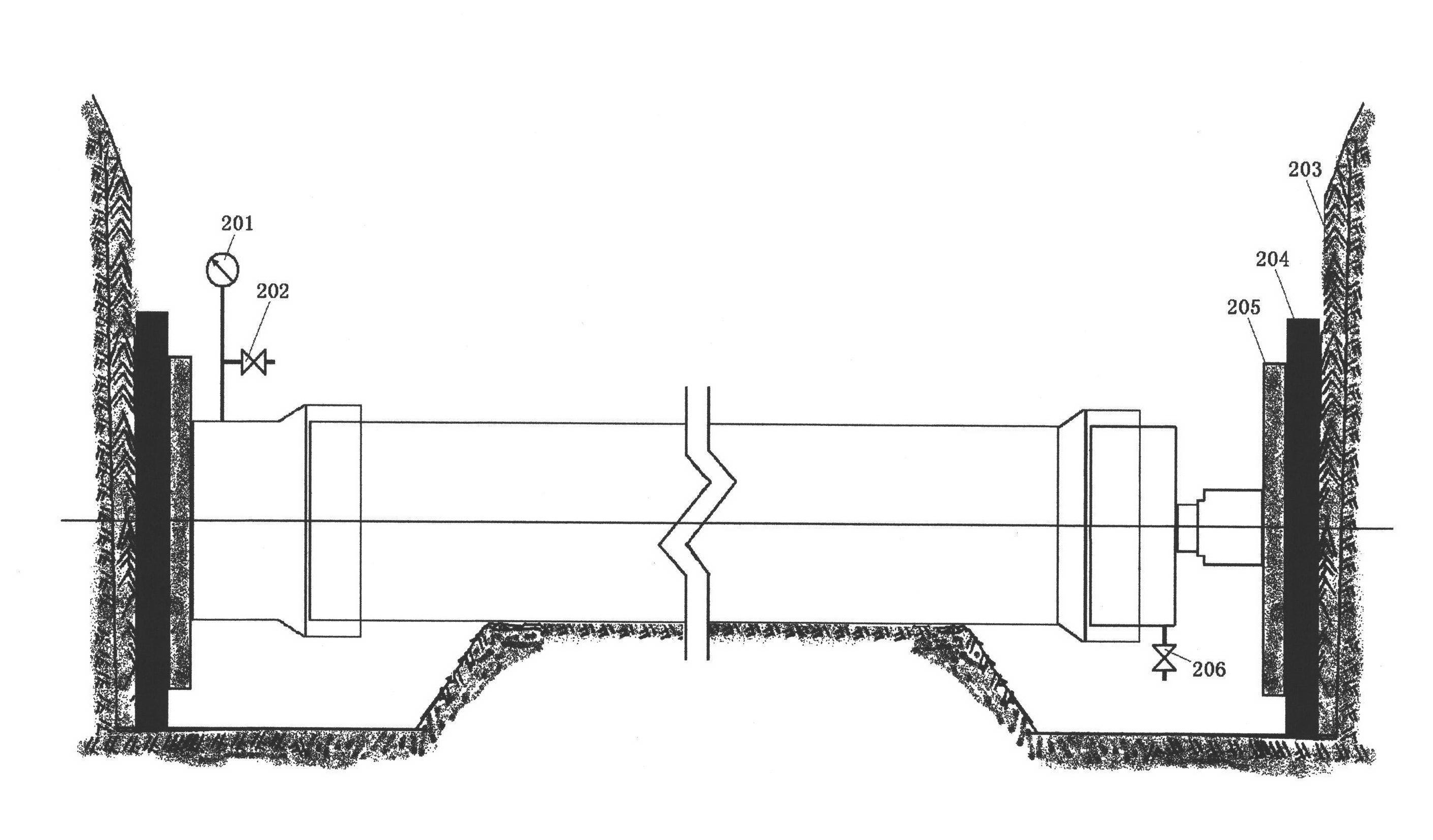

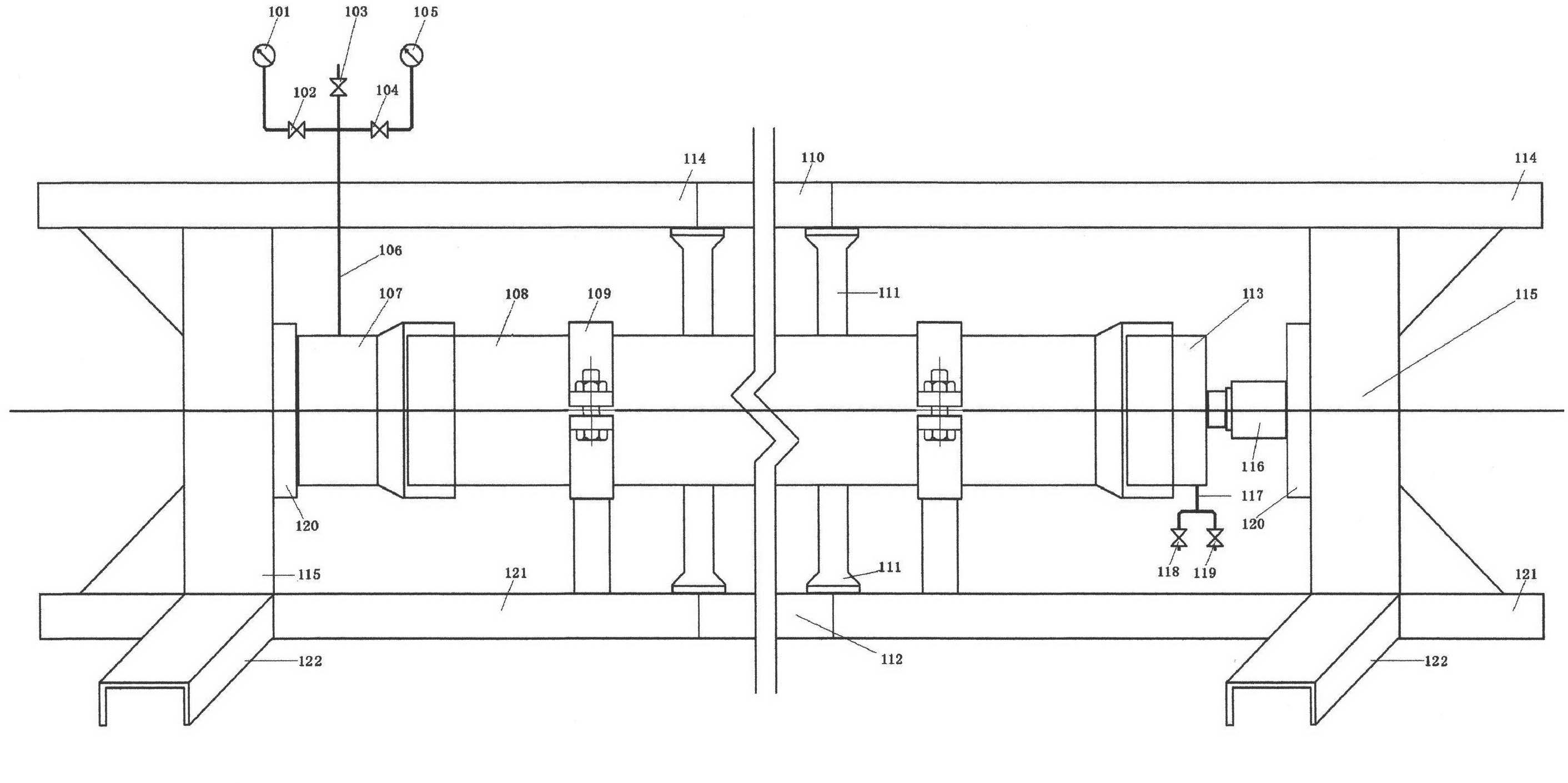

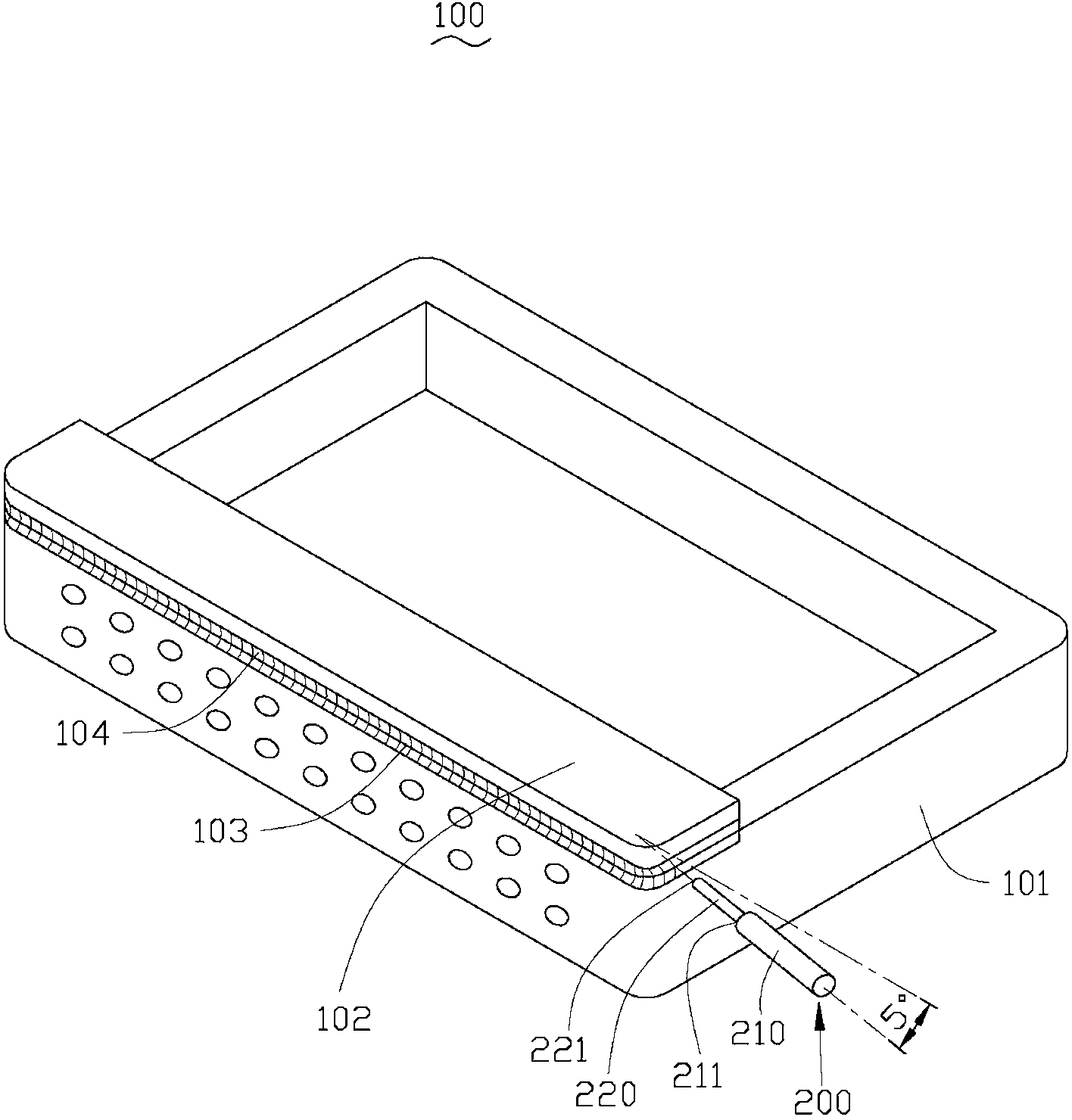

Non-metal pipeline hydraulic pressure seepage verifying attachment

InactiveCN102426084ALess investmentLow costMeasurement of fluid loss/gain rateExhaust valveWater flooding

The invention provides a non-metal pipeline hydraulic pressure seepage verifying attachment. A system of the non-metal pipeline hydraulic pressure seepage verifying attachment comprises a rectangle framework body, a bell end bulkhead, a jack bulkhead, a pipeline holt hoop iron, a jack, a water flooding pressure measurement system on the bell end bulkhead, and an operation method. The invention is characterized in that: the rectangle framework body forms a rectangle through channel steel welding, length of the rectangle is set according to length of a segment of pipeline, width of the rectangle is set according to a maximal diameter of a detected pipeline, and the rectangle framework body is provided with the pipeline holt hoop iron inside; one end of an intake and exhaust connecting pipe is connected with the bell end bulkhead, the other end of the intake and exhaust connecting pipe is connected with one end of a pressurization opening valve, an intake and exhaust valve and a pressure maintaining opening valve respectively, the other end of the pressurization opening valve is connected with a pressurization pressure gauge, and the other end of the pressure maintaining opening valve is connected with a pressure maintaining pressure gauge; the operation method is carried out according to certain steps. The verifying attachment has small investment, low cost and low technology difficulty, and is applied to a field pipeline construction site and a small scale pipeline production manufacturer.

Owner:YUNNAN NO 5 CONSTR ENG

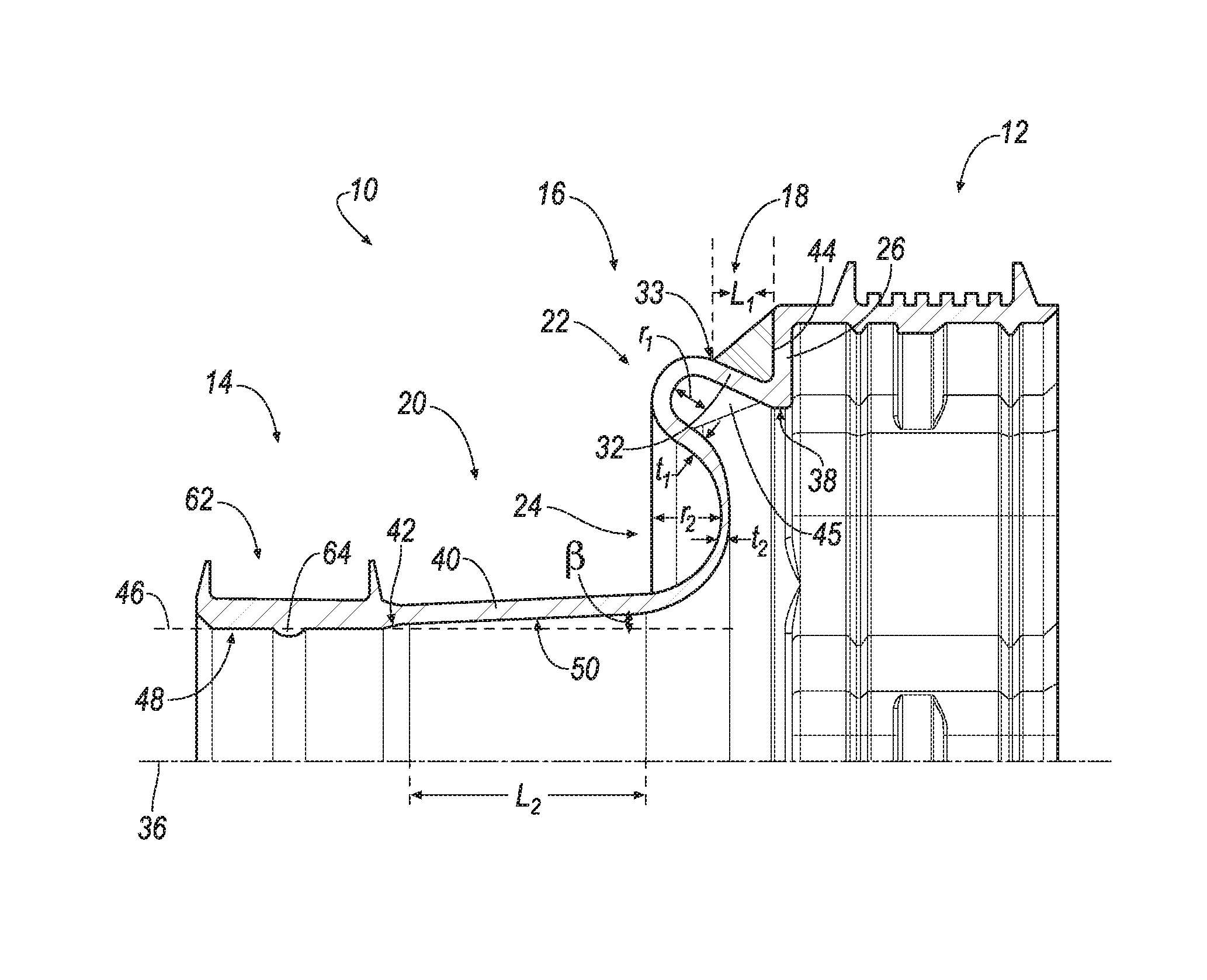

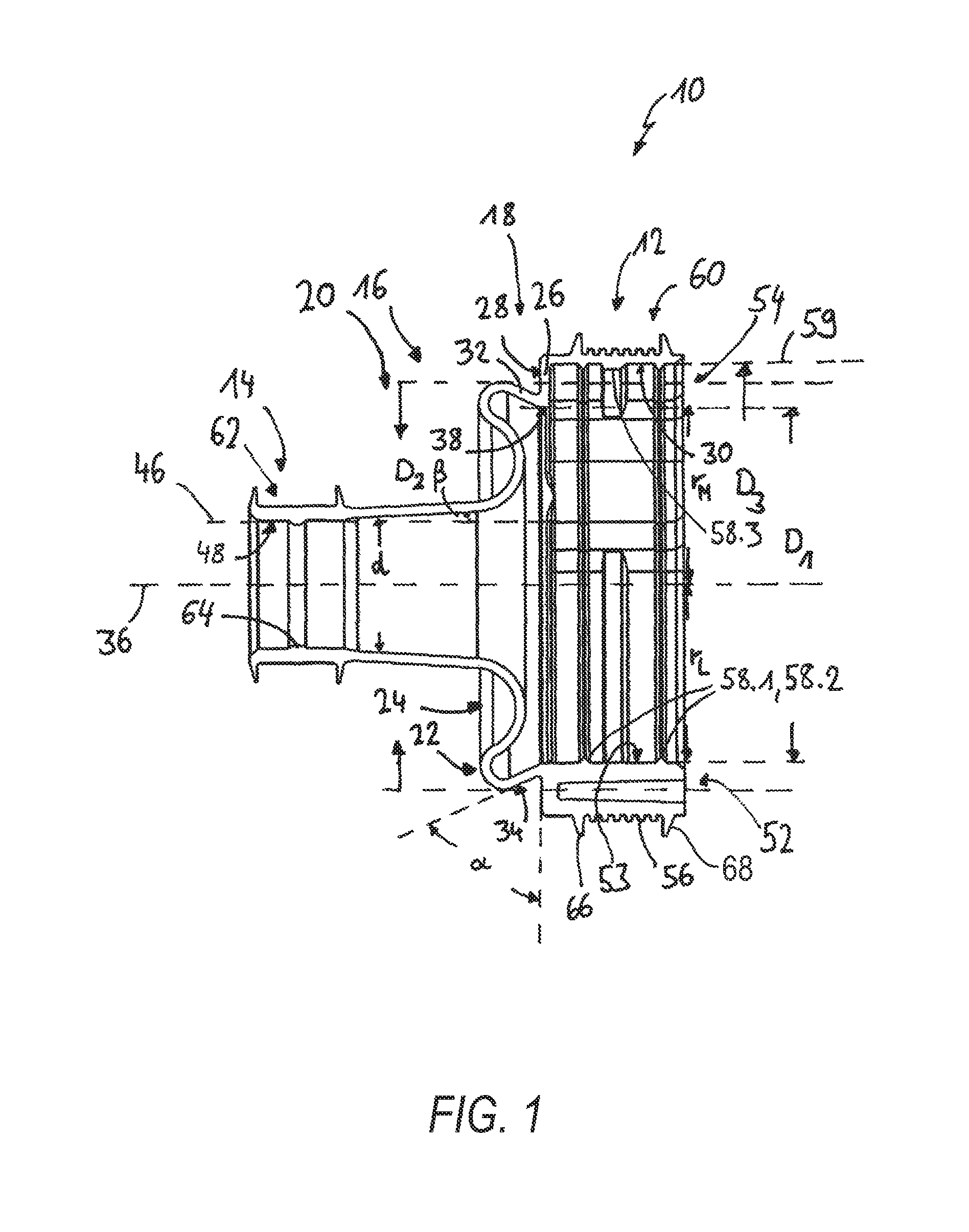

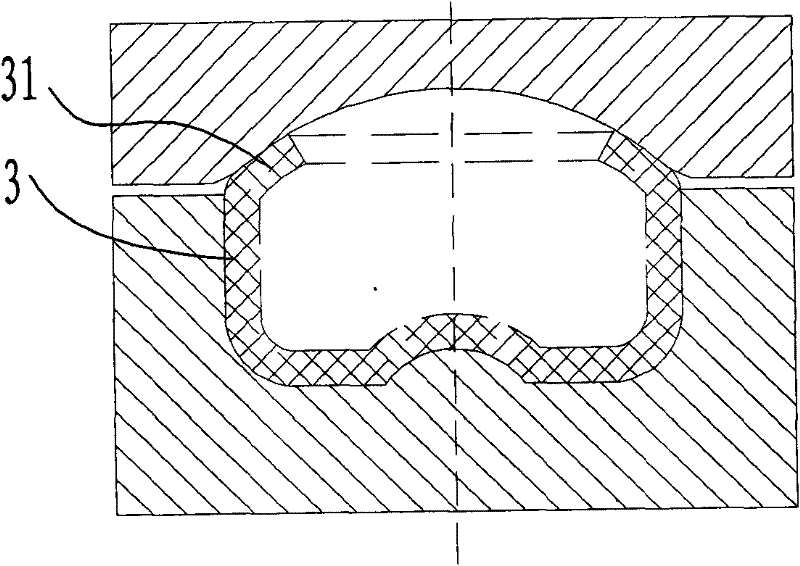

Rolling boot with transition region

ActiveUS9494199B2Improve molding stabilityReduce riskYielding couplingRotary machine partsSacroiliac jointFlange

A rolling boot comprises a first fastening region for fastening the boot to a joint casing, a second fastening region for fastening the boot to a shaft, and a fold region between the first and the second fastening region with a first fold near to the first fastening region and a second fold near to the second fastening region. The boot further comprises, between the first fastening region and the first fold, a first transition region comprising a first flange neighboring the first fastening region with a bottom. A ratio between a first minimal diameter D1, defined by the bottom of the first flange of the first transition region, and a second maximal diameter D2, defined by the first fold, where both are viewed in a longitudinal section direction along the main axis, is between approximately 1:1.01 to approximately 1:1.25.

Owner:GKN DRIVELINE INT GMBH

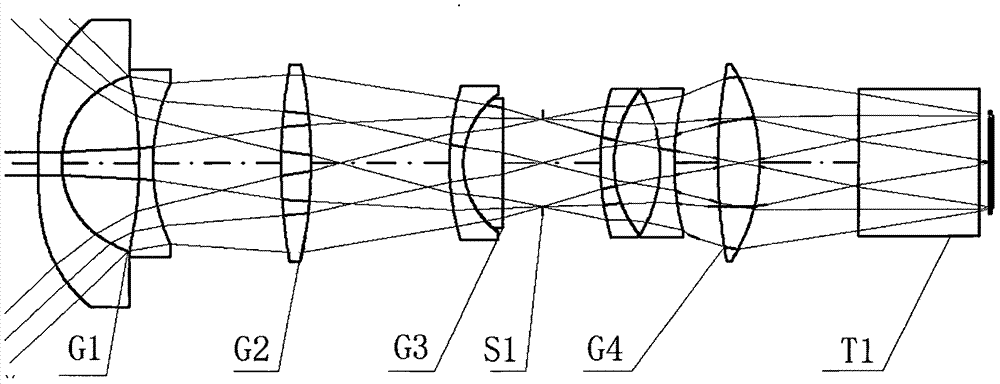

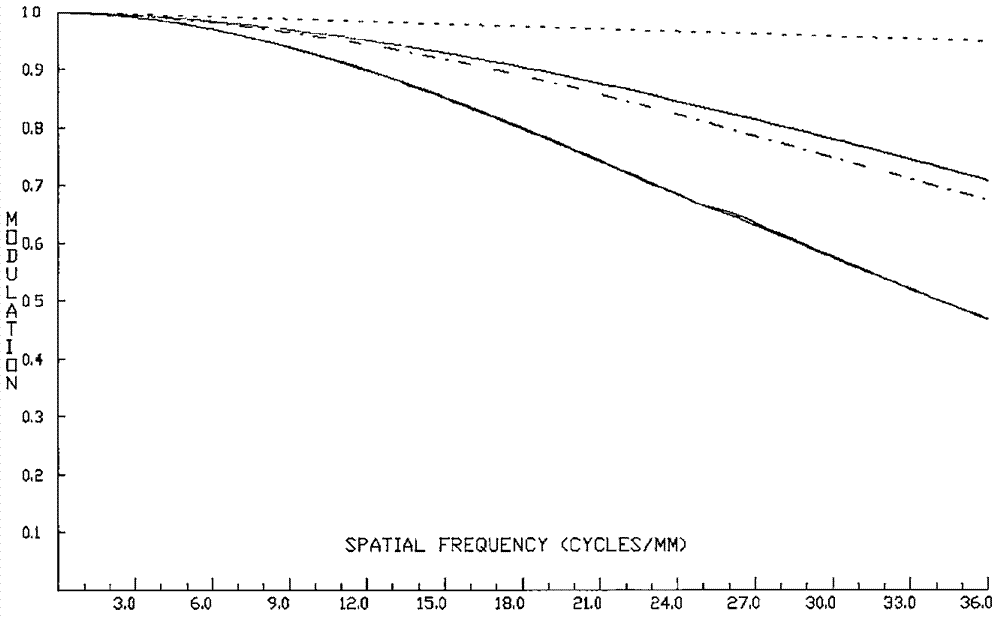

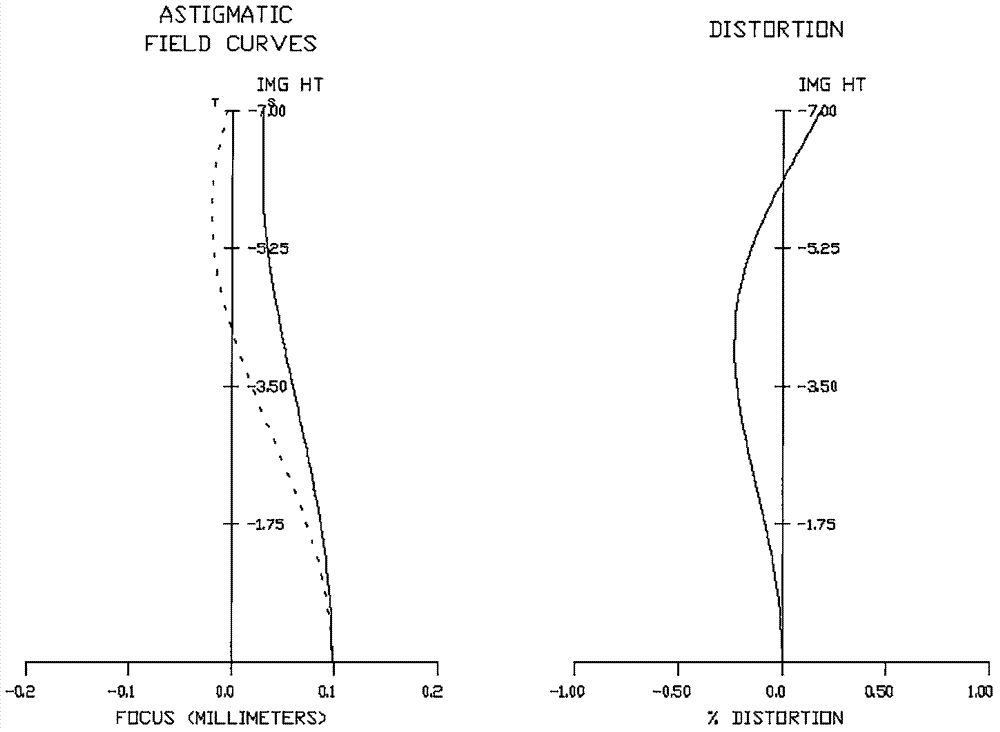

Universal short focus projection optical system

InactiveCN107065406AThe solution cannot be sharedCost advantageProjectorsOptical elementsProjection opticsLCD projector

The invention discloses a universal short focus projection optical system. The system includes optical lenses, a diaphragm and an optical prism. The system is provided with a first lens unit having negative focal power, a second lens unit having positive focal power, a third lens unit having negative focal power, the diaphragm, a fourth lens unit having positive focal power and the optical prism arranged successively. The first lens unit includes an aspheric surface resin element. The fourth lens unit contains low dispersion glass material. The focal length of the universal short focus projection optical system is f and the focal length of the first lens unit is f1, wherein -0.15<f / f1<-0.6. The rear focal length of the universal short focus projection optical system is BFL, wherein 13<BFL<17. The maximal diameter of the universal short focus projection optical system is D, wherein D<60mm. According to the invention, universal design of the projection system in a DLP projector or a LCD projector is achieved. At the same time, the production cost is reduced further.

Owner:北京和光科技有限公司

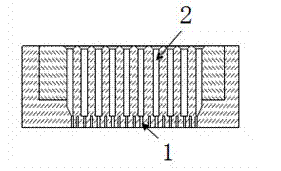

Preparation method of ultralarge high-pore-density honeycomb ceramic mold

The invention relates to a preparation method of a ultralarge high-pore-density honeycomb ceramic mold, which is characterized in that a mud guide porous plate is added in front of a traditional honeycomb ceramic mold to thicken the large high-pore-density honeycomb mold and to realize a purpose for enhancing the mold; and meanwhile, a mud guide hole on the front section of the mold is divided into two parts to be manufactured, the depth of the mud guide hole on the front end of the mold is greatly reduced, the difficulty for machining a small blind hole is reduced, the danger that a drill bit is broken in the machining process of a deep small blind hole is reduced, and the manufacturing efficiency of the mold can be greatly improved; and meanwhile the verticality of the mud guide hole on the front section of the mold can be improved, so that more precision for positioning the mud guide hole of the mold and the center of a cutting groove on the rear end can be realized, and the quality of the mold is improved. Due to adopting the preparation method, the thin-wall ultralarge honeycomb ceramic mold with pore density being less than or equal to 600 meshes, wall thickness being more than or equal to 0.1mm, maximal diameter being less than or equal to 500mm and the forming pressure being more than 15MPa can be manufactured.

Owner:李少荣

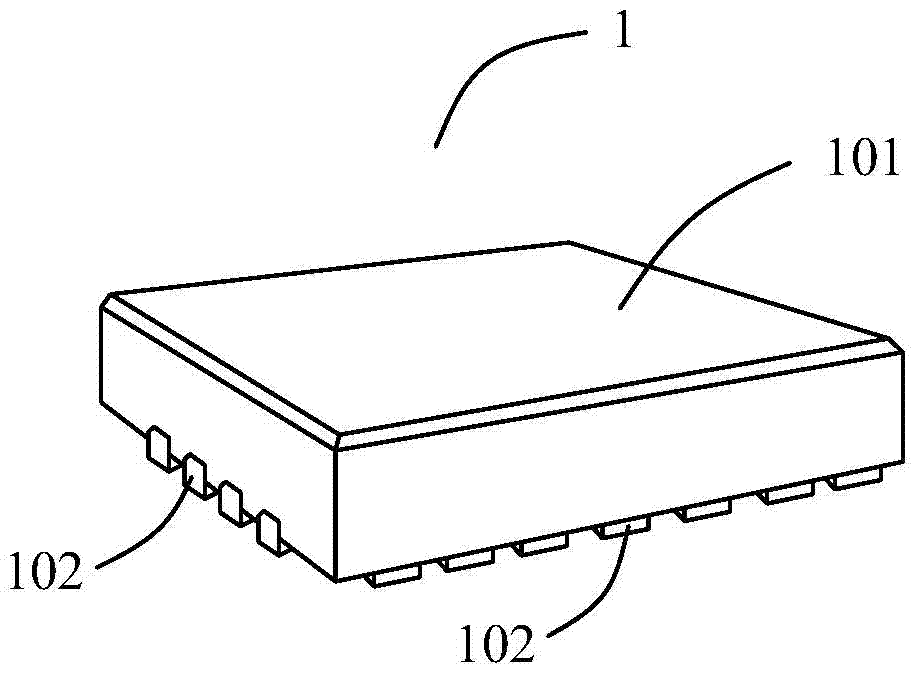

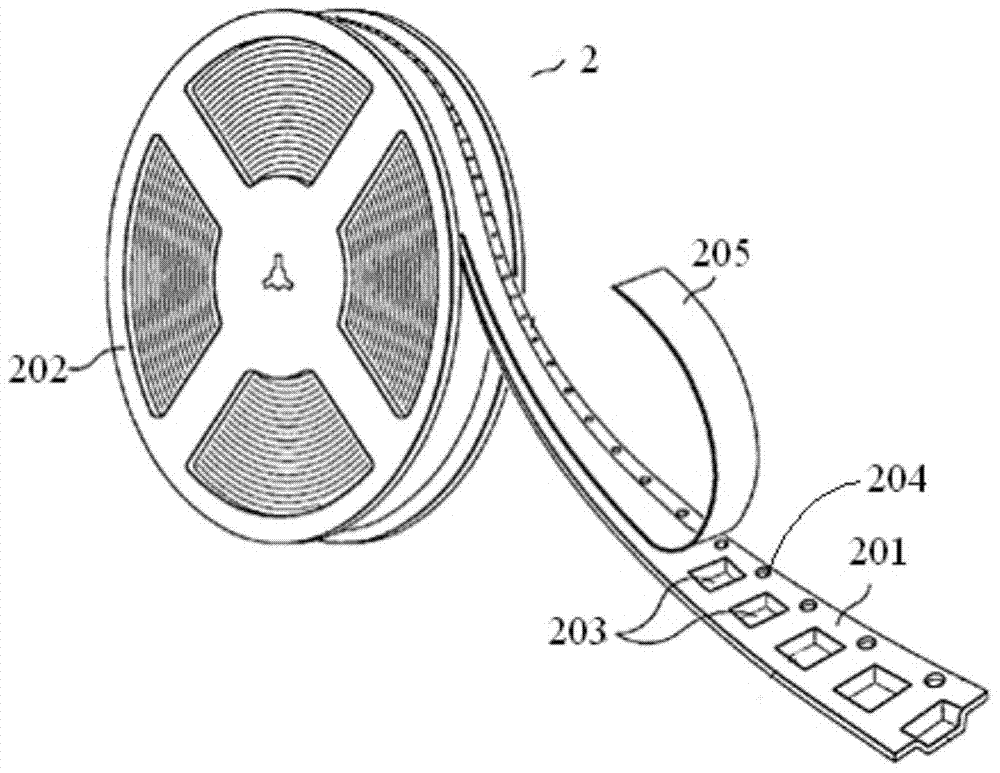

Storage card for surface-mounted component, feeder and automatic chip mounter

InactiveCN104754931ASimple structureIncrease packing densityElectrical componentsSurface mountingDiagonal

The invention discloses a storage card for a surface-mounted component, a feeder and an automatic chip mounter. The storage card for the surface-mounted component provided by the invention includes a rectangular card having a front surface, a rear surface, a left surface, a right surface, an upper surface and a lower surface, wherein the area of each of the front and rear surfaces is more than that of each of the other four surfaces; the card is provided with a plurality of component bins penetrating through the card and used for accommodating chip components; the cross section of the component bin is polygonal, circular or oval in shape; when the cross section of the component bin is polygonal in shape, the longest diagonal line of the cross section of the component bin is smaller than the body diagonals of the chip components; when the cross section of the component bin is circular or oval in shape, the maximal diameter of the cross section of the component bin is smaller than the body diagonals of the chip components. The storage card is simple in structure, high in package density, compact in volume, low in costs, easy to put in and take out the chip components, and good in popularization prospect.

Owner:弗兰克·魏

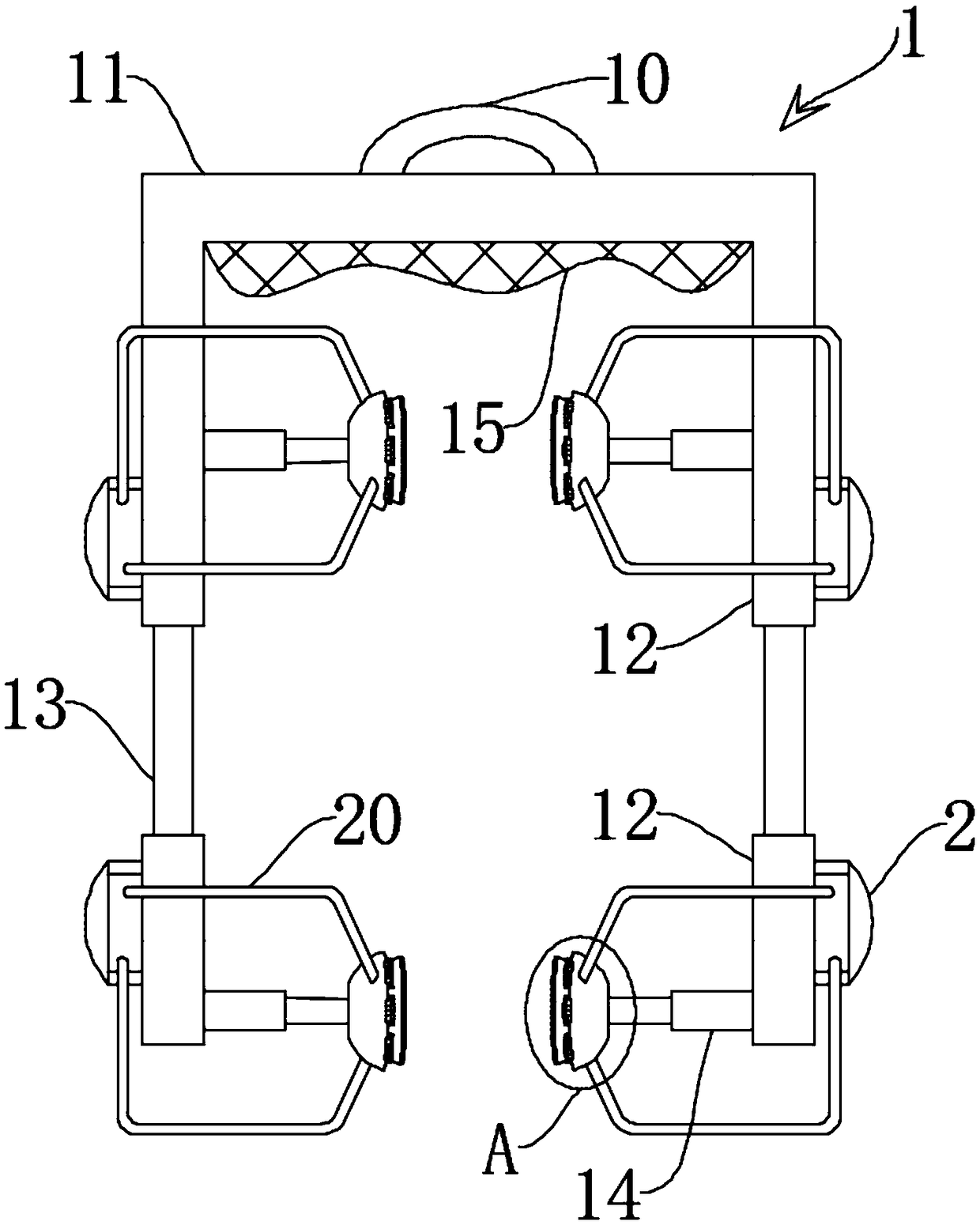

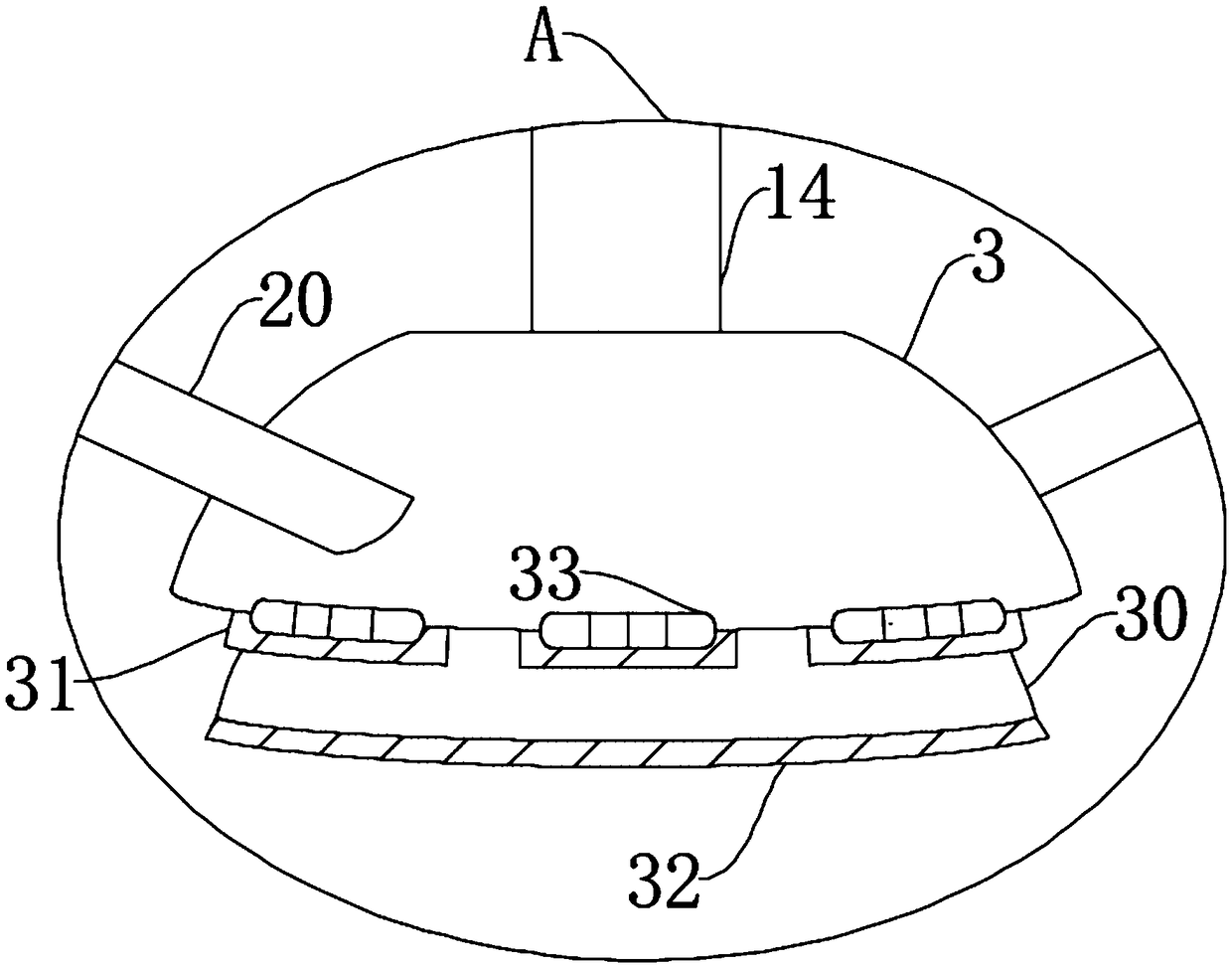

Rapid clamping and lifting equipment for motor equipment

InactiveCN108622799AGood cushioning of the contact surfaceImprove buffering effectLoad-engaging elementsCushioningEngineering

The invention discloses rapid clamping and lifting equipment for motor equipment. The rapid clamping and lifting equipment comprises lifting equipment, two groups of two pairs of fixing blocks are oppositely arranged on a bearing framework, two fixing blocks in each group always keep parallel, a buffer block is fixed on the inner wall, facing the fixing block, of the bearing framework, the four fixing blocks adsorb and clamp the motor equipment from two directions when the novel structure is used, a buffer air bag is also adsorbed and clamped; the fixing blocks and the buffer air bag are arranged in a disc shape, the minimum diameter of the fixing block is equal to the maximal diameter of the buffer air bag, the fixing block and the buffer air bag are fixedly connected, the lower end faceof an antislip friction block and a limiting block are always on the same horizontal plane, the limiting block inclines outside on the basis of the buffer air bag, the buffer air bag and the fixing block adsorb and clamp a product stably when the structure works, the cushioning between the buffer air bag and a contact surface of the motor equipment is good, and the airtightness is better.

Owner:苏州睿鑫莱机电科技有限公司

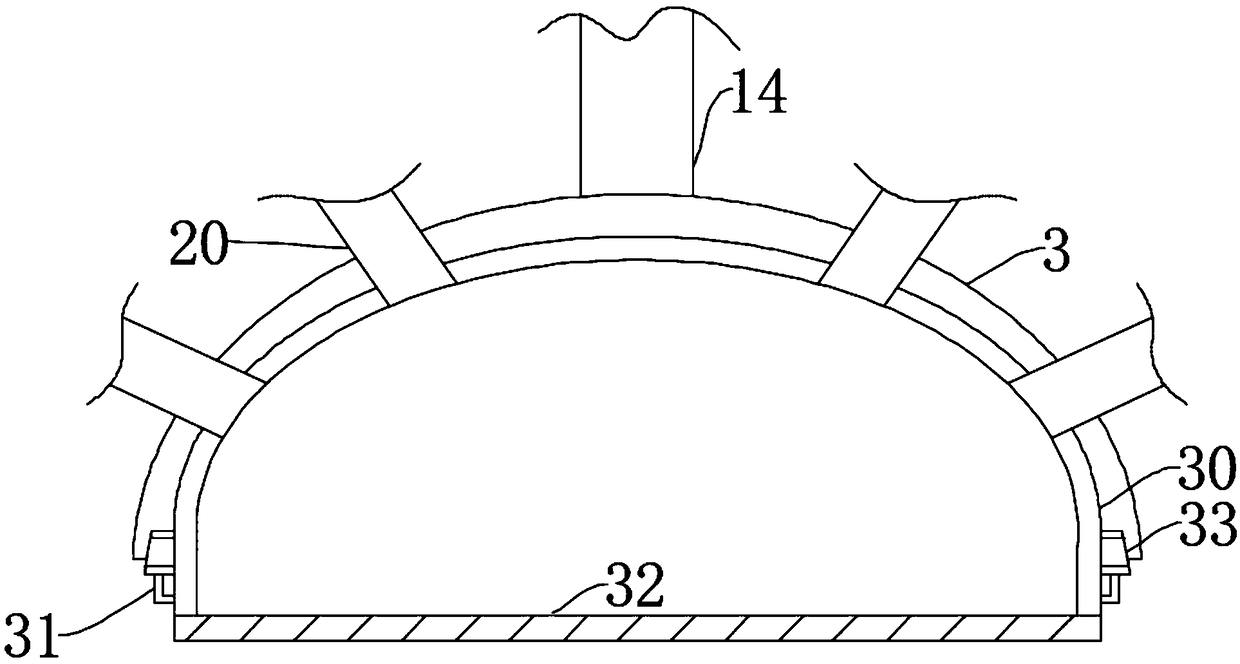

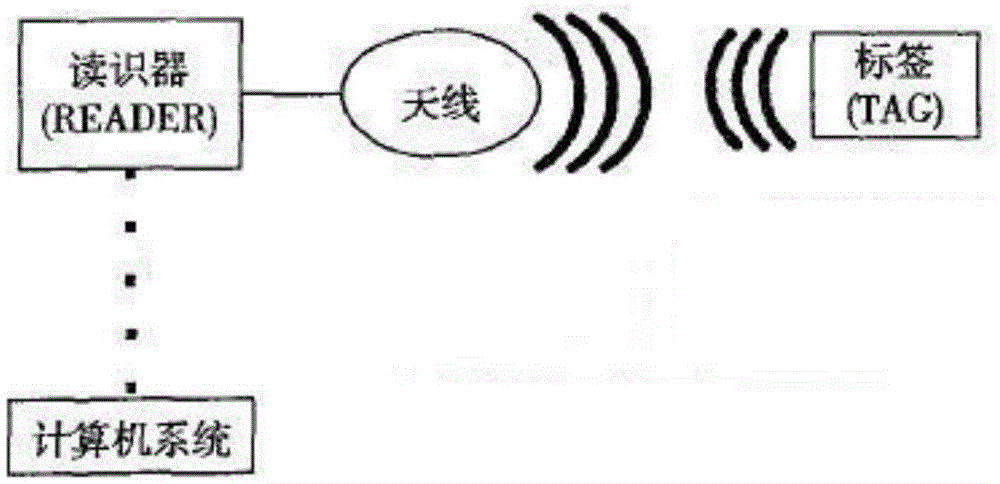

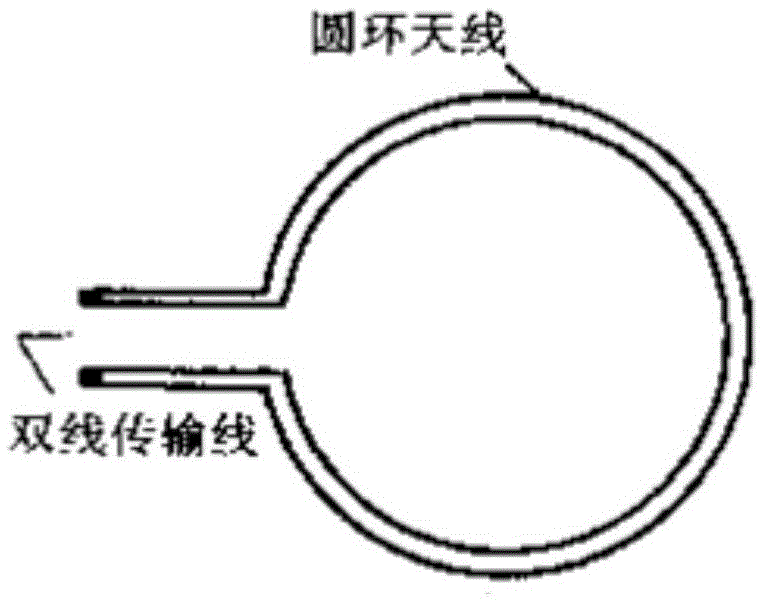

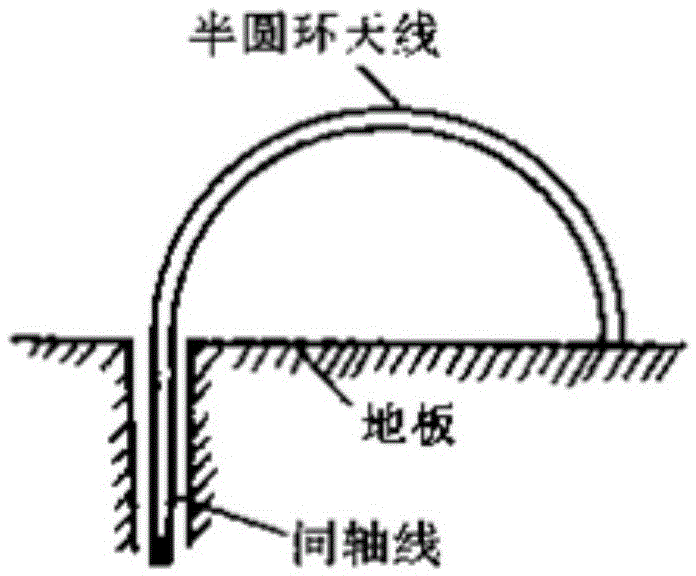

Near-field antenna for RFID system

InactiveCN105576354AIncrease radiation intensityEasy to processRadiating elements structural formsRadiating element housingsEngineeringCopper

The invention provides a near-field antenna for an RFID system. The near-field antenna comprises a substrate, a bottom shell and a connection feeder, wherein three concentric copper rings with different widths and radiuses are paved on a copper-paved radiation surface of the substrate; the copper ring with the maximal diameter is connected with a core wire of an N-type connector through the connection feeder; the substrate is fixed on the bottom shell through a positioning column at the bottom part; and an antenna cover is arranged on the bottom shell. The near-field antenna for the RFID system has the advantages that the form of a microstrip line with the concentric rings is adopted by the antenna, so that the near-field antenna is easy to process and high in efficiency; an aluminum shell at the lower part of a radiation panel can strengthen the antenna radiation intensity; and an upper shell right above the radiation panel is made of a PC (polycarbonate) material which does not affect radiation right above the antenna, so that the near-field antenna has high radiation intensity, high gain and stable performance.

Owner:ZTE INTELLIGENT IOT TECH

Gastroretentive drug delivery system, preparation method and use thereof

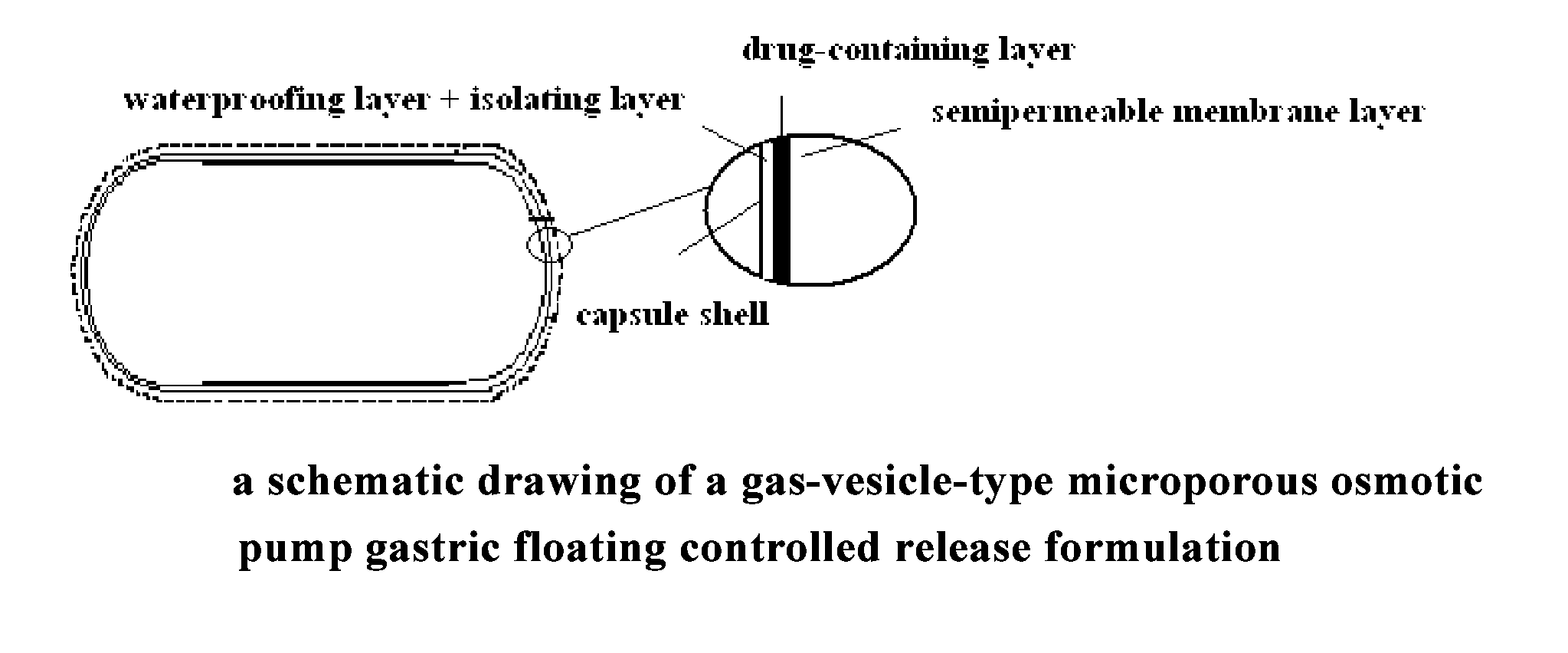

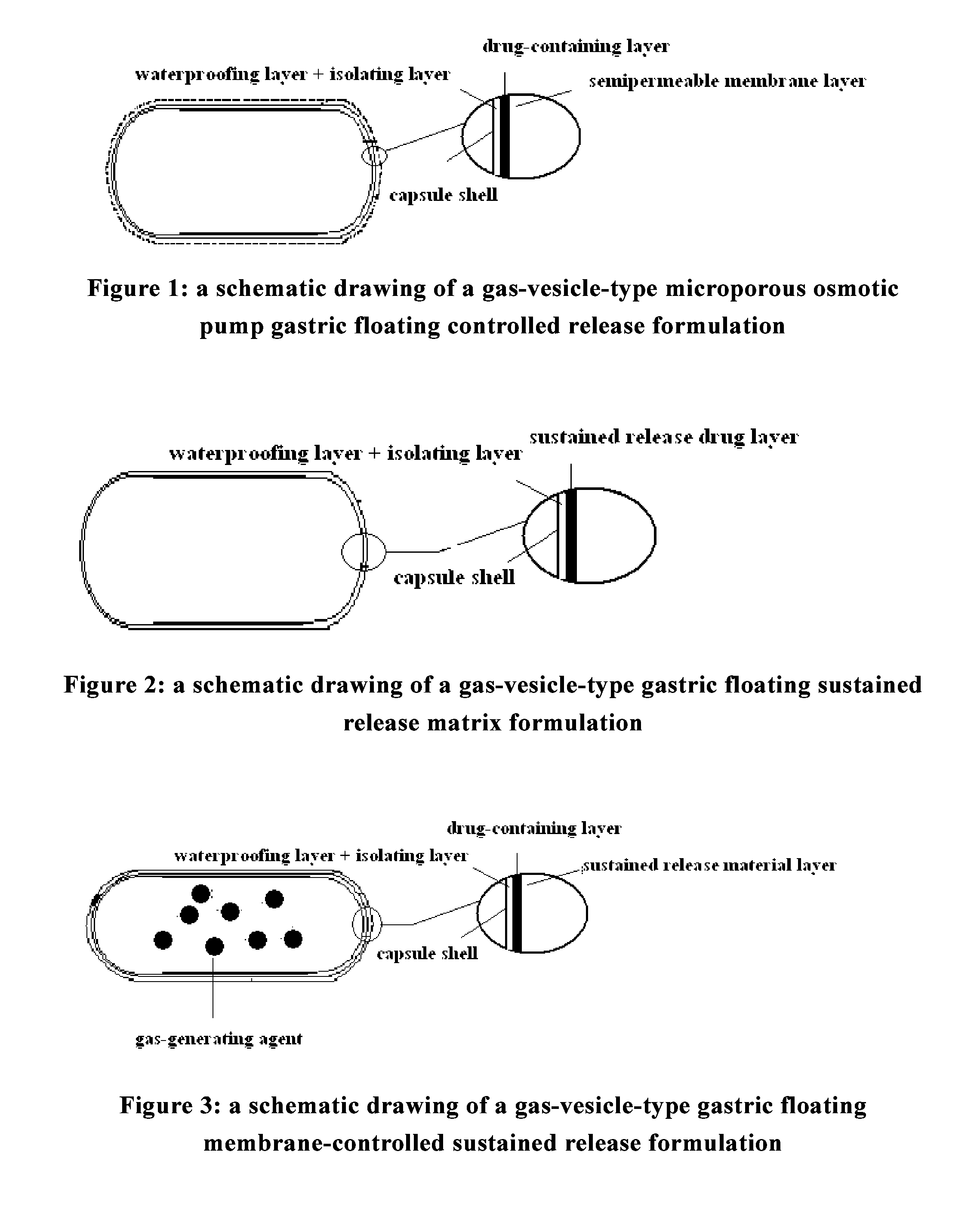

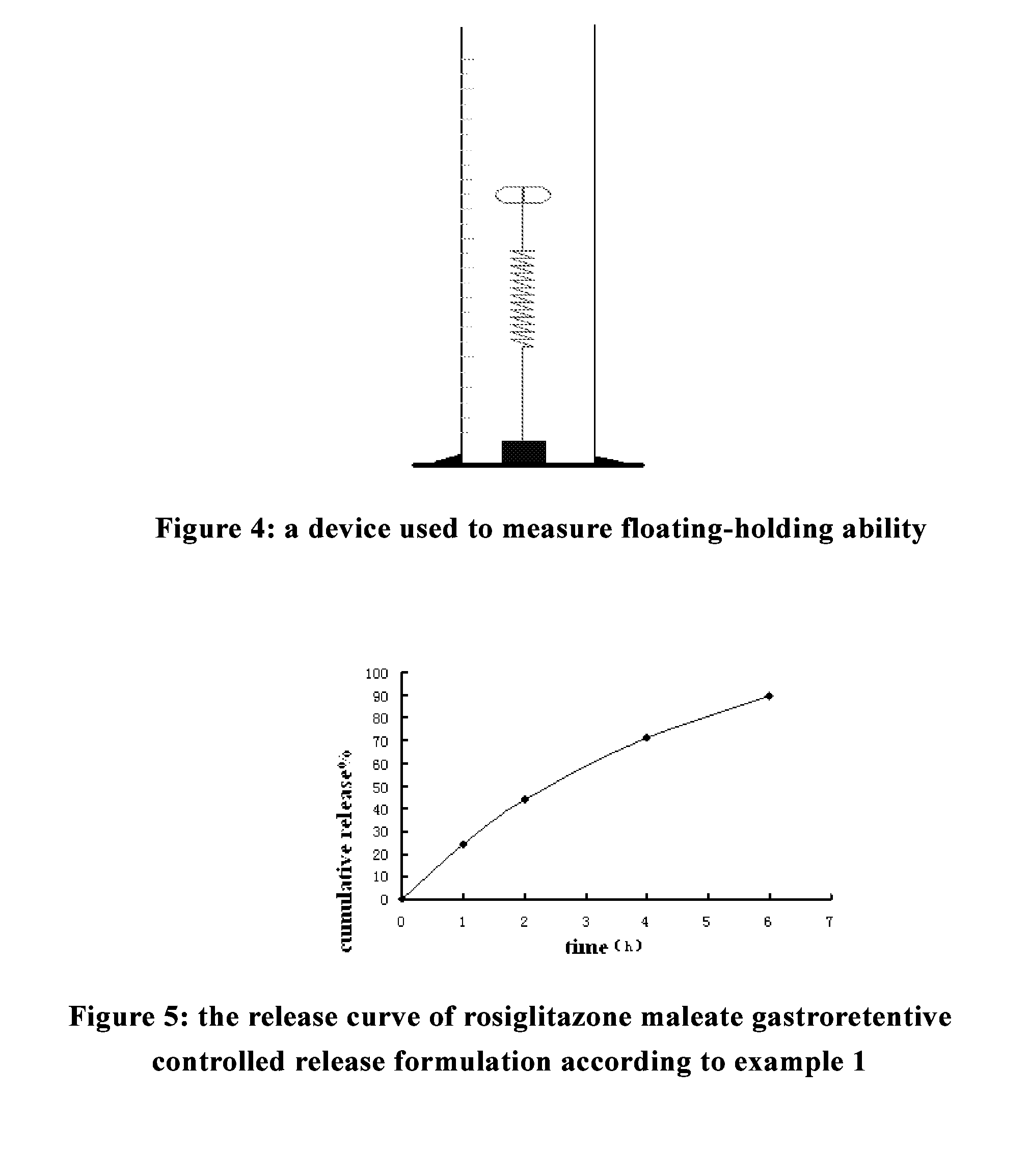

InactiveUS20110171275A1Efficient implementationLow densityBiocideSenses disorderMedicineSingle chamber

A gastroretentive drug delivery system is provided. Said system comprises a hollow vesicle and a drug-containing layer which surrounds the hollow vesicle. Said hollow vesicle preferably has a single chamber structure. The size in maximal diameter direction of said hollow vesicle is preferably 0.5-3.5 cm. The gastroretentive drug delivery system preferably contains an isolating layer and / or waterproofing layer between the hollow vesicle and the layer containing drug.

Owner:TEAM ACAD OF PHARMA SCI

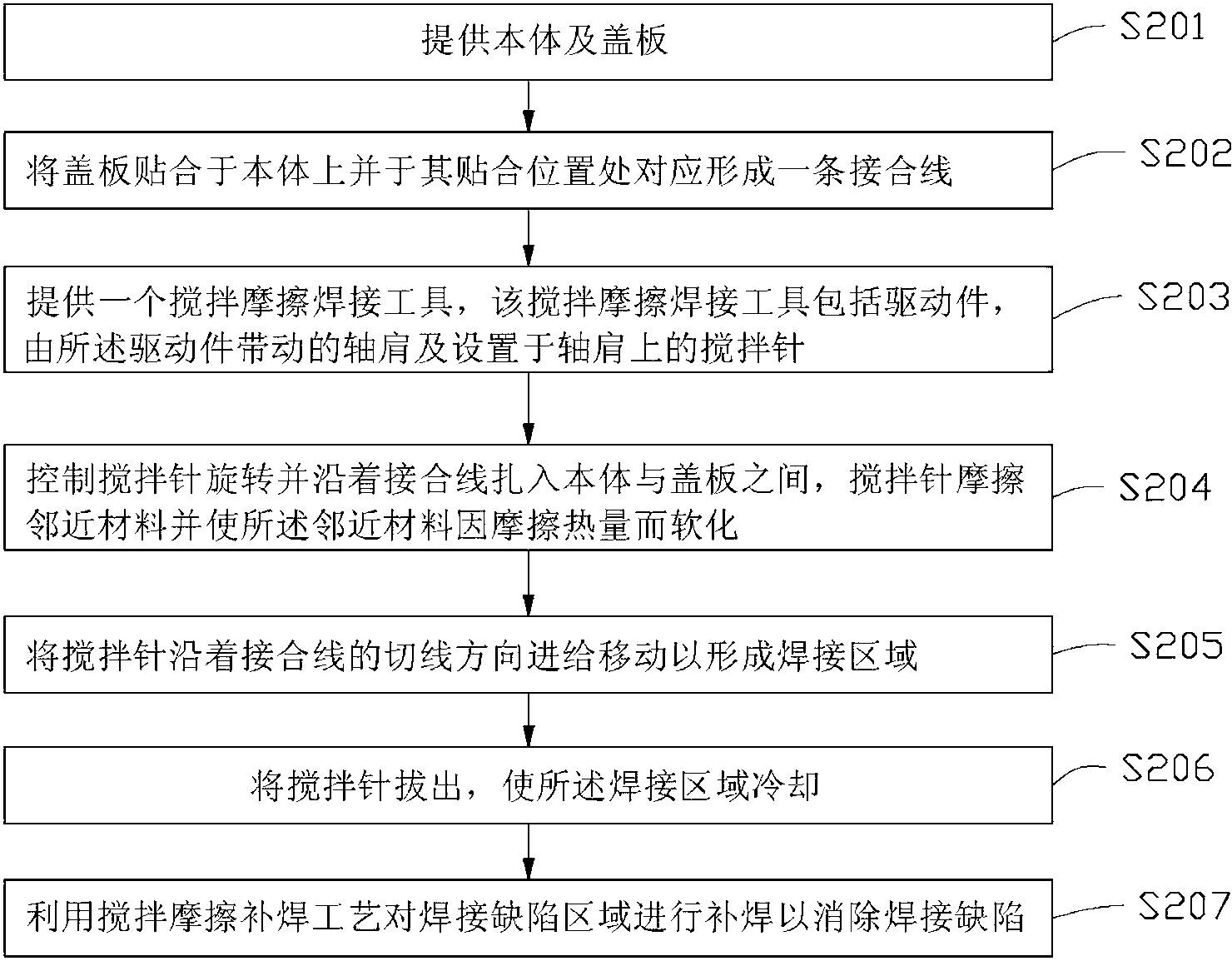

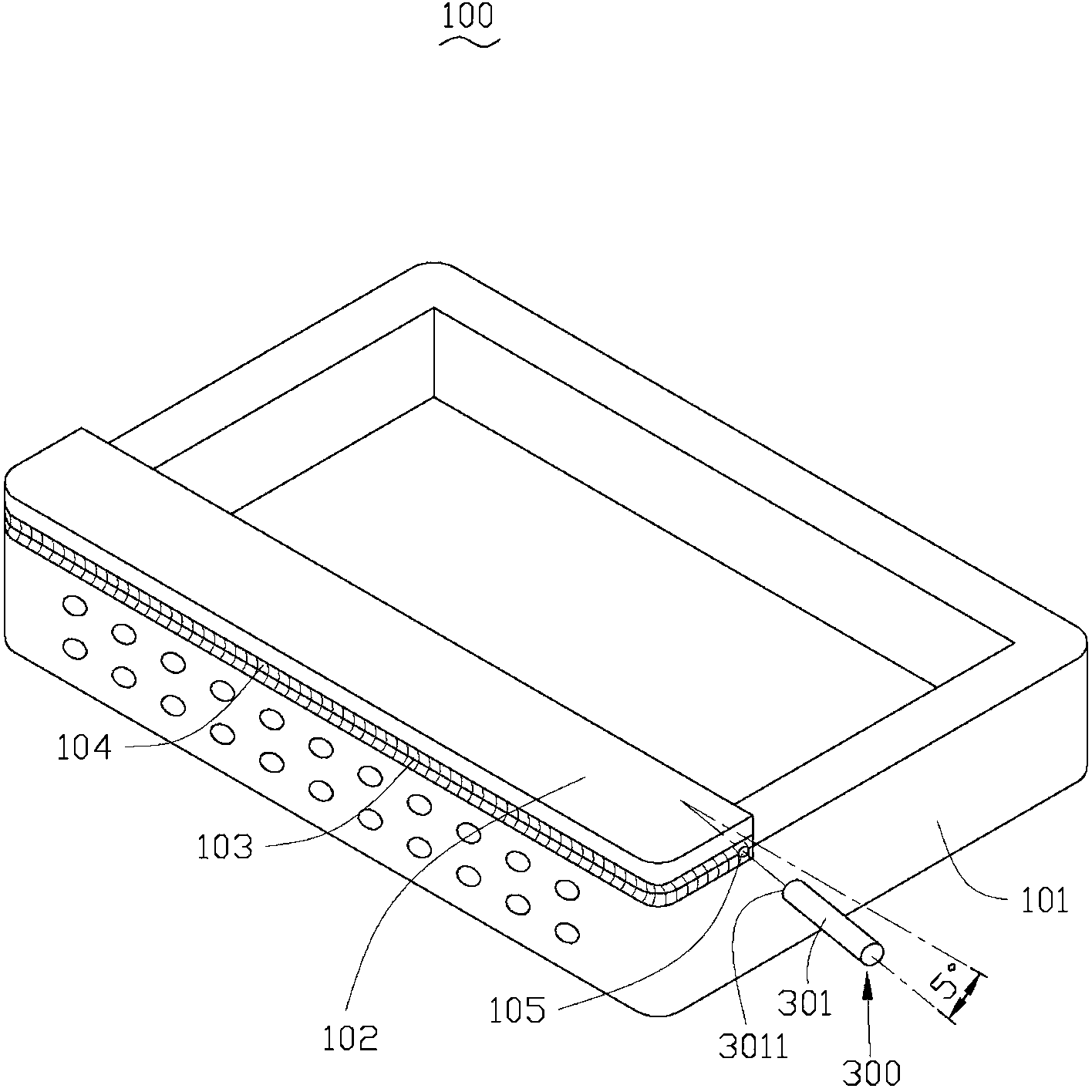

Stirring friction repair welding process and stirring friction welding method adopting same

A stirring friction repair welding process is used for eliminating a welding defect area on a workpiece and comprises the following steps of providing a repair welding tool, wherein the repair welding tool comprises a drive member and a stirring rod which is driven by the drive member, the stirring rod is provided with a working end part, and the distance between two most remote points on the edge of the cross section of the working end part is greater than the maximal diameter of the welding defect area; controlling the stirring rod to rotate and utilizing the working end part to penetrate an adjacent area of the welding defect area; moving the stirring rod along the direction towards the welding defect area so as to completely cover the welding defect area; and unplugging the stirring rod and cooling the welding defect area. The invention also provides a stirring friction welding method adopting the repair welding process. Since the repair welding tool only comprises the drive member and the stirring rod, the manufacturing cost is low, and the procedures and the working time can be saved through the stirring friction repair welding process.

Owner:FU TAI HUA IND SHENZHEN +1

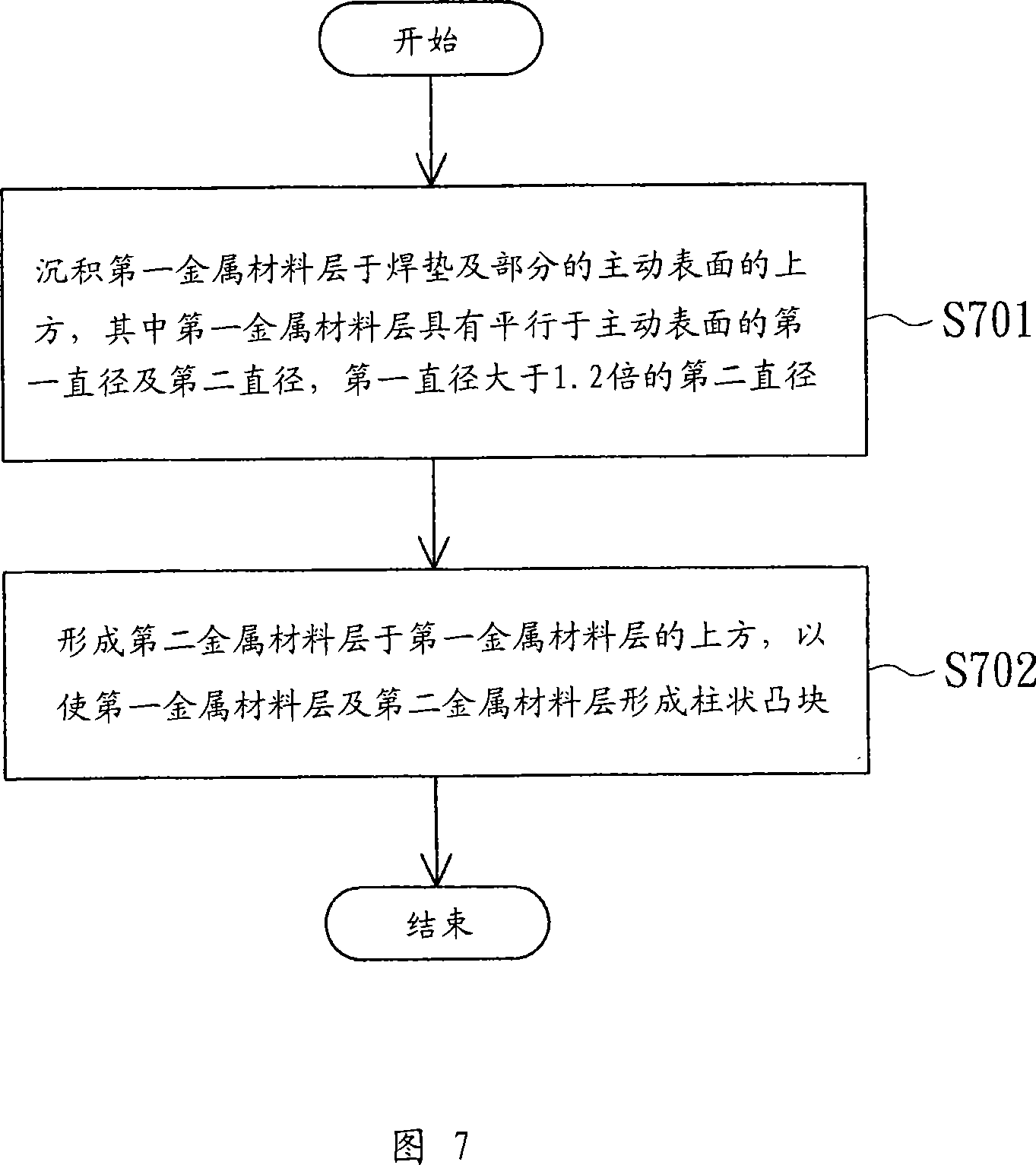

Chip and its making method

ActiveCN101165885AImprove structural strengthImprove yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The semiconductor component comprises at least coupling member whose maximal diameter is less than 100 micron and one lug bulge. The coupling member is located on the driving surface. The bulge is located on the coupling member in order to make the coupling member to electrically connect to the driving surface. The bulge comprises a cylinder part and a top part; the cylinder part is located on the coupling member; the top part is located on the top of the cylinder part; the cylinder part has a first diameter length and a second diameter length parallel to the driving surface; the first diameter length is 1.2 times longer than the second diameter length.

Owner:ADVANPAK SOLUTIONS PTE

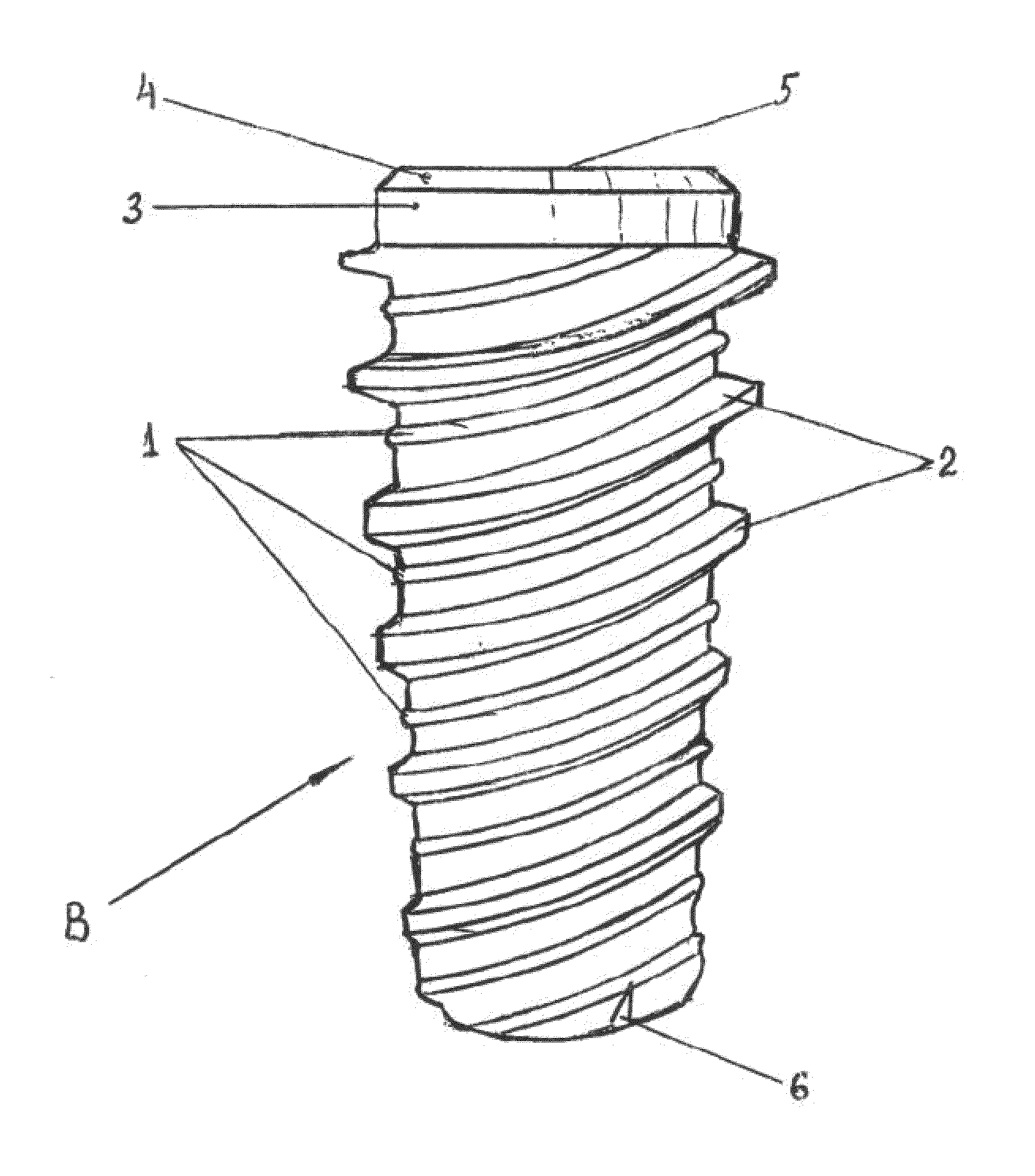

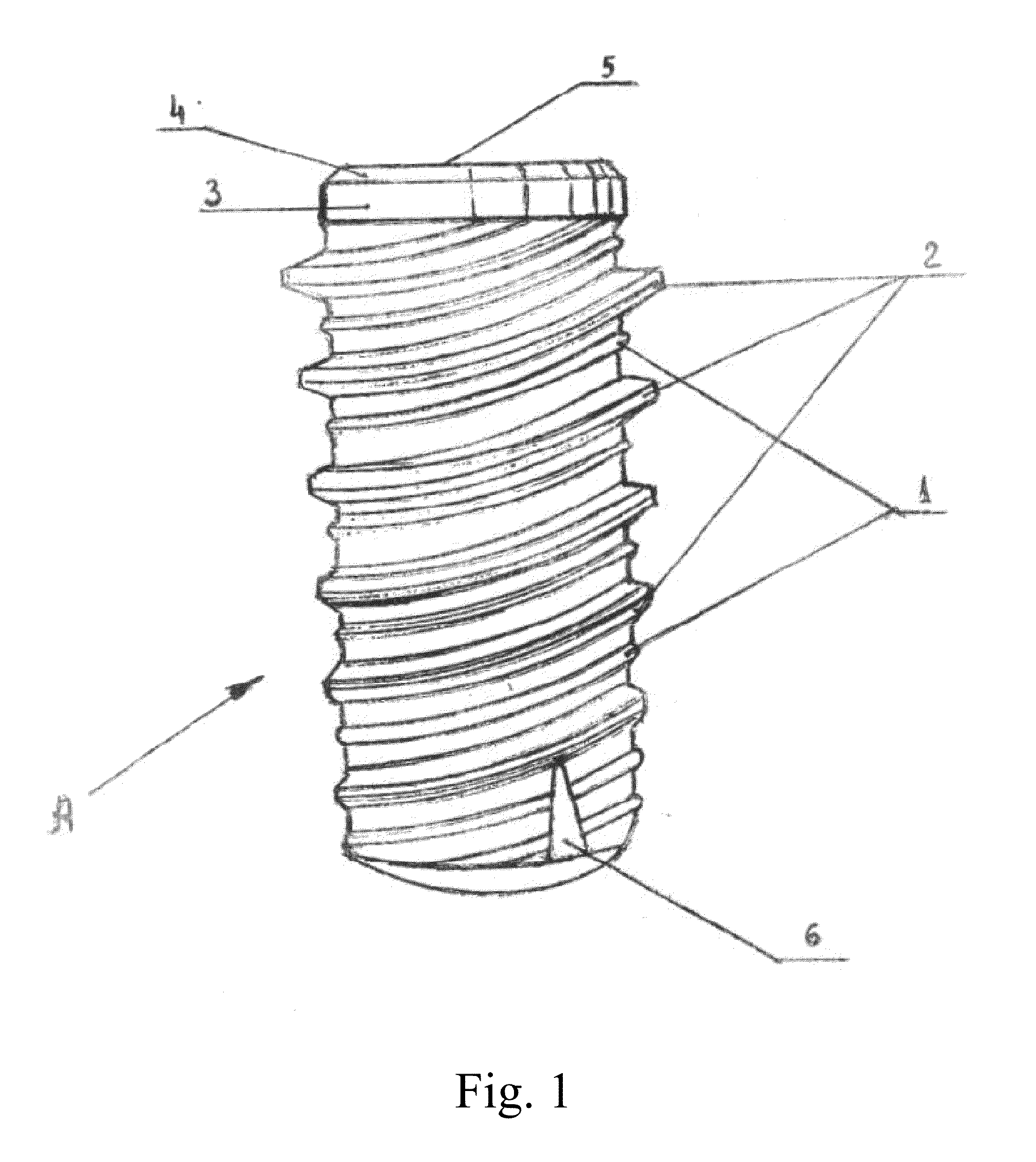

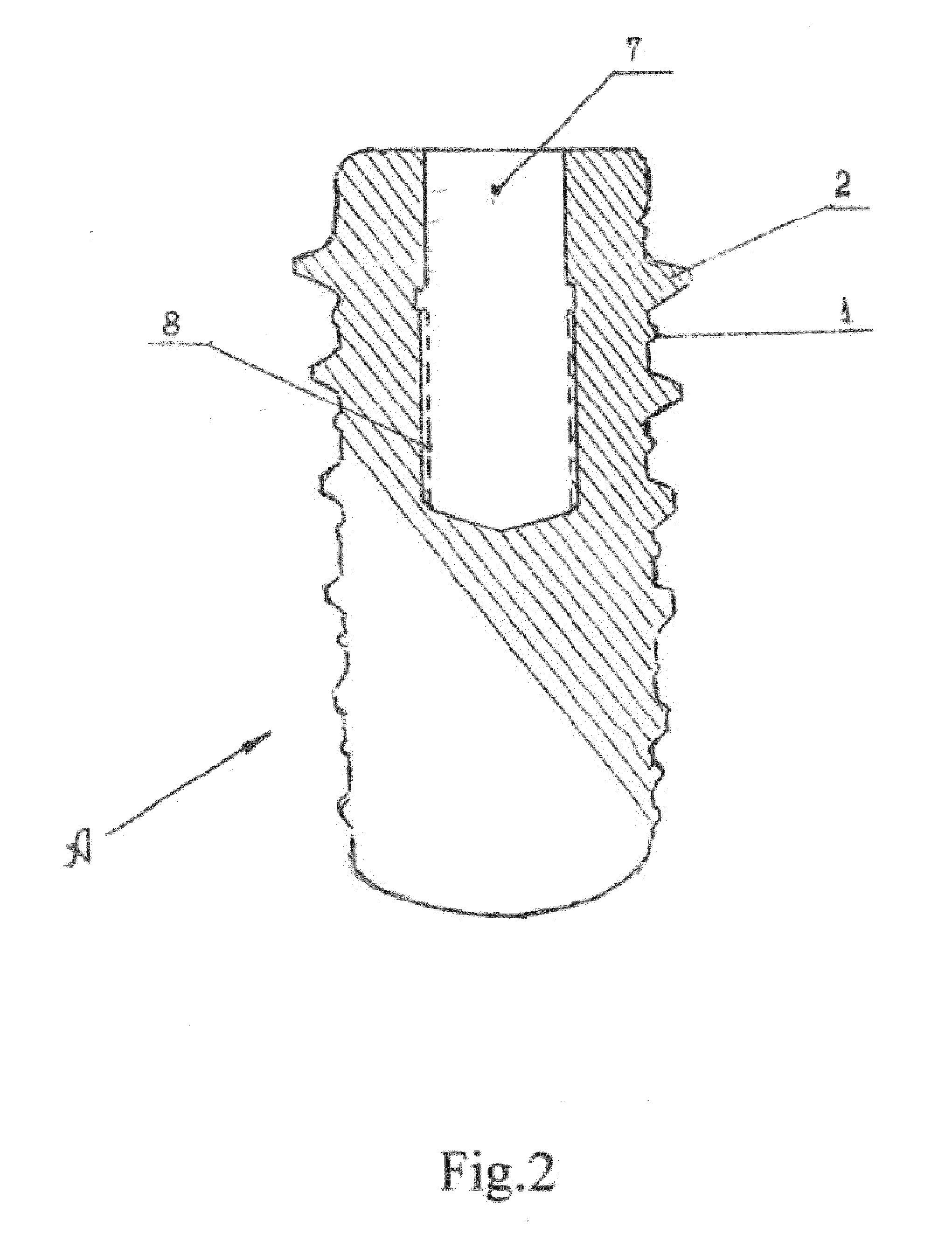

Dental implant

The invention provides a dental implant, characterized by a cylindrically threaded shaft section with at least a double lead thread. One lead thread is micro carved, while the other lead thread is carved with teeth of any shape, for instance V-shaped, buttress-shaped or square-shaped. The dimension of teeth increases gradually from zero in the lower part of the said implant (with constant or cone diameter) to approximately 0.1-0.2 of the diameter of the micro carving from the upper part of the said body implant. The maximal diameter of the said implant equals approximately 1.2-1.4 of that of the lower part. Thereto the internal body is supplied by a lead thread in order to block the said implant and may further be used for attachment of the key to turn in the said implant.

Owner:KRUSH VICTOR +1

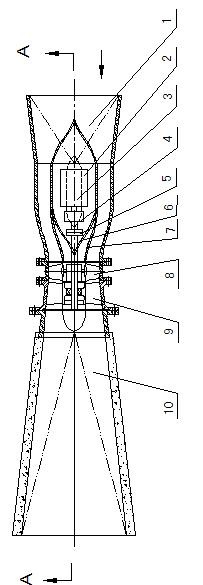

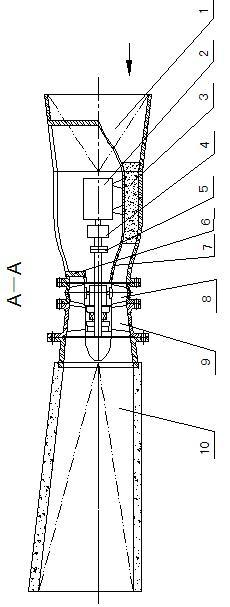

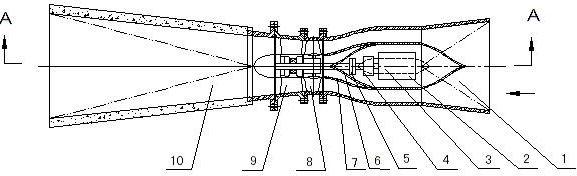

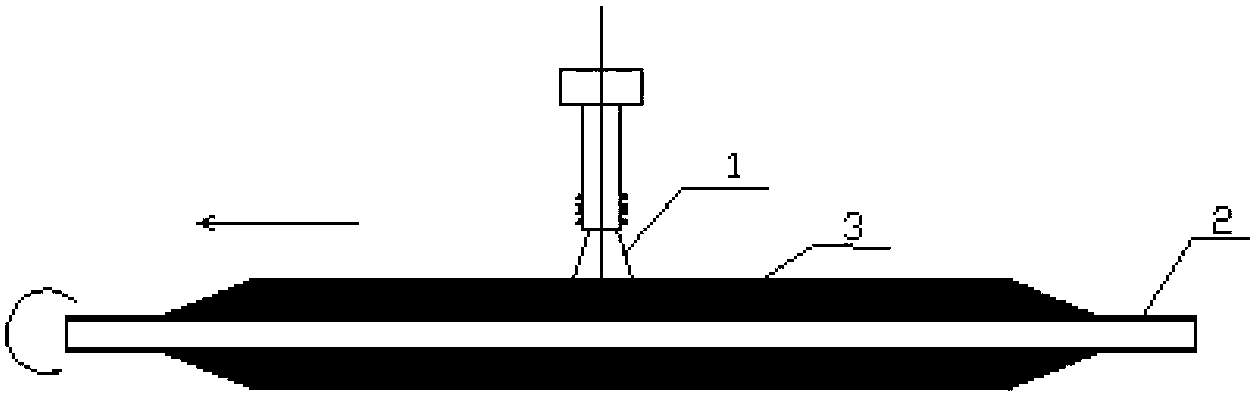

Composite tubular pump device

InactiveCN102182690AGood water conditionsEasy to install and maintainRadial flow pumpsNon-positive displacement fluid enginesWalnut NutMechanical engineering

The invention relates to a composite tubular pump device which comprises a water inflow runner (1), a semi-vertical semi-bulb water inflow structure, a horizontal water pump unit and a water outflow runner (10) which are connected sequentially, wherein the semi-vertical semi-bulb water inflow structure comprises a metal shell; the metal shell comprises an upper vertical well (6) and a lower bulb body (7), wherein the cross section shape of the upper vertical well is a walnut-shaped streamline shape with two tip ends and a large middle part; the maximal width of the upper vertical well is the same with the maximal diameter of the lower bulb body; and a motor (2) of the horizontal water pump unit and a transmission device (4) are installed in the metal shell. The semi-vertical semi-bulb water inflow structure is adopted for the composite tubular pump device provided by the invention, and integrates the advantages of a vertical-well-type tubular pump device and a bulb-type tubular pump device, thus a favorable water inflow condition can be provided for the water pump, the energy property and cavitation erosion of the water pump are exerted, the structure is compact, the ventilation and heat radiation conditions are good, the pump unit is convenient to install and overhaul, and the composite tubular pump device is good for running and managing.

Owner:YANGZHOU UNIV

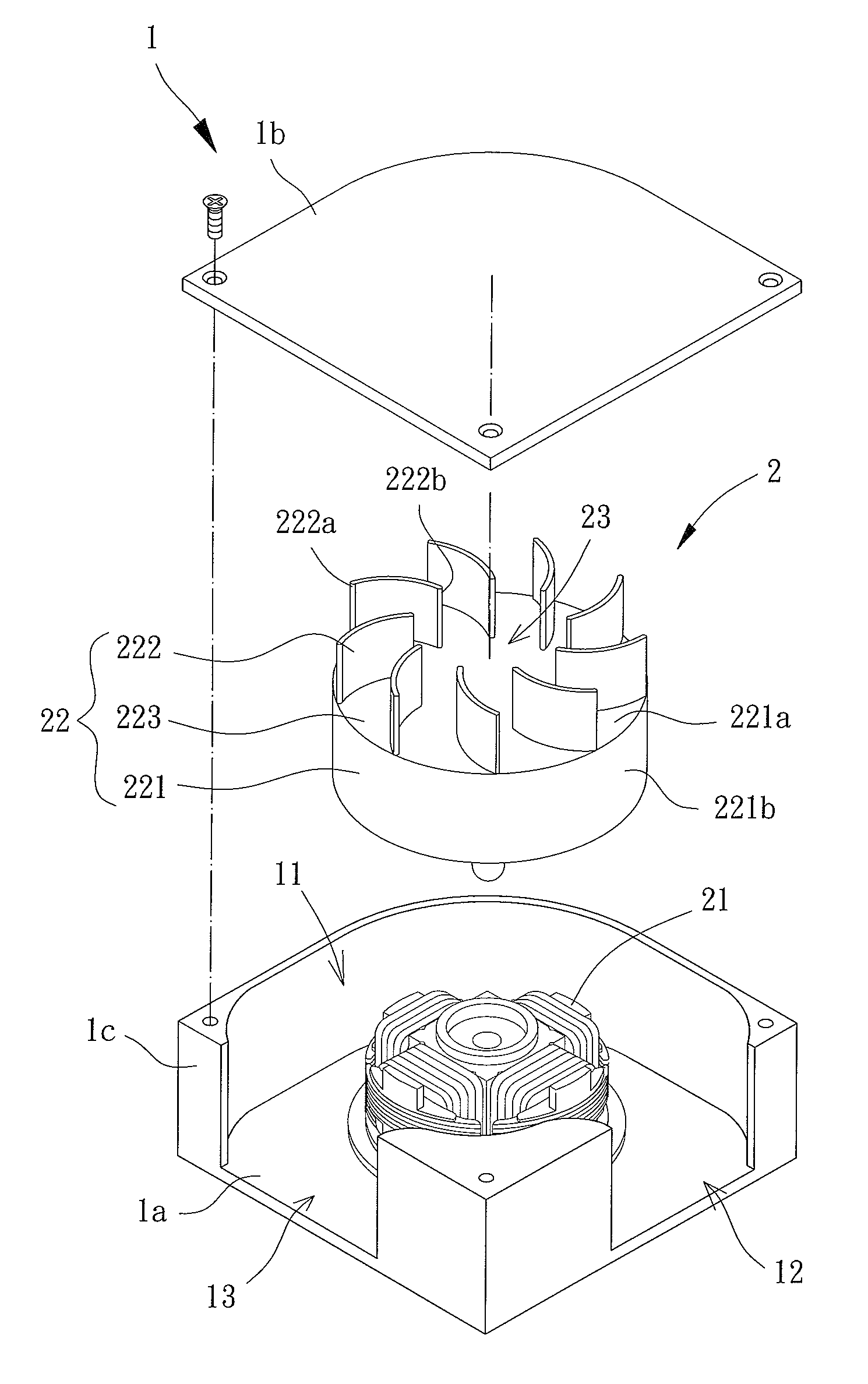

Fan

InactiveUS20130011255A1Prevent airflowPump componentsDigital data processing detailsImpellerEngineering

A fan includes a housing and a motor. The housing has a compartment, at least one lateral air inlet and at least one lateral air outlet. The lateral air inlet and lateral air outlet communicate with the compartment. The motor has a stator and an impeller. The impeller is coupled with the stator and includes a hub and a plurality of blades coupled with a top face of the hub. Each blade has first and second ends. The first ends of the blades face outwards, and the second ends of the blades define an air-guiding room encompassed by a virtual geometric pattern formed by a virtual line linking the second ends of the blades. The virtual geometric pattern has a maximal diameter. A gap is formed between the second ends of two adjacent blades. The gap is smaller than the maximal diameter of the virtual geometric pattern.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

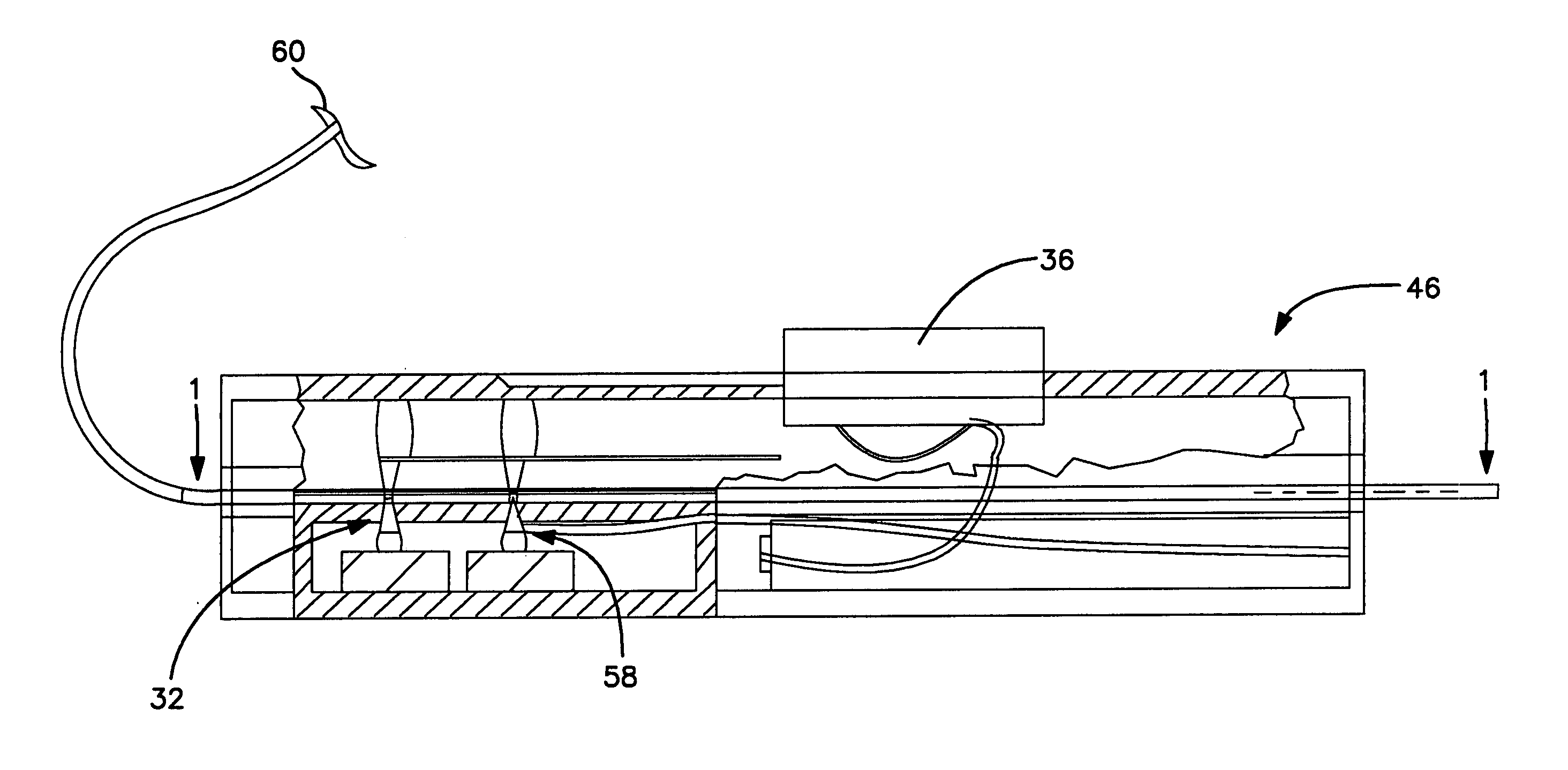

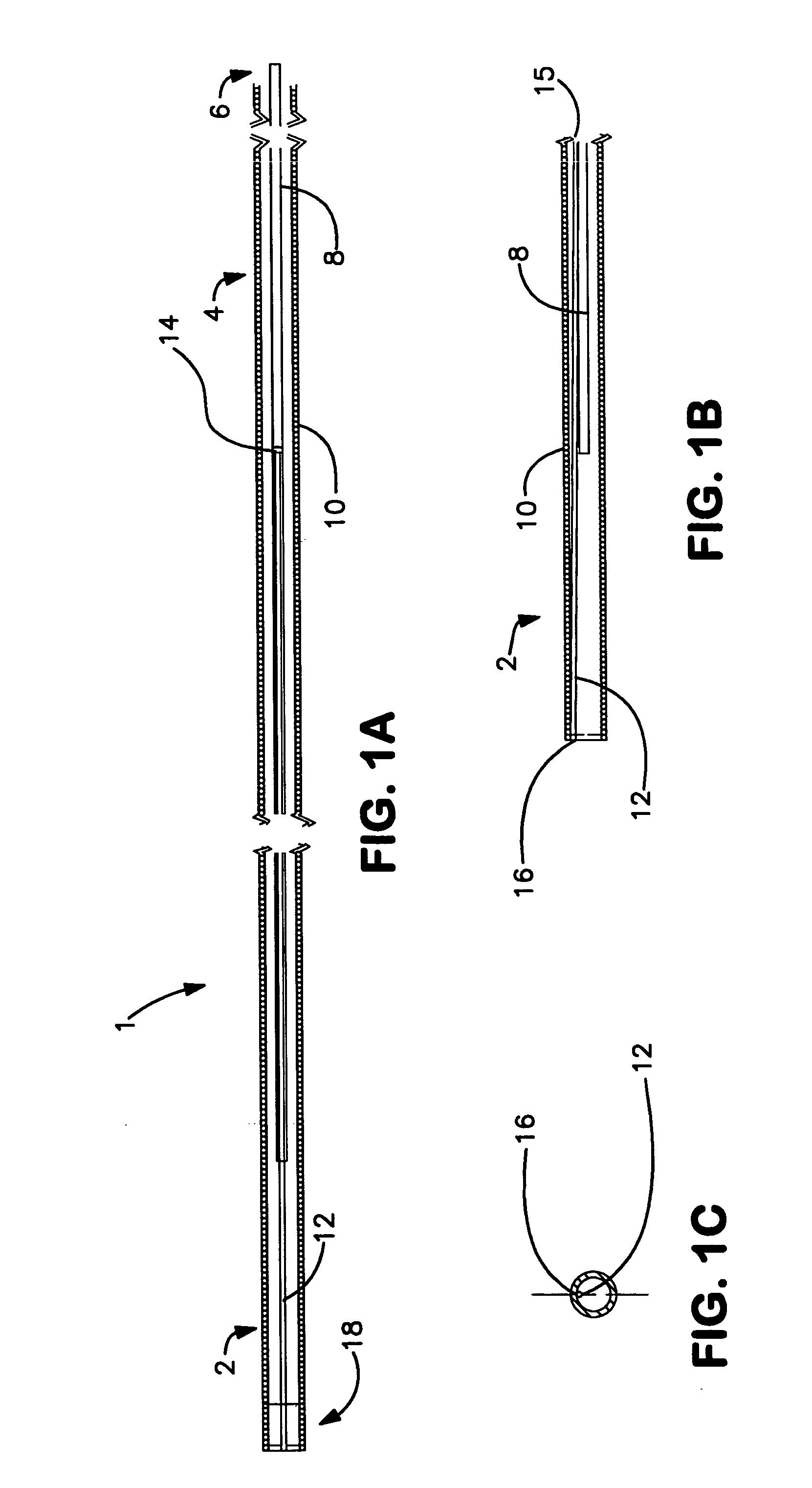

Energizer for vascular guidewire

InactiveUS20050277988A1Reduce traumaLow profileGuide wiresHeart defibrillatorsDistal portionBlood vessel

An energizer for use with a guidewire, such as a vascular guidewire, in one embodiment engages a proximal end of the guidewire and applies energy to be transmitted to a distal portion of the guidewire. A jack or other receptacle accommodates, in a releasably secured fashion, a proximal portion of the guidewire having a diameter that is not substantially larger than, but preferably is equal to or less than, the maximal diameter associated with the guidewire. The jack may be structured so that designated portions of the proximal end of the guidewire will be disposed in selective contact with corresponding portions of the jack in order to permit, for example, an electrical potential to be applied across such portions, thereby energizing an electrically controllable part of the guidewire, such as a steering mechanism. In this manner, the energizer permits rapid engagement and disengagement of a proximal portion of the guidewire. Equipment such as catheters may conveniently be fed coaxially over the proximal portion of the guidewire and up toward the distal end and conveniently exchanged with reduced complexity of, and disturbance to, the guidewire, its environment, and the energizing mechanism.

Owner:WINDCREST

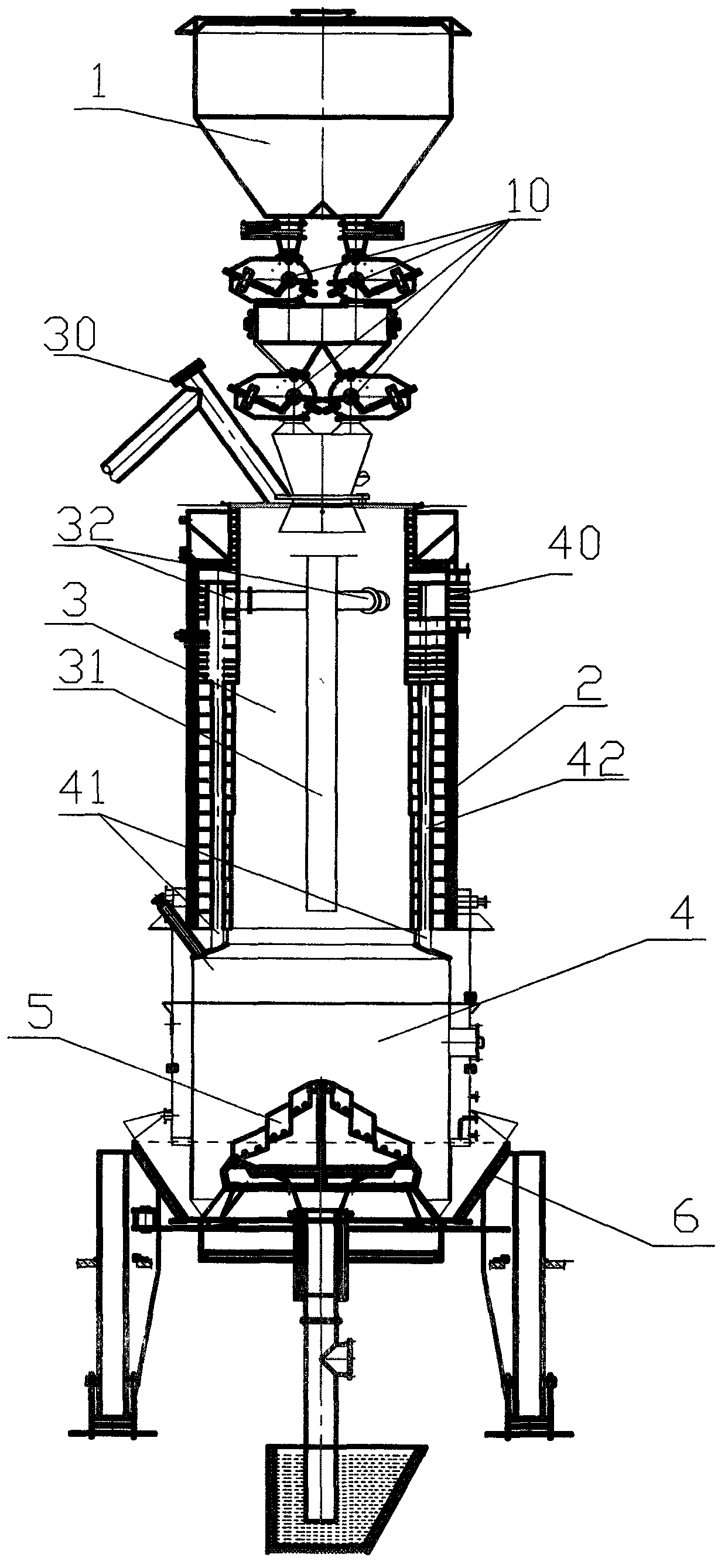

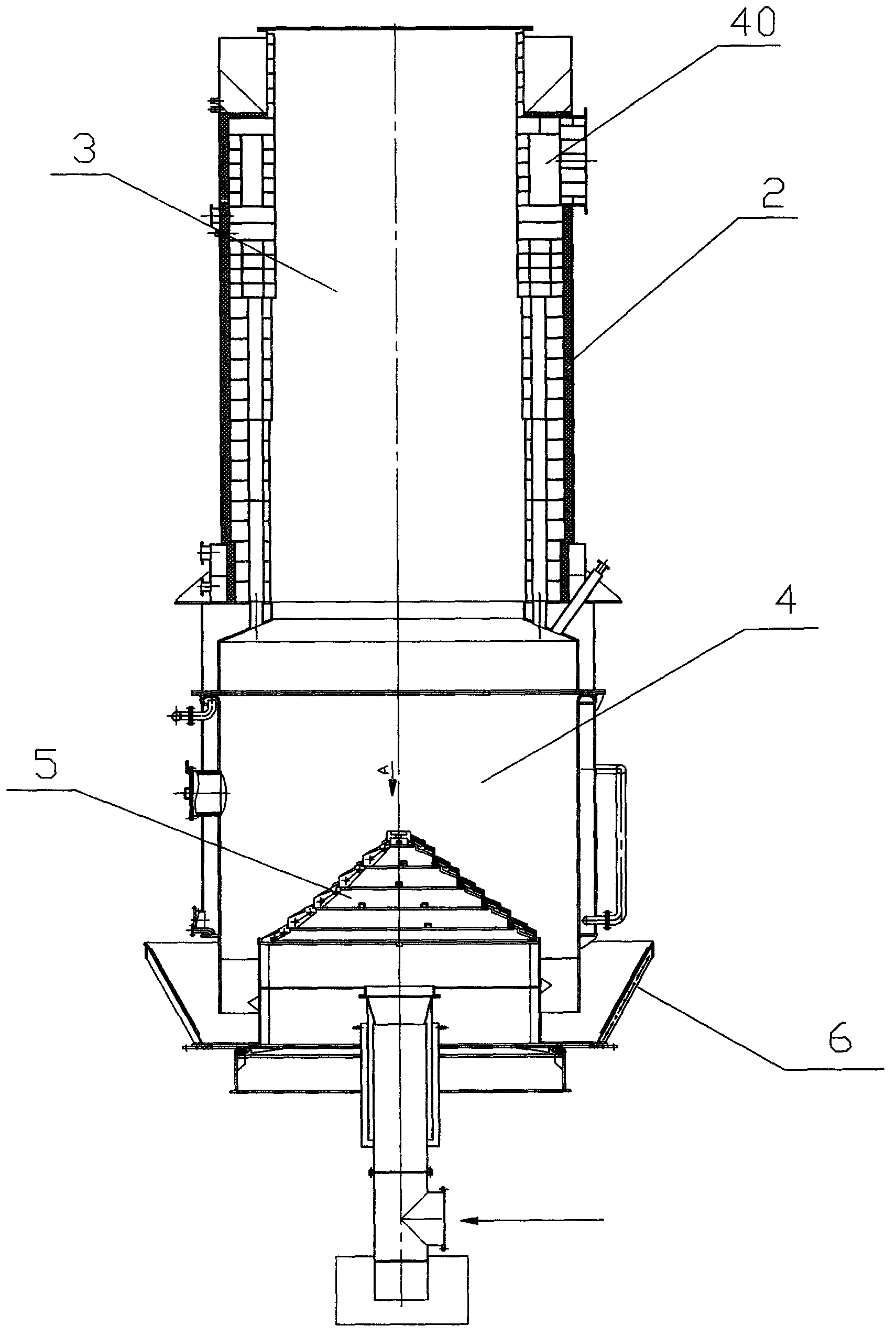

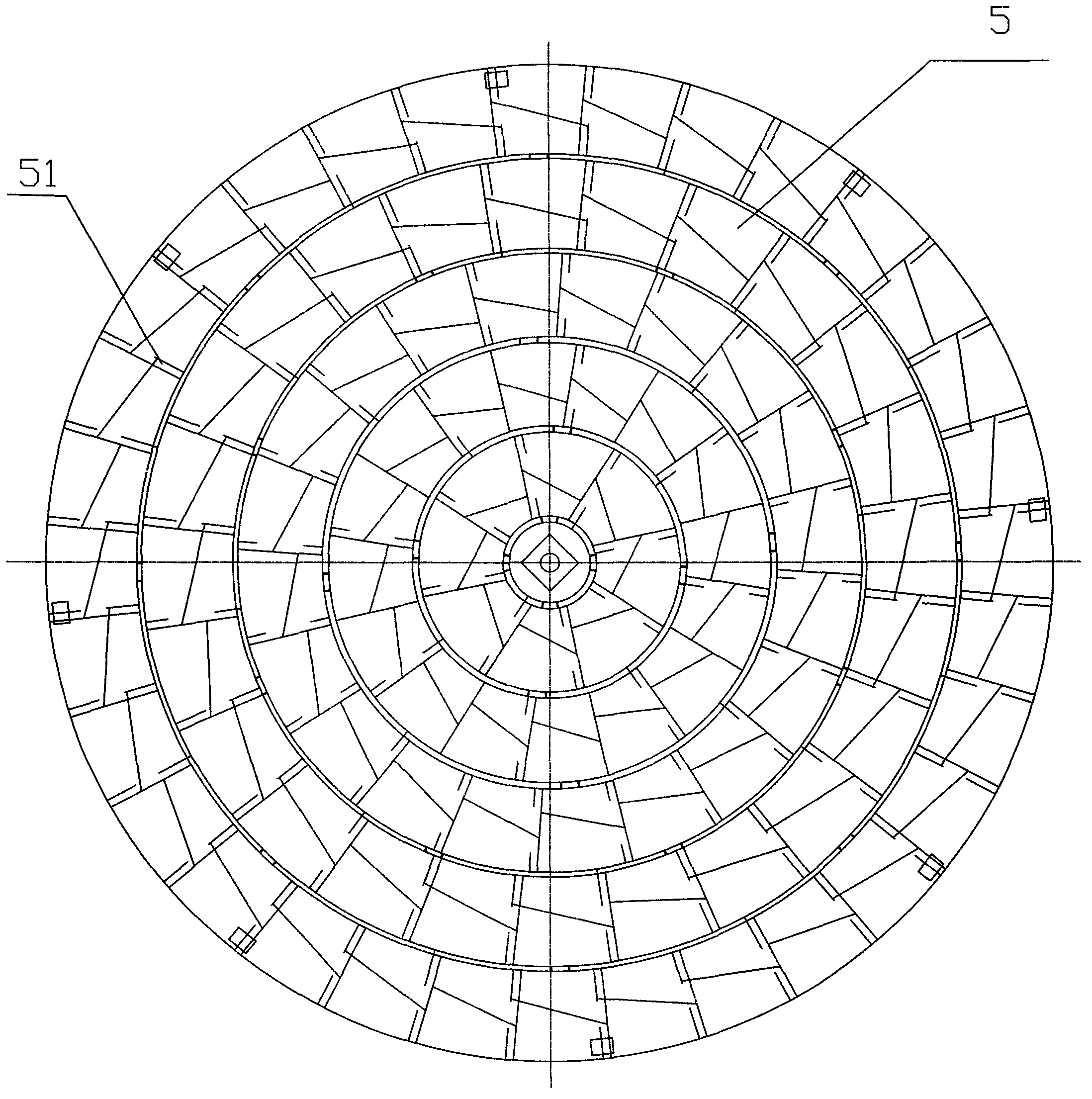

Two-stage coal gas generating device

ActiveCN103194273AHigh gas output rateQuality improvementChemical industryCombustible gas productionProcess engineeringThermal efficiency

The invention discloses a two-stage coal gas generating device, which solves the problems of the traditional coal gas generator that the air distribution is non-uniform, the utilization rate of the coal is low, and the gas yield is low. A grate bar of a six-layer composite structure is adopted, so that the maximal diameter of the grate bar can reach 3.22m, the inner diameter of an entire furnace can reach 4 to 20m, the utilizable area inside the entire furnace is increased, the coal gas output of a single furnace is improved, two elongated air distribution ports, i.e. an upper air distribution port and a lower air distribution port with inclination angles of 27 DEG and 22 DEG are respectively arranged in an air outlet of the grate bar, the elongated upper air distribution port and the elongated lower air distribution port are staggered to each other to integrate the air distribution of an upper large inclination angle and the air distribution of a lower small inclination angle, so that the gasification agent is more uniformly distributed in the generator through the alternating air distribution, the gasification is more adequate, the heat efficiency is greatly improved, the energy is saved, the air distribution in the entire generator is uniform, the coal gas yield is high, the coal gas quality is stable, less land area is occupied, and the energy conservation and consumption reduction can be better realized; and the two-stage coal gas generating device is applicable to different two-stage coal gas generators.

Owner:FOSHAN WELKIN MACHINERY

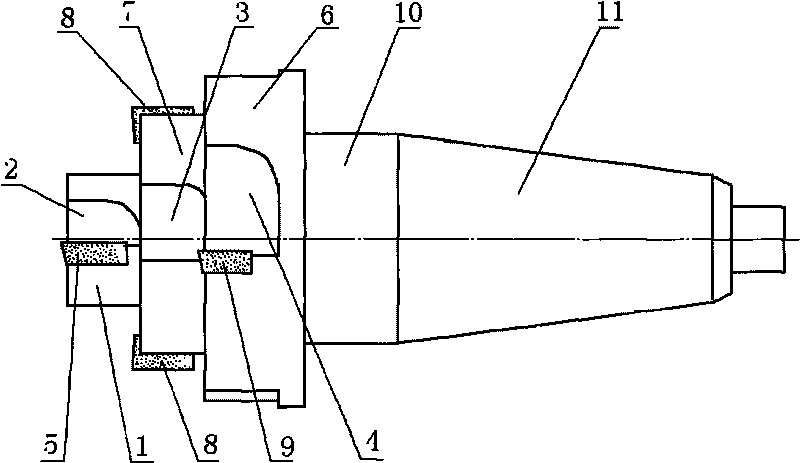

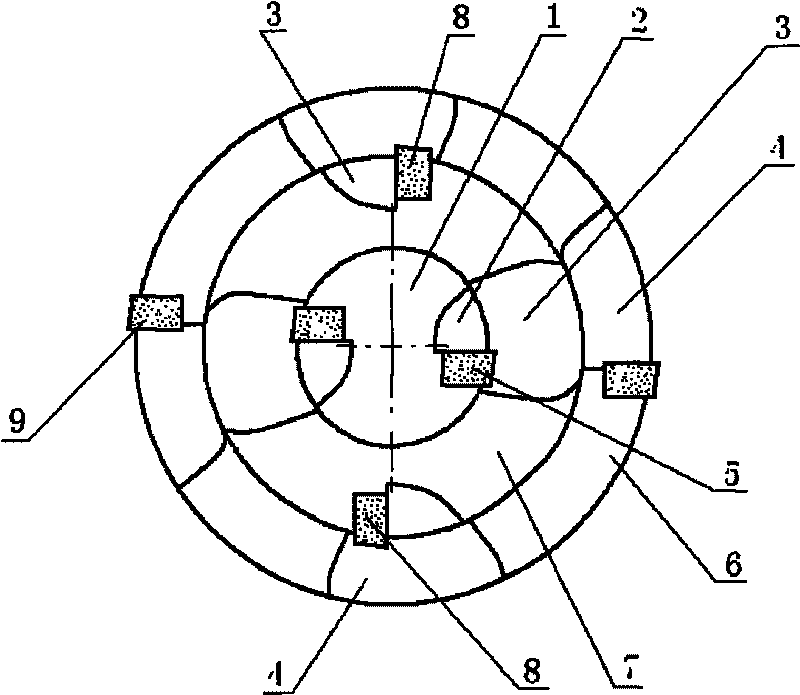

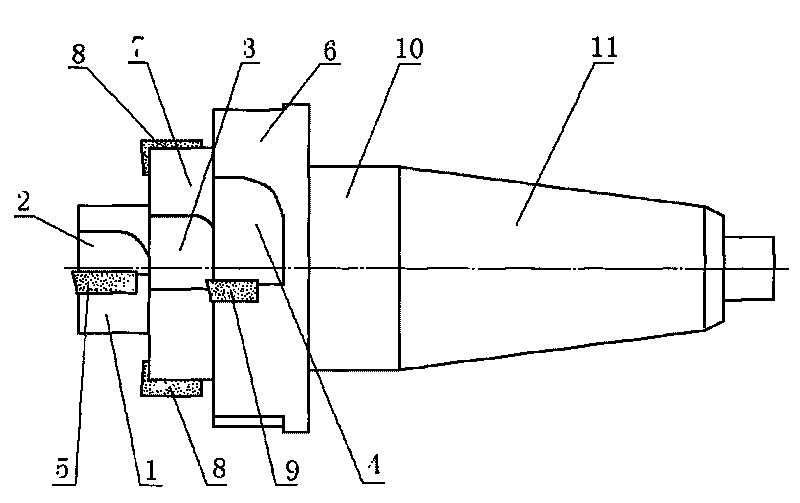

Cutter for processing step hole workpiece on lathe and using method thereof

InactiveCN101758251AIncrease profitImprove processing efficiencyTurning toolsAttachable boring/drilling devicesEngineeringProcessing cost

The invention discloses a cutter for processing a step hole workpiece on a lathe and a using method thereof. The cutter is formed by sequentially integrating a first cutting section, a second cutting section, a third cutting section with maximal diameter, a cutter transition section and a cutter matching section, wherein the first cutting section comprises a first cutting body, two symmetrical first cutting body blades and a first cutting body chip discharge groove; the second cutting section comprises a second cutting body, two symmetrical second cutting body blades and a second cutting body chip discharge groove; the third cutting section comprises a third cutting body, two symmetrical third cutting body blades and a third cutting body chip discharge groove; and the sizes of the first cutting body, the second cutting body and the third cutting body are suitable for a step hole workpiece. The cutter for processing the step hole workpiece on the lathe and the using method thereof can process the qualified step hole workpiece in such a way by utilizing the lathe, the step hole workpiece is processed and finished at one step, the processing efficiency is improved, and the processing cost is reduced.

Owner:芜湖长胜机械制造有限公司

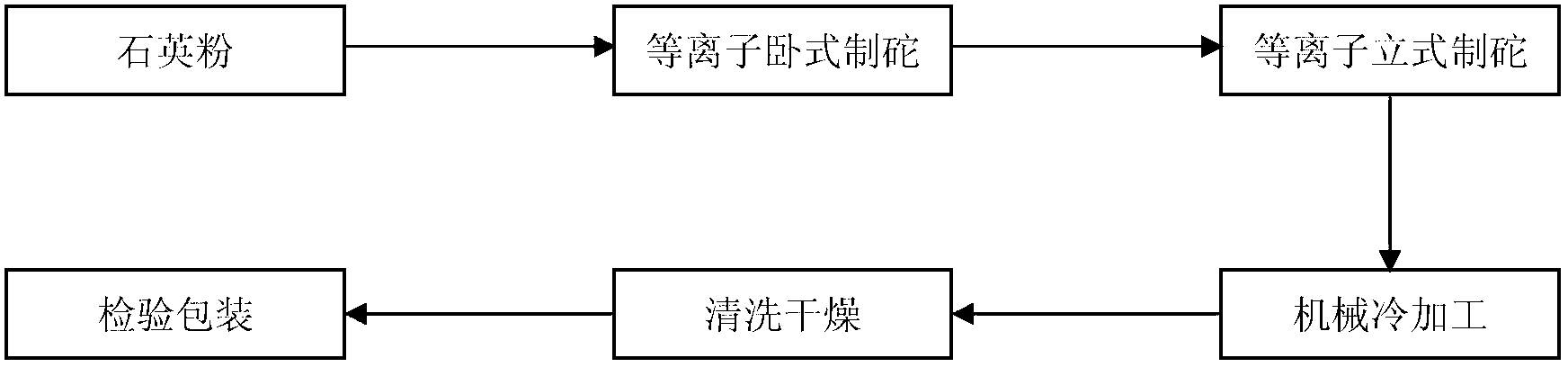

Method for preparing low-water-peak large-diameter optical fiber preform sleeve pipe

ActiveCN103224326AHigh purityAchieve productionGlass making apparatusUltimate tensile strengthPlasma flame

The invention discloses a production method for preparing a low-water-peak large-diameter optical fiber preform sleeve pipe. The method comprises the steps that: 1, a hollow quartz blank piece is prepared with a plasma horizontal solid-phase external deposition method, such that the diameter of the blank piece reaches 150-160mm; and 2, smelting is continued on the basis of the blank piece with the plasma vertical solid-phase external deposition method, such that a quartz pipe piece with a maximal diameter larger than 300mm is produced. According to the invention, plasma flame heating is adopted, and horizontal process is combined with vertical process, such that the problem of the impossibility of realizing large-diameter blank piece load bearing of a traditional horizontal plasma solid-phase external deposition method is solved. The obtained large-diameter blank piece is further processed into the low-water-peak large-diameter optical fiber preform quartz sleeve pipe. The product provided by the invention has the advantages of high purity, less bubble, low hydroxyl group, and high strength. The method can be applied in the field of low-water-peak optical fibers.

Owner:久智光电子材料科技有限公司 +1

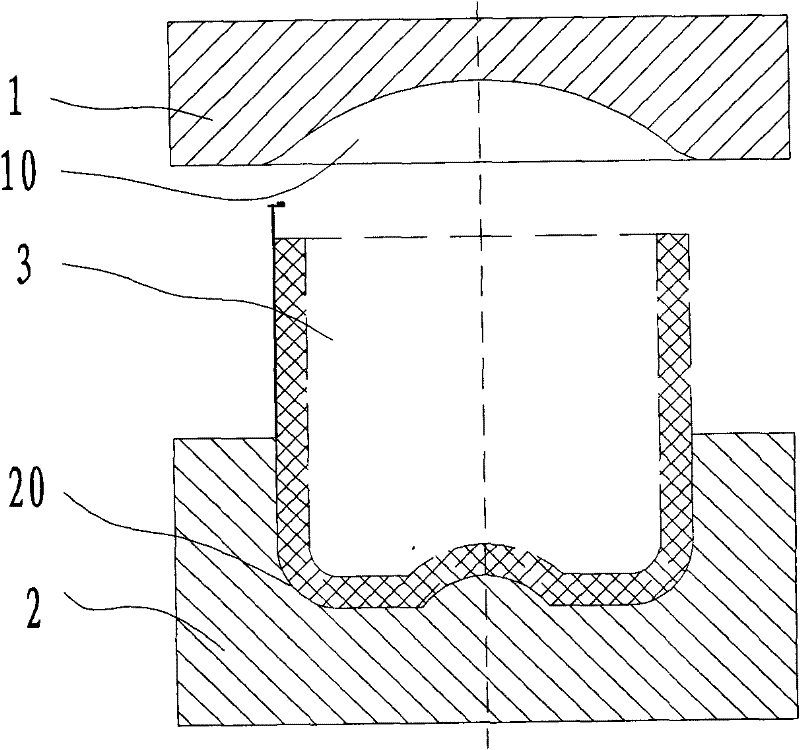

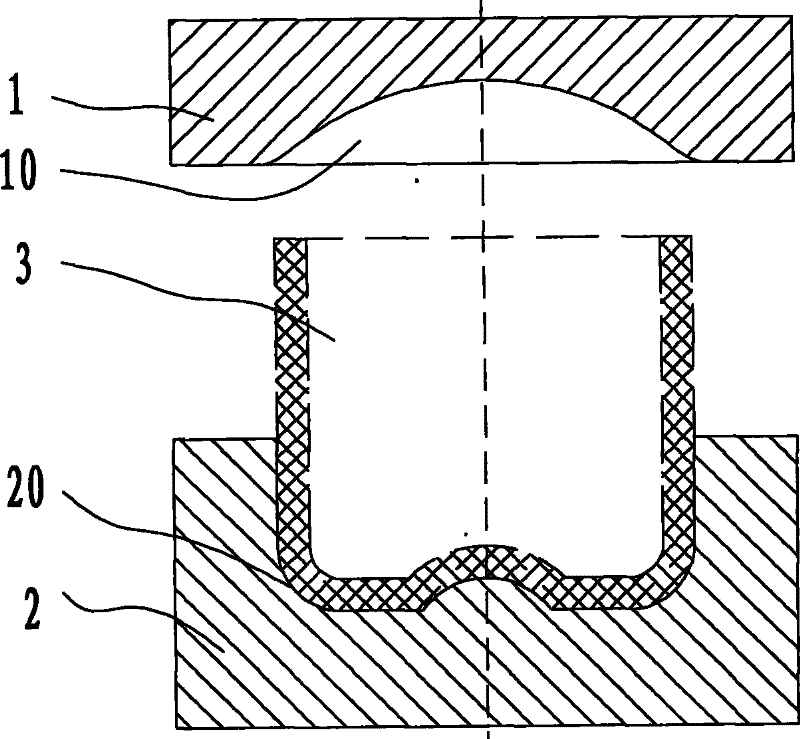

Opening closing mould of pressure equalizing barrel

InactiveCN102672044AImprove plastic deformation abilityImprove efficiencyShaping toolsFlangingAluminium alloy

The invention relates to an opening closing mould of a pressure equalizing barrel, and relates to an opening closing mould of an inward flanging of a barrel opening of a pressure equalizing barrel made of aluminum alloy material. The opening closing mould is characterized by simple structure and low cost, and comprises an upper mould and a lower mould, wherein the lower mould comprises a mould cavity which is identical to the surface outline of a barrel body on the lower part of the pressure equalizing barrel; the bottom surface of the upper mould is provided with a spherical-crown groove; and the maximal diameter of the notch of the spherical-crown groove is larger than the diameter of the barrel opening of the pressure equalizing barrel. According to the opening closing mould provided by the invention, material characteristics is combined; a mould pressing proposal using a stamping one-time forming method is disclosed; because the aluminum material has preferable plastic deforming capacity correspondingly to a cold board and a hot board, a smooth opening closing structure can be stamped for one time on a condition that the shape of the upper mould is suitable; situations such as draping, cracking and the like cannot be happened; and the opening closing mould is characterized by high mould efficiency, precise size, low cost and smooth appearance of a finished product.

Owner:JIANGSU YONGLONG ELECTRIC

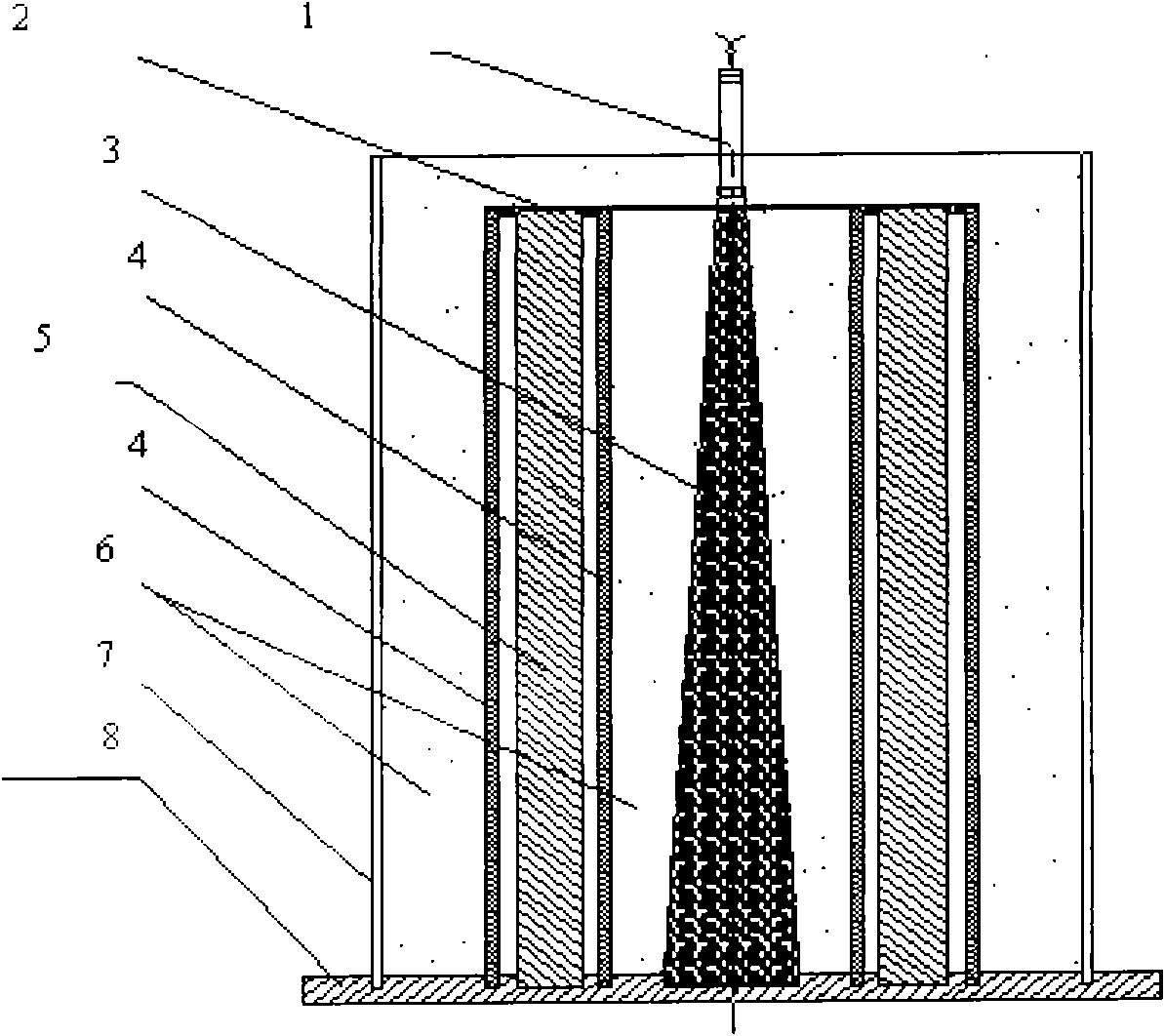

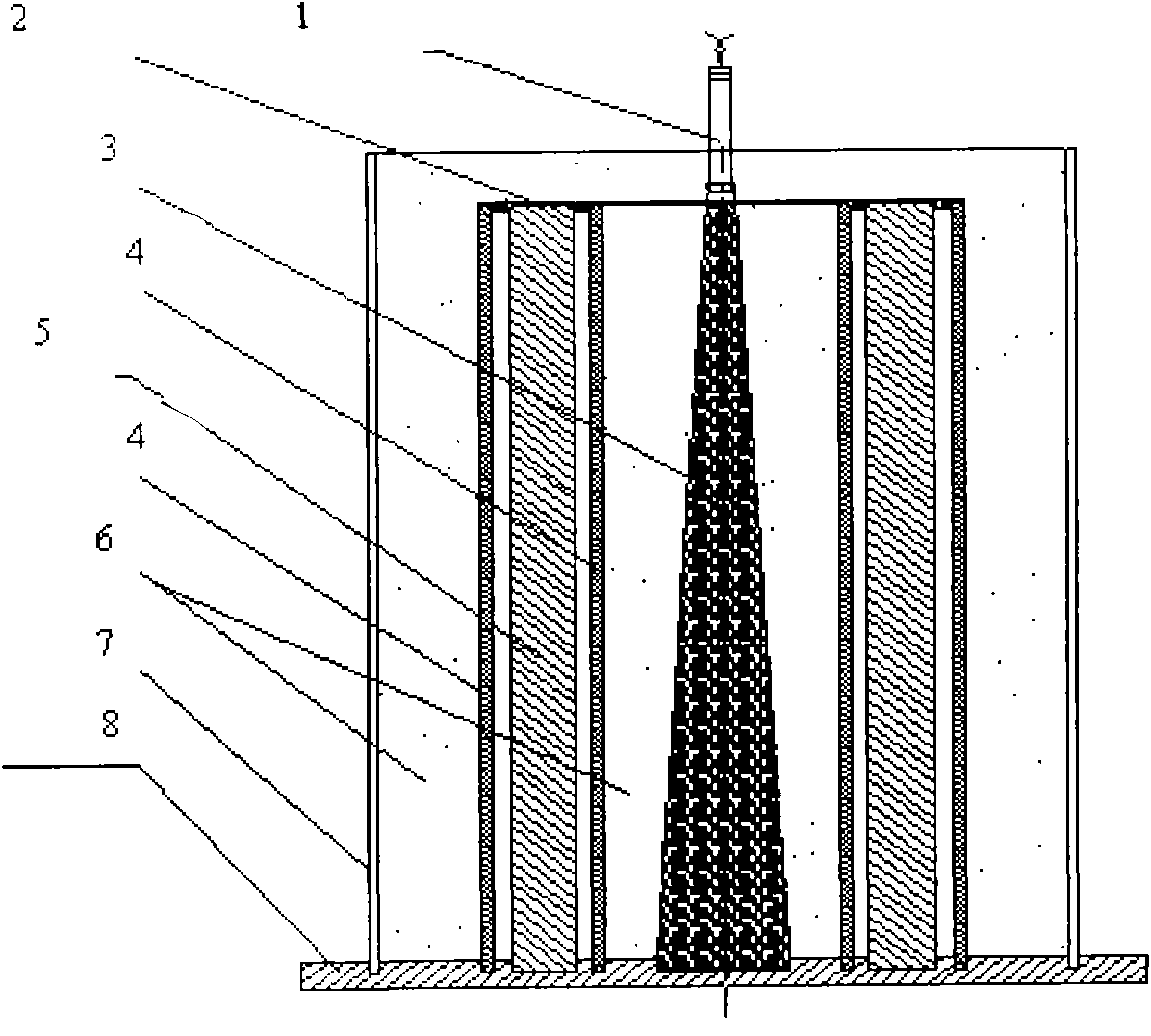

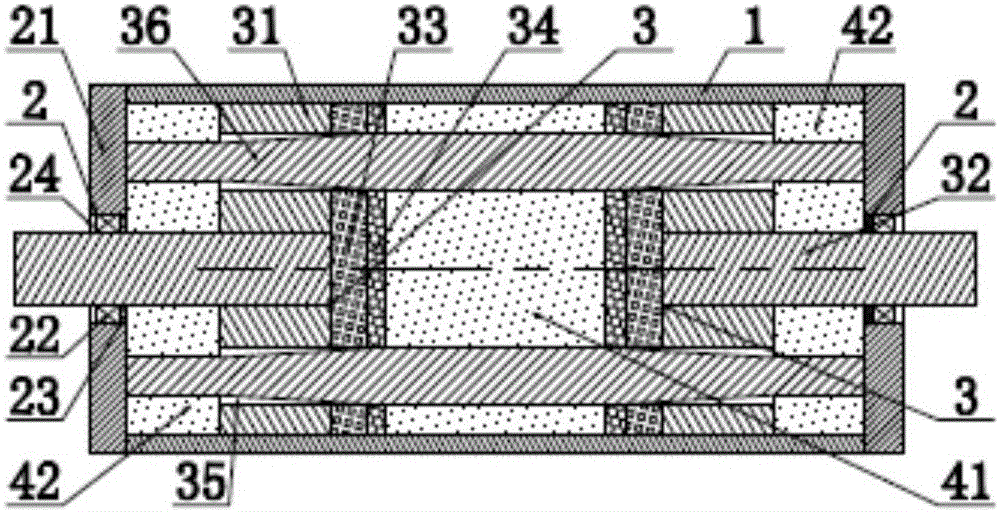

Double-rod variable-orifice passive single-control variable-damping magnetorheological damper

InactiveCN105156570ALarge damping forceSimple structureNon-rotating vibration suppressionCylinder blockEnergy consumption

The invention discloses a double-rod variable-orifice passive single-control variable-damping magnetorheological damper and belongs to the field of variable-damping magnetorheological fluid instruments. The variable-damping magnetorheological damper comprises a rheological fluid cylinder body, two end cover modules identical in structure, and two magnet piston modules. The two magnet piston modules are identical in structure and are symmetrically arranged in the rheological fluid cylinder body. The magnet piston modules comprise piston bodies, piston rods, permanent magnets arranged on the inner sides of the piston bodies, and magnet protective layers arranged on the permanent magnets. Orifices with the unchanged internal diameters are formed in the piston bodies. A gradually-changing throttling column parallel to the piston rods is arranged between the two end cover modules. The gradually-changing throttling column is a conical rod, the diameter of the middle of the gradually-changing throttling column is maximal, the diameters of the two ends of the gradually-changing throttling column are minimal, and the diameters of the other portions of the gradually-changing throttling column linearly change. The internal diameters of the orifices are equal to the maximal diameter of the gradually-changing throttling column. The magnetorheological damper is reasonable in structure and free of energy consumption, and damping force has no upper limit range.

Owner:CHANGZHOU UNIV

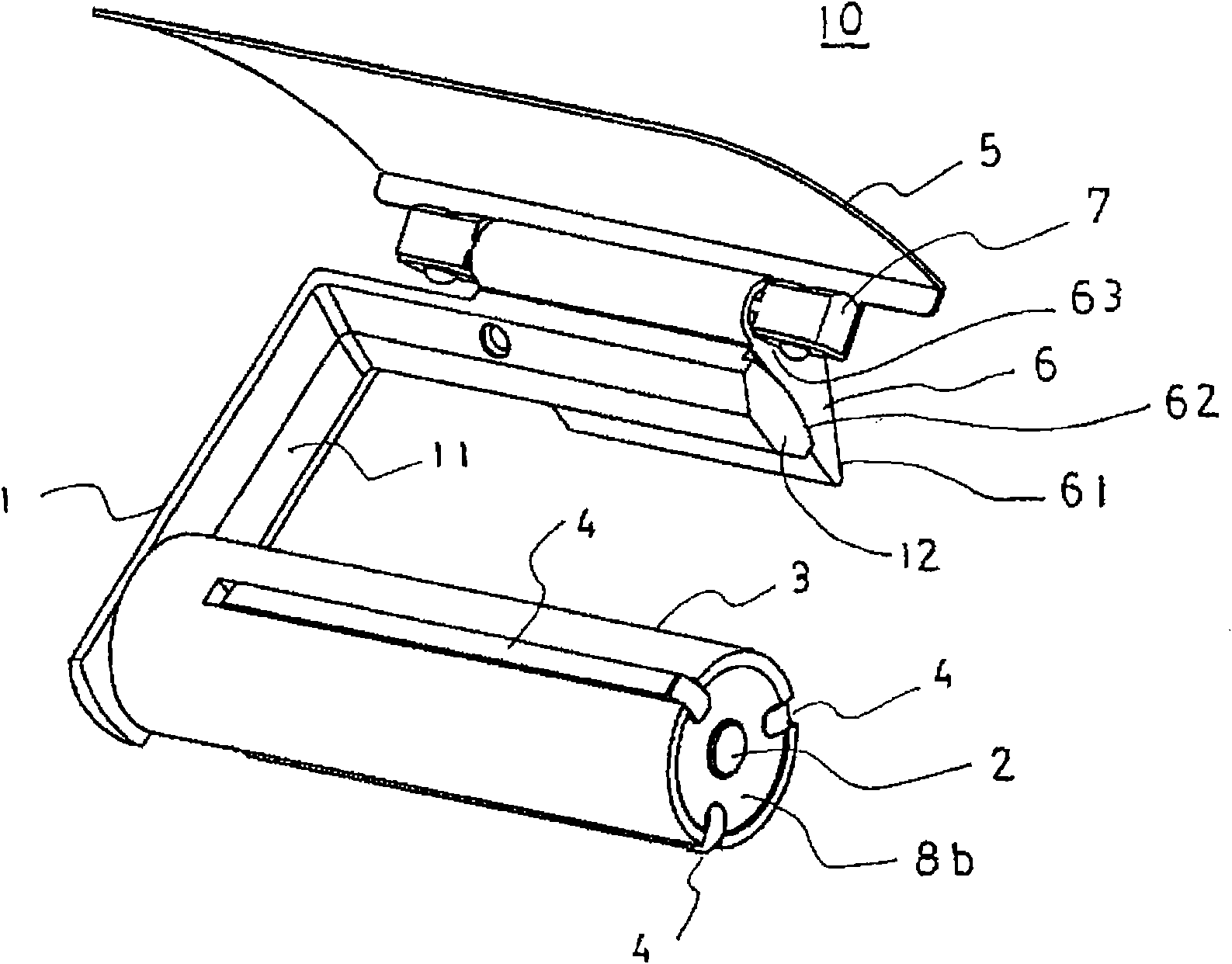

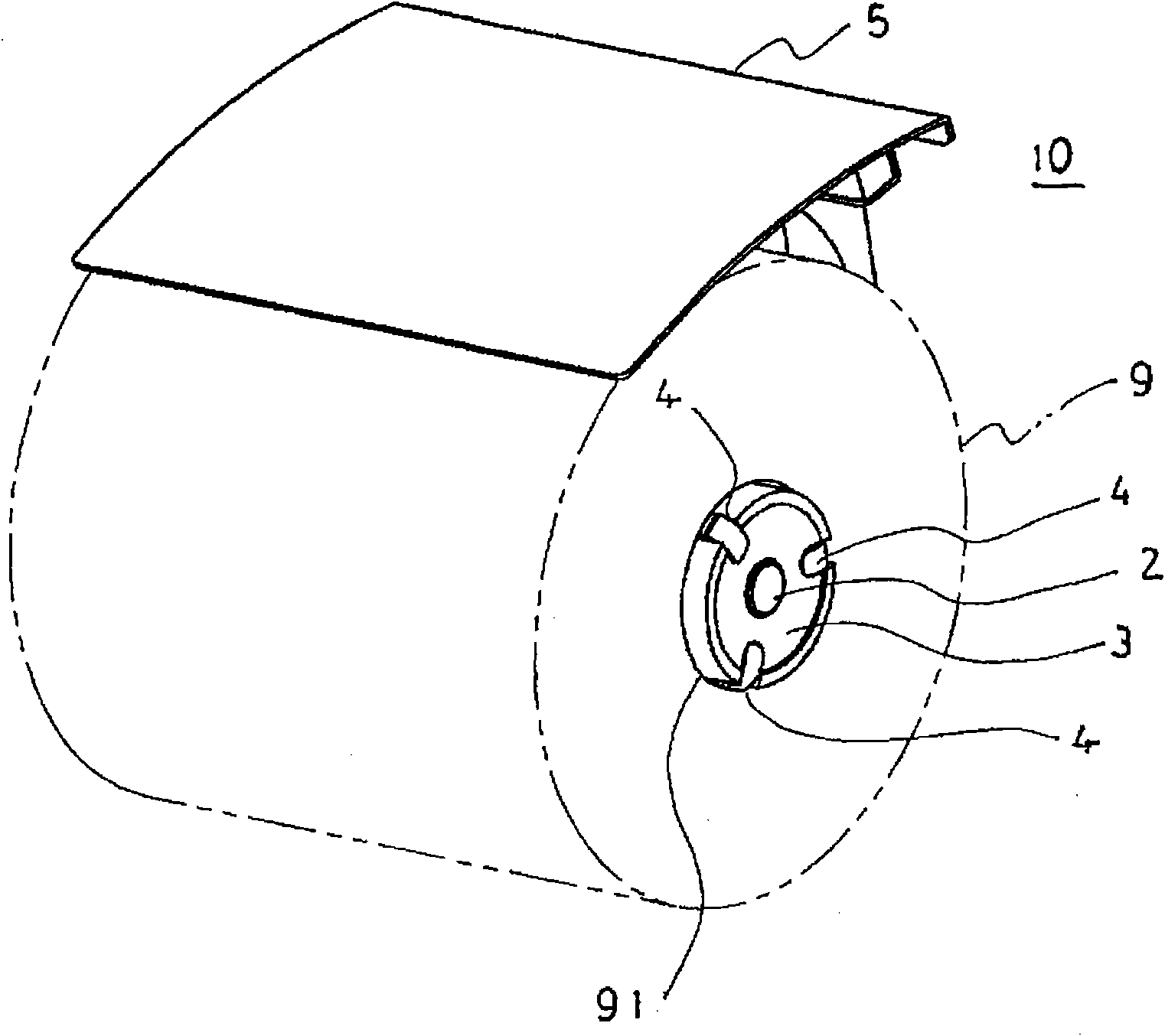

Toilet paper holder

The invention provides a toilet paper holder which is capable of suppressing noises generated by rotating of a core pipe and pulling operation during pulling a toilet paper. The toilet paper holder (100) comprises a fixed supporting shaft (2) extending inwards from the front end of a side plate (11), a rotating body (3) rotatably fixed on the fixed supporting shaft (2) and having a maximal diameter smaller than the inner diameter of the core pipe (91) of a toilet paper (9), and a spring member (4) installed on the rotating body (3) and being in press contact with the inner circumferential surface of the core pipe (91) under the force of the spring.

Owner:KAWAJUN KK

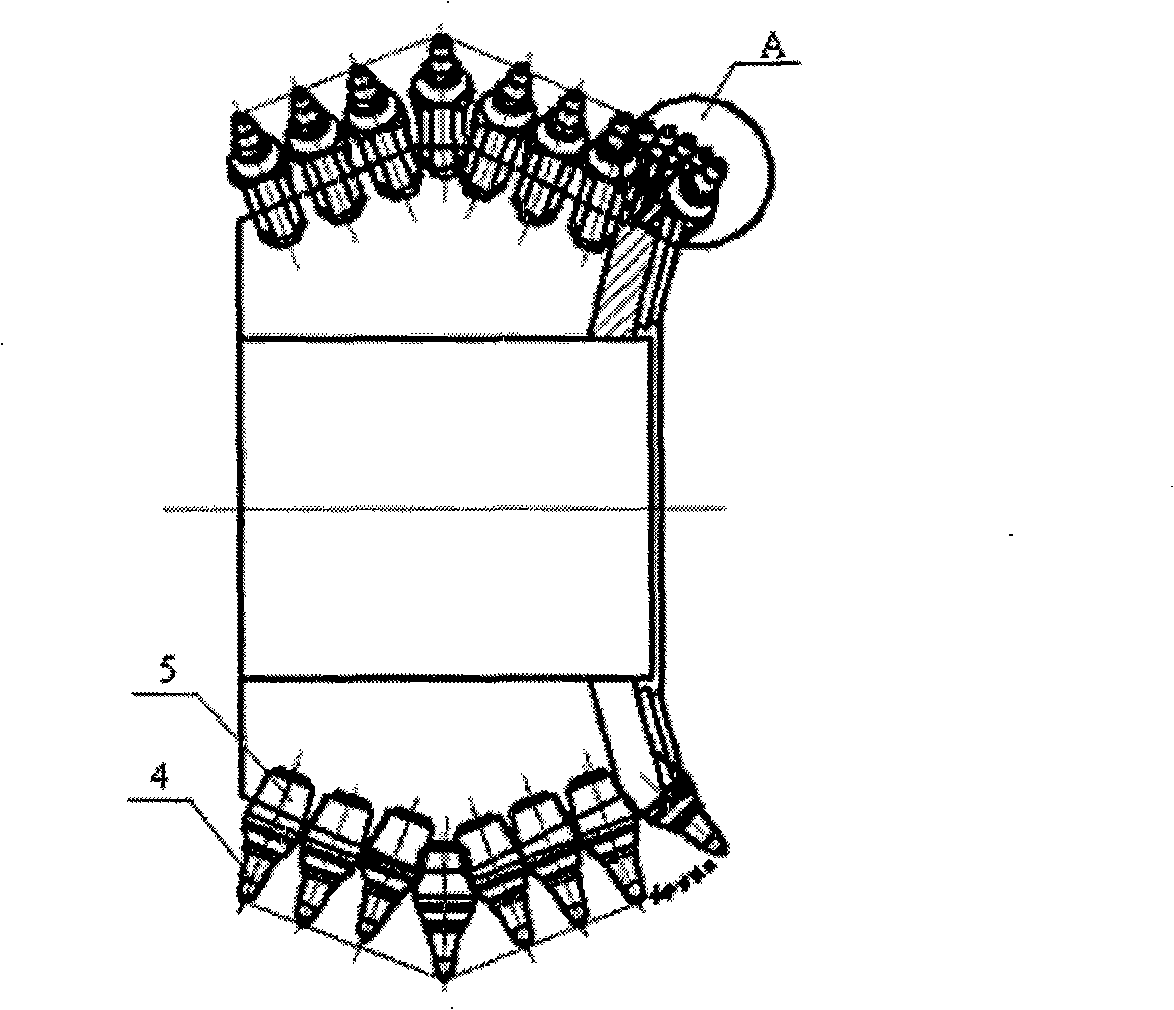

Hob cutter type coal cutter drum

InactiveCN101338671AGood for coal cuttingImprove cutting efficiencyCutting machinesElevation angleEngineering

The present invention relates to a hob type shearer roller which is particularly fit for the exploration of a gangue coal bed and a harder coal bed. The hob type shearer roller comprises a cylinder hub, spiral vanes and an end plate which are arranged on the cylinder hub, cutting picks on the spiral vane, a pick holder and end plate cutting picks. The diameter of the spiral vane is increased gradually from the end plate. The diameter of the spiral vane is maximal at the middle position of the cylinder hub and then is reduced gradually. The diameter of the spiral vane at the two ends of a cylinder body is equal to the diameter of the end plate. The cutting pick elevation angle at the position of the maximal diameter of the spiral vane is zero, and the rest cutting picks incline for certain degrees towards the two sides on the boundary; the cutting picks at the side of the end plate incline towards the end plate; the cutting picks at a goaf side incline towards the goaf side; the whole structure of the roller is the hob type. The roller uses the characteristic that coal rock can resist pressure but can not resist pull, except the cutting picks at the position of the maximal diameter of the spiral vane, the rest cutting picks are all arranged slantways; the cutting picks at the position of the maximal diameter of the spiral vane of the roller are that the cutting picks at the two sides cut a free surface, thereby not only improving the cutting efficiency but also improving the efficiency of cutting range coal.

Owner:CHINA UNIV OF MINING & TECH

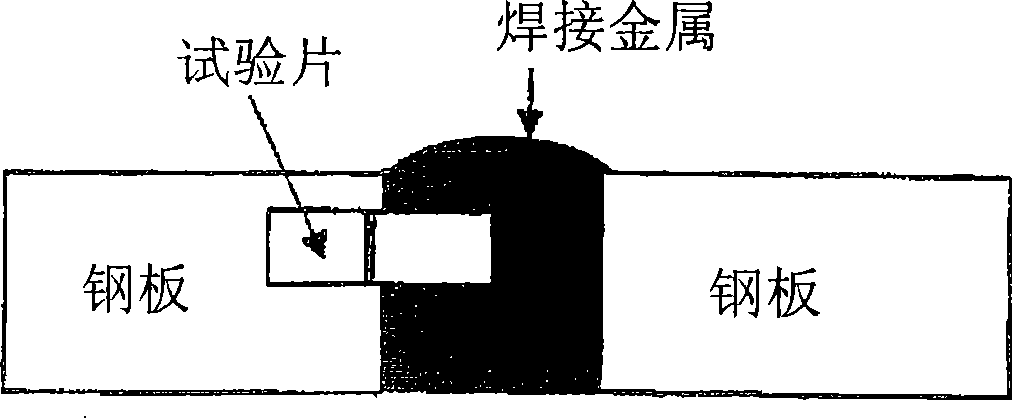

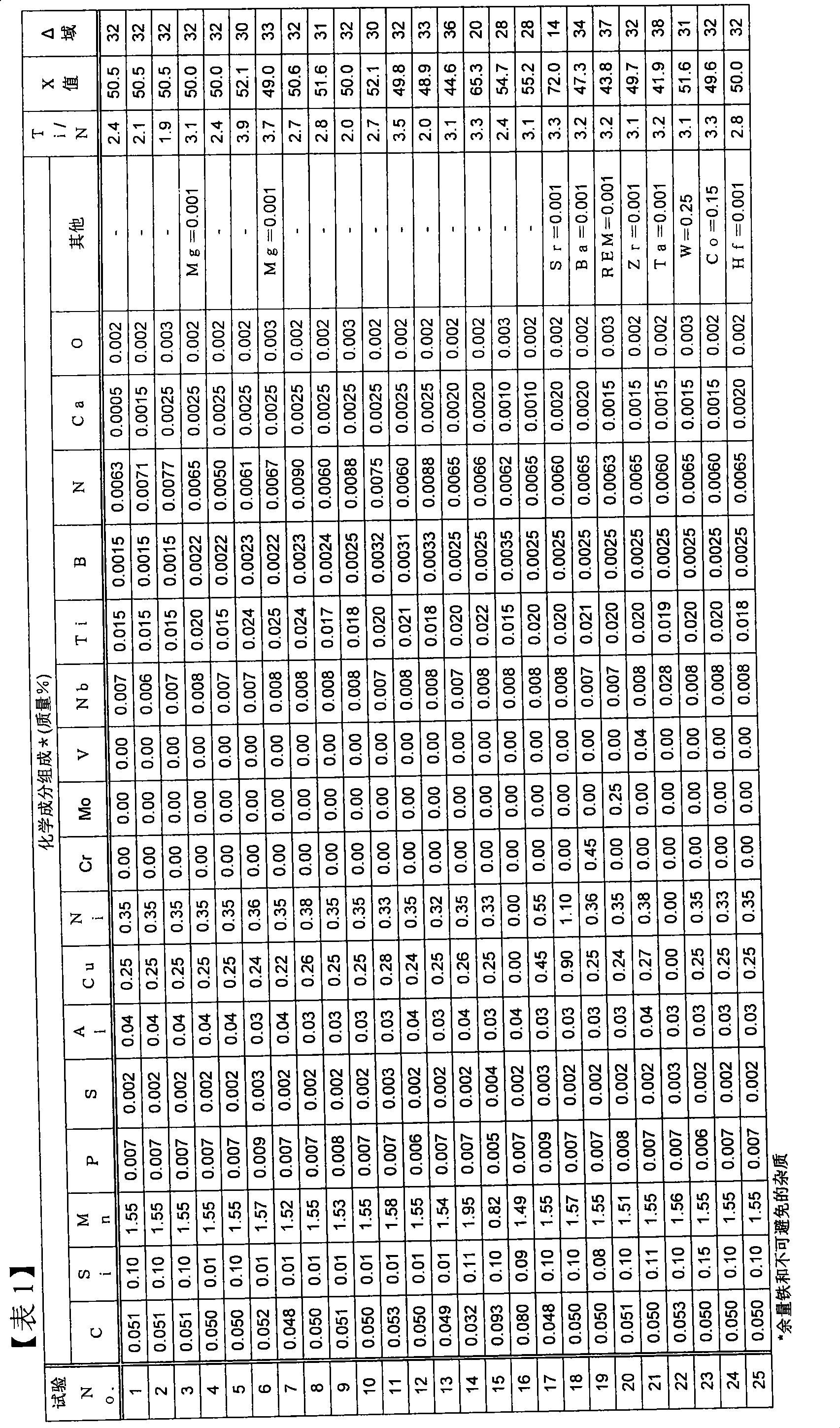

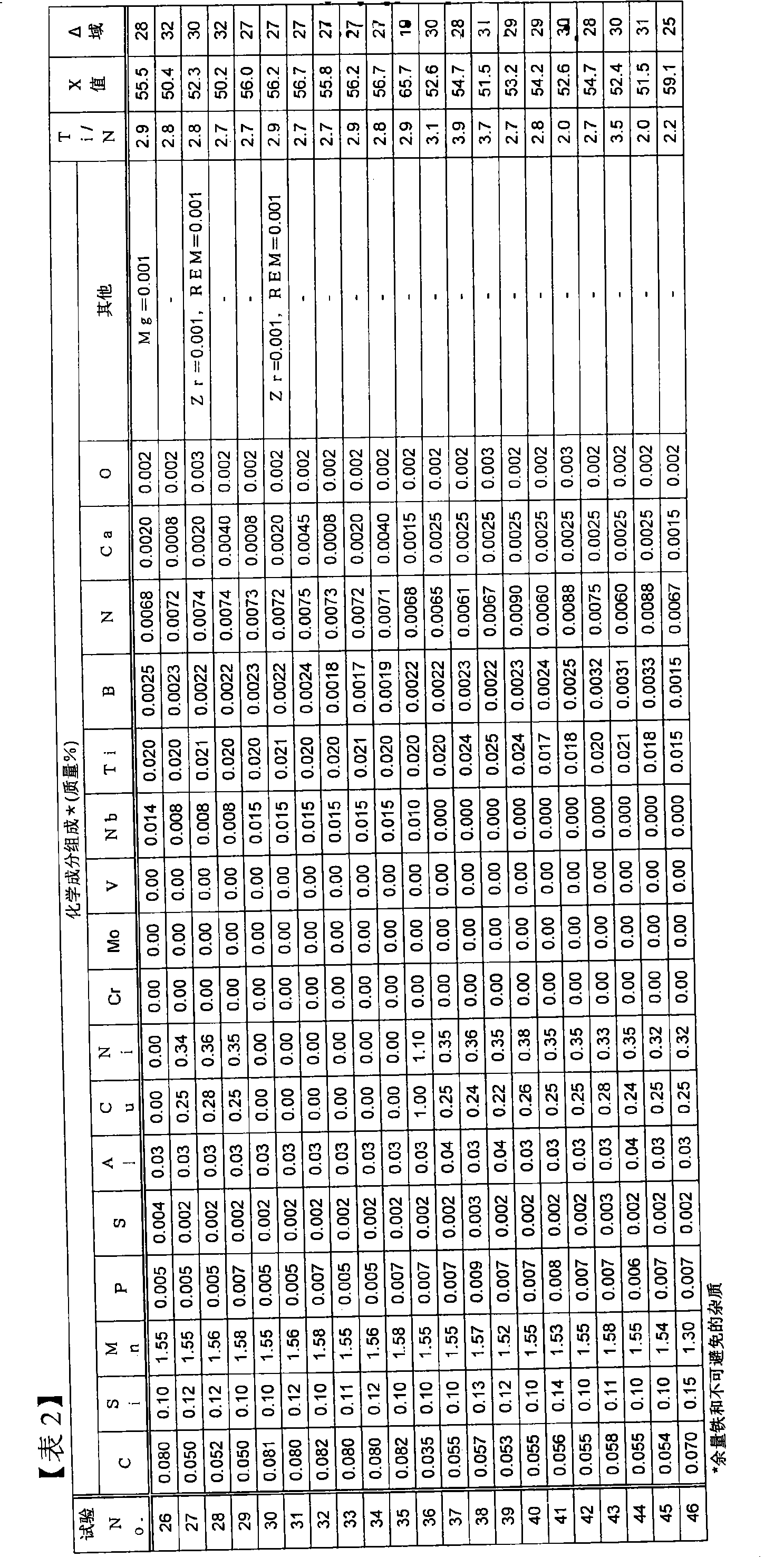

Thick steel plate for high heat input welding with excellent shear property

A plate steel that displays great HAZ toughness under high heat input weld and has excellent shearing property without shear fissure even if it is cut by a shearing press. The plate steel of the invention adjusts chemical components properly and meets formulae (1) and (2) and has tissue with bainite ratio that is above 95 area%. Average diameter of equivalent circle of a block size of the bainite is below 40 microns and a difference of a maximal diameter of equivalent circle of a block size of the bainite and the average diameter of equivalent circle is below 40 microns. [Ti] / [N] is more than or equal to 1.5 but less than or equal to 4.0 (1); X is more than or equal to 40 but less than or equal to 160 (2), X=500[C]+32[Si]+8[Mn]-9[Nb]+14[Cu]+17[Ni]-5[Cr]-25[Mo]-34[V], (in the formula, [] represents content (mass%) of each element.

Owner:KOBE STEEL LTD

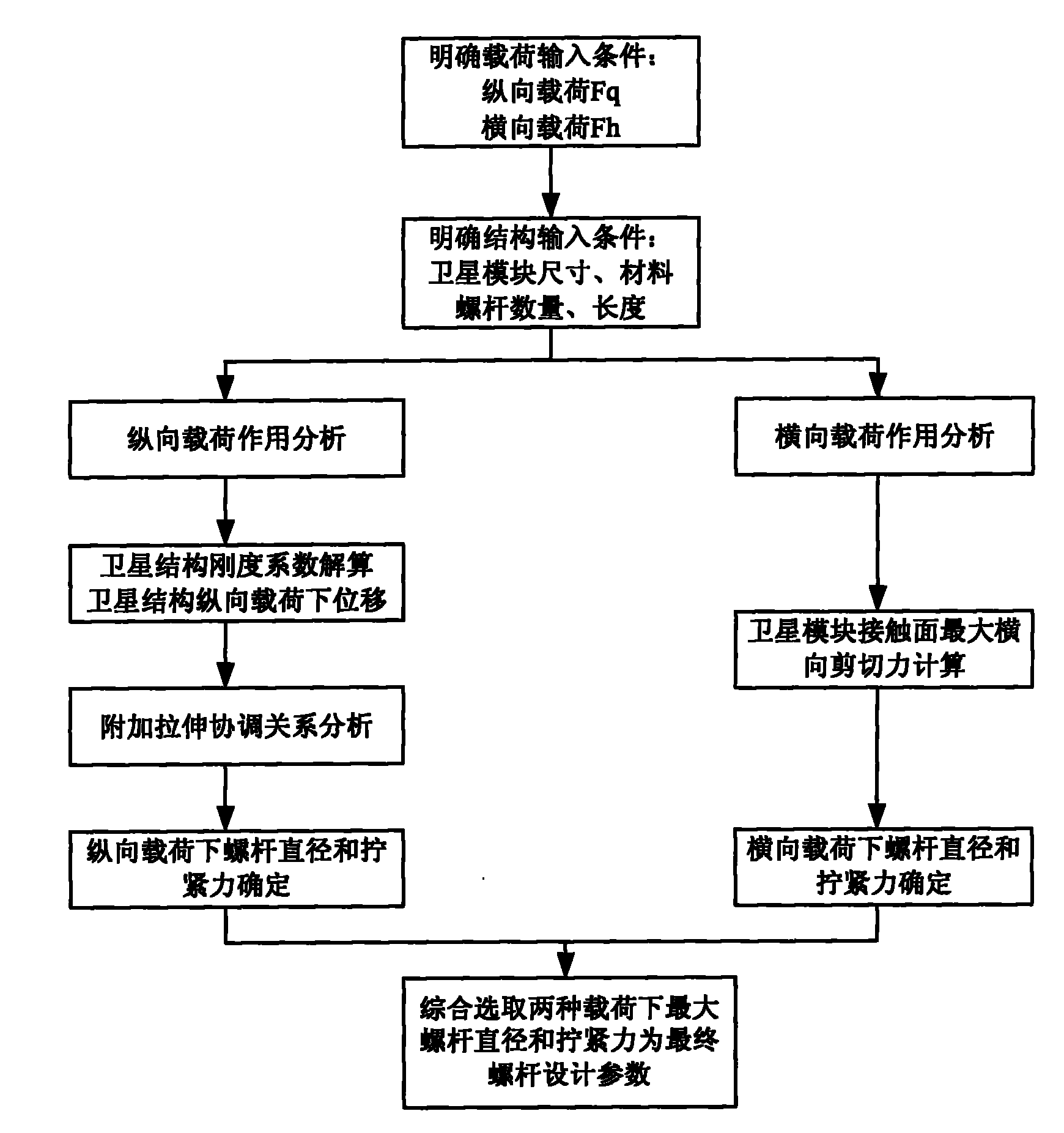

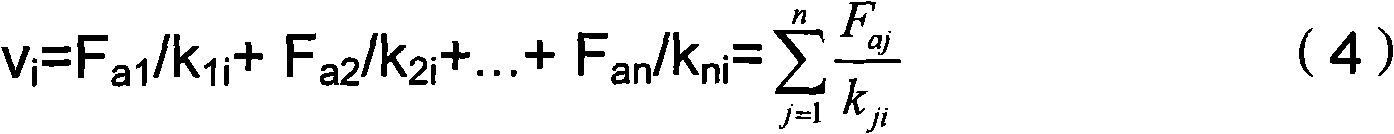

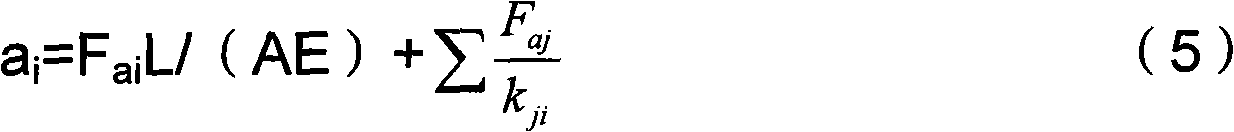

Method for determining compression parameters of modular satellite

ActiveCN102129490ATroubleshooting Compression Mechanics AnalysisClear designSpecial data processing applicationsComputer moduleModularity

The invention discloses a method for determining the compression parameters of a modular satellite, which is used for determining the diameter and the screwed force of compression screw rods and comprises the steps of: (1) determining a longitudinal load Fq and a transverse load Fh applied to the whole satellite; (2) determining the number n of screw rods selected during the overall design of the satellite, and determining the length L of the screw rods according to the sum of the heights of various modules; (3) calculating the diameter and the screwed force of the screw rods, which are required to ensure the compression between the satellite modules under the action of the longitudinal load Fq; (4) calculating the diameter and the screwed force of the screw rods, which are required to ensure the compression between the satellite modules under the action of the transverse load Fh; and (5) taking the maximal diameter and the maximal screwed force of the screw rods as the finally needed minimal diameter and minimal screwed force of the screw rods according to the results of the step (3) and the step (4). The method of the invention provides a guidance method for the compression design of the screw rods of the modular satellite, and can improve the deficiency that selection and experimental verification are performed only according to experience.

Owner:AEROSPACE DONGFANGHONG SATELLITE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com