Non-metal pipeline hydraulic pressure seepage verifying attachment

An inspection device, non-metallic technology, applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of inconvenient fixing, etc. The effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

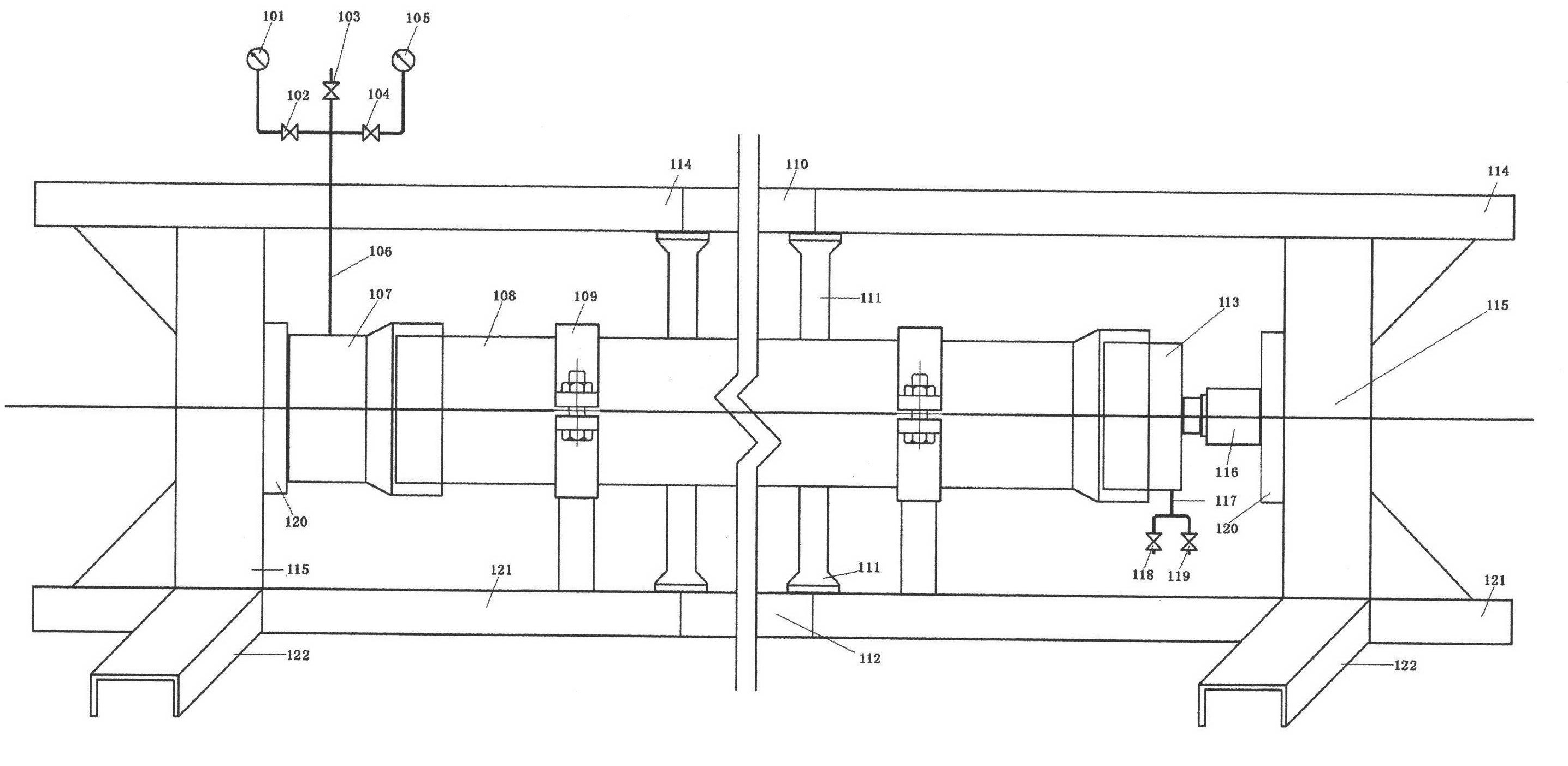

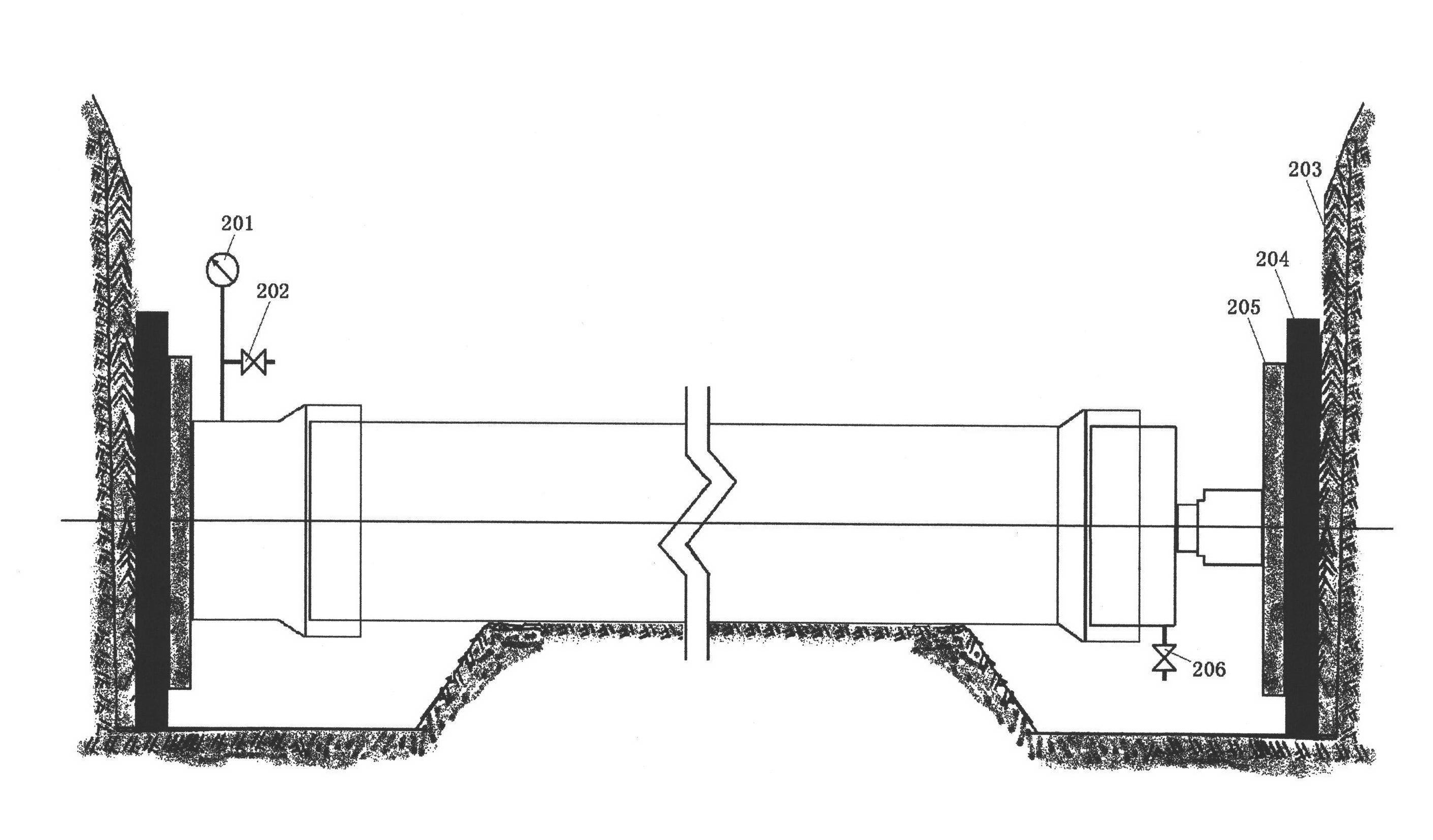

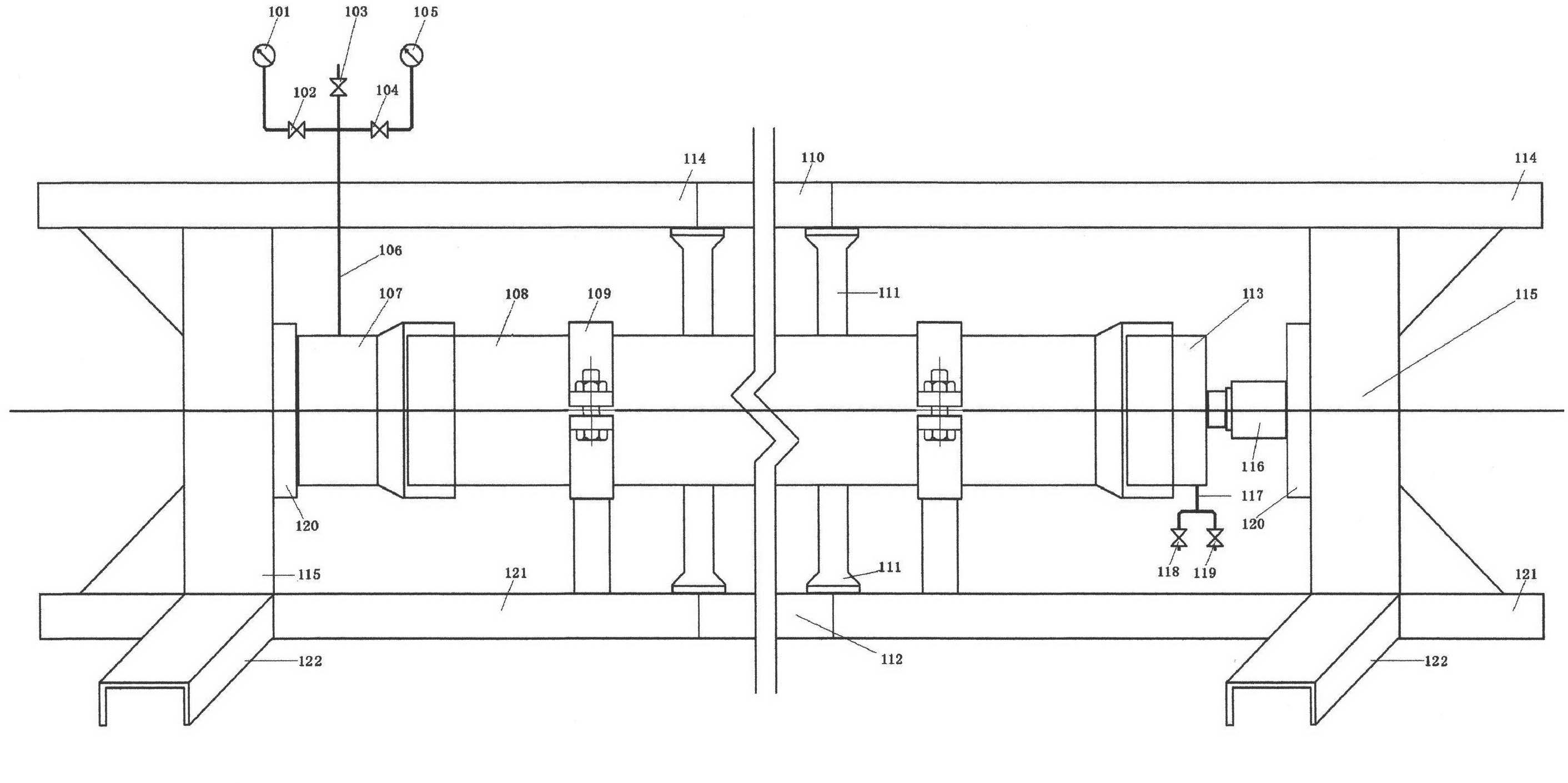

[0029] like figure 1 As shown, the non-metallic pipeline hydraulic leakage inspection device provided by the present invention includes a rectangular frame body, a socket plug, a socket plug, a pipe hoop, a jack, a water injection pressure measuring system on the socket plug, and an operation method.

[0030] The rectangular frame body is composed of channel steel welded into a rectangle, which is characterized in that: the length of the rectangle is determined according to the length of a section of pipe, and the rectangle is formed by welding the upper side length 114 of the rectangle and the extended upper side 110 of the rectangle One long side, and the other long side is formed by welding the lower side of the rectangle 121 and the extended lower side of the rectangle 112; in order to avoid the sagging of the super long channel steel, a vertical support rod 111 is added in the middle, and the vertical support rod 111 is welded on the upper side of the rectangle Length 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com