Cutter for processing step hole workpiece on lathe and using method thereof

A technology for stepped holes and cutting tools, which is applied to tools for lathes, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to guarantee the qualified rate of processing and many processing procedures, so as to reduce processing costs, improve processing efficiency, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

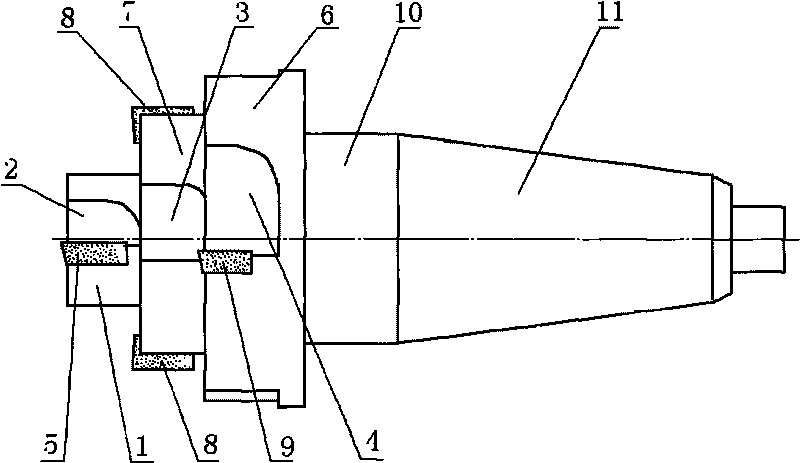

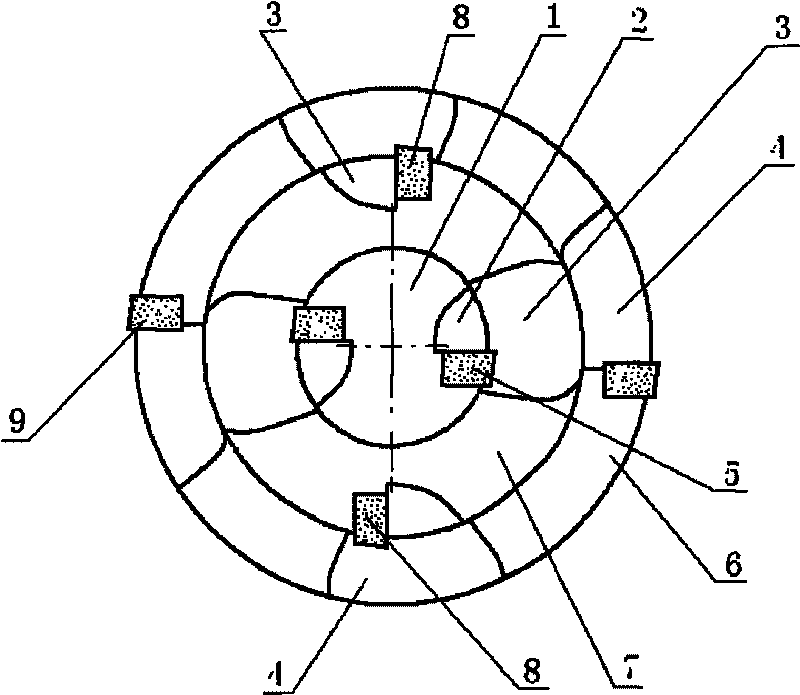

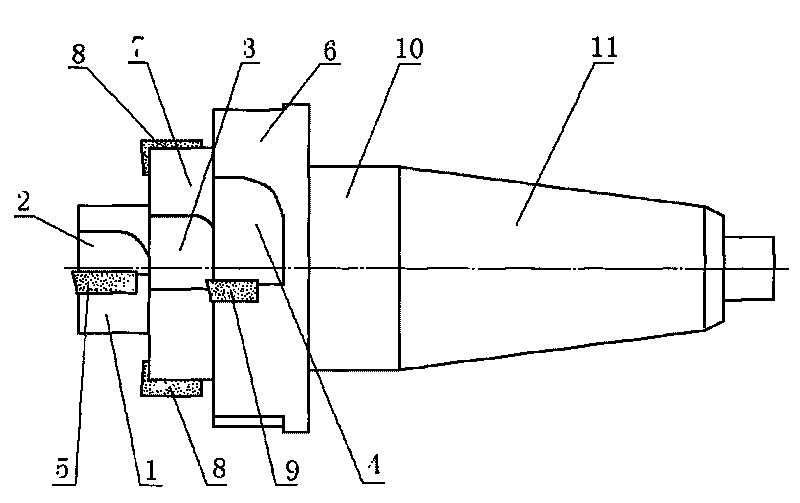

[0014] Such as figure 1 , figure 2 As shown, a tool for machining a stepped hole workpiece on a lathe is composed of the first cutting section, the second cutting section, the third cutting section with the largest diameter, the tool transition section 10 and the tool matching section 11. The first cutting section The segment is composed of the first cutting body 1, two symmetrical first cutting body blades 5 on the first cutting body 1 and the cutting groove 2 of the first cutting body, and the second cutting segment is composed of the second cutting body 7, the second cutting body The two symmetrical second cutting body blades 8 on the body 7 and the cutting groove 3 of the second cutting body are composed, and the third cutting section is composed of the third cutting body 6 and two symmetrical third cutting bodies on the third cutting body 6 The body blade 9 and the third cutting body cutting groove 4 are formed, and the dimensions of the first cutting section, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com