Patents

Literature

261results about "Attachable boring/drilling devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

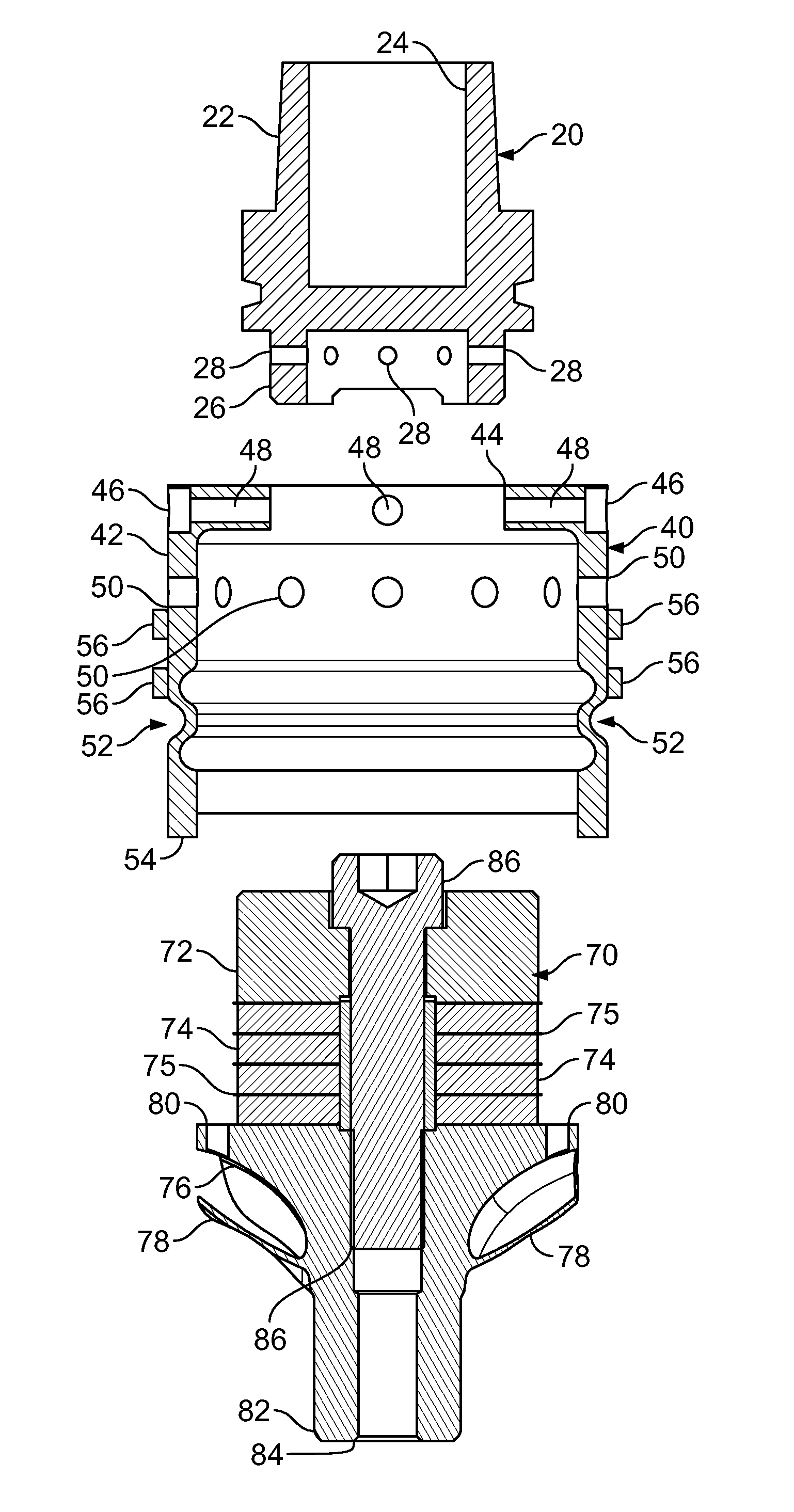

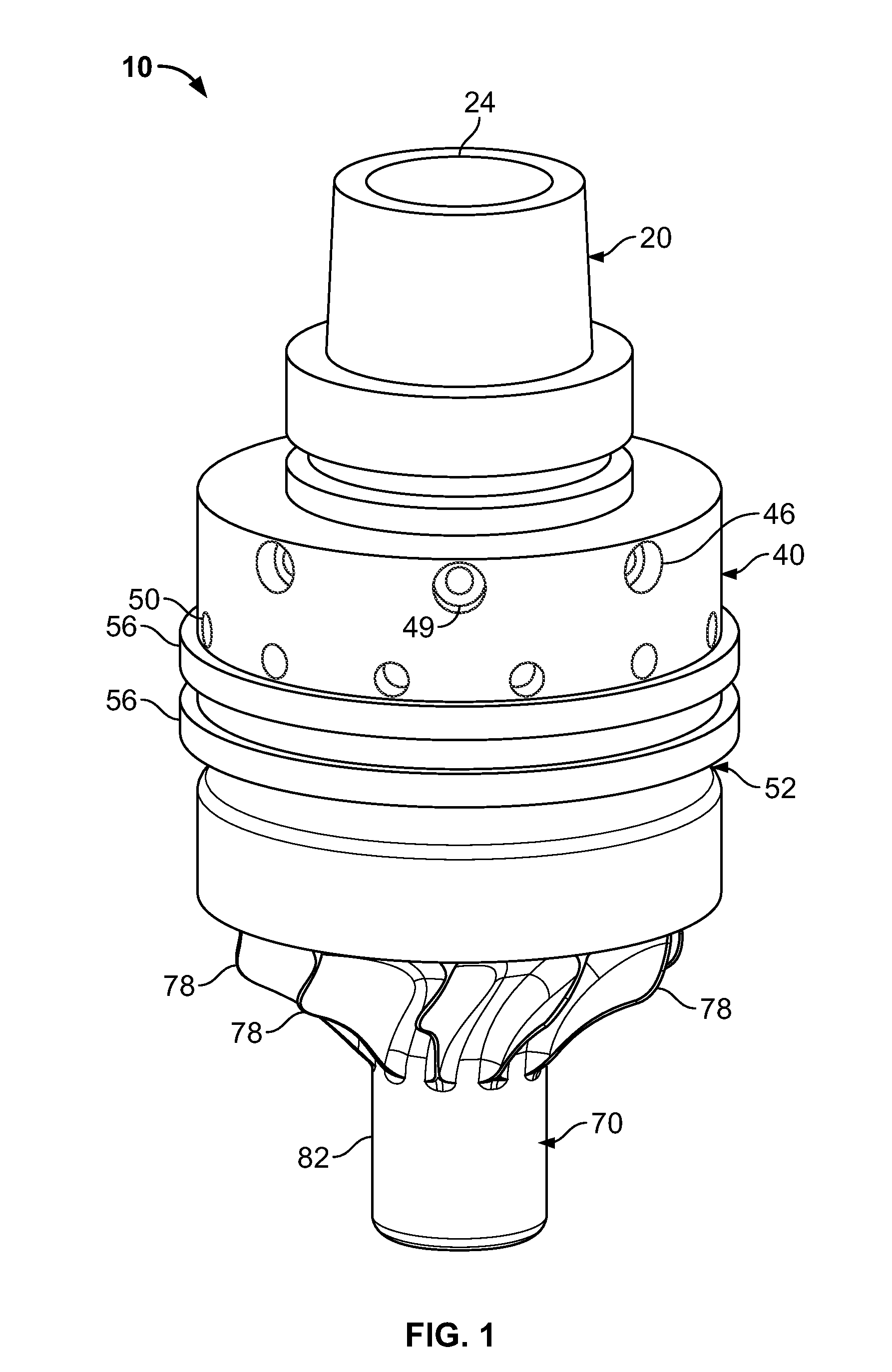

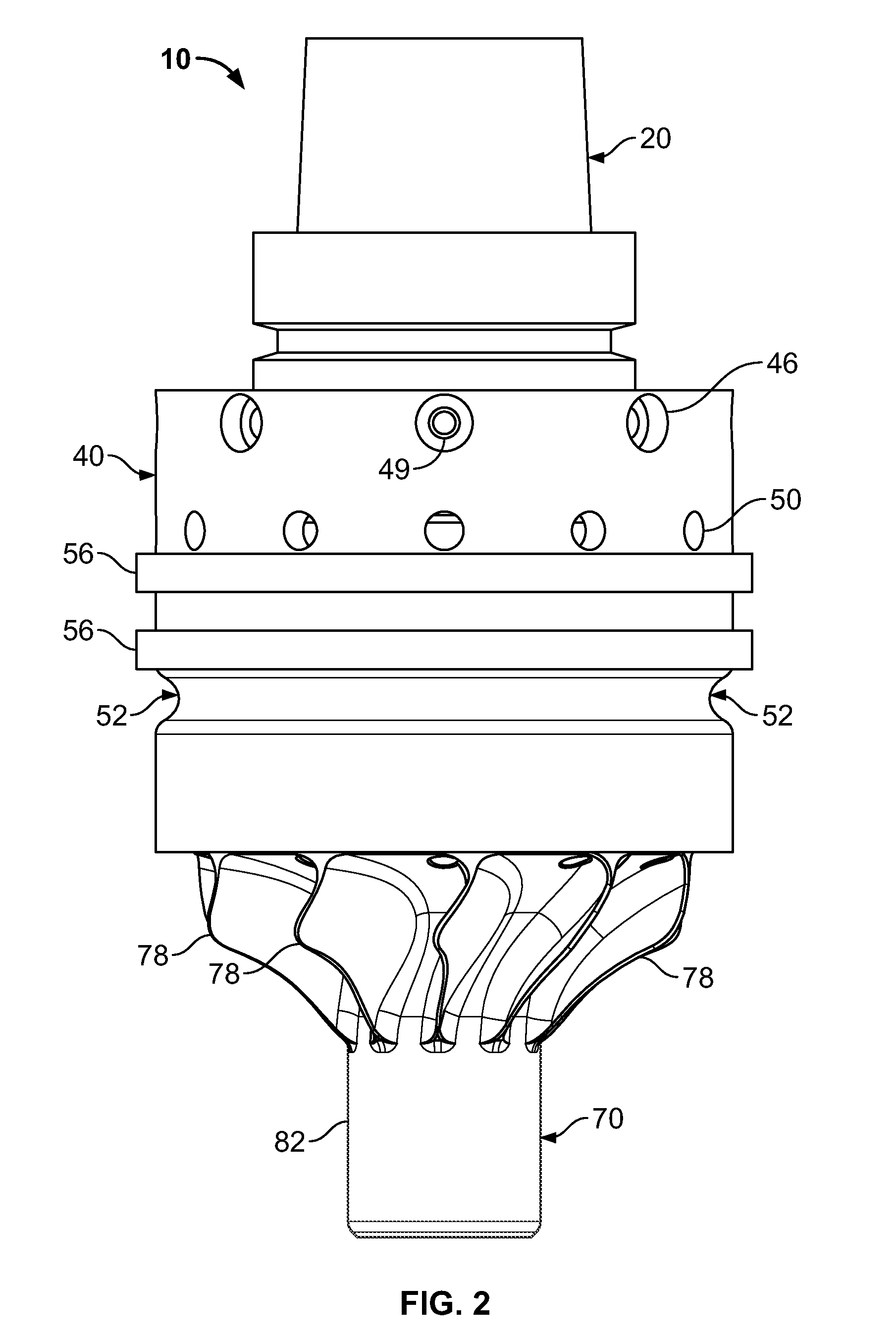

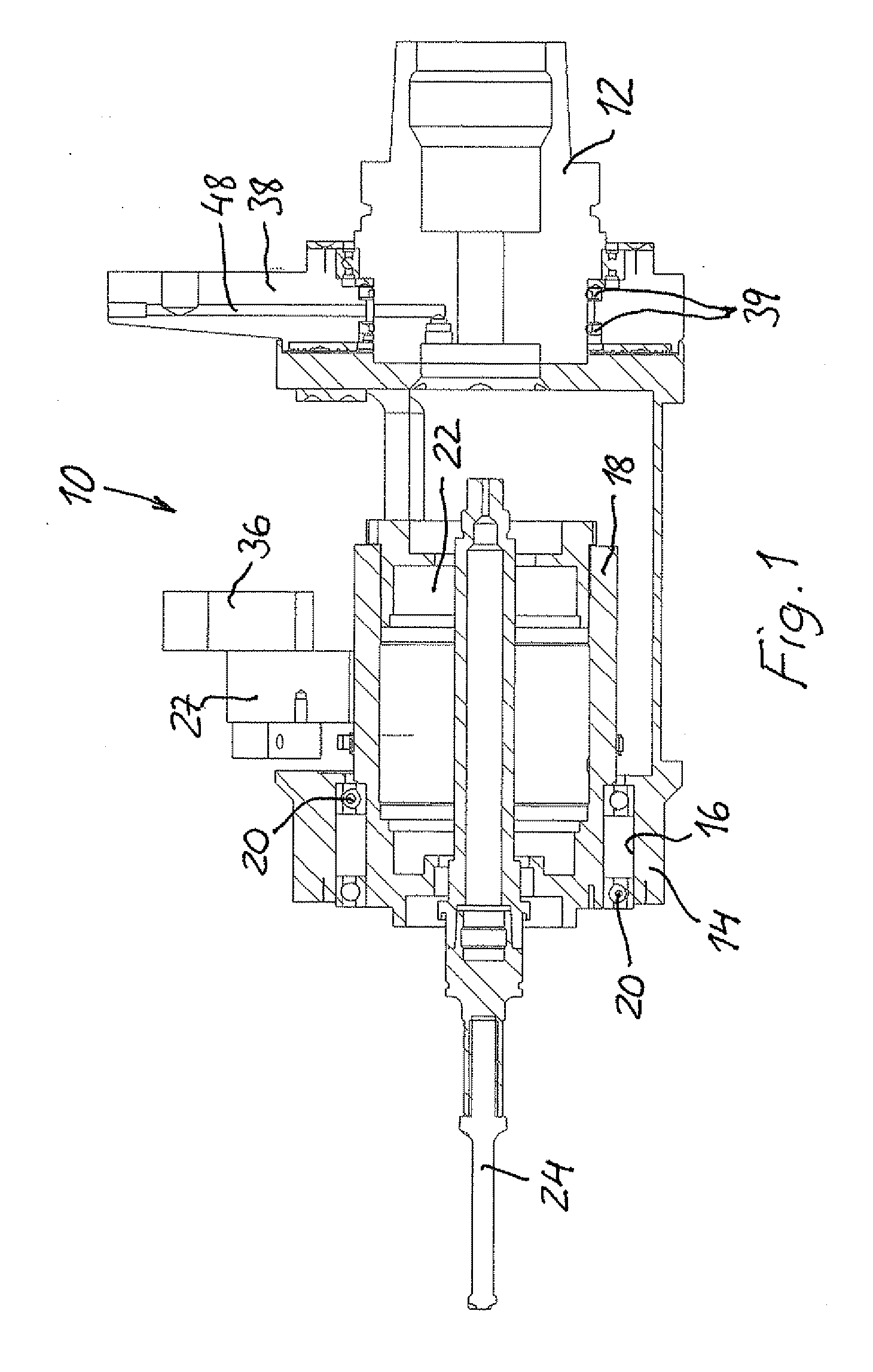

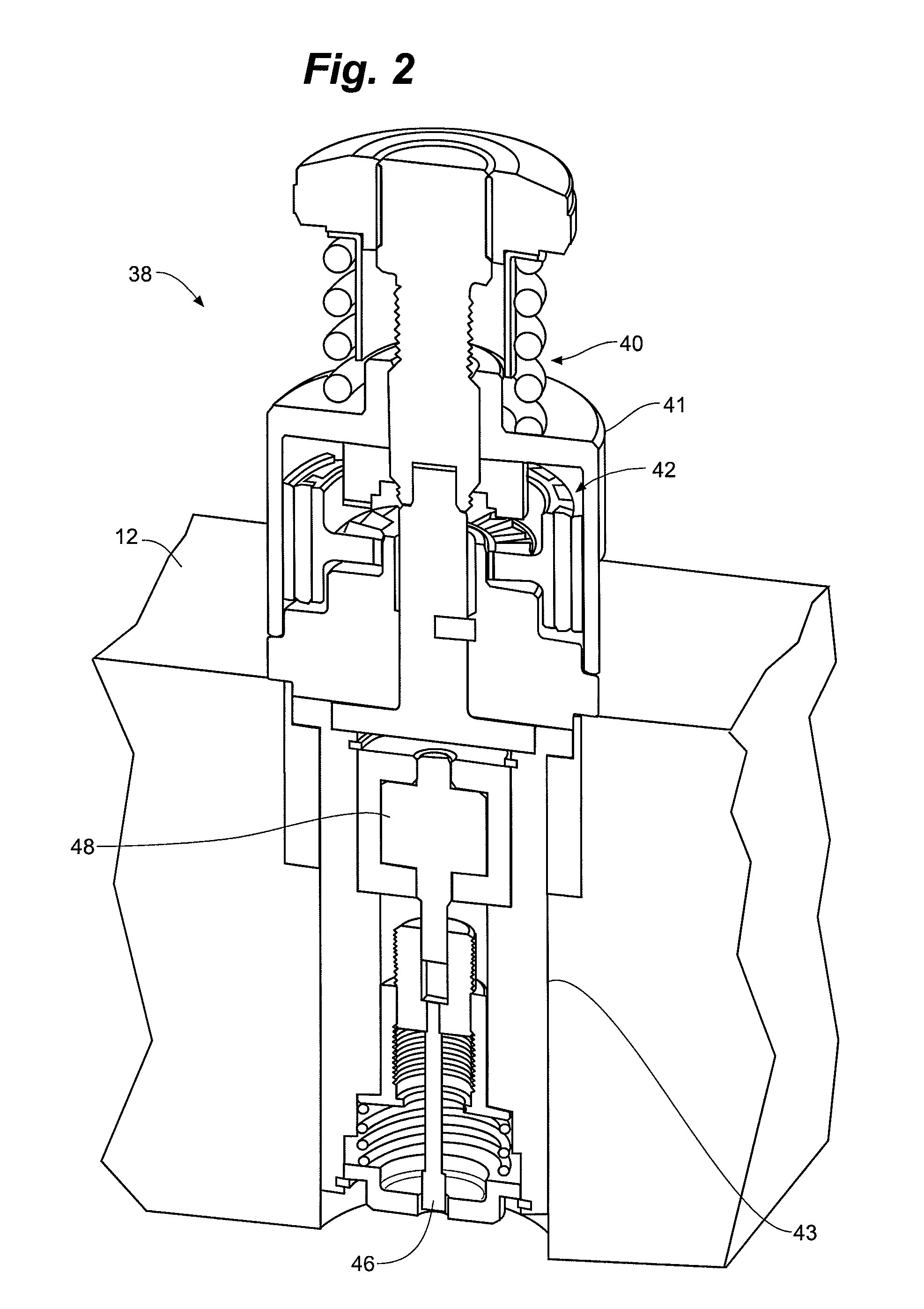

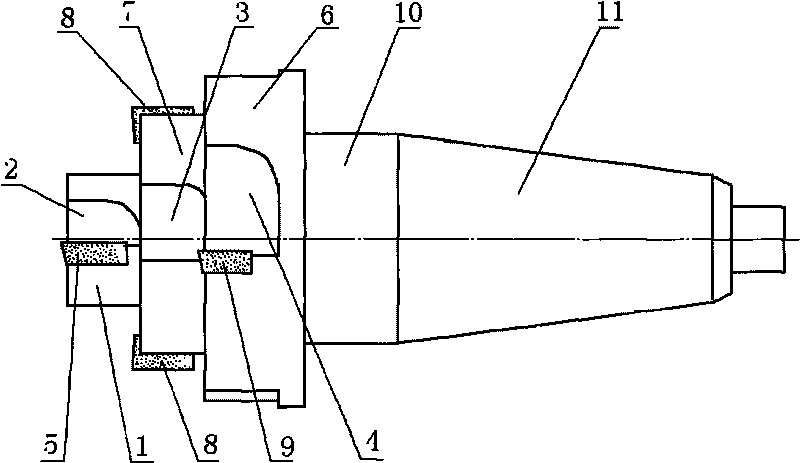

Ultrasonic machining module

A device for use in a machining system, including an ultrasonic transducer, wherein the ultrasonic transducer is adapted to receive a tool bit; a housing adapted to be both compatible with the machining system and to receive the ultrasonic transducer, wherein the housing is operative to isolate all radial and other vibrations generated by the ultrasonic transducer except the axial vibrations transmitted to the tool bit; and a tool holder, wherein the tool holder and the top portion of the housing are mechanically coupled to one another.

Owner:EDISON IND INNOVATION

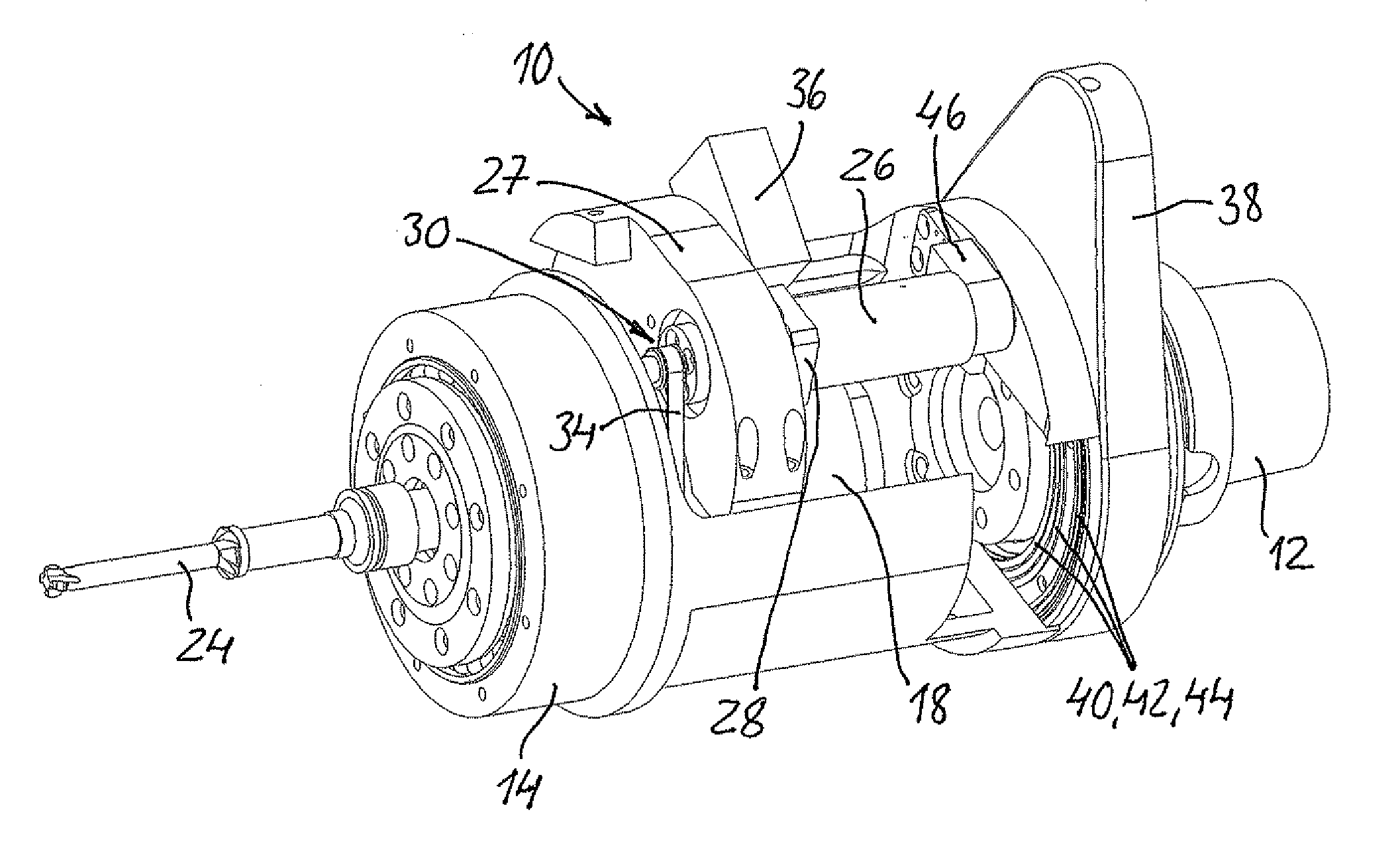

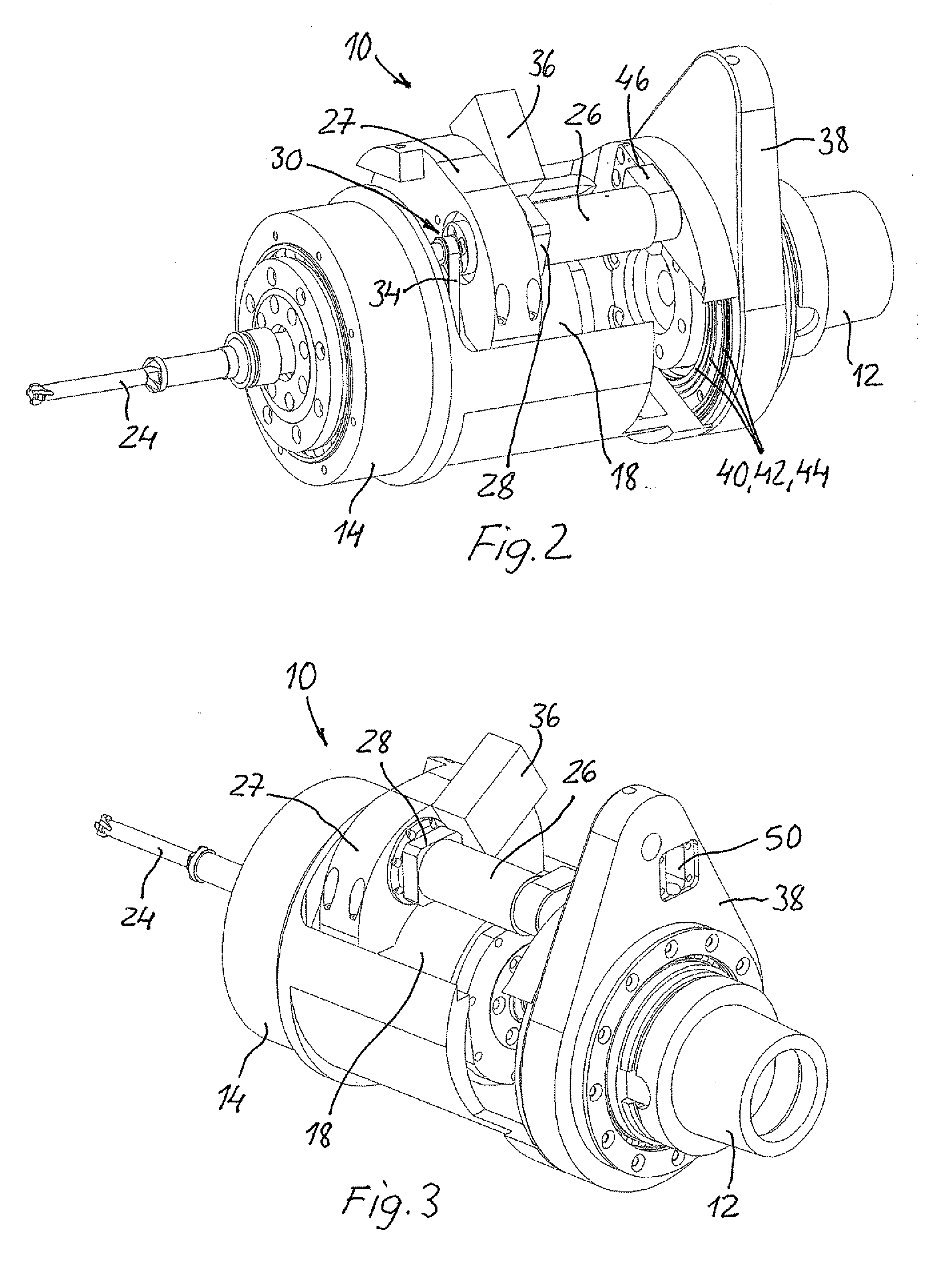

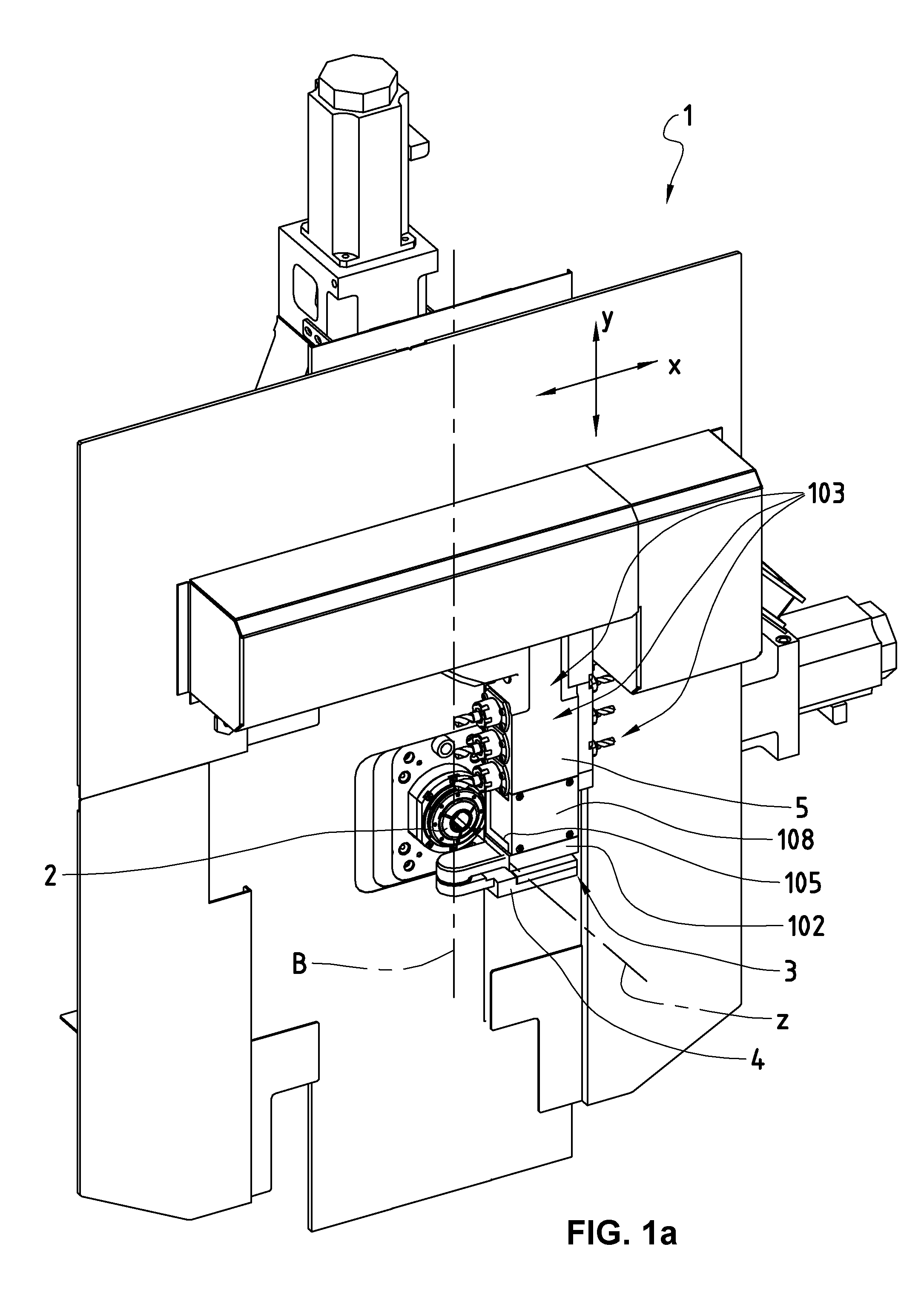

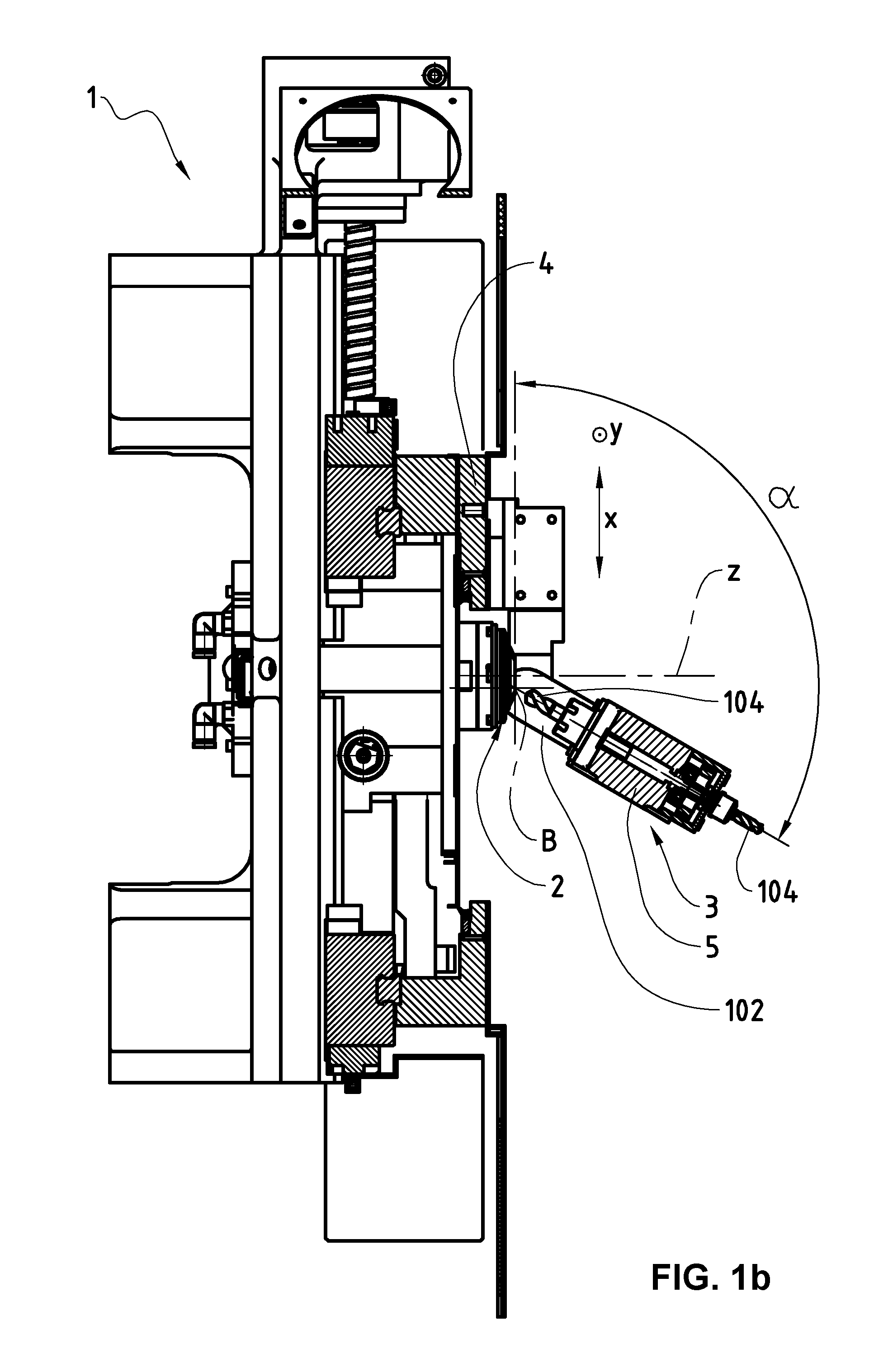

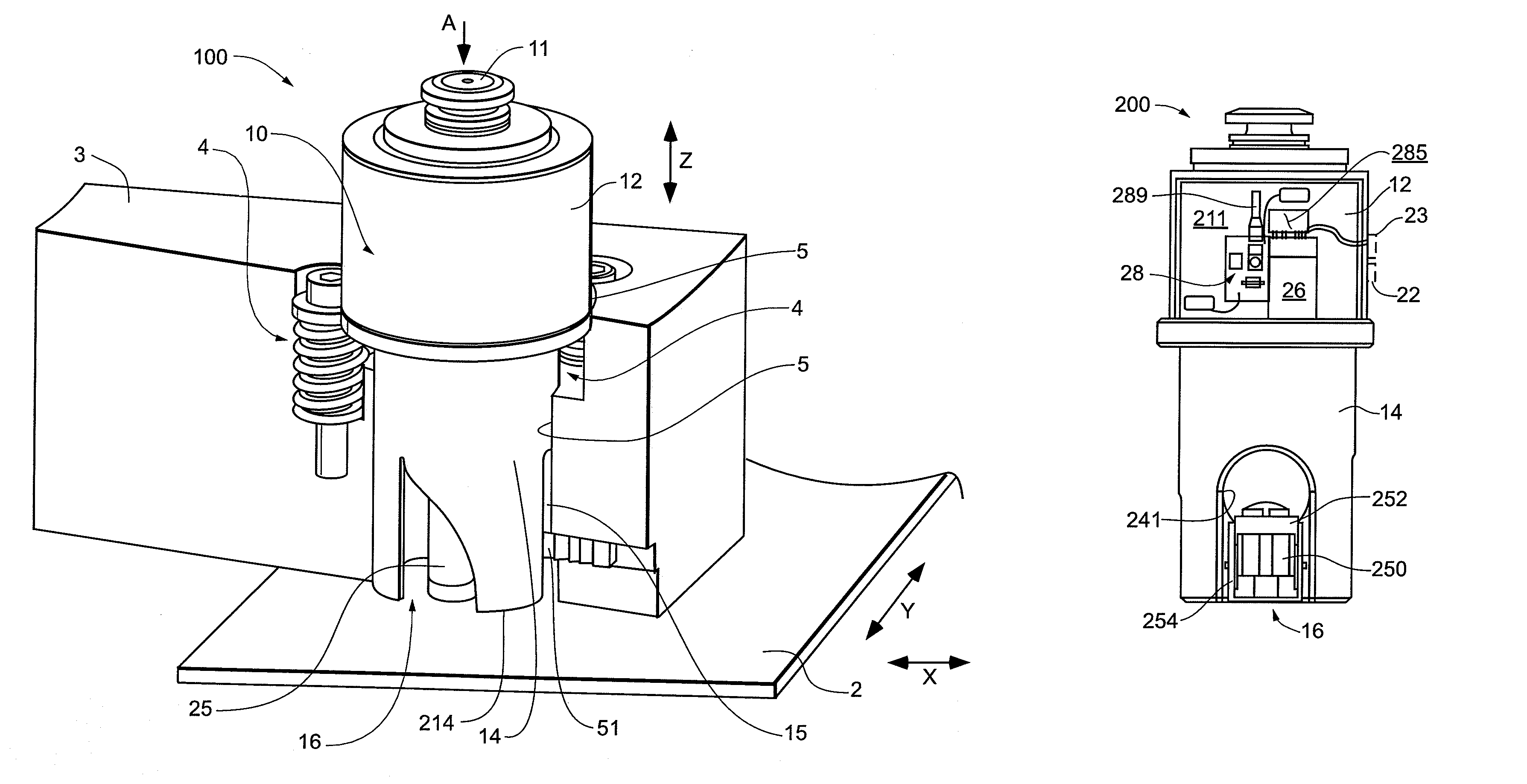

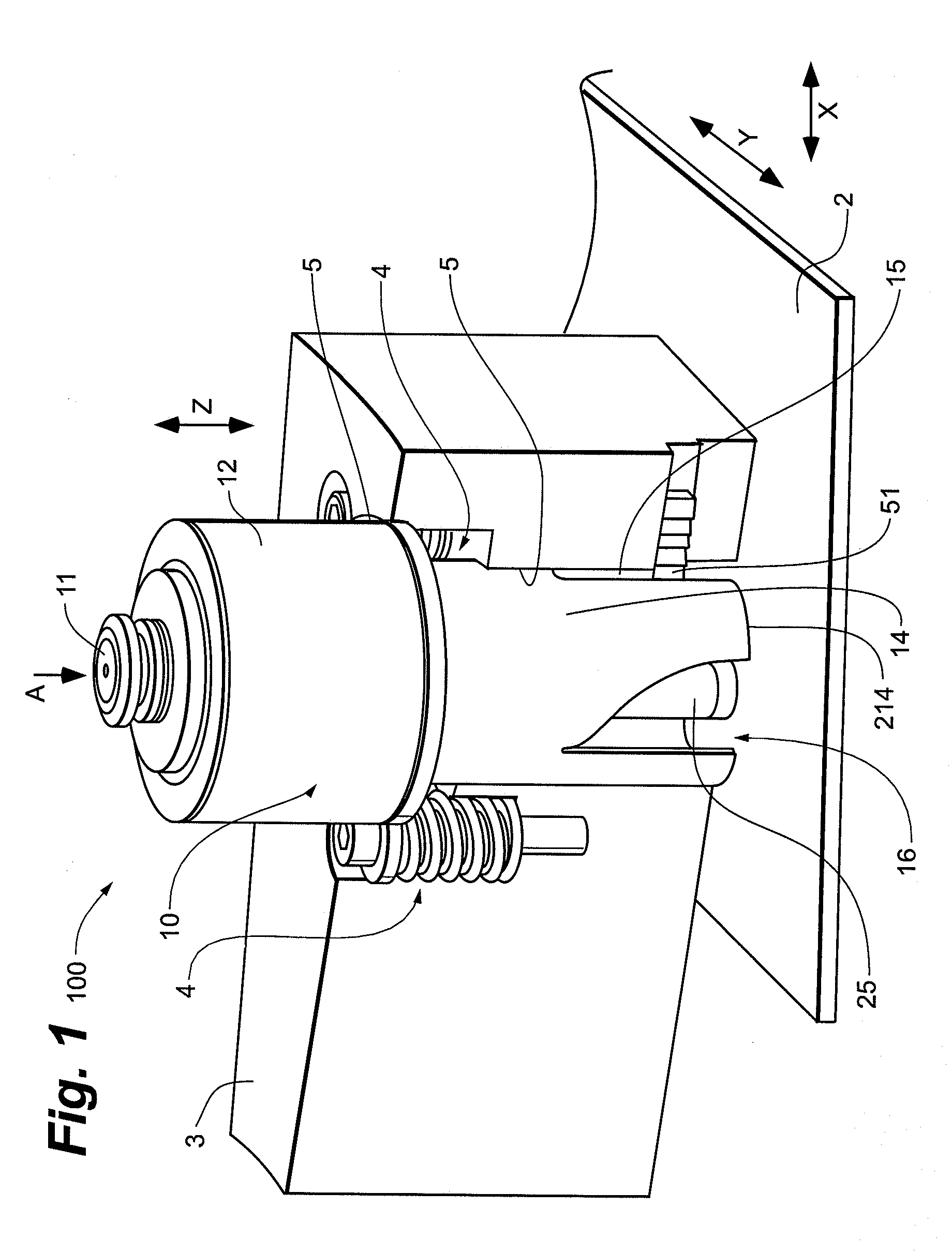

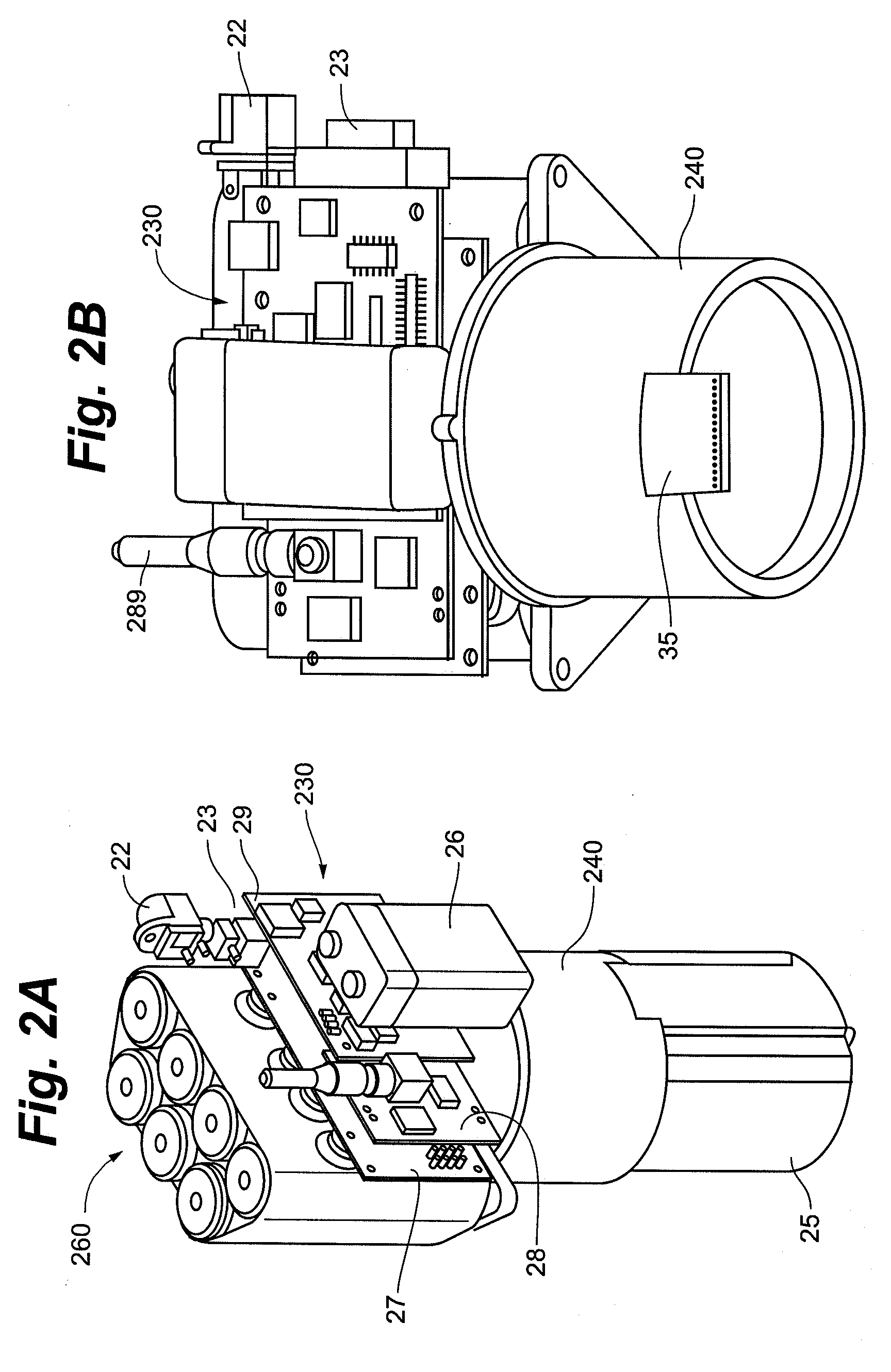

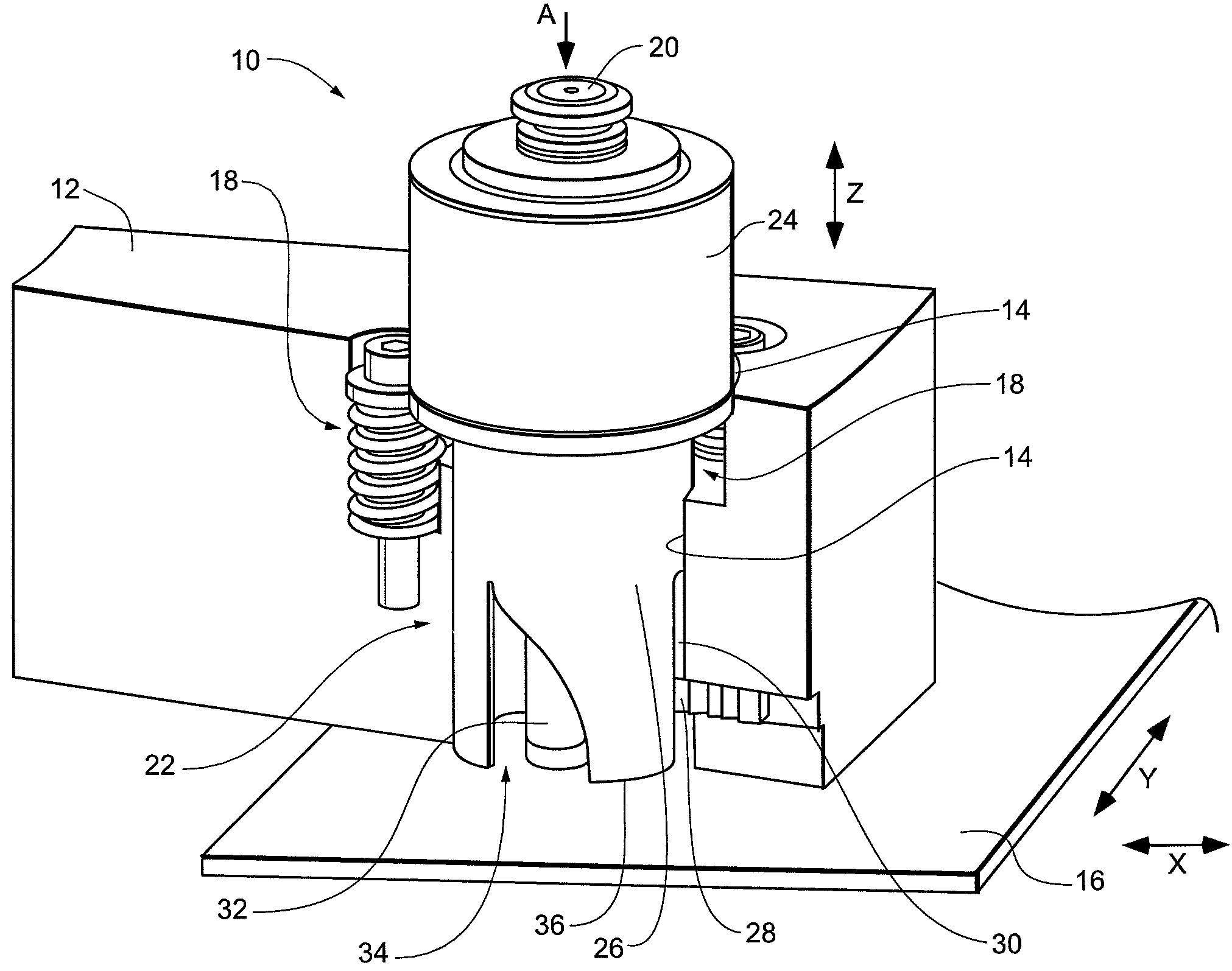

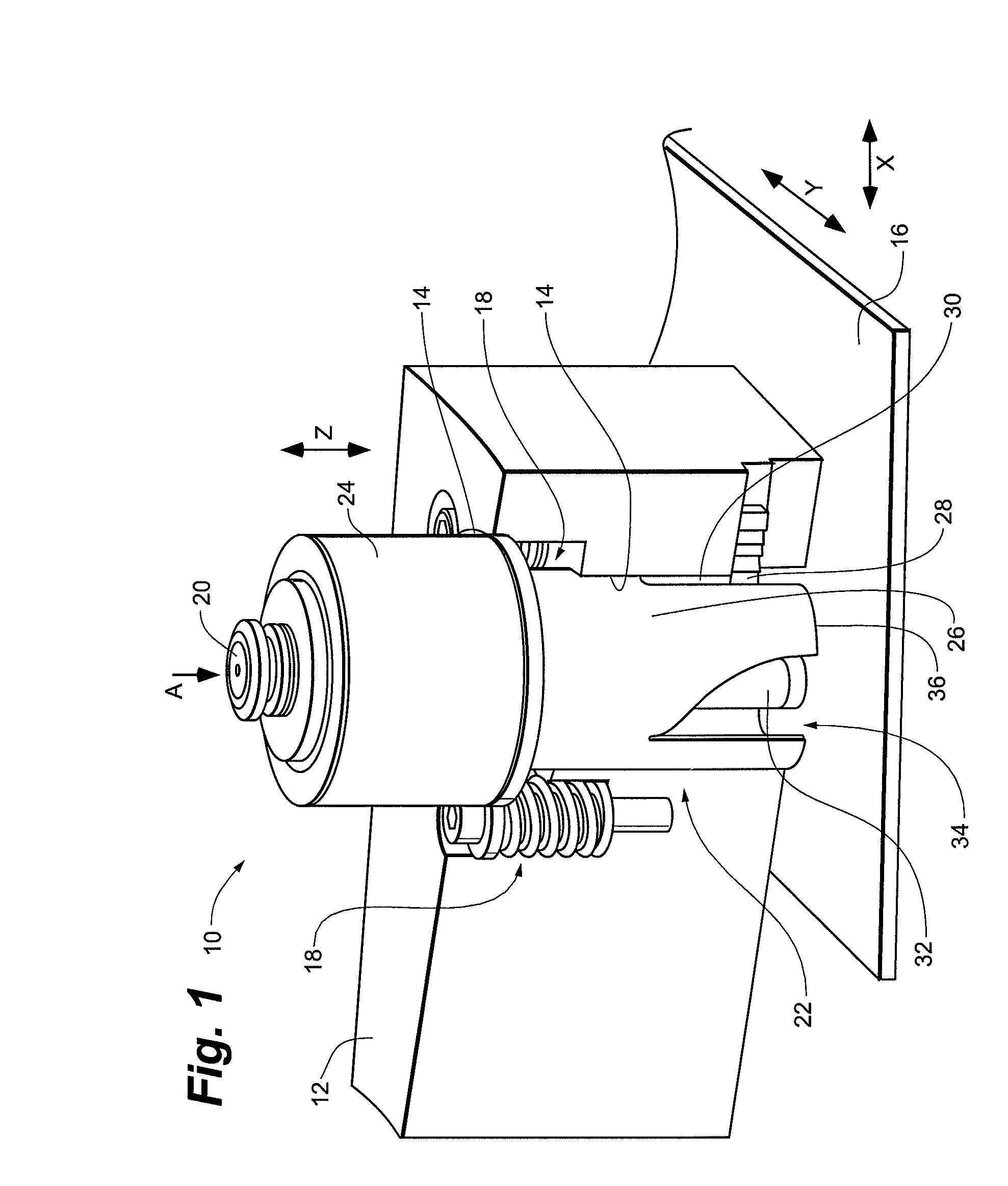

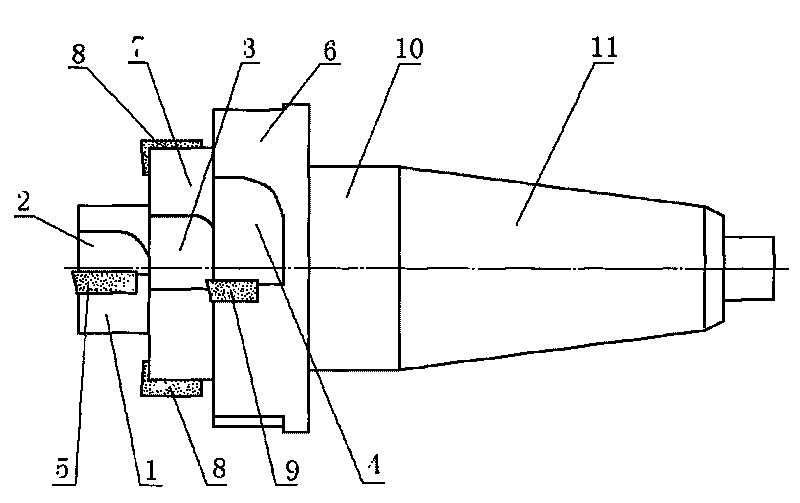

Orbital drilling tool unit

InactiveUS20100183395A1Easy to implementReduce the overall diameterMilling machinesLarge fixed membersEngineeringMachine tool

An orbital drilling tool unit configured to be detachably mounted to a rotatable spindle of a stationary machine tool. The tool unit comprises an outer eccentric body having an eccentric, longitudinally extending cylindrical hole, an inner eccentric body rotatably supported in the eccentric hole of the outer eccentric body and having likewise an eccentric, longitudinally extending cylindrical hole, a spindle motor for detachably supporting a cutting tool and rotatably supported in the eccentric hole of the inner eccentric body. The machine tool end of the outer eccentric body is configured to be concentrically mounted to a tool holder attached to the machine tool spindle for rotating the outer eccentric body. A radial offset adjusting means is configured for rotating the inner eccentric body relative to the outer eccentric body for adjusting the radial offset of the spindle motor center axis relative to the center axis of the machine tool spindle, and a means is provided for transferring power to the spindle motor for rotating the cutting tool.

Owner:NOVATOR

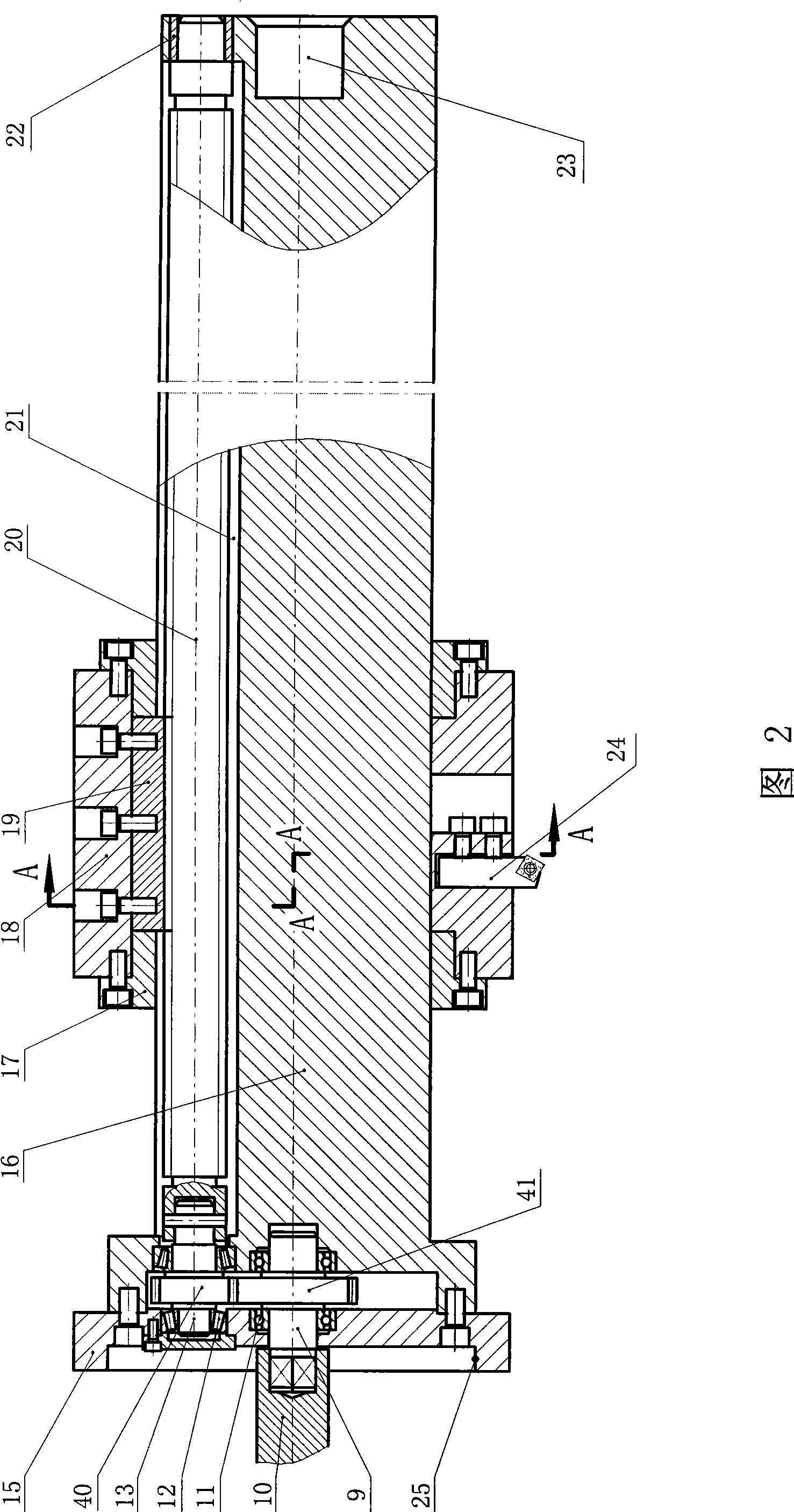

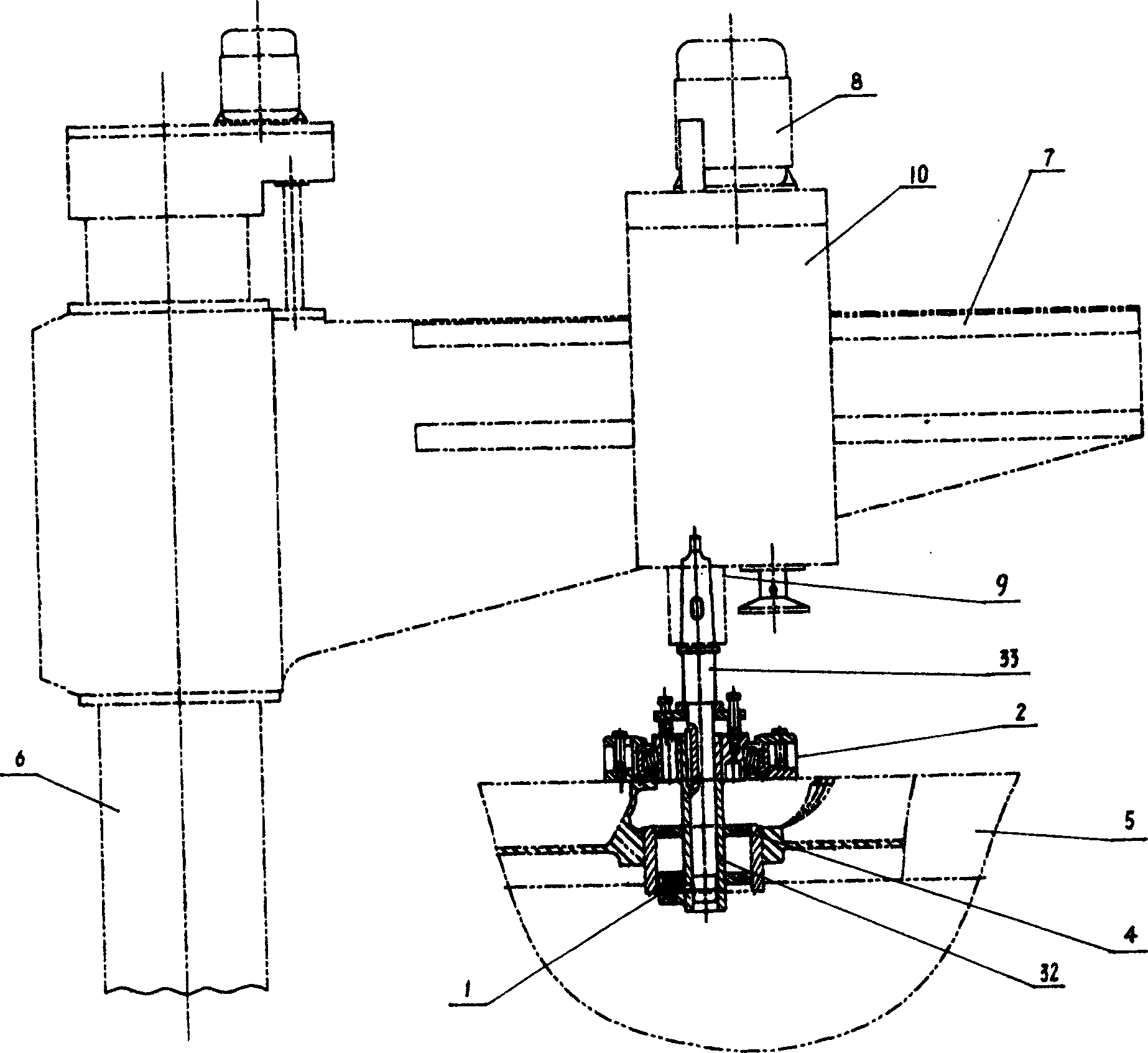

Cylinder boring device and method for processing cylinder using the device

InactiveCN101337287AUniform wall thicknessGuaranteed StrengthBoring/drilling componentsAttachable boring/drilling devicesGyrationEngineering

The invention discloses a cylinder barrel boring device and a method of using the device to process the cylinder barrel, wherein the cylinder barrel boring device comprises a guide rail and a boring head arranged on the guide rail; a boring cutter is arranged on the boring head; the boring head is in axial sliding fit with the guide rail through a power transmission device; and the guide rail is a cylindrical boring bar. According to the method of using the cylinder barrel boring device to process the cylinder barrel, the device is mounted on a lathe and directly positioned by the excircle of the cylinder barrel, thus eliminating the technological process of processing the exterior angles of the two ends of a reversed cylinder barrel in the traditional cylinder barrel boring; the excircle of the cylinder barrel and the gyration center of the boring bar are consistent; the axis of the inner hole of the bored cylinder barrel and the excircle of the cylinder barrel are concentric; even thickness of the wall of the processed cylinder barrel is realized in the aspect of processing technology, thereby ensuring the required strength of the cylinder barrel.

Owner:HENAN YUJIAN TECH

Butterfly valve center hole processing fixture

InactiveCN101954599ASimplify the fitter line drawing processIncrease productivityPositioning apparatusMetal-working holdersEngineeringButterfly valve

The invention relates to a butterfly valve center hole processing fixture which is characterized by mainly comprising a bent plate, a butterfly valve inner diameter positioning plate, a drill jig and a pressure plate which are connected with a lathe spindle, wherein the positioning plate is fixedly connected on the right-angle plane of the bent plate, and is provided with set bolts perpendicularly along the central line thereof, the pressure plate is sleeved on the bolts, and the drill jig is fixed on the positioning plate along the center axial line of a lathe. The butterfly valve center hole processing fixture has the advantages that the drill jig arranged can keep a drill bit stable during drilling. The procedure that fitters draw lines is simplified, and the production efficiency is greatly improved. Meanwhile, the fixture further can machine a spigot on a top disc of a butterfly valve.

Owner:天津津通瓦特阀门制造有限公司

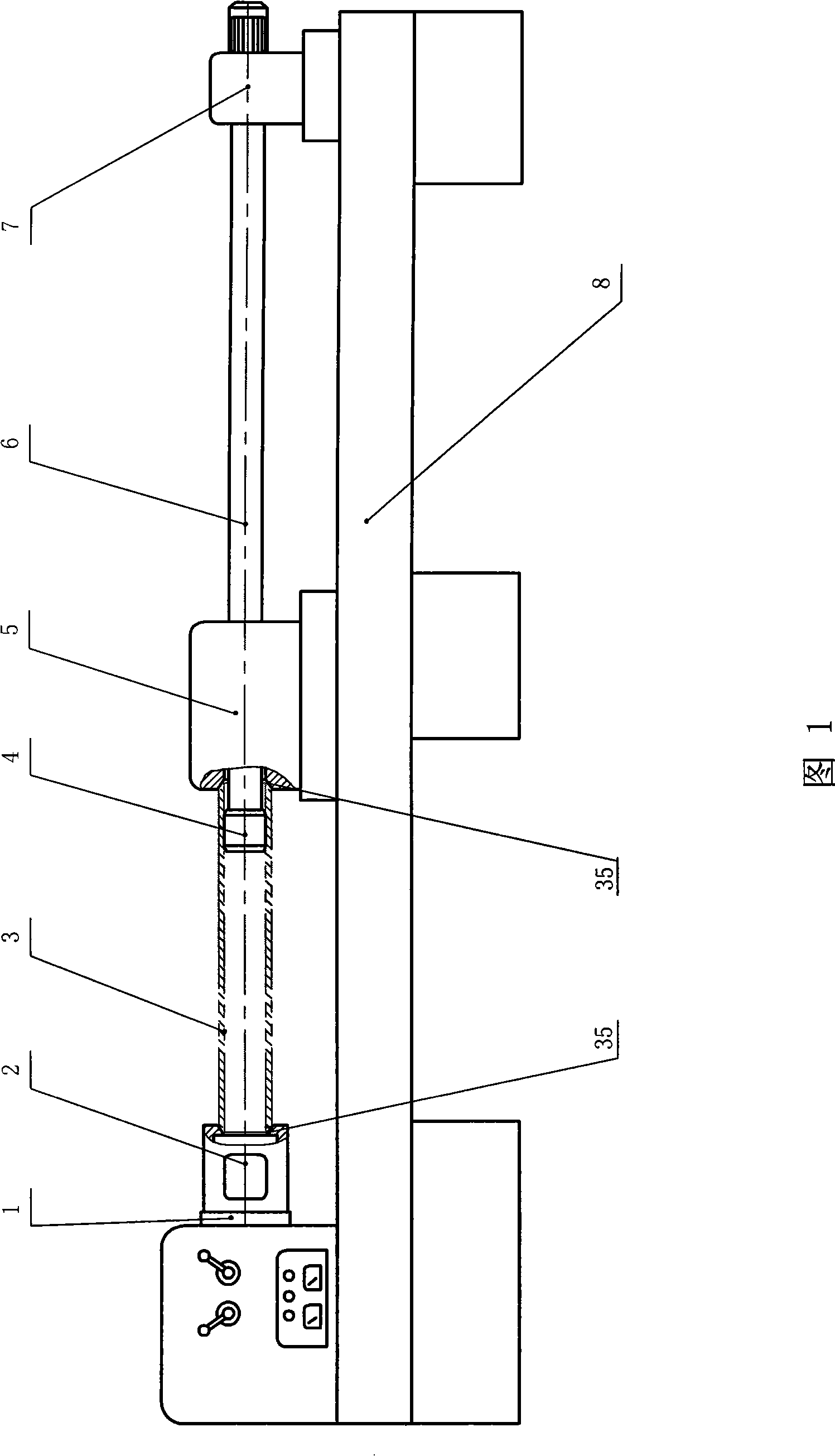

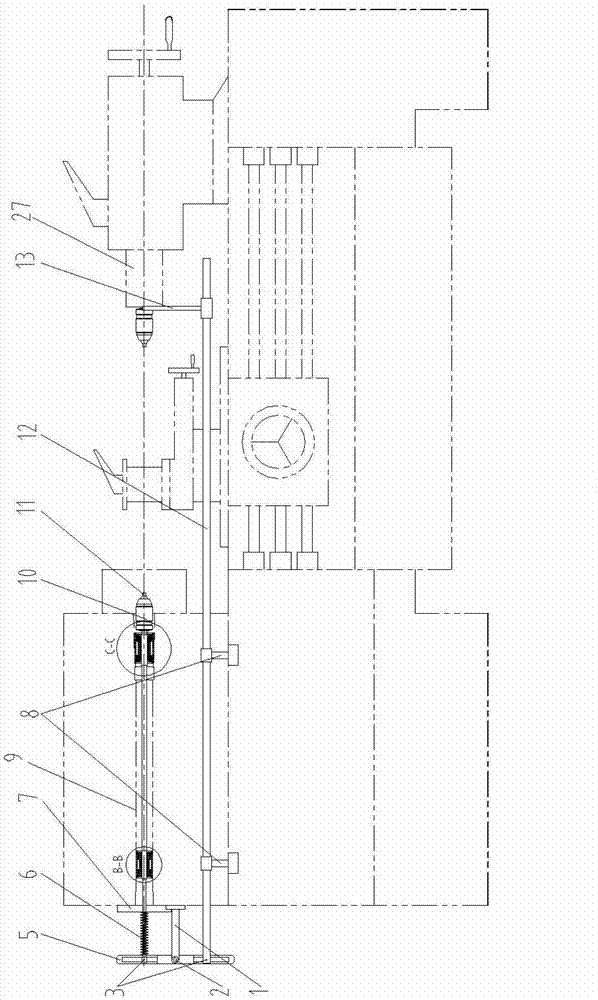

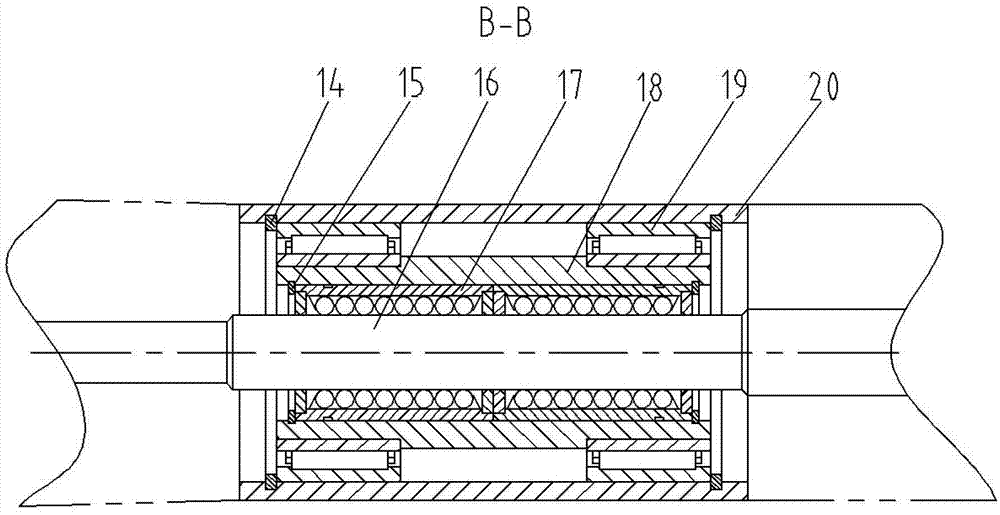

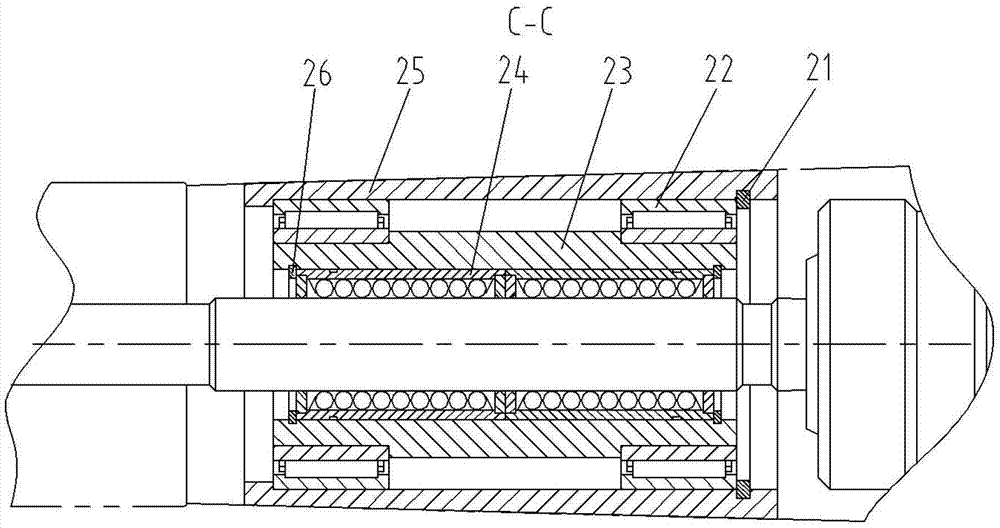

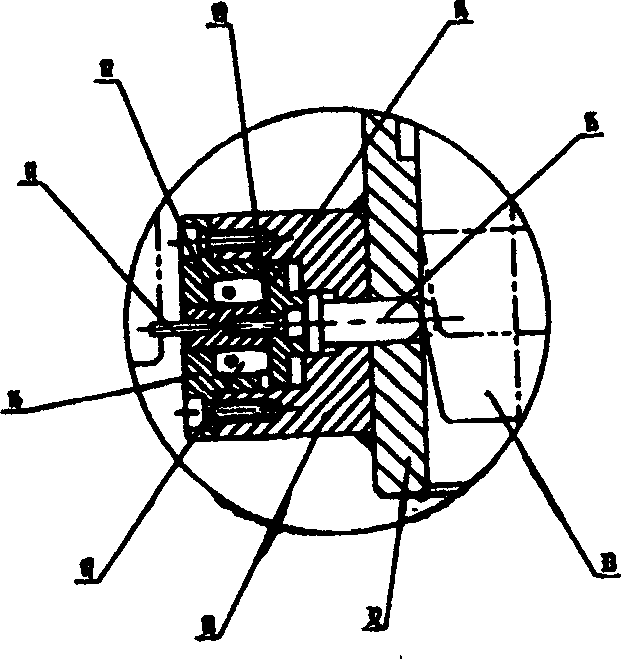

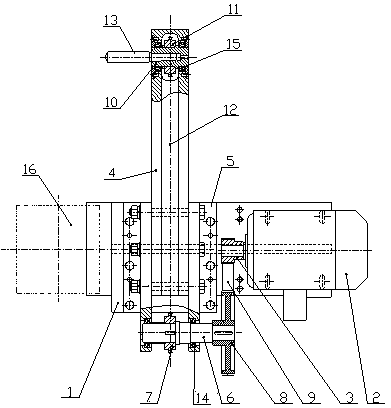

Processing device for double-center hole punching of common lathe

InactiveCN102784946APerformance is not affectedDoes not interfere with normal operationAttachable boring/drilling devicesNeedle roller bearingBall bearing

The invention discloses a processing device for double-centre hole punching of a common lathe. The processing device comprises a proportional reversing feeding device, two groups of shaft hole feeding devices arranged in main shaft holes, a drill chuck connecting rod, a drill chuck and a central drill, wherein the central drill is arranged at a front end of the drill chuck connecting rod through the drill chuck; two groups of shaft hole feeding devices are respectively arranged at front and back parts of the drill chuck connecting rod; each group of the shaft hole feeding devices structurally comprises a liner sleeve, needle rolling bearings, an shaft sleeve and a linear ball bearing which are arranged in the main shaft holes, wherein the linear ball bearing is tightly sleeved on the drill chuck connecting rod; the shaft sleeve is tightly sleeved on the linear ball bearing; the needle rolling bearings are respectively arranged at two ends of the shaft sleeve; and the liner sleeve tightly arranged in the main shaft hole is sleeved on the needle rolling bearing; and one end of the proportional reversing feeding device is connected with a rear end of the drill chuck connecting rod, and the other end of the proportional reversing feeding device is connected with a tail seat of a lathe main body for arranging the drill chuck. By adopting the processing device to punch centre holes at two ends of parts, such as shafts, clamping time can be reduced, efficiency can be improved, precision can be improved, the precision of coaxiality of processing workpieces can be ensured, and meanwhile, workpieces with central holes with different depth and different types at a left end and a right end can be processed through a left central drill and a right central drill with different-ratio feeding rate and feeding volume.

Owner:GUANGXI UNIV

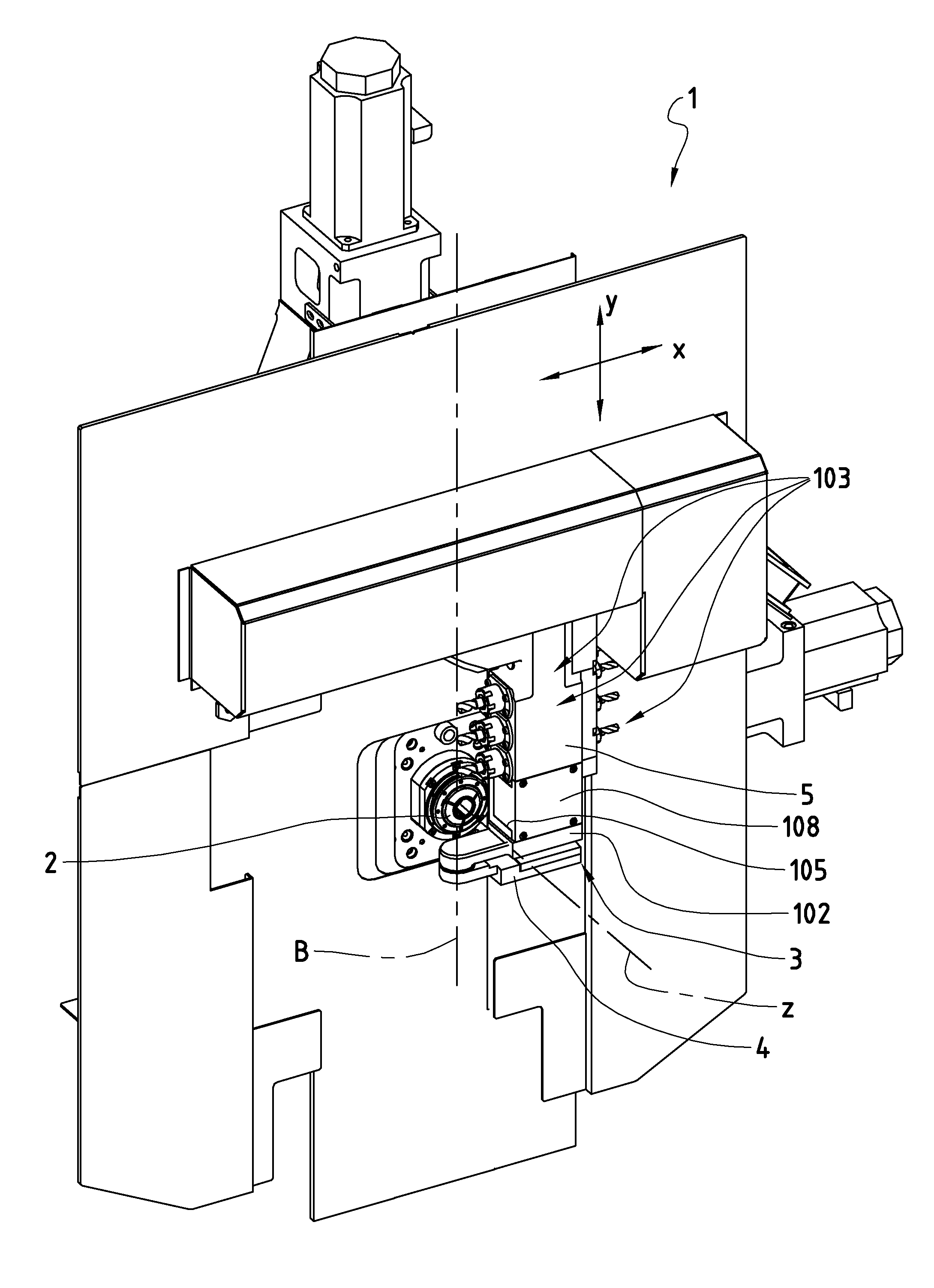

Equipment with a detachable accessory and assembly for a machining lathe, and machining lathe with digital control

ActiveUS20160256932A1Easy to carryHighly versatileAutomatic/semiautomatic turning machinesLarge fixed membersSupporting systemEngineering

An equipment for a machining lathe with digital control comprising a movable carriage, a tool support system with integrated drive which is mounted so as to pivot on this movable carriage so as to be able to pivot about a pivot axis, as well as a device for actuating the tool support system with integrated drive with respect to the movable carriage. The tool support system with integrated drive comprises at least one mounting location to detachably receive a detachable accessory to support and drive a tool.

Owner:USINES TORNOS FAB DE MACHINES MOUTIER

Device and method for machining metal beryllium single-blade outer chip removal deep hole

InactiveCN103658737AImprove processing yieldSolve chip breakingBoring/drilling machinesAttachable boring/drilling devicesEngineeringAlloy

The invention relates to a device and method for machining a metal beryllium single-blade outer chip removal deep hole. According to the device, a mounting plate used for clamping a workpiece, a tool bar guiding and supporting sleeve sued for supporting a tool and a connecting structure used for being connected with an oil pressure system and the tool are arranged on a common lathe, the tool is a hard alloy deep hole gun drill and is clamped on a three-jaw chuck of the lathe, the mounting plate is arranged on a middle supporting plate of the lathe, and the tool bar guiding and supporting sleeve is arranged between the three-jaw chuck and the mounting plate. Compared with the prior art, the method for machining the metal beryllium single-blade outer chip removal deep hole solves the problems of chip breakage, chip discharge, cooling, lubrication, guidance, drilling deviation and the like existing in the existing metal beryllium deep hole machining process, and therefore the machining finished product rate of beryllium is effectively improved, the deep hole with a draw ratio of 50-150 and an aperture phi smaller than or equal to 20mm of metal beryllium materials is machined successfully, hole machining precision can reach IT8, and surface smoothness can reach Ra0.8.

Owner:西北稀有金属材料研究院宁夏有限公司

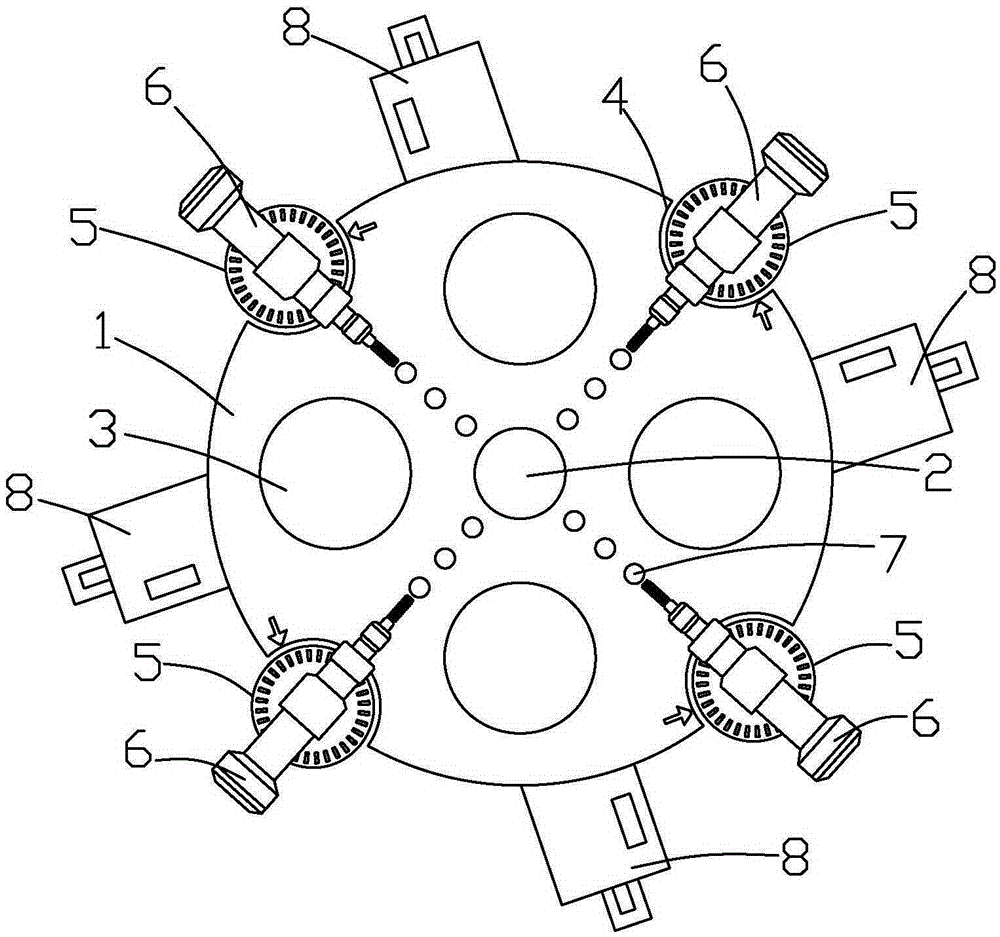

Aluminum strip drilling device for hollow glass molecular sieve filling machine

ActiveCN105414603AReduce weightFlexible rotationMaintainance and safety accessoriesAttachable boring/drilling devicesMolecular sieveHydraulic cylinder

The invention discloses an aluminum strip drilling device for a hollow glass molecular sieve filling machine. The aluminum strip drilling device comprises a main rotary disc, a pneumatic drilling device and drill bit converting frames. At least four semicircular grooves are evenly formed in the outer circumference of the main rotary disc and internally provided with positioning rotary discs. The pneumatic drilling device is connected with the positioning rotary discs through clamping mechanisms. A boosting hydraulic cylinder is arranged at the bottom of the main rotary disc and connected with a horizontal supporting plate through a piston rod. A motor is arranged on the top face of the horizontal supporting plate. Inner cavities are formed in the positioning rotary discs. Annular racks are arranged on the side walls of the inner cavities. The drill bit converting frames are evenly distributed on the outer circumference of the main rotary disc. The aluminum strip drilling device is simple in structure and high in practicability, and aluminum strips of different sizes and specifications can be drilled. Flexible replacement of drill bits can be automatically achieved, the remote positions and the positions hard to machine can be drilled, and the work range of the pneumatic drilling device is widened; and meanwhile the stability of the pneumatic drilling device during rotating is improved.

Owner:江苏铝翔航空科技有限公司

Novel multifunctional deep hole drill oiler for lathe optimization

InactiveCN103817560ASimple structureEasy to installMaintainance and safety accessoriesAttachable boring/drilling devicesHigh pressureMachining

The invention discloses a novel multifunctional deep hole drill oiler for lathe optimization, belongs to the field of machining, and solves the problem of single usage and poor generality of a deep hole drill oiler in the prior art. The oiler can be used for machining deep holes of a rotating workpiece and also a static workpiece with a rotating drill bit. The novel multifunctional deep hole drill oiler is characterized by comprising a base, a bearing, a changeable drill sleeve, a covering plate, a liquid delivering nozzle and a seal ring; the covering plate is connected to one end of the base, the other end of the base is provided with the bearing, the changeable drill sleeve penetrates the bearing and presses the inner ring of the bearing, high-pressure coolant enters the inner cavity of the base through the liquid delivering nozzle, the oiler drill sleeve can rotate with a workpiece and can be changed according to different diameters, and the covering plate and the changeable sleeve play roles of supporting and centering. The novel multifunctional deep hole drill oiler is simple in structure, good in centering performance, low in using and maintenance costs, and widely applicable and has large practical value.

Owner:LIYANG HONGDA MACHINERY EQUIP

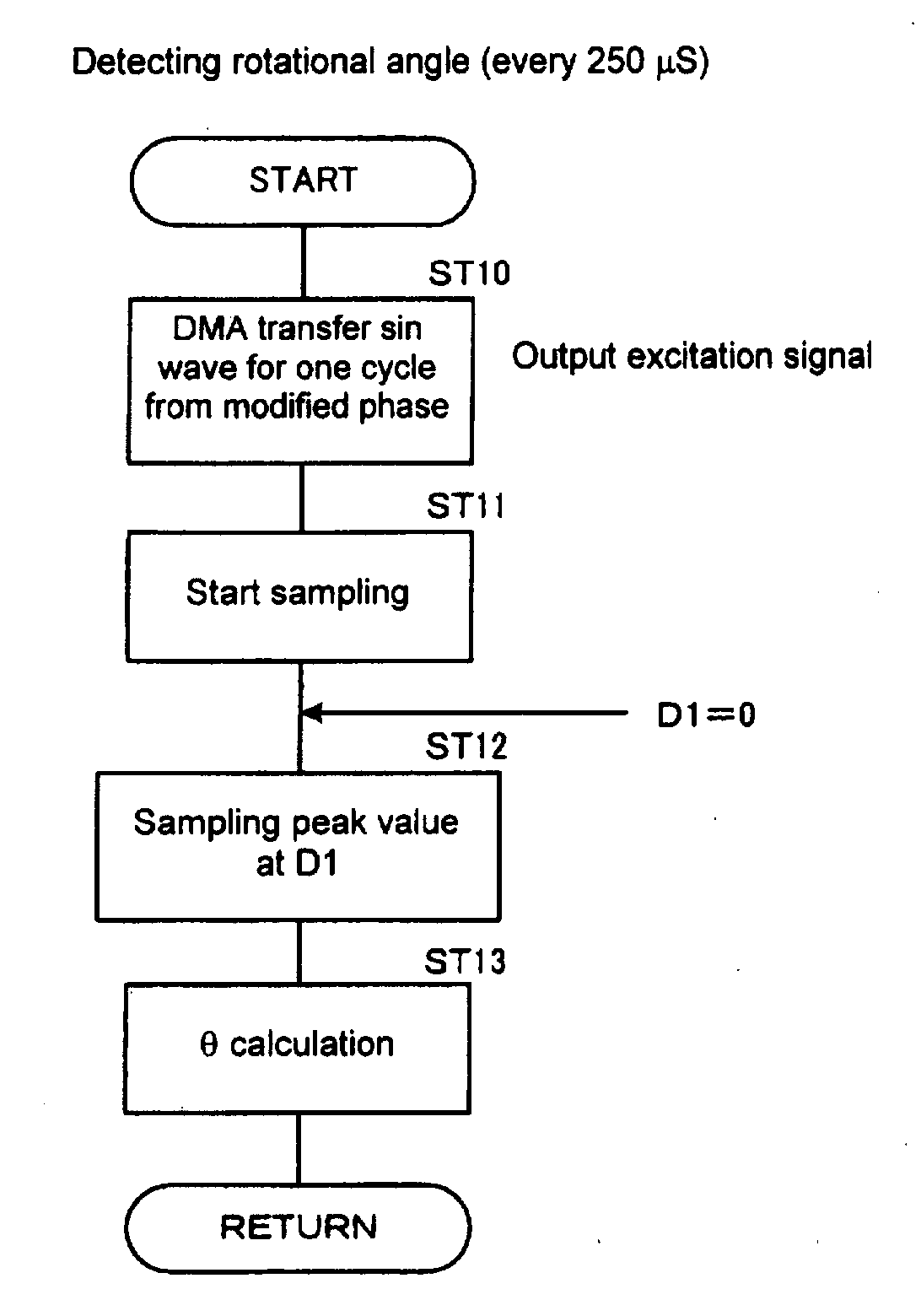

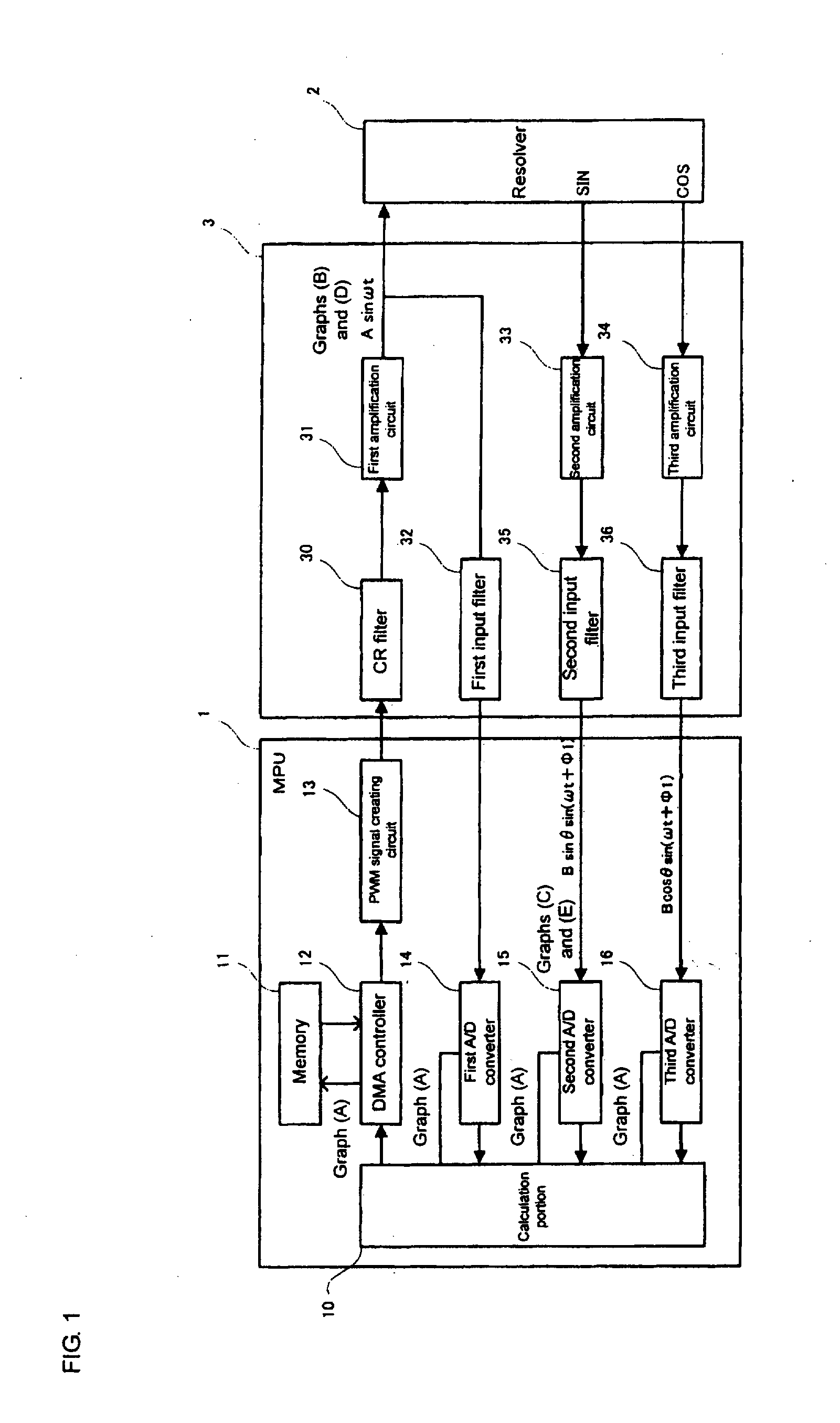

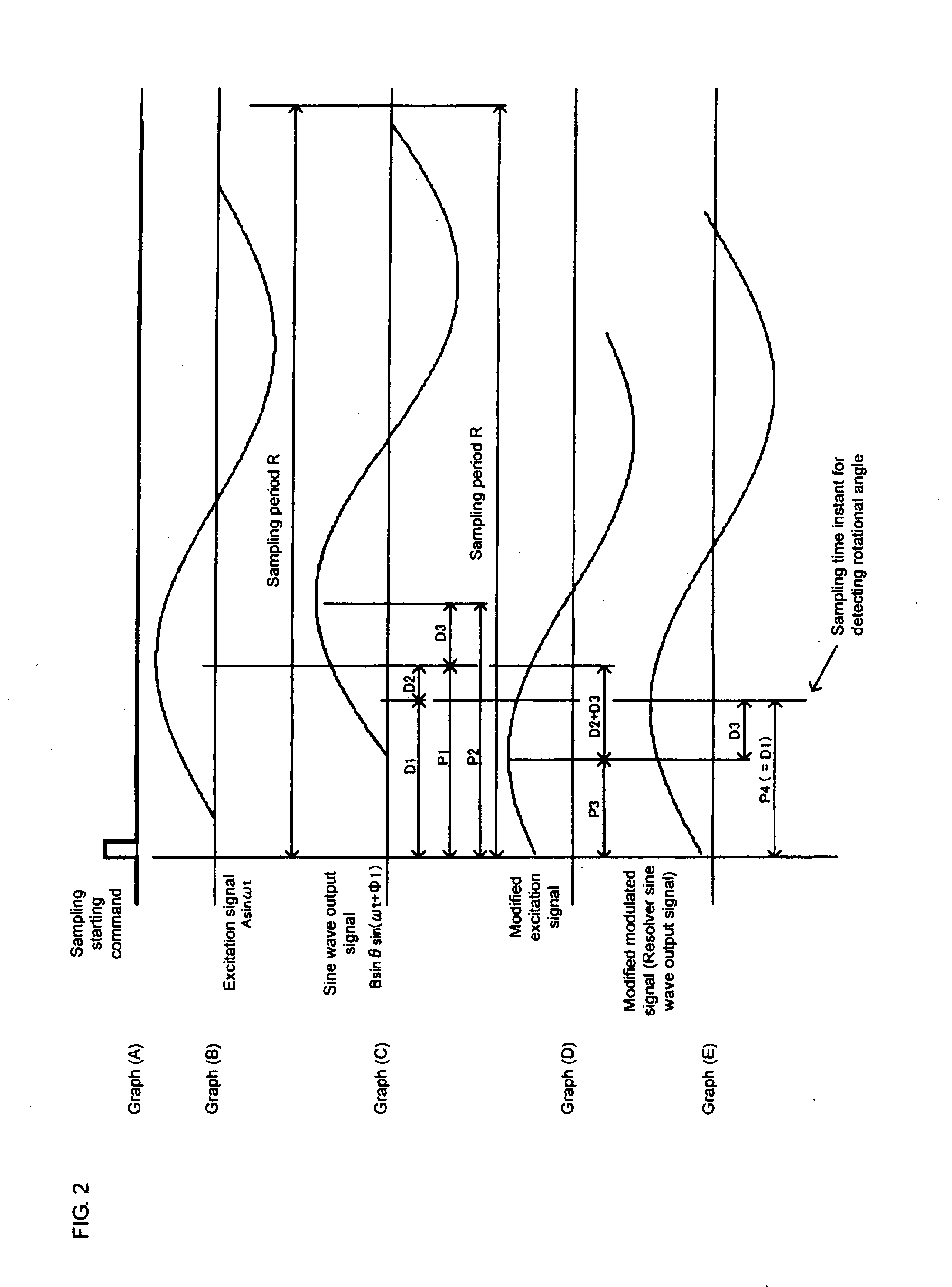

Resolver signal processing device

ActiveUS20070219733A1Reduce the burden onThe process steps are simpleDigital computer detailsSpeed measurement using gyroscopic effectsResolverSoftware engineering

A resolver signal processing device includes a control portion, a resolver, and an input / output portion. The control portion includes a memory for storing sine wave data for two cycles, and a DMA controller for transmitting to the resolver the excitation signal including a sine wave. A calculation portion provided in the control portion commands, in initial setting, DMA transfer of the sine wave data for one cycle from a reference phase as the excitation signal, and commands, in detecting the rotational angle, DMA transfer of the sine wave data for one cycle from a modified phase as the excitation signal. The modified phase is determined, in the initial setting, based on the phase difference between the excitation signal and a sine wave output signal or a cosine wave output signal, and the rotational angle of the resolver.

Owner:OMRON AUTOMOTIVE ELECTRONICS CO LTD

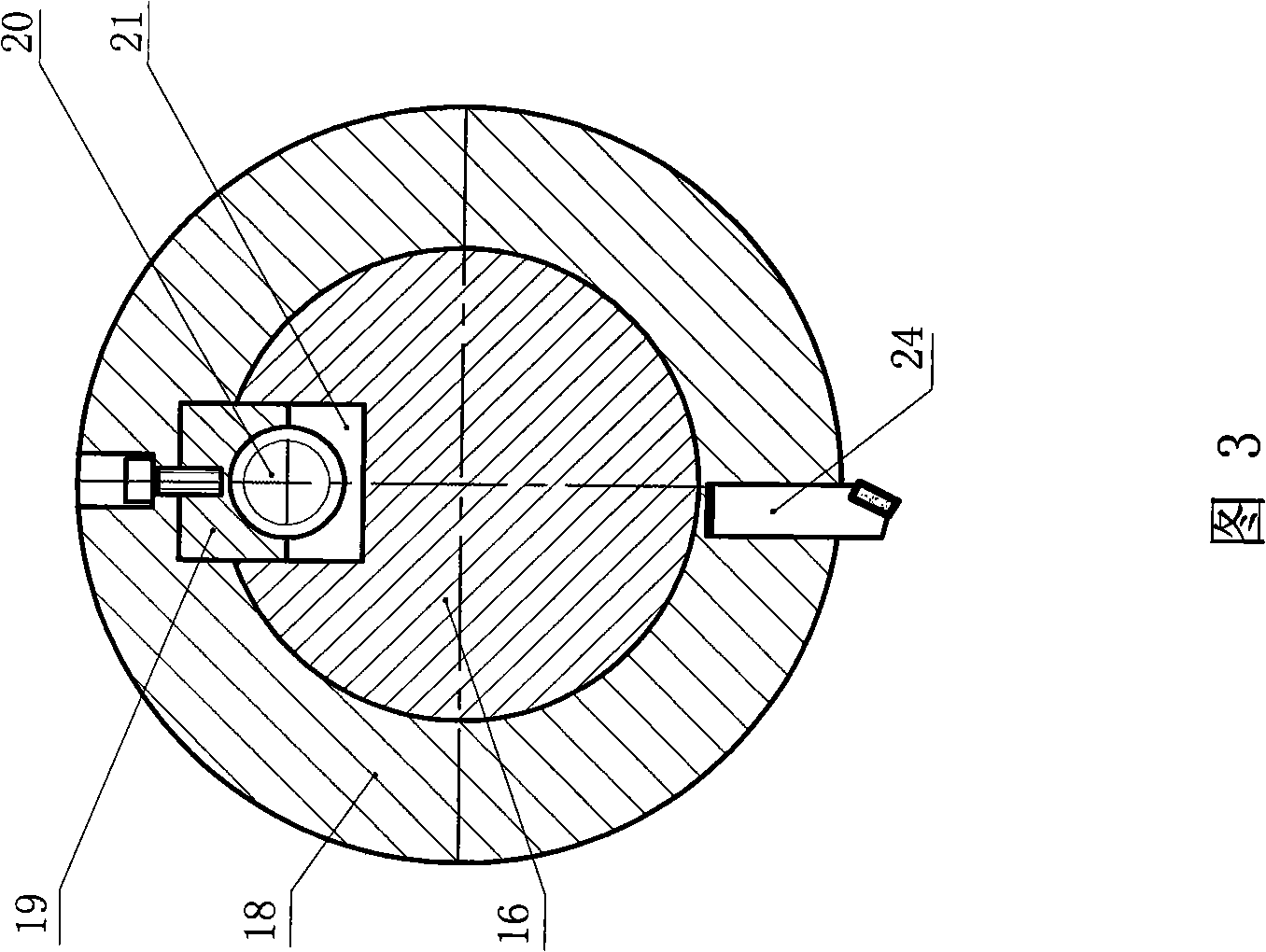

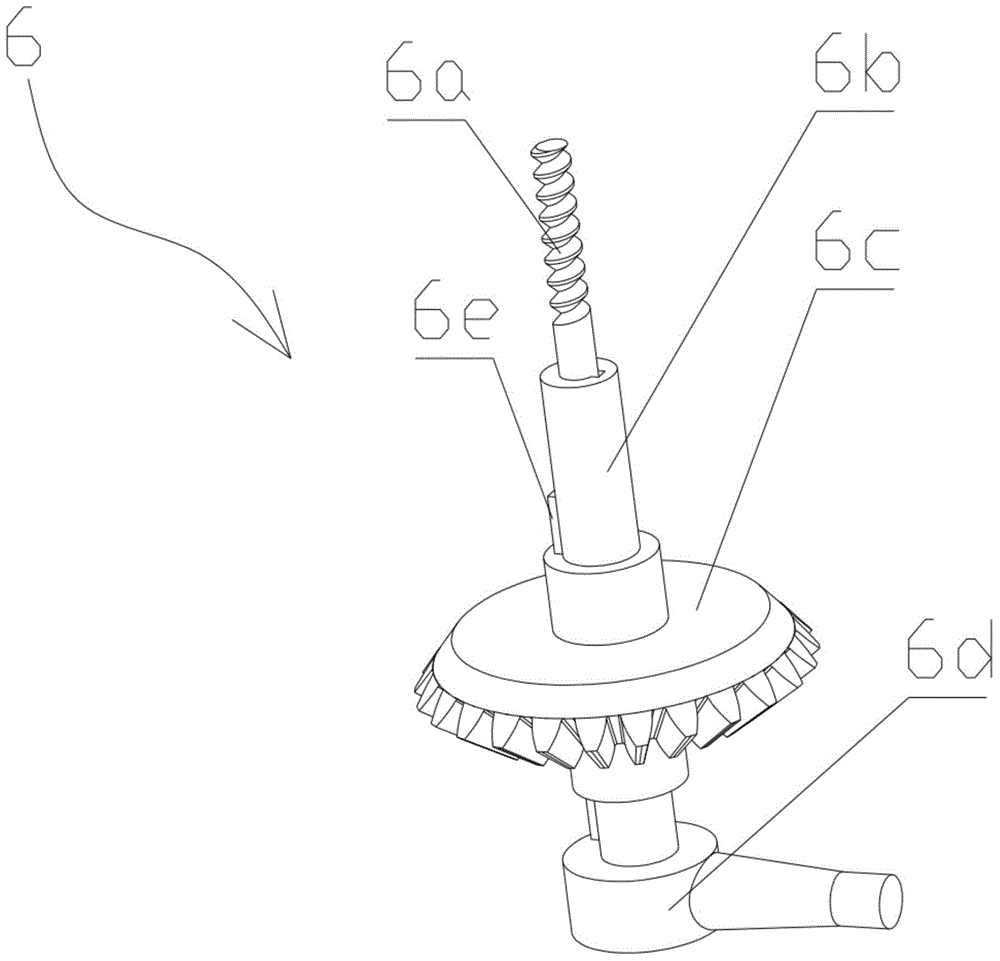

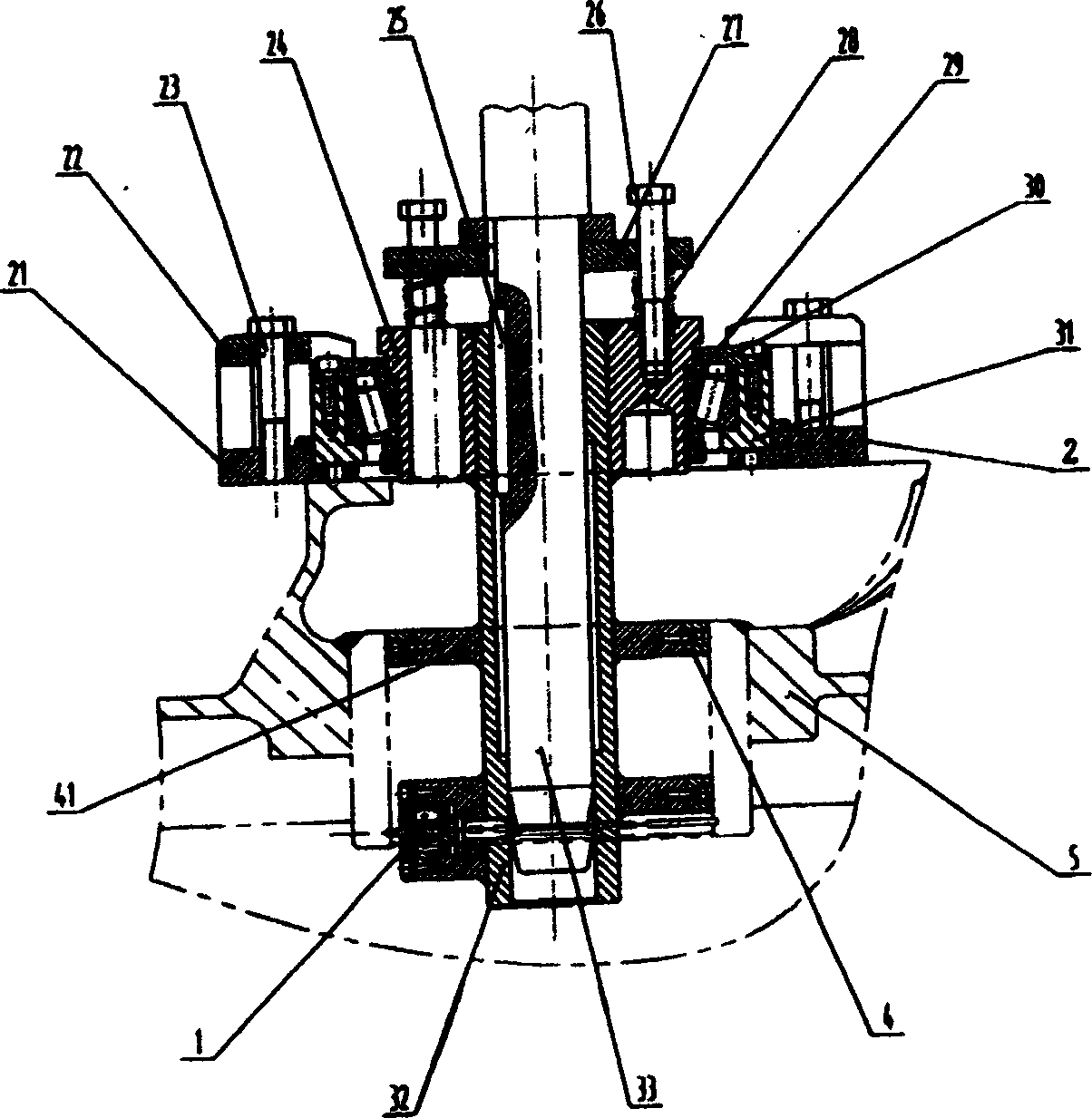

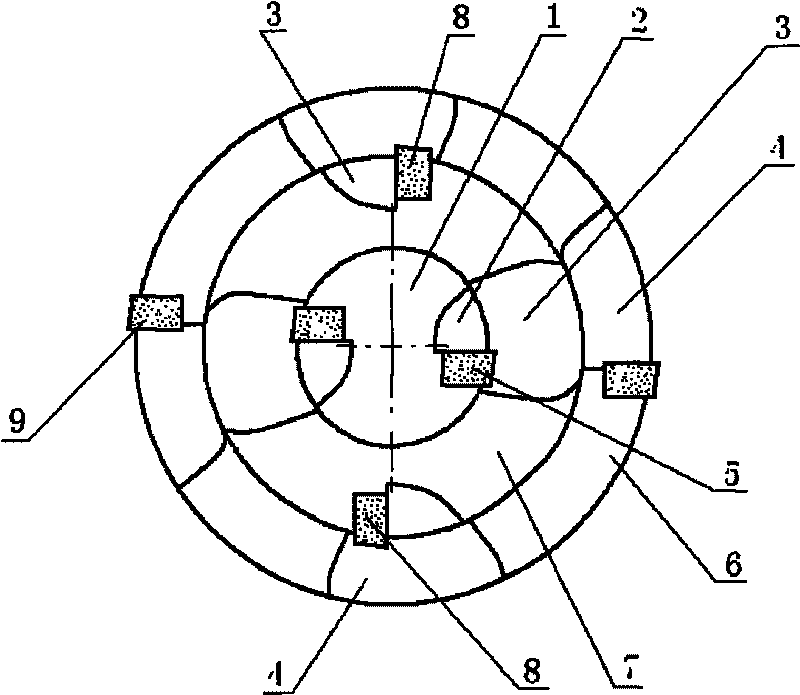

Self-feed differential planet flat turn disc

InactiveCN101279381AAvoid precisionSolve the precision problemBoring/drilling componentsAttachable boring/drilling devicesLinear motionReliable transmission

The invention relates to a self-feed differential planetary horizontal rotating disk, which can effectively solve the radial feed accuracy of a boring machine and improve the mechanical processing quality problem; the structure thereof is that: a boring and milling shaft is connected with the horizontal rotating disk by an end-surface key, the horizontal rotating disk and the boring and milling shaft simultaneously rotate, the boring and milling shaft is externally provided with a fixed wheel gear to be meshed with a planetary gear on the horizontal rotating disk, the fixed wheel gear and the planetary gear have the teeth difference, the rotation drives the planetary gear to rotate, the planetary gear is arranged on a planetary driving gear shaft, a driving gear is arranged on the same shaft, the driving gear is meshed with a driven gear on a worm drive shaft, a coaxial worm is arranged on the worm drive shaft, the coaxial worm is connected with a worm wheel, a worm is arranged on the worm wheel, a drive sliding plate is arranged on the horizontal rotating disk, a worm strip is arranged on the sliding plate, the worm is connected with the worm strip, the worm wheel drives the worm to rotate, thus driving the worm strip on the sliding plate to do the radial linear motion; the self-feed differential planetary horizontal rotating disk has simple structure, reliable transmission and convenient usage, which is a creation on the processing by a mechanical machine and has great economic benefits.

Owner:宋保通

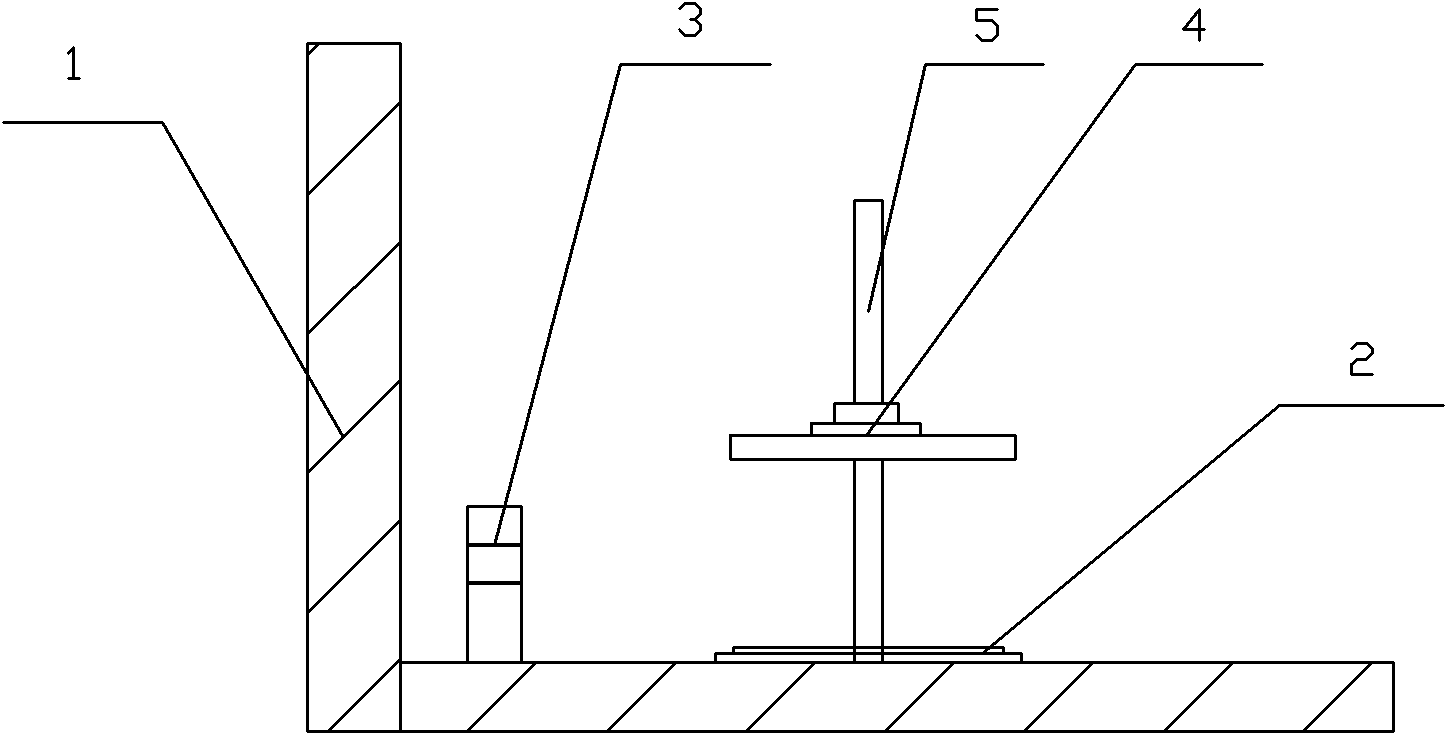

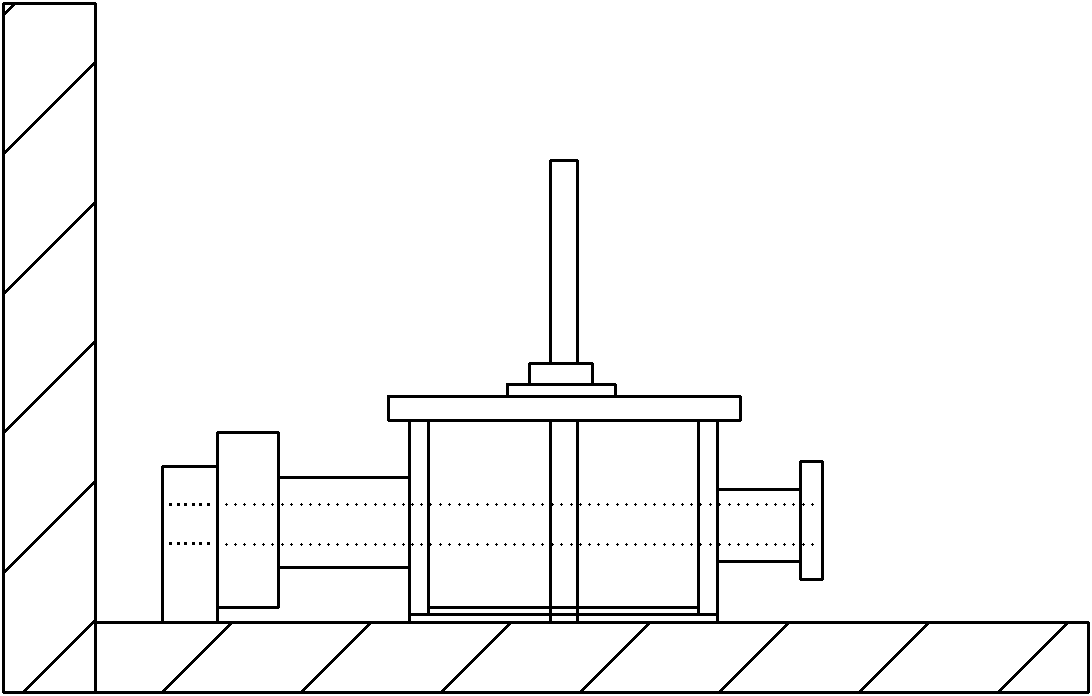

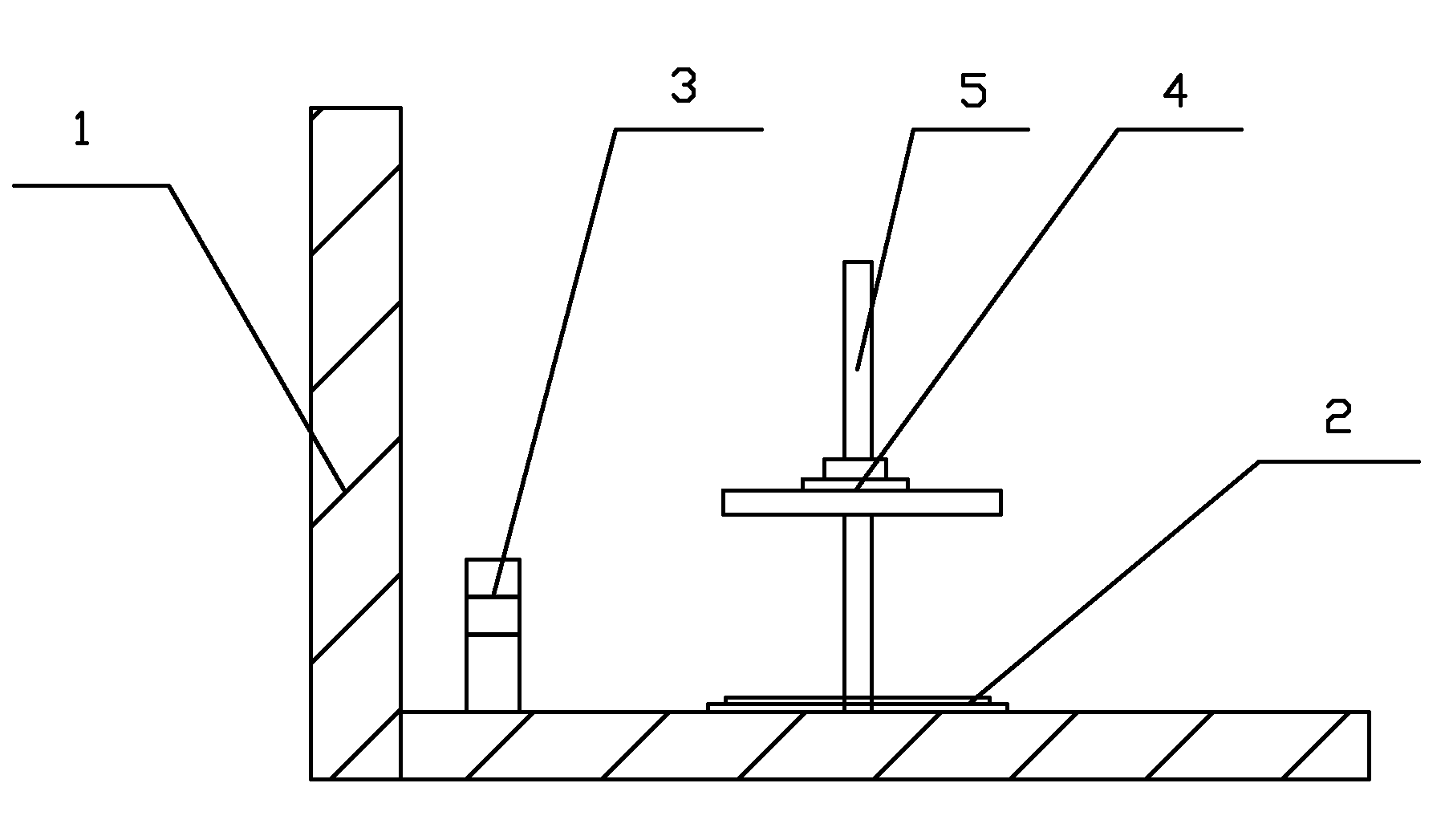

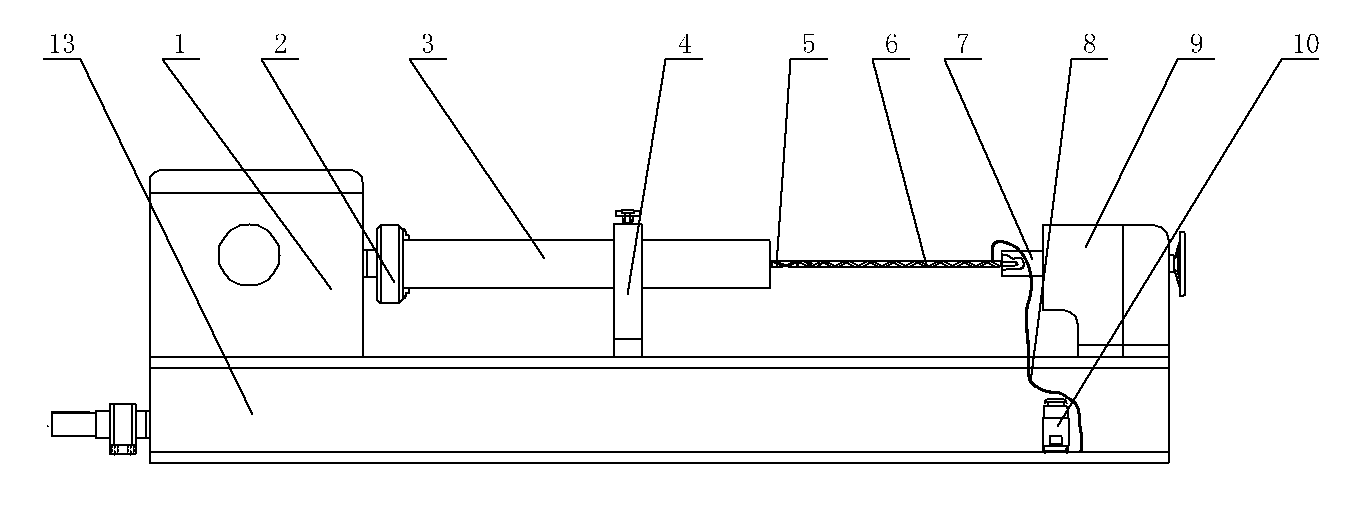

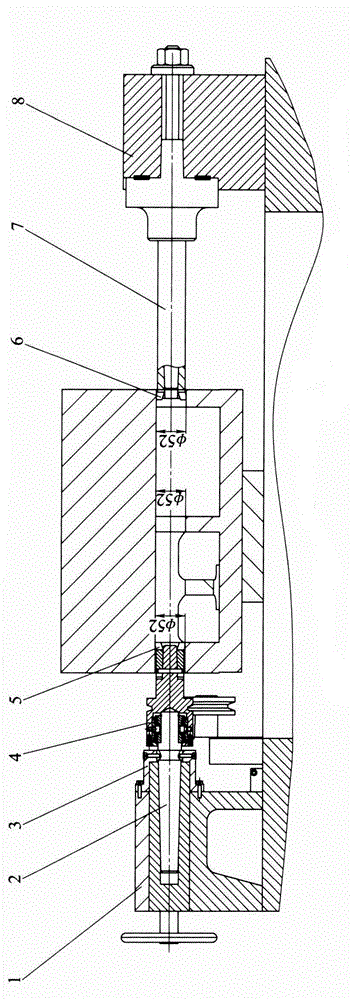

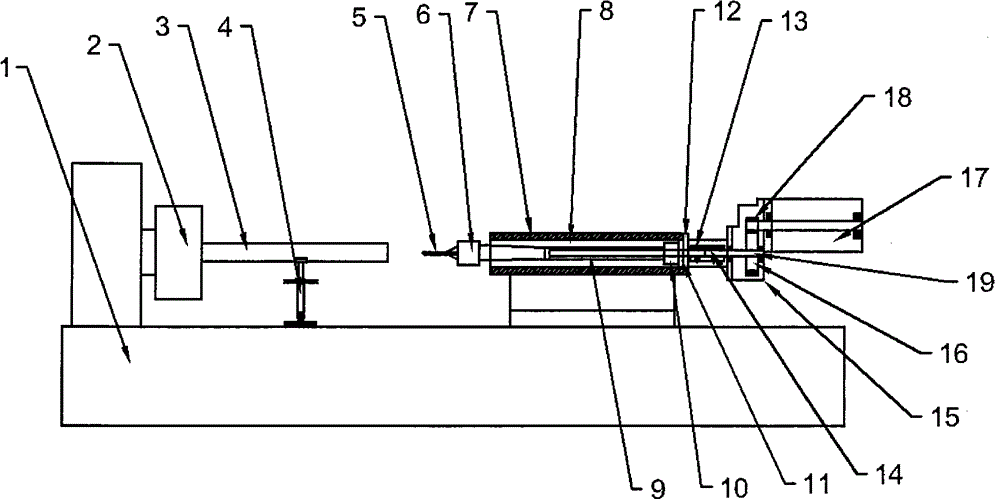

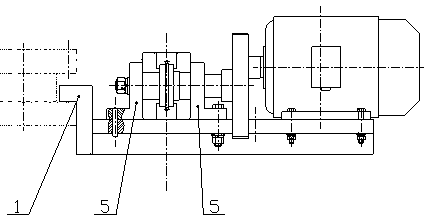

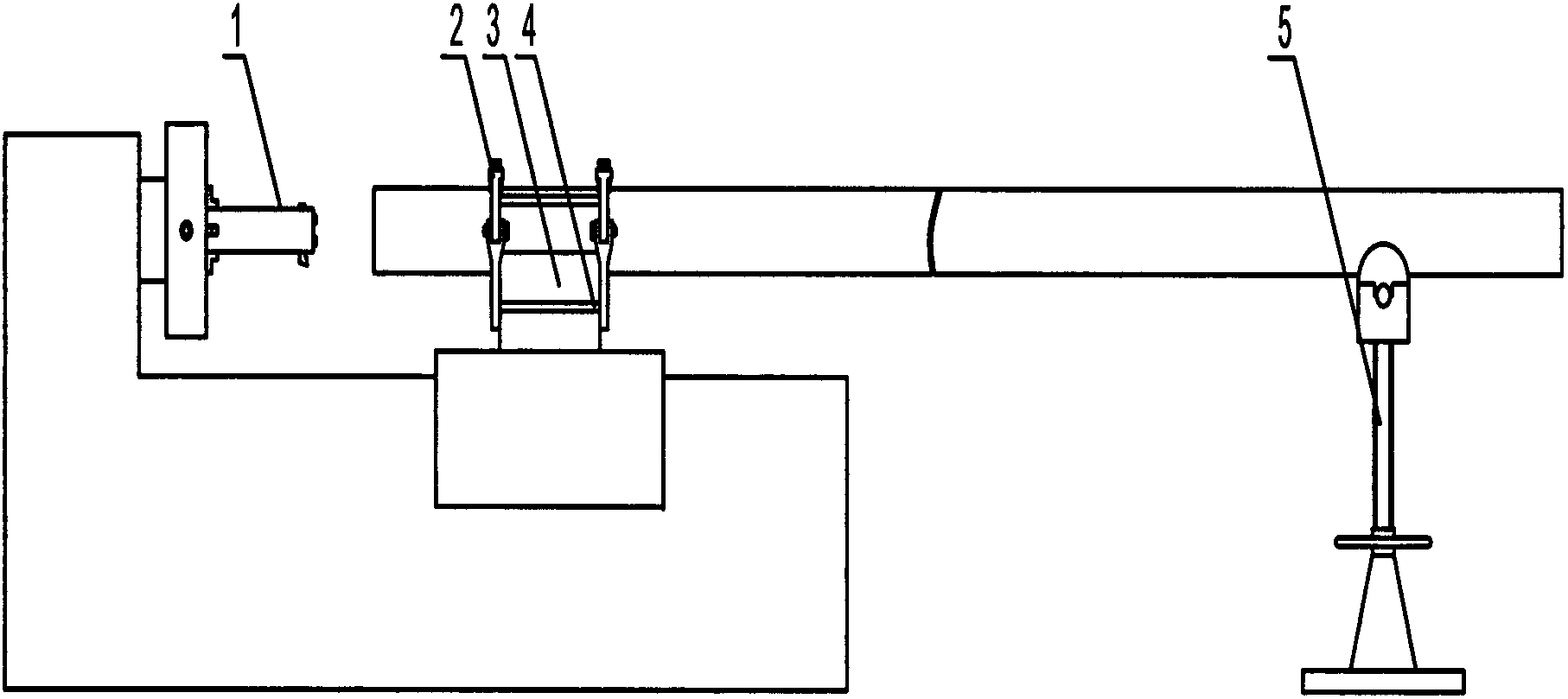

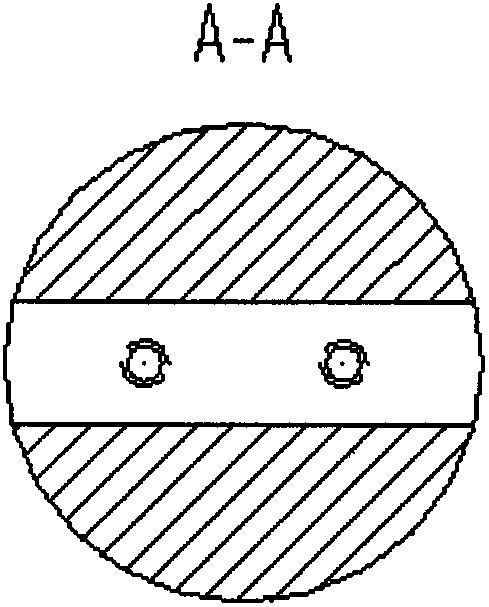

Engine lathe deep hole working device

InactiveCN101941088AGuaranteed cooling effectSimple structureLarge fixed membersTwist drillsEngineeringTailstock

The invention provides an engine lathe deep hole working device, which has simple structure, is convenient to use, can process a longhole of about phi 45mm and 4.2m deep on an engine lathe, improves the use ratio of the engine lathe, reduces the acquisition expenses of a heavy type deep hole drilling machine and greatly reduces the equipment cost. The device comprises a lathe bed of the engine lathe; one end of the lathe bed is provided with a main spindle box; and the other end of the lathe bed is provided with a tailstock. The device is characterized in that a center frame is arranged on the middle of the lathe bed, and between the main shaft and the tailstock; the front end of the tailstock is provided with a tailstock sleeve; the tailstock sleeve is internally provided with an extension arm; and the front end of the extension arm is provided with an auger bit in a connection mode.

Owner:WUXI JULI HEAVY IND OFF

Inner cavity drilled multi-cutter machining device

ActiveCN105057738AImprove processing efficiencyEasy clampingFeeding apparatusDriving apparatusEngineeringBlind hole

The invention discloses an inner cavity drilled multi-cutter machining device. The device comprises a cutter mechanism, a transmission driving mechanism and a feeding mechanism mounted in a box, and a support mechanism connected between the outer wall of the box and a workpiece in a supporting manner, wherein the transmission driving mechanism is connected with the cutter mechanism to drive the cutters to rotate; the feeding mechanism is connected with the cutter mechanism, and controls the radial movement of the cutter mechanism; the cutter mechanism comprises multiple sets of cutter components uniformly distributed in the periphery; and each set of cutter components is mounted in the radial direction, and is arranged towards the inner wall of the workpiece. The device can synchronously machine multiple peripheral blind holes or through holes in the inner cavity of the part, needs no extra fixture in machining to achieve the clamping convenience, and can automatically and quickly center to greatly improve the machining efficiency.

Owner:ZHEJIANG UNIV

Tool assembly for a ram driven press responsive to the stroke of the ram driven press

Assemblies and methods for processing a workpiece in a ram-driven press employ an active tool contained by a housing that is interchangeable with a passive forming tool assembly in a mounting assembly of the press. The active tool includes a microprocessor and a functional head coupled to the microprocessor. Some assemblies including the active tool include a switch for activating the functional head; the switch may be mounted to the housing such that, when the housing is mounted in the mounting assembly of the press, the switch is triggered by movement of the housing in response to the ram stroke of the press.

Owner:WILSON TOOL INT

Valve boring lathe tool

InactiveCN104148691AHigh precisionReduce mistakesFeeding apparatusLarge fixed membersNumerical controlSlide plate

The invention discloses a valve boring lathe tool which comprises a tool base, a numerical control four-station rotating table, a longitudinal sliding rail, a Z-axis servo motor, a sliding saddle, a transverse sliding rail, an X-axis servo motor, a sliding plate, a boring power head, a boring cutter head, a main motor, a boring cutter drive mechanism, a boring cutter servo motor and a boring cutter. The valve boring lathe tool has the advantages of being high in precision, small in error, high in efficiency and the like; by means of the four-station rotating table, an outer circle of a flange plate with a plurality of flange faces can be machined at a time, and a plurality of flange faces, a boss, a water line and the outer circle can be machined by means of the boring cutter drive mechanism.

Owner:SHENYANG NORTH SPECIAL MACHINE TOOL DESIGN INST

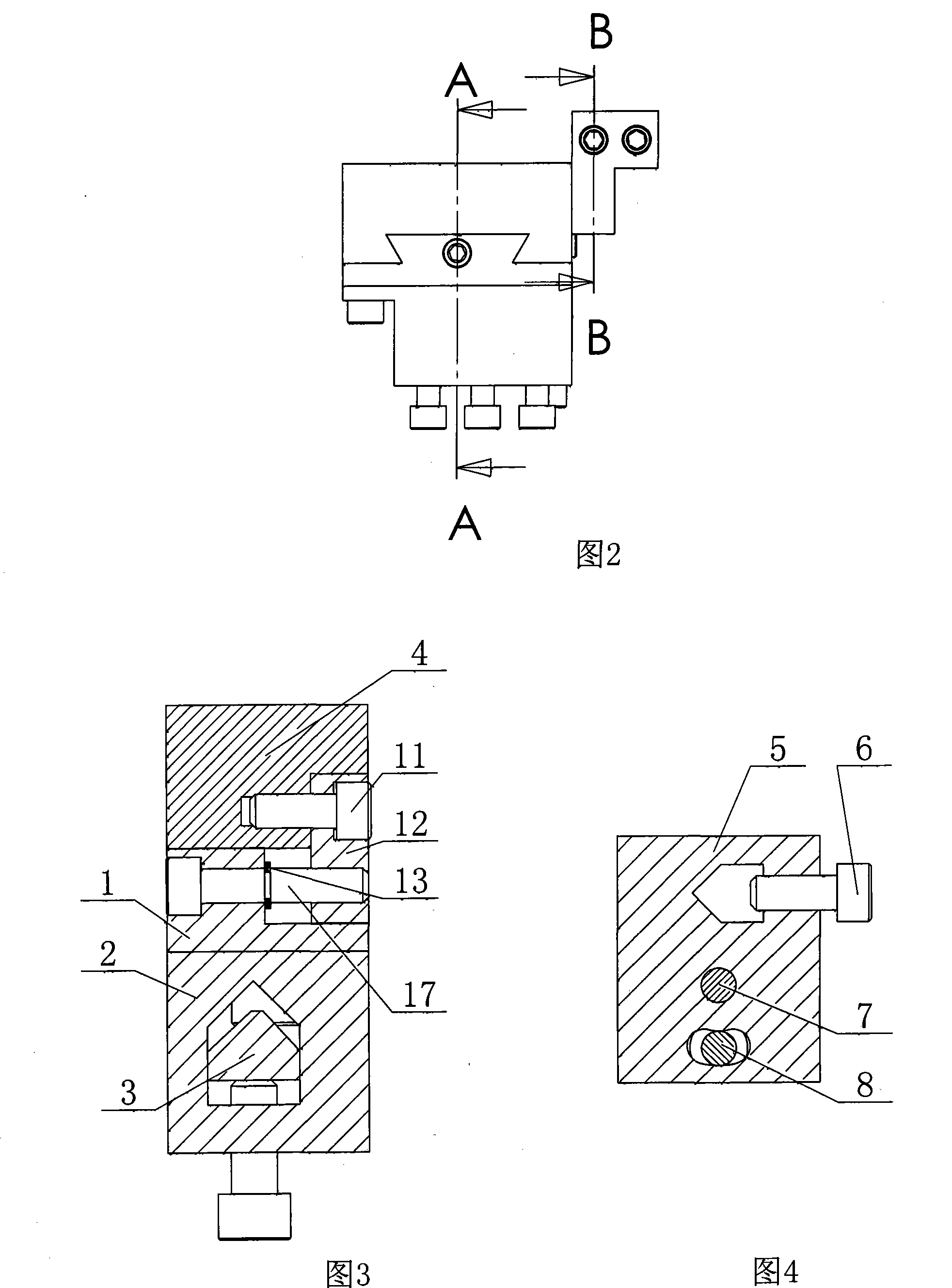

Adjustable tool rest drill clamp of digital control lathes

InactiveCN101219484ARealize automatic drillingRealize functionTool holdersAttachable boring/drilling devicesNumerical controlEngineering

The invention relates to a drill point of a tool carrier of an adjustable numerical control lathe, which comprises a drill sleeve, a sliding block, a fastening block, central drill sleeve, which is characterized in that: the fastening block is provided with concave dovetail slot matching with convex dovetail slot of the sliding block; the bottoms of the concave and convex dovetails are provided with panel board groove for installing panel board; the drill sleeve and sliding block are fastened by bolts; central line of the drill sleeve is horizontally provided with a V-shaped groove matching with a drill head and V-shaped block; the drill head is fastened by bolts; the central drill sleeve is connected to a fastening block using bolts. The invention has the advantages of simple structure, two knife position being provided with a clamping apparatuses, drill head and central drill or cutter knife being capable of arranging at the same time, having height and level adjustment function, high precision, convenient use, realizing numerical control and automatically drilling and reaming function and high production efficiency.

Owner:广西达业科技有限公司

Method for machining equated holes of large-sized rotating member by gear hobbing machine

InactiveCN101653839AReduce manufacturing costHigh indexing accuracyAttachable boring/drilling devicesHobbing

The invention relates to a method for machining equated holes of a large-sized rotating member by a gear hobbing machine. In the method, the gear hobbing machine is provided with a boring power head,the boring power head is utilized to machine the equated holes of the large-sized rotating member, and after centering and leveling, a position of a boring bar is centered on the spherical outside surface of the rotating member according to pitch circle scribing of the equated holes of the large-sized rotating member scribed by a vertical lathe so as to ensure that the axis of the boring bar is overlapped with the axes of the equated holes; and the boring power head performs rough machining and finishing on the equated holes. The method has the advantages of convenient operation, high machining accuracy and low manufacturing cost.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

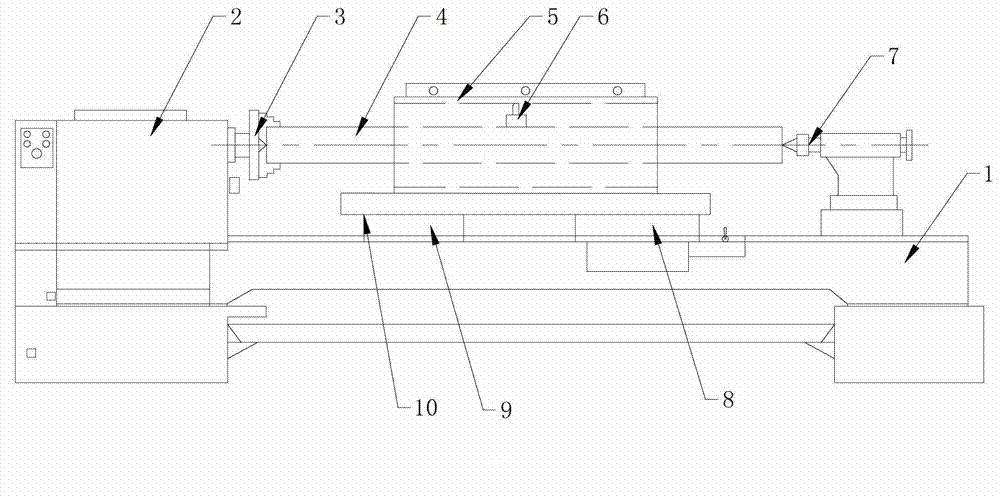

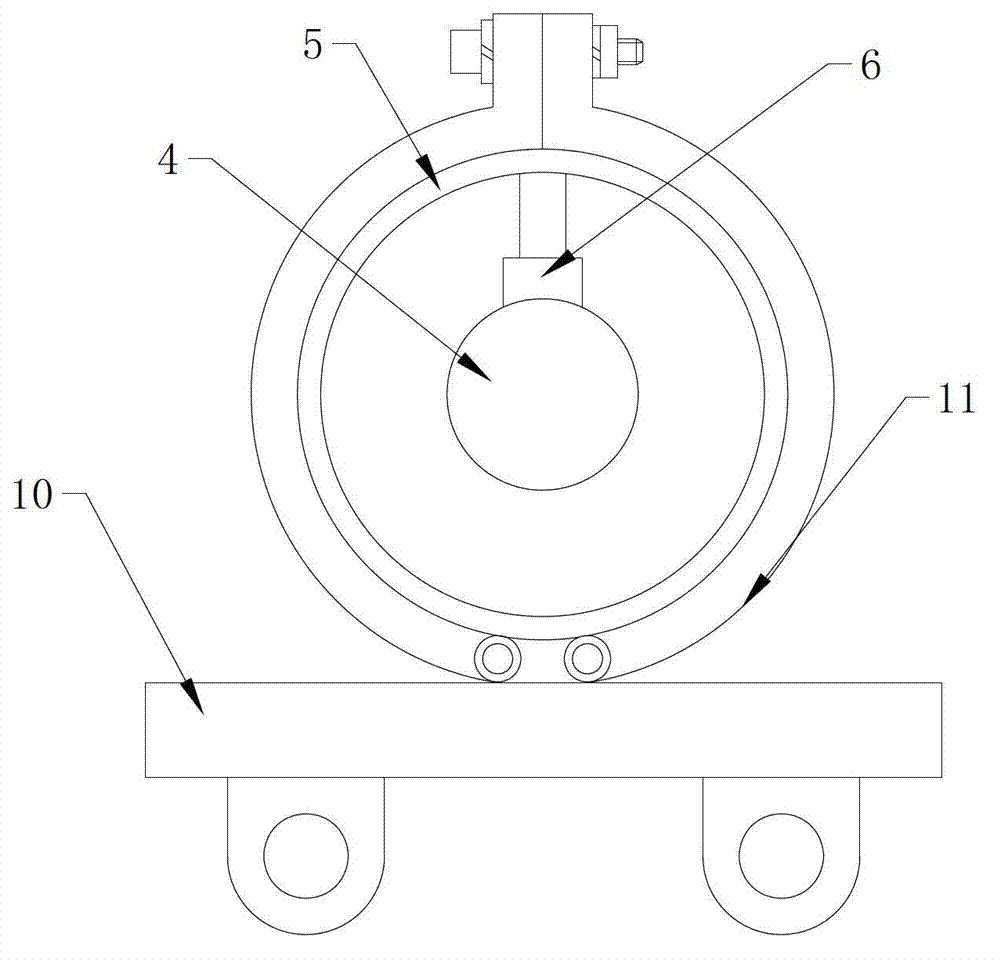

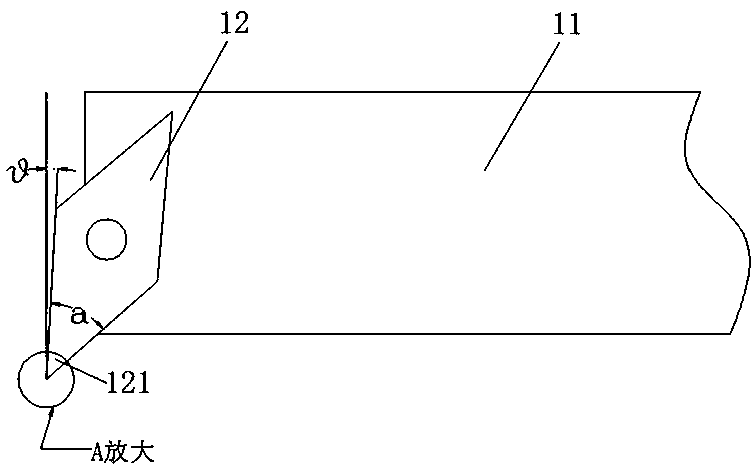

Boring machine for inner wall of drying drum

InactiveCN102861936AReplace at any timeReduce output powerBoring barsPositioning apparatusEngineeringTailstock

The invention discloses a boring machine for the inner wall of a drying drum. The boring machine comprises a base, and a head and a tailstock which are installed on the base. A chuck driven by a main power device is installed on the head, a centre is installed on the tailstock, the centre and the chuck are arranged coaxially, a driving supporting seat and a driven supporting seat are installed between the head and the tailstock on the base in a sliding mode, the driving supporting seat is driven by an auxiliary power device to slide, fixing plates are arranged on the driving supporting seat and the driven supporting seat, a fastening device for fixing the drying drum is installed on each fixing plate, a boring bar is installed between the chuck and the centre, one end of the boring bar is clamped on the chuck, the other end of the boring bar is tightened by the centre, and a boring tool assembly is installed on the boring bar. According to the boring machine, through improvement of the original common centre lathe, not only corresponding boring bars can be selected according to the inner diameter of the drying drum and requirements for the machining accuracy, but also power output of the main power device can be reduced, energy resources are saved, and the service life of the machine is prolonged.

Owner:JIANGSU HUAXIN HEAVY IND EQUIP

Aluminum alloy inner hole ultra-precise machining tool and machining method

PendingCN108994352ASolve the problem of resonanceNot easy to scratchTransportation and packagingBoring/drilling machinesMicrometerRound bar

The invention discloses an aluminum alloy inner hole ultra-precise machining tool and machining method. The aluminum alloy inner hole ultra-precise machining tool comprises a round bar tool handle made of a hard alloy, and a blade. The tool nose part of the blade is cut to add a sleeking edge. The side face included angle alpha of the sleeking edge is 85 degrees, the front face included angle betaof the sleeking edge is 84 degrees, the top rake theta of the sleeking edge is 7 degrees, the tool nose of the sleeking edge is of a small arc structure, the structure is practical in function, workpieces are not likely to be scratched, and the precision of the machined workpieces is effectively improved. The aluminum alloy inner hole ultra-precise machining method adopting the aluminum alloy inner hole ultra-precise machining tool includes the steps of inner hole rough boring machining, semi-fine boring machining and fine boring machining, the workpiece rotation speed, the boring cutter feedrate and the cutting depth are stipulated in each step, it can be ensured that the aluminum alloy inner hole roughness is not larger than 0.2 micrometer, and ultra-precise machining is achieved. Thealuminum alloy inner hole ultra-precise machining tool and the aluminum alloy inner hole ultra-precise machining method are easy to operate, high in machining precision and high in machining efficiency, the machining cost is reduced, and practicability is high.

Owner:GUIYANG BOYA MACHINERY MFG

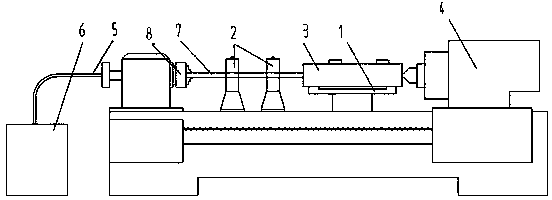

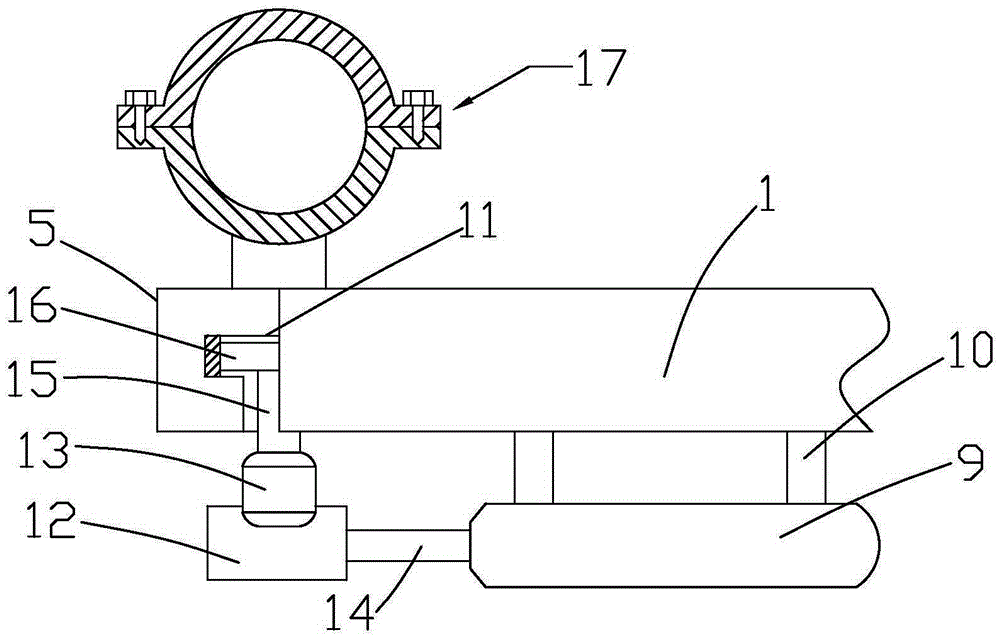

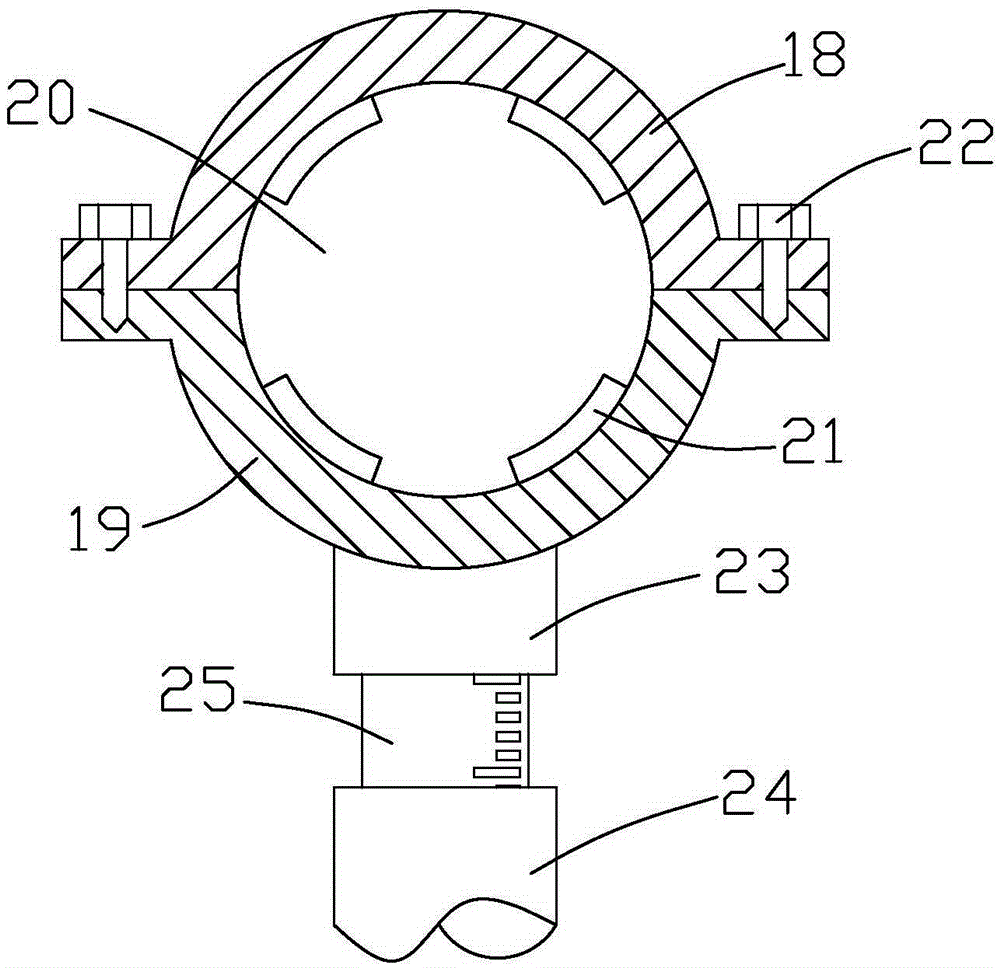

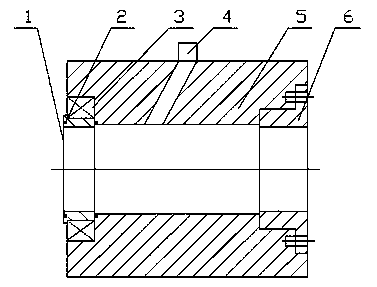

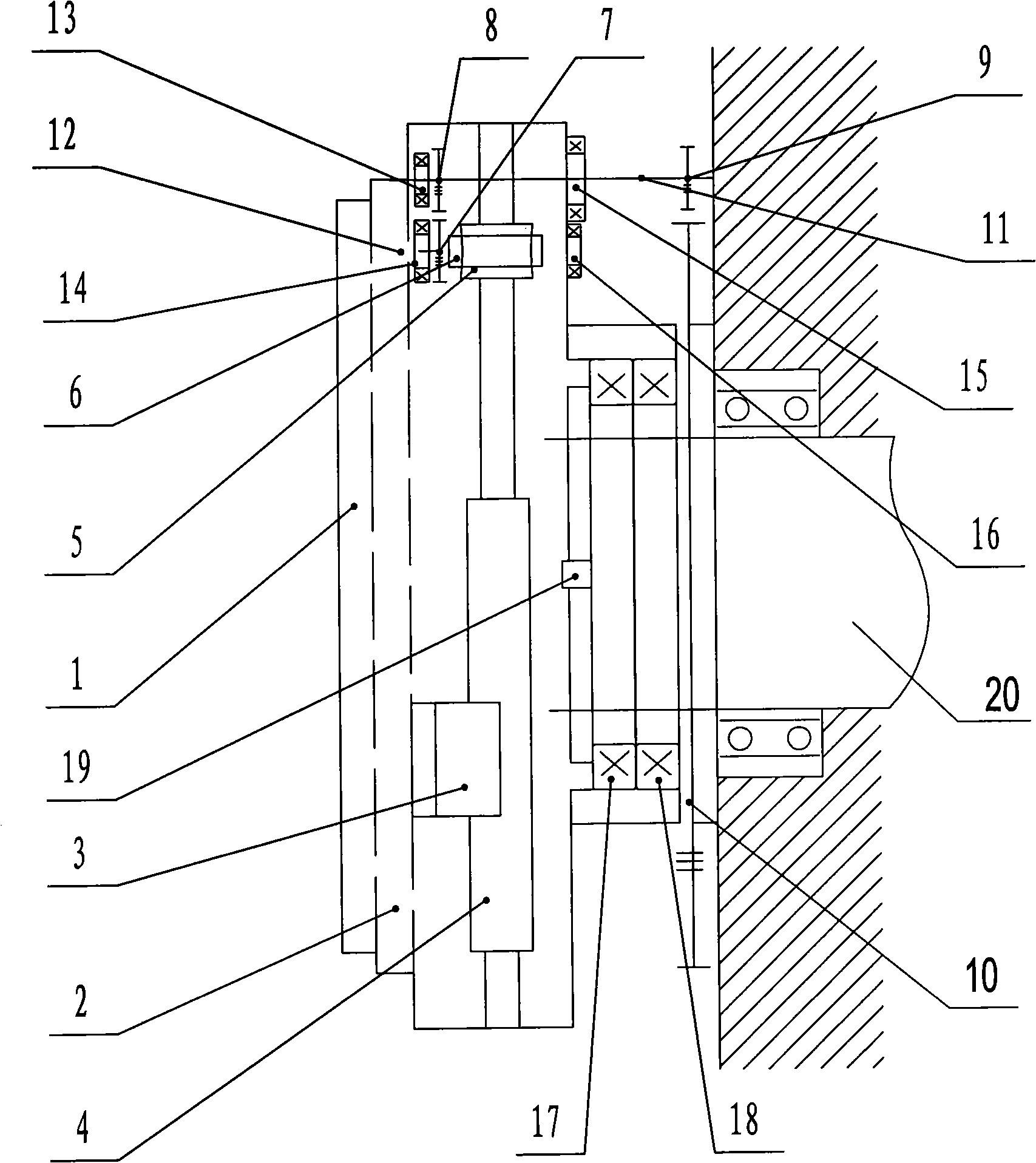

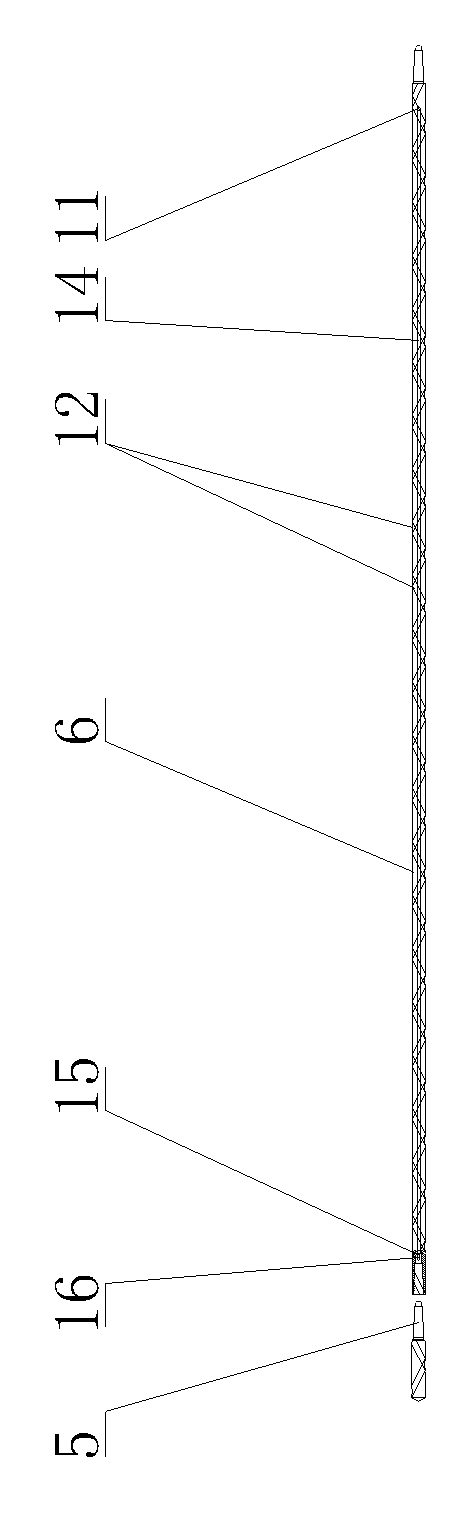

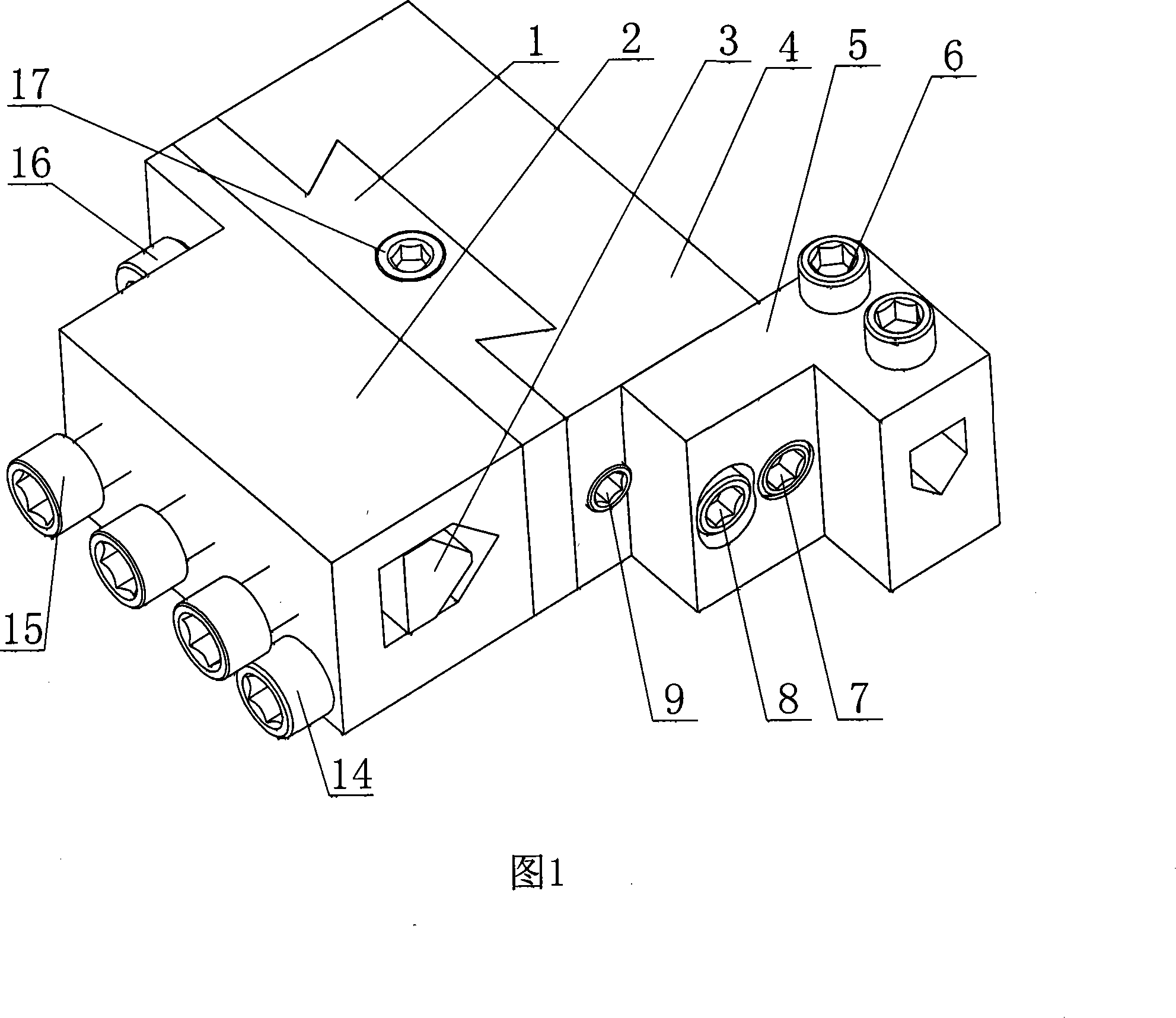

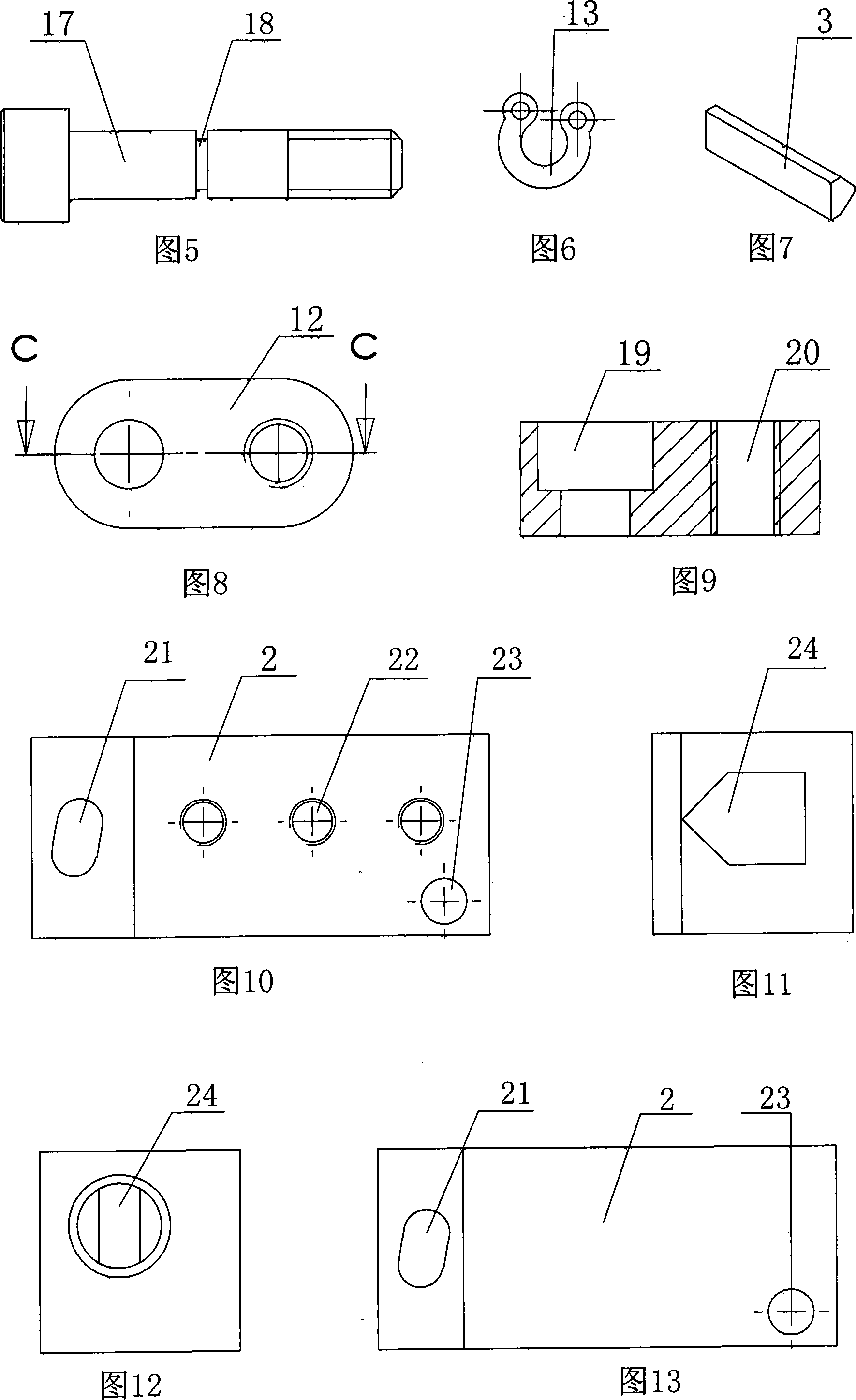

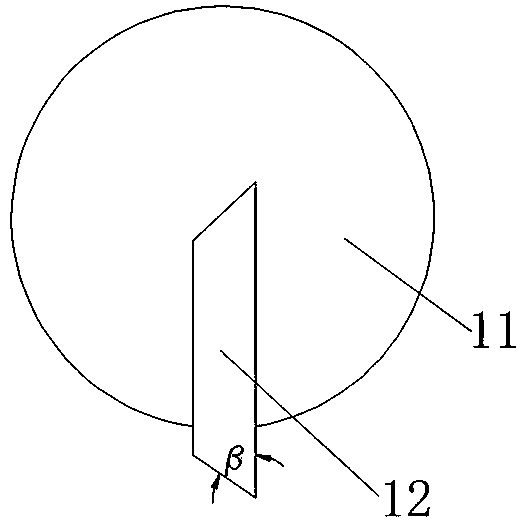

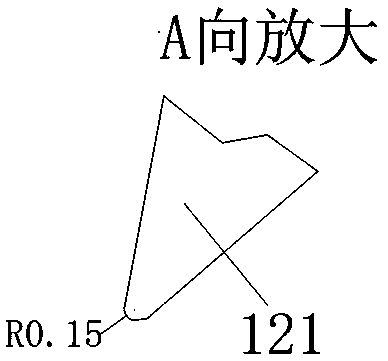

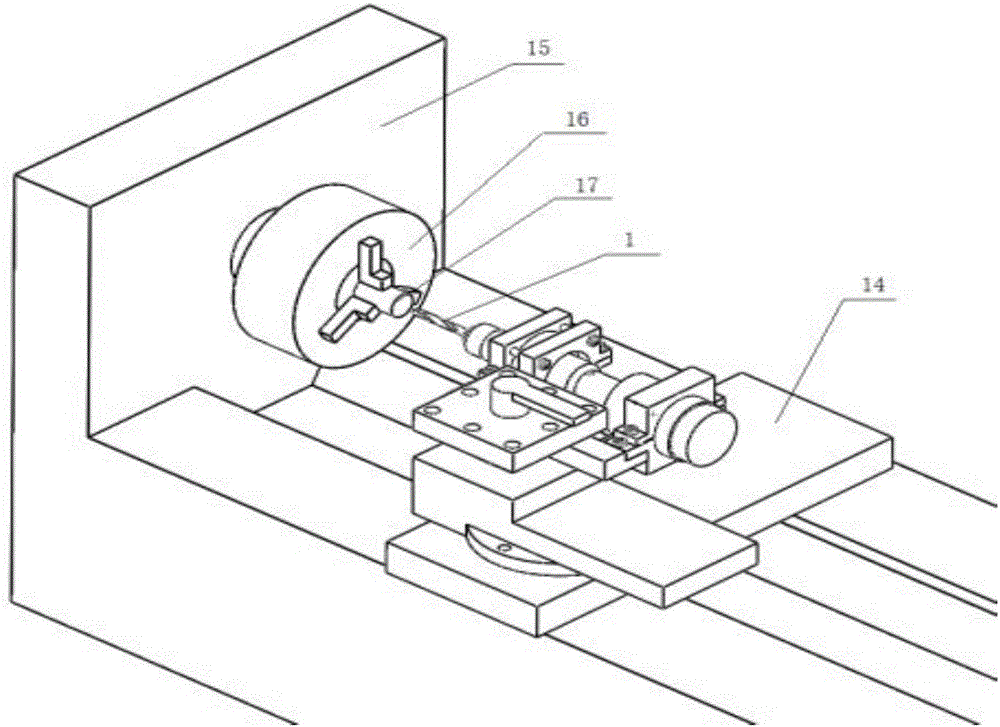

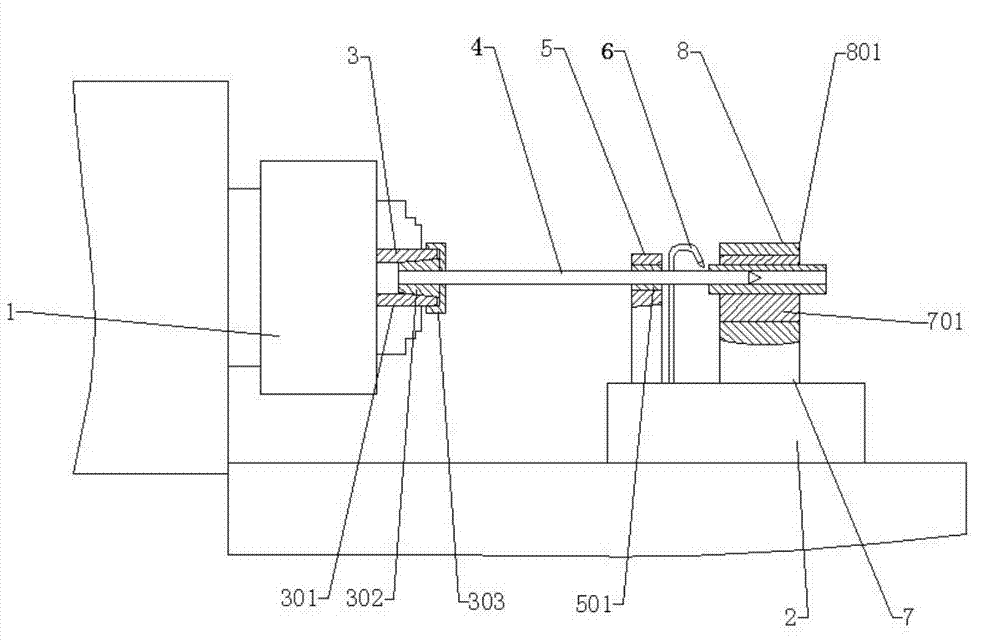

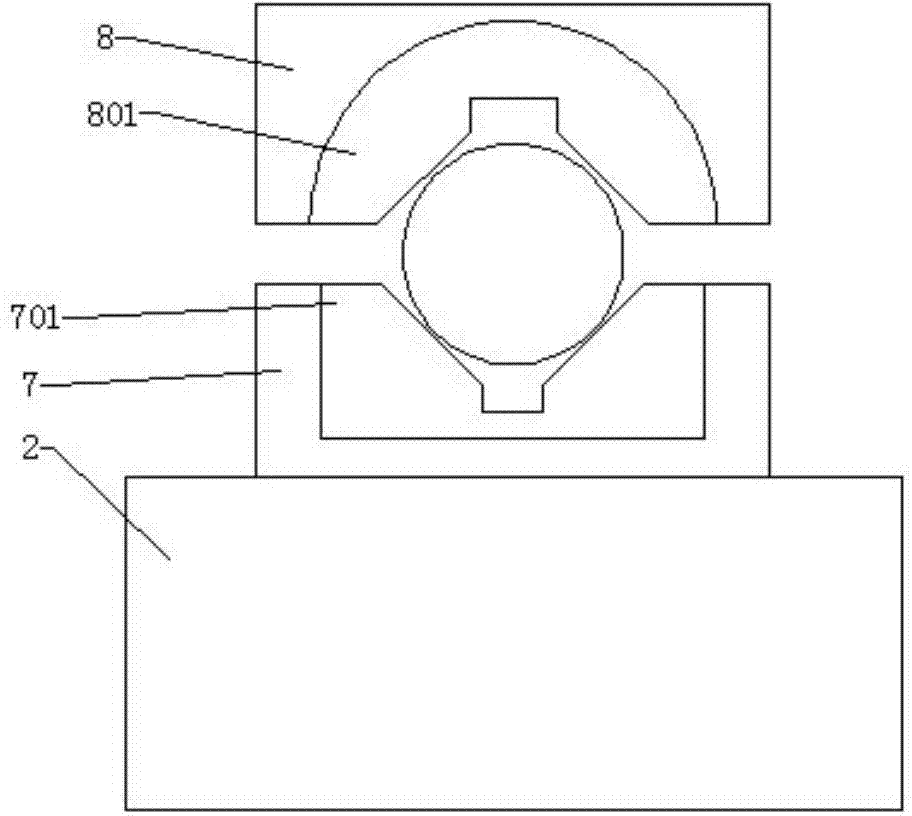

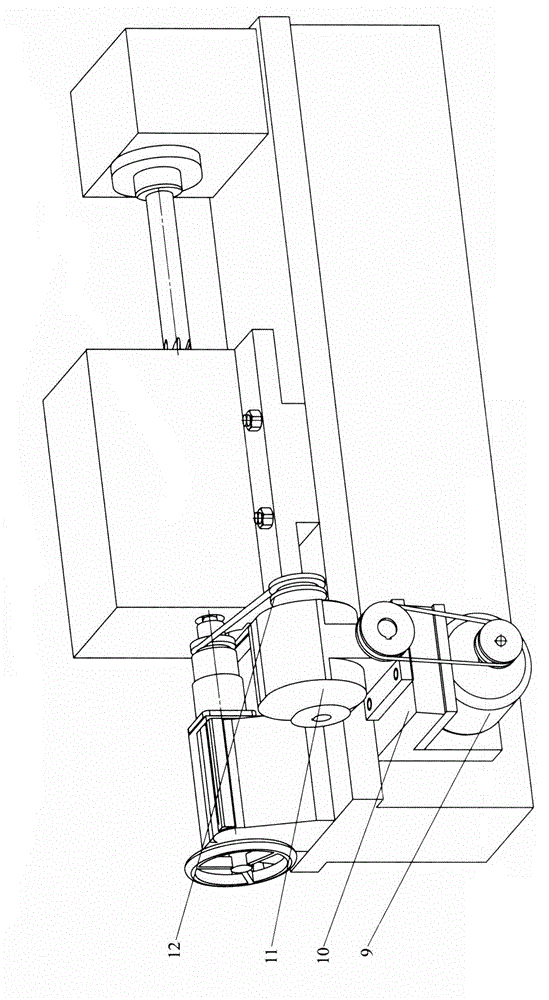

Axial ultrasonic vibration drilling device fixed by lathe carriage

InactiveCN106424836ASimple structureEasy to installMechanical vibrations separationBoring/drilling componentsTransducerEngineering

Provided is an axial ultrasonic vibration drilling device fixed by a lathe carriage. The axial ultrasonic vibration drilling device fixed by the lathe carriage comprises a drill, an amplitude-change pole, a transducer, a beam hanging type fixed device and an ultrasonic generator electrically connected to the transducer. The beam hanging type fixed device comprises a hanging beam fixed on the lathe carriage and a front pressing plate and a rear pressing plate, wherein the front pressing plate and the rear pressing plate are fixedly connected to the hanging beam, the front pressing plate fixes the front end of the amplitude-change pole, the rear pressing plate fixes the transducer, a fixed pressing plate fixes the middle part of the amplitude-change pole, and the front pressing plate, the rear pressing plate and the fixed pressing plate are all divided into upper and lower two parts and are assembled through bolts. Compared with a drilling device achieved on a drilling machine, there is no need to conduct any special refit on a machine tool; in addition, a method of workpiece revolution is adopted, there is no need to use assembly units such as a ring manifold or a carbon brush, thus the structure is simplified, the cost is saved, and the axial ultrasonic vibration drilling device fixed by the lathe carriage is convenient to disassemble and assemble and is beneficial to a proceeding of ultrasonic vibration drilling.

Owner:NORTHEASTERN UNIV

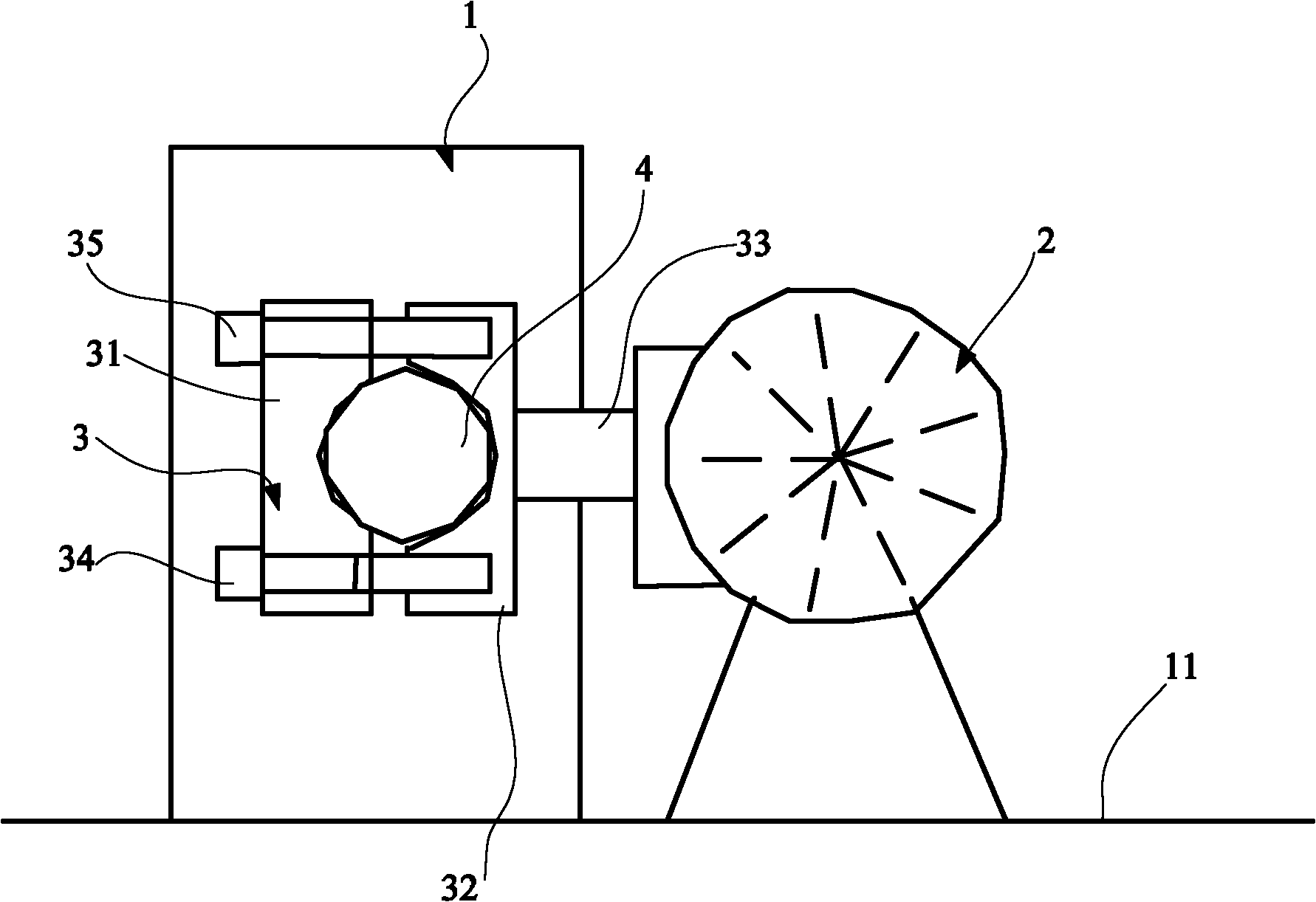

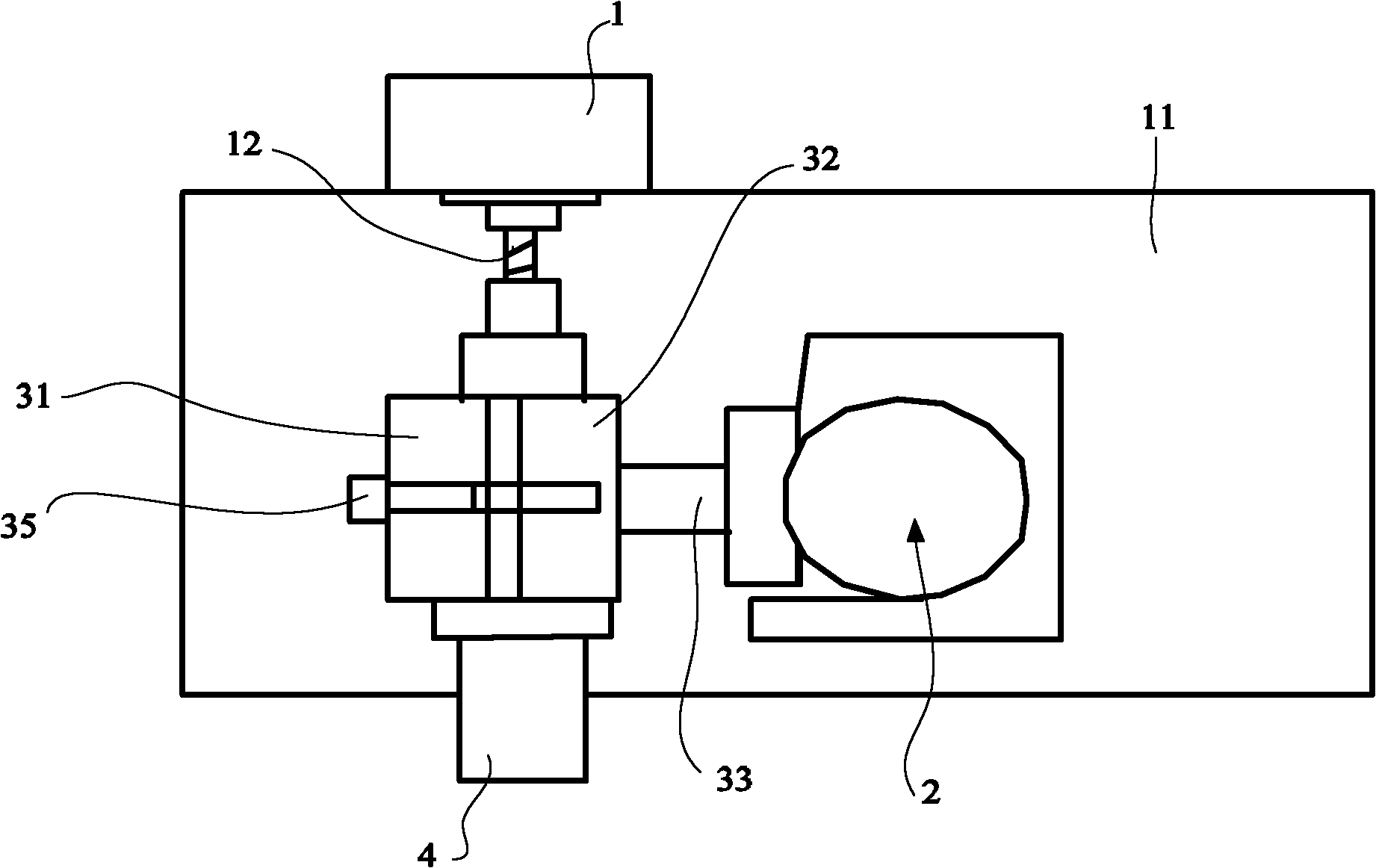

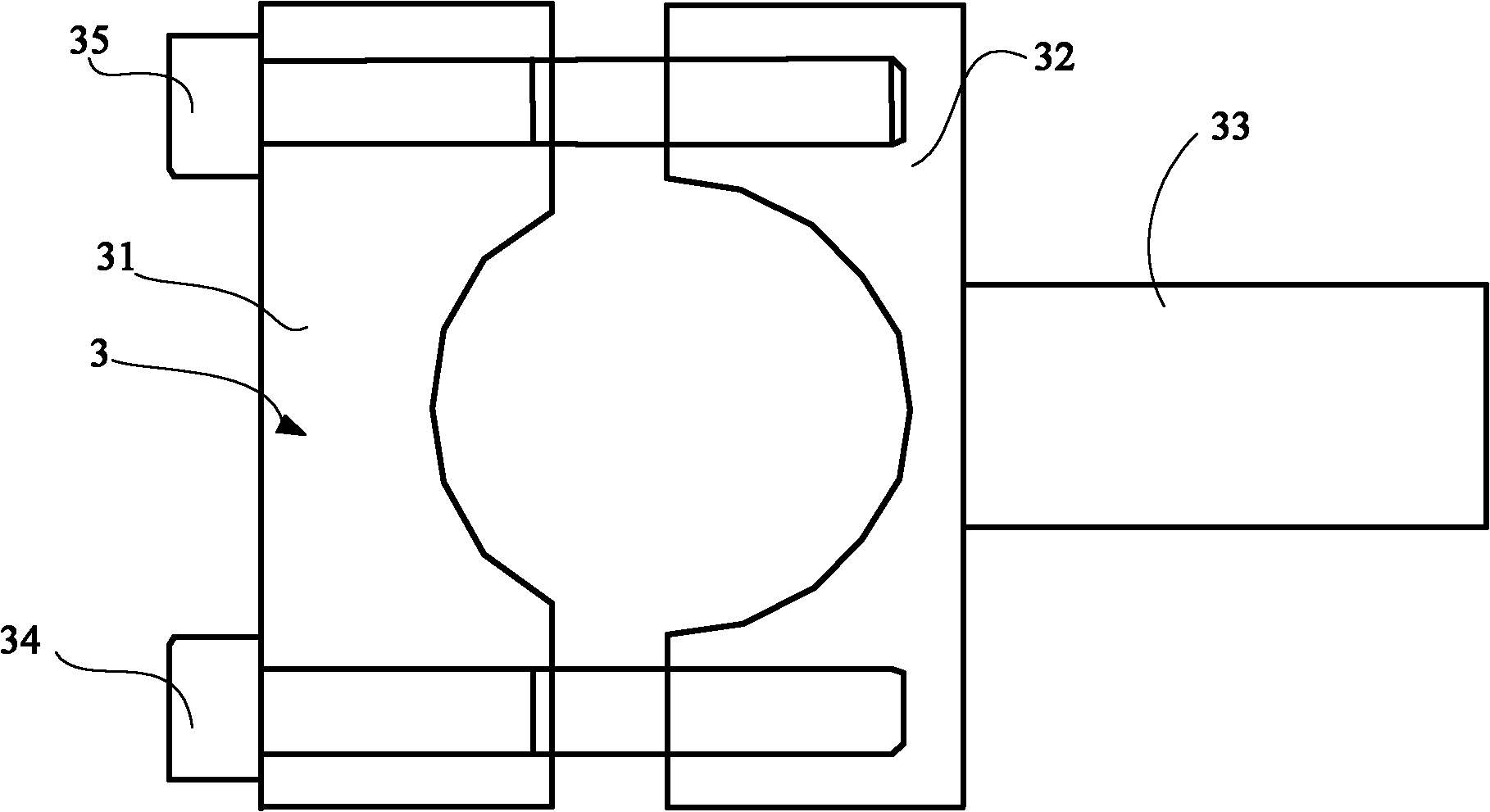

Central hole processing system and processing method of eccentric shaft

InactiveCN102039437ARealize positioning installationSolve the clamping problemPrecision positioning equipmentPositioning apparatusPulp and paper industryMachining system

The embodiment of the invention discloses a central hole processing system of an eccentric shaft, comprising a horizontal type milling machine, an indexing head and an eccentric shaft clamp, wherein a three-jaw chunk of the horizontal type milling machine is provided with a drilling bit; the indexing head is arranged on a working platform of the horizontal type milling machine; and the eccentric shaft clamp is fixedly connected with the indexing head. In the central hole processing system, the indexing head is arranged on the horizontal type milling machine and is fixedly connected with the eccentric shaft clamp for clamping the eccentric shaft, the positioning and the installation of the eccentric shaft on the working platform of the horizontal type milling machine are realized, and the processing of the central holes at the two ends of the eccentric shaft is realized by rotation of the indexing head. By utilizing the processing system provided by the invention, the problems that when the eccentric shaft below 600mm is processed on a boring machine in the prior art, the size of the working platform of the boring machine is larger, the clamping, the positioning and the alignment of a workpiece are difficult.

Owner:LAIWU IRON & STEEL GRP

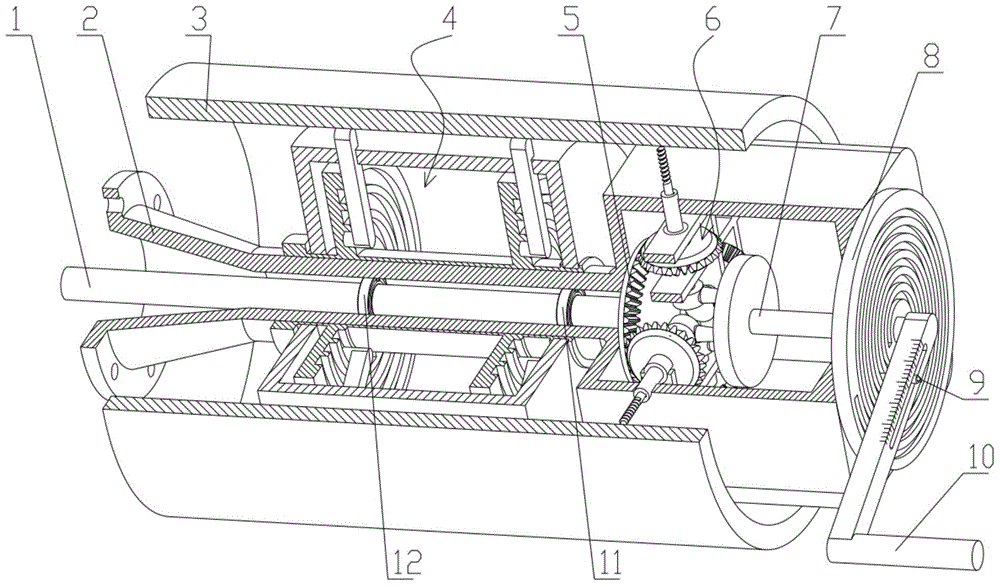

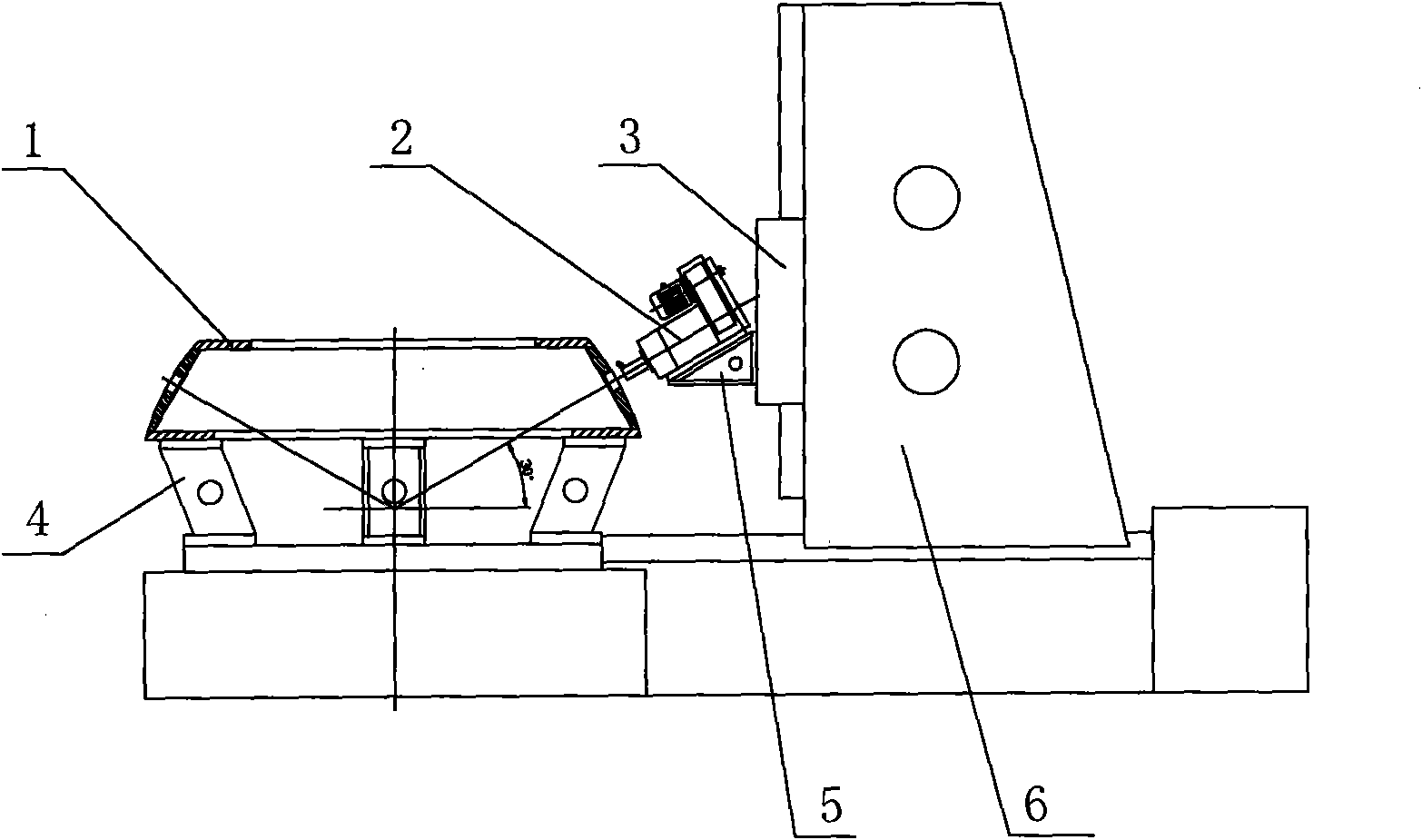

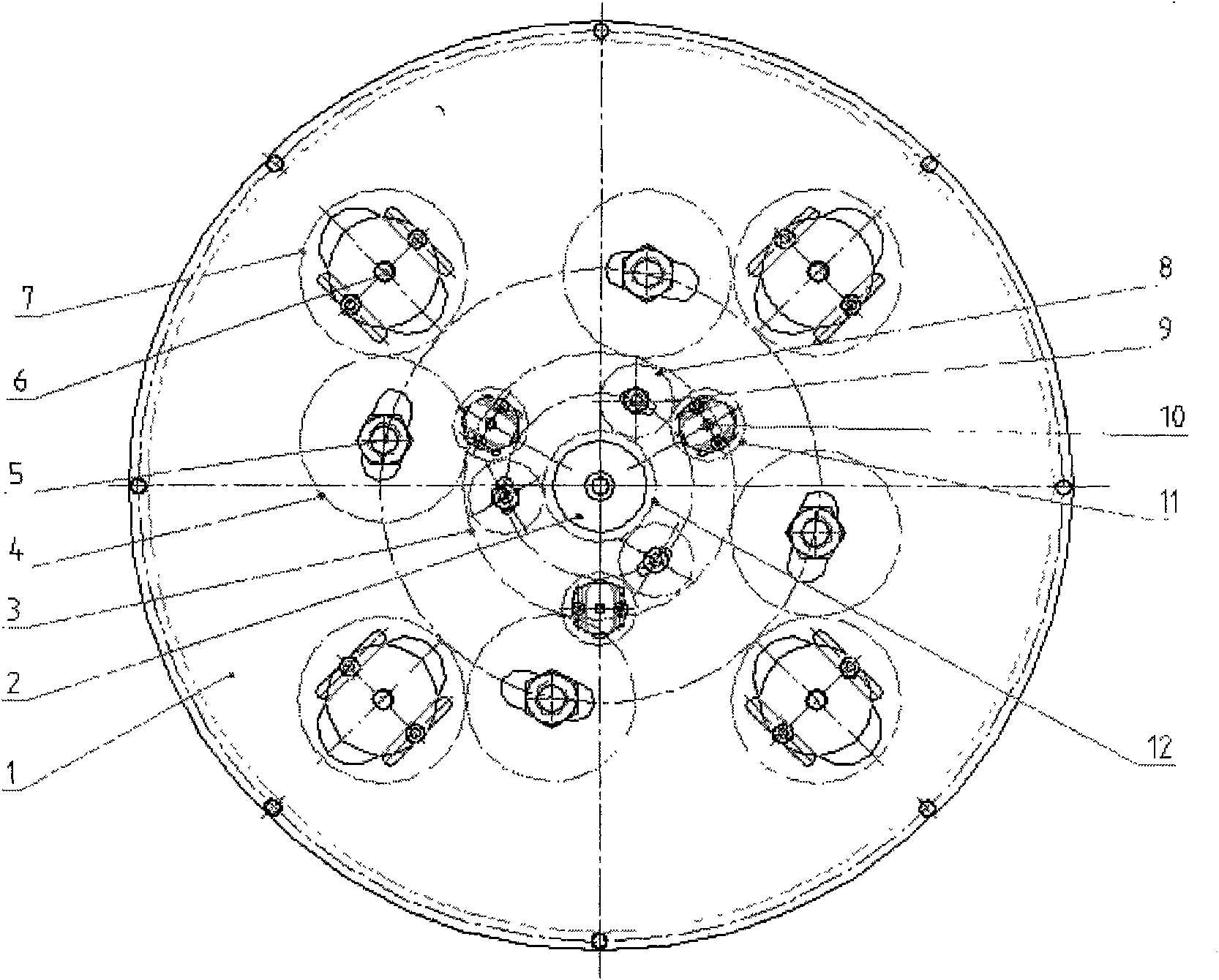

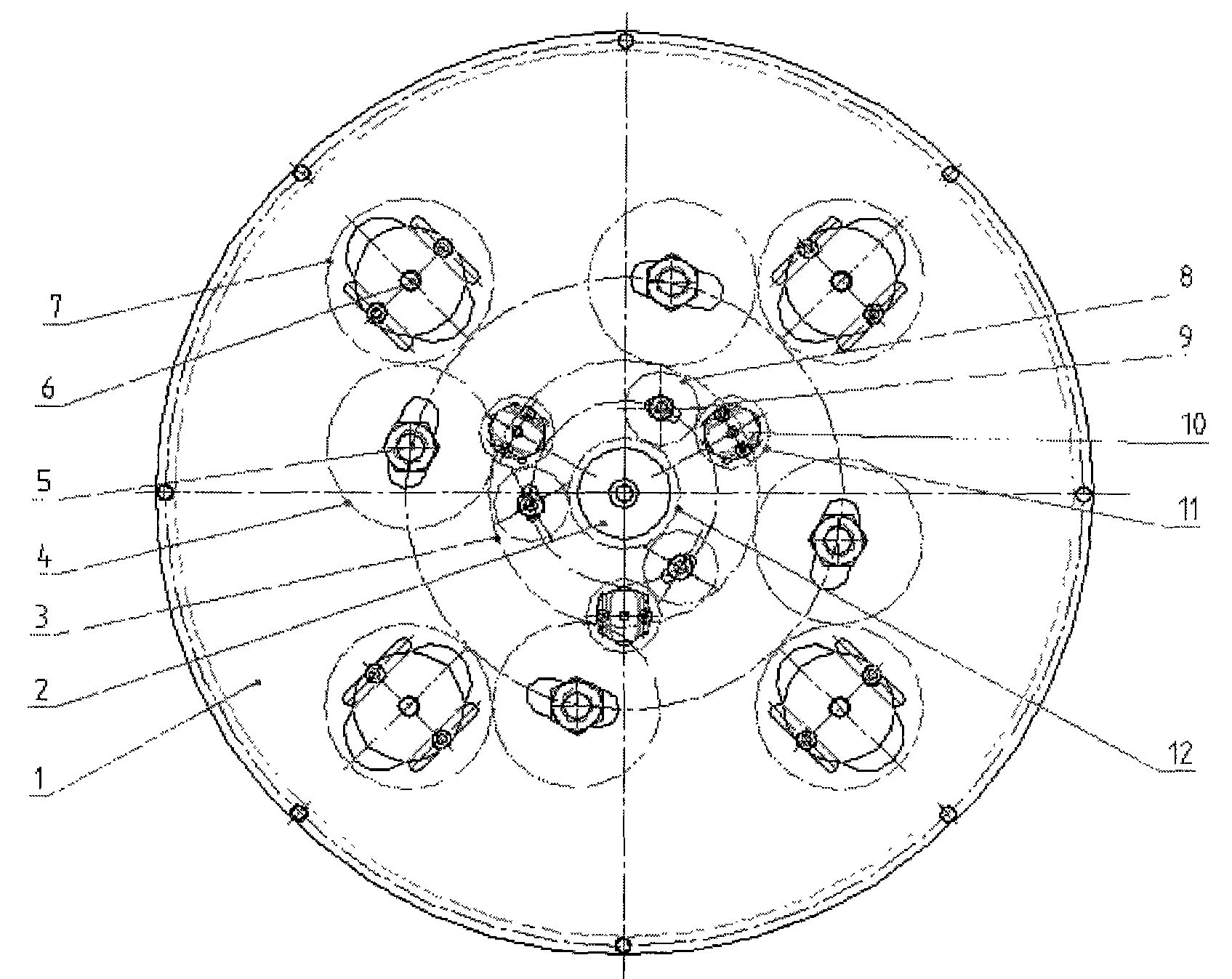

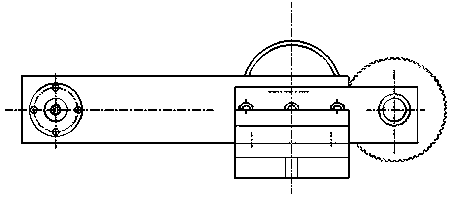

Drilling device for end cover of motor

InactiveCN101987372ASimple structureEasy to operateBoring/drilling componentsAttachable boring/drilling devicesFailure rateEngineering

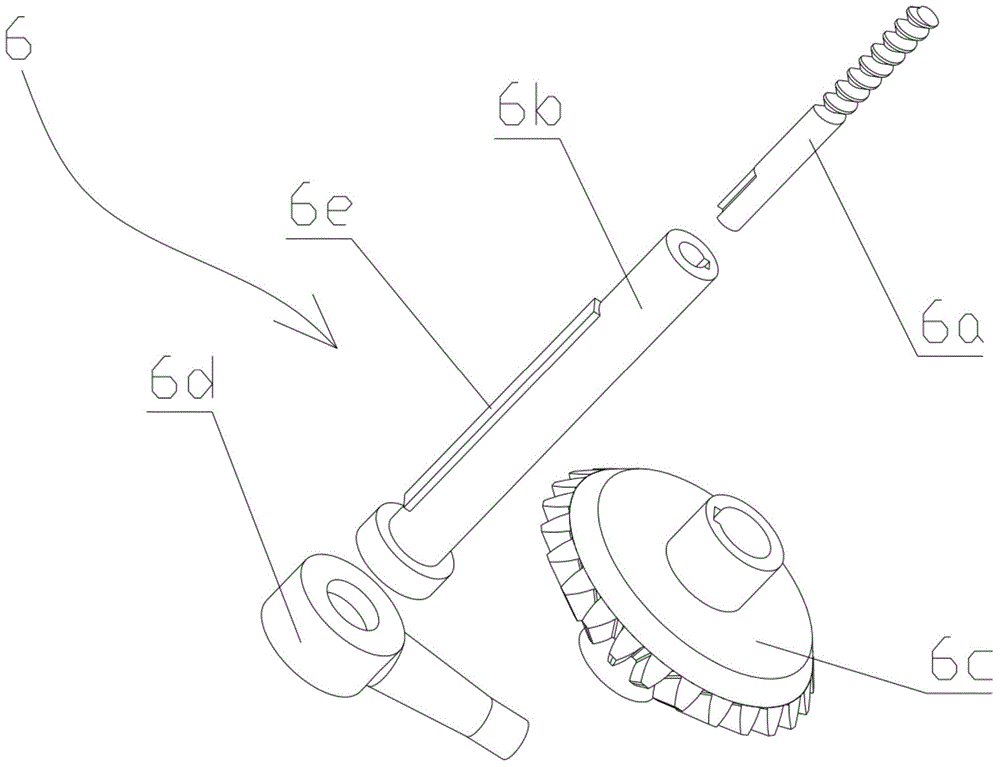

The invention relates to a mounting hole-machining device for the end cover of a motor, comprising a gear box, a master gear shaft, an auxiliary gear shaft, a boundary wheel shaft, a gear, a bearing, a bearing cover and the like. The device is characterized in that the power of the device is supplied by the movement of the master shaft of a common machine lathe, namely the master gear shaft is arranged in the master shaft of the lathe, and a drill sleeve is arranged on the auxiliary gear shaft; the gear on the boundary wheel shaft is simultaneously engaged with the gears of the master shaft and the auxiliary gear shaft; the boundary wheel shaft and the auxiliary gear shaft are manufactured into be in a removable structure; the position of the auxiliary gear shaft can be adjusted by adjusting the position of the boundary wheel shaft so as to reach the process requirements of drilling the end covers with different models; and the essence is that the engagement of the gears is utilized to transmit torque so as to realize the purpose of drilling. The device has the advantages of simple structure, low cost and low failure rate.

Owner:张成

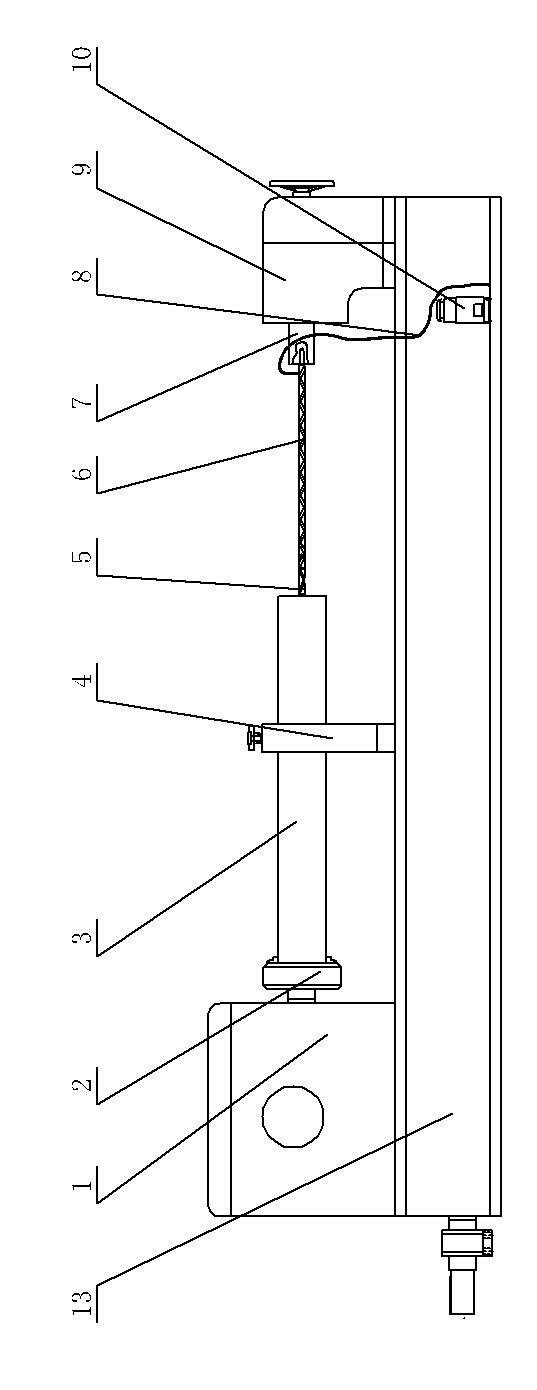

Deep hole drilling device for turning

InactiveCN104493246AAvoid scrappingGuaranteed accuracyFeeding apparatusPositioning apparatusEngineeringHigh pressure water

The invention discloses a deep hole drilling device for turning. The deep hole drilling device for turning comprises a lathe chuck, a tool rest, a clamp, a deep hole drill, a supporting seat, a high-pressure water gun, a positioning seat and a pressure block. The clamp is positioned at the center of the front end of the lathe chuck, and the clamp and the lathe chuck are connected movably; the deep hole drill is positioned at the inner center of the clamp, and the deep hole drill and the clamp are in movable connection; the supporting seat is positioned at the center of the upper right end of the tool rest, and the supporting seat and the tool rest are in threaded connection; the high-pressure water gun is positioned on the rear side of the upper-end center of the tool rest, and the high-pressure water gun and the tool rest are in threaded connection; the positioning seat is positioned at the center of the upper end of the tool rest, and the positioning seat and the tool rest are in threaded connection; the pressure block is positioned at the center of the upper end of the positioning seat, and the pressure block and the positioning seat are in threaded connection. Compared with the prior art, the deep hole drilling device for turning has the advantages that the deep hole drill is clamped on a lathe spindle by the aid of the clamp and is supported and kept linear by the supporting seat, and the deep hole drill is slowly fed for drilling holes by the aid of the tool rest, so that precision is guaranteed, workpiece scrappage is avoided, and production efficiency is improved.

Owner:池州共康汽车零部件有限公司

Live tooling systems for machine tools

In conventional ram-driven presses, the downward stroke of the ram into a tool causes acceleration of the tool, thereby facilitating an operation on a workpiece by the tip of the tool. While the ram stroke is found to impart sufficient dynamic energy to the tool to facilitate the necessitated operation by the tool tip, there are other more efficient, and in turn, more effective, means and methods of actuating the tool tip, with such means and methods being facilitated from energy derived from the tool's acceleration or from energy from other external sources.

Owner:WILSON TOOL INT

Radial drilling machine capable of conducting boring processing

InactiveCN1544190AEasy to processExpand the scope of processingBoring/drilling machinesAttachable boring/drilling devicesEngineeringKnife blades

The invention is a rocker drill press which can make boring processing, including machine body, rocker, electric machine, spindle support and spindle, where the rocker is covered on the body, able to rotate round the central axis of the body and moves up and down along the central axis, the spindle support is placed on the rocker and able to transversely move in guidance made in the rocker, the electric machine is fixed on the spindle support, there is a spindle driven by the electric machine to rotate and move up and down at the same time, set in the spindle support, and its characteristic: the spindle is connected with a boring bar shaft, which is covered with a case positioned by positioning component and there is a boring cutter combined block, on which the cutter blades can shift radially with the movement of the boring bar shaft, set on the front end of the case. It makes full use of the character of convenient and flexible processing of the rocker drill press and designs a special boring clamp according to the movement characteristic of the drill press, reasonable and convenient to operate, and achieves the design purpose of making inner groove in bearing hole of the box body on the rocker drill press and at the same time can enhance processing ability of the rocker drill press and widening its processing range.

Owner:SANY AUTOMOBILE MFG CO LTD

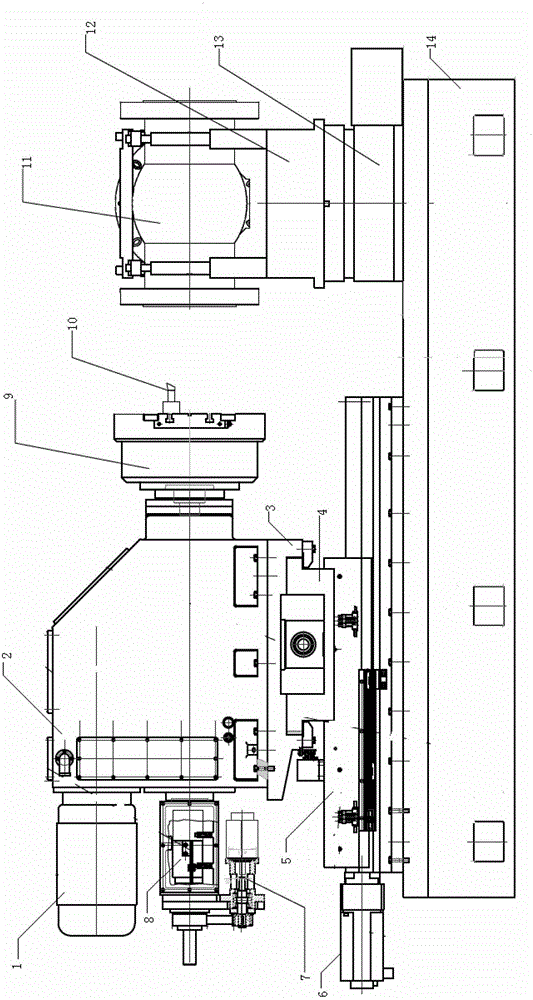

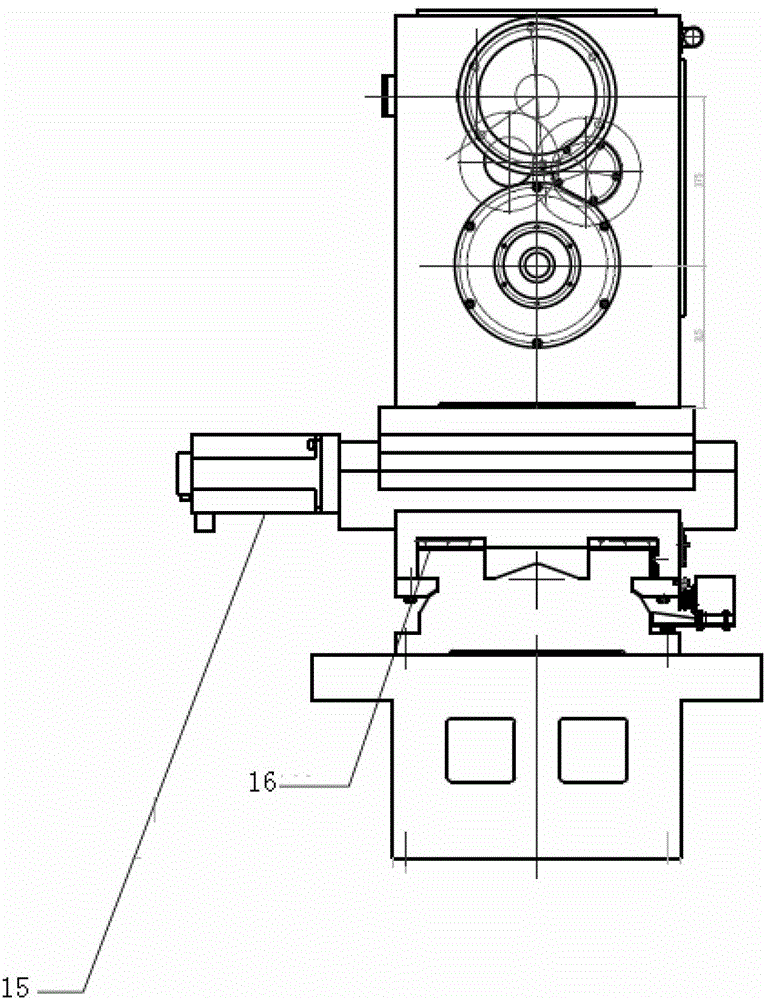

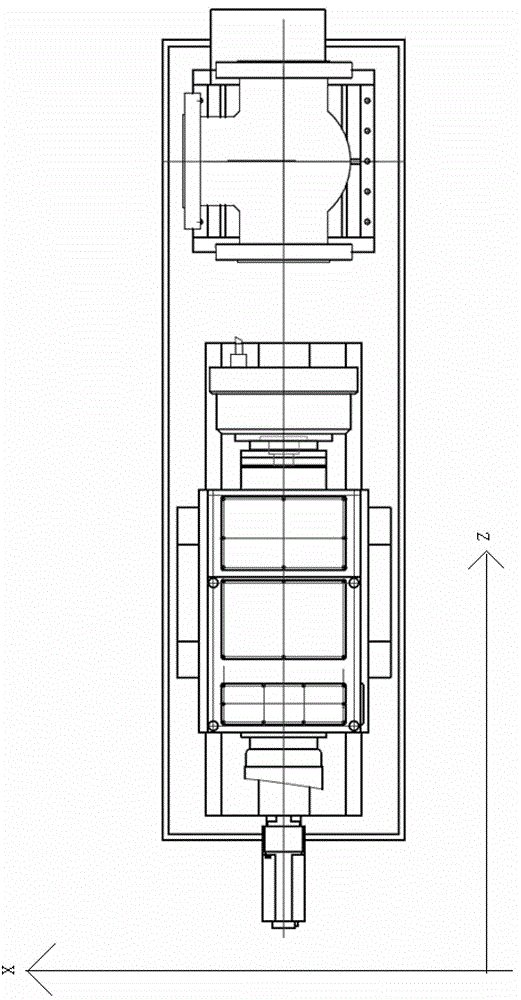

One-lathe double-end hole boring machine

InactiveCN104625154AImprove machining accuracyImprove processing efficiencyBoring/drilling machinesAttachable boring/drilling devicesReducerTailstock

The invention discloses a one-lathe double-end hole boring machine. The one-lathe double-end hole boring machine comprises a machine frame and further comprises a lathe tailstock, a boring frame shaft, a shaft fixing sleeve, a boring cutter holder, a boring cutter, a clamp, a two-hole boring cutter, a long boring rod and a spindle box which are sequentially arranged on the machine frame from left to right, wherein the shaft fixing sleeve installs the boring frame shaft on the lathe tailstock; the left end of the boring cutter holder is rotationally connected with the right end of the boring cutter shaft; the middle of the boring cutter holder is a drive portion; the boring cutter is connected to the right end of the boring cutter holder; the spindle box is located at the right end of the machine frame; the left end of the spindle box is connected with the long boring rod; the left end of the long boring rod is fixedly connected with the two-hole boring cutter; the clamp can slide along a guide rail on the machine frame; a speed reducer driven by a motor is arranged at the left end of the machine frame and provided with a belt wheel; the belt wheel and the rotary portion of the boring cutter holder are in transmission through a belt. The efficiency is greatly improved, and the space is saved.

Owner:CHONGQING SANGUI MACHINERY MFG

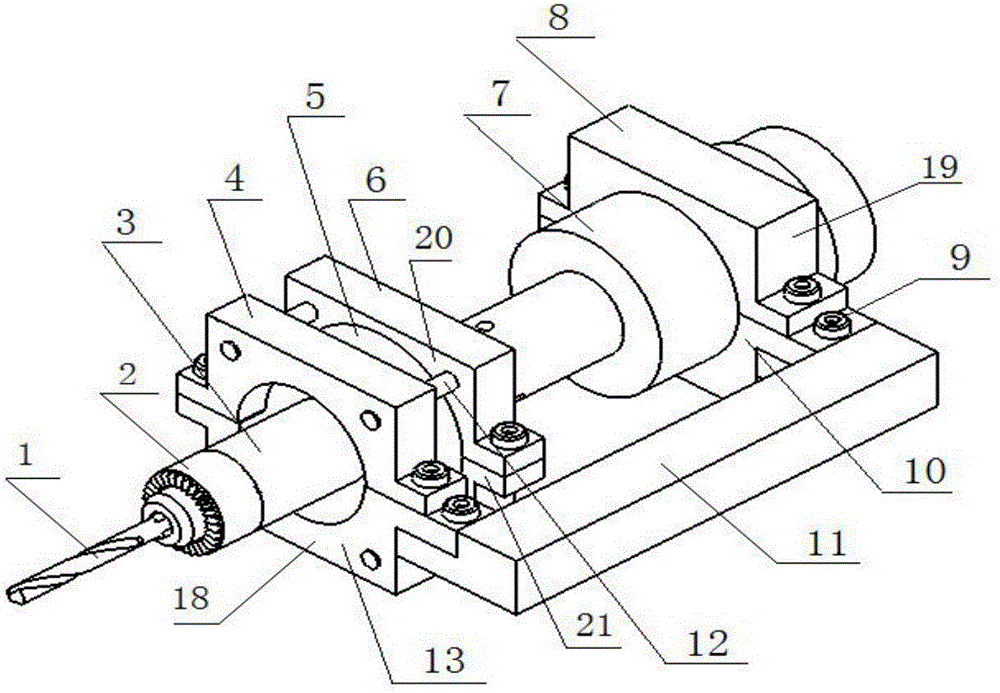

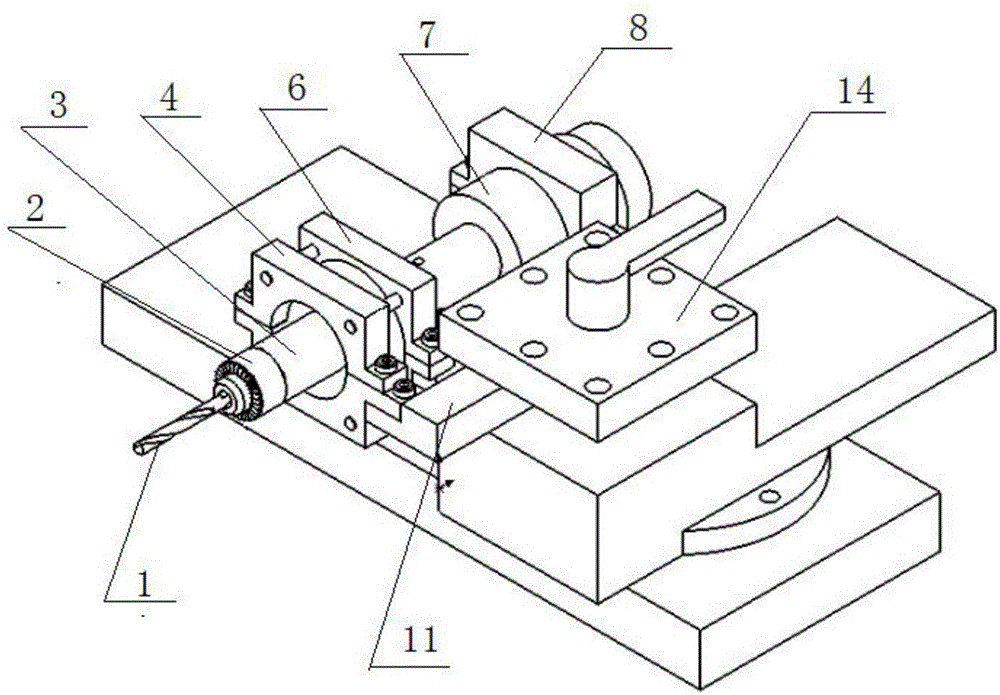

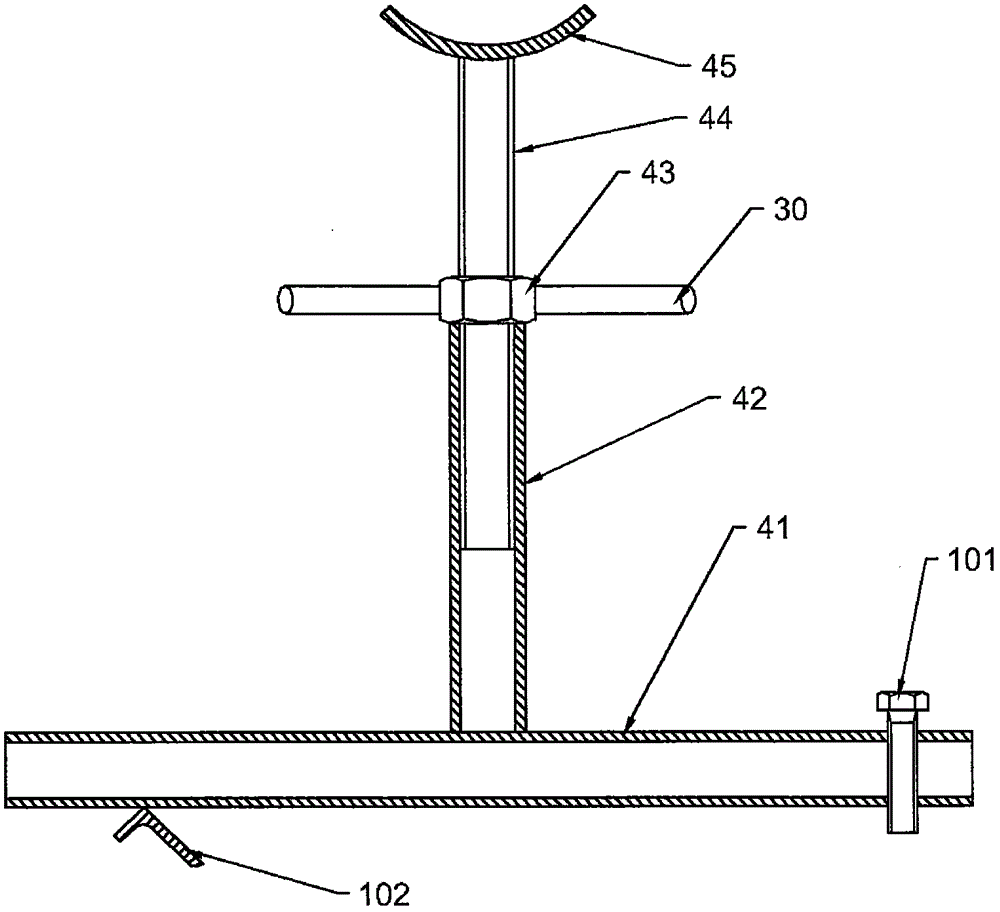

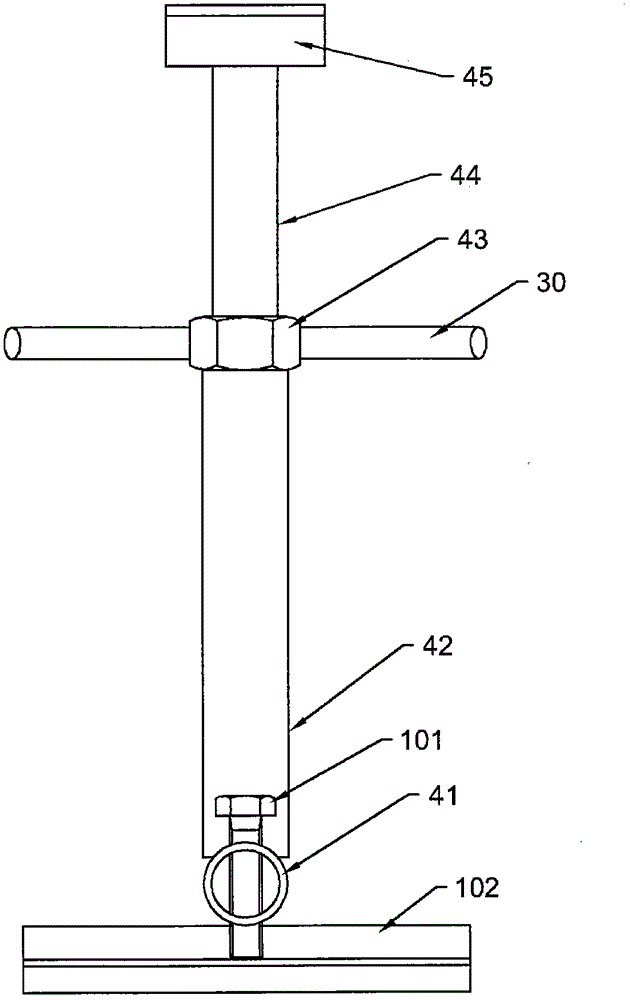

Shaft processing device

InactiveCN104907603AReduce labor intensityImprove processing qualityFeeding apparatusBoring/drilling componentsEngineeringUltimate tensile strength

The invention discloses a shaft processing device. The shaft processing device comprises a rack. A chuck is arranged at the left side above the rack, a shaft bracket is arranged at the right side of the chuck, and a processing device is arranged at the right side of the shaft bracket. The shaft bracket comprises a bracket base. A guide sleeve stretching vertically is arranged on the bracket base. A supporting screw rod is assembled in the guide sleeve in a guiding and sliding mode, and an arc-shaped supporting plate used for cooperating with the peripheral face of the shaft is arranged at the upper end of the supporting screw rod. The processing device comprises a stepping motor, a numerical control system, a connecting bolt, a shaft and a tailstock. A drill chuck is arranged at the left end of the screw rod, and a straight shank drill is connected to the drill chuck. According to the shaft processing device, the motor is used as a power source, deep hole machining by a machine tool is realized, a tailstock sleeve handwheel is replaced, the processing quality and the productivity are improved, the labor intensity of a worker is relived greatly at the same time, the shaft bracket is arranged on the machine body, the structure is simple, manufacturing is convenient, the processing cost is lowered greatly, the processing efficiency is improved, and the a large amount of time is saved.

Owner:何小平

Cutter for processing step hole workpiece on lathe and using method thereof

InactiveCN101758251AIncrease profitImprove processing efficiencyTurning toolsAttachable boring/drilling devicesEngineeringProcessing cost

The invention discloses a cutter for processing a step hole workpiece on a lathe and a using method thereof. The cutter is formed by sequentially integrating a first cutting section, a second cutting section, a third cutting section with maximal diameter, a cutter transition section and a cutter matching section, wherein the first cutting section comprises a first cutting body, two symmetrical first cutting body blades and a first cutting body chip discharge groove; the second cutting section comprises a second cutting body, two symmetrical second cutting body blades and a second cutting body chip discharge groove; the third cutting section comprises a third cutting body, two symmetrical third cutting body blades and a third cutting body chip discharge groove; and the sizes of the first cutting body, the second cutting body and the third cutting body are suitable for a step hole workpiece. The cutter for processing the step hole workpiece on the lathe and the using method thereof can process the qualified step hole workpiece in such a way by utilizing the lathe, the step hole workpiece is processed and finished at one step, the processing efficiency is improved, and the processing cost is reduced.

Owner:芜湖长胜机械制造有限公司

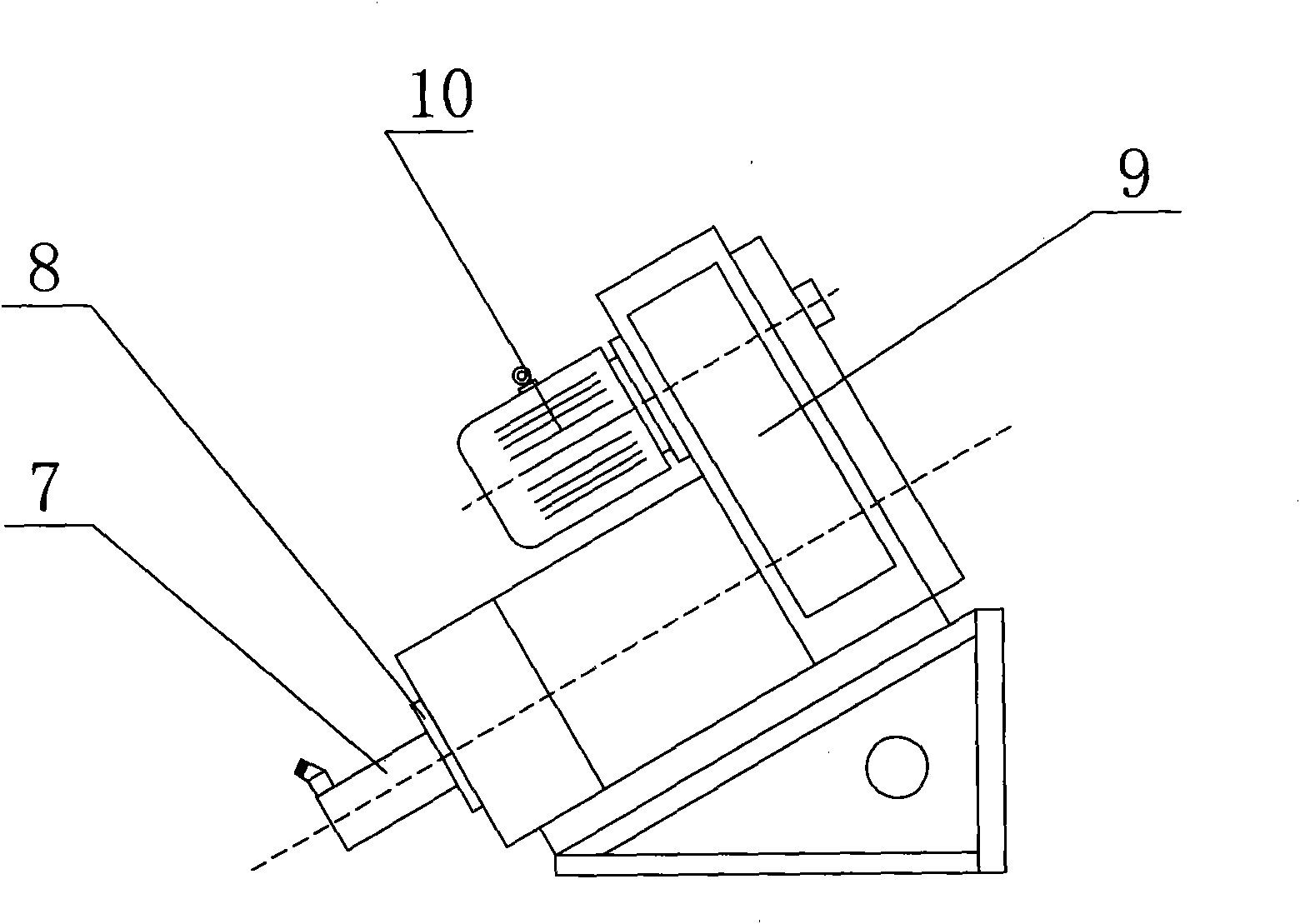

Power device of lathe for drilling blind holes in inner walls of embedded bearings

InactiveCN103752898ASolving the Problem of Drilling the Blind Hole on the Inner Wall of the Inlaid BearingEasy to operateBoring/drilling componentsAttachable boring/drilling devicesEngineeringSprocket

The invention relates to a power device of a lathe for drilling blind holes in the inner walls of embedded bearings. A lathe knife rest is fixedly connected with a support base which is provided with a motor, an output shaft of the motor is connected with a small belt wheel, the small belt wheel is in transmission connection with a large belt wheel at the output shaft end of a mandrel through a synchronous belt, the mandrel is arranged at the rear end of a knife blade through a pair of angular contact bearings, the middle of the mandrel is fixedly connected with a chain wheel, the knife blade is connected with the support base through two fixed corner brackets, a Mohs taper sleeve shaft is arranged at the cantilever end of the knife blade through a pair of conical bearings, the middle of the Mohs taper sleeve shaft is fixedly connected with another chain wheel, one chain wheel is connected with the other chain wheel through a chain in a transmission mode, and a drilling tool is connected inside the Mohs taper sleeve shaft in a matched mode. According to the power device, when the lathe is used for drilling the blind holes in the inner walls of the embedded bearings, the axis of the tool and the axes of the embedded bearings are in a right-corner state, and the machining tool conducts rotational motion. A large carriage is moved so as to conduct axial locating of the distances between the blind holes in the inner walls of the embedded bearings, a middle carriage is moved in the radial direction so as to control the depths of the machined blind holes, and therefore it is achieved that the lathe is used for drilling the blind holes in the inner walls of the embedded bearings.

Owner:SHANGHAI INST OF TECH

Device for machining pipe fitting by using lathe

InactiveCN102430776ASolve processing problemsRealize processingAttachable boring/drilling devicesPipe fittingStructure and function

The invention relates to a device for machining a pipe fitting by using a lathe. The device comprises a knife rest, a clamp unit, a V-shaped locating block, a transition connecting plate and a compression cushion block, wherein one end of the knife rest is clamped on a chuck of a lathe spindle, a knife mounting hole is arranged on the circumference at one end of the knife reset, and a knife fixing hole mutually perpendicular to the knife mounting hole is formed on the end face of the end of the knife rest; the clamp unit is fixed on the transition connecting plate through a connecting plate on a lower clamp body; the transition connecting plate is fixedly connected with a drag plate in the lathe; the clamp unit comprises an upper clamp body and the lower clamp body, the upper clamp body is inserted into clamp plates at both end heads of the lower clamp body and is connected with the clamp plates through shaft pins; and the compression cushion block is fixed on the inner surface of the lower clamp body through clamp bolts. According to the invention, the difficulty in machining an inner hole at the end of a bimetal composite pipe is solved, the machining efficiency is improved, and the machining cost is lowered. After the device is removed, a small drag plate, a knife rest system and a tailstock of the original lathe are installed, and the structure and the function of the original lathe can be recovered.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com