Shaft processing device

A technology for processing devices and shaft brackets, applied in feeding devices, boring/drilling devices, metal processing equipment, etc., can solve the problems of large manpower, material resources, financial resources, increased processing costs, and complex bracket structures, etc., to reduce labor Strength, saving time, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

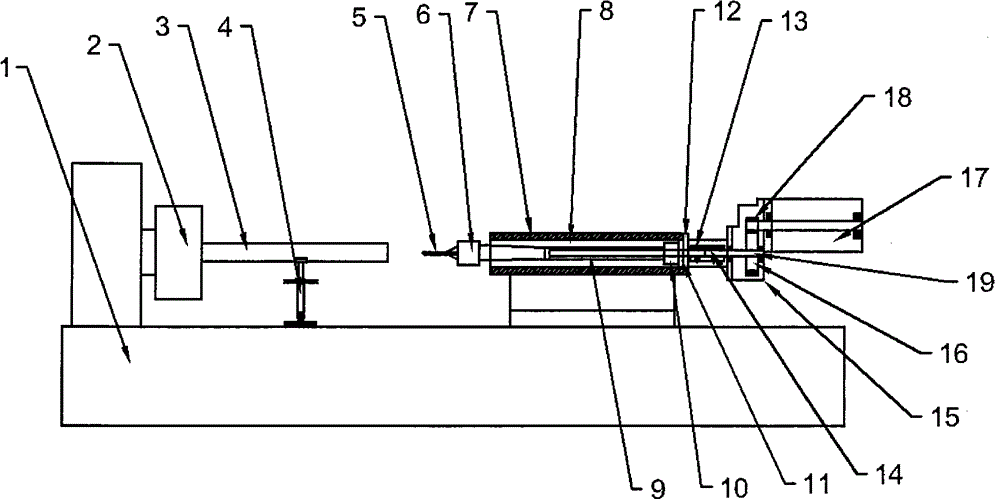

[0021] see Figure 1-4 , a shaft processing device, comprising a frame 1, a chuck 2 is provided on the left side above the frame 1, the chuck 2 is used to fix the end of the shaft workpiece 3, and a shaft bracket is provided on the right side of the chuck 2 4. The right side of the shaft bracket 4 is provided with a processing device.

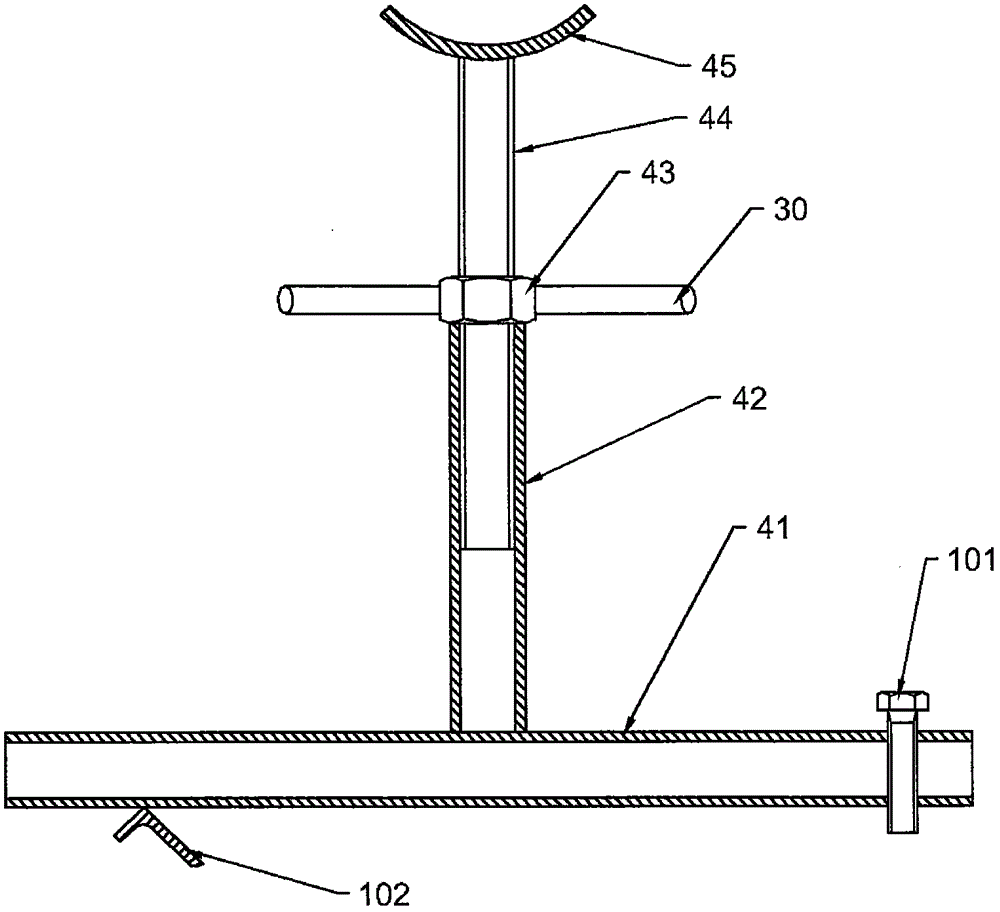

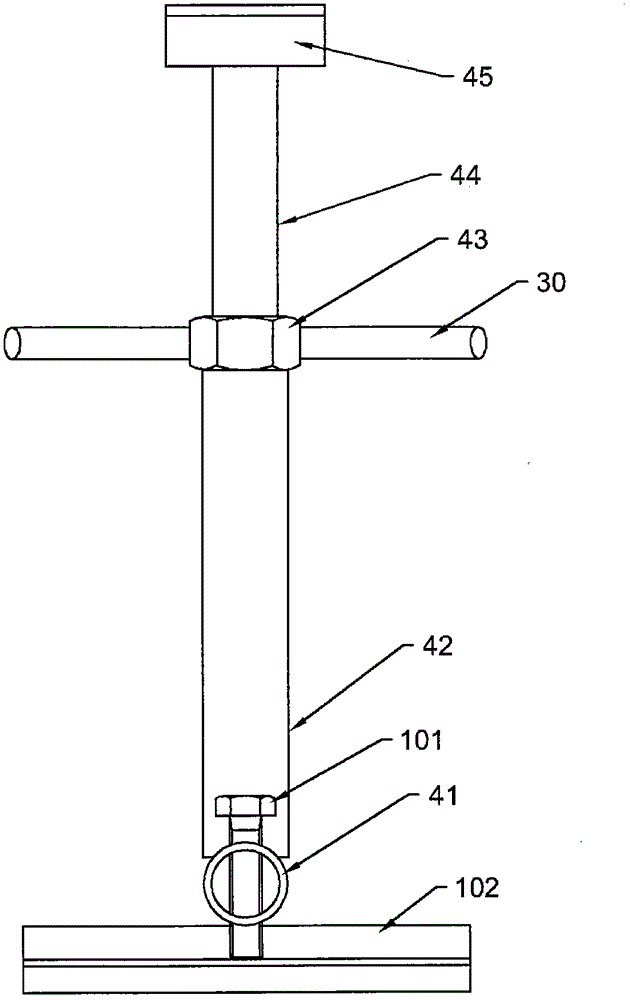

[0022] Shaft bracket 4 comprises bracket base, and bracket base is provided with the guide sleeve 42 that extends vertically, and guide slide is equipped with support screw rod 44 in the guide sleeve 42, and the upper end of support screw rod 44 is provided with and is used for cooperating with the outer peripheral surface of shaft. The arc-shaped supporting plate, the supporting screw rod 44 is screwed with an adjusting nut 43 that is used to compress the upper end of the guide sleeve 42 and rotate with the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com