Patents

Literature

2929 results about "Tailstock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tailstock, also known as a foot stock, is a device often used as part of an engineering lathe, wood-turning lathe, or used in conjunction with a rotary table on a milling machine. It is usually used to apply support to the longitudinal rotary axis of a workpiece being machined. A lathe center is mounted in the tailstock, and inserted against the sides of a hole in the center of the workpiece. A tailstock has a Dead Center, while headstock has Live Center. A Tailstock is particularly useful when the workpiece is relatively long and slender. Failing to use a tailstock can cause "chatter," where the workpiece bends excessively while being cut.

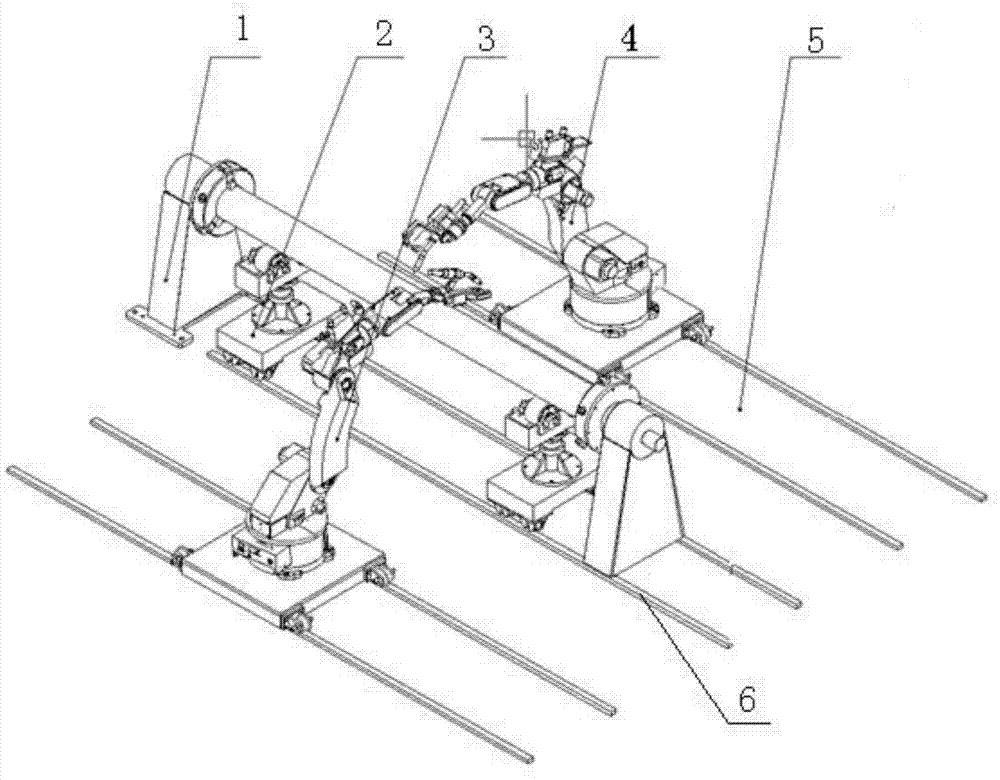

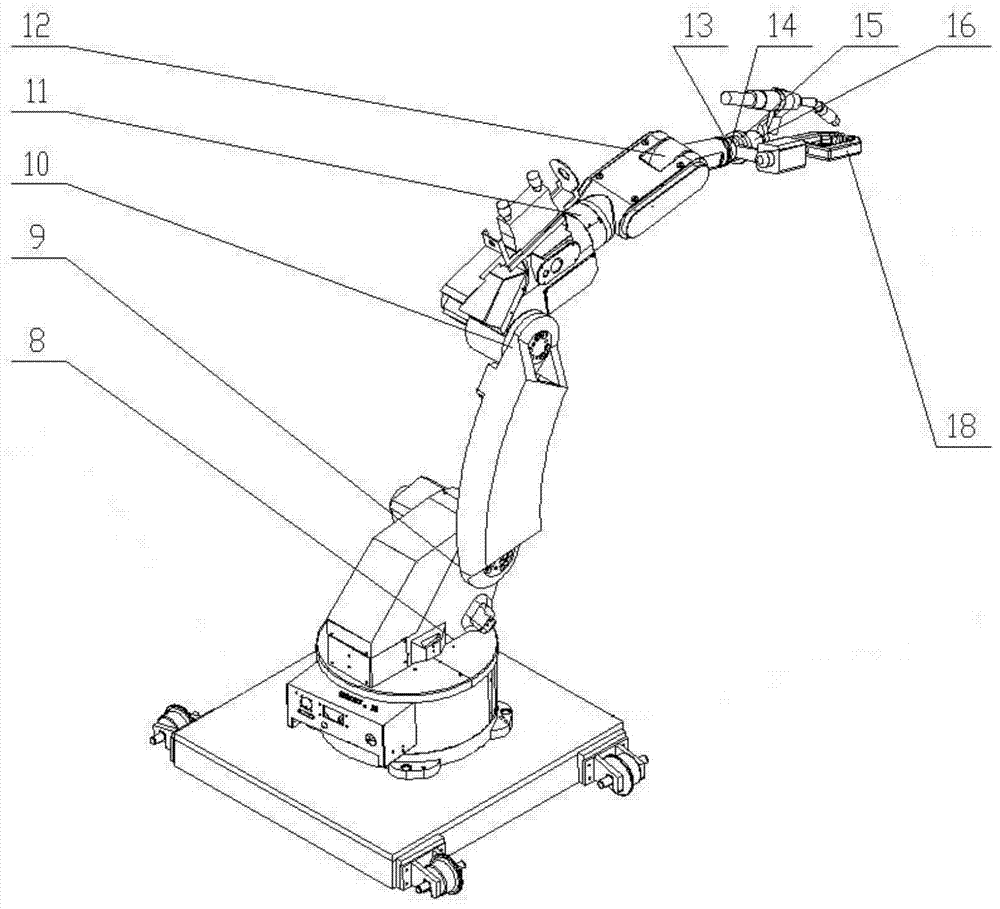

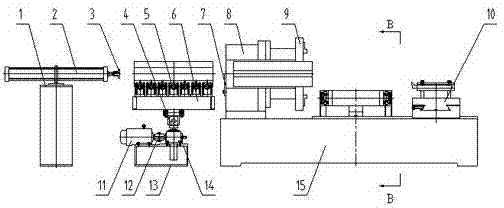

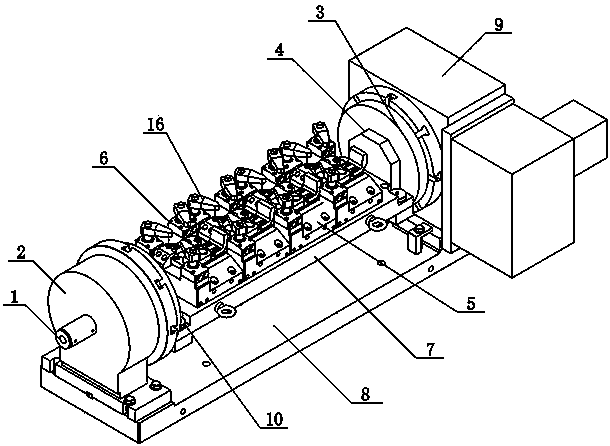

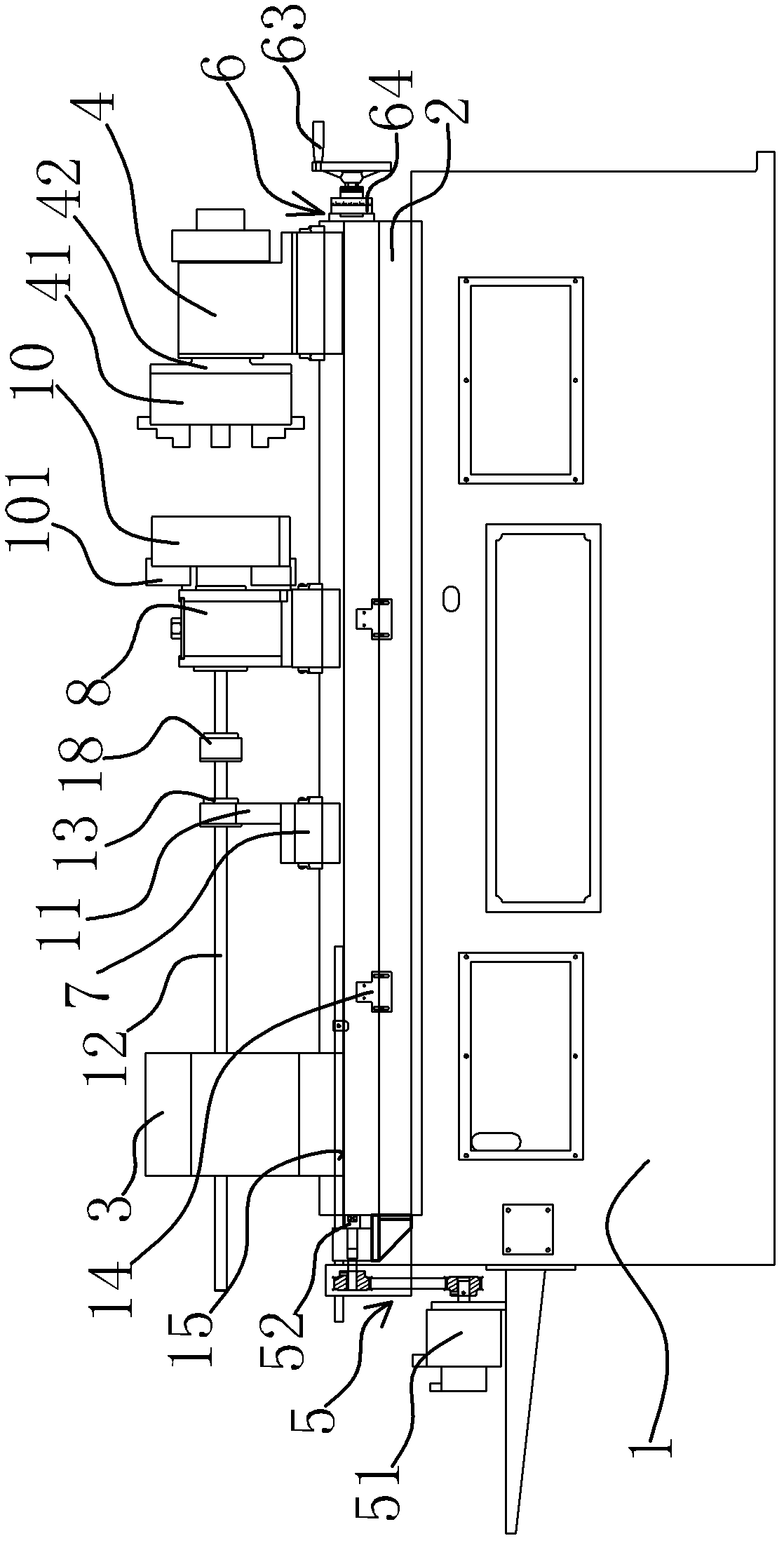

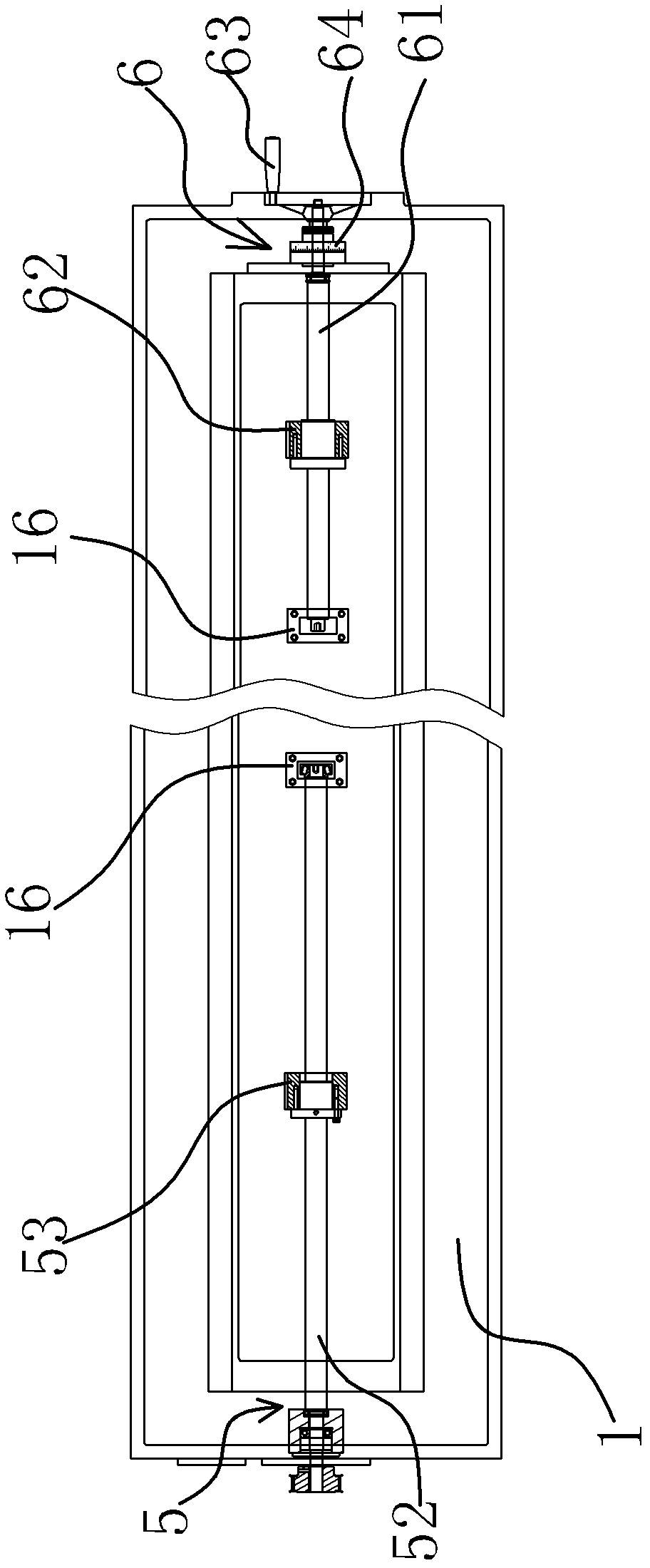

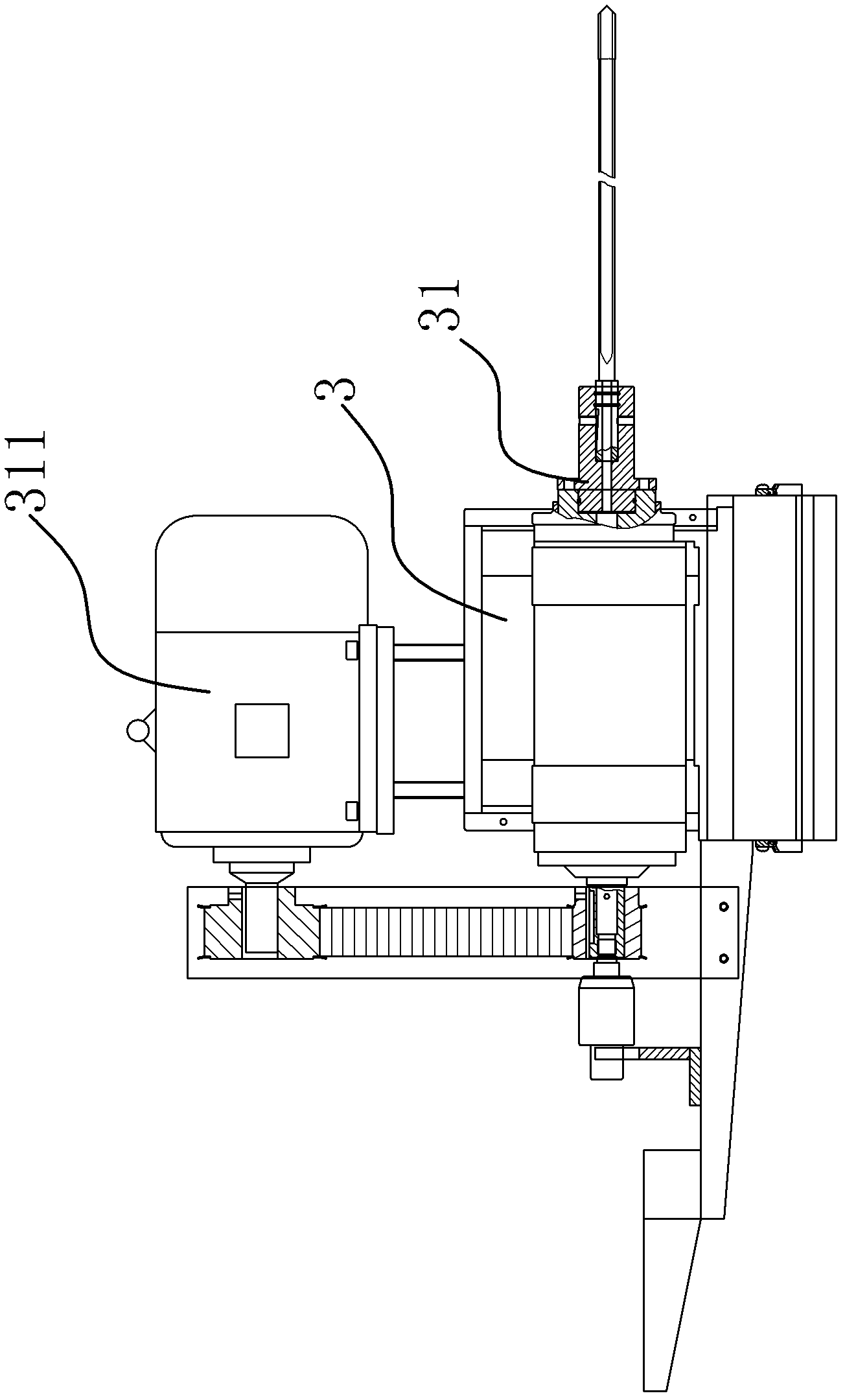

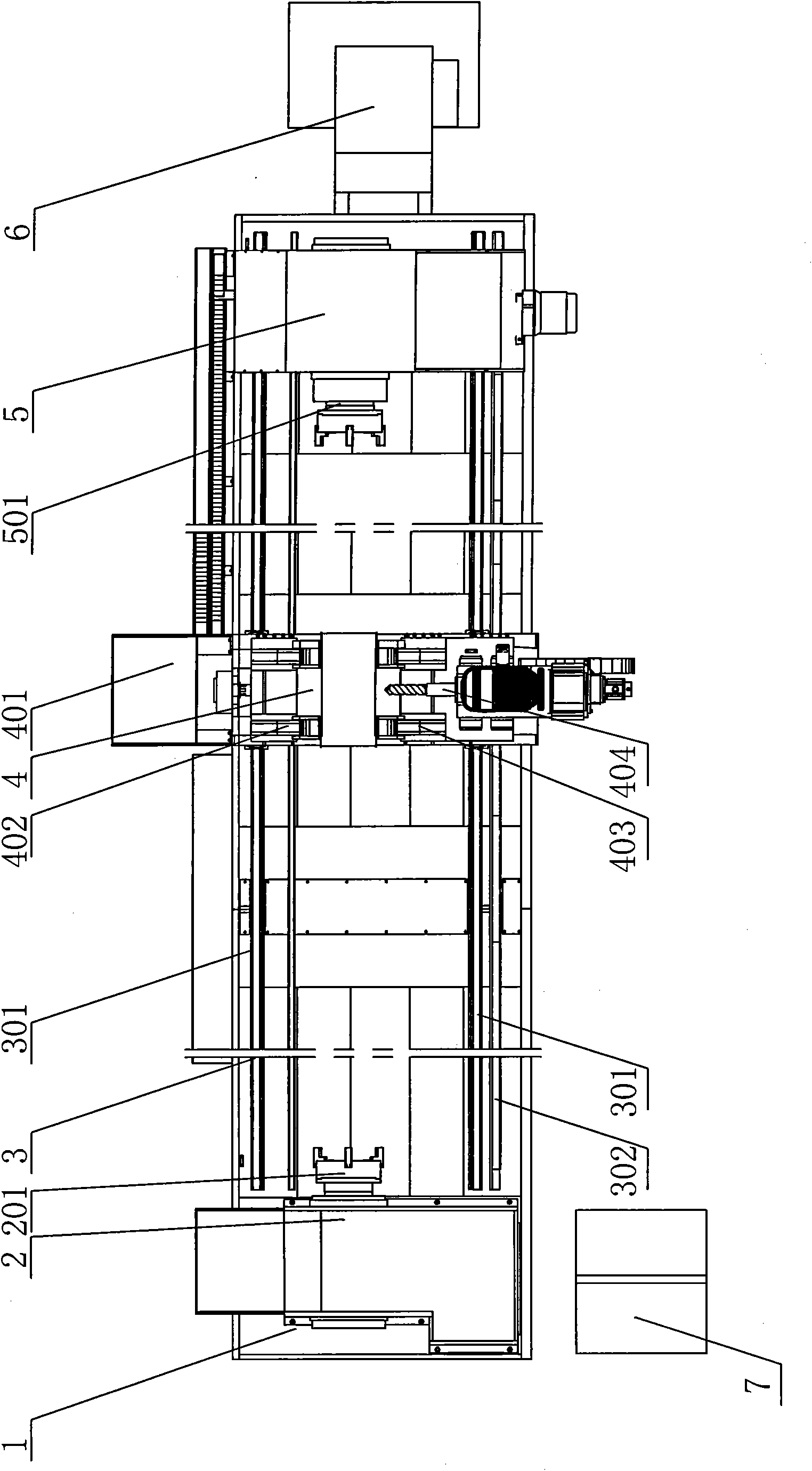

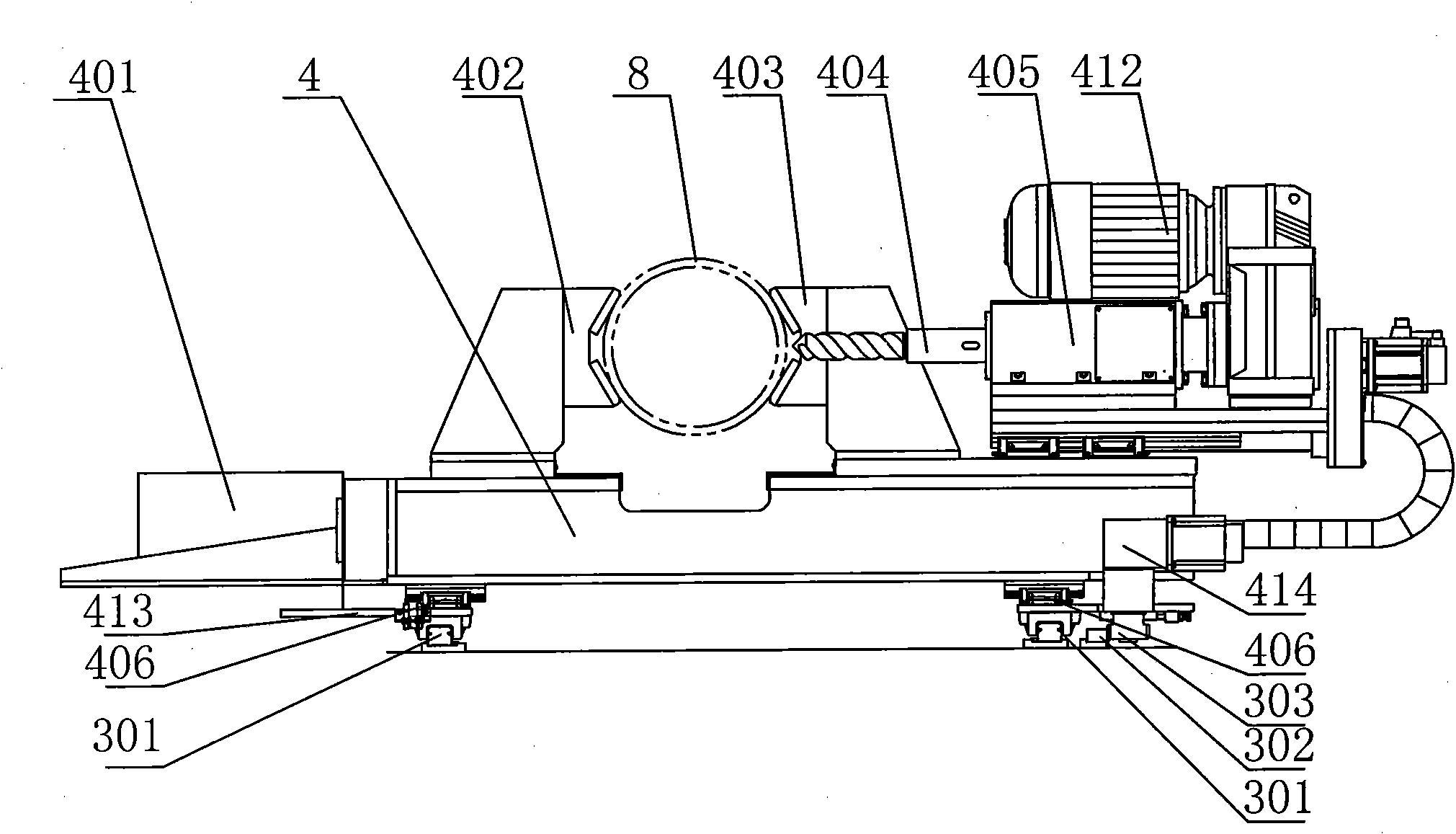

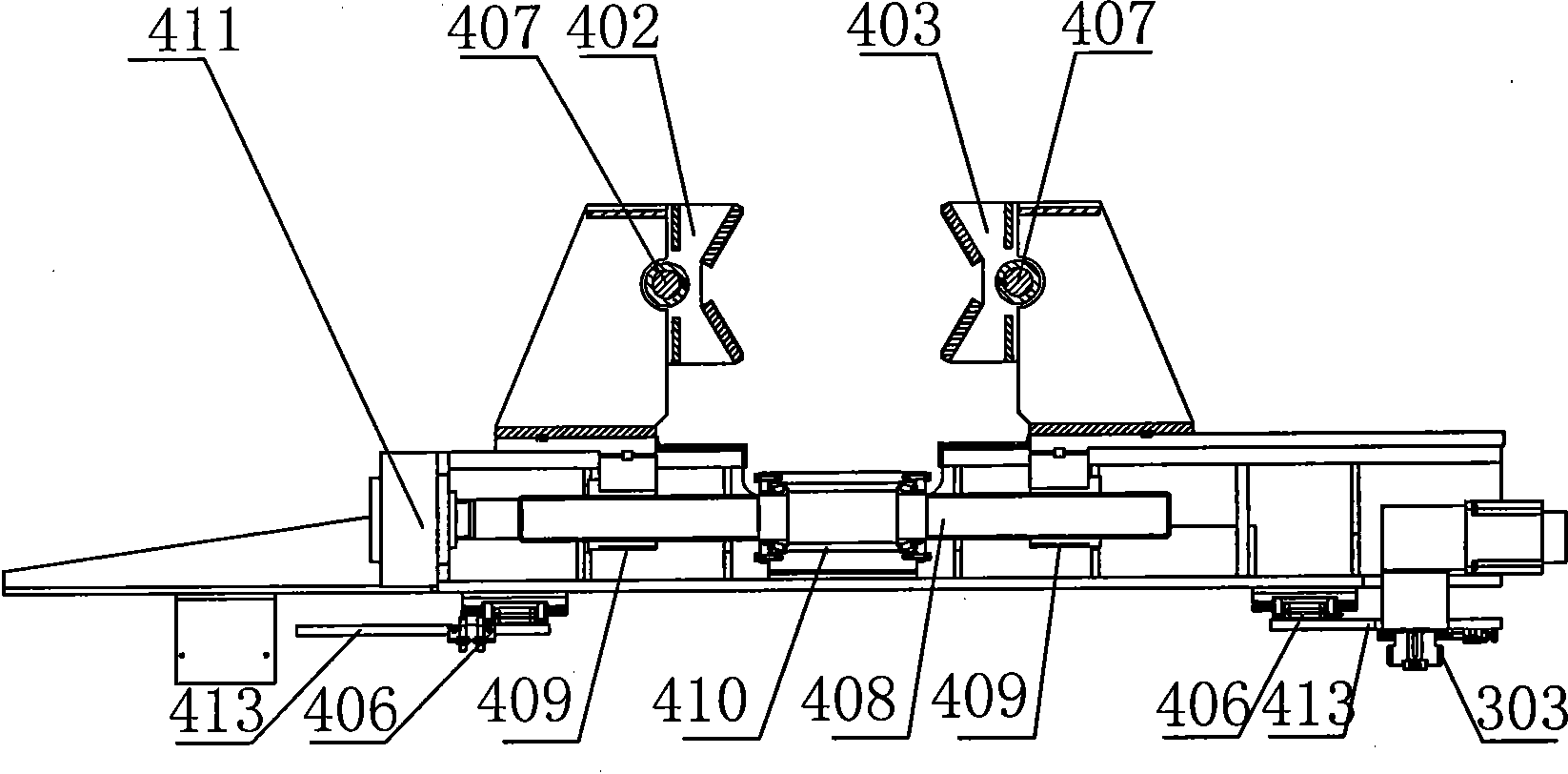

Integrated workstation based on robot cutting, welding and carrying in pipe processing

ActiveCN103567677AImprove processing qualityImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall footprint

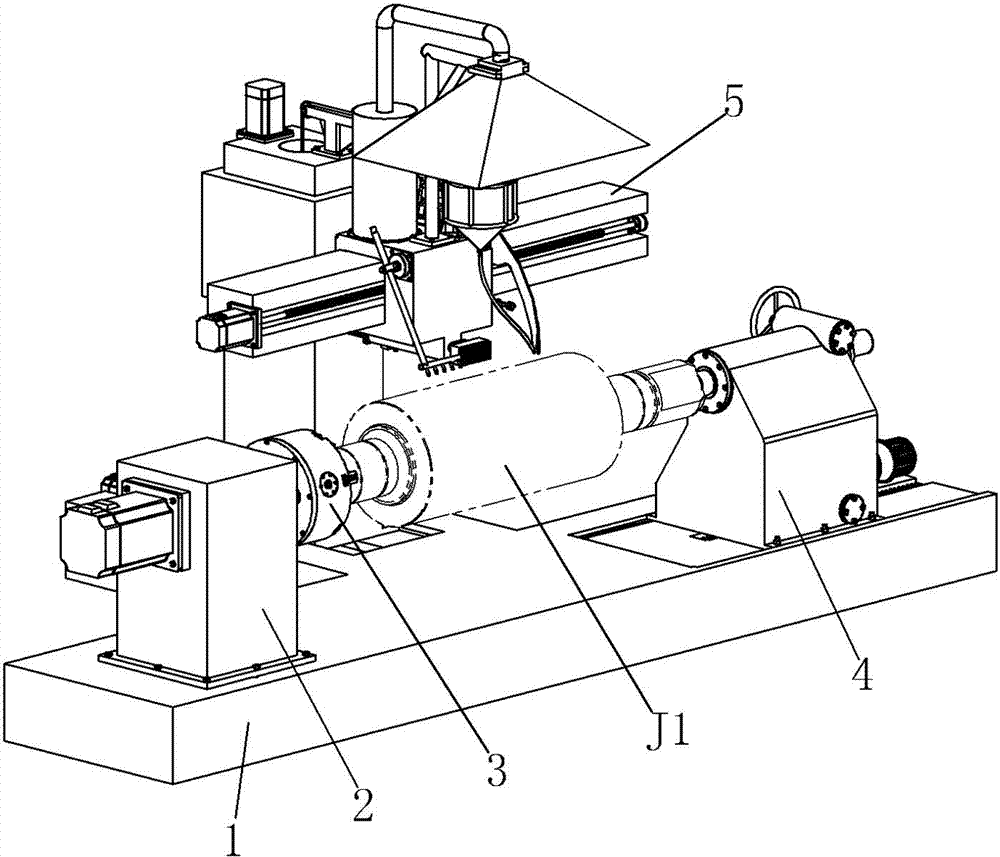

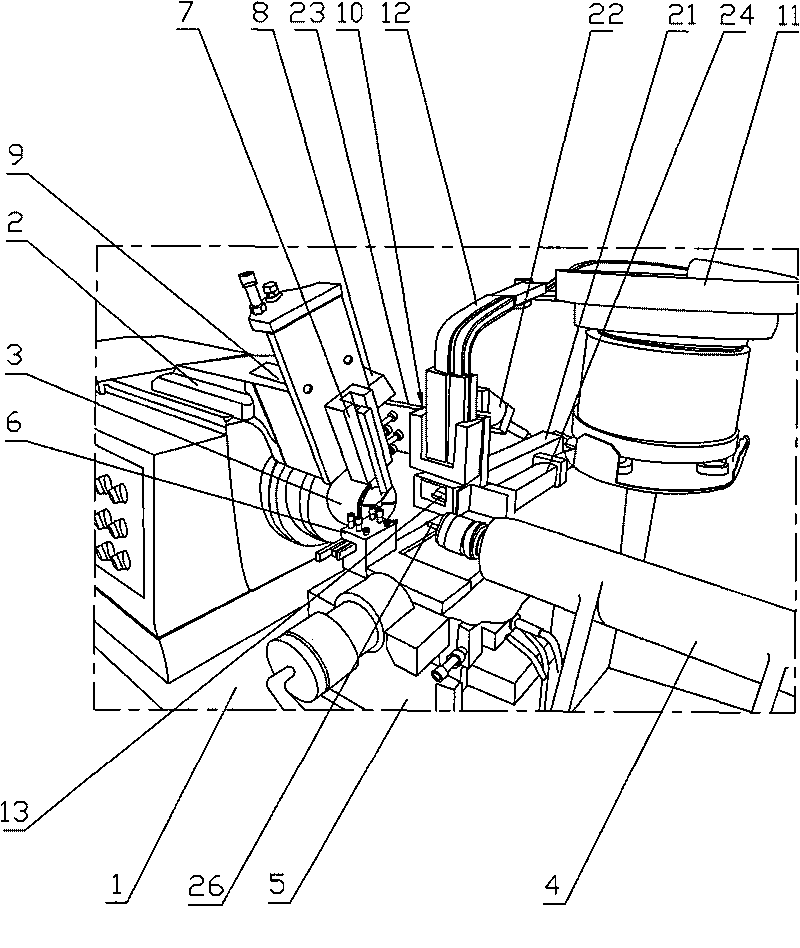

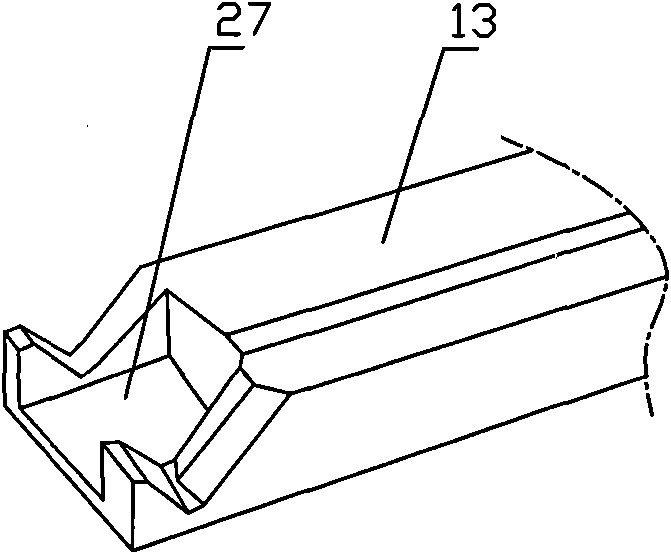

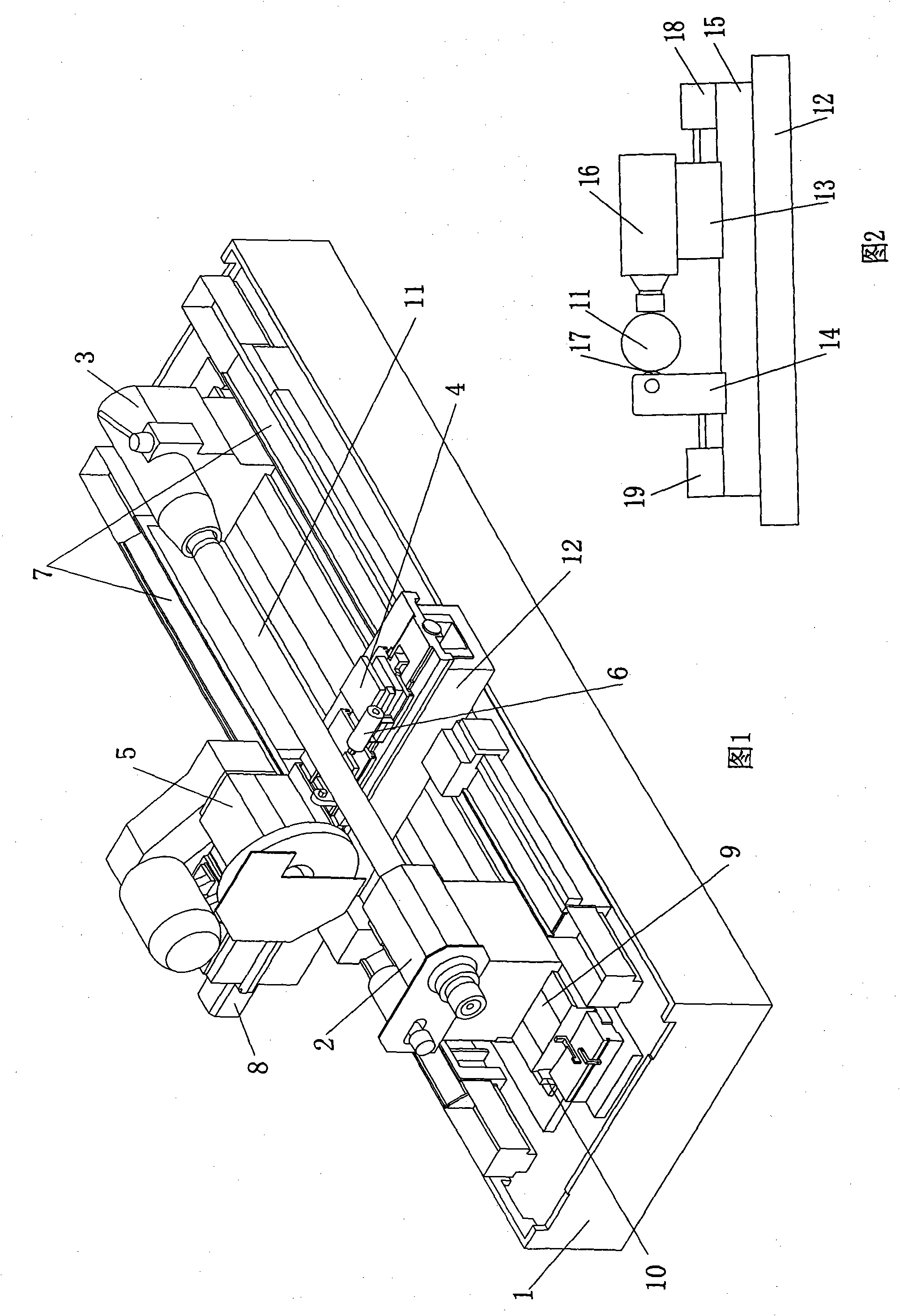

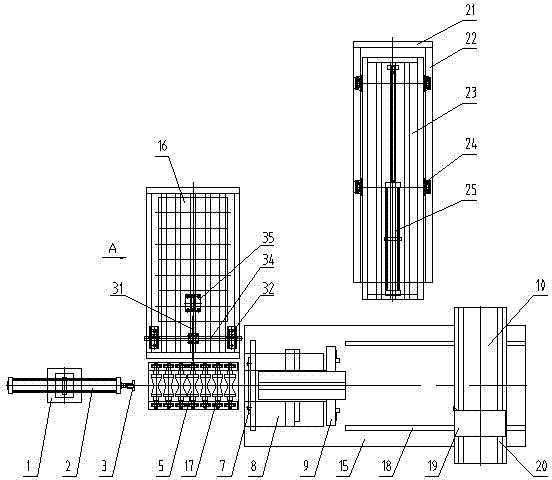

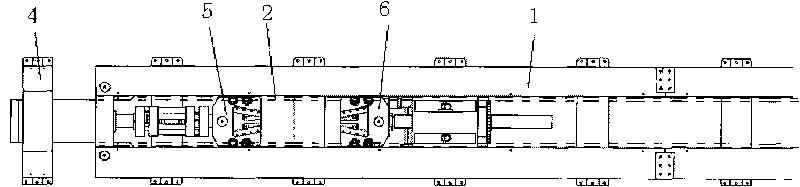

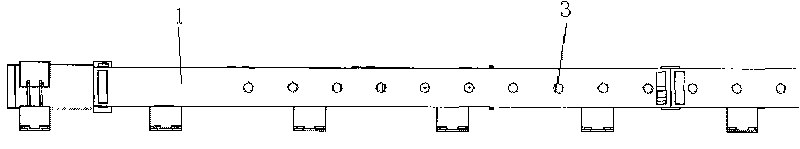

The invention discloses an integrated workstation based on robot cutting, welding and carrying in pipe processing. The integrated workstation comprises a headstock and tailstock position changer, a movable support, a welding robot, a cutting robot, a middle sliding rail and two side sliding rails, wherein the headstock and tailstock position changer comprises a headstock base and a tailstock base; a pipe workpiece is clamped between clamping and fixing devices on the headstock base and the tailstock base; a lifting driving device is installed on a sliding base of the movable support; a roller is installed on the lifting driving device and is tangent with the pipe workpiece; the welding robot and the cutting robot are slidably installed on the two side sliding rails on the two sides of the pipe workpiec respectively to finish carrying, cutting and welding operation and the like. The integrated workstation based on the robot cutting, welding and carrying in pipe processing is an integrated working system, can ensure good consistency in pipe processing, improves the processing quality and the processing precision of the whole pipe workpiece, and is simple in structure, less in equipment and small in occupied area.

Owner:NANJING PANDA ELECTRONICS +1

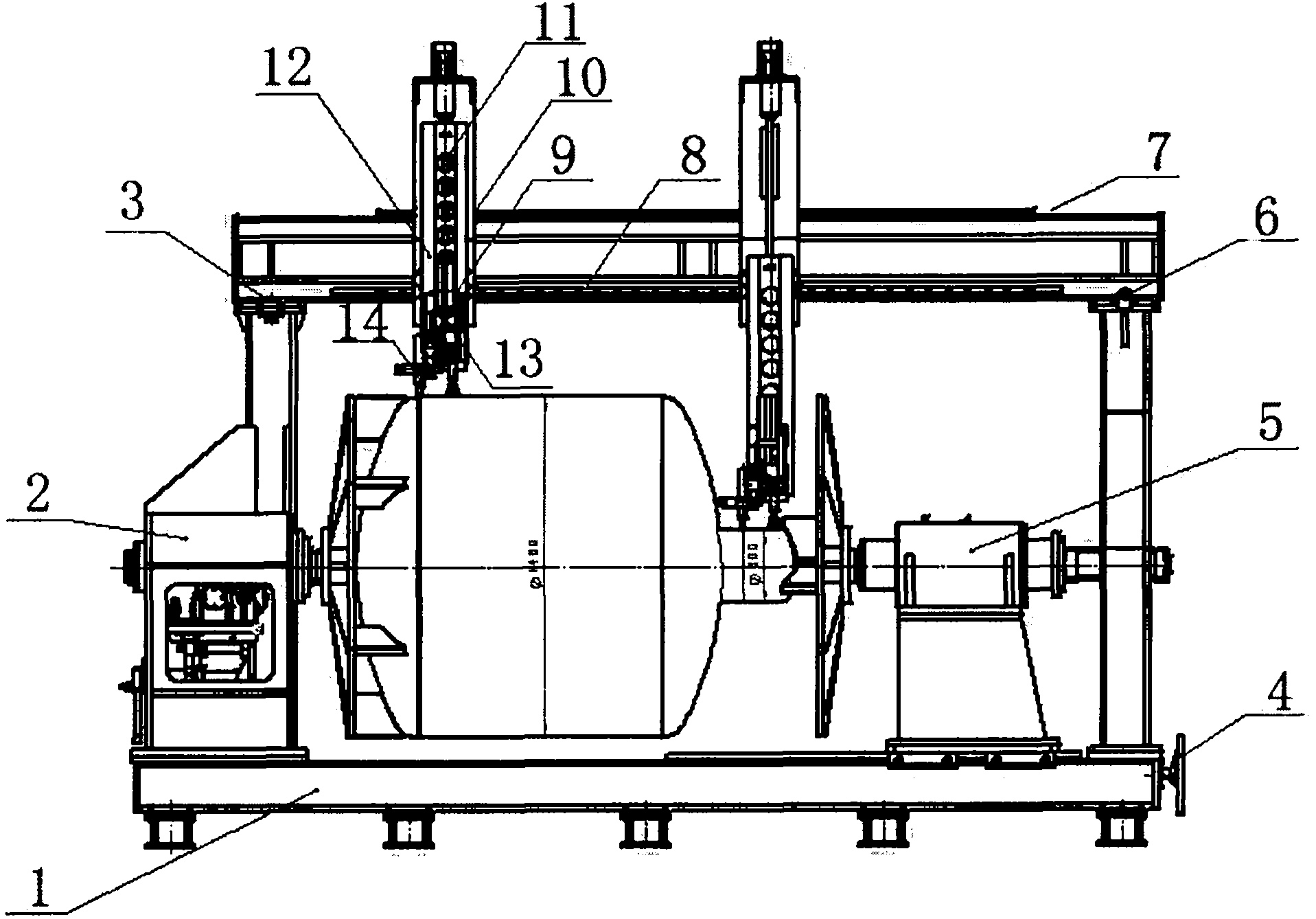

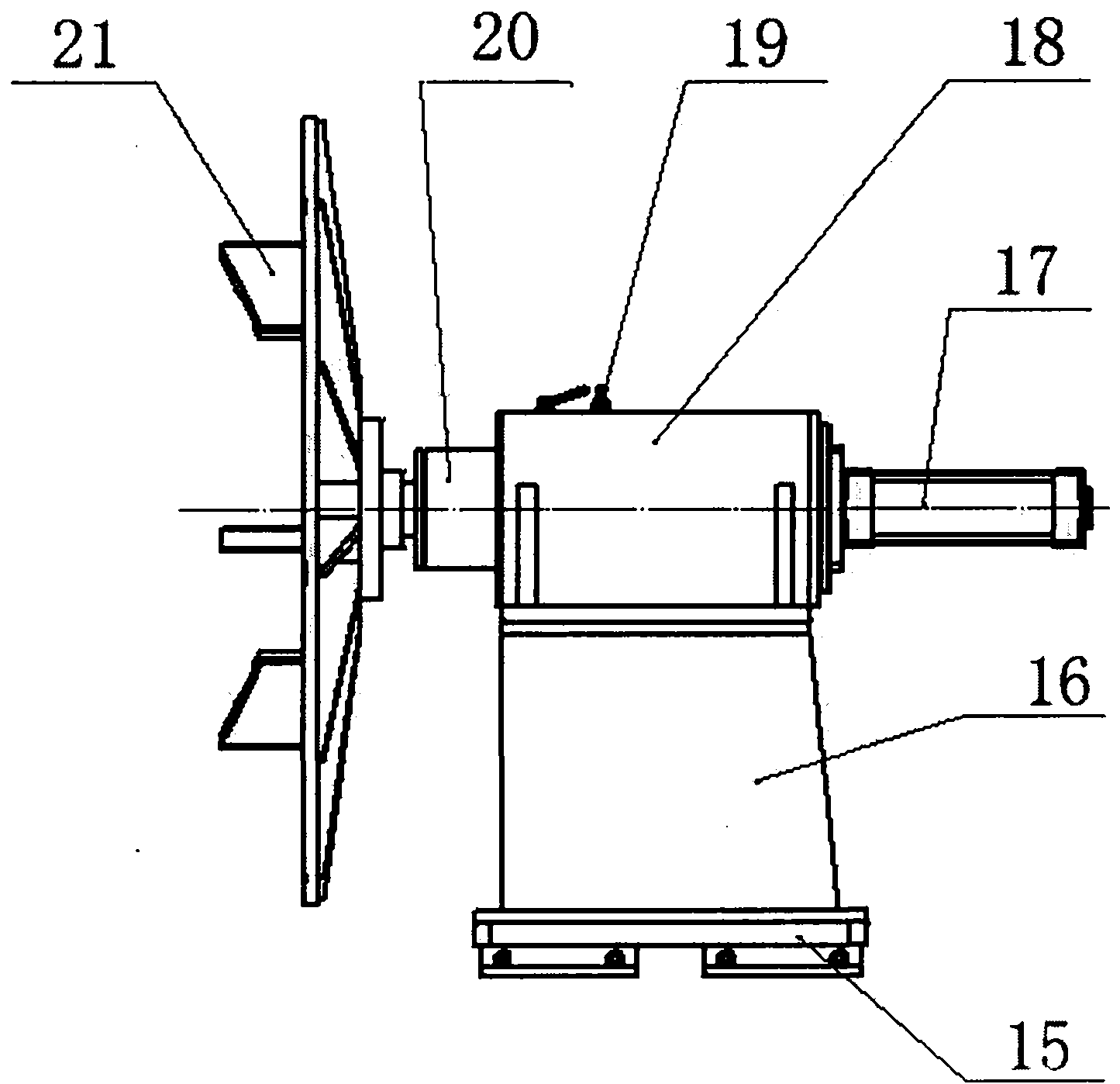

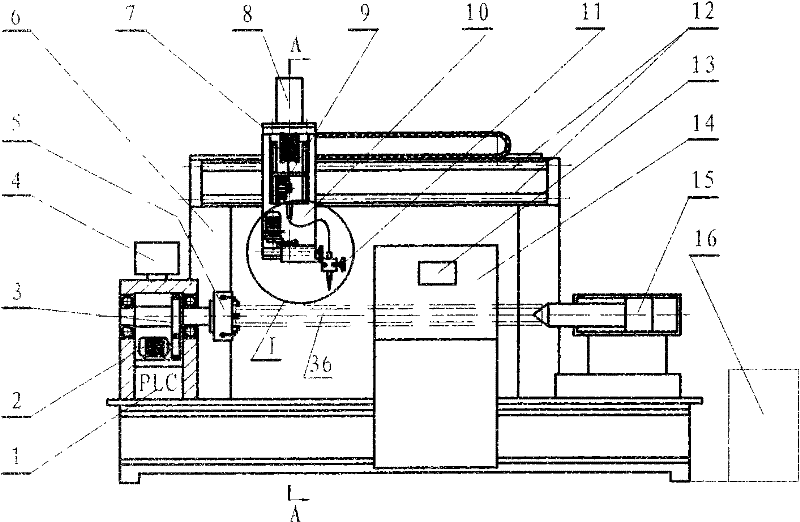

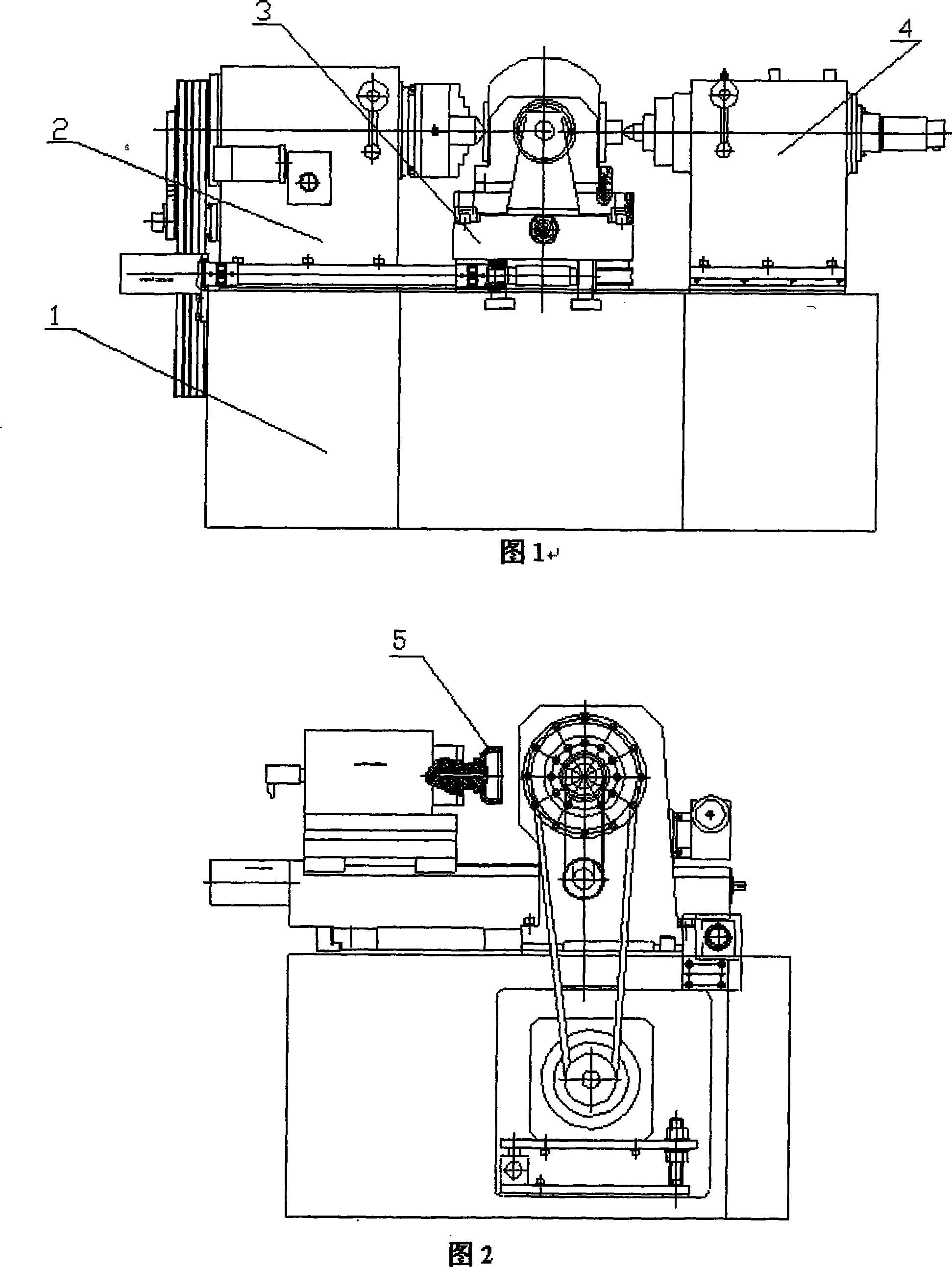

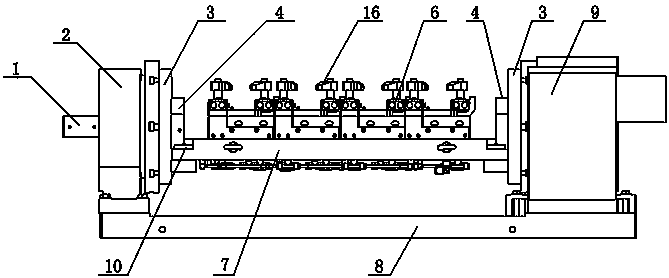

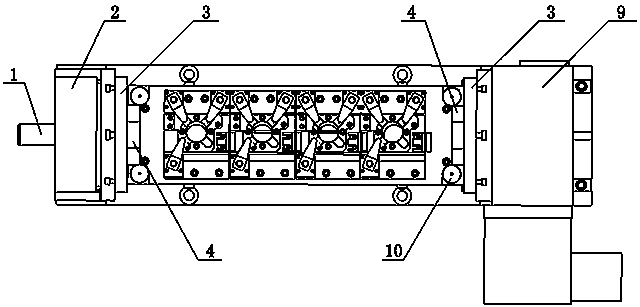

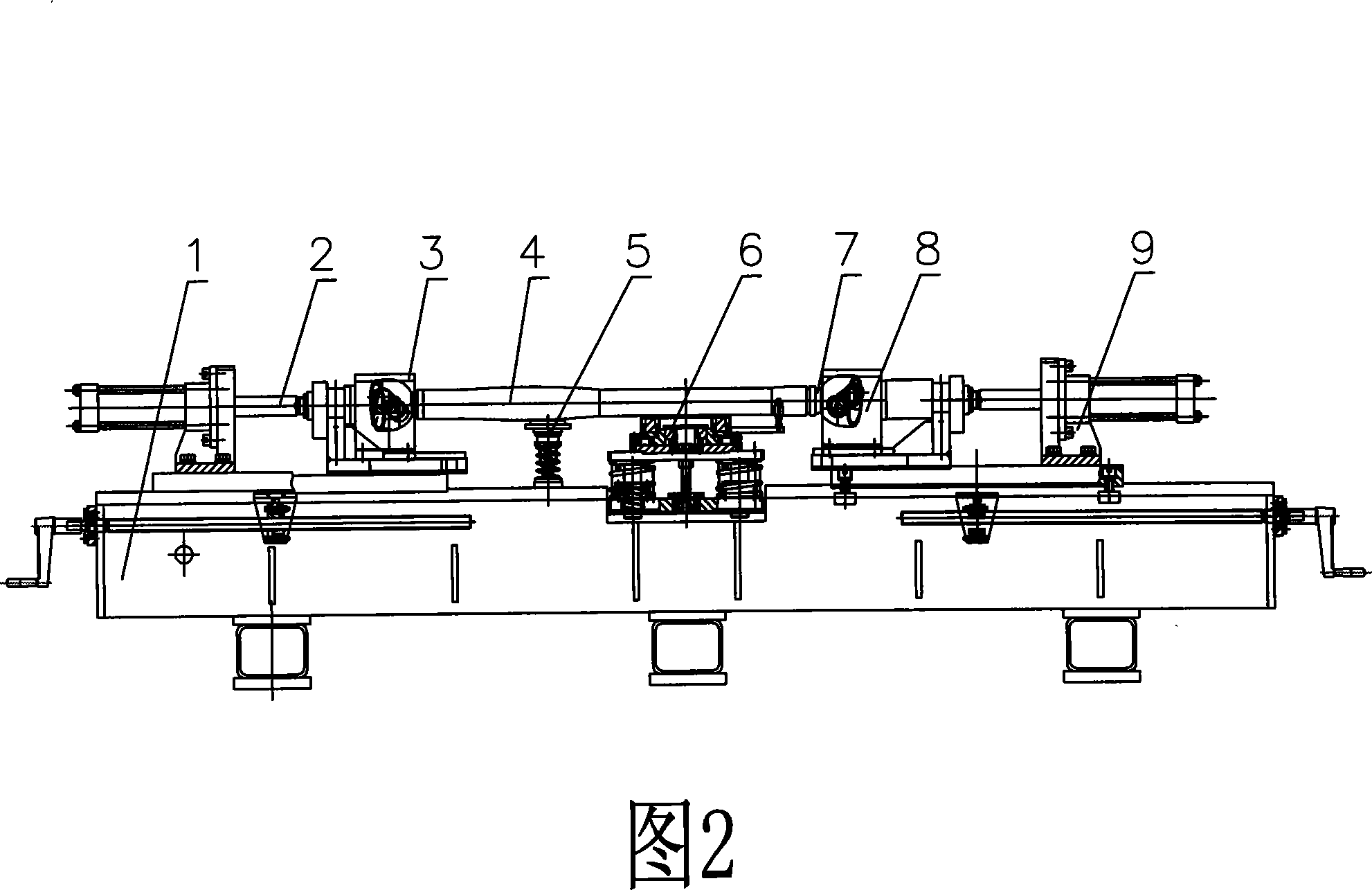

Speed-variable circular and longitudinal seam welder applied to multi-specification tank bodies

InactiveCN101913040ACompact structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSeam welding

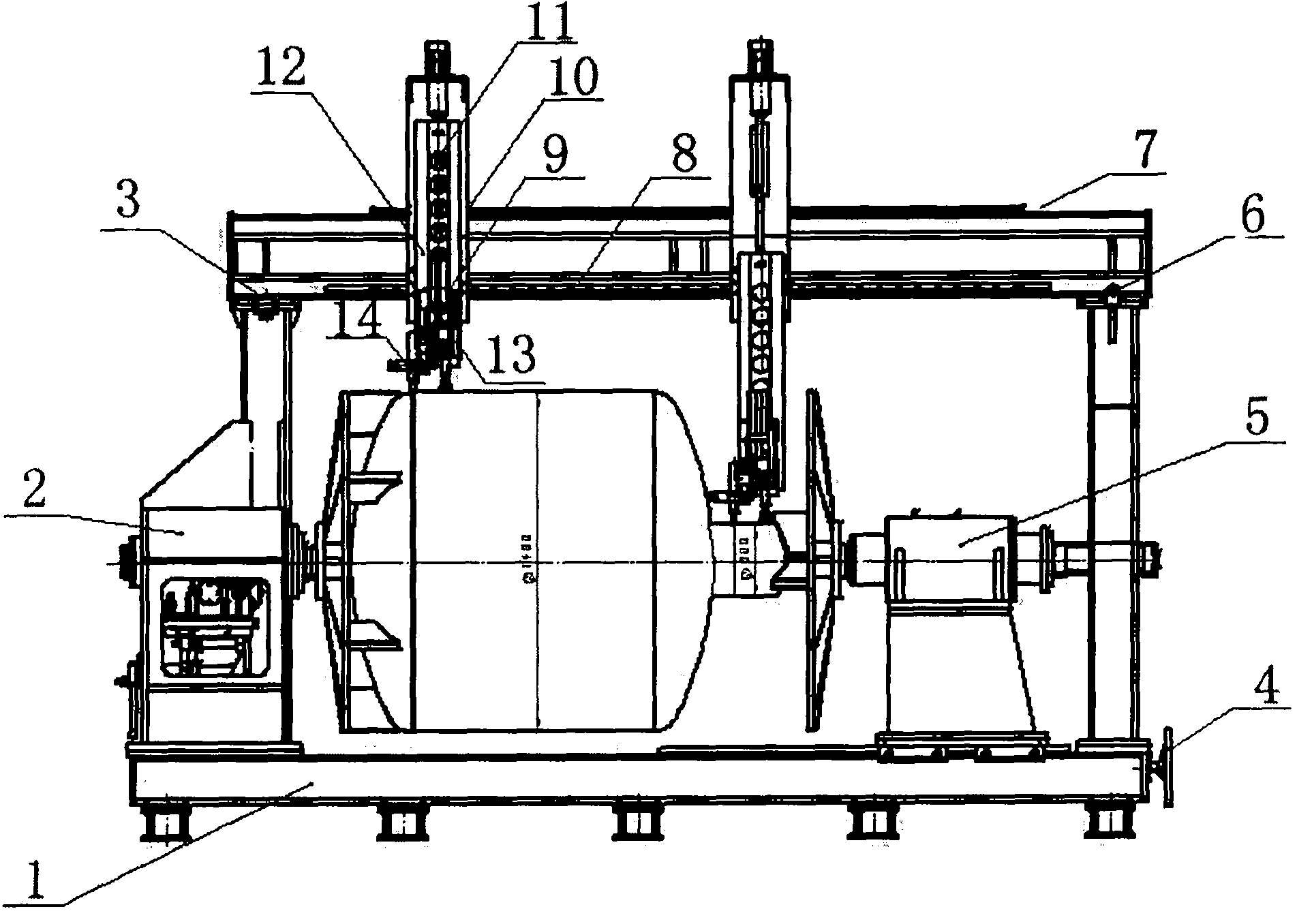

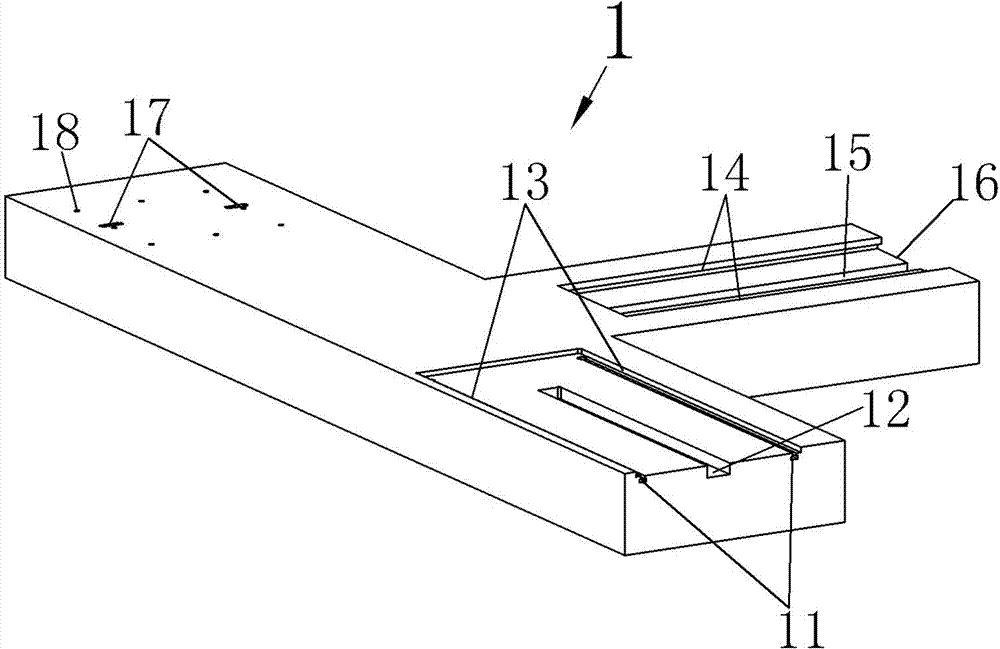

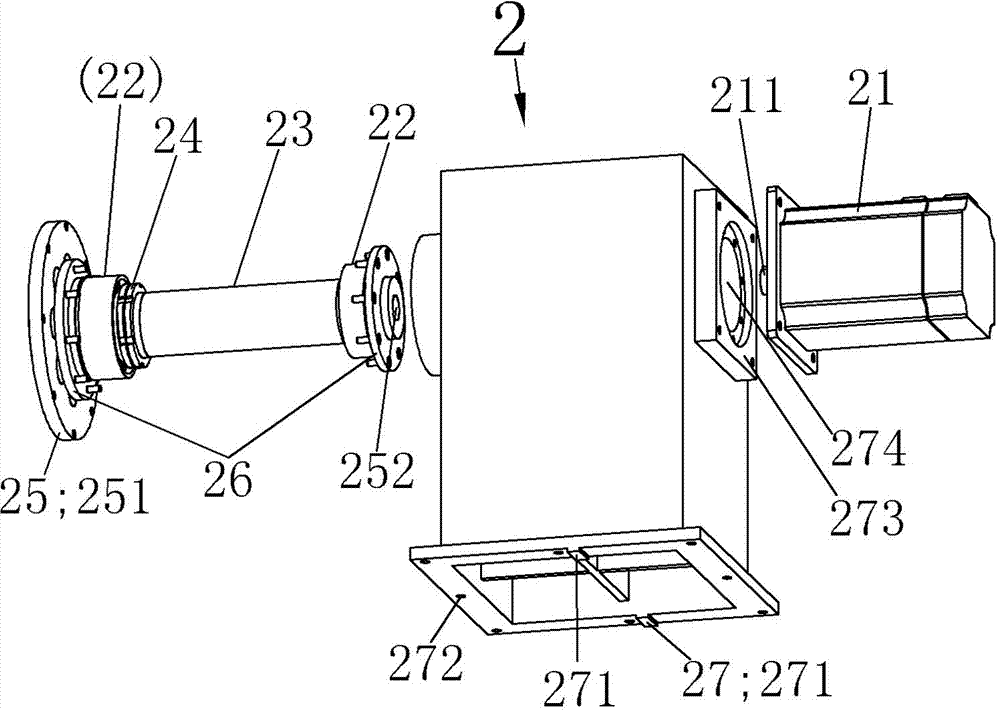

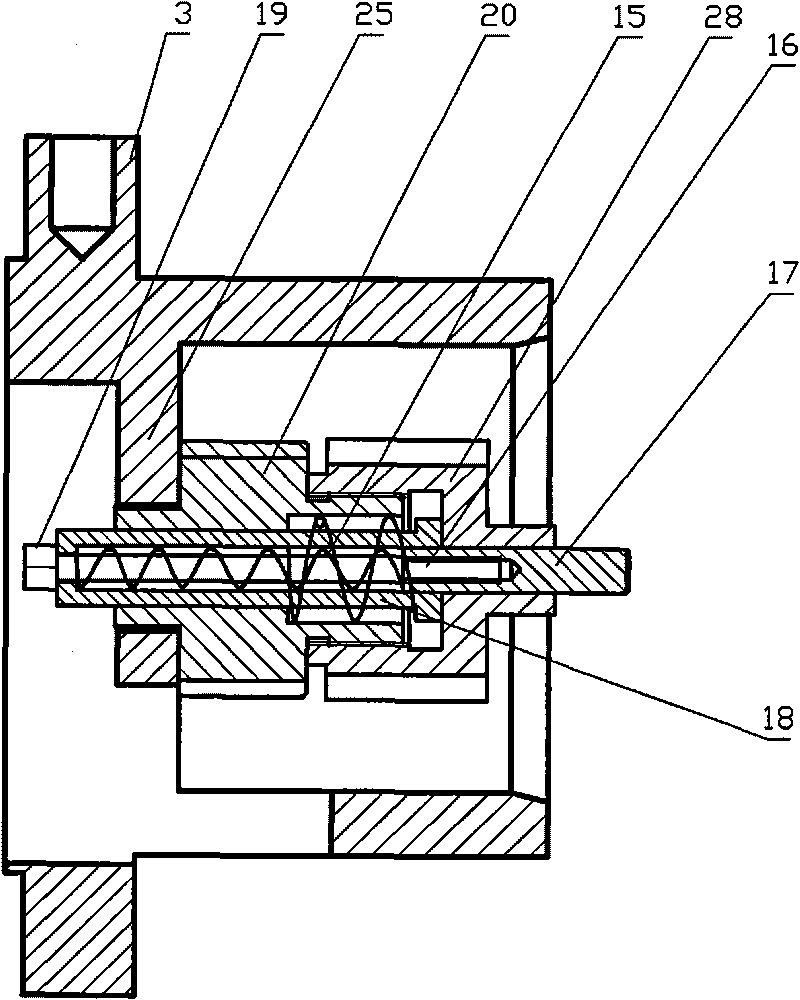

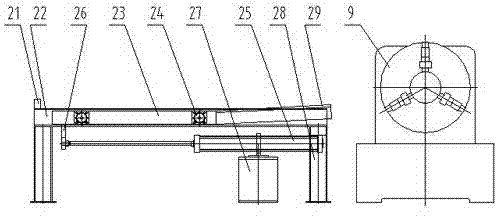

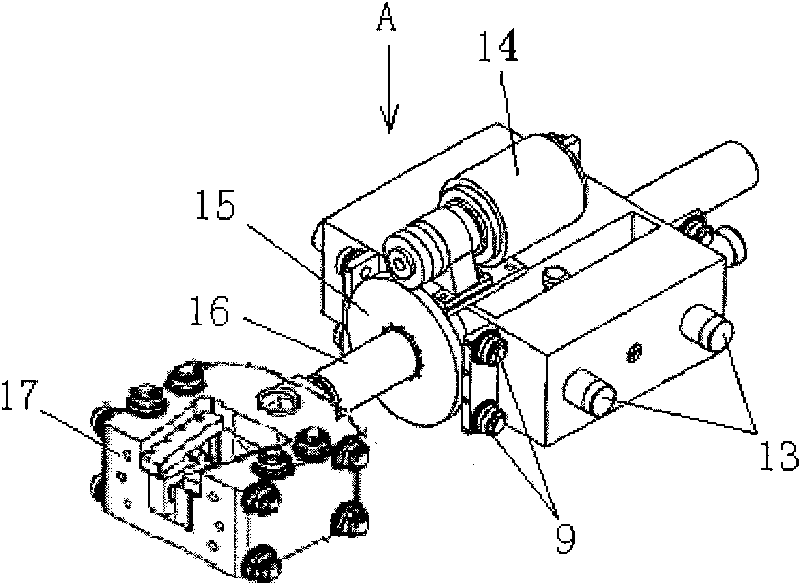

The invention relates to a welding device, in particular to a circular and longitudinal seam welder special for automatically welding multi-specification tank bodies. The speed-variable circular and longitudinal seam welder applied to the multi-specification tank bodies mainly comprises four parts, namely a bed body (1), a headstock (2), a beam mechanism (12) and a tailstock (5). Compared with the prior art, the circular and longitudinal seam welder has the advantages of adapting to the change of the tank body diameter range of phi300 to 1,400mm and welding linear speed range of 200 to 1,200mm / min, realizing edge sealing and dual circular and longitudinal seam welding of the tank bodies, along with multiple functions, compact structure, convenient operation, high stability and low production cost.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

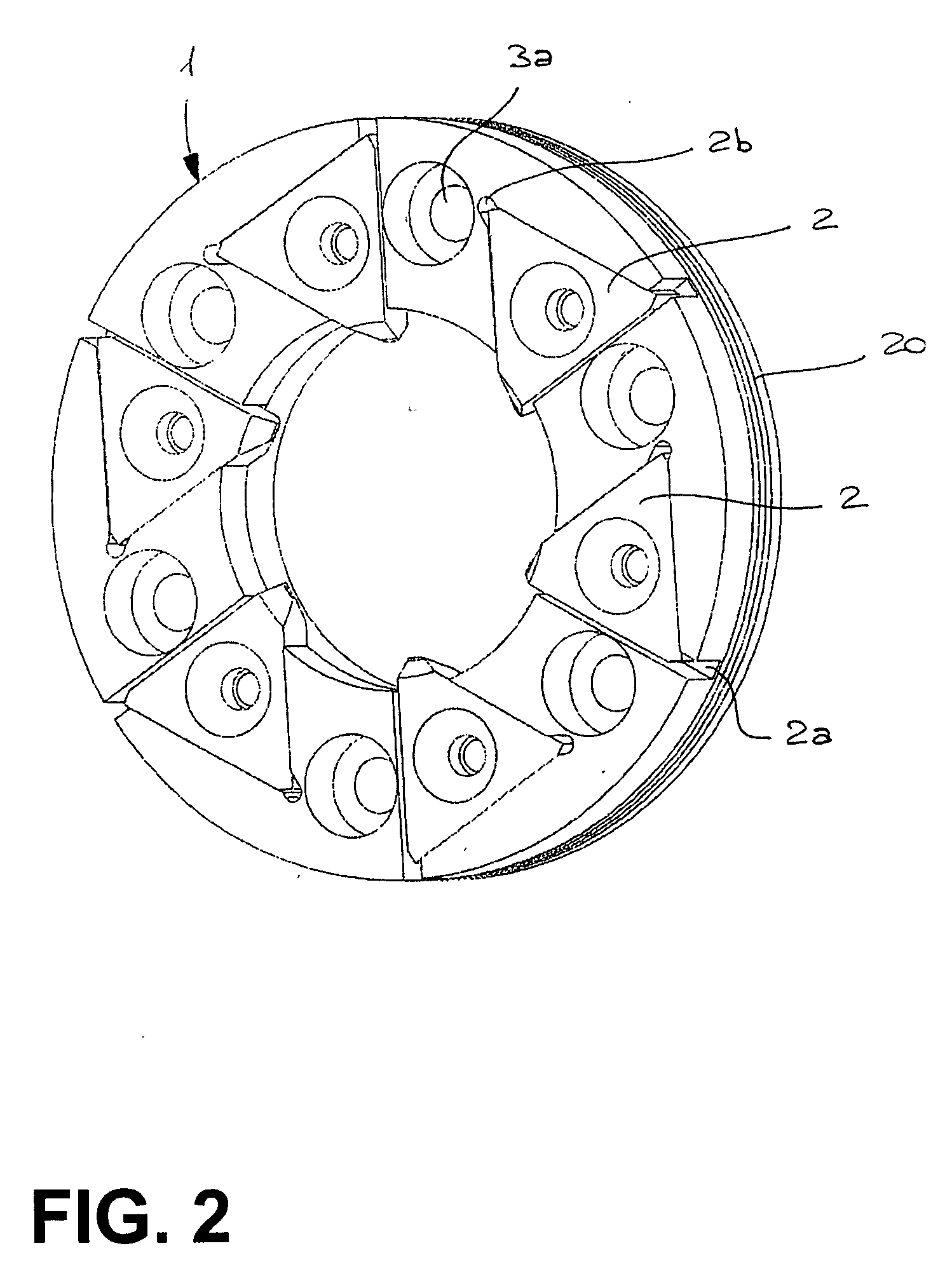

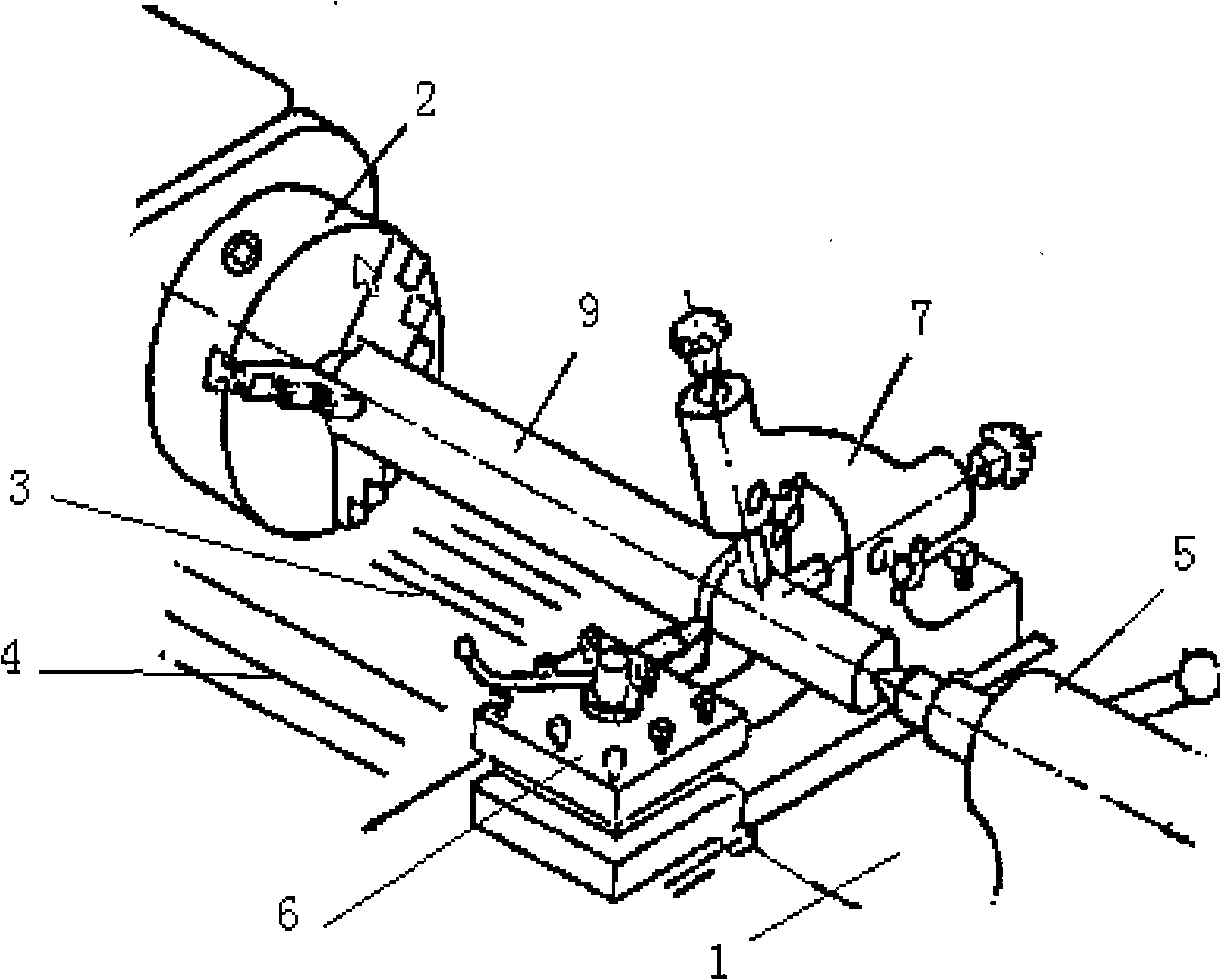

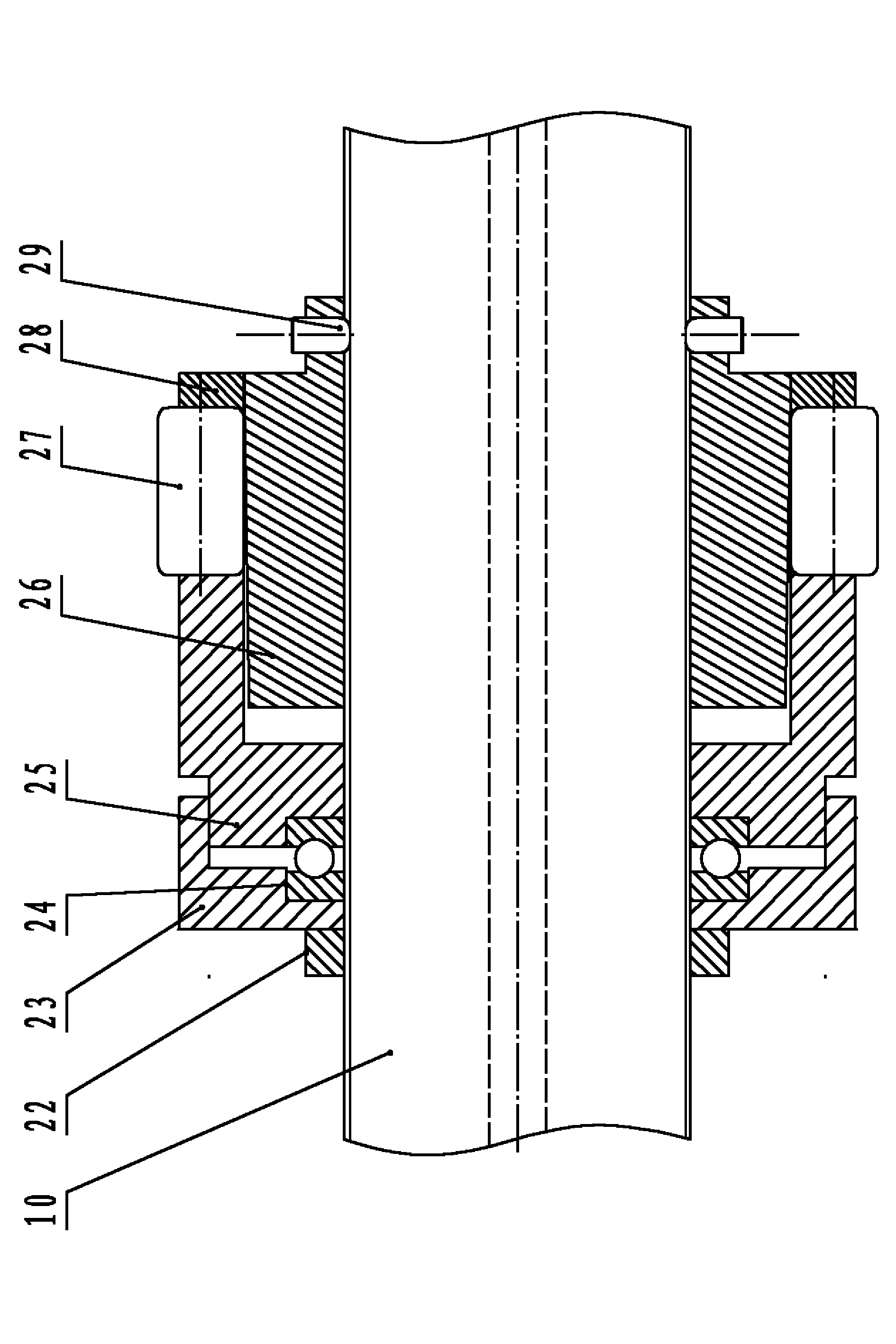

Whirling head and its use

The frame of the whirling head comprises the rigid casing (7), in which the part (10) contains the drive pulley (15) solidly attached to the coupling member (17) connected to the drive shaft of the spindle (26). By means of the belt (19), this pulley (15) drives the pulley (8) solidly attached to the connecting cone (4), which in turn comprises the internal milling cutter (1) which cuts the thread of the screw shaft (27) supported between the bar advance unit (28) and the tailstock centre (29). The latter is mounted as an exchangeable tool on the return unit (32).

Owner:WILLEMIN MACODEL

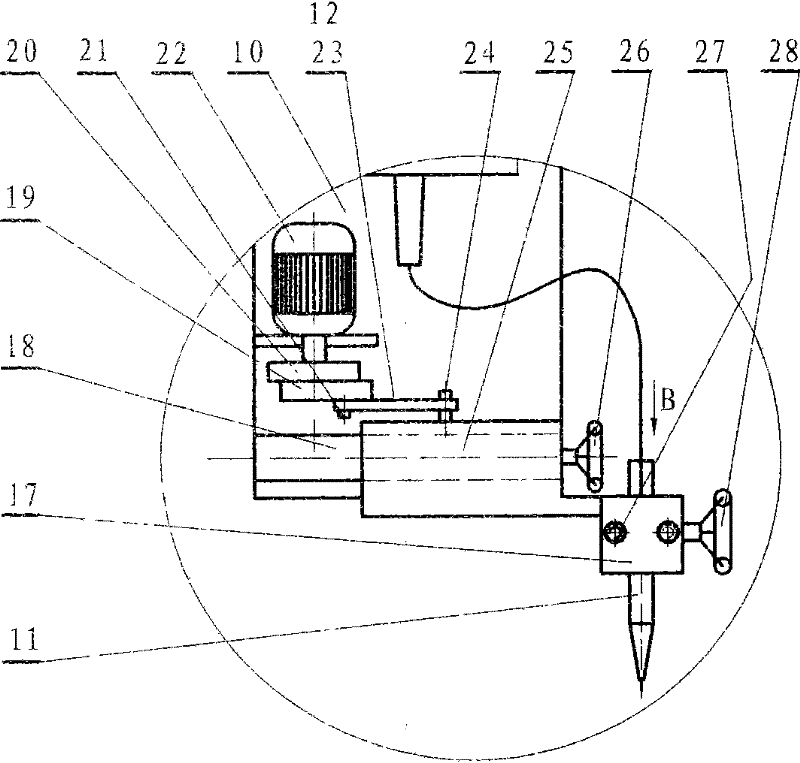

Program-controlled side-moving oil cylinder peripheral seam welding machine

InactiveCN102275032AHigh degree of automationImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlPower flow

The invention relates to a program-controlled side-moving oil cylinder circumferential seam welding machine, which consists of seven parts: an automatic control system, a power clamping mechanism, a lateral shifting device, a vertical lifting device, a welding torch swinging device, a position fine-tuning device and a welding mechanism. The invention adopts a PLC programmable controller as a main control unit, and adopts a Chinese display and video touch screen as a parameter adjustment dialogue interface. The touch screen can set the welding voltage, current welding speed and swing speed of each layer, and it is equipped with automatic and manual buttons for welding torch up and down. The invention adopts the mode of rotating the workpiece and fixing the welding torch; the welding torch is equipped with a fine-tuning mechanism and a two-axis angle adjustment device, which can adjust different welding angles; the welding torch is controlled by air pressure, and the micro DC motor drives the welding torch to swing; the tailstock is tightened by air pressure, and the machine head The three-jaw clamping method is adopted to realize automatic, manual and semi-automatic operation. The invention has the advantages of high degree of automation, good welding quality, safety and reliability.

Owner:YANCHENG EAST MACHINERY MFG CO LTD

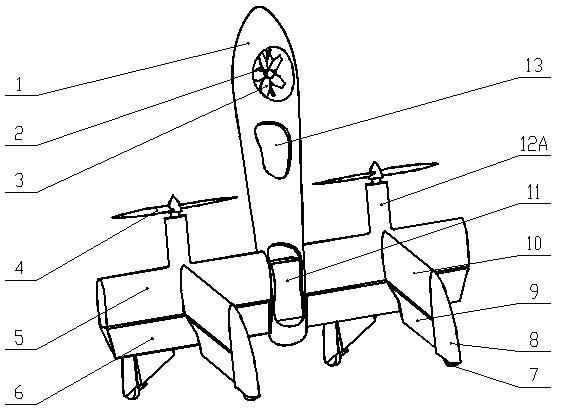

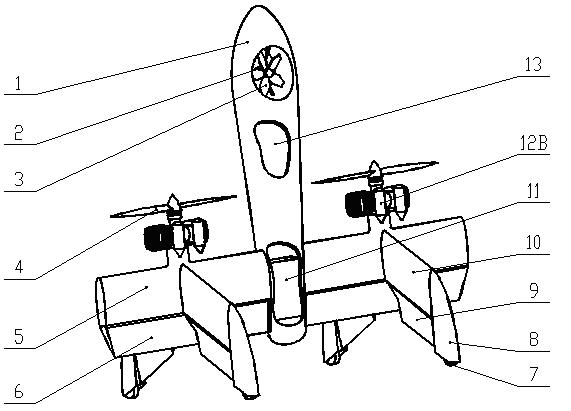

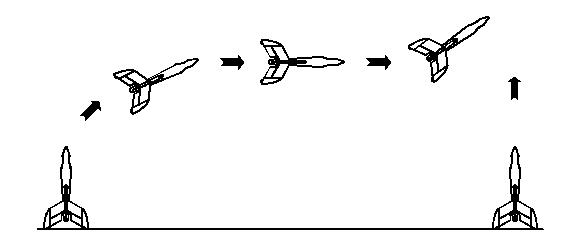

Tailstock type vertical take-off and landing unmanned aerial vehicle

The invention discloses a tailstock type vertical take-off and landing unmanned aerial vehicle. A pitching fan is mounted at the head of a body; the tail of the body is connected with wings; four vertical tails are distributed on the wings in a vertically and bilaterally symmetric manner; an off-course rudder and a landing gear are mounted behind the vertical tails; and two mutually independent propellers are fixed at the junction of the wings and the vertical tails. According to the invention, as the tailstock type fixed-wing vertical take-off and landing technology is adopted, the unmanned aerial vehicle not only can vertically take off and land and hover as a helicopter, but also can cruise at a high speed as a fixed-wing aircraft; and the structure is simple, the power is simplified, and the manipulation is flexible. Due to the pitching fan at the head of the body, the aerial vehicle can fly more actively; and particularly in transitional flying from a vertical state to a horizontal state or from a horizontal state to a vertical state, the advantages are more obvious, and the vertical-to-horizontal conversion can be finished only by rising a short distance or in a hovering state.

Owner:SHANGHAI UNIV

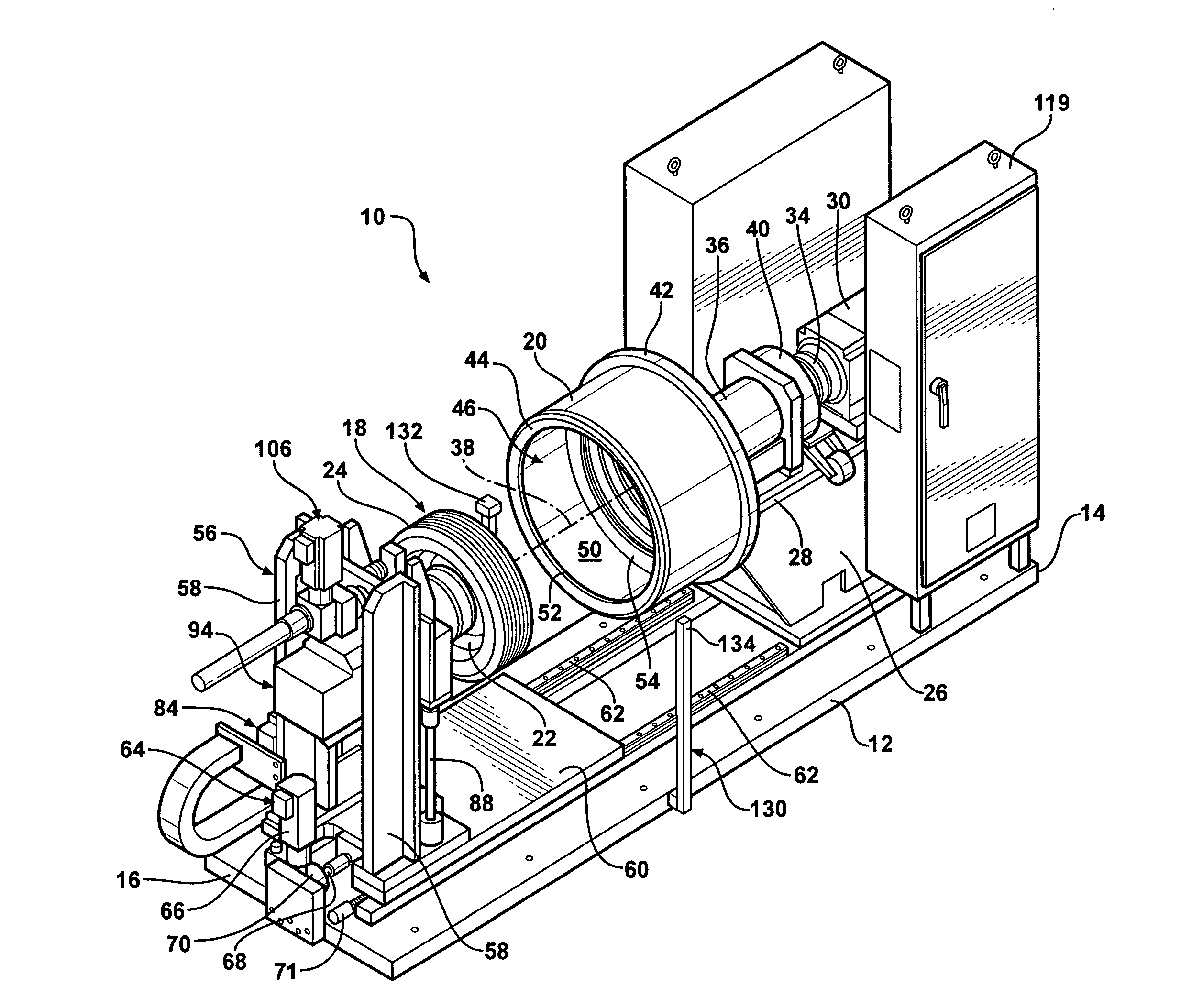

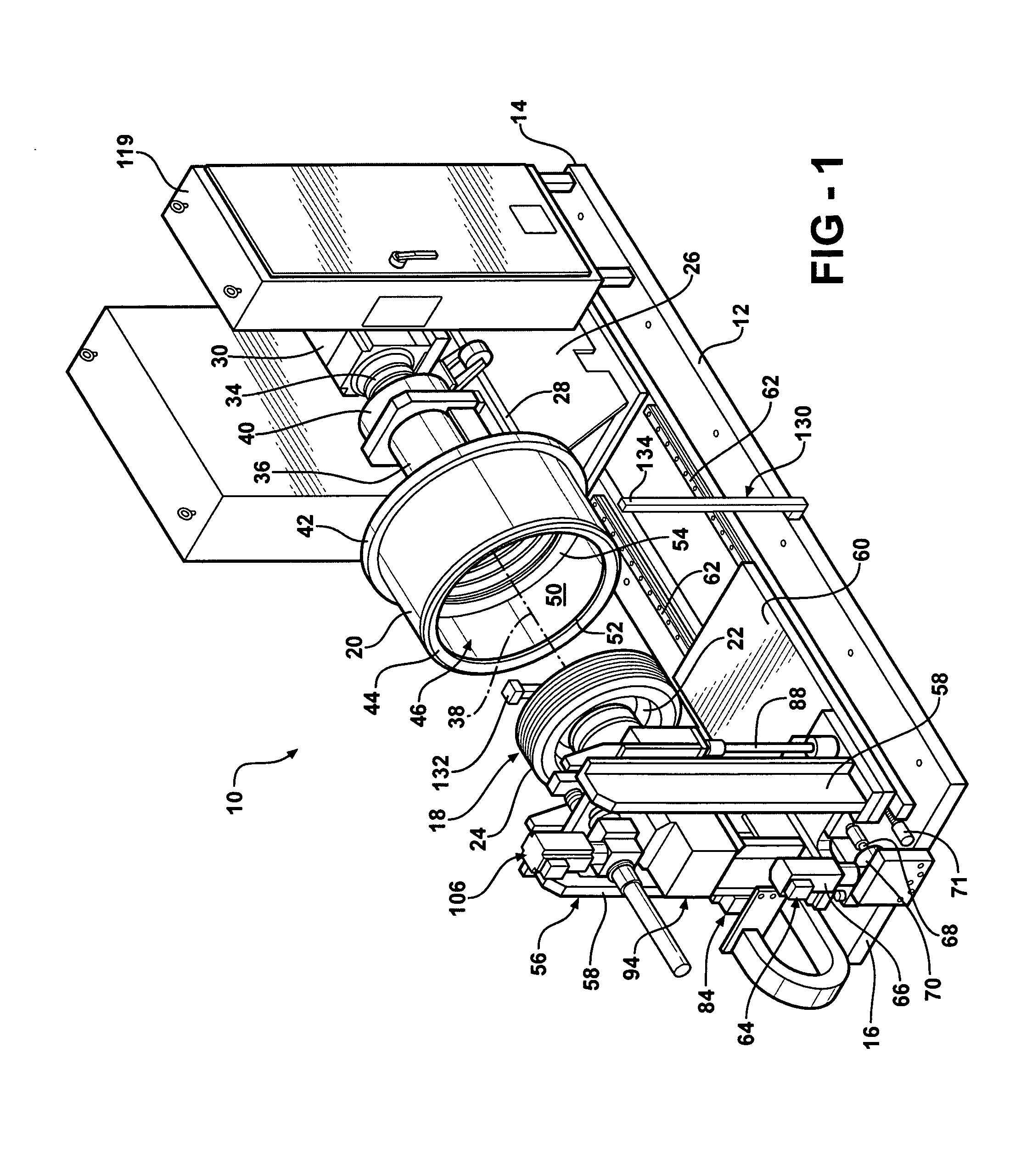

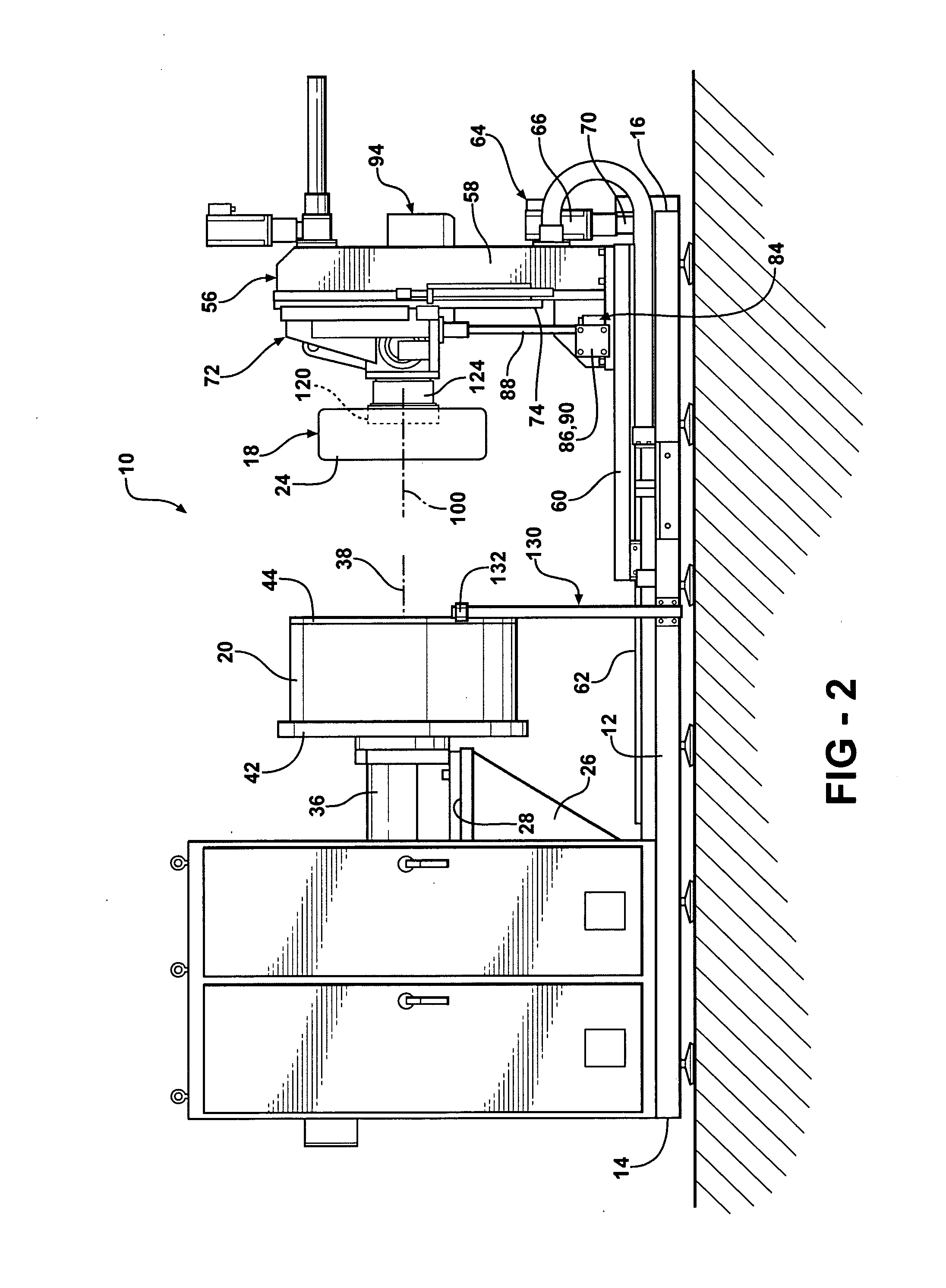

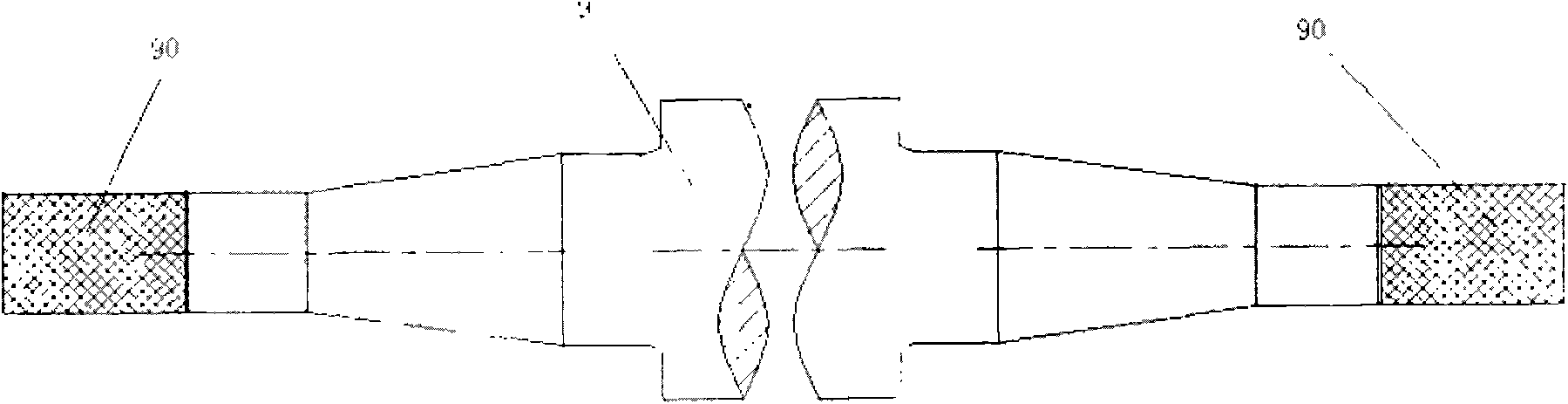

Biaxial wheel test assembly

A wheel test assembly for testing a wheel-and-tire assembly includes a drum operatively mounted to a base for rotation of the drum. The drum includes an inner circumferential surface. A tailstock assembly is slidably coupled to the base for movement in a lateral direction relative to the drum. A support assembly is slidably coupled to the tailstock assembly for movement in a vertical direction for positioning the wheel-and-tire assembly into rolling contact with the inner circumferential surface of the drum. A spindle assembly is pivotally coupled to the support assembly to adjust a camber angle of the wheel-and-tire assembly. The wheel-and-tire assembly is mounted to the spindle assembly for rotation of the wheel-and-tire assembly.

Owner:LINK ENG

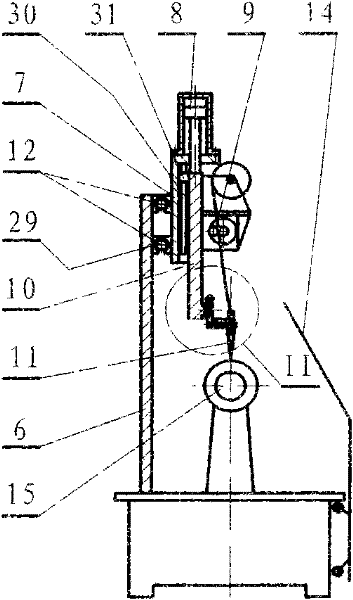

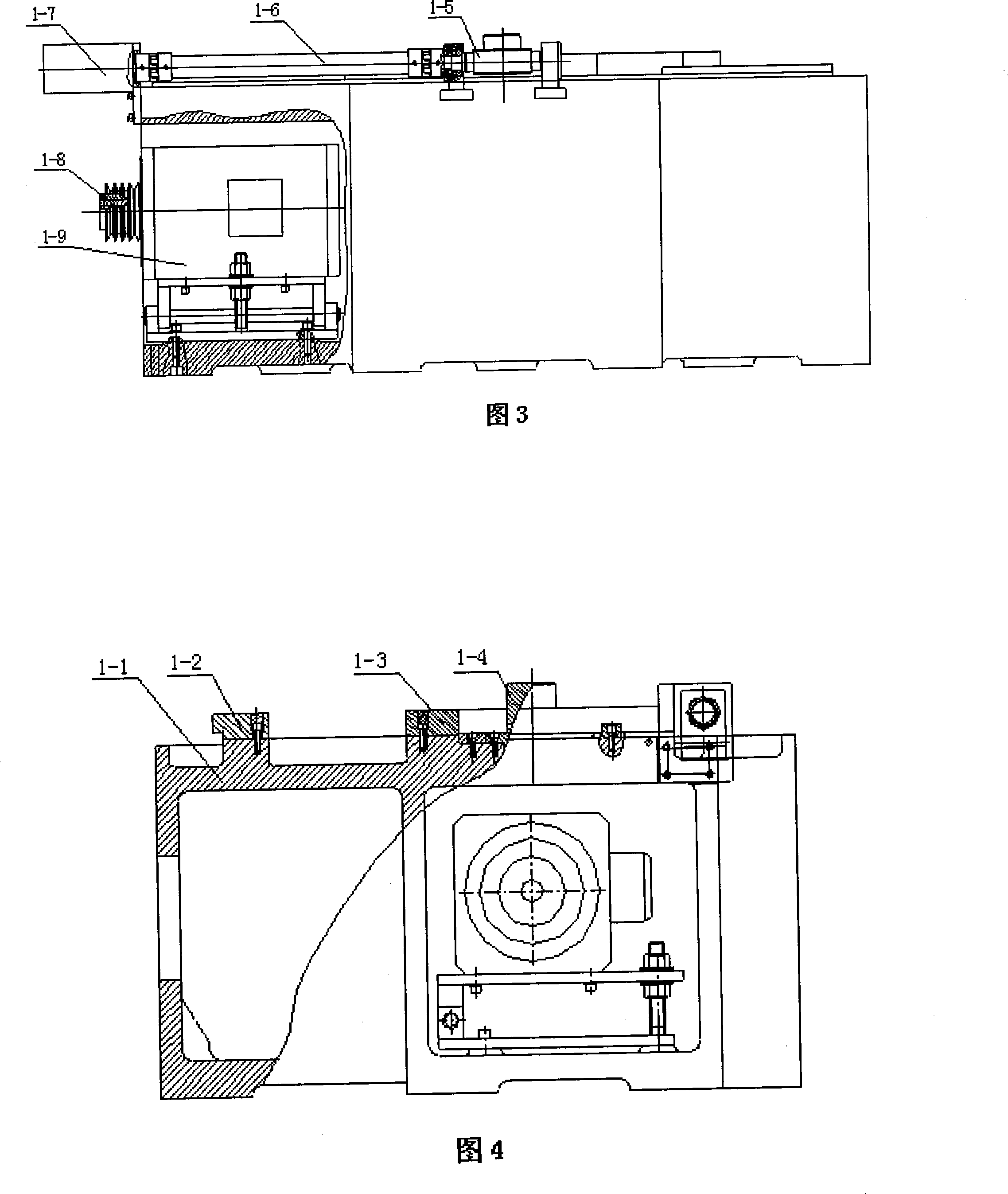

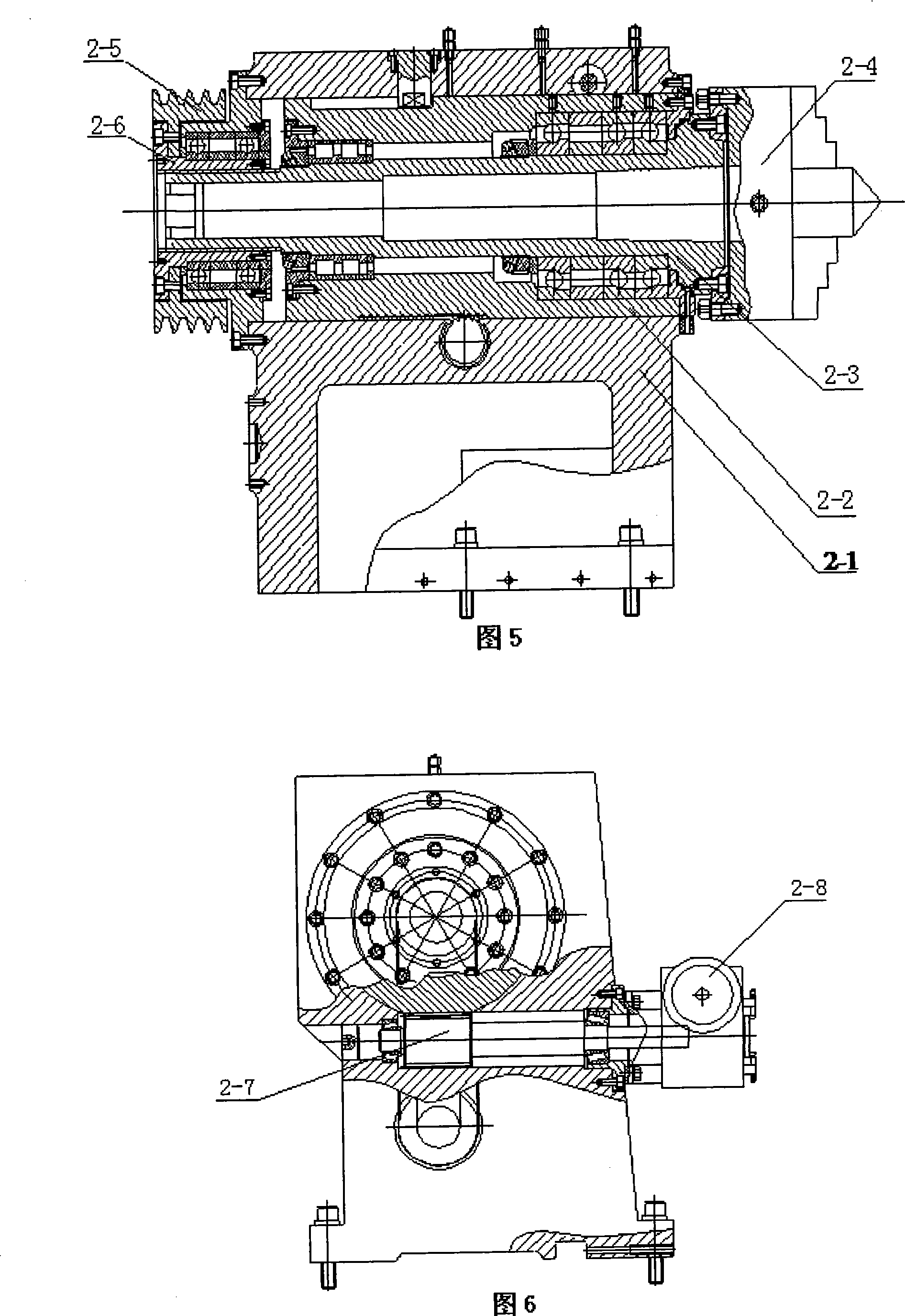

High-rigidity turning spherical surface numerical control accurate grinding equipment

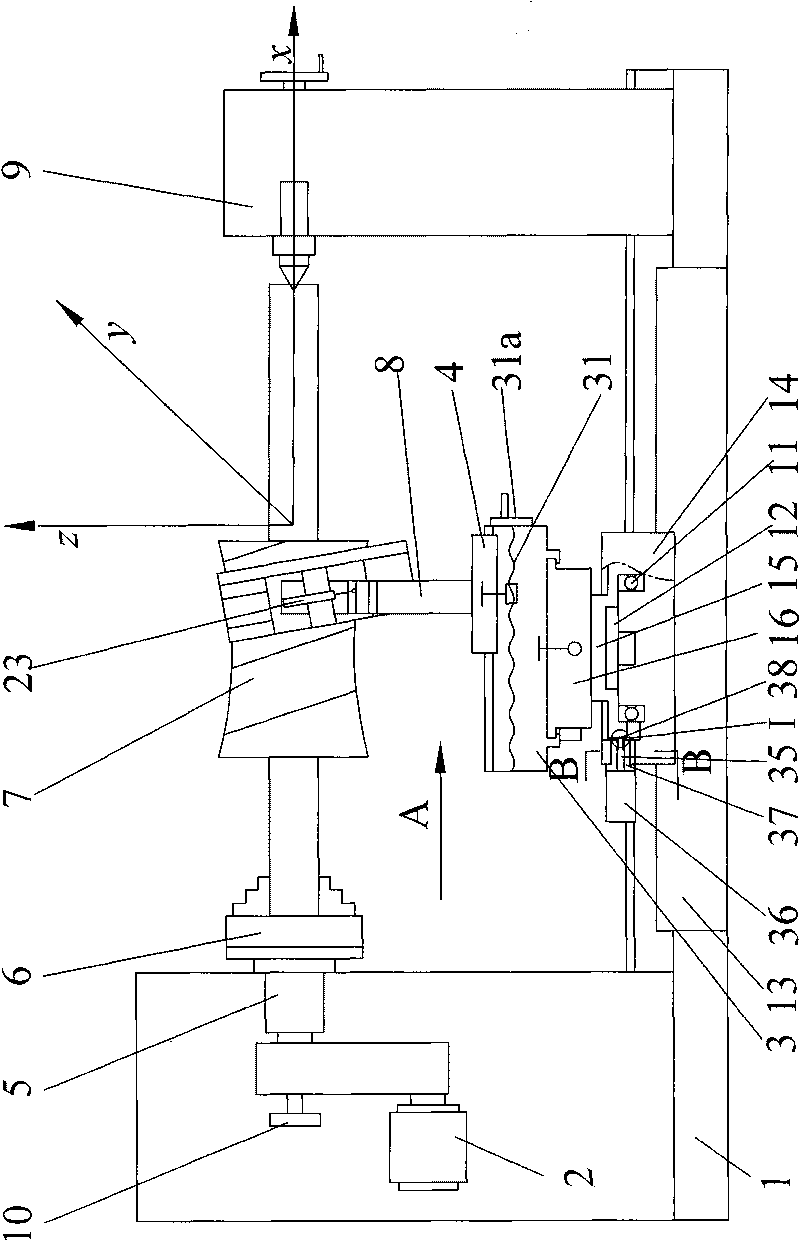

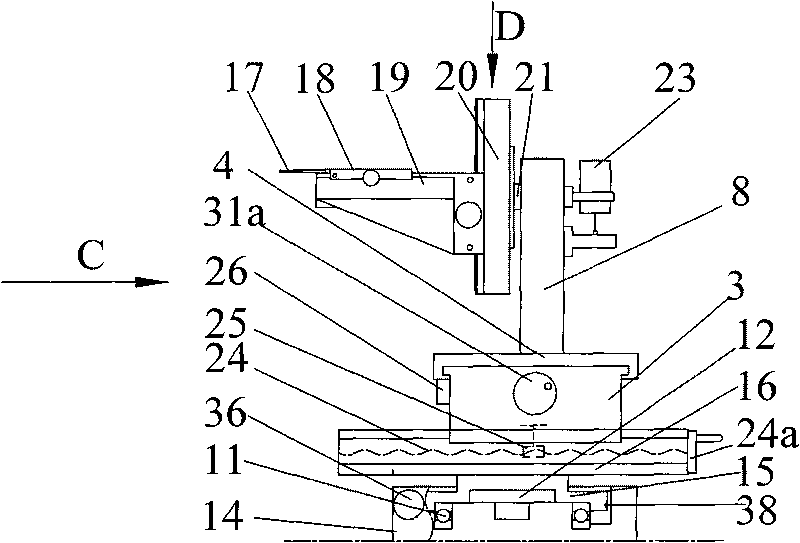

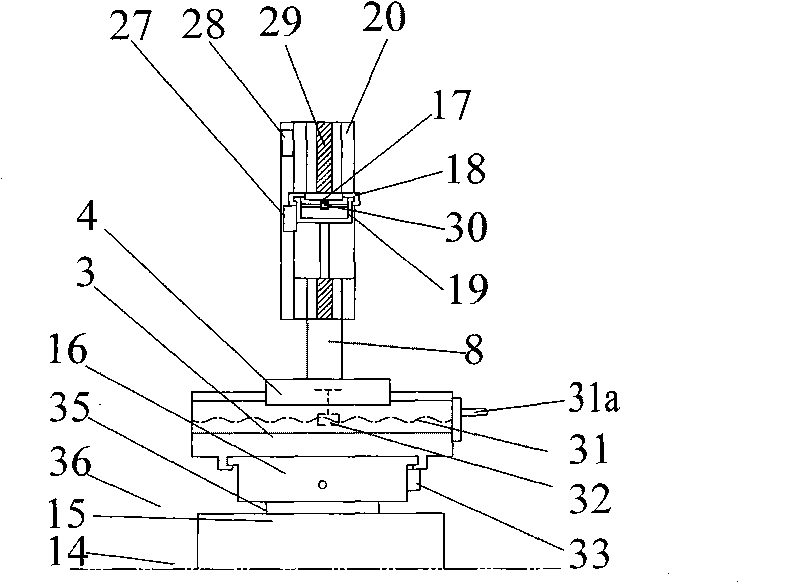

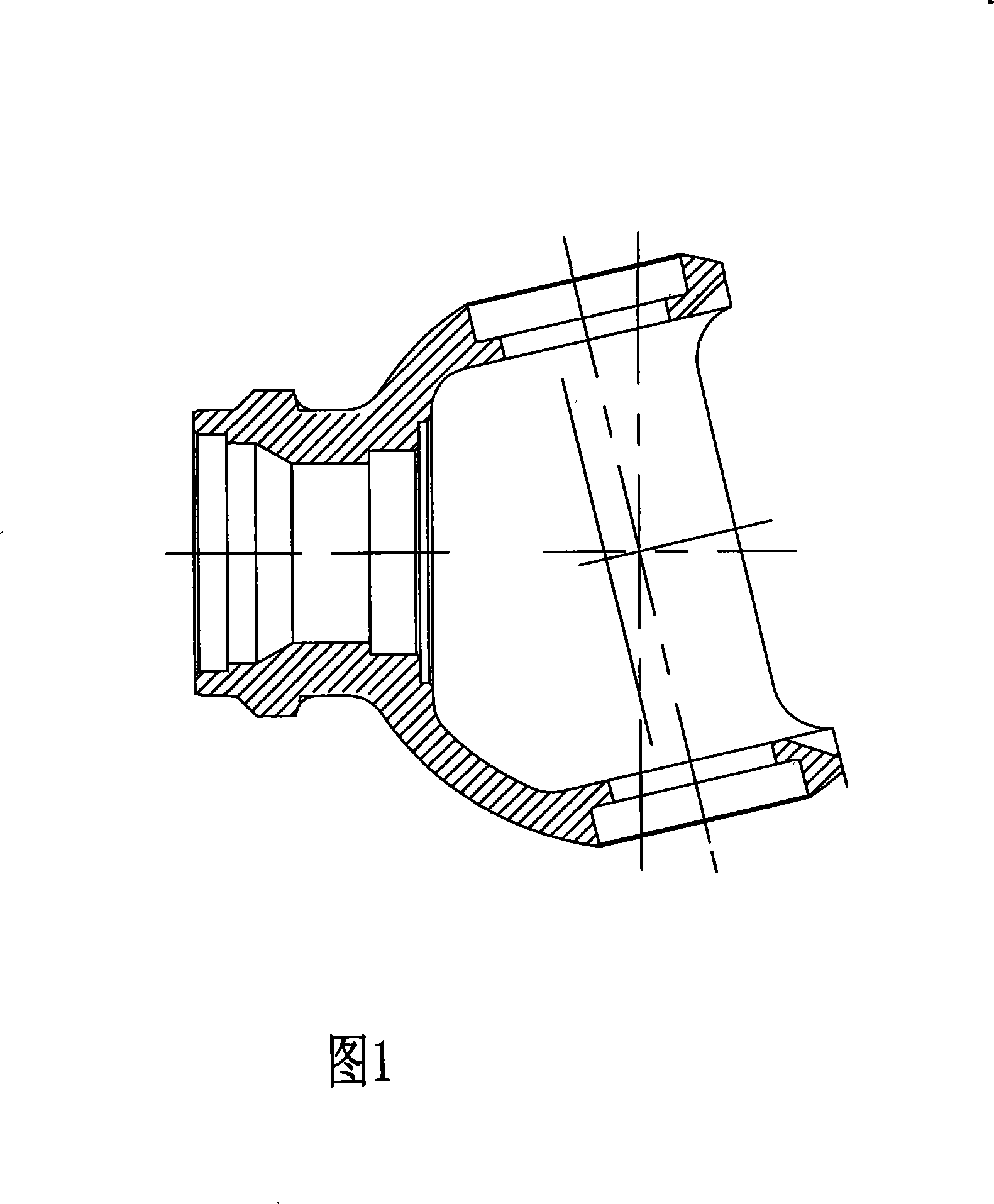

InactiveCN101172330AFast precision grindingRapid grindingGrinding carriagesSpherical surface grinding machinesNumerical controlMotor drive

The invention relates to a rotating spherical surface numerically controlled accurate grinding equipment with high hardness. The equipment comprises a bed body part, a main spindle box part, a wheel stand rotating table part, a tail seat part and a grinding wheel. The main spindle box part and the tail seat part are fixed on the bed body through a bolt; the wheel stand rotating table part is supported on a circular arc guide rail and a circular ring guide rail, a winding and fixed axle moves to and fro through a worm rod and a sector worm wheel under the driving of an actuating motor; the actuating motor drives a wheel stand slide seat to do direct feed motion on the guide rail on the wheel stand rotating table through a feed screw nut pair; the grinding wheel composed of a grinding wheel disc and a grinding wheel block is directly connected with an electric principal axis through a connecting shaft, thereby the propose that the grinding wheel with diameter is used for grinding a rotating spherical surface work piece with high hardness and different diameters though the high speed rotation movement of the grinding wheel, the rotation movement of the rotating spherical surface work piece, the feed movement of the grinding wheel stand and the reciprocating motion of the grinding wheel stand.

Owner:SHANGHAI JIAO TONG UNIV

Traffic vehicle flow detection method based on video

InactiveCN101777263AAvoid interferenceHigh precisionRoad vehicles traffic controlCharacter and pattern recognitionTraffic capacityComputer graphics (images)

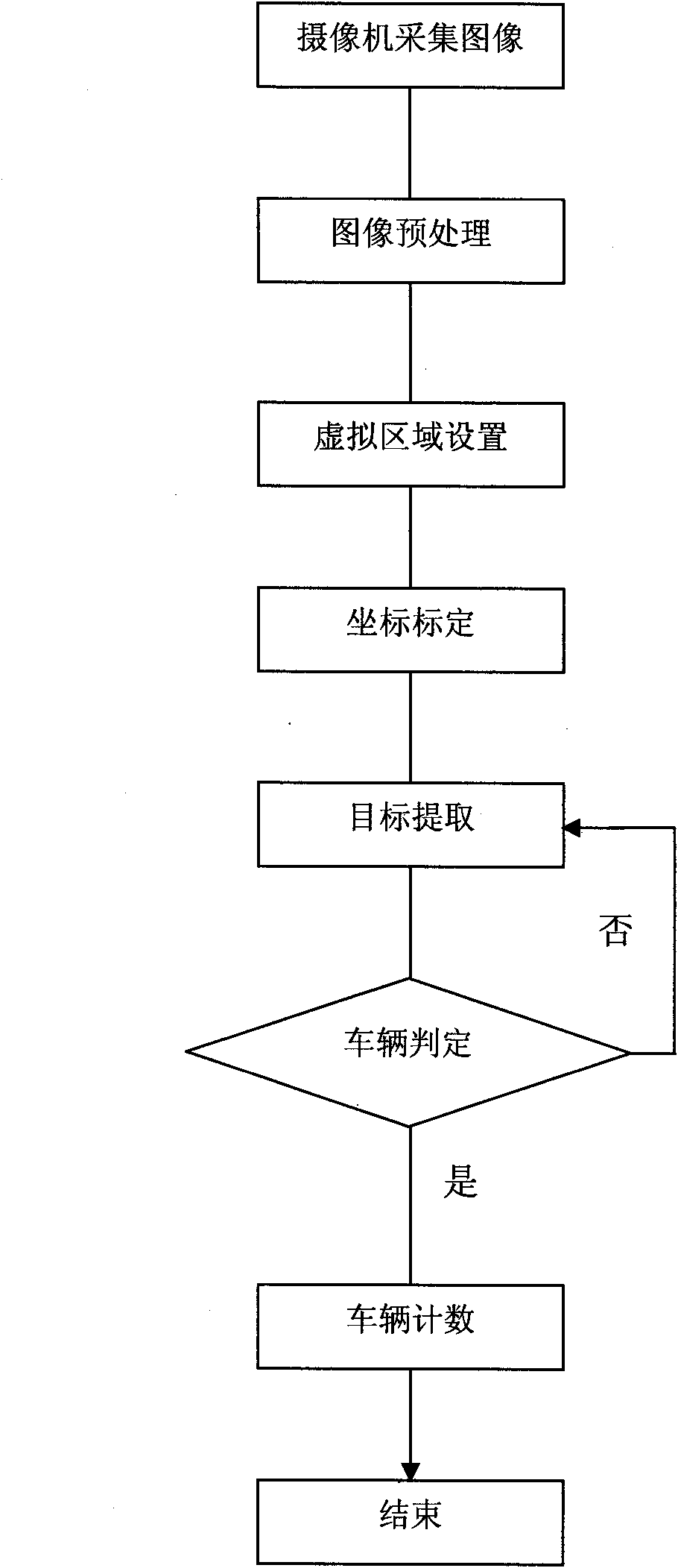

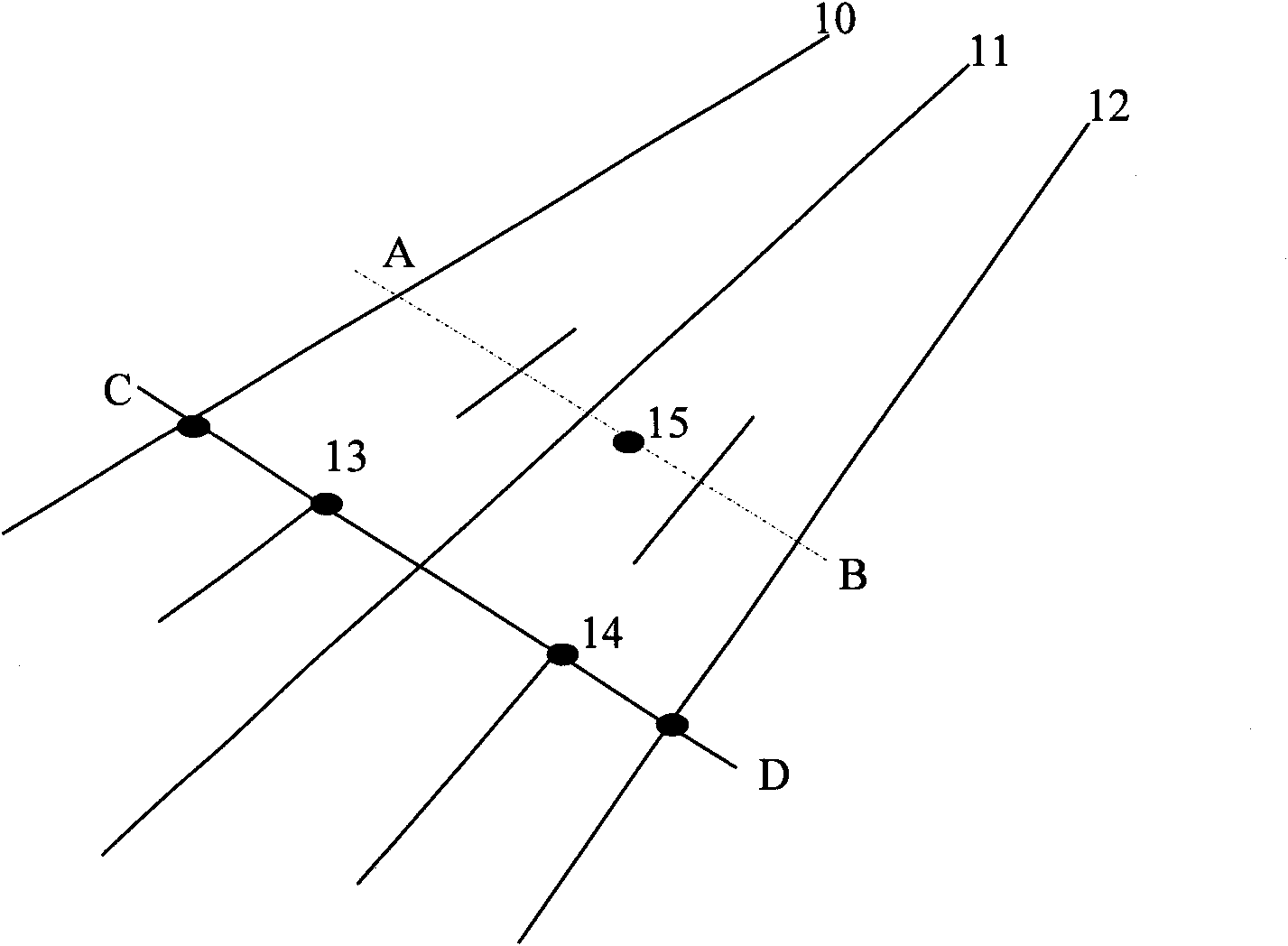

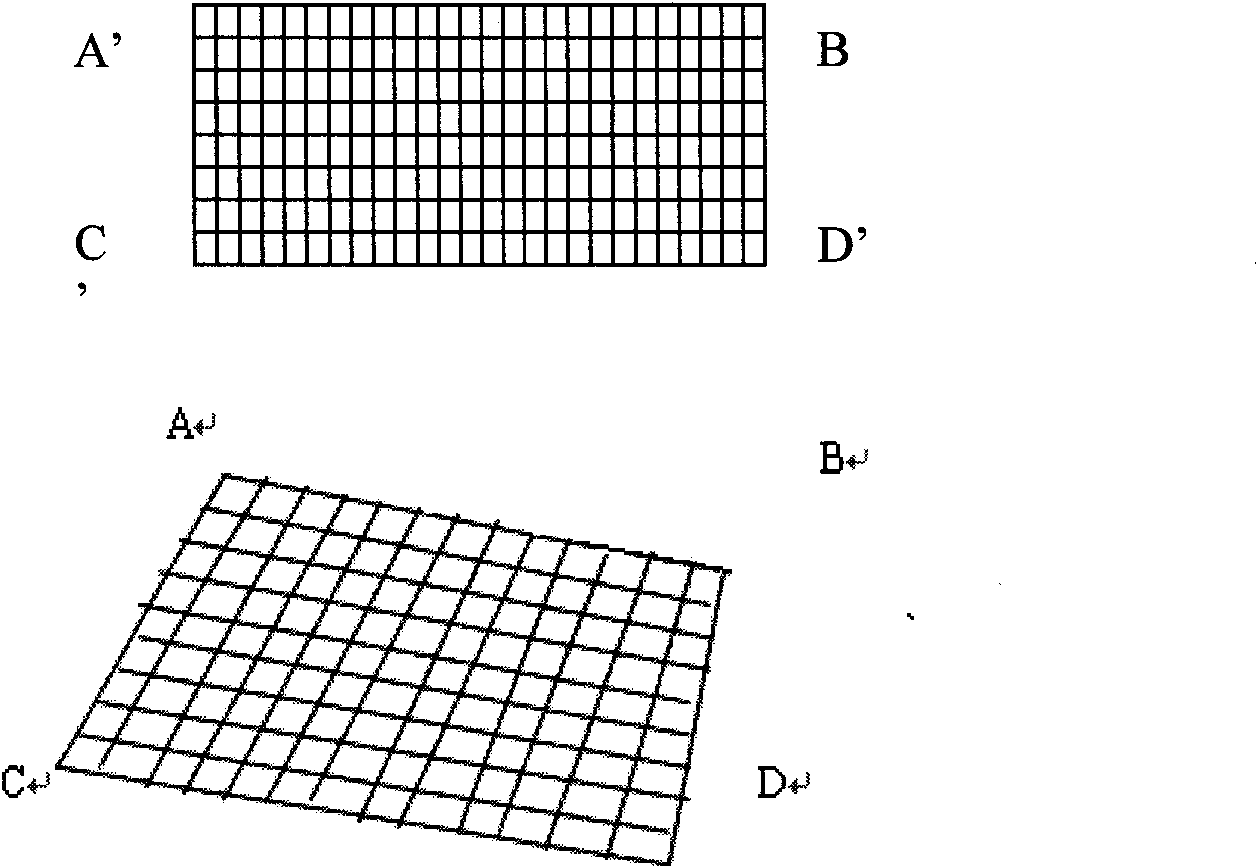

A traffic flow vehicle detection method based on a video comprises the following steps: acquiring information; preprocessing images; setting a virtual detection area by the steps of reading whole video data, setting a virtual area or the virtual detection area for a first frame image, and selecting an area which has proper size and is vertical to the traveling direction of a vehicle as the virtual detection area of the processing analysis of vehicle detection; calibrating coordinates: finding the corresponding perspective relationship of the actual road image and the shot video image and converting the coordinates on the virtual detection area; extracting a target: carrying out the binarization division on a target area and analyzing binarization characteristic patterns; judging the vehicle by using the two-dimension information of the vehicle edge; detecting the side edge and the tailstock position of each target in the virtual detection area, if being detected to simultaneously have the side edge and the tailstock, the target is taken as the vehicle, entering the next step, or returning to continue to extract the target; calculating the vehicle, and ending the detection.

Owner:CHANGAN UNIV

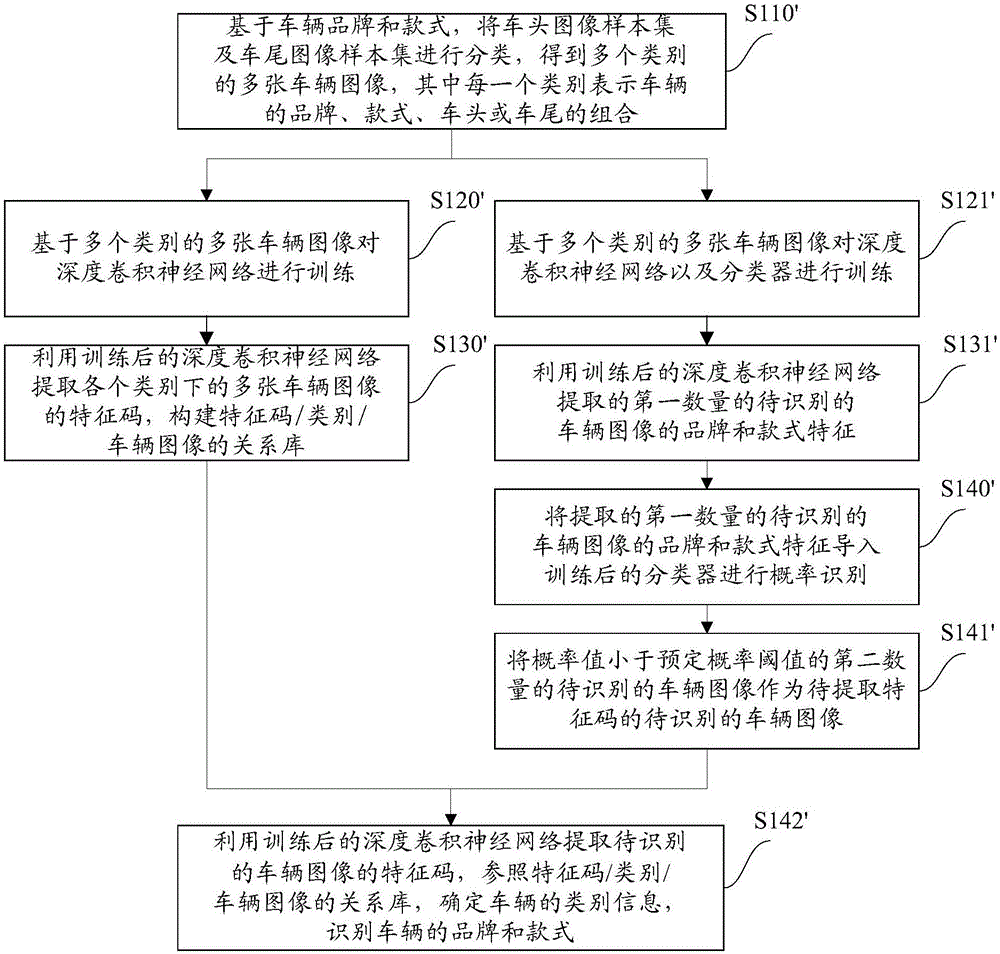

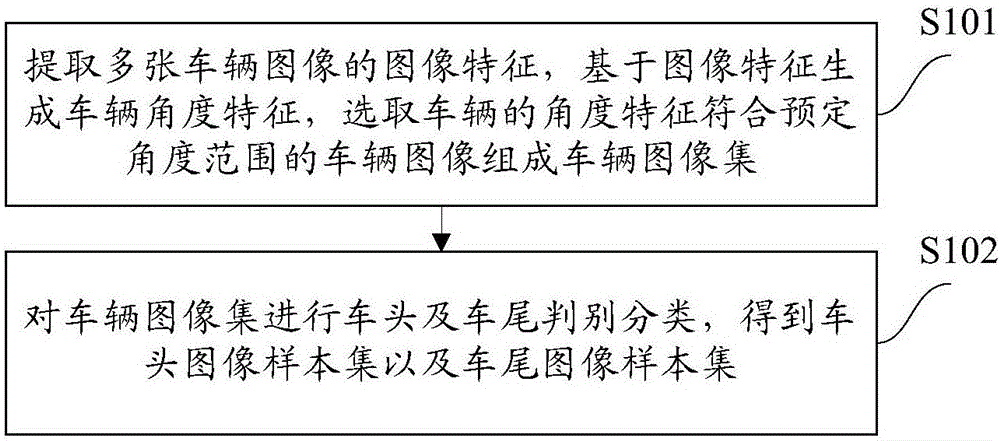

Vehicle type identification method and system

InactiveCN106295541AImprove accuracyImprove identification management efficiencyCharacter and pattern recognitionComputer visionMultiple category

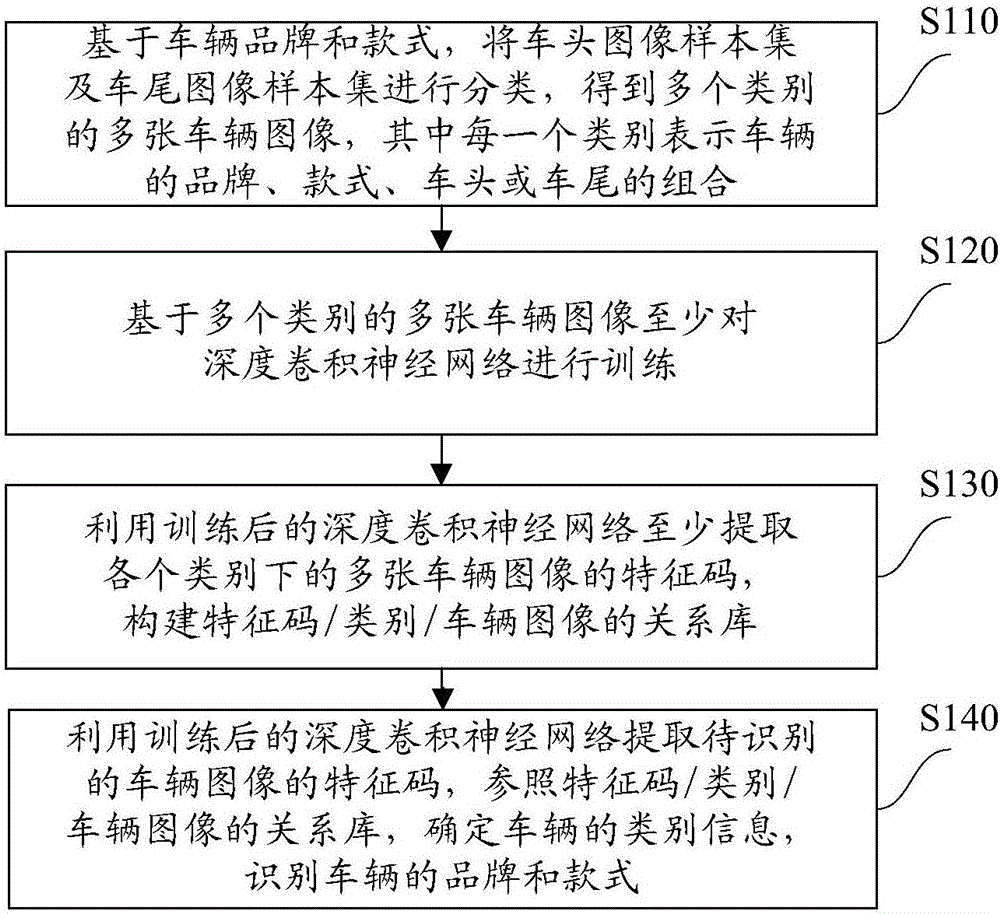

The invention provides a vehicle type identification method. The method comprises steps that on the basis of a vehicle brand and a pattern, headstock image sample sets and tailstock image sample sets are classified to acquire multiple categories of multiple vehicle images; on the basis of the multiple categories of multiple vehicle images, a depth convolution neural network is at least trained; at least characteristic codes of multiple vehicle images of various categories are respectively extracted through utilizing the trained depth convolution neural network, and a characteristic code / type / vehicle image relationship database is constructed; the trained depth convolution neural network is utilized to extract a characteristic code of to-be-identified vehicle images, the type information of a vehicle is determined according to the characteristic code / type / vehicle image relationship database, and the vehicle brand and the pattern of the vehicle are identified. The invention further provides a vehicle type identification system. The method and the system can adapt to various environments, accuracy of identifying the vehicle category information is improved, and the method and the system have wide application prospects.

Owner:LETV HLDG BEIJING CO LTD +1

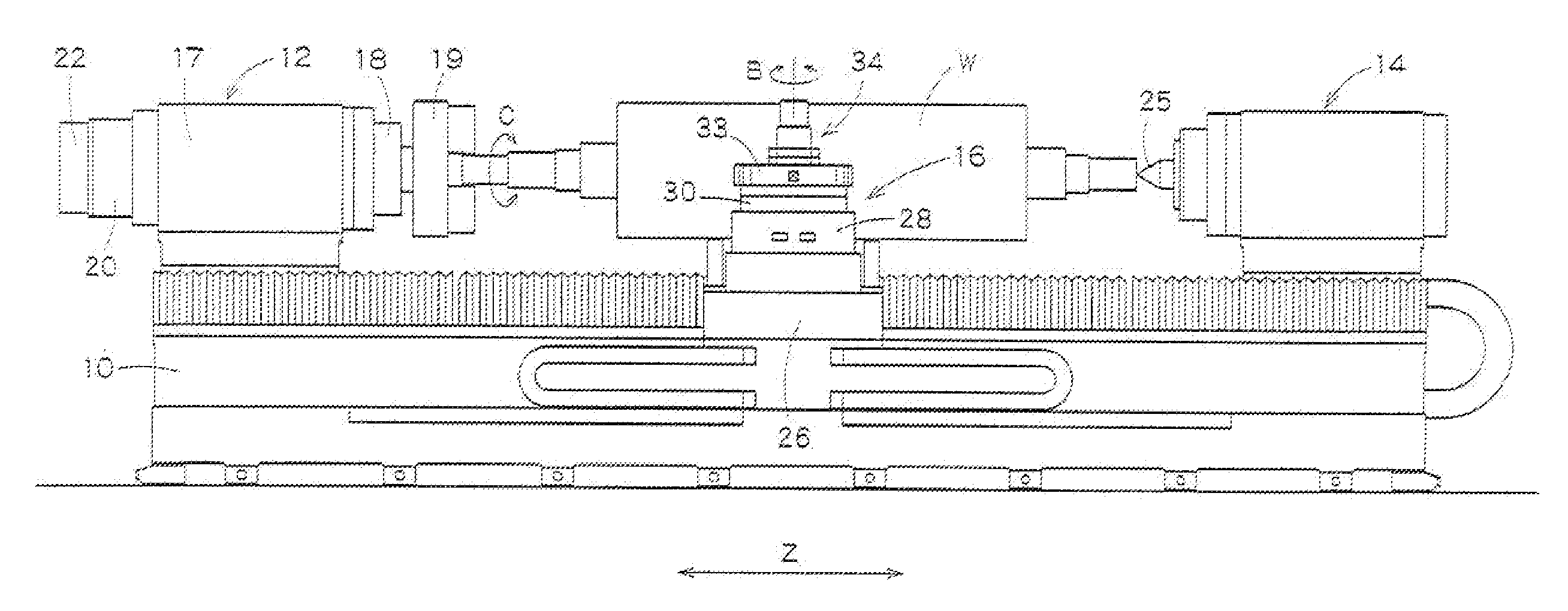

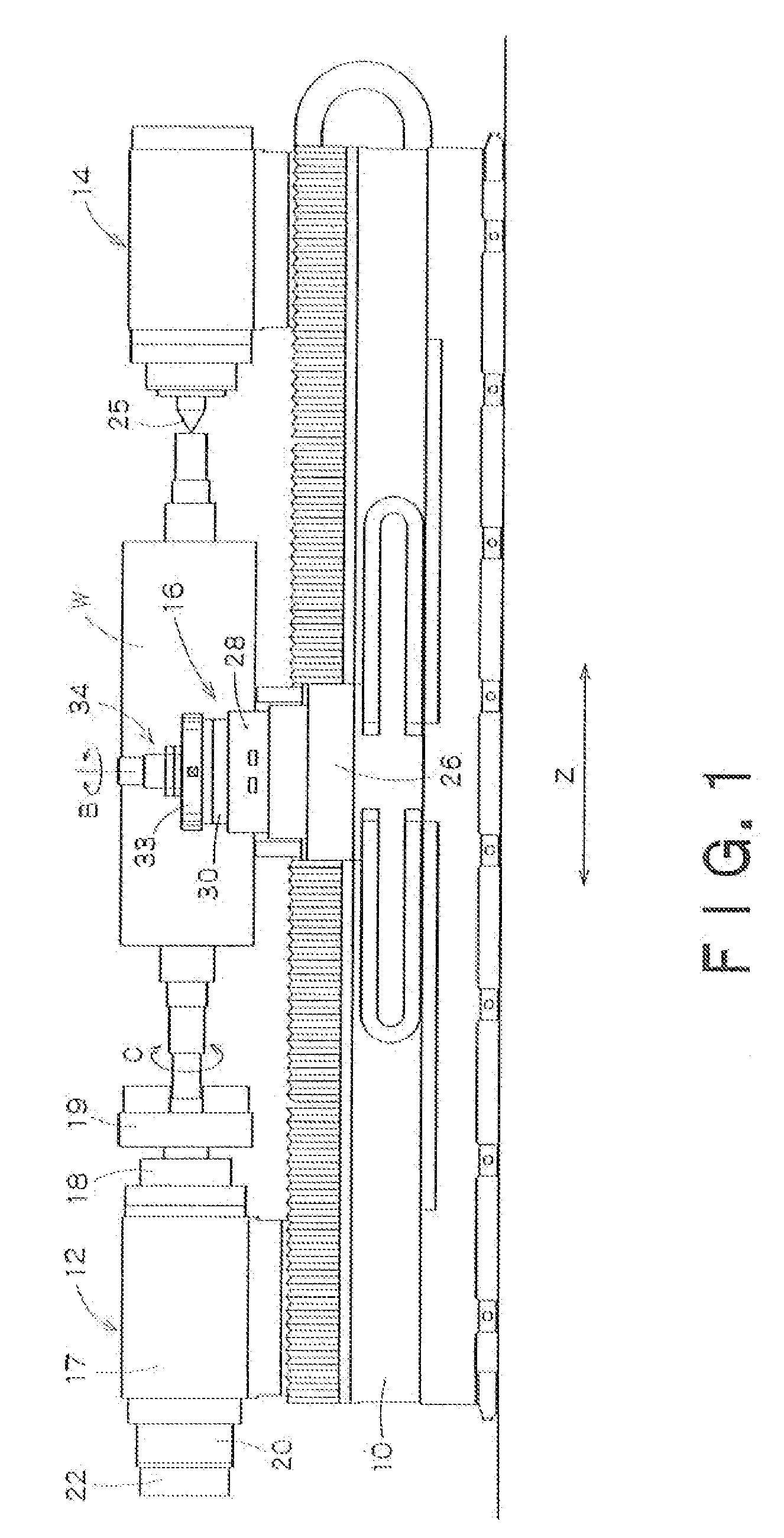

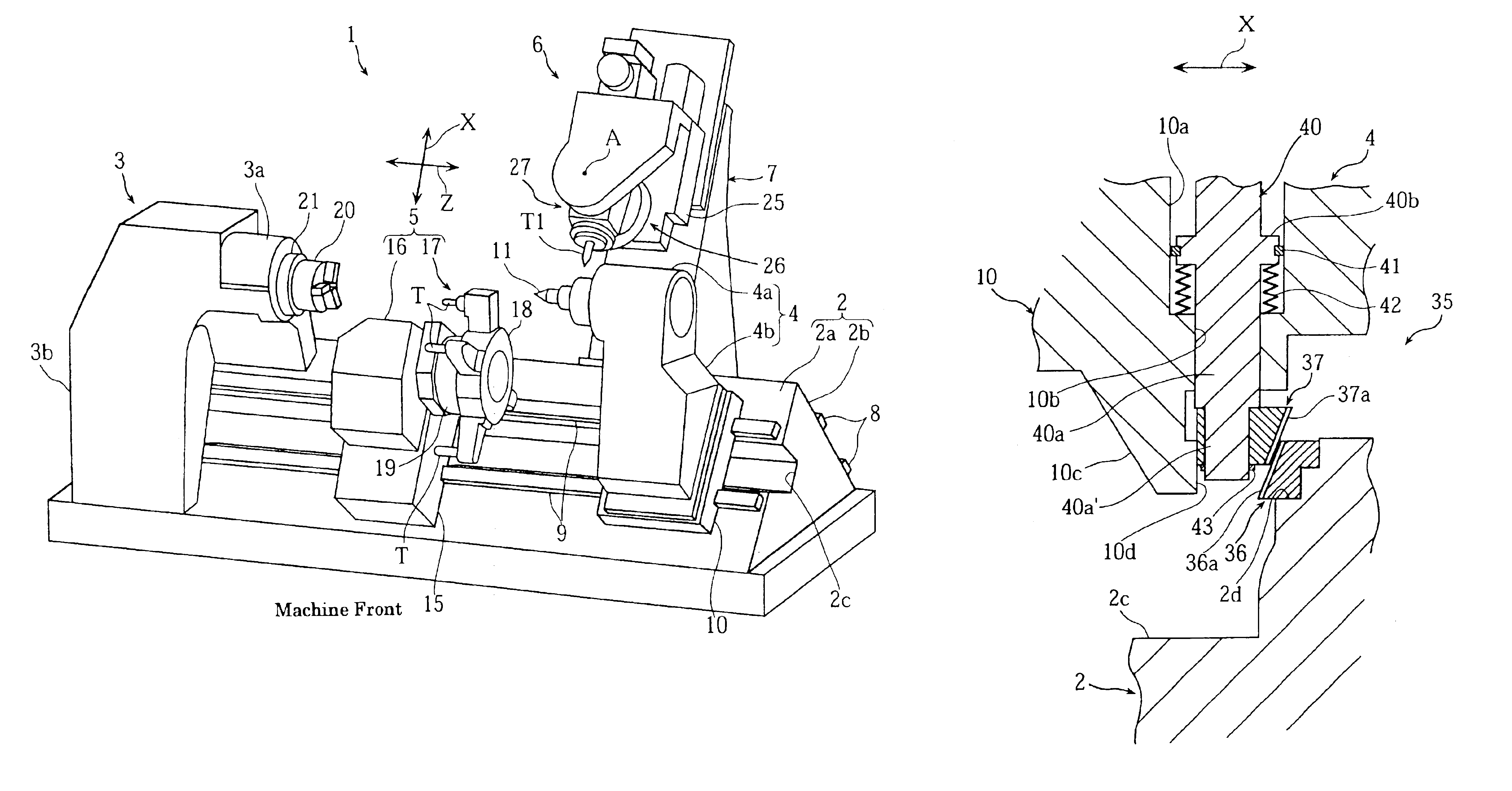

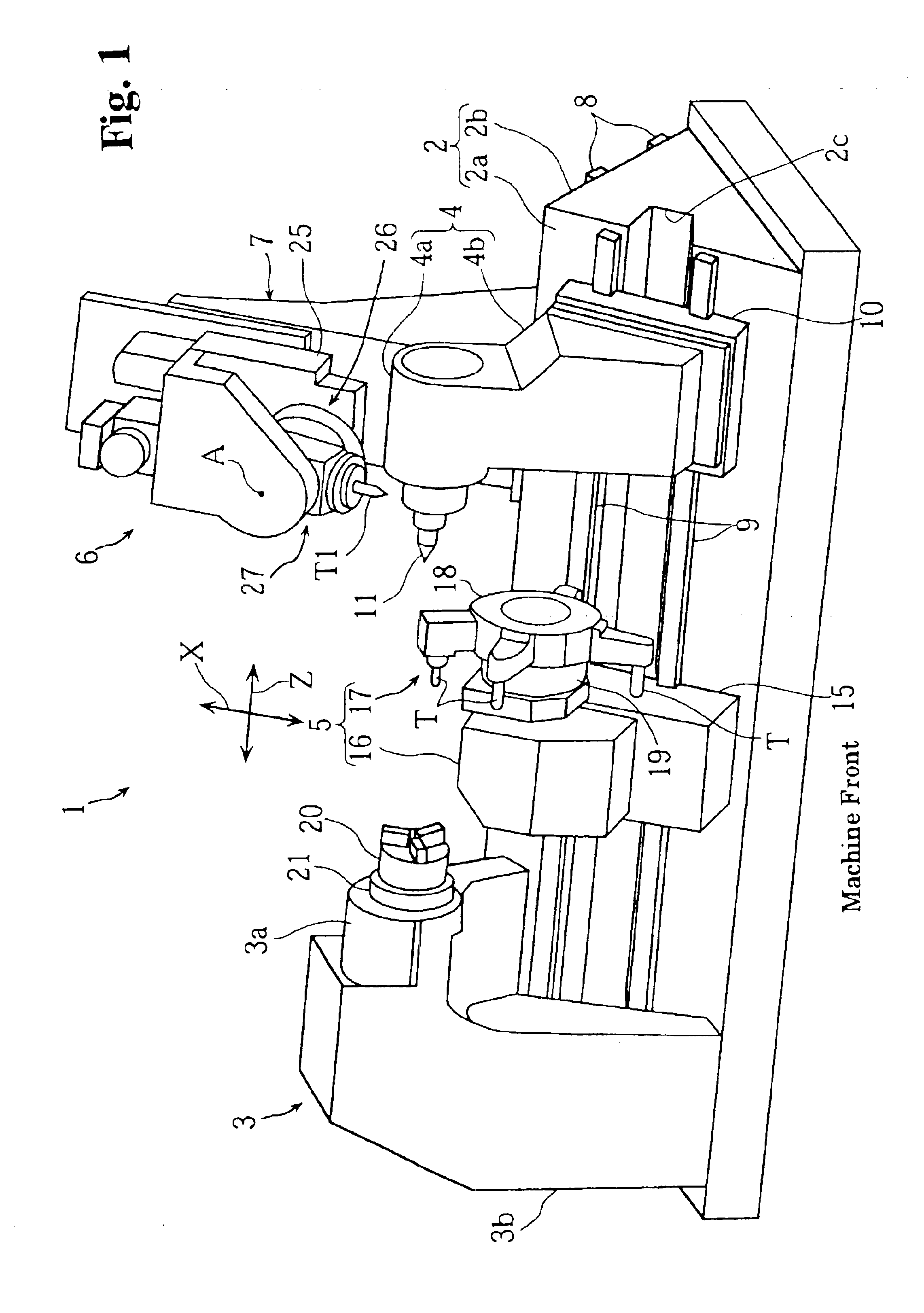

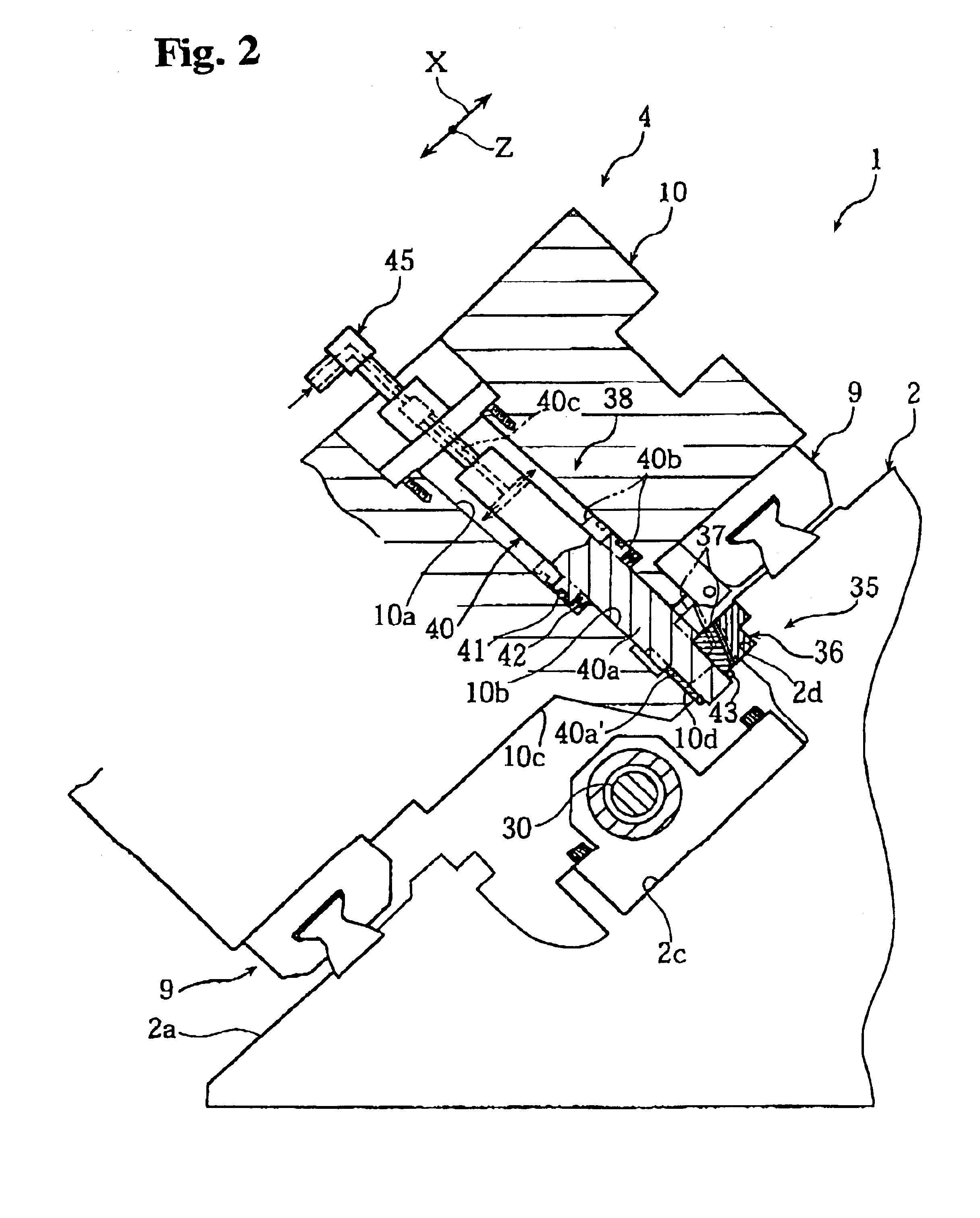

Precision roll turning lathe

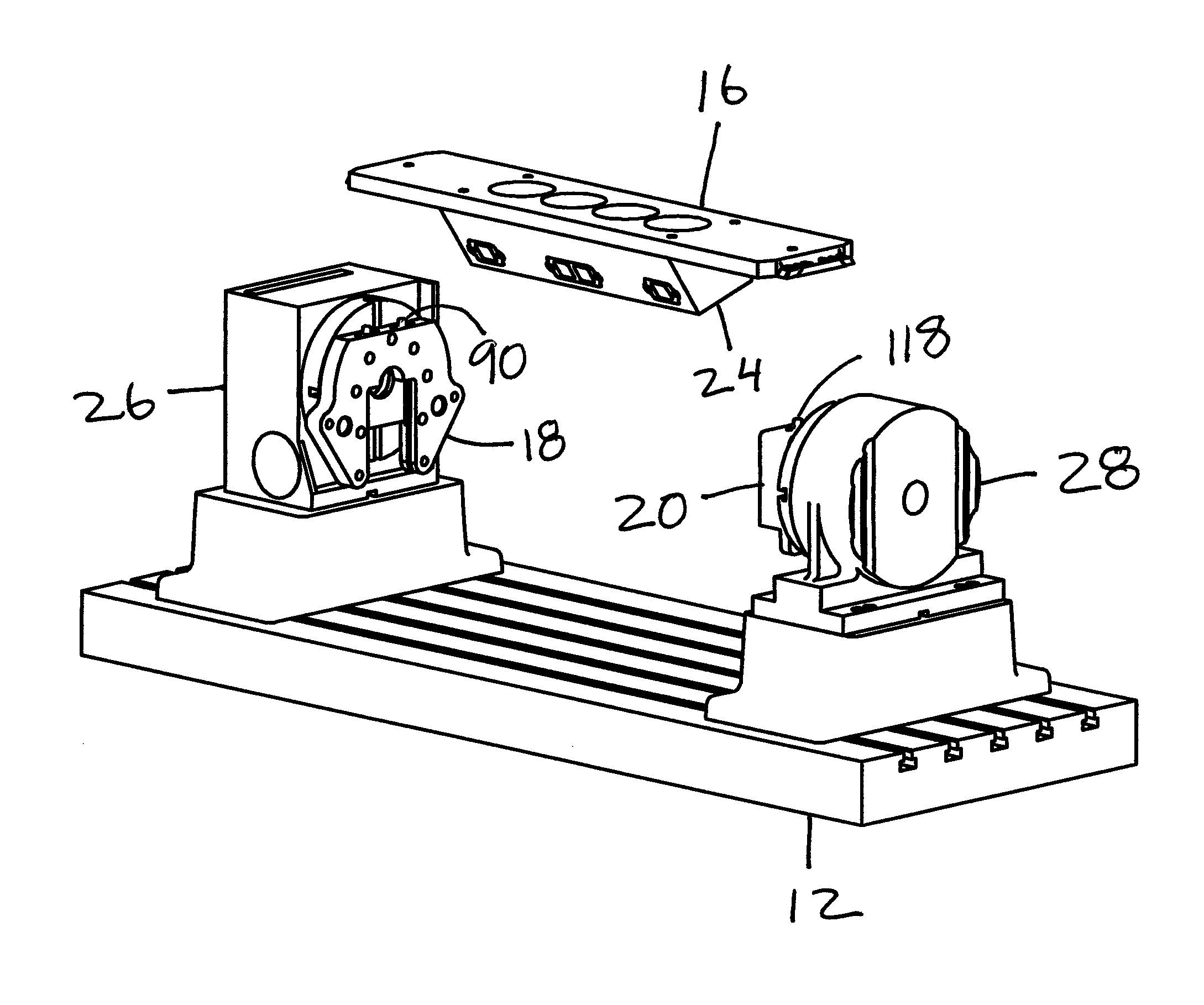

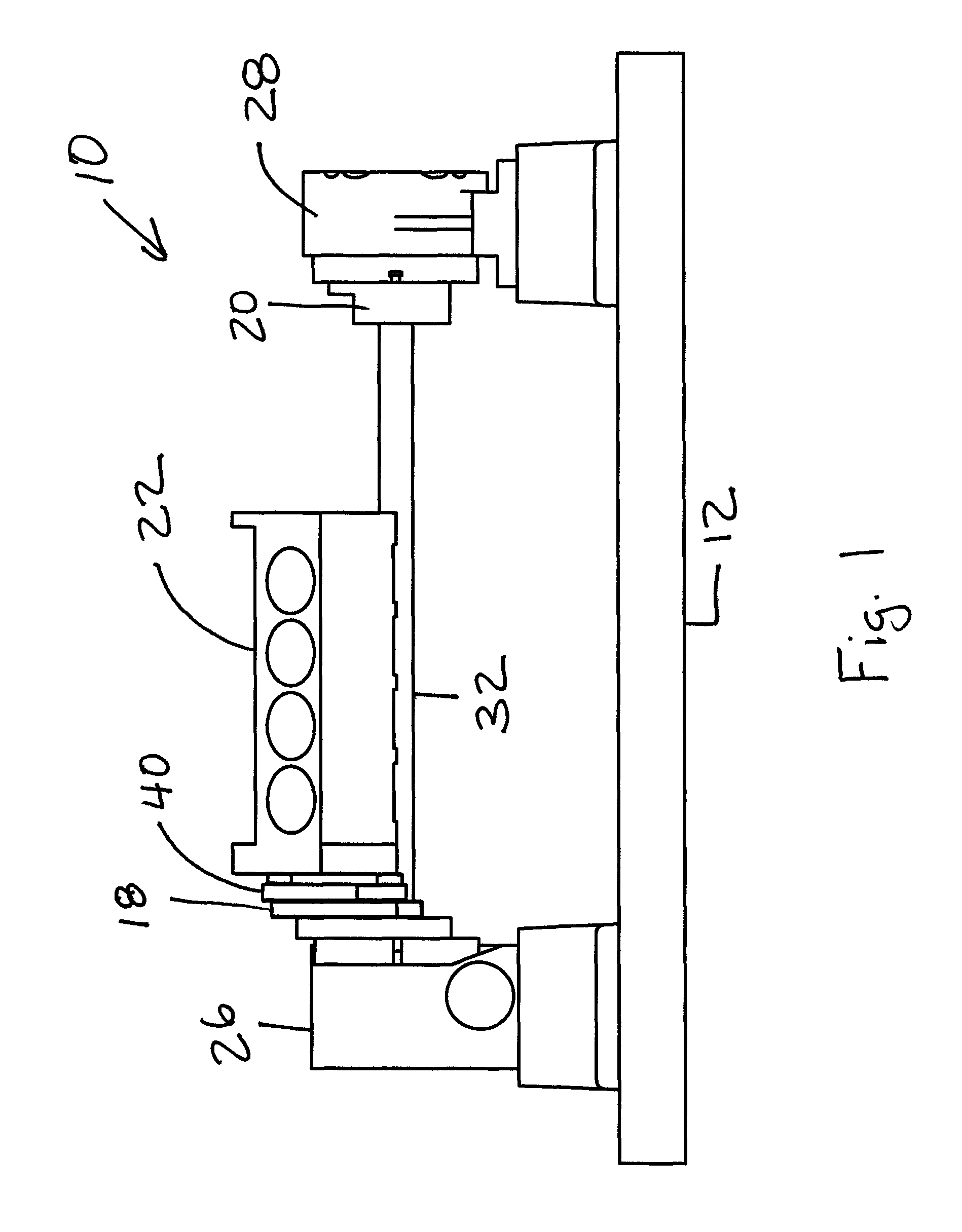

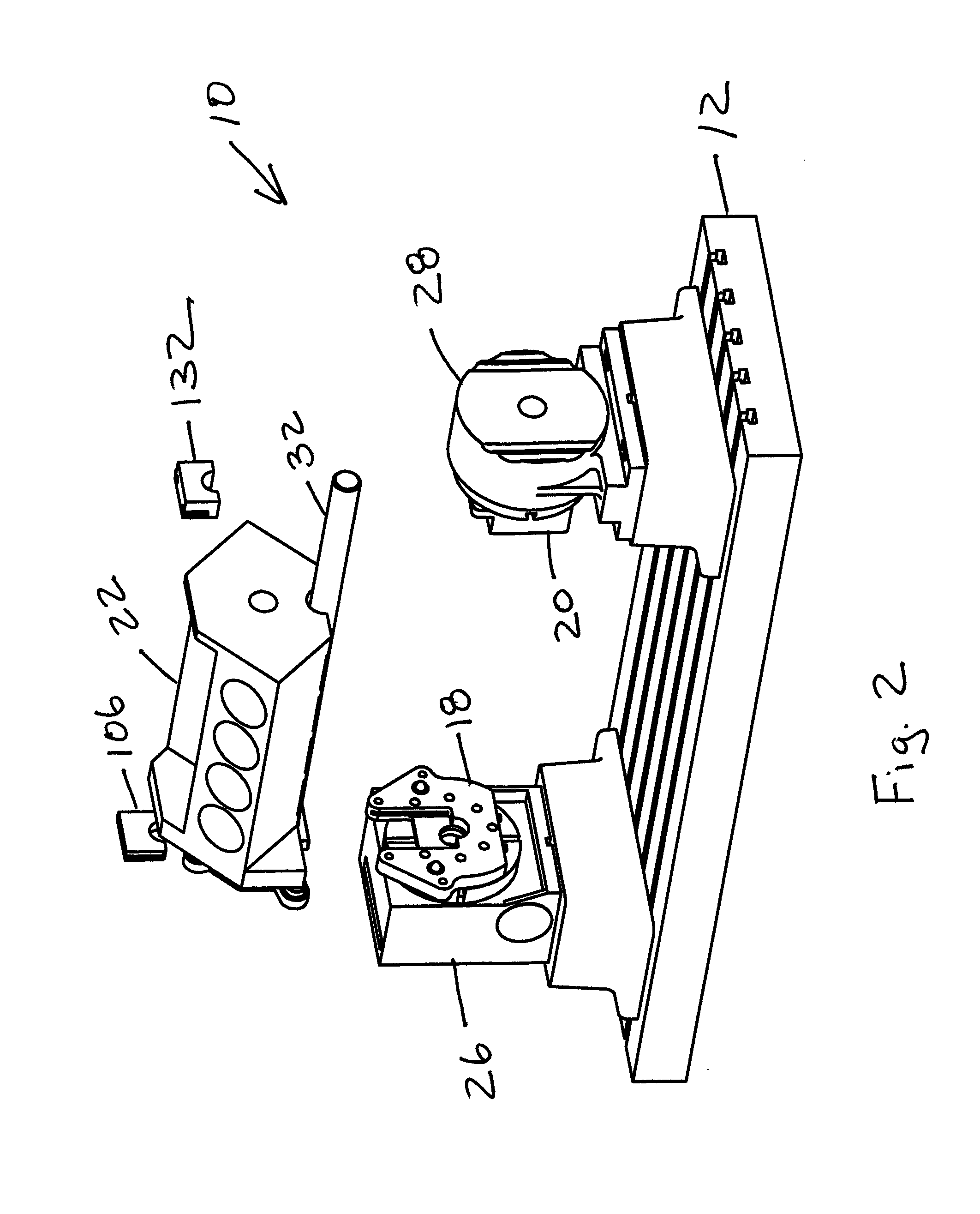

ActiveUS20070251360A1High precision machiningAvoid low machining accuracyAutomatic/semiautomatic turning machinesPropelling pencilsTransverse grooveHeadstock

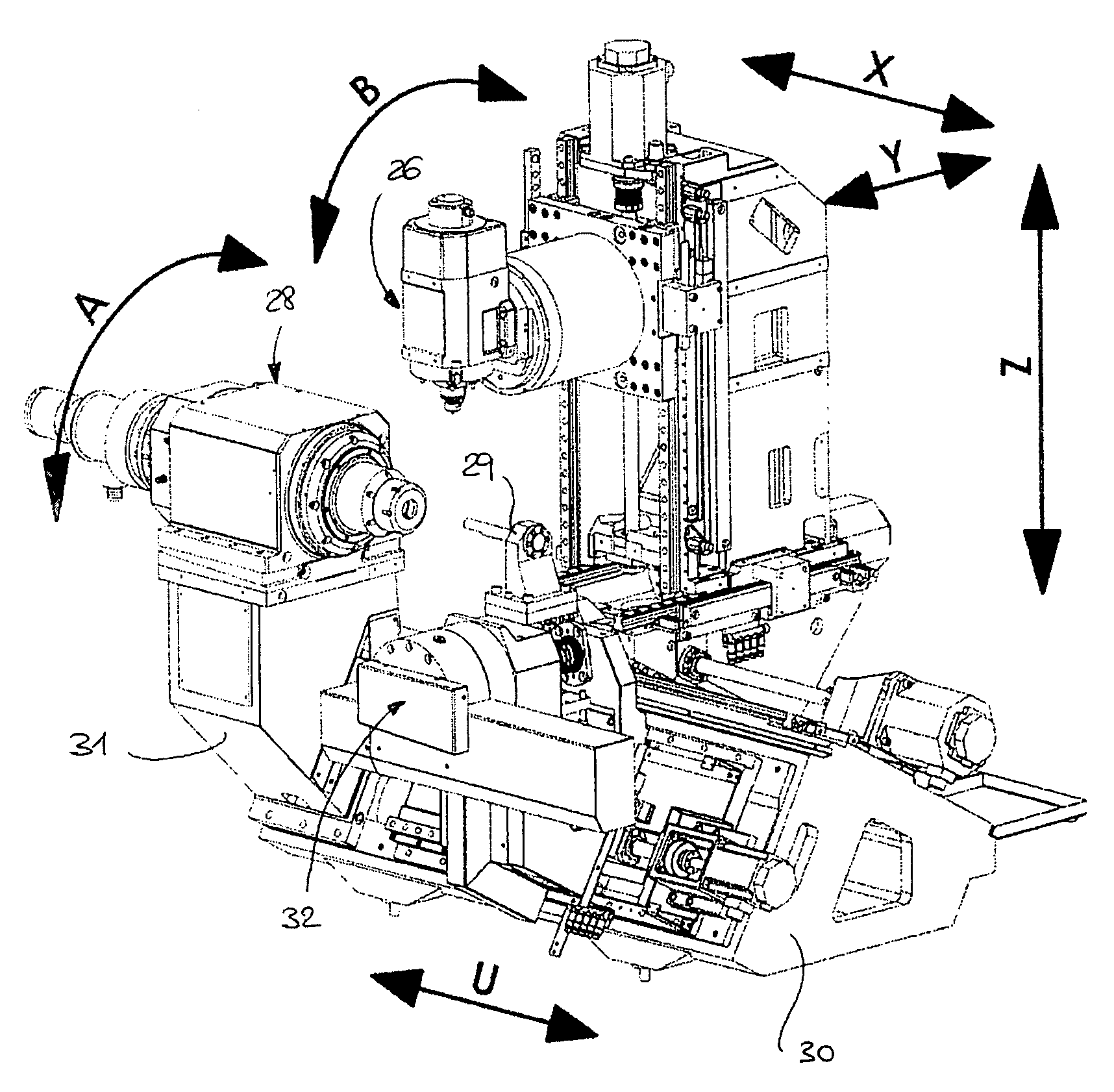

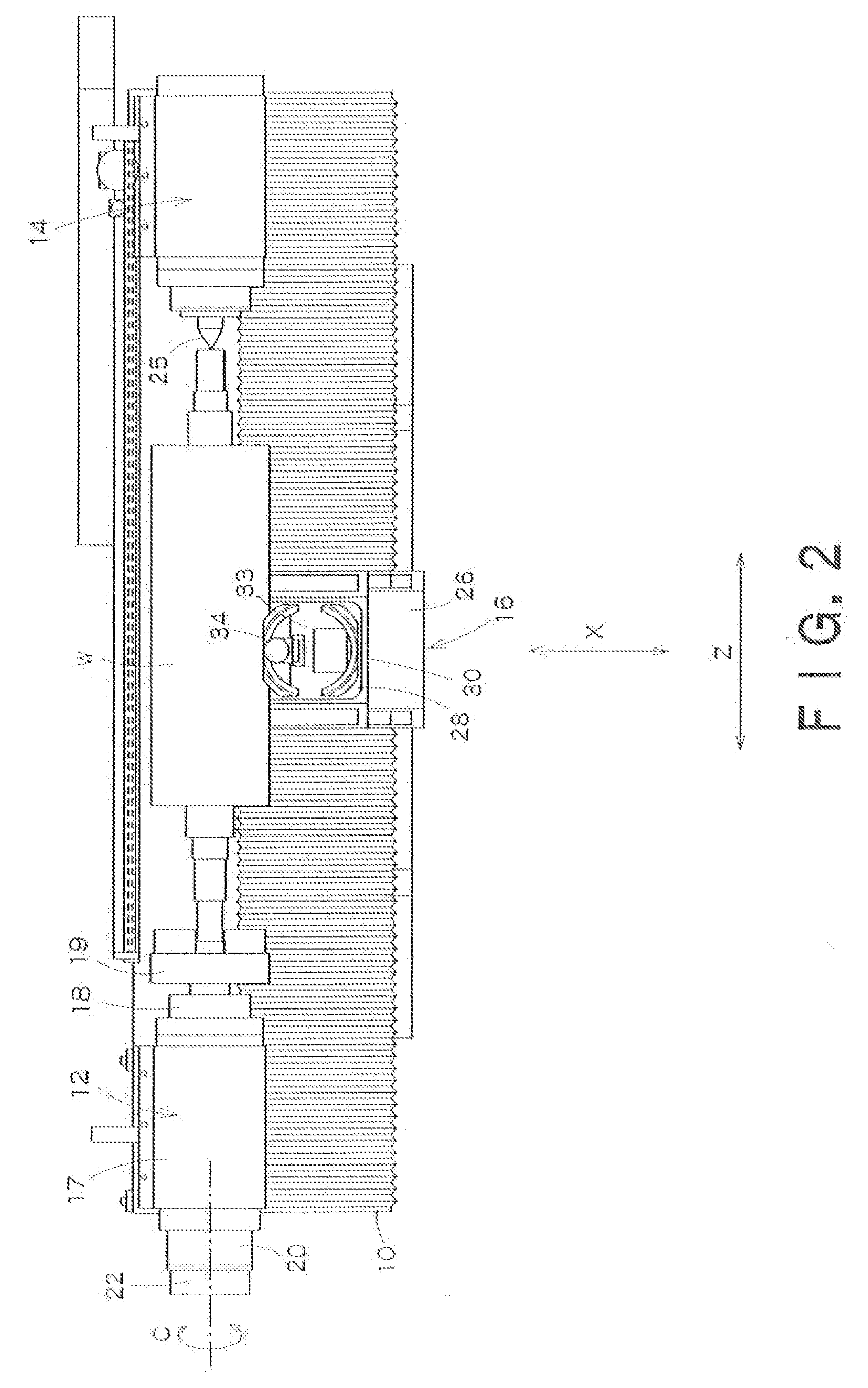

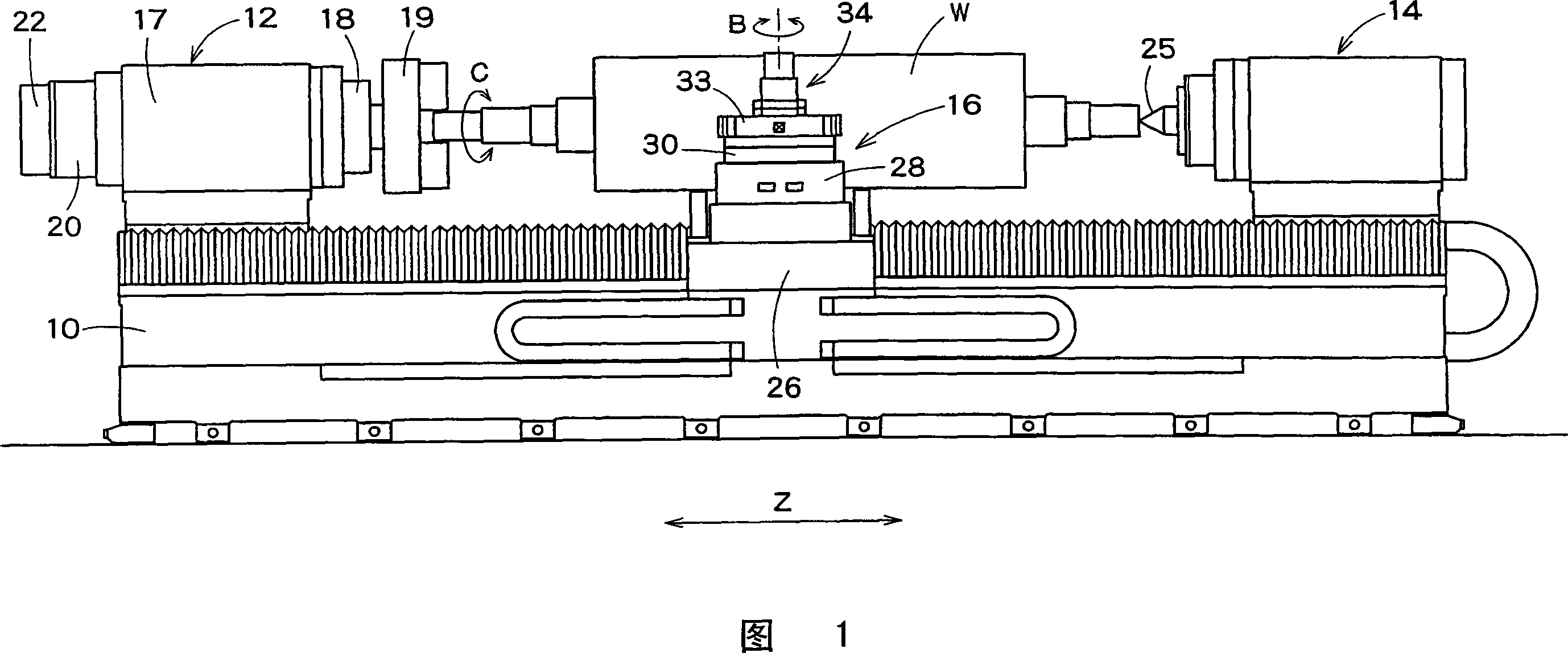

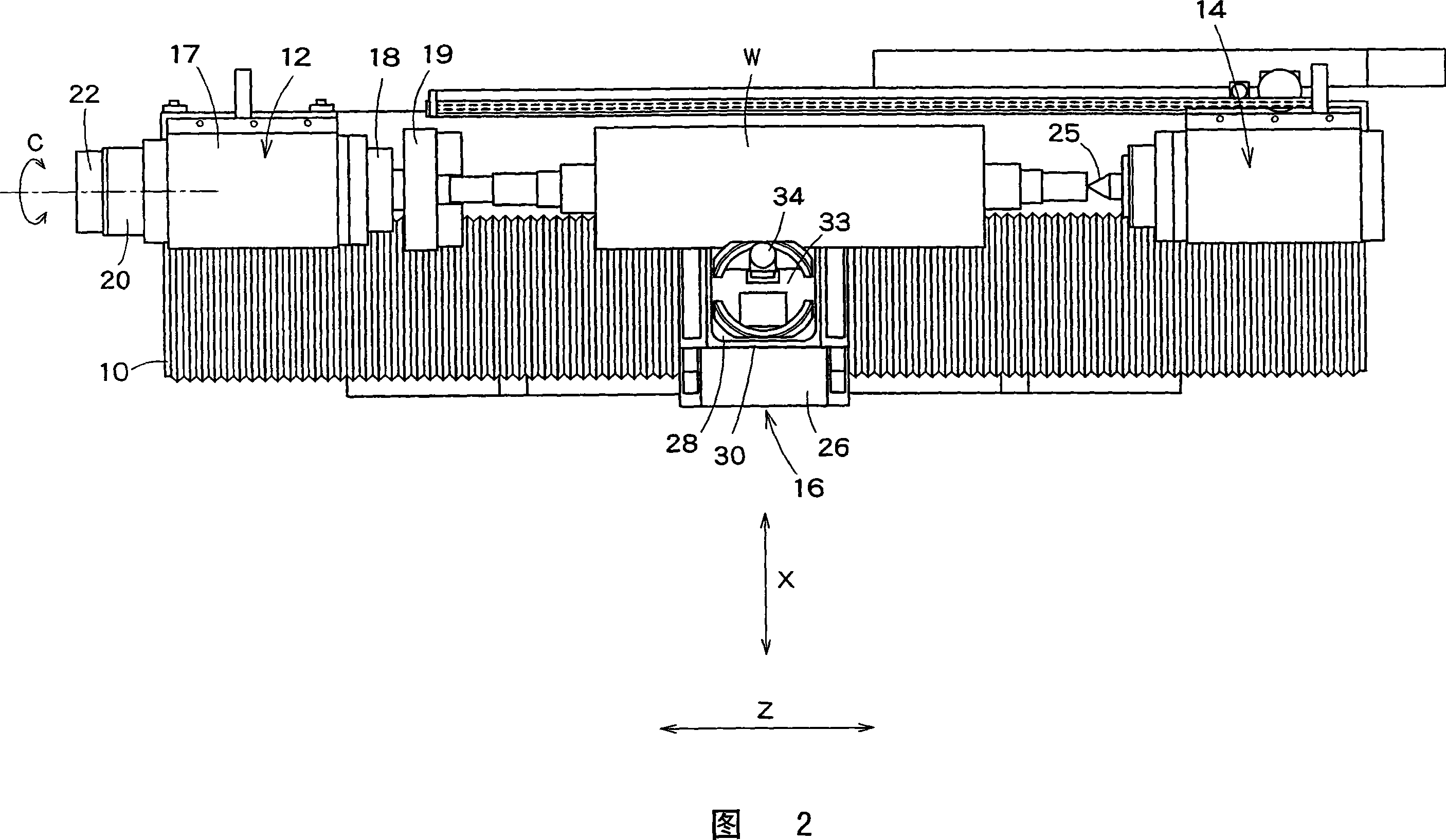

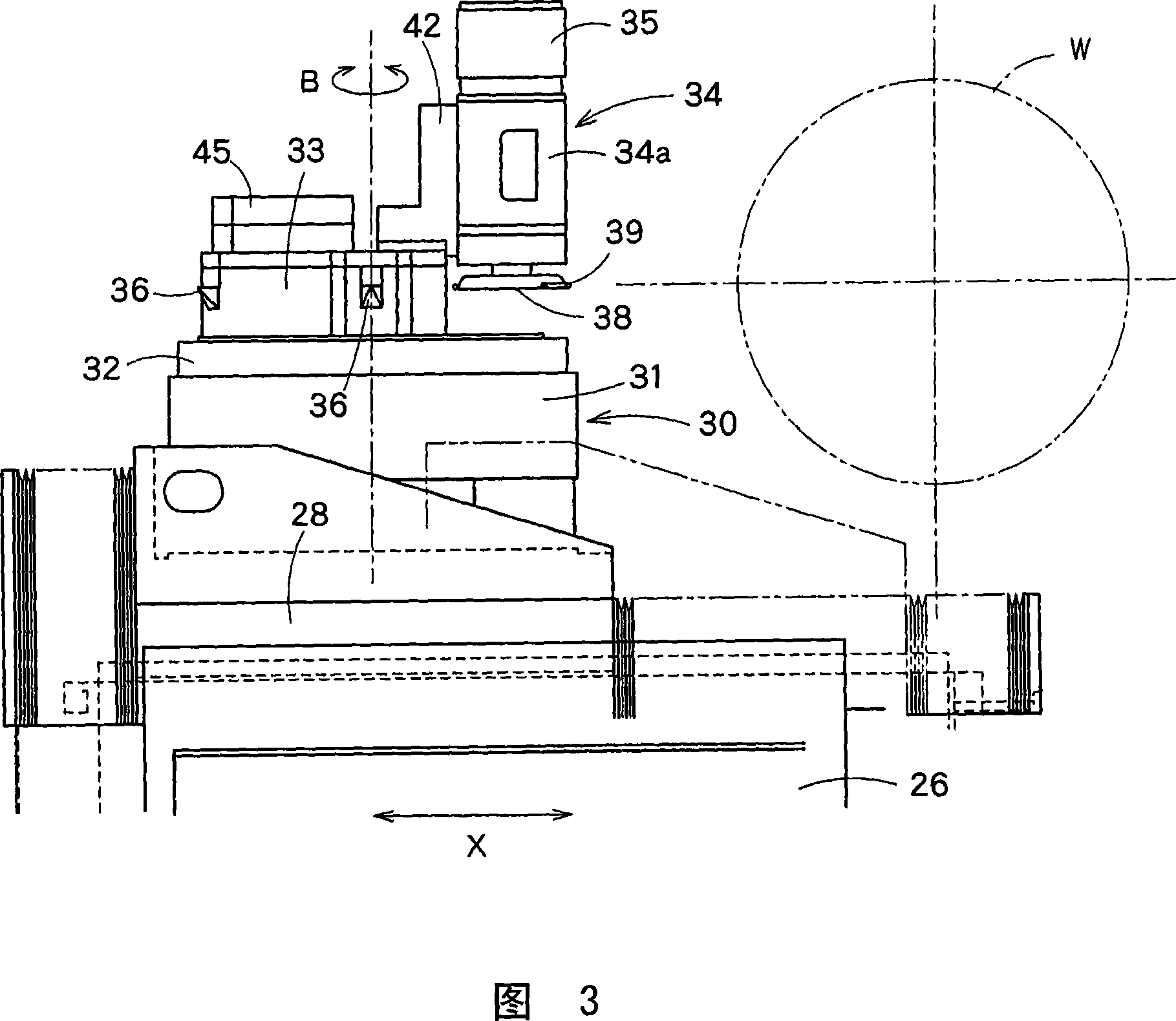

There is provided a precision roll turning lathe which can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface. The precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 34 and having a cutter spindle for rotating a fly cutter 39.

Owner:TOSHIBA MASCH CO LTD

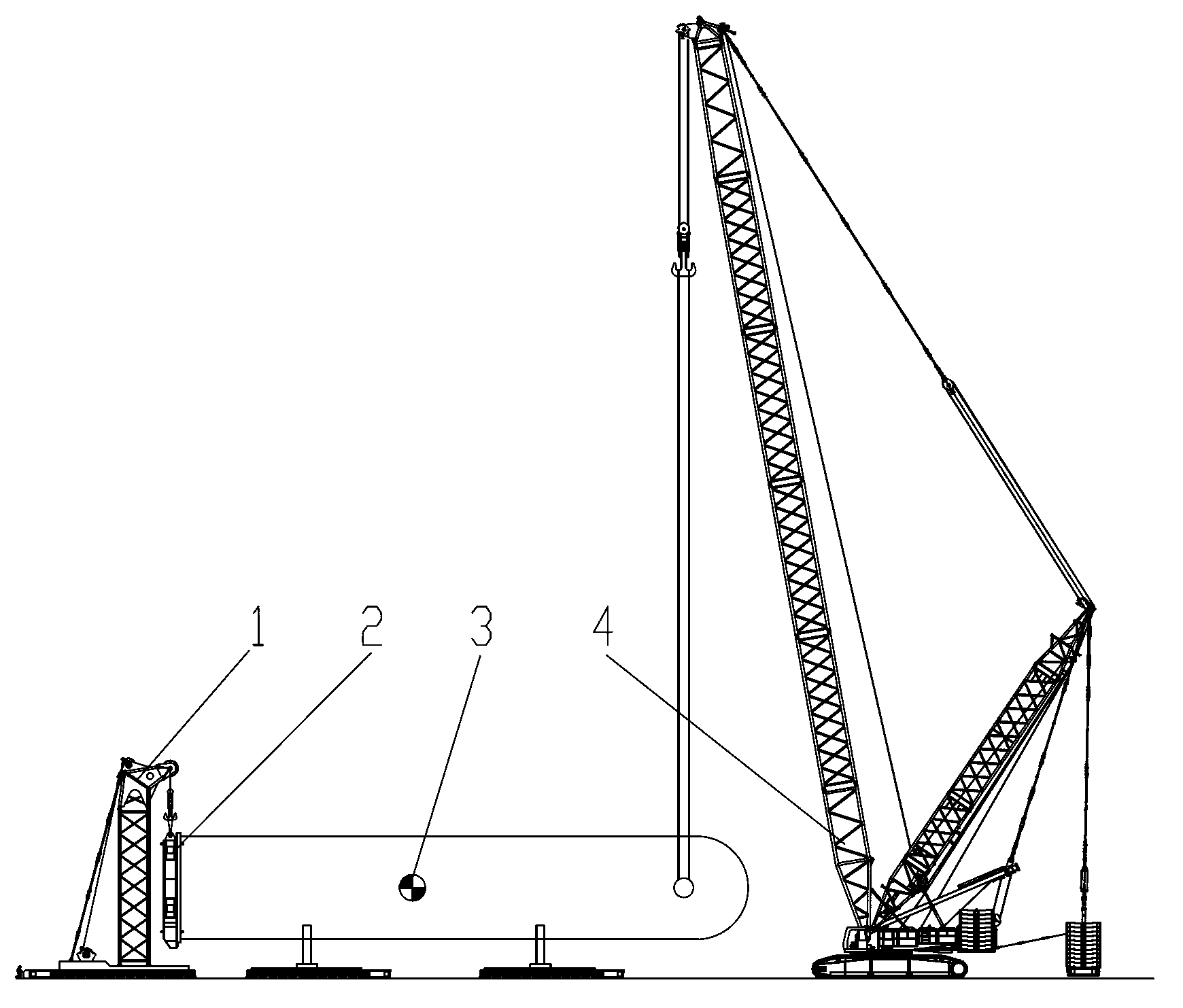

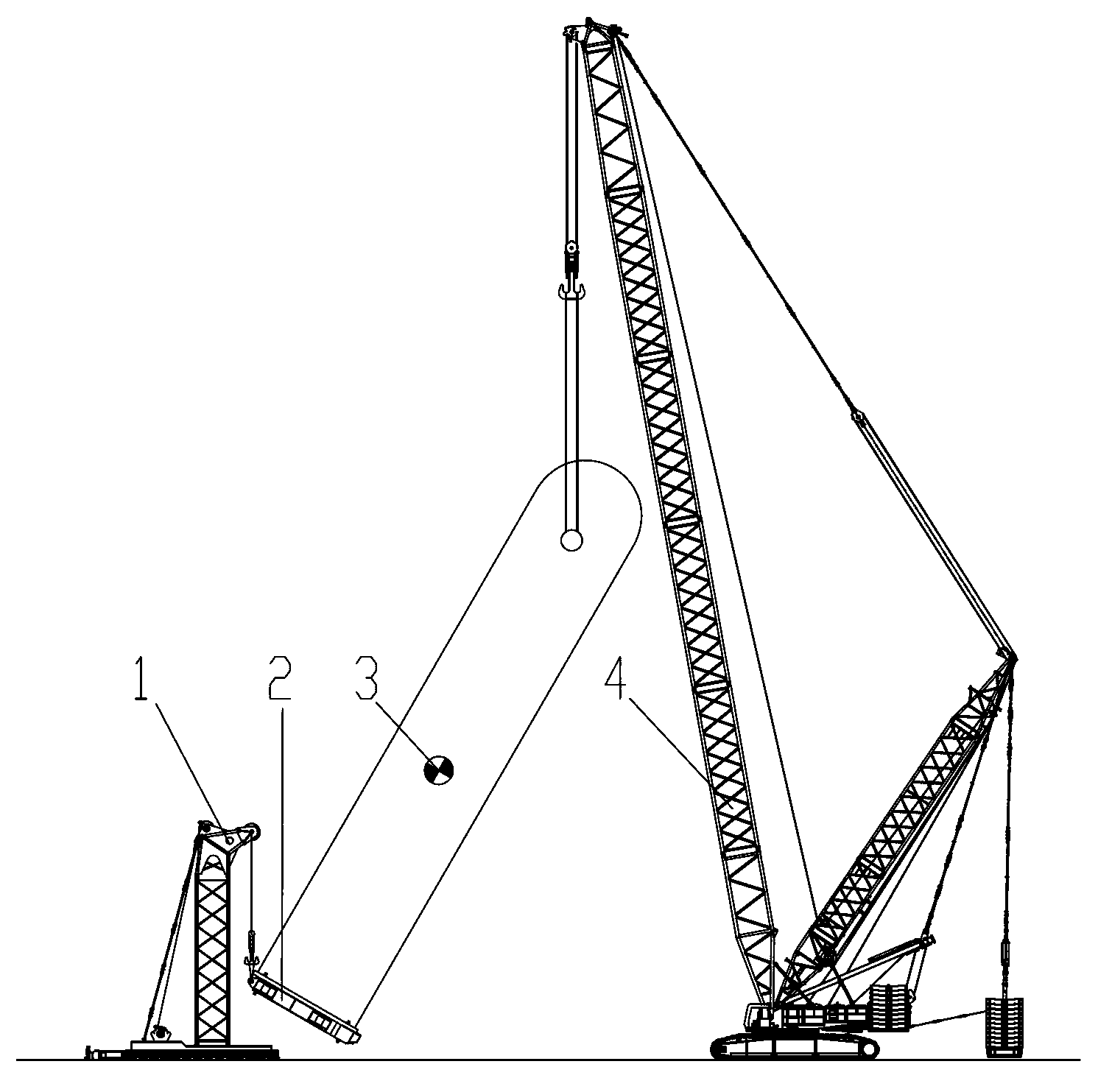

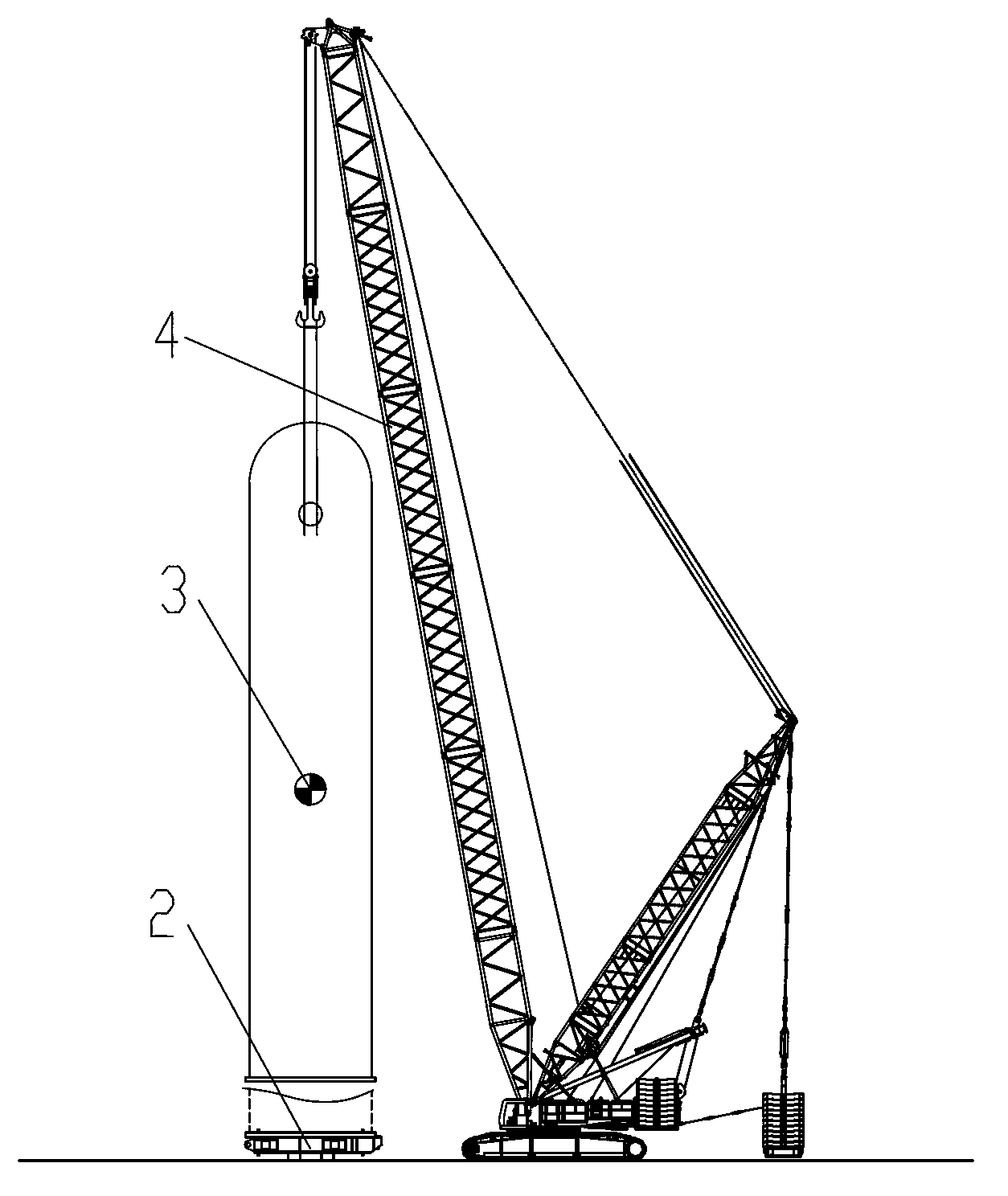

Tail device and tail dragging method

InactiveCN103058054AGuaranteed connectionStable equilibriumLoad-engaging elementsEngineeringGravity center

The present invention discloses a tail device and a tail dragging method. The tail device comprises: a tail end row which at least comprises a boom system, a travelling mechanism and a lifting mechanism, wherein the boom system is provided with a lifting mechanism and is supported on the travelling mechanism; and a tailstock which is used for being removably fixed to the lower part of a lifted device, and is provided with lifting holes. In the process of lifting the lifted device from the ground, the lifting mechanism is in hanging connection with the lifting holes, and the lifting holes are located at the end deviating from the ground. When the tail device is use for lifting a device, the center of gravity of the lifted device can be guaranteed to be always located below a connection line between the lifting point of main lifting equipment and the lifting point or the support point of the tail end row. The tail device has the advantages of good security, small weight borne by the tail end row, low lifting cost, etc.

Owner:SANY HEAVY IND CO LTD (CN)

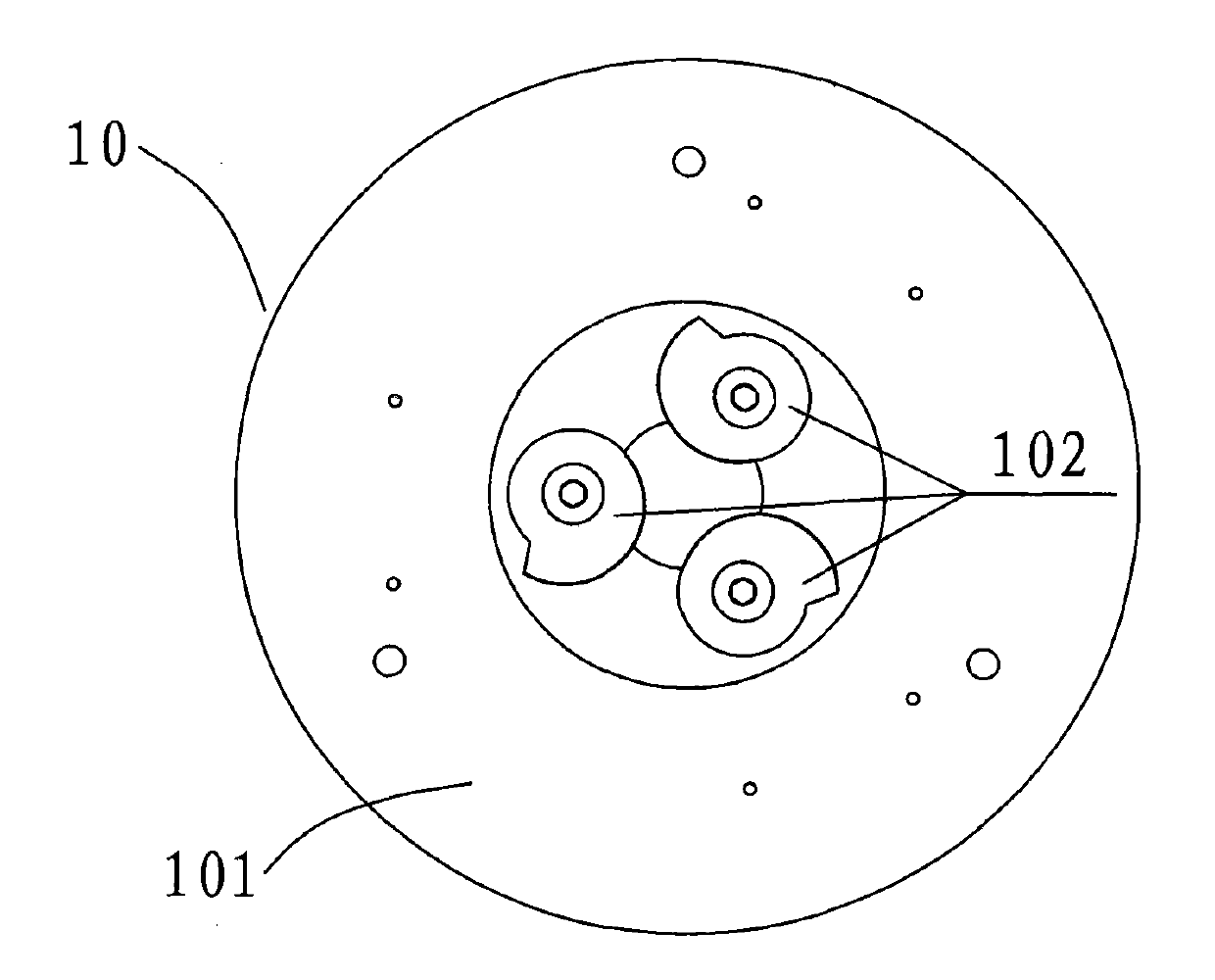

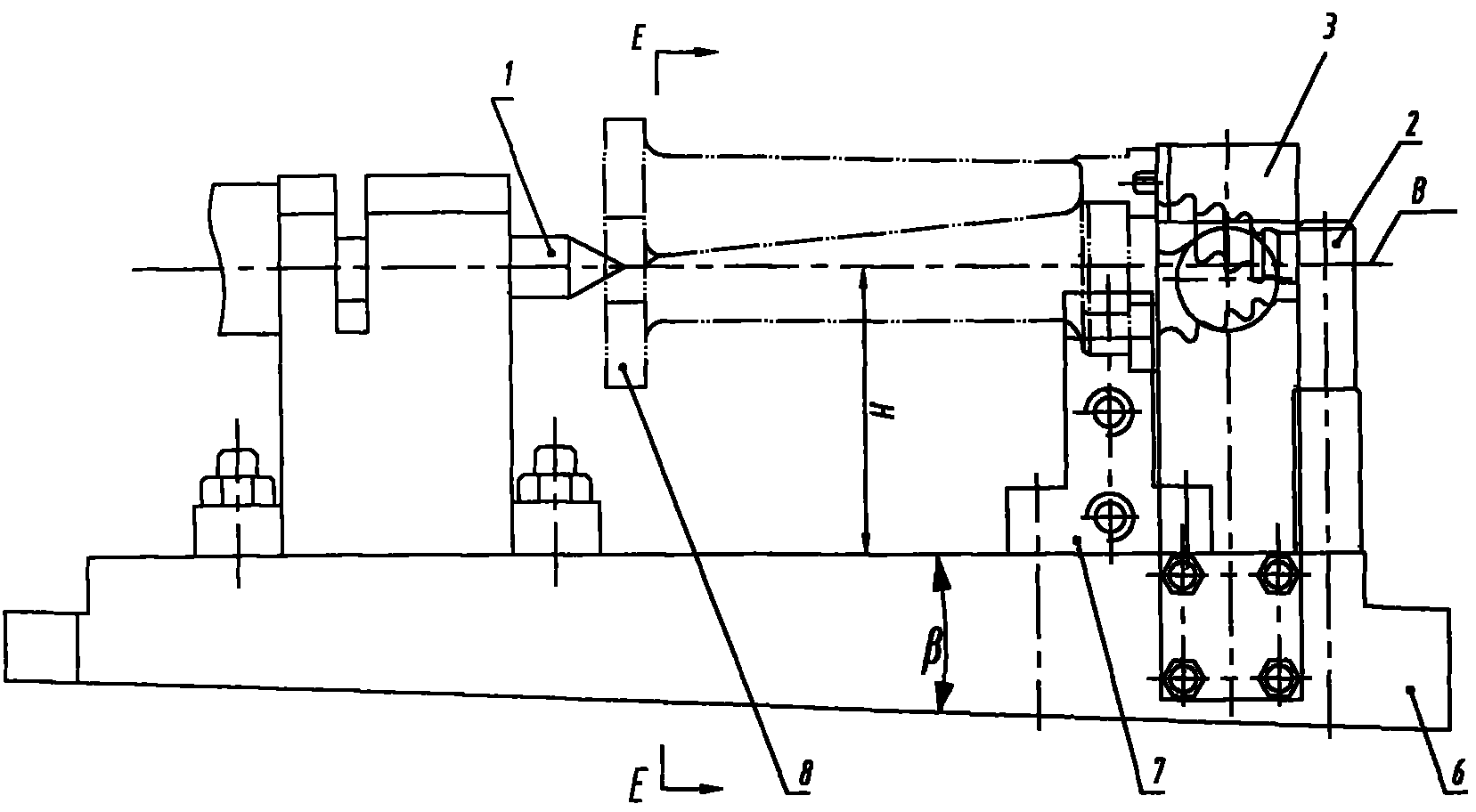

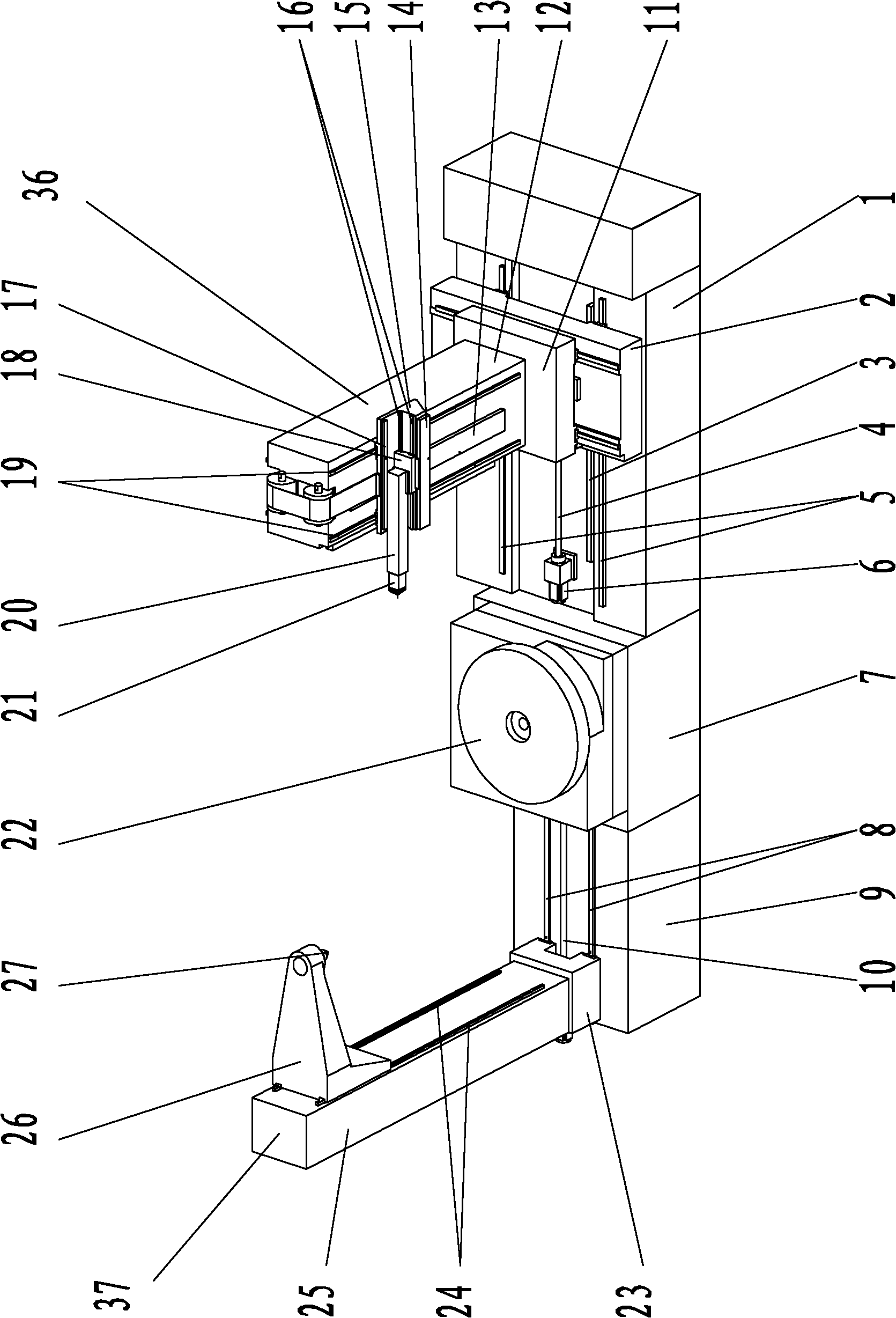

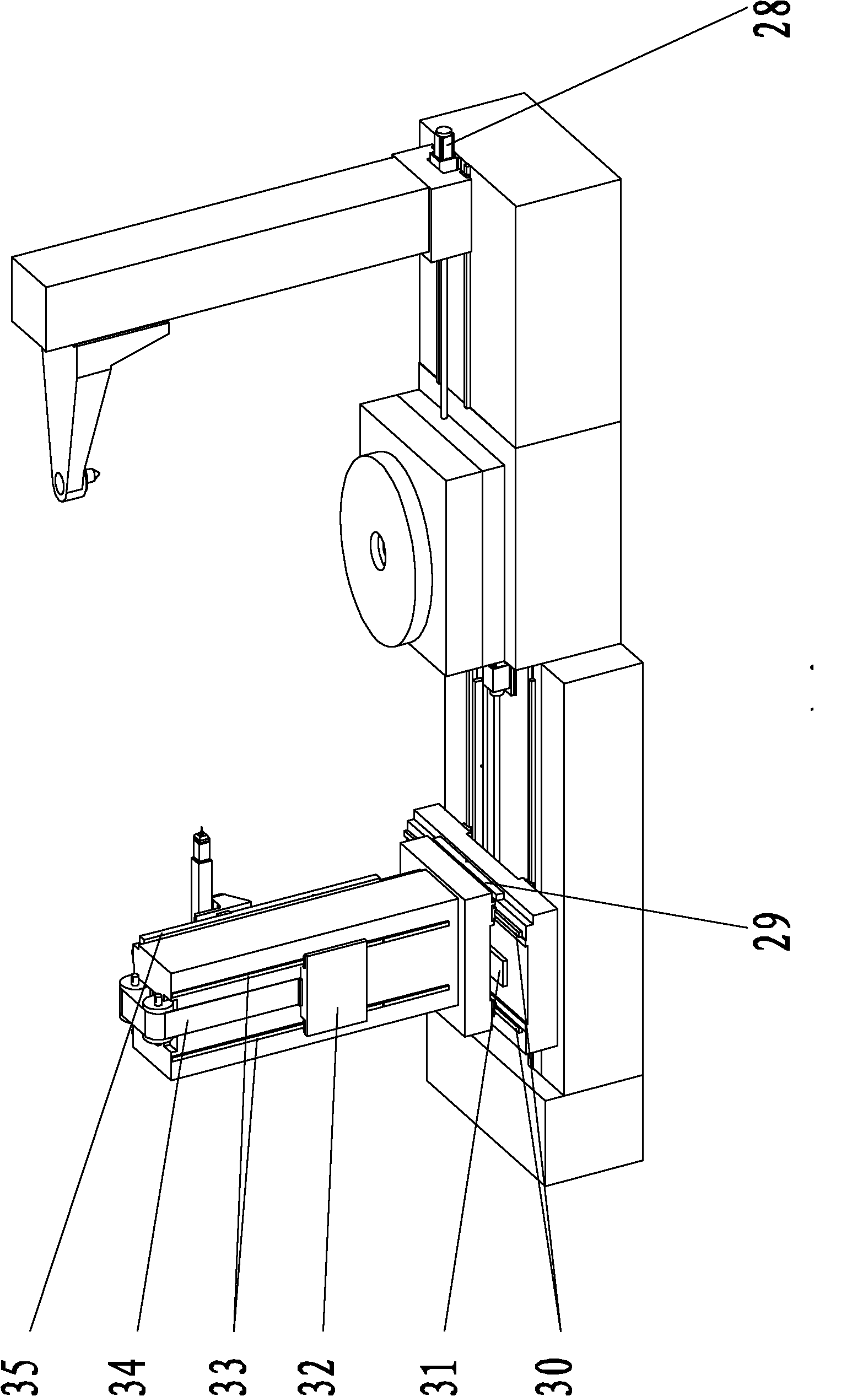

Roller repairing surfacing machine

InactiveCN107088696AReliable clamping functionReduce distortionWelding/cutting auxillary devicesAuxillary welding devicesSurface cleaningTailstock

The invention discloses a roller repairing surfacing machine and belongs to the field of metal welding. The roller repairing surfacing machine has a pre-welding preheating function, an automatic surfacing function, a welding fume removing function and a welding surface cleaning function, and also has the characteristics that a surfacing station can be adjusted rapidly, and the dimension expansion capacity of a surfacing workpiece is high. The roller repairing surfacing machine is provided with a foundation base, a headstock, a six-jaw chuck, a tailstock centre device and a working device. According to the technical scheme, a single stand column cross beam structure is adopted by the working device, surfacing, preheating, welding fume removing and welding surface cleaning are integrated onto one working head, thus, the structure is compact, and energy saving and environmental friendliness are achieved; a repairing roller is clamped through the six-jaw chuck and the tailstock center device, and clamping is fast and reliable; and the roller repairing surfacing machine is simple in structure, easy to manufacture and convenient to maintain.

Owner:KUNMING UNIV

CNC fixture

A fixture for a milling machine to position and manipulate related work pieces. The fixture has a first sub fixture powered to rotate a rotary plate and a second sub fixture. The fixture includes one of a first plate fixture and a second plate fixture for the mounting of work pieces. The rotary plate is mounted to the first sub fixture such that the rotary plate can be rotated by the first sub fixture. The rotary plate attaches to one of the first plate fixture and the second plate fixture. The rotary plate includes a first precision surface adapted for mounting of the first plate fixture and a second precision surface adapted for mounting of the second plate fixture. The fixture includes a tailstock plate mounted to the second sub fixture. The tailstock plate attaches to one of the first plate fixture and the second plate fixture.

Owner:MCCULLOCH JOSEPH W

Machine tool and method for machining over-long diameter ratio shaft exceeding machine tool standard

InactiveCN101574743AIncrease profitIncrease travelLarge fixed membersTurning machinesFinialLongest Diameter

The invention discloses a machine tool and a method for machining an over-long diameter ratio shaft exceeding the machine tool standard. The method comprises the following steps: firstly, leaving a section of chuck dock with an effective length respectively at two ends of a workpiece in advance, and drilling central holes on two end surfaces of the workpiece; secondly clamping one end of the workpiece on a chuck of a headstock, and supporting the other end by a finial on a tailstock; thirdly, coarsely turning the excircle of each section of the workpiece, and reversing the workpiece for turning when a knife rest feeds to the tail end of a knife rest lead rail; fourthly, finely turning the excircle of each section of the workpiece, and reversing and clamping the workpiece for turning when the knife rest feeds to the tail end of the knife rest lead rail; and finally, milling the chuck docks at the two ends and the chamfer angle on a boring lathe, a milling machine or other machine tools. The machine tool and the method for machining an over-long diameter ratio shaft exceeding the machine tool standard achieve the purpose of machining long-shaft parts over 15 m on a common machine tool for machining long shaft parts, thereby reducing the production cost.

Owner:SHANGHAI HEAVY MACHINERY PLANT

Guide pipe machining lathe

InactiveCN101698238AImprove work efficiencyReduce processing costsTurning machinesHydraulic cylinderSingle degree of freedom

The invention discloses a guide pipe machining lathe, which comprises a main shaft box, a chuck, a tail seat, a primary tool rest, a secondary tool rest and a secondary tool rest driving hydraulic cylinder. The secondary tool rest driving hydraulic cylinder is fixedly arranged on the main shaft box, a downward inclined track is arranged on the main shaft box, the secondary tool rest is arranged on the track and is driven by the secondary tool rest driving hydraulic cylinder to slide along the track in single degree of freedom, the secondary tool rest is provided with at least two lathe tools along the central line of the chuck, and the tool noses of the lathe tools point to the central line of the chuck obliquely downwards; and the primary tool rest is provided with at least two lathe tools along the central line of the chuck. By arranging the secondary tool rest and the lathe tools on the main shaft box to feed, groove and machine inlet and exhaust guide pipes of a motorcycle engine and arranging the lathe tools on the primary tool rest to longitudinally feed and cut the inlet guide pipes, the purpose of completely machining and shaping machined pieces once is achieved only by clamping the machined pieces once, the work efficiency is greatly improved, and the machining cost is saved. Meanwhile, the machined pieces are automatically fed and clamped and automatically popped and discharged, and the whole machining process realizes full automatic operation.

Owner:CHONGQING ZHIBO POWDER METALLURGY

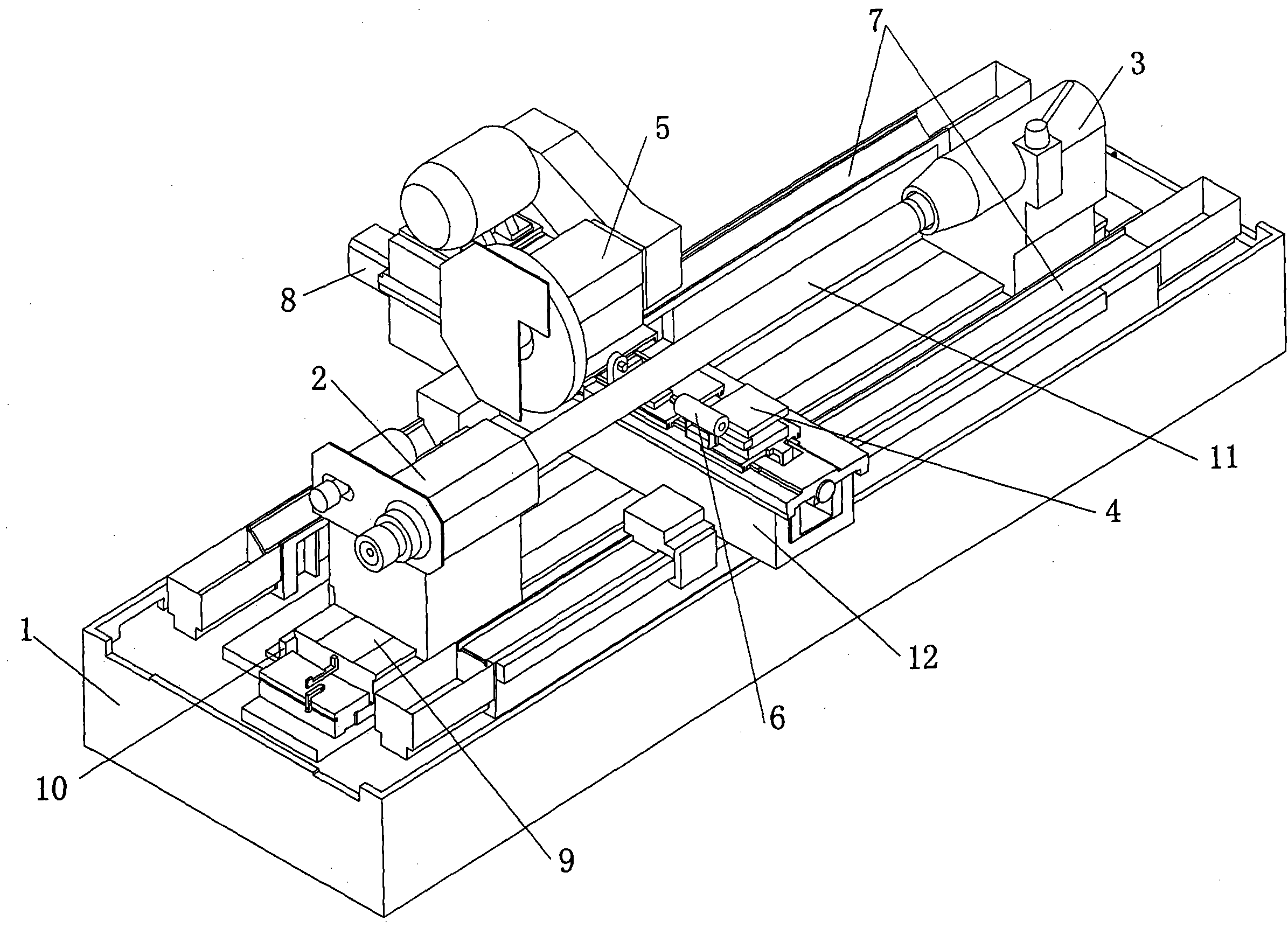

Precision roll turning lathe

ActiveCN101062543AHigh precision machiningSuppress feverPropelling pencilsWorkpiecesMilling cutterTransverse groove

There is provided a precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 33. The precision roll turning lathe can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface.

Owner:TOSHIBA MASCH CO LTD

Shaft-like workpiece multi-operation composite processing machine tool

InactiveCN101890640AReduce surface roughnessGuaranteed machining accuracyFeeding apparatusOther manufacturing equipments/toolsUltrasonic machiningSurface roughness

The invention provides a shaft-like workpiece multi-operation composite processing machine tool, which comprises a machine tool body, a worktable, a headstock, a tailstock, a saddle, turning fixture, a milling device and an ultrasonic processing device, wherein the machine tool body is provided with two longitudinal guide rails, the saddle is arranged on the two longitudinal guide rails of the machine tool body, a screw feeding mechanism is arranged on the machine tool body, and the saddle is connected with the screw feeding mechanism; the worktable is arranged on the machine tool body and between the two longitudinal guide rails, and the headstock and the tailstock are arranged at two ends of the worktable respectively; and the turning fixture, the milling device and the ultrasonic processing device are all arranged on the saddle of the guide rails. In the invention, through one time of clamping, the three functions required for processing shaft-like workpieces, namely turning, milling and ultrasonic surface processing, can be completed, a milling or turning device can be used to meet the requirements on dimensional tolerance, shape tolerance and the like of parts, and the ultrasonic processing device can be used to complete reducing surface roughness of the parts.

Owner:赵显华

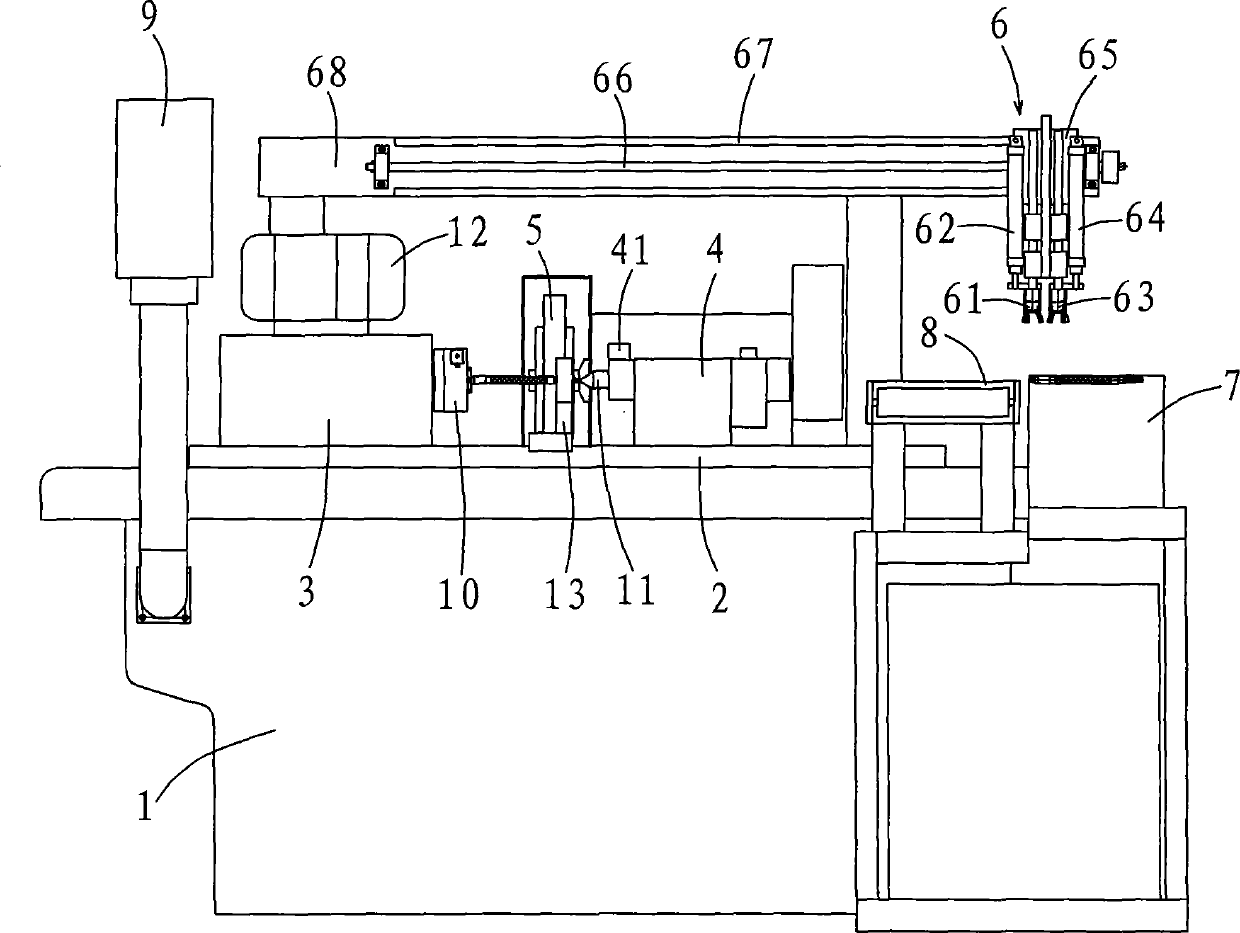

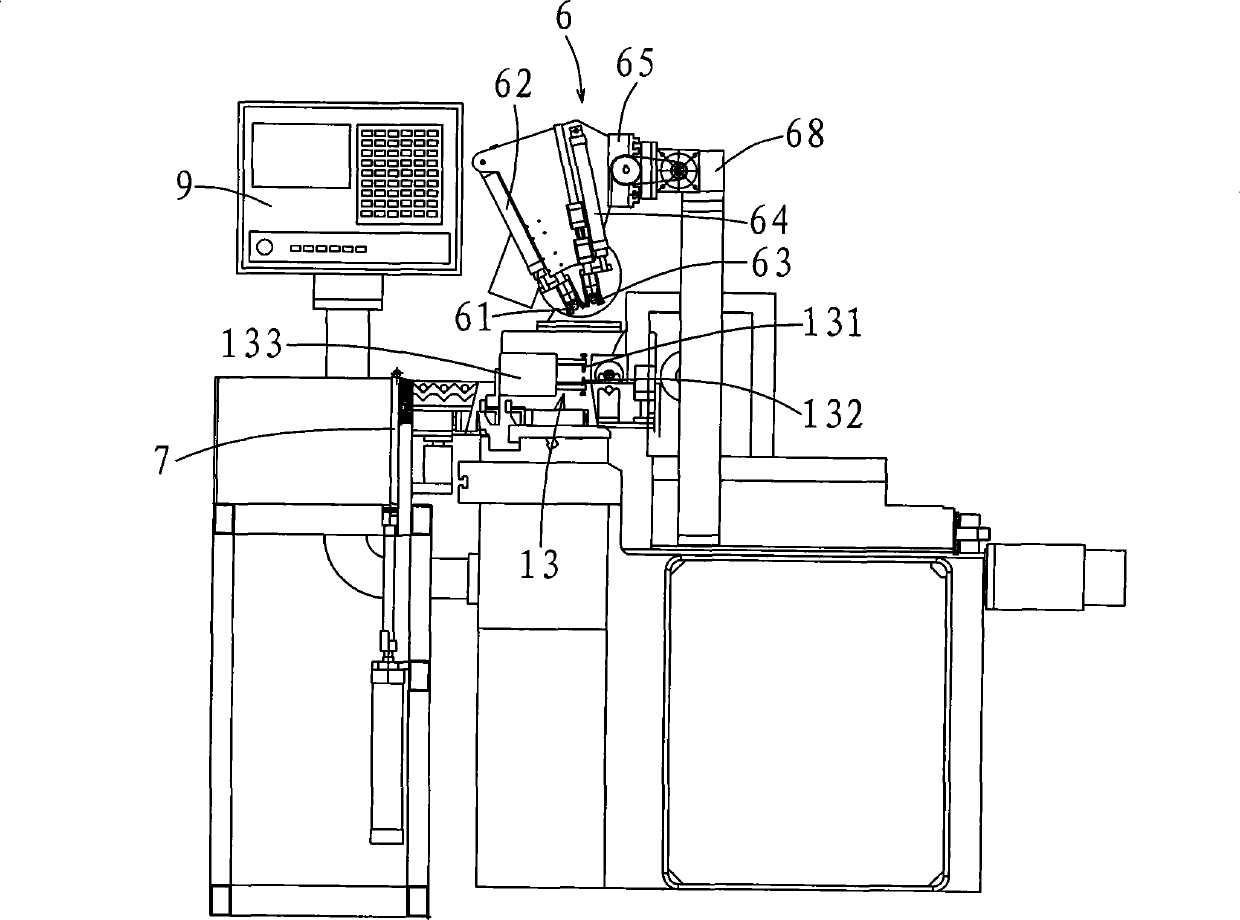

Fully-automatic grinder

InactiveCN103962901AHigh degree of automationReduce labor intensityRevolution surface grinding machinesGrinding feed controlNumerical controlMulti machine

The invention relates to a fully-automatic grinder comprising a base, a workbench, a headstock, a tailstock, a grinding wheel mechanism, a feeding and discharging manipulator, an automatic feeding mechanism, an automatic discharging mechanism and a numerical control device. A chuck and a centre are arranged on opposite faces of the headstock and the tailstock respectively and concentrically. The feeding and discharging manipulator comprises a taking pneumatic gripper, a taking cylinder, a putting pneumatic gripper, a putting cylinder, a guide slide fixing frame, a ball screw, a linear guide rail and a guide rail bracket, the taking pneumatic gripper, the taking cylinder, the putting pneumatic gripper and the putting cylinder are all mounted on the guide slide fixing frame, the taking pneumatic gripper and the putting pneumatic gripper are arranged at an included angle forward and backward and arranged parallelly leftward and rightward, and the guide slide fixing frame is in sliding fit with the ball screw and the linear guide rail. The grinder is high in automation degree, the whole process of feeding, discharging, clamping, machining, on-line measurement and the like of workpieces is completed automatically through the numerical control device, one-man multi-machine operation can be realized, production efficiency and production quality are improved, and labor intensity and production cost of workers are lowered.

Owner:JIAHE TOOLS

Special fixture used for processing open slot on spatial dihedral angle slope of turbine blade

ActiveCN102371491AExpand the scope of processingComply with positioning installation requirementsPositioning apparatusMetal-working holdersSurface finishBaseboard

The invention provides a special fixture used for processing an open slot on a spatial dihedral angle slope of a turbine blade, and the special fixture is characterized by comprising a slope baseboard component capable of adjusting a radial gradient, wherein a tailstock tip component and an end face positioning component are oppositely arranged at two radial ends of the slope baseboard component; a slope cushion component which is capable of adjusting an axial gradient and a height is arranged on the slope baseboard component between the tailstock tip component and the end face positioning component; a side wall positioning component is also arranged on the slope baseboard component; the side wall positioning component can axially feed a side wall positioning element which is contained in the side wall positioning component; a clamping component is also arranged on the slope baseboard component; and a pressing head capable of feeding downward is arranged at the tail end of the clamping component. The fixture provided by the invention can firmly and accurately position a device, can quickly and efficiently process the open slot meeting a design demand on a size precision and a position precision, and has ultrahigh surface glossiness.

Owner:四川省自贡市海川实业有限公司

Large bar chamfering machine tool

The invention discloses a large bar chamfering machine tool, comprising a bed body, a machine tool bedside box, a three-claw chuck and transverse guide rails, as well as a loading device, a lifting device, a bar propulsion device and an unloading device, wherein the machine tool bedside box is installed on the front end of the bed body; the three-claw chuck is installed on the machine tool bedside box; the transverse guide rails are installed on the bed body and located behind the machine tool bedside box; a tool tail seat is installed on the transverse guide rails; longitudinal guide rails are arranged on the tool tail seat; the loading device is used for conveying large bars; the lifting device is located ahead of the bed body; the bar propulsion device is arranged ahead of the lifting device as well; and the unloading device is located on the side of the bed body. With the adoption of the chamfering machine tool provided by the invention, the automatic loading and unloading of the large bars are realized, the production efficiency is improved, the labor intensity is decreased, and the safety performance is good; and in addition, the large bar chamfering machine tool is compact in structure, simple to operate, reliable to work and convenient to control, and can effectively adapt to the rapid clamping and processing of the bars with various diameters and lengths.

Owner:ZHEJIANG JIULI HI TECH METALS

Large gear measuring instrument

ActiveCN102022990AImprove horizontal accuracyImprove detection accuracyUsing optical meansMeasurement deviceMeasuring instrument

The invention provides a large gear measuring instrument. The gear measuring instrument comprises a measuring device and a rotary worktable mutually independent and arranged side by side, and the measuring device is located on one side of the rotary worktable; the rotary worktable is centered and assembled on a pedestal of the rotary worktable through a liquid hydrostatic slideway bearing and a liquid hydrostatic bearing; and the rotary worktable is driven by a twin-worm backlash eliminating transmission mechanism installed on the pedestal of the rotary worktable. The large gear measuring instrument comprises three mutually independent parts including the three-dimensional measuring device, the liquid hydrostatic rotary worktable and a tailstock pillar device, and the liquid hydrostatic rotary worktable can bear loads with large mass; the split type structure can reduce the influence of loads with small mass on measurement accuracy so as to meet the purpose of precision measurement on gears with large mass and large inertia.

Owner:秦川机床工具集团股份公司

Insulator horizontal tensile testing machine

ActiveCN101706394AAdjustable distanceEasy to adjust the distanceMaterial strength using tensile/compressive forcesLocking mechanismControl system

The invention relates to an insulator horizontal tensile testing machine, which comprises a working platform, wherein a rail is arranged on the working platform; the rail is provided with a headstock and a tailstock; the side wall of the working platform is provided with a plurality of through pin holes; the tailstock comprises a traveling mechanism, locking mechanisms and a fine adjustment mechanism, and is provided with a travel switch; the traveling mechanism comprises a driving motor, and an output end of the driving motor drives a pulley block through a middle transmission mechanism; the locking mechanisms are divided into two groups and are symmetrically arranged on two sides of the tailstock, each group of the locking mechanisms comprises a locking motor, an output end of the locking motor is connected with a transverse screw rod, a sliding block provided with a plug pin is inserted on the screw rod, and the position of the plug pin corresponds to the through pin holes; and the fine adjustment mechanism comprises a fine adjustment motor, an output end of the fine adjustment motor is connected with a rotating wheel, a longitudinally arranged screw rod is inserted on the rotating wheel, and the front end of the screw rod is connected with a tailstock clamp. The insulator horizontal tensile testing machine is also provided with a loading cylinder which is controlled by a remote measurement and control system. The insulator horizontal tensile testing machine adopts the movable tailstock, and has macro-movements, positioning and micro-adjustments so that the distance between the headstock and the tailstock on the working platform is convenient to adjust to adapt to tensile tests of insulators with different lengths.

Owner:CHINA ELECTRIC POWER RES INST +1

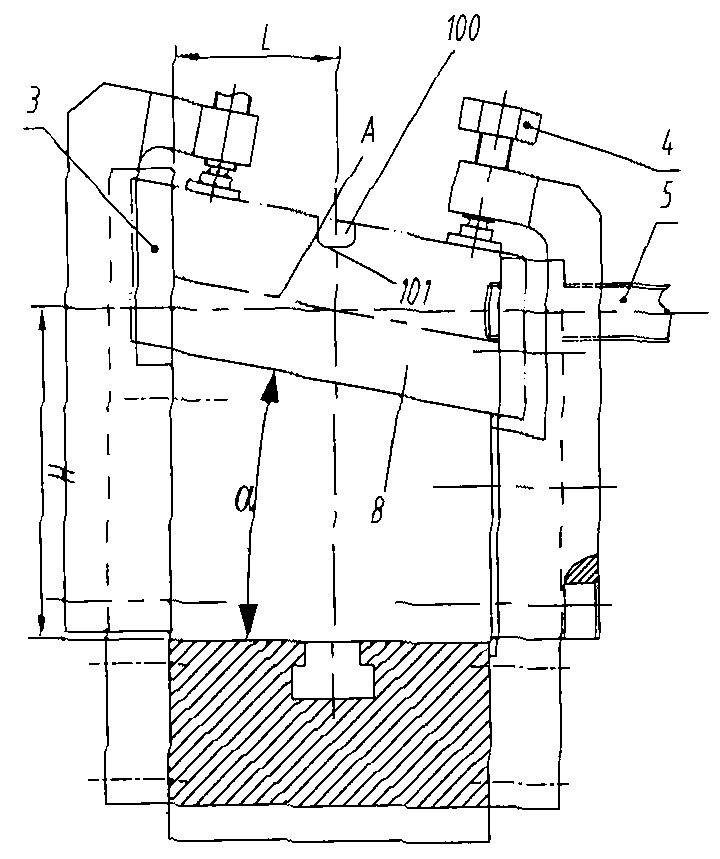

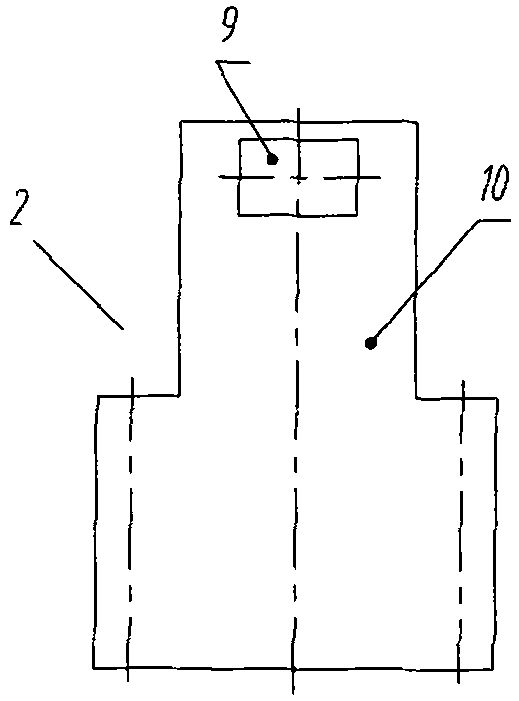

Machine and turntable clamp for four-axis processing center

InactiveCN104325324ASimple changeover operationQuick changeoverMeasurement/indication equipmentsPositioning apparatusProduction lineModular design

The invention relates to a machine and turntable clamp for a four-axis processing center. The clamp comprises a clamp bottom plate (8), a tail seat (2), a dividing head (9), an oil / gas path distributor component (1), L-shaped plates (4), a bridge plate (7) and clamp location clamping units, wherein the tail seat (2) and the dividing head (9) are fixedly arranged on the clamp bottom plate (8); the oil / gas path distributor component (1) is arranged on the outer side face of the tail seat (2); two L-shaped plates (4) are oppositely arranged and are respectively connected with the tail seat (2) and the dividing head (9) by a transition plate (3); two ends of the bridge plate (7) are respectively connected with the L-shaped plates (4); a plurality of clamp location units are provided and are uniformly spaced and fixed on the bridge plate (7) in sequence. The machine and turntable clamp has the advantages that a modular design and a ball lock location system are used for realizing fast changing the clamp when the type of a production line is changed; hydraulic clamping is used, so that a reliable clamping force is provided; an airtight detection technology and a fast assembling / disassembling limit block are used, so that an error proofing function is available.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

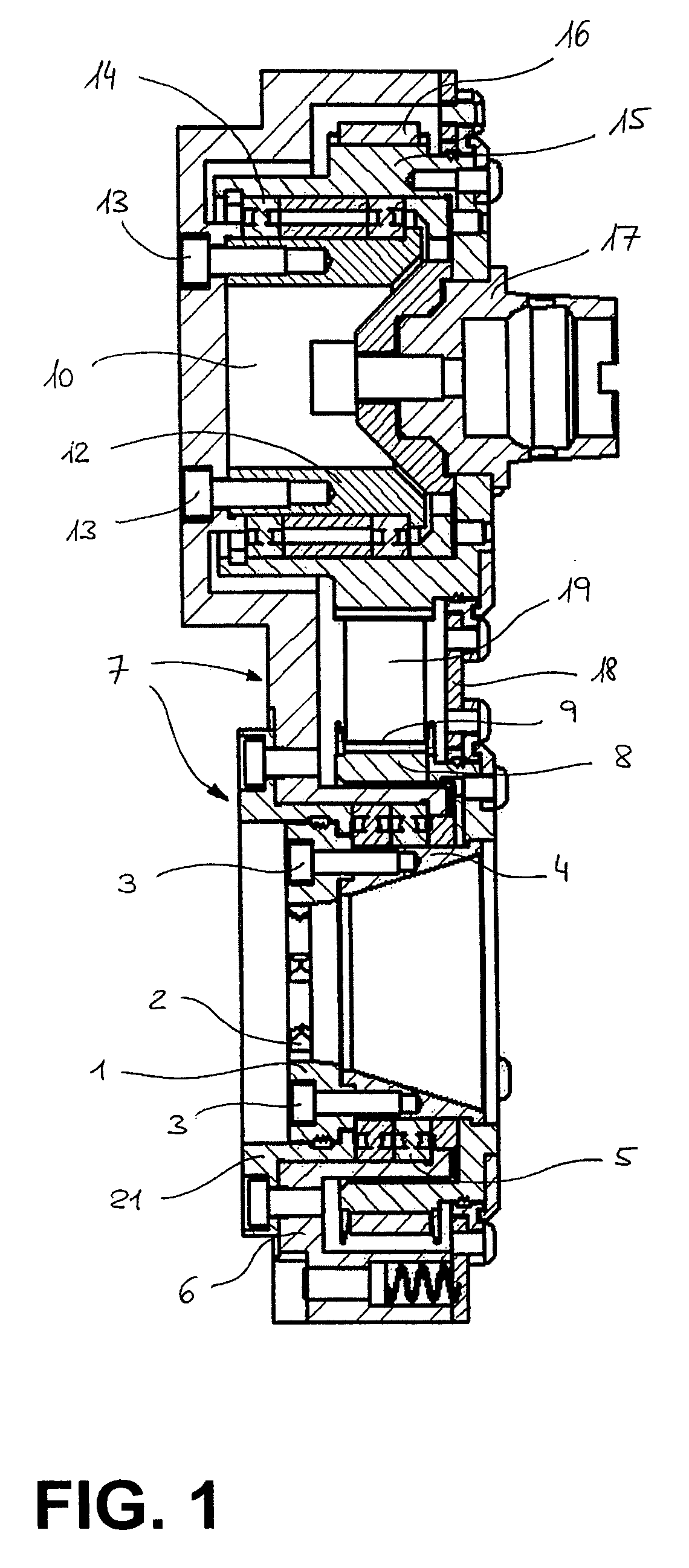

Clamping device for machine tools

A clamping device for machine tools is disclosed that is capable of ensuring the clamping force for a tailstock while maintaining a small overall size of the device and a reduced number of parts. The tailstock (movable carriage) movably mounted on a fixed bed is clamped at a specified position to the fixed bed. A stationary rack (stationary fitting member) extending in a direction of movement is fixed to the fixed bed. A movable rack (movable fitting member) is provided on the tailstock so as to be movable in a direction transverse to the direction of movement of the tailstock. Wedge-shaped fitting surfaces are formed at mutually opposing portions of the stationary rack and the movable rack. The movable rack is driven to perform advance-and-retreat motions between a clamping position where the movable rack fits together with the stationary rack and an unclamping position where the clamping state is released.

Owner:DMG MORI SEIKI CO LTD

Deep hole drilling machine

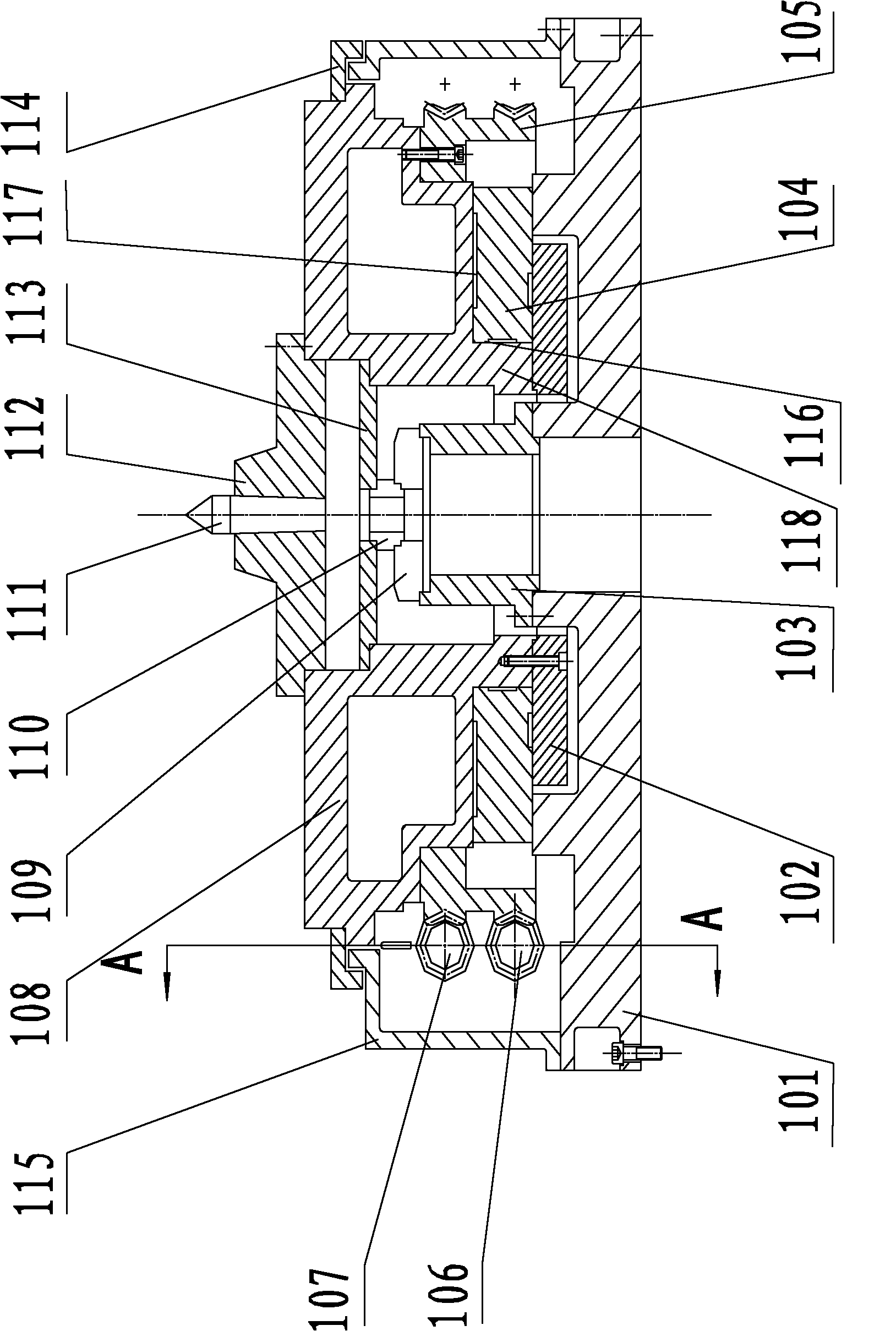

ActiveCN102198529AReasonable designCompact structureBoring/drilling componentsBoring/drilling machinesEngineeringTailstock

The invention provides a deep hole drilling machine which belongs to the technical field of machining equipment. The drilling machine solves the problems that the traditional deep hole drilling machine has poor guidance, poor stability, no high machining precision, no high efficiency and a not enough compact structure. The deep hole drilling machine comprises a lathe bed, a power head and a tailstock, wherein the lathe bed is provided with a horizontally arranged slide rail ; the tailstock and the power head are arranged on the slide rail; the power head is provided with a horizontally arranged feed main shaft and a driving motor I for driving the feed main shaft to rotate; one end of the feed main shaft can be connected with a cutting tool; a driving mechanism I is arranged between the power head and the lathe bed and can drive the power head to slide along the slide rail; the tailstock is provided with a jig; and a driving mechanism II is arranged between the tailstock and the lathe bed and can drive the tailstock to slide along the slide rail. The lathe bed of the deep hole drilling machine is provided with the driving mechanism I for driving the power head to slide along the slide rail and the driving mechanism II for driving the tailstock to slide along the slide rail, so that the design is reasonable and the structure is compact; moreover, the lathe bed is provided withthe guide rail and a guide holder, thereby the machining precision of deep holes is improved.

Owner:ZHEJIANG XILING

Drilling platform of pipe numerical control drilling machine

InactiveCN101954501AMove preciselyProcessing automationAutomatic control devicesFeeding apparatusNumerical controlGear drive

The invention relates to a drilling platform of a pipe numerical control drilling machine. The drilling platform is arranged between a main shaft rotating device and a tailstock; the electrical and hydraulic control can be realized by a numerical control platform; a pipe wall clamping assembly and a drilling power head assembly are arranged on the drilling platform; a guide rail sliding block arranged at the bottom of the drilling platform is matched with a linear guide rail at the upper part of a machine body; and a gear driven by a motor, which is arranged on the drilling platform, is meshed with a rack at the upper part of the machine body. The drilling platform can be conveniently, quickly and accurately moved to the required position by numerical control programming so as to be used for firmly clamping the machined pipe, safely and stably drilling and machining a through hole on the outer wall of the pipe automatically, efficiently, conveniently and safely.

Owner:WUXI HUALIAN PRECISION MACHINERY

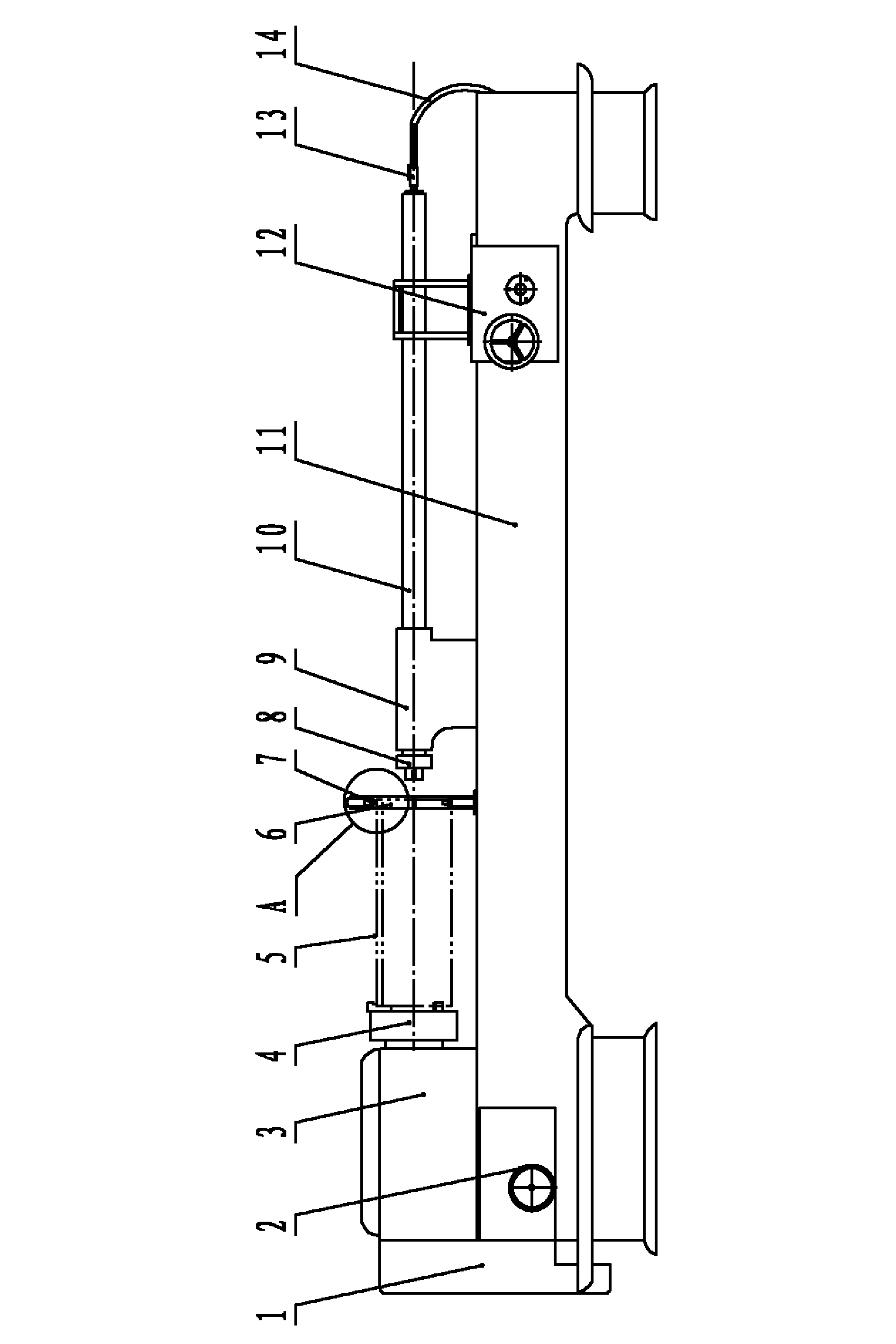

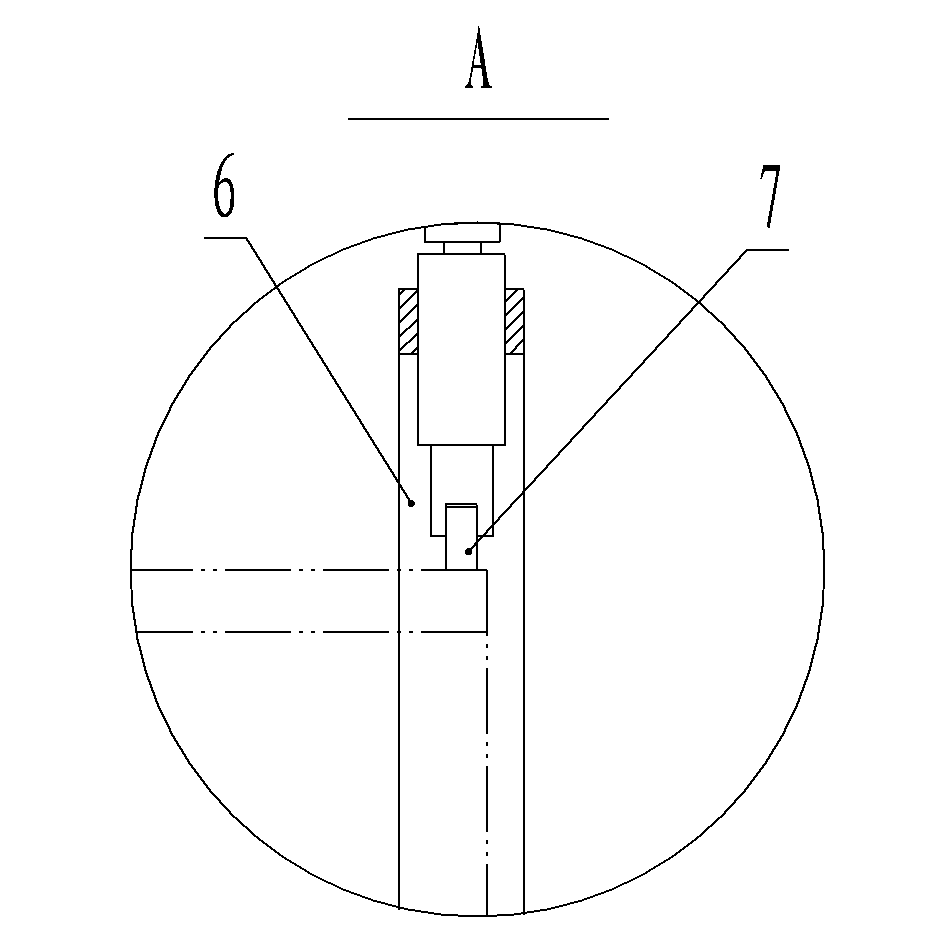

Error detection device for hourglass worm

ActiveCN101750006AConform to shape characteristicsEliminate the effects ofElectric/magnetic contours/curvatures measurementsUsing electrical meansRotary stageMotor drive

The invention discloses an error detection device for a hourglass worm, comprising a body, a spindle unit and a measuring unit, wherein the spindle unit comprises a spindle servo motor, a spindle, a workpiece fixture to be measured and a tailstock; the spindle servo motor drives the spindle to rotate; the workpiece fixture to be measured is fixedly matched with the spindle in the circumferential direction; the measuring unit comprises a base, a rotating table, a measuring contact, a data acquisition system and a computer; the rotating table is arranged on the base in the manner of rotating around a z-axis; and the measuring contact is arranged on the rotating table in the manner of adjustable position along an x-axis, a y-axis and the z-axis and can rotate around an axis parallel to the z-axis. The coordinate measurement can be carried out for the hourglass worm by adopting the arc measuring method, the line by line measurement can be carried out, the efficiency is higher than that of the point by point measurement in the prior art, the influences of subjectivity of human intervention and mechanical error of the standard worm on the detection results are avoided, as different types of measuring contacts are adopted, various errors of the worm can be accurately detected, and the universality is strong.

Owner:CHONGQING UNIV

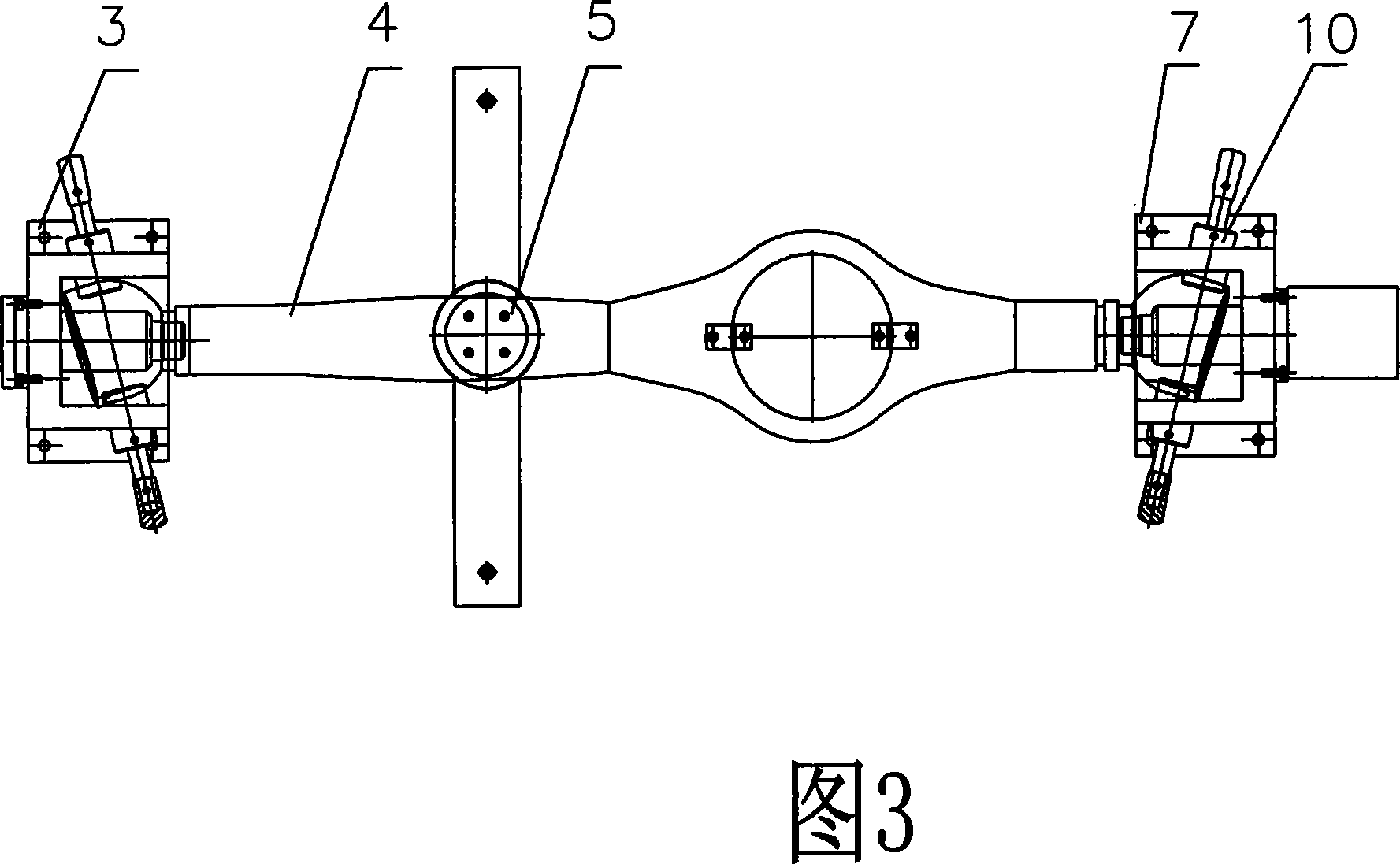

Welding clamp and welding process for axle housing assembly

InactiveCN101185998ANo positioning errorEliminate welding distortionWelding/cutting auxillary devicesArc welding apparatusEngineeringTailstock

The invention relates to an axle housing assembly welding technique and a special clamp, belonging to welding machining technique and equipment field. A head seat 2 is connected with a tail seat 9 respectively through a guide rail and a machine body 1. An axle housing assembly balance-support device 5 and an axle housing assembly central positioning device 6 are connected with the machine body 1 through a connecting key. A support left-clamp body 3 and a support right-clamp body 8 are respectively connected through connecting keys with the head seat 2 and the tail seat 9. The support left-clamp body 3 and the support right-clamp body 8 are respectively connected with a hydraulic power device and a compressing device. The welding technique is that assembling is done first and point-welding is carried out for fixing, then the axle housing assembly is welded. In the welding process of the invention, a difference between the size between a round support and an axle housing body and the size of the drawings is preserved when in point-welding according to the distortion rule of welding, and after welding the size is eventually equal to that on the drawing through welding distortion.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

Processing method for inner hole of cylinder

The invention discloses a processing method for an inner hole of a cylinder. After being finely bored, the inner hole of the cylinder is rolled; the coarse boring, fine boring, and rolling of the processing method are all implemented by a special machine tool manufactured by configuring an engine lathe; a guide tail seat of the machine tool is arranged between a chuck and a slide carriage; the upper surface of the slide carriage is fixedly connected with a boring rod penetrating through a through hole of the guide tail seat; a cylinder bracket is arranged between the guide tail seat and the chuck; a roller is arranged at the support end of the cylinder bracket and used for supporting and locating the other end of the cylinder; a cylinder is adopted as a running pulley of a rolling head, and the cylindrical surface and the two end surfaces of the running pulley are in smooth transition; a bearing body is connected with an outer thread of the boring rod through an inner thread; a conical cylinder is adopted as the outer side surface of the bearing body; and a limiting pin is arranged between the bearing body and the boring rod. Compared with the prior art, the processing method for the inner hole of the cylinder can solve the problems of high rejection ratio and high processing cost of a current processing method for the inner hole of the cylinder.

Owner:LIUZHOU SHUANGJI MACHINERY

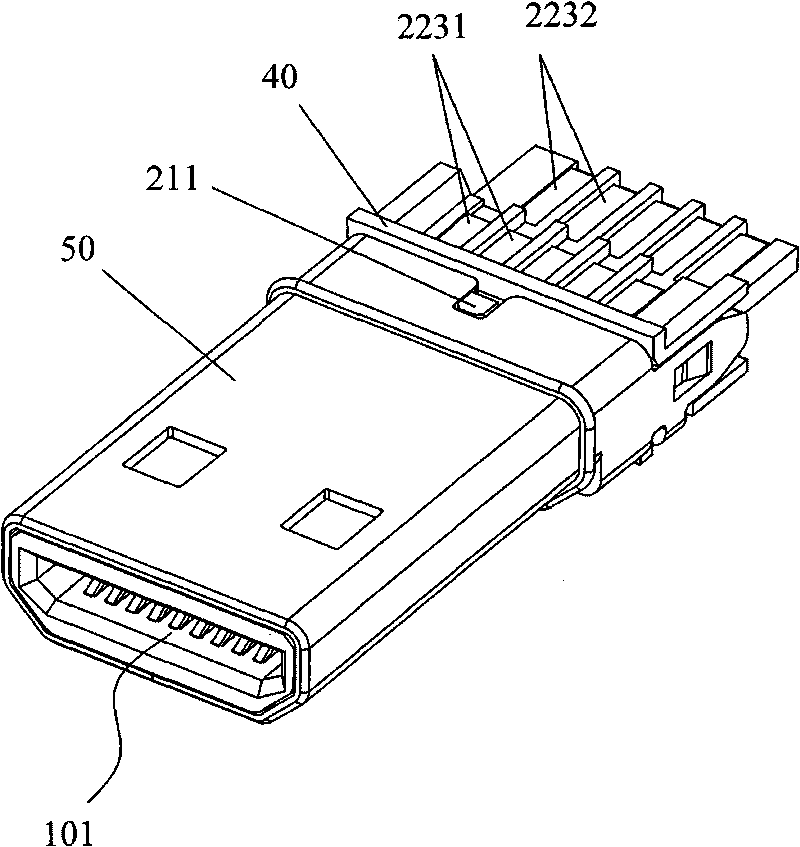

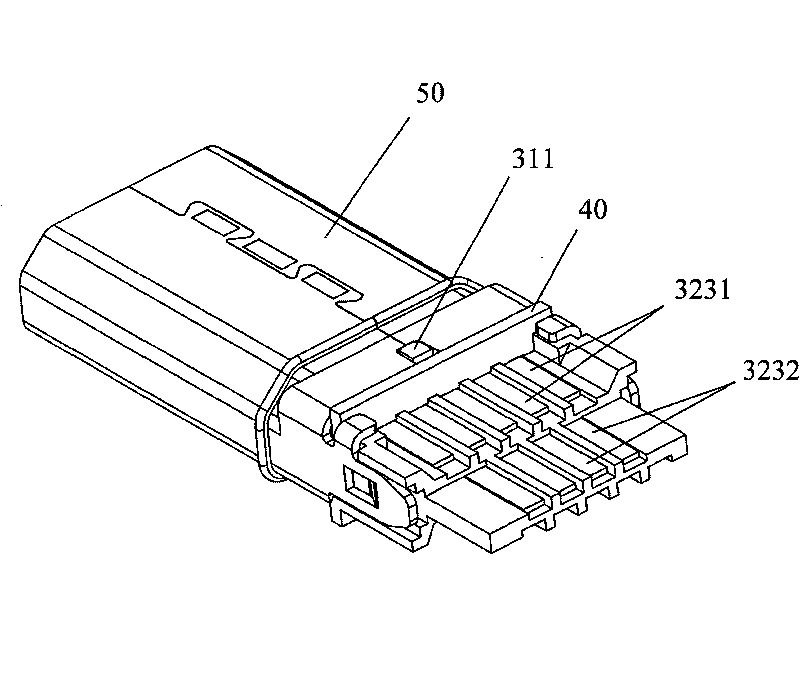

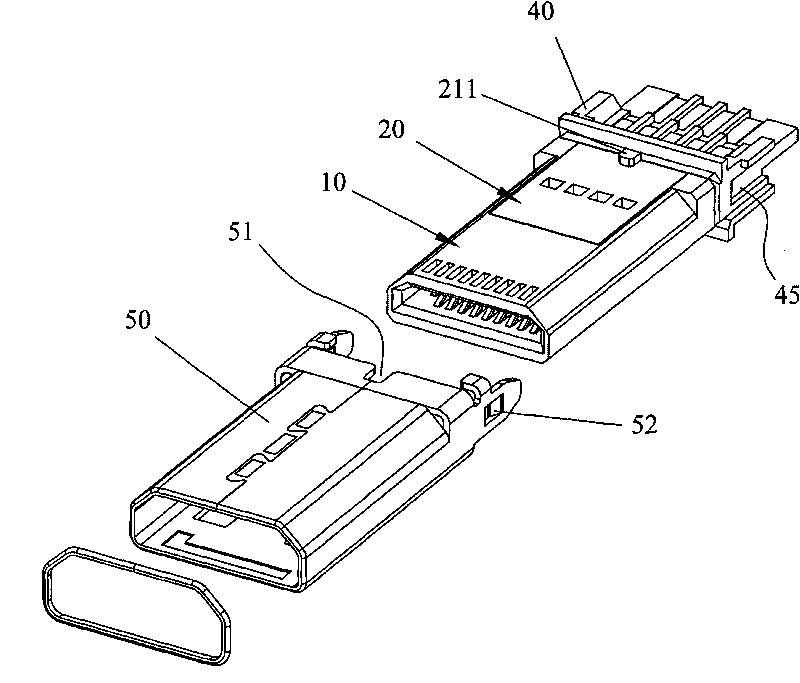

Miniature HDMI connector and manufacturing method thereof

InactiveCN101697386ASolving Wire Bonding ProblemsNeat and stable and reliable installation and positioningContact member assembly/disassemblySoldered/welded conductive connectionsHDMIEngineering

The invention discloses a miniature HDMI connector and a manufacturing method thereof. The miniature HDMI connector comprises an insulating body, a first terminal block, a second terminal block, an insulating tailstock and a shield shell; and weld line parts of all terminals in the HDMI connector are divided into four rows, wherein the weld line parts of the first row of terminals adopt a front-and-back staggered upper and lower two-layer distribution structure, and the weld line parts of the second row of terminals also adopt the front-and-back staggered upper and lower two-layer distribution structure, so that the weld line parts of all the terminals are fully staggered with each other, large effective weld line areas are obtained, and the aim of solving the problem of weld line operation between the terminals and wires is achieved.

Owner:T-CONN PRECISION (ZHONGSHAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com