Insulator horizontal tensile testing machine

A horizontal tensile test and insulator technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. problem, to achieve the effect of convenient adjustment of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

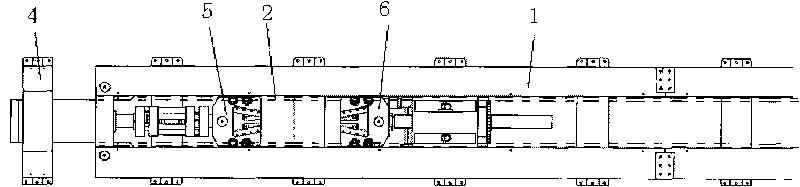

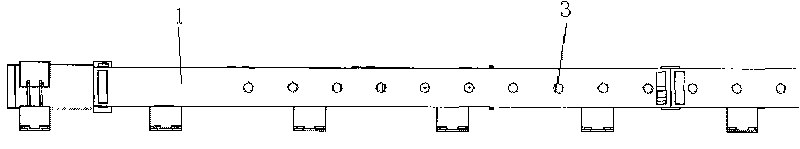

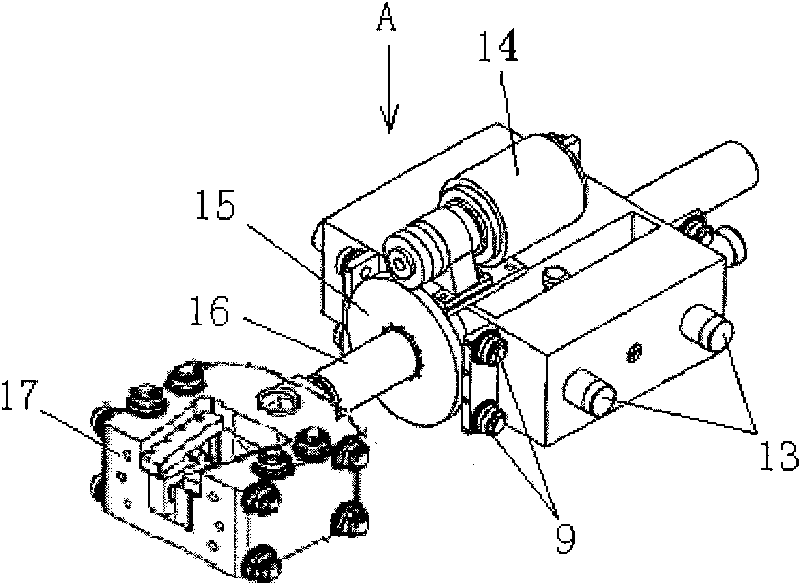

[0016] Such as figure 1 , figure 2 As shown, the horizontal tensile testing machine of the present invention comprises a strip-shaped workbench 1, and the top of the workbench 1 is a slotted type, and on both sides of the groove, each side is equipped with a track 2, for stable For sake of sake, upper and lower two tracks 2 can be installed on each side. The positions of the mounting rails 2 are staggered, and several pin holes 3 are also provided on the sides. One end of the workbench 1 is set as the loading end, and an oil cylinder main body 4 is arranged at the loading end, and the oil cylinder main body 4 is connected with a head seat 5 , and the head seat 5 is placed on the track 2 . The rear end of track 2 is also placed with free-moving tailstock 6 simultaneously, and tailstock 6 is based on tailstock body, and three groups of power mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com