Patents

Literature

360results about How to "Easy to adjust the distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

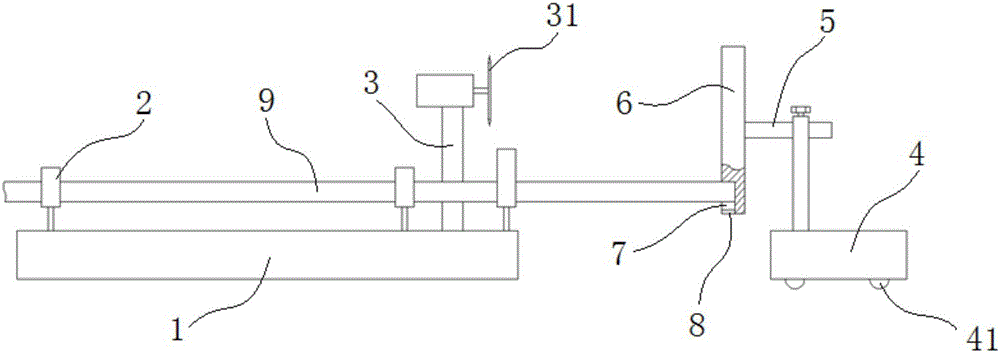

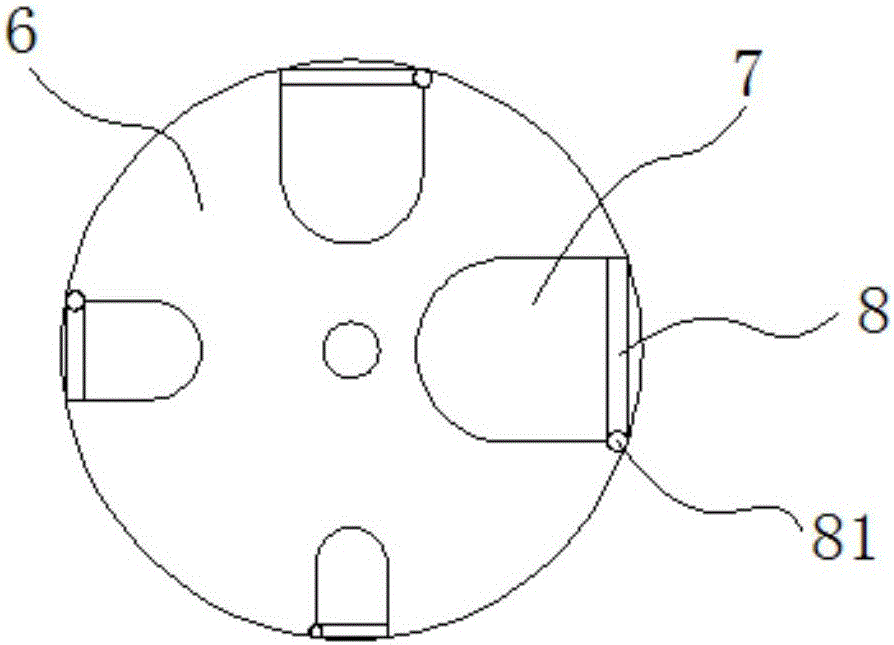

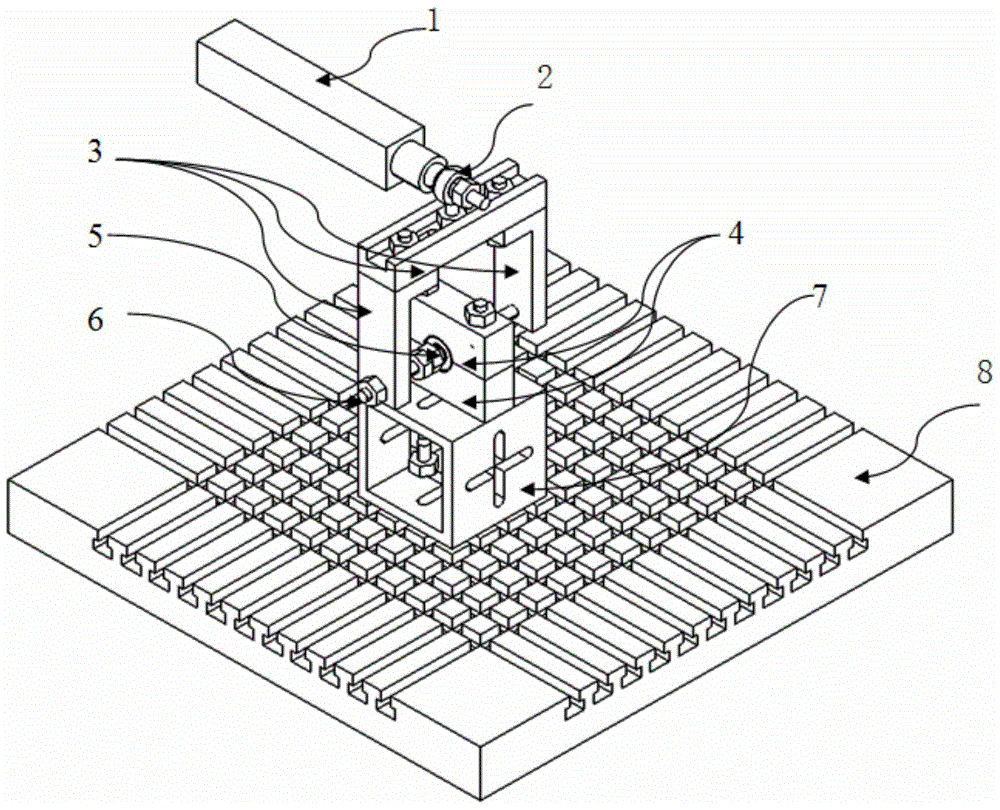

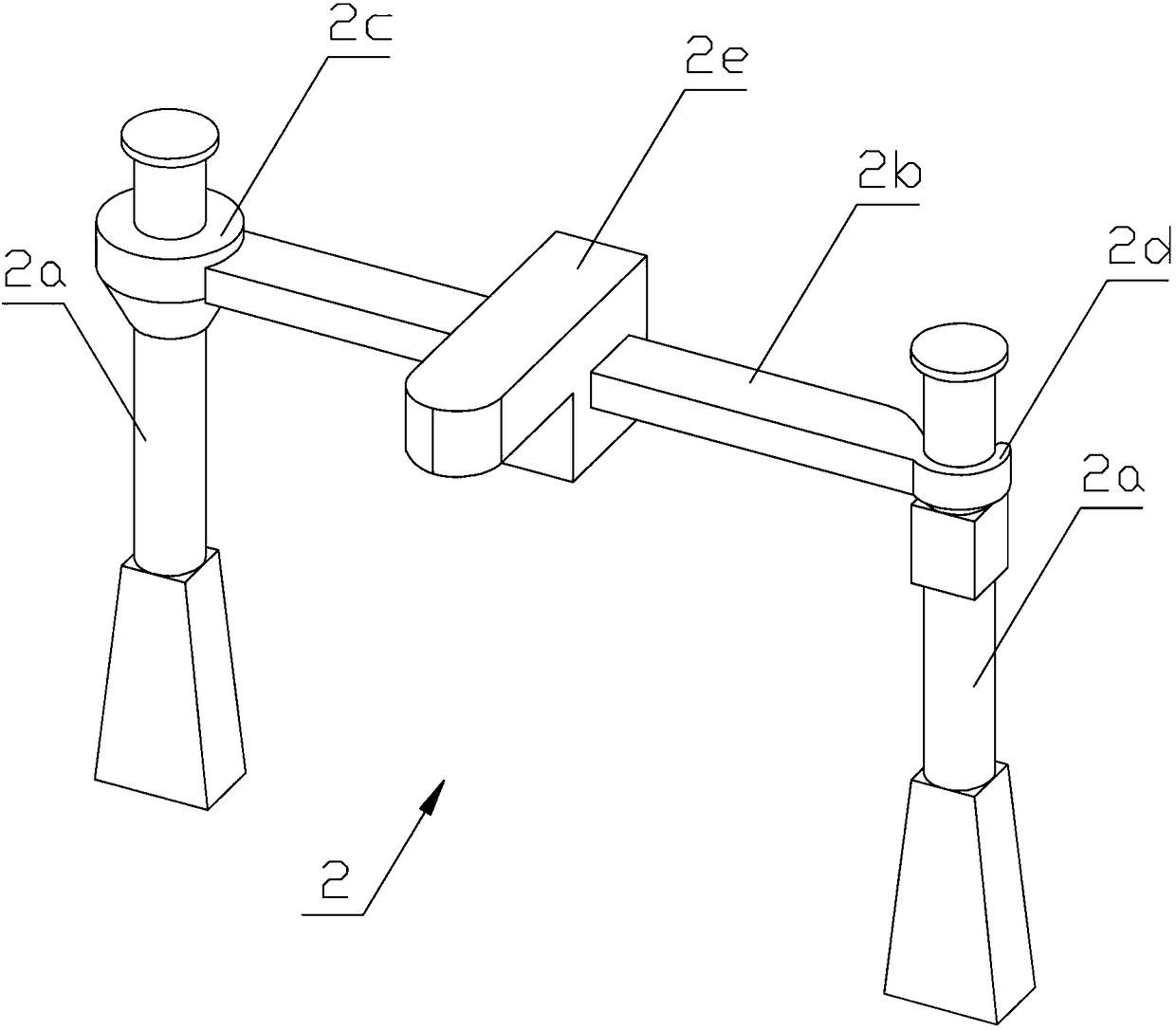

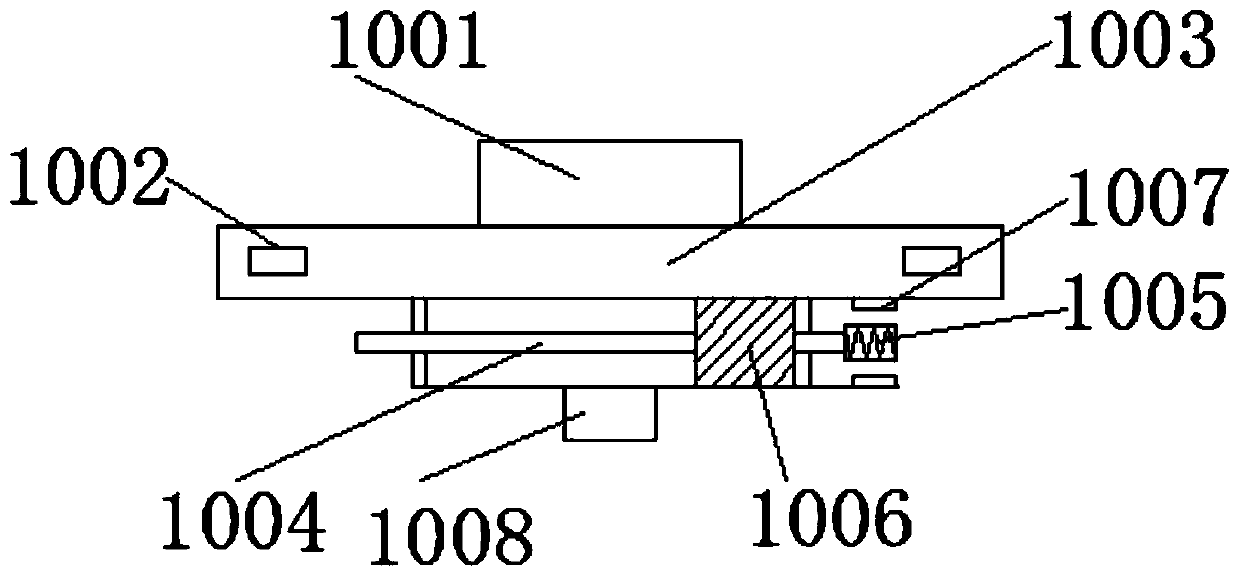

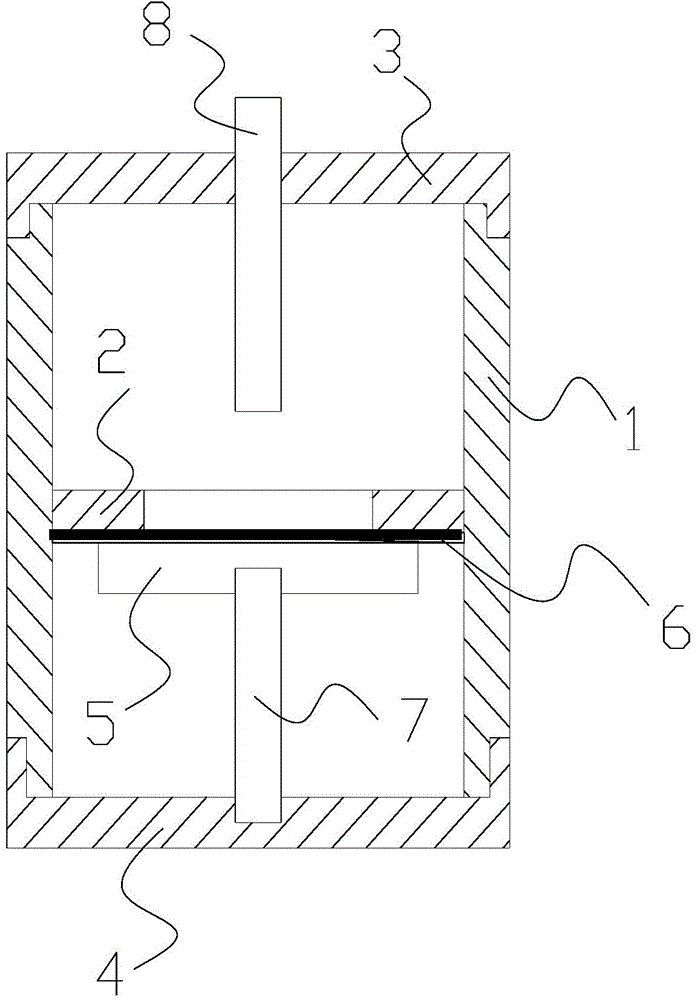

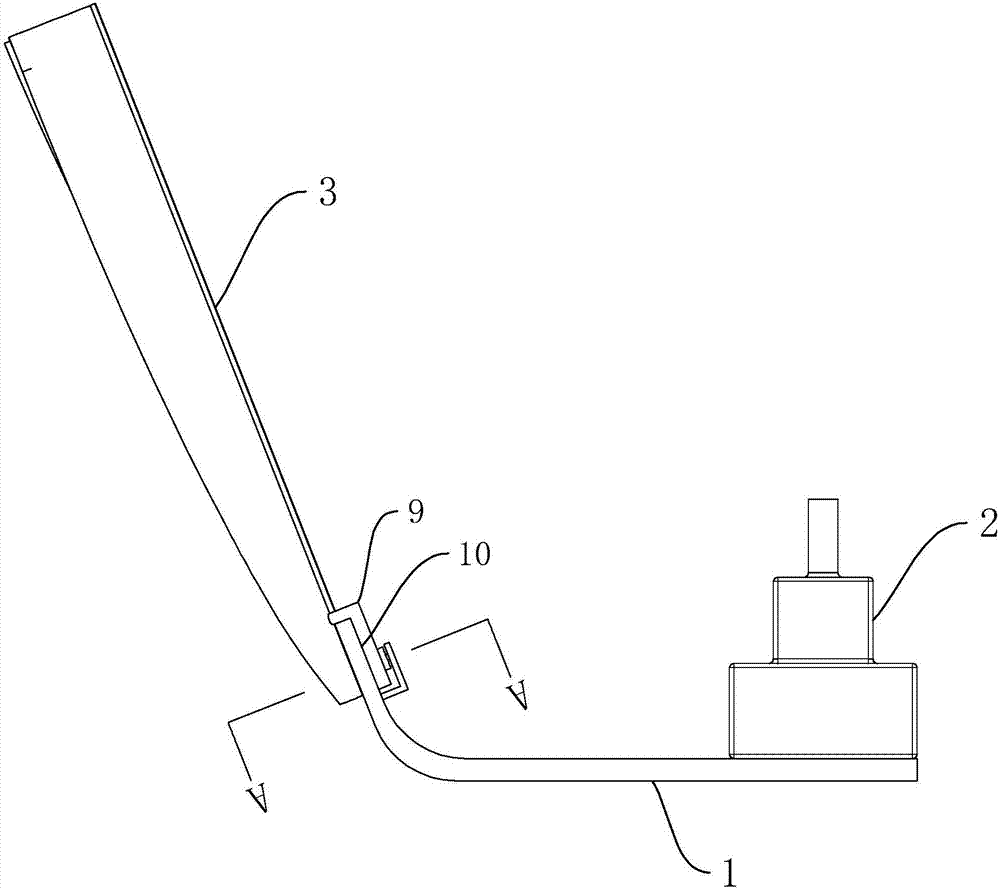

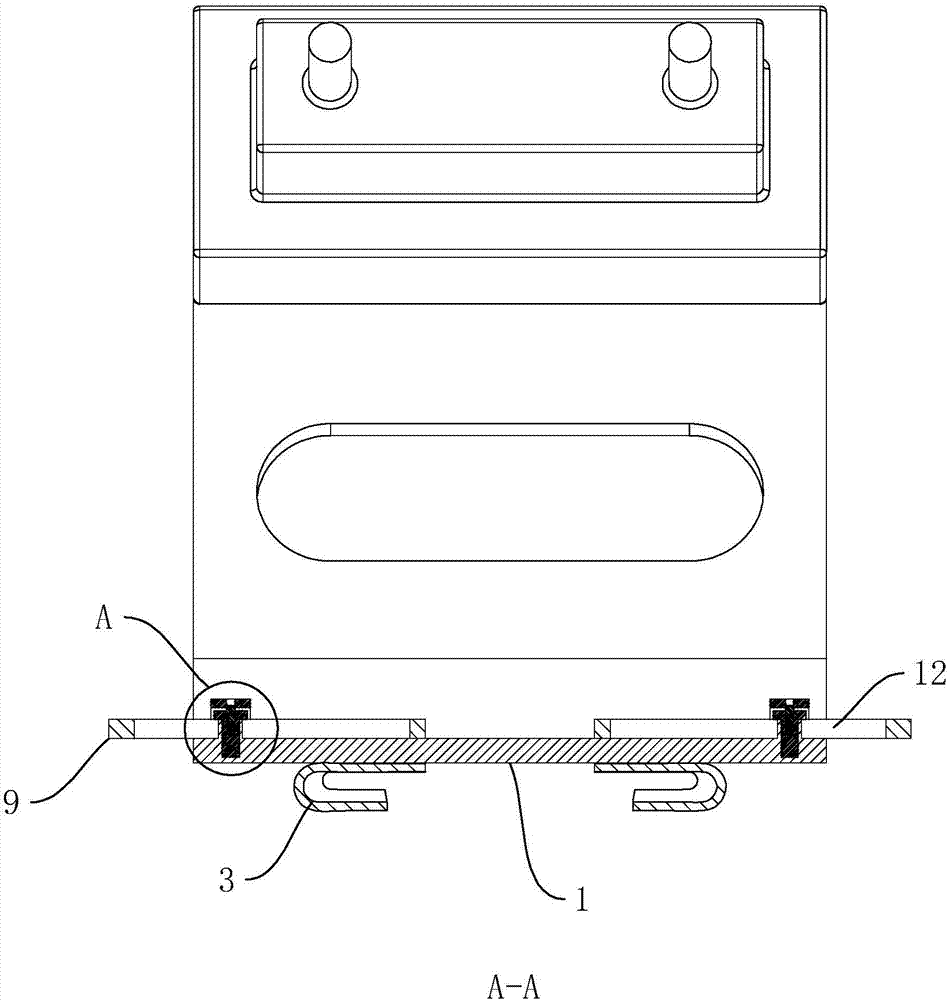

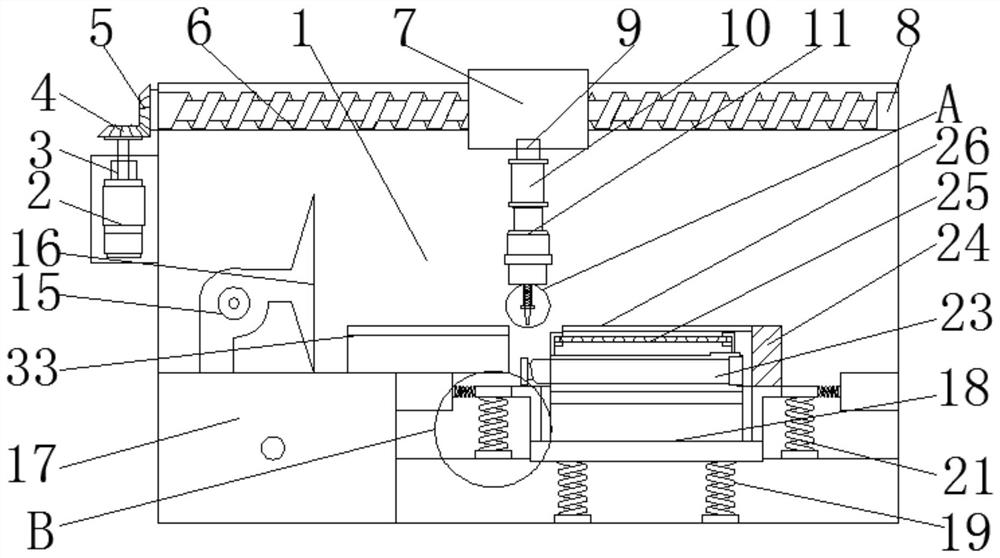

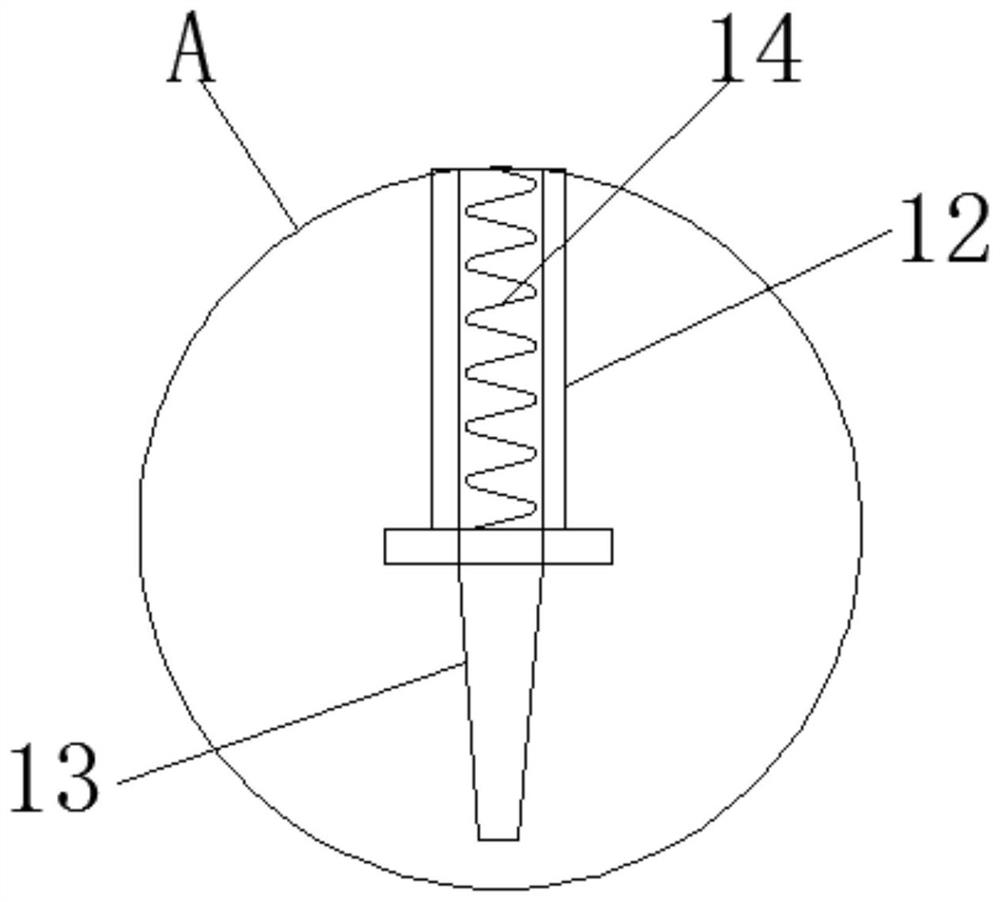

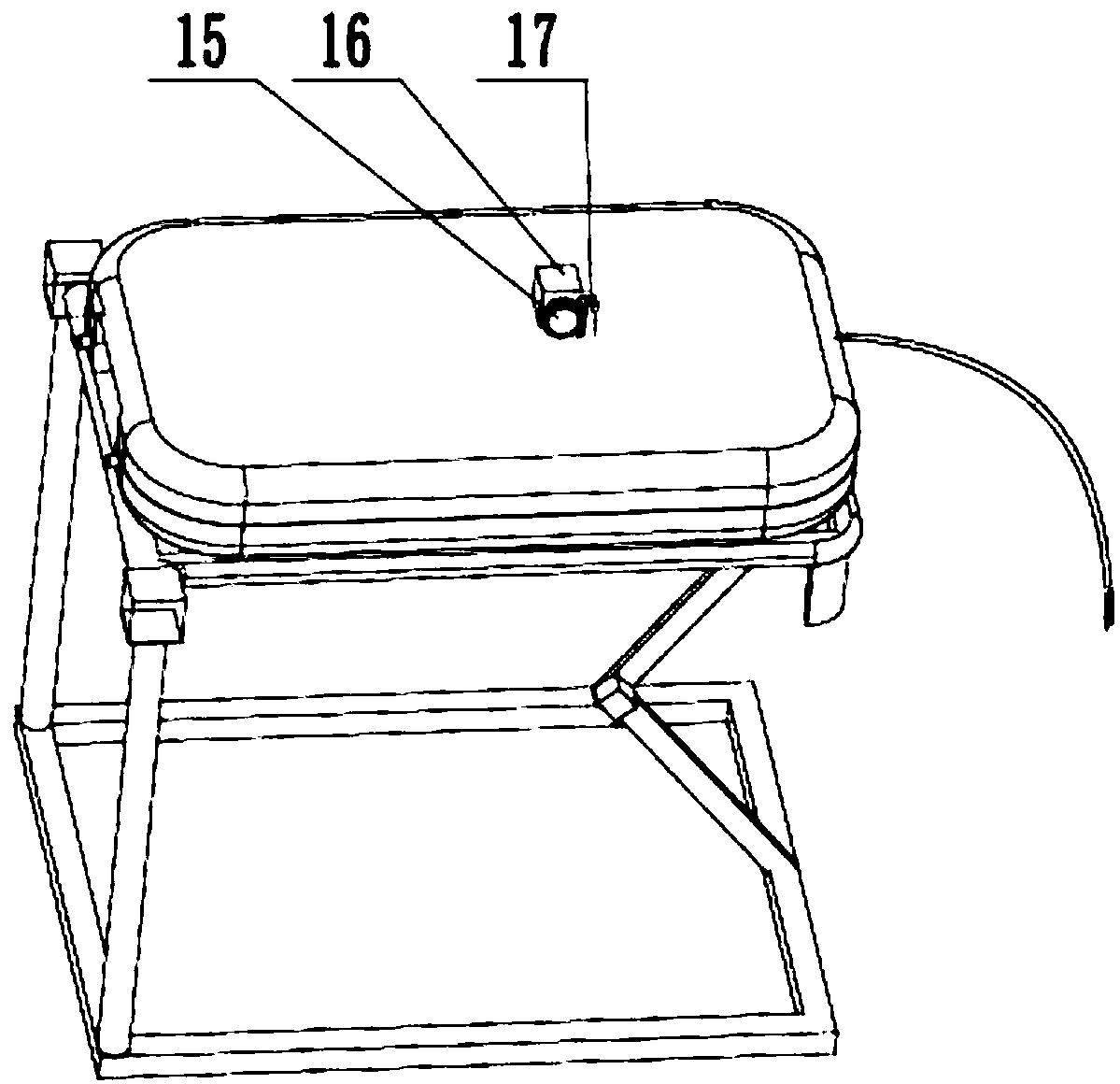

Fixed-length cutting device for tubes

ActiveCN105689788AEasy to cut to lengthImprove securityTube shearing machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses a fixed-length cutting device for tubes. The fixed-length cutting device comprises a cutting table, a cutting device, support elements, a location table, a support shaft, a location disc and baffles, wherein the cutting device is arranged at the front end of the cutting table; the plurality of support elements are arranged on the cutting table along the same straight line, wherein the support element at the forefront is located in front of the cutting device; the location table is arranged in front of the cutting table; the support shaft is erected on the location table in a manner of being capable of sliding forwards and backwards; the location disc is rotatably arranged at the rear end of the support shaft in a sleeving manner, a plurality of U-shaped grooves are arranged in the rear end surface of the location disc in a sinking manner along a peripheral direction, and the opening of each U-shaped groove penetrates through the sidewall of the location disc; one baffle is arranged at the opening of each U-shaped groove in a covering manner; and one end of each baffle is hinged at one side of the opening of the corresponding U-shaped groove through a pin shaft, and a torsional spring is arranged on each pin shaft in a sleeving manner. The fixed-length cutting device disclosed by the invention is capable of conveniently carrying out fixed-length cutting on the tubes, safe and efficient in cutting process, and low in cost.

Owner:海宁经开产业园区开发建设有限公司

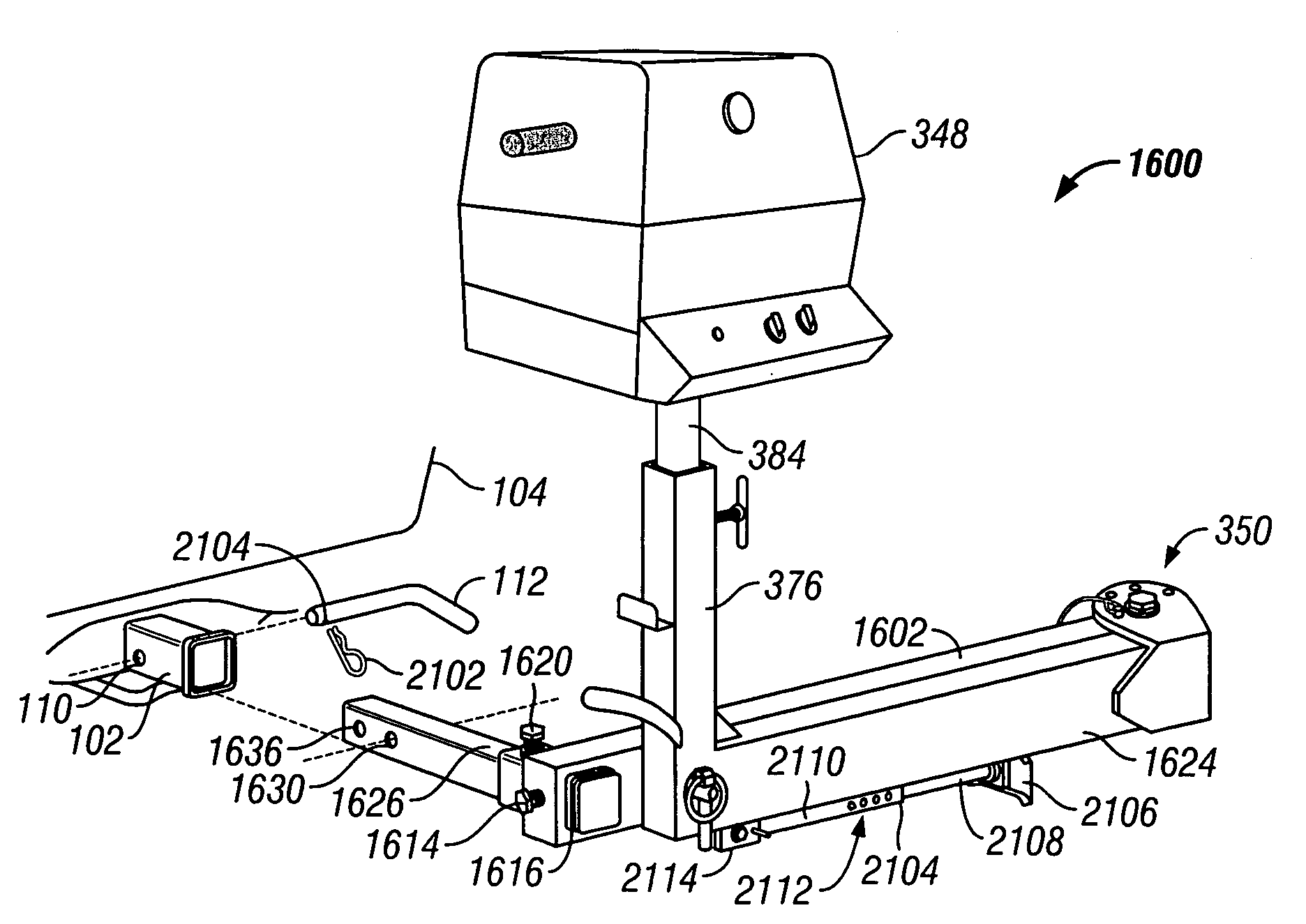

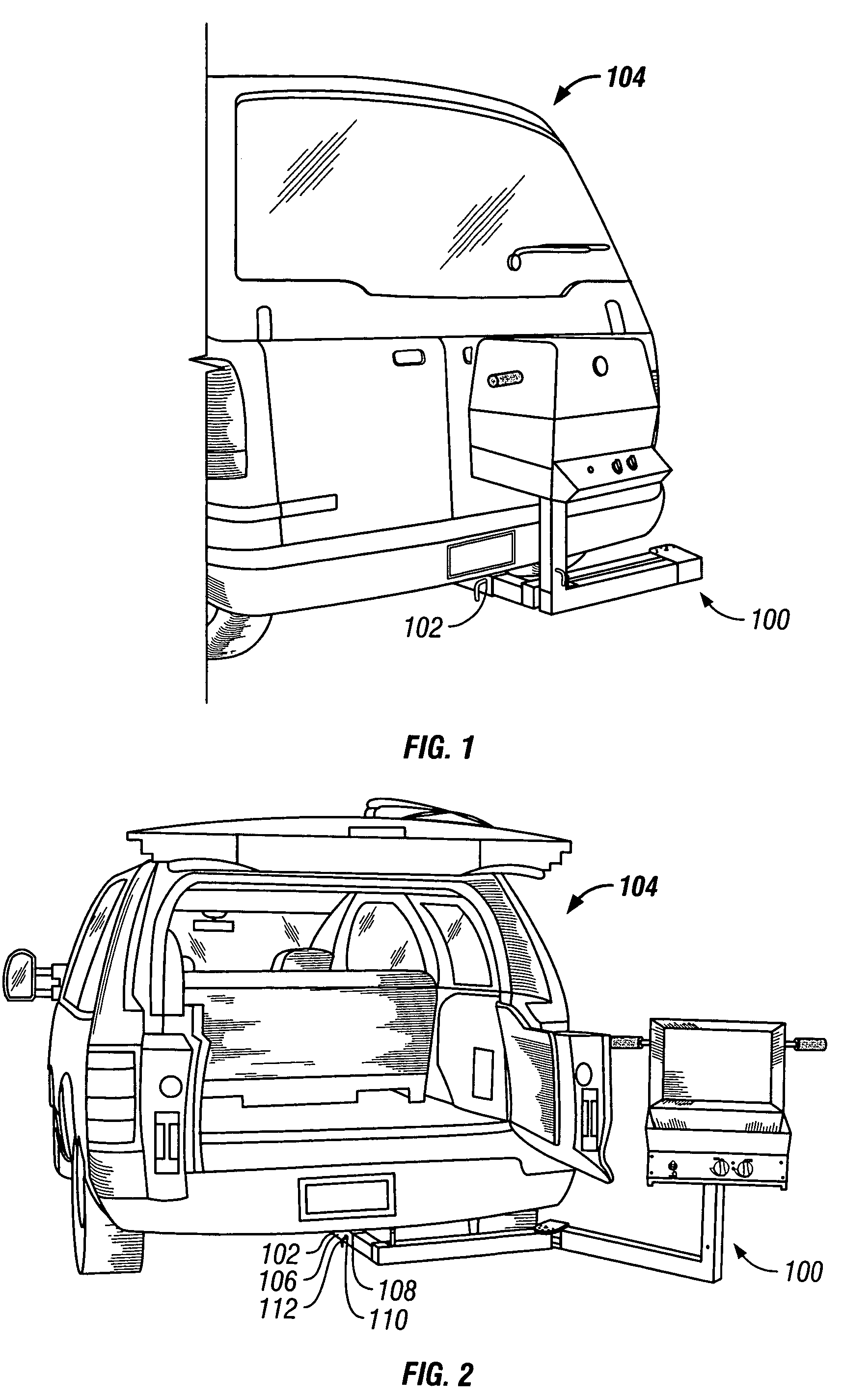

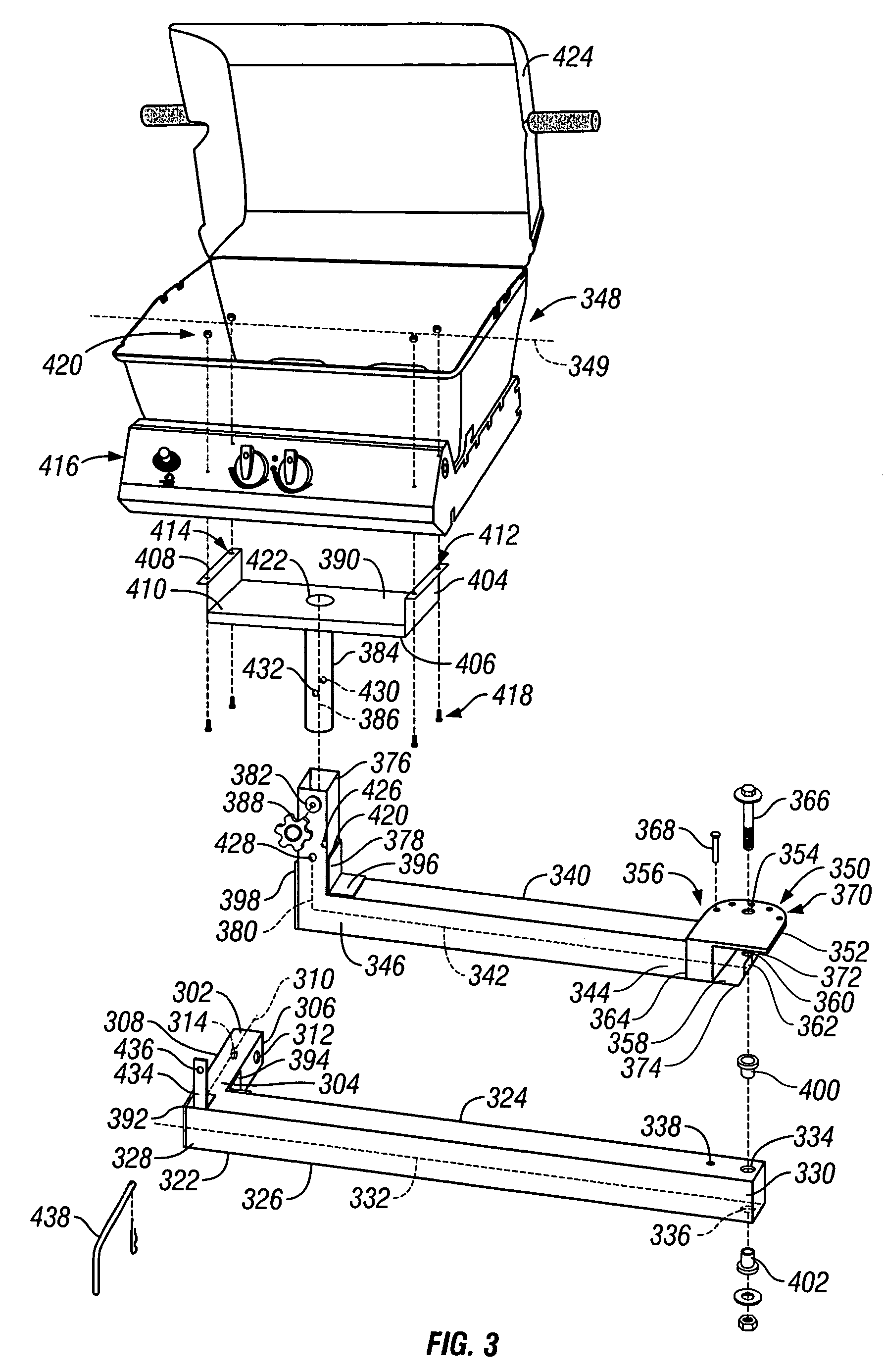

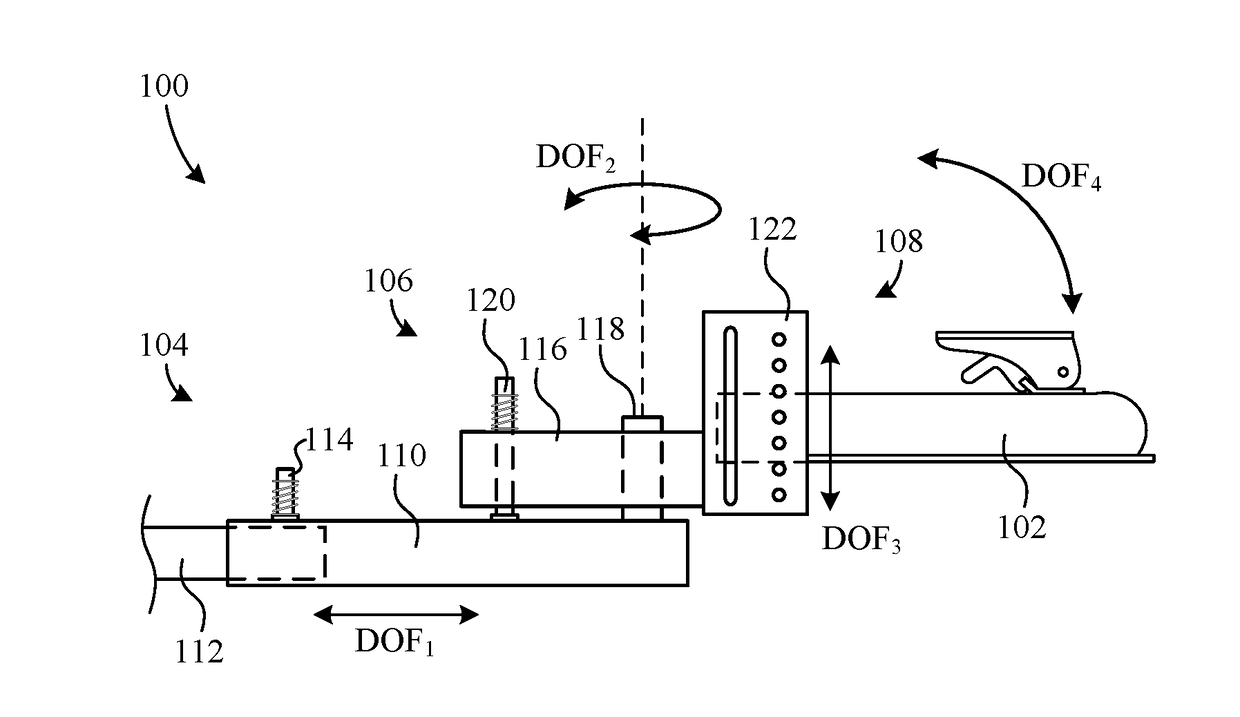

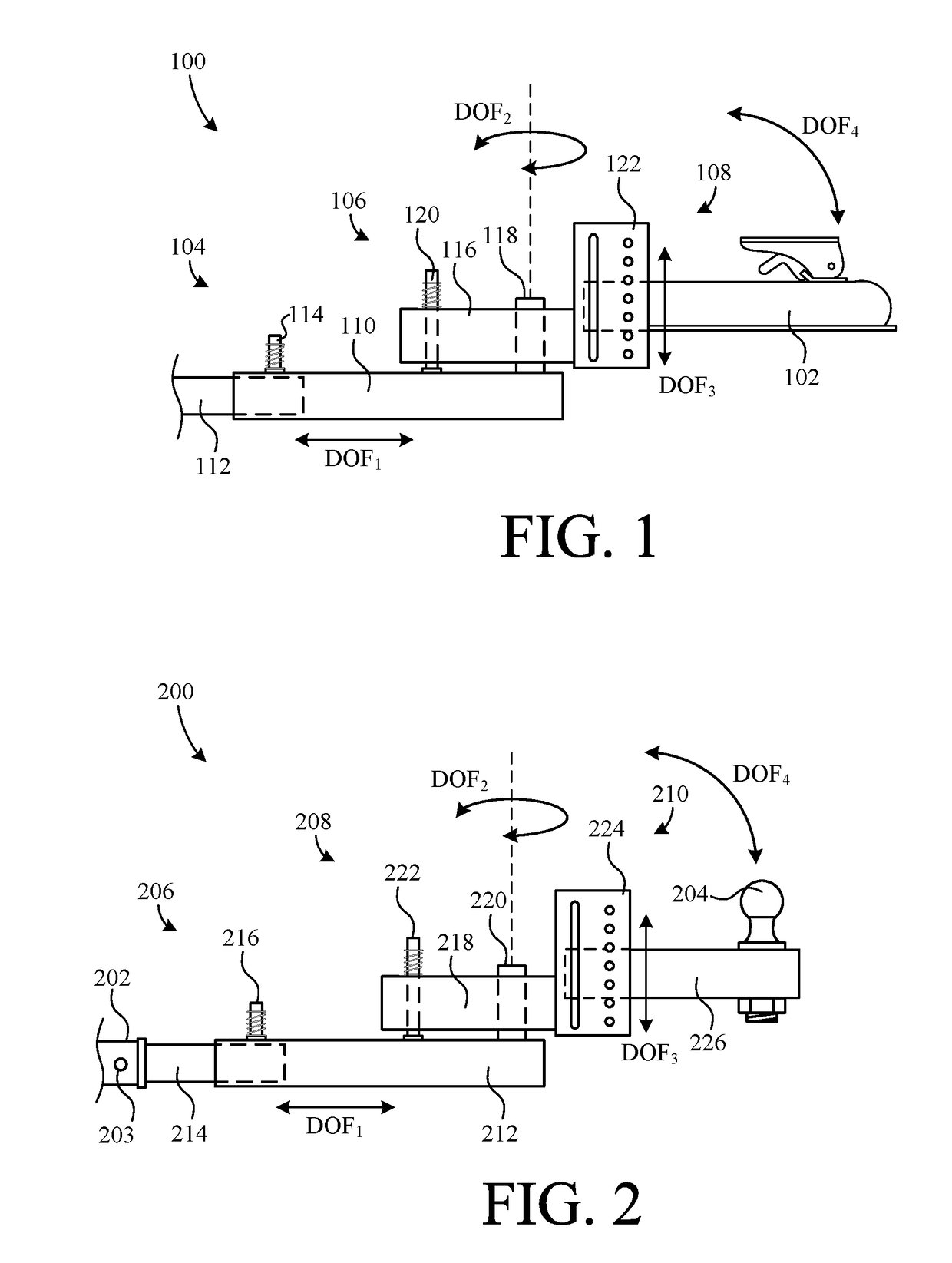

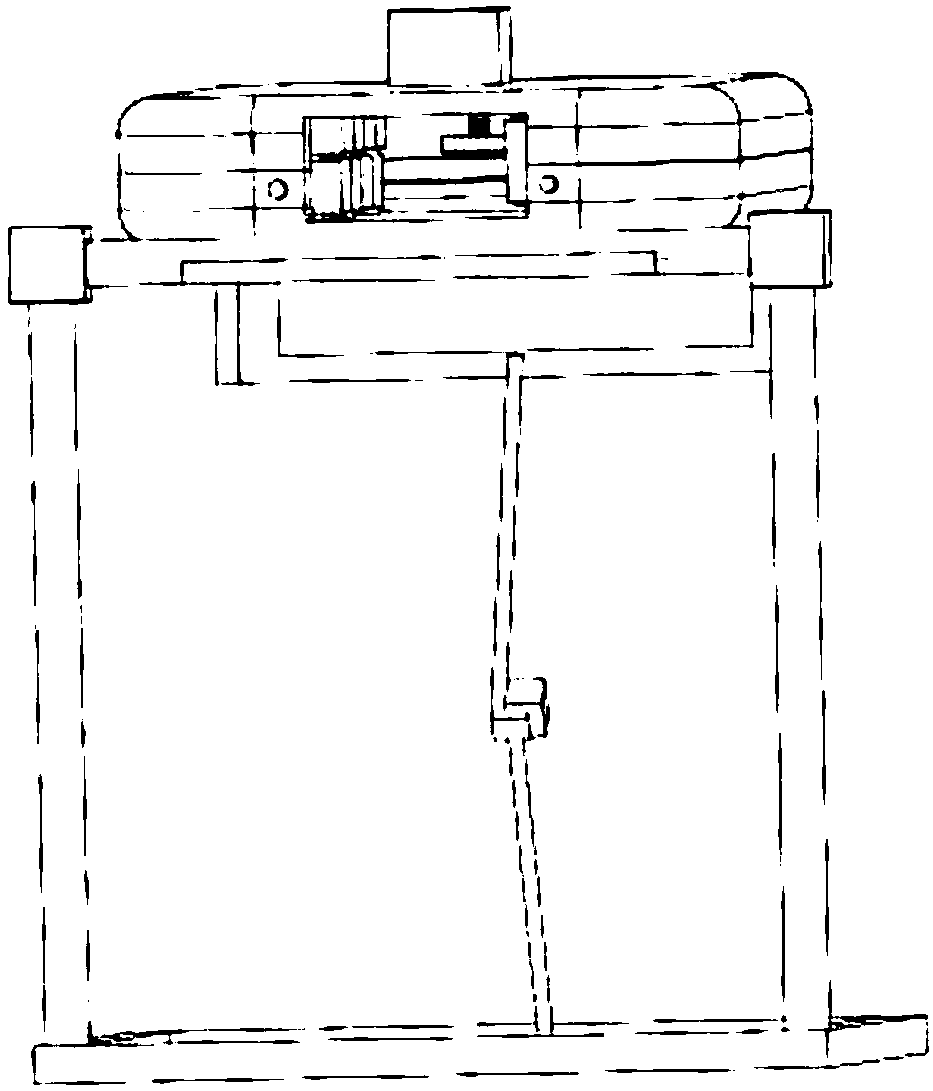

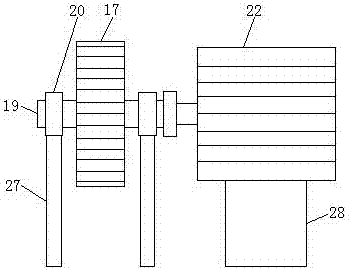

Swingable apparatus attachable to a vehicle for transporting a device and permitting access to the vehicle

InactiveUS7591404B2Easily be unattachedEasy to adjust the distanceDomestic stoves or rangesLiquid heating fuelEngineeringHinge angle

One aspect of the invention is an apparatus that is selectively attachable to a vehicle, for transporting a device and positioning the device in an orientation that permits access to the vehicle. The apparatus may include a support arm defining a support arm longitudinal axis, wherein the support arm has a hitch collar hole. The apparatus may also include a primary swing arm defining a primary swing arm longitudinal axis. The apparatus may further include a primary hinge assembly coupled to the support arm and the primary swing arm.

Owner:SUNBEAN PROD INC

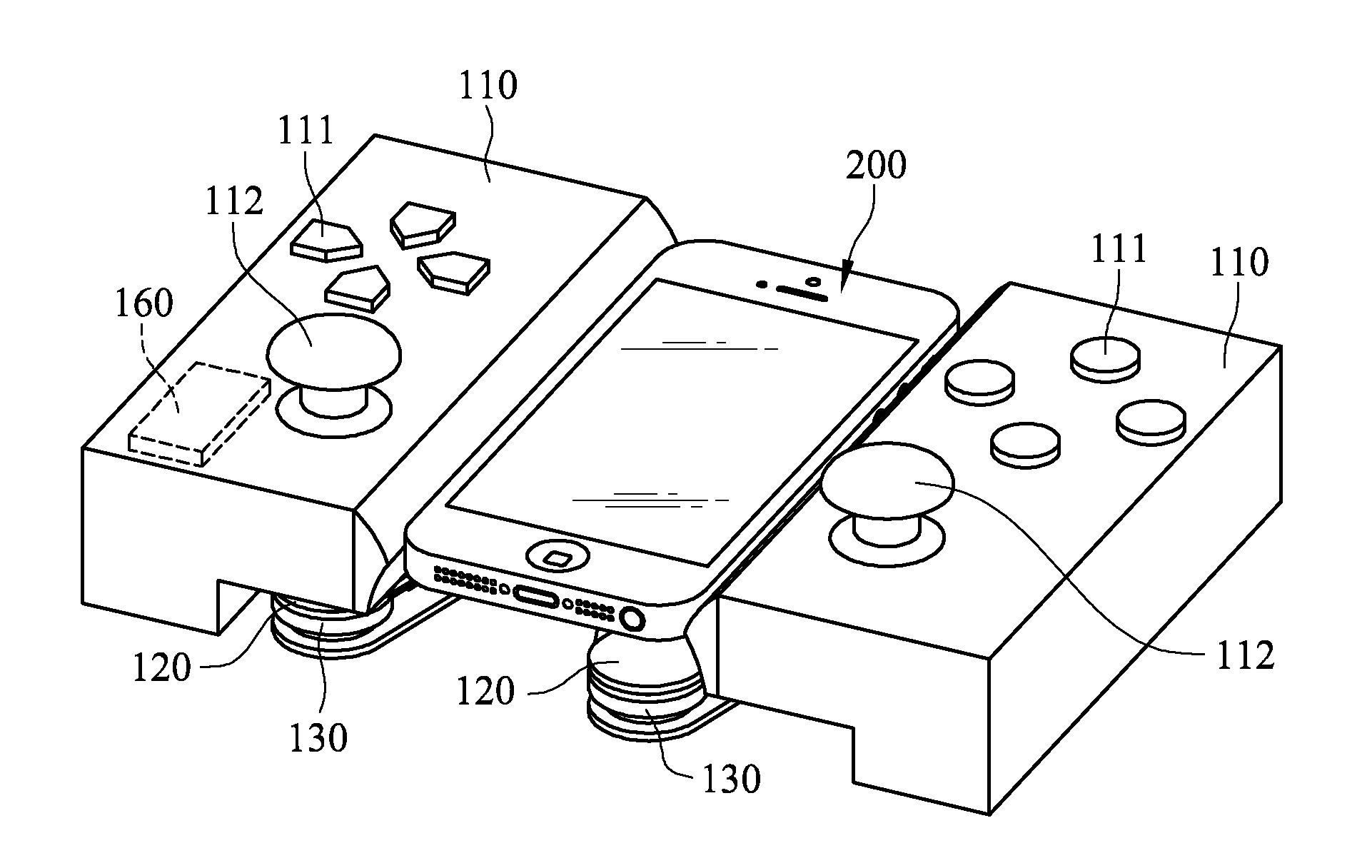

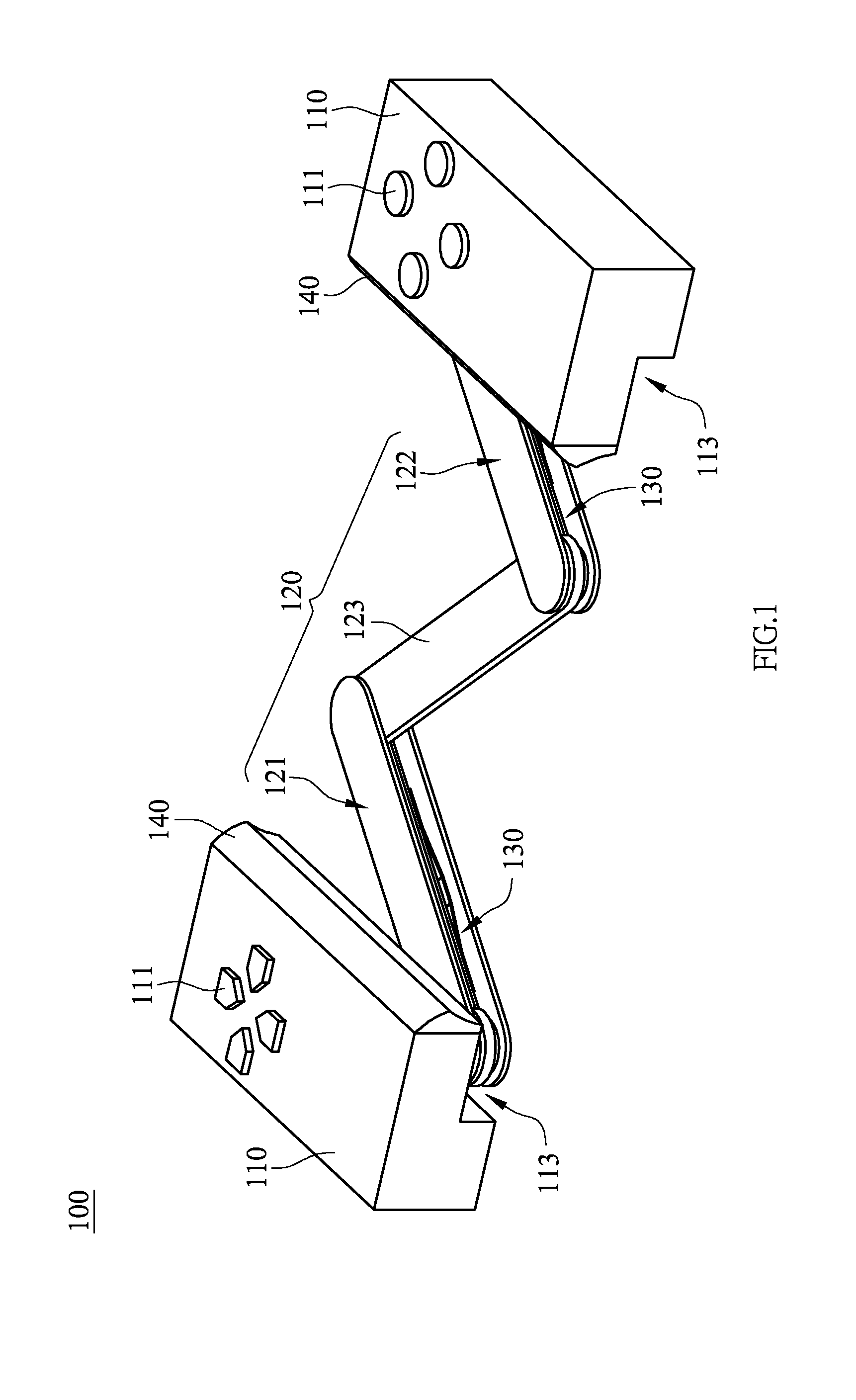

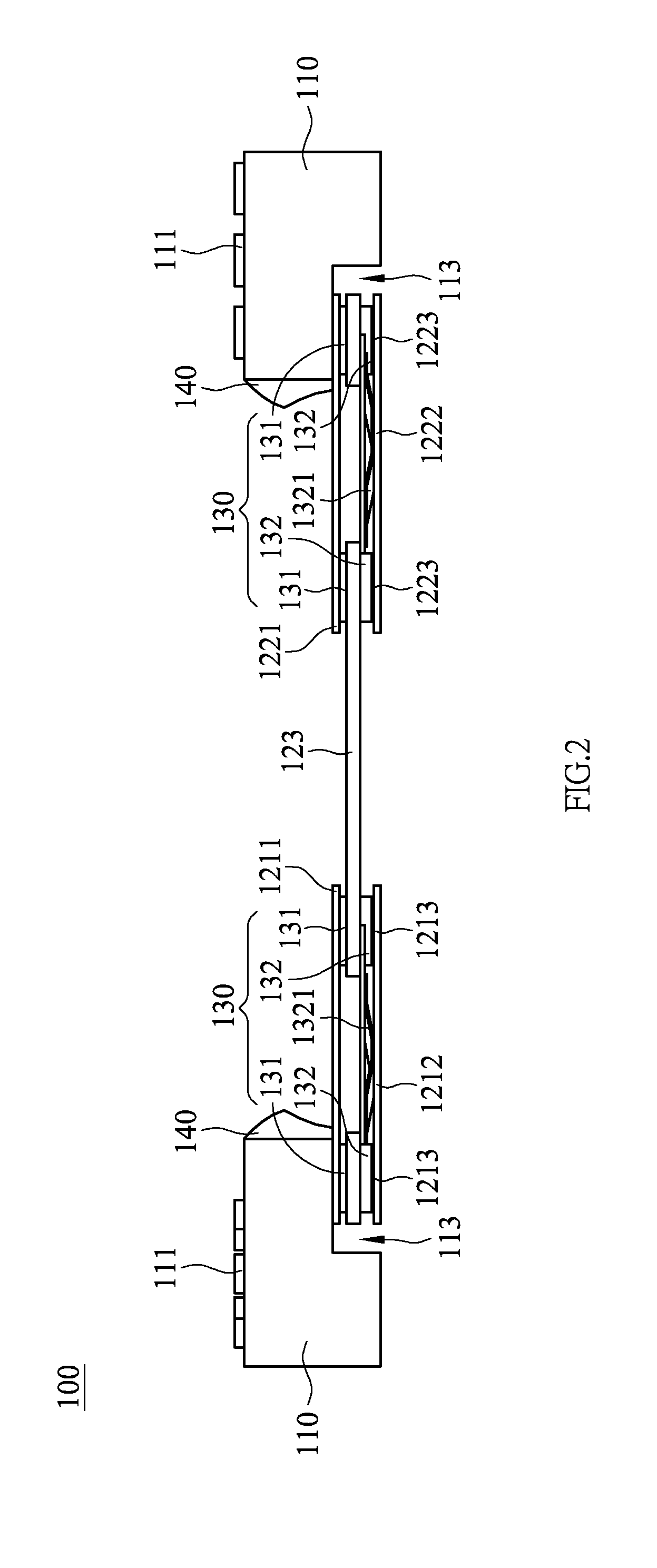

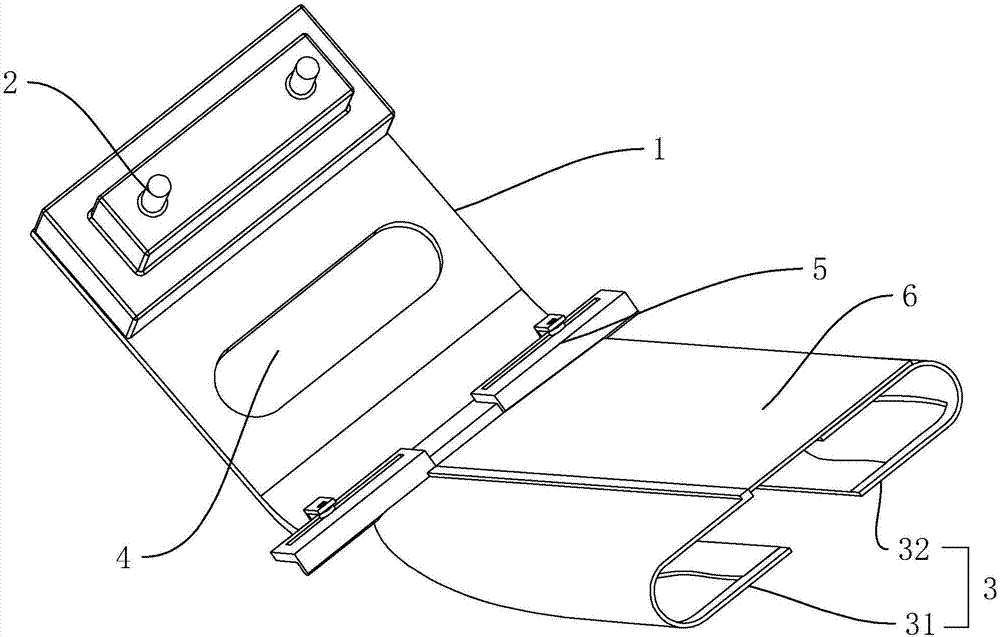

External control pad

InactiveUS20150205328A1Easy to adjust the distanceImprove applicabilityDigital data processing detailsVideo gamesEngineeringMobile device

An external control pad for incorporating a mobile device includes two handheld parts, a movable set, and two fastening mechanisms is provided. The movable set is disposed in between the two handheld parts, and each said fastening mechanism is disposed on the movable set. When placing the mobile device in between the two handheld parts, a user adjusts the distance between the two handheld parts by altering the movable set such that the two handheld parts move closer to or away from, the mobile device. The fastening mechanisms for securing the distance posed by the movable set allows the mobile device to be clamped and fixed in between the two handheld parts so that the mobile device is incorporated into the external control pad for users' convenience and ease of use.

Owner:GIGA BYTE TECH CO LTD

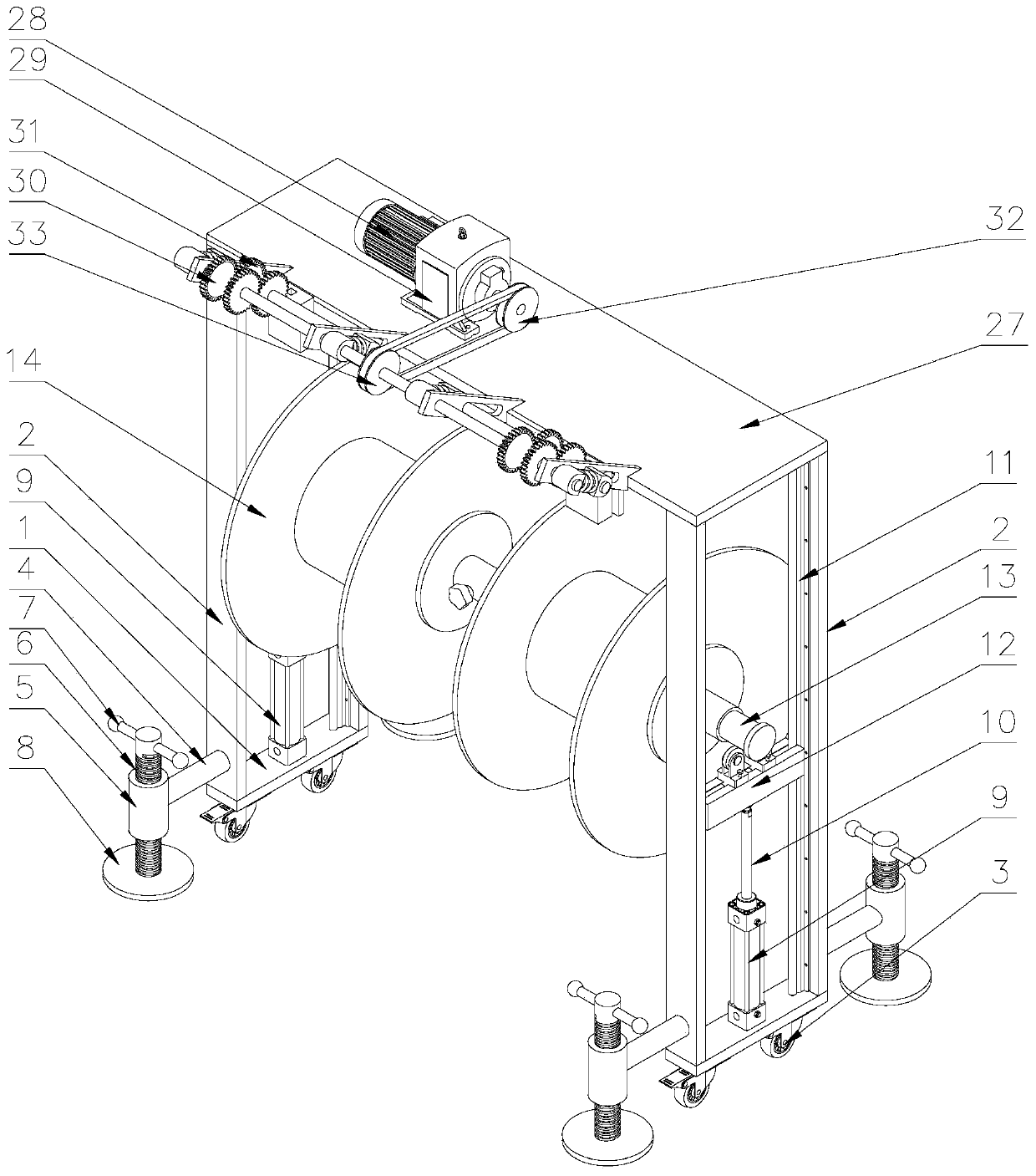

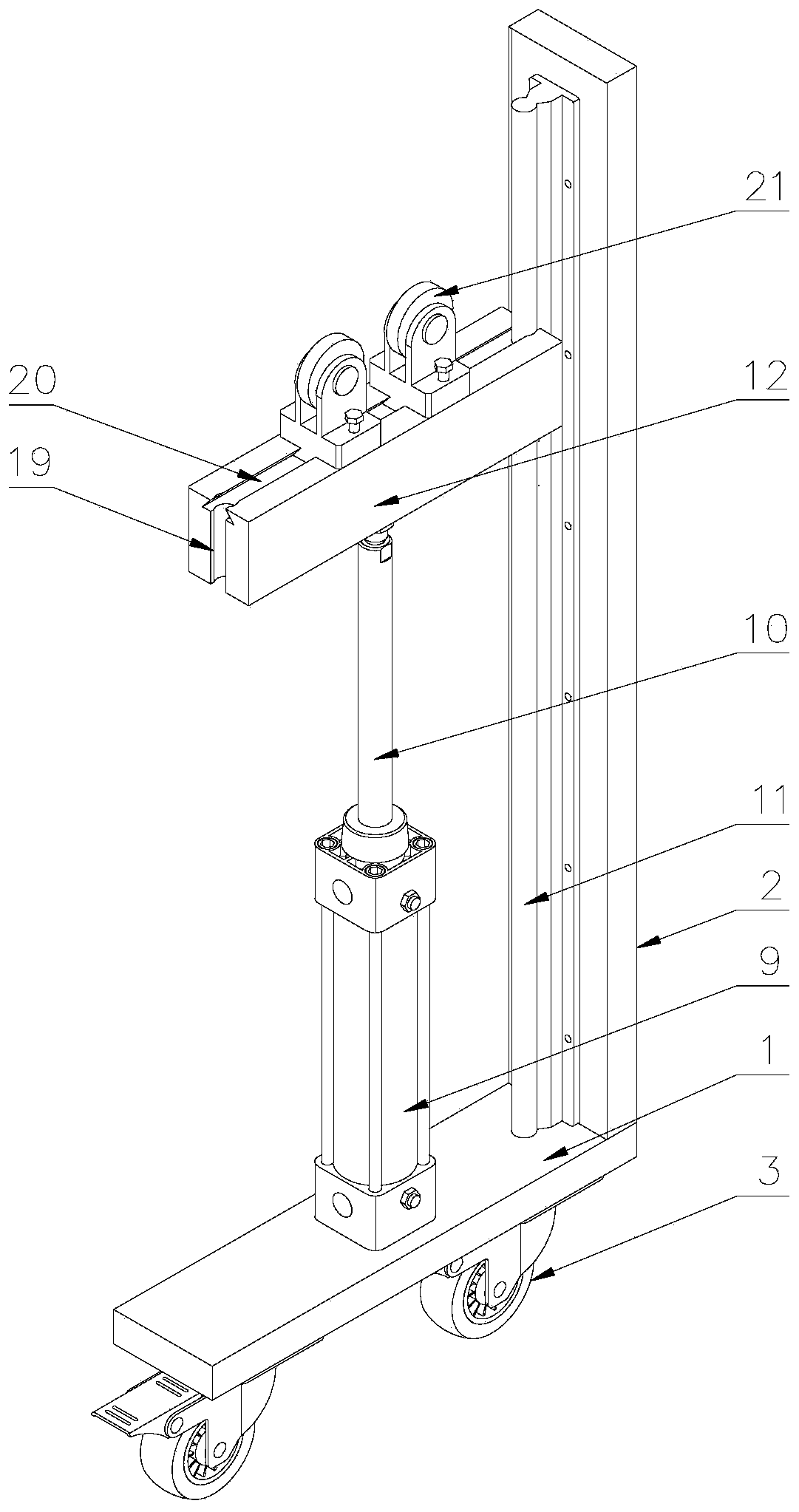

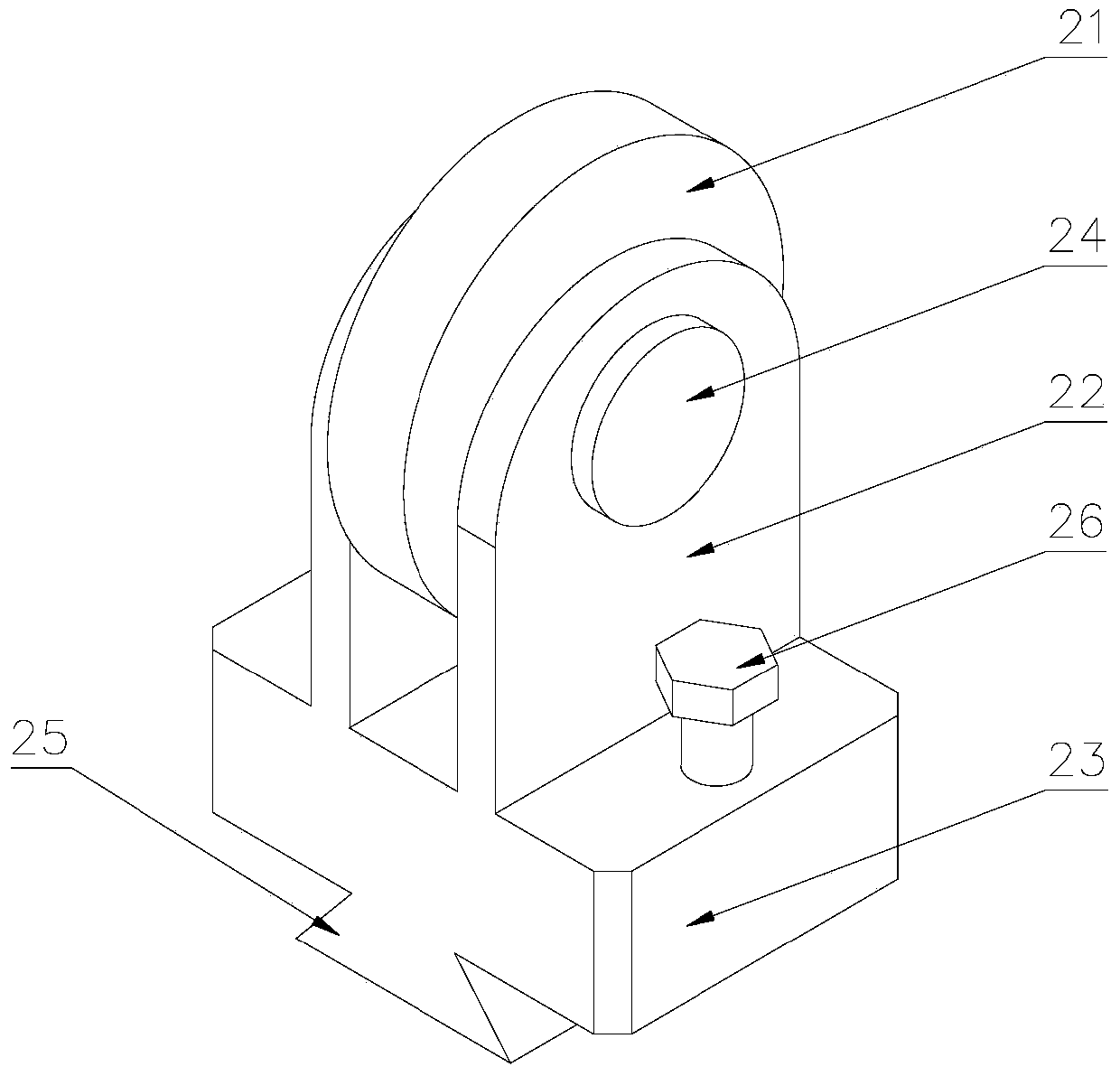

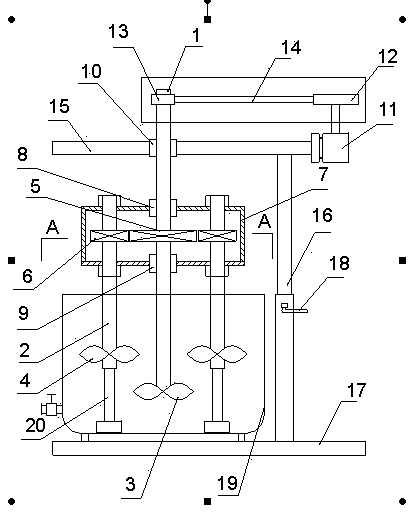

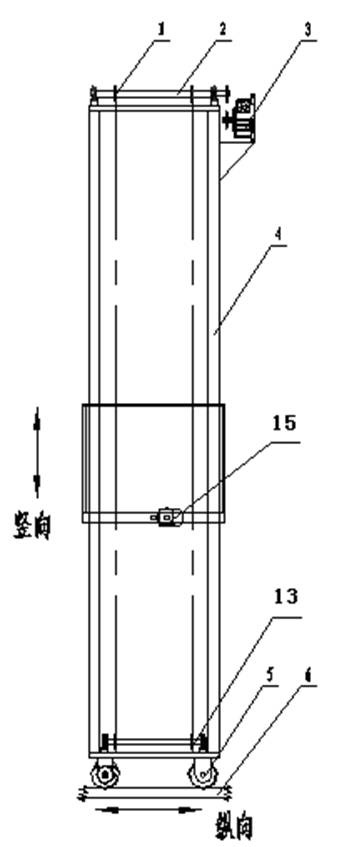

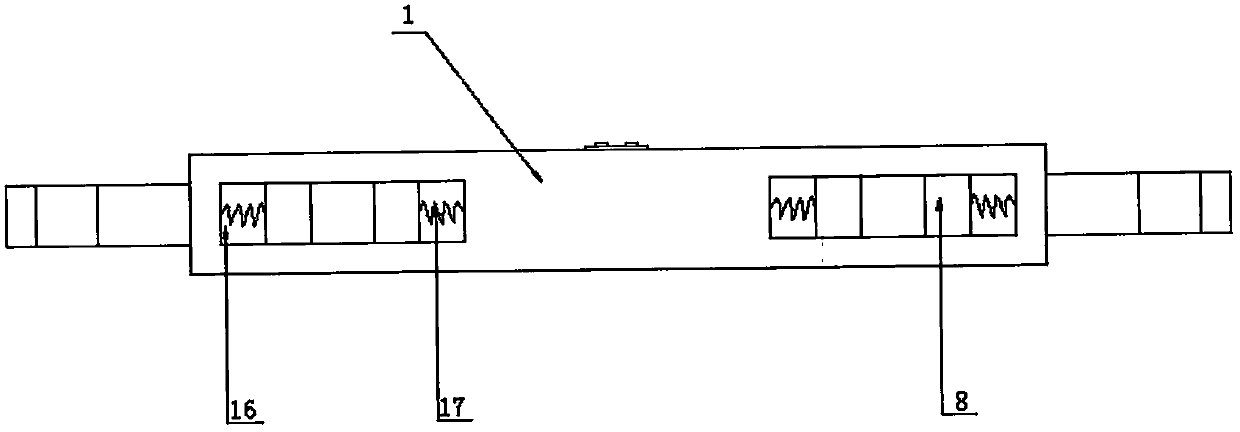

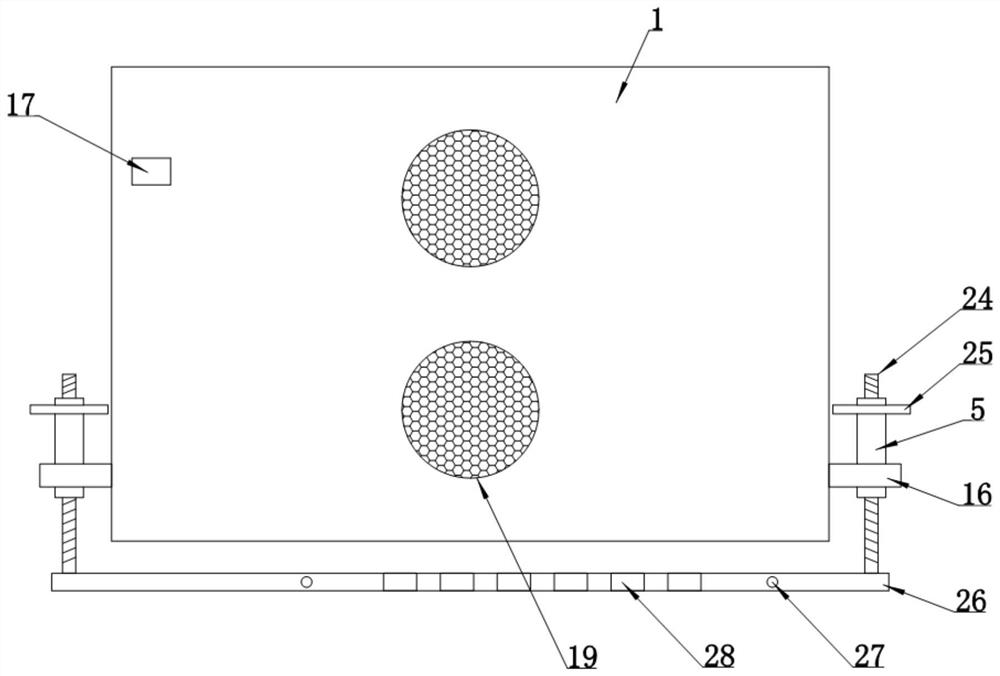

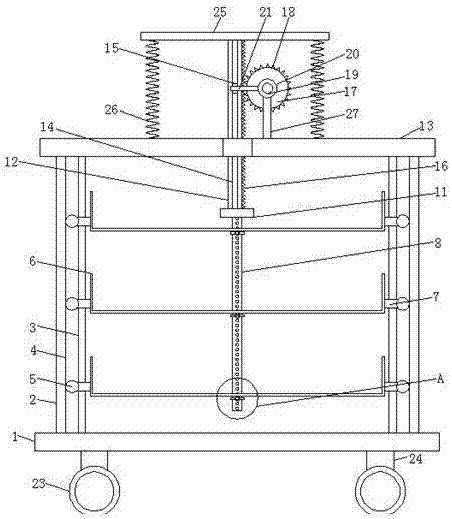

Cable pay-off device for power construction

ActiveCN110061451AReduce difficultyImprove laying efficiencyApparatus for laying cablesEngineeringConductor Coil

The invention discloses a cable pay-off device for power construction. Vertical posts are arranged at two ends of a bottom plate, a guide rail is arranged at one side of each vertical post, an air cylinder is fixedly arranged on the bottom plate, a first sliding block is arranged at an upper end of a piston rod of the air cylinder, upper ends of the vertical posts at two sides are connected by a top plate, two ends of a second connection rod are placed on the first sliding block, a plurality of cable discs are arranged on the second connection rod, a plurality of second supports are arranged at one side f the top plate, a first rotation shaft is arranged on the second supports, a plurality of winding wheels are movably arranged on the first rotation shaft, the numbers of the first windingwheels are equal to the numbers of the cable discs, and the first winding wheel slides among the second supports along an axial direction of the first rotation shaft. The cable disc is jacked up by the air cylinder, the cable disc is prevented from being contacted with ground, so that the friction between the cable disc and the ground is prevented, and the cable pay-off difficulty is reduced; andmoreover, multiple groups of cable discs are arranged on the second connection rod and are used for unwinding, the labor intensity of a worker is reduced, and the cable laying efficiency is greatly improved.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

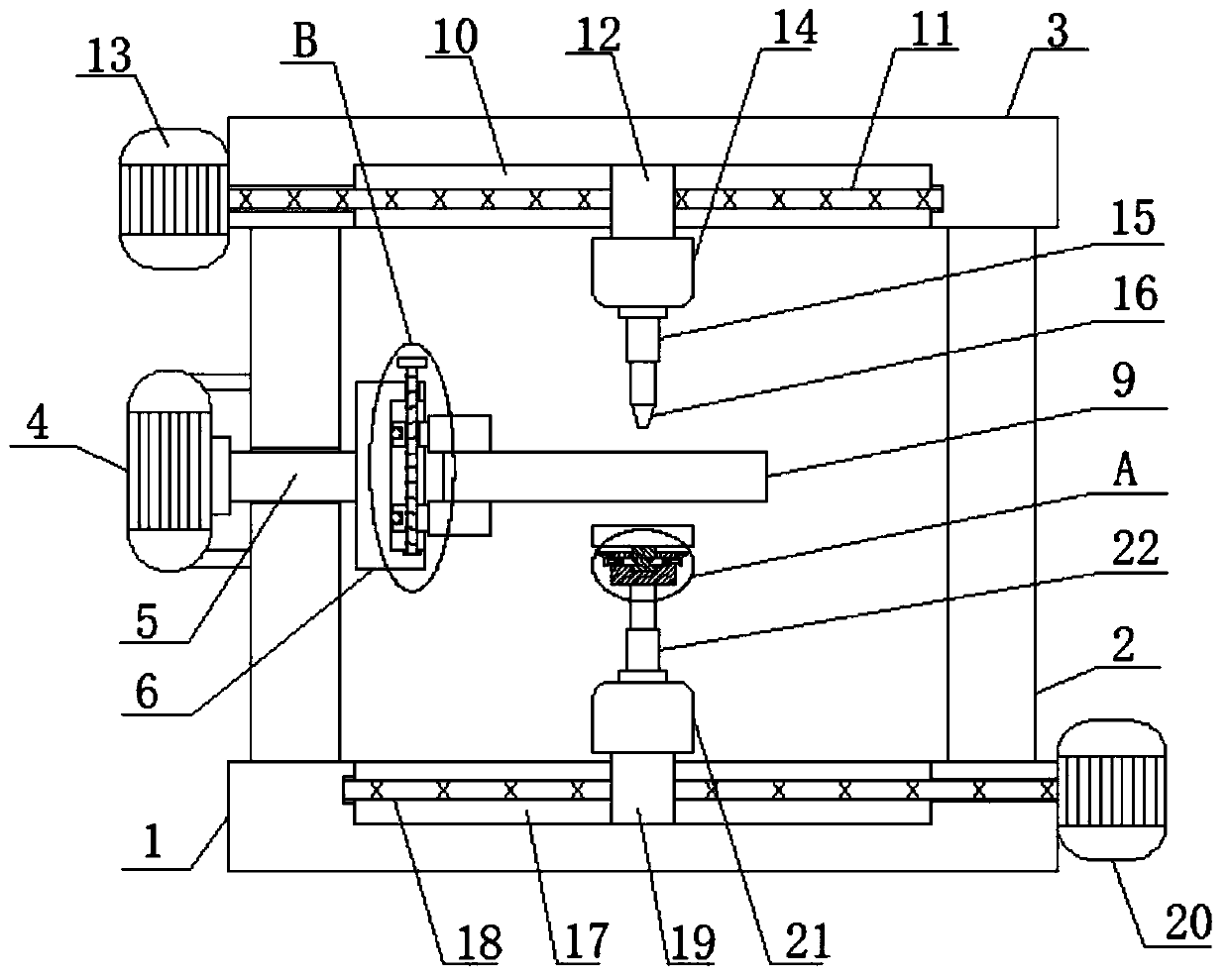

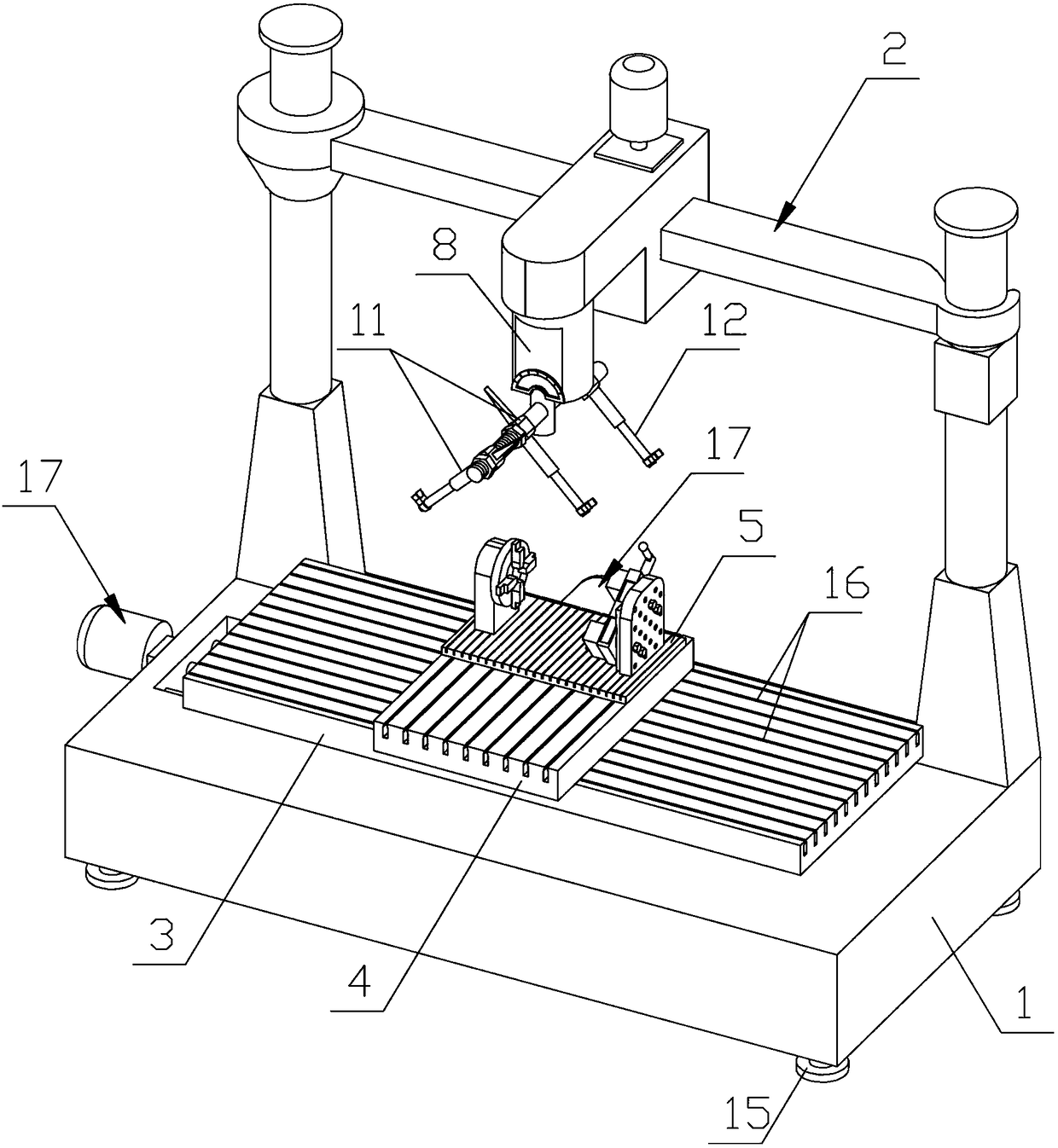

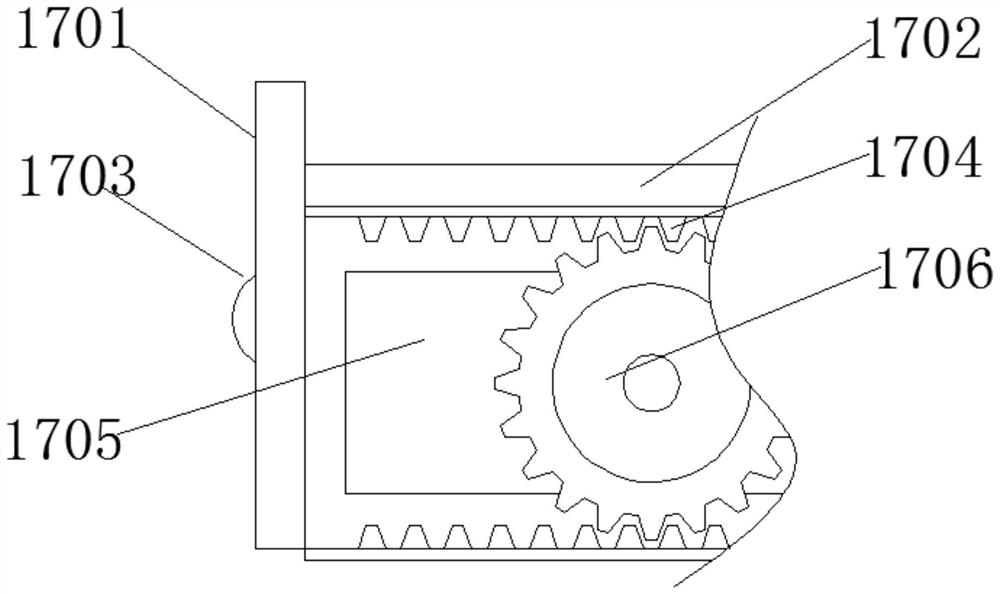

Turning and grinding integrated machine for numerical control machining

InactiveCN110281020AEasy to adjust the distanceFixed and clampedOther manufacturing equipments/toolsRear quarterNumerical control

The invention relates to the technical field of numerical control machining and discloses a turning and grinding integrated machine for numerical control machining. The turning and grinding integrated machine for numerical control machining comprises a bottom plate; the upper surface of the bottom plate is symmetrically and fixedly connected with side plates; the other ends of the two side plates are jointly and fixedly connected with a top plate; a first driving motor is fixedly arranged on the outer side wall of one side plate through a connecting frame; the output end of the first driving motor is fixedly connected with a rotating shaft; the other end of the rotating shaft runs through the corresponding side plate and is fixedly connected with a rotating plate; the rotating shaft is rotatably connected with the side plates; the rotating plate is connected with two symmetrical clamps through an adjusting mechanism; a machining piece is arranged between the two clamps; a first sliding groove is formed in the lower surface of the top plate; and the internal part of the first sliding groove is rotatably connected with a first reciprocating screw rod. The turning and grinding integrated machine for numerical control machining integrates turning and grinding of a workpiece, effectively improves the machining efficiency and can rapidly replacea grinding plate according to requirements conveniently.

Owner:安徽佰尧电子科技有限公司

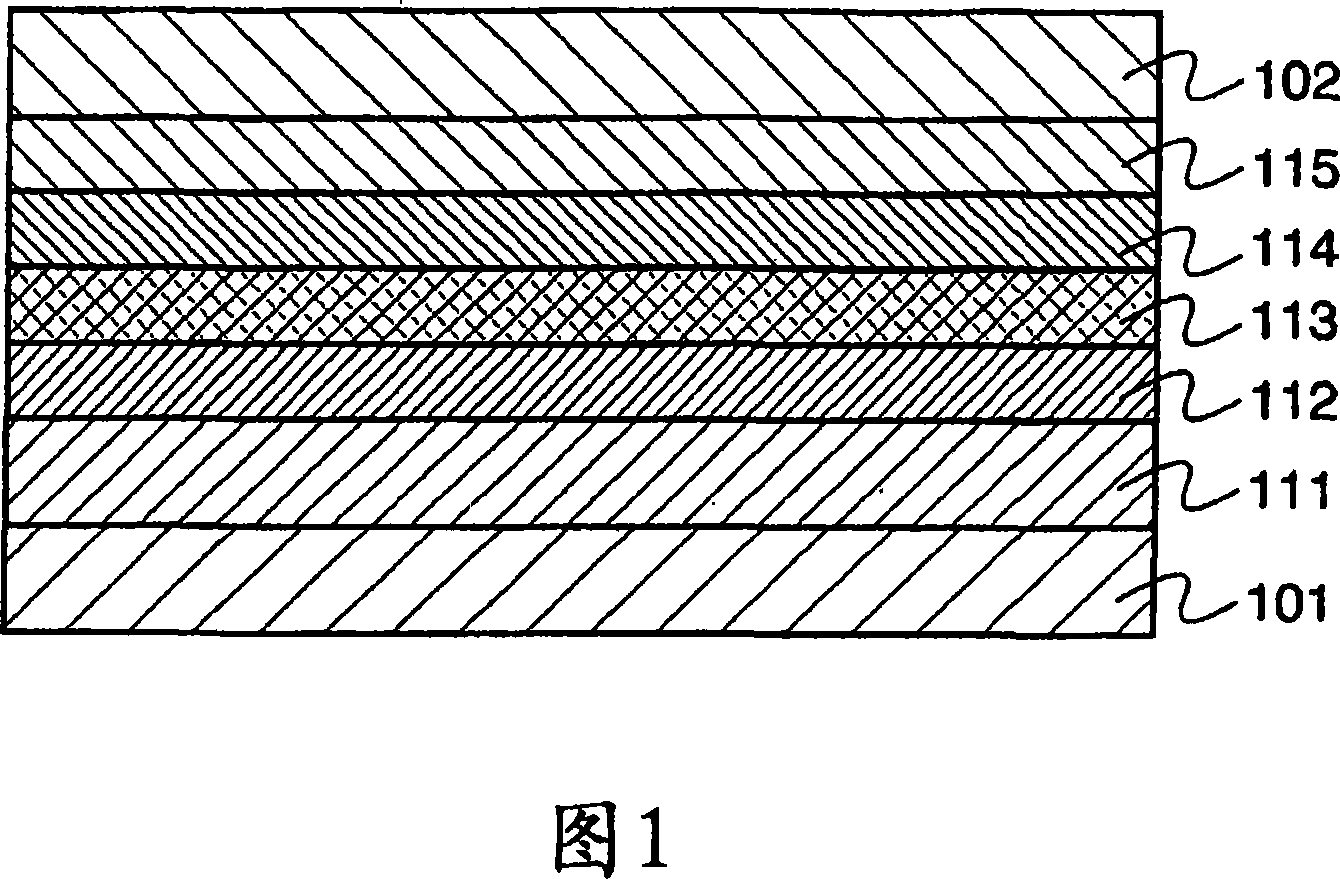

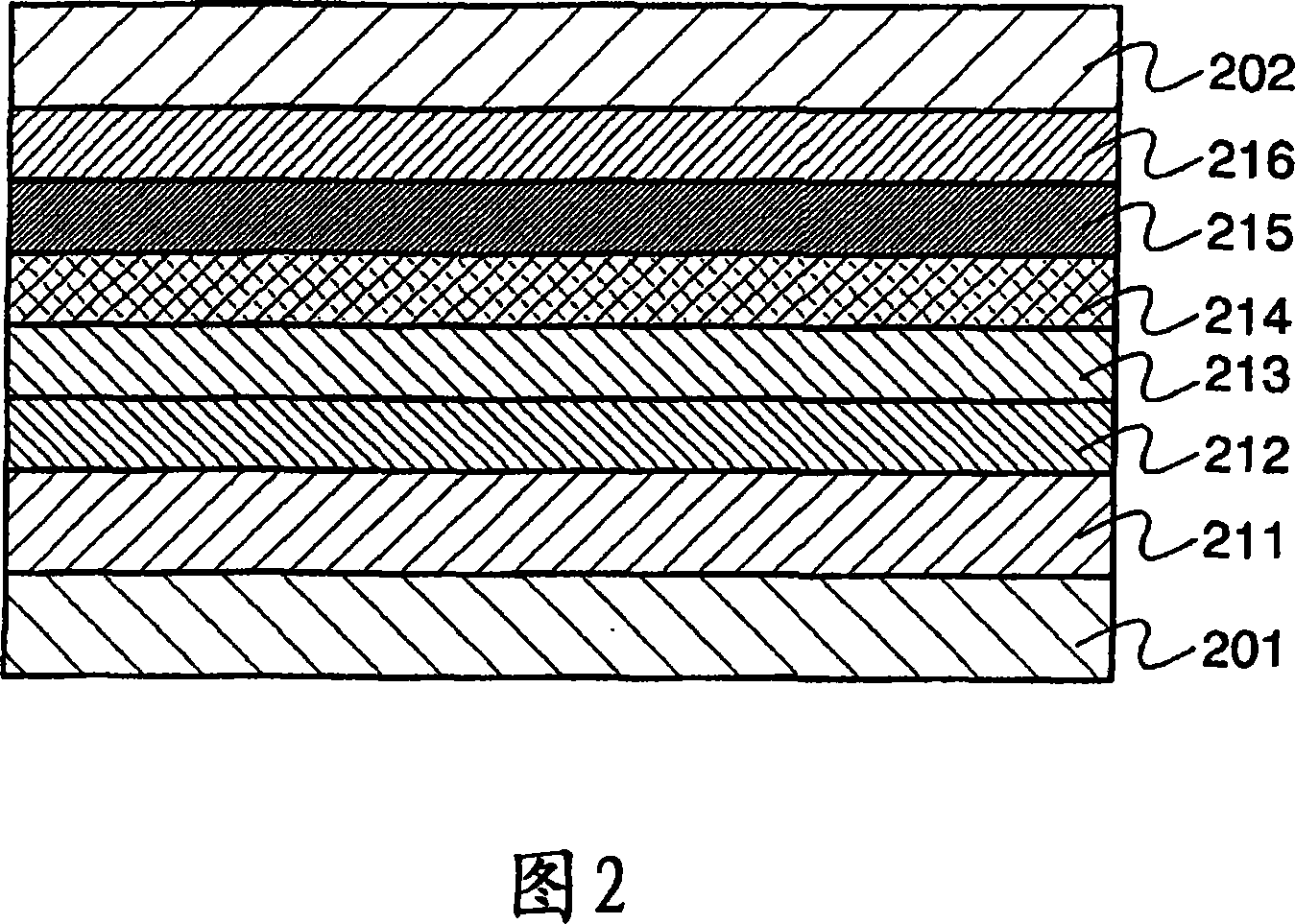

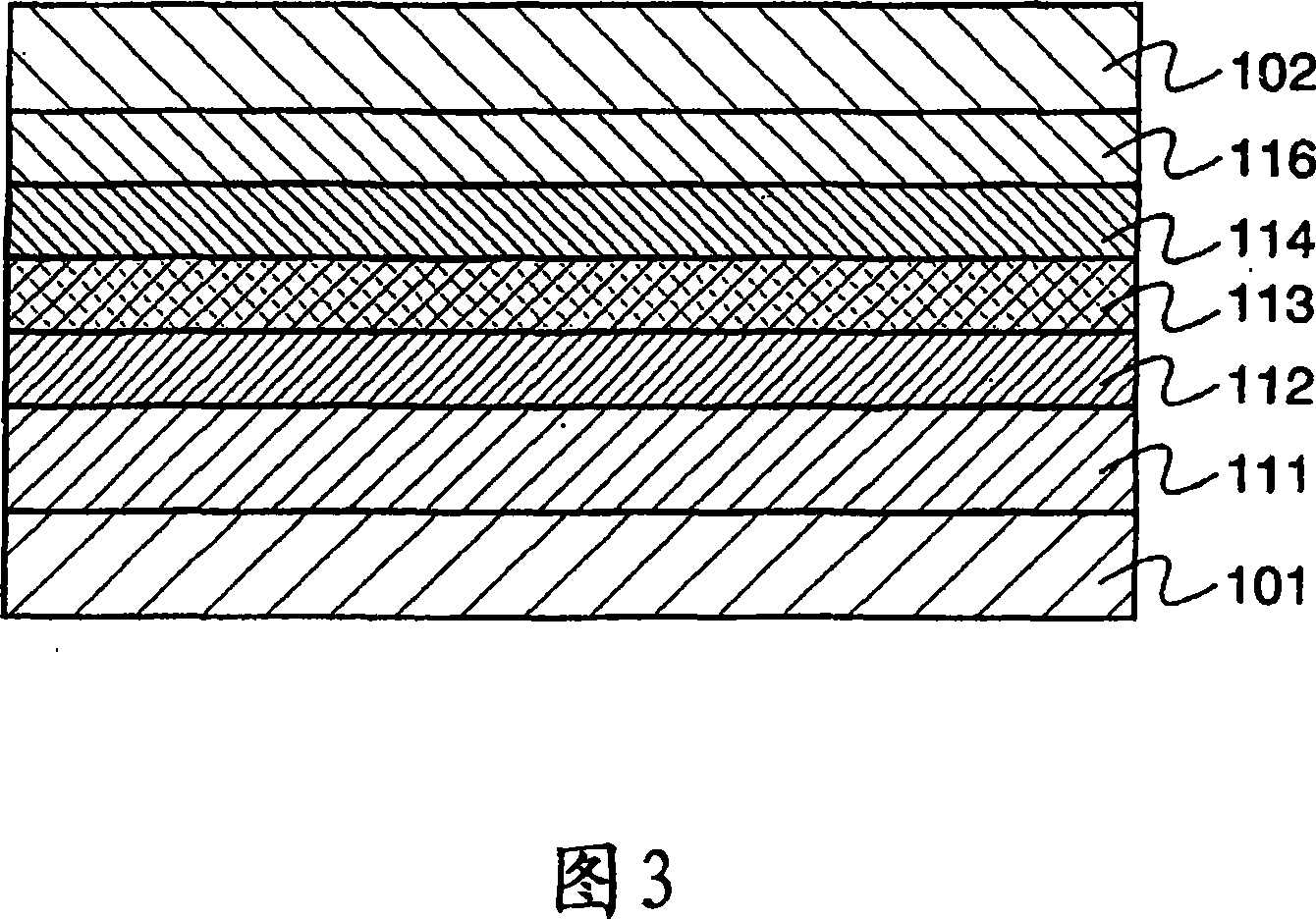

Light emitting element, light emitting device and electronic apparatus

ActiveCN101203968ANot easy to crystallizeReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingVanadium oxideTert butyl

Owner:SEMICON ENERGY LAB CO LTD

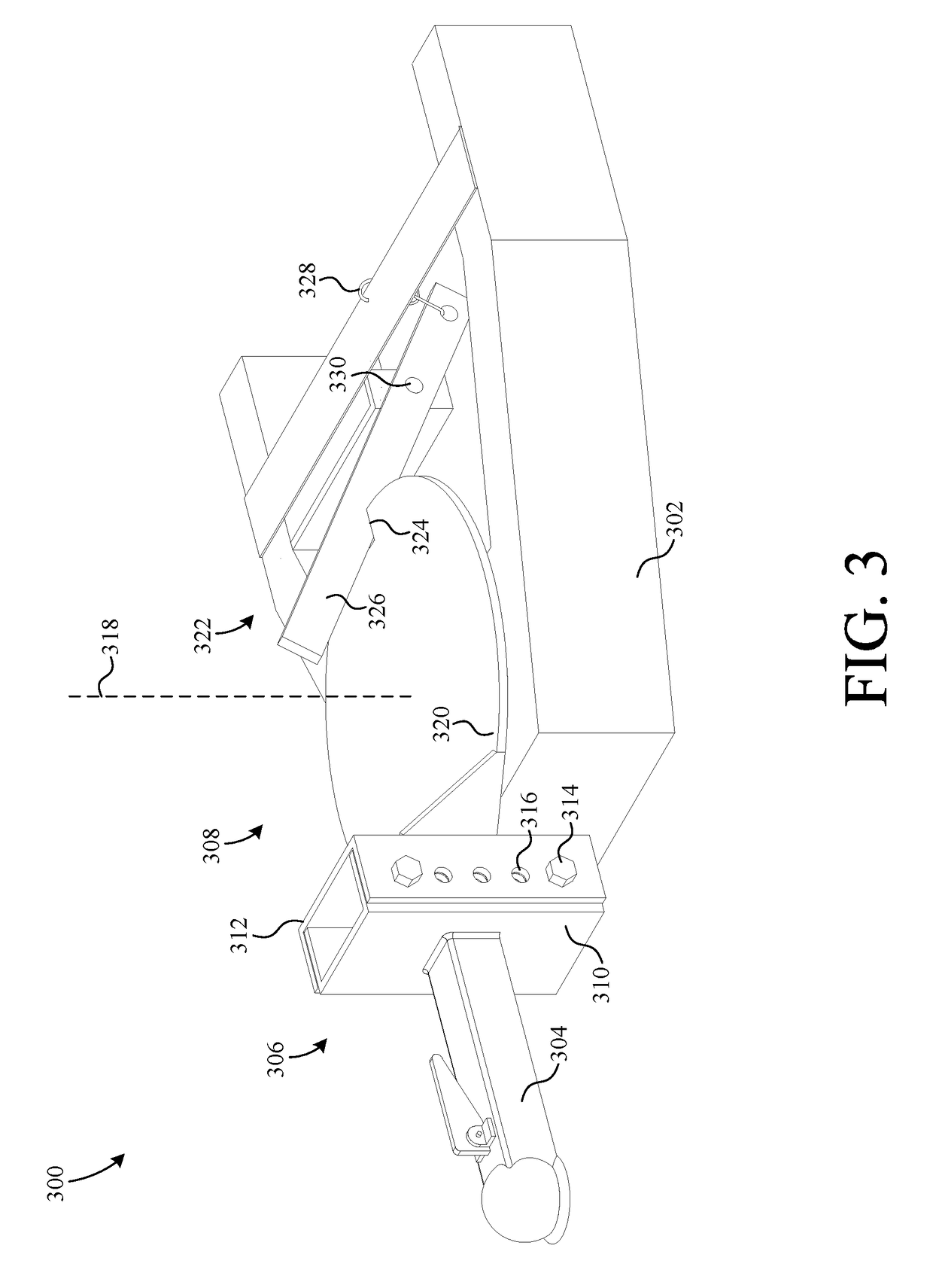

Pivoting trailer hitch

ActiveUS20180126811A1Increase contactOvercome problemsTowing devicesEngineeringMechanical engineering

A trailer coupling mechanism includes a first end, a second end, a height adjustment assembly, a first swivel assembly, and a second swivel assembly. The first end is adapted to couple to one of a trailer and a vehicle. The second end is adapted to couple to the other of the trailer and the vehicle. The height adjustment assembly is coupled between the first and second ends and is operative to adjust the relative height between the first and second ends. The first swivel assembly is coupled between the height adjustment assembly and the first end and facilitates rotation of the first end with respect to the height adjustment assembly about a first axis. The second swivel assembly is coupled between the second end and the height adjustment assembly and facilitates rotation of the height adjustment assembly with respect to the second end about a second axis parallel to the first axis.

Owner:SHAFFER RYAN E AS

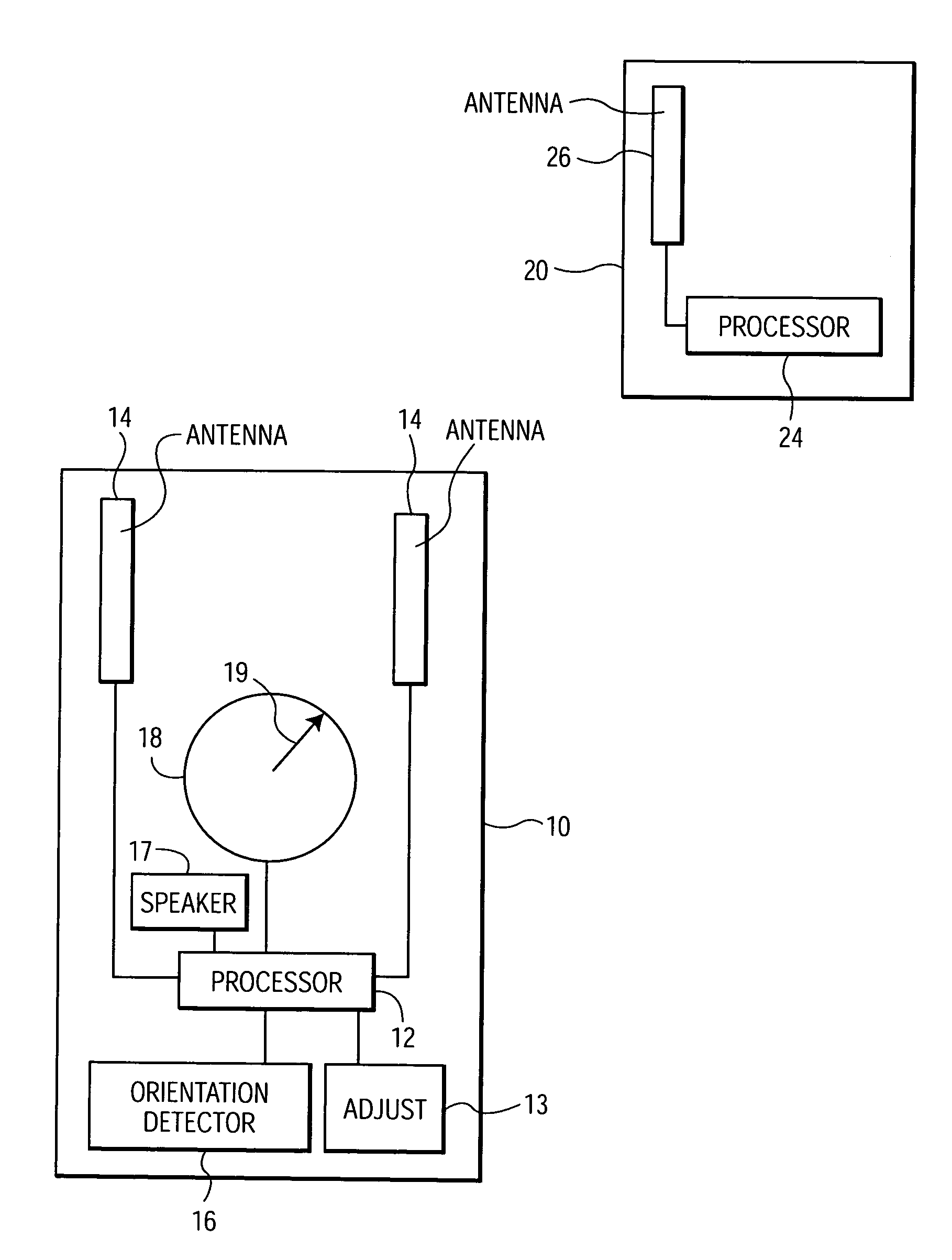

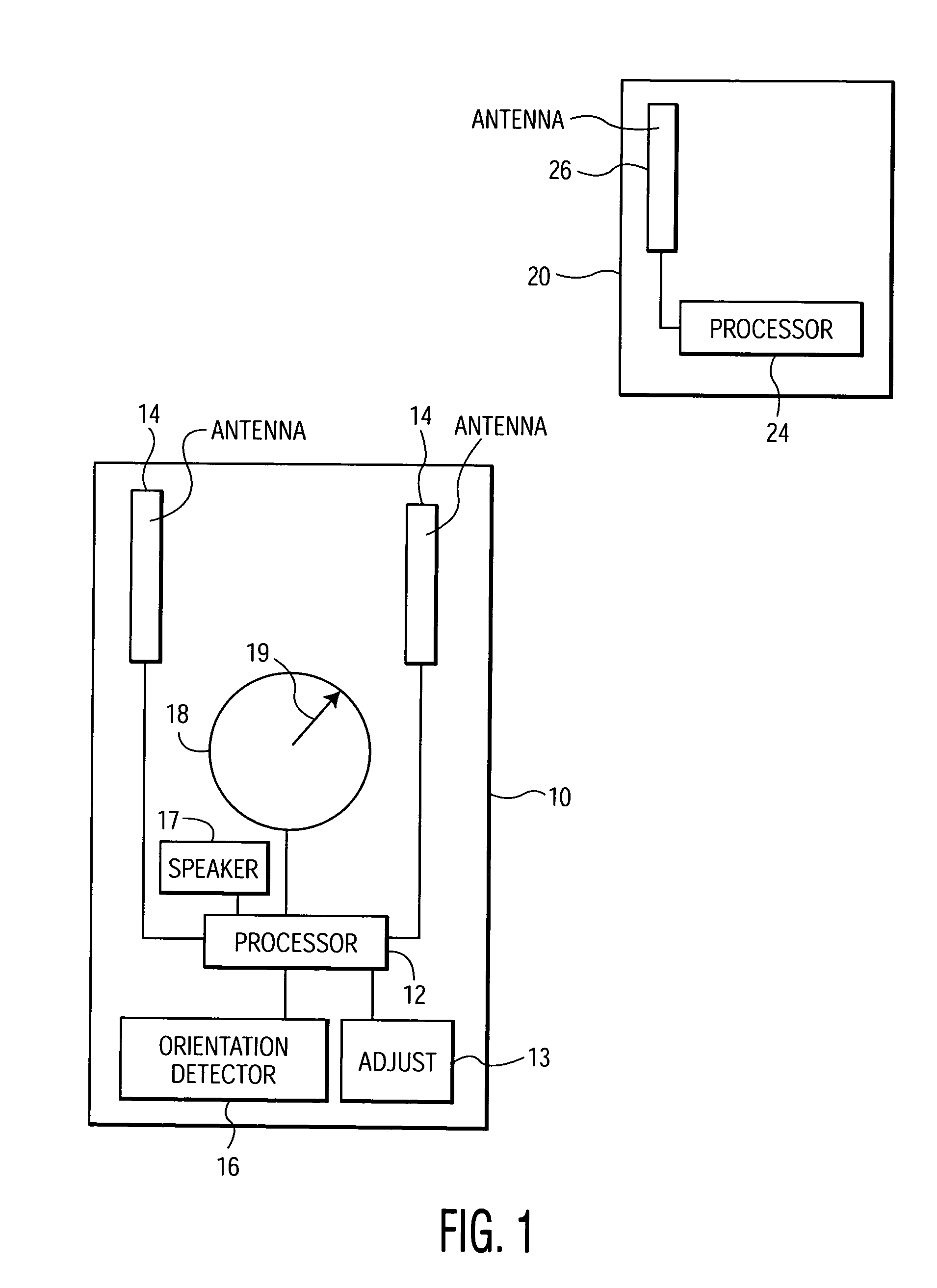

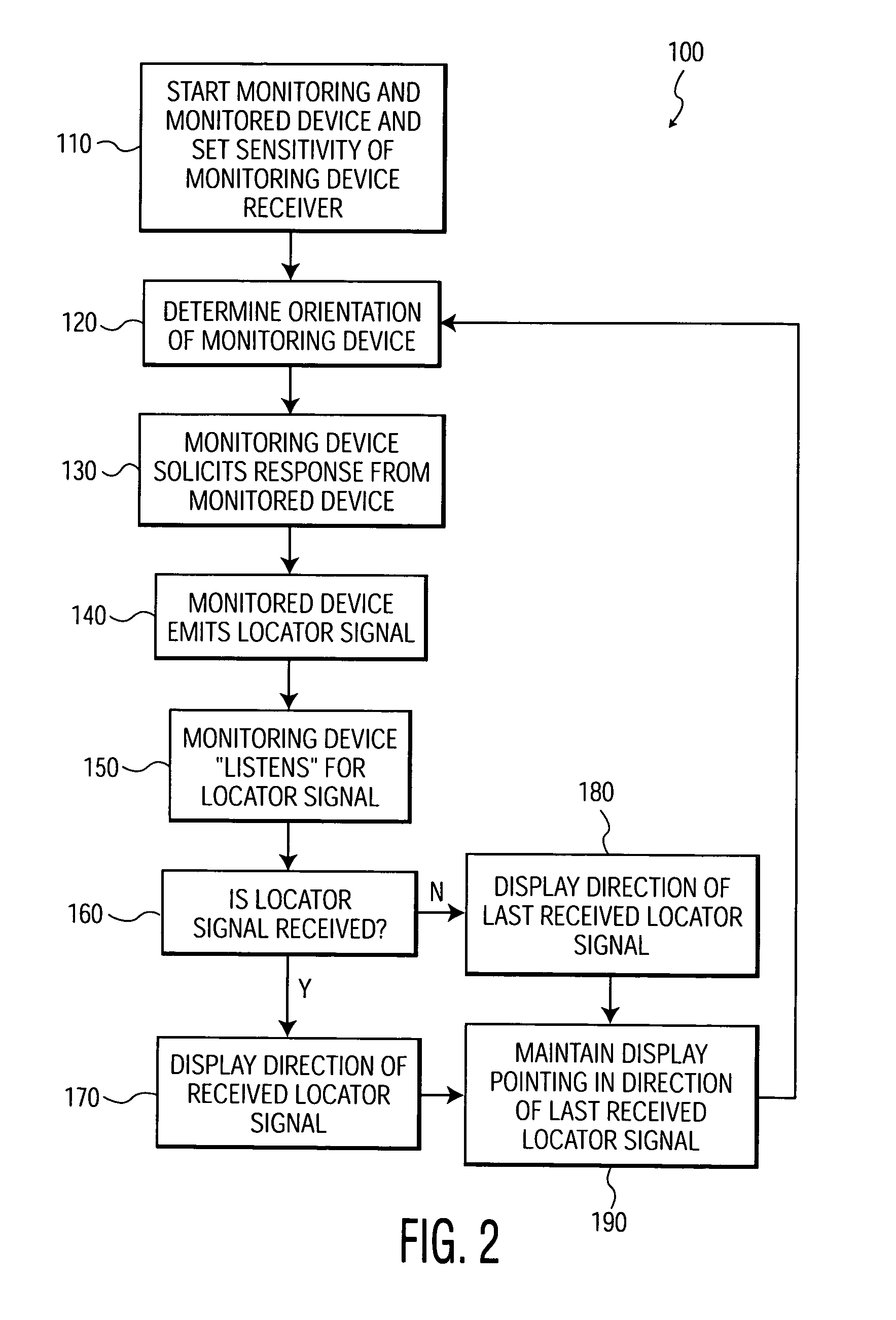

Out-of-range detector

InactiveUS7019643B2Readily adjust distanceEasy to adjust the distanceElectric signal transmission systemsAnimal huntingEngineeringMonitoring system

A monitoring system for monitoring a direction of a monitored device when the monitored device is positioned further than a predetermined distance from a monitoring device. The monitoring device receives a locator signal from the monitored device and produces a direction indication that indicates the direction of the received locator signal. If the monitoring device no longer receives the locator signal, the direction indication indicates the direction of the last received locator signal.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

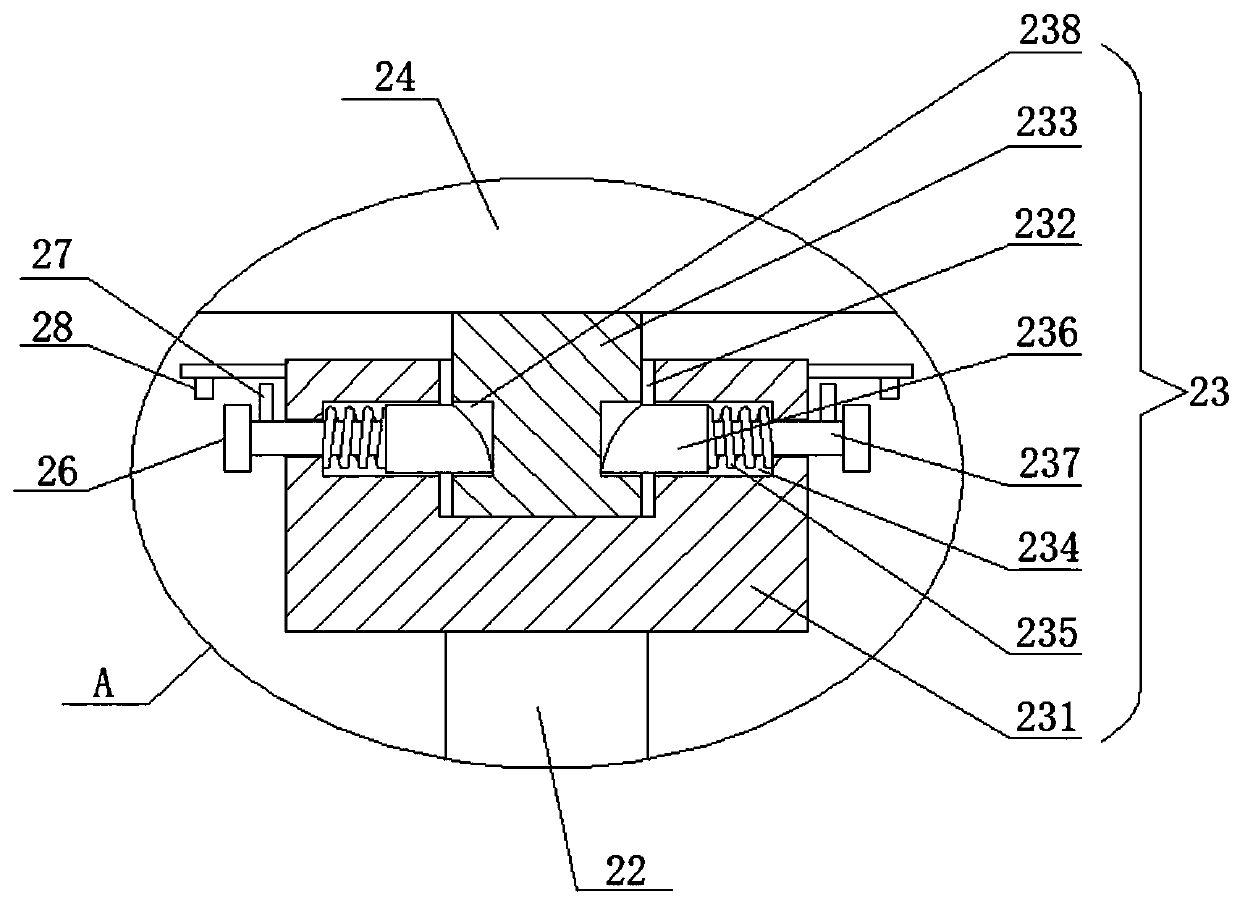

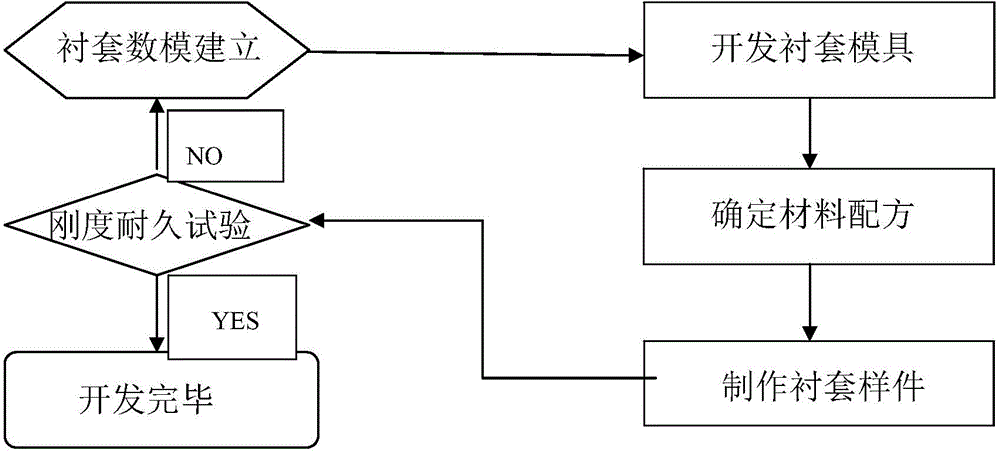

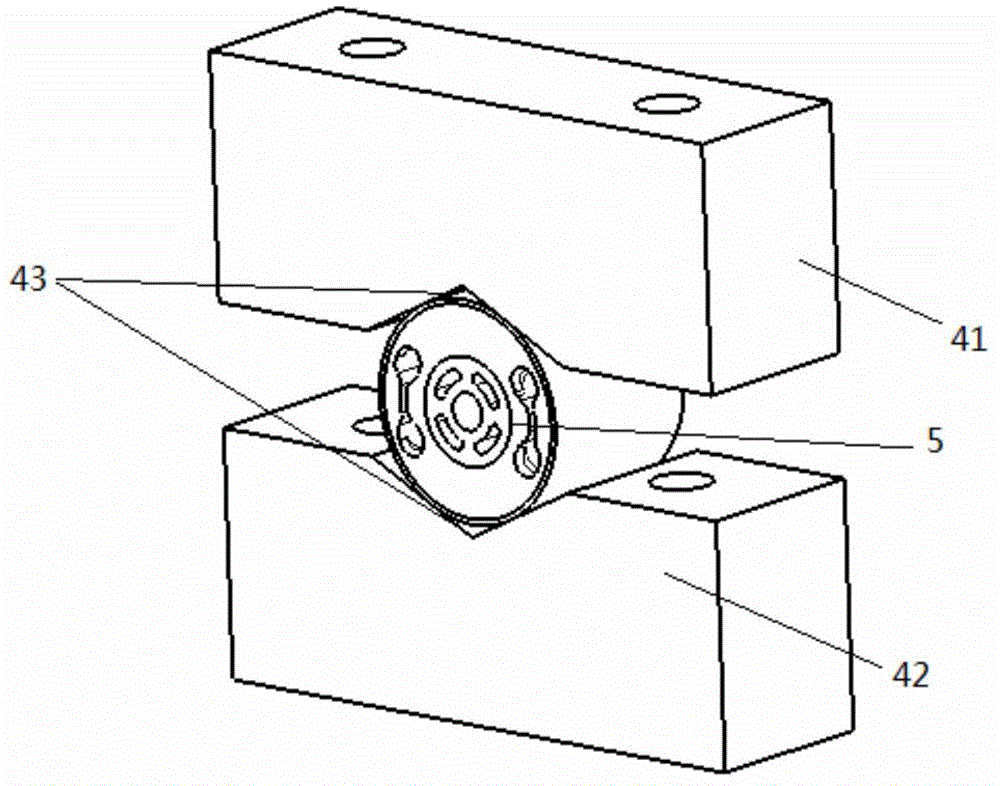

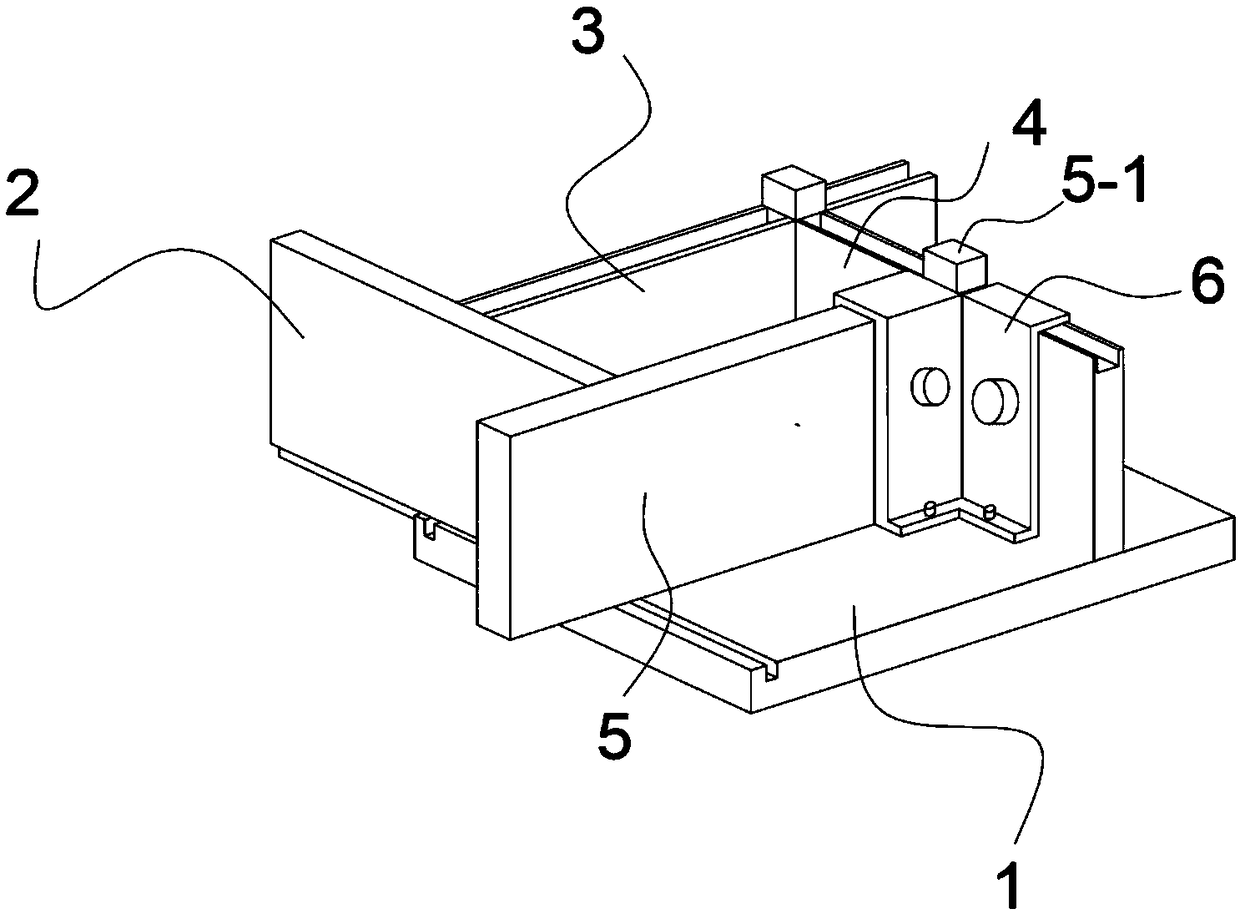

Measuring device for rigidity of rubber bushings and usage method thereof

ActiveCN104406850AEasy to installEasy to operateMaterial strength using tensile/compressive forcesPetroleum engineering

The invention discloses a measuring device for rigidity of rubber bushings. The device comprises a working table, a connecting support seat fixed on the working table, and a lower fixing bracket assembly used for fixing the rubber bushings, and further comprises a dynamic tester, a connecting shaft penetrating through inner rings of the rubber bushings, and an upper fixing bracket assembly fixedly connected with both ends of the connecting shaft, wherein the working end head of the dynamic tester is connected with the upper fixing bracket assembly to apply force to the upper fixing bracket assembly, and a ball cardan joint for connection is arranged between the upper fixing bracket assembly and the working end head of the dynamic tester. The device can be used for measuring the static rigidity and the torsion rigidity of the rubber bushings at the same time, and besides, the structure is simple, the adjustment is convenient, and the device can be applied to the field of the rigidity measurement of the rubber bushings in a standard manner.

Owner:CHERY AUTOMOBILE CO LTD

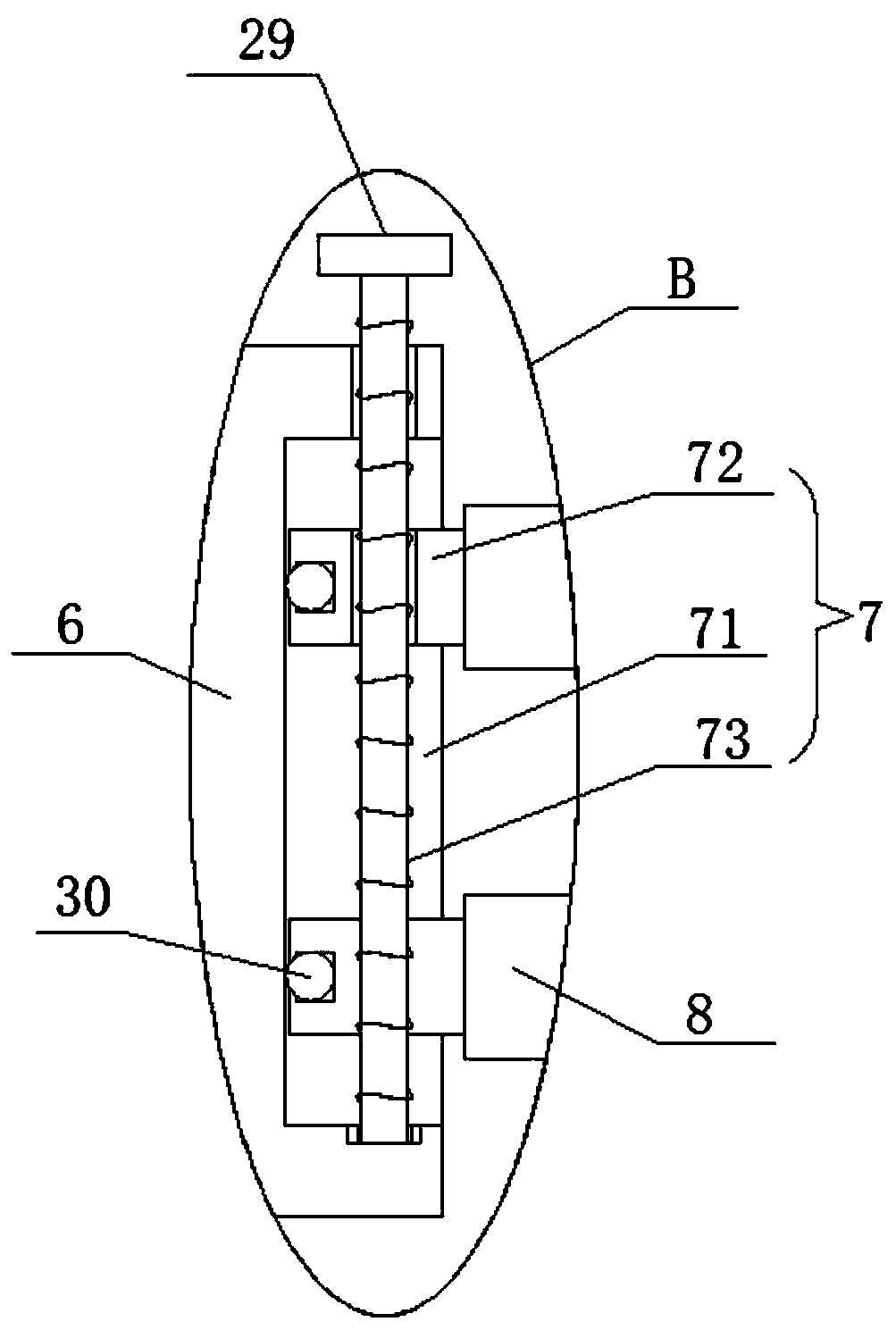

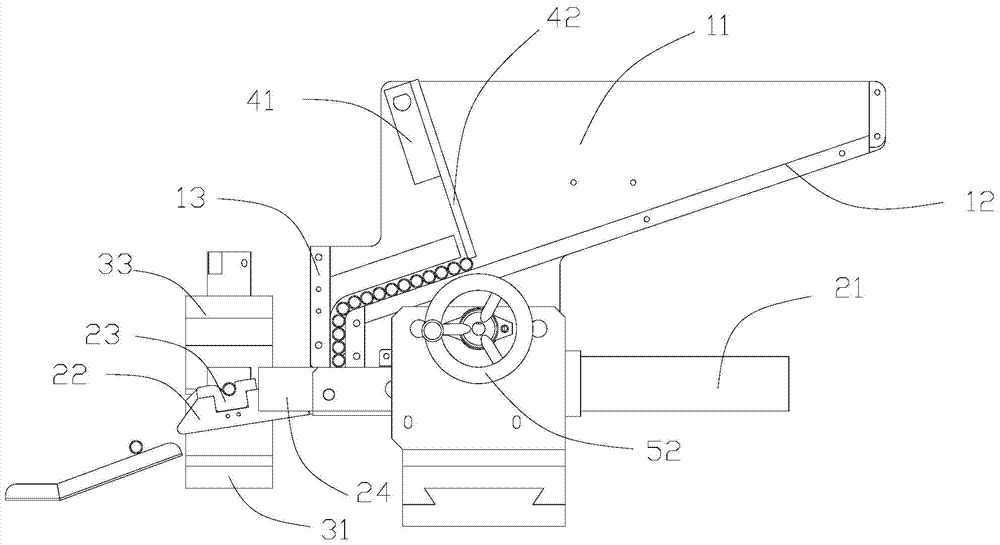

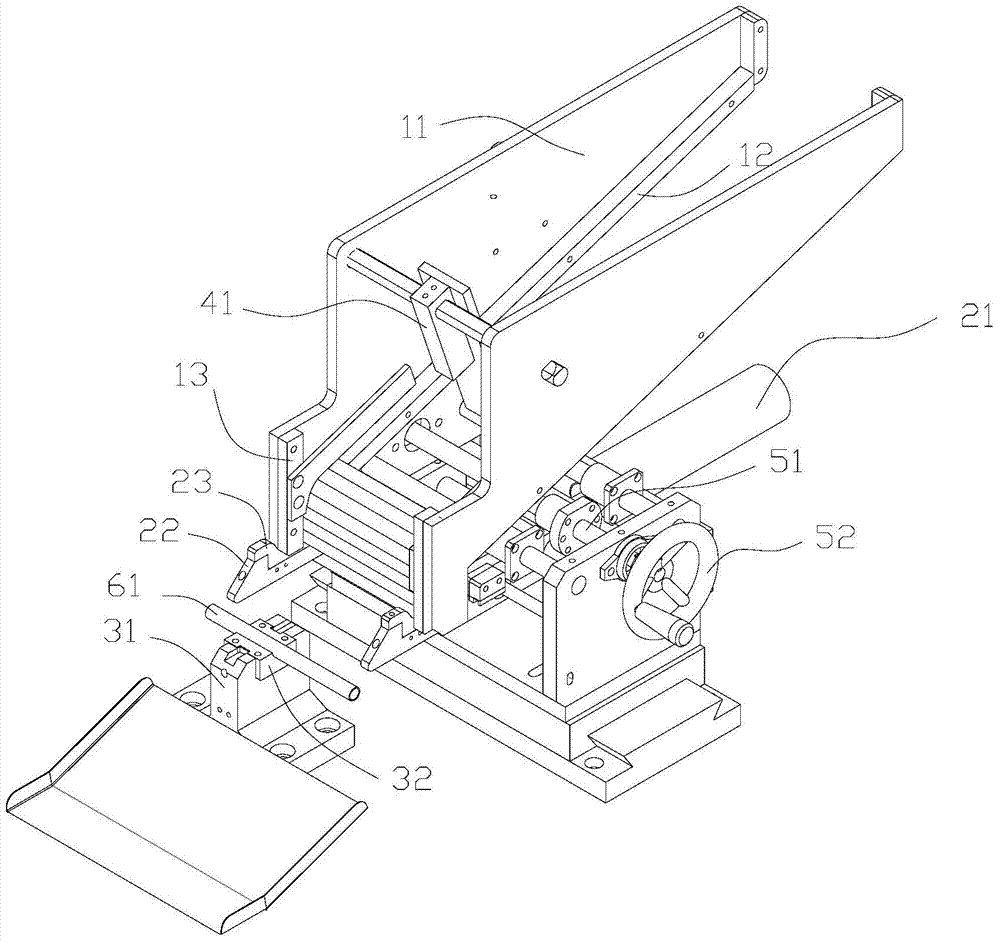

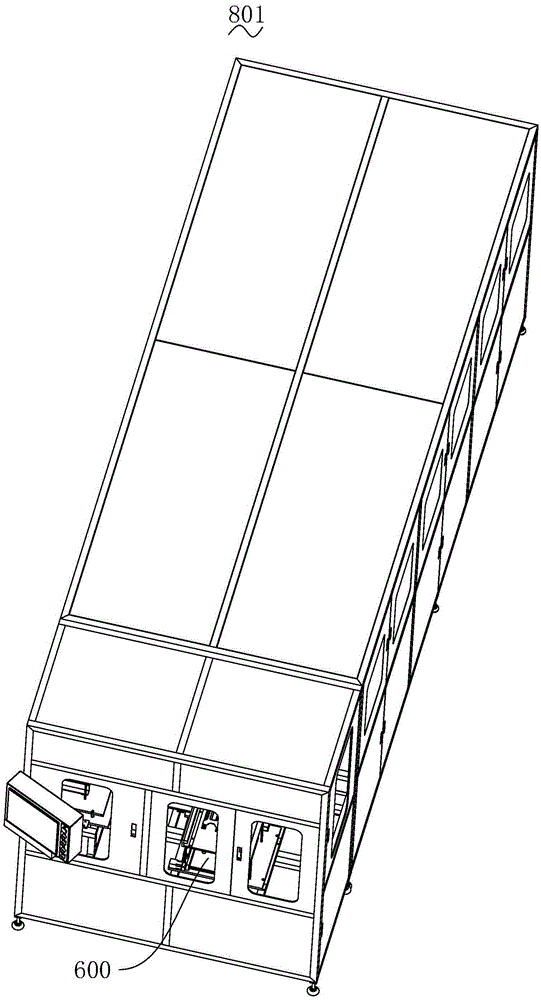

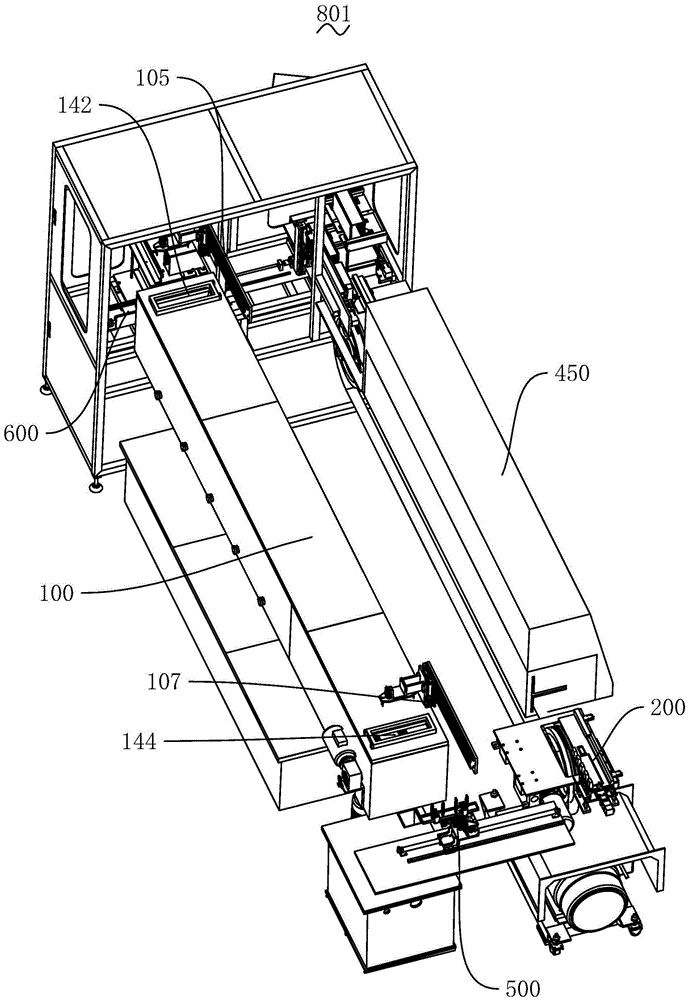

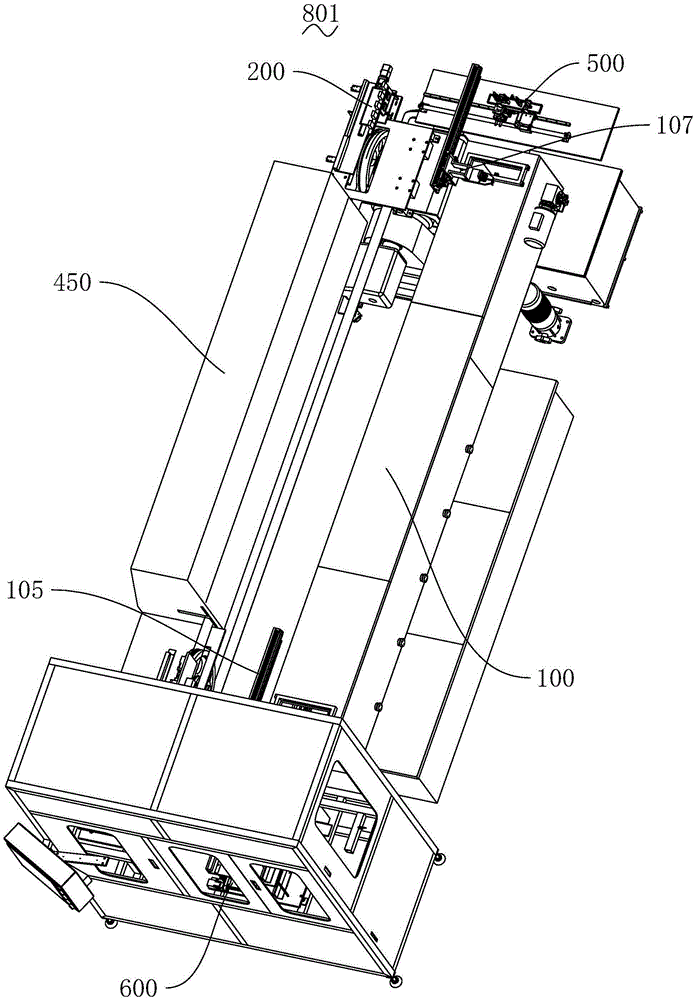

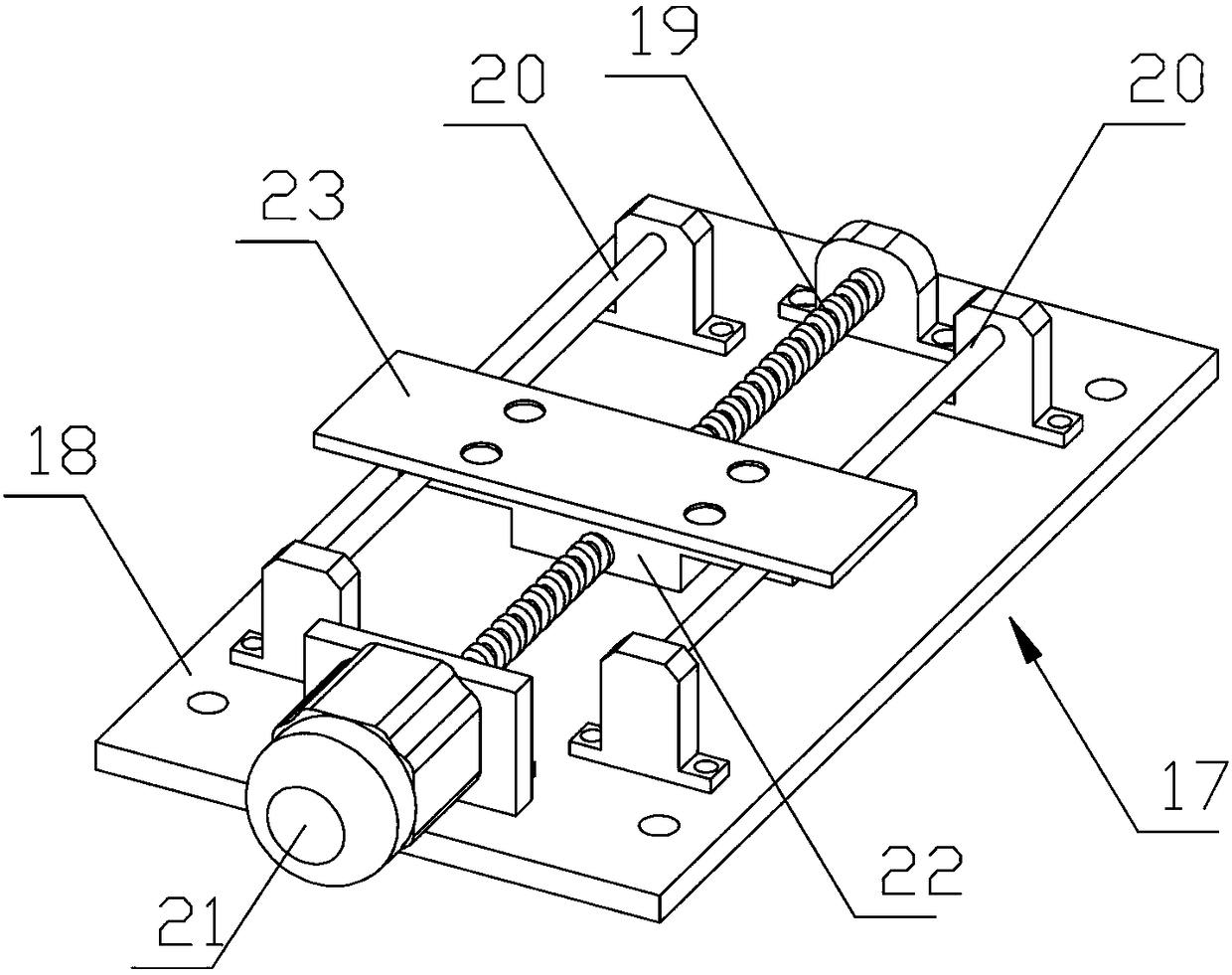

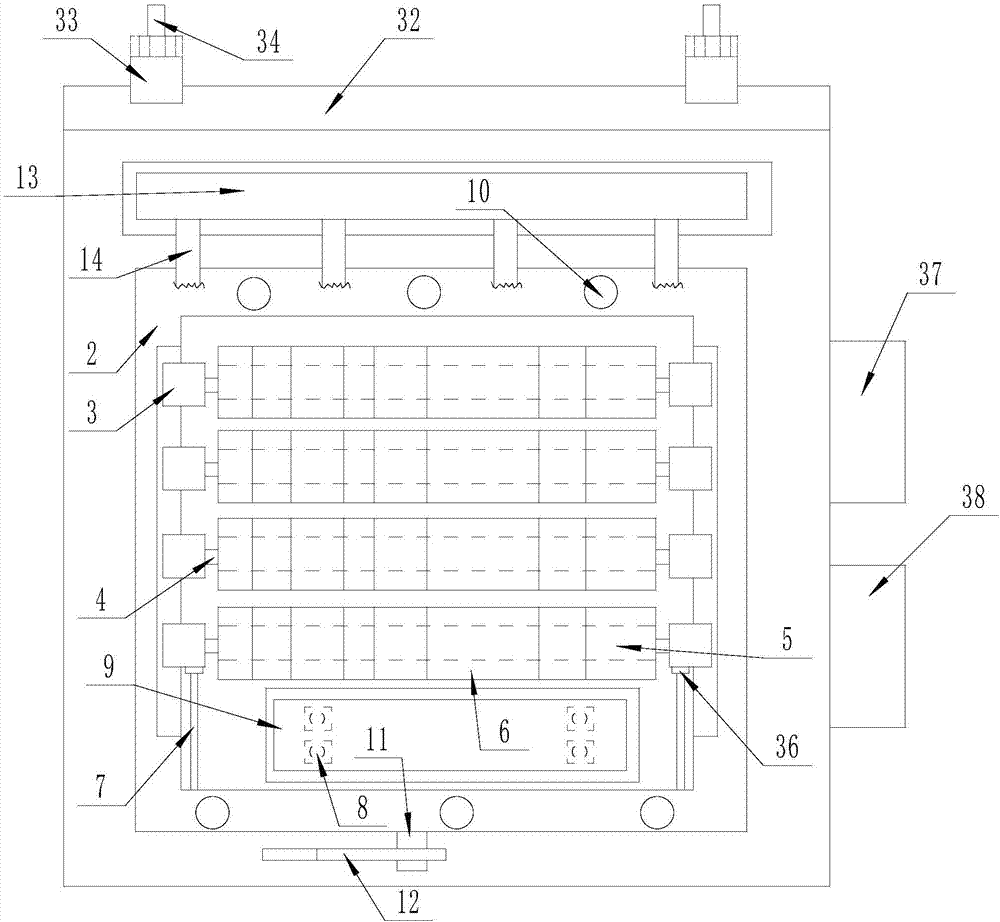

Automatic feeding and discharging system for pipe fitting machining device

ActiveCN103496585ASimple structureImprove processing efficiencyLarge containersLoading/unloadingPipe fittingStructural engineering

The invention discloses an automatic feeding and discharging system for a pipe fitting machining device. The automatic feeding and discharging system for the pipe fitting machining device comprises a hopper, a pushing device and a clamping device. The hopper is arranged above the pushing device, and a guiding track where pipe fittings pass is arranged in the hopper. The pushing device comprises a pushing rod of a first groove where the pipe fittings are placed and a power device, the power device pushes the pushing rod forward to enable the pipe fittings in the first groove to be arranged at the position of a second groove of the clamping device and enables the pushing rod to retract back, and the power device can be composed of a feeding air cylinder. A slope used for pushing the pipe fittings in the second groove to be out of the clamping device is arranged at the front end portion of the pushing rod. The tail end of the guiding track is arranged above the first groove of the pushing device. Due to the fact that the slope is arranged at the front end of the pushing rod, when the pushing rod carries out forward pushing, the machined pipe fittings arranged in a lower clamping die can be pushed out of the second groove and are replaced by new pipe fittings to be machined, one pushing action can finish the actions of feeding and discharging, and the automatic feeding and discharging system for the pipe fitting machining device is simple in structure and improves machining efficiency.

Owner:广州捷晟自动化控制设备有限公司

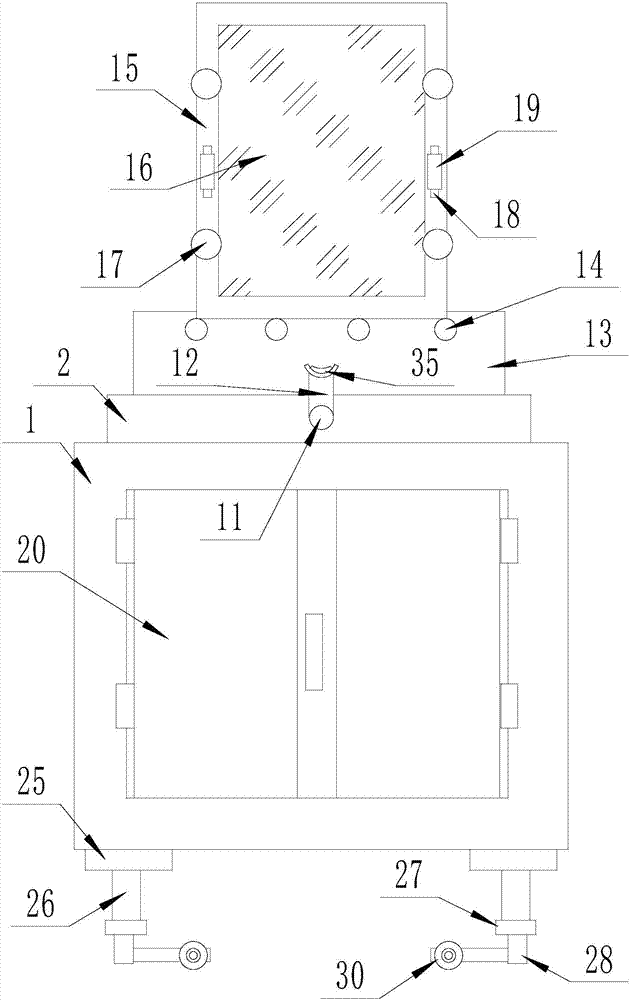

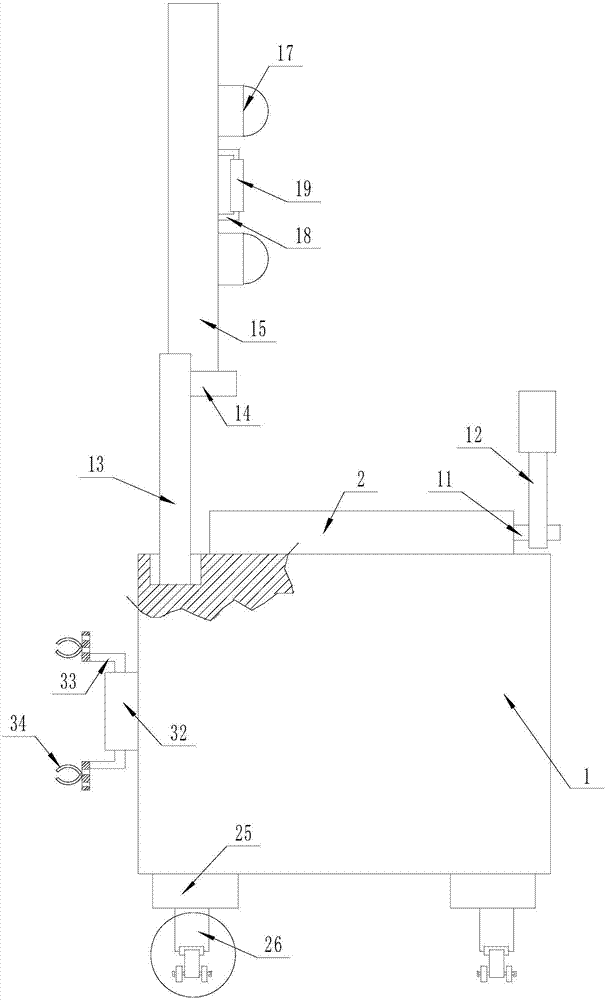

Treatment production line of lead frame

ActiveCN105428284AEasy to moveAvoid damageSemiconductor/solid-state device manufacturingProduction lineChemical treatment

The invention discloses a treatment production line of a lead frame. The treatment production line of the lead frame comprises a material taking mechanism, a lead frame treatment groove, a lead frame jig, lead frame pushing equipment and a water jet cutter, wherein a material pushing device of the material taking mechanism is driven by a first driving device and can realize automatic working; an immobilizing mechanism of the lead frame treatment groove is used for maintaining a semiconductor lead frame at a vertical position, so that the semiconductor lead frame is small in occupied space and long in soaking time, and a better soaking effect is obtained; a liquid receiving groove formed in the lead frame jig can be used for completely receiving a chemical treatment solution dripping from the lead frame, so that the phenomenon that since the chemical treatment solution drips on structures such as an air cylinder and guide rails, the corrosion is caused is avoided.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

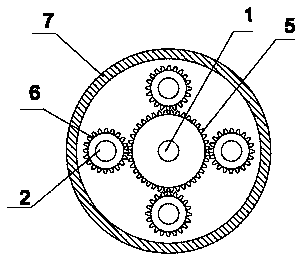

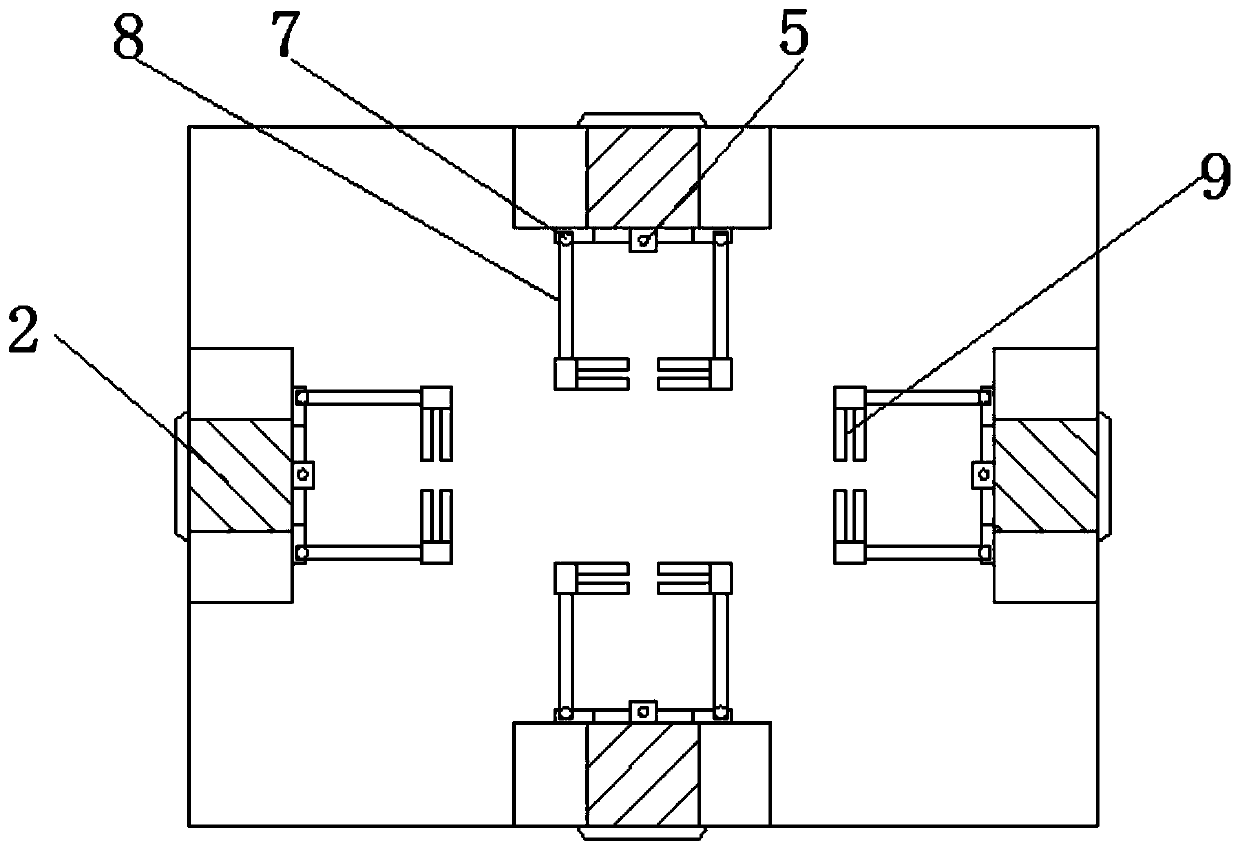

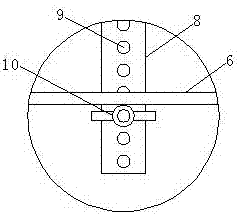

Multi-head printing ink mixing machine

ActiveCN103949175AAll-round three-dimensional mixingImprove stirring efficiencyRotary stirring mixersProcess engineeringPrinting ink

The invention relates to a multi-head printing ink mixing machine. The multi-head printing ink mixing machine comprises a mixing supporting device, a power device, a stirring device and a floating bottom-scraping device, wherein the power device and the stirring device are fixedly arranged on the mixing supporting device. The multi-head printing ink mixing machine is characterized in that the stirring device comprises a main stirring shaft, auxiliary stirring shafts, main stirring blades, auxiliary stirring blades, a gear box and a master gear and pinions, which are arranged in the gear box, wherein the gear box is fixedly arranged at the upper part of the main stirring shaft by a first bearing and a second bearing, the master gear is arranged at the center of the gear box and is fixedly connected with the main stirring shaft, the pinions are uniformly distributed at the periphery of the master gear, are meshed with the master gear and are fixed on the gear box by the auxiliary stirring shafts, and the main stirring blades and the auxiliary stirring blades are arranged on the main stirring shaft and the auxiliary stirring shafts, respectively. The multi-head printing ink mixing machine has the beneficial effects of solving the problems of low slurry stirring efficiency and poor slurry stirring effect.

Owner:烟台市裕同印刷包装有限公司

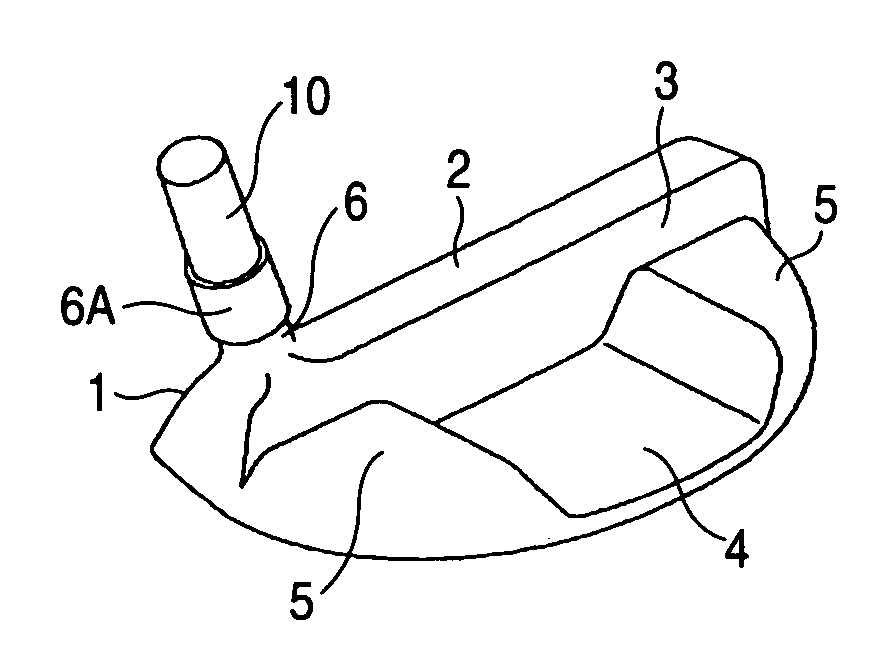

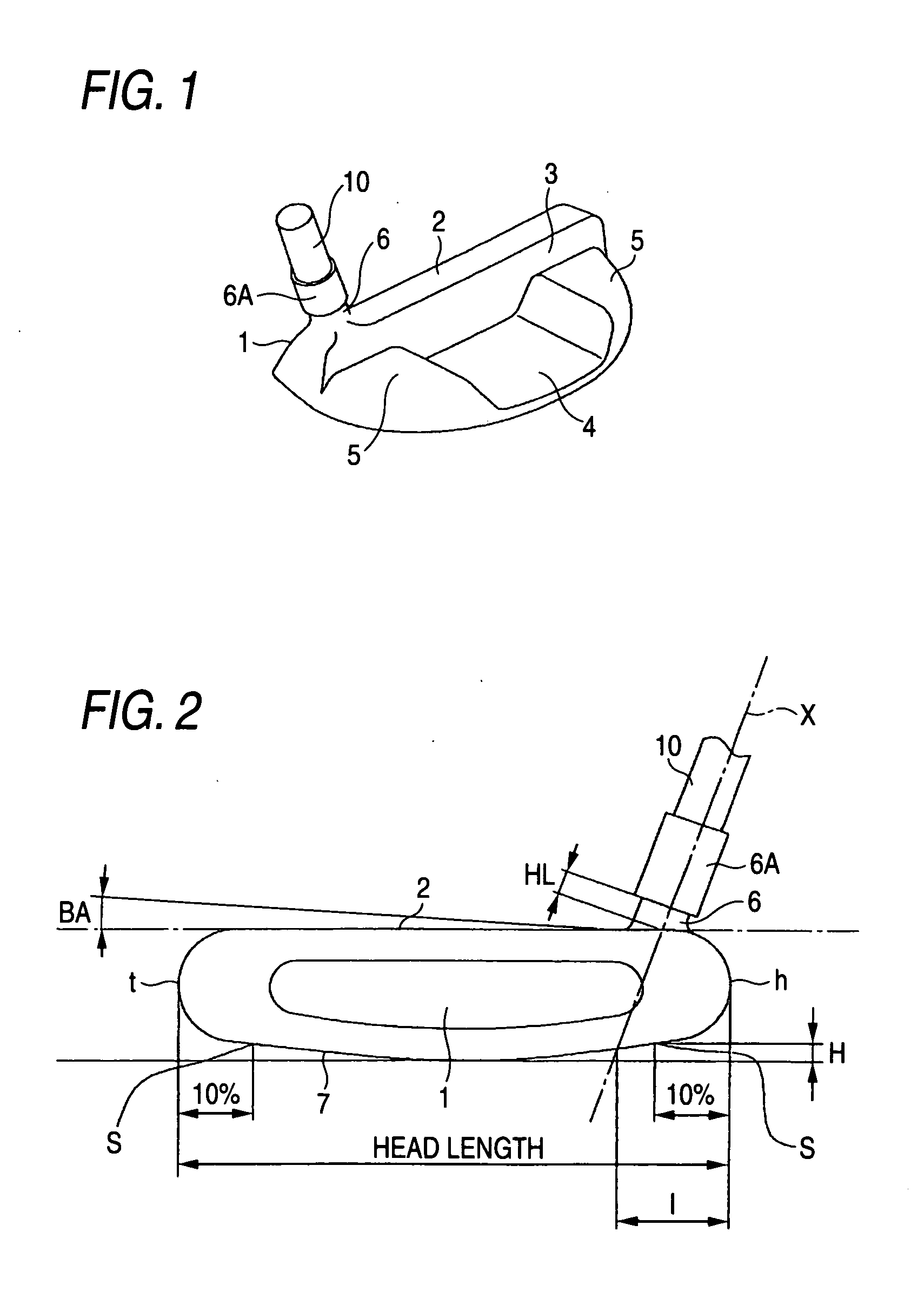

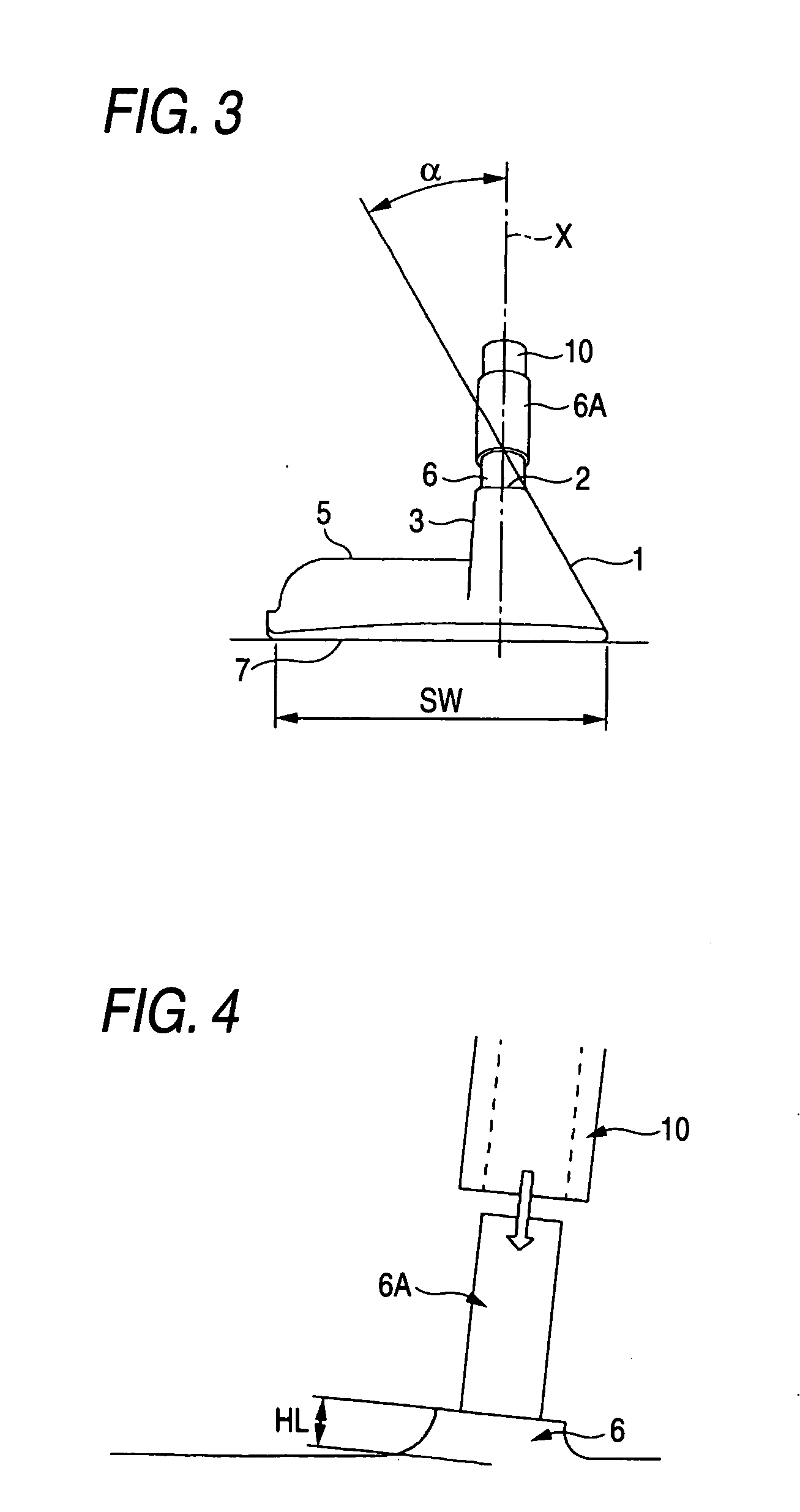

Golf club head and golf club

InactiveUS20070032311A1Improve stabilityReduce probabilityGolf clubsRacket sportsEngineeringGolf Ball

In a golf club head having a shape of a Mallet-type patter, a width of a sole face is in a range of 30 mm to 80 mm. A loft angle of the golf club head is in a range of 10° to 40°. A thickness A of a top blade satisfies a relationship:10 mm≦A≦SW−5 mm.A weight of the golf club head is in a range of 350 g to 450 g.

Owner:BRIDGESTONE SPORTS

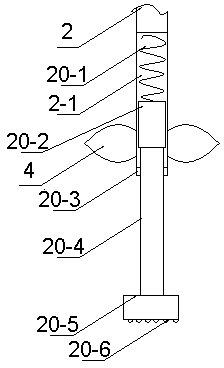

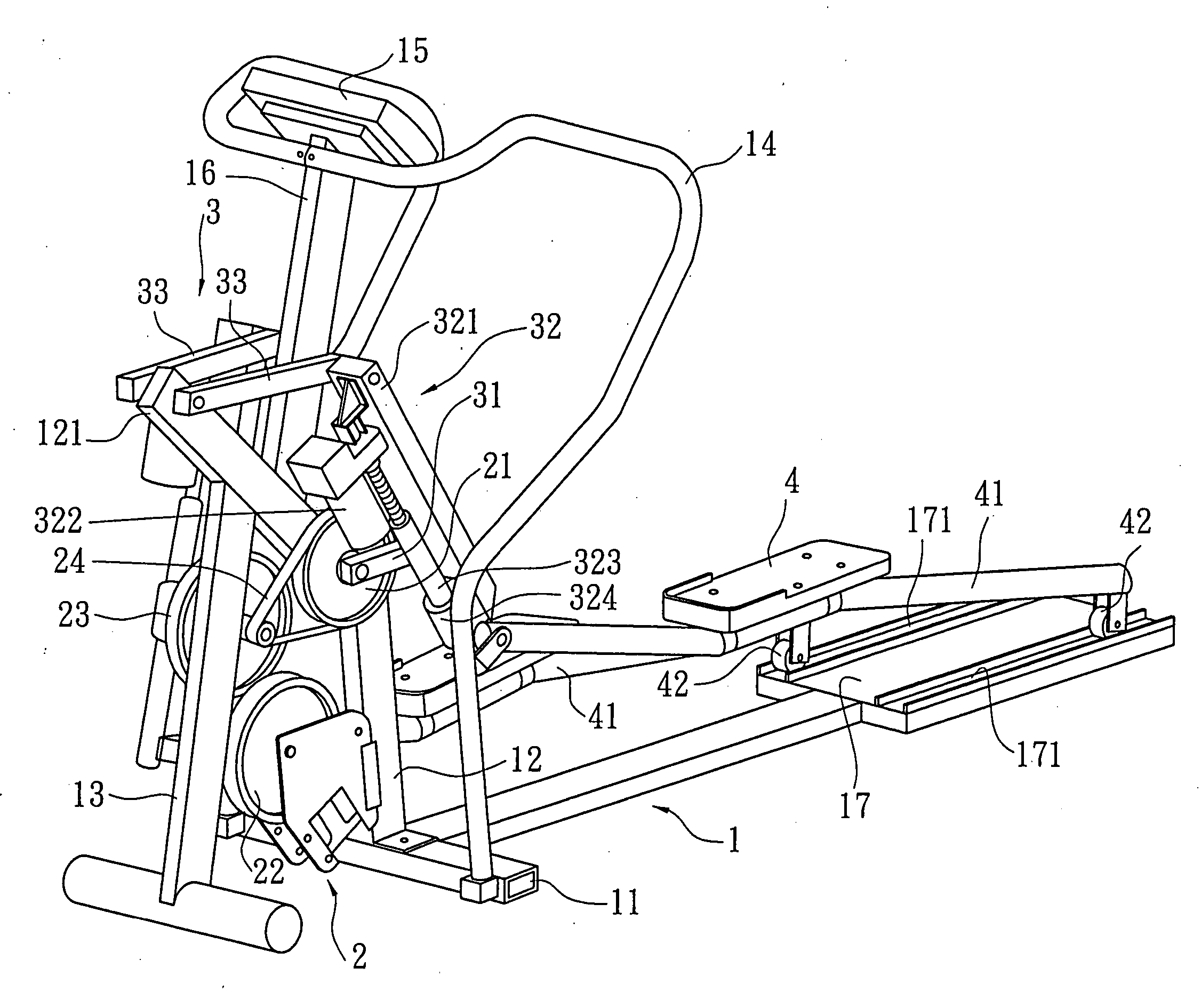

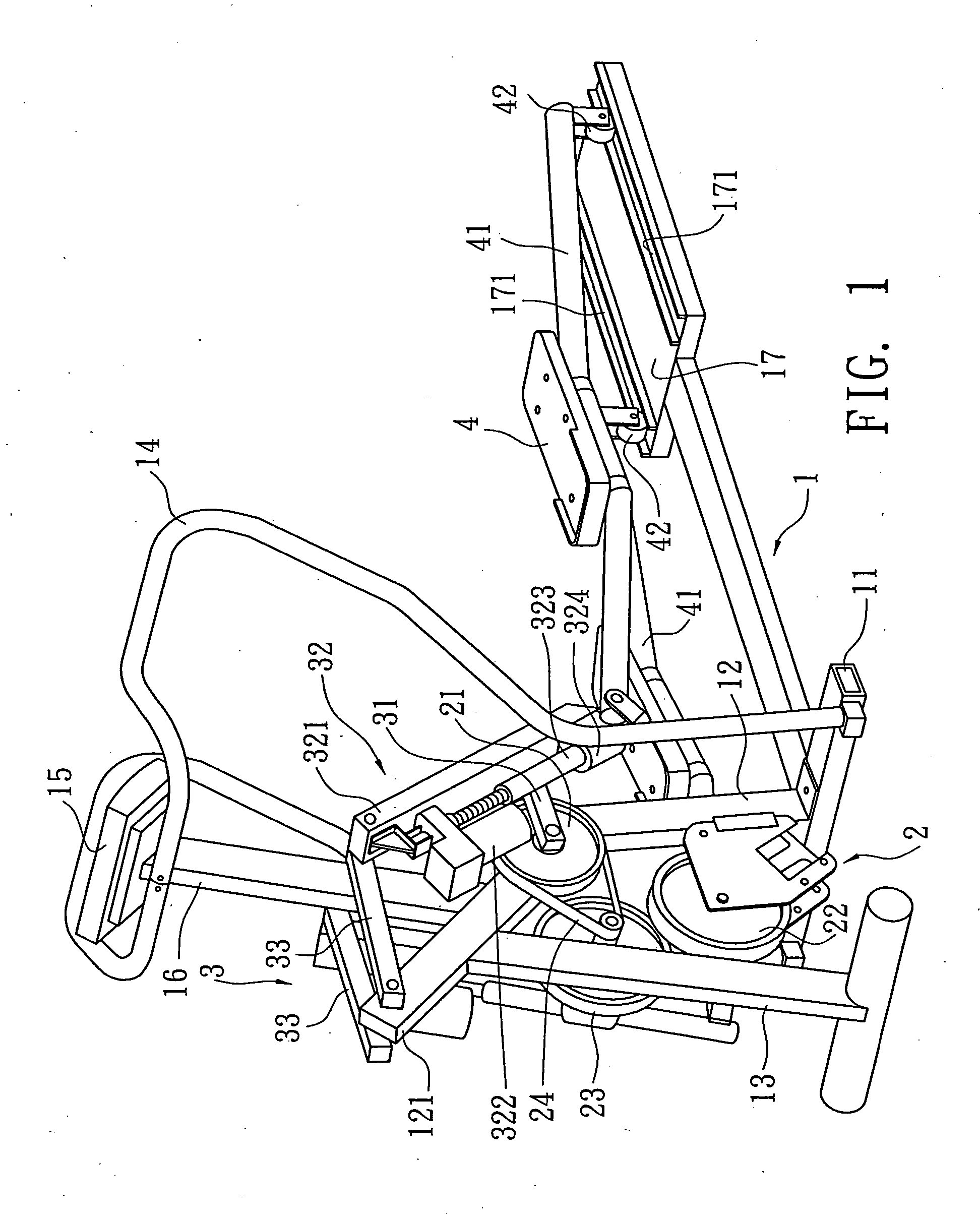

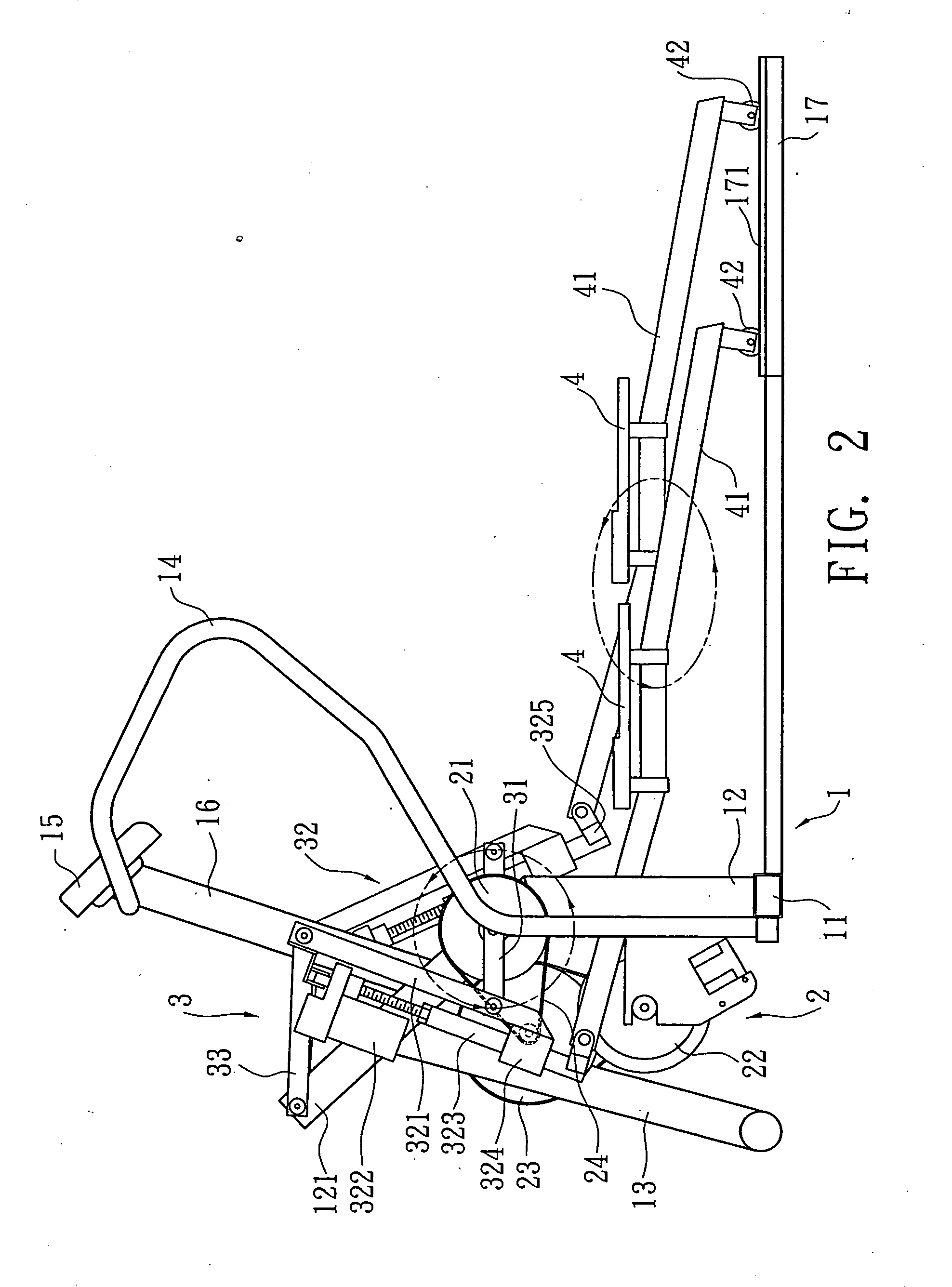

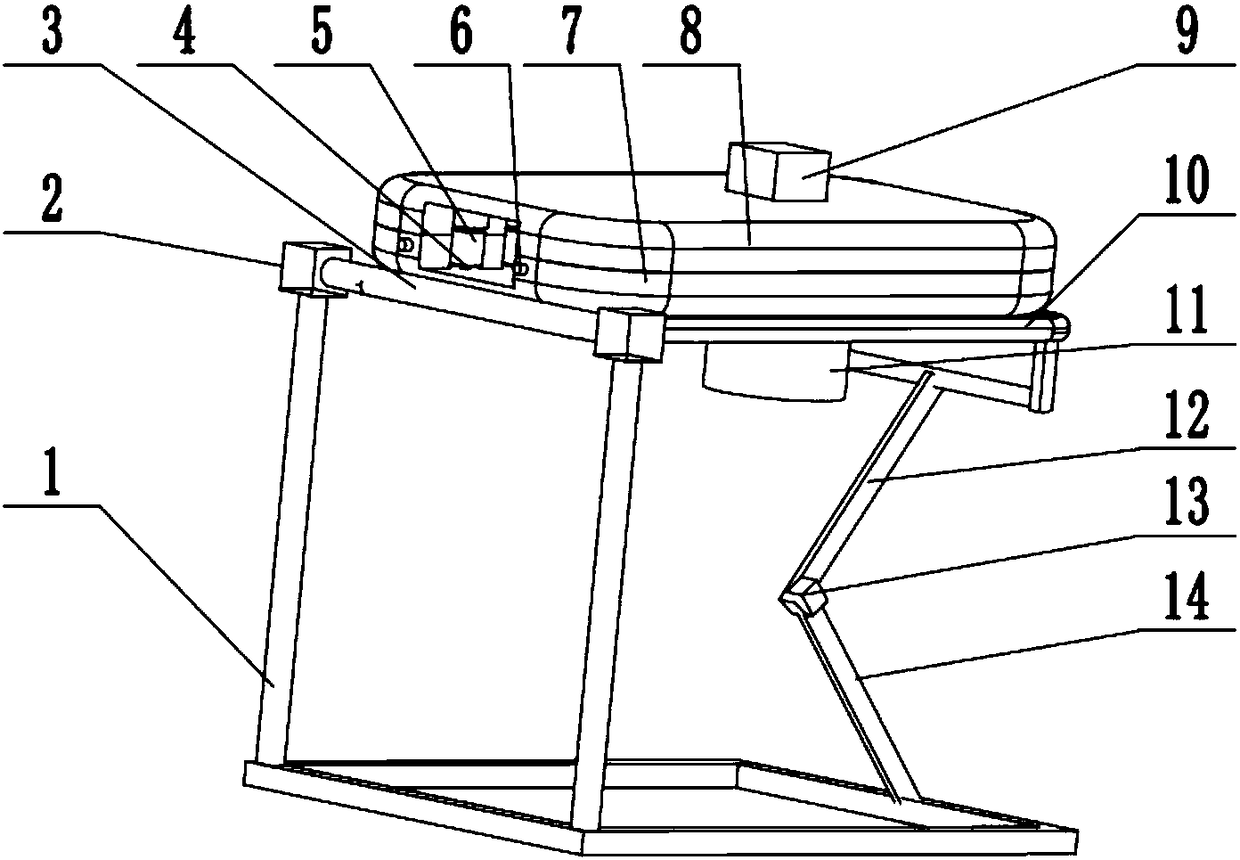

Elliptic-track treadmill with adjustable travel

InactiveUS20060250753A1Smooth movementEasy to adjust the distanceSubstation/switching arrangement detailsMovement coordination devicesEngineeringTreadmill

An elliptic-track treadmill with adjustable travel, including: a bed placed on the ground, an upright stem upward extending from one end of the bed; a transmission unit mounted on the upright stem; and a linking mechanism drivable by the transmission unit to drive two pedals to move in an elliptic track. The linking mechanism includes a pair of cranks drivable by the transmission unit. One end of each crank is pivotally connected with one end of an adjustment member. The adjustment member has an axially telescopic free end pivotally connected with the crank. The free end is connected with the pedal. The other end of the adjustment member is pivotally connected with one end of a link. The other end of the link is pivotally connected with each side of top end of the upright stem of the bed.

Owner:CYCLING & HEALTH TECH IND R & D CENT

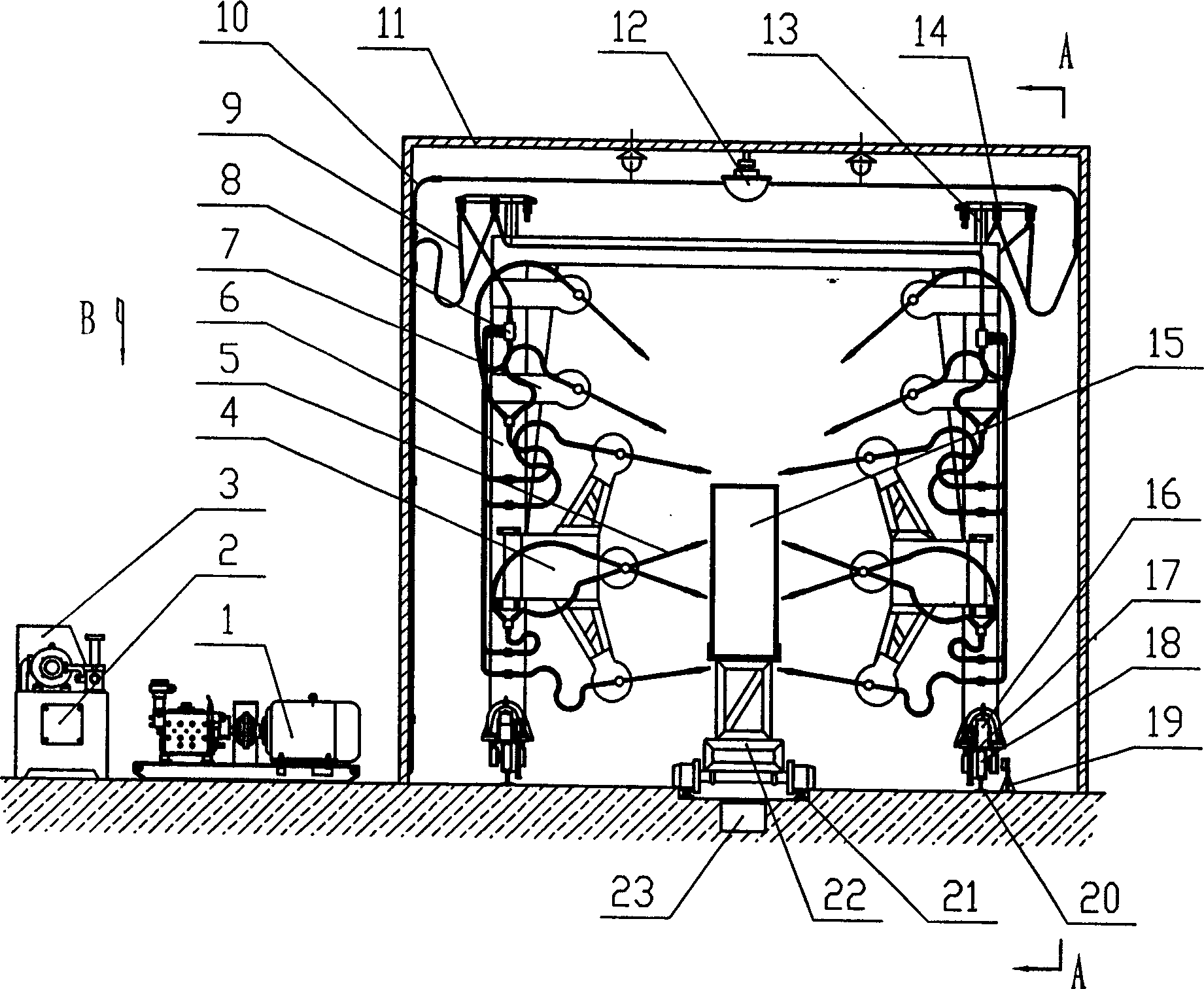

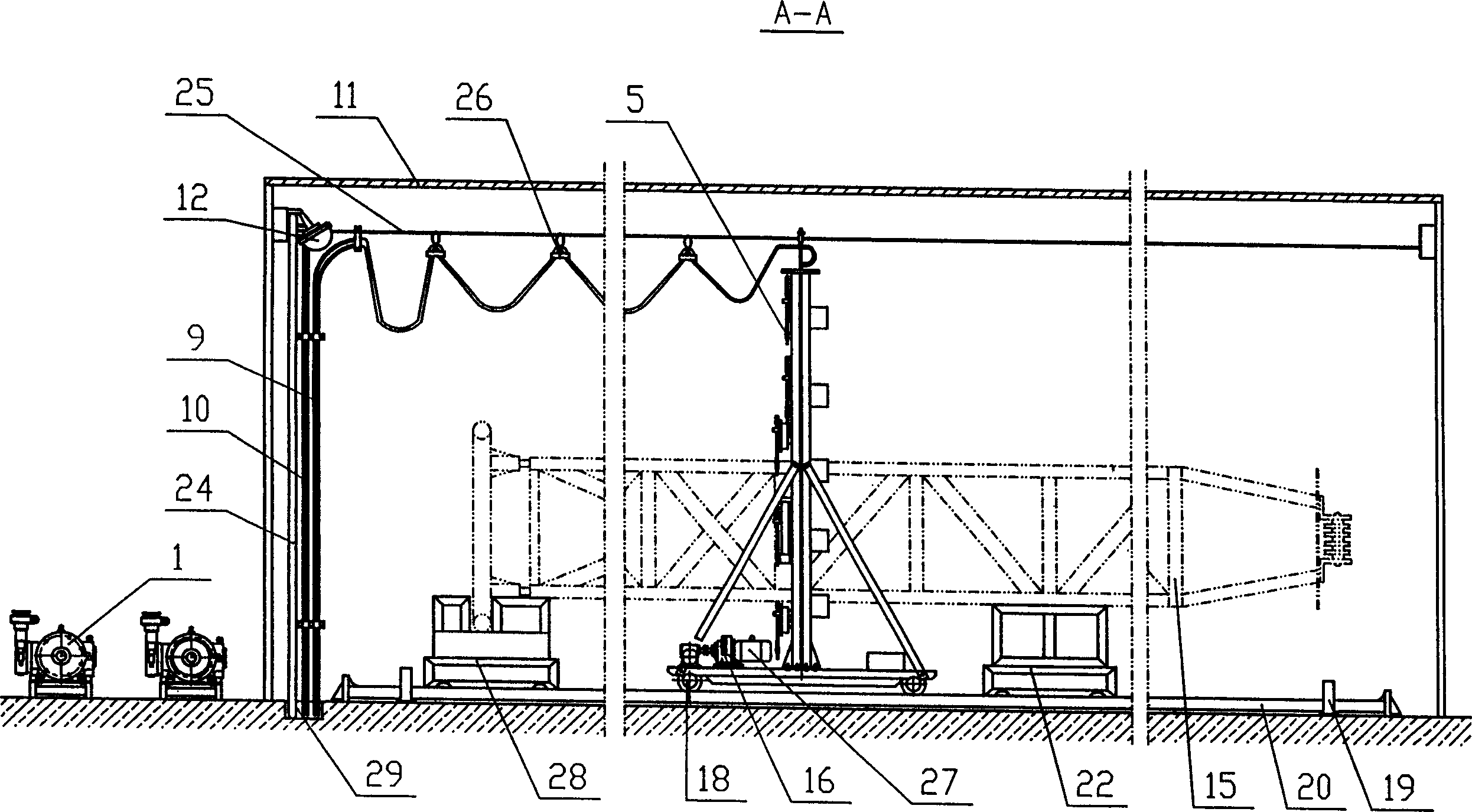

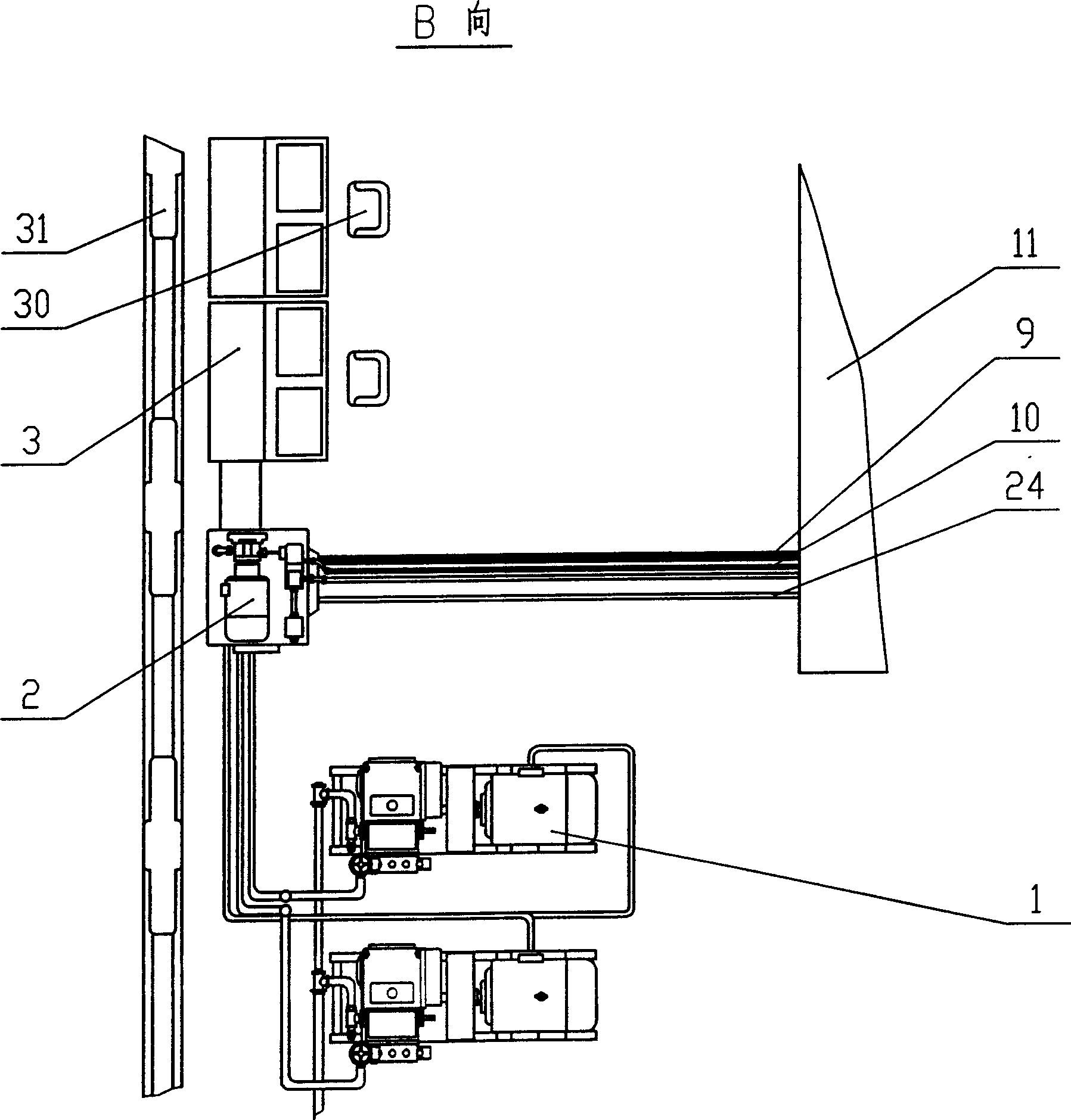

Automatic flushing device for oil field working equipment

InactiveCN1603014AEasy to adjust the distanceImprove cleaning efficiencyCleaning using liquidsAutomatic controlAutomated control system

One kind of oil field work equipment automatic purifier, including the rack,the nozzle above the assembly, the high-pressured water jet flow cleansing agent, the automatic control system,Among it the rack uses the gate type walking rack, the rack two sides hoop separately uses the electricity machine to actuate, and separately establishes the fixed manipulator and the active manipulator, installs the high pressure clear ramrod on the manipulator and the long target distance nozzle which is controled by the long-distance control equipment, the high-pressured clean spurts pole is separately connects with automatic control system hydraulic control return route the oil motor outputs axle-box.Its structure is reasonable, operation is simple, adjustment is convenient,realizate intelligence automatic control the clean work, may thoroughly eliminates the dirt in the oil field work equipment, the movement is quick, safe is reliable, reduces operator's labor intensity, remarkably enhances the clean working efficiency and the distinct improvement clean effect, saves water, does not have the pollution, is advantageous to improve the working condition and the protection environment, and makes the foundational work in advance to sentence and accurately analysis the service life of the equipment.

Owner:SHENYANG ACAD OF INSTR SCI

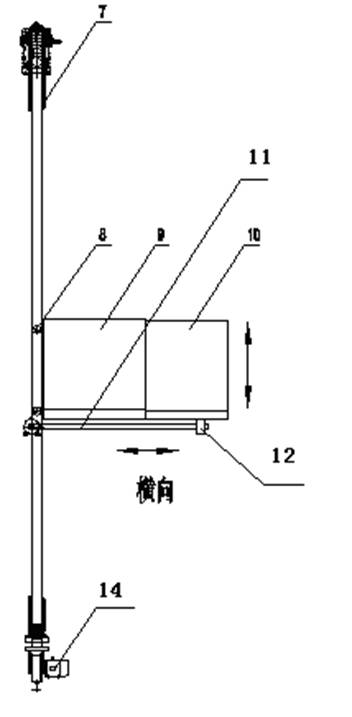

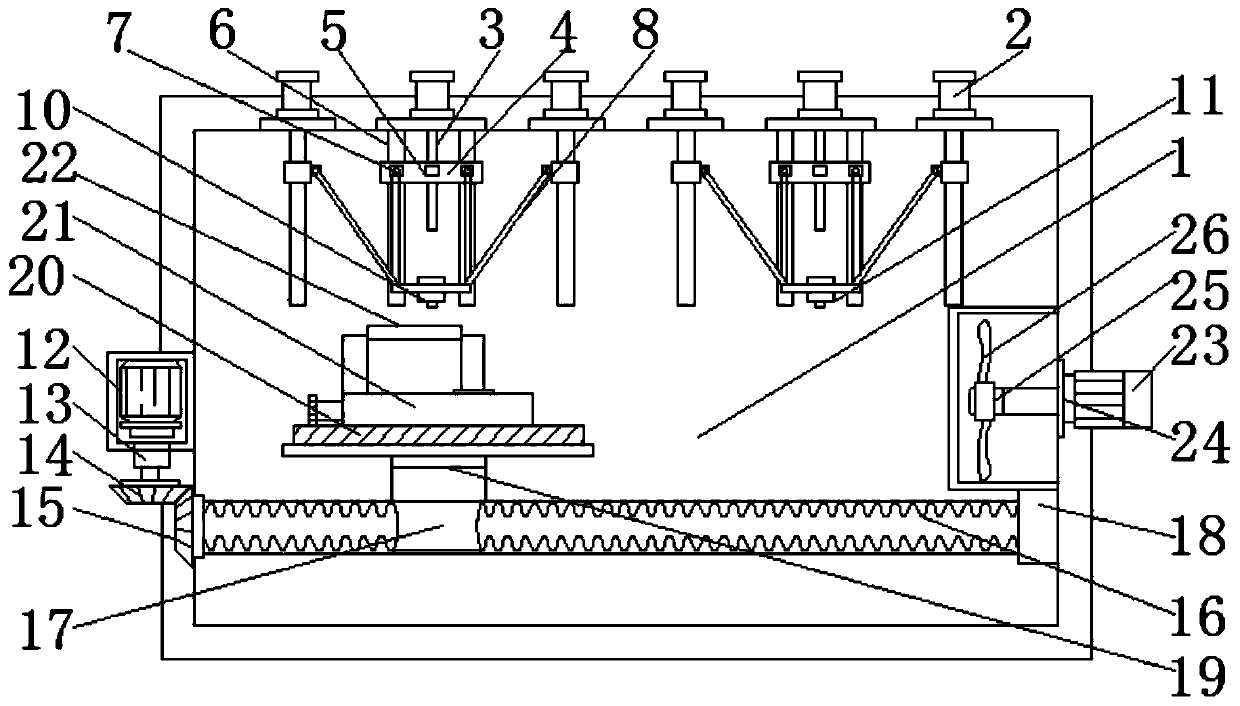

Full-automatic welding tool capable of achieving flat welding and vertical welding simultaneously

PendingCN108526782AVersatileReduce difficultyWelding/cutting auxillary devicesAuxillary welding devicesTransverse axisEngineering

The invention relates to a full-automatic welding tool capable of achieving flat welding and vertical welding simultaneously. The tool comprises a rack comprising a base and a hoisting bracket, wherein an X direction sliding table is mounted on the base; a Y direction sliding table is mounted on the X direction sliding table; a horizontal workbench is mounted on the Y direction sliding table; a left fixing seat and a right fixing seat are arranged on horizontal workbench; a clamping device is mounted between the left fixing seat and the right fixing seat; a mechanism case is fixed on the hoisting bracket and internally equipped with a main shaft extending in a Z direction; a cross shaft is mounted at the extension end of the main shaft; at least one welding connecting rod and a defect detection connecting rod are mounted on rod bodies on the two sides of the cross shaft; welding guns and a defect probe are correspondingly mounted at fastening ends of the welding connecting rods and thedefect detection connecting rod; pointers are mounted at non-fastening ends of the welding connecting rods and the defect detection connecting rod; and an angle scale is arranged on a front / rear sidewall of the mechanism case. The tool achieves welding and defect detection of a spatial complicated piece in the X, Y and Z directions, effectively improves welding efficiency, guarantees welding quality and has broad space and prospects.

Owner:HUBEI POLYTECHNIC UNIV

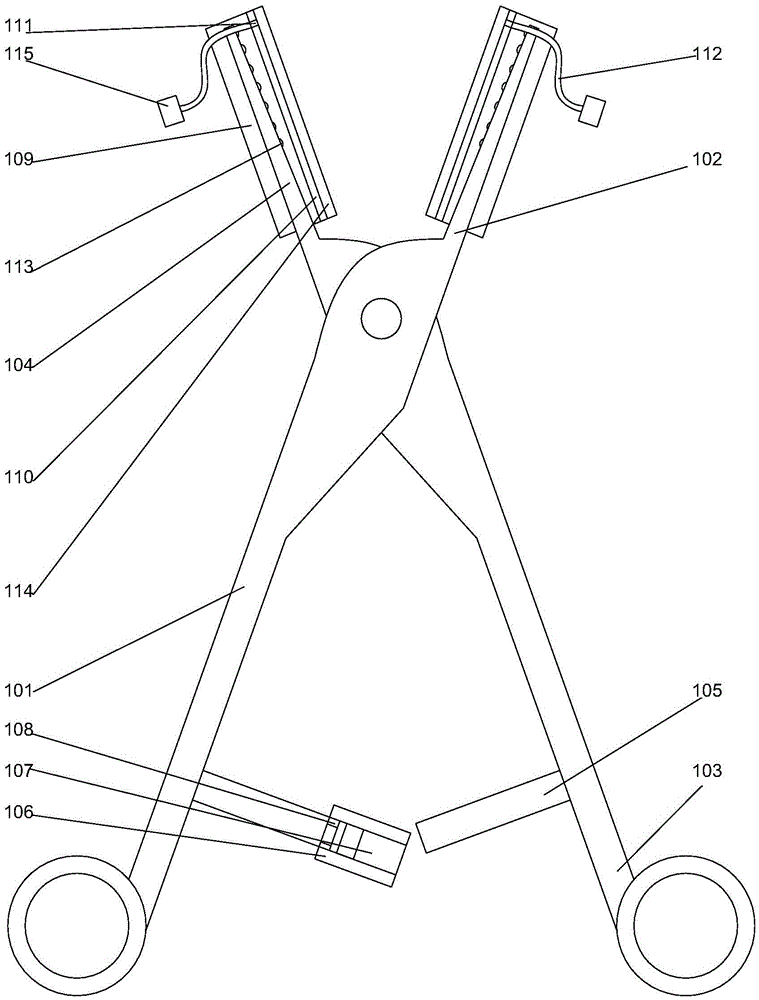

Surgical hemostatic forceps for general surgery department

The invention discloses a pair of surgical hemostatic forceps for a general surgery department. The pair of surgical hemostatic forceps comprises a left forceps handle, a right forceps head connected with the left forceps handle, a right forceps handle and a left forceps head connected with the right forceps handle. The left forceps handle and the right forceps handle are hinged through a pin shaft. The opposite faces of the left forceps handle and the right forceps handle are provided with locking strips respectively. Threads are arranged on the locking strips respectively. An annular groove is formed in the locking strip on the left forceps handle. A fixing rod is arranged on the locking strip on the left forceps handle. A thread blind hole is formed in the end, away from the annular groove, of the fixing rod. An external thread is arranged on the locking strip on the right forceps handle. The locking strip on the right forceps handle is connected into the thread blind hole in a threaded mode. According to the pair of surgical hemostatic forceps, the adjustable fixing rod structure is adopted, the left forceps handle and the right forceps handle are fixed relatively, the structure stability is improved, and meanwhile the fixing sleeve structure is adopted, so that the pair of surgical hemostatic forceps is not likely to slide down in the using process.

Owner:AFFILIATED HOSPITAL OF JINING MEDICAL UNIV

Cosmetic cabinet with sorting function

Owner:南通米乐智能家居有限公司

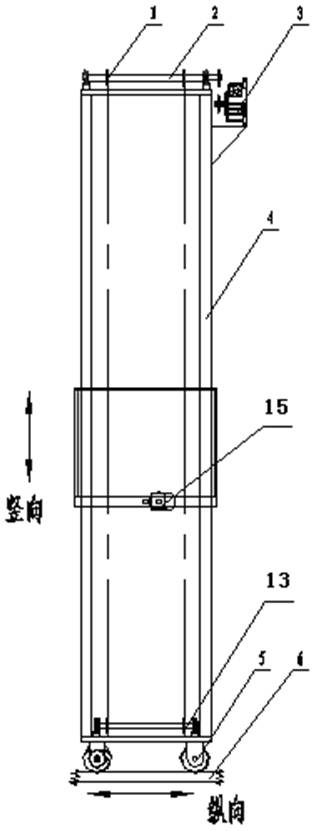

Three-dimensional lifting platform trolley

Owner:济南华北升降平台制造有限公司

Anti-shifting coating device for semiconductor production

ActiveCN110773381AAvoid offsetEasy to adjust the positionPretreated surfacesCoatingsEngineeringFan blade

The invention discloses an anti-shifting coating device for semiconductor production. The anti-shifting coating device for semiconductor production comprises a device main body, a vertical screw rod,a connecting sleeve, a first rotating shaft, a clamping groove, a second coating device, a second rotating shaft, a second gear, a first screw rod, a first bearing, a rotating turntable, a to-be-processed semiconductor and fan blades, wherein a first motor is arranged at the upper end of the device main body. A fixing device is arranged in the anti-shifting coating device for semiconductor production, a second screw rod is rotated by manually rotating a knob on the fixing device, and the second screw rod is in threaded connection with a first clamping block, so that the first clamping block moves on the horizontal plane, a sliding block is driven to move on a sliding rail, and the position of the first clamping block is convenient to adjust. The distance between the first clamping block and a second clamping block is conveniently adjusted by adjusting the position of the first clamping block, so that the to-be-processed semiconductor is clamped, and the to-be-processed semiconductor isprevented from being shifted.

Owner:江苏钰晶半导体科技有限公司

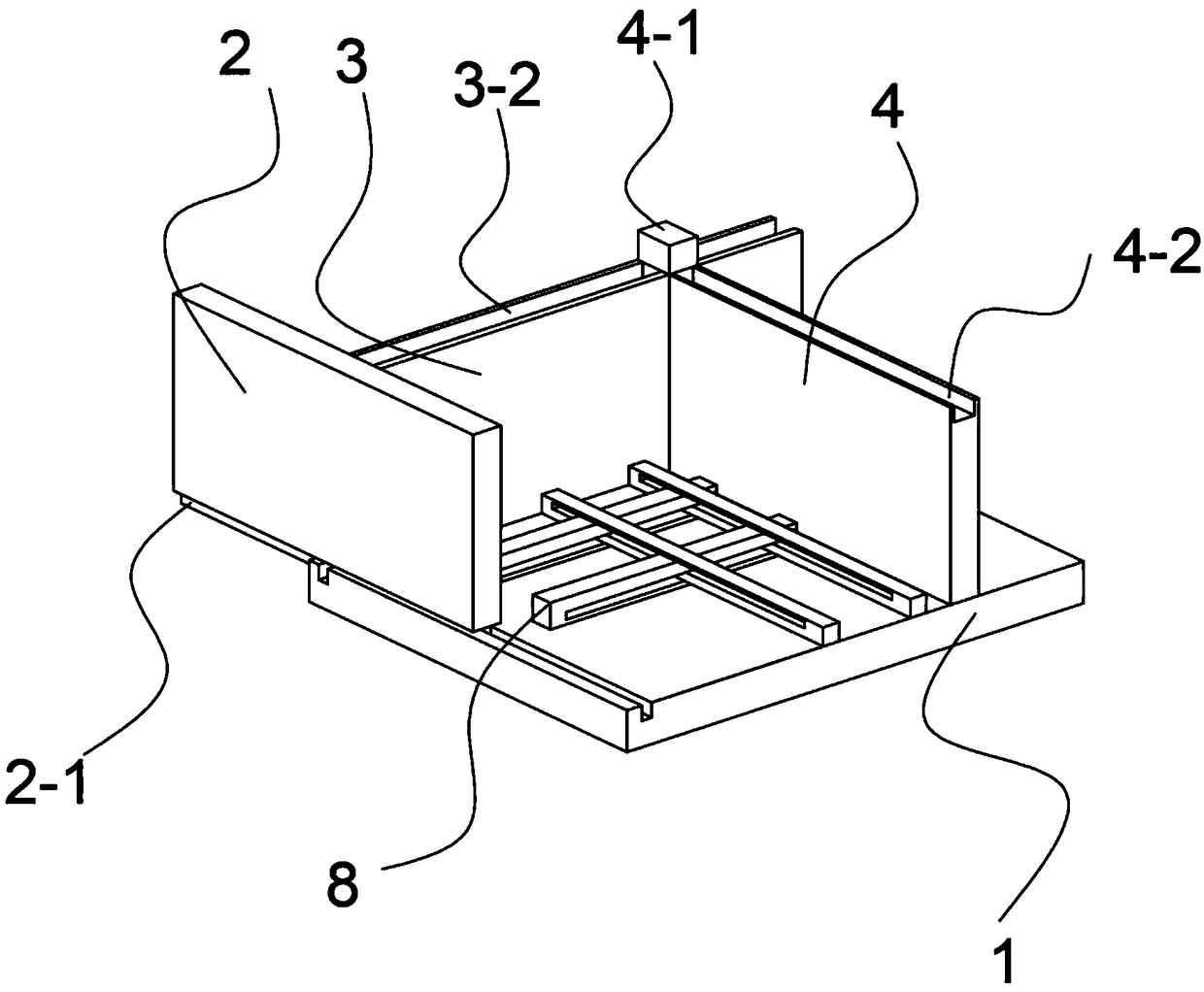

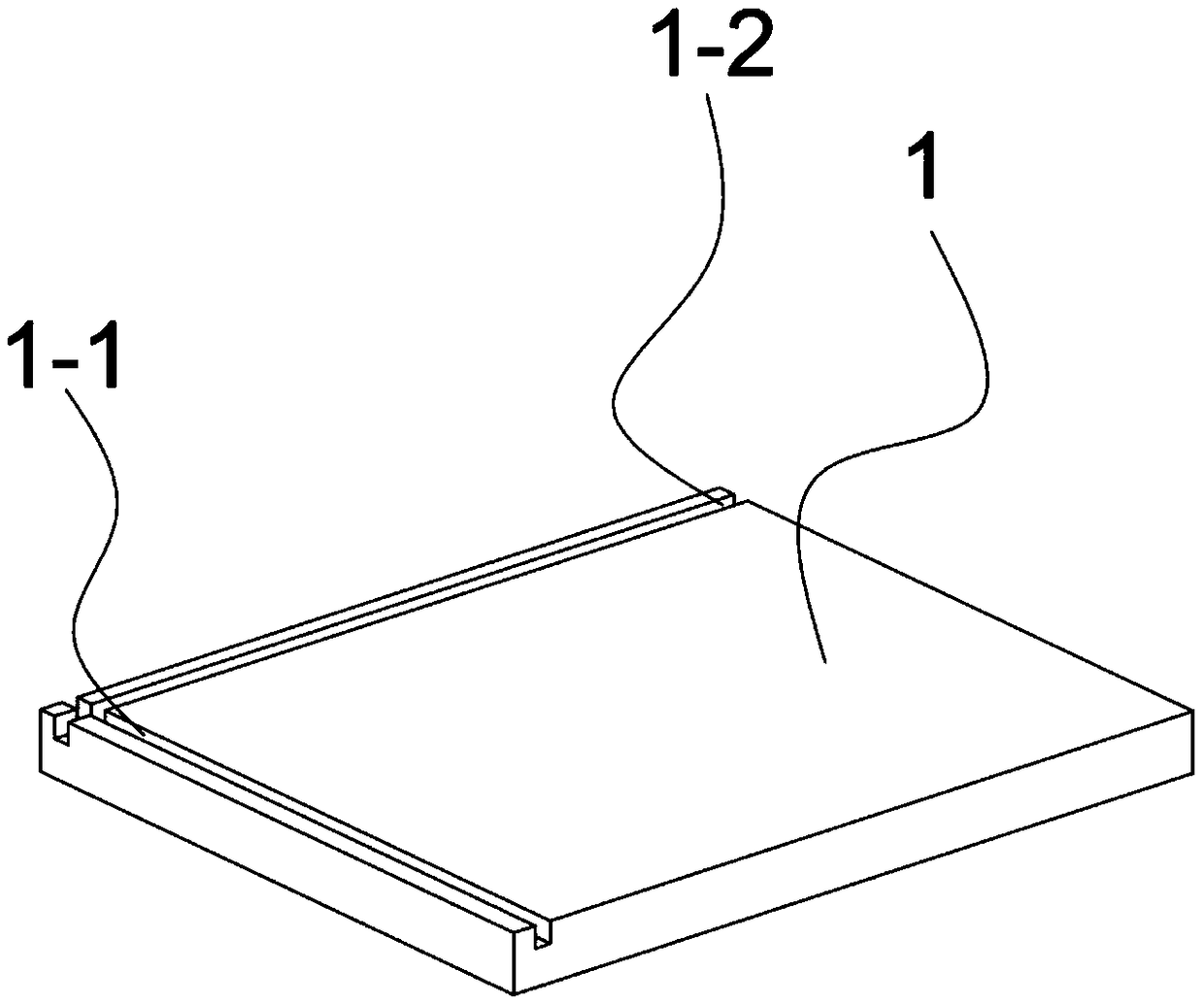

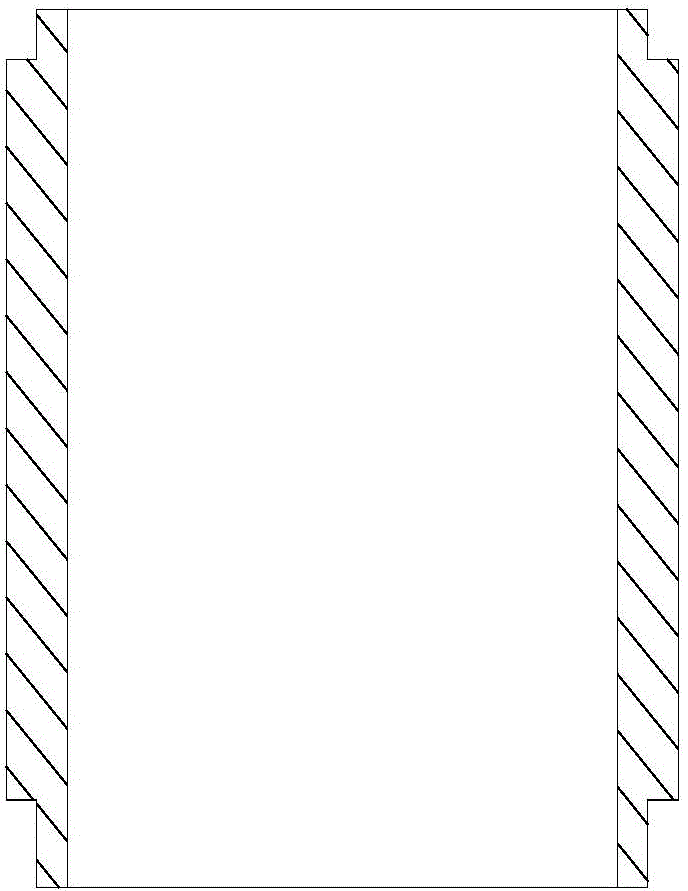

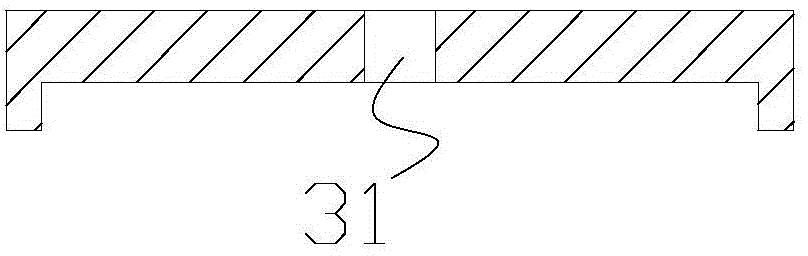

Machining mold for prefabricated outer wall component

The invention discloses a machining mold for a prefabricated outer wall component. The machining mold comprises a bottom mold, a first side mold, a second side mold, a third side mold and a fourth side mold, wherein the first side mold, the second side mold, the third side mold and the fourth side mold are arranged at the top of the bottom mold in a sliding mode; a first sliding groove is formed in the top of the bottom mold along the length direction of the bottom mold, and a second sliding groove is formed along the width direction of the bottom mold; a first sliding block matched with the first sliding groove is arranged at the bottom of the first side mold, and a second sliding block matched with the second sliding groove is arranged at the bottom of the second side mold; a third sliding groove is formed in the top of the second side mold, and a third sliding block matched with the third sliding groove is arranged on the third side mold; and a fourth sliding groove is formed in thetop of the third side mold, and a fourth sliding block matched with the fourth sliding groove is arranged on the fourth side mold. The outer walls with different sizes are poured by adjusting the first side mold, the third side mold and the fourth side mold, so that the adjustment is convenient, the whole machining mold is simple in structure.

Owner:CHENGDU JIANGONG INDZATION BUILDING CO LTD

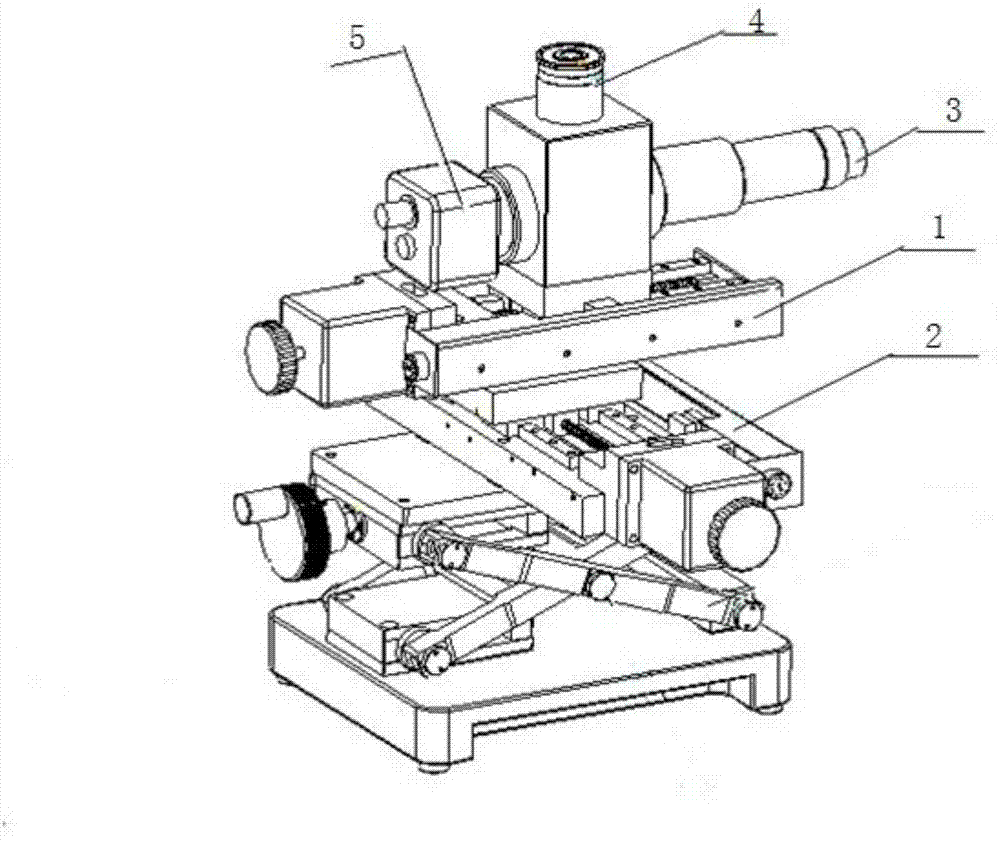

Assembly and adjustment method of double-view-field axial zoom optical system

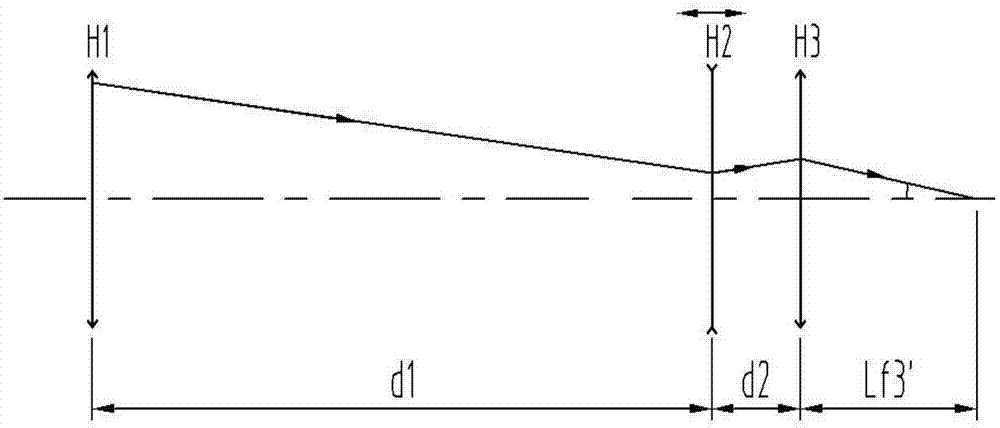

InactiveCN103033946AEasy to adjust the distanceImprove directionOptical elementsComputational physicsOptic system

The invention relates to an assembly and adjustment method of a double-view-field axial zoom optical system. The method includes firstly measuring defocusing amount between a big view field and a small view field and focal length of each filed view of the measured double-view-field axial zoom optical system; confirming an optical path of the optical system and selecting a proper zoom lens group according to specific optical parameters of the optical system; by means of the defocusing amount of the big view field and the small view field and the focal length of the small view field ( or the focal length of the big view field), optimizing ideal focal length and multiplying power of the big view field and the small view field and distance (best adjustment distance and direction of a limit mechanism) that a zoom lens needs to move forwards and backwards relative to a defocus view field in the ideal big view field (or the ideal small view field); and instructing assembly debugging according to calculation results and achieving optimized results. According to the assembly and adjustment method, operation is simple and convenient, axial assembly and adjustment for the double-view-field axial zoom optical system can be carried out, and the precision is high.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Automobile front anti-collision beam device

InactiveCN107901861AEasy to adjust the distancePlay a buffer roleBumpersIsosceles trapezoidCushioning

The invention discloses an automobile front anti-collision beam device, which comprises a beam, a strip-shaped arch plate, a buffer foam block, a shock absorbing mechanism, a fixing groove, a telescopic mechanism, an arched support frame, an electric control box, a control panel, and a limit groove and the storage battery, the top of the beam is connected to the buffer foam block through an arch support frame, the top of the buffer foam block is equipped with a strip arch plate, the corresponding two sides of the beam are provided with fixing grooves, and the fixing grooves A telescopic mechanism is installed in the interior of the crossbeam. Limiting grooves are provided on both sides of the bottom of the beam. A shock absorbing mechanism is installed inside the limit groove. An electric control box is installed on one side of the beam. A control panel is installed on one side of the box, and a storage battery is installed inside the electric control box. Composed of plates and limit springs, the anti-collision beam device is conducive to buffering and shock absorption.

Owner:GUANGXI HONGXING MACHINERY CO LTD

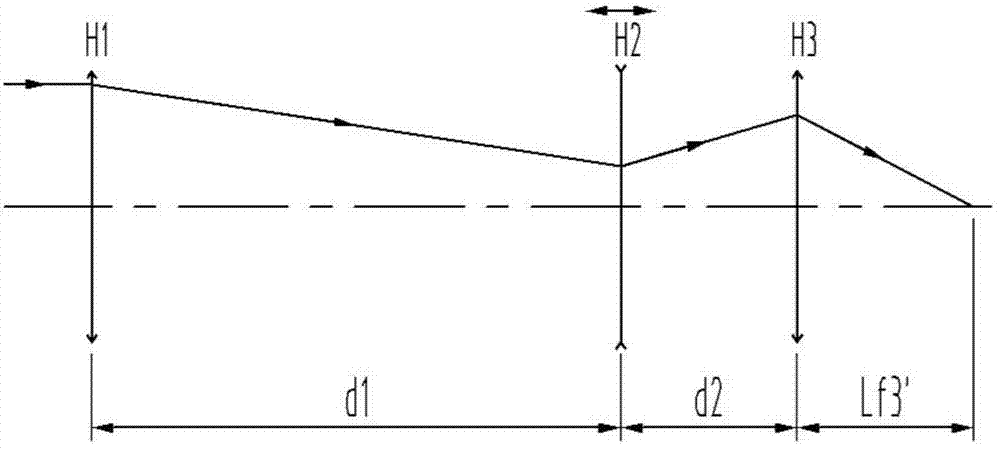

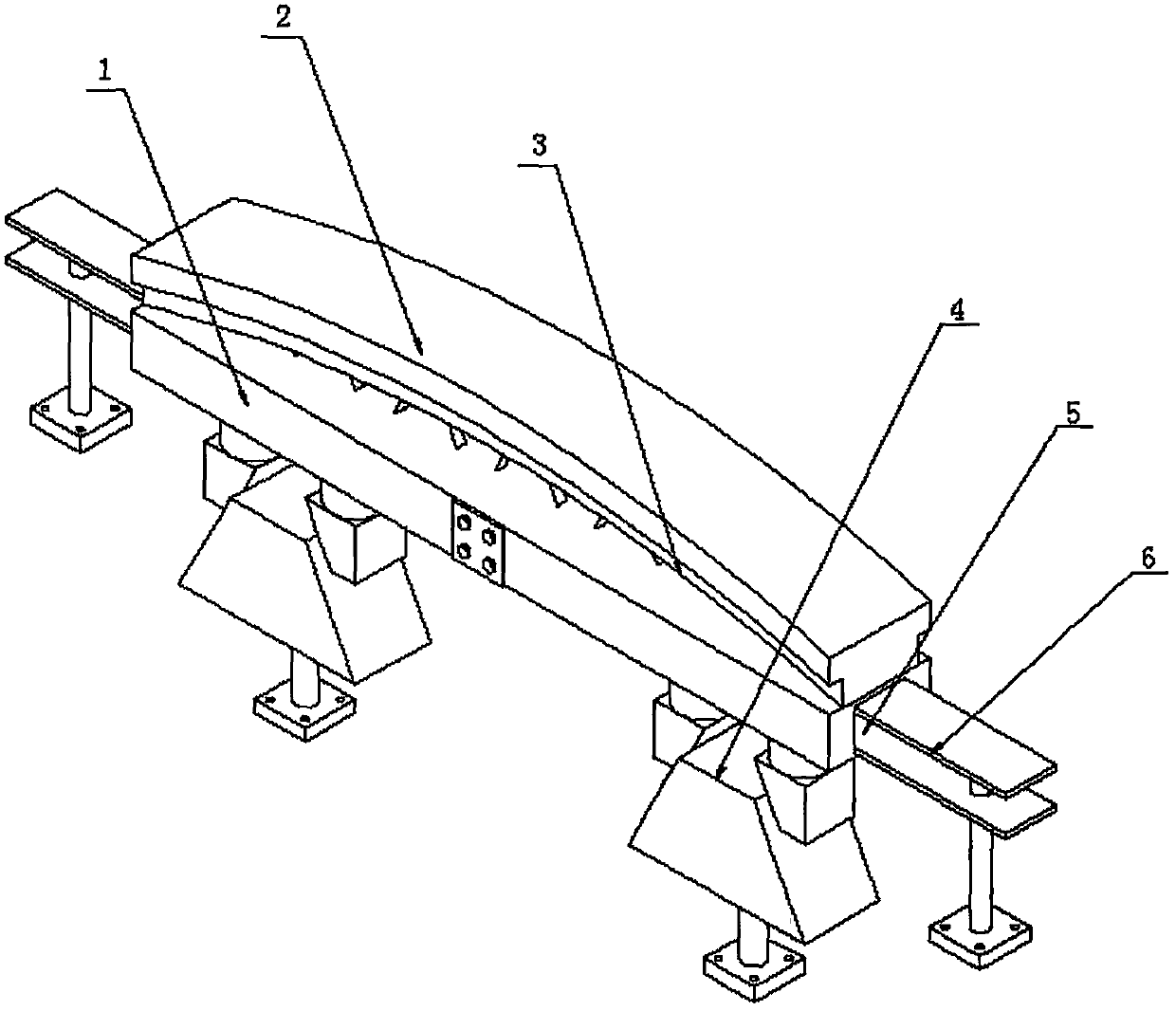

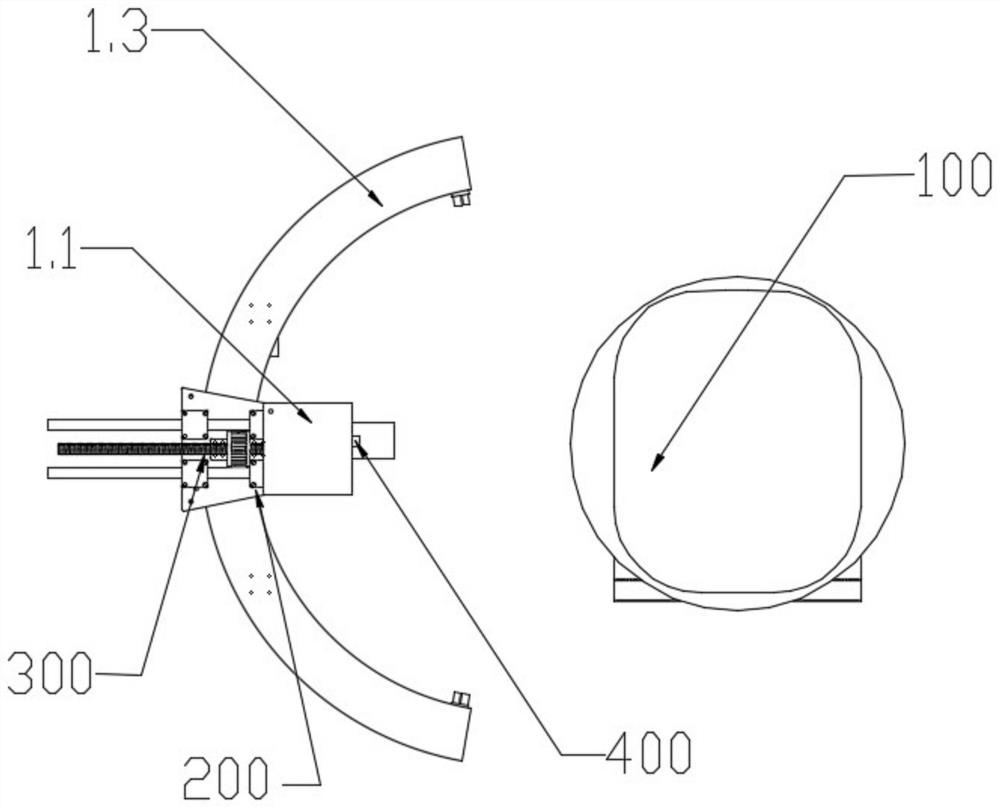

Arc-shaped motion platform for insulator laser cleaning

ActiveCN113102389AExpand the scope of cleaningReduce frequency of movementCleaning processes and apparatusEngineeringMechanical engineering

The invention discloses an arc-shaped motion platform for insulator laser cleaning. The arc-shaped motion platform comprises an arc-shaped track, a first moving device, a second moving device, a mounting table and a first detection piece. The mounting table is mounted on the second moving device and is used for fixing a laser sweeper; the second moving device is mounted on the first moving device and used for driving the mounting table to move in the radial direction of the arc-shaped track; the first moving device is mounted on the arc-shaped track and used for driving the second moving device to move in the circumferential direction of the arc-shaped track; and the first detection piece is used for detecting the distance between the laser sweeper and the surface of the insulator to be swept. The cleaning range is expanded, the cleaning efficiency is improved, accurate movement adjustment of the mounting table in the radial direction of the arc-shaped track can be achieved, the distance between a laser head of the laser cleaner and the surface of the insulator to be cleaned can be conveniently adjusted, focusing is guaranteed to improve the cleaning effect, and the applicability is good.

Owner:JIANGMEN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID

Partial discharge test oil cup for oil-paper insulation

ActiveCN104820171AEasy to replaceEasy to adjust the distanceTesting dielectric strengthPolymethyl methacrylateEngineering

A partial discharge test oil cup for oil-paper insulation is characterized in that the partial discharge test oil cup comprises a polymethyl methacrylate tube which has a smooth inner wall; the upper opening of the polymethyl methacrylate tube is provided with a polymethyl methacrylate upper cover, and the lower opening is provided with an aluminum lower cover; the polymethyl methacrylate upper cover is provided with a through hole at the central part; a first metal guide rod penetrates through the through hole; a sink hole is arranged at the middle part of the top surface of the aluminum lower cover; a vertical second metal guide rod is fixed in the sink hole; the upper end of the second metal guide rod is inserted into the sink hole at the bottom surface of a brass circular-plate-shaped electrode; an annular polymethyl methacrylate pressure plate is arranged between the first metal guide rod and the brass circular-plate-shaped electrode; the brass circular-plate-shaped electrode pressure plate is in vertically movable clearance fit with the brass circular-plate-shaped electrode tube; the internal diameter of the brass circular-plate-shaped electrode pressure plate is smaller than that of the circular-plate-shaped electrode; the upper end of the first metal guide rod is connected with a high-voltage power supply; and the aluminum lower cover is connected with a ground wire. High-voltage electrode replacement and adjustment for space between the high-voltage electrode and a grounding electrode are facilitated. The insulation paper is flattened and fixed at a required position and does not float.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

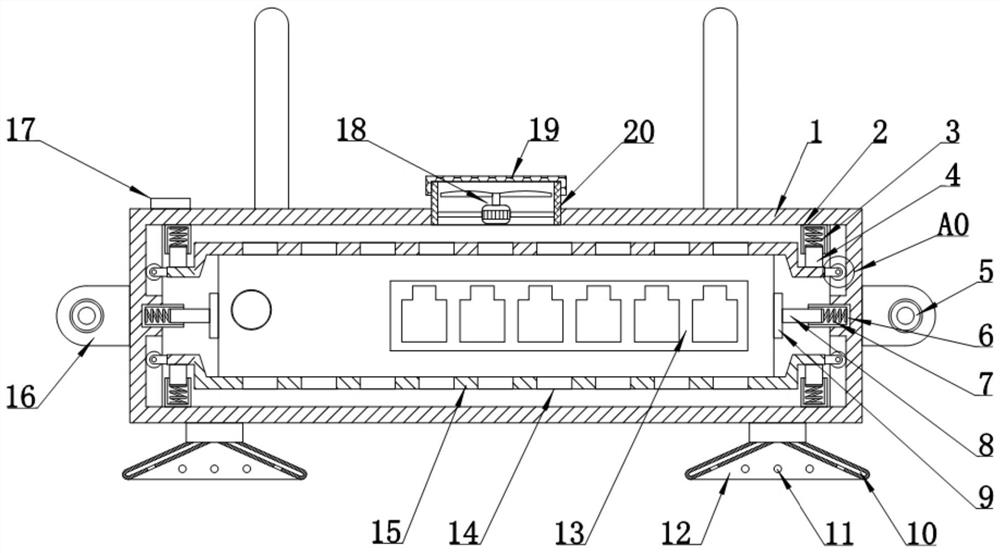

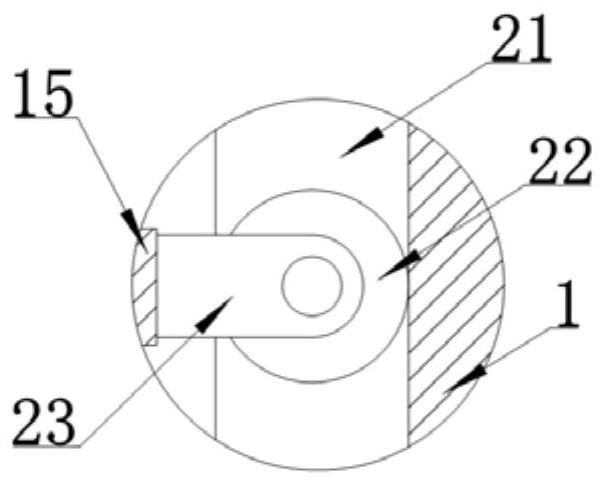

Internet of Things router protection device capable of fixing plug and use method

InactiveCN111884943AConditions that reduce service lifeAvoid damageData switching networksCooling/ventilation/heating modificationsThe InternetControl switch

The invention relates to the technical field of router protection devices, in particular to an Internet of Things router protection device capable of fixing a plug and a using method. The using methodis applied to the device, and the device comprises a frame body and an Internet of Things router body arranged in the frame body, a first cavity is formed in the frame body, a clamping assembly usedfor clamping and fixing the Internet of Things router body and providing collision buffering is arranged in the first cavity, and a ventilation assembly used for discharging heat in the first cavity is arranged at the top of the frame body; the ventilation assembly comprises an air outlet pipe, a fan is fixedly connected to an inner cavity of the air outlet pipe through a support, and the fan abuts against the clamping assembly; the left side of the top of the frame body is fixedly connected with a control switch, and the control switch is electrically connected with the fan. The router solvesthe problem that when the router is collided or works for a long time, internal parts are easy to damage, so the service life of the router is shortened.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

Sticker pressure foot and sewing machine with same

The invention discloses a sticker pressure foot and a sewing machine with the same, and belongs to sewing devices. The sticker pressure foot comprises a pressure plate, a pressure rod and a folder, the pressure plate and the pressure rod are arranged on the pressure plate, a needle penetrating hole is formed in the pressure plate, the folder comprises a left half body and a right half body, the left half body and the right half body are mutually, remotely or closely and slidably connected on the pressure plate, and a positioning mechanism for positioning the left half body and the right half body is arranged on the pressure plate. The sticker pressure foot can be matched with stickers of a plurality of different widths, and the application range of the pressure foot is widened.

Owner:平湖龙凤时装有限公司

High-speed automatic chip mounter capable of avoiding chip mounting deviation

PendingCN112055530AAvoid offsetGuaranteed accuracyCleaning using gasesElectrical componentsElectric machineryStructural engineering

Owner:孙传保

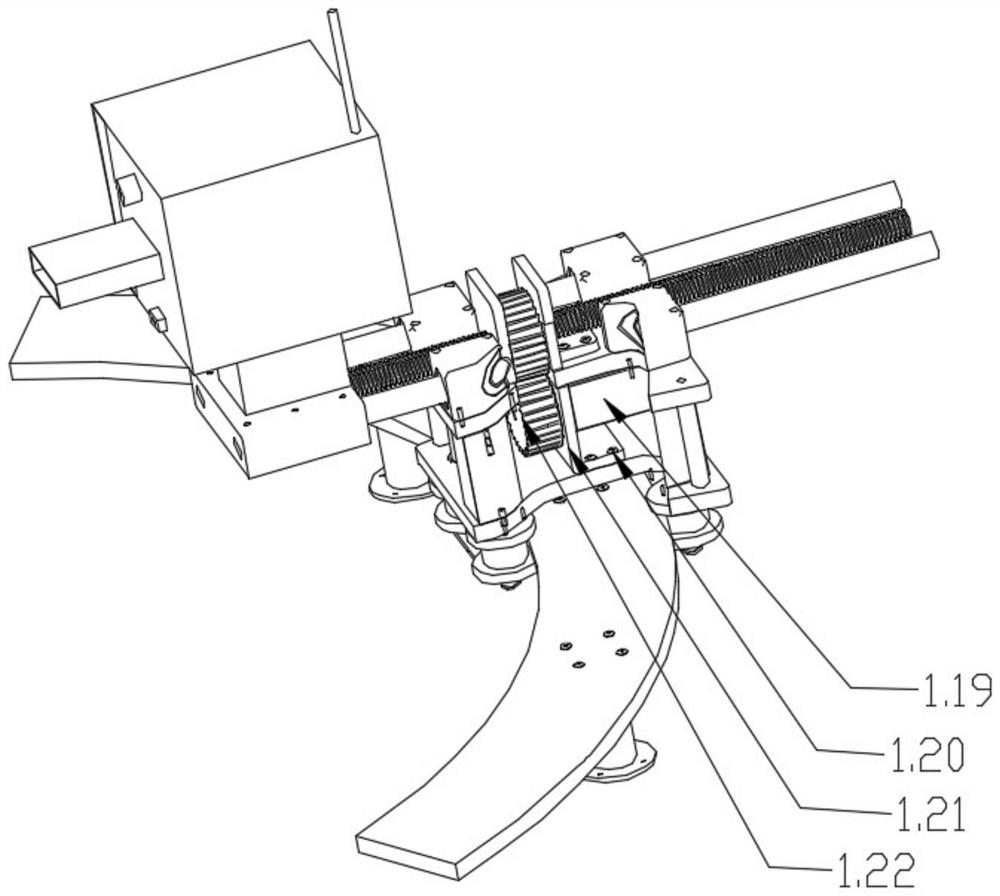

Flying disc ejection robot

ActiveCN108094252AEasy to adjust the distanceRealize continuous flying outTaming and training devicesLaser transmitterEngineering

The invention relates to a flying disc ejection robot. The flying disc ejection robot is composed of a bracket, bearing fixators, a bearing rod, a motor fixing device, a flying disc acceleration mechanism, a laser emitter, a lower base, a flying disc memory fixing slot, an upper cover, a stepping motor protection cover, a flying disc support bracket, a flying disc memory and other components. Tworods on the bracket are fixedly connected with the bearing fixators respectively, the bearing rod is radially connected with the bearing fixators through bearings in the bearing fixators, the flying disc acceleration mechanism is fixed to one side of a groove in the upper surface of the lower base, rubber acceleration wheels are located on the other side of the groove in the upper surface of the lower base, the upper cover is fixedly connected with the lower base, the flying disc suction and picking mechanism is fixed to the upper surface of the upper cover, and one end of the flying disc support bracket is fixedly connected to the bearing rod. Specifically, the flying disc ejection robot uses high-speed direct current motors and rubber wheels to conduct acceleration, relies on lasers to conduct locating, and belongs to the field of pet training equipment.

Owner:宁波迪竞智能科技有限公司

Multi-layer planting rack for flower seedling breeding

InactiveCN107873339AEasy to adjust the distanceSmooth liftPlanting bedsCultivating equipmentsHorticultureEngineering

The invention relates to the technical field of flowers, and discloses a multi-layer planting rack for flower seedling breeding. The planting rack comprises a fixed base. Through holes are formed in the inner side of an adjusting rod at equal intervals. Top rods are inserted in the through holes. A support is connected with the top of the adjusting rod. The top of the support is connected with a movable plate. The top of the support is connected with a fixed plate. Limiting blocks are connected into limiting grooves in a sliding mode. The right side of a movable plate is connected with a toothed rail. A rotating plate is arranged on the top of the right side of the toothed rail. The outer side of the rotating plate is connected with teeth at equal intervals. The right sides of the teeth are meshed with the toothed rail. By using the adjusting rod, the top rods, the movable plate, the toothed rail, the rotating plate and the teeth in cooperation, when the top rods are inserted in the through hole of the adjusting rod, the adjusting rod can drive planting plates to rise and fall, and when the top rods are inserted in different through holes, the lifted planting plates can be subjected to distance adjustment.

Owner:无锡市鹅湖玫瑰园艺文化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com