Assembly and adjustment method of double-view-field axial zoom optical system

A technology of optical system and adjustment method, applied in optics, optical components, instruments, etc., to achieve the effect of simple operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

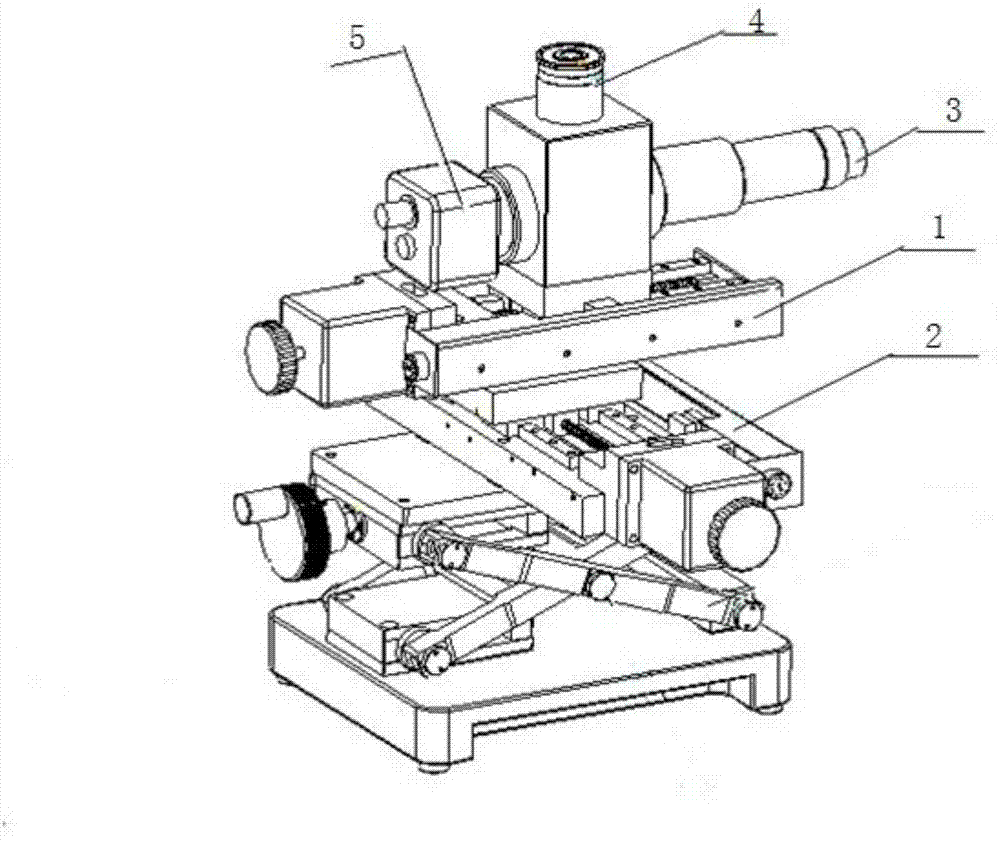

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

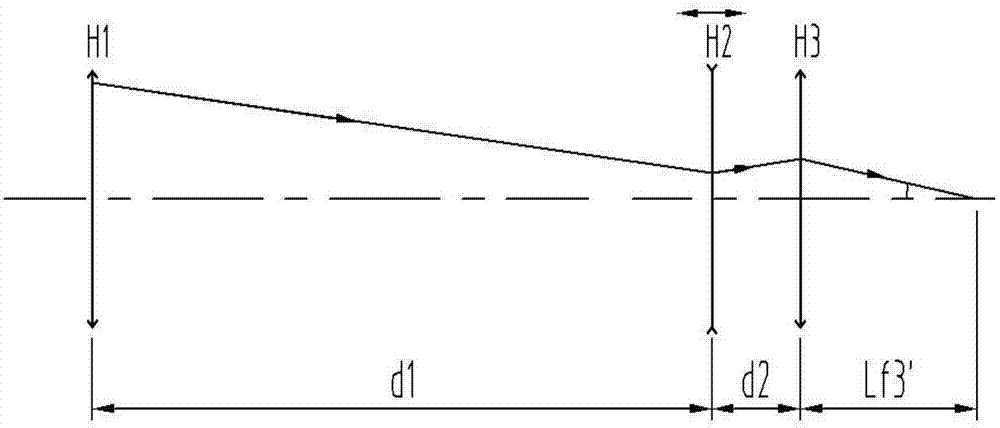

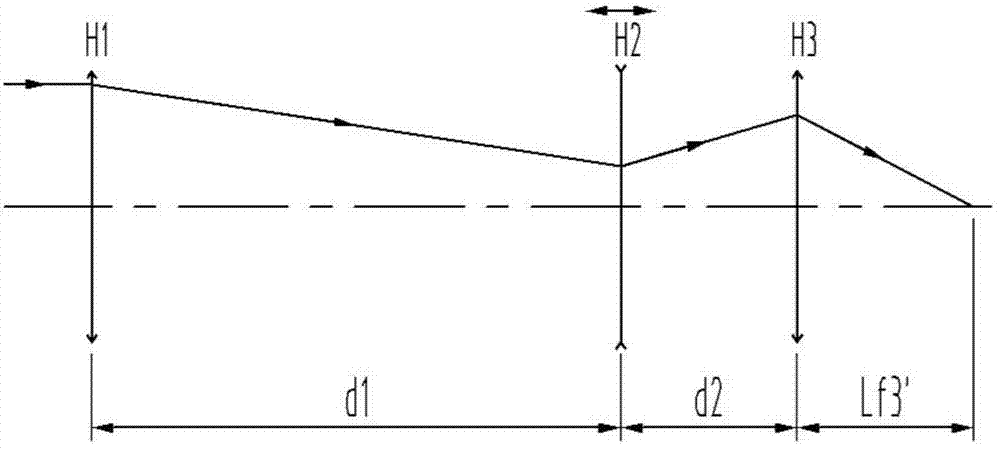

[0022] as Figure 2-a and Figure 2-b The shown dual field of view variable power telescopic system is taken as an example to illustrate the installation and adjustment method of the dual field of view axial variable power optical system of the present invention. Composed of H2 and rear group H3, the positions of objective lens group H1 and rear group H3 are fixed, and the distance between them is d1+d2=160mm. The movement of moving zoom lens group H2 forms a corresponding large and small field of view. The small field of view zoom lenses are located at d1=119.6mm and d1=150.5mm respectively. When the zoom barrel moves to the two limit positions, it will be positioned by two limit mechanisms. Due to errors in the processing and assembly of optical and mechanical parts, the positions of the two limit mechanisms must be adjustable. In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com