Flying disc ejection robot

A robot and frisbee technology, applied in the field of pet training equipment, can solve the problem of heavy workload and achieve the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

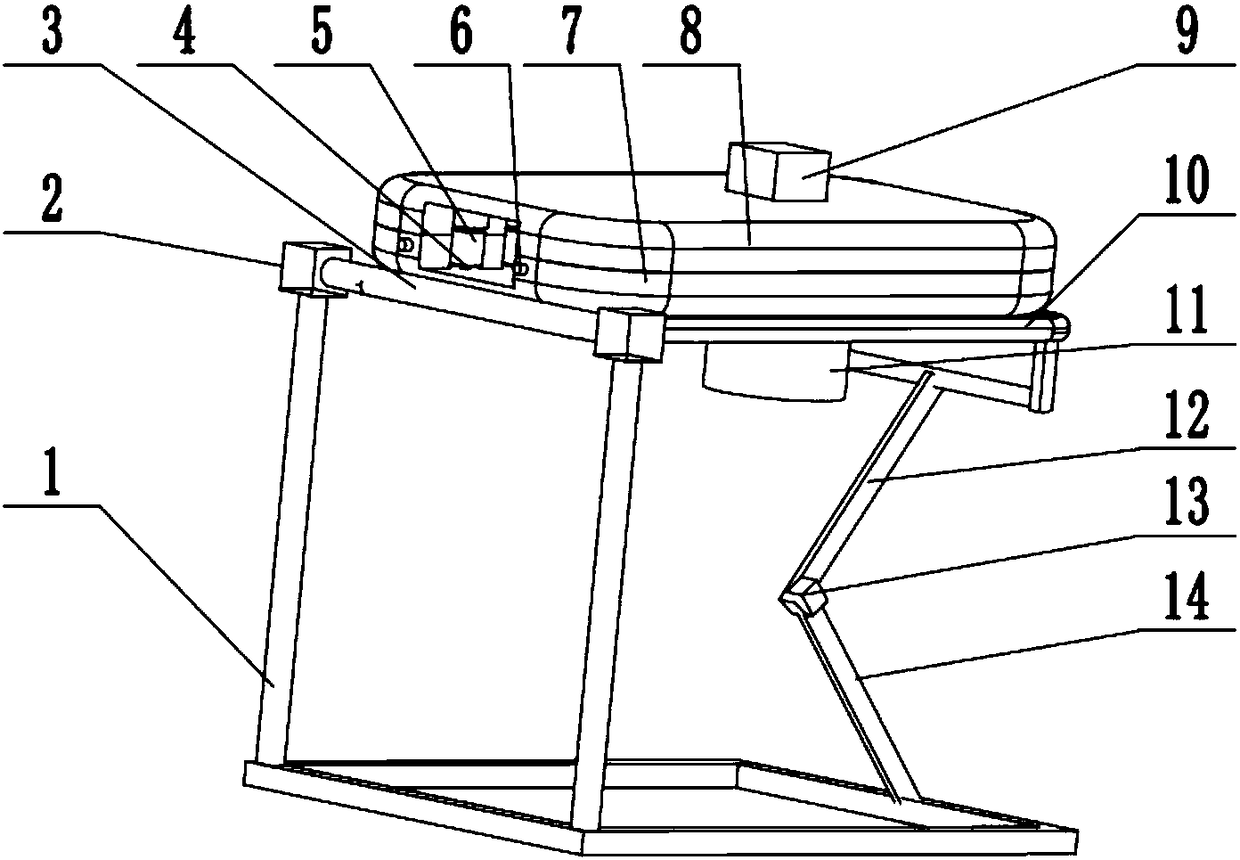

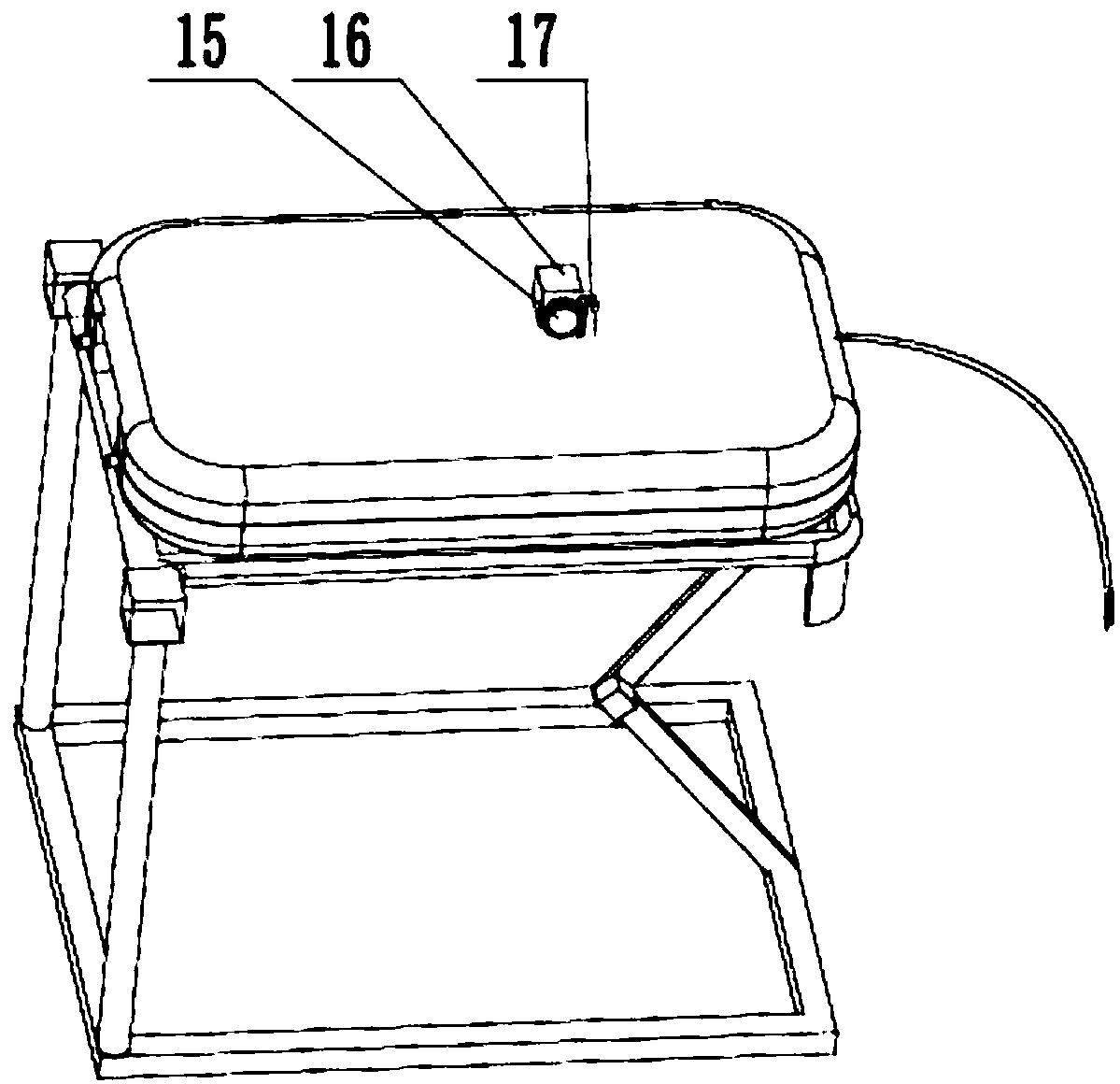

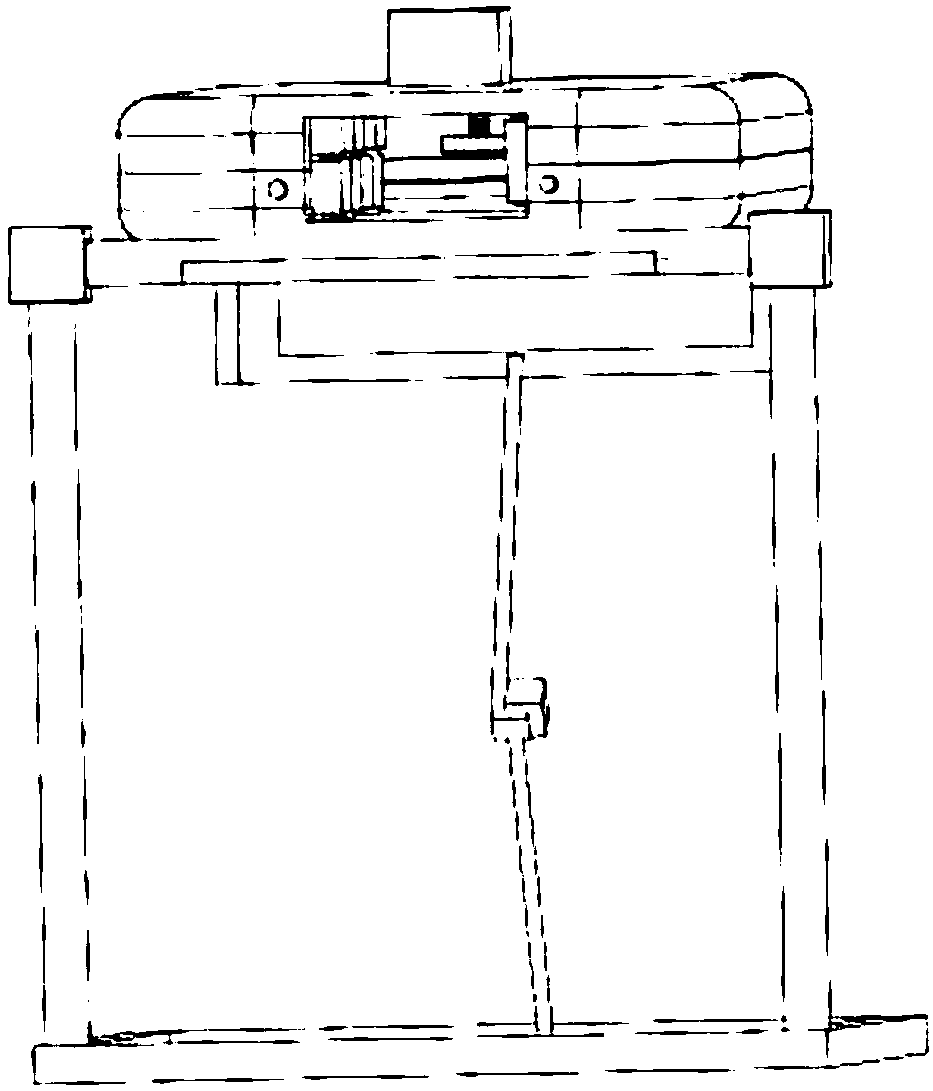

[0023] A flying disc ejection robot is composed of a bracket 1, a bearing fixer 2, a bearing rod 3, a motor fixing device 4, a flying disc acceleration mechanism 5, a high-speed DC motor 501, a rubber wheel 502, a laser transmitter 6, a lower bottom 7, and a flying disc storage Device fixing groove 701, upper cover 8, stepper motor protection cover 9, flying disc support frame 10, flying disc storage 11, flying disc storage installation edge 1101, first movable support rod 12, ratchet device 13, second movable support rod 14 , spur gear 15, stepper motor 16, flying disc suction device 17, small sucker 1701, sucker seat 1702, rack 1703, rubber acceleration wheel 18, barrier plate 19, flying disc 20, cylinder tube 21, flying disc driving mechanism 22, the first A limit rod 2201, a cylinder telescopic rod 2202, a cylinder 2203, a second limit rod 2204 and a push block 2205 are formed. The two rods on the support 1 are fixedly connected with the bearing holder 2 respectively, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com