Automatic feeding and discharging system for pipe fitting machining device

A technology of automatic loading and unloading, processing machine, applied in the direction of conveyor objects, packaging, loading/unloading, etc., can solve the problems of low work efficiency, low efficiency, complicated operation, etc., to achieve the effect of simple structure and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

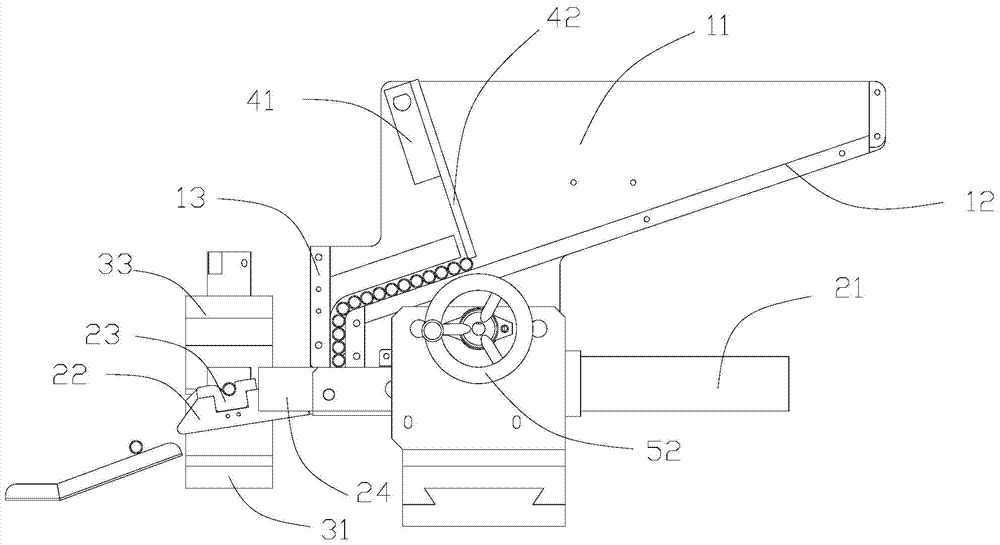

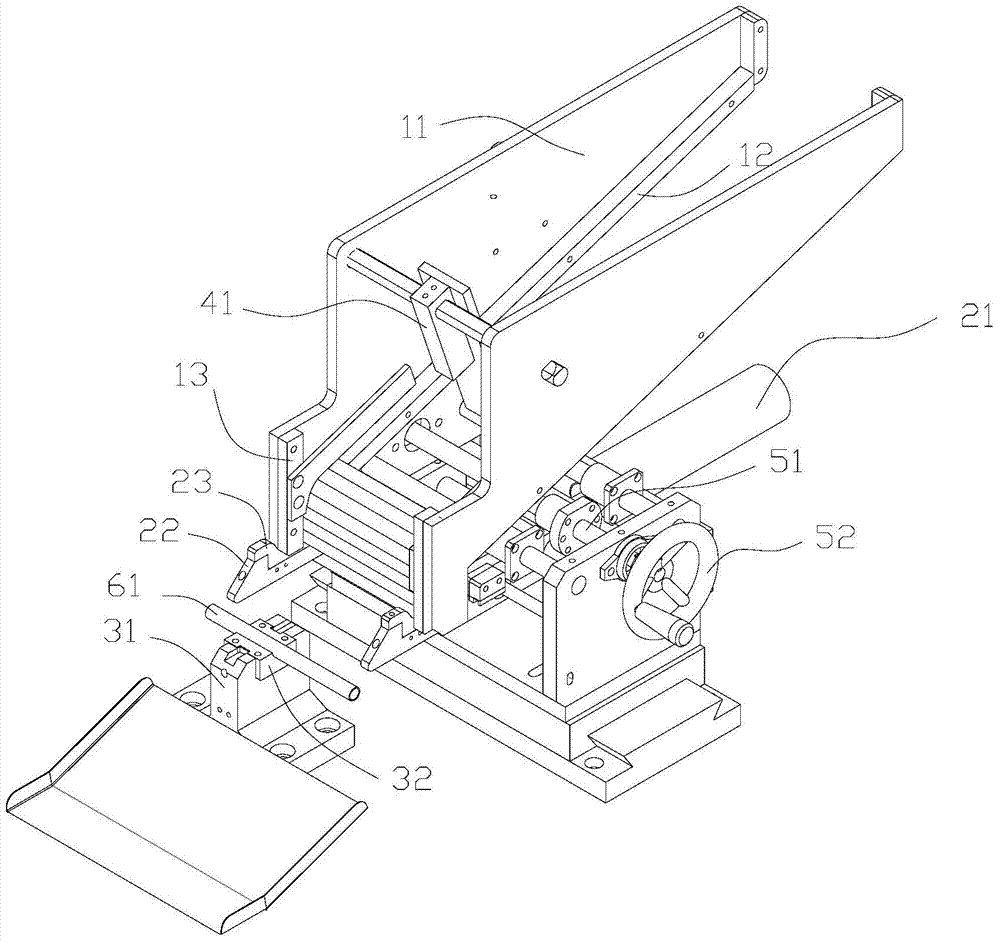

[0029] Such as figure 1 and figure 2 As shown, an automatic loading and unloading system of a pipe fitting processing machine includes a hopper, a push device and a clamping device; the hopper is located above the push device, and a guide track for the pipe fittings to pass is arranged in the hopper; the clamping device is located in front of the push device, The clamping device comprises a lower clamping die 31 and an upper clamping die 33, and the lower clamping die 31 is provided with a second groove for placing pipe fittings; The push rod pushes forward to make the pipe placed in the first groove be located in the second groove position of the clamping device and the power device 21 that retracts the push rod backward, the power device 21 can be constituted by a feeding cylinder. The front end of the push rod is provided with a slope for pushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com