Patents

Literature

1047results about How to "Improve laying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

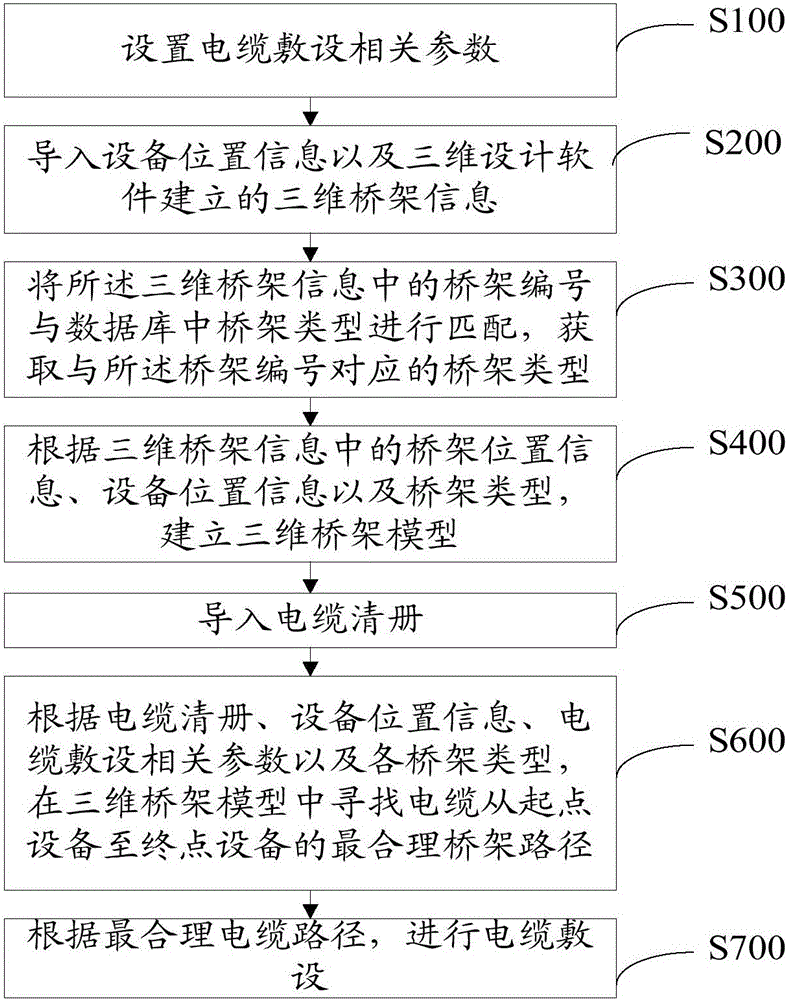

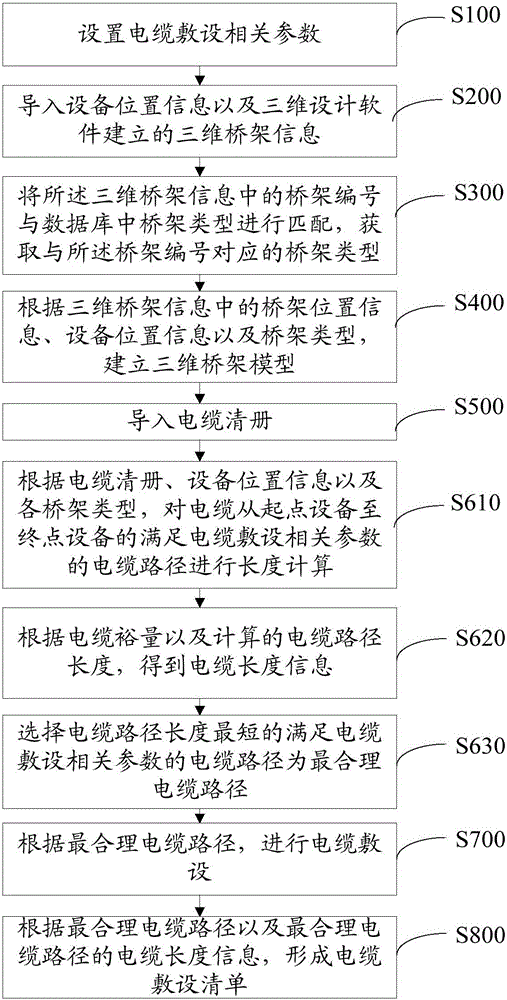

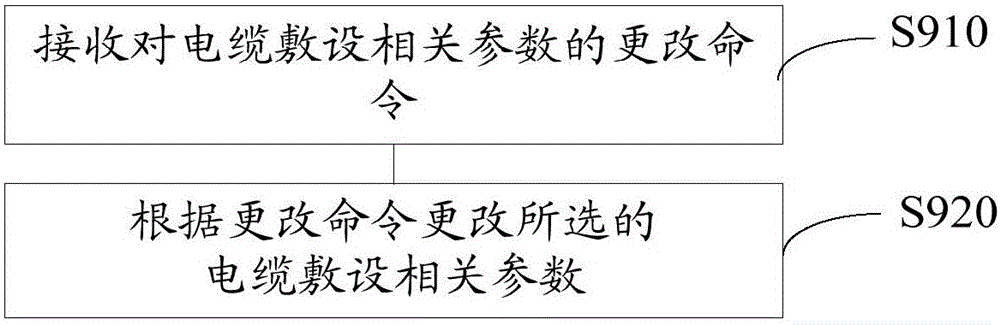

Cable laying method and system

ActiveCN105005659AImprove laying efficiencyImprove efficiencyForecastingSpecial data processing applicationsBridging positionBridge type

The invention relates to a cable laying method and system. The cable laying method comprises the following steps of: acquiring three-dimensional (3D) bridge information built by 3D design software; matching a bridge number in the 3D bridge information with a bridge type in a database to find the bridge type corresponding to the bridge number and realize the conversion of the bridge number to the bridge type; and forming a 3D bridge mode according to imported bridge position information, device position information and the bridge type in the 3D bridge information. By the cable laying method, the bridge position information, the device position information and the bridge type are unnecessarily reset in the cable laying system to build the 3D bridge model; through information matching, the bridge number in the 3D bridge information built by the 3D design software is converted into information required for cable laying, namely the bridge type, the bridge type is unnecessarily set, and thus the laying efficiency is improved; and the most reasonable cable path is searched according to parameters related to cable laying, rapidness and accuracy are achieved, manual labor is not needed to search the path, and the laying efficiency is improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

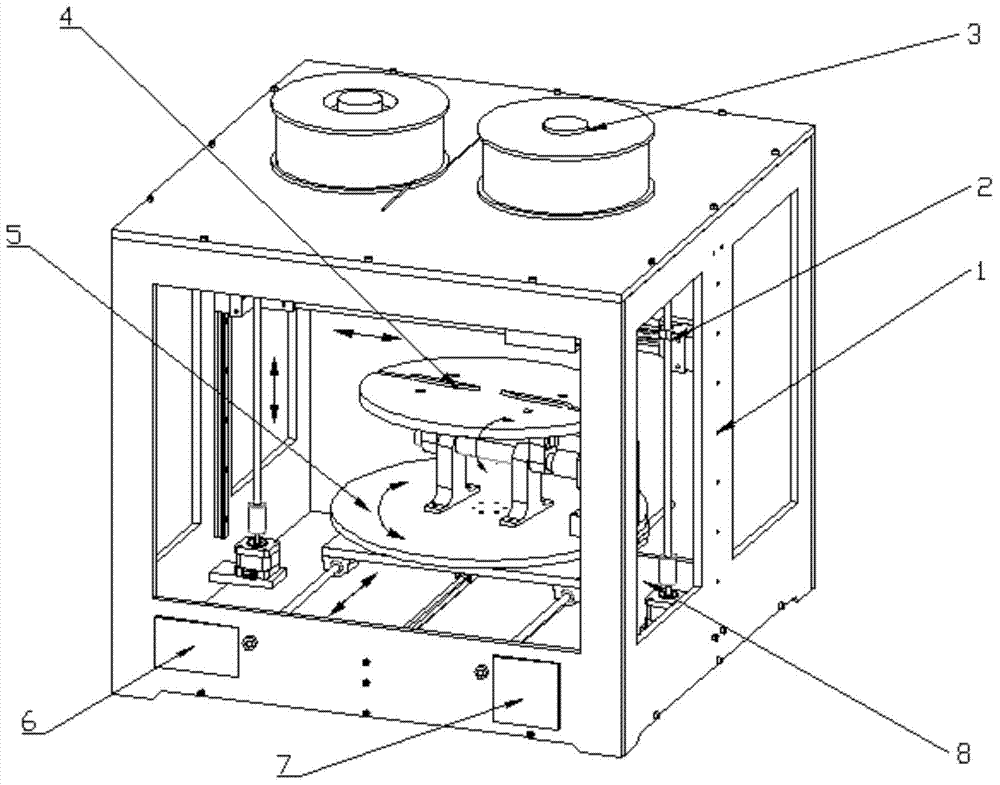

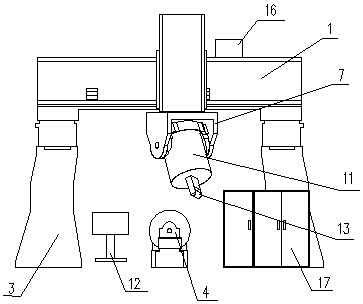

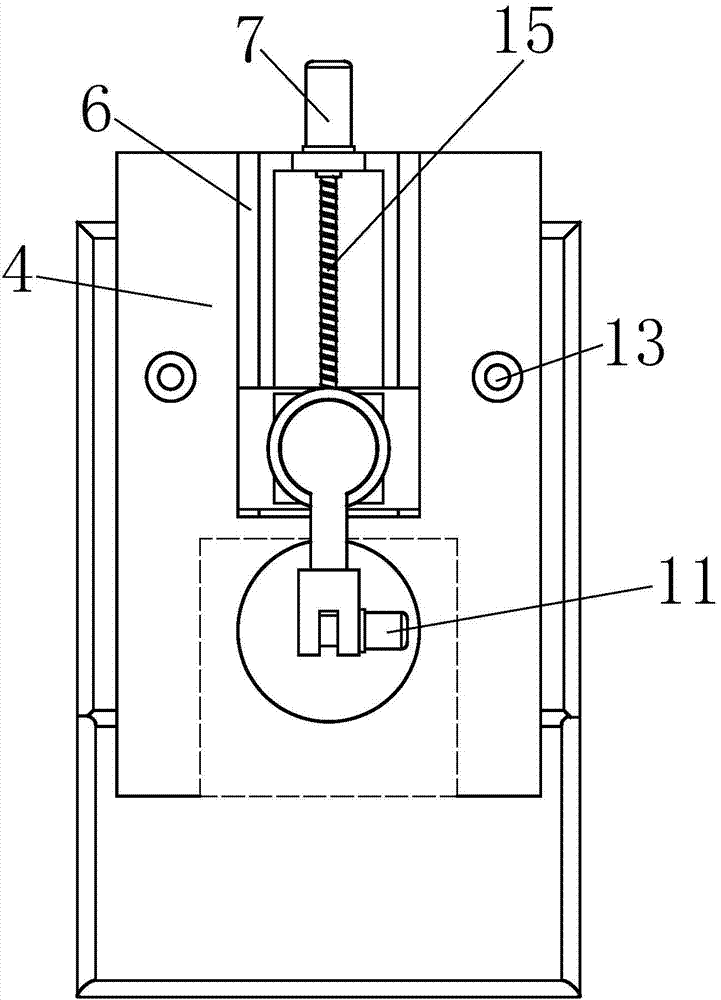

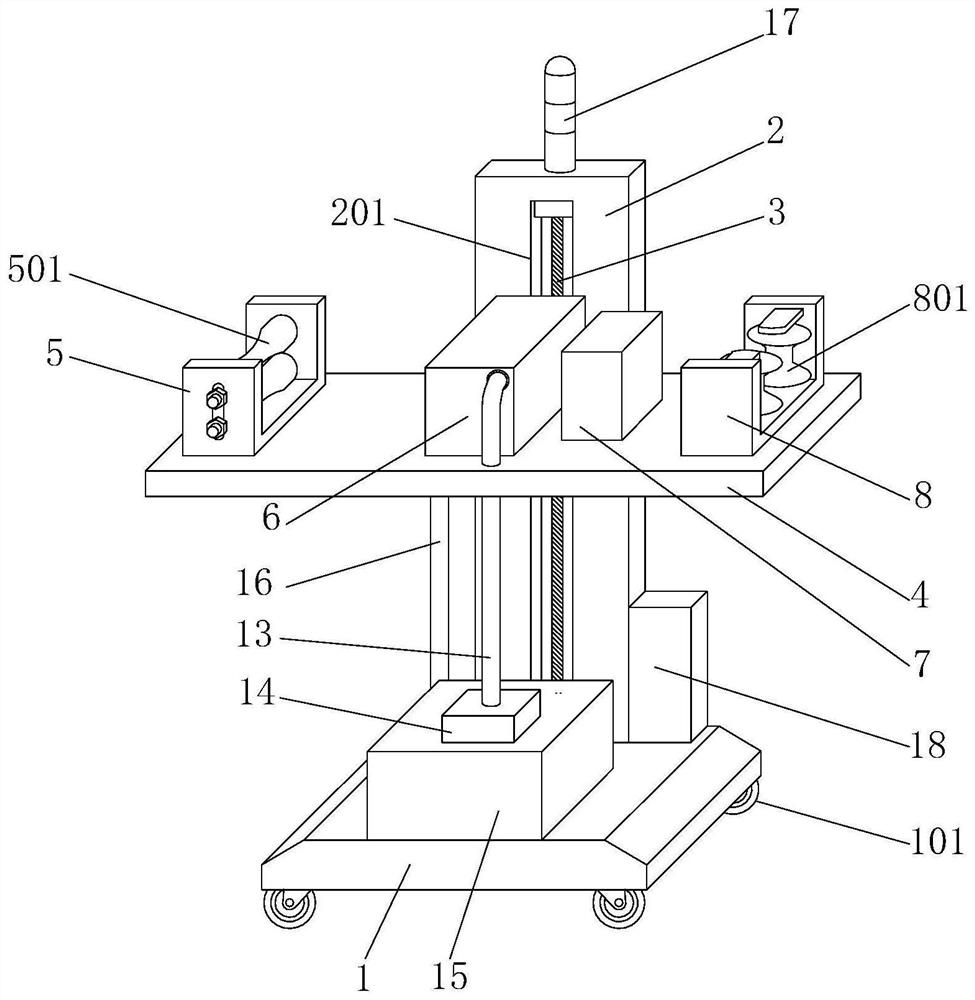

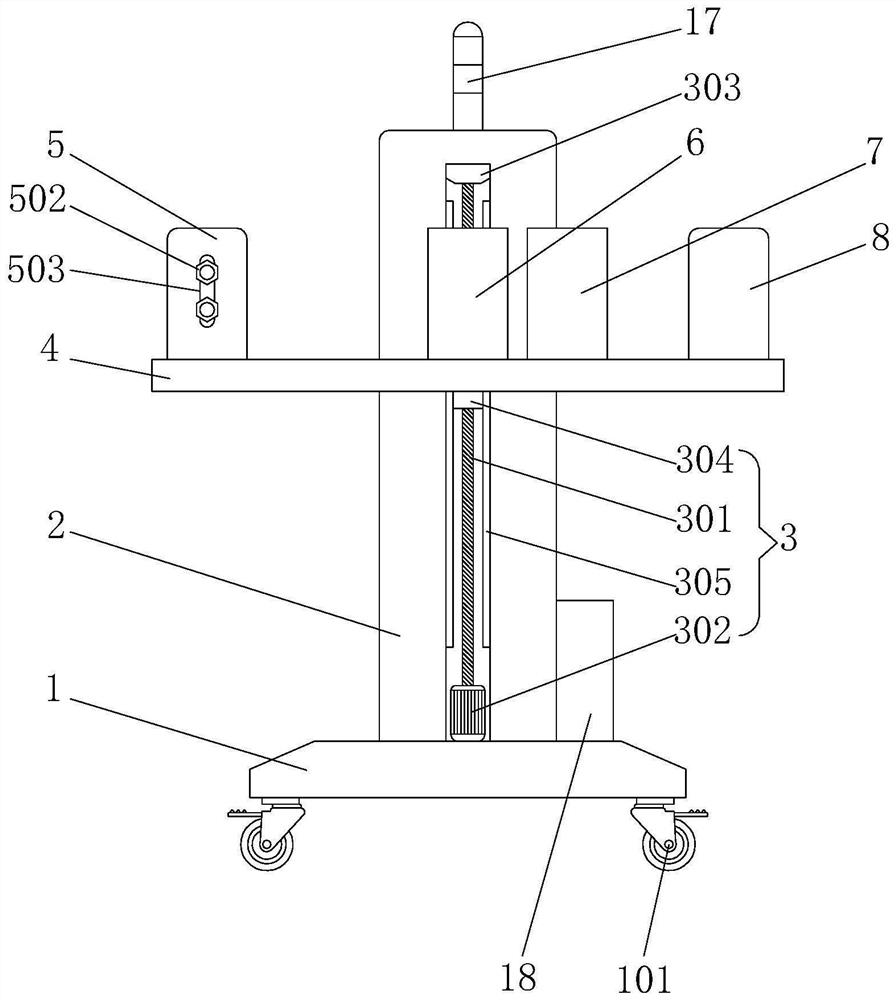

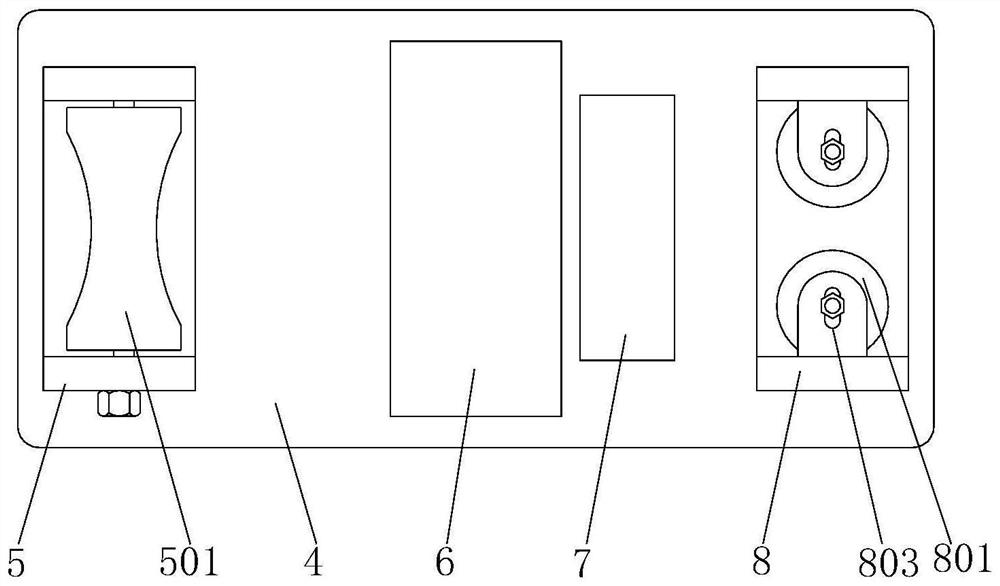

Five-freedom-degree rapid forming processing apparatus

InactiveCN104842557AEliminate the step effectImprove laying efficiencyAdditive manufacturing apparatusForm processingForms processing

The present invention discloses a five-freedom-degree rapid forming processing apparatus, which comprises a frame (1), material disks (3) on the top portion of the frame (1), an operating plate (6), a screen (7), and a control plate (8), and further comprises a two-freedom-degree spraying head assembly (2) capable of freely moving along X axis and Z axis, a clamping device (4), and a three-freedom-degree platform assembly (5) capable of freely rotating along Y axis, Z axis and A axis, wherein the operating plate (6) and the screen (7) are arranged on the bottom portion in front of the frame (1). With the five-freedom-degree rapid forming processing apparatus of the present invention, the step effect can be eliminated, the surface quality of the printed inclined plane can be increased, the processing efficiency on the circular cross-section parts is high, the processing on the spherical platform can be achieved, and the space utilization rate is good.

Owner:CHINA UNIV OF MINING & TECH

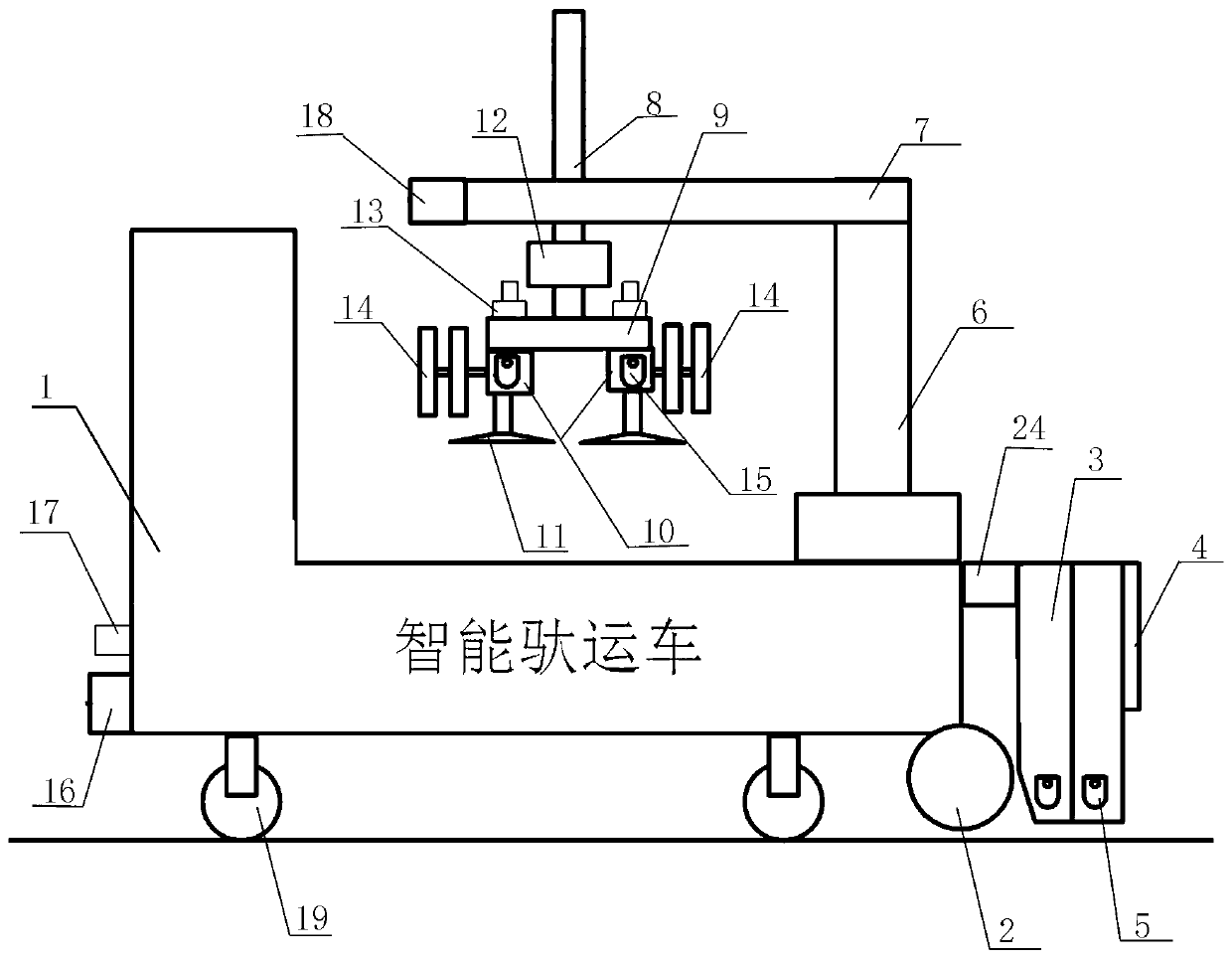

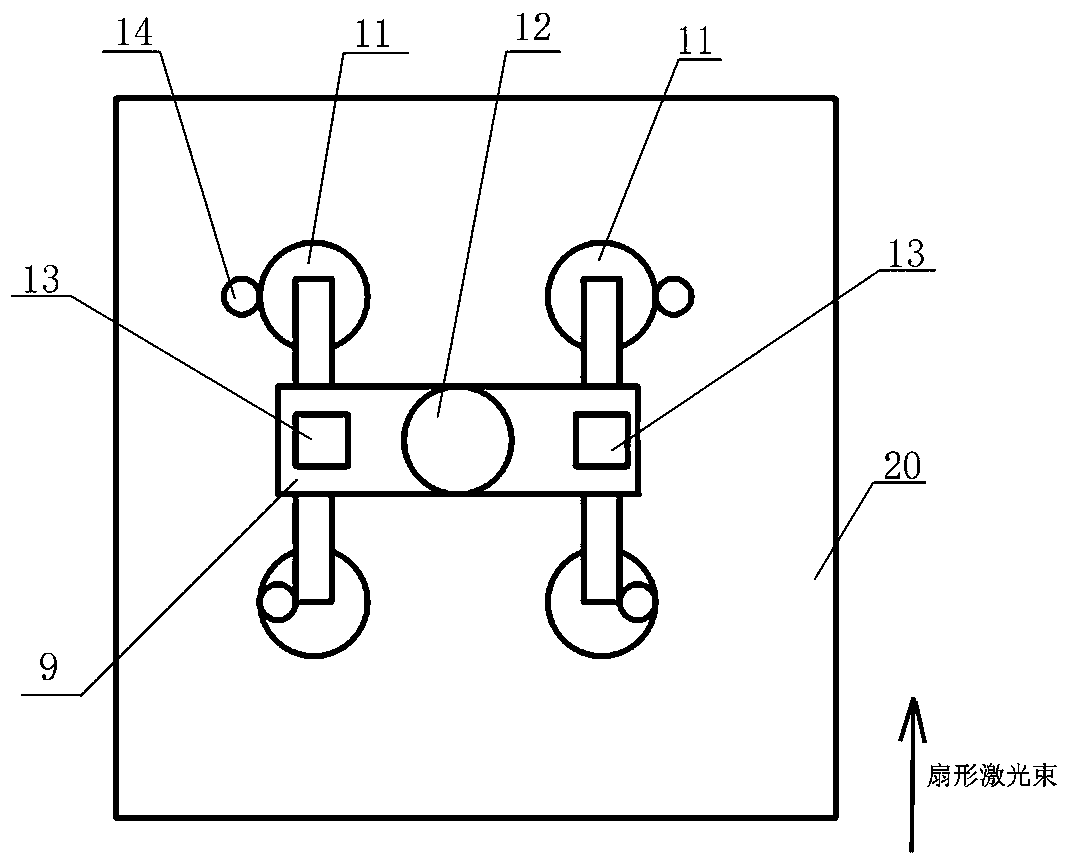

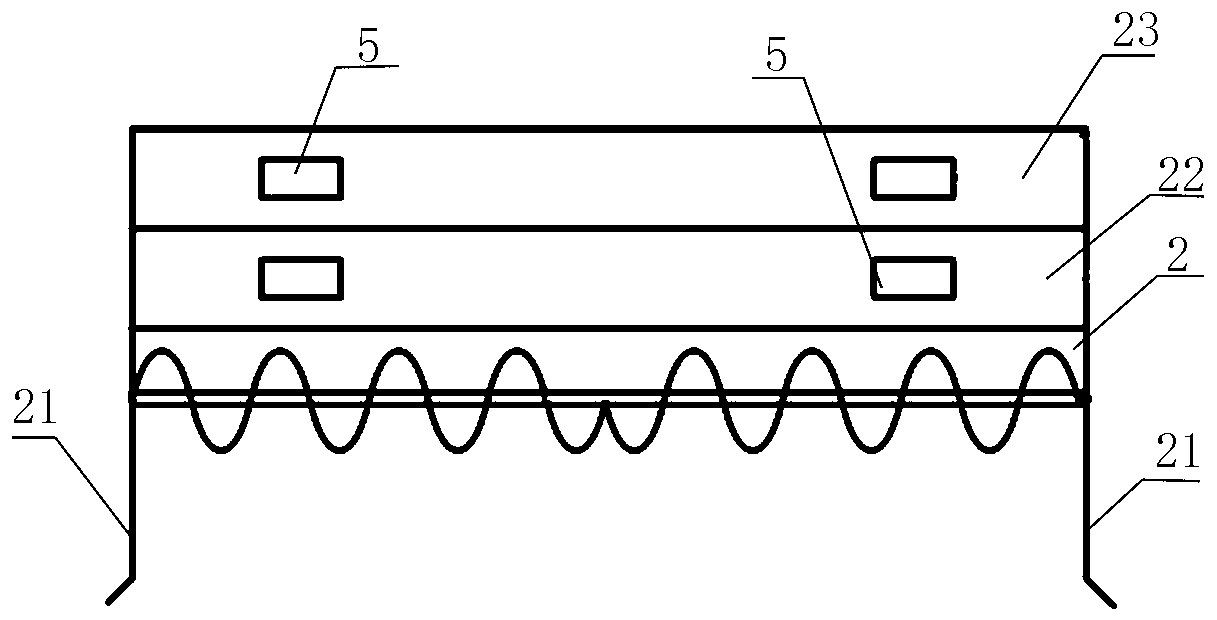

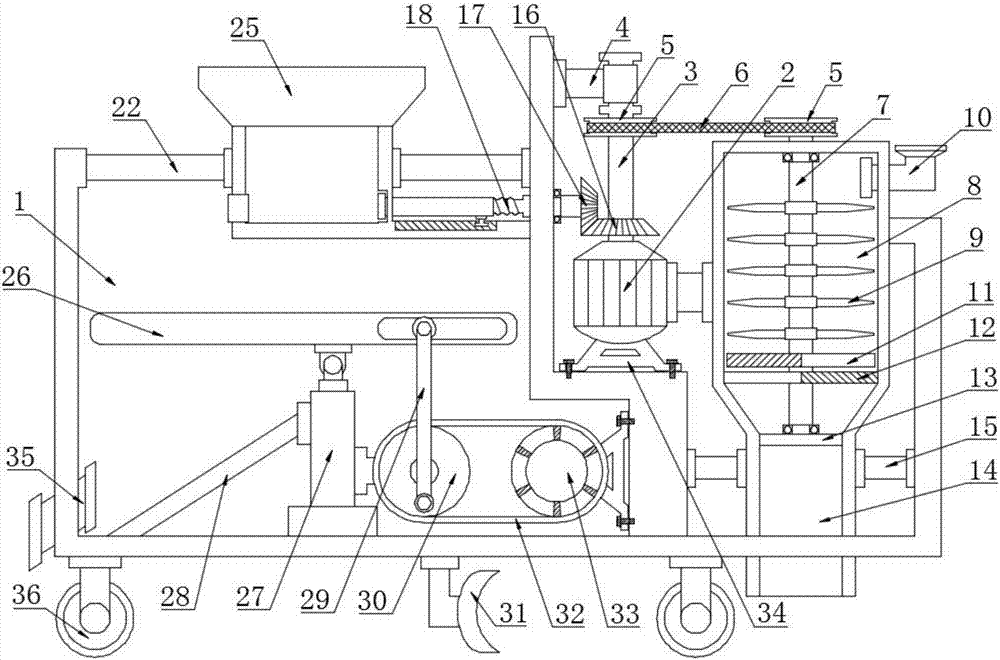

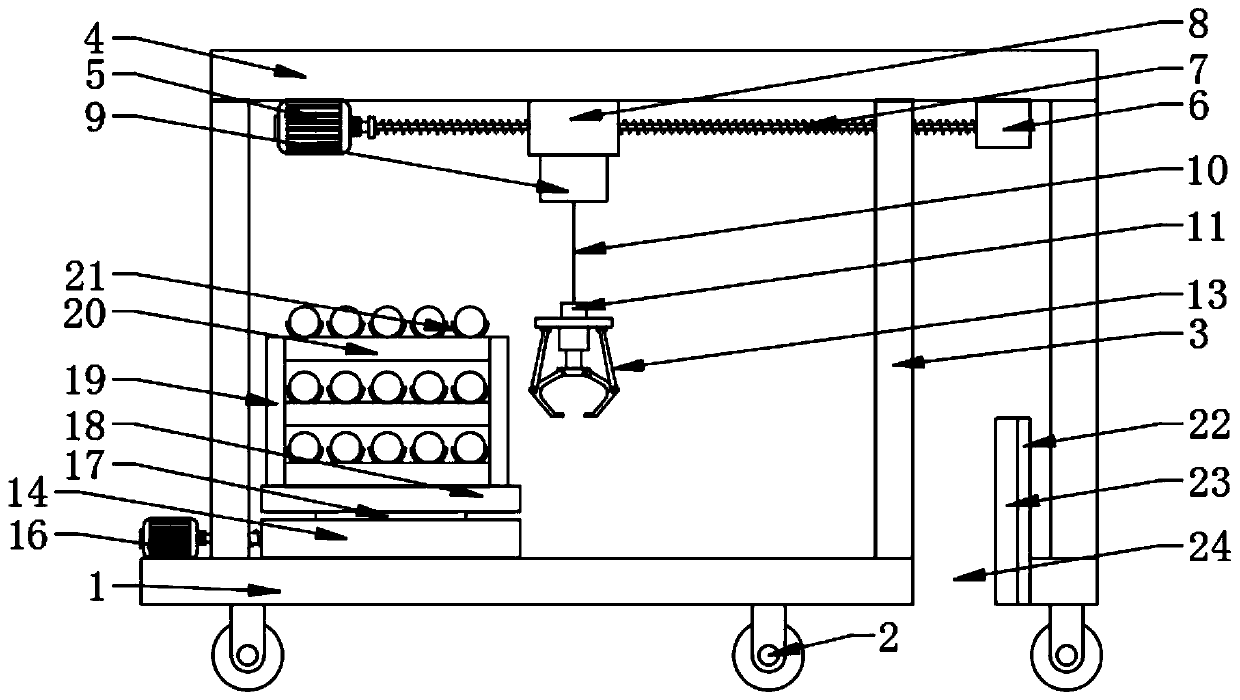

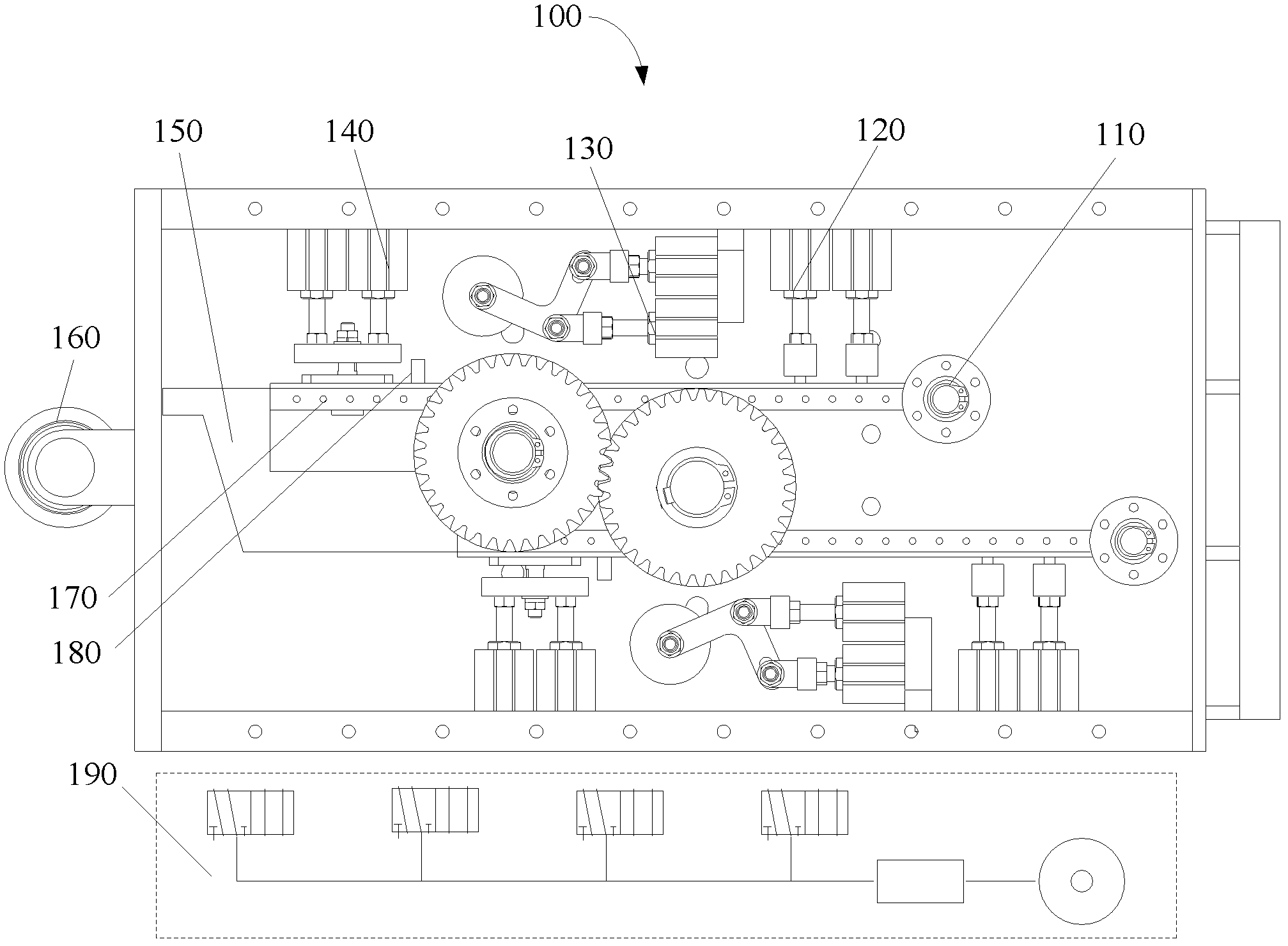

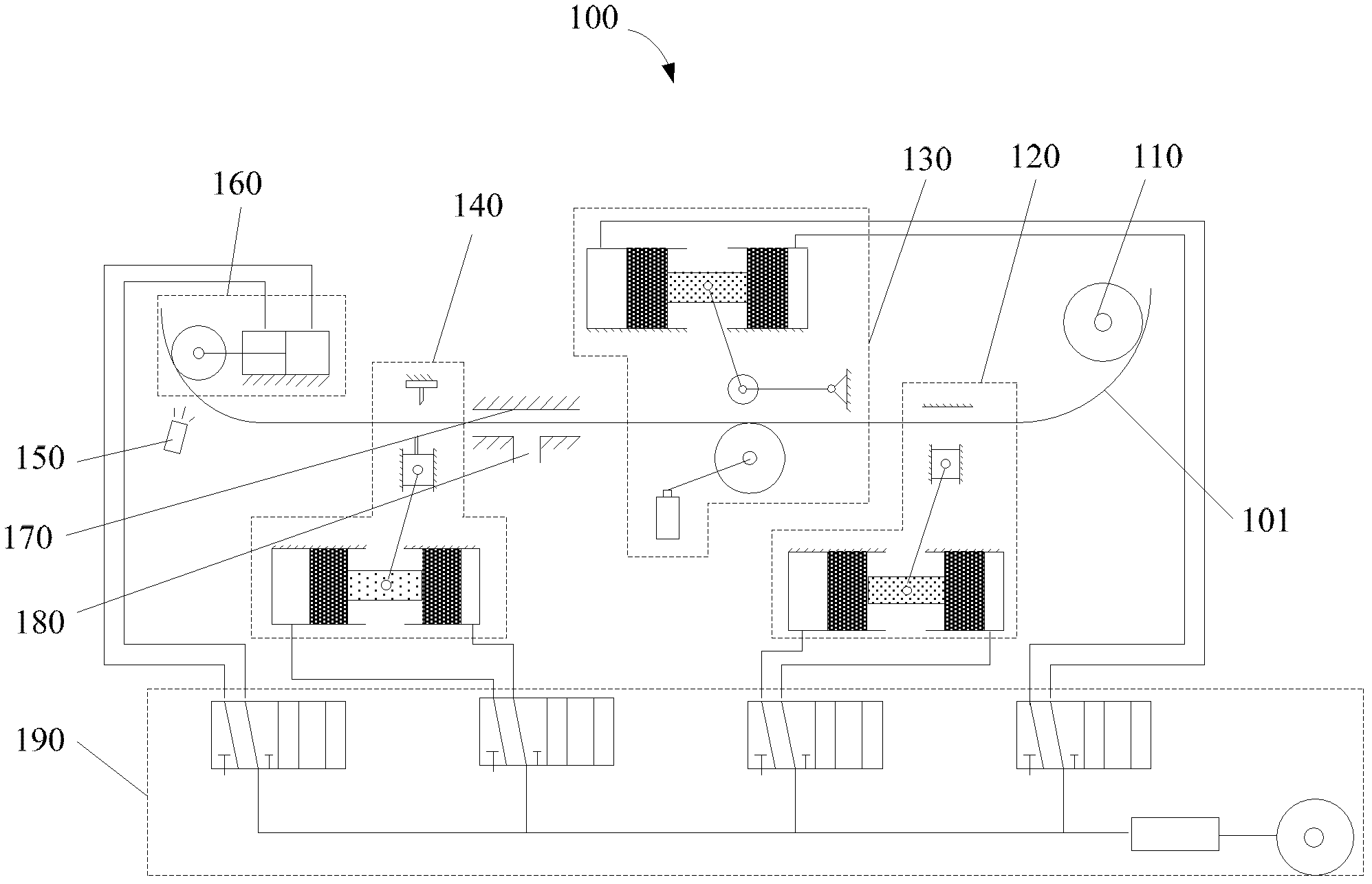

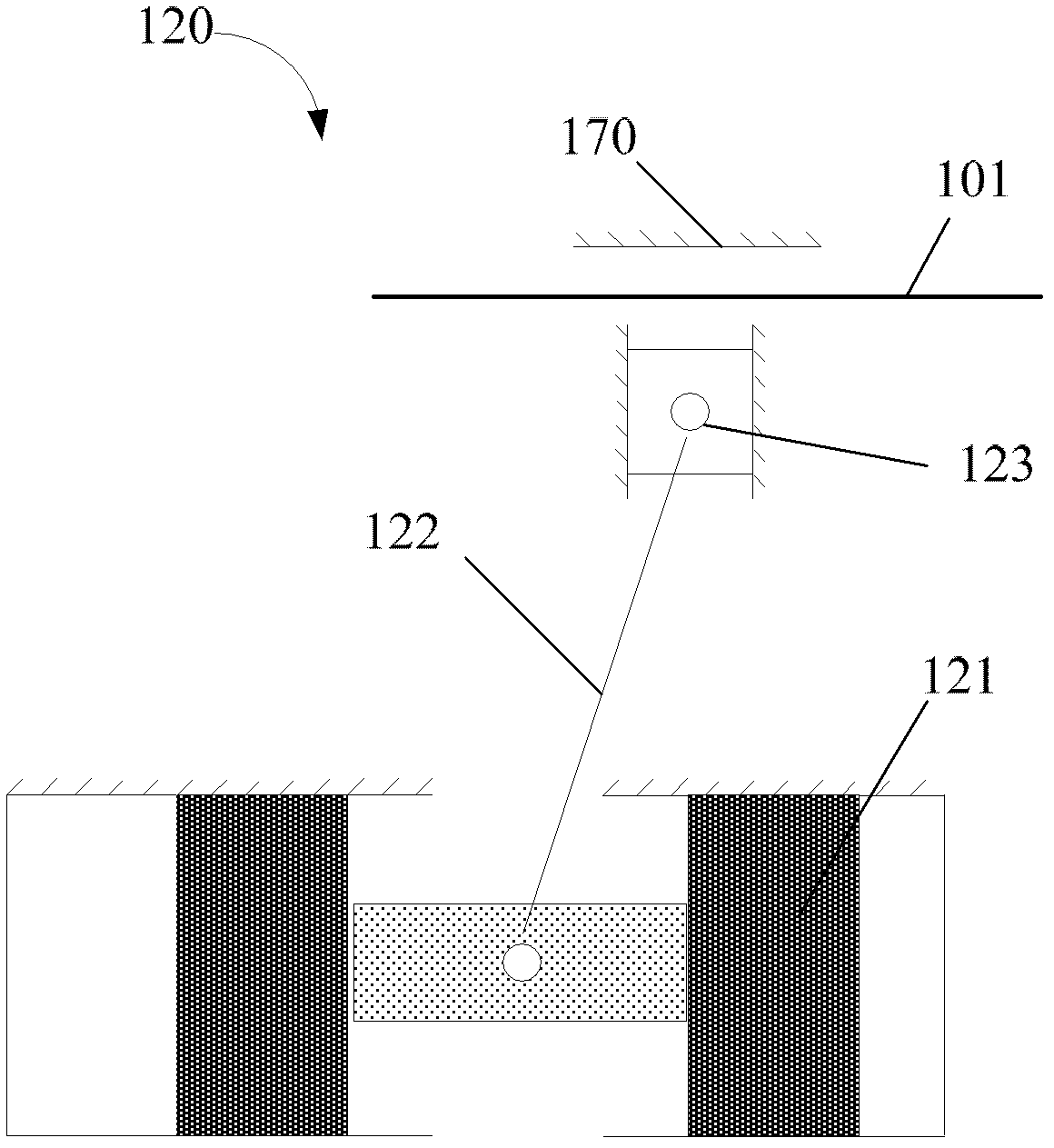

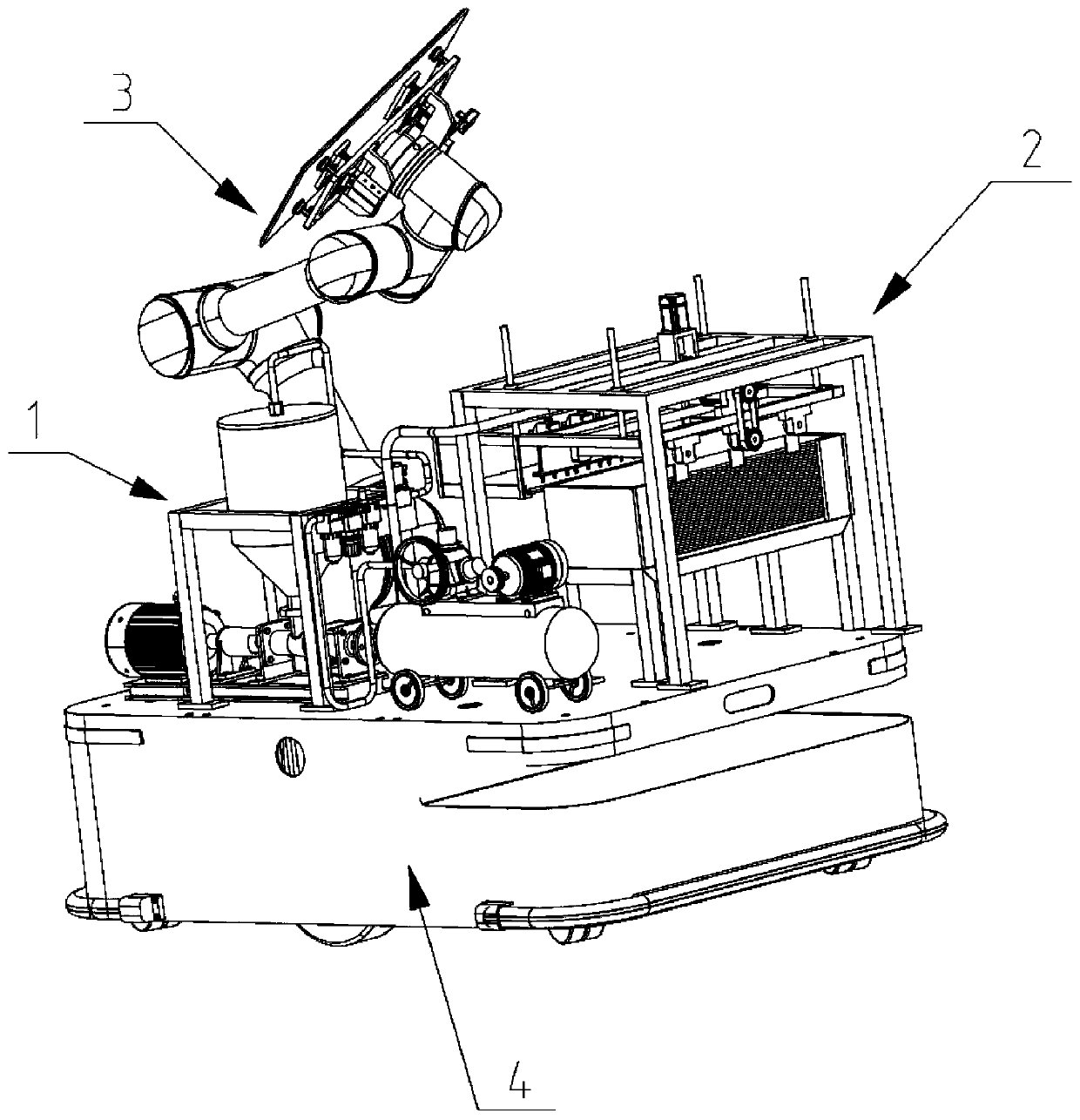

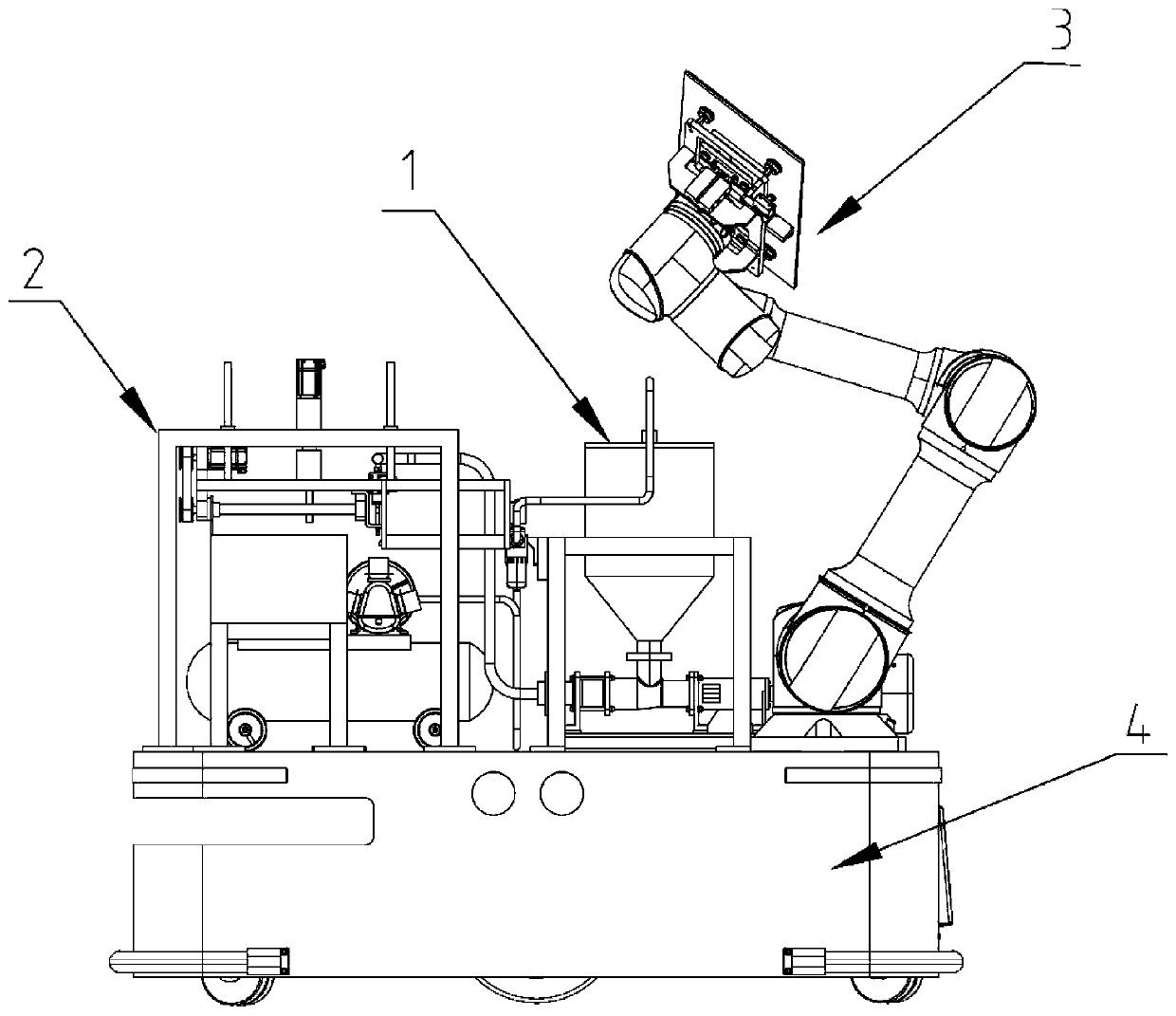

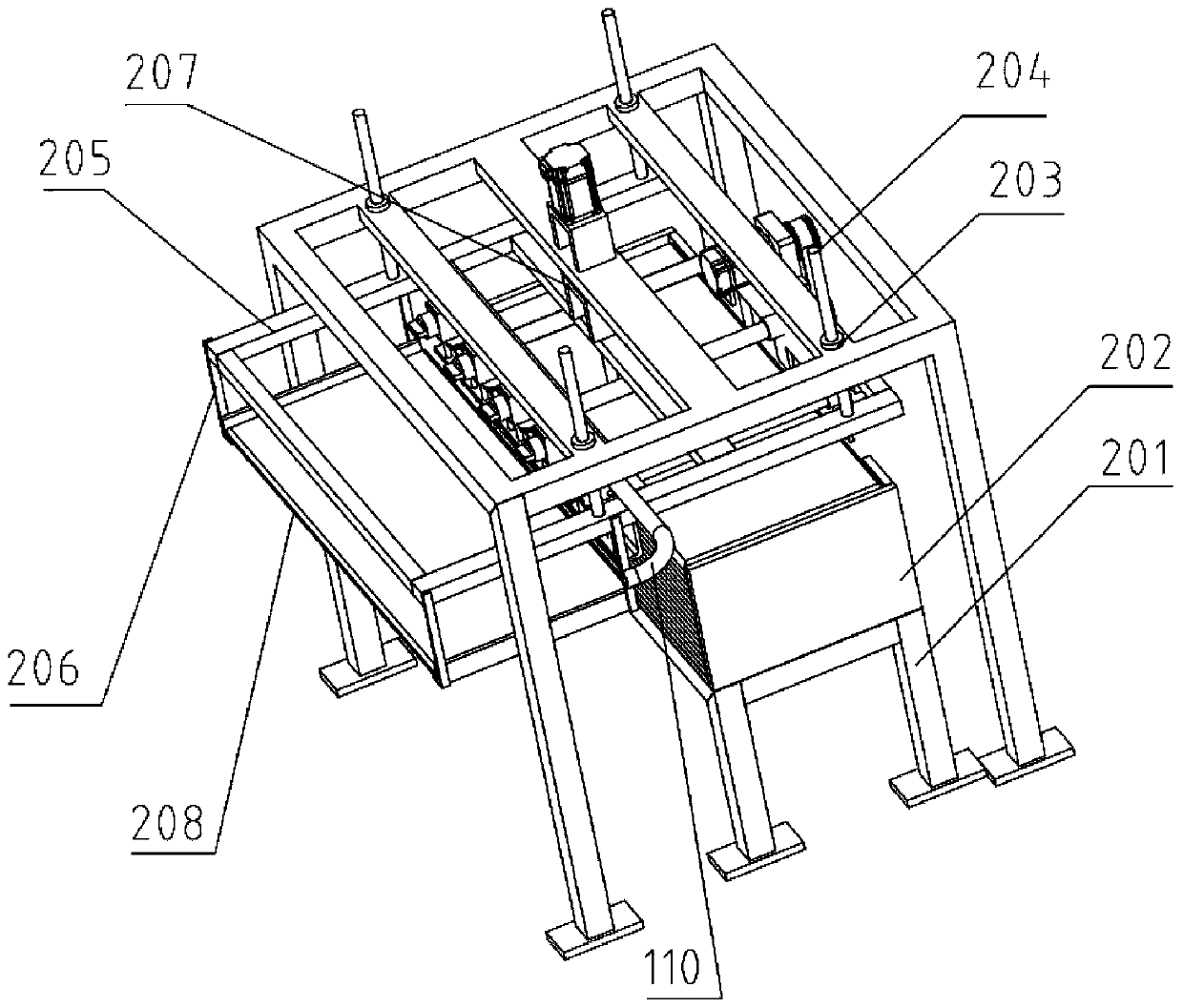

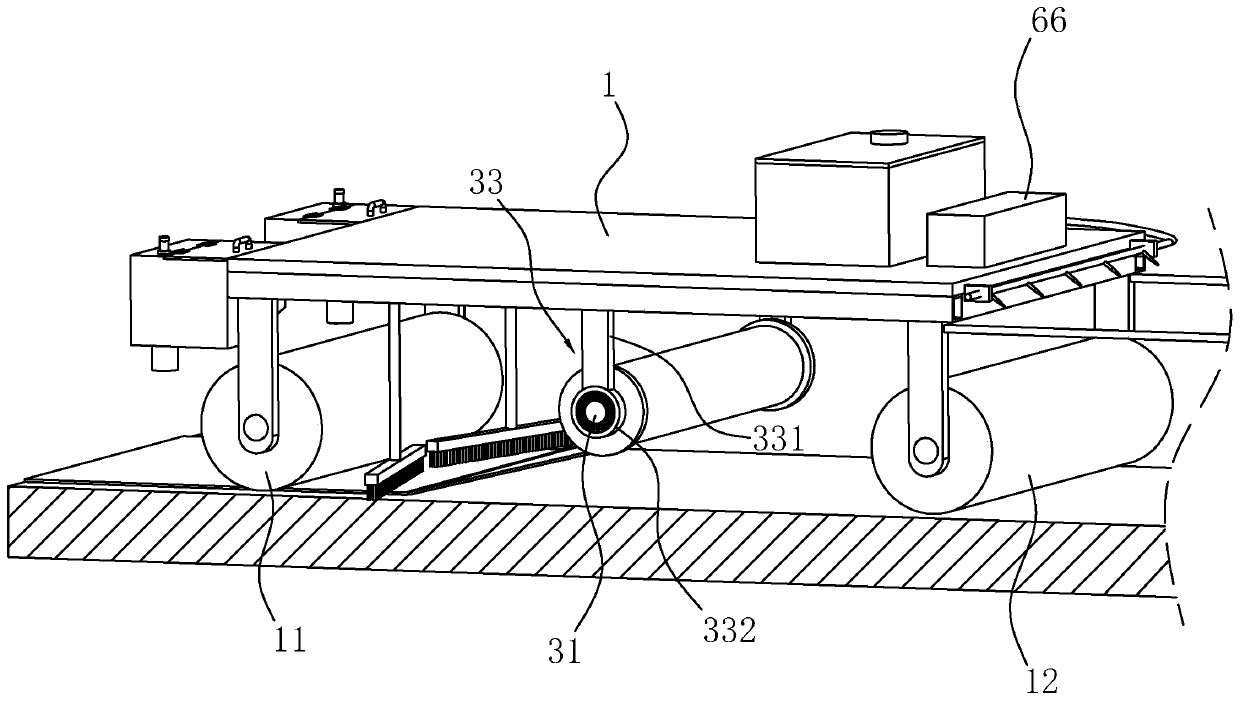

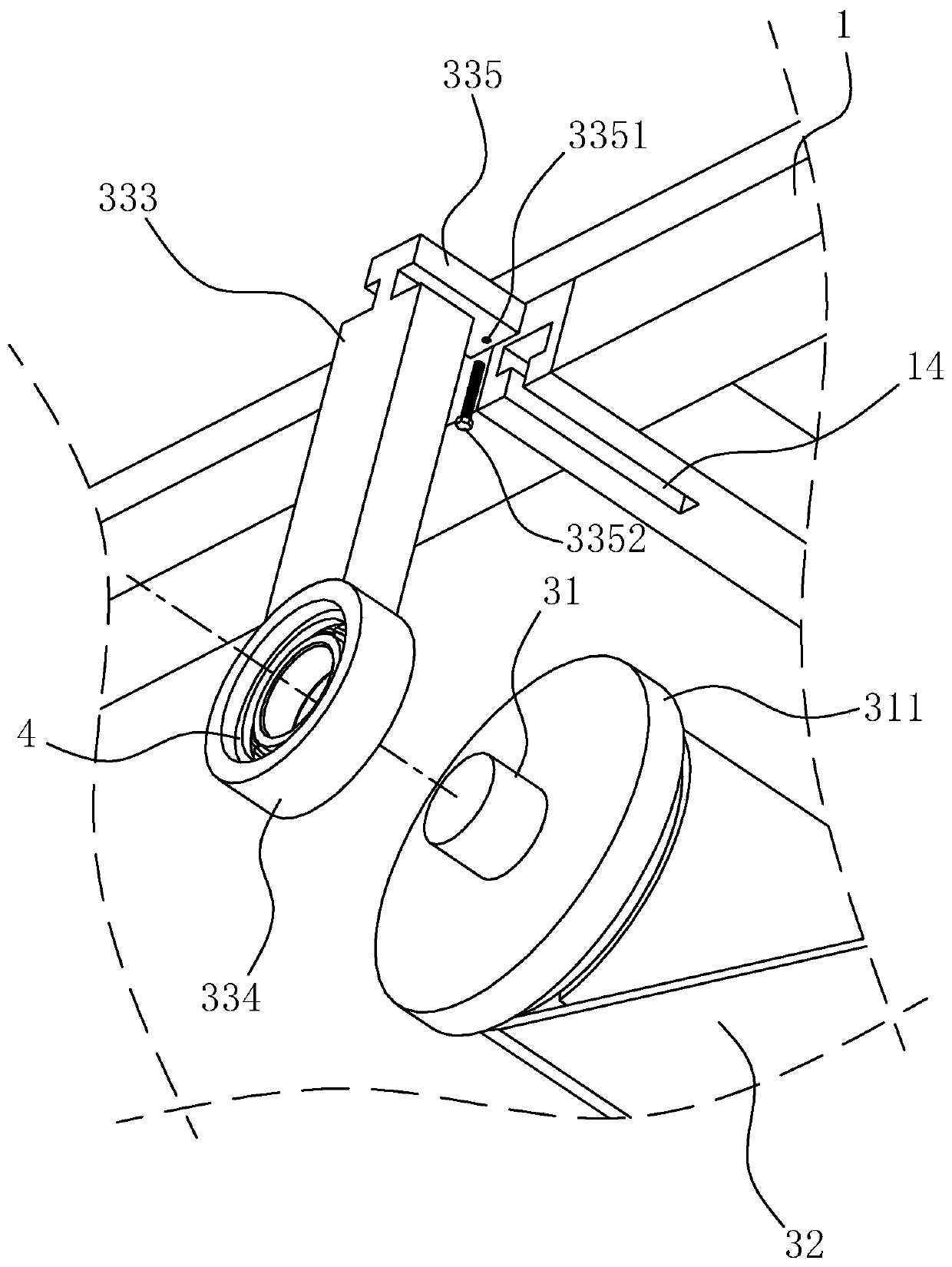

Full-automatic laying equipment and method for ceramic tiles

PendingCN109736554AAvoid hollowingImprove laying efficiencyBuilding constructionsMetallurgyDistributor

The invention discloses full-automatic laying equipment for ceramic tiles, comprising an intelligent carrying vehicle, a spiral distributor, a base material laying device, a ceramic tile grabbing device, a laser level and a visual detection device, the spiral distributor and the base material laying device are arranged behind the carrying vehicle, the laser level is used for forming a horizontal fan-shaped laser beam, and the visual detection device calibrates the driving direction of the intelligent carrying vehicle and the laying angle of ceramic tiles by collecting ground images. The tile laying method comprises the following steps: a) establishing a laser reference plane; B) controlling the carrying vehicle; C) laying a base material; D) detecting the height of the base material; E) carrying and transporting ceramic tiles; F) placing the ceramic tiles; and G)compacting the ceramic tiles. According to the full-automatic ceramic tile laying equipment and method, the hollowing phenomenon of laid ceramic tiles can be avoided, the technical problem that when the ceramic tiles are laid in a large area, the overall flatness is difficult to guarantee manually is solved, the labor intensity is reduced, and the laying efficiency of the ceramic tiles is improved.

Owner:SHANDONG JIAOTONG UNIV

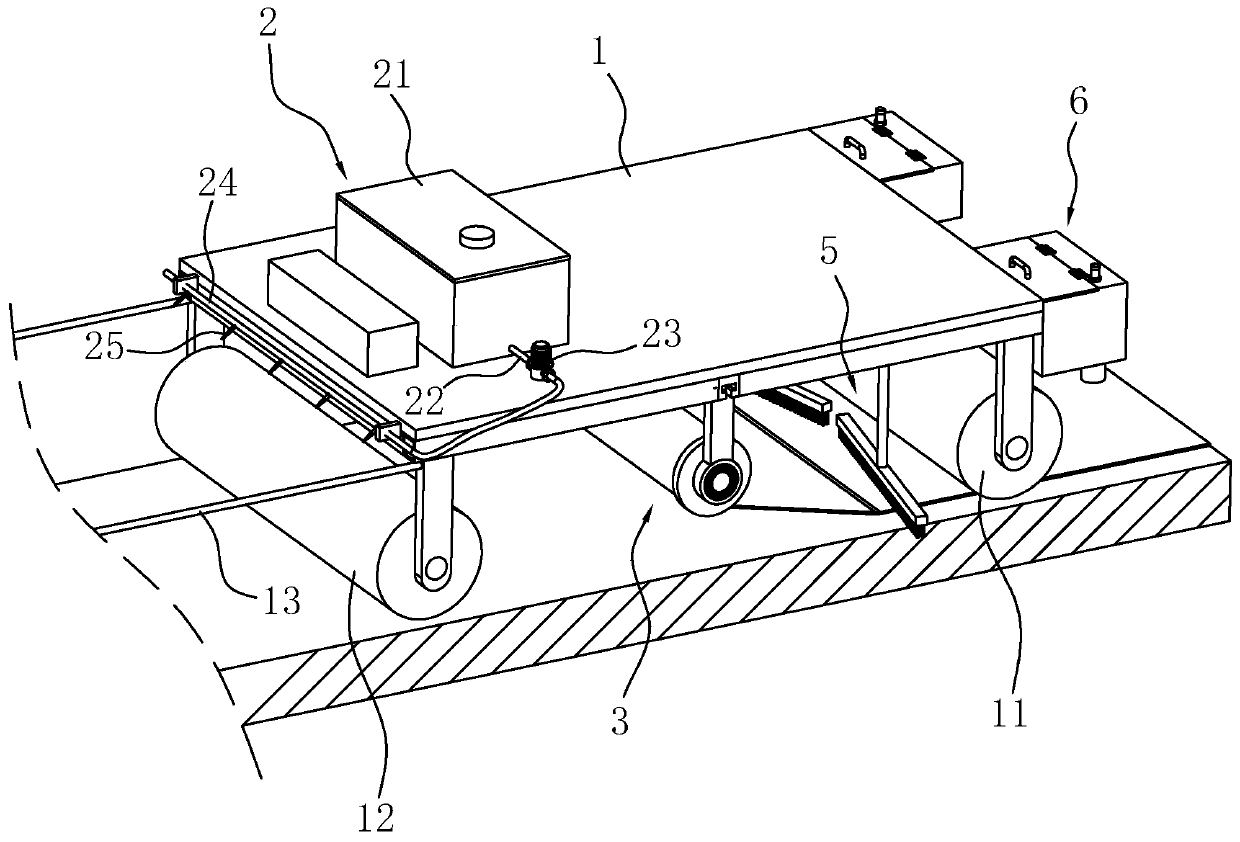

Paving device for floor tiles

ActiveCN109667415AHigh degree of automationImprove laying efficiencyBuilding constructionsSlurryMaterial resources

The invention relates to a paving device for floor tiles. Under a reversing action of a transition belt, floor tiles are conveyed to the front side or rear side of the paving device; the paved floor tiles are not ground during the advancing process of a trolley; a slurry paving device is additionally arranged, so that the two processes of paving slurry and paving floor tiles are respectively arranged in the reciprocating process; during the process of paving floor tiles, a reduction box is connected with an axle end of a wheel and an output shaft of the reduction box is connected with a triggering device through a first driving lever, so that the floor tiles are paved on the paved slurry under a synergistic effect of a first rack, an electric expansion link and a gripping device; due to the existence of reduction box, the intervals of paved floor tiles can be manually adjusted; the paving device is high in practicability; the paving device has a smart structure and is capable of greatly increasing degree of automation of floor tile paving, saving a large quantity of manpower and material resources and greatly increasing paving efficiency of floor tiles.

Owner:ZHENGZHOU NO 1 CONSTR ENG GRP

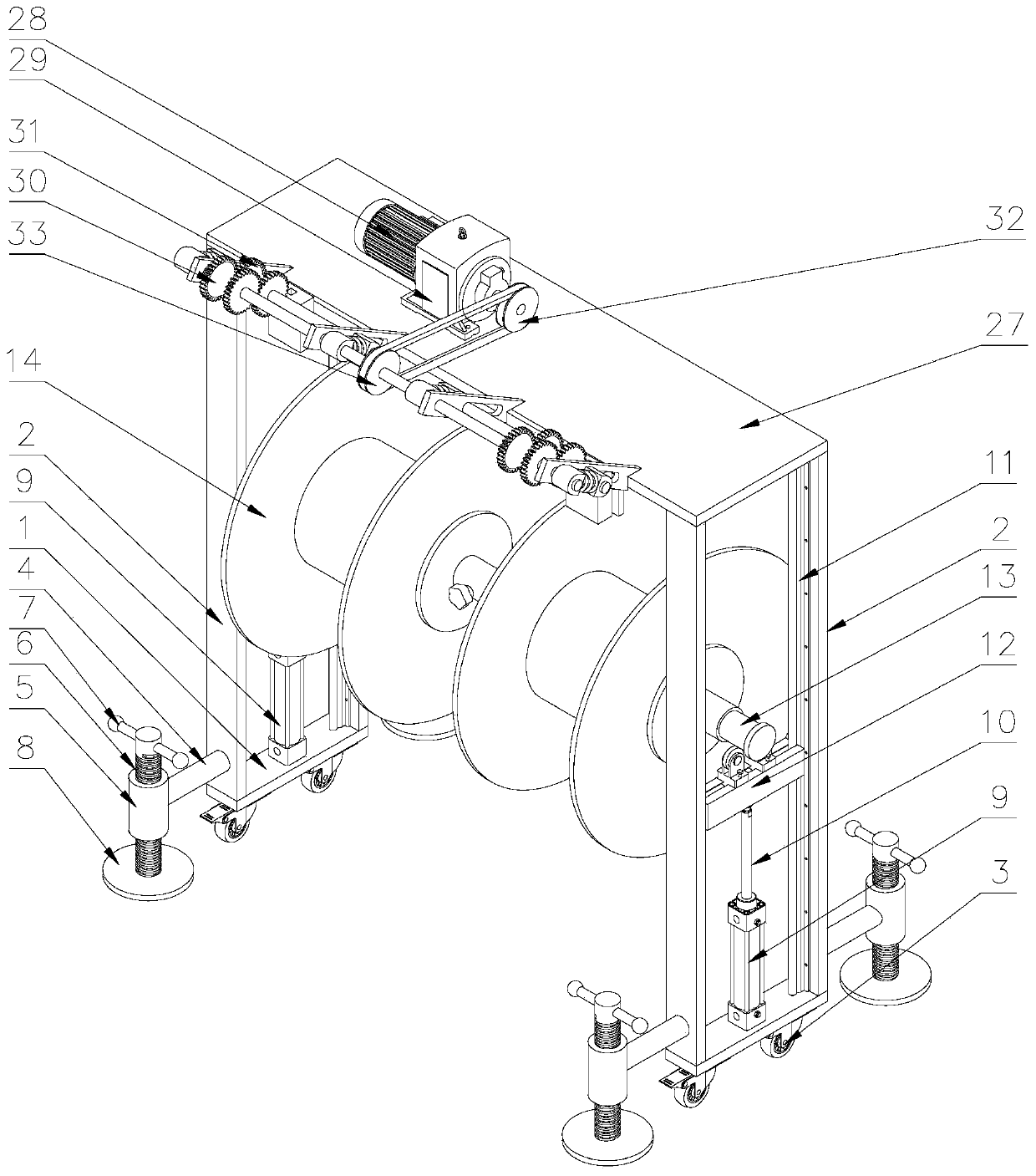

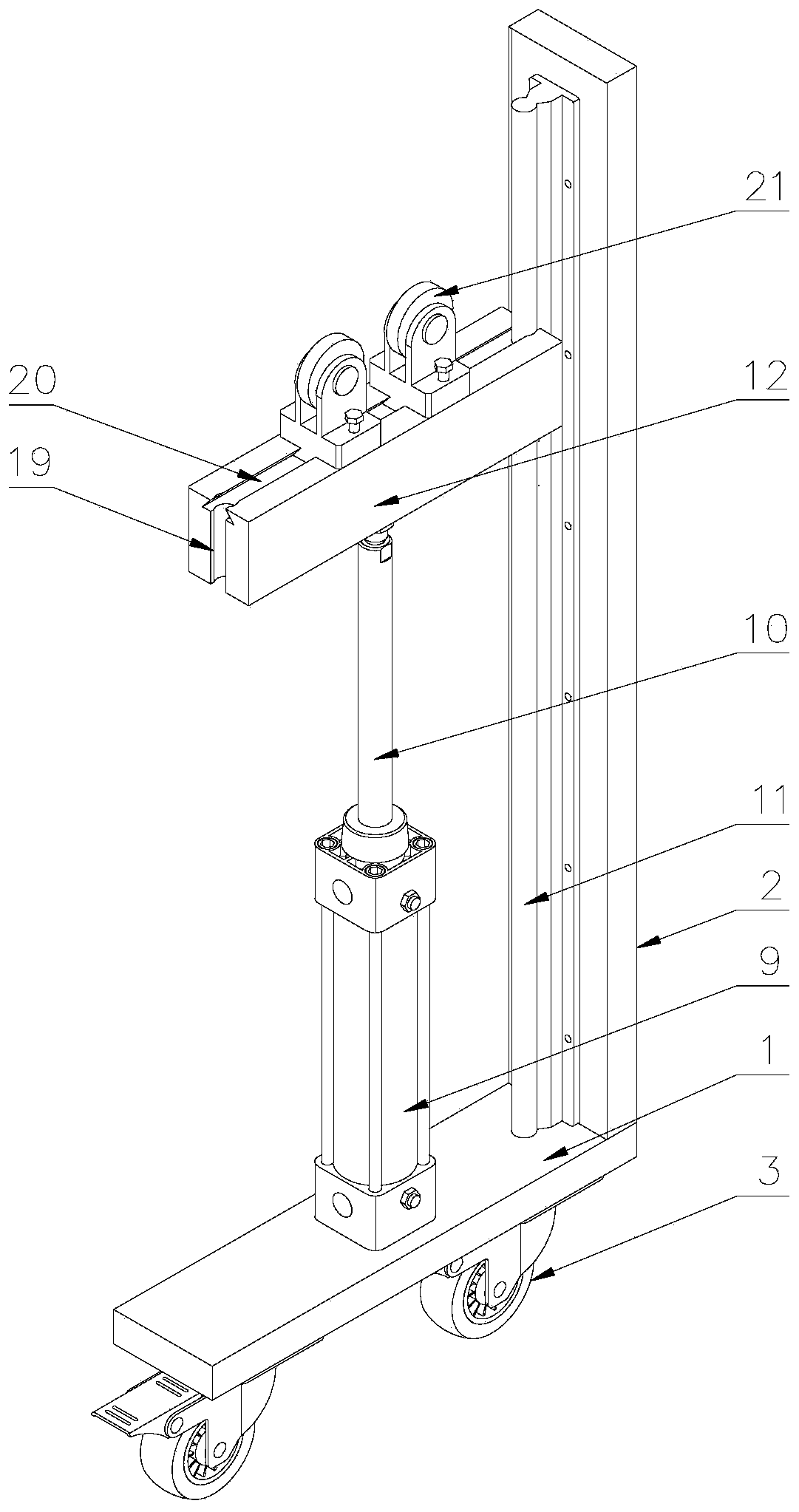

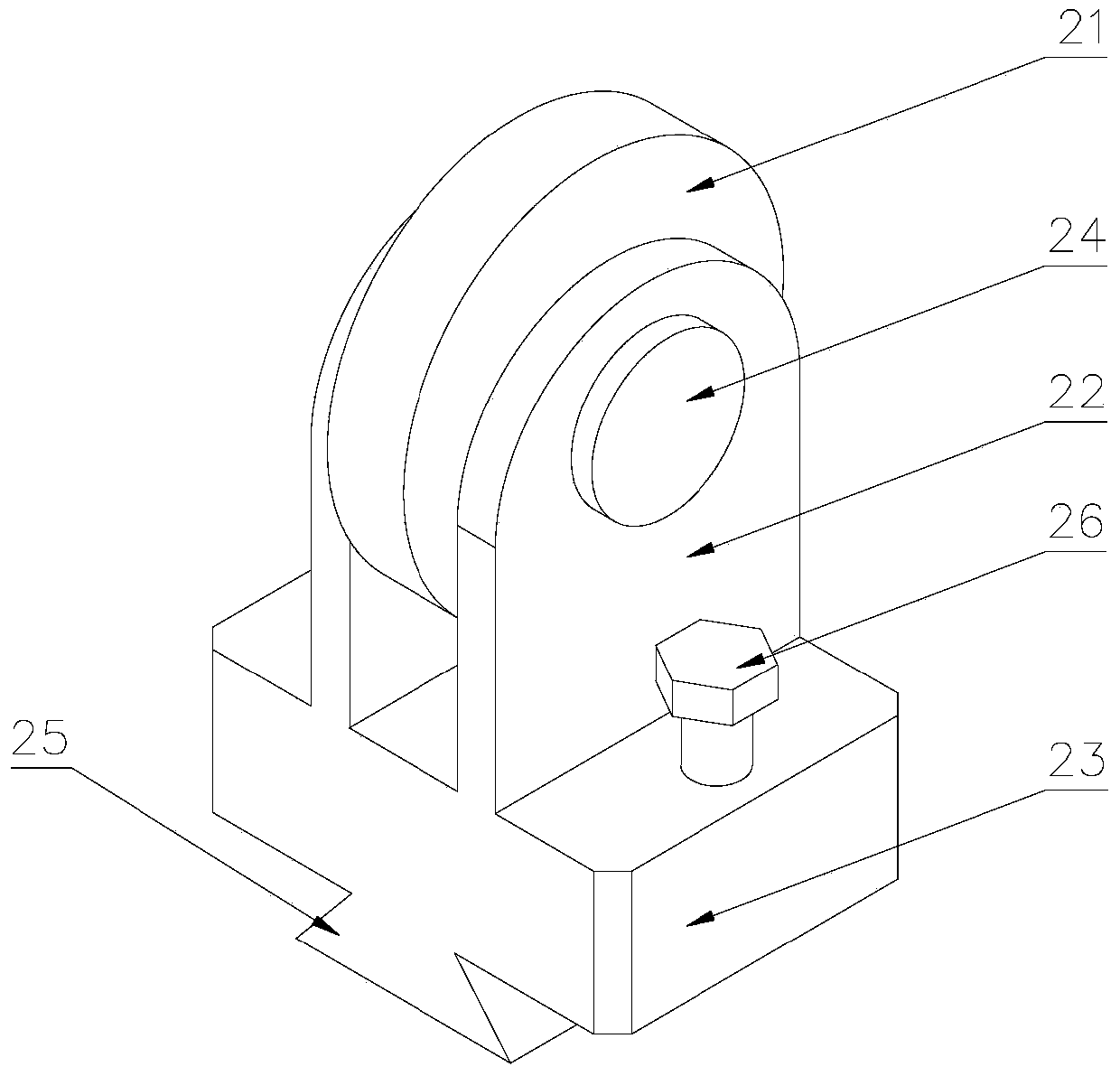

Cable pay-off device for power construction

ActiveCN110061451AReduce difficultyImprove laying efficiencyApparatus for laying cablesEngineeringConductor Coil

The invention discloses a cable pay-off device for power construction. Vertical posts are arranged at two ends of a bottom plate, a guide rail is arranged at one side of each vertical post, an air cylinder is fixedly arranged on the bottom plate, a first sliding block is arranged at an upper end of a piston rod of the air cylinder, upper ends of the vertical posts at two sides are connected by a top plate, two ends of a second connection rod are placed on the first sliding block, a plurality of cable discs are arranged on the second connection rod, a plurality of second supports are arranged at one side f the top plate, a first rotation shaft is arranged on the second supports, a plurality of winding wheels are movably arranged on the first rotation shaft, the numbers of the first windingwheels are equal to the numbers of the cable discs, and the first winding wheel slides among the second supports along an axial direction of the first rotation shaft. The cable disc is jacked up by the air cylinder, the cable disc is prevented from being contacted with ground, so that the friction between the cable disc and the ground is prevented, and the cable pay-off difficulty is reduced; andmoreover, multiple groups of cable discs are arranged on the second connection rod and are used for unwinding, the labor intensity of a worker is reduced, and the cable laying efficiency is greatly improved.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

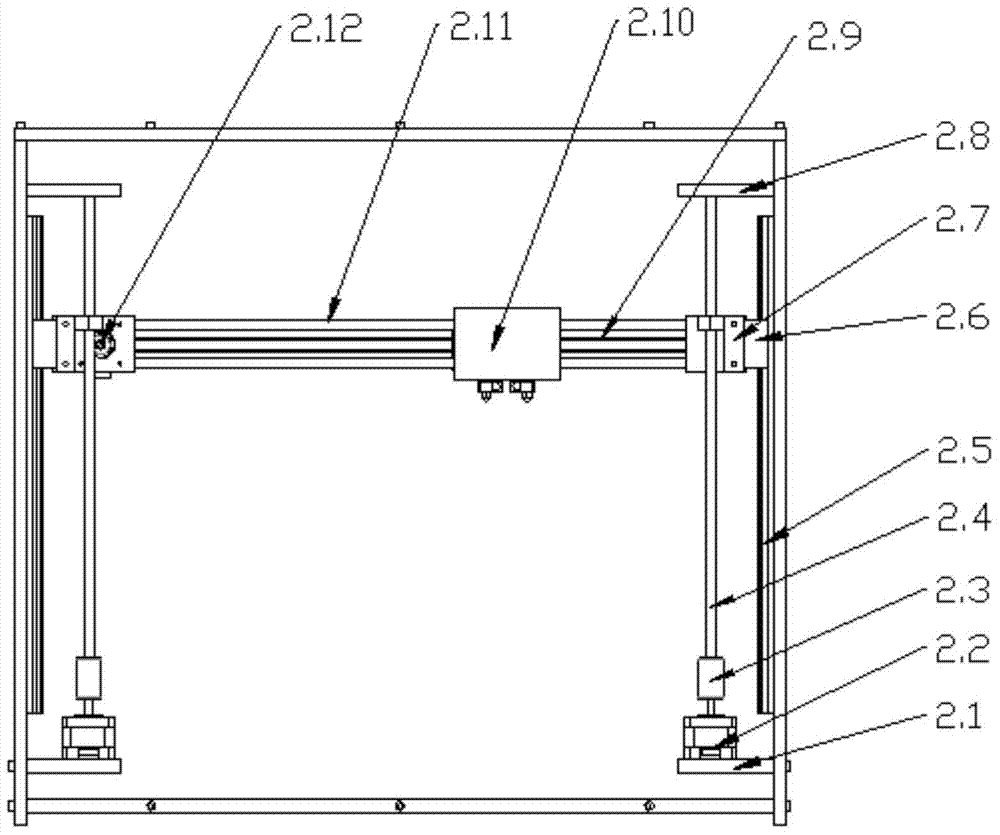

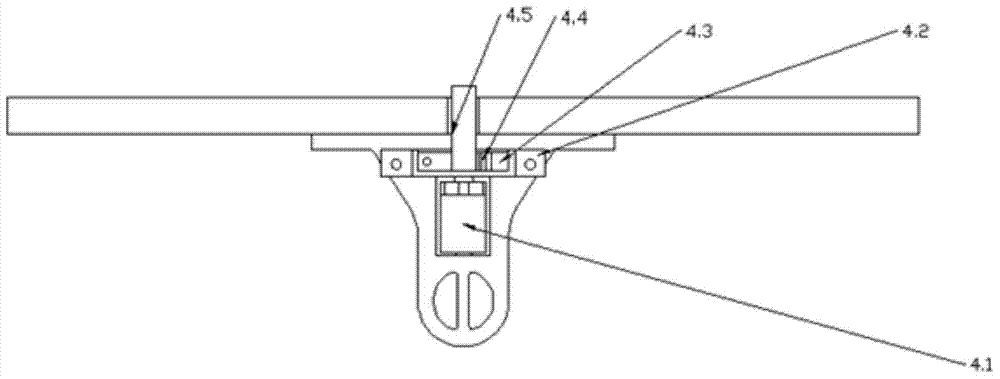

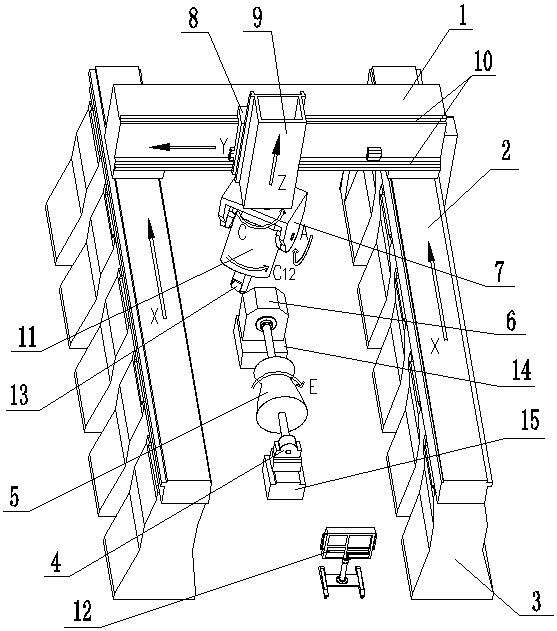

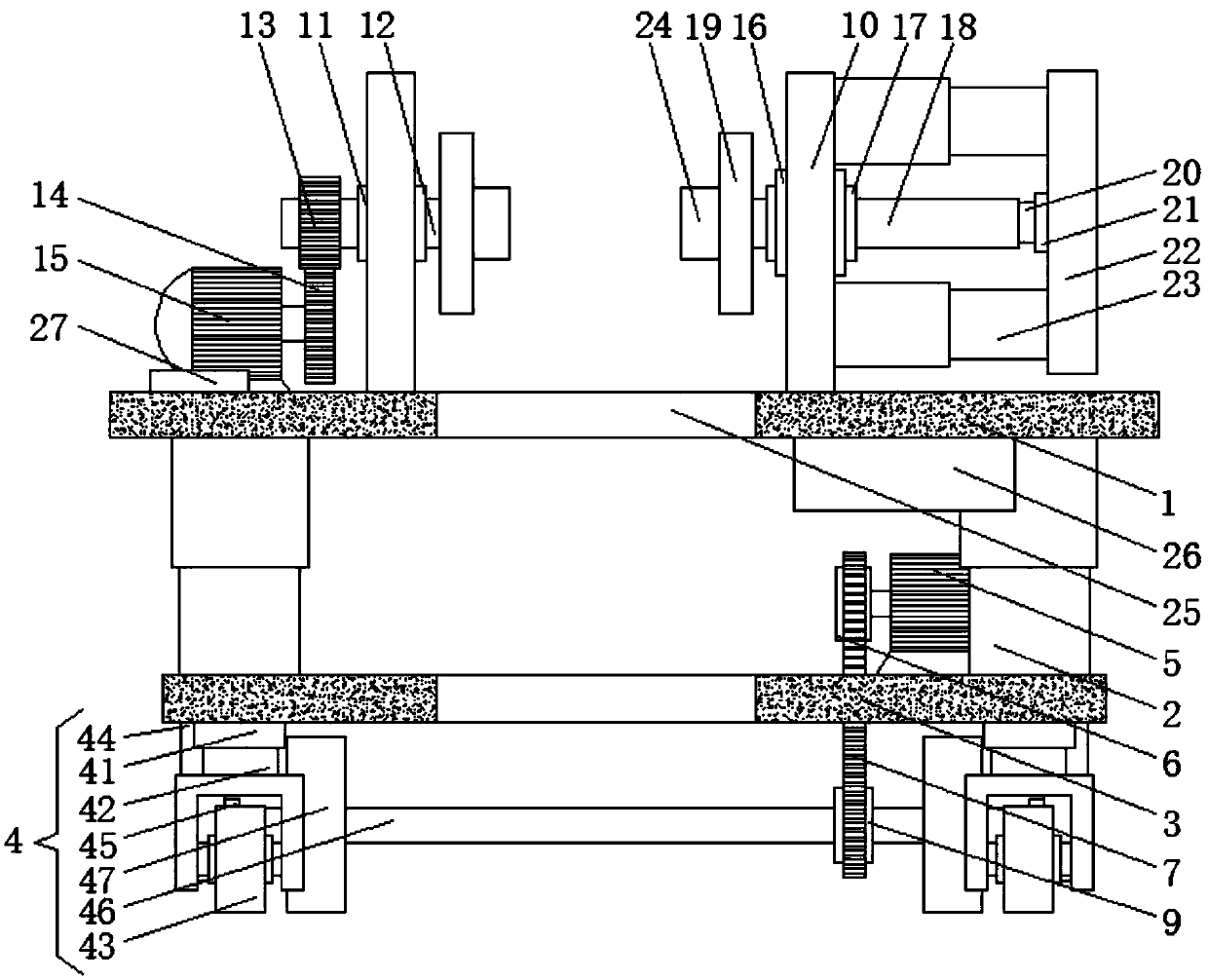

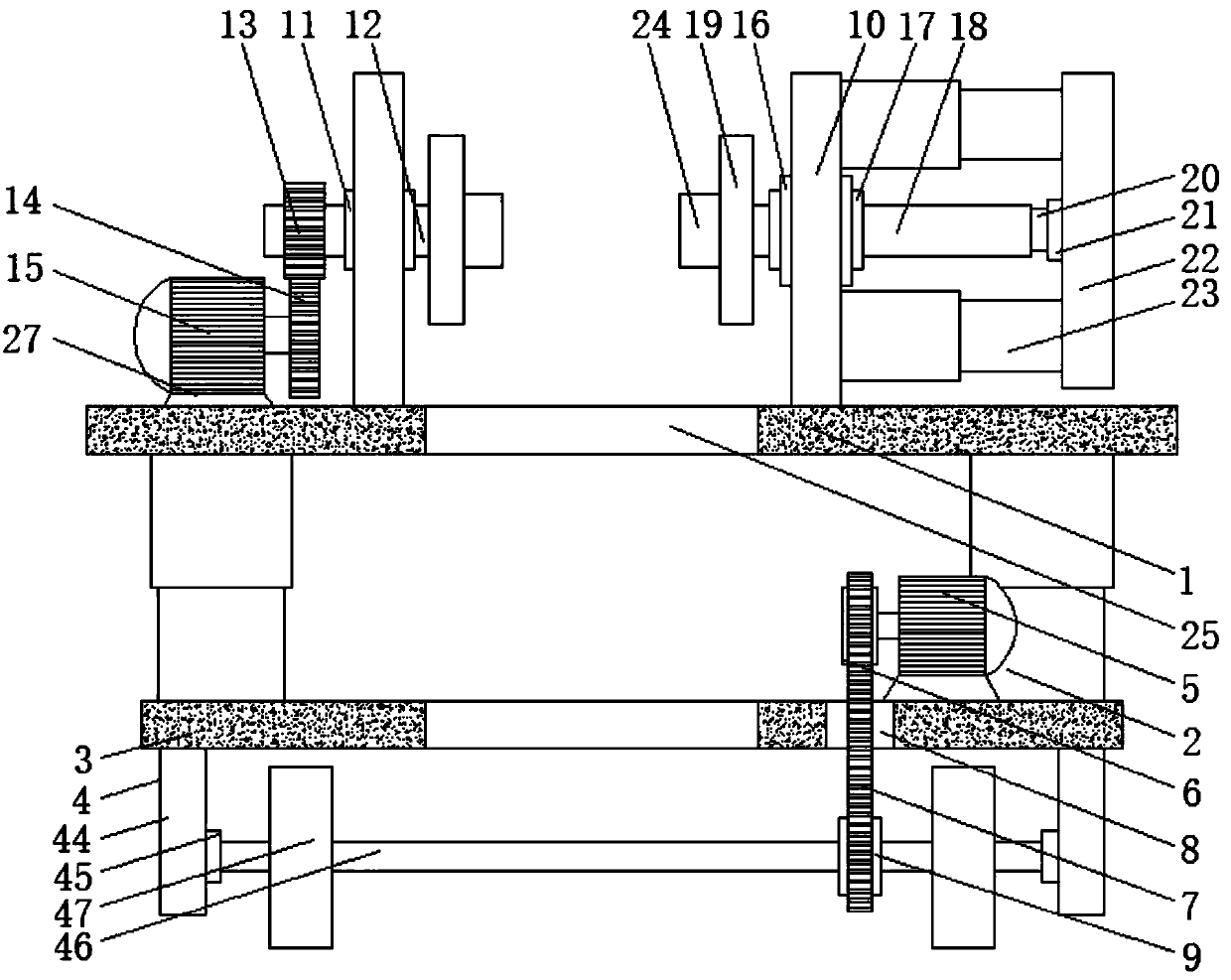

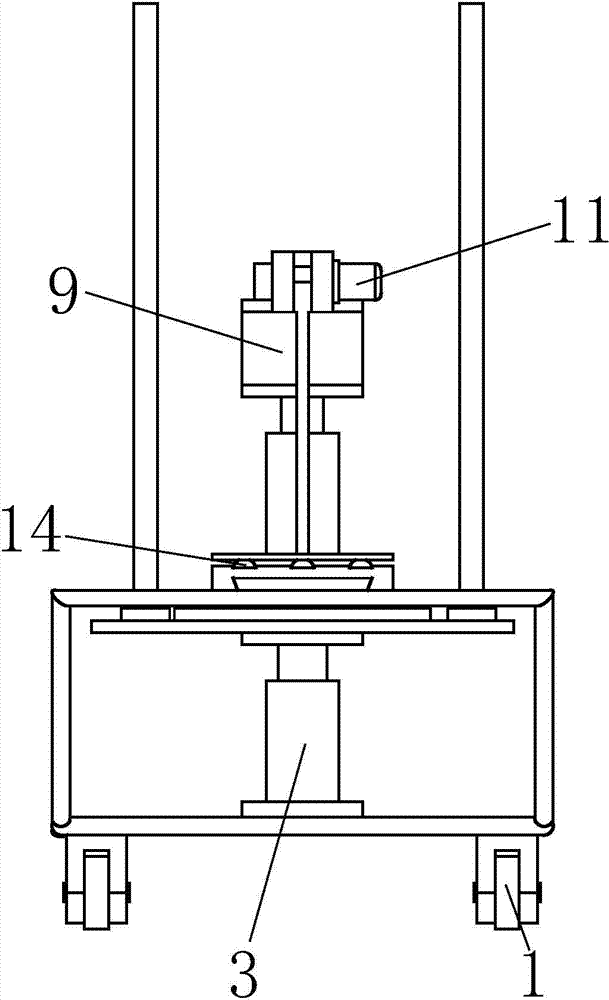

Automatic fiber placing device for placing fibrous composite material

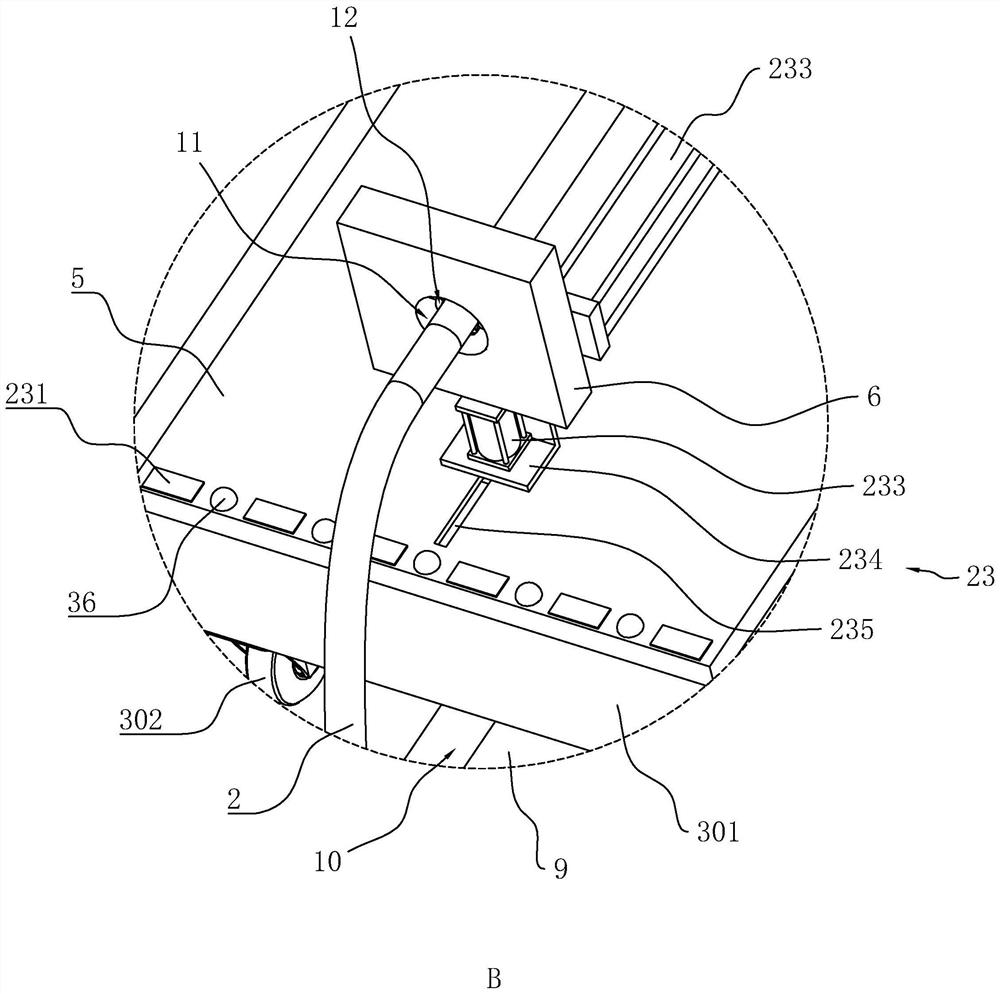

PendingCN108422685ATurn freely and convenientlyGuaranteed rotation attitude at any angleHead pressingControl system

The invention discloses an automatic fiber placing device for placing a fibrous composite material. Two servo motors A drive two output gears to be rotated along an X-directional long rack, so a crossbeam is driven to be slid along a longitudinal beam; a servo motor B drives a sliding base to be slid along the cross beam; a servo motor C drives a Z-directional screw rod to be rotated, so a ram isdriven to be upwards and downwards slid along the sliding base; a C-axis rotation mechanism fixed on a fixing body drives a C-axis rotation body to be rotated along a C-axis of a center shaft of theC-axis rotation body; an A-axis rotation mechanism drives a swinging body to be rotated along an A-axis of an axial lead of two coaxial shafts; a C1-axis rotation mechanism fixed on the swinging bodydrives a creel to be rotated along a C1-axis of a center shaft of the creel; a fiber placing head and a fiber placing head press roller are fixed at the lower end of the creel; a control system controls the C-axis, C1-axis and A-axis rotation mechanisms and a brake device to be operated; and a servo motor D drives a workpiece to be rotated along a rotation principal axis of the workpiece. The automatic fiber placing device is high in placement precision, rapid in speed, high in placement working efficiency, and stable in placement quality.

Owner:BAODING BIAOZHENG MACHINE TOOL

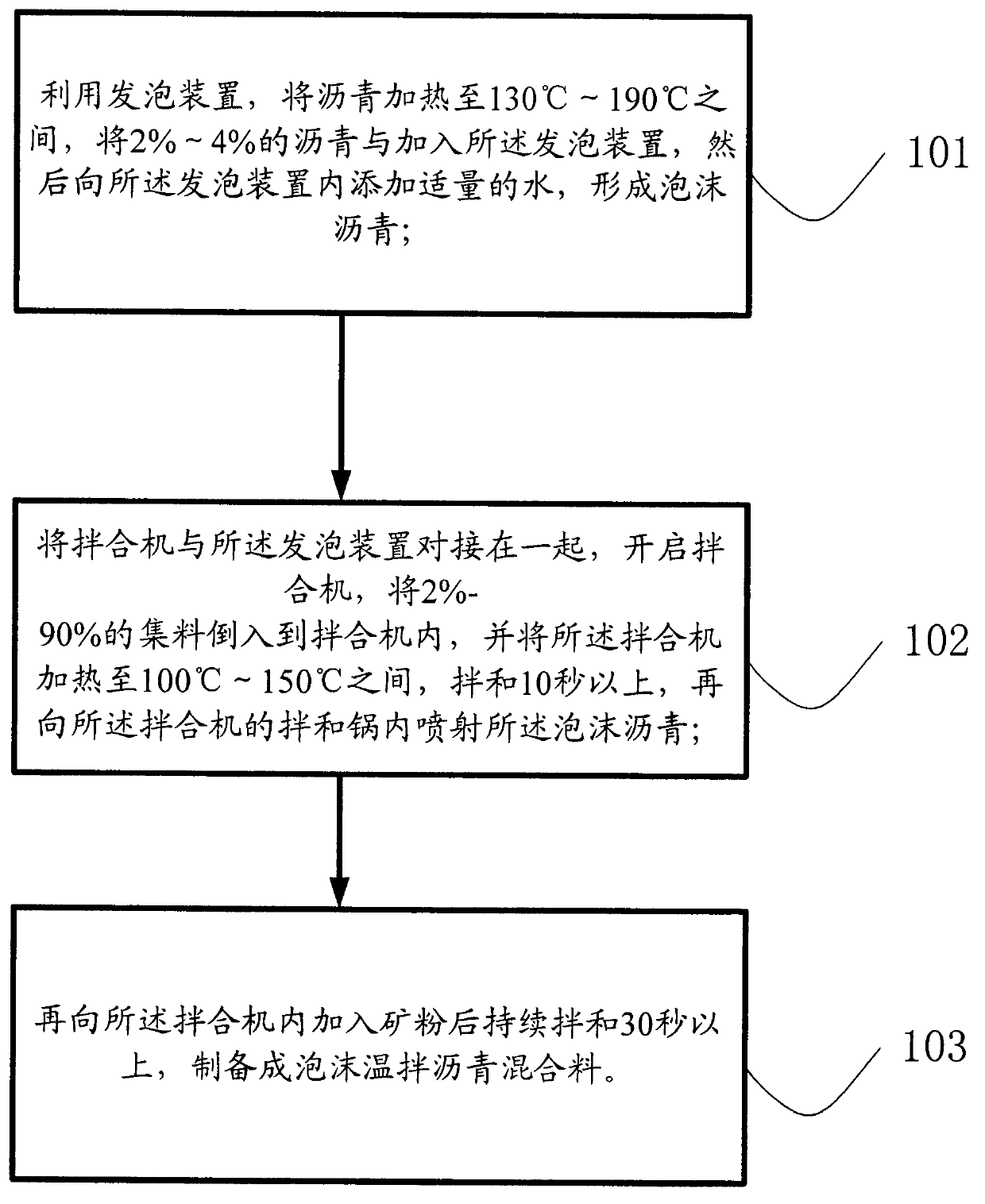

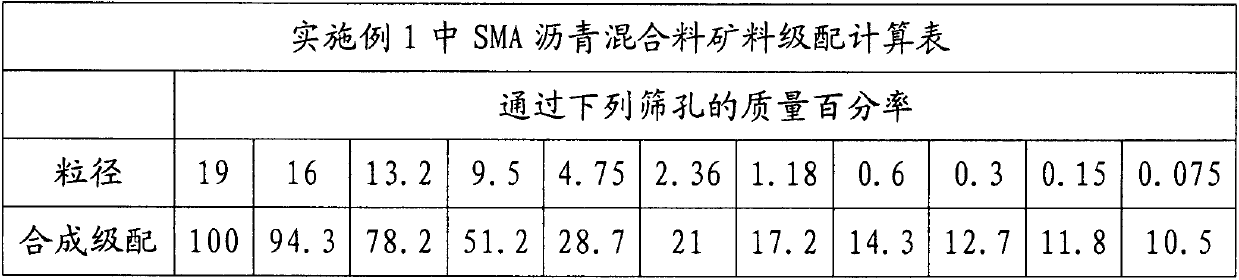

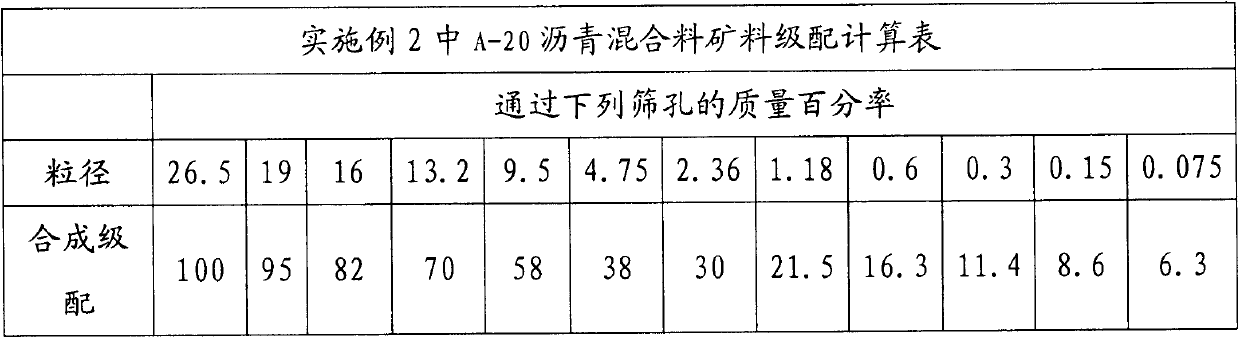

Foamed warm mix asphalt mixture and preparation method thereof

InactiveCN103102108AIncrease in sizeReduce energy consumptionClimate change adaptationRoad surfaceViscosity

The invention discloses a foamed warm mix asphalt mixture and a preparation method thereof. The foamed warm mix asphalt mixture is obtained by treating 2-8.5% of foamed asphalt, 2-90% of novel aggregate (or 6-90% of old asphalt pavement material) and 1-15% of mineral powder according to a special process. Asphalt is foamed through the special process, the volume of the foamed asphalt is increased by above 10 times, and the viscosity is remarkably reduced. Therefore, the mixture can be uniformly mixed at a lower temperature of 100-150 DEG C, so that asphalt fume in the production process is avoided, and the energy consumption for preparing asphalt mixture is lowered. The asphalt mixture is completely attached to the surface of the building stones to form asphalt films. After the water is volatized, the asphalt mixture with better performance is formed. Compared with conventional asphalt mixture, the foamed warm mix asphalt mixture has the advantages that the mixing temperature can be reduced by 30-60 DEG C, and the paving difficulty is reduced.

Owner:栾海

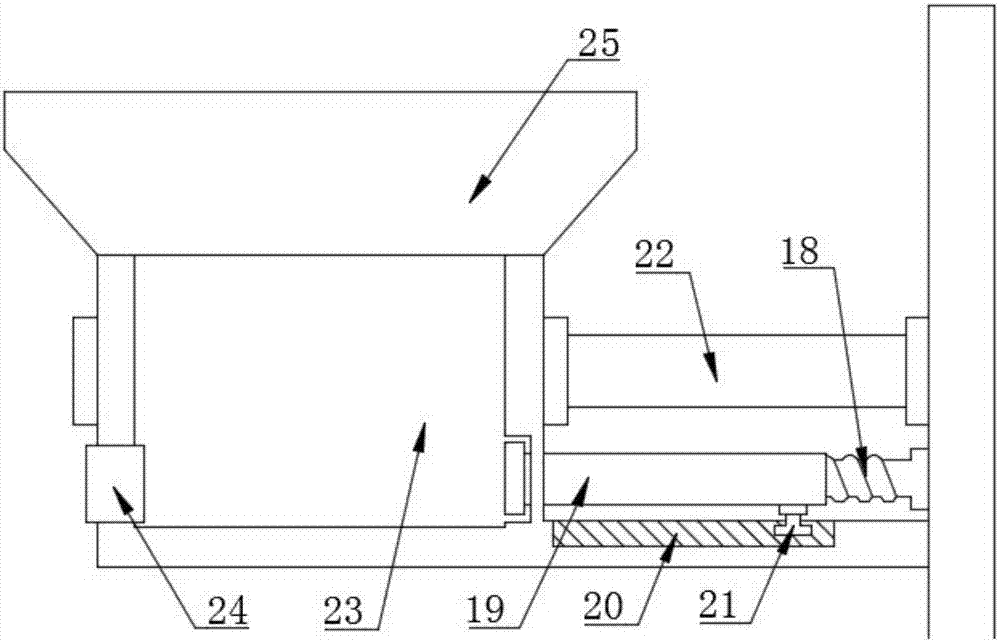

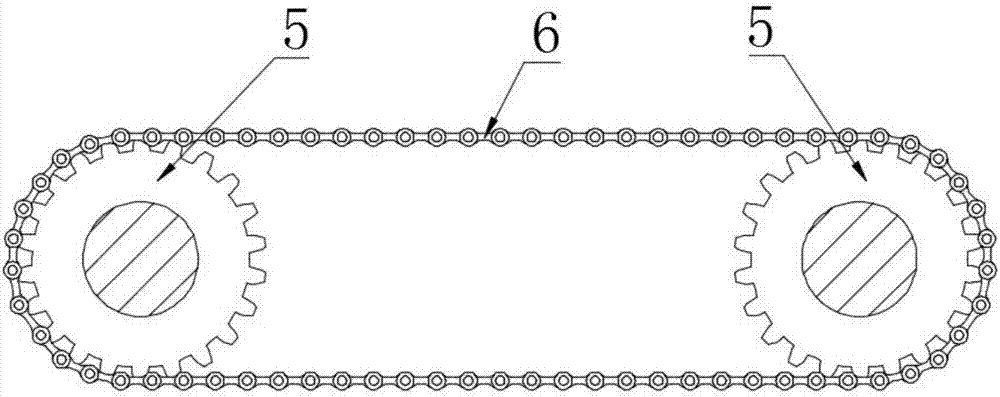

Building floor tile laying device

InactiveCN107575017AImprove laying efficiencyReasonable structural designBuilding constructionsBrickDrive shaft

The invention discloses a building floor tile laying device. The upper end of a driving shaft is connected with the right end of a sleeving rod in a sleeved mode; the left end of the sleeving rod is fixedly connected with a device body; the upper end of the driving shaft is fixedly connected with a chain wheel; the chain wheel is in engaged connection with the left end of a chain; the right end ofthe chain is engaged with a right chain wheel; the right chain wheel is fixedly connected with a driven shaft, and the upper end of the driven shaft is rotationally connected with a slurry tank through a bearing, and the lower end of the driven shaft is rotationally connected with a buffer plate; the buffer plate is fixedly connected with the lower portion of the slurry tank; the lower end of thedriven shaft is fixedly connected with a movable groove plate; and a fixed groove plate is arranged at the lower end of the movable groove plate. According to the building floor tile laying device, the driven shaft rotates to stir cement slurry; a lead screw drives a thread sleeve to move horizontally in a reciprocating mode, and thus single tile supply is achieved; and intermittent discharging is conducted under the effect of the movable groove plate, and a transverse plate is inclined in a reciprocating mode to be horizontal so as to lay tiles stably. The device is reasonable and applicablein structural design, the laying efficiency of the building floor tiles is improved greatly, and the automation degree is high, so that the function of simultaneous cement grouting and floor tile laying is achieved, and the engineering progress is accelerated.

Owner:刘晓菊

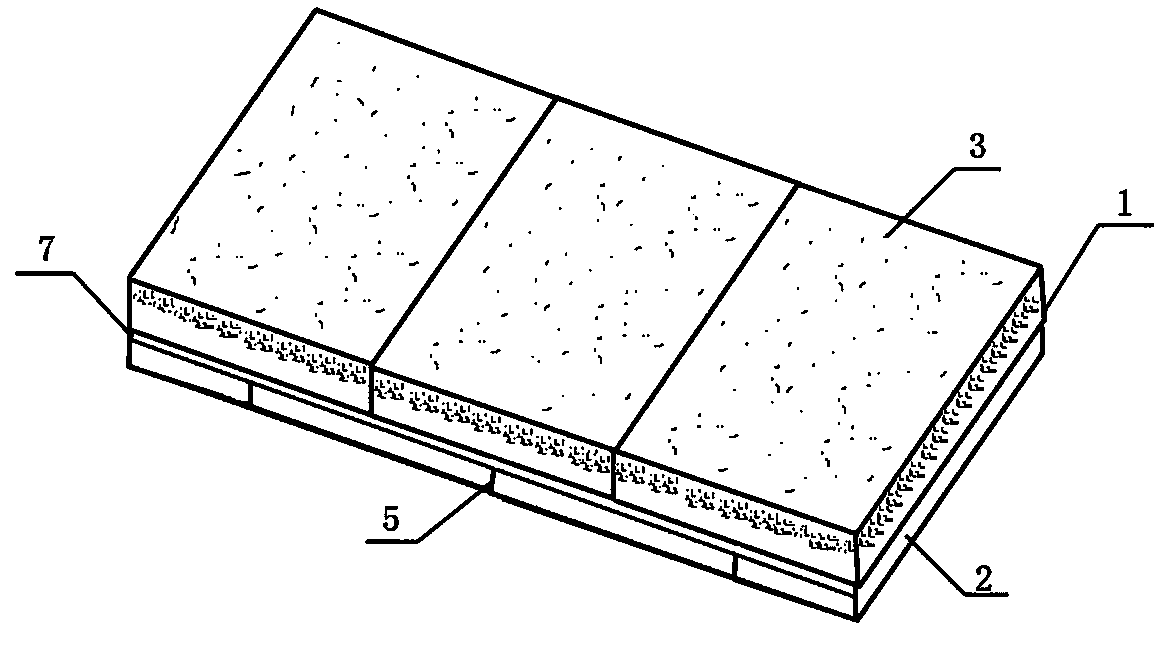

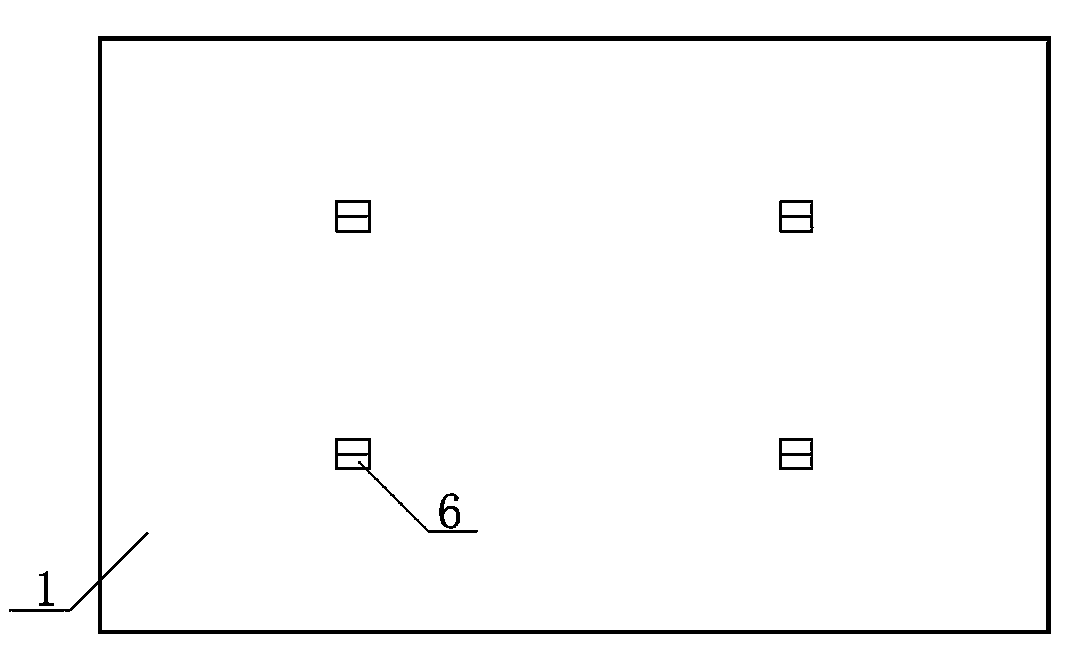

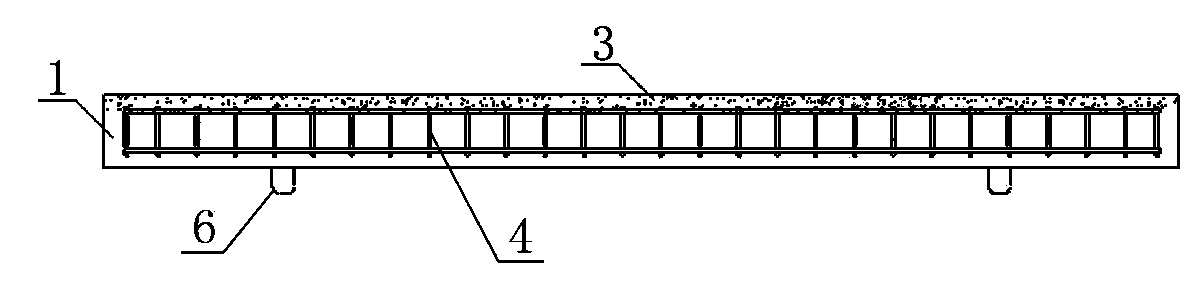

Novel fabricated vehicle bearing pavement and construction method thereof

InactiveCN103866670AImprove structural strengthEasy to transportSingle unit pavingsTemporary pavingsFiberWear resistant

The invention discloses a novel fabricated vehicle bearing pavement and a construction method thereof. The novel fabricated vehicle bearing pavement is formed by superposing, assembling and laying fabricated reinforced concrete plate members in double layers, wherein double-layer bidirectional steel reinforcement frameworks are uniformly distributed inside upper pavement slabs and lower pavement slabs; lifting rings are embedded on lower parts of the frameworks in advance; rubber films are laid between the upper pavement slabs and the lower pavement slabs; a wear-resistant steel fiber concrete layer is arranged on the upper parts of the upper pavement slabs. The construction method comprises the following steps: 1. fabricating reinforced concrete pavement members; 2. lifting and transporting the prefabricated pavement members; 3. flattening the roadbed, laying the lower pavement slabs, rubber films and upper pavement slabs sequentially, laying the pavement slabs in a manner of staggering from each other according to seams, namely the seams between the slabs are not communicated with one another. The construction quality is easily guaranteed, the prefabricated pavement member is light in structure, high in strength, and convenient to transport and construct, can be repeatedly used and is particularly suitable for laying temporary vehicle bearing roads on the construction site, the rubber films can achieve a buffer effect, the friction force between the pavement slabs can be increased, and the pavement slabs are prevented from slipping.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

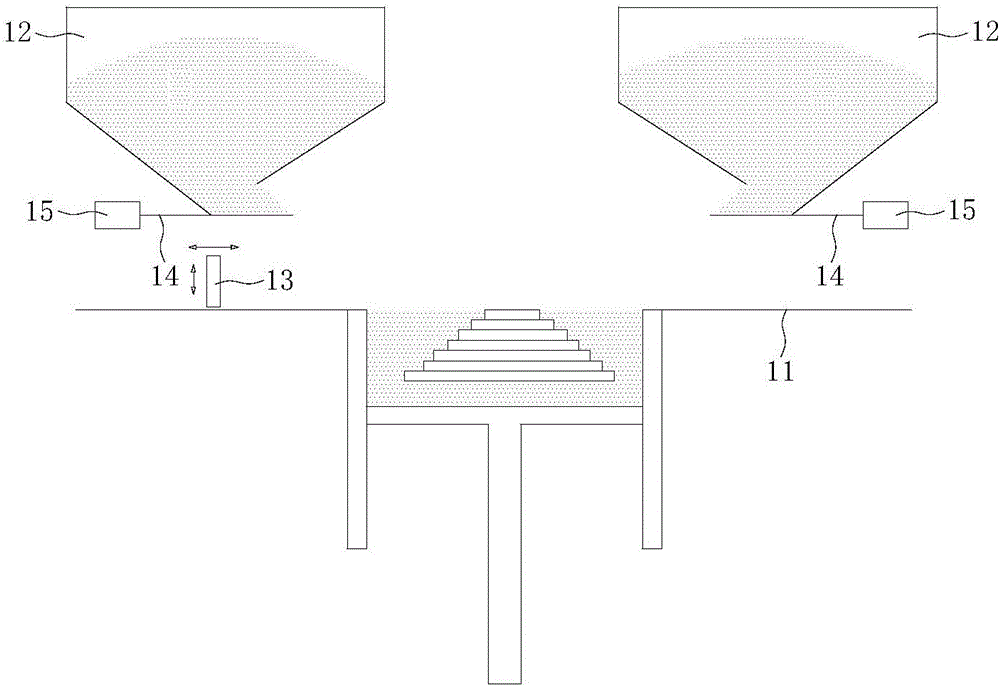

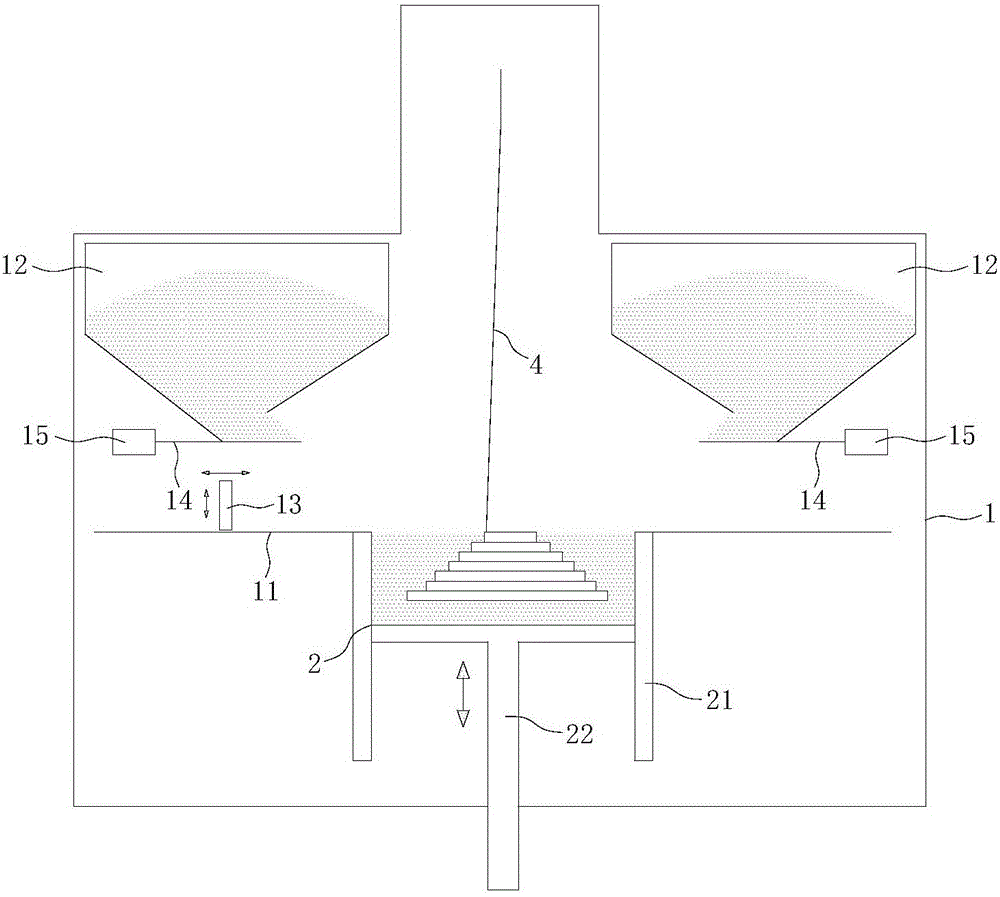

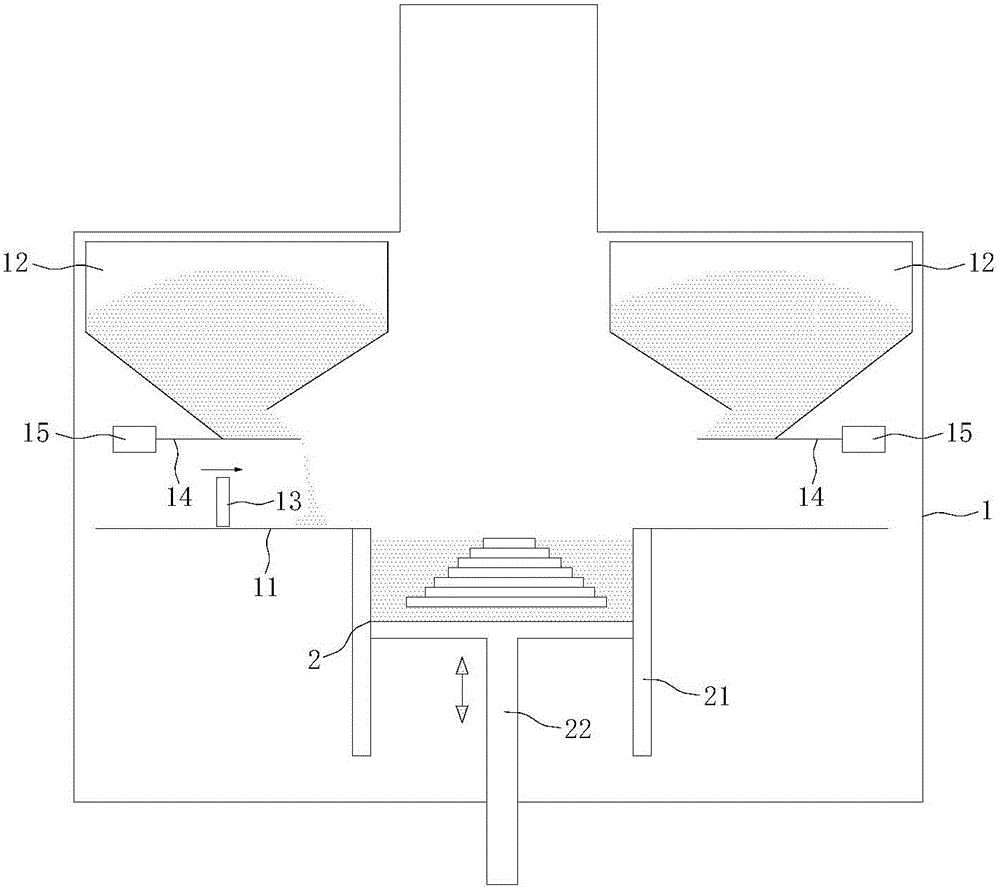

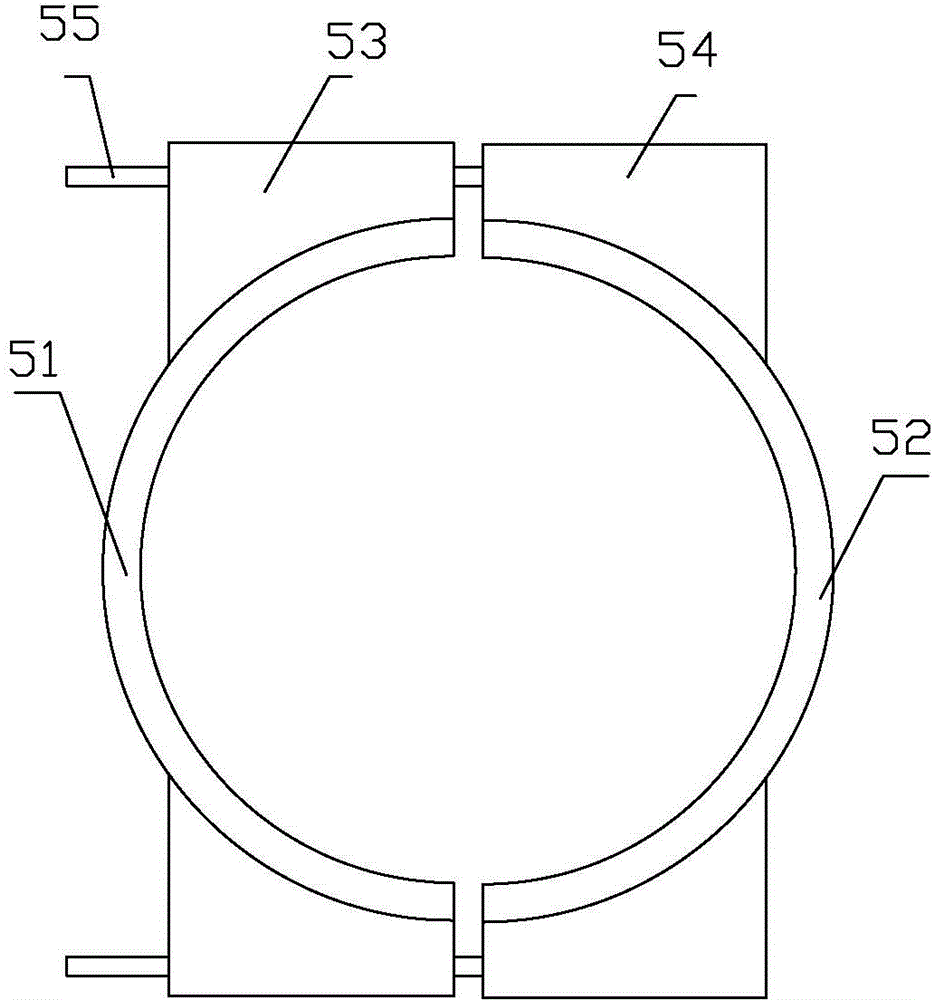

Powder distribution device and additive manufacturing device

InactiveCN105855548AUniform thicknessImprove spreading efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyAdditive layer manufacturing

The invention belongs to the field related to additive manufacturing and discloses a powder distribution device and an additive manufacturing device. The powder distribution device comprises a powder spreading platform and hoppers arranged above two sides of the powder spreading platform, powder materials are placed in the hoppers, powder-material placing locations are arranged on the two sides of the powder spreading platform, the powder materials are transferred to the powder-material placing locations through the hoppers, scrapers vertically arranged above the powder spreading platform are allowed to move along the horizontal direction as well as the vertical direction, and the scrapers are respectively located on one sides of the powder-material placing locations when moving along the vertical direction. The powder distribution device is provided with the scrapers allowed to move along the horizontal direction as well as the vertical direction, two-way powder scraping is realized, thickness of powder layers is evener as compared with the existing one-way powder scraping, and powder spreading efficiency is improved. Further more, the scrapers are vertically arranged, so that two-way powder scraping can be better realized, and waste of the powder materials is avoided.

Owner:QUICKBEAM CO LTD +1

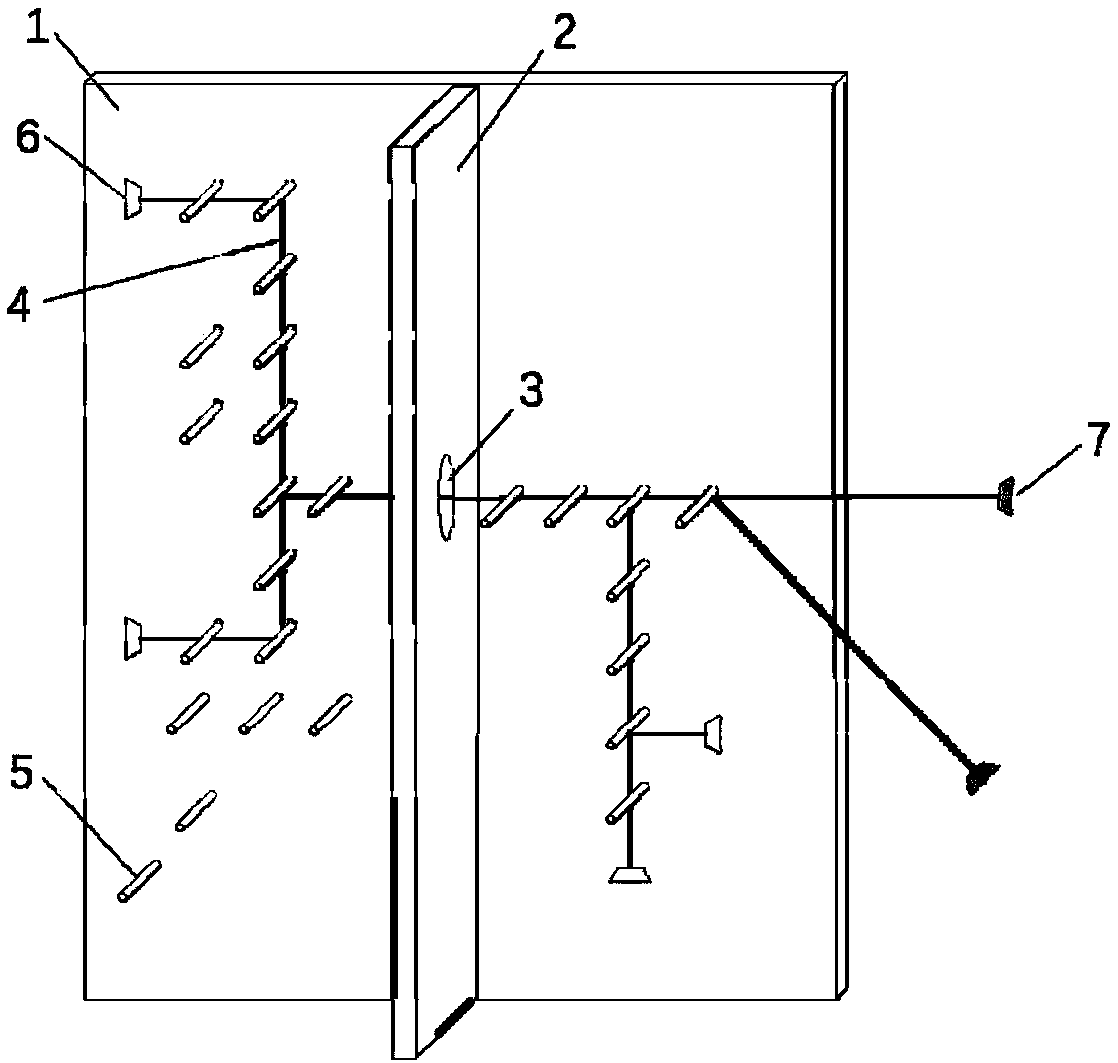

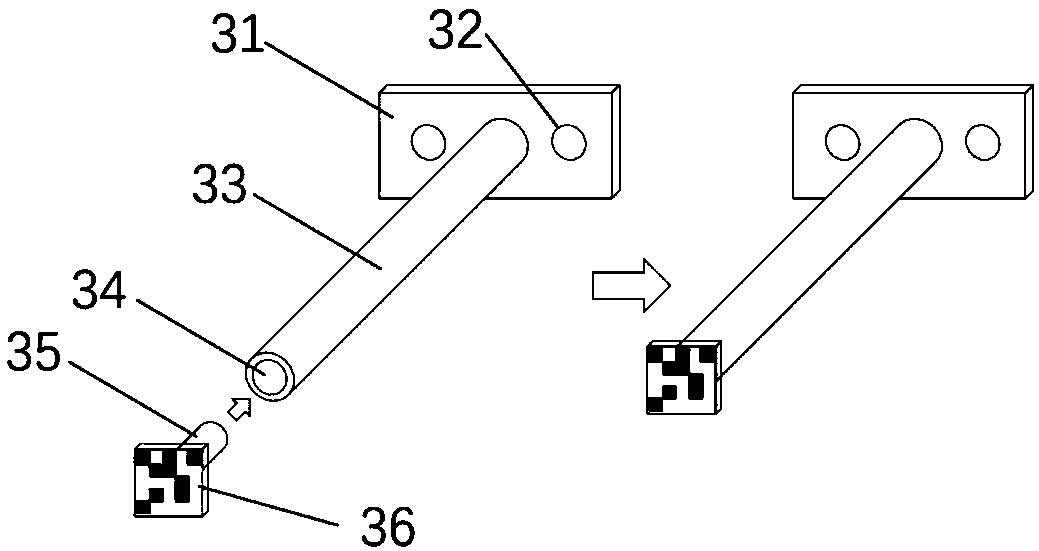

Fabricated type cable through-wall fixing device and cable through-wall laying construction method

ActiveCN104600643AImprove laying efficiencyGuaranteed uptimeApparatus for laying cablesBuilding construction

The invention discloses a fabricated type cable through-wall fixing device and a cable through-wall laying construction method. The fabricated type cable through-wall fixing device comprises a left support and a right support, and is characterized in that cross arms are fixed between the left support and the right support through bolts, and combined sleeves are arranged between every two adjacent cross arms. The method includes the following steps of laying cables in cable channels, fixing the left support and the right support, fixedly arranging one cross arm at the top ends, installing the corresponding combined sleeves on the cables, lifting the four cables in one set, inserting left rib plates and right rib plates on the upper sides of the sleeves into the gaps of the cross arm on the top, fixedly arranging the second cross arm below the set of cables, inserting left rib plates and right rib plates on the lower sides of the combined sleeves into the gaps of the second cross arm, fixing the two ends of the second cross arm to the left support and the right support, repeatedly executing the steps, pouring concrete and completing construction. Construction and installation are easy and convenient, the cable laying efficiency is improved, and the normal running of transformer substations and circuits is ensured.

Owner:STATE GRID CORP OF CHINA +2

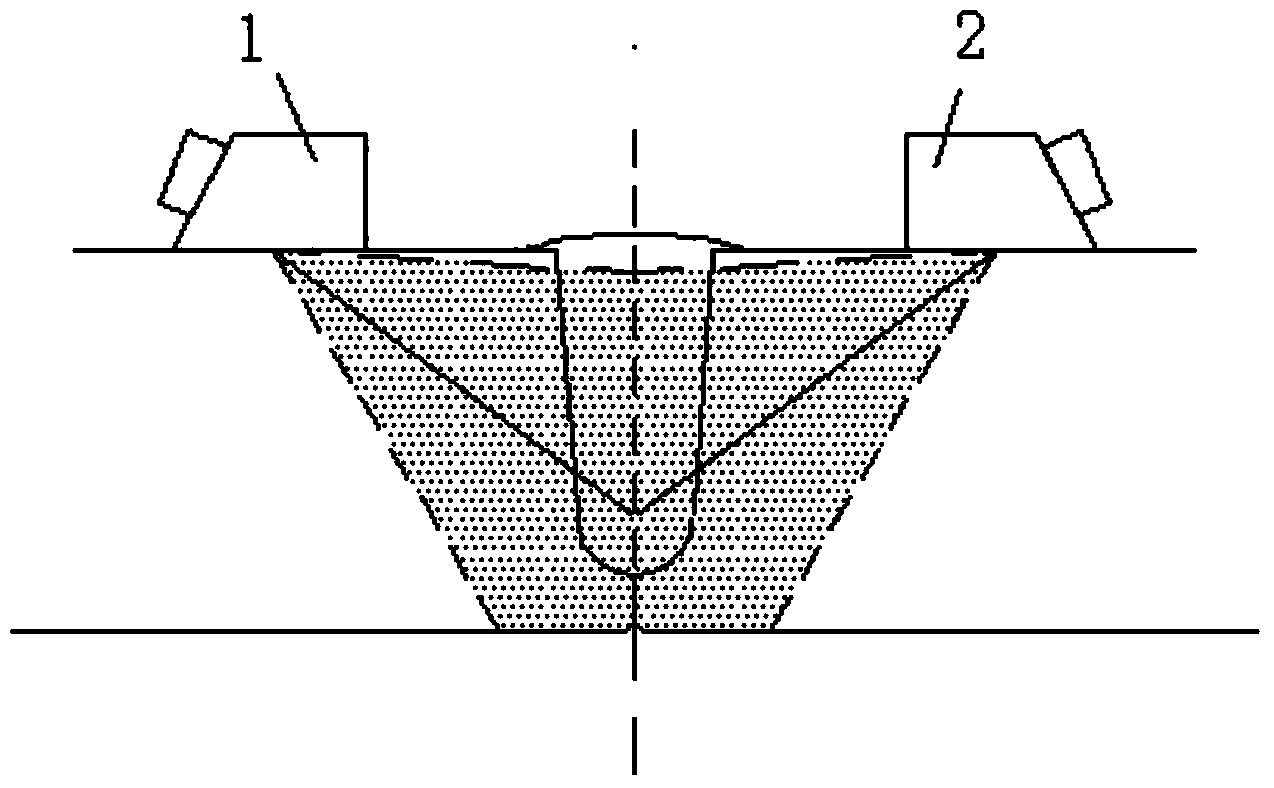

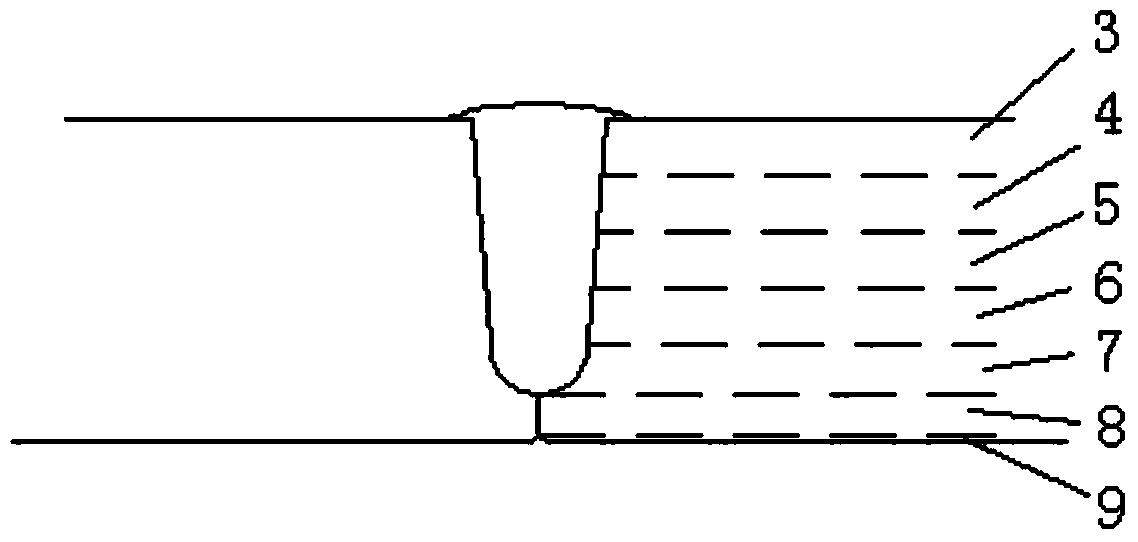

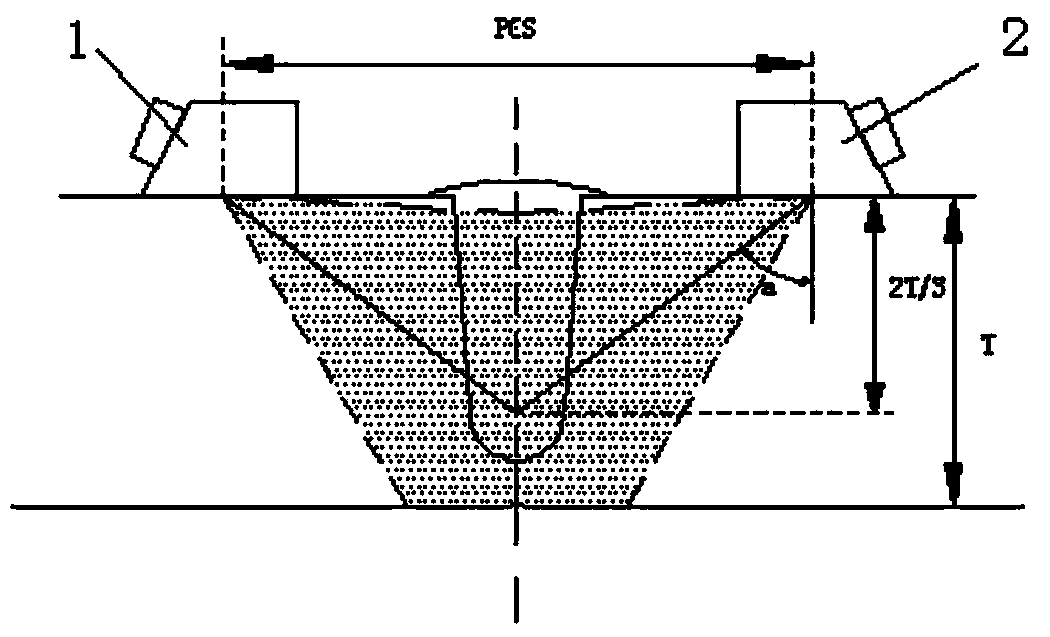

Method for accurately quantifying flaw height of girth welding seam in submarine pipeline

InactiveCN104359976ASolve the problem of low pass rateAccurate defect height quantitative accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesOcean bottomChannel parameter

A method for accurately quantifying the flaw height of a girth welding seam in a submarine pipeline comprises the following inspection steps: (1) setting the depths of focuses of a diffractive ultrasonic emission probe and a diffractive ultrasonic receiving probe at a position of 2 / 3T of the wall thickness of the welding seam; (2) calculating the probe center distance; (3) performing sound velocity measurement, wedge delay calibrations, and detection system calibrations on sound velocity probes separately on a submarine pipeline sound velocity test block; (4) importing the ultrasonic time-of-flight diffraction channel parameter into the embedded flaw position of the girth welding seam in the submarine pipeline; (5) finding lateral wave signals and bottom surface reflected wave signals, and finding upper tip diffraction signals and lower tip diffraction signals from the embedded flaw; (6) comparing the wall thickness parameter of the girth welding seam of the submarine pipeline with the phase variation of the ultrasonic time-of-flight diffraction; (7) accurately quantifying the height of the embedded flaw; (8) carrying out comparative analysis on the macroscopic flaw section height and the height quantified by adopting the ultrasonic time-of-flight diffraction technology. The method has the advantages that the problem of low qualification rate of welding seams can be solved, the welding quality of the submarine pipeline can be ensured, and the submarine pipeline laying efficiency can be improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

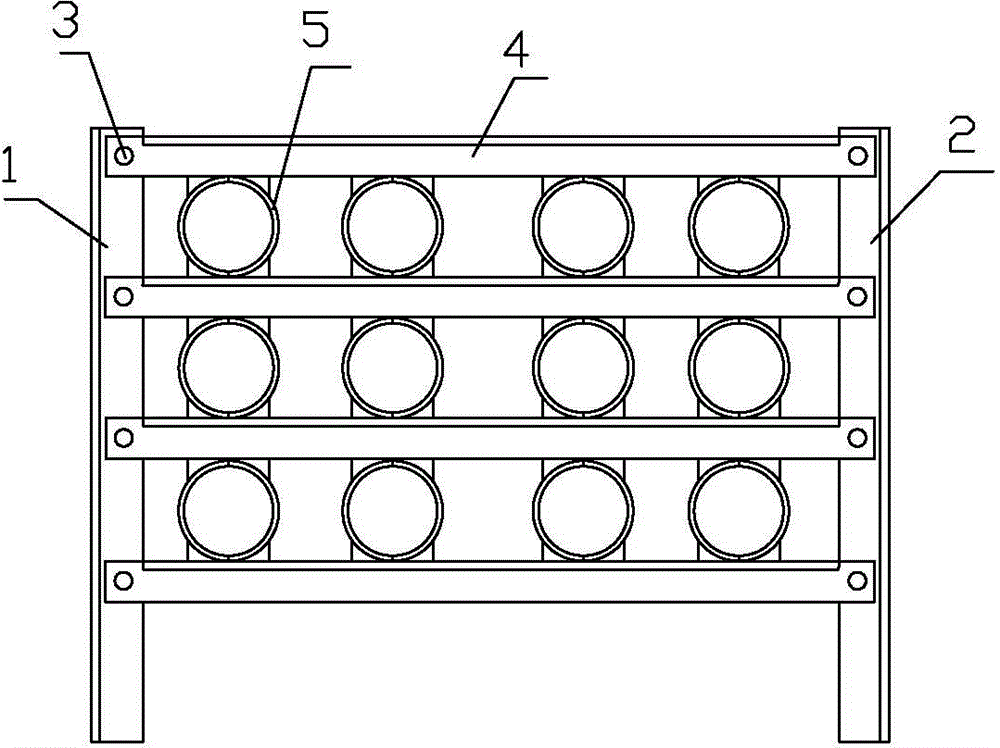

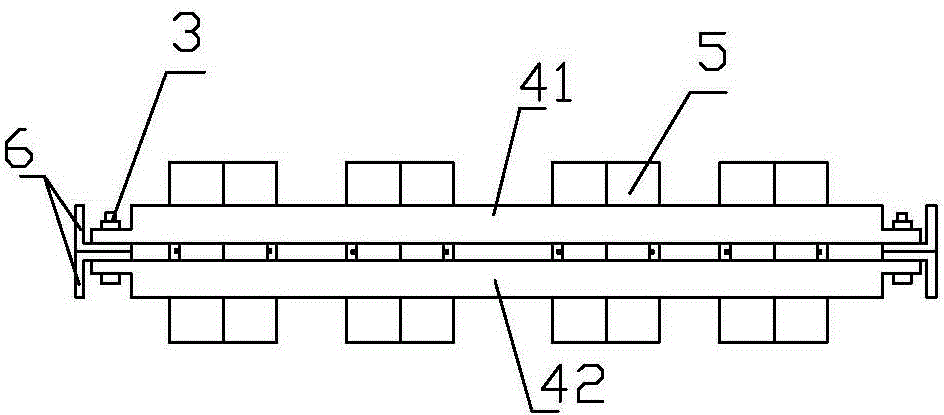

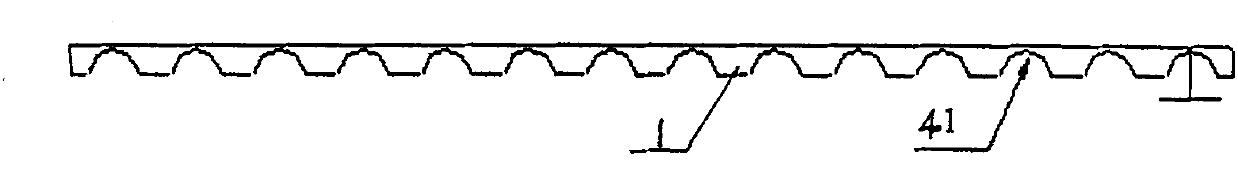

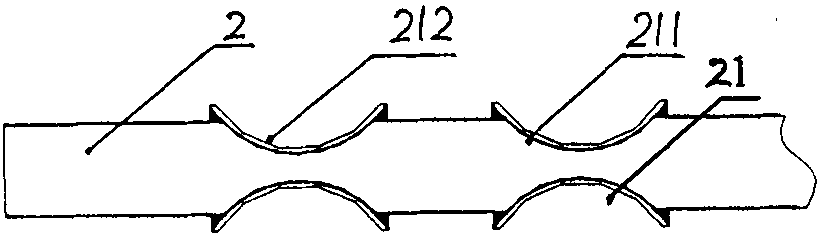

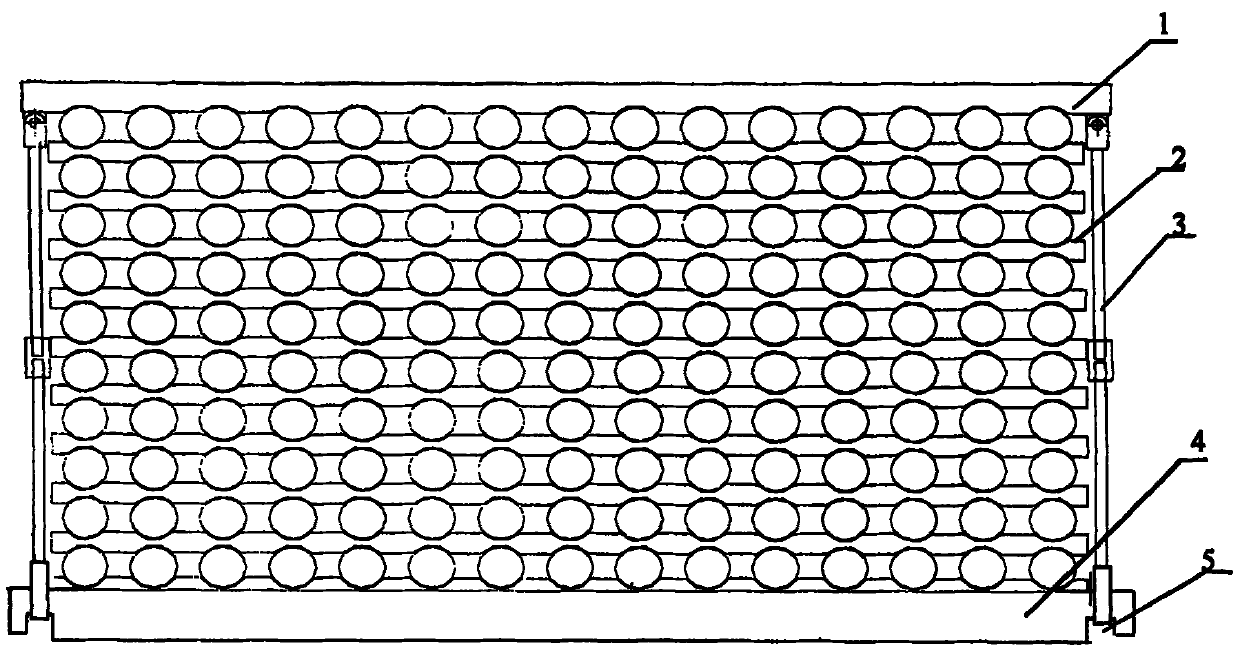

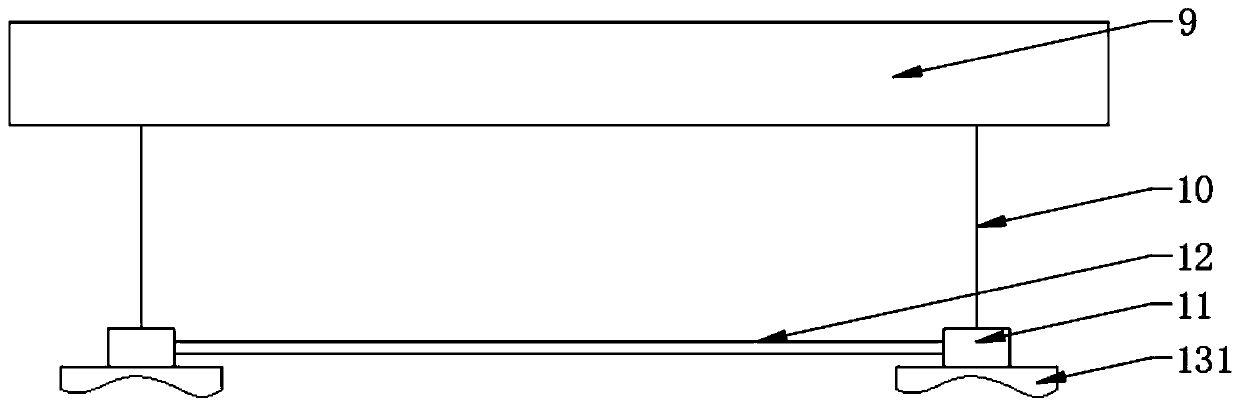

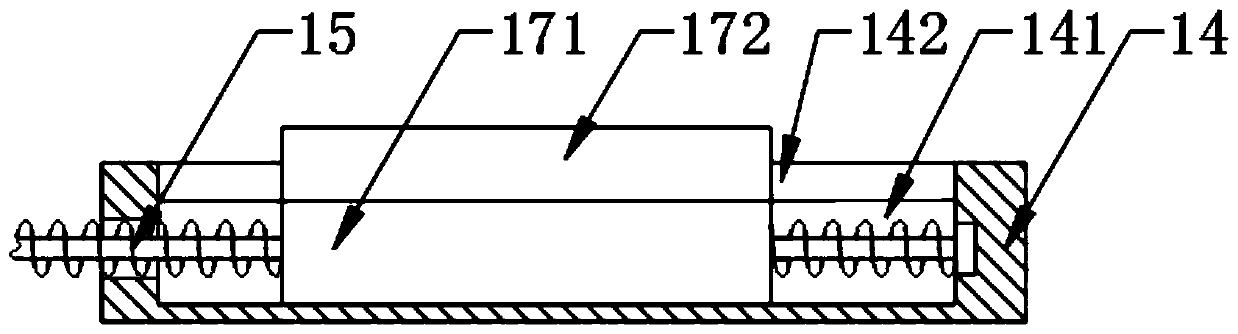

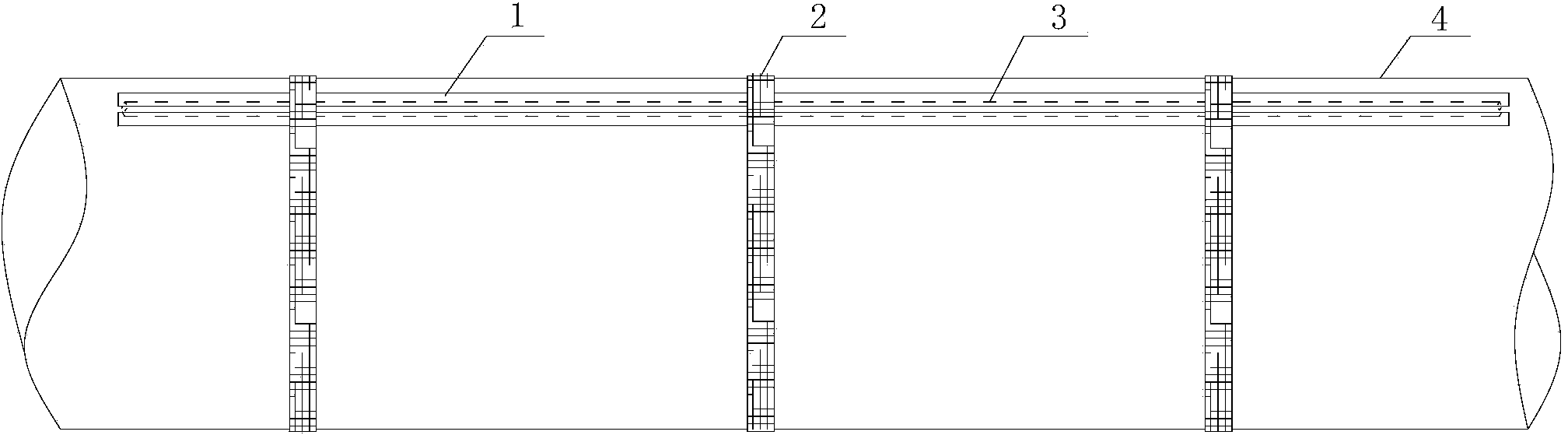

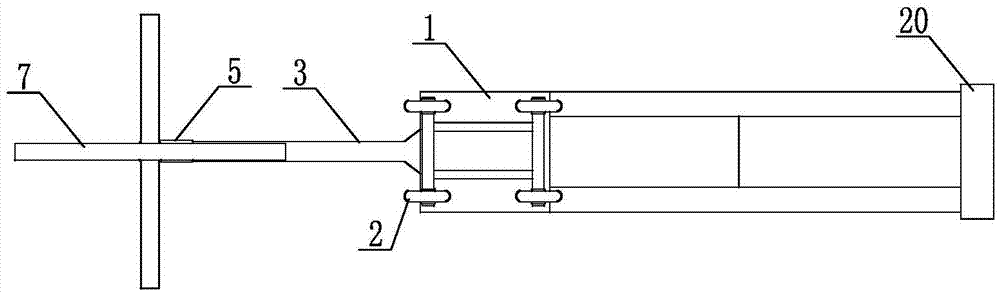

Pipe bunching device

InactiveCN101905785AEasy to removePrecise positioningPackage recyclingContainers to prevent mechanical damageStructural engineering

The invention relates to a pipe bunching device, which consists of upper beams, lower beams, positioning partition pipes and a fastening device. The two upper beams and the two lower beams are parallel to each other in a horizontal direction of the top surface and the bottom surface respectively; the lower beams support lowest bunched pipes from the bottom, and the upper beams press the bunched pipes from the top; the upper beams and the lower beams are connected with the fastening device respectively; and positioning slots for positioning the pipes are distributed on the upper beams and the lower beams in the length direction uniformly at intervals. The positioning partition pipes are distributed between two layers of the pipes; the positioning slots for positioning the pipes are distributed on upper and lower surfaces of each positioning partition pipe in the length direction of the partition pipe uniformly at intervals; and the interval between the positioning slots is consistent with that of pipe slots on the upper beams and the lower beams. The fastening device is connected between end heads of the upper beams and the lower beams to play a role in tensioning the upper beams and the lower beams and comprises a pull rod, a double ratchet, a twin nut and the like. The bunching device has the advantages of simple structure, convenient use and reuseability, can conveniently bunch the pipes manually or mechanically without using other equipment in a warehouse or outdoors, realizes mechanized loading and unloading and transporting, and can be matched with a pipe distributing vehicle.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Pipeline embedding device for water conservancy projects

InactiveCN110937518AAchieve placementEasy to placePipe laying and repairBase supporting structuresElectric machineryHydraulic engineering

The invention discloses a pipeline embedding device for water conservancy projects, and relates to the technical field of pipeline embedding devices. A winch is fixedly installed at the bottom of a threaded seat, a support rod is fixedly connected between two groups of connecting steel blocks, the bottom ends of the two groups of connecting steel blocks are fixedly equipped with clamping devices,the left end of a second lead screw penetrates through a fixing seat to be fixedly connected to a second motor, an inner cavity of the fixing seat is provided with a guide seat connected to the outerwall of the second lead screw in a sleeving manner, an object containing plate is fixedly arranged between fixing frames, the top of the object containing plate is evenly and fixedly provided with limiting rings, two groups of guide plates are fixedly arranged on the right side of the top of a base, protection plates are fixedly assembled on the side walls between the two groups of guide plates, and a discharging channel is arranged between the two groups of protection plates. Automatic clamping and laying of pipelines are realized, pipeline protection can be realized, the needs of continuouspipeline placing and laying are met, and the pipeline laying efficiency is improved.

Owner:宁夏中康建设集团有限公司

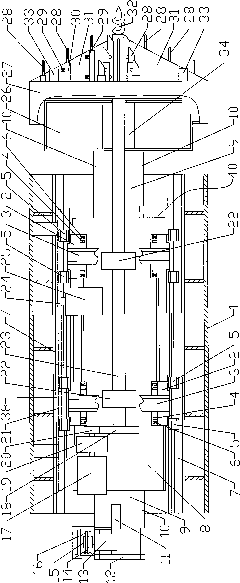

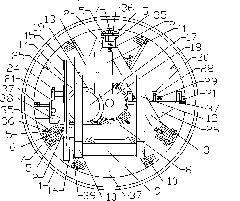

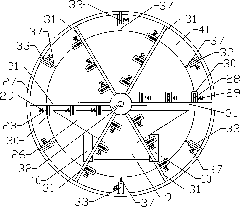

Shield machine

The invention relates to a shield machine which comprises a shell, wherein the front part of the shell is provided with a cutting device, a slide seat is arranged in the shell, the upper part of the slide seat is provided with a cutting power transmission device and a feeding power transmission device, the lower part of the slide seat is provided with a conveying device; the cutting device comprises a tool rest shell, the tool rest shell is provided with a plurality of cutter bodies, each cutter body is provided with a plurality of cutting tools, and the cutting tools are arranged in a way that the distance between the cutting edge of each cutting tool and the end surface of the tool rest shell successively decreases along the radial direction of the tool rest shell from inside to outside; and in the cutting process, the cutting tool adjacent to the center of the tool rest shell perform the cutting operation first, and then, the cutting tools away from the center of the tool rest shell successively perform the cutting operation, thereby high cutting efficiency is achieved, and the pipeline laying efficiency is improved. Besides, the cutting angle of the cutting tools can be adjusted by sliding the adjusting device, thereby the laying of the bent pipeline is realized.

Owner:唐兆连

Method for laying submarine pipeline leakage detection optical cable

ActiveCN103926670ARealize full line protectionReduce investmentOptical fibre/cable installationOcean bottomEngineering

A method for laying a submarine pipeline leakage detection optical cable includes the steps that a pay-off rack is arranged on the stern of a pipe laying ship, and rubber pad strips, glue and flexible binding belts are arranged in the construction position; the rubber pad strips adhere to the outer surface of a pipeline through glue in a subsequent end-to-end connecting mode; the pay-off rack is controlled to release the sensing optical cable and the sensing optical cable is installed in an optical cable mounting groove of the rubber pad strips; one flexible binding belt is bound to the outer envelope surface formed by the pipeline and the rubber pad strips every certain distance; the pipeline is laid on the seabed sequentially in a downstream mode; the pipeline is buried under the submarine mud face through operation of a trencher; the completeness of the sensing optical cable is tested, and one end, connected with a platform or the land, of the sensing optical cable is connected into a system host through a terminal box. According to the method for laying the submarine pipeline leakage detection optical cable, laying of the optical cable is completed on the pipe laying ship, the operability is high, personnel investment is substantially saved, laying construction difficulty and laying cost are reduced, and laying efficiency is improved. The sensing optical cable is installed in the rubber pad strips which are longitudinally connected in a butted mode in sequence along the pipeline, and thus the whole optical cable can be protected.

Owner:E TECH ENERGY TECH DEV CORP

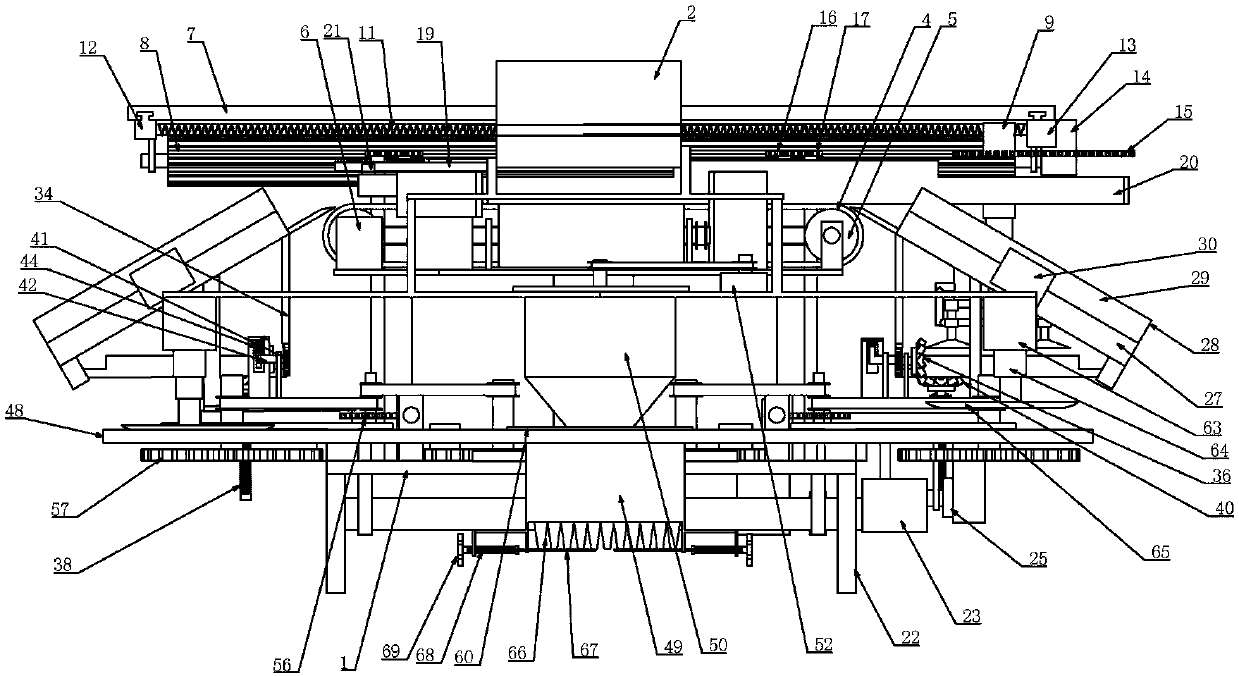

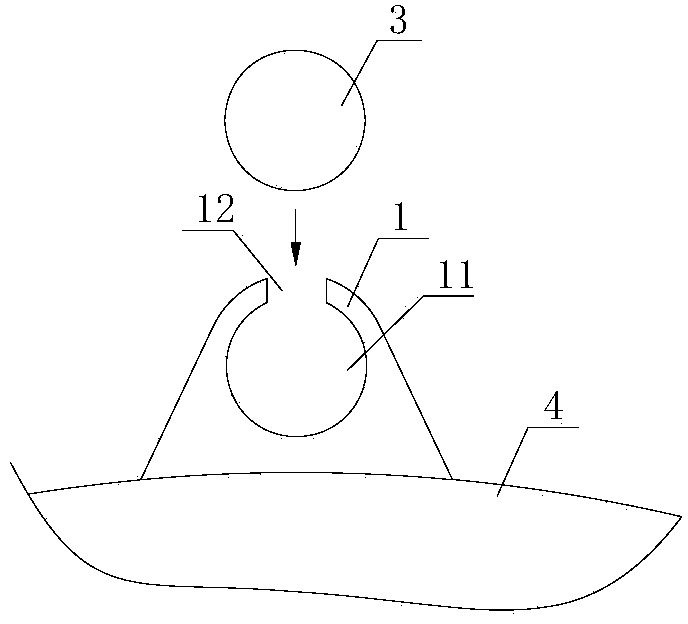

Placement head device

The invention relates to a placement head device comprising a tow channel, a guiding module, a fastening module, a re-conveying module, a shearing module, and a pressuring module. The guiding module is used for delivering the tows into the tow channel. The fastening module is used for fastening the tows by clamping before shearing. The re-conveying module is used for conveying the tows. The shearing module is used for shearing the tows. The pressuring module is used for compactly pressing the tows onto a product. A heating and gathering module is used for heating the tows and gathering the tows. According to the placement head device provided by the invention, through the cooperation of the modules, each stream of tows can be independently controlled, such that molding problems such as complicated curved surfaces, variable thicknesses, and reinforcement can be solved; product quality can be improved; and placement quality can be stabilized. Also, mechanized operations are adopted, such that placement efficiency is improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

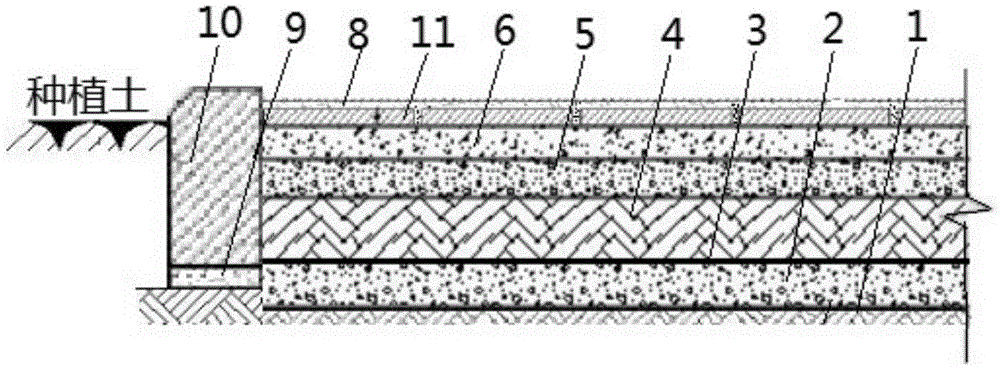

Water-permeable wear-resistant garden path and construction method thereof

InactiveCN105463967AThe overall structure is ingeniously designedImprove water permeabilityPaving gutters/kerbsClimate change adaptationCushionSubgrade

The invention discloses a water-permeable wear-resistant garden path and a construction method thereof. The water-permeable wear-resistant garden path comprises a pavement main body and flat curbs, wherein the flat curbs are arranged on curb bases at two sides of the pavement main body; the pavement main body sequentially comprises a roadbed, a crushed stone drainage layer, a base layer, a cushion layer, a binding layer and a surface layer from bottom to top; the roadbed is formed by pure soil; the crushed stone drainage layer is uniformly filled and compacted by crushed stones; the base layer is tamped by a concrete base, a transverse slope of 2-3% is formed on the base layer, and at least a layer of reverse filtration geotextile is arranged between the crushed stone drainage layer and the base layer; the cushion layer is filled and compacted by lime soil in which the ratio of lime to soil is 3:7; the binding layer is formed by hard cement mortar in which the ratio of cement to mortar is 1:3; the surface layer serves as the uppermost layer of the pavement main body; and water-permeable bricks are used for paving, and a gap between adjacent water-permeable bricks and the surface layer are filled with water-permeable resin mortar. The garden path with the structure has relatively high strength, stiffness and wear resistance and good water permeability; the adopted paving process has high efficiency and low construction cost; and complaints of users are reduced.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

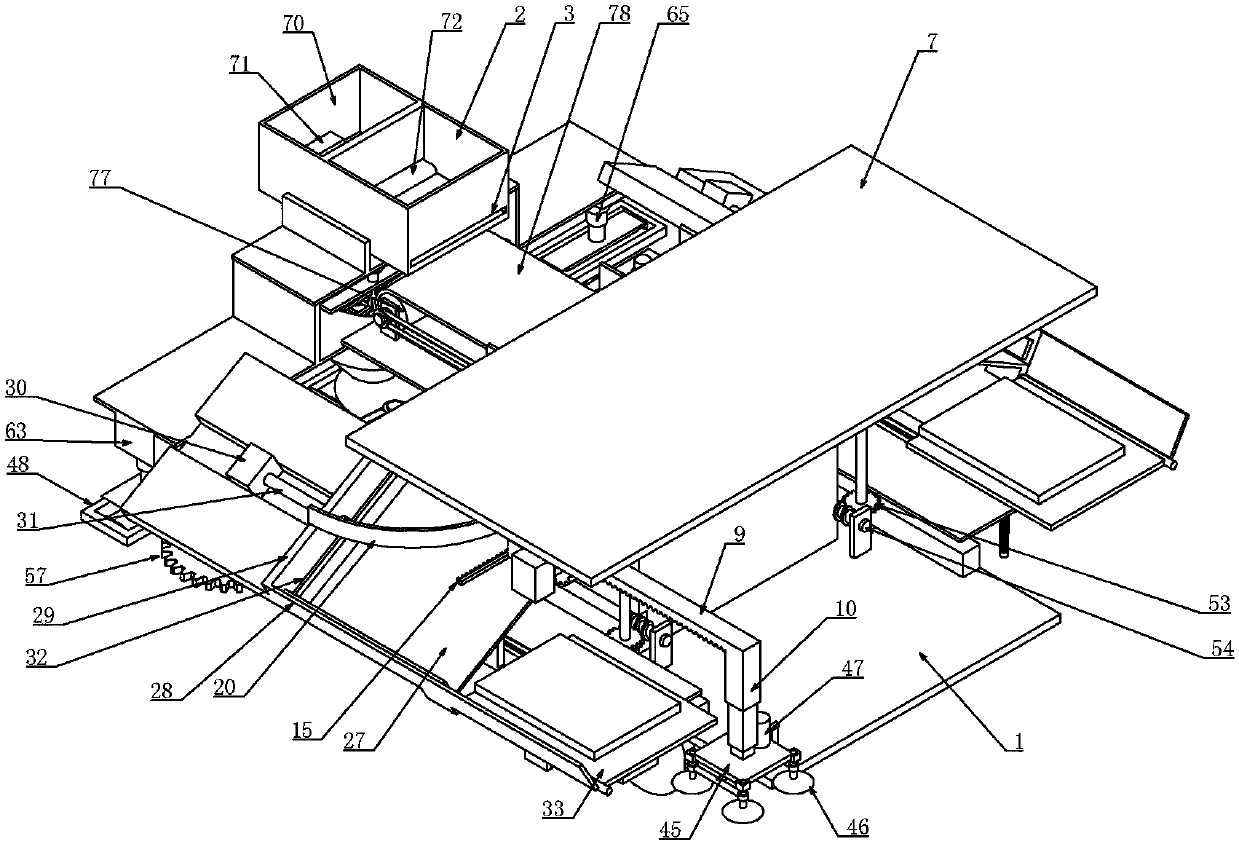

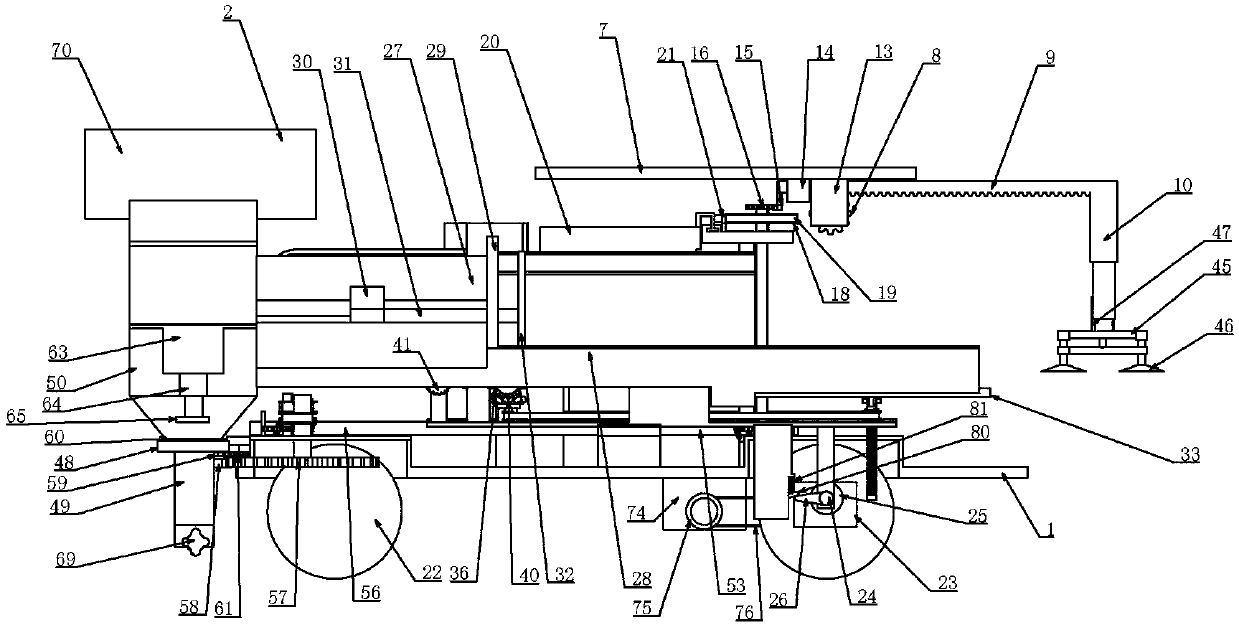

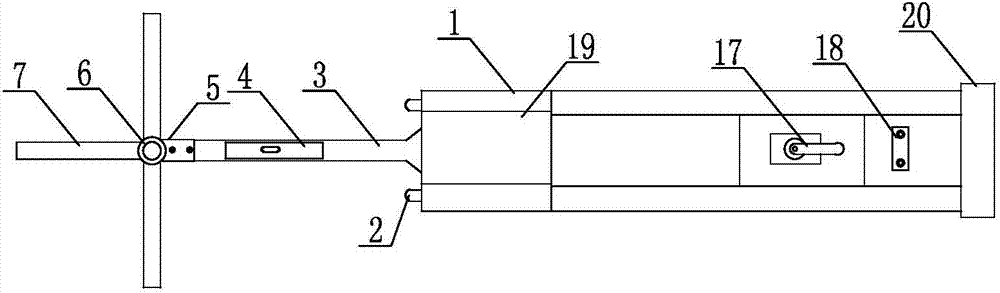

Automatic single-color mosaic-particle lay-up device and lay-up method thereof

ActiveCN104085241AImprove laying efficiencyHigh speedOrnamental structuresConveyor partsEngineeringAutomatic testing

The invention provides an automatic single-color mosaic-particle lay-up device and a lay-up method of the automatic single-color mosaic-particle lay-up device. The automatic single-color mosaic-particle lay-up device comprises a stander, a mosaic forming die which is arranged on the stander, at least one automatic mosaic-particle single-track lay-up unit, a loading device and a controller, wherein each automatic mosaic-particle single-track lay-up unit is used for gradually collecting mosaic particles one by one after transporting the mosaic particles one by one, arranging the mosaic particles into rows / columns according to a preset rule and then driving the entire row / column of mosaic particles to enter a loading procedure; the loading device is connected with the stander and used for sequentially transporting and loading the well-arranged entire row / column of mosaic particles in each automatic mosaic-particle single-track lay-up unit into the mosaic forming die; the controller is respectively connected with each automatic mosaic-particle single-track lay-up unit and the feeding device by signals. The automatic single-color mosaic-particle lay-up device is high in lay-up stability, high in lay-up speed and capable of effectively improving the lay-up efficiency and lay-up accuracy of the mosaic particles. The automatic lay-up method is used for substituting the traditional manual lay-up process, so that the problems that the current mosaic industry is low in automation degree and low in production efficiency can be solved.

Owner:FOSHAN UNIVERSITY

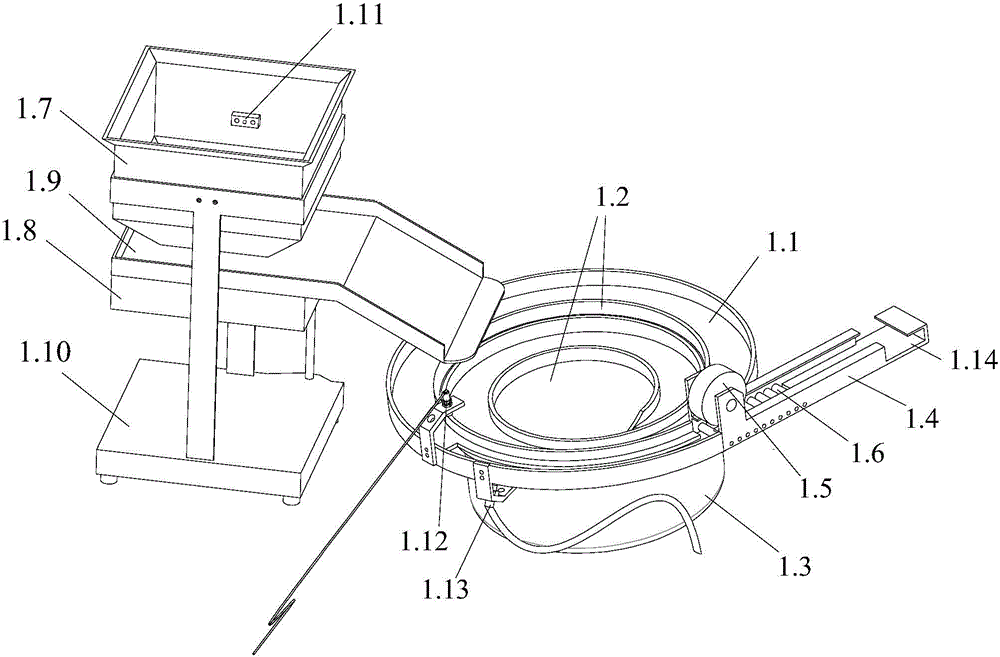

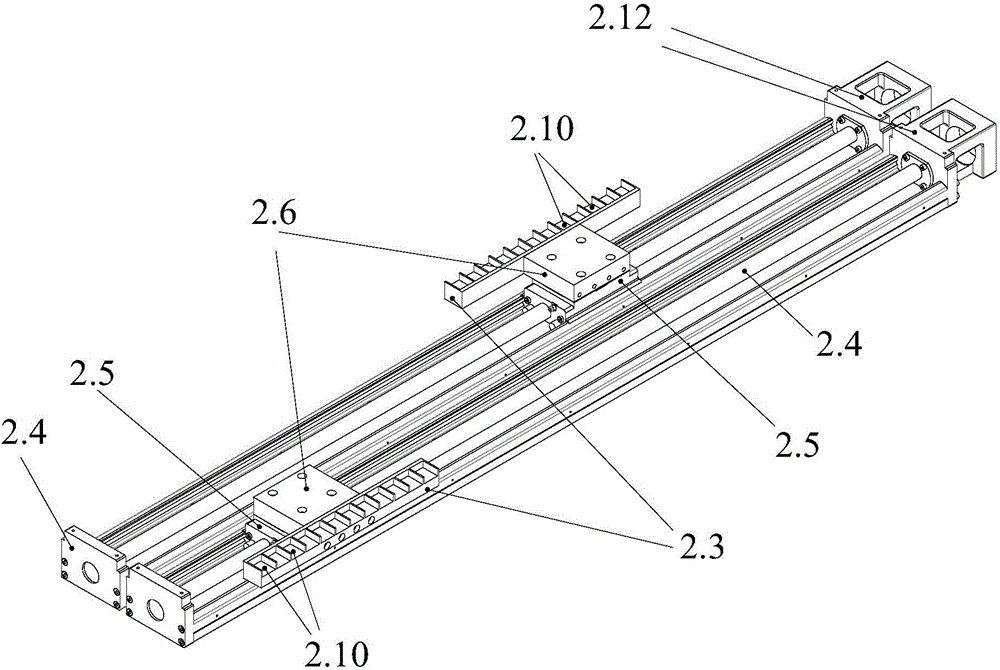

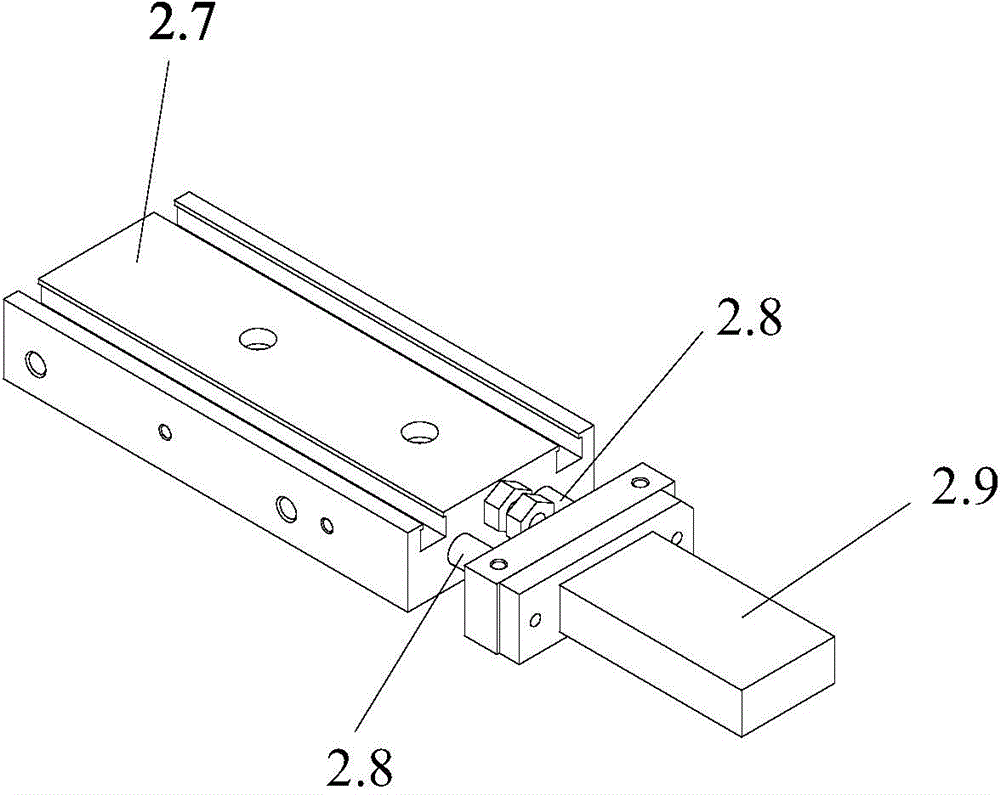

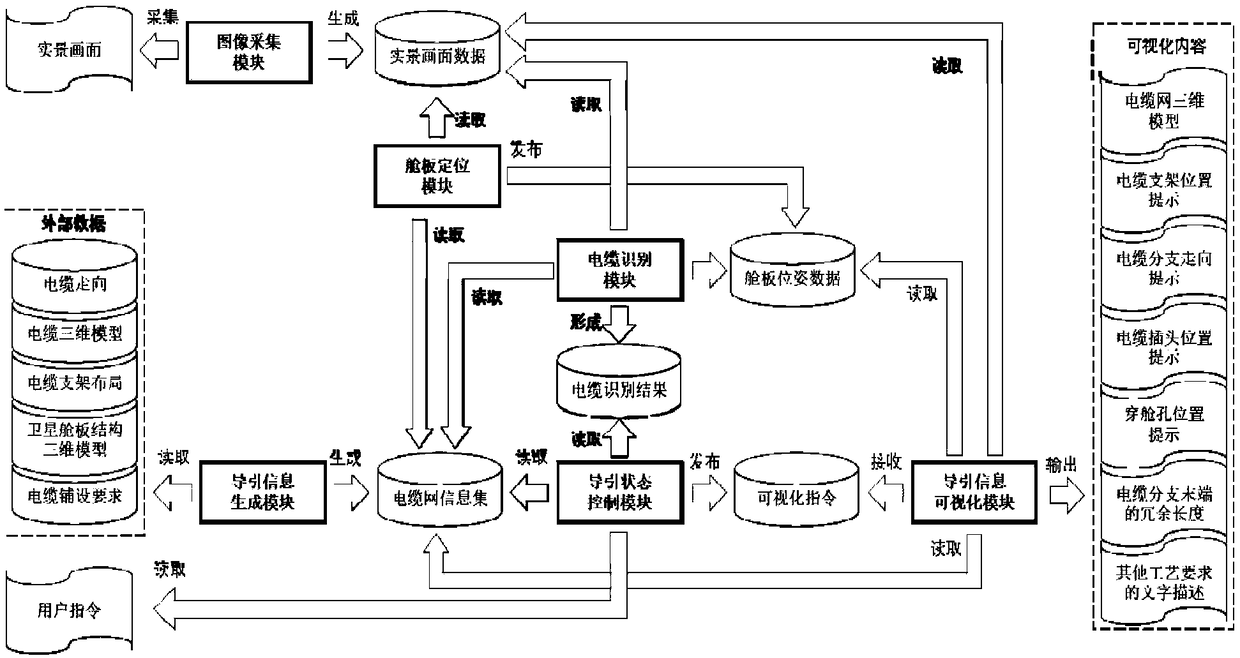

Augmented reality-based satellite cable laying guidance system and method

ActiveCN108664722AImprove laying efficiencyEliminate understandingGeometric CADSpecial data processing applicationsNatural satelliteGuidance system

The invention discloses an augmented reality-based satellite cable laying guidance system. The system comprises a guidance information generation module, an image collection module, a cable identification module, a capsule plate locating module, a guidance information visualization module and a guidance state control module. An operator is guided to quickly realize satellite cable assembly in an augmented reality mode. In addition, the invention discloses an augmented reality-based satellite cable laying guidance method. The cable laying efficiency and the convenience of cable net informationquery in a complex satellite assembly scene are improved; the cable laying error generation efficiency is reduced; and the predefinition process of guidance process information is simplified.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

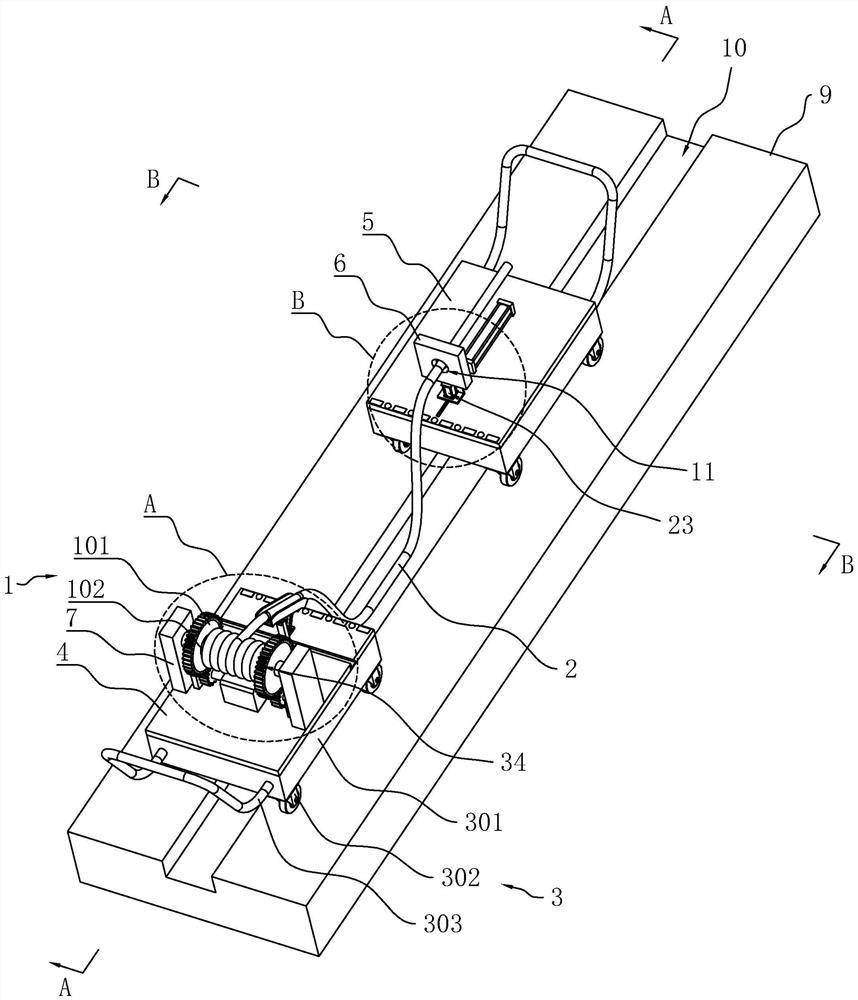

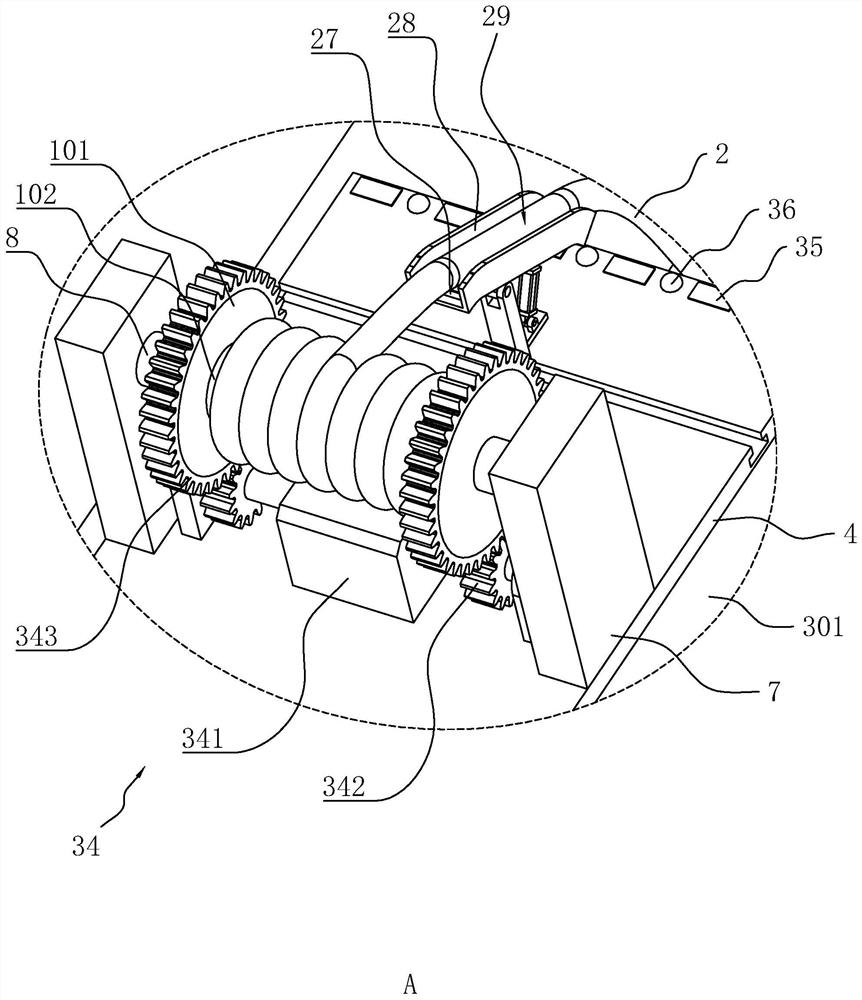

Cable ground laying device

ActiveCN111682455AAvoid affecting power supply reliabilityExtended service lifeApparatus for laying cablesStructural engineeringElectric cables

The invention relates to a cable ground laying device. The invention relates to the technical field of cable laying. The cable ground laying device comprises two trolleys which are oppositely erectedon the ground and located above a cable trench, a pay-off base and a traction base which are installed on the two trolleys respectively, a clamping table which is arranged on the traction base, two supporting tables which are oppositely arranged on the pay-off base, and installation columns which are rotationally arranged on the opposite side walls of the two supporting tables respectively. The side wall of the clamping table is provided with a fixing groove for insertion of a cable. A locking assembly used for fixing the cable is arranged in the fixing groove. An automatic receding assembly used for preventing the cable from making contact with the side wall of the traction base is arranged on the upper surface of the traction base. The two installation columns are fixedly connected withthe two side walls of two cable reels respectively, and a driving assembly used for driving the cable reels to rotate is arranged on the pay-off base. The laying device replaces manpower to drag the cable for laying, which saves time and labor, and improves the cable laying efficiency. Friction damage between the cable and the ground can be prevented, and the power supply reliability of the cableis prevented from being affected.

Owner:南京东瑞水电工程有限公司

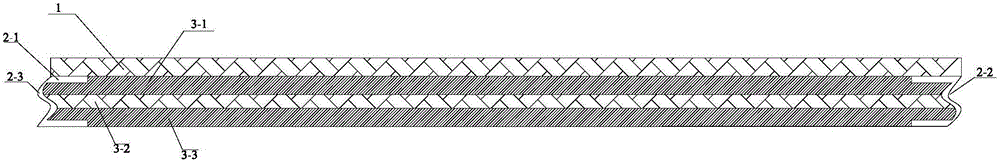

Spliced floor tile, preparation technology and paving technology of spliced floor tile

The present invention relates to a spliced floor tile, a preparation technology and paving technology of the spliced floor tile. The spliced floor tile comprises a tile and a bed shaped and sized to match the tile; the lower surface of the tile and the upper surface of the bed are bonded together; and the side surface of the bed is provide with locking splicing structures which can be matched with each other. The preparation technology of the spliced floor tile includes the preparation of a mold, the preparation of a frame A, the arrangement of a reinforcing steel bar mesh, the paving of plain cement slurry and concrete and the like. The spliced floor tile of the invention is simple in structure and convenient to pave; and the spliced floor tile can be spliced and removed, so that the spliced floor tile can be recycled, and therefore, construction wastes can be to reduced, and update is convenient.

Owner:CSCEC STRAIT CONSTR & DEV

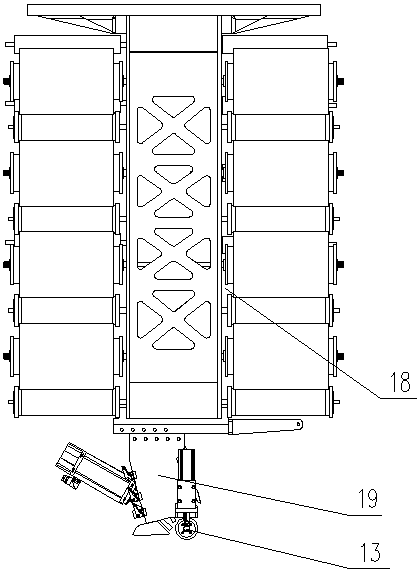

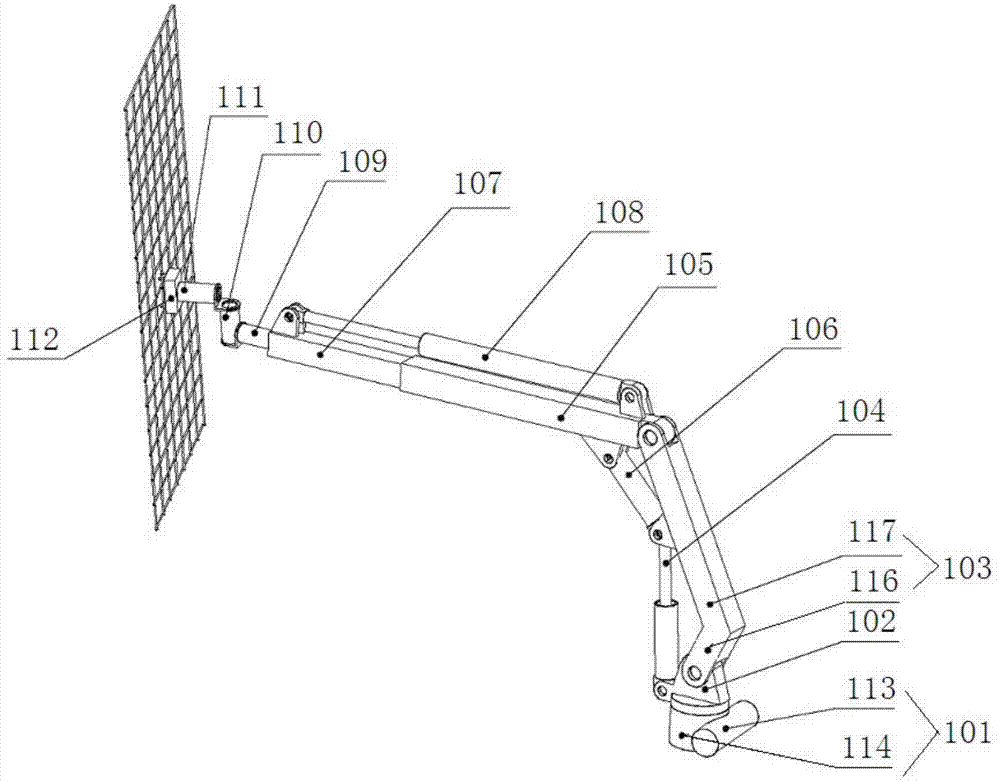

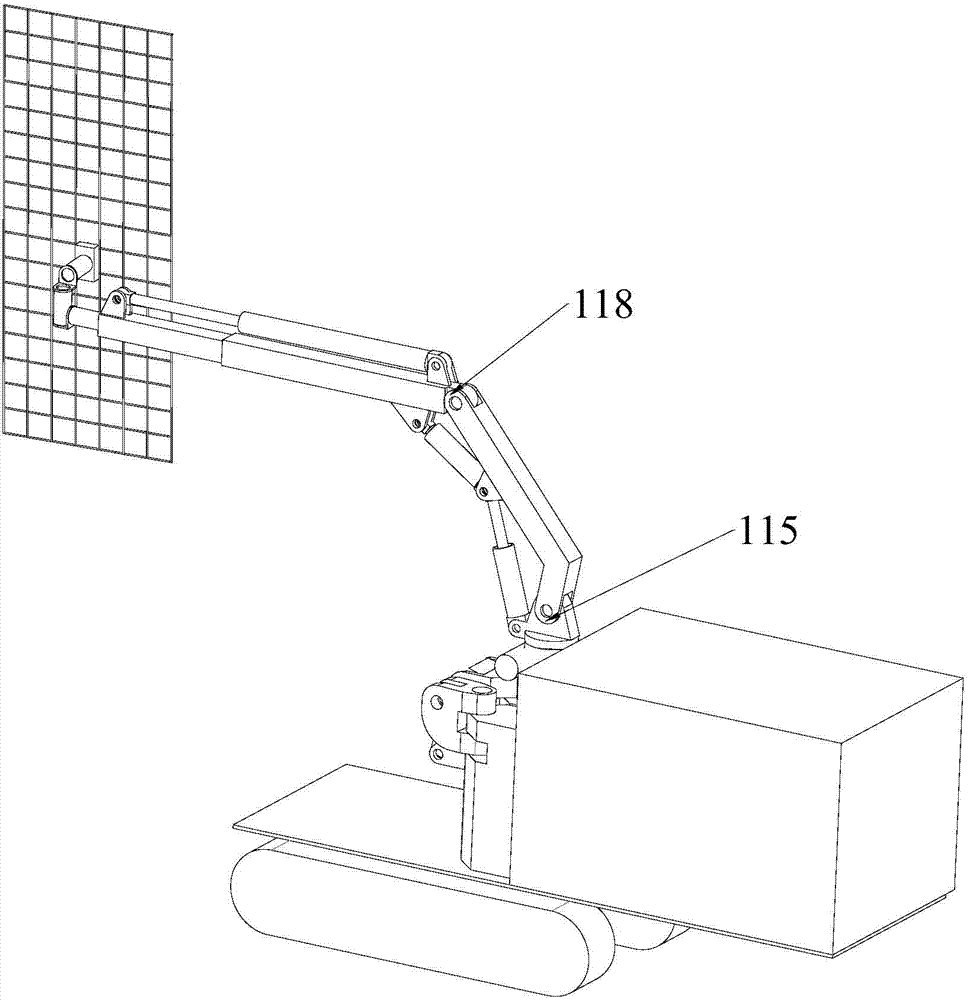

Automatic net paving device of anchor rod drill carriage for coal mine

InactiveCN104847386AAchieve left and right translationRealize up and down translationDerricks/mastsDrilling machines and methodsRotational degrees of freedomRock bolt

The invention discloses an automatic net paving device of an anchor rod drill carriage for a coal mine. The device comprises a rotating base, a lug base, a first arm, a first oil cylinder, a second arm, a second oil cylinder, a third arm, a third oil cylinder, a first spiral swing cylinder, a second spiral swing cylinder, a third spiral swing cylinder and a magnetic manipulator. The automatic net paving device of the anchor rod drill carriage for the coal mine realizes horizontal translation of the magnetic manipulator through the rotation of a worm wheel of the rotating base, realizes vertical translation of the magnetic manipulator through the telescopic motions of the first oil cylinder and the second oil cylinder, realizes front-back translation of the magnetic manipulator through the telescopic motion of the third oil cylinder, and realizes three degrees of rotating freedom of the magnetic manipulator through the rotation of the three spiral swing cylinders; and the magnetic manipulator realizes the grabbing and the pavement of reinforcement meshes, so that the automatic net paving device of the anchor rod drill carriage for the coal mine can realize automatic pavement of the reinforcement meshes so as to improve the paving efficiency of the reinforcement meshes.

Owner:王发秀

Pay-off unit for power construction

InactiveCN107777449AShorten the timeEasy to fixFilament handlingApparatus for laying cablesCable trayArchitectural engineering

The invention discloses a pay-off unit for power construction. The pay-off unit comprises a first supporting plate, wherein the lower surface of the first supporting plate is fixedly connected with the upper surface of a second supporting plate by virtue of four first electric push rods; the four first electric push rods are respectively positioned at four corners of the upper surface of the second supporting plate; a moving device is arranged on the lower surface of the second supporting plate and comprises two first bearings; the two first bearings are respectively clamped on the left and right sides of the lower surface of the second supporting plate; and first rotating shafts are connected into the two first bearings in a sleeving manner. According to the pay-off unit for power construction, due to the arrangement of the first electric push rods, the moving device, a first motor, a clamping plate, second electric push rods, a first gear, a second gear and a second motor, the operation of manually pulling cables is avoided by moving and rotating a cable tray, so that the labor intensity of workers is reduced, the physical strength of the workers is saved, and the cable laying time is shortened; and therefore, the cable laying efficiency is improved.

Owner:成都一叶舟科技有限公司

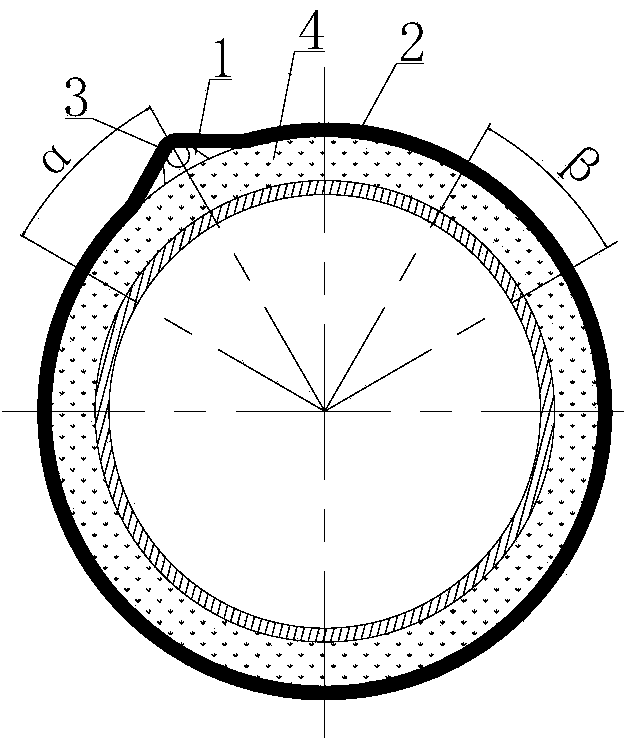

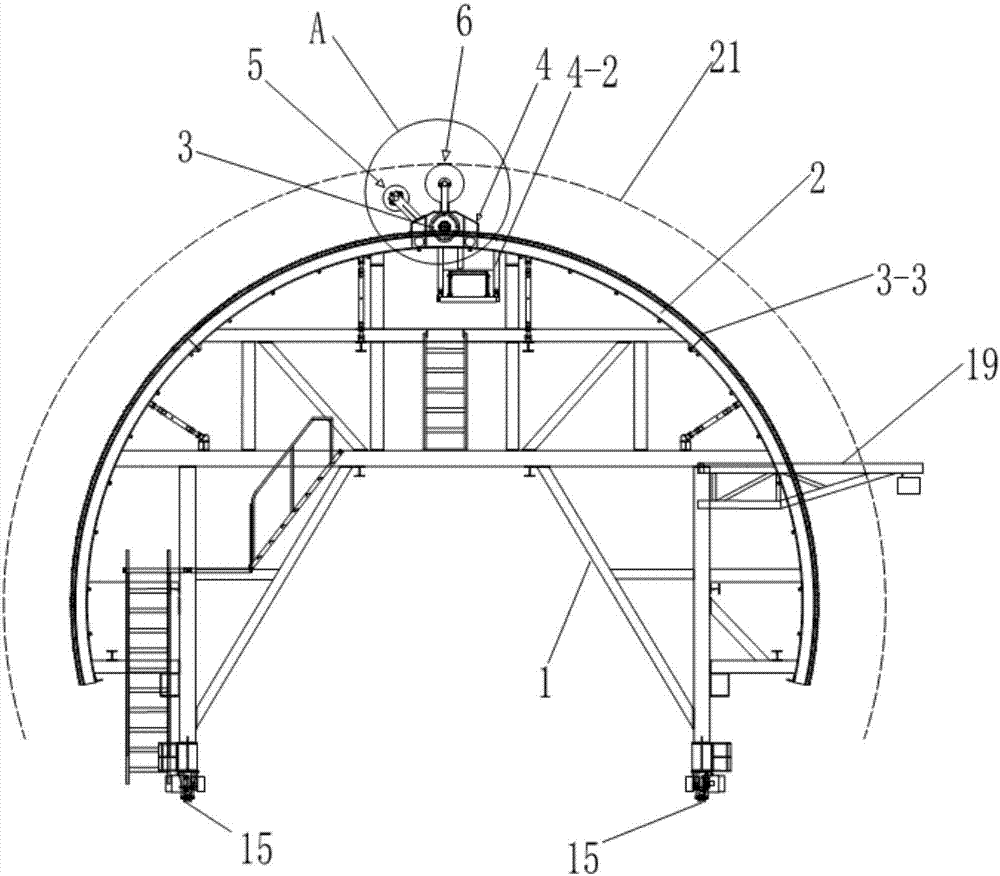

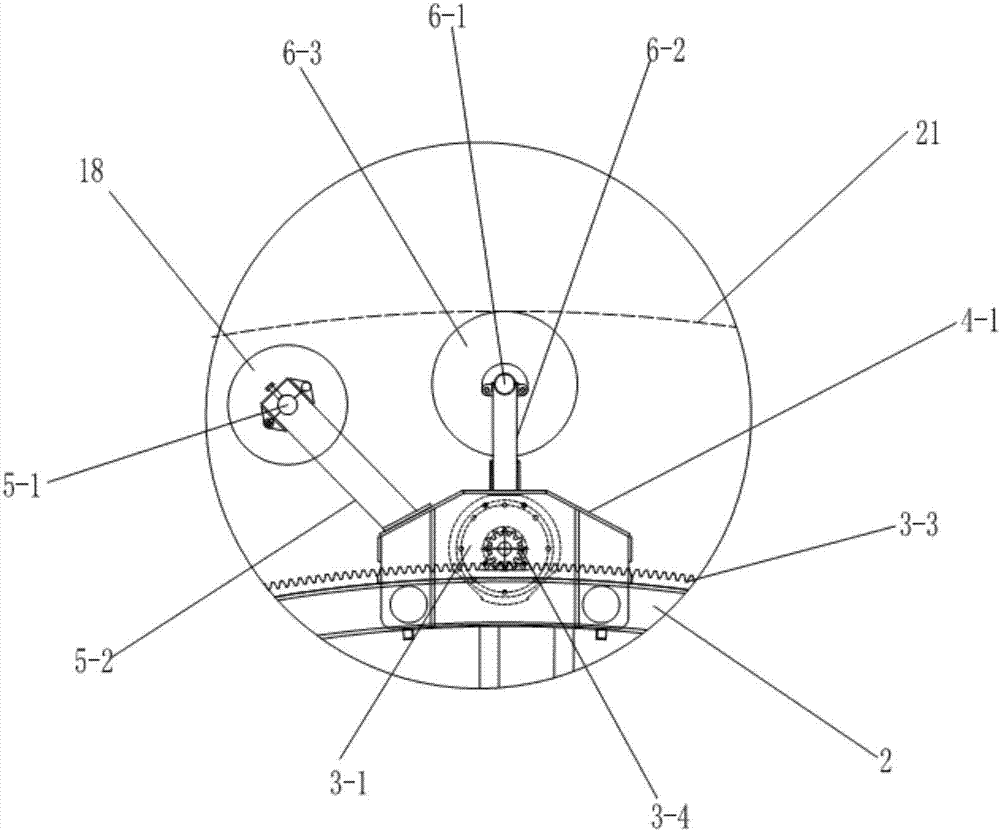

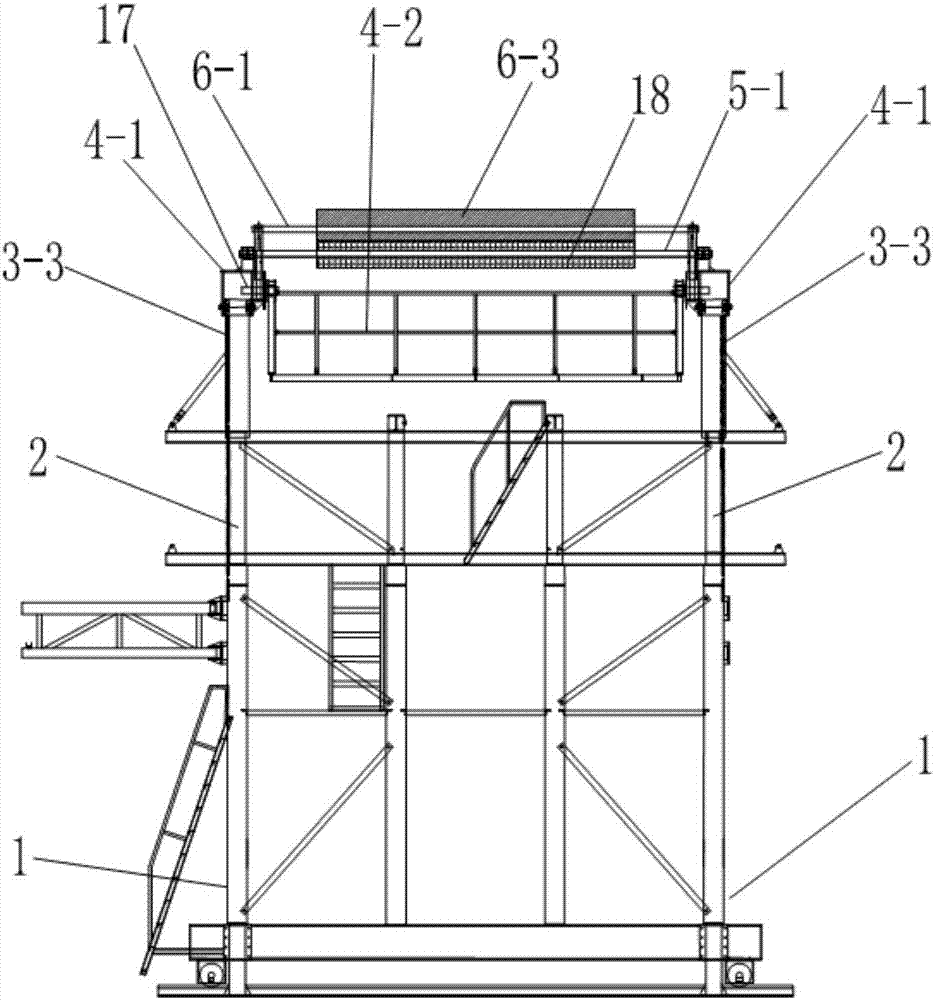

Tunnel waterproof plate laying trolley

ActiveCN107327309AGuarantee laying qualityFit tightlyUnderground chambersTunnel liningThrough transmissionEngineering

The invention discloses a tunnel waterproof plate laying trolley which comprises a plurality of trolley portals which are distributed in parallel. The trolley portals are provided with arch rings matched with the inner wall of a tunnel. A climbing mechanism is arranged on every two adjacent arch rings. The climbing mechanisms are installed on the arch rings in a transmission mode through transmission assemblies. A laying assembly and a leveling assembly are arranged on each climbing mechanism. Each climbing mechanism comprises two climbing boxes which are connected to the two corresponding adjacent arch rings in a transmission mode respectively, and a climbing trolley installed between the two climbing boxes, wherein the climbing trolley is installed on the climbing boxes through rotating shafts in a rotating mode. The climbing mechanisms can move in the circumferential direction of the arch rings, in this way, the laying assemblies can be driven to lay waterproof plates along the inner wall of the tunnel, meanwhile the leveling assemblies can level up the waterproof plates laid on the inner wall of the tunnel, it is guaranteed that the waterproof plates laid on the inner wall of the tunnel are closely attached to the inner wall of the tunnel, the laying efficiency of the waterproof plates is improved, and the laying quality of the waterproof plates is effectively guaranteed.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

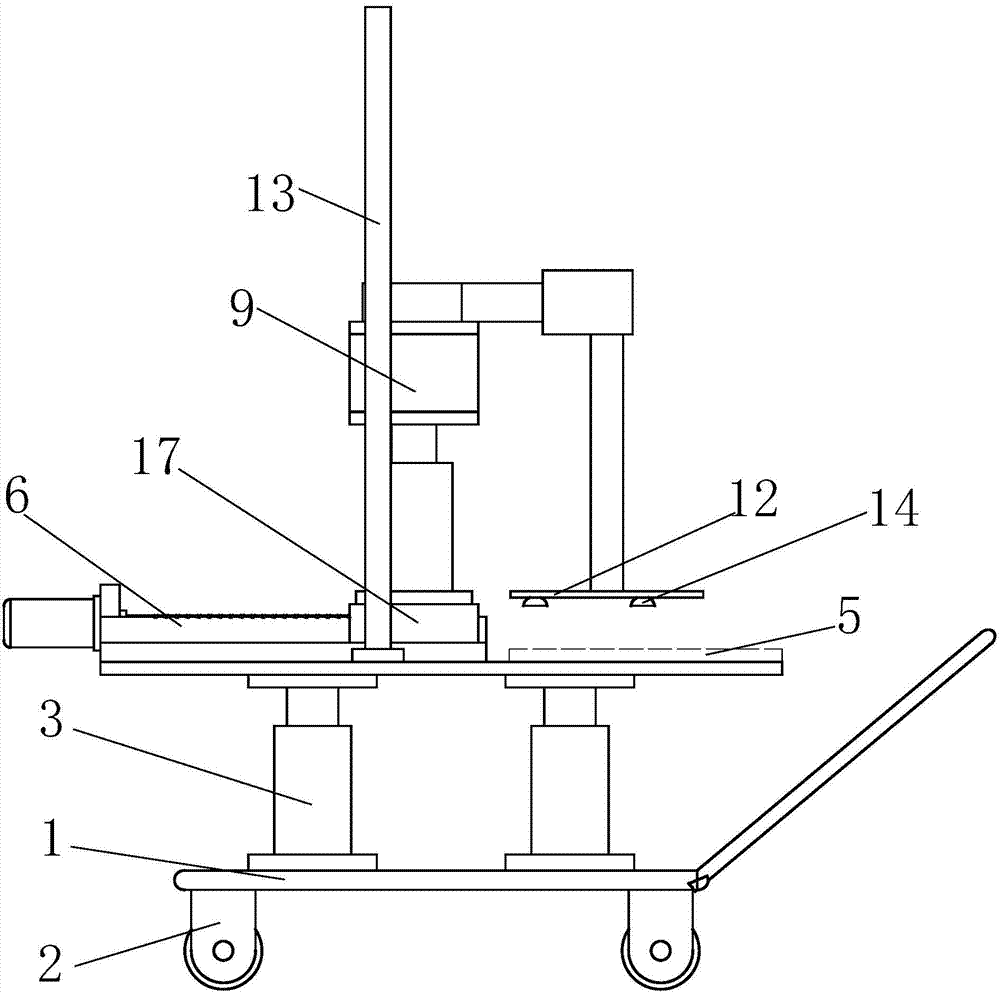

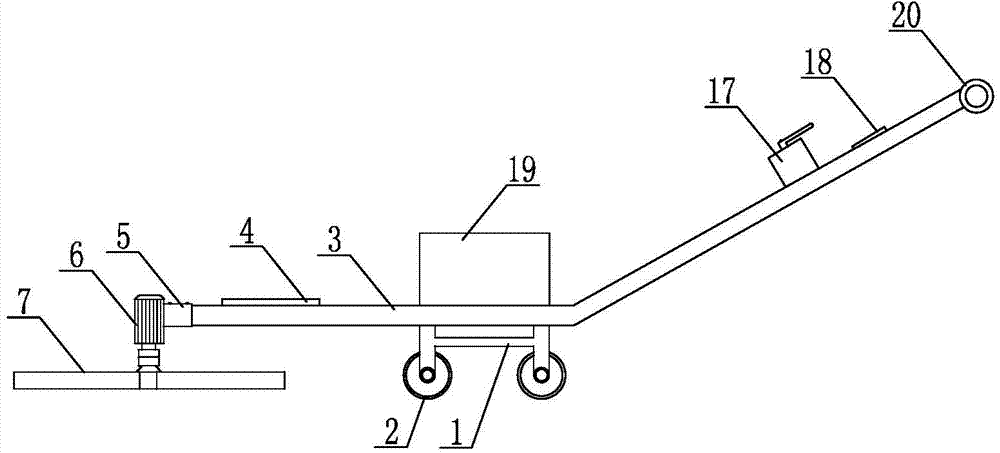

Laying machine

ActiveCN104499696AAutomatic layingPlay a protective effectBuilding constructionsEngineeringReference alignment

The invention relates to a laying machine. The laying machine comprises a machine body, travelling wheels, a reference alignment device and a loading laying device, wherein the travelling wheels are fixed at the bottom of the machine body, a handle is arranged at the front part of the machine body, the reference alignment device is mounted on the upper end surface of the machine body, and the loading laying device is mounted at the middle part of the upper end of the reference alignment device. The laying machine disclosed by the invention has the advantages of being reasonable in structural design, high in automation degree, convenient to operate and control, and the like, can realize automatic laying of ceilings, replaces a traditional manner that builders climb a ladder for laying, improves the laying efficiency and has the protective effect on the builders.

Owner:WUHU YINXING AUTO PARTS

Floor tile laying machine and method for laying floor tiles through machine

ActiveCN104746859ASave effortImprove laying efficiencyBuilding constructionsEngineeringUnit structure

The invention discloses a floor tile laying machine. The machine comprises a rack and rollers and further comprises a sand cement leveling unit and a floor tile absorption laying unit. A mounting horizontal rod extending forwards is arranged at the front end of the rack, a level gauge is fixed on the mounting horizontal rod. The sand cement leveling unit and the floor tile absorption laying unit are mounted at the end of the mounting horizontal rod detachably alternately. A power supply is arranged on the rack and is electrically connected with the sand cement leveling unit or the floor tile absorption laying unit. The invention further relates to a method for laying floor tiles through the machine. By means of the sand cement leveling unit, sand cement stacked on laying places can be leveled, floor tiles can be absorbed and transferred to laying positions through the floor tile absorption laying unit, the laid floor tiles can be leveled and fixed, and accordingly, the floor tile laying can be completed through the laying machine for one step. The machine is effort saving to be used, high in laying efficiency, simple in unit structure and convenient to operate.

Owner:SHANDONG ELECTRIC POWER CONSTR NO 2

Electric power communication engineering cable laying device

PendingCN111799703ANot easy to damageAvoid wear damageFilament handlingCleaning using toolsEngineeringStructural engineering

The invention discloses an electric power communication engineering cable laying device which comprises a base, a first supporting plate, a second supporting plate, a guide roller mechanism and a guide mechanism. The guide roller mechanism and the guide mechanism are sequentially arranged according to the moving direction of a cable; one end of the first supporting plate is arranged on the upper surface of the base, and the second supporting plate can move up and down along the first supporting plate; the guide roller mechanism comprises two guide rollers and a guide roller frame, the guide roller frame is fixedly arranged on the upper surface of the second supporting plate, the guide rollers are rotatably mounted on the guide roller frame, and a gap allowing a cable to penetrate through is formed between the two guide rollers; the guide mechanism comprises two guide wheels and a guide wheel frame, the guide wheel frame is fixedly arranged on the upper surface of the second supportingplate, the guide wheels are rotatably installed on the guide wheel frame, and a gap allowing a cable to penetrate through is formed between the two guide wheels. When cables are laid, the cables are not easy to abrade and pull apart.

Owner:ZHONGWEI POWER SUPPLY COMPANY OF STATE GRID NINGXIA ELECTRIC POWER

Wall tile gluing device and wall tile gluing and laying robot

ActiveCN110607896AImprove gluing efficiencySmall footprintBuilding constructionsEngineeringMechanical engineering

The invention discloses a wall tile gluing device and a wall tile gluing and laying robot. The wall tile gluing device comprises a tile discharging box for storing to-be-glued tiles, a tile receivingbox for receiving the glued tiles, a gluing mechanism, a tile conveying mechanism and a lifting driving mechanism, wherein the gluing mechanism is used for coating the back surface of the tiles with tile glue; the tile conveying mechanism is used for conveying the to-be-glued tiles from the tile discharging box to the gluing mechanism and conveying the glued tiles to the tile receiving box; the lifting driving mechanism is configured to drive the tile receiving box, the tile conveying mechanism and the gluing mechanism to lift together. The wall tile gluing device achieves automatic gluing andgreatly improves gluing efficiency of the wall tiles, the tile receiving box, the tile conveying mechanism and the gluing mechanism can be driven to descend together by distance of one tile after gluing of one tile, the next tile is glued continuously, and space can be saved by the structural design.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Mulching film machine for garden road construction

ActiveCN110055868AImprove laying efficiencyImprove spreading efficiencyRoads maintainencePlastic mulchEngineering

The invention discloses a mulching film machine for garden road construction. According to the technical scheme, the mulching film machine comprises a frame body, a first travelling roller and a second travelling roller, and the first travelling roller and the second travelling roller are arranged on the frame body, rotatably connected with the frame body, and parallel to each other; the frame body is provided with a mulching film paving device and a water spraying device, and a pulling rope driving the frame body to move is arranged on one side of the frame body; the mulching film paving device comprises a support roller erected on the frame body and a mulching film roll-collected on the circumferential surface of a support shaft, the support roller is rotatably connected with the frame body, and the support roller is further parallel to the first travelling roller; when the frame body is moved, the end part of the mulching film is pressed on the lower part of the first travelling roller; and the water spraying device comprises a water tank arranged on the frame body, a first water outlet pipe, a water pump, a second water outlet pipe and a spraying nozzle, the first water outletpipe, the water pump, the second water outlet pipe and the spraying nozzle are sequentially connected with the water tank, and the spraying nozzle is arranged on the second travelling roller and sprays towards the direction deviating from the first travelling roller. The mulching film machine for garden road construction has the advantages that water spraying and mulching film paving can be conducted simultaneously.

Owner:北京绿视点园林景观工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com