Paving device for floor tiles

A technology for laying devices and floor tiles, which is applied in the direction of construction and building construction, can solve the problems of large labor consumption, low laying efficiency, and low degree of automation, and achieve the effects of increasing automation, improving laying efficiency, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

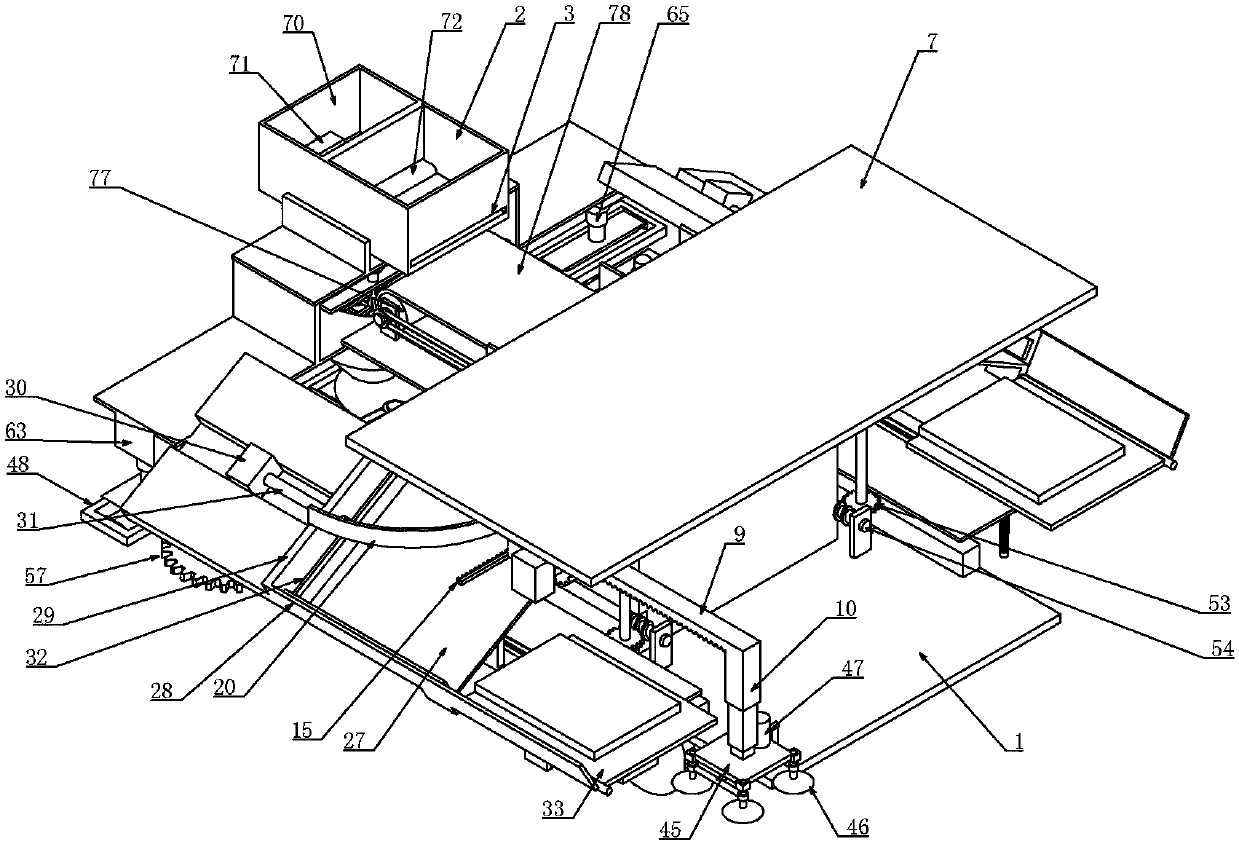

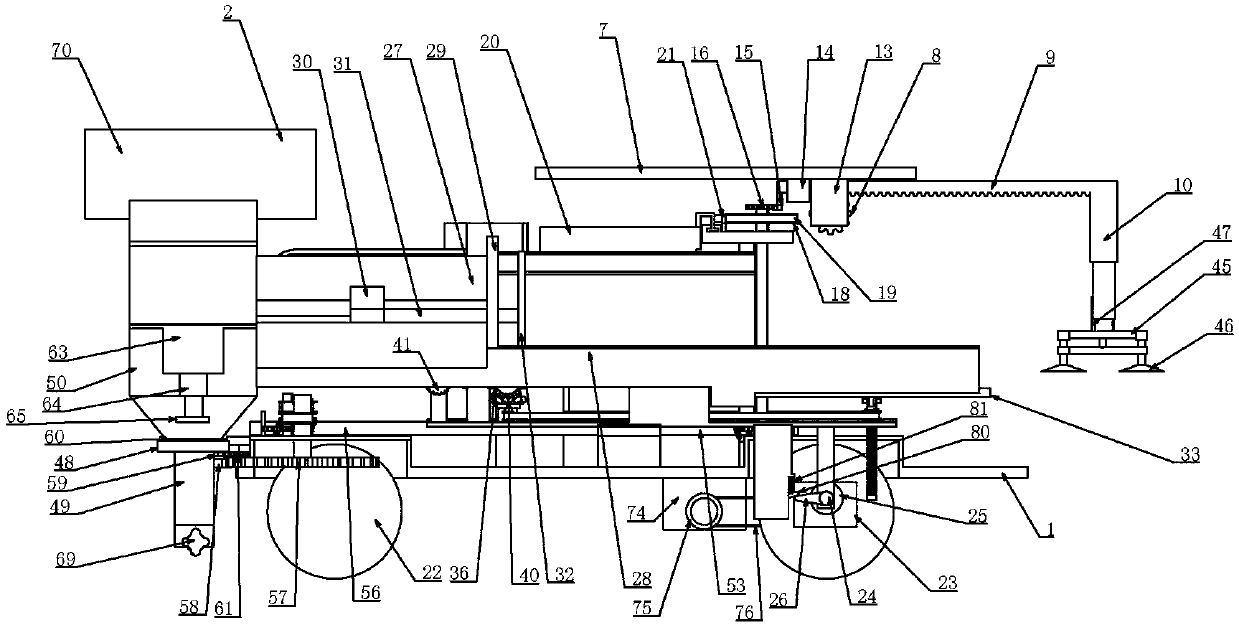

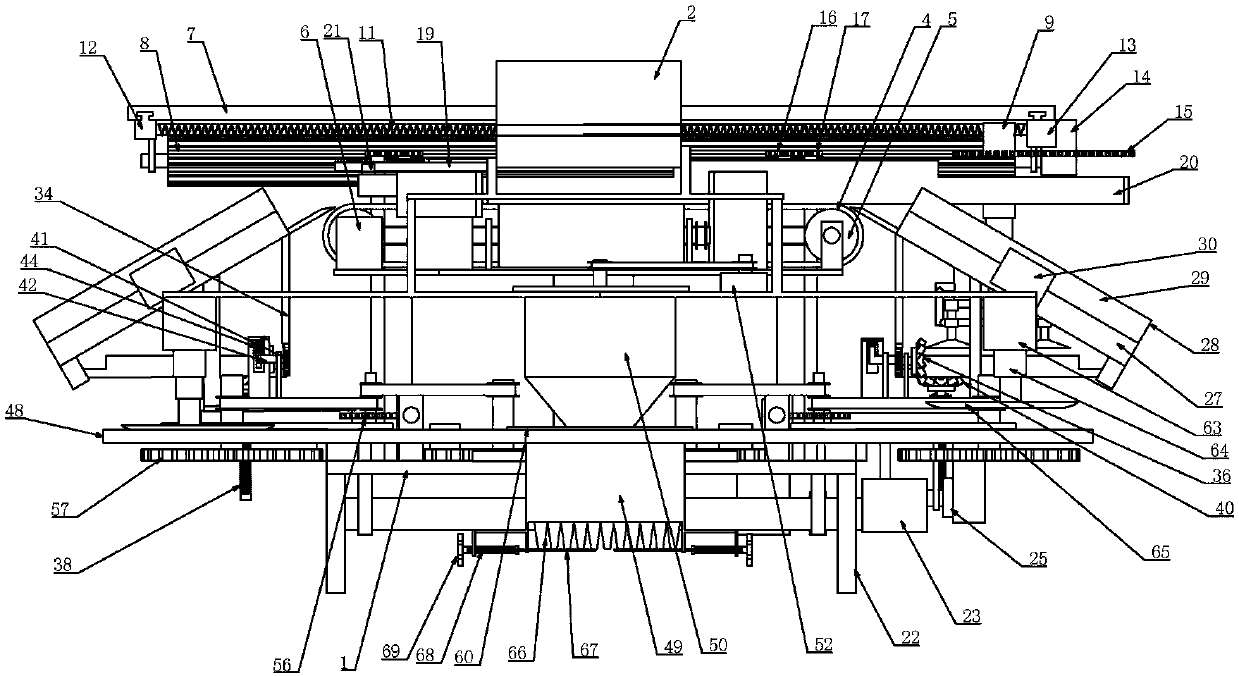

[0040] Example one, combined with Figure 1-17 , A floor tile laying device, comprising a frame 1, characterized in that the upper end of the frame 1 is connected to a brick storage box 2, the upper end of the storage transfer box is open, and the size of the brick storage box 2 matches the size of the tiles to be laid , Or slightly larger than the size of the tiles to be laid, there is a brick outlet 3 at the lower end of the right side of the storage box, and the brick outlet 3 is opened on the right side of the bottom of the storage box. A tile can be produced, the brick outlet 3 is elongated, the brick storage box 2 is connected with a pushing device, and the pushing device can push the floor tiles in the brick storage box 2 from the brick outlet 3, and the pushing device is connected The controller, the controller can trigger the pushing device to complete a stroke, and then push the tiles in the storage box from the brick outlet 3. The pushing device here will be given in...

Embodiment 2

[0044] The second embodiment, on the basis of the first embodiment, combined with the attached Figure 1-17 The tilting device includes an object receiving plate 27 arranged at the exit of the transition belt 4 and placed obliquely. The lower end of the object receiving plate 27 extends out of a barrier 28, and the object receiving plate 27 is formed between the barrier 28 The connecting plate 27 can place the floor tiles on the transition belt 4 on the connecting plate 27. Since the floor tiles are square, when sliding on the connecting plate 27 to the stop bar 28 at the bottom of the connecting plate 27, Self-alignment due to gravity. Of course, the upper end surface of the object plate 27 should be smooth enough. The object plate 27 is connected with a partition rod 29, which is arranged longitudinally along the object plate 27 at its upper end. A hydraulic cylinder 30 placed on the left side of the partition plate is connected to the object plate 27. The hydraulic cylinder ...

Embodiment 3

[0045] The third embodiment, on the basis of the first embodiment, combined with the attached Figure 1-17 The grasping device includes a horizontal plate 45 installed at the lower end of the electric telescopic rod 10, four sets of vacuum suction cups 46 are connected around the horizontal plate 45, and the vacuum suction cup 46 is connected to the upper end of the horizontal plate 45 through a gas pipe. In the vacuum pump 47, the vacuum pump 47 is connected to the control module through the controller. The grasping device here adopts the structure of the vacuum suction cup 46. The structure of the vacuum suction cup 46 has an ideal grasping effect and reliable grasping. The controller and control Module connection, the vacuum pump 47 is controlled by the control module to pump and deflate the working state, so as to complete the grasping and lowering actions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com