Patents

Literature

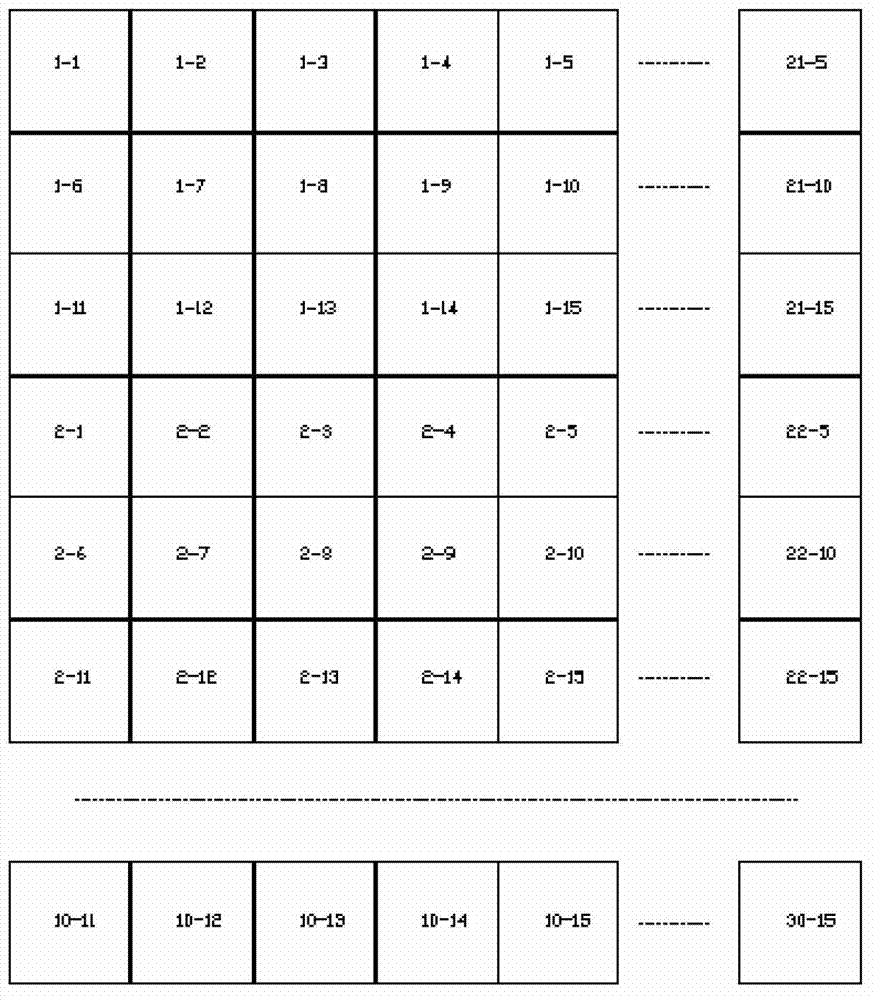

89results about How to "Guarantee laying quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

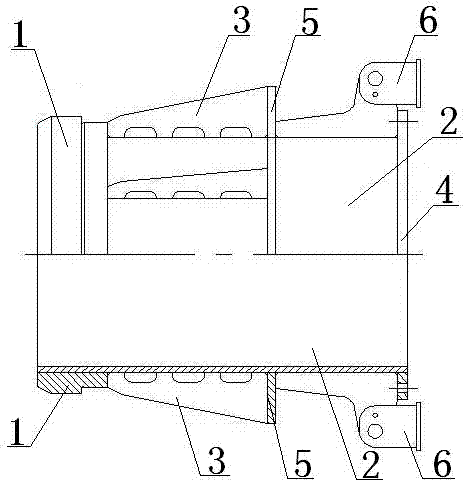

Waterproof board installation trolley for tunnel

ActiveCN106194220ACompact structureImprove construction efficiencyUnderground chambersTunnel liningEngineeringRebar

The invention discloses a waterproof board installation trolley for a tunnel and belongs to the technical field of tunnel construction. The waterproof board installation trolley comprises a main body rack and a walking mechanism. Arc-shaped crawling rails are installed at the two ends of the main body rack correspondingly. The walking mechanism is installed at the bottom of the main body rack. The waterproof board installation trolley further comprises a winding and unwinding mechanism, a jacking mechanism and a locating mechanism. The jacking mechanism is fixedly connected with the main body rack and used for jacking a completely unwound waterproof board or bound rebars in place. The locating mechanism is connected to the lower end of the main body rack. The locating mechanism places the coiled waterproof board through a drawer type structure and is used for making the waterproof board be located and providing support for winding and unwinding of the waterproof board. The winding and unwinding mechanism comprises a drum, a clamping structure and a crawling structure. The drum is assembled in a subsection mode. According to the waterproof board installation trolley, overall jacking, fast function conversion and rail type walking are achieved, the height of the main body rack can be adjusted, and laying of the wide waterproof board and jacking of the rebars can be conducted.

Owner:SHIJIAZHUANG TIEDAO UNIV

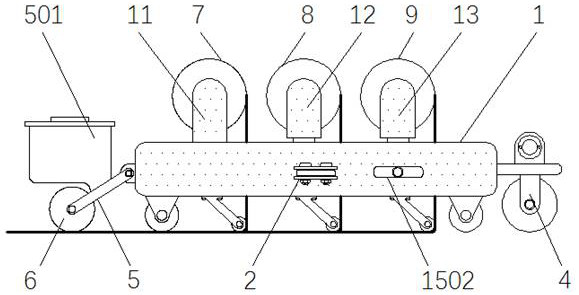

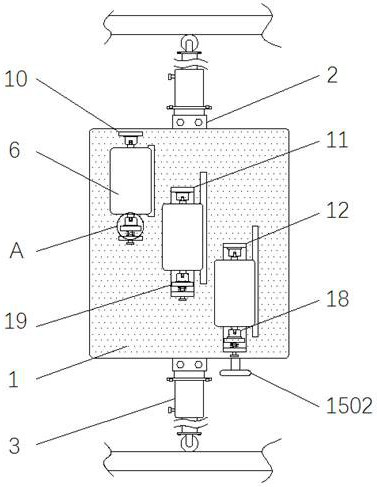

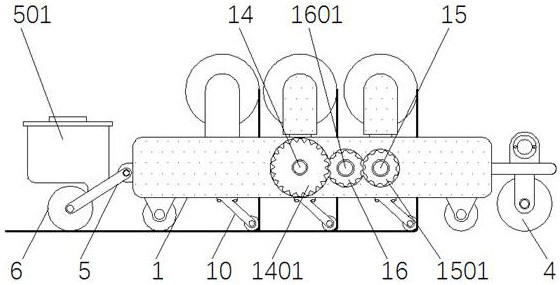

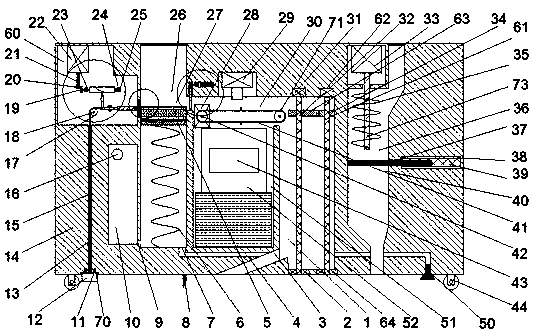

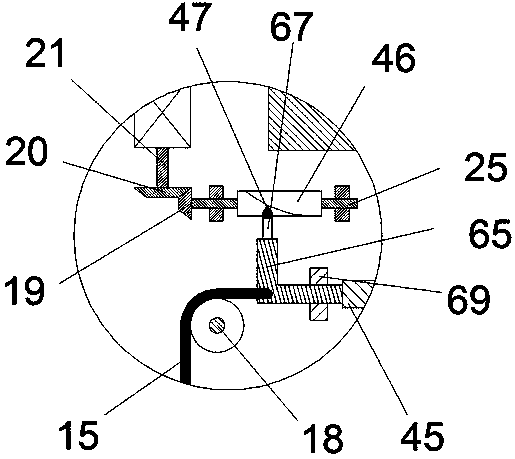

Automatic intelligent equipment for efficiently paving building surface layer and paving method of equipment

InactiveCN102808502AReduce in quantityReduce labor intensityBuilding constructionsSurface layerEngineering

The invention relates to automatic intelligent equipment for efficiently paving a building surface layer and a paving method of the equipment. The equipment comprises a body, a base platform, a multi-shaft motion mechanism and a multifunctional fixture, wherein the base platform is arranged on the body; the multi-shaft motion mechanism is arranged on the base platform; the multifunctional fixture is arranged on the multi-shaft motion mechanism; a levelness measuring sensor and a horizontal adjustment support pillar are also arranged on the base platform and used for automatically leveling the base platform; a running device is also arranged on the body and used for horizontally moving the whole equipment; the multi-shaft motion mechanism is a motion mechanism of more than two dimensions; and a taking and putting device, a spraying device and an information acquisition module are arranged on the multifunctional fixture. A vision device is used for intelligent identification, and a distance measuring device scans the height of an area to be paved, and is matched with a high-accuracy multi-dimensional motion mechanism, so that the building surface layer can be fully automatically paved at high accuracy.

Owner:中瑞华(北京)科技有限公司

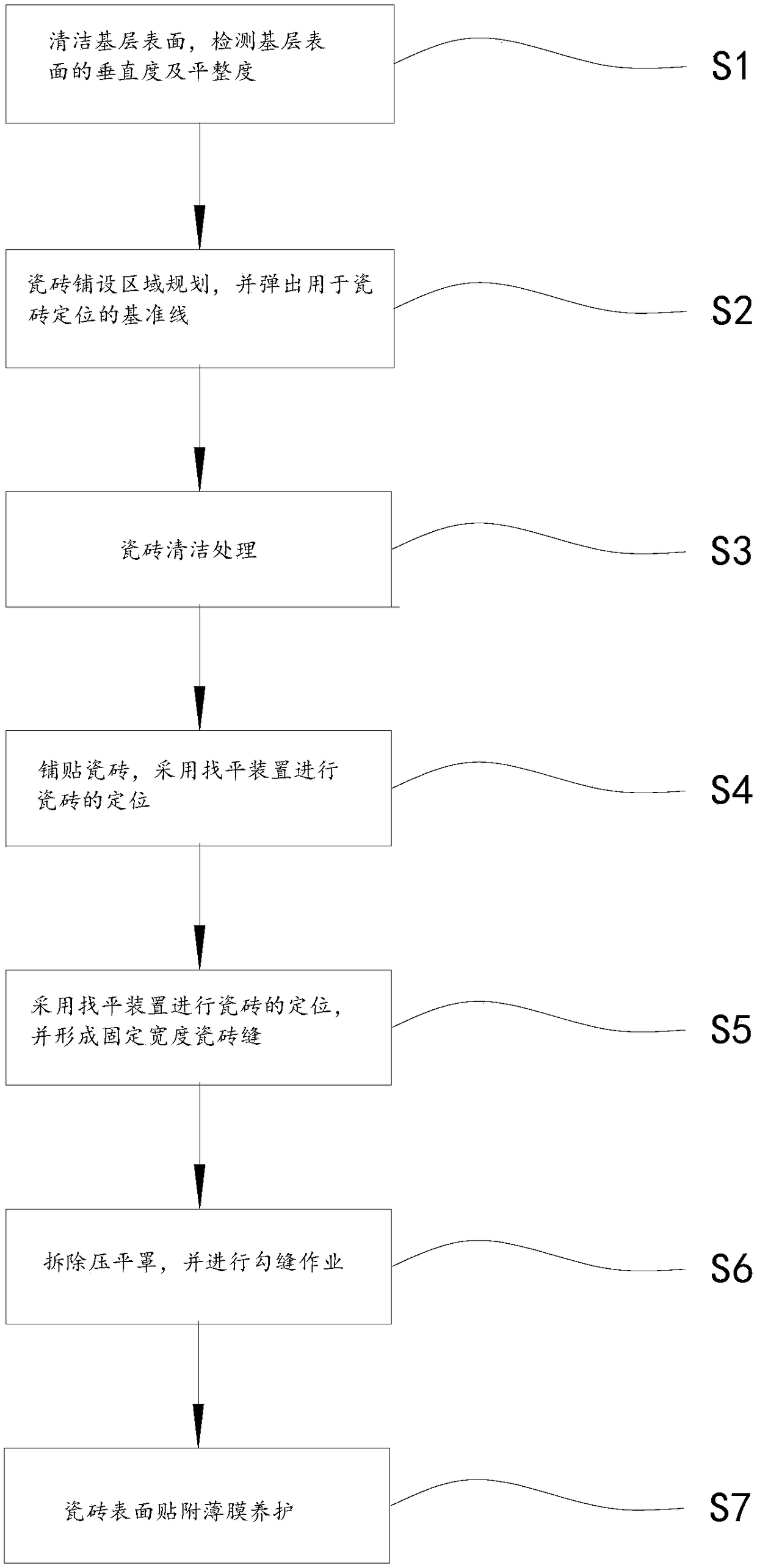

Tile paving method

InactiveCN108222450AAvoid misalignmentGuaranteed aestheticsBuilding constructionsDislocationCivil engineering

The invention provides a tile paving method. The tile paving method comprises the following steps that the base surface is cleaned, and the perpendicularity and flatness of the base surface are detected; planning is carried out according to an area needed to be tiled, and the vertical and horizontal datum lines used for tile positioning are popped up; tiles are cleaned, and it is ensured that corners and the two surfaces of the tiles are free of oil fouling; the tiles are paved, the tiles are positioned using a leveling device, the tiles are leveled using the leveling device, and the tile seamwidth formed between every two adjacent tiles is 1.5-3 mm; after mortar is solidified, a flattening cover is removed, and pointing operation is carried out; and after the pointing is completed, a thin film is attached to the surface of the tiles after paving for conserving for 5-10 days. According to the tile paving method, dislocation phenomenon of the tiles is avoided during leveling, gaps between the tiles are controlled to be reasonable, and the beauty and practicability of the tiles after paving are enhanced.

Owner:广州炬隆卫浴制品有限公司

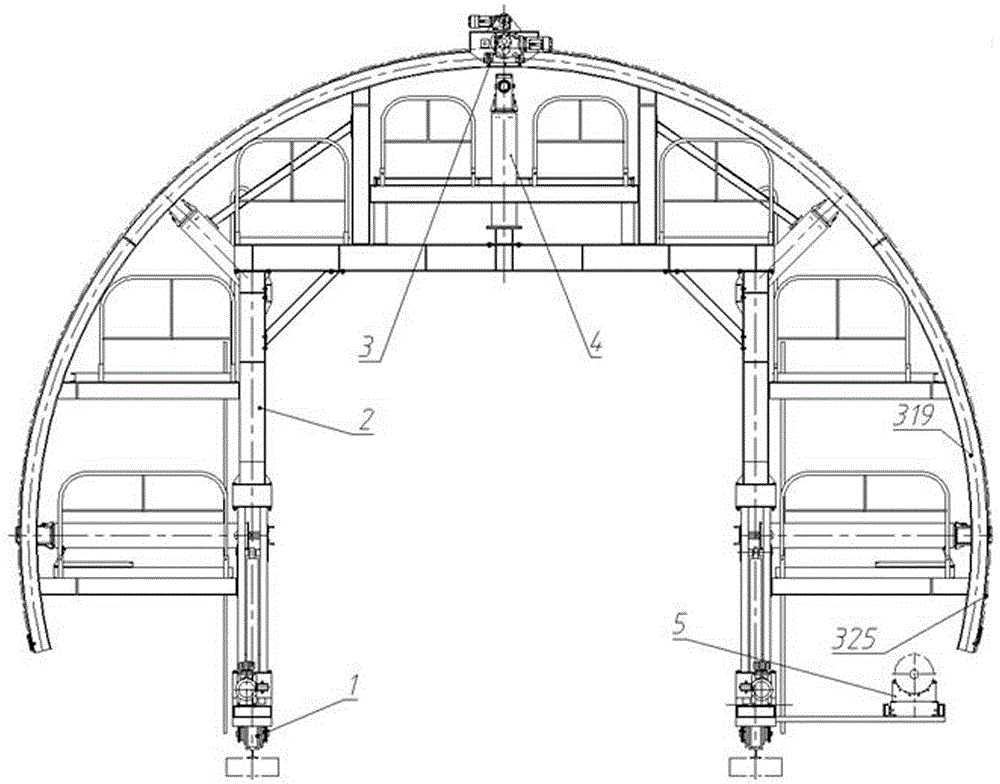

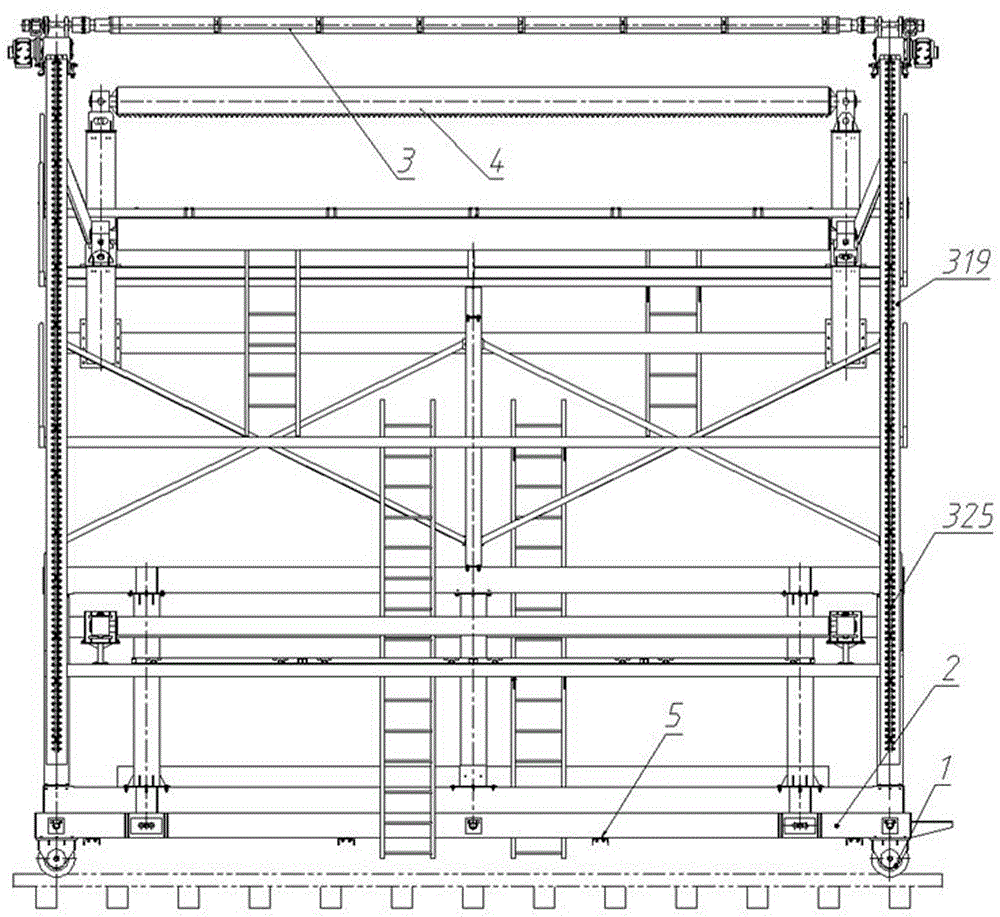

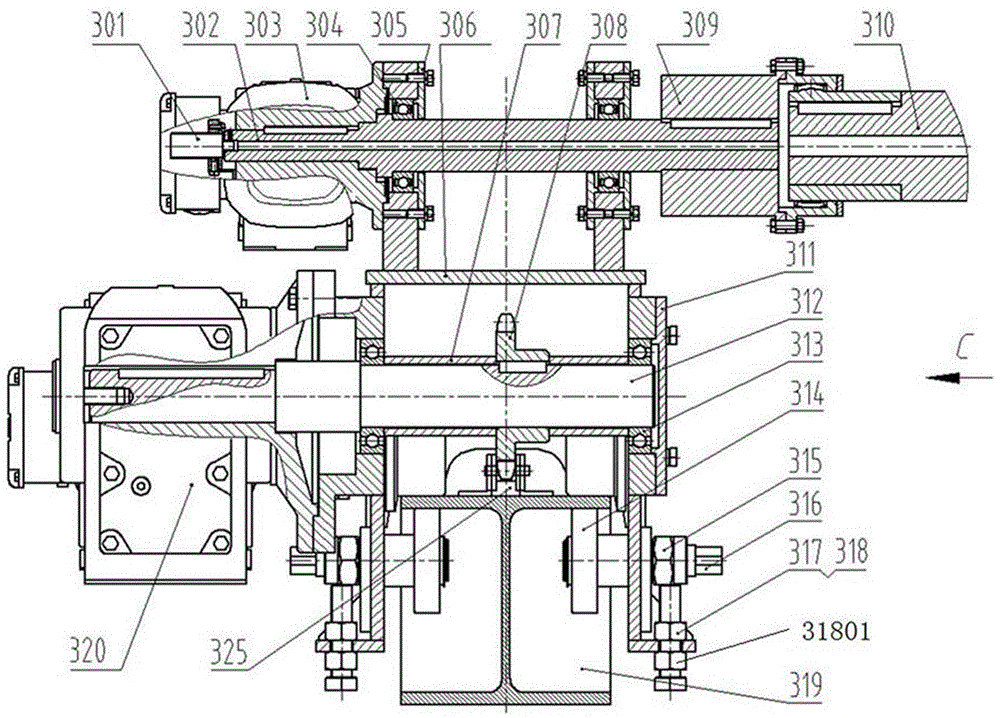

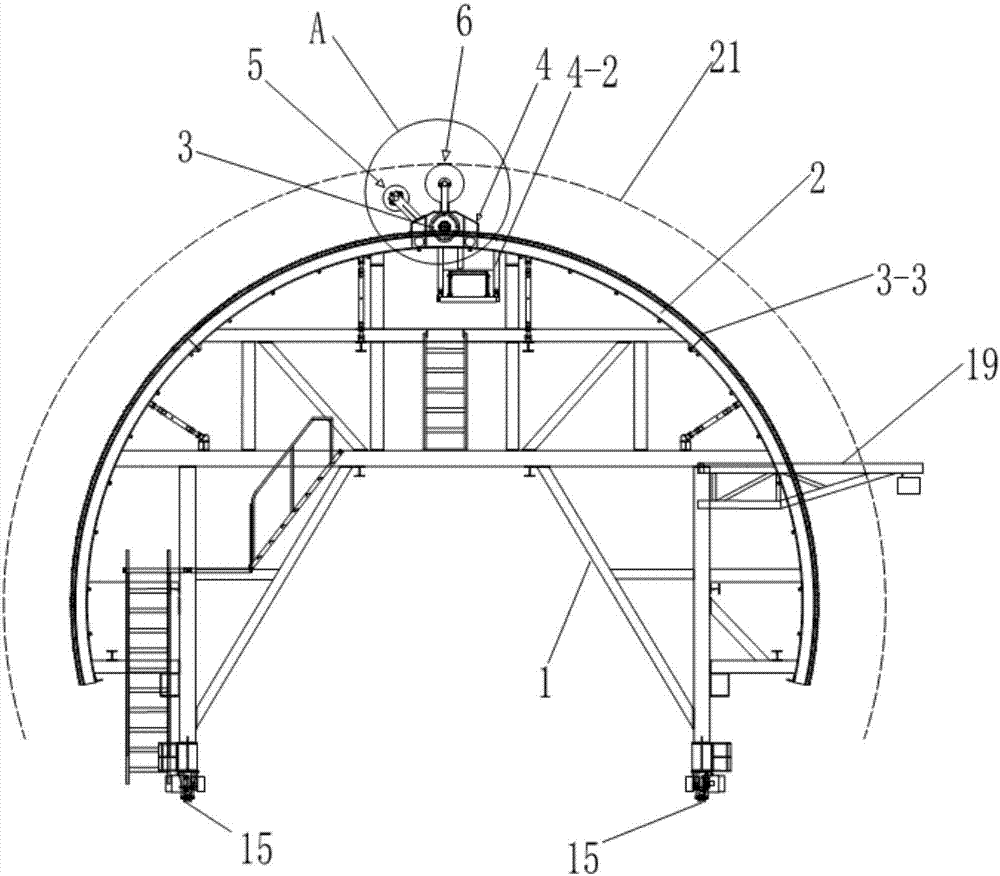

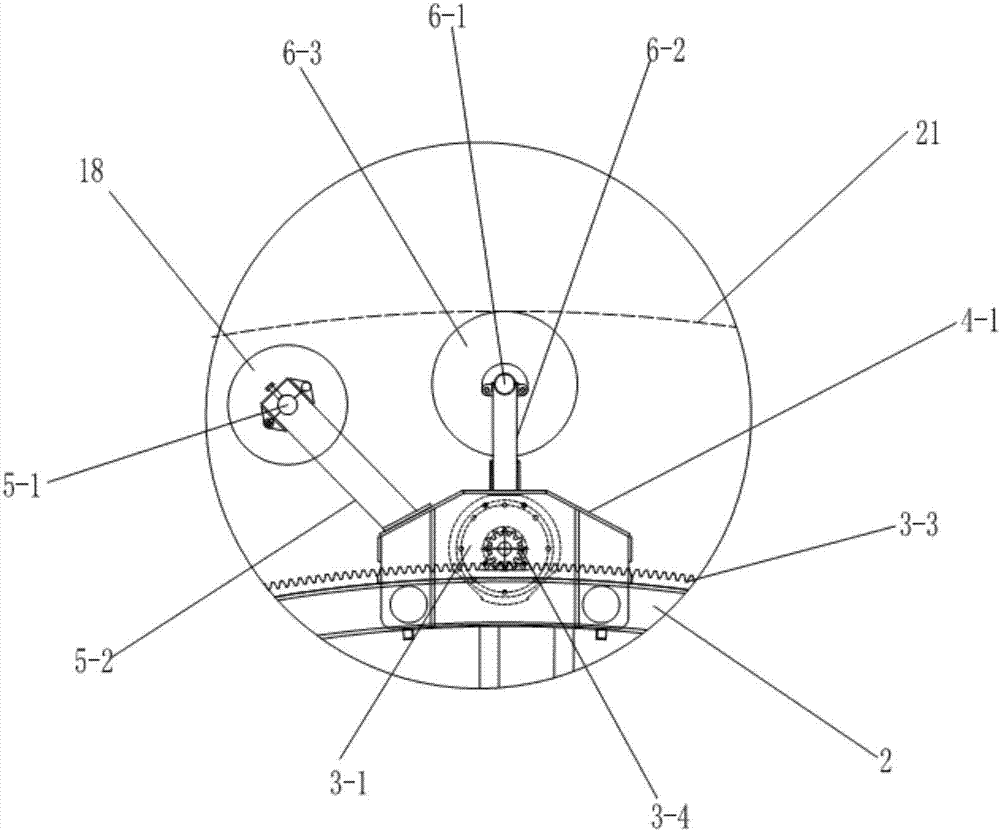

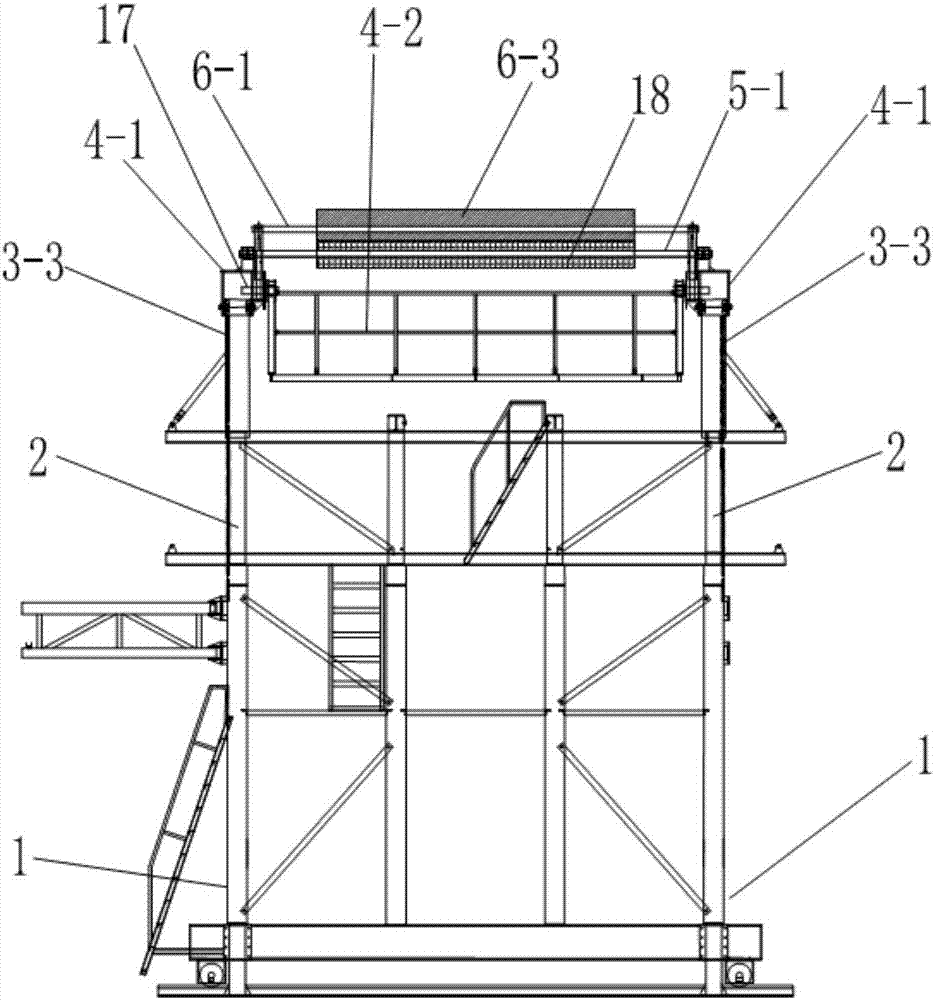

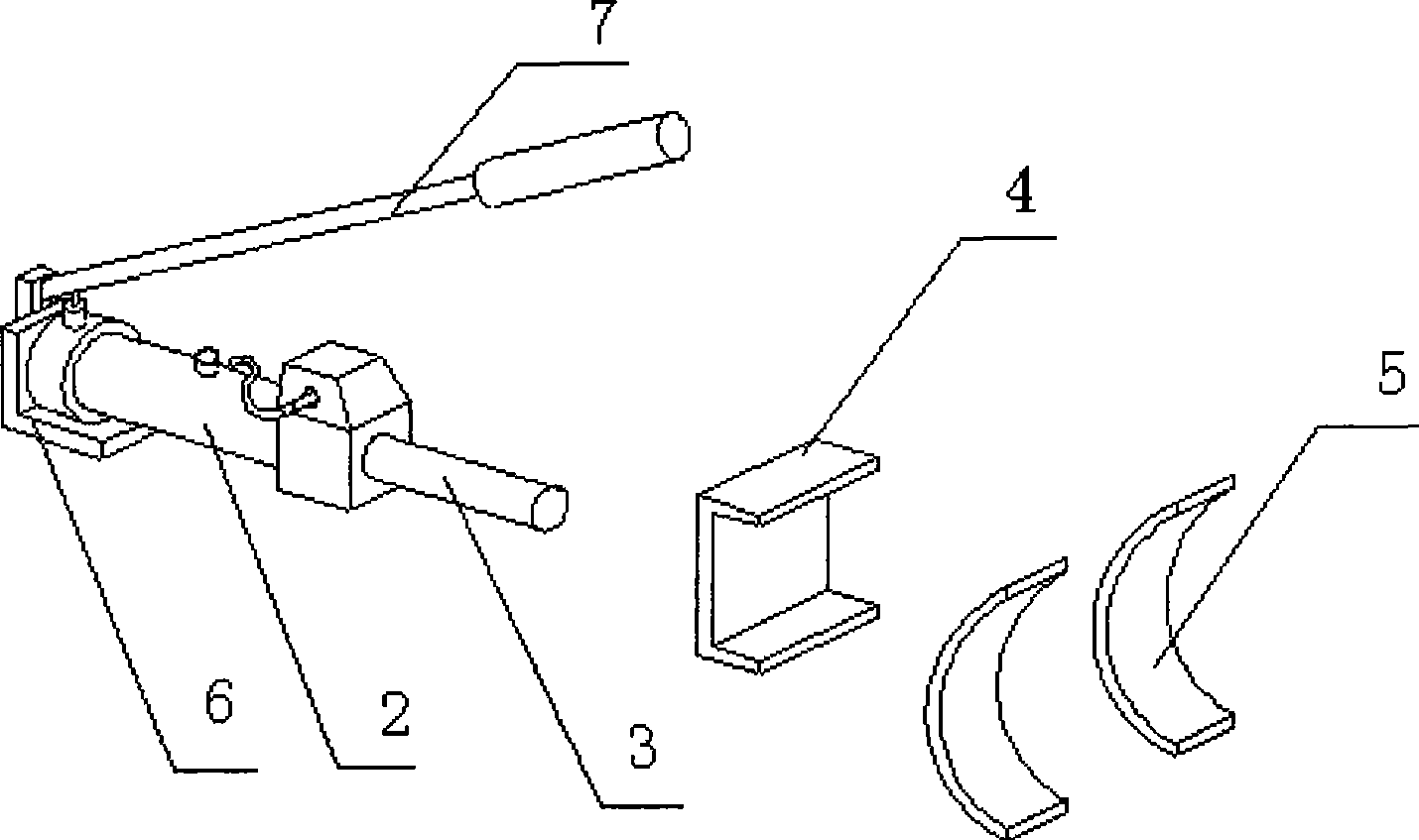

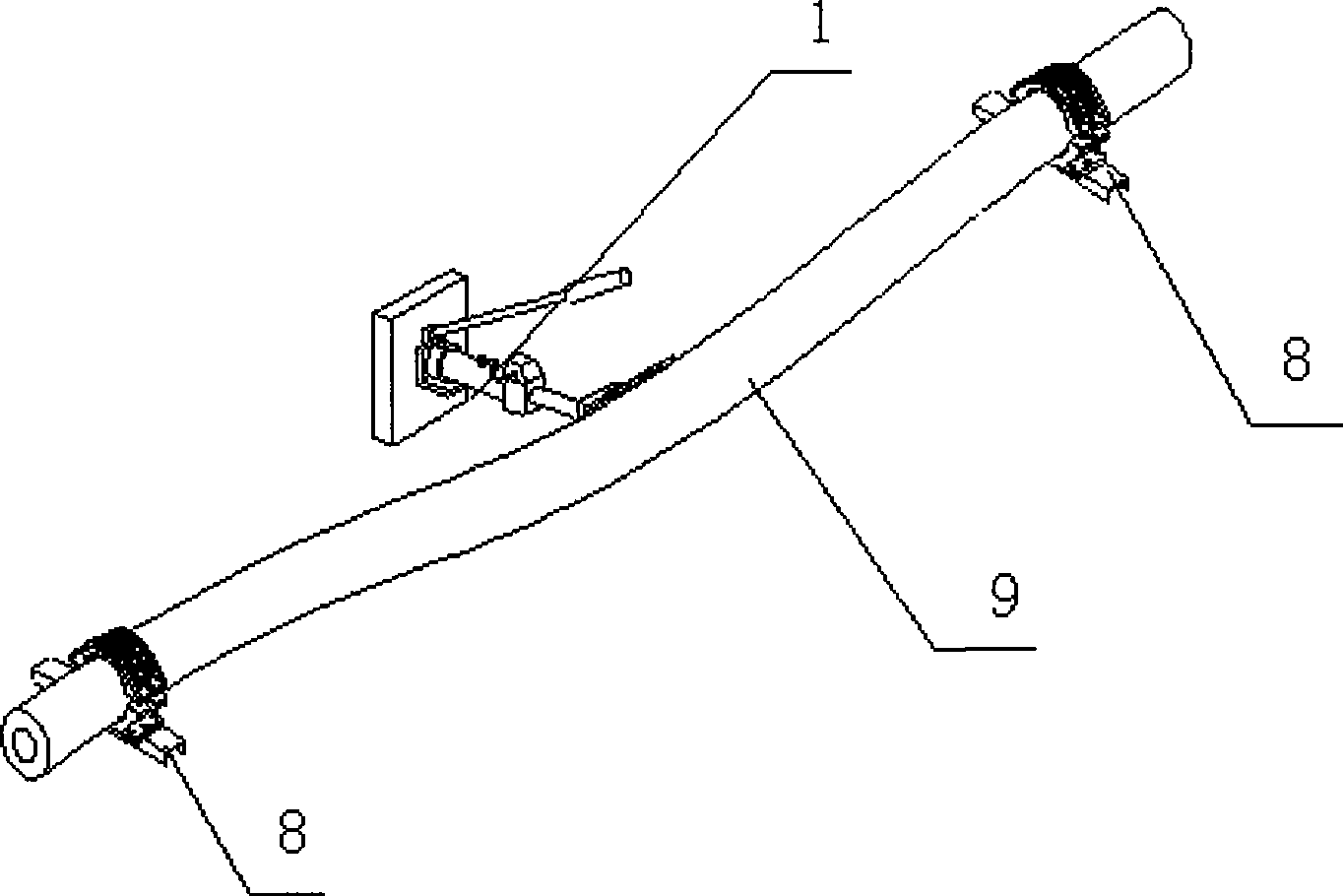

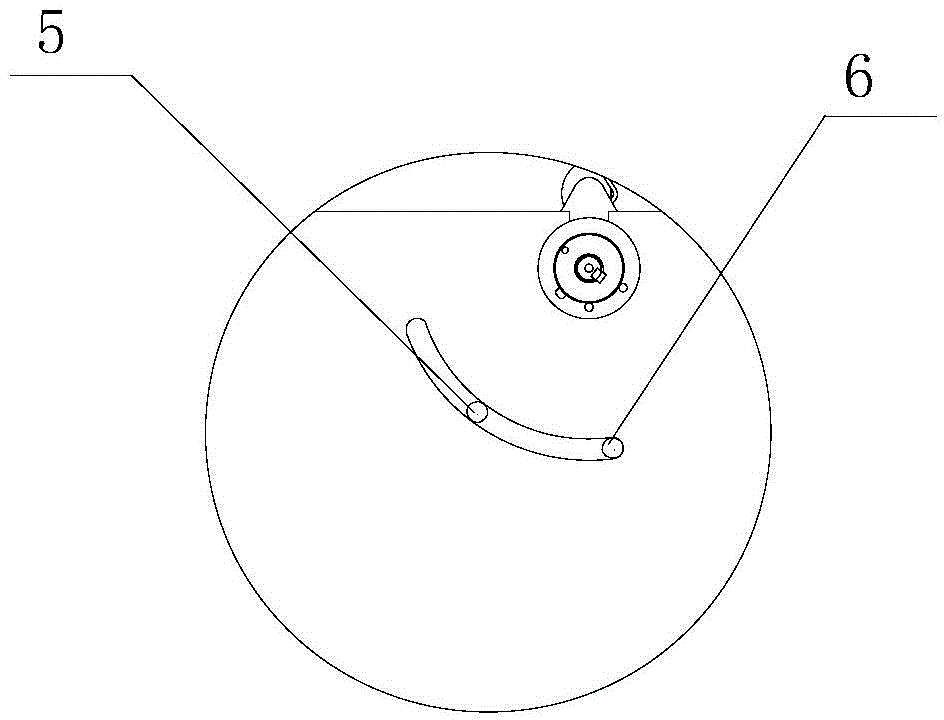

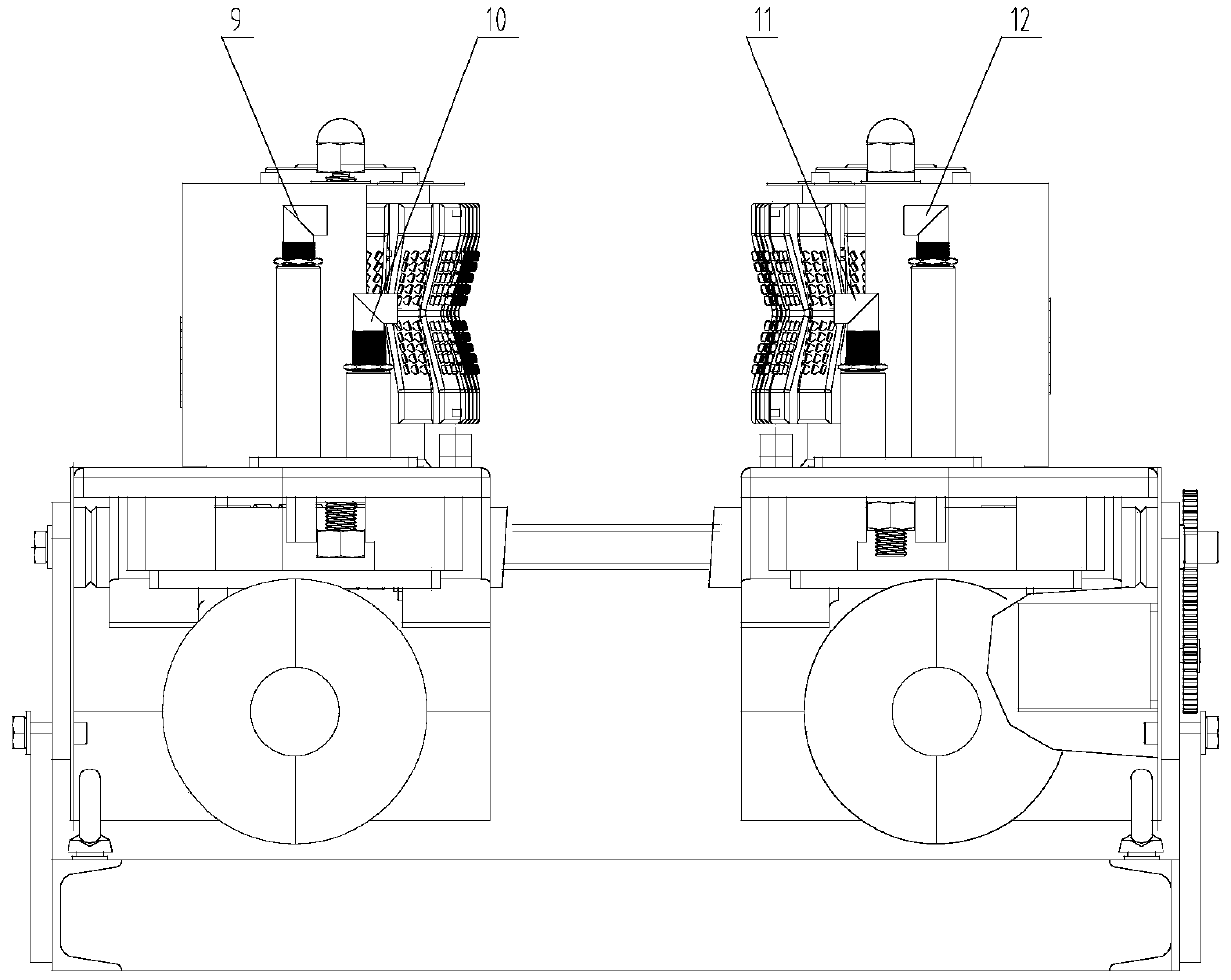

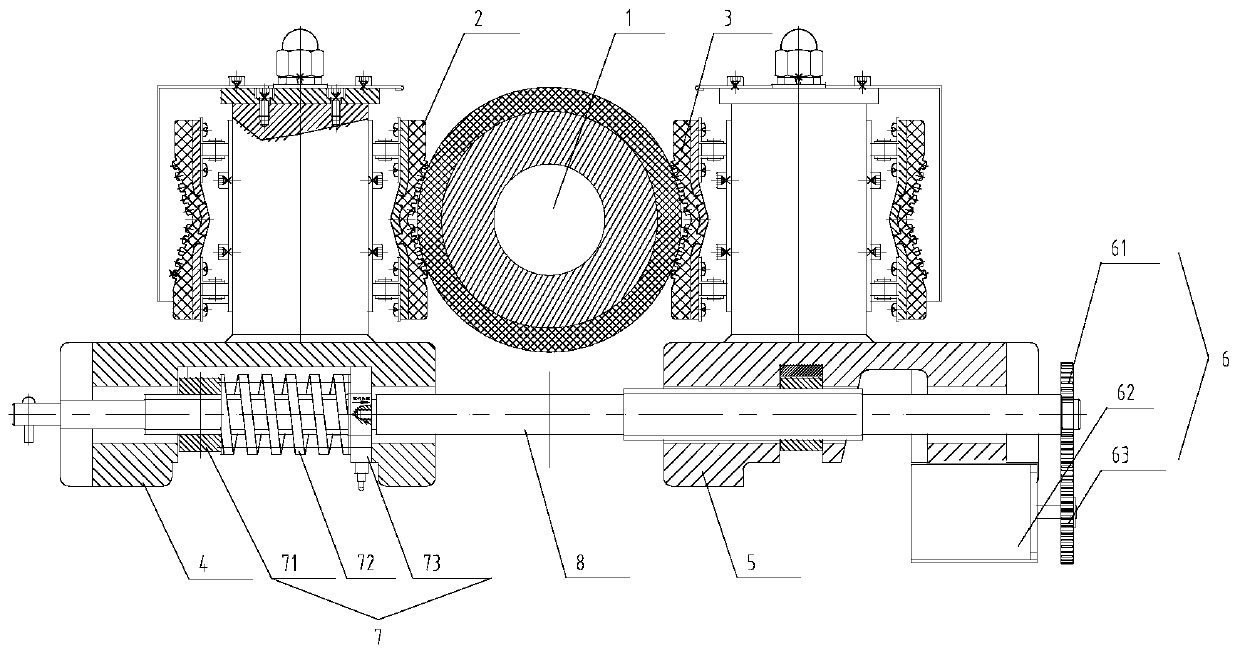

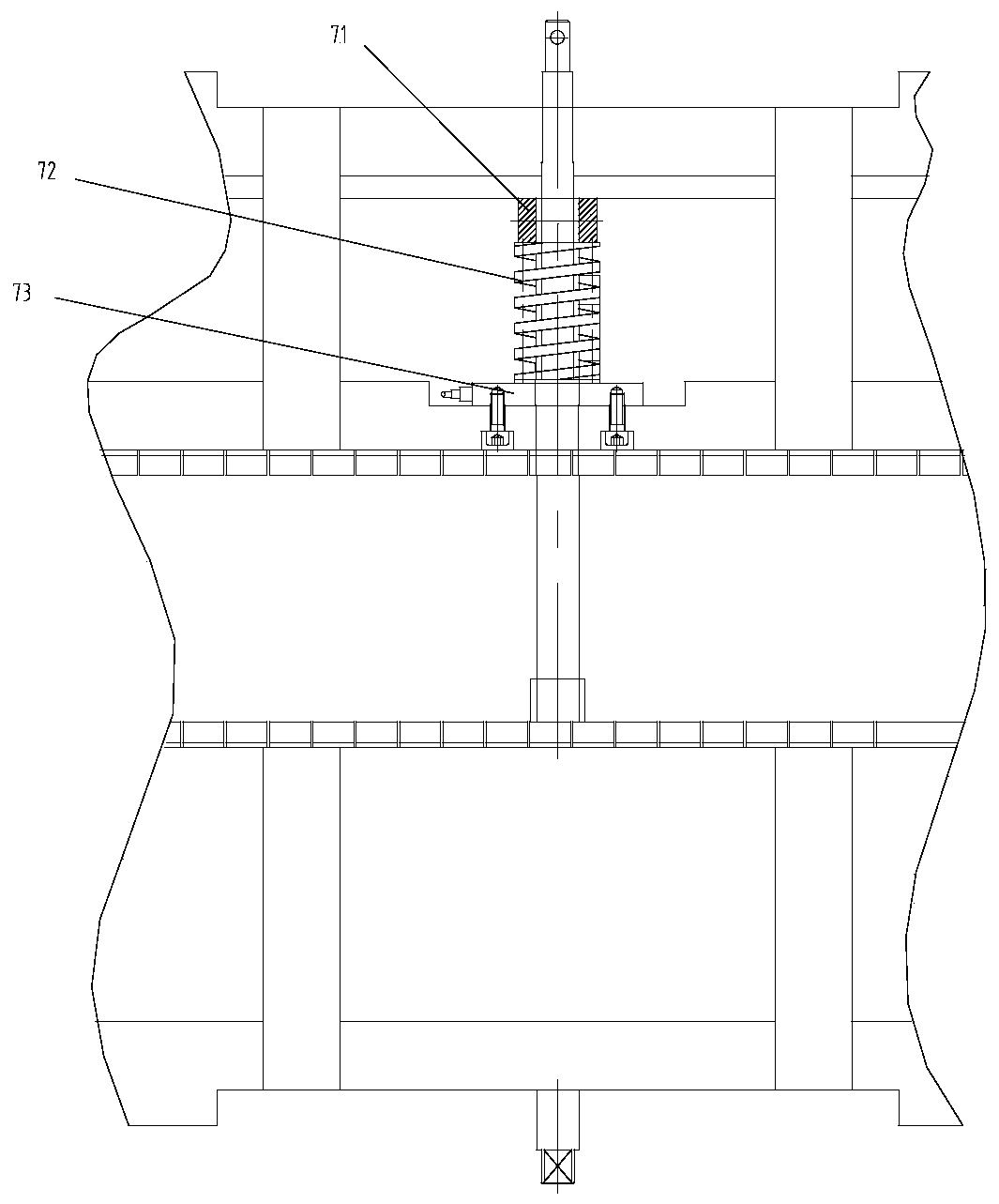

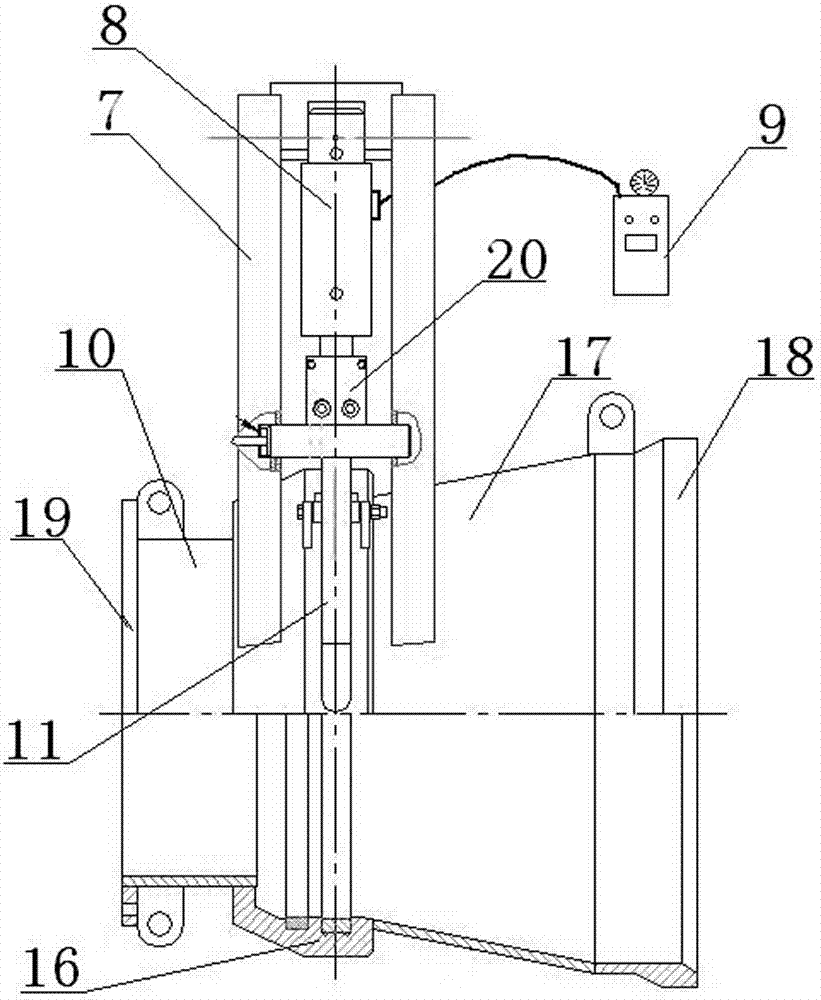

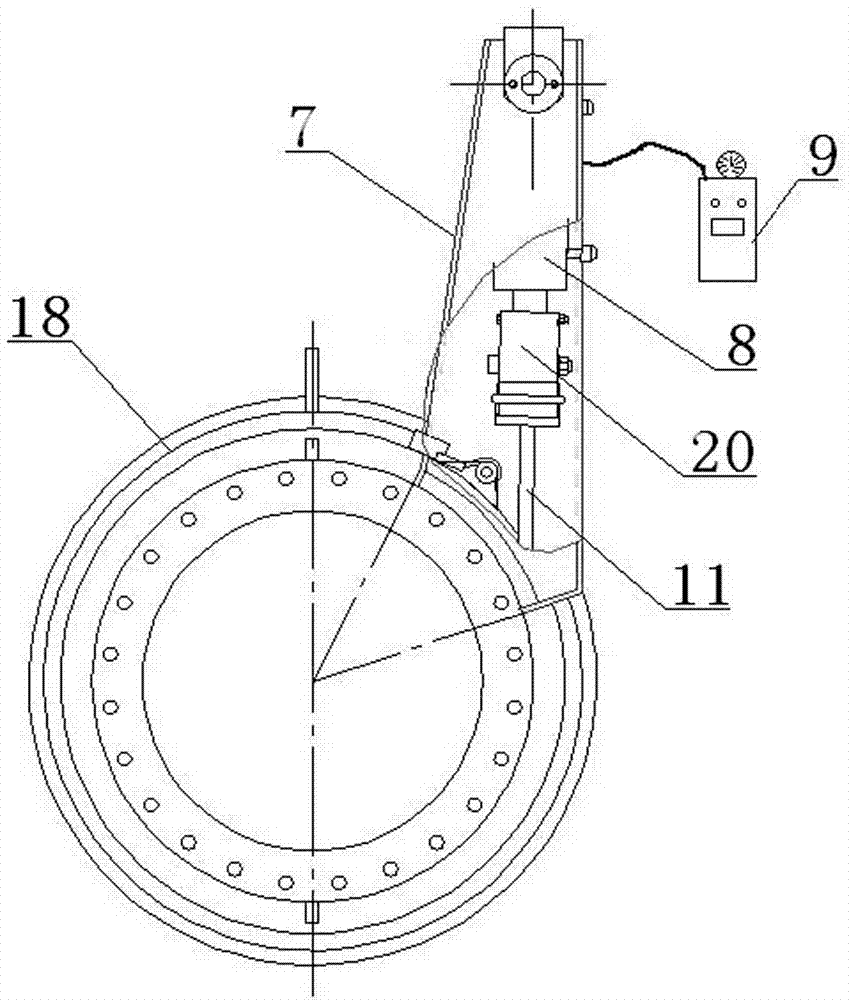

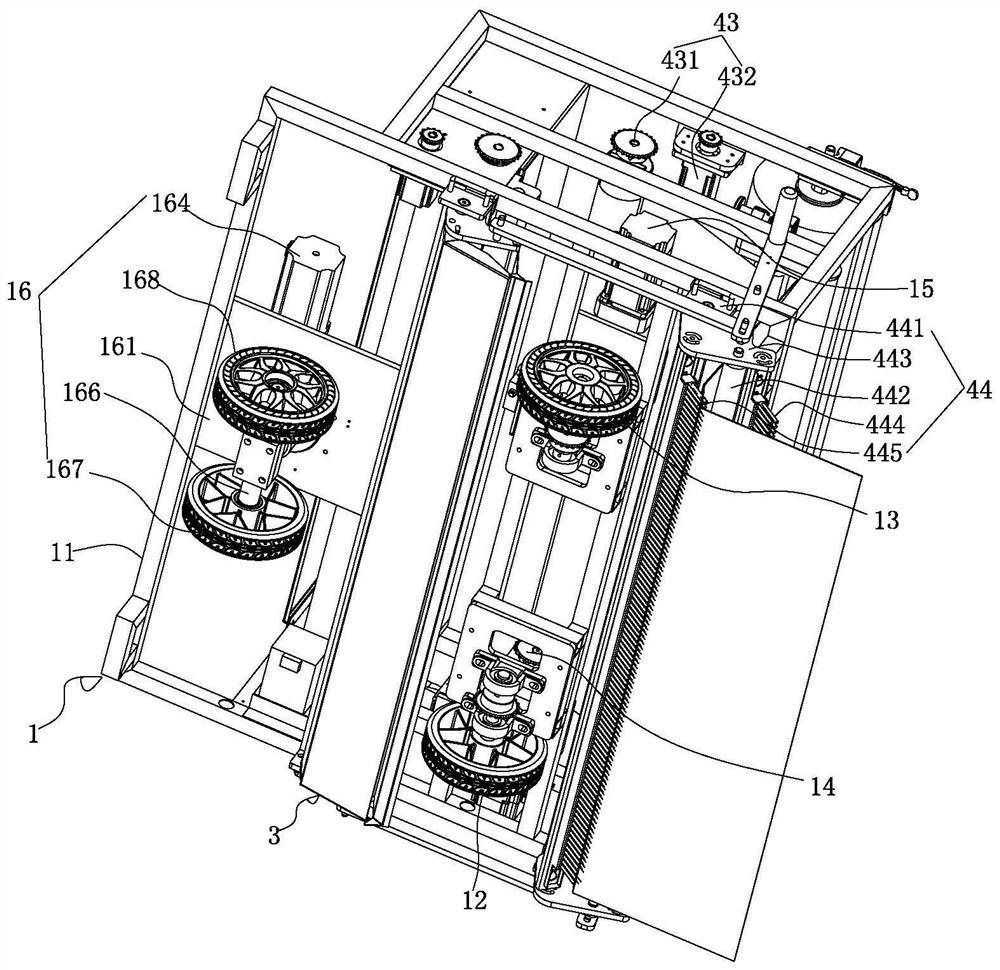

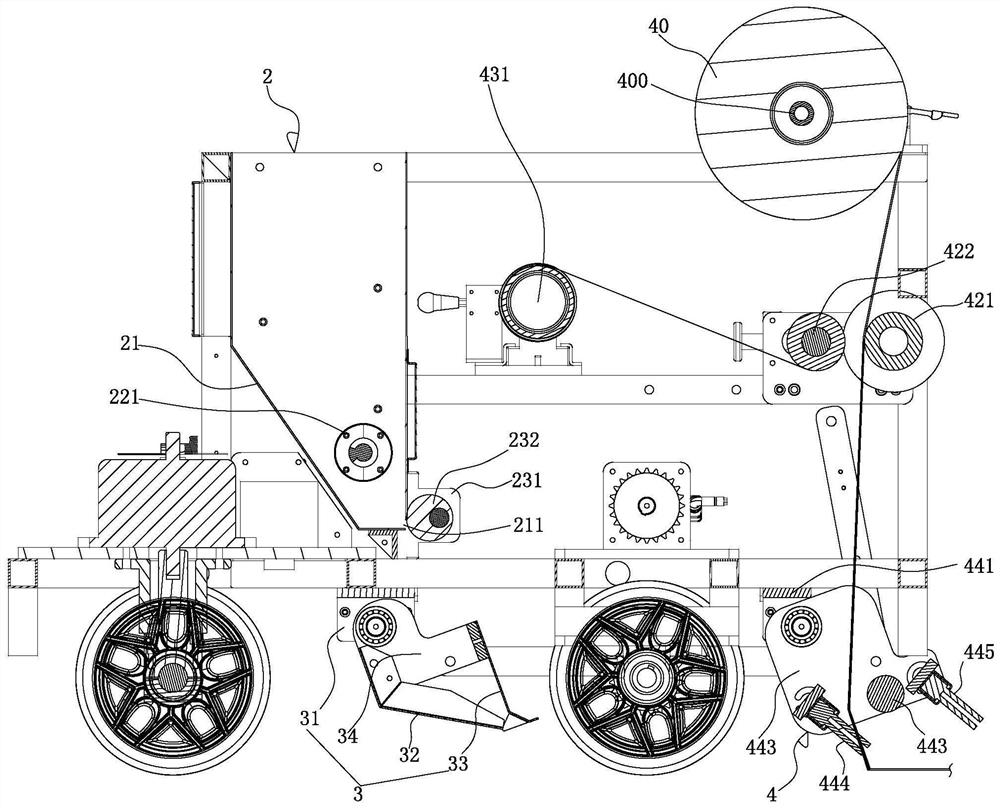

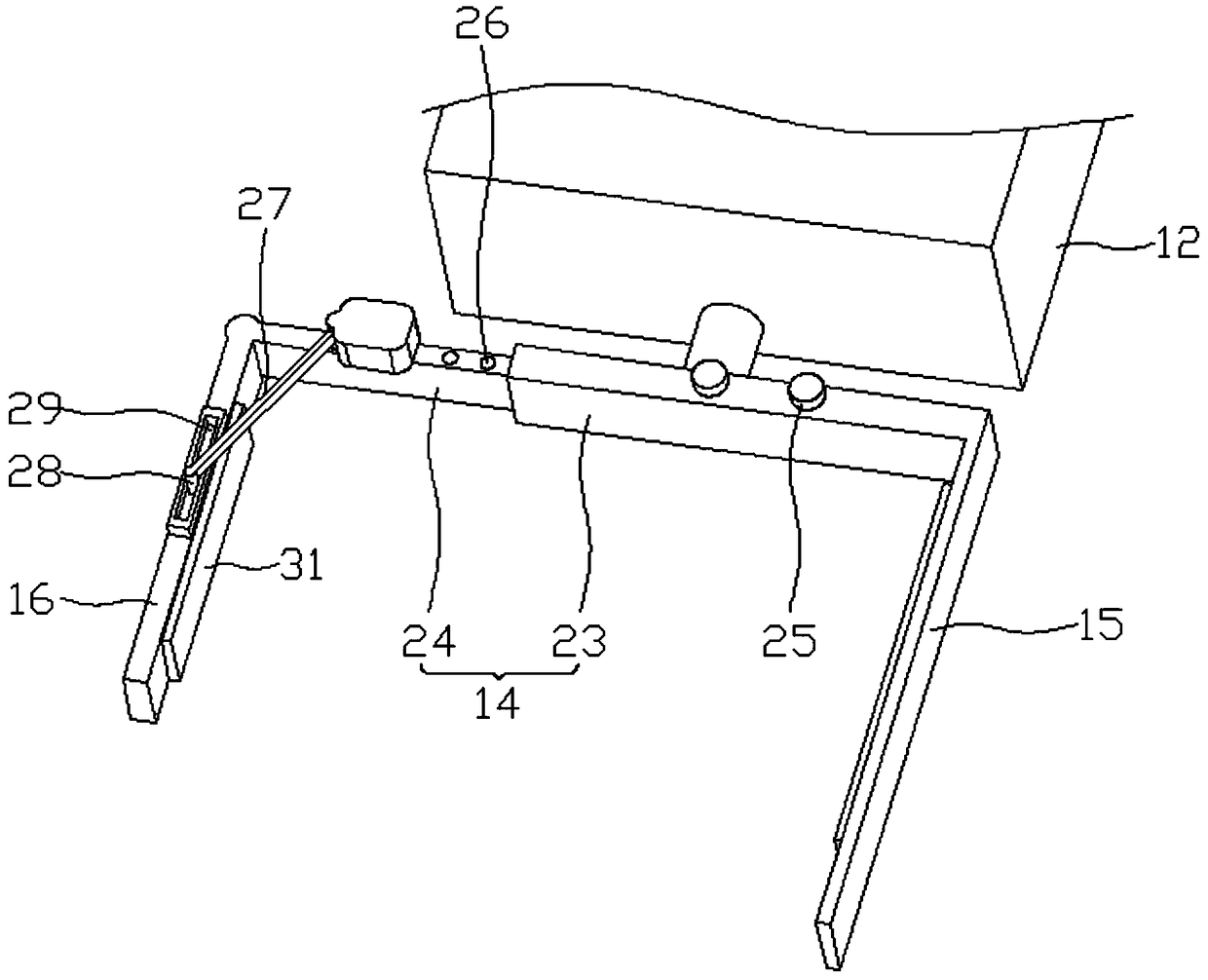

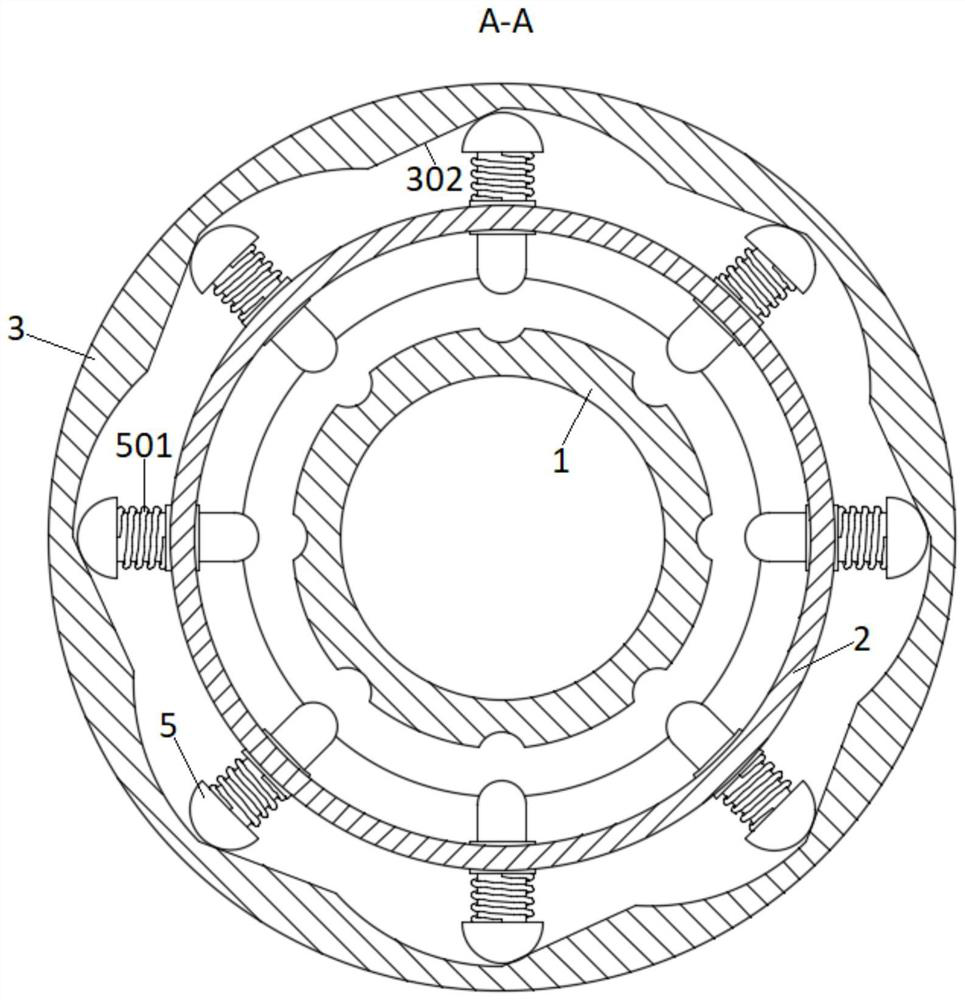

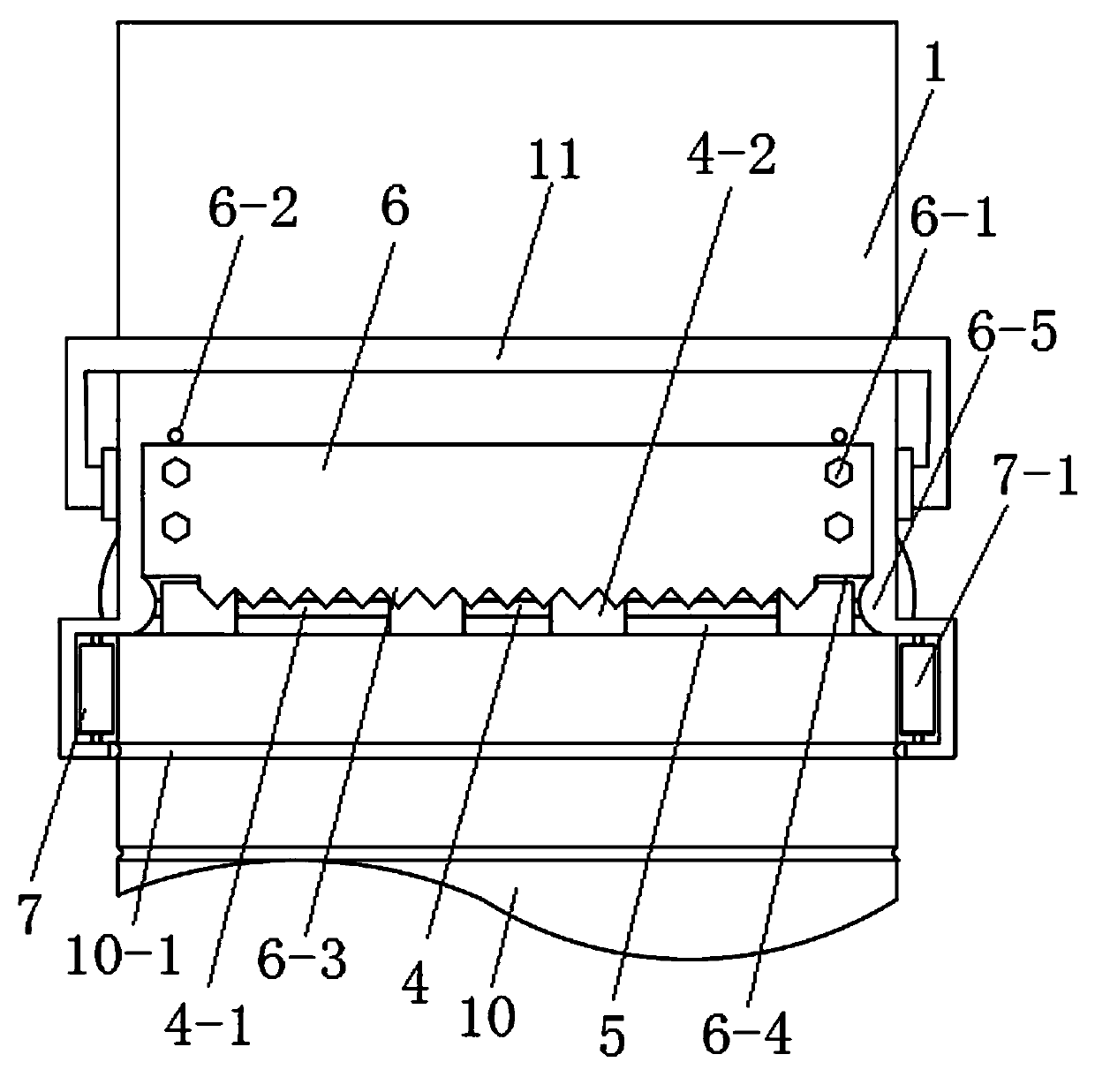

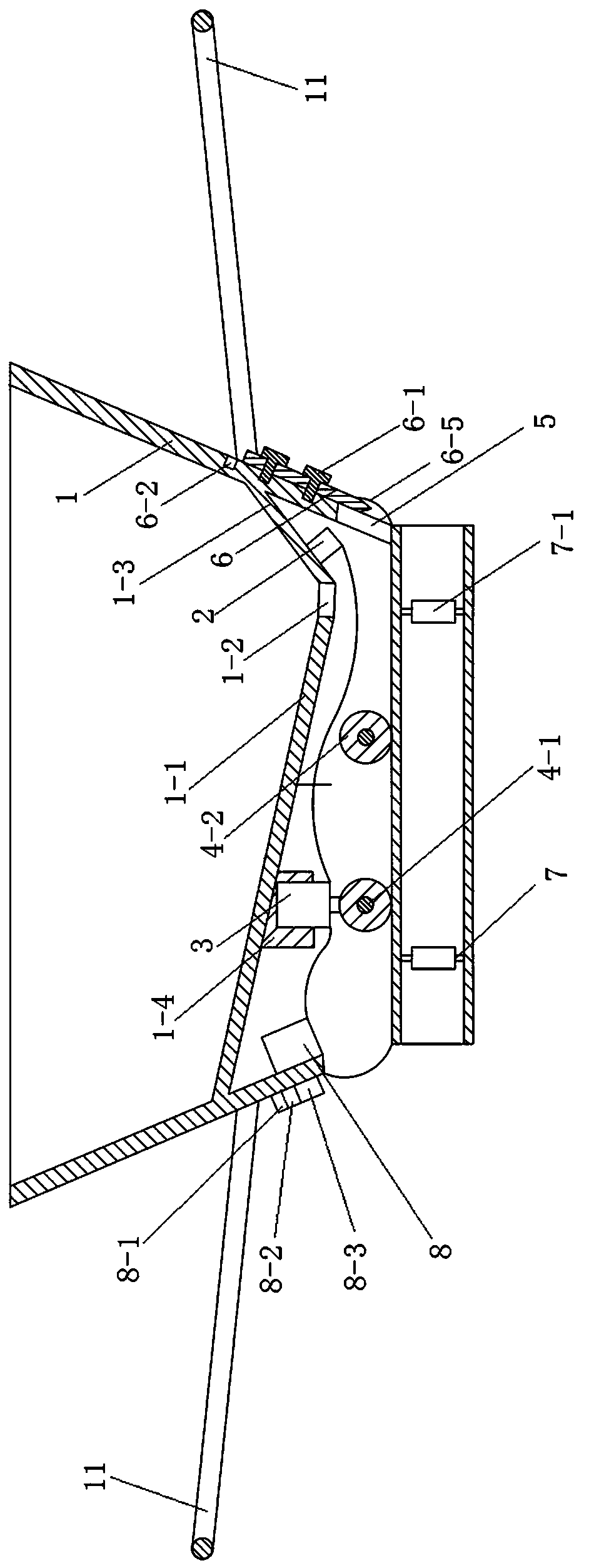

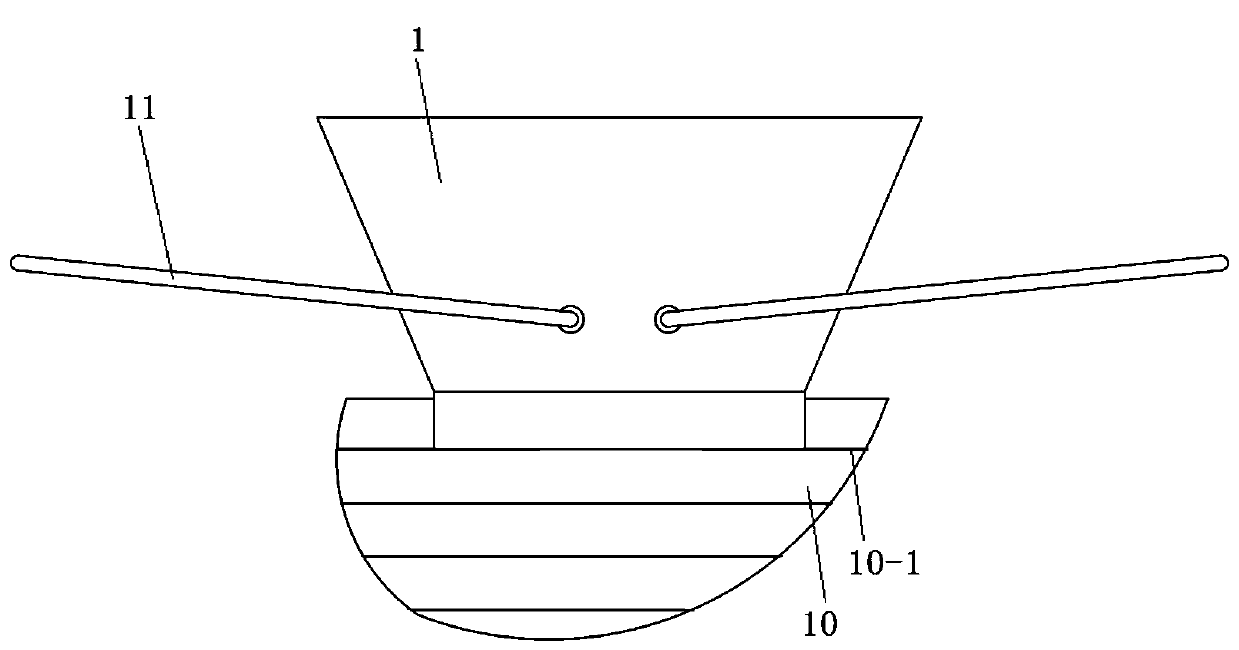

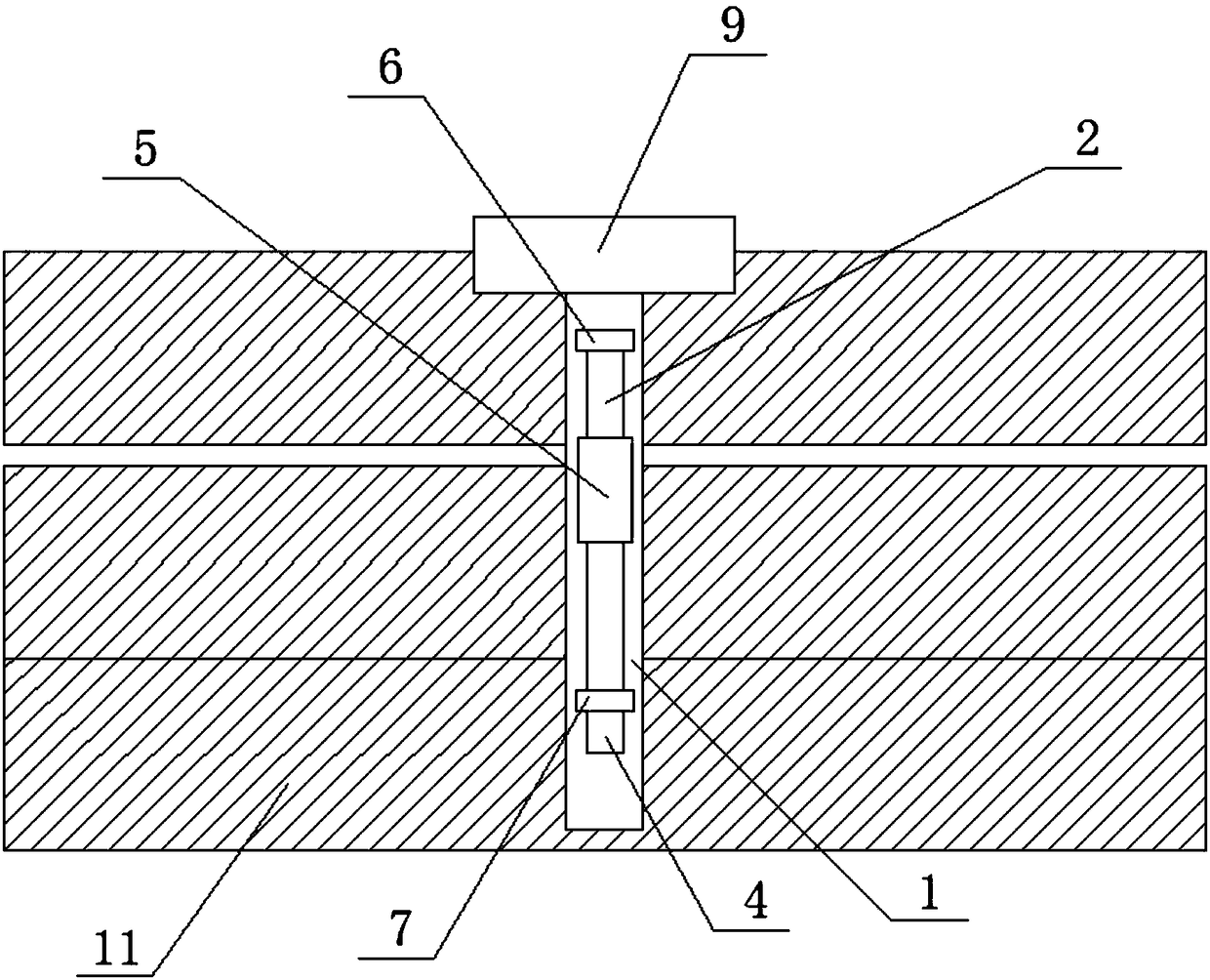

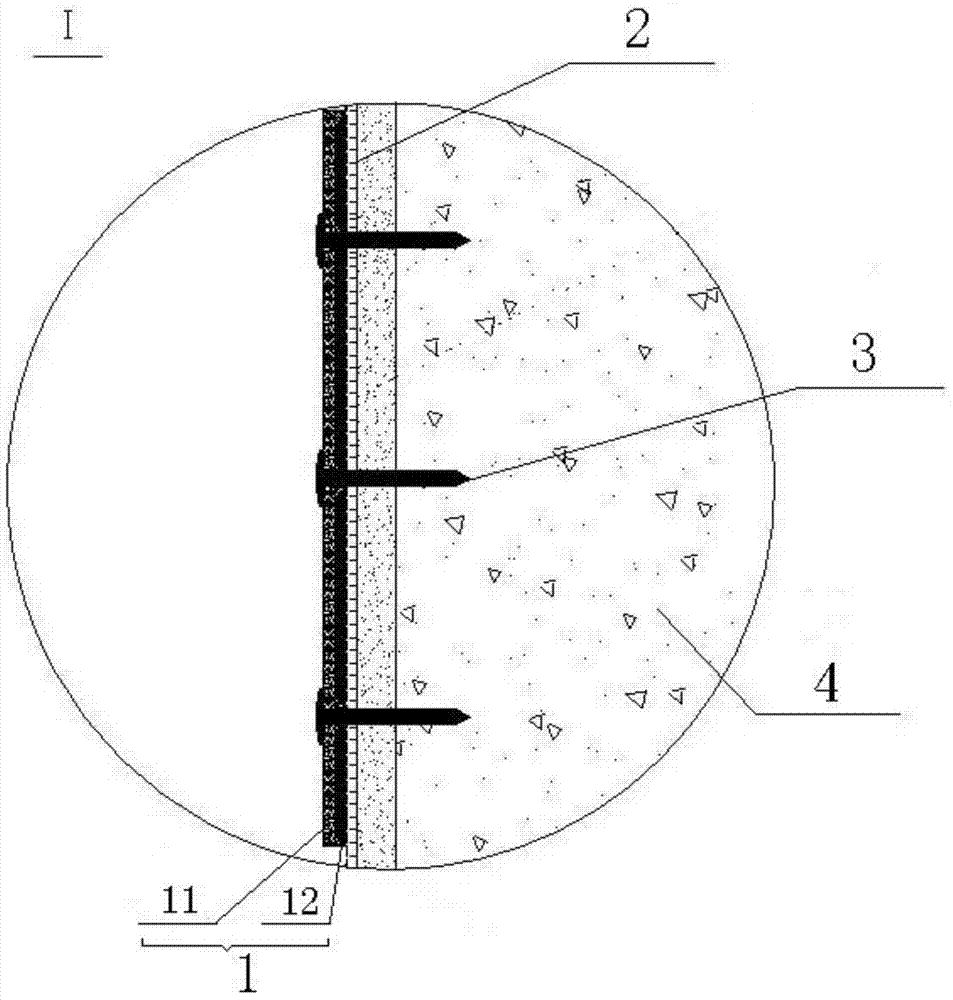

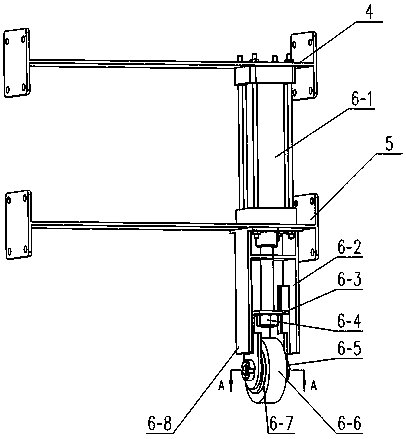

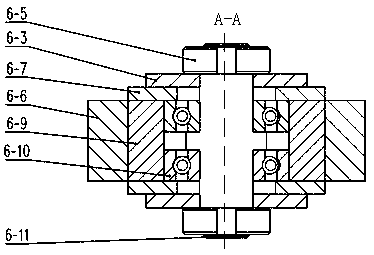

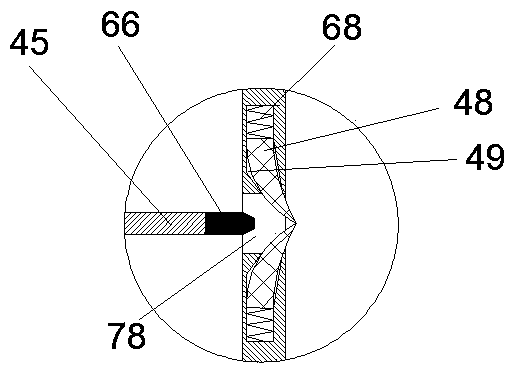

Tunnel waterproof plate laying trolley

ActiveCN107327309AGuarantee laying qualityFit tightlyUnderground chambersTunnel liningThrough transmissionEngineering

The invention discloses a tunnel waterproof plate laying trolley which comprises a plurality of trolley portals which are distributed in parallel. The trolley portals are provided with arch rings matched with the inner wall of a tunnel. A climbing mechanism is arranged on every two adjacent arch rings. The climbing mechanisms are installed on the arch rings in a transmission mode through transmission assemblies. A laying assembly and a leveling assembly are arranged on each climbing mechanism. Each climbing mechanism comprises two climbing boxes which are connected to the two corresponding adjacent arch rings in a transmission mode respectively, and a climbing trolley installed between the two climbing boxes, wherein the climbing trolley is installed on the climbing boxes through rotating shafts in a rotating mode. The climbing mechanisms can move in the circumferential direction of the arch rings, in this way, the laying assemblies can be driven to lay waterproof plates along the inner wall of the tunnel, meanwhile the leveling assemblies can level up the waterproof plates laid on the inner wall of the tunnel, it is guaranteed that the waterproof plates laid on the inner wall of the tunnel are closely attached to the inner wall of the tunnel, the laying efficiency of the waterproof plates is improved, and the laying quality of the waterproof plates is effectively guaranteed.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Electric cable bending machine

InactiveCN101459323AReduce stress concentrationSimple processing methodApparatus for laying cablesEngineeringElectric cables

A cable curving machine comprises two collar clamps and a jacking device, and the jacking device is arranged between the two collar clamps. The jacking device comprises an ejector bar, wherein a cable contact face corresponding to the shape of a cable is arranged at the top end of the ejector bar, and a force applying device is connected to the tail end of the ejector bar. By applying the cable curving machine, cables in different environments and laying modes can meet requirements and has good effect.

Owner:JIANGSU ELECTRIC POWER CO

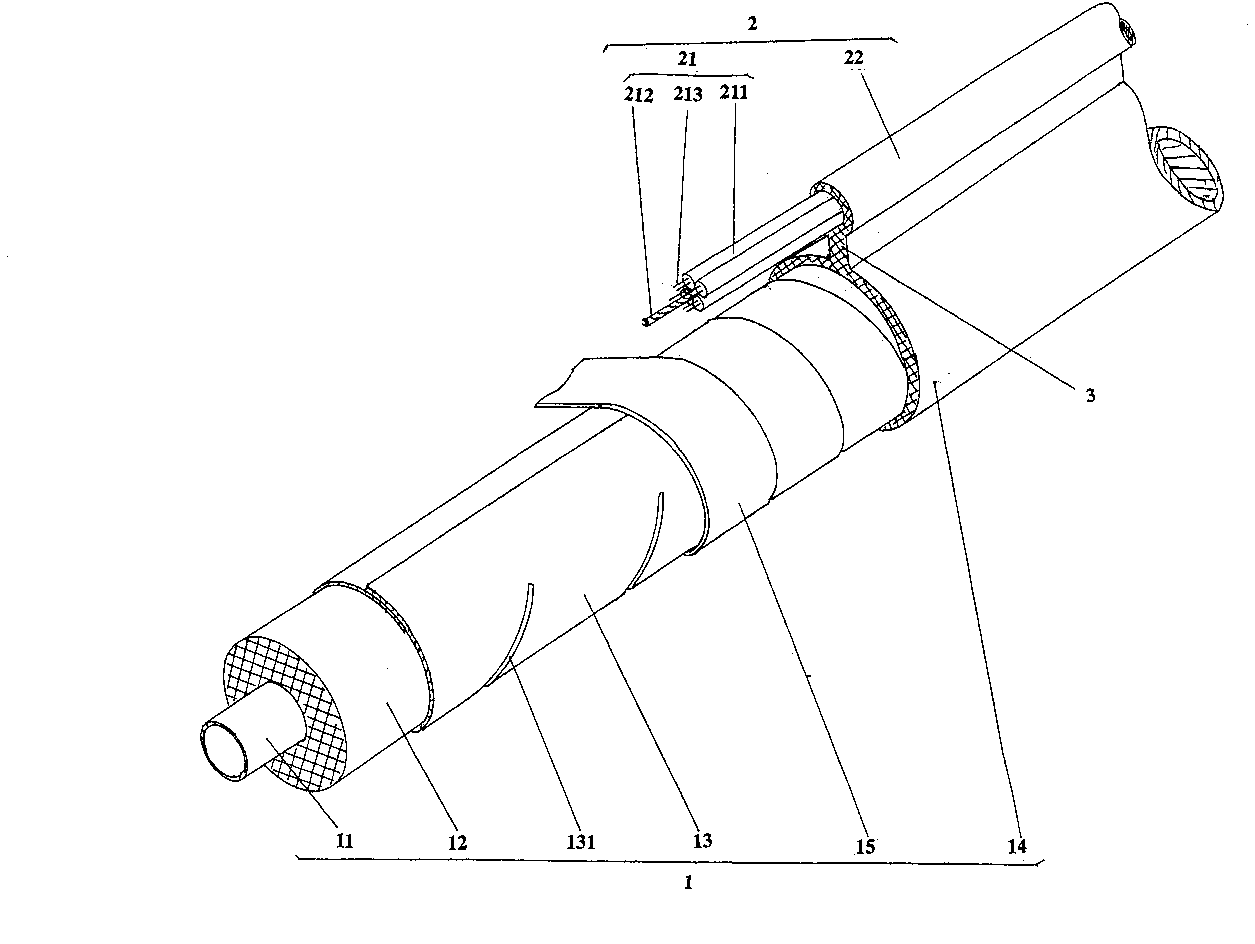

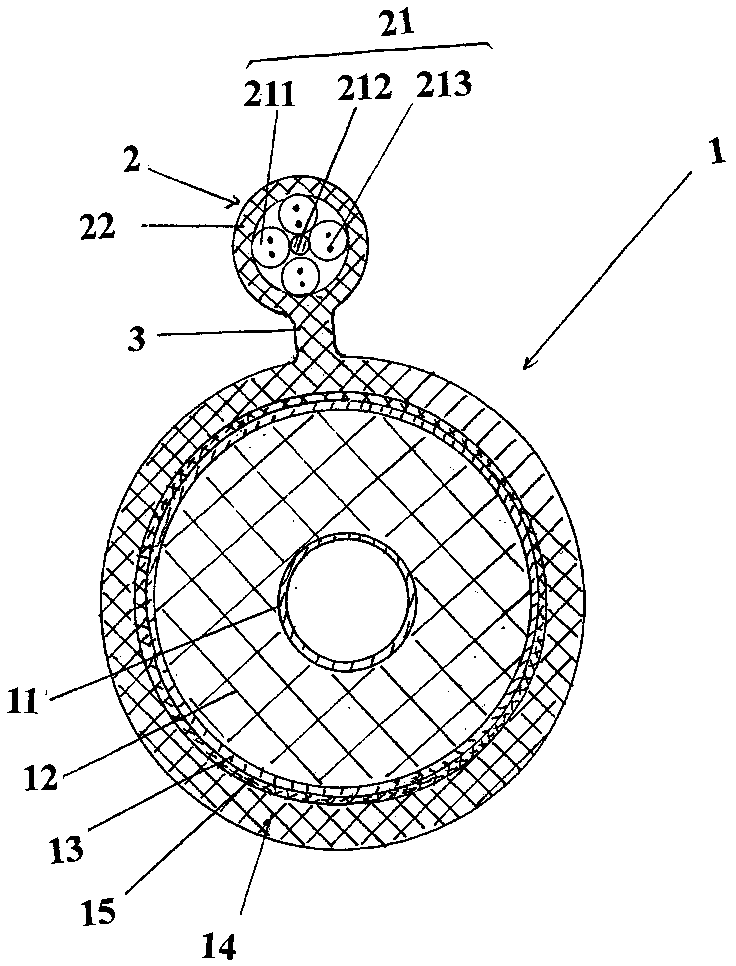

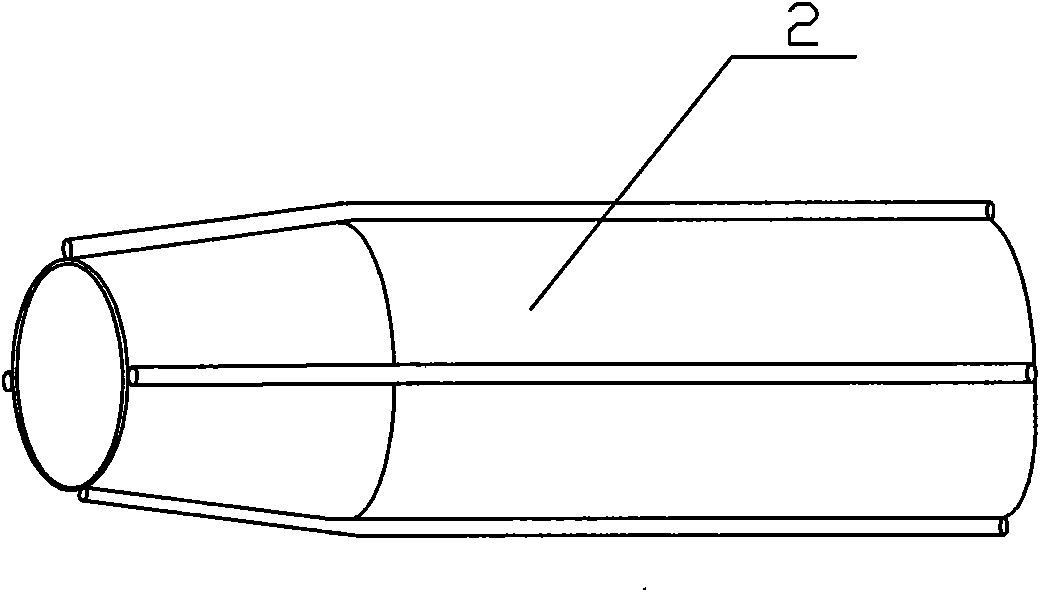

Leaky-waveguide coaxial cable

InactiveCN103021554AReduce process linksSave laying construction costsCommunication cablesManufacturing cost reductionCoaxial cable

The invention discloses a leaky-waveguide coaxial cable and belongs to the technical field of communication cables. The leaky-waveguide coaxial cable comprises a leaky-waveguide coaxial cable body and an optical cable, and is characterized in that the optical cable and the leaky-waveguide coaxial cable body are integrated and jointly form a structure with 8-shaped cross section. The leaky-waveguide coaxial cable has the advantages that technical links during manufacturing is evidently reduced, an independent mould is saved, cabling efficiency is favorably improved, and manufacturing cost can be reduced. Arrangement and construction cost is beneficially saved, and maintenance and protection are facilitated. Since the optical cable and the leaky-waveguide coaxial cable body form the structure with 8-shaped cross section, resistance to external extrusion can be improved obviously, joint connection of the leaky-waveguide coaxial cable body and joint connection of the optical cable are beneficially facilitated during arrangement, mutual interference is avoided and arrangement quality is guaranteed beneficially.

Owner:JIANGSU ZHONGLI GRP CO LTD

Method for butting buried cable steel tube on site during construction

InactiveCN101832435AReduce the occurrence of impenetrableGuarantee laying efficiencySleeve/socket jointsCable installations in underground tubesSlagRebar

The invention relates to the technical field of electric engineering construction, in particular to a method for butting a buried cable steel tube on site during construction. The method comprises the following steps of: (1) manufacturing a wedge-shaped chambering tube; (b) wedging the wedge-shaped chambering tube into a ring opening tube to expand the tube diameter of the ring opening tube, and welding fixed diameter steel bars to side walls on two sides of the opening of the ring opening tube to form a butting sleeve; (c) sleeving the tube ends of two polished cable steel tubes into the butting sleeve, and cutting off the fixed diameter steel bars on the butting sleeve; (d) totally fitting the tube orifices of the cable steel tubes, fixing the cable steel tubes by spot welding, and then tightly welding each connector; and (e) polishing the welding slag at the welded part, and coating anti-rusting paint on the cable steel tubes so as to finish butting the cable steel tubes. By using the method, materials are taken from the construction site, no extra material is needed, the manufacturing process is simple and practical, on-site construction is convenient, the construction cost is saved, the butting misalignment and burrs of the tube orifices can be reduced, and the efficiency and quality of paving cables are guaranteed.

Owner:CHINA FIRST METALLURGICAL GROUP

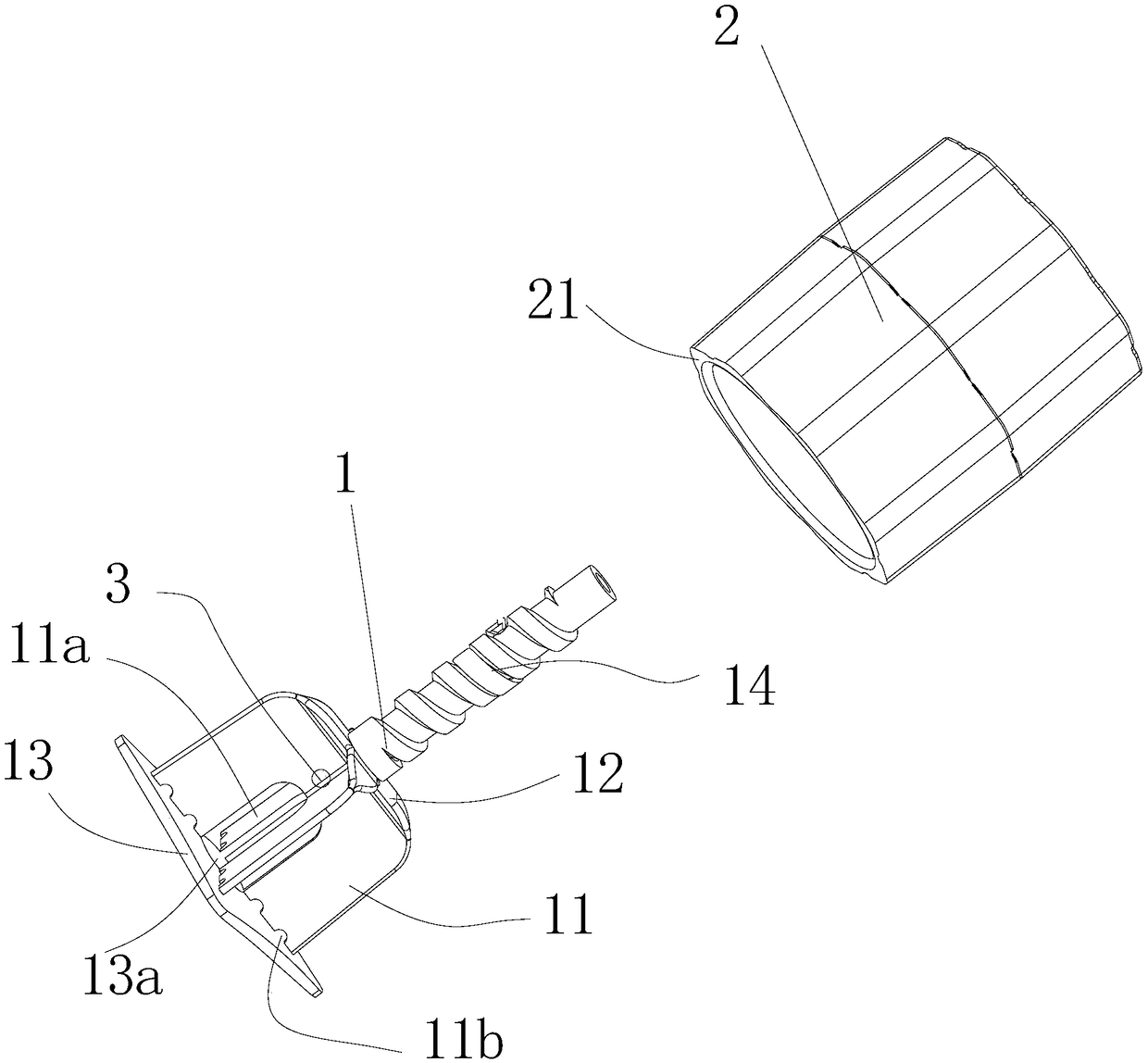

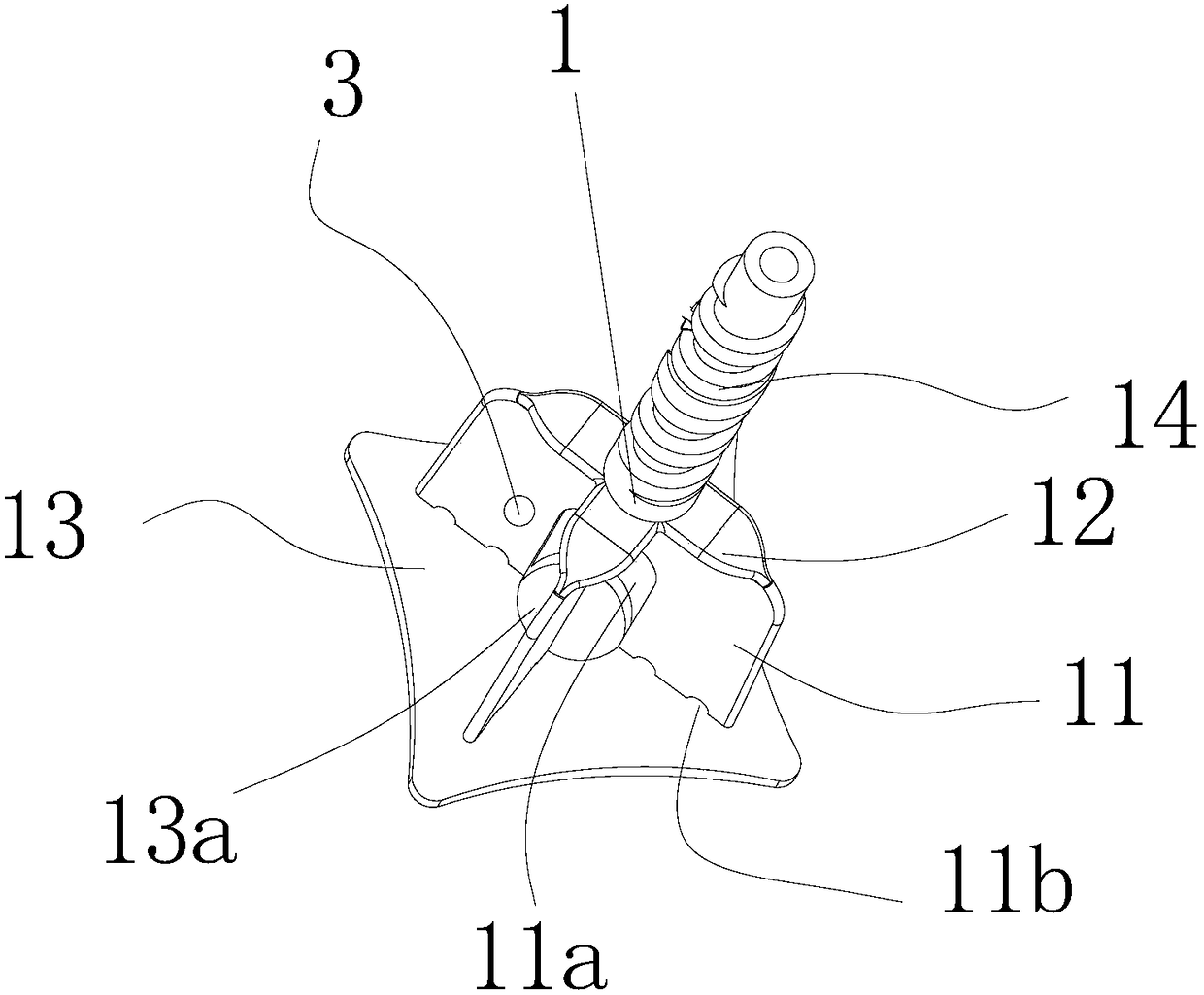

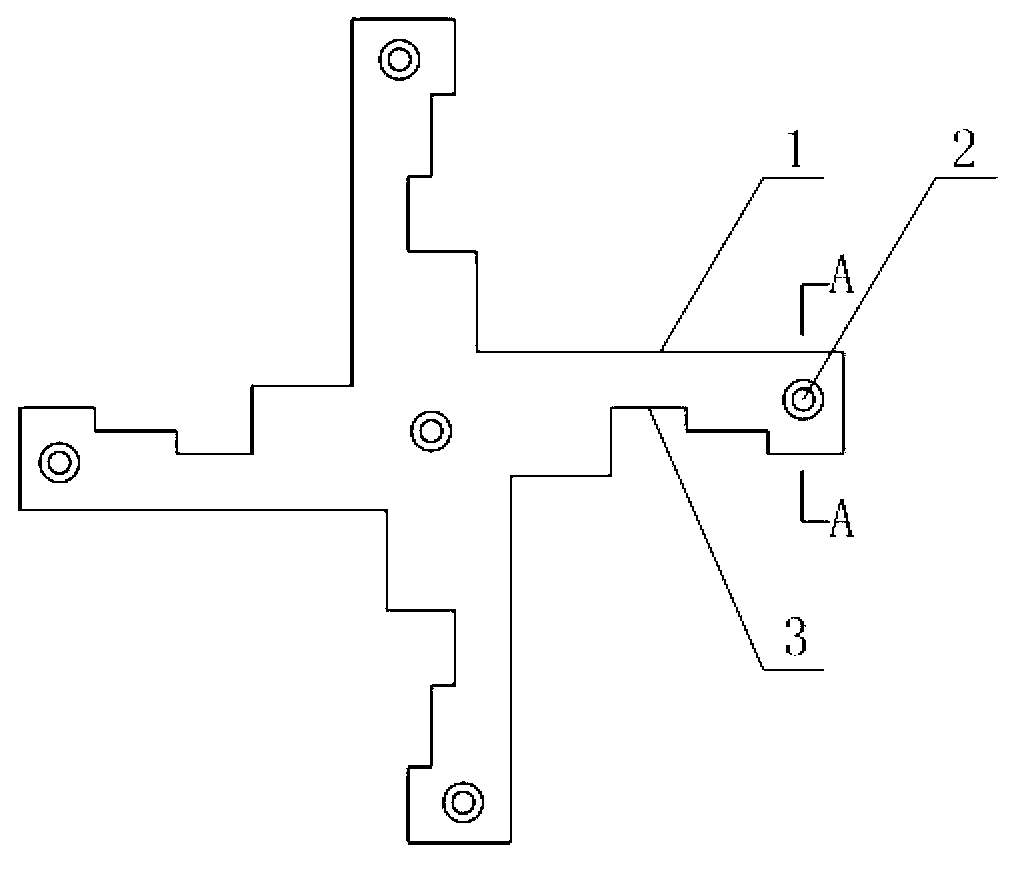

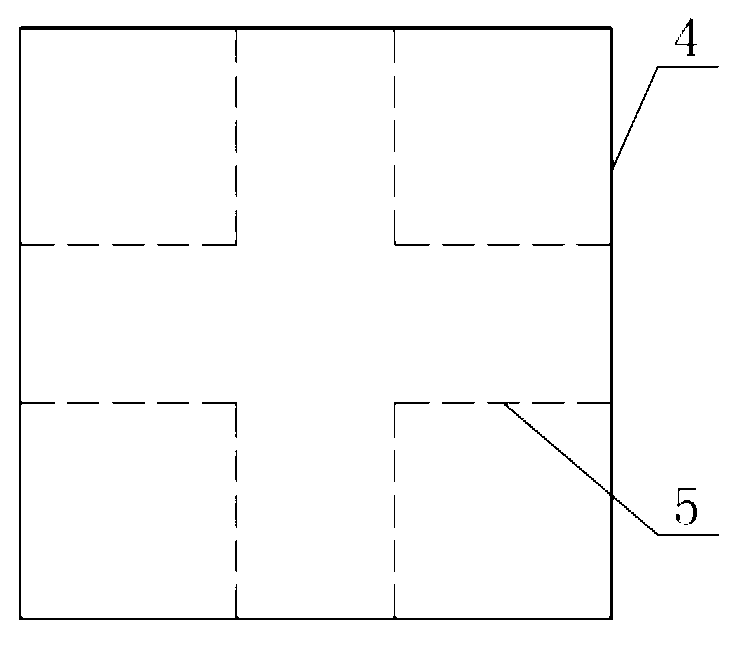

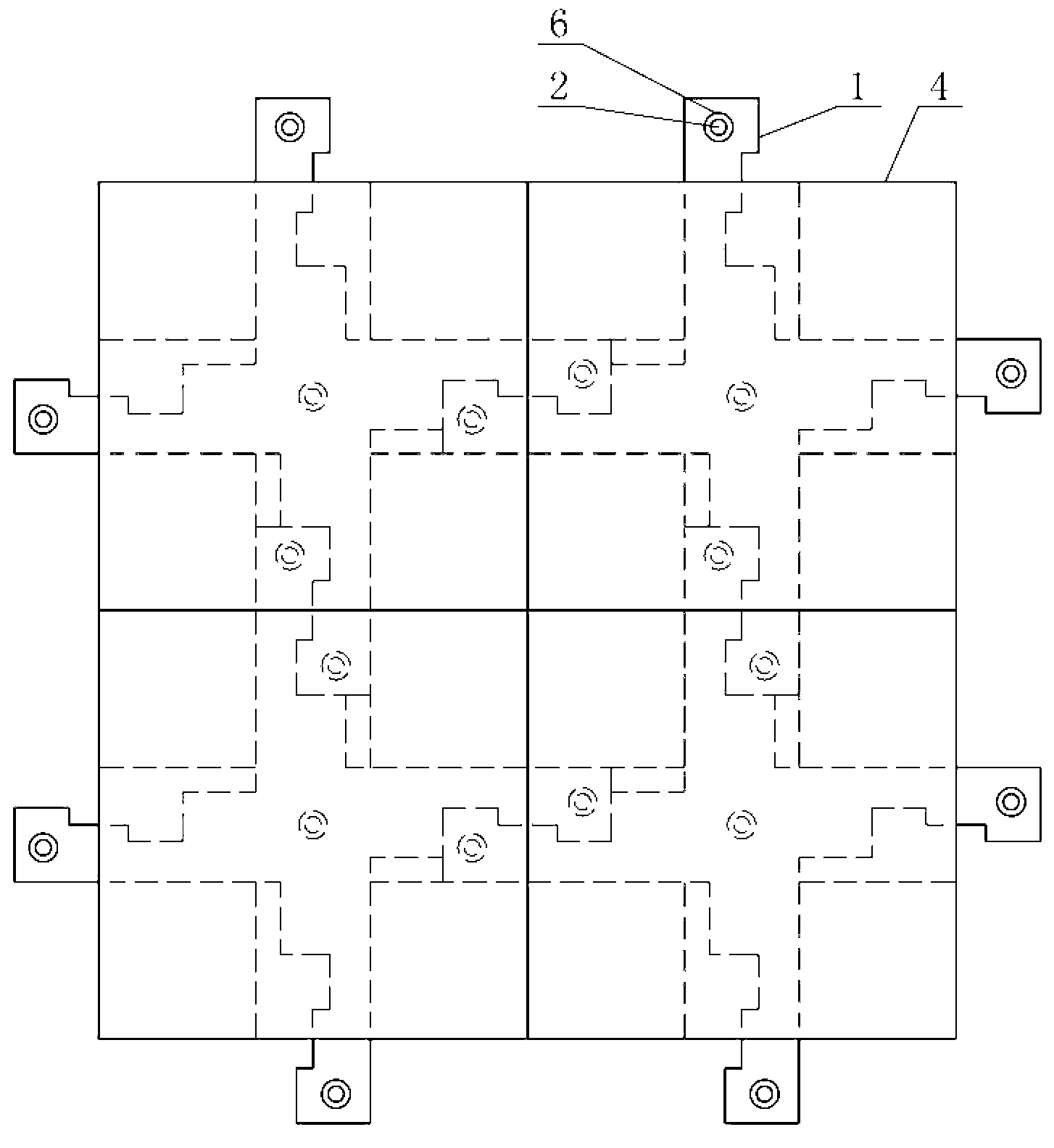

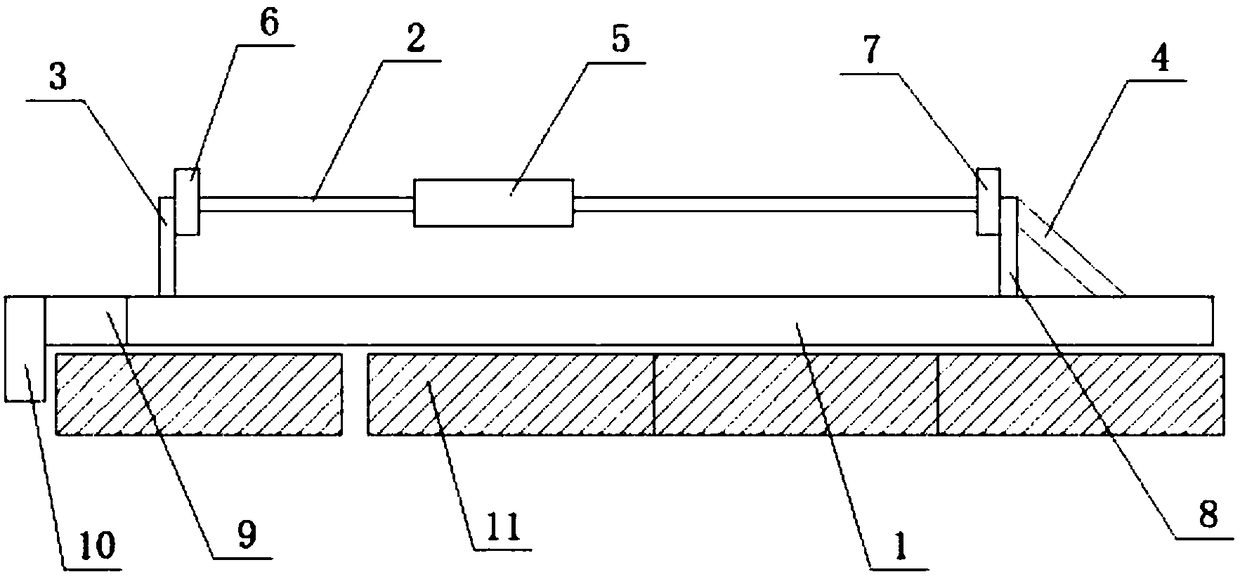

Support rib framework positioning type splash-proof floor tile for sidewalk

ActiveCN103015290AImprove anti-settling performanceDoes not affect the vertical positionSidewalk pavingsStructural engineering

The invention relates to the technical field of constructional engineering and in particular relates to a support rib framework positioning type splash-proof floor tile for a sidewalk. The support rib framework positioning type splash-proof floor tile comprises cross ribs, tooth-shaped notches, floor tiles, positioning slots, fastening nuts and positioning nails, wherein each of the cross ribs is formed by four wing bars which are orthogonal with each other; one step-shaped tooth-shaped notch is arranged in each wing bar; each positioning nail comprises a nail top rod, a nail support ring and a nail body, and the nail body is in the shape of a cylinder formed by vertically superposing a plurality of cones which are big on the tops and small on the bottoms; the lower end of the nail body is a tip end; the crossed positioning slot is arranged in the bottom surface of each floor tile; a plurality of cross ribs are locked with each other by the tooth-shaped notches to form a well-shaped framework on the plane; and each cross rib is arranged in the positioning slot in the bottom surface of the floor tile and is integrally spliced with the positioning slot. Compared with the prior art, the support rib framework positioning type splash-proof floor tile provided by the invention have stronger stability, so that a water splashing condition is avoided.

Owner:NANTONG BINWU IND CO LTD

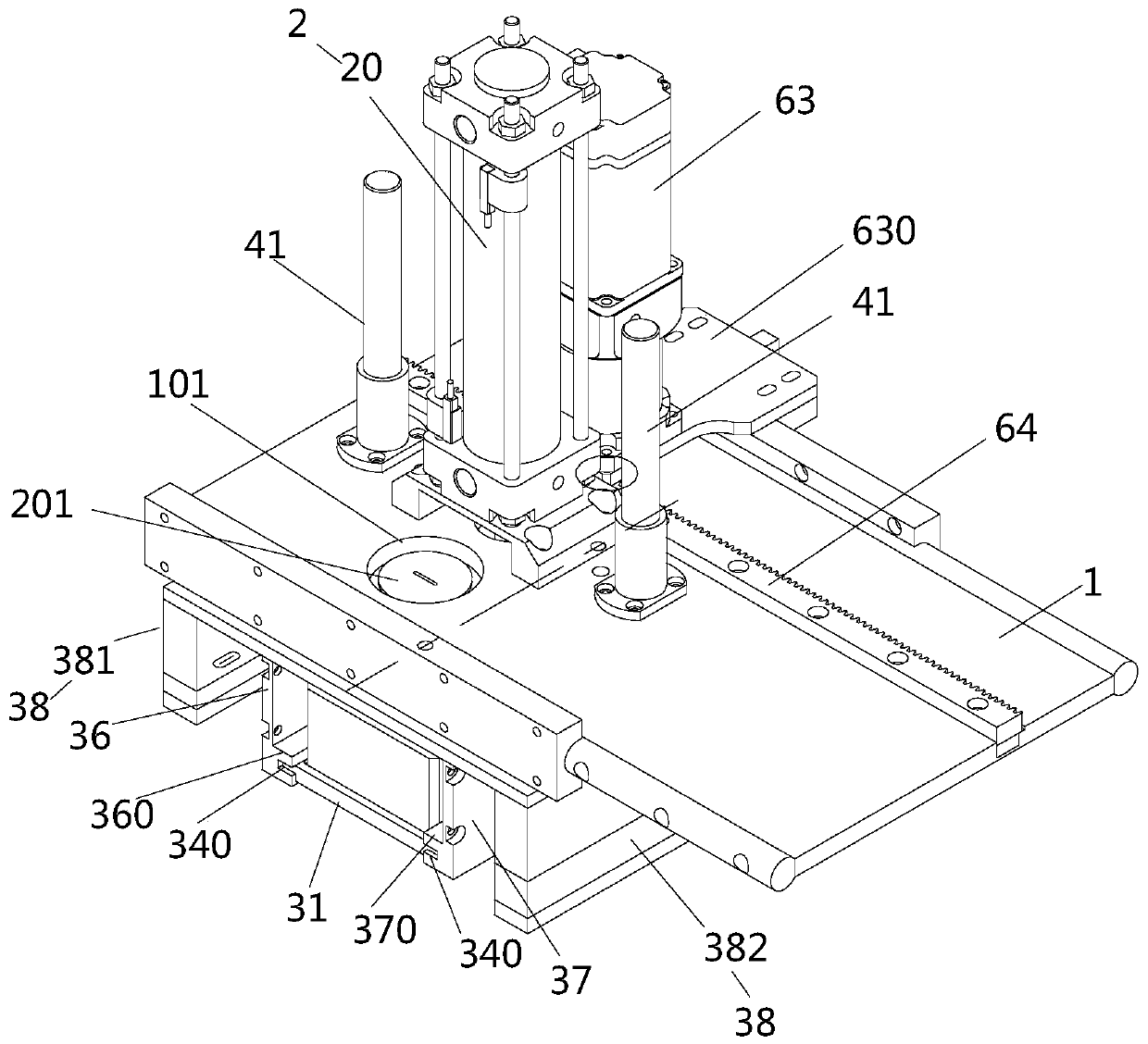

Material automatic spreading device and material spreading robot

The invention relates to a material automatic spreading device and a material spreading robot. The material automatic spreading device comprises a material storage mechanism, a feeding mechanism and amaterial spreading mechanism, wherein the material storage mechanism is used for storing slurry materials needed for spreading; the feeding mechanism is connected with the material storage mechanismin a matched mode, and the material storage mechanism is used for supplying the slurry materials to the feeding mechanism; and the material spreading mechanism is connected with the feeding mechanismin a matched mode, the feeding mechanism is used for transferring the slurry materials to the material spreading mechanism, and the material spreading mechanism is used for the slurry materials to theground to be laid. The whole operation process does not need manpower to participate, so that the labor cost can be greatly reduced, the construction efficiency is improved, the smoothness of slurrymaterial spreading can be ensured to a large extent, and then the quality of subsequent floor tile laying is ensured.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

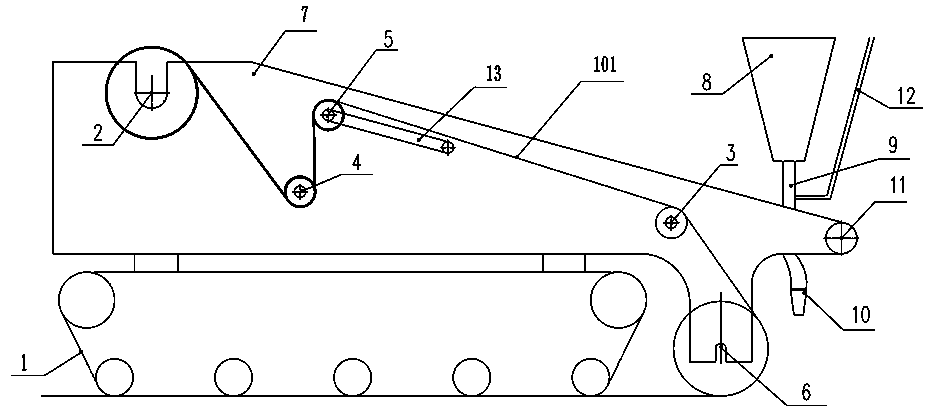

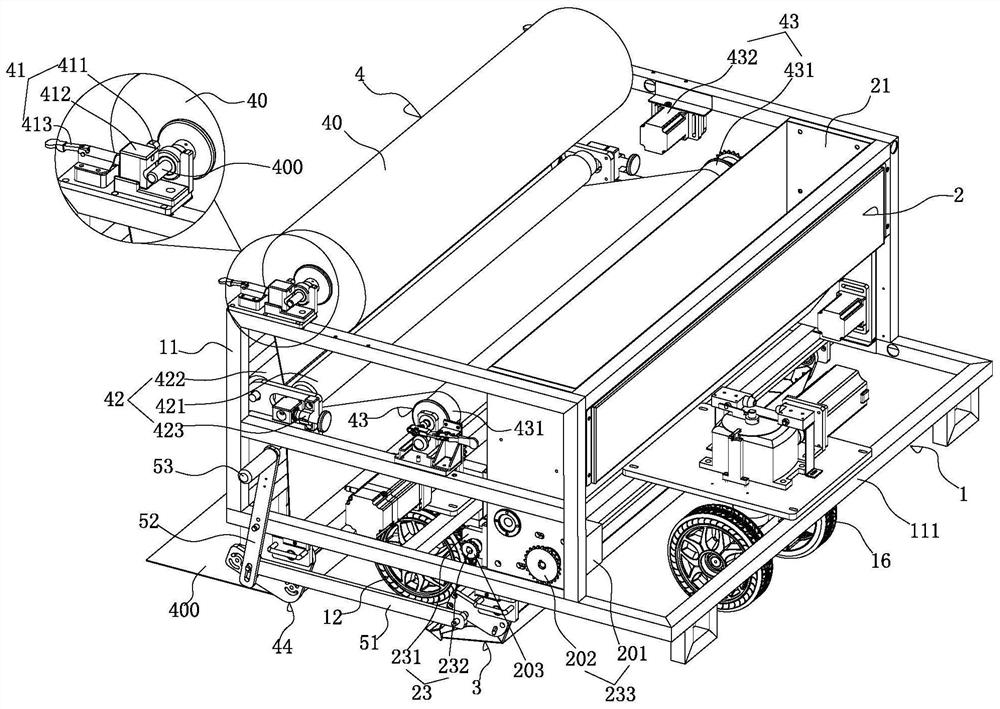

Automatic glue spraying and paving integrated machine for waterproof roll

PendingCN110158875AThe overall structure is simple and reliableFunction increaseRoof toolsBuilding insulationsEngineeringHigh pressure

The invention discloses an automatic glue spraying and paving integrated machine for a waterproof roll. A frame with a crawler belt type walking mechanism and a roll paving mechanism arranged on the frame are included. The roll paving mechanism comprises a roll carrier roller horizontally arranged at the rear portion of the frame and used for bearing the roll, and a front guiding roller located atthe front portion of the frame. The part, close to the roll carrier roller, of the frame is sequentially provided with a guiding carrier roller and a protection film recycling roller up and down in aspaced manner. A roll flattening roller is arranged on the part, at the front portion of the crawler belt type walking mechanism, of the frame, and the roll placed on the roll carrier roller extendsto the position below the walking mechanism sequentially through the guiding carrier roller, the protection film recycling roller, the front guiding roller and the roll flattening roller. A coating bin is fixed to the part, at the front portion of the roll flattening roller, of the frame, a discharging pipe at the bottom of the coating bin downwards extends to the front portion of the roll flattening roller, and the end portion of the discharging pipe is provided with a high-pressure coating nozzle. The automatic glue spraying and paving integrated machine is simple and reliable in structure and complete in function, glue spraying and paving are finished at a time, the work efficiency is high, the quality is stable, and environment friendliness and safety are achieved.

Owner:平顶山环宇星防水科技有限公司

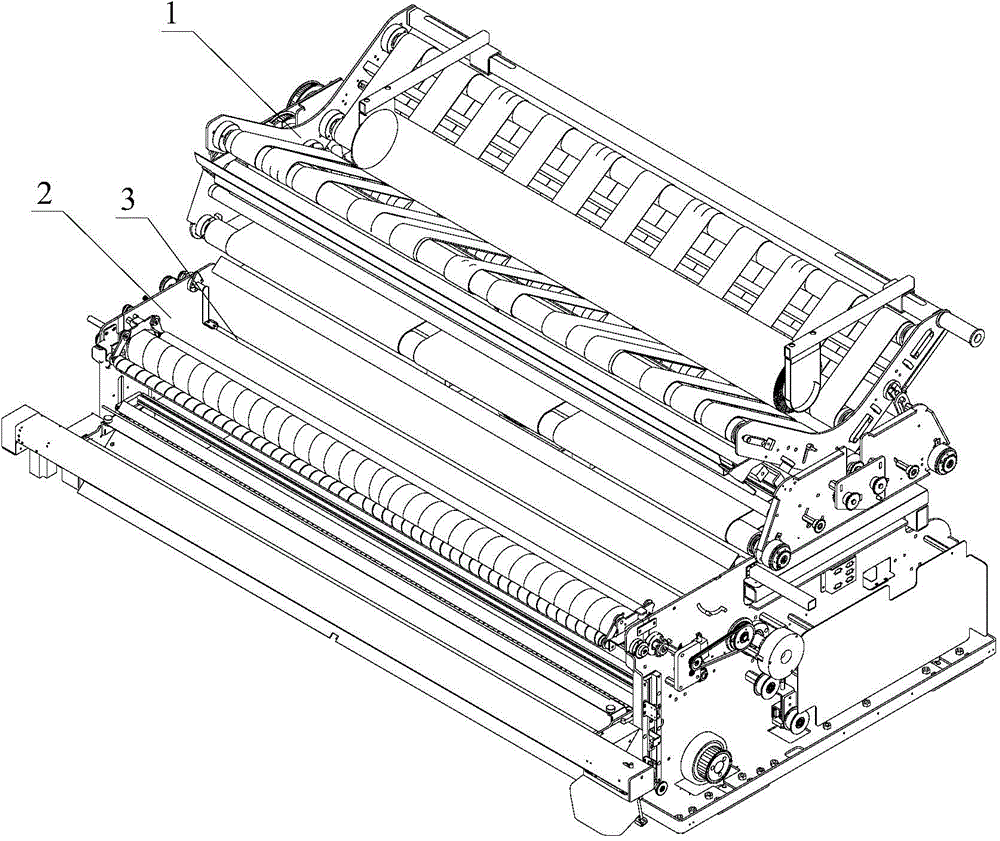

Fabric spreading speed control device and method for fabric spreading machine

ActiveCN104692183AGuarantee laying qualityImprove crop qualityFolding thin materialsNumerical controlEngineering

The invention relates to the technical field of a numerical control machine tool, and discloses a fabric spreading speed control device and method for a fabric spreading machine. The fabric spreading machine comprises a fabric conveying mechanism and a fabric spreading table. The fabric spreading speed control method for the fabric spreading machine comprises the following steps: the fabric conveying mechanism conveys to-be-spread fabric to the fabric spreading table through a fabric pressing mechanism, wherein the position of the fabric pressing mechanism is changed with change of the fabric conveying speed of the fabric conveying mechanism; when the fabric conveying speed exceeds a preset range, a position sensing mechanism senses the position of the fabric pressing mechanism and outputs the position to a controller; the controller acquires the fabric conveying speed according to the received data, and adjusts the fabric conveying speed of the fabric conveying mechanism to be within the preset range. Compared with the prior art, the fabric conveying speed of the fabric conveying mechanism is detected in real time and is adjusted according to a detection result, a to-be-spread material can be spread to an accurate preset length, the cutting accuracy is improved, the defective rate is reduced, materials are saved, and loss is reduced.

Owner:长园和鹰科技(河南)有限公司

Intelligent automatic cable conveyor

PendingCN109879111AReduce manual operation efficiencyReduce labor intensityFilament handlingLoop controlClosed loop

The invention relates to an intelligent automatic cable conveyor. A position sensor group for detecting a position of a cable is arranged at the inlet of a cable conveying channel, so that a caterpillar band is driven automatically to move through a conveying motor when the position sensor group senses the cable. A left bracket and a right bracket are driven by a lead screw electric driving mechanism to move synchronously oppositely or reversely, so as to clamp the cable placed in the cable conveying channel automatically. A pressing force detecting device for detecting a pressing force of thecable is arranged in the right bracket. The intelligent automatic cable conveyor can achieve automatic clamping of the cable, adjustable speed and automatic conveying and form closed-loop control, sothat the pressing force of the cable is adjusted automatically according to a set threshold value. Meanwhile, the conveyor can be adjusted in speed according to the field construction situation, so that the labor intensity and the cost of constructors are reduced greatly, and the intelligent automatic cable conveyor has the advantages of high cable paving quality and high efficiency.

Owner:CHANGLAN CABLE ACCESSORIES

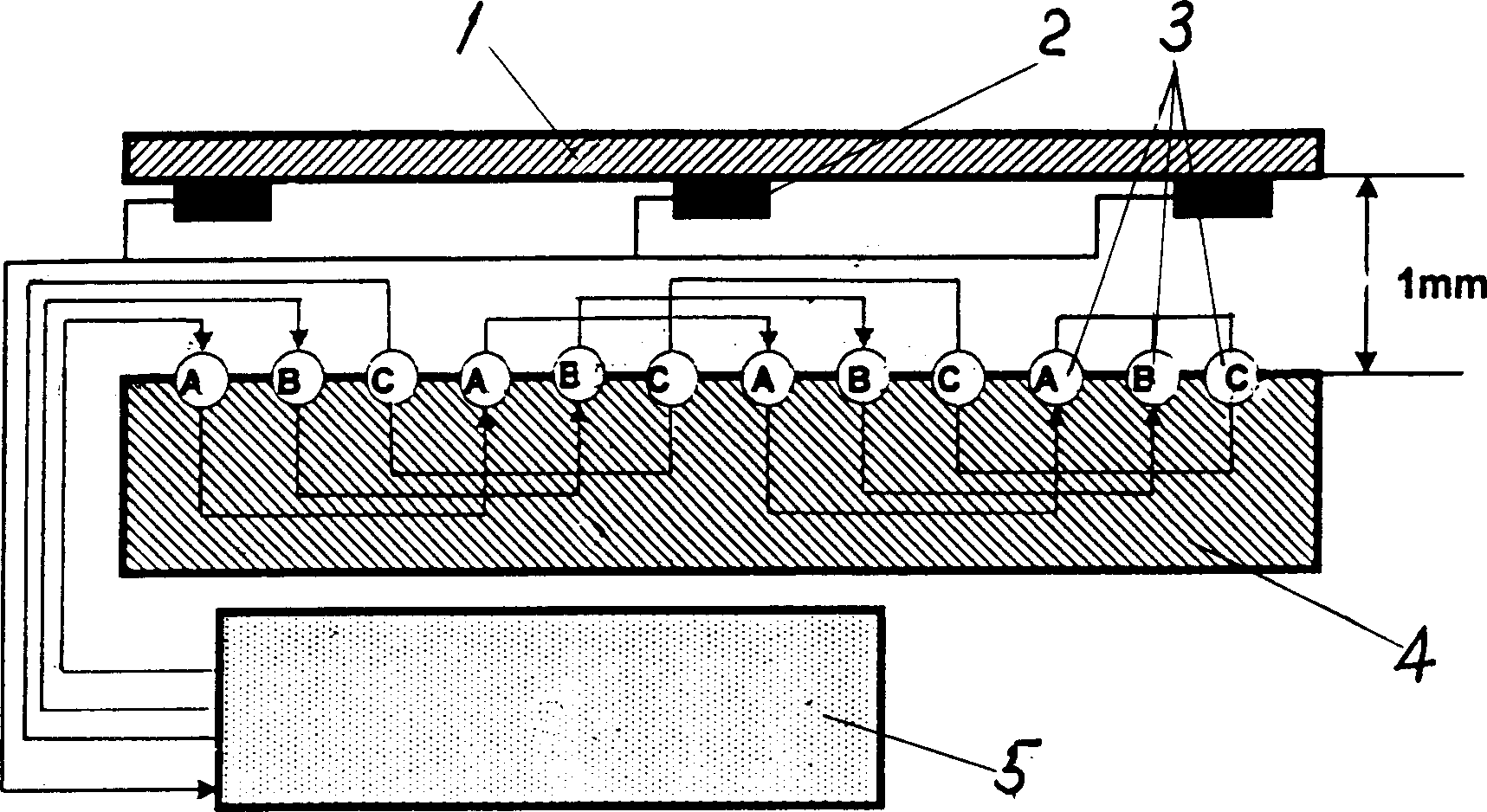

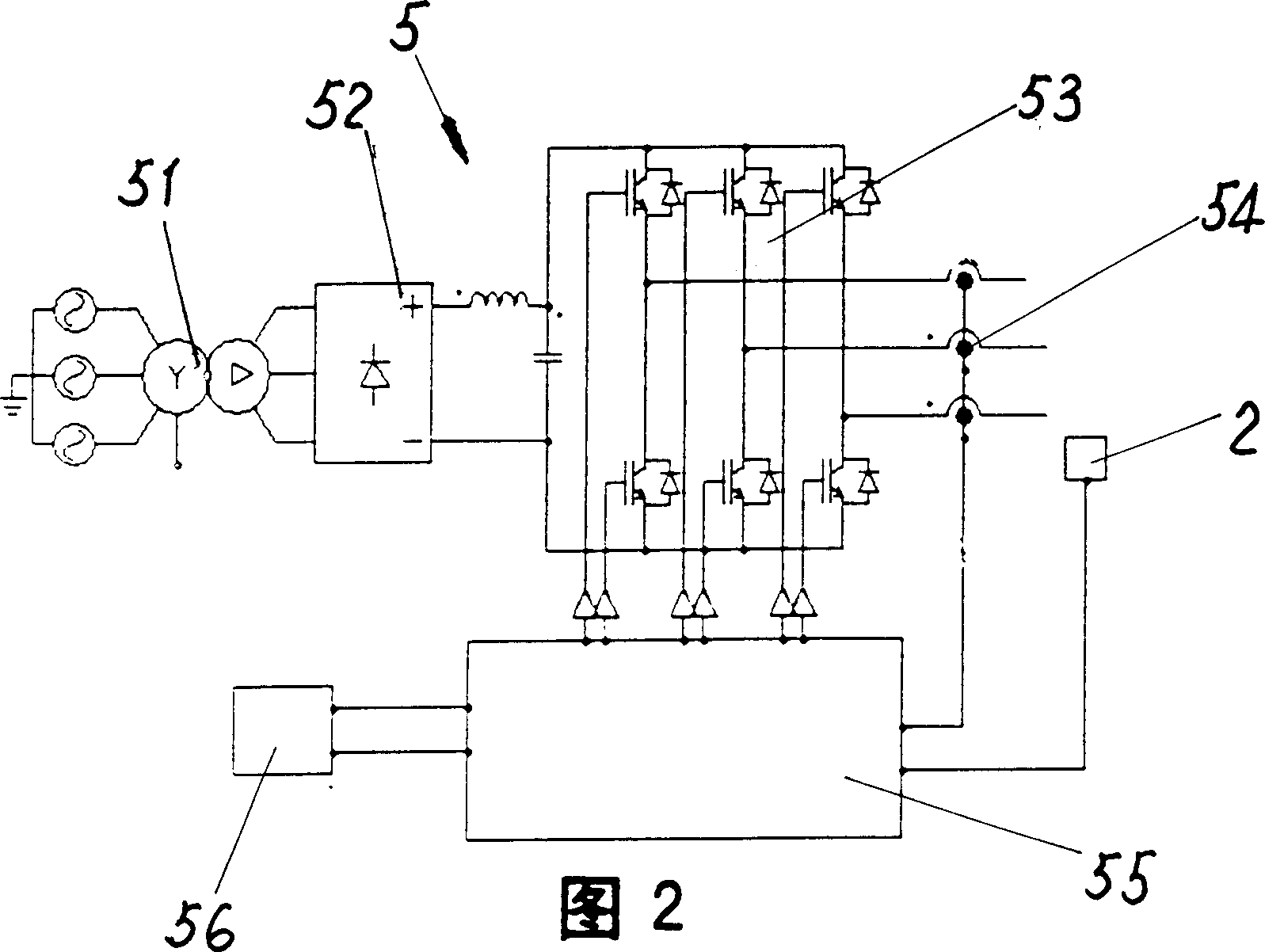

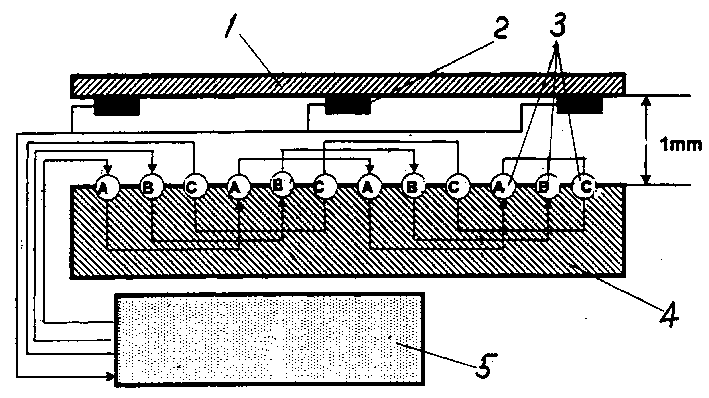

Long-stator iron core electric performance testing device

InactiveCN1460866AGuarantee laying qualityGuaranteed normal operationMagnetic property measurementsElectricityLoop control

The testing equipment of electric performance of long-stator iron core has a magnetic induction block, a fluxgate sensor positioned on the above-mentioned magnetic induction block, a three-phase armature winding can be inlaid in the slot of long-stator iron core to be tested and a measurement control system which is respectively electrically connected with the above-mentioned fluxgate sensor and three-phase armature winding and contains input transformer, rectifier, inverter and three-phase current cloosed-loop control system.

Owner:TONGJI UNIV +1

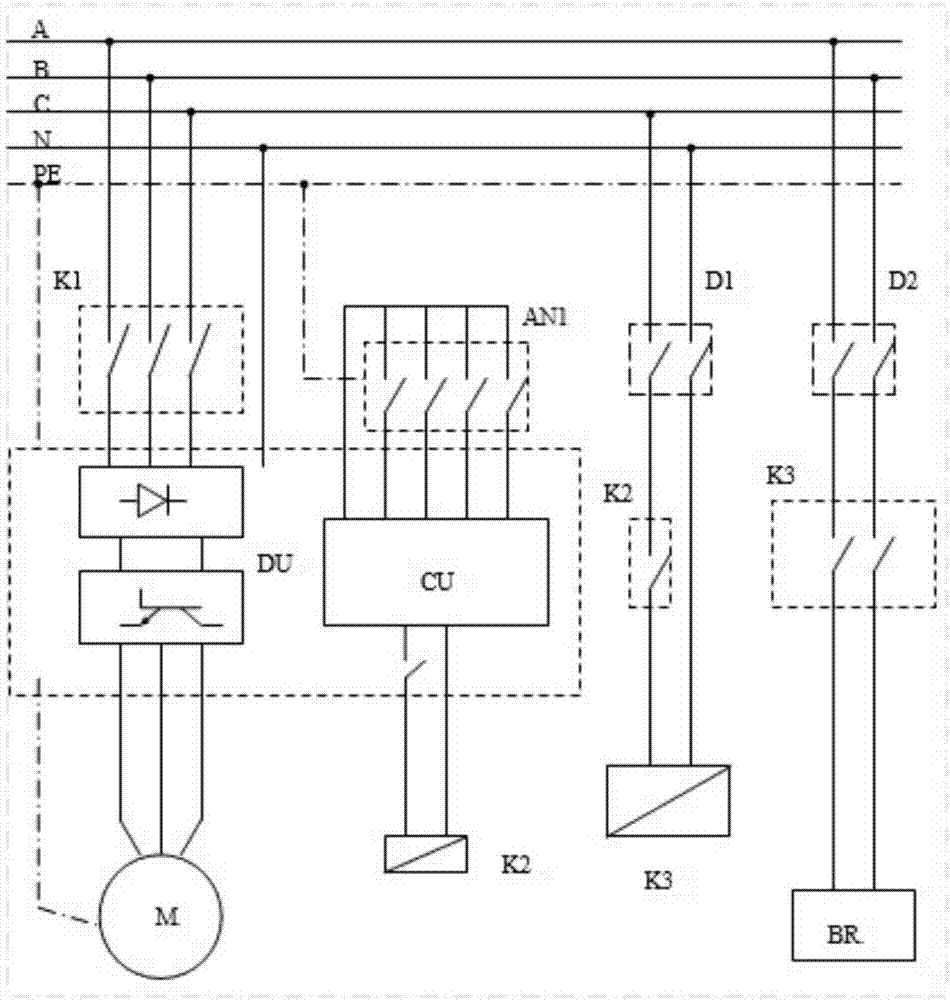

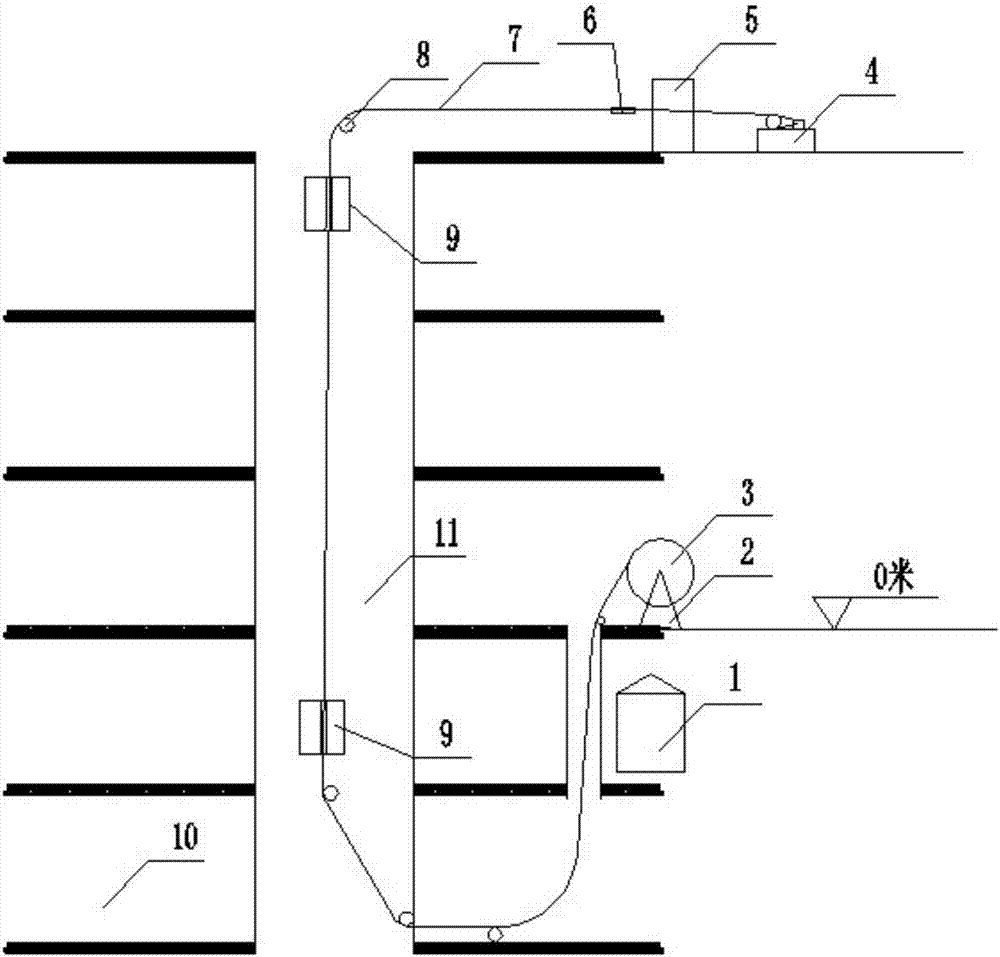

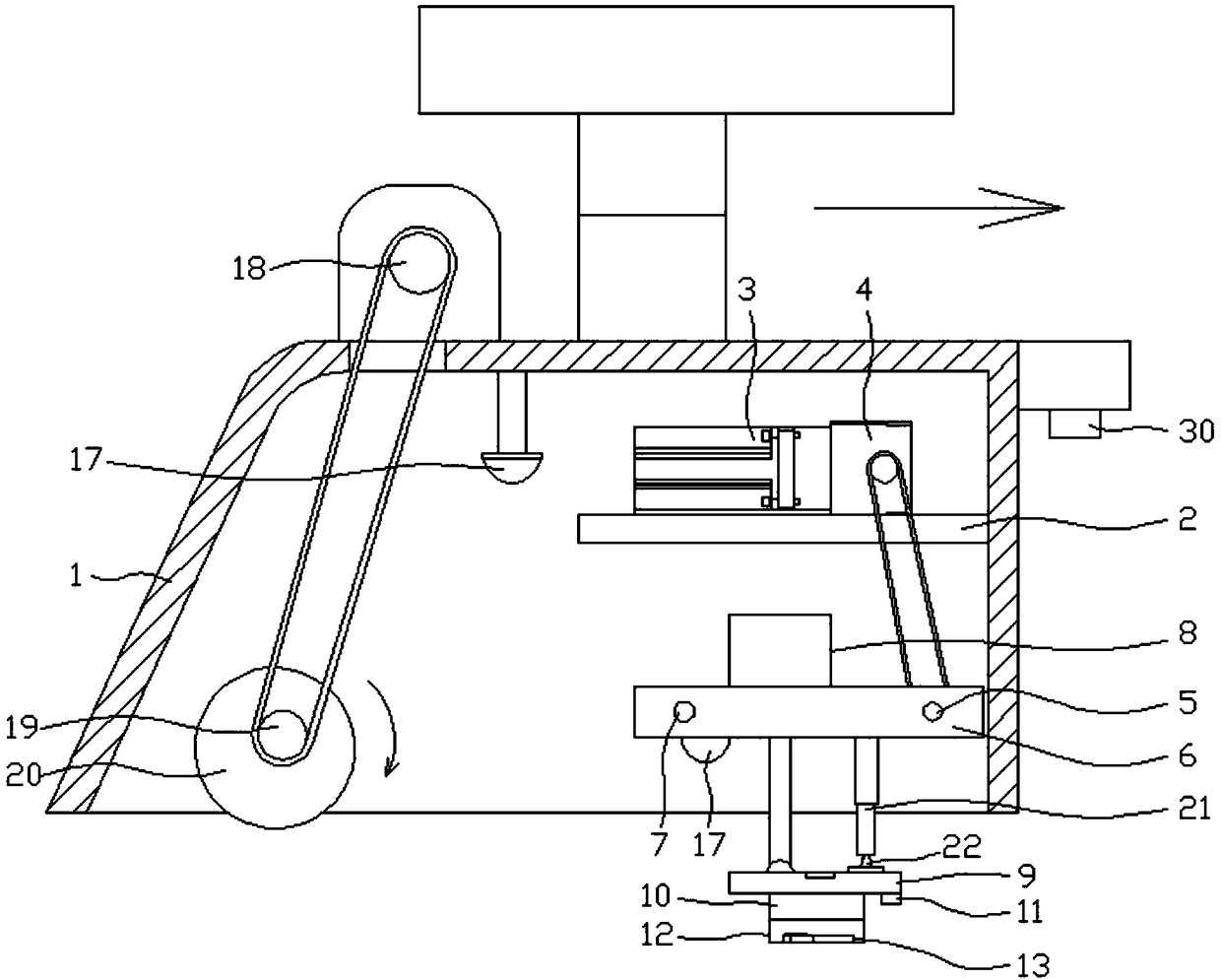

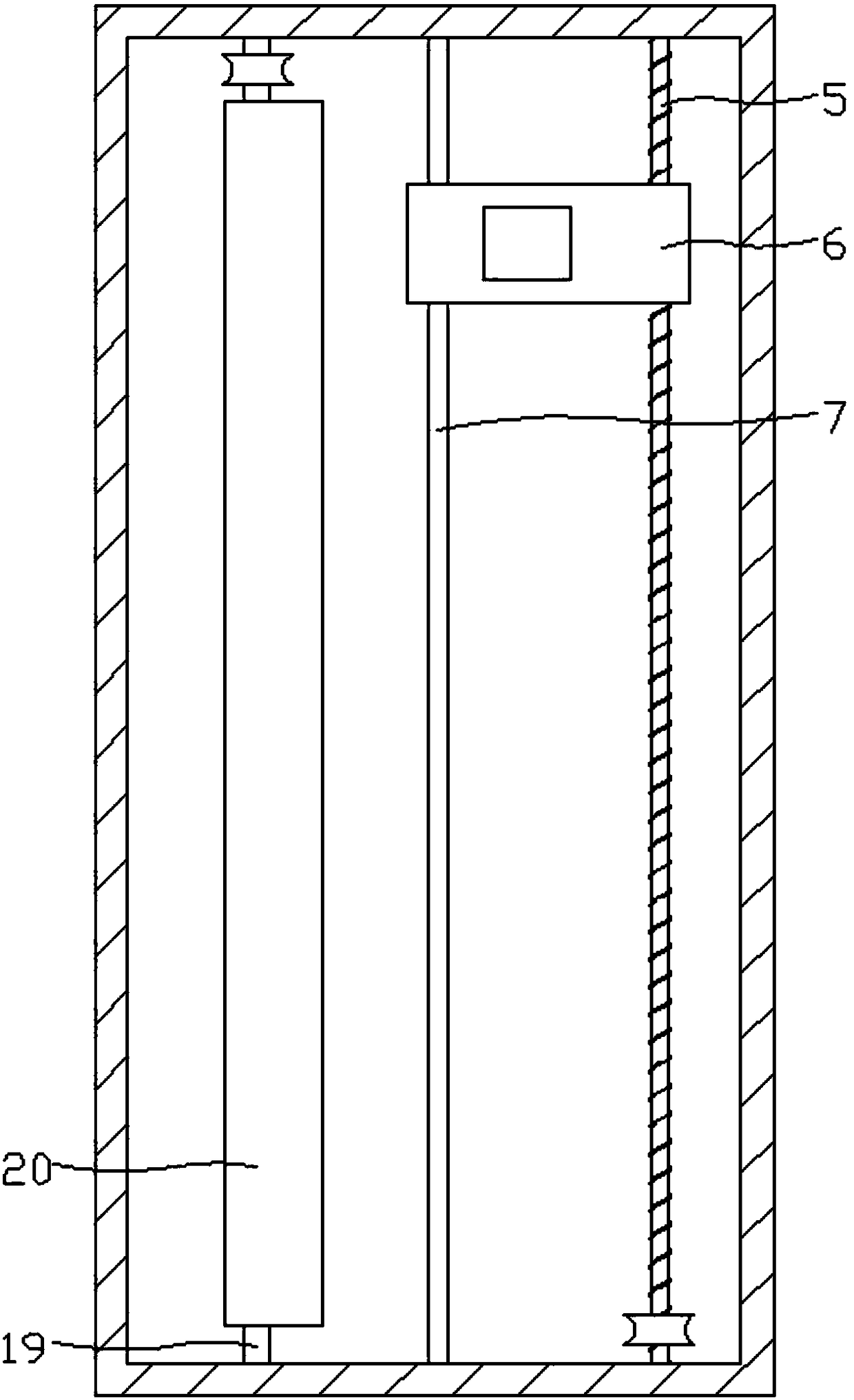

High-rise residential building cable laying control system and method

PendingCN107394682ASimple structureEasy to operateApparatus for laying cablesFrequency changerElectricity

The invention provides a high-rise residential building cable laying control system and a high-rise residential building cable laying control method. The high-rise residential building cable laying control system comprises a control unit, a power unit and an auxiliary unit. The control unit is electrically connected with the power unit. The power unit and the auxiliary unit are connected by means of a cable. The control unit comprises a frequency converter and a button box. The power unit comprises a hoisting machine and a brake. The frequency converter is electrically connected with the hoisting machine, the frequency converter is electrically connected with the button box, and the hoisting machine is electrically connected with the brake. The high-rise residential building cable laying control system and the high-rise residential building cable laying control method have the beneficial effects that: the frequency converter is connected with the hoisting machine, so that the whole high-rise residential building cable laying system is simple in structure and convenient in operation; the frequency conversion technology is combined with a high-rise residential building cable laying method, the unique frequency conversion technology is utilized, the frequency conversion technology is combined with a low-speed hoisting and traction cable laying method, the cable laying speed is accelerated, and the cable laying quality is guaranteed; and the automation level is high, the labor cost is saved and the working efficiency is improved.

Owner:TIANJIN 20 CONSTR

Cutter suction dredger over-water floating pipe hydraulic fast connector

ActiveCN103174895AReduce the impact of unfavorable docking due to bumps and shakesEasy to makeCouplingsButt jointBuilding construction

The invention provides a cutter suction dredger over-water floating pipe hydraulic fast connector and relates to equipment based on over-water movable dredge pipe fast butt joint. The fast connector is suitable for fast butt joint of a cutter suction dredger and over-water dredge pipes (also known as over-water floating pipes) of a dredging hydraulic reclamation project, and saves time and labor. The over-water dredge pipe fast connector comprises a connector body, a connecting sleeve, a hydraulic transmission device and a steel belt collection and release locking device. The hydraulic transmission device is arranged on the outer surface of the connecting sleeve and connected with the steel belt collection and release locking device through a connecting device. When the hydraulic transmission device and the steel belt collection and release locking device are in a connection state, the connector body is locked in the connecting sleeve. According to the fast connector, in the construction process of paving the dredge pipes on water, a guiding function of a guiding device of a male connecting sleeve is utilized, and therefore unfavorable influence on butt joint due to the fact that stormy waves cause the dredge pipes to bump and rock is reduced, and fast butt joint of the over-water dredge pipes and fast butt joint of the over-water dredge pipes and the dredger can be achieved through tightening of a traction steel wire. Accordingly, the fast connector is widely suitable for paving of the dredge pipes on the water where water current flow states are turbulent and the stormy waves are strong.

Owner:NANJING CHANGJIANG WATERWAY ENG BUREAU

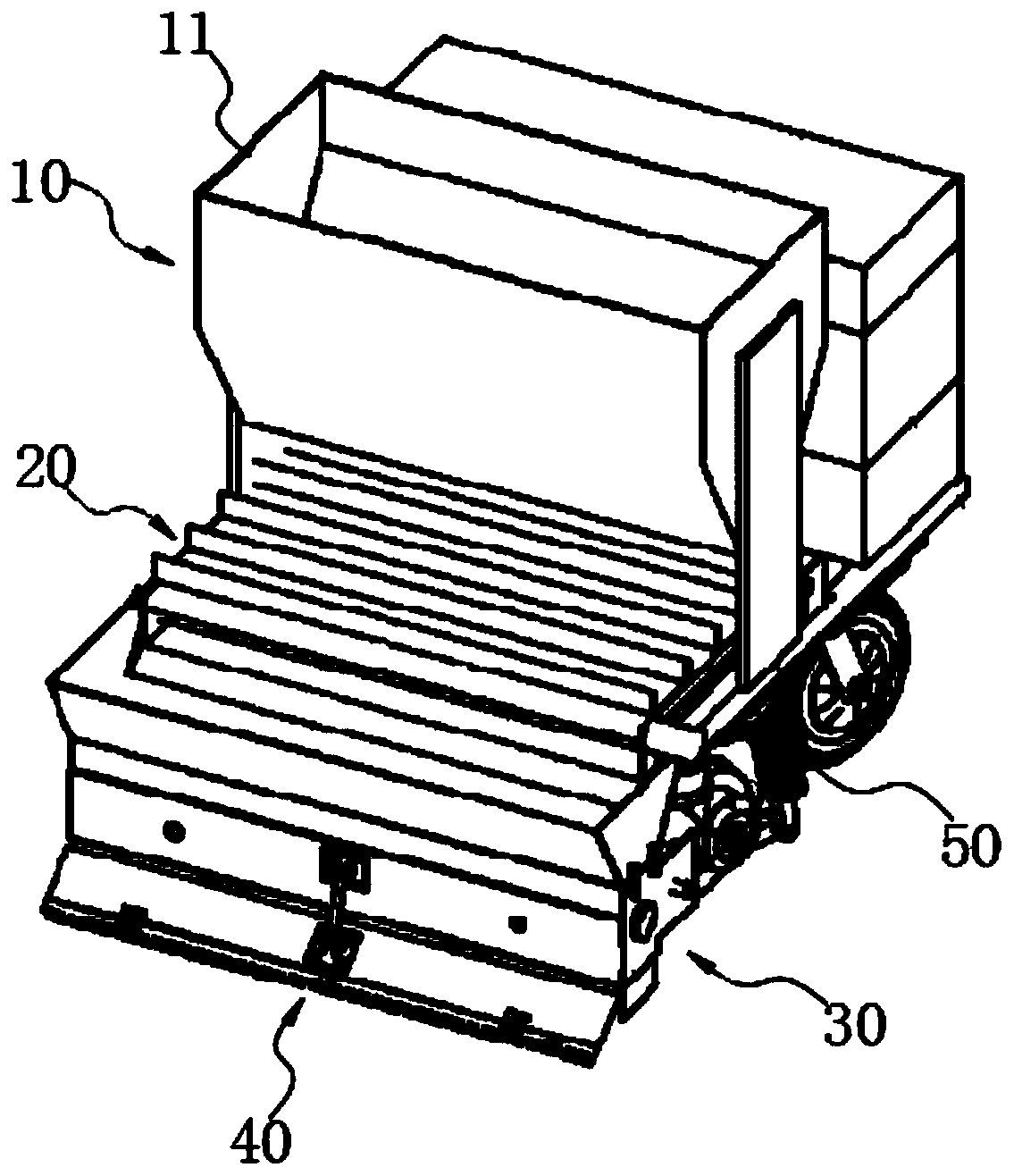

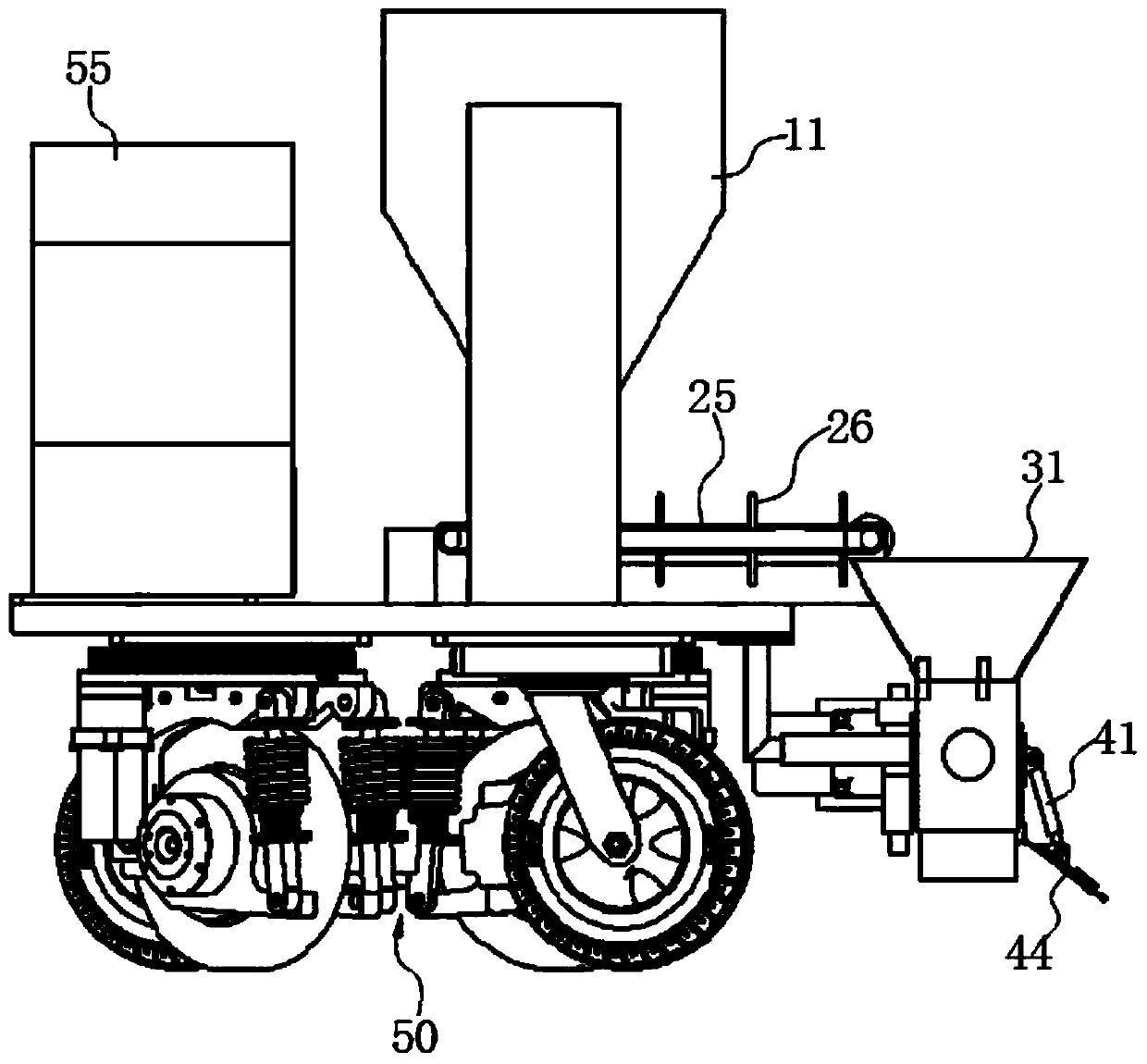

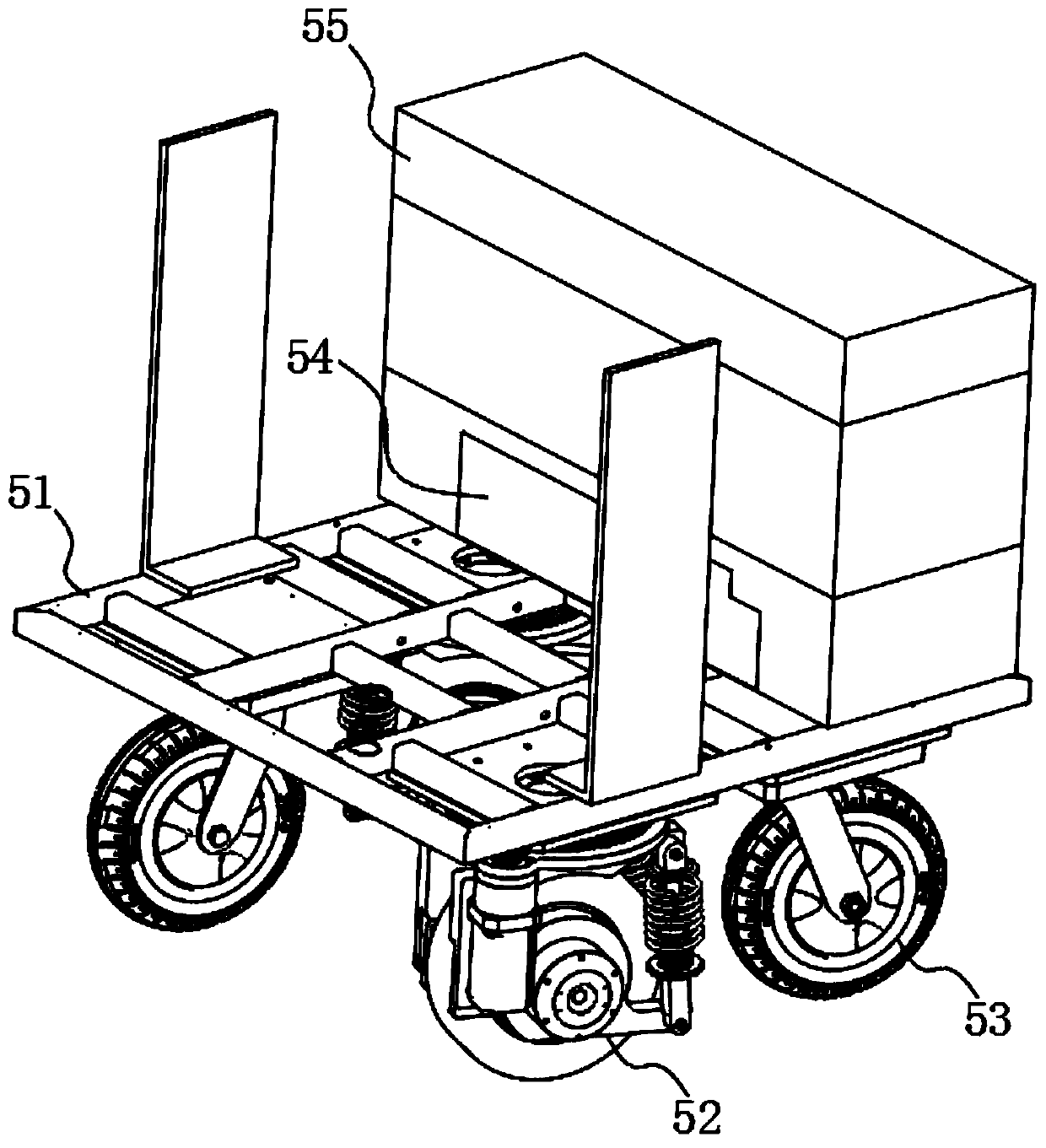

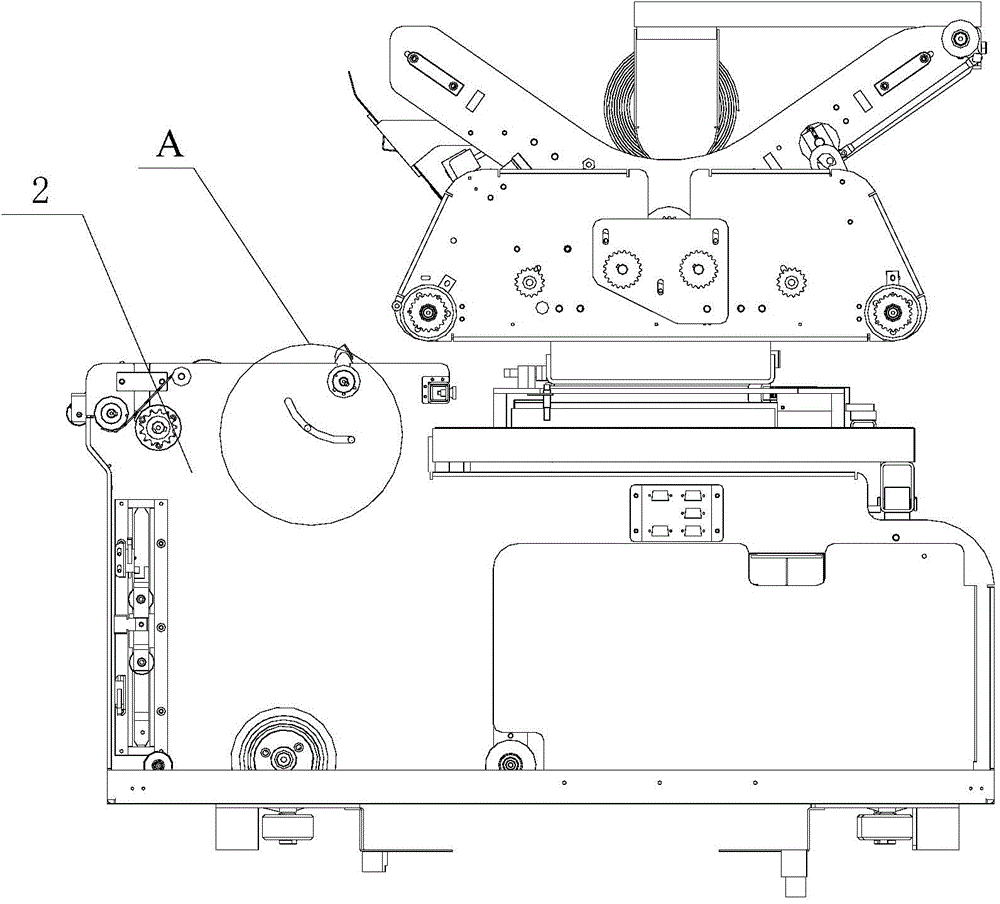

Mud flat machine for prefabricated waterproof roll

PendingCN111764232AFully automatedGuarantee laying qualityRoads maintainenceBuilding material handlingSlurryMechanical engineering

The invention discloses a mud flat machine for a prefabricated waterproof roll. The mud flat machine comprises a remotely-controlled walking trolley, a slurry extrusion device, a dragging material scraper thickness adjusting device, and a coiled material laminating device, wherein the slurry extrusion device includes a hopper, an extrusion mechanism and a switch valve; the extrusion mechanism is used for extruding a slurry along a strip-shaped discharge hole of the hopper; the dragging material scraper thickness adjusting device includes a support, a first rotating frame installed at the lowerend of the support in a rotatable mode, a material flow guide plate and a scraper; the material flow guide plate is installed in the first rotating frame in an inclination angle adjustable mode and is used for guiding the slurry extruded by the slurry extrusion device to flow to a walking plane of the walking trolley, and the scraper is used for adjusting the thickness of the slurry and scrapinga mud flat; a gap is formed between the scraper and the material flow guide plate; and the coiled material laminating device includes a coiled material placing mechanism, a coiled material correctingand adjusting mechanism mounted below the coiled material placing mechanism, an automatic film collecting mechanism mounted beside the coiled material correcting and adjusting mechanism, and a coiledmaterial paving and automatic flattening mechanism used for paving and flattening the waterproof roll on the upper end surface of the slurry scraped by the dragging material scraper thickness adjusting device.

Owner:广东铠怡融科技有限公司

Automatic floor tile laying equipment

Automatic floor tile laying equipment comprises a casing with the lower end open, a partition board is arranged in the casing, a motor and a speed reducer connected with the motor are arranged on thepartition board, an output shaft of the speed reducer is connected with a screw penetrating through a sliding seat, and the sliding seat is movably arranged on a guide rail; a lift cylinder is vertically arranged on the sliding seat, a piston rod of the lift cylinder is connected with a carrying plate, a hydraulic turning plate and a distance measuring sensor are arranged at the lower end of the carrying plate, a support is arranged at the lower end of the hydraulic turning plate, a telescopic cylinder is arranged in the support and connected with a floor tile clamping device; cameras are arranged in the casing and at the lower end of the sliding seat. The automatic floor tile laying equipment is simple in structure and can replace workers to lay floor tiles and reduce the labor intensityof the workers.

Owner:HUNAN CITY UNIV

Self-propelled waterproof roll laying device for bridge construction

ActiveCN111719431AConsistent lap widthIncrease the laying areaBridge erection/assemblyRoads maintainenceArchitectural engineeringStructural engineering

Owner:山西振兴公路监理有限公司

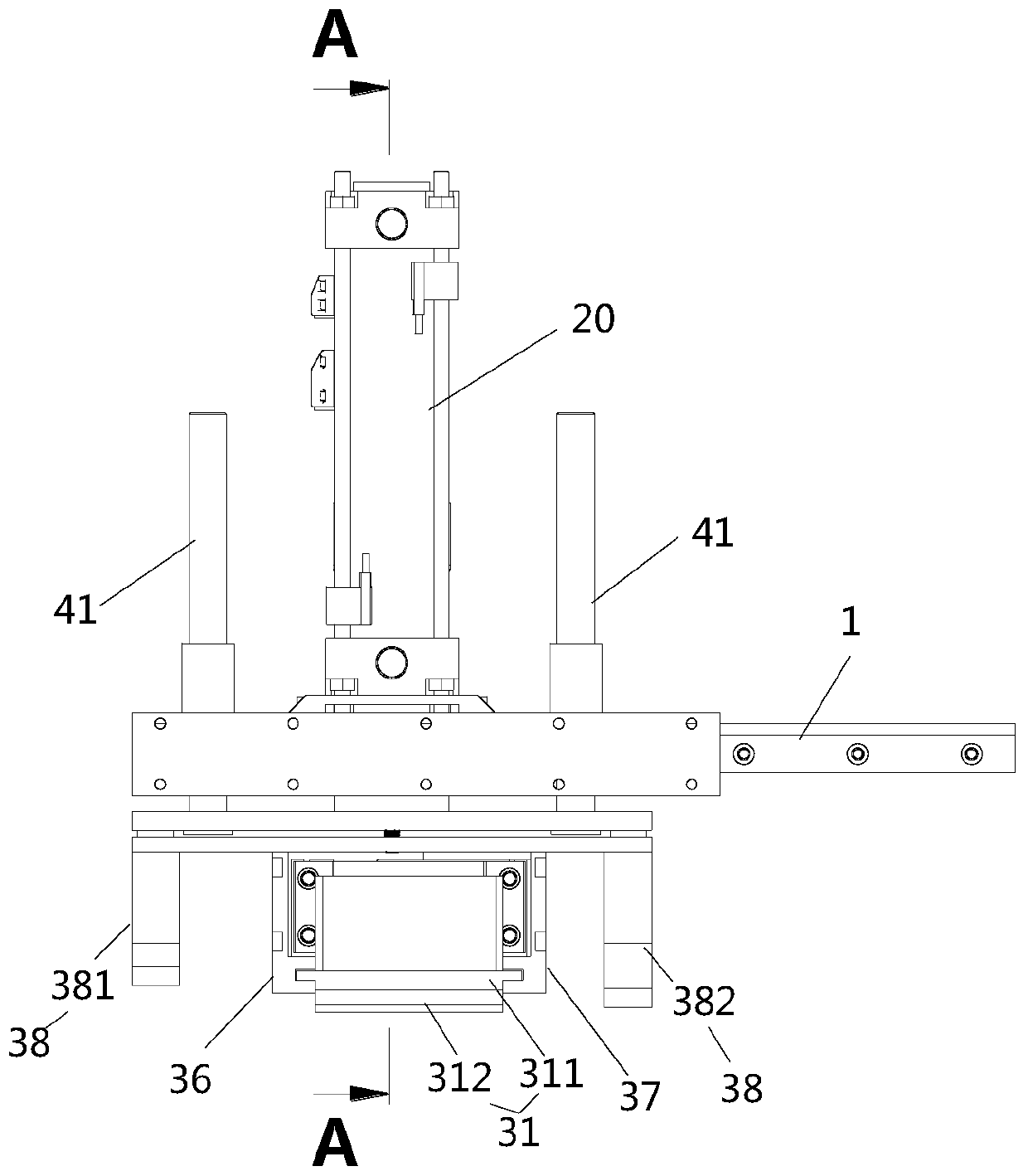

Floor lateral knocking device and floor installing robot

ActiveCN110872903AConsistent strengthGuarantee laying qualityBuilding constructionsStructural engineeringElectrical and Electronics engineering

The invention provides a floor lateral knocking device and a floor installing robot. The floor lateral knocking device comprises a base plate, a knocking mechanism and a vertical driving part, whereinthe base plate is provided with a conical positioning hole, the aperture of the conical positioning hole is gradually reduced from top to bottom, the knocking mechanism is arranged on the lower sideof the base plate and provided with a conical positioning column matched with the conical positioning hole, at least part of the conical positioning column is inserted in the conical positioning hole,and the vertical driving part is installed on the base plate and in driving connection with the knocking mechanism so as to drive the knocking mechanism to move in the vertical direction. The problemthat a floor lateral knocking device is low in installing precision in the prior art is solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

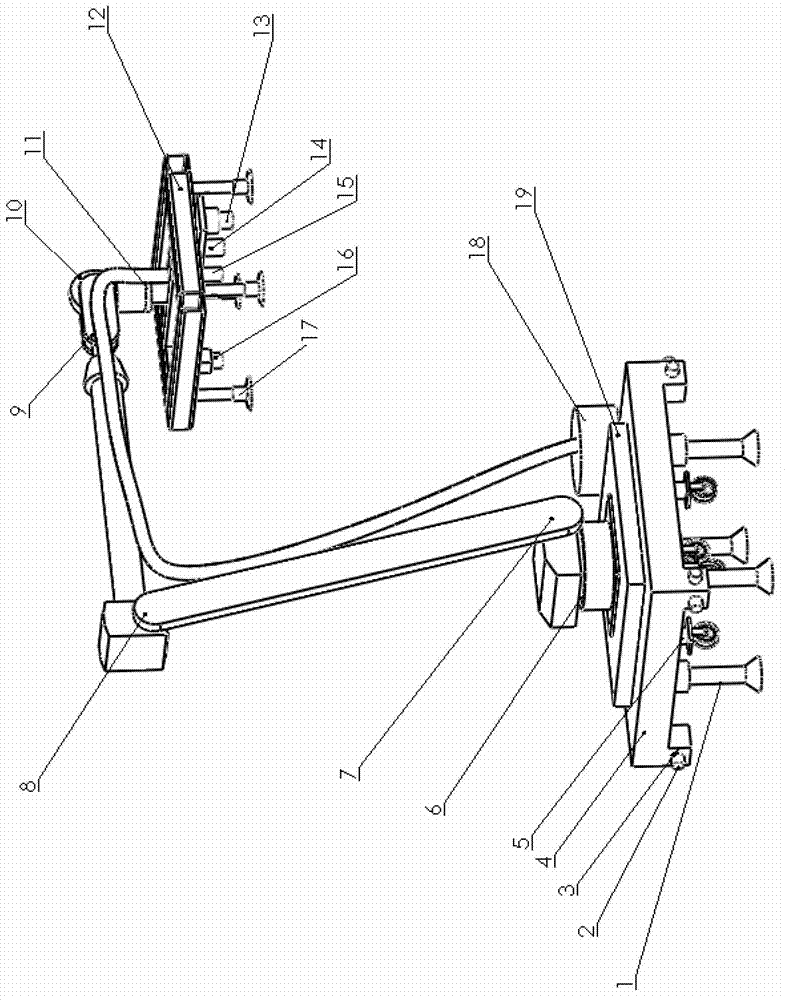

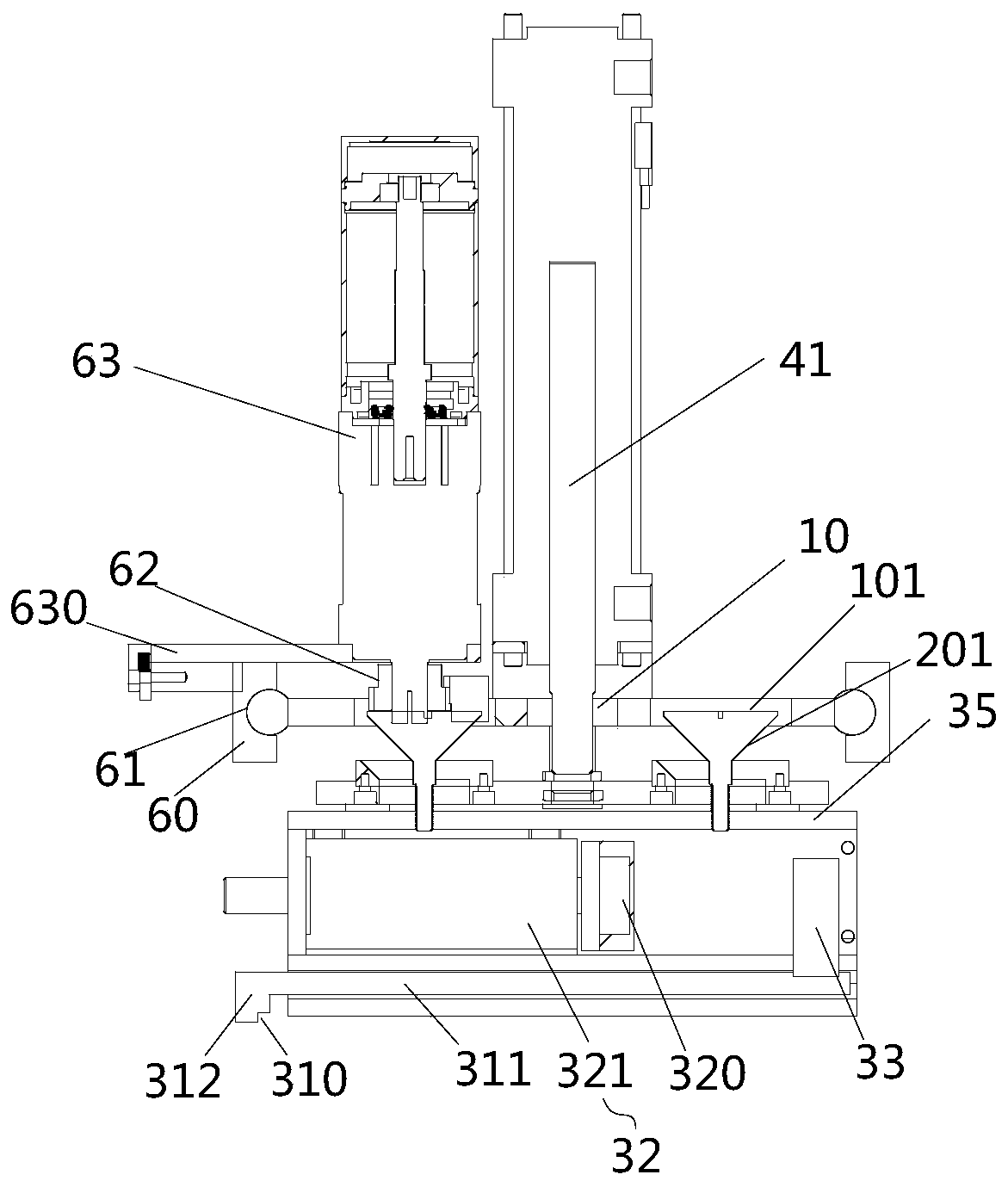

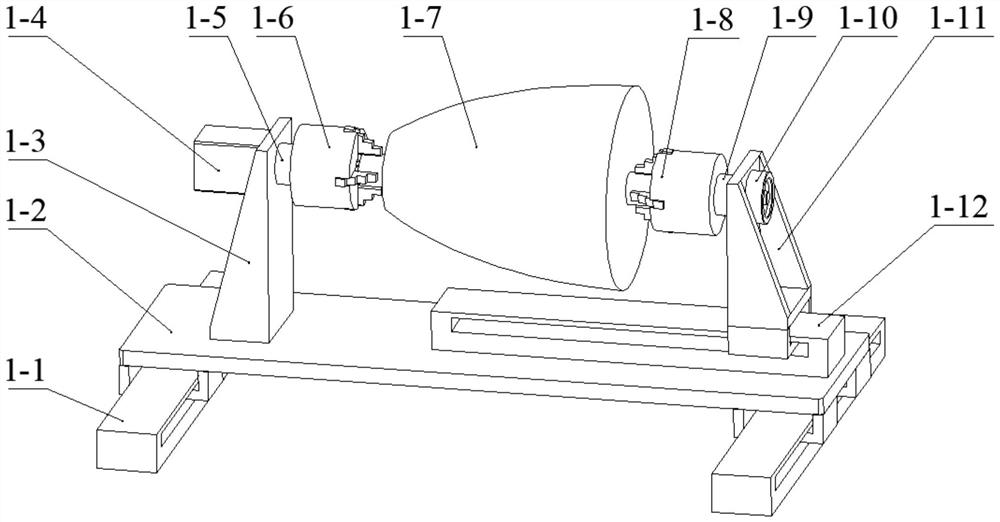

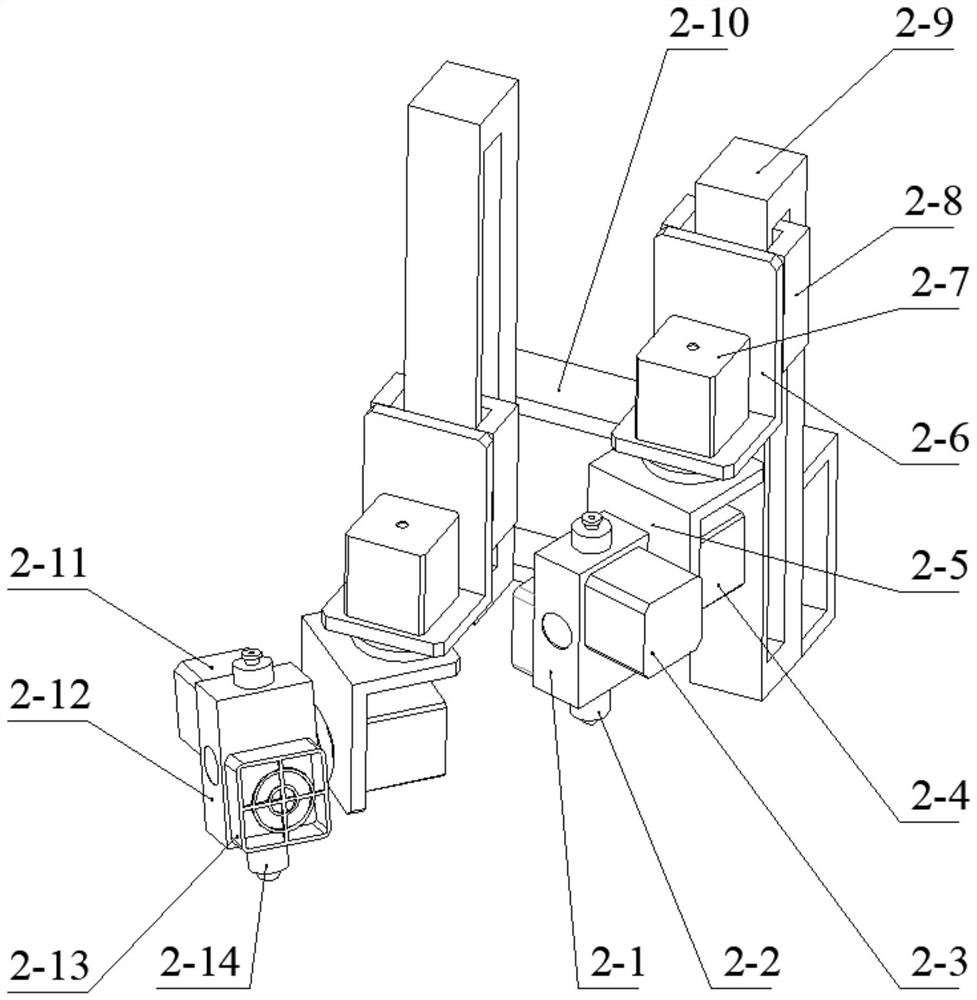

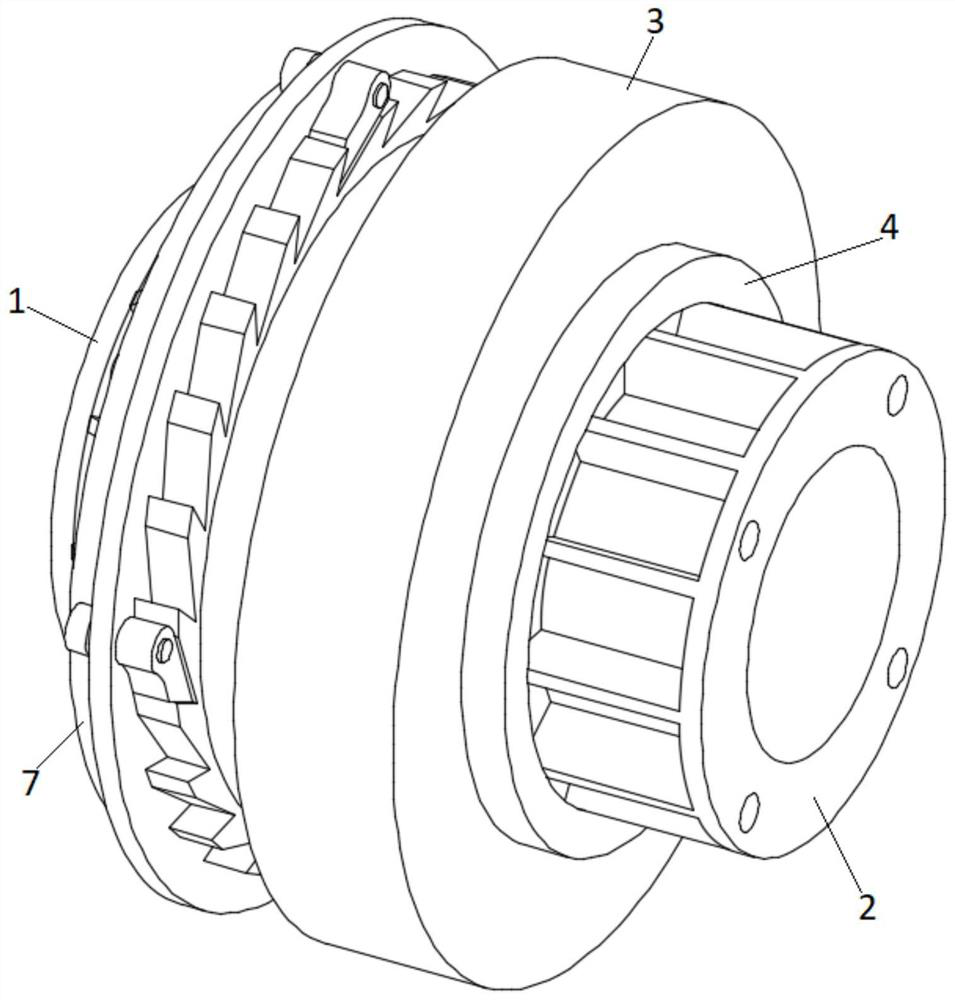

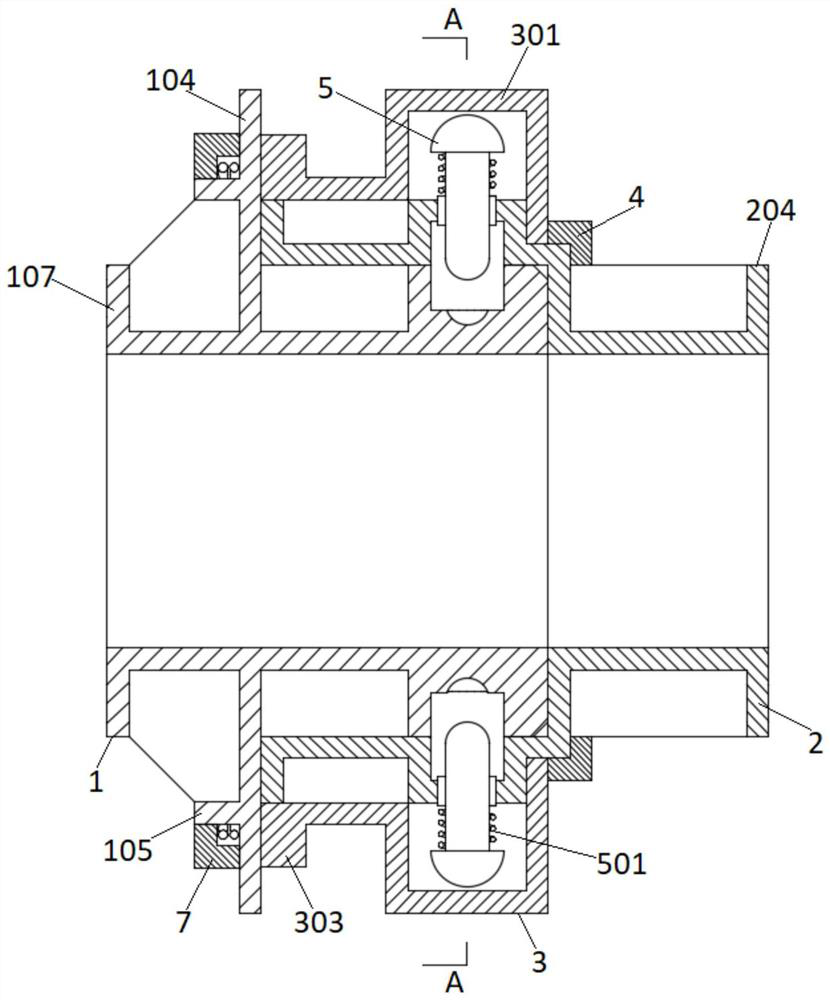

Rotary curved surface structure composite material additive manufacturing device

InactiveCN112140529AGuarantee laying qualityHigh strengthAdditive manufacturing apparatus3D object support structuresFiberMechanical engineering

The invention relates to a rotary curved surface structure composite material additive manufacturing device, and belongs to the technical field of composite material rapid forming equipment. The device comprises a device frame structure, a core mold clamping driving device, a fiber printing spray head, a resin printing spray head, a spray head position and posture adjusting device and a material extrusion printing device. The device frame structure above the core mold clamping driving device is connected with the fiber printing spray head and the resin printing spray head through the spray head position and posture adjusting device, and the fiber printing spray head and the resin printing spray head are connected with the material extrusion printing device. According to the rotary curved surface structure composite material additive manufacturing device, through linkage control of the double-spray-head position and posture adjusting device and the core mold clamping driving device, a fiber material and a base material are laid on a rotary curved surface along a set curve path and spray head postures, the laying quality of the fiber material and the base material is guaranteed, andthe strength of a rotary curved surface structure composite material part obtained through additive manufacture and the utilization rate of the fiber mechanical property are improved.

Owner:DONGHUA UNIV

Quick connector device for floating pipe of cutter suction dredger

ActiveCN113074286AImprove connection efficiencyImprove laying efficiencyCouplingsStructural engineeringMechanical engineering

The invention discloses a quick connector device for a floating pipe of a cutter suction dredger, and relates to the technical field of dredgers. The quick connector device comprises a first connector and a second connector which are coaxially arranged; the first connector can be moved into the inner side of the second connector; the periphery of the second connector is rotationally sleeved with a reducing sleeve; a positioning assembly is arranged between the reducing sleeve and the second connector; the positioning assembly is used for oppositely connecting the second connector and the first connector; a locking assembly is arranged between the first connector and the reducing sleeve; and the locking assembly is used for conducting position connection between the first connector and the reducing sleeve. The quick connector device is reasonable in structural design and convenient to operate, effectively improves the connecting efficiency between a dredger pipe body and the floating pipe, and has high market application value.

Owner:BENGBU SHENZHOU MACHINERY

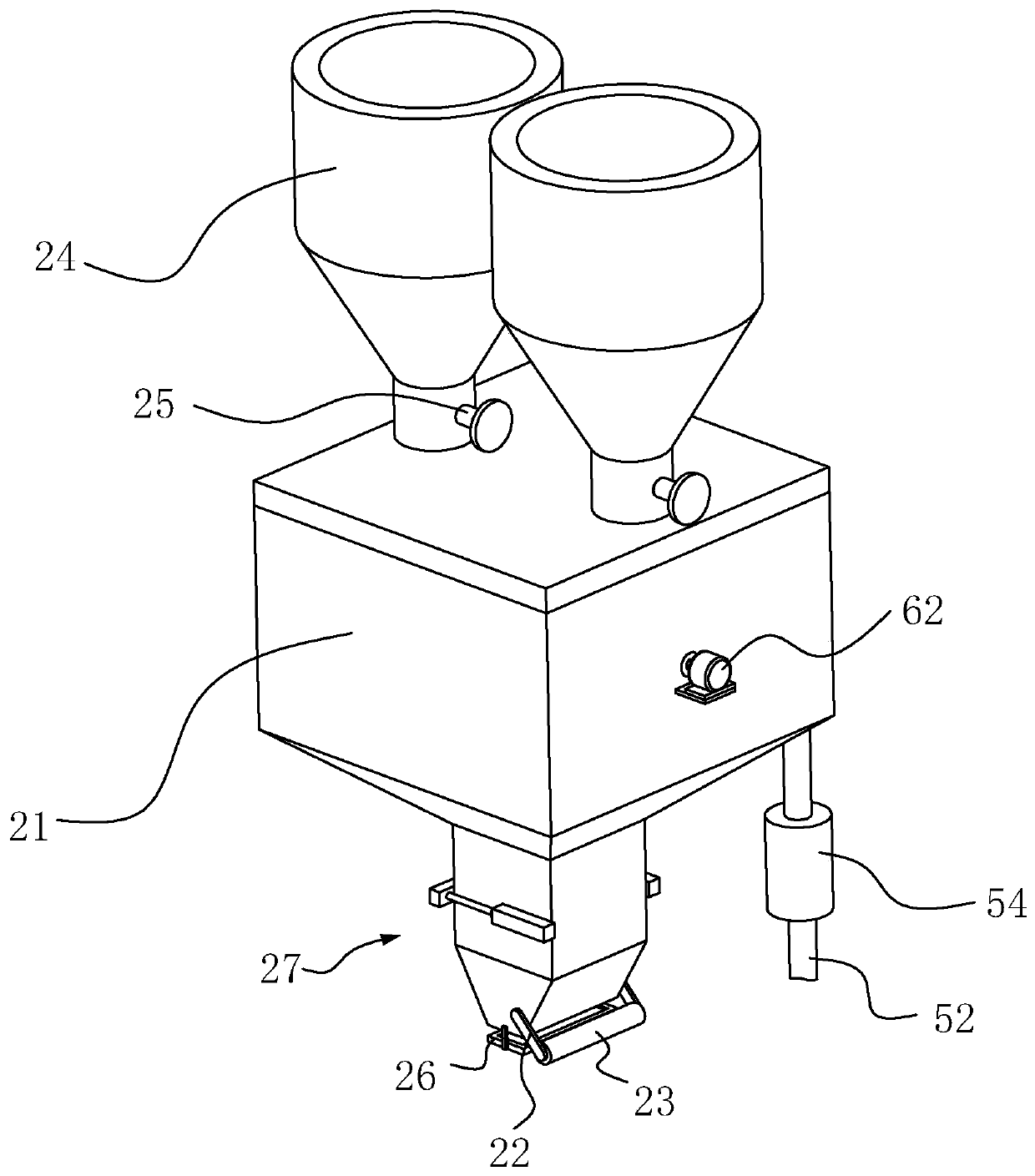

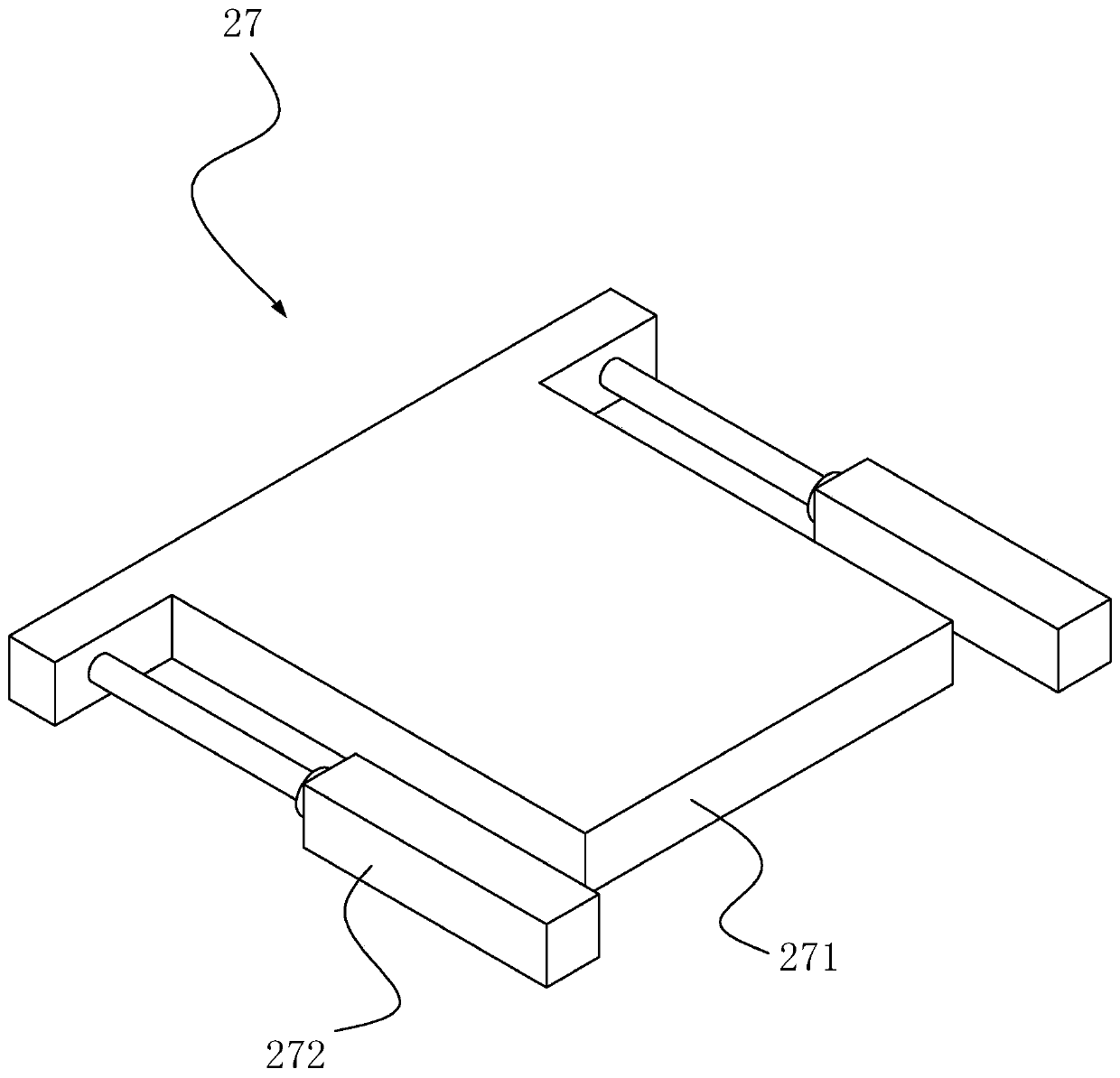

Masonry mortar rapid-laying and anti-falling device

The invention discloses a masonry mortar rapid-laying and anti-falling device. The masonry mortar rapid-laying and anti-falling device includes a mortar bin movably clamped on the two sides of a wall body, the bottom wall of the mortar bin is located between the top and bottom of the mortar bin and provided with a grout discharging opening, the lower part of the bottom wall is provided with a vibrator and a driving motor, two driving wheel groups are installed between the left and right side walls of the mortar bin, the driving motor is connected with the driving wheel groups through a retarder, the mortar bin is provided with a control unit connected with the driving motor and the vibrator, the rear side wall of the mortar bin is provided with a plastering opening, a regulation plate is arranged to be matched with the plastering opening, the lower parts of the left and right side walls of the mortar bin are correspondingly provided with roller groups, and rollers of the roller groups are matched with the wall face of the wall body in a rolling mode. According to the masonry mortar rapid-laying and anti-falling device, mortar can be automatically and rapidly laid on bricks, and the laying thicknesses of the mortar can be adjusted according to different requirements; and at the same time, when the mortar is laid, it is ensured that the mortar cannot fall down, and lower layer brick seams can be synchronously repaired.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

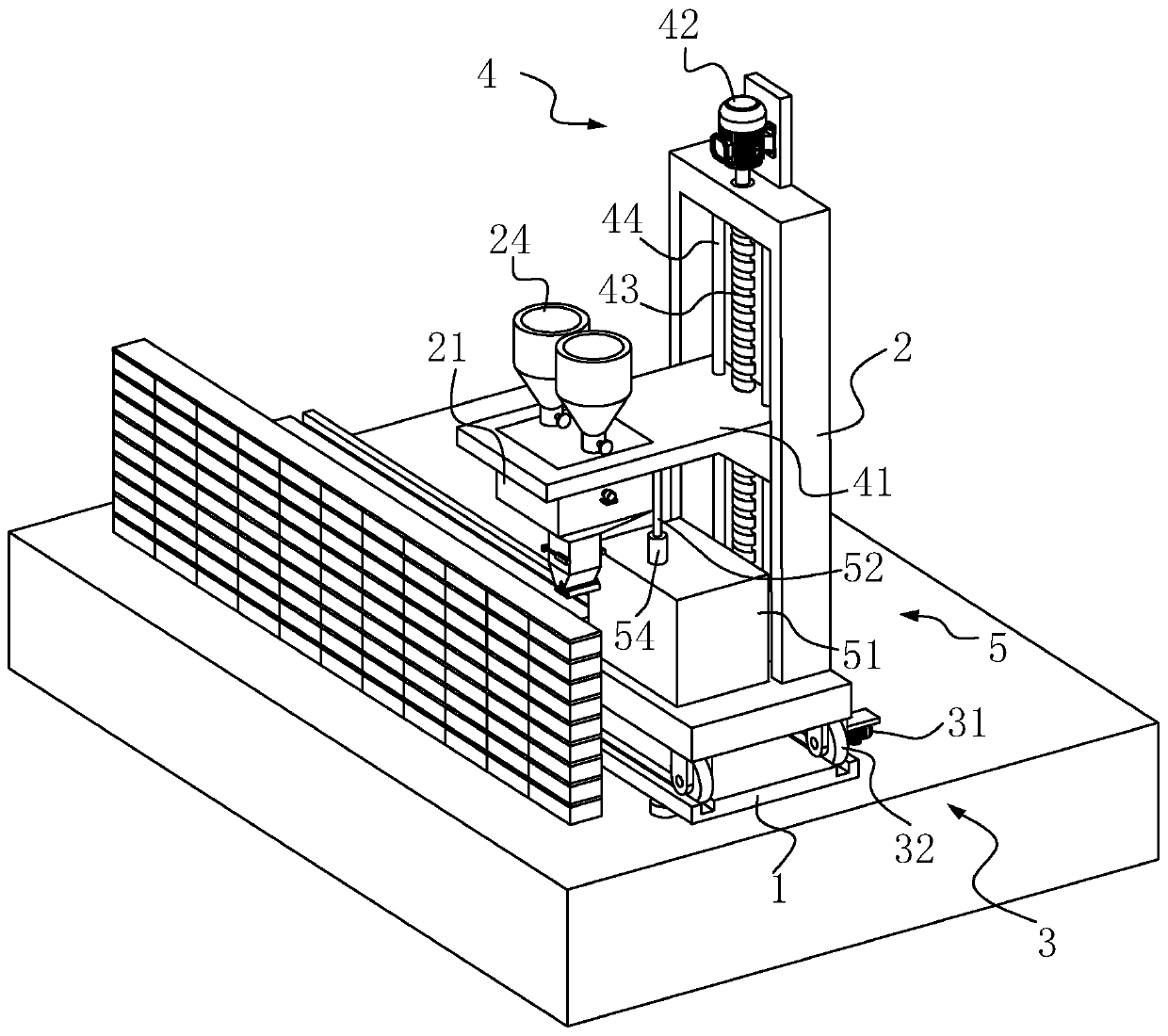

Intelligent retaining wall construction machine for geotechnical engineering

ActiveCN110374135AEfficient and convenient layingGuarantee laying qualityArtificial islandsUnderwater structuresSlurryRetaining wall

The invention relates to an intelligent retaining wall construction machine for geotechnical engineering, and belongs to the technical field of rock and soil construction equipment. According to the technical scheme, the intelligent retaining wall construction machine is characterized in that a guide rail, a rack and a walking mechanism driving the rack to walk in the length direction of the guiderail are included; a slurry hopper is arranged on the rack, connecting frames are fixed to the two sides of a discharging port of the slurry hopper and areprovided with a material roller, and the material roller is rotationally connected with the connecting frames around a horizontal straight line; the position of a discharging port of the slurry hopper is provided with a discharging control assembly for controlling slurry discharging; the intelligent retaining wall construction machine for geotechnical engineering further comprises a lifting driving mechanism driving the slurry hopper to move in the vertical direction; the problems that when an existing retaining wall is constructed, applying of concrete slurry between building blocks is mainly laid through manual work, manpower is consumed, and the work efficiency is low are solved; and during retaining wall construction, workers can be assisted in pavement of the concrete slurry between the building blocks, manpower is saved, and the work efficiency is high.

Owner:东莞市建安桩基础工程有限公司

Wood floor edge closing-up device

The invention discloses a wood floor edge closing-up device. The wood floor edge closing-up device comprises a fixing plate, an L-shaped stop block is arranged at the end of the fixing plate, and thelength of the cross section of the L-shaped stop block is larger than that of the cross section of the fixing plate, a cross beam is arranged on the fixing plate, and a longitudinal beam is arranged at the head end of the cross beam. An oblique beam is arranged at the rear end of the cross beam, the longitudinal beam and the oblique beam are fixedly connected to the fixing plate, and the cross beam is sleeved with a handheld device. A front stop block is fixedly connected to the head end of the cross beam and is tightly attached to the longitudinal beam, and the tail end of the cross beam is sleeved with a rear stop block. The edge of a wood floor is hooked through the L-shaped stop block, the handheld device is utilized to rapidly move to the rear stop block from the front stop block along the cross beam to impact the rear stop block, the L-shaped stop block is driven to generate acting force to the edge of the wood floor, the wood floors gradually close up, seams existing in wood floor laying at wall corners are eliminated, the wood floor laying quality is ensured, and the wood floor laying efficiency is improved.

Owner:赵翔

Novel waterproof board laying construction method

InactiveCN103527222ASimplify laying operation processImprove laying efficiencyUnderground chambersTunnel liningArchitectural engineeringHot melt

The invention discloses a novel waterproof board laying construction method and belongs to the field of tunnel construction. The method includes the following steps: fixing slave pieces on a tunnel excavating outline face with organic hooks facing the outside; connecting the slave pieces and master pieces in a contact pressing overlapping mode through the hooks and threads to form joints, removing a hot melt adhesive protection film on the back of each master piece, bonding waterproof boards to the hot melt adhesive faces of the backs of the master pieces in a contact pressing mode, repeating the steps for multiple times and arranging the slave pieces and the master pieces on the arch crown, the lateral wall and a base board the tunnel excavating outline face to finish laying of the waterproof boards on the tunnel excavating outline face. Compared with a waterproof board laying construction method in the prior art, the novel waterproof board laying construction method utilizes the characteristics of snap fastener pieces, the waterproof boards are laid on the tunnel excavating outline face, a waterproof board laying operation process is simplified, laying construction efficiency is improved, labor intensity of workers is reduced, and laying cost is saved. Meanwhile, the waterproof boards cannot be damaged in the laying process, and waterproof board completeness and laying quality are ensured.

Owner:张俊峰

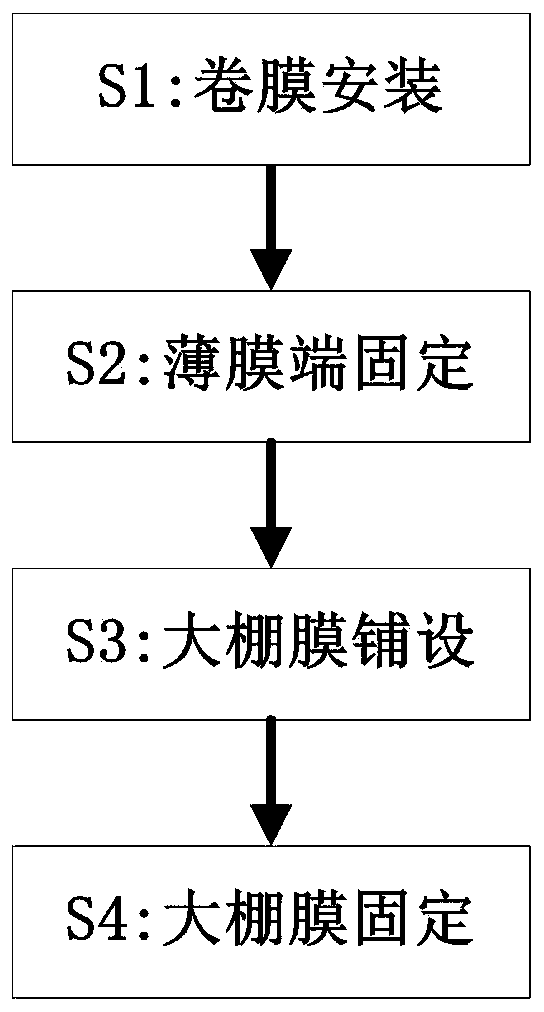

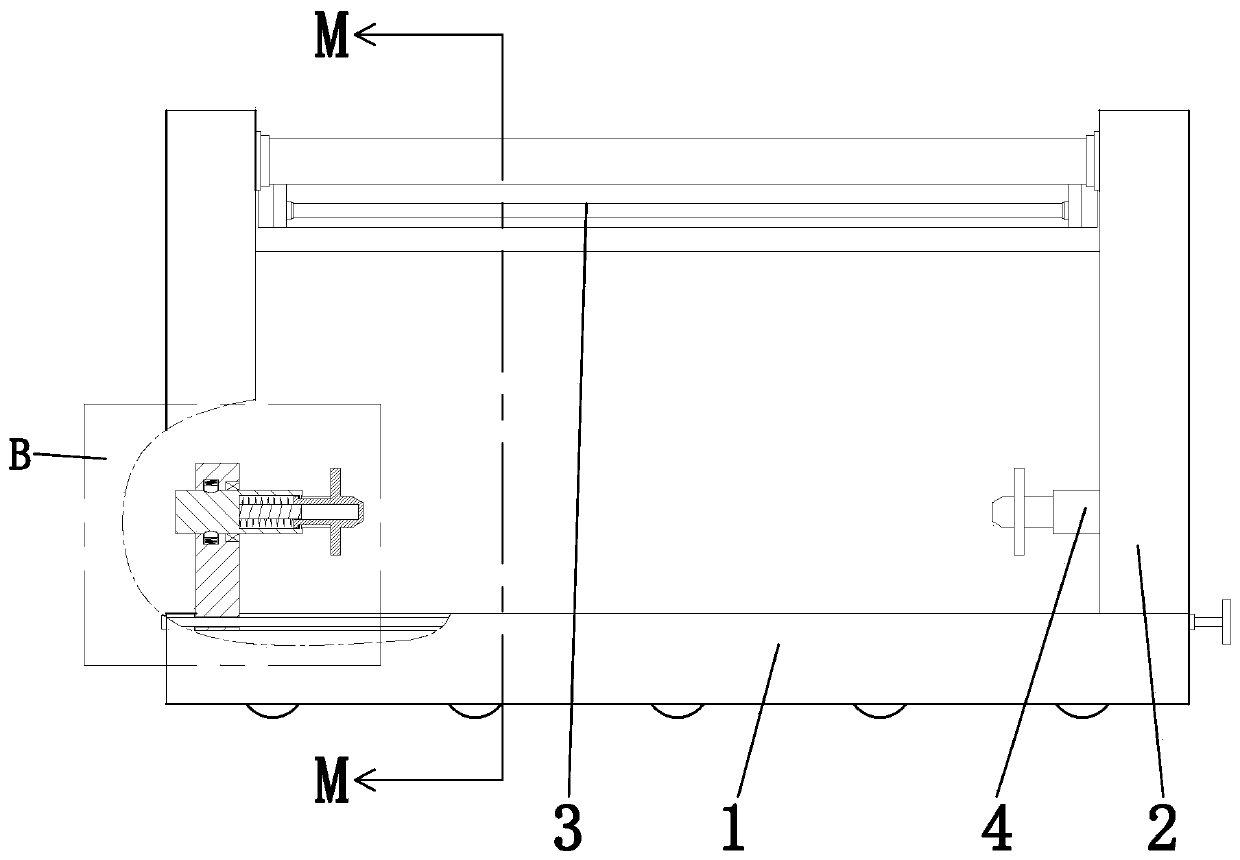

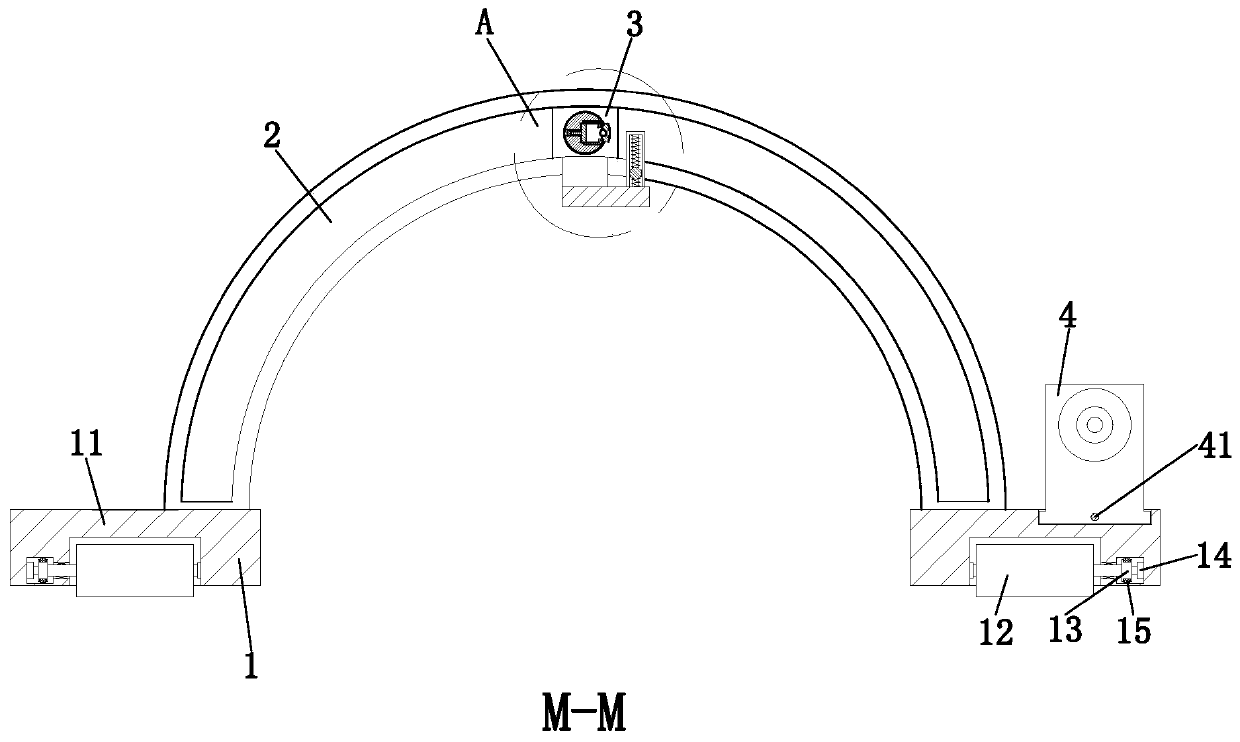

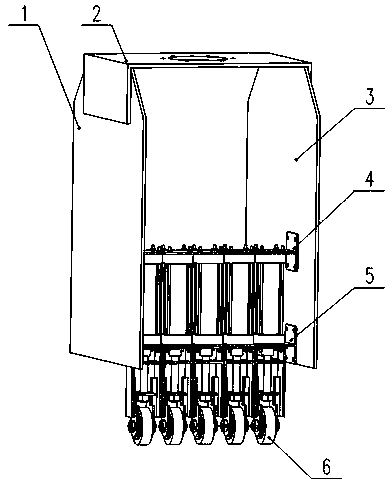

Agricultural greenhouse plastic film mulching construction method

ActiveCN111567276AGuarantee laying qualityImprove laying efficiencyClimate change adaptationGreenhouse cultivationEnvironmental resource managementGreenhouse

The invention provides an agricultural greenhouse plastic film mulching construction method. Mulching construction of an agricultural greenhouse plastic film is completed through cooperation of movingplatforms, arc sliding rails, a laying device and an unreeling device. By means of the agricultural greenhouse plastic film mulching construction method, the problems, which mainly exist in a processof manual replacement of a greenhouse film, that the greenhouse film is generally liable to be scratched by a greenhouse skeleton during replacement, consequently the greenhouse film is very liable to be torn, thus the greenhouse film laying efficiency is affected, when the greenhouse film is laid on the greenhouse skeleton manually, due to different height of the greenhouse skeleton, a worker needs to assist other climbing facilities so that the greenhouse film can be made to stride over the highest position of the greenhouse skeleton and be laid on the greenhouse skeleton, tensioning of thegreenhouse film is hard to maintain when the greenhouse film is laid manually, consequently the greenhouse film is loose as a whole after being laid, thus light transmittance and a heat preservationeffect of the plastic film are severely affected, and the like can be solved.

Owner:山东东大塑业有限公司

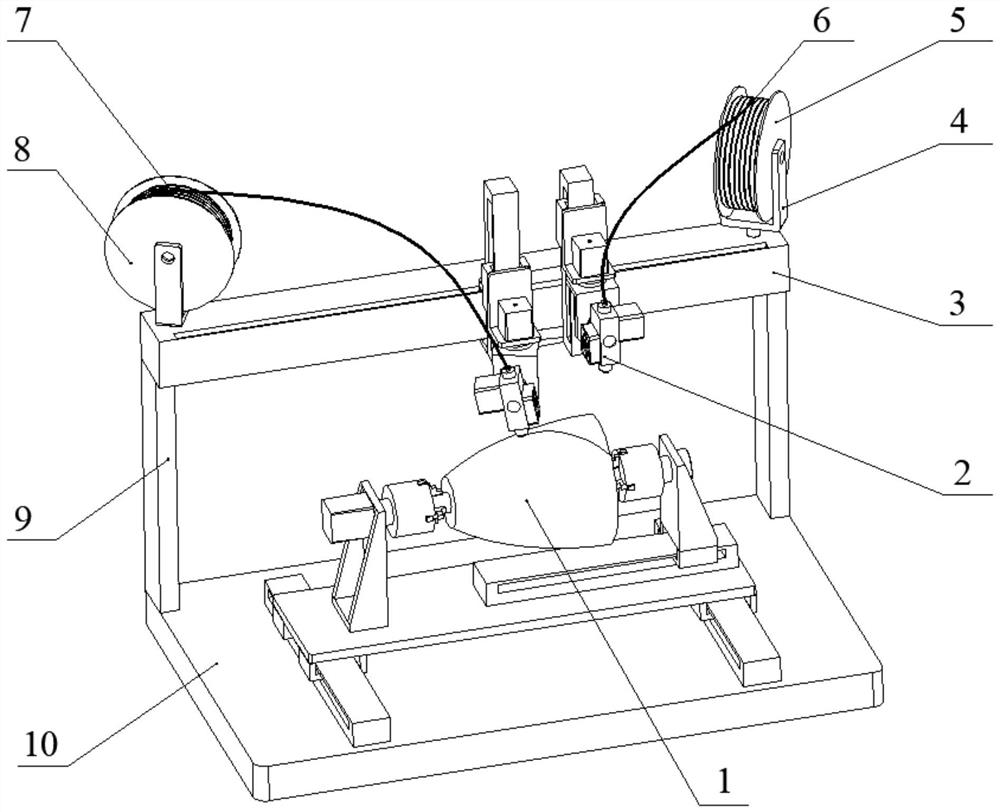

Compression roller mechanism suitable for curved surface laying of composite material

InactiveCN111113939AImprove laying efficiencyGuarantee laying qualityStructural engineeringPneumatic cylinder

The invention relates to a compression roller mechanism suitable for curved surface laying of a composite material. The compression roller mechanism comprises independent pneumatic compression rollermechanism bodies, and the upper ends and the lower ends of cylinder barrels of pneumatic cylinders in the independent compression roller mechanism bodies are connected with an upper air cylinder baseand a lower air cylinder base respectively; the left ends and the right ends of the upper air cylinder base and the lower air cylinder base are connected with a left rack and a right rack respectively; and compression roller bases are connected with cylinder rods of the pneumatic cylinders, compression rollers are driven to move up and down through stretching and retracting of the cylinder rods ofthe pneumatic cylinders, composite material laying of curved surfaces with different curvatures can be adapted, and pressure control in the laying process is achieved through the pneumatic cylinders.The compression roller mechanism is provided with the multiple independent pneumatic compression roller mechanism bodies, the stretching amount and pressure of the pneumatic cylinder in each independent pneumatic compression roller mechanism can be independently controlled, and therefore composite material laying of multiple track curved surfaces can be completed at a time, the laying efficiencyis greatly improved, and the laying quality is guaranteed.

Owner:WUHAN UNIV

Floor tile transportation and laying device

ActiveCN110984543AShorten the timeSimplify laying stepsBuilding constructionsStructural engineeringBrush

The invention discloses a floor tile transportation and laying device. The floor tile transportation and laying device comprises a machine body, wherein a hard brush is arranged on the lower end faceof the machine body, a soaking cavity with an upward opening is formed in the machine body, a bearing spring is arranged at the bottom of the soaking cavity, a top plate which slides up and down in the soaking cavity is connected with the top of the bearing spring, a transmission cavity is formed in the left side of the upper part of the soaking cavity, a jacking device is arranged at the top of the inner part of the transmission cavity, and a floor tile knocking device is arranged at the lower part of the transmission cavity. According to the floor tile transportation and laying device, the process of manually painting concrete can be reduced, floor tiles can be put in place at the maximum limit, the labor intensity is relieved, and the laying quality is guaranteed.

Owner:浙江国建建设有限公司

Method for butting buried cable steel tube on site during construction

InactiveCN101832435BReduce the occurrence of impenetrableGuarantee laying efficiencySleeve/socket jointsCable installations in underground tubesSlagDirect-buried cable

The invention relates to the technical field of electric engineering construction, in particular to a method for butting a buried cable steel tube on site during construction. The method comprises the following steps of: (1) manufacturing a wedge-shaped chambering tube; (b) wedging the wedge-shaped chambering tube into a ring opening tube to expand the tube diameter of the ring opening tube, and welding fixed diameter steel bars to side walls on two sides of the opening of the ring opening tube to form a butting sleeve; (c) sleeving the tube ends of two polished cable steel tubes into the butting sleeve, and cutting off the fixed diameter steel bars on the butting sleeve; (d) totally fitting the tube orifices of the cable steel tubes, fixing the cable steel tubes by spot welding, and thentightly welding each connector; and (e) polishing the welding slag at the welded part, and coating anti-rusting paint on the cable steel tubes so as to finish butting the cable steel tubes. By using the method, materials are taken from the construction site, no extra material is needed, the manufacturing process is simple and practical, on-site construction is convenient, the construction cost issaved, the butting misalignment and burrs of the tube orifices can be reduced, and the efficiency and quality of paving cables are guaranteed.

Owner:CHINA FIRST METALLURGICAL GROUP

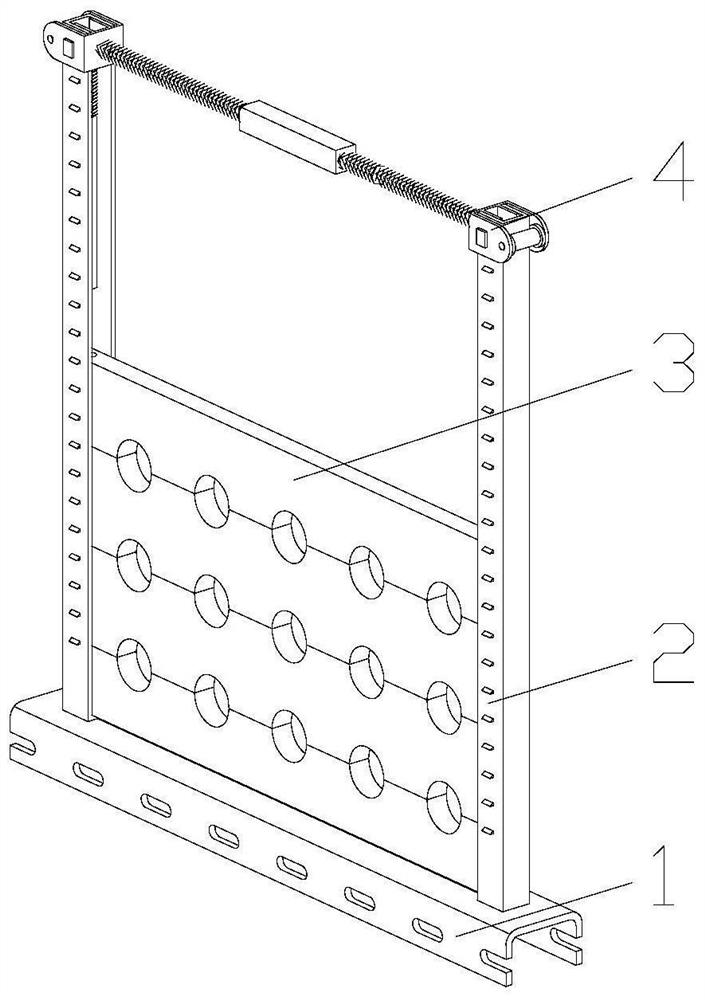

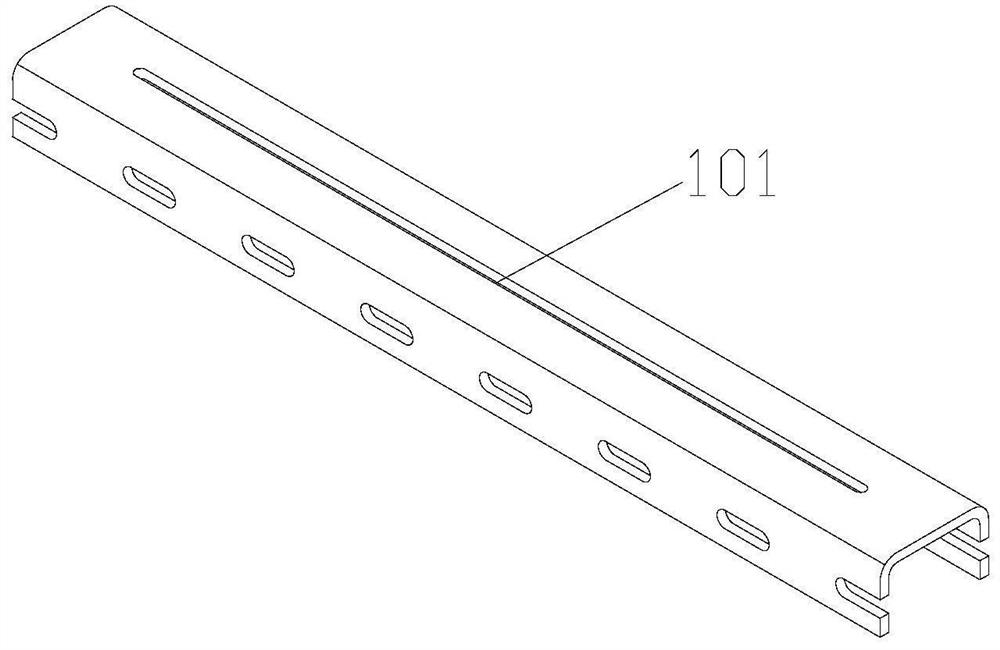

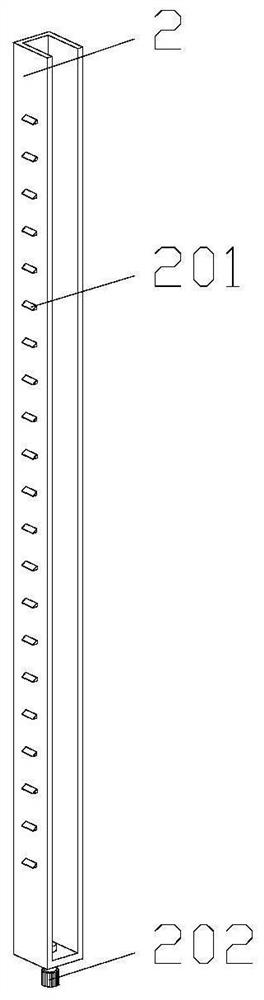

Secondary cable laying support

ActiveCN113315049AImprove laying efficiencyImprove fixation efficiencyElectrical apparatusStructural engineeringElectric cables

Owner:PINGYIN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com