Leaky-waveguide coaxial cable

A leaky coaxial cable and coaxial cable technology, applied in the direction of communication cables, cables, circuits, etc., can solve the problems of increasing process links and molds, affecting production efficiency, increasing the difficulty of management and maintenance, and achieving enhanced resistance to external extrusion capacity, save laying construction costs, and ensure the effect of laying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

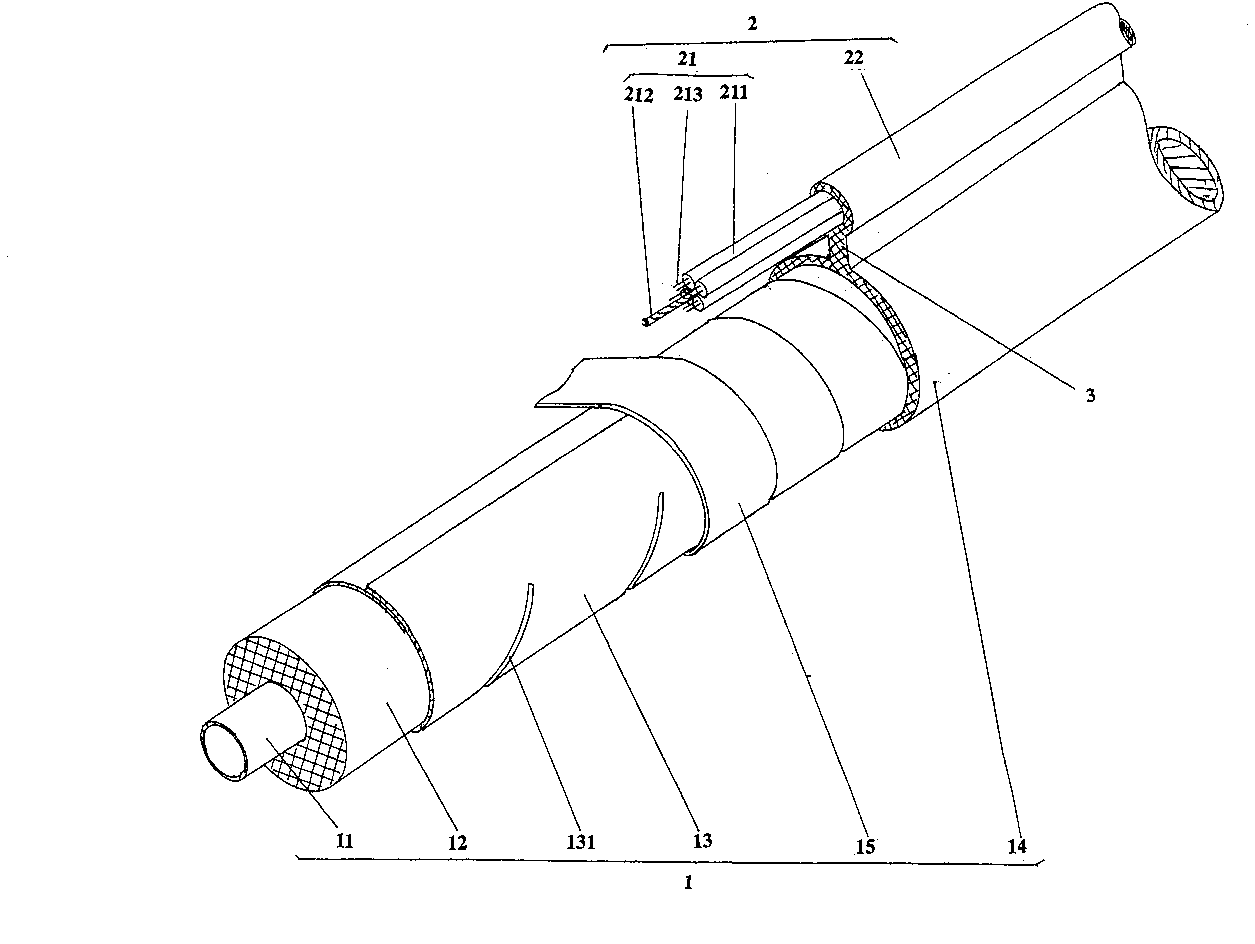

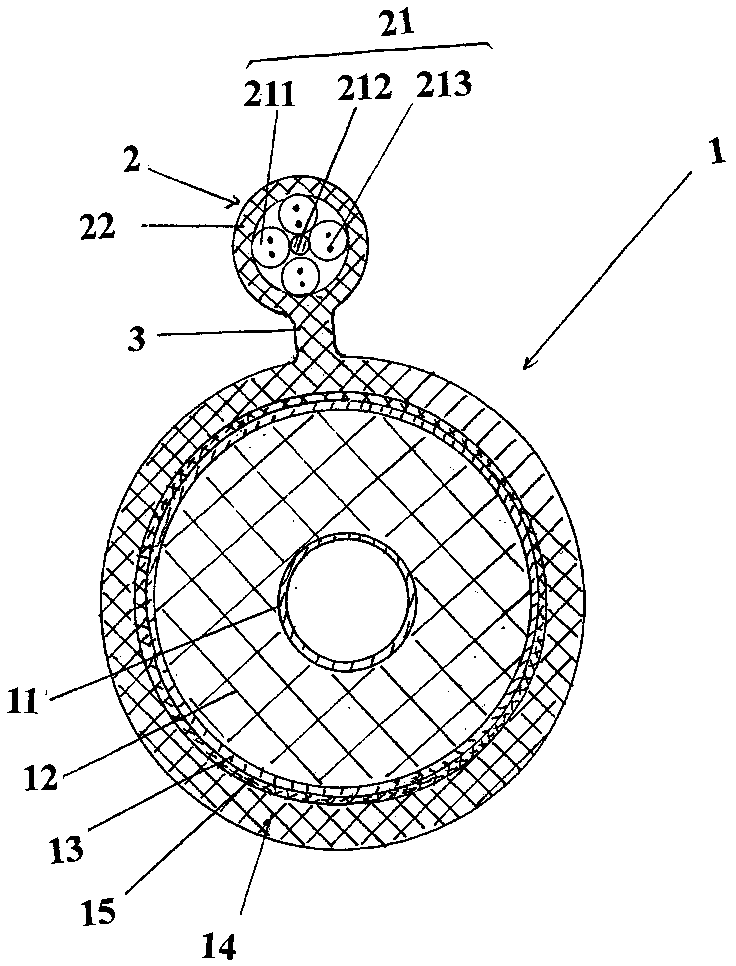

[0023] Please see figure 1 and figure 2 , provides the leaky coaxial cable body 1 and the optical cable 2 as the structural system of the leaky waveguide coaxial cable of the present invention, by figure 1 and figure 2 From the structure shown, it can be seen that the optical cable 2 and the leaky coaxial cable body 1 form an integral structure with each other, and the cross-sectional shape formed is an 8-shaped structure of Arabic numerals. This structure can fully reflect the applicant's technical effect in the above column All technical effects described.

[0024] It can be seen from the diagram that the structure of the leaky coaxial cable body 1 is as follows: from the inside to the outside, there are the inner conductor 11, the insulating layer 12, the outer conductor 13 and the first outer sheath 14, and the inner conductor 11 is made of a 0.4mm wall thickness. Copper tube; the insulating layer 12 is wrapped in the inner conductor 11, and the material is f...

Embodiment 2

[0029] Only change the wall thickness of the inner conductor 11 to 0.65mm, change the thickness of the insulating layer 12 to 45mm, change the materials of the first and second outer sheaths 14 and 22 to polyethylene, and the rest are the same as in Example 1 description of.

Embodiment 3

[0031] Only change the wall thickness of the inner conductor 11 to 0.55mm, and change the thickness of the insulating layer 12 to 32mm, and the rest are the same as the description of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com