Patents

Literature

523results about How to "Reduce process links" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

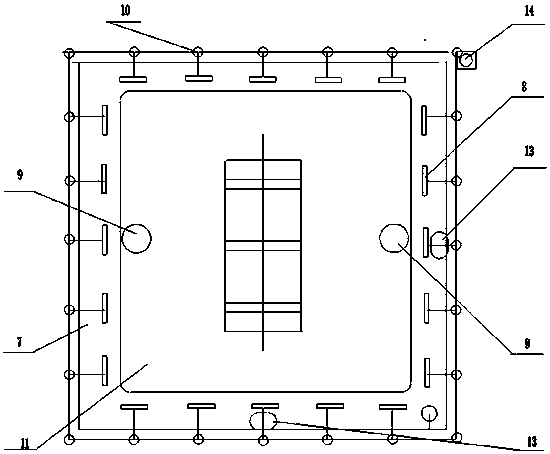

Flat plate fatigue bending machine

InactiveCN101271052ASimple structureSmall sizeMachine part testingMaterial strength using repeated/pulsating forcesFatigue testingAcoustic emission

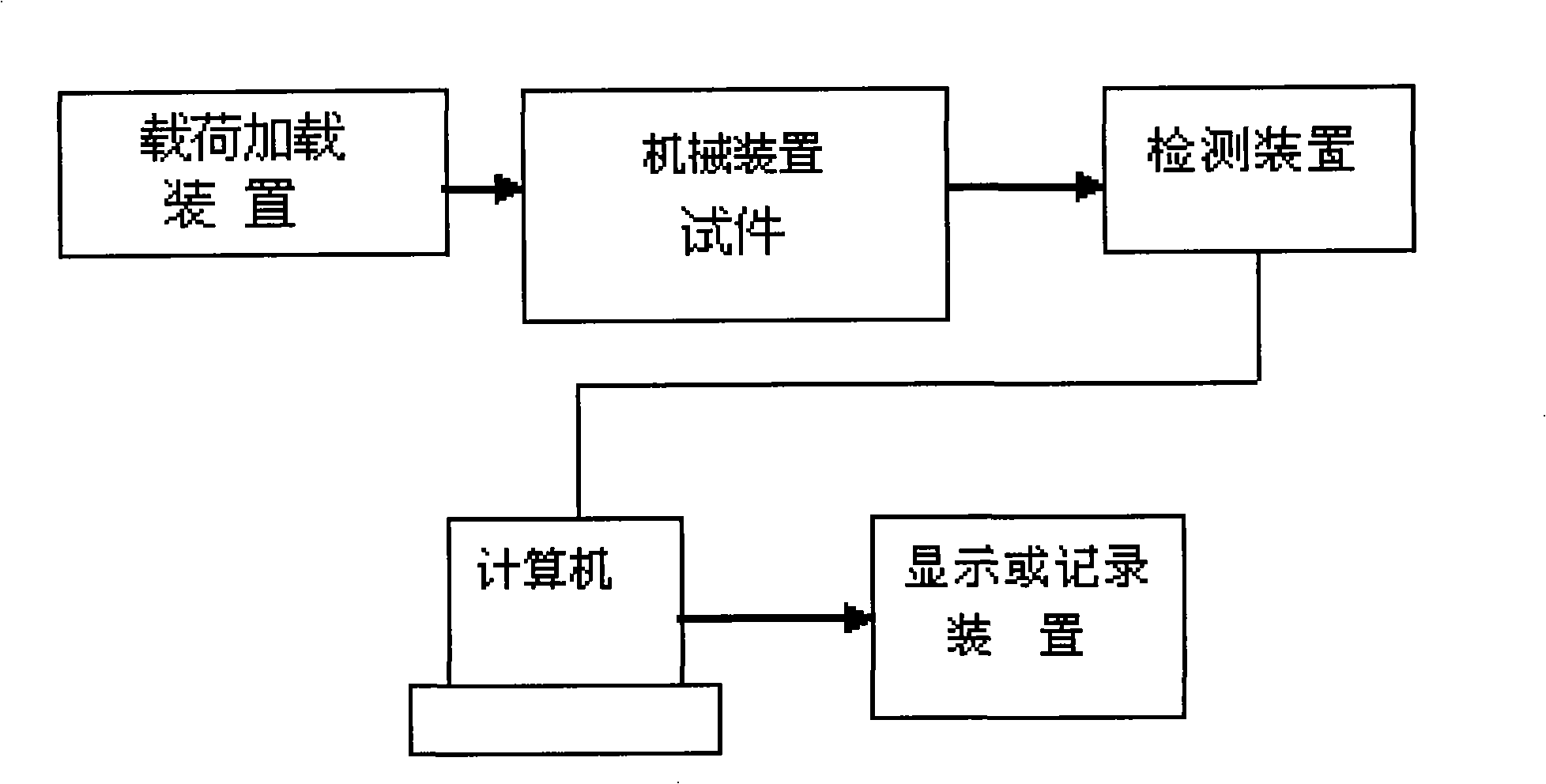

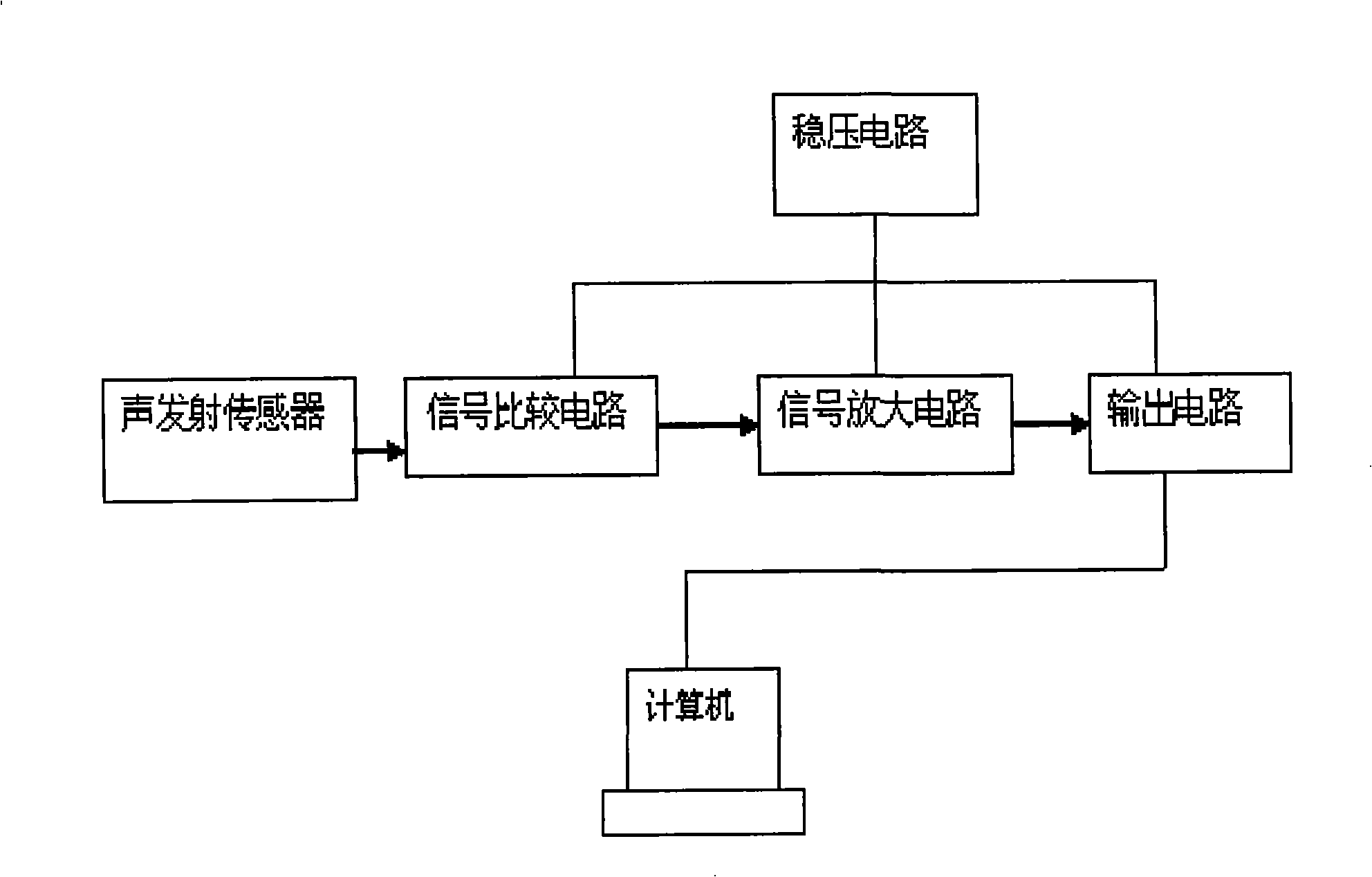

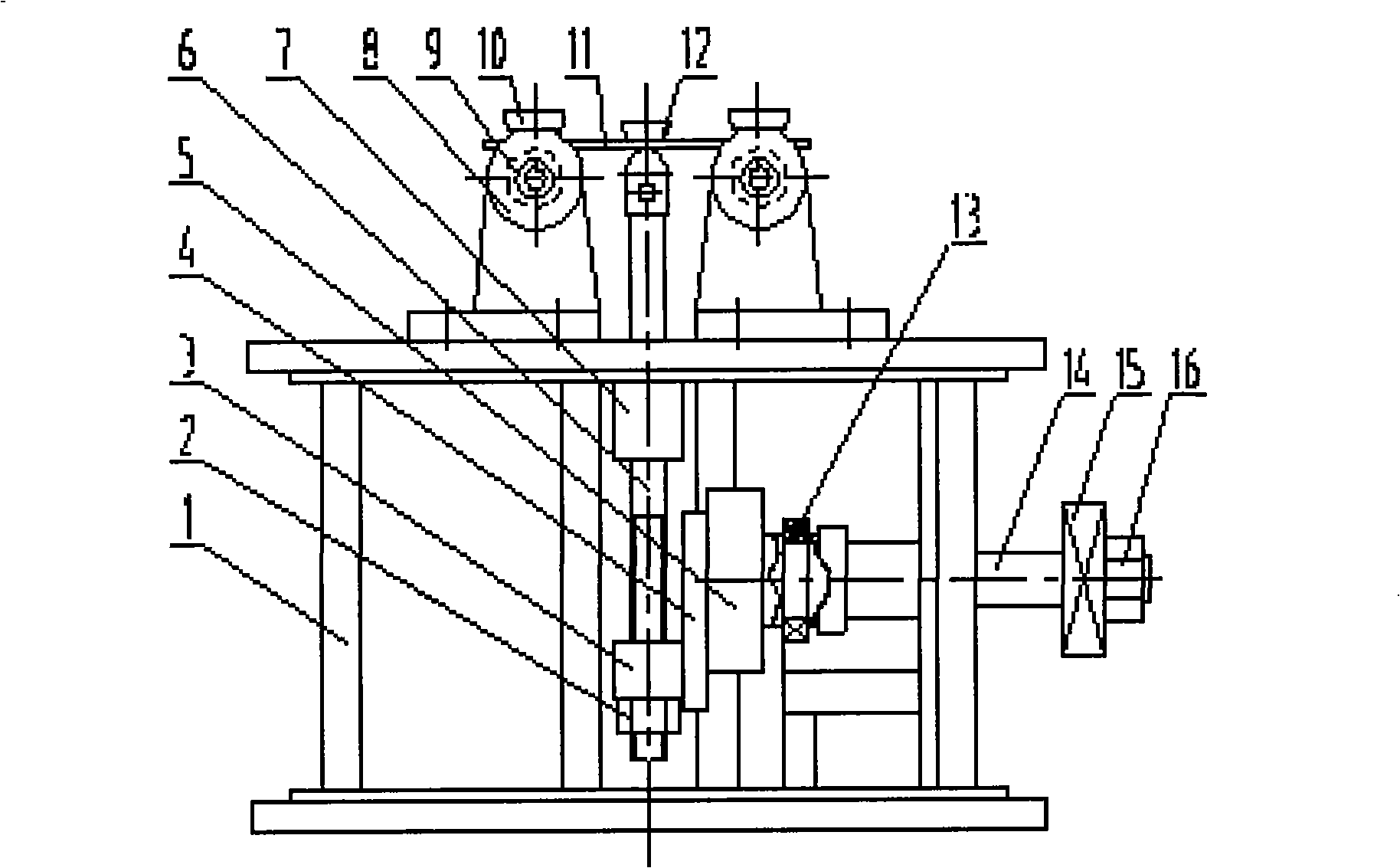

A small flat bending fatigue test machine can dynamically monitor and test the fatigue of a specimen (material) and is based on an acoustic emission technology. The machine includes a plurality of parts, such as a mechanical device, a loading device, a tester, a display or recording device, etc. The mechanical device and the loading device are integrated and adopt an eccentric wheel rotating mechanism and a dynamic loading method; the tester includes two parts, namely a load test system and a specimen test system; the load test system consists of a limit switch, an electronic accumulation calculator, etc.; the specimen test system adopts an acoustic emission sensing electronic technology and a computer technology; the specimen is arranged on the mechanical device and the loading device; the loading device pressurizes the specimen on the mechanical device; the specimen is provided with an acoustic emission sensor; the acoustic sensor is connected with a load tester; the signal is input into the computer technology, and the display or record device obtains the bending fatigue test result of the material.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A method for making semi-processed cold rolled silicon steel in thin slab continuous casting and continuous rolling process

ActiveCN1864879ALess investment in equipmentReduce process linksMelt-holding vesselsRoll mill control devicesThin slabAluminium

The invention relates to a method for using sheet blank continuous casting continuous rolling to produce silicon steel. In the BOF smelt process, it uses bottom argon blow technique in the whole processes; adds composite deoxidant and aluminum into steel pack when outputting steel to remove oxygen; adds manganese, silicon steel and ferro-phosphorus to alloy; blows argon to the melt steel in all process; uses LF furnace to refine the melt steel; using CSP continuous casting machine to cast the melt steel into casting blank; heats the casting blank via TF furnace to be rolled by continuous rolling machine to be hot rolling sheet coil; acid washes hot rolling plate to be cold rolled via rough roller cold rolling machine to be cold rolled sheet coil; anneals via the anneal furnace; flattens the annealed sheet coil via flatten machine group while the extending rate is 2-18%; corrects the sheet shape via correct machine; packs and stores the coil into the storehouse. The inventive method can reduce the cost of producing device and improve the additive value of sheet blank continuous casting continuous rolling product.

Owner:湖南华菱涟钢特种新材料有限公司 +1

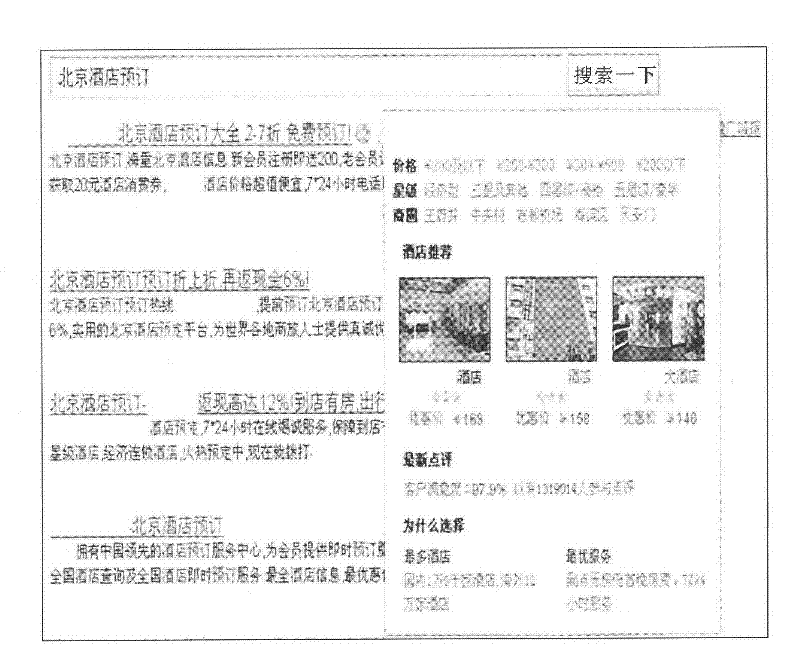

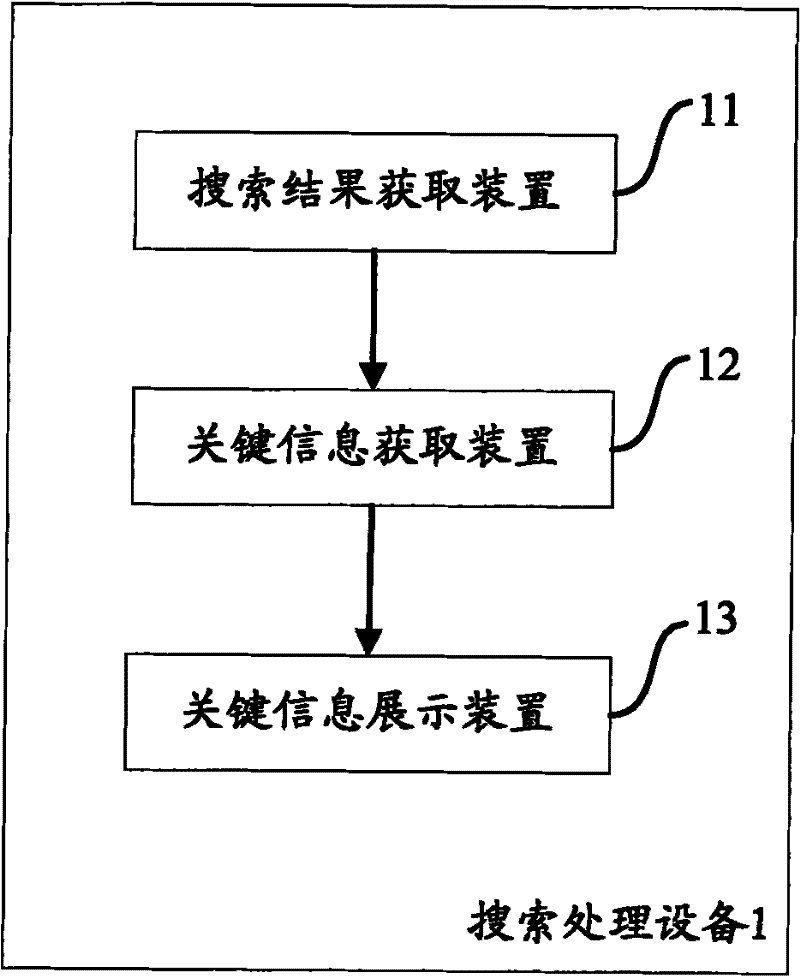

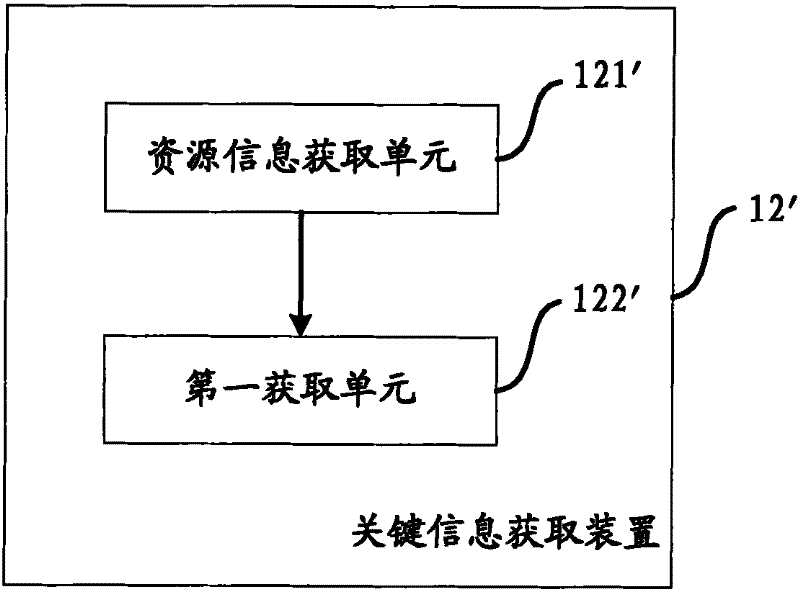

A computer-implemented method and device for displaying search results

InactiveCN102298615AImprove experienceReduce process linksSpecial data processing applicationsRelevant informationInformation retrieval

The object of the present invention is to provide a method and device for displaying search results. Wherein, the search processing device obtains the search result selected by the user; according to the search result, obtains at least one set of key information of resources corresponding to the search result; and presents the key information to the user. Compared with the prior art, the present invention has the following advantages: on the one hand, it can clearly display relevant information of search results in a limited display space without reducing the amount of displayed content information, and improve user experience; on the other hand, it can Provide targeted promotion information for search promotion applications, so that users have more opportunities to learn and use the promotion information, thereby improving the effect of search promotion.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

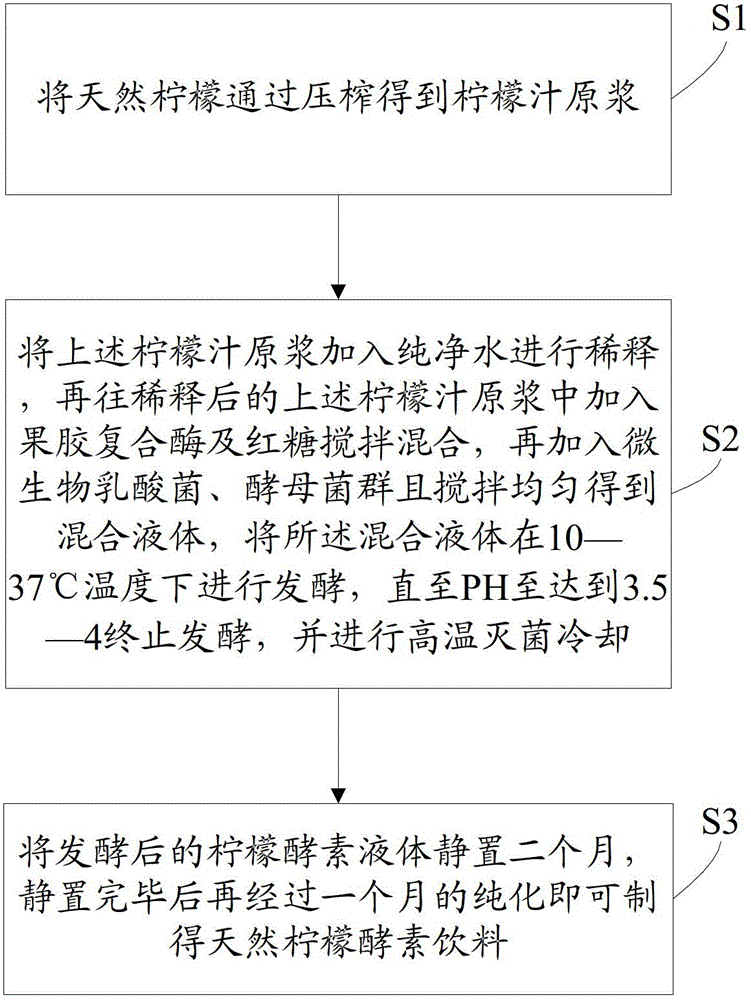

Natural lemon enzyme beverage and preparation method and application thereof

InactiveCN102907726AShort fermentation time periodImprove health benefitsConfectioneryAlcoholic beverage preparationLimoniumLemon juice

The invention provides a natural lemon enzyme beverage and a preparation method and application thereof. The method includes the steps: S1, squeezing natural lemons so as to obtain lemon juice primary pulp; S2, adding purified water into the lemon juice primary pulp for dilution, adding pectin compound enzymes and brown sugar into the diluted lemon juice primary pulp with uniformly stirring, adding microbial lactic acid bacteria and yeast group series with uniformly stirring so as to obtain mixed liquid, fermenting the mixed liquid at the temperature of 10-37 DEG C, terminating fermentation until the pH (potential of hydrogen) reaches 3.5-4, and performing high-temperature sterilizable cooling; and S3, standing the fermented lemon enzyme liquid for two months, and purifying for one month after standing is completed, so that the natural lemon enzyme beverage can be prepared. The natural lemon enzyme beverage and the preparation method and application thereof have the advantages that since the pure natural organic lemons are used, no pollution, safety and reliability are achieved, fermentation time cycle is short, process links are fewer, operation is simple and easy, investment and operating cost can be saved, and various health-care efficacy and high additional value of enzymes are improved effectively.

Owner:广东盆地一号生物产业有限公司

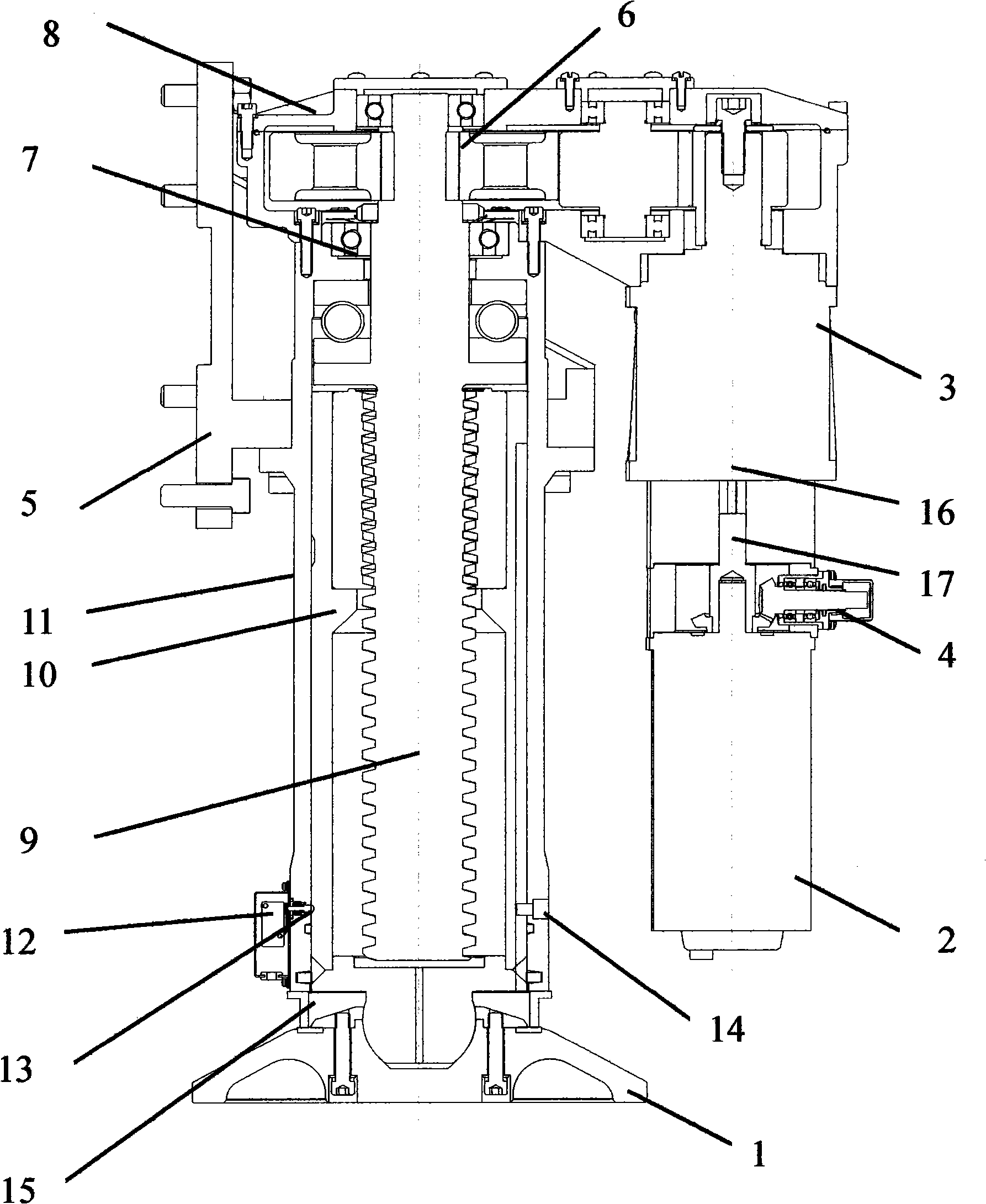

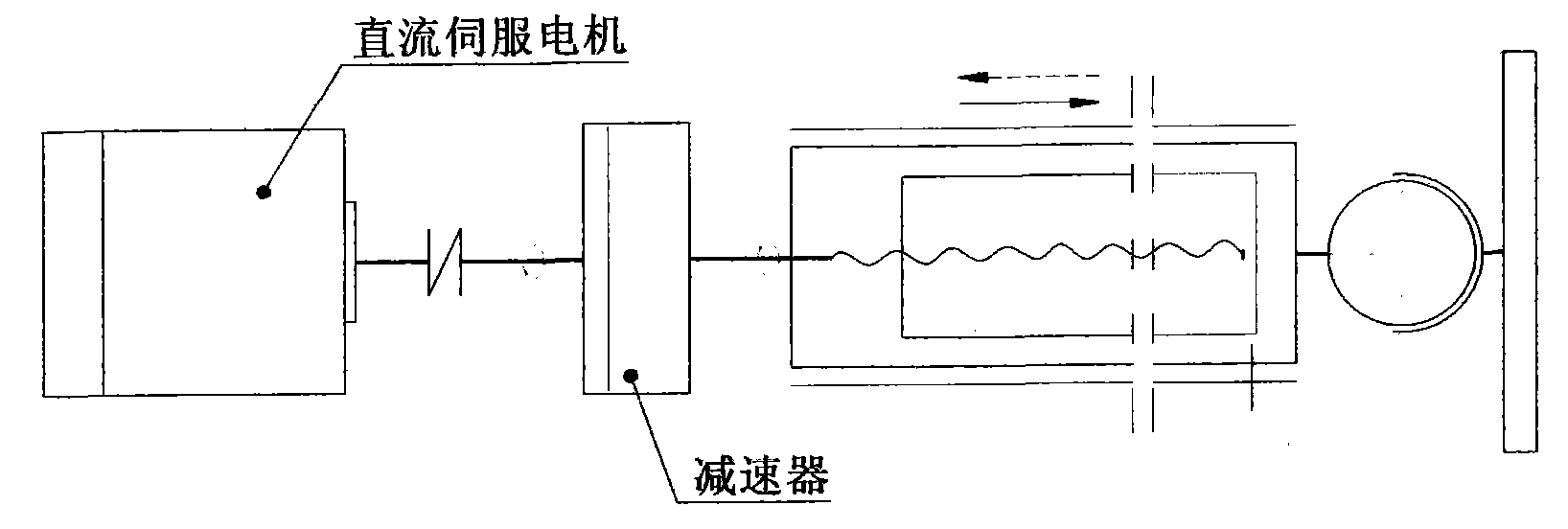

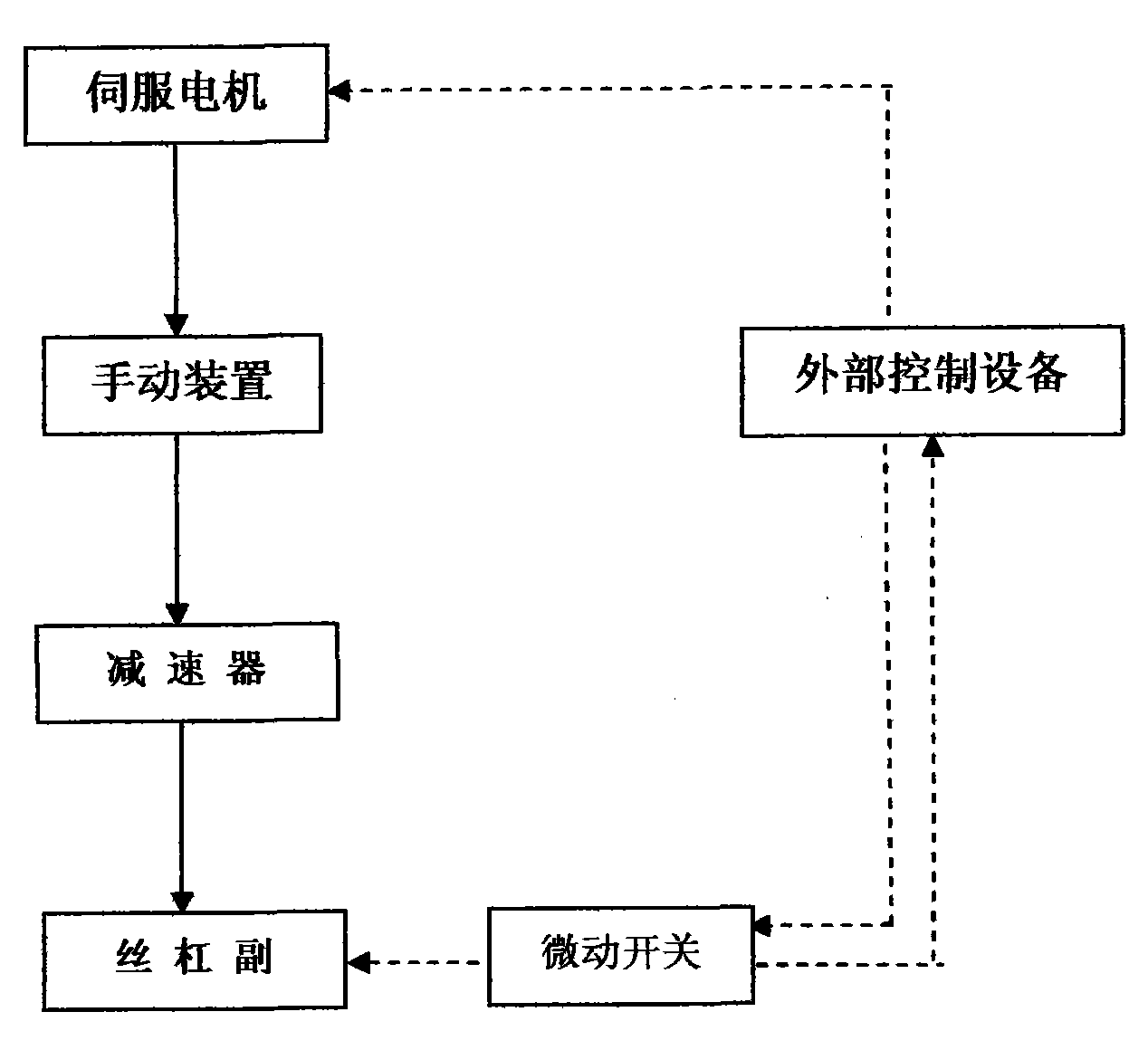

Electric automatic levelling brace

InactiveCN101561071ASmall footprintTouchdown fastStands/trestlesControl using feedbackReduction driveClosed loop

The invention relates to an electric automatic levelling brace for realizing multipoint electric automatic levelling, and aims to provide an electric automatic levelling brace with large lifting weight, rapid and reliable touchdown, good repeatability of levelling precision, high precision, safety, convenience, convenient maintenance and simple electric connection. The electric automatic levelling brace comprises a levelling bearing disc connected with a levelling brace cylinder body and a direct current servo motor with an electric control unit. The top of the levelling brace cylinder body is provided with a transmission chain which is connected with an output shaft of a speed reducer and a leading screw pair for rotary motion; the leading screw pair drives a levelling telescopic cylinder body manufactured with a screw and the levelling bearing disc fixedly connected with the leading screw pair together to do linear lifting motion; a microswitch for feeding back the lifting position to an external control system is arranged on the cylinder wall of the levelling brace cylinder body; a small displacement triggering shaft records the moving position, triggers the microswitch at a triggering point and transfers an electrical signal of the lifting position of the levelling brace to the outside; and the small displacement triggering shaft is connected external control equipment through the microswitch and forms a closed loop levelling system with the servo motor connected with the speed reducer .

Owner:LINGBAYI ELECTRONICS GRP

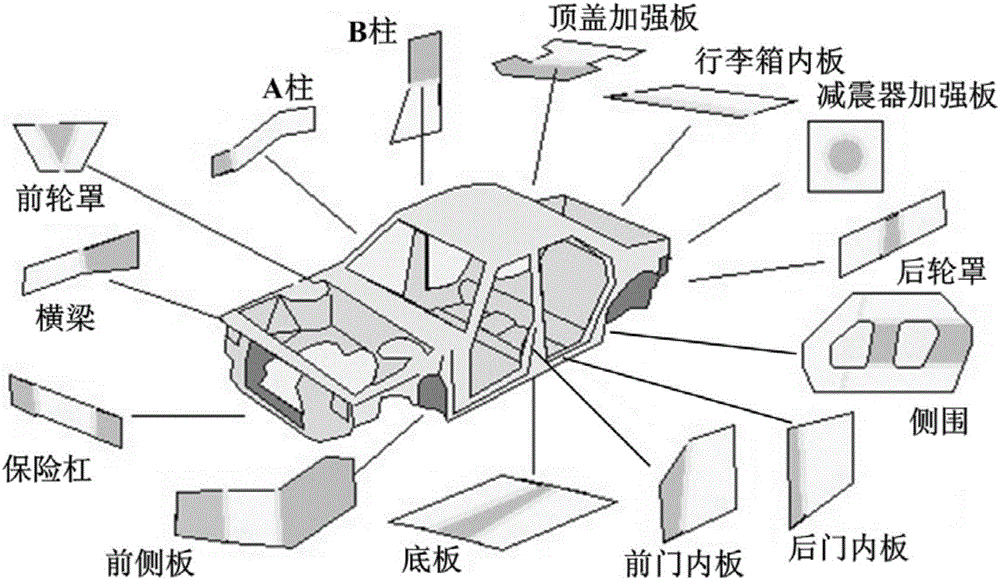

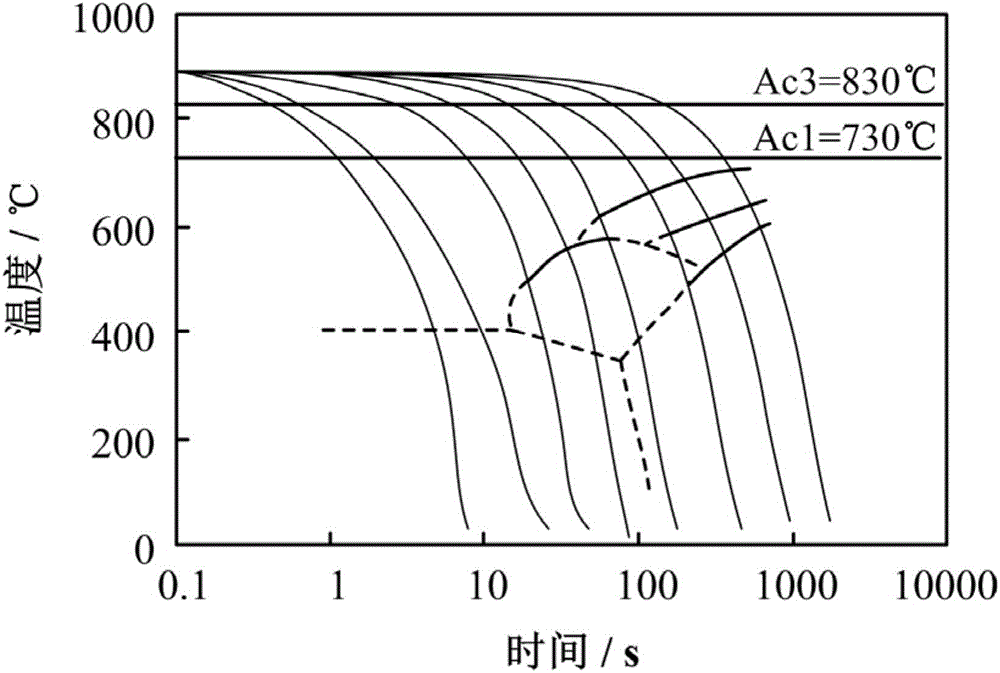

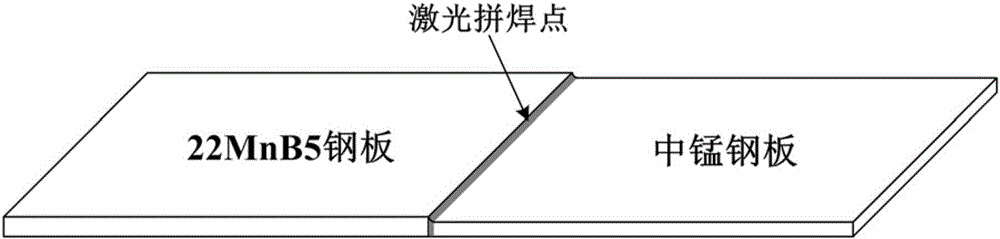

Laser tailor-welded high-strength steel warm forming preparation method

InactiveCN106350741AReduce manufacturing costLow quenching rateLaser beam welding apparatusThree-phaseQuenching

The invention discloses a laser tailor-welded high-strength steel warm forming preparation method. The laser tailor-welded high-strength steel warm forming preparation method is characterized by comprising the following steps: manufacturing a 22MnB5 steel plate and a medium manganese steel plate into a steel part for later use; carrying out laser tailor-welded connection treatment; carrying out heating treatment on the steel part for later use, which is subjected to laser tailor-welding; transferring the steel part onto a stamping mold to carry out stamping forming and quenching; finally obtaining a two-phase or three-phase microstructure formed by lots of ferrite, martensite or bainite in the 22MnB5 steel area of the tailor-welded steel part; and obtaining a martensite organization structure in the medium manganese steel area, thereby forming a warm forming technology of the laser tailor-welded high-strength steel, which has no need for coating treatment in advance and has gradient distributed mechanical property. The laser tailor-welded high-strength steel warm forming preparation method has the beneficial effects that the process combination of laser tailor-welding and the warm forming technology is realized; the warming forming technology is used for enabling 22MnB5 steel to form the two-phase or three-phase microstructure; the two-phase or three-phase microstructure is matched with medium manganese steel having martensitic structure in the end to obtain a custom-made warm forming part with gradient distributed performances; the technological process is simplified; and the production efficiency is improved.

Owner:DALIAN UNIV OF TECH

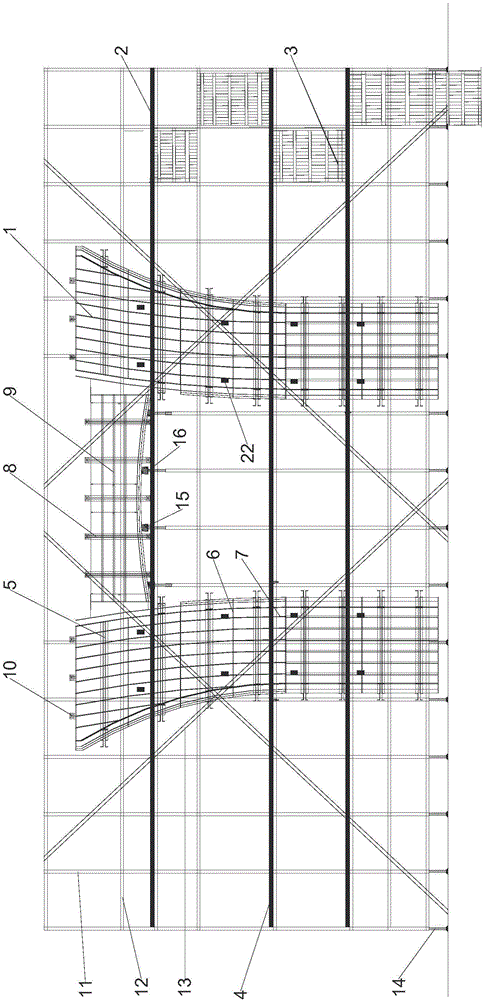

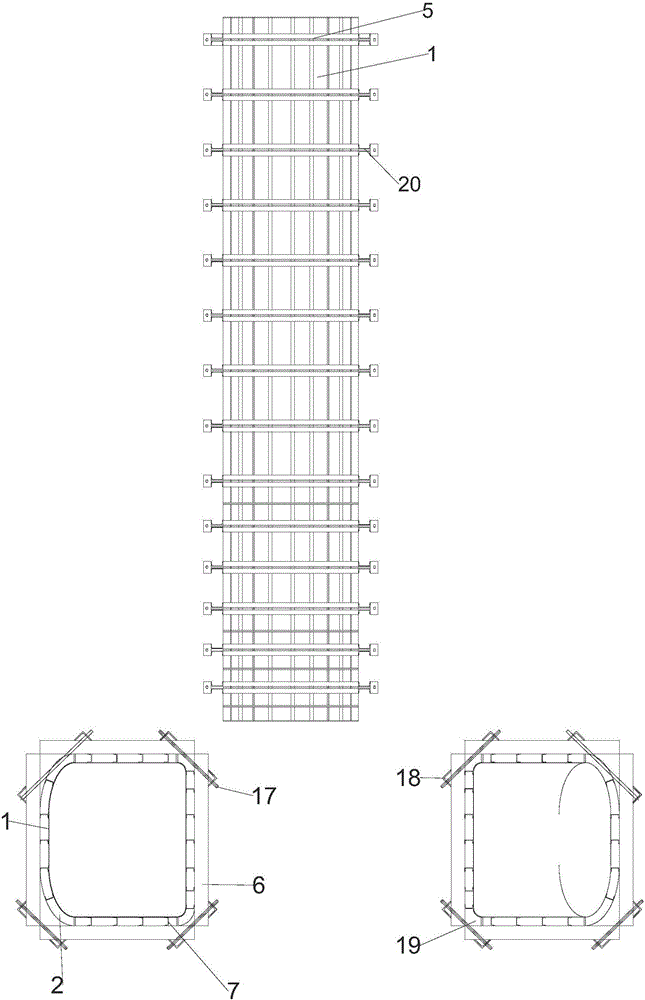

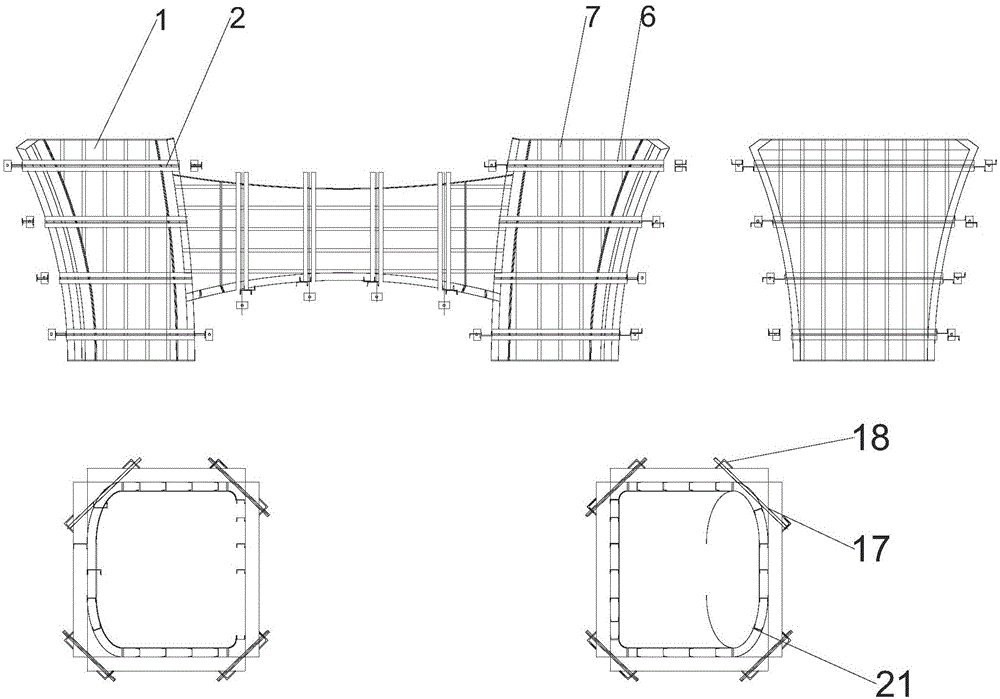

Construction method for overall formwork one-time forming structure of pier

ActiveCN106677069AAvoid loose concreteReduce difficultyBridge structural detailsBridge erection/assemblyRebarPre stress

The invention relates to a construction method for an overall formwork one-time forming structure of a pier. The method includes the following steps of (1) bearing platform surface treatment, (2) erection of a temporary scaffold for pier stud construction, (3) steel bar manufacturing and mounting, (4) formwork mounting, (5) concrete pouring, (6) formwork dismantling and curing, and (7) prestress tensioning and mortar pressing for tie beams. The construction method has the advantages of environmental friendliness, convenient construction, low manufacturing cost and the like.

Owner:JIANGXI PROVINCE LUQIAO ENG GRP

Continuous colloid mixer and its application

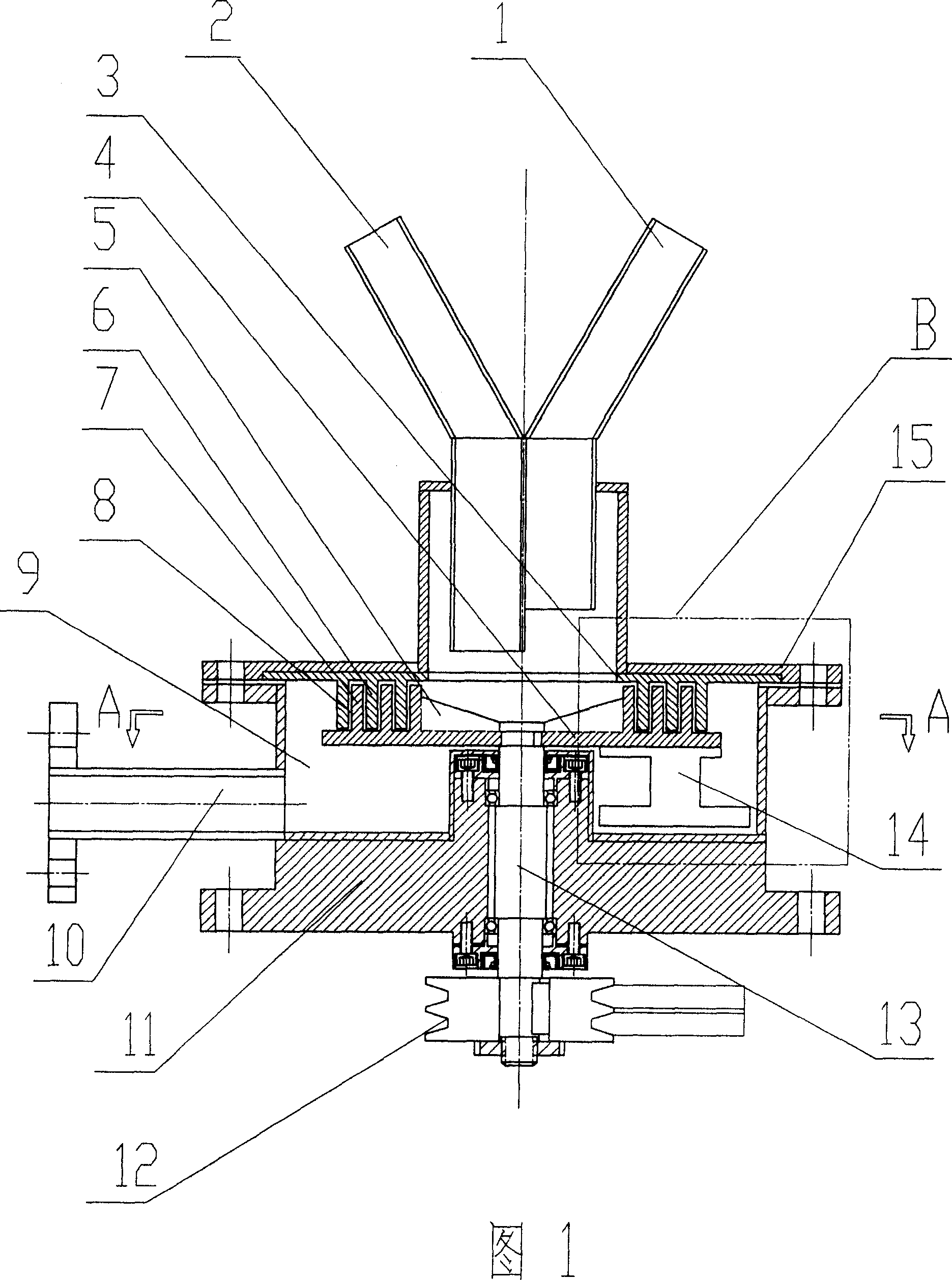

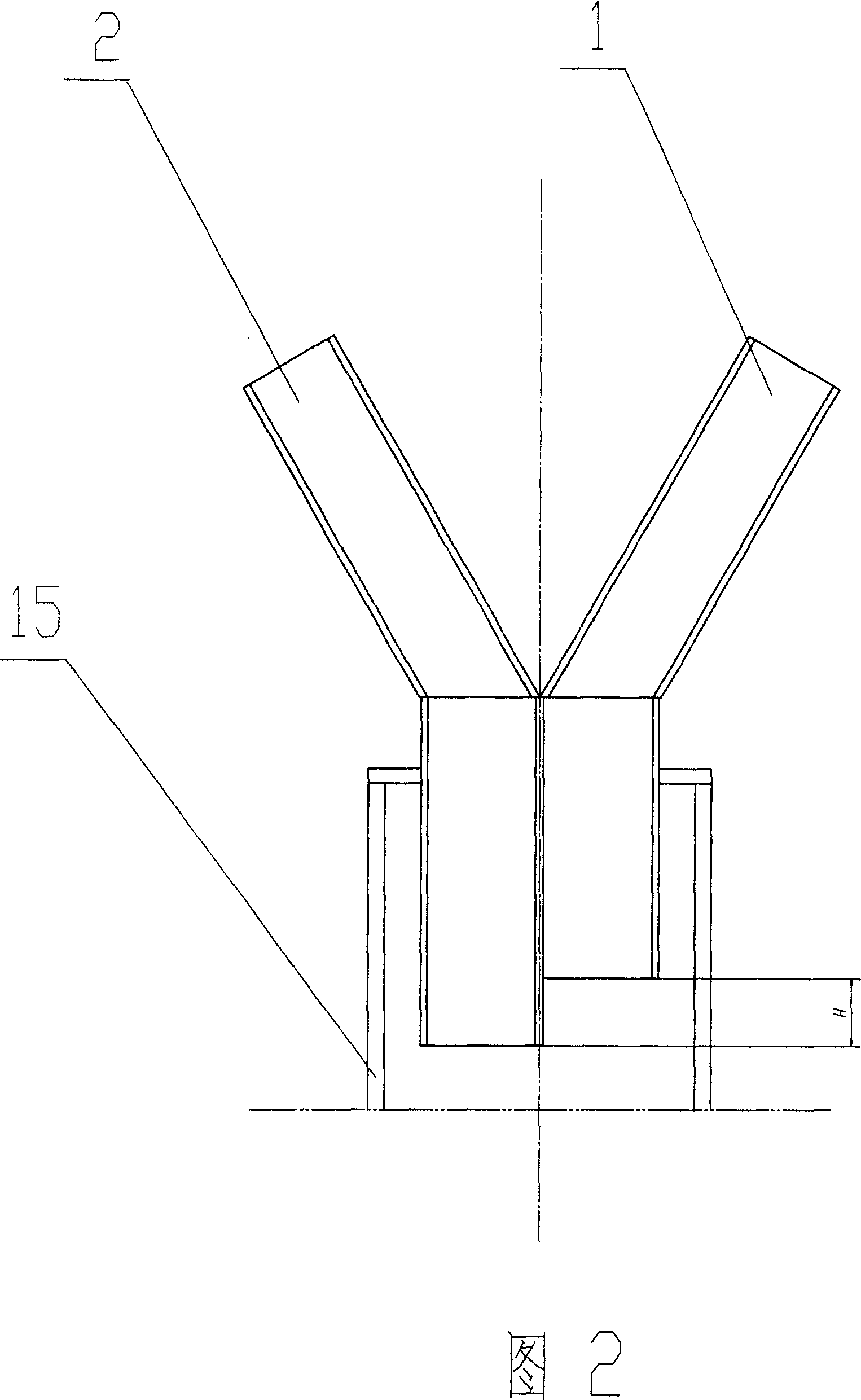

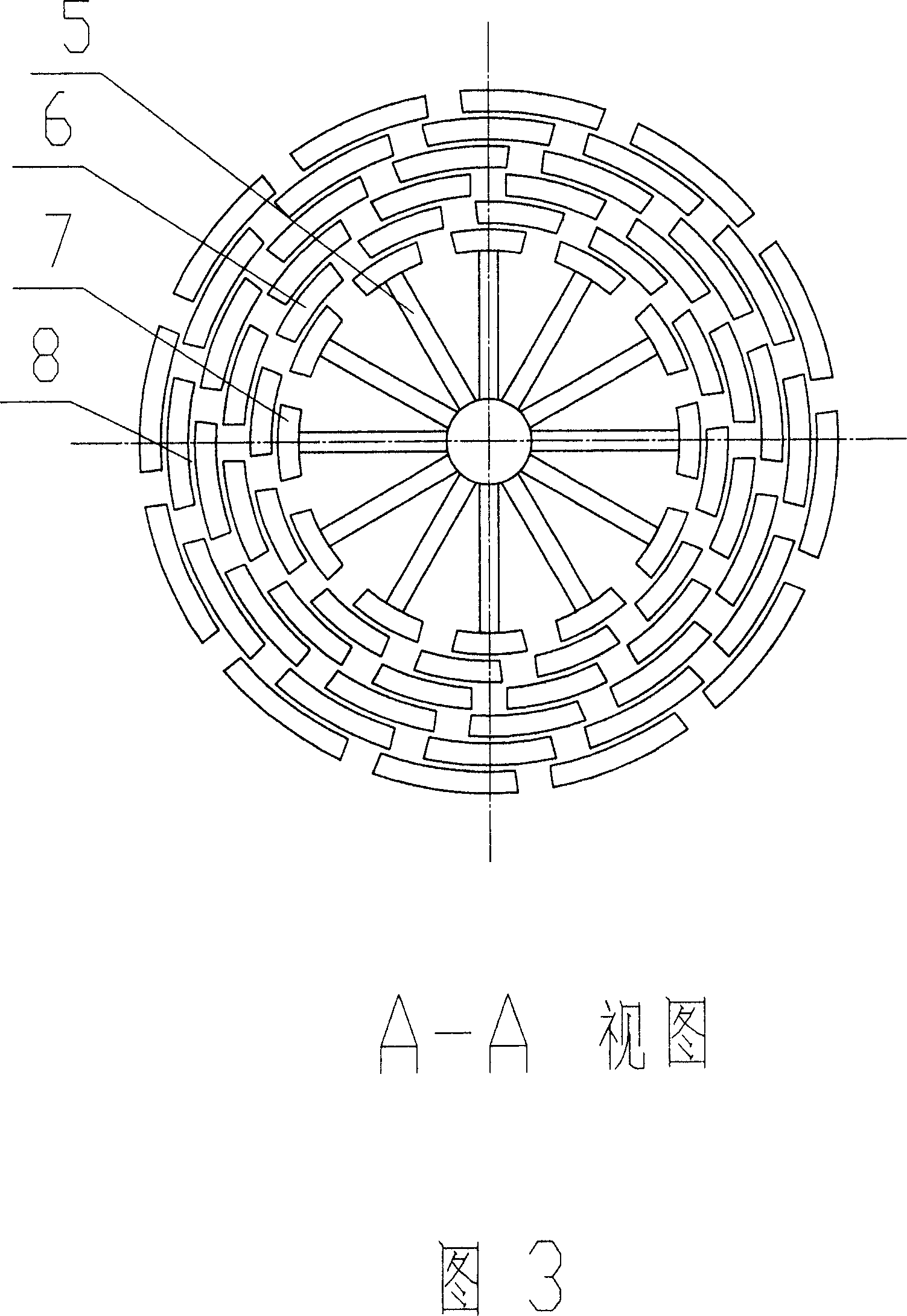

ActiveCN1986064ASolve the problem that continuous production cannot be realizedIncrease productivityRotary stirring mixersCocoaDrive shaftEngineering

The continuous colloid mixer includes the following members: solid feeding pipe, liquid feeding pipe, stator, rotor, pedestal, discharge port, rotating shaft and driving shaft. The continuous colloid mixer can mix solid powder and liquid to prepare colloid continuously in high production efficiency, and is used in the continuous production of cracking catalyst. Compared with available intermittent mixer, the present invention has lowered manufacture cost, continuous and stable production and improved product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

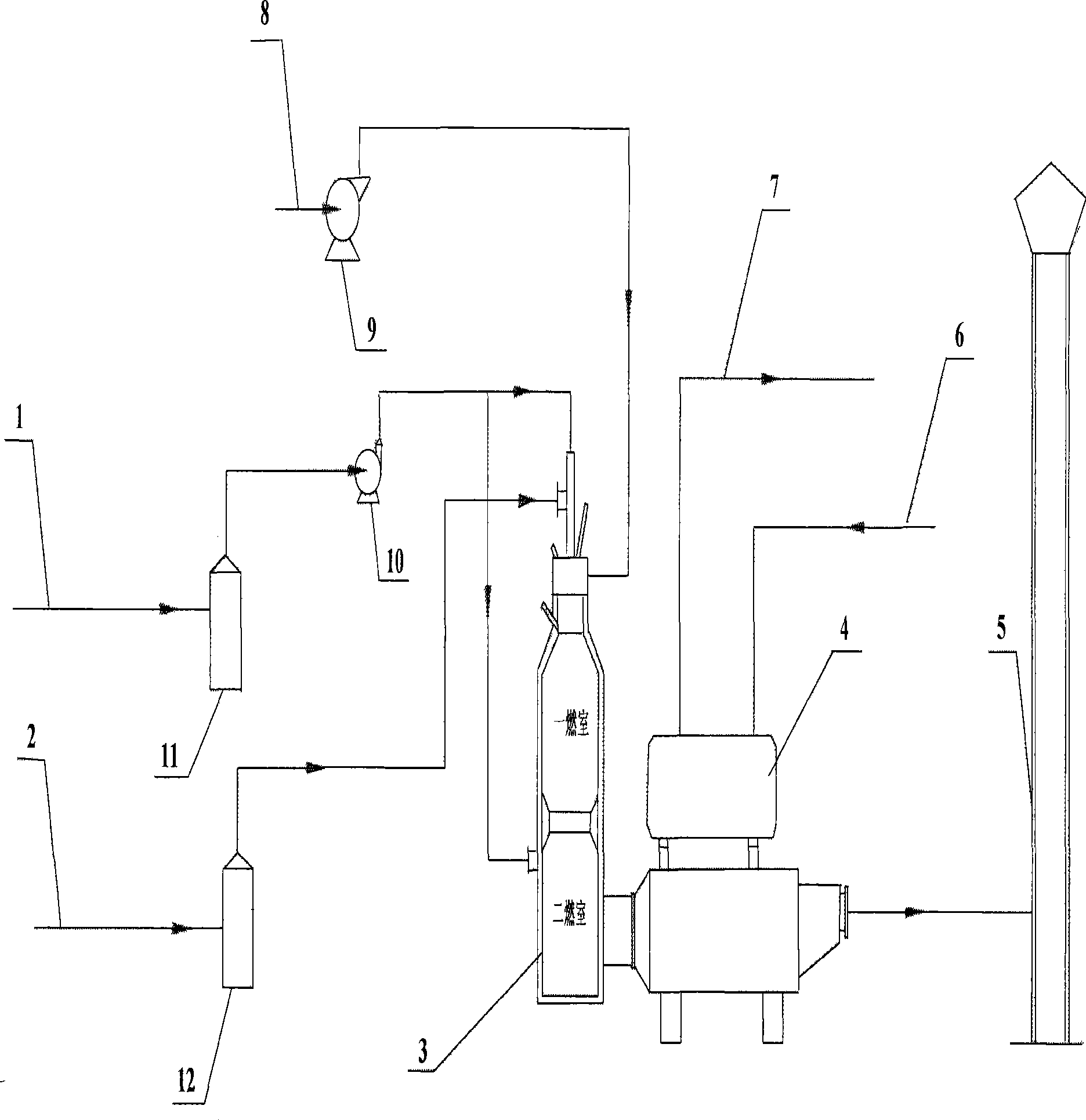

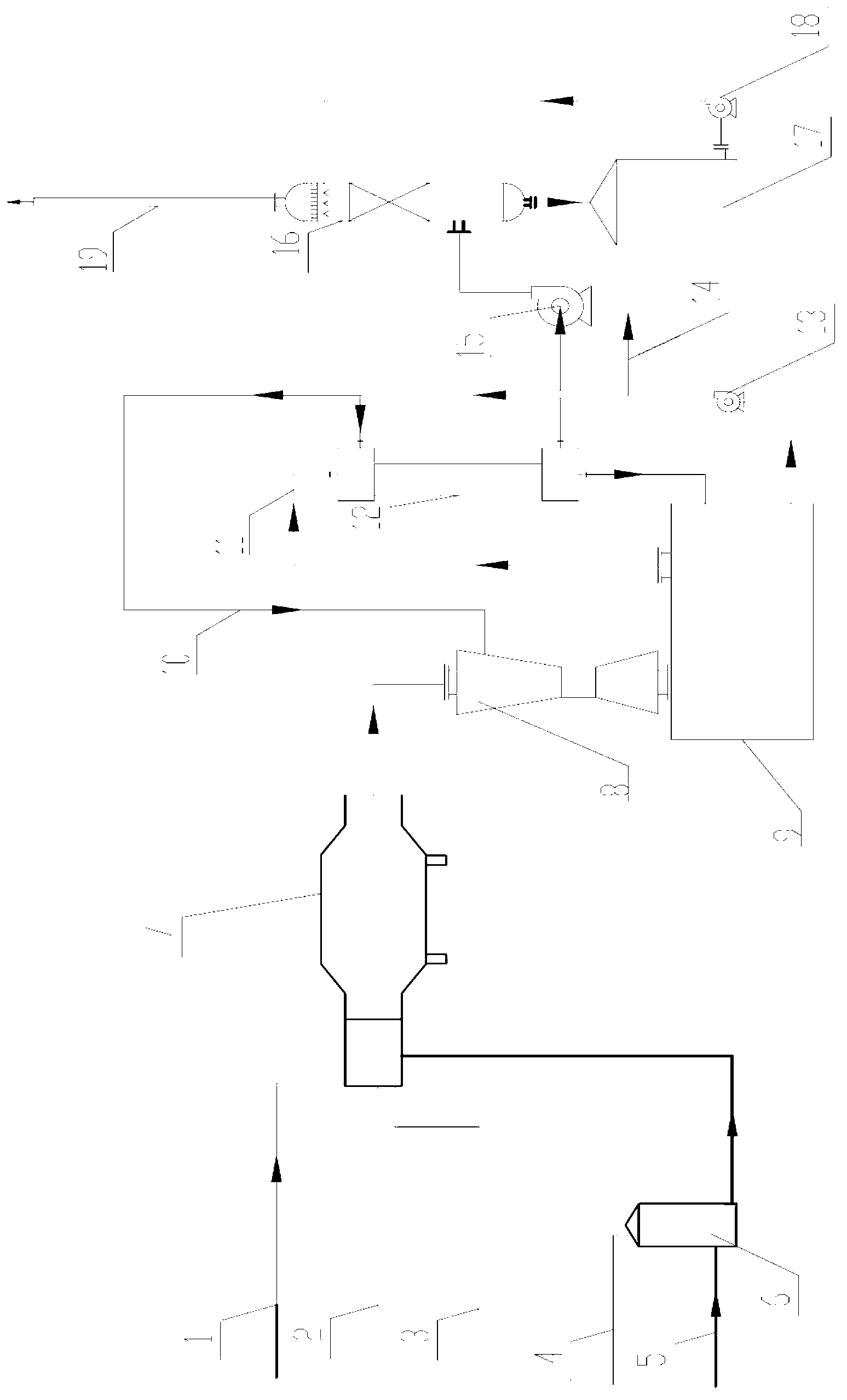

Incineration process for processing ammine containing exhaust gas and system thereof

InactiveCN101451711AReduce heat loadImprove decomposition rateDispersed particle separationIncinerator apparatusCombustion chamberHandling system

The invention relates to an incineration technique for processing waste gas containing ammonia and a system thereof. The technique is to divide the waste gas containing ammonia into two parts which enter two combustion chambers of an incinerator at the same time. In one combustion chamber, the ammonia in the waste gas containing ammonia is decomposed and oxidized at a high temperature; in the other combustion chamber, the ammonia in the waste gas containing ammonia has oxidation-reduction reaction with NO and NO2 from reaction products of the first combustion chamber. The system comprises an incinerator which has two communicated combustion chambers respectively connected with a processing waste gas containing ammonia supplying system. The incinerator is respectively connected with a fuel gas supplying system and a combustion air assisting system. The reaction products of the two combustion chambers are connected with a reaction product post-processing system. The invention can effectively decrease consumption of the fuel gas and generation of NOX, thus meeting requirements of saving energy and protecting environment.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

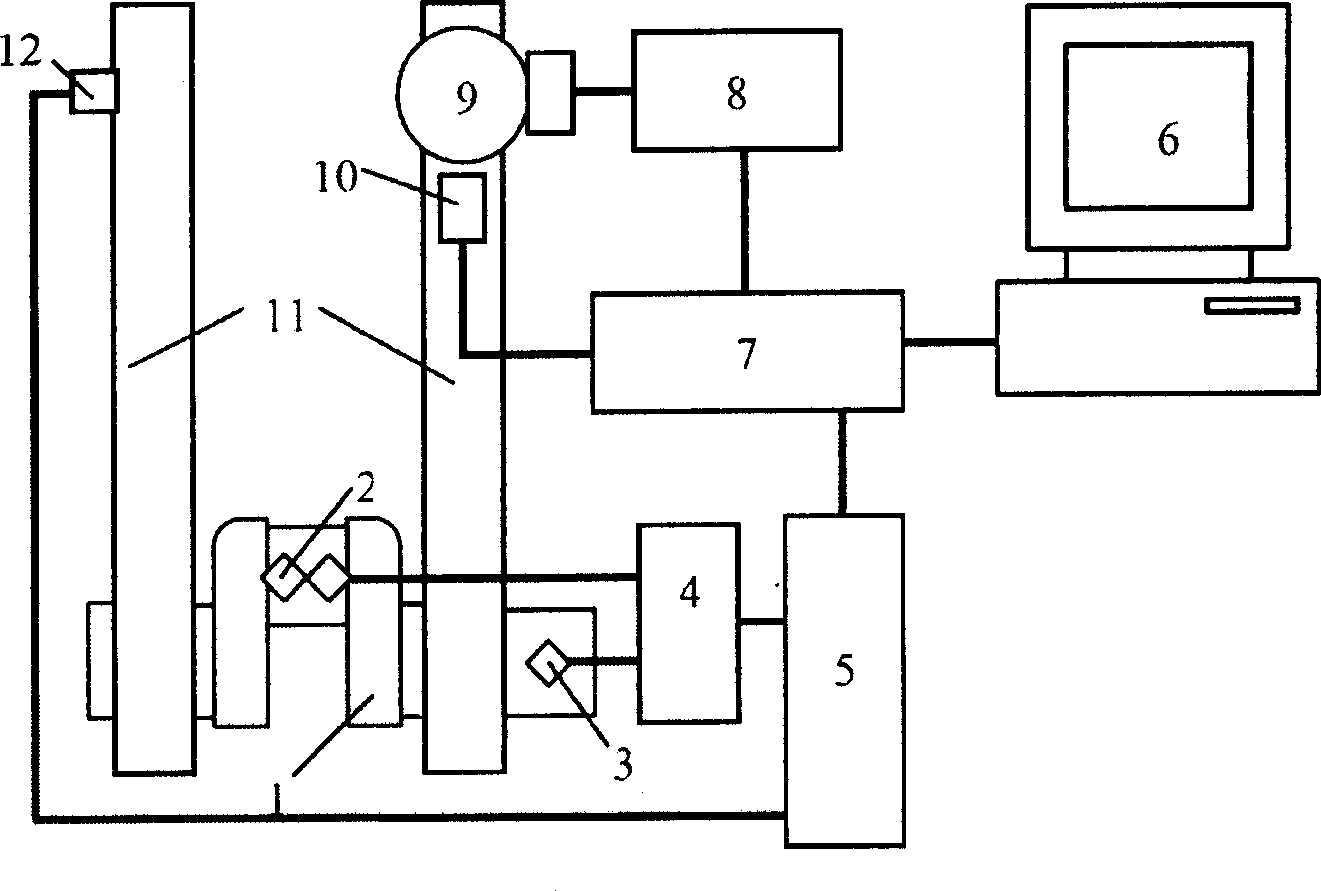

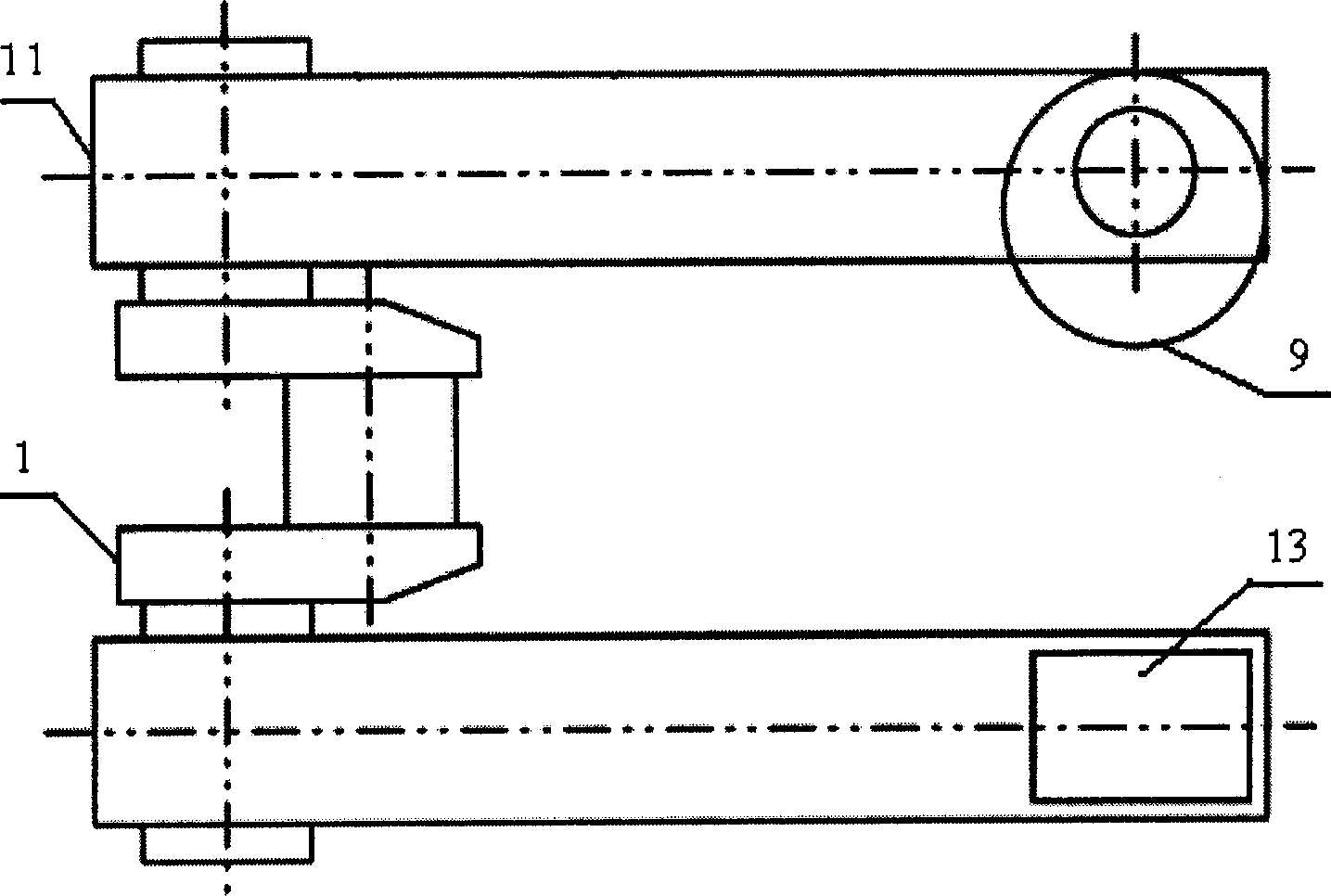

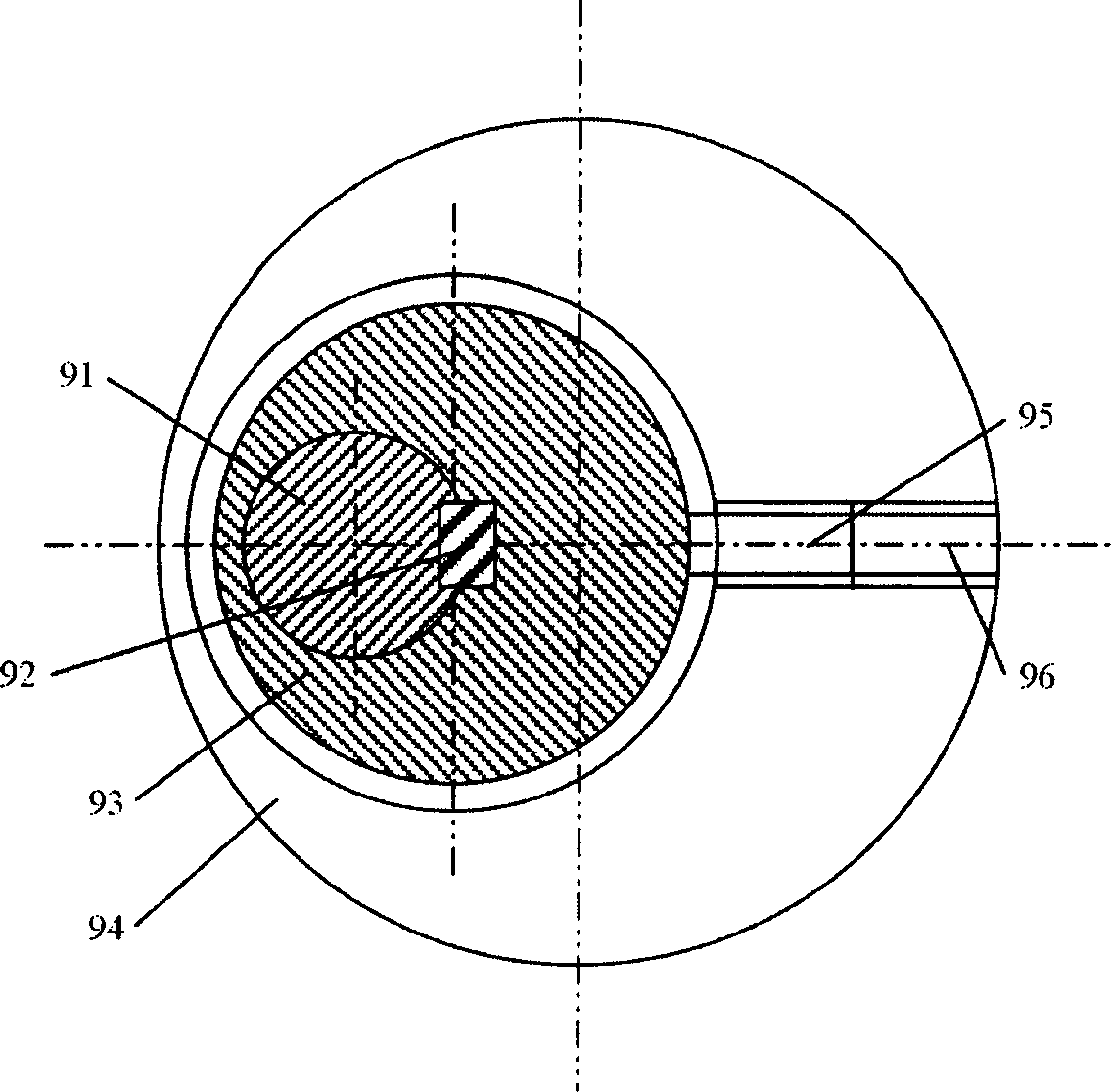

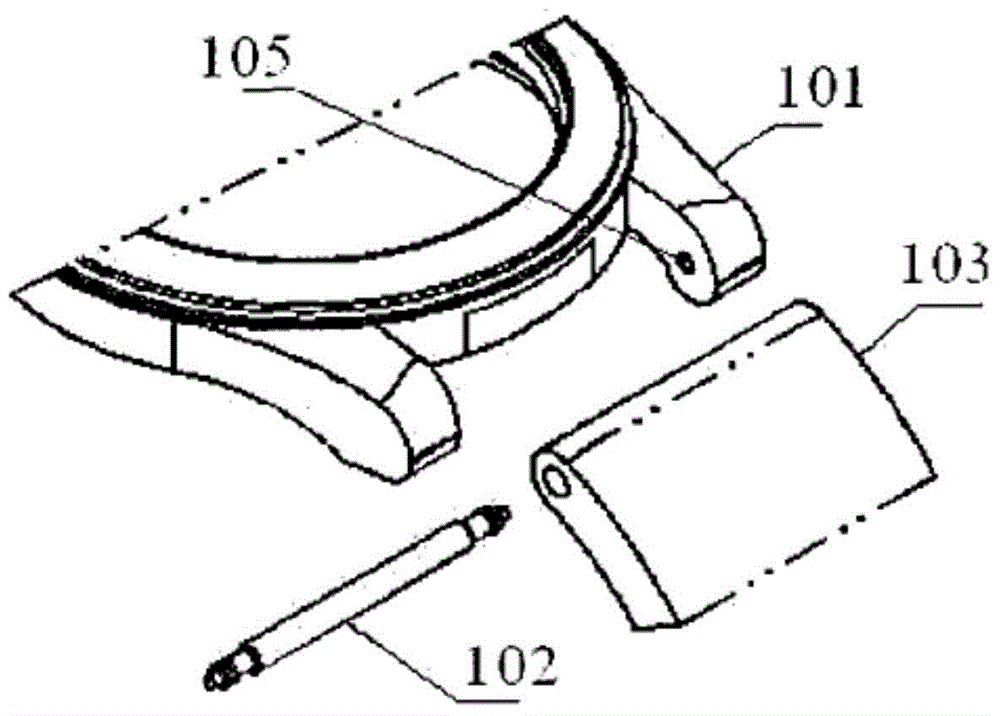

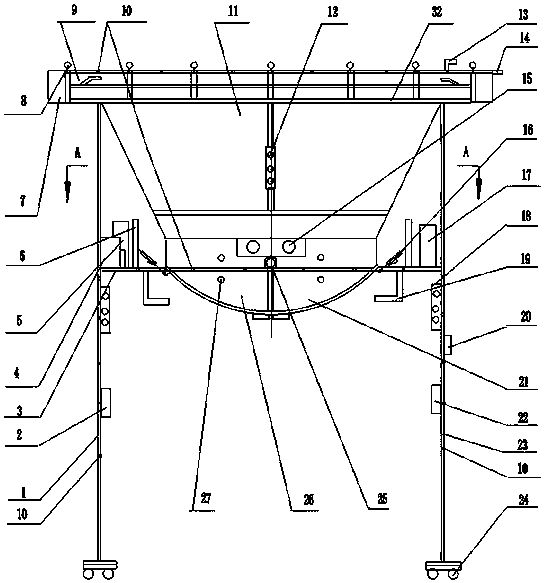

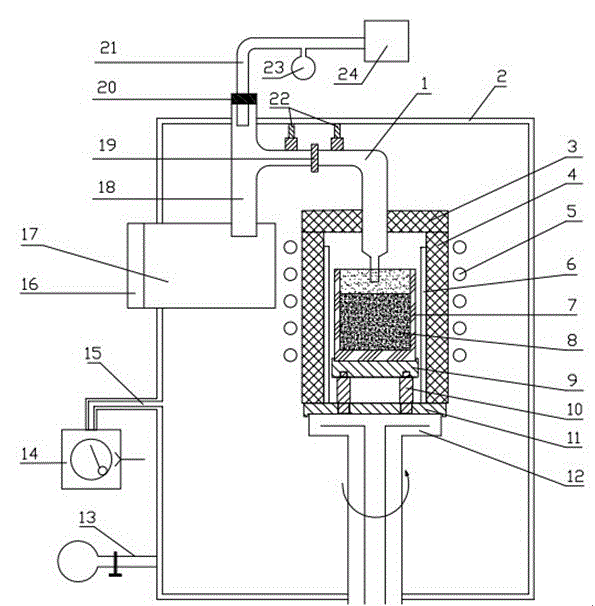

Crankshaft bend fatigue test system and method

InactiveCN1598528AEasy to operateHigh precisionUsing mechanical meansStrength propertiesProgrammable logic controllerResonance

The invention discloses a crank bending fatigue experiment system and method. The system is mainly made up of resonance desk, vibration generator, transducer, programmable logic controller, sensor group, stress amplifier and computer. The invention reduces the manpower burden; the operation is simple and convenient. The accuracy is upgraded greatly.

Owner:ZHEJIANG UNIV

Biological-envelope organic and inorganic microbial fertilizer and preparation method thereof

ActiveCN105061085AImprove disease resistanceImprove stress resistanceFertilizer mixturesOrganic inorganicCrop quality

The invention belongs to the technical field of fertilizer, and particularly relates to biological-envelope organic and inorganic microbial fertilizer and a preparation method thereof. The fertilizer is prepared from, by weight, 10-30% of compound microorganism bacterium agents, 10-50% of major elements, 2-15% of medium trace elements, 5-50% of organic matter, 10-40% of calcium carbonate, 10-40% of kieselguhr and 1-10% of lactate, wherein the organic matter comprises one or more of molasses, polyaspartic acid and humic acid. According to the biological-envelope organic and inorganic microbial fertilizer and the preparation method thereof, the compound microorganism bacterium agents are used, so that the microorganism bacterium agents and the major elements can be applied together and the activity of the major elements cannot be lowered, the strain survival rate is high, the chemical fertilizer applying quantity is reduced, soil is improved, the soil fertility is enhanced, the soil ecology environment is improved, and the crop quality and yield are improved.

Owner:寿光圣德源生物科技有限公司

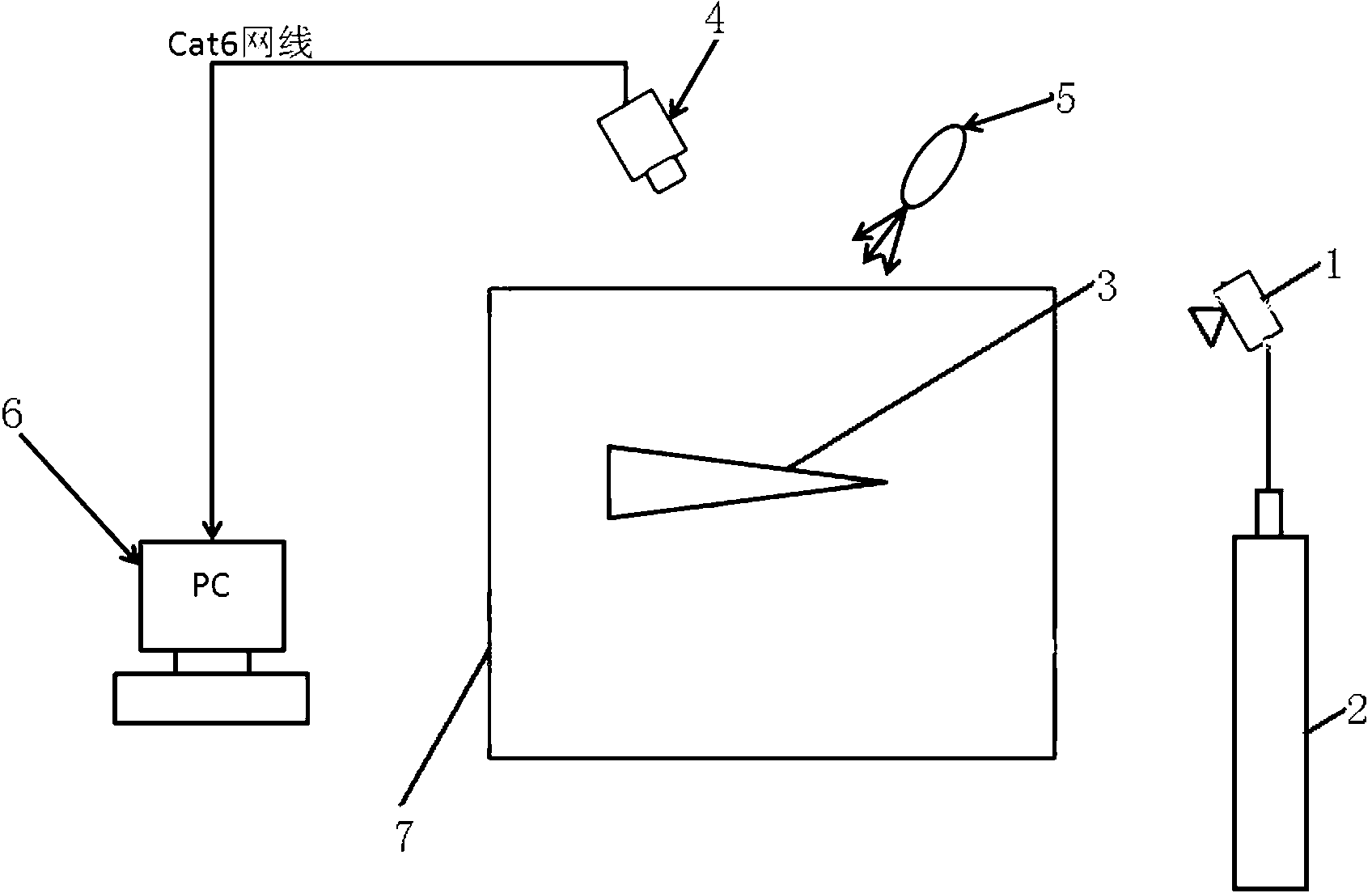

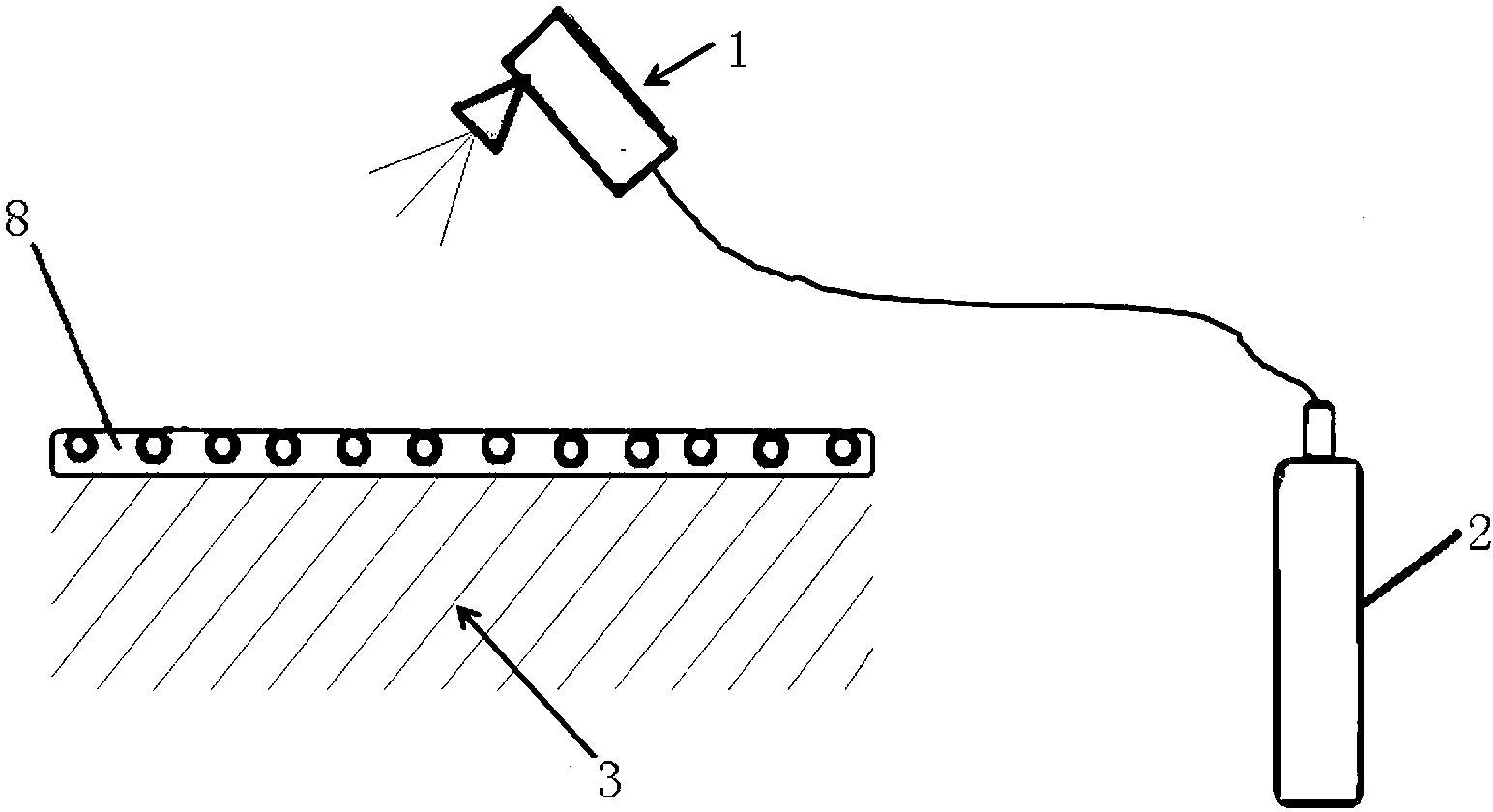

Device and method for measuring fluorescent oil flow friction force field

ActiveCN103267622AEvenly distributed paintReduce links and costsAerodynamic testingFluorescenceEngineering

A device for measuring a fluorescent oil flow friction force field comprises a CCD video camera, an LED light source, a computer, a test wind tunnel and a spraying device, wherein the spraying device is composed of a spraying gun and a high pressure air source which is a nitrogen source, the CCD video camera and the LED light source are respectively installed outside an observation window of the test wind tunnel, the LED light source can irradiate a model testing piece arranged in the test wind tunnel, the CCD video camera can effectively shoot image information of the model testing piece, the LED light source is connected with an external power source through a wire, an information output end of the CCD video camera is connected with a corresponding interface of the computer through a cat6 network line, and a medium inlet of the spraying gun is connected with a medium outlet of the high pressure air source. By means of the device and method for measuring the fluorescent oil flow friction force field, coatings on the surface of a model can be evenly distributed and can reach a stable state as quickly as possible under the function of a flow field, machining links and machining cost of the model are reduced, measurement cost is greatly reduced, and influence on the flow field on the surface of the model by measurement devices is reduced.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

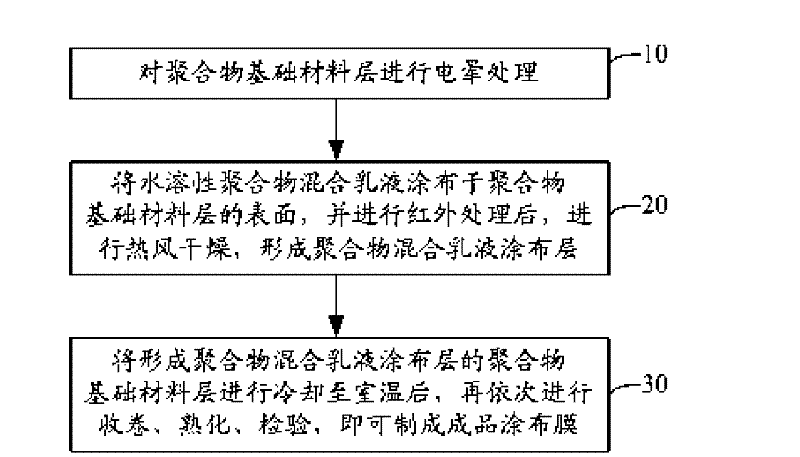

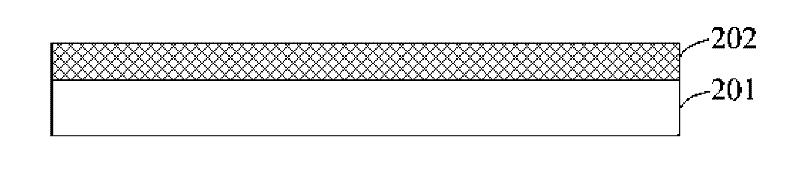

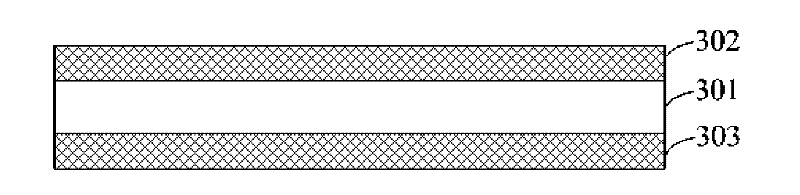

Water soluble polymer mixed emulsion, coating and preparation method thereof

InactiveCN102127277AReduce manufacturing costIncrease productivitySynthetic resin layered productsPaper coatingPolymer scienceEmulsion

The invention relates to water soluble polymer mixed emulsion, coating and a preparation method thereof. The mixed emulsion comprises water soluble polymer emulsion, an adhesive, an adhesion promoter and a surface treating agent, wherein the mass ratio of the water soluble polymer emulsion to the adhesive to the adhesion promoter to the surface treating agent is 100:(0.01-30):(0.001-5):(0.01-5). In the invention, the coating product prepared by using the water soluble polymer mixed emulsion reaches or excesses the technical and use requirements of national standards; meanwhile, the process steps of quantitatively coating adhesive and drying by hot air are saved on the basis of the conventional coating process which is universally used at home and abroad, so that the production cost of coating is reduced greatly, energy and raw materials are saved, the complexity of the production process is lowered, the labor intensity is relieved, the production efficiency is improved, and energy conservation and environmental protection are promoted.

Owner:苗小胜 +1

Negative-pressure incineration disposal system and negative-pressure incineration disposal method for fluorine-containing organic waste liquid and exhaust gas

ActiveCN103292332AExtend your lifeImprove conversion rateFluorine/hydrogen-fluorideIncinerator apparatusCombustion chamberDecomposition

The invention provides a negative-pressure incineration disposal system and a negative-pressure incineration disposal method for fluorine-containing organic waste liquid and exhaust gas. The negative-pressure incineration disposal system comprises an incinerator, a fluorine-containing organic waste liquid and exhaust gas supply system, a fuel supply system, a negative-pressure air supply system, a flue gas chilling and HF (hydrogen fluoride) recycling system and an alkali cleaning system. The negative-pressure incineration disposal method includes respectively and simultaneously feeding the fluorine-containing waste liquid and exhaust gas into combustion chambers of the incinerator; enabling the fluorine-containing waste liquid and exhaust gas to carry out high-temperature decomposition reaction at the 1100-1200 DEG C reaction temperature of the inside of the incinerator, under the -50Pa pressure of the inside of the incinerator and in the presence of oxygen; filling H<2> or CH<4> into the incinerator to promote redundant organic fluorine to be converted into inorganic hydrogen fluoride so as to guarantee that all the organic fluorine is converted into inorganic hydrogen fluoride ultimately; treating reaction products discharged from the combustion chambers of the incinerator and then discharging the treated reaction products into the atmosphere via a chimney. The negative-pressure incineration disposal system and the negative-pressure incineration disposal method have the advantages that the parameter adjustment quantity and parameter adjustment links are reduced, operation is facilitated, and long-period stable production running can be maintained.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

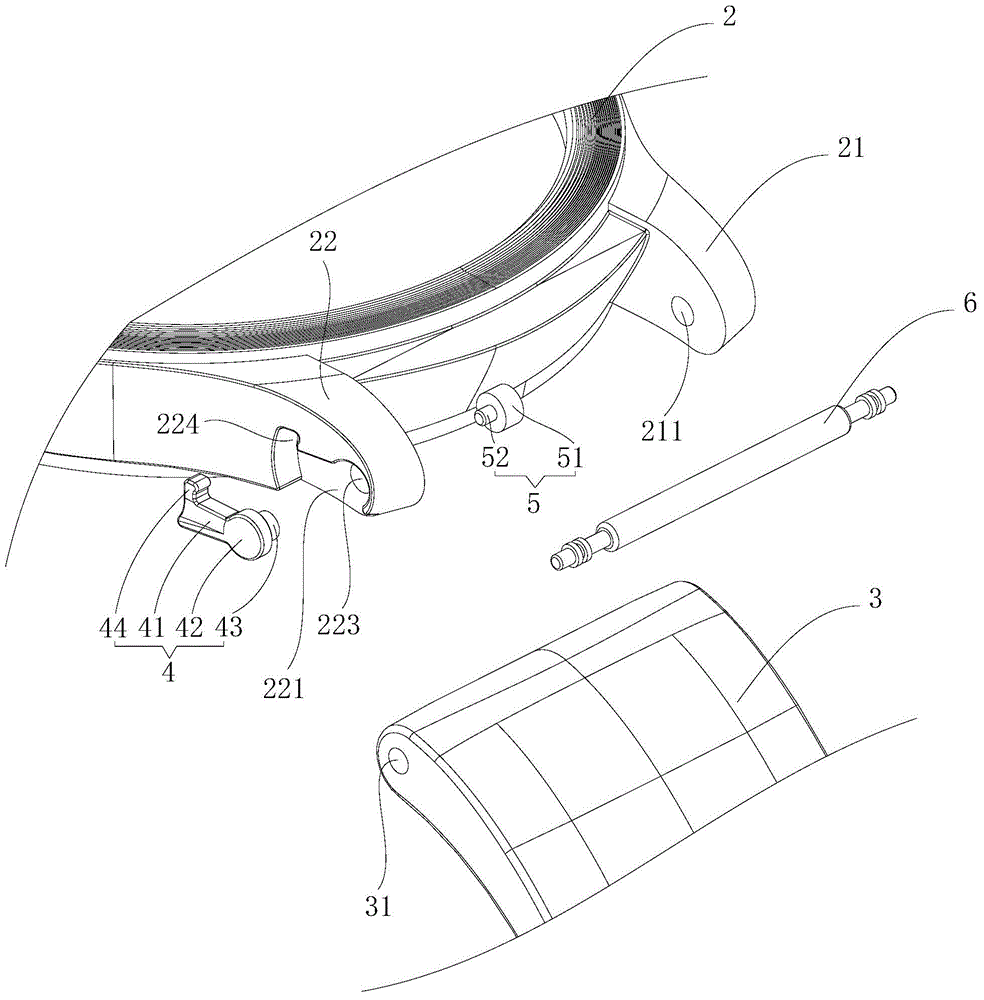

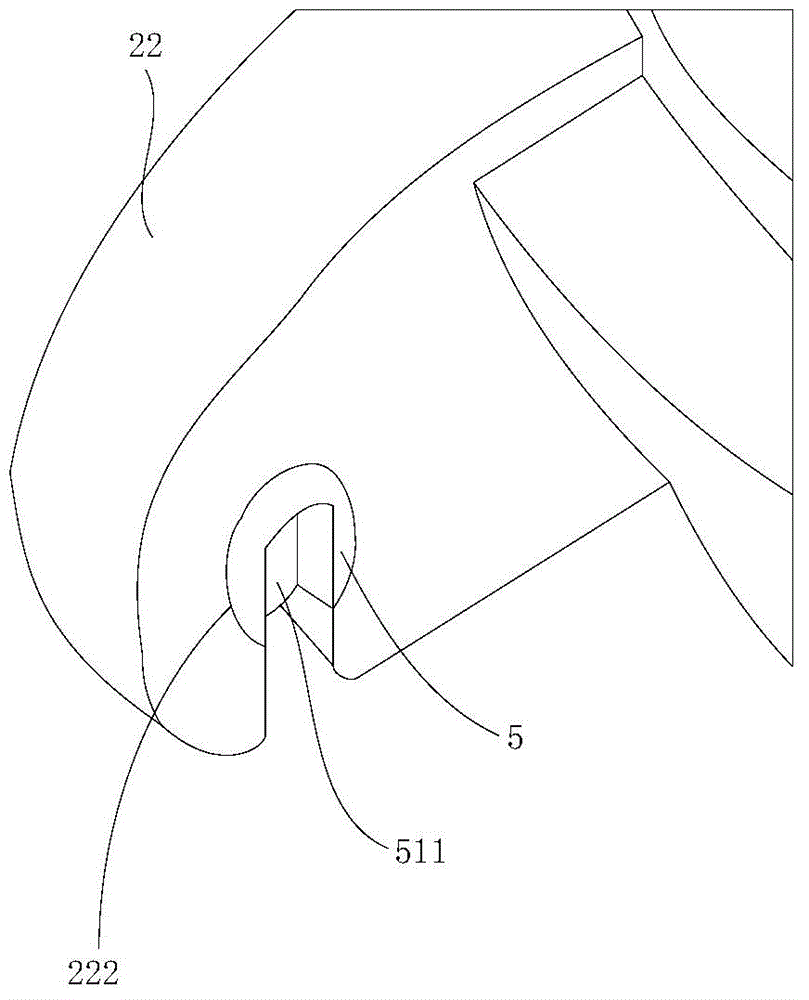

Watch with watchband easy to disassemble

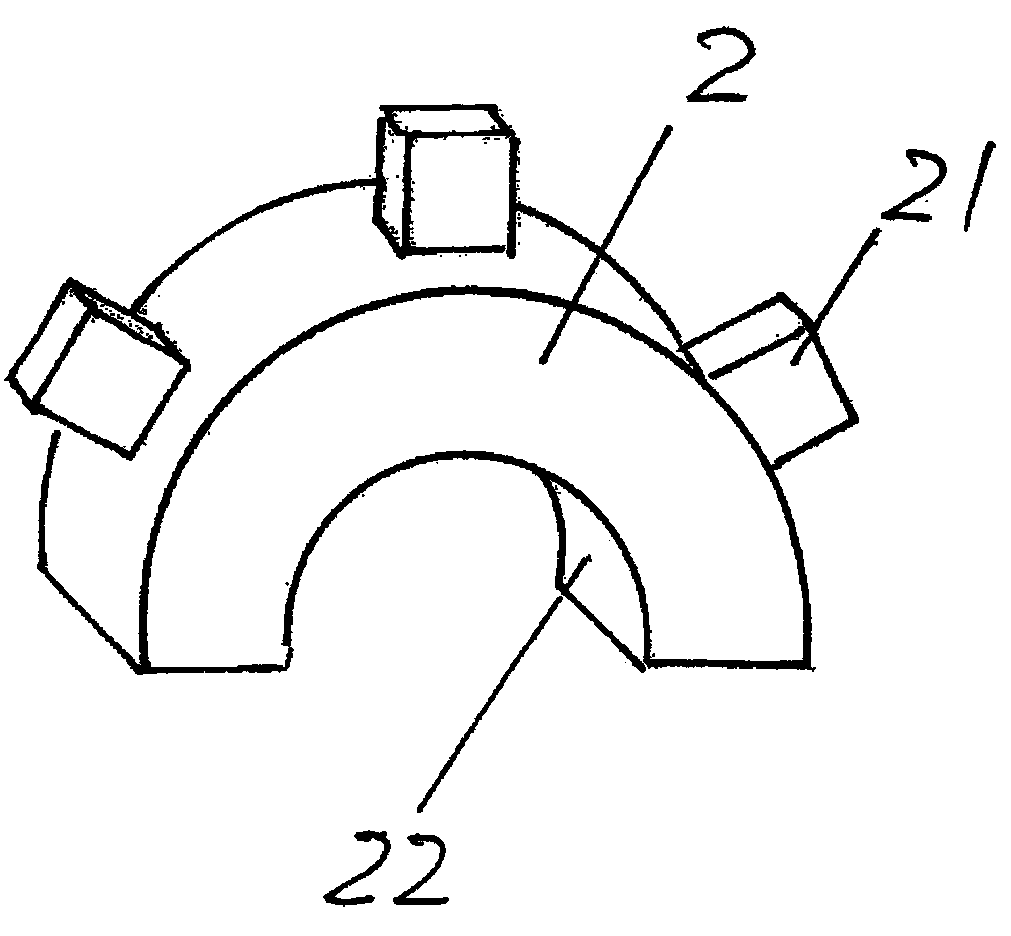

ActiveCN104698810AEasy to operate and disassembleReduce process linksClockwork casesBraceletsEngineeringElectrical and Electronics engineering

The invention discloses a watch with a watchband easy to disassemble. The watch comprises a watchcase (2), a watchband (3), a first knob (4), a second knob (5) and a watch spring bar (6), wherein a blind hole (211) is formed in a first shell lug (21) of the watchcase (2), a first slot (221) and a second slot (222) with opening bottom ends are respectively formed in the two sides of the watchcase (2) and the first shell lug (21), and a through hole (223) is formed between a slot bottom at one end of the first slot (221) and a slot bottom of the second slot (222); the first knob (4) is fixedly connected with the second knob (5) through the through hole (223), a third slot (511) with one opening end is formed in the second knob (5), and the watch spring bar (6) is arranged in a through hole (31) formed in the watchband (3); one end of the watch spring bar (6) is placed in the blind hole (211), and the other end of the watch spring bar (6) is placed in a third slot (511) along an opening bottom end of the second slot (222) and an opening bottom end of the third slot (511).

Owner:HUIZHOU TCL MOBILE COMM CO LTD

Bulk material discharging, storage and transportation equipment and transportation method

PendingCN108328360ARealize human-computer interactionReduce misuseConveyorsLarge containersControl systemHouse building

The invention discloses bulk material discharging, storage and transportation equipment which comprises a transportation hopper installed on the upper portion of a frame. The lower end of the transportation hopper is provided with a discharge outlet, and the discharge outlet is provided with a bin door capable of being opened and closed. The equipment further comprises a bin door opening-closing and detection system, a vehicle positioning indication human-machine interaction system, a transportation hopper material level detection and indication system, an upper spraying device and a lower spraying device which are connected with a control system, wherein the upper spraying device is installed on the upper portion of the transportation hopper, and the lower spraying device is installed onthe lower portion of the transportation hopper. Transportation vehicle automatic monitoring and reminding are achieved, a boat discharging door machine can work without interruption, the storage capacity of the transportation hopper can be displayed in real time, the bin door is automatically opened and closed for discharging, the lower portion of the transportation hopper is provided with a material weighing system, an empty vehicle weight house, a heavy vehicle weight house and a discharging, storage and transportation device are integrated into a whole, loading and weighing are completed ina one-stop mode, the automobile weight house building cost is reduced, processes are reduced, and production efficiency is improved. The invention further provides a transportation method for transporting bulk materials through the bulk material discharging, storage and transportation equipment.

Owner:RIZHAO PORT +1

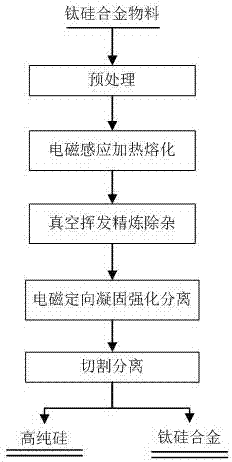

Method for directly preparing high-purity silicon and titanium-silicon alloy from titanium-silicon materials

InactiveCN107572532AHigh recovery rateImprove separation efficiencySilicon compoundsSilicon alloyMaterial resources

The invention relates to a method for directly preparing high-purity silicon and titanium-silicon alloy from titanium-silicon materials, and belongs to the technical field of efficient and comprehensive utilization of titanium-silicon material resources. Titanium-silicon materials with different contents of silicon are adopted as raw materials, electromagnetic induction is adopted for heating andmelting, and vacuum volatilization is conducted on the molten alloy materials under air pressure for refining and impurity removal; electromagnetic stirring is conducted on the molten materials obtained after the impurity removal for directional solidification and strengthened separation, and during the directional solidification, silicon which is preferentially precipitated deposits on the bottomof a crucible under the action of an electromagnetic stirring force and a temperature gradient; however, a titanium-silicon alloy phase is precipitated on the upper part of the crucible, and two products, the high-purity silicon and the titanium-silicon alloy, are obtained; the products is cut along an interface of separation, and the high-purity silicon with low contents of boron and phosphorusand the titanium-silicon alloy with low content of iron are obtained. According to the method for directly preparing the high-purity silicon and the titanium-silicon alloy from the titanium-silicon materials, the purity of the obtained high-purity silicon is more than 99.995%, and the content of titanium in the titanium-silicon alloy is 20-30%; compared with a traditional preparation technology of the high-purity silicon and the titanium-silicon alloy, the method has the advantages of being short in process, low in cost and the like, and mass production is easy to achieve.

Owner:KUNMING UNIV OF SCI & TECH

Coenzyme composition preparing method

InactiveCN101023968ALower requirementAvoid destructionMetabolism disorderPlant ingredientsActivated carbonUltrafiltration

The present invention relates to a preparation method of coenzyme compound. Said invention adopts mature technical processes of temperature difference wall breakage and reduced pressure concentration, and utilizes the steps of ultrafiltering separation, column chromatography to make purification, concentration and precipitation so as to obtain the invented coenzyme compound.

Owner:NANTONG XINPING GARMENTS

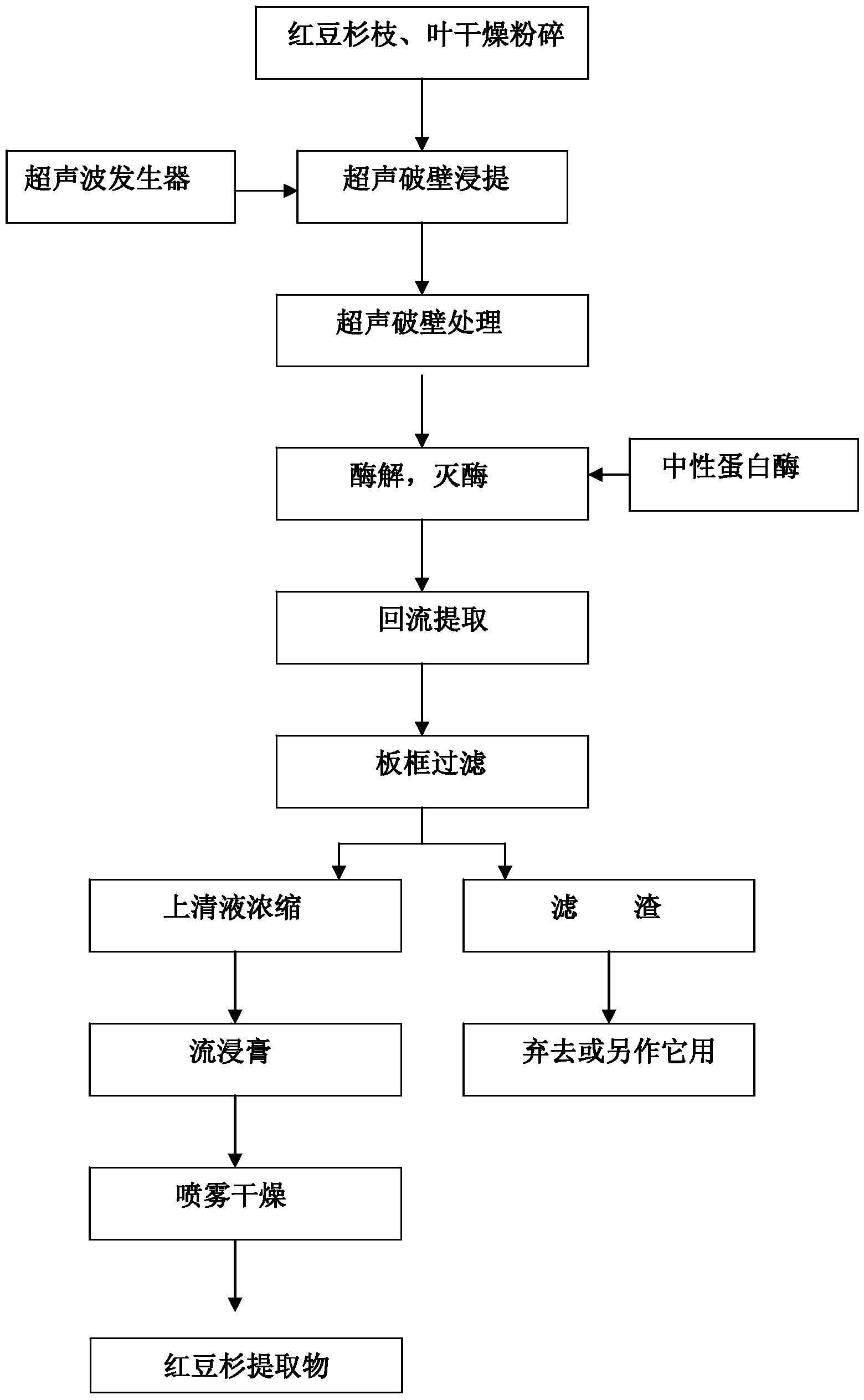

Preparation method for taxus chinensis extractive and application of taxus chinensis extractive

ActiveCN104248649AImprove dissolution rateReduce process linksMetabolism disorderAntipyreticChemistryTaxus species

The invention discloses a preparation method of taxus chinensis extractive. The preparation method comprises the following steps: (1) preparing a taxus chinensis raw material; (2) conducting ultrasonic wall-breaking treatment, soaking the taxus chinensis raw material in a soaking agent in a stirring manner to obtain a soak solution, and conducting the ultrasonic wall-breaking treatment on the soak solution to obtain a material liquid; (3) performing enzymolysis: transferring the material liquid to a reaction container, adding neutral protease which is 0.3-1.0% of the taxus chinensis raw material in weight to the reaction container, obtaining a mixed liquor, regulating the pH value of the mixed liquid to 6.8-7.0, conducting enzymolysis to hydrolyze free proteins in glycoprotein and glycan, deactivating enzyme, and obtaining a pulp liquid; (4) conducting reflux extraction on the pulp liquid to obtain an extracting solution, filtering and concentrating the extracting solution to obtain a concentrated solution, and filtering the concentrated solution to obtain a filter liquor; (5) conducting spray drying to obtain the taxus chinensis extractive. The preparation method increases the dissolution rate and accelerates the extraction rate.

Owner:无锡紫杉药业股份有限公司

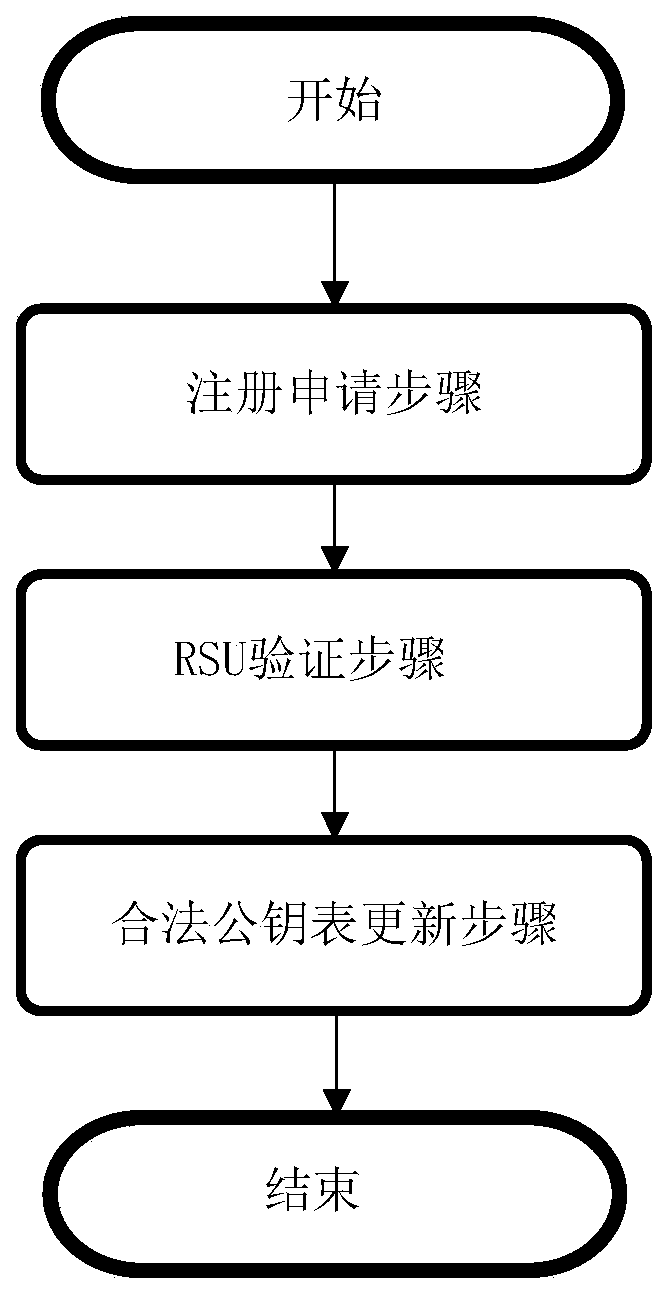

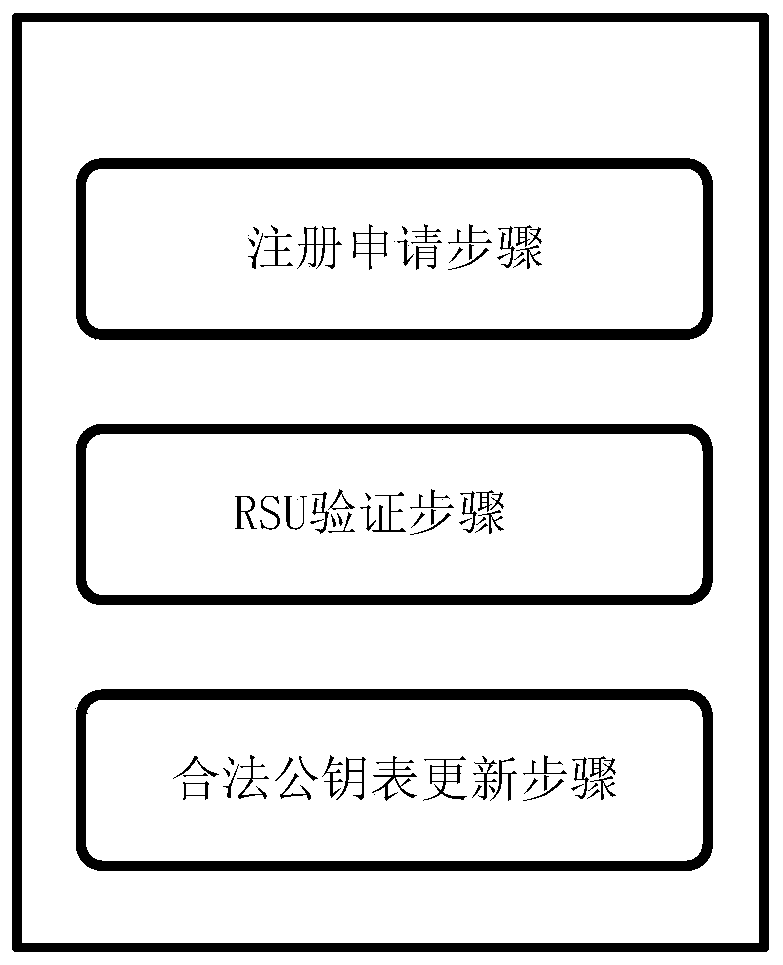

Node identity authentication method and system suitable for Internet of Vehicles

ActiveCN110831004AComprehensive verificationReduced authenticationParticular environment based servicesUser identity/authority verificationInternet privacyEngineering

The invention provides a node identity authentication method and system suitable for Internet of Vehicles, and the method comprises a registration application step: enabling a vehicle unit to apply for registration to an RSU, and obtaining registration application result information; an RSU verification step: the RSU verifies the vehicle identity corresponding to the vehicle unit, and obtains thecorresponding vehicle identity verification result information; acquiring legal public key table broadcast information according to the corresponding vehicle identity verification result information;and a legal public key table updating step: according to the legal public key table broadcast information and the vehicle local legal public key table parameters, comparing the legal public key tablebroadcast information with the vehicle local legal public key table parameters, updating the vehicle local legal public key table, and obtaining legal public key table updating result information andvehicle unit identity confirmation result information. According to the scheme based on the legal public key table, more messages can be verified in unit time, and higher efficiency is achieved.

Owner:SHANGHAI JIAO TONG UNIV +1

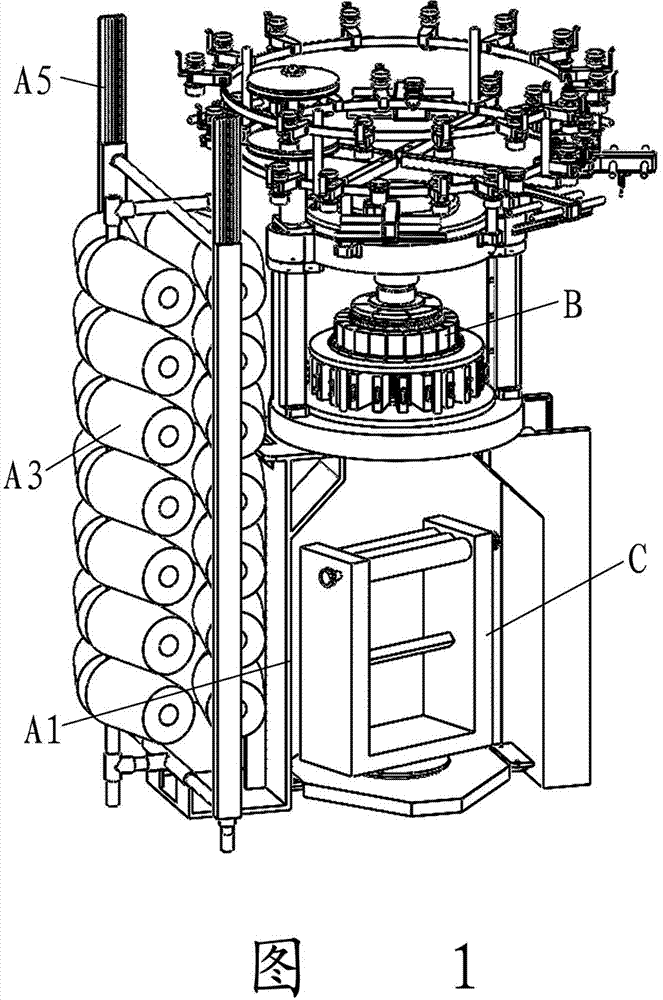

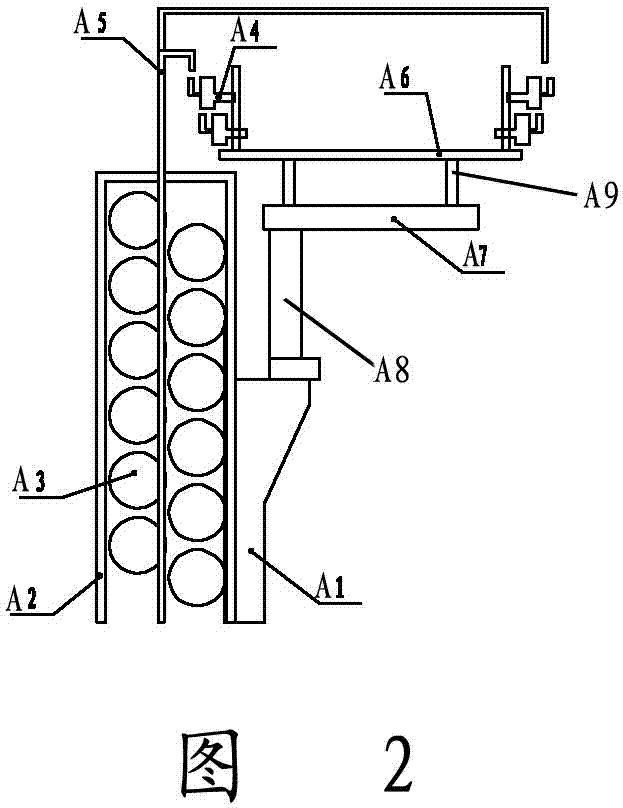

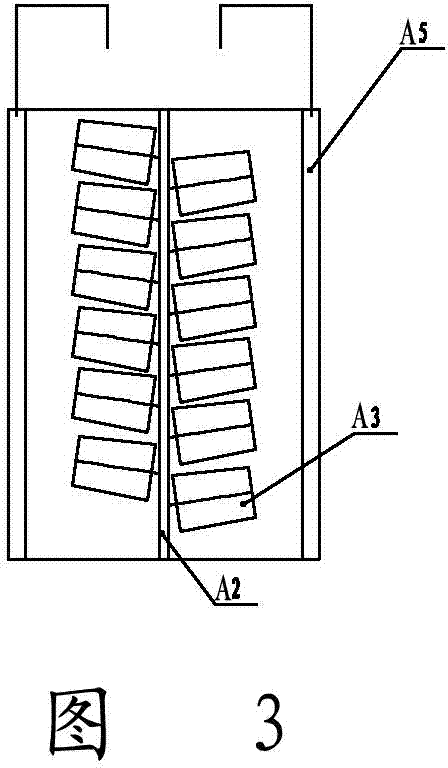

Panty-hose machine

A panty-hose machine is composed of a yarn feeding mechanism, a weaving mechanism and a batching mechanism. The panty-hose machine is characterized in that the yarn feeding mechanism is fixed through machine legs, a leg support is arranged on the bottom among the machine legs, the batching mechanism is mounted and fixed on the leg frame, a rack used for mounting the weaving mechanism is arranged on a top fixing frame of the machine legs, a plurality of frame rods are arranged between the upper portion and the lower portion of the rack, the weaving mechanism is mounted and fixed on the rack and is arranged above the batching mechanism, and a machine top yarn frame in the yarn feeding mechanism is supported at the top end of the upper portion of the rack through a plurality of stand rods. The panty-hose machine has the advantages that the panty-hose machine is novel in structure, more compact in structure combination, small in occupied space, light in whole machine weight, low in cost, simple in debugging, and high in safety and working efficiency, a machine table is more stable in running and precision, and the operation of technology changing is easy and convenient.

Owner:王坤锋

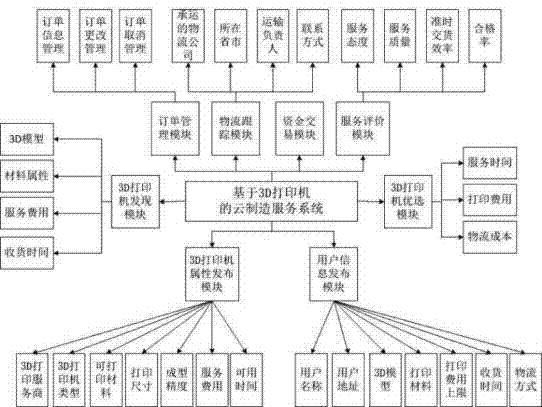

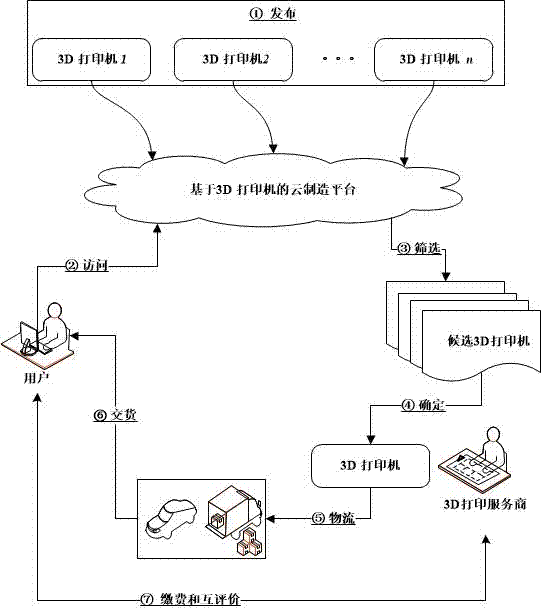

3D printer based cloud manufacturing service system

InactiveCN105447644AReduce process linksRealize Distributed ManufacturingResourcesLogisticsService systemPersonalization

The invention discloses a 3D printer based cloud manufacturing service system. The system comprises a 3D printer attribute release module, a user information release module, a 3D printer discovery module, a 3D printer optimization module, an order management module, a logistic tracking module, a fund transaction module and a service evaluation module. By applying the system, centralized virtual management and distributed remote service f 3D printers can be realized and remote and synchronous efficient sharing of various 3D printers is realized; process links in conventional manufacturing are greatly reduced, the efficiency of plastic processing and complex mechanical parts processing can be remarkably improved, and distributed manufacturing is realized; and a service network established by numerous 3D printers is constructed to provide personalized product customization services for various users.

Owner:SOUTHWEST PETROLEUM UNIV

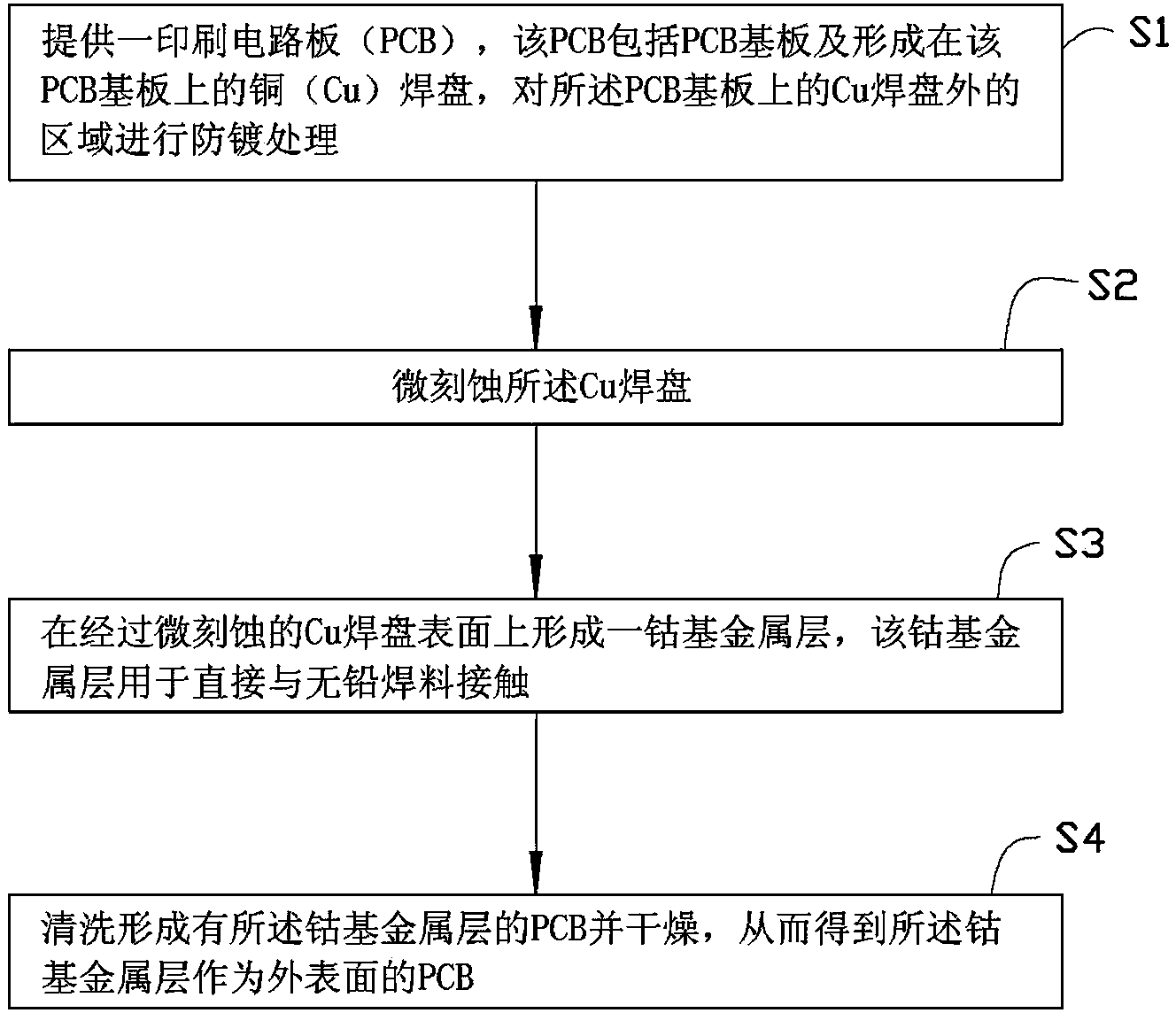

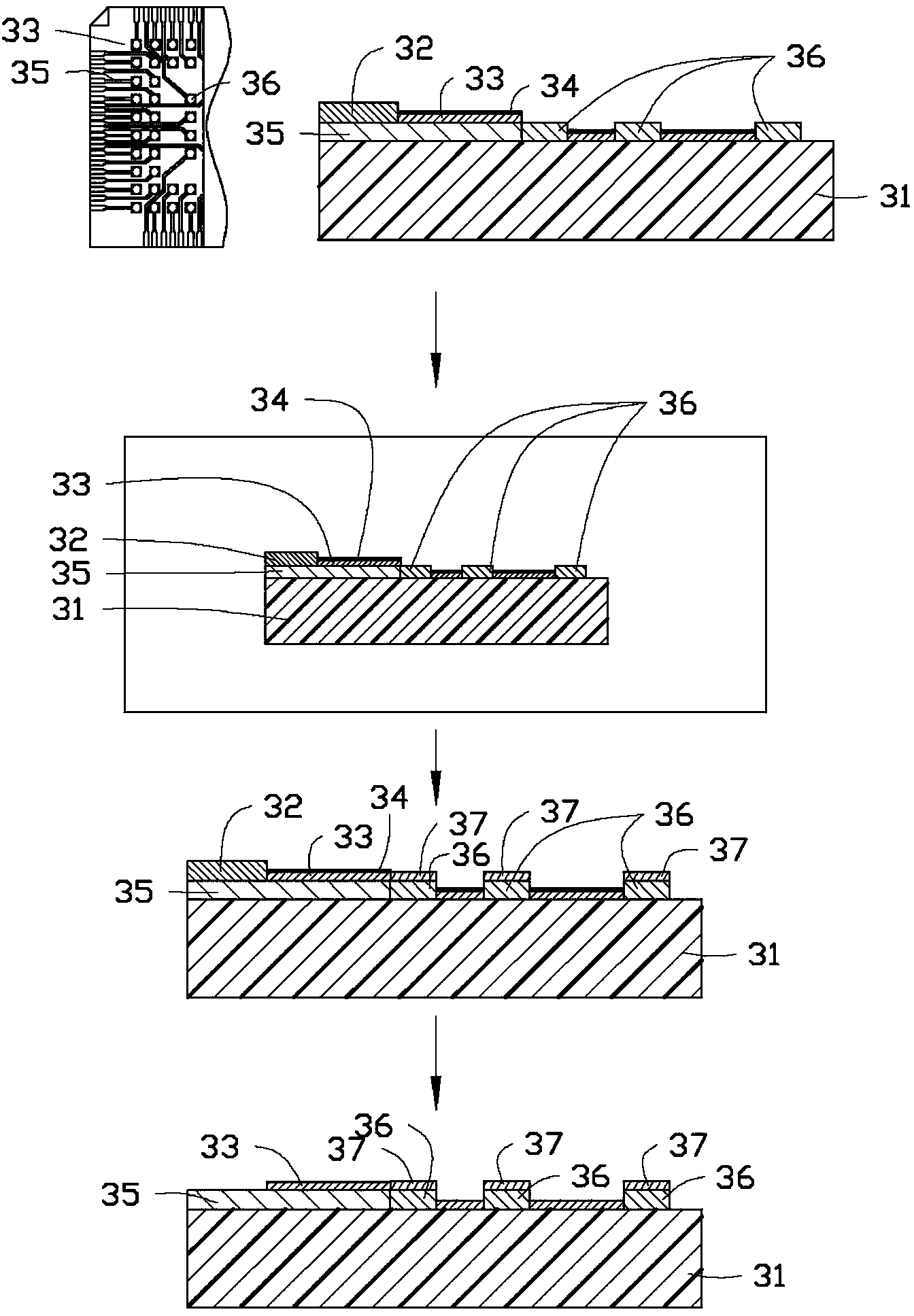

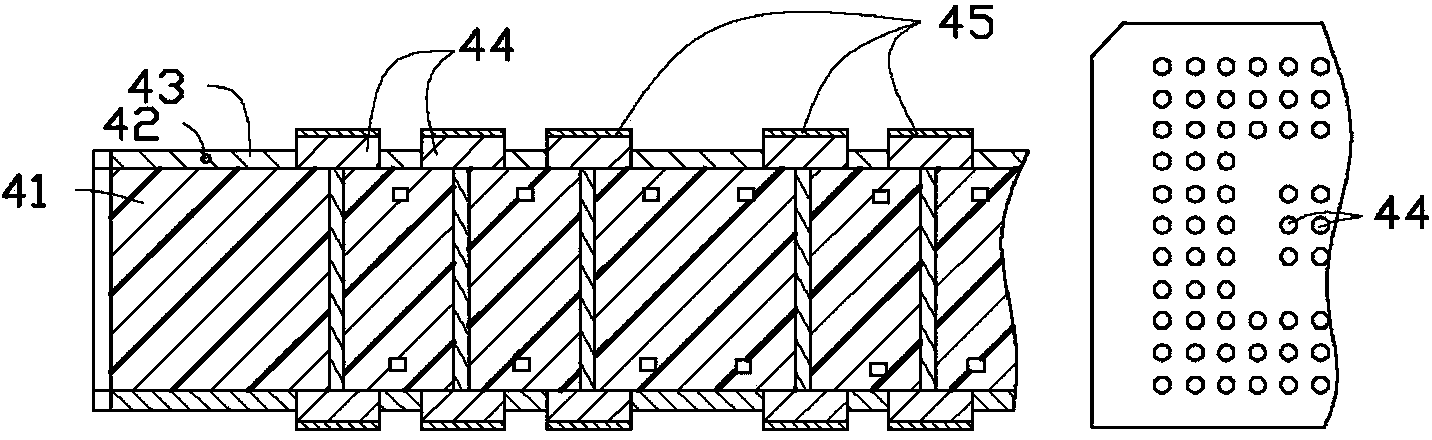

Printed circuit board and method for processing surface of printed circuit board

The invention discloses a method for processing the surface of a printed circuit board. The method comprises the steps that the printed circuit board is provided, the printed circuit board comprises a printed circuit board substrate and a brazing disc formed on the printed circuit board substrate, welding resistance processing and anti-plating processing are conducted on zones outside the brazing disc on the printed circuit board substrate; micro-etching is conducted on the brazing disc; a cobalt-based metal layer is formed on the surface of the brazing disc which undergoes micro-etching and the cobalt-based metal layer is used for directly making contact with lead-free solder, and the printed circuit board with the cobalt-based metal layer is cleaned and dried. The invention further provides the printed circuit board which undergoes the processes.

Owner:TSINGHUA UNIV

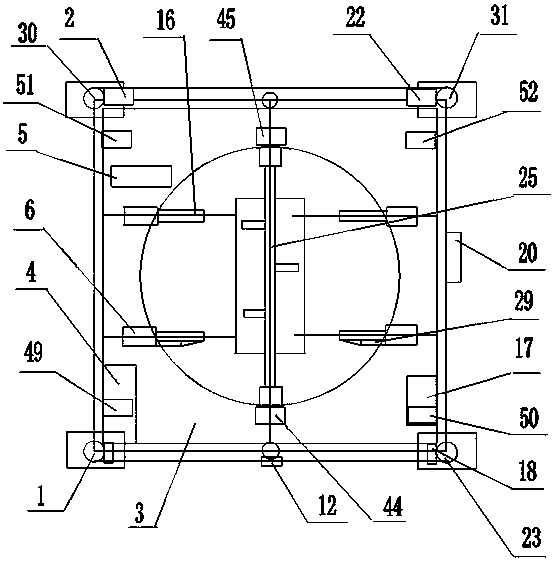

Method and equipment for rapid collection and purification of polycrystalline silicon through directional solidification of tailing

The invention belongs to the technical field of metallurgy purification, and particularly relates to a method and equipment for directional solidification and purification of polycrystalline silicon through taking tailing. According to the method, under the inert gas shielding environment, abluent silicon is heated to be fully melted so as to carry out directional solidification; ingot pulling is stopped when solidification is completed by 85-90%, a graphite bent pipe is stretched into surplus unset silicon at the upper layer, then the other end of the graphite bent pipe is vacuumed through a vacuum unit, so that the surplus unset silicon at the upper layer enters the graphite bent pipe under the action of pressure difference and enters a water cooling collection box through the guide of the graphite bent pipe; heating is stopped after all the surplus unset silicon at the upper layer enters the water cooling collection box, and cast ingot solidified in a crucible is silicon cast ingot of high purity. Due to the method, back-diffusion of impurity is prevented, technology processes are reduced, and the yield of cast ingot is improved. The equipment is convenient to improve and install, and a tailing collection device can be used repeatedly, can collect more tailings, and is safe and reliable.

Owner:QINGDAO NEW ENERGY SOLUTIONS

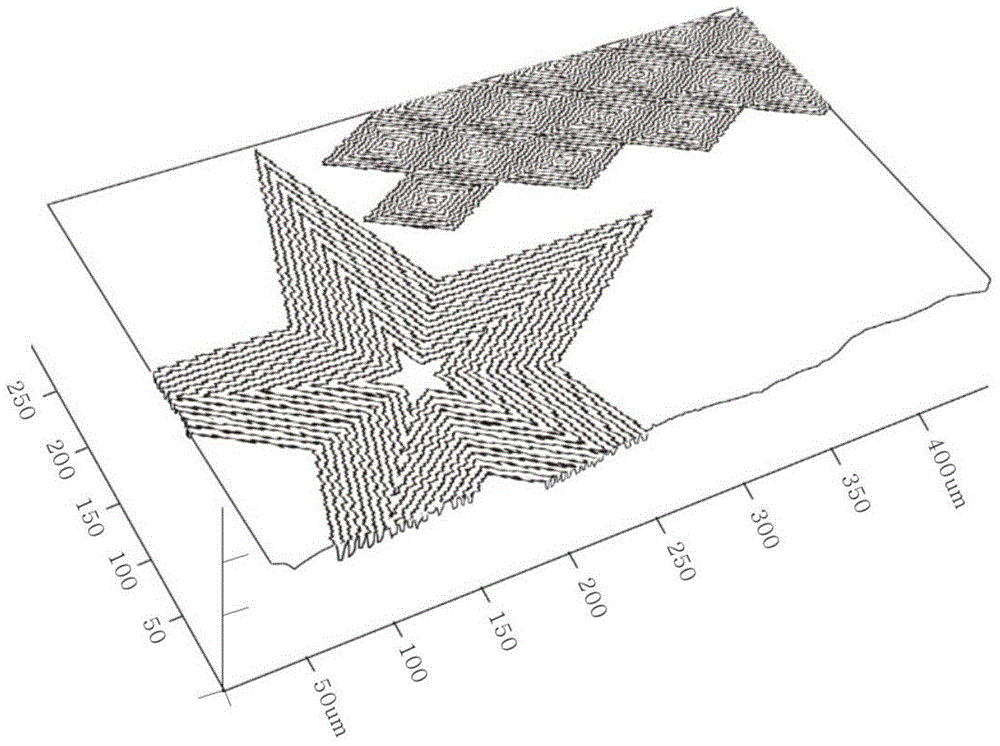

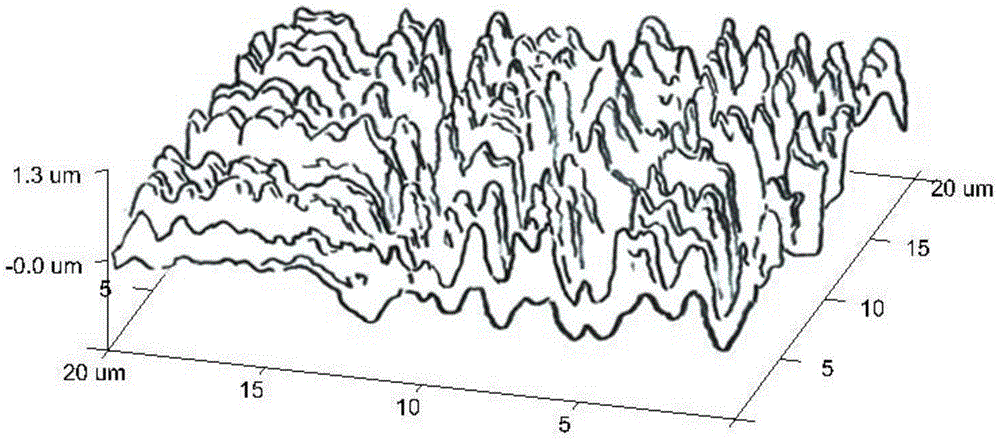

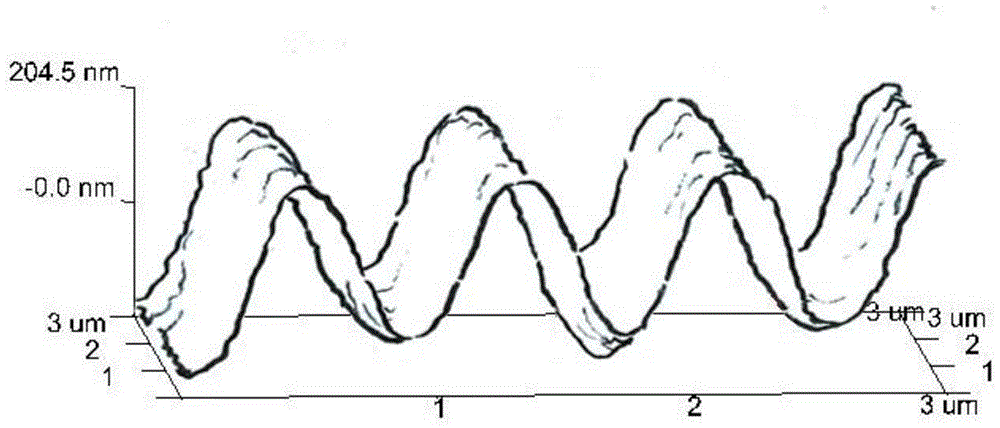

Manufacturing method of ink-free printing package

The invention relates to the fields of printing and packaging, in particular to a manufacturing method of an ink-free printing label or package. According to the structure, black and white display and color display of words and images are achieved by utilizing diffraction, scattering, reflection, refraction and the wave guide phenomenon of guide which are generated by a microstructure. The microstructure is characterized in that speckles at specific rules and lines with composite periods are displayed as black and white comparison when the frequency is 10 micrometers-150 micrometers, are displayed as color diffraction images when the regular period frequency is 0.3 micrometer-10 micrometers and are displayed as three-dimensional images when the irregular period frequency is 1 micrometer-2 micrometers. According to the method, graphics and text information is converted into the microstructure structure design to be expressed, the printing label or the package can be molded at a time through mould copying, so technological links are reduced, the cost is lowered, and environment protection and low carbon can be achieved better; a traditional oil printing package can be updated and replaced by the ink-free printing package, and the ink-free printing package has the advantages of being environmentally friendly, scientific, fashionable, safe and resistant to fake and the like.

Owner:SUZHOU IMAGE LASER TECH

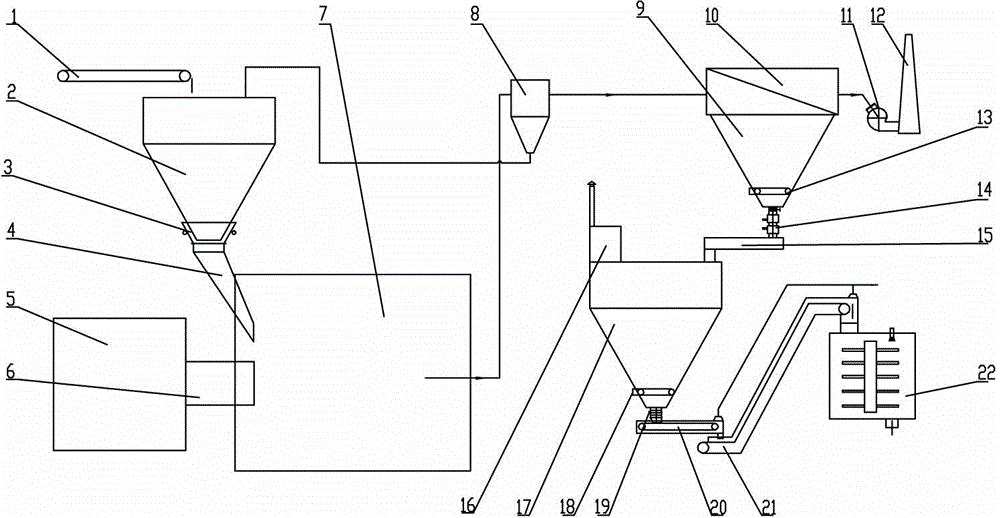

Pellet iron ore concentrate fine grinding pelletizing system and process

The invention relates to a pellet iron ore concentrate fine grinding pelletizing system and a pellet iron ore concentrate fine grinding pelletizing process. The pellet iron ore concentrate fine grinding pelletizing system comprises a feeding belt conveyer, a raw material ore bin, a vibrating funnel, a feed chute, a ball mill, a finished product ore groove, a quantitative feeder, a collection belt conveyer and a mixer, wherein the finished product ore groove, the quantitative feeder, the collection belt conveyer and the mixer are connected with the ball mill in sequence; the system is characterized in that the side face of the ball mill is connected with a hot air furnace through a hot air pipeline; a powder selector and a storage bin are arranged between the ball mill and the finished product ore groove; the powder selector is connected with a discharge port end, the raw material ore bin and the storage bin through conveying pipelines respectively; the upper part of the storage bin is provided with a high-efficiency dust remover; the high-efficiency dust remover is connected with an induced draught fan and a chimney; the storage bin is communicated with the finished product ore groove through an air chute; the upper part of the finished product ore groove is provided with a bin top dust remover. The pellet iron ore concentrate fine grinding pelletizing system has the advantages of simple process flow, low overhaul rate, capability of saving water resource and high pelletizing rate when being used for pelletizing.

Owner:中冶北方(大连)工程技术有限公司

Uvioresistant fleece fabric and preparation method thereof

ActiveCN103820939ALong-acting antibacterialImprove wash resistanceFibre typesWarp knittingFiberPolyester

The invention discloses an uvioresistant fleece fabric, which comprises the following raw materials in percentage by mass: 20% to 40% of bottom layer tissue and 80% to 60% of fleece yarn tissue, wherein at least one of the bottom layer tissue and the fleece yarn tissue is made of uvioresistant fiber, and the uvioresistant fiber is uvioresistant polyester fiber. The invention also discloses a preparation method of the uvioresistant fleece fabric, and the method comprises the following steps of selecting of raw materials, warping, weaving, slitting, thermal shaping, dying or printing and post arrangement. By adopting the method, the prepared uvioresistant fleece fabric has the uvioresistant function for a long time.

Owner:CHANGSHU XINXIN WARP & KNITTING

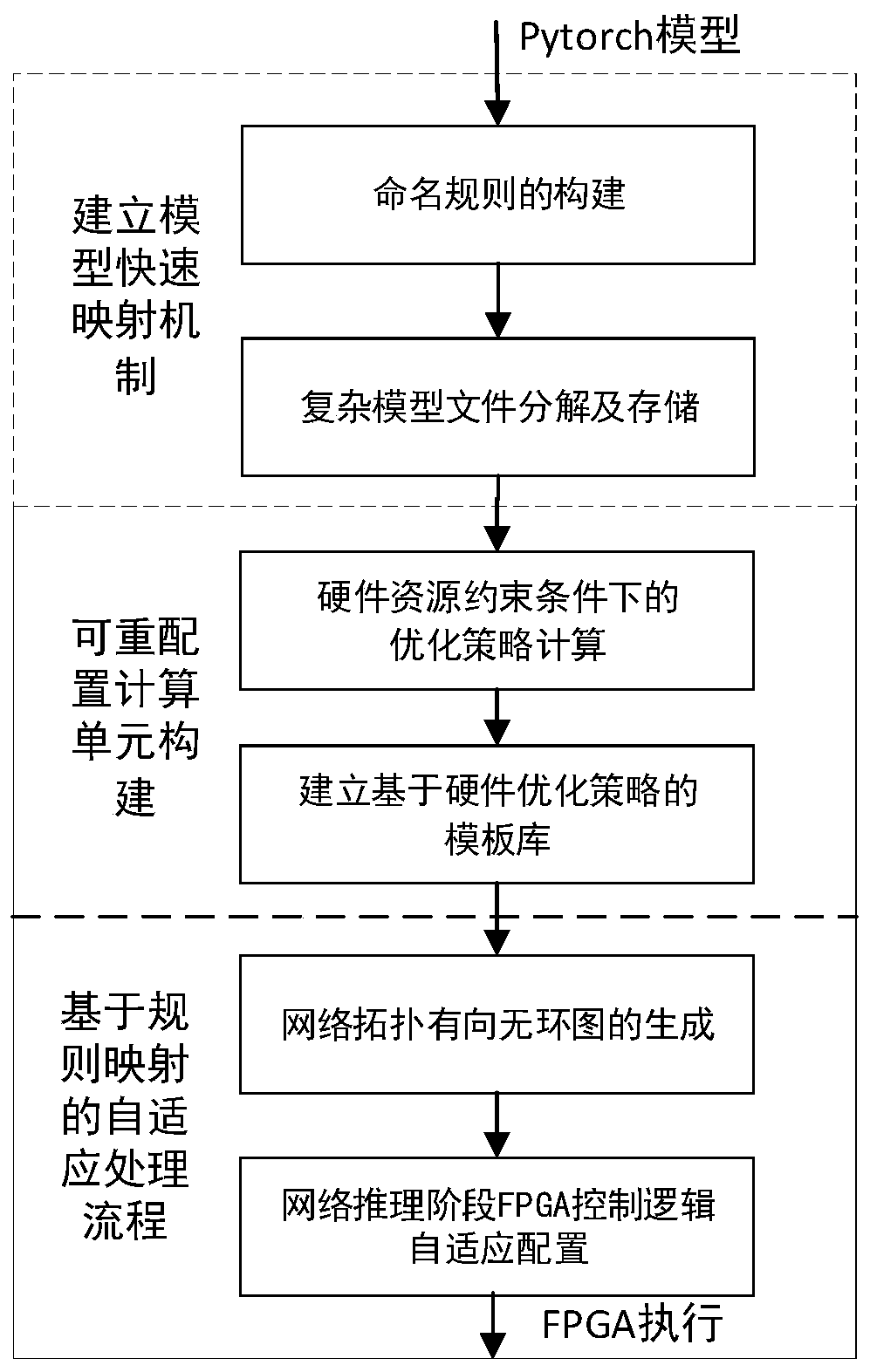

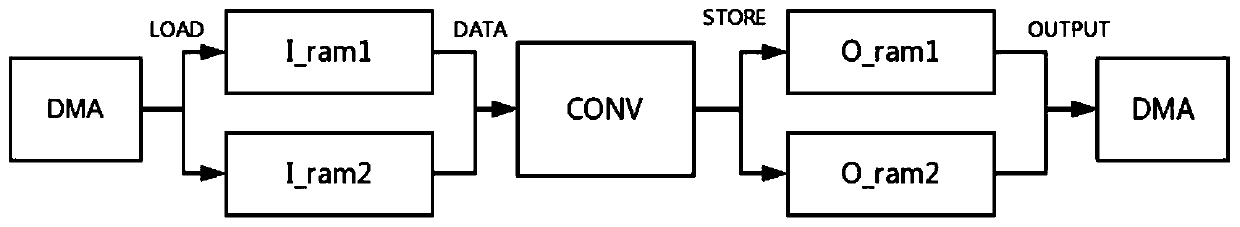

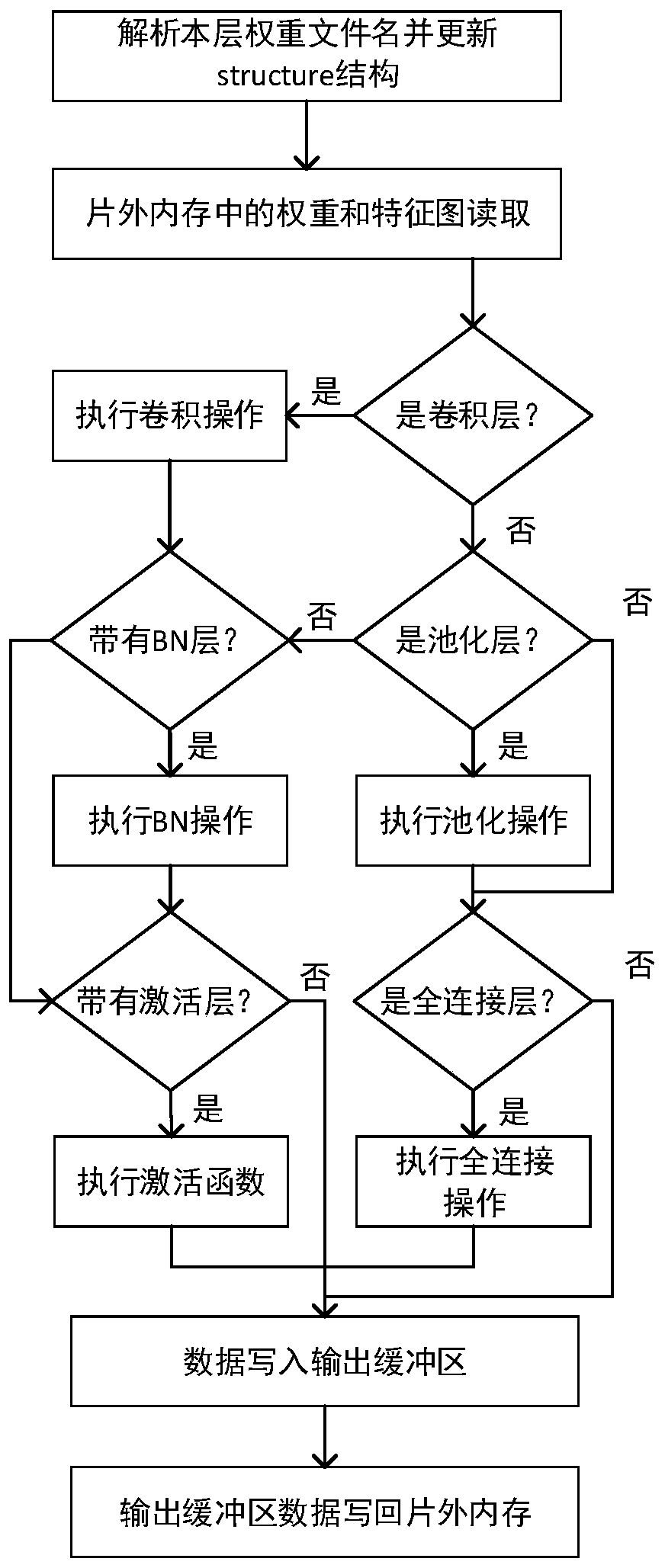

Method for quickly deploying convolutional neural network on FPGA (Field Programmable Gate Array) based on Pytorch framework

ActiveCN111104124AMake up for the problem of not including network topology informationVersatilityNeural architecturesPhysical realisationTheoretical computer scienceReconfigurable computing

The invention discloses a method for quickly deploying a convolutional neural network on an FPGA (Field Programmable Gate Array) based on a Pytorch framework. The method comprises the steps of establishing a model quick mapping mechanism, constructing a reconfigurable computing unit and carrying out self-adaptive processing flow based on rule mapping; when a convolutional neural network is definedunder a Pytorch framework, establishing a model fast mapping mechanism through construction of naming rules; making optimization strategy calculation under a hardware resource constraint condition, establishing a template library based on a hardware optimization strategy and creating a reconfigurable calculation unit i at an FPGA end; and finally, decomposing the complex network model file at the FPGA end in the self-adaptive processing flow based on rule mapping, abstracting the network into a directed acyclic graph, and finally generating a neural network accelerator to realize an integrated flow from the model file of the Pytorch framework to FPGA deployment. The directed acyclic graph of the network can be established through a model fast mapping mechanism, the FPGA deployment process can be completed only by inputting hardware design variables in the FPGA deployment process, and the method is simple and high in universality.

Owner:BEIHANG UNIV

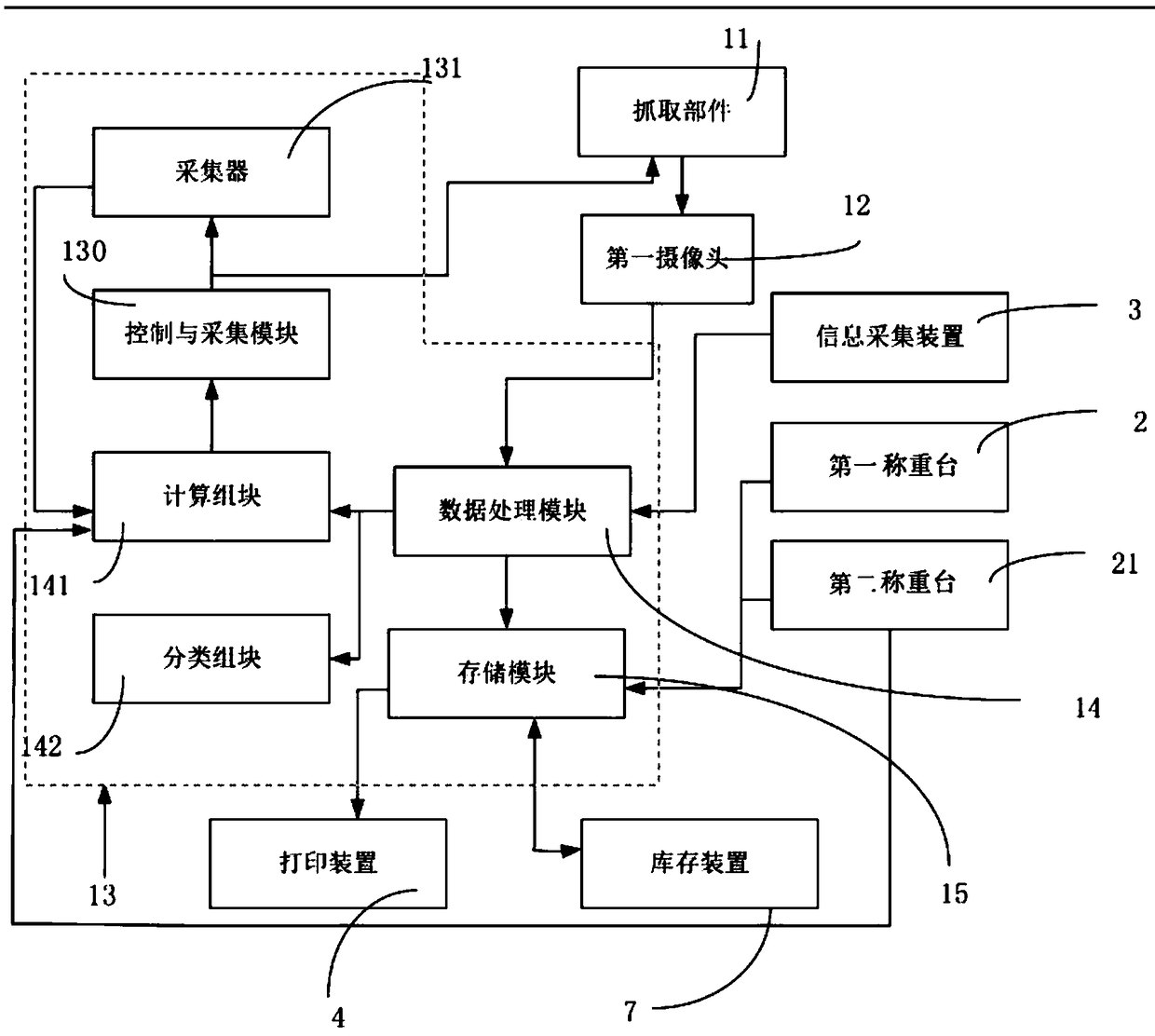

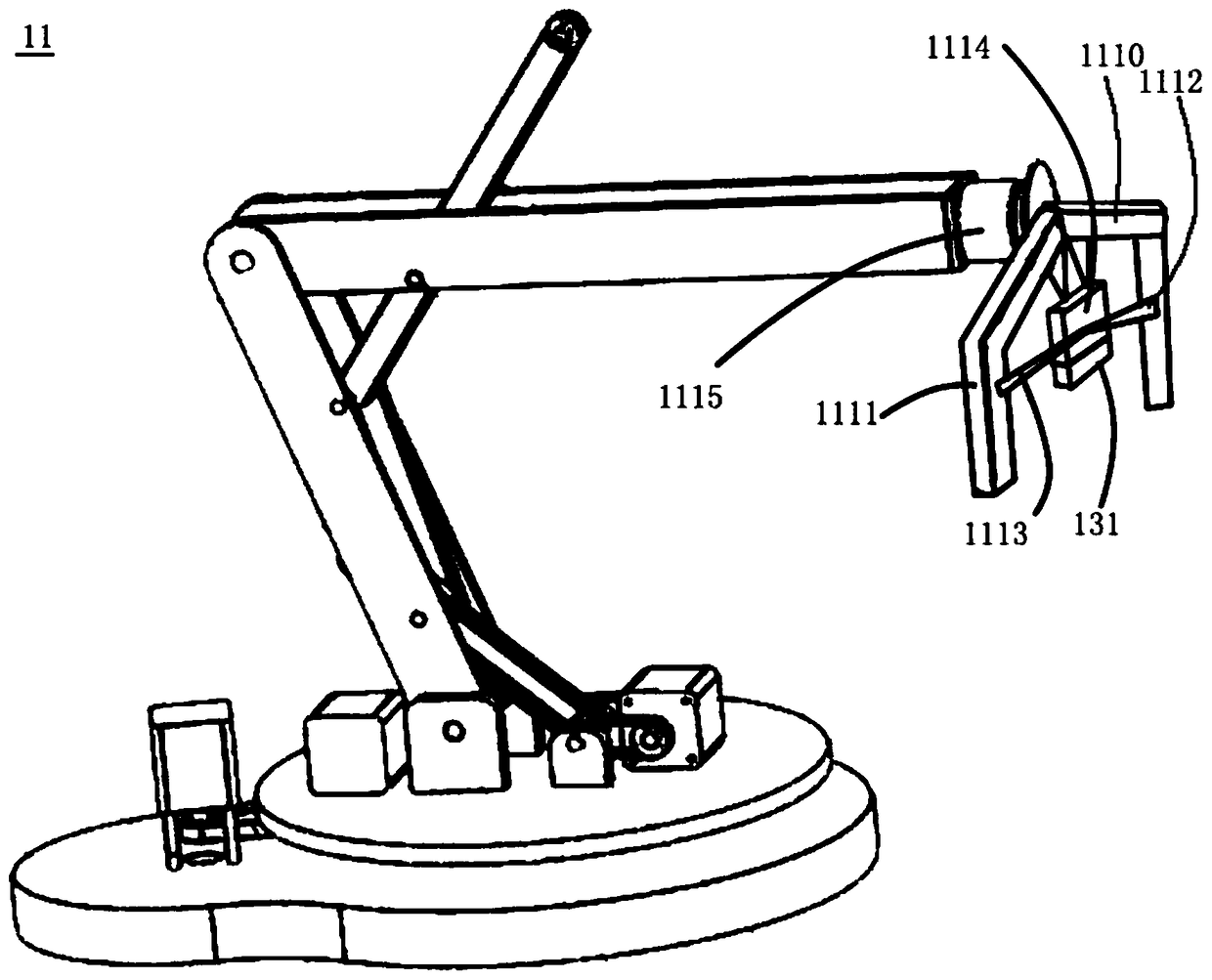

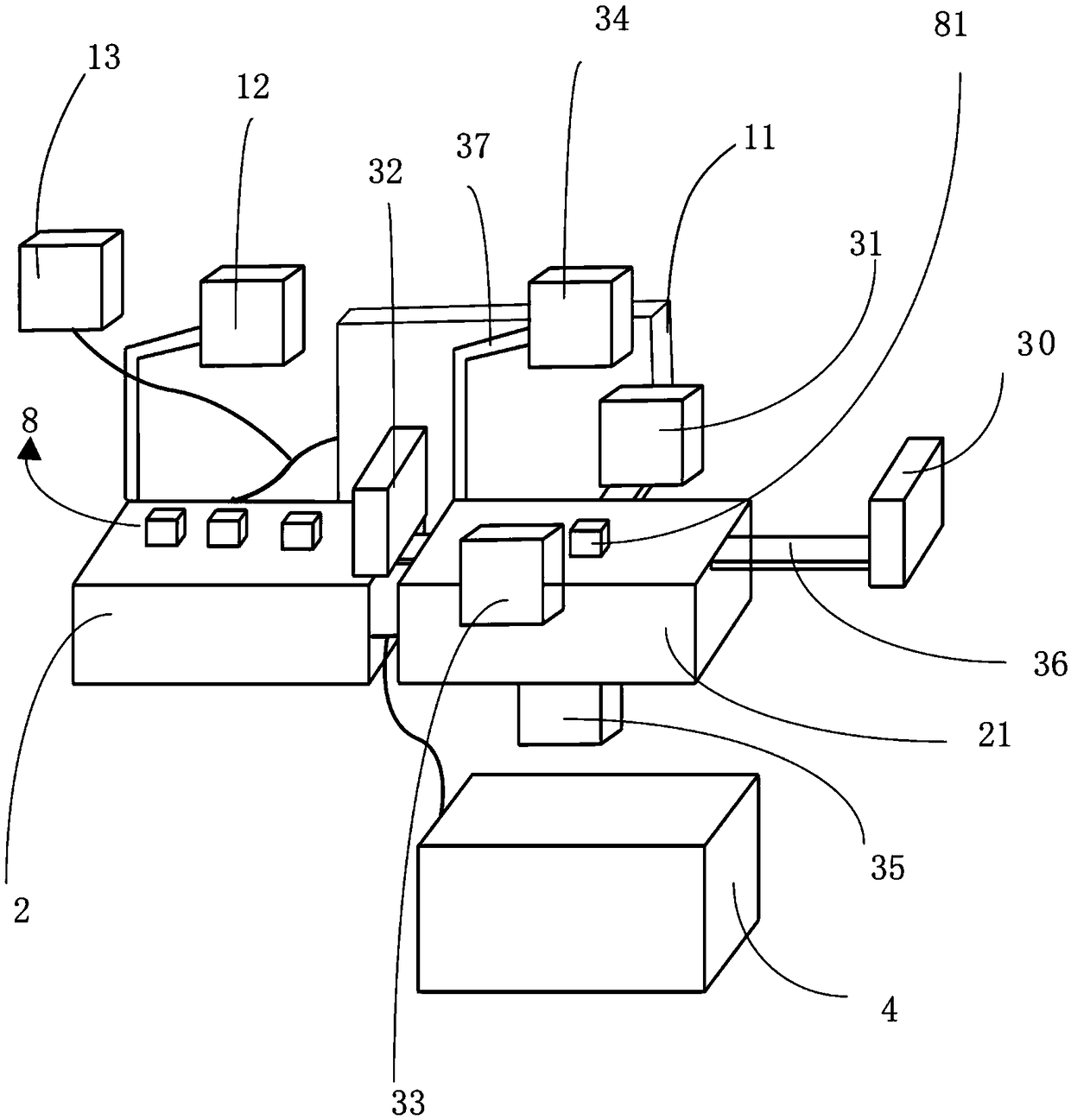

Sorting device, a sorting system and a sorting method

PendingCN109389351APrecise identification of gripping pointsGuaranteed accuracyInvestigating jewelsUsing optical meansManipulatorData processing

The invention relates to a sorting device, a sorting system and a sorting method. The sorting device includes a grasping part comprising a mechanical arm, a first camera, a control circuit module which comprises a control and acquisition module, a data processing module and a storage module, wherein the data processing module is respectively connected with the control and acquisition module, the storage module is respectively connected with the data processing module and the first camera head, and the grasping part is connected with the control and acquisition module. A sorting system includesa sorting device, a first weighing station, a second weighing station, an information collecting device, a printing device, and an inventory device. A sorting method comprises a sorting step, a warehouse building step and a printing step. The sorting device can accurately identify and grasp the gripping point of the jewelry.

Owner:金富智能软件(深圳)有限公司

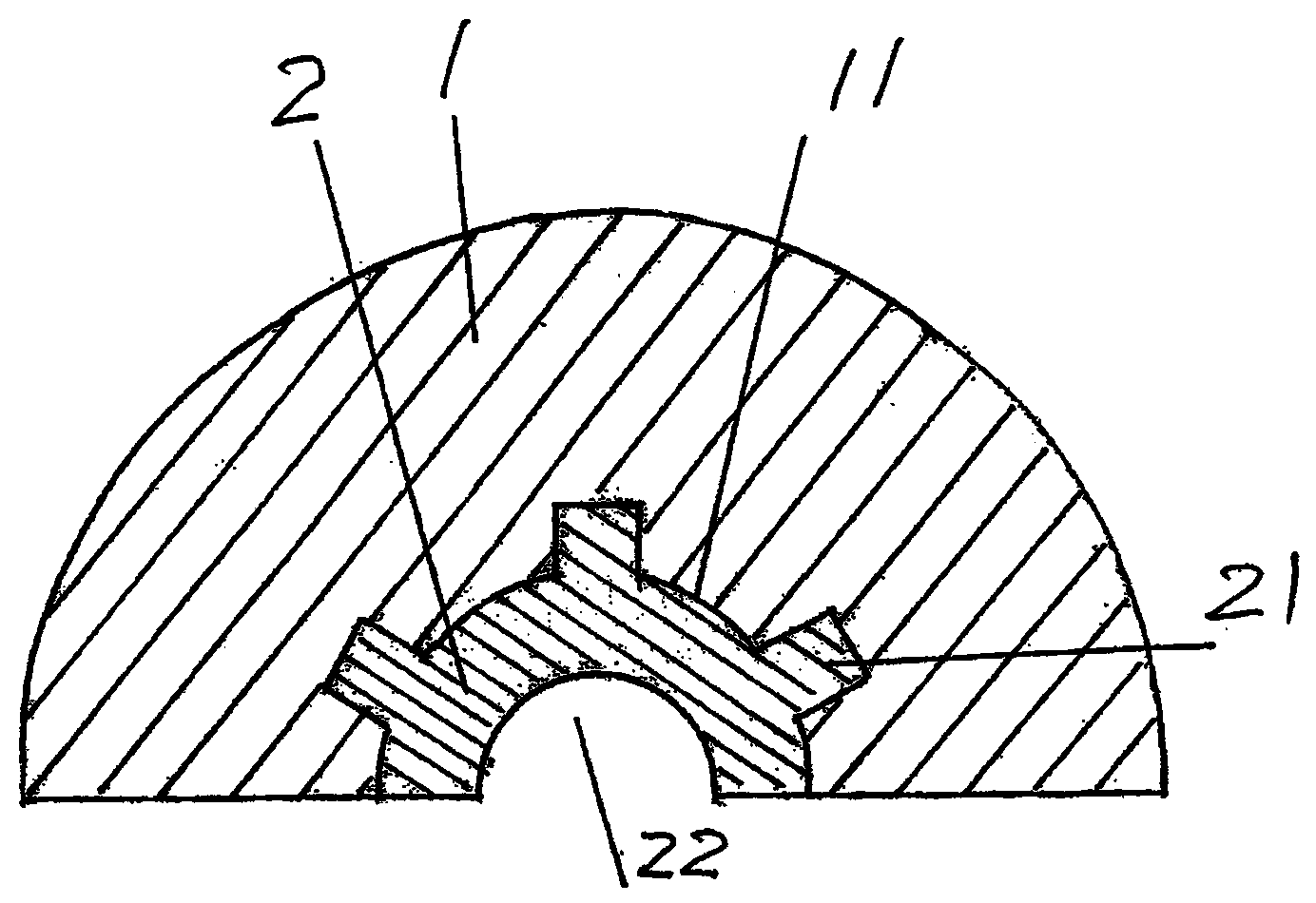

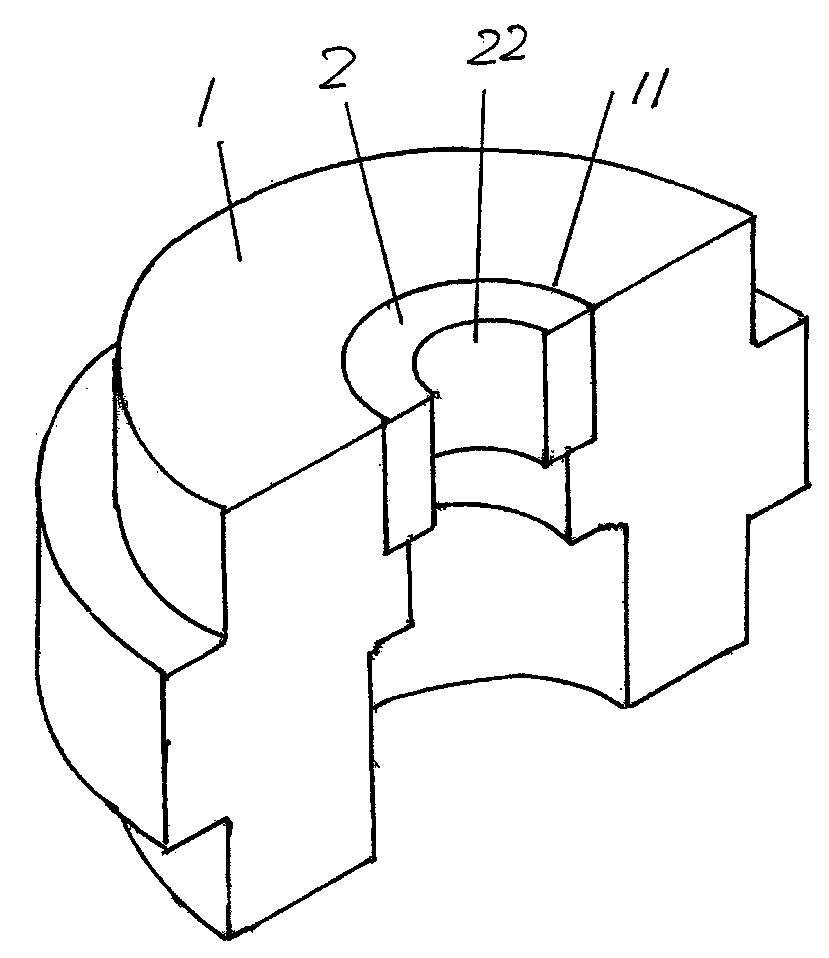

Glass mold die structure for manufacturing glass container

ActiveCN102730943BReduce work intensityAvoid crackingGlass shaping apparatusMortise and tenonWear resistance

The invention relates to a glass mold die structure for manufacturing a glass container, belongs to the technical field of glass molds. The glass mold die structure comprises a die body with a semicircular die body cavity and a semicircular wear resistance body combining with the die body. The glass mold die structure is characterized in that: the wear resistance body is fixed with the die body in a mortise and tenon match manner during die body forming by adopting as an independent member, and is positioned inside the die body cavity. The glass mold die structure of the present invention has the following advantages that: cracking in the use process can be avoided, and the service life can be prolonged; the wear resistance body can be preliminarily obtained by adopting the industrial mass production manner so as to significantly increase manufacturing efficiency; compared with the spray welding in the prior art, the work intensity of the worker can be significantly reduced and the influence due to human factors of the worker is not generated; and the wear resistance body is combined with the die body along with the die body forming, such that the process steps are less so as to provide the energy saving characteristic.

Owner:CHANGSHU JIANHUA MOLD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com