Electric automatic levelling brace

An automatic leveling and leveling technology, which is applied in the direction of supporting machines, machine platforms/supports, and feedback control, etc., can solve the problems of complex installation and leveling support space, difficult controllability, and heavy lifting weight , to achieve the effect of improving safety workability, occupying a small space, and lifting a large weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

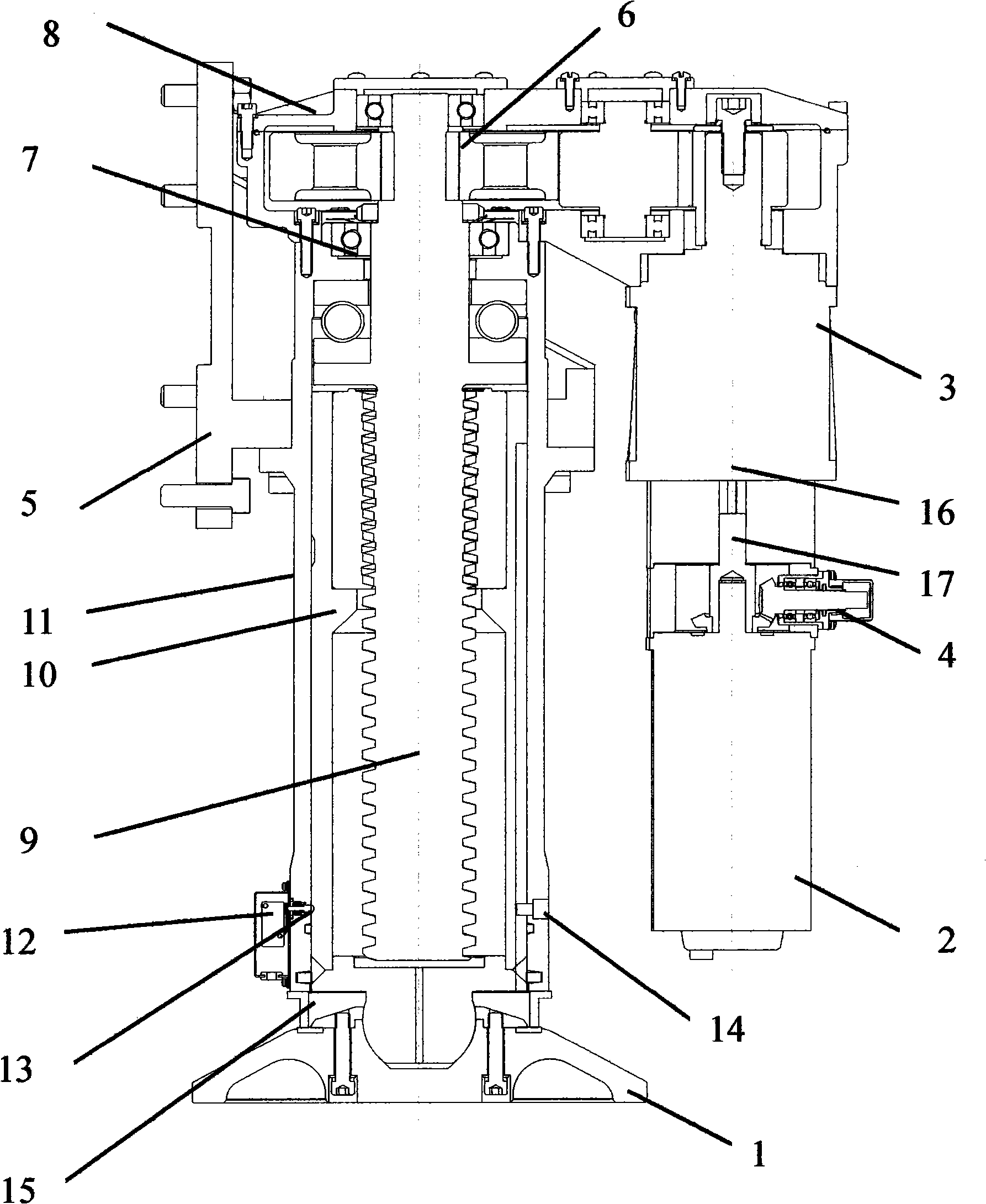

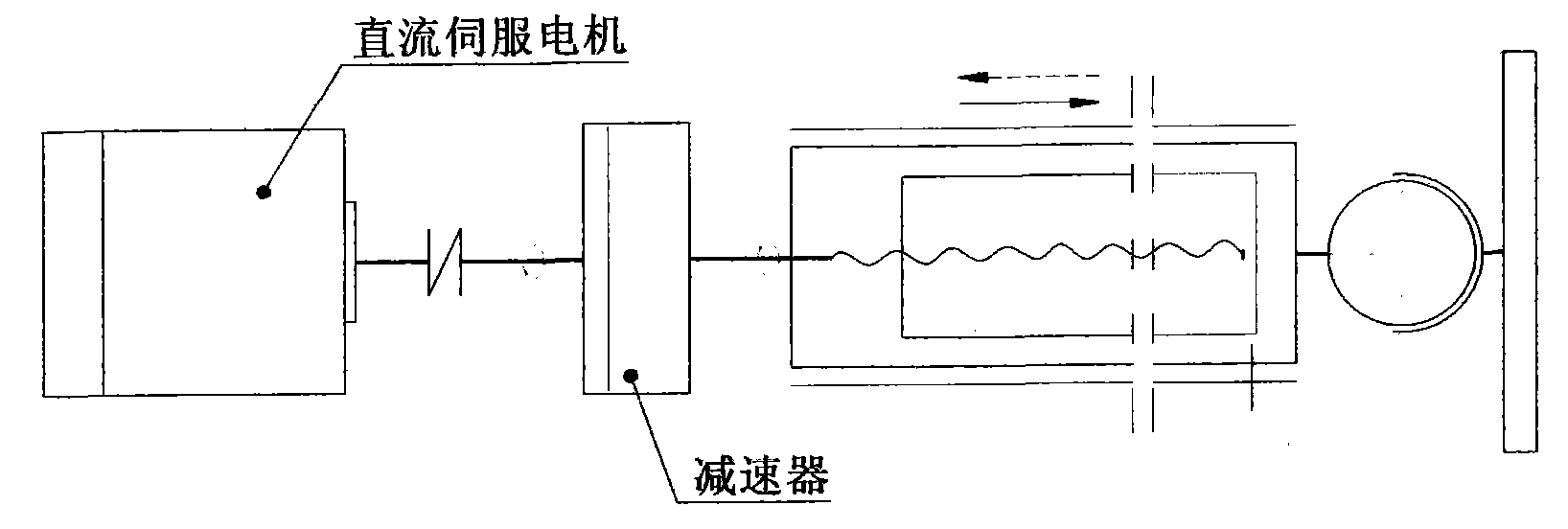

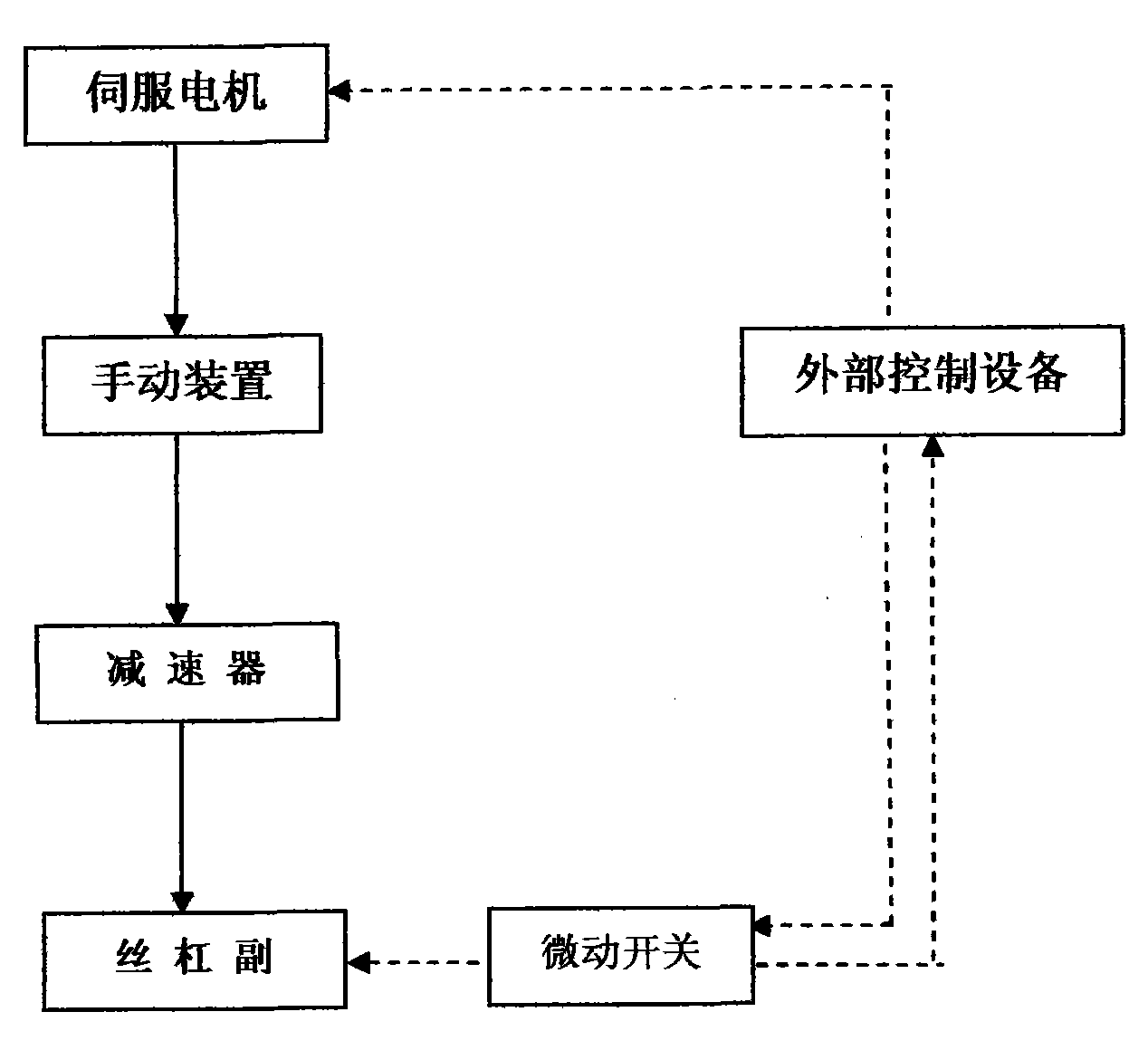

[0018] refer to figure 1 . It is mainly composed of a leveling support cylinder 11, a screw pair 9, a reducer 3, a micro switch 12, a leveling pressure plate 1 connected with a leveling telescopic cylinder 10, and a DC servo motor 2 with an electrical control unit Electric self-leveling support. The top of the leveling support cylinder 11 is provided with a drive chain 6 that connects the output shaft of the reducer 3 and the screw pair 9 for rotational movement. The output shaft of the servo motor 2 is connected with the manual device 4 . The shaft gear 16 in the manual device 4 is installed on the output shaft of the servo motor 2 with a transition fit, and the shaft gear 16 is connected with the coupling 17 of the speed reducer 3 . Between the servo motor 2 and the reducer 3. The bevel gear in the manual device 4 meshes and transmits to the shaft gear 16, and through the connection between the shaft gear 16 and the coupling 17 in the speed reducer 3, the rotation is tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com