Patents

Literature

47results about How to "Large lifting weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

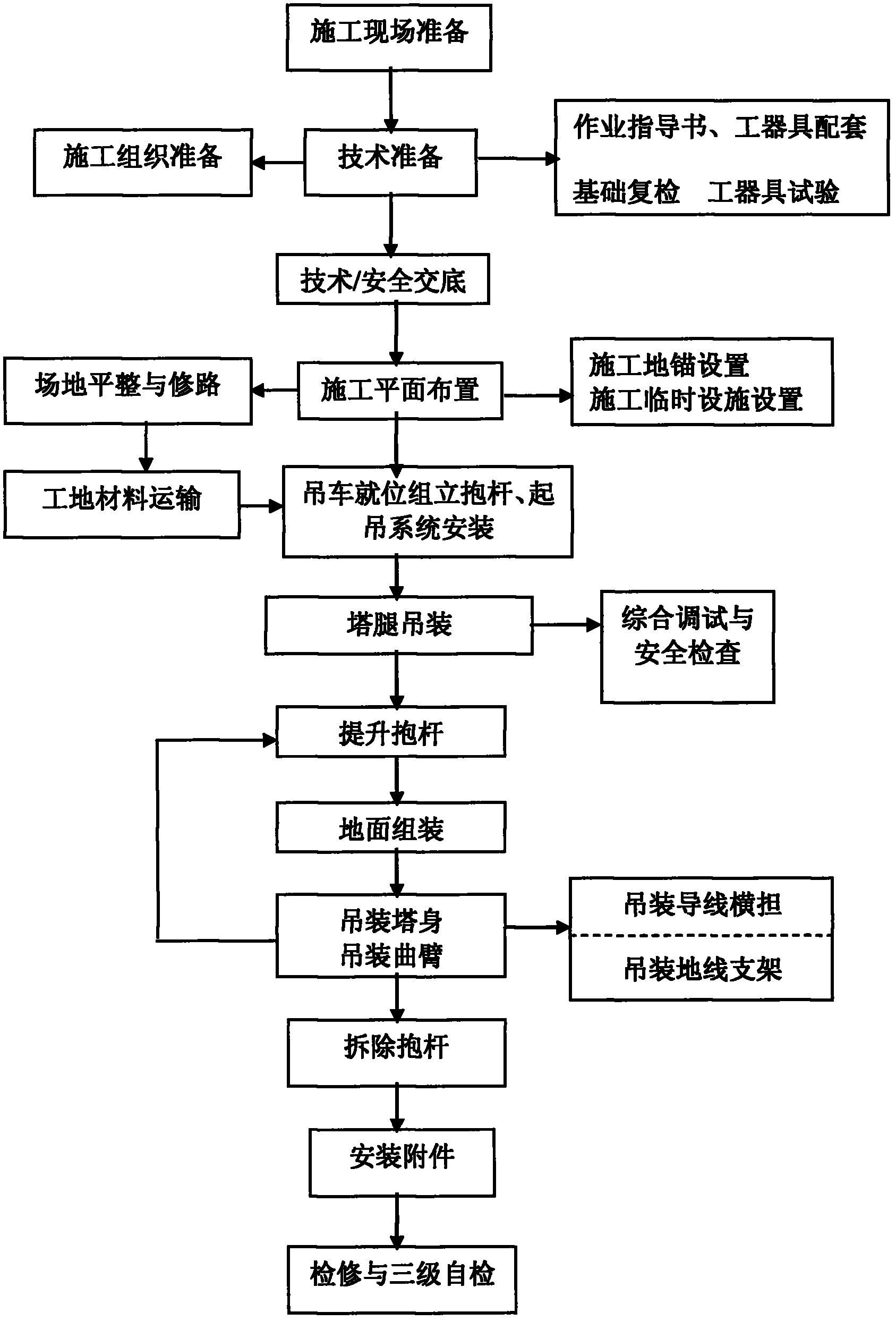

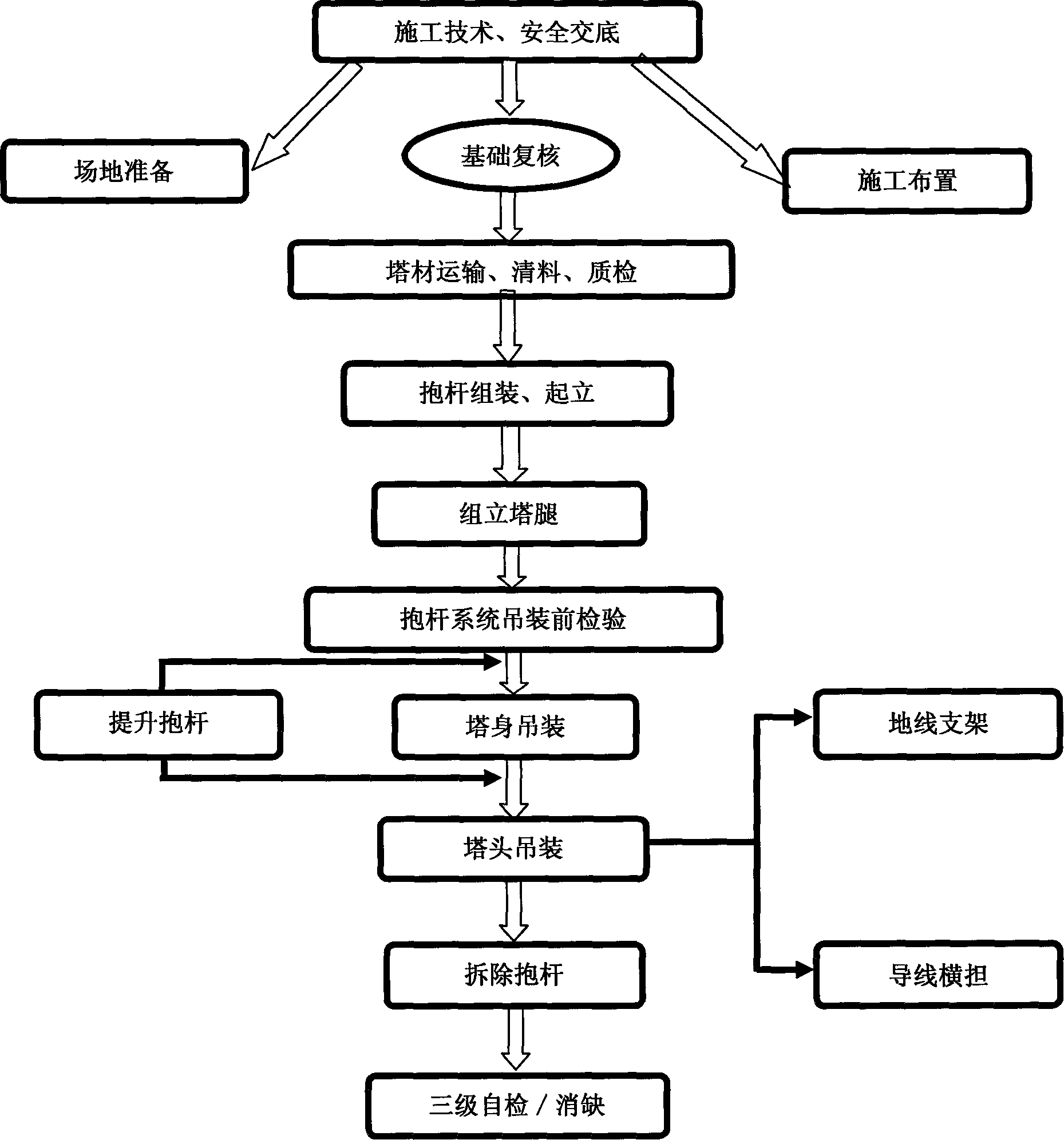

Extra-high voltage common circuit iron tower assembling method

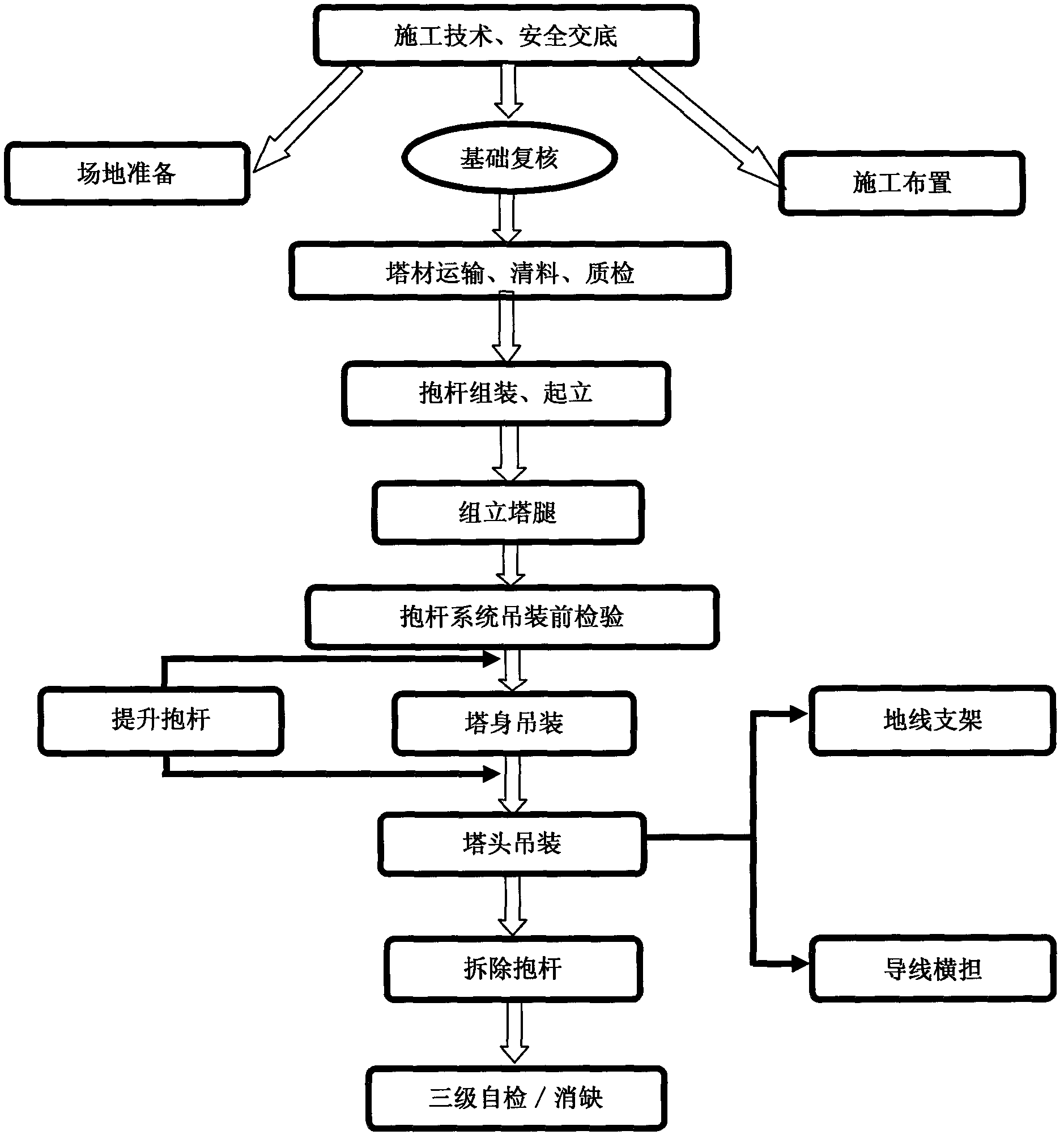

The invention discloses an extra-high voltage common circuit iron tower assembling method, which belongs to the technical field of electric transmission and transformation electric power circuit construction processes. The method comprises the following steps of: 1, performing construction preparation, namely cleaning a construction field, arranging the construction field, preparing a construction ground foundation, and transporting tower materials required by iron tower assembly; 2, assembling a pole, erecting the pole and assembling tower leg lower sections; 3, assembling and erecting towerlegs, lifting the pole, and hoisting iron tower crank arms; and 4, lifting the pole, hoisting a tower head, mounting a ground wire bracket, hoisting iron tower cross arms one by one in a segmentationmode, mounting iron tower accessories and disassembling the pole. The method has the advantages of reducing the working amount of aloft operation, along with a short construction period, a small number of hoisting times and high safety; by the method, safety risks are reduced, required aloft operation personnel is greatly reduced, and labor cost is reduced; and the method has extremely good economic and social benefits.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

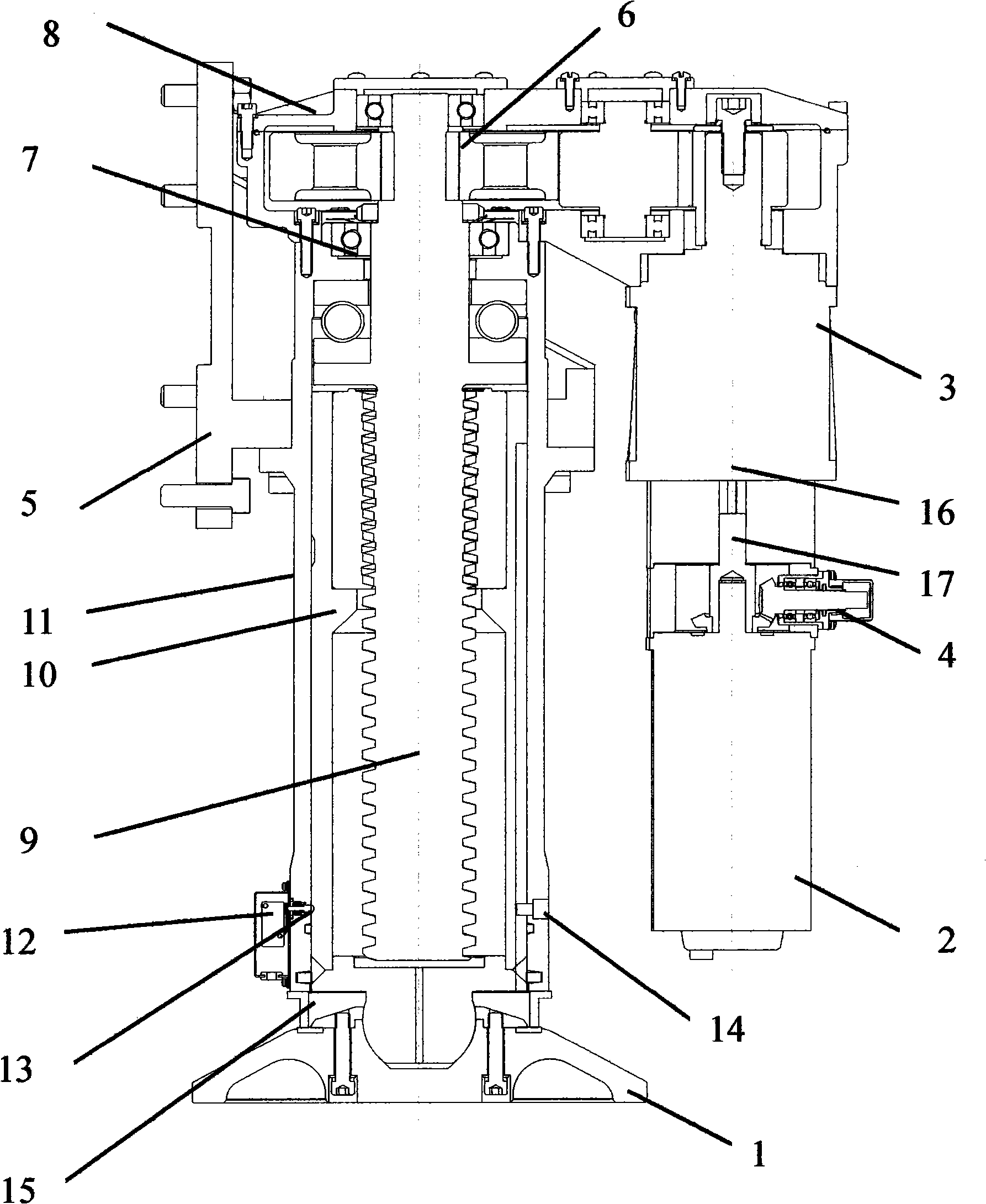

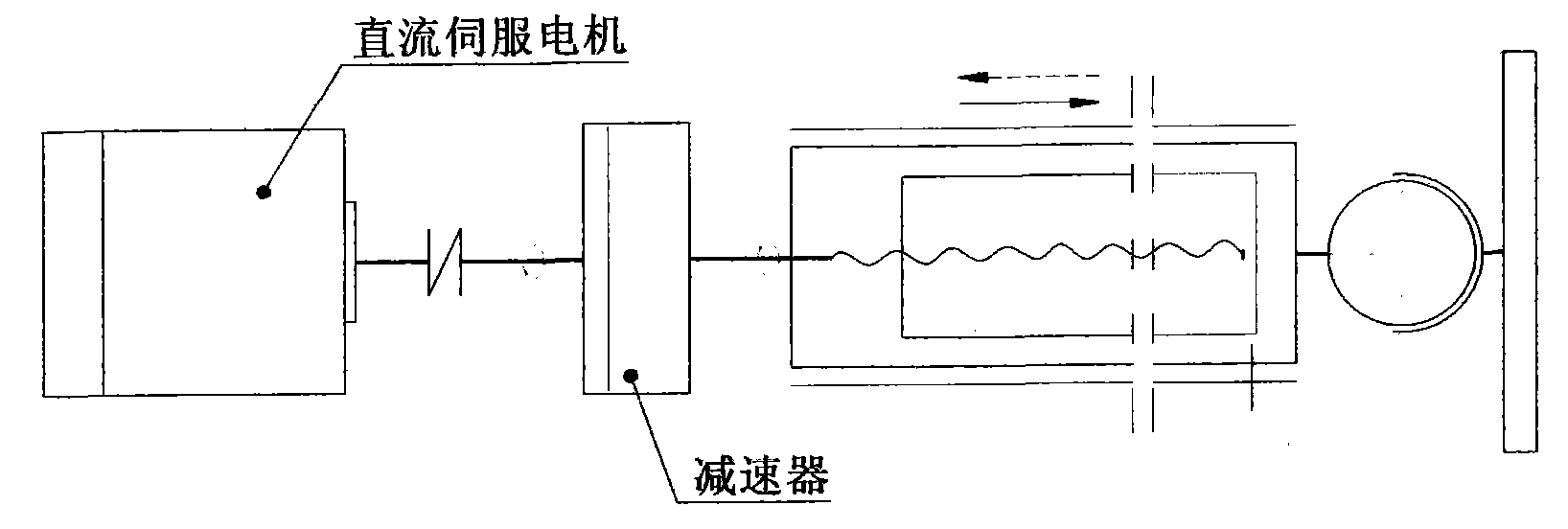

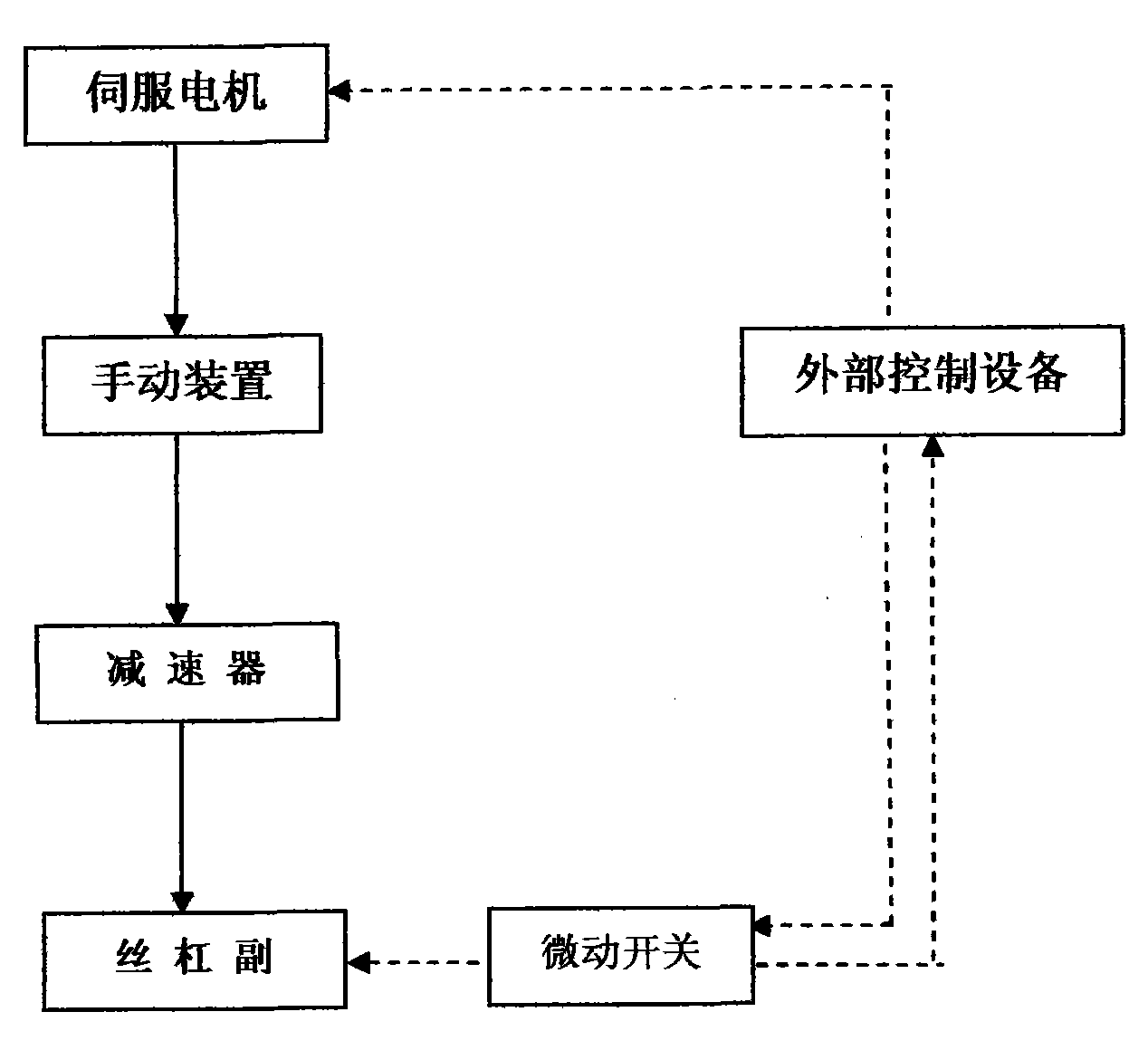

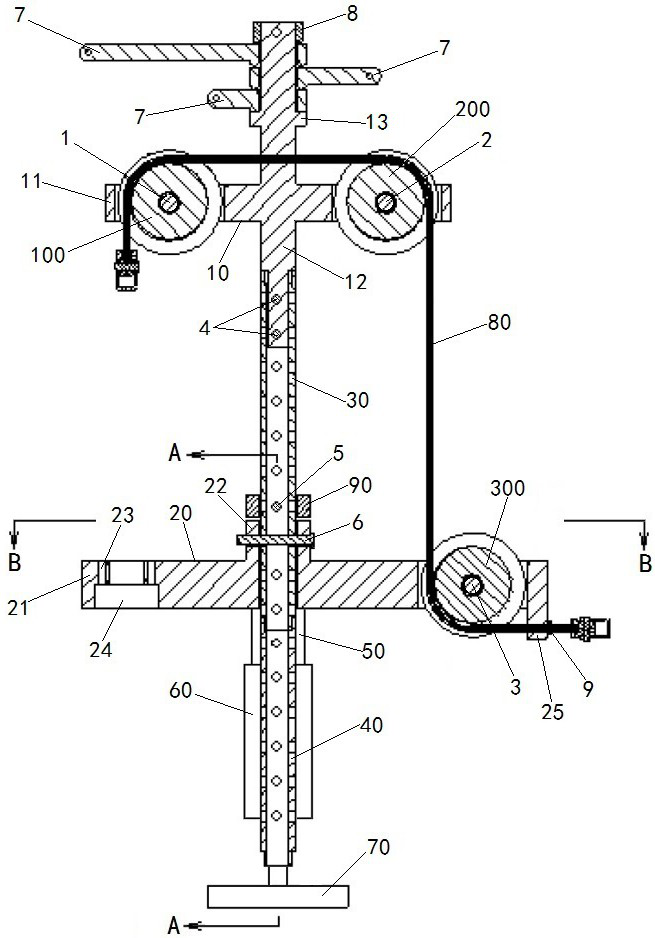

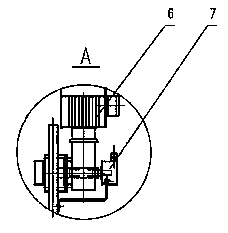

Electric automatic levelling brace

InactiveCN101561071ASmall footprintTouchdown fastStands/trestlesControl using feedbackReduction driveClosed loop

The invention relates to an electric automatic levelling brace for realizing multipoint electric automatic levelling, and aims to provide an electric automatic levelling brace with large lifting weight, rapid and reliable touchdown, good repeatability of levelling precision, high precision, safety, convenience, convenient maintenance and simple electric connection. The electric automatic levelling brace comprises a levelling bearing disc connected with a levelling brace cylinder body and a direct current servo motor with an electric control unit. The top of the levelling brace cylinder body is provided with a transmission chain which is connected with an output shaft of a speed reducer and a leading screw pair for rotary motion; the leading screw pair drives a levelling telescopic cylinder body manufactured with a screw and the levelling bearing disc fixedly connected with the leading screw pair together to do linear lifting motion; a microswitch for feeding back the lifting position to an external control system is arranged on the cylinder wall of the levelling brace cylinder body; a small displacement triggering shaft records the moving position, triggers the microswitch at a triggering point and transfers an electrical signal of the lifting position of the levelling brace to the outside; and the small displacement triggering shaft is connected external control equipment through the microswitch and forms a closed loop levelling system with the servo motor connected with the speed reducer .

Owner:LINGBAYI ELECTRONICS GRP

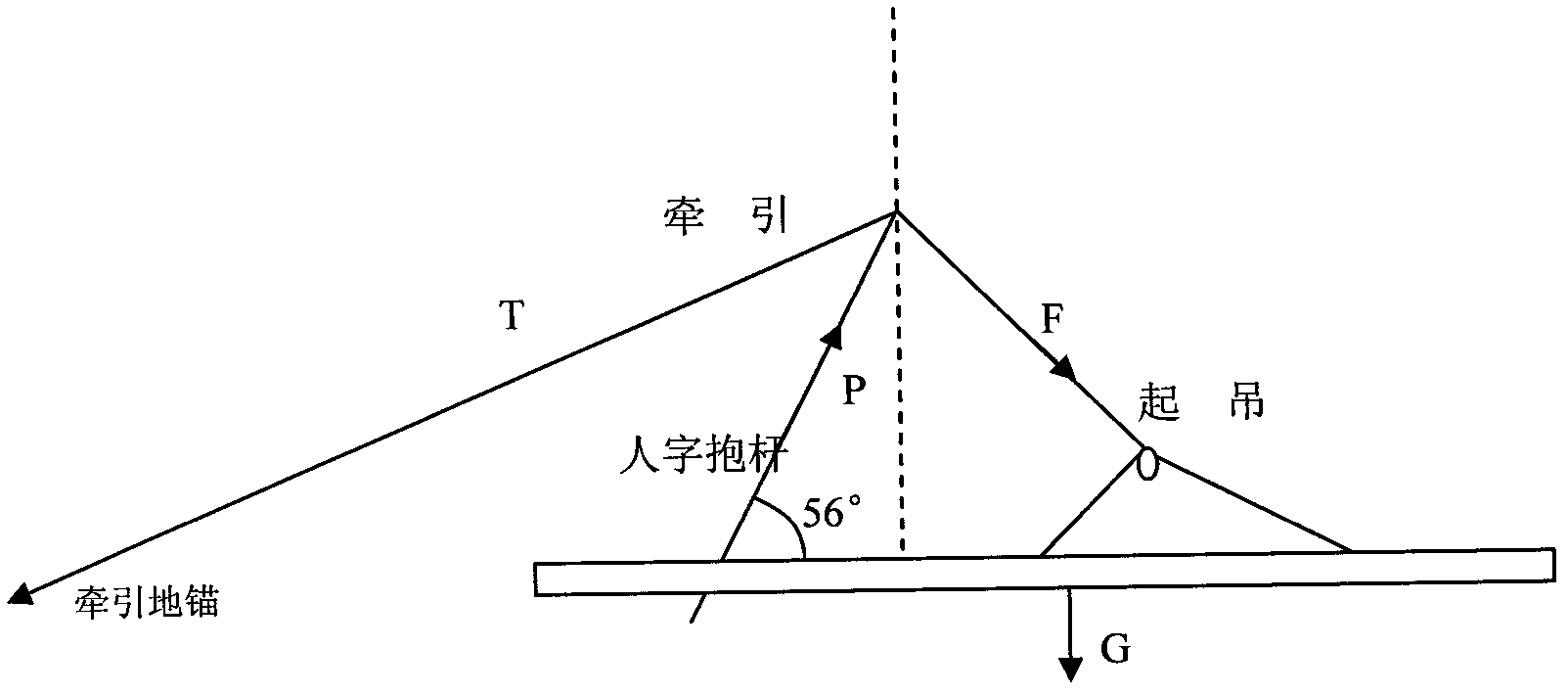

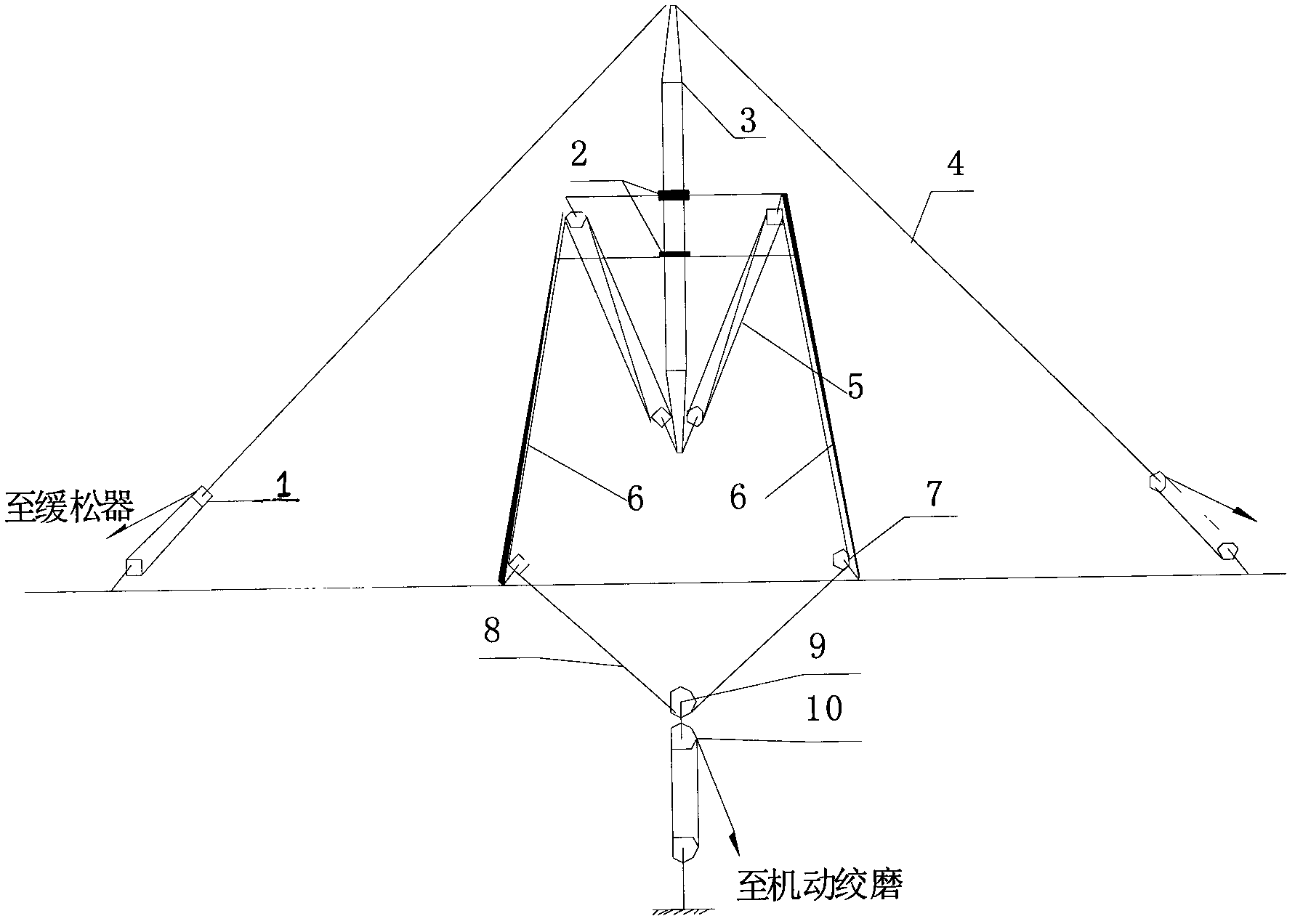

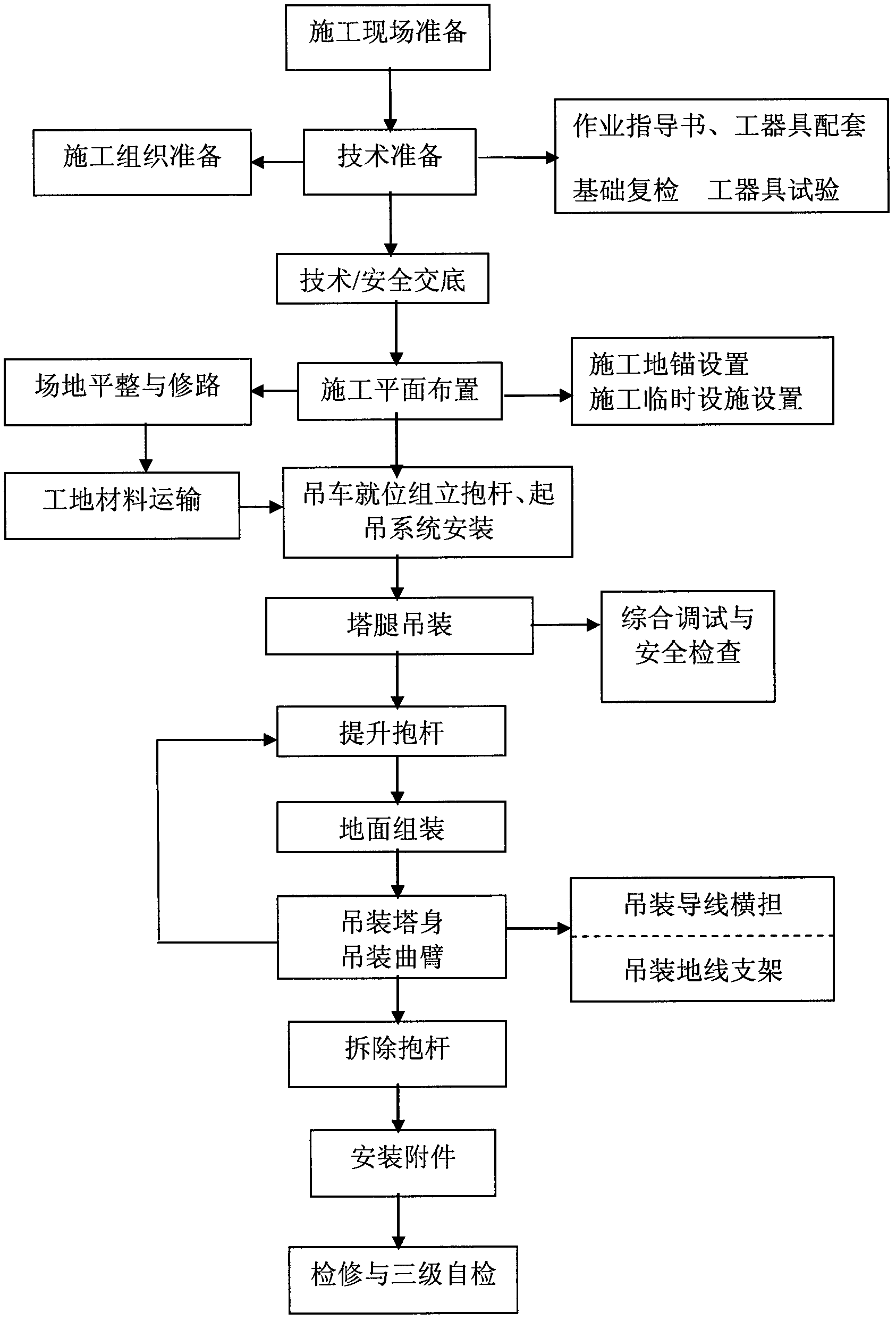

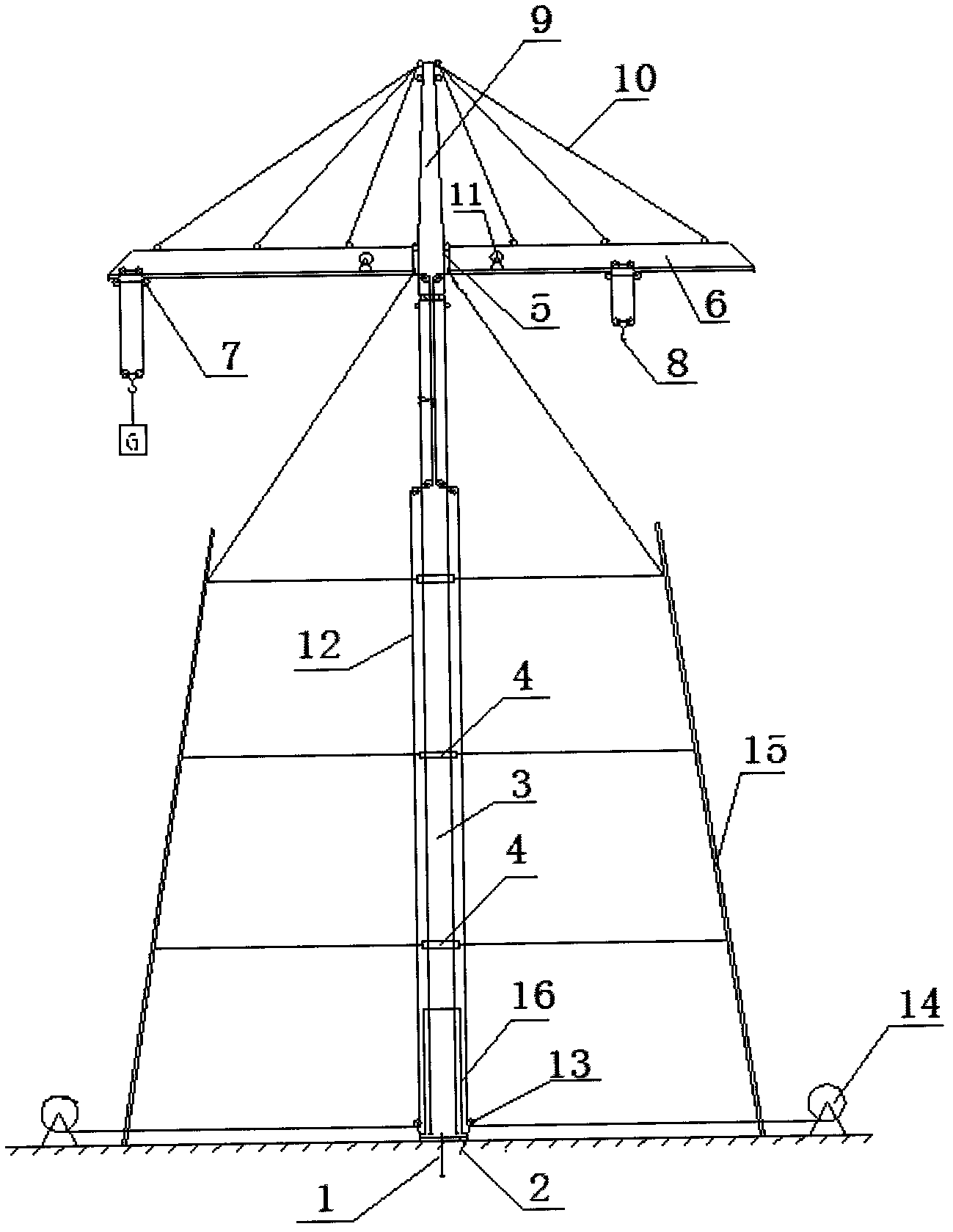

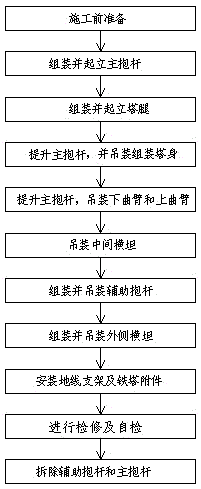

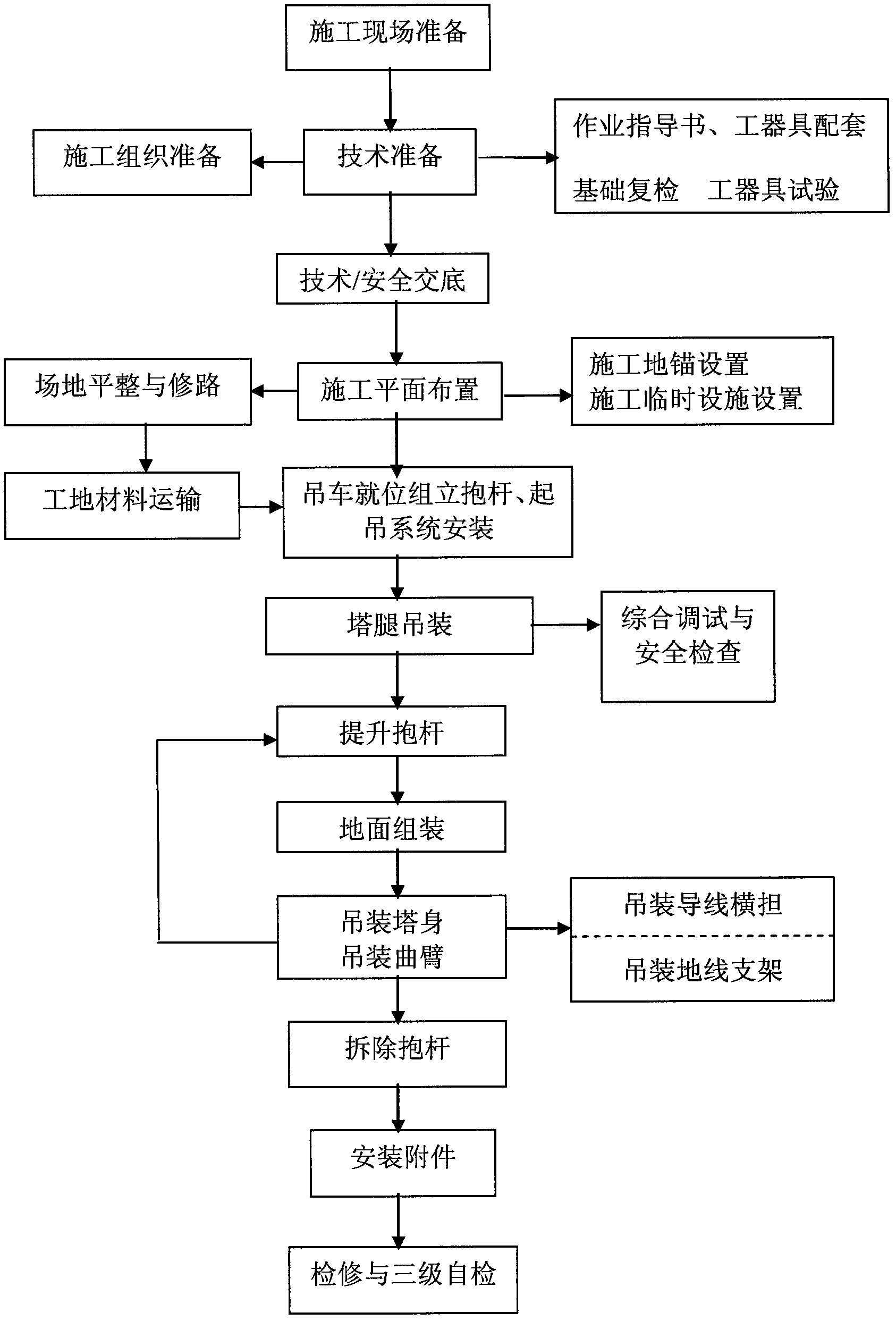

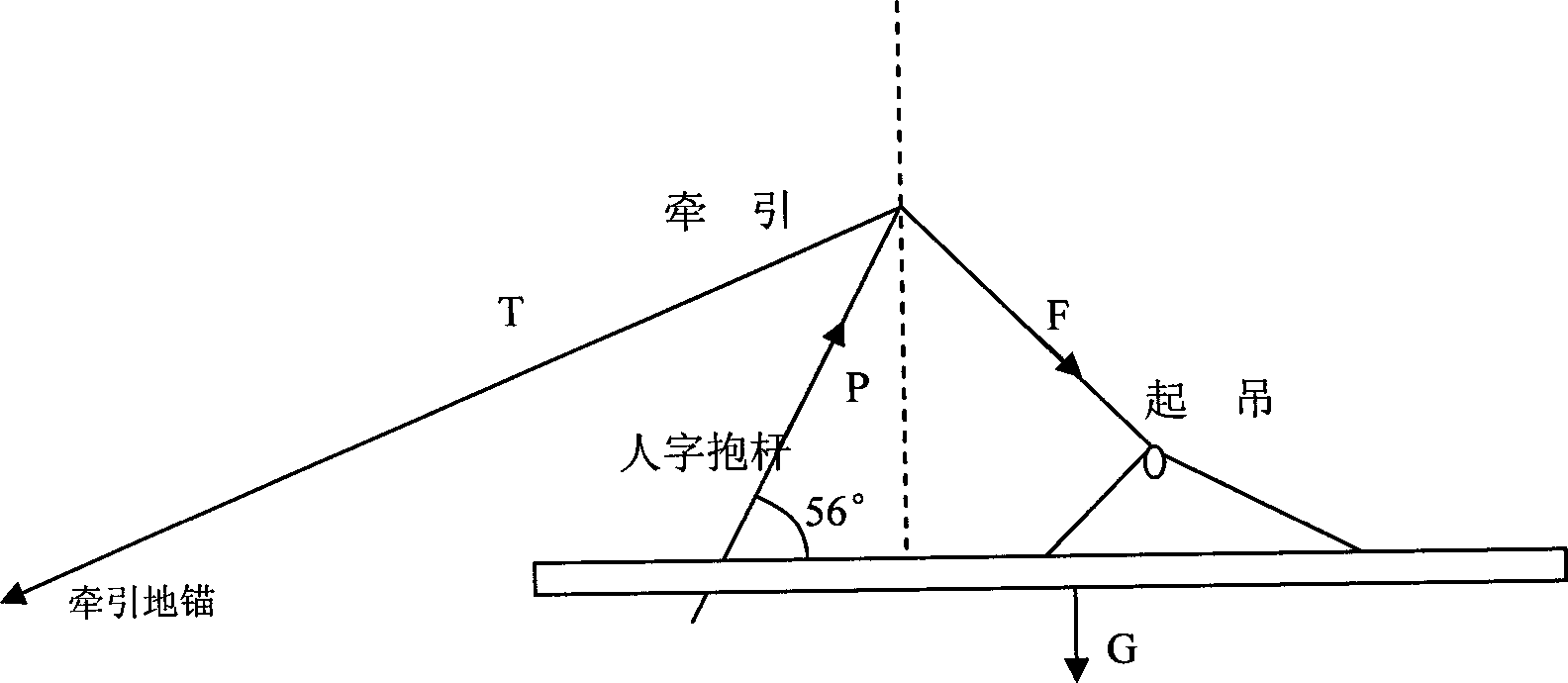

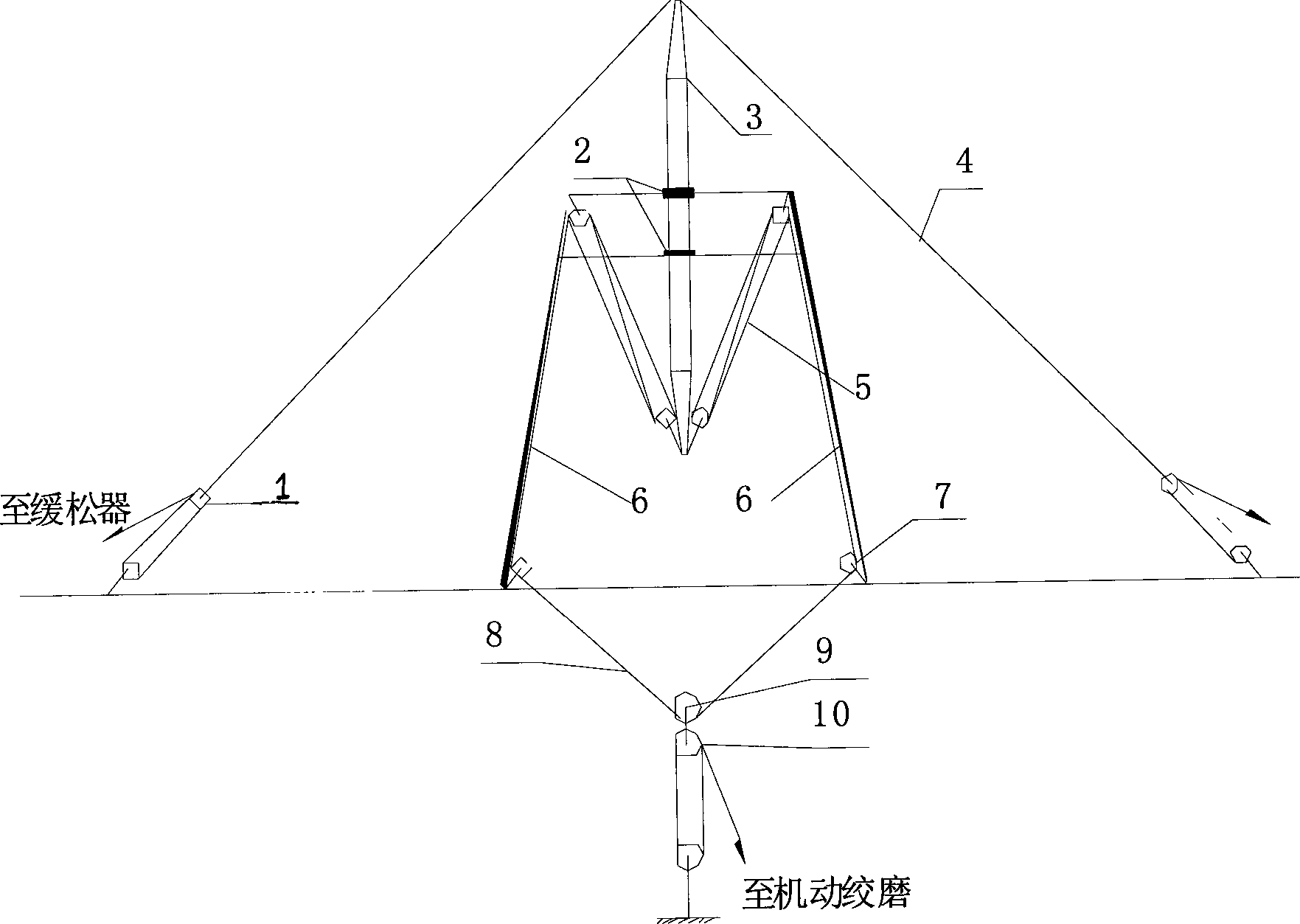

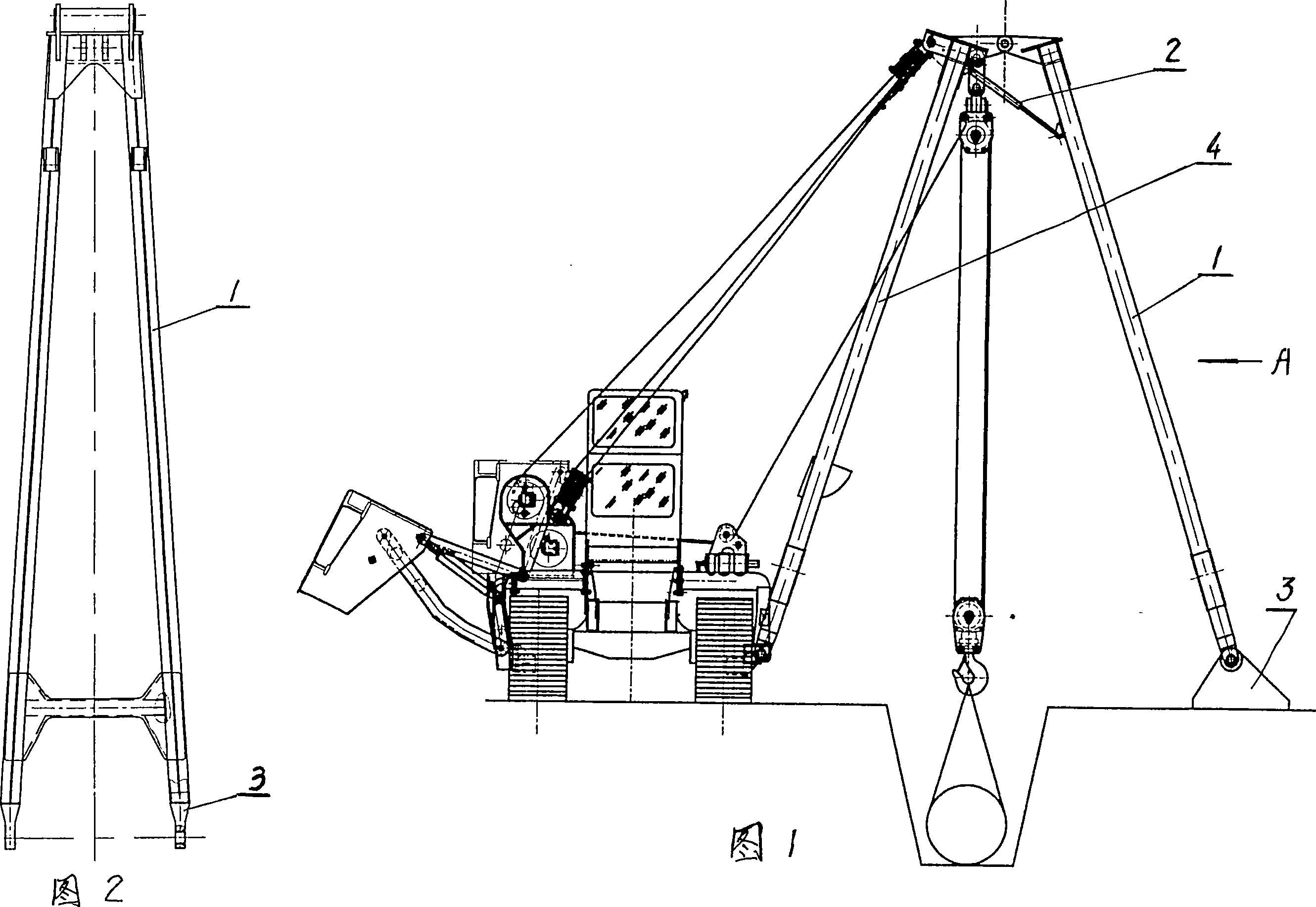

Extra-high voltage large-span iron tower assembling method

The invention discloses an extra-high voltage large-span iron tower assembling method, which belongs to the technical field of electric transmission and transformation electric power circuit construction processes. The method comprises the following steps of: 1, arranging a construction site, namely arranging a ground anchor, performing pole foundation construction, and arranging main material single pieces and tower sheets of an assembled iron tower body on the ground; 2, assembling a pole, mounting a hoisting system, and hoisting iron tower legs, wherein the assembled pole is a spinning self-elevating ground pole which is provided with horizontal double arms and a hydraulic downward jacking stock; 3, lifting the pole, hoisting the iron tower body section by section, and finally hoistingiron tower cross arms one by one in a segmentation mode; and 4, mounting iron tower accessories, disassembling the pole, and finally overhauling and self-checking to finish the construction. The method has the advantages of reducing the working amount of aloft operation, along with a short construction period, a small number of hoisting times and high safety; by the method, safety risks are reduced, required aloft operation personnel is greatly reduced, and labor cost is reduced; and the method has extremely good economic and social benefits.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

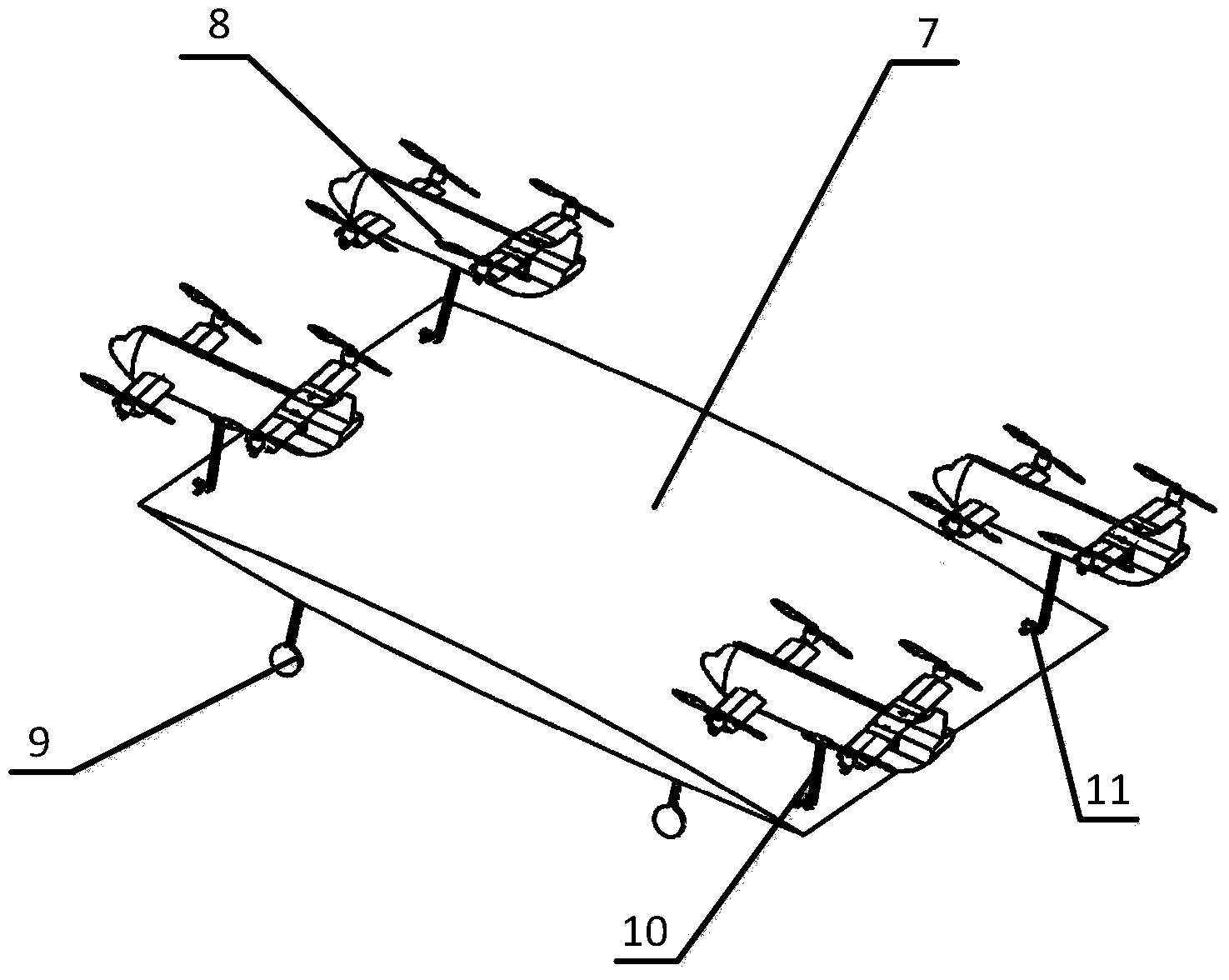

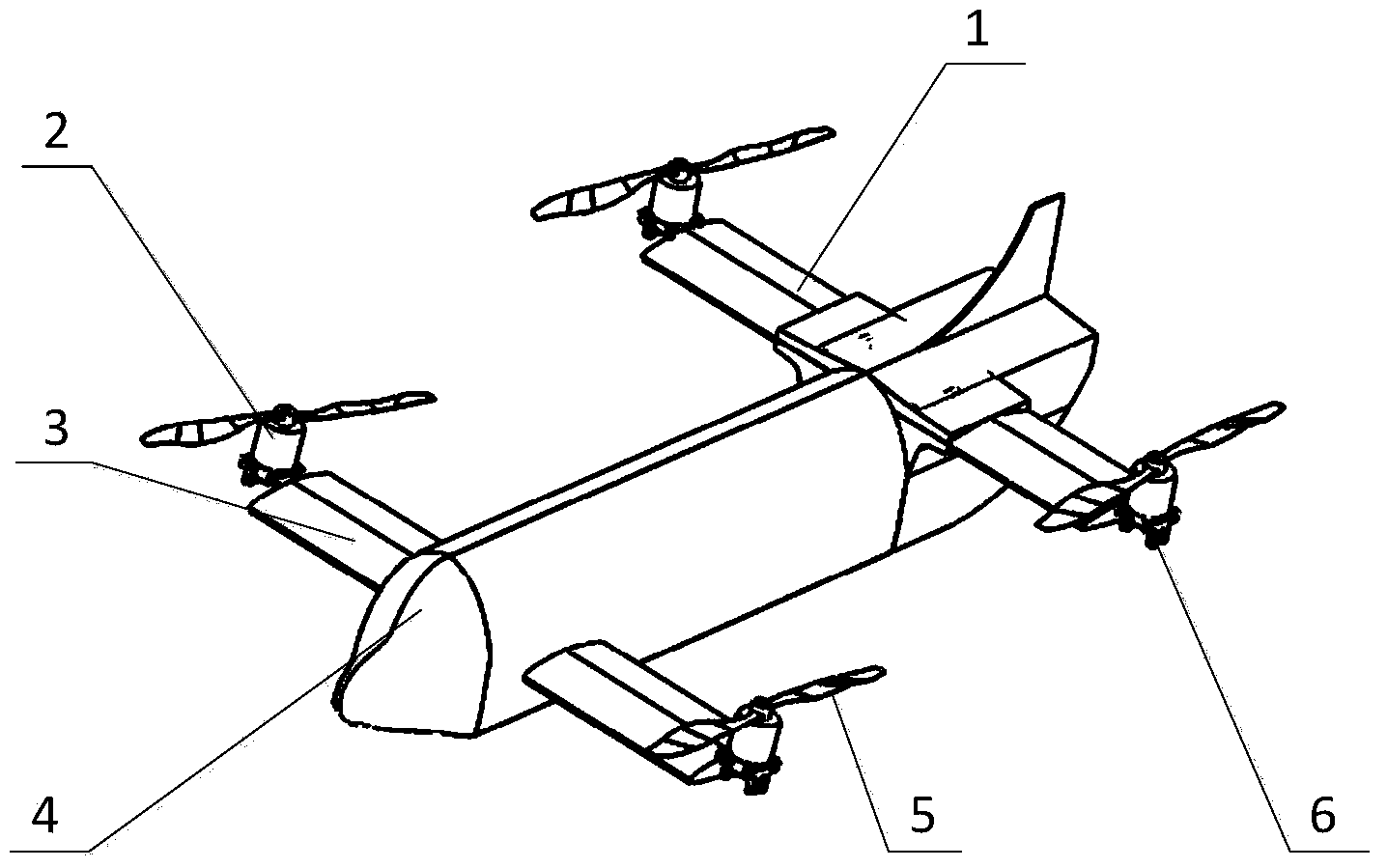

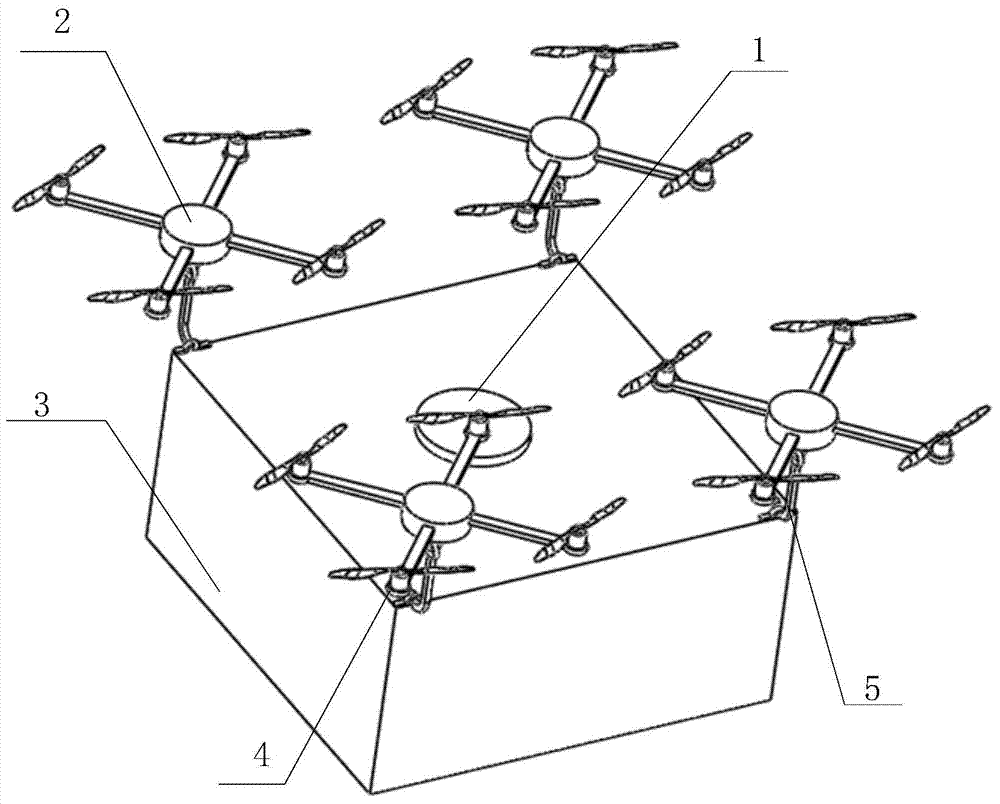

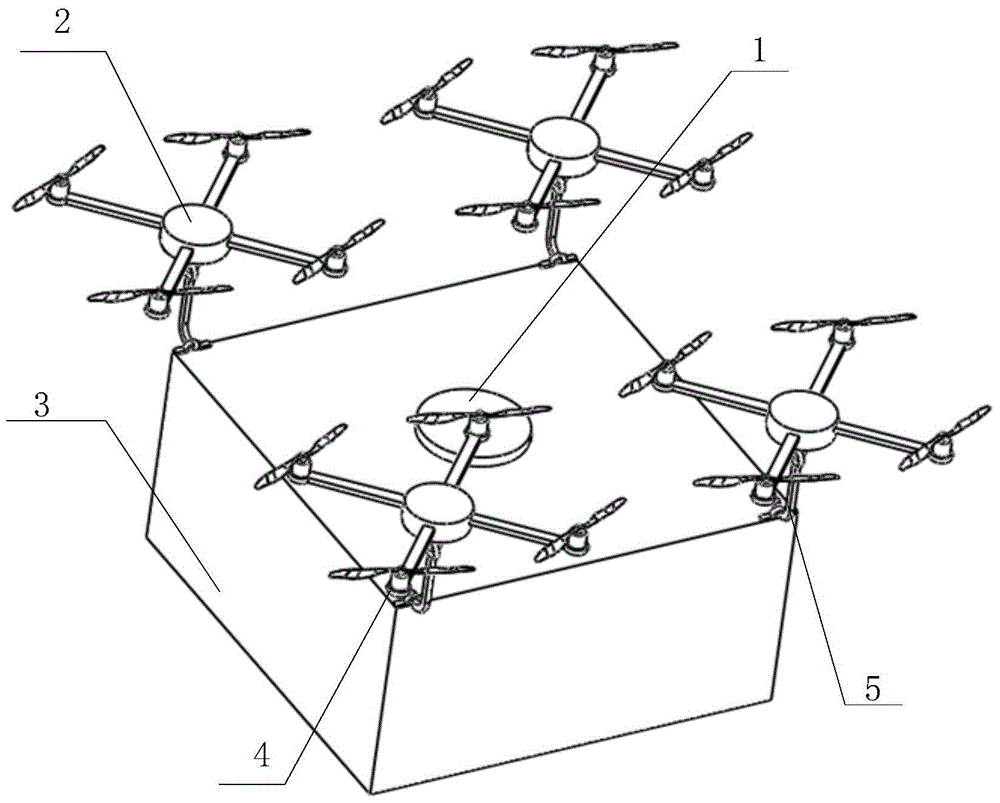

Tilted four-rotor aircraft cooperative lifting and transporting device

InactiveCN103935509AAchieve vertical takeoffIncrease or decrease quantityFreight handlingRotocraftEngineeringLifting weight

The invention provides a tilted four-rotor aircraft cooperative lifting and transporting device. The tilted four-rotor aircraft cooperative lifting and transporting device comprises a warehouse, a landing gear, lifting hooks, buckles and a plurality of tilted four-rotor aircrafts used as a power source, wherein the lifting hooks are arranged at the bottoms of the tilted four-rotor aircrafts used as the power source, the buckles are installed on the warehouse, and the lifting hooks are connected with the buckles. As the tilted four-rotor aircraft cooperative lifting and transporting device provided by the invention adopts the tilted four-rotor aircrafts, the cooperative lifting and transporting device has two take-off modes, namely the vertical take-off of the lifting and transporting device is realized through cooperative lifting of the plurality of tilted four-rotor aircrafts, and the tilted four-rotor aircrafts drive the warehouse to realize high-speed glide and take-off. The cooperative lifting and transporting device provided by the invention adopts the tilted four-rotor aircrafts as the power source for lifting equipment so as to overcome the difficulty of high-altitude lifting, and by utilizing the plurality of aircrafts for cooperative lifting, the lifting weight can be increased, and the number of the aircrafts can be increased or decreased according to the change of the lifting weight, so that the cooperative lifting and transporting device has certain flexibility; in addition, the cooperative lifting and transporting device has the advantages of heavy lifting weight, high flight speed and the like.

Owner:XI AN JIAOTONG UNIV

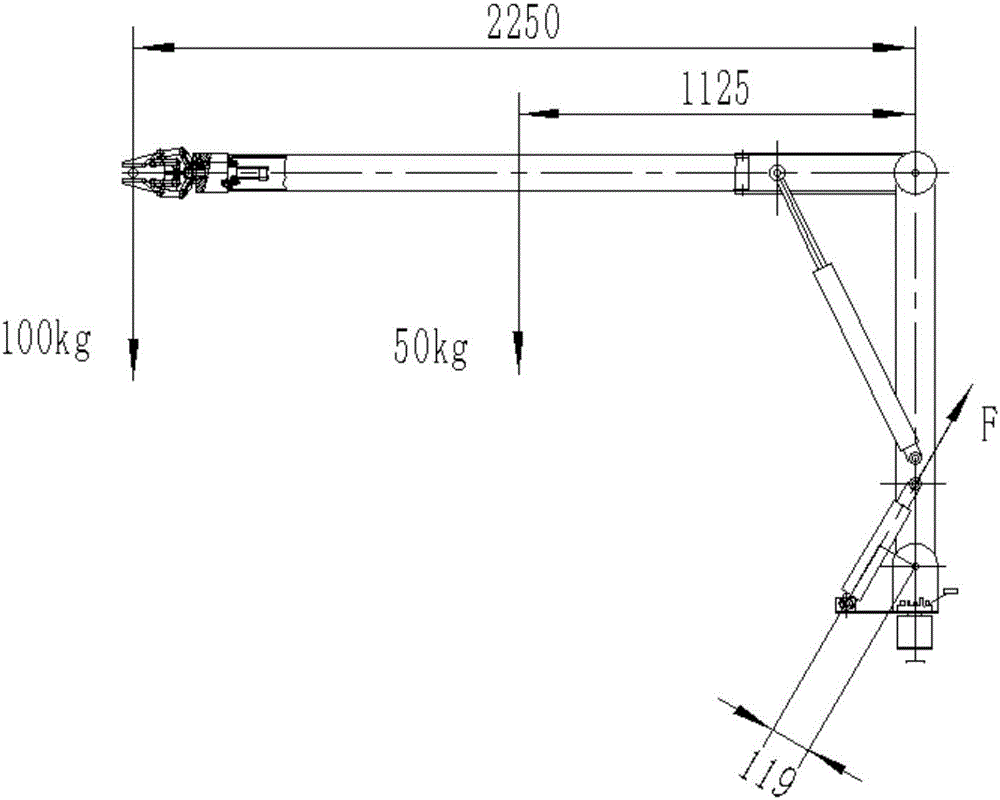

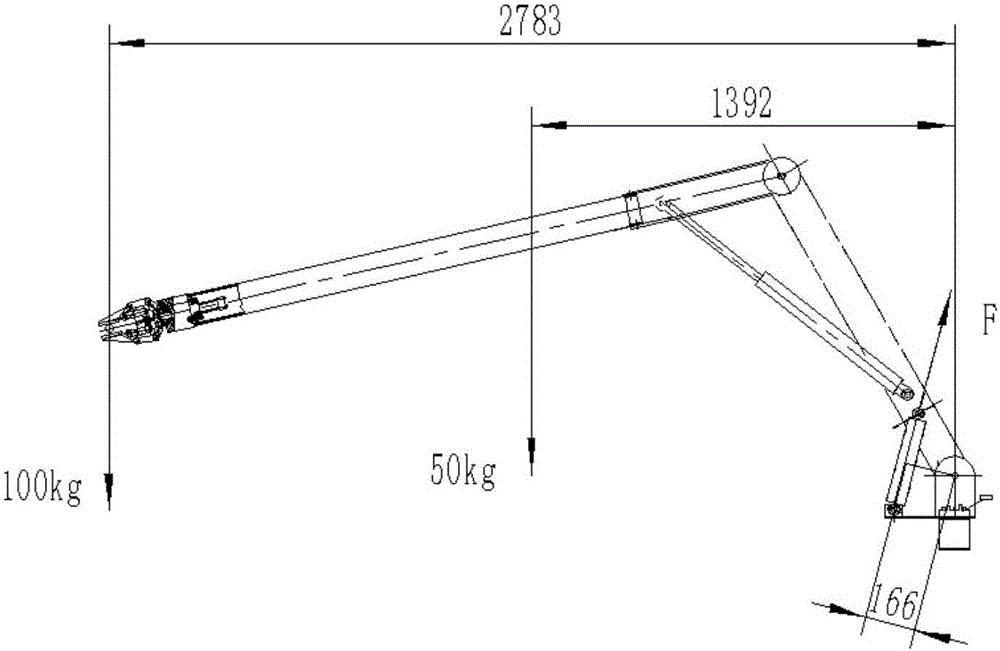

Auxiliary mechanical arm used for live working and robot

The invention discloses an auxiliary mechanical arm used for live working and a robot. The auxiliary mechanical arm comprises a base, a large arm, a front arm and a gripper. A hydraulic swing oil cylinder is arranged on the base and drives the large arm to rotate by 180 degrees in the horizontal plane. A pitching oil cylinder I driving the large arm to do pitching motion is hinged to the large arm. The front arm perpendicular to the tail end of the large arm is hinged to the tail end of the large arm. The front arm is driven by a pitching oil cylinder II to do pitching motion. The gripper is installed at the tail end of the front arm. The front arm is made of insulating material glass fiber reinforced plastic and can conduct direct live working. The auxiliary mechanical arm comprises the gripper which can be freely opened and closed and can freely conduct grasping.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

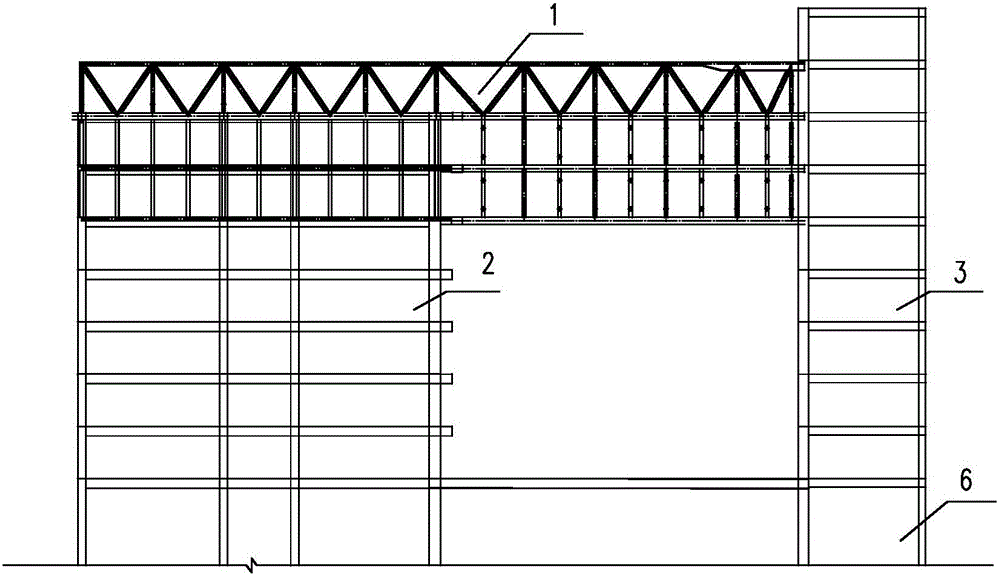

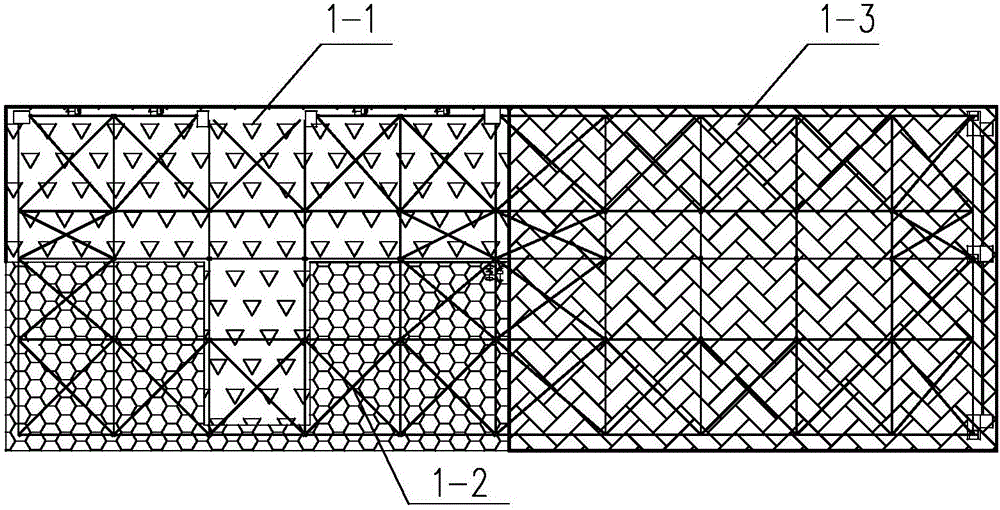

Construction method for long-span overhung specially-shaped limit exceeding structure steel corridor

ActiveCN106013419AStrong targetingSave man hoursBuilding material handlingArchitectural engineeringEngineering

The invention discloses a construction method for a long-span overhung specially-shaped limit exceeding structure steel corridor. The method includes the following steps that firstly, the steel corridor is divided into construction units, wherein the inner part of a corridor structure and middle strip blocks of an upper steel structure of a corridor overhung part are classified as the first construction unit, the remaining part of the corridor overhung part is classified as the second construction unit, and a corridor suspension part is classified as the third construction unit; secondly, a high-altitude bulk assembly method and a cantilever installation method are adopted for finishing construction of the first construction unit on a floor panel of a tower A; thirdly, construction of the second construction unit is finished through integral lifting; and fourthly, construction of the third construction unit is finished through sliding after integral lifting. The high-altitude bulk assembly technology, the integral lifting technology, the sliding after integral lifting technology and the like are applied, work hours are reduced, the material cost and equipment cost are saved, and the requirements for integral control over multiple aspects of the construction process, the quality, the safety, the schedule, the cost and the like are met.

Owner:中建六局第一建设有限公司 +1

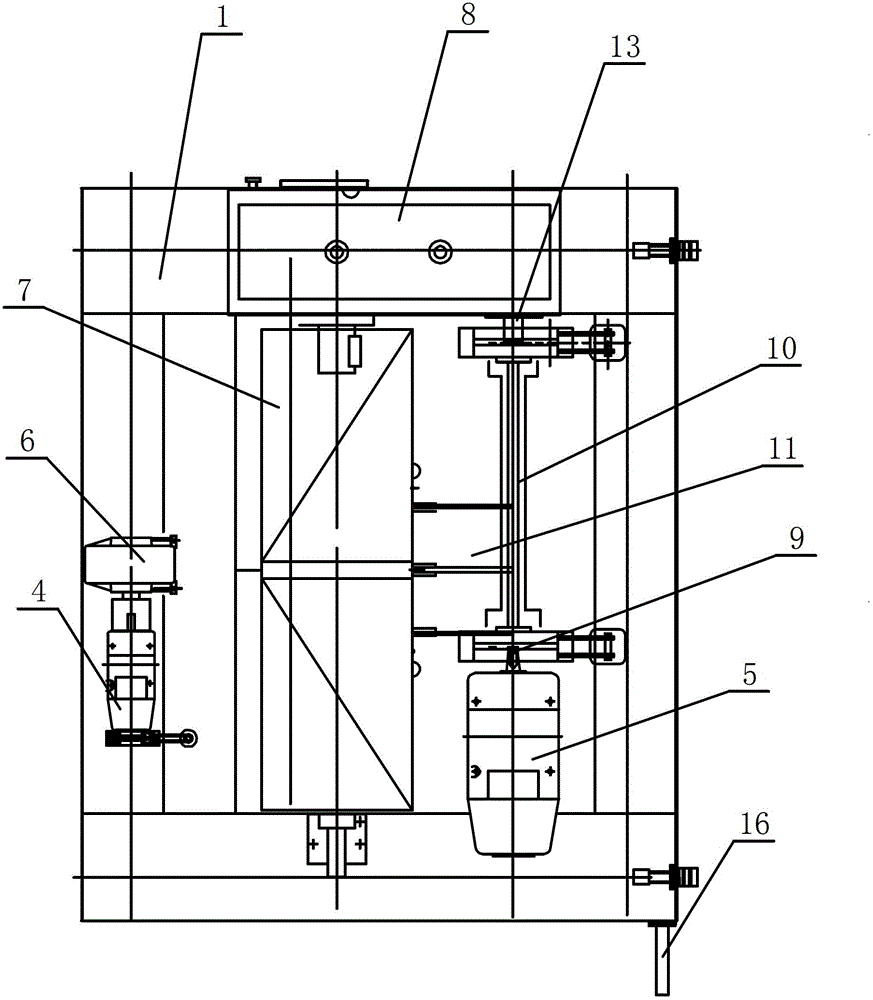

Crane trolley

The invention discloses a crane trolley, which relates to the technical field of crane machinery. The crane trolley comprises a trolley frame, wherein travelling wheels are arranged at the bottom of the trolley frame; an operating motor and an elevating motor are arranged on the trolley frame; the operating motor is connected with a speed reducer to drive the travelling wheels to move; a winding drum is arranged on the trolley frame in a position on one side of the elevating motor; the winding drum is connected with an elevating speed reducer; the elevating speed reducer and the elevating motor are connected with each other through a coupling and a transmission shaft; a fixed pulley block is arranged on the transmission shaft; the fixed pulley block is connected with a hoisting hook through a steel wire; and the elevating speed reducer is provided with a brake. The crane trolley has the advantages of large hoisting weight, small size, wide application range and safety and reliability in running.

Owner:WUXI XIEXING PORT MACHINERY

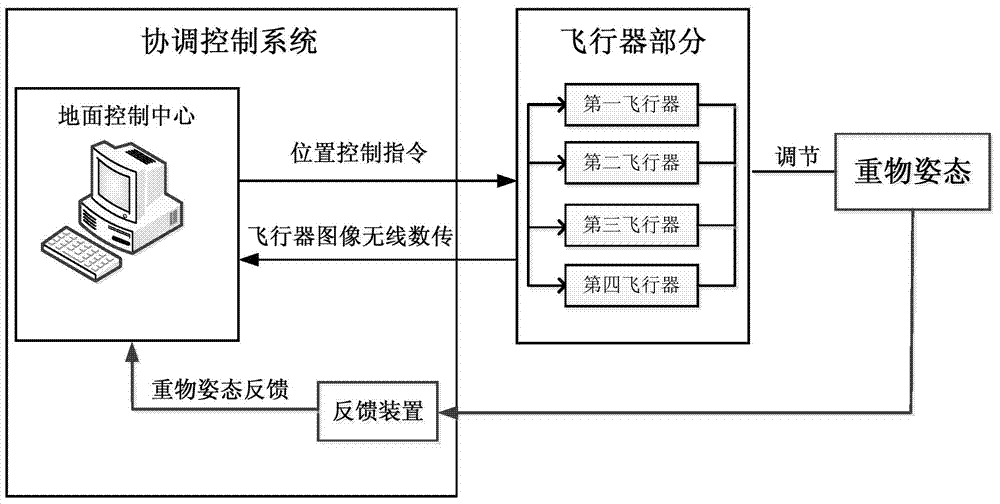

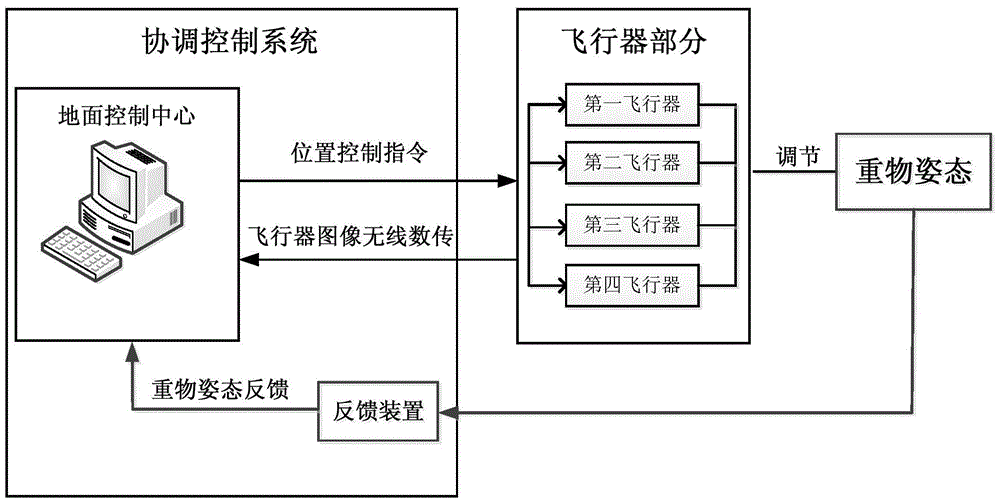

Multi-aircraft hoisting coordinated control system

ActiveCN103699133AEasy to operateStable hoistingPosition/course control in three dimensionsFlight heightControl system

The invention discloses a multi-aircraft hoisting coordinated control system, which comprises a ground control center and a feedback device, wherein the ground control enter is used for controlling a plurality of aircrafts; the feedback device is used for measuring the current attitude information, the current acceleration and the current flight height information of a weight; each aircraft is provided with an on-board controller; the feedback device is arranged on the weight hoisted by the aircrafts; an inertial attitude measuring unit and a height sensor are integrated in the feedback device; measured information is sent to the ground control center by the feedback device; real-time control signals are sent to all the aircrafts by the ground control center after being optimized and distributed; attitude adjustment is performed on the aircrafts according to the received control signals, so that the weight is kept stable all along. The coordinated control system disclosed by the invention does not stick to the species of the aircrafts; as long as the control port protocol of the ground control center is met, a user can freely select the types of the aircrafts. The multi-aircraft hoisting coordinated control system disclosed by the invention has the advantages that the application range is broad; the operation is simple; the stability during a hoisting process is realized.

Owner:XI AN JIAOTONG UNIV

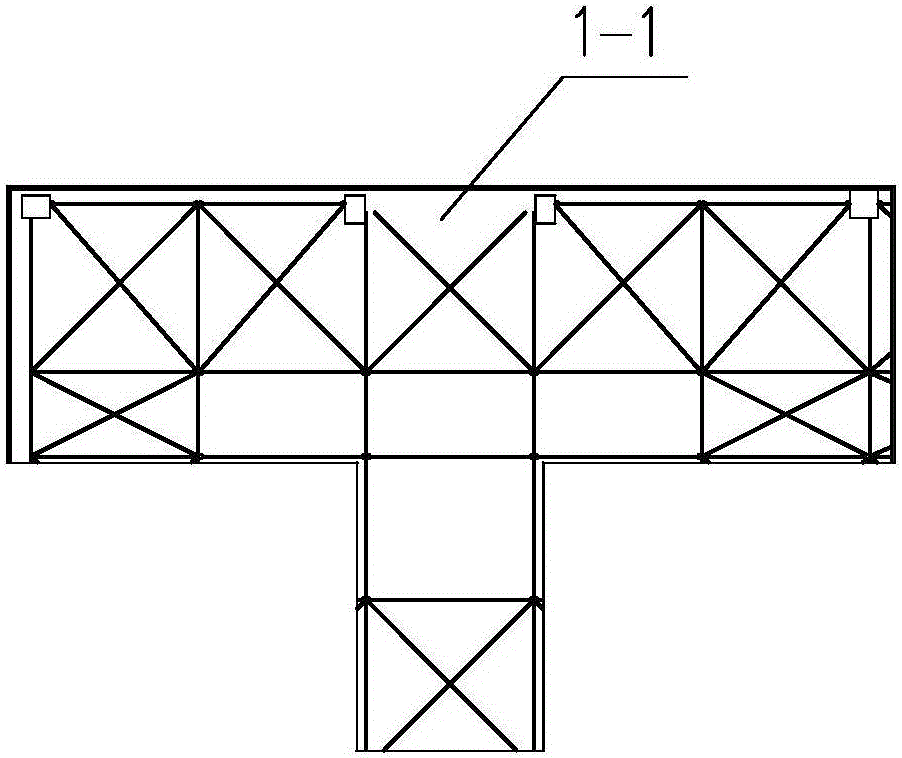

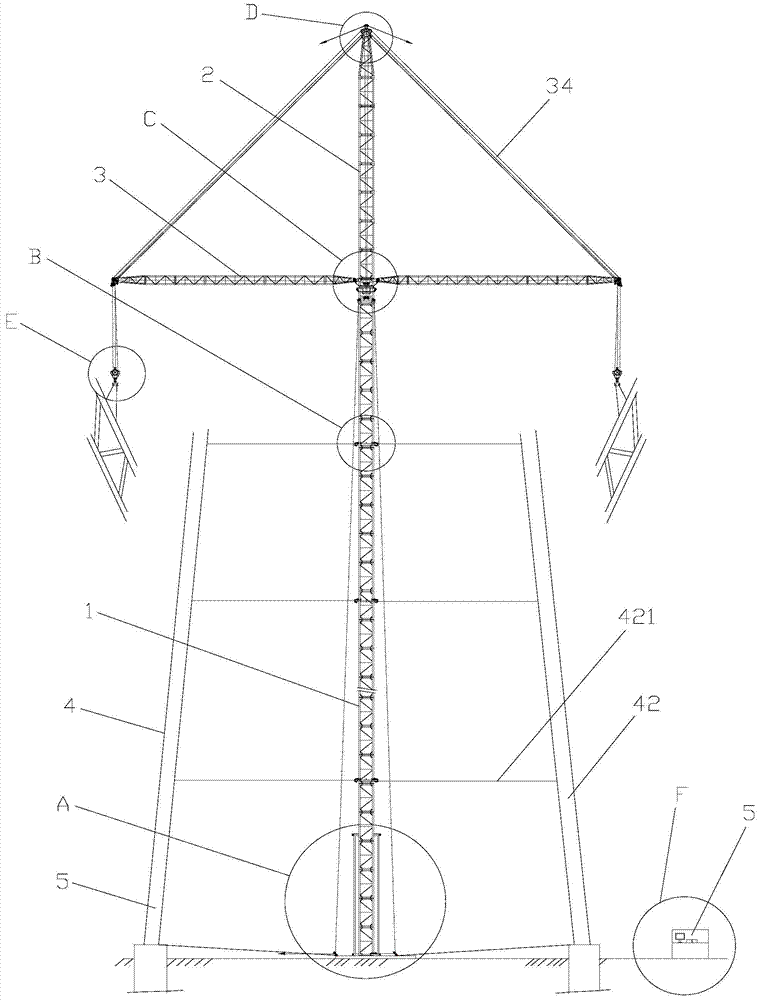

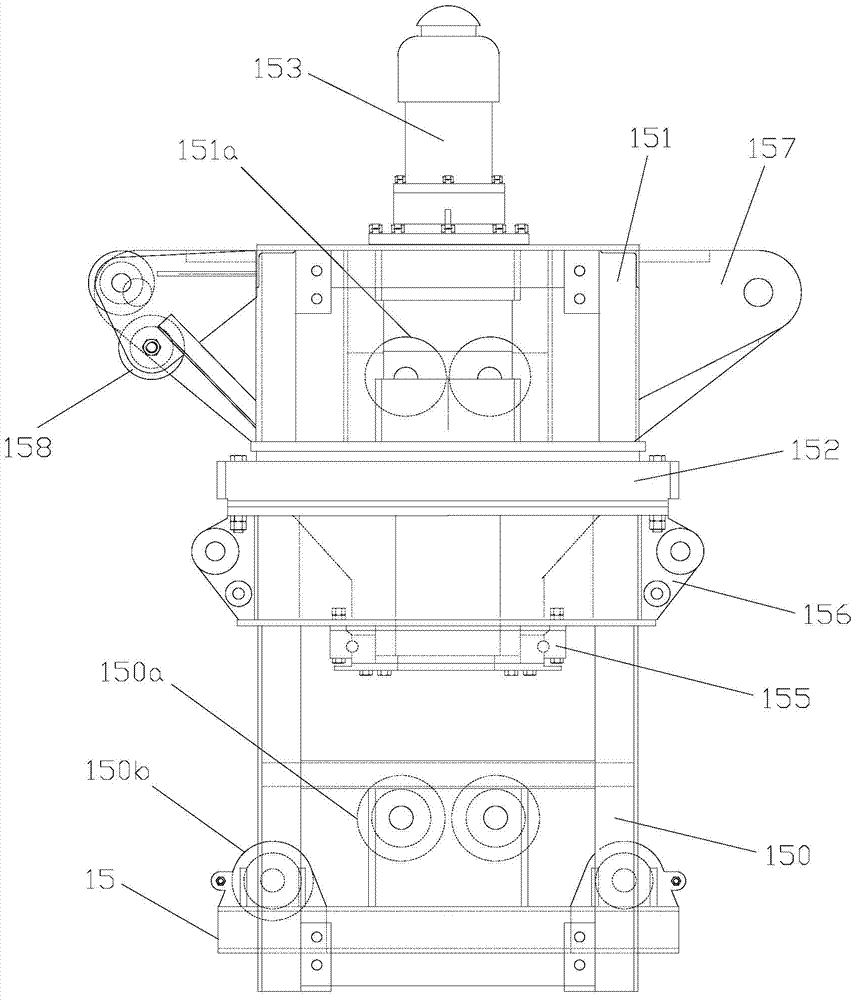

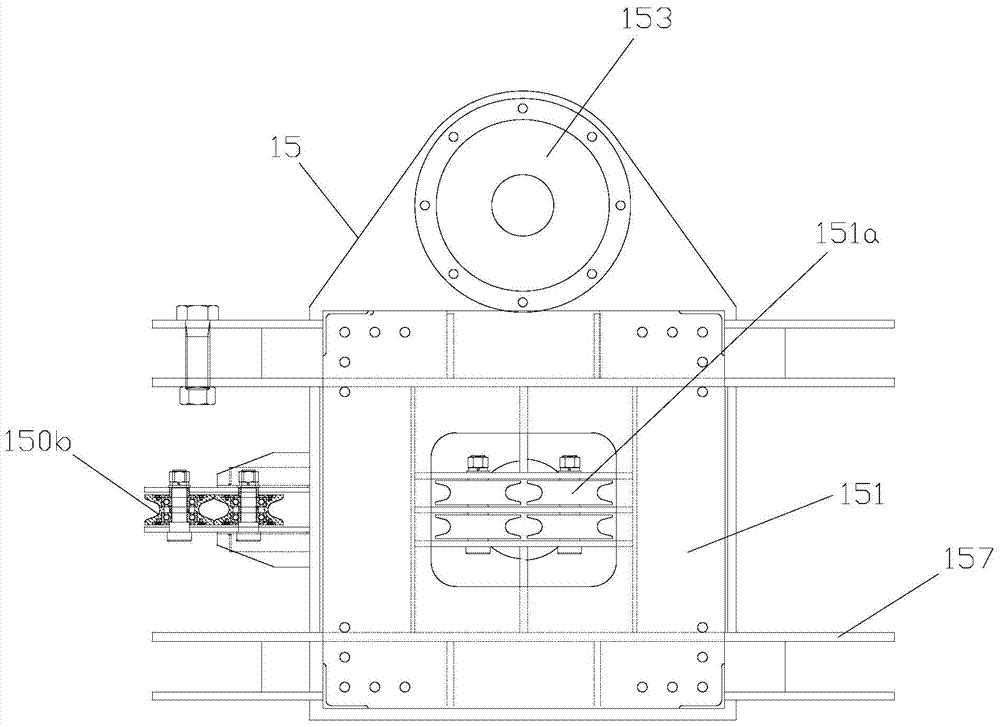

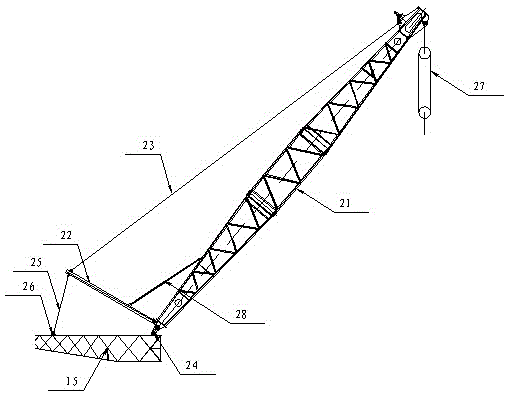

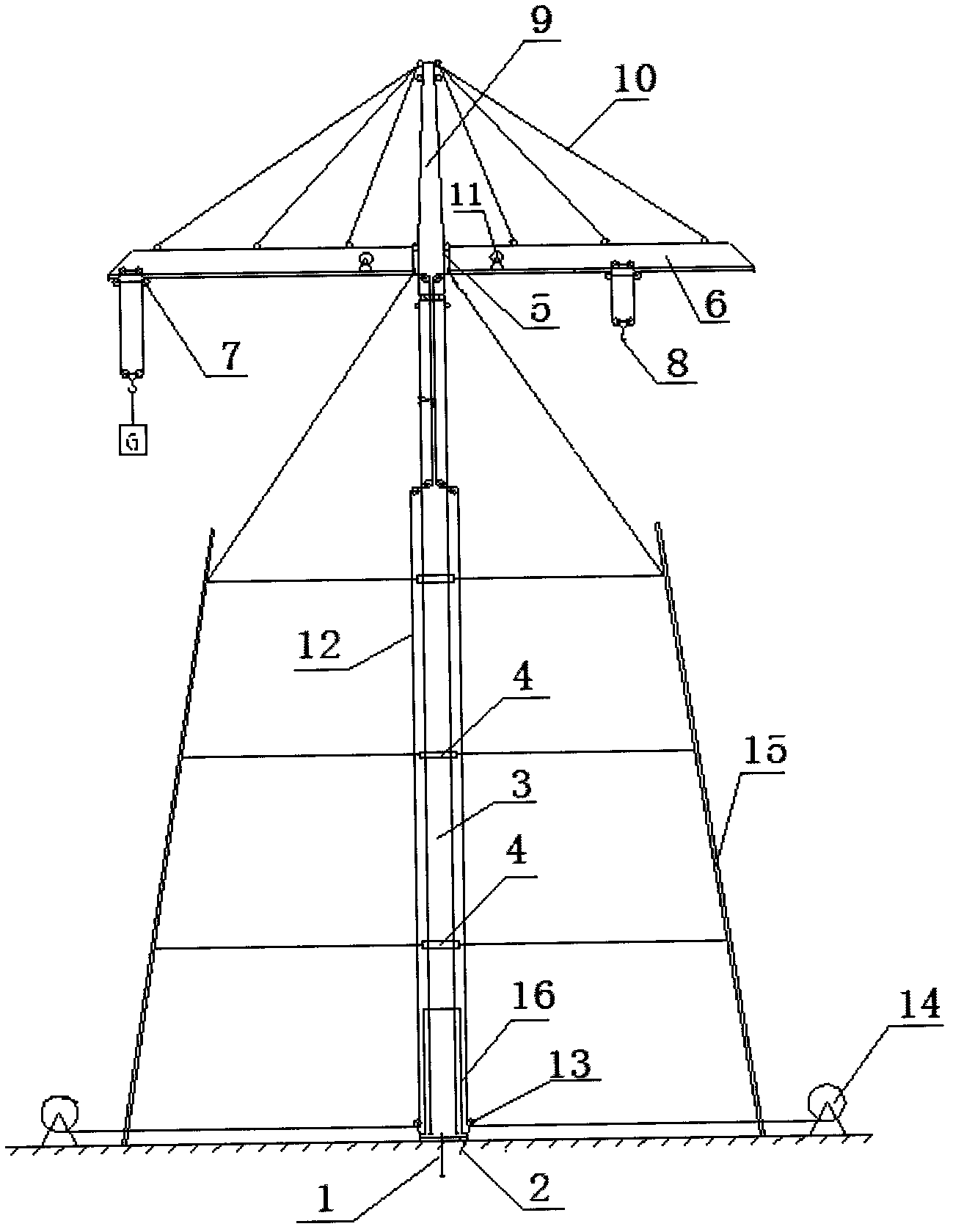

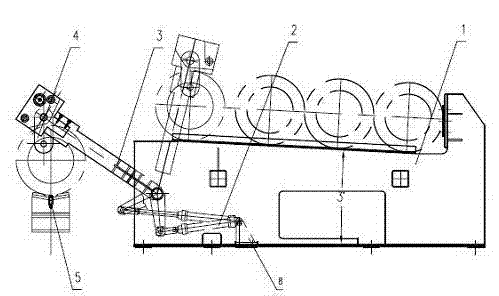

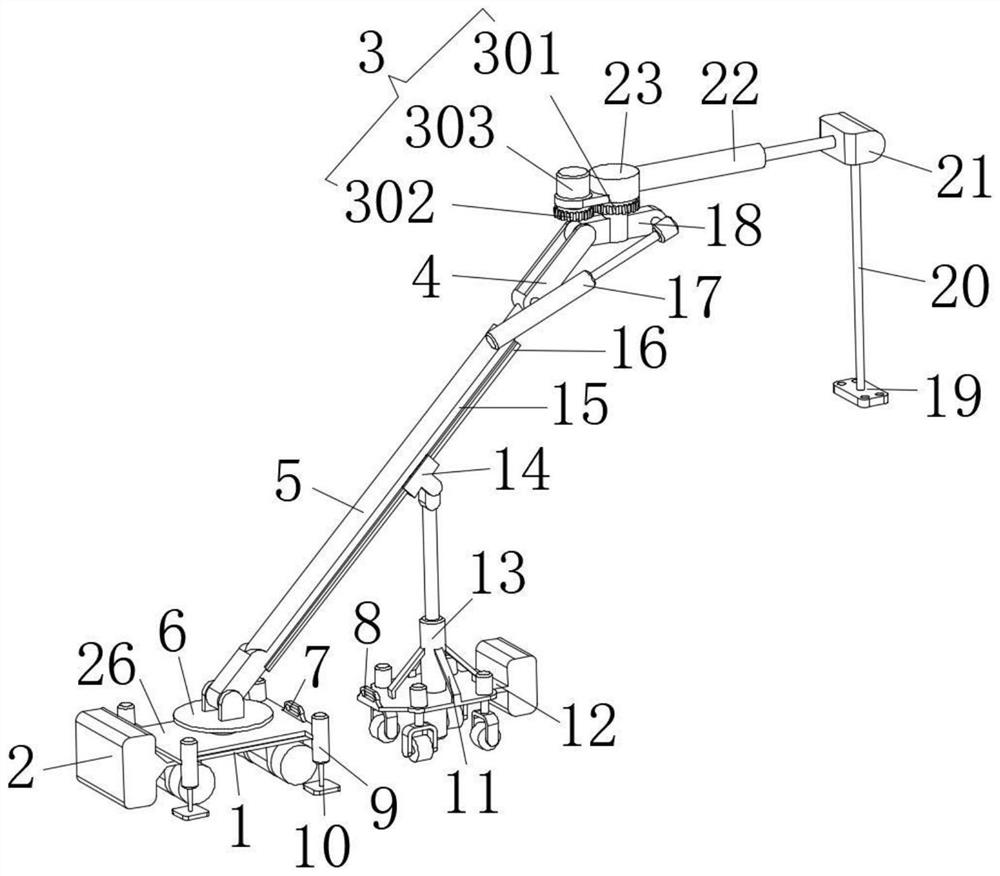

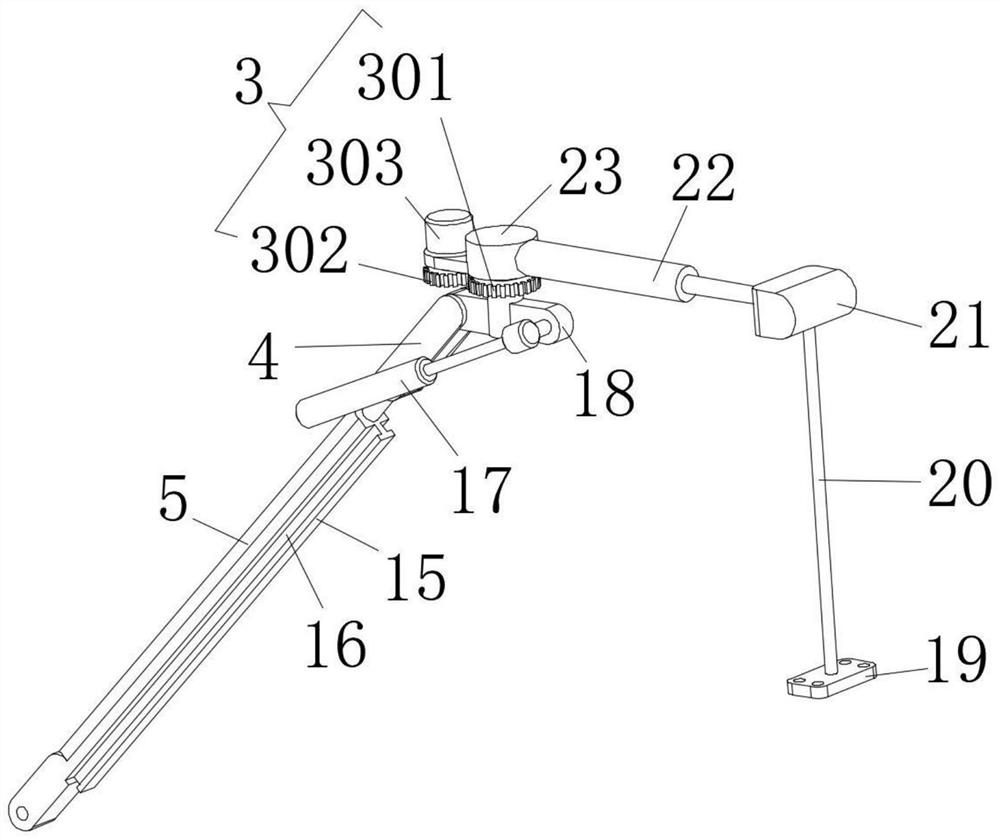

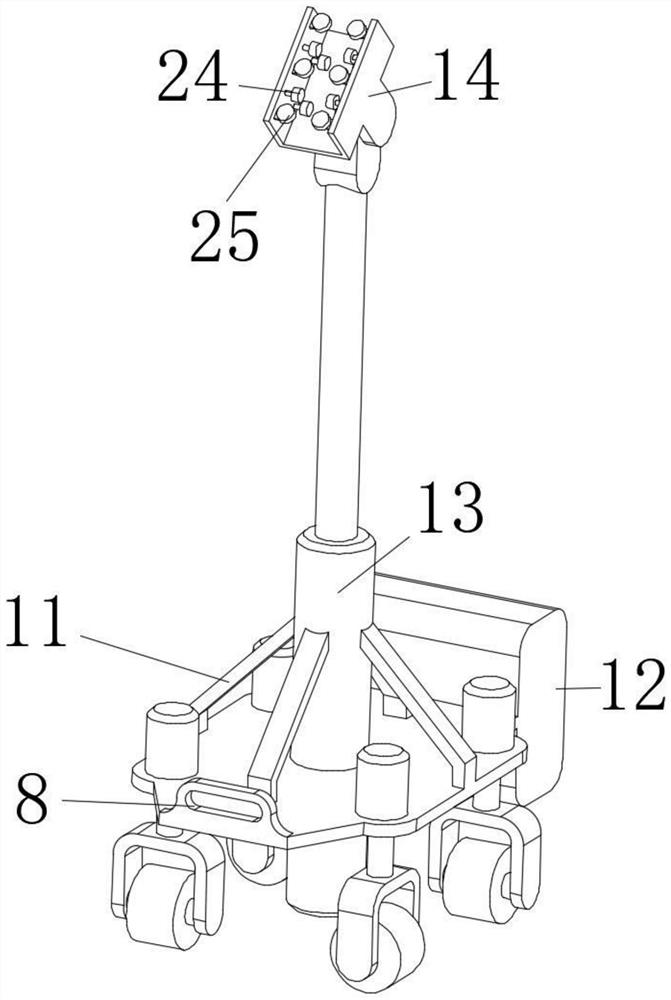

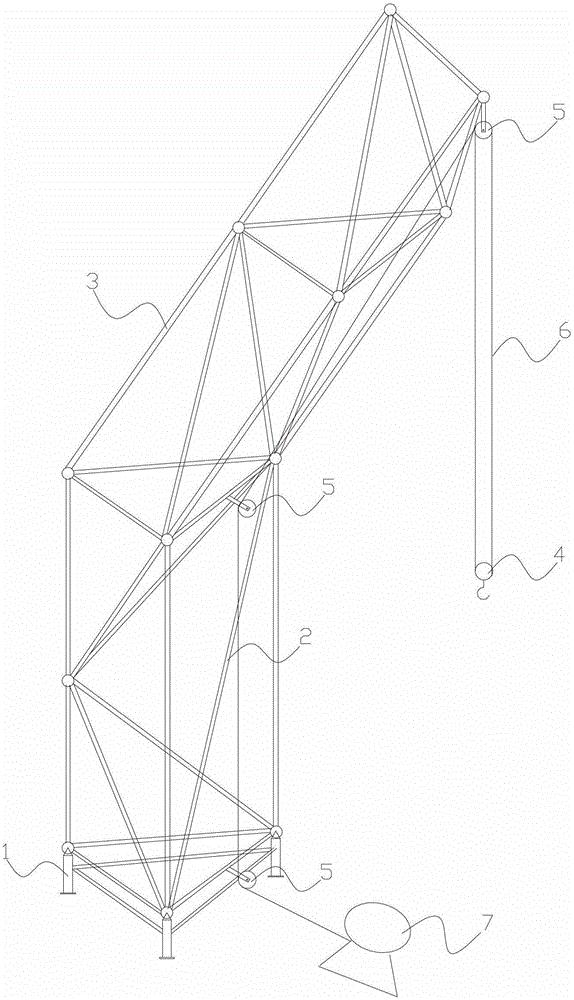

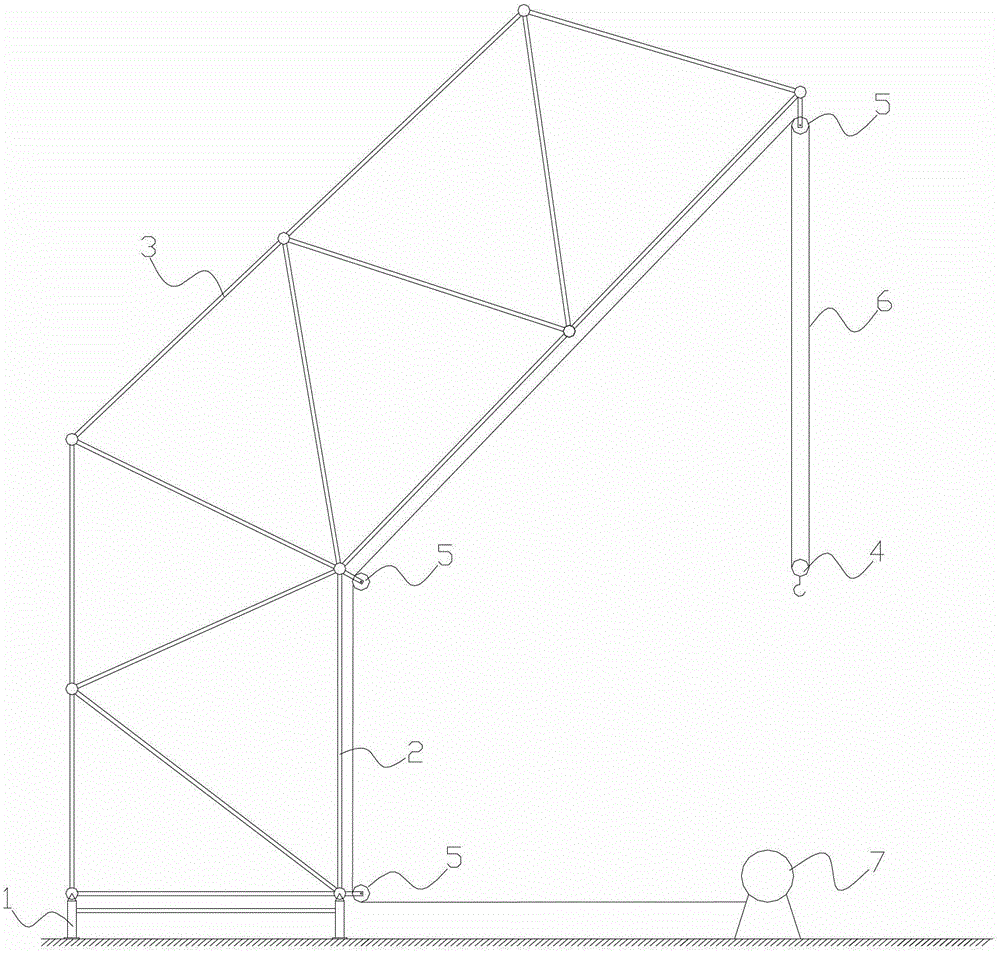

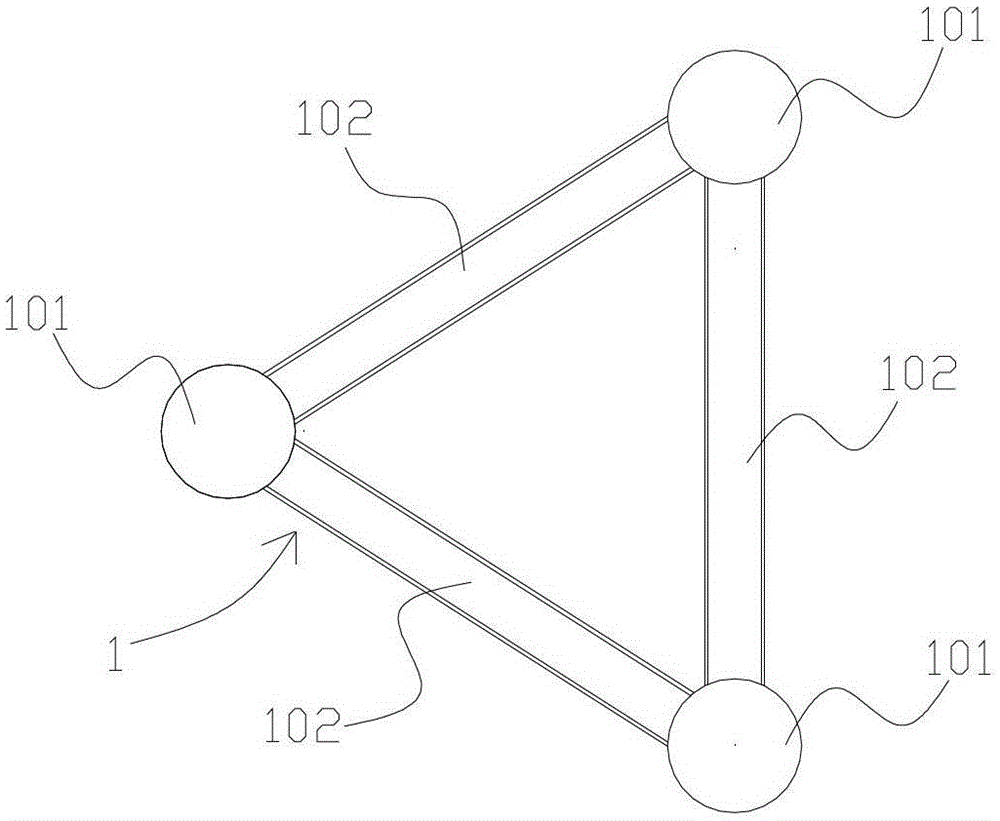

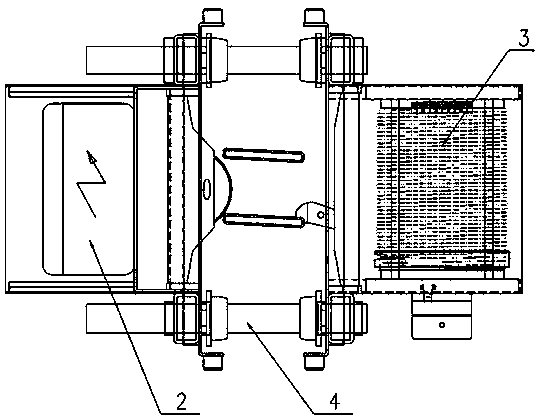

Double-rocker-arm electric control rotation derrick

ActiveCN104120913AEasy assembly and applicationSafe Assembly ApplicationsTowersTransducerIntegrated operations

The invention relates to a double-rocker-arm electric control rotation derrick which comprises a vertically-arranged main rod section, a mast, a derrick operation platform and at least one pair of rocker arms. The main rod section comprises a combination type lower base, a hydraulic lifting support, a main column and an electric rotation hinge base. The electric rotation hinge base is controlled by the derrick operation platform to conduct rotation and comprises a supporting frame, a hinge base body, a rotation bearing fluted disc, a motor, a reduction box and a rotation bearing base; angle transducers are arranged on the root portions of the pair of rocker arms and provided with anti-abrasion rope structures to be hinged to a connecting arm of the electric rotation hinge base; the derrick operation platform comprises a control cabinet, a monitoring display screen, a speed controller and a display limitation alarm device. The double-rocker-arm electric control rotation derrick is simple and reasonable in structural design, easy and convenient to assemble and apply and capable of achieving integrated operation such as electric control, detection, monitoring and alarming, the construction safety and the construction reliability are improved, the assemblage construction requirements of extra-high voltage line iron towers can be met, and the labor efficiency can be improved.

Owner:陕西九天电力科技有限公司

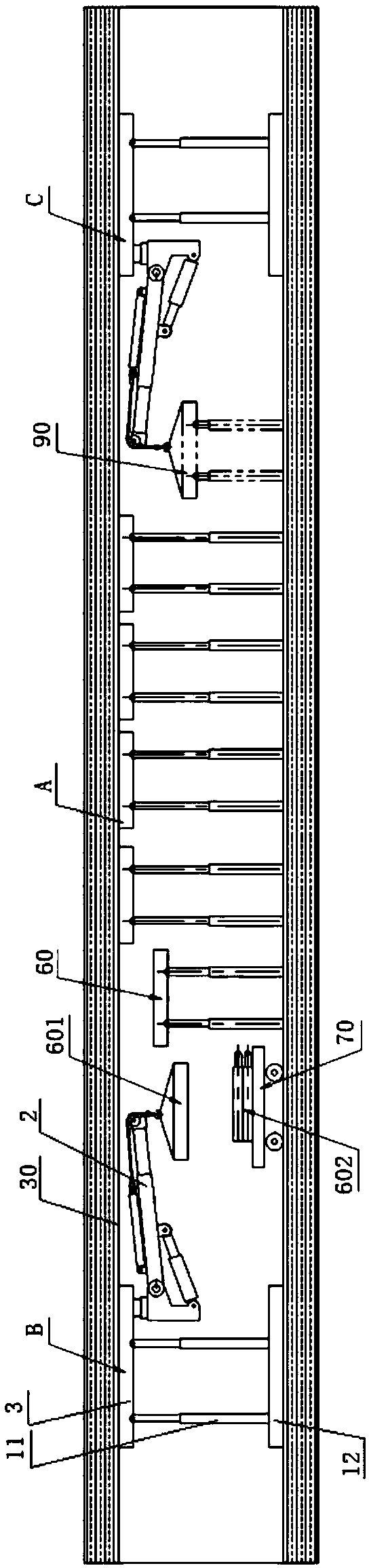

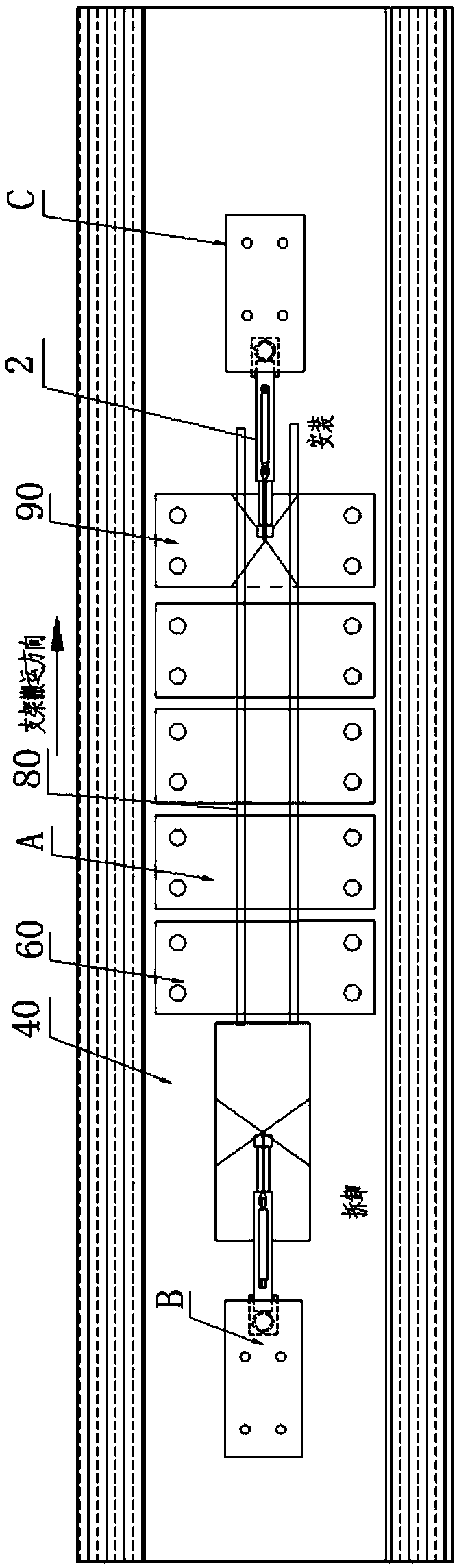

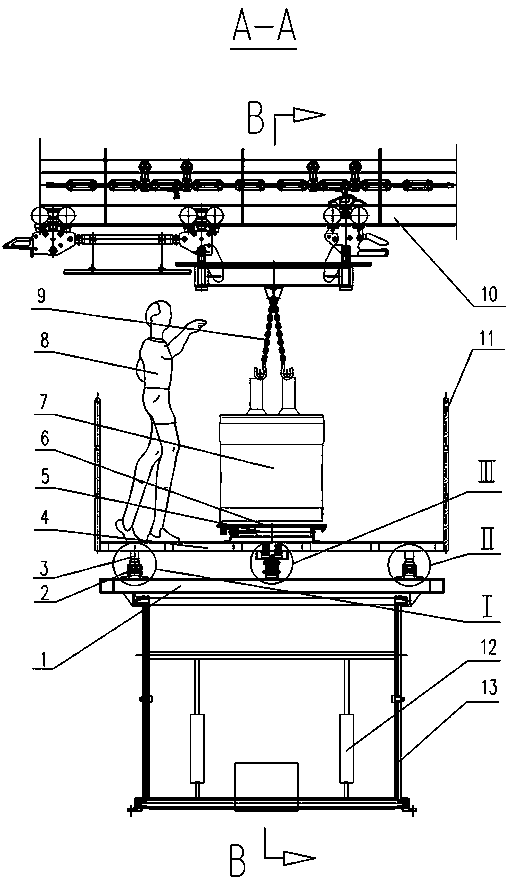

Roadway advance support disassembling and assembling system and method

PendingCN108798736ADoes not compromise securityAvoid repeated support failureMine roof supportsProps/chocksWorkloadTransportation safety

The invention discloses a roadway advance support disassembling and assembling system and method. A plurality of roadway brackets form a roadway advance support in a roadway. The roadway advance support disassembling and assembling system comprises a ground transport vehicle, and further comprises a head bracket type hydraulic crane and a tail bracket type hydraulic crane which are located at thetwo ends of the roadway advance support; the ground transport vehicle is located below a support channel formed by the roadway advance support; the head bracket type hydraulic crane is used for lifting the roadway brackets, under the disassembly state, at the end of the roadway advance support onto the ground transport vehicle; the ground transport vehicle transports the disassembled roadway brackets to a to-be-mounted area in the tail of the roadway forward support; and the tail bracket type hydraulic crane lifts and mounts the roadway brackets in the to-be-mounted area. The roadway bracketsin the roadway advance support disassembling and assembling system are forwards circularly propelled in a disassembled mode, repeated support damage to a roadway roof is avoided, the workload of forward moving of the advance support is small, and the disassembling, assembling and transportation safety of the roadway brackets is high.

Owner:BEIJING CHENGTIAN HENGYE COAL MINE EQUIP CO LTD +1

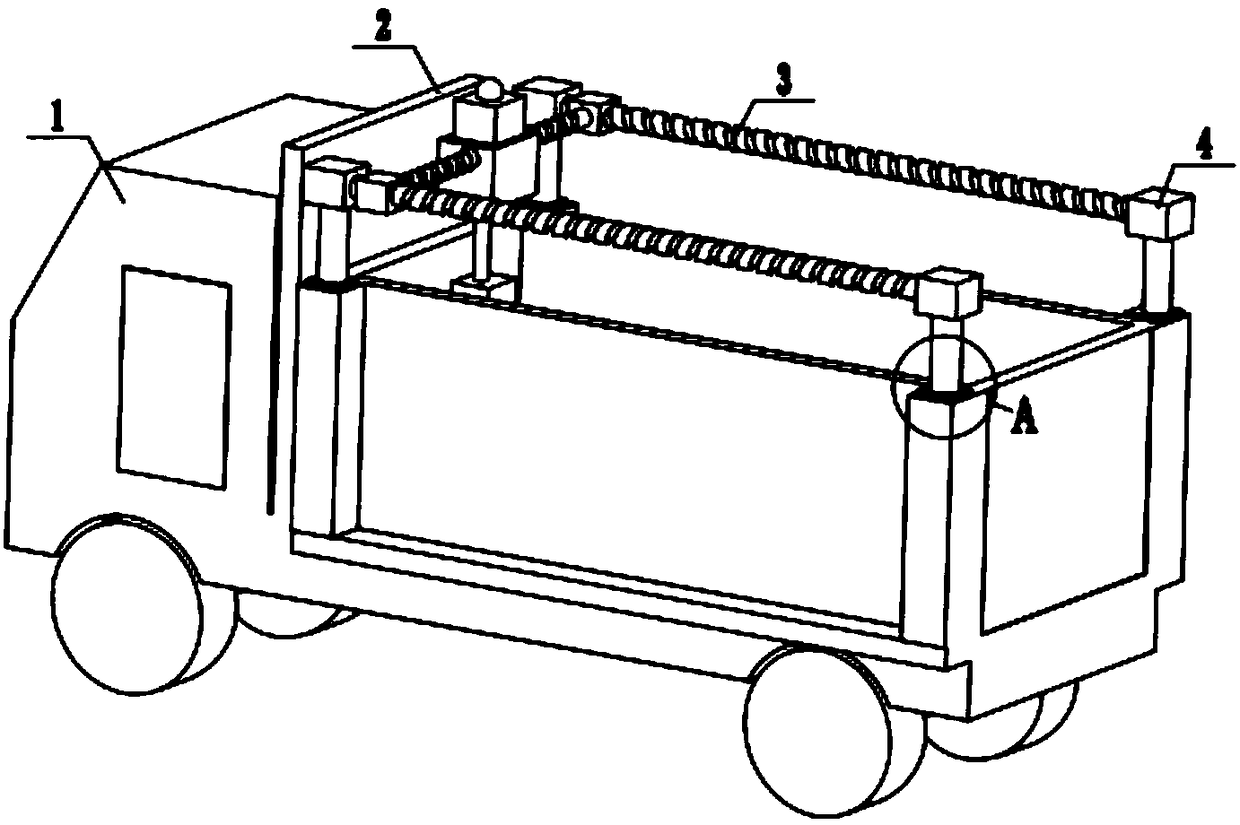

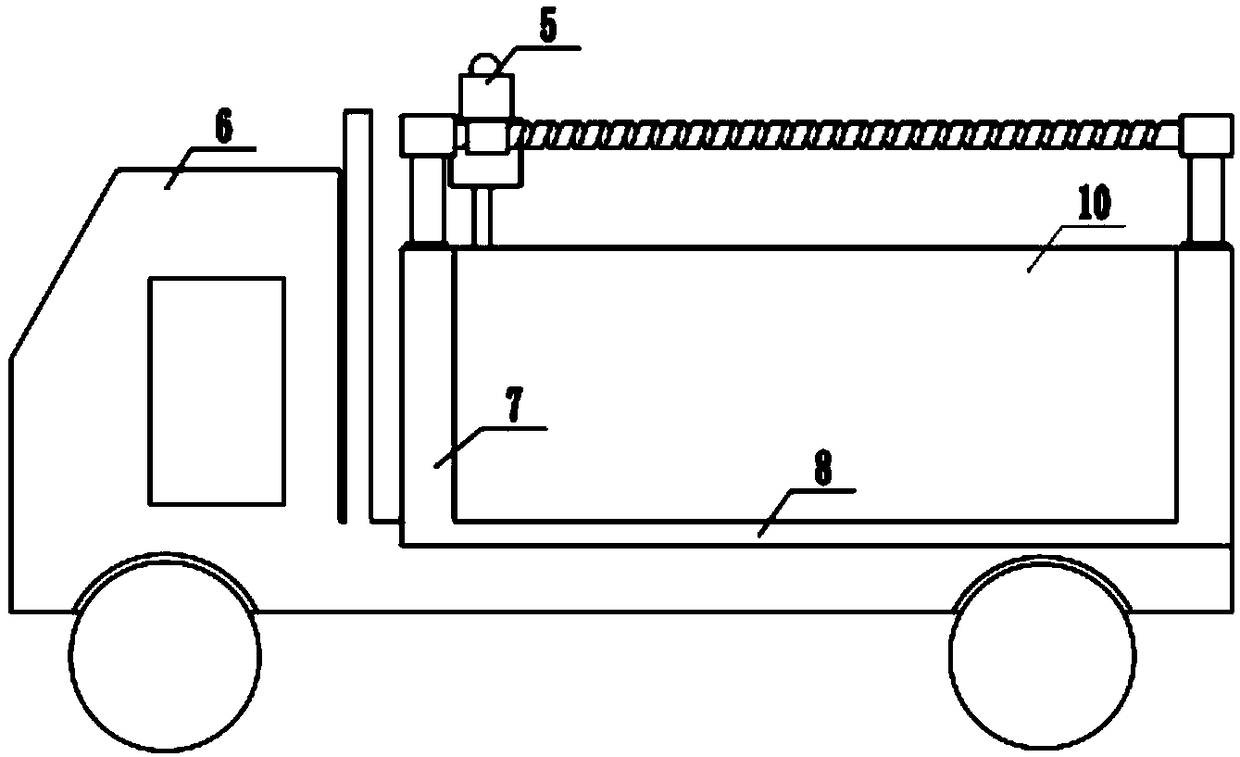

Engineering vehicle lifting equipment

InactiveCN108705966AEnsure safetyLow costVehicles with cranesTransportation itemsDrive shaftEngineering

The invention discloses engineering vehicle lifting equipment. The engineering vehicle lifting equipment comprises an engineering vehicle, transmission shafts, a lifting device and lifting cylinders.The engineering vehicle comprises a compartment and a cab. The lifting cylinders comprises piston rods and four cylinder barrels, and the four cylinder barrels are separately arranged on two sides ofthe front end and the rear end of the compartment and are fixedly connected with the compartment. The piston rods are disposed in cushion blocks and are slidably connected to the cylinder barrels, andsupporting blocks are arranged at the upper ends of the two piston rods disposed on the rear side of the compartment. The transmission shafts include conveying shafts and a fixing shaft, and the supporting blocks and conveying motors which are disposed on the same side are connected through the conveying shafts. The lifting device comprises an adjusting motor, a rope box, a rope and a hook, and sliding holes are formed in the rope box. The sliding holes are matched with the fixing shaft, and the adjusting motor is disposed at the upper end of the rope box. One end of the rope is disposed in the rope box, and the other end of the rope is disposed outside the lower end of the rope box. The cab is internally provided with a control device which is electrically connected with the adjusting motor, the lifting cylinders and the conveying motors.

Owner:周伟冬

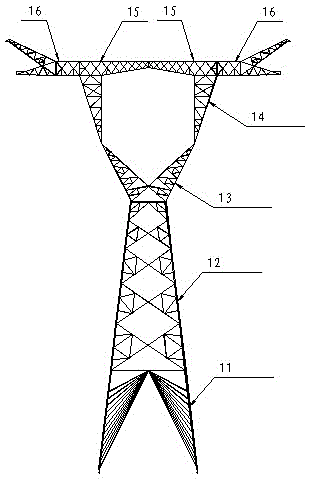

A method for installing a wine glass-shaped iron tower of an UHV transmission line

ActiveCN103924816BImprove construction efficiencySolve the problem of difficulty in hoisting in placeTowersGlasses typeUltra high voltage

Owner:SHANDONG ELECTRIC POWER TRANSMISSION & SUBSTATION ENG CO

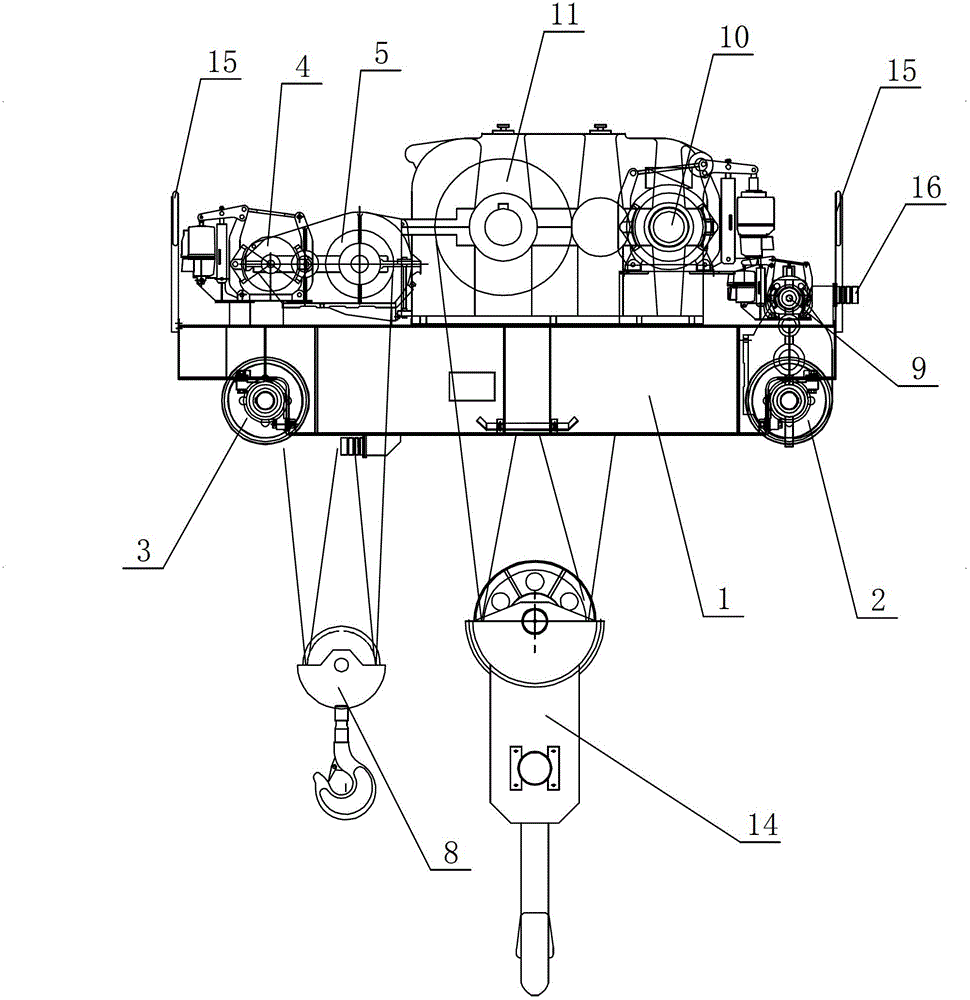

Hoisting trolley for double beam bridge crane

InactiveCN102718139AReduce volumeCompact and reasonable structureTrolleysBlock and tackleEngineering

The invention discloses a hoisting trolley for a double beam bridge crane. The hoisting trolley comprises a trolley frame, traveling wheels are installed at the bottom of the trolley frame, a first hoisting component and a second hoisting component which are independent are arranged on the trolley frame, the first hoisting component comprises a first driving device, a transmission component, a first decelerating mechanism, a first winding drum, a first fixed pulley set and a first hoisting hook, and the second hoisting component comprises an operation driving device, a hoisting driving device, a second winding drum, a second decelerating mechanism, a second fixed pulley set and a second hoisting hook. Since two independent hoisting units are integrated into the trolley, the hoisting trolley for the double beam bridge crane has the advantages of compact and reasonable structure, high hoisting weight, small size, wide service range and safety and reliability in operation.

Owner:WUXI XIEXING PORT MACHINERY

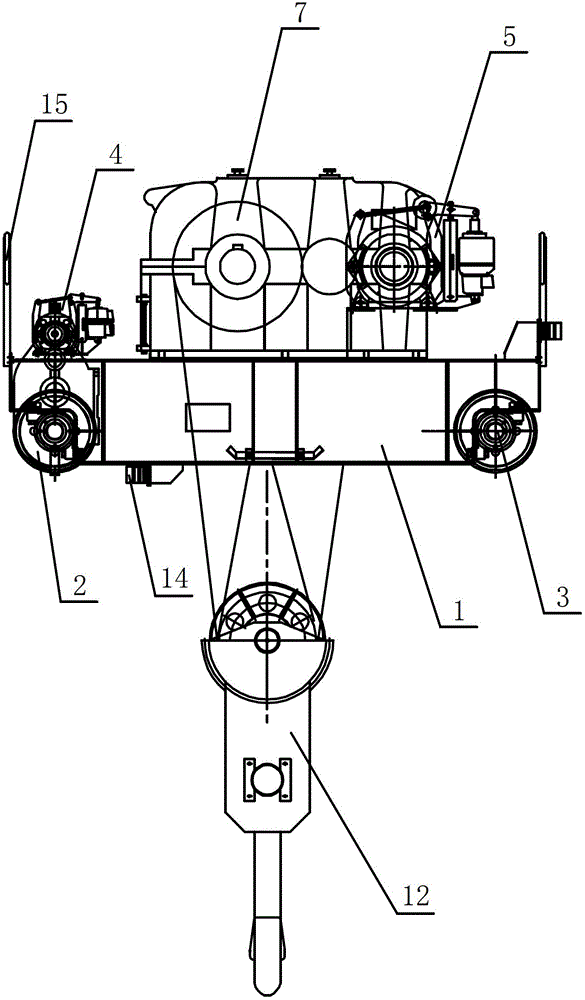

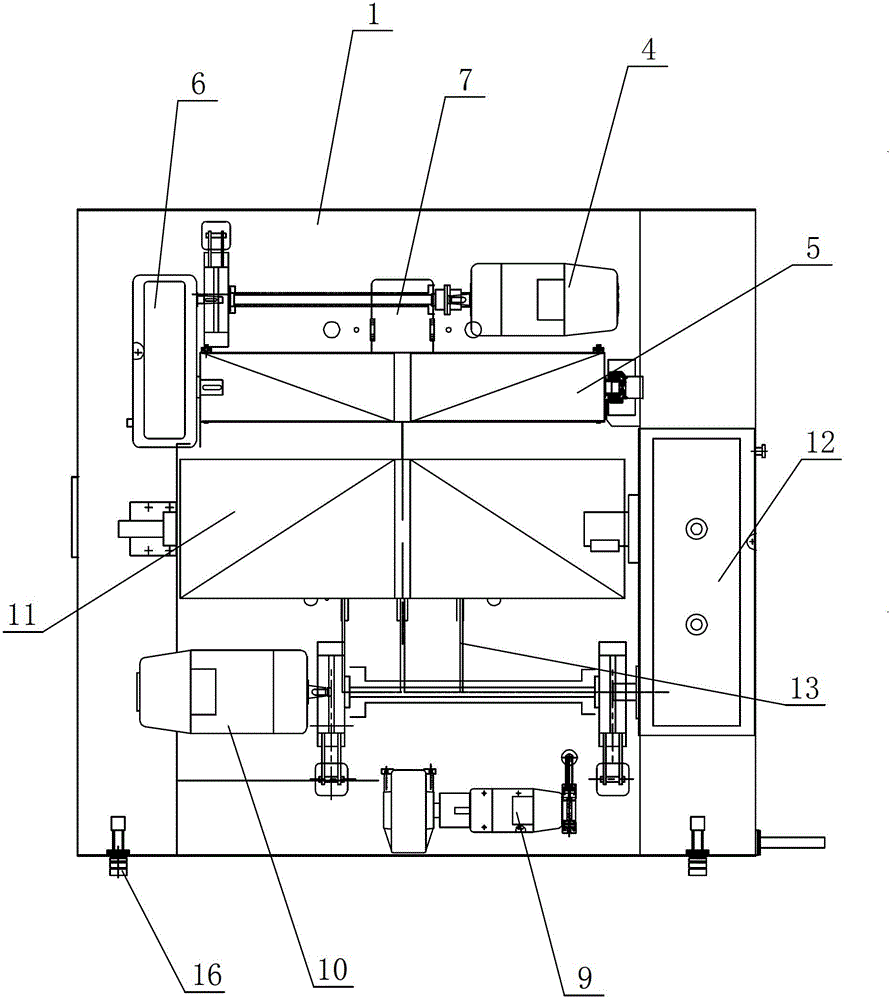

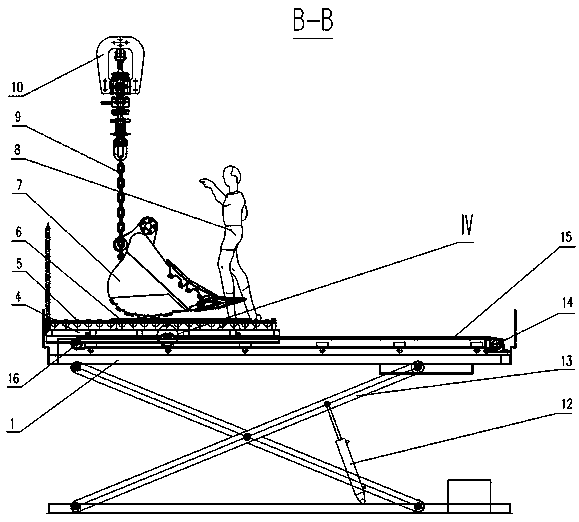

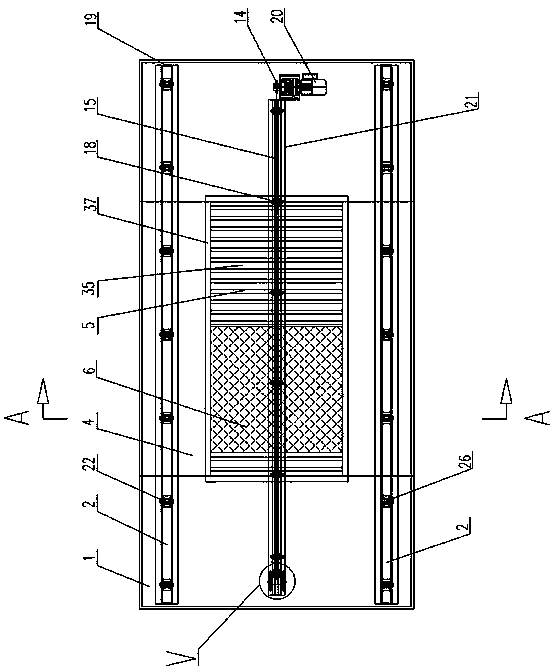

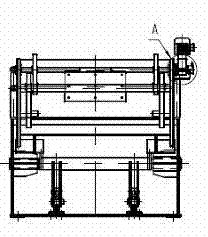

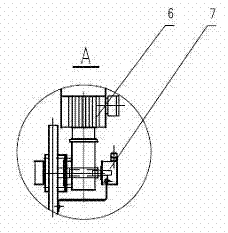

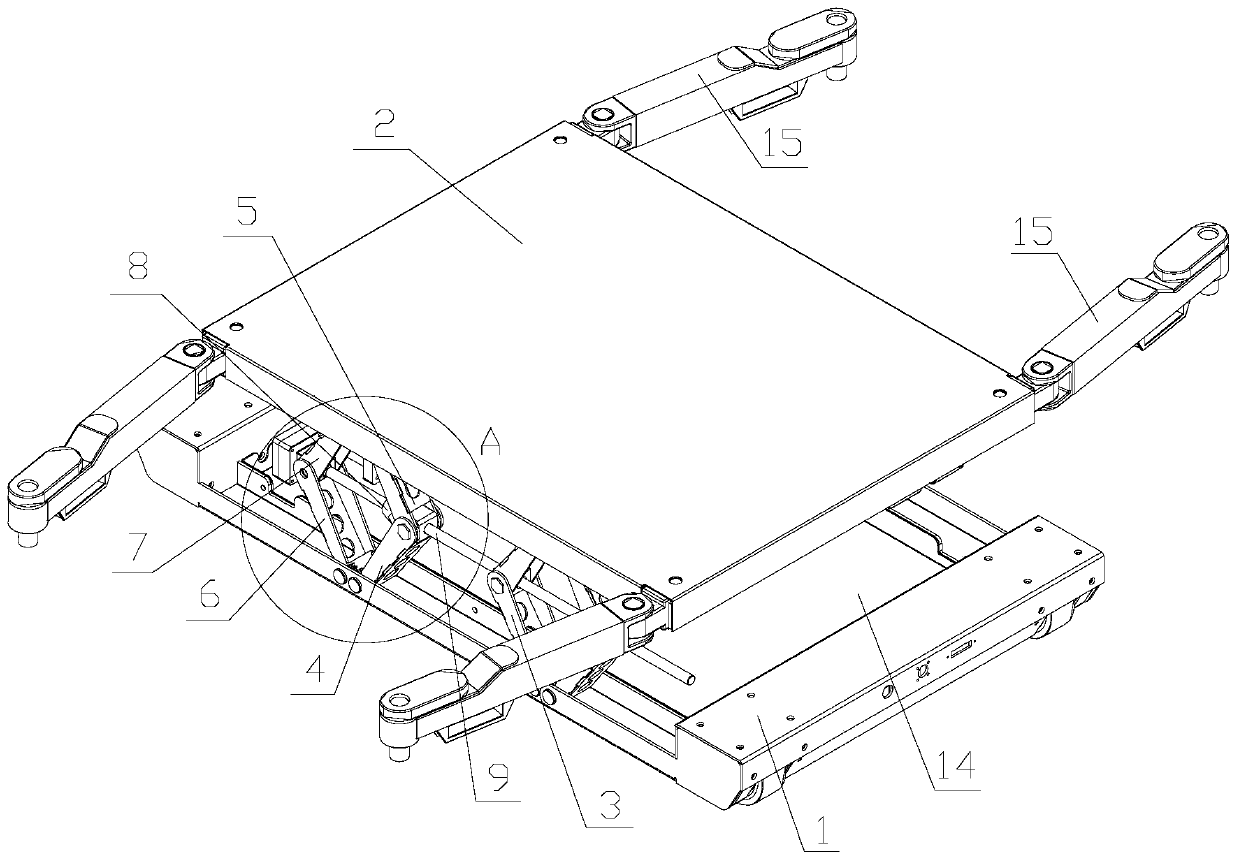

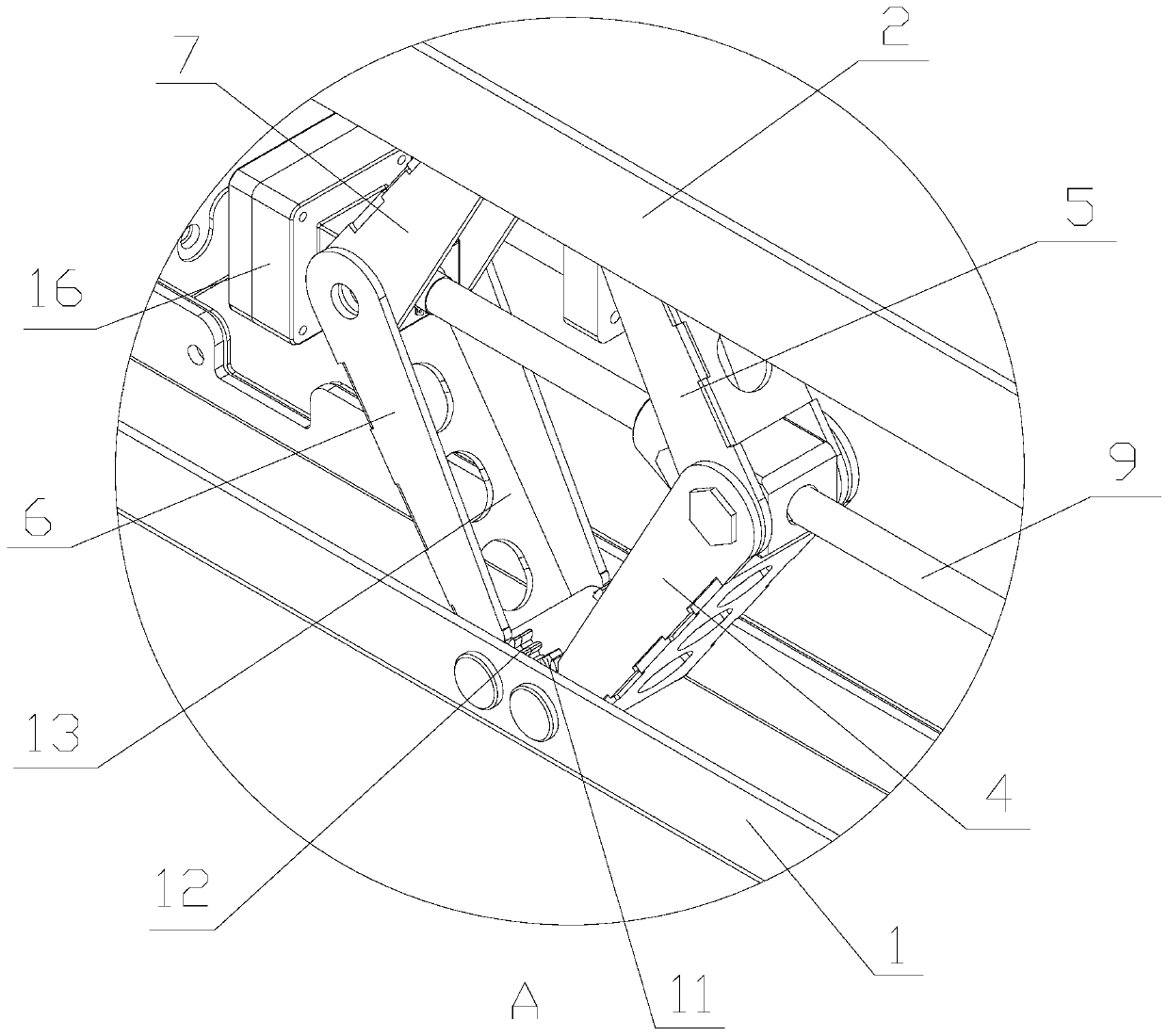

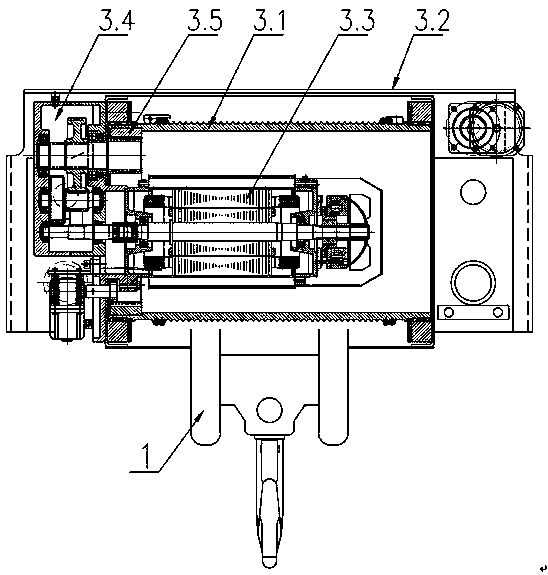

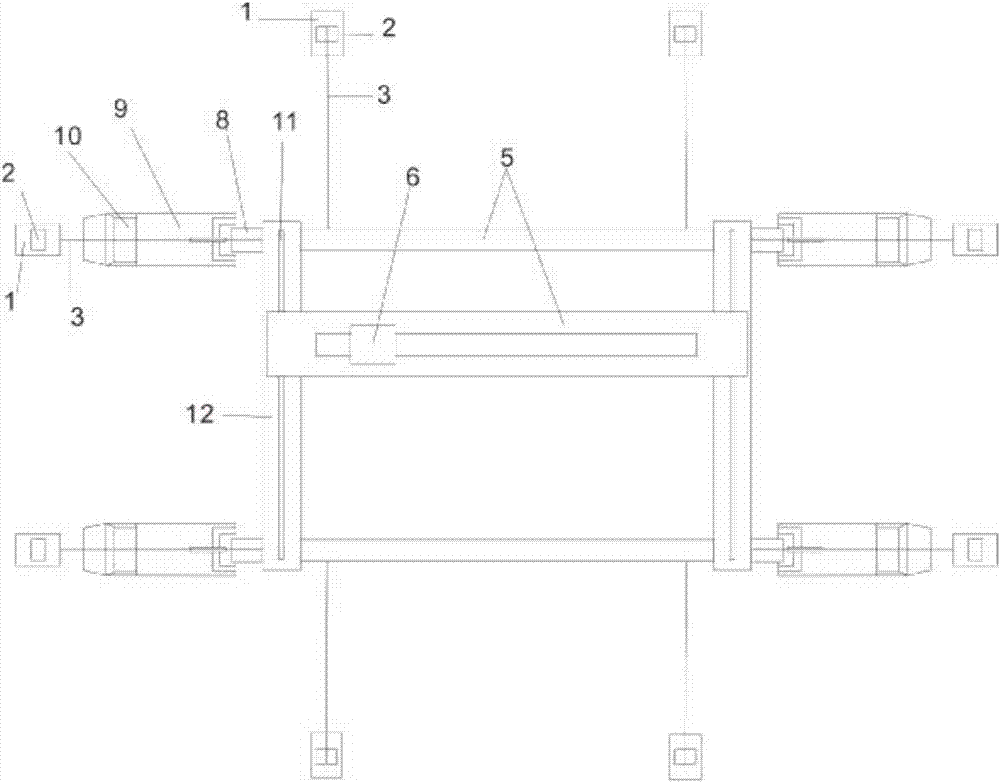

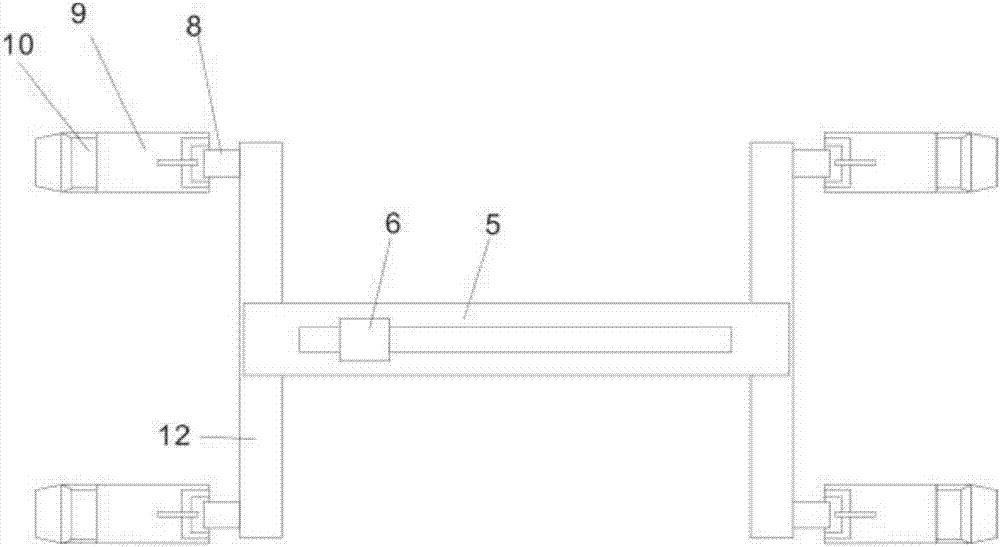

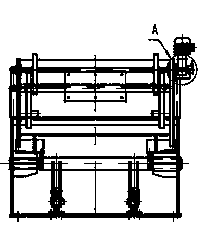

Workpiece charging and discharging auxiliary device for large-scale special-shaped workpiece

PendingCN110466949AImprove performanceLarge lifting weightConveyorsSpraying apparatusEngineeringGravity center

The invention relates to a workpiece charging and discharging auxiliary device for a large-scale special-shaped workpiece. The workpiece charging and discharging auxiliary device integrates three functions of lifting, moving and follow-up posture correcting, and consists of a hydraulic lifting platform (1), a horizontal moving platform (4) and a follow-up posture correcting platform (6). The horizontal moving platform (4) is supported on a hydraulic lifting platform (1) through a moving rail (2) and is driven by a transmission chain (15). The follow-up posture correcting platform (6) is placedon a unpowered follow roller way (5) on the horizontal moving platform (4); and the workpiece (7) is directly placed on the follow-up posture correcting platform (6), and the posture can be automatically corrected along with the change of the workpiece gravity center on the follow roller way (5), so that the impact force of the workpiece charging on the conveying line is reduced, the damage to operators caused through turnover or shaking of the workpiece is reduced, and the safety of the workpiece charging is improved.

Owner:江苏剑桥涂装工程股份有限公司

Extra-high voltage large-span iron tower assembling method

The invention discloses an extra-high voltage large-span iron tower assembling method, which belongs to the technical field of electric transmission and transformation electric power circuit construction processes. The method comprises the following steps of: 1, arranging a construction site, namely arranging a ground anchor, performing pole foundation construction, and arranging main material single pieces and tower sheets of an assembled iron tower body on the ground; 2, assembling a pole, mounting a hoisting system, and hoisting iron tower legs, wherein the assembled pole is a spinning self-elevating ground pole which is provided with horizontal double arms and a hydraulic downward jacking stock; 3, lifting the pole, hoisting the iron tower body section by section, and finally hoisting iron tower cross arms one by one in a segmentation mode; and 4, mounting iron tower accessories, disassembling the pole, and finally overhauling and self-checking to finish the construction. The method has the advantages of reducing the working amount of aloft operation, along with a short construction period, a small number of hoisting times and high safety; by the method, safety risks are reduced, required aloft operation personnel is greatly reduced, and labor cost is reduced; and the method has extremely good economic and social benefits.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

Large-bearing-capacity sleeve unloading mechanism

InactiveCN102491184AFully automatedAchieve mechanical propertiesCranesLoad-engaging elementsCylinder headEngineering

The invention relates to a large-bearing-capacity sleeve unloading mechanism characterized in that: the mechanism is mainly composed of connected components of a sleeve collecting rack, a boom driving oil cylinder, a boom, a lifting hook, a sleeve detecting sensor, a lifting hook opening rate adjusting motor, an absolute value encoder, and a driving oil cylinder pedestal. A sleeve storing working face of the sleeve collecting rack is an inclined plane; holes used for installing the boom are provided on two sides of the sleeve collecting rank; the driving oil cylinder pedestal is fixed in the inner cavity of the sleeve collecting rack; the driving oil cylinder pedestal is hinged with the driving oil cylinder; a cylinder head of the boom driving oil cylinder is connected with a jib of the boom; the boom is connected to the sleeve collecting rack through a sliding bearing; the lifting hook is connected to the boom; the sleeve detecting sensor is connected to a roll loading trolley; the sleeve detecting sensor is used for detecting whether a sleeve is on the trolley; the absolute value encoder penetrates the jib through a shaft; two ends of the absolute value encoder form a clearance fit with the inner ring of the sliding bearing. With the mechanism provided by the invention, automation of sleeve unloading can be fully achieved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

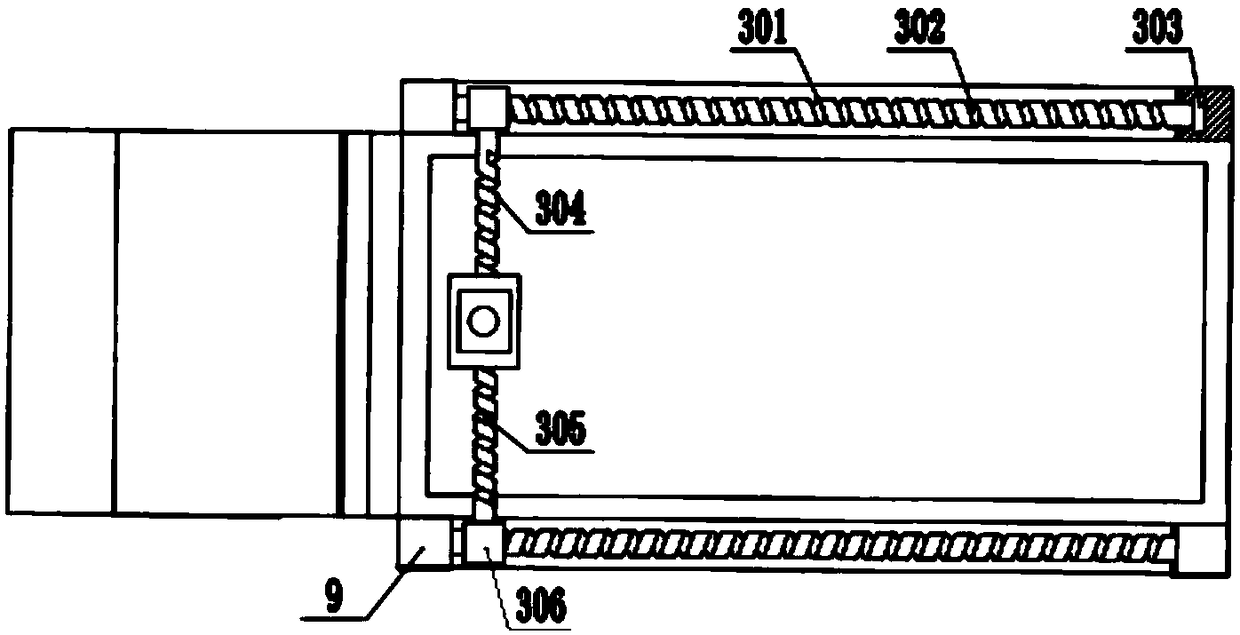

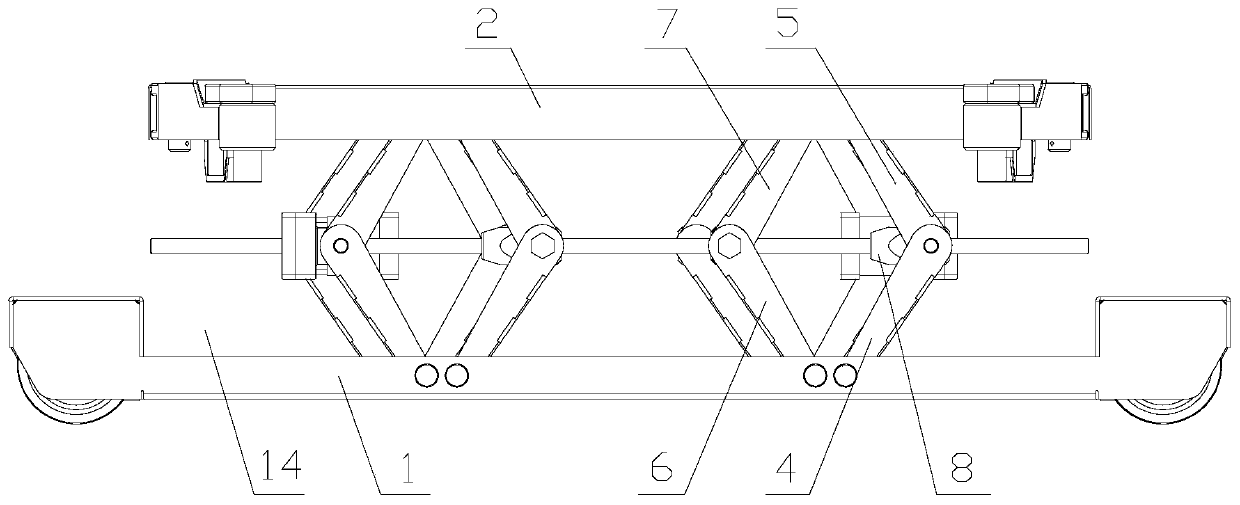

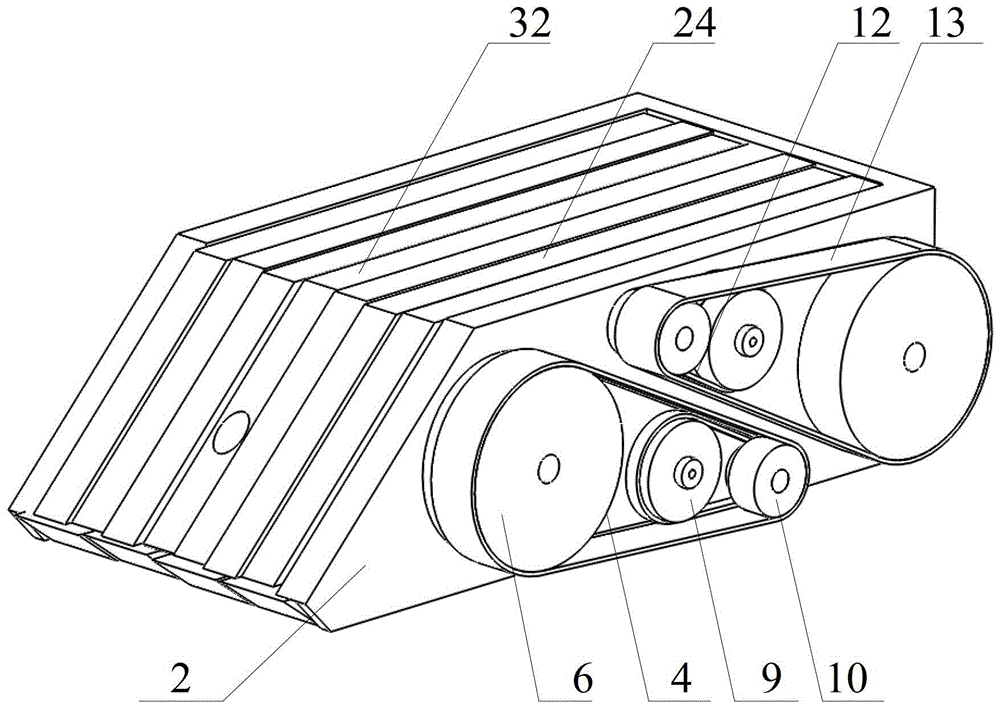

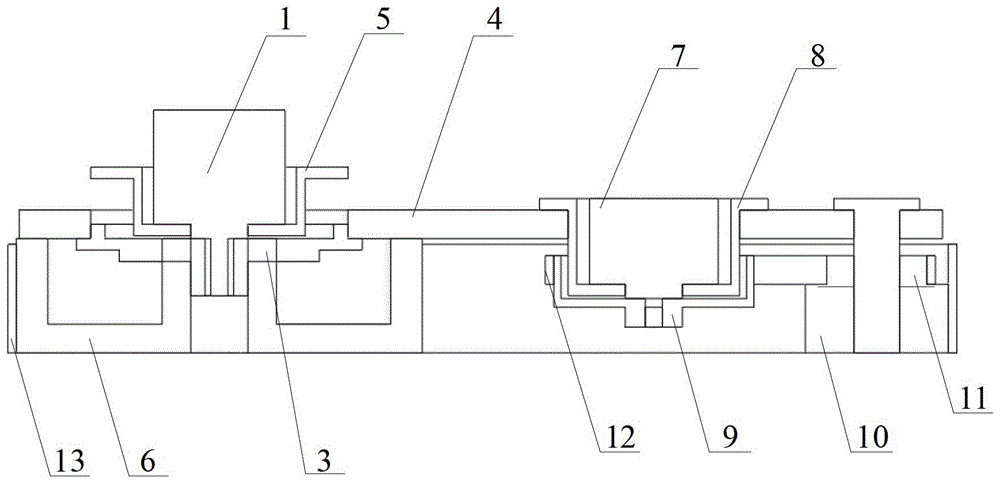

Movable lifting device

The invention belongs to the technical field of lifting equipment and discloses a movable lifting device. The movable lifting device comprises a chassis (1) capable of walking freely and a tray (2) arranged above the chassis (1), a lifting mechanism (3) is arranged between the chassis (1) and the tray (2) and controls the tray (2) to ascend or descend, and the lifting mechanism (3) comprises a lifting frame, a lead screw (9) and a driving motor (10). The lifting frame comprises a first lower support (4) and a first upper support (5), one end of the first lower support (4) is rotationally connected with the chassis (1), the other end of the first lower support (4) is movably connected with a lead screw nut (8), one end of the first upper support (5) is rotationally connected with the firstlower support (4), the other end of the first upper support (5) is rotationally connected with the tray (2), and the lead screw (9) is connected with the lead screw nut (8). According to the movable lifting device, rapid movement of a vehicle can be realized, the lifting weight is large, and the reliability is high.

Owner:成都大秦民安消防科技有限公司

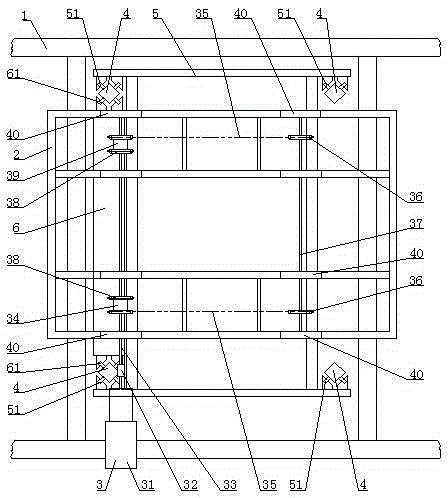

Four-post four-lifting-point chain type lifter for car side wall

The invention discloses a four-post four-lifting-point chain type lifter for a car side wall. The four-post four-lifting-point chain type lifter comprises an auxiliary beam, a fixed rack, a drive device, a movable framework, a counterweight block and four guide posts, wherein the fixed rack is arranged on the auxiliary beam. The four-post four-lifting-point chain type lifter is characterized in that four corners of the movable framework are symmetrically provided with four movable framework guide wheels; upper and lower ends of the counterweight block are symmetrically provided with counterweight block guide wheels; the drive device comprises a motor speed reducer, a shaft coupler, a drive chain wheel transmission shaft, a duplex chain wheel I, a driven chain wheel transmission shaft, a duplex chain wheel II, two long transmission chains, two driven chain wheels, two short transmission chains and a plurality of bearing bases; the two long transmission chains and the two short transmission chains are open type chains; and the motor speed reducer is arranged on the auxiliary beam. The four-post four-lifting-point chain type lifter is simple in structure, uniform in stress, stable in operation, great in hoisting weight, high in guide precision, safe and reliable, and long in service life.

Owner:HUBEI HUAXUAN AUTOMATION TECH CO LTD

Stable hoisting equipment for expressway steel box girder and hoisting construction method of stable hoisting equipment

The invention relates to the technical field of steel box girder construction, in particular to stable hoisting equipment for an expressway steel box girder. The stable hoisting equipment comprises a first carrier loader and a second carrier loader, a workbench is arranged on the first carrier loader, and a main rotary table capable of horizontally rotating is installed on the workbench through a bearing. The hoisting method of the stable hoisting equipment comprises the steps of equipment in-place, hoisting preparation, hoisting, adjustment and laying down of the steel box girder and the like. The stable hoisting equipment has the beneficial effects that a larger hoisting mechanism can be transported by utilizing the first carrier loader and the second carrier loader, so that a farther hoisting distance and a higher hoisting weight are provided; and the larger hoisting mass and the higher hoisting height can be freely adjusted by changing the supporting position of a jacking push rod on a main push rod, and the two carrier loaders are adopted in the device to support the main push rod in a distributed mode, so that compared with existing hoisting equipment carried by a single carrier loader, the hoisting equipment has better stability performance, and the use is safer.

Owner:CHINA CONSTR EIGHTH ENG DIV

Extra-high voltage common circuit iron tower assembling method

The invention discloses an extra-high voltage common circuit iron tower assembling method, which belongs to the technical field of electric transmission and transformation electric power circuit construction processes. The method comprises the following steps of: 1, performing construction preparation, namely cleaning a construction field, arranging the construction field, preparing a construction ground foundation, and transporting tower materials required by iron tower assembly; 2, assembling a pole, erecting the pole and assembling tower leg lower sections; 3, assembling and erecting tower legs, lifting the pole, and hoisting iron tower crank arms; and 4, lifting the pole, hoisting a tower head, mounting a ground wire bracket, hoisting iron tower cross arms one by one in a segmentation mode, mounting iron tower accessories and disassembling the pole. The method has the advantages of reducing the working amount of aloft operation, along with a short construction period, a small number of hoisting times and high safety; by the method, safety risks are reduced, required aloft operation personnel is greatly reduced, and labor cost is reduced; and the method has extremely good economic and social benefits.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

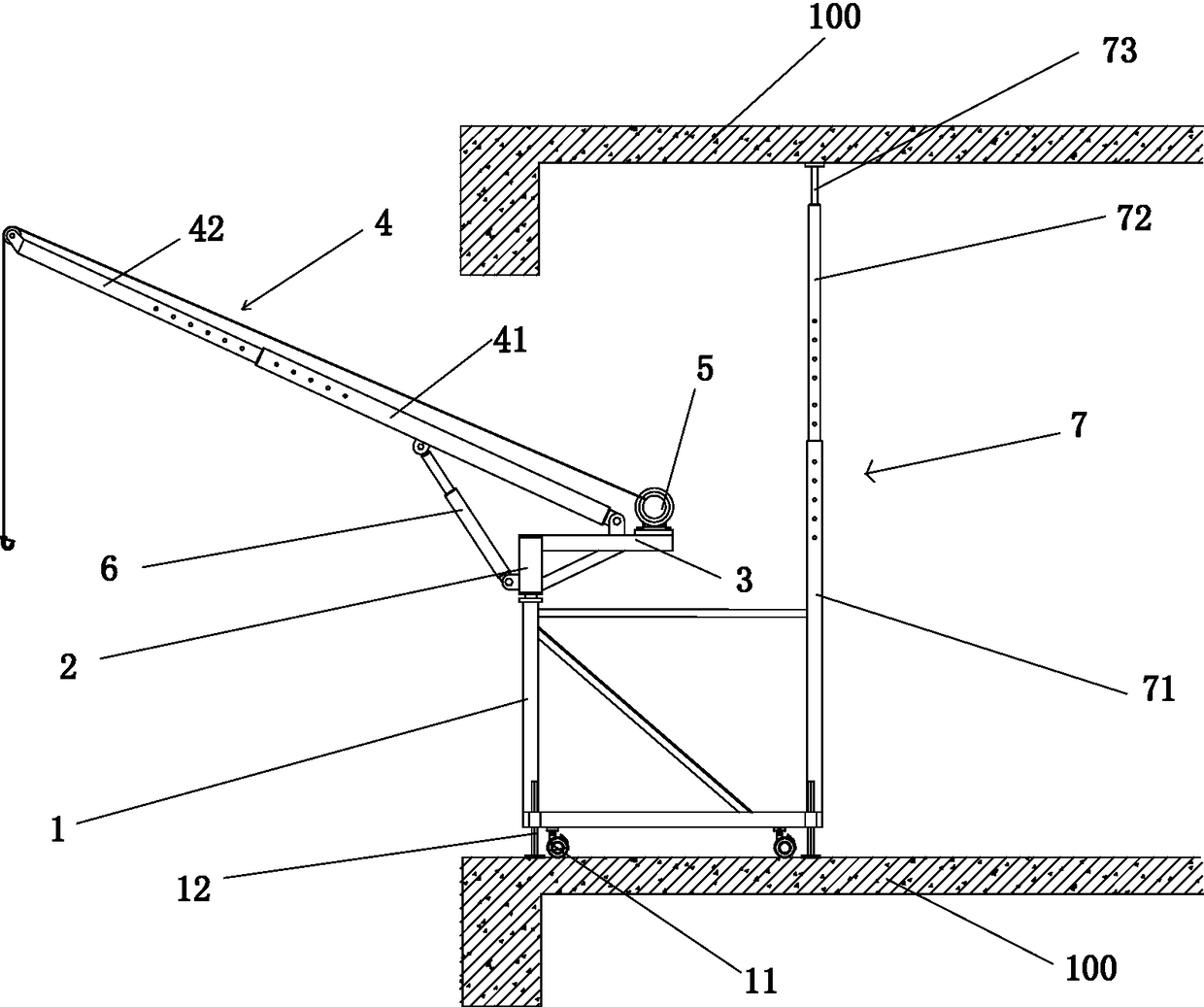

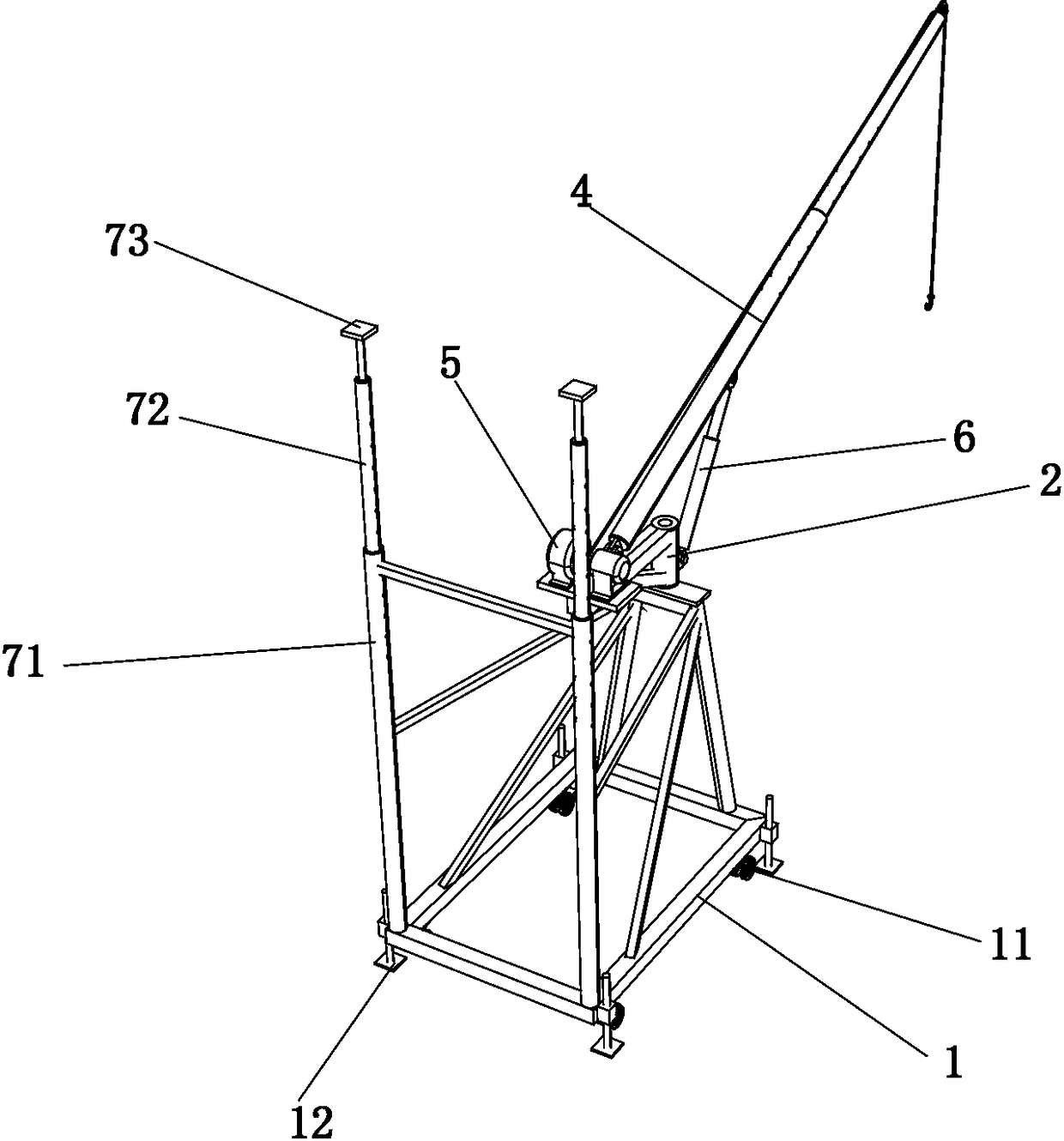

Counter weight-free crane

The invention relates to a counter weight-free crane and belongs to the field of building construction. The counter weight-free crane comprises a rack body, wherein a rotating bearing is arranged on the rack body; a moving platform is arranged on the rotating bearing; a telescopic lazy arm is arranged on the moving platform; a winch matched with the lazy arm is also arranged on the moving platform; a plurality of vertical supporting rods capable of leaning against floor slabs are also arranged on the rack body; and the vertical supporting rods are right behind the moving platform. Compared with the prior art, the crane can be jacked between upper and lower floor slabs through the supporting rods to balance the upsetting moment during hoisting. The length of the lazy arm can stretch freelyand can rotate up and down and left and right, so that the counter weight-free crane is large in hoisting range. The counter weight-free crane also has the advantages of being small in self weight, large in hoisting weight, flexible to move, convenient to position and the like, and solves many problems of existing counter weight cranes and simple cranes for buildings.

Owner:宁波建工建乐工程有限公司

Bolt Ball Truss Hoist

The invention discloses a bolt sphere truss elevator, which comprises a bolt sphere truss, a hoisting device and a power device, wherein the bolt sphere truss comprises a base, a frame body and a suspension arm frame; the frame body is fixedly mounted on the base; the suspension arm frame is fixedly connected to the frame body; the suspension arm frame has an inclination angle relative to the frame body so as to form a suspended loading space below the suspension arm frame; the hoisting device is mounted on the bolt sphere truss; and the hoisting device is matched with the power device, so that the hoisting device can hoist materials in the suspended loading space. The bolt sphere truss elevator can lift materials with a larger lifting volume and heavier weight, and is convenient to operate, easy to control and safe and reliable; and moreover, the bolt sphere truss elevator can not only be installed on the ground, but also be installed on an existing building, has strong field adaptability, is easy to install or disassemble, can be reused and has obvious economic benefits.

Owner:广州市第三建筑工程有限公司

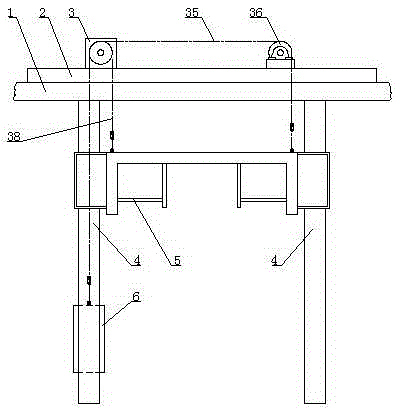

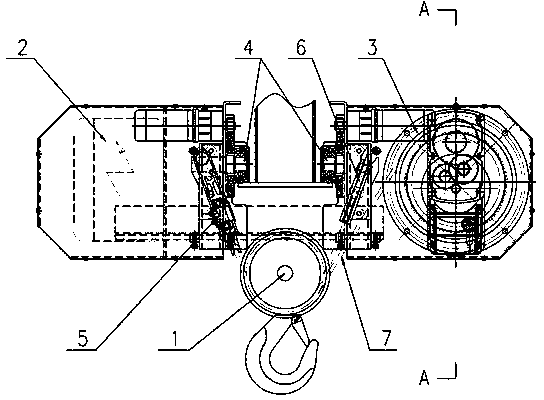

Steel-wire rope type electric block

InactiveCN104192743ASmall heightReduce building heightWinding mechanismsEngineeringBilateral symmetry

The invention discloses a steel-wire rope type electric block which comprises a lifting hook assembly, an electric appliance control box, a winding drum assembly and a steel wire rope. The electric appliance control box and the winding drum assembly are arranged in a bilateral symmetry mode, the lifting hook assembly is arranged between the electric appliance control box and the winding drum assembly, operating mechanisms are arranged on the electric appliance control box and the winding drum assembly, a pulley assembly is arranged on the electric appliance control box, and an overload limiting device is arranged on the winding drum assembly. The steel-wire rope type electric block is reasonable in structural design, the lifting hook assembly is arranged between the electric appliance control box and the winding drum assembly, the lifting hook assembly can be lifted to the clearance position between the electric appliance control box and the winding drum assembly, the lifting height is increased, the height size of the steel-wire rope type electric block is reduced, the construction height of a plant is reduced, the self weight is reduced, the cost is saved, the safety factor is improved, the hoisting weight is increased, and use and popularization are easy.

Owner:江苏鼎力重工集团有限公司

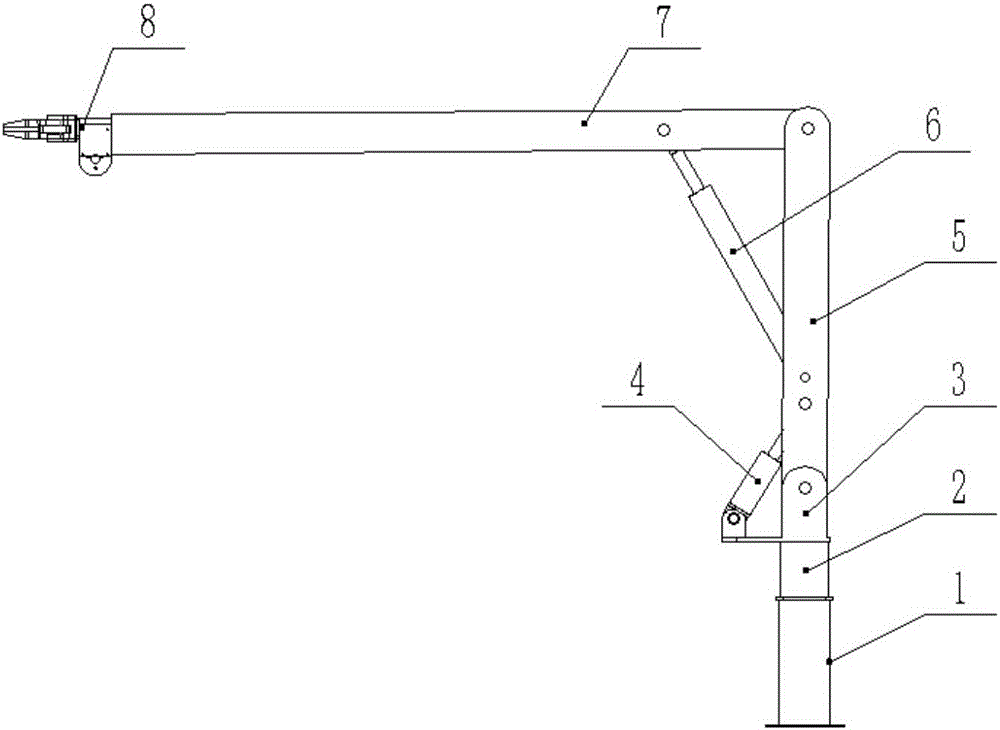

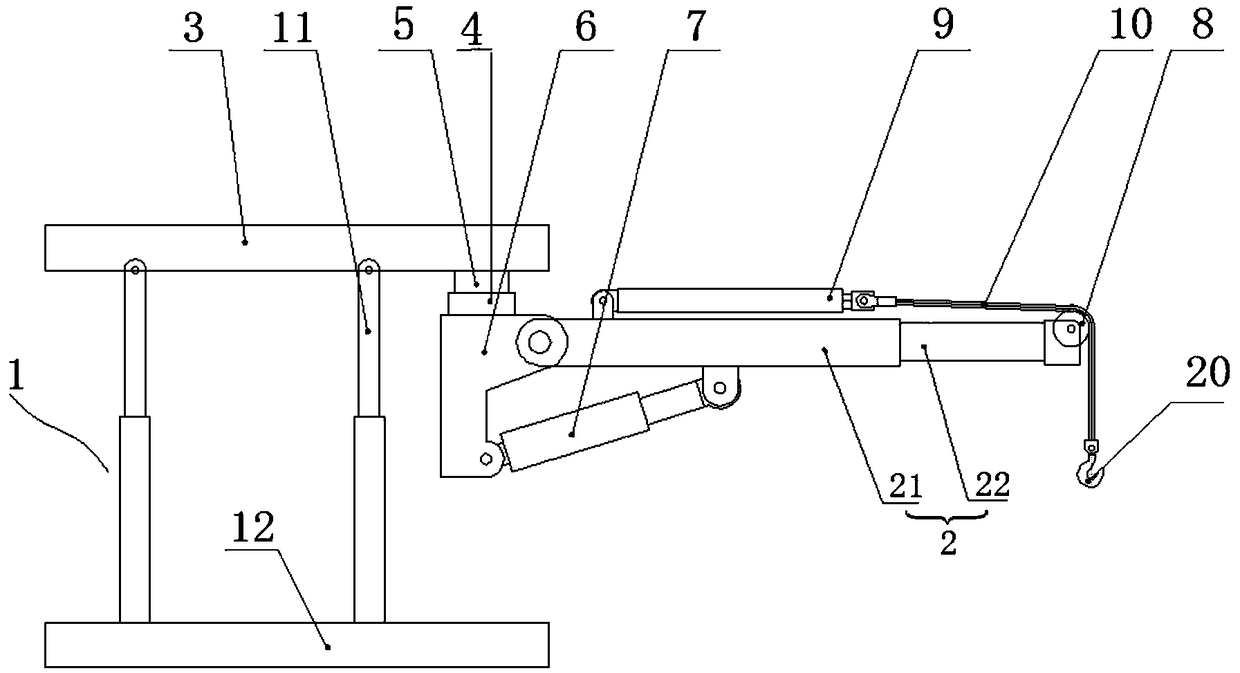

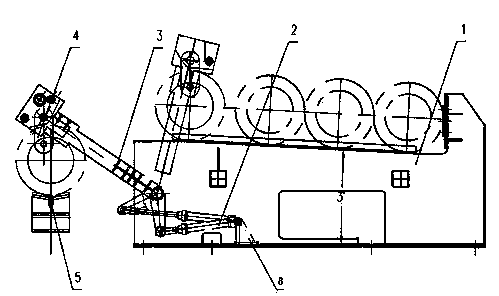

Pipe hoist sub-arm

The invention relates to an underground pipeline of a medium and small pipe hoist machine, in particular to an auxiliary hoist arm for the maintenance and cover pavement in a large caliber pipeline or the pavement of the underground pitch of the large caliber pipeline. The invention includes a supporting arm (1) with the A-typed structure, a swing oil cylinder (2), and a supporting leg (3); the upper end of the supporting arm (1) is articulated with a hoist arm (4) of the pipe hoist machine; the lower end of the supporting arm (1) is articulated with the supporting leg (3); one end of the swing oil cylinder (2) is articulated with the hoist arm (4) while the other end is articulated with the supporting arm (1). By the swing oil cylinder (2), the supporting leg (3) arranged at the lower end of the supporting arm (1) is supported on the ground. The hoist weight is commonly supported by matching with the hoist arm (4). The invention has the capability improving the hoist weight of the medium and small pipe hoist machine by matching with the hoist arm (4), can meet the requirements of the maintenance and cover pavement operation of the large caliber long-transportation pipeline and the pavement of the large caliber pipeline, and has the advantages of good stability, simple structure, convenient application, low cost, etc.

Owner:泰安市泰山工程机械集团有限公司

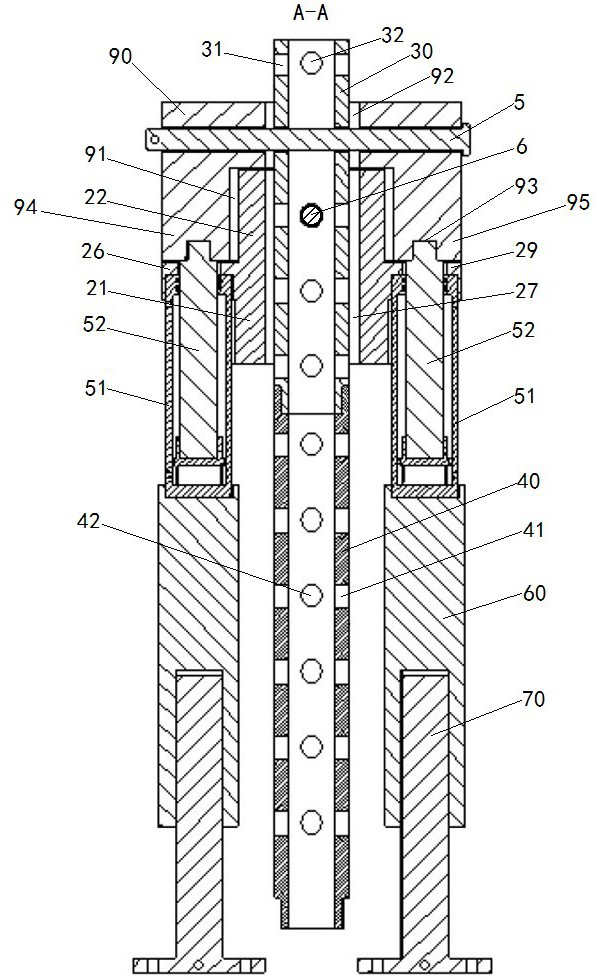

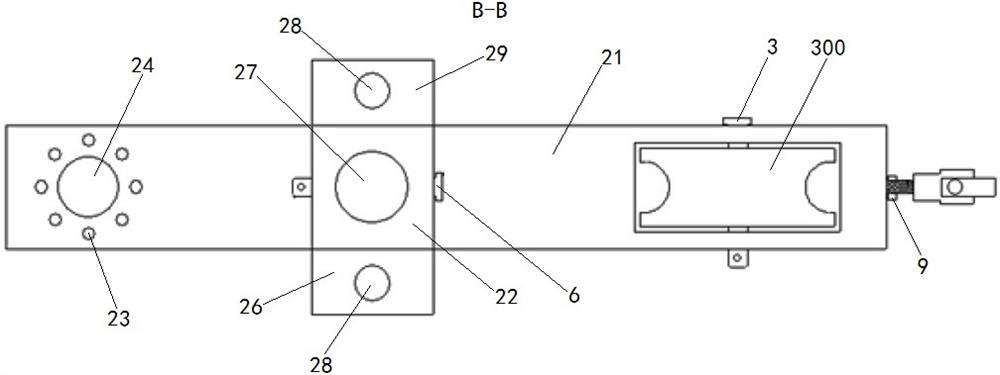

Wellhead hoisting device

ActiveCN113955661APlay a supporting roleCan control up and down reciprocating movementDrilling rodsPortable liftingCylinder blockHoist device

The invention provides a wellhead hoisting device. The wellhead hoisting device comprises a bearing bracket, a pulley yoke, a telescopic power unit, a bearing rod, a first plug pin and a second plug pin; the pulley yoke is arranged at the top of the bearing bracket; the bearing bracket comprises a bearing plate, a bearing lifting block arranged above the bearing plate and support legs; the telescopic power unit comprises a cylinder and a telescopic rod, the upper end of the cylinder is fixed to the bearing plate, the lower end of the cylinder is fixed to the supporting legs, and the telescopic rod penetrates through the bearing plate to be matched with the bearing lifting block in a pushing mode; the bearing rod penetrates through the bearing plate and the bearing lifting block, and a first through hole and a second through hole are formed in the bearing rod; the first plug pin penetrates through the bearing lifting block and the first through hole; the second plug pin penetrates through the bearing plate and the second through hole; only the first plug pin and the second plug pin are installed alternately, the telescopic rod controls the bearing lifting block to move up and down, the first plug pin drives the bearing rod to rise intermittently and is connected with the next section of bearing rod after a certain distance, and operation is repeated till a bearing rod string with a certain height is formed. The wellhead hoisting device is wide in application range, large in lifting weight and small in limitation of well site conditions, and vertical height adjustment is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

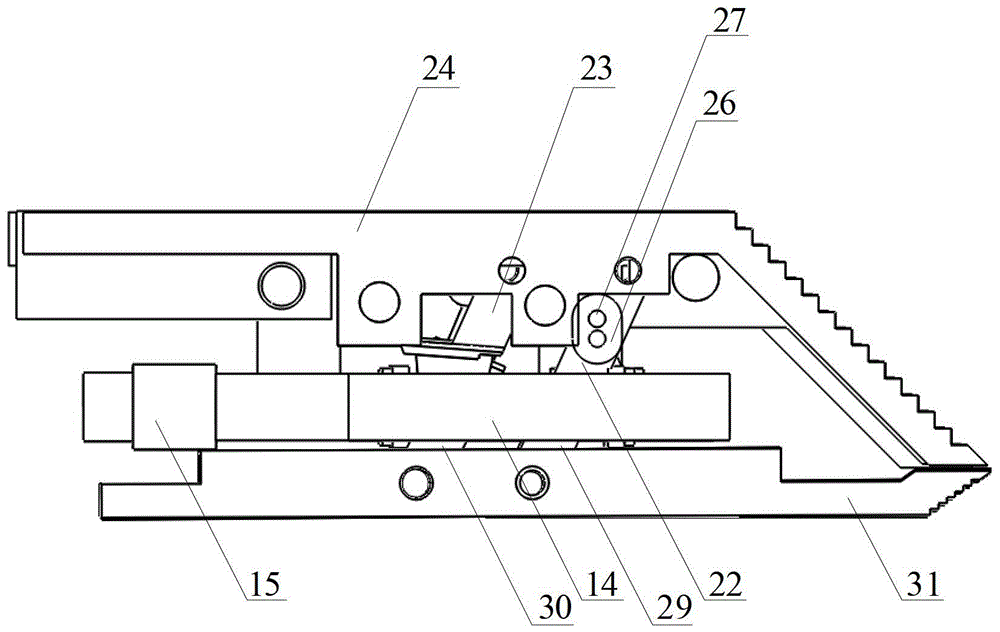

A seam starter with mobile function

InactiveCN104276531BRealize slot liftImprove environmental adaptabilityLifting devicesHoisting equipmentsEngineeringHeavy load

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

A multi-aircraft hoisting coordination control system

ActiveCN103699133BEasy to operateStable hoistingPosition/course control in three dimensionsFlight heightControl signal

Owner:XI AN JIAOTONG UNIV

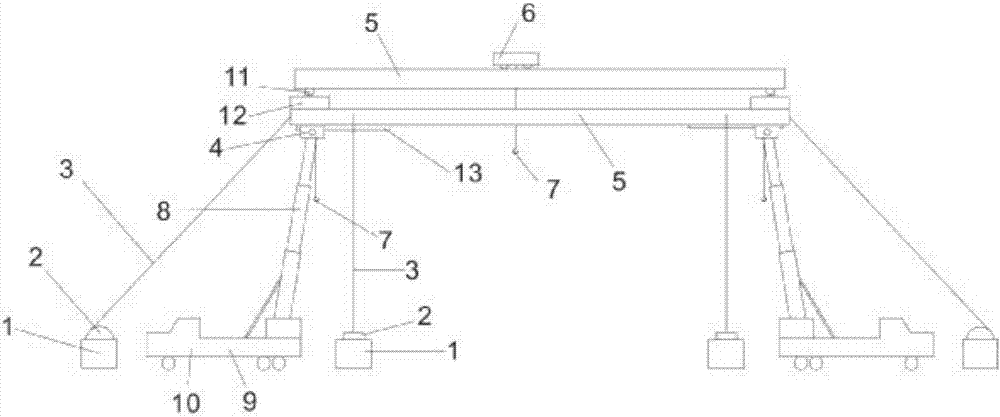

Quadrangle supporting mobile crane

InactiveCN107082379ALarge lifting weightEasy to moveCranesRunwaysOverhead craneAutomotive engineering

The invention discloses a mobile crane with four-corner support, which relates to the technical field of mechanical engineering; a beam, a longitudinal beam, a lifting trolley, a hook, a connecting device, a lifting arm, a car body and four automobiles or tire-type cranes; The beam and the longitudinal beam are connected to form an I-shaped or square frame, the lifting trolley is set on the beam, the boom is set on the car body of the automobile or tire crane, and the connecting device is set on the beam and the longitudinal beam. On the four corners and booms that make up the frame, the booms of four trucks or tire-type cranes are respectively installed on the four corners of the frame formed by beams and longitudinal beams through connecting devices; Above; the lifting weight of the present invention is large, the lifting range can exceed a crane diameter range, and it is easier to move than ordinary bridge cranes.

Owner:周睿萱

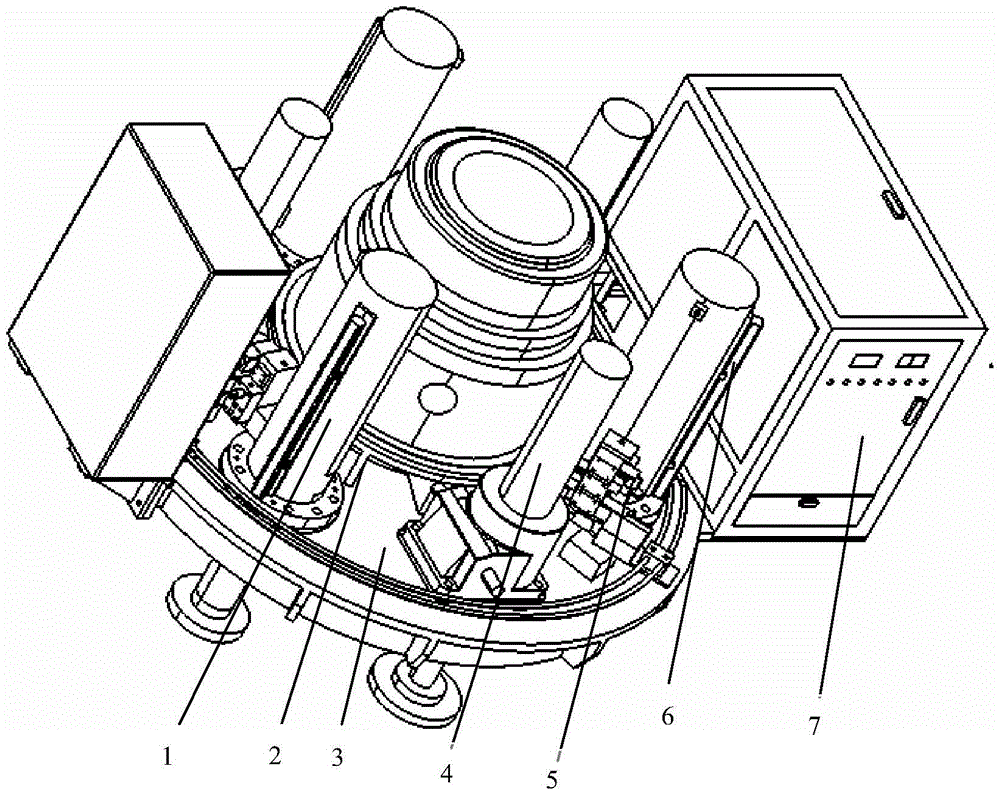

Aircraft air spring lifter

ActiveCN103616150BImprove support efficiencyShorten the timeVibration testingHydraulic cylinderAir spring

The invention belongs to aircraft suspension support technology, in particular to an aircraft air spring lifting support. The aircraft air spring lifting support of the invention includes a hydraulic station, a hydraulic lifting cylinder, a base, an auxiliary support, an air spring installation base plate, a control valve group, and a displacement sensor. The air spring installation base plate is a circular flange structure, which is set on the base for installing the air spring. Three hydraulic sound drop cylinders and three auxiliary supports are arranged around the air spring at intervals and evenly distributed on the air spring installation base plate In addition, the hydraulic lifting actuators are all provided with control valve groups and connected to the hydraulic station, and the displacement sensors are arranged on the side walls of the hydraulic lifting actuators. The air spring special lifting support for large aircraft of the present invention realizes three-point synchronous lifting of large aircraft in the support, greatly reduces the risk of aircraft support, and has extremely high safety and reliability.

Owner:CHINA AIRPLANT STRENGTH RES INST

Large-bearing-capacity sleeve unloading mechanism

InactiveCN102491184BFully automatedAchieve mechanical propertiesCranesLoad-engaging elementsCylinder headSlider bearing

The invention relates to a large-bearing-capacity sleeve unloading mechanism characterized in that: the mechanism is mainly composed of connected components of a sleeve collecting rack, a boom driving oil cylinder, a boom, a lifting hook, a sleeve detecting sensor, a lifting hook opening rate adjusting motor, an absolute value encoder, and a driving oil cylinder pedestal. A sleeve storing working face of the sleeve collecting rack is an inclined plane; holes used for installing the boom are provided on two sides of the sleeve collecting rank; the driving oil cylinder pedestal is fixed in the inner cavity of the sleeve collecting rack; the driving oil cylinder pedestal is hinged with the driving oil cylinder; a cylinder head of the boom driving oil cylinder is connected with a jib of the boom; the boom is connected to the sleeve collecting rack through a sliding bearing; the lifting hook is connected to the boom; the sleeve detecting sensor is connected to a roll loading trolley; the sleeve detecting sensor is used for detecting whether a sleeve is on the trolley; the absolute value encoder penetrates the jib through a shaft; two ends of the absolute value encoder form a clearance fit with the inner ring of the sliding bearing. With the mechanism provided by the invention, automation of sleeve unloading can be fully achieved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com