Large-bearing-capacity sleeve unloading mechanism

A technology of carrying capacity and unloading sleeves, applied in the directions of cranes, load hanging components, transportation and packaging, etc., can solve the problems of low work efficiency of crane operators, unfavorable automation and mechanization, etc., and achieve simple structure, easy maintenance and repair, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

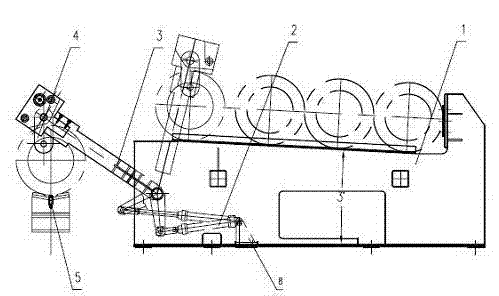

[0025] The invention is mainly used in the treatment unit of thick plate (max4mm) to unload the sleeve.

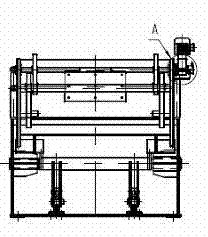

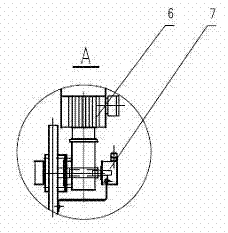

[0026] This kind of sleeve unloading mechanism with large load capacity is mainly composed of sleeve collection rack 1, boom driving cylinder 2, boom 3, hook 4, sleeve detection sensor 5, hook opening adjustment motor 6, absolute value The encoder and the drive cylinder base 8 are connected to form, the storage sleeve working surface of the sleeve collection rack 1 is an inclined plane, there are holes for installing the boom 3 on both sides of the sleeve collection rack 1, and the inner cavity of the sleeve collection rack 1 is fixed with a drive The oil cylinder base 8 is hinged with the driving oil cylinder, the cylinder head of the arm driving oil cylinder 2 is connected with the boom of the arm; the arm 3 is connected with the sleeve collecting frame 1 through the sliding bearing 3-1, and the hook 4 is connected with the arm Together; the sleeve detection sensor 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com