Patents

Literature

258results about How to "Improve support efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

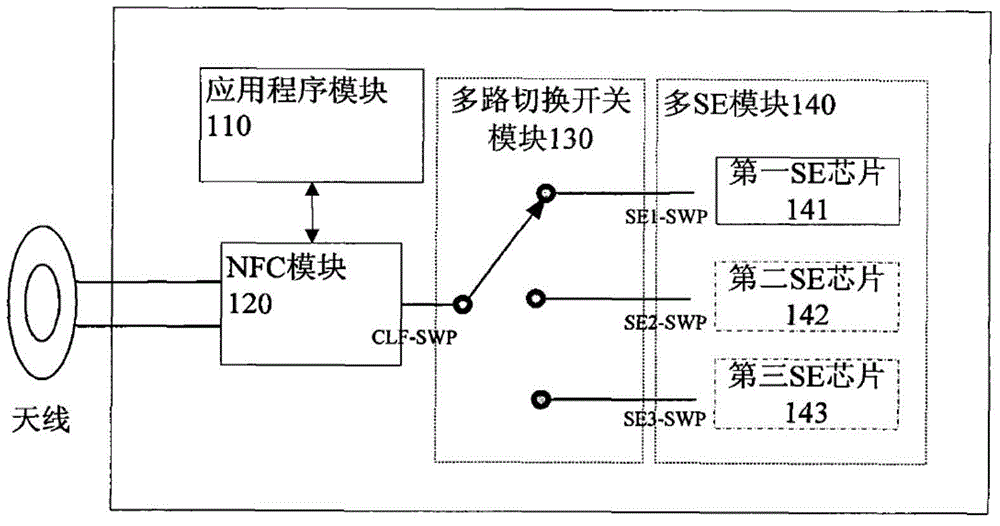

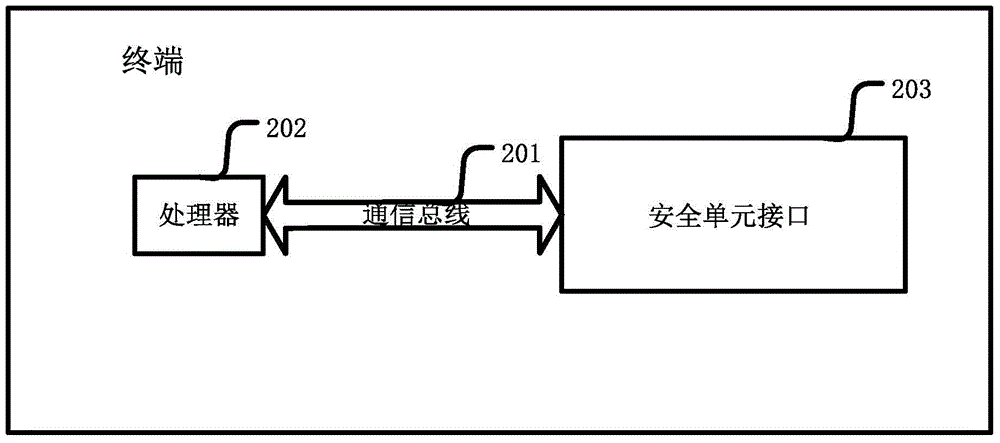

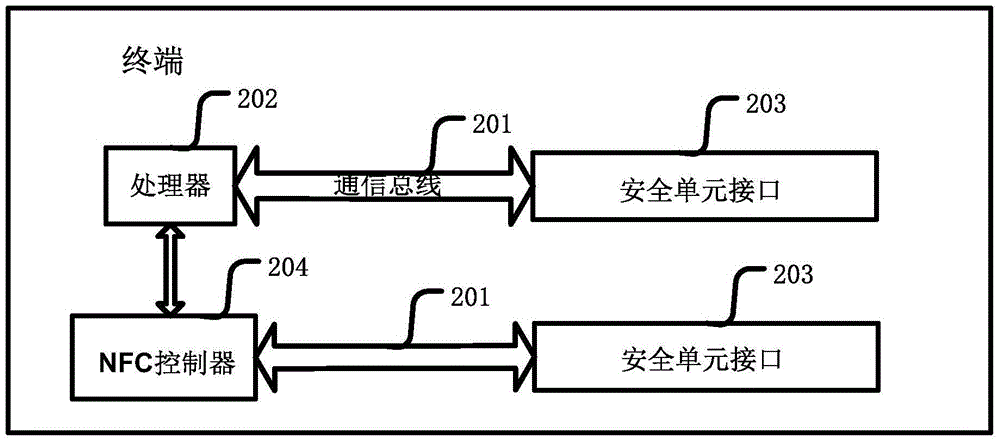

Safety unit management method and terminal

ActiveCN104471600AImprove support efficiencyNear-field transmissionPayment protocolsMobile paymentSecure unit

The embodiment of the invention provides a safety unit management method and a terminal. The method and the terminal relate to the field of mobile payment. The method comprises the following steps: when a first safety unit is accessed to the interface of the safety unit, the identification information of the accessed first safety unit is obtained; preset identification information is obtained and used for identifying an exclusive safety unit; the identification information of the first safety unit and the preset identification information are matched; when the identification information of the first safety unit and the preset identification information are matchable, the first safety unit is set to be in the normal operation state, and other safety units accessed to the terminal are in the abnormal operation state. The embodiment of the invention allows the terminal to support an exclusive safety unit management mode, meets the requirements that exclusive safety unit issuers grasp a terminal safety unit control right, and improves supporting efficiency of mobile payment.

Owner:HUAWEI DEVICE CO LTD

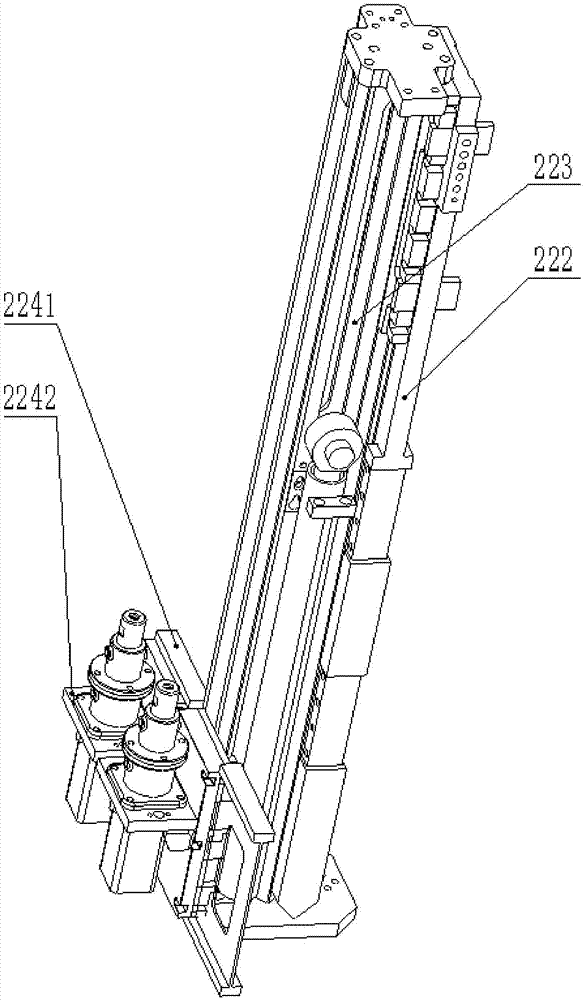

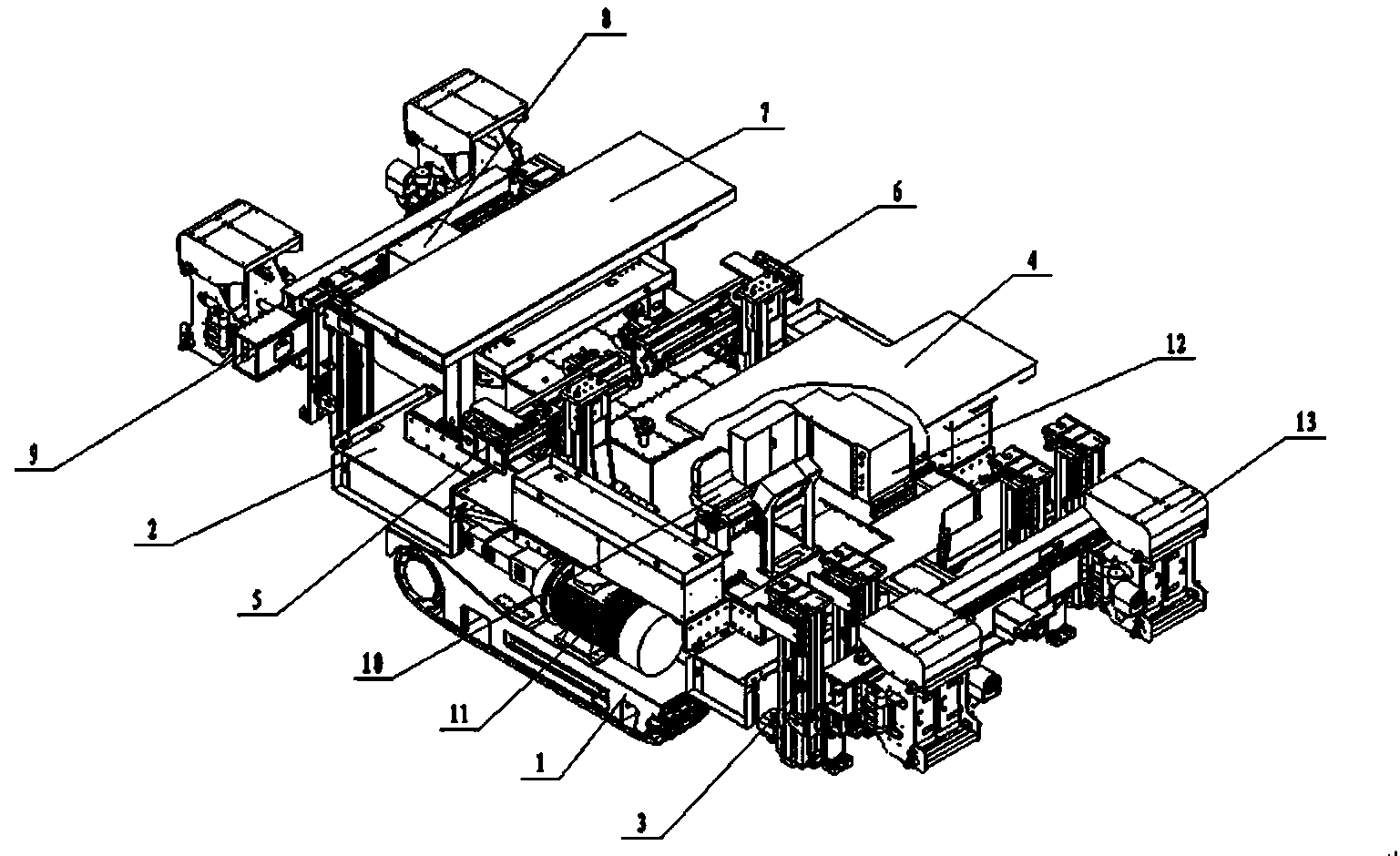

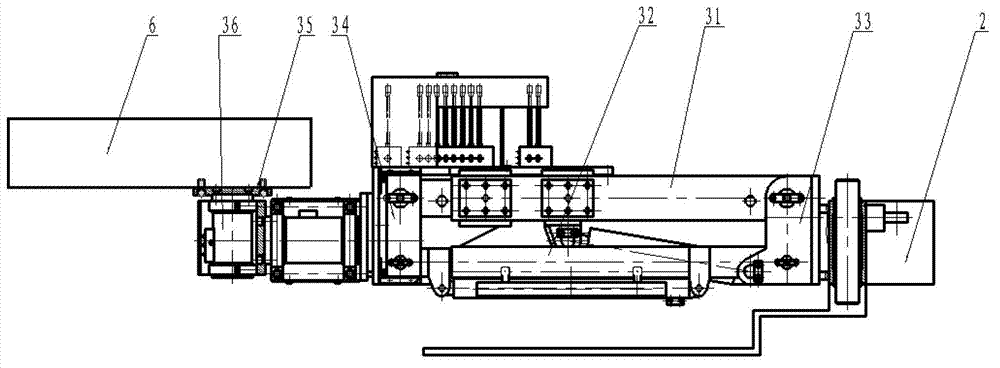

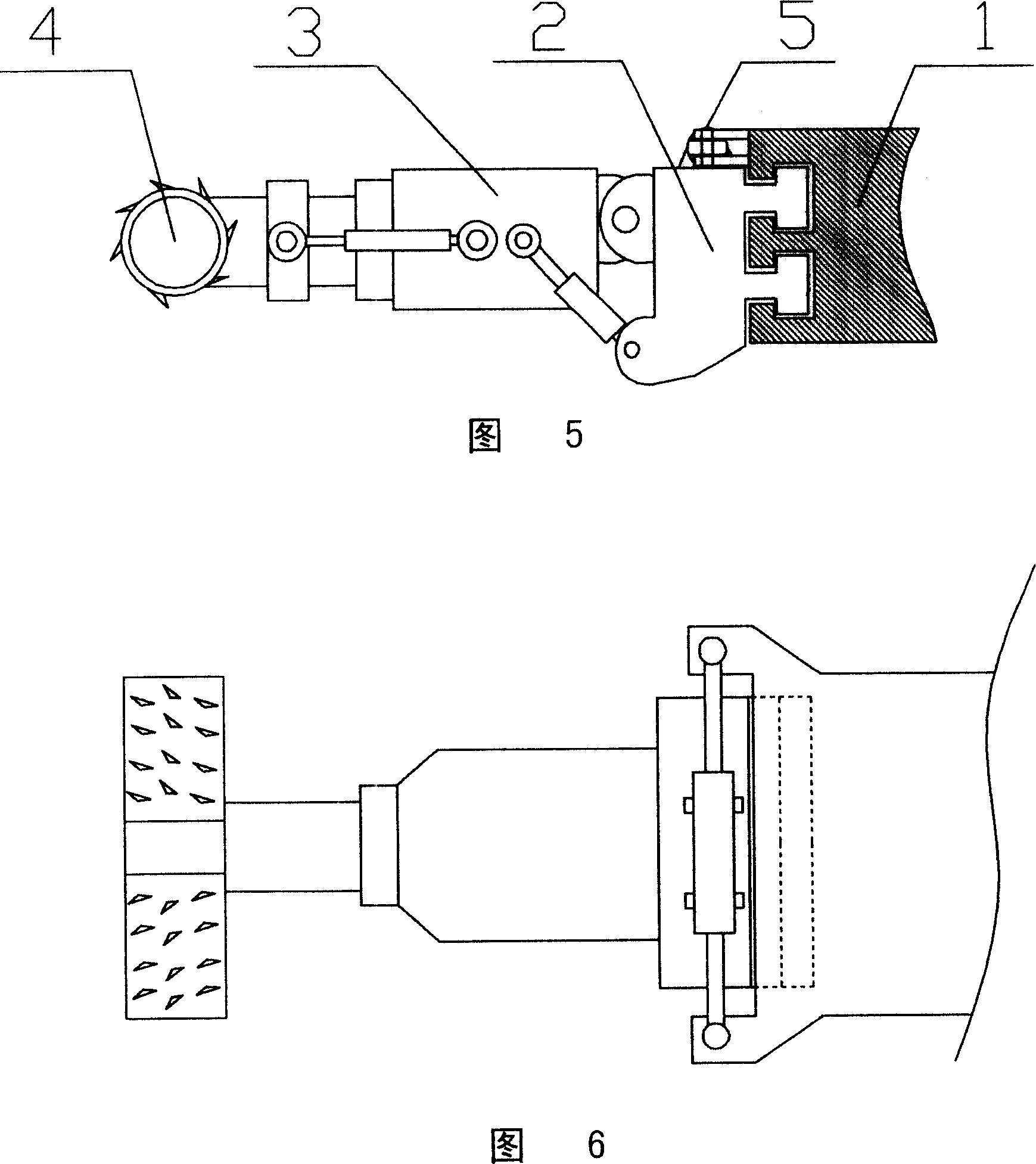

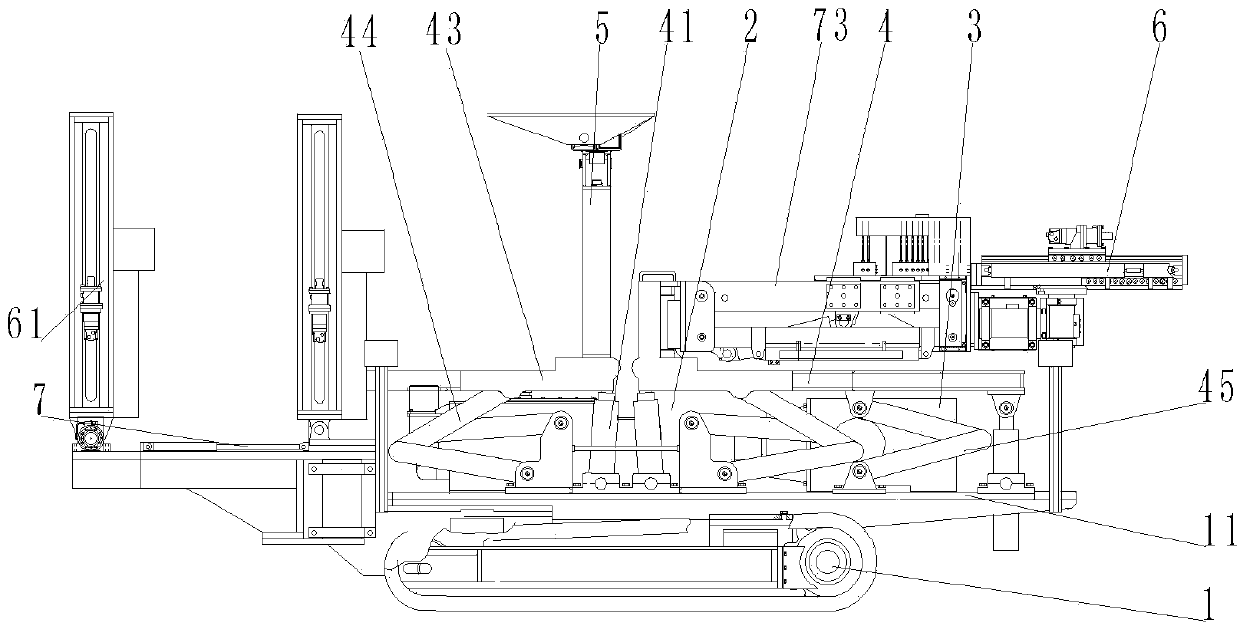

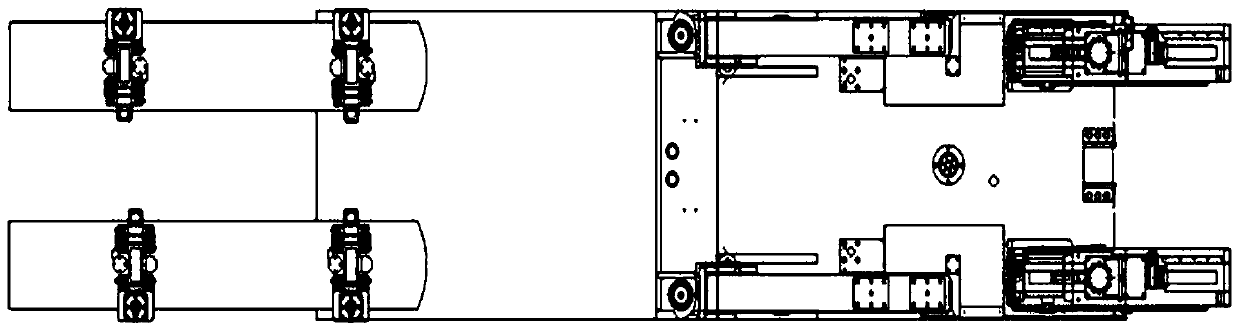

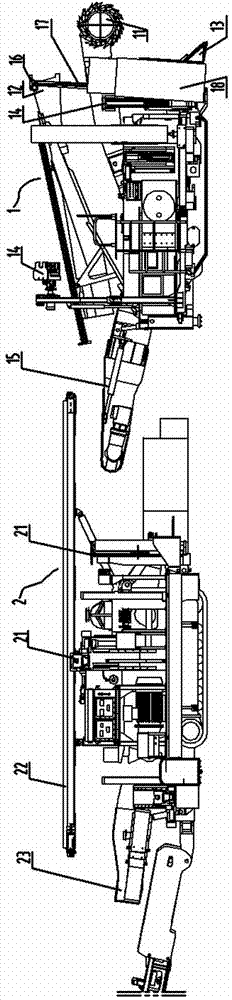

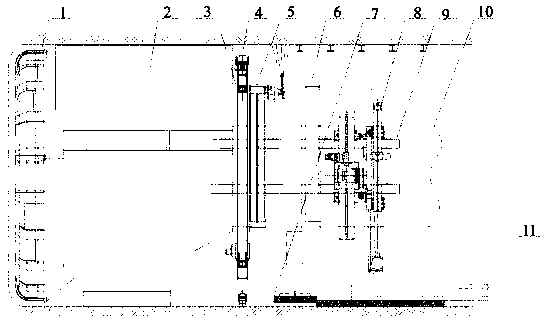

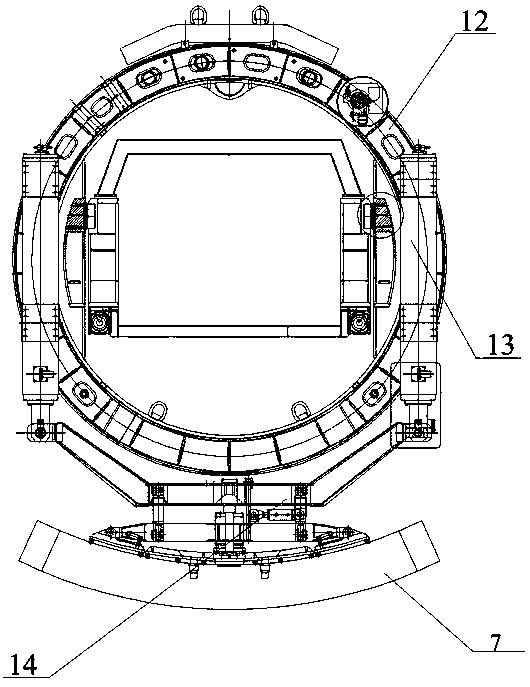

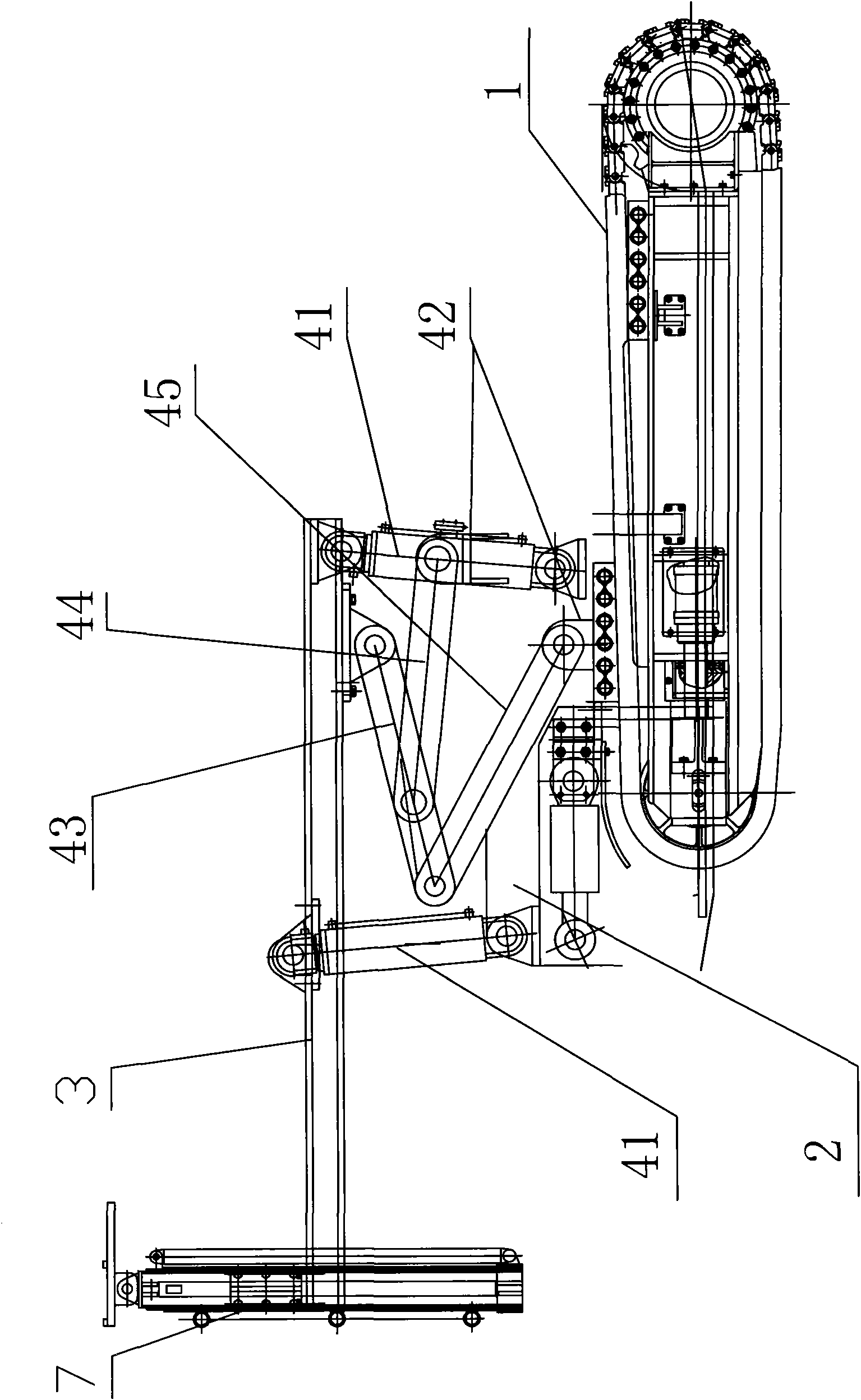

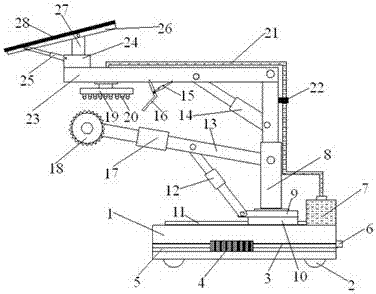

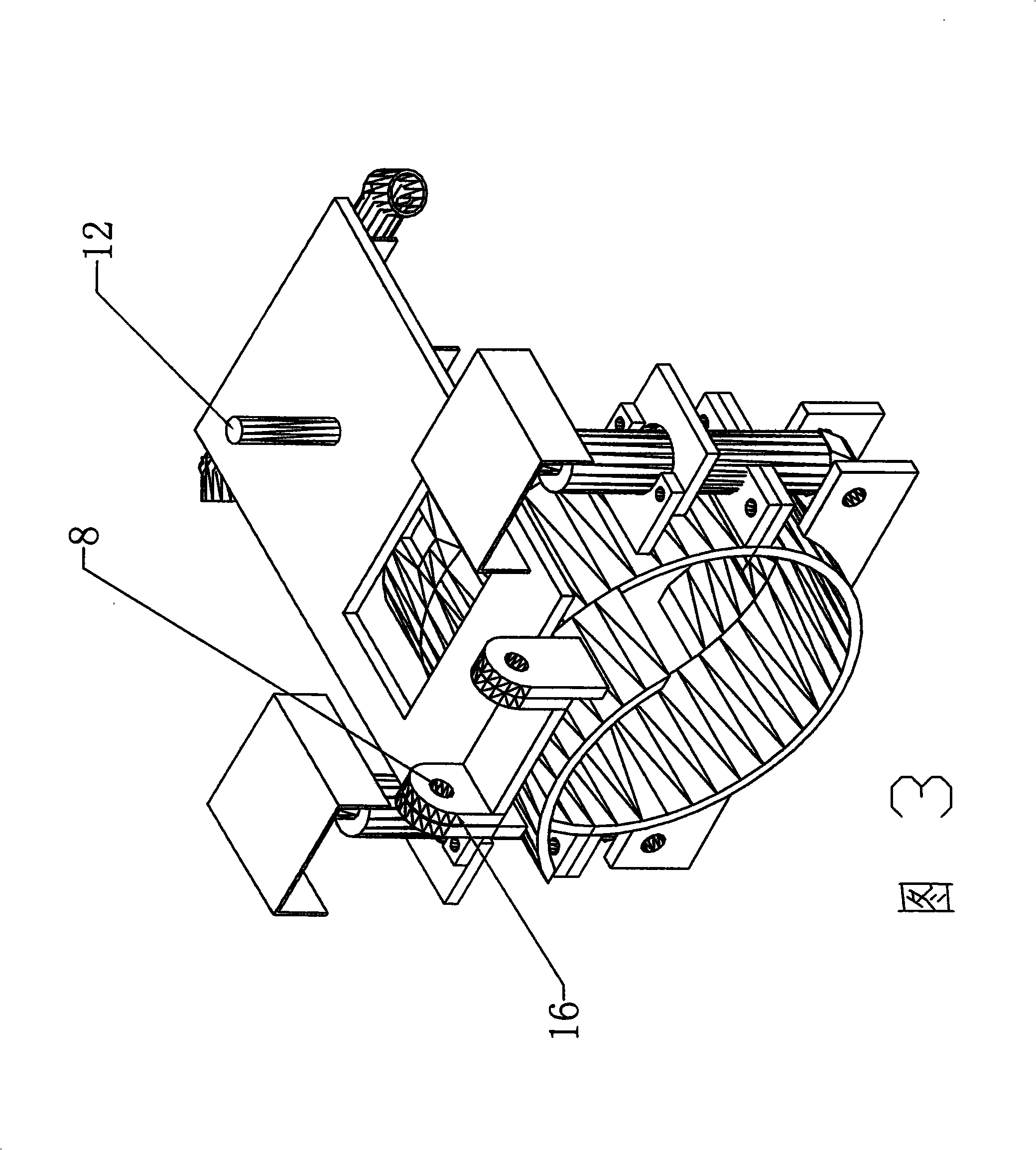

Anchor rod jacking drilling machine and anchor rod jacking drilling carriage with same

ActiveCN105443037AImprove locking abilityMechanizationDerricks/mastsAnchoring boltsUltimate tensile strengthTransferring (function)

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:蒲长晏

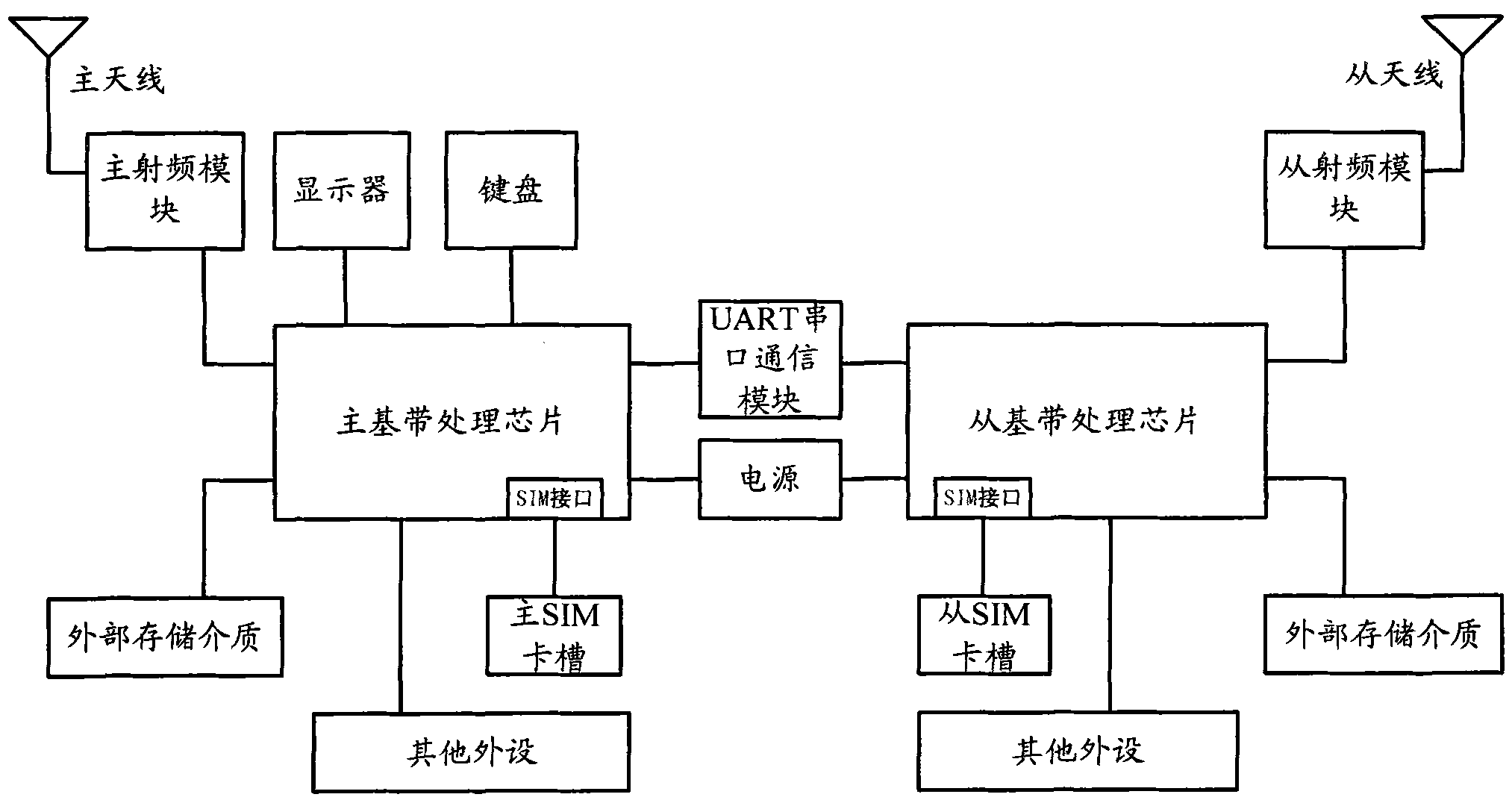

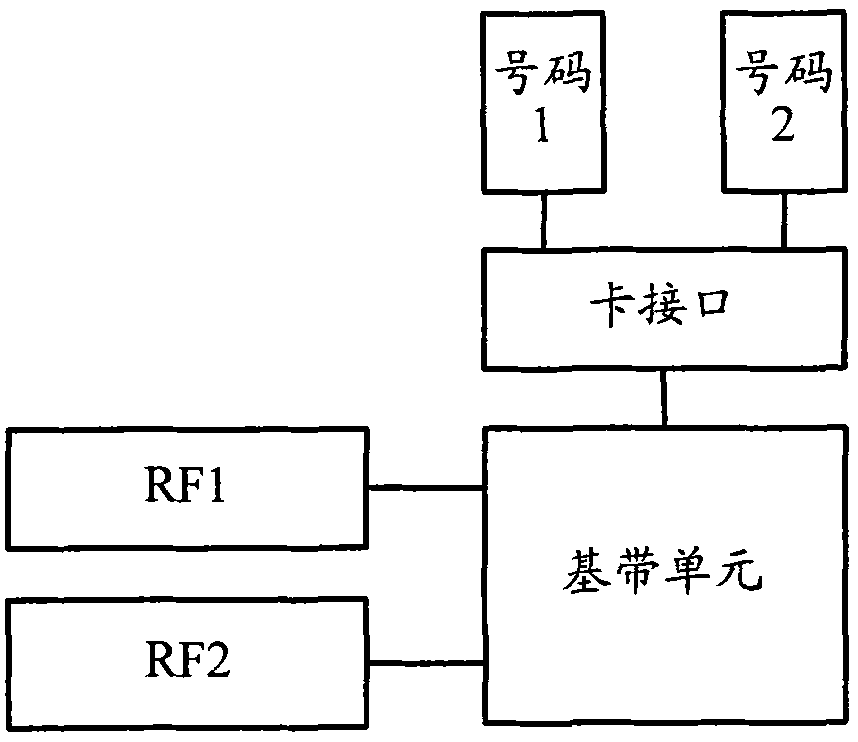

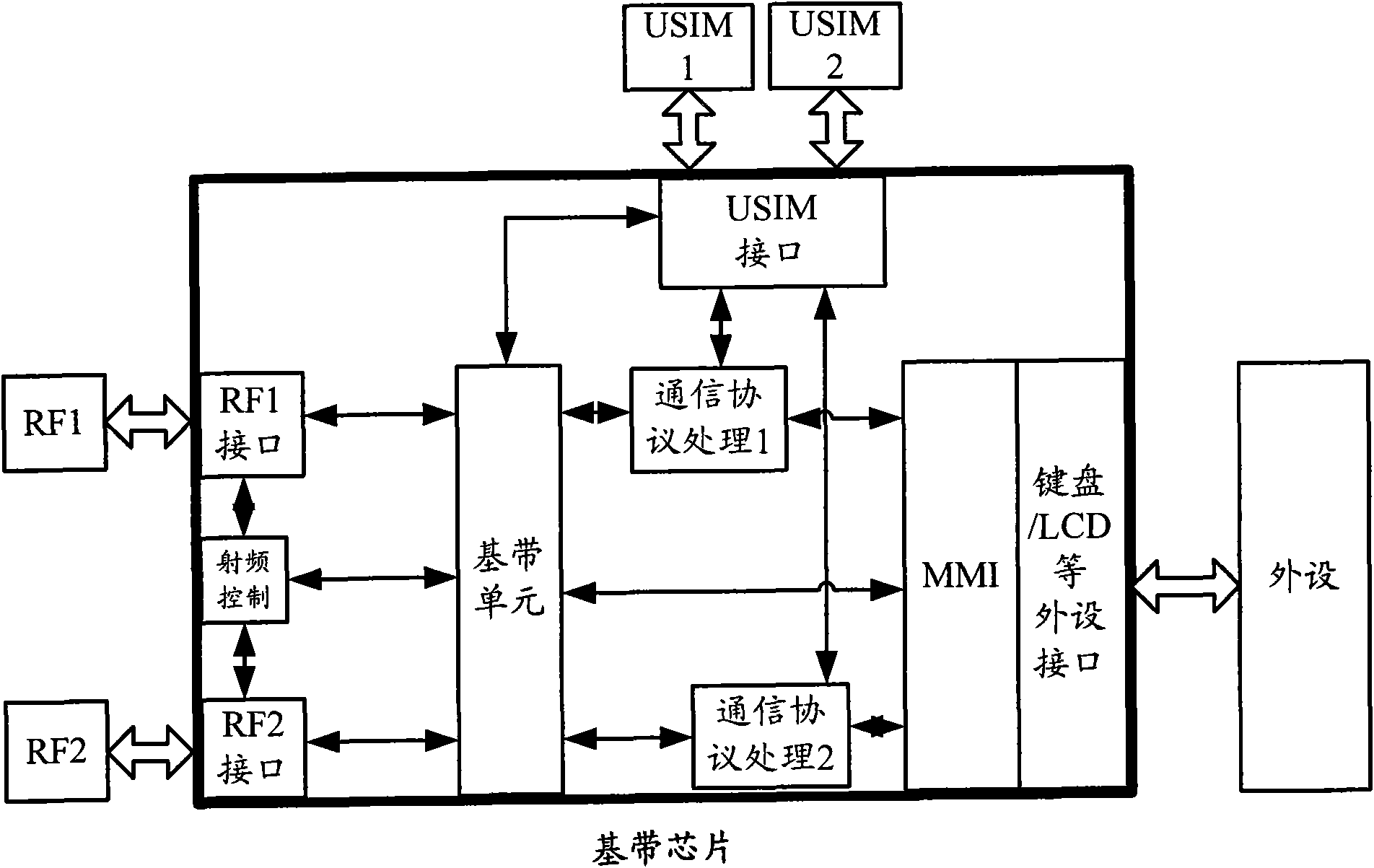

Double-standby wireless terminal

InactiveCN101990319AReduce terminal sizeLow costWireless communicationProtocol processingThird generation

The invention relates to wireless communication field and discloses a double-standby wireless terminal. In the invention, two independent radio frequency unit share a baseband unit in order to realize the simultaneous standby of two numbers and lower cost. When the two radio frequency units support 2G or 3G respectively, one of the radio frequency units is put to time division multiplexing by the baseband unit if two protocol processing units both work under 2G or 3G protocol, in order to achieve the effect of simultaneous standby of two numbers or communication under one of the numbers. When the networks supported by the two radio frequency units are identical to the networks supported by the two protocol processing units, the two protocol processing units form two combinations with different radio frequency units respectively so as to support the simultaneous standby and the simultaneous communication of the two numbers. Being further simplified, such a terminal uses one radio frequency unit and one baseband chip only and supports SIM or USIM slot and 2G or 3G protocol simultaneously, thus the terminal can be simplified into single-baseband chip single-module double-standby wireless terminal of 2G or 3G system.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

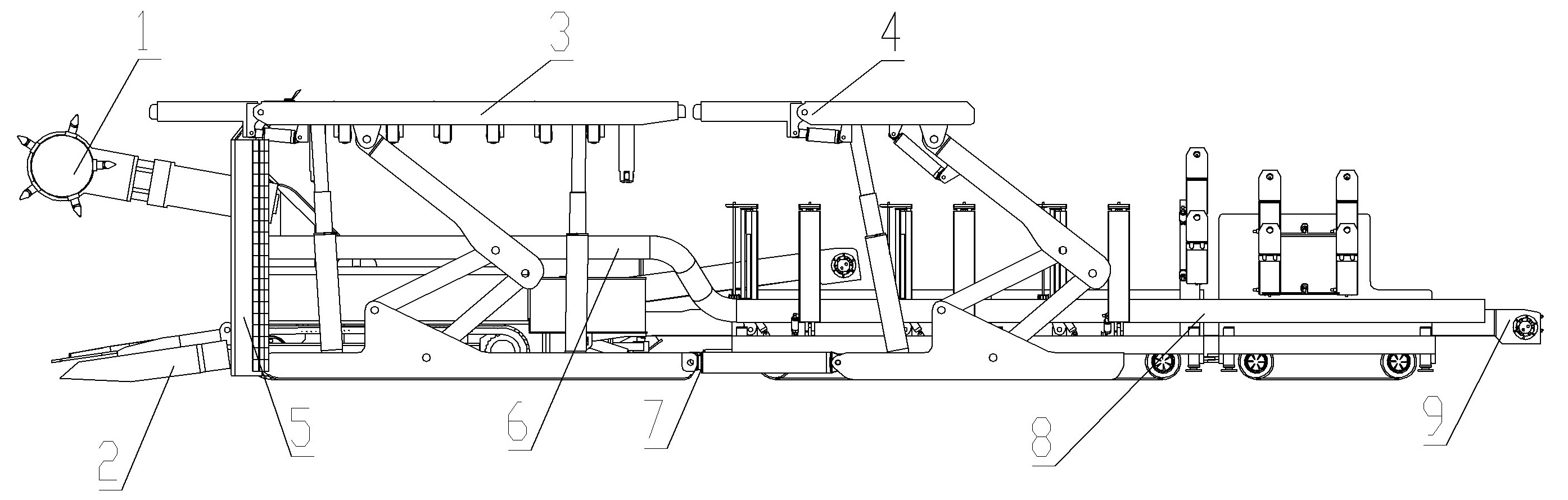

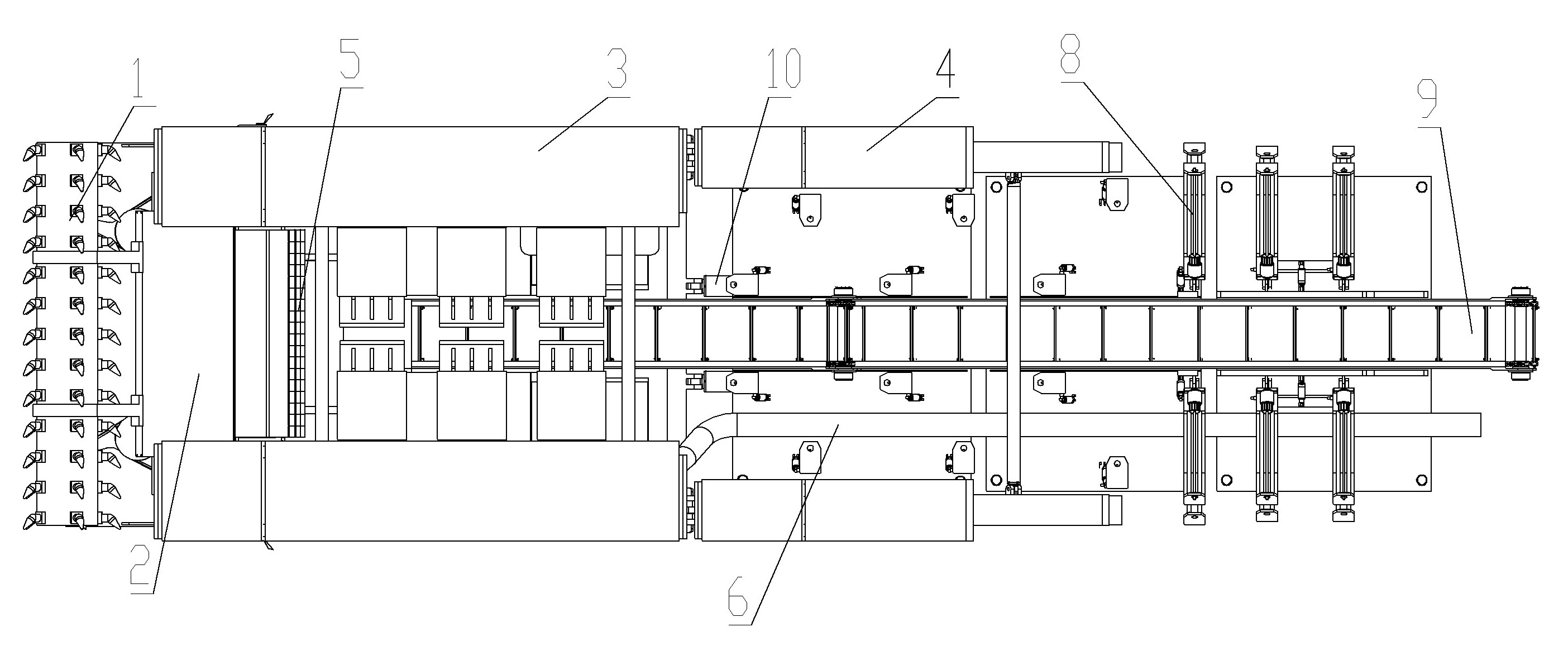

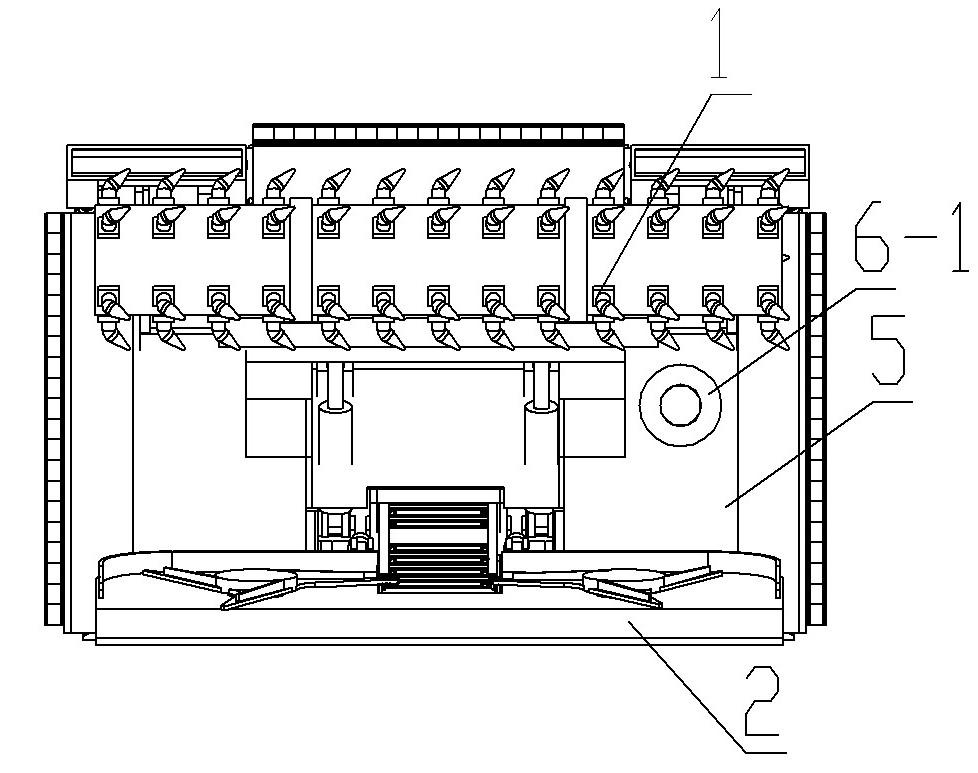

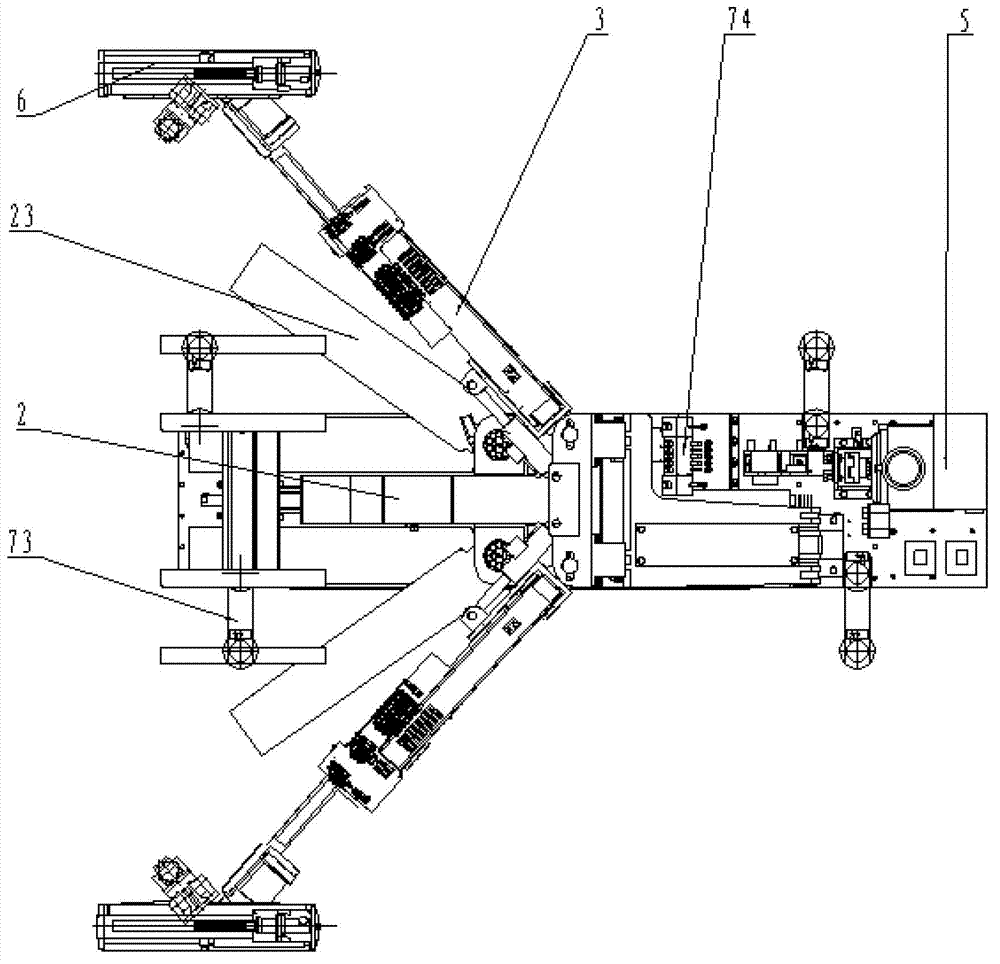

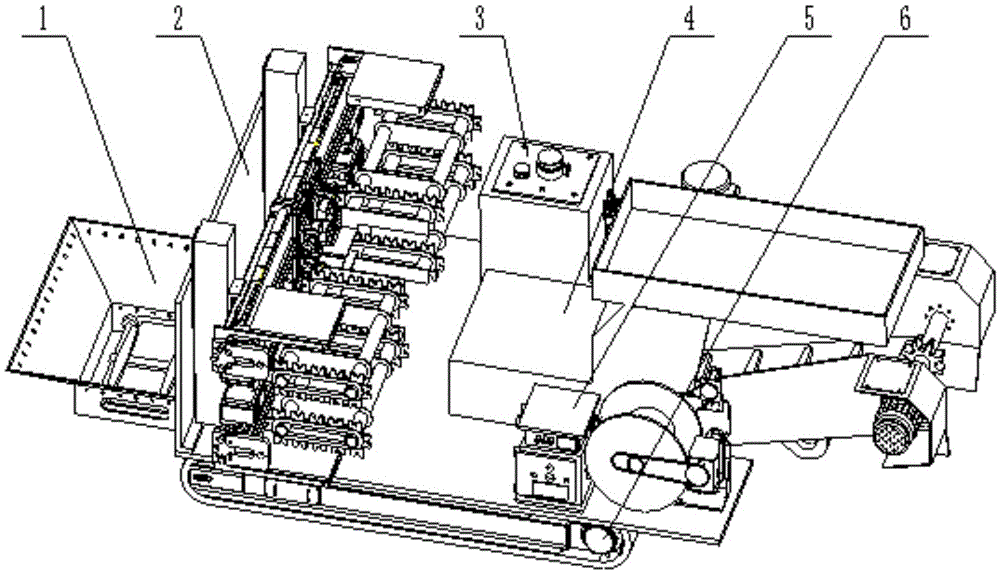

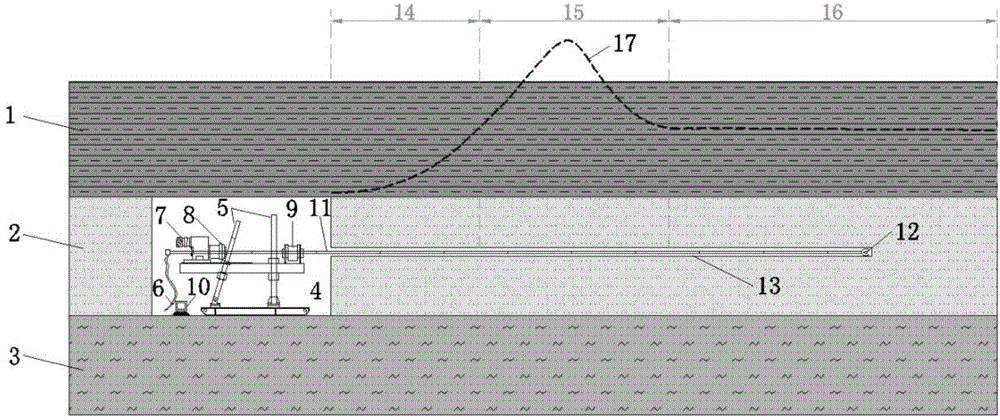

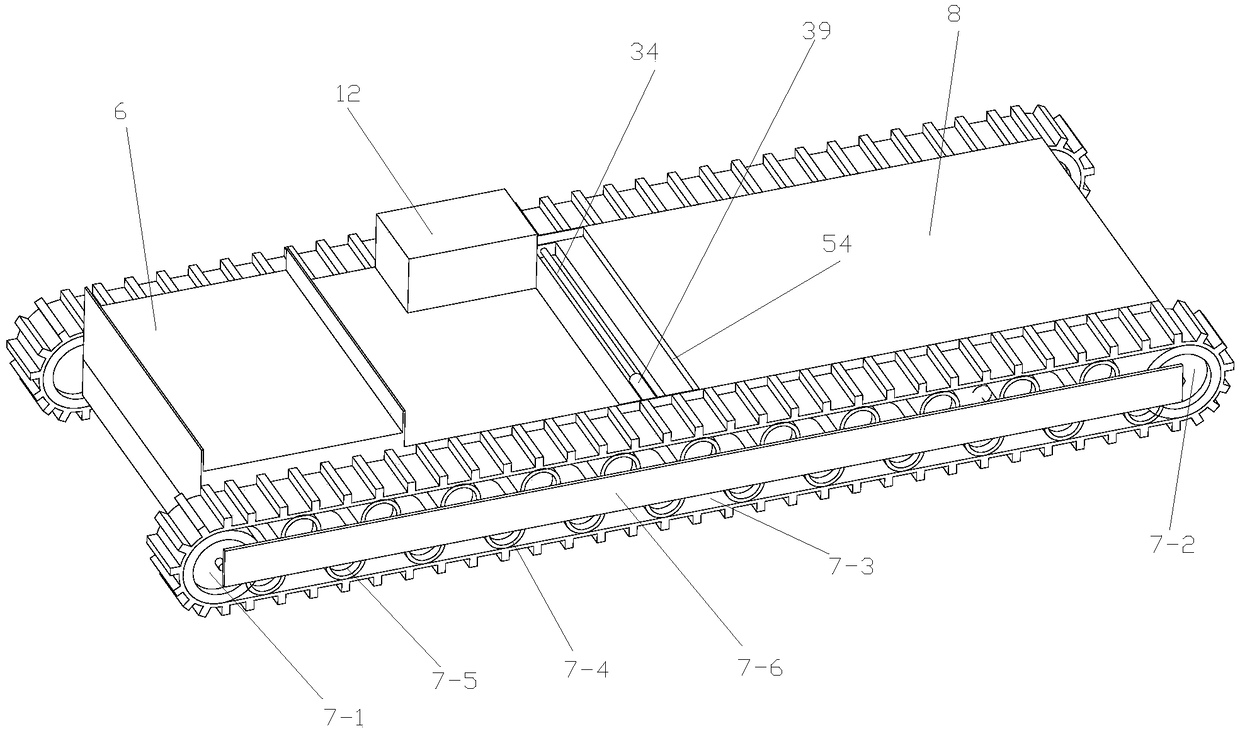

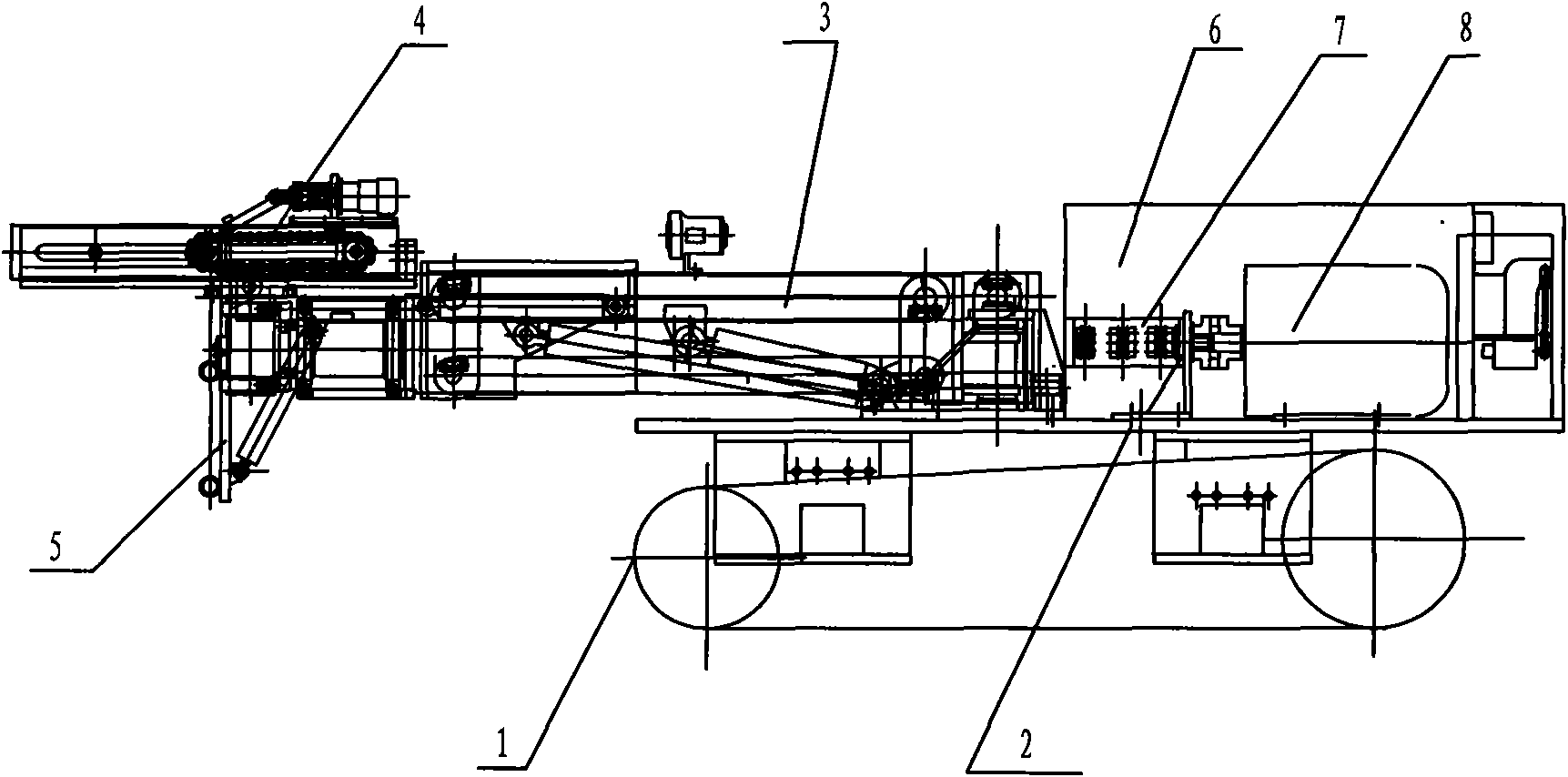

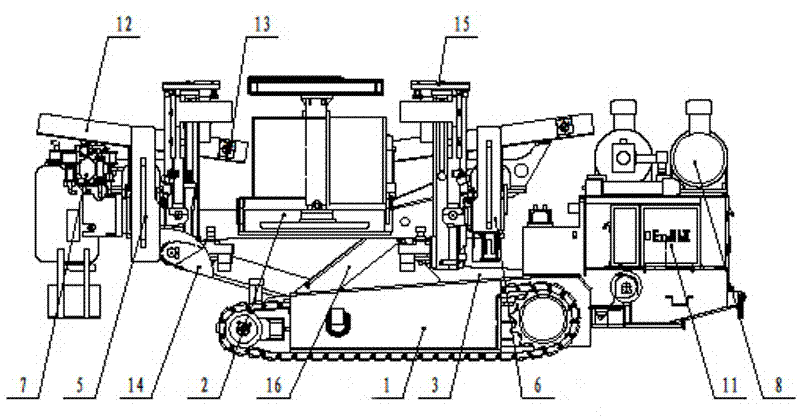

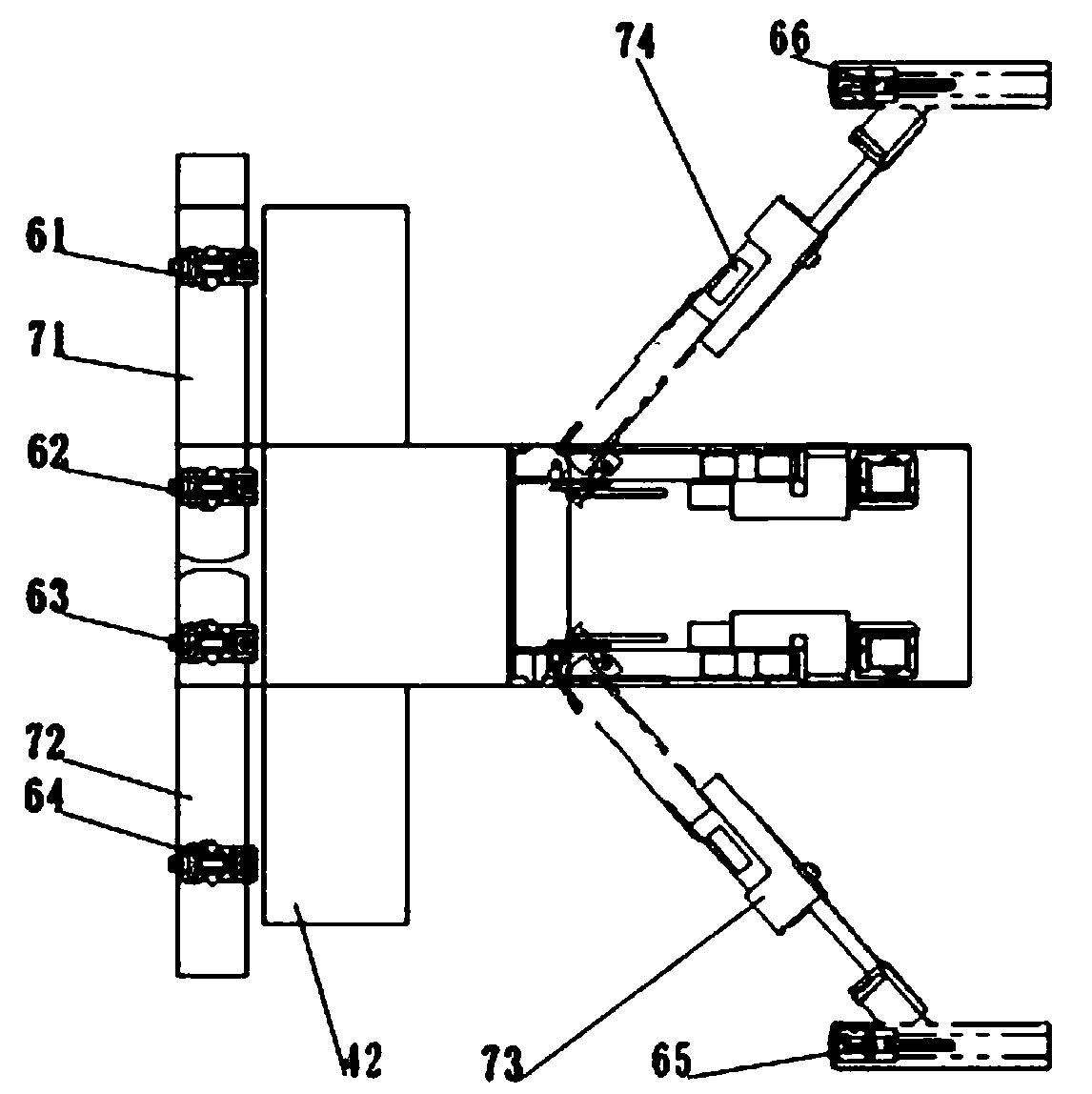

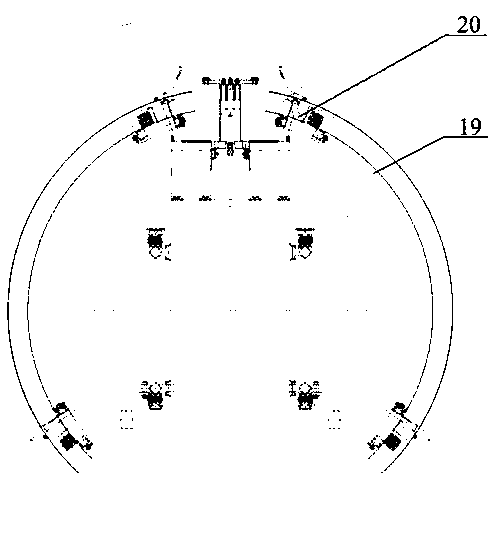

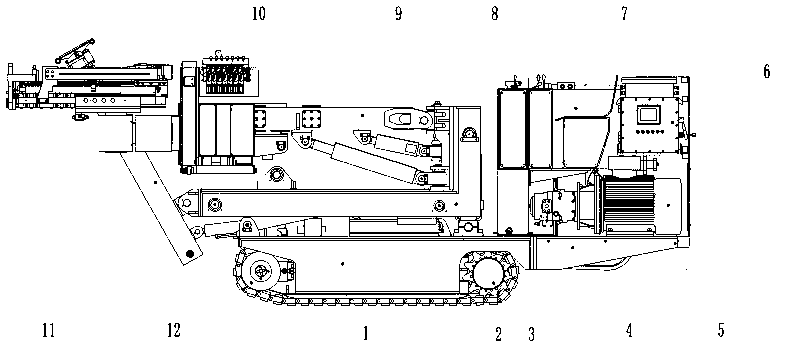

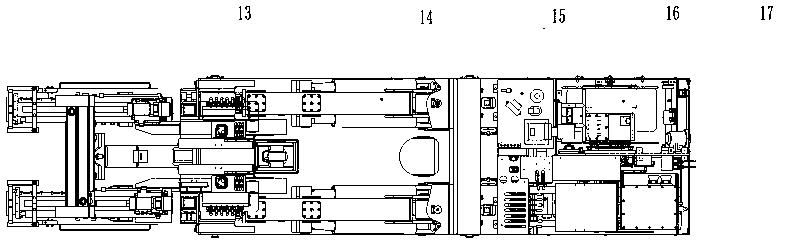

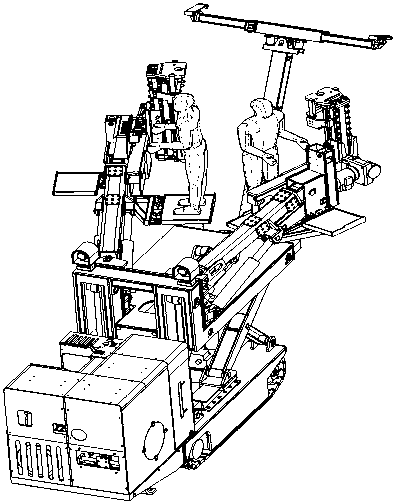

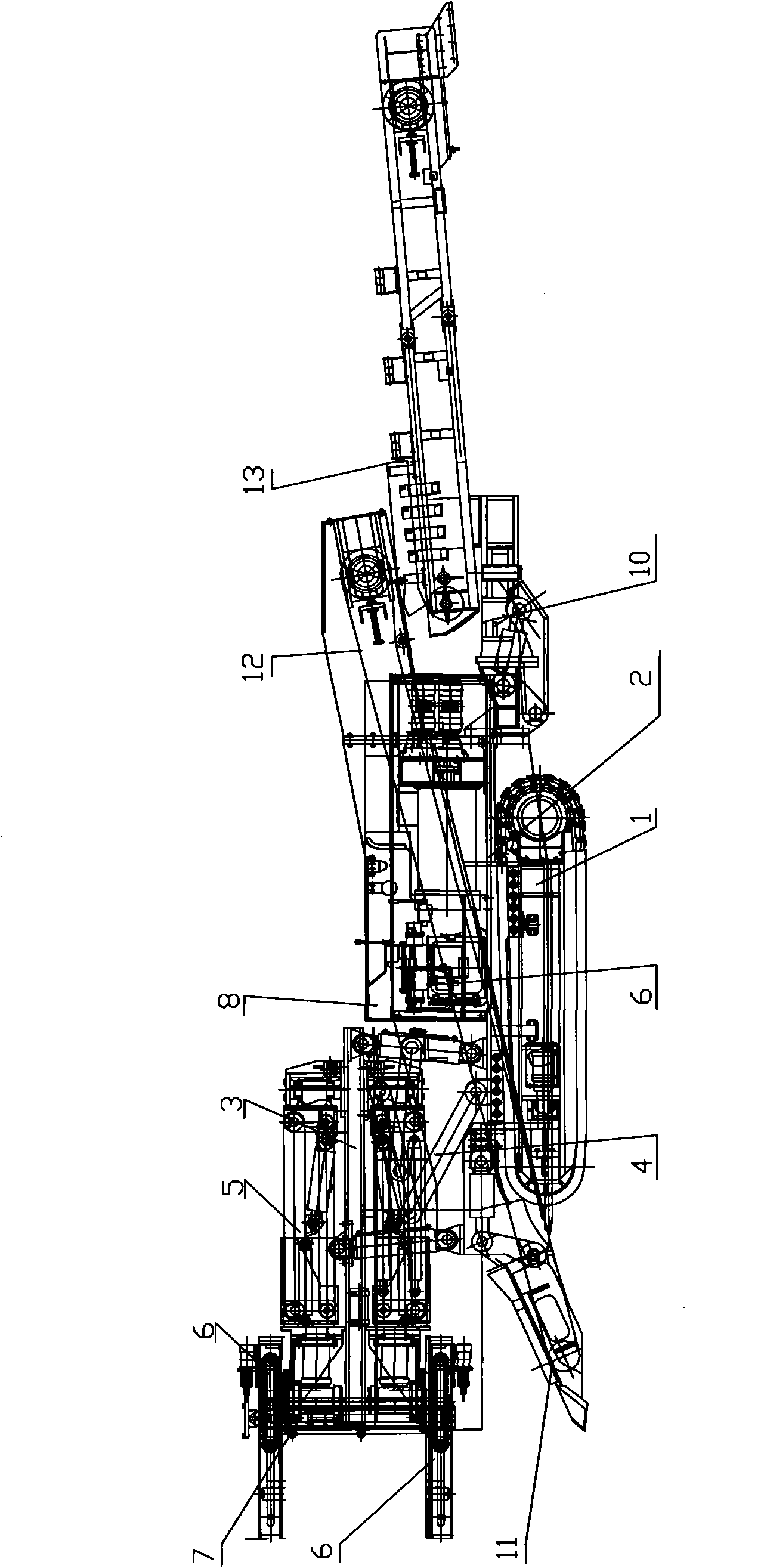

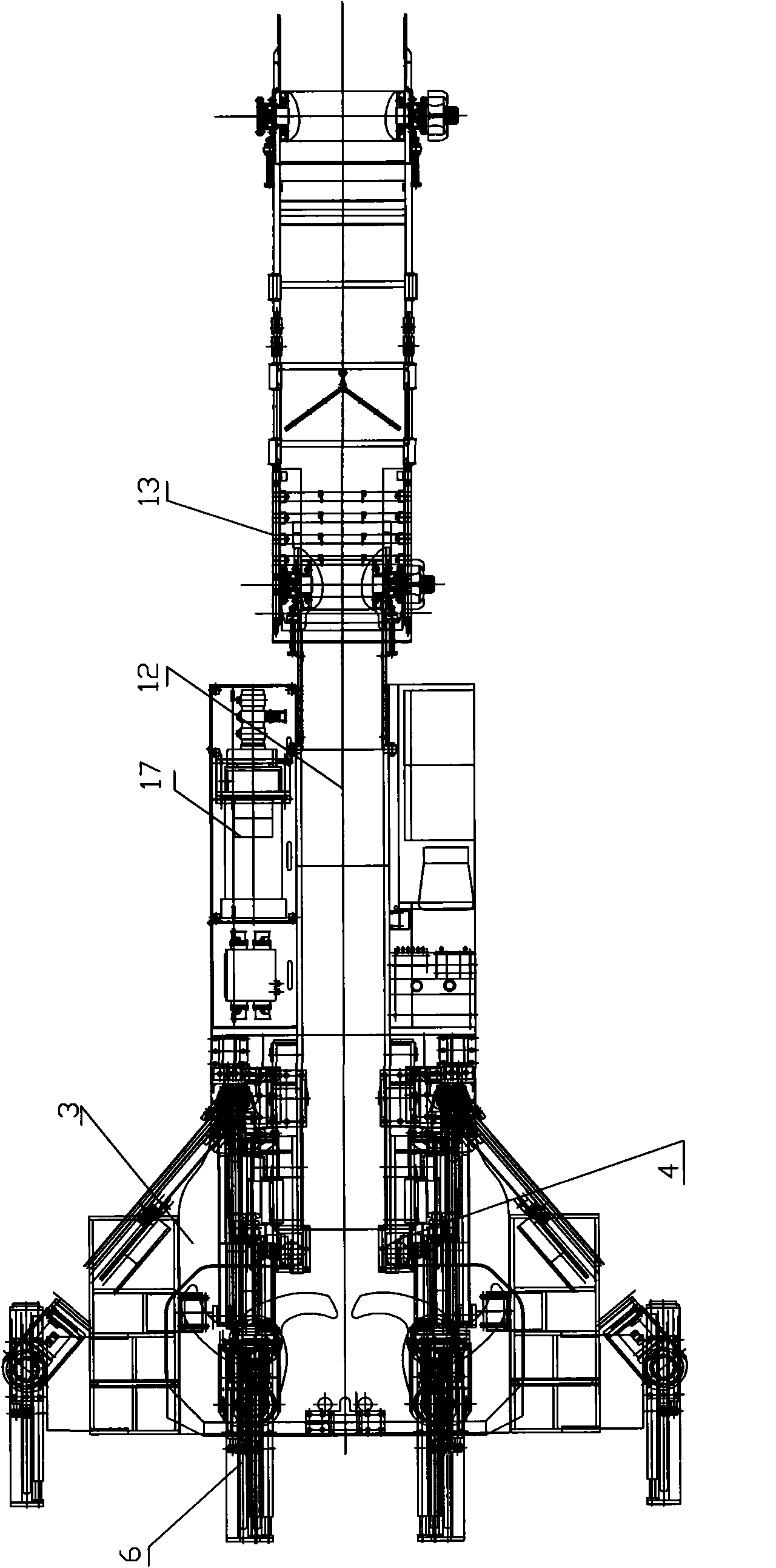

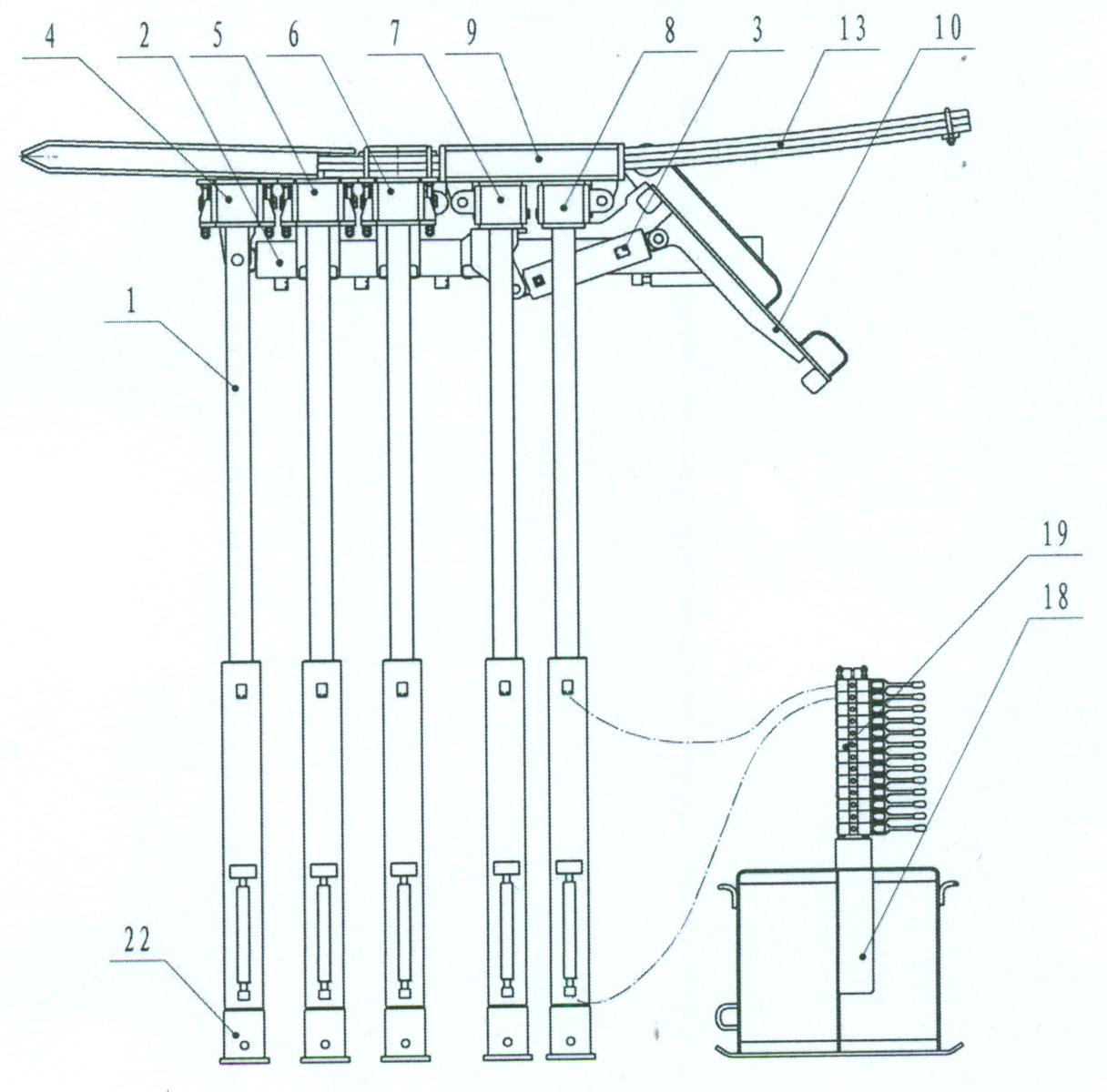

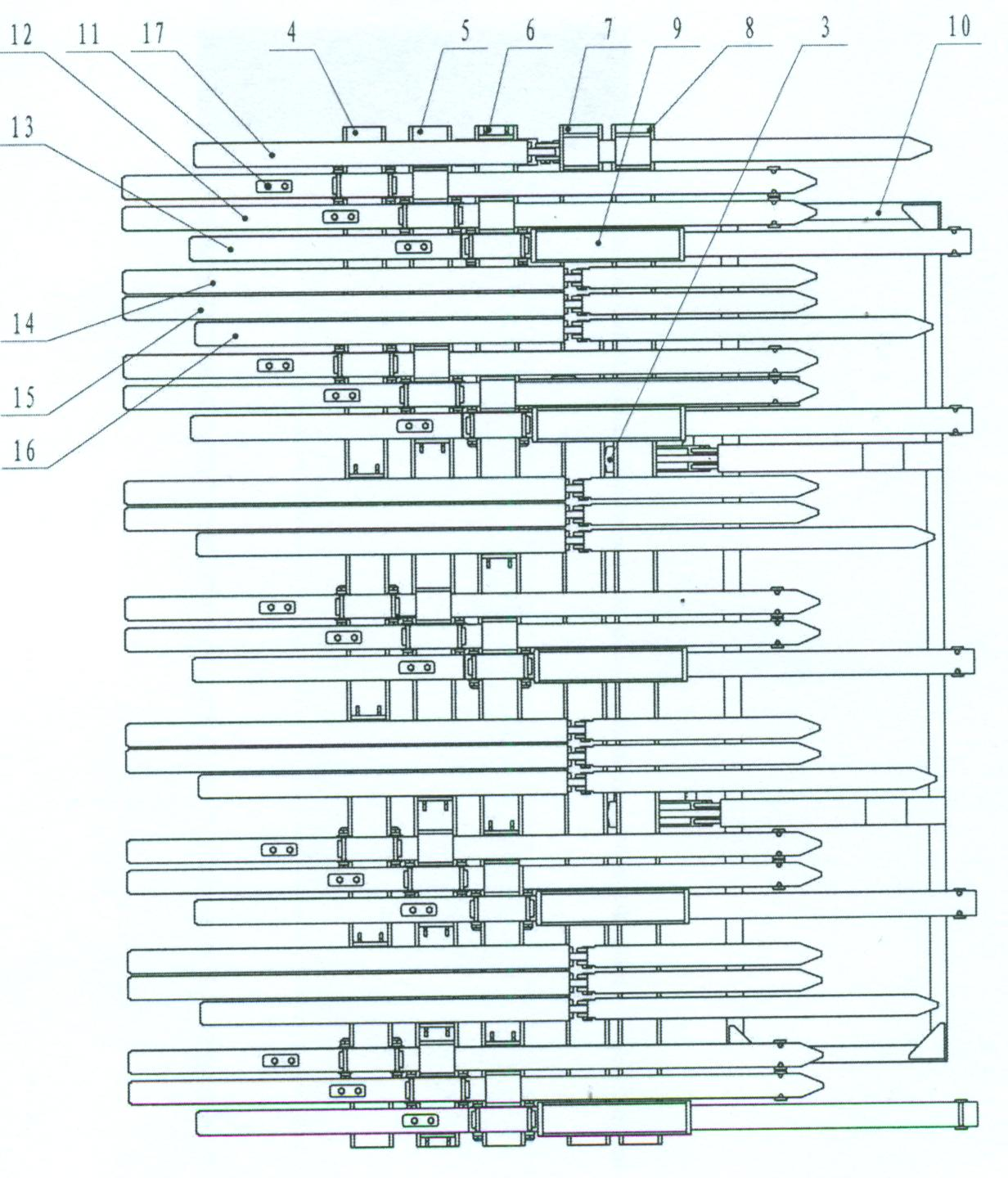

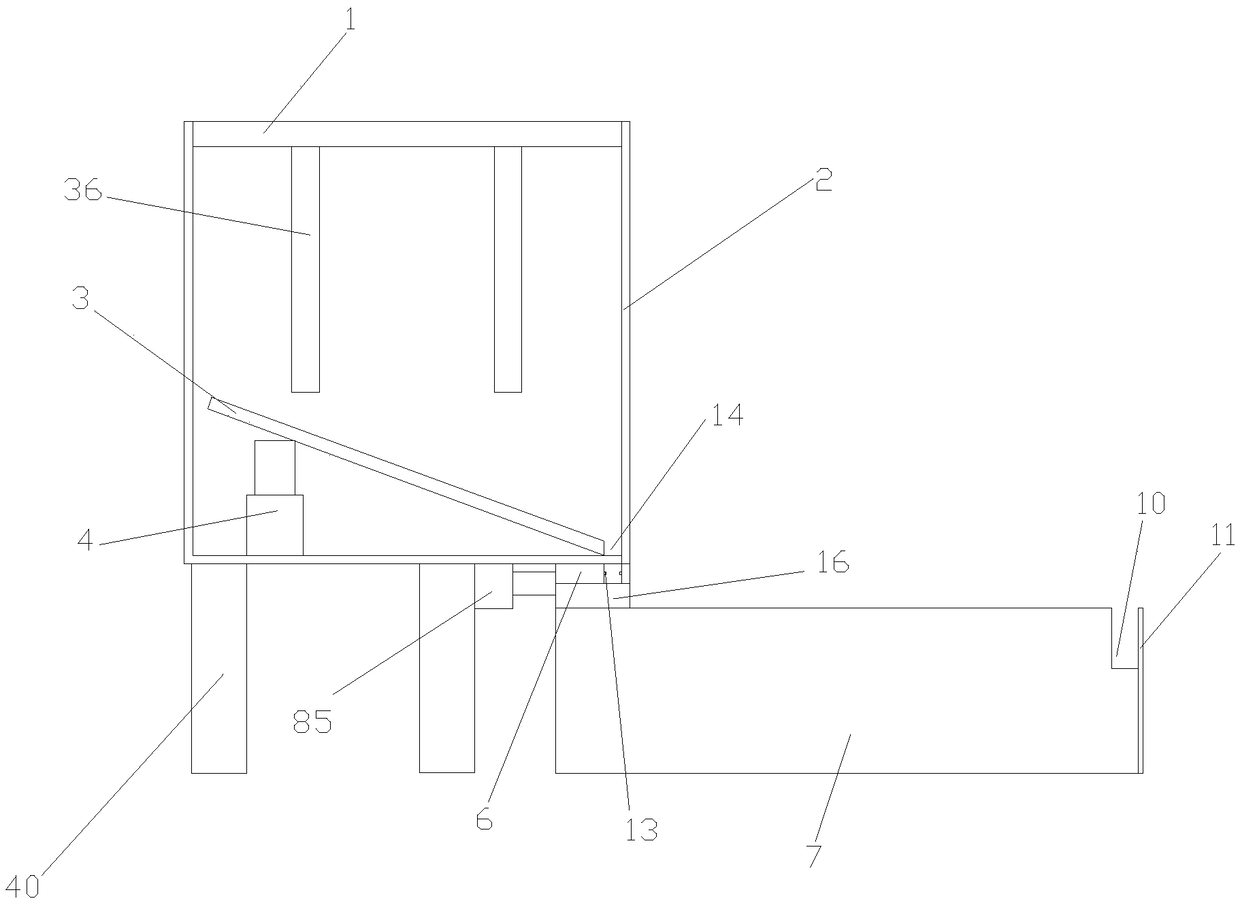

Anchor rod drill carriage integrating coal mine digging, supporting and transportation parallel fast operation

ActiveCN104213831AImprove tunneling efficiencyImplement parallel jobsDerricks/mastsSlitting machinesSelf adaptiveDrill

The invention relates to the field of coal mine underground roadway digging, in particular to an anchor rod drill carriage integrating coal mine digging, supporting and transportation parallel fast operation. The anchor rod drill carriage solves the problems of complexity and time waste of the existing machine debugging process, low roadway digging efficiency, digging and supporting unbalance and the like. A middle frame is of an arc-shaped structure, belt conveyor pin tooth transmission traction mechanisms connected with a mine traction type self-adaptive belt conveyor are symmetrically arranged at the two sides of the middle frame, and the mine traction type self-adaptive belt conveyor passes through an arc-shaped space below the middle frame and extends to a position under a digging machine discharging part; eight sets of drill arms are matched, respectively include four sets of front anchoring and protecting drill arms, two sets of back anchoring and protecting drill arms and two sets of side upper anchoring and protecting drill arms, and are arranged in three rows at the front side and the back side, in addition, each set of drill arms can slide for a certain displacement stroke, the adjustable supporting ranging distance height can be realized, 6-top 2-upper anchor rod supporting can be completed in one step through parallel operation, the supporting time is shortened, the supporting efficiency is improved, a belt conveying passage can be provided, and the one-supporting and one-conveying operation parallel operation can be realized.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

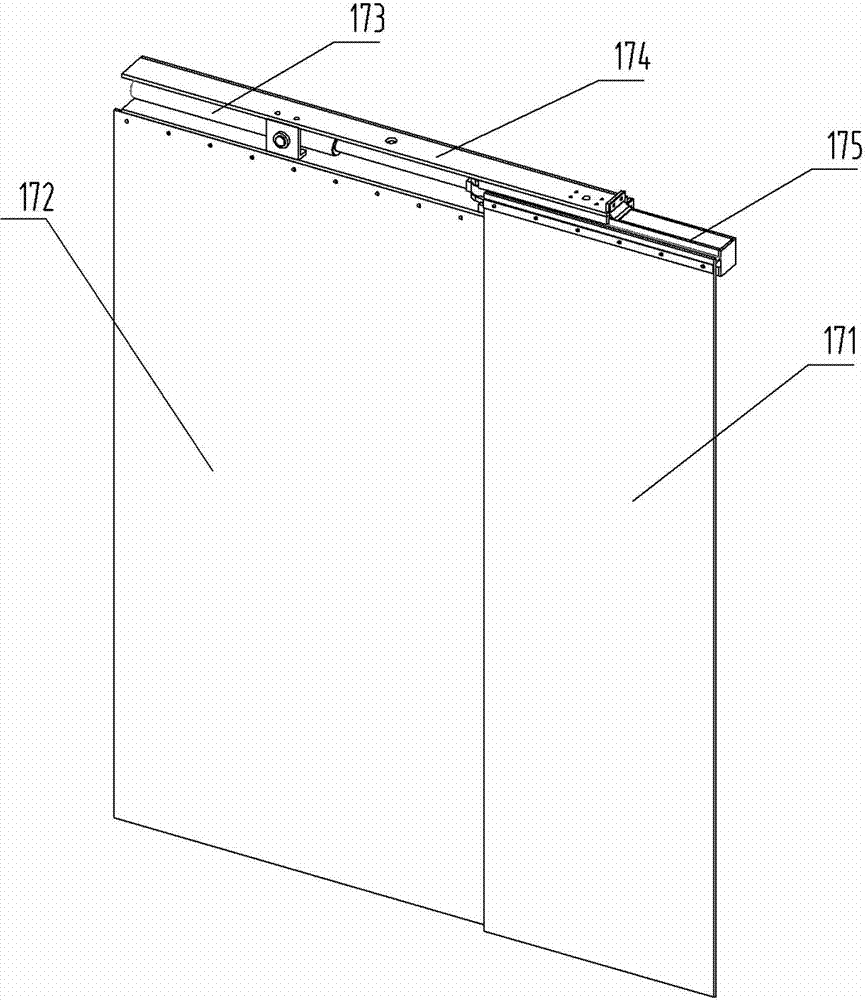

Novel quick digging and anchoring integrated machine for rectangular coal roadway

ActiveCN102606152AAvoid destructionImprove efficiencySlitting machinesAnchoring boltsSupporting systemHydraulic cylinder

The invention discloses a novel quick digging and anchoring integrated machine for a rectangular coal roadway, which comprises a heading machine, a temporary support system, an anchoring system, a conveying system and a dust removing system, and also comprises a support system, wherein a sealing device is arranged between the head of the heading machine and the front of the support system; the sealing device comprises a main body plate, a movable sealing plate and left and right movable sealing plates; support hydraulic cylinders are arranged on the main body plate and an upper movable sealing plate bracket; support hydraulic cylinders are arranged on the main body plate and left and right movable sealing plate brackets as well; meanwhile, an upper movable sealing plate, the left and right movable sealing plates are provided with flexible sealing belts; the front end of a dust removing pipeline of the dust removing system is installed on the main body plate of the sealing device; and the dust removing pipeline is communicated with the space in the front part of the sealing device. The novel quick digging and anchoring integrated machine for the rectangular coal roadway, provided by the invention, employs a novel telescopic cylinder to cut and mold the width of a roadway in one step, therefore, the high efficiency is achieved, and in addition, the damage to a base plate due to repeated displacement is avoided; through cooperation of adjusting oil cylinders with flexible sealing, a top plate and lateral walls are very adaptive, so that dust is prevented from rushing into a rear working space; and meanwhile, a working environment is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

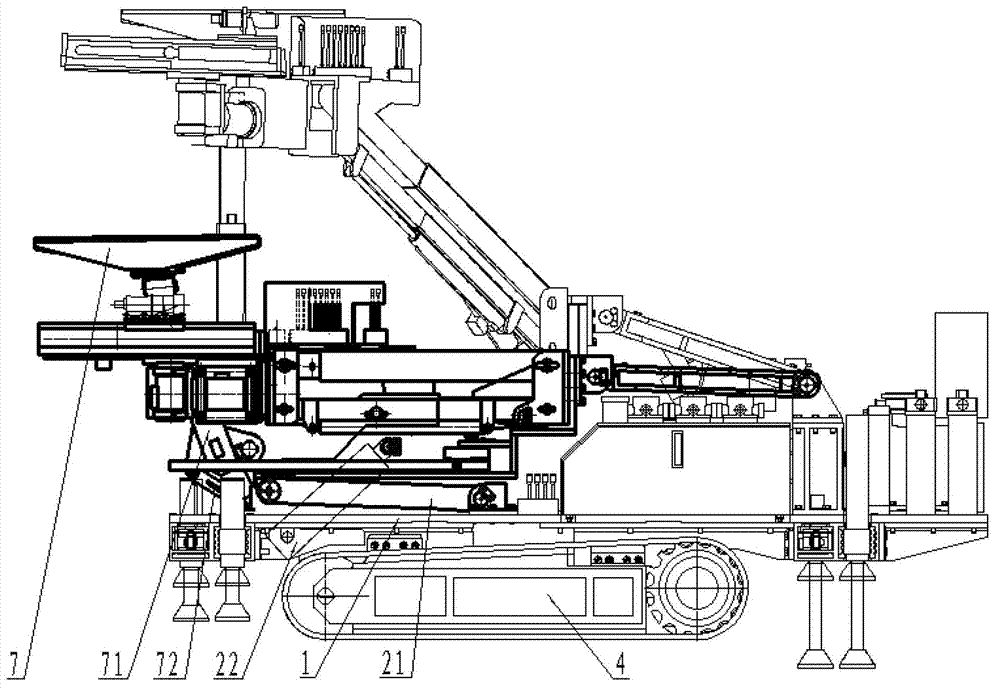

Narrow-machine-body full-hydraulic bolt and anchor cable drill carriage for coal mine tunnel

InactiveCN102900362AMechanizationIncrease the level of mechanized supportAnchoring boltsCutting machinesEngineeringRock bolt

The invention relates to a narrow-machine-body full-hydraulic bolt and anchor cable drill carriage for a coal mine tunnel. The narrow-machine-body full-hydraulic bolt and anchor cable drill carriage comprises a machine body part, a lifting platform, a drill boom mechanism, crawler-type walking mechanisms and an electric cabinet, wherein the lifting platform is arranged at the machine body part through a foldable connecting rod and a lifting oil cylinder; the drill boom mechanism is arranged on the lifting platform through a feeding mechanism; the crawler-type walking mechanisms are arranged on two sides of the machine body part; and the electric cabinet is used for controlling the lifting oil cylinder and the crawler-type walking mechanisms. According to the narrow-machine-body full-hydraulic bolt and anchor cable drill carriage disclosed by the invention, the support of an anchor rod is completely mechanized, the support efficiency and the support quality of the bolt and anchor cable are greatly improved, the standardization degree is improved, the better stabilizing action is realized and the reliable use of the drill carriage and the safe operation of operators are fully ensured.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

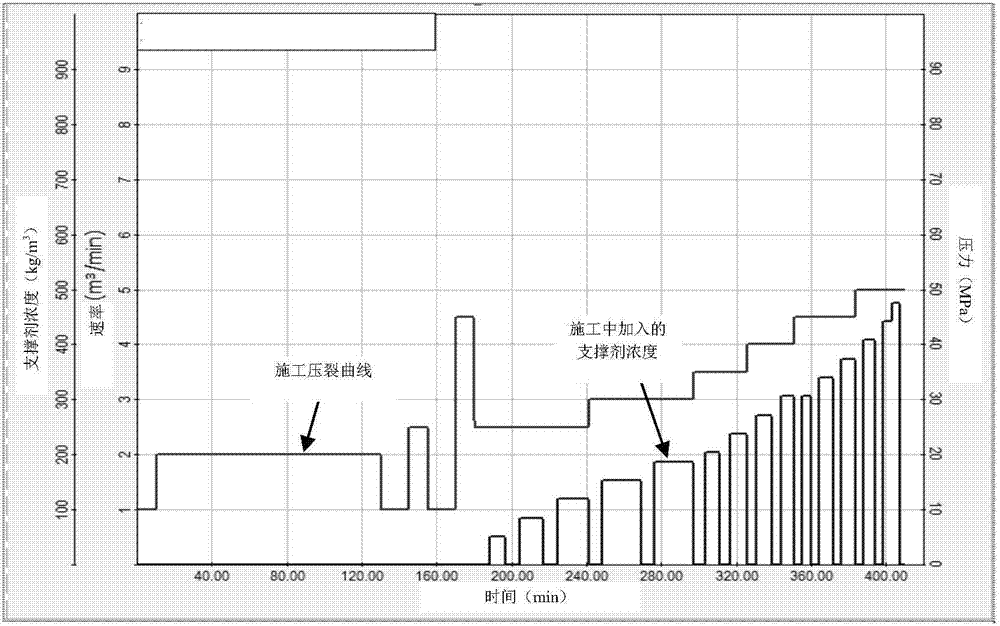

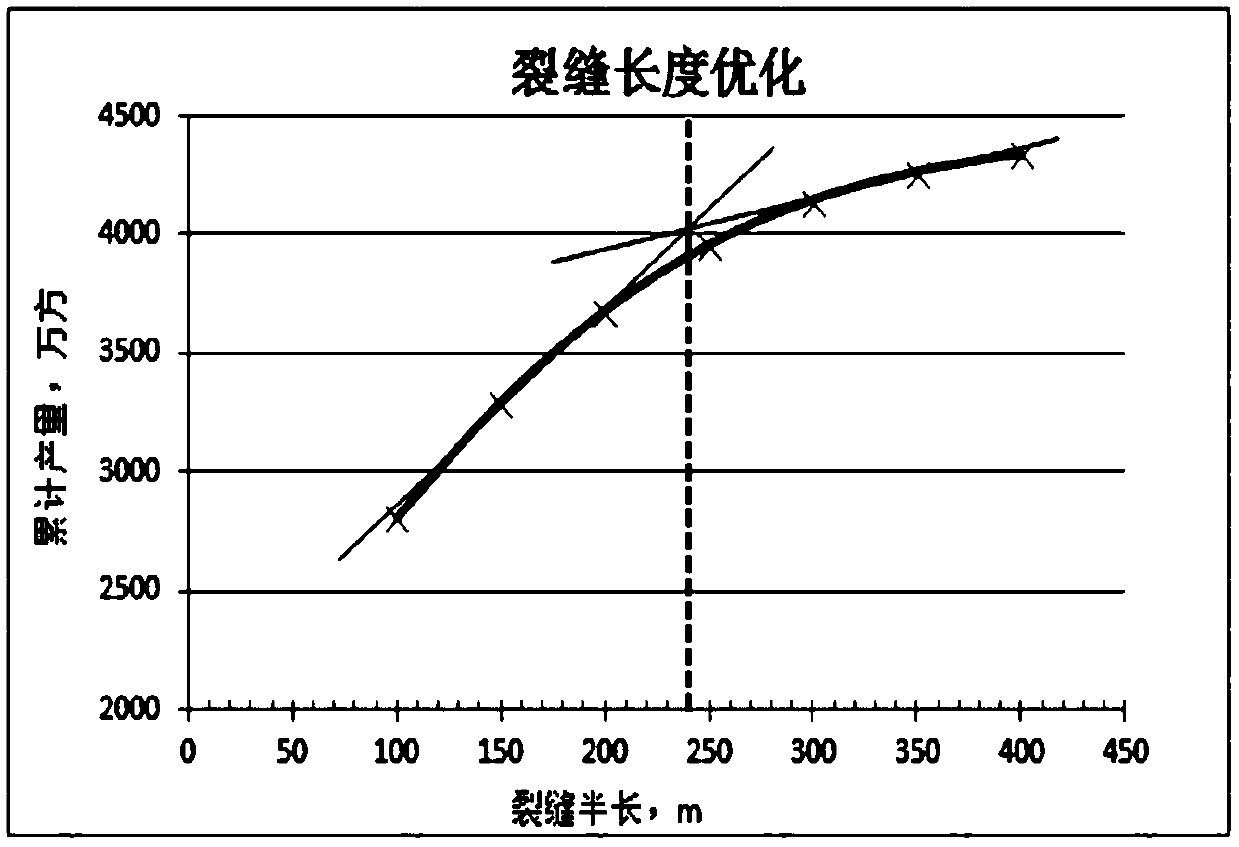

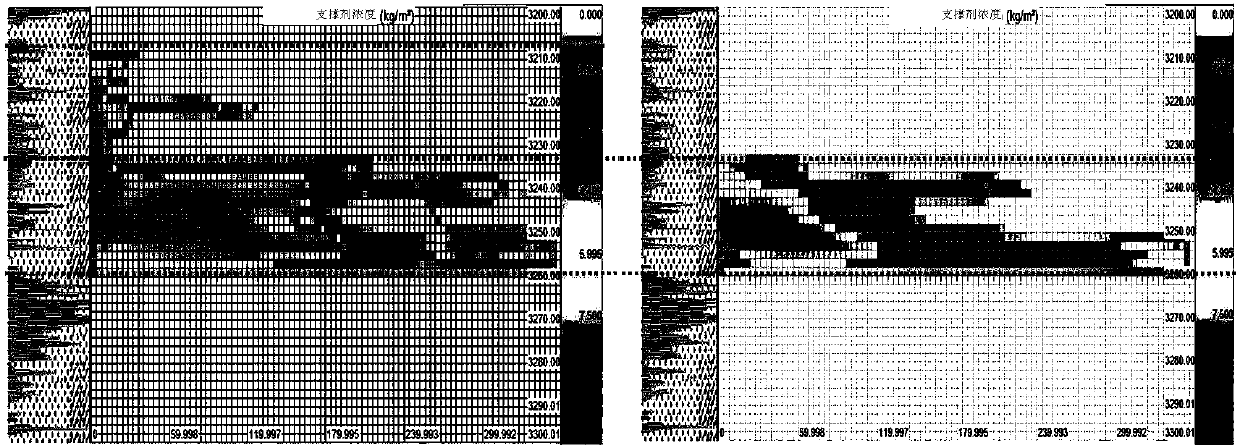

Method for slight fracture supporting, capable of increasing fracture stabilization period

ActiveCN107503729AImprove support efficiencyImprove fracturing effectFluid removalViscous fingeringStructure of the Earth

The invention discloses a method for slight fracture supporting, capable of increasing a fracture stabilization period. The method comprises the steps of (1) evaluation of a microstructure of reservoir rocks, (2) a first-stage injection phase, and (3) second-stage and third-stage injection phases. During the second step, (1) an ultralow-viscosity fracture solution carrying a micro-particle-diameter supporting agent is injected to communicate and extend natural fracture systems with micro scales, a low-viscosity fracture solution carrying a small-particle-diameter supporting agent is injected to communicate and extend natural fracture systems with large scales; a middle-viscosity fracture solution carrying a middle-particle-diameter supporting agent is injected to extend fracture systems with large scales; and (4) a high-viscosity fracture solution carrying a large-particle-diameter supporting agent is injected to extend fracture systems with the maximum scale. According to the invention, through fine evaluation of the microstructure of the reservoir rocks, alternate multi-stage injection, utilization of viscous fingering effects of various liquids with different viscosities, multi-scale sand adding and other methods, the fracture systems with the different scales within a full seam length scope of a main fracture can be fully expanded, extended and supported; and a "valid reshaping volume" of fractures and "supporting efficiency" of cracks are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

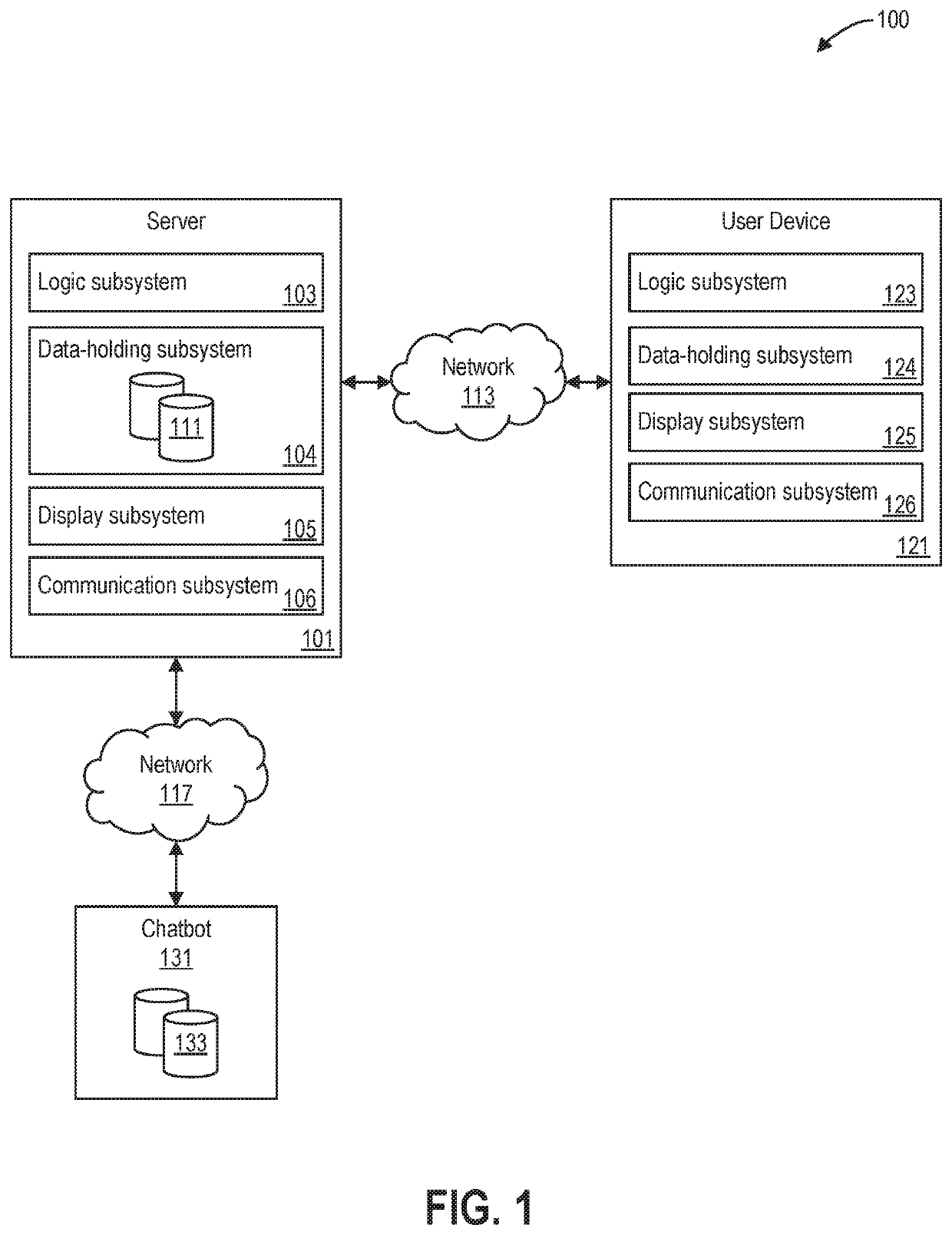

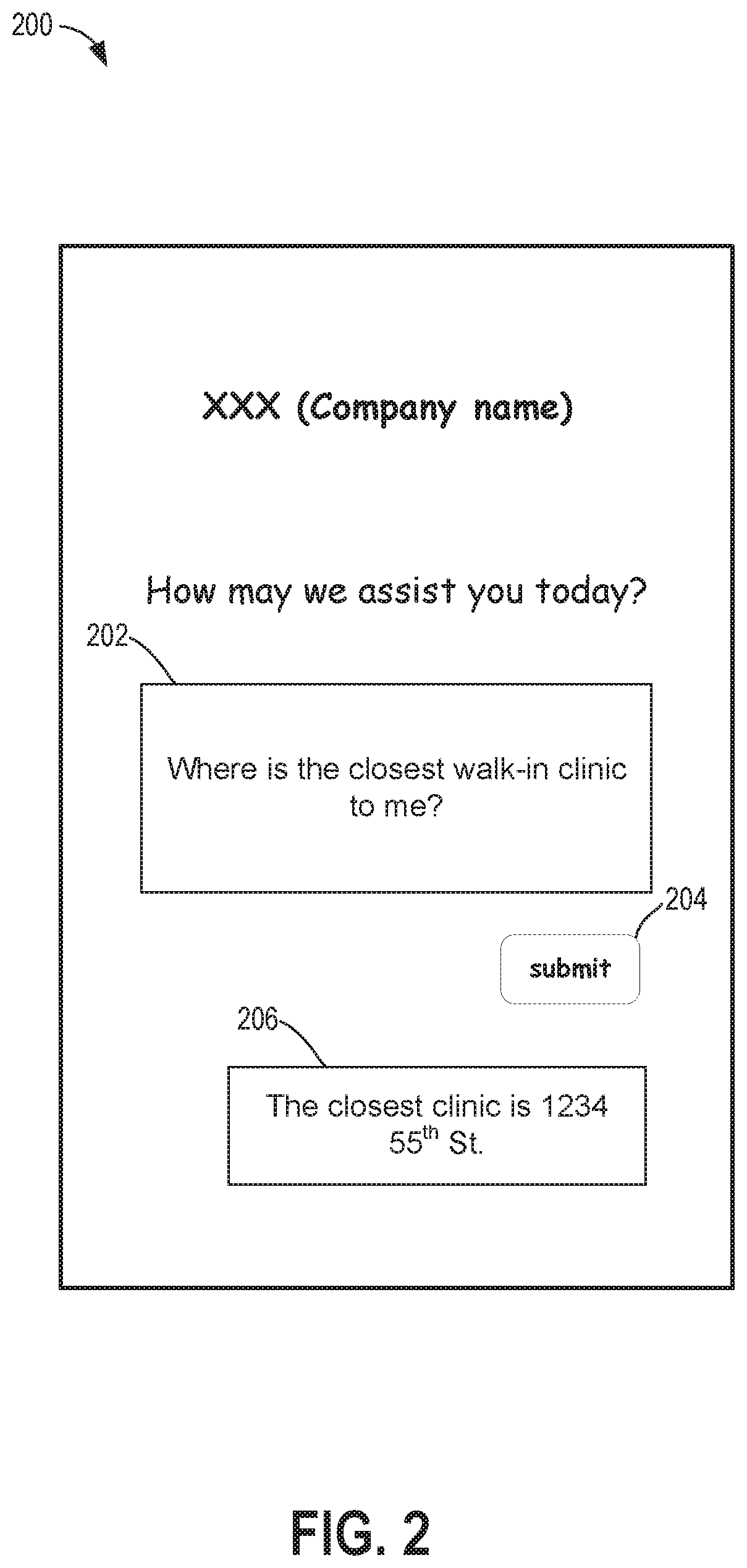

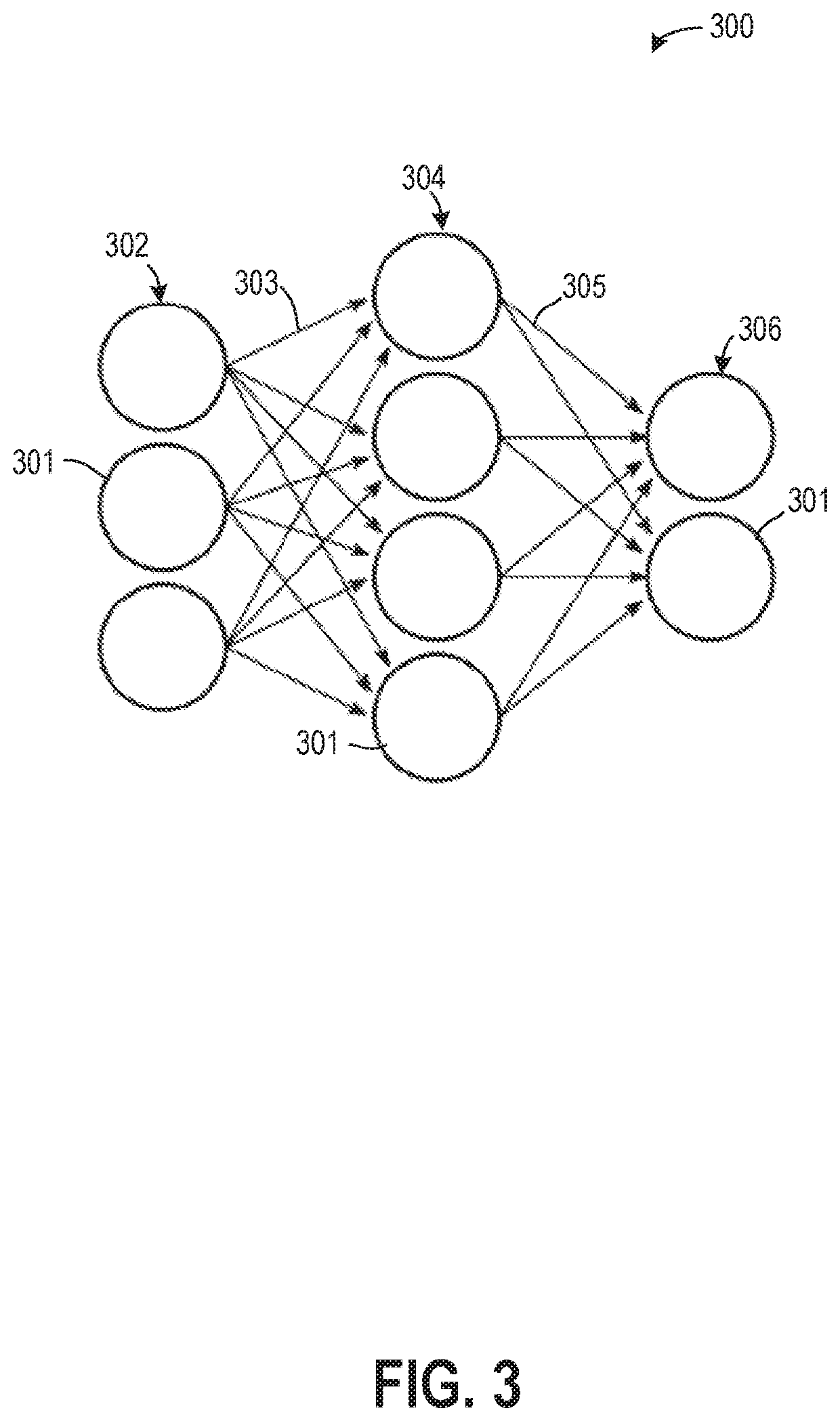

Systems and methods for continual updating of response generation by an artificial intelligence chatbot

ActiveUS20200226475A1Low costImprove efficiencySemantic analysisArtificial lifeResponse generationGenerative adversarial network

Methods and systems are provided for a natural language processing system comprising a chatbot adapted for dialog generation. In one example, the system may include a combination of a variational autoencoder (VAE) and a generative adversarial network (GAN) for generating natural responses to input queries. The VAE may convert queries into vector embeddings that may then be used by the GAN to continuously update and improve responses provided by the chatbot.

Owner:THE REGENCE GROUP

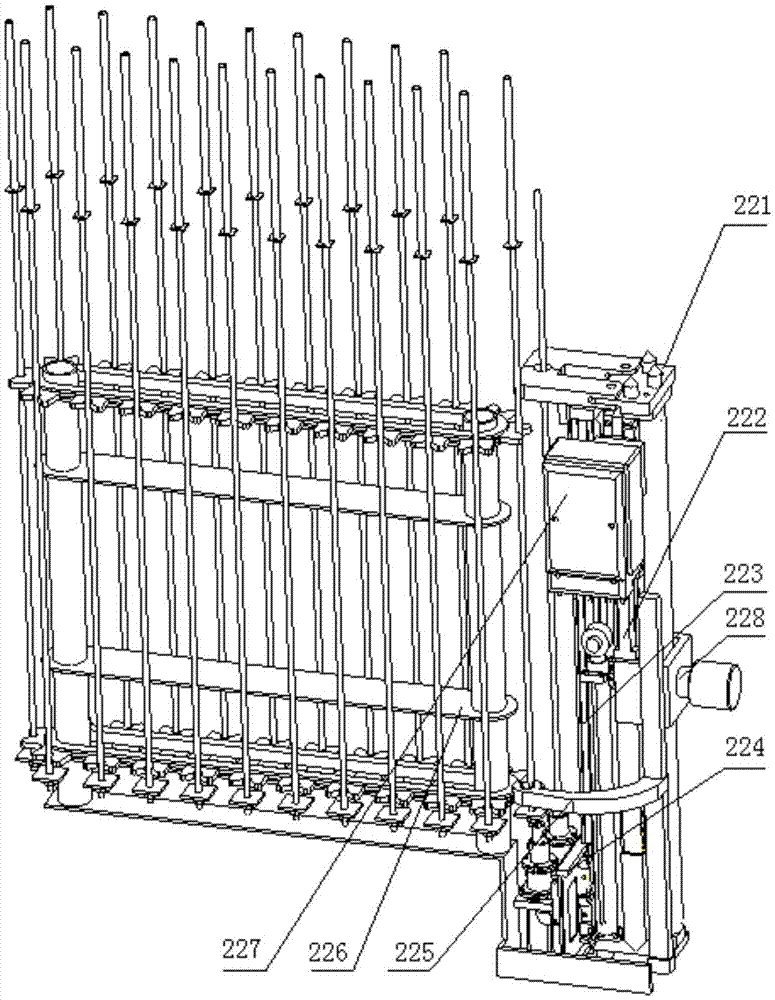

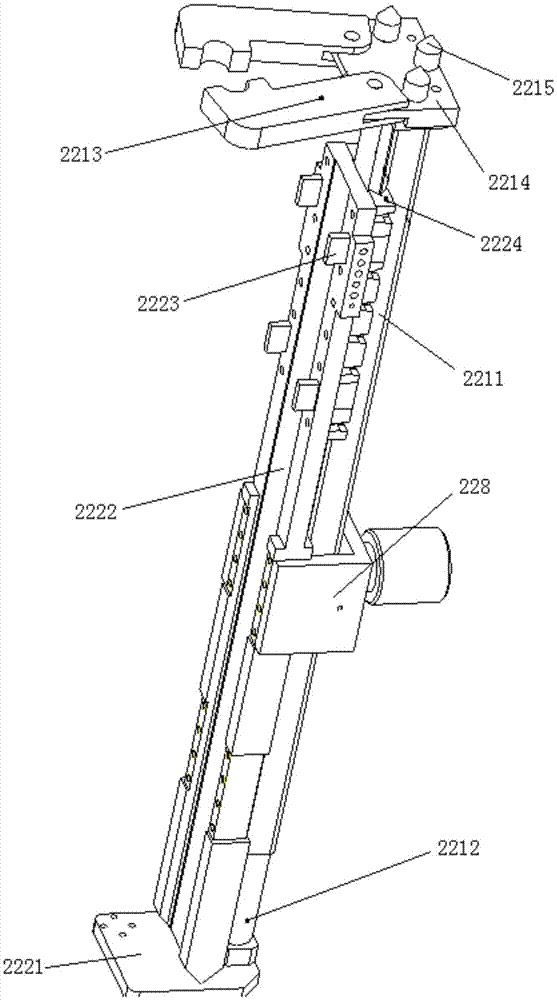

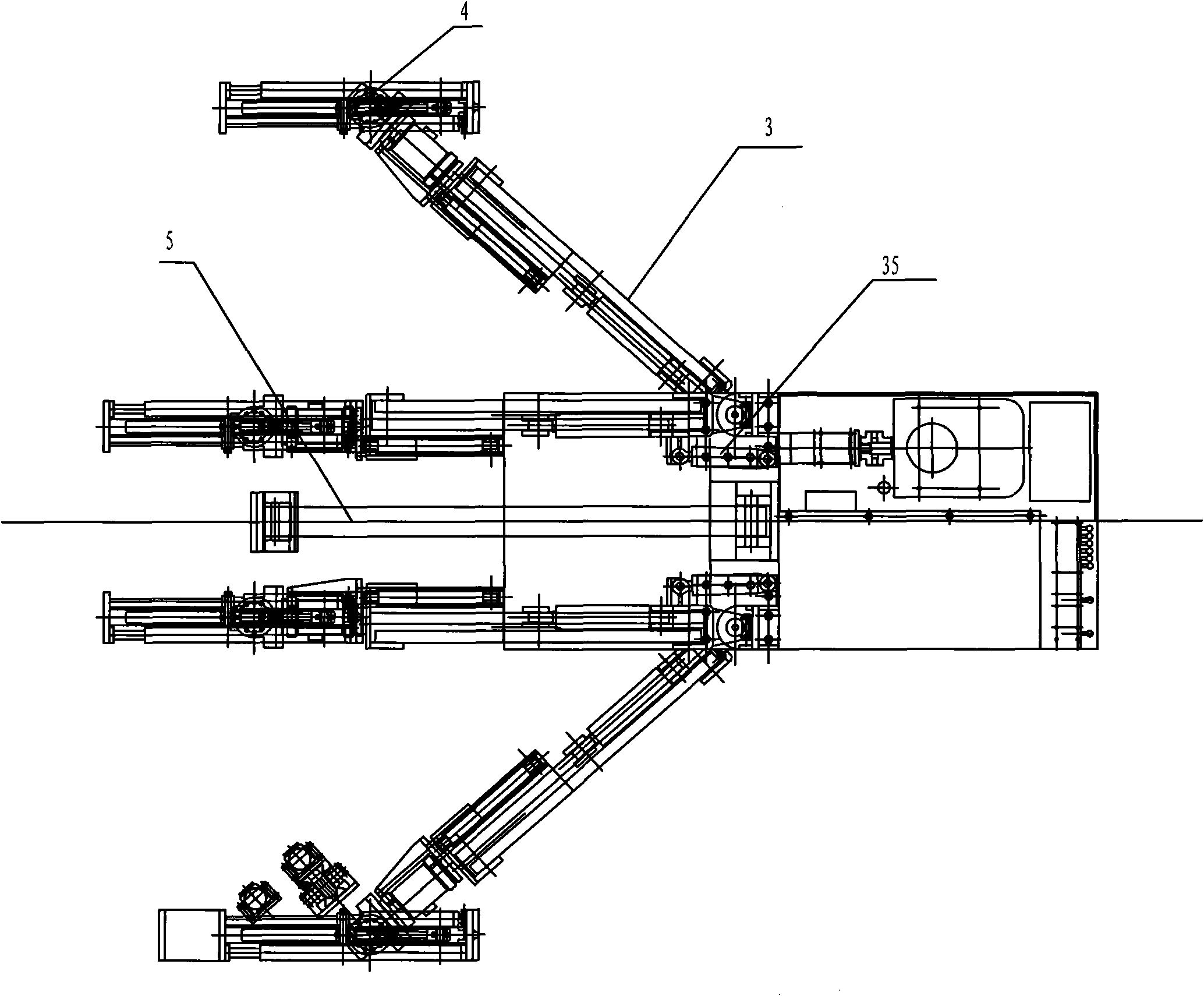

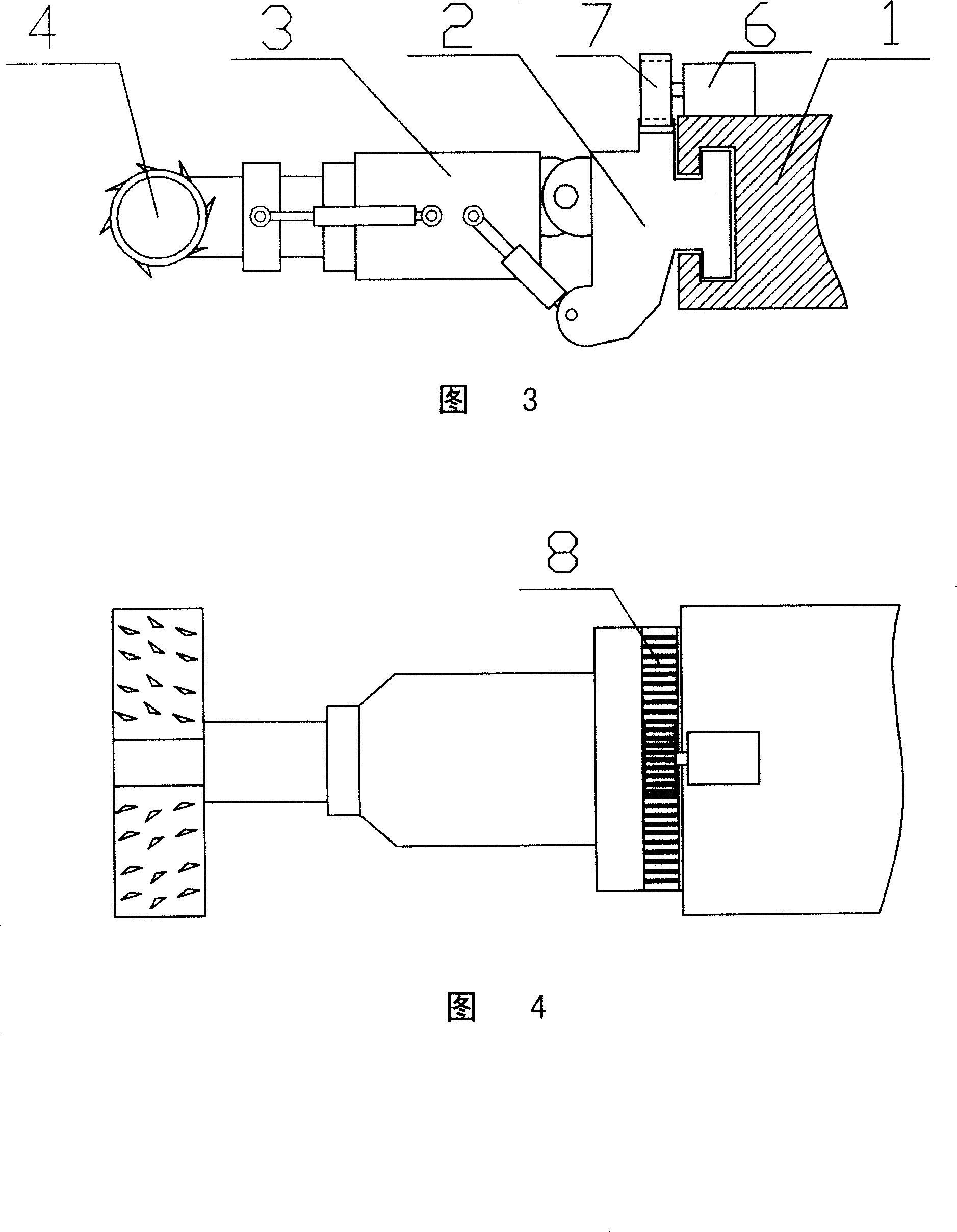

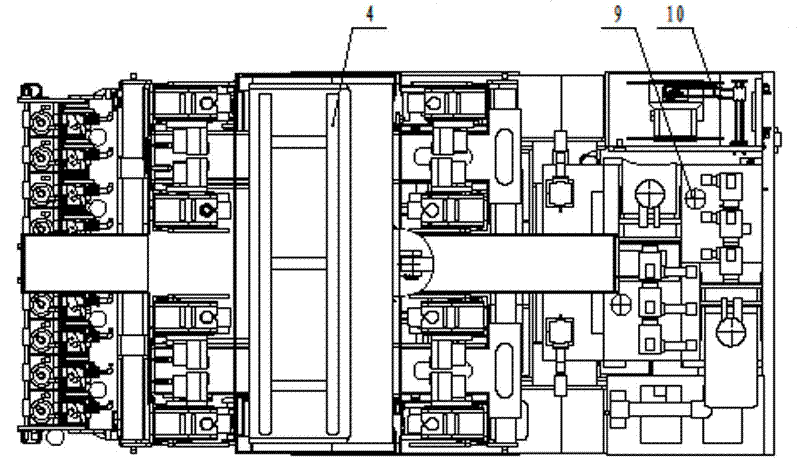

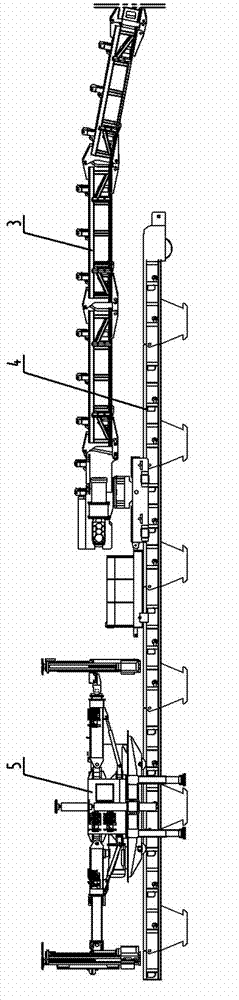

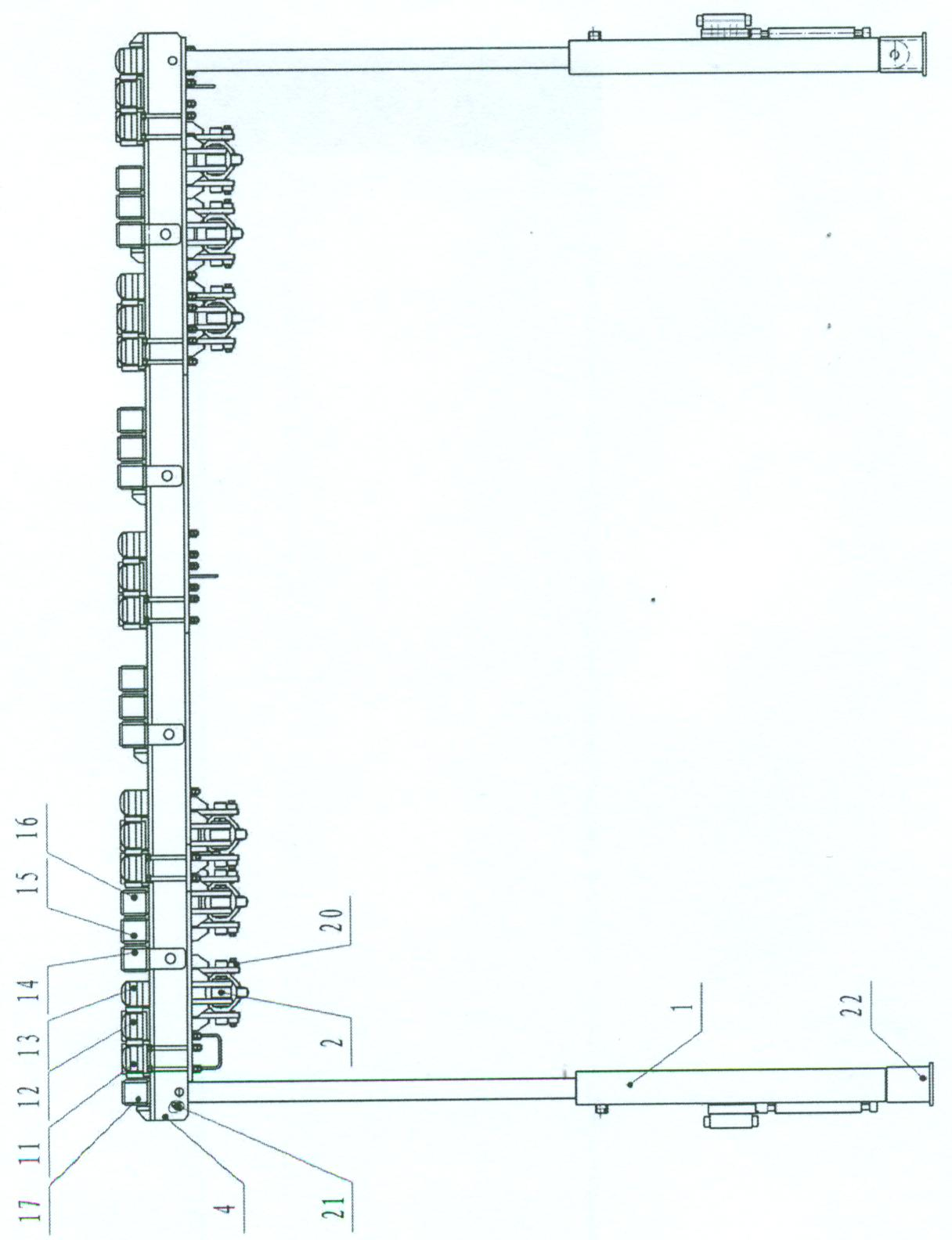

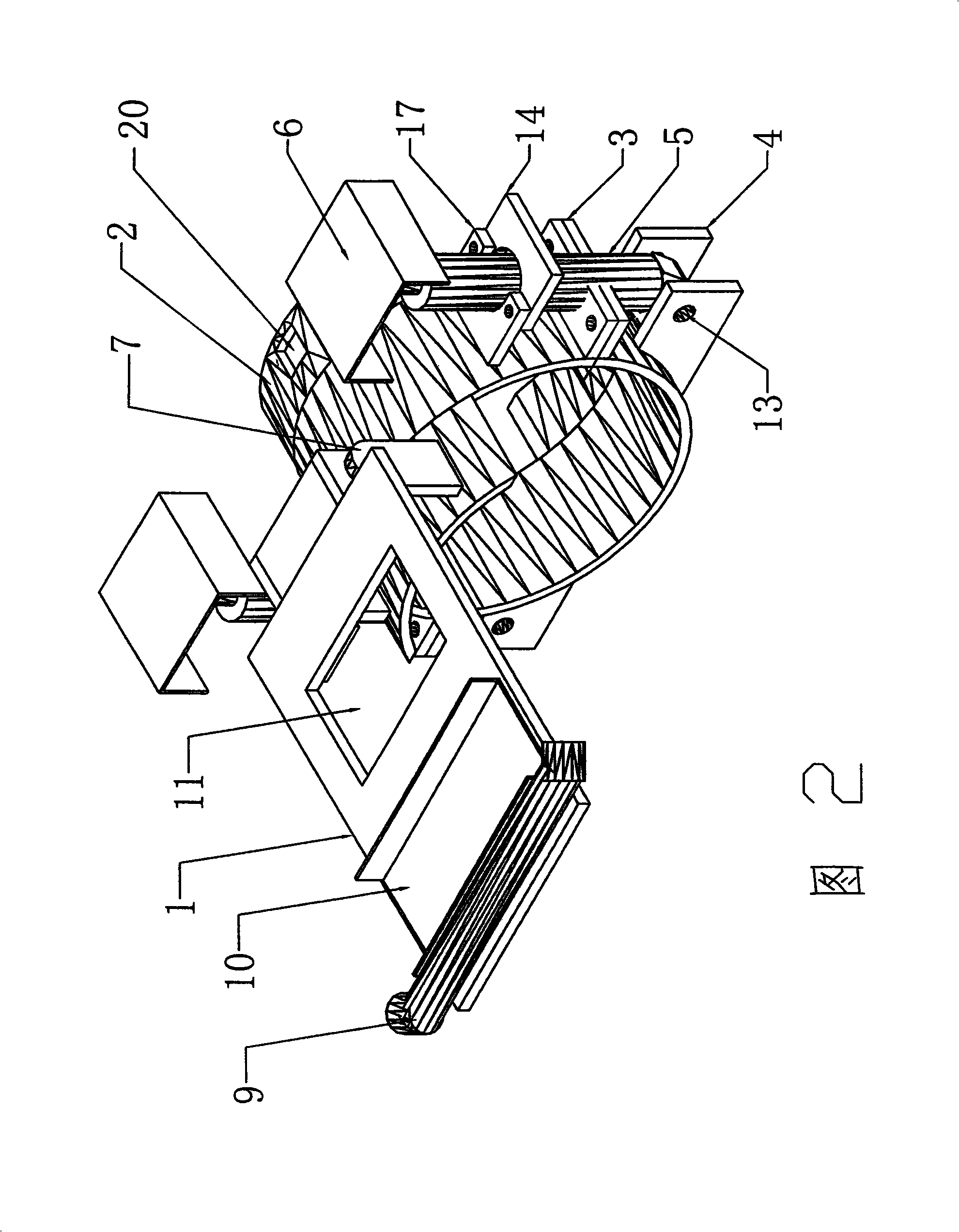

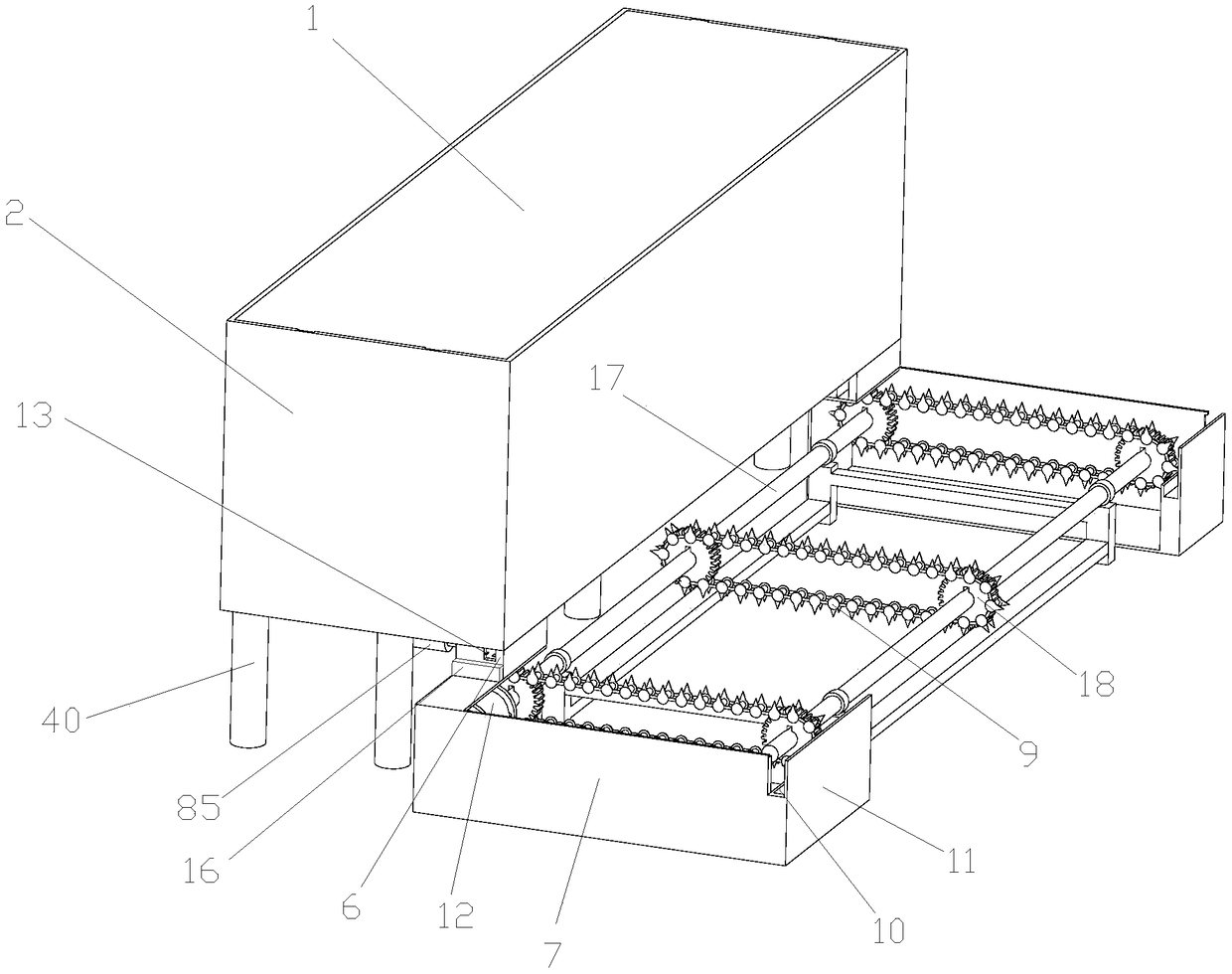

Side bolt drilling machine and side bolt drilling carriage with same

ActiveCN105626108ALarge storage capacityMeet construction needsDerricks/mastsAnchoring boltsEngineeringRock bolt

The invention discloses a side bolt drilling machine which comprises a fixing mechanism, a supporting mechanism, a sliding rack, a drilling box mechanism and a cartridge conveying box. The fixing mechanism comprises a base, a vertical plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the vertical plate. The supporting mechanism and the sliding rack are in sliding connection with the opposite side faces of the vertical plate respectively through the guide blocks, and one end of the supporting mechanism and one end of the sliding rack are connected with the base through a telescopic oil cylinder. The drilling box mechanism comprises a bottom rack and two independent drilling box sliding seats. The bottom rack is fixedly connected with the base, the drilling box sliding seats can horizontally move along the bottom rack, and when the drilling box sliding seats move to the sliding rack, the drilling box sliding seats can be connected with the other guide rail face of the sliding rack and slide along the sliding rack. The cartridge conveying box is used for completing the automatic cartridge feeding procedure of the drilling machine. The invention further discloses a side bolt drilling carriage with the drilling machine. By means of automatic cartridge feeding and automatic anchor bolt mounting, mechanization and automation of anchor bolt supporting work are achieved, the construction needs of a plurality of rows of side bolts can be met, and the side bolt drilling carriage works in cooperation with heading equipment to synchronously complete side bolt supporting and transferring functions.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

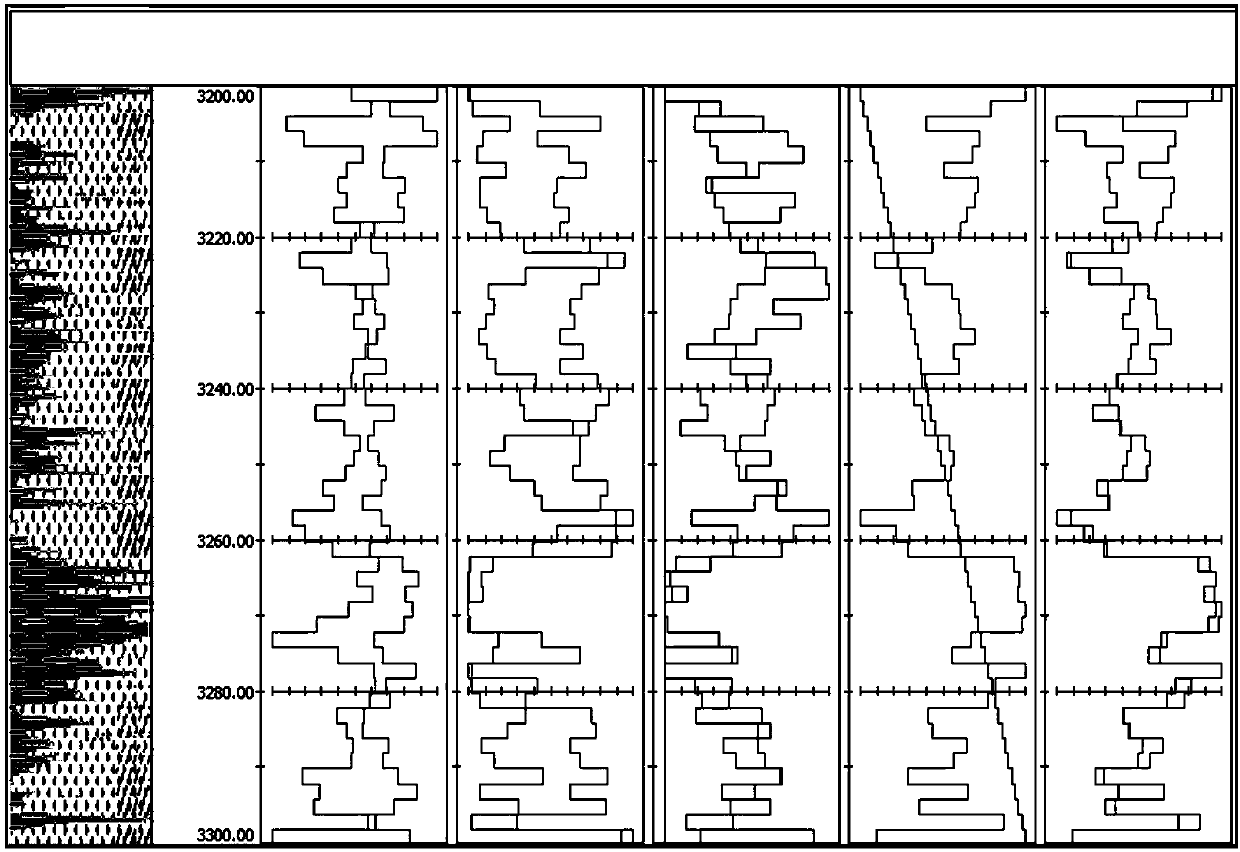

Method of surveying roadway loosening and stress concentration ranges based on drilling parameters

InactiveCN104832212AImprove targetingReduce supporting costsMining devicesStress concentrationStress conditions

The invention discloses a method of surveying roadway loosening and stress concentration ranges based on drilling parameters, which belongs to surveying of deep formation drilling ground stress concentration areas. The method comprises steps: construction of drilling long boreholes down a seam is carried out in mine coal or a rock roadway, a thrust, a rotation speed, a torque, and a drilling speed during the drilling process are recorded and calculated, drilling parameters are used for calculating energy consumed by drilling a unit rock, drilling specific energy is thus acquired, the corresponding relationship between the drilling specific energy and a drilling distance is acquired, certain response features exist between energy consumed when a coal-rock mass of the same kind is drilled and different physical and mechanical features shown by the coal-rock mass in different ground stress conditions, stress concentration and loosening area ranges at two sides of the coal-rock roadway are calculated, and a drilling speed variation trend with the constant thrust and the rotation speed is used for calculating the stress concentration and loosening area ranges at two sides of the coal-rock roadway. The method of the invention has the advantages that the supporting efficiency of the roadway is improved, the maintenance cost of the roadway is saved, guidance is provided for an effective hole sealing distance of gas pressure relief drainage and drilling, and drainage effectiveness of the gas is improved.

Owner:CHINA UNIV OF MINING & TECH

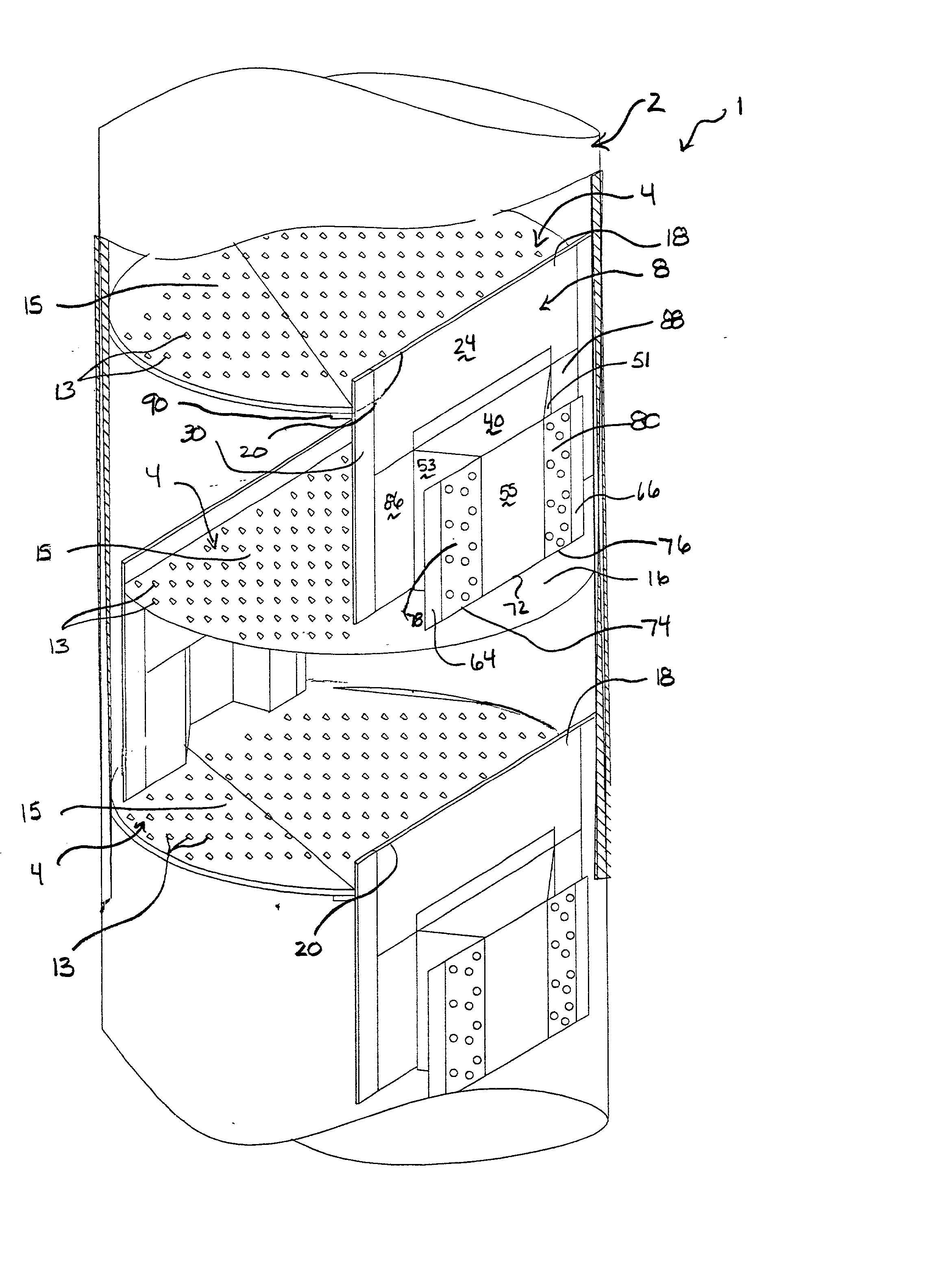

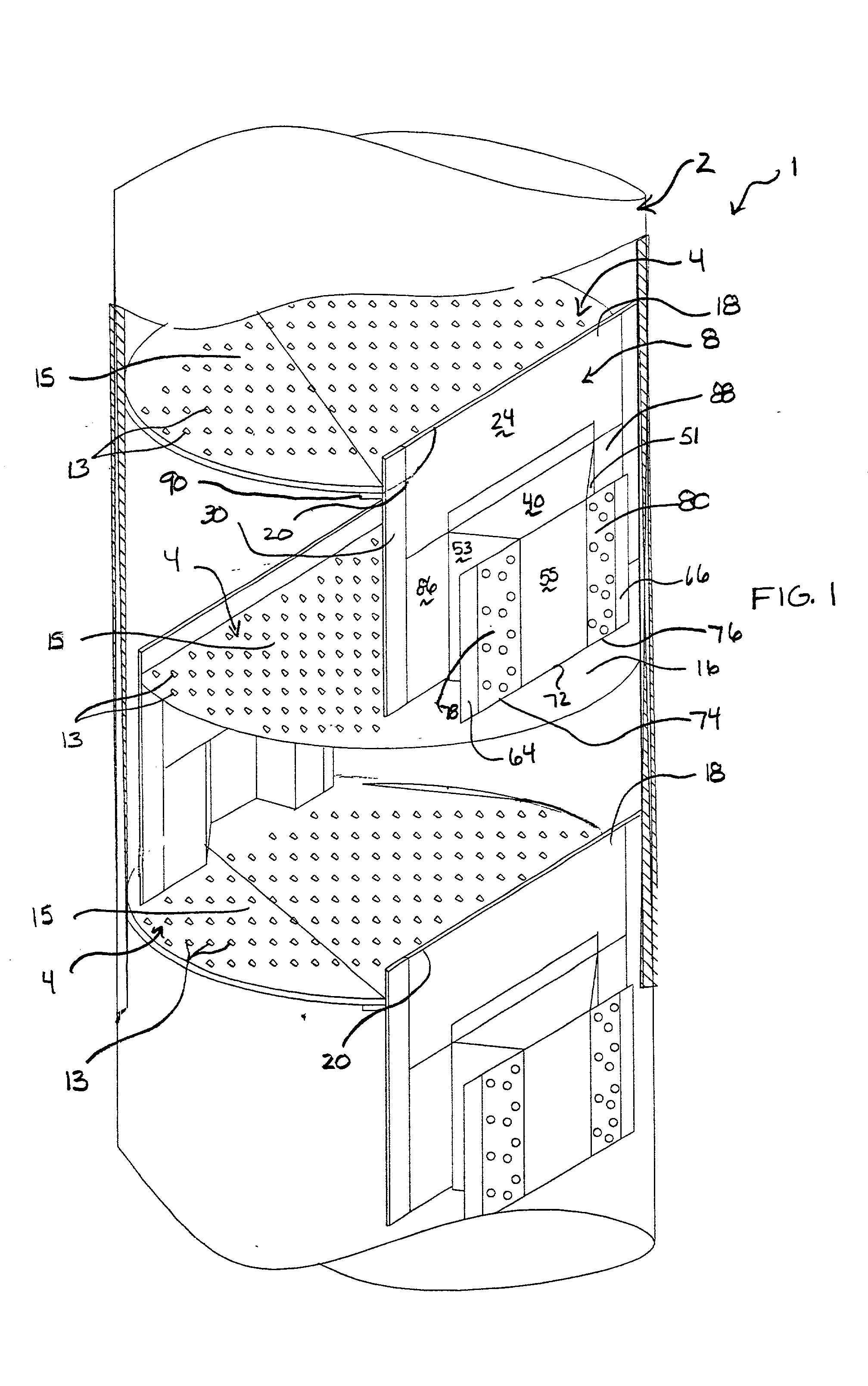

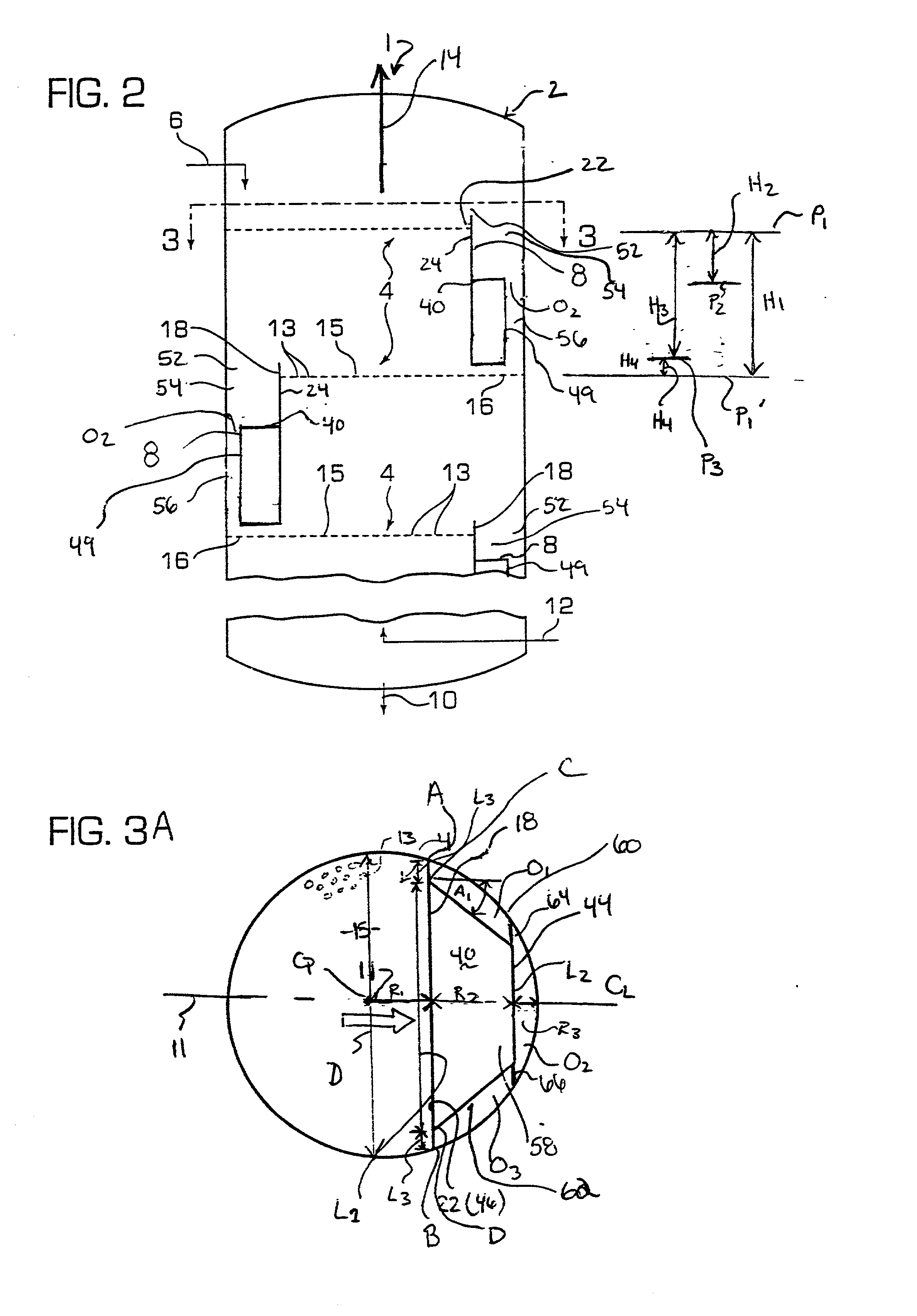

Stepped downcomer apparatus and vapor-liquid contact apparatus with same

A stepped downcomer apparatus for use in a vapor-liquid contact apparatus having an intermediate level step platform with a preferred tri-edge peripheral edge and corresponding step panels extending down from that edge to form a sealing step panel wall. As a preferred support device, extensions extend in chordal fashion out from the interior vertical edge of the opposite side step wall panels and either directly or indirectly by way of support bars into a supporting relationship with a tower of the vapor-liquid contact apparatus. A main panel extends up from the interior edge of the platform and up to the above positioned tray. A weir may extend above the above positioned tray that is an extension of the main panel. This main panel is attached to the support bars and supports the step platform and walls and extensions either alone or with added support members. A tray support ledge extends inwardly from the downcomer to provide support to the upper tray. The liquid-vapor mix contacts the step platform after passing over the weir, and off from which fluid travels both along the central axis of flow and obliquely off the opposite side panels. At opposite ends of the weir, the liquid flows directly into contact with the inlet region of the lower tray, by-passing the platform. The opposite side panel walls can slope outward to vary the downcomer lower pass through volume. An embodiment features chordal wing extensions with pressure equalization openings that extends out from opposite sides of the step wall panel also into a support relationship with the tower. The lower edge of the panels of the wall and the lower edge of the extensions control the flow of fluid as it travels under the lower edging from the inlet side of the downcomer apparatus to the active area of the tray. The relative level of the lower edges can be varied to suit the intended use. Additional or replacement downcomer structural supports include vertical support members extending from a step panel to a lower tray either in the form of support brackets or tiplet extensions.

Owner:SULZER MANAGEMENT AG

Non-sprayed-concrete anchor net supporting method of underground construction broken surrounding rocks

InactiveCN103277114AResist usage requirementsMeet the use requirementsUnderground chambersTunnel liningHigh intensityUltimate tensile strength

The invention discloses a non-sprayed-concrete anchor net supporting method of underground construction broken surrounding rocks. According to the method, eight anchor rod drill holes are formed in a roadway or a tunnel, and each row of holes are basically required to be located on the same cross section; a galvanized high-strength steel wire net prepared in advance is attached to the rock surface to be paved, so that a whole roadway or tunnel non-sprayed-concrete anchor net is supported to form a whole; tube seam type anchor rods are pressed into the anchor rod drill holes by an anchor rod mounting machine sequentially from one side of the roadway or the tunnel to the vault and the other side of the roadway or the tunnel. The method is low in cost, good in supporting effect, timely in supporting and low in labor intensity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

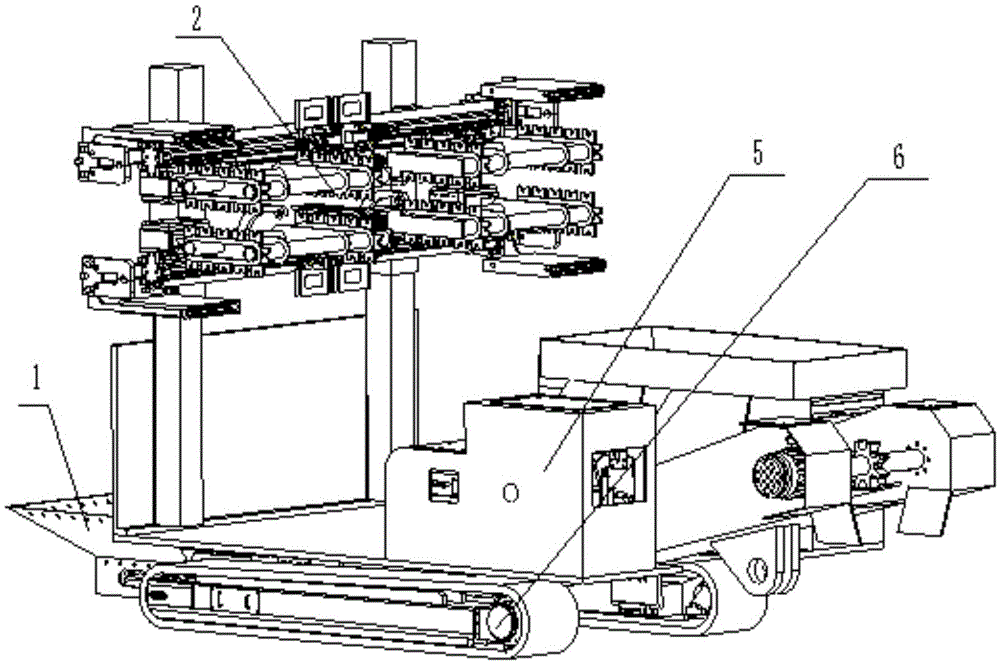

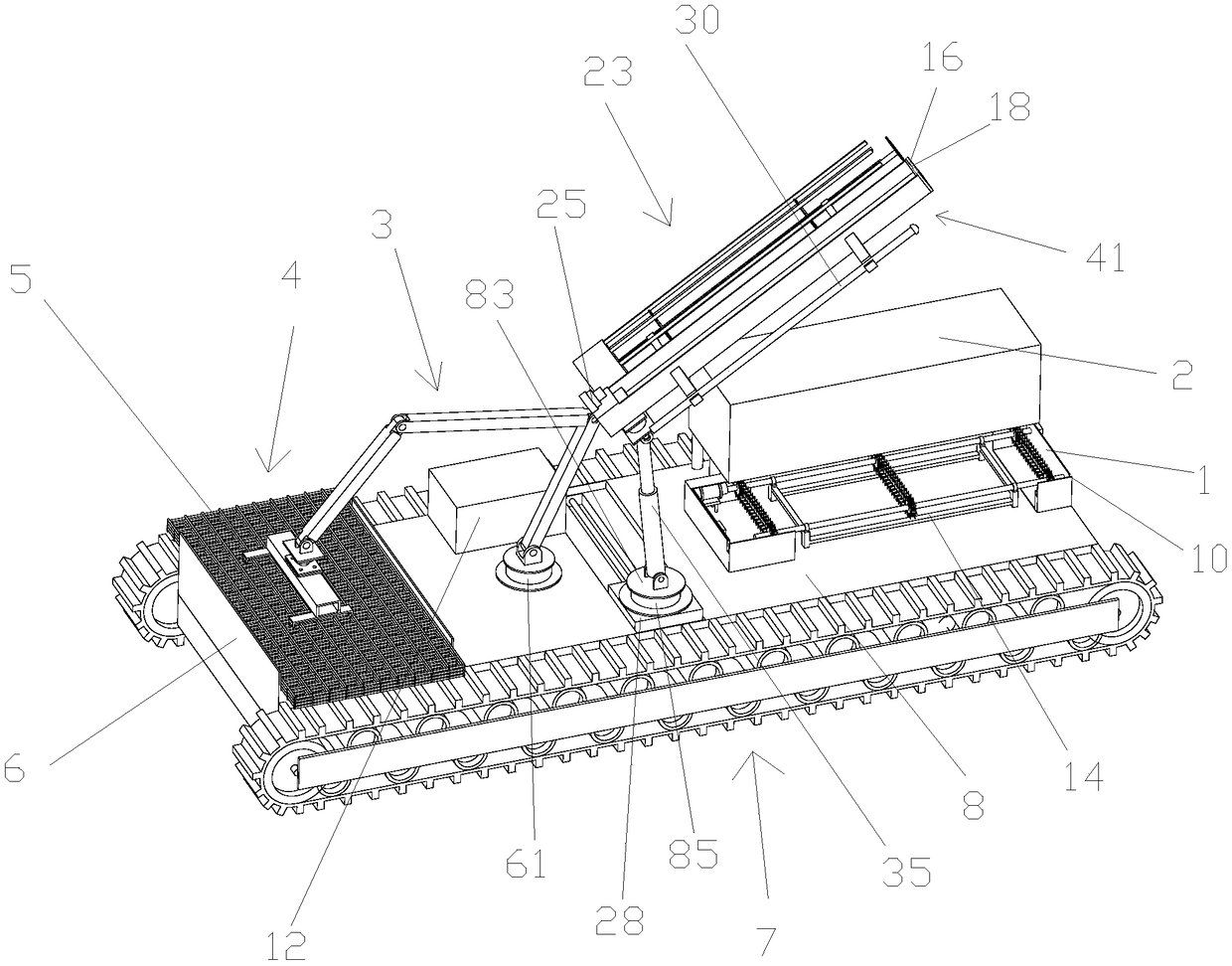

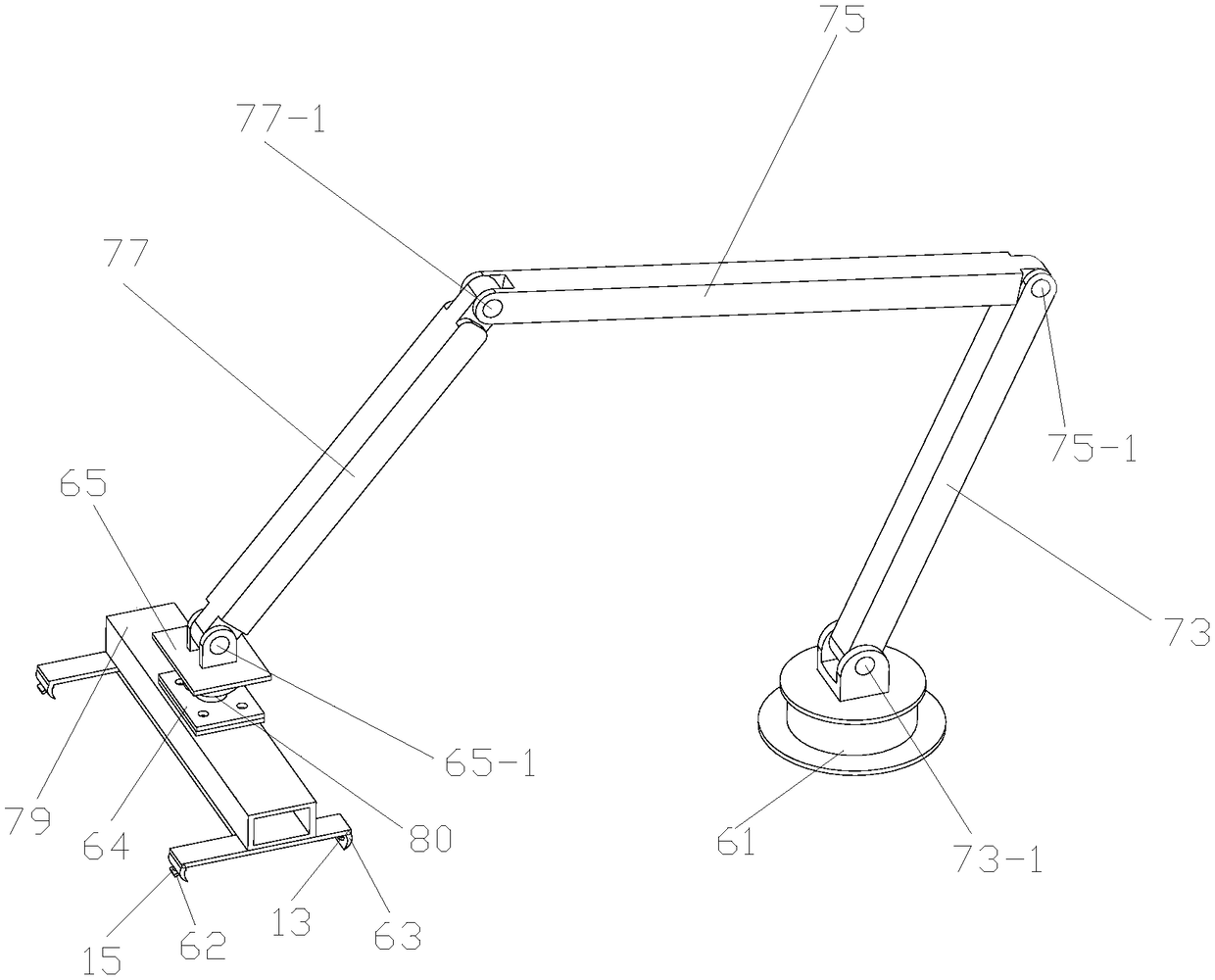

Coal mine drilling and anchoring robot and supporting method

ActiveCN108756968ASimple structureReasonable designUnderground chambersTunnel liningEngineeringManipulator

The invention discloses a coal mine drilling and anchoring robot and a supporting method. The coal mine drilling and anchoring robot comprises a robot body, a net arrangement mechanism, a drilling andanchoring mechanism and a control module; the robot body comprises a machine body, a crawler traveling mechanism and a traveling driving mechanism; the net arrangement mechanism comprises a mechanismarm mechanism and a net grabbing manipulator; a sliding mechanism is arranged on the robot body; and the drilling and anchoring mechanism comprises an anchor rod box, a bottom frame, a chain conveying mechanism and a drilling and anchoring mechanism body. The supporting method comprises the following steps that 1, the coal mine drilling and anchoring robot is inspected and initialized; 2, the coal mine drilling and anchoring robot moves; 3, anchor rod feeding operation is conducted; 4, supporting nets are grabbed by net arrangement mechanism and mounted on the to-be-supported position; and 5,holes are drilled in the net arrangement position and the anchor rods are mounted, the steps 3 to 5 are repeated for many times, and supporting is completed. The coal mine drilling and anchoring robot is reasonable in design and integrates the crawler traveling mechanism, the net arrangement mechanism and the drilling and anchoring mechanism, thus automatic and intelligent anchor rod supporting is achieved, and the supporting efficiency is improved.

Owner:XIAN UNIV OF SCI & TECH

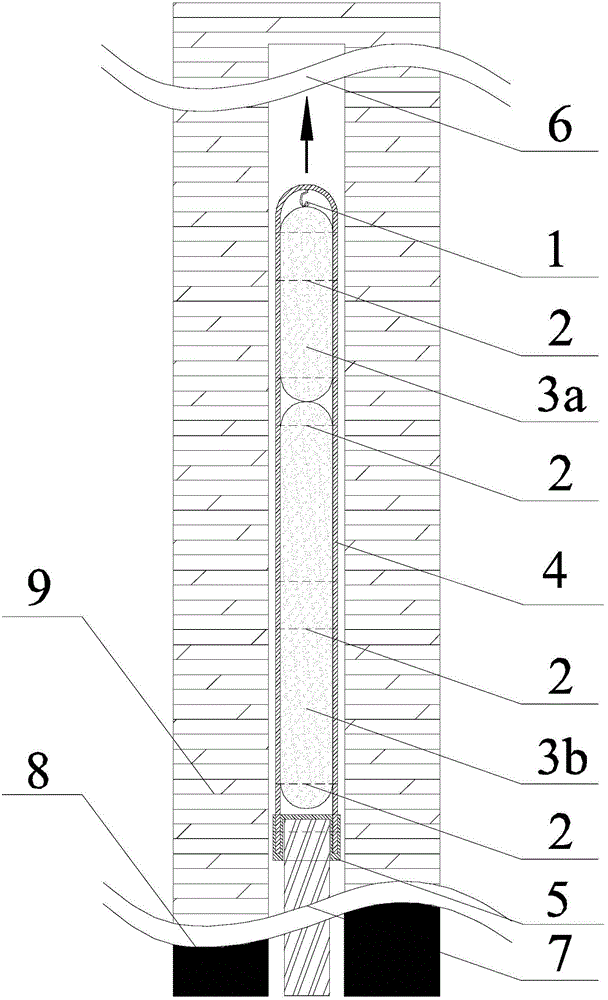

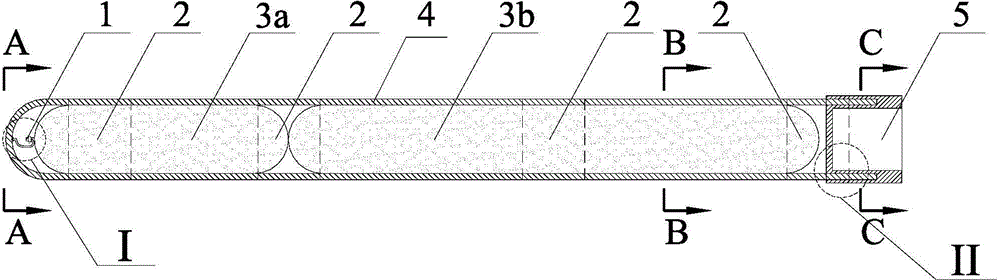

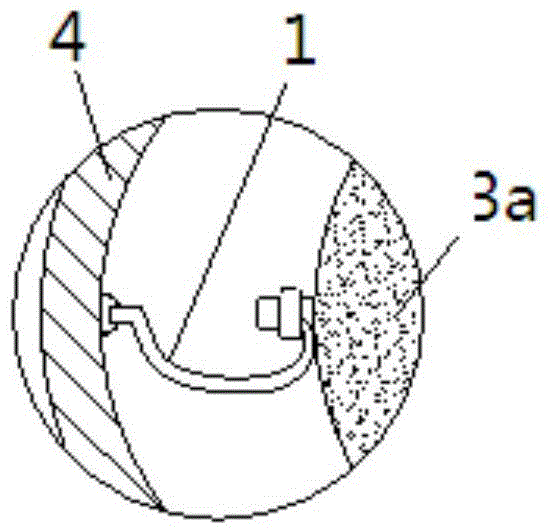

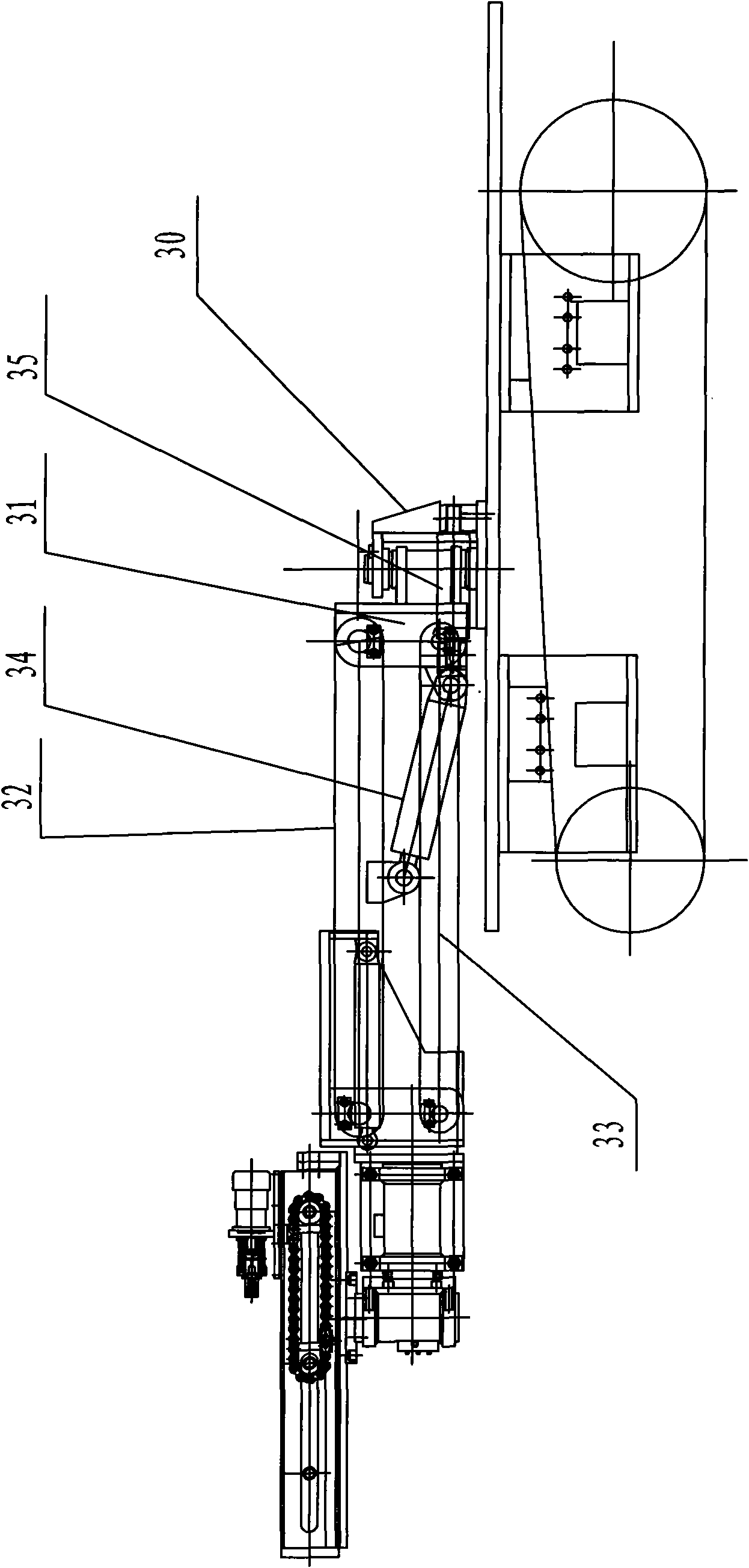

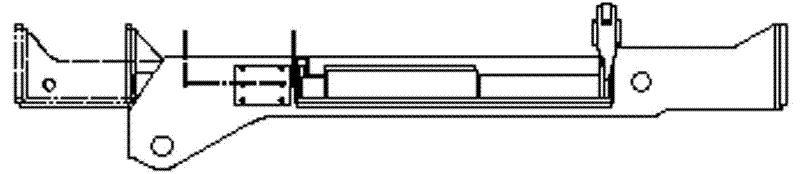

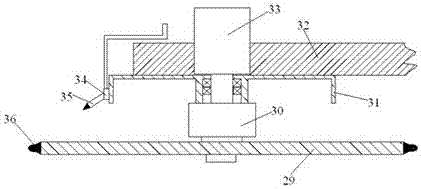

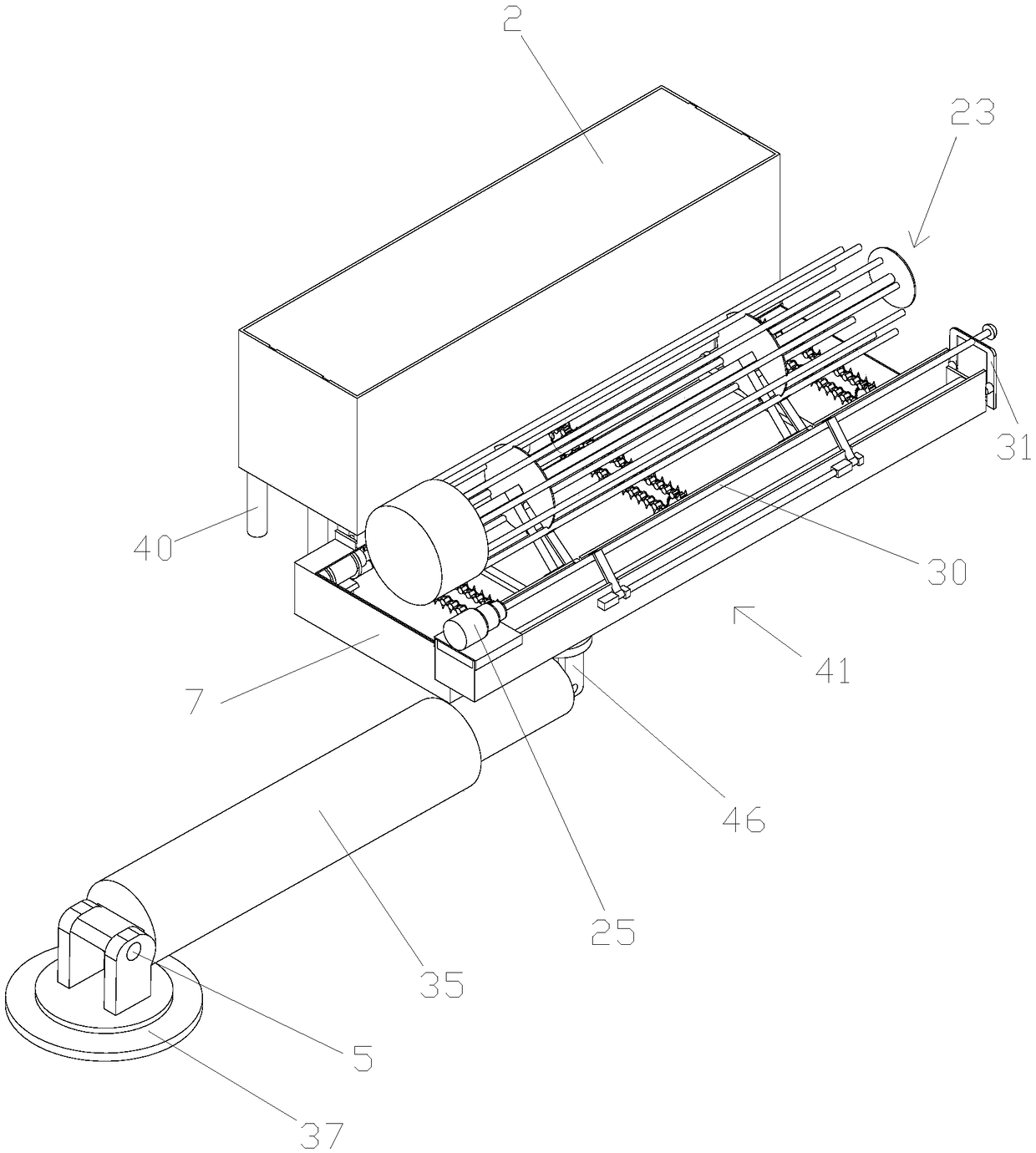

Integral push-lead type device and method for installation of tunnel anchor cable anchoring agent

ActiveCN104695990AAvoid multiple pushesReduce labor intensityAnchoring boltsHigh probabilityUltimate tensile strength

The invention discloses an integral push-lead type method for the installation of a tunnel anchor cable anchoring agent. The method comprises the following steps: connecting multiple anchoring agent cartridges filled with the anchoring agent integrally; installing the integrally connected anchoring agent cartridges in a push-lead mechanism; propping an anchor cable against a base plate at the rear end of the push-lead mechanism, and then inserting the push-lead mechanism equipped with the anchoring agent cartridges into a drilled hole formed in rock or coal; pushing the anchor cable toward a drilling direction, so that the push-lead mechanism reaches the top of the drilled hole, using a roof bolter for continuing to push and stir the anchor cable correspondingly, so that the multiple anchoring agent cartridges in the push-lead mechanism are broken, and the anchor cable is anchored in the stable rock or coal by using the anchoring agent. In addition, the invention further provides a device for the method; the device has the advantages of simple structure and good stability, and can effectively solve the problems of multiple-time installation of the anchoring agent cartridges, high probability of blockage of drilled holes, complicated installation process, long support time, high labor intensity of workers and other difficulties restricting the development of the tunnel support technology in the installation process of the existing anchoring agent cartridges.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

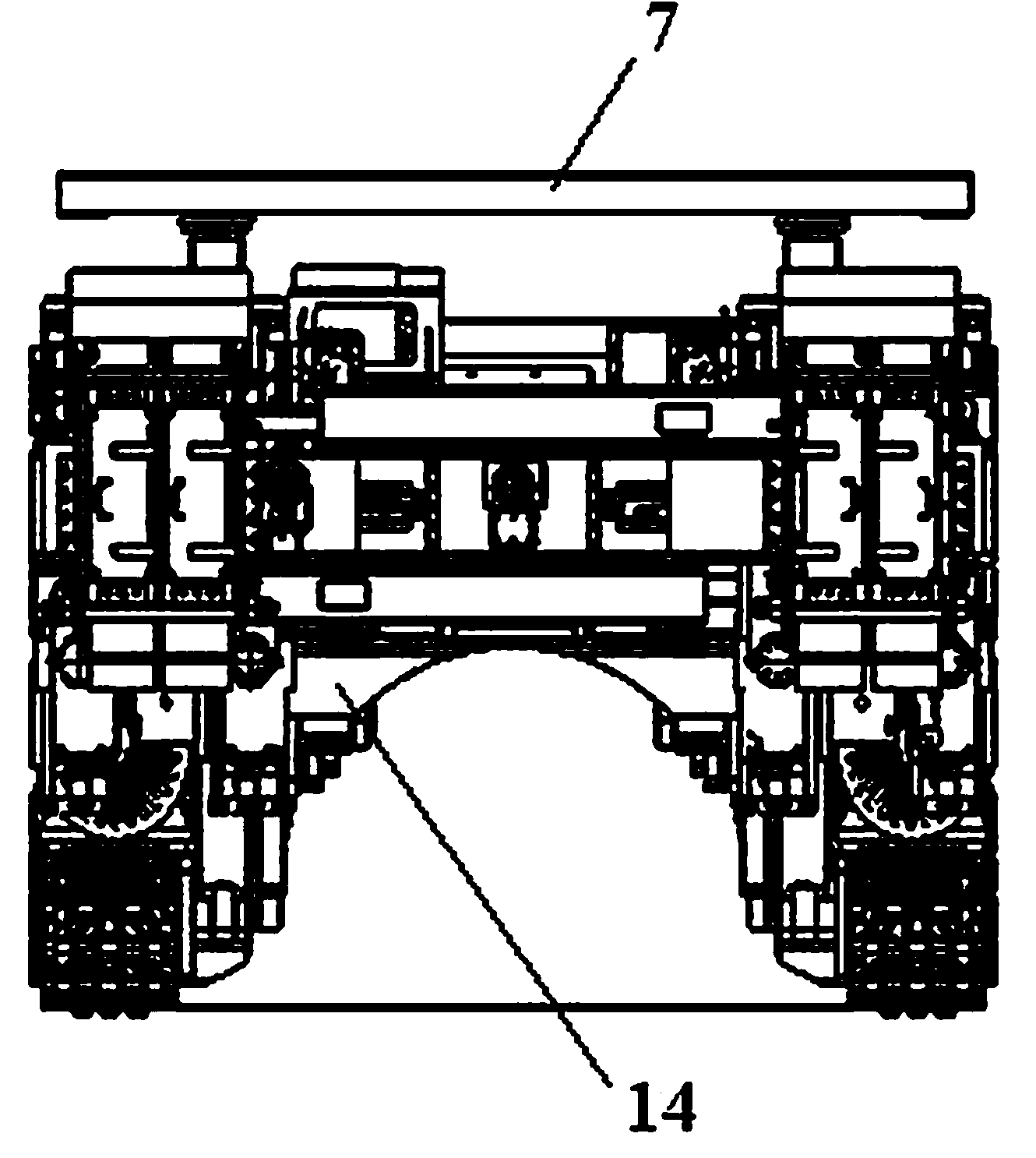

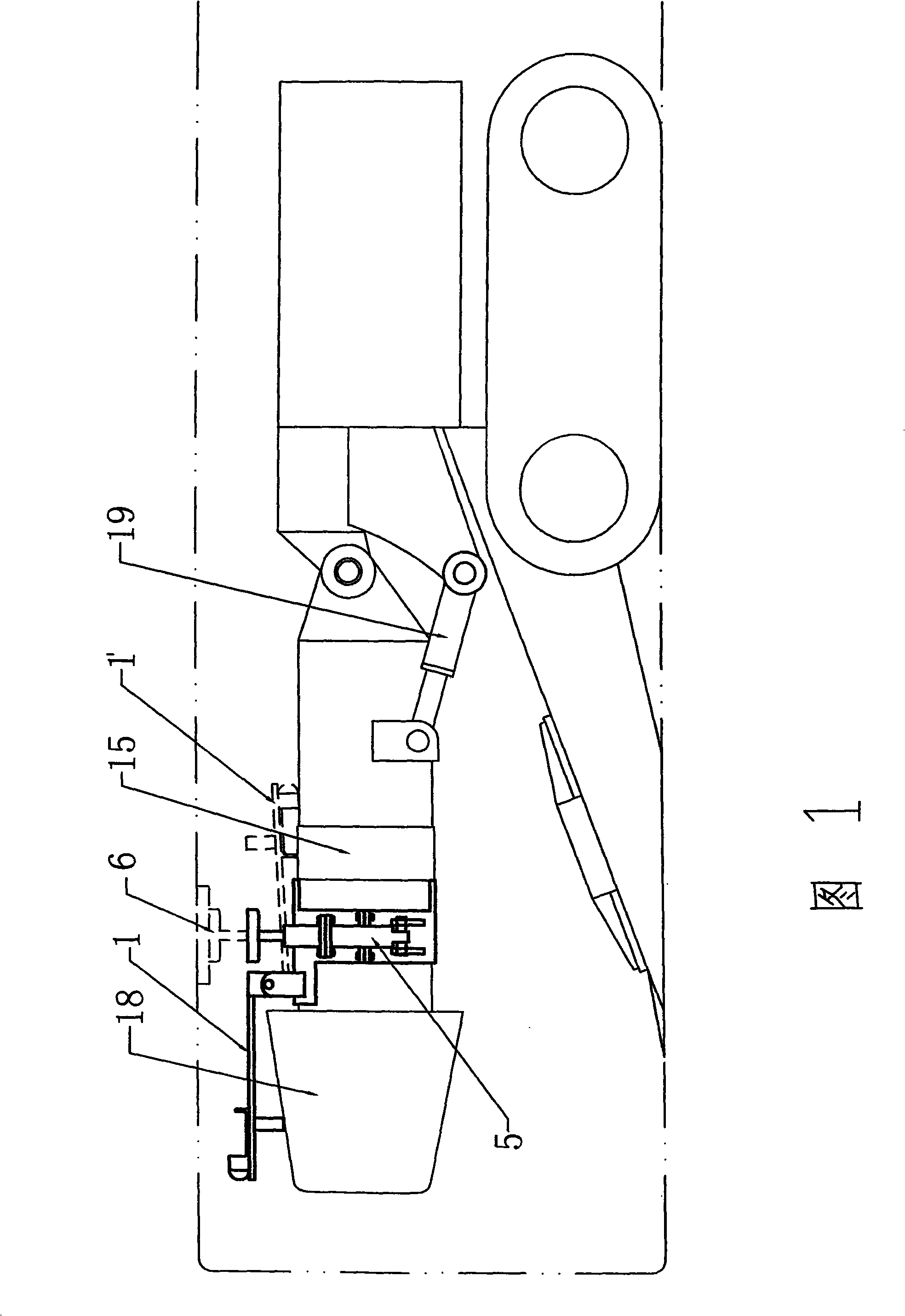

Movable two-arm hanging wall anchor rod and anchor cable construction drill carriage

ActiveCN101832103AShorten working timeImprove support efficiencyMine roof supportsAnchoring boltsEngineeringUltimate tensile strength

The invention provides a movable two-arm hanging wall anchor rod and anchor cable construction drill carriage which mainly comprises a crawler traveling part, a machine body platform, drill arm parts, a hydraulic drill device, a temporary support device and a hydraulic operation system, and is characterized in that the temporary support device comprises a temporary support base, an extension arm,a protection plate, an oil cylinder of the extension arm and an oil cylinder of the protection plate; the temporary support base is arranged on the machine body platform; the extension arm is articulated on the temporary support base; the oil cylinder of the extension arm is articulated on an extension arm seat and the extension arm; the protection plate is articulated at the top end of the extension arm; and the oil cylinder of the protection plate is articulated on the protection plate and the extension arm. The invention lowers the labor intensity of constructors, reduces the number of theconstructors, improves the tunneling speed and the operating efficiency, creates the safe operating environment, and especially has a function of carrying out top pushing type temporary support for ultrahigh tunnels and the head-on coal sides of working surfaces.

Owner:闫振东

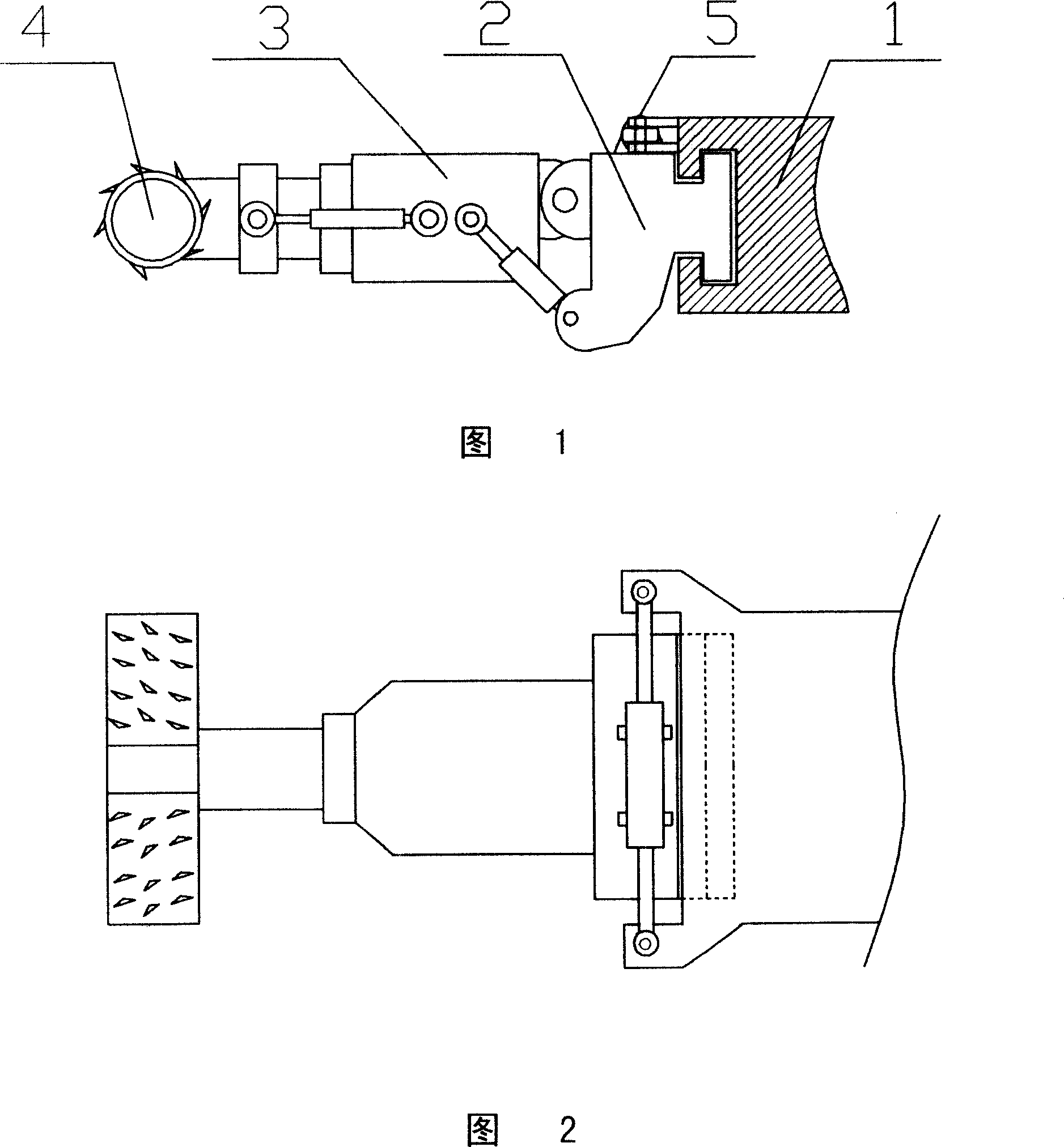

Roadheader

InactiveCN101153540AAdd supportImprove support efficiencyDriving meansCutting machinesEngineeringCantilever

A tunneling machine for tunneling gross section coal drift consists of a cutting unit, a body, a travel unit, a blade, a conveyor and a hydraulic system, etc. The cutting unit consists of a cutting head (4), a cantilever (3), a cutting motor, a cutting reduction gearbox and a telescopic part, etc. The cantilever (3) is connected with the body through a side slip guide mechanism namely a crosshead (2) is hinged onto the rear end of the cantilever (3); a guide body is arranged on the rear end of the crosshead; a guide holder (1) is fixed on the body; a guide groove is arranged on the front end of the guide holder, and the guide body is embedded in the guide groove and is in slide fit with the guide groove; or the two parts are arranged in a reverse way. A driving element or mechanism for driving the crosshead and the cantilever to make lateral movement is arranged between the guide holder and the crosshead. A cantilever tilt cylinder is hinged between the cantilever (3) and the crosshead (2). The wall of the coal drift cut by the tunneling machine is smooth, flat and easy in supporting, thereby improving supporting efficiency and effect. The cutting unit makes a large range of lateral movement, thereby realizing gross section fixed point cutting in a wider coal drift without lateral movement of the whole machine, shortening cycle time, improving tunneling speed and efficiency with great adaptability.

Owner:贾民

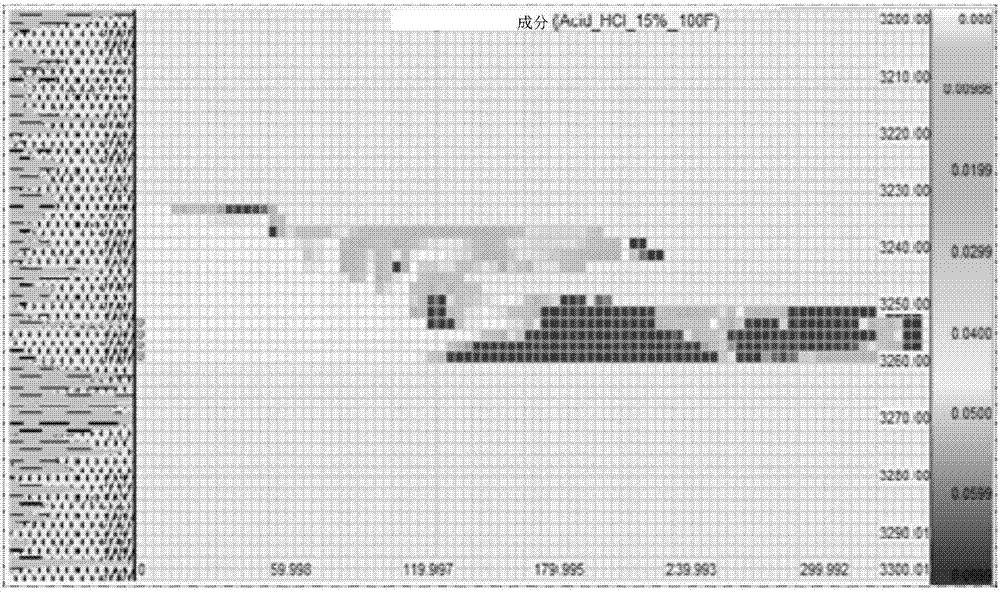

Acid injection fracturing method

The invention provides an acid injection fracturing method. The method comprises the steps that at the front liquid fissure forming stage, an alternative acid injection mode is adopted for fissure fracturing transformation, the alternative acid injection mode comprises the step that 1-5 levels of slugs are alternatively injected into fissures, and each level of slugs are composed of acid liquid and displacing liquid which are injected in sequence. According to the acid injection fracturing method, by combining with technical advantages of fracturing and acidification, through optimization of an alternative injection technology, the relation range of the acid liquid in a fissure fracturing system is enlarged to the greatest extent, and the porosity and permeability of fissure wall rock areimproved; a micro-fissure and branch fissure extension system is expanded and extended, increase of fissure complexity degree and transformation volume is promoted, and the duration time of keeping the flow diversion capacity of the fracturing system is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

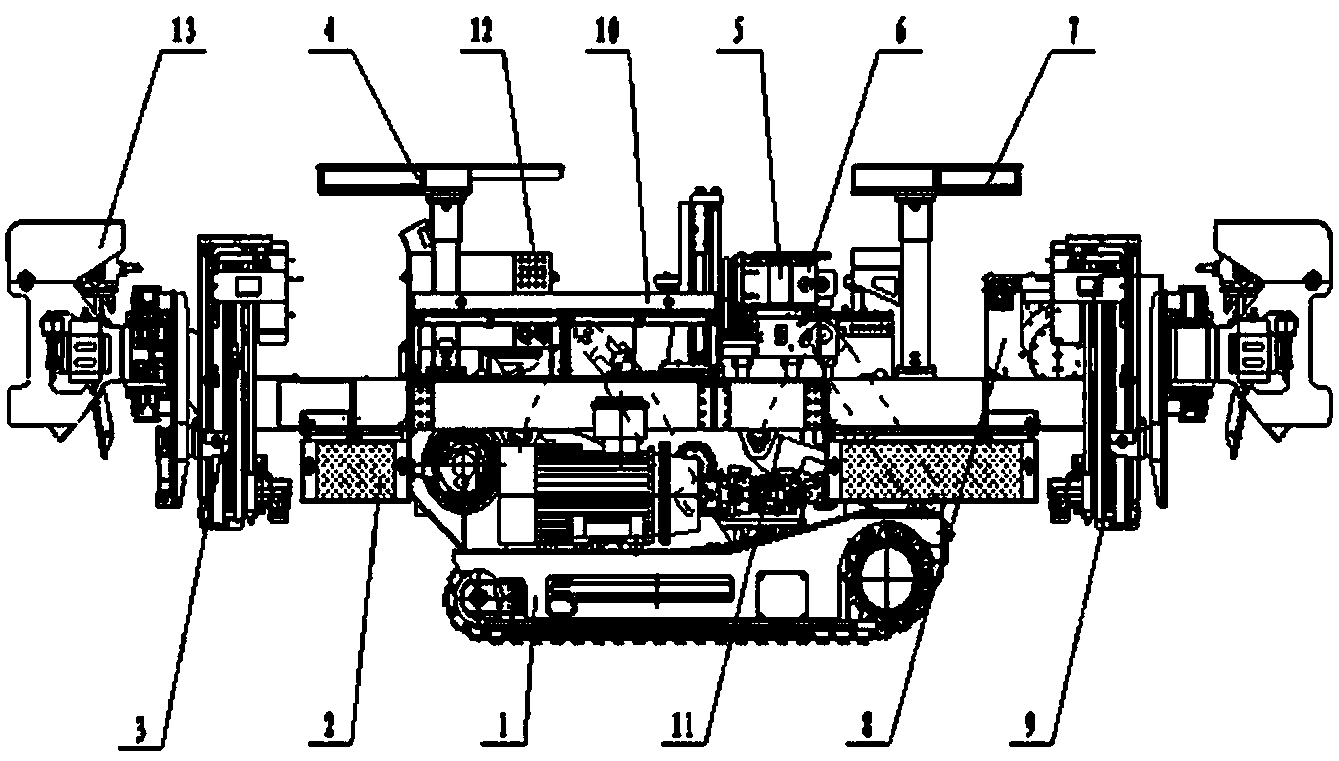

Hydraulic eight-arm anchor rod drill carriage for coal mine

ActiveCN102418540AImprove support efficiencyReduce labor intensityAnchoring boltsDrilling machines and methodsCoal miningEngineering

The invention belongs to the technical field of anchor rod drill carriages for coal mines, in particular relates to a hydraulic eight-arm anchor rod drill carriage for a coal mine, and solves the problem that the supporting speed of the conventional four-arm anchor rod drill carriage is lower than that of a continuous coal mining machine. The hydraulic eight-arm anchor rod drill carriage for the coal mine comprises a frame, a workbench, a ceiling, an anchor drill system and a dust removal system, wherein four groups of drilling frames are arranged on the front and rear sides of the workbench; and gaps among the drilling frames on the front and rear sides are adjustable. The invention has the advantages that: eight anchor rods in two rows can be supported simultaneously, the hydraulic eight-arm anchor rod drill carriage can better adapt to the construction of high-yield and high-efficiency mines at present, supporting efficiency can be obviously improved, and labor intensity is effectively reduced; and the roadway forming speed of the hydraulic eight-arm anchor rod drill carriage matched with the continuous coal mining machine can be improved to be 1.5 times that of the four-arm anchor rod drill carriage matched with the continuous coal mining machine, the contradiction of excavating and supporting is solved, and a wide market prospect is achieved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Oil and gas reservoir fracturing sand-adding method

ActiveCN109751034AImprove support efficiencyImprove fracturing effectFluid removalLiquid ratioFracturing fluid

The invention relates to an oil and gas reservoir fracturing sand-adding method which comprises the following steps: respectively adopting different fracturing fluid types in a prepad fluid fracture forming stage and different sand-carrying fluid sand adding stages, using proppants with different densities and particle sizes in a matched manner, optimizing the configuration of the proppants in a whole fracture space, and improving the flow guiding performance of fractures, so as to improve the fracturing effect. According to the invention, construction parameters such as the fracturing fluid displacements of different fracturing construction stages, the liquid amount, the sand-liquid ratio and the like are further optimized in a synergistic manner so as to enable the proppants to be evenlylaid in the whole crack space, the filling degree and the supporting efficiency of the proppants in cracks are improved, the effective flow guiding capacity after pressing is improved, and the problems that the initial yield after pressing is low, the yield is decreased progressively and rapidly, and a stable production period is short are solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Narrow-fuselage six-arm fully hydraulic anchor rod anchor cable drill carriage

InactiveCN104196443ARealize the mechanization of working face supportImprove support efficiencyDerricks/mastsAnchoring boltsRock boltFuselage

The invention provides a narrow-fuselage six-arm fully hydraulic anchor rod anchor cable drill carriage which is composed of a walking mechanism, a lifting mechanism, a temporary support mechanism, a drilling arm mechanism, a pump station part, an electrical system and a hydraulic system. According to the narrow-fuselage six-arm fully hydraulic anchor rod anchor cable drill carriage, two rotating workbenches are arranged in front of a machine body, and each rotating workbench is provided with two drilling arms which rotate by 90 degrees through the rotating workbenches, the drill carriage is folded to make the narrow fuselage state be only 1.4 m, passing of the drill carriage and an integrated extractor in a roadway is achieved, the drill carriage can be unfolded by 5 meters when reaching a roadway head-on, four front drilling arms mainly hit a top anchor rod, two rear drilling arms mainly hit a top anchor cable and a side anchor rod, the six drilling arms work simultaneously, rapid anchor protection of the roadway can be realized, support efficiency can be greatly improved, tunneling footage is greatly improved, the coal extraction imbalance contradiction is better solved, and safe, efficient and benign development of coal production is promoted.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

Rapid drivage-anchoring integrated equipment for coal road under instable surrounding rock condition

ActiveCN104747201AImprove efficiencyAvoid destructionTunnelsAnchoring boltsRubber sheetDrilling machines

The invention discloses rapid drivage-anchoring integrated equipment for a coal road under an instable surrounding rock condition. The equipment comprises a drivage-anchoring machine and an anchor rod drill carriage, the drivage-anchoring machine comprises a cutting roller, an air draft pipeline, a material collector, an anchor rod drilling machine set and a scraper conveyor, the anchor rod drill carriage comprises an anchor rod drill drilling machine set and a scraper conveyor, the anchor rod drill carriage is arranged behind the drivage-anchoring machine, the rear portion of the scraper conveyor of the drivage-anchoring machine is located over the front portion of the scraper conveyor of the anchor rod drill carriage, a roof-caving-preventing device is arranged on the drivage-anchoring machine, a sealing device is connected below the roof-caving-preventing device, the sealing device is composed of a moving sealing rubber sheet, a fixed sealing rubber sheet, a telescopic oil cylinder, a cross beam and a telescopic beam, the cross beam is connected with one end of the telescopic oil cylinder, the other end of the telescopic oil cylinder is connected with the telescopic beam, the fixed sealing rubber sheet is connected below the cross beam, and the moving sealing rubber sheet is connected below the telescopic beam. By means of the equipment, the anchoring efficiency can be matched with the drivage efficiency, and the comprehensive drivage-anchoring efficiency is promoted.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Multifunctional rock tunnel boring machine support system and method

InactiveCN110284895AClose in timeImprove adaptabilityUnderground chambersTunnel liningSupporting systemCombined use

The invention discloses a multifunctional rock tunnel boring machine support system and method. The support system comprises a shield, a steel arch mounting machine, a front-mounted mixed spraying machine, a segment mounting machine and a roof bolt driller. The shield is disposed between the front part of a main beam of the boring machine and a cutter head, and the steel arch mounting machine, the front-mounted mixed spraying machine, the segment mounting machine and the roof bolt driller are sequentially and slidably disposed on a main beam on the rear side of the shield; the steel arch mounting machine and the front-mounted mixed spraying machine are disposed in an adjacent mode; and a segment feeding machine is arranged below the roof bolt driller, and the segment feeding machine is connected with the boring machine through a traction mechanism. The multifunctional rock tunnel boring machine support system and method integrate various supporting methods, can realize the combined use of various supporting methods, enhance the adaptability of a open type TBM to the weak broken stratum, can realize the timely sealing of the surrounding rock, and improve the driving efficiency and the supporting strength.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +2

Electro-hydraulic anchor protection control double basket type two arm anchor cable anchor rod drill truck

PendingCN111287652ALarge lifting rangeIncrease freedomDerricks/mastsDirectional drillingReduction driveMarine engineering

The invention belongs to the technical field of equipment for drilling, anchor cable and anchor rod installation and fastening, and particularly relates to an electro-hydraulic anchor protection control double basket type two arm anchor cable anchor rod drill truck. The electro-hydraulic anchor protection control double basket type two arm anchor cable anchor rod drill truck includes a walking chassis, a vertical lifting platform, a rear machine frame, a left anchor protection large arm, a right anchor protection large arm, an advance support device and an automatic cable winding mechanism, wherein the vertical lifting platform is arranged right above the walking chassis to realize vertical lifting and lowering, a walking reducer is installed on the rear side of the walking chassis, a guide wheel is installed on the front side of the walking chassis, the vertical lifting platform is symmetrically provided with the left anchor protection large arm and the right anchor protection large arm which can realize height adjustment and swing adjustment on both sides, the advance support device is hinged to the front end of the vertical lifting platform, the rear machine frame is arranged inthe rear of the walking chassis, a motor, a pump station and an oil tank are sequentially installed on the top left of the rear machine frame to form a power system, a driving room and an electric control box are arranged above the power system, the automatic cable winding mechanism and a cable winding guide supporting roller group are installed on the left side of the driving room, and a rear stabilized shoe is installed at the bottom of the rear machine frame.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

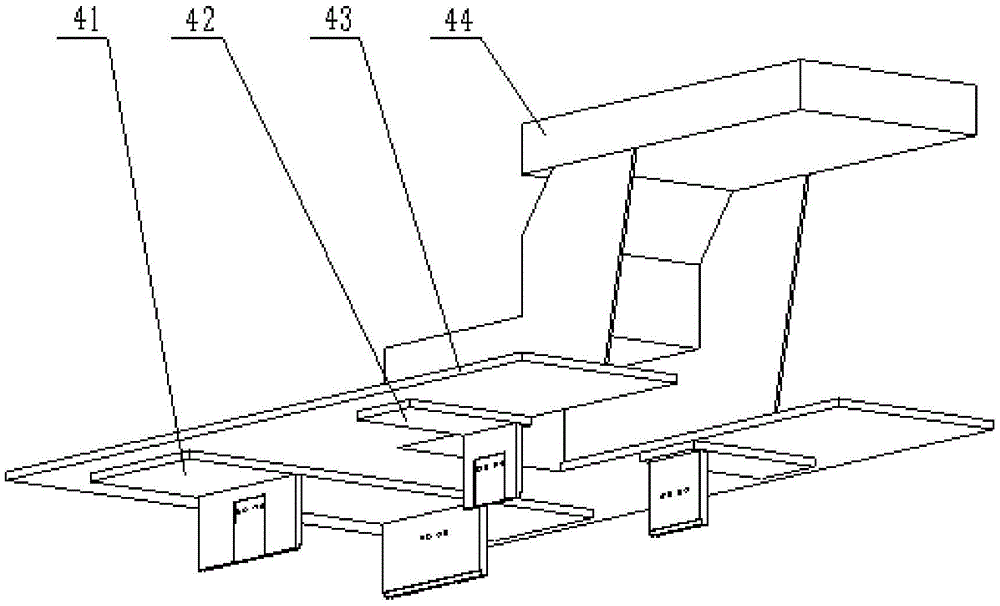

Drilling, loading, transporting and anchoring integrated machine with dual platforms and four arms for coal roadway

InactiveCN101858213AShorten working timeImprove support efficiencySlitting machinesMine roof supportsEngineeringHeadworks

The invention provides a drilling, loading, transporting and anchoring integrated machine with dual platforms and four arms for a coal roadway, comprising a caterpillar travel part, an engine body platform, four drill arm parts, four hydraulic drilling rig parts, a provisional supporting device, a hydraulic and operation system, a pump station part, a rear support part, a shovel plate part, a first conveyor and a second conveyor and being characterized in that the integrated machine also comprises a lifting platform and a platform lifter; the platform lifter is arranged on the engine body platform, and the lifting platform is connected above the platform lifter; four drill arm parts and four hydraulic drilling rig parts are installed at the rear sides of the upper and lower parts and the left and right sides of the lifting platform; and the provisional supporting part is fixedly installed on the front end of the lifting platform. The integrated machine in the invention can complete all procedures such as drilling, coal loading, coal transporting, anchor bolts and anchor cables construction, provisional supporting and the like, and improves the centrality, flexibility and systematicness of tunneling equipment, thus reducing mechanical handing, installing and dismounting operations on headwork faces, lowering labor intensity for workers and increasing work efficiency of tunneling.

Owner:闫振东

Telescopic tunneling immediate support device

ActiveCN102121390AQuick push and pull movementEnhancing the ratio of reasonable assignmentsMine roof supportsHydraulic cylinderOperating environment

The invention discloses a telescopic tunneling immediate support device, which effectively solves the problem of unavailable continuous roof contact or poor roof contact capability existing in the prior art during use. The support device comprises hydraulic upright posts, beams and longitudinal beams, and is characterized in that: the bottom of each hydraulic upright post is provided with a base;the beams comprise a front beam, a middle beam, a rear beam, a main support beam and an auxiliary support beam which are arranged in parallel with one another; the longitudinal beams comprise a frontelastic longitudinal beam, a middle elastic longitudinal beam, a rear elastic longitudinal beam, a front rigid longitudinal beam, a middle rigid longitudinal beam, a rear rigid longitudinal beam and a side rigid longitudinal beam which are arranged in parallel with one another and are vertical to the beams; a push hydraulic cylinder is hinged between every two beams respectively; and the elastic longitudinal beams and the rigid longitudinal beams are fixed on corresponding beams respectively, inserted in limiting guide sleeves of corresponding beams and driven to move along the limiting guidesleeve in a reciprocating way by the beams. The support device has the advantages of reasonable structural distribution, convenience for adjusting continuous roof contact, stable supporting and capabilities of improving the operating environment of workers, better meeting the requirement on matching job of an underground laneway support and a roadheader and remarkably improving the support quality and tunneling operation efficiency of a laneway top plate.

Owner:沈阳天安特种机器人有限公司

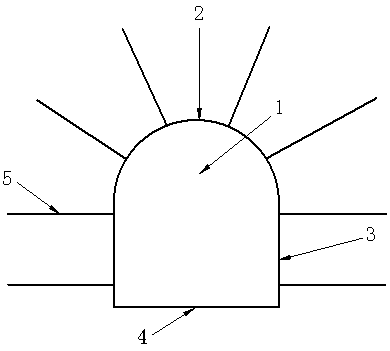

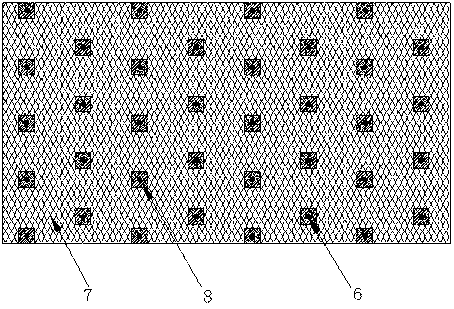

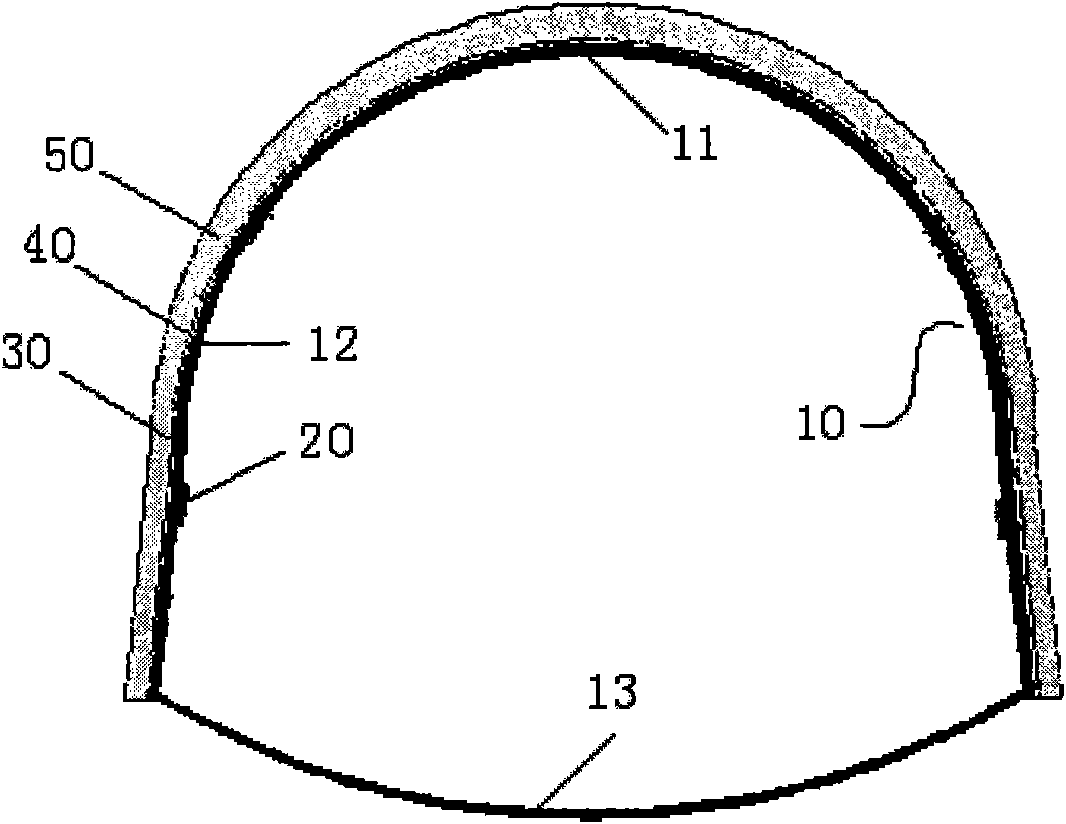

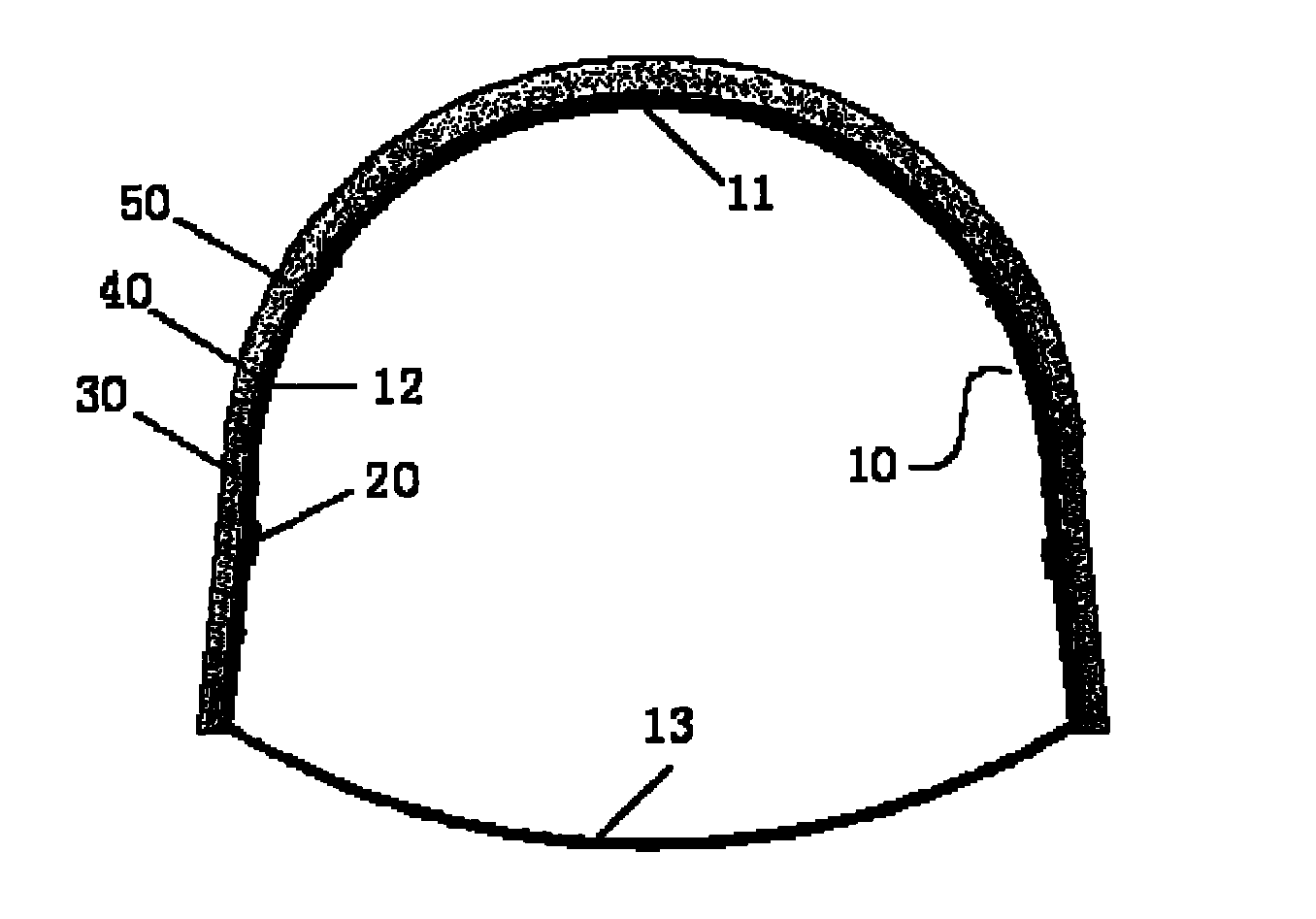

Method for supporting and protecting soft, collapsible and super thick coal seam tunnel based on filling behind support and device thereof

The invention discloses a method for supporting and protecting a soft, collapsible and super thick coal seam tunnel based on filling behind a support and a device thereof, relating to the supporting and protecting technology of the coal seam tunnel. The method comprises the following steps of: (1) the tunnel is supported and protected by a sealing retractable U-shaped steel support which consists of a top arch, a side wall and an inverted arch; (2) the inner wall of the side wall is provided with a waist beam; (3) the top arch and the outer wall of the side wall are suspended with a metal mesh; (4) the metal mesh is externally paved with a double resistance cloth; and (5) the outer side of the double resistance cloth is injected with a high-expansion chemical filling material behind the support. The device has the following structure: the waist beam (20), the sealing retractable U-shaped steel support (10), the metal mesh (30), the double resistance cloth (40) and the high-expansion chemical filling material (50) are sequentially connected with each other from the inside to the outside. The invention is suitable for supporting and protecting the super thick, soft and collapsible coal seam tunnel, and the landslide and soft tunnel.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

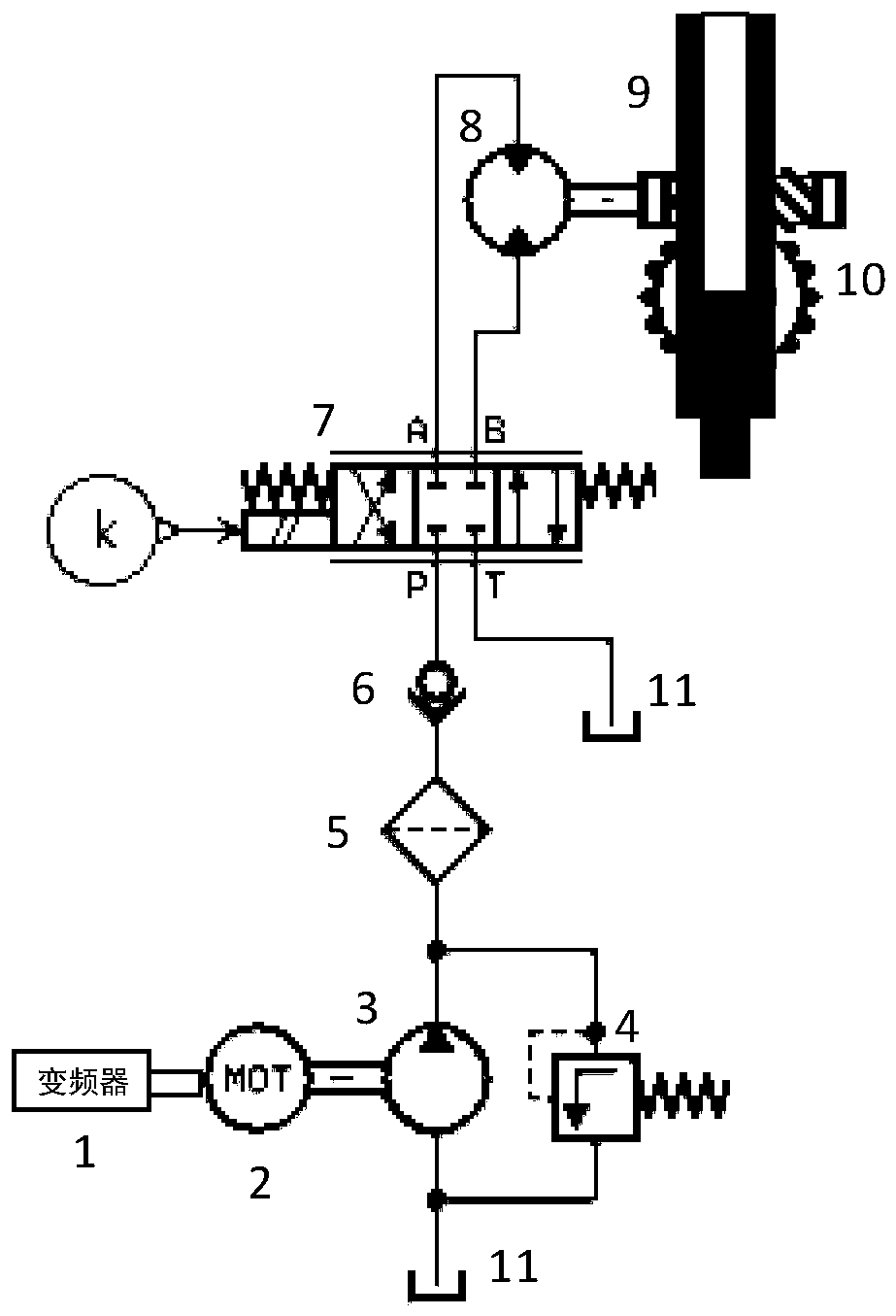

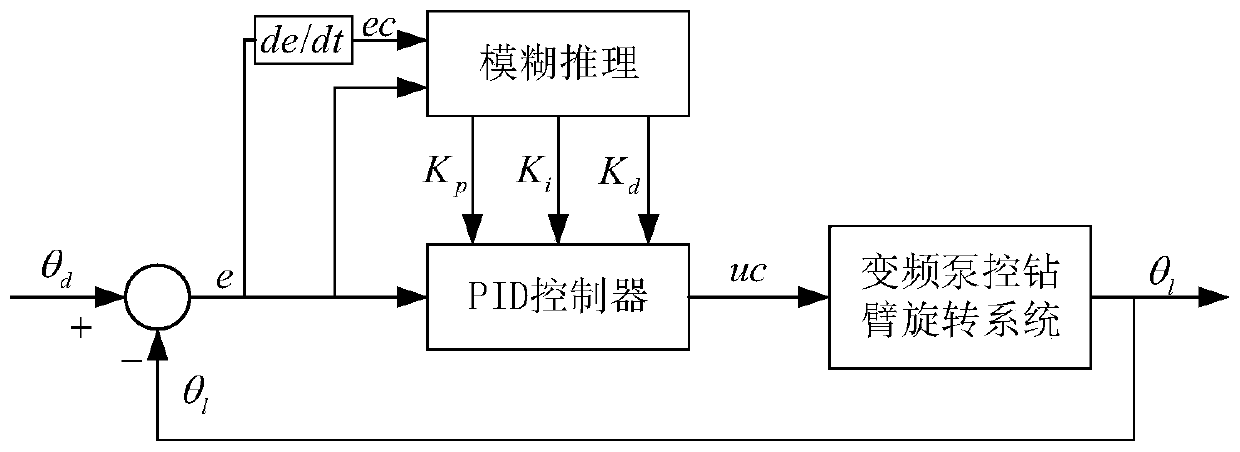

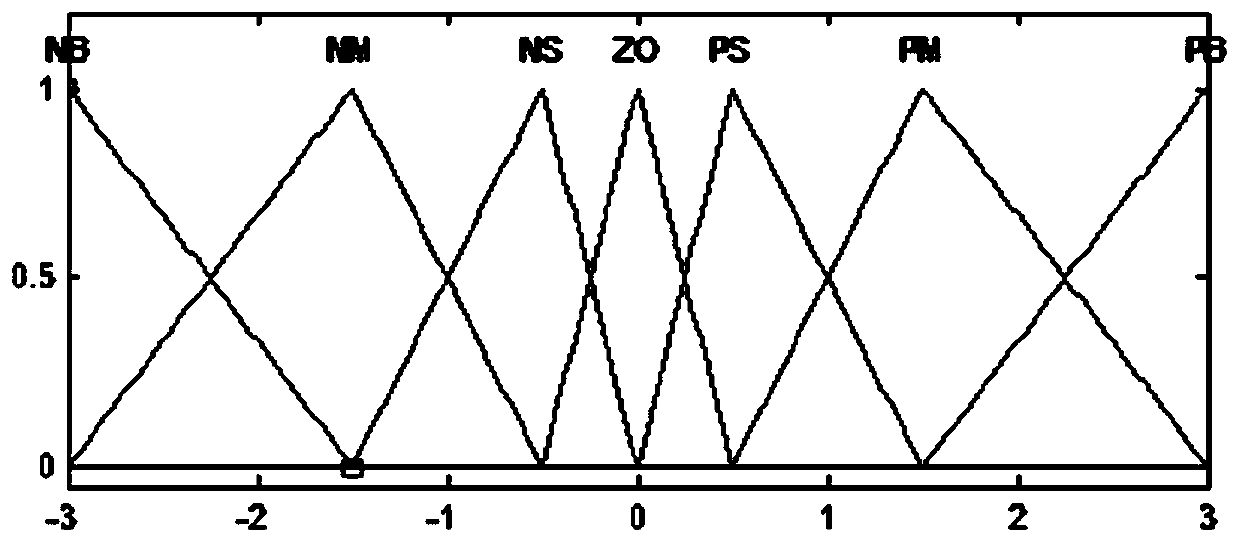

Fuzzy PID (proportion integration differentiation) control method for swing angle of drill boom of variable frequency pump controlled hydraulic drilling rig

InactiveCN109946961AImprove work efficiencyMeet the maximum swing angle error requirementsControllers with particular characteristicsMathematical modelEngineering

The invention provides a fuzzy PID (proportion integration differentiation) control method for a swing angle of a drill boom of a variable frequency pump controlled hydraulic drilling rig, and belongsto the technical field of variable frequency pump control. A variable frequency pump controlled hydraulic drilling rig drill boom rotating system is constructed, and a frequency converter converts 380V / 50Hz power-frequency AC (alternating current) into a voltage signal with specific frequency to drive an asynchronous motor; the asynchronous motor drives a constant delivery pump to rotate, and a certain flow of high-pressure oil is output; the high-pressure oil passes through a filter, a one-way valve and a reversing valve to drive a two-way hydraulic motor to rotate; then the drill boom is driven by a worm gear / worm reducing mechanism to deflect; low-pressure oil at an oil outlet of the hydraulic motor passes through the reversing valve and flows back to an oil tank. The variable frequency pump controlled hydraulic drilling rig drill boom rotating system is constructed on the basis of the control requirement of the swing angle of the drill boom of the variable frequency pump controlled hydraulic drilling rig; a mathematic model of the novel drilling rig drill boom rotating system is established; the method is suitable for accurate position control of an anchor rod / anchor rope in acomprehensive mechanized mining roadway support, has better control performance when applied to the variable frequency pump controlled hydraulic drilling rig drill boom control system, and verifies correctness and effectiveness of the variable frequency pump controlled drill boom rotating system model.

Owner:CHINA UNIV OF MINING & TECH

Auxiliary supporting device for digging roadway of coal mine

ActiveCN106958451AImprove tunneling efficiencyImprove support efficiencyDust removalFire preventionEngineeringCoal

The invention discloses an auxiliary supporting device for digging a roadway of a coal mine. A mobile wheel is arranged below a chassis; a digging component is arranged on a rotary mobile component; the rotary mobile component is slidingly arranged on the chassis; a supporting component is arranged on the rotary mobile component; an auxiliary supporting component is arranged at the top of the supporting component and is used for supporting a to-be-mounted roadway bracket in an auxiliary manner; a removable counterweight component is also arranged on the chassis. According to the auxiliary supporting device disclosed by the invention, an effect of supporting while digging in a process of digging the roadway is realized; in the digging process, dust can be degraded by spraying water mist; the auxiliary supporting component can be used for supporting a supporting beam in an auxiliary manner, the supporting angle is adjustable, and the supporting is flexible; a removable counterweight block is also arranged, so that the supporting and digging effects of the device are ensured, and the balance of the device in the supporting and digging process is ensured, therefore, the roadway digging and supporting efficiency can be greatly improved, and the construction safety is ensured.

Owner:HENAN POLYTECHNIC UNIV

Digging laneway temporary support device

InactiveCN101338672AReduce labor intensitySpeed up temporary supportSlitting machinesCutting machinesGeological structureHorizontal diameter

The present invention relates to a drivage temporary supporting device which belongs to the drivage supporting machinery and solves the problems that a top plate is delaminated and collapsed easily if the unsupported roof distance of a new drivage is more than two meters due to the geological structural development of the top plate of a mine. The drivage temporary supporting device is characterized in that the supporting device is installed at the telescopic boom of a roadheader by a fastening ring. The upper ring edge and the lower ring edge of the fastening ring are provided with connecting boards for installing and fixing. The bottom of the lower ring of the fastening ring is provided with a support pedestal. The two ends of the support pedestal are symmetrically and vertically connected with lifting hydraulic jacks. The tops of a pair of lifting pillars of the hydraulic jacks are provided with saddles. The connecting boards which are used for fixing the hydraulic jacks are symmetrically arranged at the two sides of a wall which is vertical to the upper ring arc line of the fastening ring. Shafting brackets are symmetrically arranged at the arc line at the front part of the upper ring of the fastening ring vertical to the axial line of the telescopic boom. The shafting brackets are matched with an engaging lug at the back end of a bracket and are connected by a pin roll. A whiffletree is arranged at the front section of the face of the bracket which is connected with the fastening ring by the pin roll. A bracket slot is arranged at the inner side of the whiffletree. A hollow frame is dug at the middle section of the bracket, and the back of the bracket is provided with a support leg.

Owner:HUAYANG NEW MATERIAL TECH GRP CO LTD

Coal mine anchor drilling robot autonomous anchor drilling device and method

The invention discloses a coal mine anchor drilling robot autonomous anchor drilling device and method. The coal mine anchor drilling robot autonomous anchor drilling device comprises a control module, an anchor rod warehouse, an anchor rod conveying mechanism and an anchor drilling mechanism. The anchor drilling mechanism includes a hydraulic telescoping mechanism, a drilling mechanism and an anchor bolt frame, an anchor rod feeding mechanism and an anchor rod installation frame. The drilling mechanism includes a drill pipe feeding mechanism, a drilling machine, a drill pipe adjusting mechanism, a drill pipe and a hydraulic clamping mechanism. The method comprises the following steps of 1, inspection and initialization of coal mine anchor drilling robot autonomous anchor drilling device;2, anchor rod feeding operation; 3, rod drilling; and 4, anchor bolt installation. The coal mine anchor drilling robot autonomous anchor drilling device and method is reasonable in design, realizes the robot drilling, anchor rod feeding and anchor rod installation, effectively improves the underground support efficiency of a coal mine, reduces the labor intensity of underground workers, maximizesthe liberation of productivity, and realizes the automation of the fully mechanized excavation face support of the coal mine, and is high in practicability.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com