Narrow-fuselage six-arm fully hydraulic anchor rod anchor cable drill carriage

A fully hydraulic, drilling rig technology, applied in the installation of bolts, drilling equipment, earthwork drilling, etc., can solve the problems of inability to support the fully mechanized excavator, unable to meet the support efficiency, limited support efficiency, etc. Good, free and reliable, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

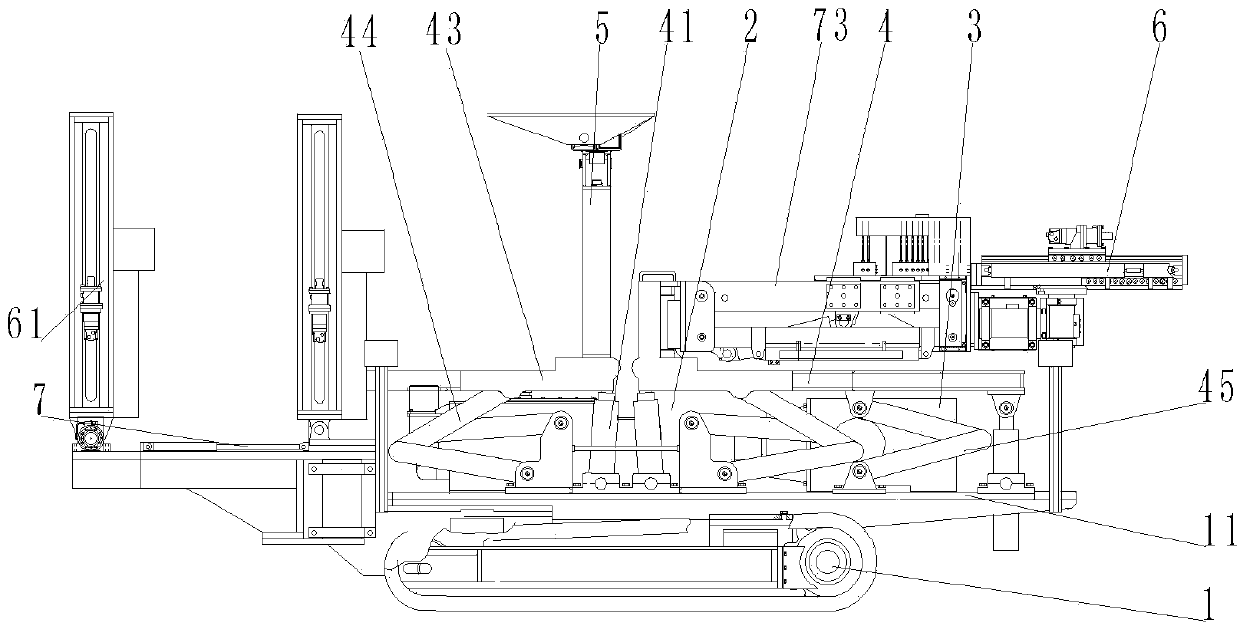

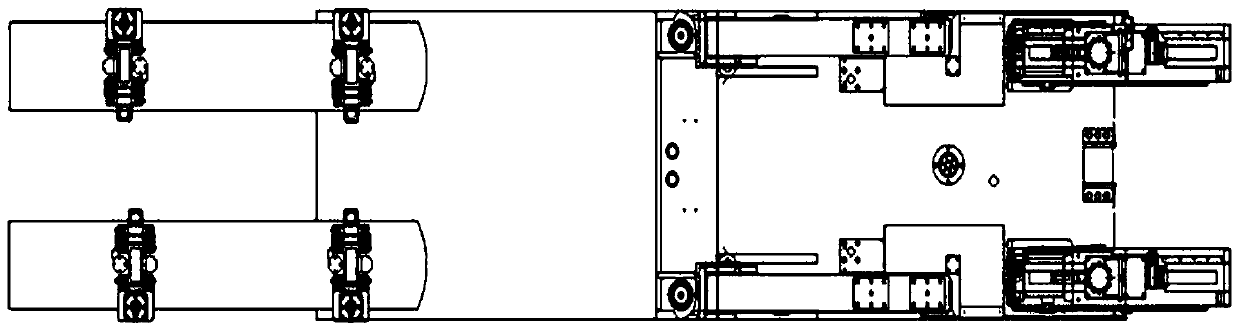

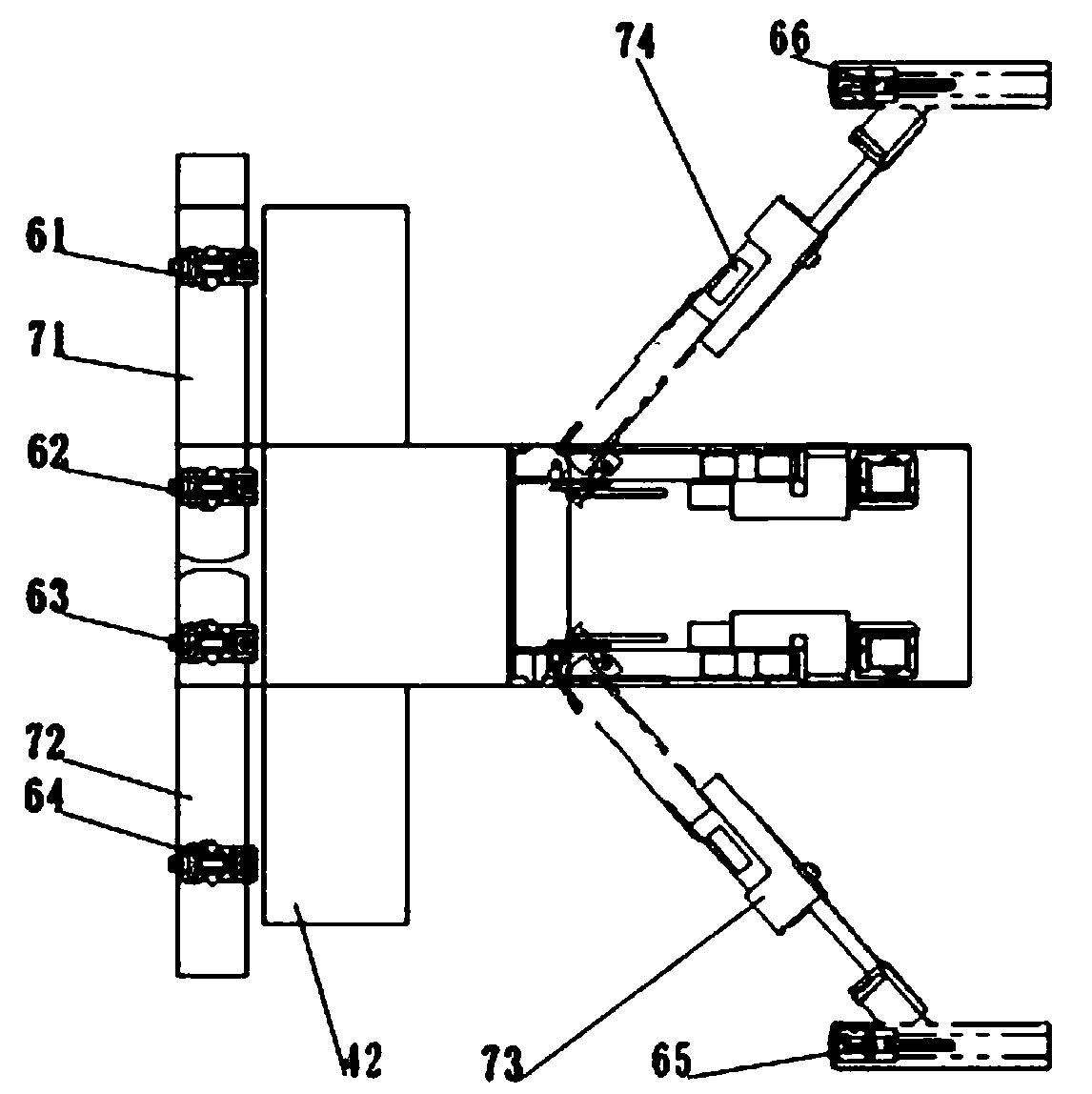

[0040] Refer to the attached Figure 1-8 As shown, the present invention provides a narrow-body six-arm full-hydraulic bolt-and-rope drilling rig, which is mainly composed of a traveling mechanism 1, a lifting mechanism 4, a temporary support mechanism 5, a drilling arm mechanism 7, a pump station part 2, an electrical system 3 and a hydraulic system, wherein a drilling mechanism 6 is installed at the front end of each drilling arm mechanism 7, the lifting mechanism 4 includes an installation platform and a lifting platform, the installation platform is located on the upper part of the walking mechanism, and the temporary support mechanism is fixed on the lifting platform. There are six drill boom mechanisms, four drill boom mechanisms are arranged in front of the drilling rig, two drill boom mechanisms are arranged at the back, and two rotary worktables are installed at the front end of the lifting platform. When in the retracted state, the two rotary worktables are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com