Digging laneway temporary support device

A temporary support and roadway technology, applied in cutting machinery, earthwork drilling, cutting machinery, etc., can solve the problems of high roof pressure, roof separation, easy breakage, etc., to achieve large initial support force and high safety , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

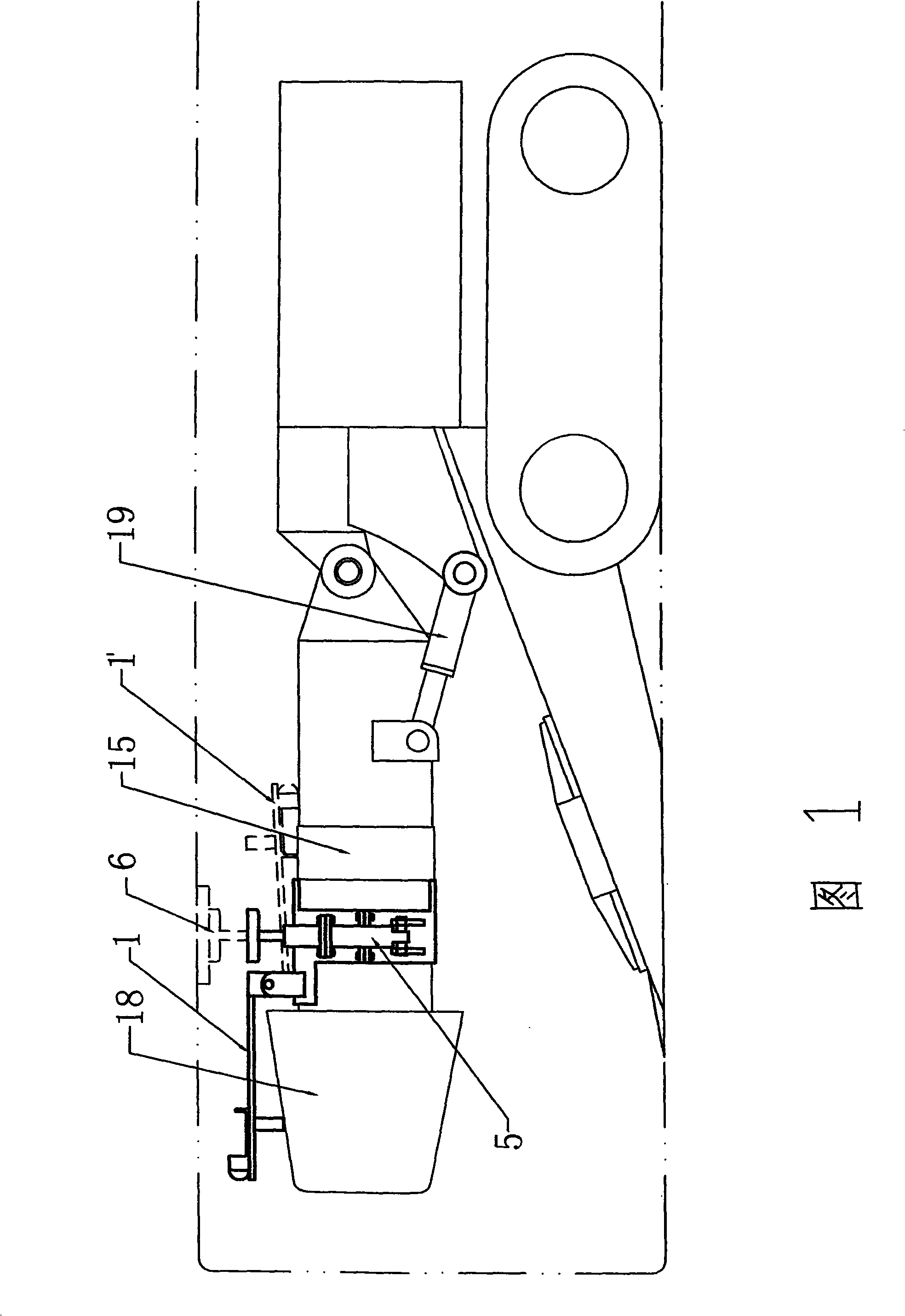

[0016] Describe as follows in conjunction with accompanying drawing: the bracket 1 that the solid line part of accompanying drawing 1 shows is the state schematic diagram when implementing the temporary support operation, the hydraulic jack of the dotted line part has shown the state of the temporary support roof; the bracket 1 shown in the dotted line part 1 It is a schematic diagram of the flipped state during the tunneling operation of the roadheader. The bracket in the flipped state will not affect the tunneling operation of the roadheader operator. The bracket can be deployed forward or turned backward with the shaft pin 8 as the axis, which can be implemented manually.

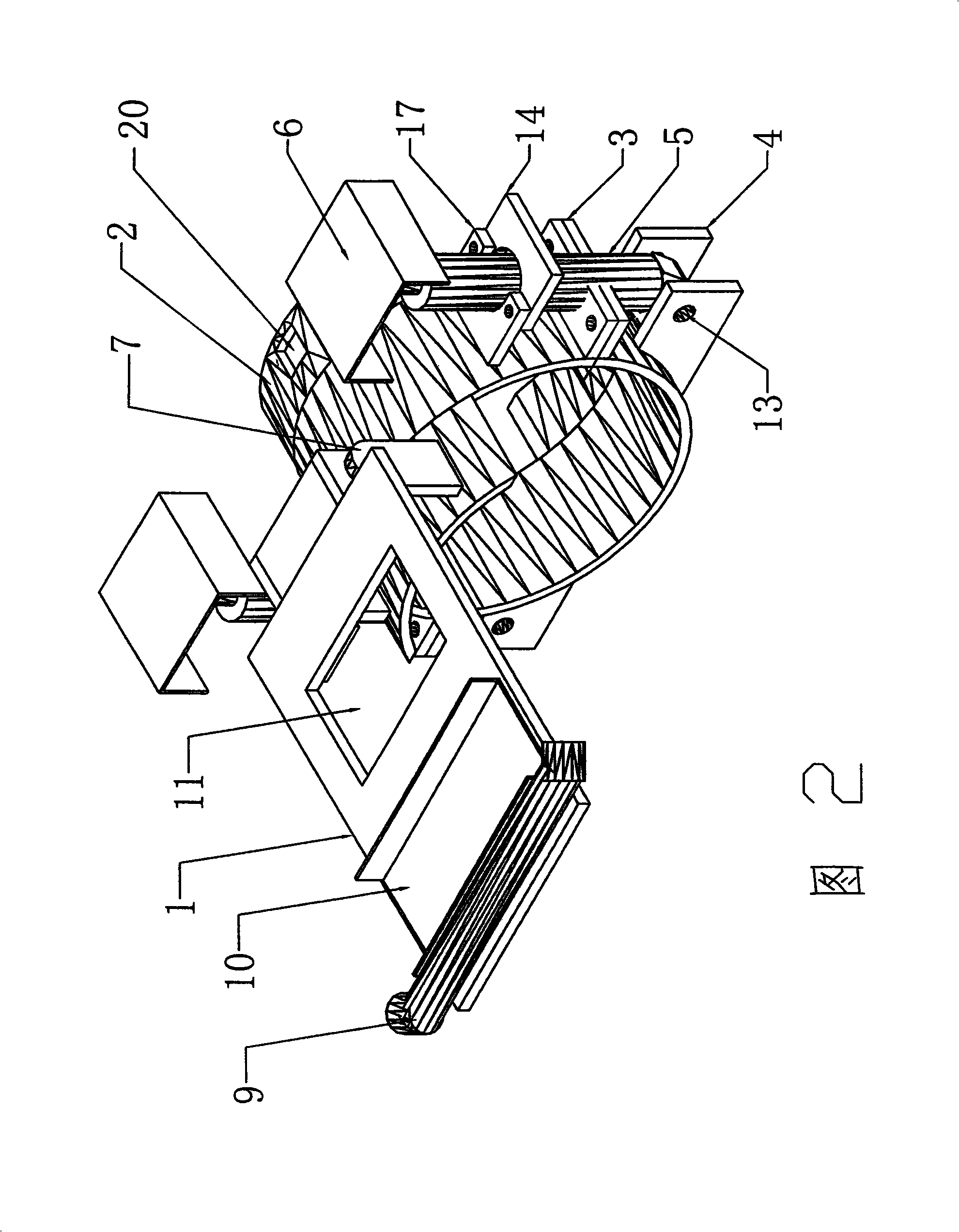

[0017] The roadway temporary support devices of the present invention are all made of steel materials. The thickness of the steel plate used for the bracket 1 and the fastening ring 2 is not less than 20 mm. A hole on the boss of the oil injection hole of the arm ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com