Fuzzy PID (proportion integration differentiation) control method for swing angle of drill boom of variable frequency pump controlled hydraulic drilling rig

A technology of hydraulic drilling rig and control method, which is applied to electric controllers, controllers with specific characteristics, etc., can solve the problems of variable frequency pump-controlled hydraulic drilling rigs, such as fuzzy PID control methods for the swing angle of drill arms, and the inability of adaptive adjustment of controller parameters. , to improve the support method, improve the support efficiency, and achieve the effect of small heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

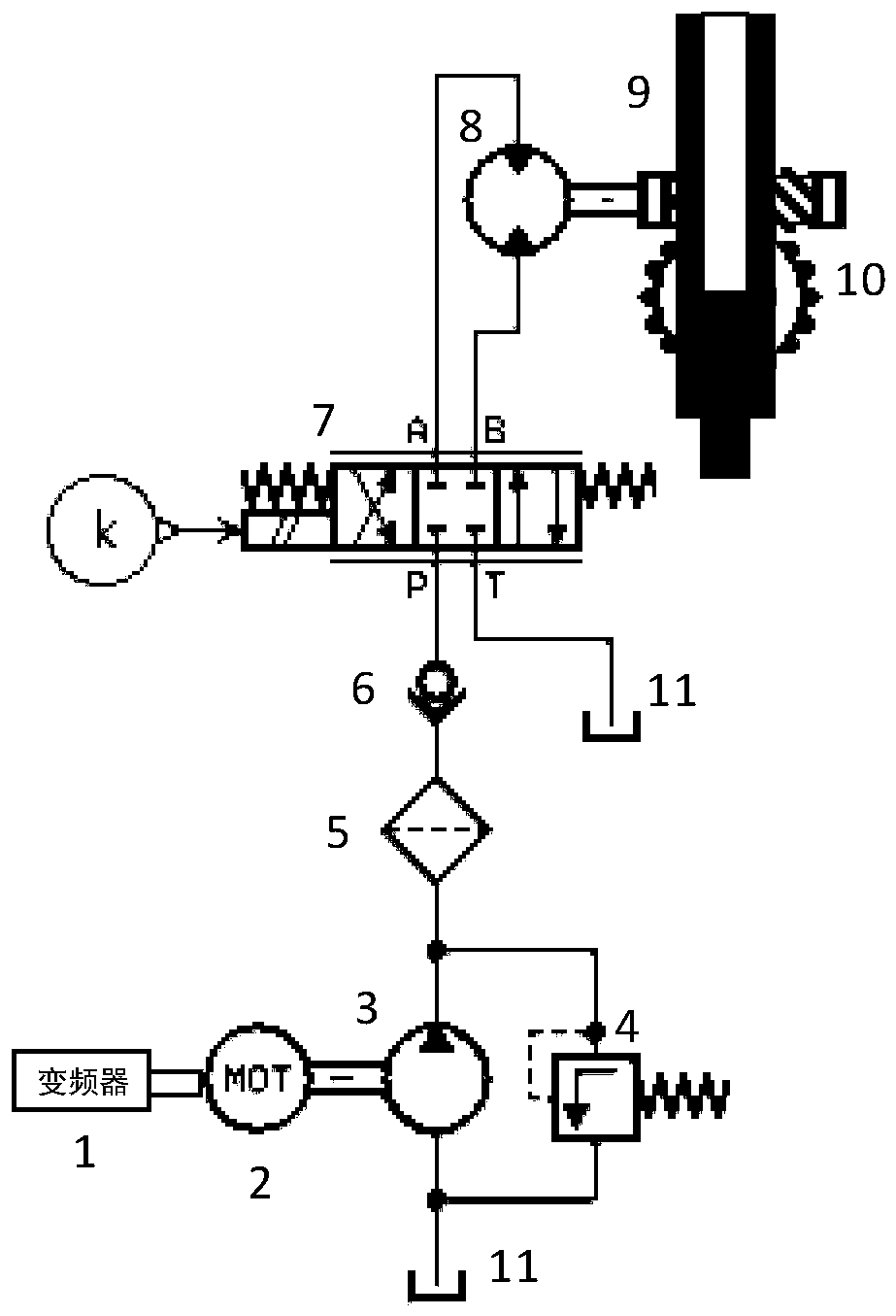

[0085] Embodiment 1: The working principle of the drill arm rotation system of the frequency conversion pump-controlled hydraulic drilling rig involved in the present invention, such as figure 1 As shown, the frequency converter 1 converts 380V / 50Hz power frequency alternating current into a voltage signal of a specific frequency, and drives the asynchronous motor 2; 1. The electro-hydraulic reversing valve 7 drives the two-way hydraulic motor 8 to rotate; then, the worm gear / worm reduction mechanism 10 drives the drill arm 9 of the bolter to deflect; then, the low-pressure oil at the oil outlet of the two-way hydraulic motor 8 passes through the reversing valve , flow back to tank 11.

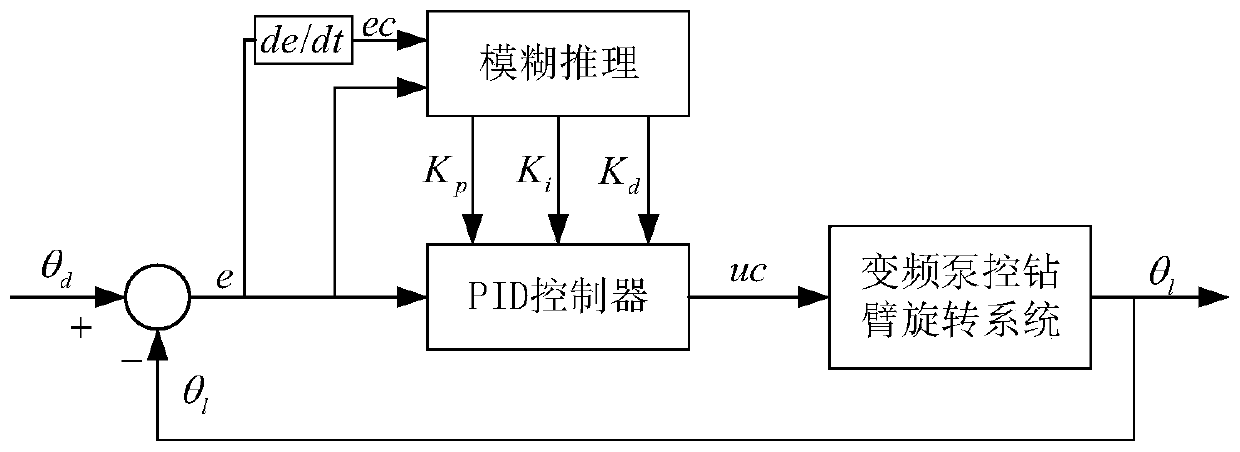

[0086] After using the frequency conversion pump to control the boom rotation system of the hydraulic drilling rig, the proposed swing angle control method is as follows:

[0087] In the description of this method, several dots appearing above the unknown letter represent the derivatives of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com