Method for supporting and protecting soft, collapsible and super thick coal seam tunnel based on filling behind support and device thereof

A technology for roadway support and extra-thick coal seam, applied in the direction of temporary shield, earthwork drilling, pillar/support, etc., can solve the problems of low support efficiency, coal roadway deformation, support damage, etc. , The effect of reducing the section size and shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

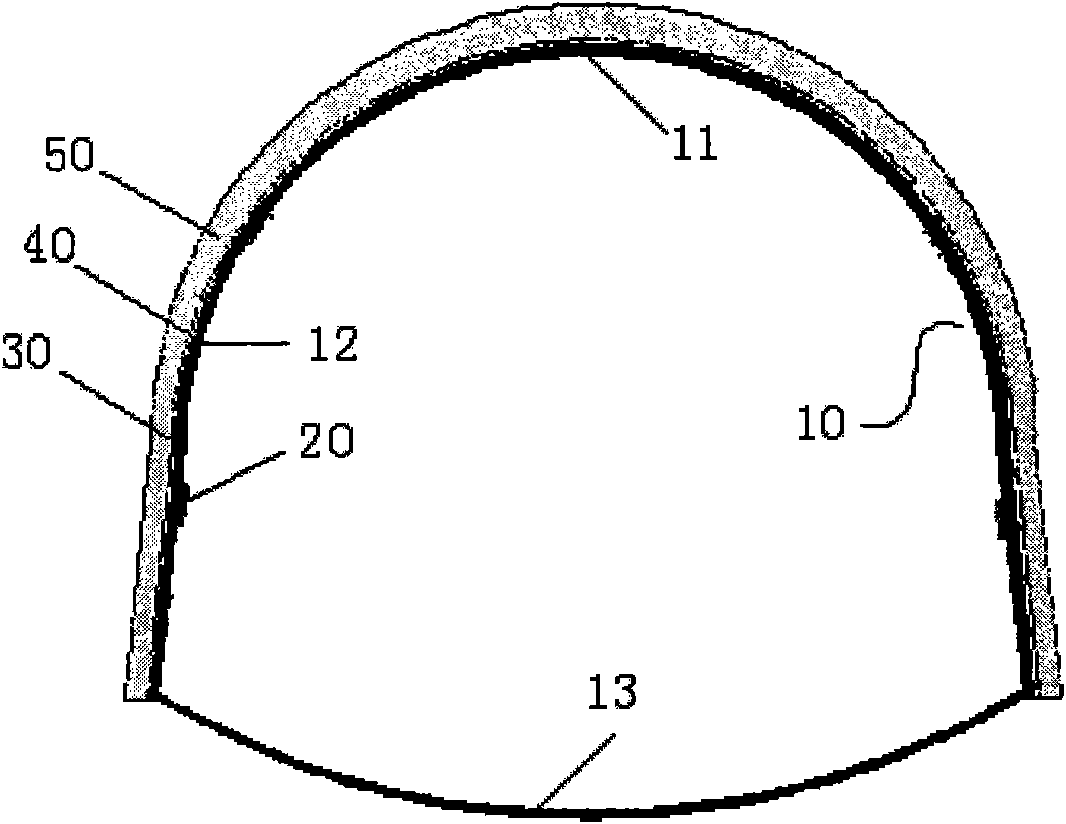

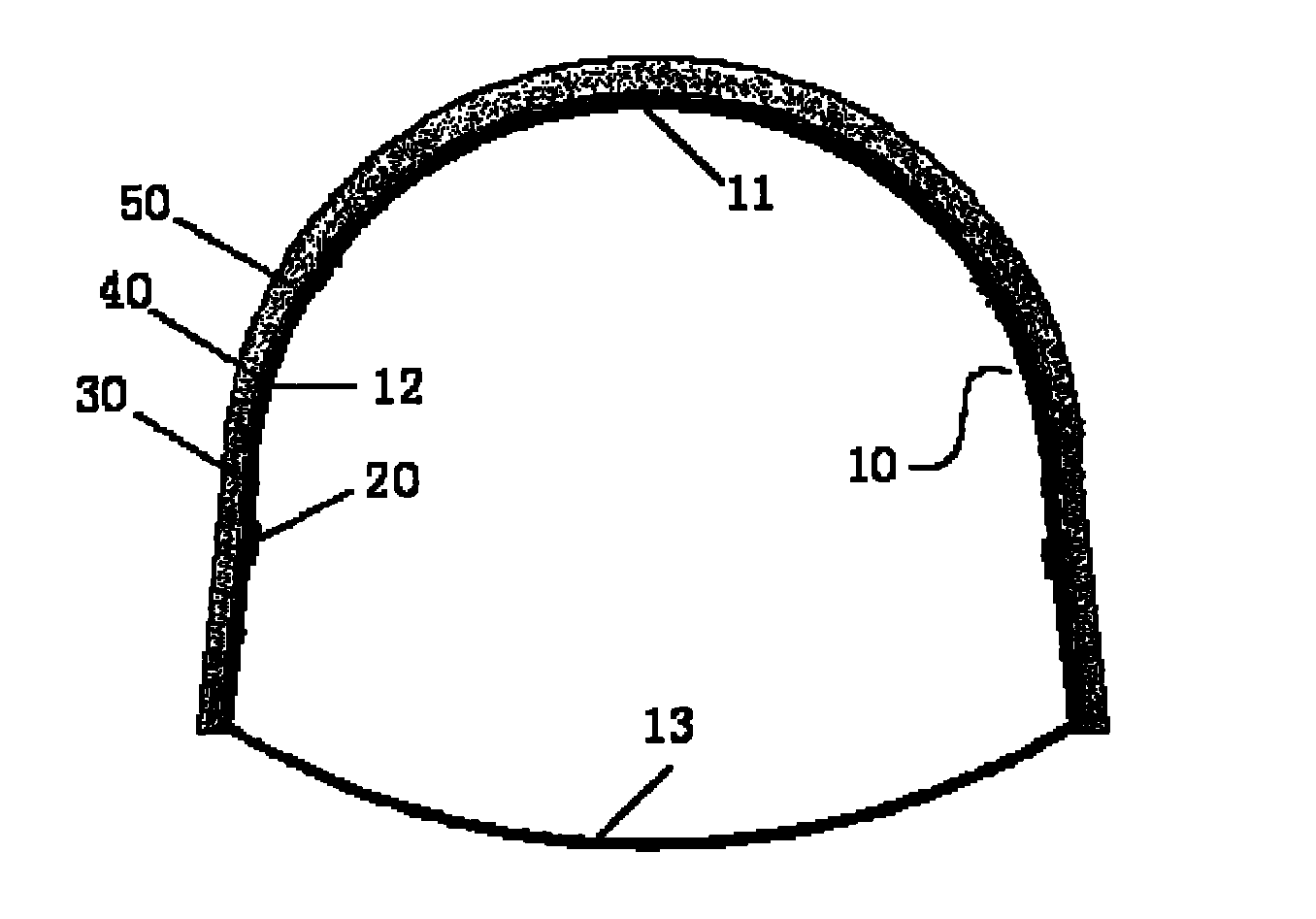

[0050] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0051] 1. Method

[0052] 1. Closed shrinkable U-shaped steel bracket installation

[0053] As shown in Figure 1, the construction steps and processes are as follows:

[0054] Preliminary excavation into lanes, advance temporary support, use the front probe beams to pre-set shed beams, dig leg nests under the cover of side guards, plant shed legs, install cables, waists over the roof, install roof arches, and tighten clamps The cable meets the design requirements, connects to the net, and forms a permanent support; installs the waist beam; clears the bottom of the roadway to meet the design requirements, installs the inverted arch and bottom beam, and closes the U-shaped shed.

[0055] Precautions for U-shaped scaffolding:

[0056] The U-shaped shed must be erected on a solid base, and the brackets should be perpendicular to the center line of the roadway. The brackets should be conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com