Patents

Literature

107results about How to "Reduce model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

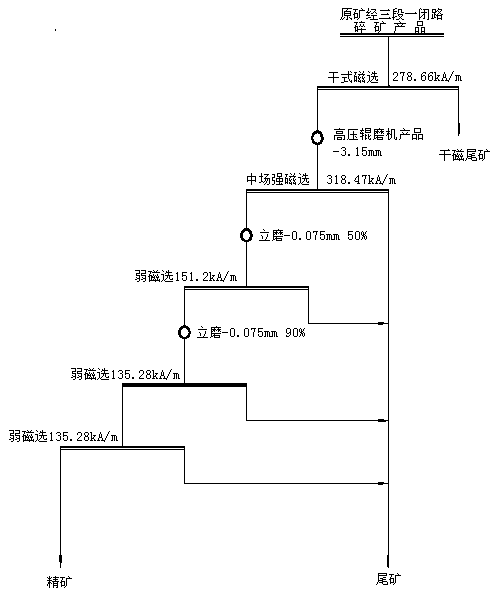

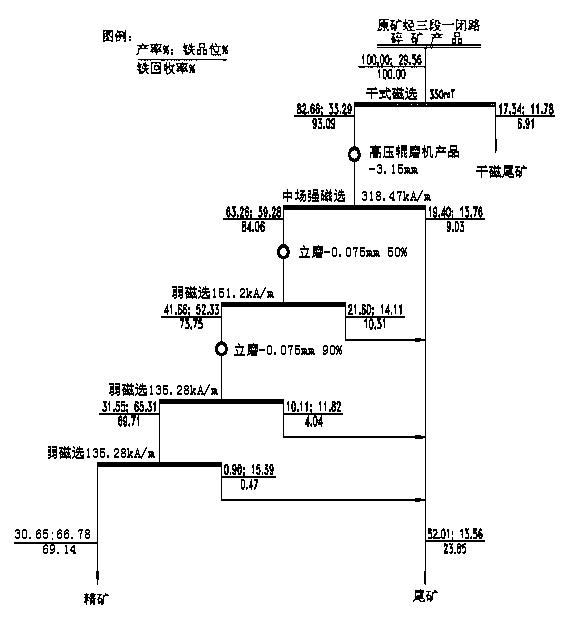

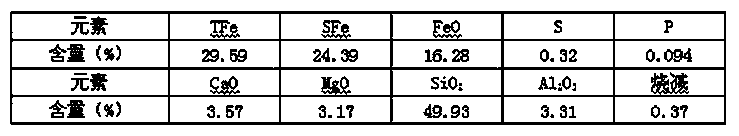

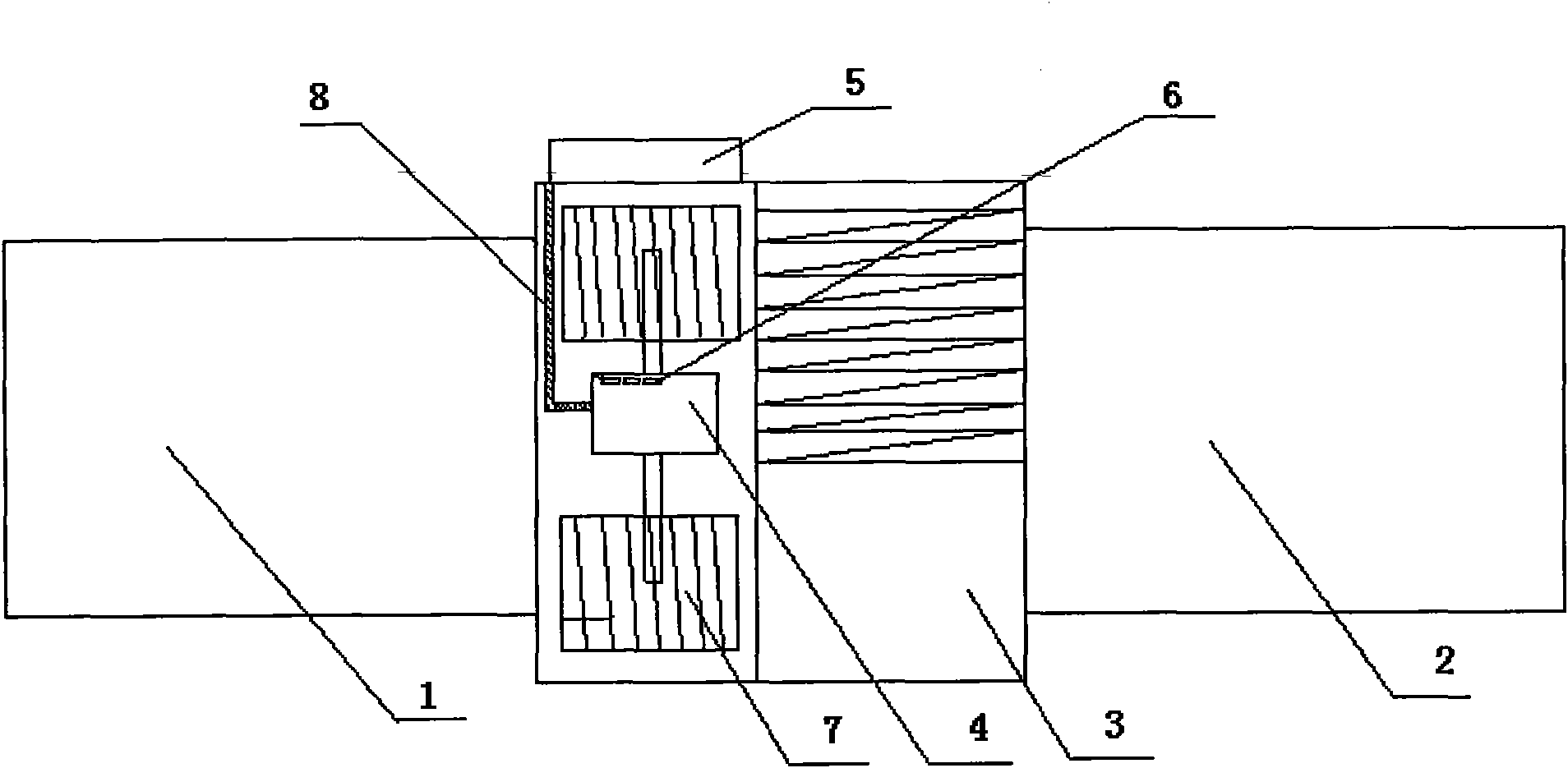

High-efficiency and energy-saving new lean magnetite combined milling magnetic separation method

ActiveCN104162475AReduce consumptionReduce energy consumptionMagnetic separationGrain treatmentsMagnetiteSteel ball

The invention discloses a high-efficiency and energy-saving new lean magnetite combined milling magnetic separation method. A high pressure roller mill is used as an ultrafine crushing device, and a vertical mill substitutes a ball mill. The method comprises the following steps: crushing, screening, carrying out dry pre-concentration, milling through the high pressure roller mill, carrying out medium field intensity wet magnetic separation, carrying out vertical coarse milling, carrying out weak magnetic roughing, carrying out vertical fine milling, and carrying out low intensity magnetic separation. The method allows a large number of coarse grain waste ores to be abandoned before milling, so the milling amount is reduced, the over milling problem during mineral liberation is effectively solved, and the consumption of steel balls and lining plates of the ball mill is significantly reduced, thereby the operation cost of the whole process is reduced. The method improves the grade of raw ores by above 2% after the weak magnetic dry separation, improves the relative grindability of roller mill products by above 30%, and reduces the energy consumption by 35-50% by adopting the vertical stirred mill to substitute the ball mill; and the power consumption of per unit of the raw ores and the consumption of the steel balls and the lining plates of the method in the invention are 65.37% and 59.26% lower than those of with routine three stage closed loop + two stage ball milling + two stage weak magnetic separation milling technologies in ore separation work respectively.

Owner:马钢集团设计研究院有限责任公司

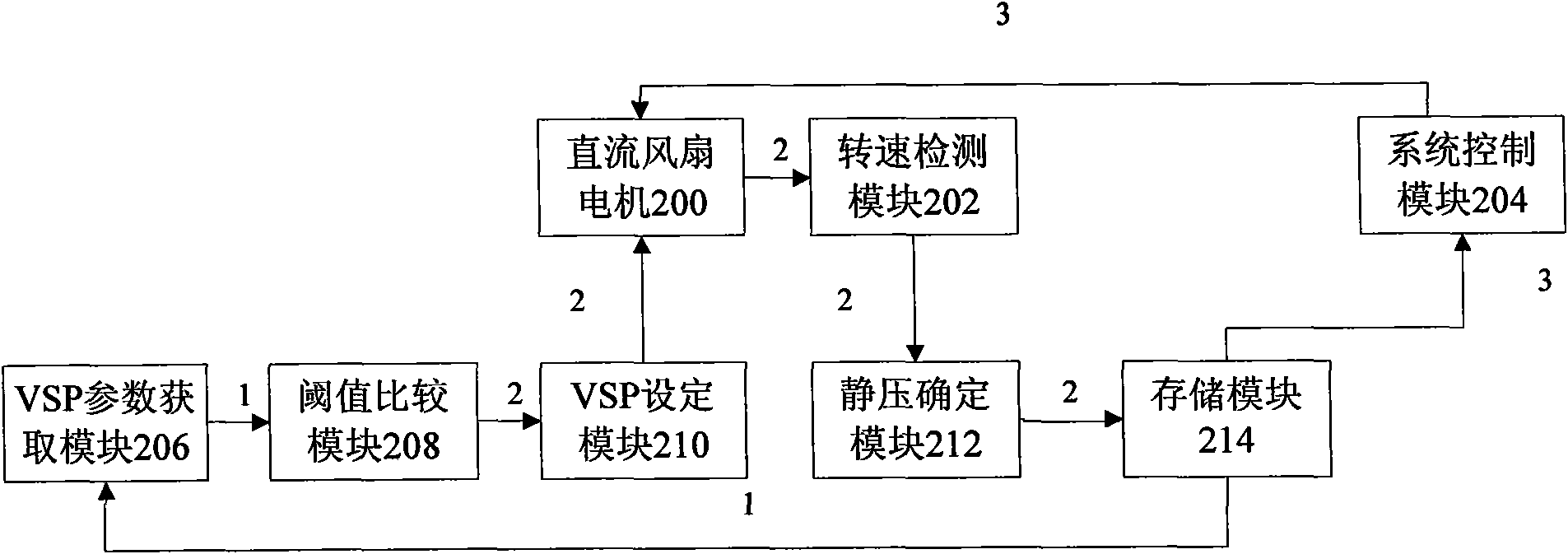

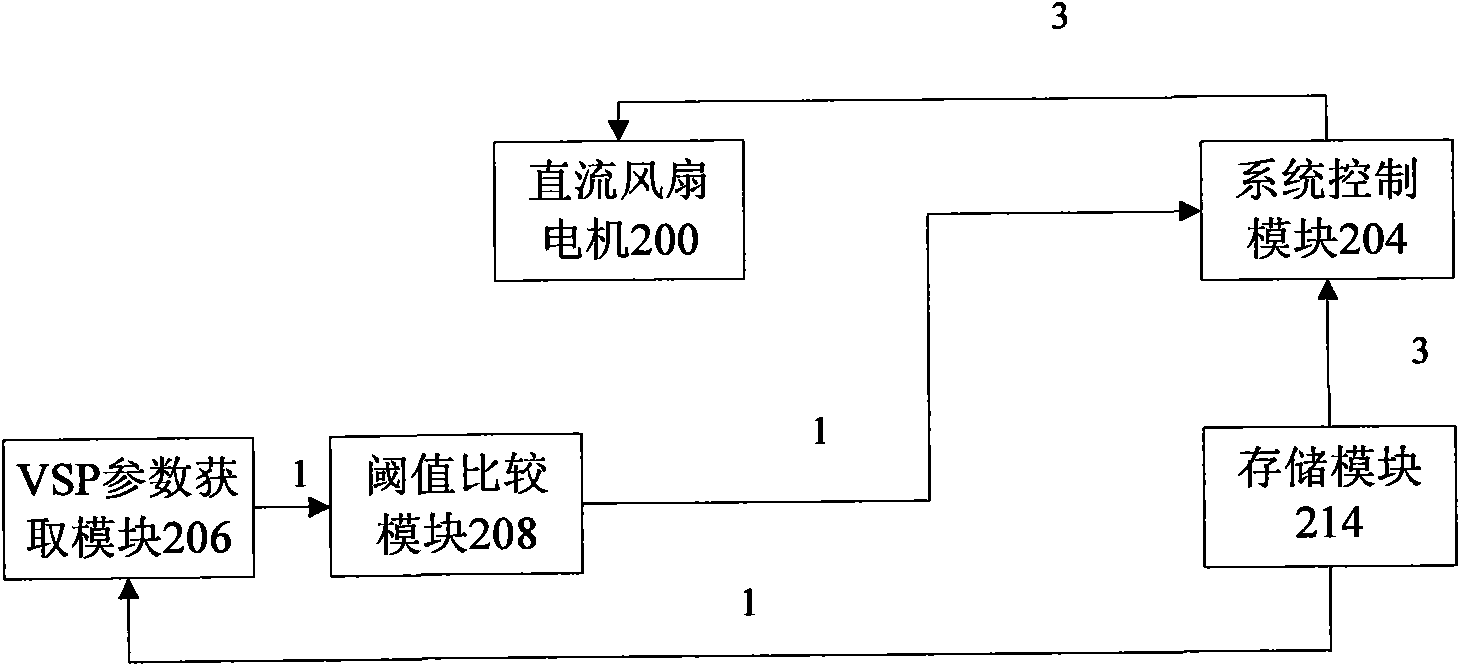

Automatic recognition method for static pressure of air duct type air conditioning indoor machine and system thereof

ActiveCN101603718AChange the static pressure settingRealize the function of static pressure automatic identificationSpace heating and ventilation safety systemsLighting and heating apparatusSystem stabilityAir conditioning

The invention discloses an automatic recognition method for static pressure of air duct type air conditioning indoor machine and a system thereof. The automatic recognition method comprises the following steps: obtaining the actual control voltage VSP and preset control voltage VSP and offset threshold value of VSP of a DC fan motor, and comparing the actual control voltage VSP and the preset control voltage VSP to judge whether the actual control voltage VSP and the preset control voltage VSP exceed the range of the threshold value; under the condition that the compared result exceeds the range of the threshold value, determining static pressure tap position corresponding to the rotary speed and further modifying a control parameter corresponding to the static pressure tap position by momentarily setting VSP value and detecting the rotary speed of a motor fan after a period of time; controlling a DC fan motor according to the control parameter. The invention does not distinguish high-low static pressure machine types any longer, which reduces more than 50% of types. Simultaneously, on-site installation and design becomes convenient, and the system stability is increased.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

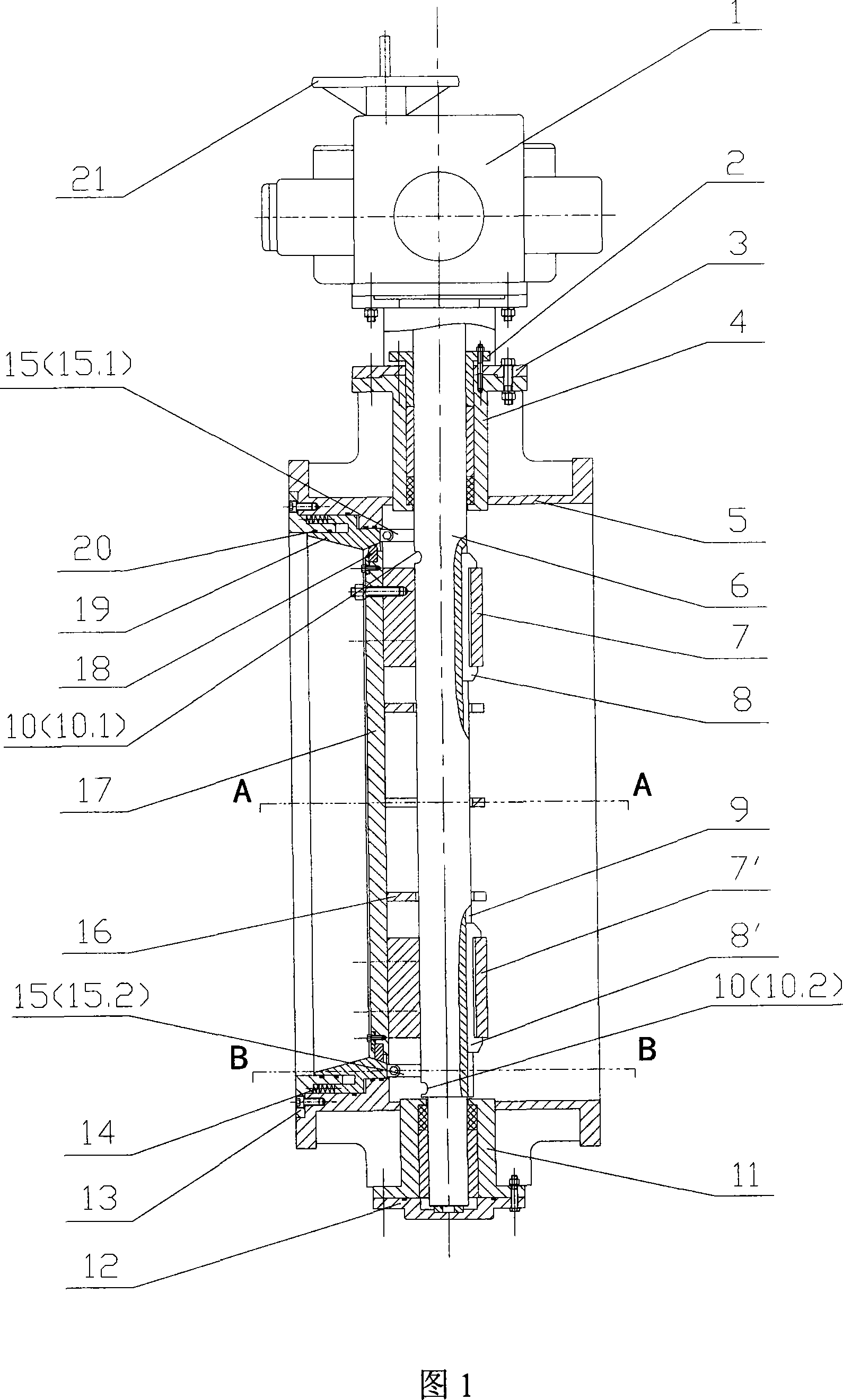

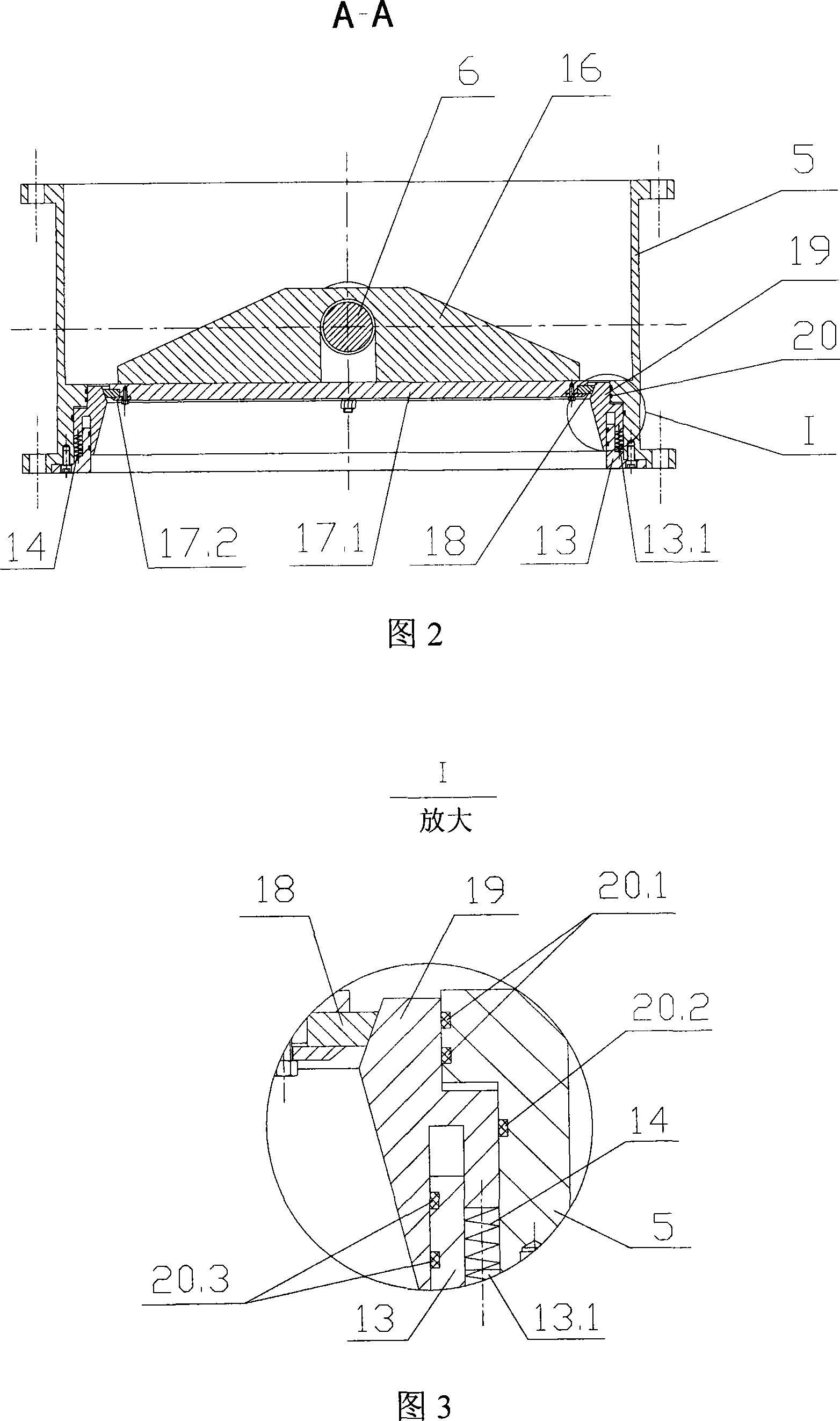

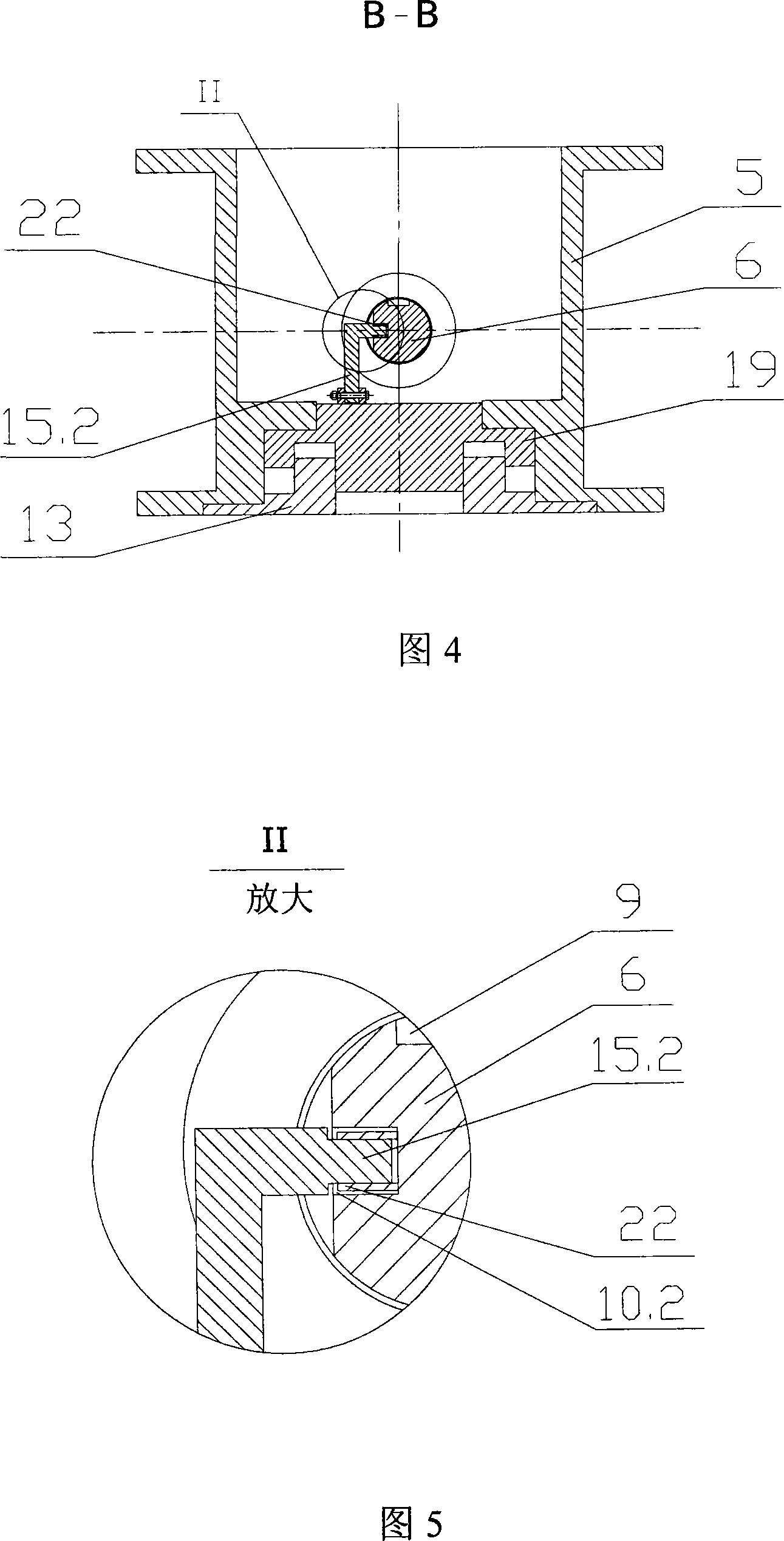

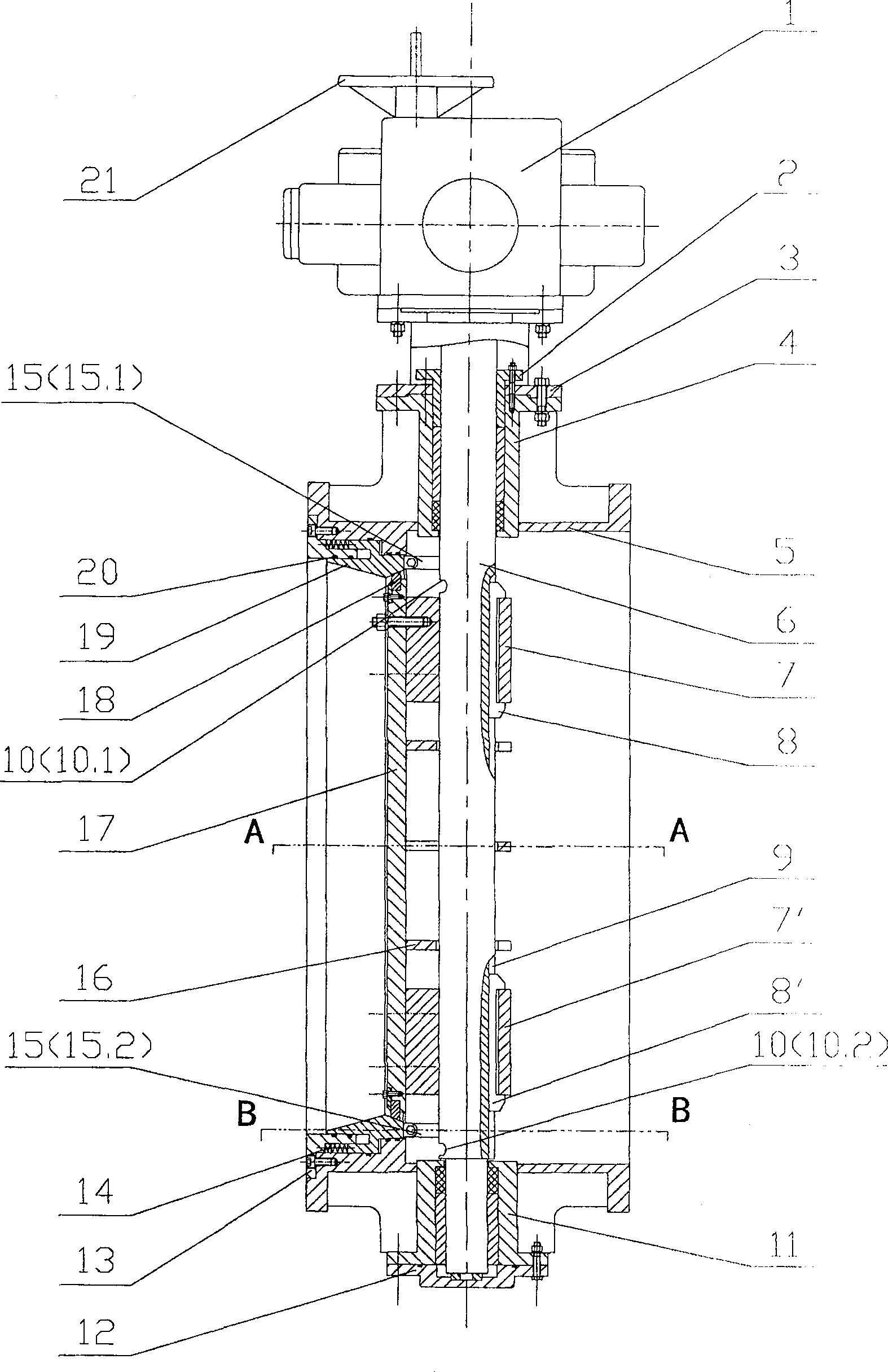

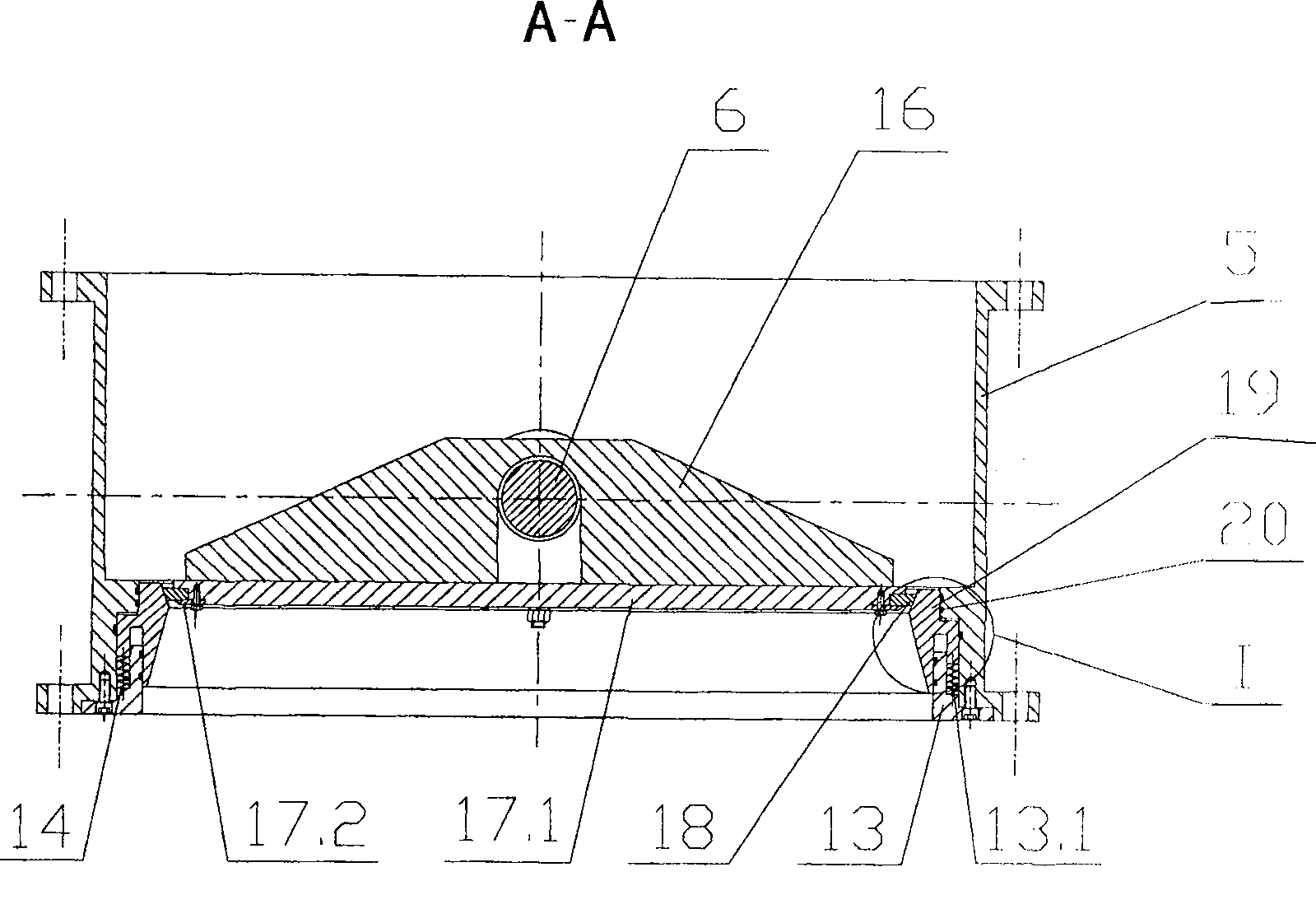

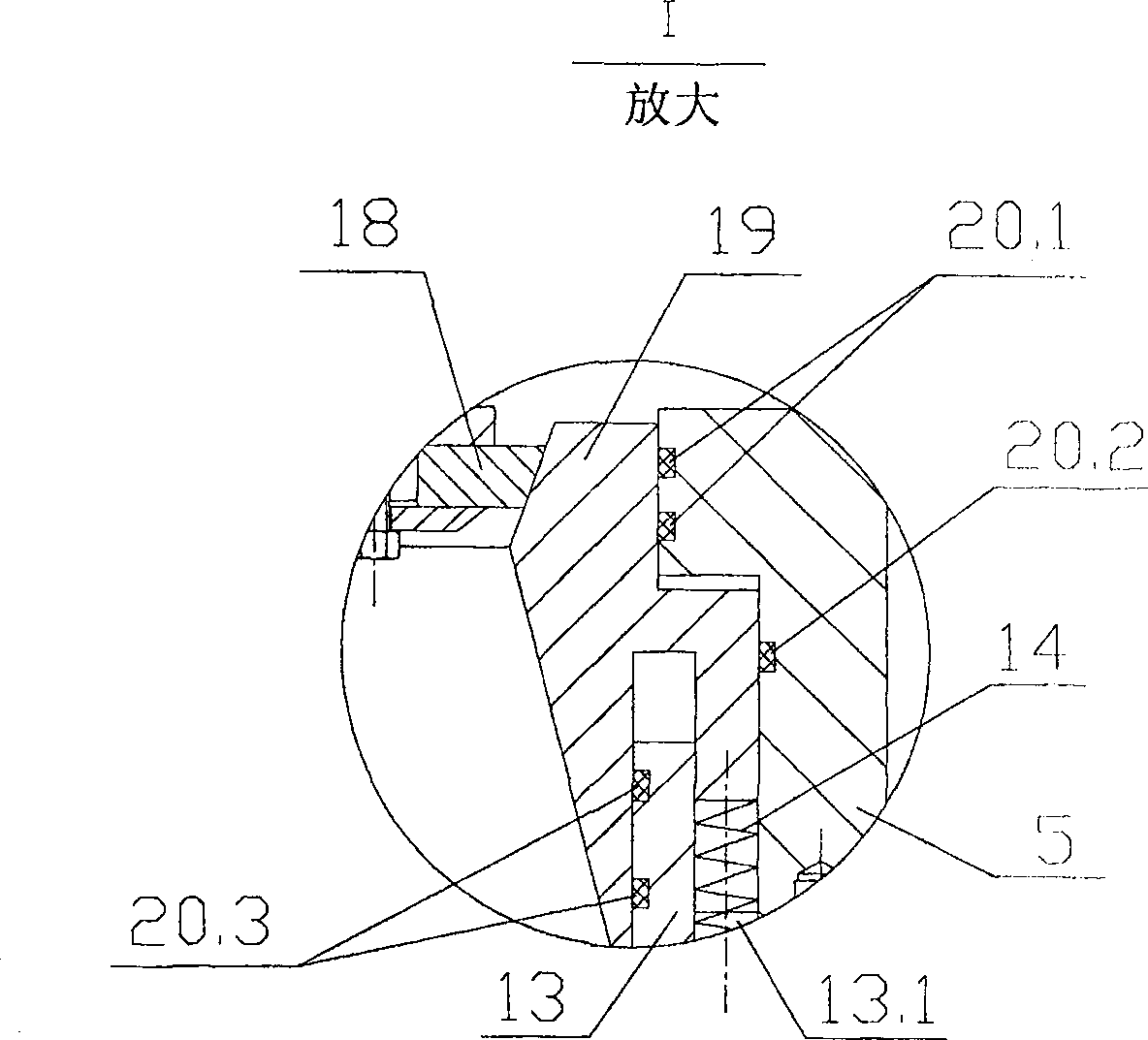

Non-abrasion hard-sealing butterfly valve

The invention relates to a non-loss hard seal butterfly valve which consists of a valve body, a valve rod, a butterfly plate and a valve seat. The invention is characterized in that the valve seat can be a movable valve seat which can axially move along the inner wall of the valve body; one side of the valve body is provided with a lateral body; seal rings are arranged both between the valve seat and the valve body, between the valve seat and the lateral body; a seal component is fixed on a butterfly plate frame; moving fit clearances are reserved between an inner side surface and an outer side surface of the valve seat, between the valve body and the lateral body; a spring is arranged between an outer end surface of the valve seat and the lateral body, an inner end surface of the valve seat is connected with the valve rod through a push rod; an inner end surface of the lateral body is provided with a spring; an upper end and a lower end of the valve rod are respectively provided with a curved slot; an upper curved slot and a lower curved slot are respectively formed by a skewed slot and an arc slot; the middle part of the valve rod is also provided with a long keyway, and an upper sliding key and a lower sliding key which are respectively fixed on an upper connecting seat and a lower connecting seat, and the upper connecting seat and the lower connecting seat are respectively fixed on the butterfly plate; the push rod consists of an upper push rod and a lower push rod, one end of the upper push rod and one end of the lower push rod are both provided with a roller, one end of the lower push rod is embedded in the lower curved slot and capable of sliding, while the other end of the lower push rod is hinged with the inner end surface of the movable valve seat; the upper push rod and the lower push rod are symmetrically arranged; a uni-eccentric structure is formed between a butterfly plate rotating axis and a seal pair plane.

Owner:HEBEI UNIV OF TECH

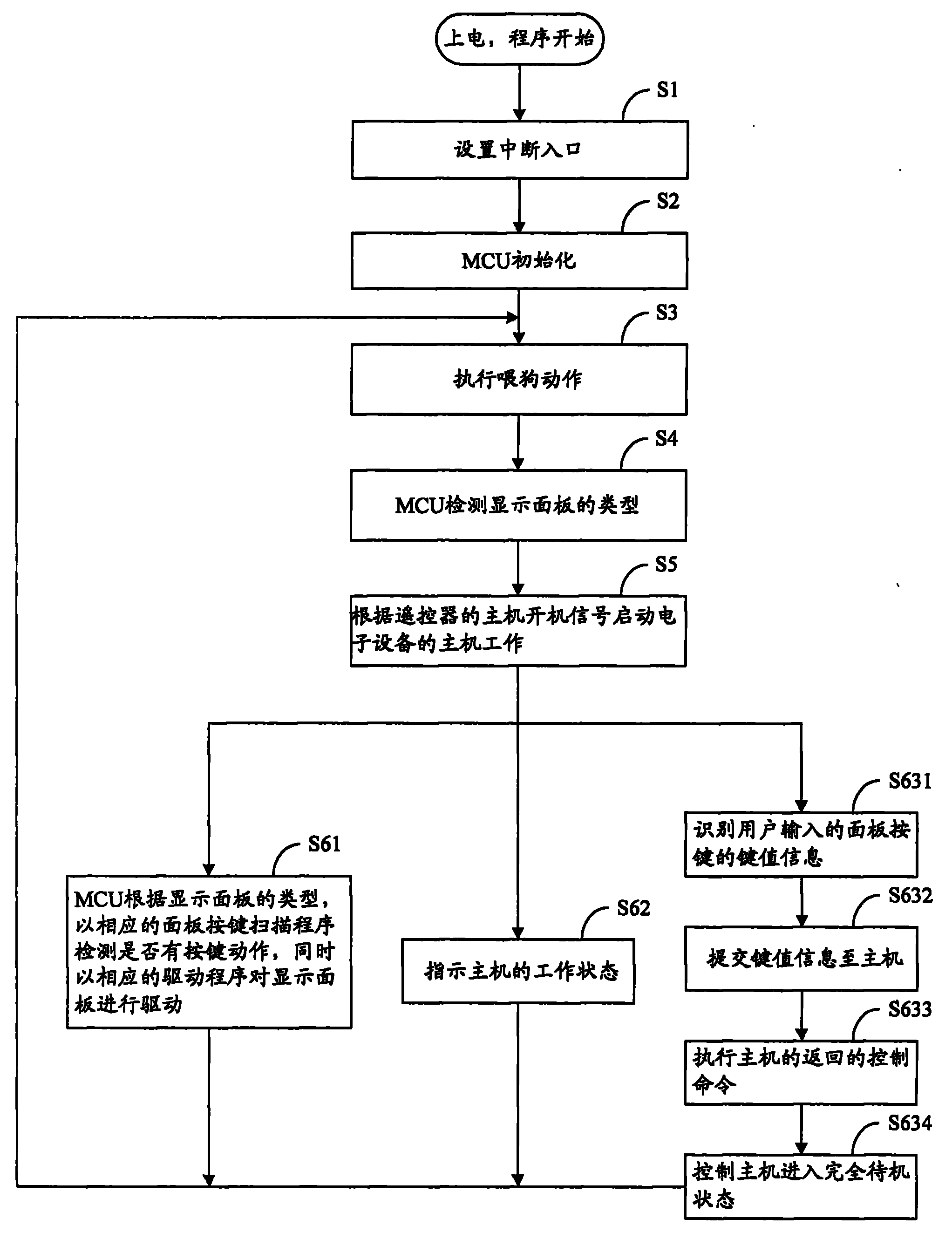

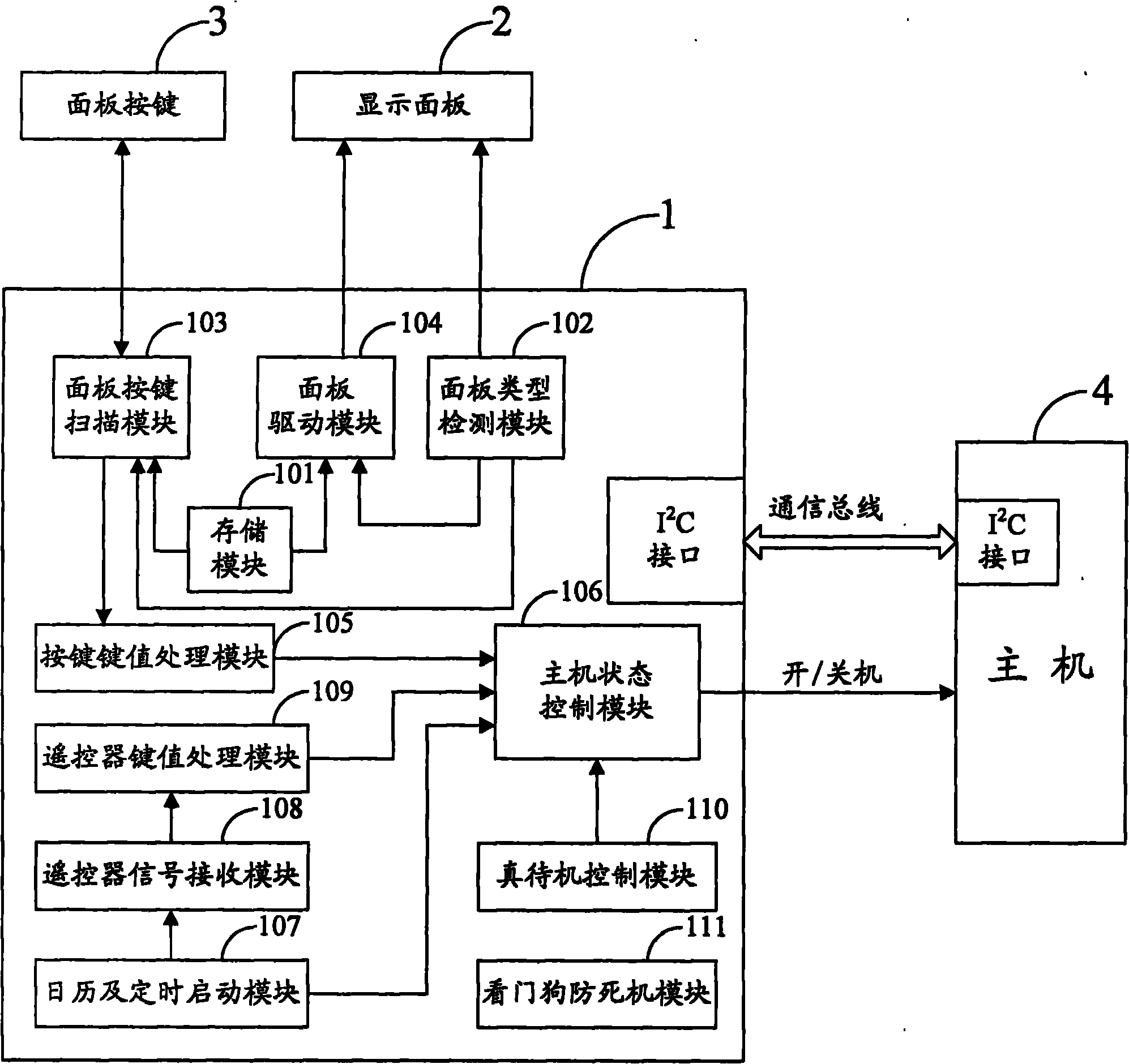

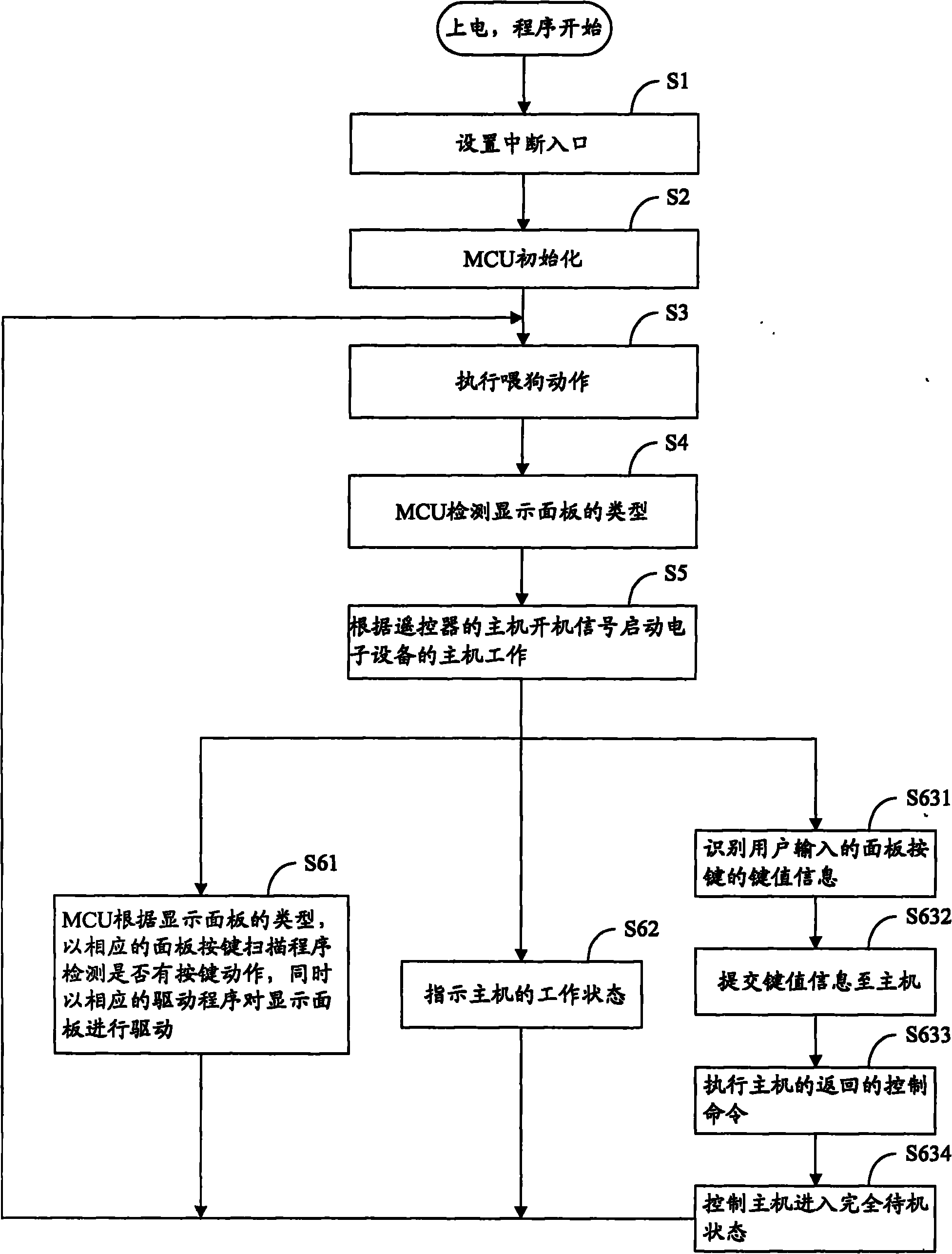

Electronic equipment and driving method of display panel

InactiveCN101814280AImprove versatilityReduce hardware product modelsCathode-ray tube indicatorsEmbedded systemType number

The invention is suitable for the technical field of display, and provides electronic equipment and a driving method of a display panel. The driving method comprises the following steps of: detecting the type of the display panel by an MCU (Microprogrammed Control Unit); transferring a corresponding driver from a plurality of drivers stored in advance to drive the display panel by the MCU according to the detected type of the display panel. In the invention, the electronic equipment can flexibly integrate the drives of various display panels (LED / VFD / LCD and the like), carries out uniform compatibility and has very high generality. In addition, display screen driver entries of other types can be also left on the electronic equipment, and new types of display panels can be continuously increased. The invention is convenient for use and uniform management, reduces the types of hardware products and saves the cost.

Owner:SHENZHEN JIUZHOU ELECTRIC

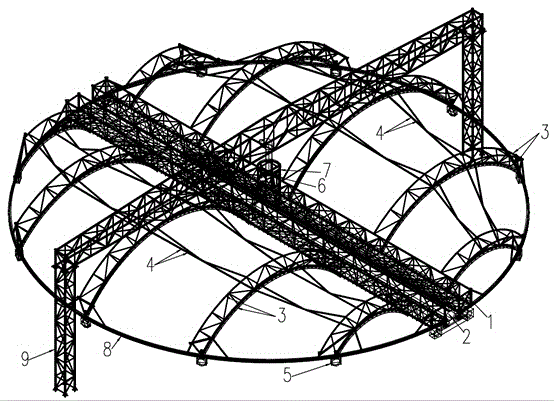

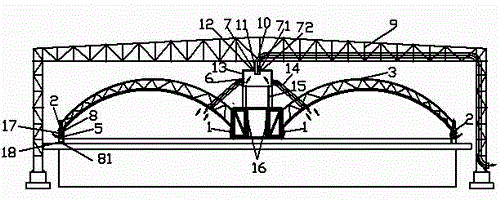

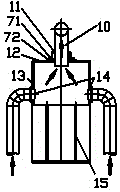

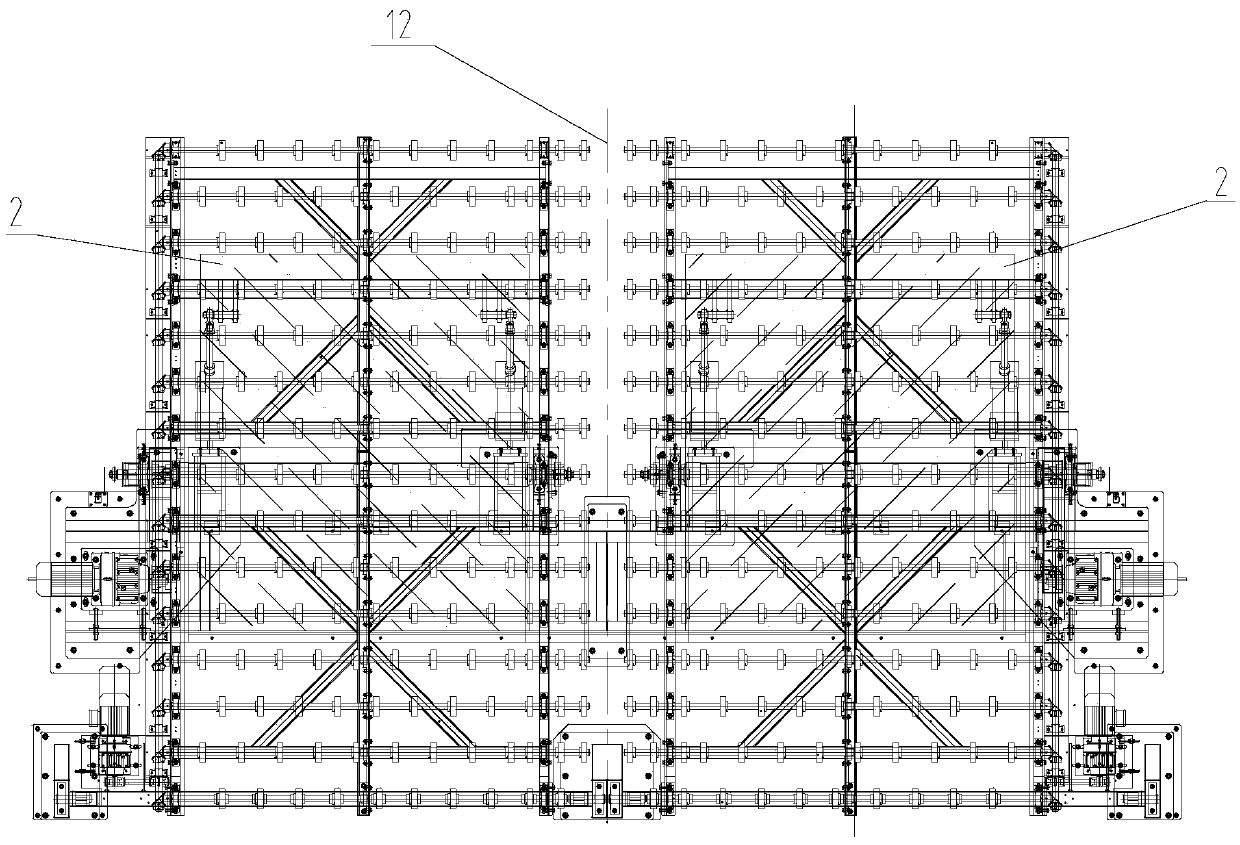

Sealing cover for circular pond body of synchronous-rotation reverse hanging membrane structure

The invention discloses a sealing cover for a circular pond body of a synchronous-rotation reverse hanging membrane structure. The sealing cover comprises a girder and a circular track beam. The girder is in rigid connection with the circular track beam. Upward-arch truss beams are connected between the circular track beam and the girder in a spaced mode. A connecting truss beam is arranged between every two adjacent upward-arch truss beams. The girder, the circular track beam, the upward-arch truss beams and the connecting truss beams form a rigid support. A sealing membrane is fixedly arranged on the lower face of the rigid support in a reverse hanging mode. The periphery of the sealing membrane falls naturally and forms a sliding sealing face with a concrete walkway plane of the circular pond body. Bearing travelling wheels are installed on the lower edge of the circular track beam. The sealing cover is further provided with a gas collecting device for collecting gas inside the circular pond body. The gas collecting device collects gas inside the pond body in the mode of middle shaft air and peripheral air supplementation. The sealing cover is rapid to install, good in mobility, long in service life and applicable to any large-span pond body, and reduces occupation of a site.

Owner:GUANGZHOU GELOR SYST ENVIRONMENTAL PROTECTION ENG

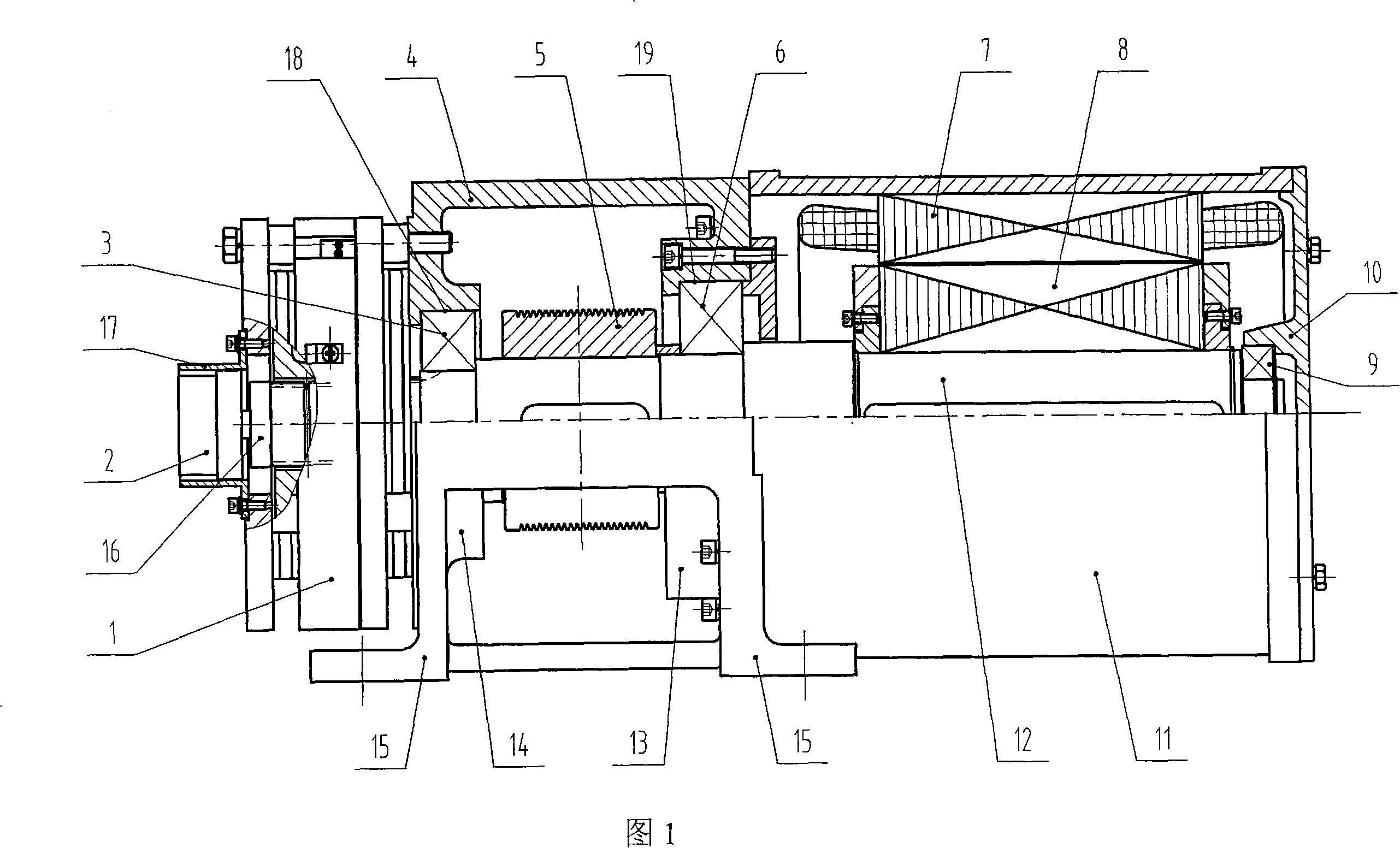

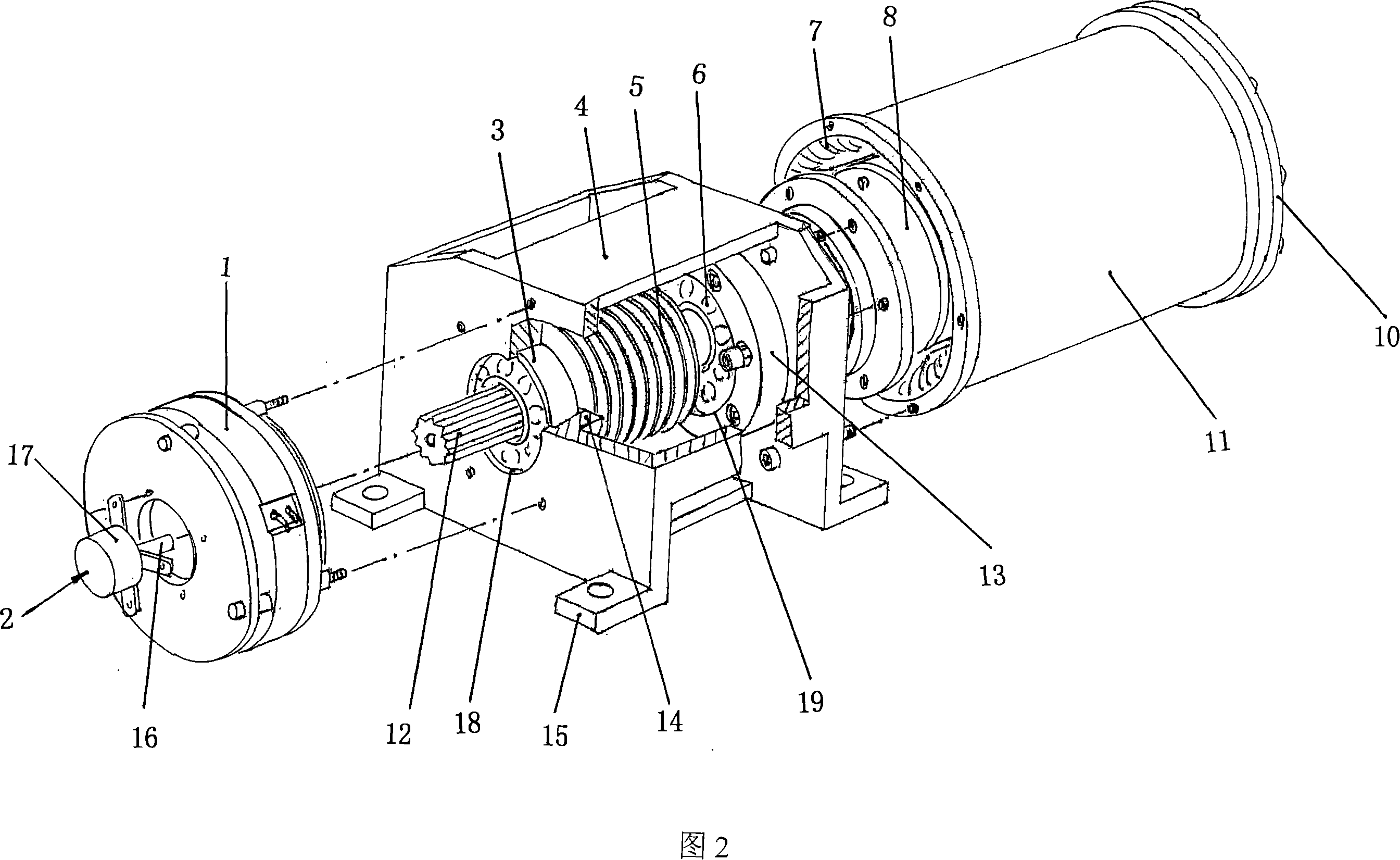

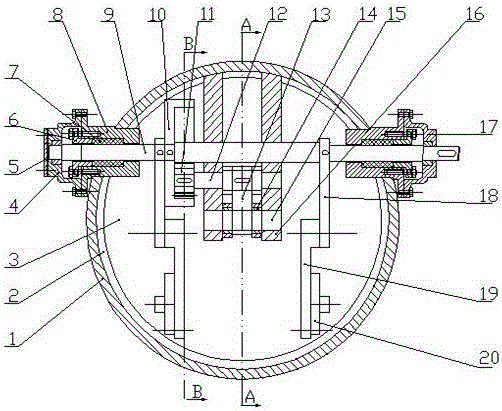

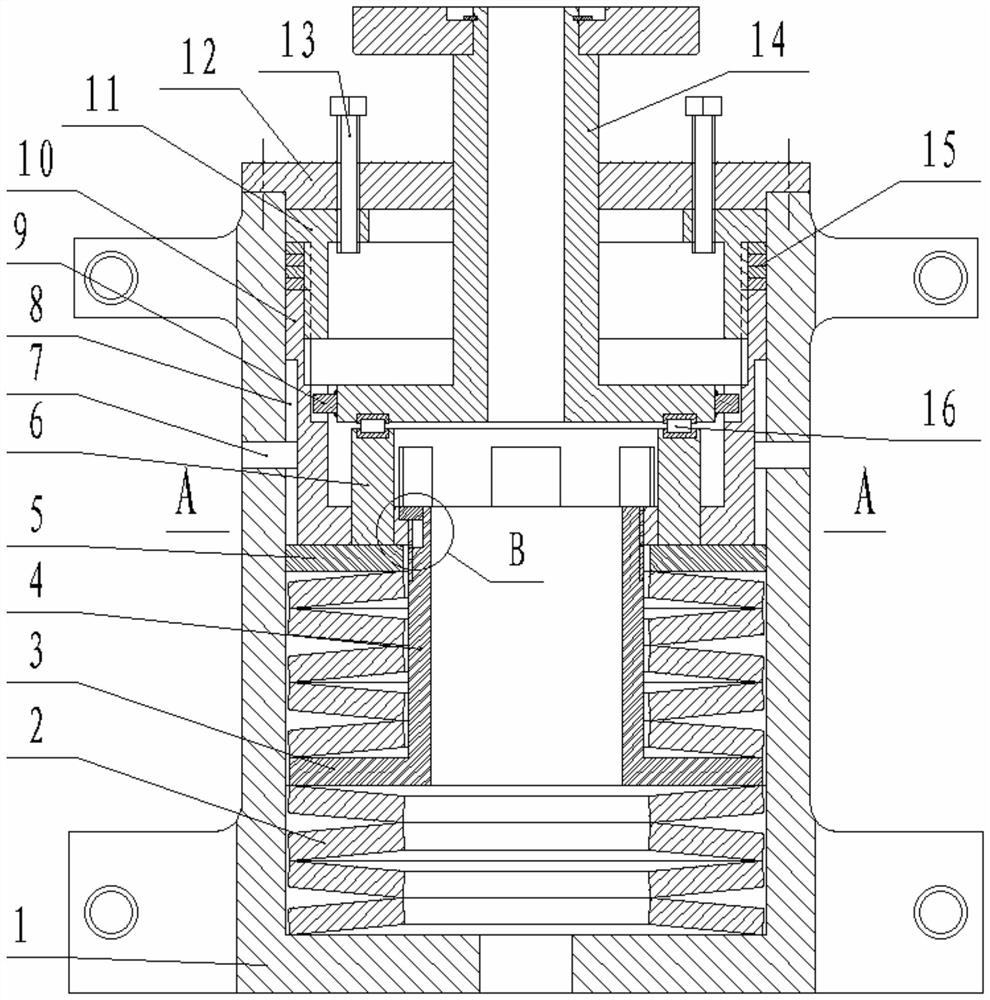

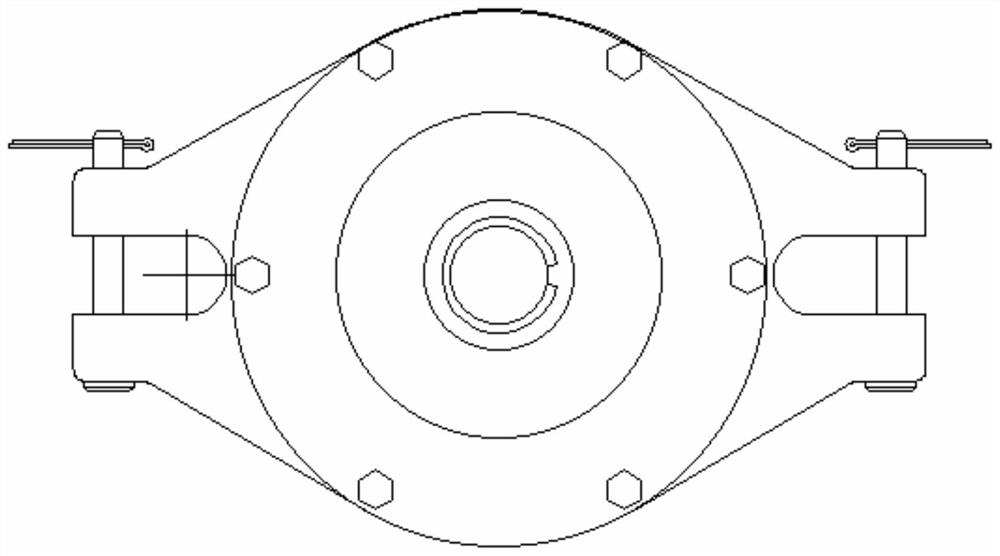

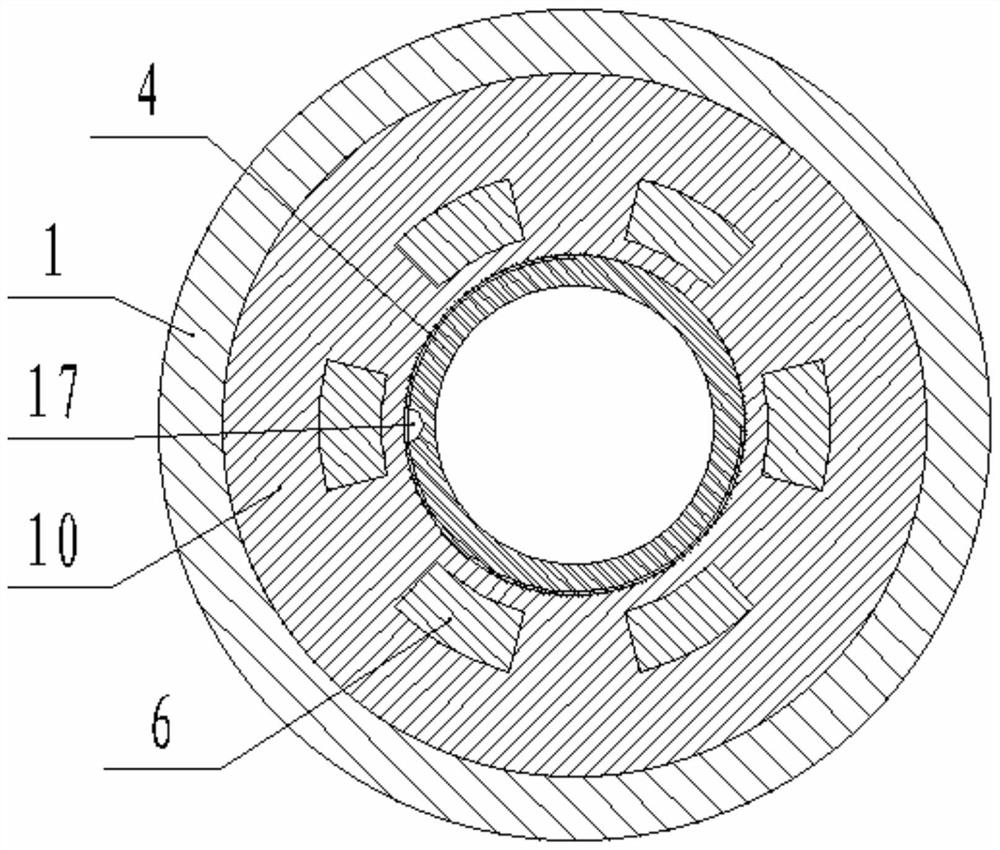

Minitype permanent magnetism synchronization gear wheel free traction machine

A small permanent-magnetic synchronous gearless traction machine belongs to the technical field of lifting facilities, which comprises a base, a brake, a coder, a traction wheel, a main shaft, and a permanent-magnetic synchronous motor. The left and right sides of the base are provided with a couple of first and second bearing bases the centers of which are respectively provided with a first and a second mounting hole. The traction wheel is arranged in the base and sheathed on the main shaft, while the main shaft via first and second bearings is supported on the first and second bearing bases. The permanent-magnetic synchronous motor is an internal-rotor permanent-magnetic synchronous motor, fixed at the outer side of one end of the base. The brake is in disc type, fixed at the outer side of another end of the base. The coder is fixed on the brake and connected with the main shaft via the rotation shaft of the coder. The invention has the advantages that the invention can improve the operation stability, reduce noise and prolong service life of the main shaft, improve the safety of the whole invention, effectively reduce the bearing volume, the invention has small volume, small thickness, high bearing load, easy installment and maintenance, and the invention can eliminate the wire baffle rod used by traditional traction machine.

Owner:SUZHOU TORIN DRIVE EQUIP

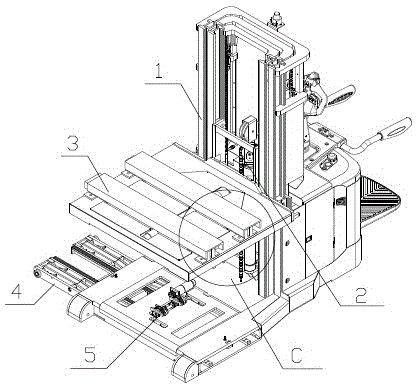

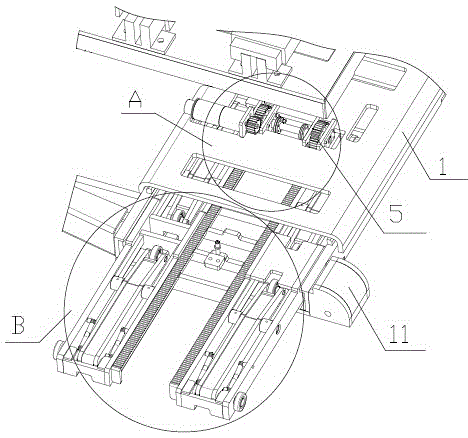

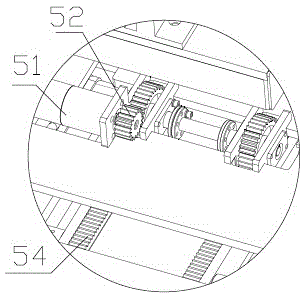

Light bidirectional stacking carrier

ActiveCN105036004AImprove work efficiencyImprove stabilityLifting devicesDrive wheelMechanical equipment

The invention relates to the field of mechanical equipment, in particular to a light bidirectional stacking carrier. The technical purpose of the stacking carrier is achieved through the following technical scheme. The light bidirectional stacking carrier comprises a carrier body, a fork body installed on the carrier body and a lifting device used for enabling the forking body to ascend and descend on the carrier body, and the fork body can move laterally in two directions. Front wheels and a drive wheel of the light bidirectional stacking carrier are arranged on the two sides of the fork body in the horizontal face. The light bidirectional stacking carrier further comprises a loading bearing device and a drive device, the load bearing device is used for stabilizing the gravity center of the carrier body when the fork body forks articles on the side of the carrier body, and the drive device is used for driving the load bearing device to move. According to the light bidirectional stacking carrier, the fork body can laterally extend and move in two directions, lateral supporting stability is good, the structure is simple, the dead load of the carrier body is reduced, economical efficiency is good, and popularization is facilitated.

Owner:NOBLEELEVATOR INTELLIGENT EQUIP CO LTD +1

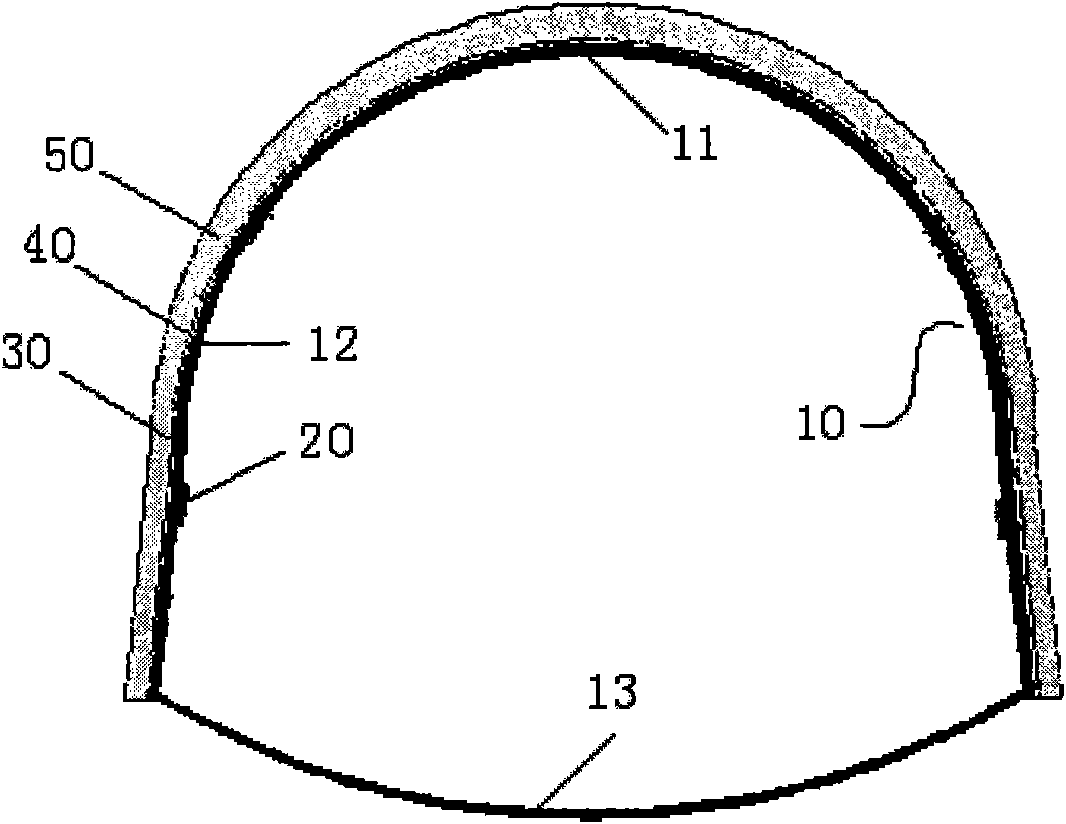

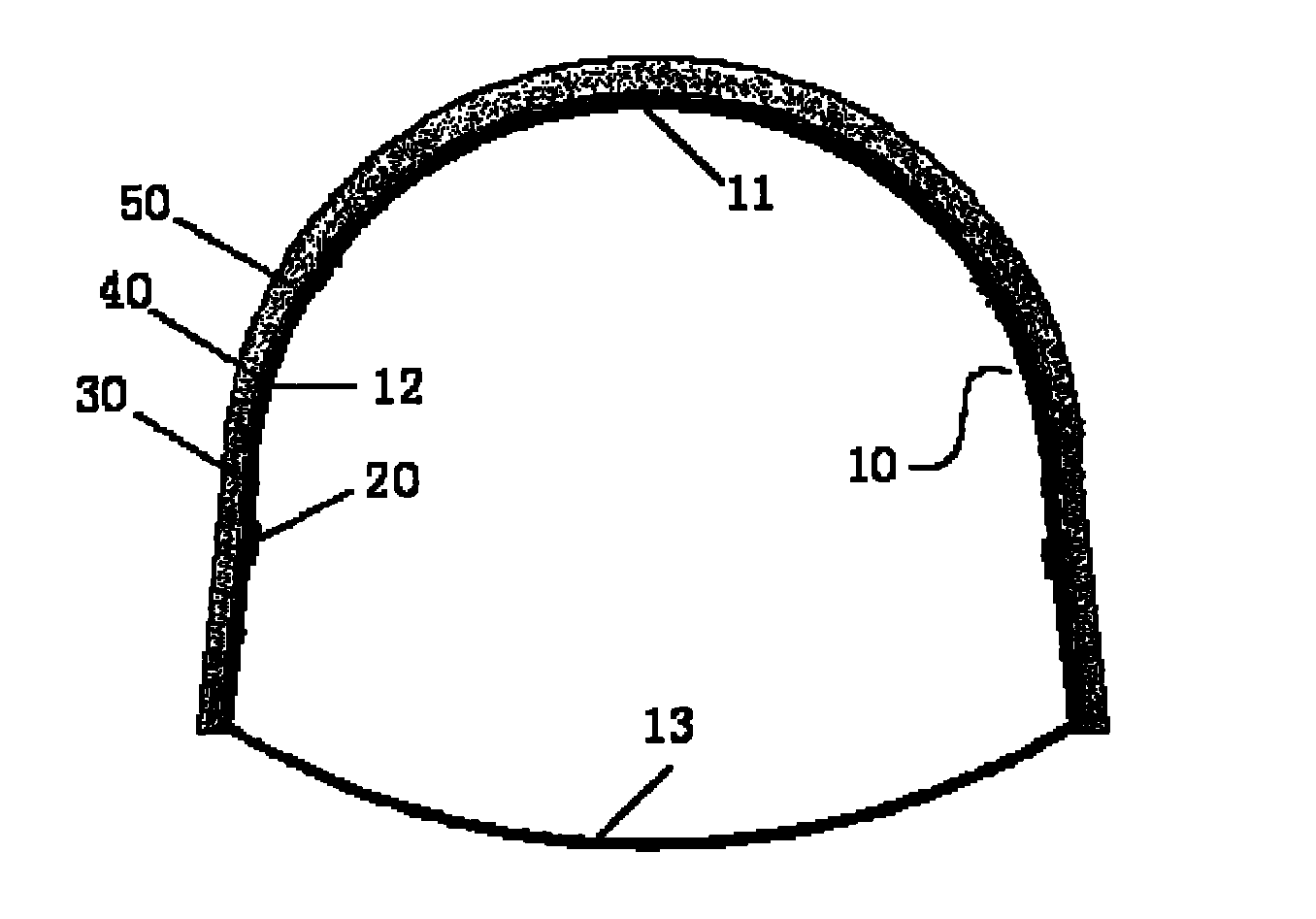

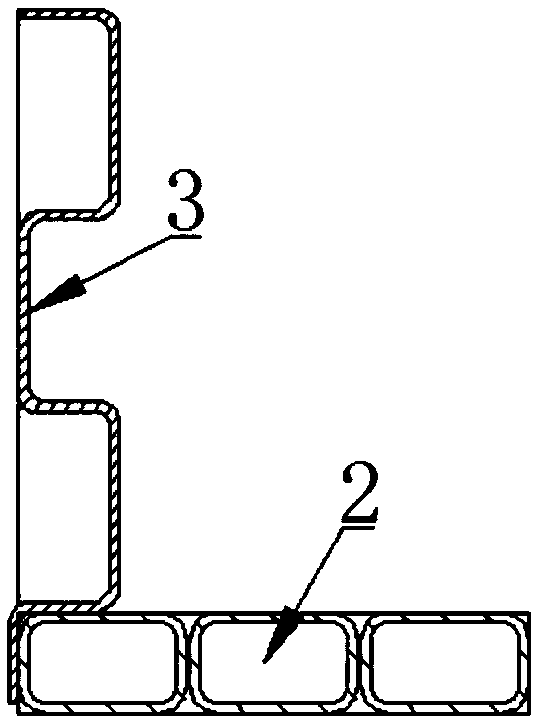

Method for supporting and protecting soft, collapsible and super thick coal seam tunnel based on filling behind support and device thereof

The invention discloses a method for supporting and protecting a soft, collapsible and super thick coal seam tunnel based on filling behind a support and a device thereof, relating to the supporting and protecting technology of the coal seam tunnel. The method comprises the following steps of: (1) the tunnel is supported and protected by a sealing retractable U-shaped steel support which consists of a top arch, a side wall and an inverted arch; (2) the inner wall of the side wall is provided with a waist beam; (3) the top arch and the outer wall of the side wall are suspended with a metal mesh; (4) the metal mesh is externally paved with a double resistance cloth; and (5) the outer side of the double resistance cloth is injected with a high-expansion chemical filling material behind the support. The device has the following structure: the waist beam (20), the sealing retractable U-shaped steel support (10), the metal mesh (30), the double resistance cloth (40) and the high-expansion chemical filling material (50) are sequentially connected with each other from the inside to the outside. The invention is suitable for supporting and protecting the super thick, soft and collapsible coal seam tunnel, and the landslide and soft tunnel.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

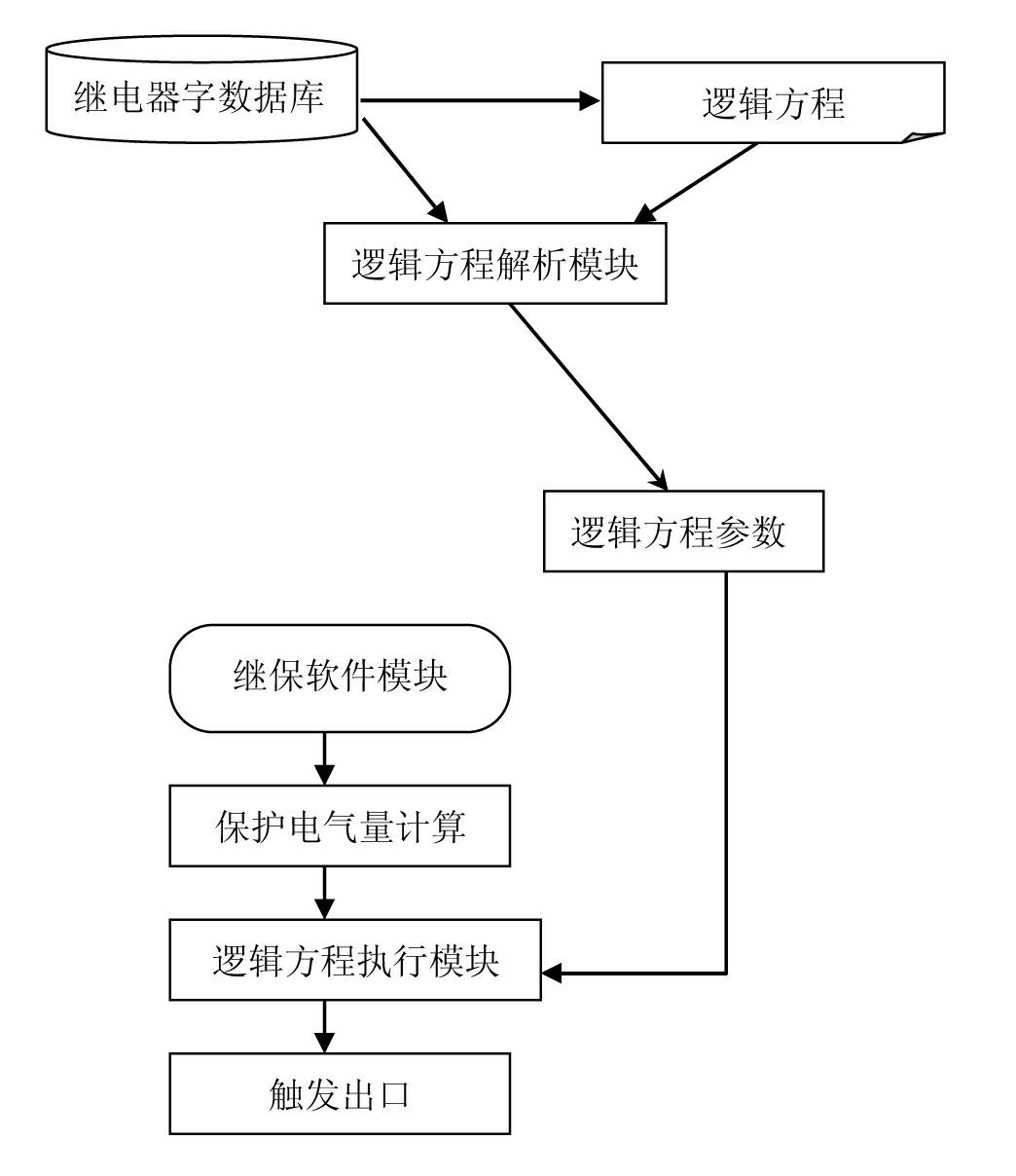

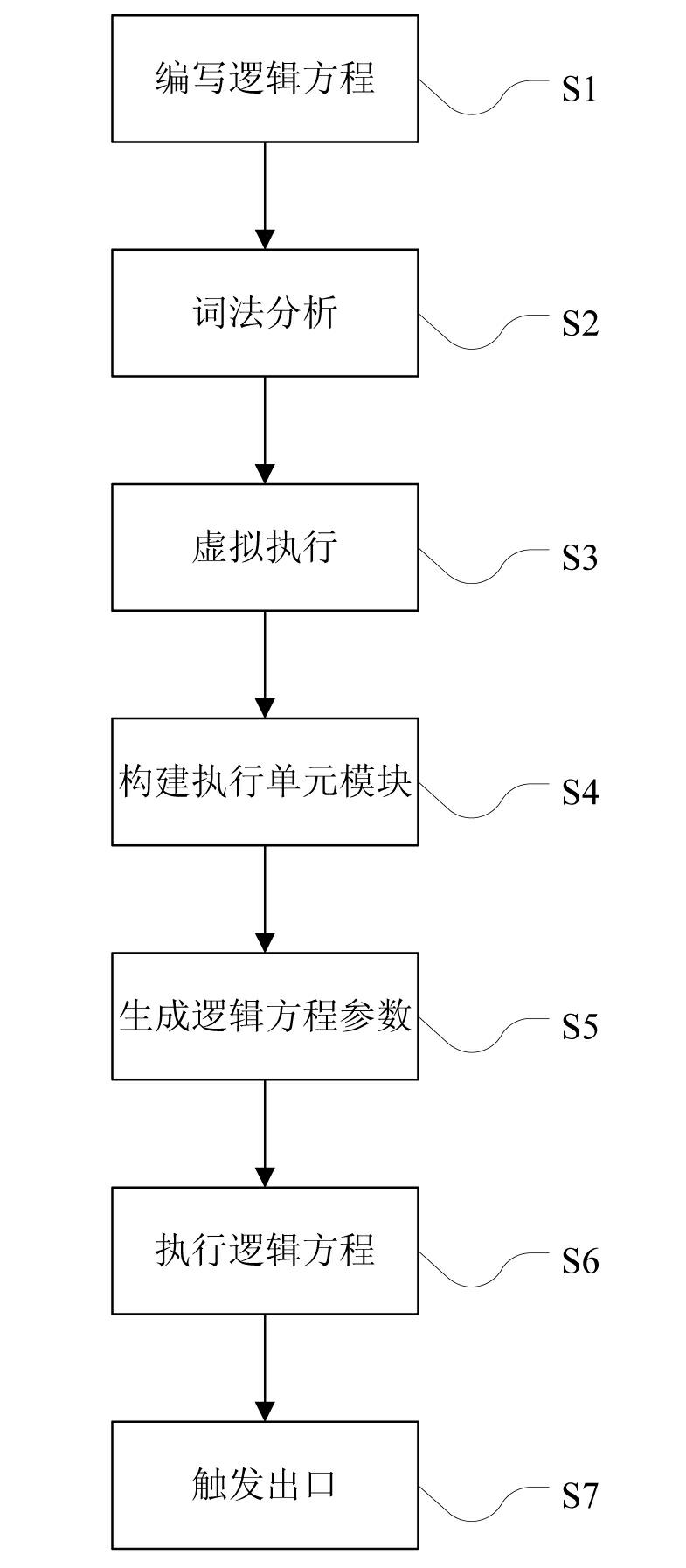

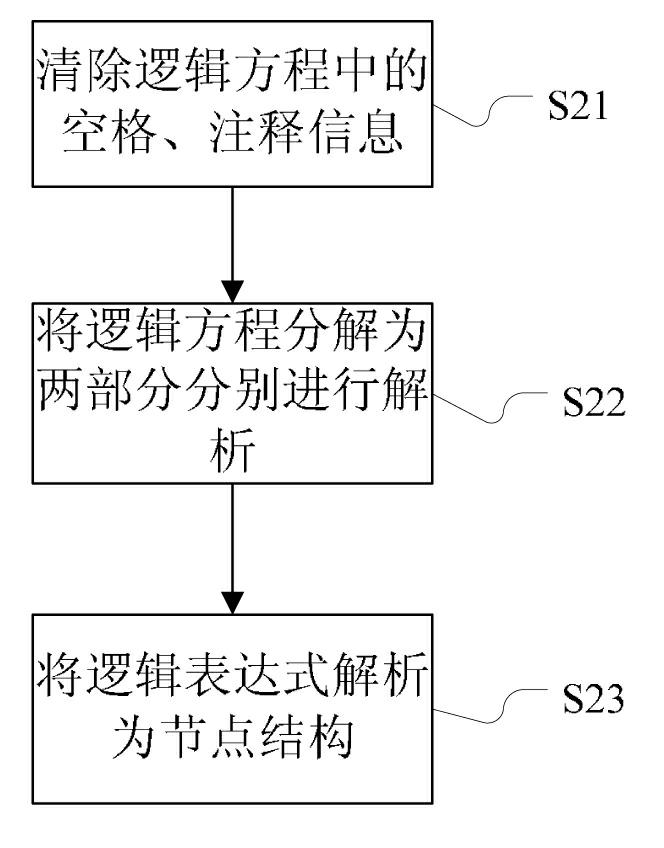

Relay protection logical equation analyzing method

InactiveCN102122242AMeet strong real-time requirementsReduce modelEmergency protective circuit arrangementsProgram controlProgramming languageSyntax error

The invention discloses a relay protection logical equation analyzing method which comprises the following steps of: writing a logical equation according to a relay word database; analyzing morphology and the logical equation into a node structure; detecting the syntax error in the equation through virtual execution; establishing an execution unit module; generating a logical equation parameter; executing the logical equation by a relay protecting device according to the logical equation parameter; and triggering an outlet according to the execution result of the logical equation. In the relay protection logical equation analyzing method, the logical equation is established according to relay words, and analyzed and executed by an analyzing module and an executing module; and the outlet of a relay protector is triggered by using the execution result of the logical equation. The logical equation analyzing method has high executing speed and meets the high real-time requirement of the relay protection system; and based on the programmable relay protector developed by the method not only reduces the models of the relay protector, but also simplifies the working amount of maintenance on site.

Owner:GUANGZHOU TOSHIBA BAIYUN ELECTRICAL EQUIP

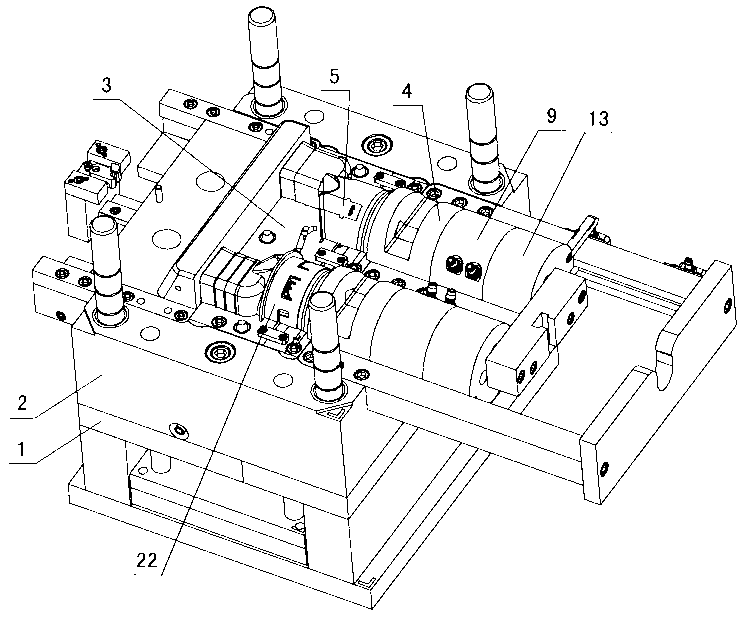

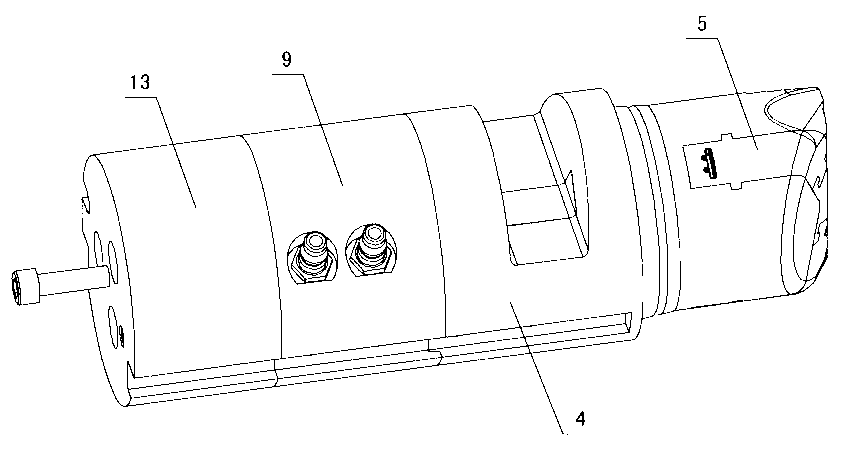

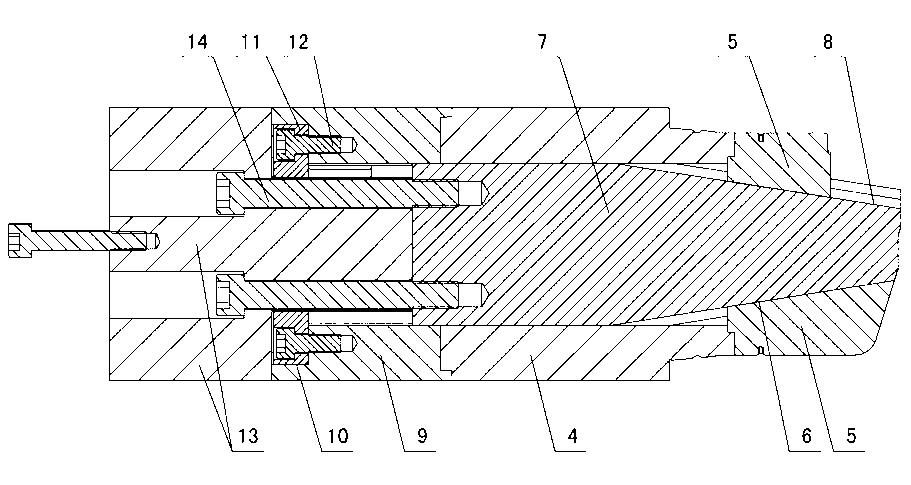

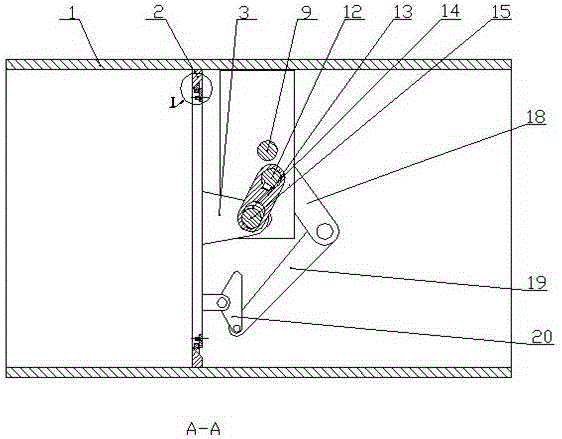

Reducing coupling injection mold core-pulling mechanism

The invention discloses a reducing coupling injection mold core-pulling mechanism which comprises a movable mold base plate and a movable template, wherein a movable mold insert is arranged on the movable template; a secondary internal core-pulling mechanism is arranged on the movable template; floating core-pulling mechanisms are arranged on the movable mold base plate, the movable template and the movable mold insert; according to the secondary internal core-pulling mechanism, an inner inclined sliding surface is formed in a core-pulling small slide block connected in front of a main mold core; an outer inclined sliding surface formed on a sliding rod arranged in the main mold core is matched with the inner inclined sliding surface; a fixing plate is arranged in a mounting groove formed in the rear end of a connecting seat behind the main mold core and is fixed together with the connecting seat through a screw; the sliding seat and the sliding rod are fixed through a bolt; according to the floating core-pulling mechanism, one end of a spring arranged in the movable template is contacted with the movable template, and the other end of the spring is contacted with the movable mold base plate; a core-pulling slide block arranged in the movable mold insert is matched with an external fastener; the core-pulling slide block is provided with a T-shaped clamping block; inclined guide slots formed in an I-shaped locking module are formed in the movable template and the movable mold insert; the upper part of the I-shaped locking module is matched with the T-shaped clamping block through the inclined guide slots; and the lower part of the I-shaped locking module and the movable mold base plate are fixed together.

Owner:TAIZHOU HUANGYAN WEIDA PLASTIC MACHINERY

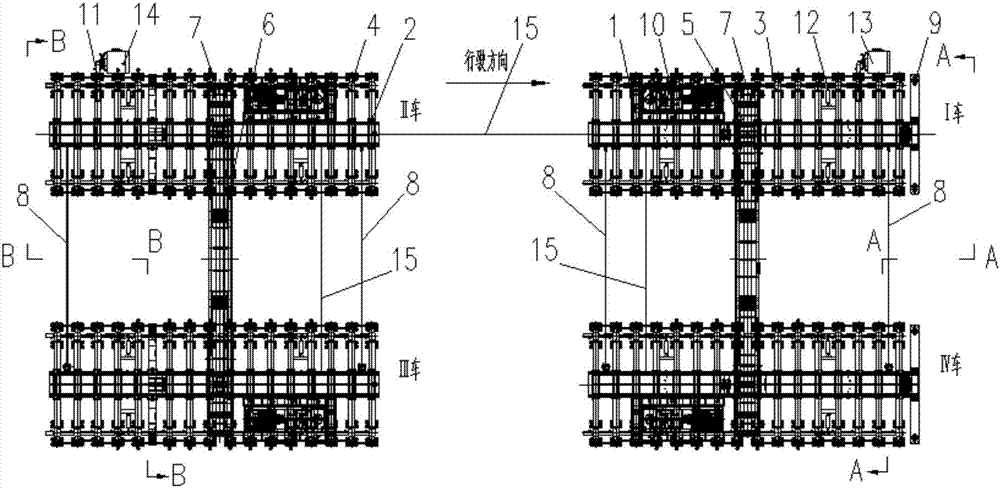

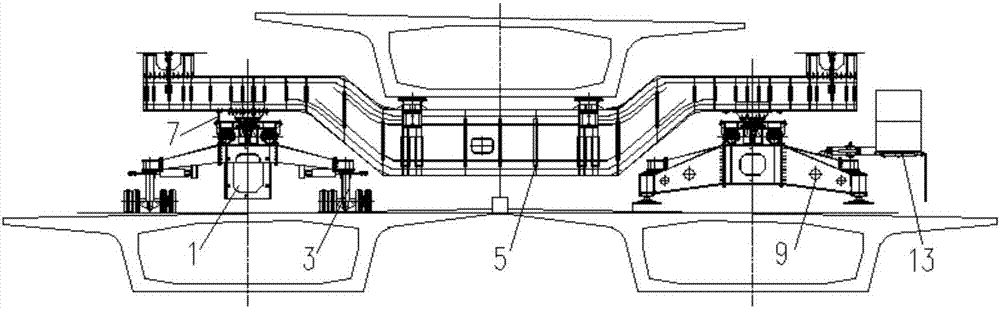

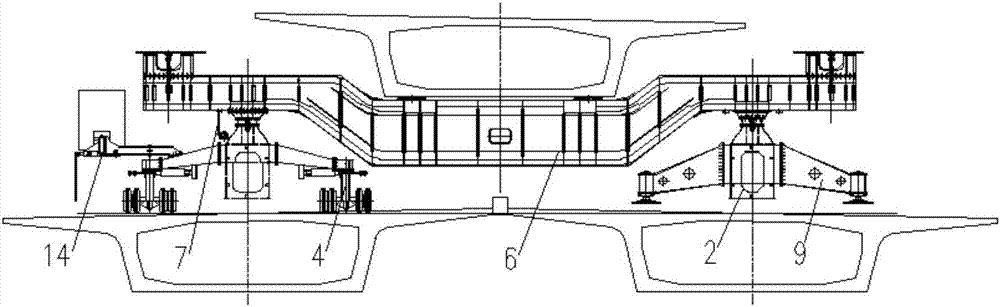

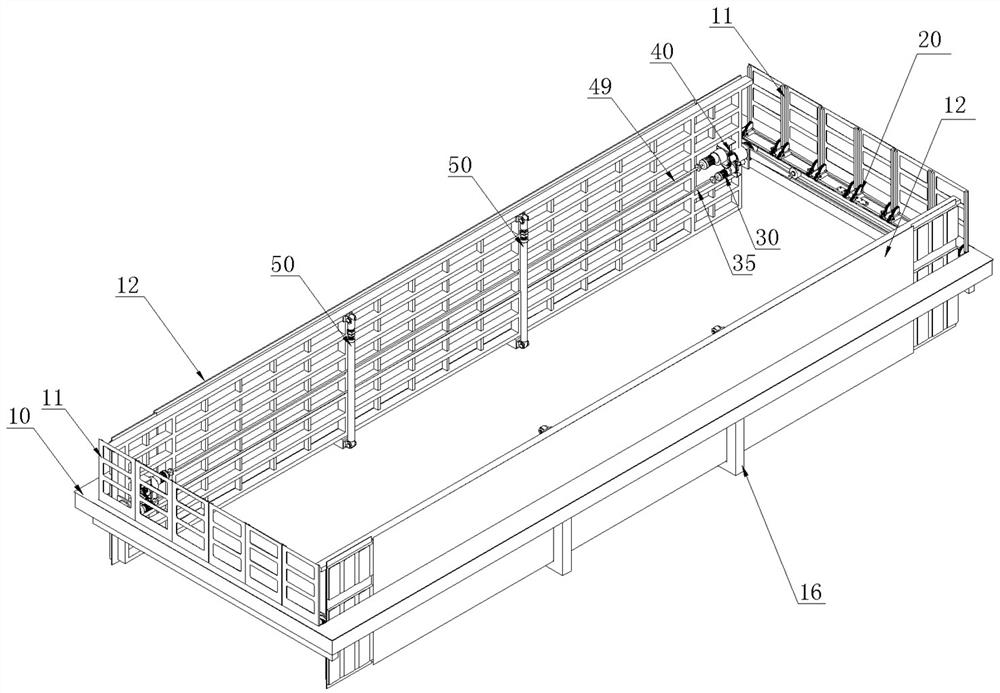

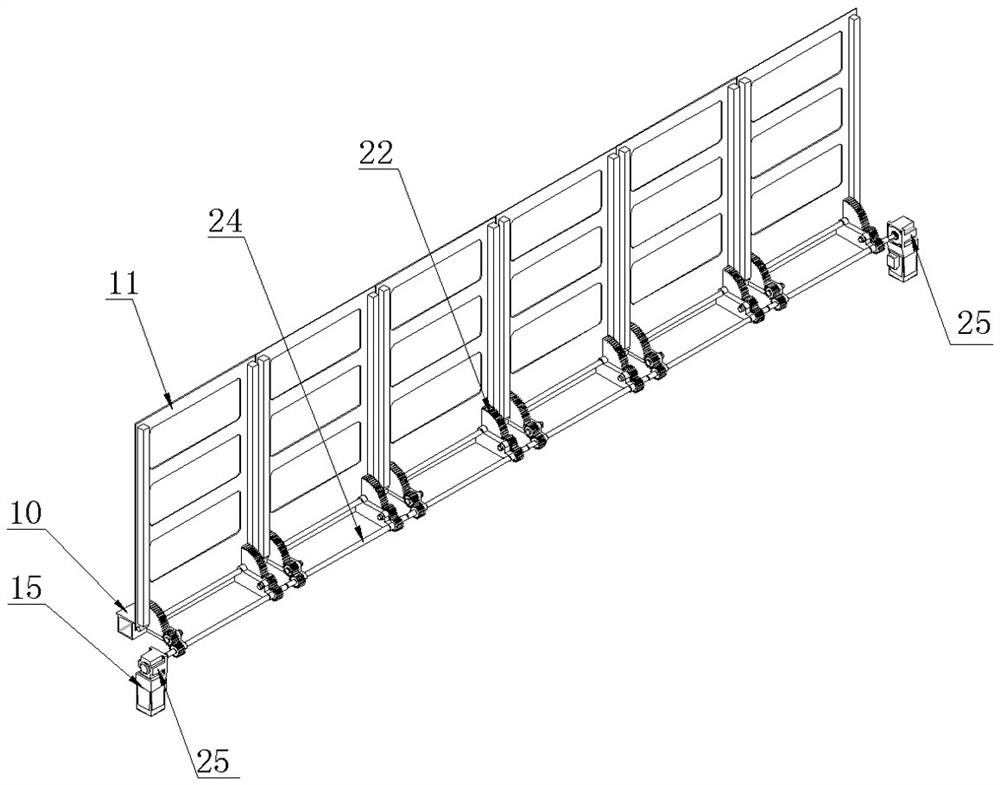

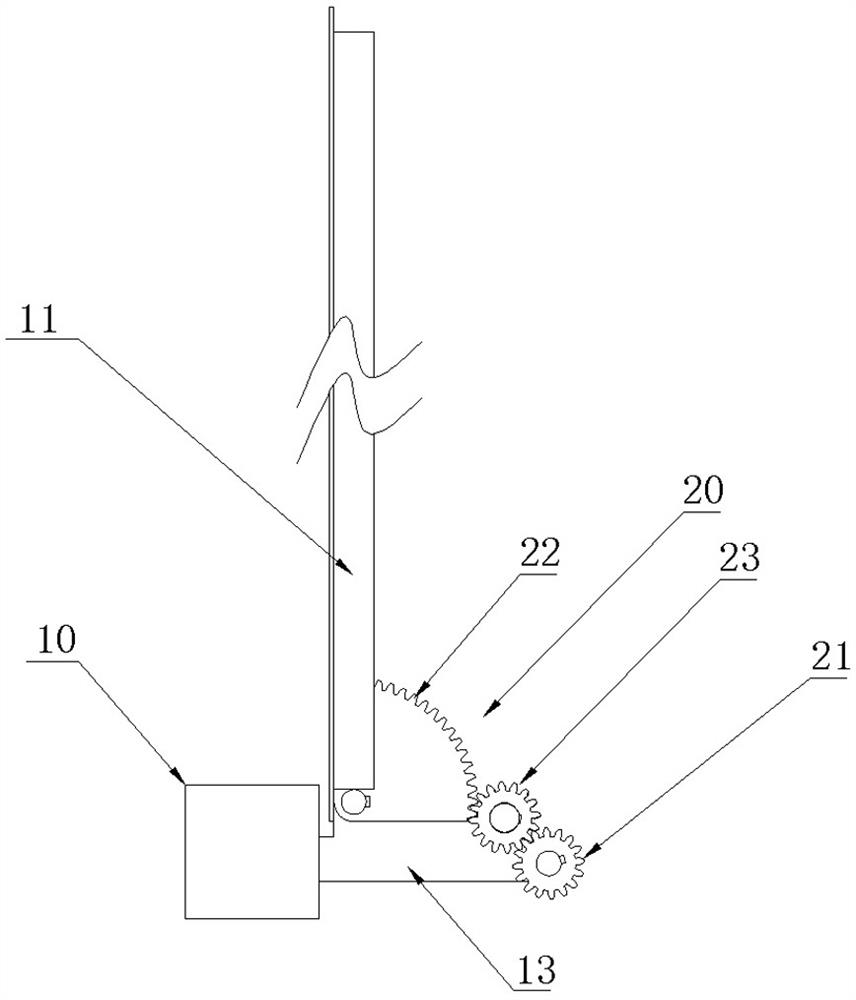

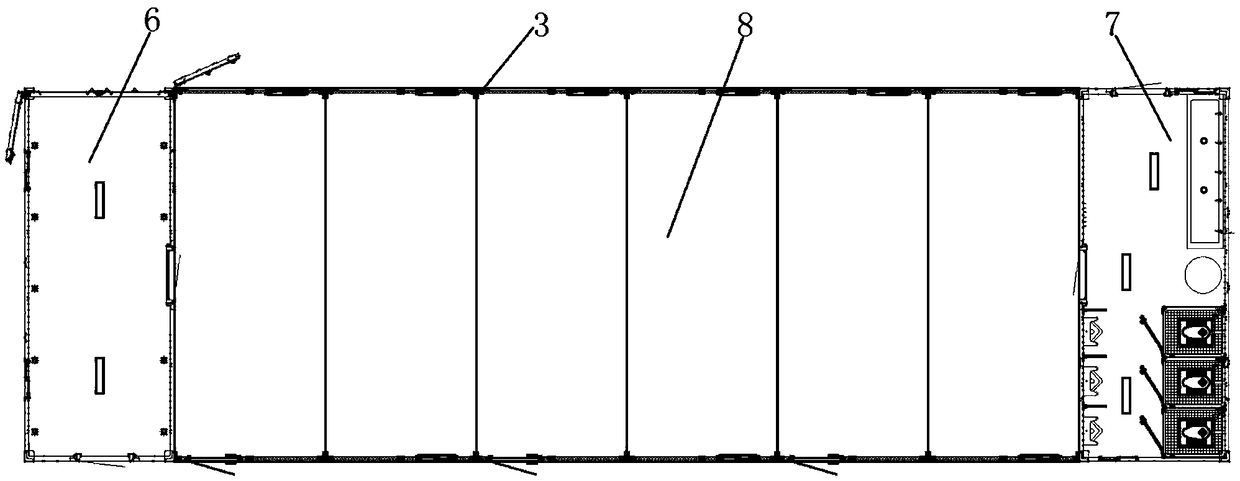

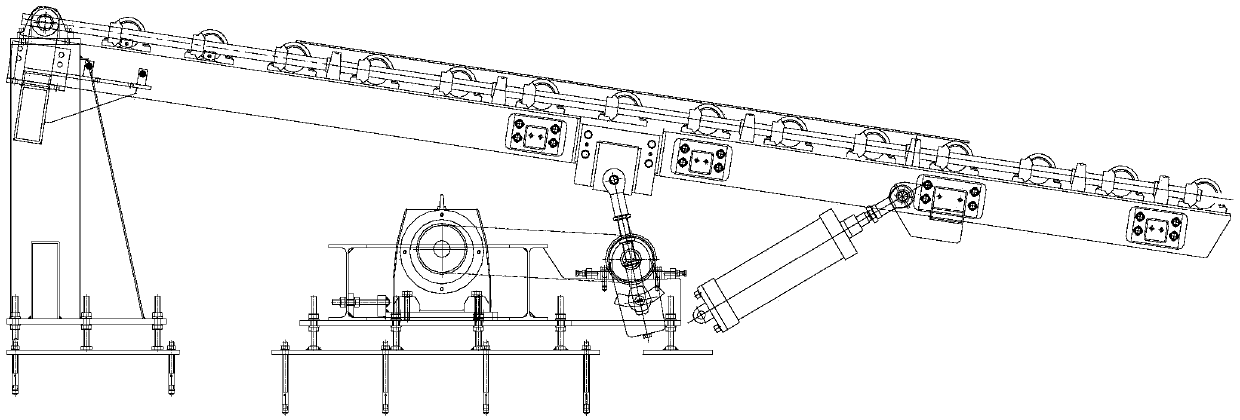

PID loop-based synchro-control system and method for multiple wagons of girder transporting vehicle

PendingCN107237269ATroubleshoot Synchronous Control IssuesImprove securityBridge erection/assemblyControllers with particular characteristicsLine sensorControl system

The invention relates to a synchro-control system and method for multiple wagons, belongs to the technical field of bridge construction, and in particular relates to a PID loop-based synchro-control system and method for multiple wagons of a girder transporting vehicle. The system and method integrate a corner sensor device, a pull wire sensor device, a PLC control system as well as actuating components such as a pump, a motor and an oil cylinder for participating in control together, thereby improving the synchro-control effect. The invention provides a new angle measuring device, the rotation condition of an independent flat wagon is judged by measuring the angle of rotation of a spherical hinge, thereby providing more precise angle reference data for synchro-control. The invention also provides a new pull wire sensor device, the position postures of two wagons can be accurately judged by the change of the pull wire values of the two ends of the two wagons, and further the distance between the two wagons can be judged, thereby providing more precise distance reference data for synchro-control.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

Double-rocker friction-free hard seal butterfly valve

ActiveCN105221768AImprove performanceReduce modelOperating means/releasing devices for valvesLift valveEngineeringMovable type

The invention discloses a double-rocker friction-free hard seal butterfly valve. The butterfly valve is characterized by comprising a valve body, a valve main body, a valve seat, a main valve shaft, a small valve shaft, a guide shaft, a guide groove, a butterfly plate, an incomplete big gear, a pinion, a shifting rod, a linkage rod, an intermittent mechanism and a drive device, wherein a through hole is formed in the valve main body, a valve neck is welded at the through hole, meanwhile, the valve seat is welded in the inner circle surface of the valve main body, and the outer circle surface of the valve seat is conical; the butterfly plate is of an annular structure, a movable butterfly plate with a hard seal ring is installed at the outer circle position of the butterfly plate, the movable type is a movement structural manner that the butterfly plate is capable of horizontally moving in the axial direction of the valve main body first, and then rotating by taking the guide shaft as a centre, and the butterfly plate is opened in a zero-friction mode, the butterfly plate is connected with the guide shaft, a self-lubricating shaft sleeve is installed at the junction of the butterfly plate and the guide shaft through interference fit, the self-lubricating shaft sleeve is in clearance fit with the guide shaft, and the guide shaft is installed in the guide groove; and a compression spring is installed in the guide groove.

Owner:HEBEI UNIV OF TECH +1

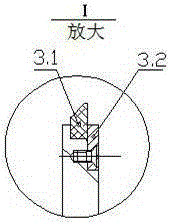

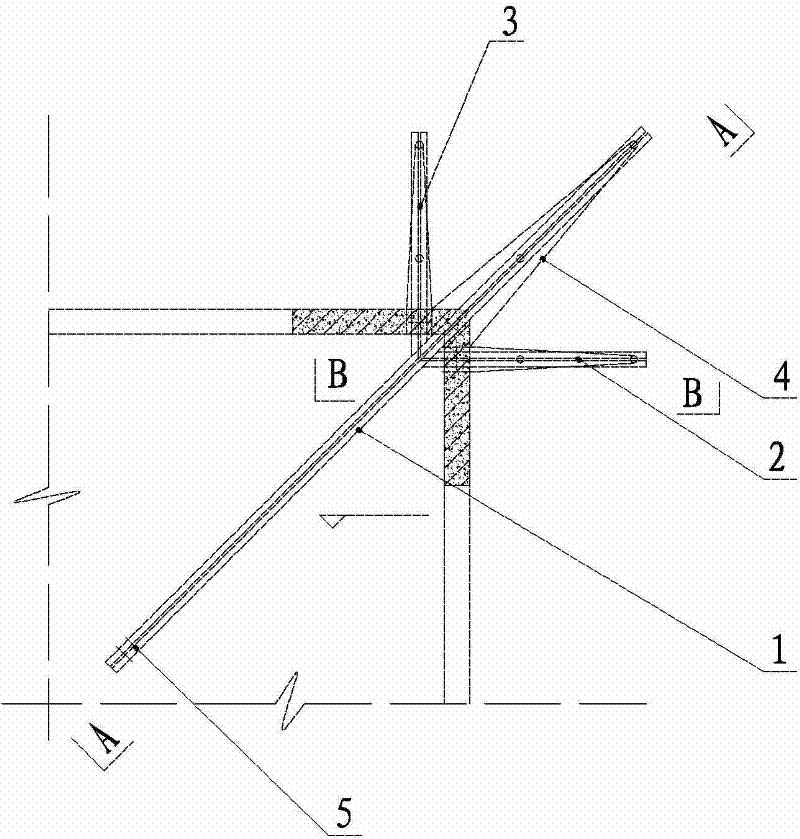

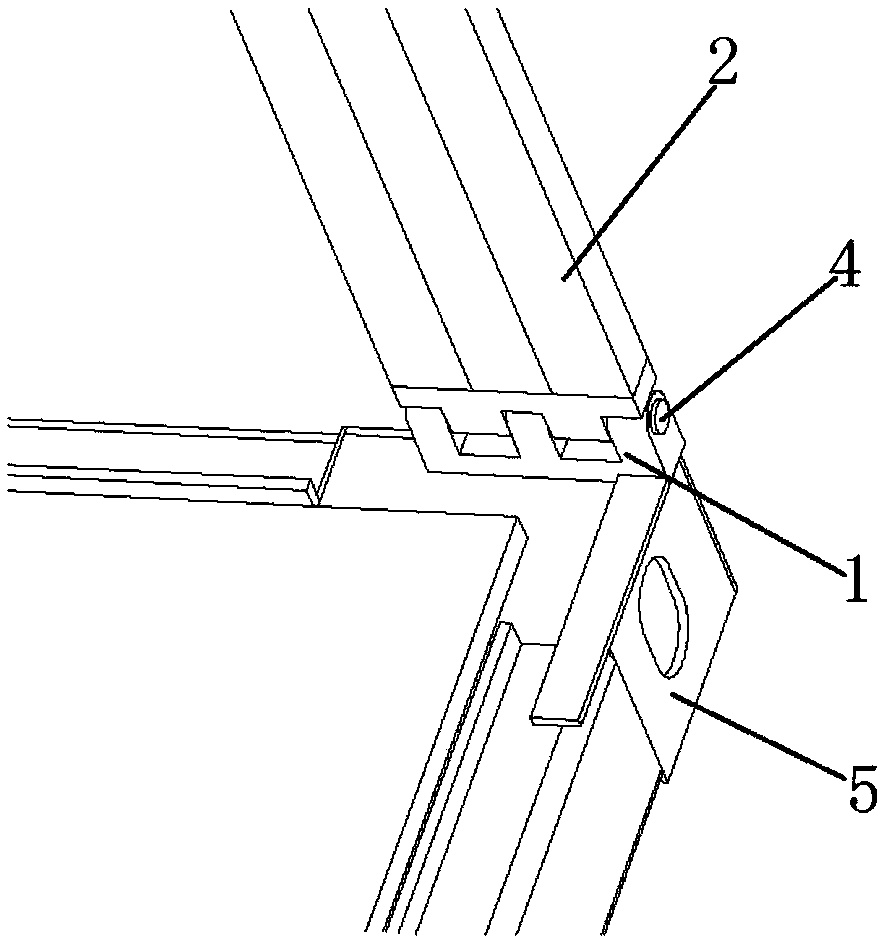

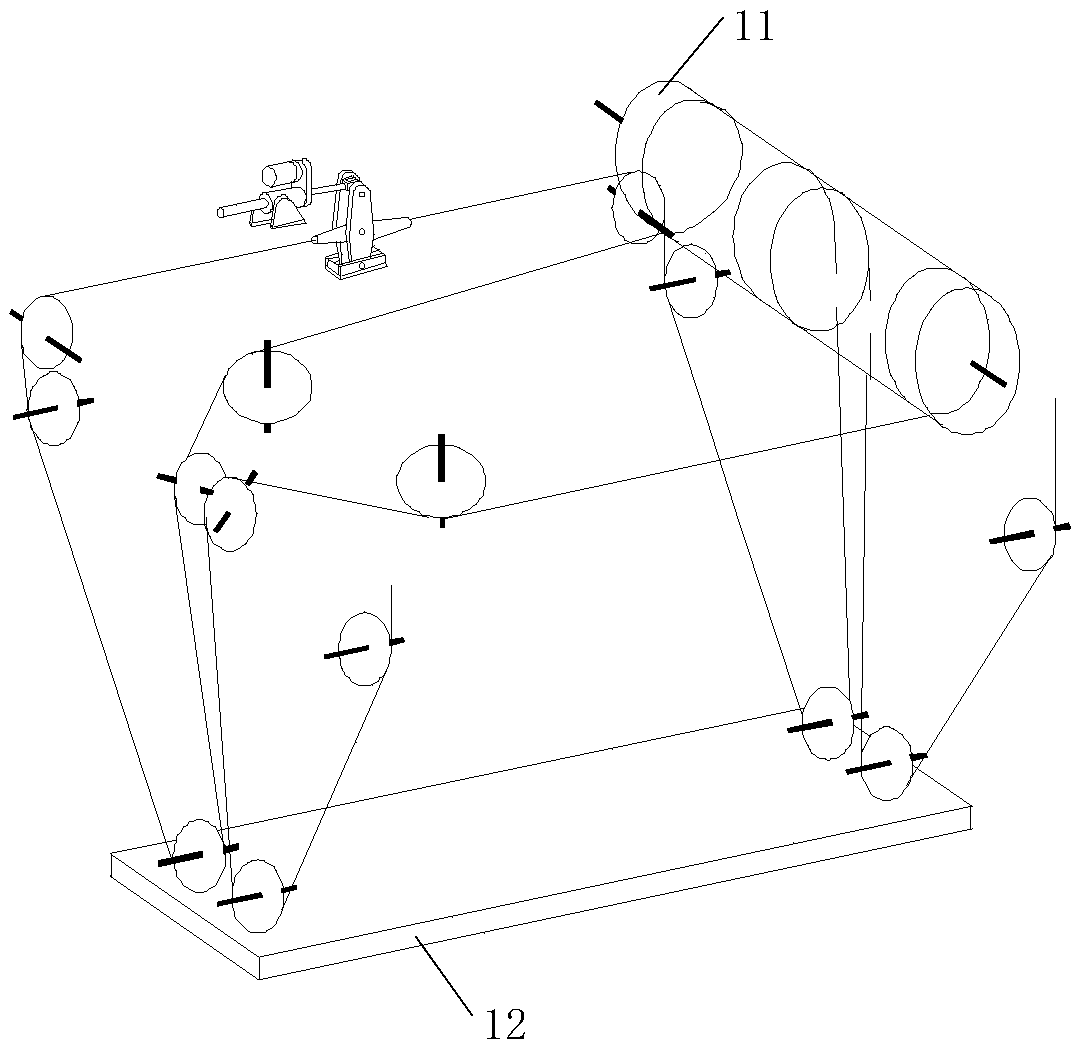

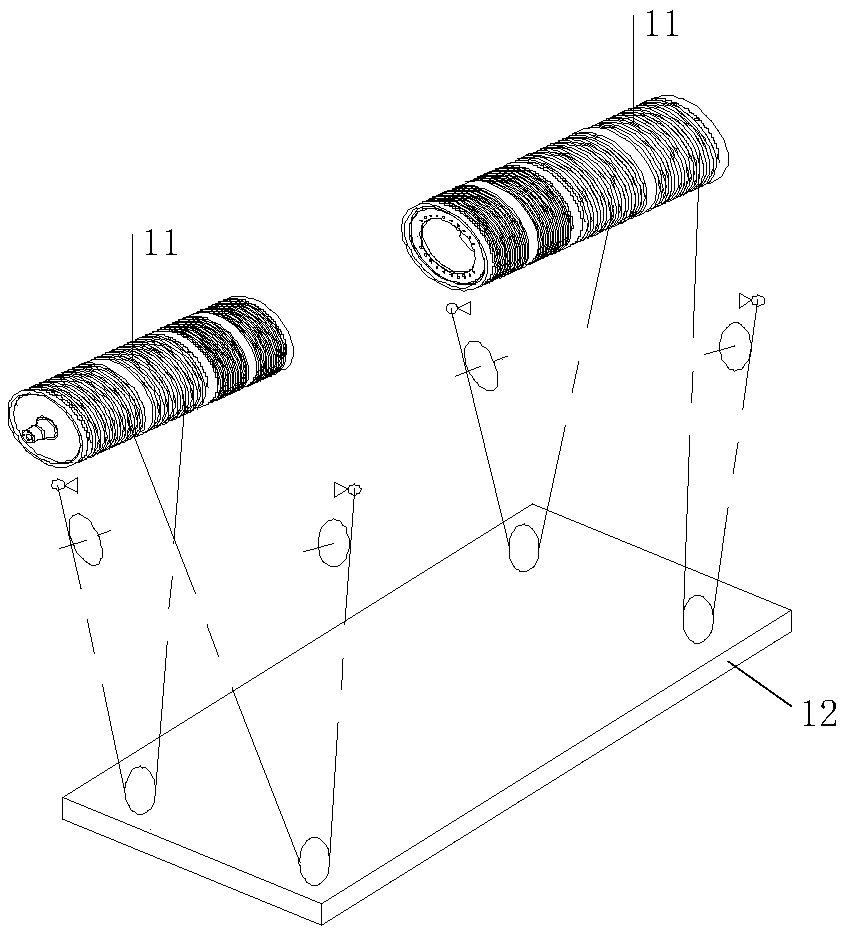

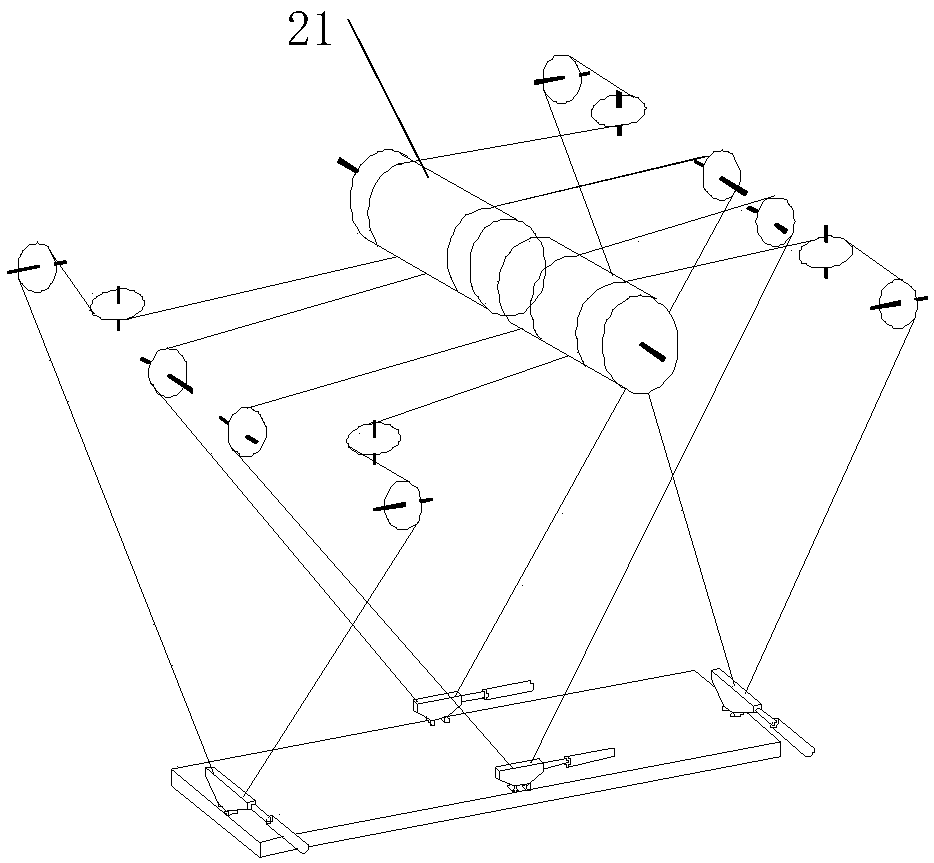

The bearing structure of the frame body at the male corner of the segmented scaffolding

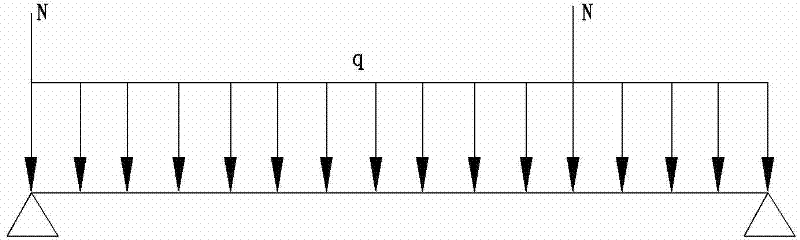

InactiveCN102296798AReduce free lengthReduce the absolute value of the bending momentScaffold accessoriesBuilding support scaffoldsBeam angleEngineering

The invention discloses a frame body load-bearing structure at the male corner part of a scaffold erected in sections with a simply supported structure, which overcomes the defects of stress concentration and uneven appearance of the existing cantilever beam structure, is economical and reasonable, and can ensure The construction is safe, and the appearance of the scaffolding is beautiful and uniform. The frame load-bearing structure includes 3 steel beams and 6 cable-stayed wire ropes. The 3 shaped steel beams include: main beam (1), left sub-beam (2), right sub-beam (3); 6 cable-stayed steel wire ropes (4) are respectively arranged at the outer ends of the 3 shaped steel beams, that is, each shaped steel The beam is equipped with two cable-stayed steel wire ropes, one of which is used as a stress rope and the other as a safety protection rope. The main girder is arranged along the bisector of the sun angle, and the left sub-beam and the right sub-beam are respectively arranged on both sides of the main girder, and the included angle with the main girder is 45 degrees, and the intersection of the three is welded into a whole. The length of the left and right sub-beams of the shaped steel beams is the same, and the direction is horizontal. The length of the shaped steel beams other than the corners of the external corners is the same as that of the sub-beams, as long as they are arranged in parallel according to the calculated longitudinal distance of the scaffolding poles. , easy to operate and beautiful in appearance.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Method for operating flexible powering frequency changing regulating speed control apparatus of direct control oil pumping unit

InactiveCN1787361AReduce installed powerReduce modelAC motor controlFluid removalFrequency changerKey pressing

This invention discloses an operation method for a soft drag frequency conversion adjusting control device of a direct-control pumping unit including a frequency converter and a control device and the control device includes a test module, a key module, a central processing module, a display module, an output module and a control volume input module circuit, among which, the test module and the key module circuit send the test signals of current and voltage and key orders to the CPU, which outputs or displays the result and display volume and converts them to analog signals to be sent to the analog control input end of the converter, the analog volume input module circuit has two output ends, one of which is connected with the CPU, the other with the output module circuit, the CPU sends the output analog signals and 0-10V analog signals output by a potentiometer to the converter to realize the conversion control to drag motors.

Owner:盘锦北申智能控制有限公司

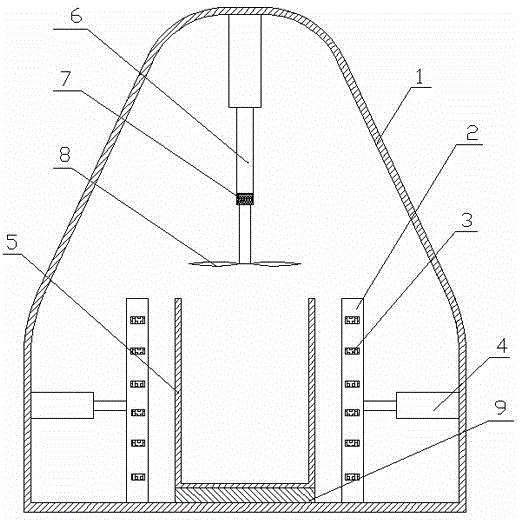

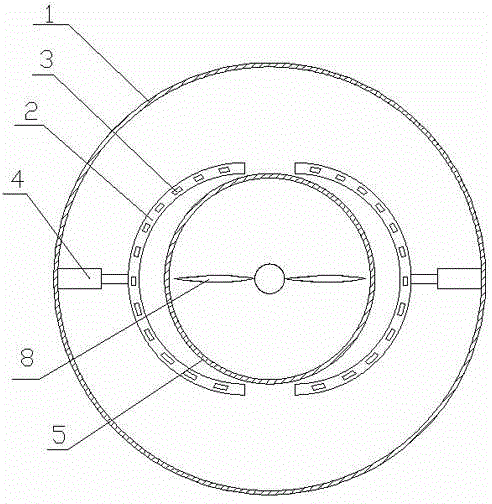

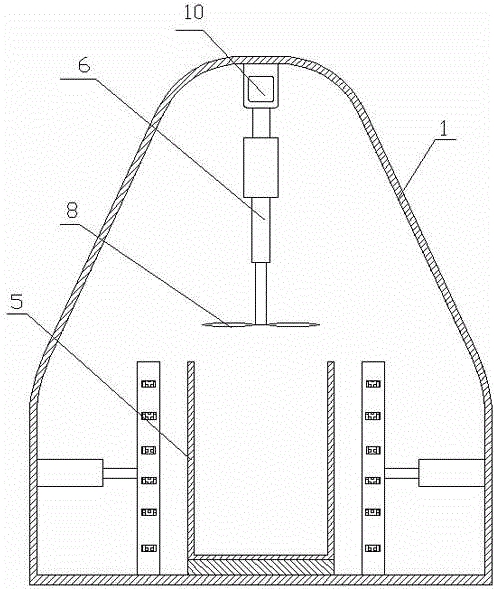

Ultrasonic wave stirrer

ActiveCN104383838AReduce device modelLow costShaking/oscillating/vibrating mixersSolid solvent extractionReciprocating motionUltrasound - action

The invention discloses an ultrasonic wave stirrer which comprises a shell, a stirring barrel and an ultrasonic wave generation mechanism, wherein ultrasonic wave vibrators are arranged in the ultrasonic wave generation mechanism; the ultrasonic wave generation mechanism can be used for transmitting ultrasonic waves into the stirring barrel and can be also used as a clamping mechanism for the stirring barrel; the ultrasonic wave stirrer is also provided with a stirring device with expansion devices; the stirring device is used for enabling a stirring wheel in a rotating state to do up-and-down reciprocating motion in the stirring barrel to uniformly mix raw materials. According to the ultrasonic wave stirrer, extracts and a solution are fully combined; the ultrasonic wave generation mechanism capable of doing expansion motion can be used for transmitting the ultrasonic waves to the stirring barrels with different sizes, so that the types of equipment are reduced and the cost is lowered; the stirring barrel can be fixed and locked; in an extracting process, the ultrasonic wave generation mechanism can be used for avoiding the phenomenon that ultrasonic wave extraction is affected by vibration of the stirring barrel, so that extraction is complete, and the efficiency is improved; the ultrasonic waves act on the periphery of the stirring barrel, so that the extracts are high in combining speed, and the mixing effect is enhanced.

Owner:HENAN HENGRUIYUAN IND

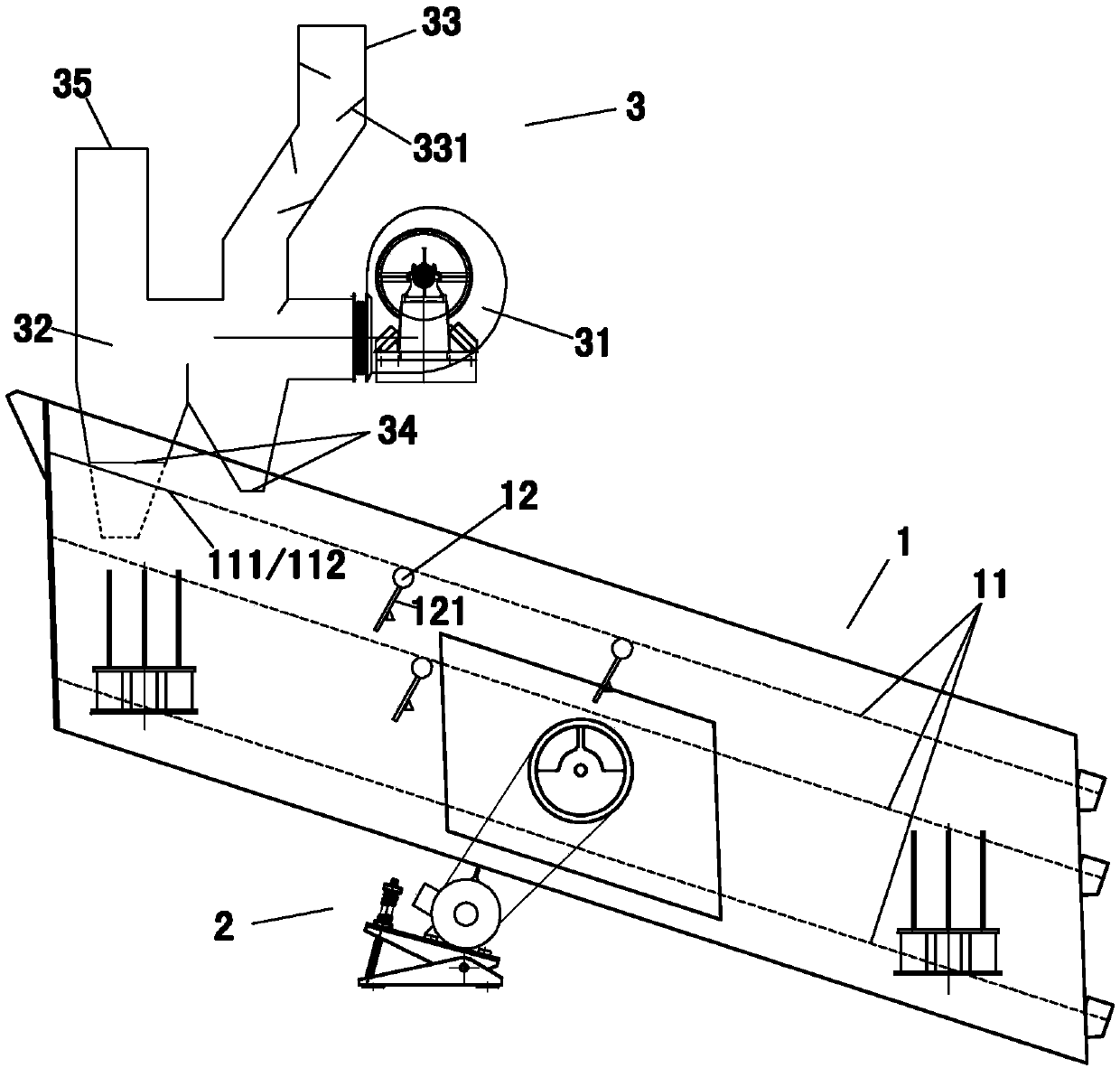

Pre-grading device and vibration screening machine with same

The invention discloses a pre-grading device and a vibration screening machine with the same and relates to the field of gravel screening machines. The pre-grading device comprises an air blower, a main grading cavity, a feeding channel and a plurality of discharging channels. The main grading cavity is provided with an air inlet, a feeding opening and a plurality of discharging openings, and an air outlet of the air blower is connected with the air inlet; the feeding opening is formed in the upper portion of the main grading cavity and connected with the feeding channel, and all the discharging openings are formed in the lower portion of the main grading cavity and are connected with the discharging channels in a one-to-one corresponding mode; and all the discharging openings are formed in an arrayed mode in the direction opposite to the air inlet along the air inlet, and the feeding opening corresponds to the discharging opening closest to the air inlet or is closer to the air inletthan the discharging opening. The vibration screening machine comprises a screen cloth device with a plurality of layers of screen clothes being vertical arranged at intervals and further comprises avibrating mechanism and the pre-grading device which are connected with the screen cloth device; the pre-grading device is arranged above the front section of the screen cloth device, and the front ends of all layers of the screen cloths, except the screen cloth of the bottommost layer, of the screen cloth device are each provided with a lower layer falling opening; and the discharging openings ofall the discharging channels correspond to all the screen clothes from top to bottom in one-to-one and layer-by-layer modes in the direction opposite to the air inlet along the air inlet, and the layer number of the screen clothes of the screen cloth device is matched with the number of the discharging channels.

Owner:FUJIAN NONNON TECH

Lifting hole cover plate of electric turnover structure

ActiveCN113802958ARealize automatic opening and closingRealize automatic movement flip opening and closingShutters/ movable grillesPower-operated mechanismEngineeringStructural engineering

Owner:江苏至善尚合电力科技有限公司

Mobile house combined and constructed by box modules and constructing method of mobile house

PendingCN108894332ARealize rotation buildAchieve withdrawalBuilding constructionsEngineeringFunctional module

The invention discloses a mobile house combined and constructed by box modules and a constructing method of the mobile house. Standard box modules are packed and stored, a plurality of double-pitched-roof living house modules are transported, and functions modules which guarantee basic life demands are assorted; a packaging module, a plurality of double-pitched-roof living house module bottom frames and the functional modules are successively constructed, rotary corner posts and roof truss structures are successively mounted, an integral framework structure of a middle double-pitched-roof living house is mounted by rotating strengthening and connection and fixing, finally, floors, wall panels, box barge covers and roof slabs are mounted, a mobile house guaranteeing system which is combinedby box modules on two sides and the middle modular double-pitched-roof mobile house is assembled, the two sides of the house are constructed by the boxes rapidly, safely and conveniently, the integral wind resistance, structural strength and rigidity are greatly enhanced, and diversified guaranteeing requirements under the conditions of rapid maneuvering, construction and field operations of force are met.

Owner:中国人民解放军陆军研究院特种勤务研究所

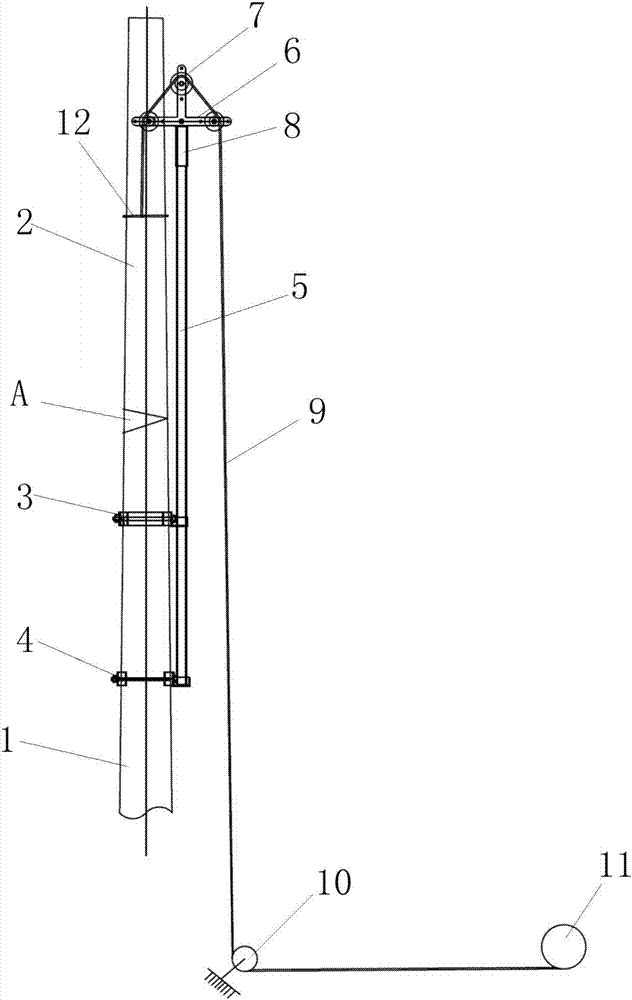

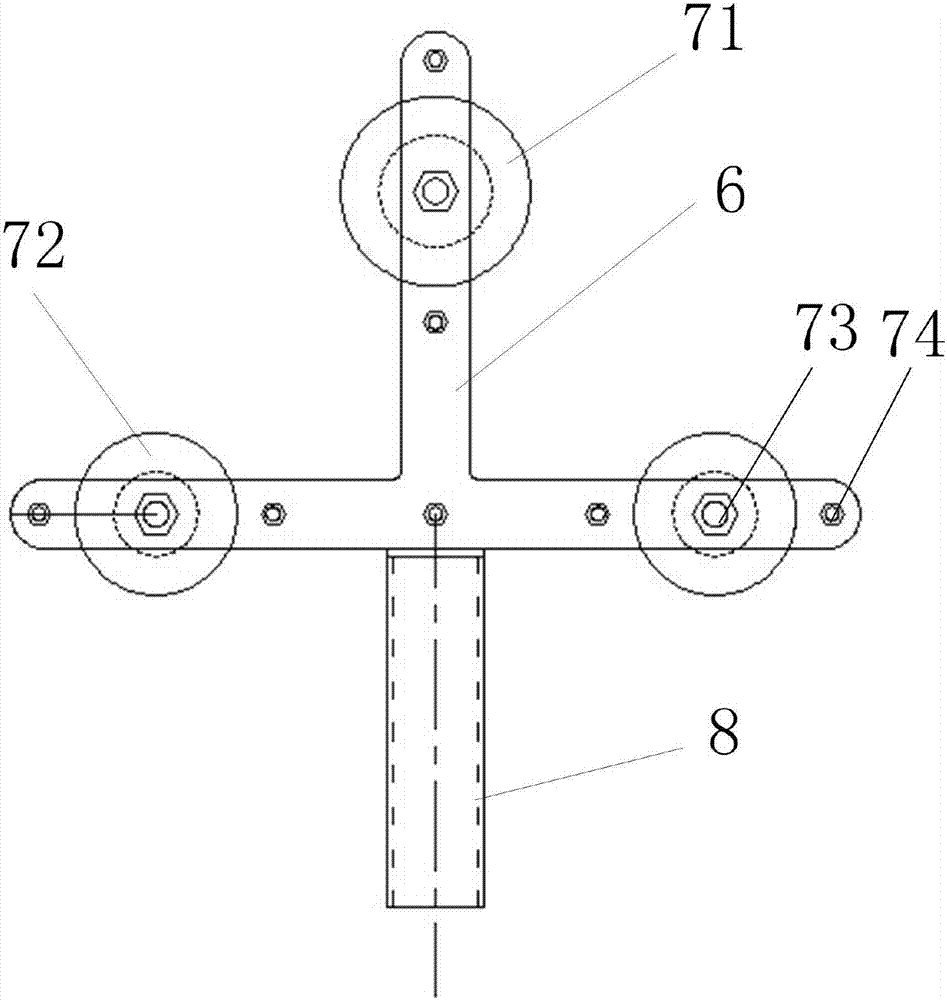

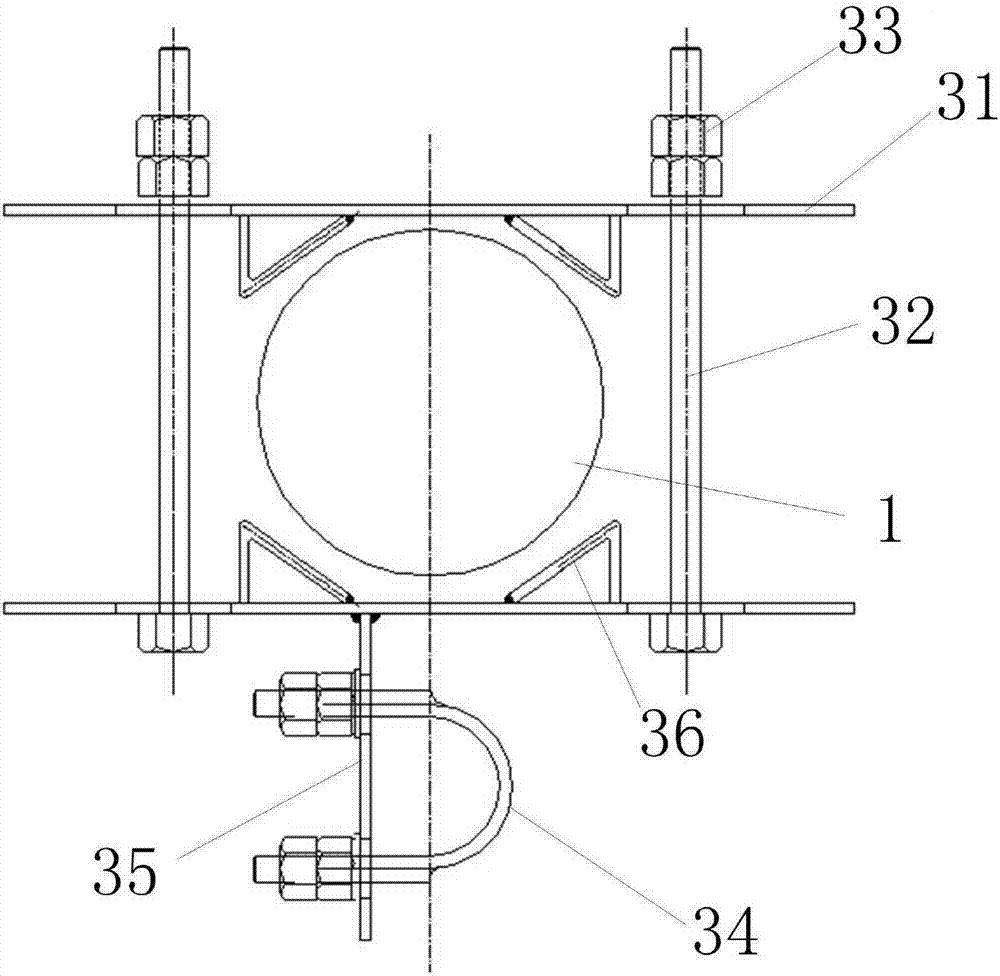

Lifting auxiliary device and lifting operation method of part to be operated

PendingCN107215799AImprove work efficiencyEasy to disassemble and installPortable liftingWire ropeBlock and tackle

The invention provides a lifting auxiliary device and a lifting operation method of part to be operated. The lifting auxiliary device is matched with a steel wire rope to which the part to be operated is hung, so that the part to be operated ascends or descends on a body to operated. The lifting auxiliary device comprises a holding mechanism, a supporting frame and a pulley assembly. The holding mechanism is installed on the body to be operated and used for supporting the supporting frame and preventing toppling. The supporting frame is supported on the holding mechanism and used for supporting the pulley assembly. The pulley assembly is installed on the top of the supporting frame and used for supporting the steel wire rope and changing the direction when the steel wire rope winds around the pulley assembly. In the using process, the lifting auxiliary device is installed on the body to be operated, the steel wire rope is connected with the part to be operated, the steel wire rope winds around the pulley assembly and is driven to ascend or descend through the drive mechanism, and the part to be operated is lifted. The device is simple in structure and can adapt to an area with a narrow space, and thus large crane mechanisms like a lifting machine can be omitted. Moreover, the lifting auxiliary device is directly installed on the body to be operated, and a supporting mechanism is omitted.

Owner:重庆西鹏防雷电子有限公司

Crane bothway anti-swing mechanism and crane

ActiveCN108946473AReduce model and costGood anti-shake effectLoad-engaging elementsEngineeringWire rope

The invention provides a crane bothway anti-swing mechanism and a crane. The crane bothway anti-swing mechanism comprises a trolley support, a hoisting tool upper support and a coiling block; the coiling block is arranged on the trolley support; a first-direction anti-swing assembly is further included and comprises a first steel wire rope, a first upper support sliding wheel arranged on the hoisting tool upper support, a winding-out assembly and a first winding-back assembly, and the winding-out assembly and the first winding-back assembly are evenly arranged on the trolley support; the firstend of the first steel wire rope is connected with the coiling block, and the second end of the first steel wire rope is wound out from the coiling block to pass through the winding-out assembly, thefirst upper support sliding wheel and the first winding-back assembly to form an inverted triangle shape.

Owner:SANY MARINE HEAVY IND

Anti-eccentric wear protection device for sucker rod rotation

ActiveCN111188582BNo wearing partsReduce maintenance frequencyDrilling rodsDrilling casingsThrust bearingStructural engineering

The invention belongs to the field of oil pumping unit accessory equipment, and particularly relates to a sucker rod rotation anti-eccentric-wear protection device. The device comprises a shell, a disc spring set and an automatic rotation mechanism, wherein the automatic rotation mechanism comprises a guide sleeve and a rotation sleeve; a strip-shaped groove is formed in the outer side of the guide sleeve, and the length direction of the strip-shaped groove is consistent with the axis direction of the shell; an anti-rotation bolt is arranged on the side face of the shell and corresponds to thestrip-shaped groove, the tail end of the anti-rotation bolt is inserted into the strip-shaped groove so as to prevent the guide sleeve from rotating, a guide sliding way is arranged on the inner wallof the guide sleeve, and the guide sliding way is of a concave structure located on the inner wall of the guide sleeve; and the bottom of the rotation sleeve is supported on the disc spring set through a thrust bearing and a supporting structural part, a guide column is fixedly arranged on the edge of the bottom of the rotation sleeve, and the guide column extends into the guide sliding way. According to the device, the automatic rotation mechanism with the guide sliding way as the core is adopted, and quick-wear parts do not exist in the mechanism, so that the maintenance frequency is lower,and the service life is longer.

Owner:龙沃科技开发有限公司

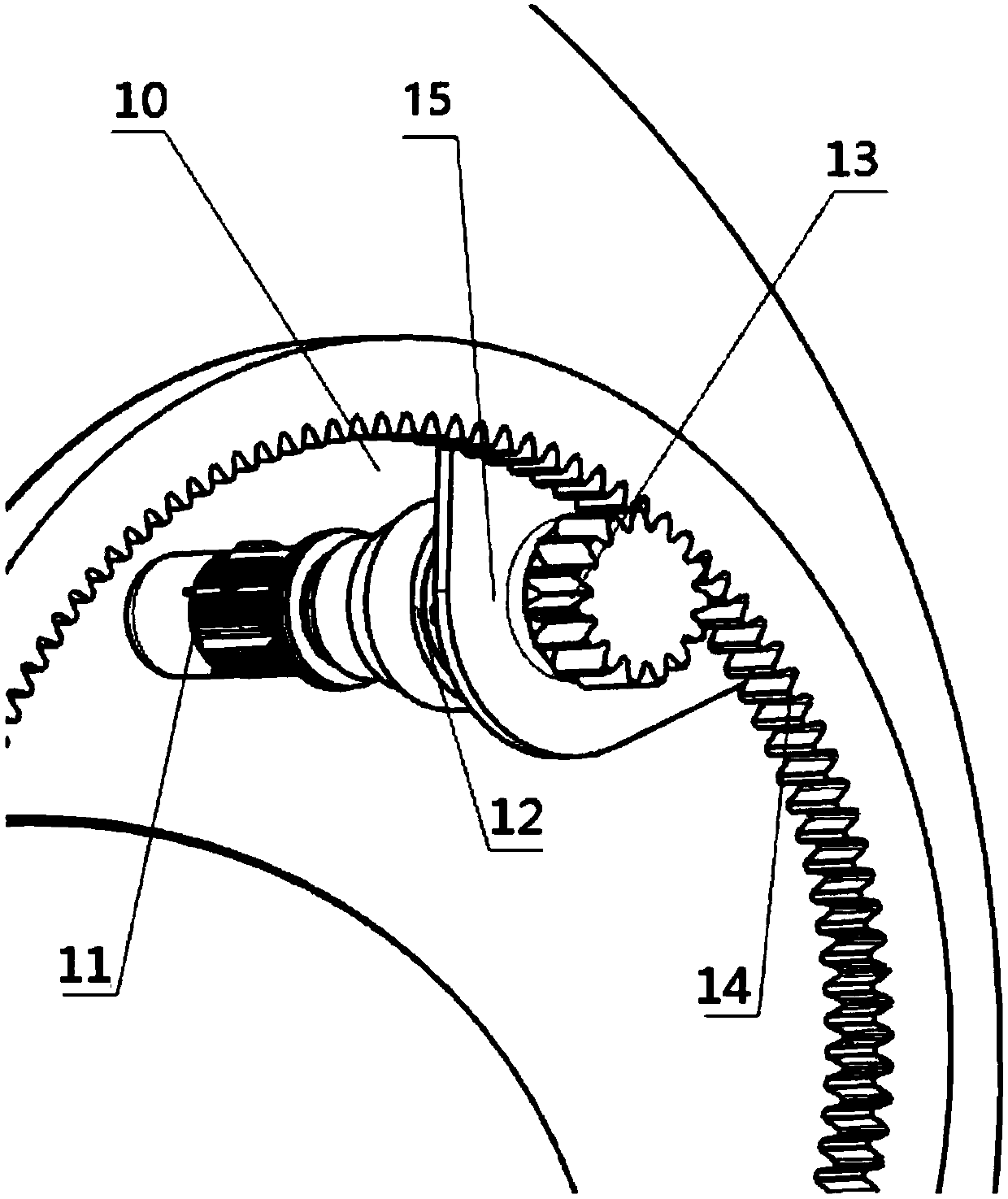

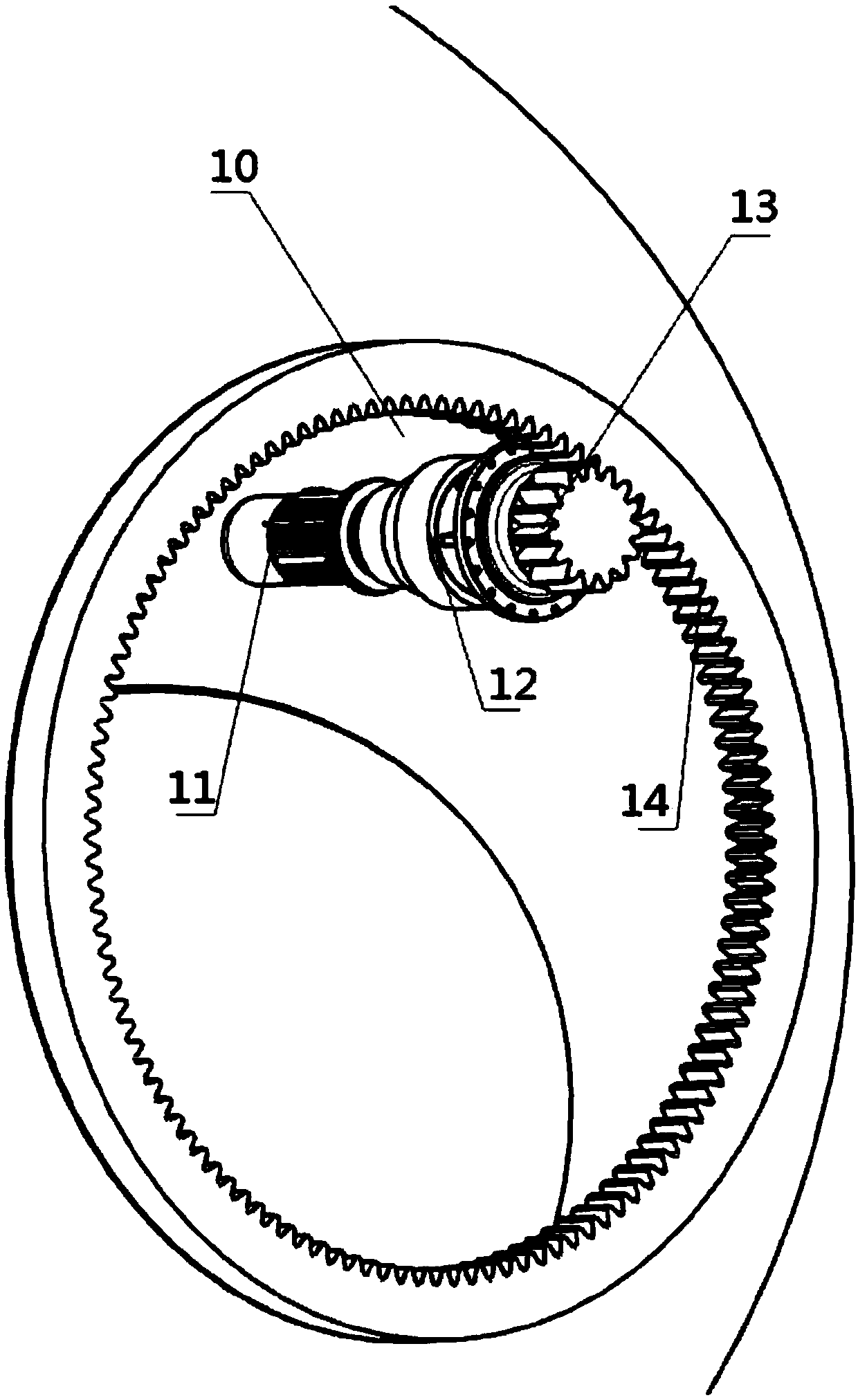

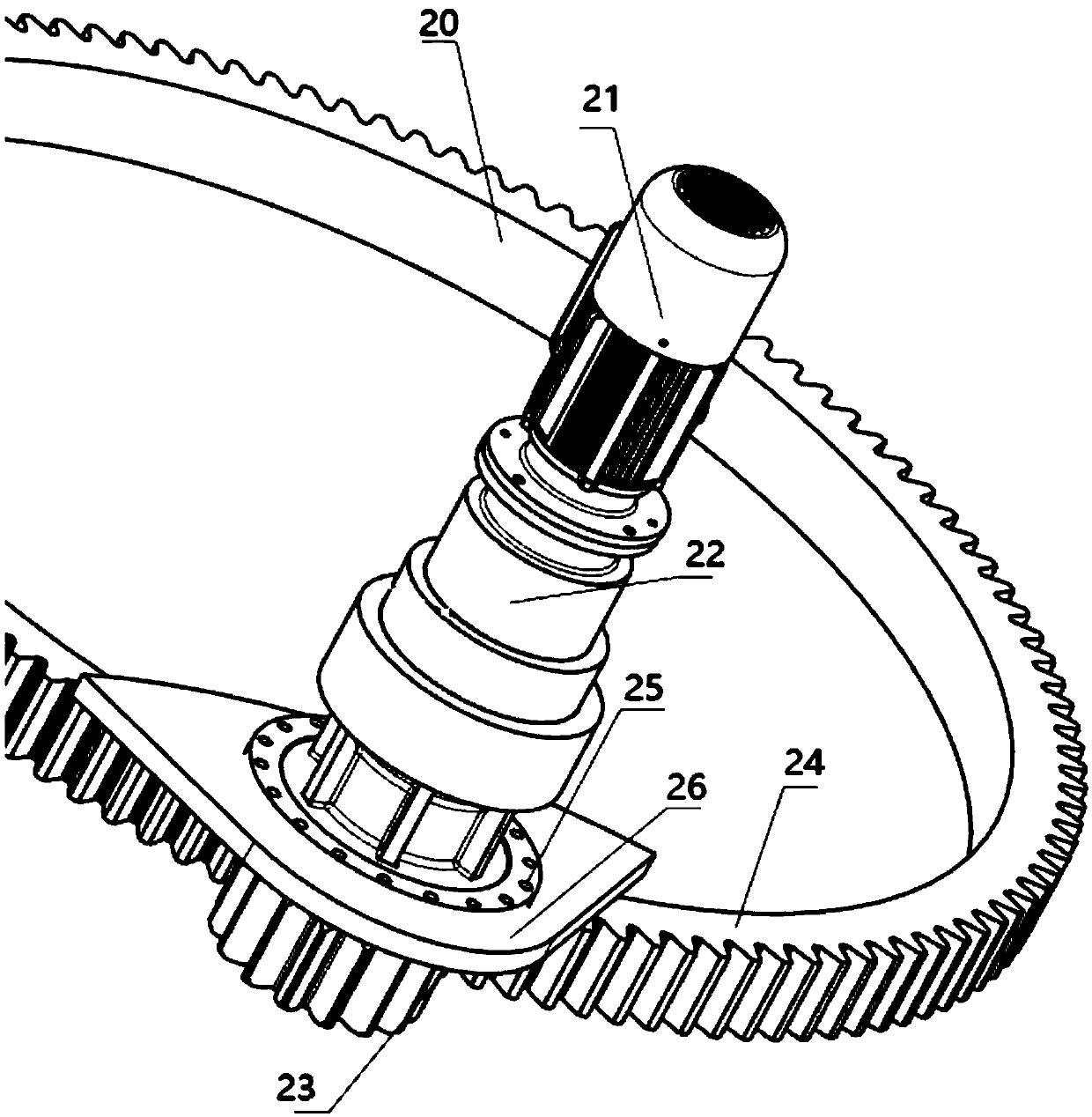

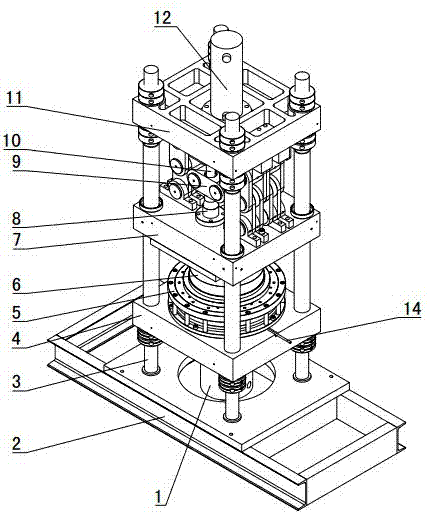

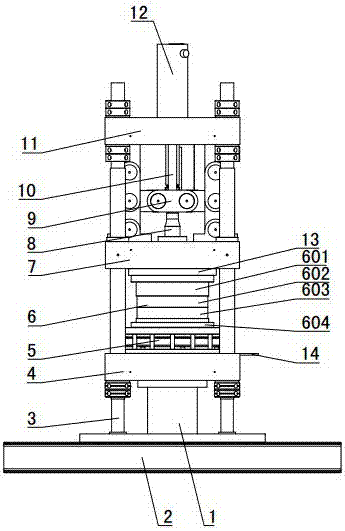

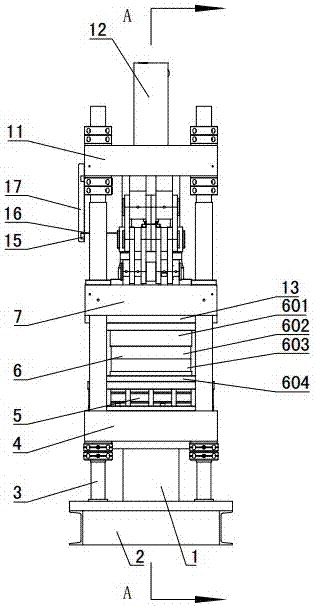

Yaw variable pitch mechanism

ActiveCN109653950AShorten the development cycleReduce modelWind motor controlMachines/enginesNacelleEngineering

The invention discloses a yaw variable pitch mechanism. The yaw variable pitch mechanism comprises a variable pitch device for adjusting the windward angle of blades of a wind driven generator, and ayaw device for adjusting the yaw direction of a cabin of the wind driven generator; the variable pitch device comprises a variable pitch motor, a variable pitch gearbox, a variable pitch output gear and a blade bearing gear ring; the yaw device comprises a yaw motor, a yaw gearbox, a yaw output gear and a yaw gear ring; the yaw gear ring and the blade bearing gear ring are the same in module and pressure angle; and the variable pitch gearbox and the yaw gearbox are the same in structure. The yaw variable pitch mechanism further comprises a first machine seat for installing the variable pitch gearbox, and a second machine seat for installing the yaw gearbox; and a machine seat connector, used for being connected with the variable pitch gearbox, of the first machine seat and a machine seat connector, used for being connected with the yaw gearbox, of the second machine seat are the same. The yaw gearbox and the variable pitch gearbox have the universality, the development cycle is shortened, the types of the gearboxes are decreased, and the scale effect is improved.

Owner:NANJING HIGH SPEED GEAR MFG

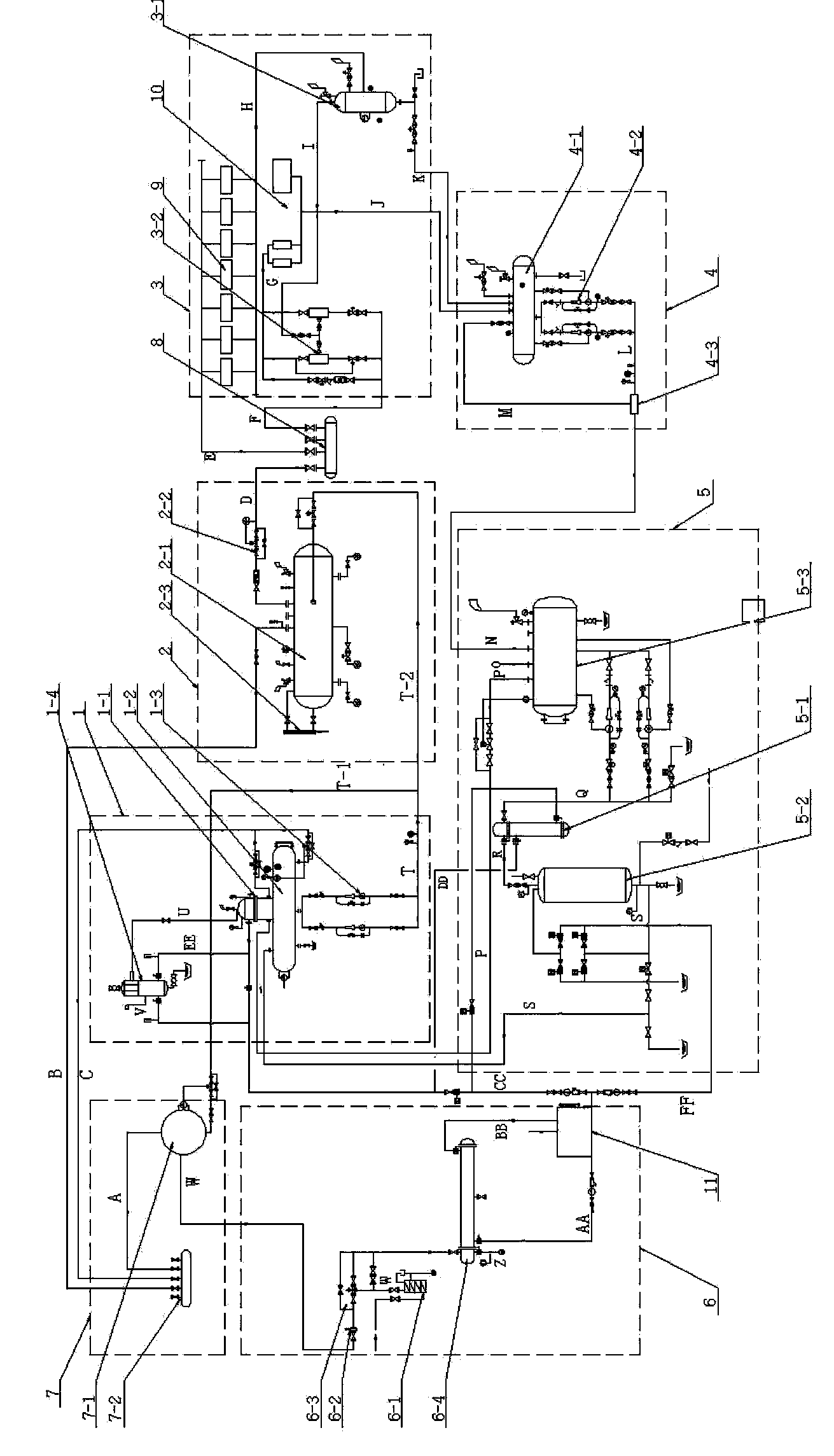

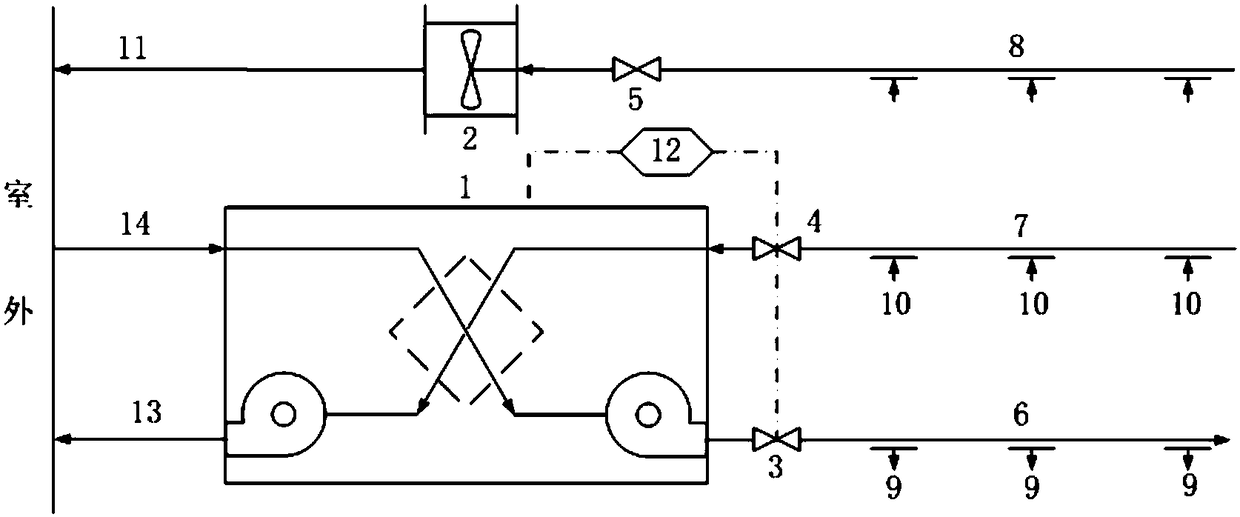

Efficient steam heat supply and waste heat recovering system

ActiveCN103644589AArchitectural simplificationSave civil costSteam generation plantsSteam central heatingWater qualityPollution

The invention discloses an efficient steam heat supply and waste heat recovering system. The efficient steam heat supply and waste heat recovering system comprises a heat accumulator (2), an automatic boiler sewage discharge system (6), and a boiler steam distribution system (7). The efficient steam heat supply and waste heat recovering system is characterized in that a low position heat power deoxidization system (1), a steam gradient utilization system (3), and a condensed water iron removal system (5) are arranged in the efficient steam heat supply and waste heat recovering system. The efficient steam heat supply and waste heat recovering system, provided by the invention, can improve boiler efficiency, avoid discharge waste and energy level waste, avoid heat discharge and environment pollution, ensure that the water quality of condensed water reaches the requirement of boiler reuse, fully recycle the sewage heat quantity, simplify the boiler room construction, and reduce civil engineering cost.

Owner:DALIAN HUINENG SCI & TECH

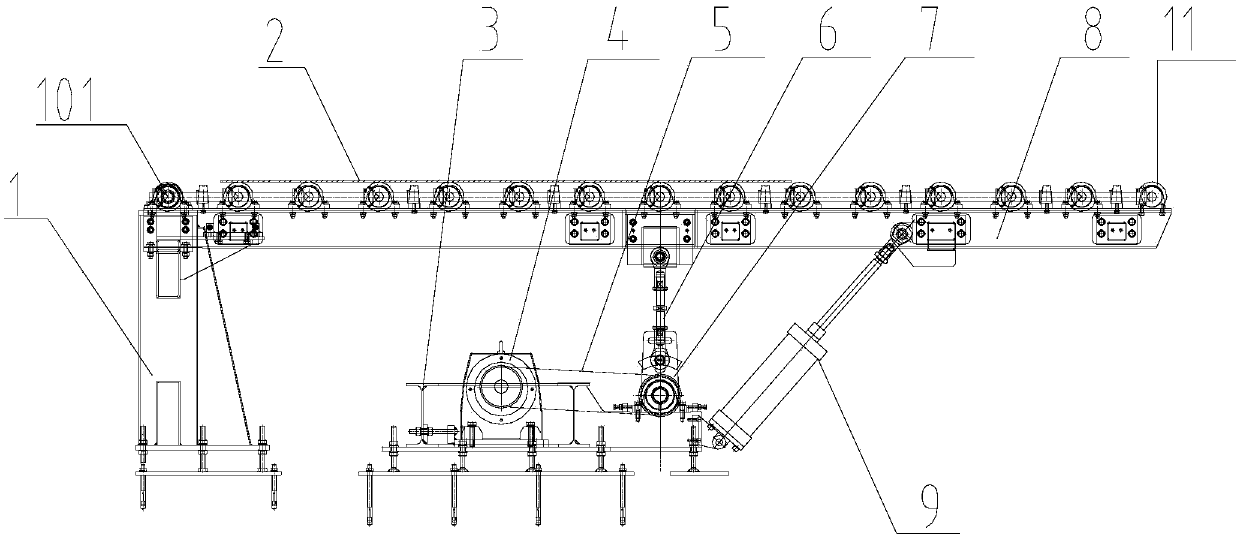

Rapid two-plate falling device for float glass

The invention discloses a rapid two-plate falling device for float glass. The device comprises a conveying roller and a lifting device. When the conveying roller is in the horizontal state, the conveying roller conveys glass plates backwards. When the conveying roller is in the falling state, the conveying roller feeds the glass plates into a crusher to be crushed, and the lifting device enables the conveying roller to rapidly ascend and descend. According to the rapid two-plate falling device for the float glass, a gear reducer motor drives a crank-link mechanism and an air cylinder to act at the same time; due to the fact that the thrust of the air cylinder can bear part of the weight of the conveying roller, the gear reducer motor can be started to run at a large accelerated speed, and the conveying roller is made to ascend and descend within a short period of time.

Owner:CHINA TRIUMPH INT ENG

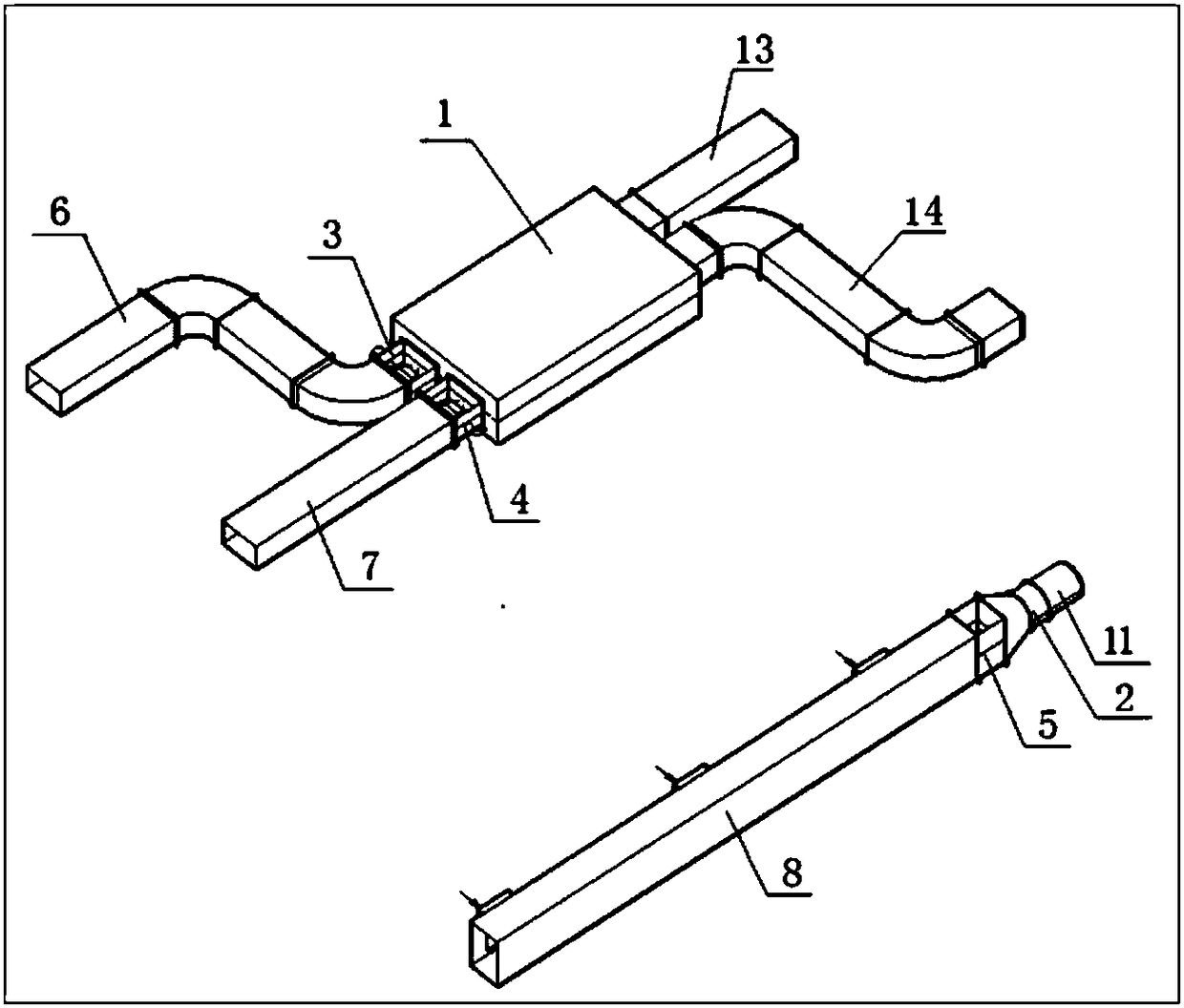

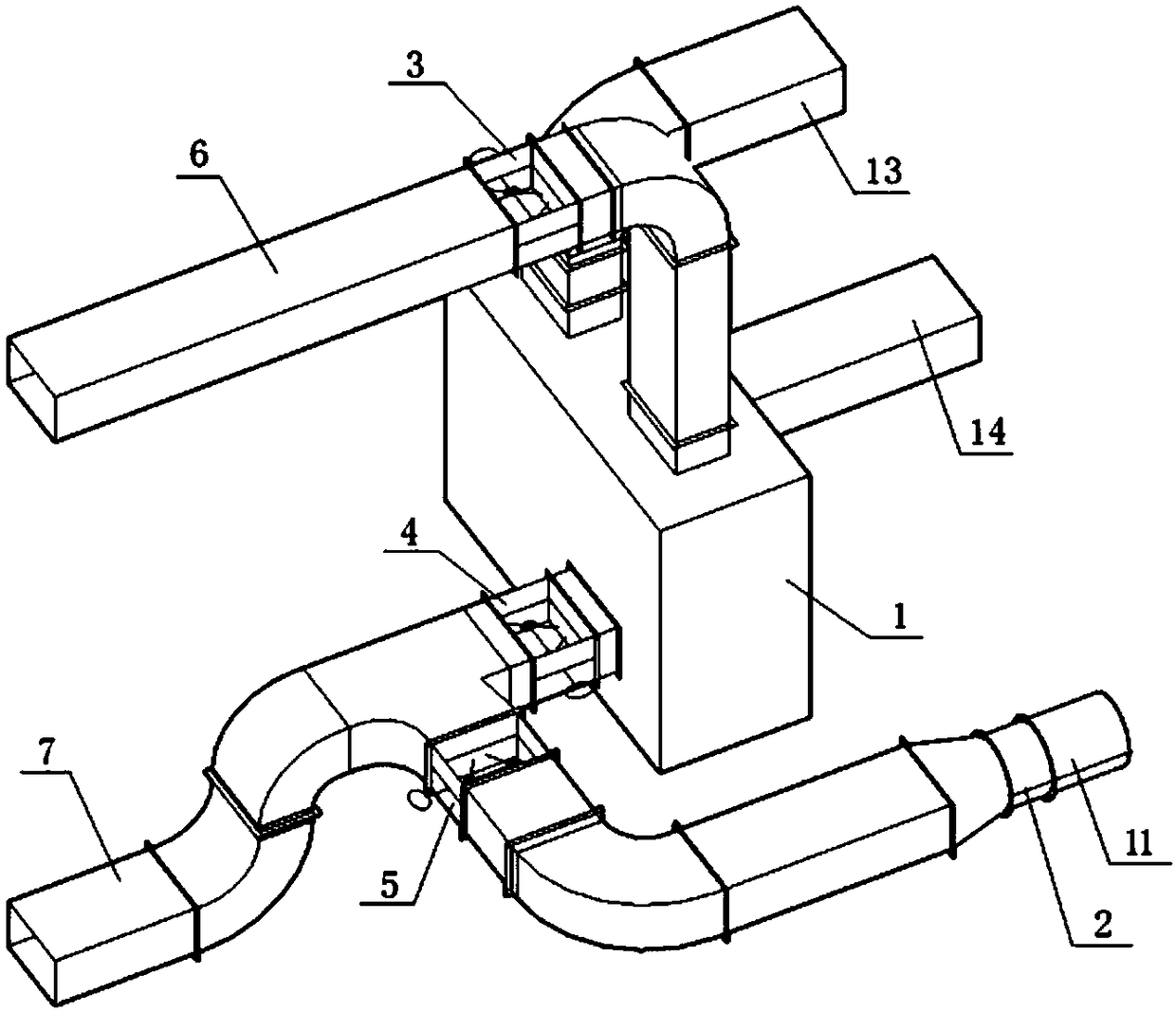

Exhaust air and fresh air combined ventilation system of gas fire control room

PendingCN108613322AReduce in quantityReduce modelDucting arrangementsMechanical apparatusFire controlFresh air

The invention provides an exhaust air and fresh air combined ventilation system of a gas fire control room. The exhaust air and fresh air combined ventilation system of the gas fire control room comprises a fresh air ventilator and an exhaust fan which are arranged in parallel. The fresh air ventilator is internally provided with a first channel and a second channel which are arranged in an intersected manner. The two ends of the first channel are connected with a fresh air inlet pipe and a fresh air outlet pipe correspondingly. The two ends of the second channel are connected with an exhaustair outlet pipe and an exhaust air inlet pipe correspondingly. The two ends of the exhaust fan are connected with a second exhaust air inlet pipe and a second exhaust air outlet pipe correspondingly.A first exhaust air inlet pipe and the second exhaust air inlet pipe are combined through a tee joint. The fresh air outlet pipe is provided with a first electric air valve, the first exhaust air inlet pipe is provided with a second electric air valve, and the second exhaust air inlet pipe is provided with a third electric air valve. By combining exhaust air in the gas fire control room to a freshair renewal system, an air pipe independently exhausting air and a draught fan are reduced, the work amount and the investment are reduced, the utilization space of the room is increased, and the utilization rate of ventilation facilities is increased.

Owner:XIAN CHANGQING TECH ENG

A pot body stretching machine

Owner:山东多星电器有限公司

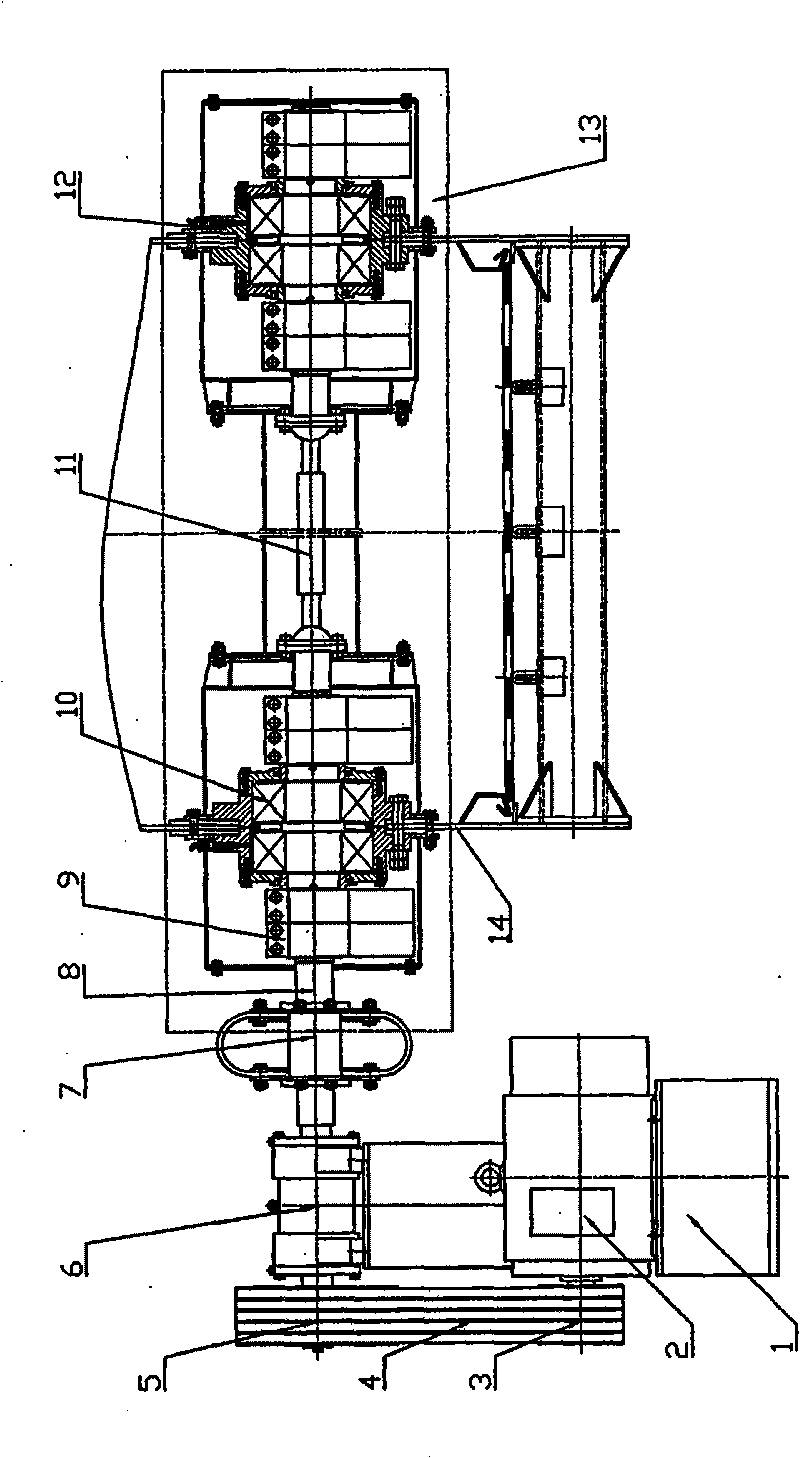

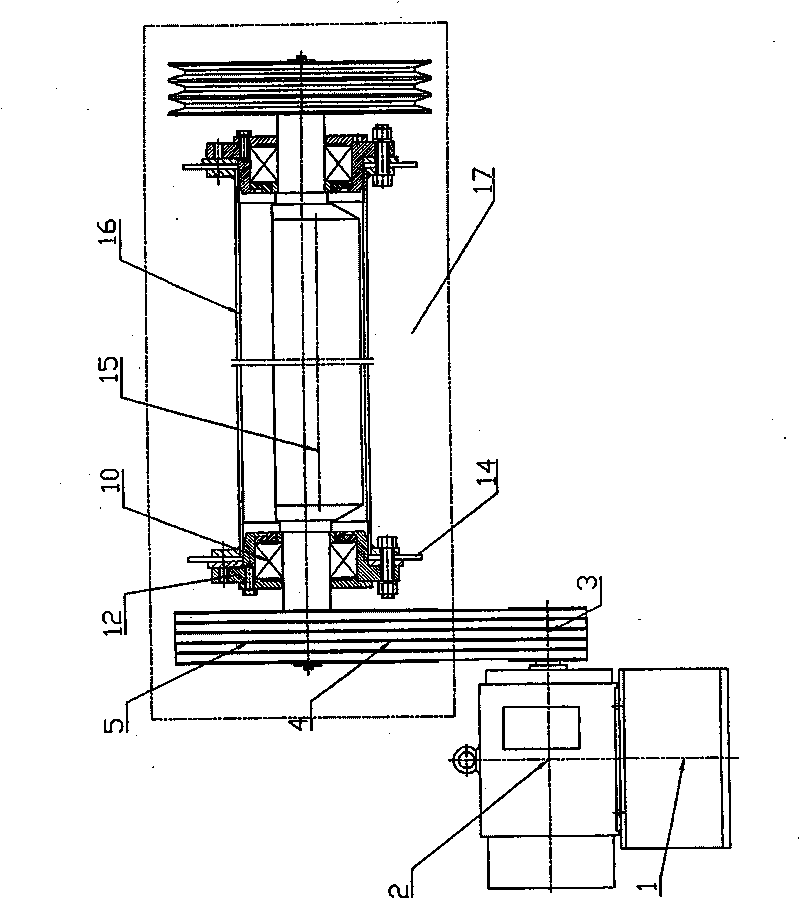

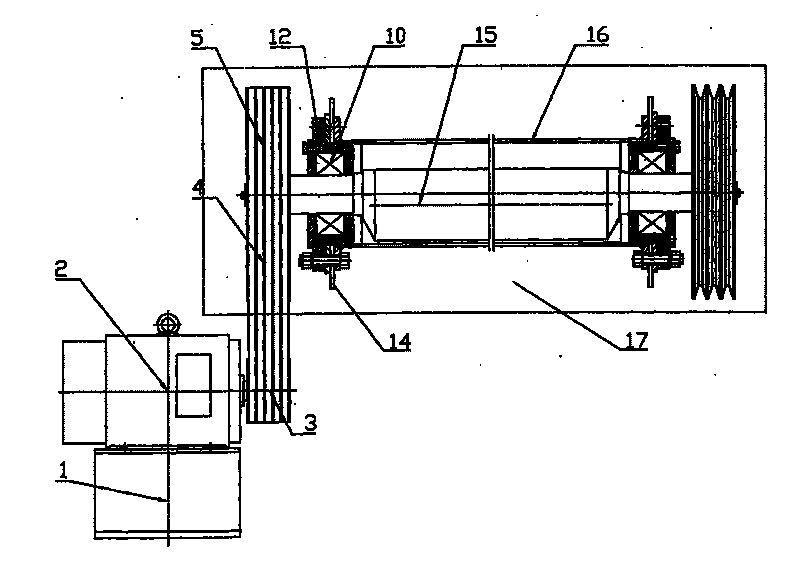

Duplex-bearing self-adjusting aligning web plate type round vibrating screen

The invention discloses a double-bearing self-adjusting aligning web plate type round vibrating screen formed by connecting with a belt wheel device on a common motor. The belt wheel device is connected with an intermediate driving device which is connected with an eccentric device through a flexible coupler; the eccentric device is connected with a bearing chamber through a universal driving shaft; the belt wheel device consists of a larger belt wheel, a small belt wheel and a V-shaped belt; the eccentric device consists of an aligning bearing, an eccentric block and a shaft head flange; a web plate type vibration generator is arranged below the bearing chamber; and the lower end of the eccentric device is connected with the bottom of the web plate type vibration generator through the screen edge. The defects of an eccentric shaft structure can be avoided by using the structure.

Owner:樊建春

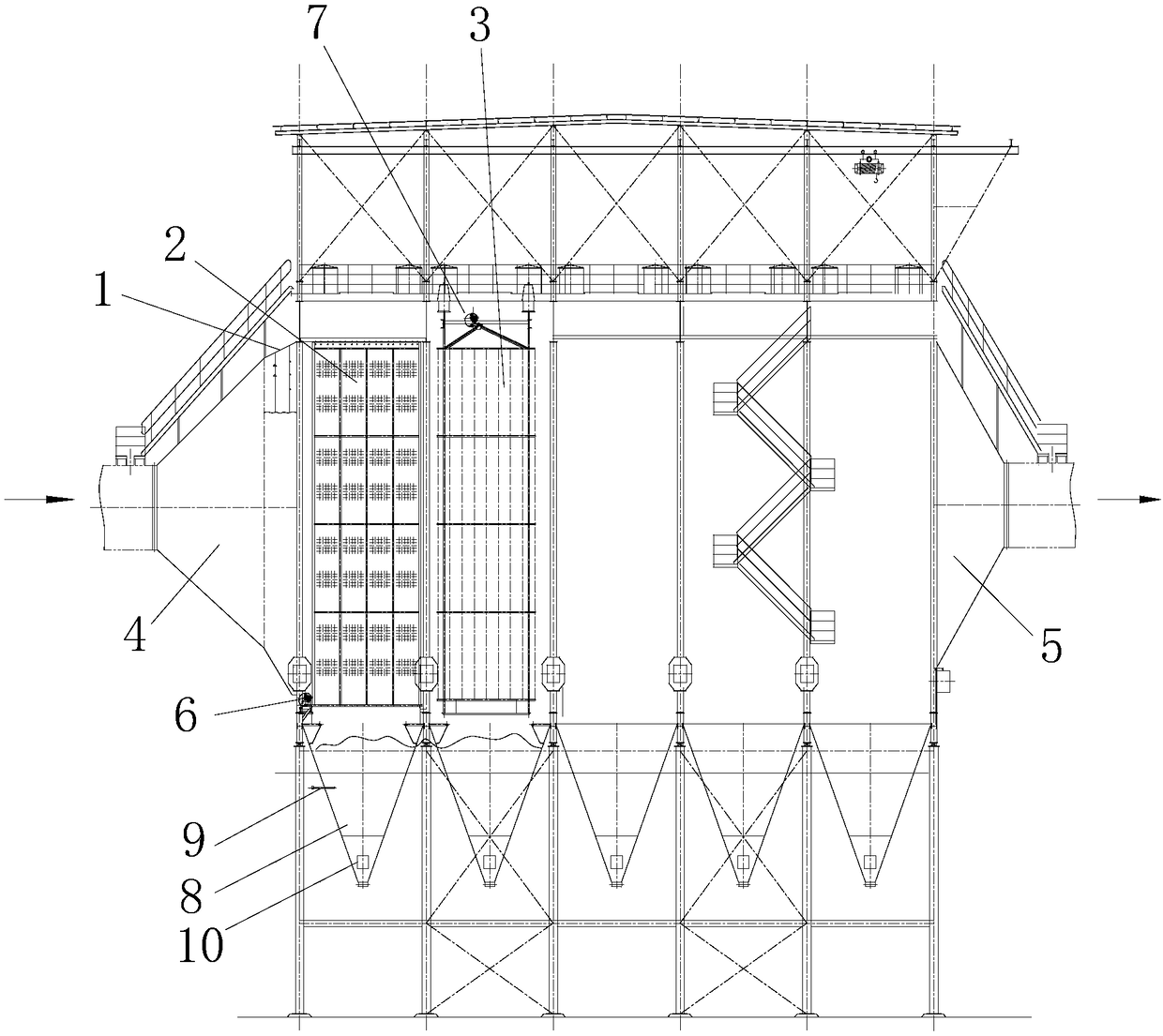

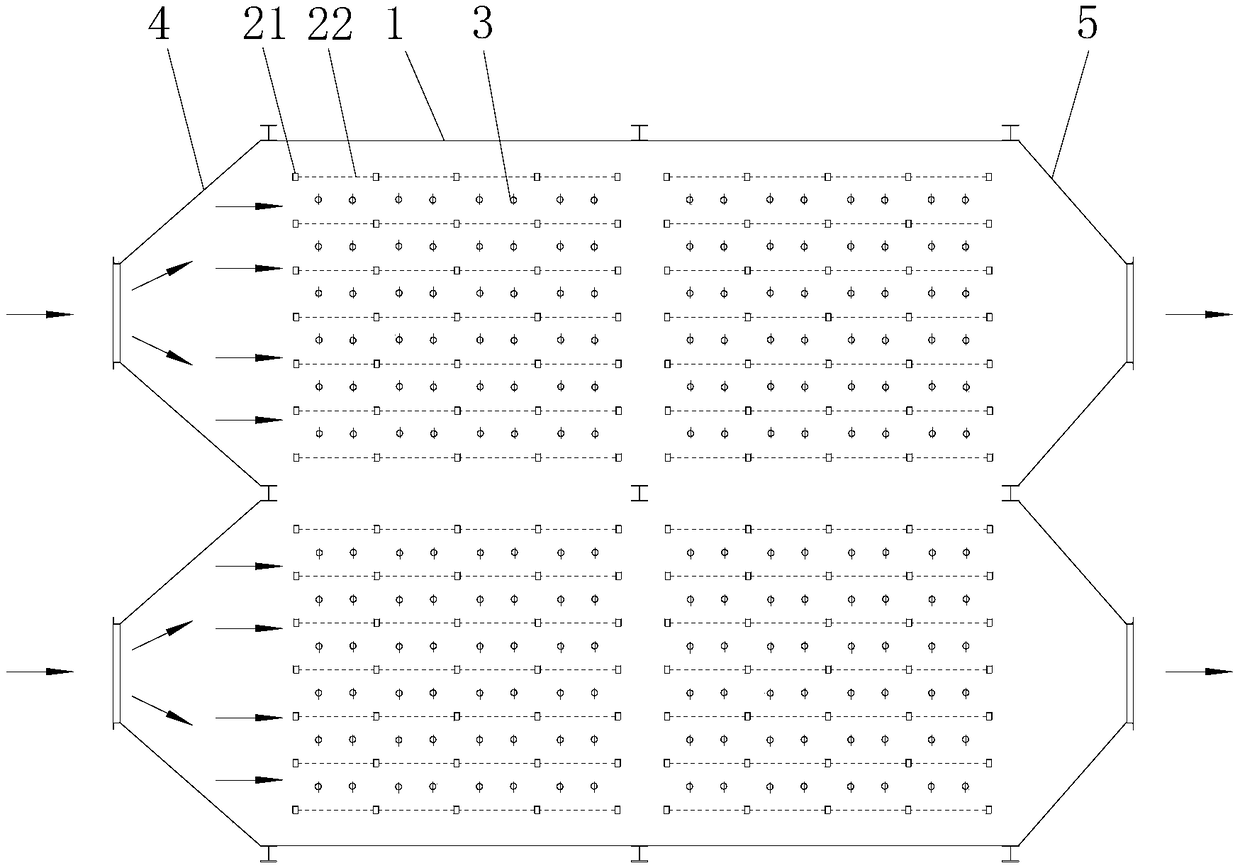

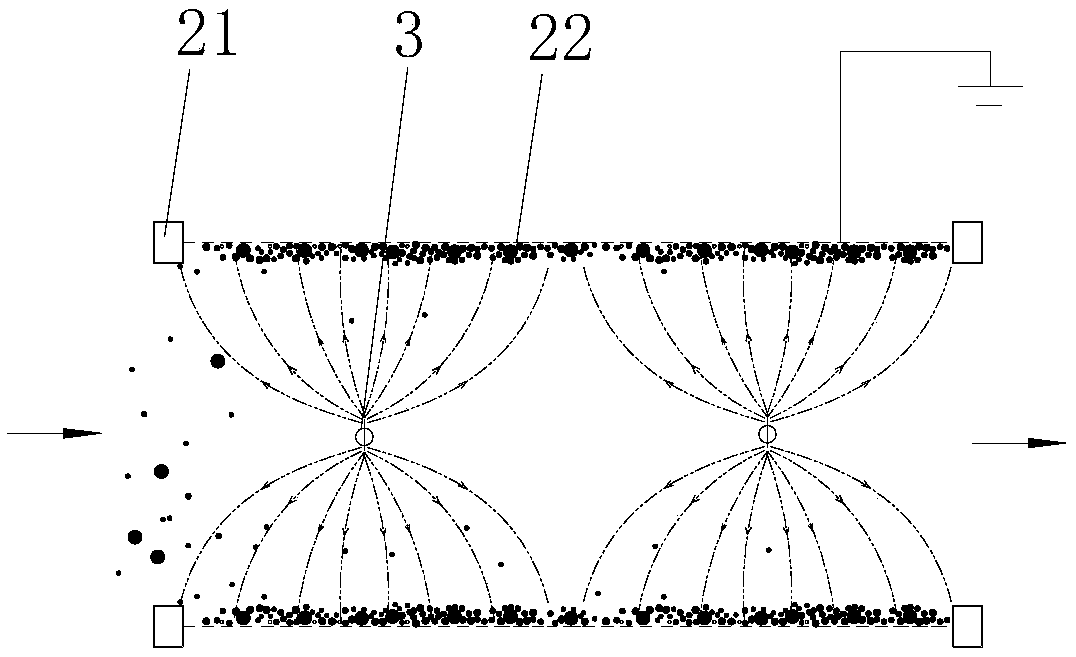

Dry electric precipitator with metal mesh anode plate

PendingCN109013060AReduce design requirementsReduce operating energy consumptionCleaning using gasesExternal electric electrostatic seperatorVoid ratioOperating energy

The invention discloses a dry electric precipitator with a metal mesh anode plate. The dry electric precipitator comprises a shell, the anode plate and an corona line, the anode plate and the corona line are arranged in the shell, the anode plate and the corona line are arranged alternately and in parallel, and an electric field is formed between the anode plate and the corona line; and the anodeplate comprises a frame and a metal mesh, the metal mesh is fixed in the frame, and the void rate of the metal mesh is 8-20%. The dry electric precipitator has the advantages that through the metal mesh, the lateral scour force of the ion wind on the anode plate is weakened, the production of secondary raising dust is reduced, the pressure of the overall device is lowered below 250 Pa, the equipment resistance is reduced, the fan design requirements and operating energy consumption are reduced simultaneously, and the fact that the outlet particle concentration is below 10 mg / m3 can be achieved; and the current density is significantly reduced, the total current required for the whole anode plate is reduced, the energy saving effect is obvious, the weight of the anode plate is also reduced,the total weight of the whole electric precipitator is greatly reduced, the overall steel mass, installation, manufacture and the like of the electric precipitator are reduced, and the cost is greatly reduced.

Owner:浙江菲达环保科技股份有限公司

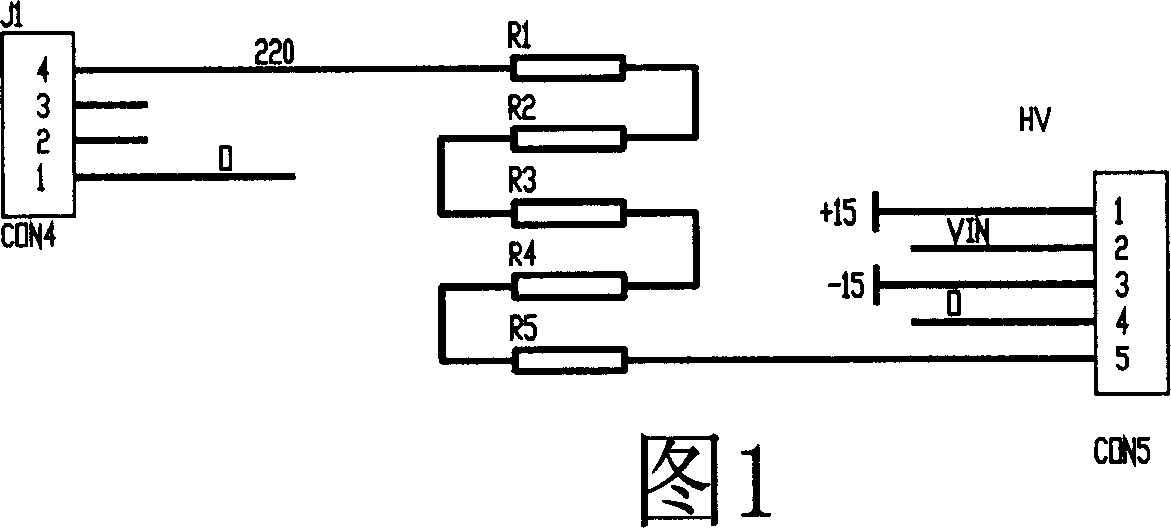

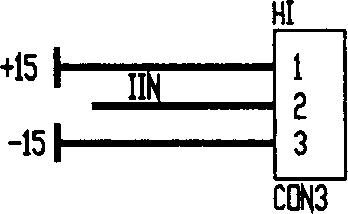

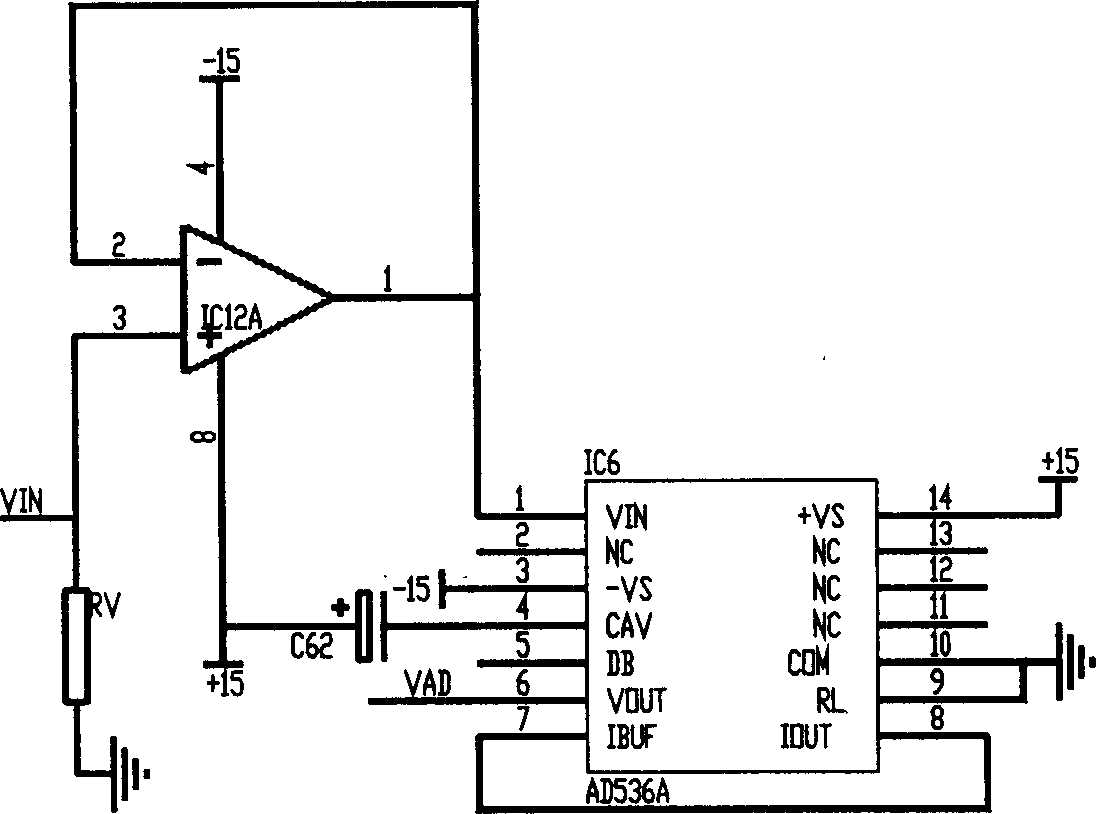

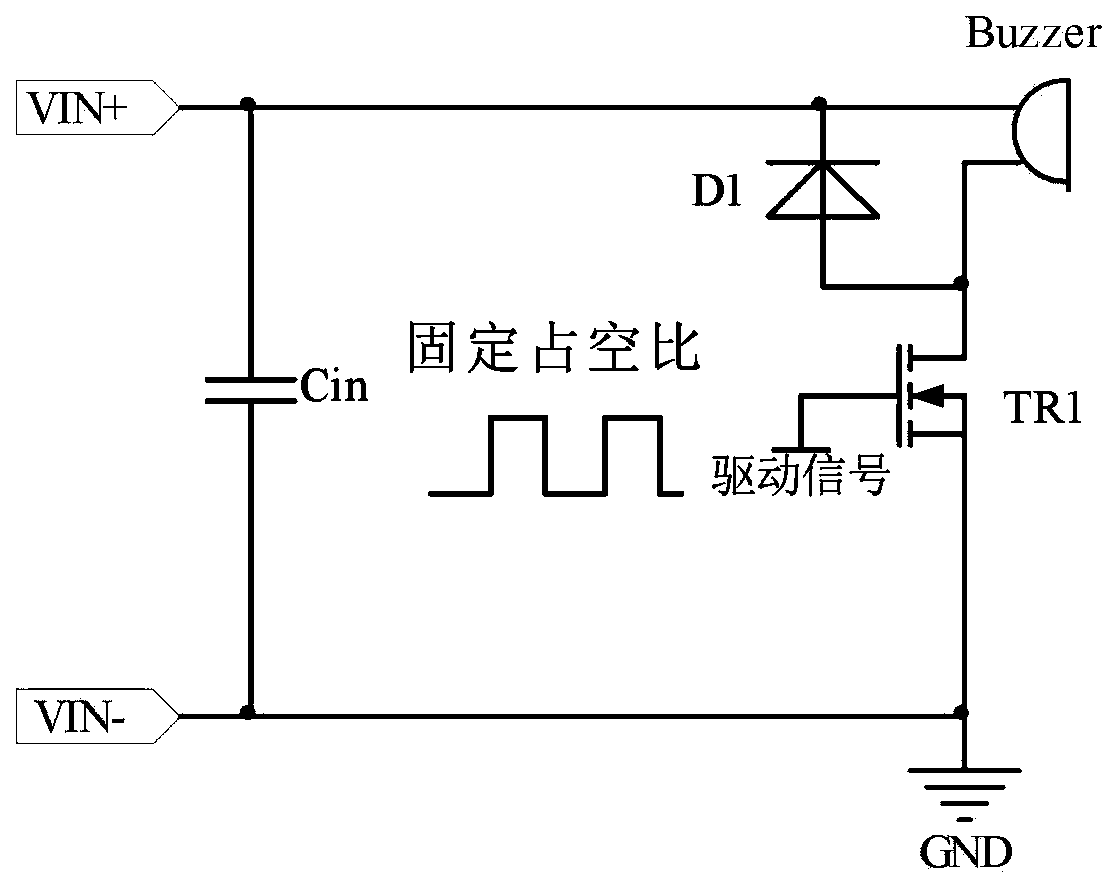

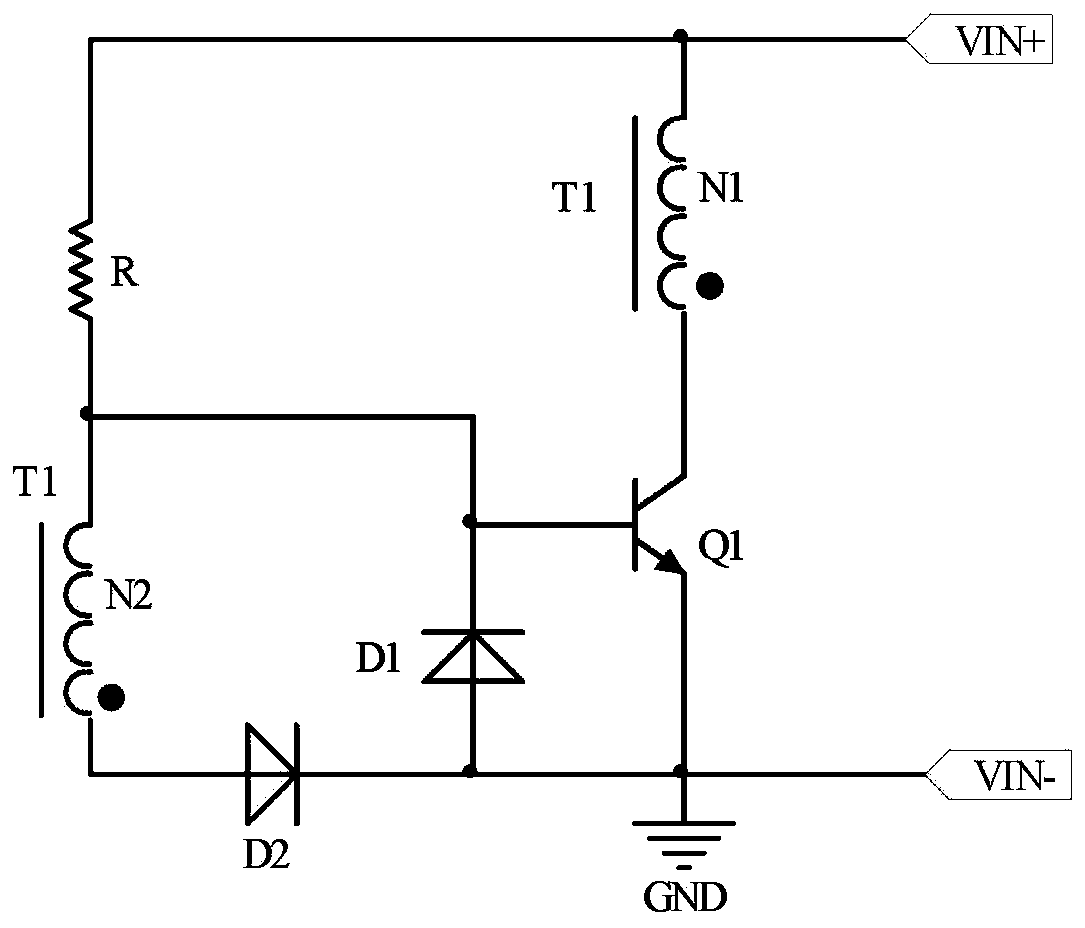

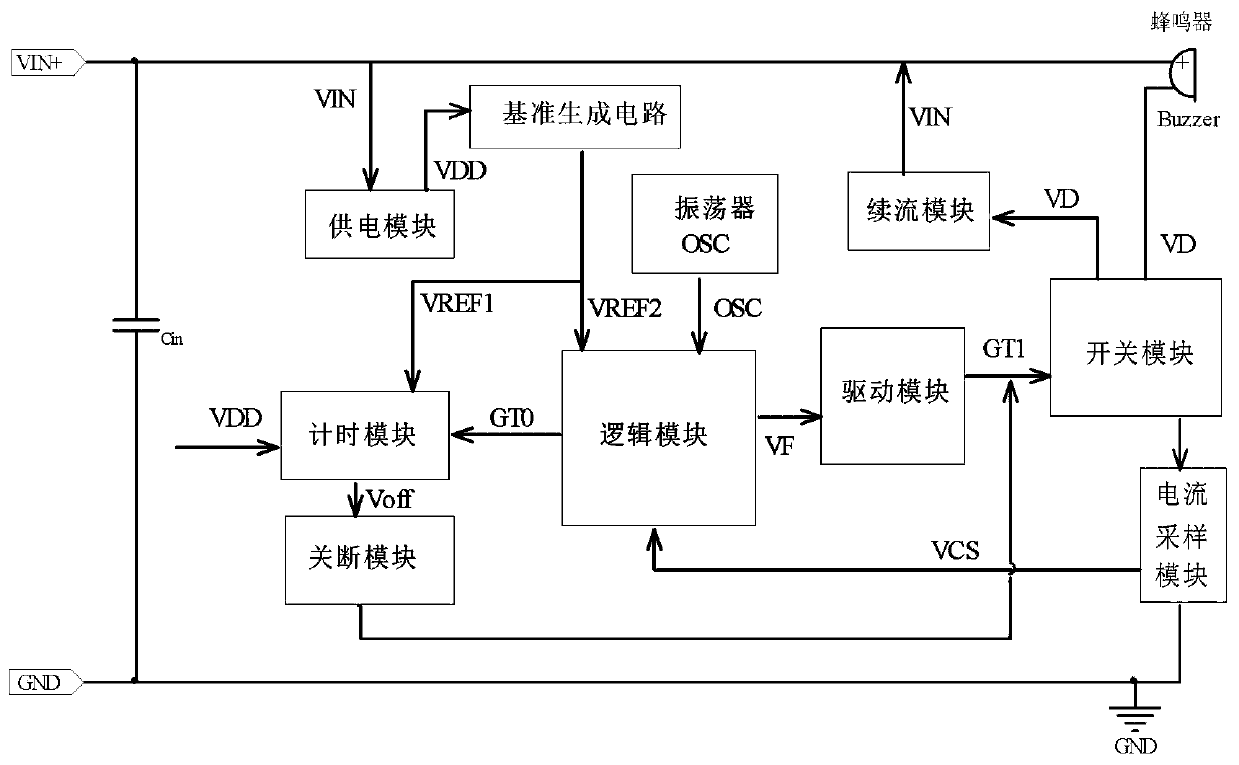

Buzzer driving method for realizing wide voltage input, and driving circuit

The invention discloses a buzzer driving method for realizing wide voltage input, and a driving circuit. The method comprises the following steps: setting constant timing time and constant buzzer peakcurrent, after beginning driving a switch tube serially connected to a buzzer loop to conduct, sampling the current on the buzzer serial loop, when the sampling current reaches the set buzzer peak current, beginning timing, and regulating the impedance change on the switch tube through the feedback of the sampling current, enabling the current passing through buzzer on the serial loop to maintainthe constancy; immediately turning off the switch tube after the timing is finished, enabling the buzzer current to pass through a follow current loop, reducing the excitation energy to zero until the switch tube is conducted repeatedly, thereby forming a complete driving cycle. The sound pressure level consistency can be reached by controlling the consistency of the current passing through the buzzer, and the consistency of the maintaining time of the current.

Owner:SHENZHEN NANYUN MICROELECTRONICS CO LTD

Non-abrasion hard-sealing butterfly valve

The invention relates to a wear-free hard-sealed butterfly valve, which includes a valve body, a valve rod, a butterfly plate and a valve seat, and is characterized in that the valve seat is a movable valve seat that can move axially along the inner wall of the valve body; one side of the valve body There is a side body; a sealing ring is installed between the valve seat, the valve body and the side body; the seal is fastened on the butterfly plate frame; there is a moving fit gap between the inner and outer sides of the valve seat and the valve body and the side body , there is a spring between the outer end surface of the valve seat and the side body, and the inner end surface is connected with the valve stem through a push rod; There is a long keyway in the middle of the valve stem, and there are upper and lower keys respectively fixed on the upper and lower connecting seats, and the upper and lower connecting seats are respectively fastened on the butterfly plate; the push rod It includes upper and lower push rods, one end of which is equipped with a roller, one end of the lower push rod is embedded in the lower curved groove, and can slide, and the other end is hinged with the inner end surface of the movable valve seat; the upper push rod and the lower push rod are installed symmetrically ; There is a single eccentric structure between the disc rotation axis and the sealing plane.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com