Sealing cover for circular pond body of synchronous-rotation reverse hanging membrane structure

A technology of synchronous rotation and sealing cover, which is applied in the direction of smoke and dust removal, cleaning methods and appliances, chemical instruments and methods, etc., and can solve the high sealing height of the fixed sealing cover, the large area occupied by the circular pool body, and the safety hazards of maintenance personnel and other problems, to achieve the effect of long service life, short installation time and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

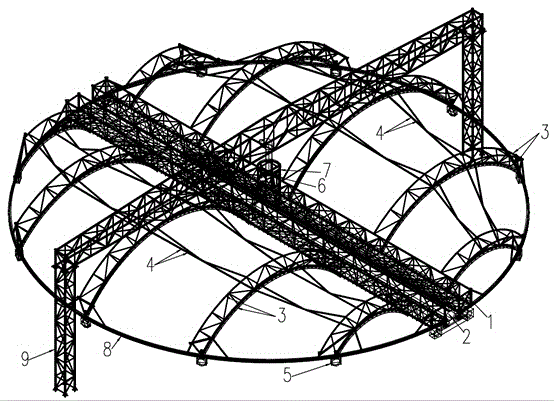

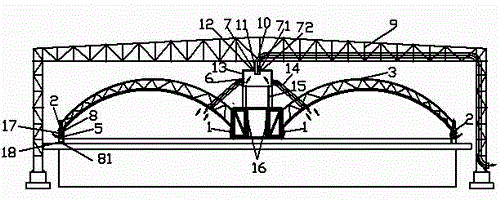

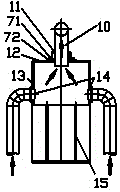

[0043] The present invention synchronously rotates the sealing cover of the circular pool body with anti-hanging film structure, including the main beam 1 used to straddle the circular pool body and rigidly connected with the driving of the mud scraper in the circular pool body, and used to connect with the mud scraper The circular track beam 2 rigidly connected to the locomotive, the main beam and the circular track beam are rigidly connected, and the circular track beam and the main beam are also connected with spaced upper arched truss beams. The adjacent two Between the arched truss beams, there is a connecting truss beam for the positioning and reinforcement of the upper arching truss beams. The main beam, the circular track beam, the upper arched truss beam, and the connecting truss beam together form a rigid support. The sealing film forms a sealing cover, and the surrounding of the sealing film is naturally sagging to be perpendicular to the plane of the concrete walkwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com